Bidirectional rough parallel arrangement micro-channel porous sound absorption structure

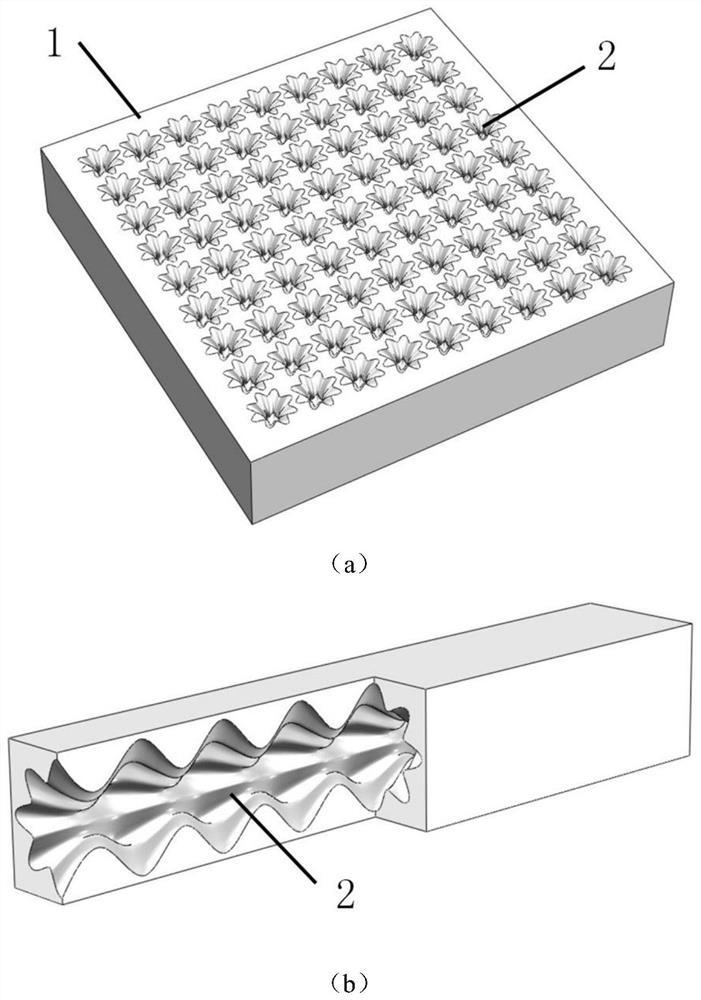

A technology of porous sound absorption and parallel arrangement, which is applied in the direction of sound emitting devices and instruments, and can solve the problems of poor adjustability of sound absorption frequency band, poor sound absorption effect, high sound absorption peak frequency, etc., and achieve excellent sound absorption performance, good Carrying capacity, efficient absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Examples of materials:

[0052] Structural steel: characterized by a density of 7850kg / m 3 , Young's modulus 200GPa, Poisson's ratio 0.2.

[0053] Air: characterized by a density of 1.29kg / m 3 , sound velocity 343m / s, dynamic viscosity coefficient 1.81×10 -5 Pa·s.

[0054] Structural dimensions and material selection of comparative examples:

Embodiment 1

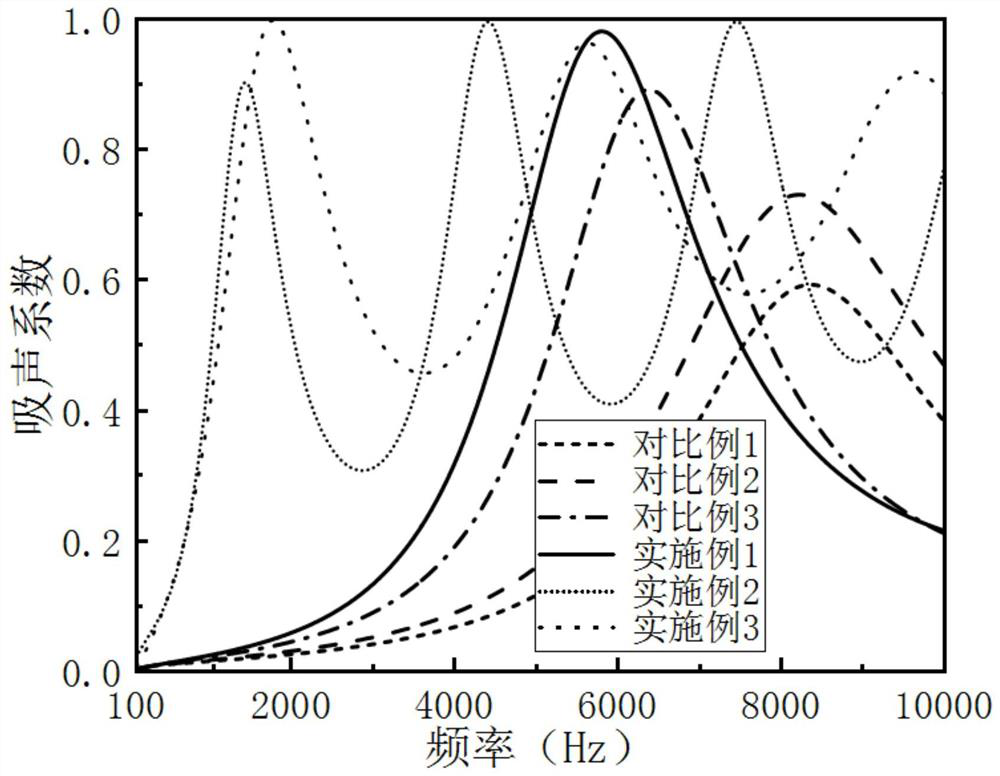

[0063] The thickness of the plate is 10mm, the porosity of the plate is 30%, the average radius of the bidirectional rough microchannel is 0.4mm, the axial relative roughness of the bidirectional rough microchannel is 0.2, the axial wave number of the bidirectional rough microchannel is 12, and the circumferential direction of the bidirectional rough microchannel is The relative roughness is 0.2, and the circumferential wave number of the bidirectional rough microchannel is 3.

Embodiment 2

[0065] The thickness of the plate is 50mm, the porosity of the plate is 40%, the average radius of the bidirectional rough microchannel is 0.5mm, the axial relative roughness of the bidirectional rough microchannel is 0.1, the axial wave number of the bidirectional rough microchannel is 8, and the circumferential direction of the bidirectional rough microchannel is The relative roughness is 0.1, and the circumferential wave number of the bidirectional rough microchannel is 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com