Sharpening unit and cutting machine comprising at least one blade and said sharpening unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

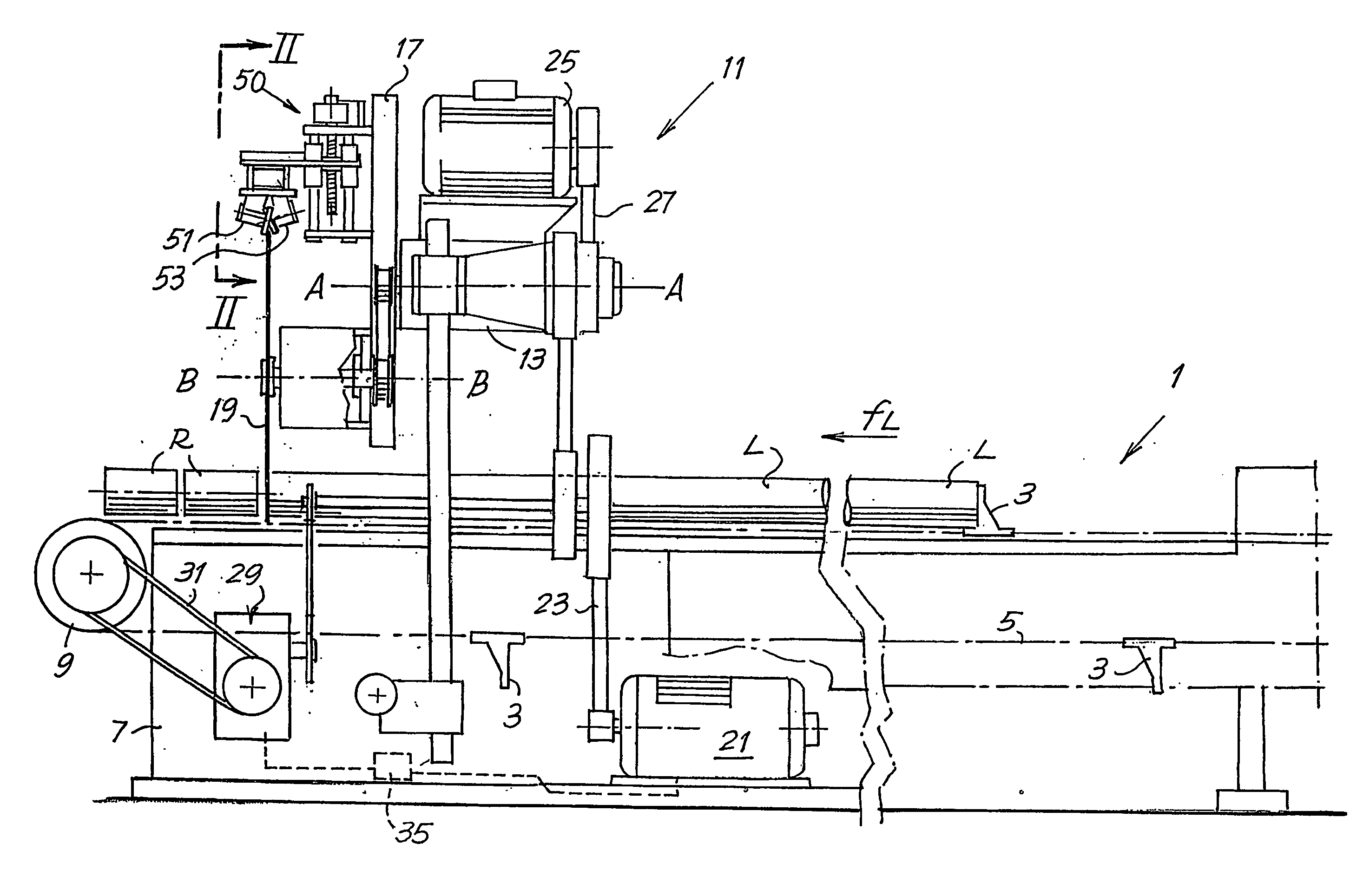

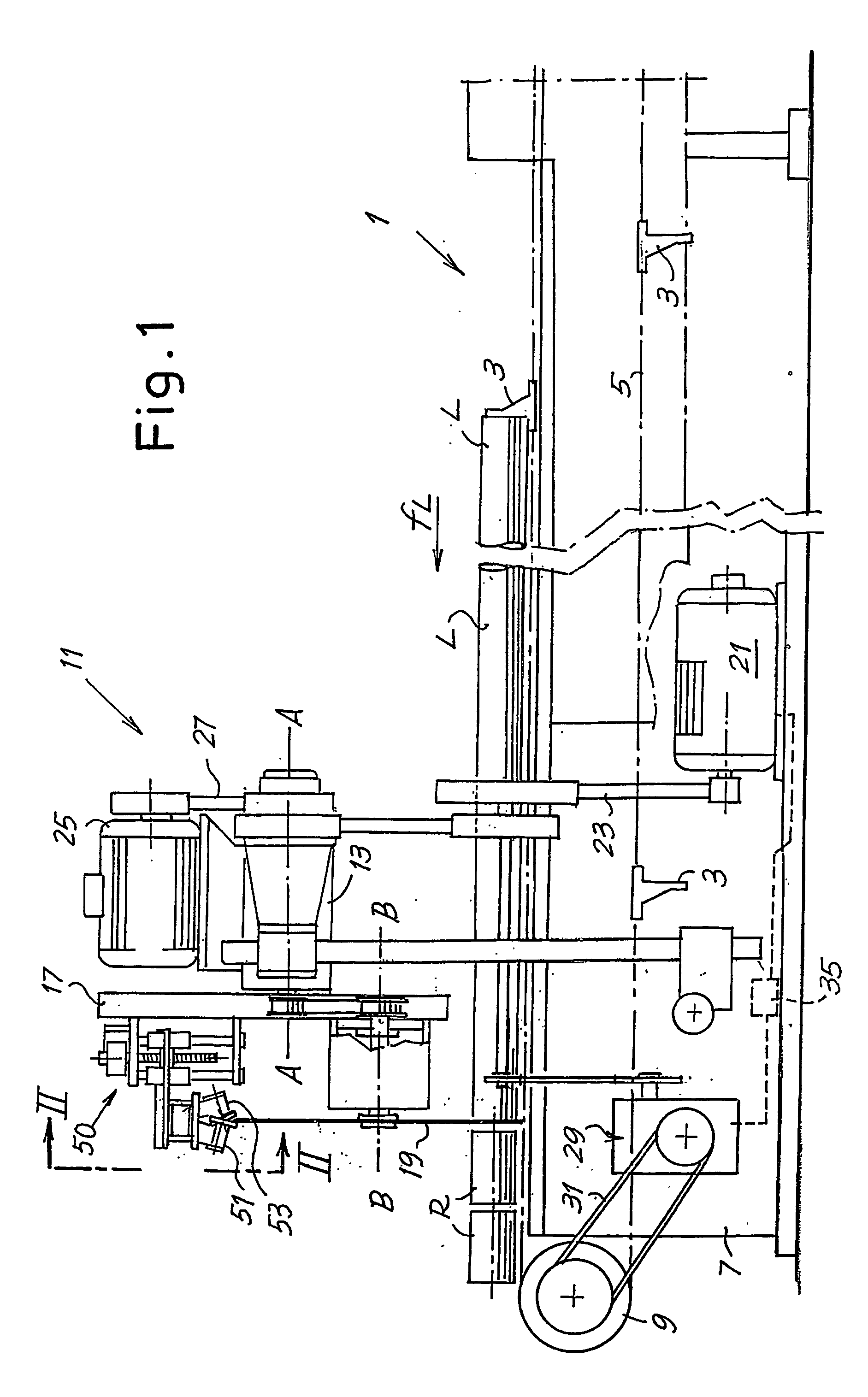

[0038]FIG. 1 schematically shows a cutting machine according to the present invention.

[0039] In this case it is a cutting machine for rolls of paper or other wound web material, wherein the cut is performed by a-disk-shaped blade rotating about its axis, carried by a unit in turn rotating about a principal axis of rotation, parallel or approximately parallel to the direction of feed of the rolls to be cut. Advantageously, a sharpening unit of the type shown in FIGS. 5 to 7 with motorized grinding wheels is applied to a machine of this type.

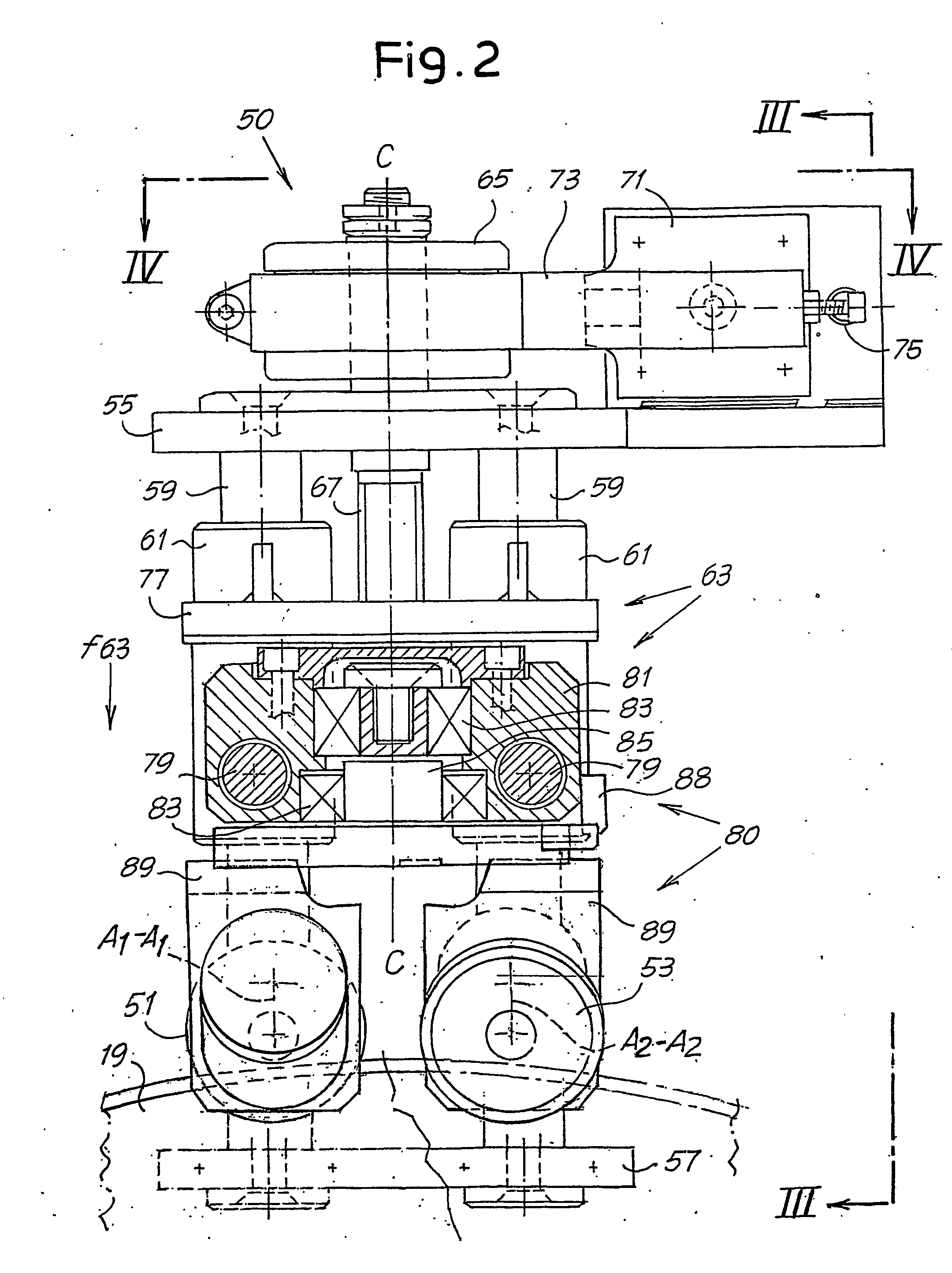

[0040] However, a sharpening unit with idle grinding wheels, of the type shown in FIGS. 2 to 4, may be applied (if need be in combination with or alternatively to it). The sharpening units, which shall be described hereunder with particular reference to FIGS. 2 to 7, may also be applied to different machines, such as cutting machines with a helical blade or with a band blade. It must therefore be understood that the machine shown in FIG. 1 must ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Gravity | aaaaa | aaaaa |

| Stress optical coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com