Patents

Literature

480 results about "Catalytic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic function refer to the substance that increase the rate of any chemical reaction within cells. Based on the options above, the substance that act as a catalyst in Cell's chemcal reaction is : Protein.

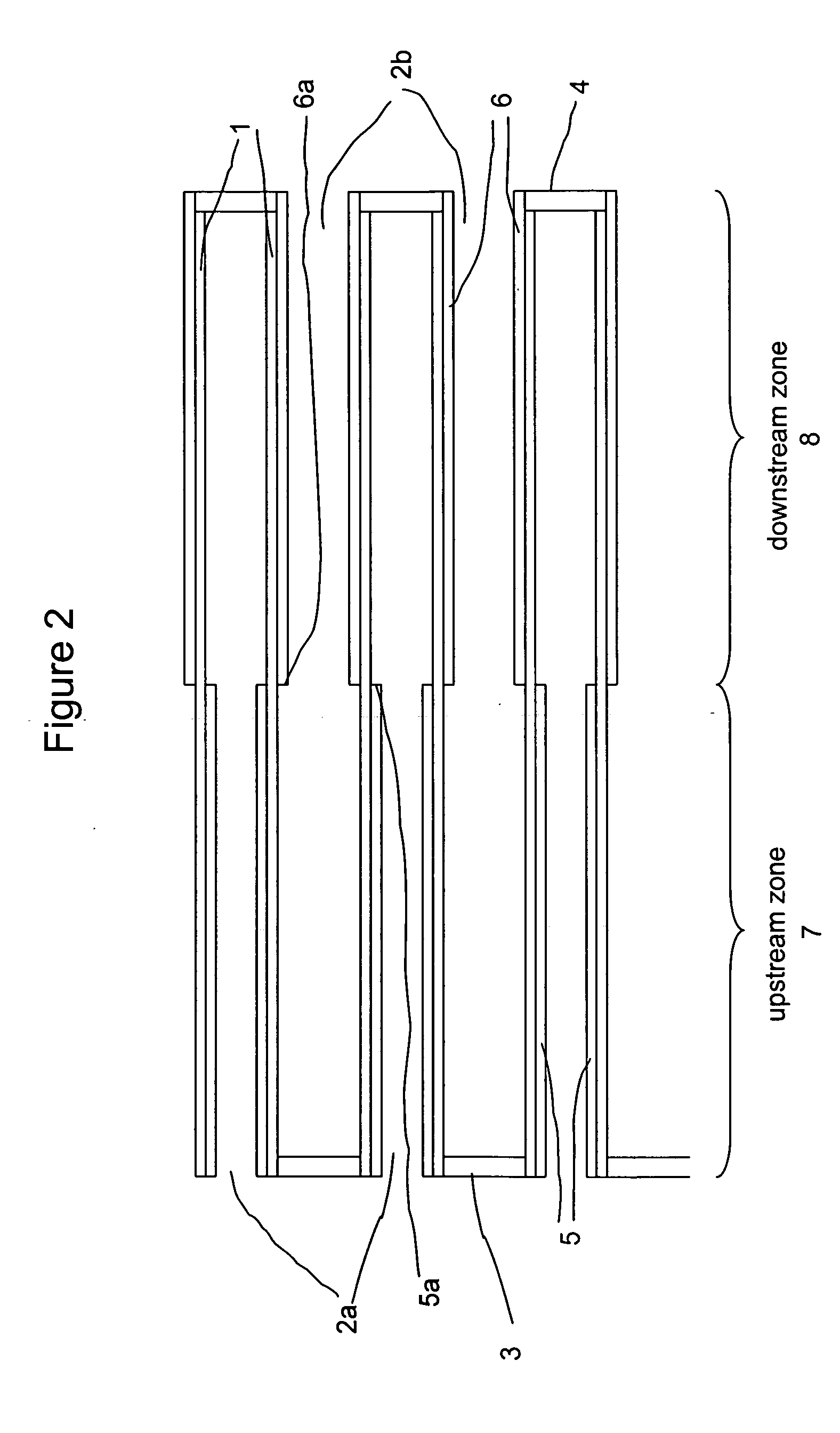

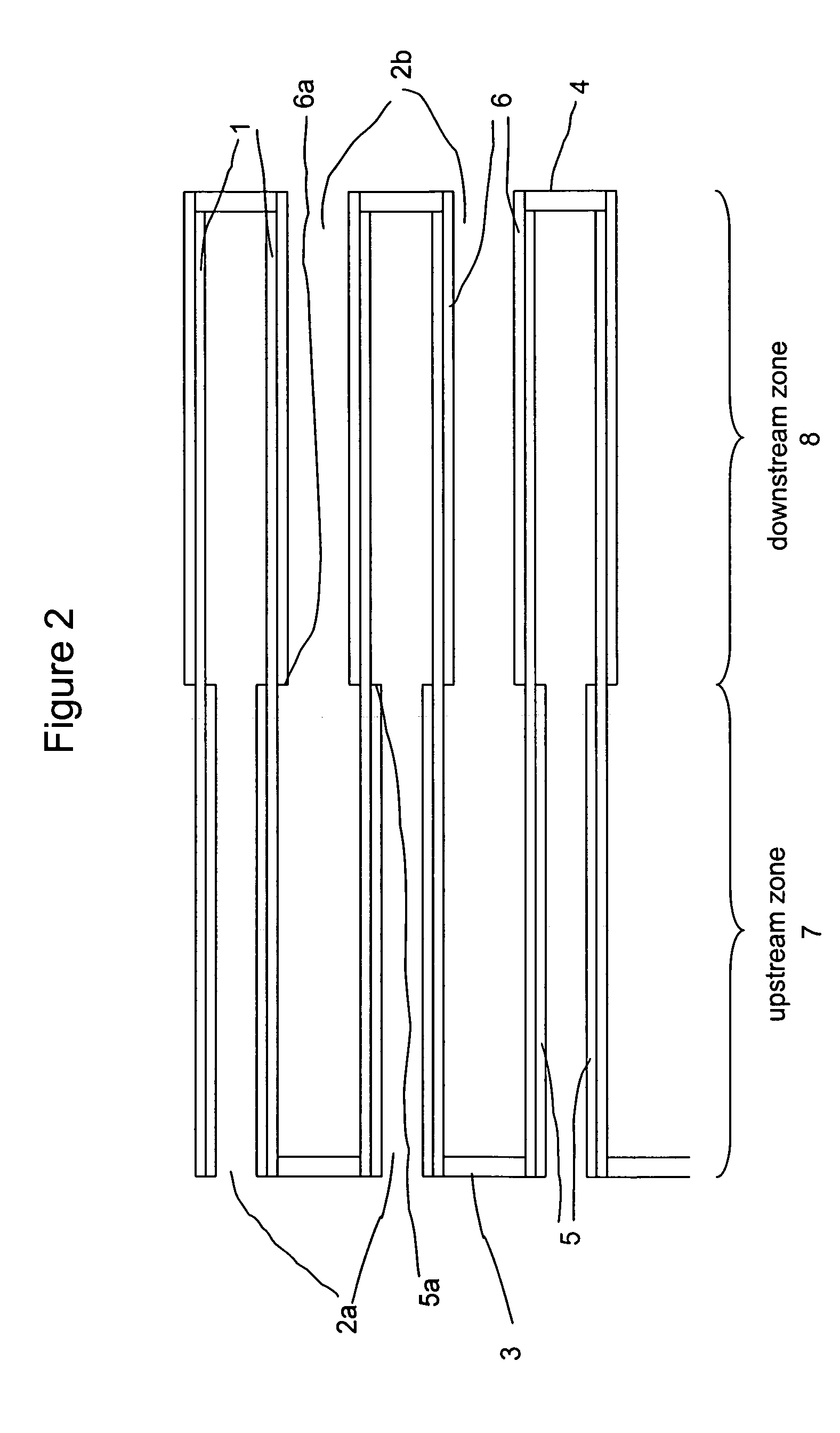

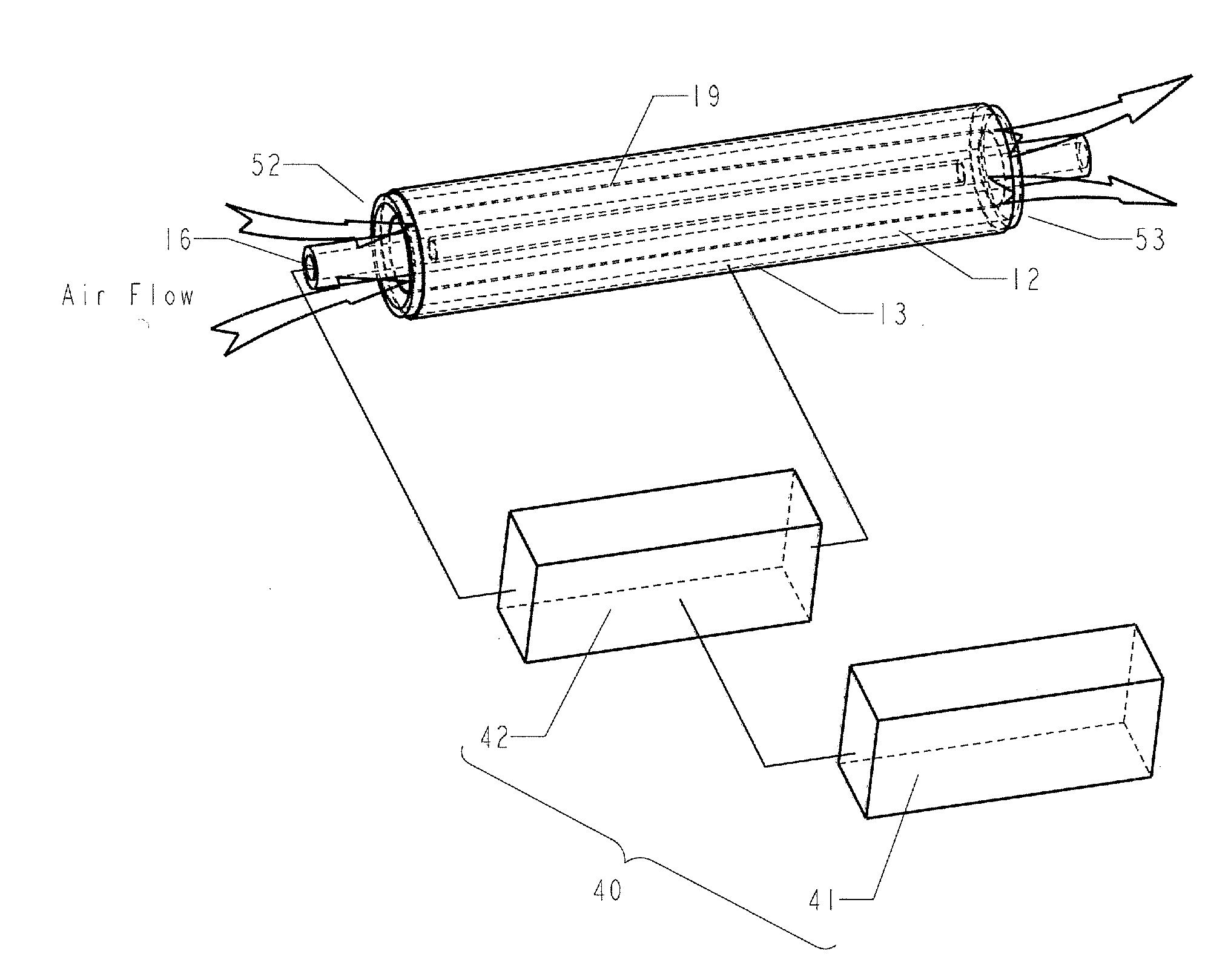

Pressure-balanced, catalyzed soot filter

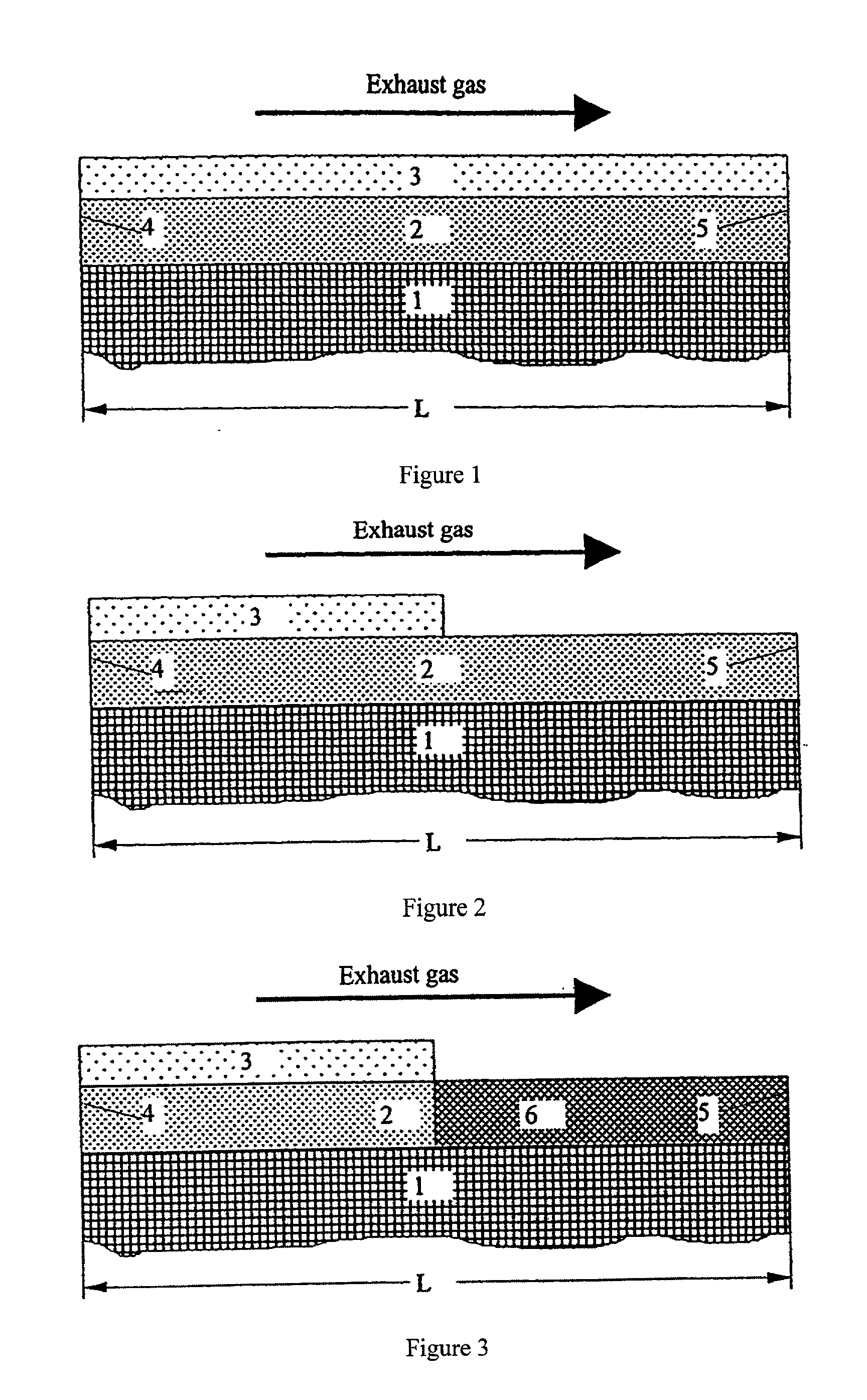

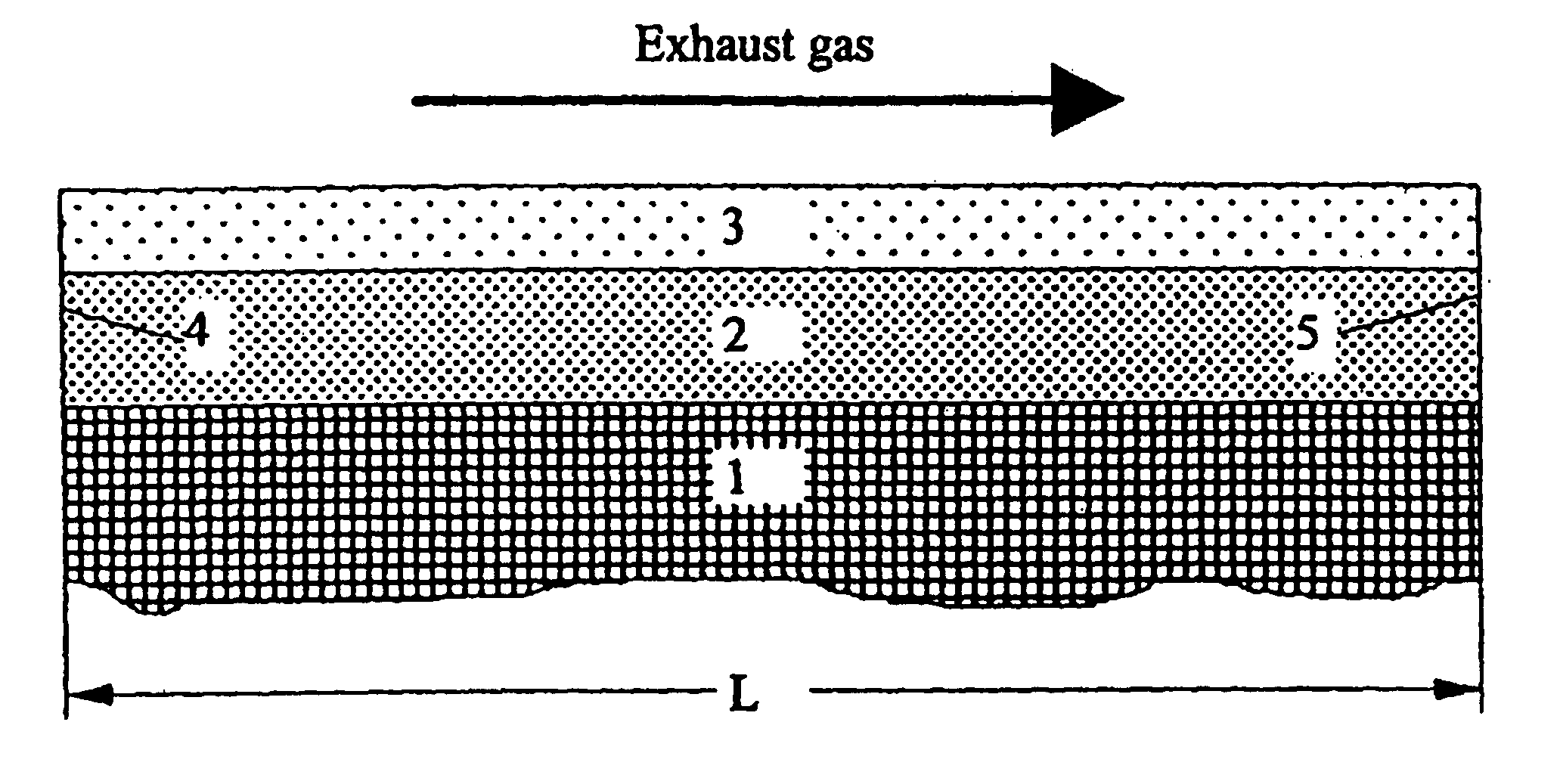

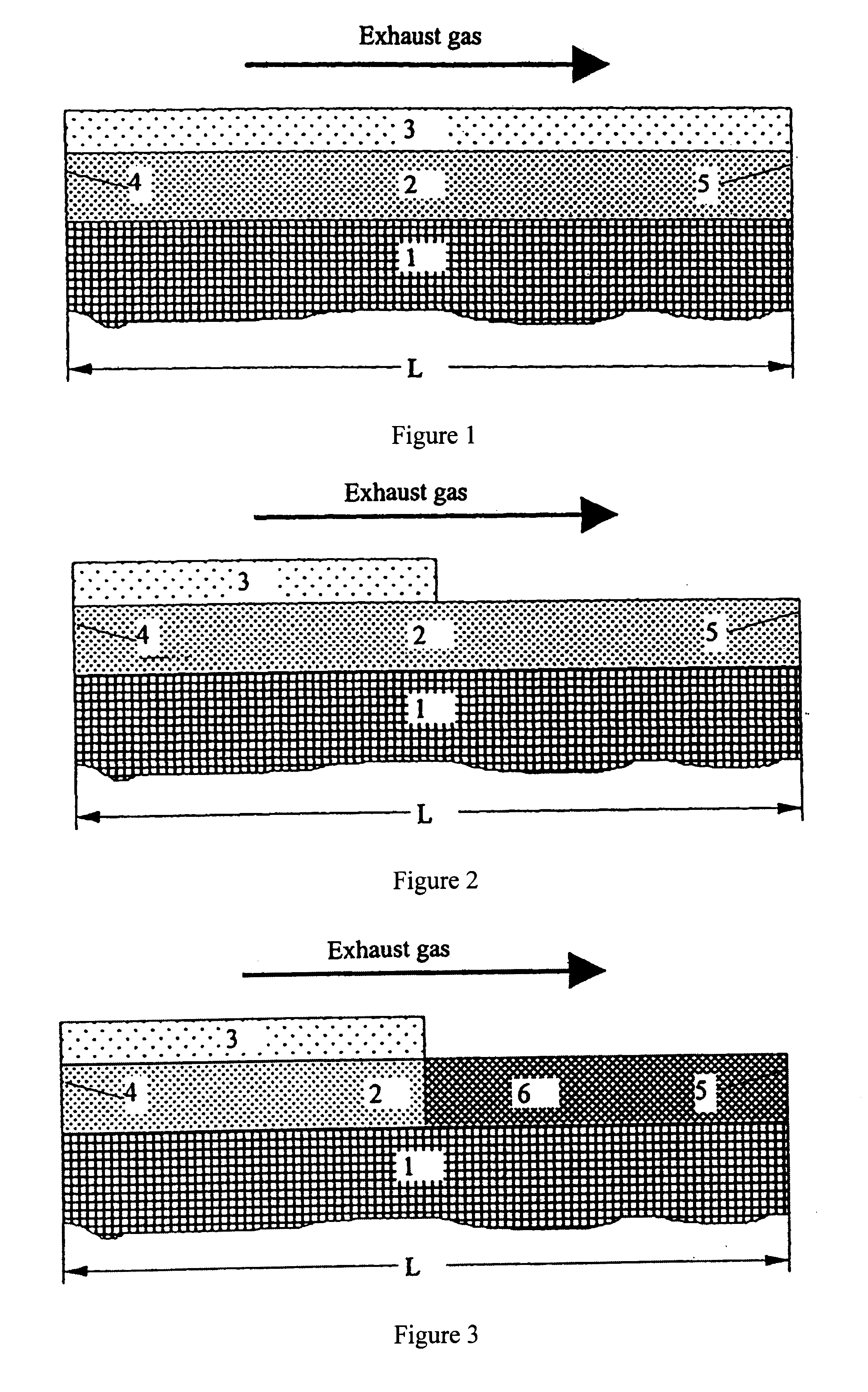

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

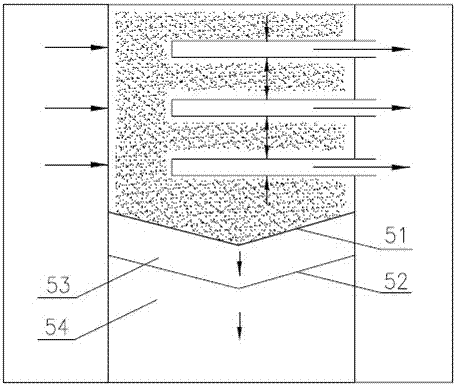

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

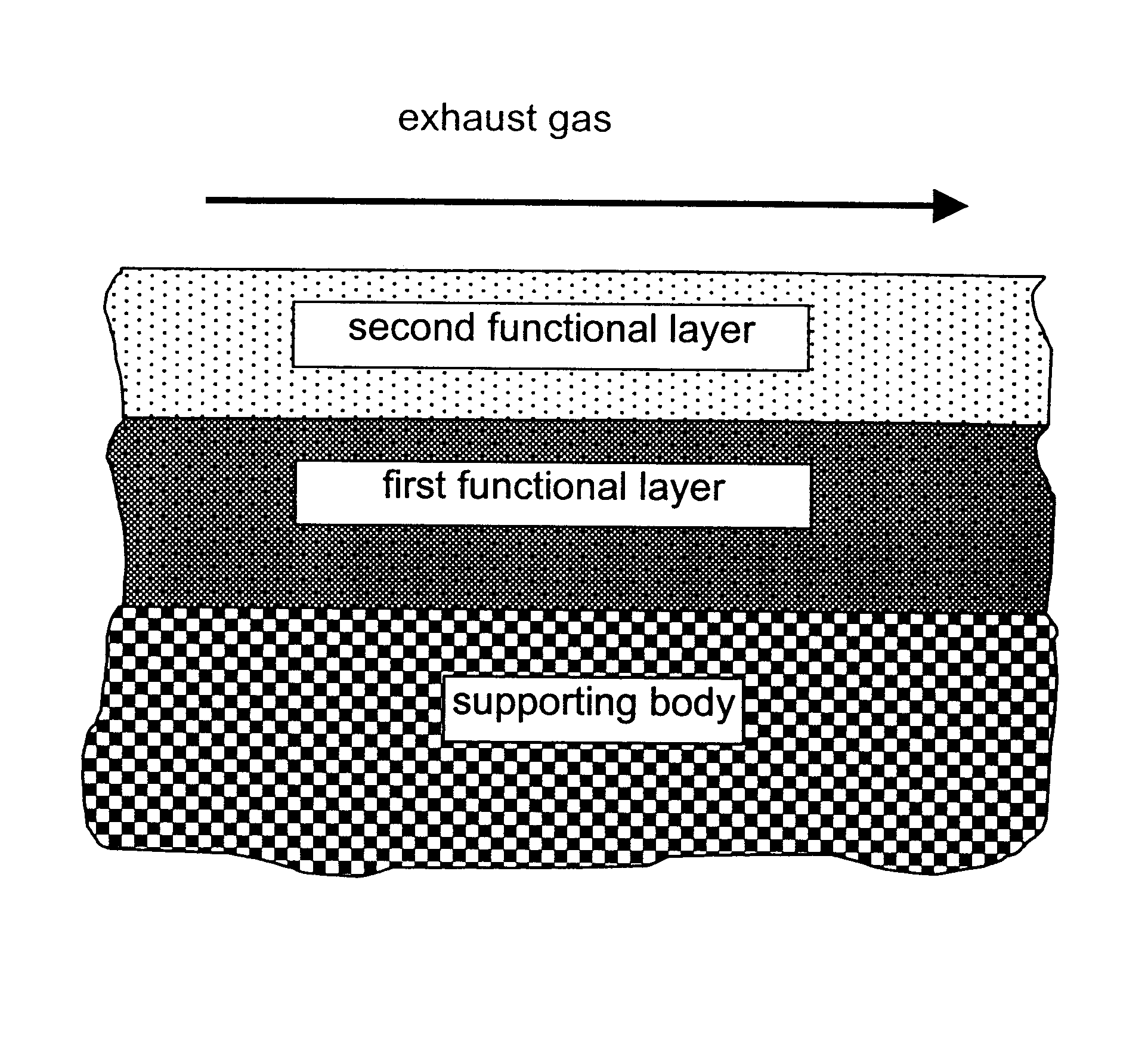

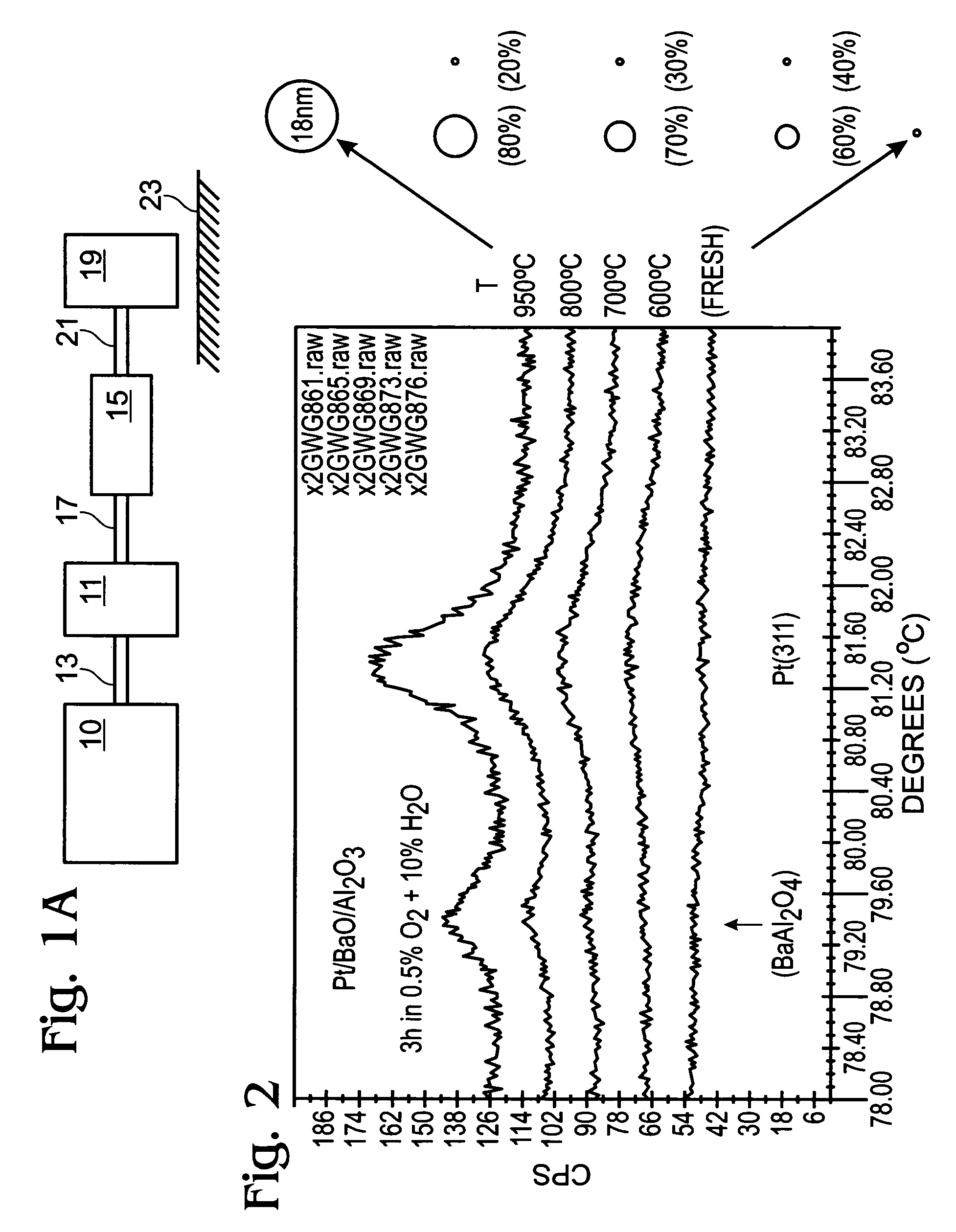

Catalyst for cleaning up the exhaust gases of a diesel engine

InactiveUS6677264B1Reduced activityReduce componentsMolecular sieve catalystsInternal combustion piston enginesCatalytic functionComponents of crude oil

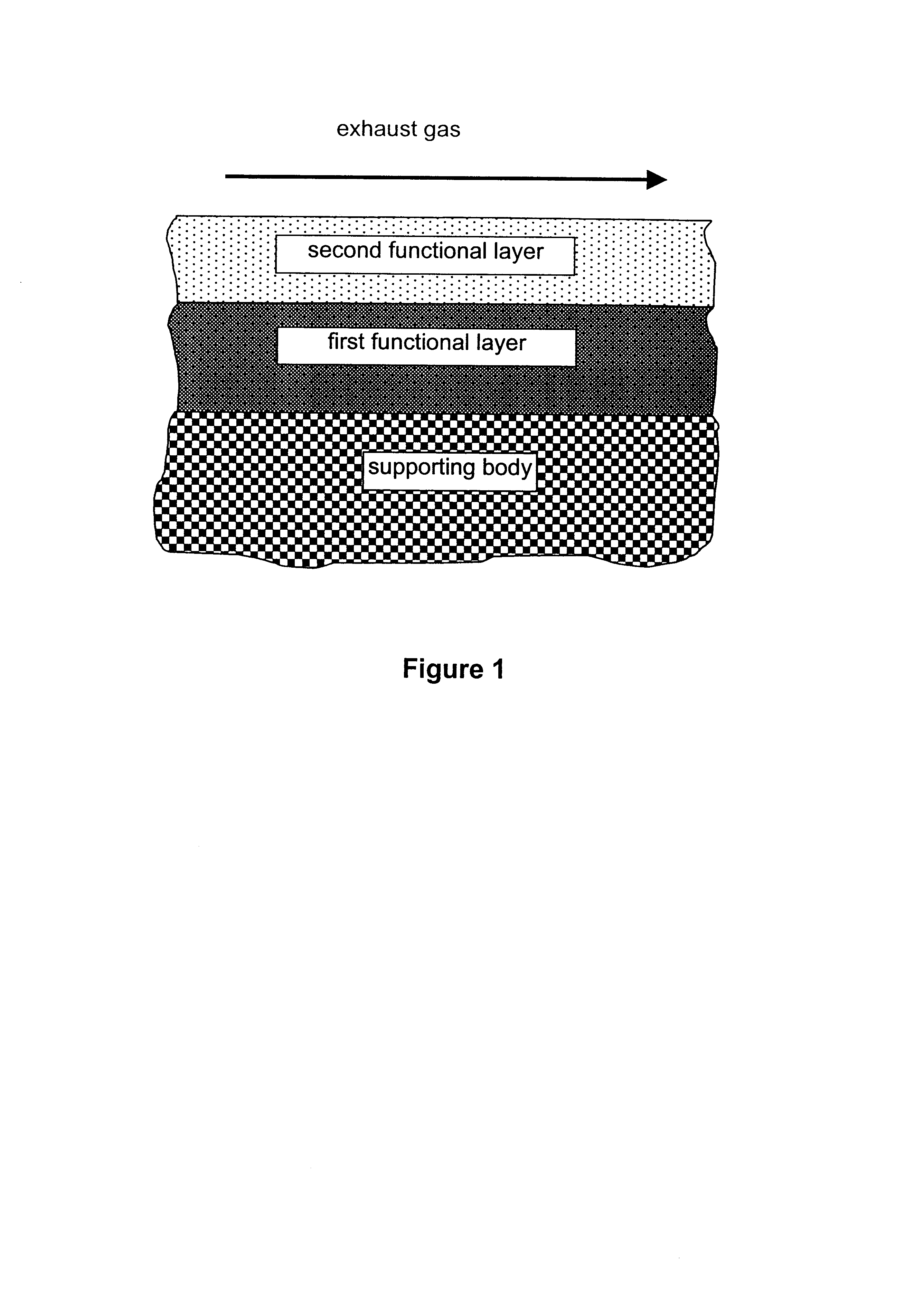

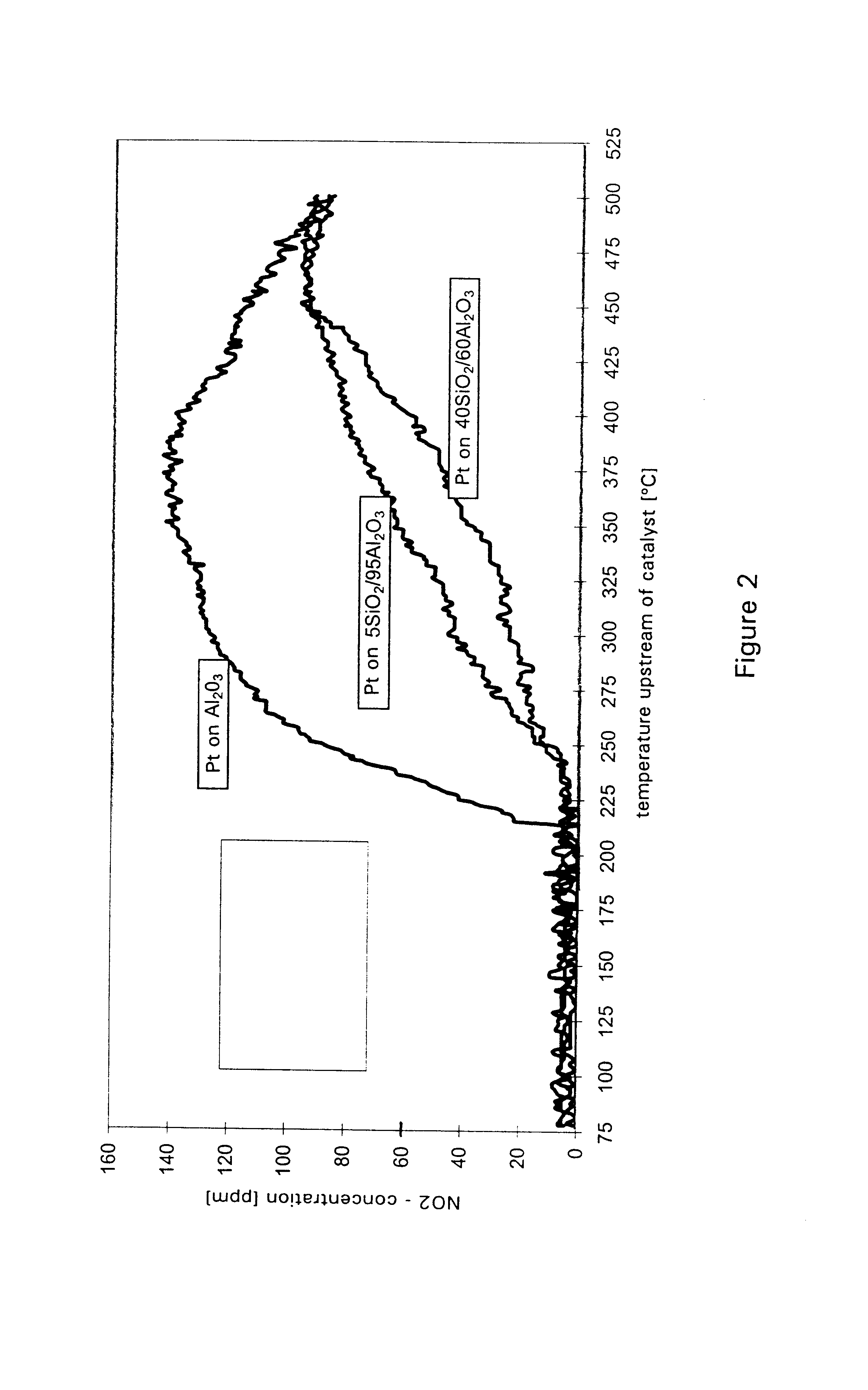

A catalyst for purifying exhaust gases of a diesel engine. The catalyst contains two functional layers superimposed on an inert supporting body, whereby the first layer, which is situated directly on the supporting body, has a nitrogen oxide storage function and the second layer, which is in direct contact with the exhaust gas, has a catalytic function. The second functional layer additionally has a hydrocarbon-storage function and its catalytic function is provided by catalytically active noble metals of the platinum group which are deposited in highly dispersed form on finely divided, acidic carrier materials. Nitrogen oxides in the oxygen-rich exhaust gas of a diesel engine can be converted with optimal utilization of the reductive constituents contained in the exhaust gas. For this purpose, no reducing agents going beyond the reductive components (carbon monoxide and hydrocarbons) which are contained as a consequence of incomplete combustion need to be added to the exhaust gas. Nevertheless, rates of conversion in respect of the nitrogen oxides are obtained, averaged over practical driving cycles, which lie distinctly above the rates of conversion of conventional reduction catalysts.

Owner:UMICORE AG & CO KG +1

Pressure-balanced, catalyzed soot filter

ActiveUS7722829B2High particulate matter reductionPromote combustionCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

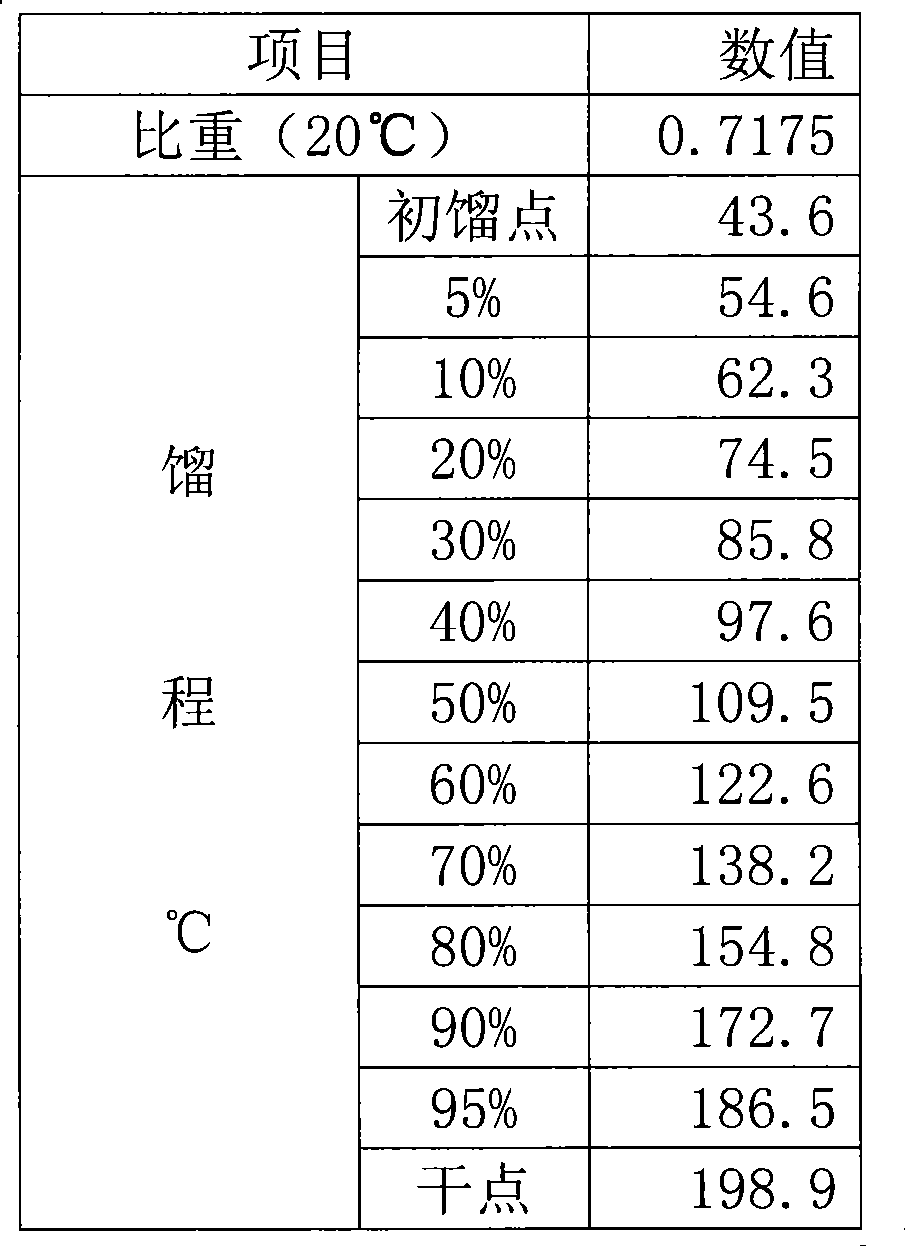

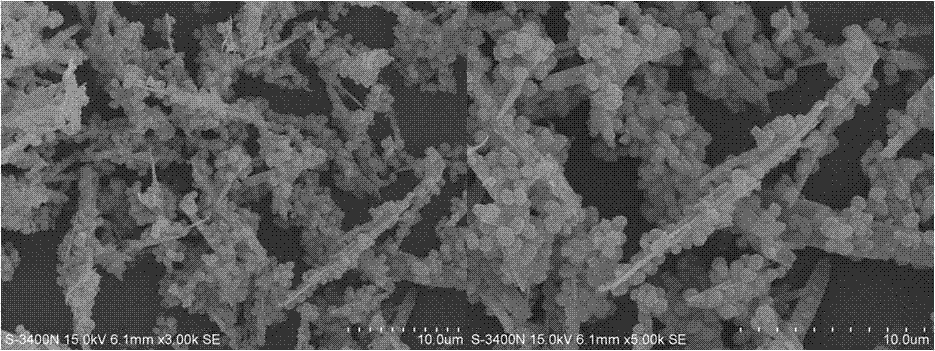

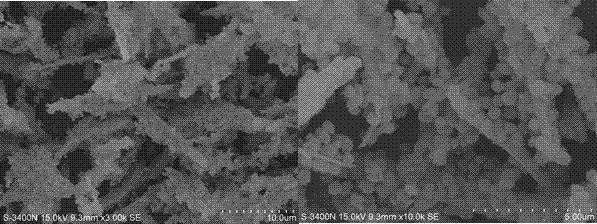

Preparation method of hydro-treatment catalyst

ActiveCN103769125AModerate decrease in viscosityImprove permeabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystUltrasonic cavitation

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

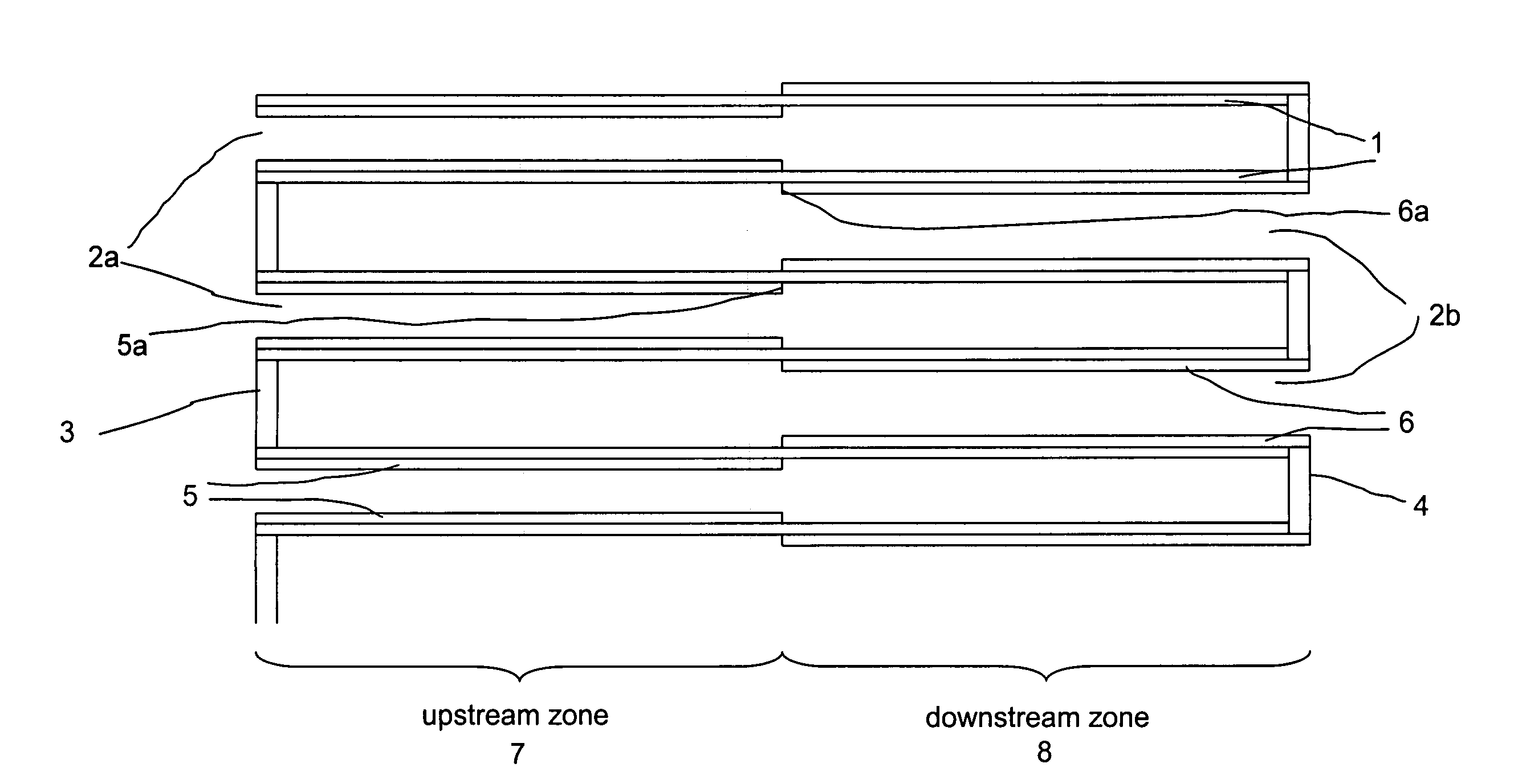

Structured catalysts for selective reduction of nitrogen oxides by ammonia using a compound that can be hydrolyzed to ammonia

InactiveUS20020025905A1Shorten the lengthImprove catalytic performanceCyanogen compoundsNitrogen compoundsCatalytic functionNitrogen oxide

A structured catalyst for selective reduction of nitrogen oxides with ammonia using an ammonia-supplying compound. The catalyst is preferably used for exhaust gas treatment of diesel vehicles powered by diesel motors. The catalyst is characterized by the fact that it contains a reduction catalyst for selective reduction of nitrogen oxides with ammonia and a hydrolysis catalyst for the hydrolysis of urea, where the hydrolysis catalyst is applied in the form of a coating onto the reduction catalyst. By this arrangement of the two catalytic functions in one catalyst the exhaust gas system can be made very compactly and space saving. Moreover, advantageous synergistic effects result from the direct contact of the hydrolysis catalyst and the reduction catalyst.

Owner:UMICORE AG & CO KG +1

Structured catalysts for selective reduction of nitrogen oxides by ammonia using a compound that can be hydrolyzed to ammonia

InactiveUS6713031B2Shorten the lengthImprove catalytic performanceCyanogen compoundsNitrogen compoundsCatalytic functionNitrogen oxide

Owner:UMICORE AG & CO KG +1

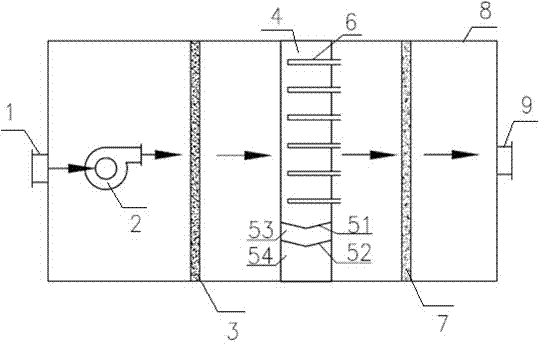

Air purifier for membrane separation

ActiveCN102824822AAvoid inactivationSuperior performance in removing volatile organic compoundsDispersed particle filtrationAir quality improvementRoom air cleanersCatalytic function

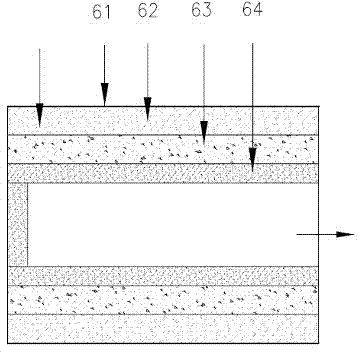

The invention relates to an air purifier for membrane separation. The purifier is an indoor air purifier integrated with the membrane filtering technology, the nanometer catalysis technology and the active carbon absorption technology. The air purifier comprises a shell, an air inlet and an air outlet arranged at the two ends of the shell. The air purifier is characterized in that the shell comprises a fan, a pre-filter net, a purifying chamber containing a separating membrane component, a dust collecting chamber and an active carbon net which are sequentially arranged; the dust collecting chamber is arranged at the bottom of the separating membrane component; the separated membrane for the air purifier has a catalytic function and removes volatile organic compound such as indoor benzene and formaldehyde when PM2.5 and germ are removed. The air purifier for membrane separation integrates a plurality of functions, is simple in structure, can continuously run and can be used for indoor air purification of families, hospitals and pharmaceutical factories.

Owner:NANJING UNIV OF TECH

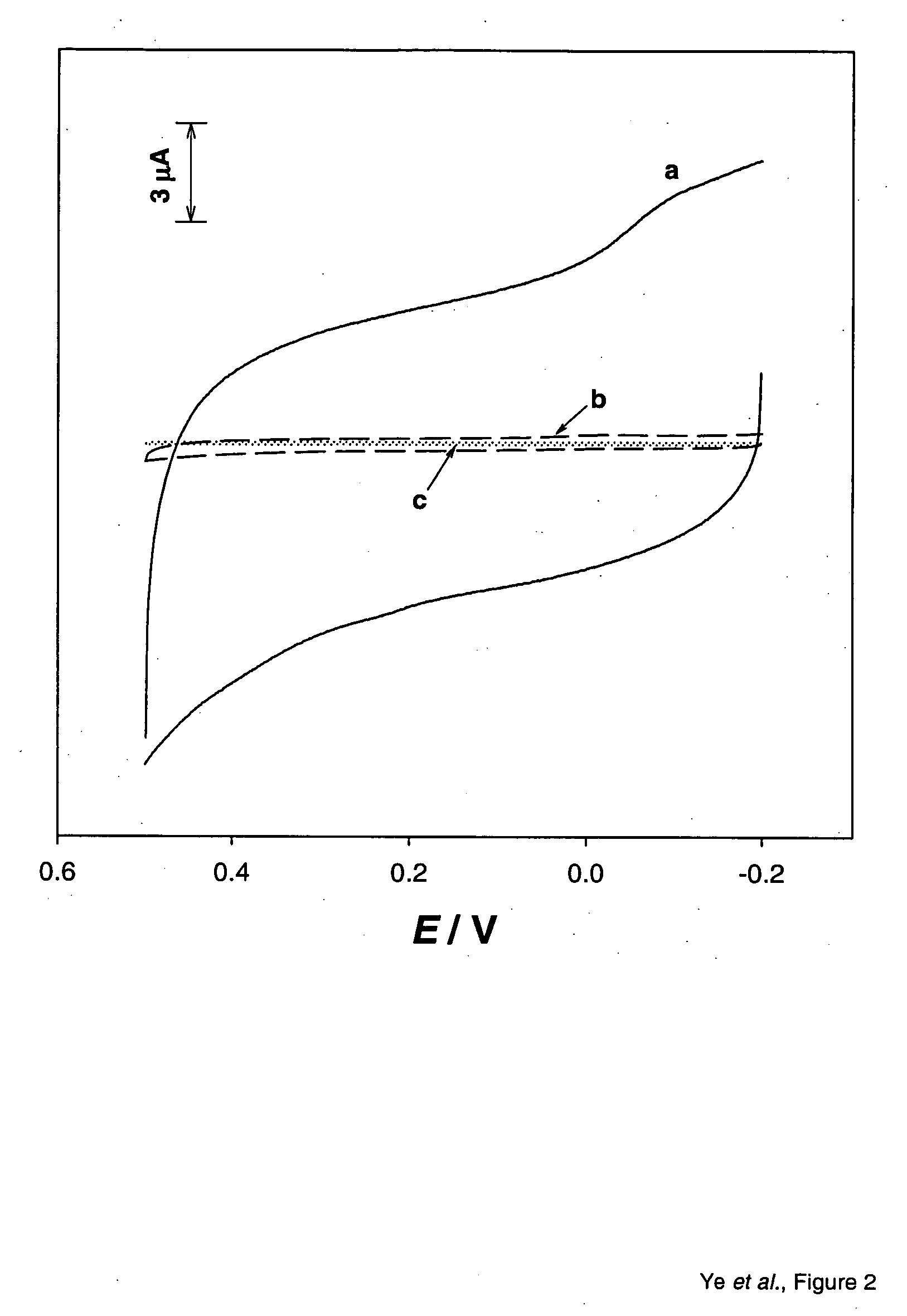

Detection of biological molecules

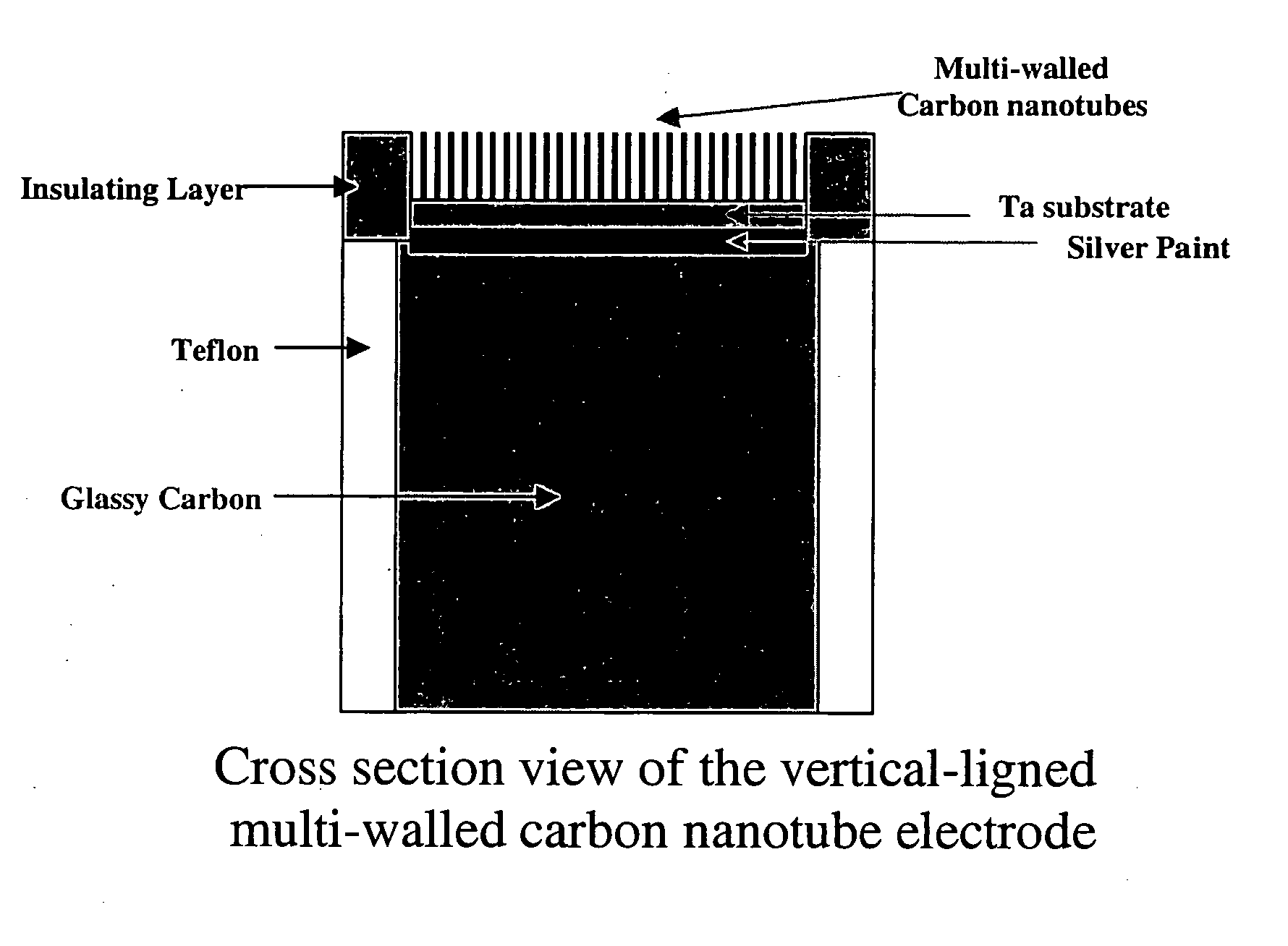

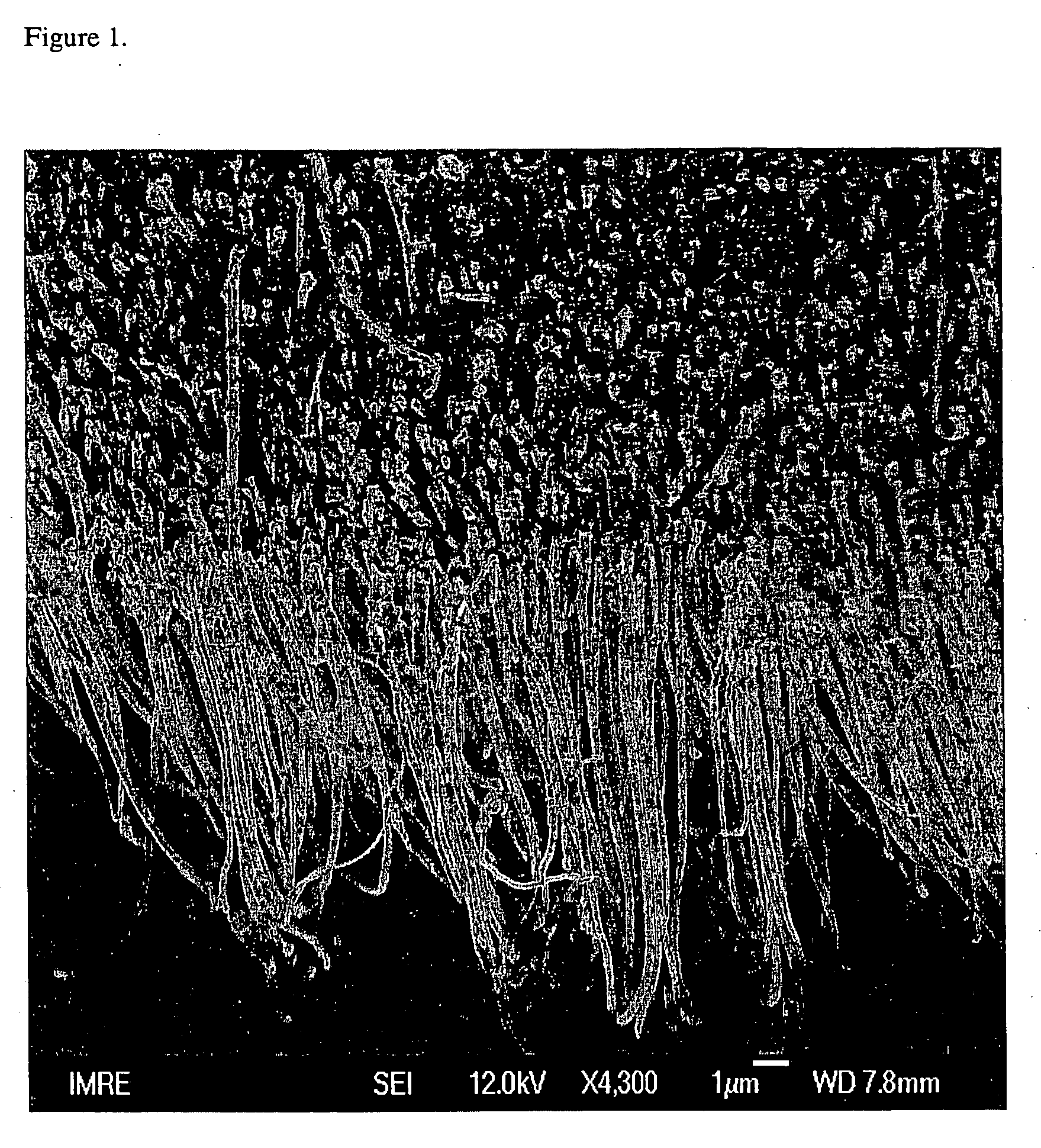

InactiveUS20060096870A1Immobilised enzymesBioreactor/fermenter combinationsHigh concentrationCorrelation coefficient

An apparatus uses carbon nanotubes for electrochemical analysis of biological molecules of interest such as Uric Acid, illustrating how the voltammetric behaviors of uric acid (UA) and L-ascorbic acid (L-AA) at a well-aligned, carbon nanotube, electrode may be used in a biochemical assay. Compared to glassy carbon, a carbon nanotube electrode reduces troublesome overpotentials. Based on its differential catalytic function toward the oxidation of UA and L-AA, the carbon nanotube electrode can be used for a selective determination of UA in the presence of L-AA. The peak current obtained from DPV was linearly dependent on the UA concentration in the range of 0.2 μM to 80 μM with a correlation coefficient of 0.997. The detection limit (3δ) for UA was found to be 0.1 μM. The device allows for detection of UA in a human urine sample, even in the presence of high concentrations of L-AA, using only simple dilution.

Owner:NAT UNIV OF SINGAPORE

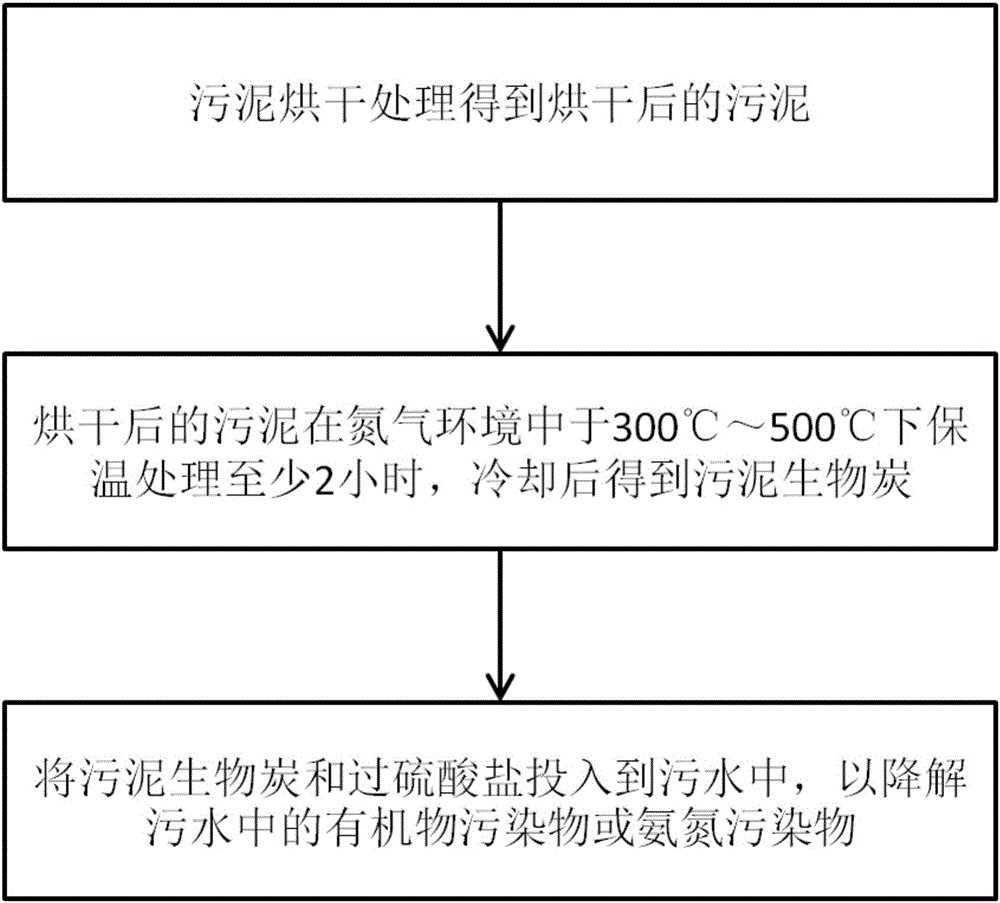

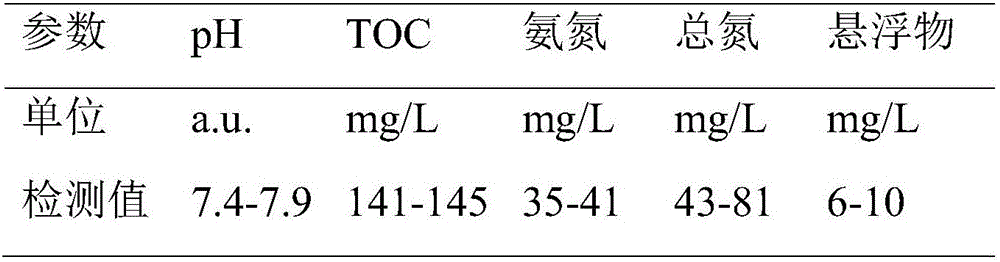

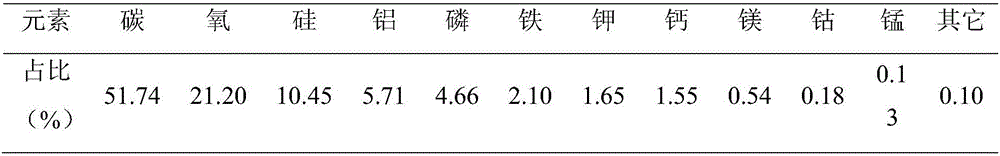

Method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar

ActiveCN106045002AEfficient degradationEasy to prepareWater/sewage treatment by oxidationPersulfateSludge

The invention discloses a method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar. The method includes the following steps that firstly, sludge is dried to obtain dried sludge, then the dried sludge is subjected to pyrolysis treatment for at least 2 h in the ammonia environment at 300-500 DEG C, and then sludge biochar is obtained after cooling; secondly, the sludge biochar and persulfate are put into sewage to degrade the organic substances or ammonia nitrogen in the sewage. By improving key preparation conditions of sludge biochar and increasing the application ratio of the sludge biochar and persulfate, under the catalytic function of the sludge biochar, persulfate can efficiently degrade the organic substances and ammonia nitrogen in sewage on the basis of catalysis and oxidization of sulfate free radicals, the problem of organic pollutant and the ammonia nitrogen pollution problem in sewage are effectively solved, and the degradation effect is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Identification and use of effectors and allosteric molecules for the alteration of gene expression

InactiveUS20050239061A1Eliminate the problemLimited utilityMicrobiological testing/measurementDrug compositionsCatalytic RNACatalytic function

The present invention relates to the construction of an allosteric control module in which a catalytic RNA forms a part of or is linked to an effector-binding RNA domain or aptamer. These constructs place the activity of the catalytic RNA under the control of the effector and require the presence of an appropriate effector for activation or inactivation. The present invention provides means to identify useful effector molecules as well as their use to evolve cognate aptamers. The invention involves both the evolution of RNA sequences which bind the effector and a selection proces in which the allosteric control modules are identified by their catalytic function in the presence and absence of the effector. The resulting regulatable catalytic RNAs may be used to alter the expression of a target RNA molecule in a controlled fashion.

Owner:AMGEN INC

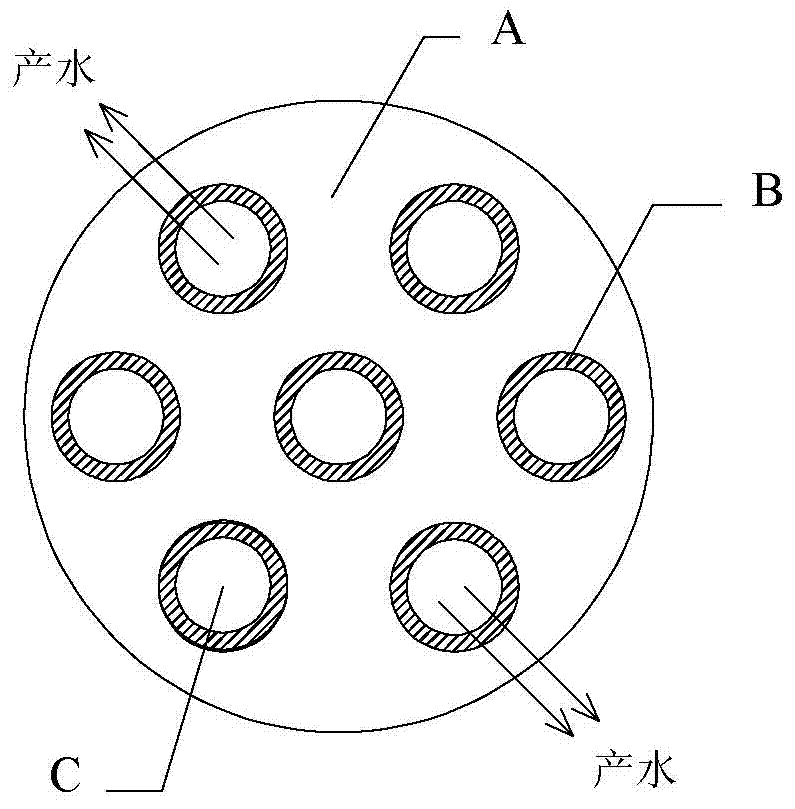

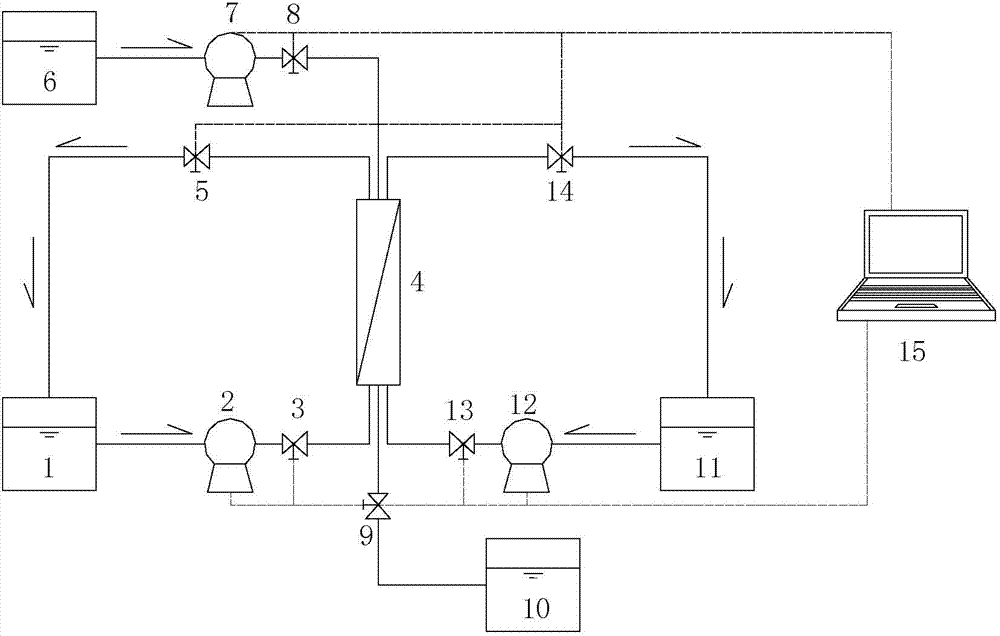

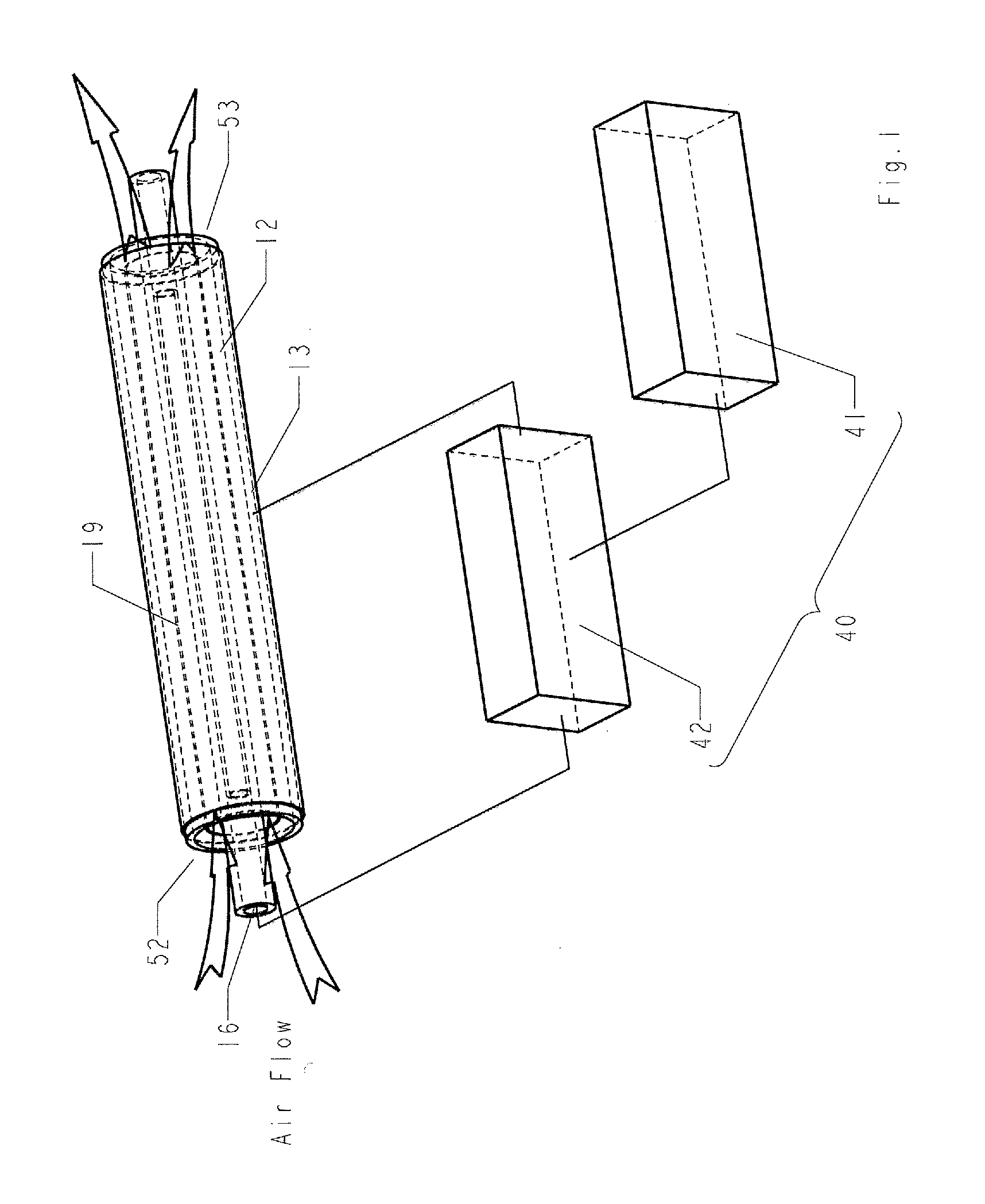

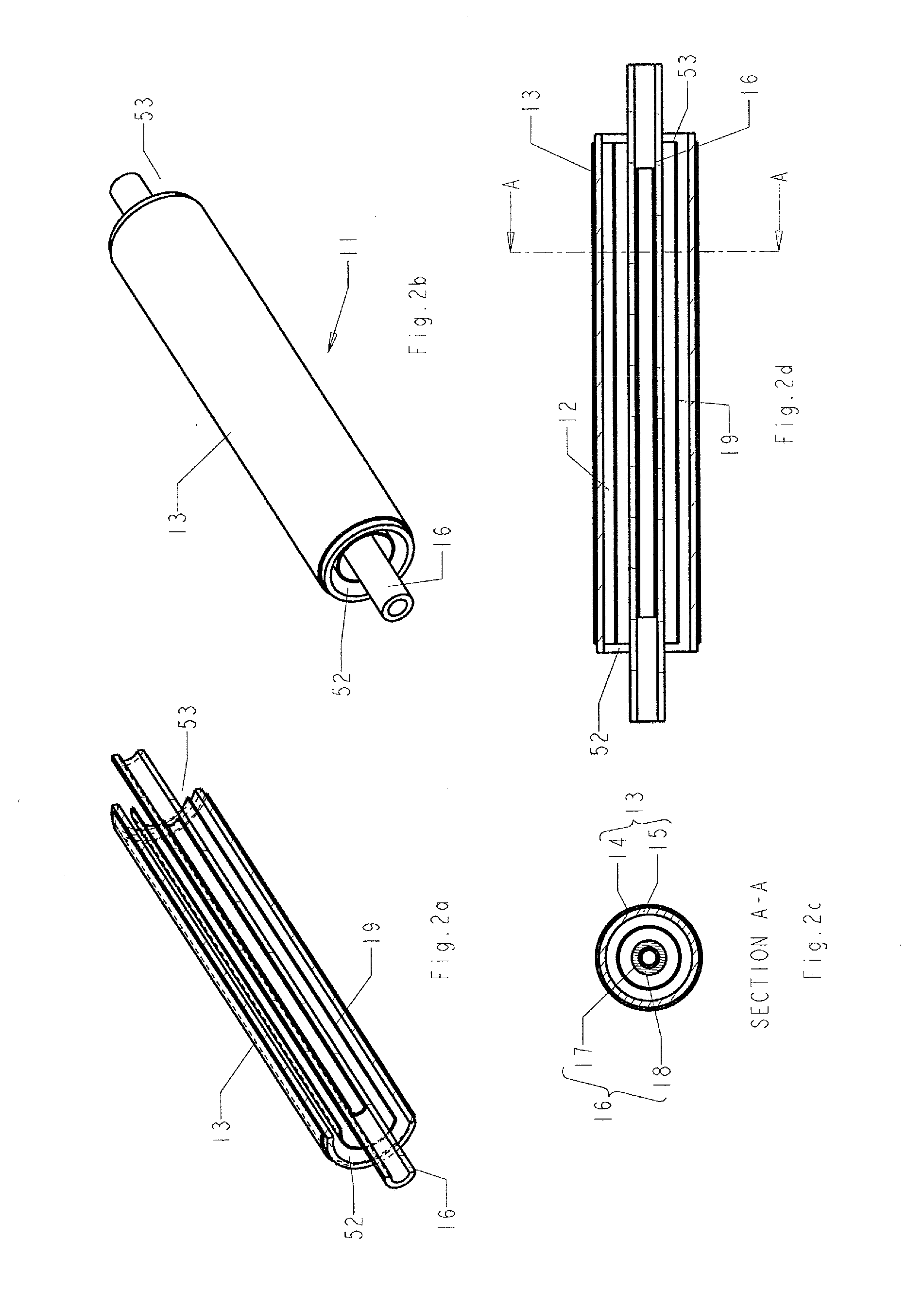

Ozone-catalytic functional ceramic membrane, preparation method thereof and circulating coating device

ActiveCN104841292AGood ozone catalytic abilityPromote degradationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCatalytic functionCatalytic effect

The invention discloses an ozone-catalytic functional ceramic membrane, a preparation method thereof and a circulating coating device, relates to the technical field of membrane material preparation, and aims at solving the problems that the ozone-catalytic efficiency of the existing ceramic membrane is low, the integration of membrane filtration and ozone-catalytic functions cannot be realized, membrane pollution cannot be effectively relieved and the like. By using a tubular ceramic membrane as a carrier, single-component or multi-component metal oxides are loaded through an impregnation method, then manganese oxide dipping coating solution is prepared, and a catalytic coating layer is prepared on the surface of the membrane through a layer-by-layer dipping coating method. The invention aims at establishing a stereoscopic multistage catalyst system, simultaneously improving the catalytic efficiency of the separation layer and supporting layer of the ceramic membrane and enabling an ozone-catalytic effect to seep into the entire ceramic membrane to fully realize the overall catalytic effect. Compared with other metal oxides, manganese oxide has better adsorption and ozone-catalytic capacities, and while the ozone-catalytic capacity is improved, the membrane pollution is effectively relieved and the integration of multiple functions such as pollutant adsorption, ozone-catalytic oxidization and membrane separation is realized.

Owner:HARBIN INST OF TECH

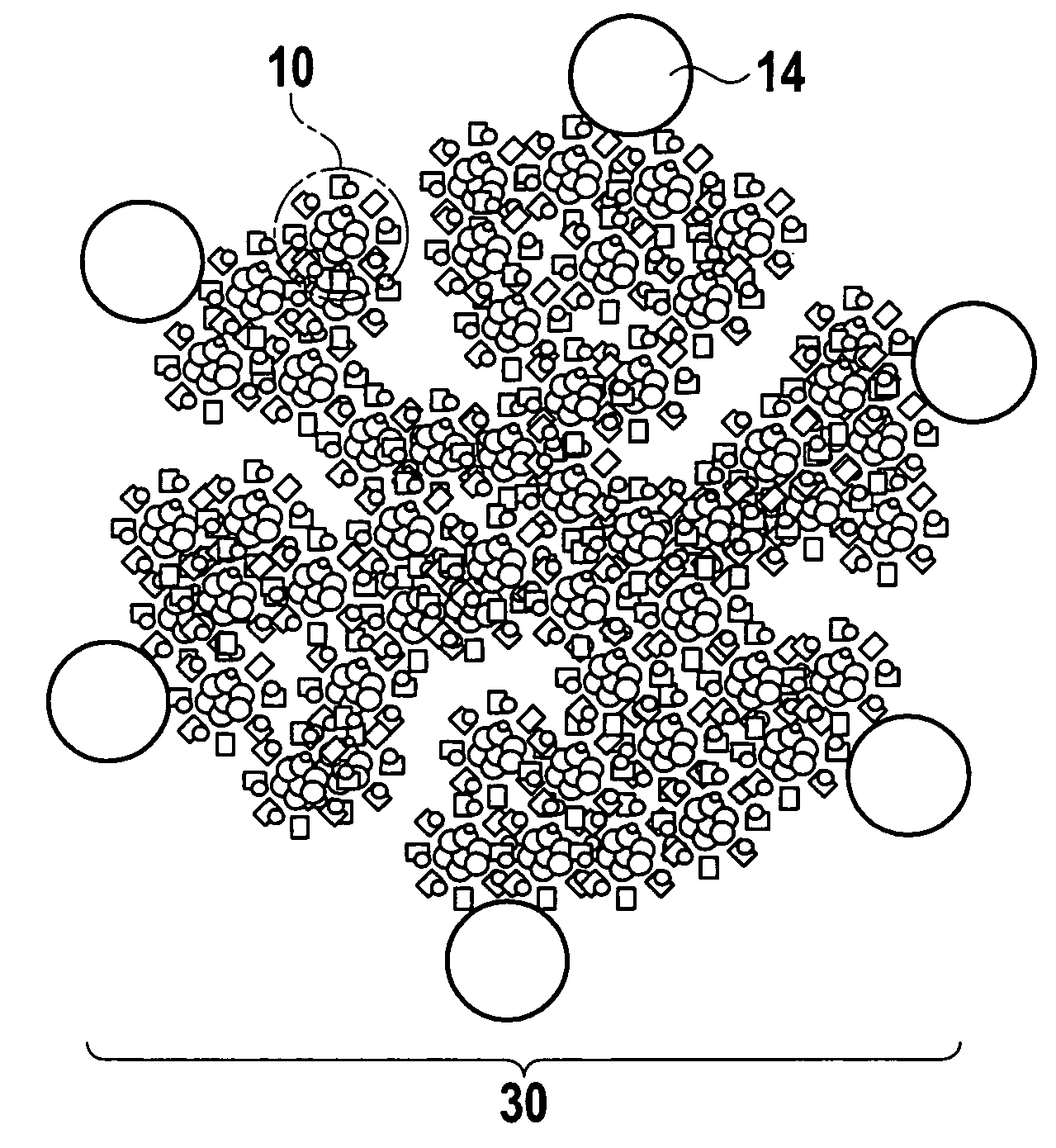

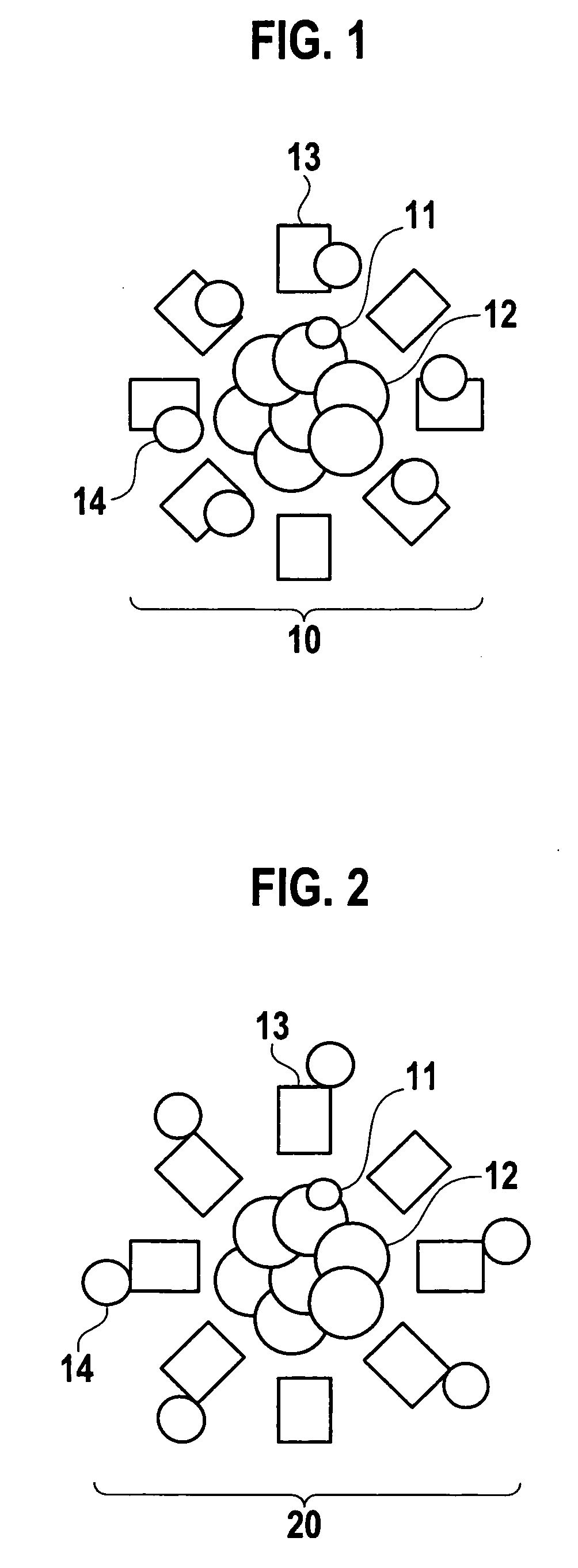

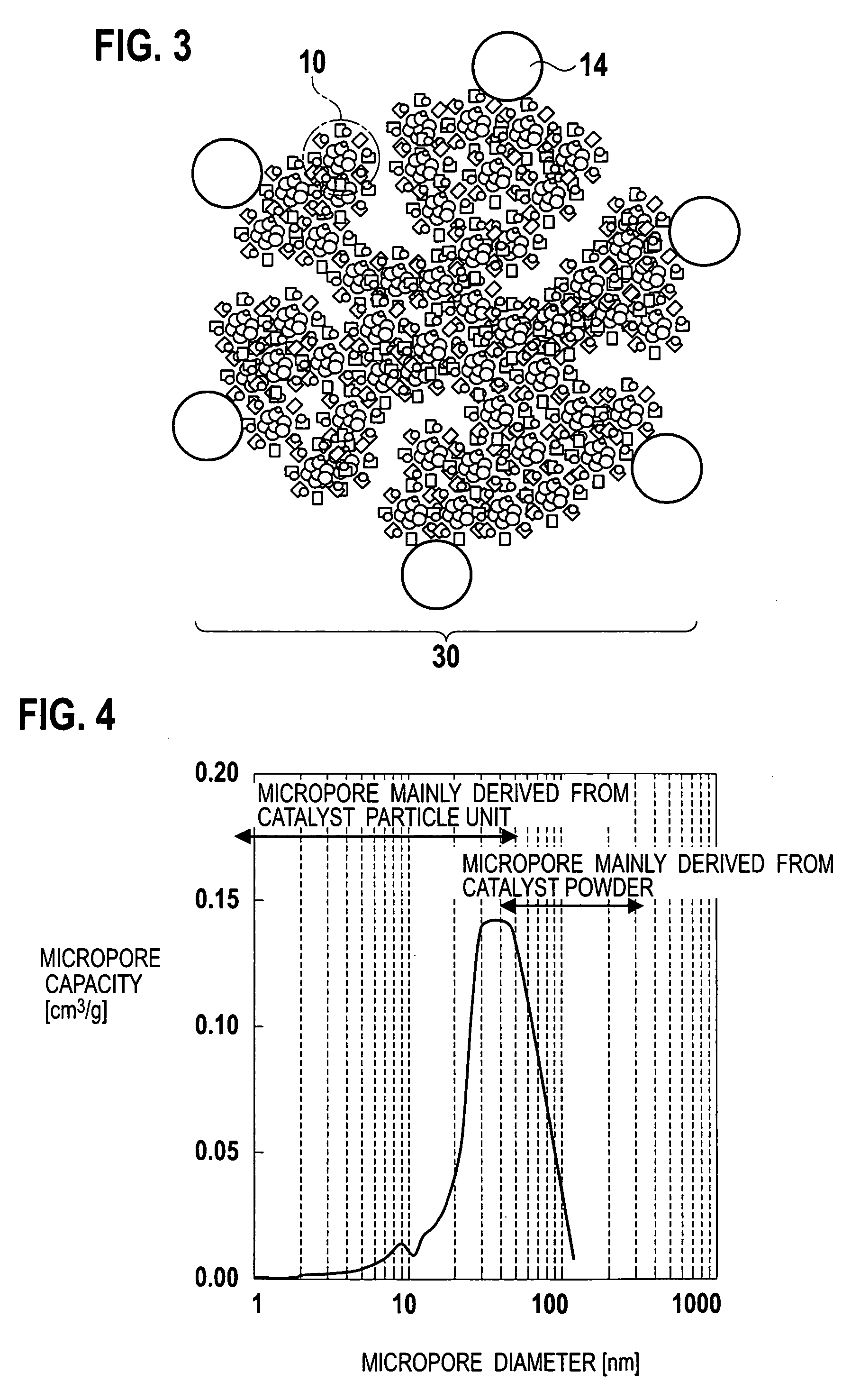

Exhaust gas purifying catalyst and producing method thereof

InactiveUS20080167181A1High activityPrevent coagulationInternal combustion piston enginesHeterogenous catalyst chemical elementsRare-earth elementAlkaline earth metal

An exhaust gas purifying catalyst includes: a catalyst particle unit having at least noble metal with a catalytic function, first oxides on which the catalyst noble metal is supported, and second oxides covering the first oxides on which the noble metal is supported. In catalyst powder formed of an aggregate of plural pieces of the catalyst particle units, at least one type of compounds selected from the group consisting of a transition element, an alkali earth metal element, an alkali metal element, and a rare earth element, which is a promoter component, are contained.

Owner:NISSAN MOTOR CO LTD

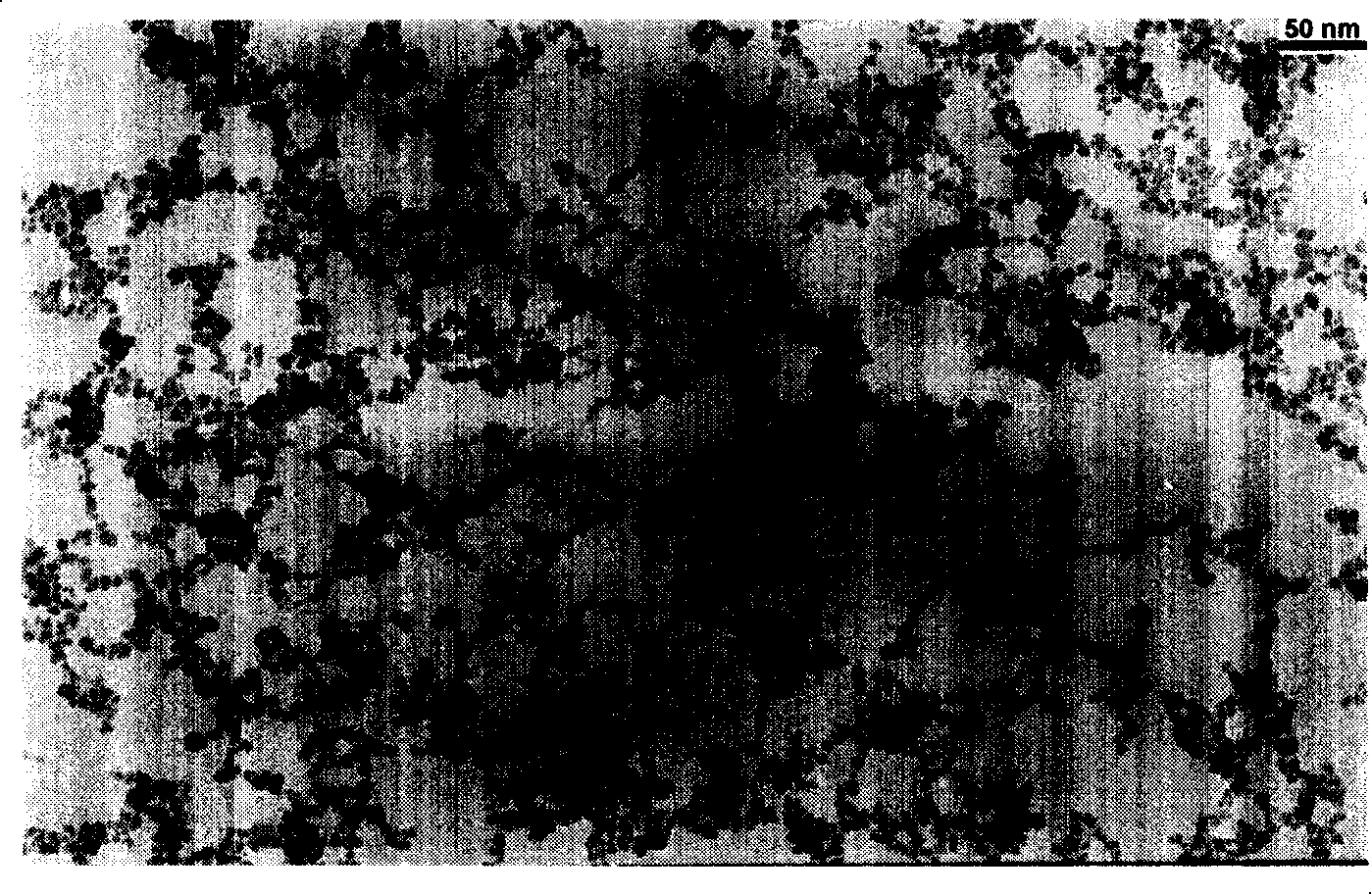

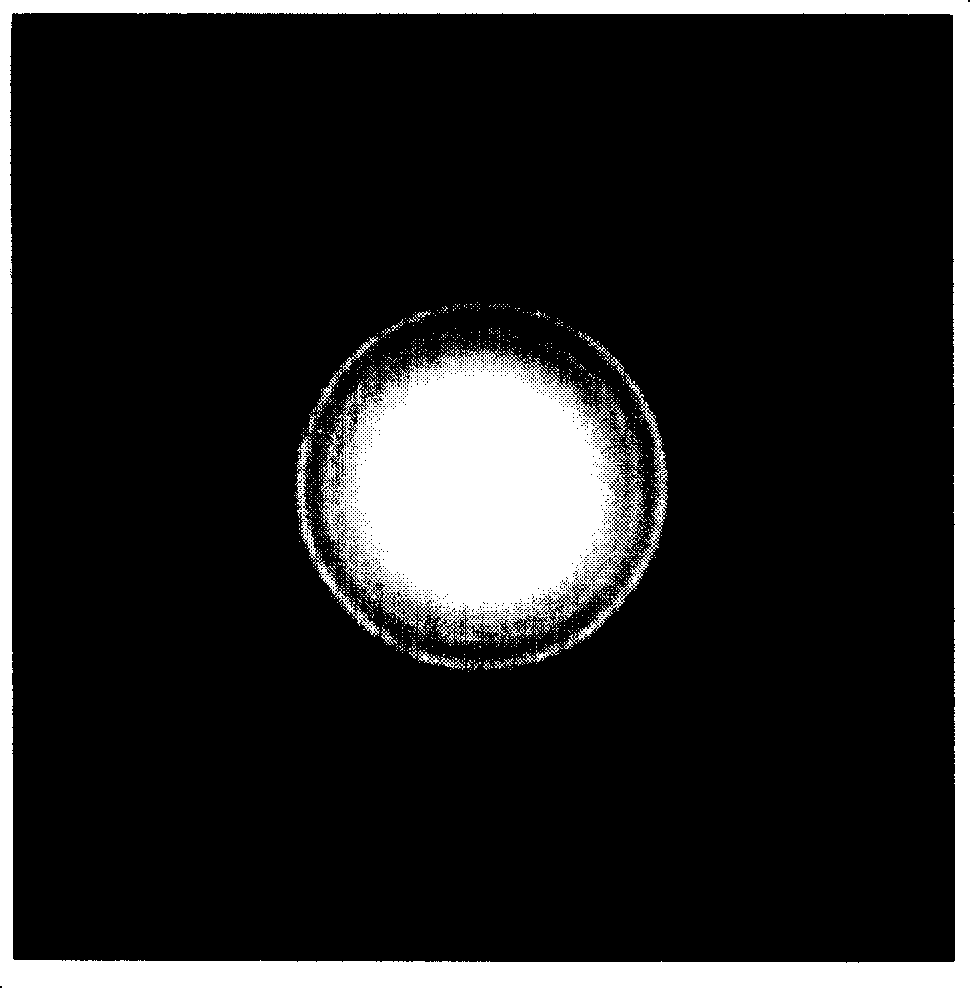

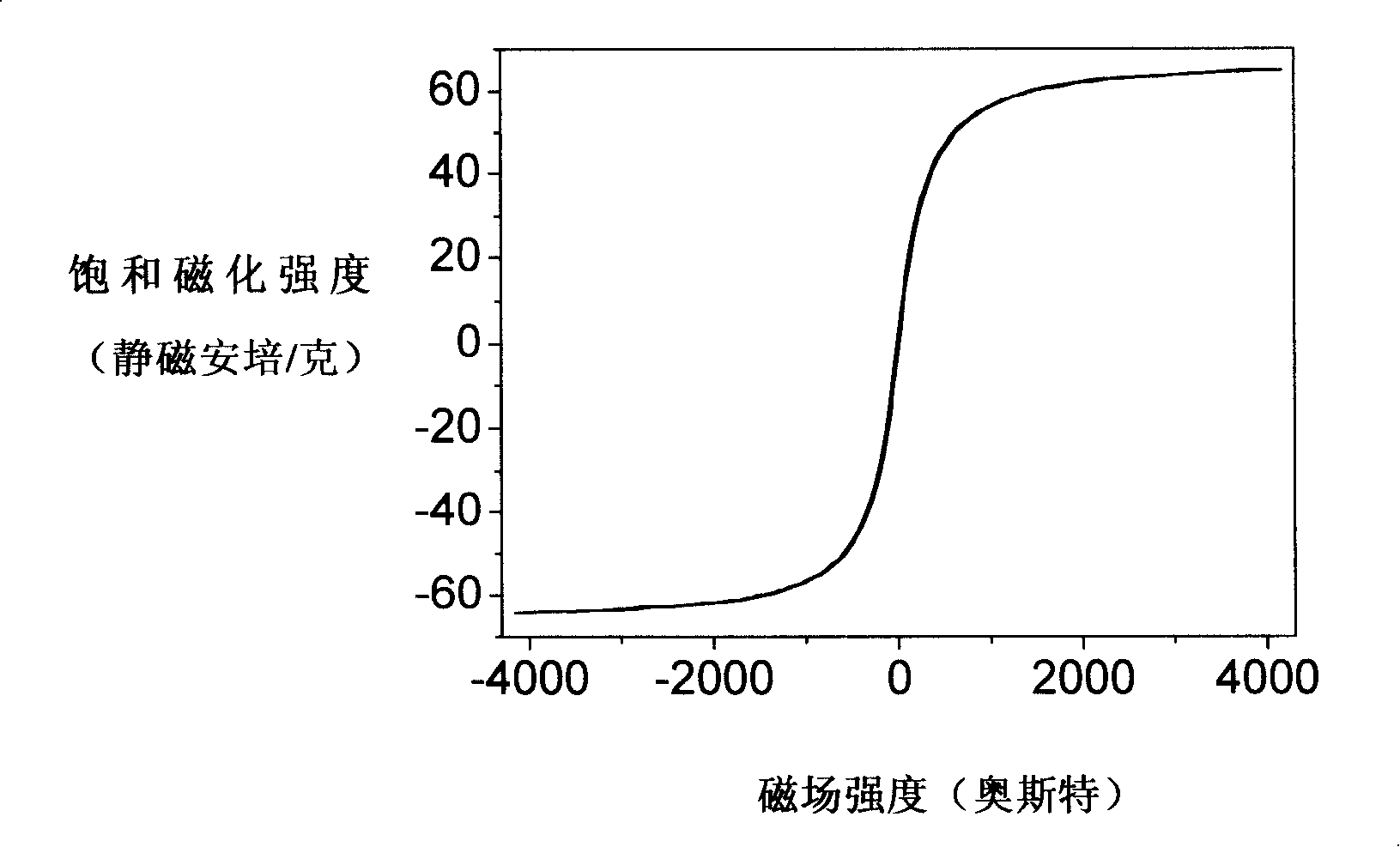

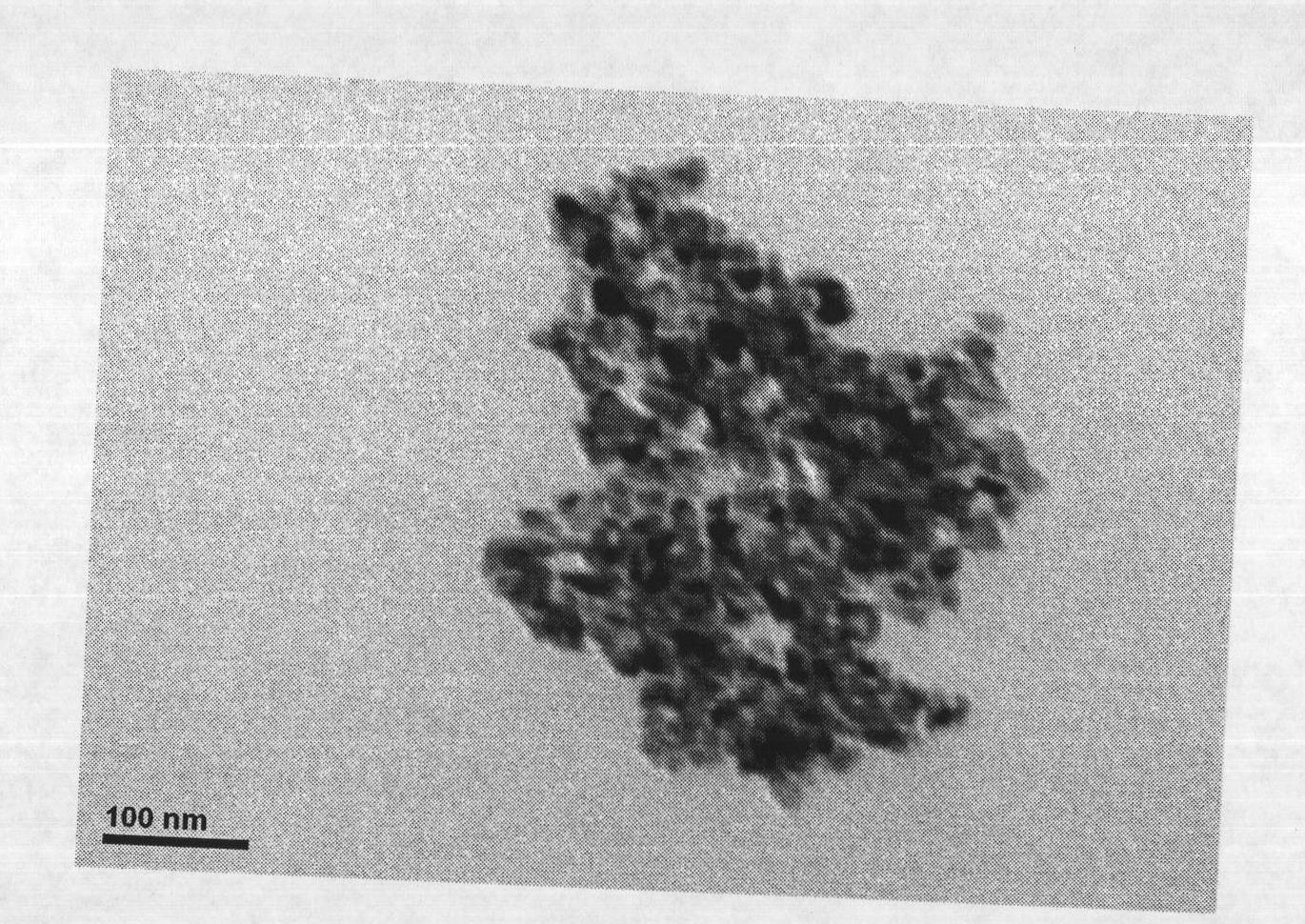

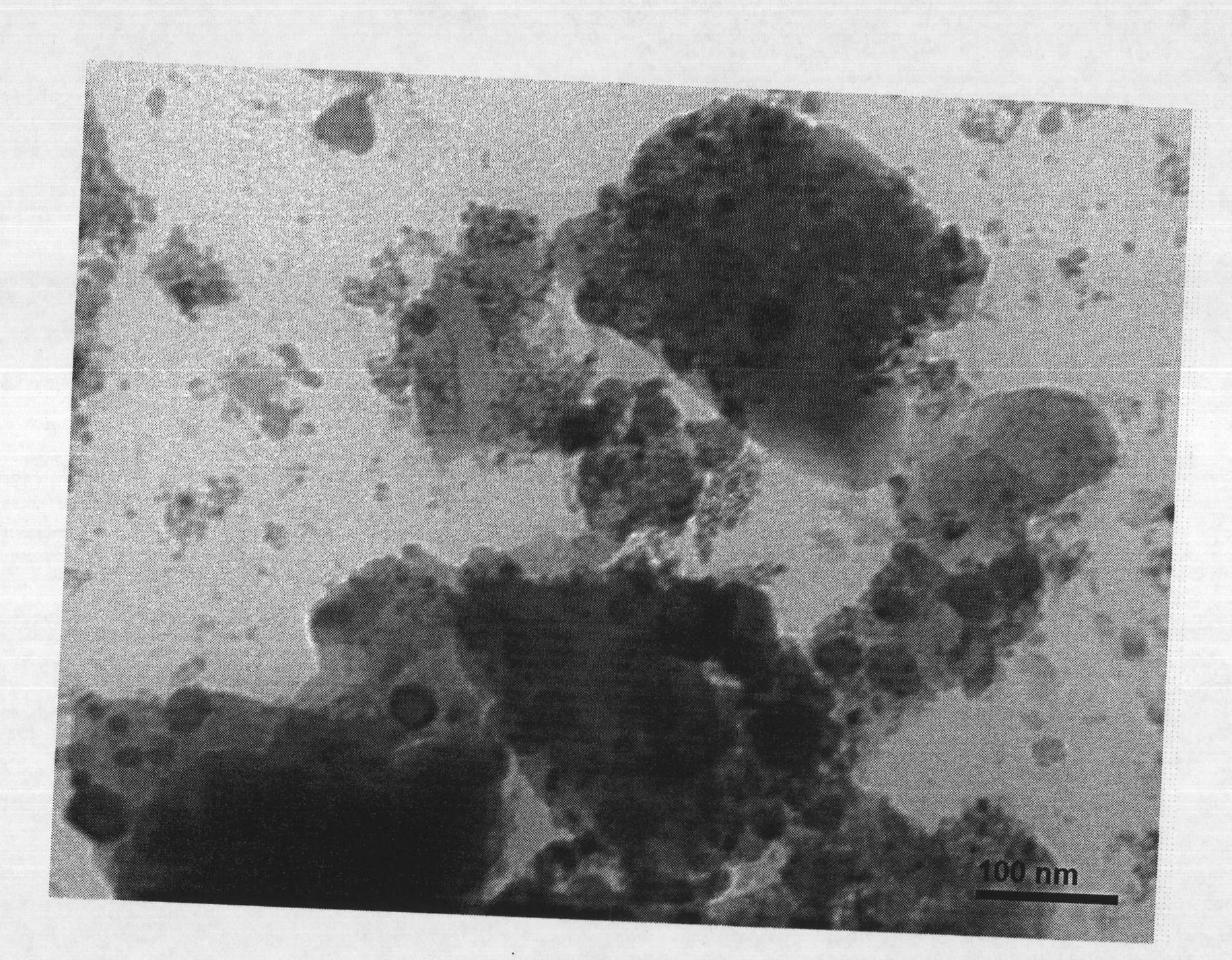

Water soluble magnetic nanometer crystal with high dissolvability and method of producing the same

ActiveCN101178961AWith directional sterilization functionNarrow particle size distributionNMR/MRI constrast preparationsPharmaceutical non-active ingredientsSolubilityCatalytic function

The technical field of the invention is material chemistry, nanoscience, catalytic chemistry and medicine, and particularly relates to the preparation of magnetic nanocrystals with high solubility and high crystallinity in neutral water by a "one-pot" method and a preparation method thereof. Its main technical feature is the use of solvothermal decomposition of organometallic precursors or metal-inorganic salt compounds with high boiling point, catalytic function, reduction function and polymerizable function, while forming magnetic nanocrystals, realizing water-soluble polymers on the surface of nanocrystals The in-situ modification of the soluble magnetic nanocrystals with high solubility is obtained. Its main feature is that it can be dissolved in neutral water (pH=6~8), and the formed solution has long-term stability; its main inorganic components include iron, Cobalt, nickel, manganese and their oxides; their shape is spherical or petal-shaped; their shape and size are controlled by controlling the concentration and heating time of the precursor of the magnetic nanocrystal-organic precursor or inorganic salt.

Owner:苏州欣影生物医药技术有限公司

Diffusive plasma air treatment and material processing

InactiveUS20080056934A1Improve efficiencyMinimizationMechanical apparatusLighting and heating apparatusCatalytic functionEngineering

The Diffusive Plasma is for effective treatment of contaminated air and material processing. Air is purified and disinfected by passing through the diffusive plasma device which includes a reactor or a plurality of reactors arranged in parallel or series and is energized by a high voltage alternating current power supply. The diffuser, being electrically isolated, provides extra nucleation sites to initiate discharges. It serves to improve the generation of uniform and consistent plasma and to reduce the variation of discharge properties among the reactors. The addition of a diffuser, thereby, enhances the overall effectiveness of decomposing chemicals and destroying microbes to achieve high air treatment and material processing performance. The diffuser can be made of suitable filtering materials to additionally serve as a filter. By incorporating suitable catalytic materials with the diffuser, the reactor becomes a catalytic plasma reactor wherein the plasma environment provides enhanced catalytic functions. Effective plasma power deposition may be obtained by controlling the amplitude, waveform period and shape of the voltage applied to the electrodes of the reactor and hence the operation of the reactors with plasma discharged of selected conditions for optimizing the treatment and processing efficiency while minimizing the generation of unwanted bi-product gases. The present invention also relates to a method for effective air treatment and material processing.

Owner:ALPHATECH INT

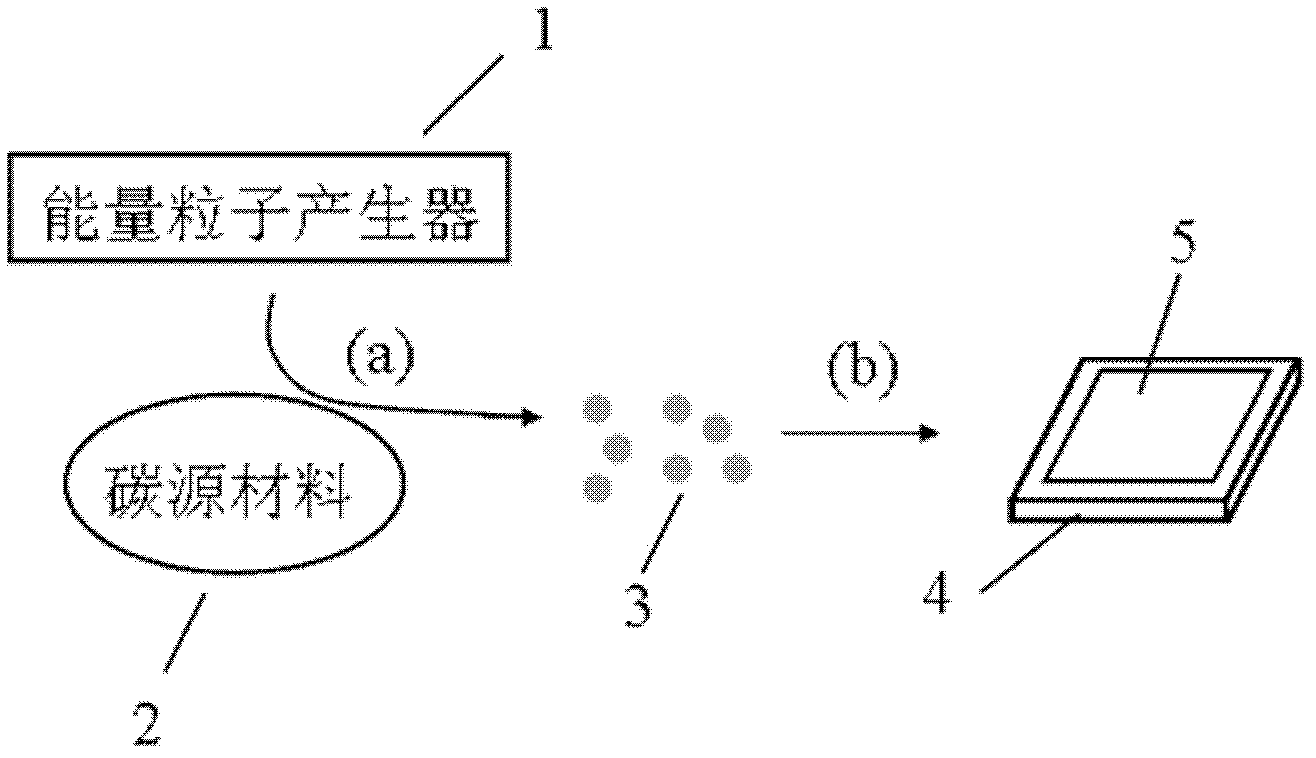

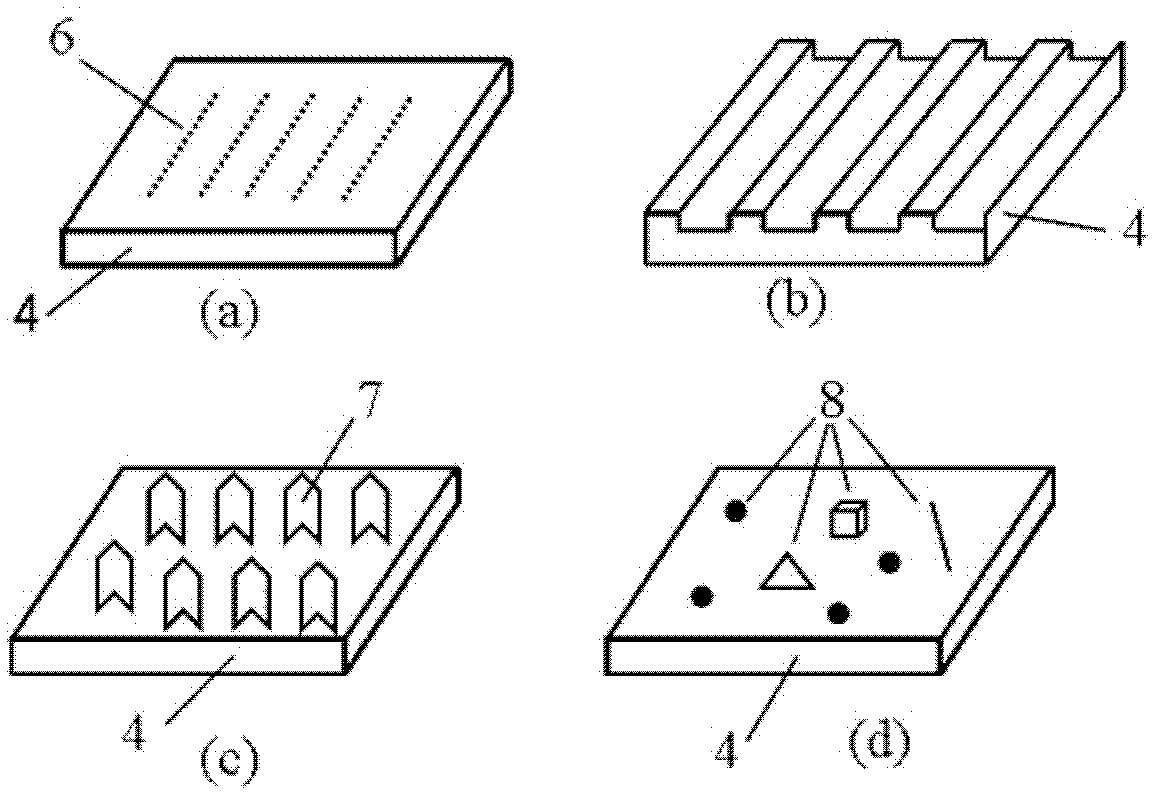

Method for synthetizing graphene film

InactiveCN103011136APerformance is not changedThickness is easy to controlGrapheneNanotechnologyEnergy particleSolid carbon

The invention discloses a method for preparing a graphene film, comprising the steps of activating carbon atoms in carbon-containing gaseous carbon source, solid carbon source and liquid carbon source or a mixed carbon source material of any two or more than two of the carbon sources by adopting the technical methods of energy particles such as laser beam, electron beam, radio frequency beam, radial, photon, neutron beam, ion beam, plasma and the like; and forming the graphene film on a substrate. The method for producing the carbon atoms needed in the graphene film synthetizing is different from a conventional method and has the advantages that the method has great selectivity, and has no special requirement on the carbon source material and no special requirement on the substrate; the graphene film can be synthetized on the substrate which has the catalytic function and can be directly synthetized on the semiconductor or insulator substrate which does not have the catalytic function; and the formed graphene film is easily controlled in the aspects of the number of layers, structure and size and suitable for manufacturing high-performance photoelectronic devices on a large scale.

Owner:ZHEJIANG UNIV

Pyrolysis furnace tube for cracking petroleum hydrocarbon

The invention provides a cracking furnace tube for cracking petroleum hydrocarbon. The furnace tube contains active components for performing catalytic cracking reaction on the petroleum hydrocarbon and has catalytic cracking activity. The components of potassium aluminate, calcium vanadate, alkaline earth metal, transition metal oxide, silicon-aluminum zeolite and the like which have catalytic activities, and / or the components of alkali metal and the like with coking resistance, are added or adhered to the inner side or the surface of the tube, or are added directly in the process of manufacturing the tube by the methods of coating, infiltration, sintering, plasma spraying and the like so as to obtain the tube which is provided with an inner surface coating, or contains the components with catalytic activities in the whole tube from the inside to the outside, and / or contains the components with coking resistance. Using the furnace tube, the prior ethene device is not necessary to be changed at all, only the furnace tube which has the catalytic function or the furnace tube which is in the cracking furnace is processed, thus the industrialization can be achieved quite easily in theprior cracking device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integral fuel gas buring catalyst and process for preparing the same

InactiveCN1504260AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic functionHigh activity

The invention discloses an integral style gas, combustion catalyst and method for the making same, wherein the base material of the catalyst is integral ceramic honeycomb body or metallic honeycomb body, the catalyst coating layer coated on the base material surface comprises catalytic functional components and coating layer aiding agents, the catalytic functional components are classified into compound catalytic functional components having at least three different catalytic functions, each of which is prepared through corresponding predecessor physical process. The catalyst by the invention has high activity, high stability, high heat efficiency and low contaminant discharge.

Owner:SICHUAN TIANJIAN CATALYTIC COMBUSTION

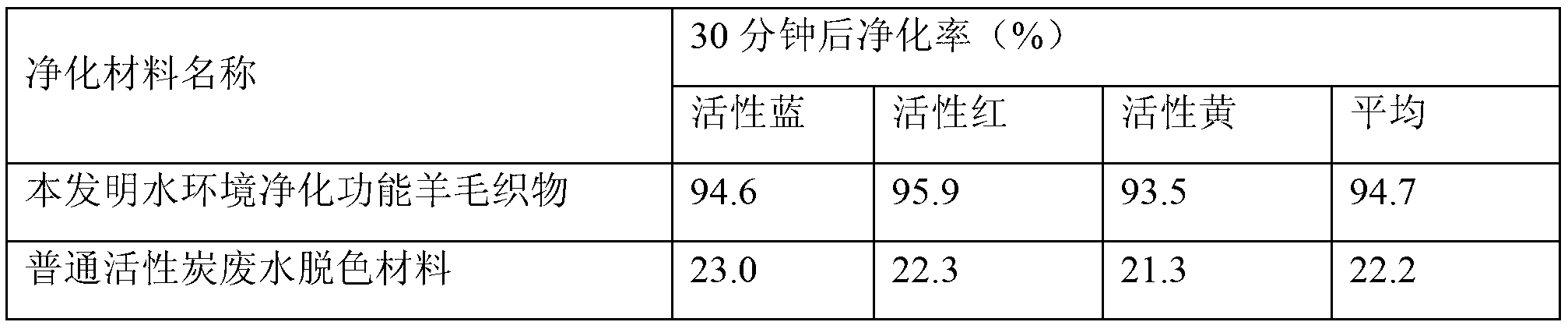

Method for treating recycled printing and dyeing sewage

InactiveCN101613167ACOO reductionWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesFiberTreatment effect

The invention discloses a method for treating recycled printing and dyeing sewage, which is applicable to the treatment and reutilization of sewage of printing and dyeing of fabrics such as wool fabrics, silk fabrics, cotton, linen, chemical fiber fabrics and the like. The method aims to overcome the disadvantages of sewage treatment of the prior printing and dyeing mills and ensure that the sewage reaches the national discharge standard of water pollutants for dyeing and finishing. The method adopts treatment technology of physicochemical-biochemical, precipitation and filtration, which comprises the following process flow: the sewage, a collecting basin, an anaerobic tank, an aerobic tan, a dosing tank, a sedimentation tank, a filter tank, and the discharge or recycling of water which achieves the standard. In addition, complex enzyme is also added; the complex enzyme has a catalytic function, and can strengthen the activation of microorganisms; the method has good treatment effect on the sewage; and the adding of the complex enzyme can strengthen the activity of the microorganisms, improve the effect of sewage treatment, can also save electric energy, reduce the loss of medicaments, and save the cost. The sewage is recycled after the filtration through a microstrainer, which saves the resource, reduces the cost once again, and truly achieves the aims of energy conservation and discharge reduction.

Owner:东莞市明珠染整实业有限公司

Composite catalyst, preparation and application thereof

InactiveCN101829577AImprove stabilityExtended service lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogen

The invention discloses a composite catalyst, a preparation method and application thereof. The composite catalyst is used for absorbing and strengthening methane steam in a reaction for reforming and manufacturing hydrogen. The composite catalyst is prepared by compounding CaO using nanometer calcium carbonate as a precursor, active nickel component using nickel nitrate as a precursor, nano ZrO2 using zirconium oxychloride as a precursor, and an alumina carrier; the mol ratio of CaO: Al2O3: NiO: ZrO2 is 1: (0.05 to 2.0): (0.05 to 3.0): (0.005 to 1.0). The composite catalyst has a catalytic function and an absorbing function of carbon dioxide, enhances stability, prolongs service life, and can be recycled 20 times or above.

Owner:ZHEJIANG UNIV

Microbialactivity enhancing liquid agent for sewage treatment

InactiveCN102107951AReduce dosageEasy to useBiological water/sewage treatmentZoogloeaIndustrial effluent

The invention relates to a microbialactivity enhancing liquid agent for sewage treatment. In the liquid agent, on one hand, a carrier, enzyme and a nutrient substance capable of promoting a catalytic function of sludge zoogloea are combined with one another, so activity of beneficial microorganism in sludge is enhanced and organic pollutants and the like are catalytically decomposed quickly; and on the other hand, the carrier enhances sewage biological treatment capacity by improving a structure of the sludge zoogloea. The liquid agent has the characteristics of convenience of use, small using amount, high-efficient and quick reinforcing ability and can be applied to biological treatment units for domestic sewage and industrial wastewater treatment.

Owner:北京金源化学集团有限公司

Magnetic solid alkalic catalyst, its preparing method and use

InactiveCN101024189ASimple production processLow costCatalyst activation/preparationLiquid hydrocarbon mixture productionBiodieselActive component

This invention involves magnetic solid base catalyst, its components including magnetic material and metal oxide or magnetic vector with a mixture of metal salt as a catalyst, activity group is alkali metal salts. Their preparation methods: magnetic material and metal oxide or metal salts fully mixed grinding and dispersed evenly to join the binder, and then roasted and insulation, get a magnetic catalyst carrier; put active component into deionized water prepared impregnating solution; Magnetic catalyst carrier parked in the above impregnated solution to response, static aging, drying, calcination and insulation, then get a magnetic solid base catalyst. The invention magnetic solid base catalyst production process is simple, low cost, used for the preparation of the bio-diesel in transesterification reaction, catalytic function is superior, separation and recovery is convenient after transesterification reaction.

Owner:中兴能源技术(武汉)有限公司

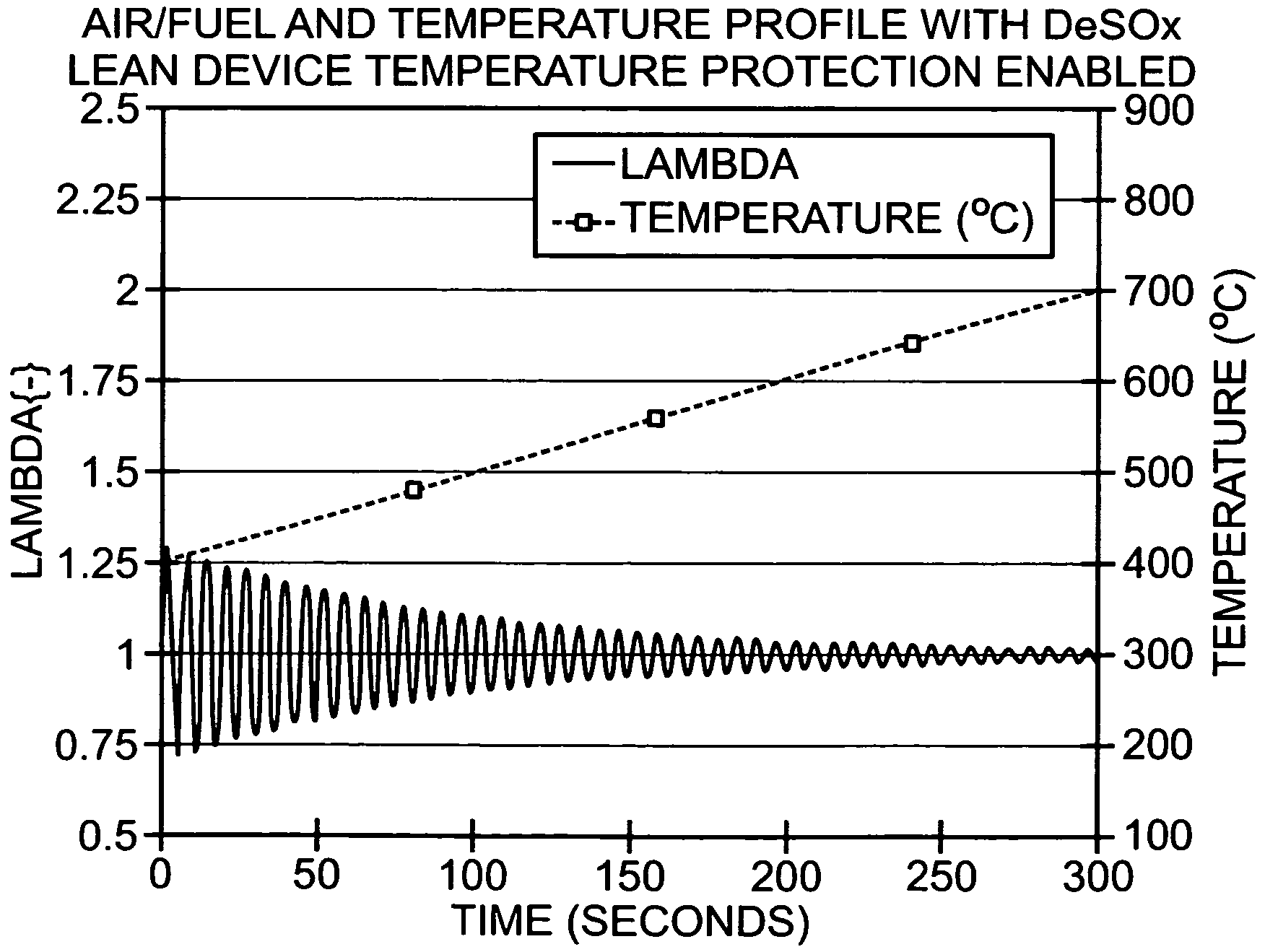

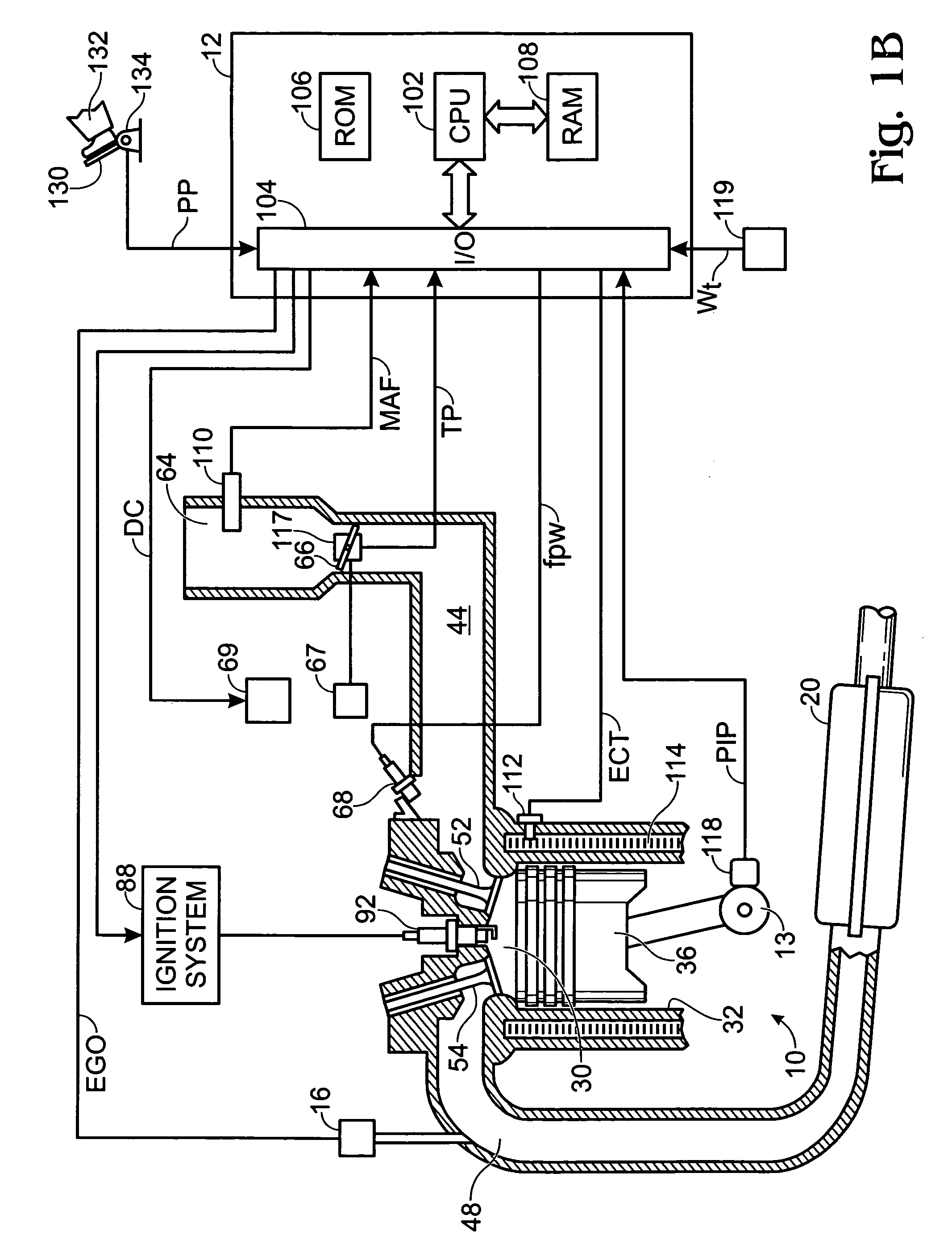

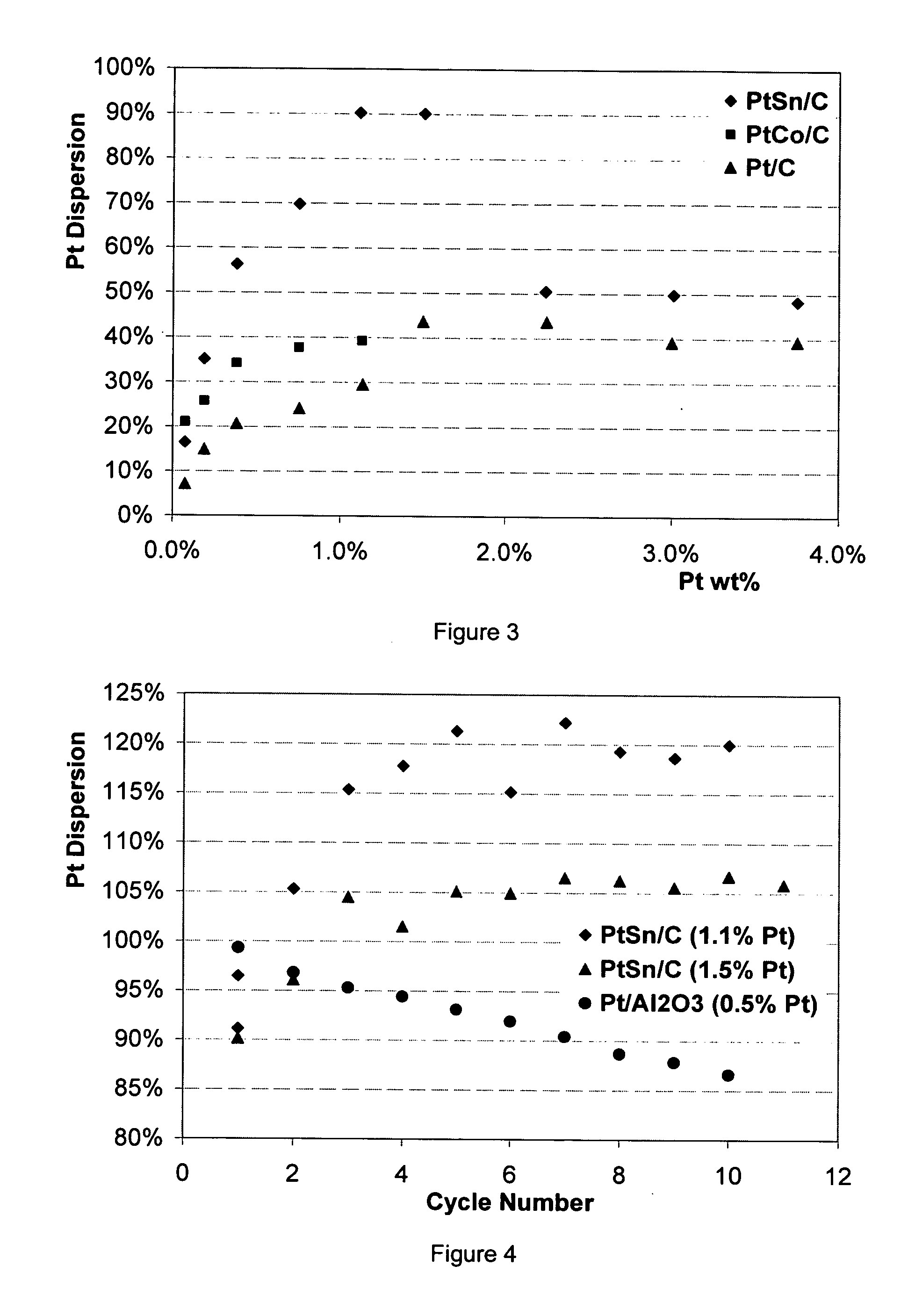

Computer device to control operation during catalyst desulfurization to preserve catalytic function

ActiveUS7284368B2Less fuelLess carbon dioxideElectrical controlExhaust apparatusCatalytic functionParticle growth

A system is described for improving engine and vehicle performance by considering the effects of exhaust conditions on catalyst particle growth. Specifically, engine operation is adjusted to reduce operating in such conditions, and a diagnostic routine is described for determining the effects of any operation that can cause such particle growth. Further, routines are described for controlling various vehicle conditions, such as deceleration fuel shut-off, to reduce effects of the particle growth on emission performance.

Owner:FORD GLOBAL TECH LLC

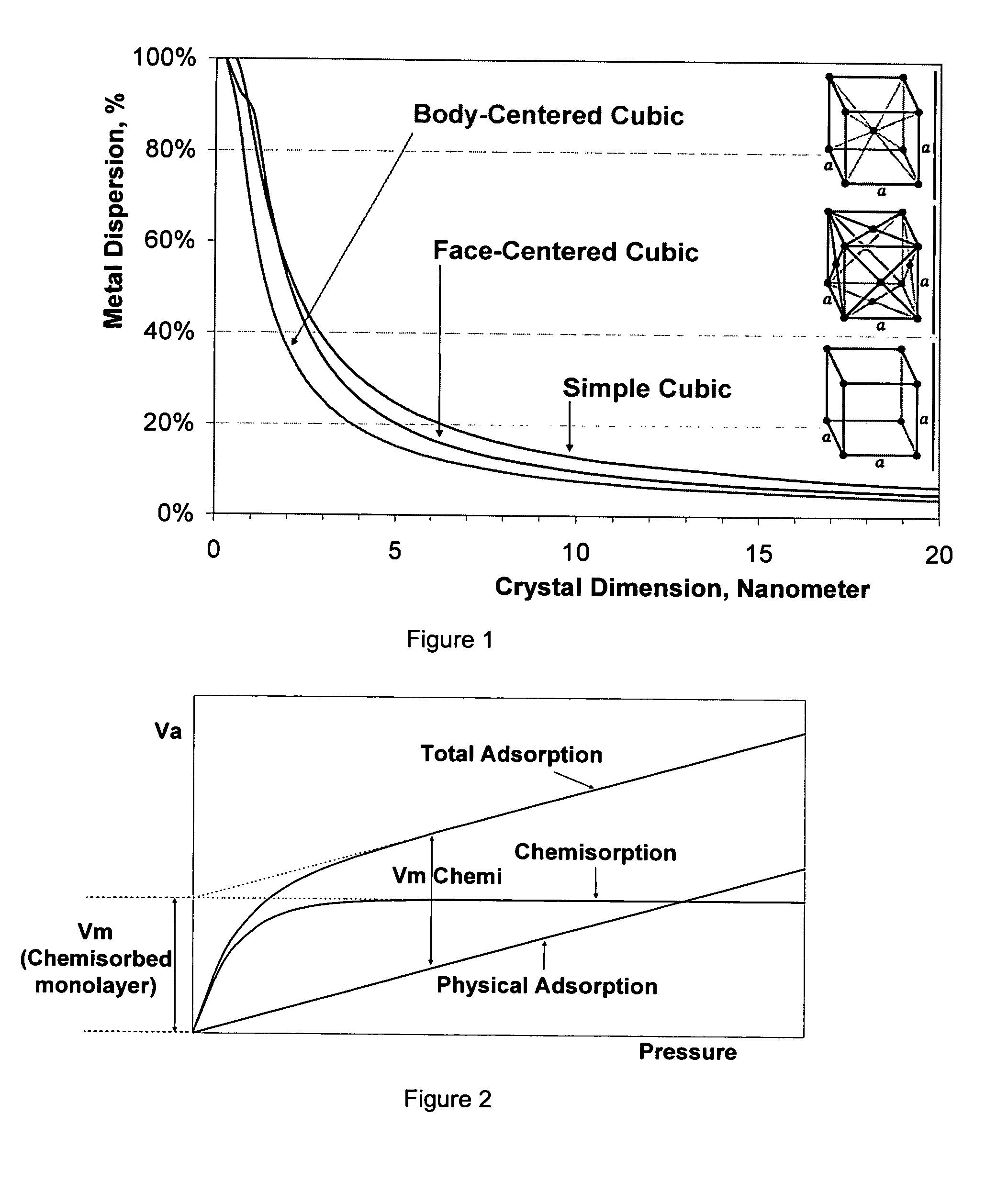

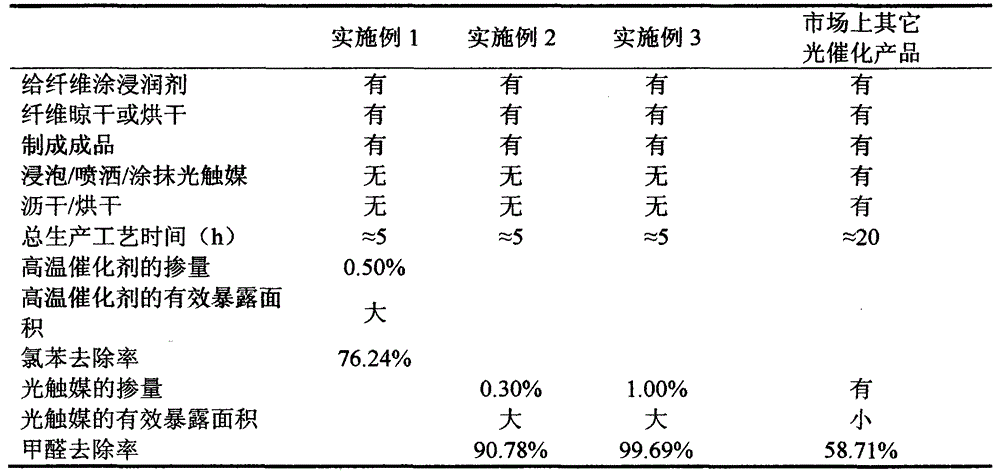

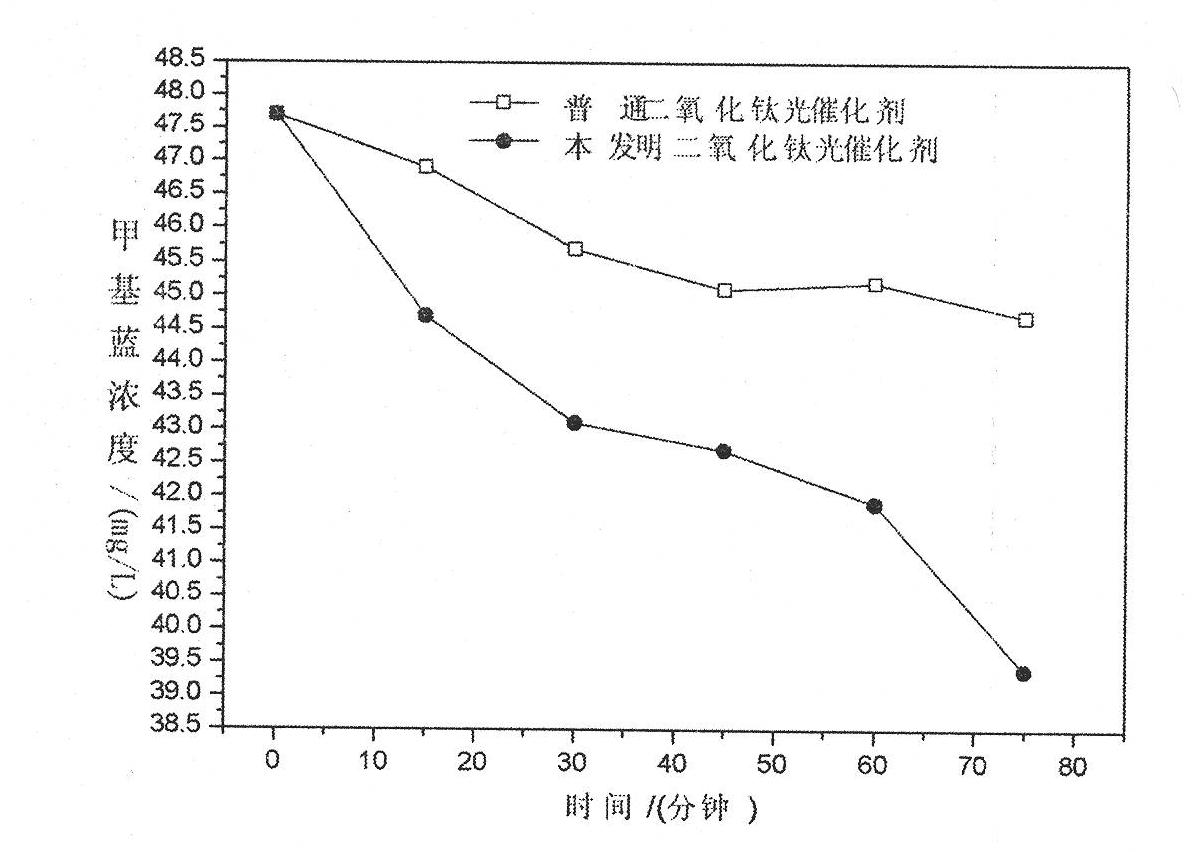

Preparation method of efficient and visible-light catalytic function textile

InactiveCN103194888AAvoid agglomeration efficiency dropEfficient degradationVegetal fibresAnimal fibresMicro nanoCatalytic function

The invention relates to a preparation method of an efficient and visible-light catalytic function textile. The preparation method comprises the following steps of: washing a textile; adding bismuth nitrate, meta-vanadate, a metal chelating agent and PEG (Polyethylene Glycol) into a nitric acid solution and reacting for 2-3 hours to obtain a solution A; adjusting the pH (Potential of Hydrogen) of the solution A, raising the temperature of the solution A to be at 90-100 DEG C, and then reacting for 2-3 hours to obtain a suspension solution B; filtering the suspension solution B, and drying and calcining to obtain BiVO4 micro-nano particles; adding the BiVO4 micro-nano particles into a silver nitrate solution and performing ultrasound treating for 20-30min; agitating for 1-2 hours to obtain a solution C; dripping a vulcanized salt solution into a solution D and reacting for 1-2 hours to obtain an AgS / BiVO4 precursor finishing solution D; and immersing the pre-washed textile into the finishing solution D; reacting at 70-90 DEG C for 4-6 hours; and drying to obtain the efficient and visible-light catalytic function textile. The preparation method disclosed by the invention is simple and has no secondary pollution; and the obtained function textile can effectively purify printing and dyeing wastewater and air pollution under the illumination of visible light.

Owner:DONGHUA UNIV +1

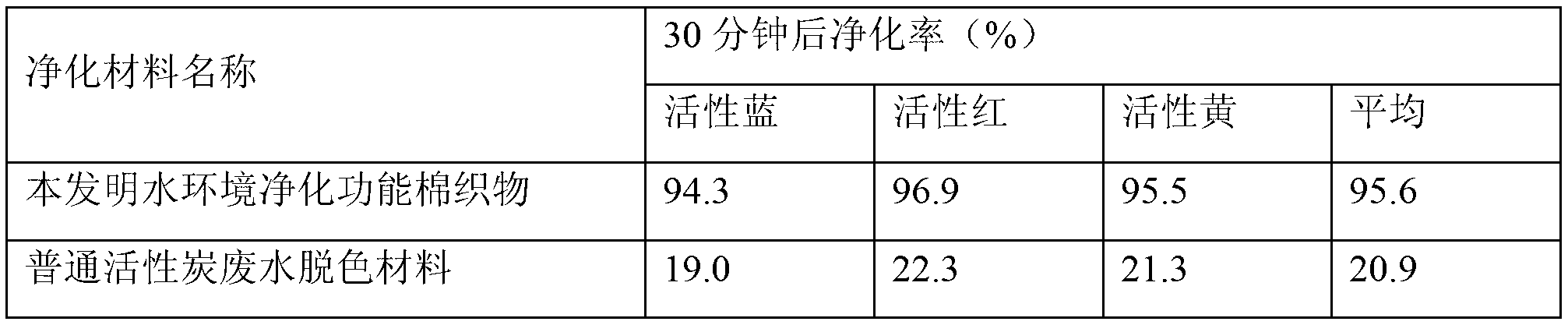

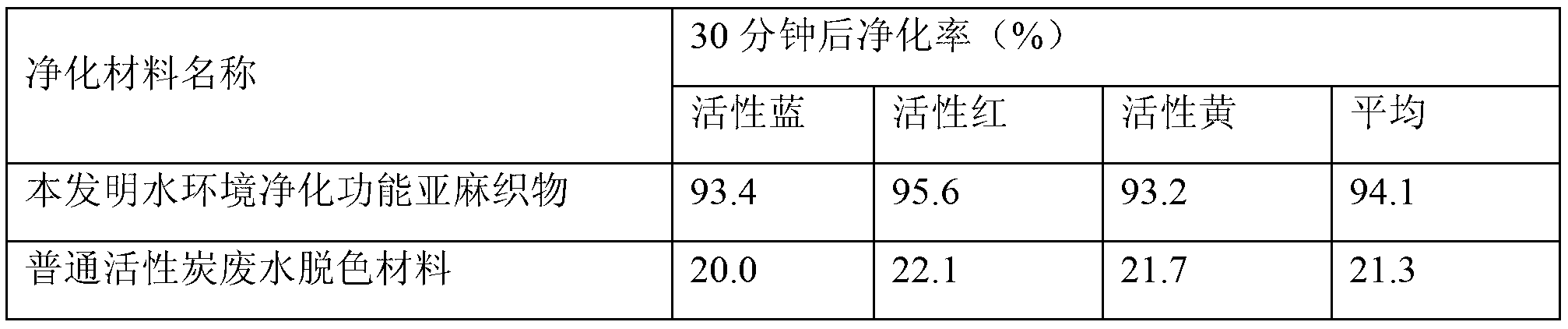

Highly dispersed metal catalyst

ActiveUS20120004098A1Small particle sizeRaise the ratioCell electrodesCatalyst activation/preparationPorous catalystMetal catalyst

A supported catalyst having an atomic level single atom structure is provided such that substantially all the catalyst is available for catalytic function. A process of forming a single atom catalyst unto a porous catalyst support is also provided.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS +1

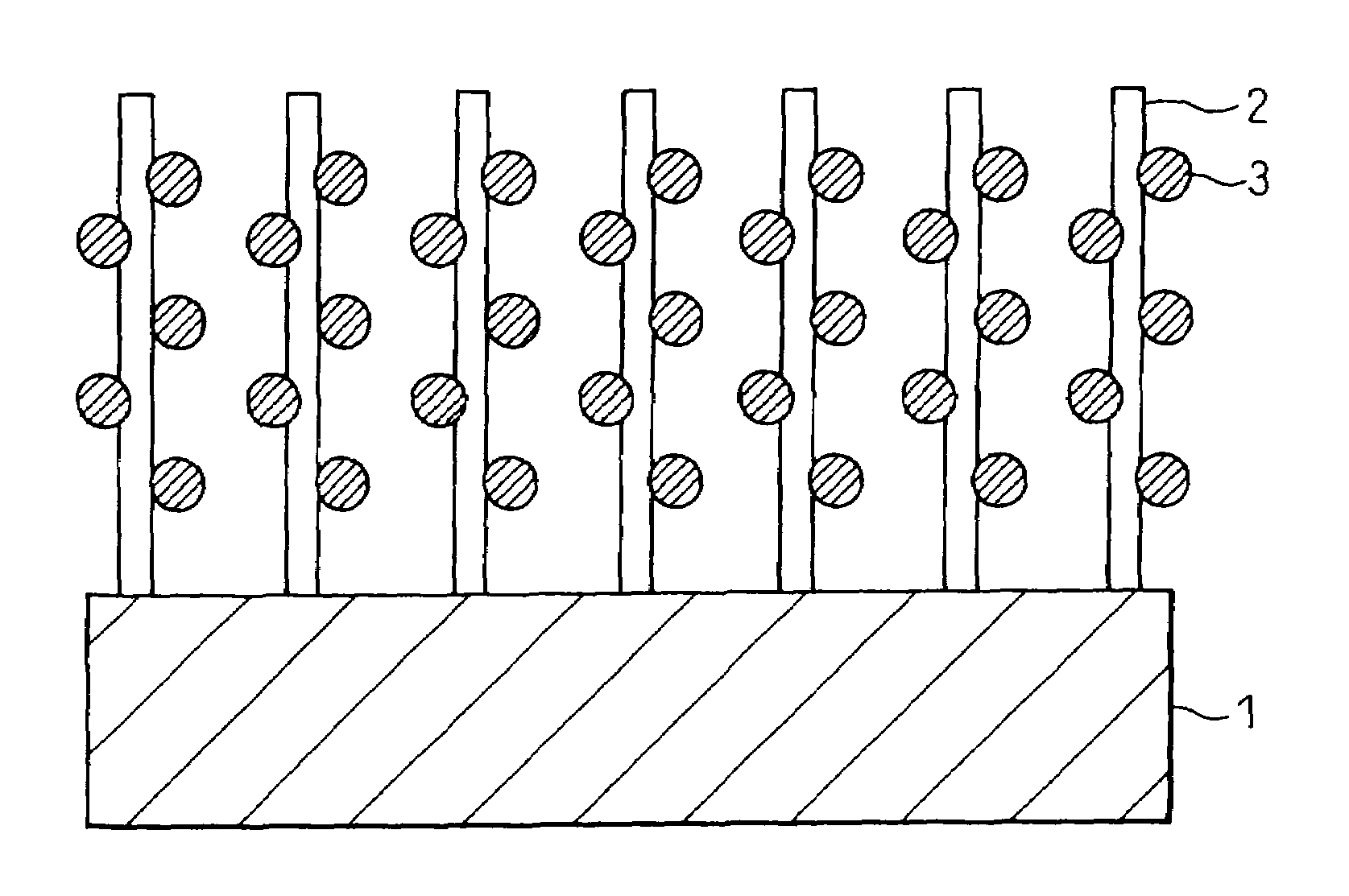

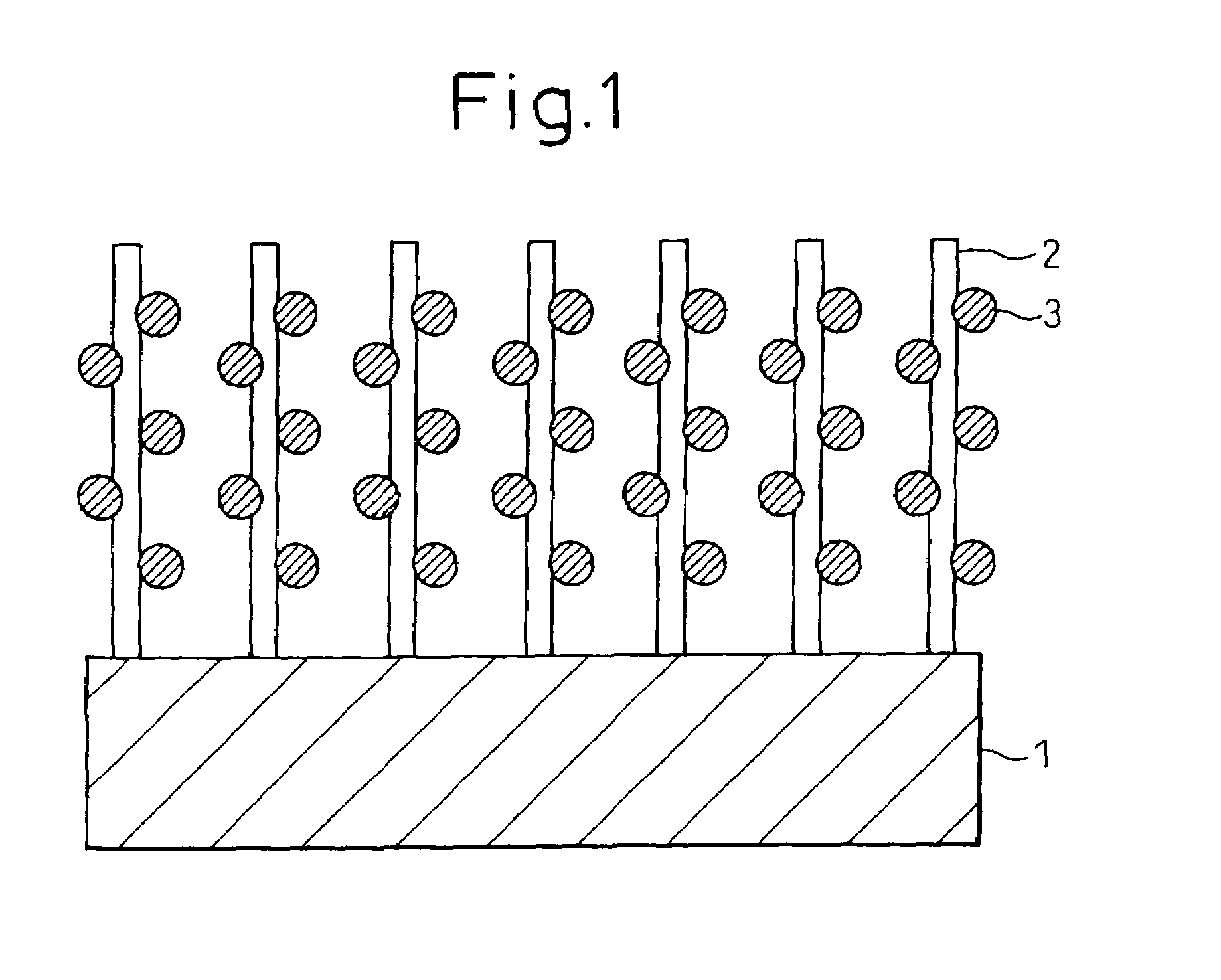

Catalyst assembly

InactiveUS7323432B2Increasing the percentage of catalystsIncrease probabilityMaterial nanotechnologyGas treatmentPolymer scienceReactive gas

A catalyst assembly comprising a substrate, nanofilaments which have a nanometer-size diameter and are formed on the substrate, and particles which have a nanometer-size diameter, at least one of the nanofilaments and the particles having a catalytic function, is provided to use a catalyst more efficiently and to provide a catalytic function more efficiently. Interstices between the nanofilaments serve as distribution channels of a reactive gas, and the reactive gas spreads sufficiently not only around the ends of nanofilaments but also inside a catalyst assembly. A combination of nanofilaments and particles enables dispersion of a catalyst at a distance of not more than about 100 nanometers.

Owner:DENSO CORP +2

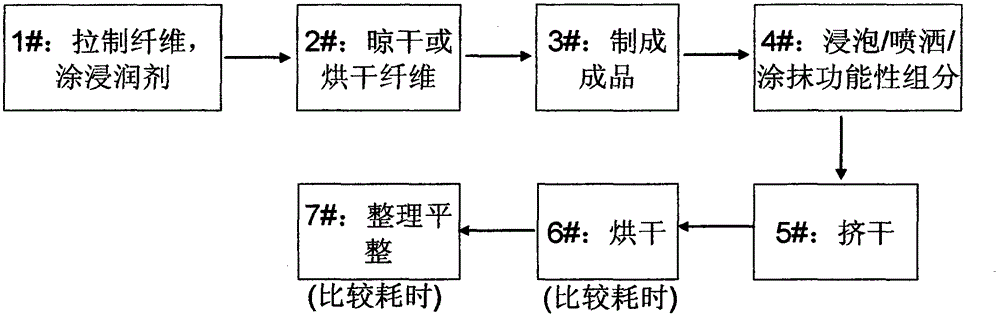

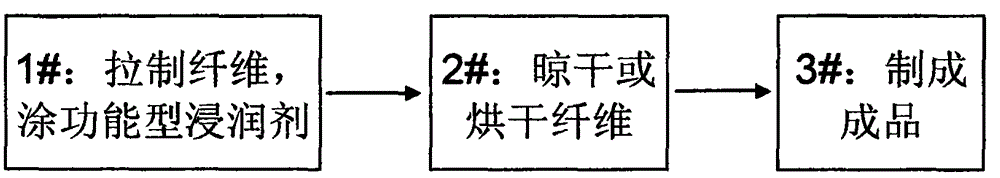

Fiber sizing agent having catalytic function and process for preparing fiber structure by adopting same

InactiveCN104894839AHas a catalytic functionImprove flatnessFibre treatmentPolymer scienceCatalytic function

The invention discloses a fiber sizing agent and in particular relates to a fiber sizing agent having a catalytic function and a process for preparing a fiber structure by adopting the fiber sizing agent. The fiber sizing agent comprises one or more of an oxidation catalyst, a reduction catalyst, a synthesis catalyst, a photocatalyst and a high-temperature catalyst, and also comprises an antistatic agent, a resin film-forming agent and a silane coupling agent. The fiber sizing agent having the catalytic function is adopted to provide mechanical strength, flexibility, lubricity and the like, and also enable the produced fiber products to immediately have the capability such as the catalytic property, and therefore, the production step is remarkably reduced, the process time is shortened and the production energy consumption and the cost are reduced; besides, the catalyst is attached on the surface of the fibers together with the fiber sizing agent; the treating liquid can be utilized efficiently and the waste is minimized, and the catalyst is distributed evenly in every part of the fiber products; in short, the effective exposed area is large and the catalytic efficiency is relatively high.

Owner:BEIJING RUNHIGH SCI & TECH

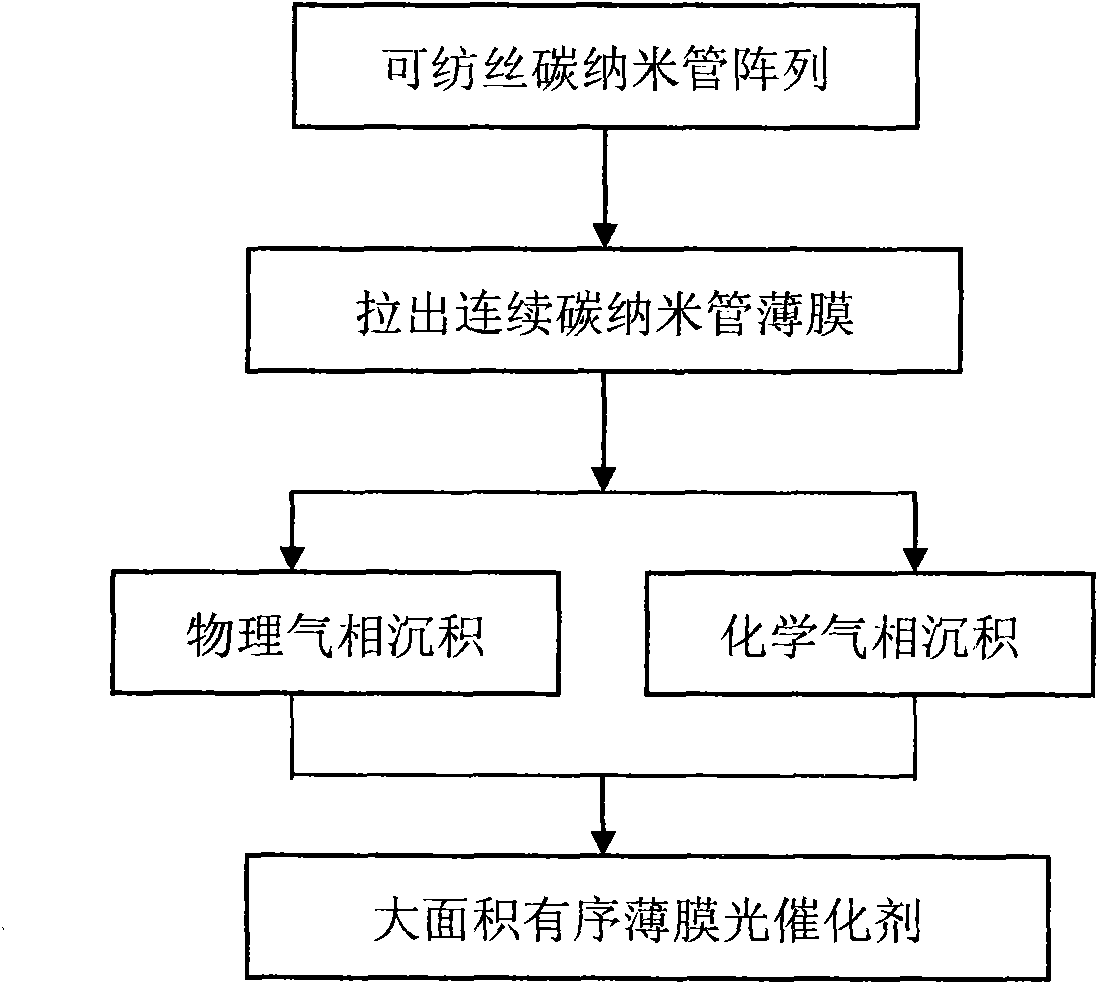

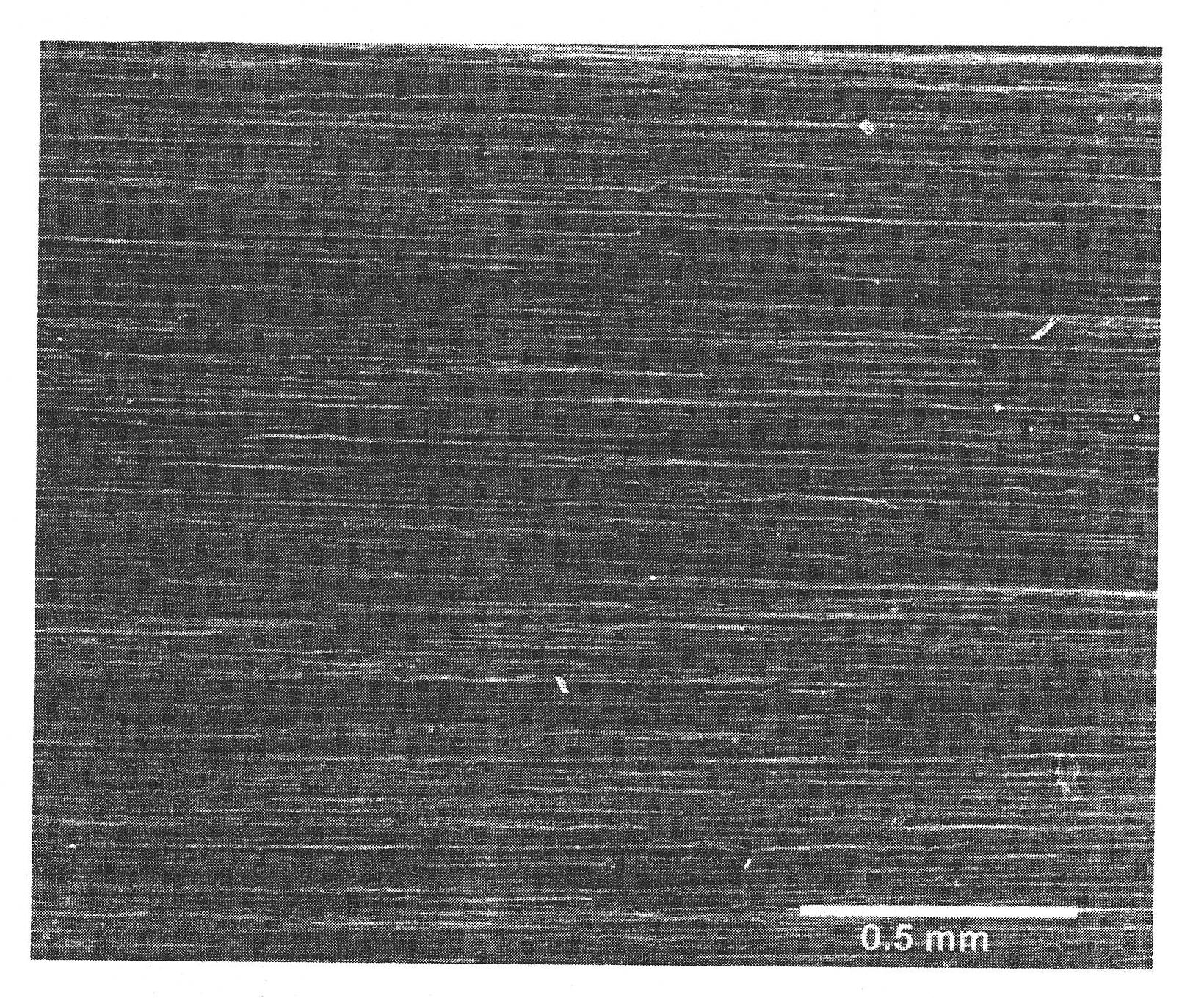

Large-area titanium dioxide nanotube film as well as preparation method and application thereof

InactiveCN101972641AIncrease the areaImprove efficiencyPhysical/chemical process catalystsTio2 nanotubeCatalytic function

The invention relates to a large-area titanium dioxide nanotube film as well as a preparation method and application thereof. The large-area titanium dioxide nanotube film comprises a template formed by a carbon nanotube order film and nano titanium dioxide layers coated on the outer walls of carbon nanotubes forming the template. The carbon nanotube orderly film is used as the template in the preparation method, and the preparation method comprises the step of coating the nano titanium dioxide layers on the carbon nanotubes forming the template to form a titanium dioxide nanotube film. The titanium dioxide nanotube film can be used as a photoelectric integrated catalytic material for application, has adjustable structure and size, the preparation method is simple and easy to apply and has high efficiency and low cost, and meanwhile, the titanium dioxide nanotube film can be applied by adopting various modes, has photoelectric integrated catalytic function and high catalytic activity, and is suitable for being widely applied to the fields of photocatalysis, solar utilization, photoelectric conversion and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

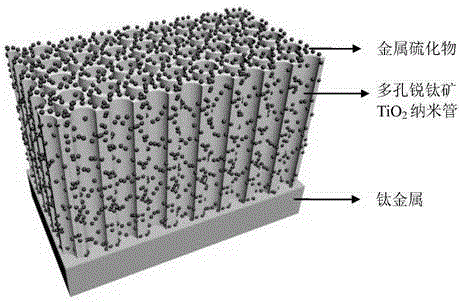

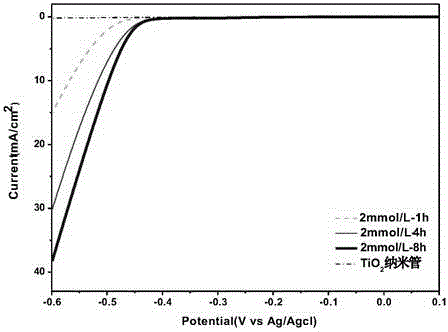

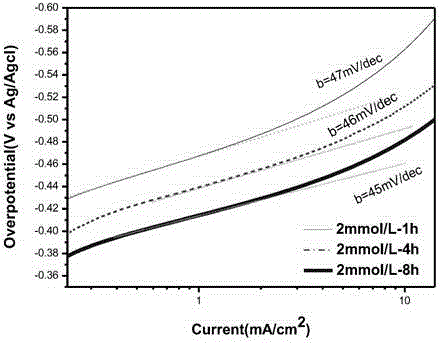

Metal sulfide electrode with hydrogen reduction activity and preparation method of metal sulfide electrode

InactiveCN104313637AThe synthesis method is simpleLow costElectrodesPorous substrateReduction Activity

The invention discloses a metal sulfide electrode with a hydrogen reduction catalytic function and a preparation method of the metal sulfide electrode, belonging to the fields of inorganic chemistry and catalysis. The electrode contains metal titanium, porous anatase TiO2 nanotubes grown on the surface of titanium and metal sulfide nanoparticles loaded on the surfaces of the nanotubes. The preparation method comprises the following steps: firstly preparing the anatase TiO2 nanotubes with a porous structure on the surface of metal titanium by an electrochemical anode oxidation method; then placing the TiO2 nanotubes into a solution containing molybdenum ions or tungsten ions, and irradiating ultraviolet light on the surface; and reducing the molybdenum ions or the tungsten ions by utilizing the photocatalytic reduction of the TiO2 nanotubes under the ultraviolet light to generate MoS2 or WS2 nanoparticles. The metal sulfide electrode prepared by the preparation method disclosed by the invention shows hydrogen reduction catalytic activity and has the characteristics of low cost, simple preparation method and environmental friendliness. In the metal sulfide electrode disclosed by the invention, a metal sulfide catalyst is directly loaded on a conductive porous substrate to form the electrode and can be directly applied to hydrogen reduction reaction, and the catalyst particles do not need to be fixed.

Owner:BEIHANG UNIV

Catalyst for hydrogen production by catalytic reforming with biological oil and preparation method

InactiveCN102974362AHigh hydrogen contentHigh calorific valueHydrogenChemical recyclingCatalytic reformingChain scission

The invention relates to a catalyst for hydrogen production by catalytic reforming with biological oil and a preparation method. The catalyst comprises catalyst active components and a catalyst carrier; the catalyst active components refer to the following components in percentage by weight of 10-15 wt% of Ni, 5-13 wt% of Mo, 5-10 wt% of Fe and the balance being attapulgite and sepiolite mixed clay pit catalyst carrier. The catalyst provided by the invention has the advantages of large surface area, strong absorption function and strong promotion function; the cheap and easiest available attapulgite and sepiolite mixed clay pit are used as the catalyst carrier; and the catalyst active components comprise nickel, molybdenum and iron composite components, so that the molecules of the biological oil are subjected to splitting and chain scission to form high-quality synthesis gas of low-molecule hydrocarbon and high-content hydrogen. The catalyst provided by the invention has the advantages of simple catalyst preparation, large strength, strong catalyst activity, and regeneration. Not only can the catalyst be used for hydrogen production by catalytic reforming with the biological oil, but also the catalyst can be applied to direct hydrogen production by catalytic gasification with biomass.

Owner:ANHUI UNIV OF SCI & TECH

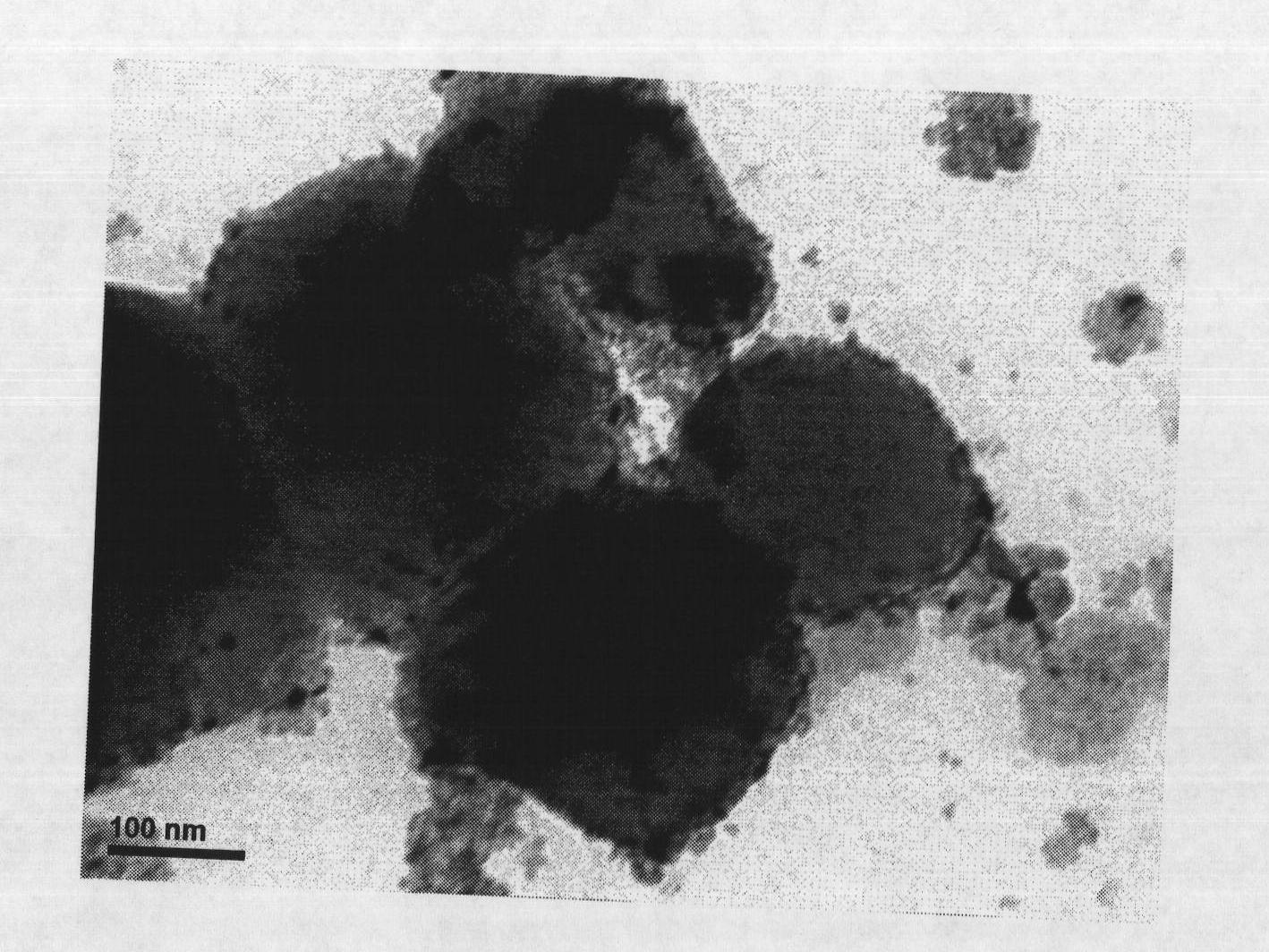

Molecular sieve-coating cerium oxide composite material and preparation method thereof

InactiveCN104492473AImprove anti-carbon performanceImprove thermal stabilityCatalyst carriersMolecular sieve catalystsTrappingSolid acid

The invention discloses a preparation method of a ZSM-5 zeolite molecular sieve-coating cerium oxide composite material. Cerium oxide is dispersed in a mother liquor for synthesizing a molecular sieve by adopting an in-situ hydrothermal method, and hydrolytic condensation polymerization, two-step in-situ hydrothermal reaction, cleaning, drying and roasting are carried out based on the mother liquor containing the cerium oxide to obtain the molecular sieve-coating cerium oxide composite material. According to the prepared molecular sieve / cerium oxide composite material, the molecular sieve uniformly and compactly covers the surface of the cerium oxide, the specific surface area is high, the thermal stability and the oxygen storage and release property of the cerium oxide can be greatly improved, and the cerium oxide has the rich surface acidity. In addition, the cerium oxide also has the certain oxidization capacity to the molecular sieve, so that the carbon deposition prevention capacity of the molecular sieve is greatly improved, and the molecular sieve-coating cerium oxide composite material can be used as a two-function catalyst simultaneously having an acid catalytic function and an oxidization catalytic function. The composite material can be widely applied to the fields such as the reaction catalyzed by solid acid at high temperature, such as catalytic cracking, volatile organic pollutant catalytic combustion, and automobile exhaust catalytic purification (a three-way catalyst carrier and a hydrocarbon trapping catalyst).

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com