Molecular sieve-coating cerium oxide composite material and preparation method thereof

A composite material and cerium oxide technology, which is applied in the field of preparation of cerium oxide composite materials, can solve the problems of reducing the surface acidity of ZSM-5 zeolite, and cannot be fully displayed and utilized, so as to improve thermal stability and oxygen storage and release performance , improve the ability of anti-carbon deposition, and generate low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

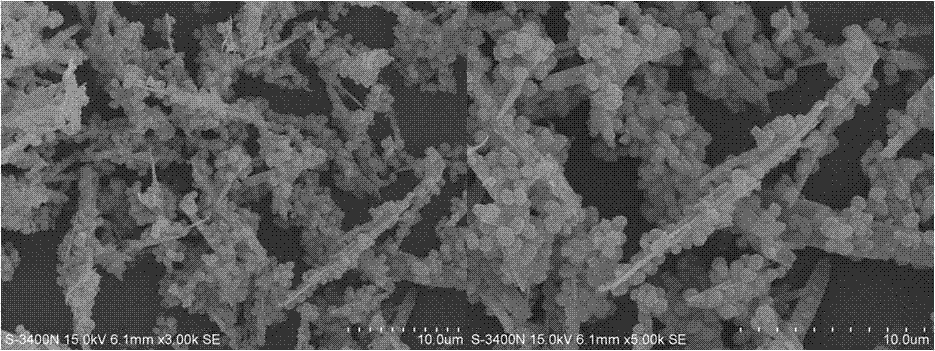

[0028] Add 0.469g of sodium chloride, 5.625g of tetrapropylammonium hydroxide, and 3.27g of ethyl orthosilicate to 40g of deionized water, stir for 10 minutes, then add 0.1g of aluminum isopropoxide, and ultrasonicate for 15 minutes, then the solution is in Continue stirring at room temperature for 24 h; add 0.75 g of cerium oxide nanosheets, ultrasonically disperse, and stir for 4 h, then transfer the solution into a crystallization kettle with a polytetrafluoroethylene liner. ) Hydrothermal treatment at 110°C for 24h, 170°C for 48h, then cooled to room temperature, filtered, washed, dried at 110°C for 12h, placed in a muffle furnace and roasted at 450°C for 4h to obtain the attached figure 1 The ZSM-5 molecular sieve-ceria composite shown.

Embodiment 2

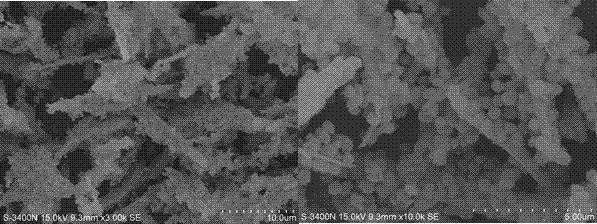

[0030] Add 0.310g of sodium chloride, 5.625g of tetrapropylammonium hydroxide, and 3.27g of ethyl orthosilicate into 25g of deionized water, stir for 10 minutes, add 0.1g of aluminum isopropoxide, and ultrasonicate for 15 minutes, then gel Continue stirring at room temperature for 24 h; add 0.75 g of cerium oxide nanosheets, ultrasonically disperse, and after stirring for 4 h, transfer the gel into a crystallization kettle with a polytetrafluoroethylene liner. / min) 110°C hydrothermal treatment for 24h, 170°C hydrothermal treatment for 48h, cooled to room temperature, filtered, washed, dried at 110°C for 12h, placed in a muffle furnace and roasted at 450°C for 4h to obtain the attached figure 2 The ZSM-5 molecular sieve-coated cerium oxide composite is shown.

Embodiment 3

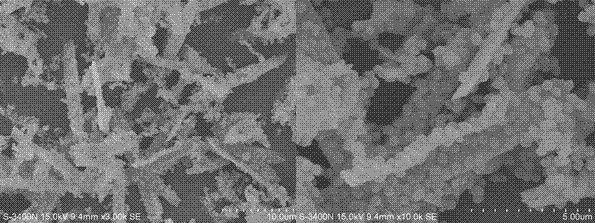

[0032]Add 0.310g of sodium chloride, 1.5g of polyethylene glycol 600, 5.625g of tetrapropylammonium hydroxide, and 0.1g of aluminum isopropoxide into 25g of deionized water, sonicate for 15 minutes, stir for 10 minutes, and then add 3.27g of orthosilicon Then, the resulting gel was stirred at room temperature for 24 h; 1 g of cerium oxide nanosheets was added, ultrasonically dispersed, and after stirring for 4 h, the gel was transferred to a crystallization kettle with a polytetrafluoroethylene liner. Under the condition of rotation (60 rpm), hydrothermal treatment at 110°C for 24h, hydrothermal treatment at 170°C for 48h, cooling to room temperature, filtering, washing, drying at 110°C for 12h, and roasting in a muffle furnace at 450°C After 4h vested image 3 The ZSM-5 molecular sieve-coated cerium oxide composite is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com