Method and equipment for preparing TMDCs (two-dimensional transition metal disulphide compound single crystals)

A transition metal and dichalcogenide technology, which is applied in the field of preparing two-dimensional transition metal dichalcogenide single crystals, can solve problems such as non-conformity and achieve the effect of avoiding waste and realizing multiple reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

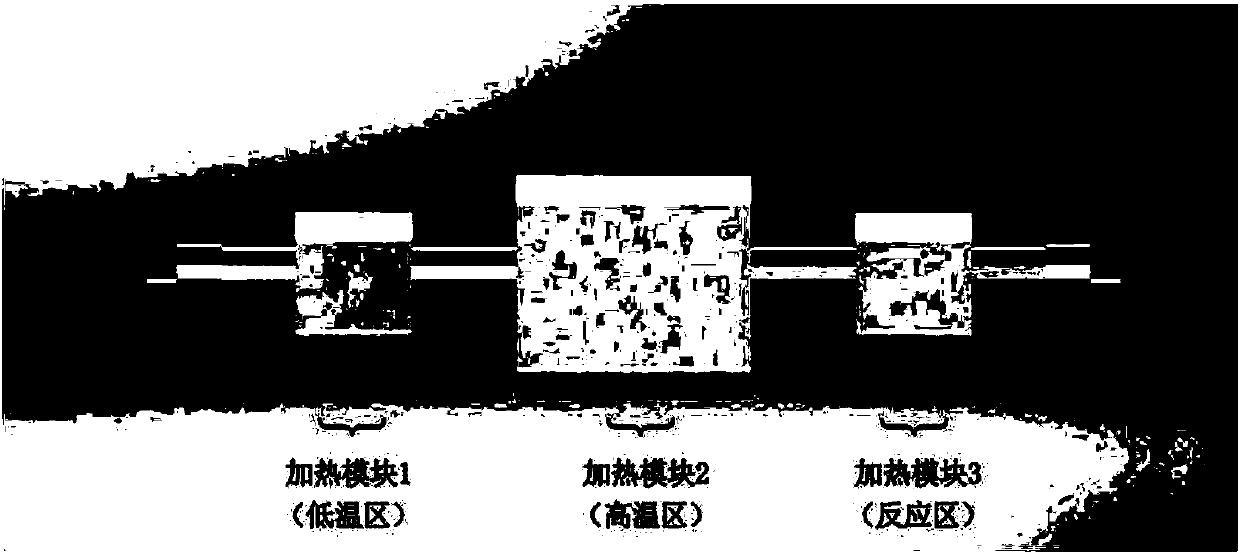

[0039] use as figure 1 In the CVD growth equipment, the heating module 1 is a low-temperature zone, the heating module 2 is a high-temperature zone, and the heating module 3 is a reaction zone.

[0040] A preparation of monolayer MoS 2 Methods. Include the following steps:

[0041] (1), at first, Mo metal foil is in the mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio=2:1) Soak for 2 hours, wash and dry. Then, the Mo metal foil is annealed. The annealing process is to raise the temperature to 500° C. at a rate of 40° C. / min, and the annealing is performed for 5 minutes. The cleaned Mo metal foil is then placed at the heating module 2 (high temperature zone) of the quartz tube;

[0042] (2), wash the cut single-throw quartz sheet and dry it for later use;

[0043] Preferably in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio = 2:1) Soak for 2 hours, then use ace...

Embodiment 2

[0048] use as figure 1 In the CVD growth equipment, the heating module 1 is a low-temperature zone, the heating module 2 is a high-temperature zone, and the heating module 3 is a reaction zone.

[0049] A preparation of monolayer WS 2 Methods. Include the following steps:

[0050] (1), first, put W metal foil in the mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio=2:1) Soak for 2 hours, wash and dry. Then, the W metal foil is annealed. The annealing process is to raise the temperature to 500° C. at a rate of 40° C. / min, and the annealing is performed for 5 minutes. Then the cleaned W metal is placed at the heating module 2 (high temperature zone) of the quartz tube;

[0051] (2), wash the cut single-throw quartz sheet and dry it for later use;

[0052] Preferably in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio = 2:1) Soak for 2 hours, then use acetone, isopr...

Embodiment 3

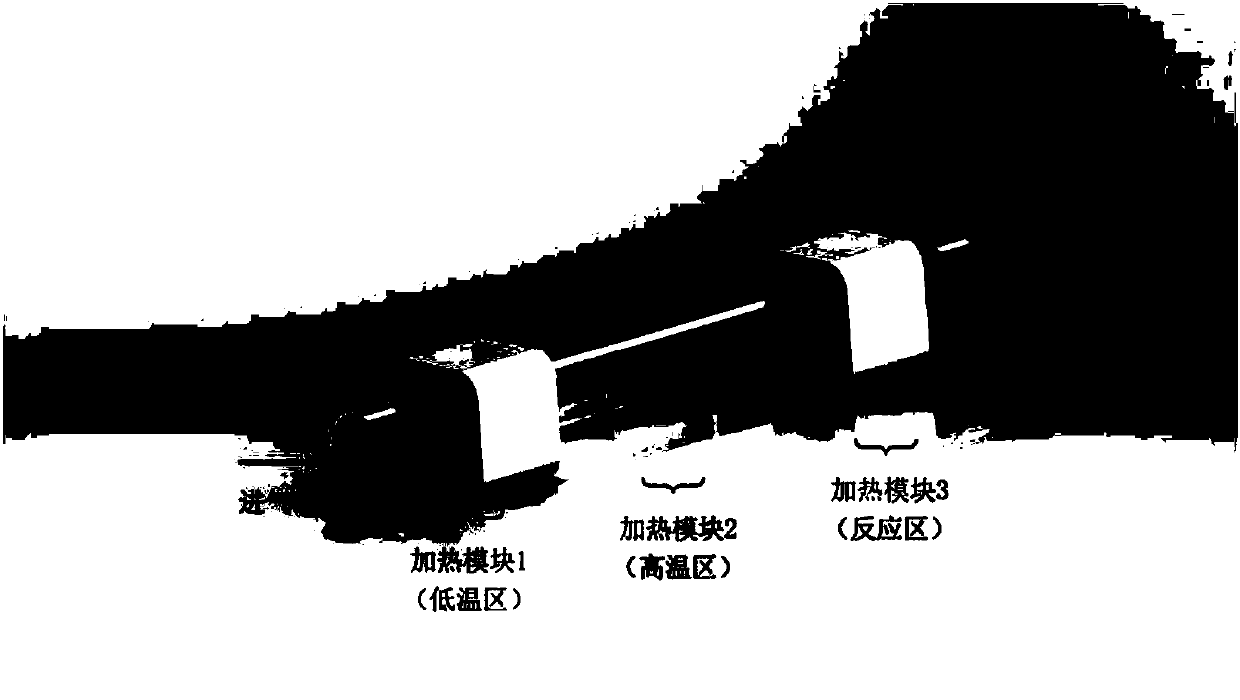

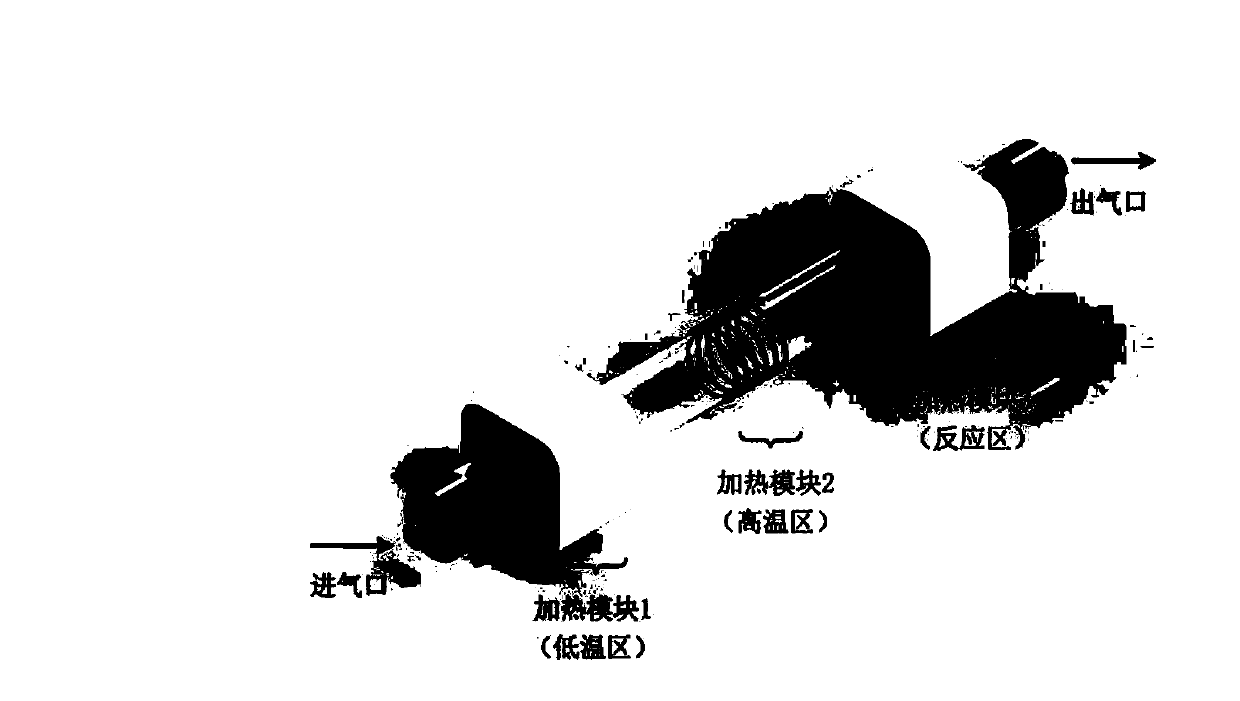

[0057] On the basis of embodiment 1 or 2, the heating method is as figure 2 Electric heating method; or for such as image 3 electric induction heating method; or for image 3 microwave heating method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com