Preparation method of oxygen carrier for producing propylene through propane chemical-looping dehydrogenation

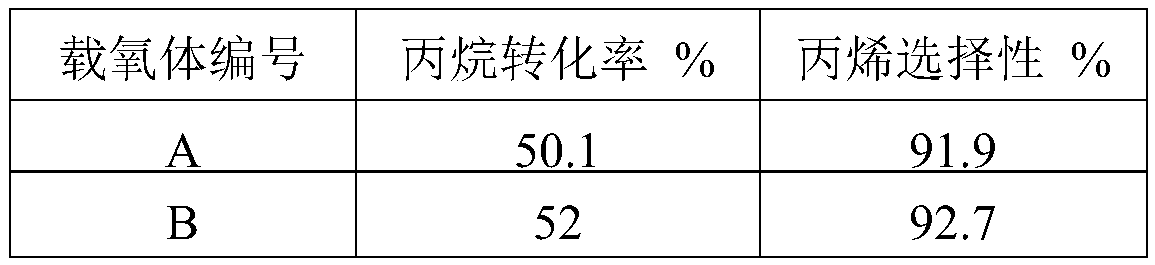

A chemical chain, oxygen carrier technology, applied in chemical instruments and methods, organic chemistry, metal/metal oxide/metal hydroxide catalysts, etc. High temperature carbon deposition inactivation and other problems, to achieve the effect of high dehydrogenation activity, increased wear resistance, and high propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

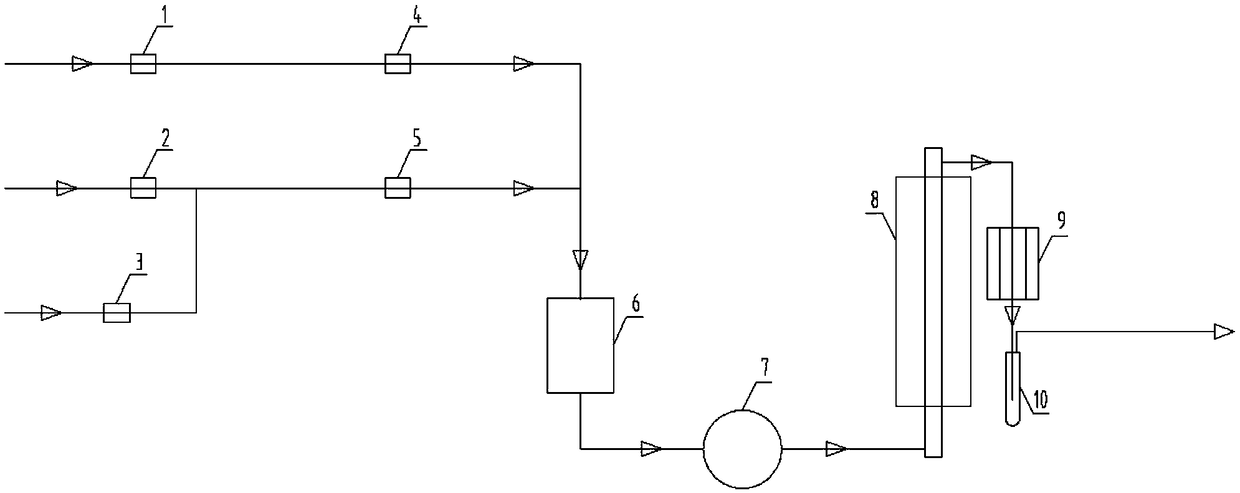

Method used

Image

Examples

Embodiment 1

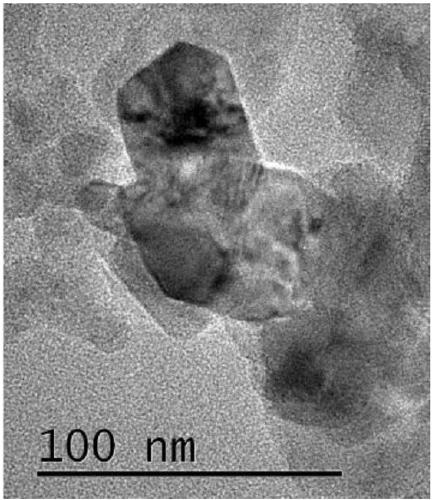

[0029] The specific process of preparing the manganese-based oxygen carrier with core-shell structure in this embodiment is as follows:

[0030] (1) Preparation of alumina carrier: screen 500g of alumina particles with a particle size of 100-500 μm, add 3-5g of scallop powder, mix well, add 100ml of 2% nitric acid aqueous solution dropwise, and place in a 100°C refrigerator after fully mixing After drying in an oven for 48 hours, calcining in a muffle furnace at 500-600°C to obtain alumina carrier particles;

[0031] (2) Preparation of manganese-containing alumina carrier: get 200 g of alumina carrier particles obtained in step (1), immerse in 500 ml of manganese nitrate deionized aqueous solution with a mass fraction of 50%, obtain the impregnated carrier after 24 hours of immersion, and then drying the impregnated particles at 90-120°C for 48 hours, and calcining at 650°C for 3-5 hours to obtain the manganese-containing alumina carrier;

[0032] (3) Preparation of manganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com