Patents

Literature

110results about How to "Improve welding pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser soldering method

InactiveCN101745711AEasy to controlPrecise positioningSoldering apparatusLaser beam welding apparatusHeat lossesSoldering

The invention discloses a laser soldering method, comprising the following steps: (1) a semiconductor laser radiates a PCB pad with set energy so that the surface of the PCB pad reaches certain preheating temperature; (2) solder wires are fed to the surface of the PCB pad by a wire feeding mechanism on condition of certain feeding parameters; (3) under the action of laser radiation, the solder wires are molten and the molten tin spreads and moistens over the surface of the PCB pad; (4) the solder wires are withdrawn and removed from the pad; (5) the semiconductor laser continues radiating the pad so that the solder wires spread over the surface of the pad fully; and (6) the laser is closed and the tin is naturally cooled to form soldering points. During the use of the method, laser is used as soldering heat source, solder wires which are used as brazing filler metal are conveyed by wire feeder, and soldering connection is realized through the action of radiation of the laser to the tin wires and the PCB pad. Due to the characteristics of local heating, rapid heating, rapid cooling and the like during soldering, the method can effectively reduce heat loss of elements and greatly enhance the qualified rate of soldering.

Owner:HANS LASER TECH IND GRP CO LTD

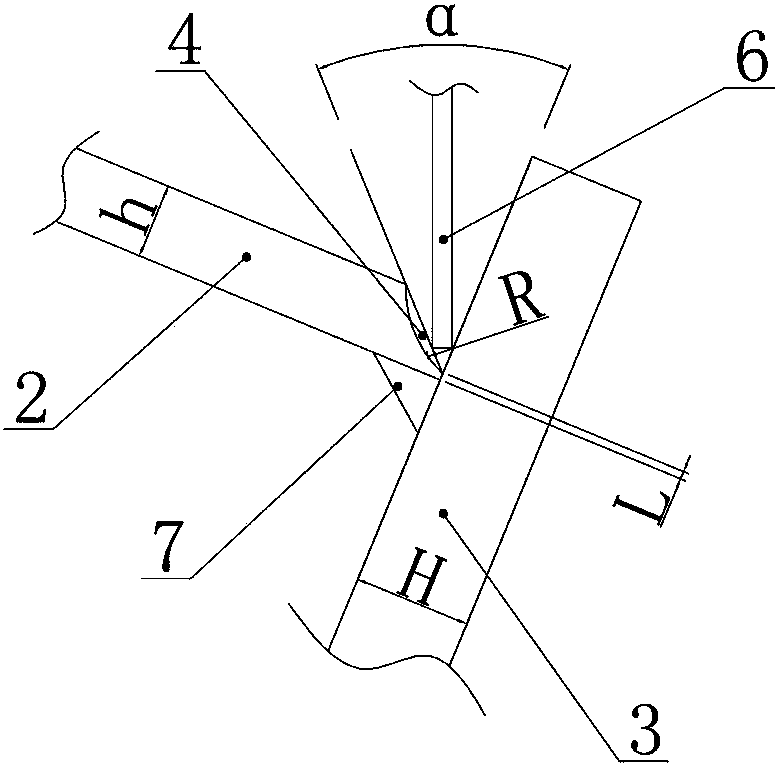

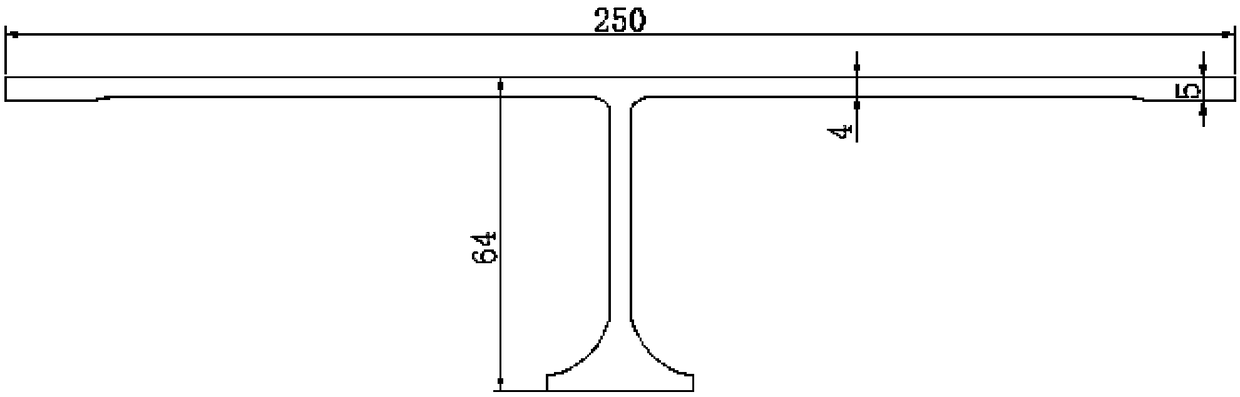

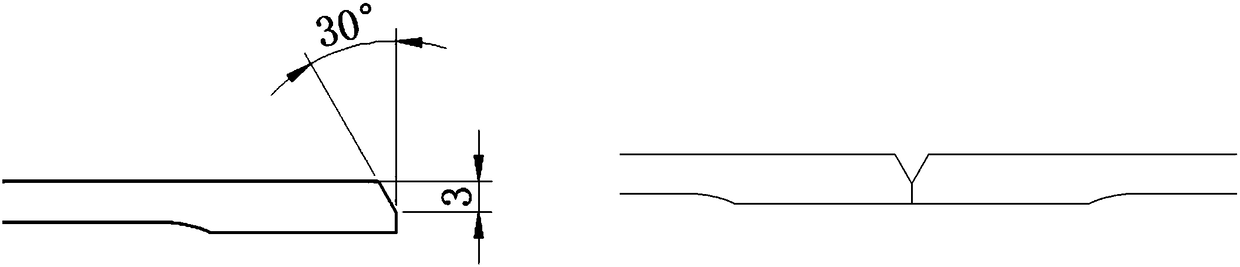

Full penetration fillet weld back-gouging-free welding technology

InactiveCN104259634AImprove rigidityImprove deformation resistanceArc welding apparatusWorkpiece edge portionsFillet weldEngineering

The invention belongs to the technical field of steel structure welding and provides a full penetration fillet weld back-gouging-free welding technology. The welding technology comprises the following steps of: 1) processing a groove of a web plate and decreasing the welding groove as much as possible, 2) fabricating a welding body, ensuring an inclination angle of the welding body to allow a center line of a welding wire to be located on a bisector of an included angle between the groove of the web plate and a wing plate during welding, 3) assembling and placing the web plate and the wing plate on the welding body in a push-against manner, ensuring the straightness and planeness of the web plate and the wing plate and accurately controlling focuses of the web plate and the wing plate, 4) selecting an appropriate welding wire material according to performance of a base material, and carrying out carbon dioxide gas shielded welding on a weld on the reverse side of the groove of the web plate to form a welding backing plate for later groove welding, 5) carrying out union melt welding as the first U-shaped groove welding, and 6) carrying out layered filling welding via the union melt welding, and finally carrying out cosmetic welding, wherein the groove of the web plate is a unilateral U-shaped or V-shaped groove.

Owner:CHINA SIXTH METALLURGICAL CONSTR

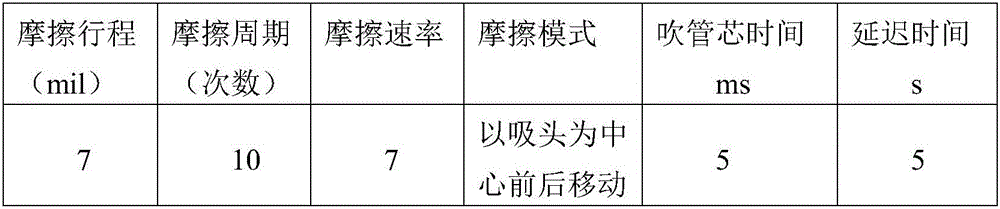

Semi-automatic eutectic soldering method of GaAs microwave power amplifier chip and product

ActiveCN105965120ASolve surface oxidationImprove solderabilitySolid-state devicesSoldering apparatusTin platingSoldering

The invention discloses a semi-automatic eutectic soldering method of a GaAs microwave power amplifier chip. The method comprises the following steps: (1) a carrier, a solder and a bare chip are cleaned; (2) the power amplifier bare chip is plated with tin; (3) the carrier is plated with tin; and (4) the eutectic soldering is performed, that is, the tin-plated bare chip is preheated; an eutectic heating soldering table provided with the tin-plated carrier is heated; meanwhile, nitrogen is opened for protection; the bare chip is absorbed; an auxiliary heating table is stopped heating; when the eutectic heating soldering table is heated above a certain temperature, the bare chip is eutectically rubbed on the carrier after accurate alignment; and the carrier is cleaned after natural cooling in air. The invention further discloses the GaAs microwave power amplifier chip prepared by the method. The method can prepare the chip with lower voidage, less pseudo soldering and excellent performances through controlling such process details as cleaning, preheating and tin plating in specific process and optimizing process parameters therein, and largely increases the welding success rate.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

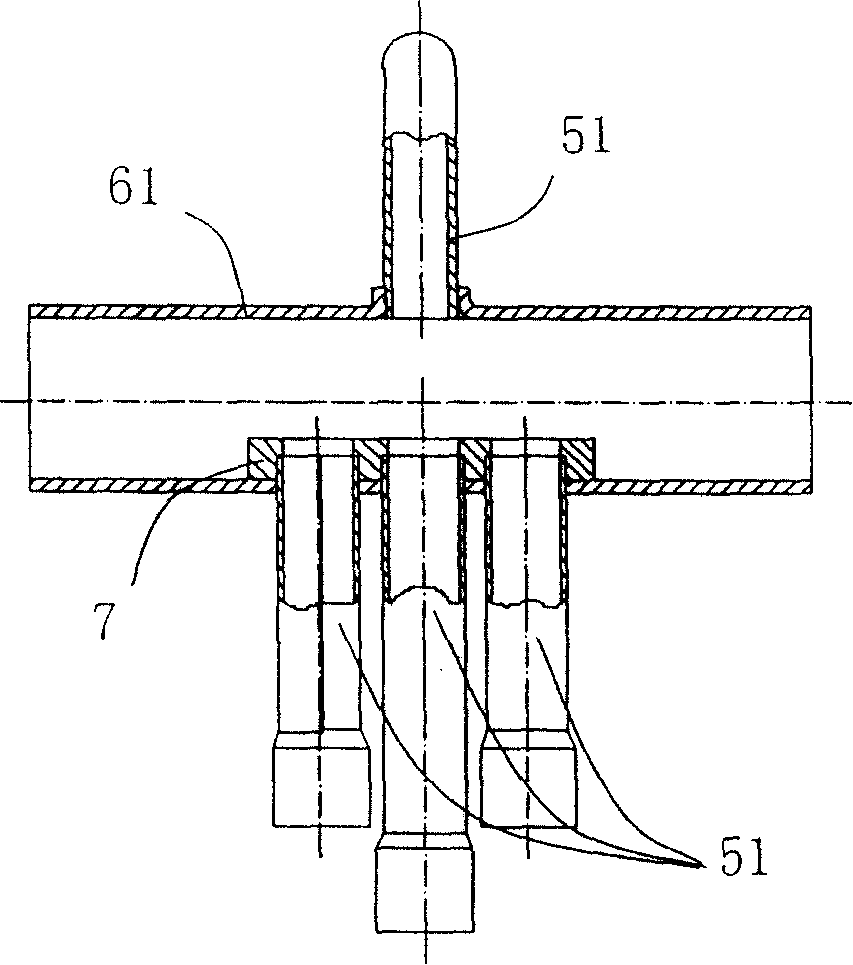

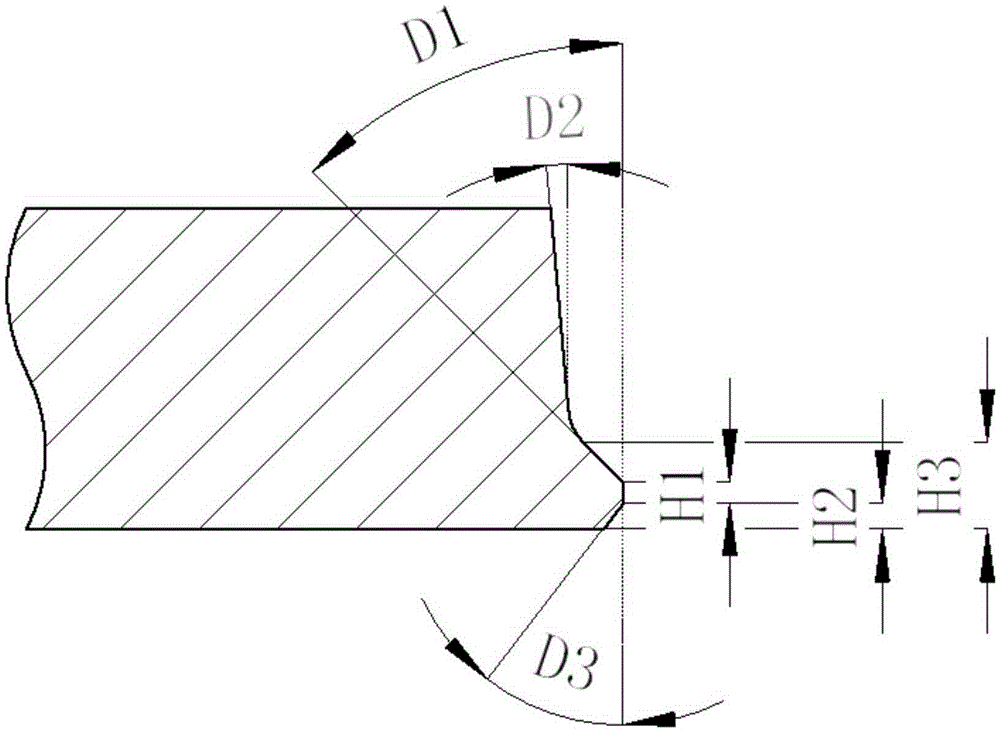

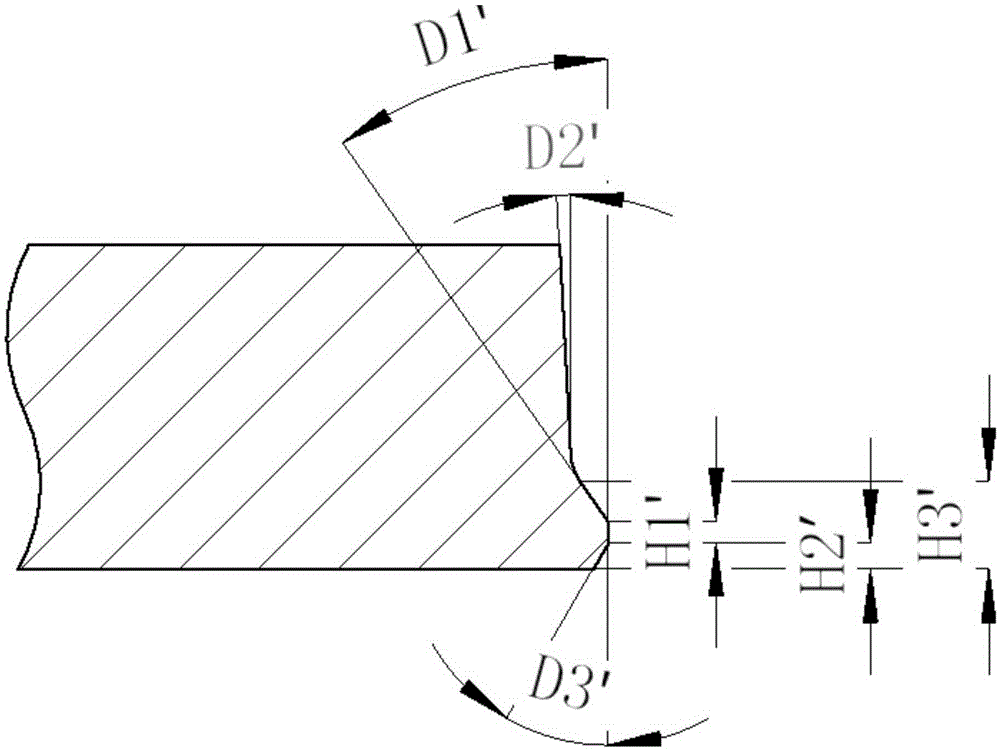

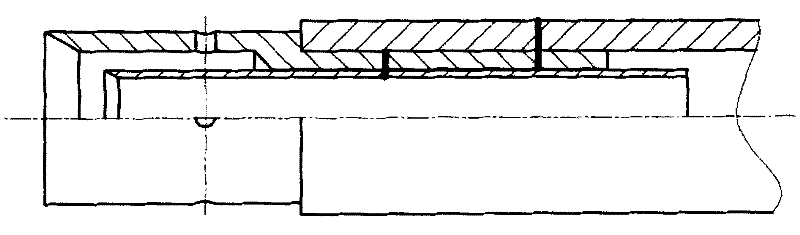

Four-way reversing valve for heat pump air conditioner

InactiveCN101173716AEasy to weldReduce heat lossOperating means/releasing devices for valvesMultiple way valvesHeat lossesEngineering

The invention relates to a four-way diverter valve used on a heat pump air-conditioner, belonging to the technical field of refrigerating accessories, which is aimed to solve the defects in prior products, such as comparatively great heat loss due to the manufacturing materials. The invention comprises a main valve, a guide valve and a coil; wherein, a capillary tube is connected between the main valve and the guide valve, a through hole is arranged on the main valve body, and a connection tube is connected at the through hole; the main valve body is made of stainless steel materials, the connection tube is a combined tube with an inner layer and an outer layer; the outer layer is made of stainless steel and the inner layer is made of copper. One end of the connection tube is folded outward into a hem fitted with the external surface of the main valve body, and the flanged hem is welded on the external surface of the main valve body corresponding to the periphery of the through hole. The invention has the advantages that: the diverter valve can be used in heat pump air conditioning system to change the flow direction of refrigerating working medium, and is favorable to reducing the heat dissipation loss of the four-way diverter valve in the heat pump air conditioners.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

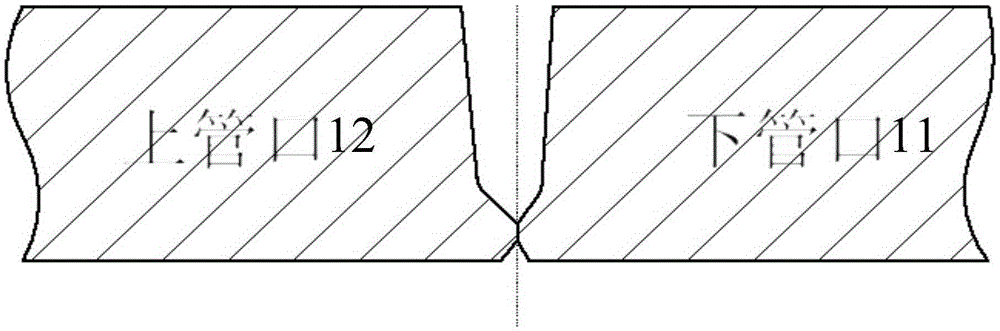

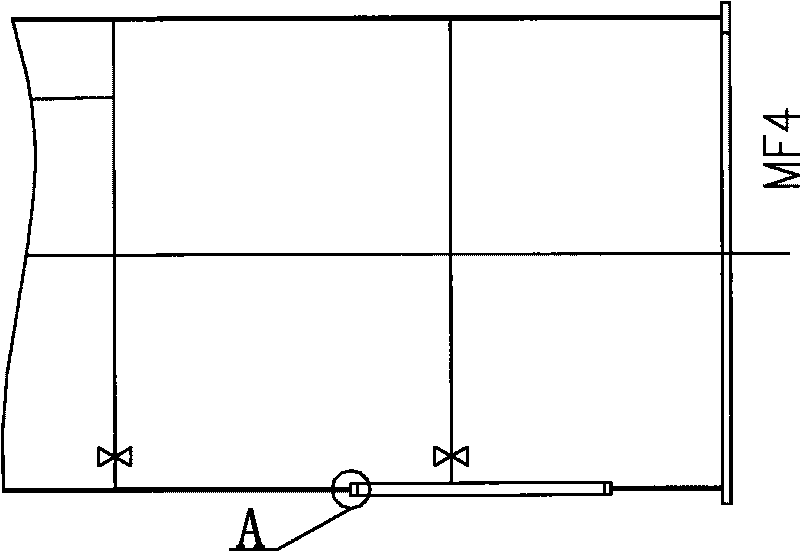

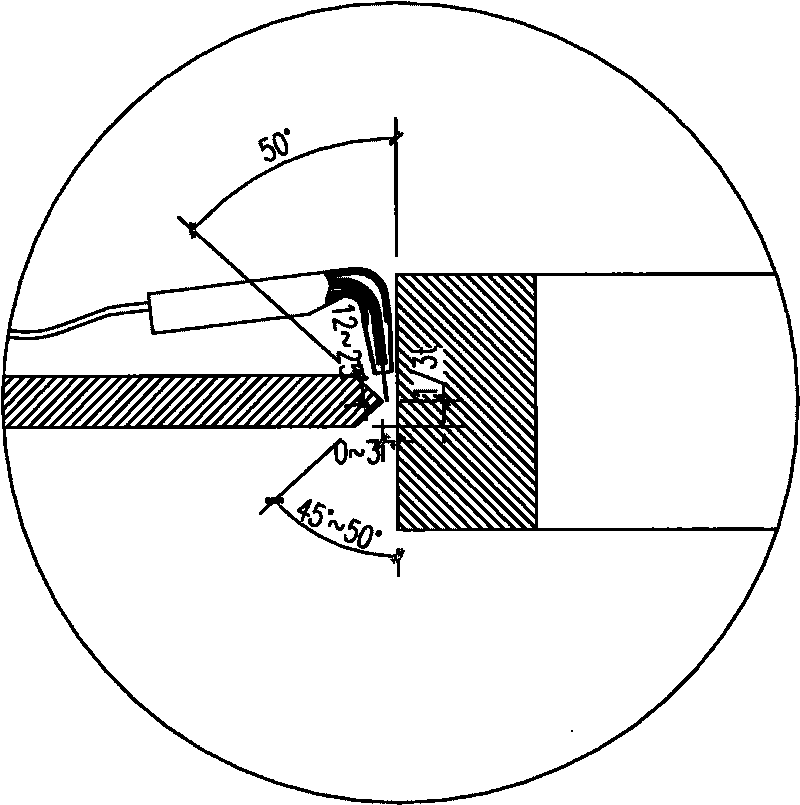

Pipeline welding process for sloping field

InactiveCN105252114ASolve the problem of automatic weldingImprove construction efficiencyArc welding apparatusThermodynamicsProcess engineering

The invention discloses a pipeline welding process for a sloping field. Groove preparation is conducted on pipe openings of two pipelines, asymmetric double-V-shaped combined grooves are formed, and then locating, pairing, preheating, root welding, hot welding, filling welding, cosmetic welding are carried out in sequence, operation is easy, stability is high, labor cost is reduced, and meanwhile reliable weld quality can be guaranteed. Furthermore, the double-V-shaped combined grooves are adopted in the process, the size of the grooves is small, required filling welding material is less, and welding cost can be lowered as well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Automatic tungsten argon arc welding method for small diameter titanium pipe

InactiveCN102266998AImprove welding qualityImprove welding pass rateArc welding apparatusPass rateCerium

The invention discloses an automatic tungsten argon arc welding method for a small-diameter titanium pipe, which comprises the following steps: placing the pipe on a rolling tire, and using an automatic tungsten argon arc welding machine to weld it; The welding wire is cleaned; when welding, the rolling tire rotates to drive the pipe to rotate, and the welding torch is in the flat welding position and remains still. The welding process parameters are: welding current: 80-100A, voltage: 10-16V, welding speed: 8 ~10cm / min, the flow rate of argon gas in the nozzle of the torch is 10~15L / min; the extension length of the welding wire is 8~12mm; the tungsten electrode adopts cerium tungsten electrode. The invention has stable welding quality, high welding qualified rate and fast welding speed.

Owner:SINOPEC THE FOURTH CONSTR

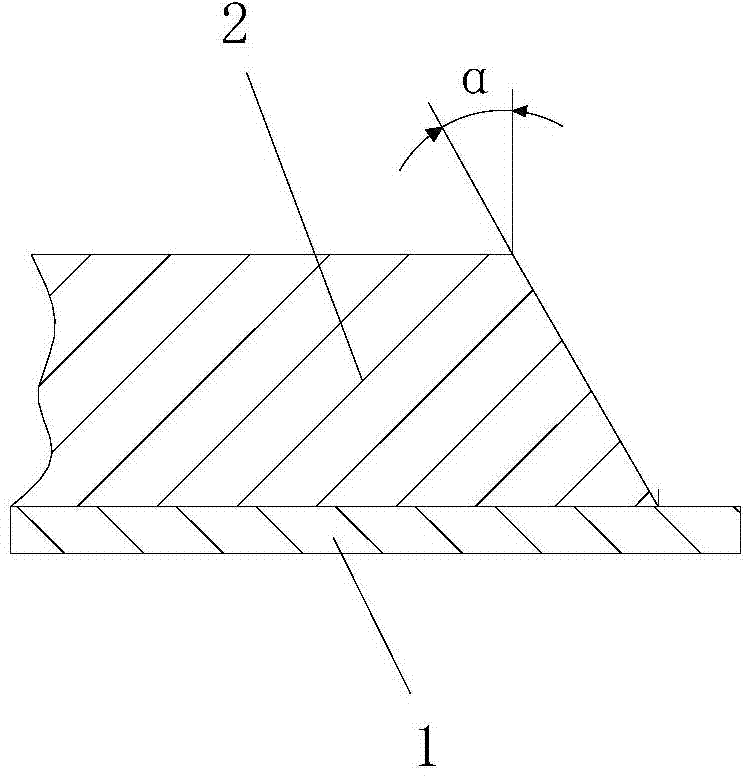

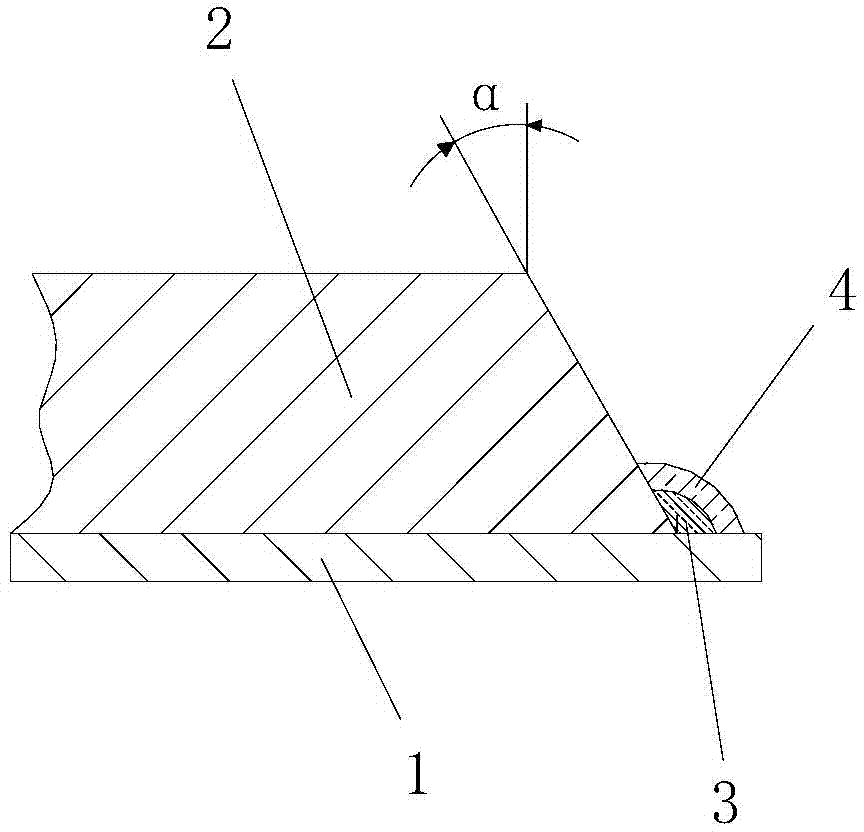

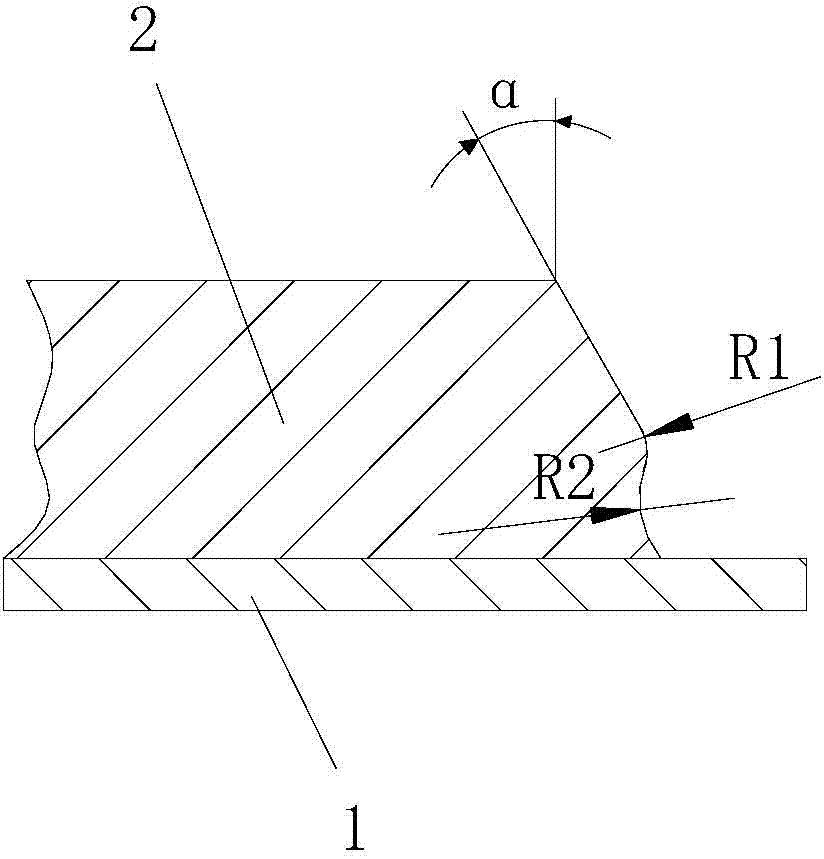

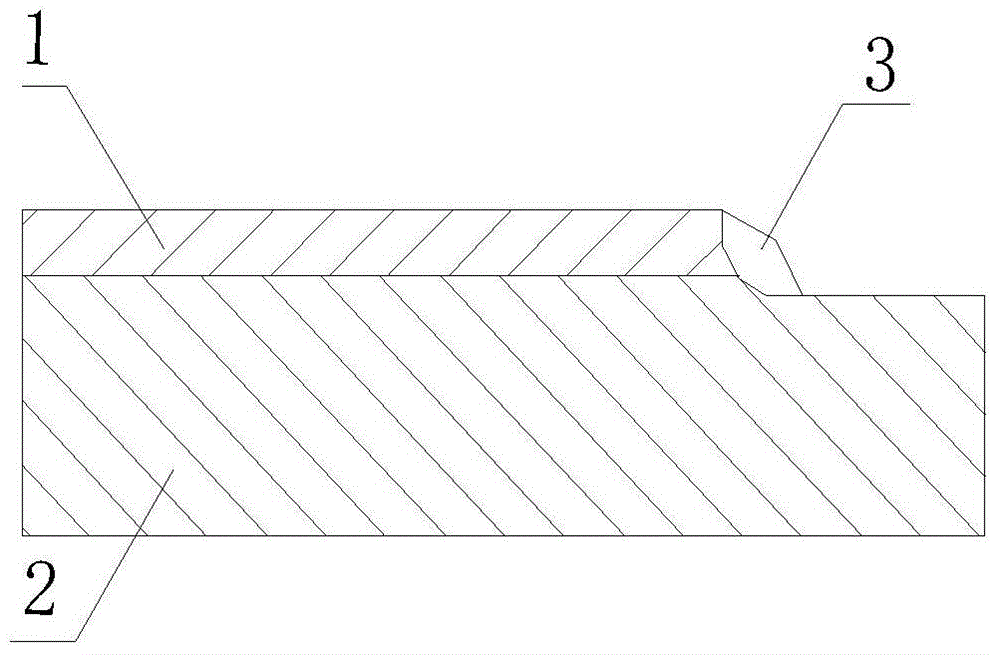

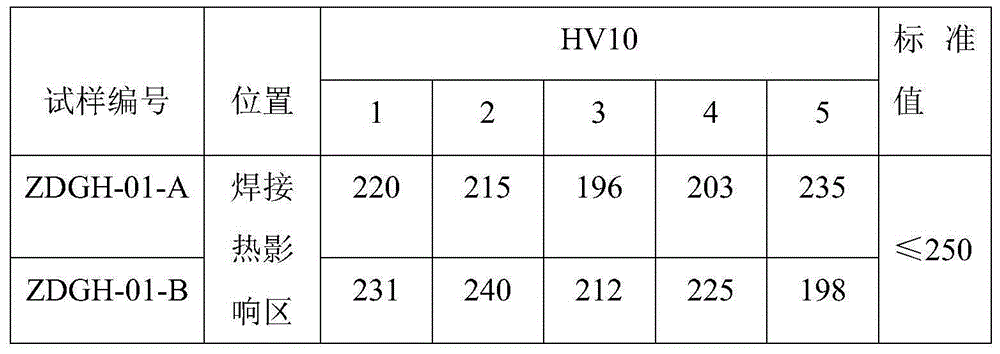

Bimetal composite pipe end sealing weld technology based on R-shaped groove

ActiveCN103612001AIncreasing the thicknessEffective protectionArc welding apparatusMetal working apparatusCarbon steelInert gas

The invention discloses a bimetal composite pipe end sealing weld technology based on an R-shaped groove. A sealing weld bimetal composite pipe is composed of a stainless steel lining pipe and a carbon steel base pipe. The technology comprises the first step of machining the R-shaped groove, namely, the R-shaped groove is formed in the carbon steel base pipe end of a bimetal composite pipe to be sealed and welded; the second step of carrying out backing weld, namely, the backing weld is carried out on the joint between a circular arc plane and the stainless steel lining pipe through an argon arc welding machine to form a backing weld layer which is located inside a circular arc section; the third step of carrying out cosmetic welding, namely, under the protection of inert gases, the cosmetic welding is carried out on the outer side of the backing weld layer through the argon arc welding machine to form a cosmetic welding layer, and the upper portion of the cosmetic welding layer is higher than the upper portion of a circular arc transmission section. The sealing weld technology steps are simple, the sealing weld technology process is controlled easily, the welding quality is good, and the problems that an existing bimetal composite pipe end sealing weld method is poor in welding quality, the welded bimetal composite pipe has the quality defect easily can be effectively solved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

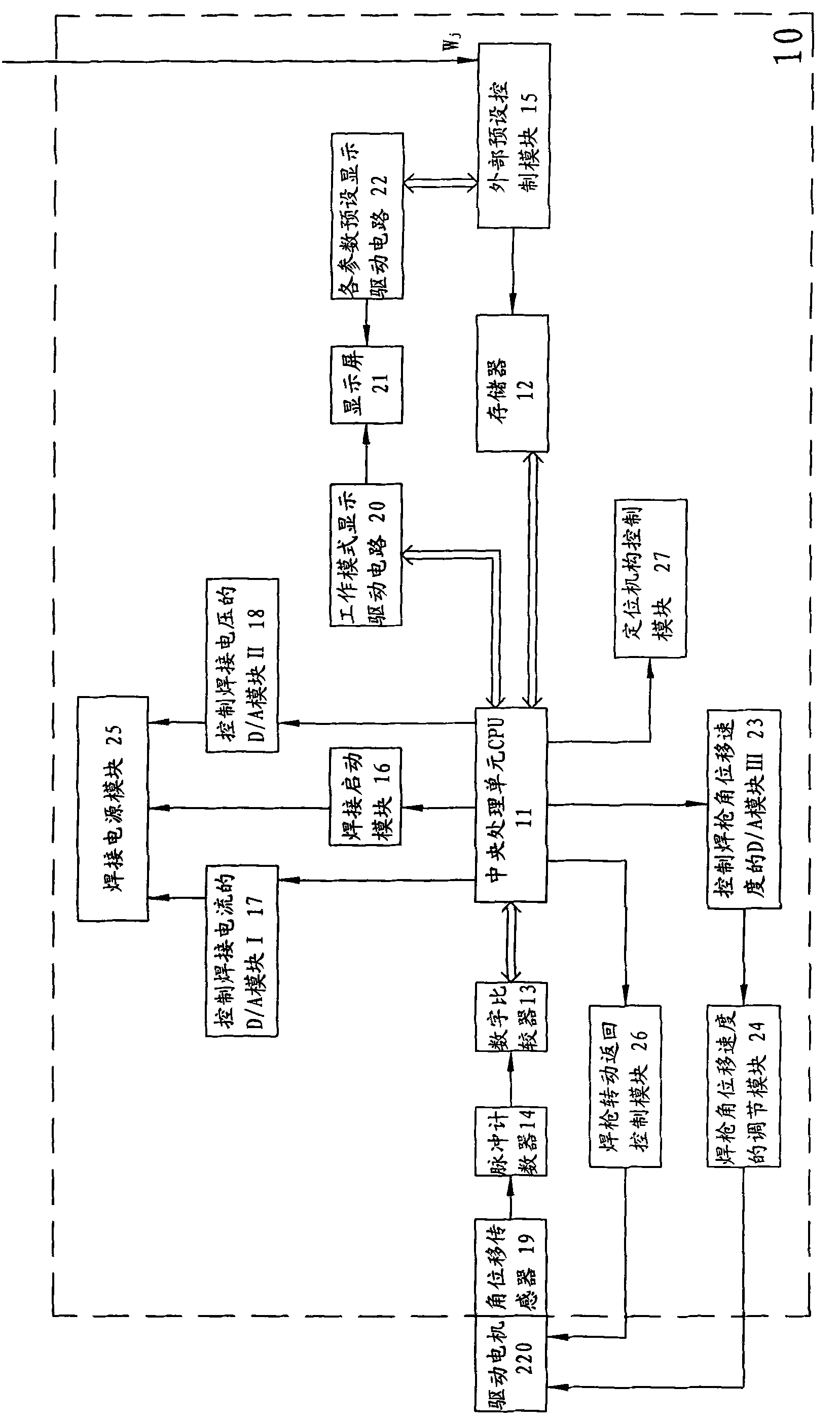

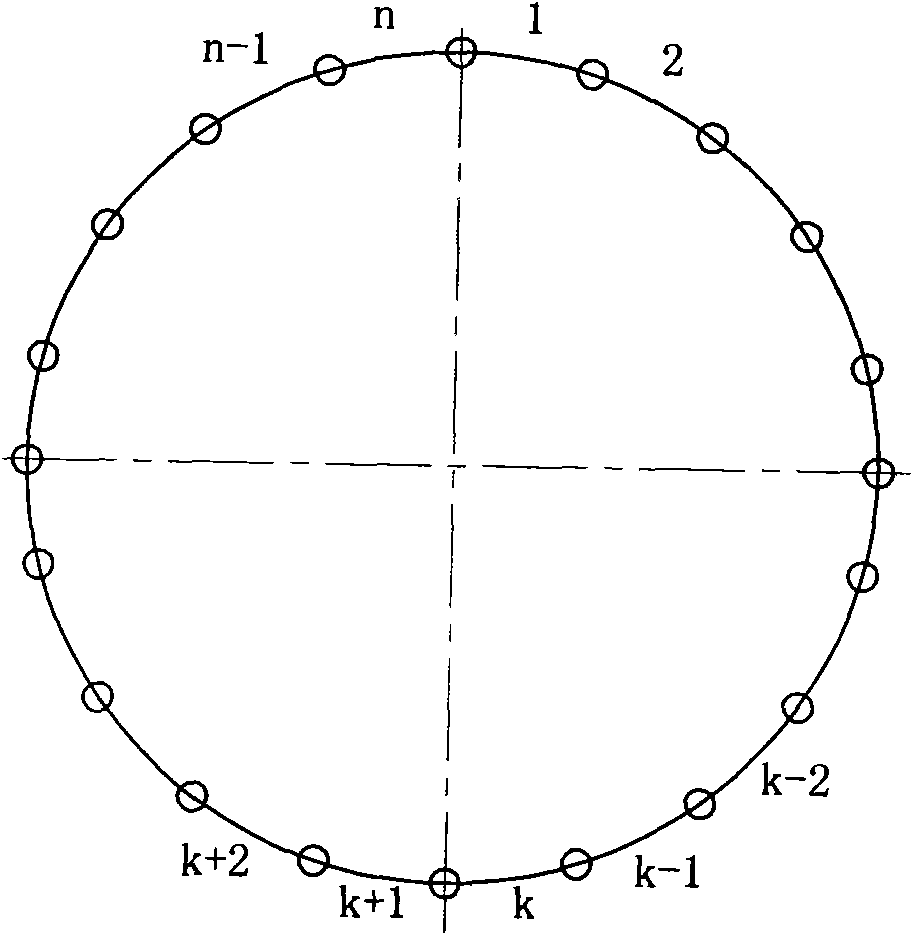

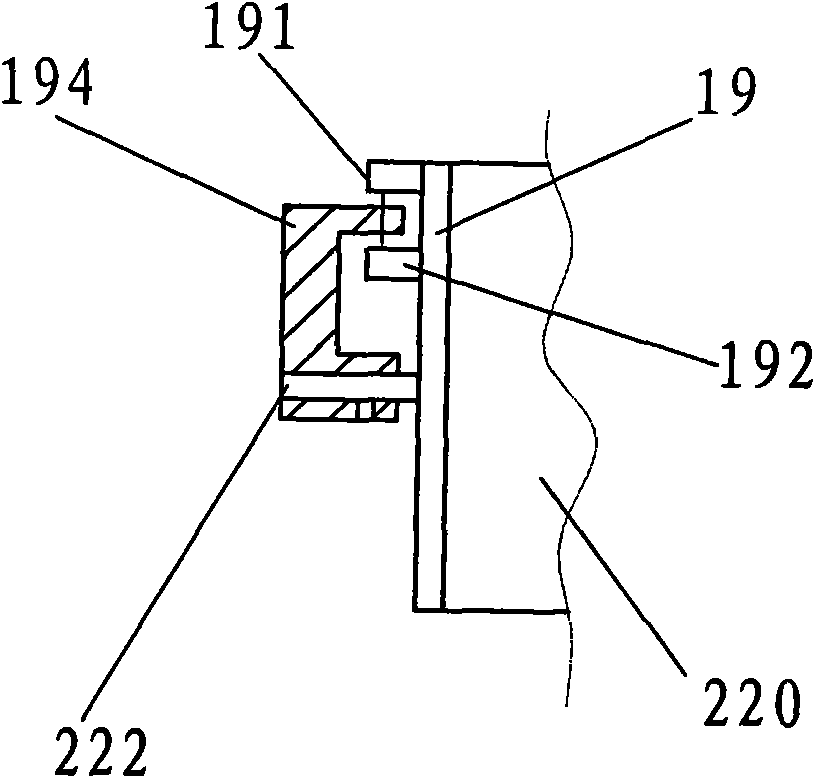

Adaptive welding method for pipe-plate circumference welding and subsection parameter setting and arc welding equipment

ActiveCN102069273ASave welding materialImprove welding efficiencyArc welding apparatusThick plateWelding power supply

The invention discloses an adaptive welding method for pipe-plate circumference welding and subsection parameter setting, which comprises the following steps of: dividing the circumferential seam of a welded workpiece pipe-plate into n arc sections, and presetting the welding parameter of each arc section; storing n groups of preset welding parameters in a memory; placing a welding gun at a welding start position; switching on a welding power supply, taking out the welding parameters from the memory under the control of a central processing unit to control welding current and voltage suppliedto the arc section by the welding power supply and control arc striking and arcing of the welding gun, and rotating the welding gun to complete the angular displacement of a given value; and after the welding gun completes welding of the arc section, taking the welding parameter of the next arc section to continuously implement welding till completing welding of all n arc sections. The adaptive welding method can save welding materials, improve the welding efficiency, improve the seam forming efficiency and improve the welding qualification rate and the like, is greatly convenient for most users, and is particularly suitable for welding thick-wall pipes and thick plates.

Owner:SHENZHEN RILAND IND

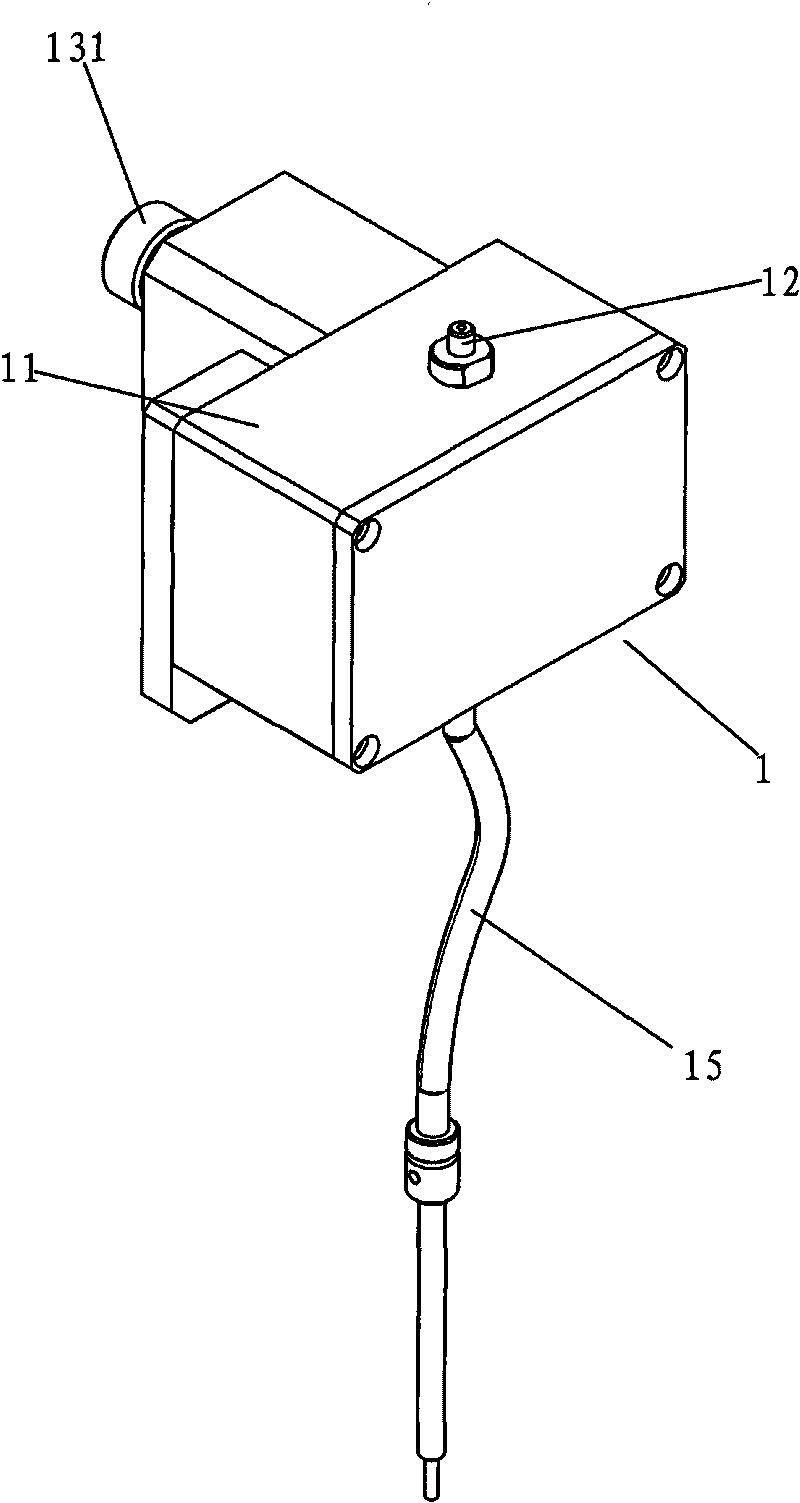

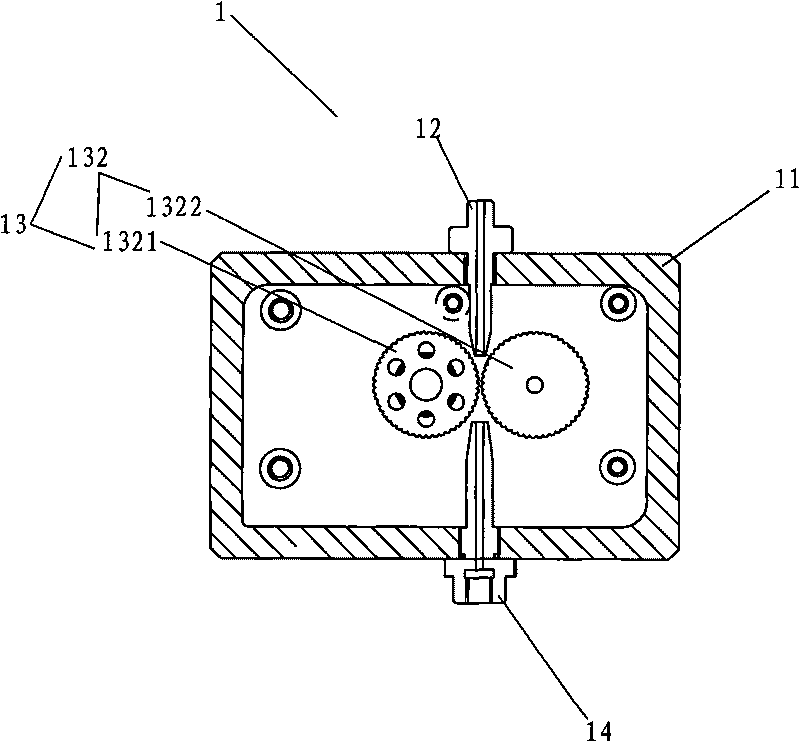

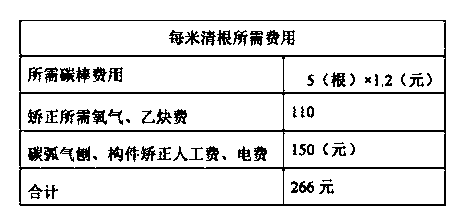

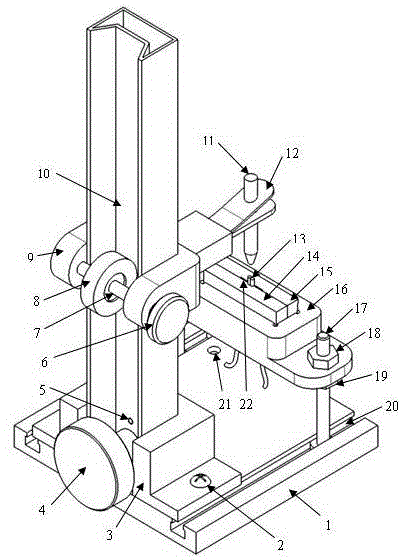

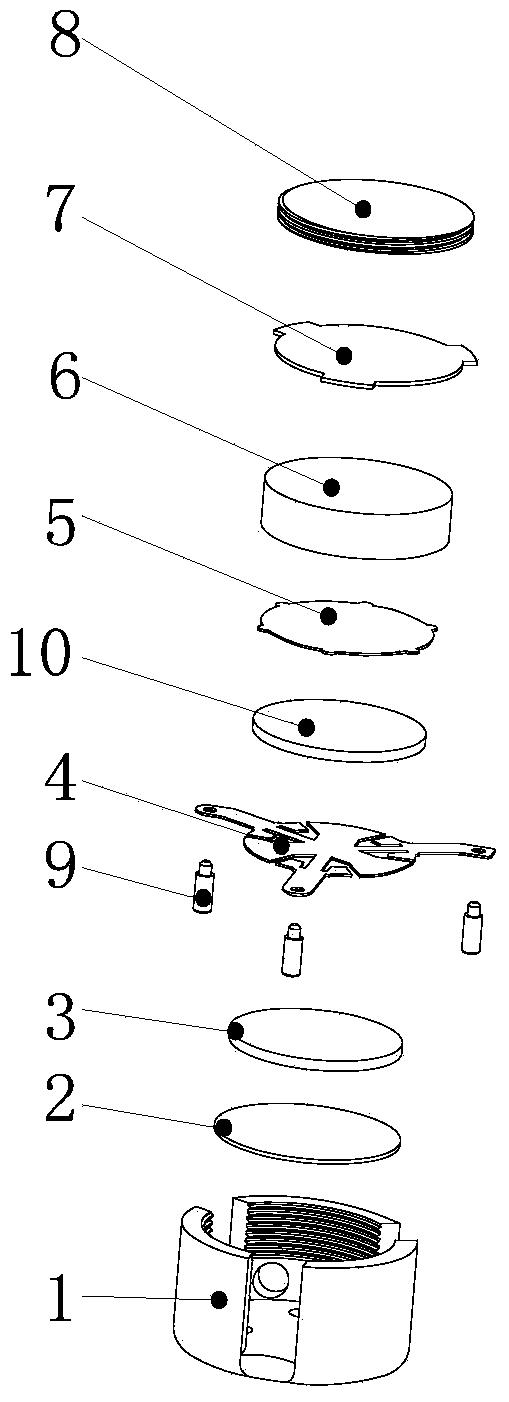

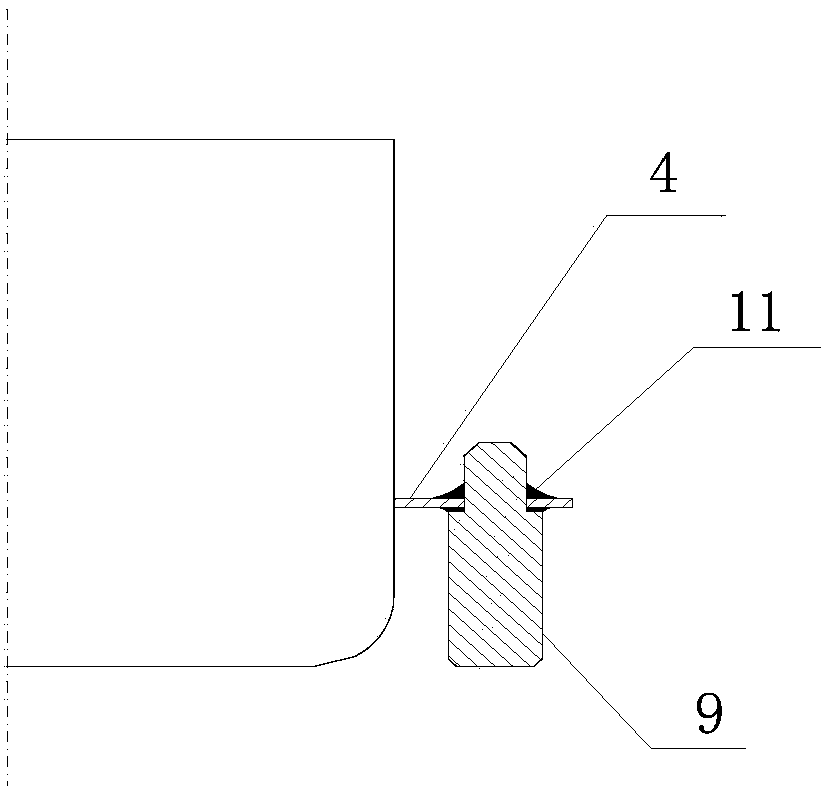

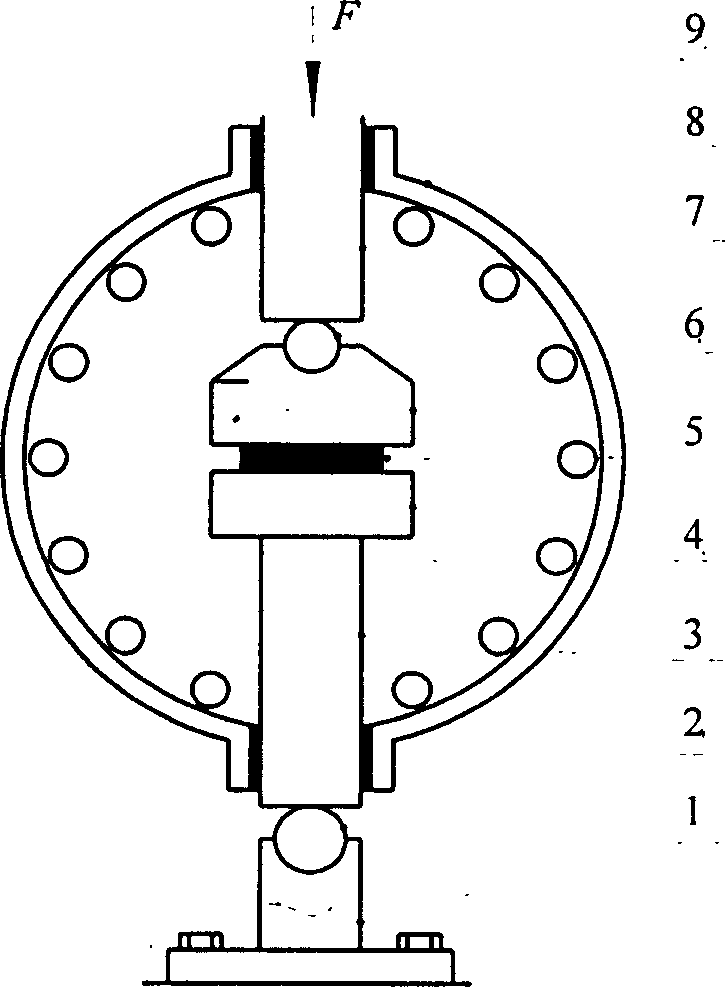

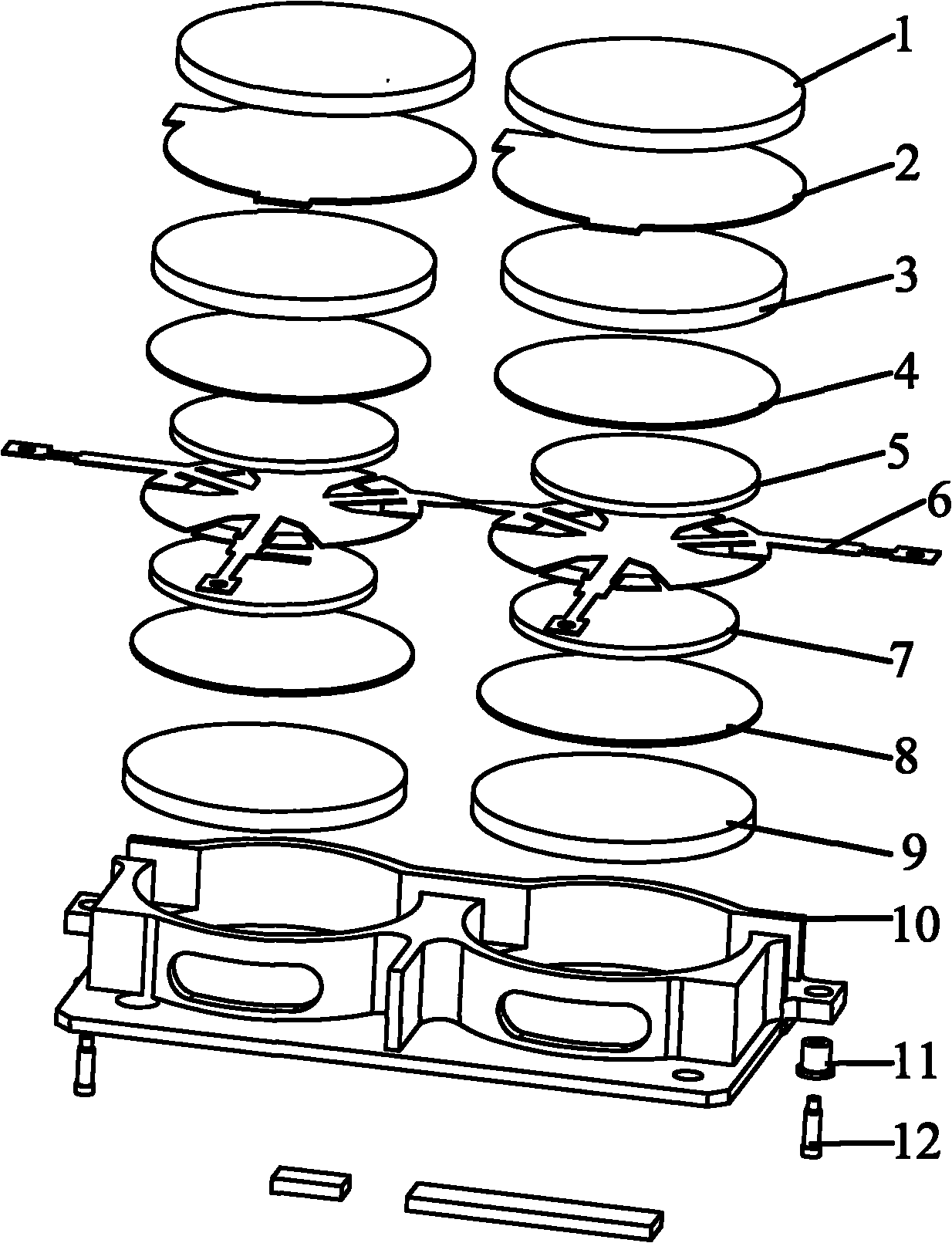

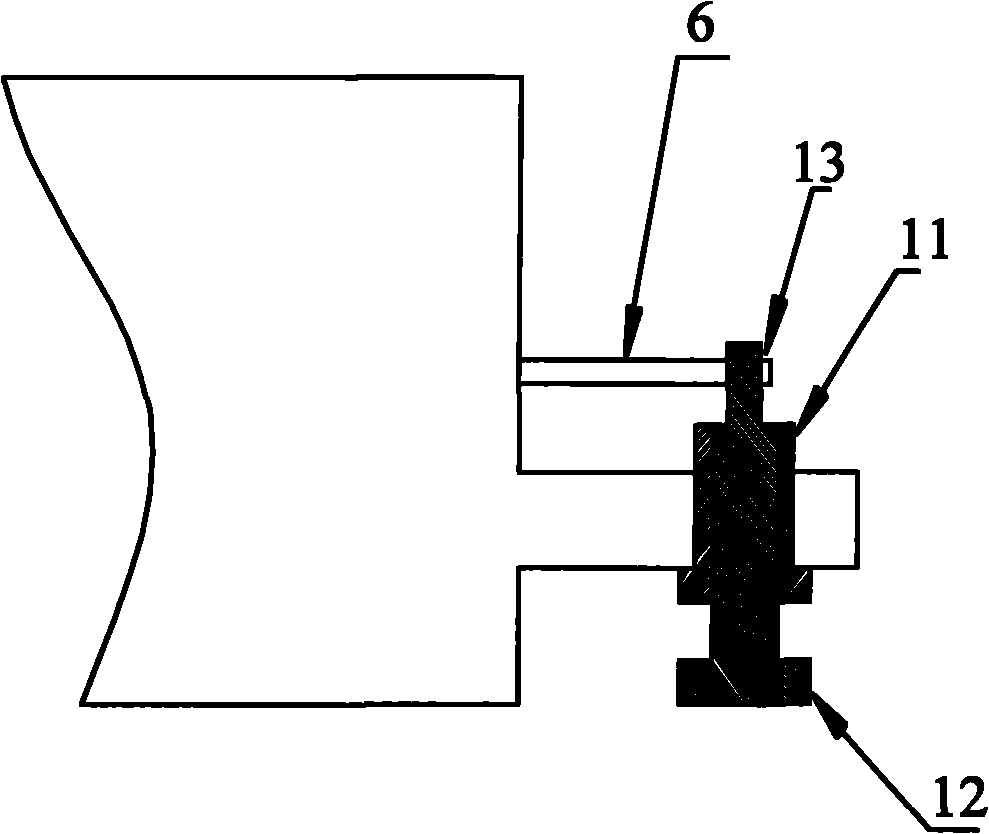

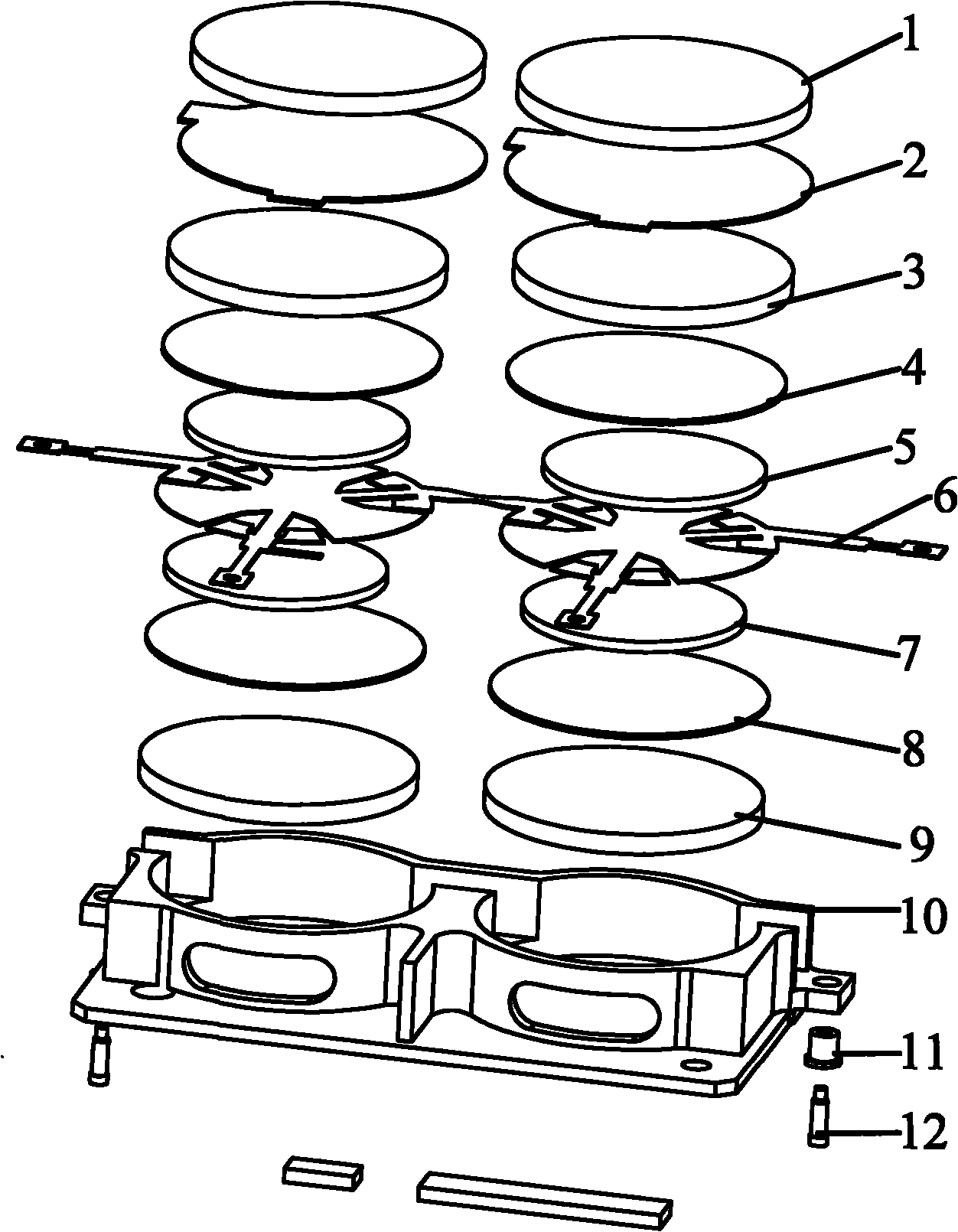

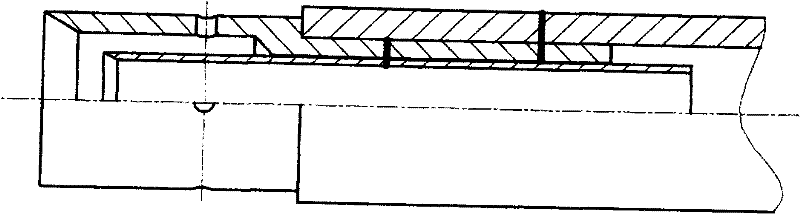

Thermocouple welding clamping device

InactiveCN104668865AImprove welding pass rateReduces weld quality degradationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermocouple

The invention relates to a thermocouple welding clamping device. The thermocouple welding clamping device consists of a base 1, a supporting seat 3, a support 10, a thermocouple clamping component and a carbon rod clamping component, wherein the support 10 is vertically fixed on the base 1 through the supporting seat 3, the supporting seat 3 is fixed on the base 1 through screws 2, the thermocouple clamping component is connected with the base 1, the carbon rod clamping component is vertically and movably connected with the support 10, and the carbon rod clamping component can move on the support 10 so as to adjust the contact distance between the carbon rod 11 on the carbon rod clamping component and a thermocouple welding surface. The problems that the thermocouple welding quality is controlled by human factors, the quality is uncontrollable, the qualified rate is low and the like in the prior art are solved.

Owner:PLA NO 5719 FACTORY

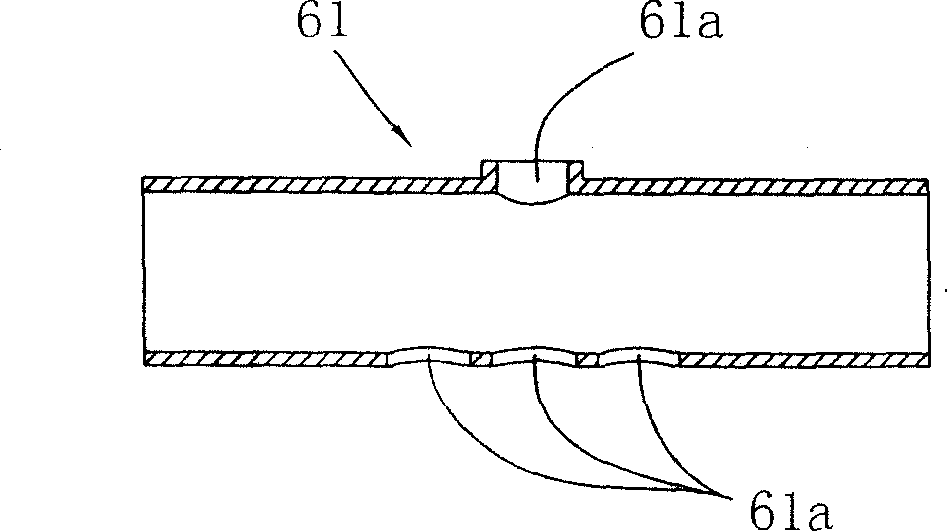

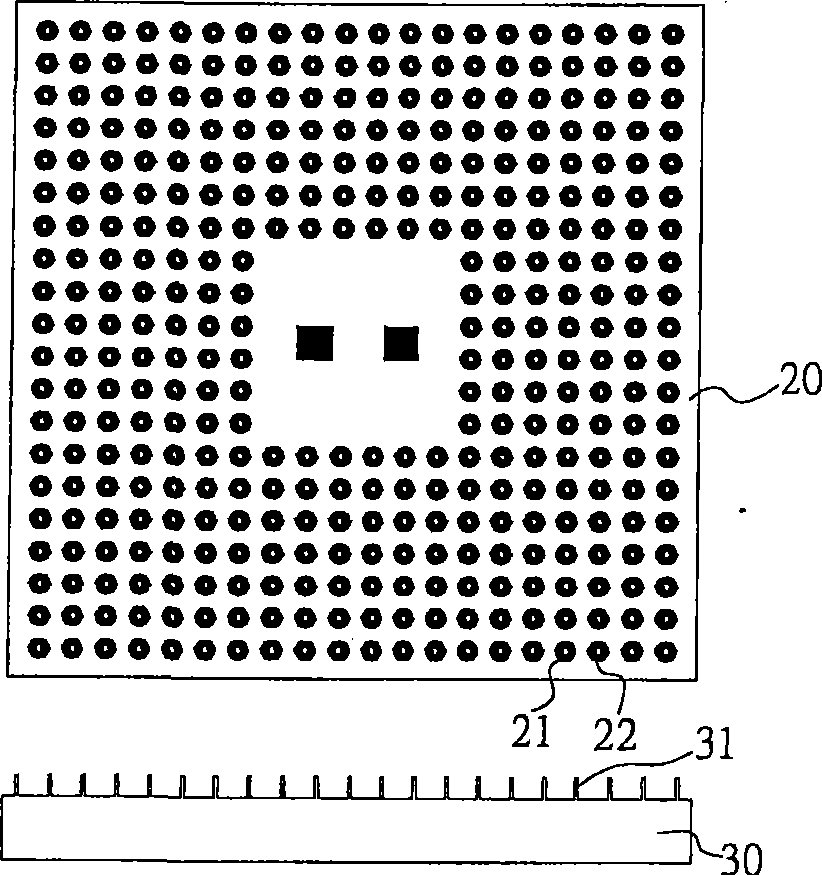

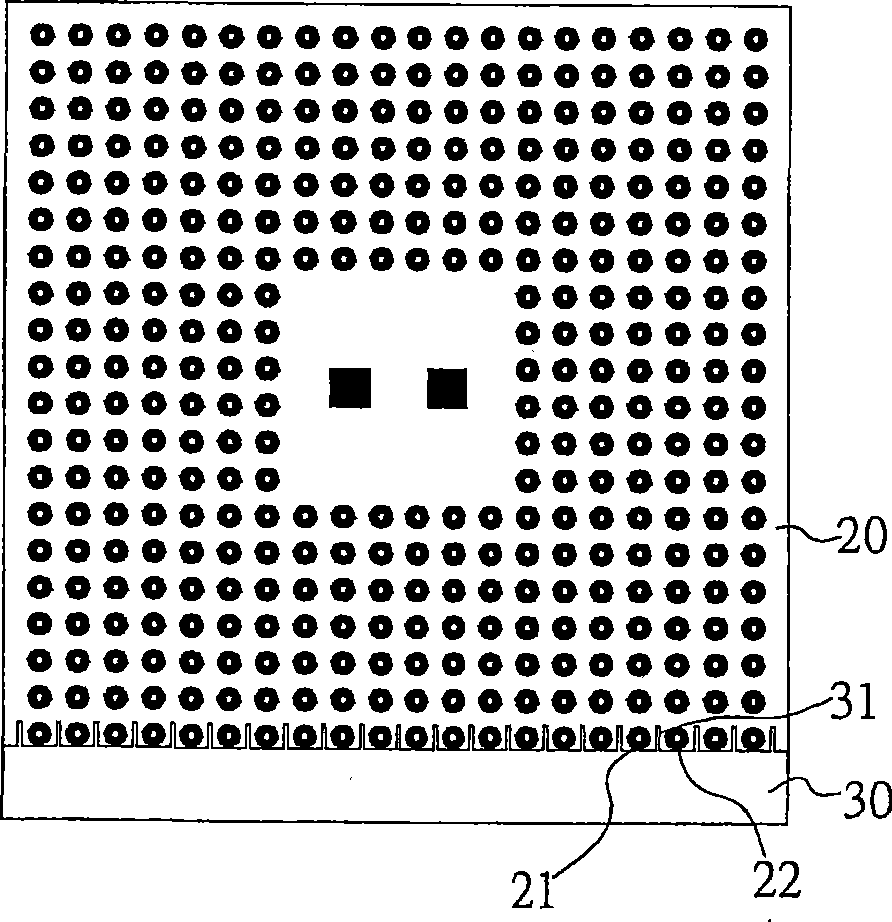

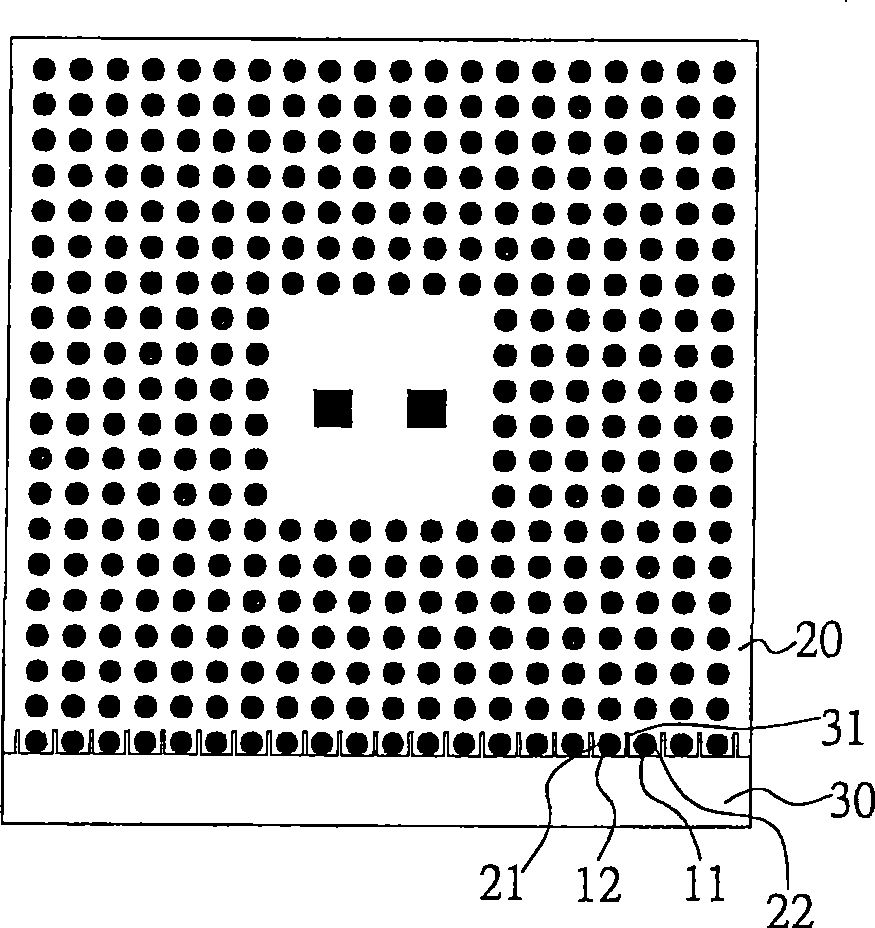

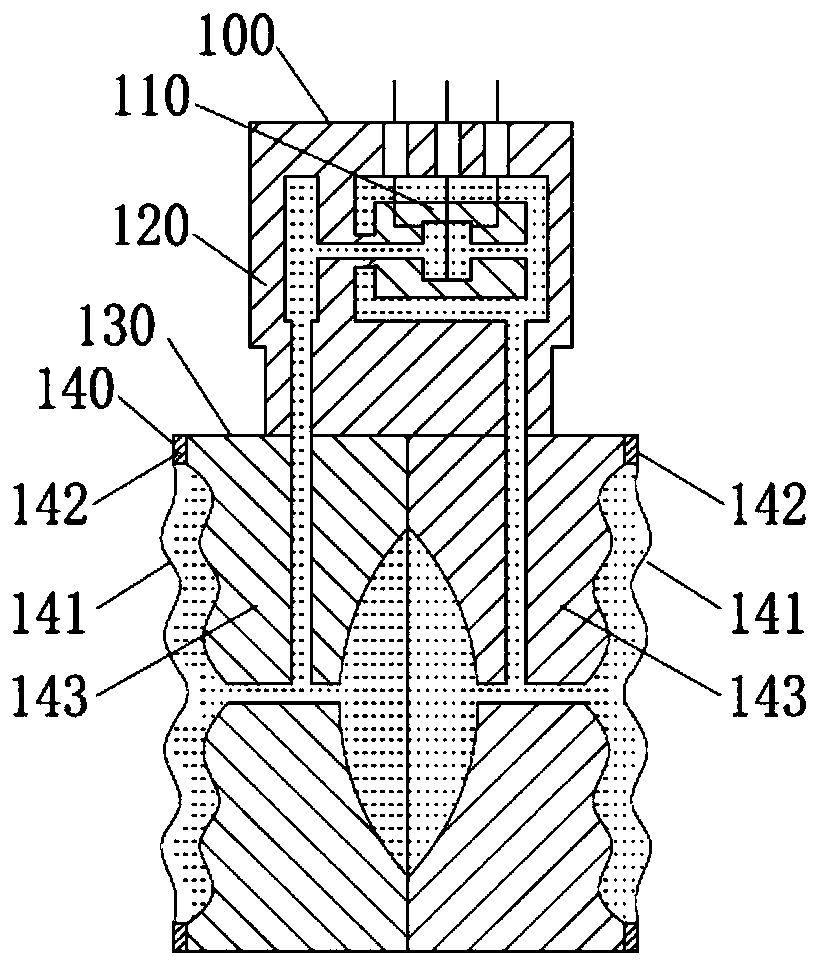

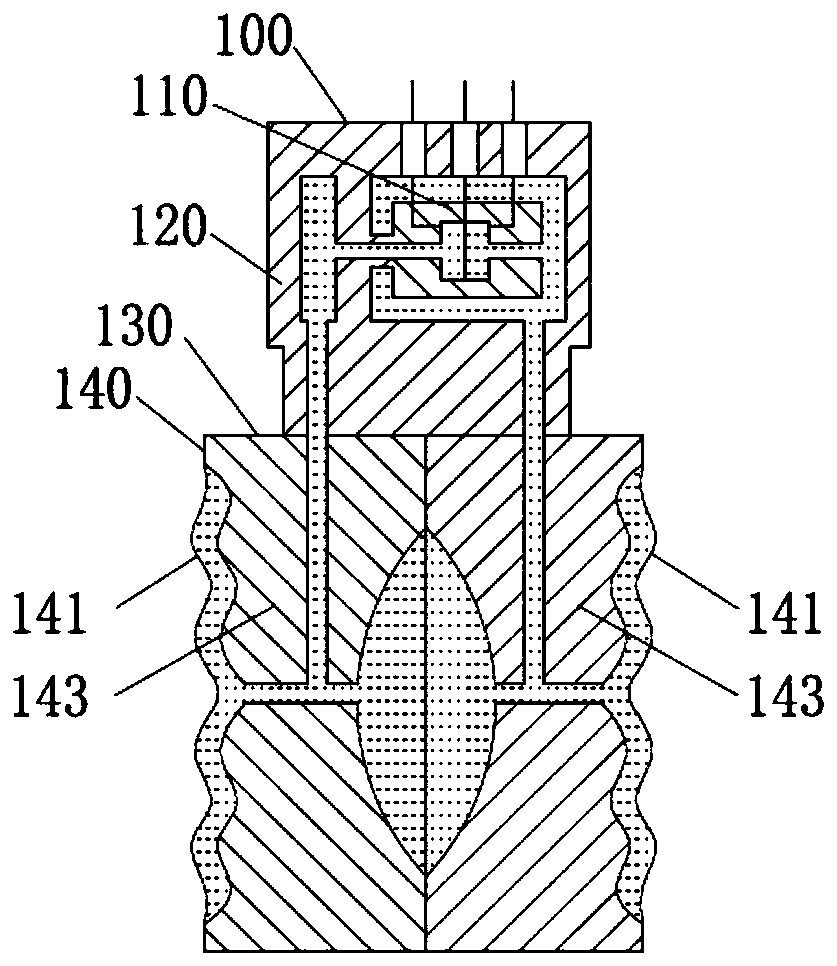

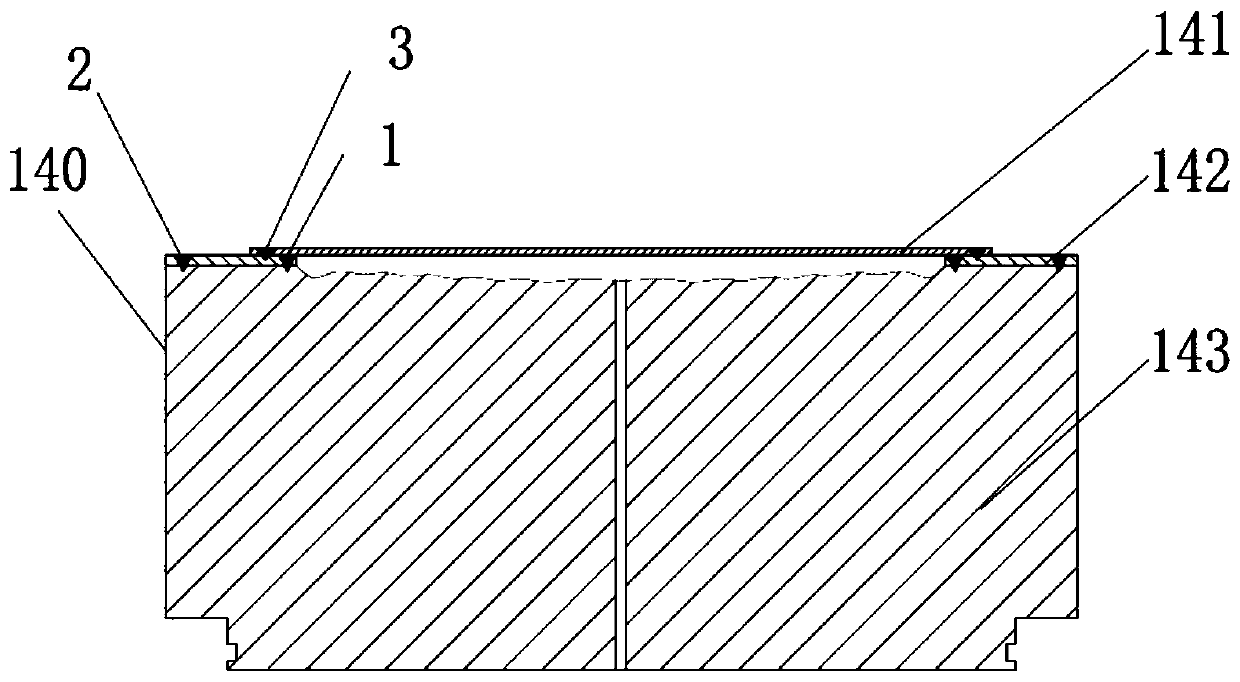

Light source component

ActiveCN108091753AImprove welding pass rateAvoid short circuit problemsSolid-state devicesSemiconductor devicesHeat conductingEngineering

The invention discloses a light source component, which comprises a substrate body and an LED chip, wherein an electrode surface of the LED chip faces the substrate body and comprises an N electrode and a P electrode; a plurality of mounting blocks for arranging the LED chip in a welding manner are formed on the substrate body; each mounting block is a mounting boss which protrudes above a board of the substrate body; a heat-conducting insulating layer covers the substrate body and the surfaces of the mounting blocks; each mounting boss is partitioned into a negative electrode area and a positive electrode area through an isolation groove; a negative electrode lead and a positive electrode lead are printed on the heat-conducting insulating layer; the LED chip is provided with an insulatingwall between the N electrode and the P electrode; and the lower end surface of the insulating wall is laminated with the upper surface of the heat-conducting insulating layer in the isolation grooves. According to the light source component, the welding yield of the LED chip in a relatively small GAP can be ensured, the heat dissipation capability of the component is improved, the stability of the welding process of the LED chip is improved, a short-circuit failure risk caused by mutual overflow infiltration of solder is avoided and the mass production requirements of a high-brightness and high-heat-dissipation light-emitting component can be met.

Owner:YANGZHOU UNIV

Application of electronic spot-welding technology for connecting coil winding lead of chip vibrating electric machine

InactiveCN1658476ACompletely lead-freeReduce manufacturing costWindingsManufacturing dynamo-electric machinesLacquerElectric machine

An application of spot welding technique to the down-lead connection of slice vibrant electrical loop winding, including the welding of the down-lead and double-faced PCB board. This invention does not need welding materials and plumbum; the enamel wire welding does not need pre-removing enamel cover and stannum soaking pre-processing, and reduces the industrial pollution caused by using lacquer removing solution and welding assistant. This invention uses half-mechanization of electronic spot welding machine, avoids the weak points of the hand welding operation, and effectively prevent of bad contact phenomenon. Therefore, this invention not only reduces the cost, but also improves the working efficiency and greatly increases the eligible ratio of the welding.

Owner:程浩川

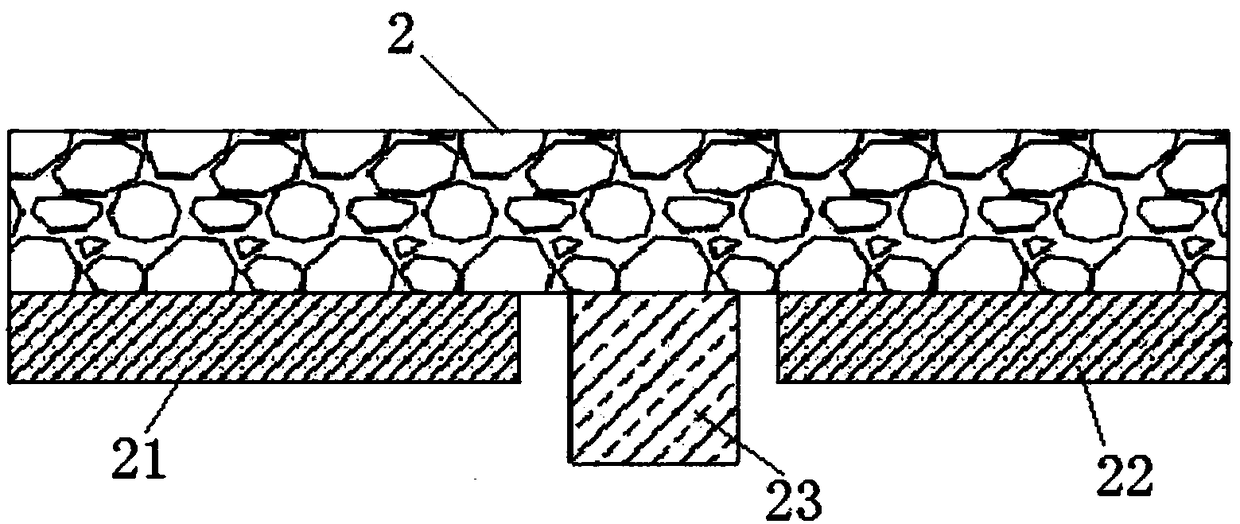

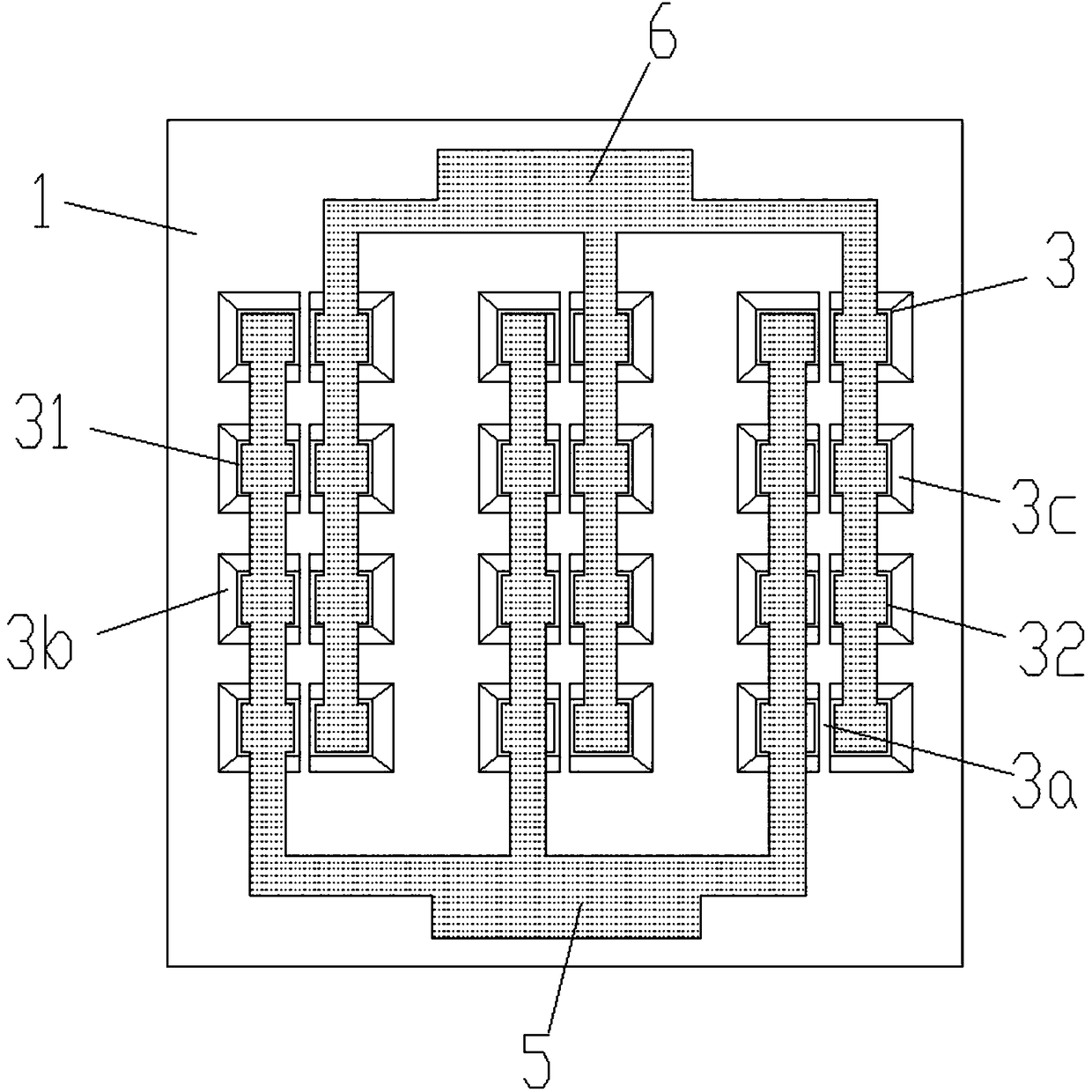

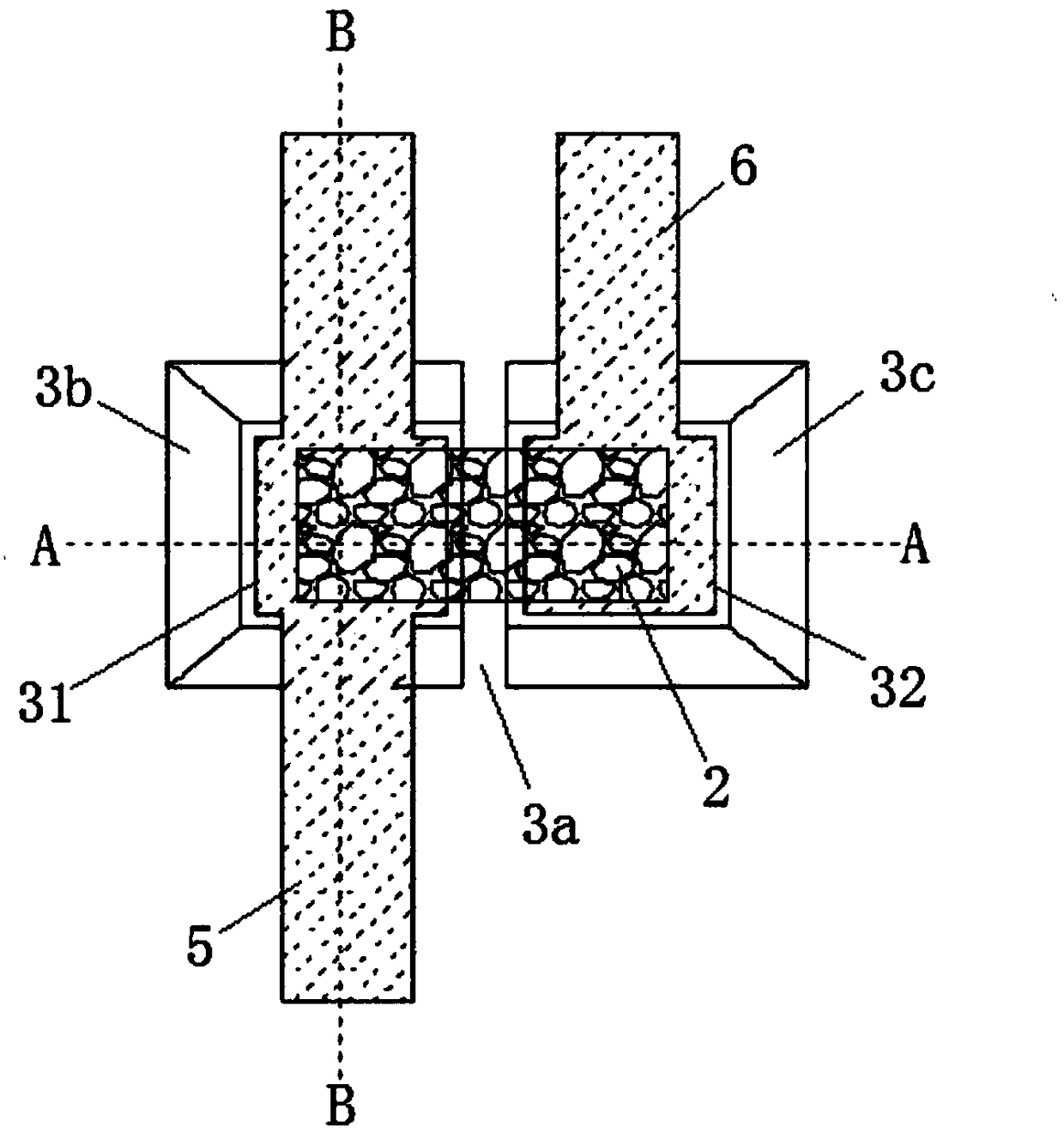

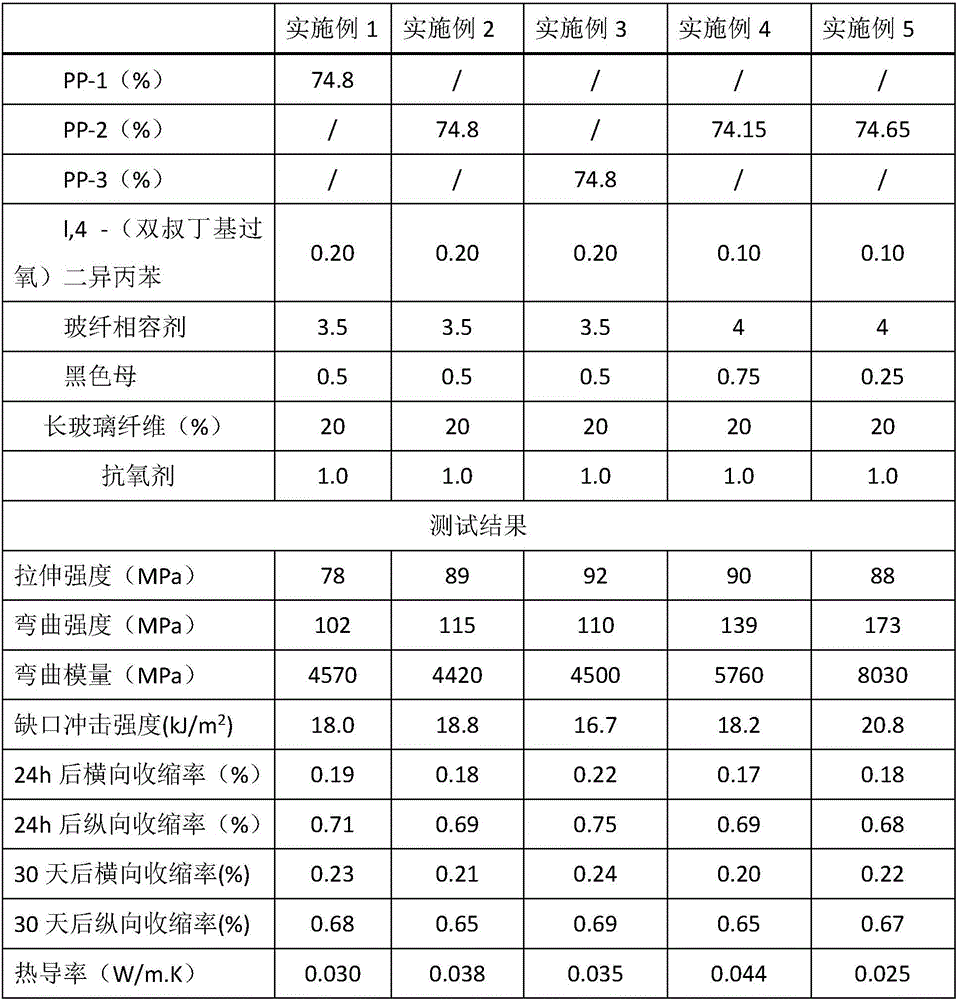

High-weld-strength and low-warpage long-glass-fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN106750969AGood dimensional stabilityGuaranteed lifetimePolypropylene compositesGlass fiber

The invention discloses a high-weld-strength and low-warpage long-glass-fiber reinforced polypropylene composite material and a preparation method thereof. The high-weld-strength and low-warpage long-glass-fiber reinforced polypropylene composite material mainly comprises, by weight, 10-40% of long glass fiber, 60-90% of modified polypropylene resin, 1-8% of a fiberglass compatibilizer PP-g-MAH, 1-5% of an inorganic filler, 0.5-5% of an antioxidant and the like. The high-weld-strength and low-warpage long-glass-fiber reinforced polypropylene composite material has the advantages that through modification of PP (propene polymer) materials, welding yield is increased during process of precision laser welding, high-temperature creep is improved, and life cycle in use of parts is guaranteed; by selection of proper resin materials, common warping in long-glass-fiber reinforced polypropylene composite material is alleviated, parts subjected to injection moulding is high in size stability, and the polypropylene composite material is good in mechanical properties such as good tensile, flexural strength and anti-shock resistance.

Owner:SHANGHAI PRET COMPOSITES +4

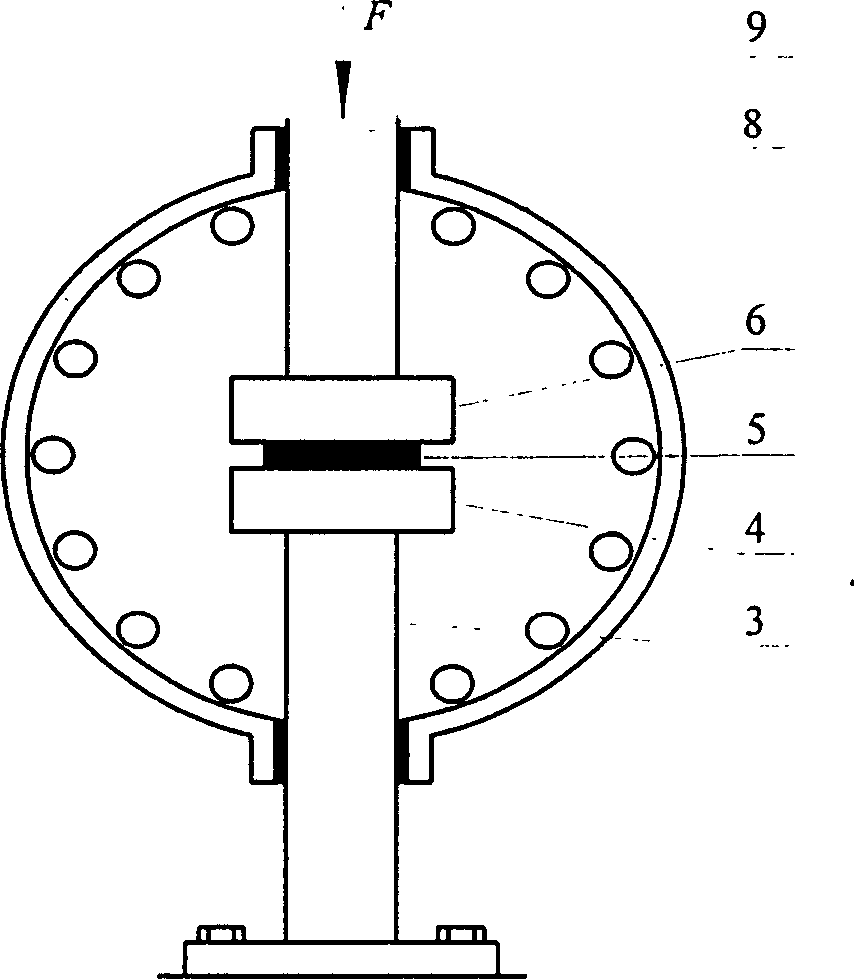

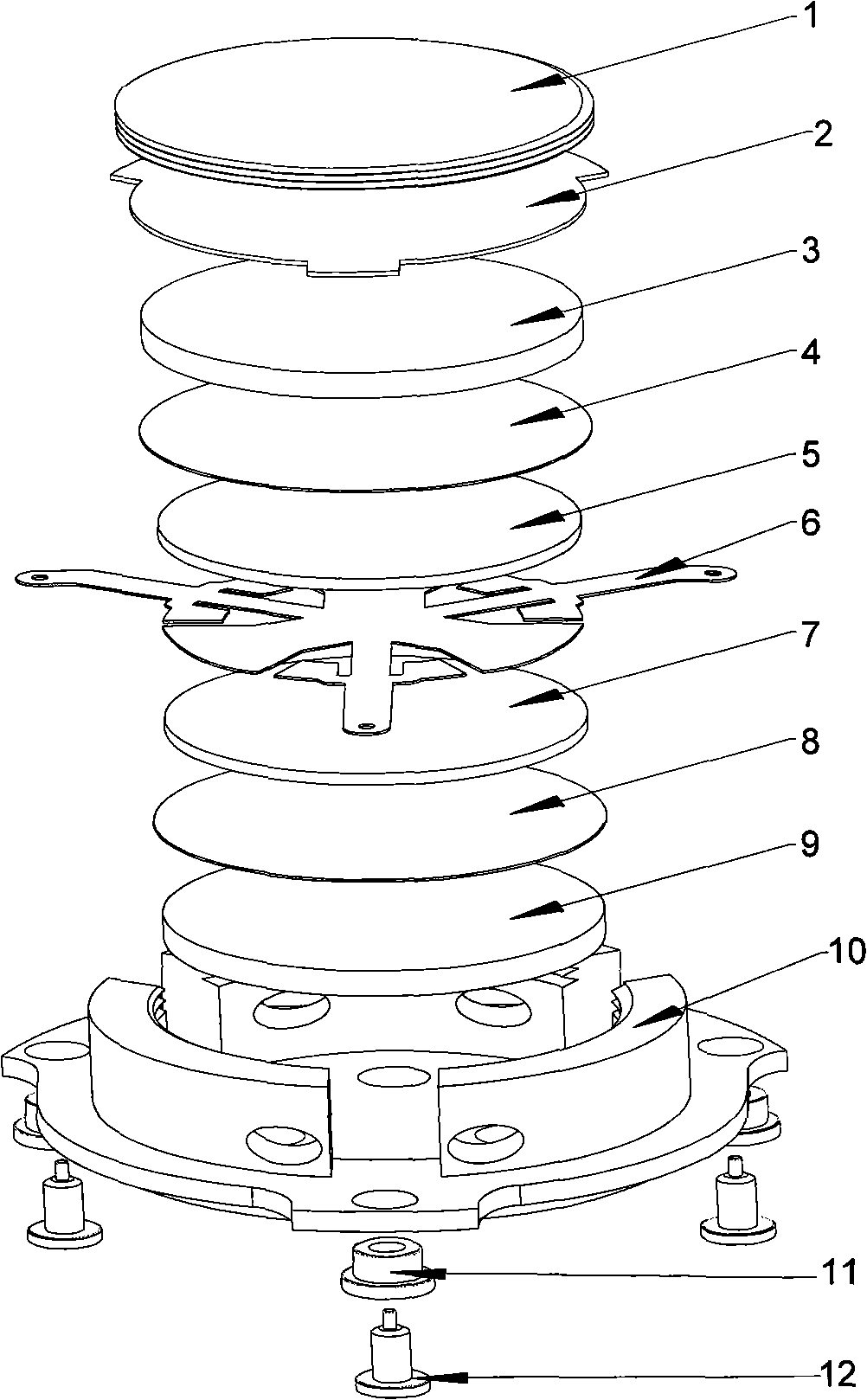

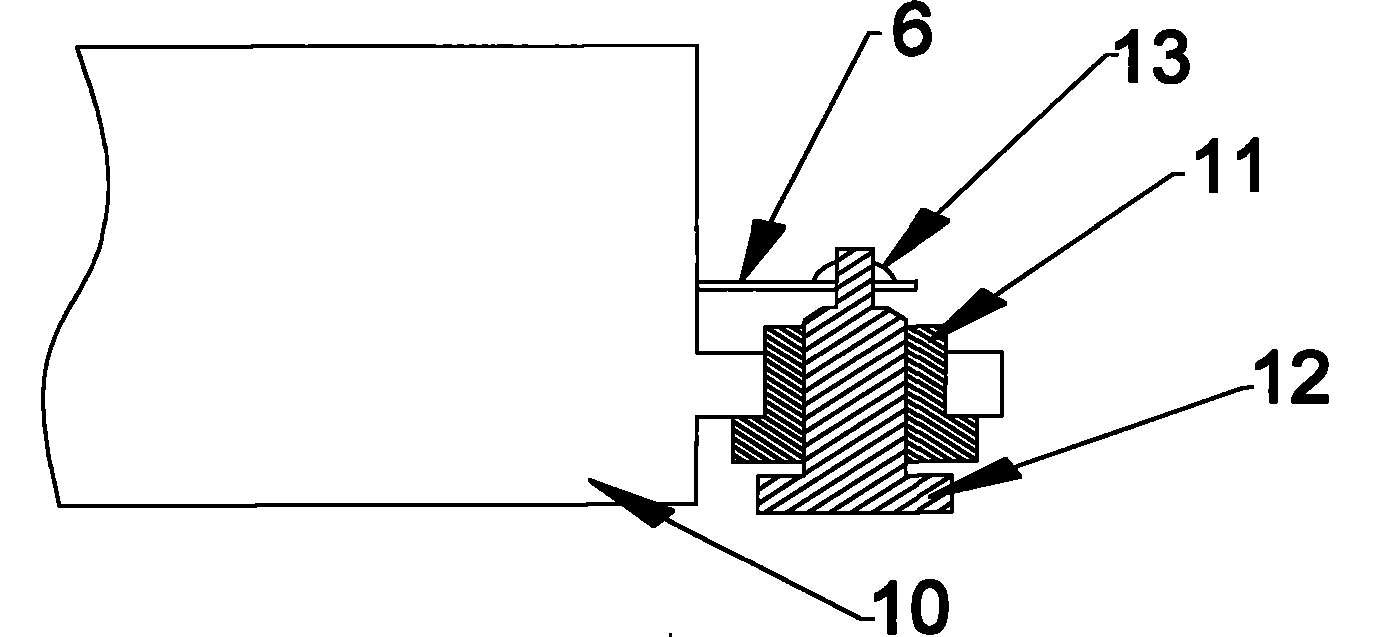

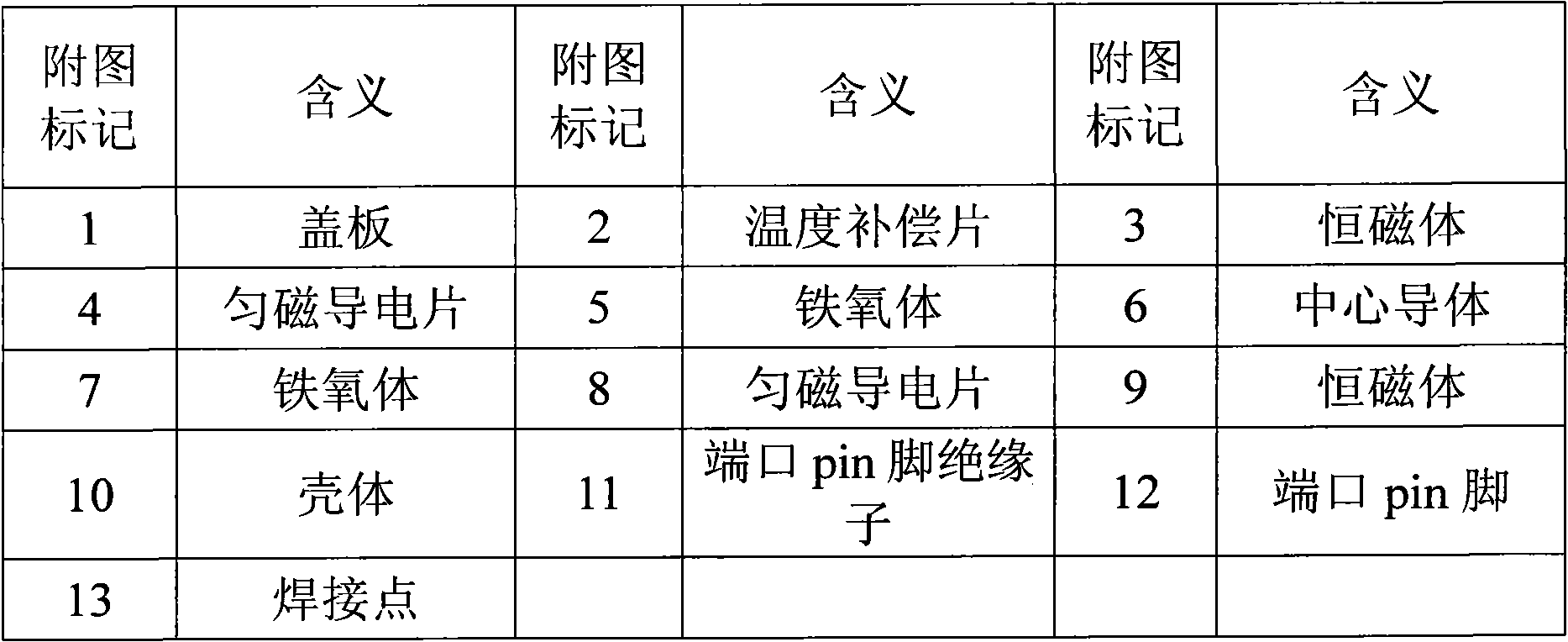

Surface-mounted microwave circulator

InactiveCN104300194AImprove reliabilityImprove welding pass rateWaveguide type devicesEngineeringElectrical conductor

The invention relates to a surface-mounted microwave circulator. The surface-mounted microwave circulator comprises a shell and a cover plate on the shell. The shell is of a semi-open cylindrical cavity structure, the side wall of the shell is provided with three openings, a gasket, a lower ferrite, a center conductor, an upper ferrite, a uniform-magnetism conducting plate, a permanent magnet and a temperature compensation plate are sequentially placed in the semi-open cylindrical cavity of the shell, the center conductor penetrates through the openings in the side wall of the shell to stretch out of the cavity, and columnar connectors are welded to the ends of the center conductor to form columnar connector ports. Through the design and welding installation of the center conductor and the columnar connectors, the flatness of the columnar connectors and the flatness of the bottom of the circulator can be automatically regulated. The single-magnet magnetic circuit structure design is adopted in the permanent magnet of the circulator. On the basis that the performance of a device is not changed by the packaging structure, the reliability of the microwave circulator is obviously improved, and the welding percent of pass is obviously increased. The circulator has the advantages of being small in size, good in performance, large in power handling, wide in temperature range and the like.

Owner:SDP TELECOM SUZHOU

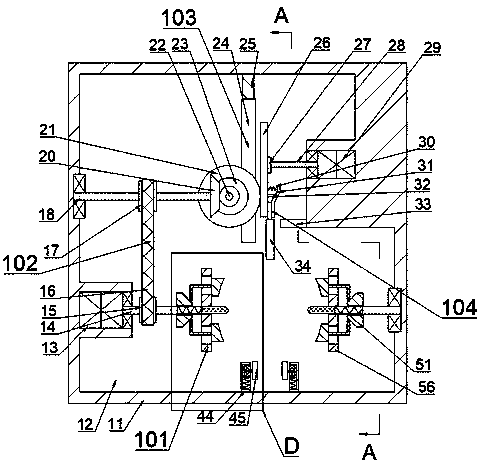

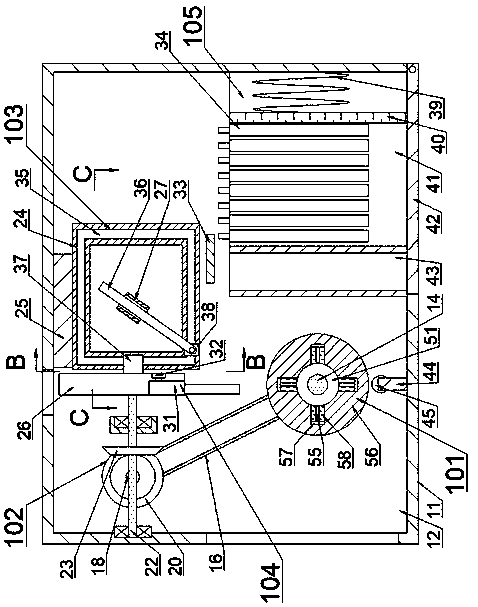

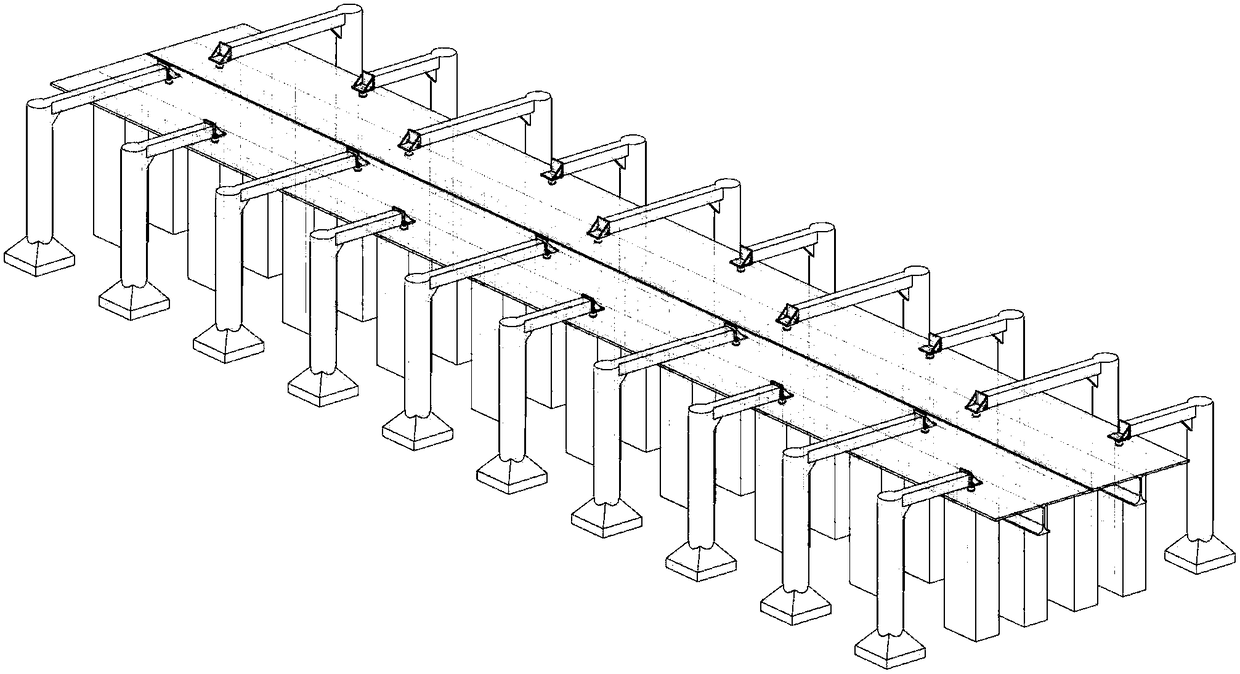

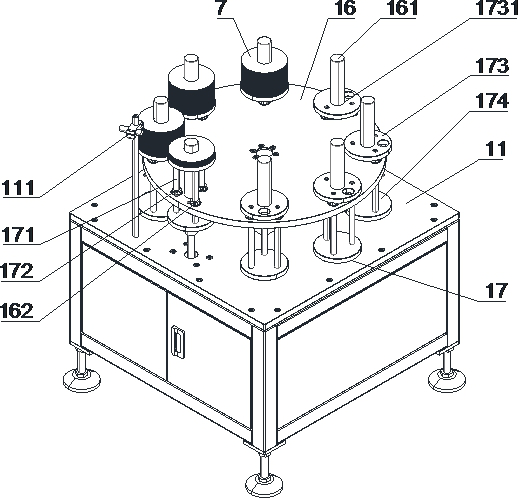

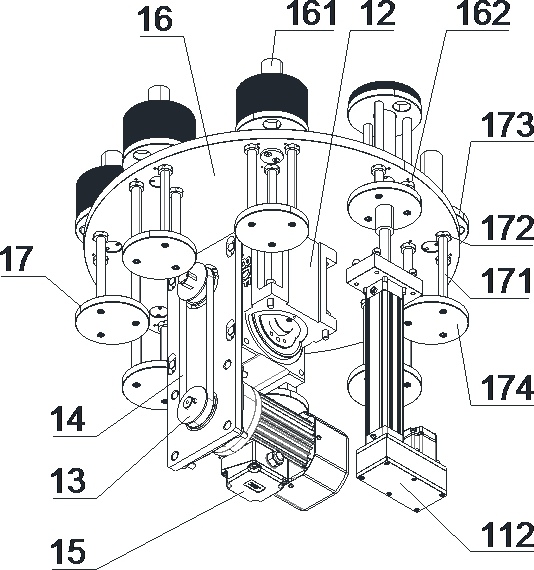

Automatic welding equipment for net rack hollow spheres

InactiveCN110193677AImprove welding pass rateReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentEngineering

The invention discloses automatic welding equipment for net rack hollow spheres. The automatic welding equipment comprises a welding box. The welding box is internally provided with a welding cavity,wherein the welding cavity is opened forwards and downwards. The welding cavity is internally provided with two sphere clamps which are symmetrical in the left-right direction. A welding feeding device is arranged inside the welding cavity, wherein the welding feeding device is located at the left side of the sphere clamps. The welding feeding device is internally provided with a welding rod fixing device. The welding cavity is internally provided with a welding rod replacing device, wherein the welding rod replacing device is located at the rear side of the welding feeding device. A welding rod supply device is arranged inside the welding cavity, wherein the welding rod supply device is located at the lower side of the welding rod replacing device and the rear side of the sphere clamps. According to the automatic welding equipment, by means of a linkage feeding device, the hollow spheres can be driven to rotate, and while, a welding device can be driven to feed downwards for welding;after a welding rod in the welding device is used up, the welding rod can be replaced automatically through the welding rod replacing device; therefore, mechanized welding is adopted, the welding rodcan be replaced automatically, production efficiency is improved, and the sphere welding qualification rate is increased; and meanwhile, the labor intensity of workers is lowered.

Owner:威海鑫瑞焊接设备有限公司

Method for avoiding solder bridge

ActiveCN101489359ANo bridgingImprove welding pass ratePrinted circuit assemblingPass rateEngineering

The present invention relates to a method for avoiding solder bridging. A plurality of insulation strips are respectively placed among a plurality of component holes of printed circuit board to be welded for insulating the adjacent component hole. Then welding is executed so that the component pins placed in the component hole are respectively combined fixedly with the printed circuit board through tin liquor, wherein the tin liquor is obstructed by the insulating strip. Thereby the improper solder bridging of two adjacent welding points on the component pins and component holes with small distance. Furthermore the welding pass rate can be increased and the maintenance cost of product in future is reduced.

Owner:MICRO-STAR INTERNATIONAL +1

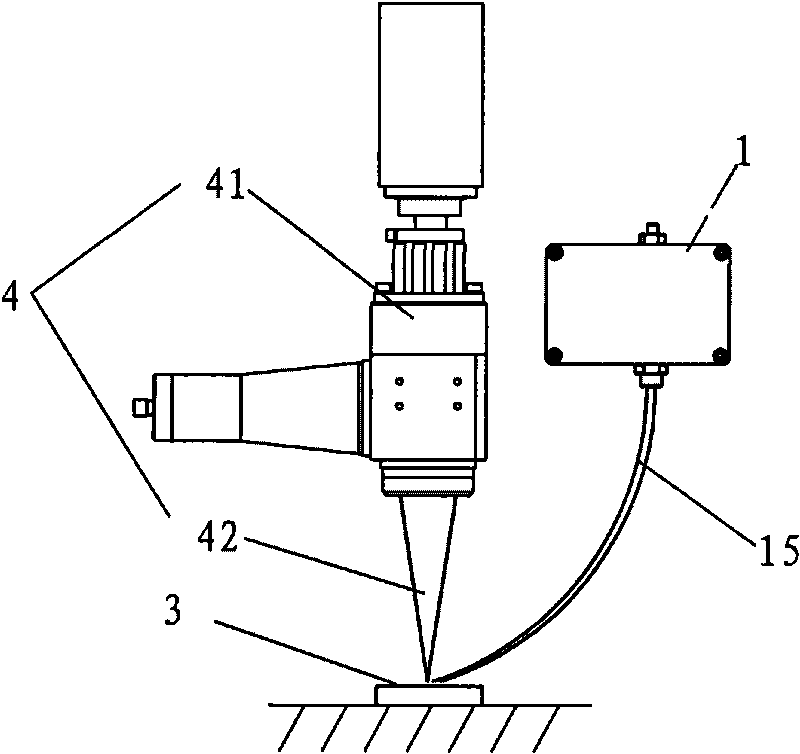

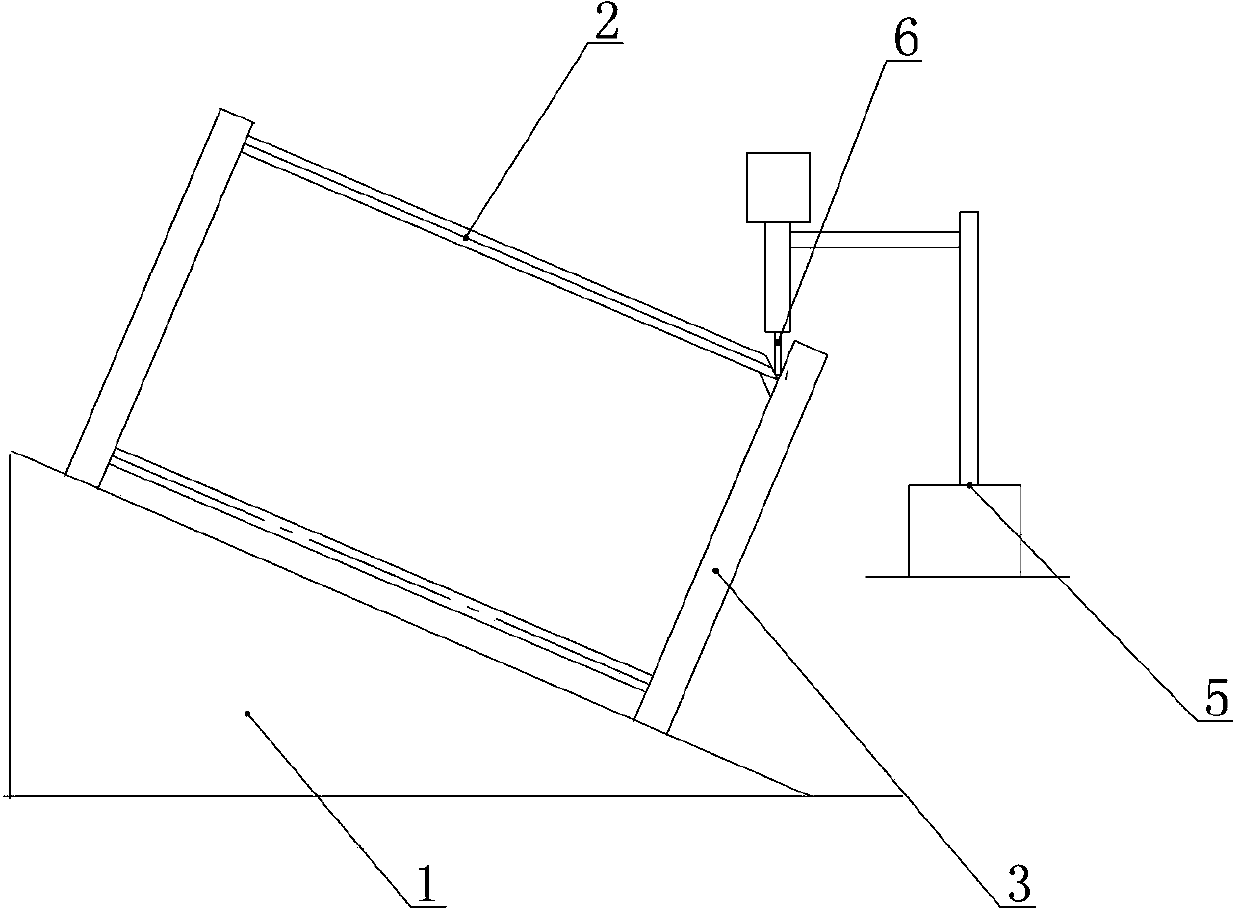

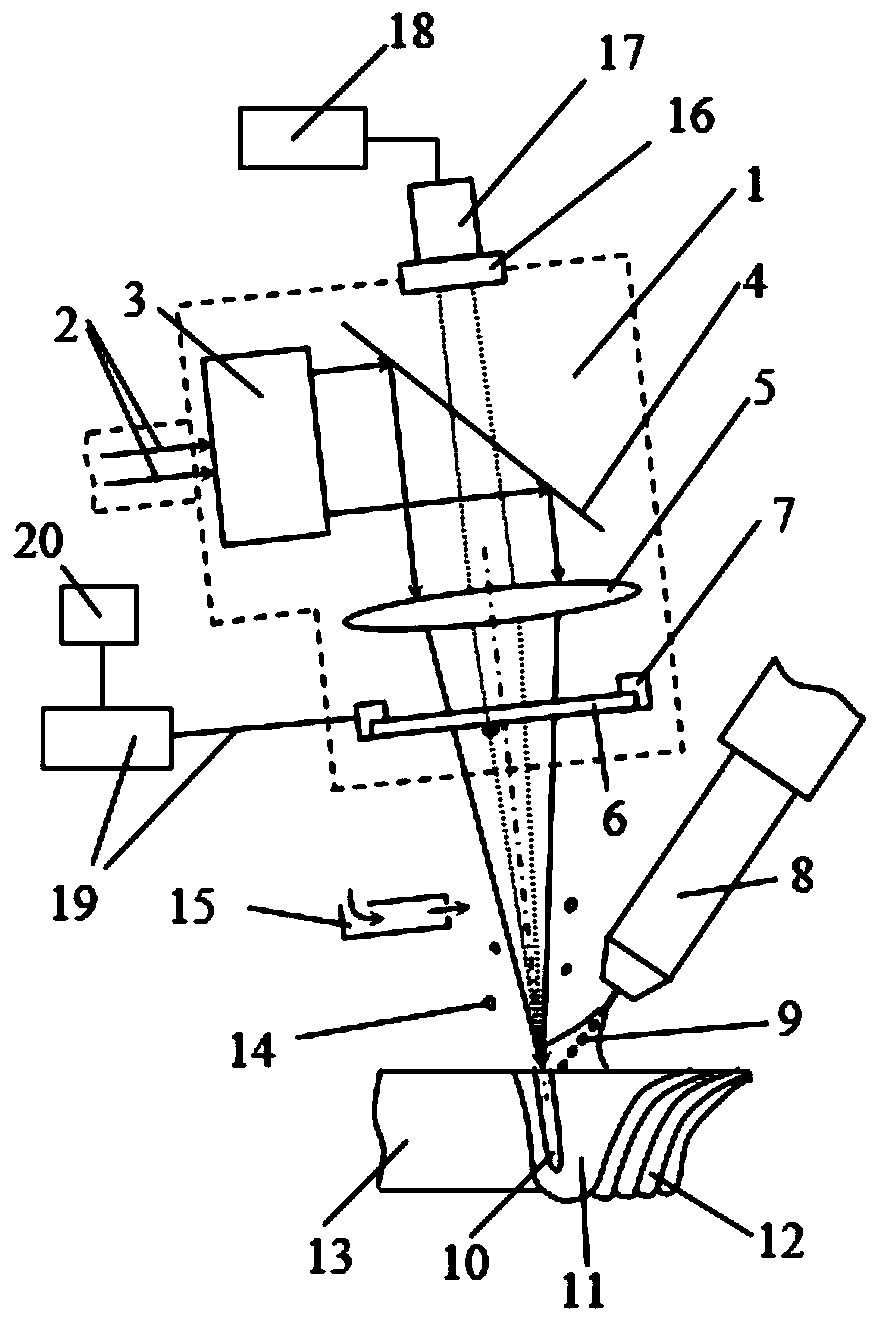

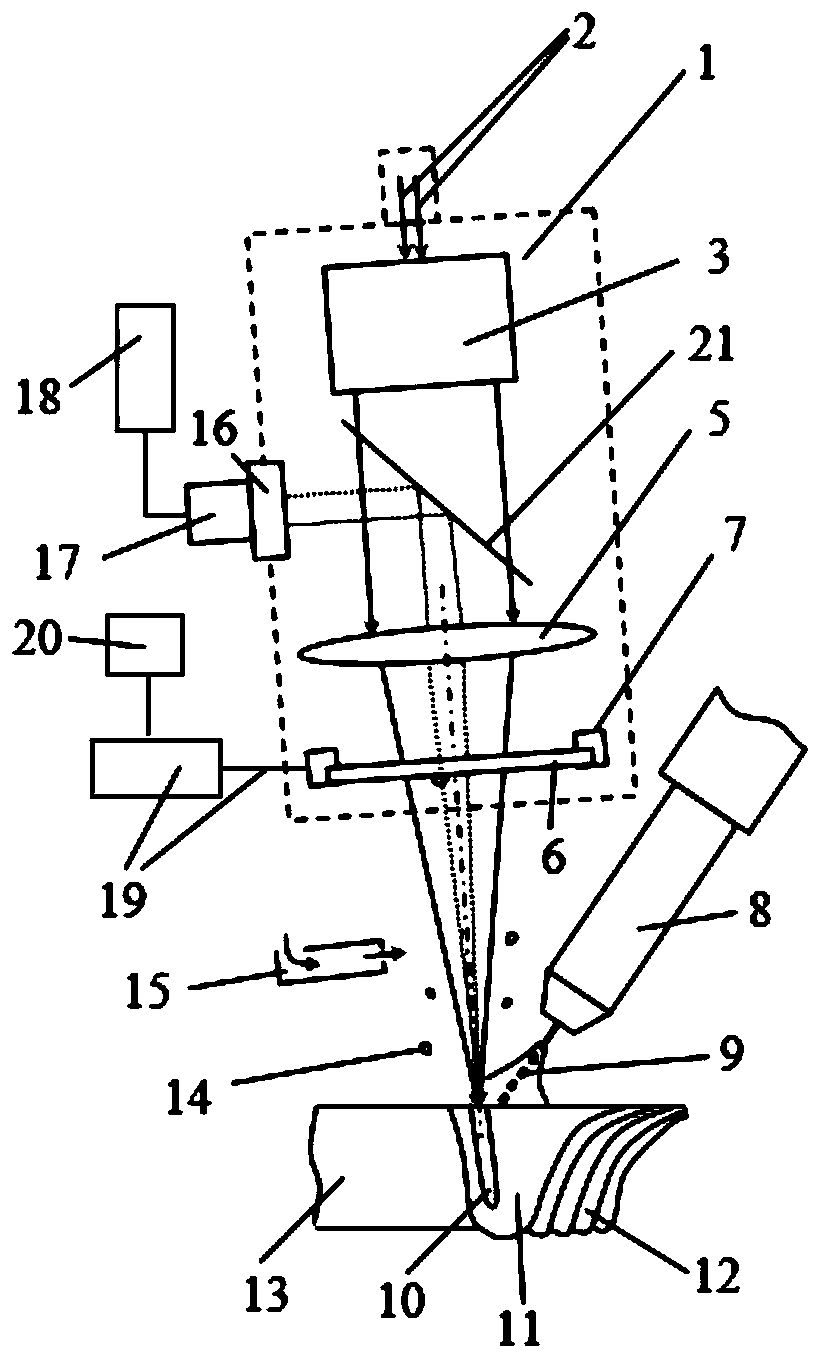

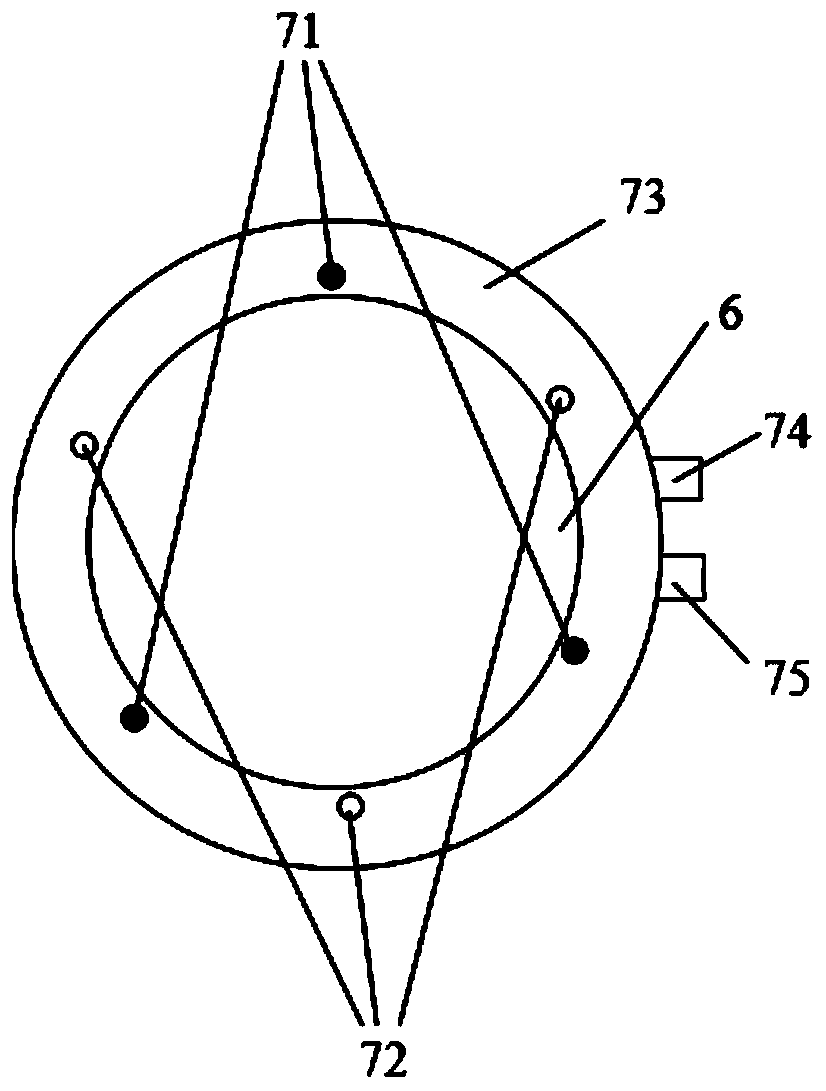

In-situ monitoring device and method for pollution of protective lens for welding laser head

InactiveCN110744213ASolving the conundrum of pollution situationsSolve only before weldingLaser beam welding apparatusEngineeringWelding defect

The invention relates to an in-situ monitoring device and method for pollution of a protective lens for a welding laser head. The in-situ monitoring device comprises the protective lens, a monitoringassembly, a data analysis assembly and an executing terminal; the monitoring assembly is used for monitoring the pollution situation of a laser transmission area on the protective lens; the data analysis assembly is used for calculating the polluted area of the laser transmission area on the protective lens in real time, and the polluted area is compared with a preset threshold value; and when thepolluted area calculated by the data analysis assembly is larger than the preset threshold value, the executing terminal executes a welding interrupt instruction, and the welding laser head stops welding. The welding process of continuous welding defects caused by serious pollution of the protective lens can be stopped in time, subsequent defect elimination and welding continuing are convenient,the obsolescence risk of weldments is lowered to the utmost extent, and the welding pass percentage is further increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Welding and repairing method of heat-resisting steel casting

InactiveCN108856945AReduce carbon increase on siteImprove welding pass rateWelding/cutting auxillary devicesAuxillary welding devicesMartensiteSteel casting

The invention belongs to the technical field of heat-resisting steel welding, particularly relates to a repairing method of a high-chromium martensite heat-resisting steel casting, and provides a welding and repairing method of a novel heat-resisting steel casting. The method comprises the main steps of defect treatment before welding, welding preheating, welding, heating after welding, and heat treatment after welding. By the adoption of the welding and repairing method, generation of weld cracks is reduced, the yield of welding and repairing is increased, the number of times of welding is reduced, and the repairing cost is reduced substantially.

Owner:KOCEL STEEL

Automatic welding method for aluminum alloy thin plates

ActiveCN108544062ALarge residual stressImprove welding effectWelding/cutting auxillary devicesArc welding apparatusButt jointLarge deformation

The invention belongs to the technical field of welding, and relates to an automatic welding method for aluminum alloy thin plates. The automatic welding method comprises the steps of pre-welding preparation for equidistant cutting of the aluminum alloy thin plates, pre-treatment of a groove at the butt joint of the aluminum alloy thin plates, uniform clamping of a hydraulic clamping tool for thealuminum alloy thin plates, welding of the aluminum alloy thin plates after being clamped by the automatic welding method and post-welding shaping of small-scale flame repairing. The problems that inthe prior art, relatively large residual stress is prone to being generated when MIG is adopted to weld the aluminum alloy thin plates, large deformation of the base metal is generated after the completion of the welding, and subsequent shaping can be used for fine-tuning but the result is still not satisfactory are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

Process of manual submerged-arc welding in welding position of doorframe and tower section

InactiveCN101733526AAchieve the effect of submerged arc weldingImprove working environmentArc welding apparatusWelding/soldering/cutting articlesWorking environmentEngineering

The invention discloses a process of manual submerged-arc welding in the welding position of a doorframe and a tower section. The process comprises the following specific operation steps of: embedding a doorframe of a wind tower in a tower cylinder; removing contaminants on the weld surface of the wind tower and a surrounding gas-cut oxidized surface; welding the front doorframe of the wind tower and the outer side of the tower body corner by adopting the automatic submerged-arc welding; and welding the doorframe of the wind tower and the inner side of the tower body corner by adopting the automatic submerged-arc welding again. By adopting a more reasonable welding sequence, the process of the manual submerged-arc welding in the welding position of a doorframe and a tower section does not need the backstep welding or the backstep welding in a small area, thereby achieving the higher qualification rate of the welding; and simultaneously, the invention improves the work environment of welders, enhances the production and work efficiency, shortens the production cycle and lowers the manufacturing cost.

Owner:TITAN (SUZHOU) METAL PROD CO LTD

Parallelism adaptive pressure head of diffusion welding machine and adaptive regulation method of pressure head

InactiveCN1785572AReduce non-parallelismOperation process to reduce non-parallelismNon-electric welding apparatusSteel ballEngineering

A parallelism-adaptive press head of diffusion weld is composed of base, lower press rod with flat lower end, lower press head, upper press rod with flat lower end, upper press head, steel ball arranged between base and lower press rod, and ceramic ball arranged between upper press head and upper press rod. Its adaptive regulation method is also disclosed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

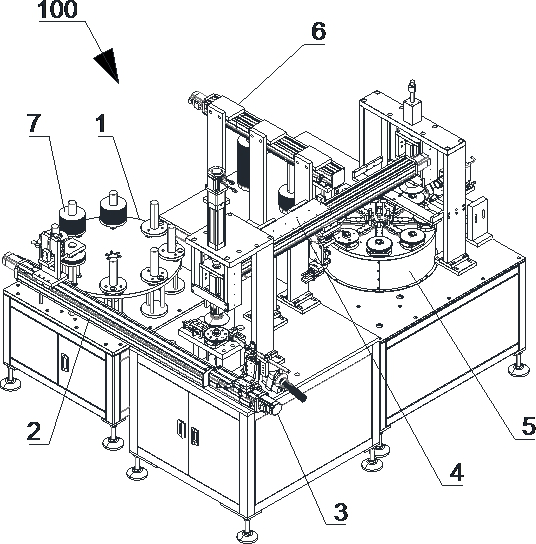

Automatic armature sheet welding equipment

ActiveCN112809240AImprove welding pass ratePrevent welding failureWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSoldering gun

The invention discloses automatic armature sheet welding equipment which comprises an automatic welding mechanism. The automatic welding mechanism comprises a positioning assembly, a rotary pressing assembly and a welding assembly; the welding assembly is arranged at one end of the positioning assembly; the rotary pressing assembly is arranged on one side of the positioning assembly; the positioning assembly comprises a positioning seat, a bearing seat installed on the positioning seat, and a welding supporting seat rotatably installed on the bearing seat; a limiting column is arranged on the welding supporting seat; a clamping groove is formed in the limiting column; the rotary pressing assembly comprises a servo motor capable of sliding and a rotary pressing block fixedly installed on an output shaft of the servo motor; the rotary pressing block is arranged over the welding supporting seat; the lower surface of the rotary pressing block is provided with a limiting groove matched with the limiting column; a clamping block matched with the clamping groove is arranged in the limiting groove; the welding assembly comprises a welding gun; and the welding gun is arranged right opposite to the welding supporting seat. The automatic armature sheet welding equipment provided by the invention can prevent an armature sheet from sliding, so that the welding qualification rate is increased.

Owner:常州金岛机电有限公司

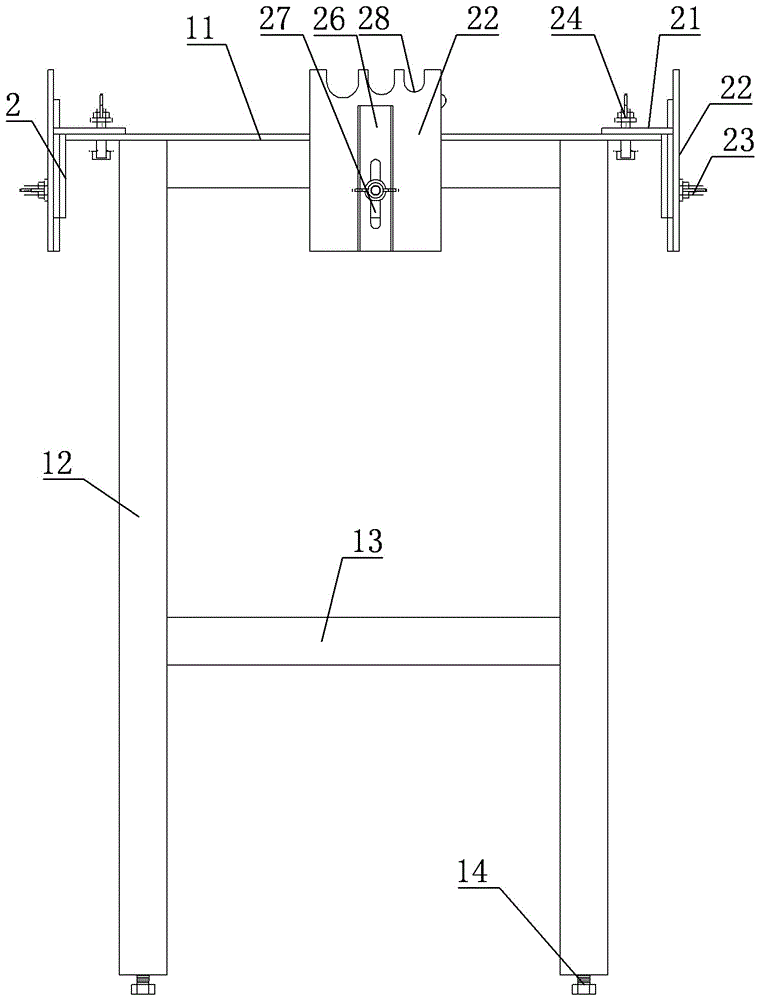

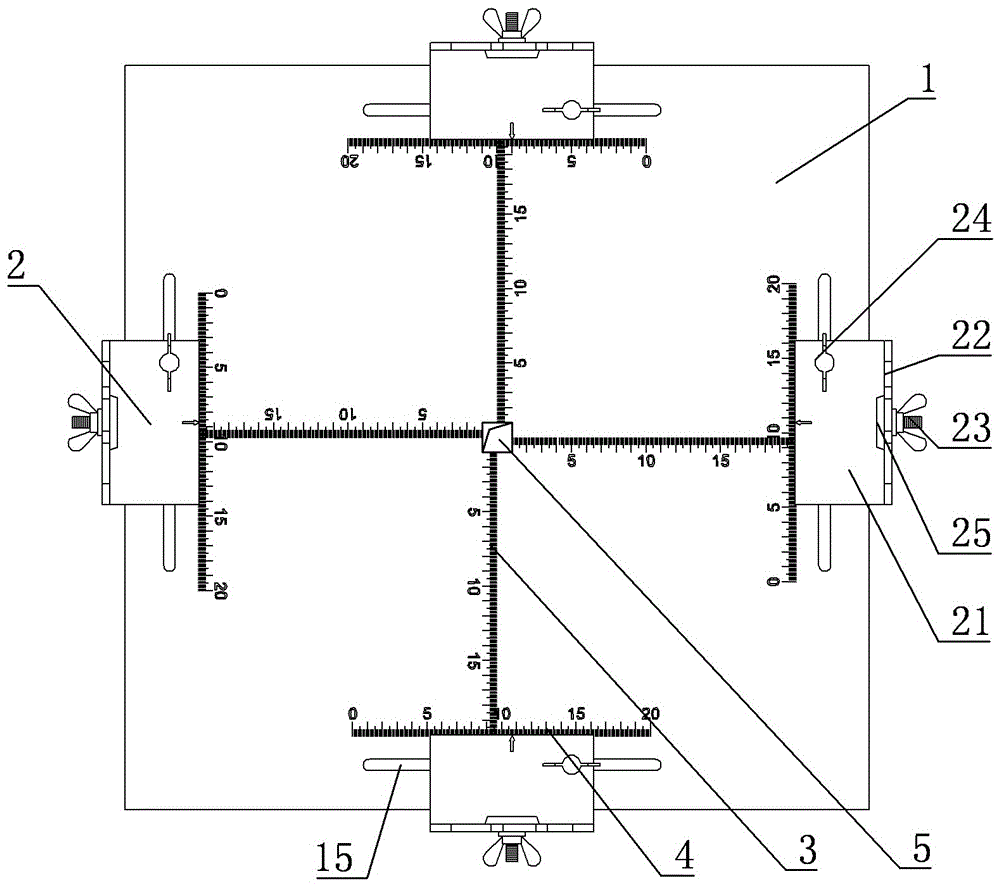

Electric wire tube welding operation platform

InactiveCN105666016ALow costEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterials processing

The invention discloses an electric wire tube welding operation platform and belongs to the field of electric installation tools. The electric wire tube welding operation platform comprises an operation platform frame body, wherein wire tube fixing and adjusting devices are symmetrically arranged on four edges of the operation platform frame body; auxiliary graduated rules symmetric along the center of a platform surface are arranged on the platform surface of the operation platform frame body; transverse graduated rules are arranged at the front parts of the wire tube fixing and adjusting devices and perpendicular to the auxiliary graduated rules; a 10X10mm reserved hole is formed in the center of the platform surface of the operation platform frame body; and a wiring box fixer is arranged on the reserved hole. The electric wire tube welding operation platform has the characteristics of being low in cost, easy for manufacturing and convenient to carry; a crossover ground wire between a welded steel tube and a wiring box can be prefabricated in a material processing region; the positioning is quick and accurate; and the welding qualification rate is high.

Owner:THE CONSTR DECORATION OF CHINA CONSTR NO 7 ENG BUREAU

Method for repairing ship cylinder end through TIG welding

InactiveCN108723556AImprove welding pass rateEasy to operateArc welding apparatusEngineeringCleansing Agents

The invention discloses a method for repairing a ship cylinder end through TIG welding. The method comprises the following steps that (1) a welding material is manufactured according to one of following methods, specifically, a body piston ring corresponding to a welded workpiece is selected and cut into small pieces as required to be used as the welding material after being degreased through a metal cleaning agent, or a casting iron welding rod CHC408 is selected, a coating is removed, and a flux core is used as the welding material; (2) the surface of the welded workpiece is treated, specifically, a to-be-repaired welded workpiece is detected, a welding repair position is determined, the welded workpiece is subjected to ultrasonic cleaning, the to-be-welded position is cleaned through grinding, new parent metal is exposed, and welding repair is instantly conducted after drying; and (3) welding repair is conducted, specifically, a TIG direct current welding method is selected, argon shielded welding parallel welding is adopted, and leftward welding is conducted. Through the method, welding is easy, the welding yield is high, fusion degree is high, the reuse rate of the cylinder end can be increased, and capital and time for recast are reduced.

Owner:广州文冲船舶修造有限公司

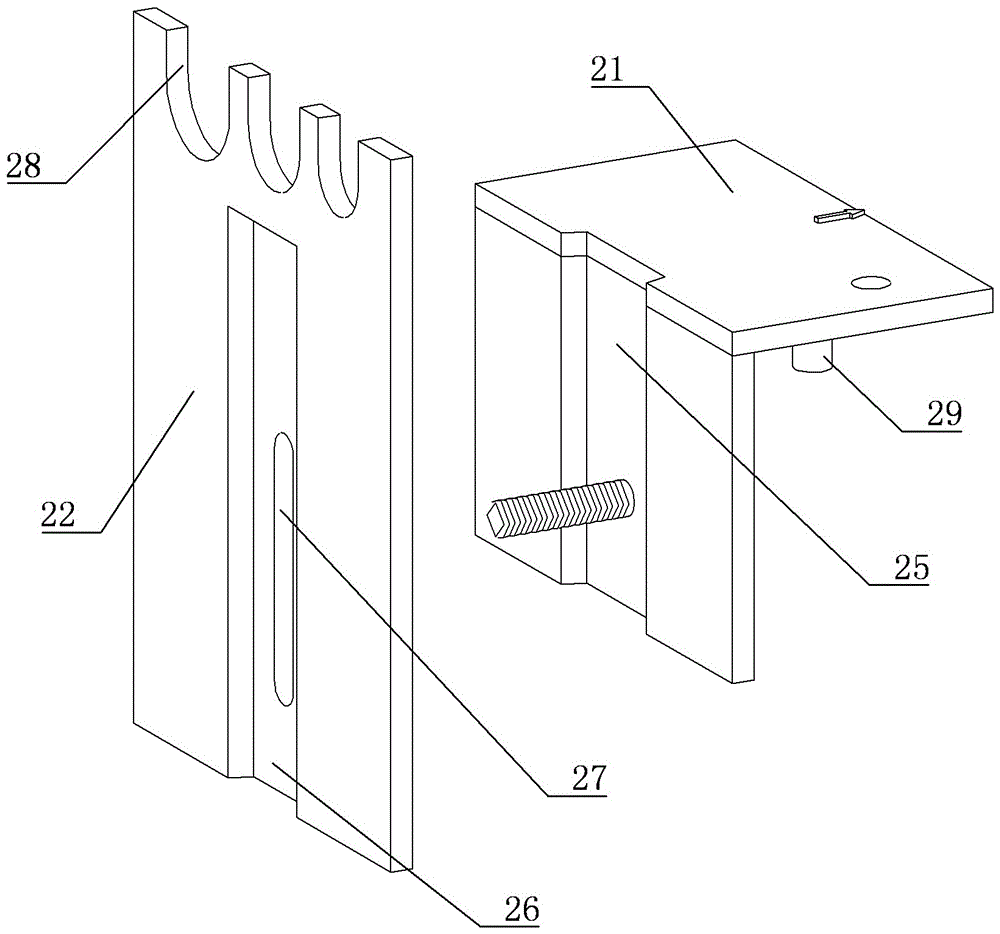

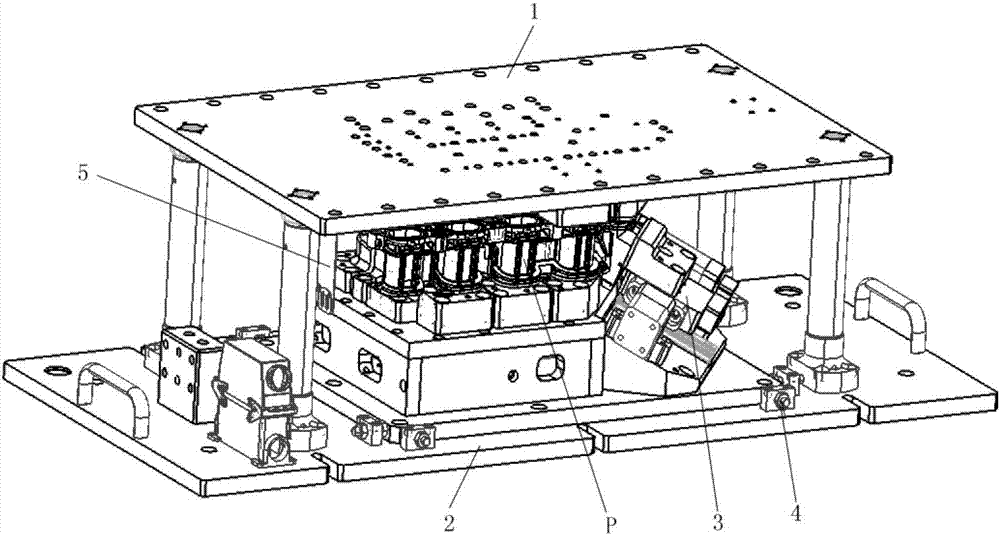

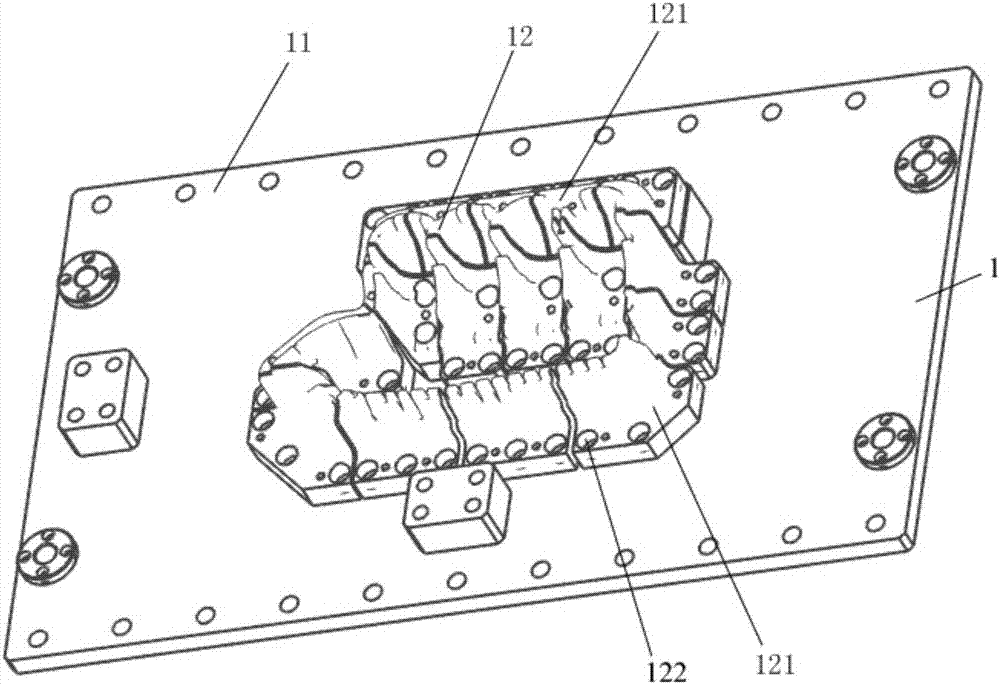

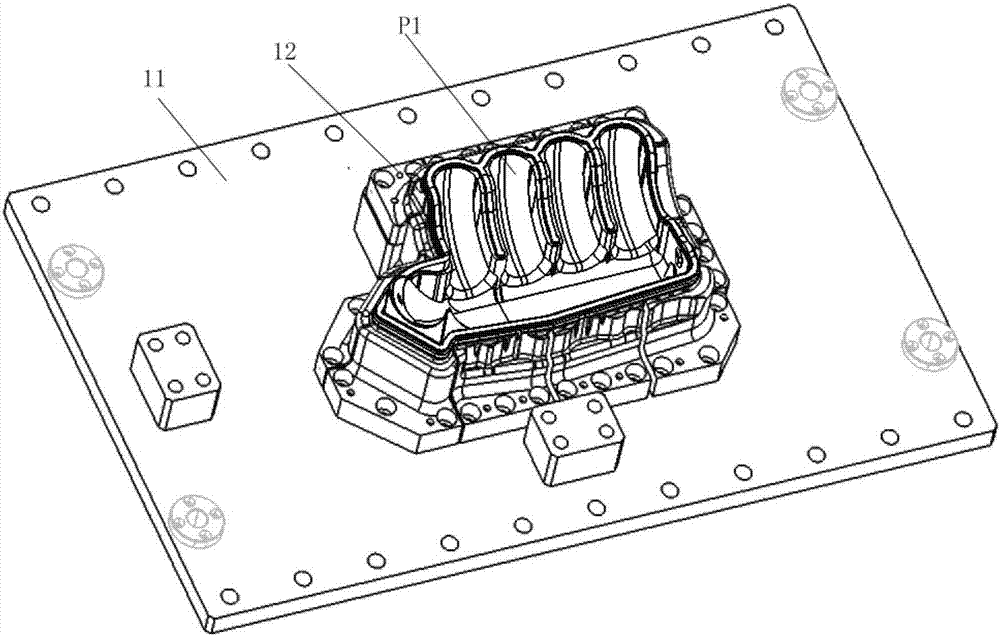

Vibration friction welding jig of sliced plastic air intake manifold

InactiveCN106945290AImprove welding strengthImprove welding reliabilityDomestic articlesFriction weldingPass rate

The invention relates to a piece-type plastic intake manifold vibration friction welding jig, which includes an upper jig and a lower jig. The upper jig includes an upper mounting plate and an upper profile that matches the profile of the upper half of the intake manifold. The support positioning assembly, the upper contour support positioning assembly is composed of a plurality of small support positioning blocks Ⅰ; the lower fixture includes the lower mounting plate, the bottom plate, the base and the lower contour support positioning assembly that matches the contour of the lower half of the intake manifold , the lower contour support and positioning component is composed of a plurality of small support positioning blocks II assembled; the bottom plate is also provided with a hole positioning device, the hole positioning device includes a position mounting seat, a displacement cylinder, a positioning cylinder, a slideway, a slider and a positioning device. Semi-circular support block for fixing intake manifold holes. The contour support and positioning components on the upper and lower fixtures of the present invention are composed of a plurality of small support positioning blocks, which can be fine-tuned according to the product contour, so that the welding strength and reliability of the intake manifold are higher, and the Welding pass rate.

Owner:柳州日高滤清器有限责任公司

Novel surface mount-type microwave isolator

InactiveCN101777681AMake electrical connectionsPractical craftWaveguide type devicesMicrowaveElectrical conductor

The invention relates to a surface mount-type microwave isolator, wherein a casing thereof is formed with a half-opened cylindrical cavity body and is provided with a port at the sidewall thereof, a lug boss which is provided with a through hole is arranged at the position, opposite to the port, on the sidewall of the casing; the half-opened cylindrical cavity body of the casing is internally provided with a permanent magnet, a uniform magnet conducting chip, a ferrite, a central conductor and a temperature compensation plate, and is also covered by a cover board, the central conductor passes through the port on the sidewall of the casing to stretch out of the cavity body; a port pin insulator is installed in the through hole of the lug boss at the sidewall of the casing, and a port pin is installed in the port pin insulator and is electrically connected with the central conductor. Due to the tight fit between the port pin insulator and the through hole of the lug boss as well as between the port pin and the port pin insulator, the central conductor is welded with the port pin so that the size and the position of the port pin are quite firm and stable, thereby obviously enhancing the reliability of the isolator on the basis of not changing the performance of devices, in addition, the surface mount-type microwave isolator is easy for large-scale production.

Owner:SDP TELECOM SUZHOU

Automatic welding method for small-diameter thin-wall multi-layer pipe

InactiveCN102451947AMany adjustable parametersSmall heat affected zoneArc welding apparatusThin walledElectric arc

The invention relates to an automatic welding method for a small-diameter thin-wall multi-layer pipe, which adopts automatic suspended arc welding (i.e. inert-gas arc welding). The automatic welding method comprises the following steps: by using pure tungsten or activated tungsten as an electrode, carrying out arc welding under the protection of inert gas; generating an arc between the end part of the tungsten electrode and a welded base material so as to carry out welding; and introducing argon gas for protection into the cavities of parts in the welding process, wherein the effective welding thickness is 0.7-1.1 millimeters; the effective welding length is 12-14 millimeters; the welding quality of the whole process can be ensured by dividing the whole welding process and adjusting the relevant parameter value of each section; the welding parameters are as follows: a positive rotation mode is adopted; the striking current is 9-11A, and the arc extinguishing current is 5-7A; the climbing time is 0.4-0.6 second, and the descending time is 2-3 seconds; and the welding process is divided into five sections. The invention has the following advantages: the automatic suspended arc welding is used instead of manual brazing; the X-ray inspection after welding shows that the welding qualified rate of pipe assemblies is increased to 90%; and the product quality is stabilized, the production cycle is shortened, and the processing cost is lowered.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Corrosion-resistant metal membrane assembly and laser welding method thereof

ActiveCN109708783AHigh cost of solutionLow costForce measurementWelding/cutting auxillary devicesEngineeringIsolation membrane

The invention, which belongs to the technical field of laser welding, relates to a corrosion-resistant metal membrane assembly and a laser welding method thereof. The corrosion-resistant metal membrane assembly comprises an isolation membrane, a gasket and a body. The gasket is fixed on the body; and the isolation membrane is arranged on the gasket. The isolation membrane assembly is formed by theisolation membrane, the gasket and the body based on steps of gasket clamping, gasket inner diameter laser welding, laser welding of the gasket outer diameter, shaping processing of a welding joint on the gasket surface, isolation membrane clamping, and isolation membrane laser welding and the like. According to the invention, With the isolation membrane and the gasket made of the corrosion-resistant materials, the problem of the high cost of the corrosion-resistant material of the body is solved based on the integrated welding structure of the gasket and the body and thus the material cost is lowered; the laser welding is used for replacing the electronic beam welding, so that the device investment is reduced, the manufacturing difficulty and the manufacturing cost are reduced, and the production efficiency is improved; and the part welding qualification rate is increased, the product characteristics can be improved, and the long-term stability and reliability of the product are enhanced.

Owner:WUXI KUNLUN FUJI INSTR CO LTD

Surface-mounted microwave circulator with novel port structure

InactiveCN101984518AAccurate and stable positioningMake electrical connectionsWaveguide type devicesSemi openMicrowave

The invention relates to a surface-mounted microwave circulator with novel port structure, wherein, a shell is of semi-open cylindrical cavity structure; the side wall of the shell is provided with three port slot holes; bosses are respectively arranged on the positions on the side wall of the shell, corresponding to the three port slot holes; the semi-open cylindrical cavity of the shell is internally provided with a permanent magnet, a uniform magnetic conducting strip, a ferrite, a central conductor and a temperature compensation strip; the top of the shell is covered with a cover board; the central conductor extends out of the cavity through the port slot holes on the side wall of the shell; the three bosses on the side wall of the shell are provided with through holes, and each through hole is provided with a port pin insulator; each port pin insulator is provided with a port pin; and the three port pins are electrically connected with the central conductor. The package structure obviously improves the reliability of the microwave circulator and obviously enhances the welding qualification rate without changing the performances of the circulator. The surface-mounted microwave circulator has the advantages of small volume, excellent performances, high power handling, wide temperature range and the like, thus being applicable to large-scale production.

Owner:SDP TELECOM SUZHOU

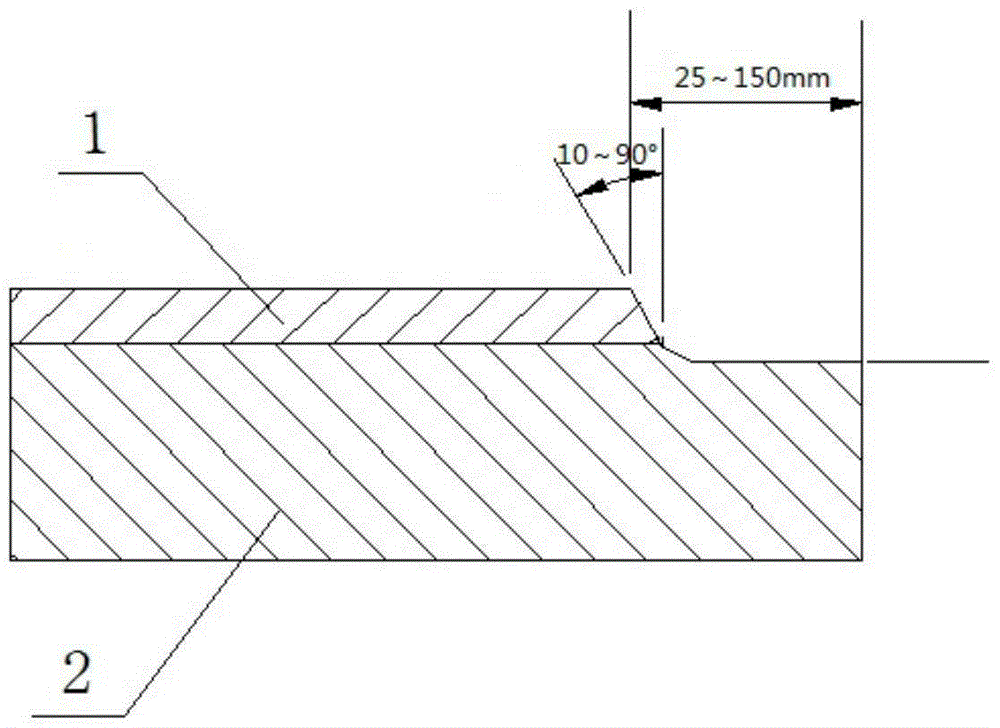

Full-automatic root welding method for pipe end of bimetal composite pipe

ActiveCN105195866ASimple processSimple and fast operationArc welding apparatusWelding/cutting media/materialsAlloyCarbon steel

The invention discloses a full-automatic root welding method for a pipe end of a bimetal composite pipe. The bimetal composite pipe subjected to root welding comprises an anti-corrosion alloy lining pipe and a carbon steel base pipe, wherein the outer side of the anti-corrosion alloy lining pipe is sleeved with the carbon steel base pipe. The method comprises the following steps: first, cutting off a 25-150 mm section of the anti-corrosion alloy lining pipe; then, processing the exposed outer side of the anti-corrosion alloy lining pipe from outside to inside into an inward slop; finally, under the protection of high-purity argon gas, performing automatic root welding on the slop from inside to outside by adopting an argon tungsten-arc welding machine, so as to form a single nickel base alloy root welding layer. According to the method, full-automatic root welding of the composite pipe can be realized through a welding process; the welding process adopts a single-pass forming mode, so as to overcome the defect that the welding efficiency is reduced due to a double-pass forming mode adopted by manual argon arc welding is overcome, and improve the welding efficiency.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

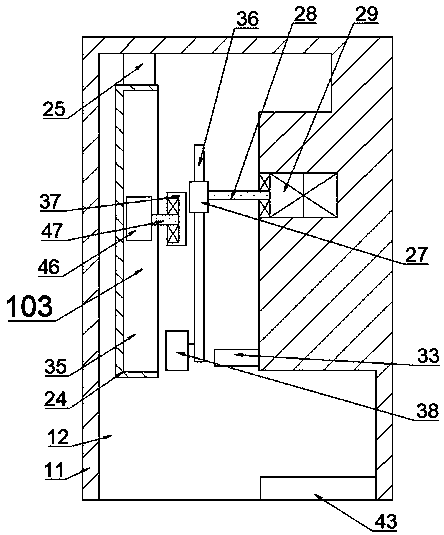

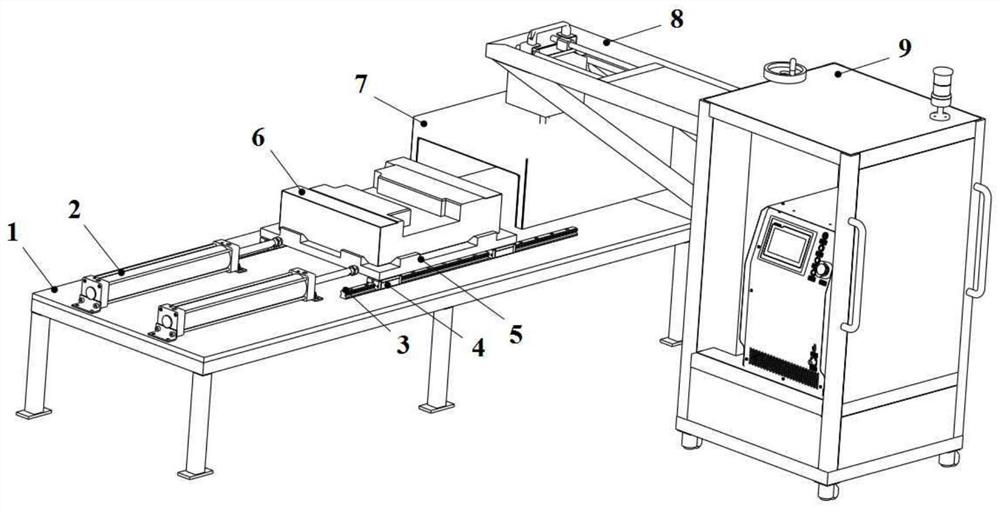

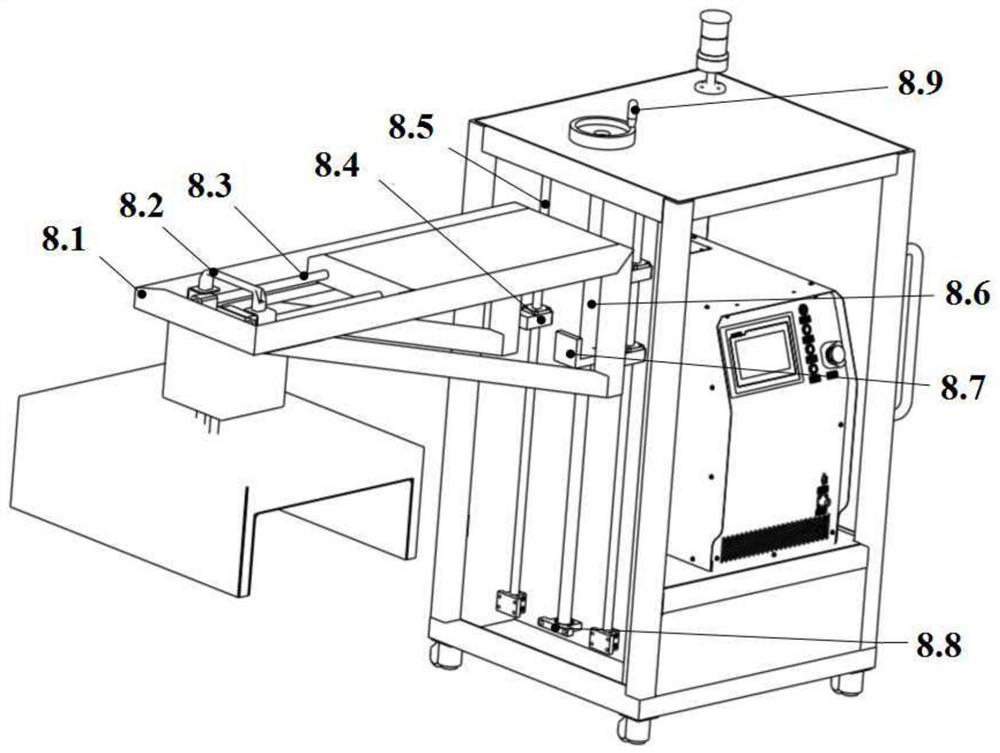

Preheating device and preheating method for TBM tool apron welding

ActiveCN111770598AEffective connectionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMovement control

The invention provides a preheating device for TBM tool apron welding. The device comprises a working platform, a feeding assembly, a cantilever adjusting mechanism and a control cabinet, the feedingassembly is arranged on the working platform, and the switching of a workpiece between a welding position and a preheating position is achieved through the feeding assembly; one end of the cantileveradjusting mechanism is movably provided with an induction heating coil used for preheating the workpiece, and the other end of the cantilever adjusting mechanism is movably arranged on the control cabinet. A moving assembly is arranged on the bottom surface of the control cabinet to move the control cabinet. According to the preheating device, the effective connection of preheating, welding and post-heating procedures is guaranteed, the carrying work of workpiece at the high temperature is omitted, and the production efficiency and the welding quality of a TBM tool apron are improved. The invention further provides a method for preheating by using the preheating device, and the labor intensity of personnel can be effectively reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com