Patents

Literature

913 results about "Tissue paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tissue paper or simply tissue is a lightweight paper or, light crêpe paper. Tissue can be made from recycled paper pulp.

Use Of A Surface-Reacted Calcium Carbonate In Tissue Paper, Process To Prepare A Tissue Paper Product Of Improved Softness, And Resulting Improved Softness Tissue Paper Products

ActiveUS20120031576A1Good flexibilityNatural cellulose pulp/paperCoatings with pigmentsSurface responseTissue paper

The present invention related to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

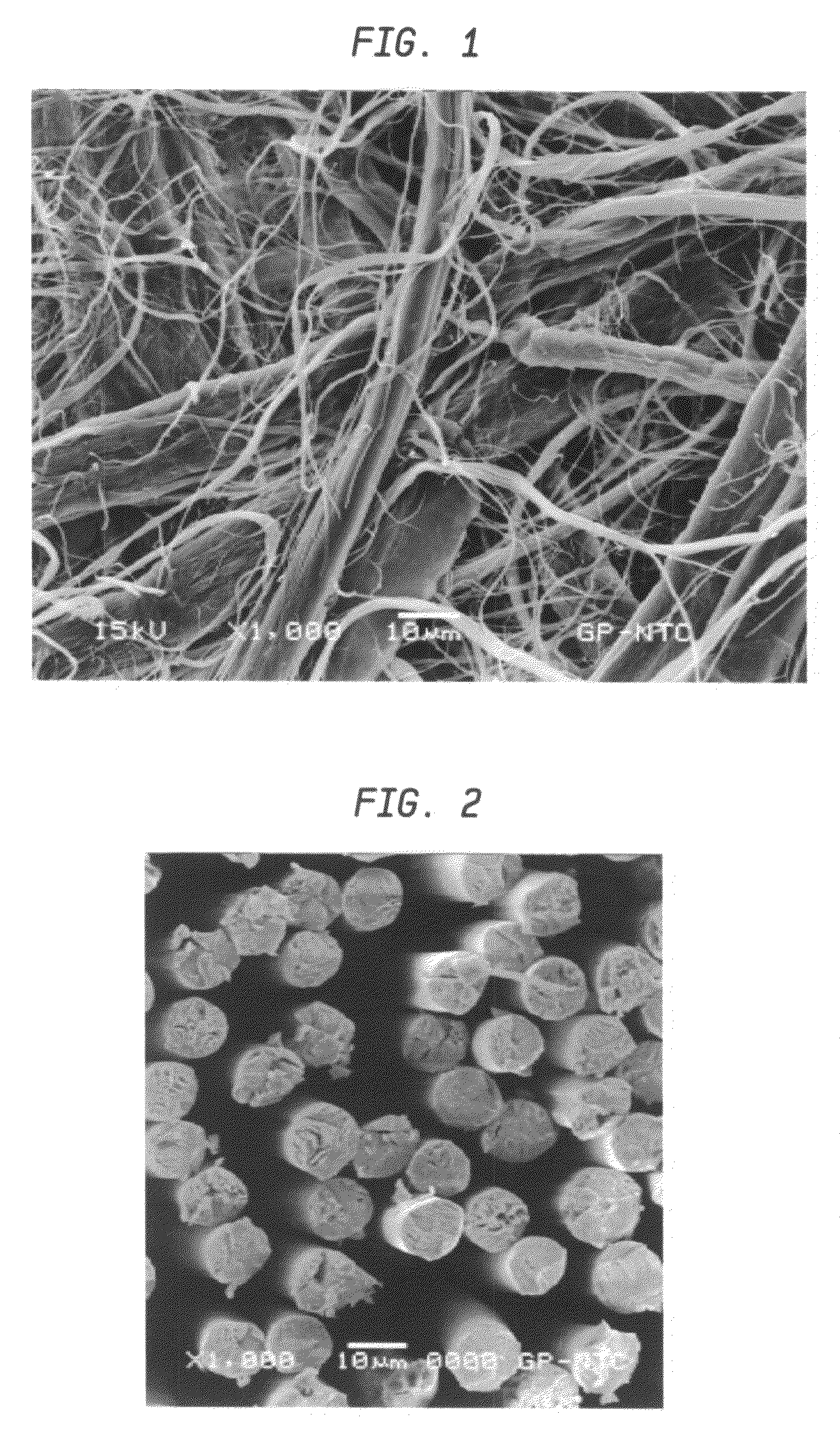

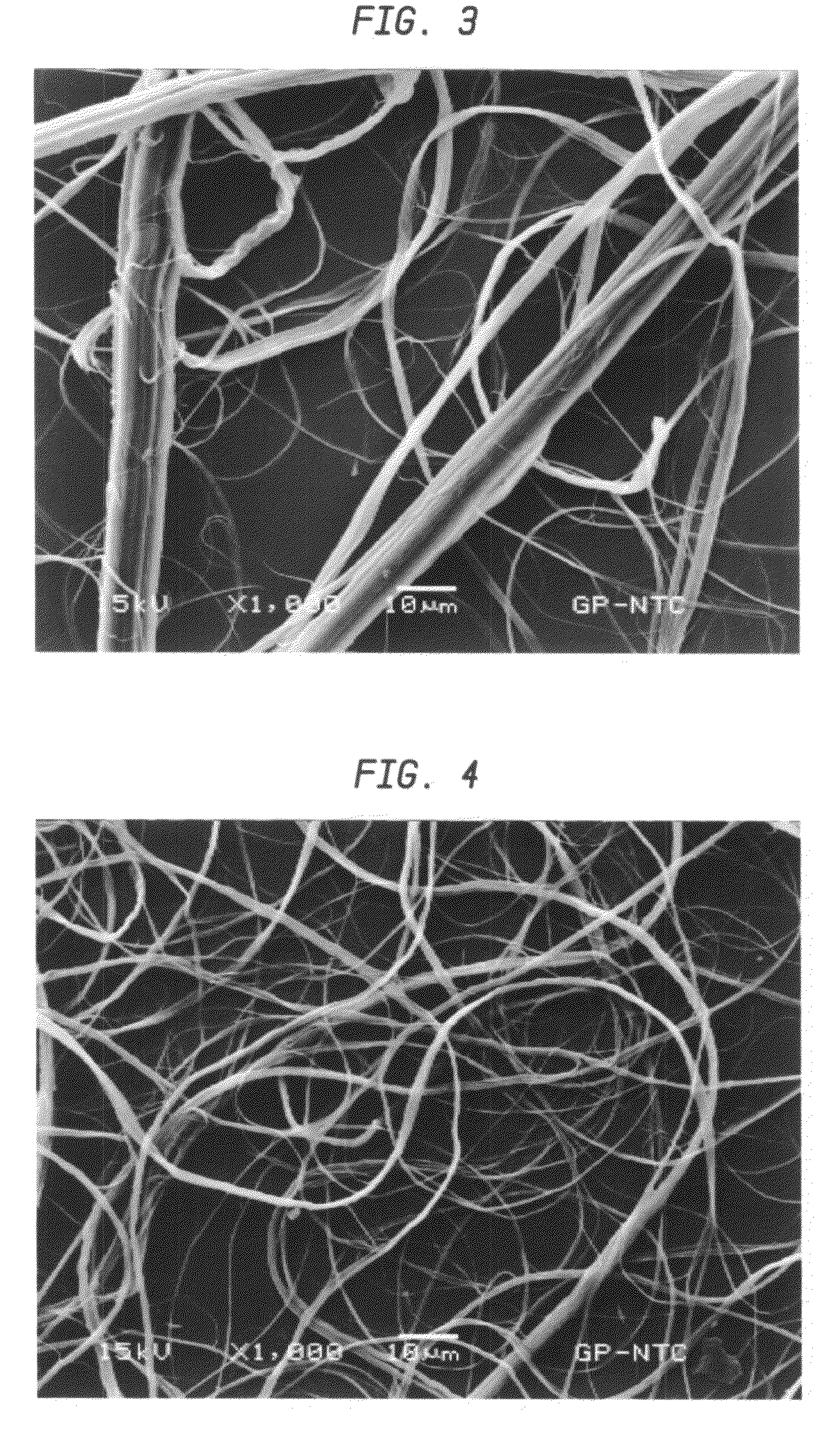

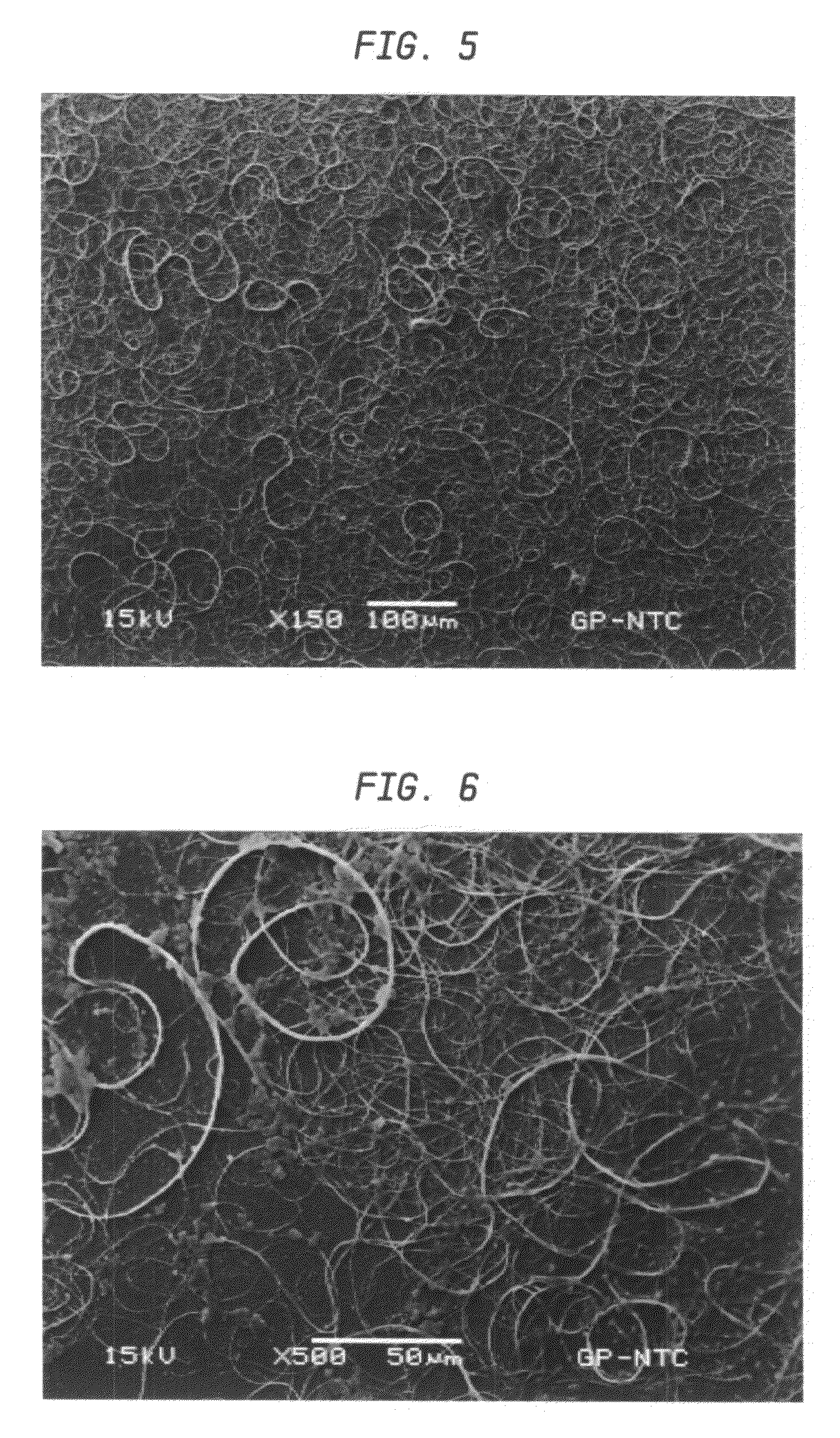

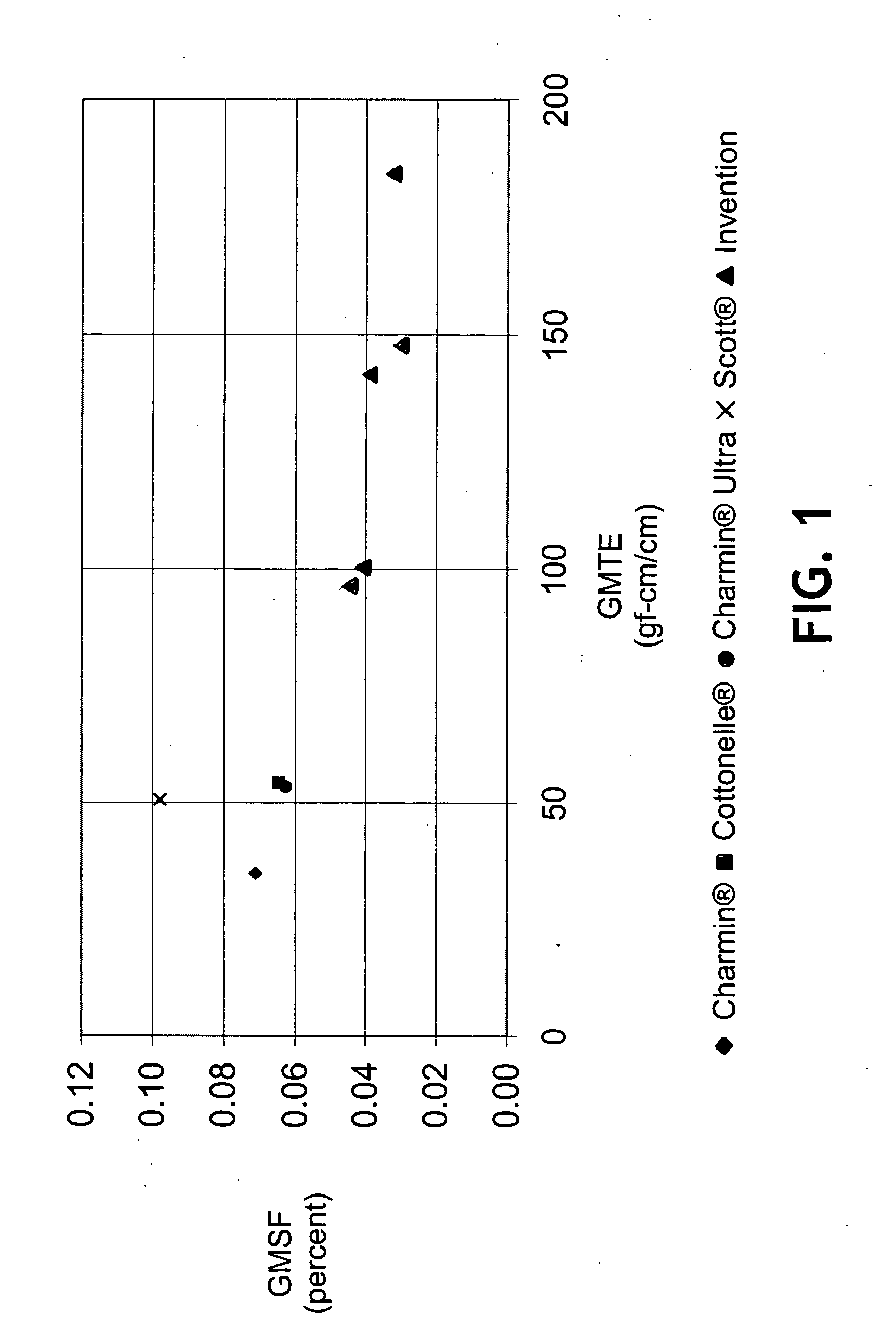

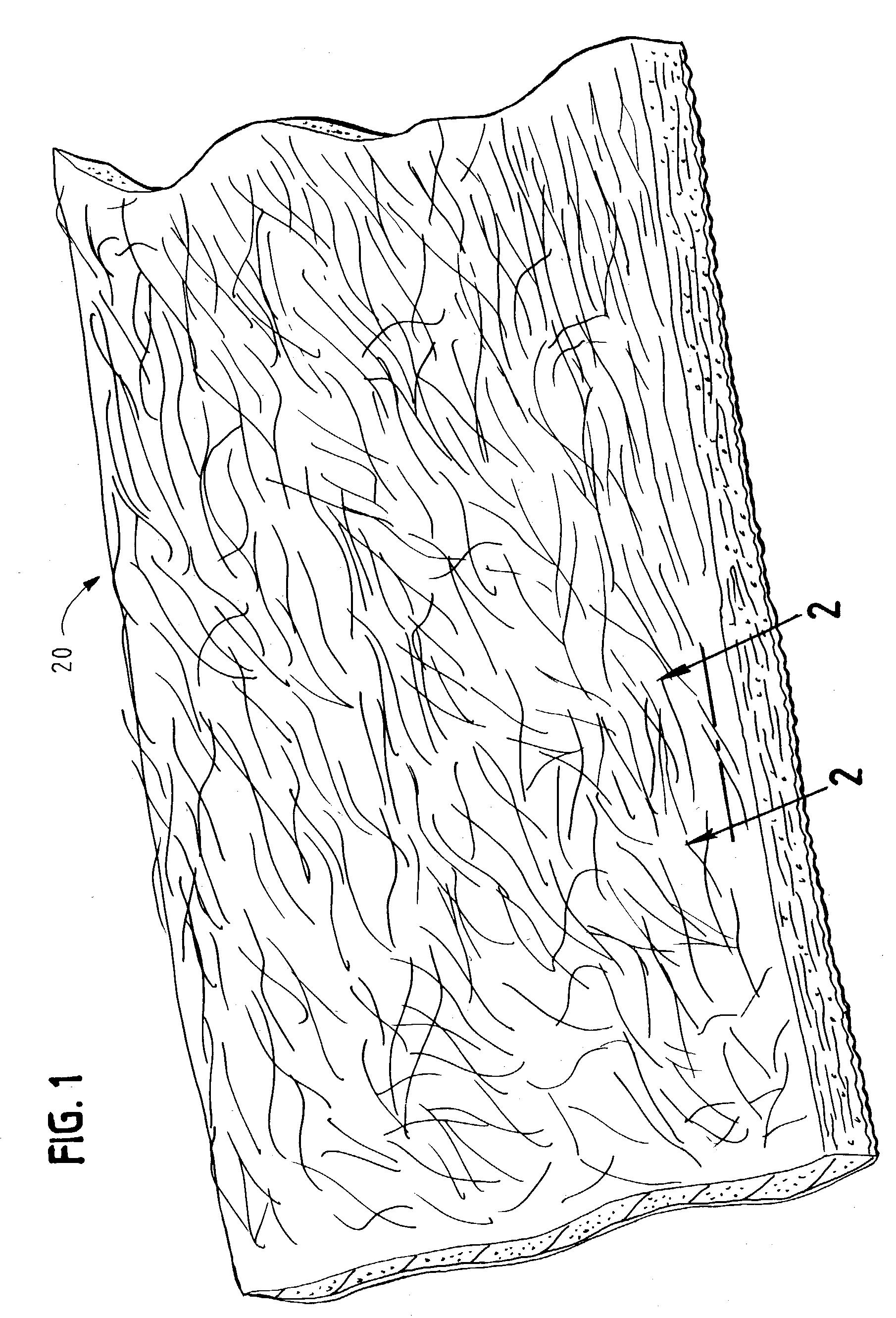

Absorbent sheet having regenerated cellulose microfiber network

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

Soft durable tissue

InactiveUS20050252626A1Improve smoothnessReduce the amount requiredNatural cellulose pulp/paperSpecial paperBiomedical engineeringFiber

Single-ply throughdried tissue sheets, particularly suitable as bath tissue, are produced with at least three layers. One or both of the outer layers suitably contain predominantly softwood fibers and a chemical bonding agent. One or more of the inner layers suitably contains a chemical debonder. The resulting tissues have a high level of durability and softness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

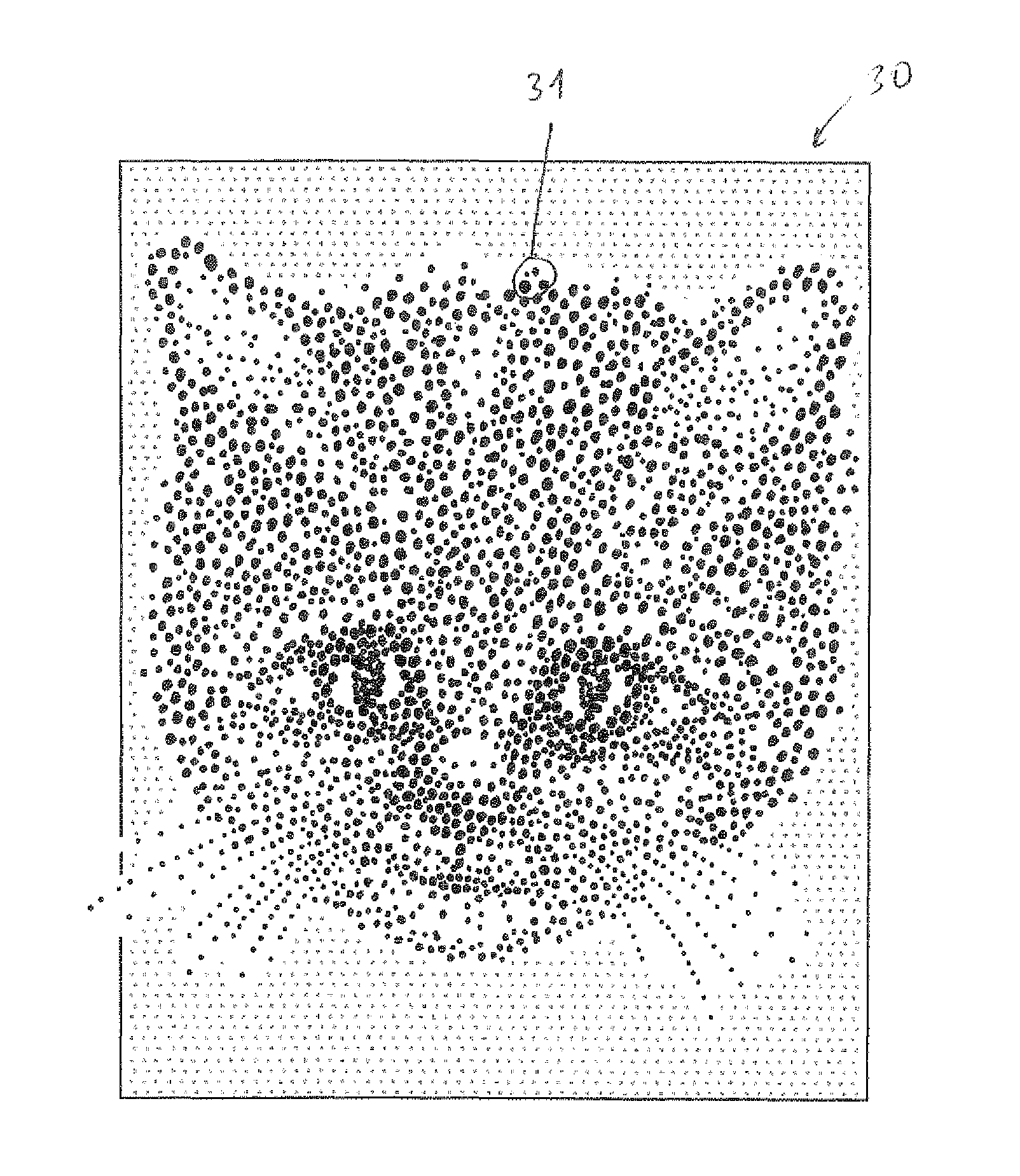

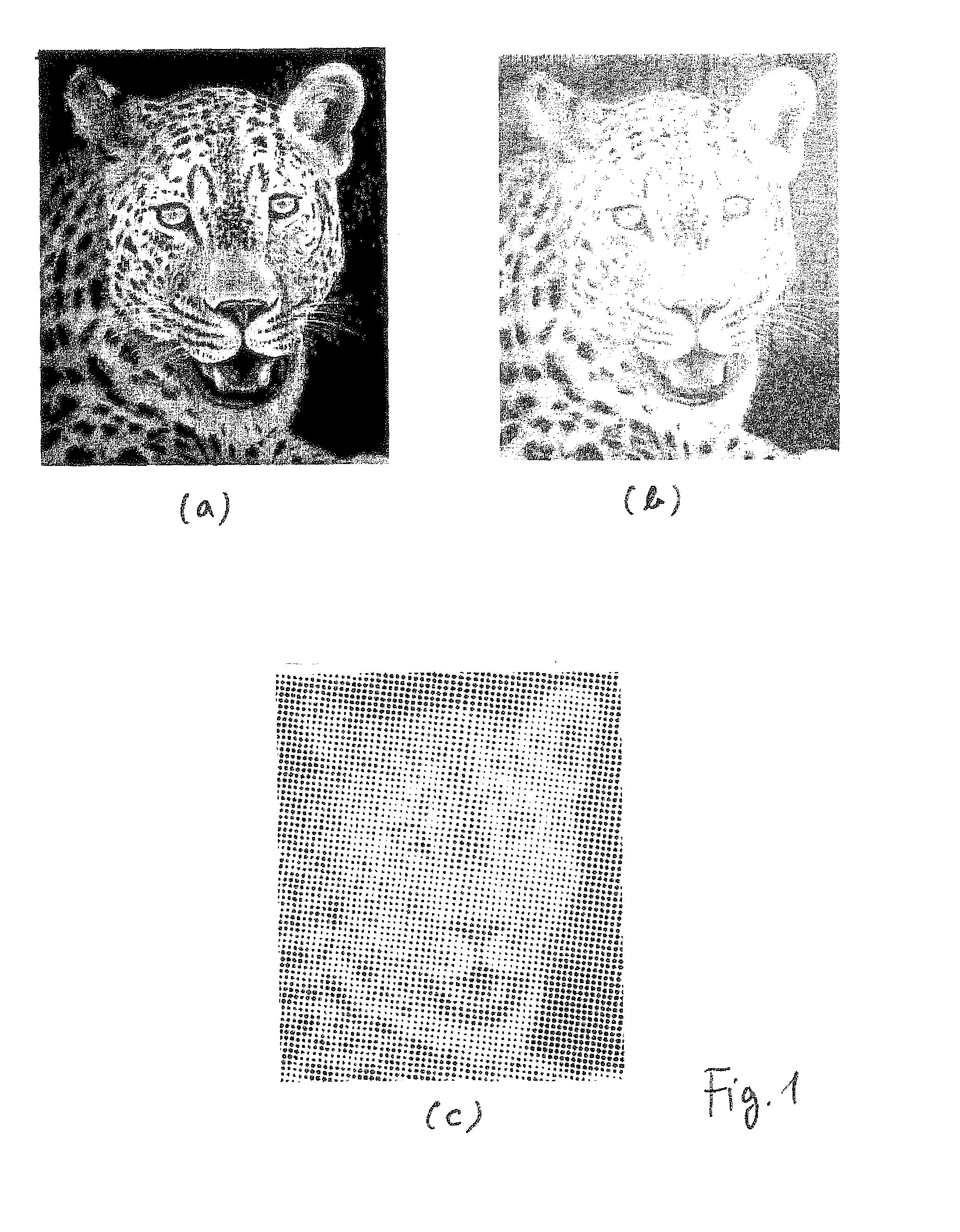

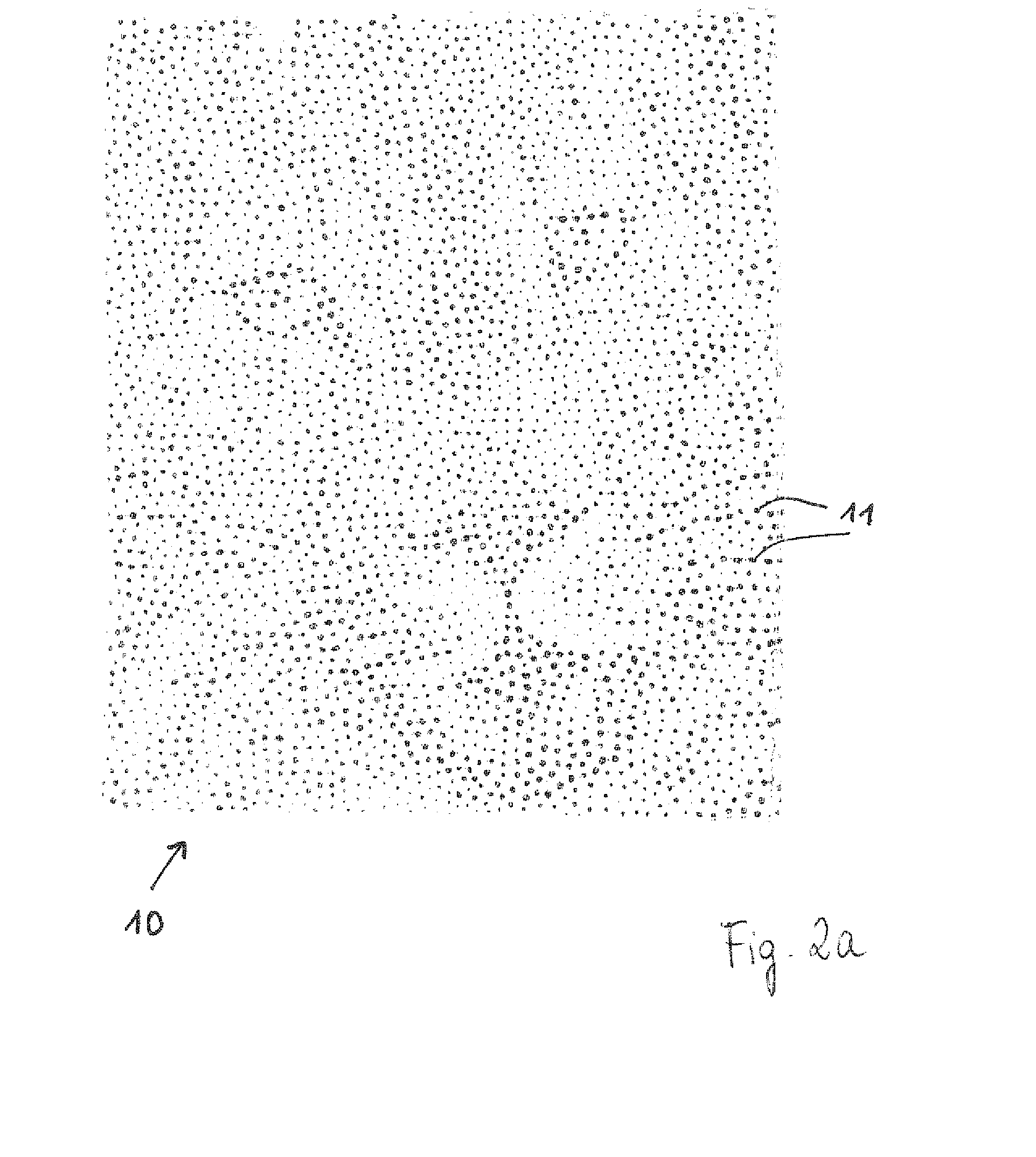

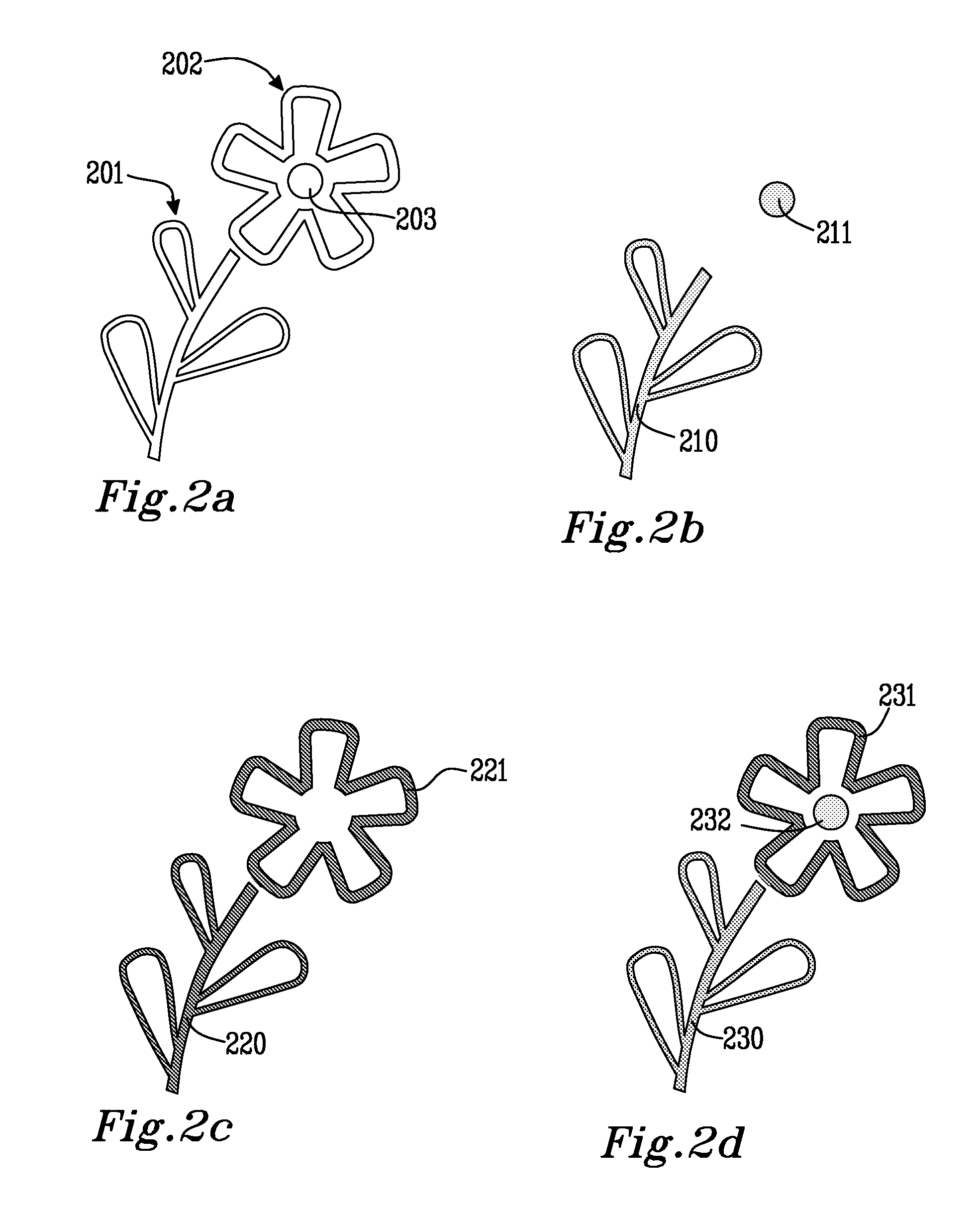

Fibrous product with a rastered embossing and method for producing same

InactiveUS20110223381A1Improve visual effectsIncrease visual appearanceSpecial visual effect coatingsMechanical working/deformationFiberGrating

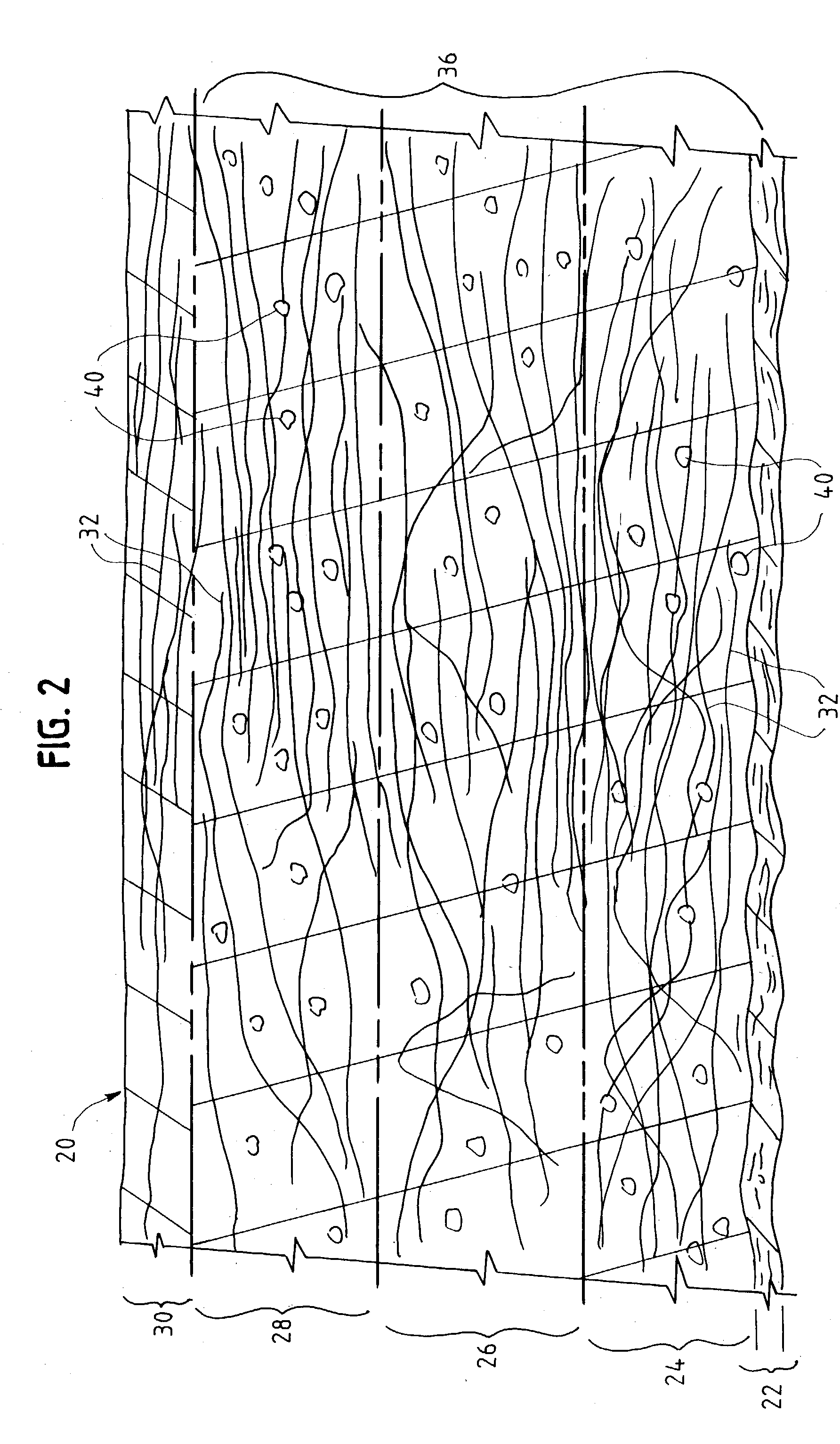

A fibrous product (10, 20, 20b, 30), especially tissue paper product, non-woven products or a hybrid thereof, and preferably hygiene and cleaning product has at least one first ply (42; 62; 84; 104) with at least one embossing pattern including embossed depressions starting from a base plane of the ply; the embossed pattern being characterized by the following features: the embossing pattern has a minimum motive surface area of at least 3 cm×3 cm; the pattern includes a high number of embossed depressions which are sized and / or positioned such as to form a motive element covering the motive surface area; wherein at least some of the embossed depressions are sized and / or positioned such that minimum distances between pairs of consecutively arranged embossed depression vary. A method for producing such a fibrous product is also described.

Owner:SCA HYGIENE PROD AB

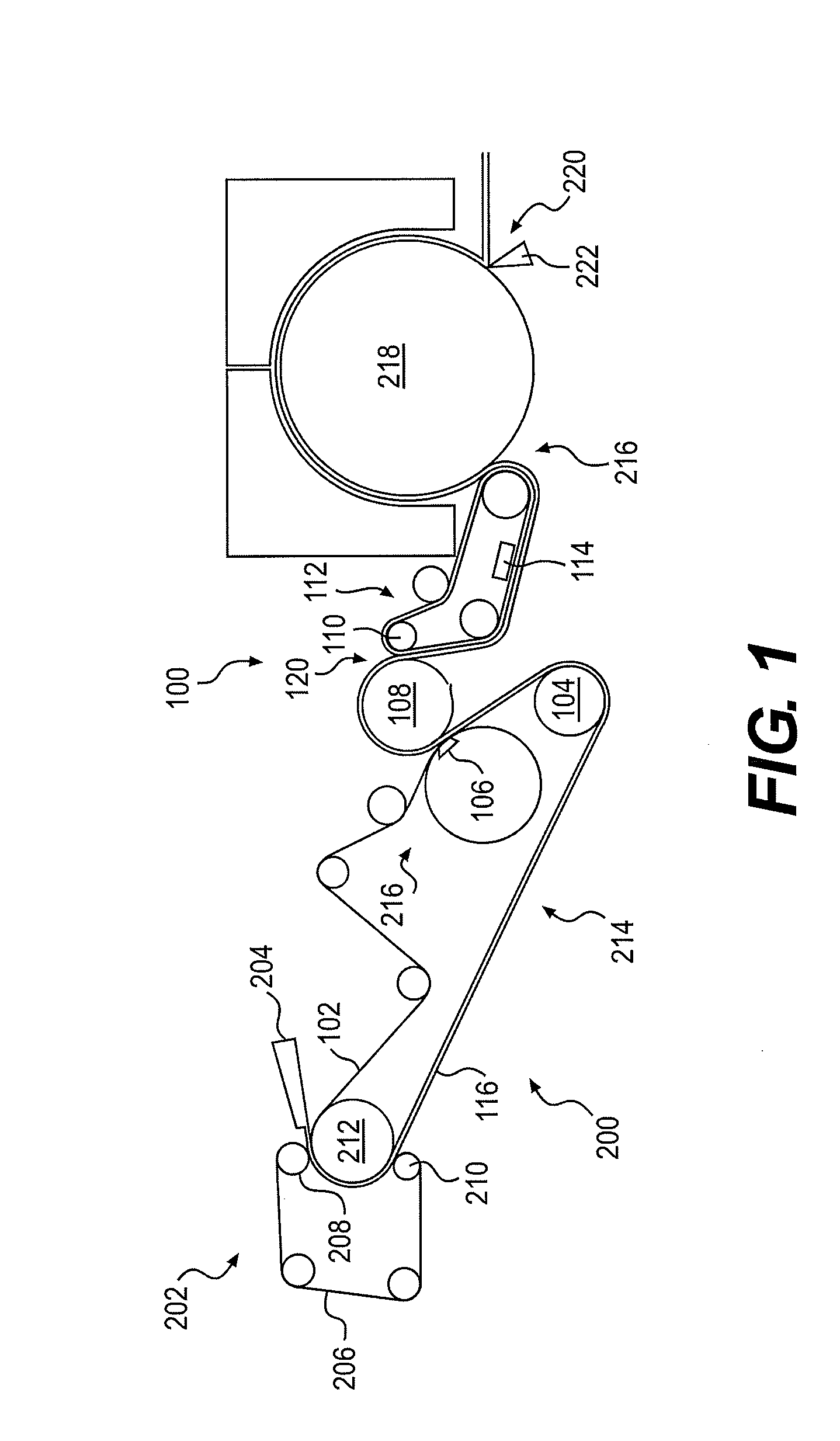

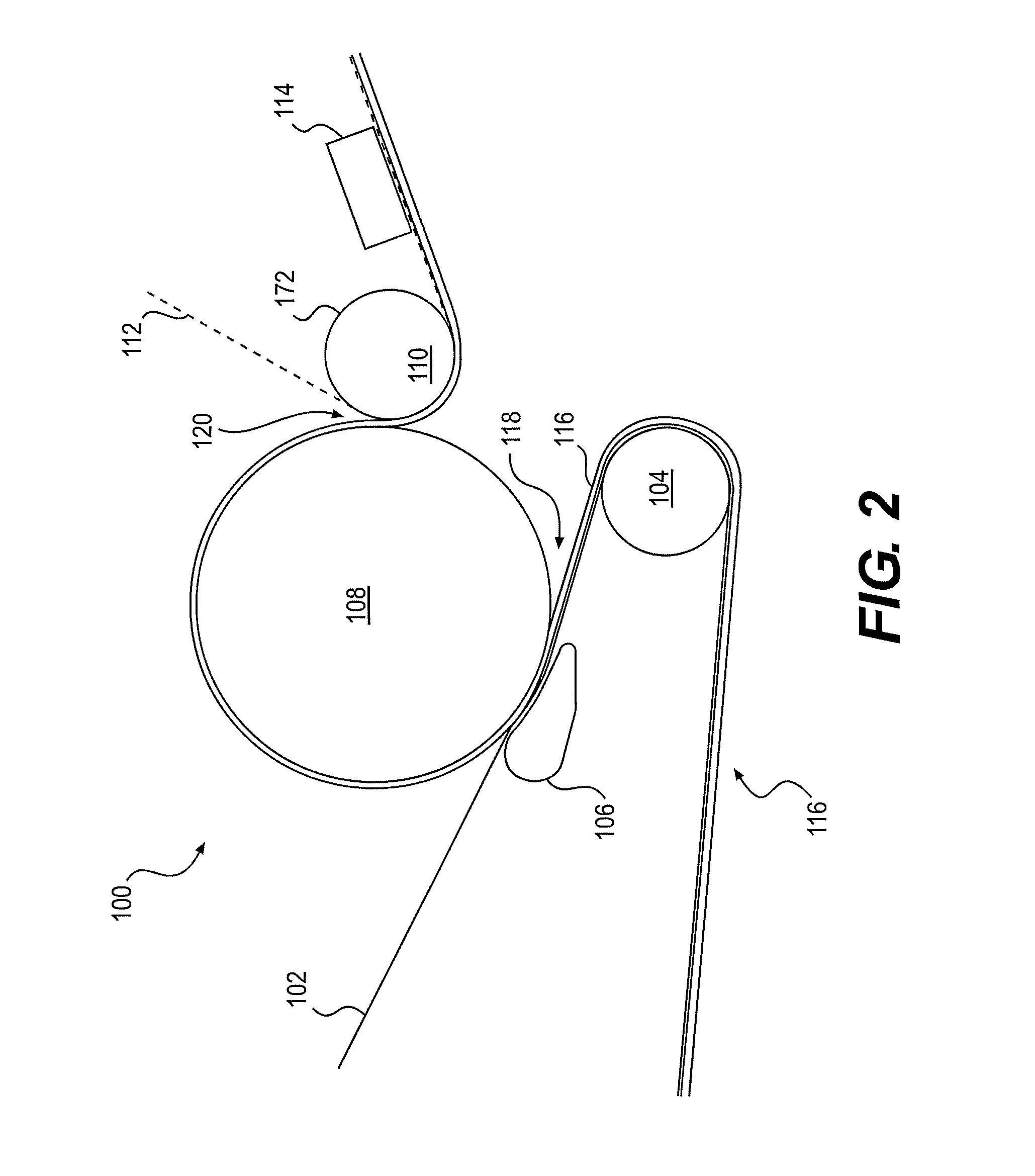

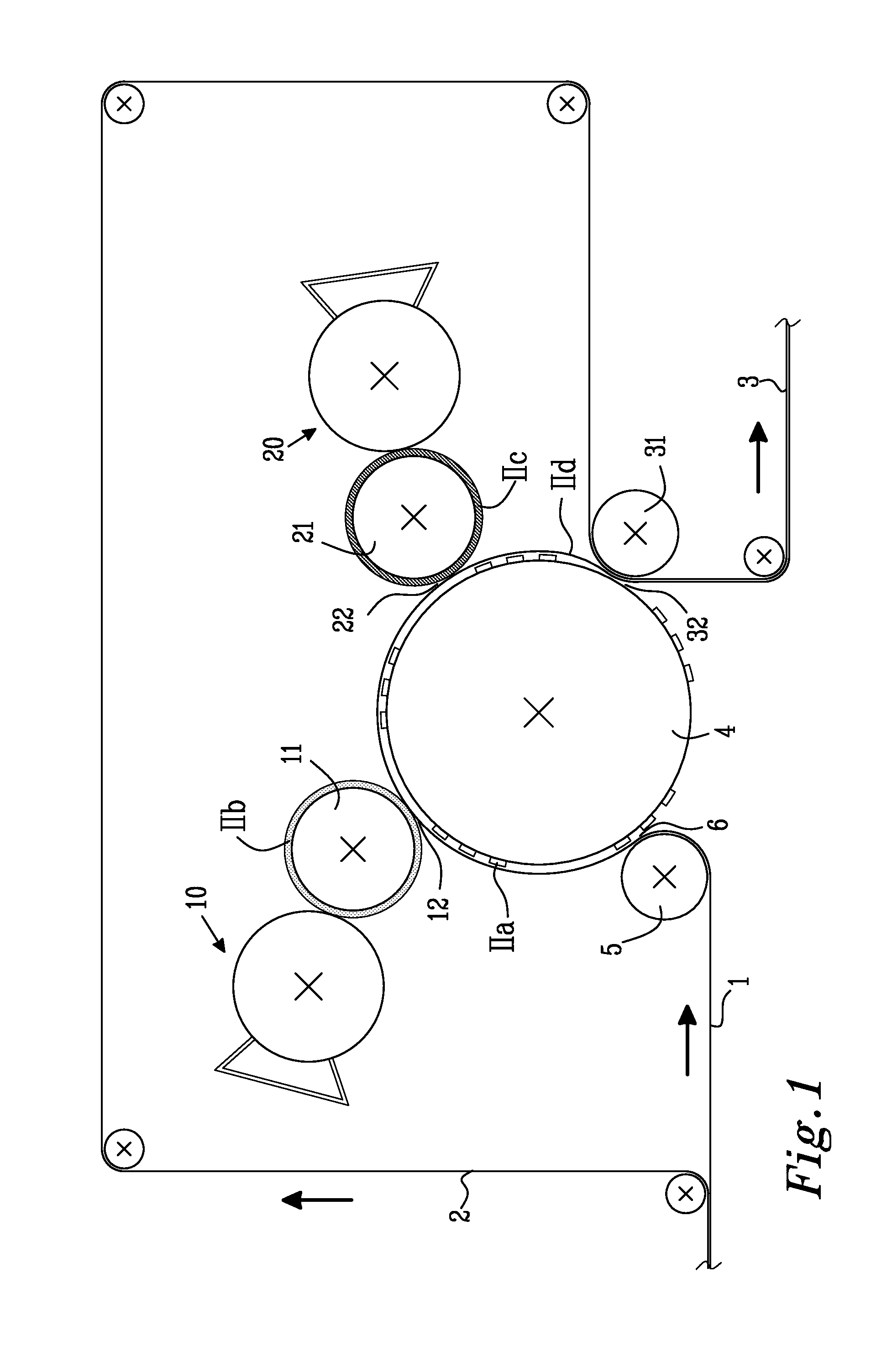

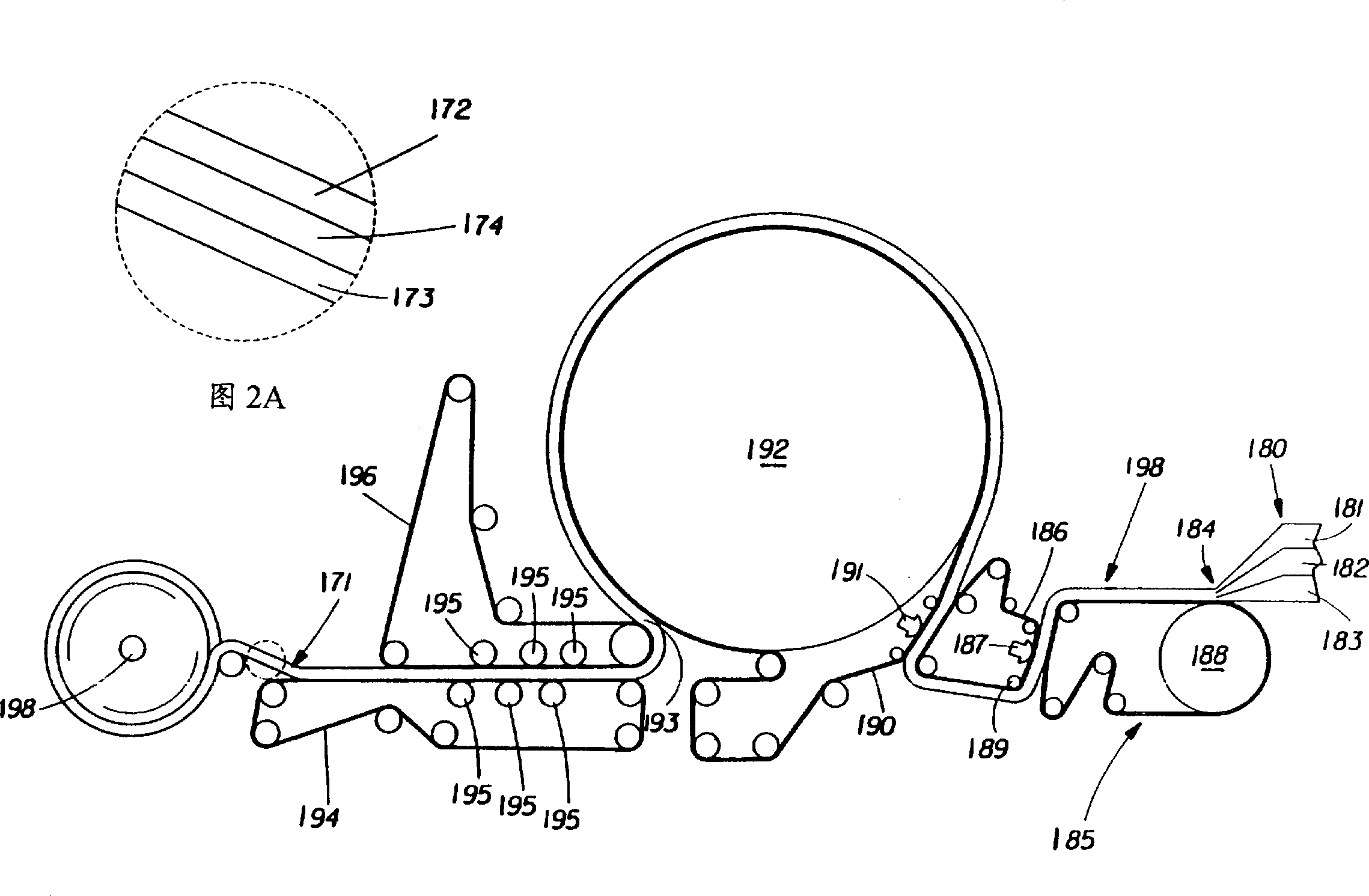

Multilayer belt for creping and structuring in a tissue making process

Owner:ALBANY INT CORP

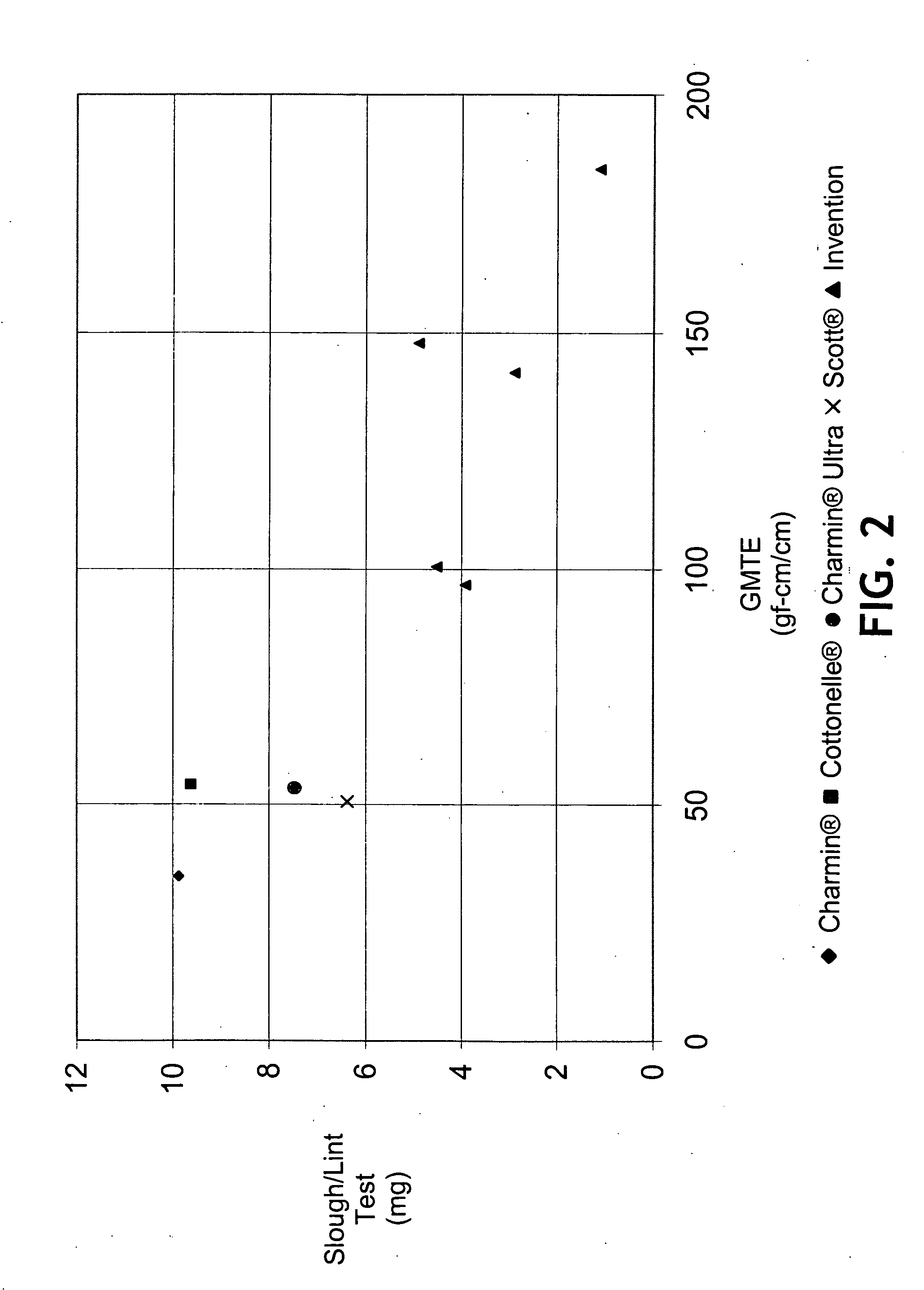

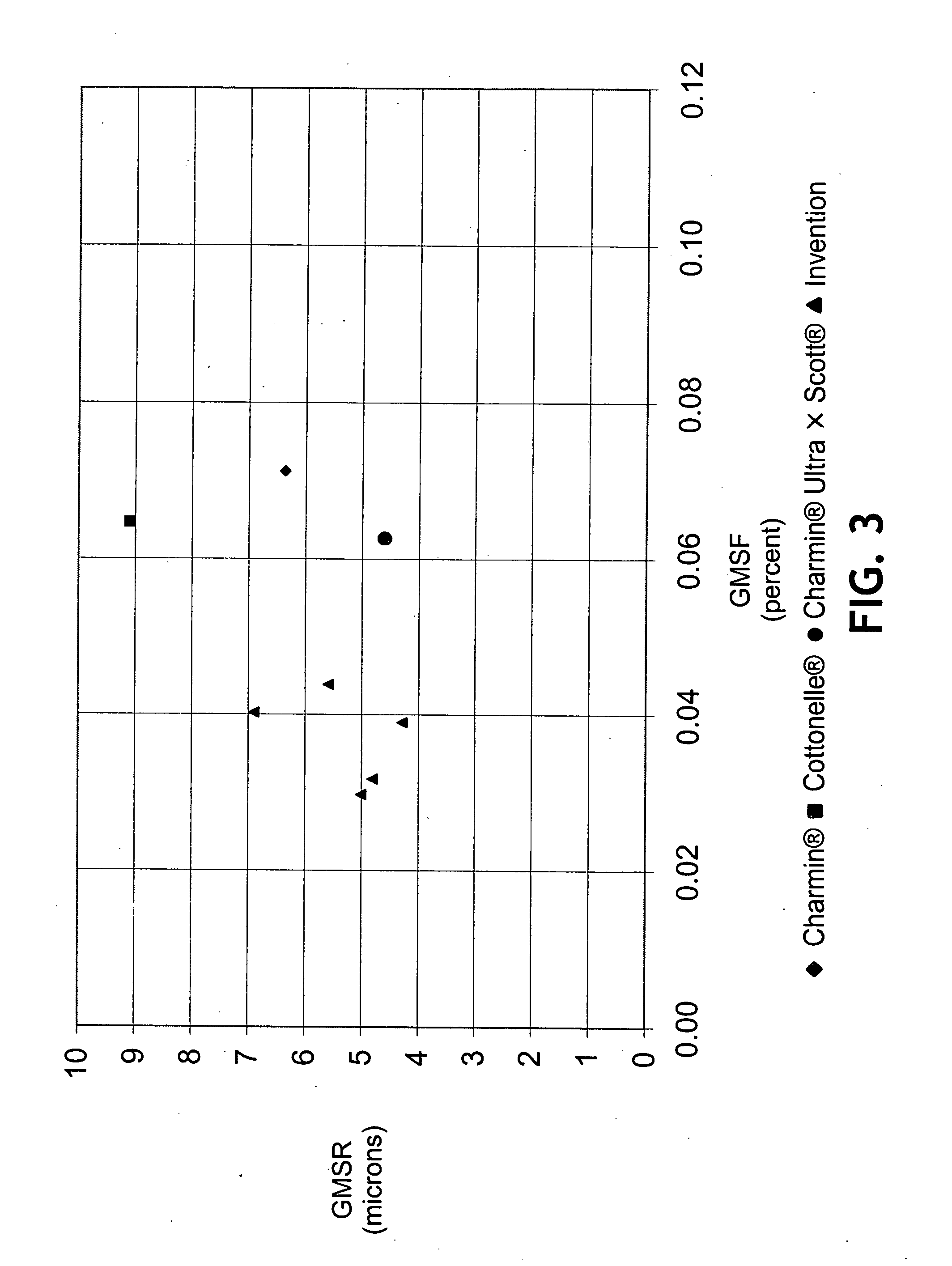

Printed, soft, bulky single-ply absorbent paper having a serpentine configuration and low sidedness and methods for its manufacture

InactiveUS6299729B1Good flexibilityLow sidednessNanotechNatural cellulose pulp/paperGramUltimate tensile strength

The present invention relates to a soft, thick, single-ply, printed, absorbent paper product having a Yankee side and an air side wherein the absorbent paper is printed on before or after embossing on the Yankee side, air side, or both sides, said absorbent paper exhibiting a serpentine configuration. This inventions also relates to a process for the manufacture of such absorbent paper product having a basis weight of at least about 12.5 lbs. per 3000 square foot ream and having low sidedness, said tissue exhibiting:a specific total tensile strength of between 40 and 200 grams per 3 inches per pound per 3000 square foot ream, a cross direction specific wet tensile strength of between 2.75 and 20.0 grams per 3 inches per pound per 3000 square foot ream, the ratio of MD tensile to CD tensile of between 1.25 and 2.75, a specific geometric mean tensile stiffness of between 0.5 and 3.2 grams per inch per percent strain per pound per 3000 square foot ream, a friction deviation of less than 0.250, and a sidedness parameter of less than 0.30. These single-ply, printed, absorbent paper products in the form of unembossed or embossed single-ply bathroom tissue, facial tissue, or napkin are useful articles of commerce. The single-ply absorbent paper products exhibit a printed sidedness value of DELTAE of less than 2.

Owner:GPCP IP HLDG LLC

Deep-nested embossed paper products

The present invention relates to embossed tissue-towel paper products comprising one or more plies of tissue paper wherein at least one of the plies of tissue paper comprises a plurality of embossments wherein the at least one embossed plies have a total embossed area less than or equal to about 15% and an average embossment height of at least about 650 μm and E factor of between about 0.0150 to about 1.0000 inches4 per number of embossments.

Owner:THE PROCTER & GAMBLE COMPANY

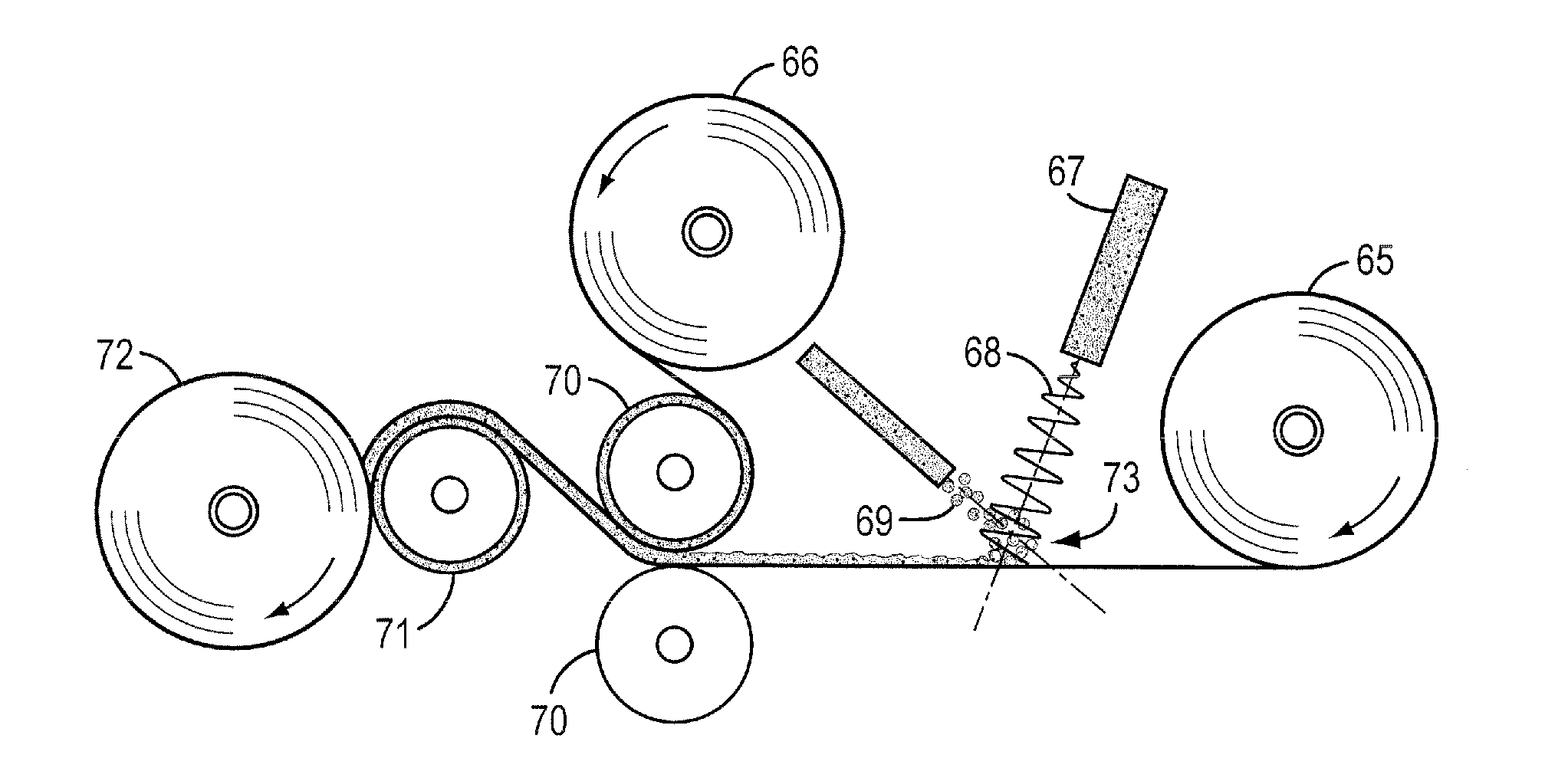

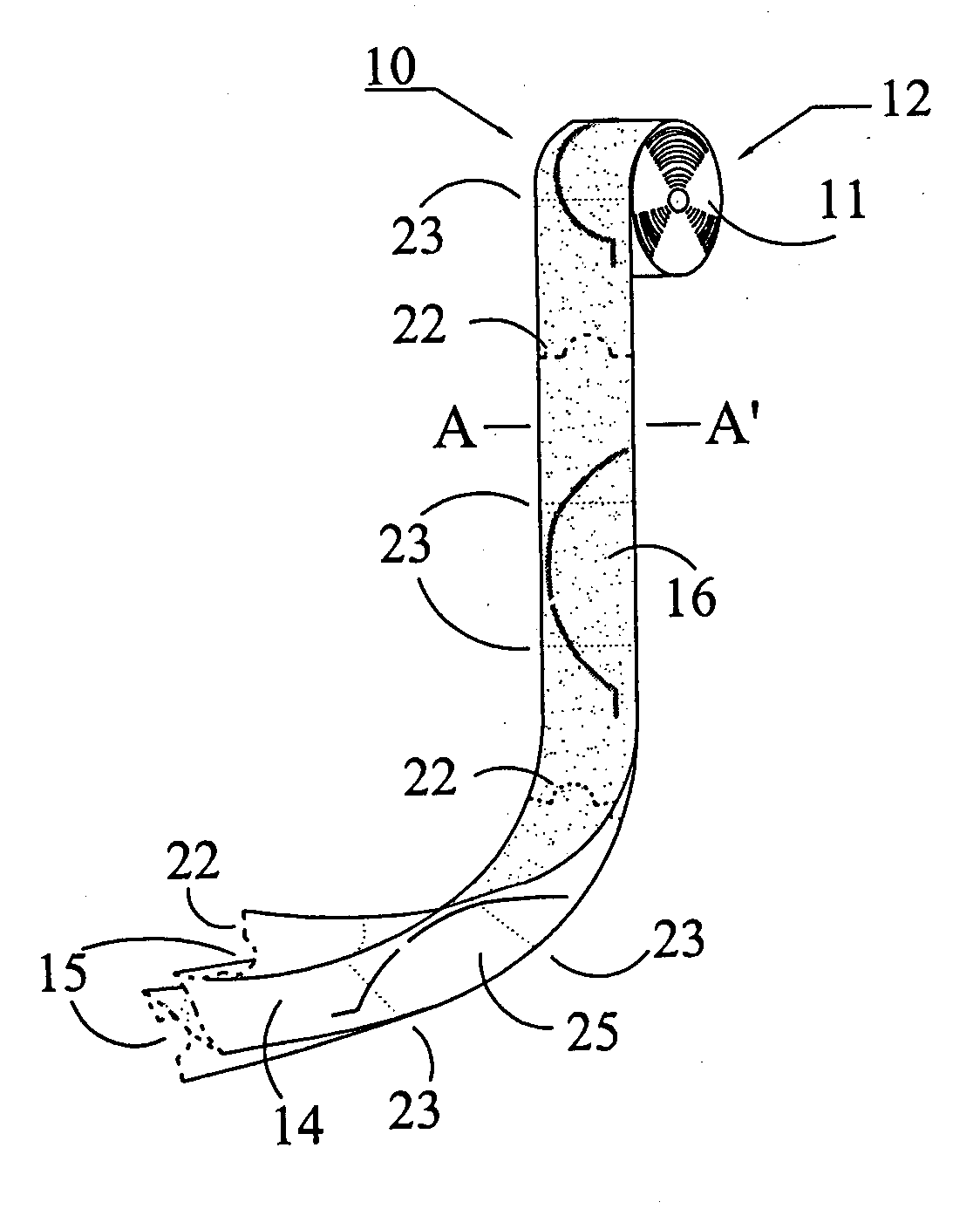

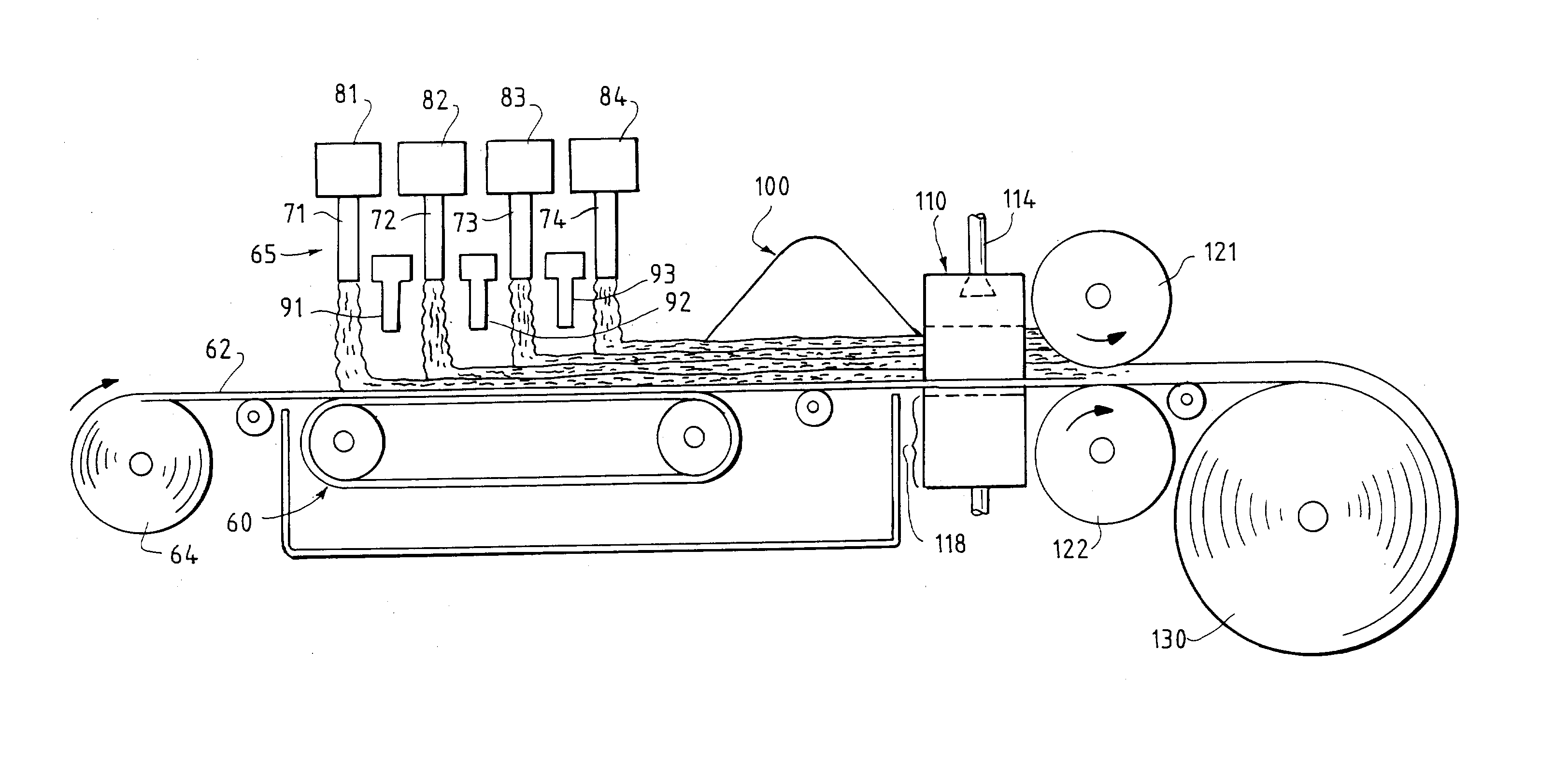

Ultra thin laminate with particulates in dense packages

The present invention is directed to a method of forming a laminate absorbent structure, and a resulting package containing a single continuous running web of the laminate material. Notably, formation of the material is effected by blending a curtain of adhesive fibers with a curtain of particulate material, and depositing the mixture on a moving substrate, preferably provided in the form of a tissue layer. A second substrate, also preferably comprising a tissue layer, is applied on top of the deposited mixture, and pressure applied to form the laminated structure. Notably, attendant to packaging of the laminated material, adjacent layers of the material tend to nest into one another, to form a sandwich in which the density of the material in the package is more than 1.5 times the density of the material after its removal from the package.

Owner:EVEREADY BATTERY CO INC +1

Soft tissue paper having a polyhydroxy compound applied onto a surface thereof

A tissue paper product having at least one ply, wherein only one outer surface of said tissue paper product has a polyhydroxy compound applied thereto by slot extrusion, said polyhydroxy compound providing said tissue paper product with a Wet Burst greater than about 90 g, a Dynamic Coefficient of Friction less than about 0.9, and a Bending Flexibility less than about 0.1 gf cm2 / cm.

Owner:PROCTER & GAMBLE CO

Fibrous sheets coated or impregnated with biodegradable polymers or polymers blends

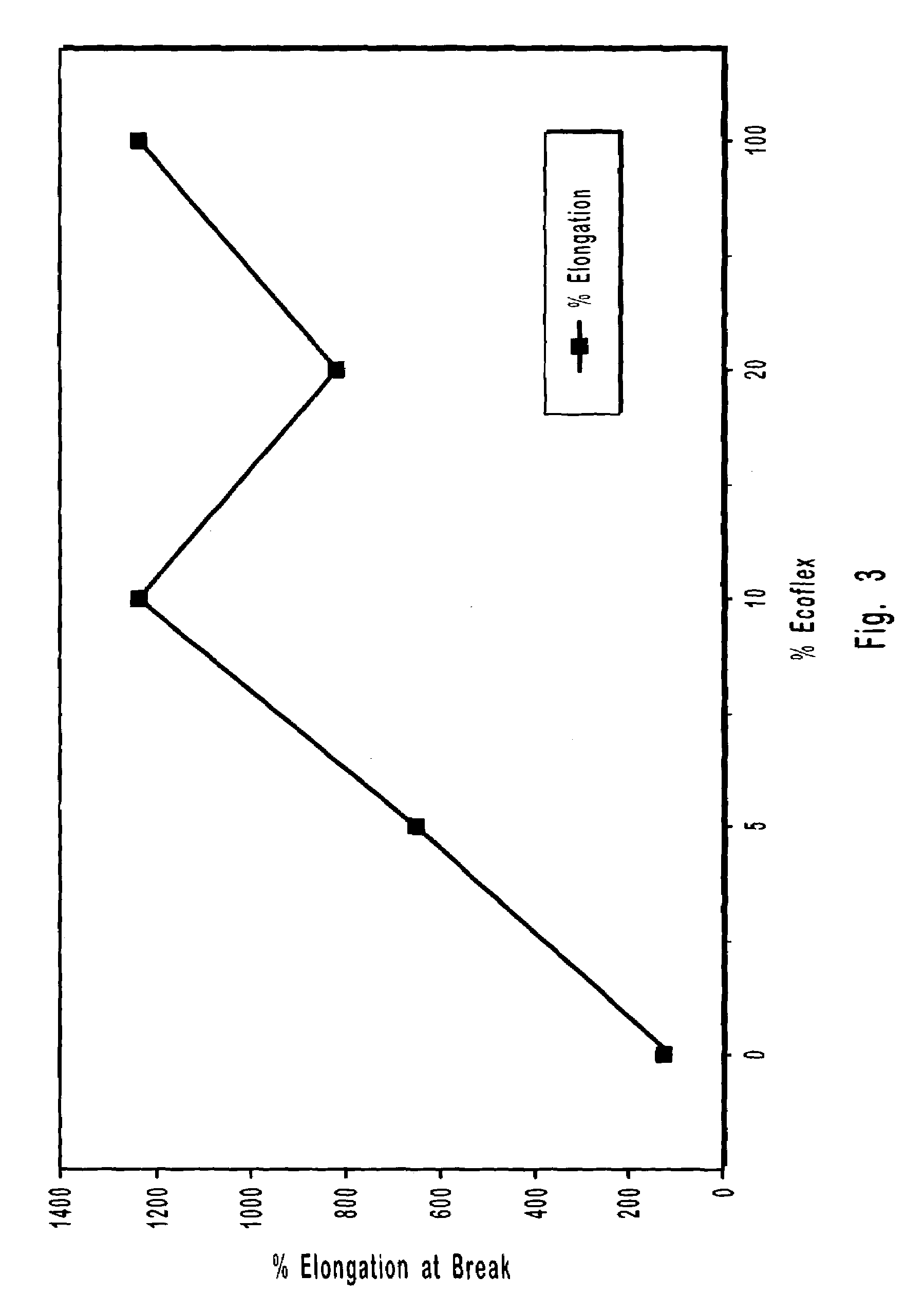

ActiveUS7172814B2High glass transition temperatureImprove the crystallization processBio-packagingPaper coatingPolymer scienceBiopolymer

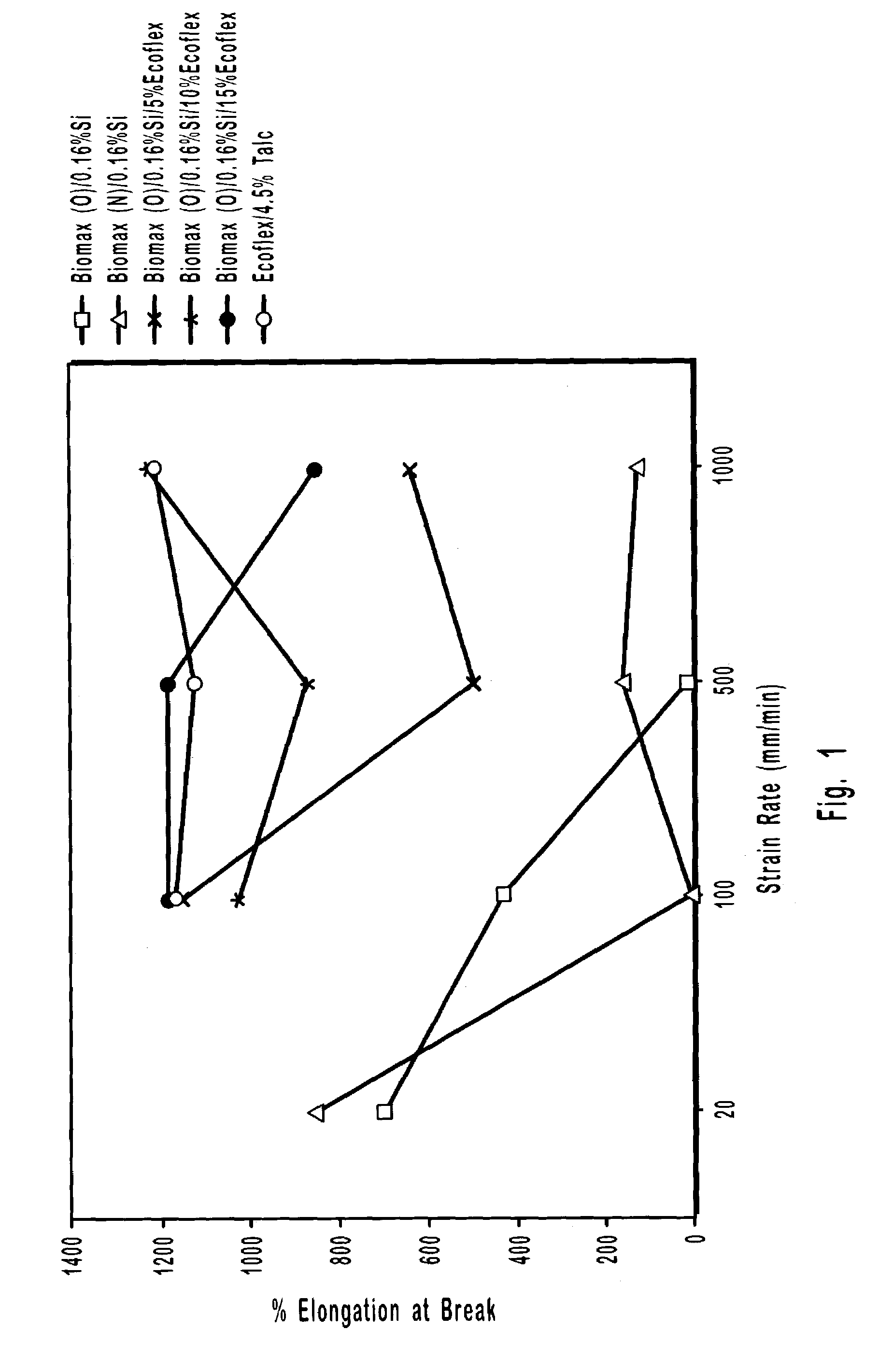

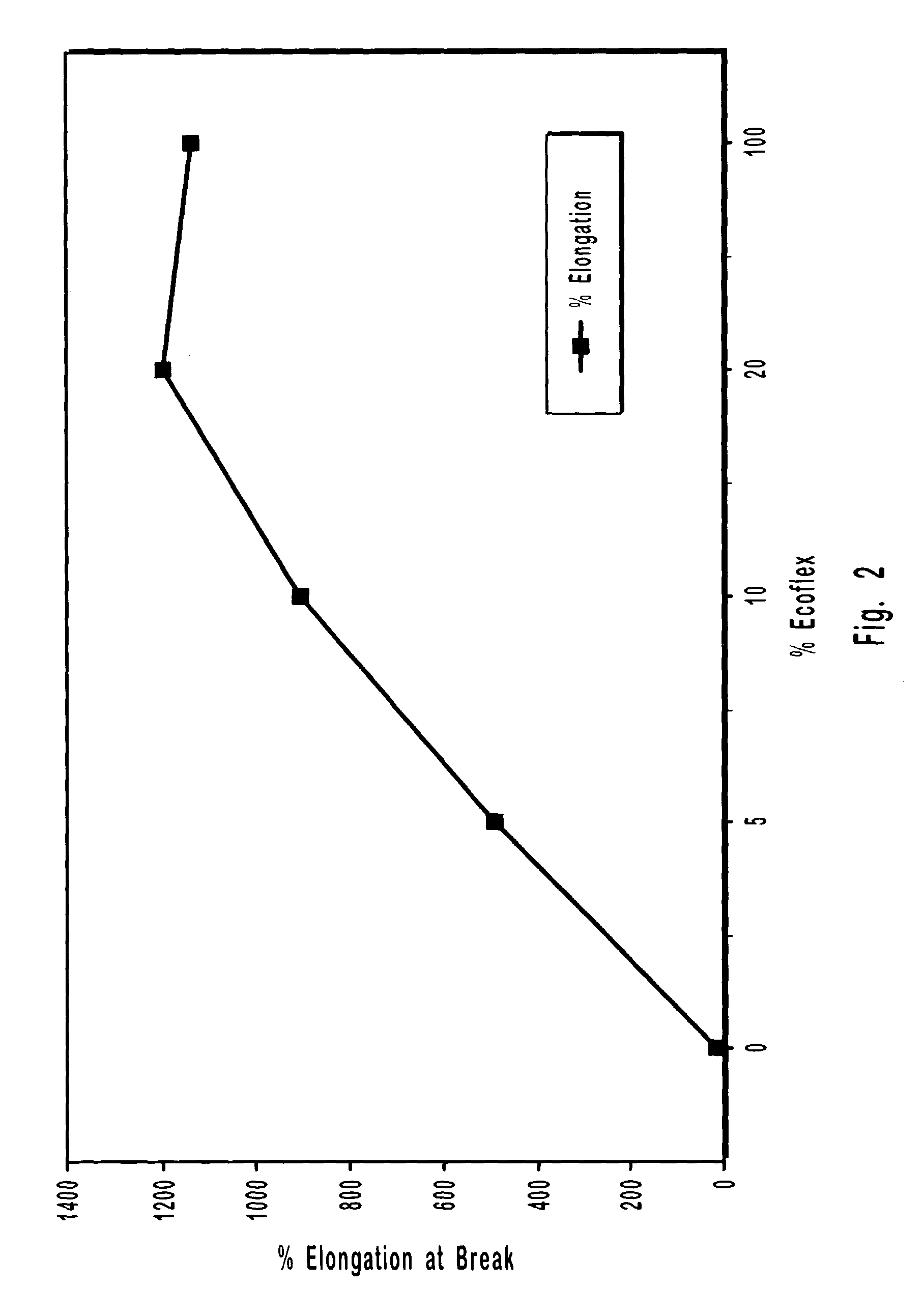

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one “hard” biodegradable polymer and at least one “soft” biodegradable polymer. “Hard” biopolymers typically have a glass transition temperature of at least about 10° C. “Soft” biodegradable polymers typically have a glass transition temperature less than about 0° C. Another useful biodegradable polymer composition includes one or more biodegradable polymers and sufficient inorganic filler so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12–15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

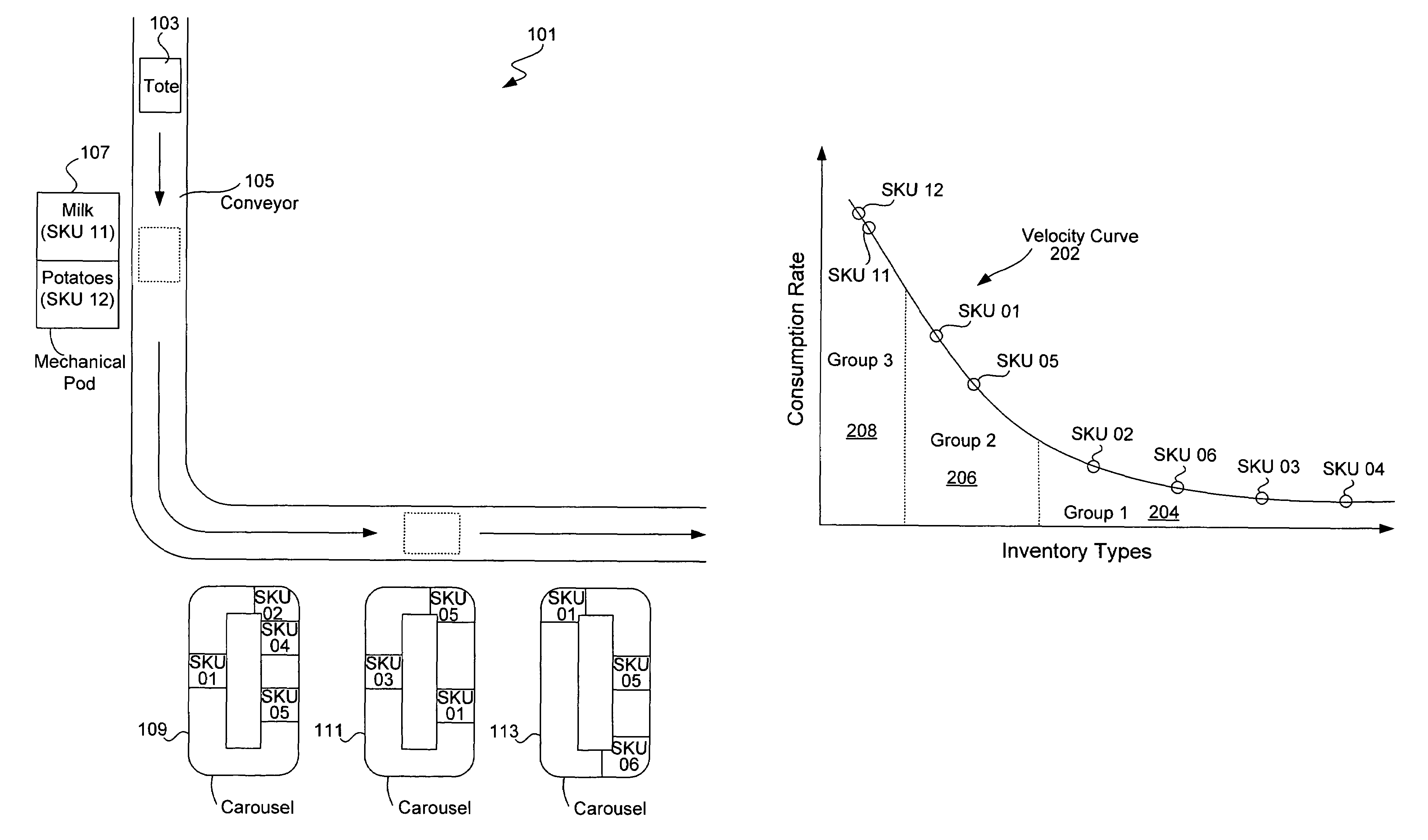

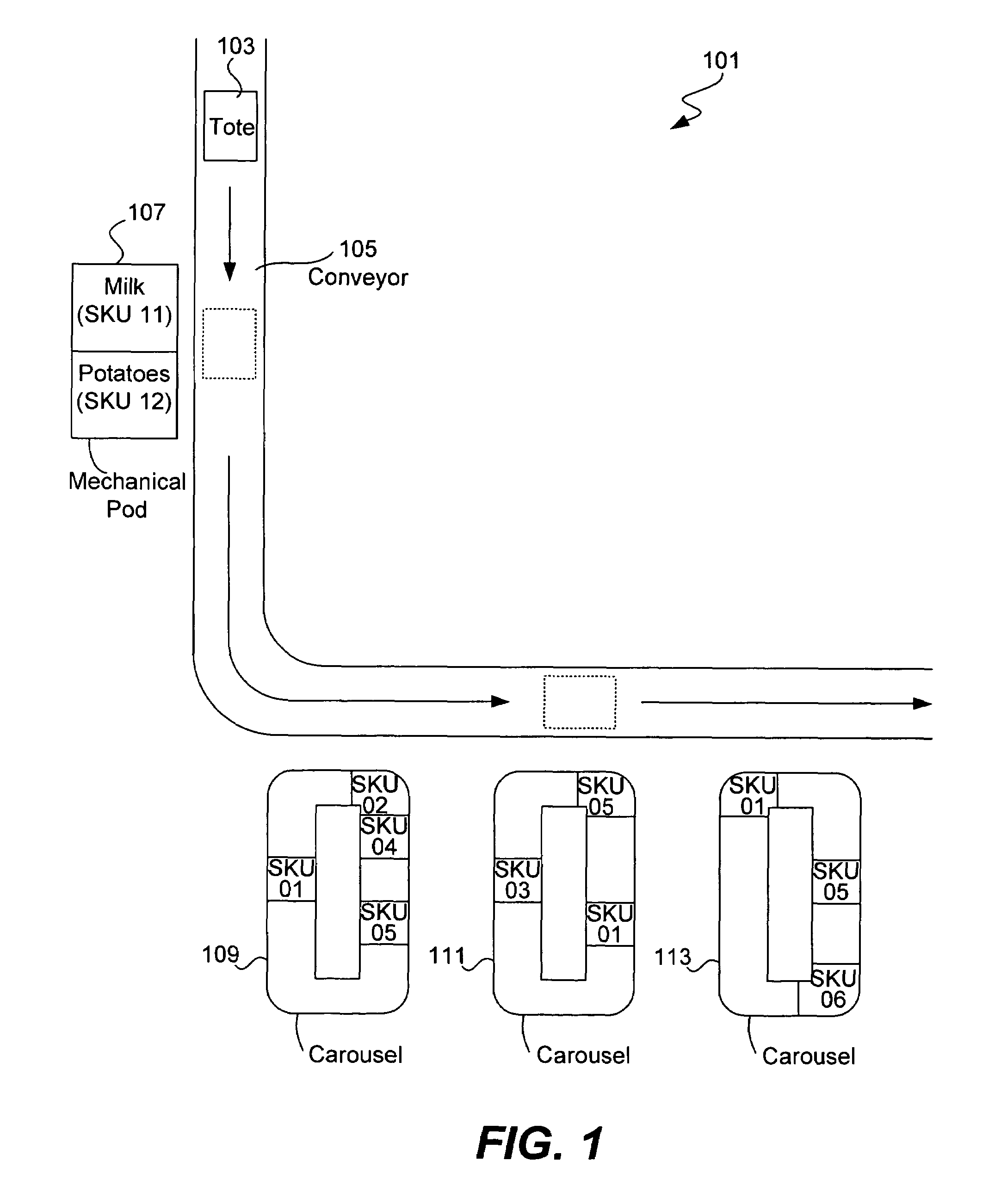

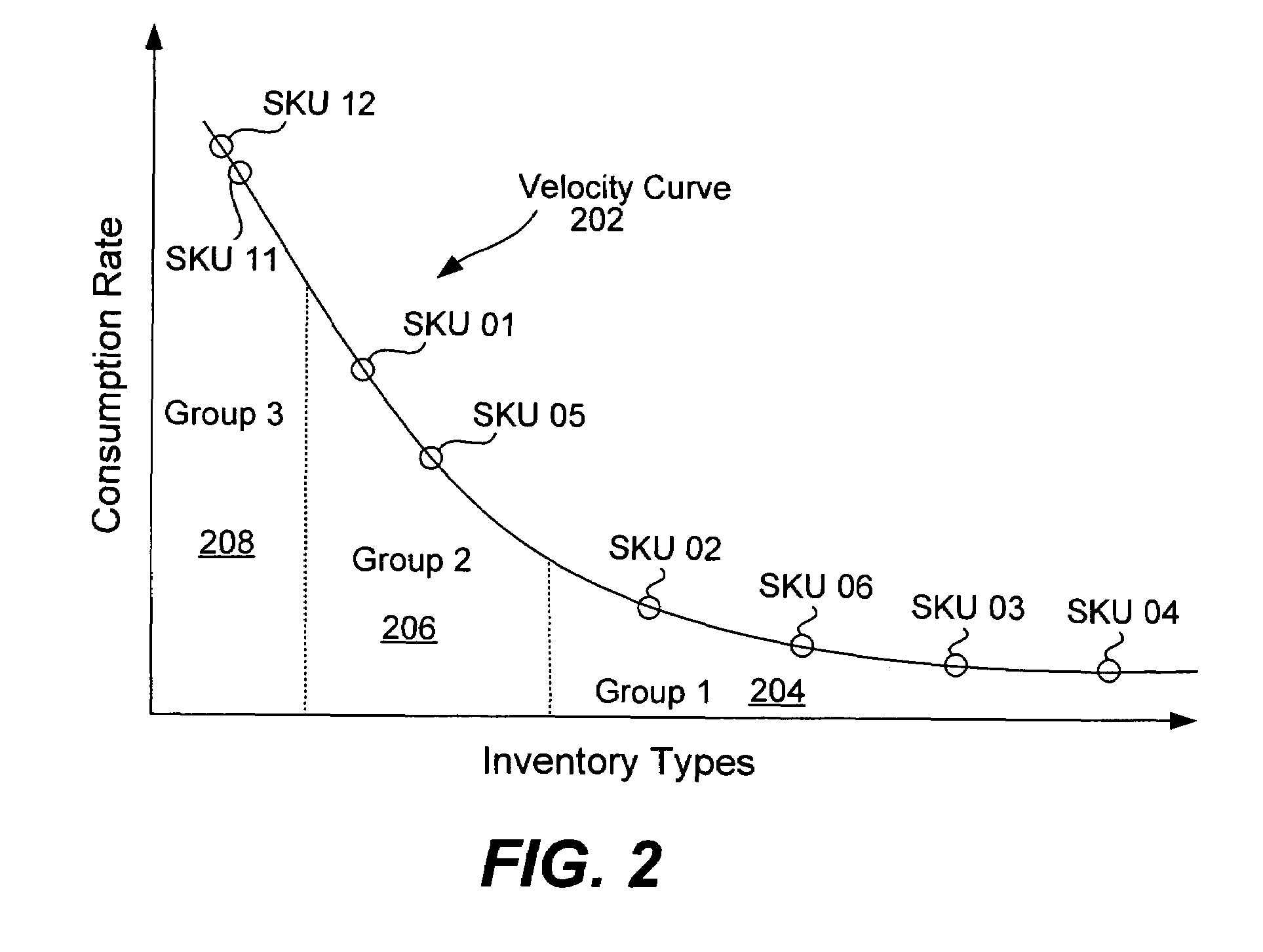

Inventory replication based upon order fulfillment rates

A load balancing technology segregates various inventory types (e.g., potatoes vs. milk, vs. pretzels, vs. tissue paper, etc.) based upon how frequently they are ordered in a distribution center. Inventory types that are ordered at the slowest rate are not “replicated” over multiple pods in the distribution center. Rather, they are constrained to reside at a single pod within the distribution center. Items that are ordered somewhat more frequently than those in the slowest group are replicated in multiple pods across the distribution center. In other words, these items are separately stocked at locations on more than one pod in the distribution center. This means that a container passing through the distribution center can obtain each of the items in the second group of item types at multiple pods in the distribution center. Thus, these items do not create a bottleneck in the order fulfillment process. Inventory types in a third group, the fastest movers, are segregated from items in the first two groups. They are stored in a separate type of pod that fulfills orders even faster than the other type of pods.

Owner:JUNE RAY

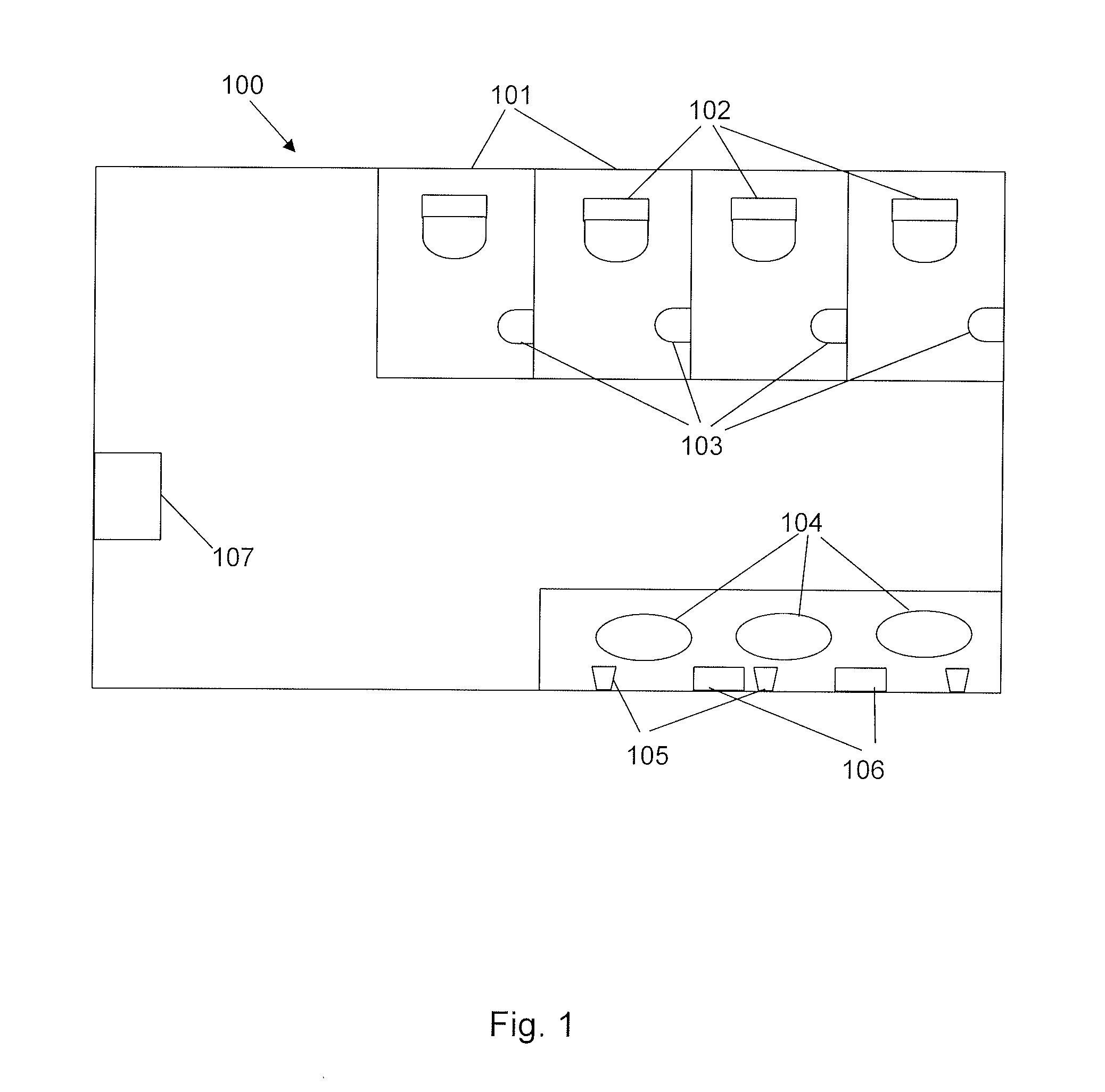

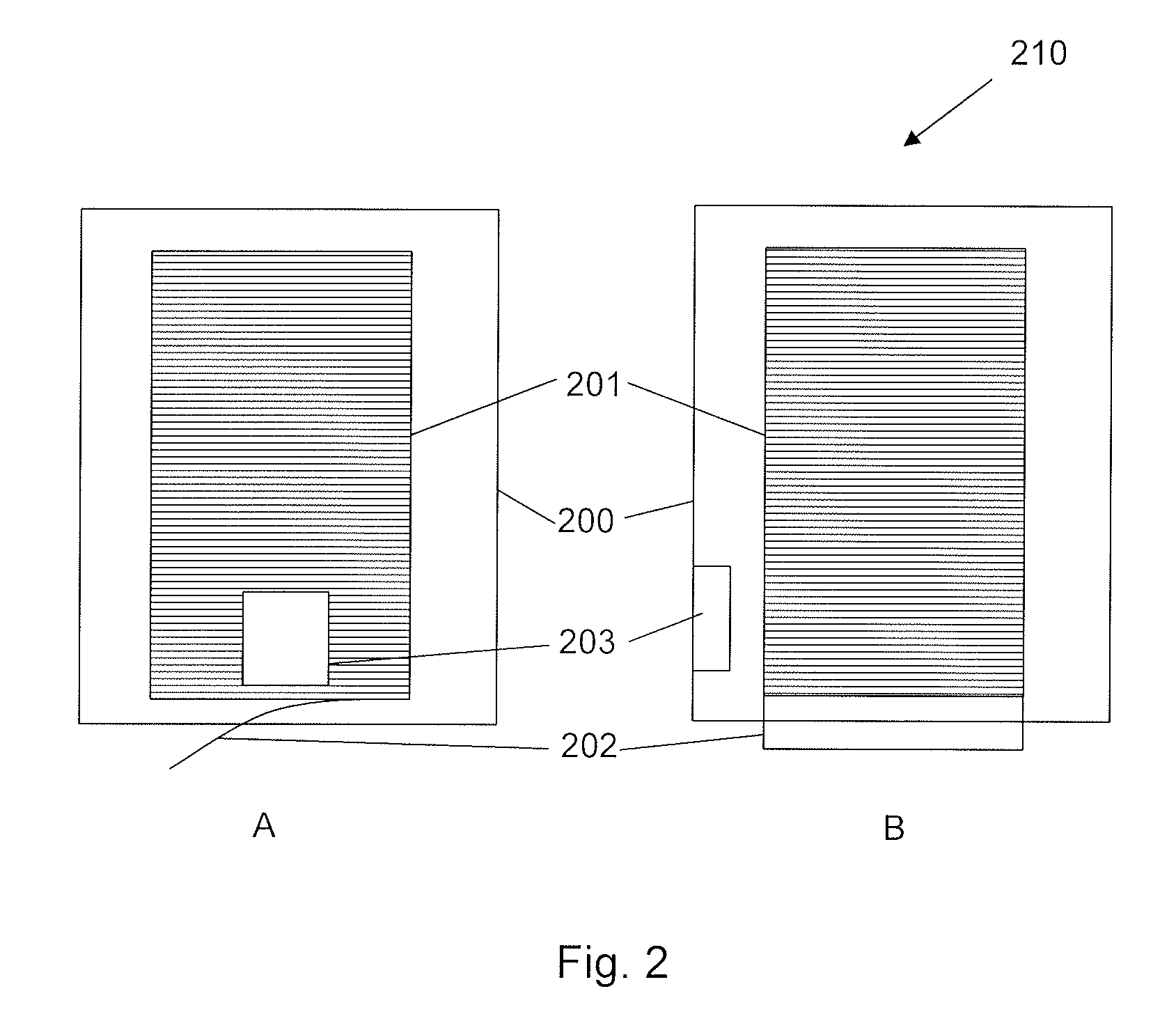

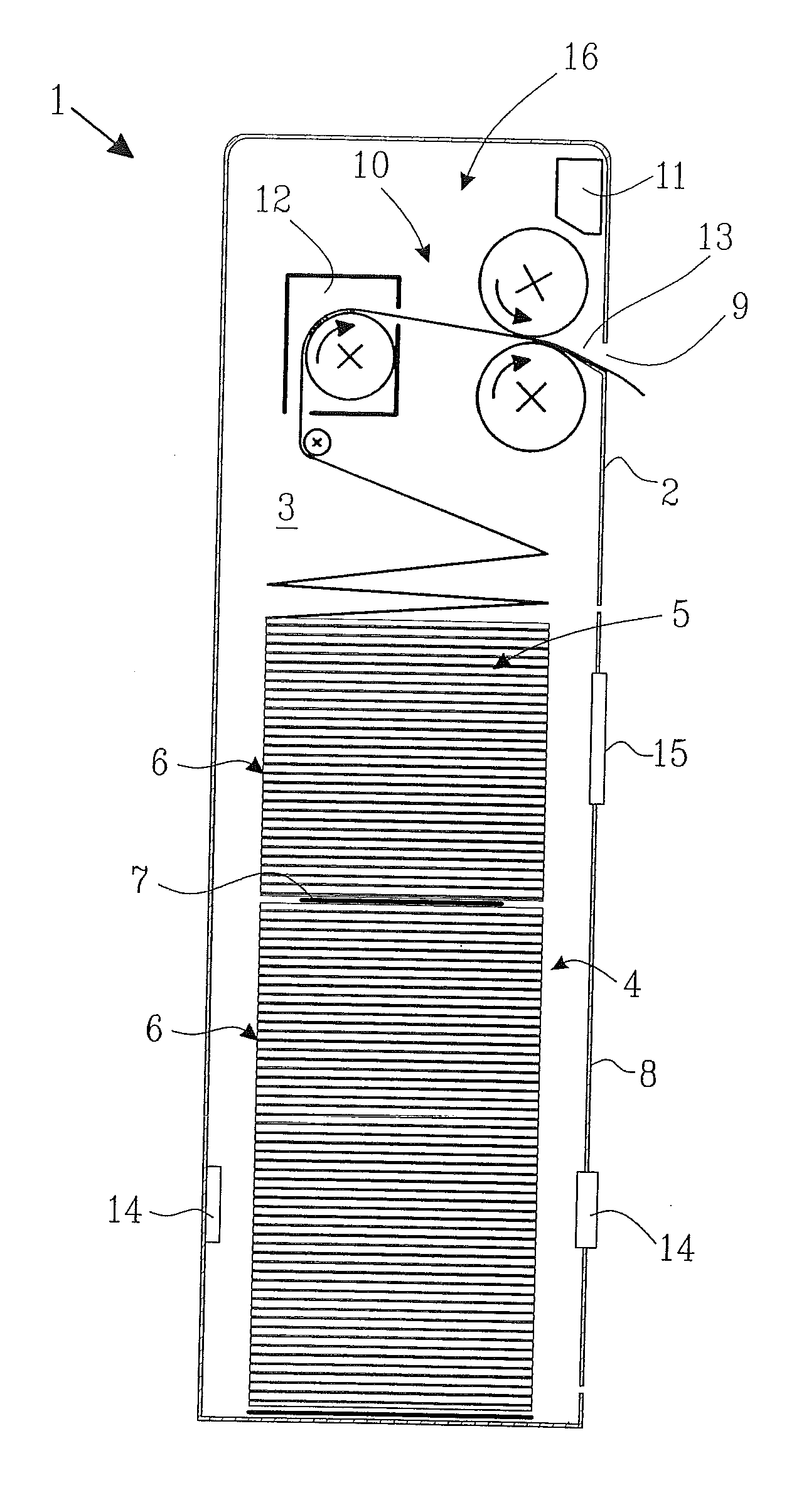

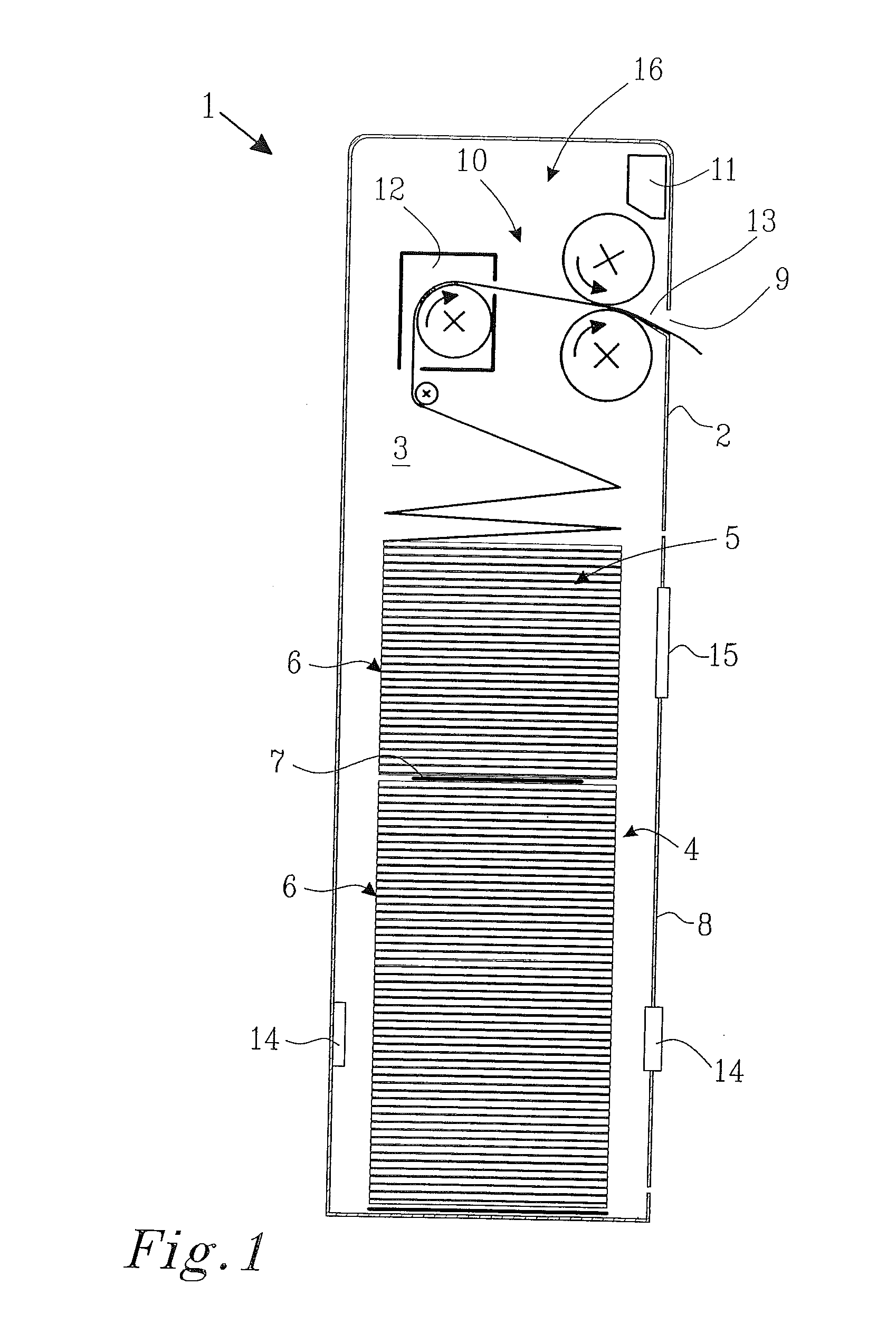

Level sensor and dispenser

ActiveUS20130240554A1Easy to installLong life-timeCoin-freed apparatus detailsDomestic applicationsLevel sensorEngineering

A solution for detecting level of a consumable tissue product (201, 301) in a tissue dispenser (103, 106) located in a washroom. This is provided in a number of aspects such as a tissue dispenser, a method, system, and a sensor unit utilizing two sensor elements (420, 430), each arranged to measure light reflected from a reflection field located on the tissue product, reflected directly from the tissue product, or measure the absence of the tissue product. Data from the sensor elements are wirelessly transmitted to a server (901) for further handling, such as for instance notification to a janitor in charge of service of the washroom.

Owner:ESSITY HYGIENE & HEALTH AB

Absorbent paper product having improved embossing

InactiveUS20040231813A1Non-fibrous pulp additionNatural cellulose pulp/paperVolumetric Mass DensityEngineering

Owner:ESSITY OPERATIONS FRANCE

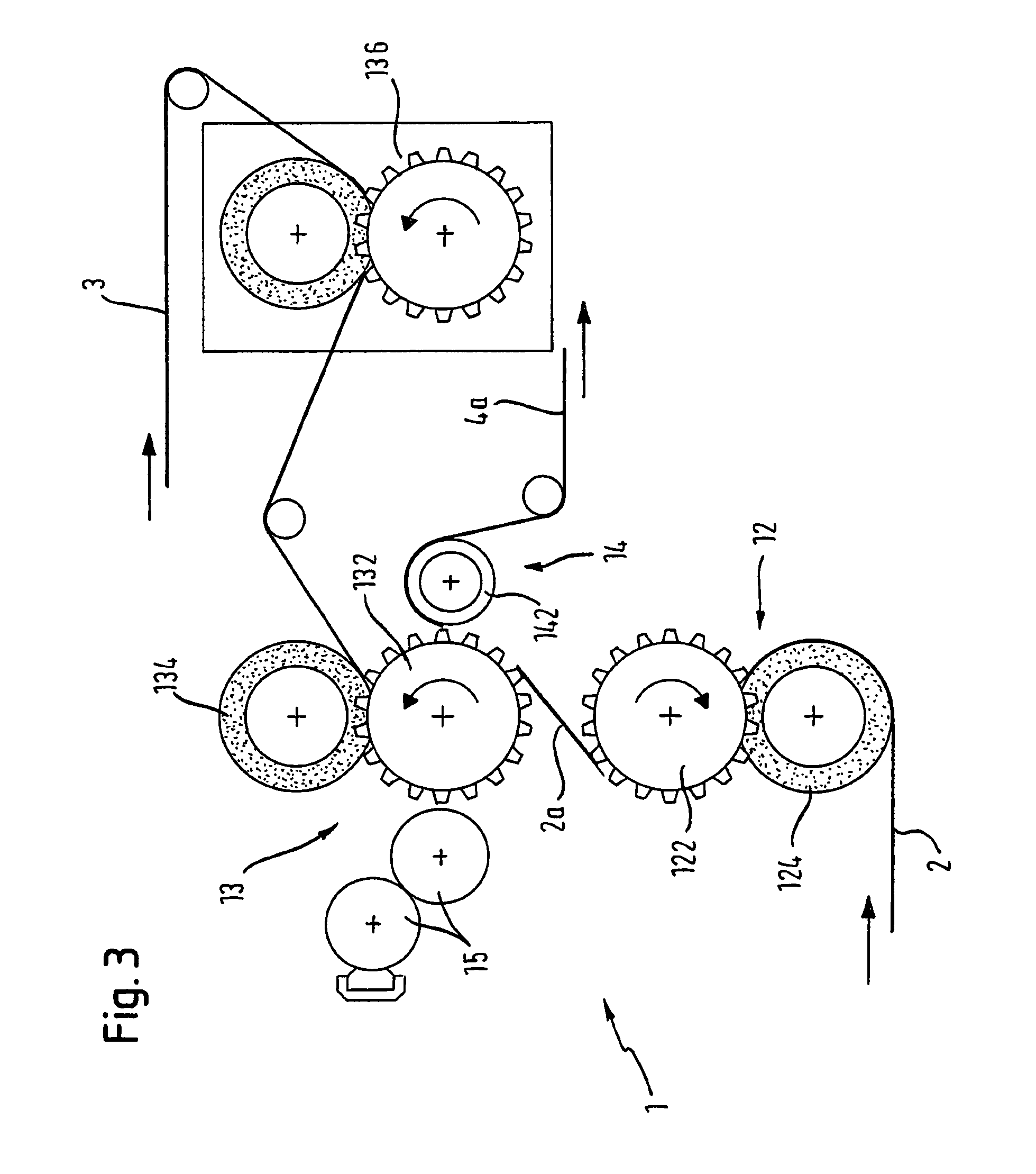

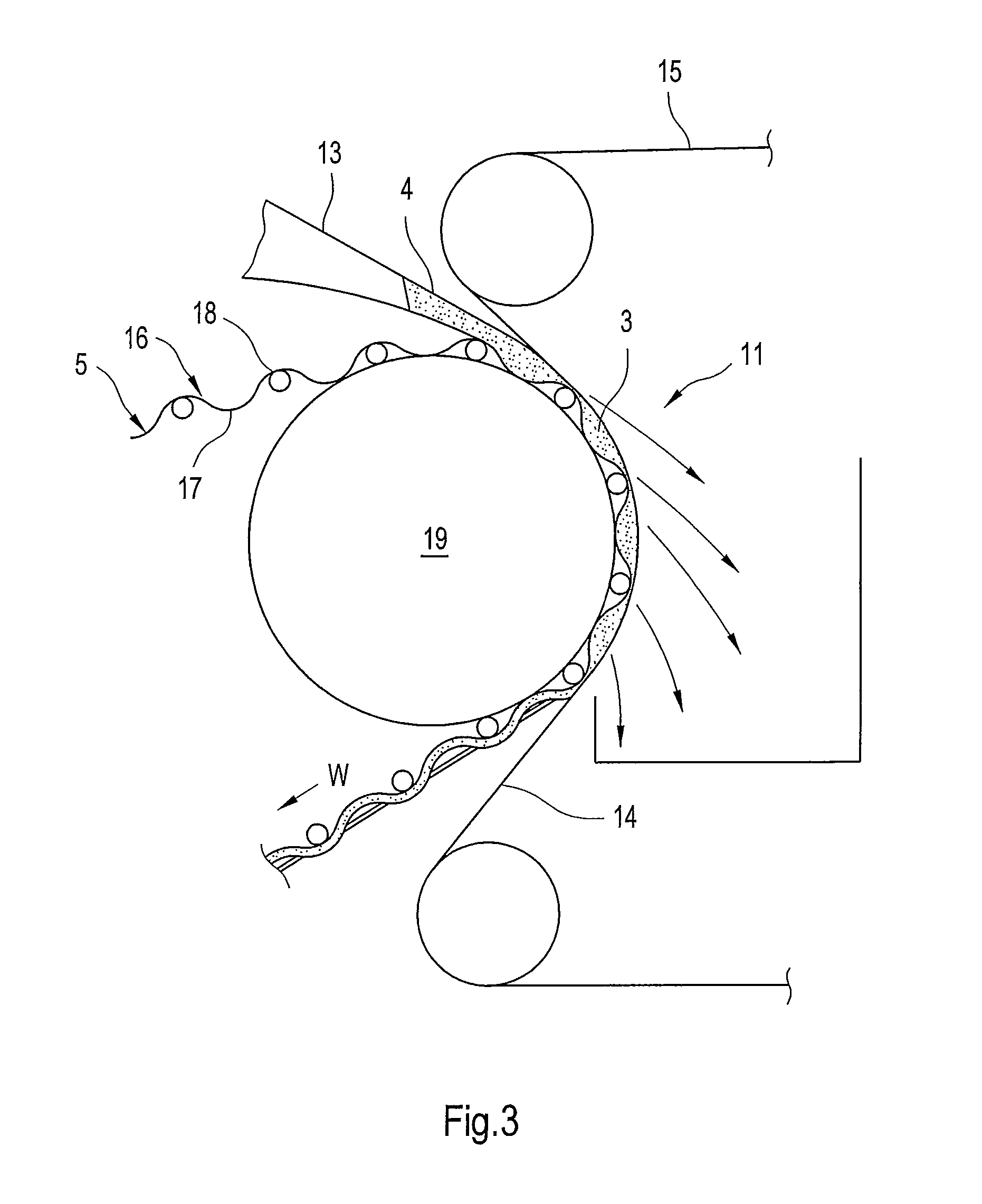

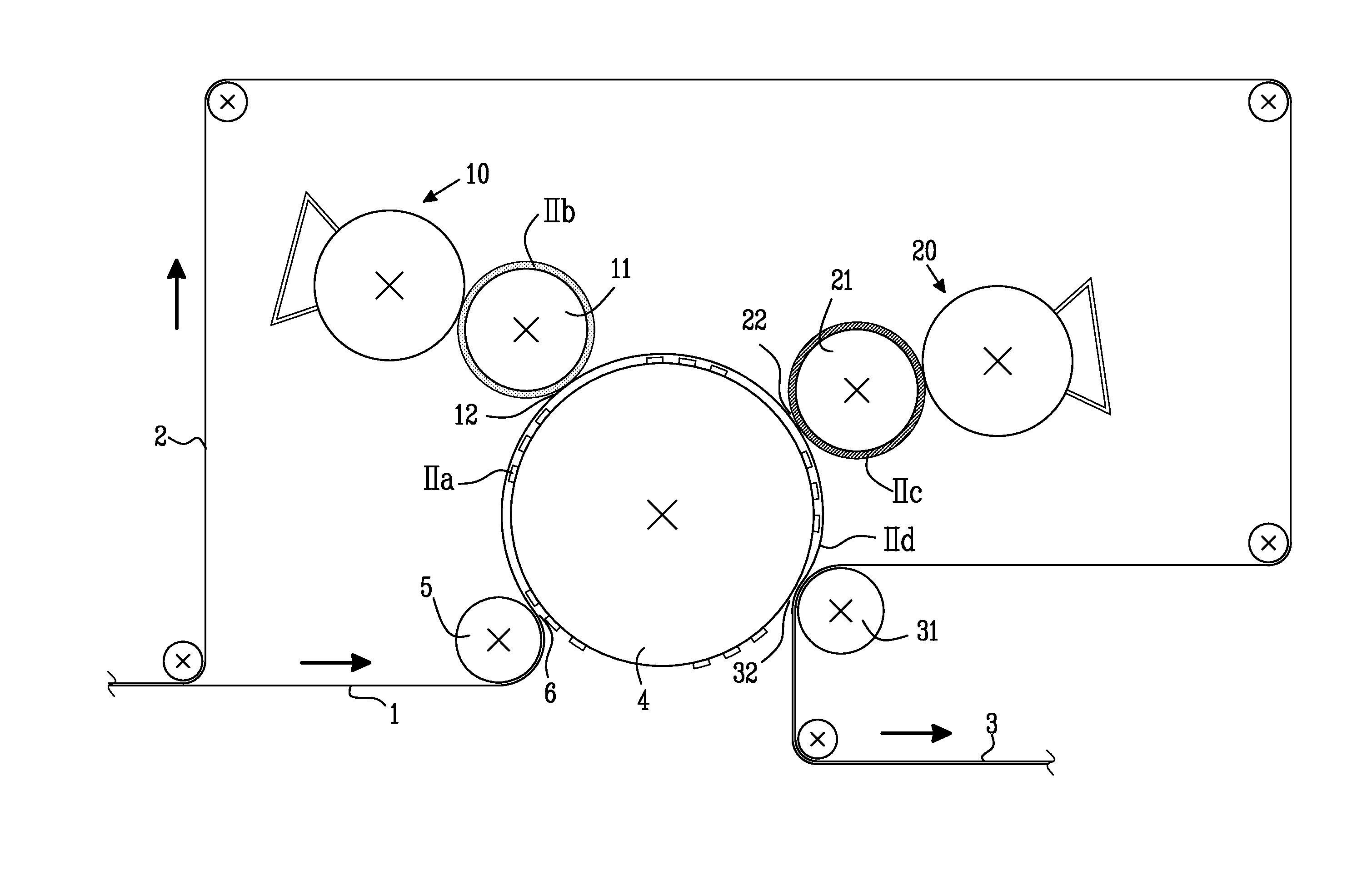

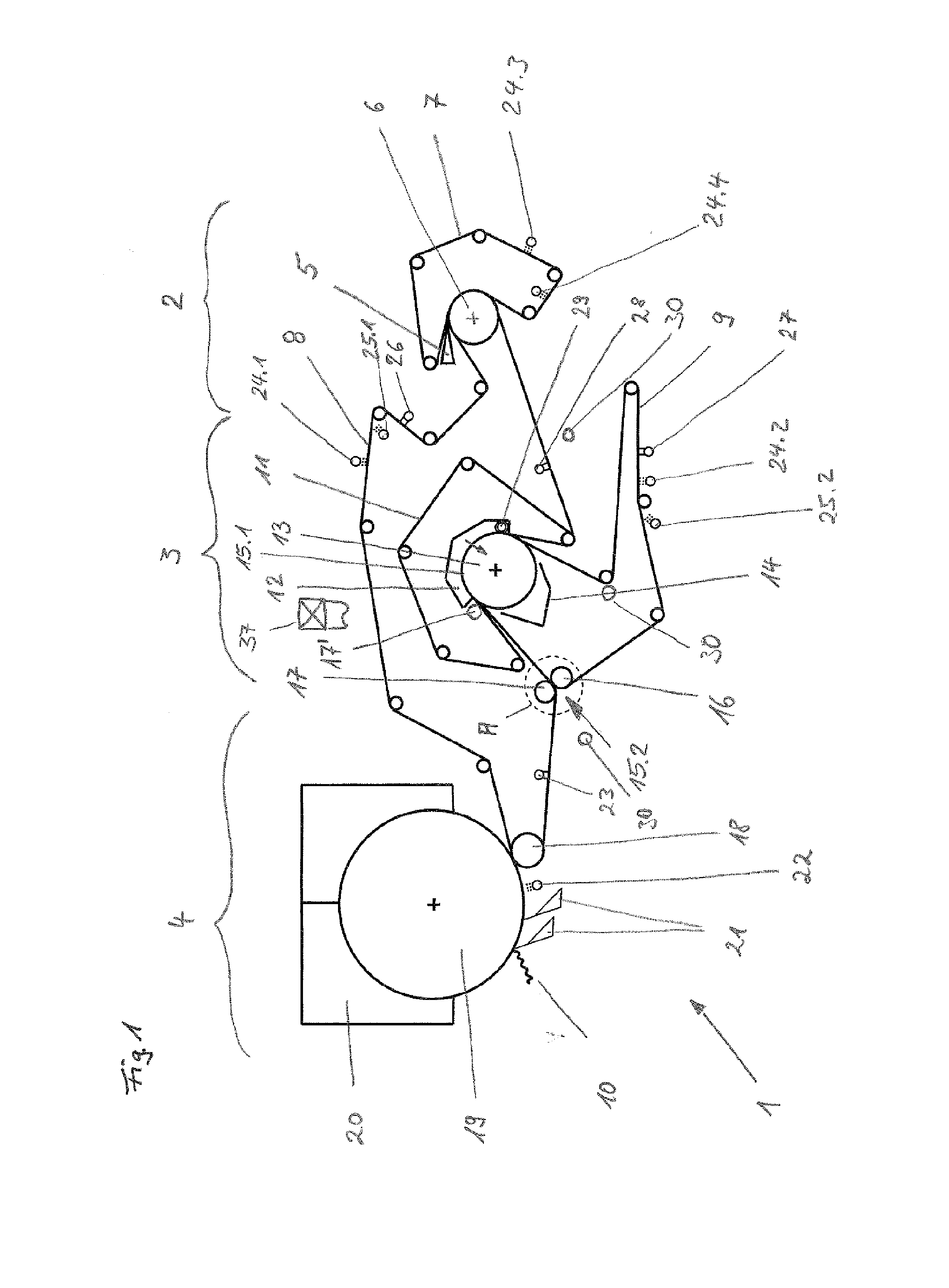

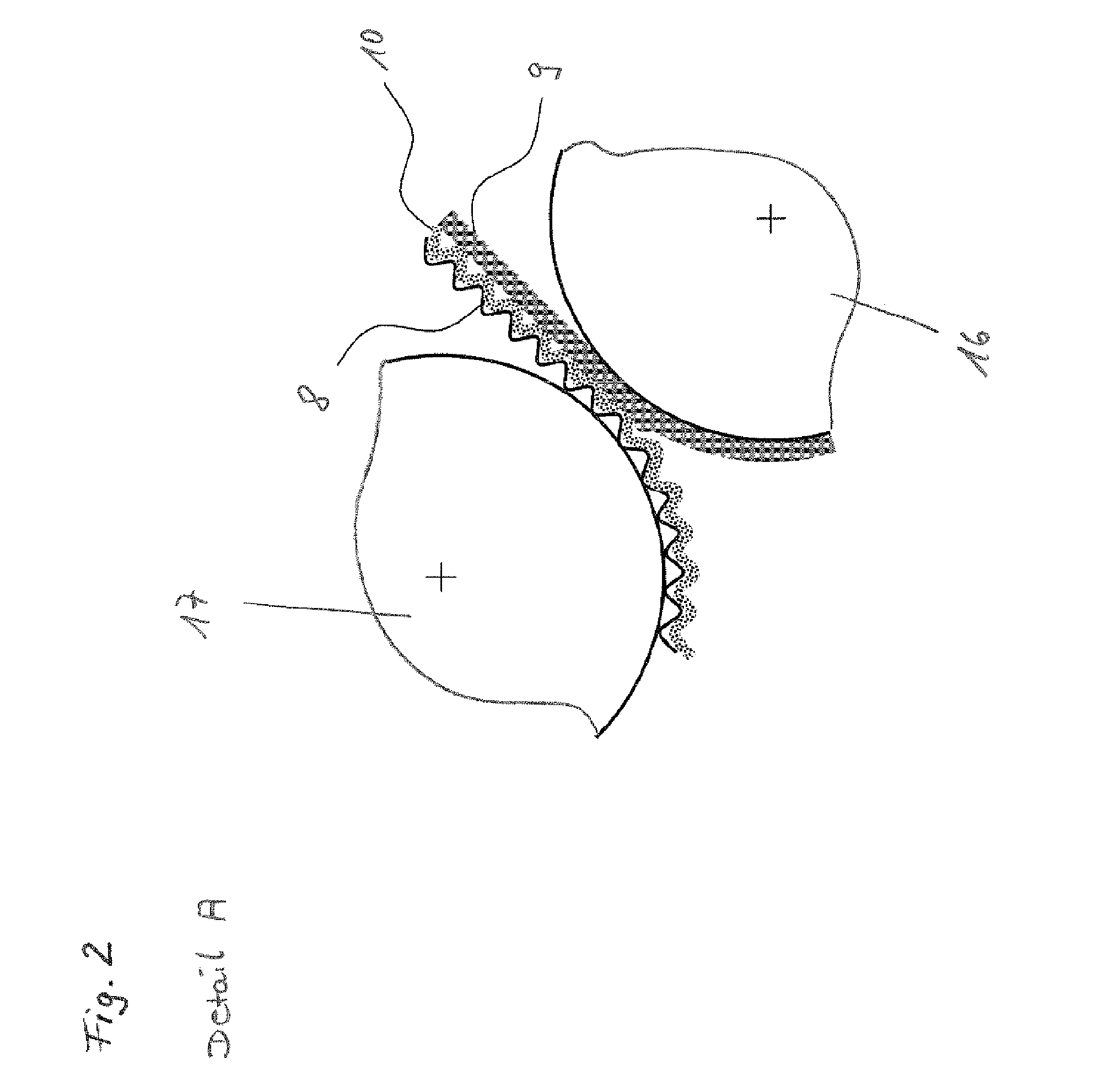

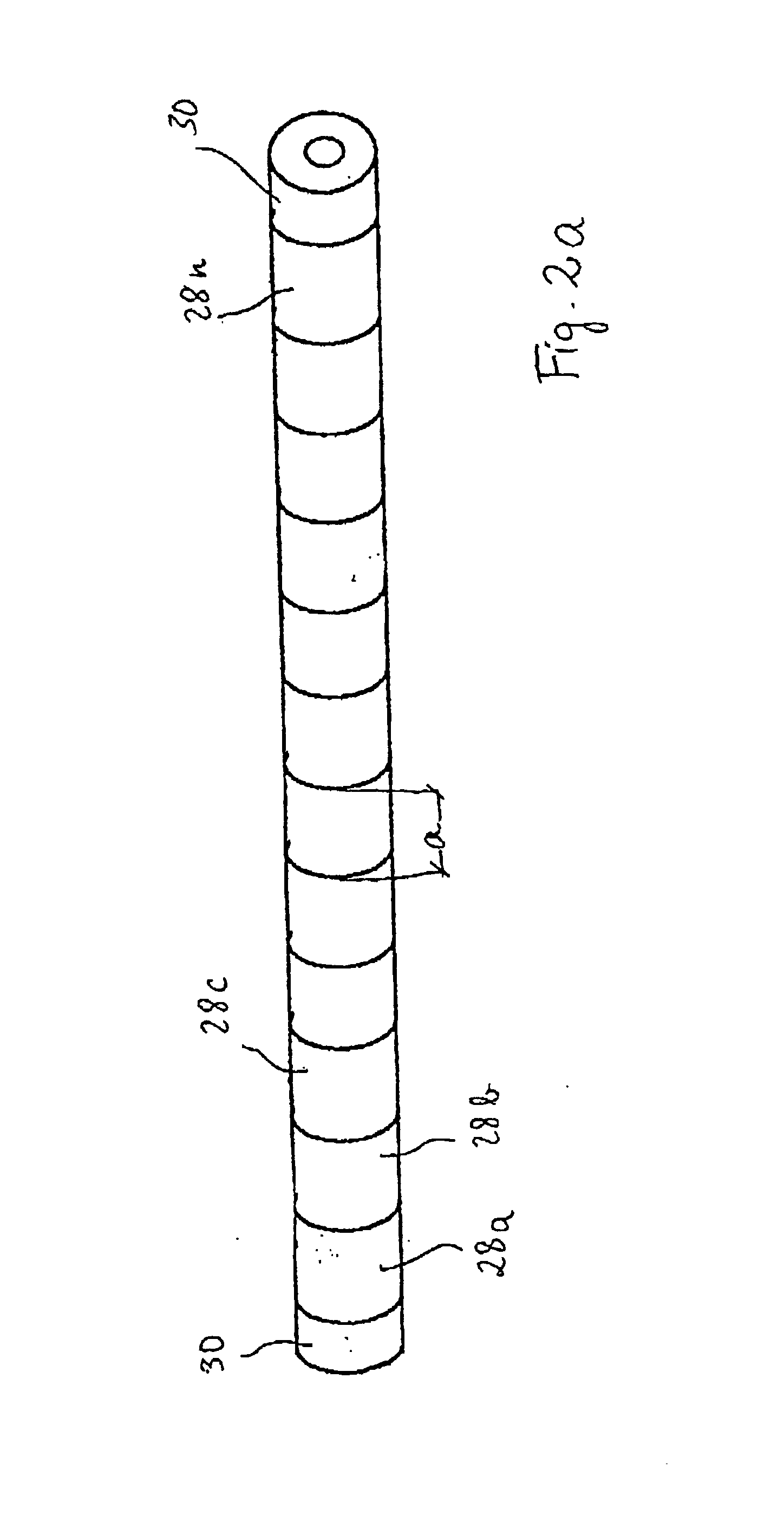

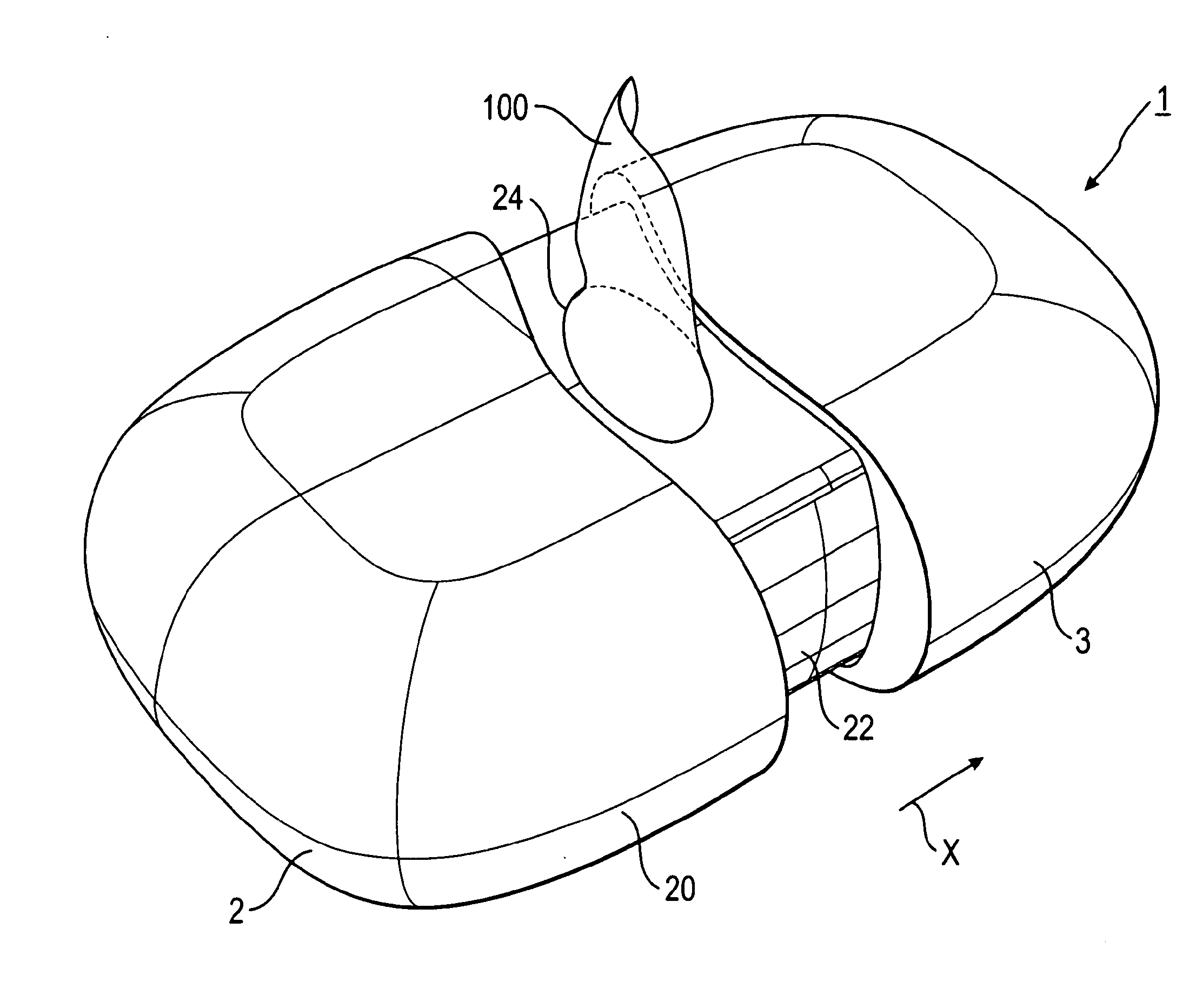

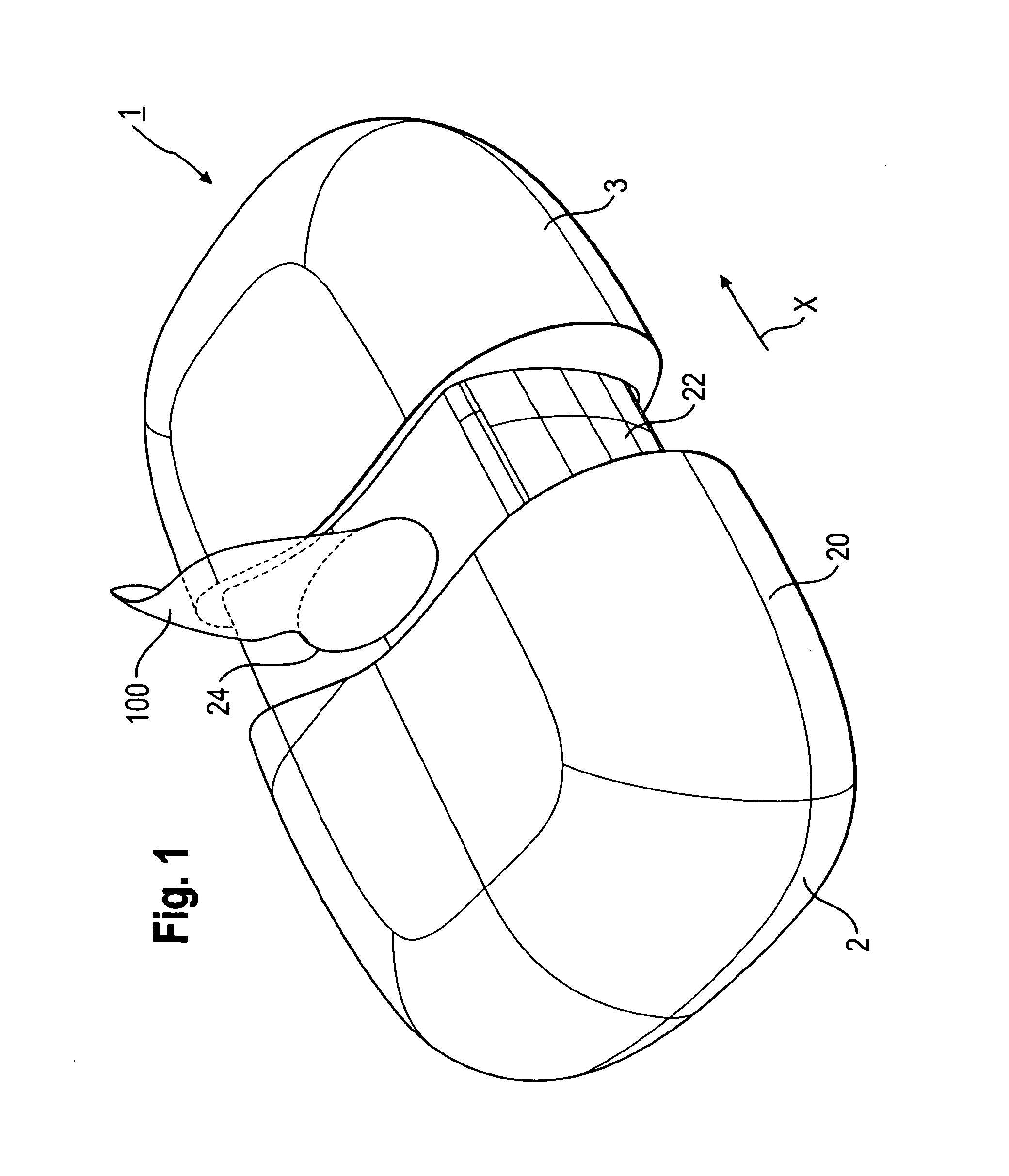

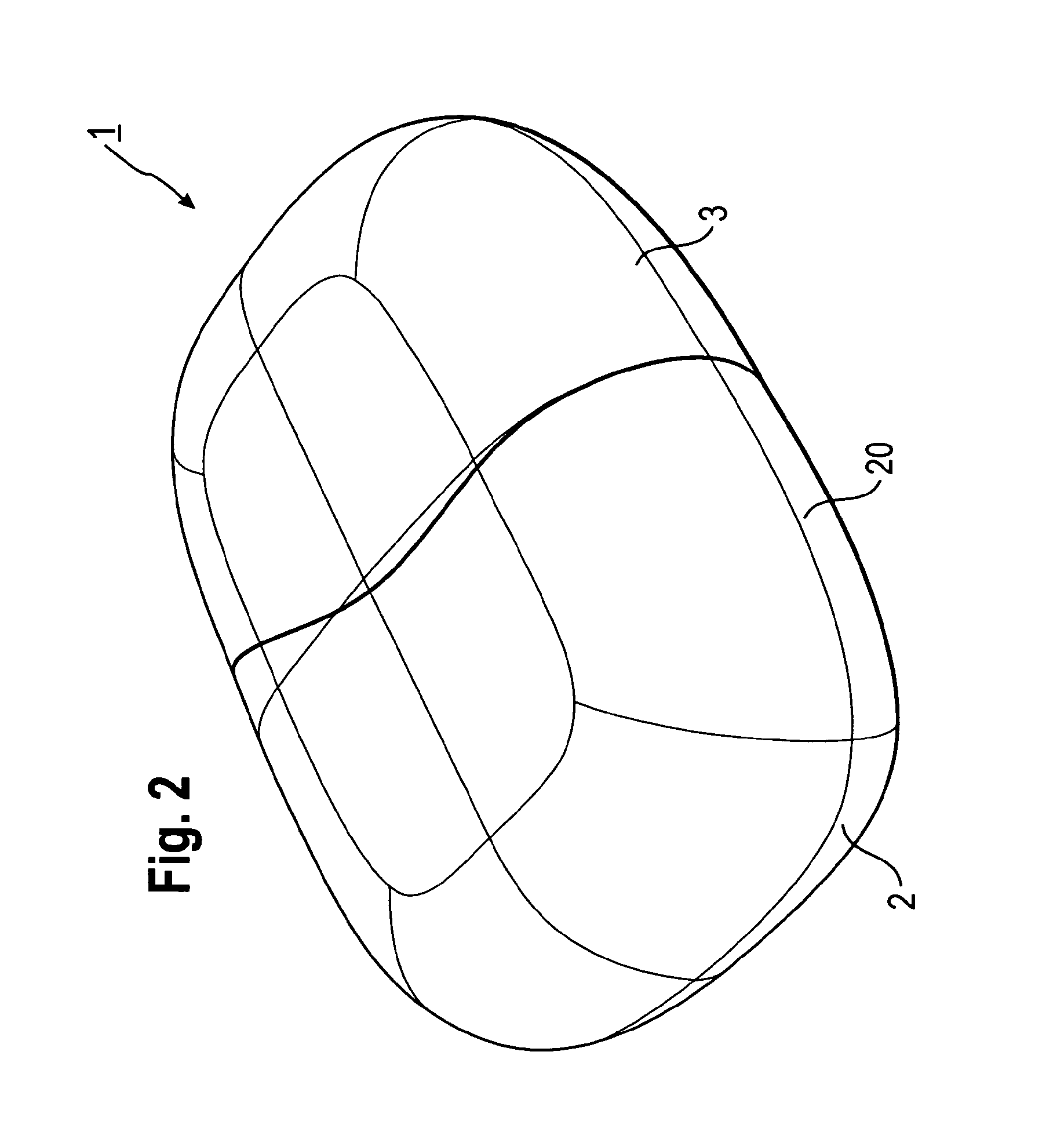

Multi-ply tissue paper, paper converting device and method for producing a multi-ply tissue paper

InactiveUS7871692B2Feel goodGood optical appearanceMechanical working/deformationPersonal careFiberBiomedical engineering

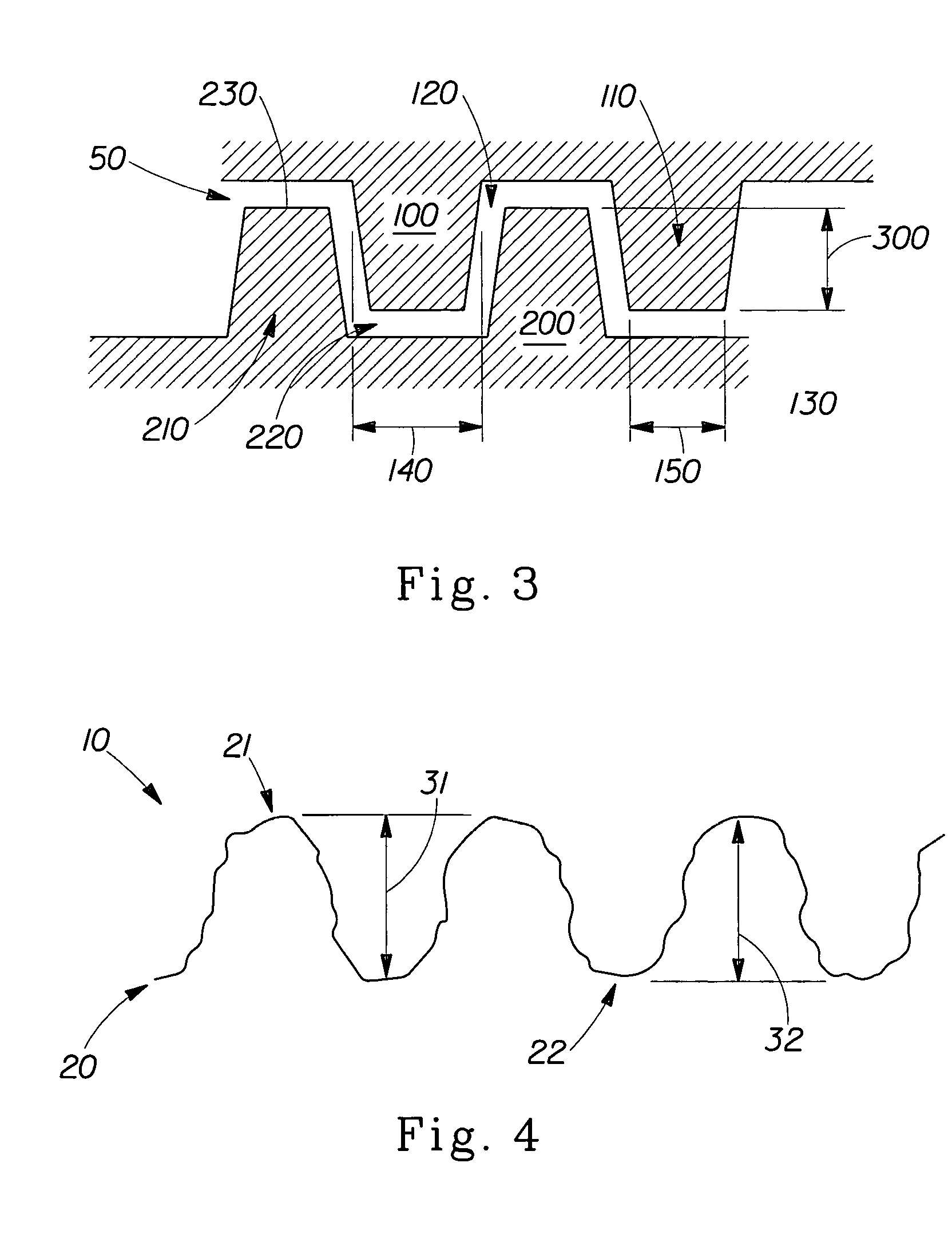

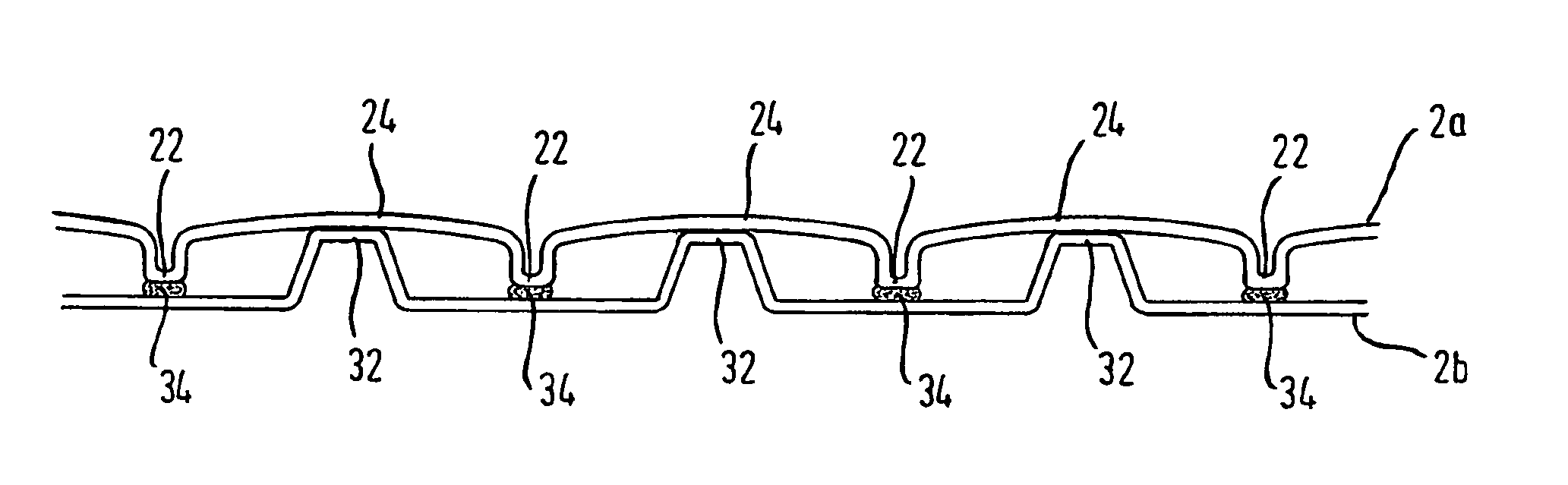

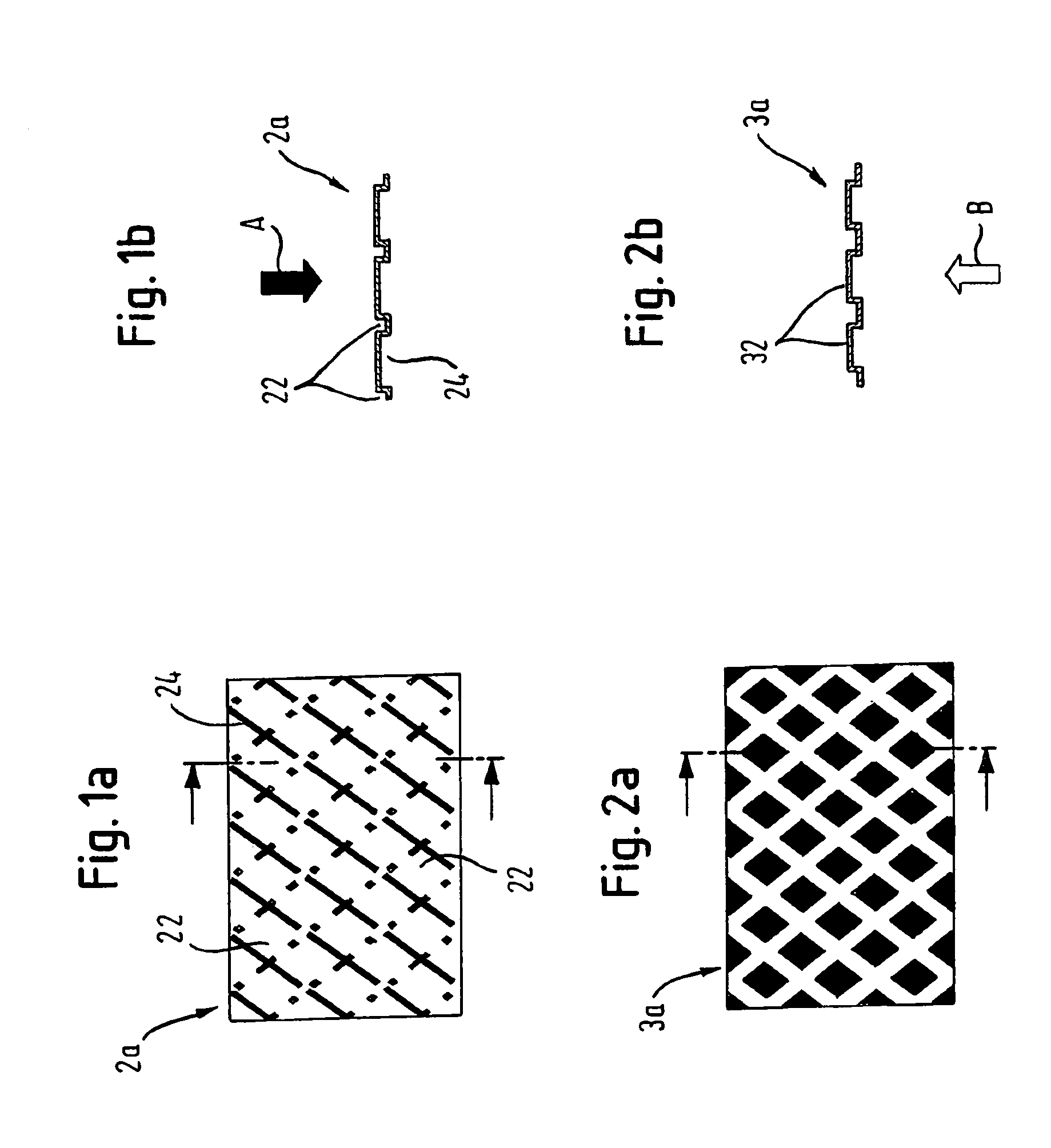

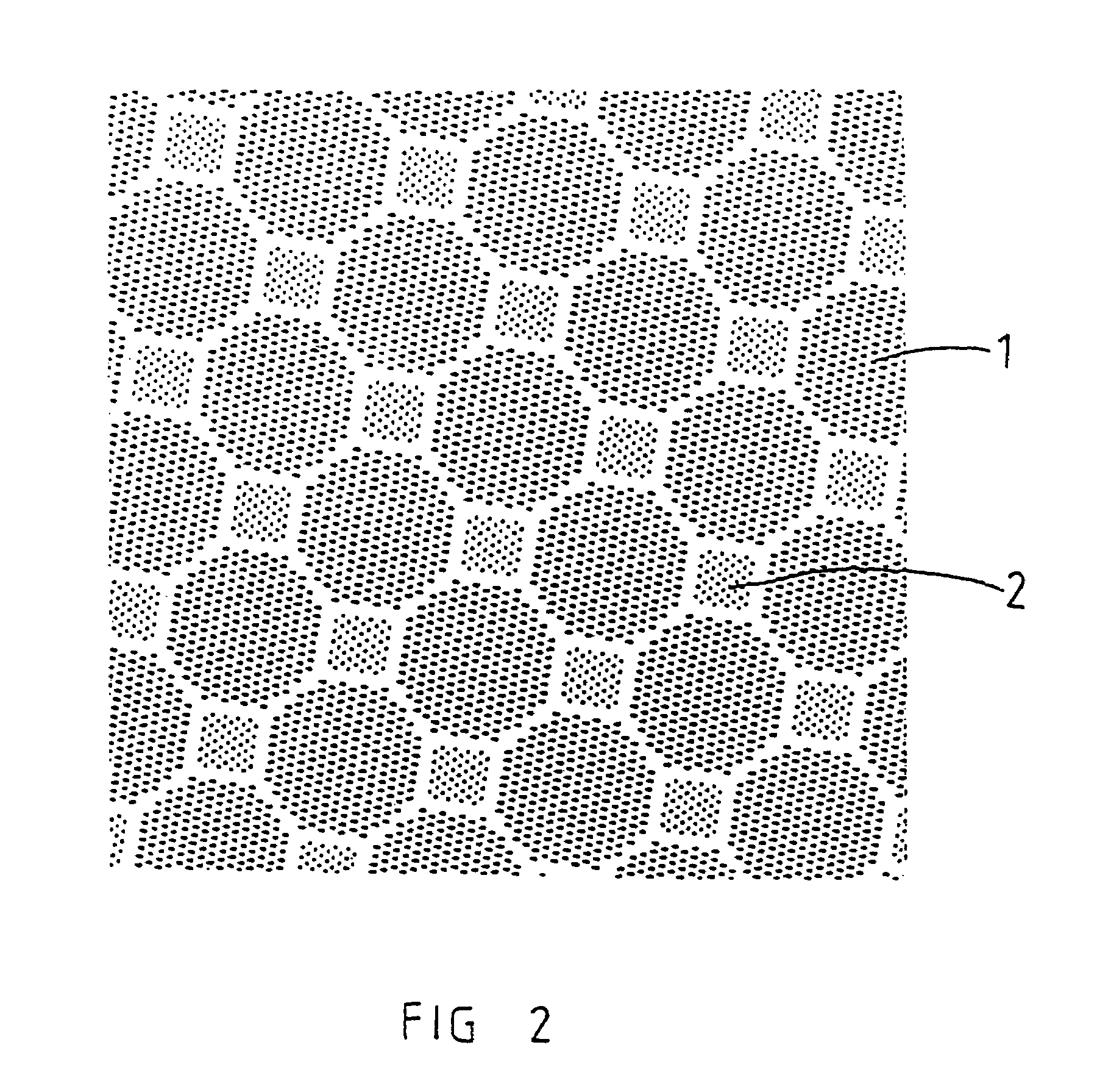

A multi-ply web of tissue paper having at least two plies comprising a first web (2a) consisting of at least one ply and being provided with a first embossing pattern forming cushions (24) limited by regions (22) of compressed material and a second web (3a) having at least one ply and being provided with a second pattern with protrusions (32) of compressed material. The first web and the second web are combined together such that the protrusions of compressed material (32) of the second web (3a) are positioned inside the cushions (24) limited by the regions (22) of compressed material (22). Further, the invention relates to a paper converting device and a method for producing such product.

Owner:ESSITY OPERATIONS MANNHEIM GMBH

Machine for the production of tissue paper

Owner:VOITH PATENT GMBH

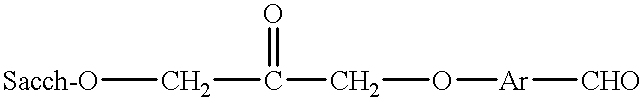

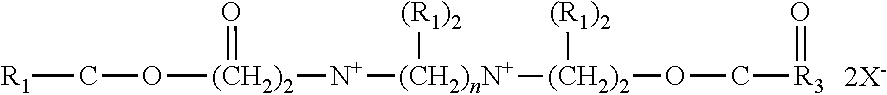

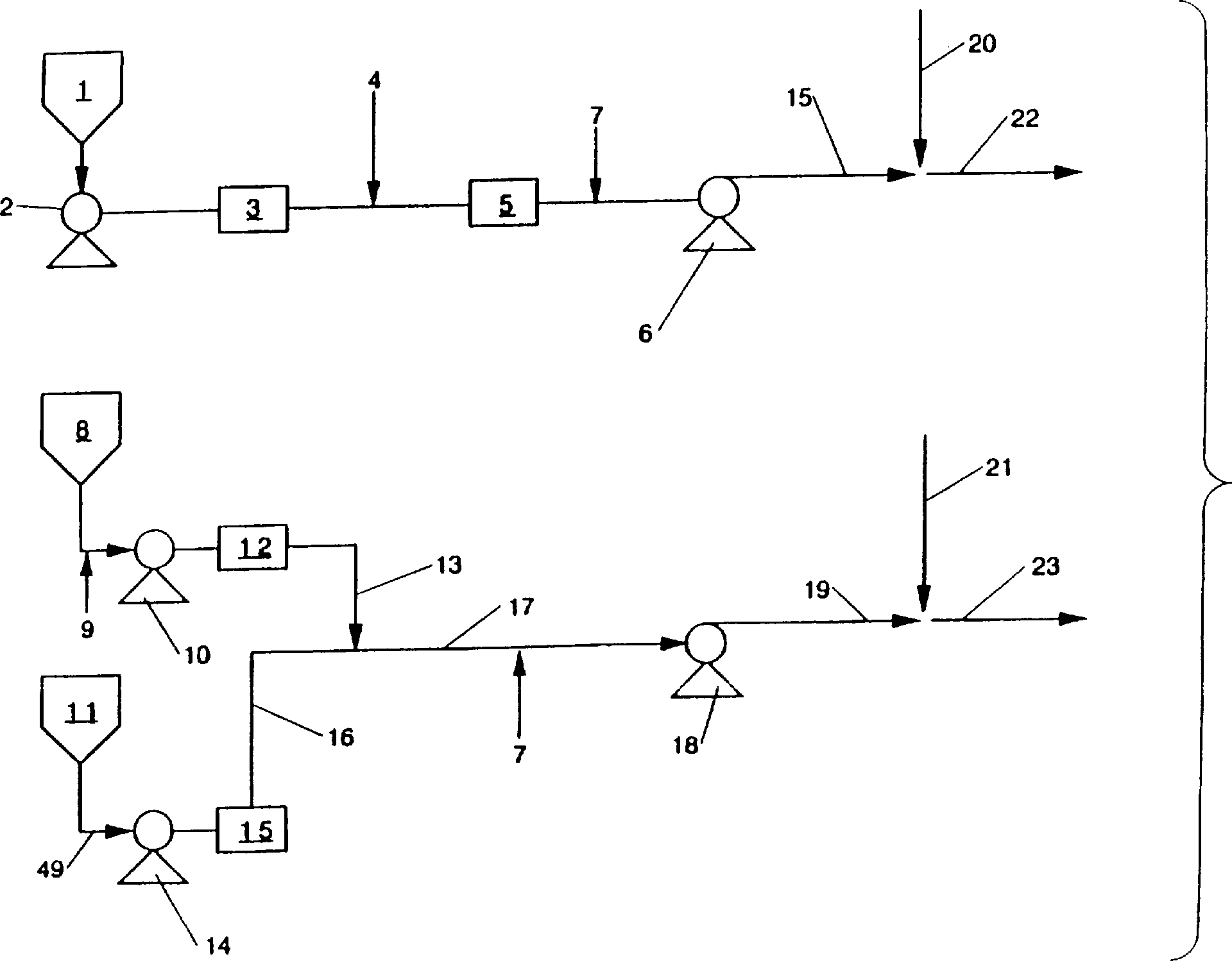

Low viscosity bilayer disrupted softening composition for tissue paper

InactiveUS6855229B2Good flexibilityAcceptable strengthNatural cellulose pulp/paperSpecial paperCelluloseAmmonium compounds

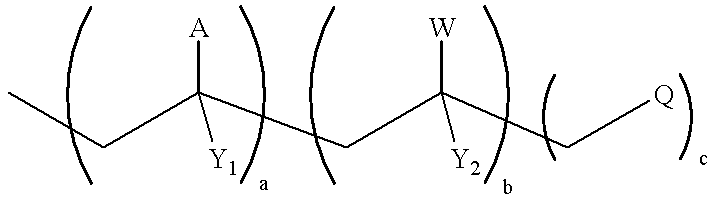

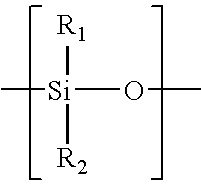

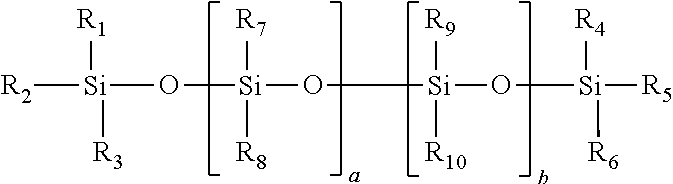

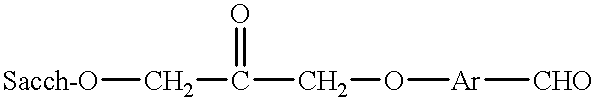

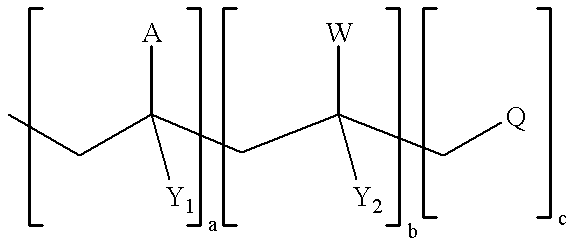

Disclosed is a composition for softening a wet laid cellulosic structure. A particularly preferred structure is an absorbent tissue. Further disclosed are tissue structures softened using the composition. The composition includes an effective amount of a softening active ingredient; a vehicle in which the softening active ingredient is dispersed; an electrolyte dissolved in the vehicle; and a bilayer disrupter. The electrolyte and the bilayer disrupter cooperate to cause the viscosity of the composition to be less than the viscosity of a dispersion of the softening active ingredient in the vehicle alone. Preferably, the softening active ingredient is a quaternary ammonium compound with the formula:(R1)4-m—N+—[(CH2)n—Y—R3]mX−the vehicle is water, the electrolyte is calcium chloride, and the bilayer disrupter is a nonionic surfactant. Also disclosed is a method of using the compound by adding it at a use concentration to the wet end of a papermaking process.

Owner:THE PROCTER & GAMBLE COMPANY

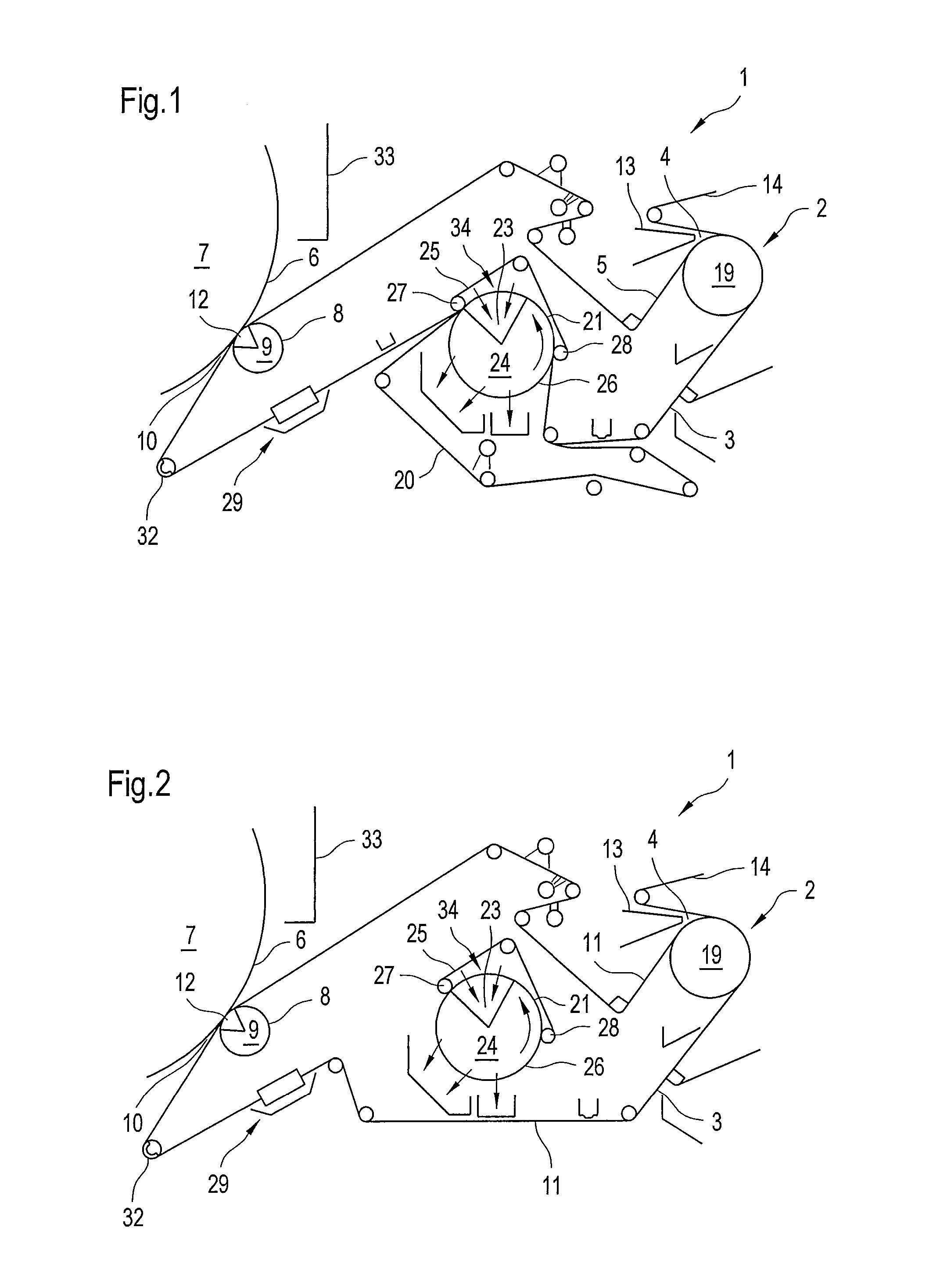

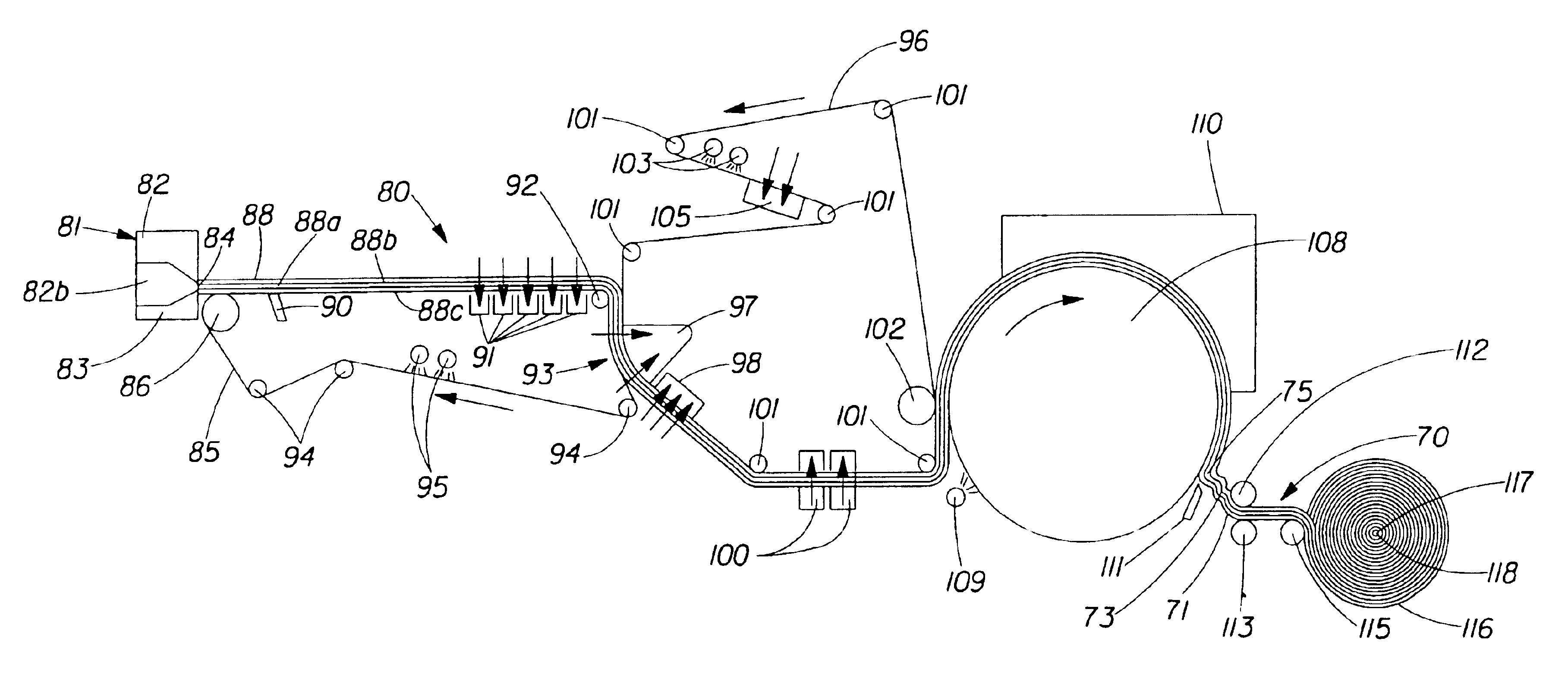

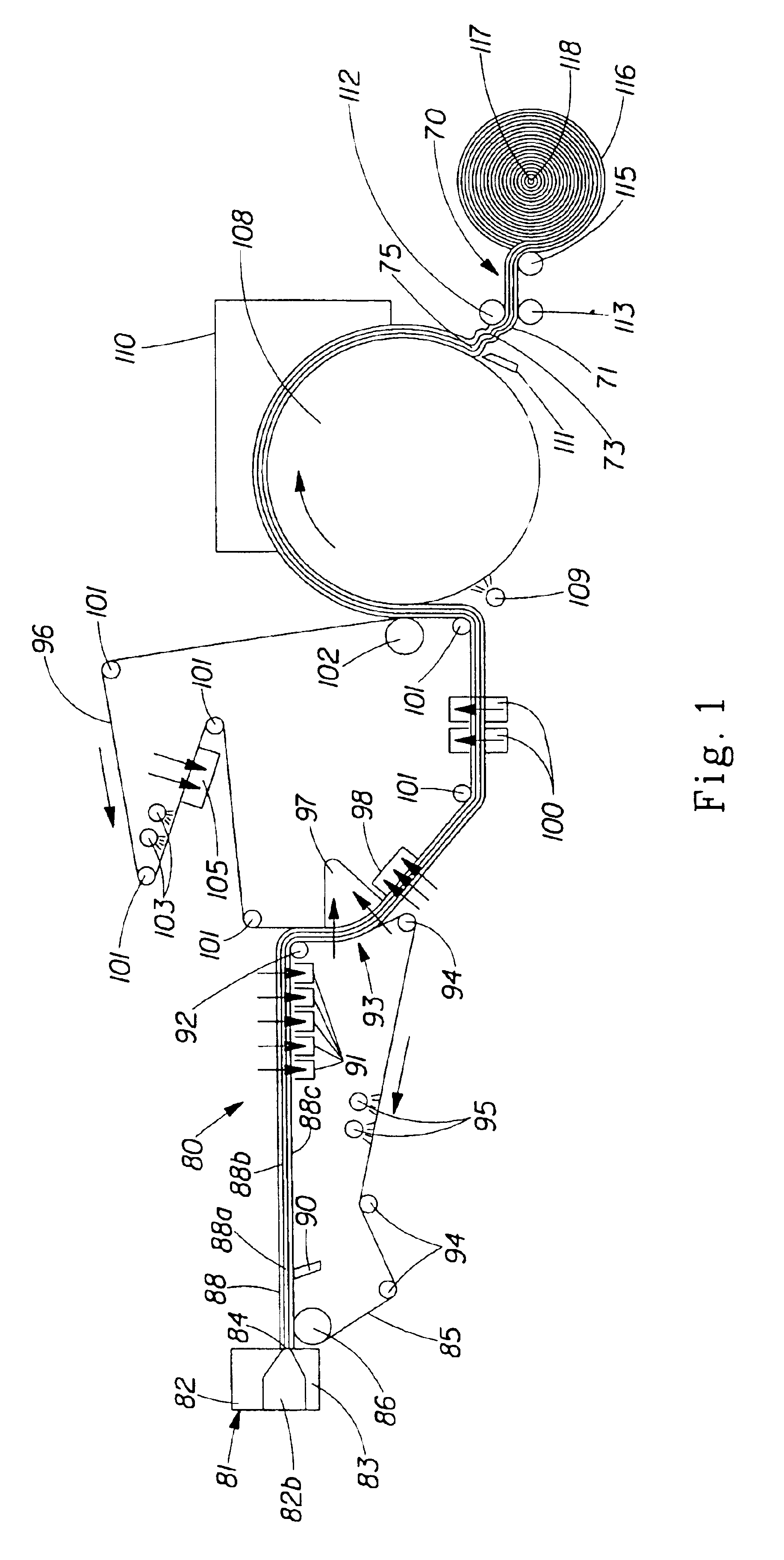

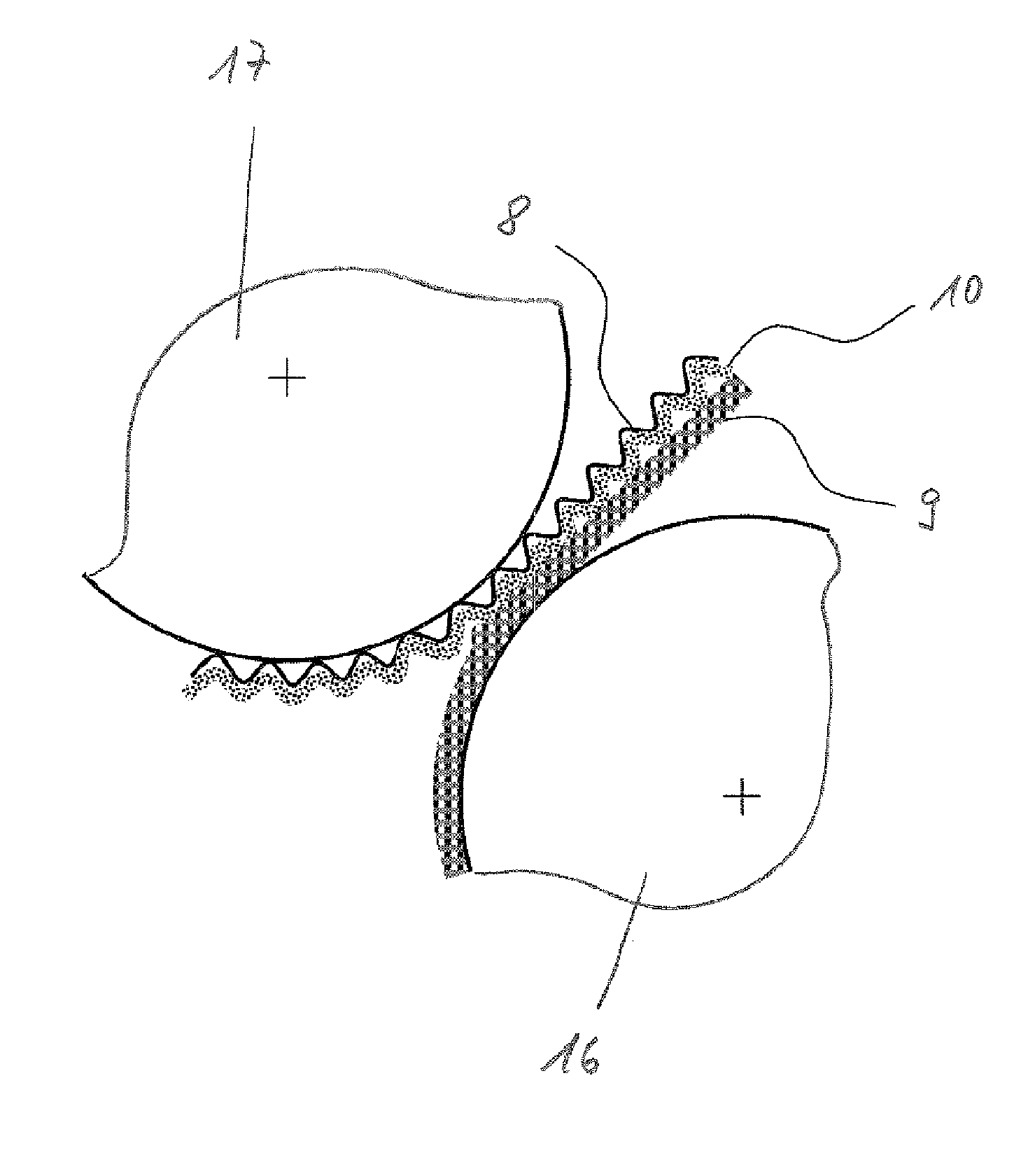

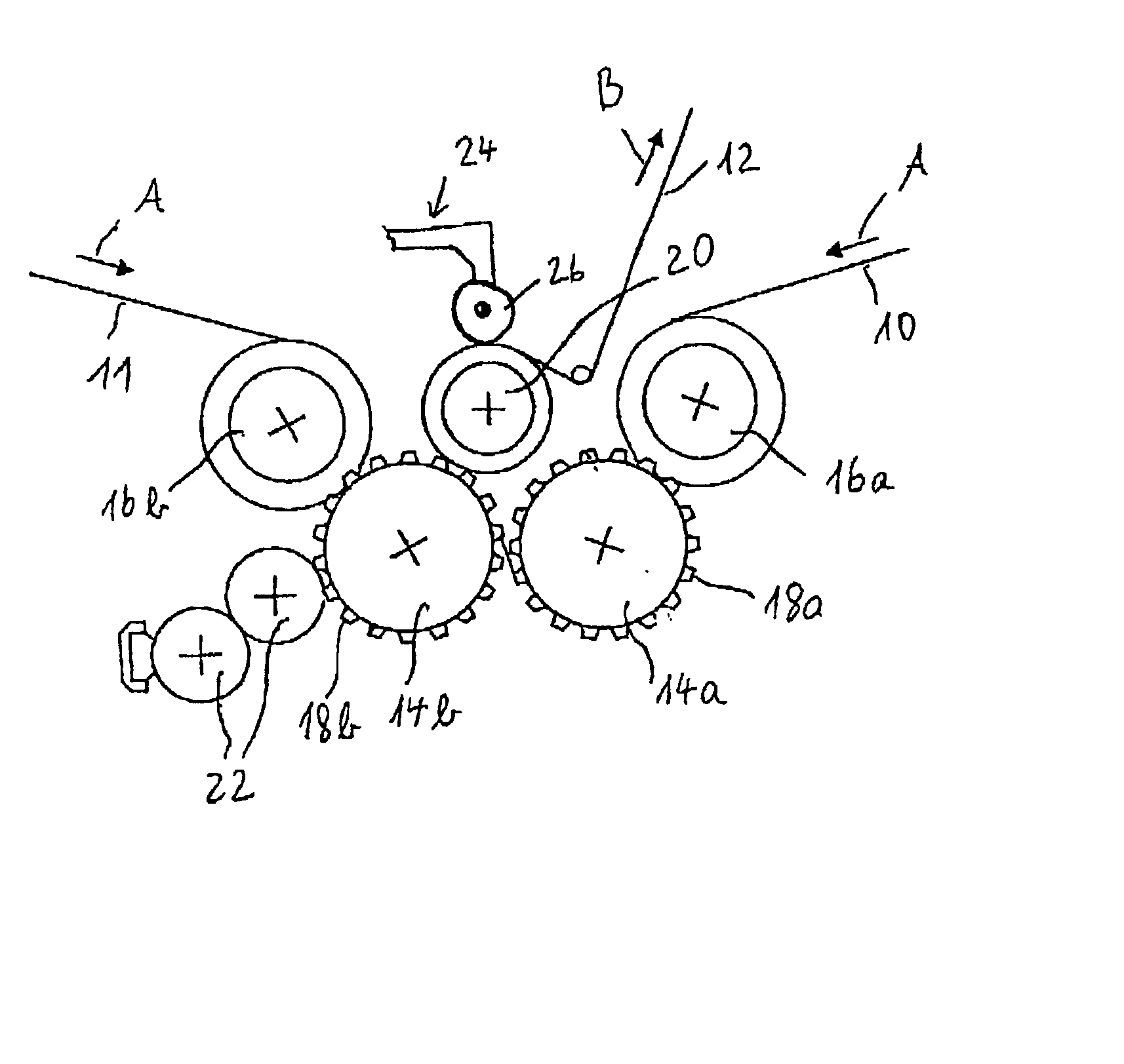

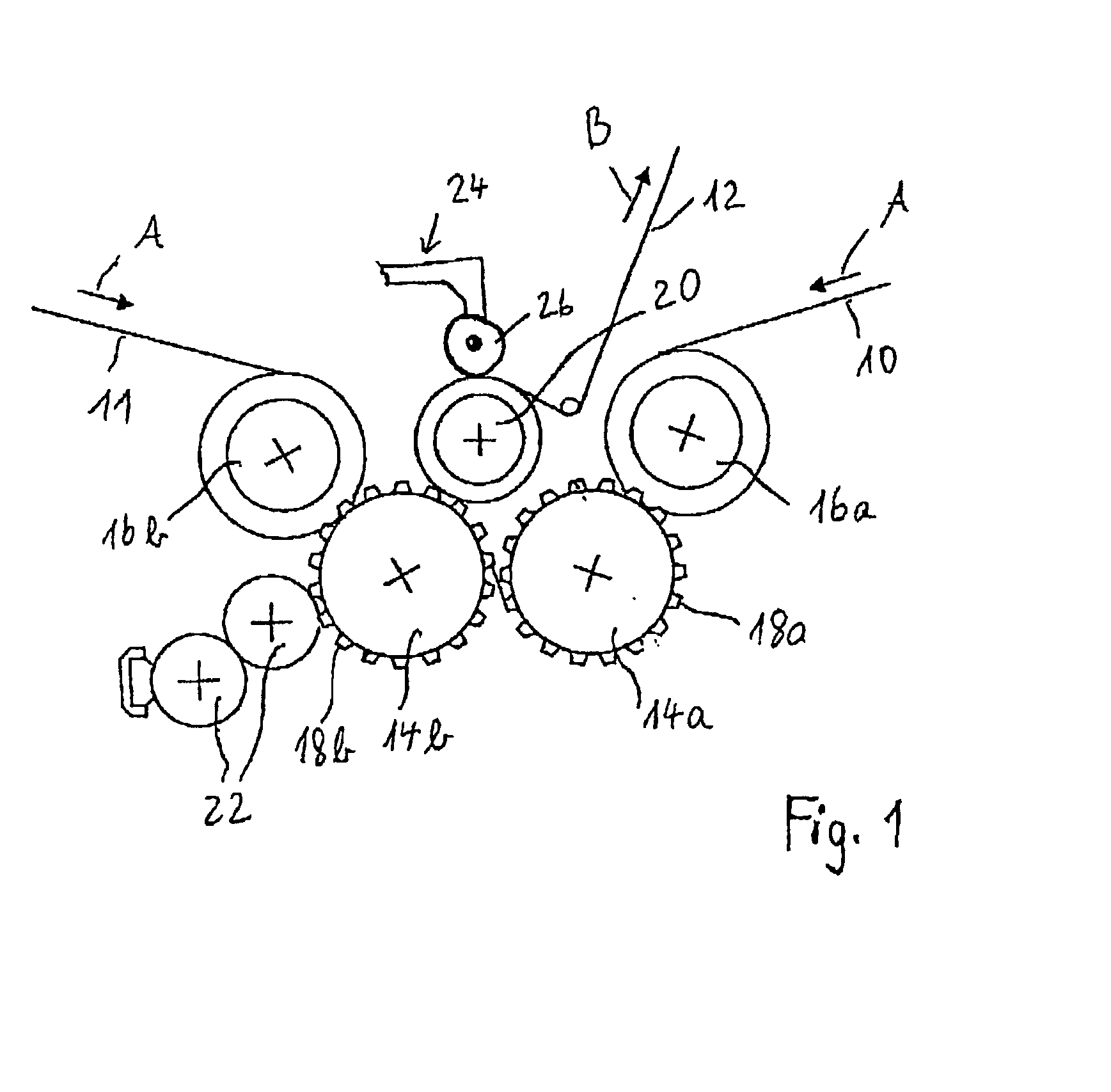

Method and device for producing a printed and embossed web

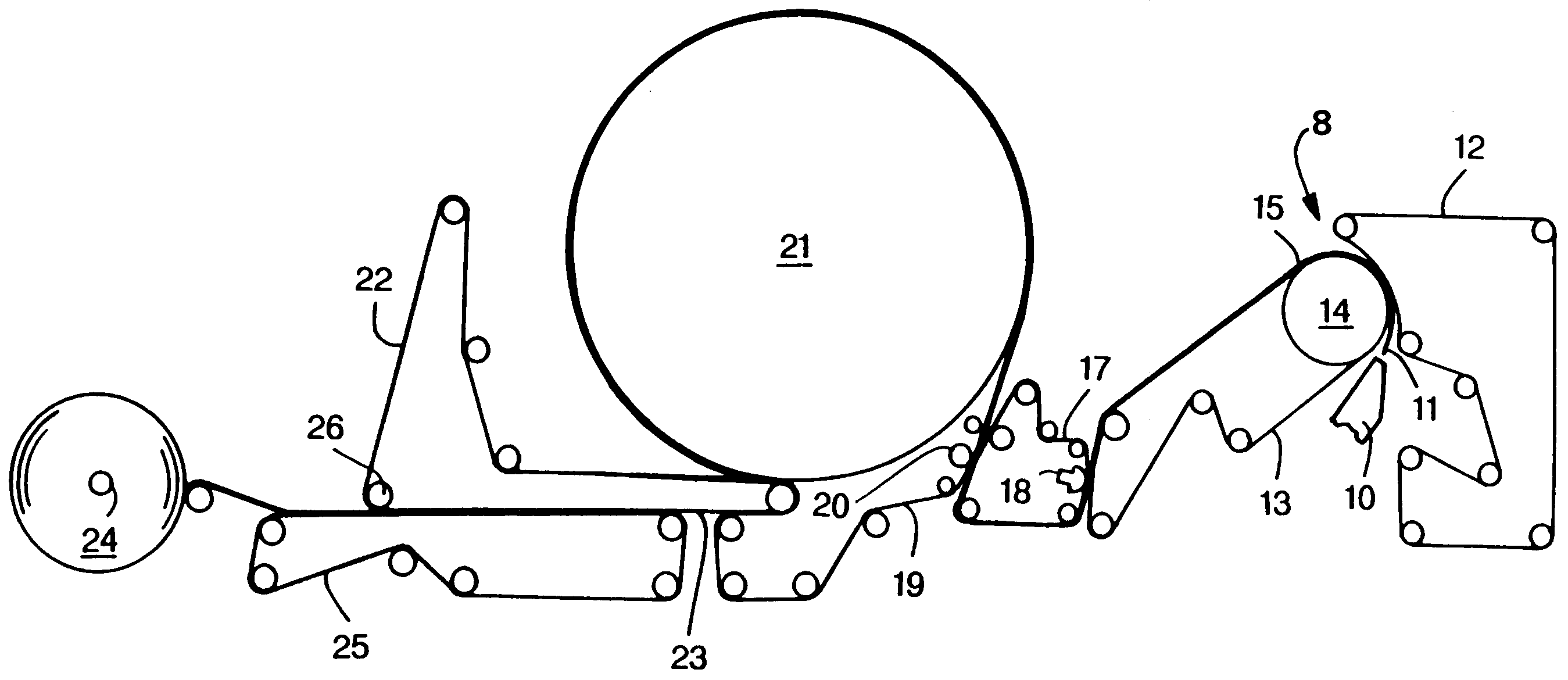

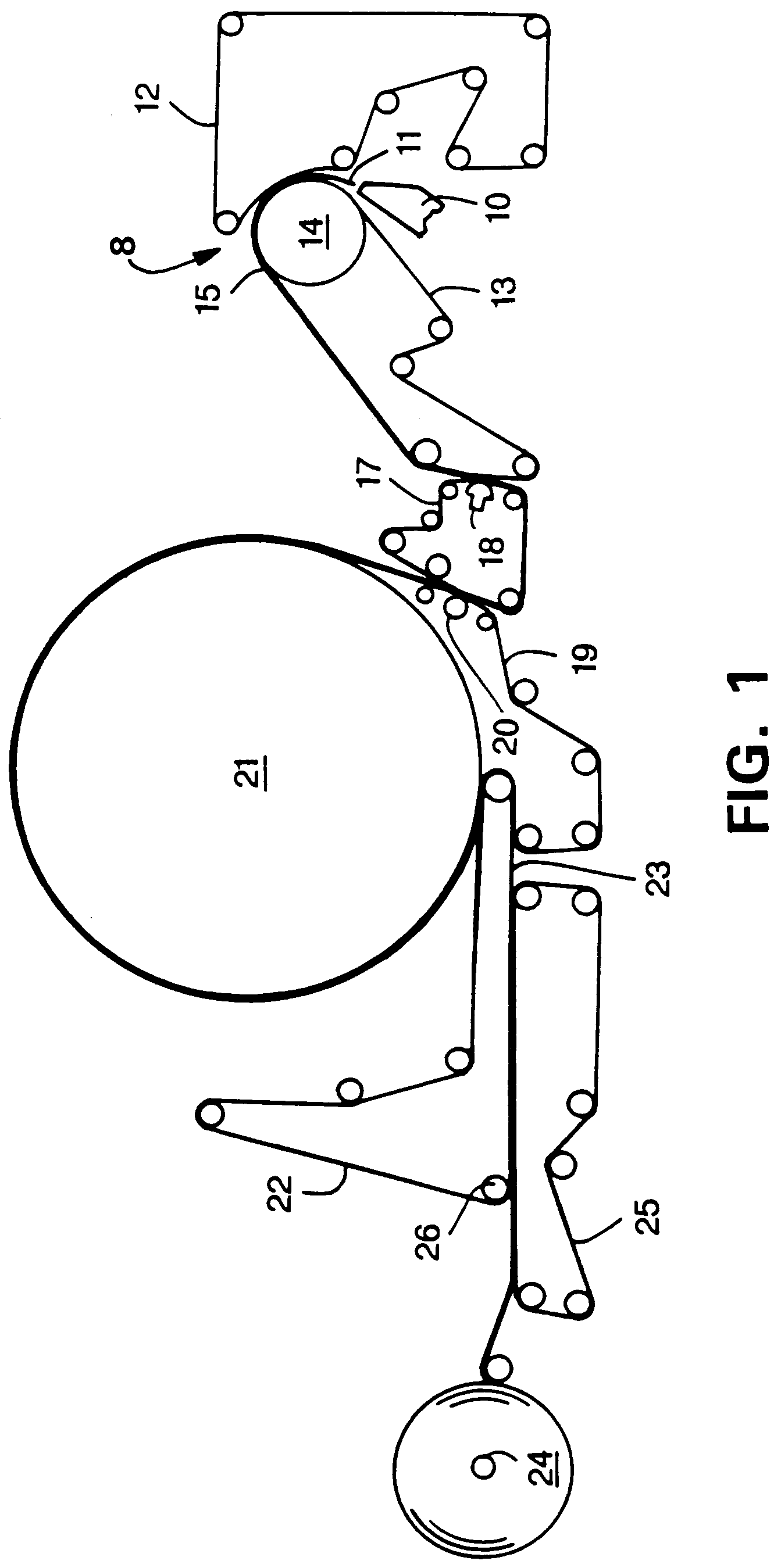

InactiveUS20100272965A1Good lookingIncrease impressionMechanical working/deformationLayered productsAdhesiveNonwoven fabric

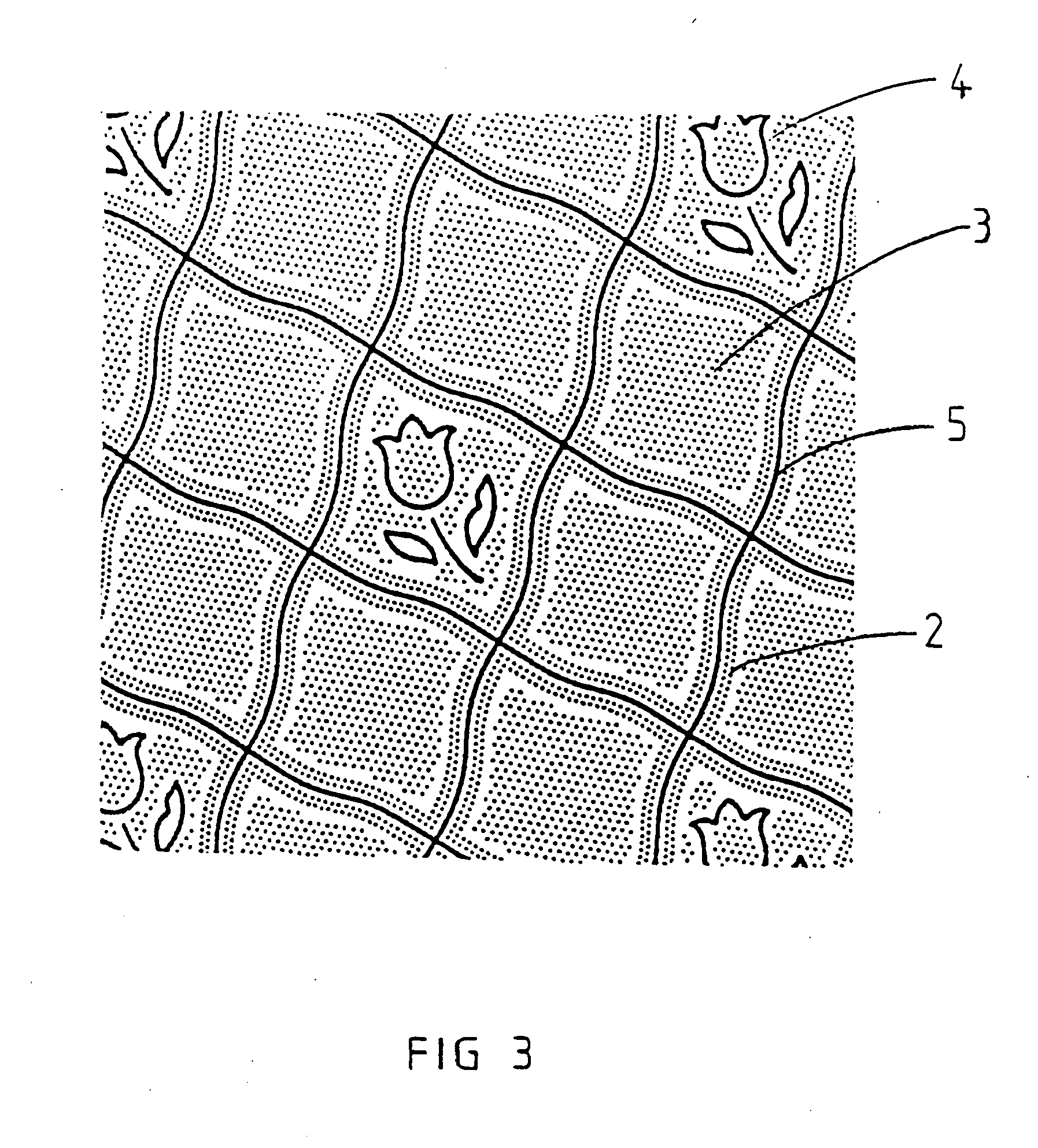

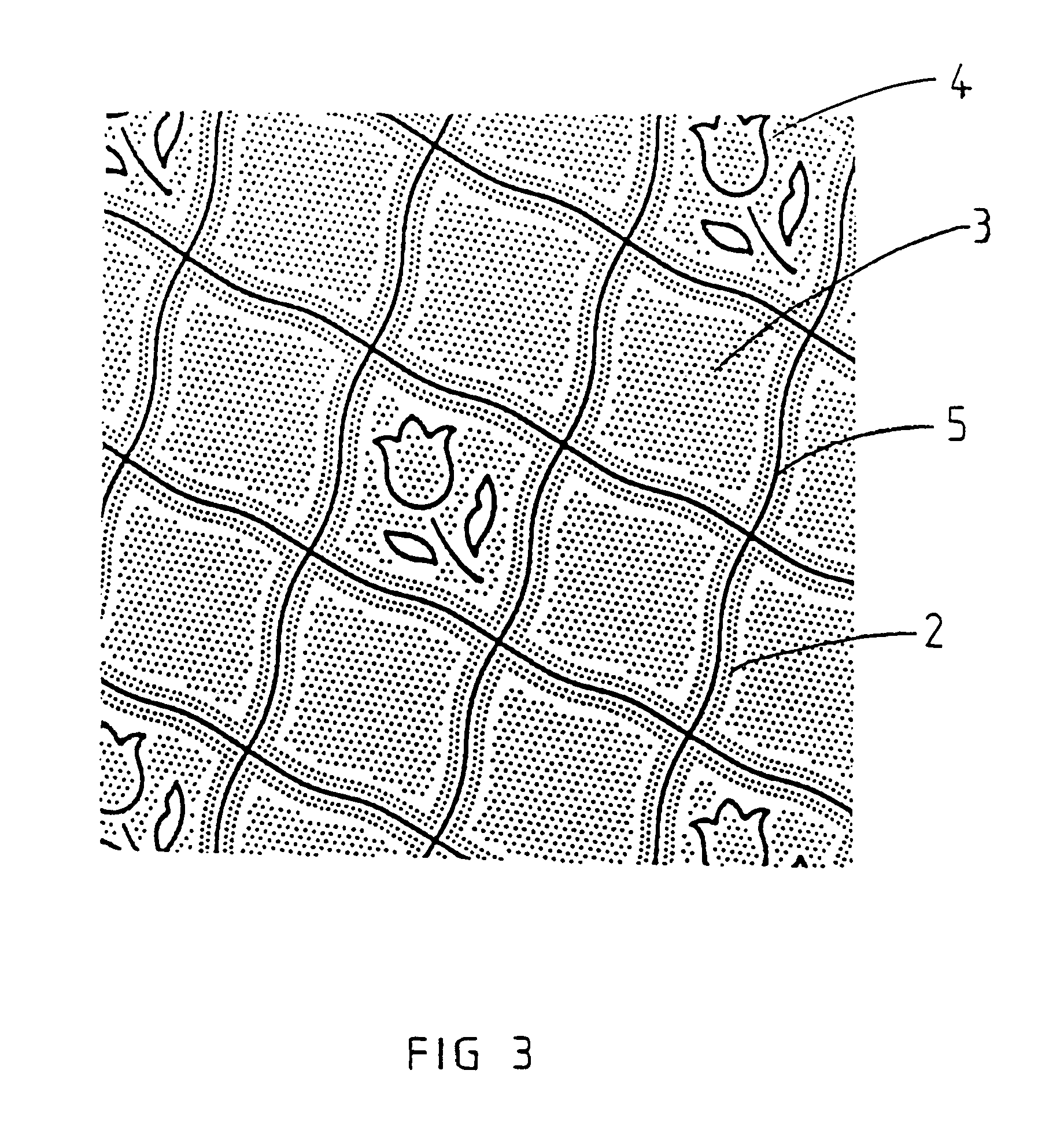

Method and device for producing a printed and embossed multi-ply web (3) of tissue paper or nonwoven having a good visual appearance. A first web-shaped material (1) is embossed in a nip (6) between a first embossing roll (4) and a counter roll (5), thereby creating a set of embossments. A first ink with a first colour is applied to a first subset of the set of embossments of the first web-shaped material while the material still resides on the first embossing roll. Thereafter an adhesive is applied to a second subset of the set of embossments of the first web-shaped material (1) while the material still resides on the first embossing roll (4). After that, the first web-shaped material is combined with a second web-shaped material (2) to form a multi-ply web (3). There is also provided a printed and embossed multi-ply web (3).

Owner:SCA HYGIENE PROD AB

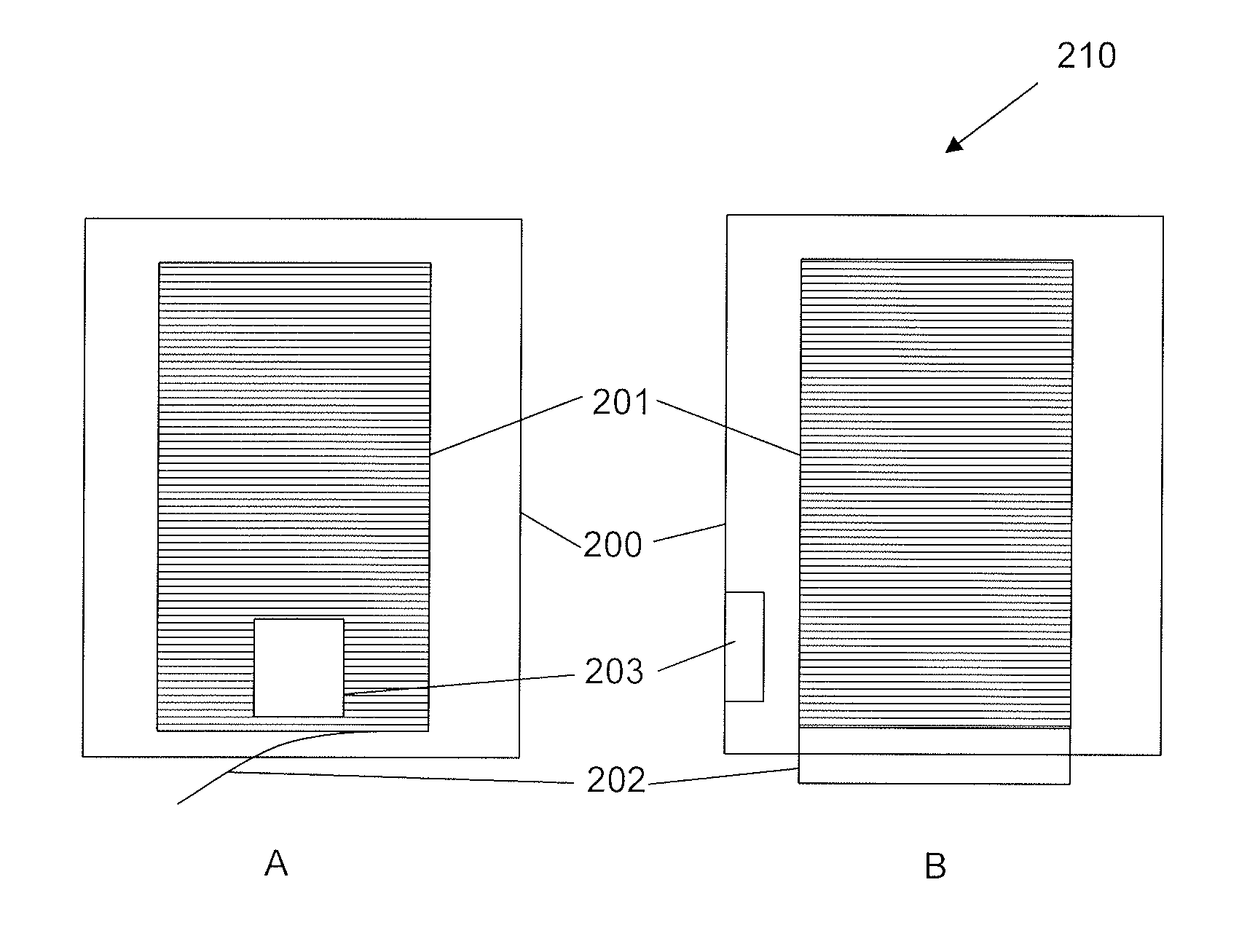

Hands-free paper towel dispenser and dispensing system

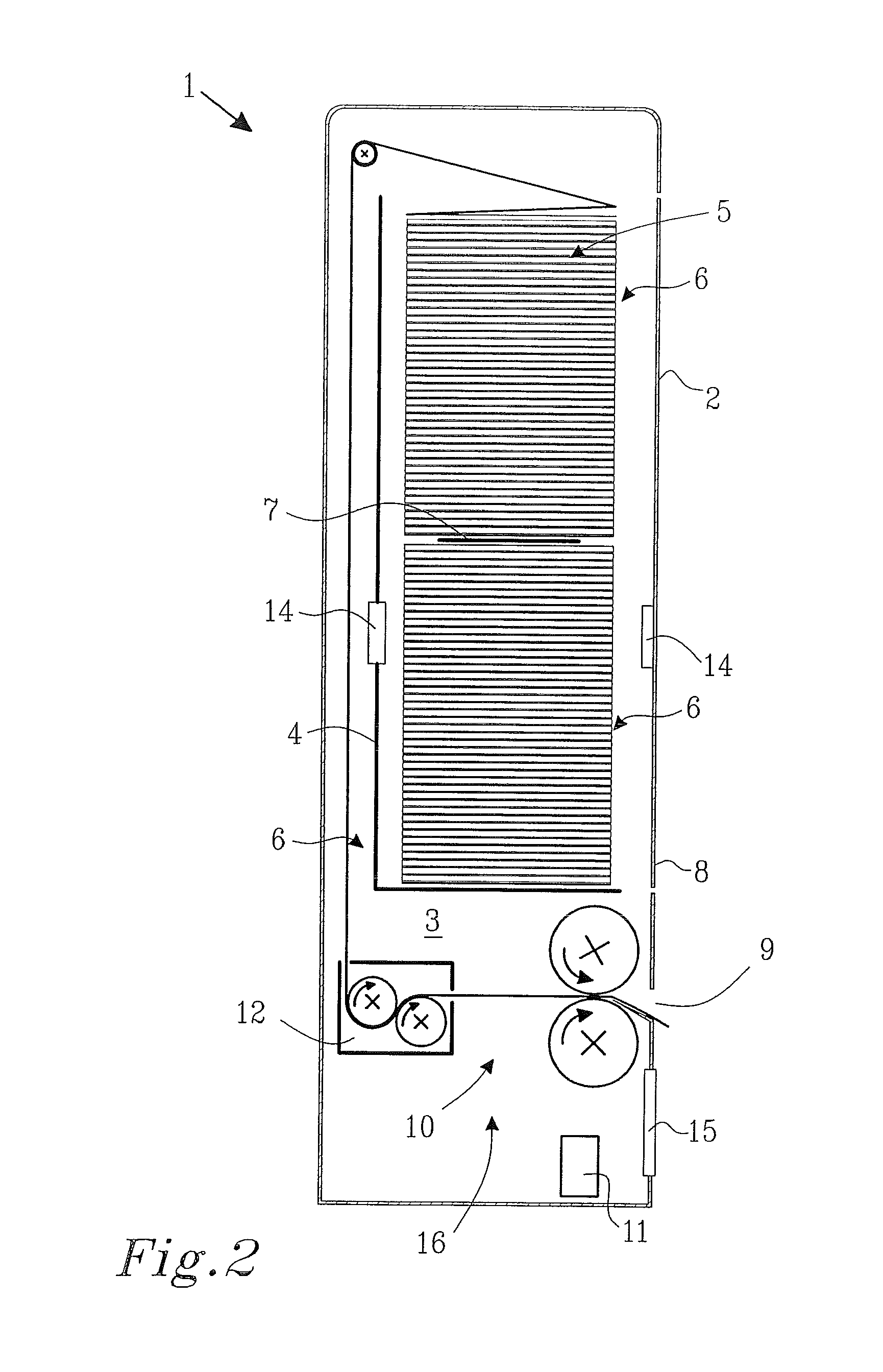

InactiveUS20110210137A1Easy to separateFlat designCoin-freed apparatus detailsMetal-working apparatusPaper towelStructural engineering

A dispensing unit includes an outer front wall, two outer side walls, a housing for holding a pile of a continuous length of accordion-like folded web of towels of tissue paper or nonwoven including bundles, the outer front wall having an access opening to the pile, a dispensing opening for the web of towels and a feeding mechanism including a member for controlling the dispensing of the web of towels, a drive unit and a braking arrangement for the web of towels. A unit of consumable articles includes the pile of bundles with connecting elements therebetween, which are inserted through the access opening into the housing in the dispensing unit and added to the bottom of the pile. The web of towels is dispensed from the upper part of the pile by a feeding mechanism, which positions the web of towels in a starting mode in the dispensing opening.

Owner:SCA HYGIENE PROD AB

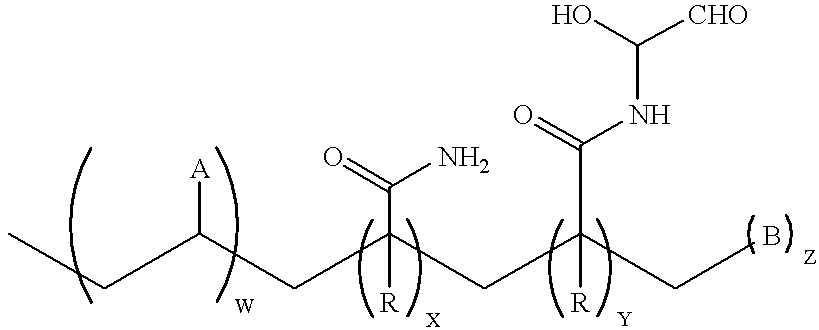

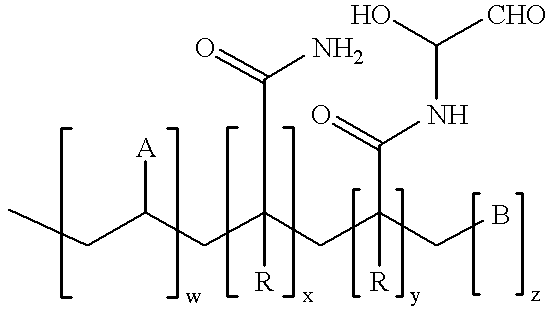

Paper softening compositions containing low levels of high molecular weight polymers and soft tissue paper products comprising said compositions

Disclosed is a composition suitable for atomizing without excessive aerosolization in the form of an oil-in-water emulsion comprising: a) a continuous aqueous phase, and b) a discontinuous oil phase wherein the rheology of the aqueous phase is modified by the addition of a water-in-oil emulsion comprising: i) a high molecular weight polymer in a discontinuous aqueous phase, and ii) a continuous organic solvent phase. Preferred embodiments of the present invention relate to compositions for softening an absorbent paper tissue comprising a) a quaternary ammonium softening active ingredient; b) an electrolyte; c) a high molecular weight polymer emulsion comprising: i) from about 20% to about 40% by weight of the premix of a high molecular weight polymer; ii) from about 40% to about 60% of water; and iii) from about 20% to about 40% of an organic solvent; and d) a vehicle in which said softening active ingredient is dispersed.

Owner:THE PROCTER & GAMBLE COMPANY

Soft single-ply tissue

InactiveUS20100051217A1Gram weight highLow stiffnessNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringThin sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, throughdried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of making a thick and smooth embossed tissue

A paper tissue such as a facial tissue or a disposable handkerchief and a method for making a tissue paper product from a tissue paper web. The method comprises the steps of passing the tissue paper web through an embossing nip formed between a first and a second embossing roll, wherein at least one of the embossing rolls comprises at least 30 embossing elements per square centimeter; and passing the tissue paper web through a calendering nip formed between a first and a second calendering roll, wherein the first and the second calendering roll are in contact with the tissue paper web over a contact length measured parallel to the direction of the axis of the first calendering roll exert a pressure onto the paper web of at least 50 N per centimeter of the contact length.

Owner:THE PROCTER & GAMBLE COMPANY

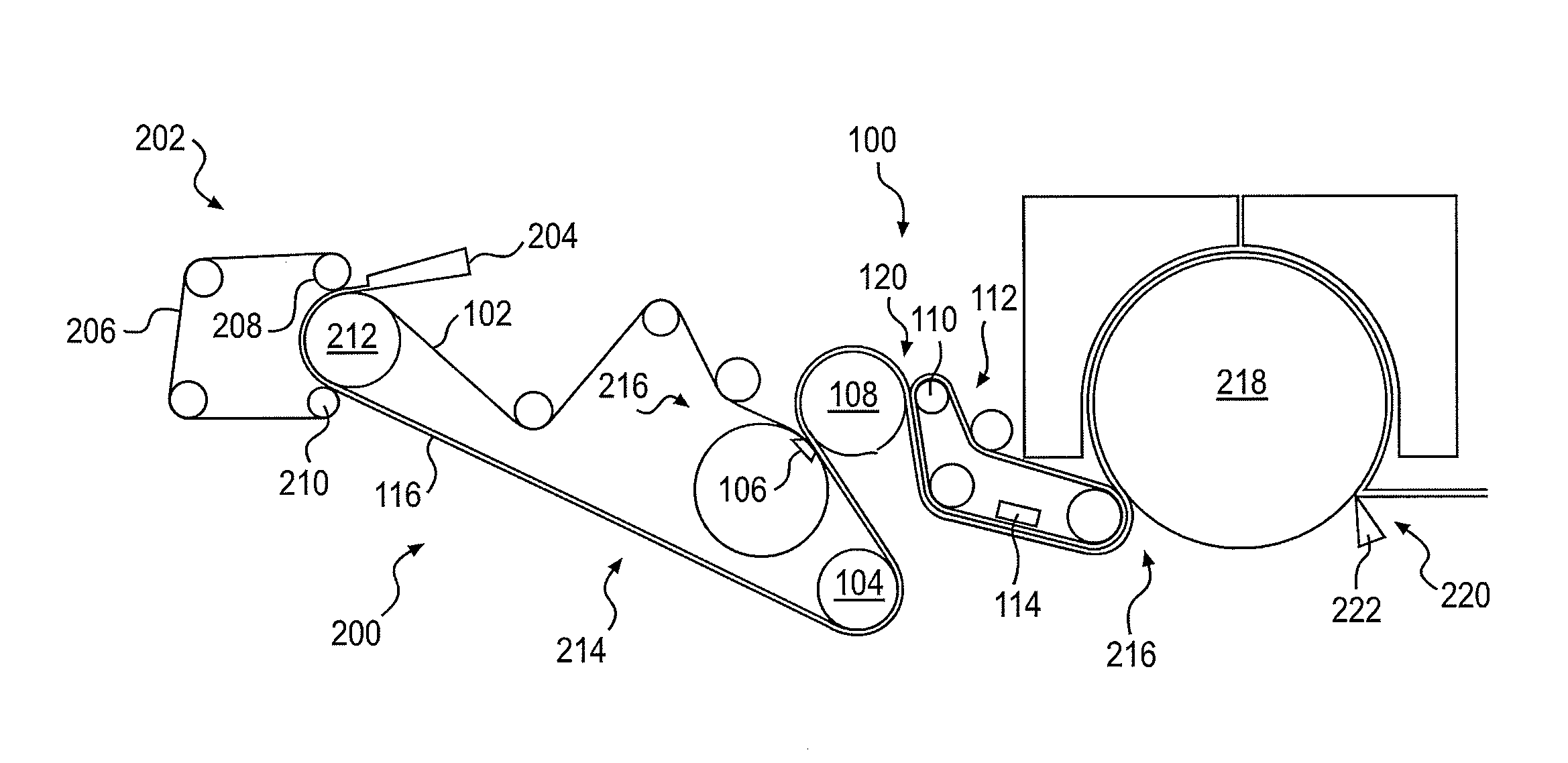

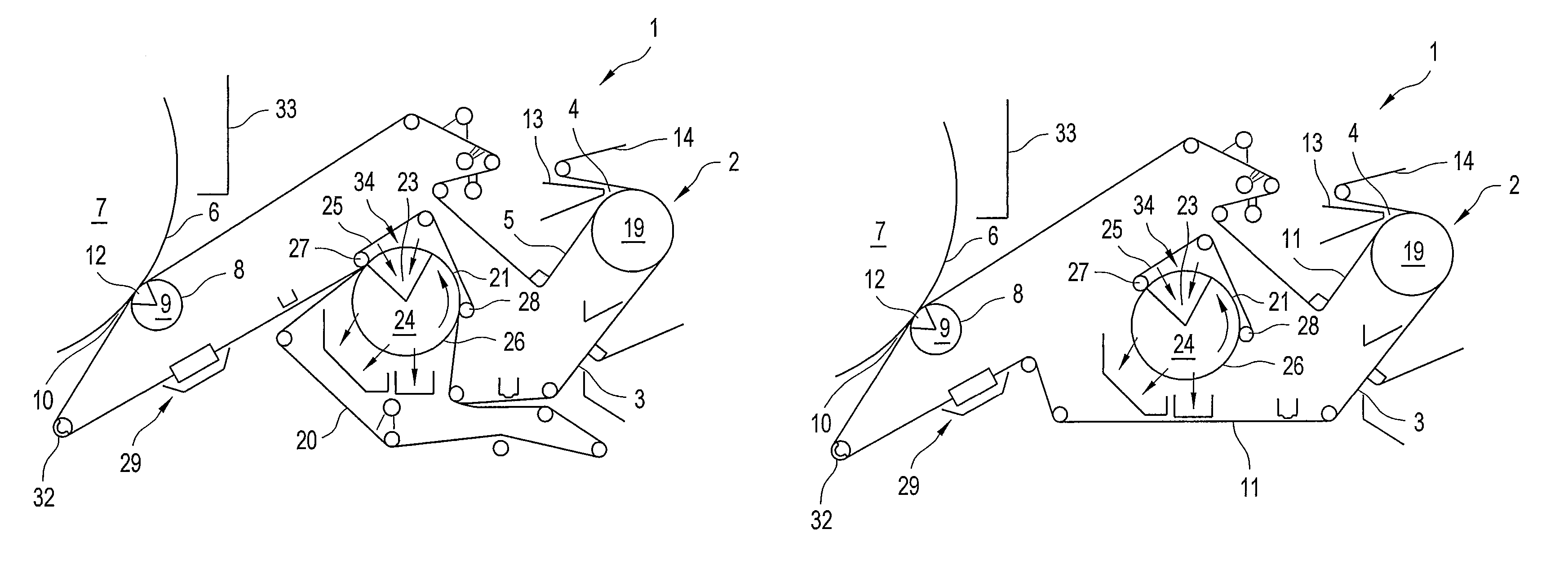

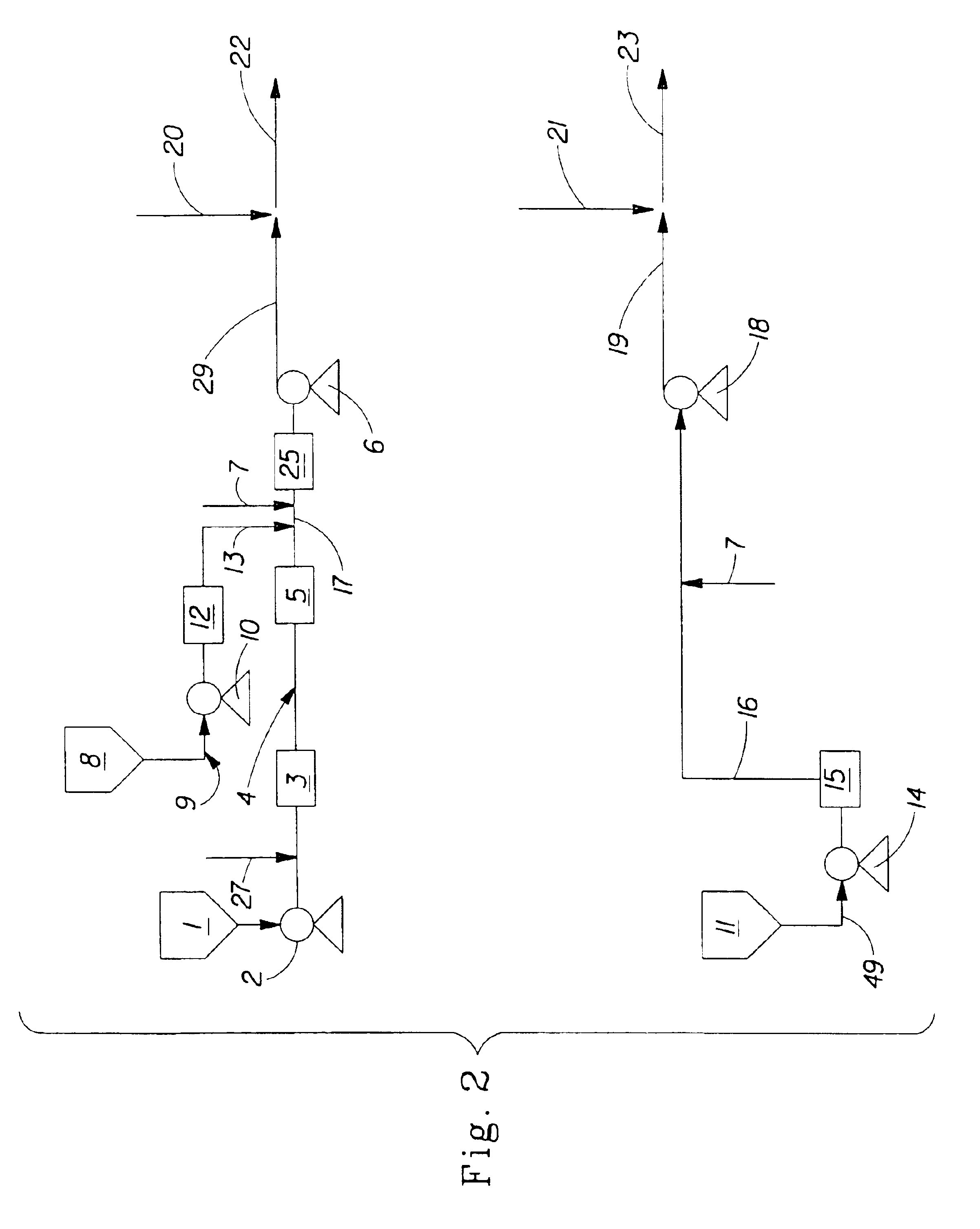

Device and method for producing a material web

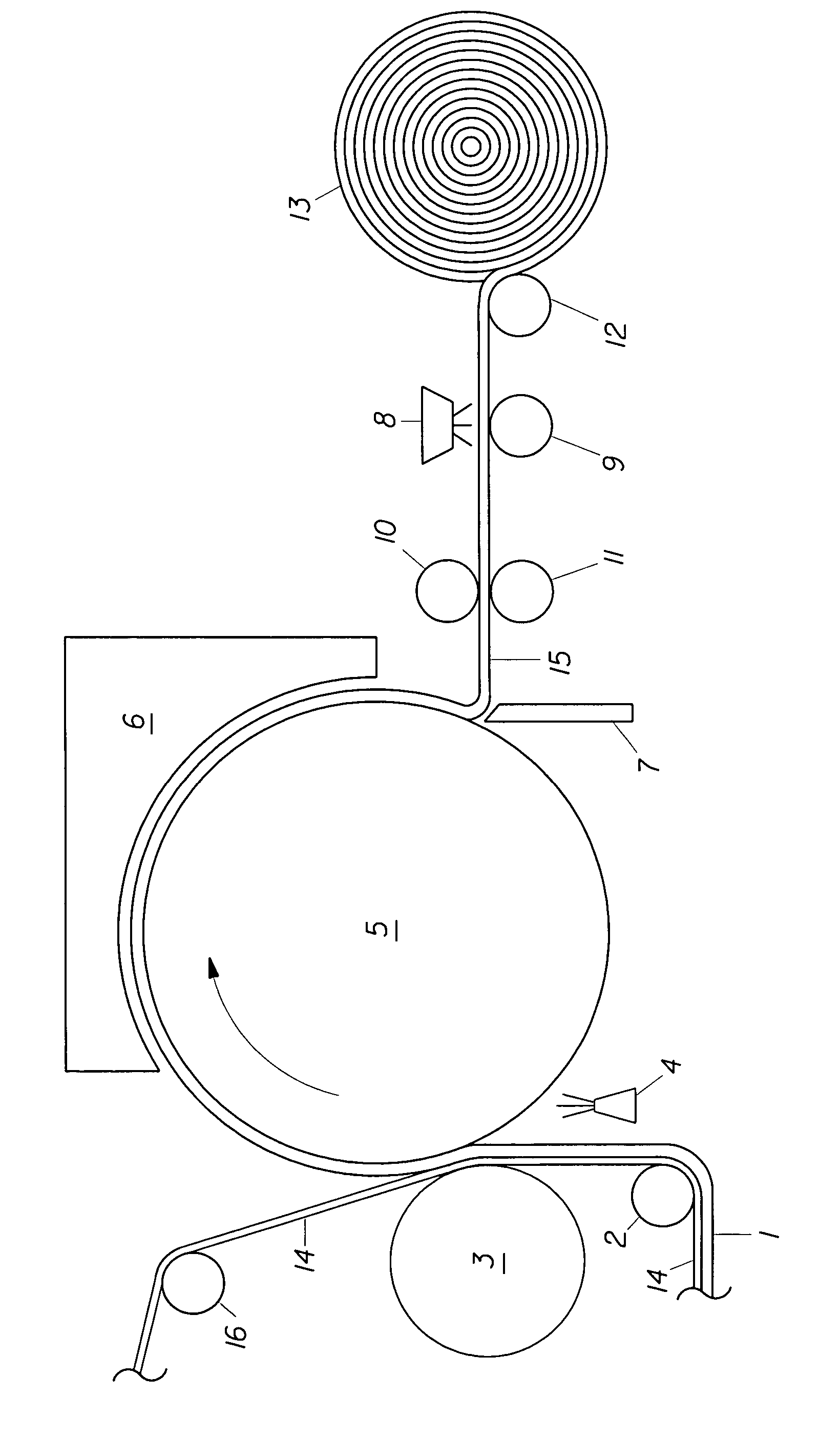

InactiveUS20110303379A1Increase contentLow compressibilityDrying solid materials with heatDrying solid materials without heatTwo bandPulp and paper industry

A device for drainage of a pulp web, particularly a tissue web, having a first pressing zone having a first pressing zone length through which the pulp web is fed horizontally between a circulating, permeable band and a circulating, permeable support band. The first pressing zone is designed such that a fluid can flow through the band, the pulp web and the support band at least on one part of the first pressing zone length. In addition, the device has a subsequent second pressing zone having a second pressing zone length. The pulp web is guided through the second pressing zone between two bands having differing compressibility.

Owner:VOITH PATENT GMBH

Soft tissue paper containing fine particulate fillers

InactiveCN1244899ALess quantityExcellent optical propertiesSpecial paperPaper/cardboardFiberWater insoluble

Soft, strong, and low dusting tissue paper webs useful in the manufacture of soft, absorbent sanitary products such as bath tissue, facial tissue, and absorbent towels are disclosed. The tissue papers copmrise fibers such as wood pulp and a non-cellulosic, water insoluble particulate filler such as kaolin clay and possess biased surface properties.

Owner:INSTITUTE OF PAPER SCIENCE AND TECHNOLOGY

Soft, bulky single-ply absorbent paper having a serpentine configuration

Owner:GPCP IP HLDG LLC

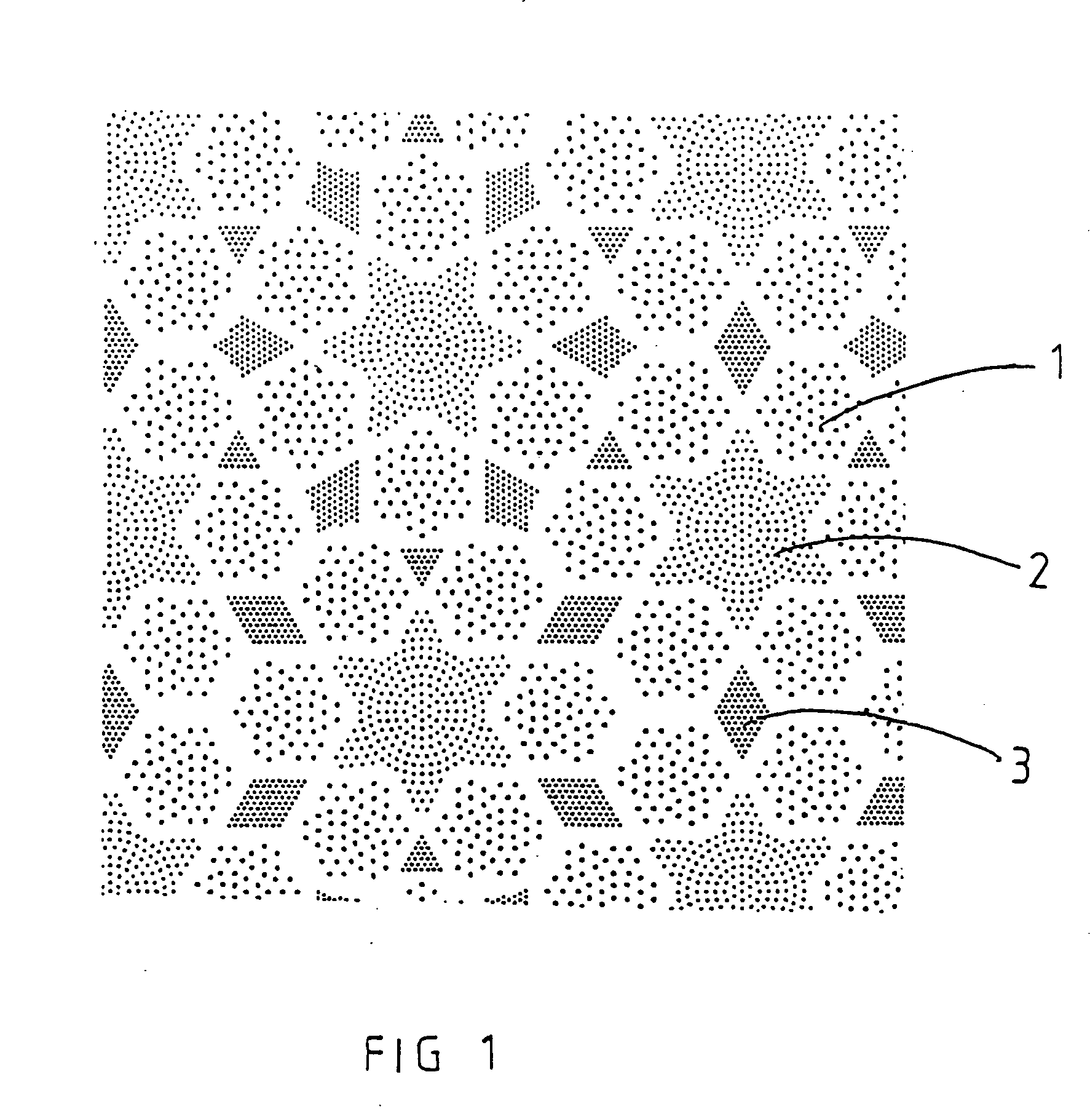

Device and method for applying a spot embossing pattern to a web of multi-ply tissue paper

A device for applying a spot embossing pattern to a web of multi-ply tissue paper being processed in a paper converting machine comprises a marrying roll and a spot embossing unit cooperating and being positioned against the marrying roll. the spot embossing unit comprises a spot embossing roll with a raised embossing pattern on its circumferential surface. The at least two plies of tissue web are combined with a marrying roll and pass between the marrying roll and the spot embossing unit.

Owner:SCA HYGIENE PROD AB

Absorbent paper product having improved embossing

InactiveUS7494564B2Natural cellulose pulp/paperMechanical working/deformationVolumetric Mass DensityMechanical engineering

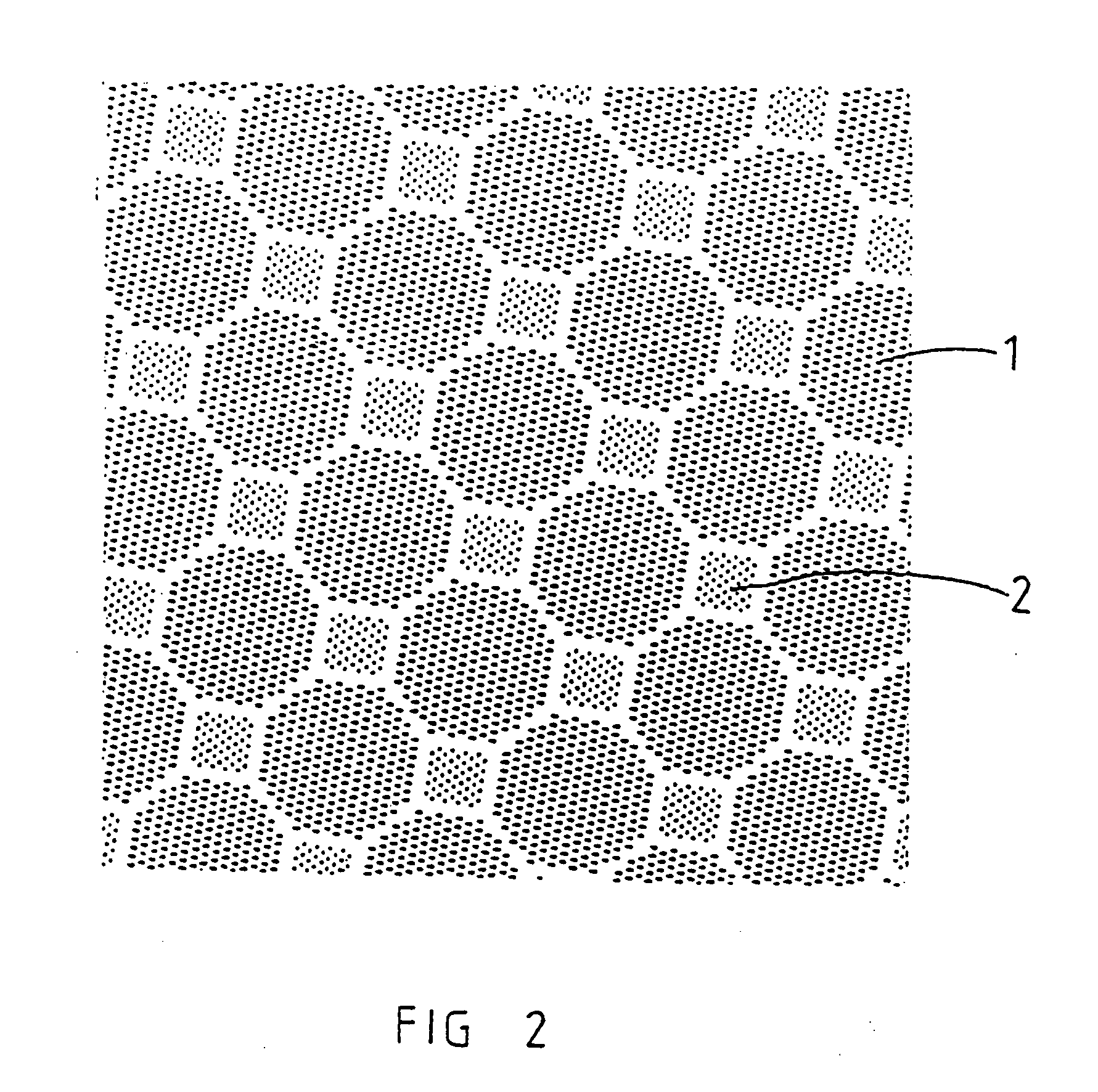

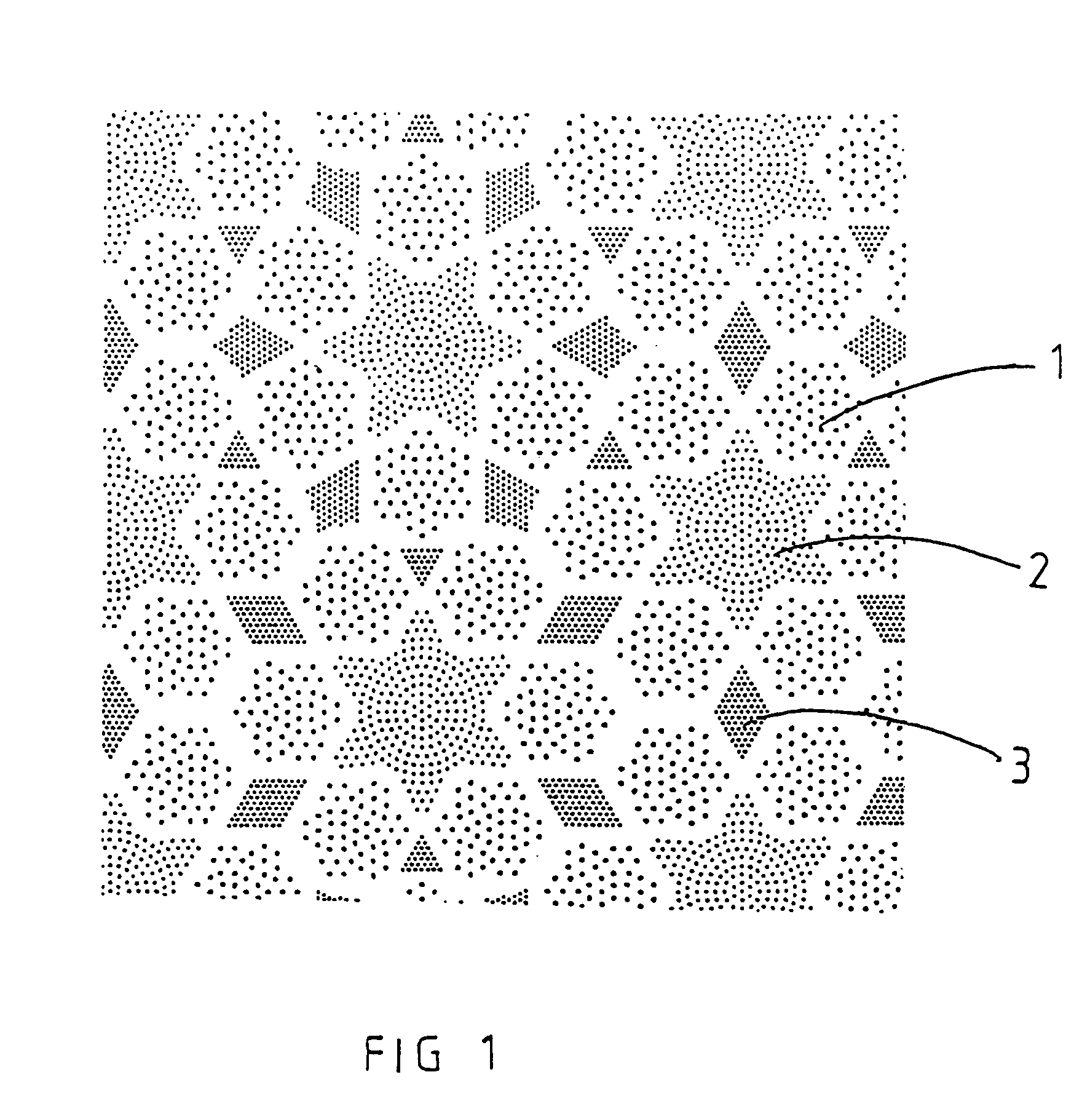

The invention relates to an absorbent paper product, made in particular of tissue paper, that includes at least two plies, at least one of which is embossed according to an embossing pattern that includes projections (1, 2, 3) with a density of 30 or more per cm2. According to the invention, the embossing patterns include at least two adjacent zones whose projections (1, 2, 3) have, respectively, a different density and / or a different surface area at the peak so as to produce a relief effect on the product.

Owner:ESSITY OPERATIONS FRANCE

Tissue and toilet seat-cover sanitary paper

InactiveUS20070209099A1Easy to expandThe process is convenient and fastBathroom coversCompound (substance)Paper towel

The present invention discloses a sanitary paper that is designed to be appropriate for dual functions: (1) as a tissue paper for wiping and cleaning by a user, and (2) as a toilet seat-cover. The sanitary paper is a folded continuous sanitary paper strip comprising detachable sections of tissue paper, where some sections are toilet seat-covers which are defined by appropriate transverse seat-cover perforation lines. Various embodiments are described regarding the folding of the sanitary paper strip. A precut bowl flap, in each of the detachable seat-covers, is provided as well. The sanitary paper strip can be made of a single or multi-ply paper. In the preferred embodiment of the present invention, the sanitary paper is made of a duplex paper, where each surface best serves the intended function of that surface. Additionally, the sanitary paper strip can be impregnated with various chemicals.

Owner:ISSACHAR DAVID

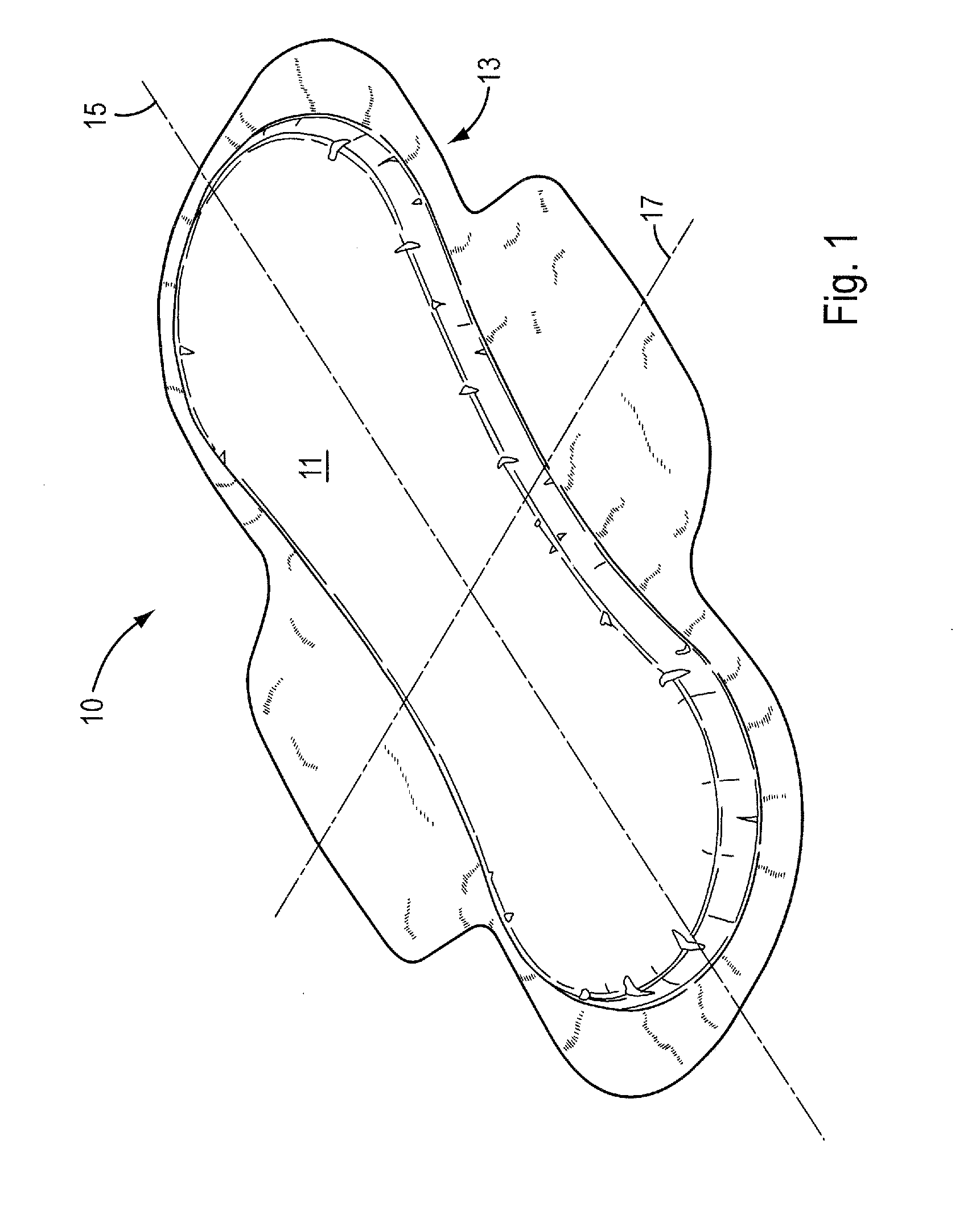

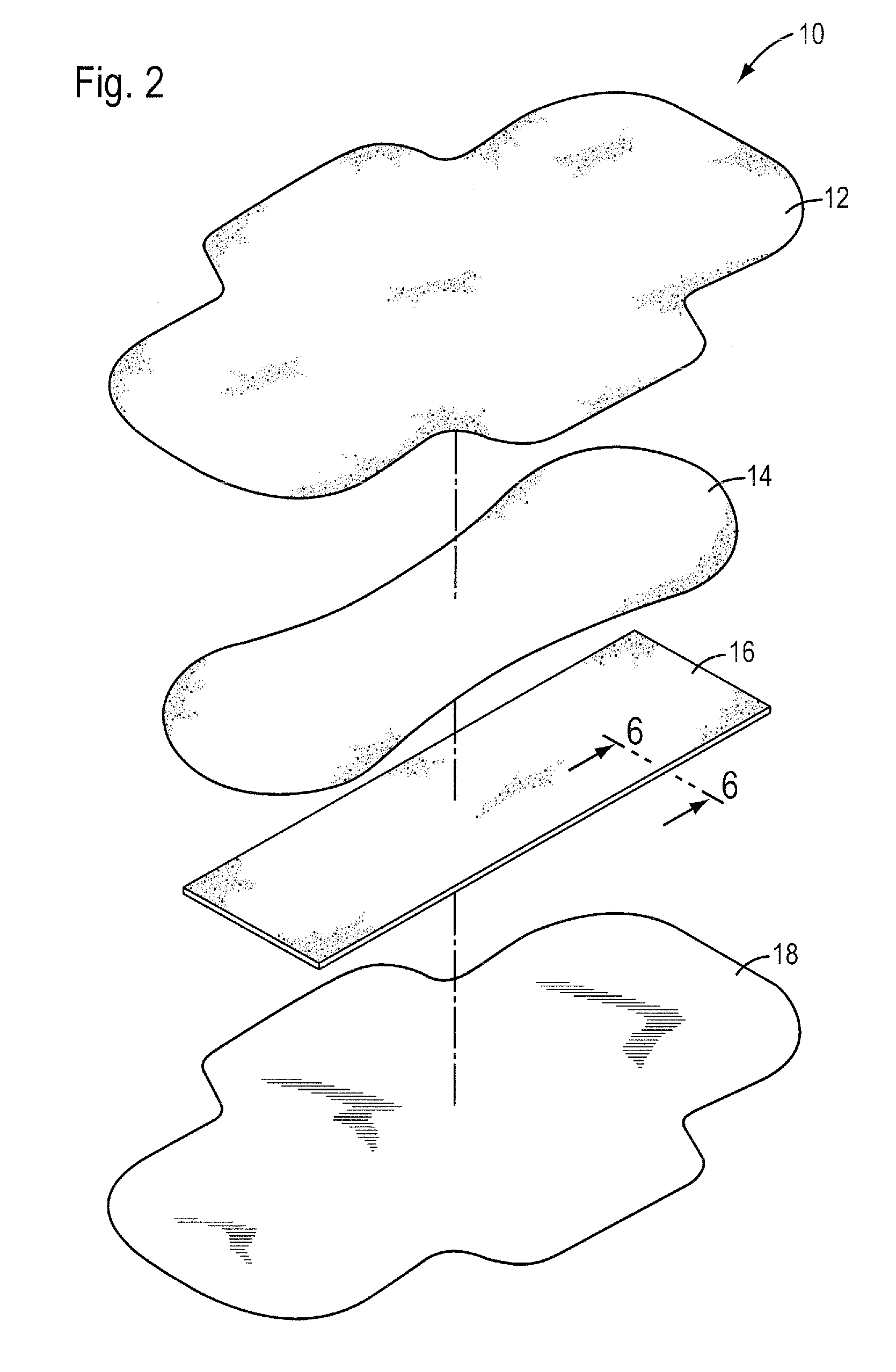

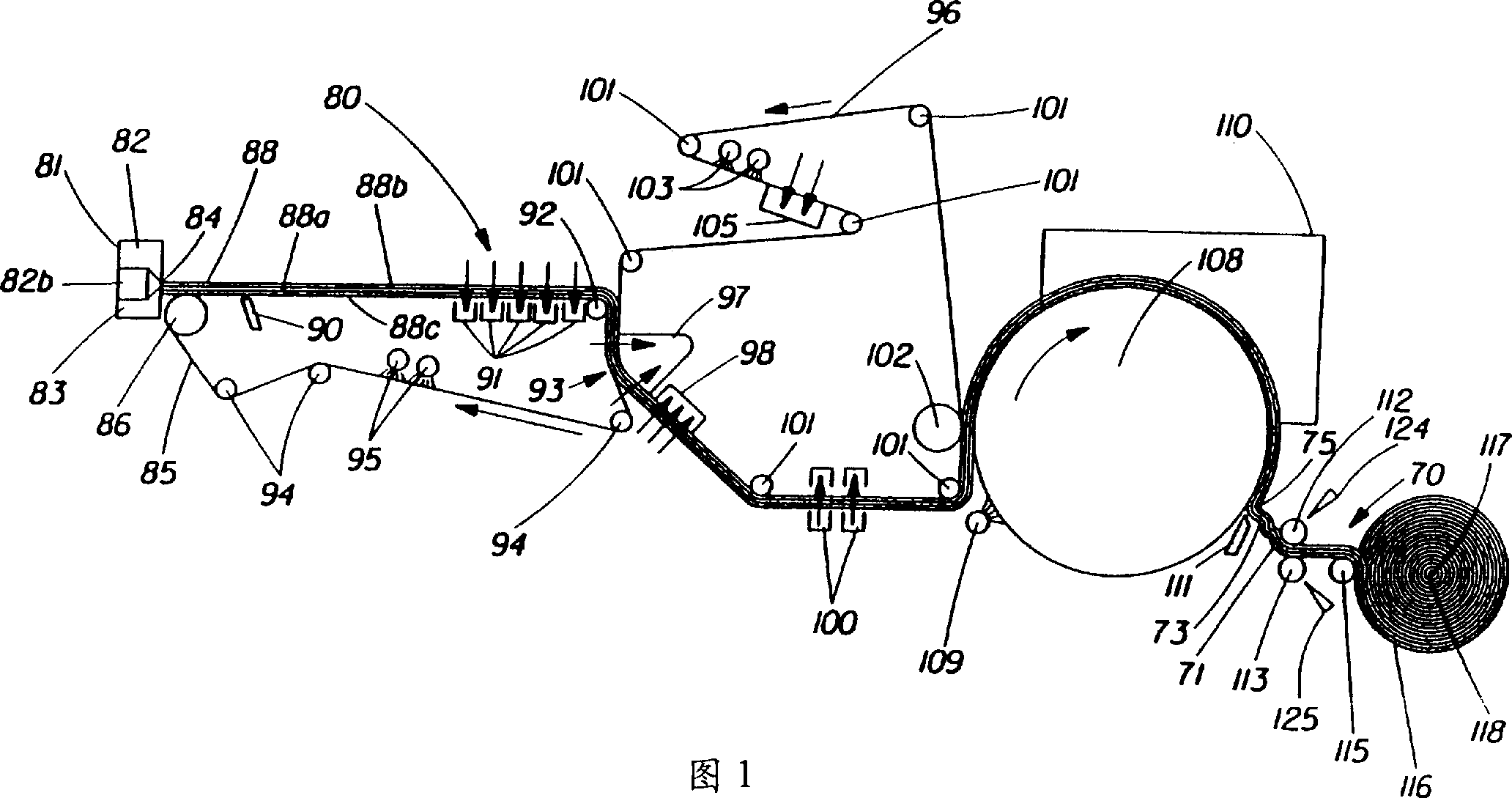

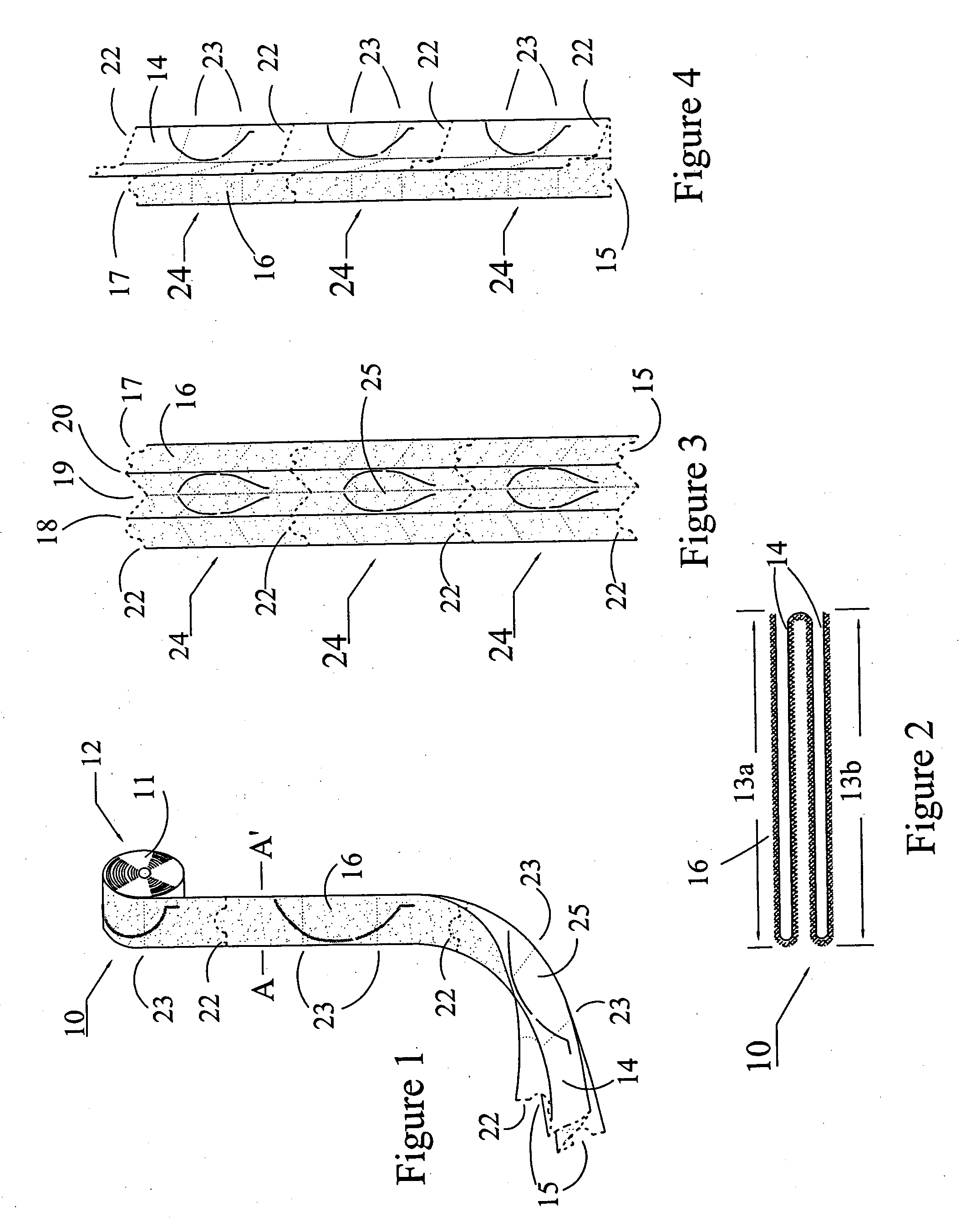

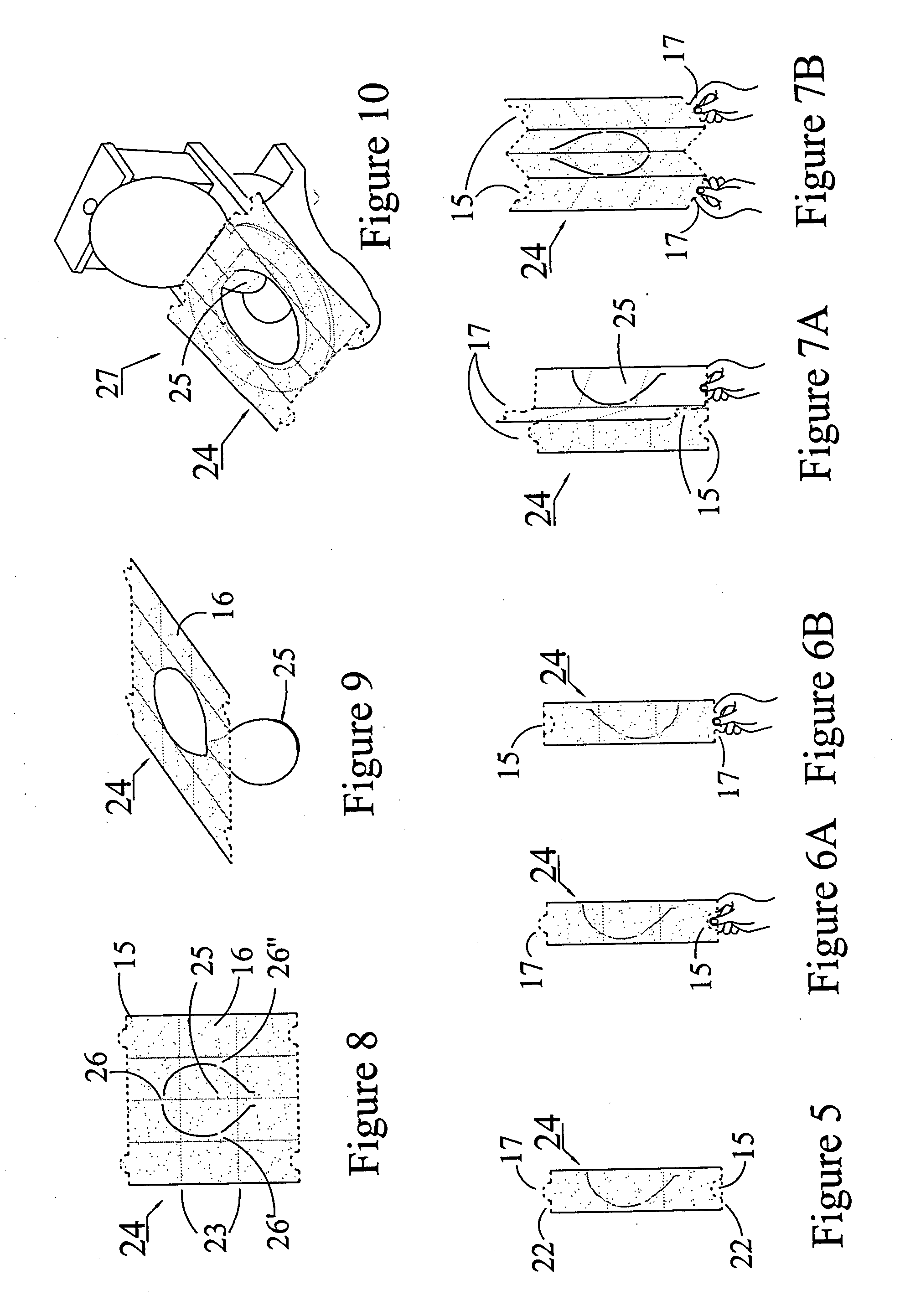

Soft, absorbent material for use in absorbent articles and process for making the material

InactiveUS20030234468A1Reduce leakageWidespread acceptanceLaminationLamination apparatusPolymer scienceCellulose fiber

An absorbent material is provided with improved characteristics. A process is provided for making the absorbent material. A web is formed with at least one layer of absorbent material, and it may include a mixture of cellulosic fibers and superabsorbent material. The moisture content of the web is increased so as to increase the web density. Then, the web is compacted at an elevated temperature to further increase the web density and preferably to also effect hydrogen bonding within the web. In one embodiment a tissue layer is provided, is wetted with water, and is bonded to the layer of absorbent material.

Owner:RANGACHARI KRISHNAKUMAR +4

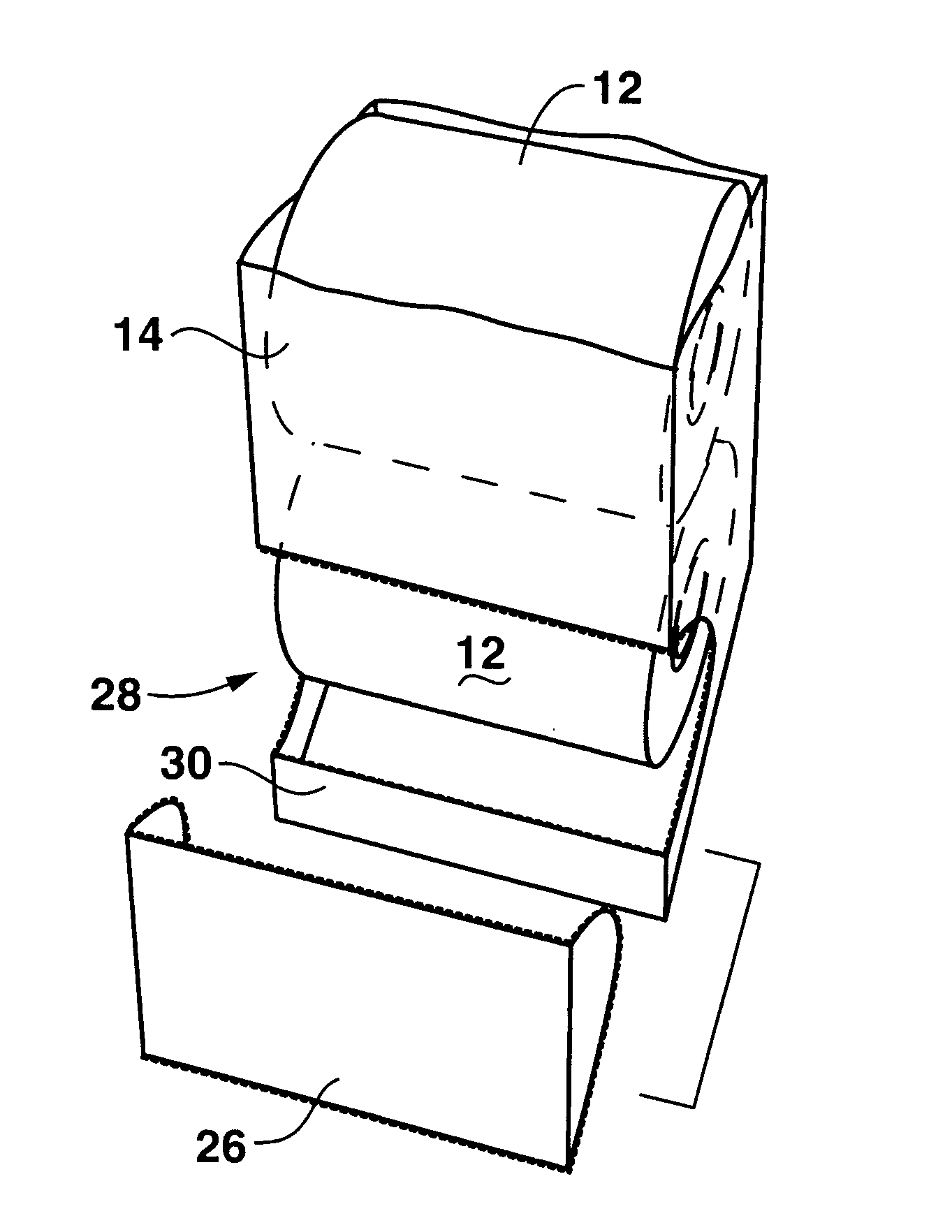

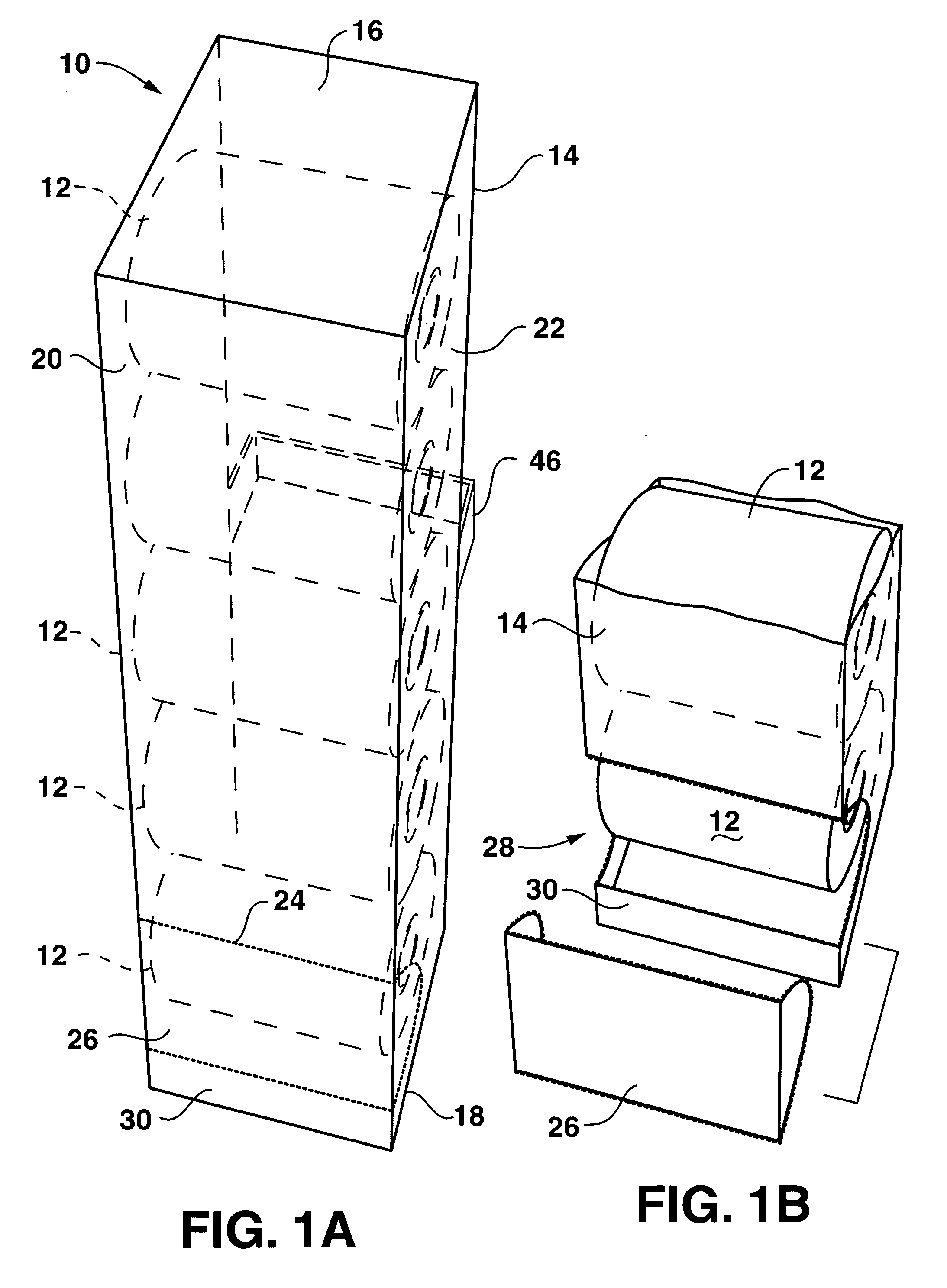

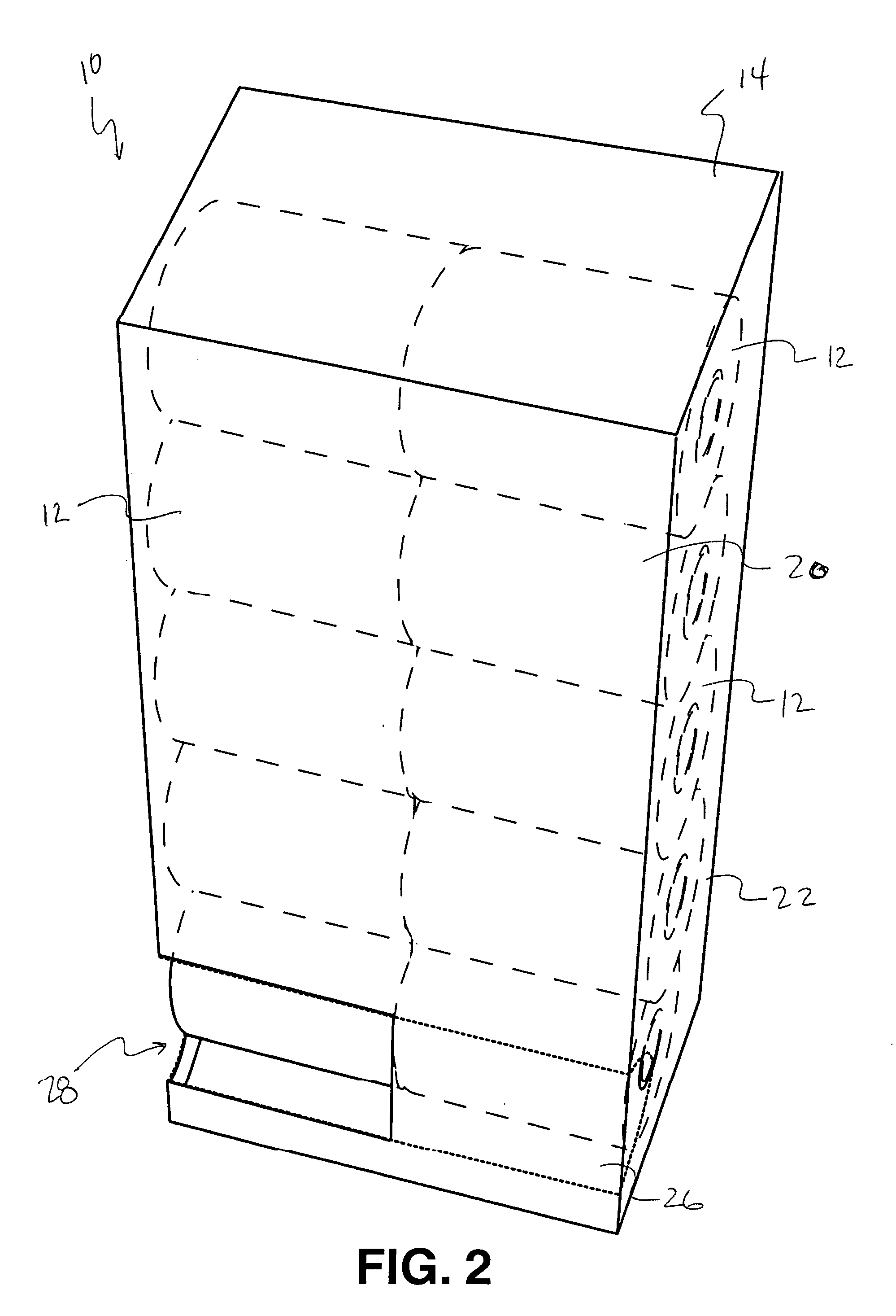

Decorative and disposable bath tissue dispenser

InactiveUS20060243739A1Avoid insufficient lengthSufficient widthRacksCoin-freed apparatus detailsCardboardPaper towel

An aesthetically pleasing and disposable tissue roll dispenser is disclosed. The tissue roll dispenser may be made from, for instance, a lightweight paperboard and may contain various design elements on the exterior surface. The tissue roll dispenser may contain at least one vertically stacked column of tissue rolls that are gravity fed through the dispenser. For instance, the dispenser may include an opening towards the base of the dispenser for dispensing the tissue rolls. In one embodiment, the opening may be covered by a plastic film that defines a slit. The slit may have a size sufficient to allow the tissue rolls to be dispensed therethrough. The plastic film may be used to protect the tissue rolls from dust, dirt and wetness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com