Patents

Literature

86 results about "Surface response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Response Surface Methodology (RSM) Response Surface Methodology is a statistical test setup with more factors on different levels combined in one experiment. It is used rwhen analyzing complex problems with a multiple of influence factors in once including interactions.

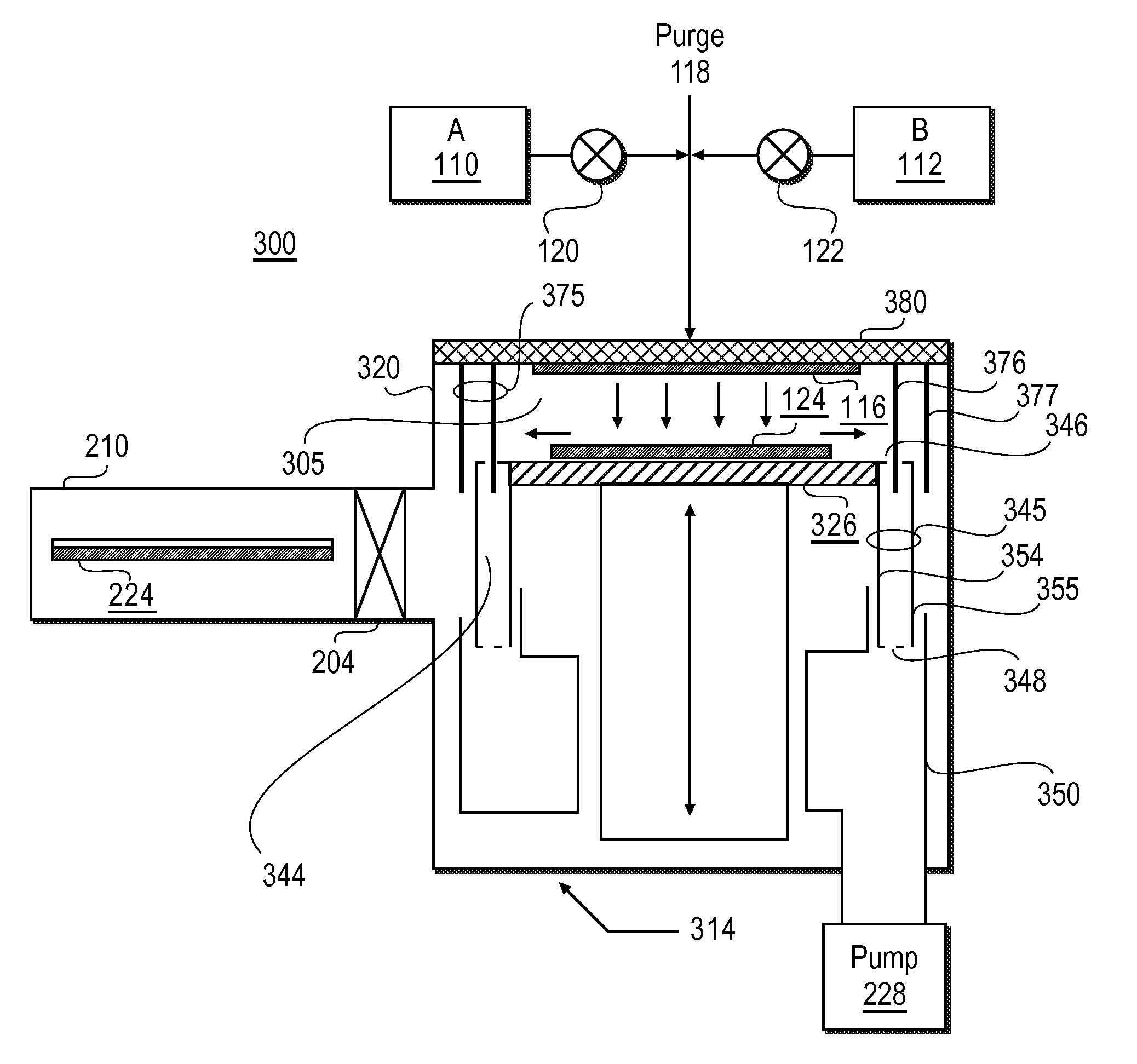

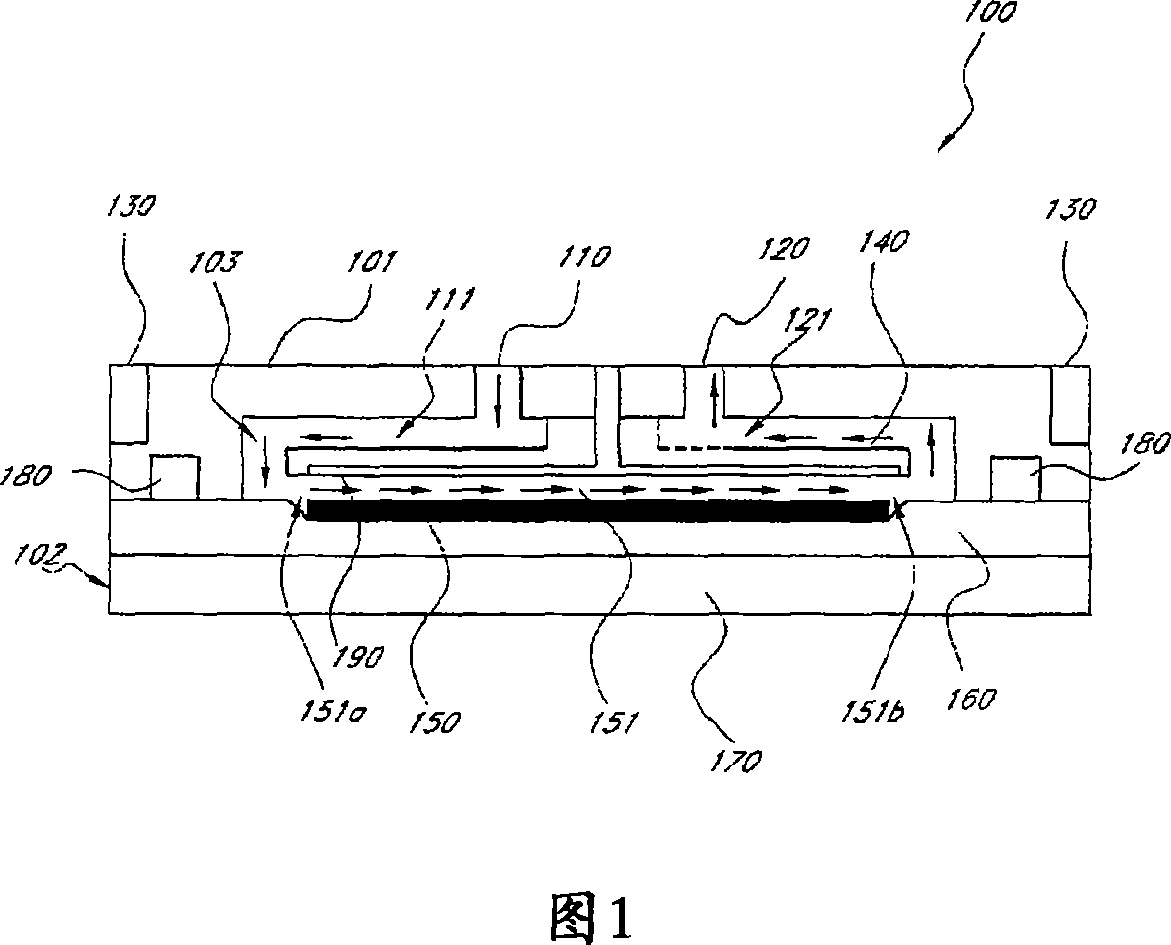

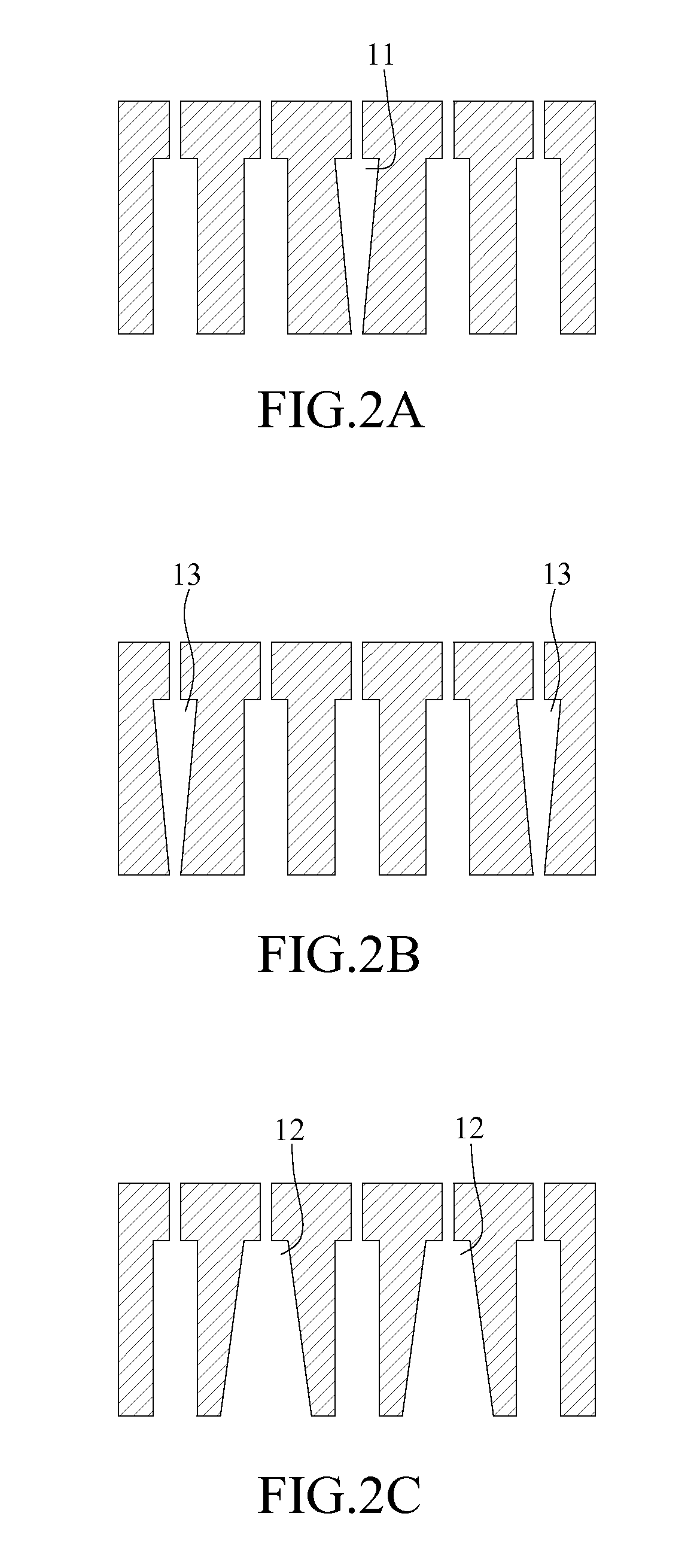

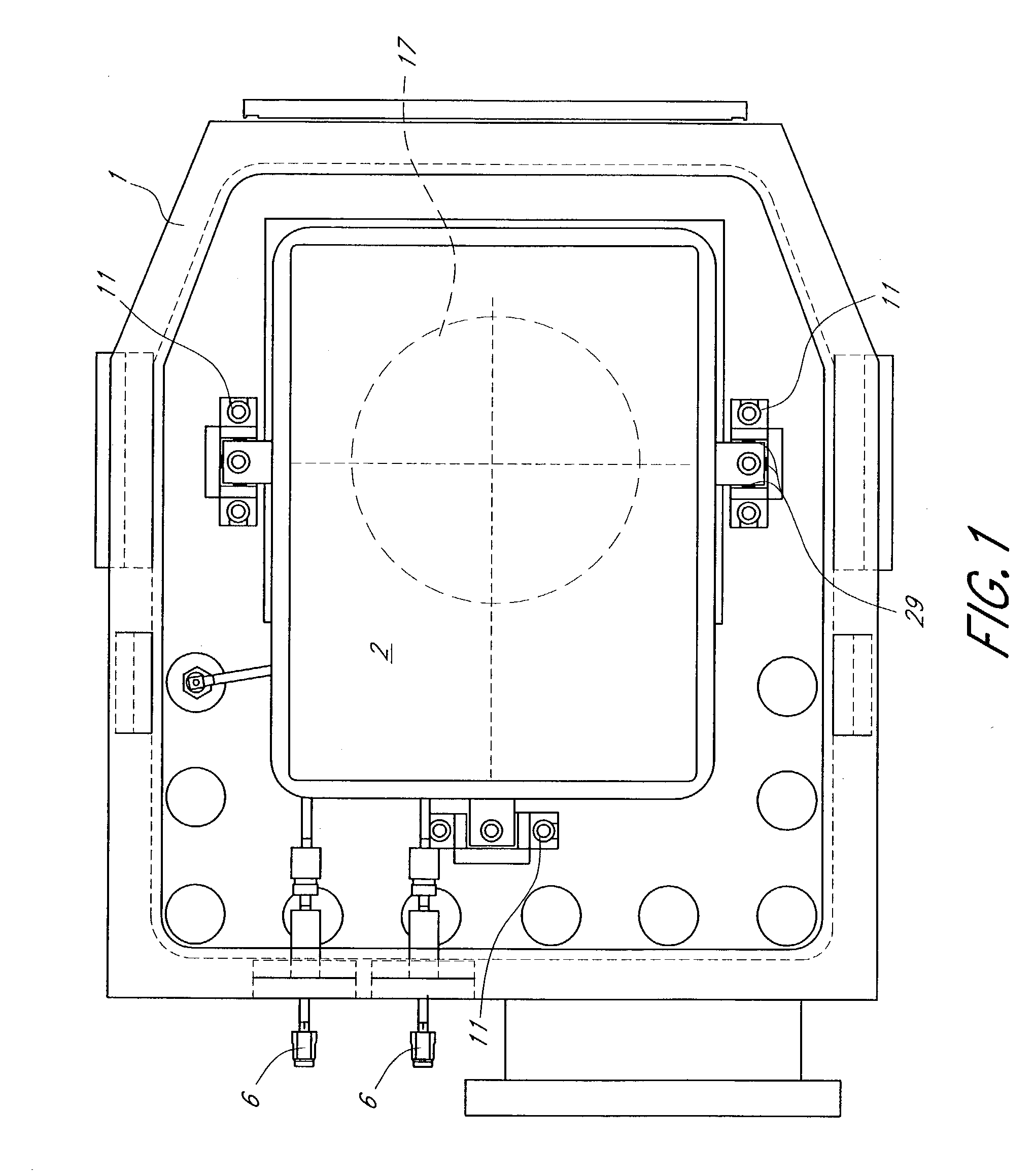

Small volume symmetric flow single wafer ald apparatus

InactiveUS20080072821A1Advance in maintenance benefitGood benefitAfter-treatment apparatusFrom chemically reactive gasesSusceptorEngineering

A reaction chamber apparatus includes a vertically movable heater-susceptor with an attached annular attached flow ring that performs as a gas conduit. The outlet port of the flow ring extends below the bottom of a wafer transport slot valve when the susceptor is in its process (higher) position, while the gas conduit formed by the flow ring has an external surface at its edge that isolates the outer space of the reactor above the wafer from the confined reaction space. In some cases, the outer edge of the gas conduit is in proximity to a ring attached to the reactor lid and, together, the ring and conduit act as a tongue-in-groove (TIG) configuration. In some cases, the TIG design may have a staircase contour, thereby limiting diffusion-backflow of downstream gases to the outer space of the reactor.

Owner:AIXTRON INC

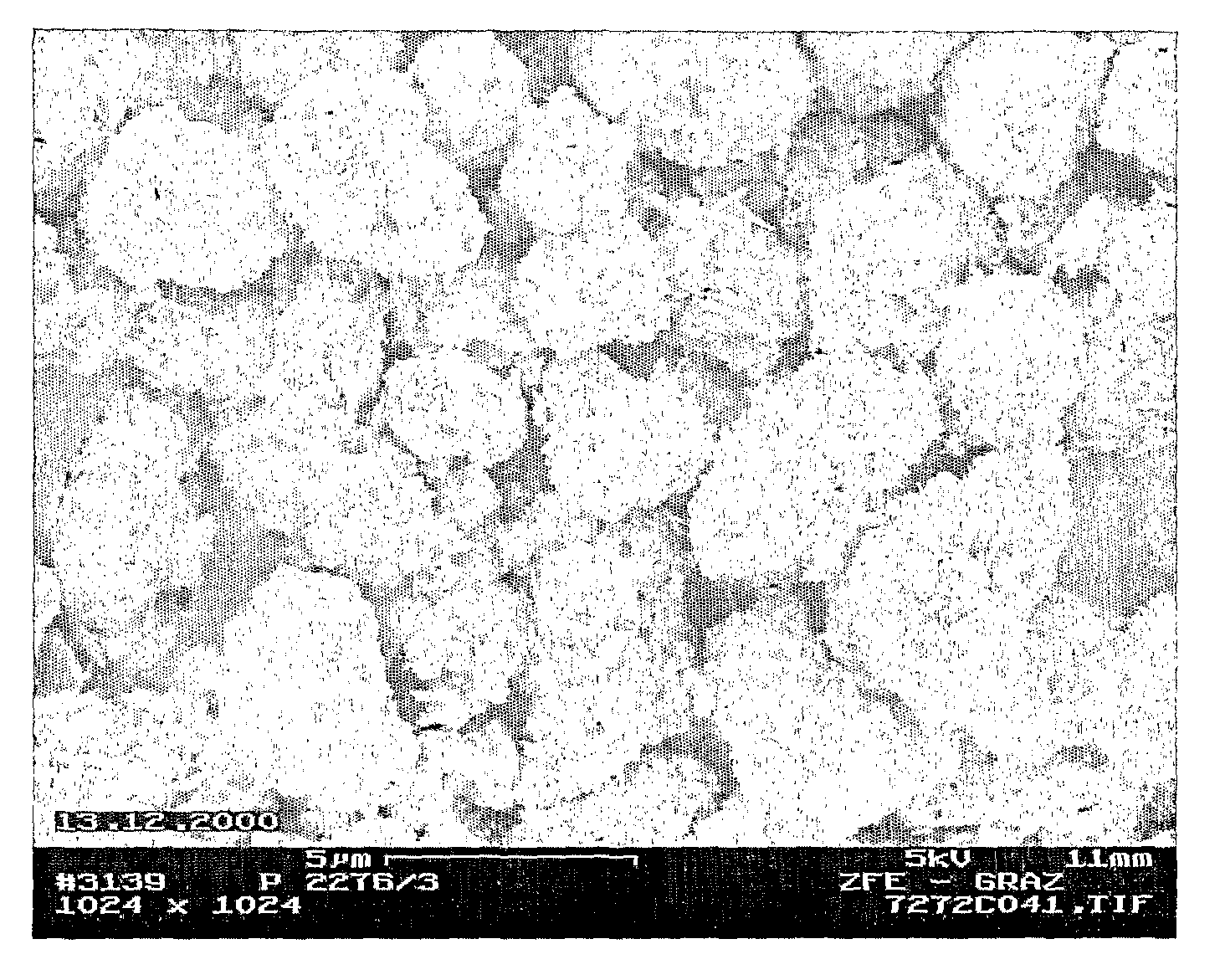

Use Of A Surface-Reacted Calcium Carbonate In Tissue Paper, Process To Prepare A Tissue Paper Product Of Improved Softness, And Resulting Improved Softness Tissue Paper Products

ActiveUS20120031576A1Good flexibilityNatural cellulose pulp/paperCoatings with pigmentsSurface responseTissue paper

The present invention related to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

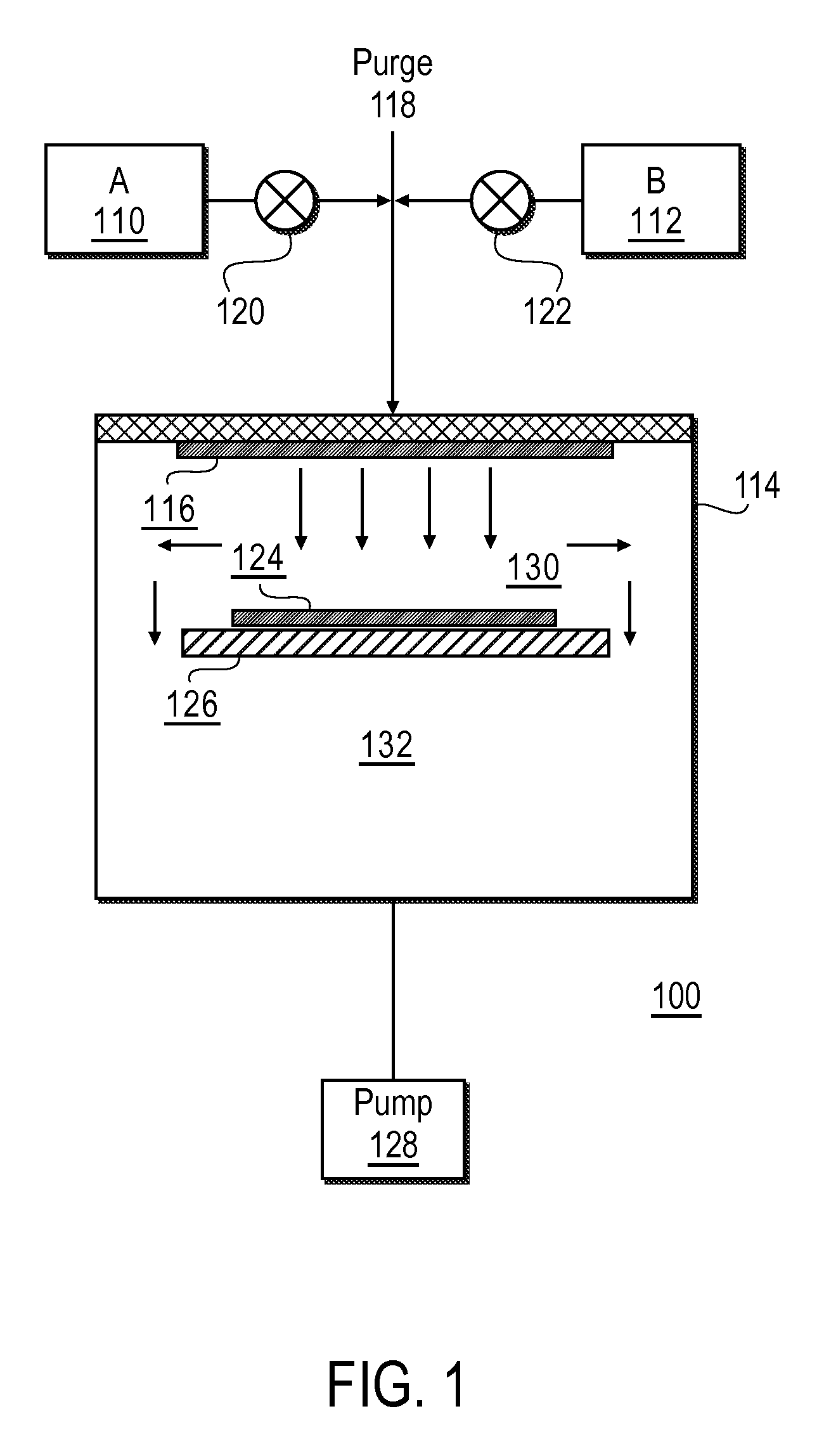

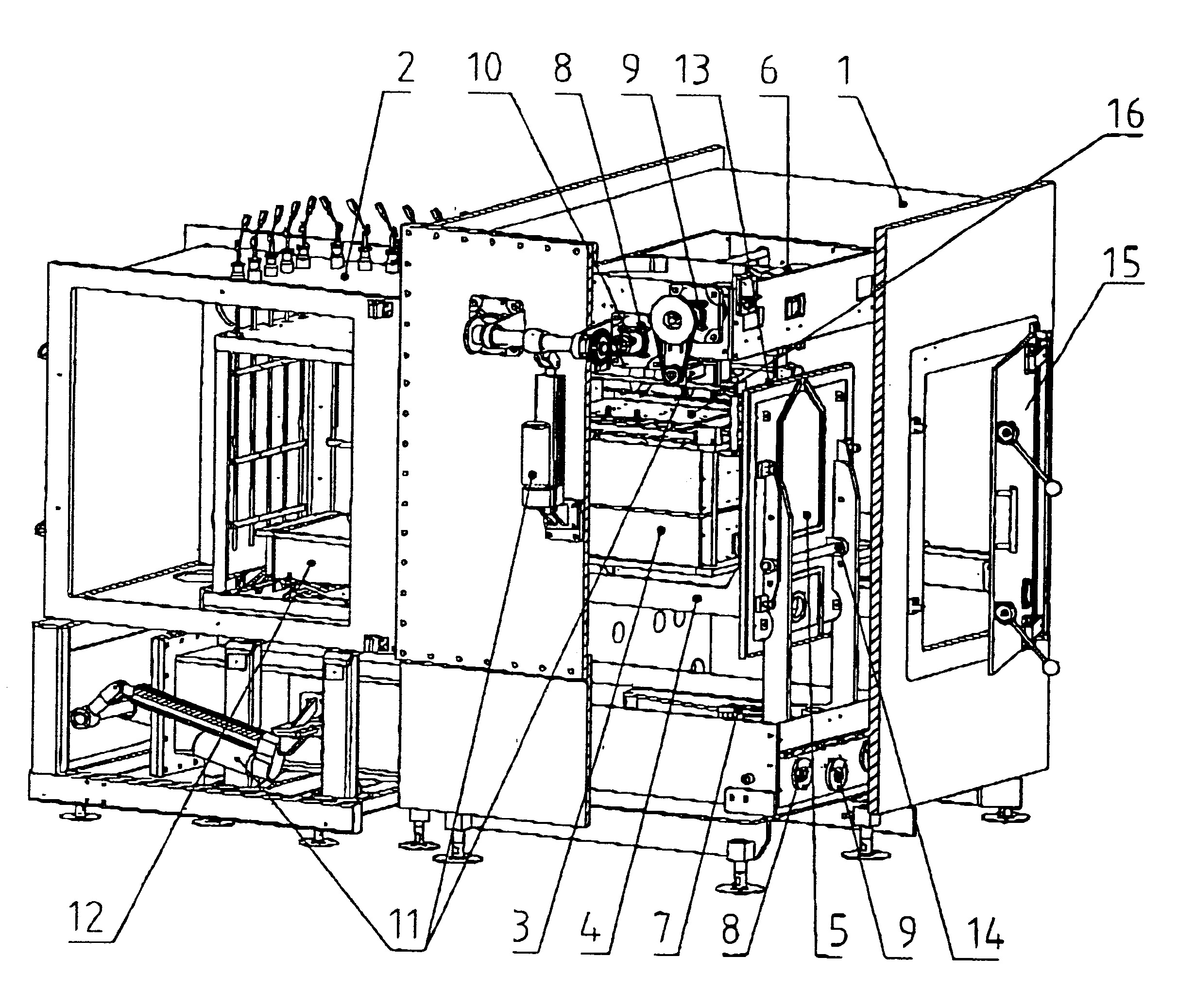

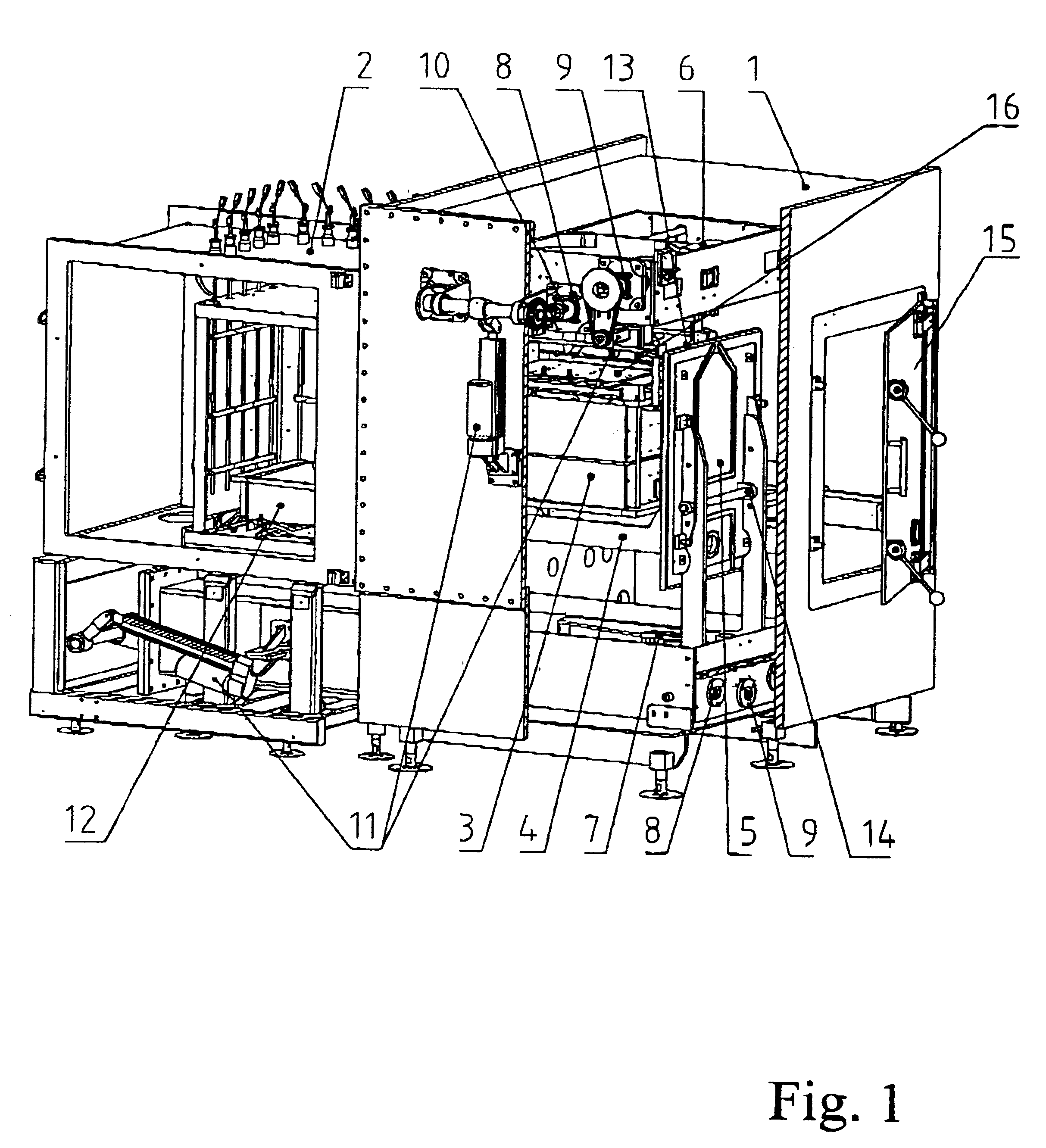

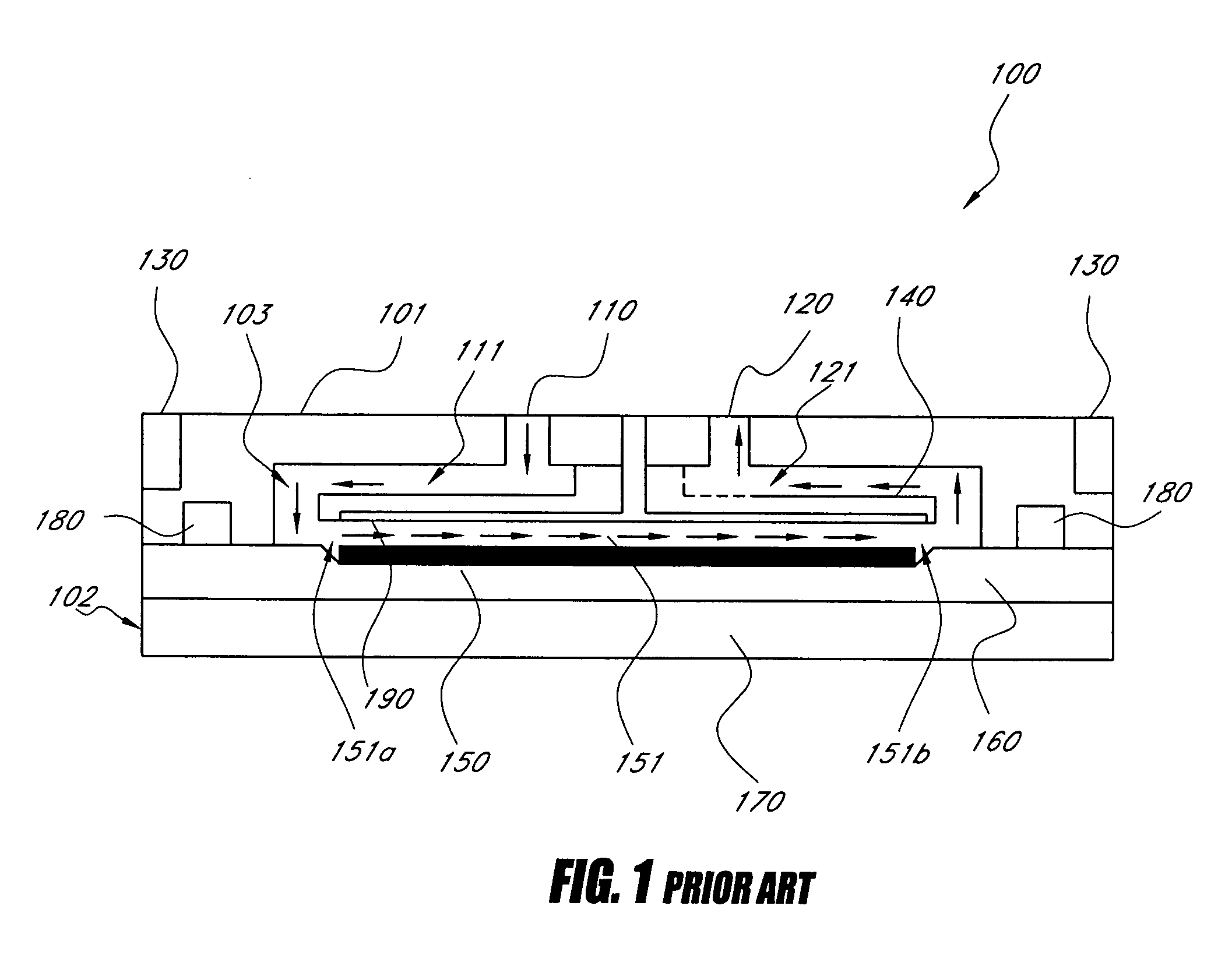

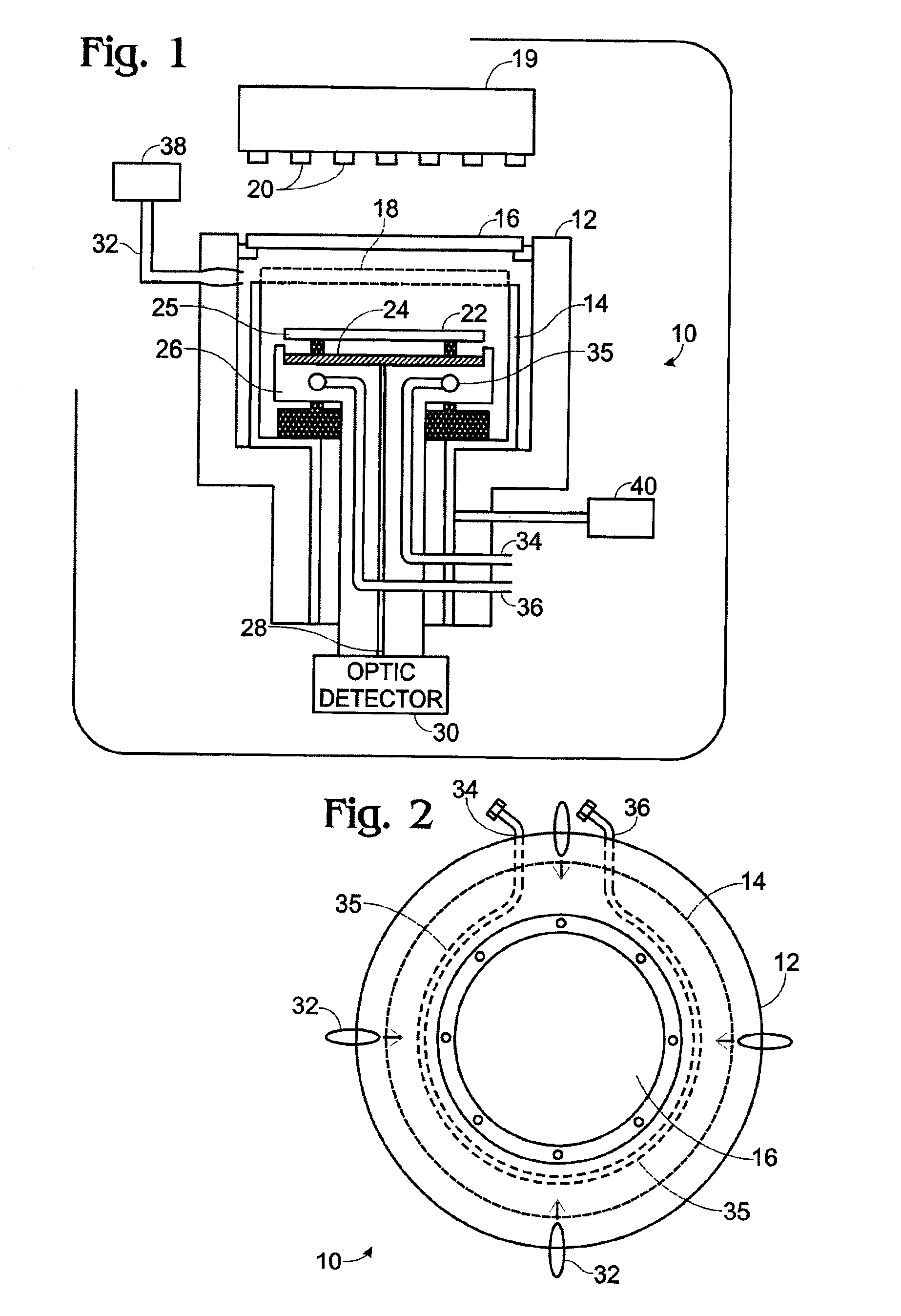

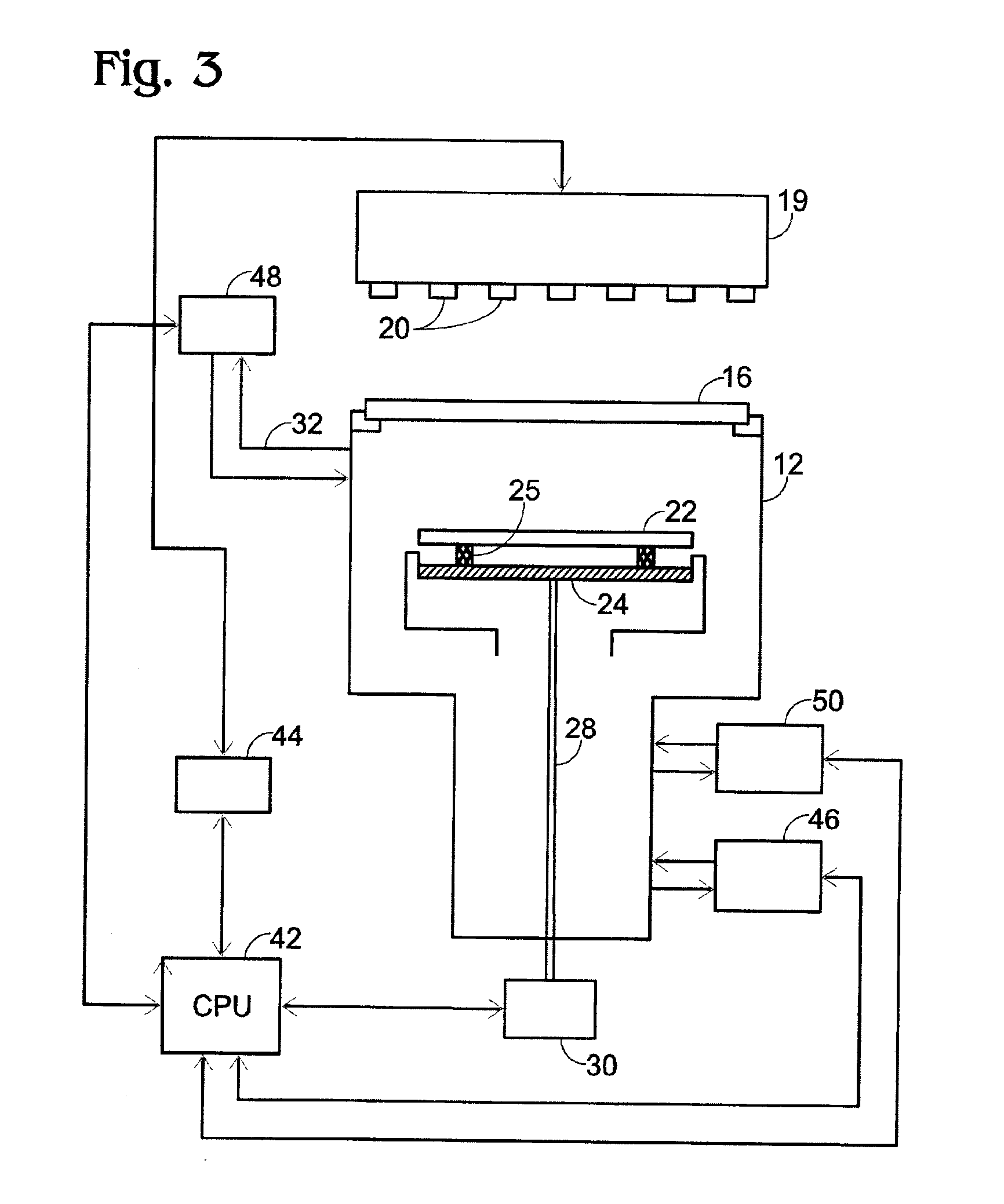

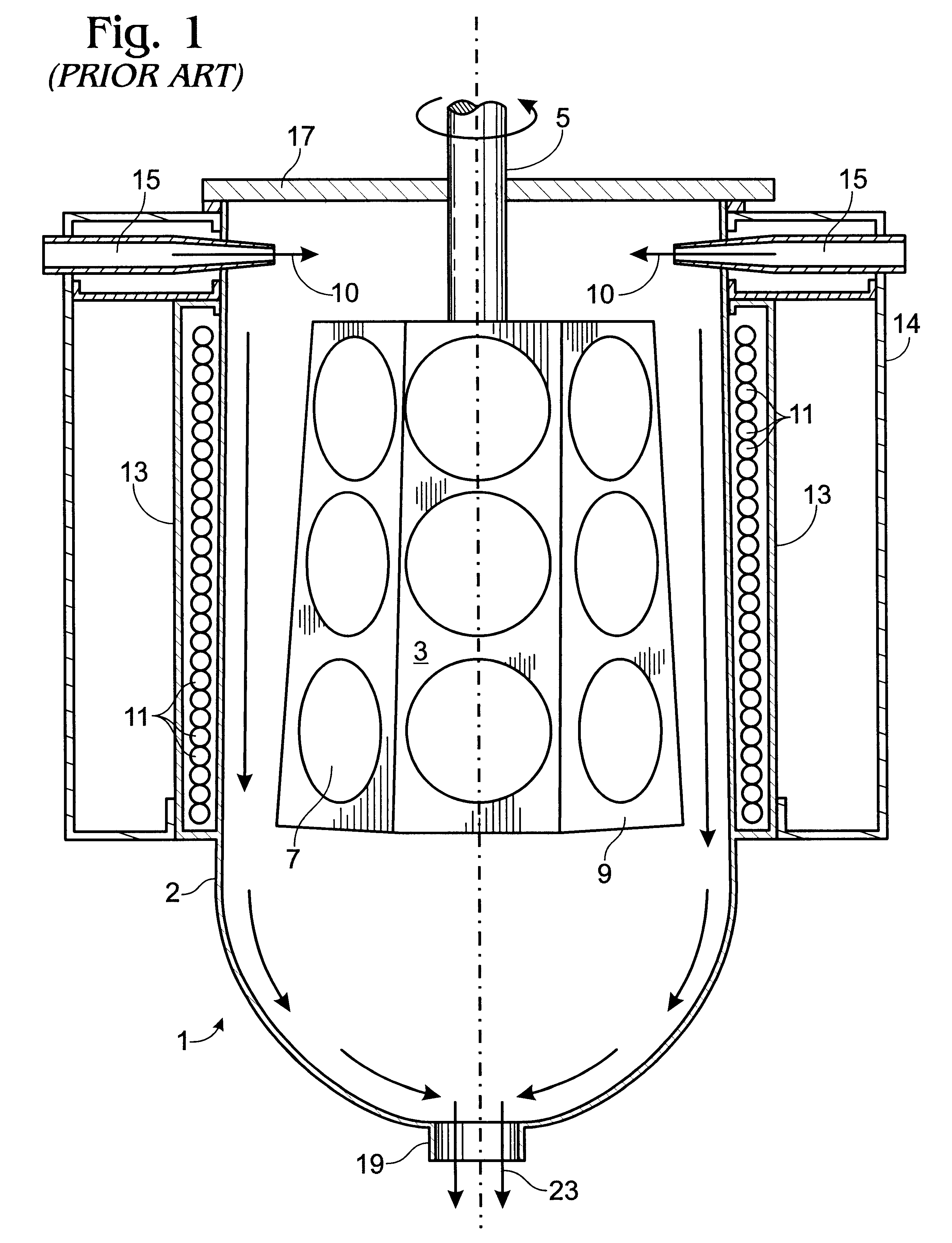

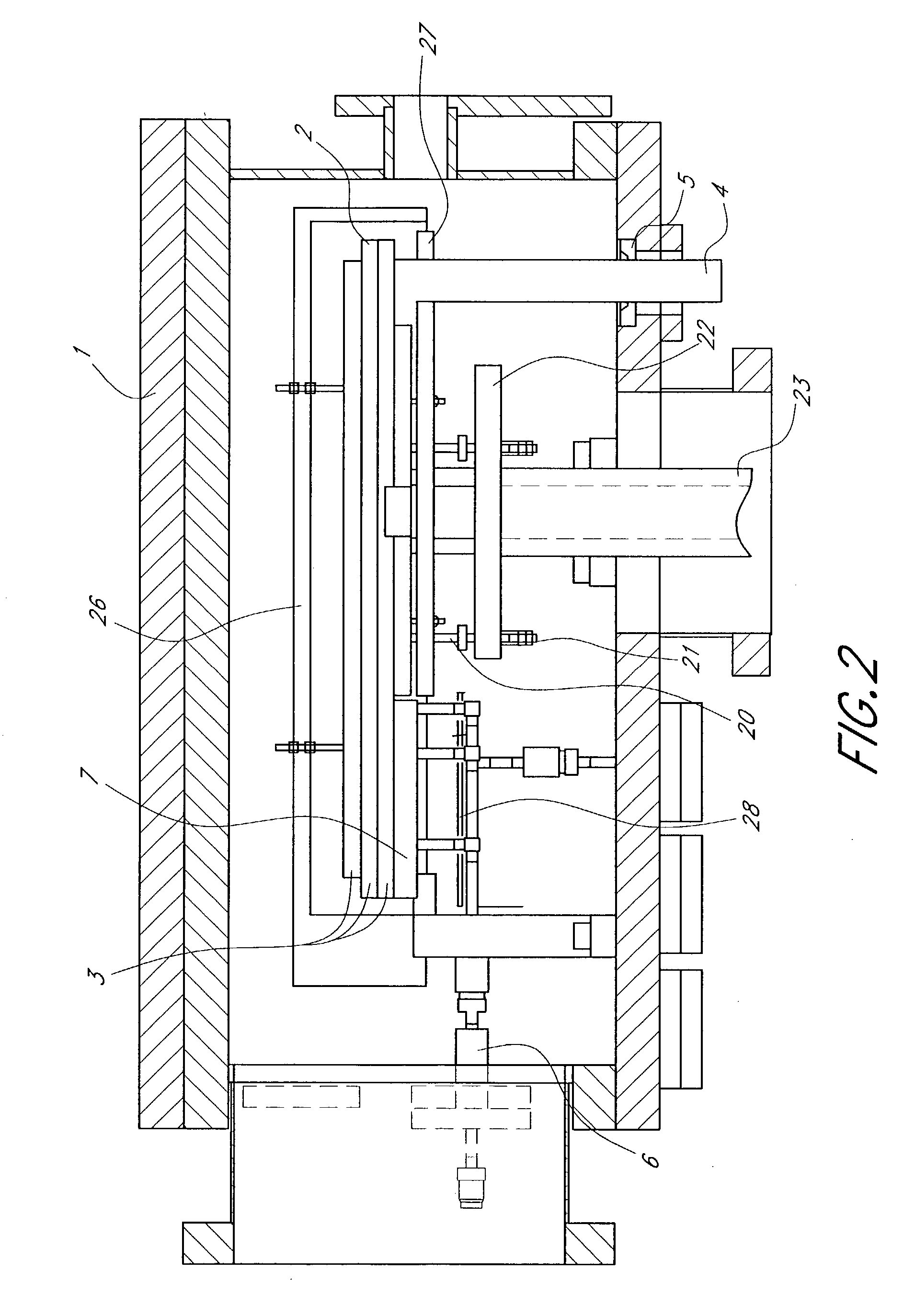

Apparatus for growing thin films

InactiveUS6447607B2Uniform thicknessAvoid possibilityAfter-treatment apparatusPolycrystalline material growthEngineeringVapor phase

The invention relates to an apparatus for growing thin films onto the surface of a substrate by exposing the substrate to alternately repeated surface reactions of vapor-phase reactants. The apparatus comprises at least one process chamber having a tightly sealable structure, at least one reaction chamber having a structure suitable for adapting into the interior of said process chamber and comprising a reaction space of which at least a portion is movable, infeed means connectable to said reaction space for feeding said reactants into said reaction space, and outfeed means connectable to said reaction space for discharging excess reactants and reaction gases from said reaction space, and at least one substrate adapted into said reaction space. At least one loading chamber is arranged to cooperate with said process chamber so as to permit said reaction space or a portion thereof to be moved into said process chamber and away from said process chamber and, further, the operating pressure of the loading chamber is arranged to be controllable independently from said pressure chamber.

Owner:ASM INTERNATIONAL

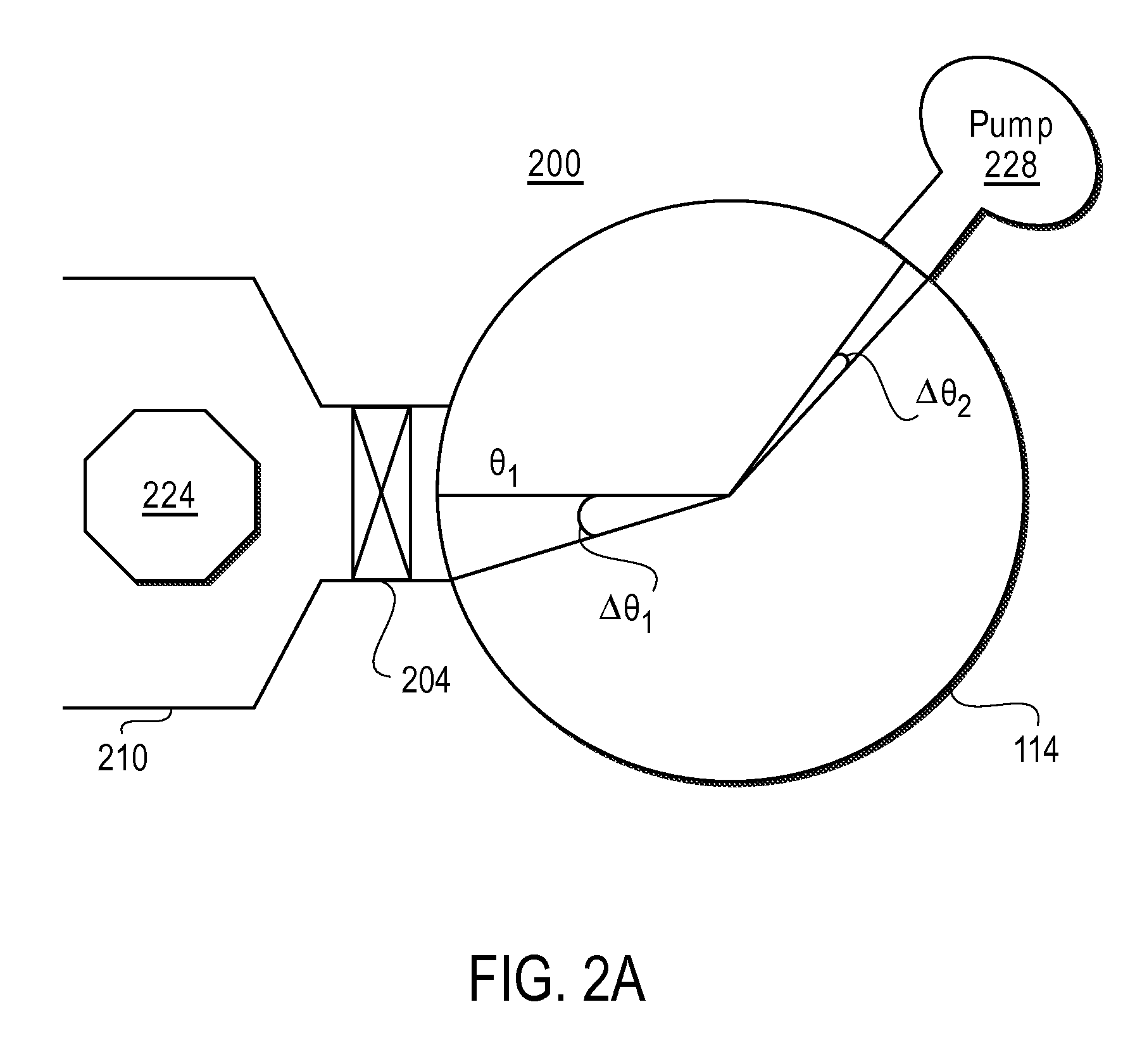

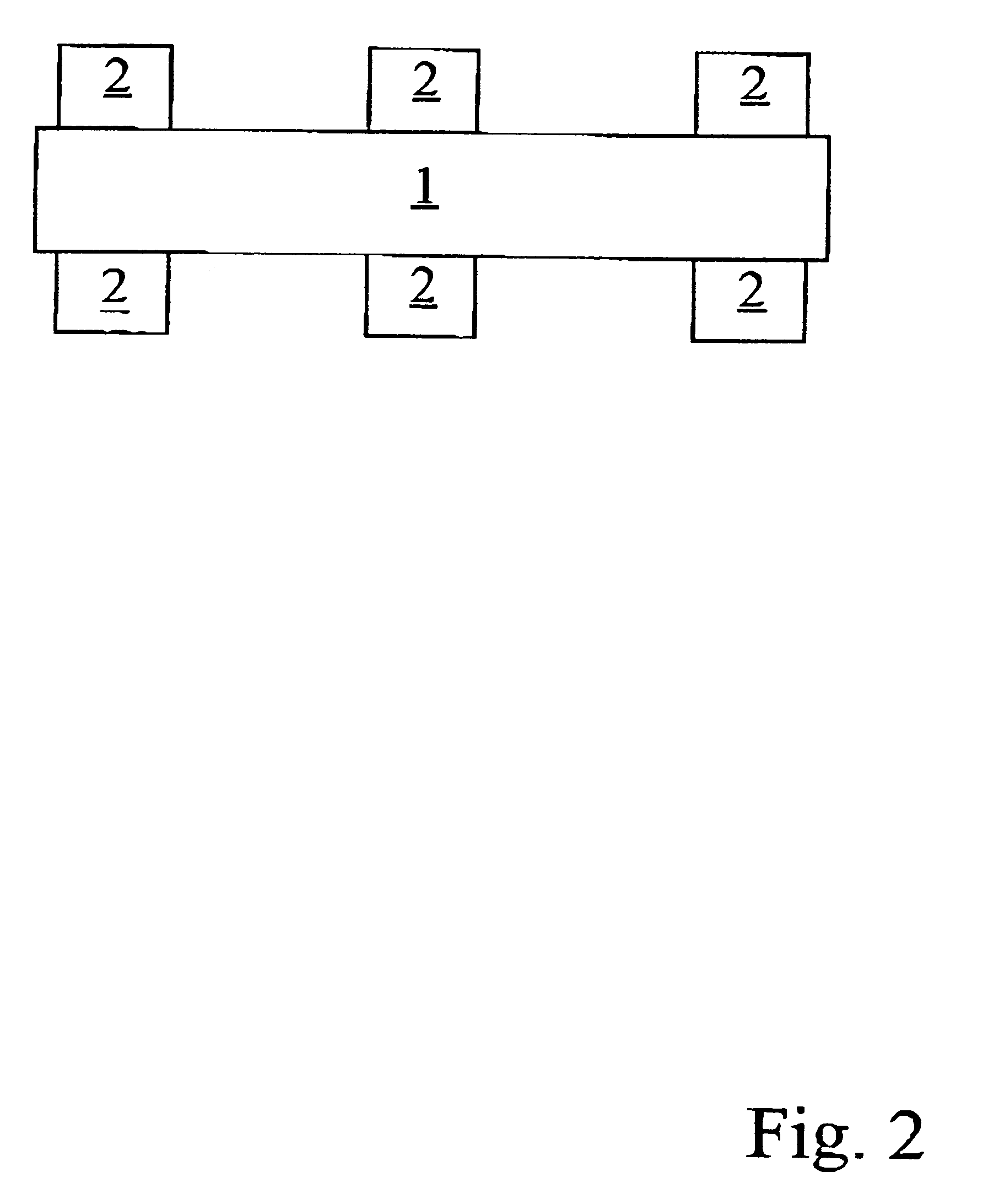

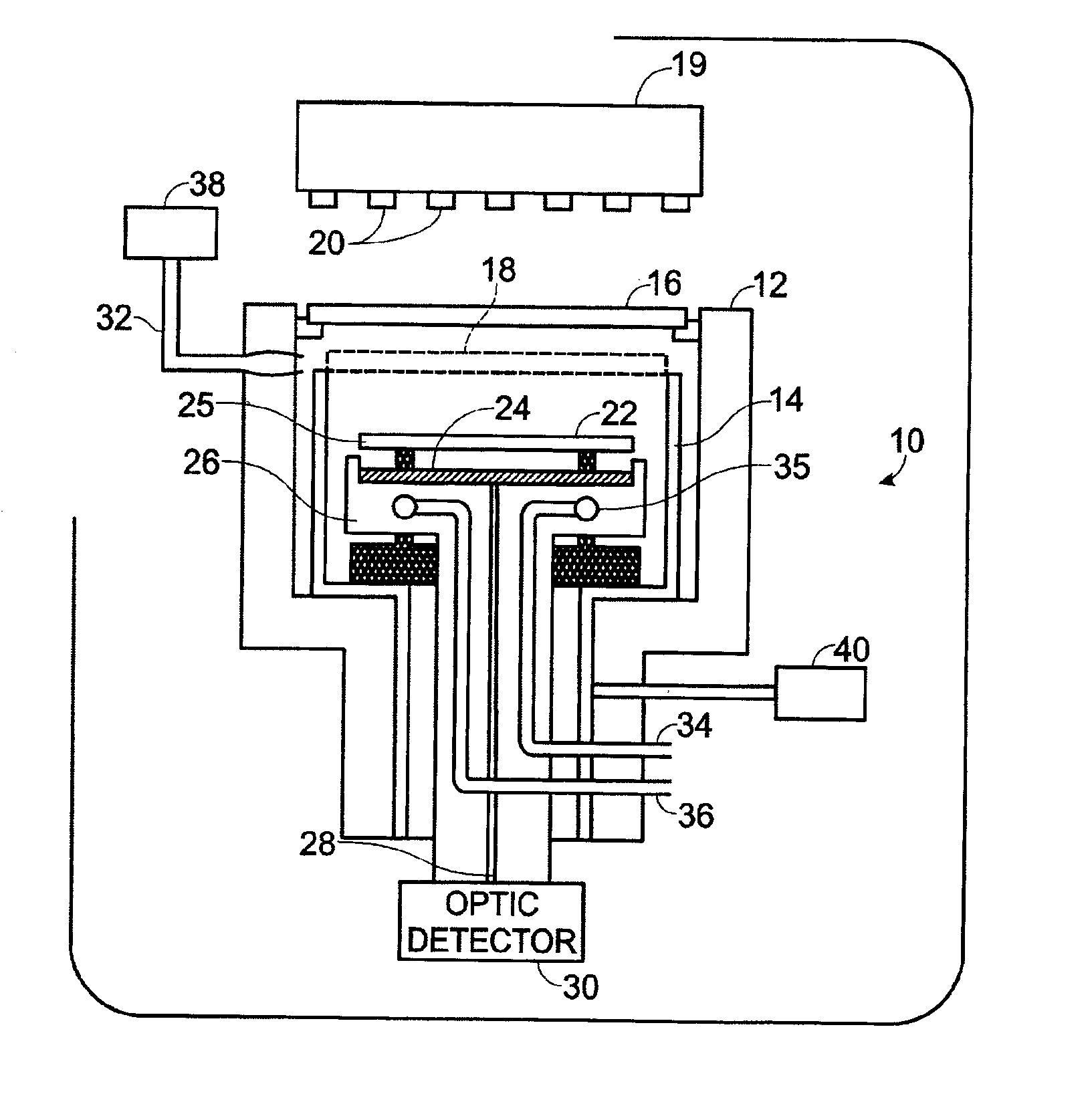

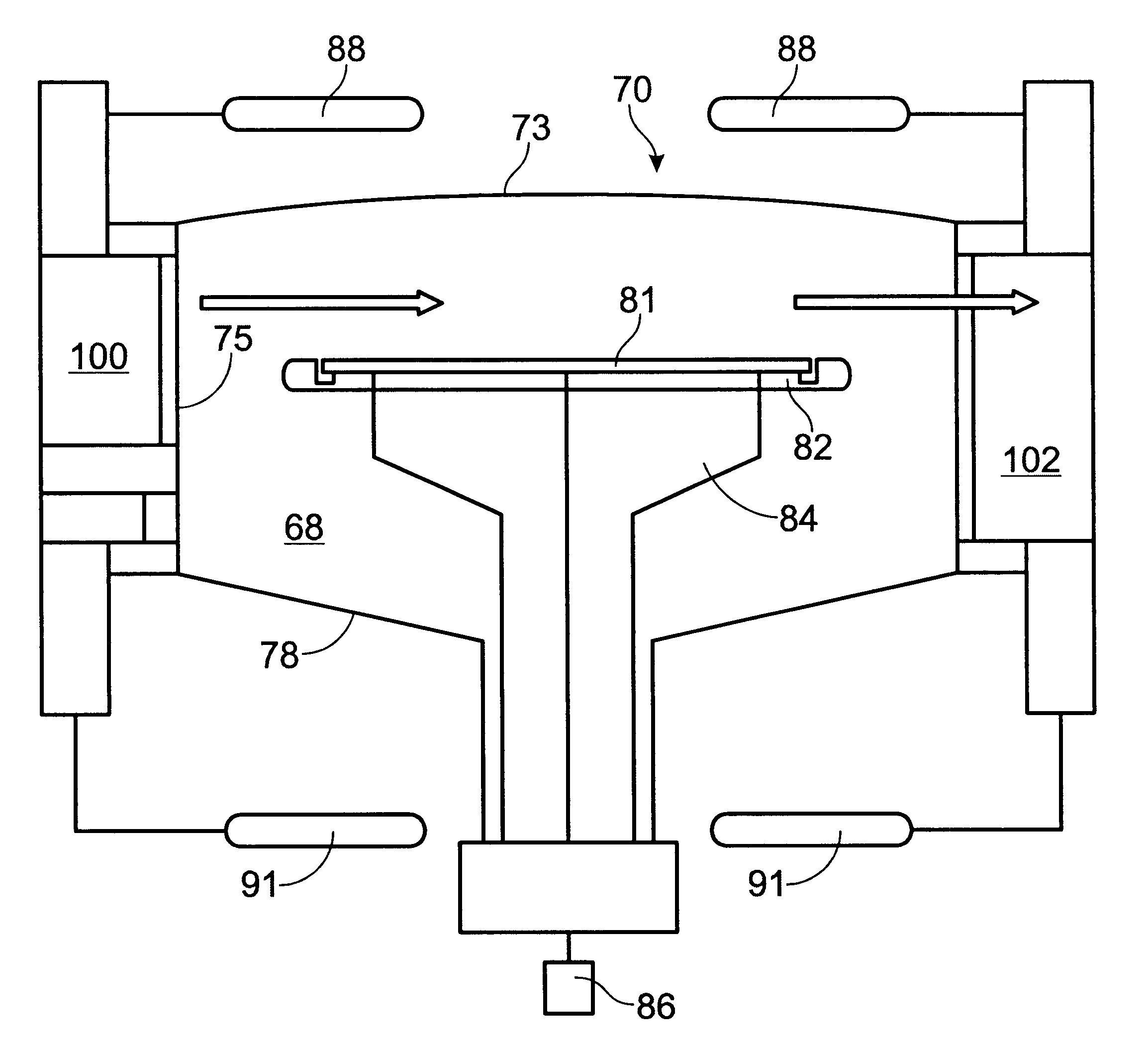

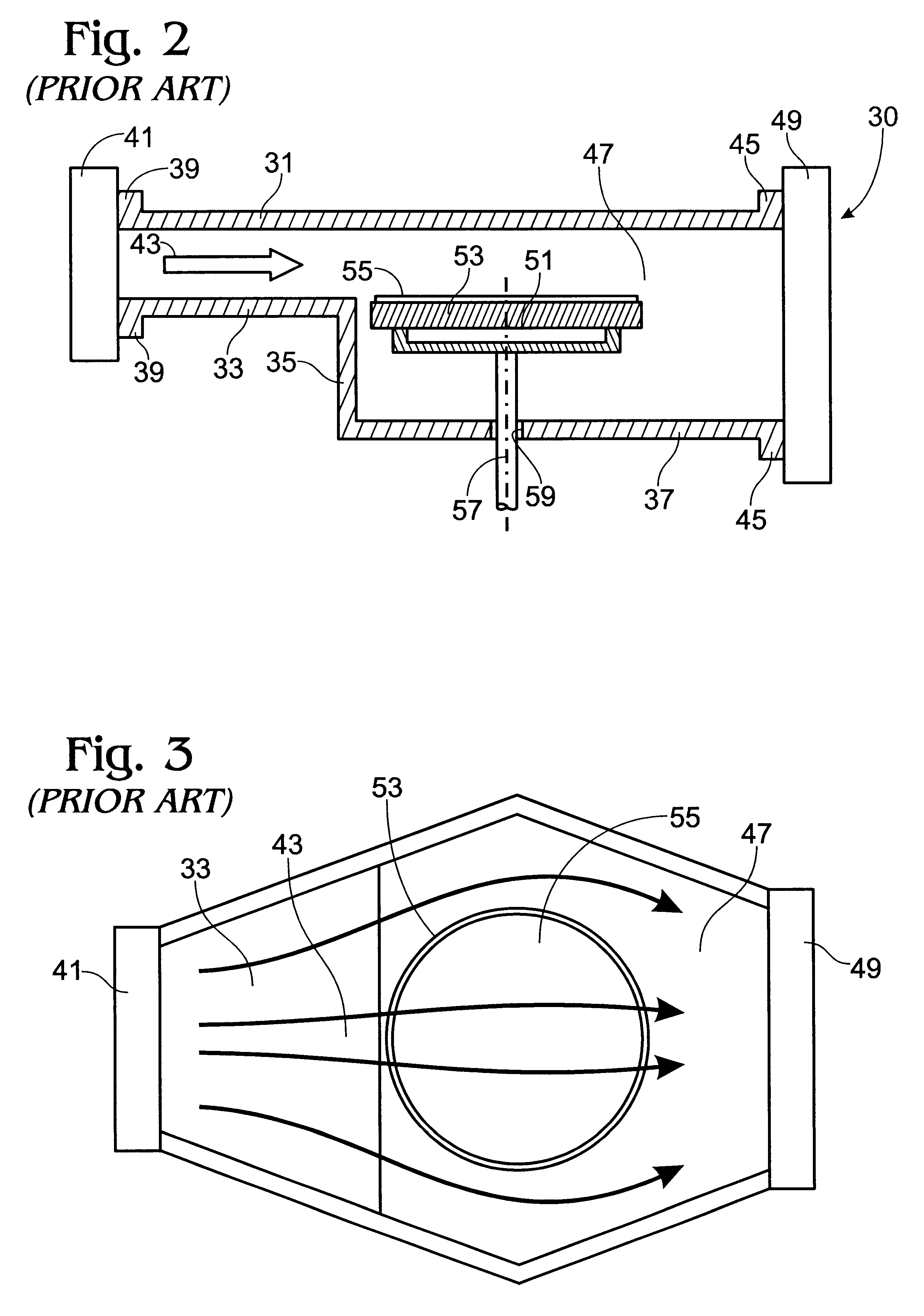

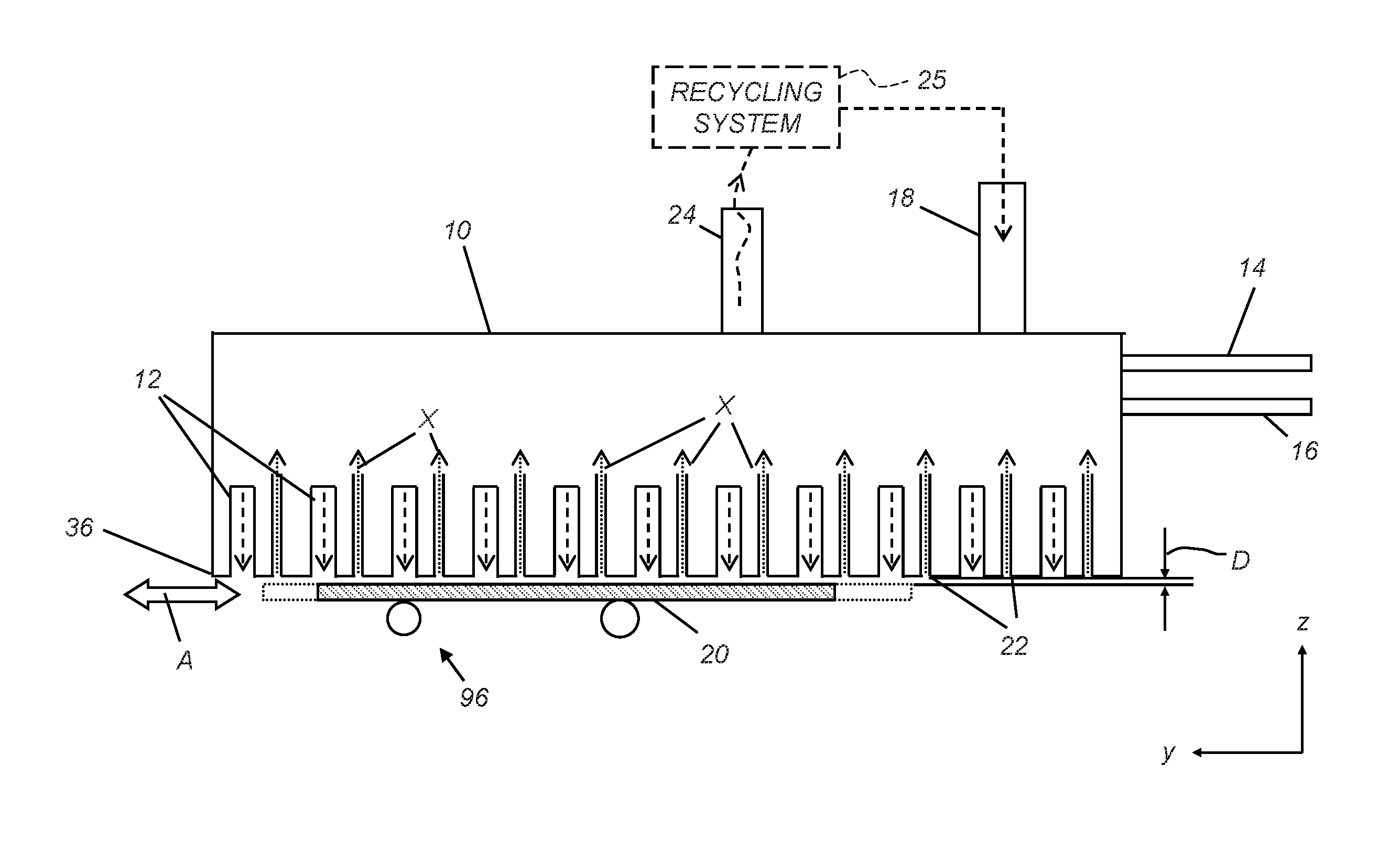

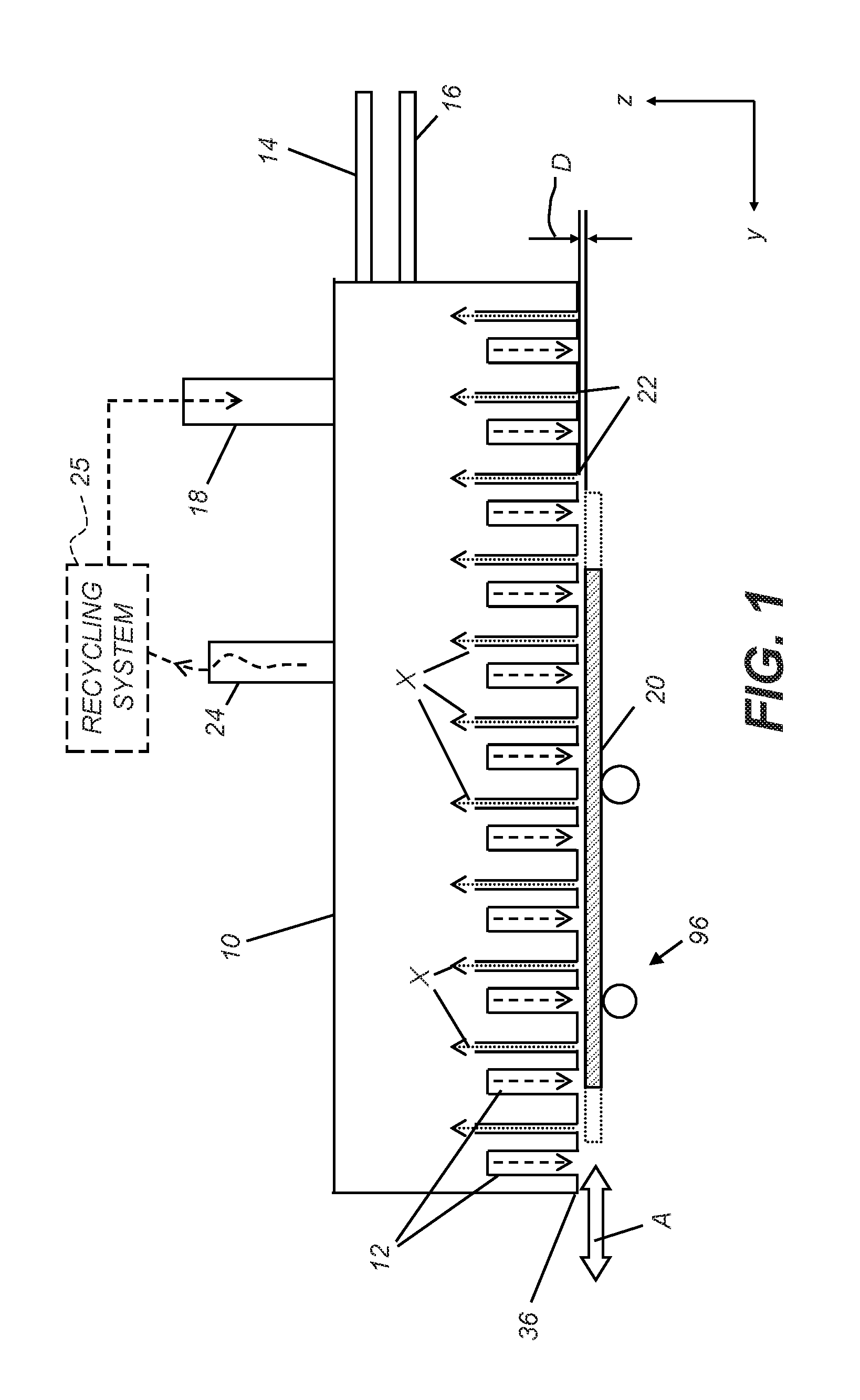

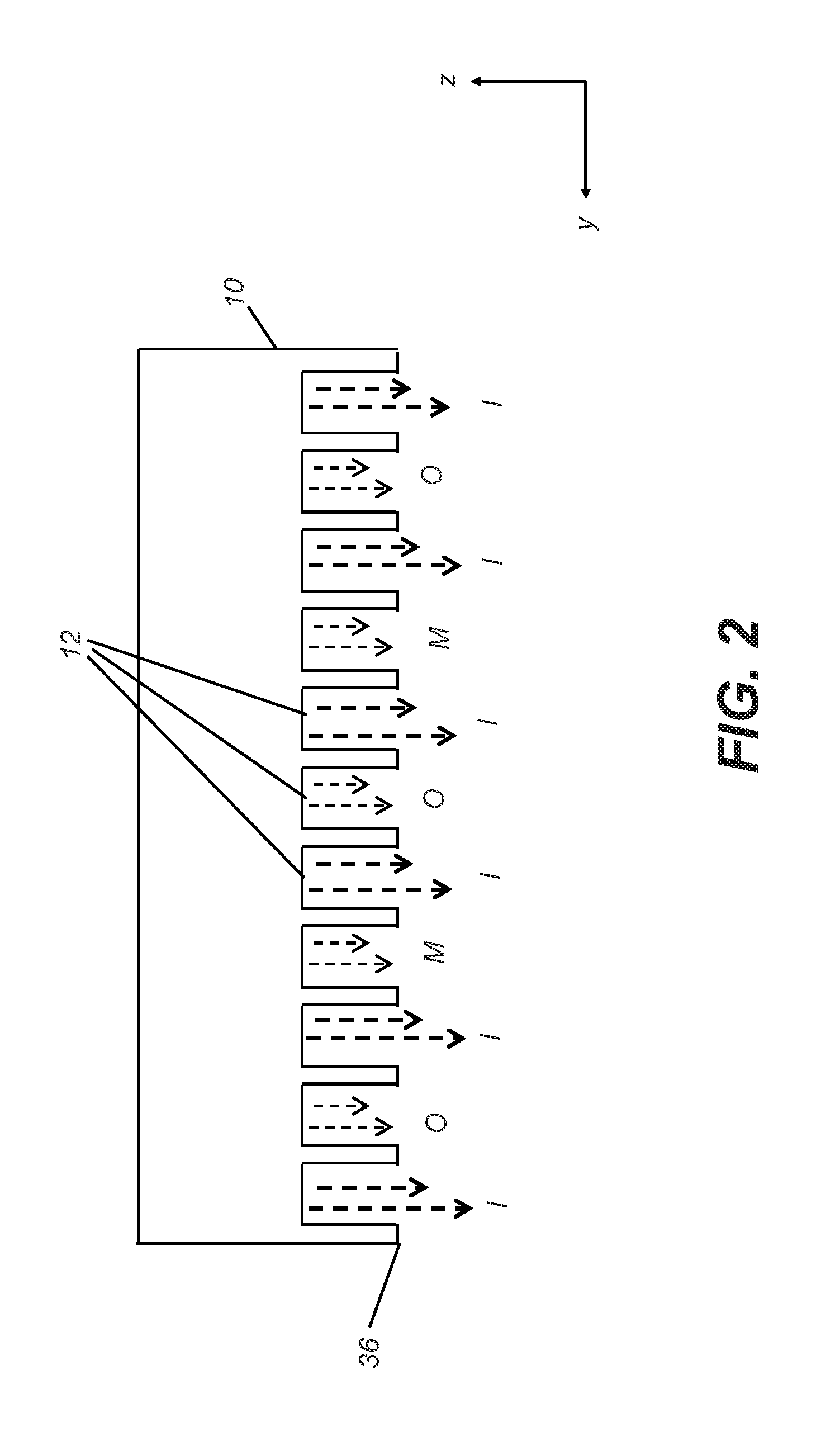

Multiple inlet atomic layer deposition reactor

InactiveUS20060249077A1Flow is rather complicatedQuick switchSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNuclear engineeringVapor phase

A reactor configured to subject a substrate to alternately repeated surface reactions of vapor-phase reactants is disclosed. The reactor includes a reaction chamber, a plurality of inlets, and an exhaust outlet. The reaction chamber includes a reaction space. The reactor also includes a gas flow control guide structure within the reaction chamber. The gas flow control guide structure resides over the reaction space and is interposed between the plurality of inlets and the reaction space. The gas flow control guide structure includes a plurality of channels, and each of the channels extends from one of the inlets to an upstream periphery of the reaction space. Each of the channels progressively widens as the channel extends from the inlet to the reaction space. The reactor further includes a substrate holder in the reaction space.

Owner:ASM GENITECH KOREA

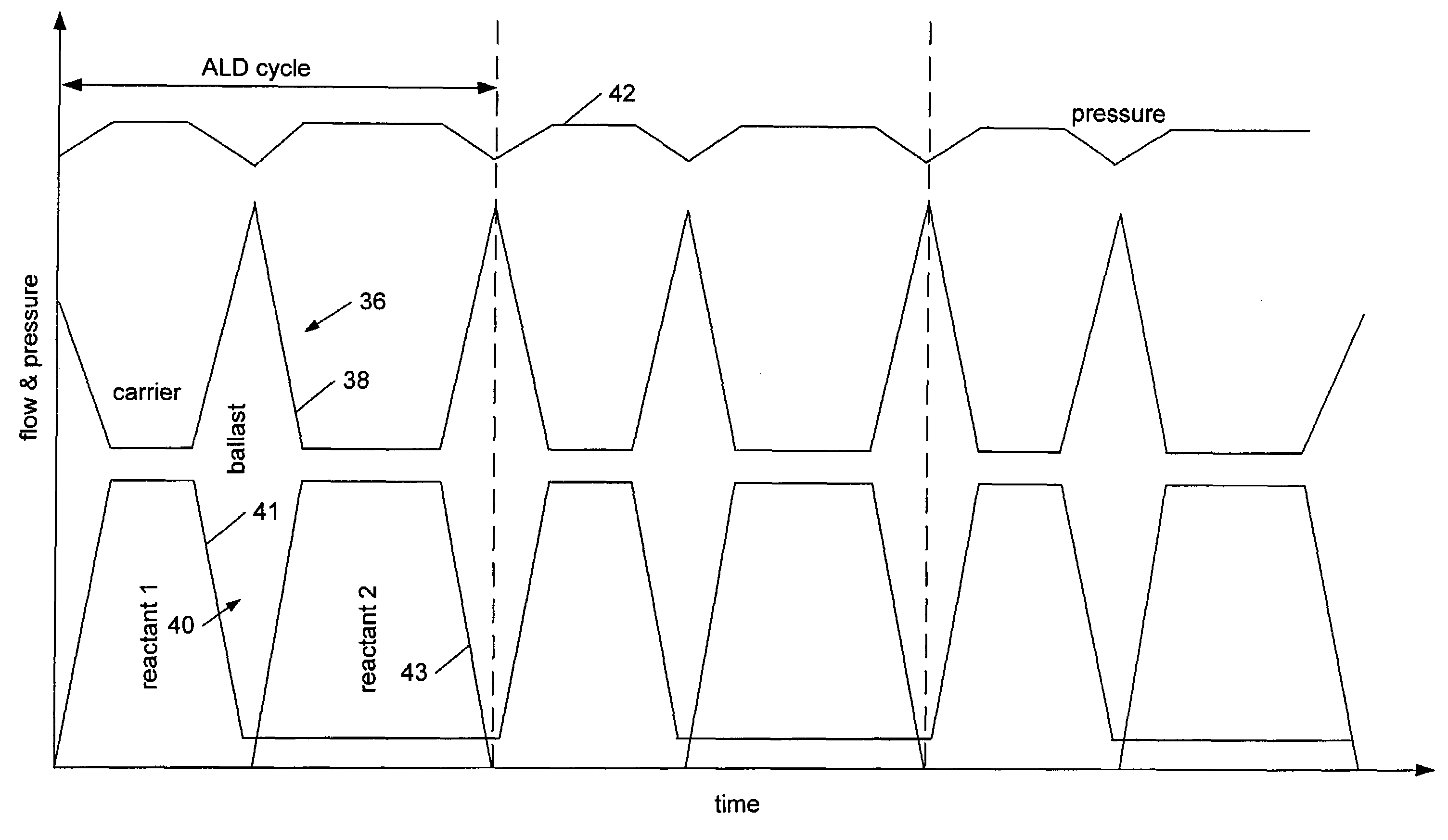

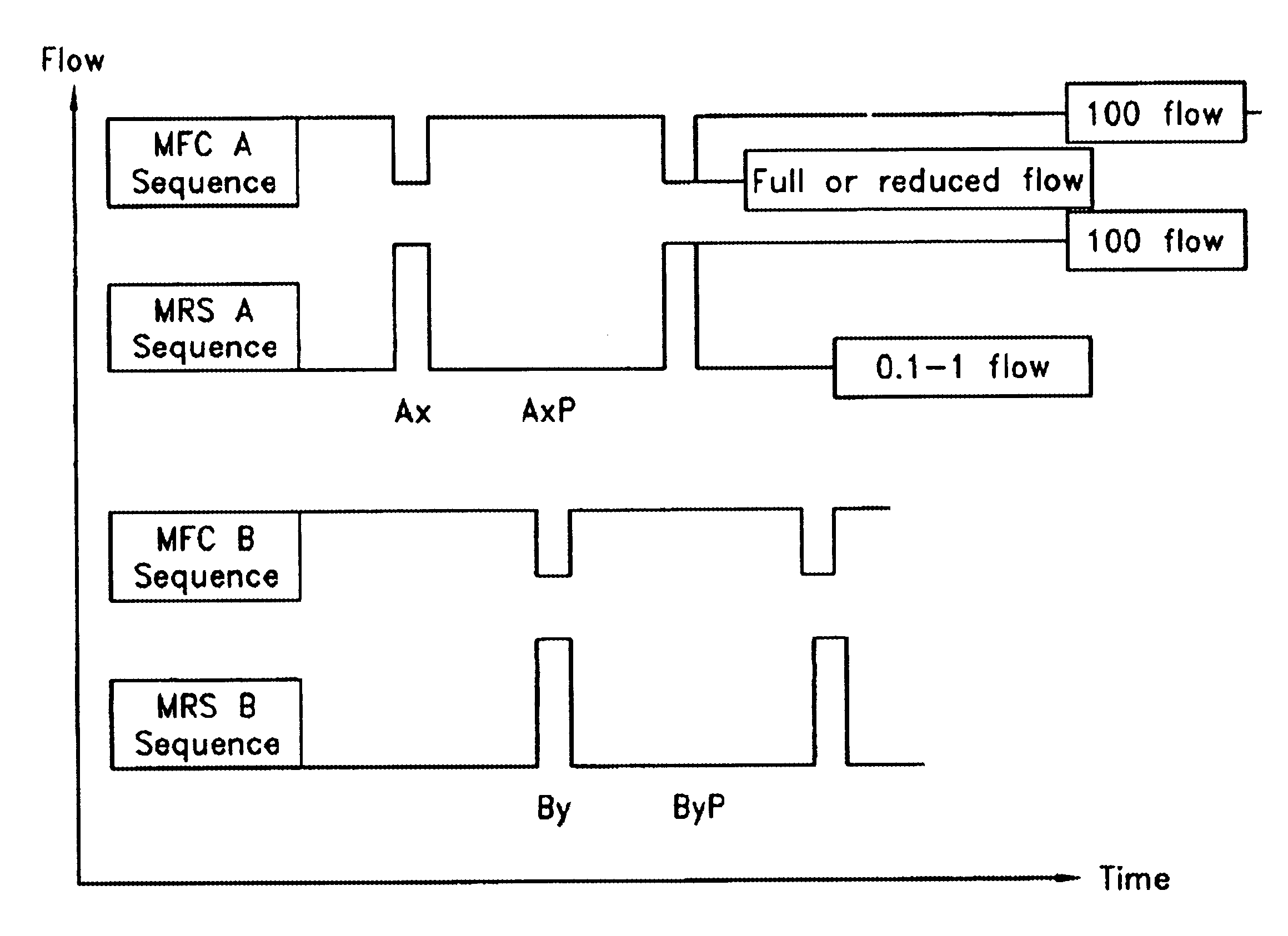

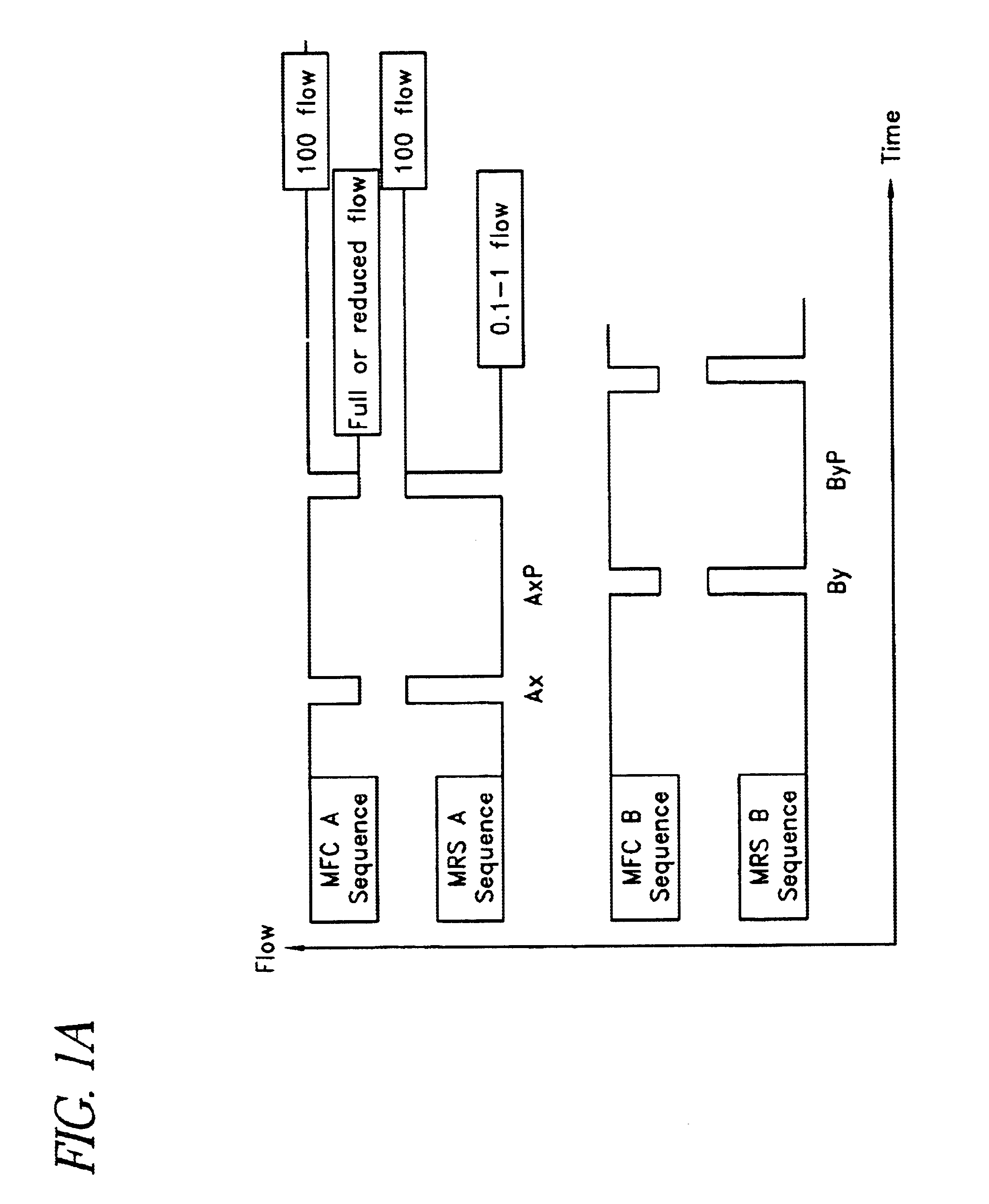

Method and apparatus for layer by layer deposition of thin films

InactiveUS7393561B2Increase wafer throughputImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingChemisorptionEngineering

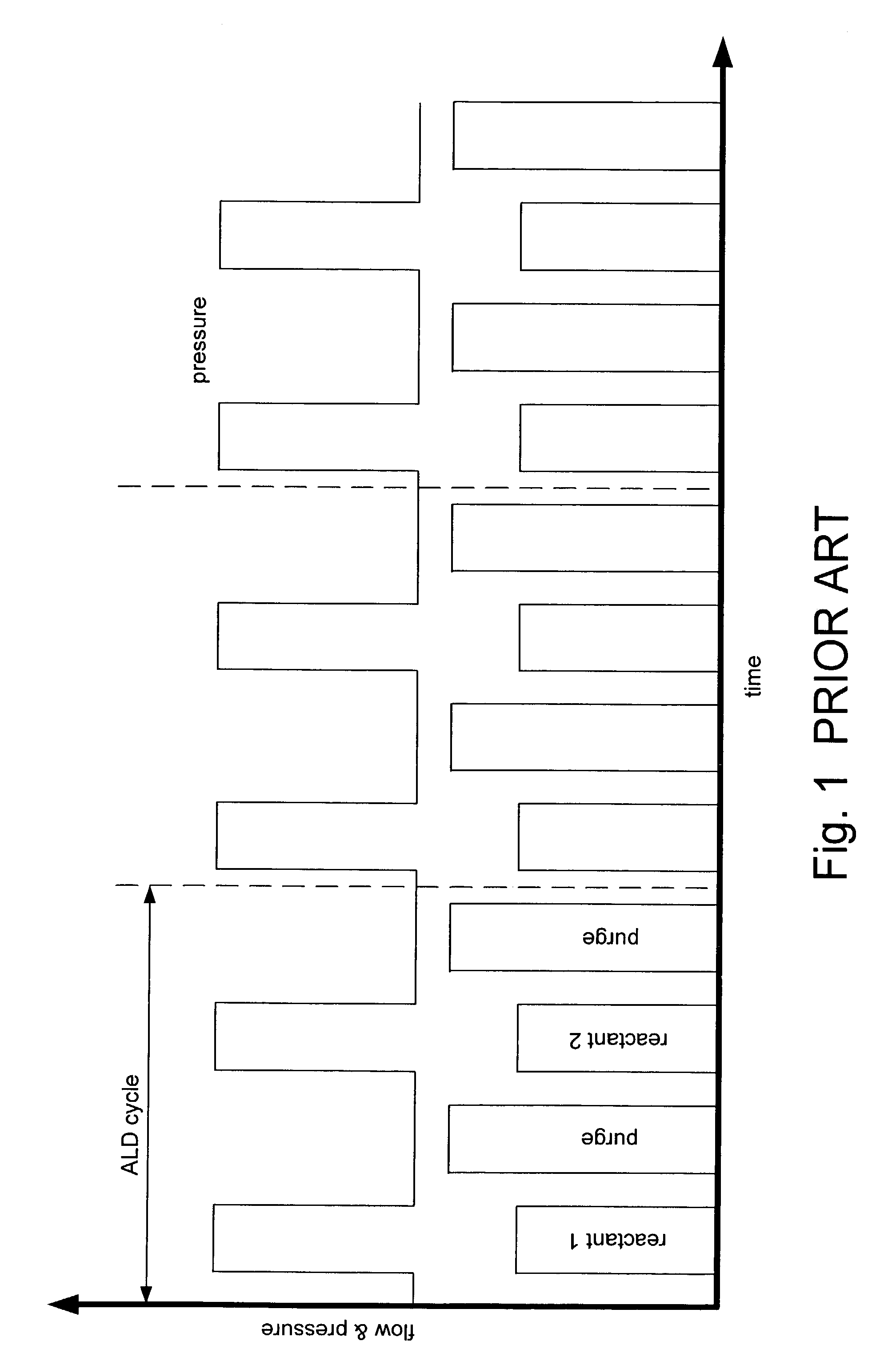

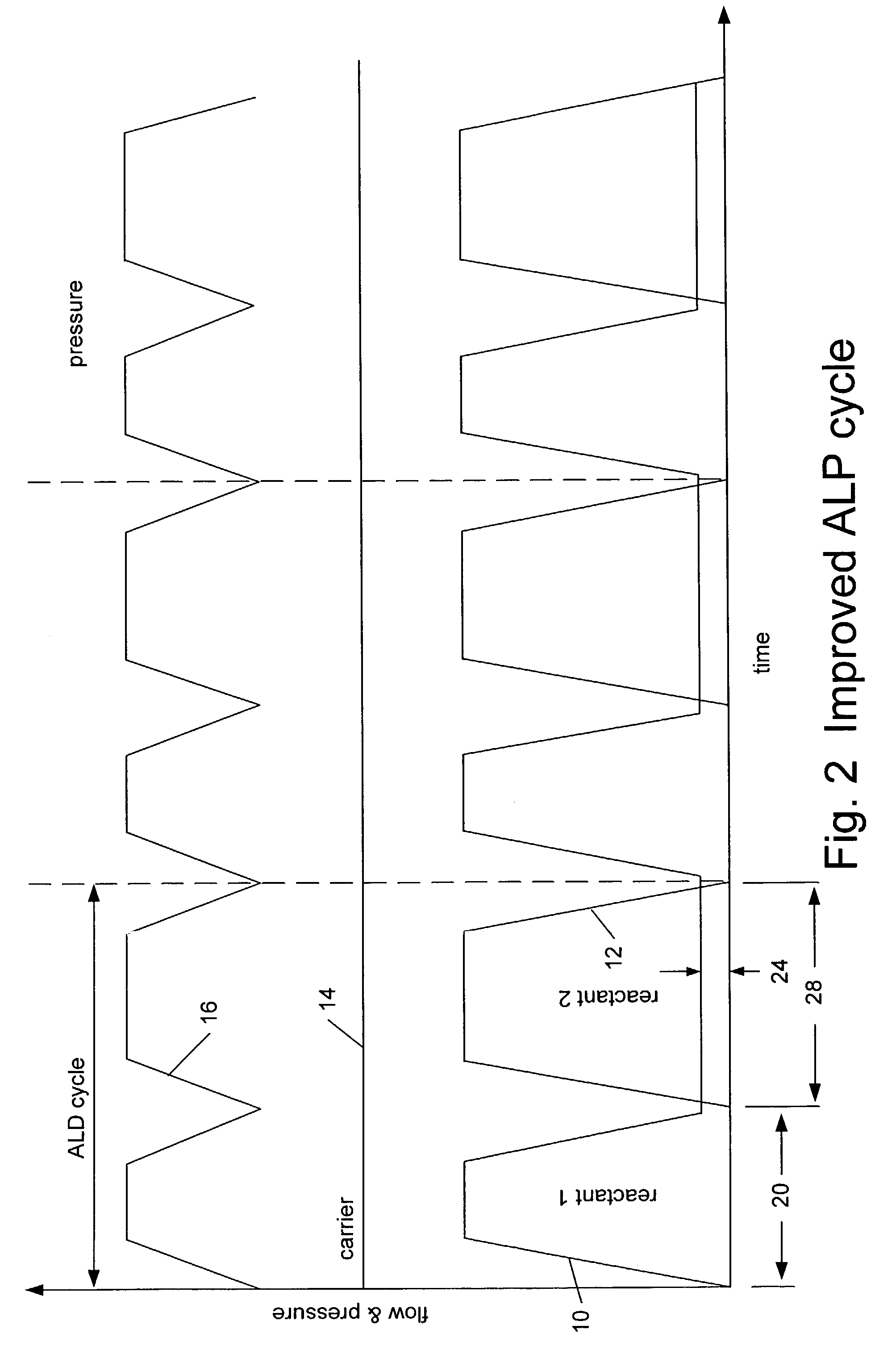

A method of increasing ALP briefly, a preferred embodiment of the present invention includes a method of increasing ALP throughput by continuously modulating gas flow in a reactor to achieve layer by layer growth on a wafer. A first reactant is introduced with a percentage of a carrier gas. After a first time interval, the first reactant flow is reduced while the carrier gas flow is increased so as to maintain an approximately constant total gas flow. When the first reactant flow reaches a minimal, predetermined amount, a second reactant flow is initiated and increased while the carrier gas flow is decreased so as to continue a constant total gas flow. The method alternatively includes introducing a substance that enhances reactant adsorption and chemisorption, either as a first applied gas that reacts with the surface or as an added ligand to the reactant. Still further alternatives include a periodic rapid thermo anneal for improving film properties, parallel wafer processing and a reactant reservoir.

Owner:APPLIED MATERIALS INC

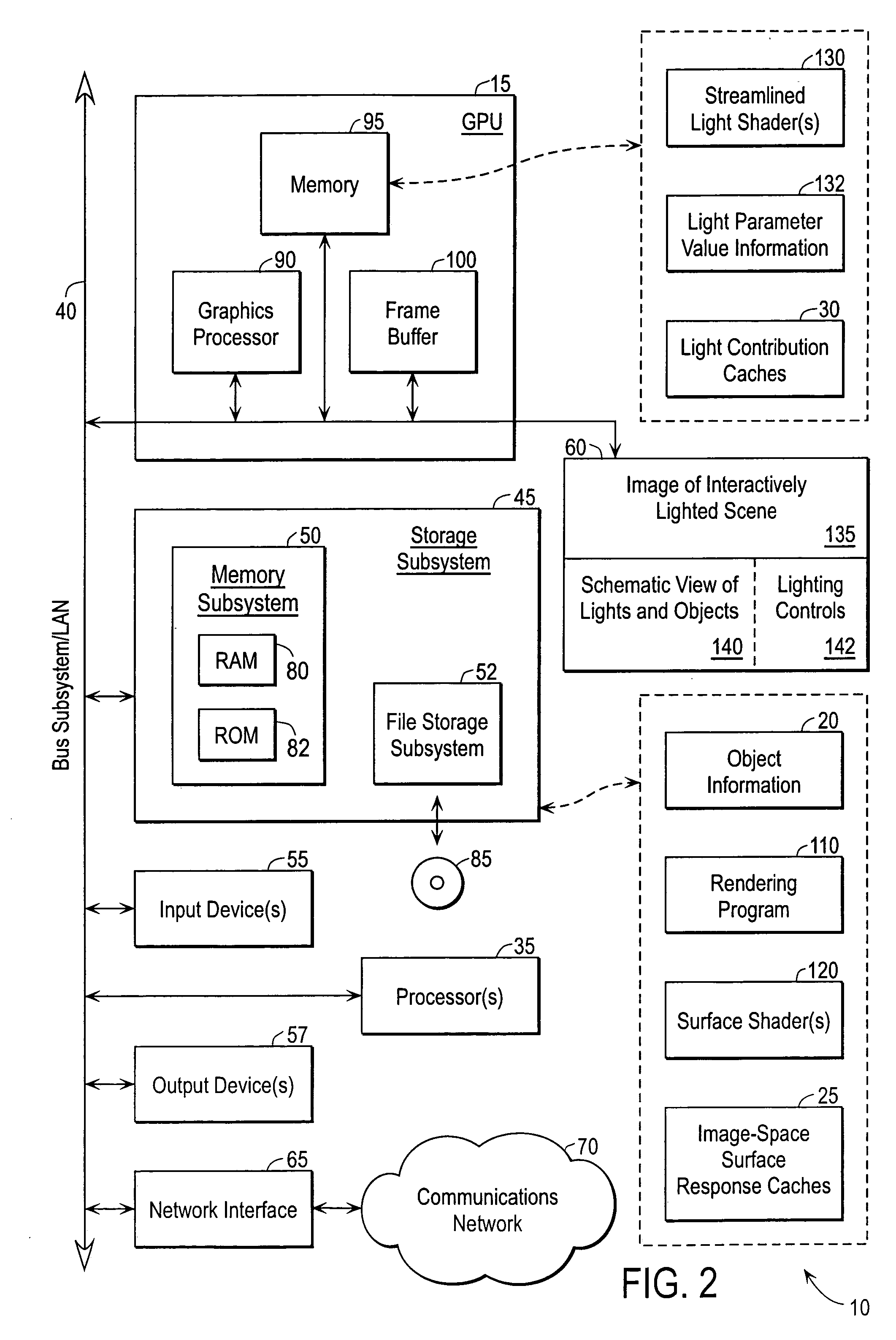

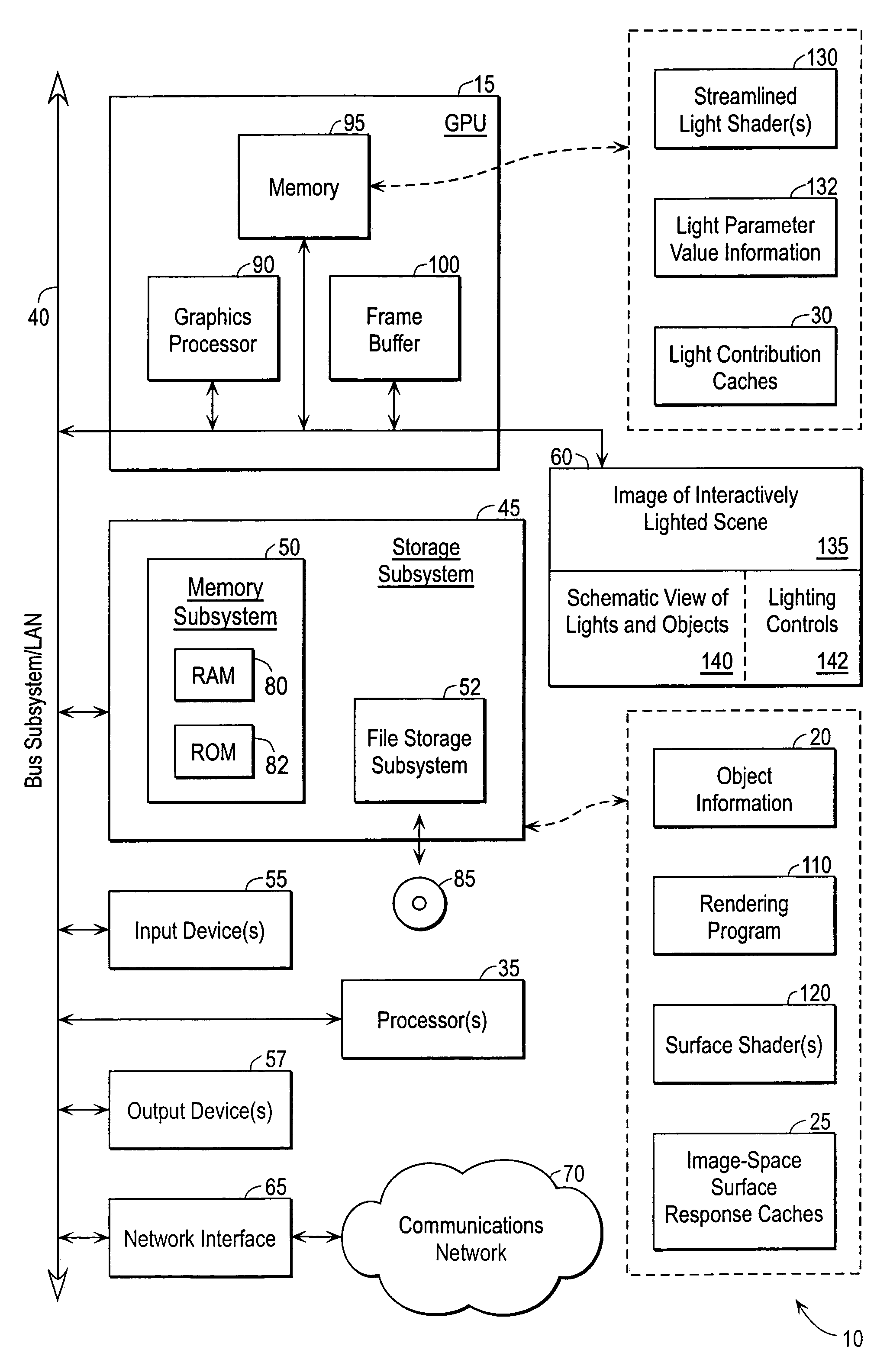

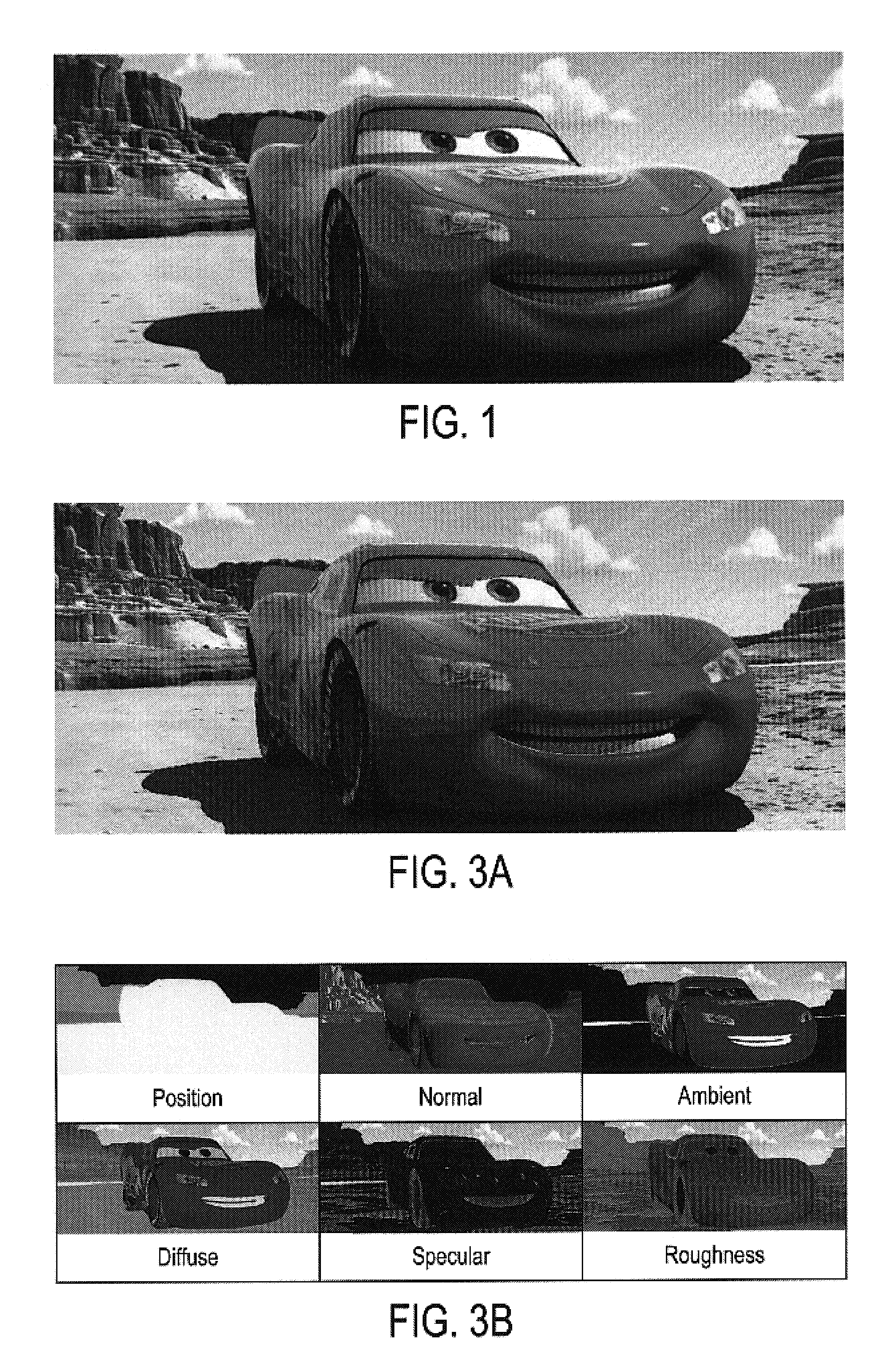

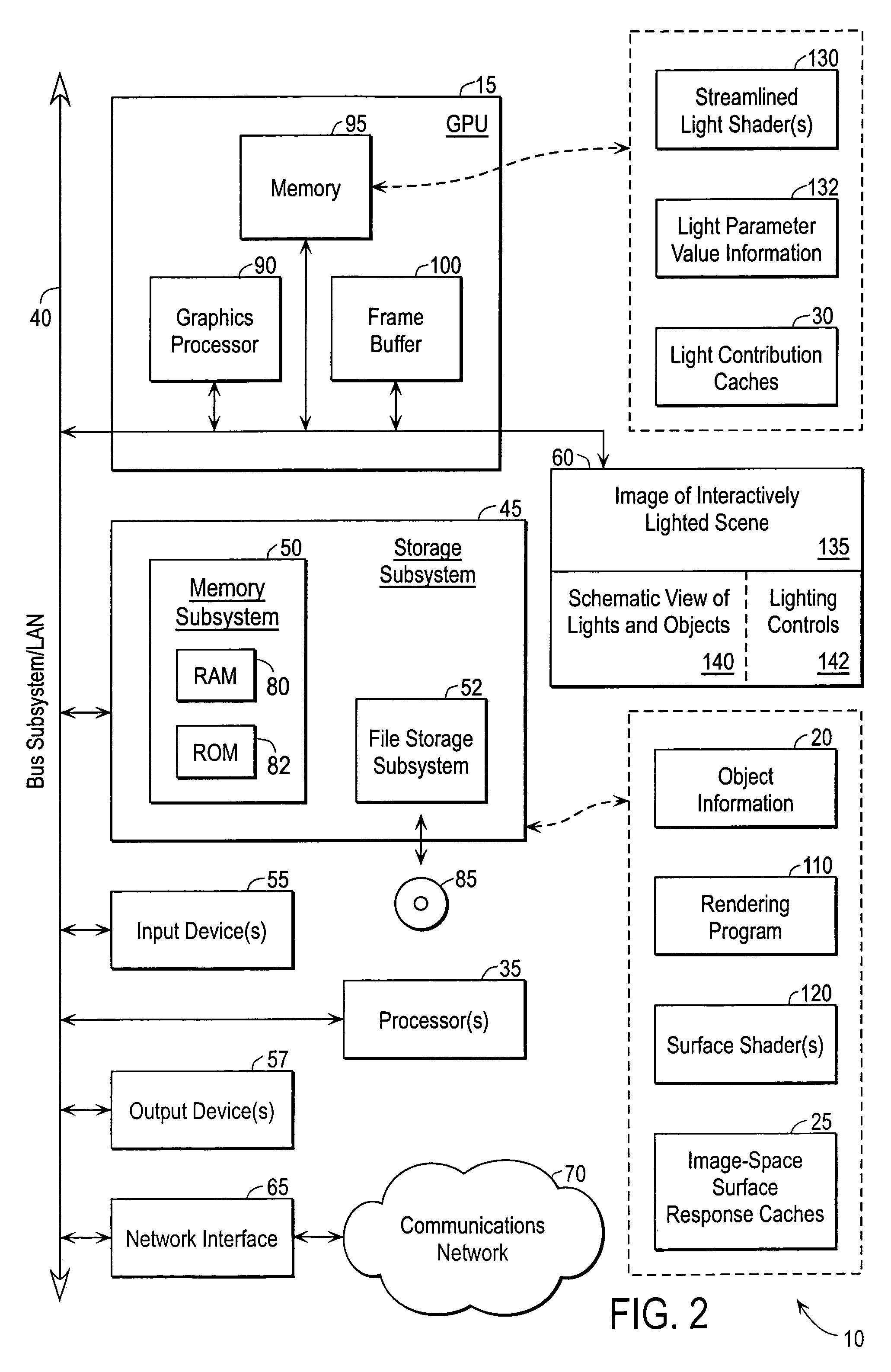

Hybrid hardware-accelerated relighting system for computer cinematography

ActiveUS20060209067A1Simple lightingIncrease speed3D-image renderingComputer animationDeferred shading

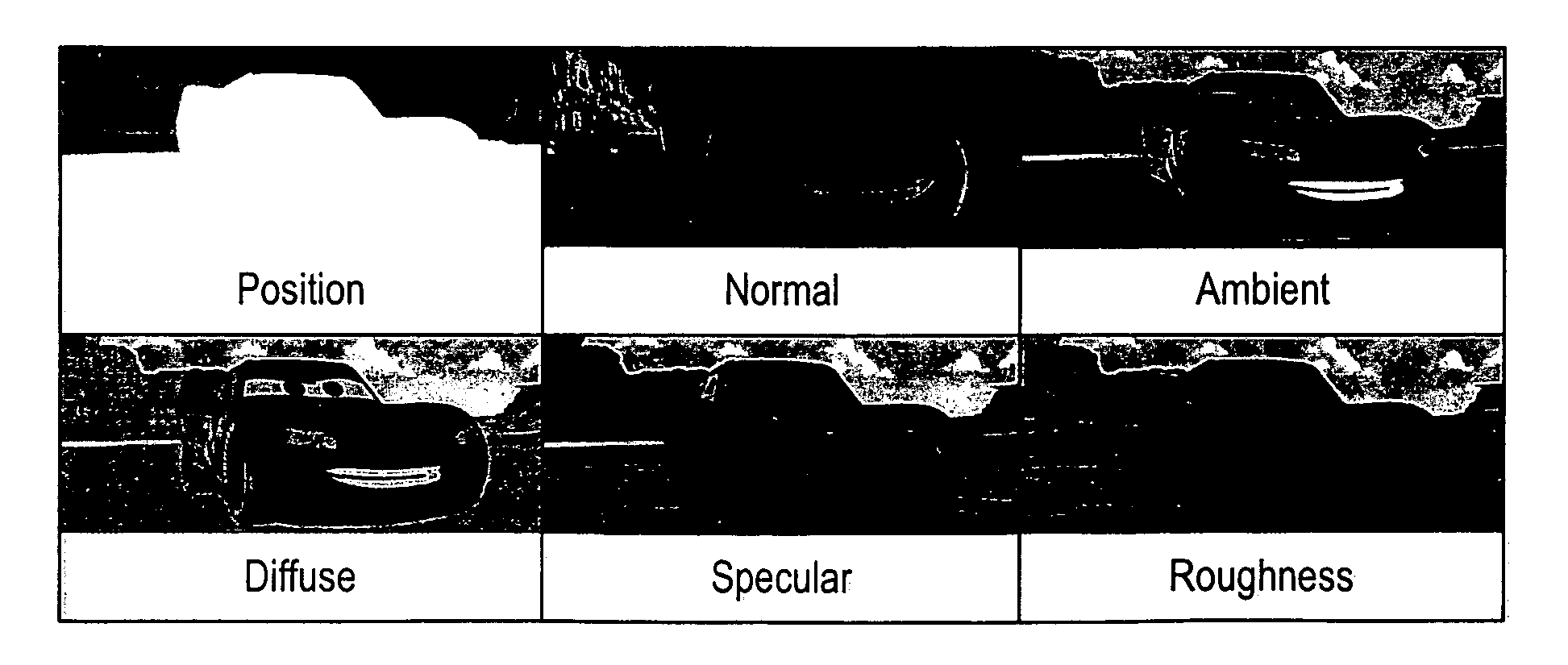

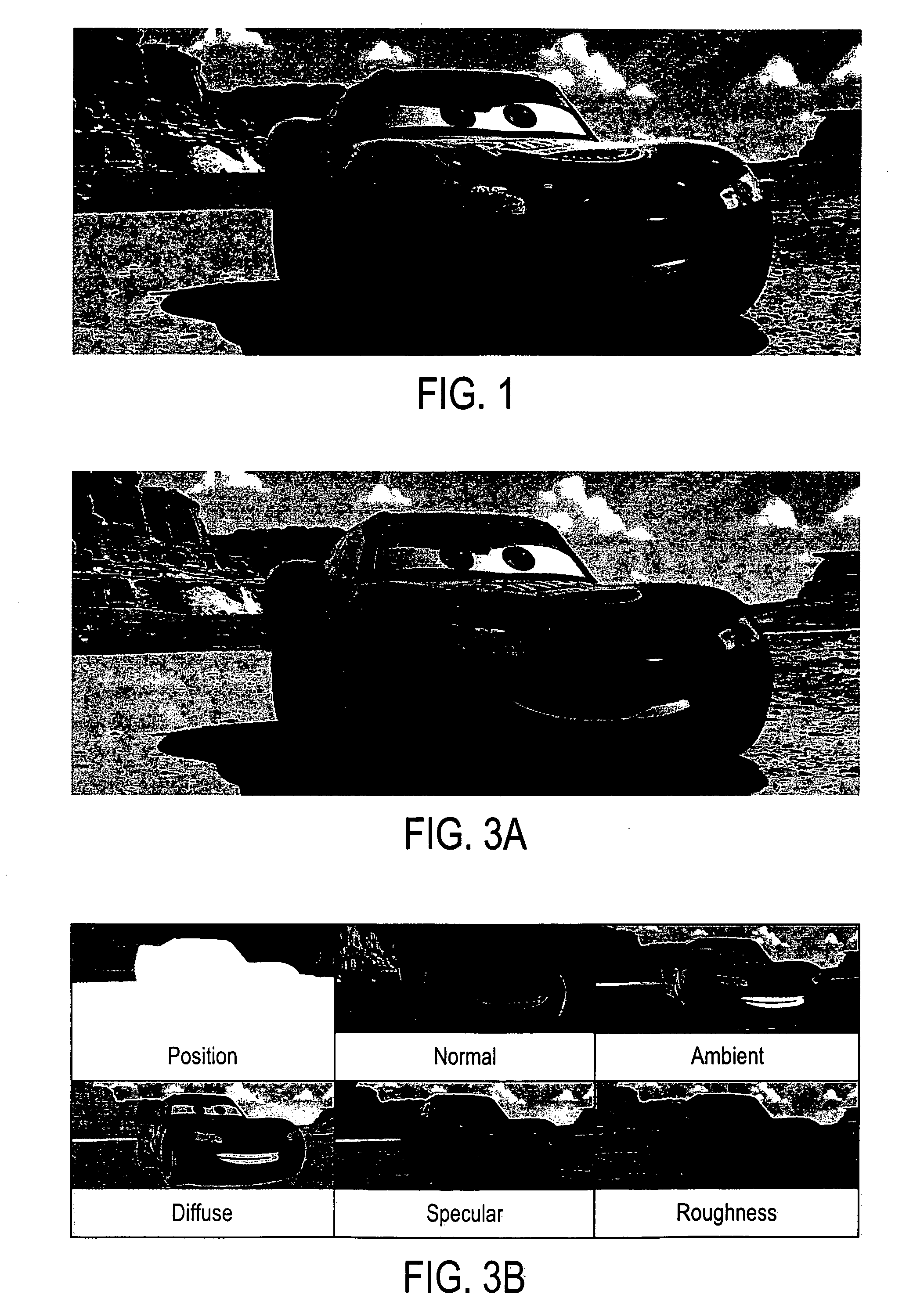

An interactive cinematic lighting system used in the production of computer-animated feature films containing environments of very high complexity, in which surface and light appearances are described using procedural RenderMan shaders. The system provides lighting artists with high-quality previews at interactive framerates with only small approximations compared to the final rendered images. This is accomplished by combining numerical estimation of surface response, image-space caching, deferred shading, and the computational power of modern graphics hardware.

Owner:PIXAR ANIMATION

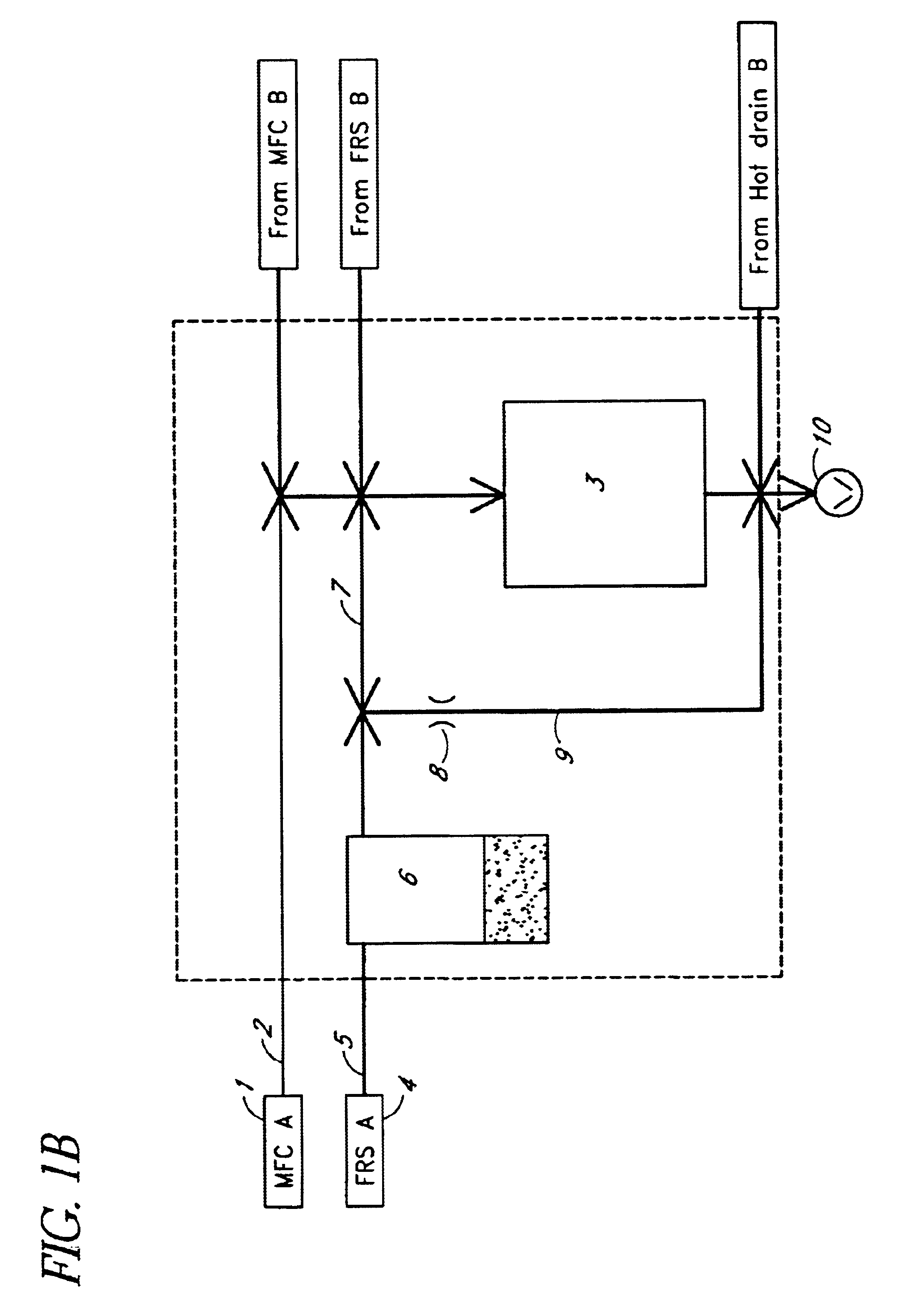

Method of growing a thin film onto a substrate

InactiveUS6881263B2Improve reliabilityReduce downtimePolycrystalline material growthFrom chemically reactive gasesGas phaseVapor phase

The present invention relates to the production of thin films. In particular, the invention concerns a method of growing a thin film onto a substrate, in which method the substrate is placed in a reaction chamber and is subjected to surface reactions of a plurality of vapor-phase reactants according to the ALD method. The present invention is based on replacing the mechanical valves conventionally used for regulating the pulsing of the reactants, which valves tend to wear and intrude metallic particles into the process flow, with an improved precursor dosing system. The invention is characterized by choking the reactant flow between the vapour-phase pulses while still allowing a minimum flow of said reactant, and redirecting the reactant at these times to an other destination than the reaction chamber. The redirection is performed with an inactive gas, which is also used for ventilating the reaction chamber between the vapour-phase pulses.

Owner:ASM INTERNATIONAL

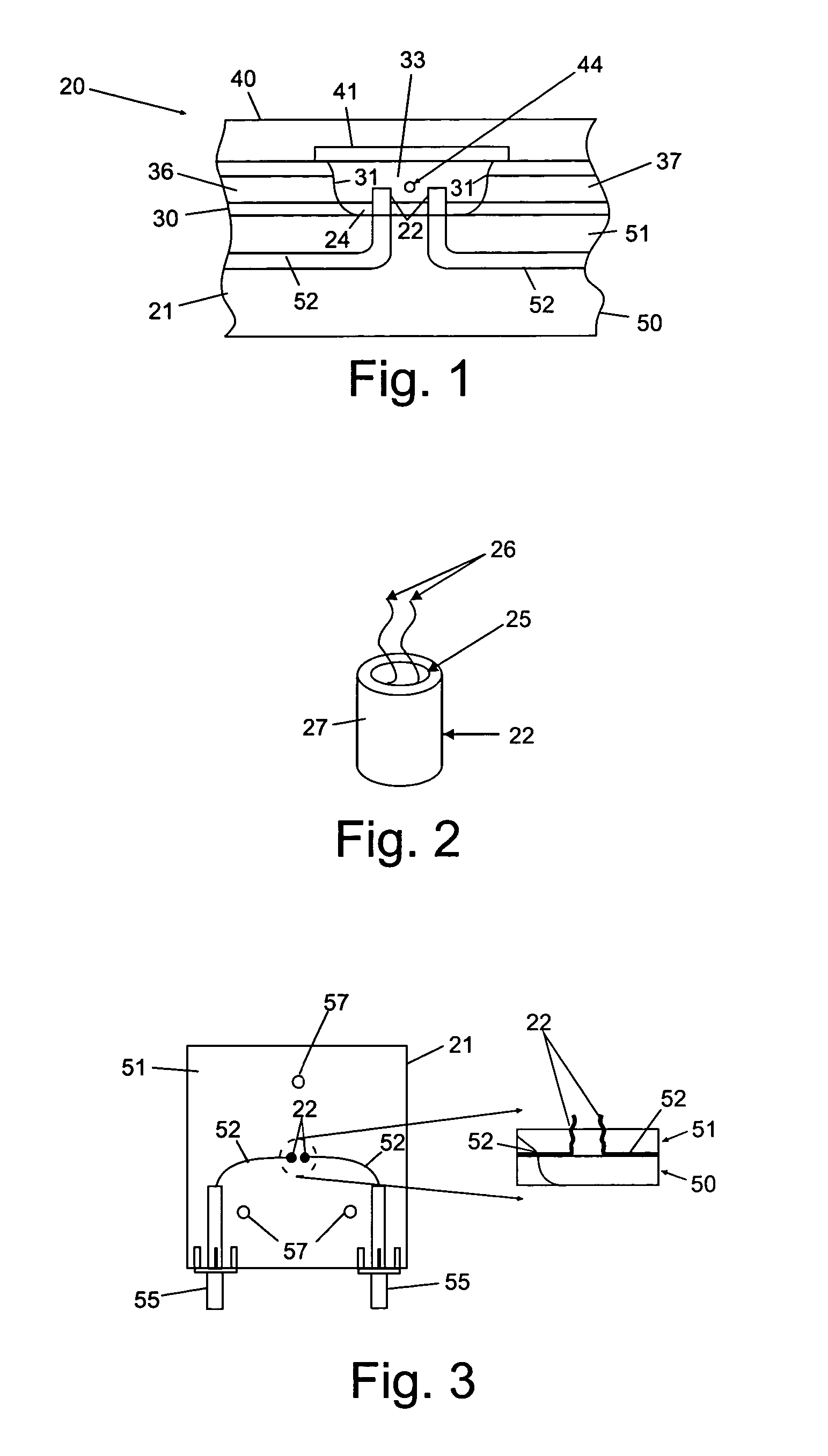

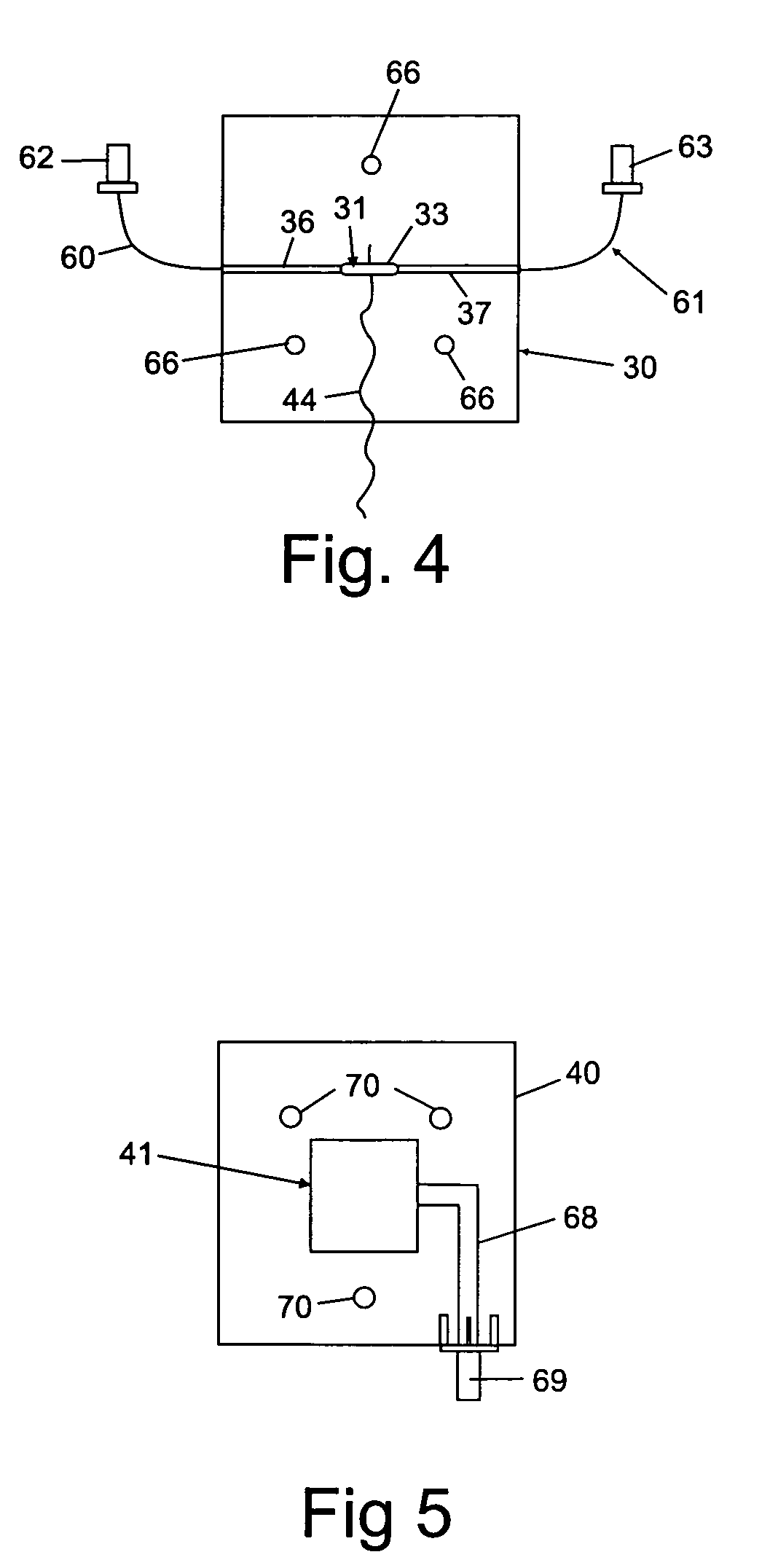

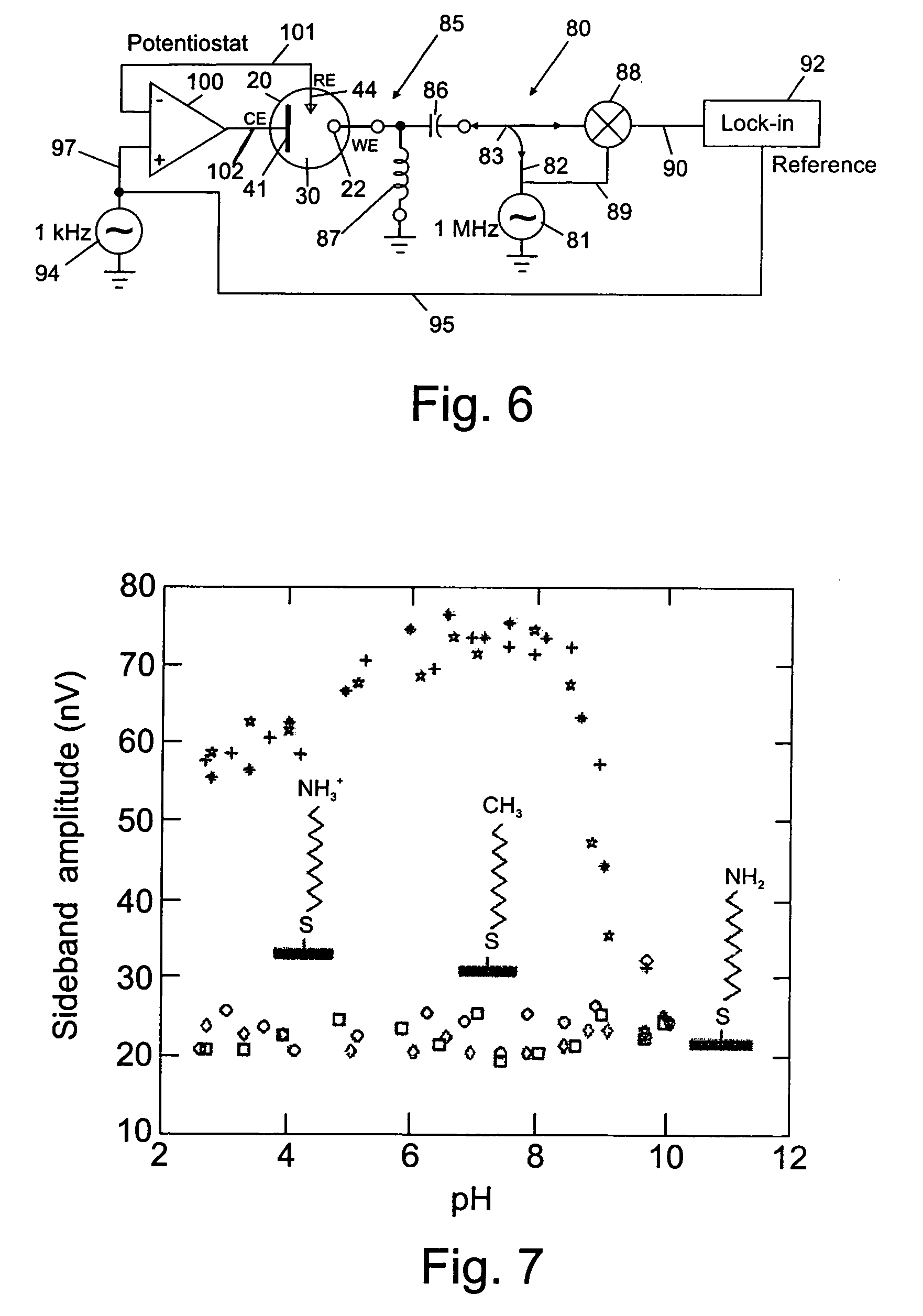

Direct radio-frequency detection of nucleotide hybridization at microelectrodes

ActiveUS7183055B2High sensitivity detectionWell mixedBioreactor/fermenter combinationsMaterial nanotechnologyCapacitanceNucleotide

Radio-frequency (RF) excitation is used for direct detection of hybridization events at microelectrodes with surface-attached DNA oligomers. A homodyne reflectometer operates on a high frequency carrier to detect the presence of a low-frequency modulation signal. Without non-linearities in an interface, the modulation signal is not impressed upon the carrier signal. As such, the reflectometer can sensitively measure changes in dielectric properties without interference from other sources of capacitance / resistance unrelated to the reaction at the surface.

Owner:WISCONSIN ALUMNI RES FOUND

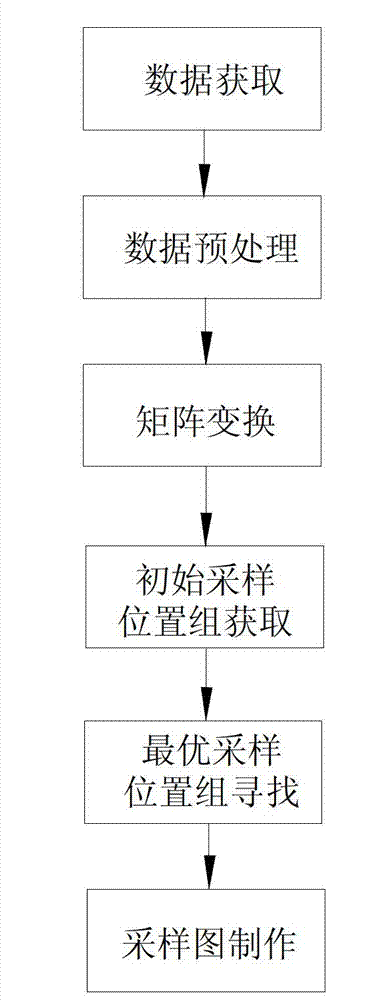

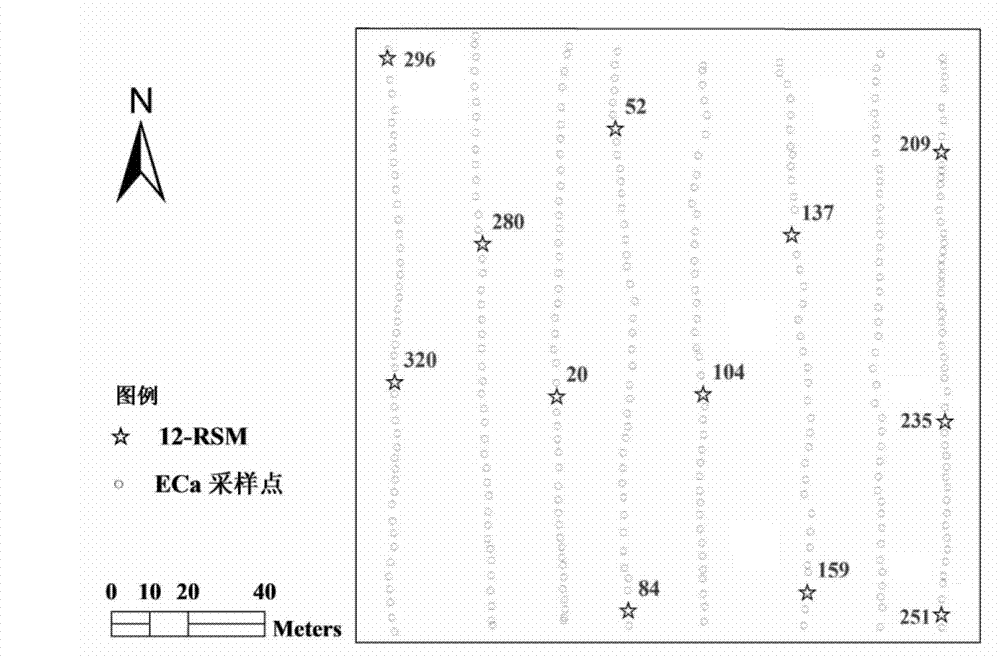

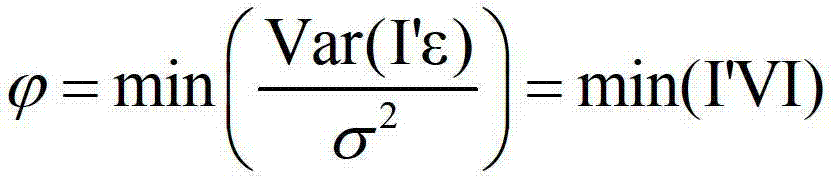

Soil sampling method based on near-earth sensor technology

The invention discloses a soil sampling method based on a near-earth sensor technology. Data quickly acquired by utilizing a near-earth sensor are transformed into a decorrelation matrix with one center by transforming a principal component and removing outliers, then the positions of initial candidate points of a curved surface response design are found by adopting a central composite response design, the position points only statistically satisfy the selection of coordinate position points of the central composite response design, afterwards the screening of the optimal position is determined by adopting iterative computation according to the standards of minimized distance and a maximized covariance structure among close positions, whether sampling positions are evenly distributed in a sample area is judged by adopting an optimized index, and finally sampling points with the coordinate positions are output in a form of graphics. Efficient sampling for soil fertility can be carried out by combining the data quickly acquired by utilizing the near-earth sensor with the curved surface sampling design, and an optimal soil sampling layout scheme can be obtained quickly and accurately, the cost is saved, and the efficiency and the representativeness of the distribution of the sampling points are improved.

Owner:ZHEJIANG UNIV

Method for performing insulating treatment on metal magnetic powder and preparing metal magnetic powder

ActiveCN104759619AImprove insulation performanceHigh resistivityInorganic material magnetismPhosphatePhosphoric acid

The invention discloses a method for performing insulating treatment on metal magnetic powder and preparing metal magnetic powder. The method comprises the following steps: reacting phosphoric acid and boric acid on the surface of metal magnetic powder, generating and absorbing a layer of phosphate and borate on the surface of the metal magnetic powder to obtain required B and P diffusion sources; under a vacuum atmosphere, performing diffusion reaction, diffusing B and P elements on the surface of the metal magnetic powder to inner part of the metal, and forming a metal gap compound containing B or P below a metal magnetic powder phosphate and borate coating layer after penetrating B and P on the surface of the metal magnetic powder. The metal gap compound and the boric acid left outside the magnetic powder have low melting point, are changed to be liquid at a high temperature to achieve the effects of an inorganic binder. The method has the beneficial effects of improving the insulation of the metal magnetic powder surface, and improving the resistance of the metal magnetic powder particles and the contact resistance of the magnetic powder; inorganic binding coater is adopted to directly form, so that the cost is reduced, the magnetic core strength is improved, and the atmospheric pollution is avoided.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

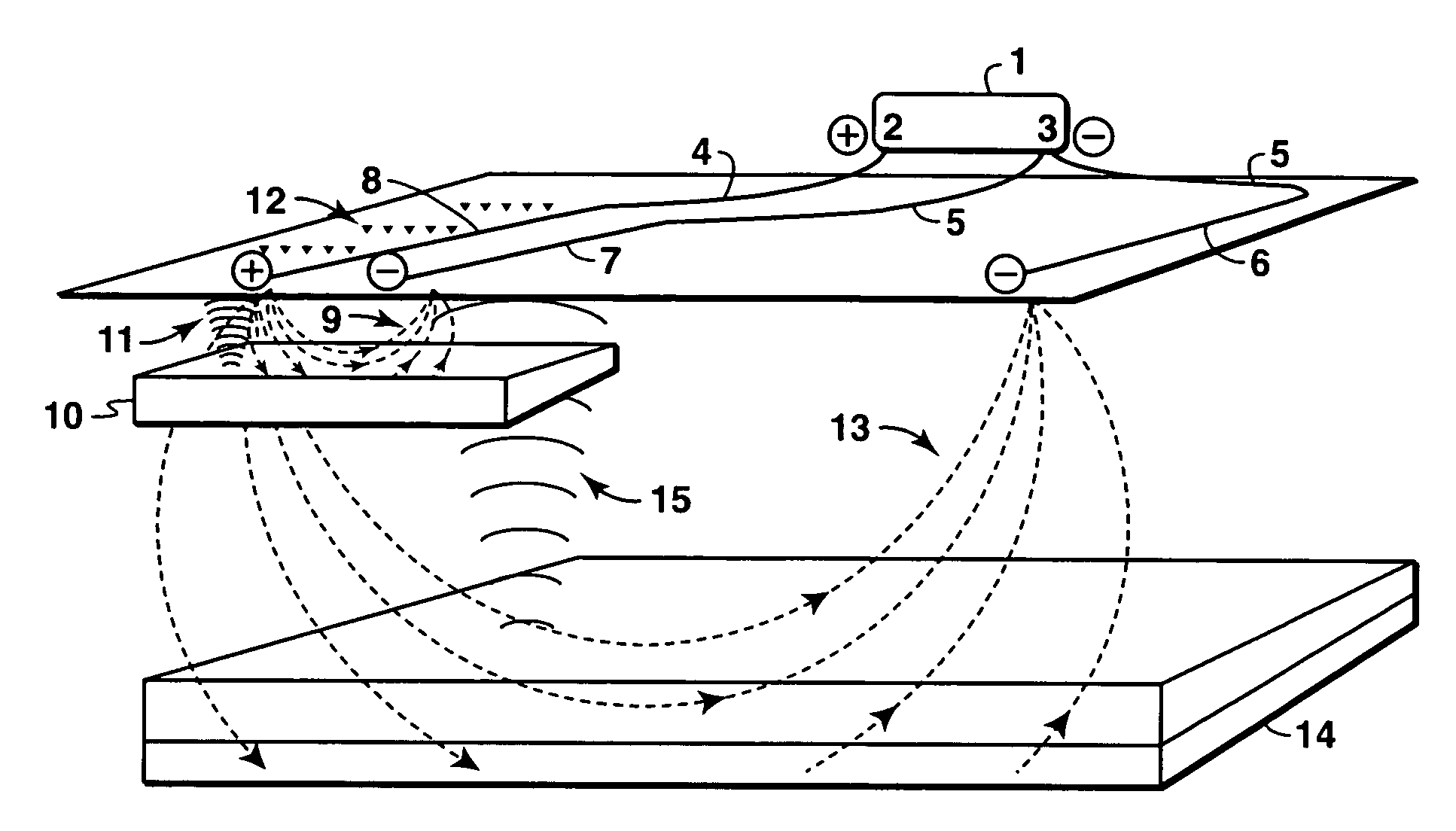

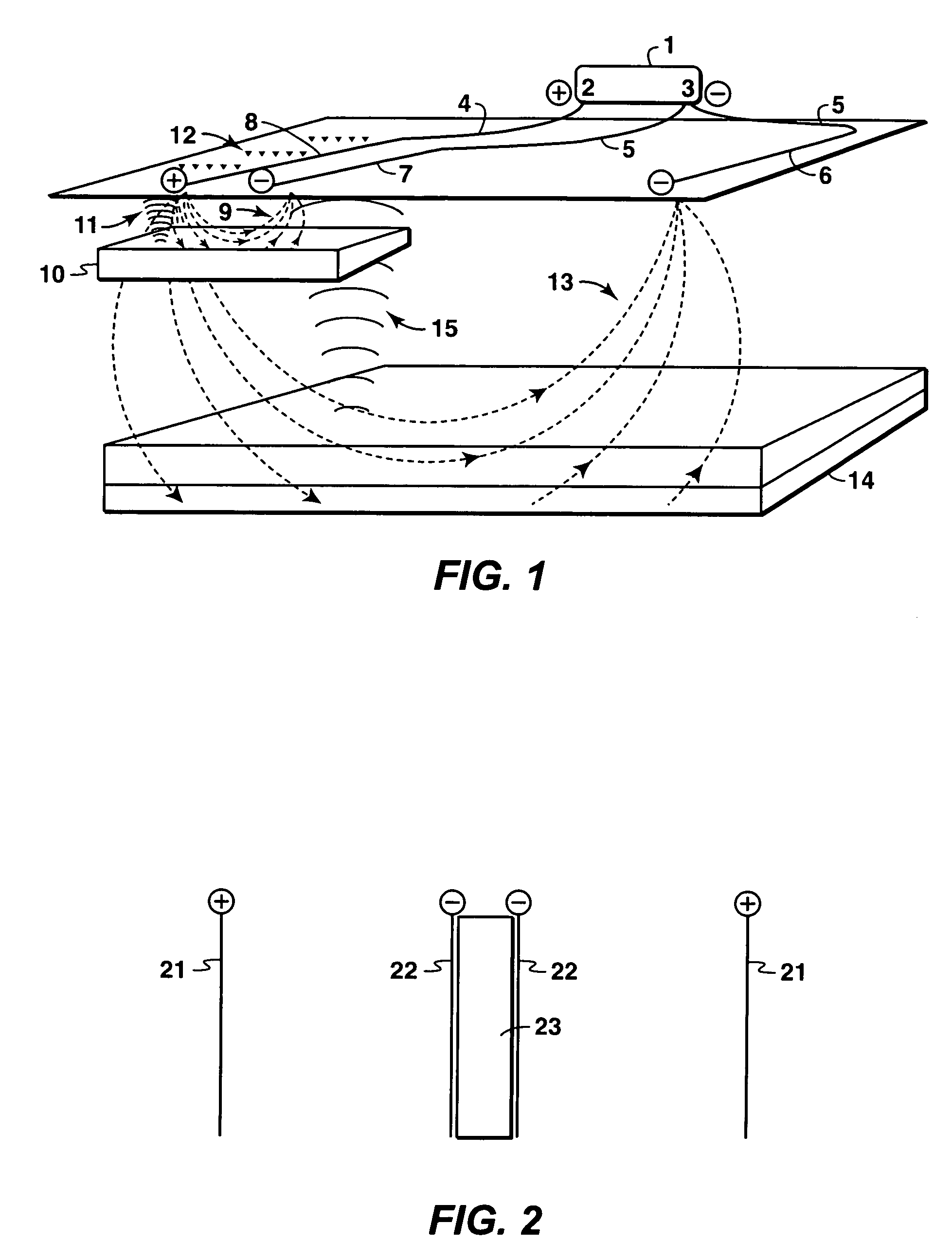

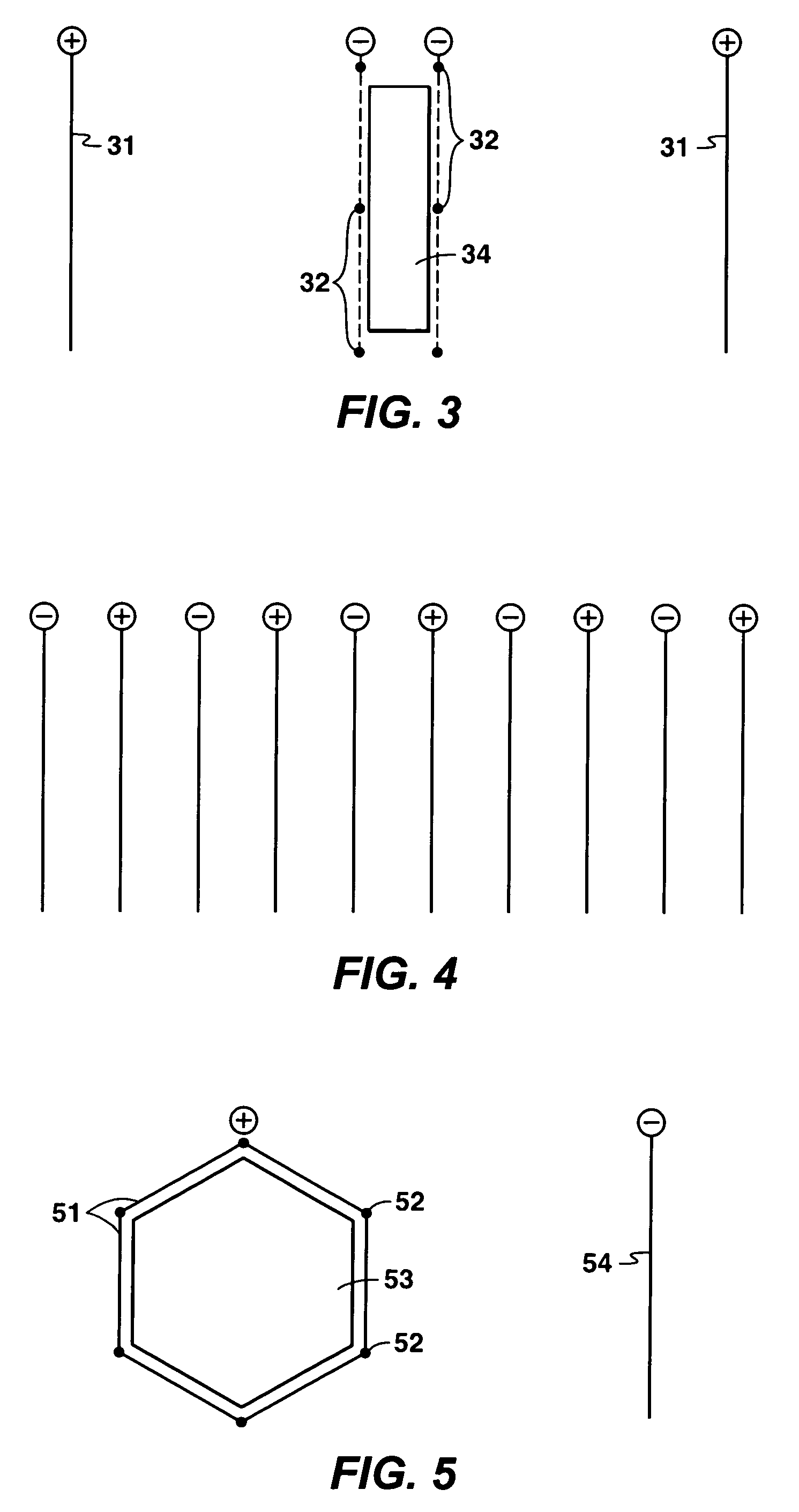

Electrode configurations for suppression of electroseismic source noise

ActiveUS7573780B2Minimize near-surface electric fieldsReduce surface noiseSeismic signal processingSpecial data processing applicationsNoise generationEarth surface

Method for survey design including configuring electrodes to reduce near-surface noise in the seismic response from an electroseismic survey of a subterranean formation. Different embodiments of the invention include (1) selective measurement of the surface noise to remove it from the data; (2) suppressing surface noise generation by reducing electric fields in the vicinity of some of the electrodes; (3) creating source signature differences between the near-surface seismic response and the deep response enabling the near surface response to be removed in data processing; (4) applying an external near-surface magnetic field to modulate the near-surface seismic response, enabling it to be removed in processing; and (5) constructing a partial Faraday cage to shield a near-surface region from fields generated by the electrodes.

Owner:EXXONMOBIL UPSTREAM RES CO

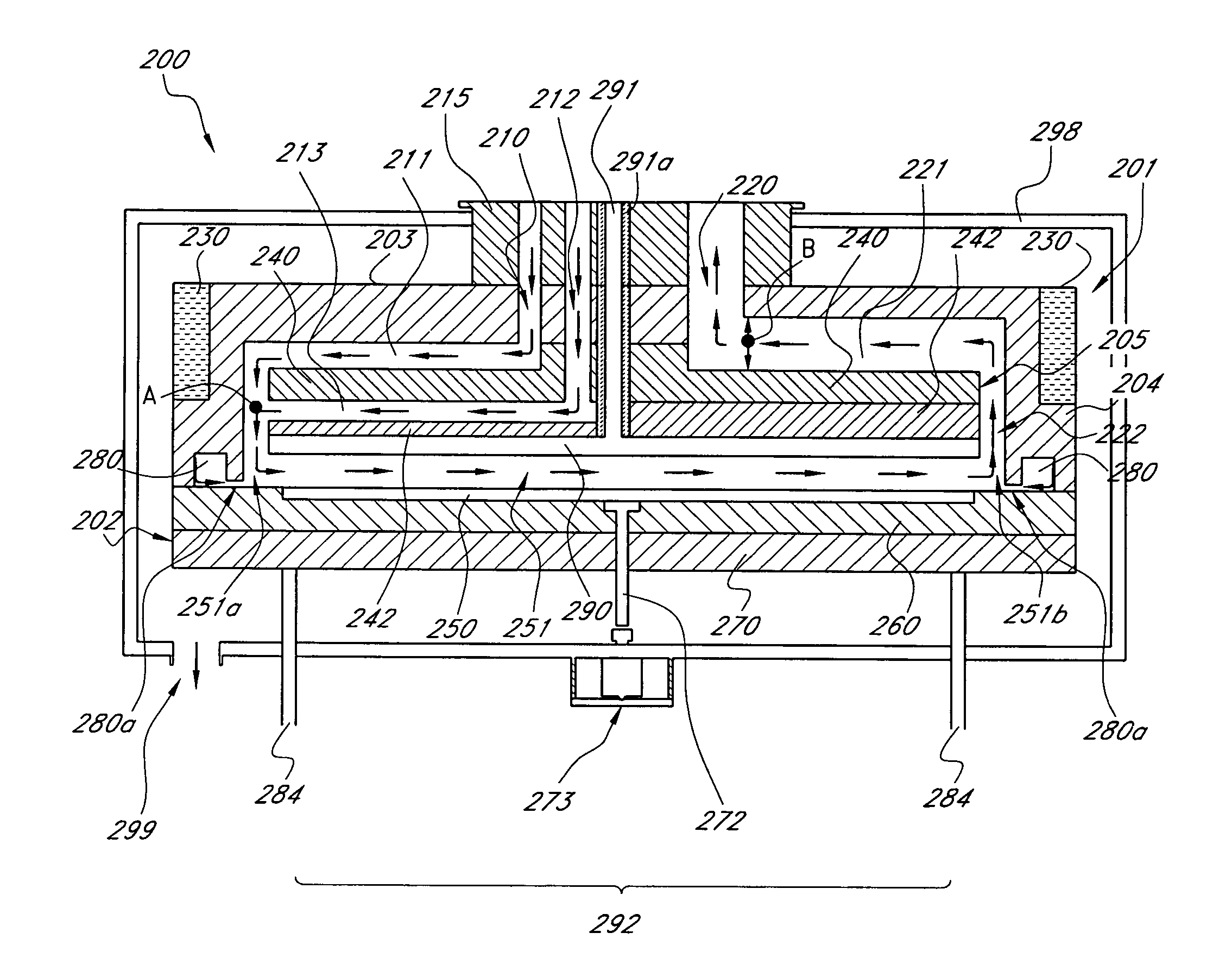

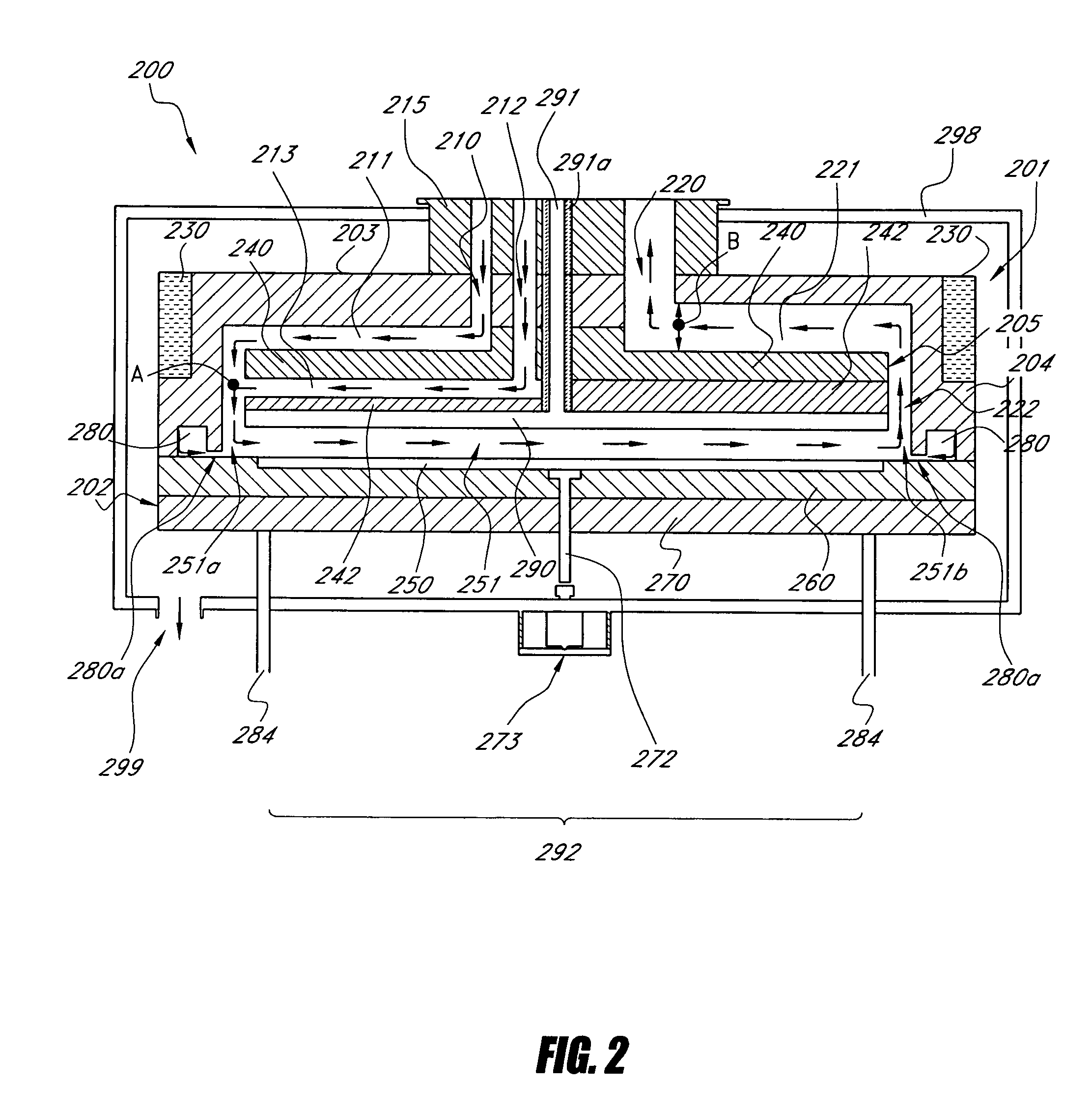

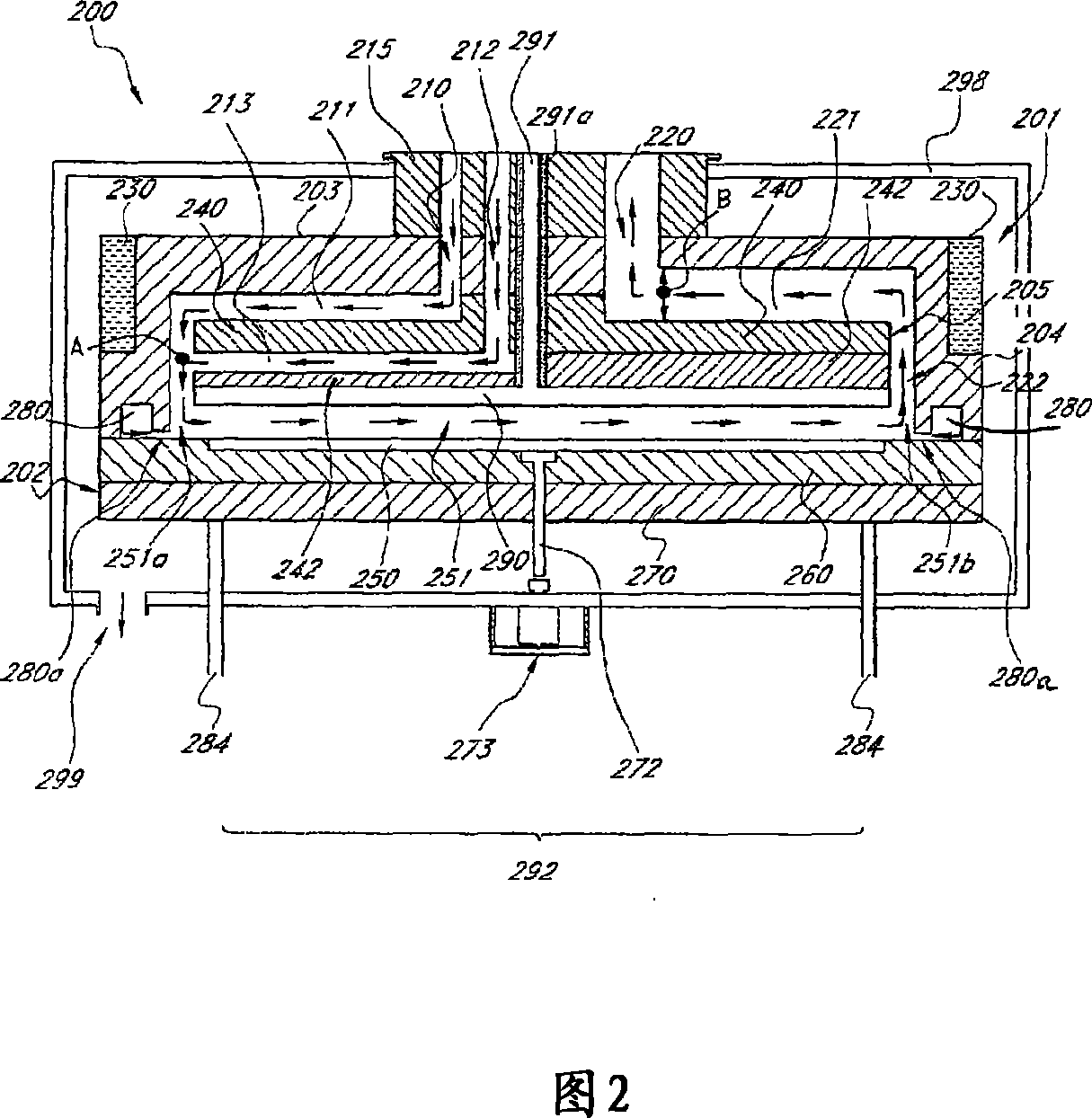

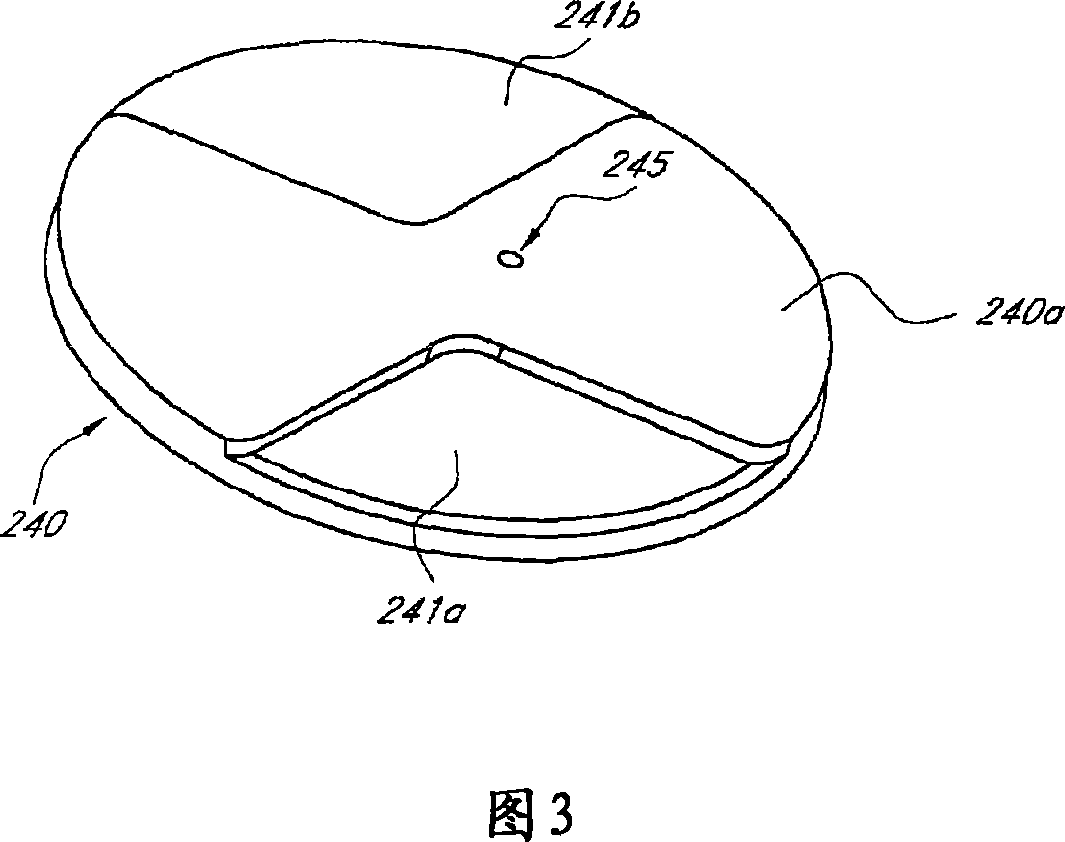

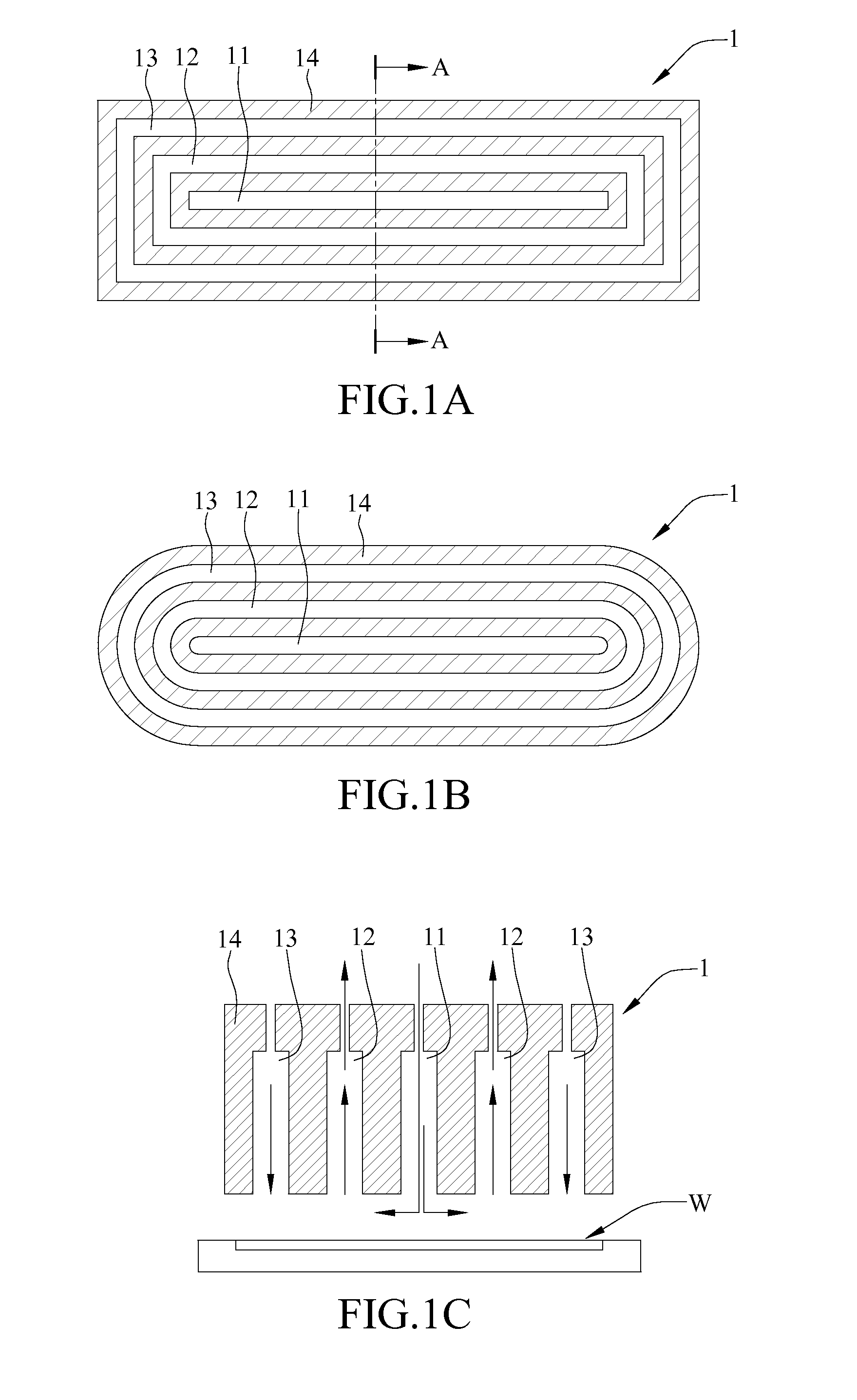

Multiple inlet atomic layer deposition reactor

ActiveCN101171365AQuick switchFirst flow path widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringAtomic layer deposition

A reactor (200) configurated to subject a substrate to alternately repeated surface of vapophase reactants is disclosed. The reactor includes a reaction chamber, a plurality of inlets (210,212), and an exhaust outles (220). The reaction chamber includes a reaction space (251). The reactor also includes a gas flow control guide structure (205) within the reaction chamber. The gas flow control guide structures (205) sides over the reaction space (251) and is interposed between the plurality of inlets (210,212) and the reaction space. The gas flow control guide structure (205) includes a plurality of channels (210,212), and each of the channels extends form one of the inlets to an upstream periphery of the reaction space. Each of the channels progressively widens as the channel extends form the inlet to the reaction space (251). The reacto further includes a substrate holder (260) in the reaction space (251).

Owner:ASM GENITECH KOREA

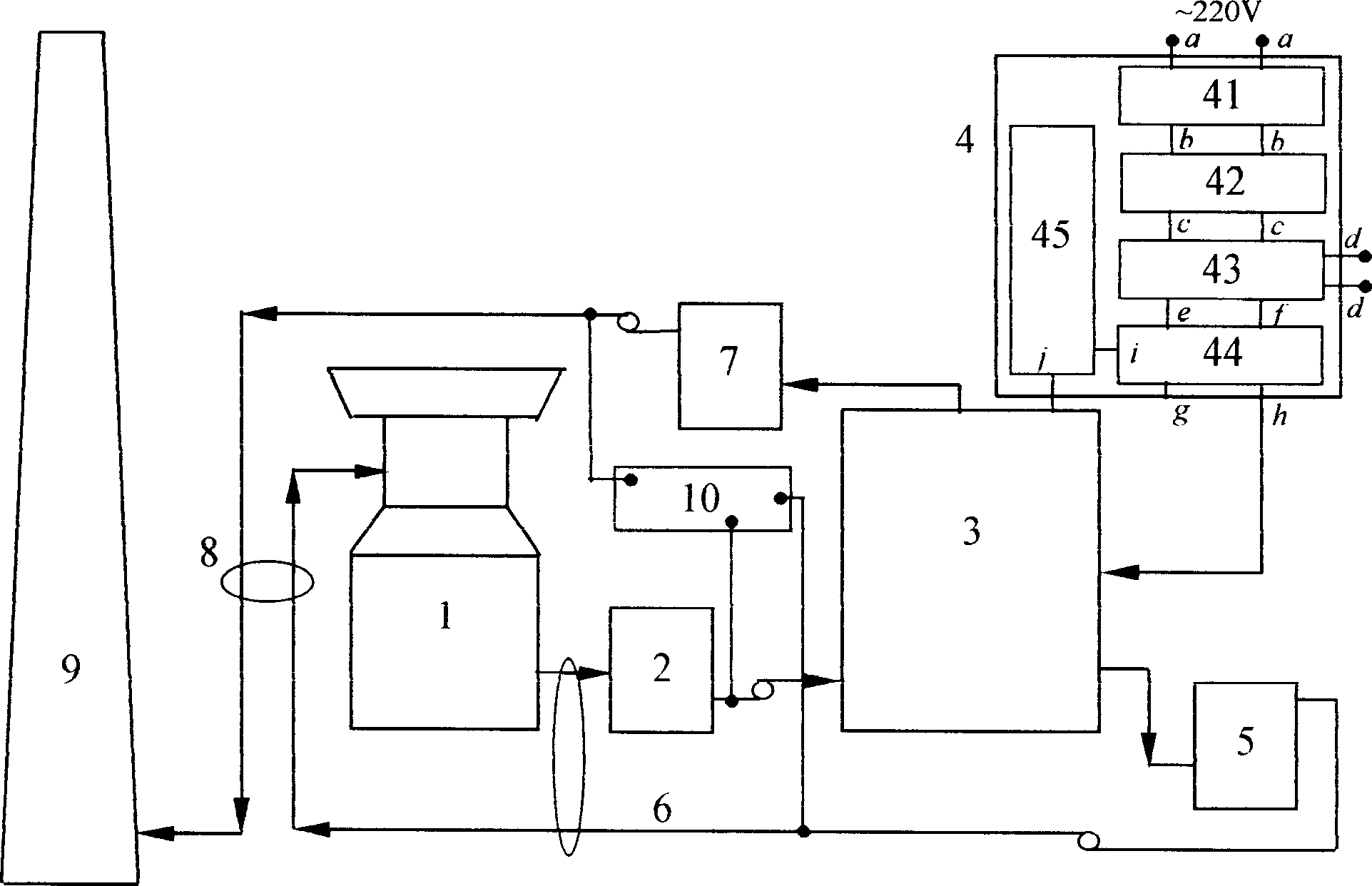

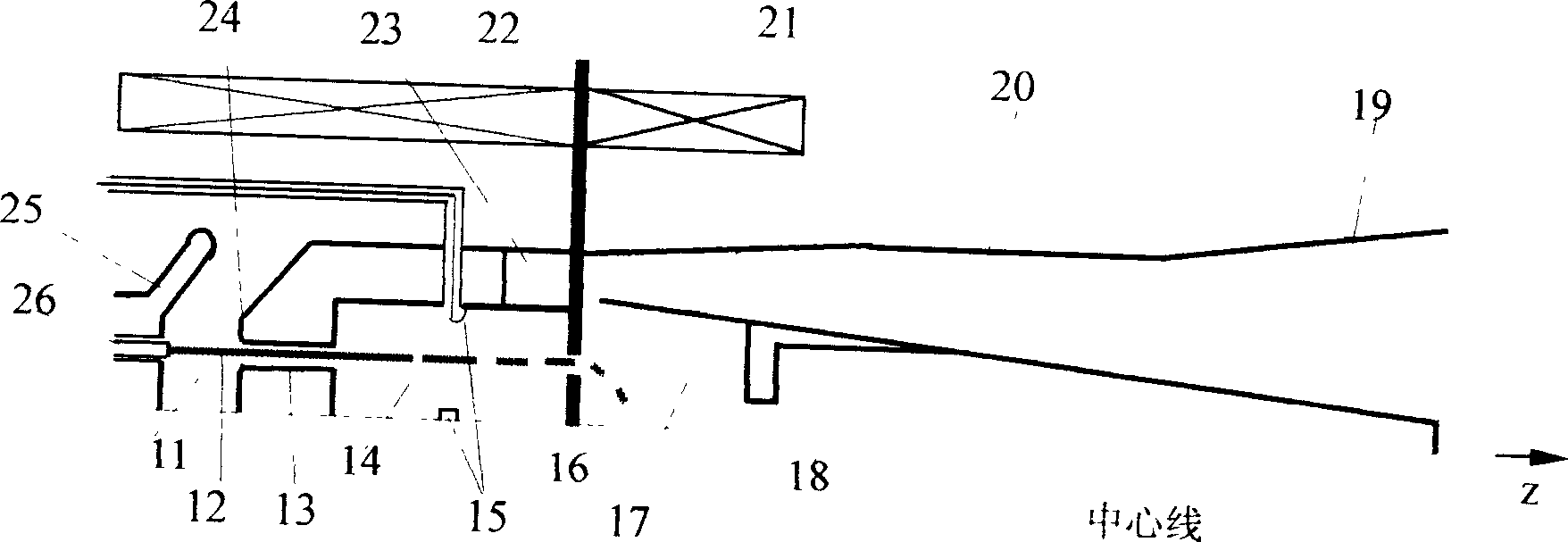

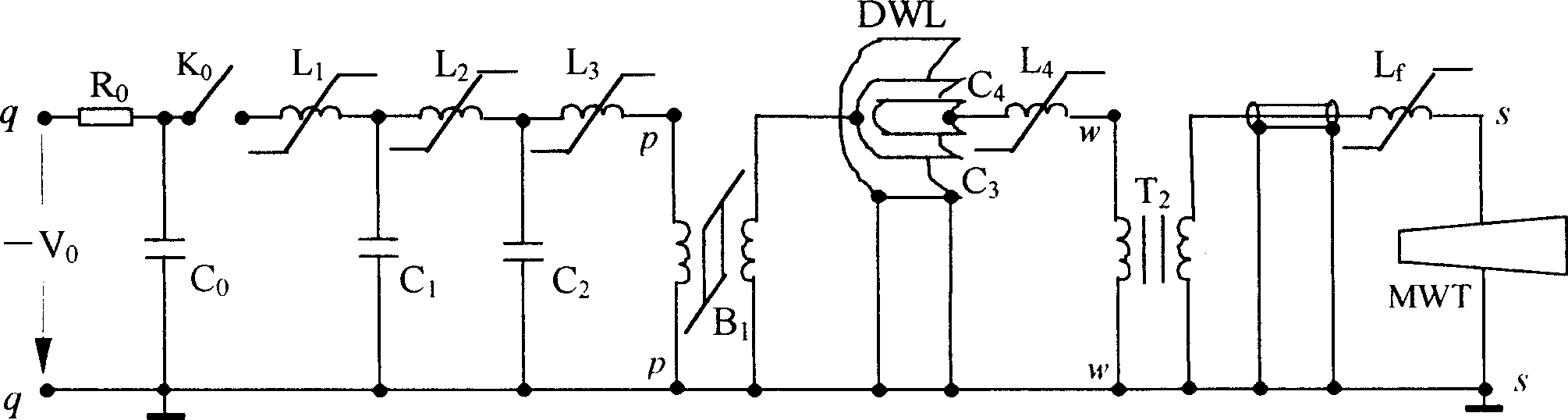

Microwave flue gas desulfurization and denitration method and apparatus

InactiveCN1454700AIncrease profitSlow heatingDispersed particle separationReaction layerOxygen compound

The invention provides a microwave smoke desulfurizing and denitrating method and the device. After the smoke is compressed, the smoke enters into the reactor which is mixed with adsorptive sensitizing agent reaction layer; it supplies microwave through the microwave device; the sulfur dioxide and nitrogen-oxygen compound reacts on the surface of the absorptive sensitizing agent in microwave environment and gets the resultant. The comprises direct current power, modulating power, stage-gathering magnetism circle pipe, connection matching and adjusting system, power measurer. The invention uses microwave energy and absorptive sensitizing agent fully, the effect is prominent; the energy utilization rate is high. The operation cost is decreased, and erosion of equipment is decreased.

Owner:张合璧

Method of processing selected surfaces in a semiconductor process chamber based on a temperature differential between surfaces

InactiveUS6881277B2Improve responseOvercome problemsLighting and heating apparatusHollow article cleaningCompound (substance)Vaporization

The present invention relates to a method of processing selected surfaces in a semiconductor process chamber by creating a temperature differential between the selected surfaces and contacting the surfaces with a reactant that preferentially react with a surface at one end of the temperature differential relative to the other selected surface(s). More particularly, the invention relates to the use of nitrogen trifluoride (NF3) gas for in situ cleaning of cold wall process chambers such as Rapid thermal Chemical Vaporization (“RTCVD”) systems.

Owner:MICRON TECH INC

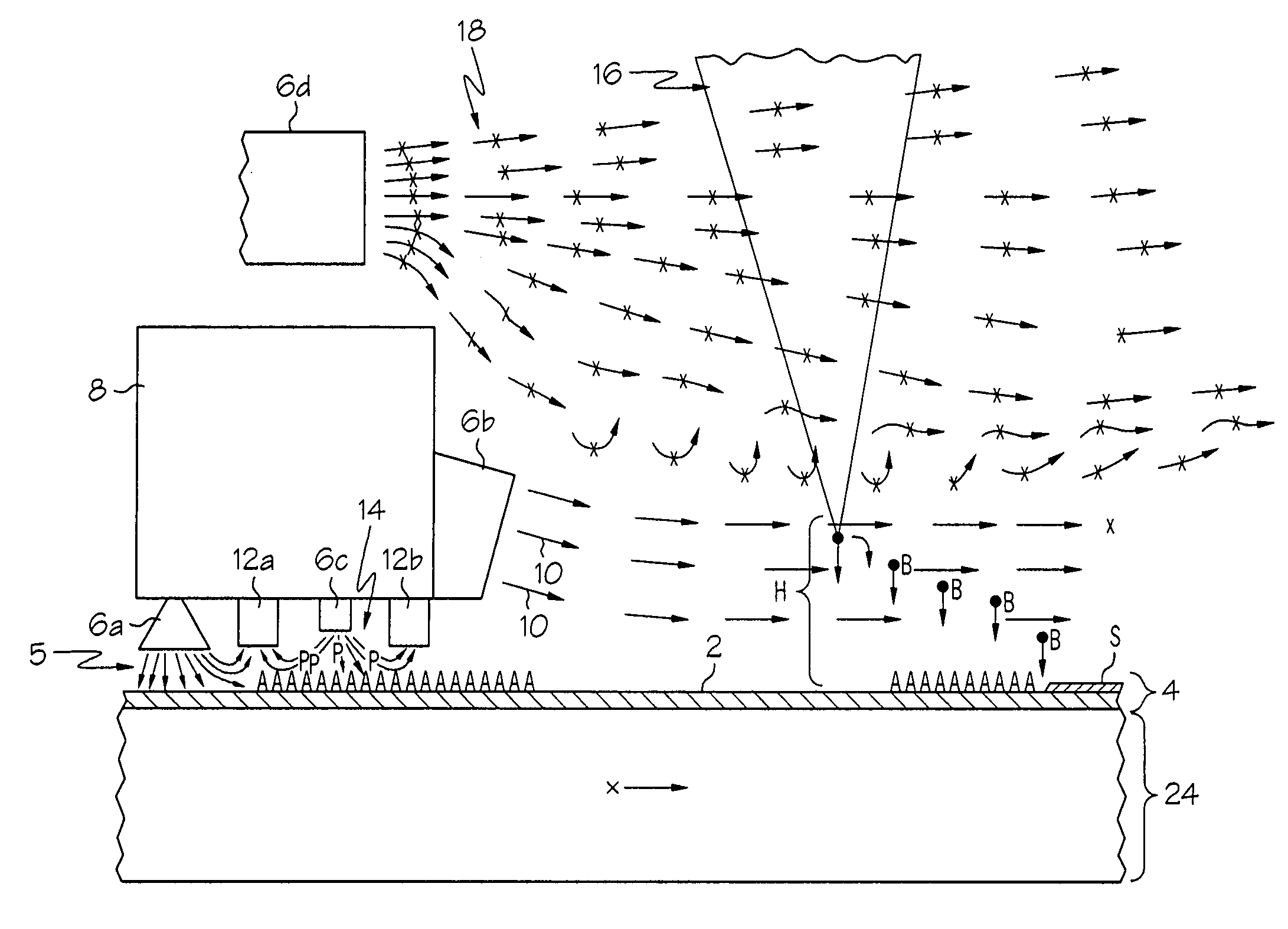

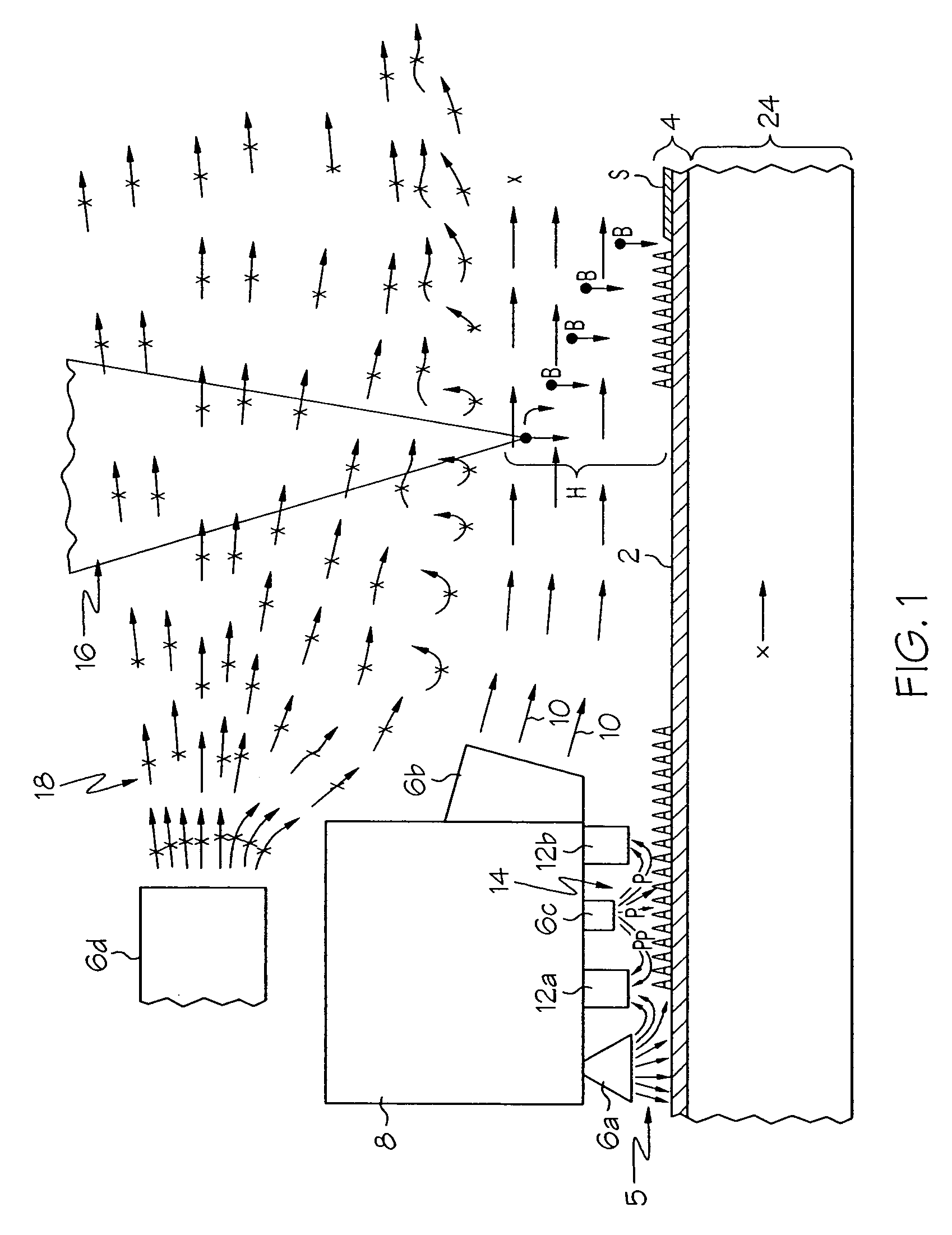

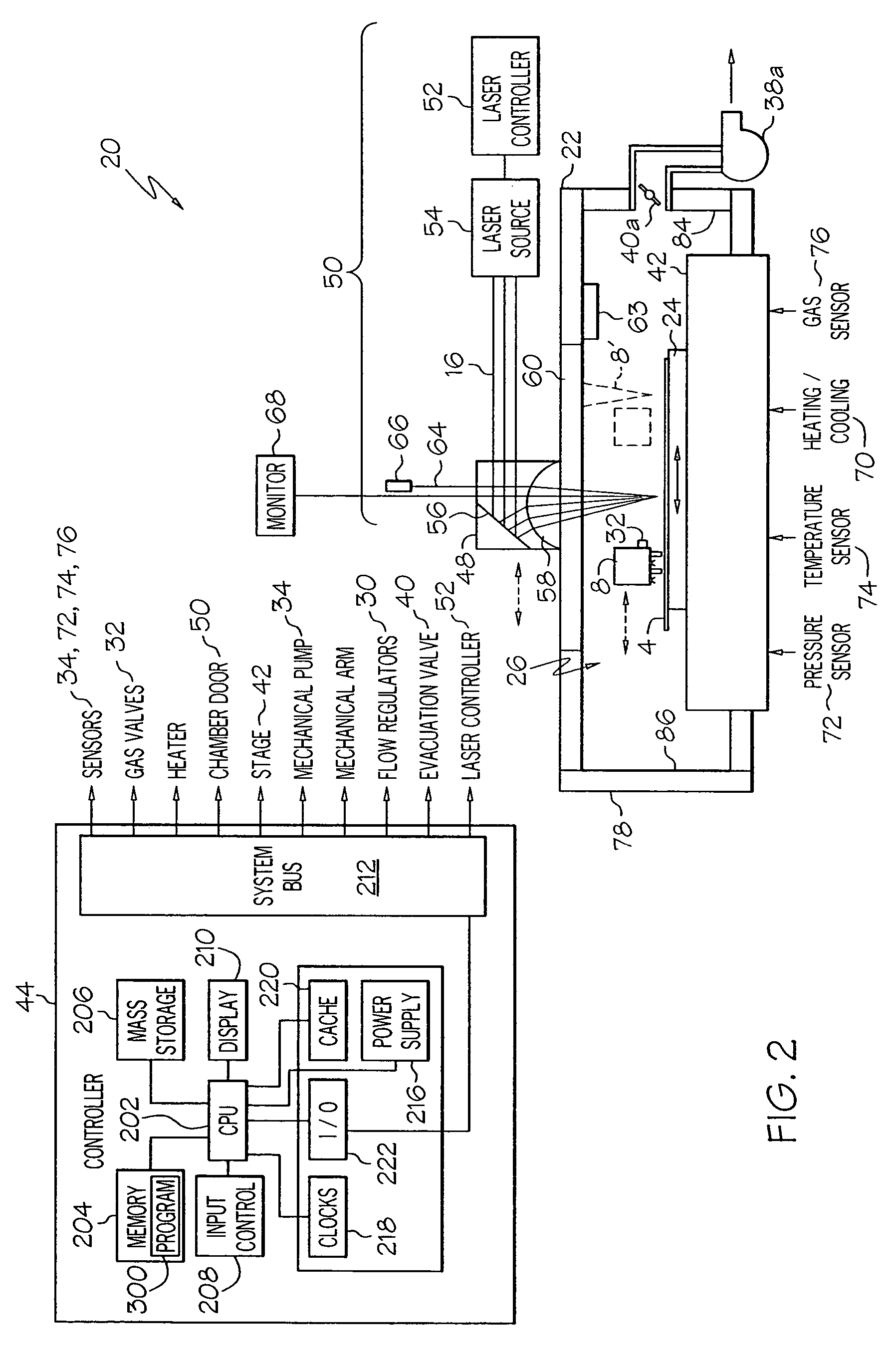

Atomic layer deposition with point of use generated reactive gas species

InactiveUS7087119B2Faster rateIncrease throughputLiquid surface applicatorsSemiconductor/solid-state device manufacturingHigh fluxReactive gas

An apparatus for atomic layer deposition preventing mixing of a precursor gas and an input gas. From the apparatus a flow of the input gas is provided over a surface of the workpiece wherein a beam of the electromagnetic radiation is directed into the input gas in close proximity to the surface of the workpiece, but spaced a finite distance therefrom. The input gas is dissociated by the beam producing a high flux point of use generated reactive gas species that reacts with a surface reactant formed on the surface of the workpiece by a direct flow of the precursor gas flown from the dispensing unit. The surface reactant and reactive gas species react to form a desired monolayer of a material on the surface of the workpiece.

Owner:MICRON TECH INC

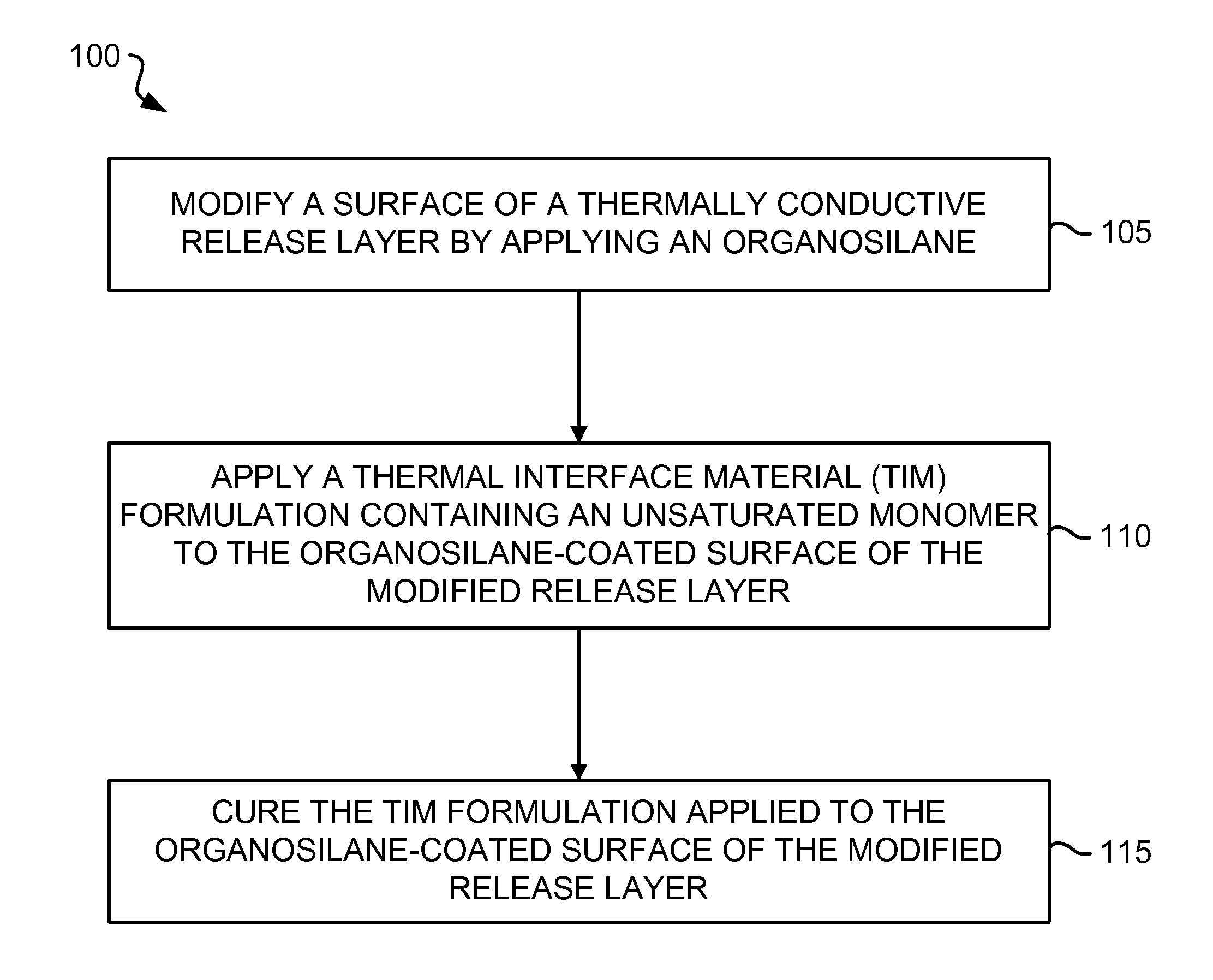

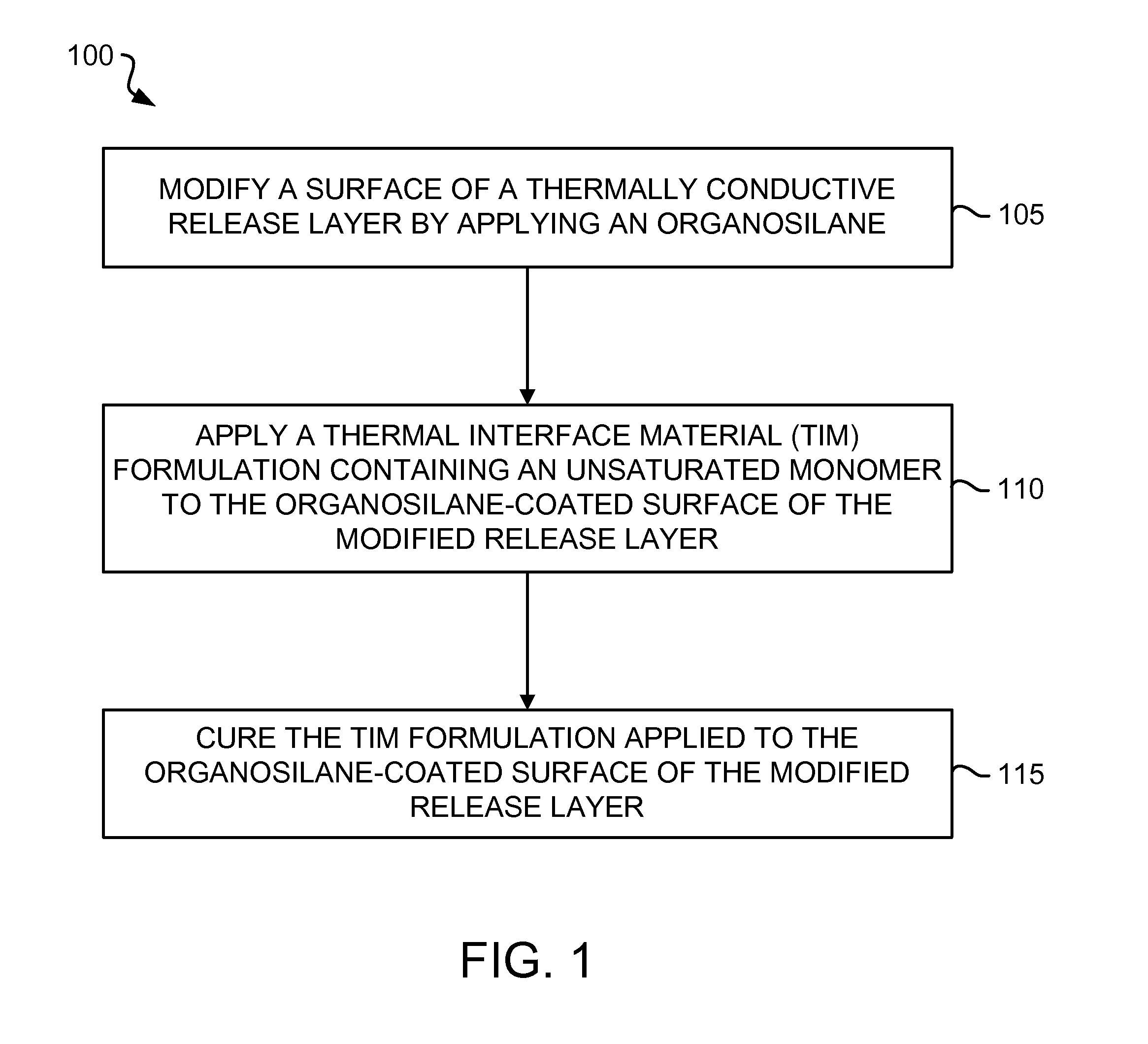

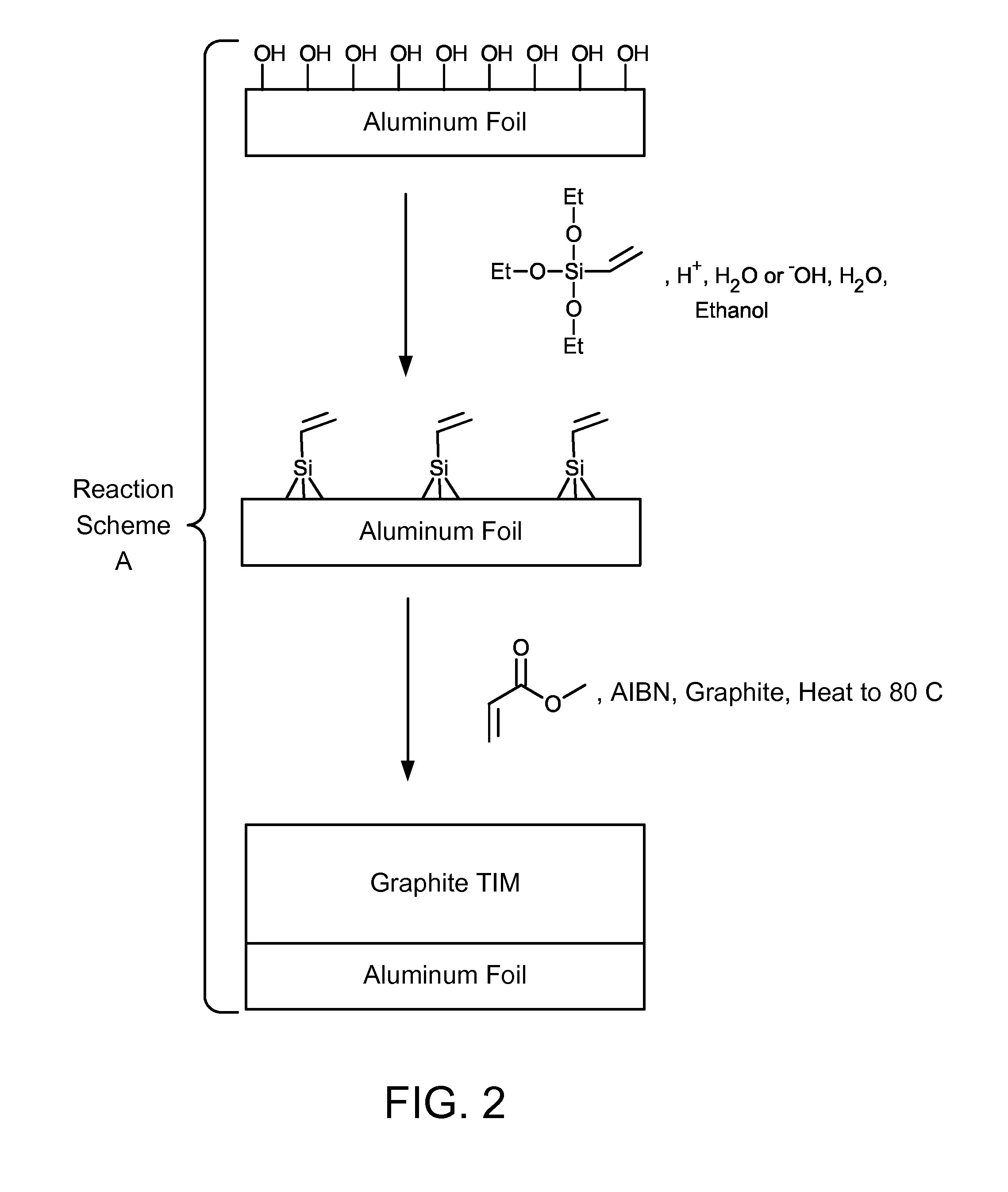

Thermal interface material (TIM) with thermally conductive integrated release layer

InactiveUS20130337273A1Semiconductor/solid-state device detailsSolid-state devicesCoated surfaceSilanes

A thermal interface material (TIM) includes a modified release layer having an organosilane-coated surface covalently bound to a TIM formulation layer. The modified release layer may be formed by applying an organosilane (e.g., vinyltriethoxysilane) to the surface of a thermally conductive release layer (e.g., aluminum foil). The organosilane reacts with hydroxyl groups on the surface of the thermally conductive release layer. The TIM formulation layer may be formed by applying a TIM formulation (e.g., a graphite TIM formulation) containing an unsaturated monomer (e.g., methyl acrylate) to the organosilane-coated surface of the modified release layer, and then curing the TIM formulation so that the unsaturated monomer of the TIM formulation reacts with the organosilane-coated surface of the modified release layer.

Owner:IBM CORP

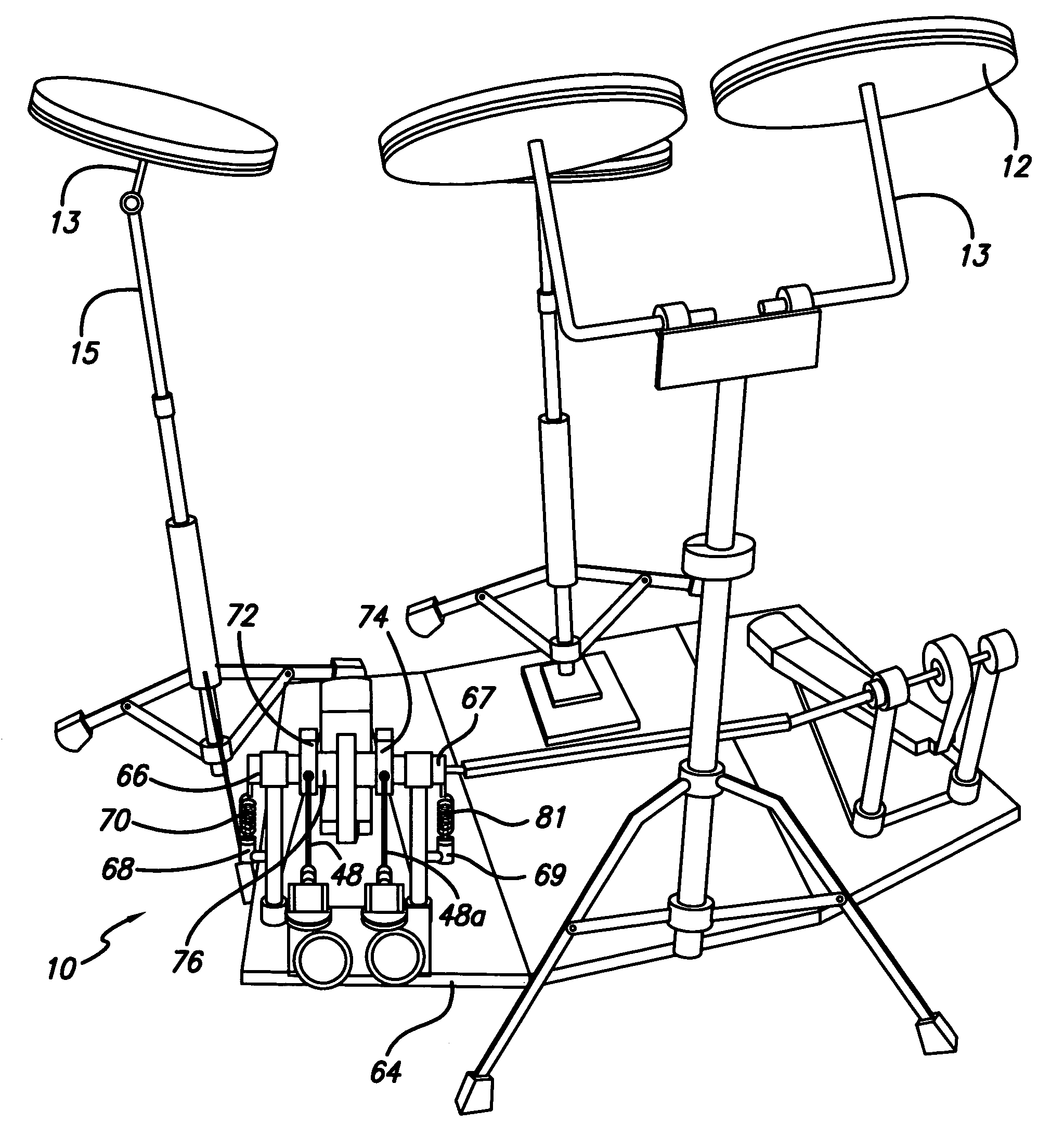

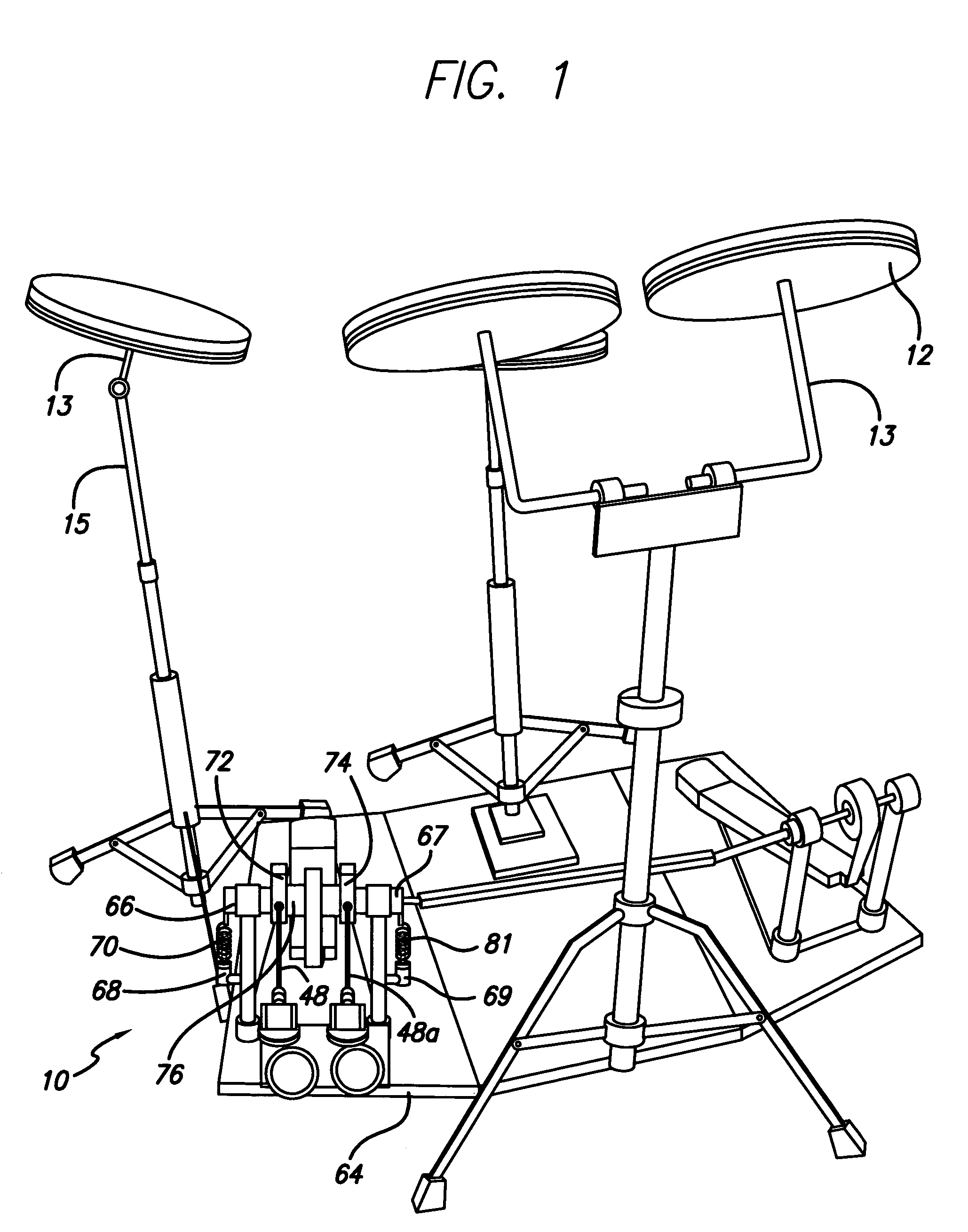

Musical drum practice pads

InactiveUS7638701B2Easy to useReduce manufacturing costPercussion musical instrumentsPercussion padCoupling

An apparatus for simulating the playing surface response characteristics of conventional percussion instruments, including one or more metal base members and one or more corresponding percussion pad members with a magnetized pad for magnetic coupling with a metal base member. Each percussion member has response characteristics corresponding to the playing surface characteristic of a particular conventional percussion instrument and is removably positioned relative to each of the metal base members. Also provided is a device for simulating the playing surface response characteristics of a bass drum.

Owner:REMO INC

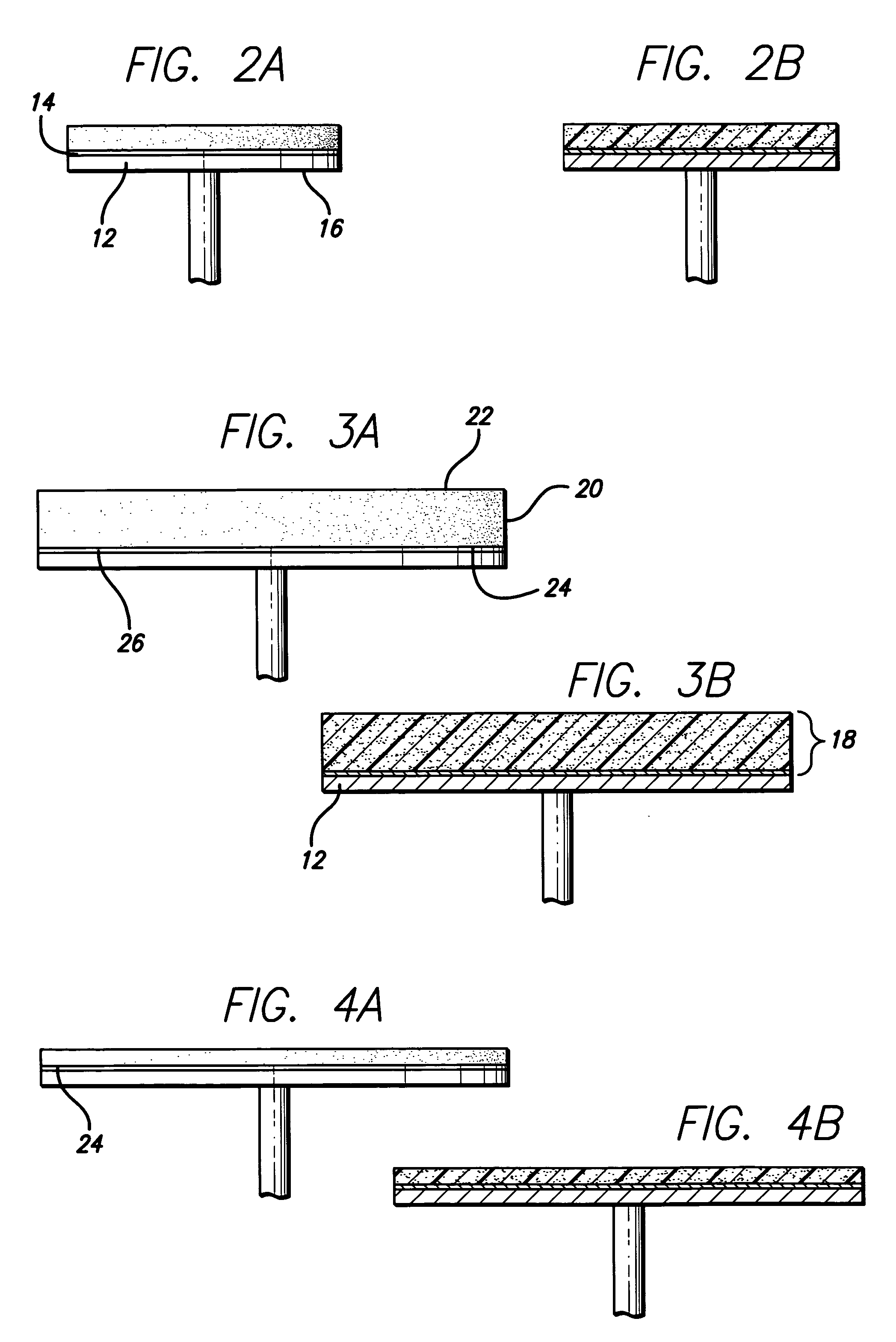

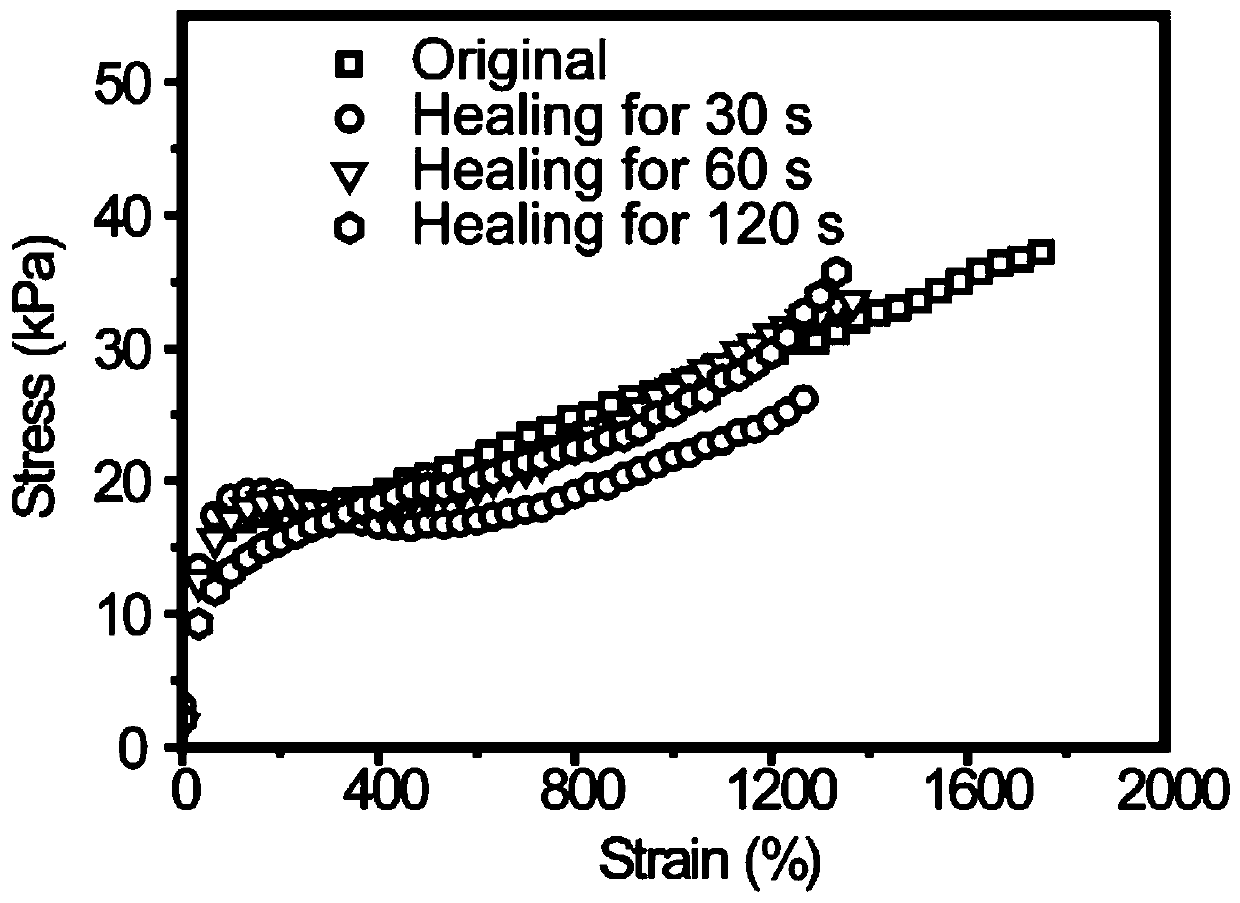

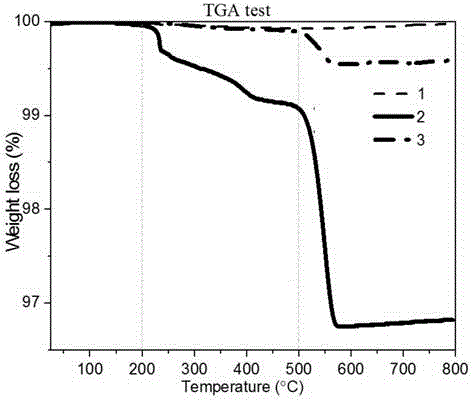

Ternary cross-linked hydrogel electrolyte, preparation method and applications thereof

The invention discloses a ternary cross-linked hydrogel electrolyte, a preparation method and applications thereof, wherein polyvinyl alcohol, a bis-catechol derivative, boric acid, potassium hydroxide and water are used as raw materials, a macromolecular cross-linking agent D-B is obtained through a condensation reaction between the boric acid and the o-hydroxyl in the bis-catechol, and the polyvinyl alcohol is cross-linked with the macromolecular cross-linking agent D-B to form a cross-linked network structure, so that the rapid self-repairing hydrogel is obtained. According to the invention, the synthesis method has characteristics of simple process, mild condition, easy operation and no product post-treatment; by changing the use amounts of the polyvinyl alcohol and the cross-linking agent, the hydrogel electrolytes with different self-repairing capacities, mechanical strengths and conductivities are obtained, and can generate viscosity and lose viscosity under electrical stimulation, wherein the viscosity responsiveness can be regulated by regulating the electrical stimulation time and the voltage; and the self-repairing hydrogel has important applications in the fields of soft robots, artificial ligaments, flexible devices, surface response materials, wall climbing robots, controllable coatings, automobile intelligent sensors and the like.

Owner:XIAMEN UNIV

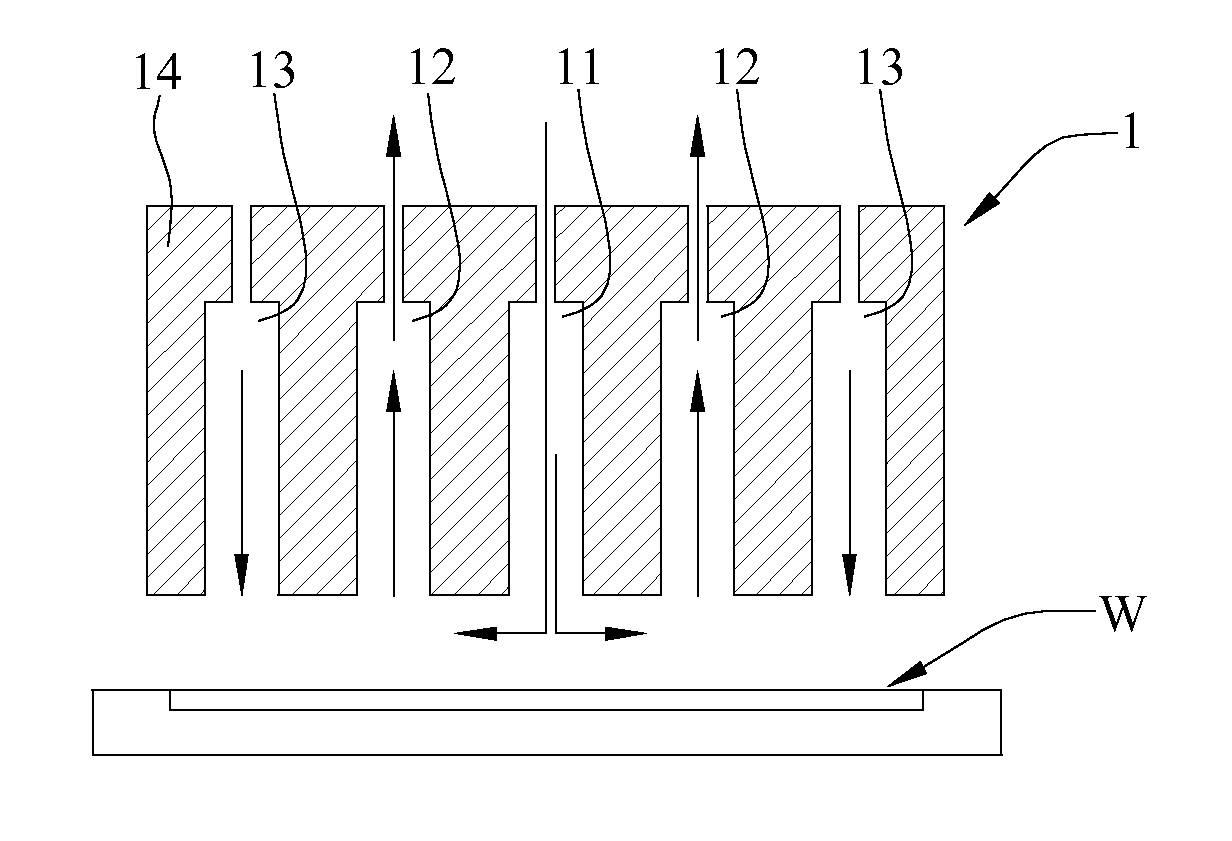

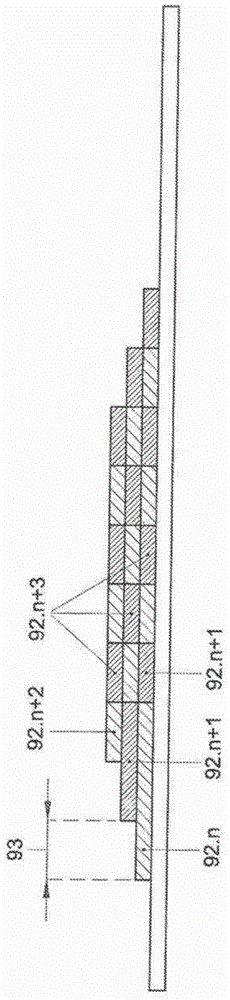

Deposition nozzle and apparatus for thin film deposition process

A deposition nozzle and a deposition apparatus include a nozzle body, a precursor passageway formed at a central region of the nozzle body for a precursor gas to be sprayed on the substrate such that the precursor gas reacts with a surface of the substrate, an extraction passageway formed in the nozzle body and located at a peripheral side of the precursor passageway, and extracting residues after the precursor gas reacts with the surface of the substrate, and an air curtain passageway formed in the nozzle body and located at a peripheral side of the extraction passageway for isolating gas to be sprayed on the substrate so as to form a closed gas flow field enclosing a process reaction region between a substrate carrier and the deposition nozzle such that the residues after the precursor gas reacts with the surface of the substrate do not leak.

Owner:IND TECH RES INST

ATRP functional modified proppant and preparation method thereof

ActiveCN106833602AImprove general performanceStrong operational innovationFluid removalTemperature controlAtom-transfer radical-polymerization

The invention relates to an ATRP functional modified proppant and a preparation method thereof. The method comprises the steps: 1) selecting an initiator, and carrying out surface modification on a proppant; and 2) selecting a monomer with functional groups, through an atom transfer radical polymerization (ATRP) method, adopting a catalyst and a ligand, at a certain temperature and under suitable conditions, after a certain time, carrying out reaction grafting on the proppant surface with functional polymer chains, and making the proppant having the functional properties of hydrophobicity, temperature control property and pH sensitivity or reaction activity and the like. The method has flexible and operationable modification, can perform functional design, has high versatility, is suitable for quartz sand, ceramsite and other conventional proppants, and can be used for design and development of new functional proppants; and according to different needs of oil reservoirs, the oil and gas yield is effectively improved.

Owner:PEKING UNIV

Hybrid hardware-accelerated relighting system for computer cinematography

ActiveUS7427986B2Simple lightingIncrease speedMultiple digital computer combinationsAnimationComputer animationDeferred shading

An interactive cinematic lighting system used in the production of computer-animated feature films containing environments of very high complexity, in which surface and light appearances are described using procedural RenderMan shaders. The system provides lighting artists with high-quality previews at interactive framerates with only small approximations compared to the final rendered images. This is accomplished by combining numerical estimation of surface response, image-space caching, deferred shading, and the computational power of modern graphics hardware.

Owner:PIXAR ANIMATION

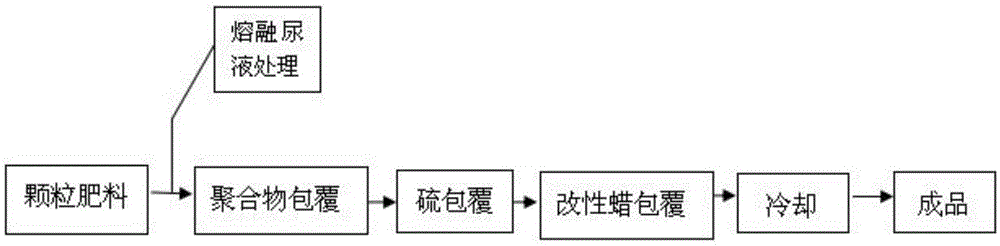

Polymer sulfur coated controlled release fertilizer and preparing method thereof

InactiveCN106316620AImprove performanceReduce dosageOrganic fertilisersUrea compound fertilisersPolymer scienceSurface response

The invention discloses a polymer sulfur coated slow-release fertilizer and a manufacturing method thereof, first of all, implement granulated fertilizer coating through melting urea, next, reaction of two or above polymer precursors on the surface of granulated fertilizer coated with urine will be achieved to form polymer wrapper, after that, coat the polymer wrapper with modified molten sulfur, and the outermost layer coating is with naturally modified polymer wax combination, which greatly reduces coating materials dosage, improves controlled release properties and nutrient content, the product toughness, abrasive resistance and impact resistance is favorable, low comprehensive cost, membrane materials can be degraded, and of eco-environment protection.

Owner:美稼农业科技(上海)有限公司 +1

In-situ post epitaxial treatment process

InactiveUS6562128B1Elimination of costly and time-consumingCostly and time-consuming and stepPolycrystalline material growthAfter-treatment detailsProtective oxideSurface response

A process for forming an epitaxial layer on a semiconductor wafer substrate is provided. The process comprises providing a semiconductor wafer substrate and an area for forming an epitaxial layer on said semiconductor wafer substrate. The formation area consists essentially of an epitaxial layer process chamber. The semiconductor wafer substrate is introduced into the epitaxial layer process chamber and an epitaxial layer is formed on at least one surface of the semiconductor wafer substrate. Then, a chemical reagent is introduced into the epitaxial layer process chamber. The chemical reagent reacts with the epitaxial layer surface in situ to form an outer protective oxide layer.

Owner:SEH AMERICA

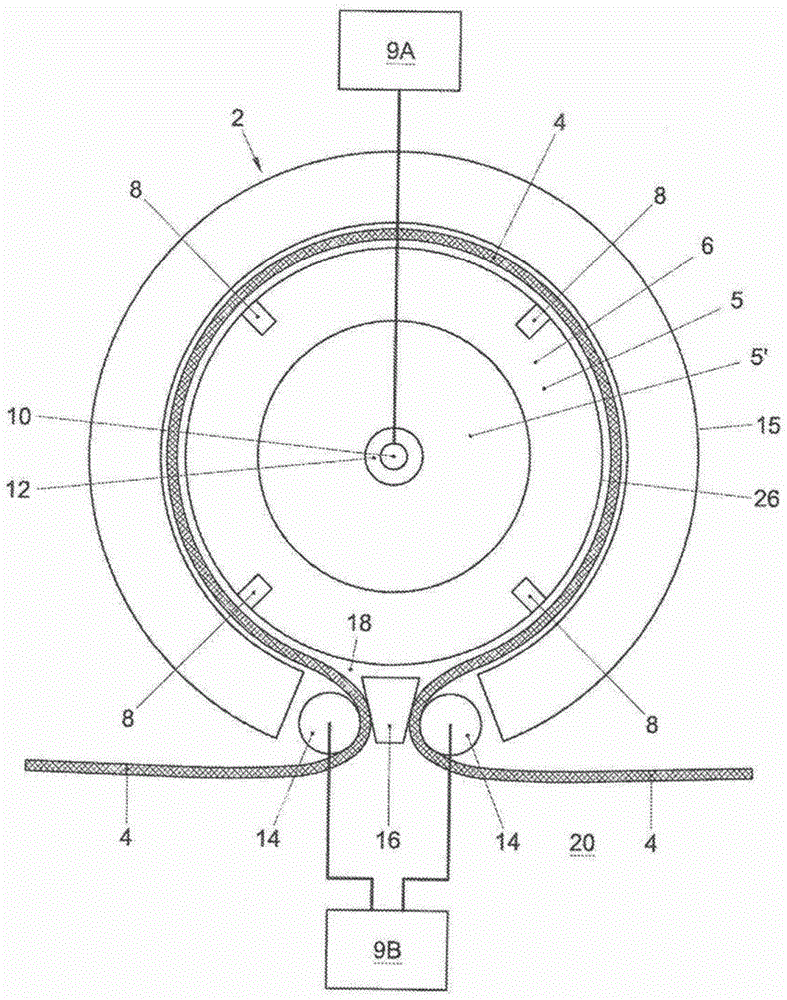

Method and apparatus for depositing atomic layers on substrate

ActiveCN105102676ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringAtomic layer deposition

Method of performing atomic layer deposition. The method comprises supplying a precursor gas towards a substrate, using a deposition head including one or more gas supplies, including a precursor gas supply. The precursor gas reacts near a surface of the substrate for forming an atomic layer. The deposition head has an output face comprising the gas supplies, which at least partly faces the substrate surface during depositing the atomic layer. The output face has a substantially rounded shape defining a movement path of the substrate. The precursor-gas supply is moved relative to the substrate by rotating the deposition head while supplying the precursor gas, for depositing a stack of atomic layers while continuously moving in one direction. The surface of the substrate is kept contactless with the output face by means of a gas bearing.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Deposition system and method using a delivery head separated from a substrate by gas pressure

ActiveUS20170029949A1Different from numberSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

Owner:EASTMAN KODAK CO

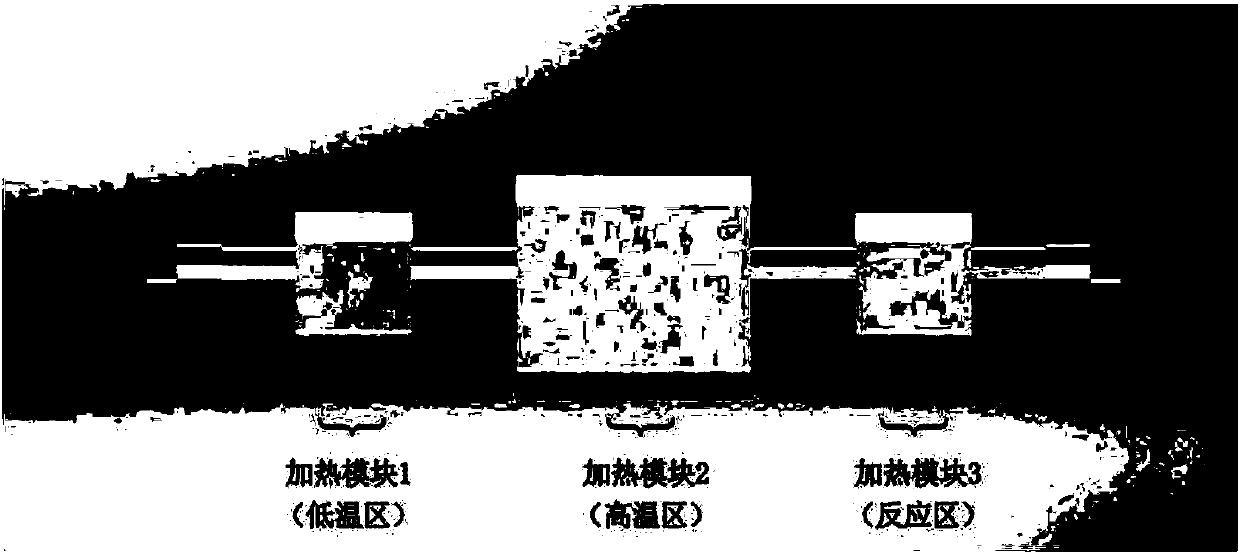

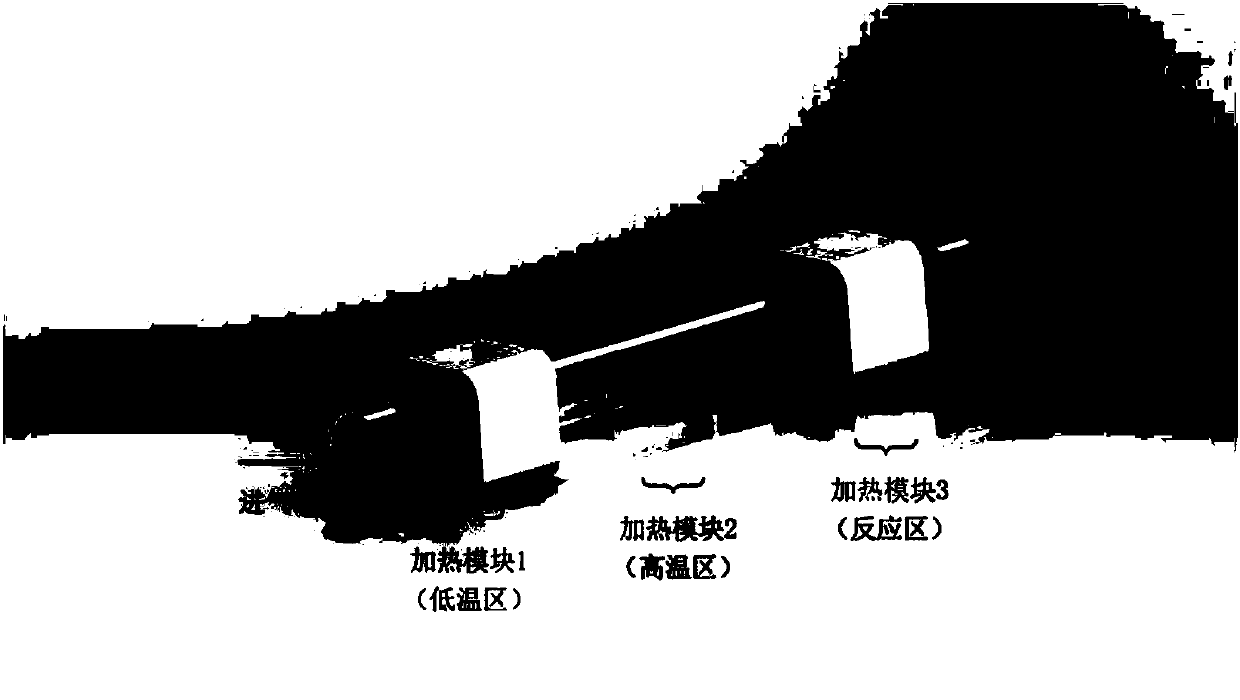

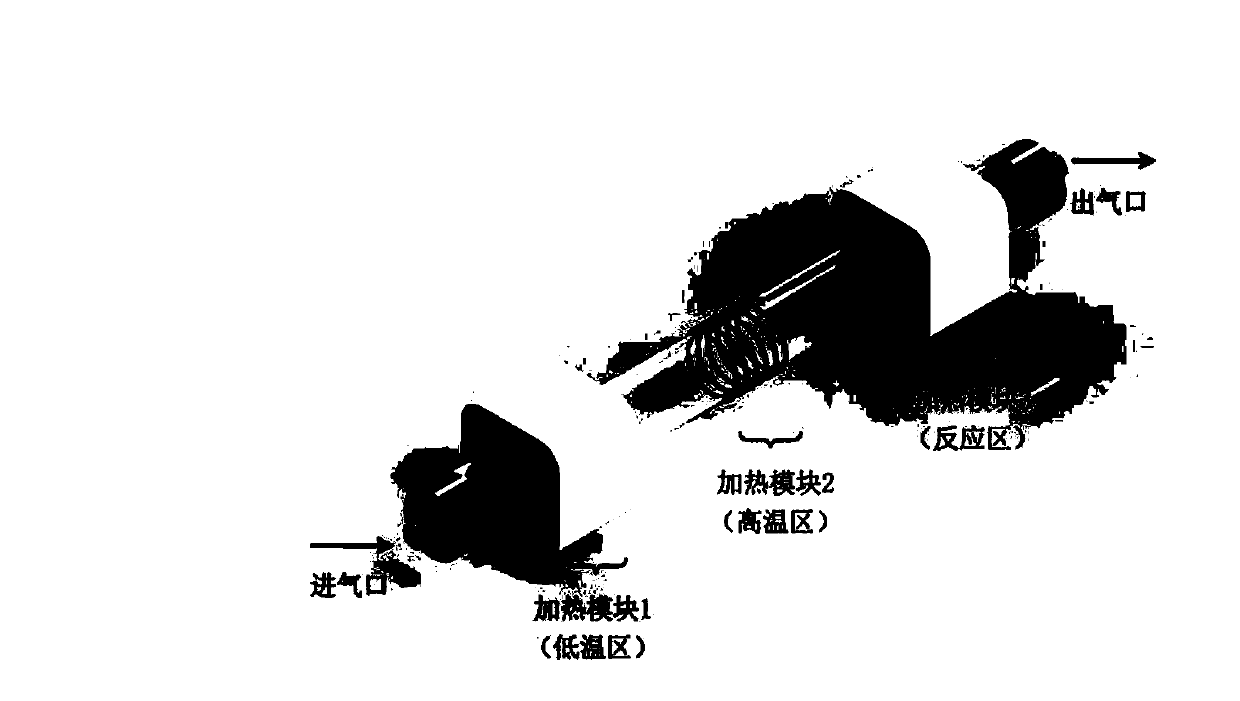

Method and equipment for preparing TMDCs (two-dimensional transition metal disulphide compound single crystals)

InactiveCN107587196ARealize multiple reuseAvoid wastingPolycrystalline material growthFrom chemically reactive gasesChemical reactionGas phase

The invention belongs to the technical field of material preparation, and particularly relates to a preparation method and manufacturing equipment for TMDCs (two-dimensional transition metal disulphide compound single crystals). The controllability and the sample quality of preparation of TMDCs samples are improved by regulating the volatilizing rate of a precursor by directly controlling the reaction temperature on the surface of a metal through current, voltage, electromagnetic waves and the like loaded on a metal foil precursor. Meanwhile, the overall gas phase deposition process is a surface chemical reaction; the consumption amount of a reaction precursor is low; the purpose of producing the TMDCs continuously for a long time can be achieved. In the process of preparing the TMDCs by adopting the equipment, metal oxide powder is not required to be taken as the precursor, so that the waste of the precursor is avoided, and the metal precursor is utilized repeatedly. The method and the equipment for preparing the TMDCs can be used for hot wall and cold wall CVD (chemical vapour deposition) systems, and has good universality.

Owner:SHENZHEN UNIV

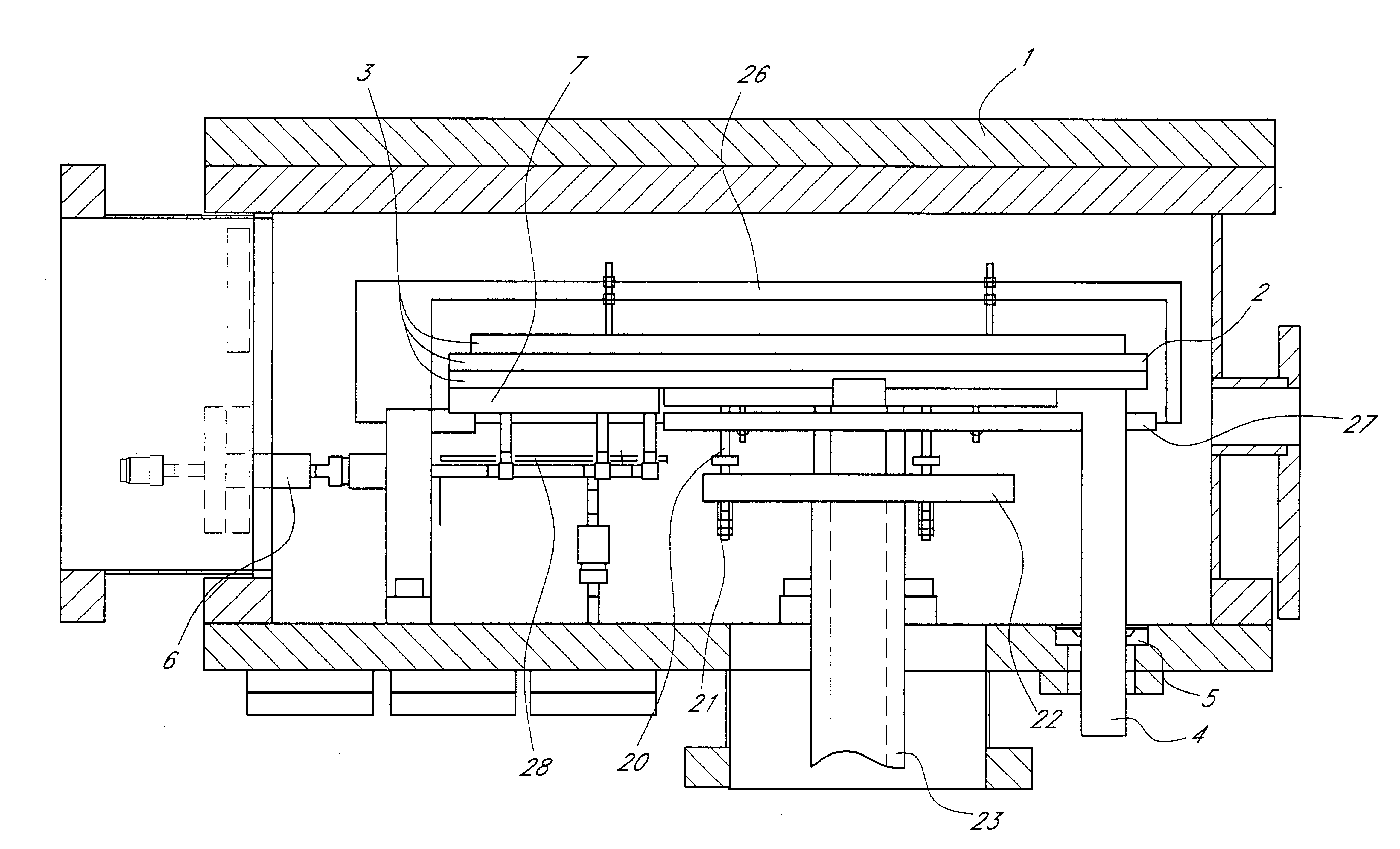

Apparatus for fabrication of thin films

InactiveUS7833352B2Avoid contactEasy loadingLiquid surface applicatorsVacuum evaporation coatingEngineeringVapor phase

The invention relates to an apparatus for growing thin-films onto a substrate by exposing the substrate to alternate surface reactions of vapor-phase reactants for forming a thin-film onto the, substrate by means of said surface reactions. The apparatus comprises a vacuum vessel (1), a reaction chamber (2) with a reaction space into which the substrate can be transferred and which has infeed channels (6) for feeding therein the reactants used in said thin-film growth process, as well as outlet channels (4) for discharging gaseous reaction products and excess reactants'. According to the invention, said reaction chamber comprises a base part (9, 10) mounted stationary in respect to the interior of said vacuum vessel (1) and a movable part (18) adapted to be sealably closable against said'base part of said reaction chamber. The invention makes it possible to improve the cleanliness of the substrate load chamber and to reduce the degree of substrate contamination. The apparatus is intended for use in the fabrication of thin-films by means of the ALE method for semiconductor layer structures and display units.

Owner:ASM IP HLDG BV

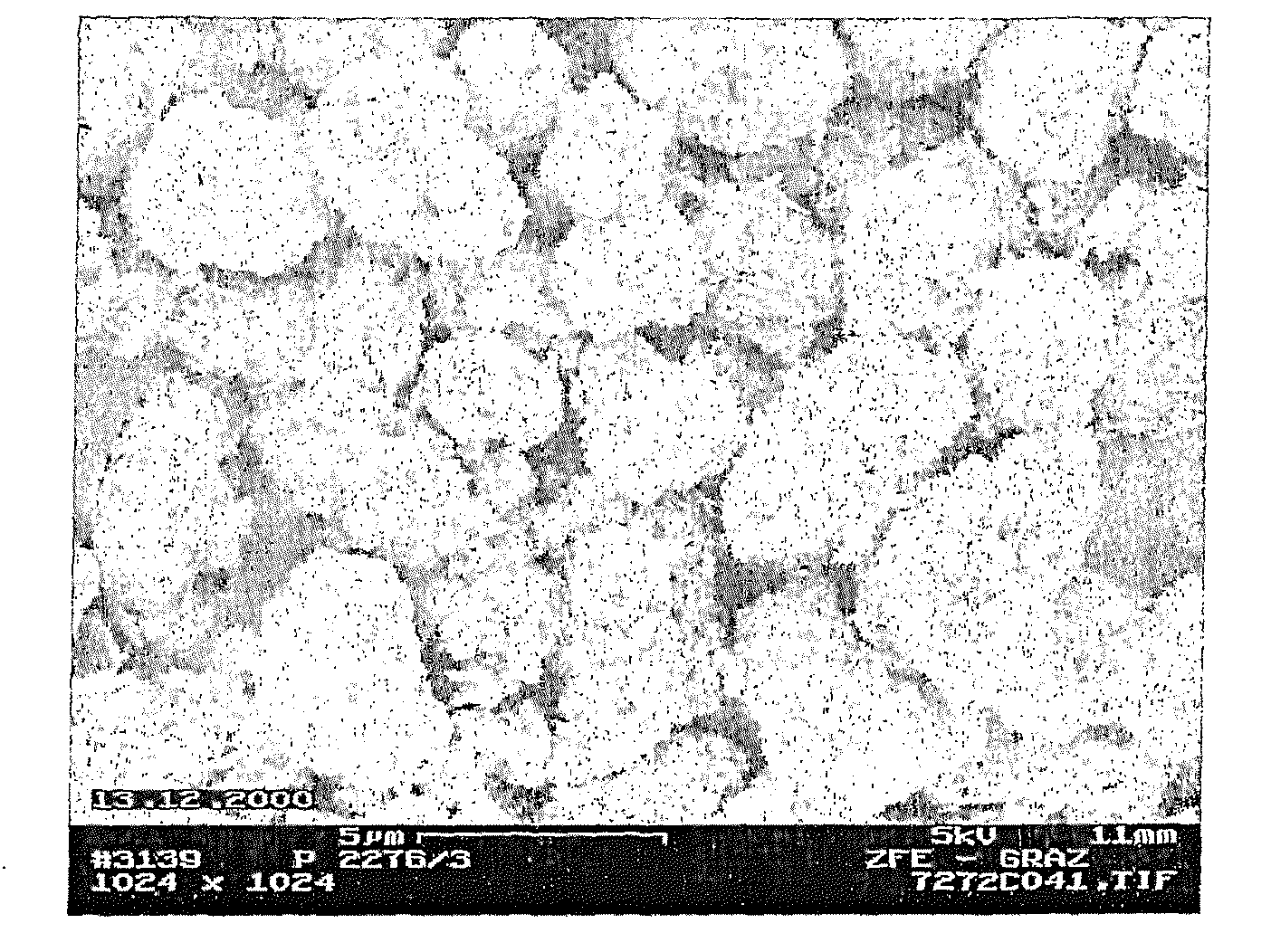

Use of a surface-reacted calcium carbonate in tissue paper, process to prepare a tissue paper product of improved softness, and resulting improved softness tissue paper products

ActiveUS20100258258A1Good flexibilityNatural cellulose pulp/paperMechanical working/deformationSurface responseTissue paper

The present invention relates to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

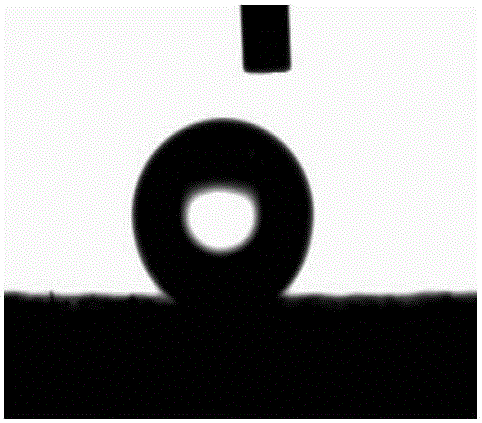

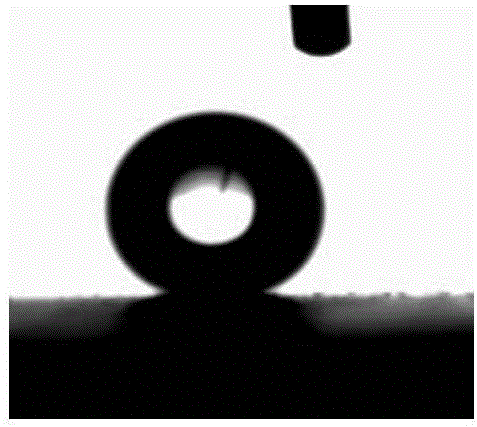

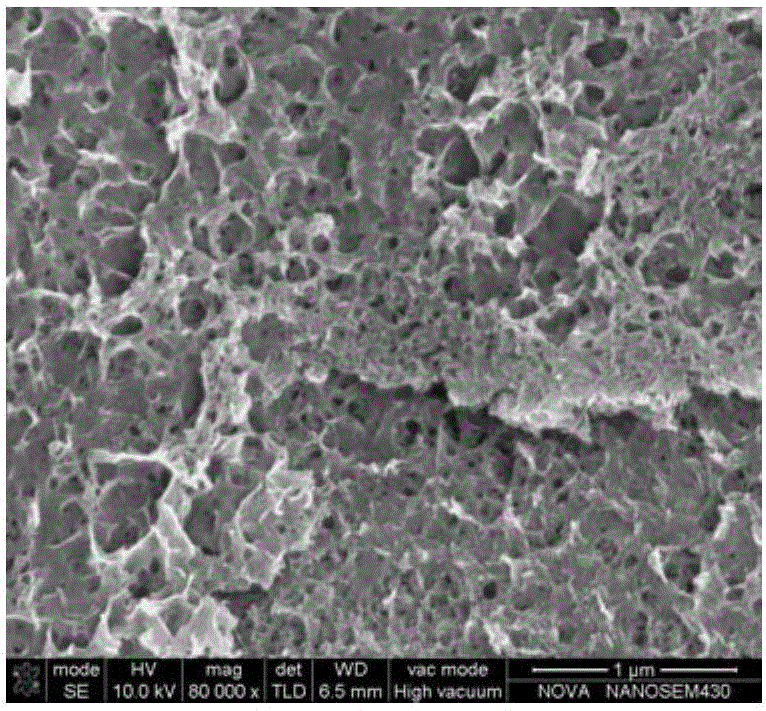

Preparation method for corrosion-resistant and super-hydrophobic aluminum oxide membrane for zinc layer

InactiveCN106011799AUniform surfaceMild reaction conditionsLiquid/solution decomposition chemical coatingAluminium isopropoxideHydrolysis

The invention discloses a preparation method for a corrosion-resistant and super-hydrophobic aluminum oxide membrane for a zinc layer. The method includes the steps of 1, adopting aluminum sources such as aluminum isopropoxide as a precursor, preparing aluminum oxide sol in a hydrolysis mode under the effect of catalysts, and placing samples into the sol or coating zinc with the sol for roughening surface structures; and 2, modifying the roughened zinc layer through low-surface energy modifying agents. The surface contact angle of the prepared super-hydrophobic membrane is greater than 150 degrees, and the slide angle of the prepared super-hydrophobic membrane is smaller than 10 degrees. According to the method, reaction conditions for preparing the super-hydrophobic membrane are mild, the surface is uniform, and the microcosmic nanostructures can be controlled by changing experiment parameters of sol preparation and dipping or coating means. The aluminum oxide membrane is arranged on the surface, and therefore the corrosion resistance of the zinc layer can be effectively improved. The membrane has the super-hydrophobic performance, and therefore the corrosion resistance of the zinc can be greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Method of depositing zinc oxide coatings on a substrate

InactiveUS20070264429A1Efficiently formedChemical vapor deposition coatingNitrogenAtmospheric pressure

A process for the production of a zinc oxide coating on a moving glass substrate provides a precursor mixture of a dialkylzinc compound, an oxygen-containing compound and an inert carrier gas. The precursor mixture is directed along a surface of the glass substrate in an atmospheric pressure, on-line, chemical vapor deposition process. The precursor mixture is reacted at the surface of the glass substrate to form a zinc oxide coating, essentially devoid of nitrogen, at a growth rate of >100 Å / second.

Owner:PILKINGTON GROUP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com