Inorganic combined seal spacer and method for making same

A sealing gasket and inorganic composite technology, applied in the direction of mechanical equipment, separation methods, chemical instruments and methods, etc., can solve problems such as comprehensive performance limitations, and achieve excellent fixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

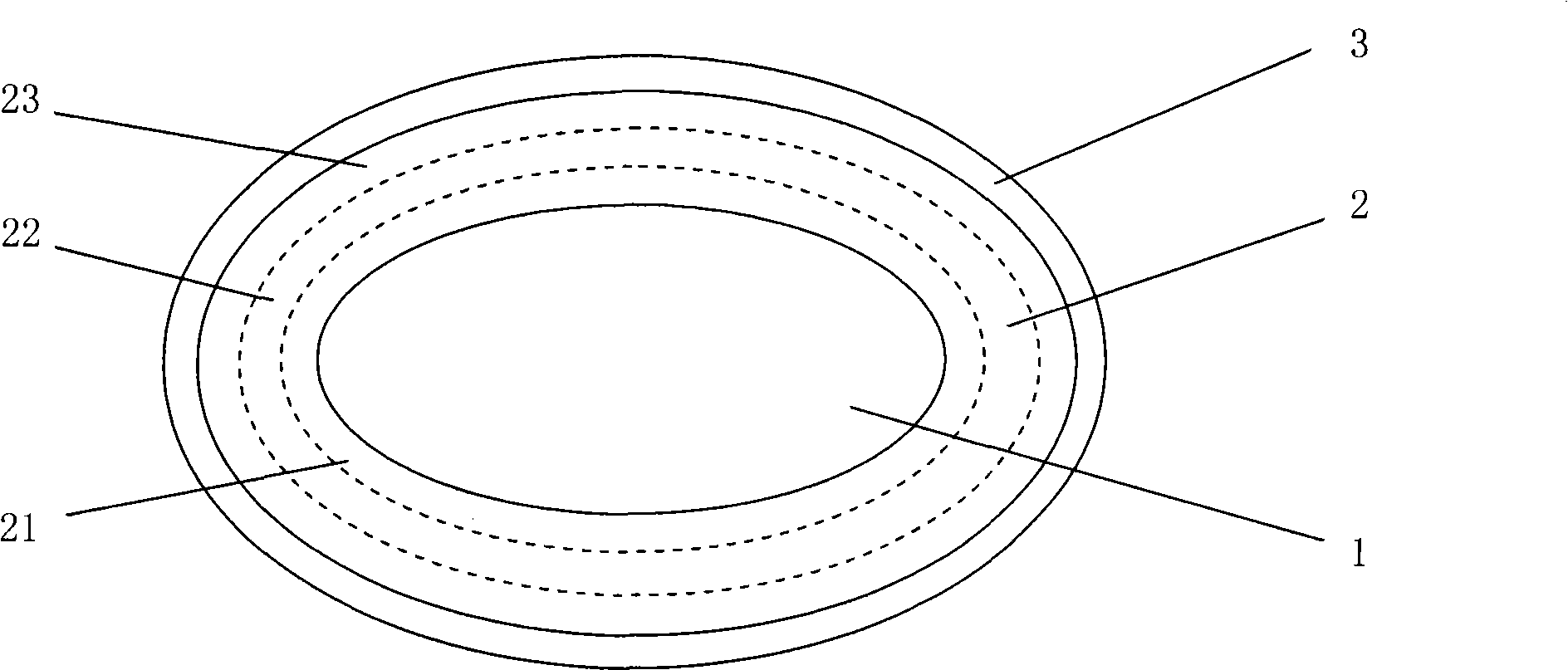

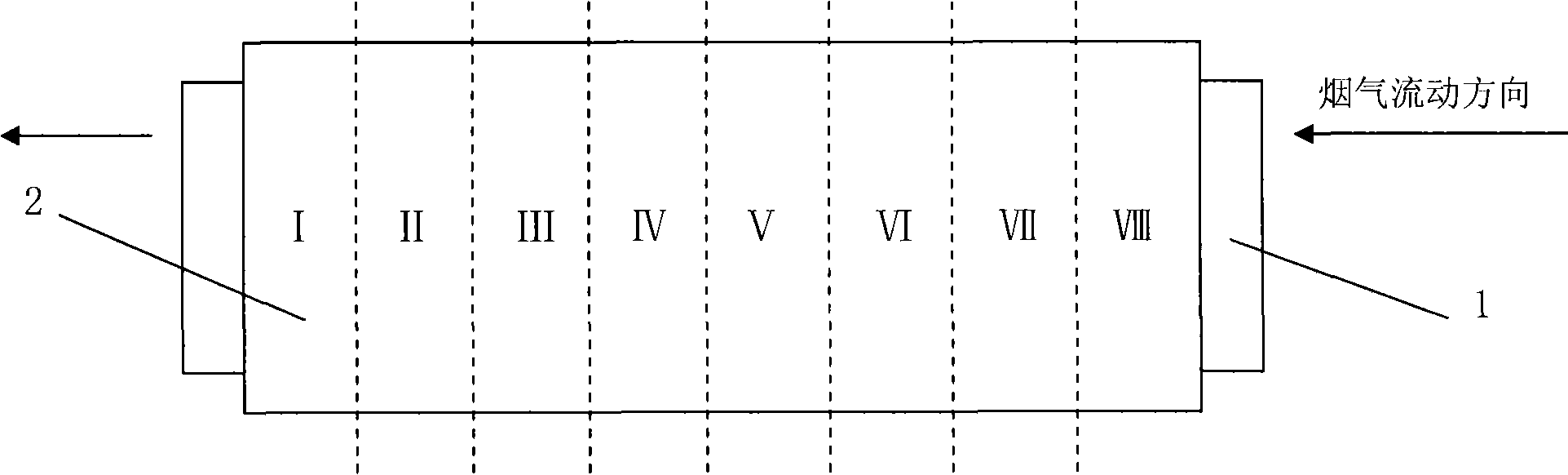

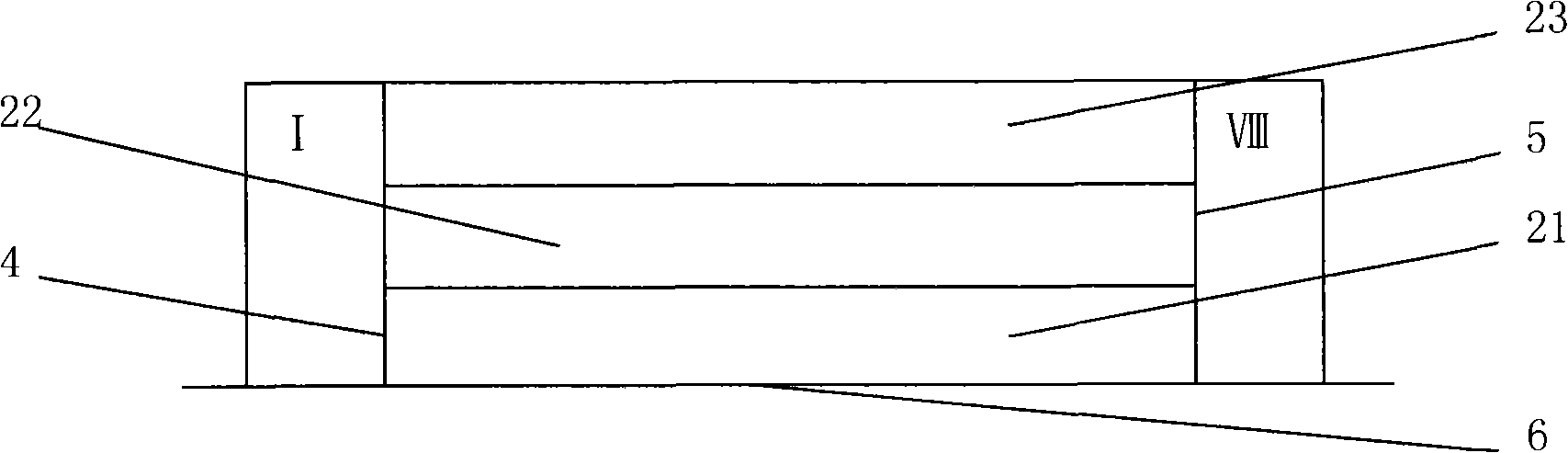

[0039] see figure 1 As shown in the schematic diagram of the sectional structure of the sealing gasket of the present invention applied in a catalytic converter, a kind of inorganic composite sealing gasket 2 is arranged between the automotive catalytic converter carrier 1 and the metal casing 3, and the sealing gasket 2. It consists of a composition including inorganic non-metallic fibers, expansive materials, and adhesives, wherein the inorganic composite sealing gasket is divided into eight width sections in the width direction, including section I, section II, and section III from left to right , Section IV, Section V, Section VI, Section VII and Section VIII; divided into three thickness layers from inside to outside, including inner layer 21, middle layer 22 and outer layer 23, each thickness layer and the liner in the width section The material components are the same or different.

[0040] Among the three thickness layers, the expandable material in the inner layer 21...

Embodiment 2

[0049] An inorganic composite sealing gasket, other structures are the same as in Example 1, except that the content of each component in the thickness layer and width section is different.

[0050] Among the three thickness layers, the expandable material in the inner layer 21 accounts for 35% of the total content of the expandable material in the entire sealing gasket 2, the middle layer 22 accounts for 35% of the total content, and the outer layer 23 Accounting for 30% of the total content; the distribution of the binder in the three thickness layers is: the inner layer 21 accounts for 40% of the total content, the middle layer 22 accounts for 20%, and the outer layer 23 accounts for 40% of the total content.

[0051] Wherein, the expansive material includes an expansive material with a low expansion start temperature, and in the three thickness layers, the proportion of the expansion material with a low expansion start temperature to the expansive material in the thickness ...

Embodiment 3

[0057] An inorganic composite sealing gasket, other structures are the same as in Example 1, except that the content of each component in the thickness layer and width section is different.

[0058] Among the three thickness layers, the expandable material in the inner layer 21 accounts for 50% of the total content of the expandable material in the entire sealing gasket 2, the middle layer 22 accounts for 30% of the total content, and the outer layer 23 Accounting for 20% of the total content; the distribution of the binder in the three thickness layers is: the inner layer 21 accounts for 38% of the total content, the middle layer 22 accounts for 24%, and the outer layer 23 accounts for 38% of the total content.

[0059] Wherein, the expansive material includes an expansive material with a low expansion start temperature, and in the three thickness layers, the proportion of the expansion material with a low expansion start temperature to the expansive material in the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com