Bearing apparatus

A bearing device and main bearing technology, applied in the direction of bearings, crankshaft bearings, bearing components, etc., can solve the problems of difficulty in forming oil film, high manufacturing cost, enlargement, etc., and achieve the effect of increasing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

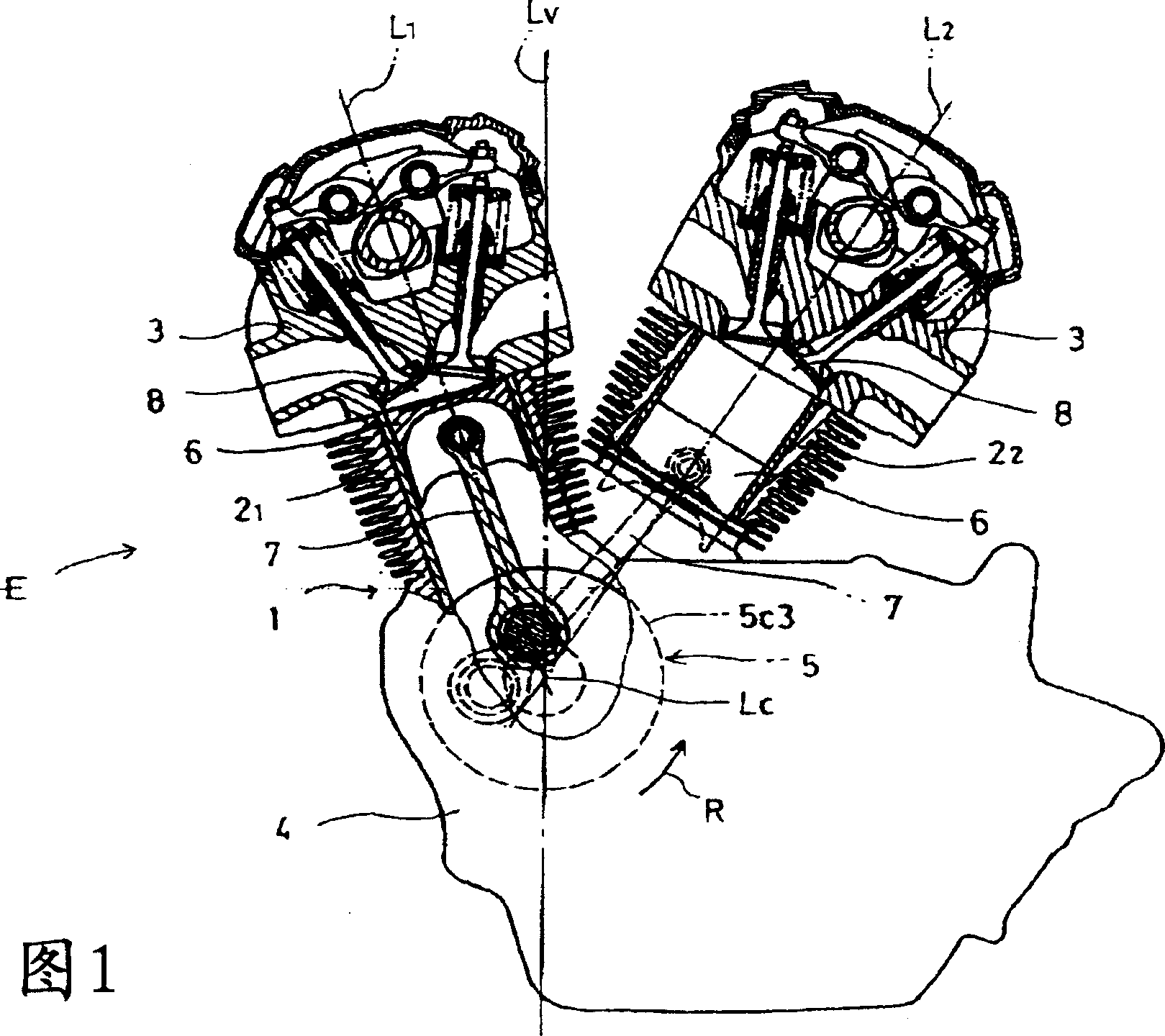

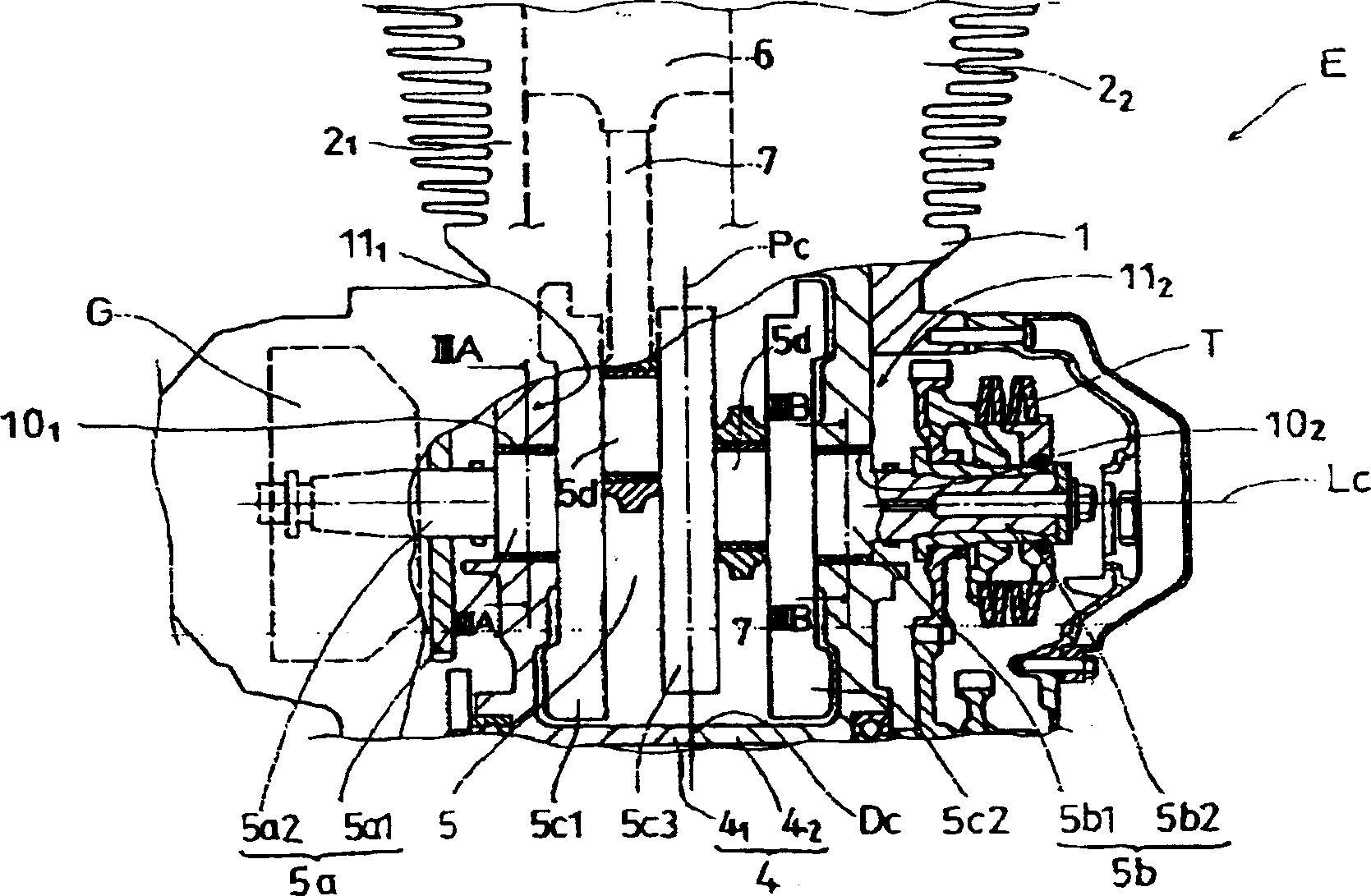

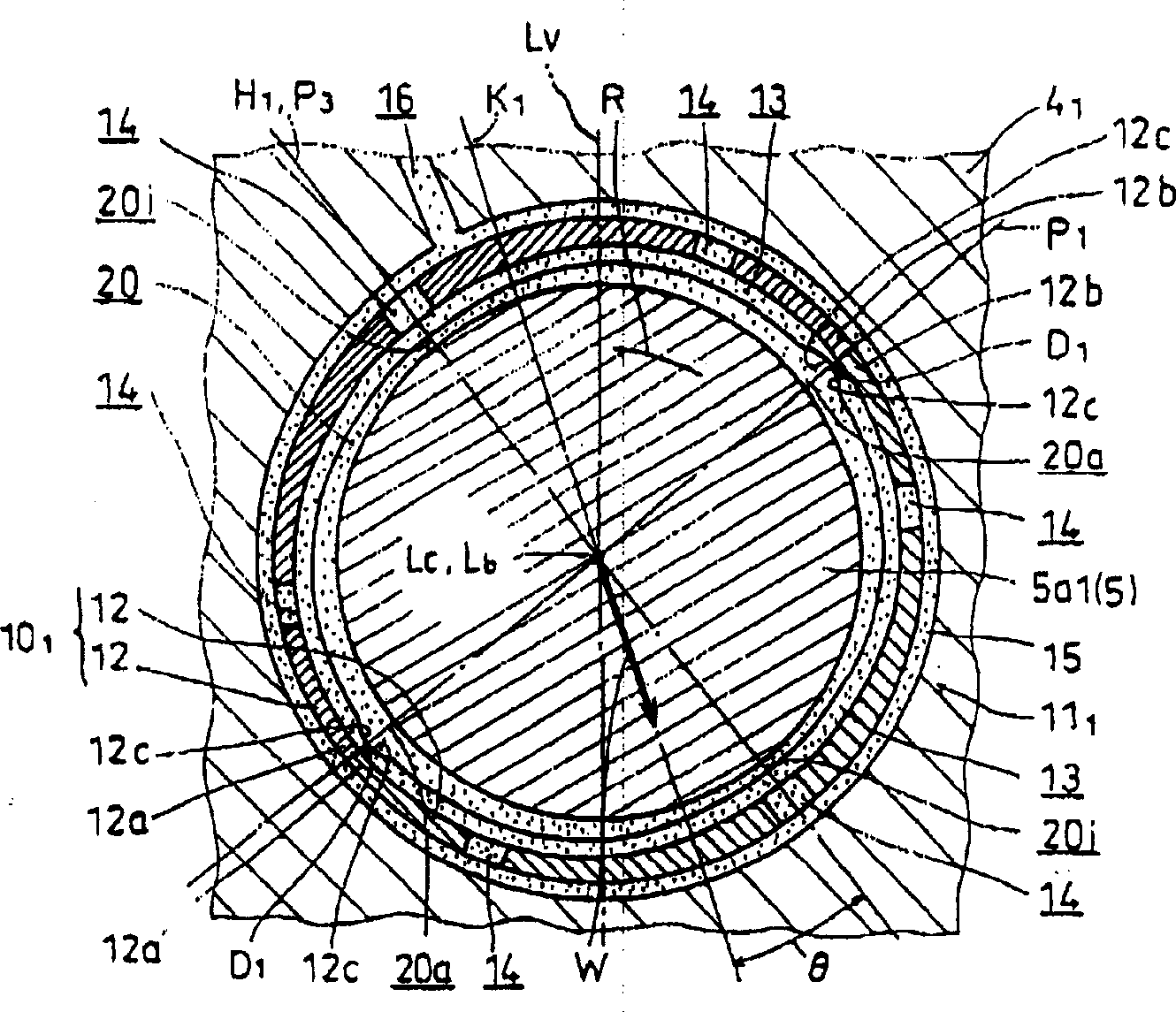

[0045] Embodiments of the present invention will be described below in conjunction with accompanying drawings 1-5.

[0046] In Figure 1 and figure 2 In , an internal combustion engine E using a bearing arrangement according to the invention is shown. The internal combustion engine E is an air-cooled type V-type two-cylinder internal combustion engine mounted on a vehicle in a state of being placed horizontally so that the crankshaft 5 points in the left-right direction. The internal combustion engine E comprises a cylinder head 1, a front-rear pair of first and second cylinders 2 1 ,2 2 are arranged side by side on the rotation axis Lc, that is, in the axial direction of the crankshaft 5 rotating in the direction R, which is the counterclockwise direction shown in FIG. Second cylinder 2 1 ,2 2 The cylinder heads 3 and 3 connected at the upper end are V-shaped. The crankcase 4 is connected with the lower part of the cylinder block 1, and forms the crankcase together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com