Patents

Literature

90results about How to "High dehydrogenation activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing 1,3-butadiene as high yield

ActiveUS20130281748A1Excellent catalytic performanceHigh dehydrogenation activityDistillation purification/separationCatalystsButenePolymer science

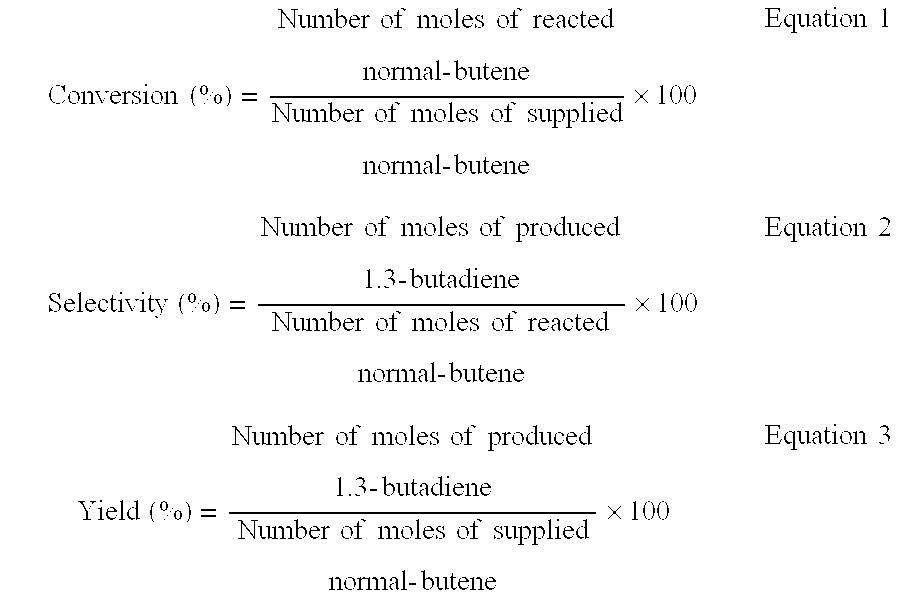

Disclosed is a method for producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using a parallel reactor in which catalysts are charged into fixed bed reactors and are not physically mixed. More specifically, disclosed is a method for efficiently producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using the parallel reactor containing multi-component bismuth molybdate-based catalysts exhibiting different activities to oxidative dehydrogenation for normal-butene isomers (1-butene, trans-2-butene and cis-2-butene), and butene separated from a C4 mixture containing normal-butene and normal-butane, as a reactant.

Owner:LG CHEM LTD

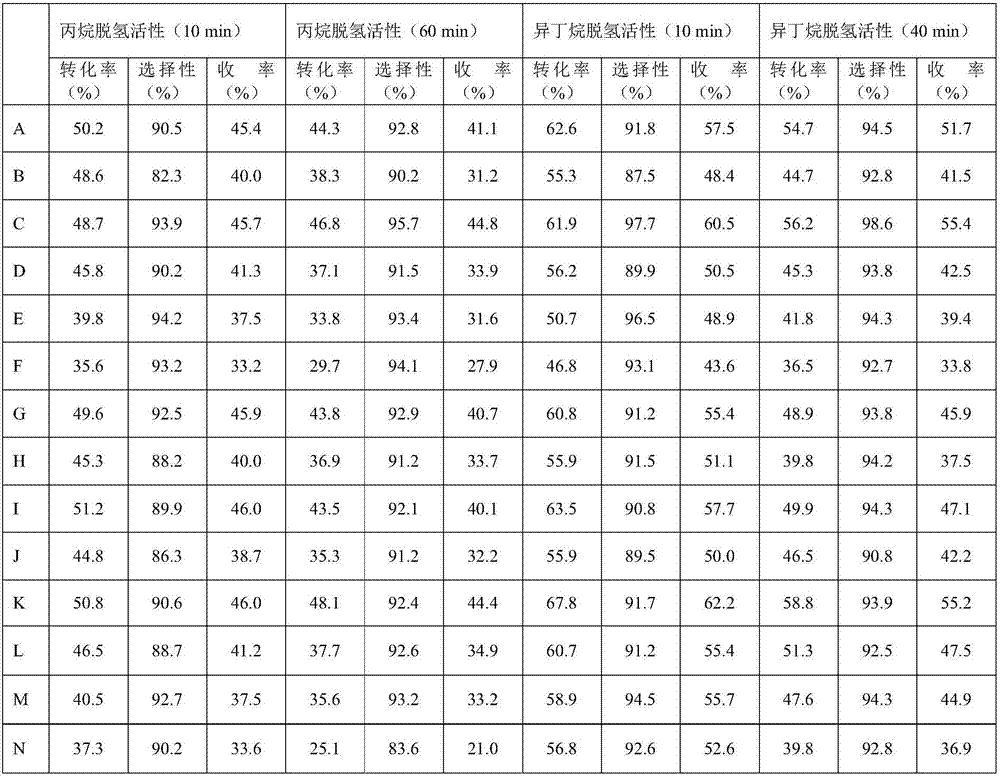

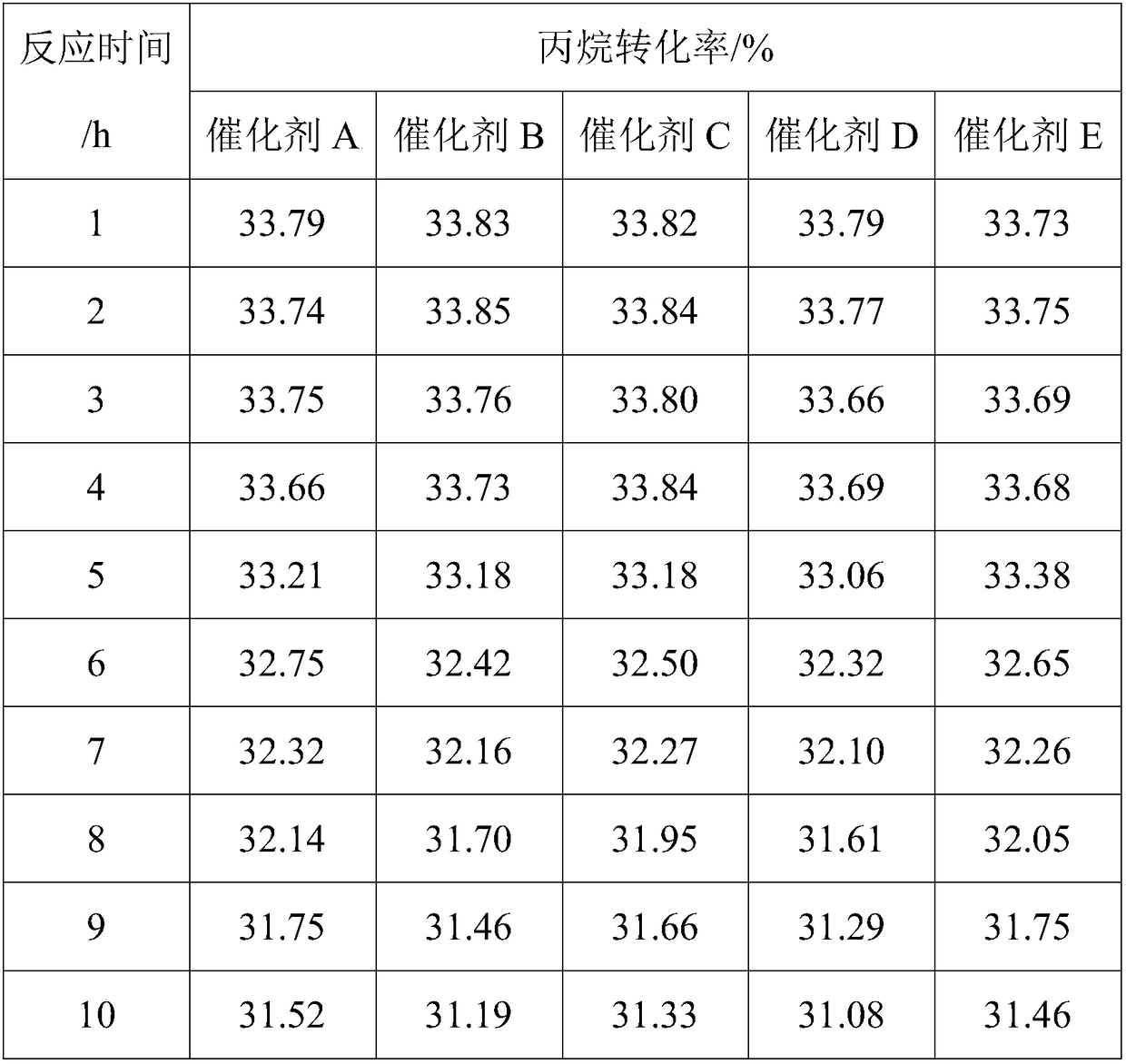

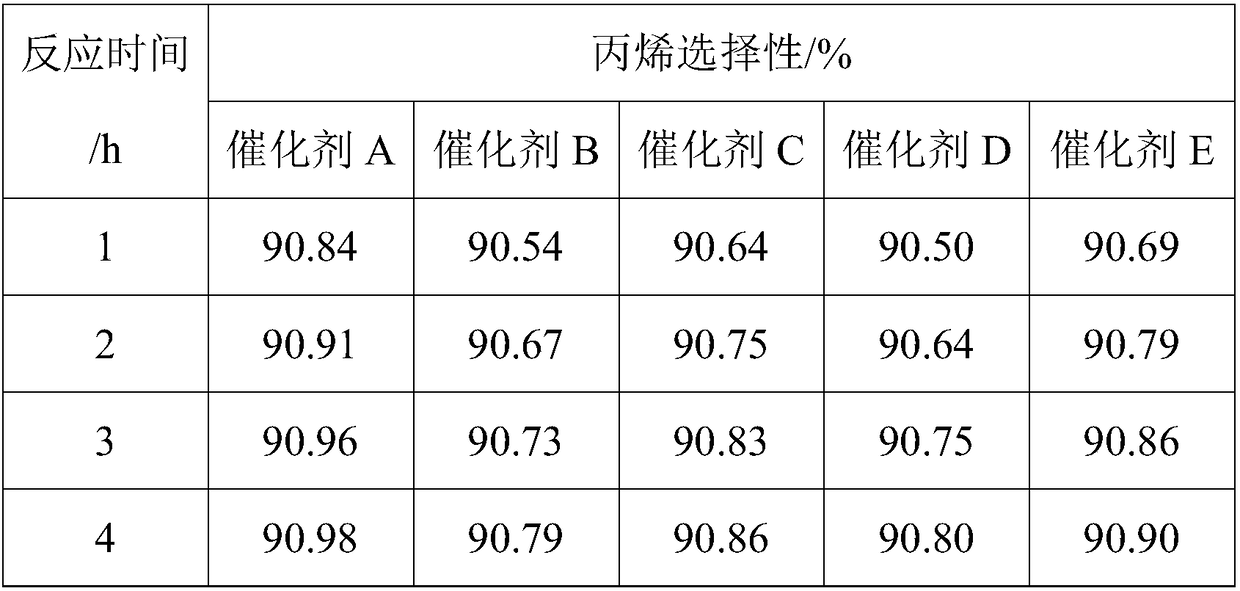

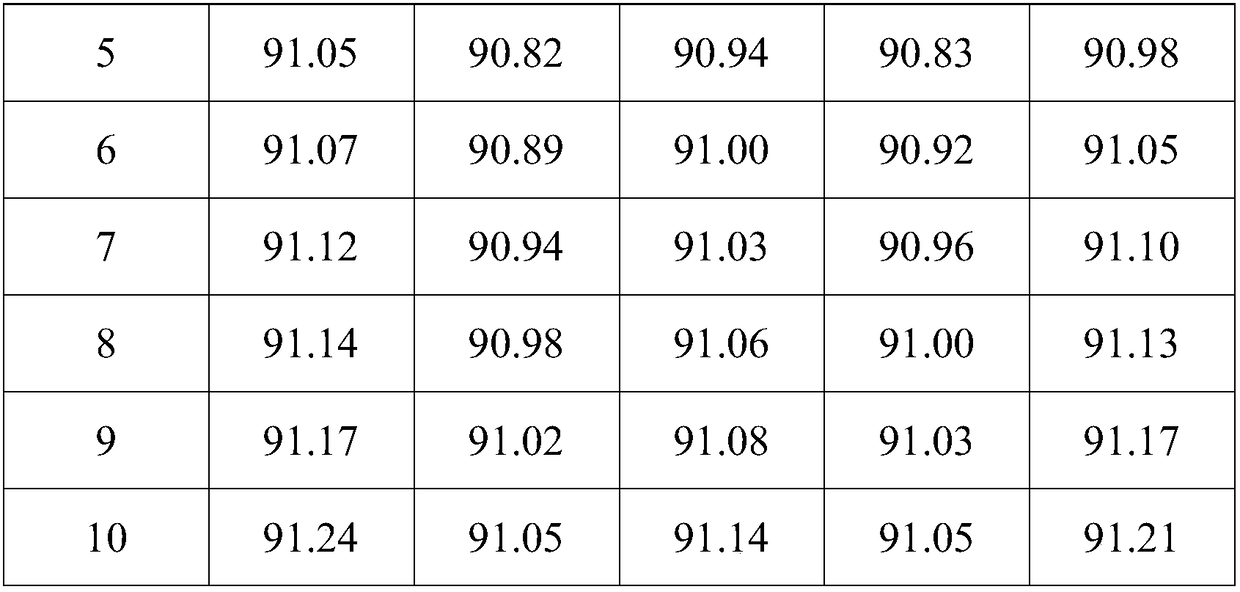

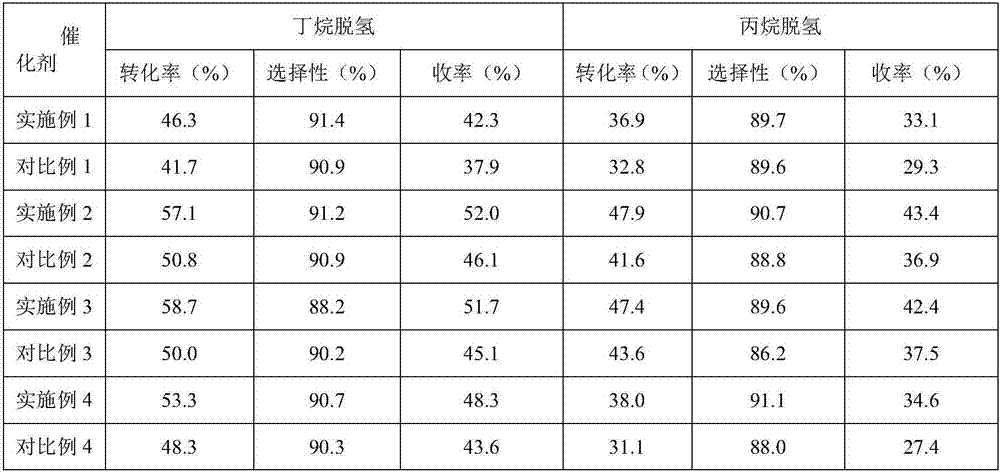

Quaternary platinum-based light-alkane dehydrogenation catalyst and preparation method thereof

ActiveCN105396586AHigh dehydrogenation activityGood dispersionCatalystsHydrocarbon preparation catalystsPlatinumAlkane

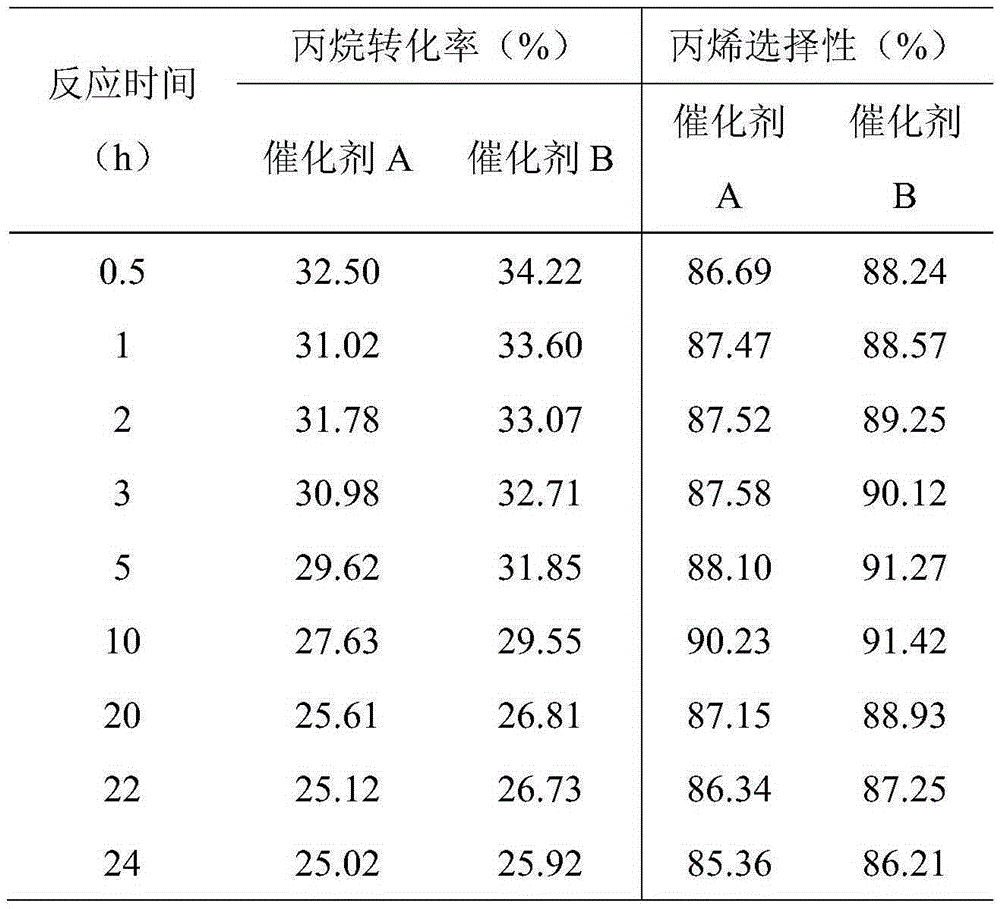

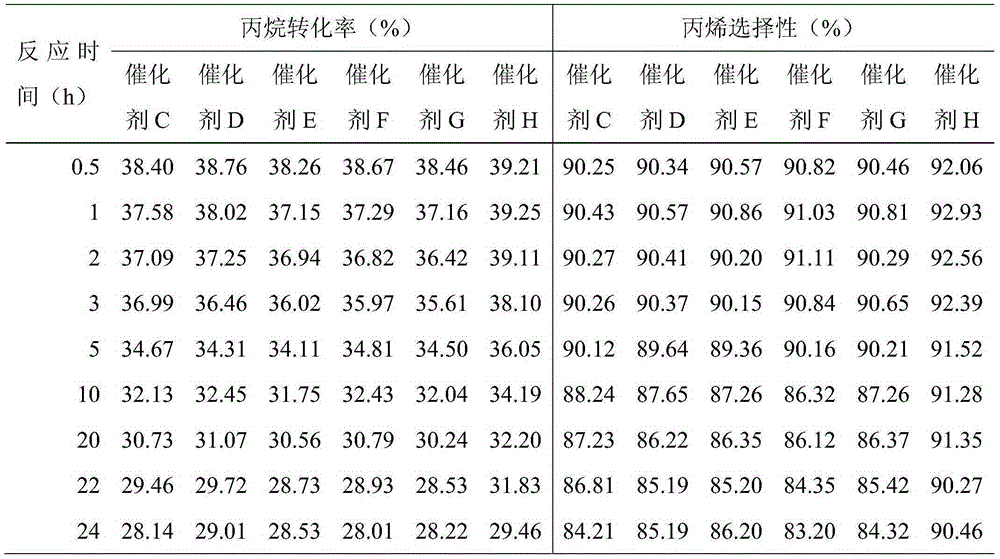

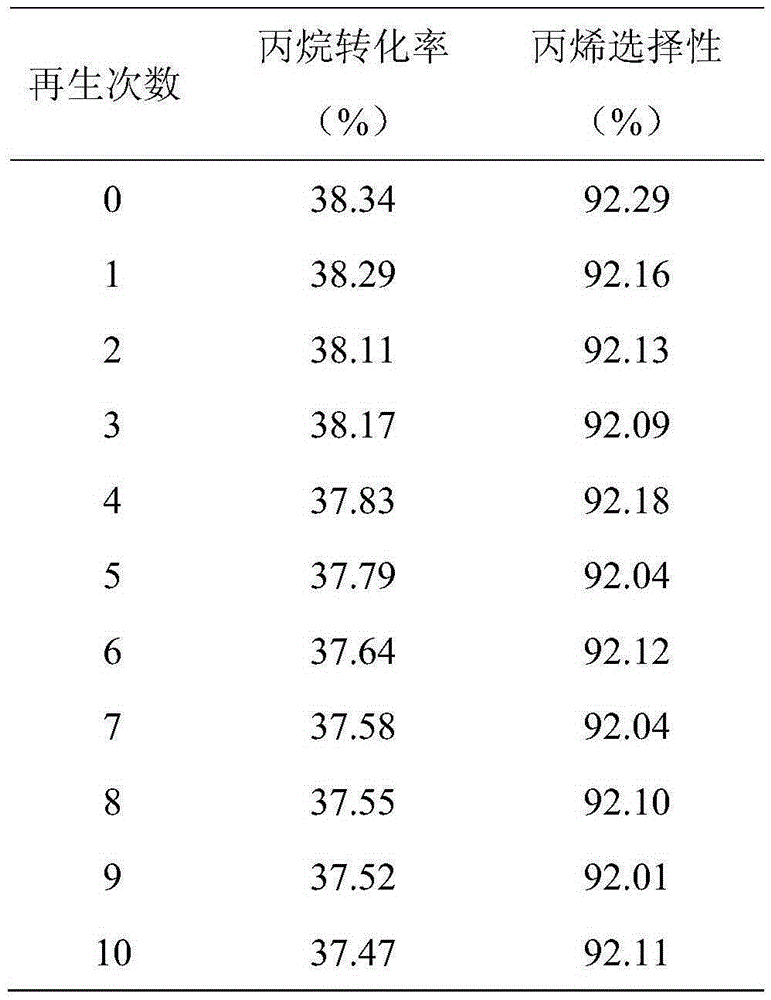

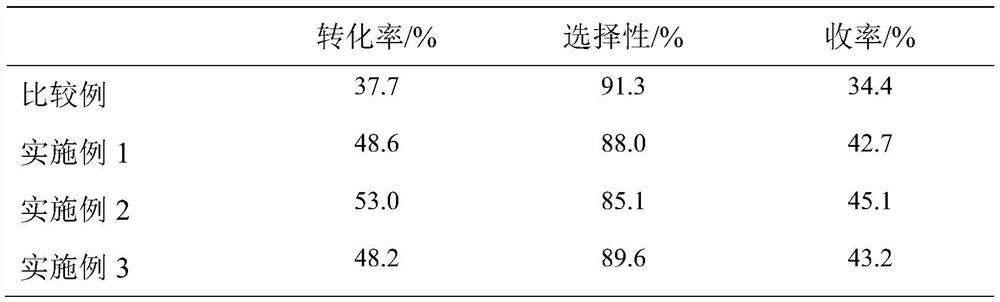

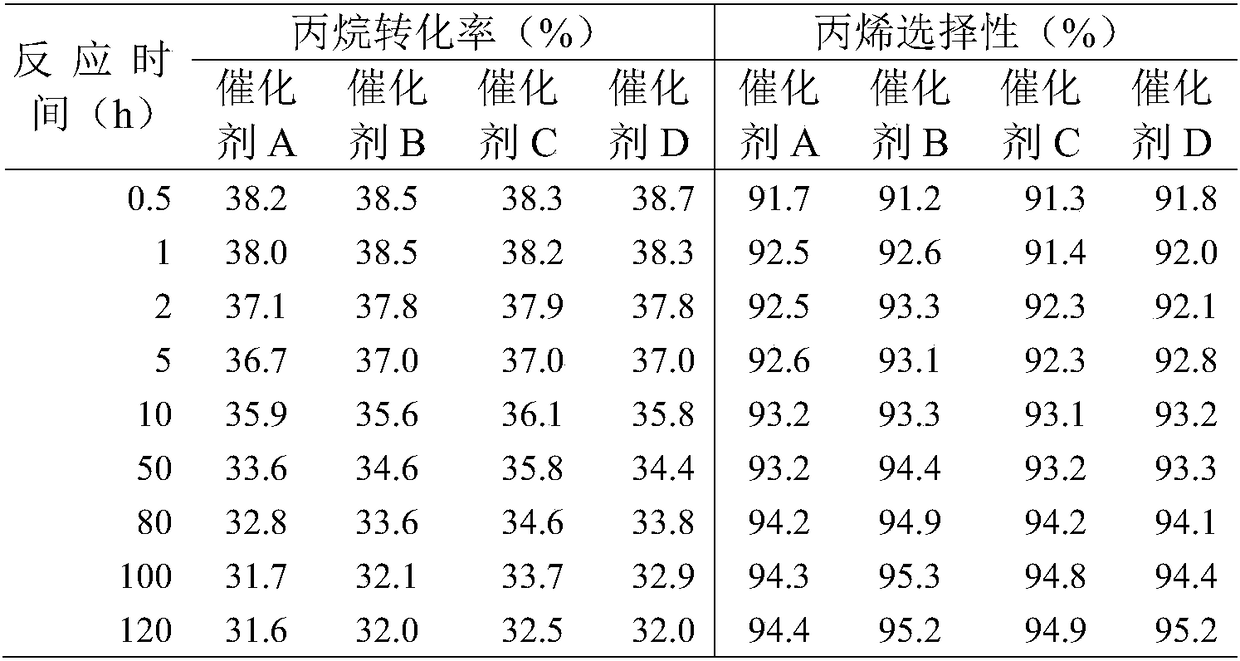

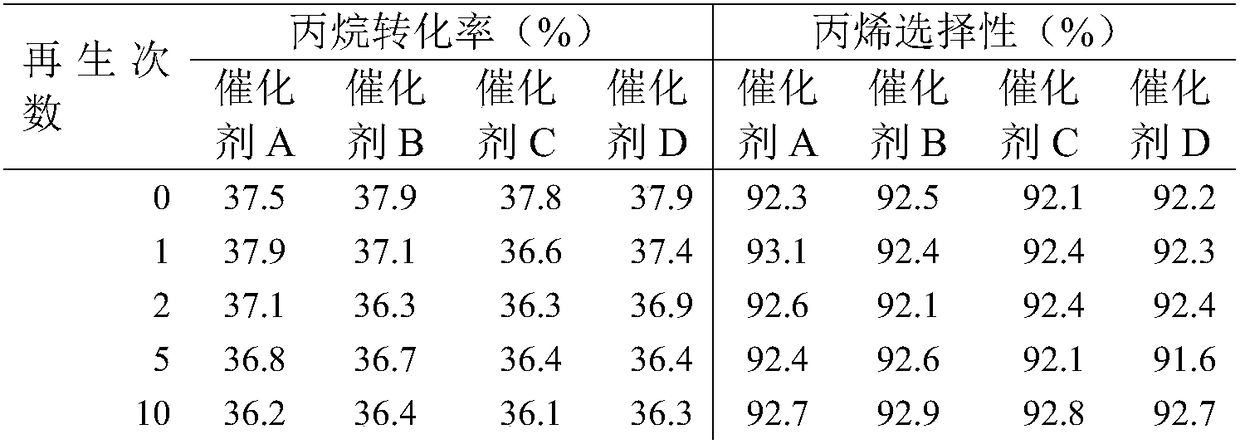

The invention discloses a quaternary platinum-based light-alkane dehydrogenation catalyst and a preparation method thereof. The catalyst comprises four components: Pt, Sn, Zr, and Ce, wherein Zr and Ce are added in the preparation of a carrier small aluminium oxide ball, and Sn and the active component Pt are uniformly loaded on the carrier by adopting an impregnation method; based on the weight of the catalyst, the content of Al2O3 is 95.0%-98.0%, the content of Pt is 0.1%-1.0%, the content of Sn is 0.1%-2%, the content of Zr is 0.5%-3.0%, and the content of Ce is 0.5%-2%. The catalyst prepared by the invention has the good catalytic activity when being used in propane dehydrogenation reaction, the catalyst has no obvious activity reduction after multiple-time regeneration, the average conversion per pass of propane is 37% and more, the propylene selection is more than 90%, and the good regeneration stability can be shown.

Owner:CHINA NAT OFFSHORE OIL CORP +3

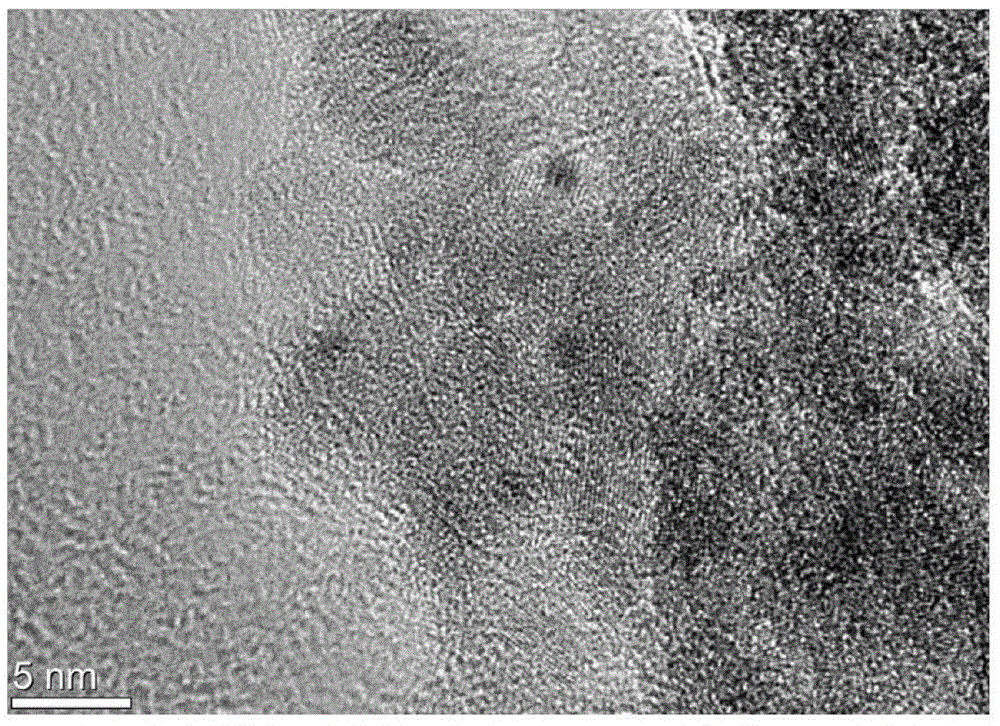

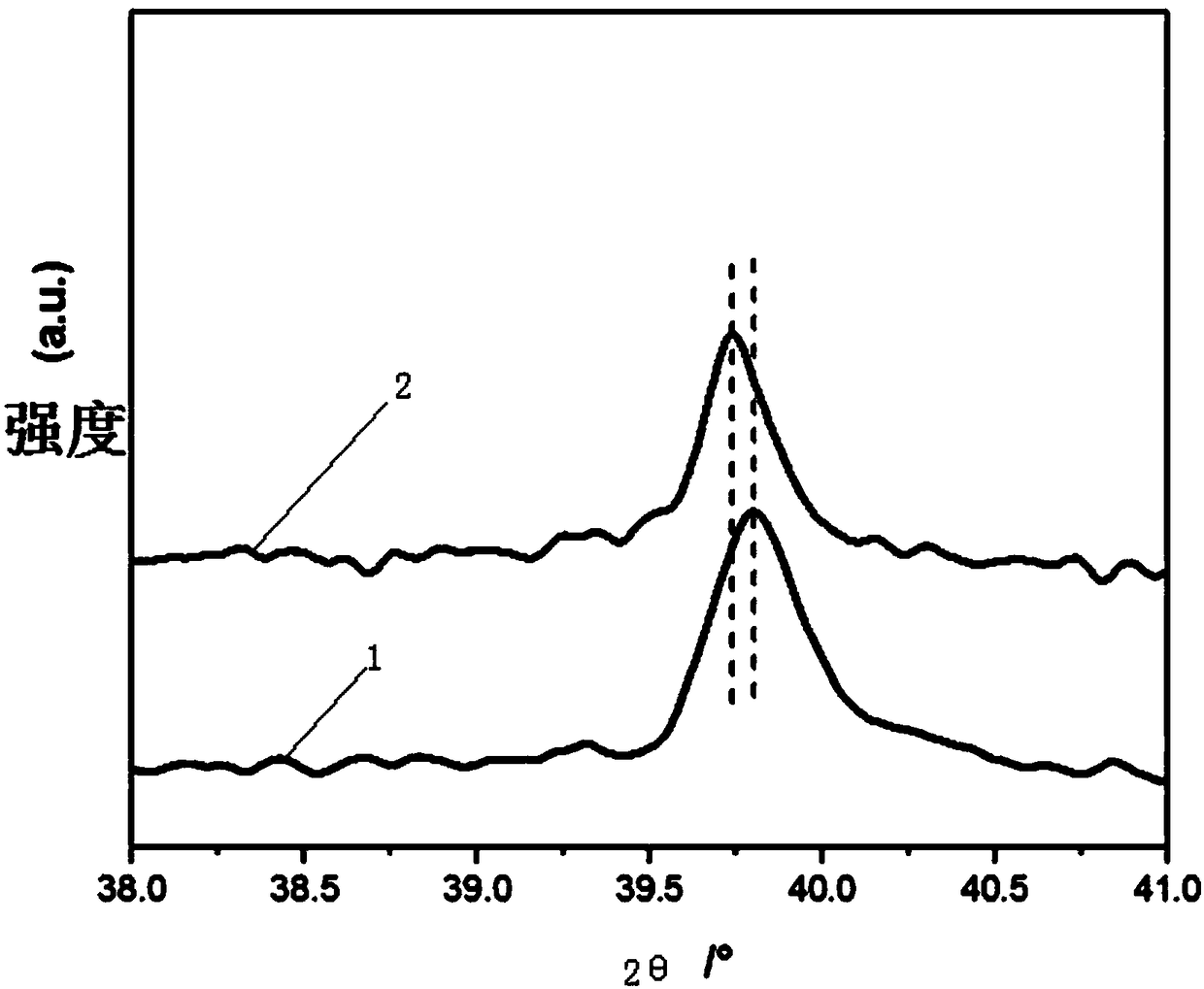

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

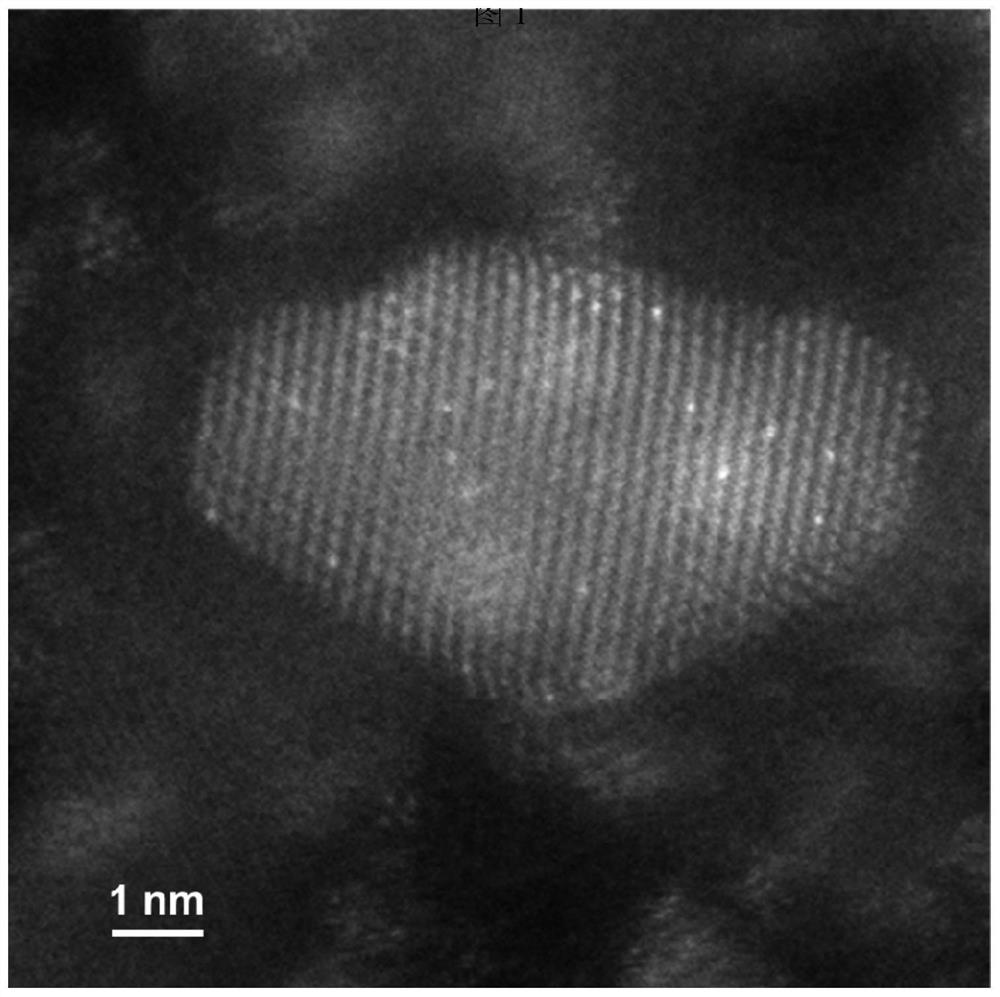

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

Low-carbon alkane dehydrogenation catalyst preparation method

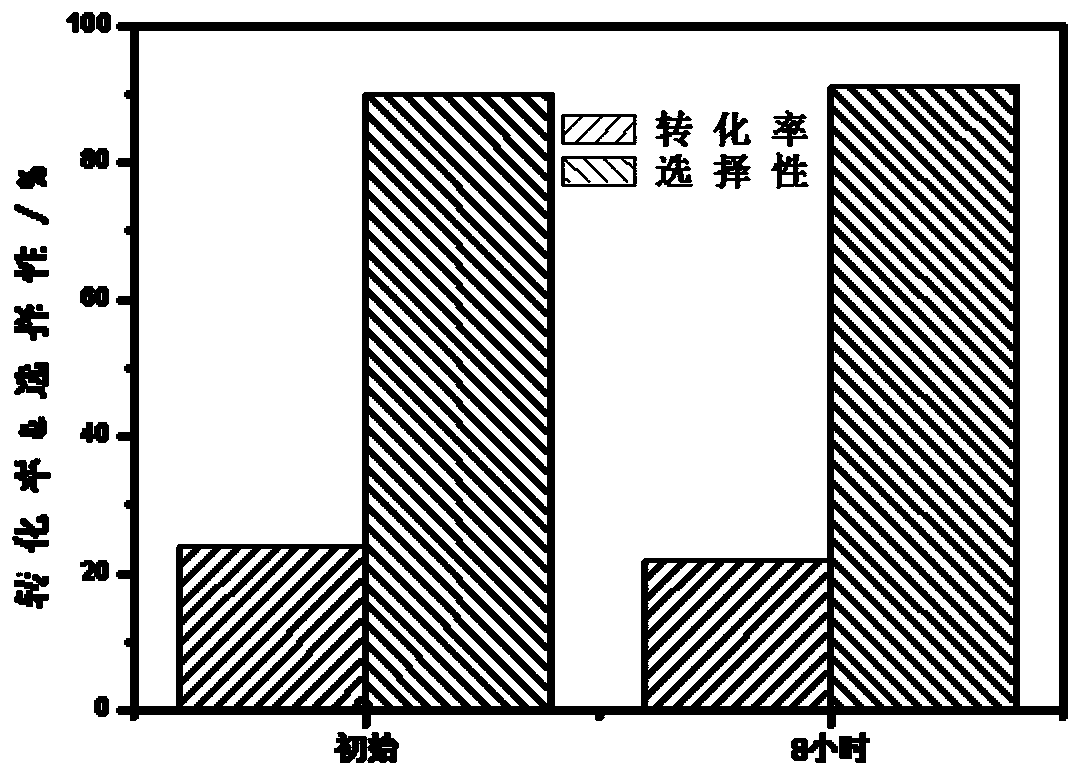

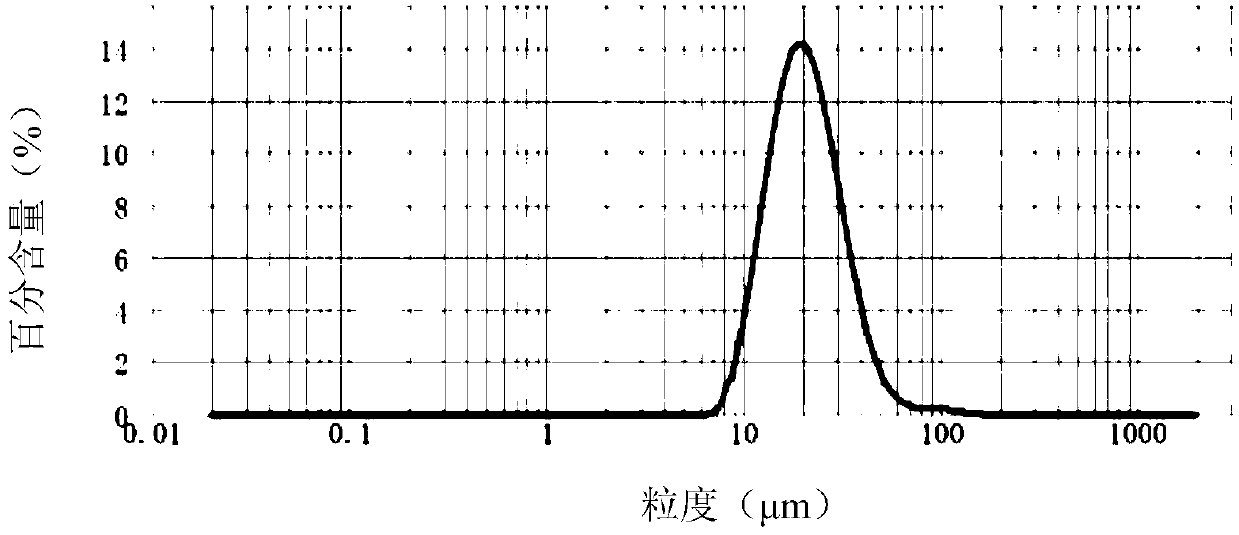

ActiveCN107486195ACluster controllableHigh dehydrogenation activityHeterogenous catalyst chemical elementsCatalystsAlkaneDehydrogenation

The invention discloses a low-carbon alkane dehydrogenation catalyst preparation method, which comprises: dissolving a high-valent chromium precursor in a reducing agent solution, impregnating into an alumina-based carrier, carrying out a reaction for 0.5-20 h at a temperature of 30-200 DEG C, washing, filtering, drying, impregnating into an aid, drying, and calcining to obtain the low-carbon alkane dehydrogenation catalyst. According to the present invention, the Cr cluster can be controlled; and the catalyst with the moderate Cr dispersion degree is obtained through the in-situ reduction method, such that the acid quantity of the acid B on the catalyst surface is reduced, the utilization efficiency of the active atom Cr is improved, and the dehydrogenation activity, the selectivity and the anti-carbon-deposition performance of the catalyst are improved.

Owner:PETROCHINA CO LTD +1

Catalyst for storing hydrogen by organic matter carrier and preparation method of catalyst

The invention relates to a catalyst for storing hydrogen by an organic matter carrier and a preparation method of the catalyst. The catalyst comprises the following components in percent by weight: 0.15-5 percent of metal active component, 0.1-4 percent of additive, 2-5 percent of adhesive and the balance of carrier. The carrier containing a rare earth metal is prepared by adopting a hydrothermal reaction and then immersed in an active metal water solution, then dried and roasted, and then mixed with the adhesive to obtain the catalyst. Compared with the prior art, the catalyst has the characteristics of proper acid strength, high reaction activity, good selectivity and the like; and the rare earth metal is added, the dispersion degree of the active metal can be increased, surface carbon deposit of the catalyst is reduced, thus the service life of the catalyst is prolonged.

Owner:上海欣年石化助剂有限公司

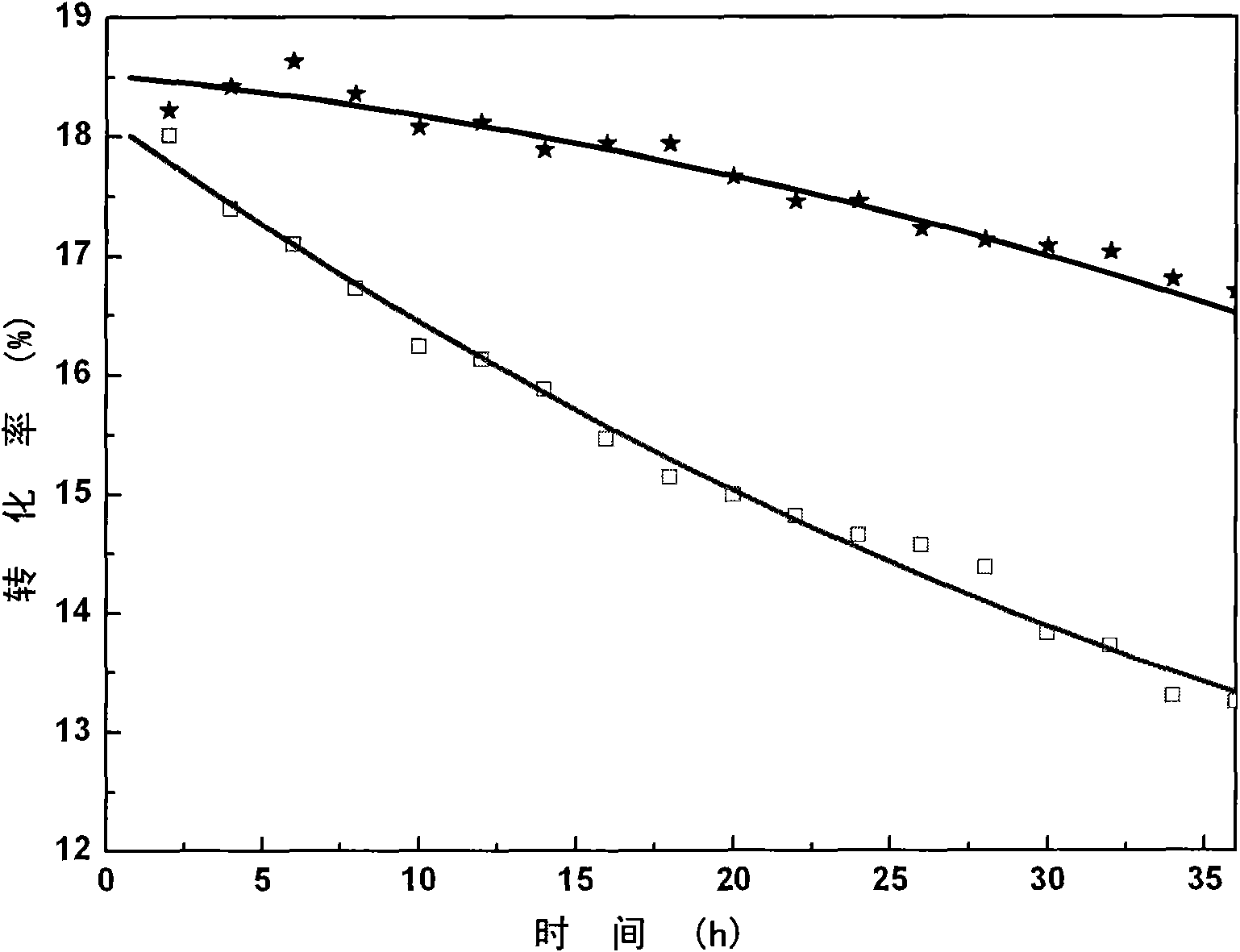

Catalyst for dehydrogenation of C16-C19 long chain normal alkanes and preparation method and application thereof

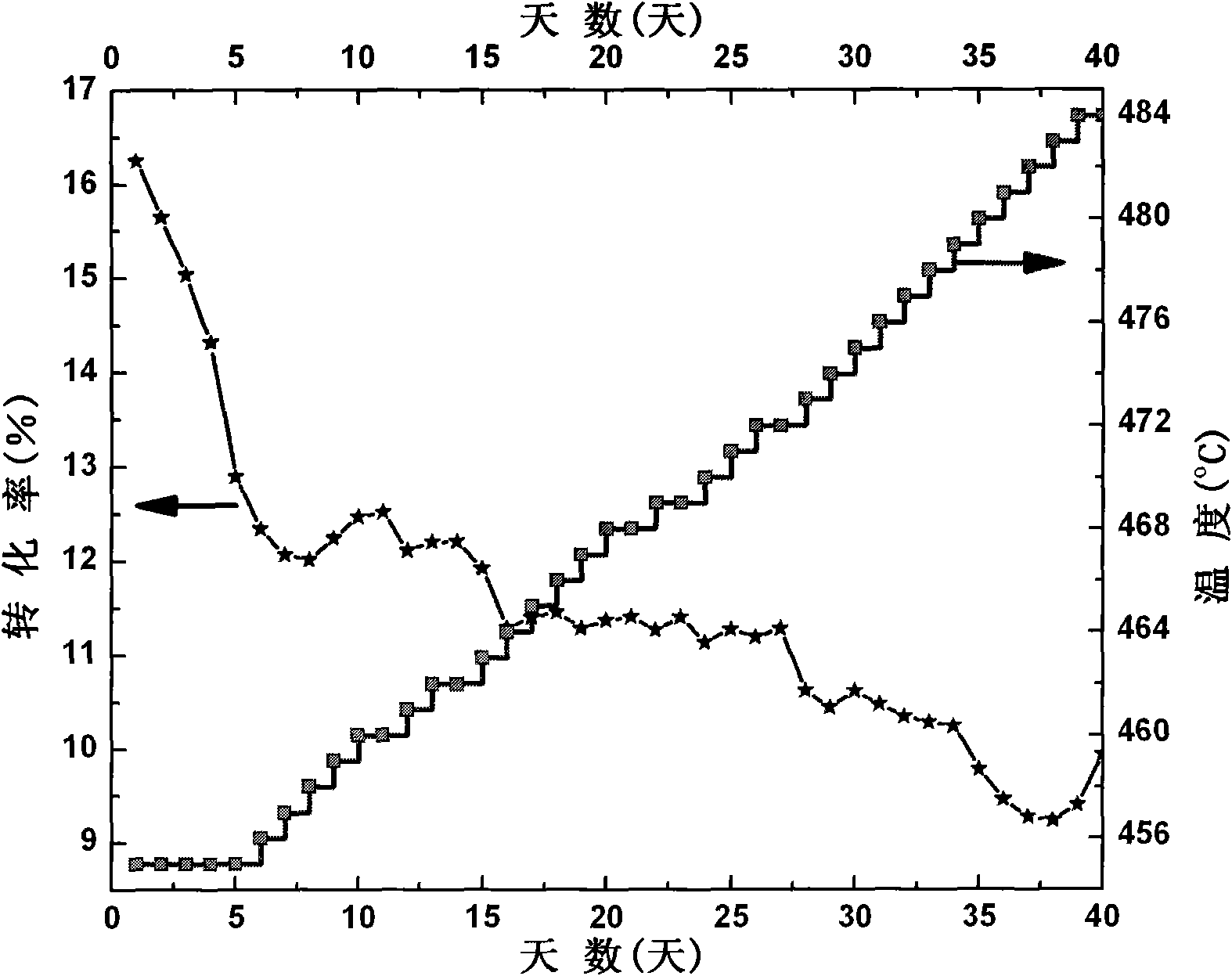

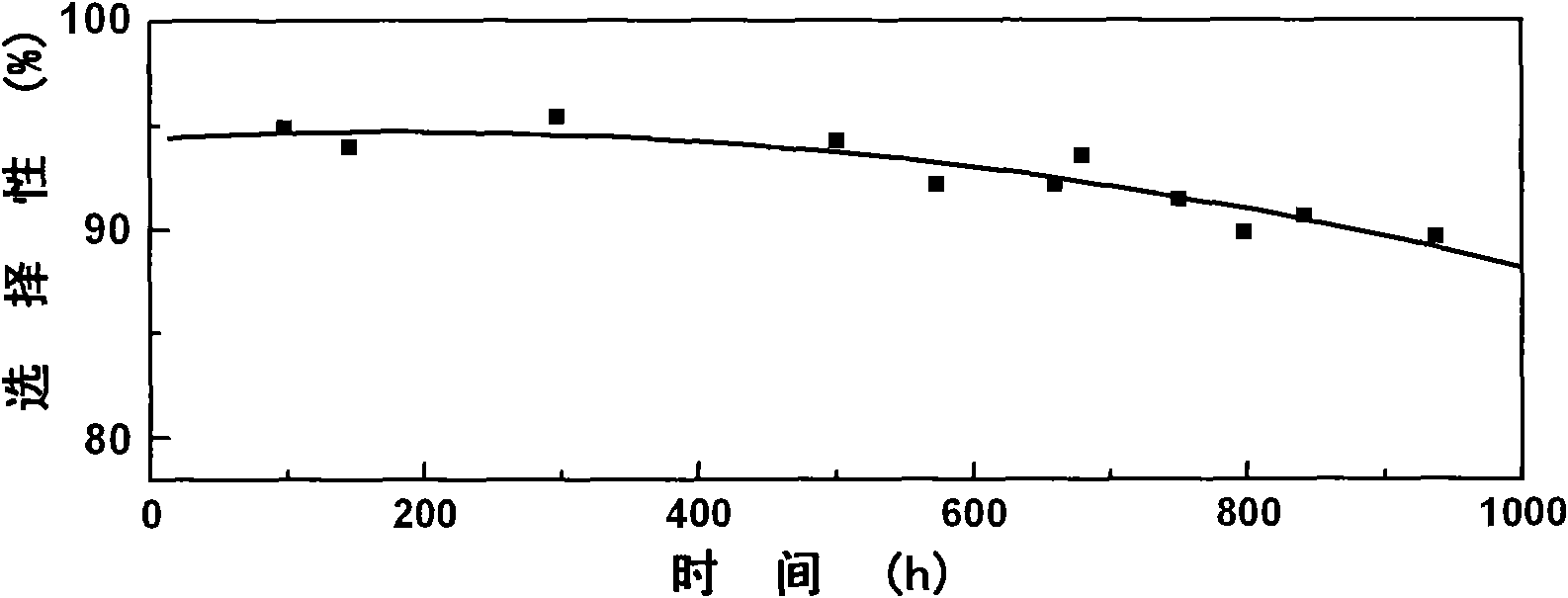

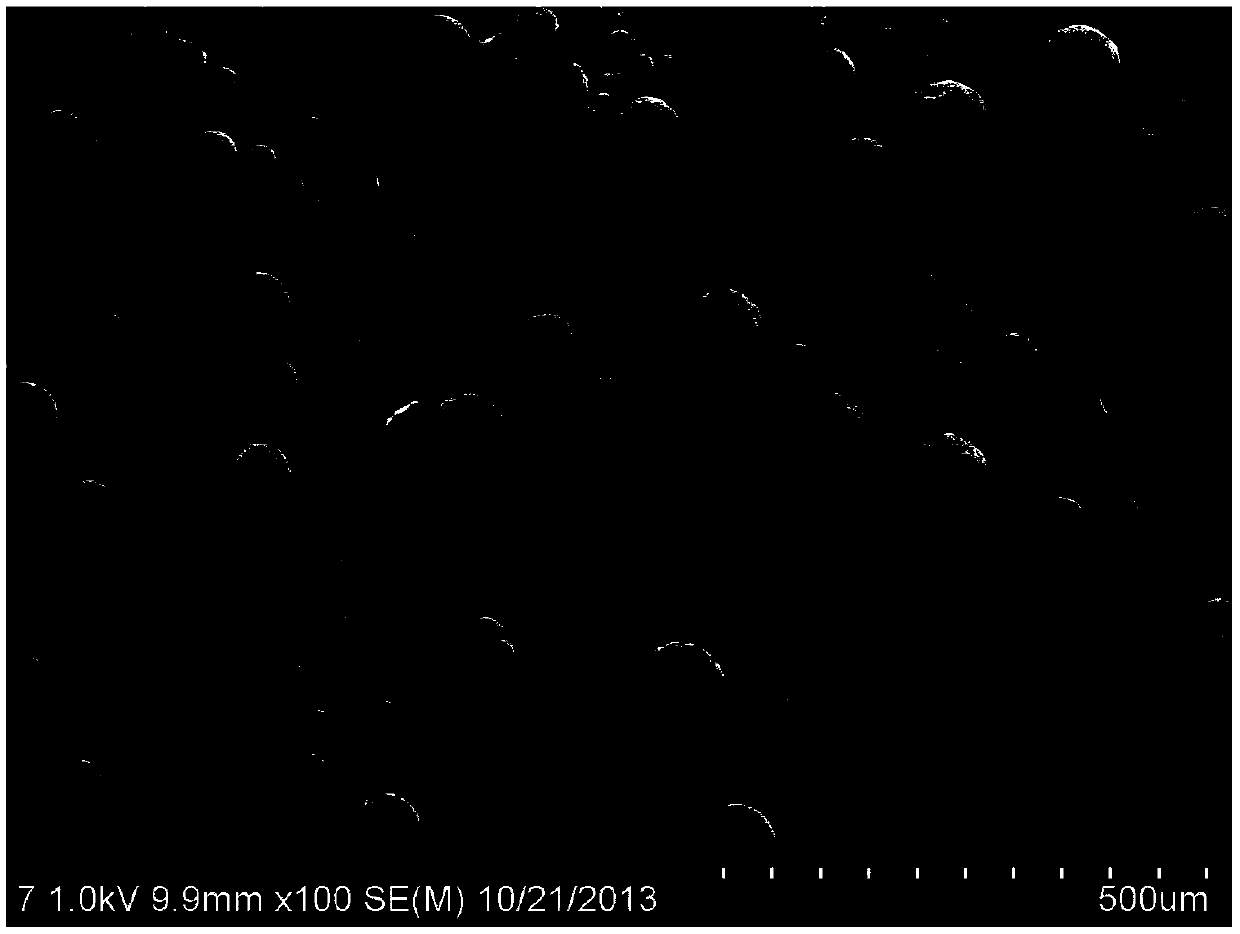

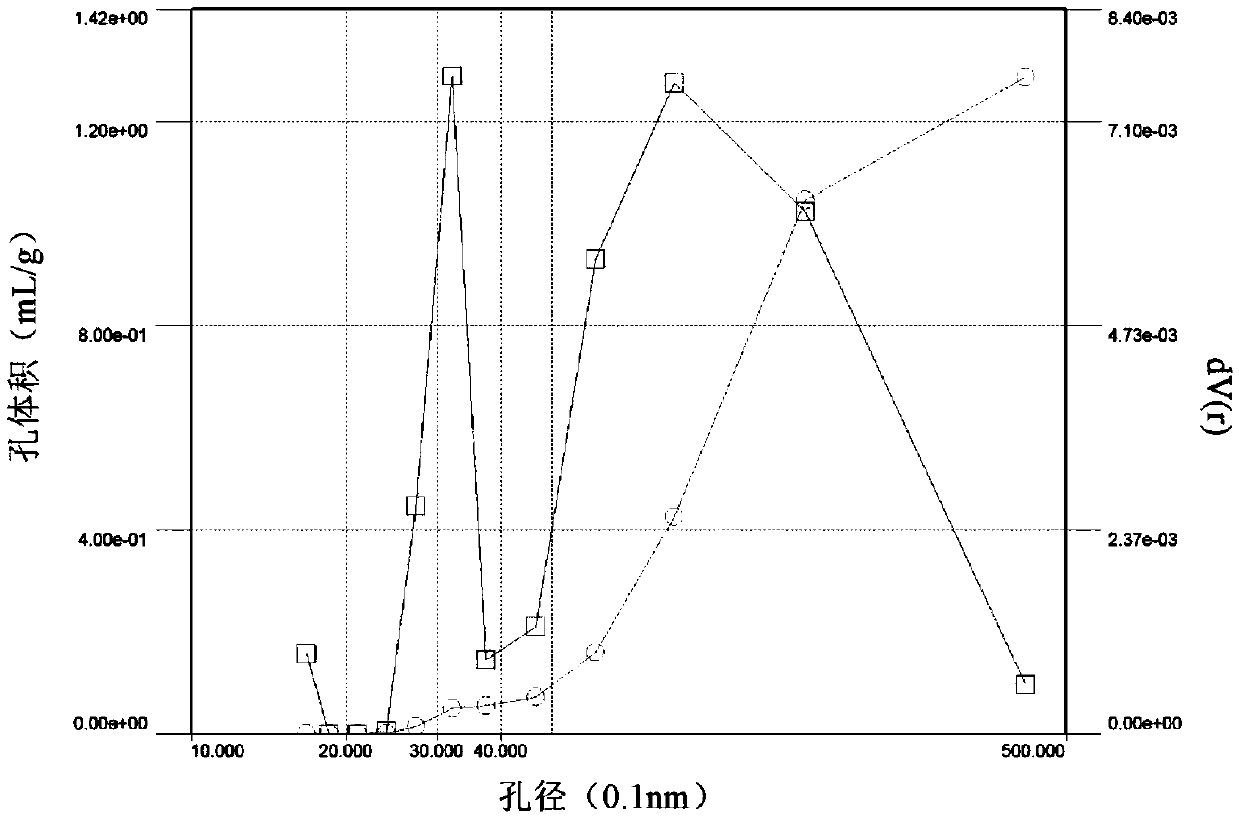

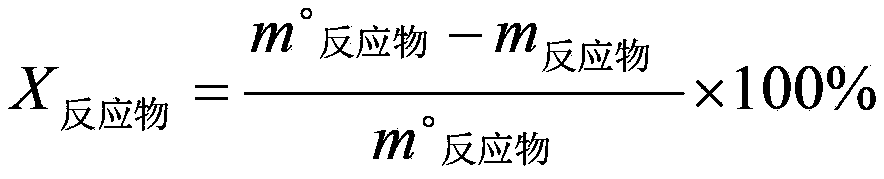

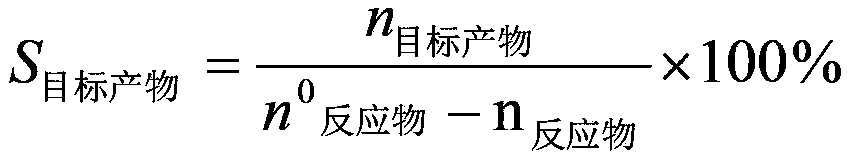

ActiveCN101642713AImprove stabilityHigh dehydrogenation activityHydrocarbonsDrilling compositionPore distributionOil water

The invention relates to a catalyst for dehydrogenation of C16-C19 long chain normal alkanes and a preparation method and application thereof. The catalyst comprises the following components in percentage by weight: 0.2 to 0.5 percent of platinum, 0.4 to 2.0 percent of tin, 0.1 to 2.0 percent of iron, 0.4 to 2.0 percent of potassium and the balance of large-pore strip alumina with dual-pore distribution; and the catalyst is used in a reaction for the dehydrogenation of C16-C19 long chain normal alkanes to prepare monoolefine, the conversion rate is 11.4 percent, and the selectivity is 91.9 percent; the catalyst can undergo C16-C19 catalytic dehydrogenation reaction for a long time; and alkylbenzene sulfonate synthesized by dehydrogenized products can have ultra interfacial tension in a wide alkali concentration range for oil-water in actual oil field, and compared with the oil displacement performance of a byproduct of C10-C13 alkylbenzene, namely heavy alkylbenzene sulfonate, the alkali concentration is shifted to the low-concentration direction, and the interface activity of a sample is better.

Owner:PETROCHINA CO LTD +1

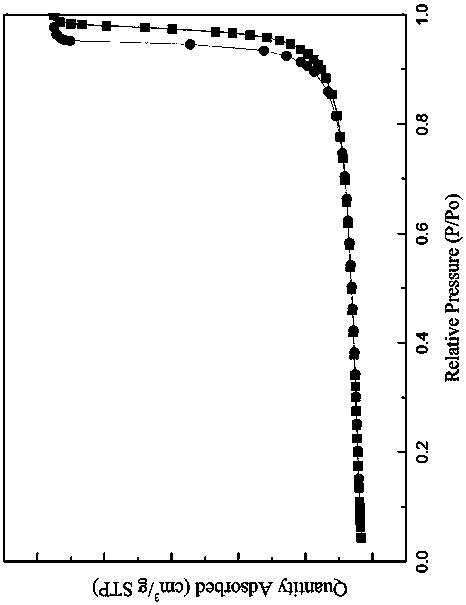

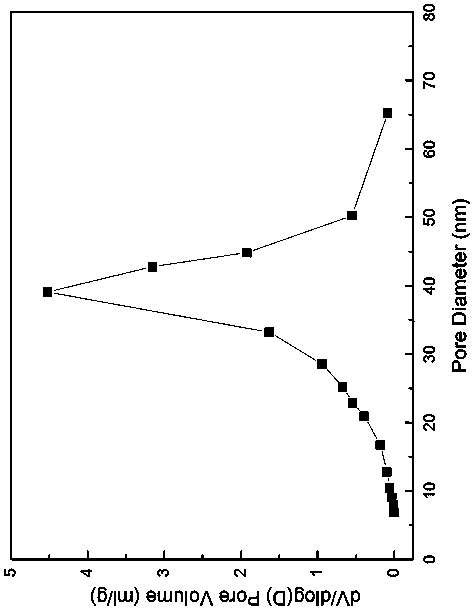

Aluminum oxide carrier and preparation method and application thereof

InactiveCN109569740AAvoid small poresAvoid non-concentrated pore size distributionCatalyst carriersHydrocarbonsPore distributionLarge pore

The invention provides an aluminum oxide carrier and a preparation method and application thereof. The aluminum oxide carrier has a diameter of 0.5-3.5mm and a specific surface area of 40-200m<2> / g, and holes in diameter of 15-20nm accounts for total hole quantity by 90% or more. The preparation method of the aluminum oxide carrier includes steps: (1) aluminum oxide sol preparation; (2) adding a pore-enlarging agent and / or a gelatinizing agent into aluminum oxide sol to form a precursor, and subjecting the precursor to thermal treatment and molding; (3) drying formed aluminum oxide at 100-150DEG C, heating to 950-1120 DEG C by a heating rate of 1-5 DEG C / min, and keeping the constant temperature for 6-10h to obtain the aluminum oxide carrier, wherein in a heating process, sequentially keeping the constant temperature for 1-10h in four temperature ranges of 200-300 DEG C, 400-500 DEG C, 600-700 DEG C and 800-900 DEG C. The aluminum oxide carrier prepared according to the method has a great and stable porous structure, is concentrated in pore distribution and uniform and controllable in pore diameter and has advantages of high specific surface area, large pore volume and high anti-crush strength.

Owner:杨斌

KL molecular sieve loaded monatomic Pt and PtxFe cluster structure catalyst and preparation method and application thereof

ActiveCN109364988AEasy to synthesizeGood repeatabilityMolecular sieve catalystsHydrocarbonsAlkaneMolecular sieve

The invention discloses a KL molecular sieve loaded monatomic Pt and PtxFe cluster structure catalyst and a preparation method and an application thereof. The KL molecular sieve loaded monatomic Pt and PtxFe cluster structure zeolite catalyst is prepared by means of advanced atomic layer deposition equipment which is high in controllability. Pt can be controlled to coexist with PtxFe (x is greaterthan 8 but less than 13) in a monatomic form and the two are highly dispersed in pores of a molecular sieve, so that contact between Pt and Fe is improved greatly. The catalyst can improve the utilization ratio of the active center of Pt greatly, the aromatization process of alkane is facilitated as a result of different structure forms of PtxFe, Pt in the monatomic form is an effective active center in a dehydrogenation process of alkane, and an intermediate specie after dehydrogenation finishes the aromatization process in the PtxFe cluster, so that the selectivity of alkane is improved greatly and the side reactions are reduced.

Owner:SYNFUELS CHINA TECH CO LTD

Preparation method of catalyst for preparing propylene by propane dehydrogenation and catalyst prepared by method

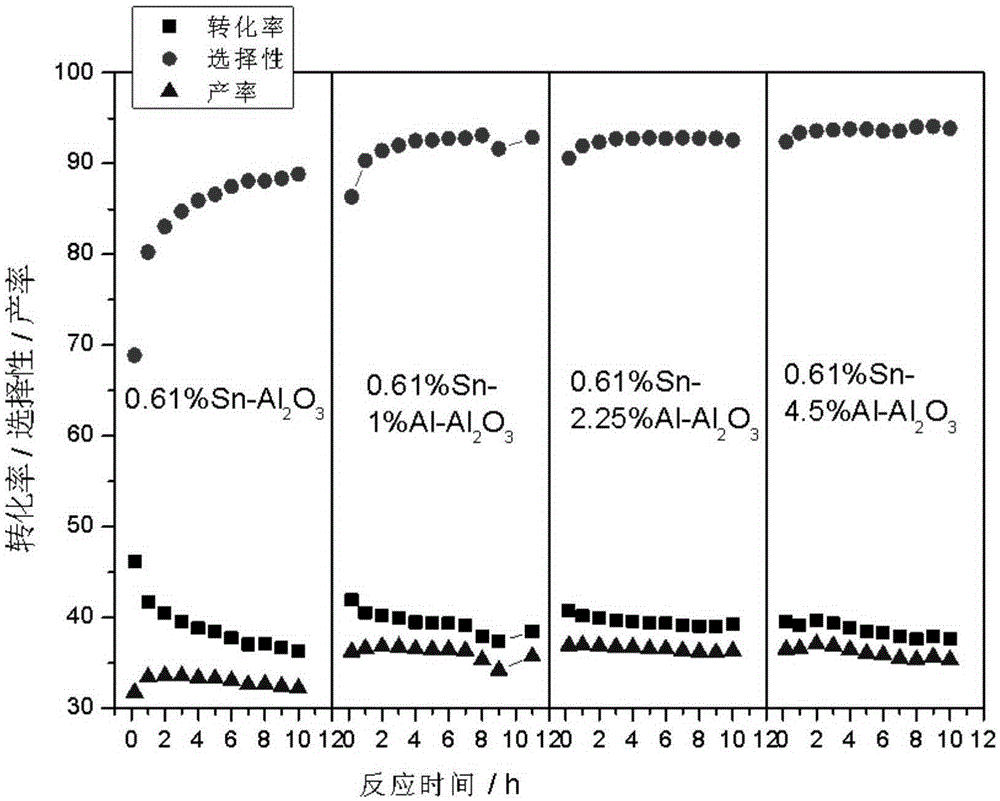

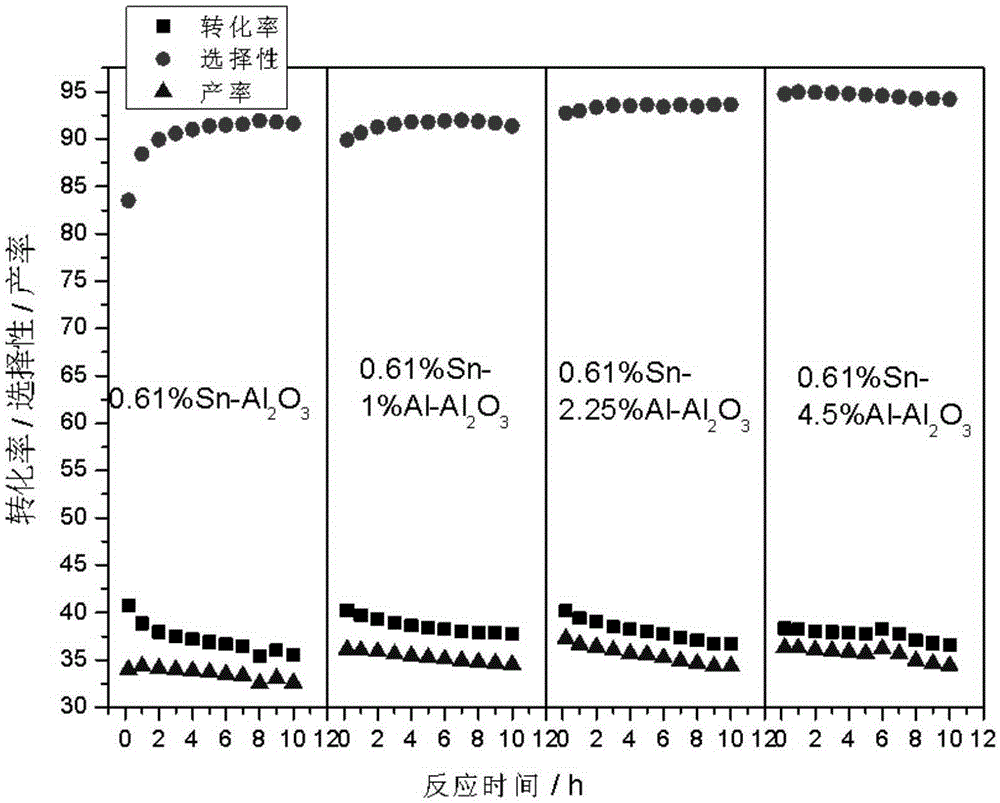

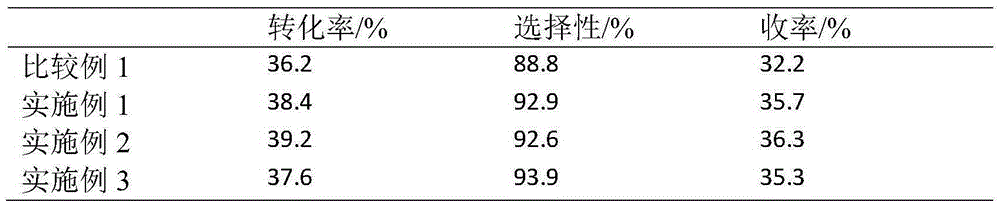

ActiveCN106807405AEvenly dispersedIncrease forcePhysical/chemical process catalystsHydrocarbonsAlkaneVulcanization

The invention relates to a preparation method of a catalyst for preparing propylene by propane dehydrogenation. The Group IV metal-Group III metal bimetal combination is used as an aid, a platinum group metal is used as the dehydrogenation active component of the catalyst, and formed alumina is used as the support. The preparation process of the catalyst comprises the following steps: introducing the alumina support into the Sn-Al aid by co-impregnation so that the Sn is dispersed in the support more uniformly on the atom level, thereby enhancing the acting force between the Sn and alumina support; impregnating the Sn-Al-containing alumina support with the dehydrogenation active component to enhance the interaction force among the metal, aid and support; and finally, carrying out drying roasting, dechlorination, alkali metal aid impregnation, dilute hydrochloric acid impregnation, vulcanization and other after-treatments to finally obtain the dehydrogenation catalyst. The catalyst can be used for low-carbon alkane dehydrogenation reaction and especially propane dehydrogenation reaction, and has the advantages of high activity, favorable selectivity, favorable stability and the like; and especially, the selectivity and stability are obviously enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for removing hydrogen through selective oxidation of CO gas mixture

ActiveCN101993073AHigh dehydrogenation activityImprove effective utilizationCarbon monoxideAlkaline earth metalReaction temperature

The invention relates to a method for removing hydrogen through selective oxidation of a CO gas mixture, mainly solving the technical problems of low hydrogen removal rate and high CO loss rate in the prior art. The invention adopts the following technical scheme: the CO gas containing hydrogen is utilized as the raw material, and the raw material is contacted with noble metal catalysts under the following conditions: the reaction temperature is 80-260 DEG C; the volume space velocity is 100-10000h-1; the molar ratio of oxygen to hydrogen is 0.5-10:1; and the reaction pressure is -0.08-5.0MPa, and the hydrogen in the raw material is oxidized into water, wherein the noble metal catalysts include (a) at least an active component from platinum metals; (b) at least an auxiliary agent from alkali metals, alkaline-earth metals, IB, IIB, VB, VIIB, VIII, IIIA, IVA or lanthanides; and (c) a layered composite carrier formed by the kernel of an inert carrier and a porous coating material shell combined with the kernel. The technical scheme better solves the problems and can be used in the industrial production for removing hydrogen through selective oxidation of the CO gas mixture.

Owner:CHINA PETROLEUM & CHEM CORP +1

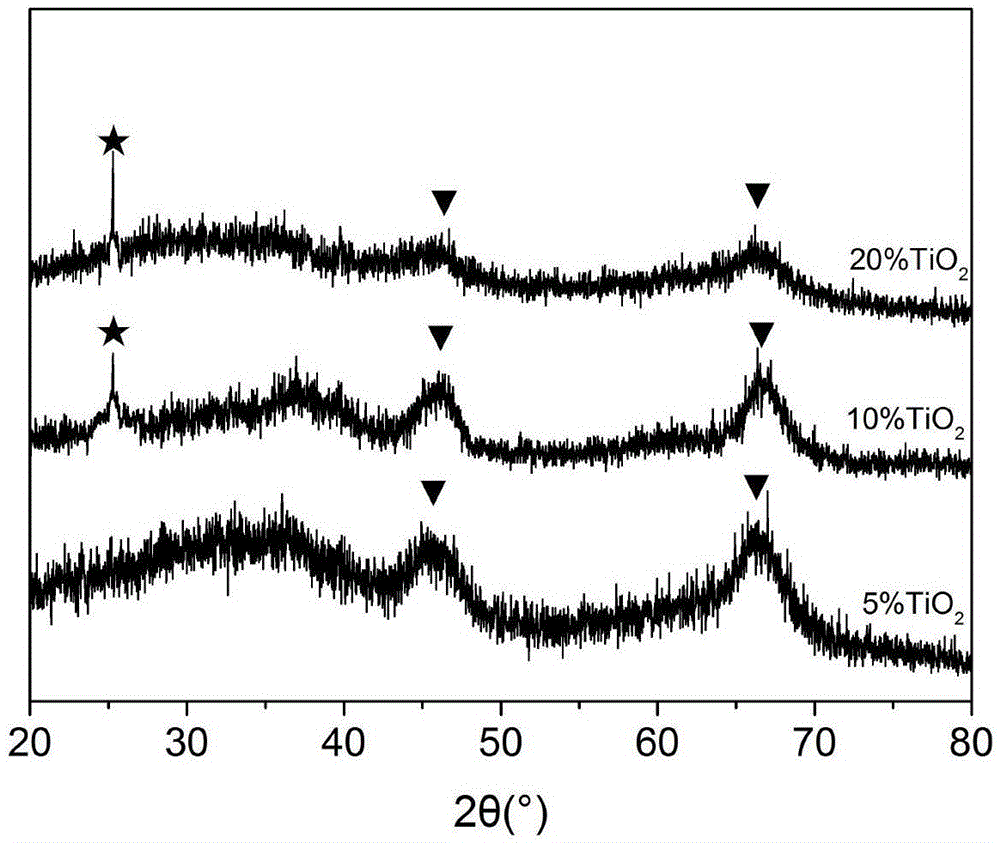

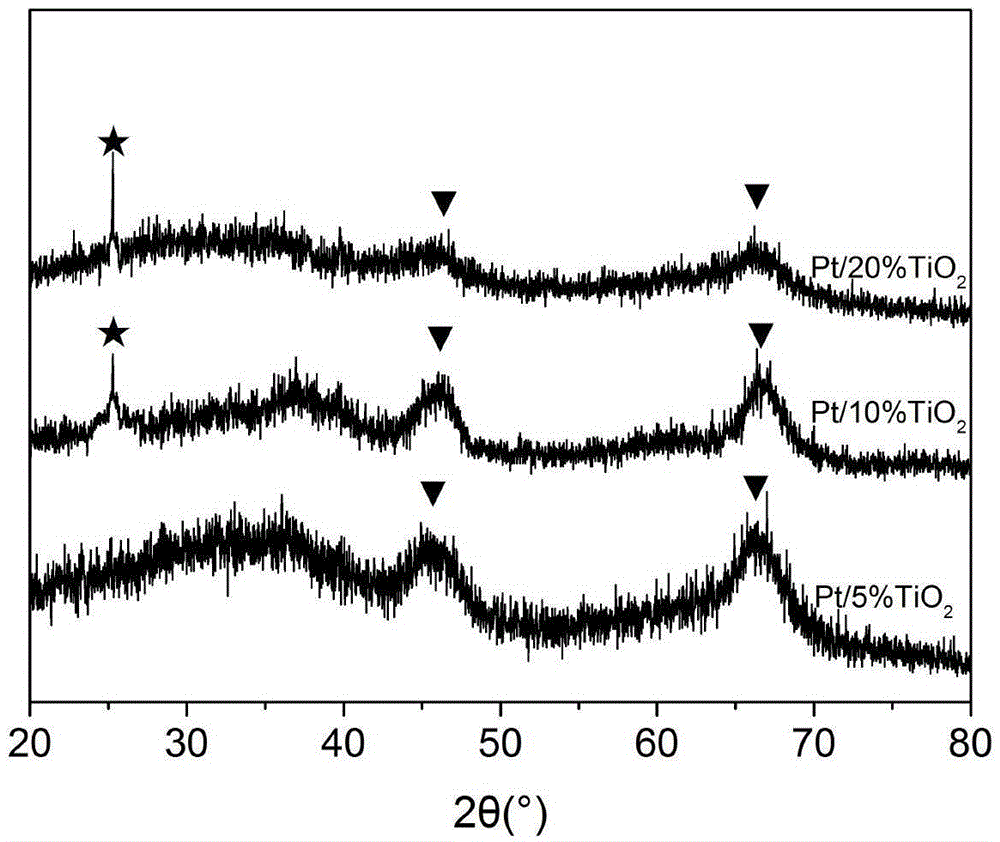

Application of platinum catalyst in preparation of propylene by dimethylmethane

ActiveCN105478107AFacilitated DiffusionEvenly distributedCatalystsHydrocarbon preparation catalystsDehydrogenationPlatinum catalyst

The invention discloses application of a platinum catalyst in preparation of propylene by dimethylmethane. The catalyst takes a TiO2-Al2O3 dual oxide as a carrier, a loaded active component is Pt, and the mass percentage composition of the Pt is 0.5-1.5 percent. The TiO2-Al2O3 dual oxide carrier is prepared by adopting a sol-gel method, and then the obtained carrier is steeped into a chloroplatinic acid solution, and is dried and calcined, thus obtaining the Pt / TiO2-Al2O3 catalyst. The catalyst is suitable for preparing the propylene by dimethylmethane dehydrogenation under a hydrogenation atmosphere; the addition of TiO2 changes the acting force of a product as well as a reactant with an active center, thus propylene selectivity and carbon deposition resistance are improved, and the catalyst is enabled to have better reaction stability under a high temperature condition.

Owner:TIANJIN UNIV

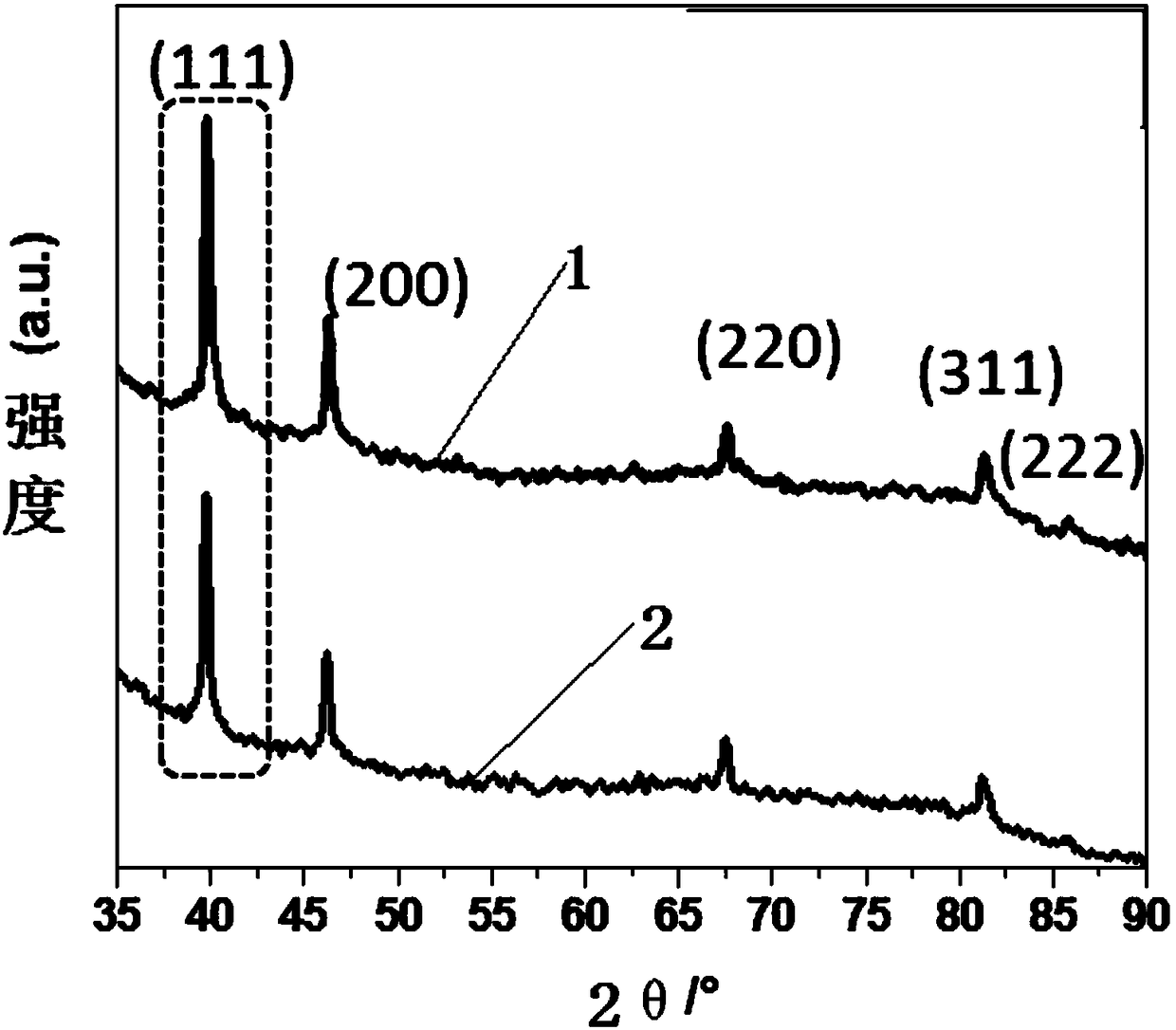

Supported type high-selectivity bimetallic catalyst with core-shell structure as well as preparation method and application thereof

ActiveCN108722469AReduce dosageAchieve reductionMolecular sieve catalystsMolecular sieve catalystHydrogen atmosphereDehydrogenation

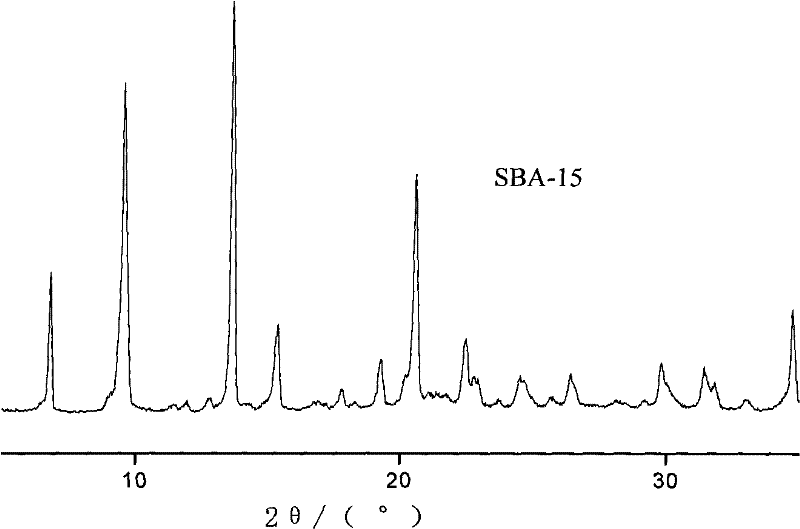

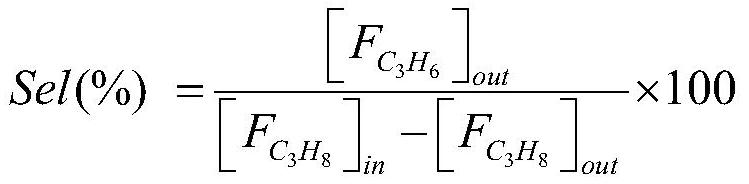

The invention discloses a supported type high-selectivity bimetallic catalyst with a core-shell structure as well as a preparation method and application thereof. An SBA-15 is taken as a supporter, Ptis taken as an active ingredient, 3d transition metal is taken as an aid, and the 3d transition metal and Pt define the bimetallic catalyst with the core-shell structure, wherein on one hand, intranuclear 3d metal is added, so that the d belt center of the surface Pt atom is reduced, and adsorption on propylene is weakened, and therefore, selectivity on propylene is improved, on the other hand, 3d transition metal is added, the dosage of Pt can be reduced, reduction of Pt is realized, and utilization of Pt is more efficient. The catalyst is suitable for hydrogen atmosphere, has very good effect on propylene prepared by propane dehydrogenation, has very high dehydrogenation activity under a high-temperature condition, has overall selectivity of 85% on propylene, and realizes very high propylene selectivity.

Owner:TIANJIN UNIV

Propane dehydrogenation catalyst and preparation method thereof

ActiveCN108067228AGuaranteed thermal stabilityGood dispersionCatalyst activation/preparationCatalytic reactionsActive componentDehydrogenation

The invention discloses a propane dehydrogenation catalyst and a preparation method thereof. The propane dehydrogenation catalyst adopts CaO-Al2O3 composite oxide balls as a carrier, adopts metal Pt as an active component, and adopts Sn and Bi as additives; by adoption of the mass of the catalyst as a reference, the content of the metal Pt is 0.1-1.0wt%, the content of the Sn is 0.1-2.0wt%, the content of the Bi is 0.1-1.0wt%, the content of CaO is 1.0-5.0wt% and the rest is Al2O3. The propane dehydrogenation catalyst and the preparation method disclosed by the invention have the beneficial effects that the catalyst is prepared by adopting a coprecipitation process and can ensure heat stability and enough specific surface area and pore volume of catalyst carriers; the reaction property andanti-carbon-deposition capability of the catalyst are excellent; the dehydrogenation activity of the catalyst is very high under a high-temperature condition, the propylene selectivity can reach 90%or more, and the stability is good.

Owner:WANHUA CHEM GRP CO LTD

Catalyst for preparation of methyl ethyl ketone from sec-butyl alcohol, and preparation method for catalyst

ActiveCN105148913AHigh dehydrogenation activityImprove thermal stabilityCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacDehydrogenation

The invention provides a catalyst for preparation of methyl ethyl ketone from sec-butyl alcohol. The catalyst comprises the following components in parts by weight: 45-55 parts of CuO, 35-55 parts of SiO2 and 2-20 parts of MO, wherein MO is at least one of CaO, MgO, ZnO and Al2O3. MO is used for modifying the Cu / SiO2 catalyst, so that the catalyst has higher dehydrogenation activity and excellent thermal stability; meanwhile, through the addition of MO, the conversion rate is increased and the selectivity of methyl ethyl ketone is improved; the modified Cu / SiO2 catalyst is prepared by combining physical and chemical methods. A preparation process is simple; when the catalyst is used in a process for preparation of methyl ethyl ketone from sec-butyl alcohol through dehydrogenation, not only is a higher conversion rate of sec-butyl alcohol kept, but also the whole reaction can be carried out in an alkaline environment through the addition of ammonia water, the prepared catalyst is high in quality, the added citric acid can ensure a physical property of the catalyst, the quality of the catalyst can be also improved due to uniform particle diameter, and the conversion rate and the selectivity of the catalyst are further improved accordingly.

Owner:NINGBO HAIYUE NEW MATERIAL

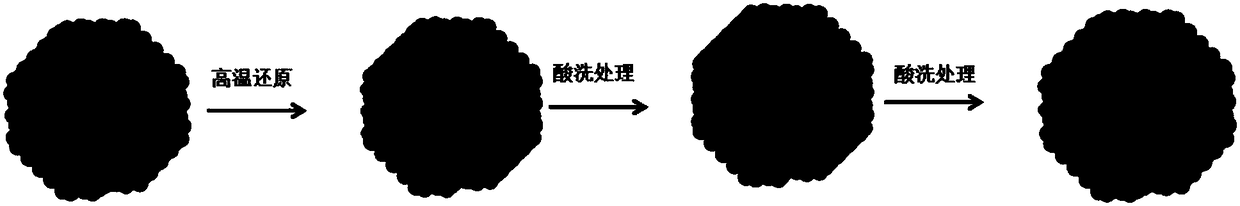

Method for activating platinum-containing light alkane dehydrogenation catalyst

ActiveCN106607105AAvoid gatheringHigh activityCatalystsHydrocarbon preparation catalystsPlatinumAir atmosphere

The invention relates to a method for activating a light alkane dehydrogenation catalyst. The method mainly solves the problem that the conversion rate and selectivity of the existing platinum-containing light alkane dehydrogenation catalyst are low. The method comprises a) carrying out grading treatment on the catalyst in an air atmosphere, b) treating the catalyst containing 1 to 10mol% of O2 and 1 to 10mol% water vapor flows to promote redispersion of an active metal component Pt and a halogen Cl, and c) reducing the active metal component at 450 to 650 DEG C in a trace hydrogen sulfide / H2 reduction atmosphere so that the deactivated catalyst is completely activated. The method solves the problem and can be used in industrial production of light alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of light alkane dehydrogenation catalyst with high thermal stability

InactiveCN104289220AImprove thermal stabilityHigh dehydrogenation activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlkaline earth metal

The invention discloses a preparation method and application of a light alkane dehydrogenation catalyst with high thermal stability. The light alkane dehydrogenation catalyst with high thermal stability is a PtSn load-type catalyst which uses Si-containing gamma-Al2O3 pellets as a carrier, and the catalyst also contains rare-earth metal elements, alkali metal elements and / or alkaline earth metal elements as auxiliaries; an element Si in the Si-containing gamma-Al2O3 pellet carrier accounts for 0.1-30 percent by weight; based on the weight of the Si-containing gamma-Al2O3 pellet carrier, the content of an element Pt loaded on the carrier is 0.3-0.5 percent by weight, the content of an element Sn is 0.6-1.0 percent by weight, the content of the rare-earth metal elements is 0.8-1.0 percent by weight, and the content of the alkali metal elements or the alkaline earth metal elements is 0.2-1.0 percent by weight. The catalyst is suitable for being used under light alkane dehydrogenation process conditions such as high temperature, long time and multiple regeneration, and is high in light alkane conversion rate and stability.

Owner:南京沃来德能源科技有限公司

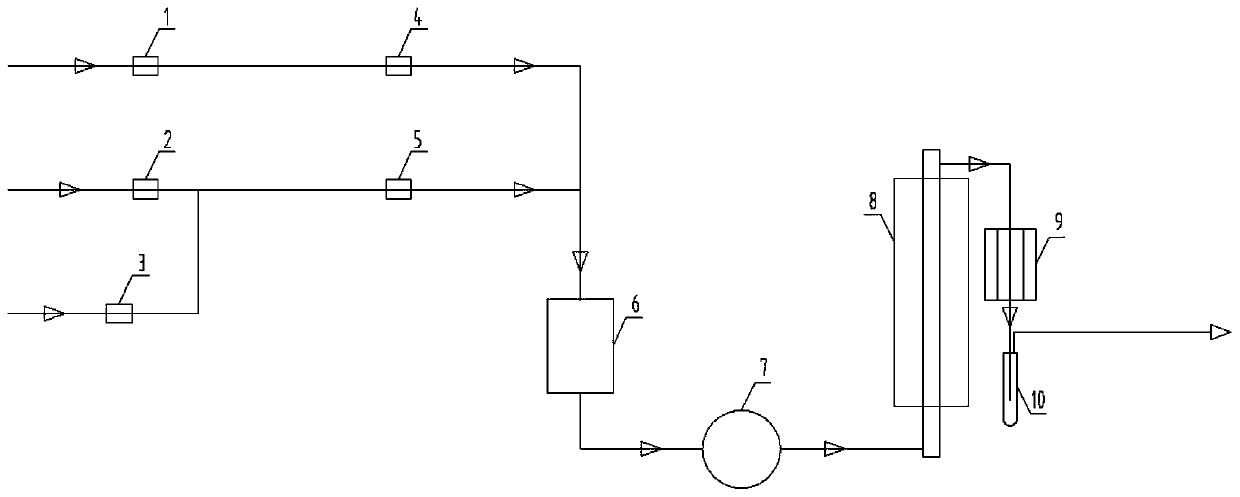

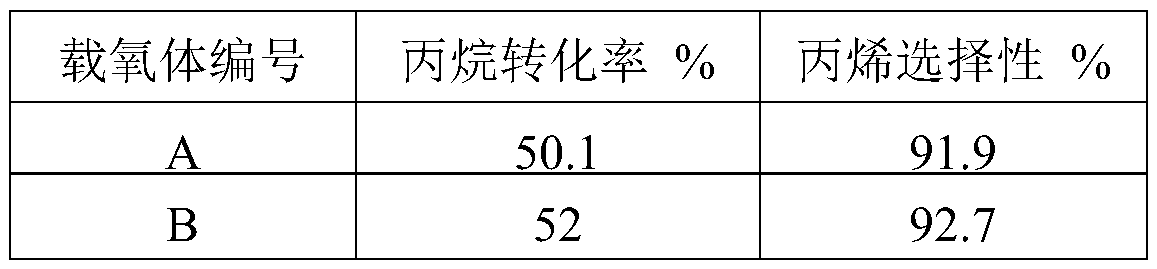

Preparation method of oxygen carrier for producing propylene through propane chemical-looping dehydrogenation

ActiveCN109482174AImprove wear resistanceSimple processCatalystsHydrocarbon preparation catalystsLithium oxideActive component

The invention belongs to the technical field of preparation of oxygen carriers, and relates to a preparation method of an oxygen carrier for producing propylene through propane chemical-looping dehydrogenation. The preparation method includes dipping aluminium oxide into precursor aqueous solution containing manganese to obtain an aluminum oxide oxygen carrier, loading a certain quantity of manganese-base active component, adding in clay and a binder into the oxygen carrier to improve wear resistance of the oxygen carrier, further, loading lithium oxide active component to the carrier so as toobtain oxygen carrier particles for producing propylene through propane chemical-looping dehydrogenation. The preparation method is simple in process; the oxygen carrier cannot cause environmental pollution in preparation and recycling process; the prepared oxygen carrier has high dehydrogenation activity, high propane conversion rate and high prpylene selectivity.

Owner:QINGDAO UNIV OF SCI & TECH

Activated carbon-supported copper-metal oxide catalyst and its preparation method and application

ActiveCN106076344BImprove stabilityHigh selectivityOrganic compound preparationHydroxy compound preparationActivated carbonFixed bed

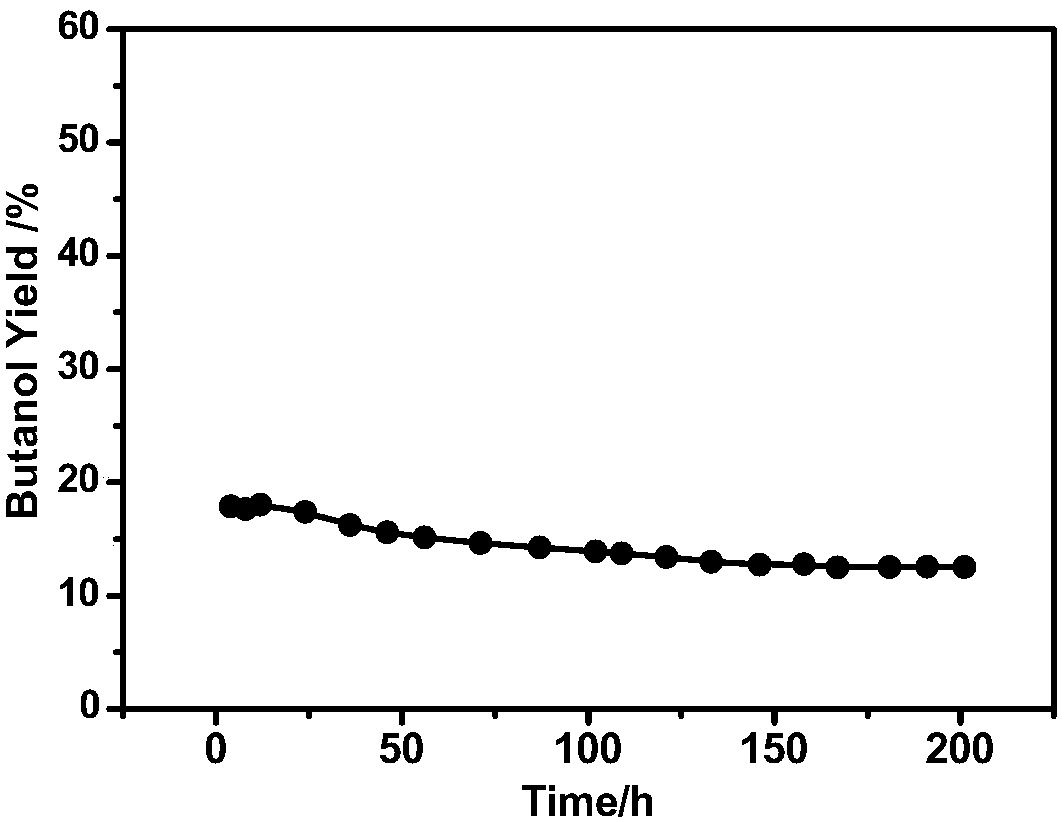

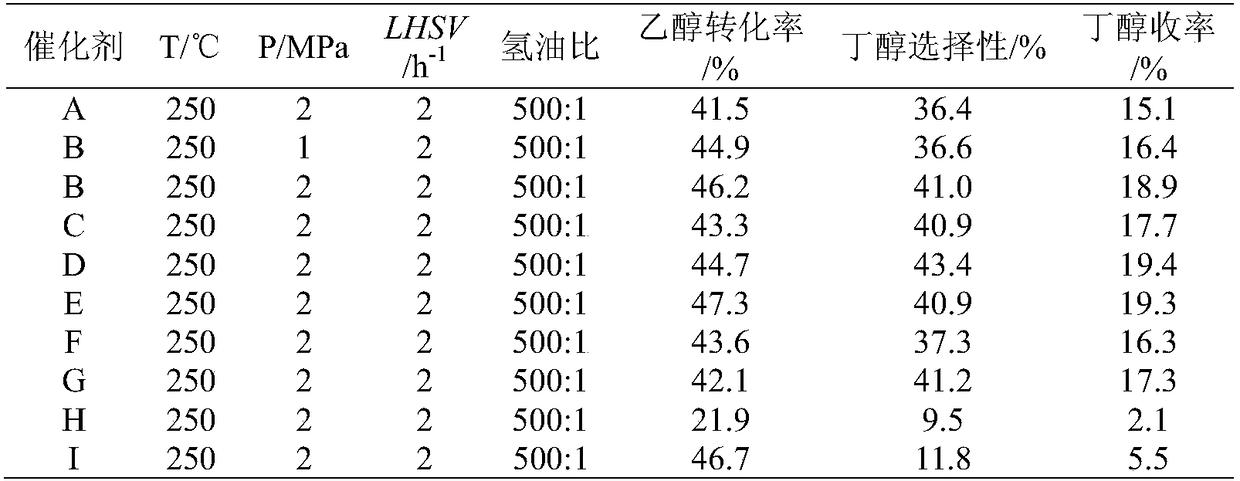

The invention provides an activated carbon-supported copper-metal oxide catalyst and its preparation method and application. The catalyst is composed of the following mass percentage components: carrier activated carbon 55% to 98%, metal Cu 1% to 20% , metal oxide MOx 1% to 25%; the catalyst of the present invention is easy to prepare and low in cost, and can be used in the reaction of ethanol dehydrogenation and condensation to produce n-butanol. When applied, a fixed-bed continuous reaction is used, the process is simple, and the reaction conditions are relatively mild , the yield of n-butanol in the product reaches 10wt%~30wt%, and the unreacted ethanol after product separation can be recycled and reused.

Owner:ZHEJIANG UNIV OF TECH

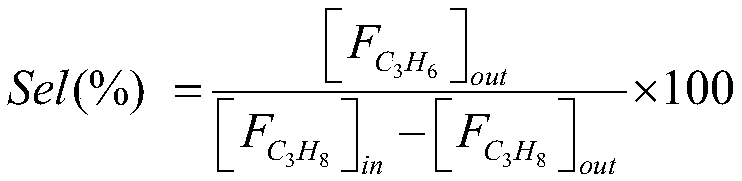

High-activity catalyst used for hydrogen production by dehydrogenation of organic hydrogen storage compound and reduced in noble metal consumption, and preparation method thereof

ActiveCN111889096AIncrease spawn rateHigh dehydrogenation activityHydrogenHydrocarbonsPtru catalystChemical composition

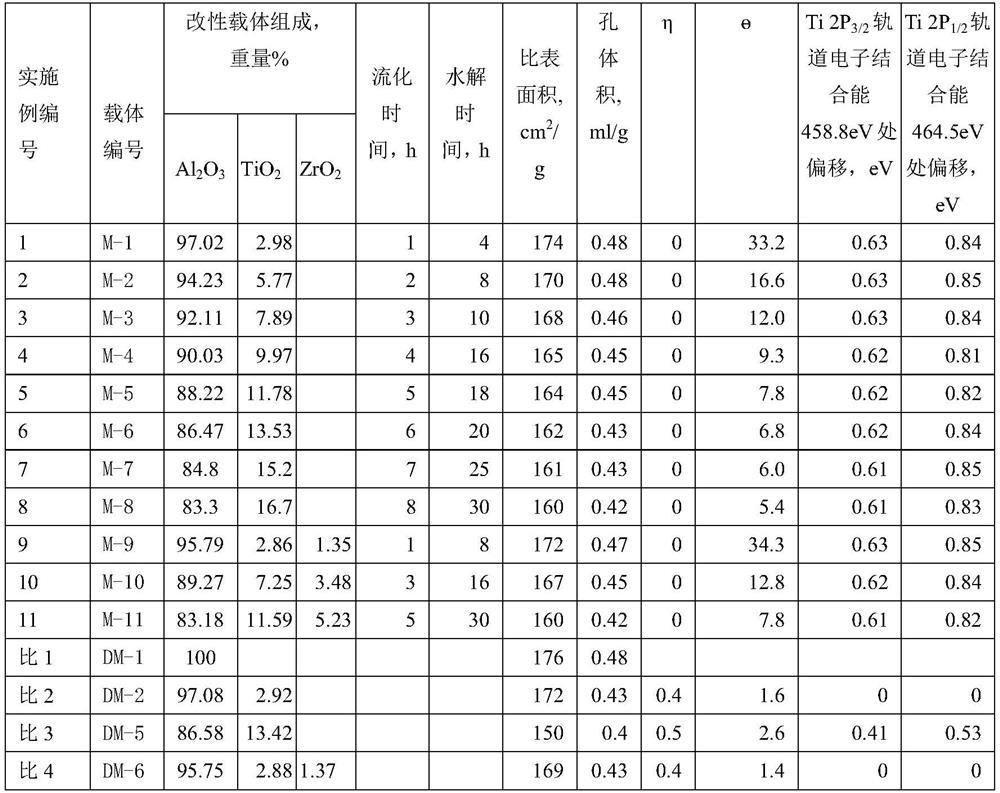

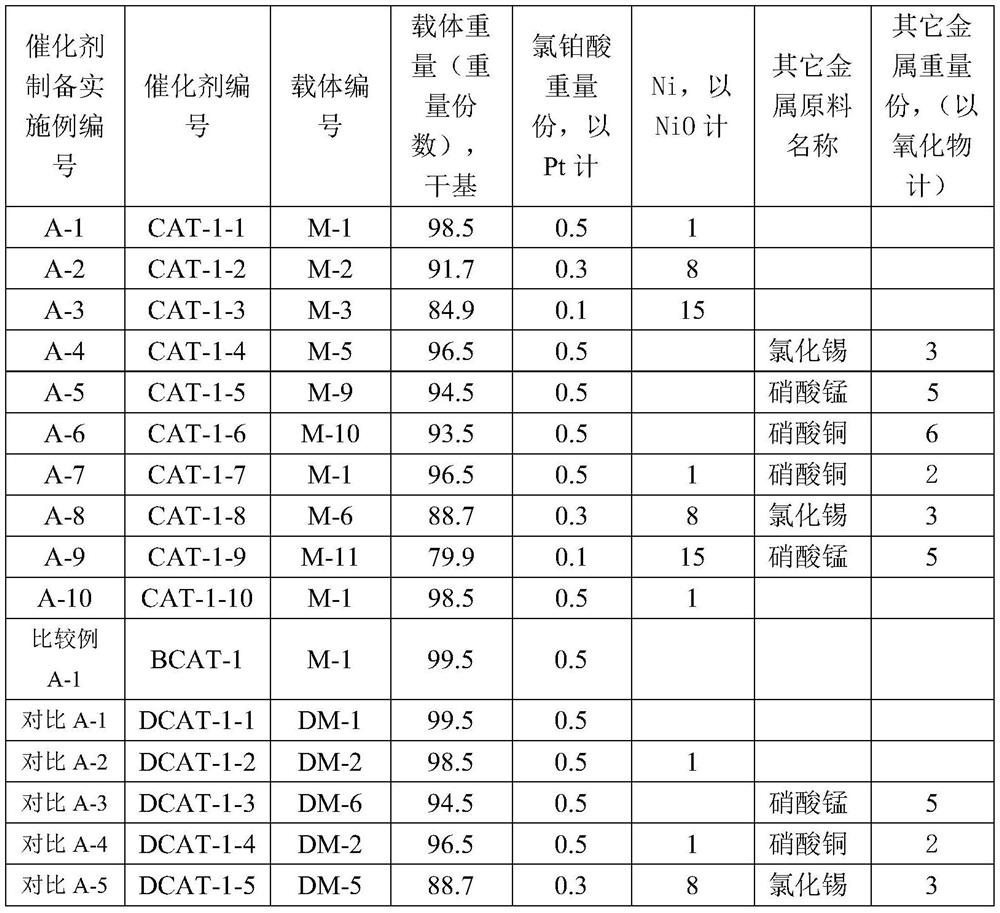

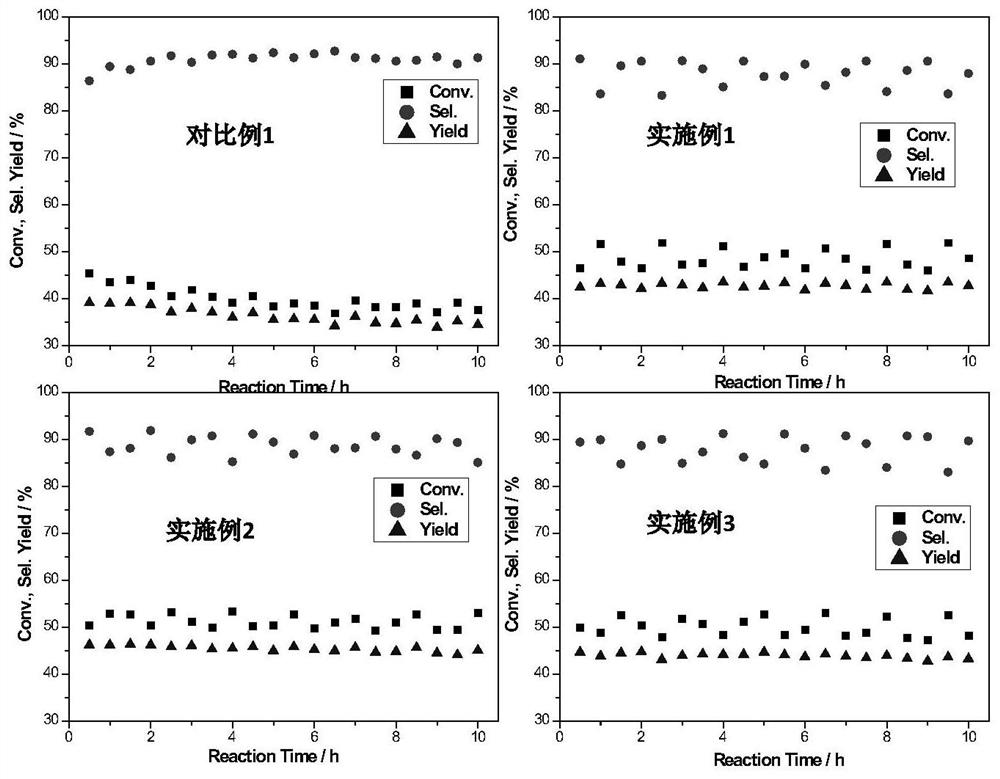

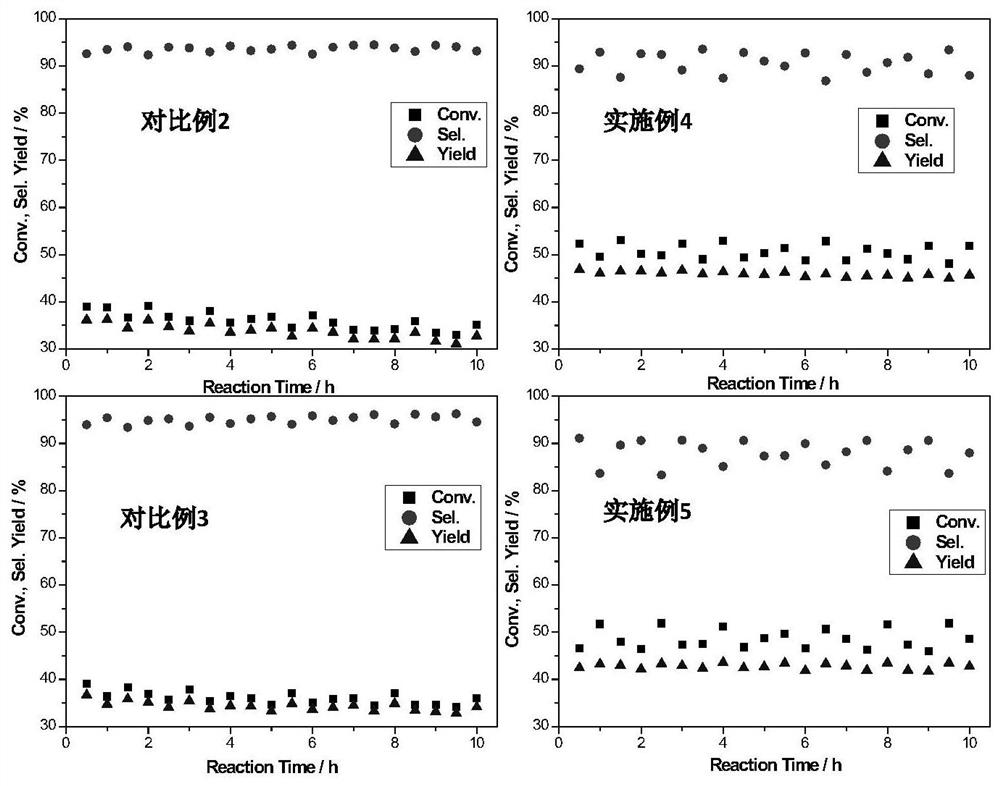

The invention relates to a high-activity catalyst used for hydrogen production by dehydrogenation of an organic hydrogen storage compound and reduced in noble metal consumption, and a preparation method thereof. The catalyst comprises Pt, a non-noble metal active component, aluminum oxide and modified metal oxide, wherein the modified metal oxide is titanium oxide and / or zirconium oxide; and the value of eta of the modified metal oxide is less than 0.3, the value of theta of the modified metal oxide is greater than or equal to 5, the value of eta is equal to a ratio of the weight percentage ofa crystalline phase modified metal oxide in a carrier composition to the chemical composition weight percentage of the modified metal oxide in the carrier composition, and the value of theta is equalto a ratio of the weight percentage of the modified metal oxide on the surface of the carrier composition to the chemical composition weight percentage of the modified metal oxide in the carrier composition.. The preparation method comprises the following steps: preparing the carrier composition containing the aluminum oxide and the modified metal oxide, conducting dipping and then performing roasting. The catalyst has high dehydrogenation activity and selectivity under the condition that noble metal consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing olefin by dehydrogenation of low-carbon alkane and preparation and application thereof

PendingCN114588898AImprove stabilityImprove olefin yieldHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsChemistryAlkane

The invention relates to a preparation method of a catalyst for preparing olefin by dehydrogenation of low-carbon alkane, which takes bimetal combined by group IV element metal and transition metal as an auxiliary agent, platinum group element metal as an active component for dehydrogenation of the catalyst, and transition metal spinel as a carrier. The preparation process of the catalyst comprises the following steps: introducing group IV element metal and a transition metal additive into a transition metal spinel carrier by adopting a co-impregnation method, so that group IV element metal atoms are more uniformly dispersed in the carrier at the atomic level, and meanwhile, the acting force between the group IV element metal atoms and the transition metal spinel carrier is enhanced; then dipping a dehydrogenation active component on a transition metal spinel carrier containing group IV element metal and a transition metal auxiliary agent, so as to improve the interaction force among the metal, the auxiliary agent and the carrier; and finally, drying, roasting, dechlorinating, dipping in an alkali metal additive, dipping in diluted hydrochloric acid, vulcanizing and the like to obtain the dehydrogenation catalyst. The catalyst provided by the invention has the advantages of high conversion rate, high olefin yield, good catalyst stability and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Alumina-supported ptcu single-atom alloy catalyst and its preparation method and application

ActiveCN108620092BHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention discloses a PtCu single-atom alloy catalyst supported by alumina and its preparation method and application. The catalyst uses Al 2 o 3 As a carrier, with Cu as an auxiliary agent, a small amount of active component Pt is loaded; the mass percentage of Pt is 0.025%-0.15%, and the mass percentage of Cu is 5%-20%; co-impregnation method is adopted during preparation, Will Al 2 o 3 The carrier is impregnated in an aqueous solution of chloroplatinic acid and copper nitrate, and after drying, roasting and high temperature reduction, PtCu / Al 2 o 3 The catalyst has high activity and high stability, low price and low toxicity. The catalyst of the present invention is suitable for the reaction of dehydrogenation of low paraffins to olefins, especially the reaction of propane dehydrogenation to propylene under a hydrogen atmosphere. The dehydrogenation activity is very high under high temperature conditions, the selectivity of propylene can reach more than 90%, and the stability is good. , and the amount of Pt is small, the utilization rate is high, and it is cheaper than industrial Pt-based catalysts.

Owner:TIANJIN UNIV

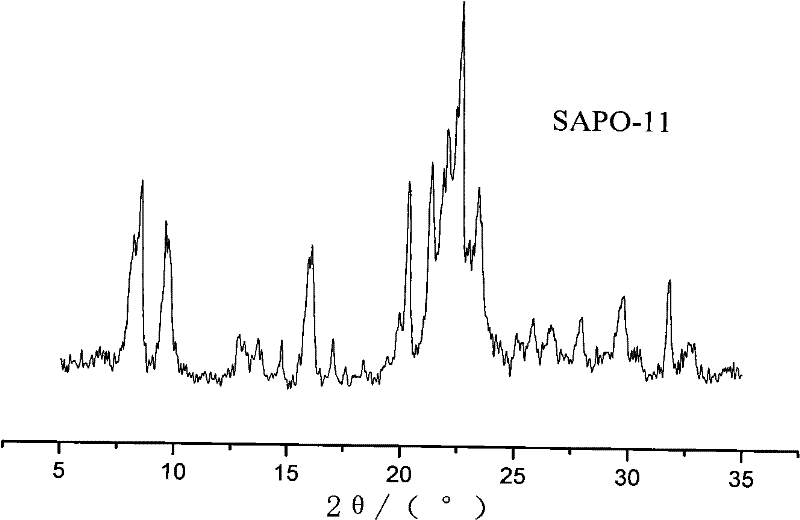

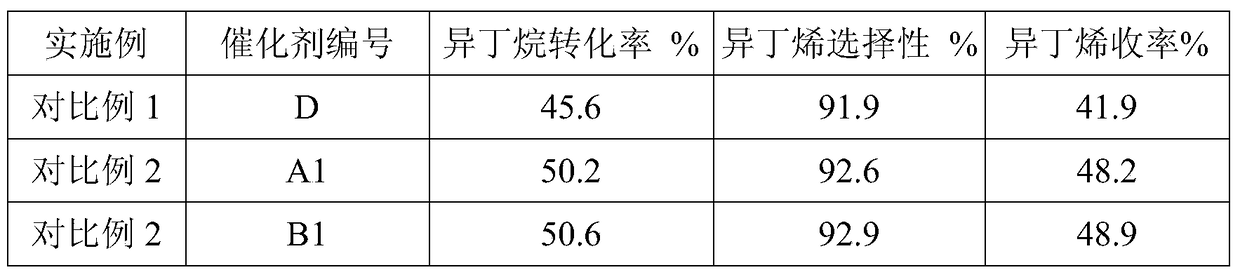

Isobutane dehydrogenation catalyst, preparation method thereof and method for preparing isobutene through isobutane dehydrogenation

ActiveCN110496635ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystSolventMolecular sieve

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene through isobutane dehydrogenation. The preparation method of the isobutane dehydrogenation catalyst comprises the following steps: (a) subjecting a template agent, a nonionic surfactant, an acid agent and industrial sodium silicateto be mixed and in contact under a solution condition to obtain a solution A; (b) crystallizing the solution A, and then sequentially conducting washing and drying to obtain mesoporous material raw powder; (c) carrying out template agent removal treatment on the mesoporous material raw powder to obtain a spherical mesoporous molecular sieve material carrier; and (d) carrying out thermal activationtreatment on the spherical mesoporous molecular sieve material carrier obtained in the step (c), then carrying out dipping treatment in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying and roasting. According to the method, the isobutane dehydrogenation catalyst with high catalytic activity can be synthesized by using a low-cost silicon source.

Owner:CHINA PETROLEUM & CHEM CORP +1

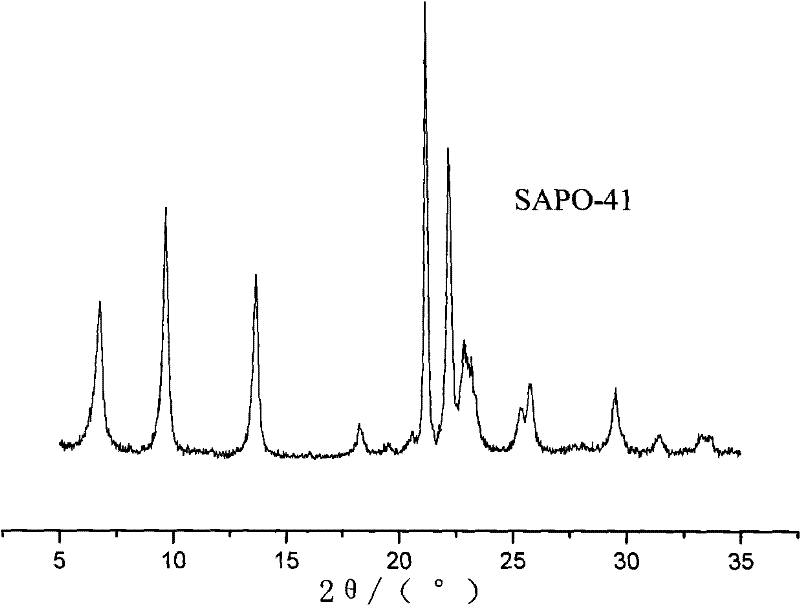

Isobutane dehydrogenation catalyst using chlorite composite material with three-dimensional cubic and hexagonal pore channel structures as carrier, preparation method and applications thereof

InactiveCN110732342ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and a methodfor preparing isobutene through dehydrogenation of isobutane. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a first mesoporous material filter cake with a three-dimensional cubic pore channel structure and a second mesoporous material filter cake with a two-dimensional hexagonal pore channel structure; (b) preparing a silica gel filter cake; (c) mixing the first mesoporous material filter cake, the second mesoporous material filter cake, the silica gel filter cake and chlorite, and sequentially carrying out ball milling, pulping, drying and templateagent removal to obtain a spherical double-mesoporous chlorite composite material carrier; and (d) carrying out dipping treatment on the obtained spherical double-mesoporous chlorite composite material carrier in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying and roasting. The obtained isobutane dehydrogenation catalyst of the invention has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydrogenation catalyst, preparation method thereof, and dehydrogenation method

ActiveCN104069875AHigh dehydrogenation activityImprove stabilityOrganic chemistryPhysical/chemical process catalystsDehydrogenationEther

The invention provides a dehydrogenation catalyst and a preparation method thereof. The preparation method comprises the following steps: mixing an aqueous nickel-containing compound with acidic sol and ethanol, adjusting the pH value of the mixture to 5 to 9 with an alkaline substance, then allowing the system to stand still for a while to carry out aging under the pH value, washing and drying so as to obtain a solid substance, mixing the solid substance with a dehydrogenation auxiliary agent component, and finally burning the mixture. The invention further provides a dehydrogenation method, which comprises a step of contacting cyclohexanediol and / or cyclohexanediol derivatives containing ether bonds with a dehydrogenation catalyst under a catalytic dehydrogenation condition, wherein the dehydrogenation catalyst is prepared by the method mentioned above. The dehydrogenation catalyst prepared by the method provided by the invention can be applied to bio-dehydrogenation of cyclohexanediol and / or cyclohexanediol derivatives containing ether bonds, and has the advantages of high dehydrogenation activity, high stability, and long service life.

Owner:昌德新材科技股份有限公司

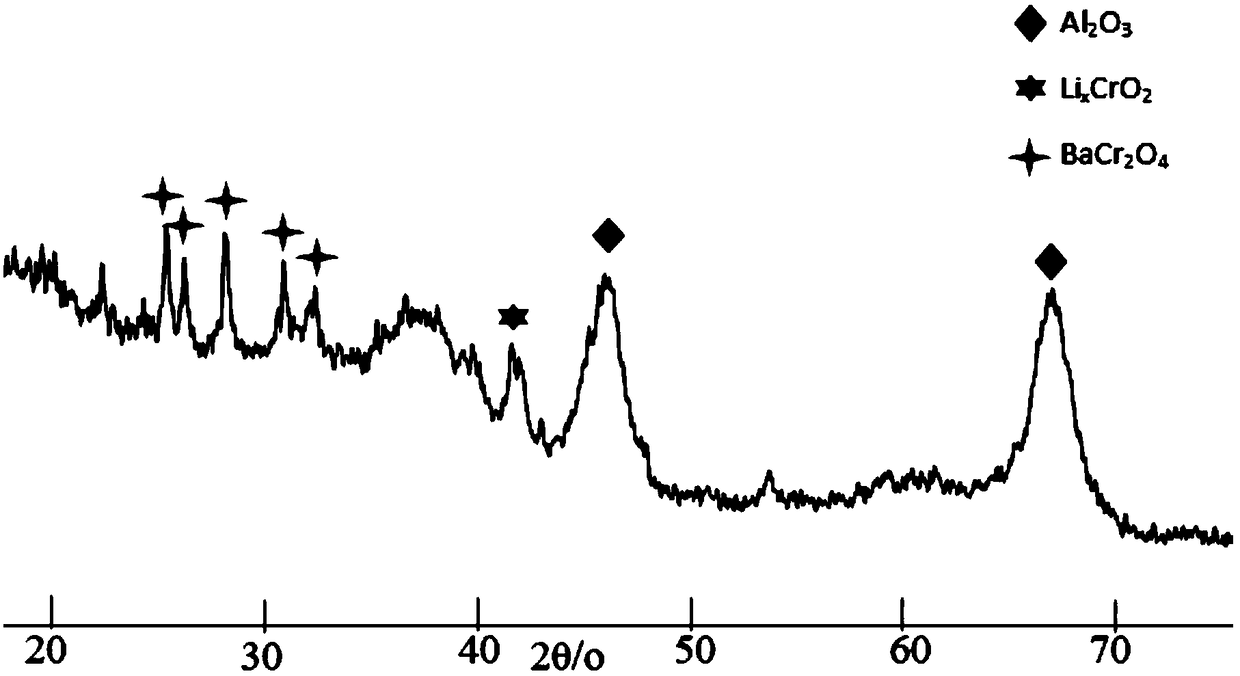

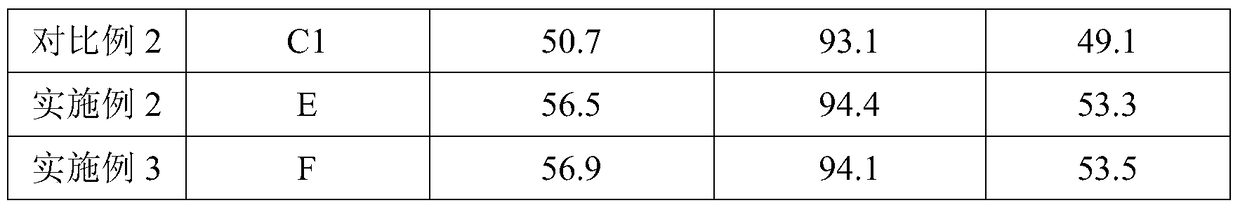

A catalyst for dehydrogenating low-carbon alkanes to olefins and its preparation method and application

ActiveCN105749986BAvoiding Condensed Gum ProblemsImprove activity stabilityCatalyst carriersHeterogenous catalyst chemical elementsLithium oxideAlkali metal oxide

The invention provides a low-carbon alkane dehydrogenation to olefins catalyst and its preparation method and application. The catalyst uses barium-containing alumina as a carrier, chromium oxide as the main active component, and alkali metal oxide as the co-active component; based on the total weight of the barium-containing alumina carrier being 100%, the The content of chromium oxide is 1-40wt%; the content of the alkali metal oxide is 0.01-5.0wt%; the alkali metal oxide includes one or a combination of several of lithium oxide, sodium oxide and potassium oxide. The invention also provides a preparation method of the above catalyst and its application in dehydrogenating low-carbon alkanes to produce olefins. The low-carbon alkane dehydrogenation to olefins catalyst provided by the invention has higher dehydrogenation activity, higher alkane conversion rate, higher olefin selectivity and higher olefin yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Isobutane dehydrogenation catalyst using three-hole hollow spherical mesoporous molecular sieve silica gel composite material as carrier, preparation method and applications thereof

InactiveCN110732343ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and a methodfor preparing isobutene through dehydrogenation of isobutane. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a mesoporous molecular sieve filter cake with one-dimensional straight-through pore channels; (b) mixing the mesoporous molecular sieve filter cake and a silica gel, mixing, carrying out first ball milling, mixing the obtained first ball-milled slurry and water, pulping, carrying out second ball milling to obtain second ball-milled slurry, carrying out spray drying on the second ball-milled slurry, screening by adopting a cyclone separation technology, and removing the template agent from the screened product to obtain a composite material; and (c) carrying out thermal activation on the composite material, carrying out dipping treatment, removing the solvent, drying, roasting, and loading a Pt component and a Zn component. According to the invention, the obtained isobutane dehydrogenation catalyst has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

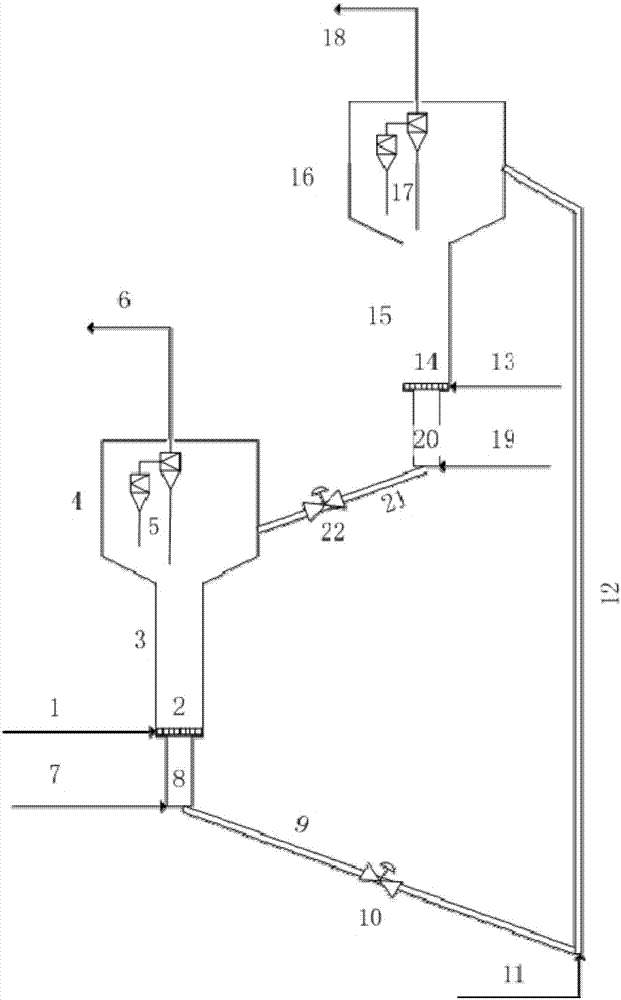

Low-carbon alkane circulating fluidized bed dehydrogenation process

ActiveCN107488096AEfficiently provideGuaranteed continuityCatalystsHydrocarbon preparation catalystsAlkaneFluidized bed

The invention discloses a low-carbon alkane dehydrogenation process method. According to the low-carbon alkane dehydrogenation process method, a circulating fluidized bed process is adopted, and a chromium-based microsphere catalyst is loaded; and the catalyst preparation method comprises: dissolving a high-valent chromium precursor in a reducing agent solution, and impregnating into an alumina microsphere carrier so as to prepare the catalyst. According to the present invention, the low-carbon alkane raw material enters the circulating fluidized bed reactor filled with the Cr2O3 microsphere catalyst and is subjected to the dehydrogenation reaction, and the reaction regeneration circulation system is formed through circulation coupling, such that the continuous performing of the catalytic dehydrogenation reaction and the effective supply of the heat can be ensured; and the low-carbon alkane dehydrogenation circulating fluidized bed process has advantages of simple process, continuous production, and low equipment investment.

Owner:PETROCHINA CO LTD

Isobutane dehydrogenation catalyst with supporter being composite material containing silica gel and hexagonal mesoporous material as well as preparation method and application thereof

InactiveCN110614097ASimple preparation processConditions are easy to controlCatalyst carriersCatalystsDehydrogenationMesoporous material

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a supporter being a composite material containing silica gel and hexagonal mesoporous materialas well as a preparation method and application of the isobutane dehydrogenation catalyst. The method comprises the following steps: (a) preparing hexagonal mesoporous material raw powder; (b) preparing a hexagonal mesoporous material; (c) carrying out activation treatment on the hexagonal mesoporous material; and (d) carrying out activation treatment on the supporter, then carrying out impregnation treatment in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying treatment and roasting treatment. According to the method, the isobutane dehydrogenation catalyst with high catalytic activity can be synthesized by using a low-cost silicon source.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon alkane dehydrogenation catalyst with highly-dispersed multi-element active components and preparation method of low-carbon alkane dehydrogenation catalyst

InactiveCN108080002AHigh dehydrogenation reactivityHigh dehydrogenation activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The invention discloses a low-carbon alkane dehydrogenation catalyst with highly-dispersed multi-element active components. The active components of the catalyst are not single precious metal and arecompounded by multiple metals, wherein three active components are Cu, Ir and Pt; the fourth active component is one or more of Rh, Pd, Ag and Au. The total content of the precious metal in the catalyst is not higher than 0.30 weight percent. By controlling the mole ratio of all the active components in the catalyst and using the preparation method for obtaining the catalyst with the highly-dispersed active components by drying, roasting and chlorination treatment under anaerobic conditions, the catalyst disclosed by the invention has the advantages that the loading amount of the precious metal can be effectively reduced and the cost of the catalyst is reduced; in addition, the catalyst has better dehydrogenation activity, slower inactivation and longer service life.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +4

A kind of oxygen carrier preparation method for propane chemical chain dehydrogenation to propylene

ActiveCN109482174BSimple processHigh dehydrogenation activityCatalystsHydrocarbon preparation catalystsLithium oxideManganese

The invention belongs to the technical field of oxygen carrier preparation, and relates to an oxygen carrier preparation method for chemical chain dehydrogenation of propane to produce propylene. The alumina oxygen carrier is first obtained by impregnating alumina into a manganese-containing precursor aqueous solution, and then Load a certain amount of manganese-based active component; then add clay and binder to the oxygen carrier to increase the wear resistance of the oxygen carrier; at the same time, load the lithium oxide active component onto the carrier, and then obtain Oxygen carrier particles used for chemical chain dehydrogenation of propane to produce propylene; its preparation method is simple, and the oxygen carrier will not cause environmental pollution during the preparation and recycling regeneration process; the prepared oxygen carrier has high dehydrogenation efficiency Activity, higher propane conversion, higher propylene selectivity.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com