Automatic welding method for small-diameter thin-wall multi-layer pipe

A multi-layer pipe, automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of ablation of the main body of thin-walled pipes, scrapped parts in batches, insufficient penetration of solder, etc., to shorten production. The effect of cycle, small heat affected zone and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

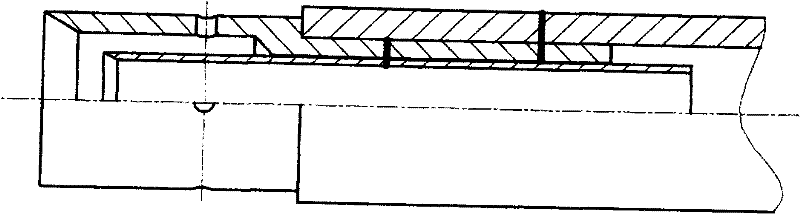

[0022] This embodiment provides an automatic welding method for small-diameter thin-walled multilayer pipes, which is characterized in that: the automatic welding method for small-diameter thin-walled multilayer pipes is automatic hanging arc welding, that is, tungsten-level inert gas shielded welding, which is Using pure tungsten or activated tungsten as the electrode, arc welding is carried out under the protection of inert gas. An arc is generated between the end of the tungsten pole and the base material to be welded to weld the base material. The inner cavity of the part is protected by argon gas during welding;

[0023] It has many adjustable parameters, can accurately control the welding heat input and the shape and size of the molten pool, the heat-affected zone is small, the welding quality is reliable, and the defects are controllable;

[0024] The effective welding thickness is 0.7 mm, and the effective welding length is 12 mm. By dividing the entire welding process ...

Embodiment 2

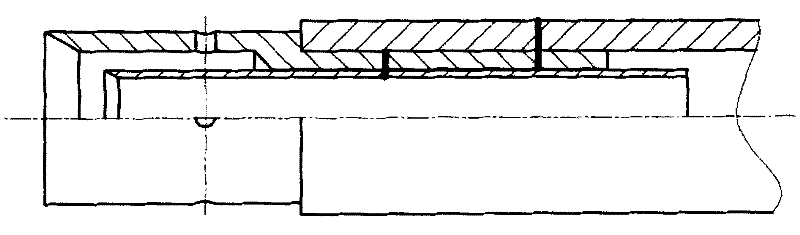

[0035] This embodiment provides an automatic welding method for small-diameter thin-walled multilayer pipes, which is characterized in that: the automatic welding method for small-diameter thin-walled multilayer pipes is automatic hanging arc welding, that is, tungsten inert gas shielded welding, which is Using pure tungsten or activated tungsten as the electrode, arc welding is carried out under the protection of inert gas. An arc is generated between the end of the tungsten pole and the base material to be welded to weld the base material. The inner cavity of the part is protected by argon gas during welding;

[0036] It has many adjustable parameters, can accurately control the welding heat input and the shape and size of the molten pool, the heat-affected zone is small, the welding quality is reliable, and the defects are controllable;

[0037] The effective welding thickness is 1.1 mm, and the effective welding length is 13 mm. By dividing the entire welding process into s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com