Patents

Literature

168results about How to "Promote positive progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

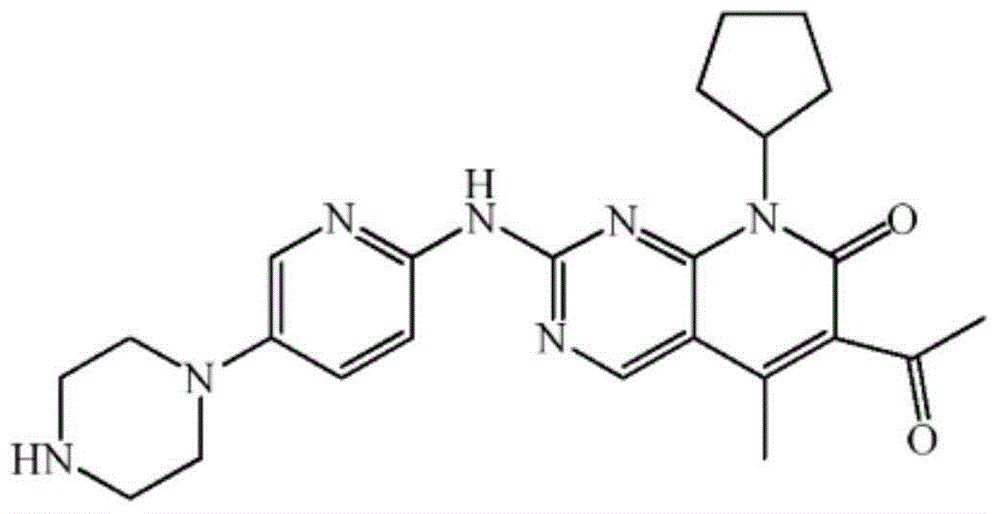

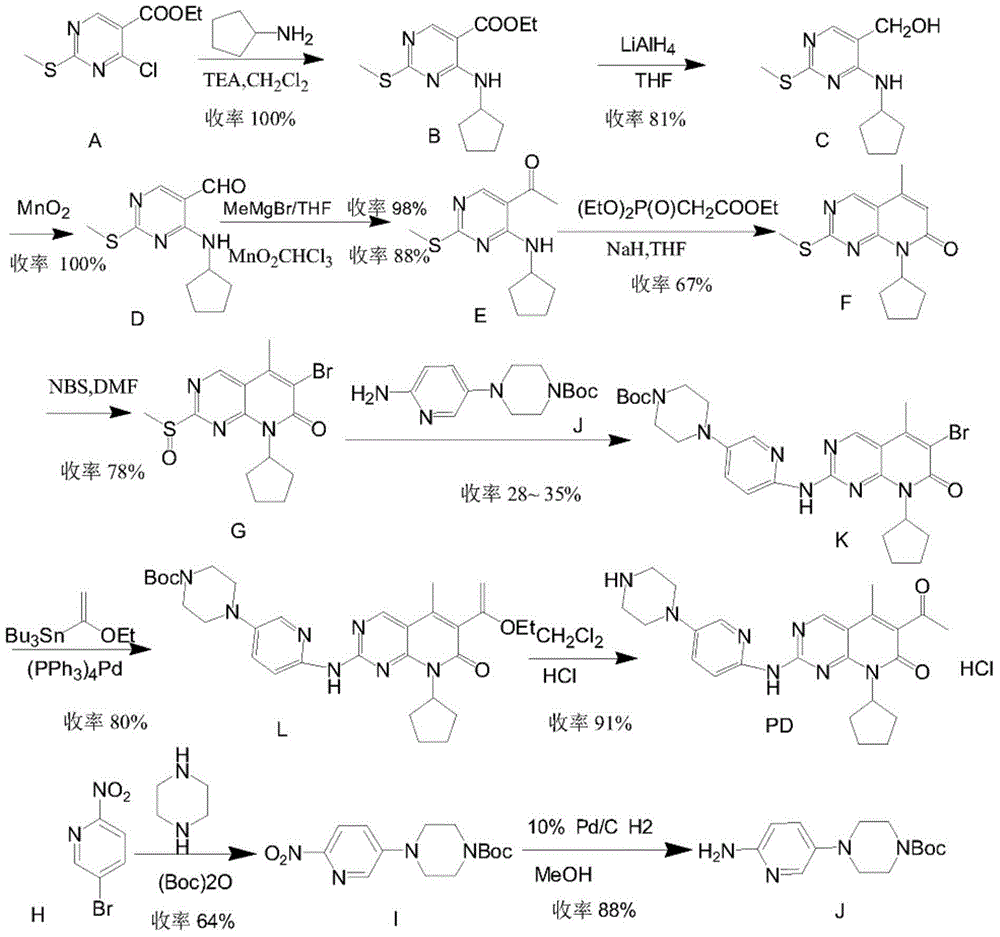

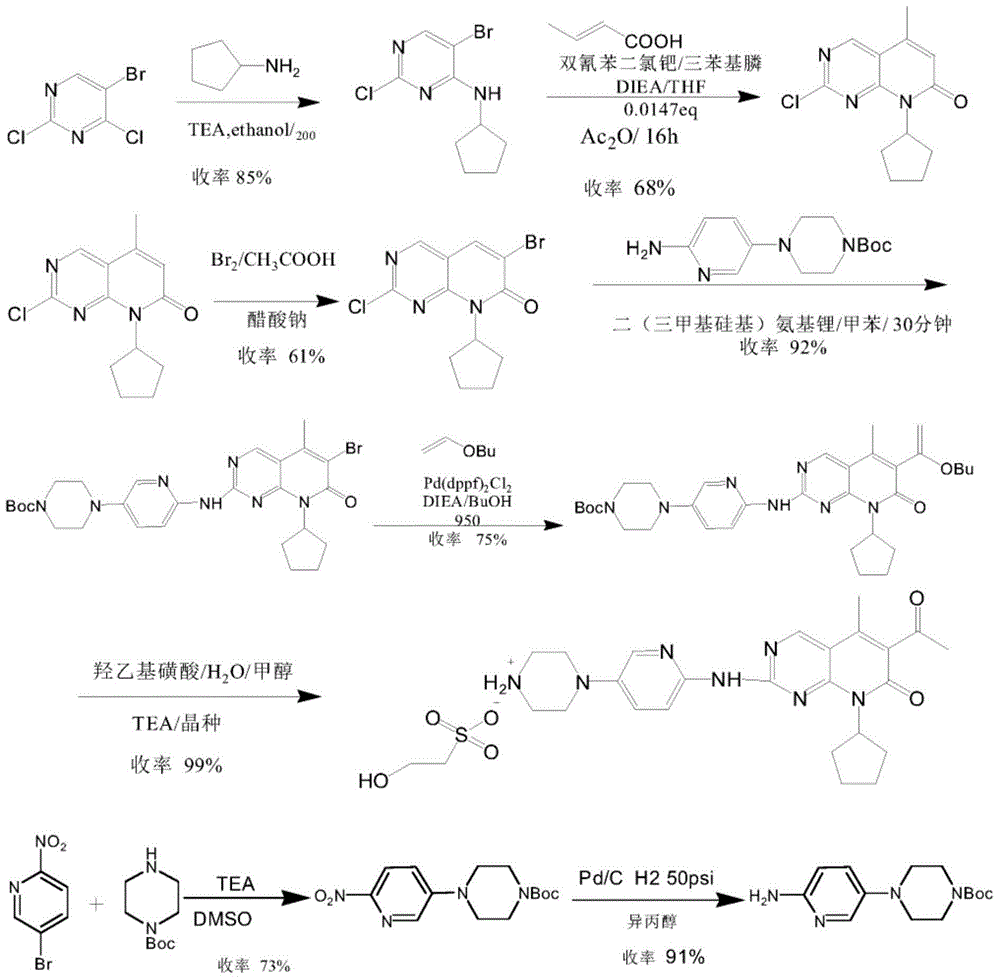

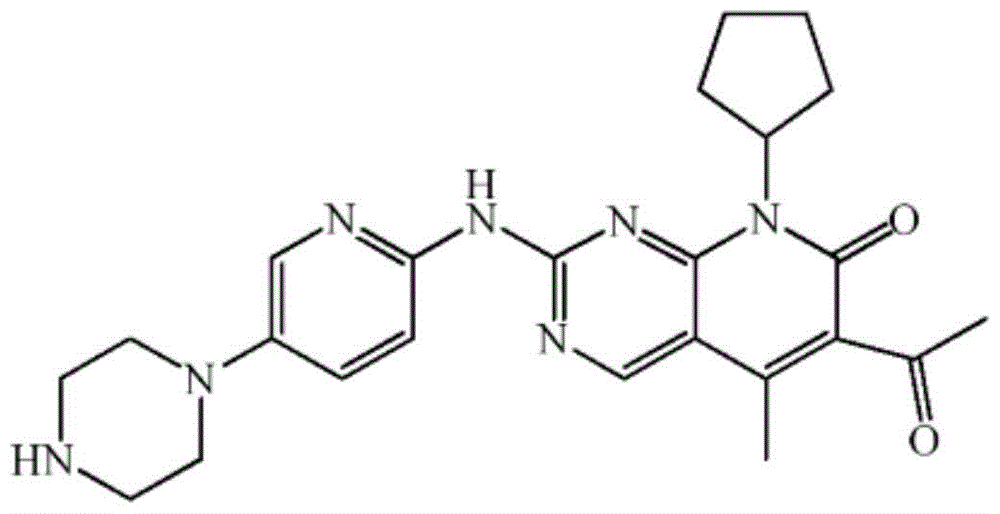

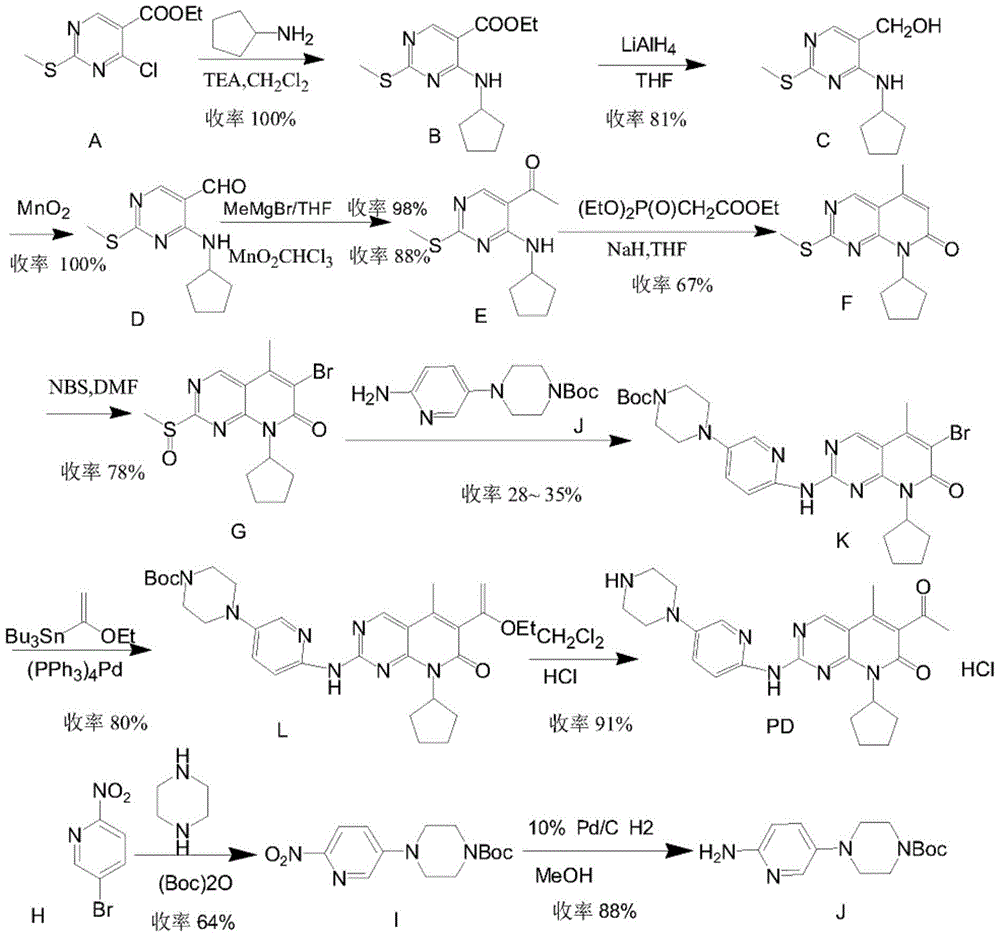

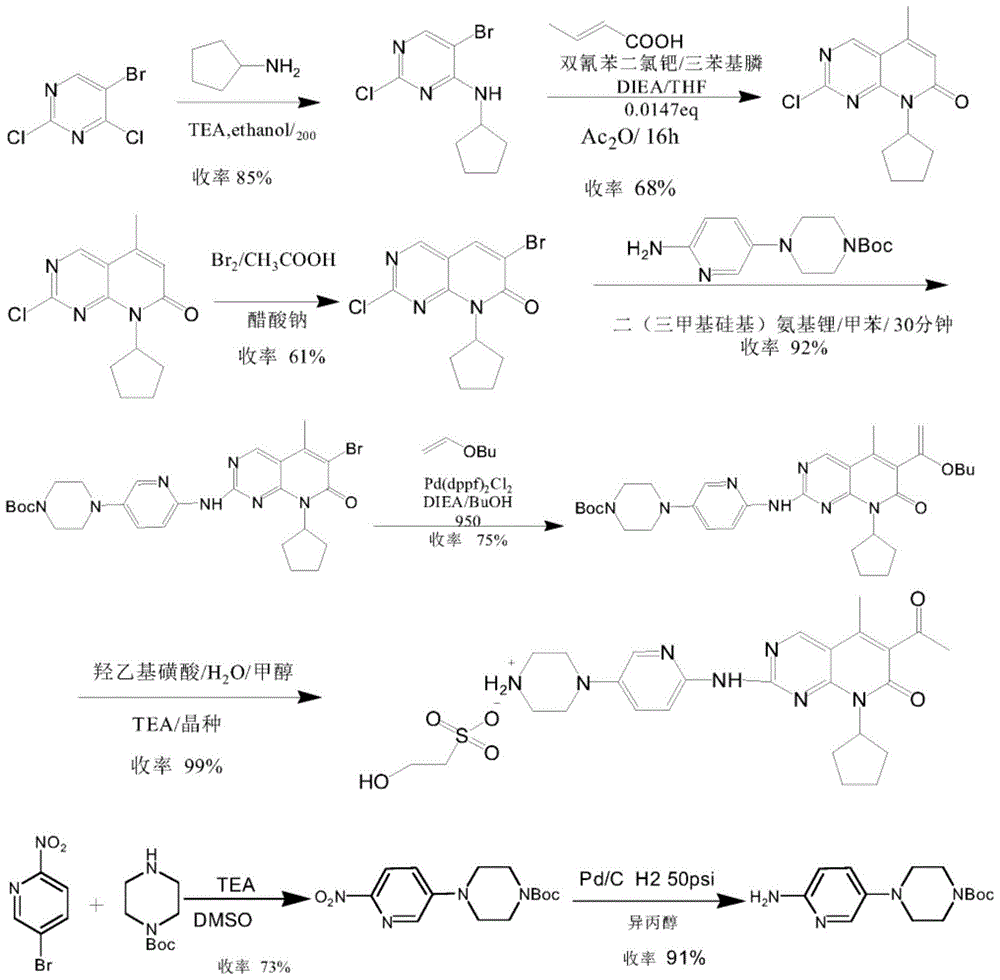

Preparation method of palbociclib

The invention belongs to the field of pharmaceutical and chemical engineering, and particularly relates to a preparation method of palbociclib. 2-acetyl-2-butenoic acid methyl ester, malononitrile and a guanidino compound III are reacted together according to an ultrasonic-microwave assisted synthesis method, and a compound IV is rapidly obtained with a high yield; then, sodium nitrite and hypophosphorous acid are subjected to a deamination reduction reaction to generate a compound V; then, the compound V and cyclopentane halide are subjected to a coupled reaction under the action of a catalyst to generate a compound VI; finally, a dehydrogenation reaction is conducted under the action of a catalyst TPND to obtain the palbociclib. The method has the advantages that reaction conditions are mild, the technological process is simple and reasonable, reaction time is short, aftertreatment is easy, product quality is high, and the yield is high.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

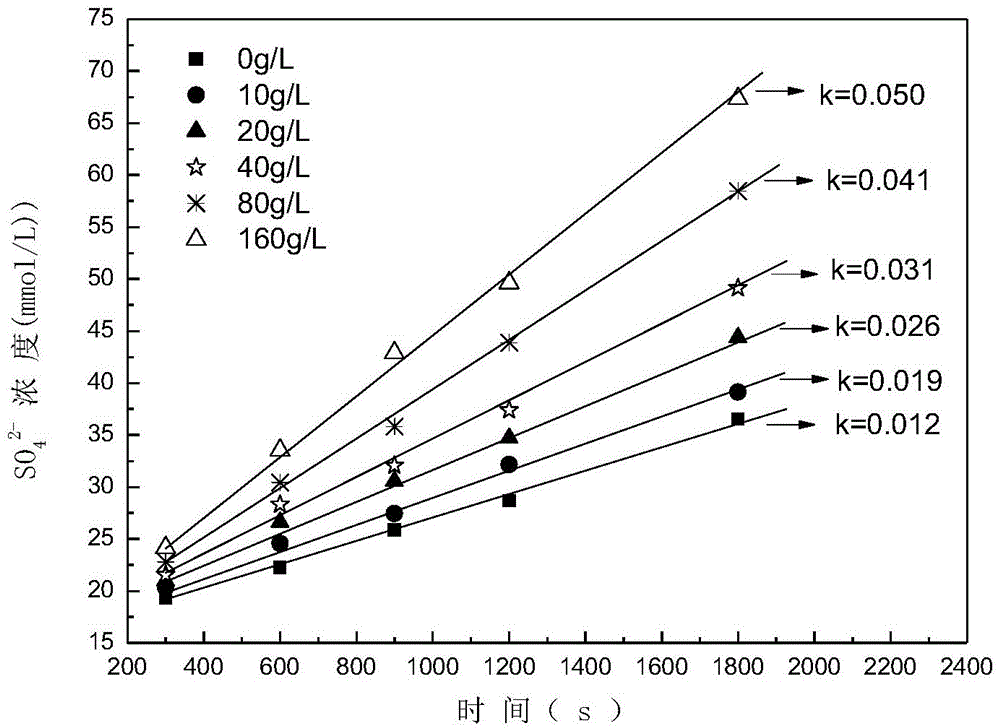

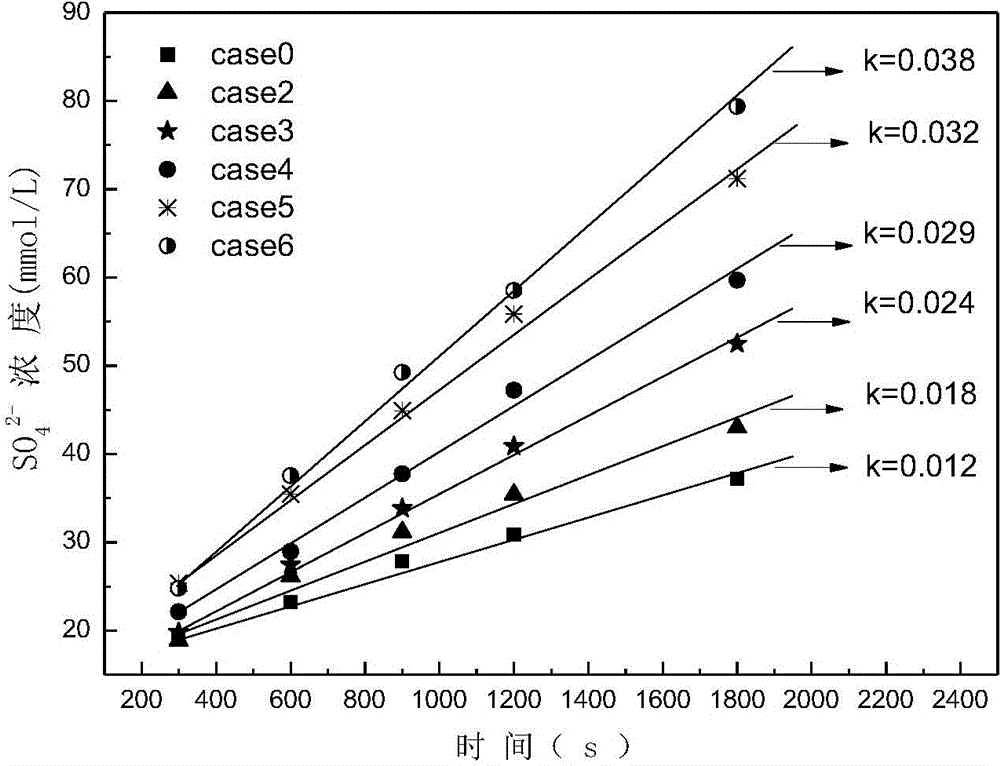

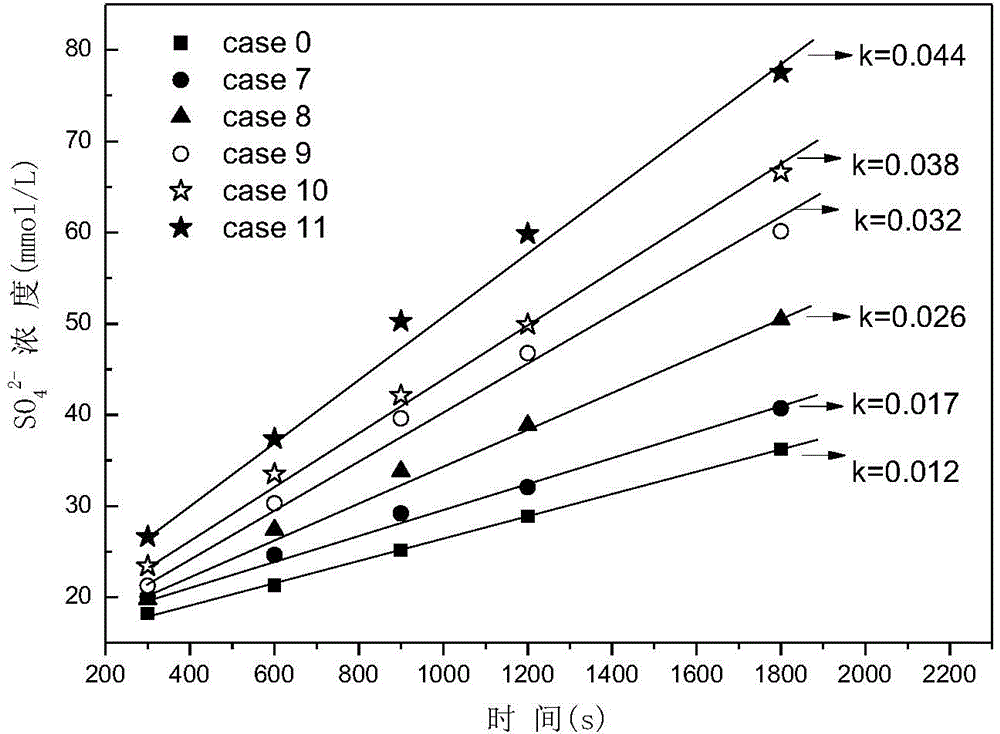

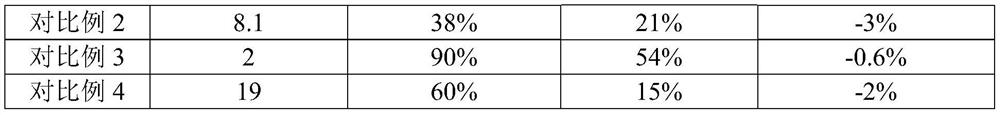

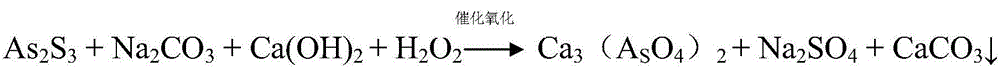

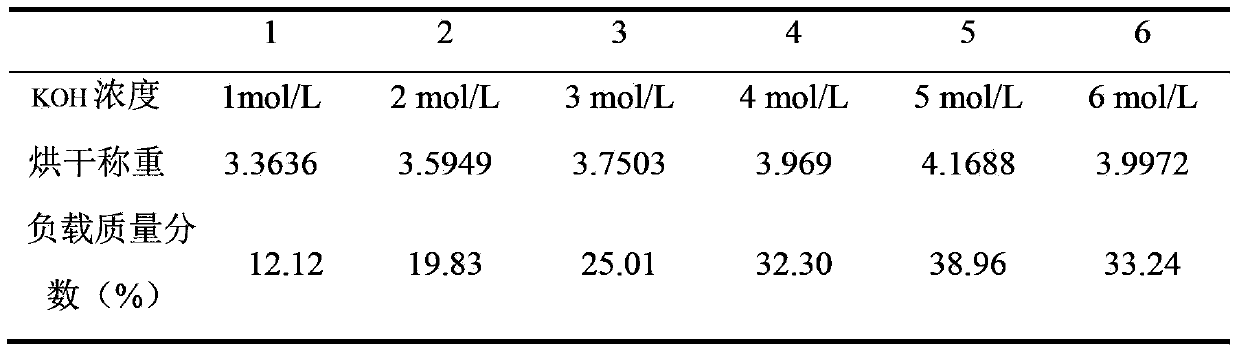

Loaded solid phase metal catalyst for magnesium desulfurization process, and preparation method thereof

ActiveCN103977832ARaw materials are easy to getSimple preparation processMolecular sieve catalystsDispersed particle separationAir volumeFiltration

The present invention discloses a loaded solid phase metal catalyst for a magnesium desulfurization process, and a preparation method thereof, and belongs to the field of flue gas desulfurization. The preparation method comprises: preparing nitrates of cobalt (II), iron (III), manganese (II) and nickel (II) into solutions, and loading the solutions on a porous spherical molecular sieve through a dynamic dipping method to obtain the loaded solid phase metal catalyst, wherein the dynamical dipping method comprises steps of vibration with a shaking table, standing, filtration, drying and calcination. According to the present invention, the raw materials are common and easily-available, the preparation process is simple, the catalysis effect of the product is significant, and the catalyst can be widely used for magnesium desulfurization systems of small and medium sized boilers having the size of more than 75 t in our country, wherein the oxidation efficiency of the sulfite oxidation system is increased by more than 50% under the condition of no change of the original oxidation wind amount; and the catalyst has characteristics of low effective component consumption, easy recovery, low solution residue, no secondary pollution problem, and promotion values.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

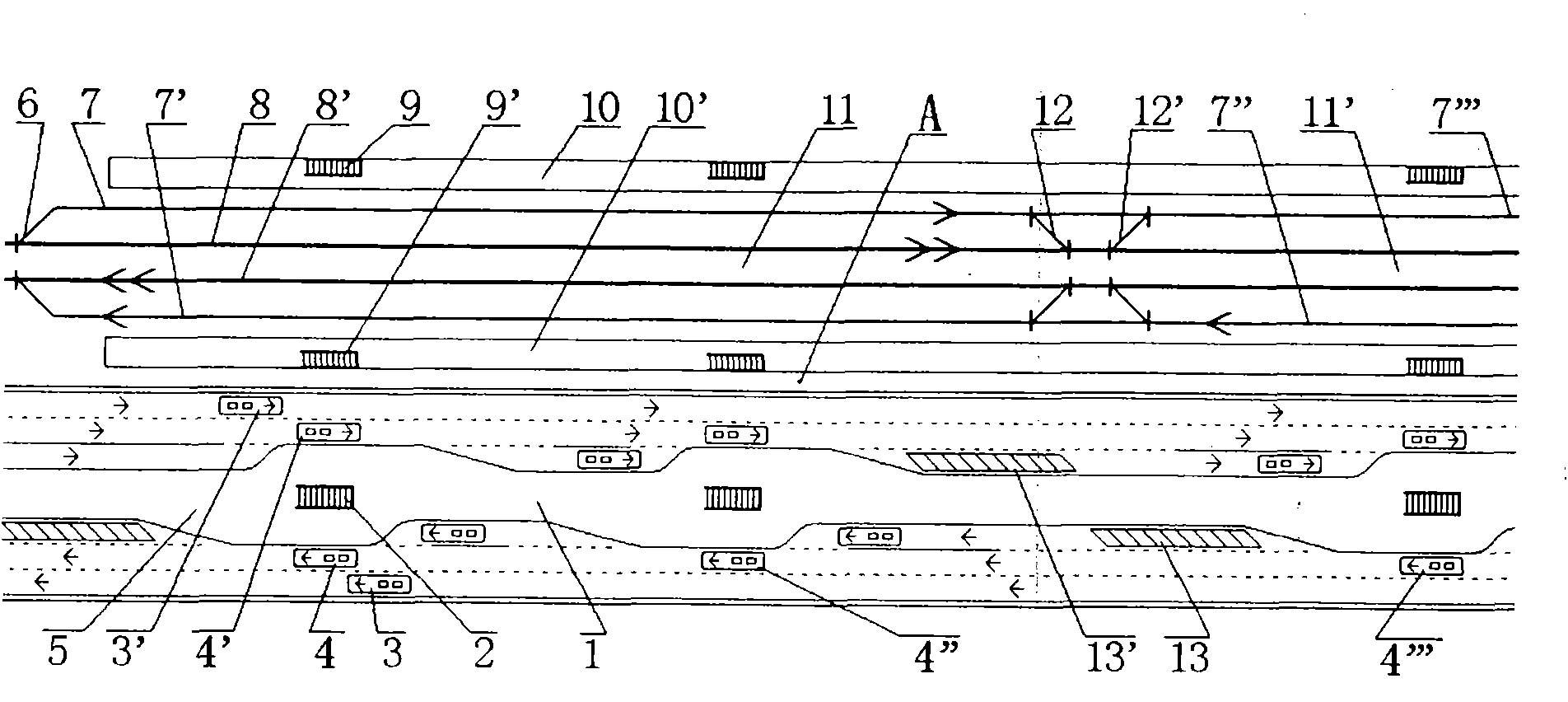

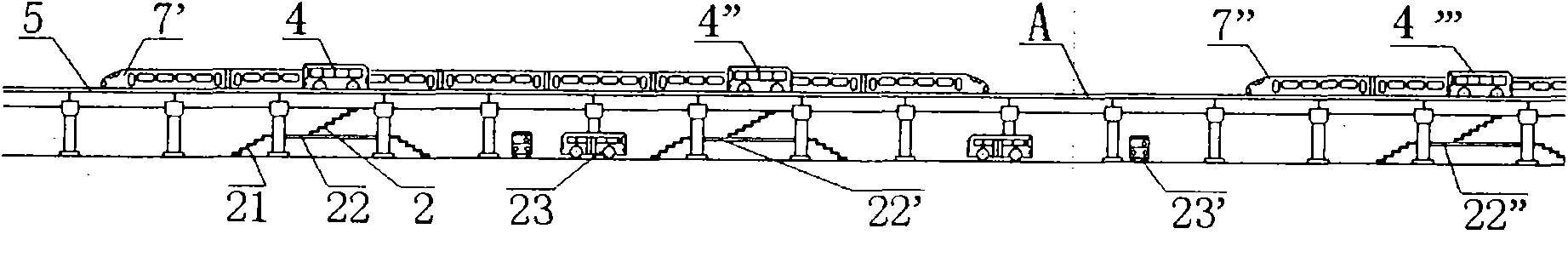

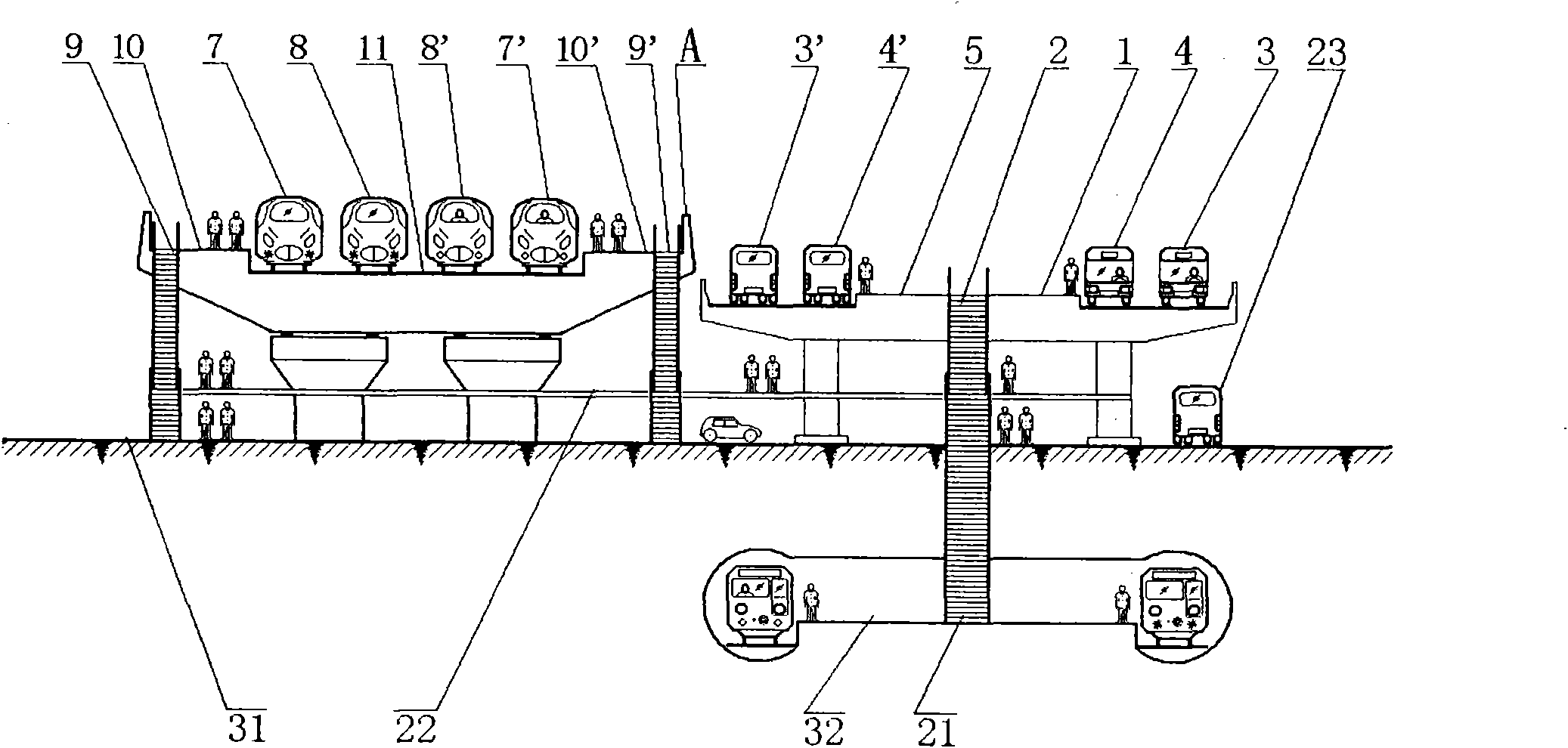

Banded transportation junction formed by paralleling parallel elevated road stations and elevated railway stations

ActiveCN101870294AAvoid overcrowdingReduce trafficRailway componentsElevated railway without suspended vehicleShortest distanceShort distance

The invention relates to a banded transportation junction formed by paralleling parallel elevated road stations and elevated railway stations, belonging to the technical field of railway station construction and aiming at solving the problem of inconvenience brought about for people by the conditions that the stations of various transport means of a large-scale integrated transportation junction are excessively concentrated, a scale is excessively huge, and transport is separated from commerce. The parallel elevated road stations are arranged parallel to one or more than one elevated railway station at short distances to form the banded transport hub; stop stations of island platforms of the parallel elevated road stations correspond to entrances / exits of the elevated railway stations, and passengers can take buses which are convenient for positive-direction and reverse-direction transfer on parallel elevated roads to reach and leave the entrances / exits of elevated railway stations on which the passengers need to take; and when the parallel elevated road stations are parallel to the elevated railway stations in an overlapping way, the parallel elevated road stations are positioned below the elevated railway stations.

Owner:田耕

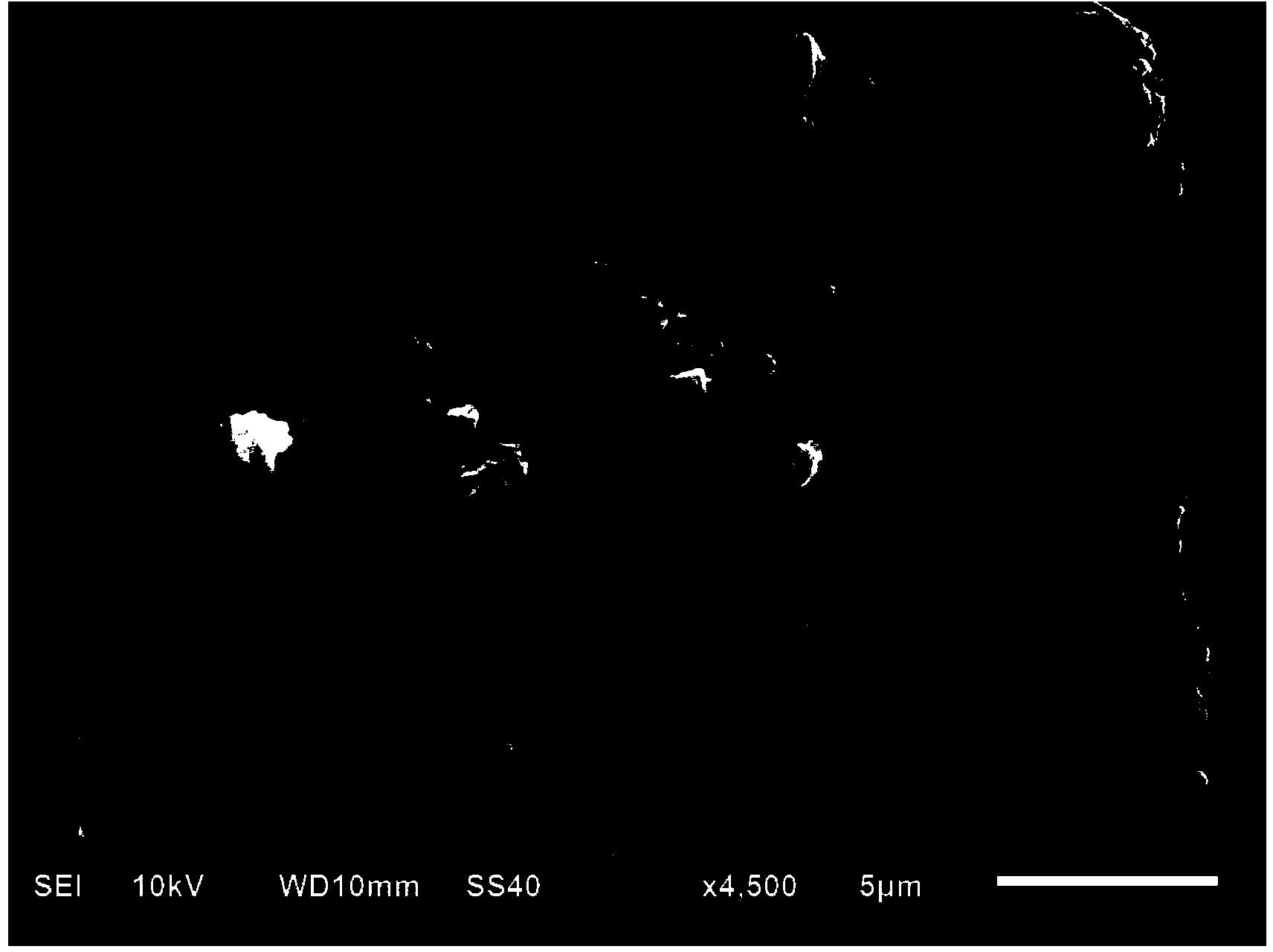

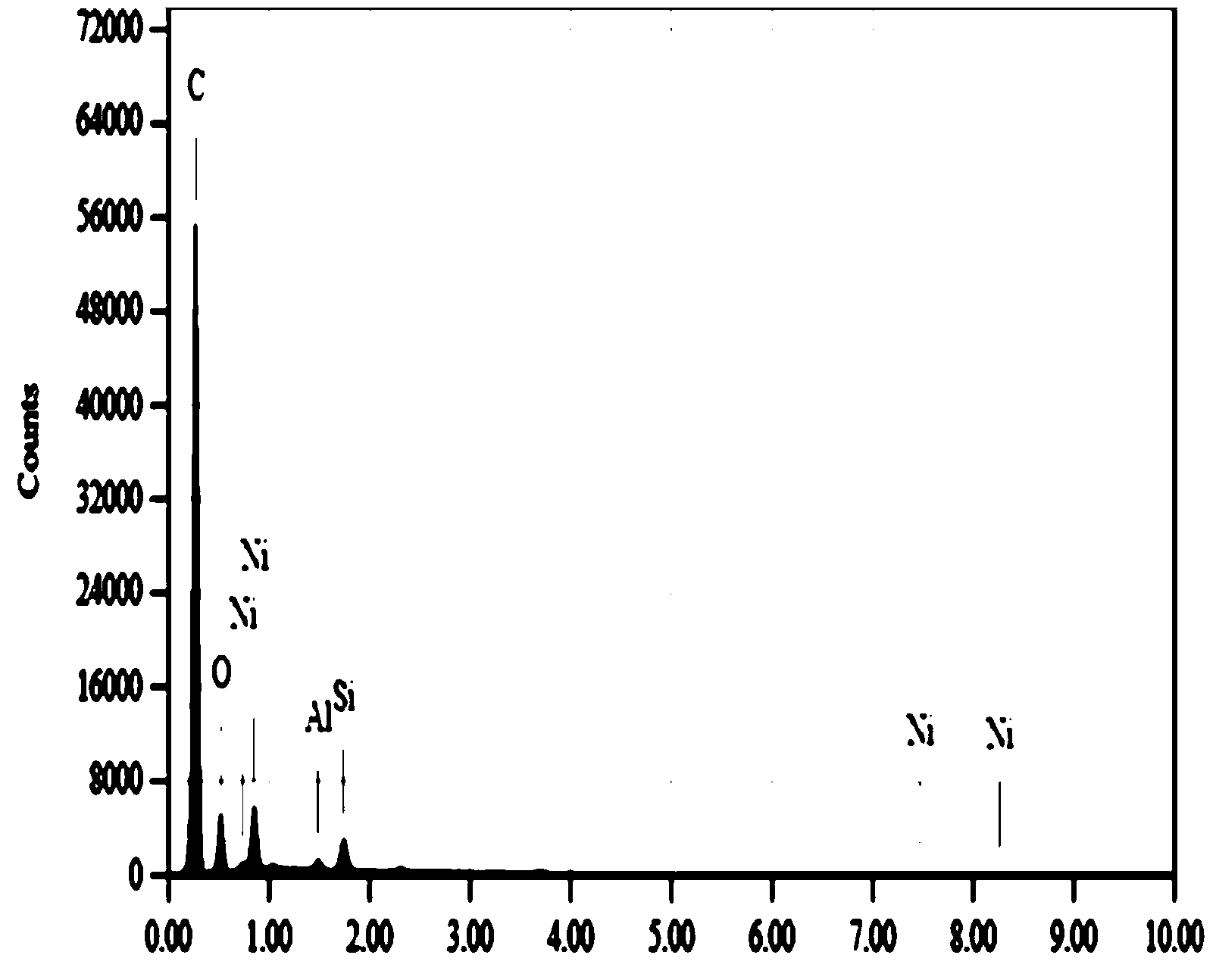

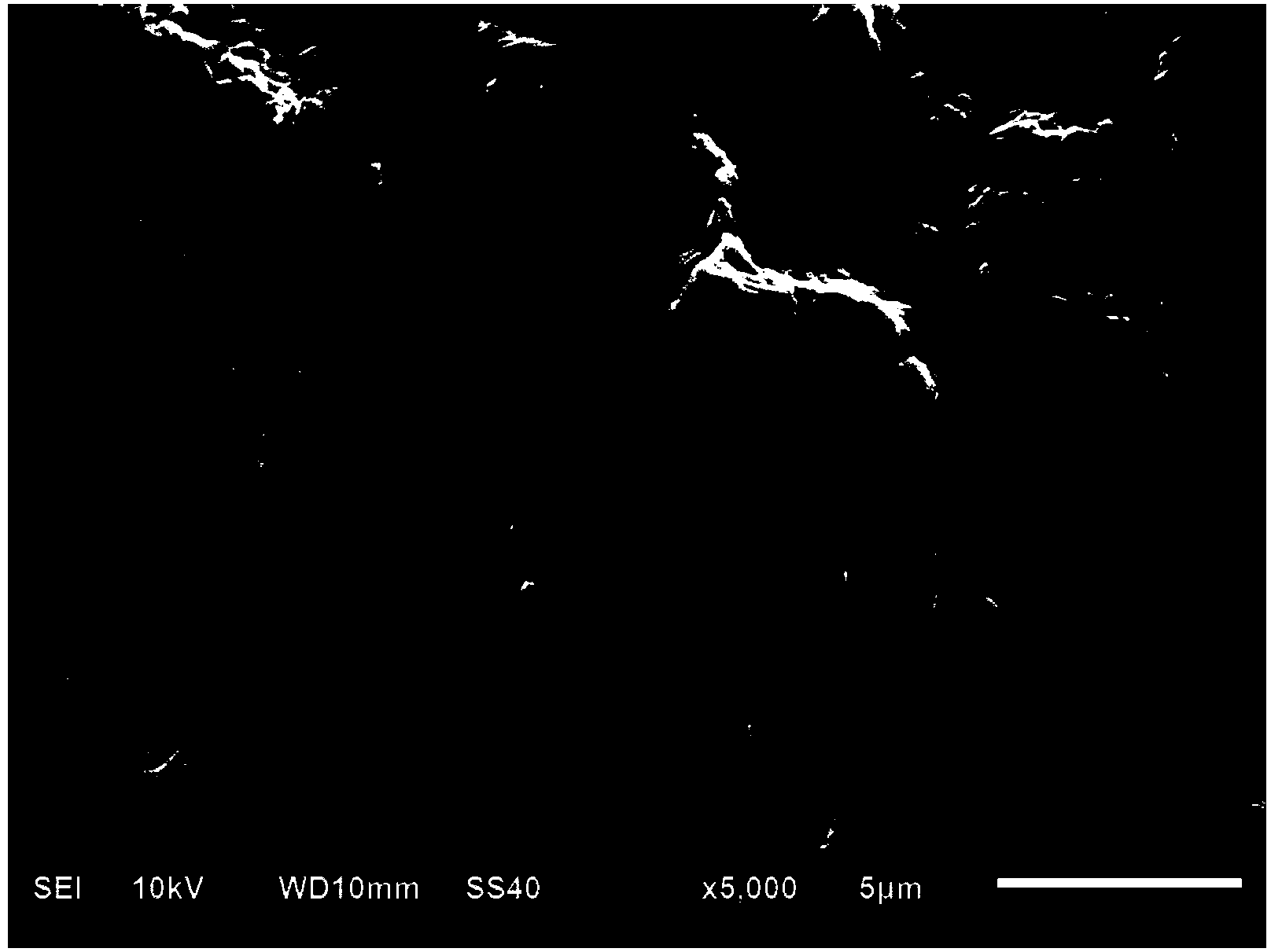

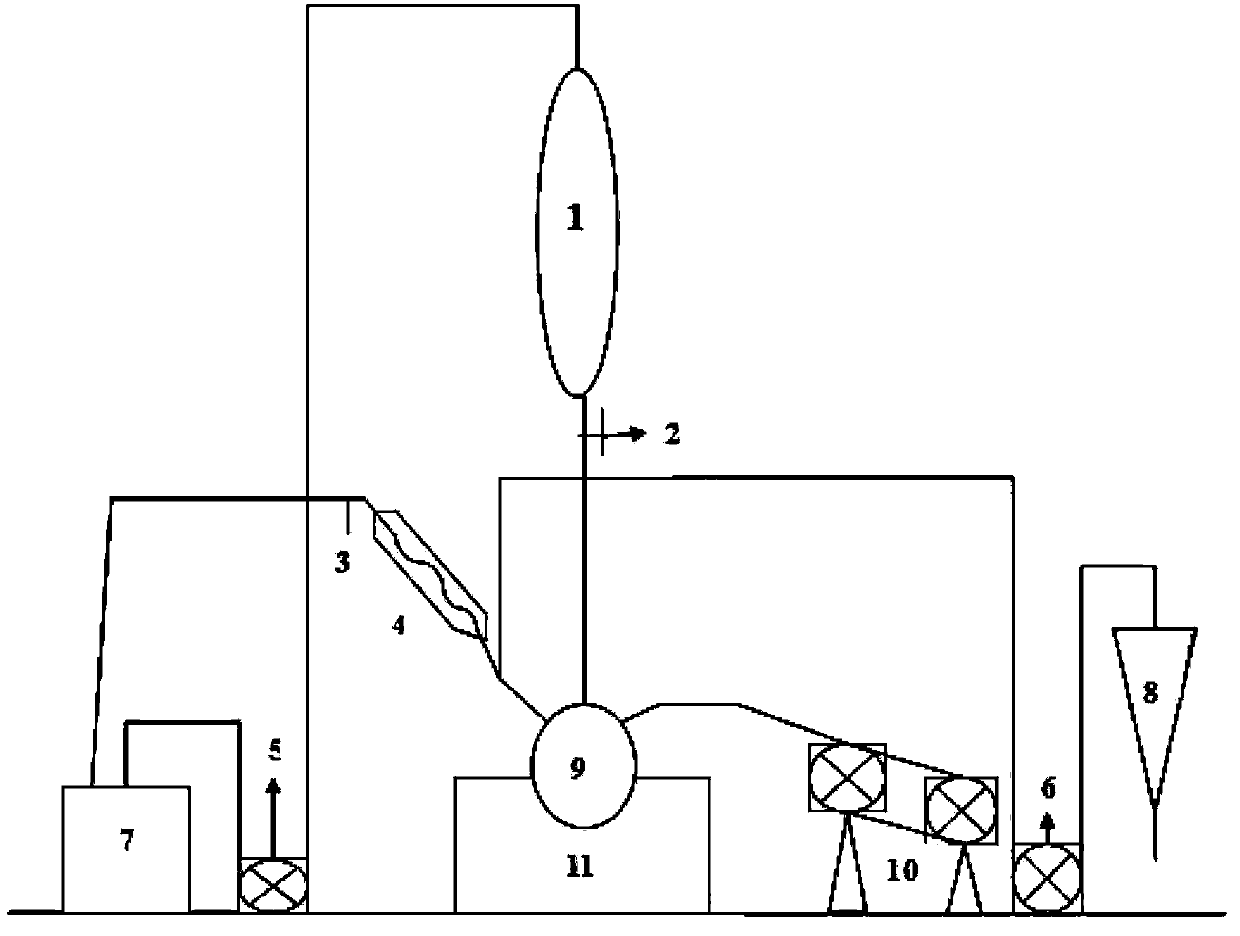

Nickel-based steam reforming catalyst for biomass tar and preparation and application method of catalyst

ActiveCN103846088ALow priceGuaranteed stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingCatalytic reforming

The invention belongs to the technical field of the energy and chemical industry and particularly relates to a nickel-based steam reforming catalyst for biomass tar and a preparation and application method of the catalyst. The catalyst adopts low-cost brown coal as a carrier and comprises the following components by weight percent: 23-25% of Ni, 64.26-66.26% of C, 6.06% of O and 6% of impurity elements. The catalyst is prepared by adopting the cooperation of an ion exchange method and an impregnation method. The catalyst has the good activity and economy, the brown coal is low in cost and large in specific surface area, after being washed by sodium hydroxide, micropores of the brown coal become mesopores and macropores, so that macromolecular compounds of the tar are relatively easy to pass; simultaneously, a relatively large quantity of new through holes are also formed in the brown coal; in the process of catalytic reformation of the tar, a relatively large quantity of effective pore channels are formed, so that the efficiency for reforming the biomass tar is relatively high; the carbon deposited amount of the catalyst and the carbon consumption amount of catalyst carrier carbon can form dynamic balance, so that the service life of the catalyst is prolonged and the catalyst is not easily inactivated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

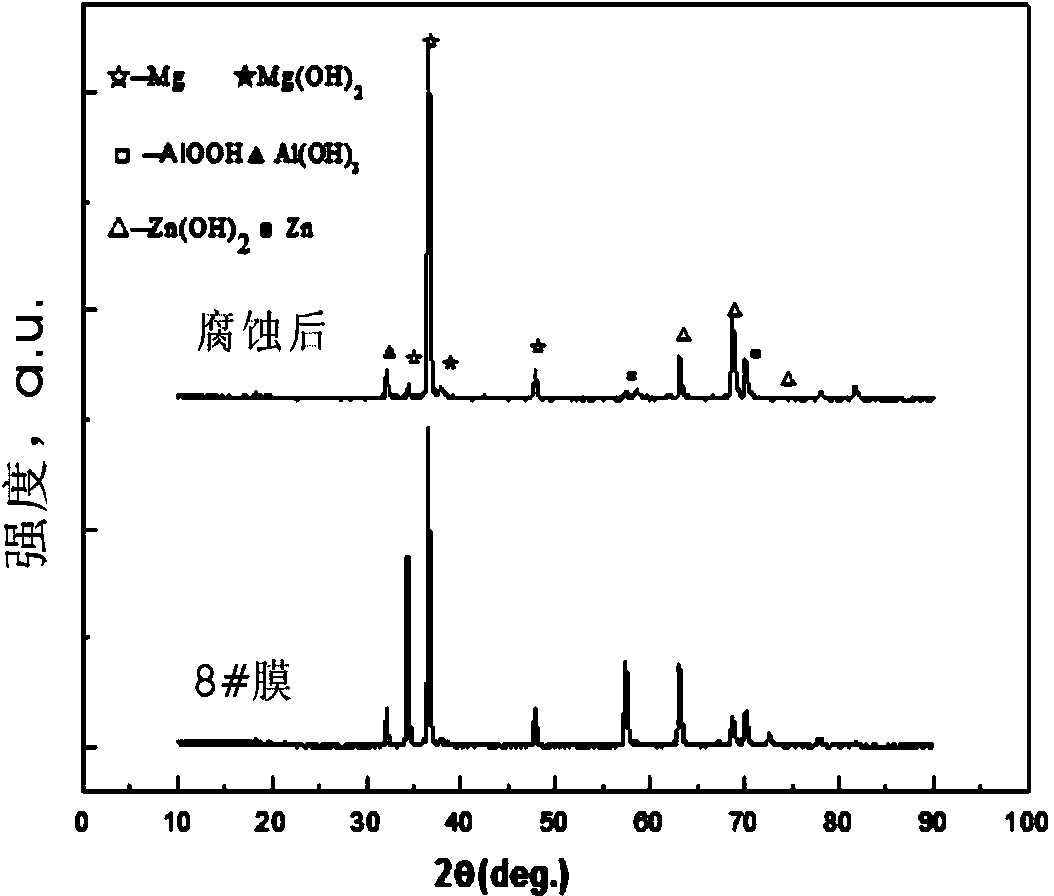

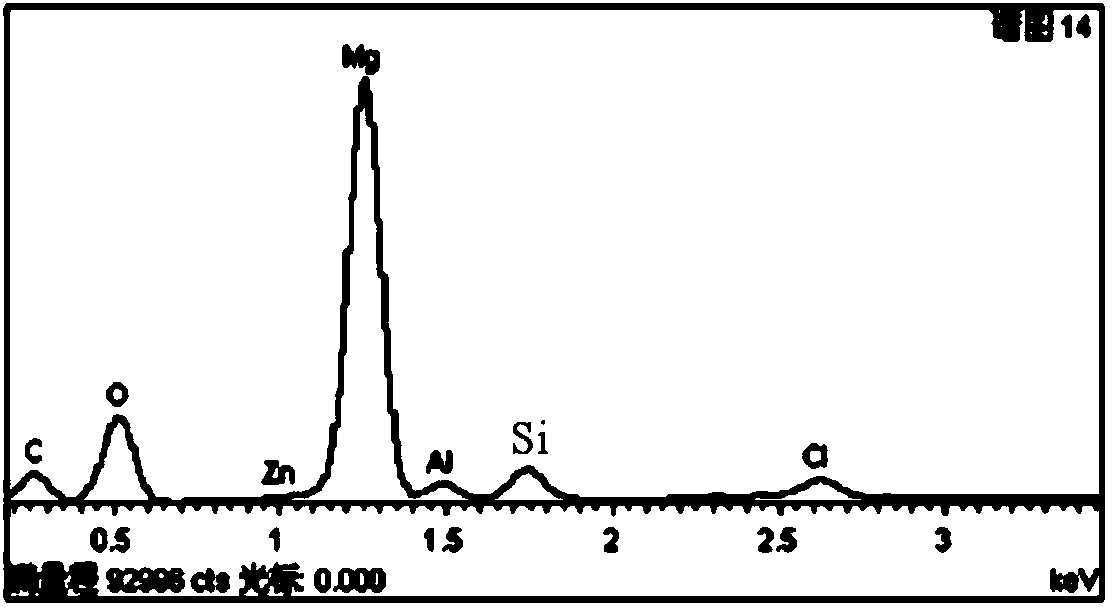

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

Monolithic catalyst for synthesizing dimethyl carbonate as well as preparation method and application method of the catalyst

InactiveCN110479287AImprove catalytic performanceImprove stabilityProductsReagentsNanoparticleActive component

The invention discloses a monolithic catalyst for synthesizing dimethyl carbonate. The catalyst is composed of active components Cu and Ni nanoparticles, a carrier that is a triphenylphosphine porouspolymer and a honeycomb ceramic matrix. The Cu and Ni nanoparticles are loaded on the triphenylphosphine porous polymer POP-PPh3, and the honeycomb ceramic matrix is coated with the triphenylphosphineporous polymer POP-PPh3 loaded with the CuNi nanoparticles to form the CuNi / POP-PPh3 monolithic catalyst. The application method comprises the following steps: putting the CuNi / POP-PPh3 monolithic catalyst into a steel pipe of a fixed bed reactor, and introducing CO2 for 5 minutes to remove other gases in a reaction system; heating to 120-180 DEG C, transporting the liquid methanol to a preheaterthrough a high-pressure constant-flow pump for gasification treatment, and reacting the mixture for 2-6 hours with the molar ratio of CH3OH to CO2 in the reaction gas being 1-3 to obtain the dimethylcarbonate. The monolithic catalyst provided by the invention is used for one-step synthesis of DMC from CO2 and methanol, and the yield of DMC exceeds 8%.

Owner:SOUTHWEST PETROLEUM UNIV

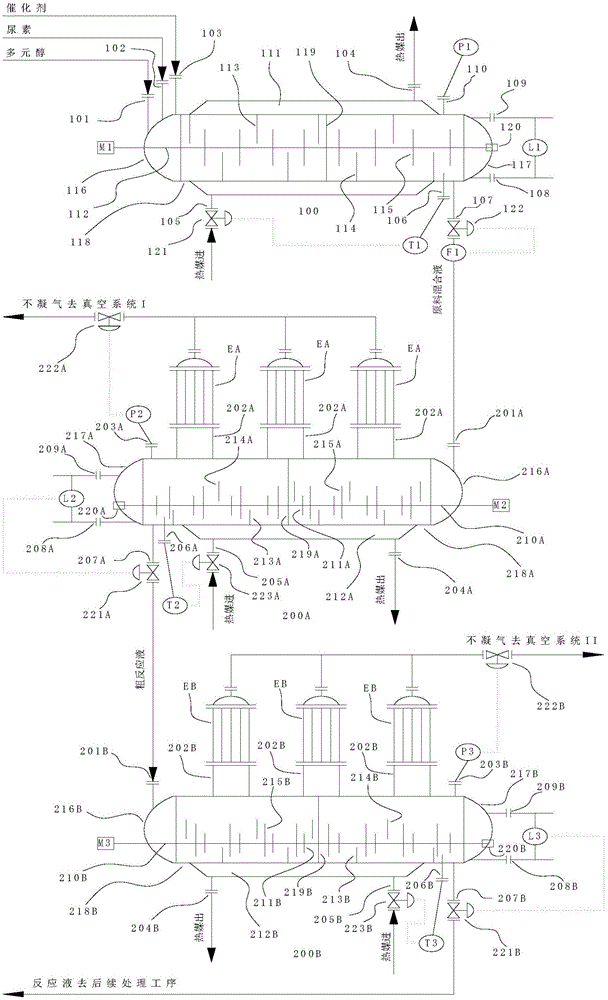

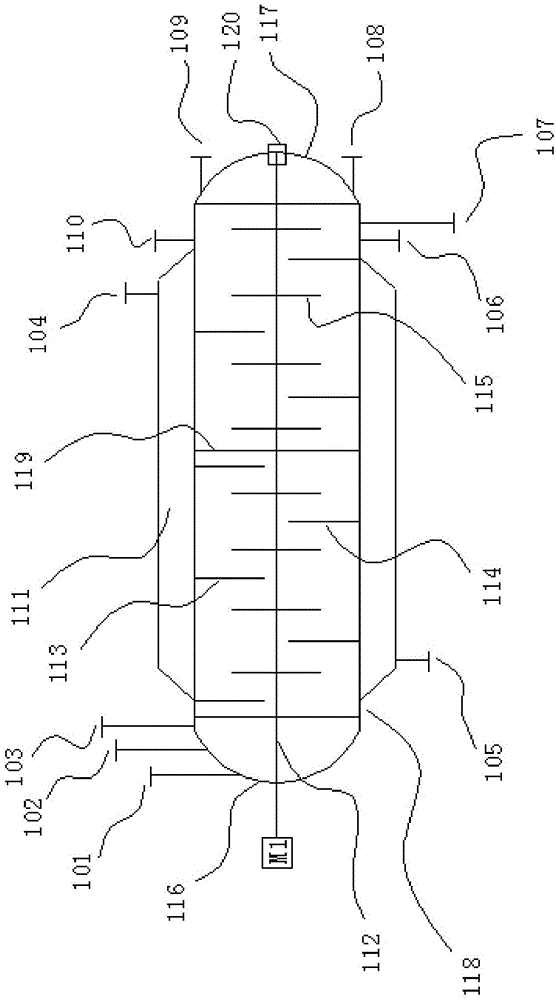

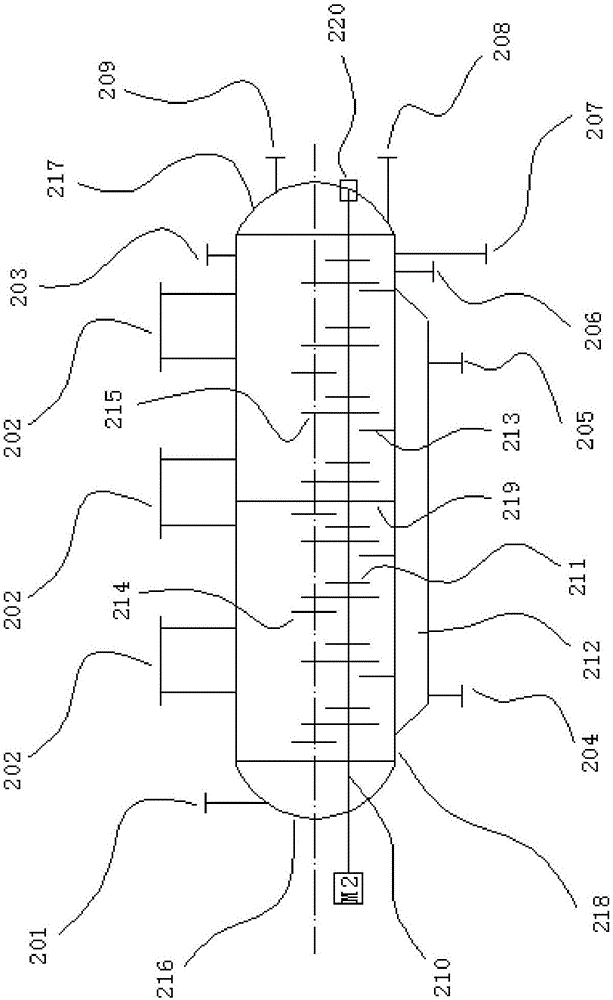

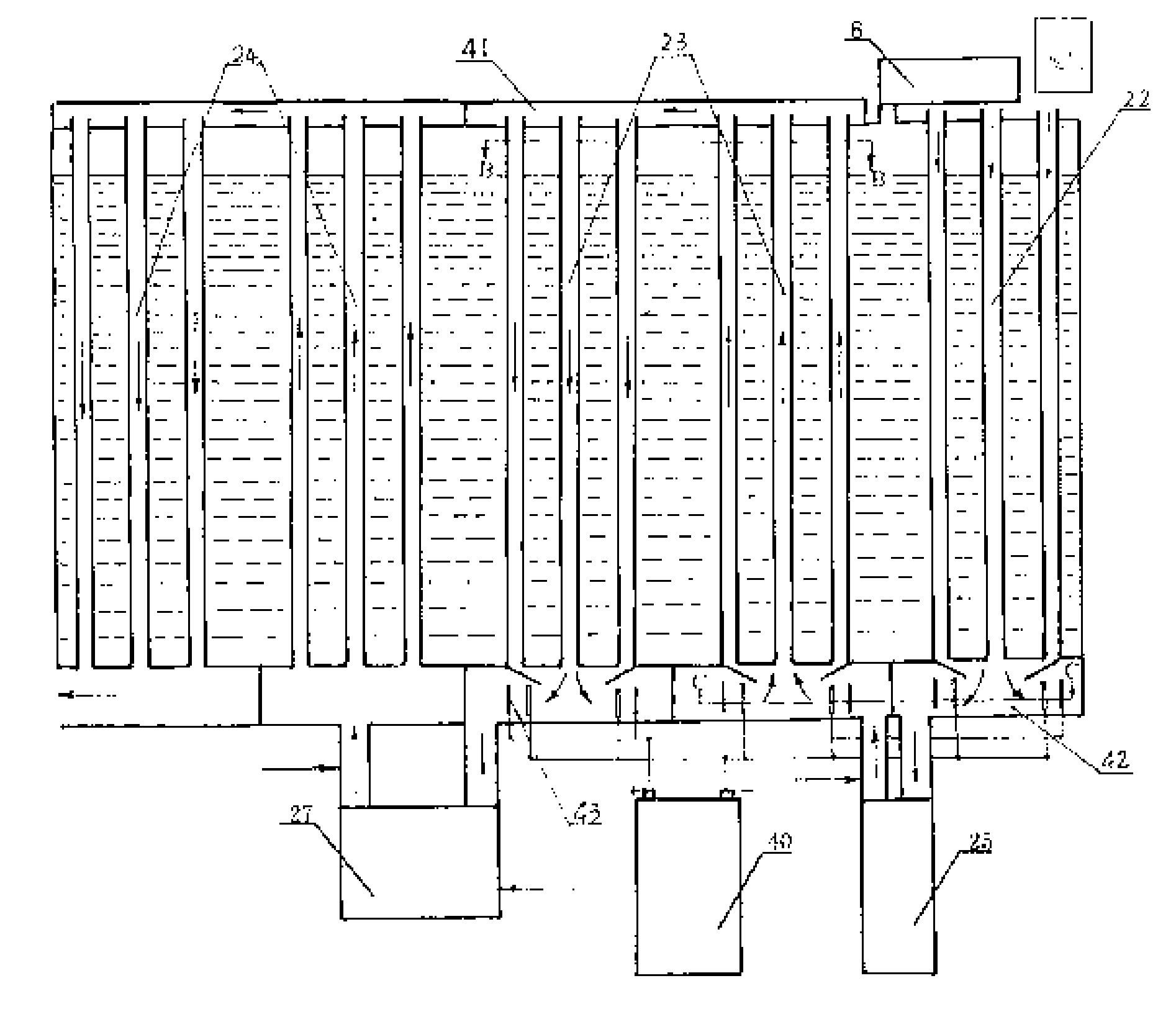

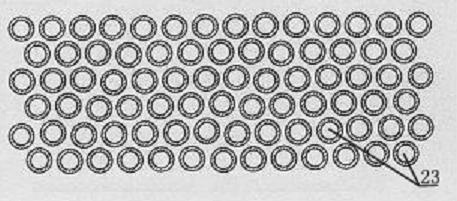

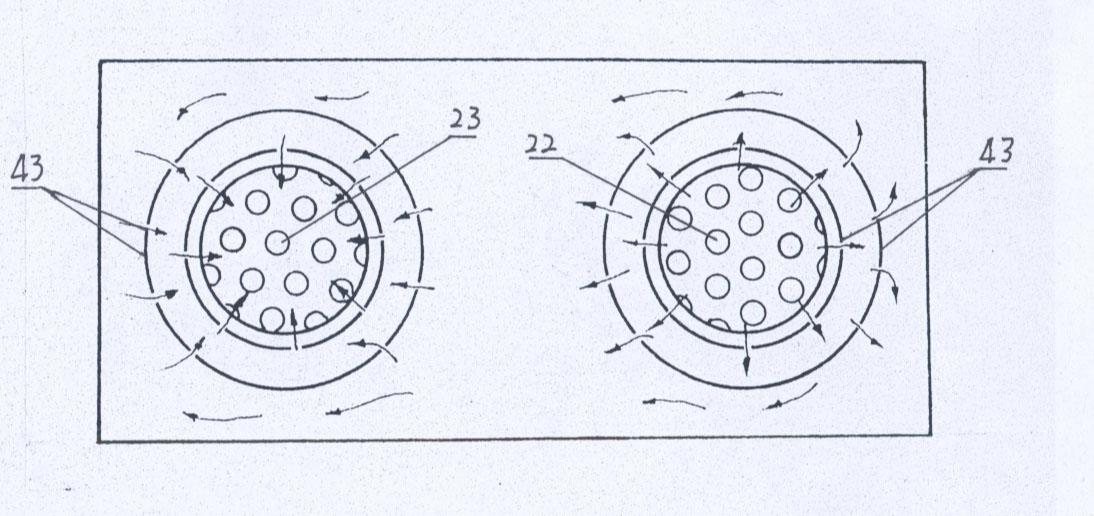

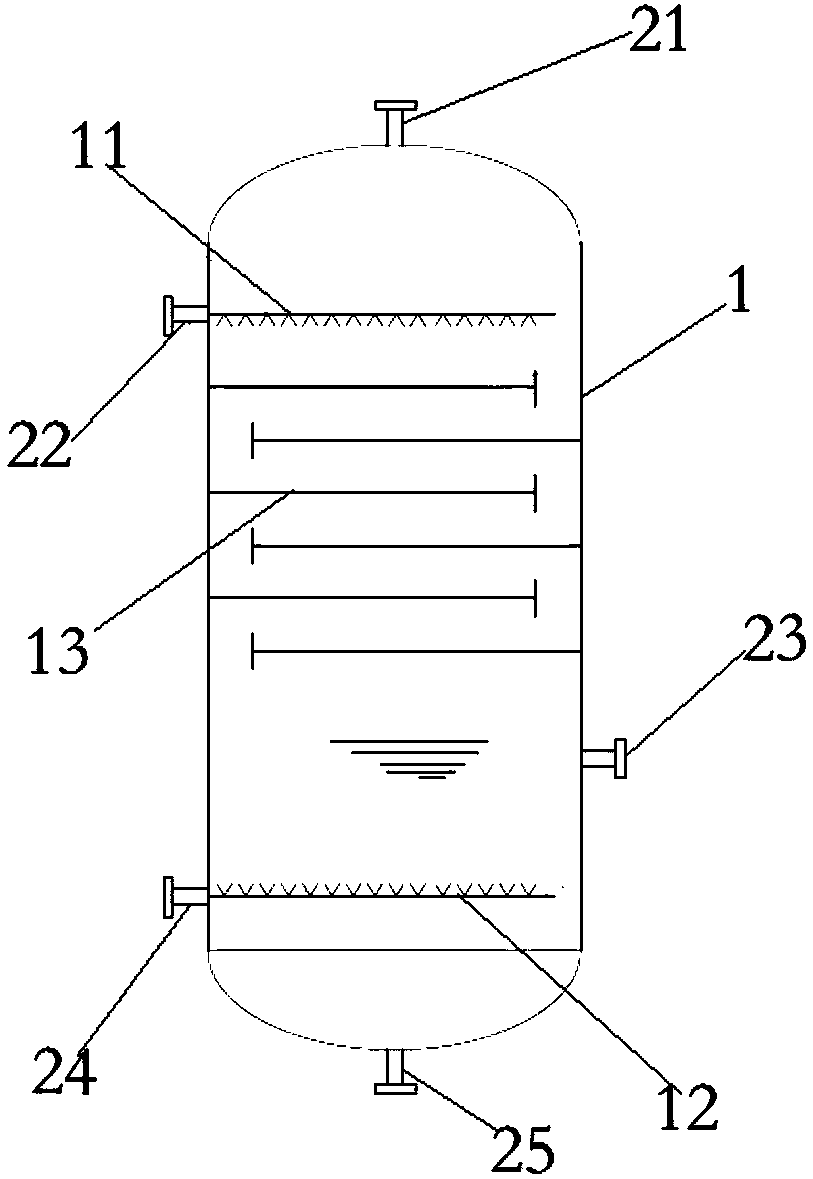

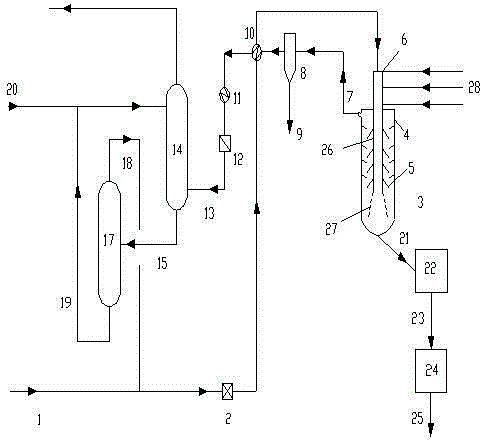

Urea synthesis cyclic carbonate continuous reaction process, horizontal raw material continuous mixer and horizontal continuous reactor

ActiveCN105017206AUniform Mass Production OperationsEasy to moveOrganic chemistryChemical/physical/physico-chemical stationary reactorsUreaContinuous reaction

A urea synthesis cyclic carbonate continuous reaction process is as follows: polyol, urea and a catalyst are separately and continuously delivered from the front; under the effect of stirring of a mixer, an upper mixer baffle and a lower mixer baffle, the mixture flows out through an outlet port of at a rear portion of the horizontal raw material continuous mixer and enters the horizontal continuous reactor through a reactor raw material inlet port at the front; and a raw material liquid mixture moves from the front to the rear and reacts in the horizontal continuous reactor, an ammonia and a polyol gas that are generated enter directly into a condenser through a gas outlet port of the reactor; the condensed polyol returns to the horizontal continuous reactor; the ammonia goes to a vacuum system; a reaction solution consisted of ungasified polyol, the cyclic carbonate and the catalyst is taken out from a reaction solution outlet port at the rear portion and then goes to a post-treatment process. The urea synthesis cyclic carbonate continuous reaction process, horizontal raw material continuous mixer and horizontal continuous reactor have the advantages of being simple in operation and being convenient for large-scale industrial implementation.

Owner:山西中科惠安化工有限公司

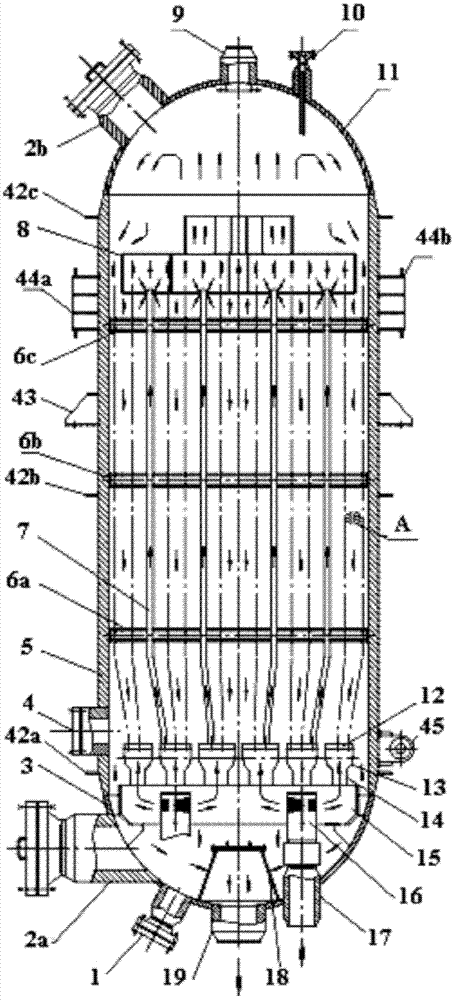

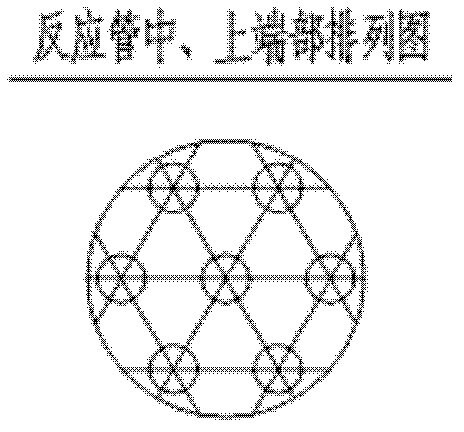

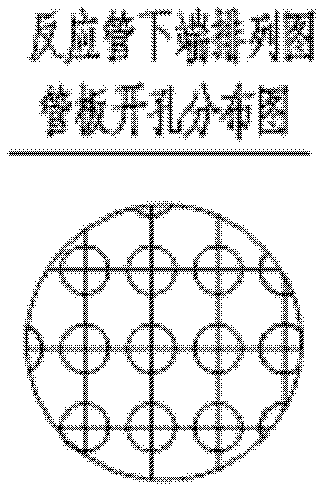

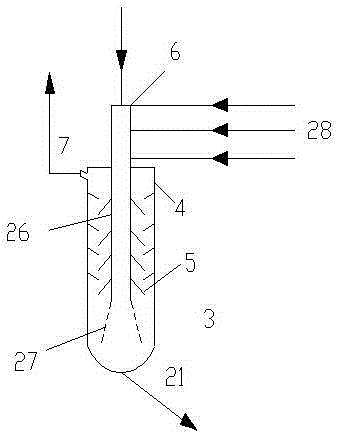

Gas-cooled methanol reactor

ActiveCN103111239AImprove production efficiencyImprove energy efficiencyOrganic compound preparationHydroxy compound preparationArchitectural engineeringMixed gas

The invention belongs to the coal-to-methanol field, and concretely discloses a gas-cooled methanol reactor. The reactor comprises a cylinder, an upper seal head packaged at the top of the cylinder and a lower seal head packaged at the bottom of the cylinder, the cylinder, the upper seal head and the lower seal head form a closed cavity, reaction tubes are arranged in the cavity, the top of each of the reaction tubes is inserted to a mixed gas tank, the middle of each of the reaction tubes is inserted to a tube support, and the bottom of each of the reaction tubes is inserted to a tube plate; tube supports are fixed on the reaction tubes, the bottom of the tube plate is fixed at the top of a U-shaped cylinder, the bottom of the U-shaped cylinder is fixed on a branch tube, the bottom of the branch tube is inserted to a manifold trunk, the top of a distribution tube is inserted to the manifold trunk, the bottom of the distribution is positioned outside the manifold trunk, and the bottom of an adaptor penetrates through the lower seal head; the top of the upper seal head is provided with a work starting gas inlet; and the bottom of the lower seal head is provided with an outlet collector, and the bottom of the outlet collector is provided with a generated gas outlet. The reactor has the advantages of methanol output improvement, cost reduction, energy saving and energy consumption reduction.

Owner:西安核设备有限公司

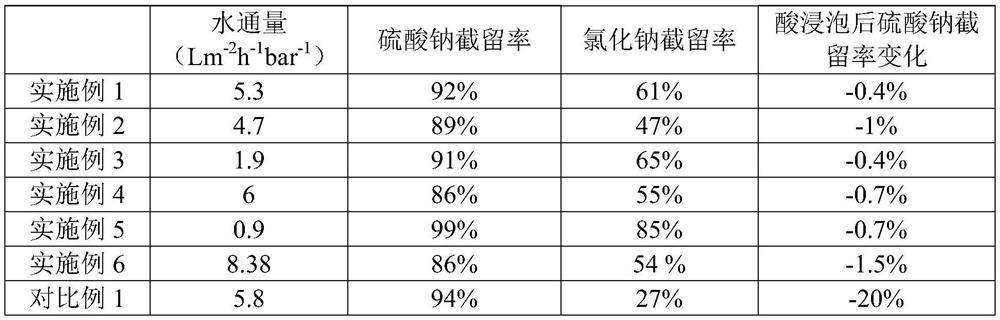

Acid-resistant nanofiltration membrane as well as preparation method and application thereof

ActiveCN112717712AGood separation ability of inorganic salt ionsImproves conjugation stabilitySemi-permeable membranesGeneral water supply conservationInorganic saltsActive agent

The invention provides an acid-resistant nanofiltration membrane as well as a preparation method and application thereof. The acid-resistant nanofiltration membrane comprises a support membrane and an active separation layer loaded on the support membrane; the separation layer comprises an interfacial polymerization product of a water-phase reactant and an oil-phase reactant, and the water-phase reactant comprises a sulfonamide monomer, an acid acceptor and a surfactant. The preparation method comprises the steps: (1) impregnating the support membrane with a water-phase reactant solution, taking out the support membrane and removing a surface solution; (2) impregnating the support membrane with an oil-phase reactant solution to perform interfacial polymerization reaction, taking out the support membrane, and removing a surface oil-phase solution; and (3) repeatedly carrying out treatment of the step (1) and the step (2) on the support membrane obtained in the step (2) to obtain the acid-resistant nanofiltration membrane. The acid-resistant nanofiltration membrane disclosed by the invention has relatively good inorganic salt ion separation capability, structural stability under an acidic condition and controllable separation capability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Solid-phase compound metal catalyst used for magnesium desulphurization technology

ActiveCN103285875AEasy to makeEasy to operateMetal/metal-oxides/metal-hydroxide catalystsIron saltsNickel salt

The invention discloses a solid-phase compound metal catalyst used for a magnesium desulphurization technology, belonging to the technical field of the preparation of compound metal catalysts. The catalyst is prepared through dissolving a divalent manganese salt, a divalent cobalt salt, a divalent copper salt, a divalent nickel salt, a trivalent iron salt and a trivalent bismuth salt in water, co-precipitating through using molybdate, drying, oven-drying, and calcining. The catalyst has the advantages of simple operation, substantial catalysis effect, realization of the increase of the system oxidation efficiency of above 50% without changing the original oxidation gas quantity, less application amount, easy recovery, less residual in the solution, and no secondary pollution problems, and has a popularization value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing high-purity chlorine dioxide through solid-state heterogeneous catalysis

The invention discloses a method for preparing high-purity chlorine dioxide through solid-state heterogeneous catalysis, which belongs to the chemical field of inorganic compound preparation. The preparation method comprises the following step: by adopting chlorate or chlorite and polyatomic acid or a polyatomic acid aquo-complex as raw materials, by adopting a silica-based molecular sieve loading transition metal as a catalyst, and by adopting a solid-state heterogeneous catalysis heating method, preparing the high-purity chlorine dioxide through controlling a molar ratio, reaction temperature and other conditions of reactants. The method adopts a solid-state method, which is different from other methods, so that the defects of corrosion of strong acid on devices, impurity products and difficulty in separation in a liquid phase method are avoided, the process is simple, other impurities such as chlorine cannot be produced, and the purity of the prepared chlorine dioxide can achieve 90 percent or more.

Owner:EAST CHINA NORMAL UNIVERSITY

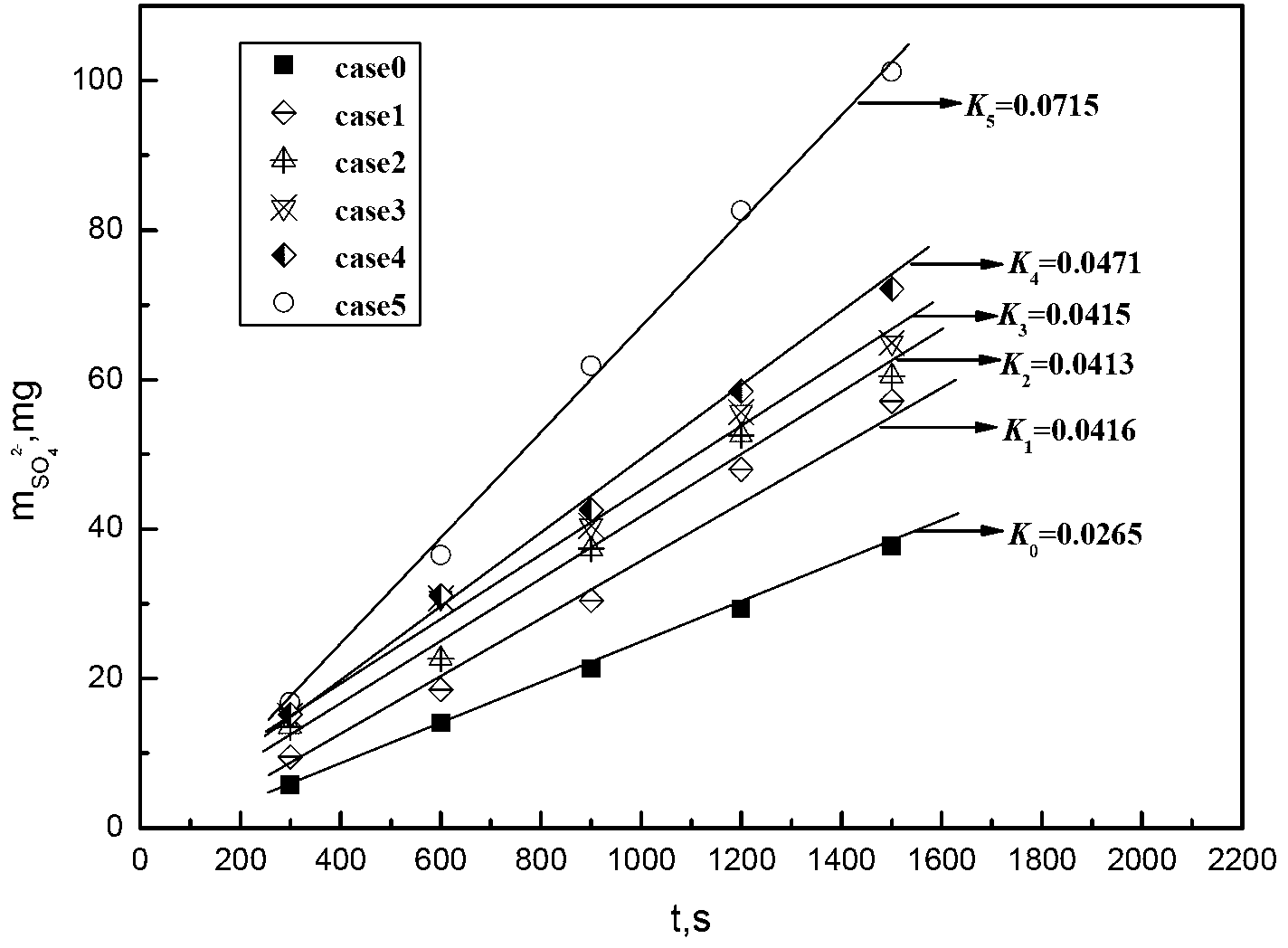

System with functions of condensing solar energy to generate steam and driving solid waste plasma gasification

ActiveCN109355101AImprove output and qualityImprove energy efficiencySolar heating energySolar heat storageSlagEngineering

The invention belongs to the related technical field of solar heat utilization and organic waste clean conversion and utilization, and discloses a system with functions of condensing solar energy to generate steam and driving solid waste plasma gasification. The system comprises a plasma solid waste gasification unit and a solar light condensation and heat collection unit. The plasma solid waste gasification unit and the solar light condensation and heat collection unit can jointly work, sunlight can be gathered to an absorption cavity by a heliostat field, air in the absorption cavity can bedelivered into a high-temperature steam generator after heat is absorbed by the air, low-temperature steam which is delivered from a gasification furnace can be heated by the aid of the heat in the air to obtain high-temperature steam, and cold air can be delivered back to the absorption cavity to continue to being heated, so that circulation can be implemented. The high-temperature steam can be delivered into the plasma gasification furnace to be used as a gasification medium, gasification reaction can be carried out on the gasification medium and solid waste, and high-quality synthesis gas and nontoxic and harmless furnace slag can be generated by means of reaction. The system has the advantages that the energy efficiency of the integral system can be obviously improved, the solar energycan be continuously utilized for treating the solid waste through out the day, the output of the synthesis gas can be effectively increased, and the quality of the synthesis gas can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

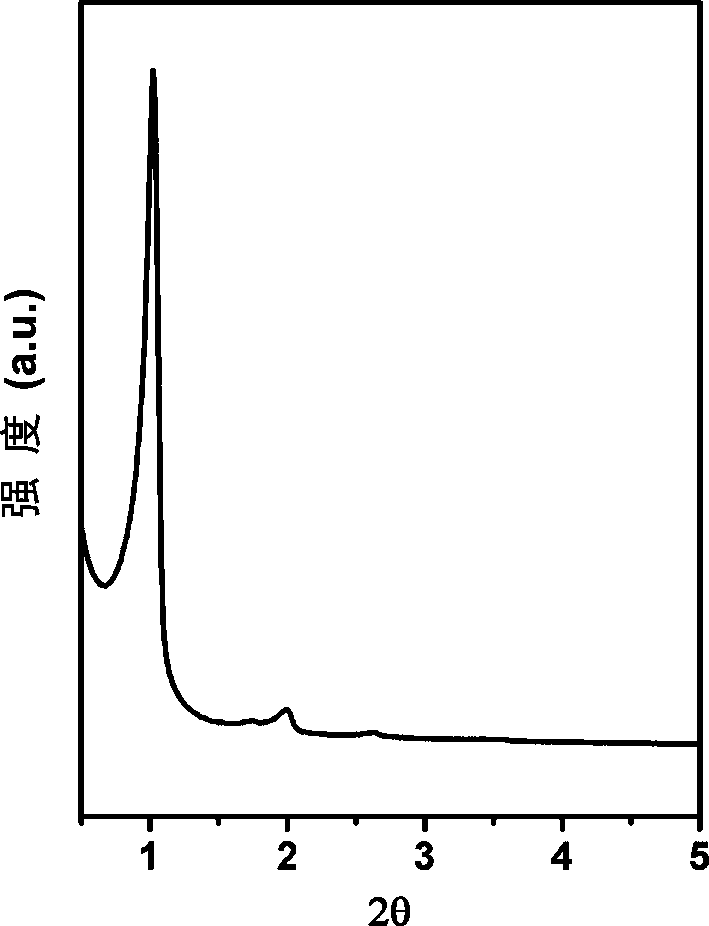

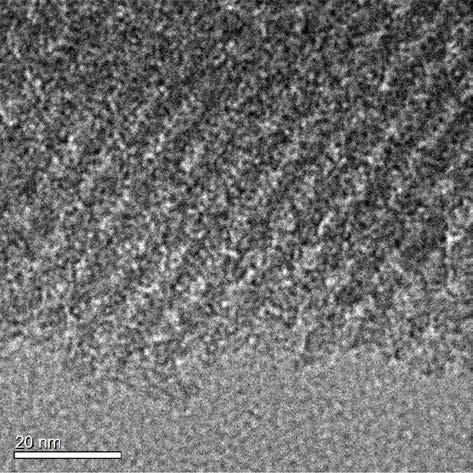

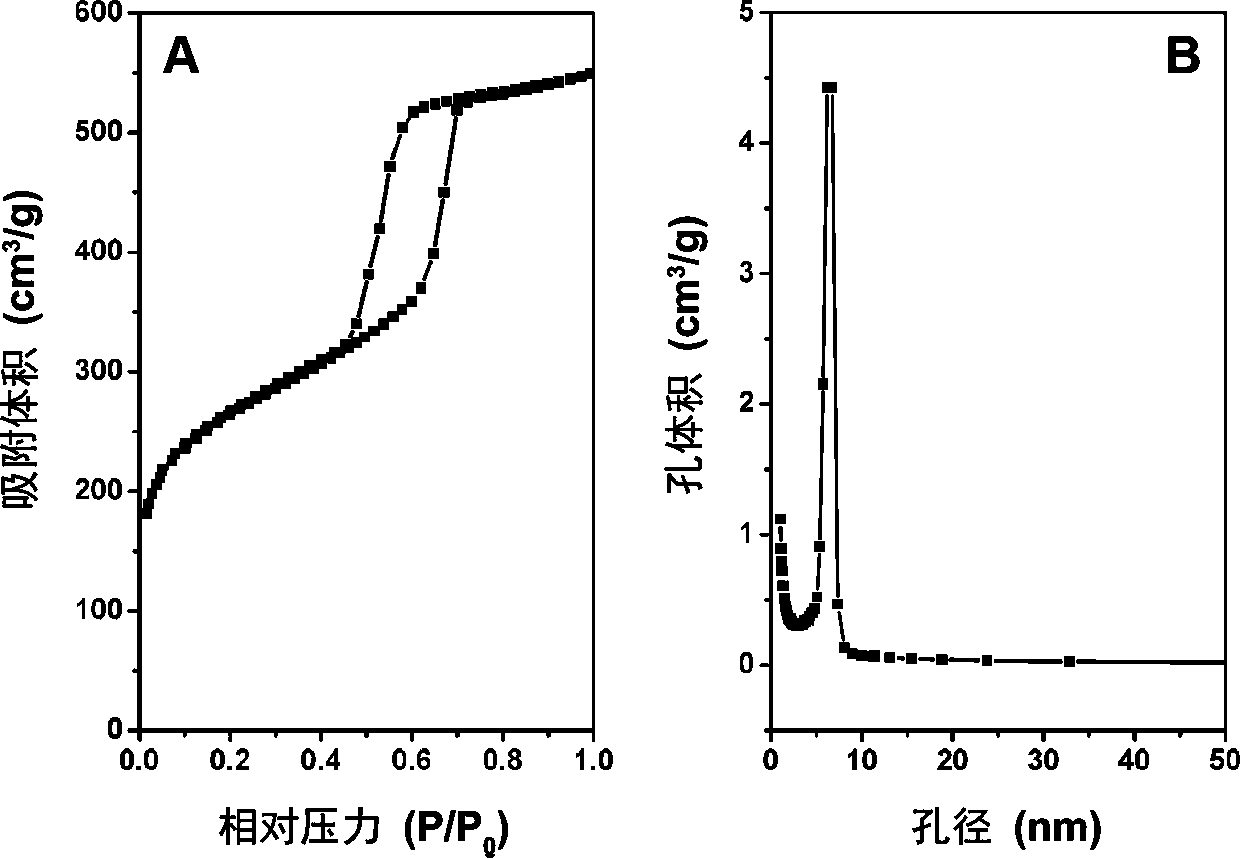

Ordered mesoporous silica material with pore wall being rich in micropore structures and preparation thereof

The invention relates to an ordered mesoporous silica material with a pore wall being rich in micropore structures. The material is formed by sequentially dissolving a triblock copolymer nonionic surfactant, organic carboxylic acid and a silicon source in anhydrous ethanol containing a small amount of deionized water, and then sequentially performing solvent thermal treatment, solvent removal andcalcination treatment. The ordered mesoporous silica material has a highly orderly two-dimensional hexagonal mesoporous structure, high porosity, large specific surface area and uniform and adjustablemesoporous aperture, contains a large quantity of micropores, with adjustable contents, in the mesoporous wall, and shows a broader application prospect compared with the traditional microporous materials and mesoporous material in the fields of adsorption, separation and catalysis.

Owner:TAIYUAN UNIV OF TECH

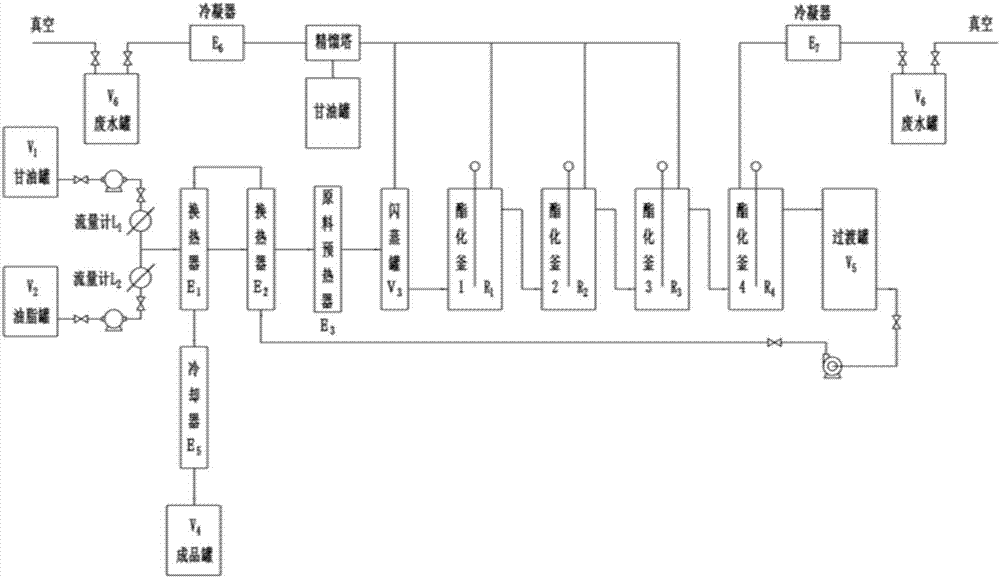

Catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin

InactiveCN107459997ASolve the problem of meeting the requirements of transesterification for the preparation of biodieselHigh boiling pointBiofuelsLiquid hydrocarbon mixture productionReaction temperatureOil production

A catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin comprises the steps of raw material mixing and delivery, mixed raw material and finished product heat exchange, mixed raw material preheating after heat exchange, flash evaporation and dehydration of mixed raw materials, continuous esterification reaction and separation of glycerin extracted in the esterification process. The problems of low esterification reaction speed and non-thorough esterification caused by untimely reaction moisture discharging due to low reaction temperature in the process of preparing biodiesel by using high-acid-value waste cooking oil and leftovers in oil production industry and using methyl alcohol as an esterifying agent for pre-esterification and acid decrease are effectively solved, and the problems of device corrosion and environmental pollution brought by a large amount of produced waste acid water due to the fact that sulfuric acid is added to serve as a catalyst in the esterification process is solved. A continuous production process is adopted for esterification reaction, heat exchange of raw materials and finished products is achieved in the continuous process, and the problems of frequent and complicated operation, high labor cost, high production energy consumption, small yield and low efficiency of an intermittent esterification process are solved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Full decontamination waste gas recovering flexible pressurization system

InactiveCN102588044AIncrease powerReduce fuel consumptionCellsInternal combustion piston enginesPlate heat exchangerGas compressor

The invention discloses a full decontamination waste gas recovering flexible pressurization system comprising a diesel engine. The diesel engine is provided with a gas inlet pipe and a gas exhaust pipe, the gas inlet pipe is connected with a gas compressor, the gas exhaust pipe is connected with a turbine generator, and the turbine generator is connected with a decontamination heat exchanging device through a pipeline. The decontamination heat exchanging device comprises a heat exchanging box body communicated with the turbine generator through the pipeline, a water chamber is arranged in the heat exchanging box body, a steam storage chamber is arranged above the water chamber, a superheater is arranged between the water chamber and the steam storage chamber, one end of the superheater is communicated with the water chamber, and the other end of the superheater is communicated with the steam storage chamber. A synchronous valve is arranged on a steam transferring pipe, and the gas exhaust end of a steam turbine is connected with a condenser. A composite heat exchanger, a reduction heat exchanger and an oxidation heat exchanger which are connected in series are arranged in the water chamber, the gas inlet end of the composite heat exchanger is communicated with the heat exchanging box body, and the gas outlet end of the oxidation heat exchanger is communicated with a desulfurizing device. With the adoption of the full decontamination waste gas recovering flexible pressurization system, the power of the diesel engine is increased, and the oil consumption rate is reduced.

Owner:张建元

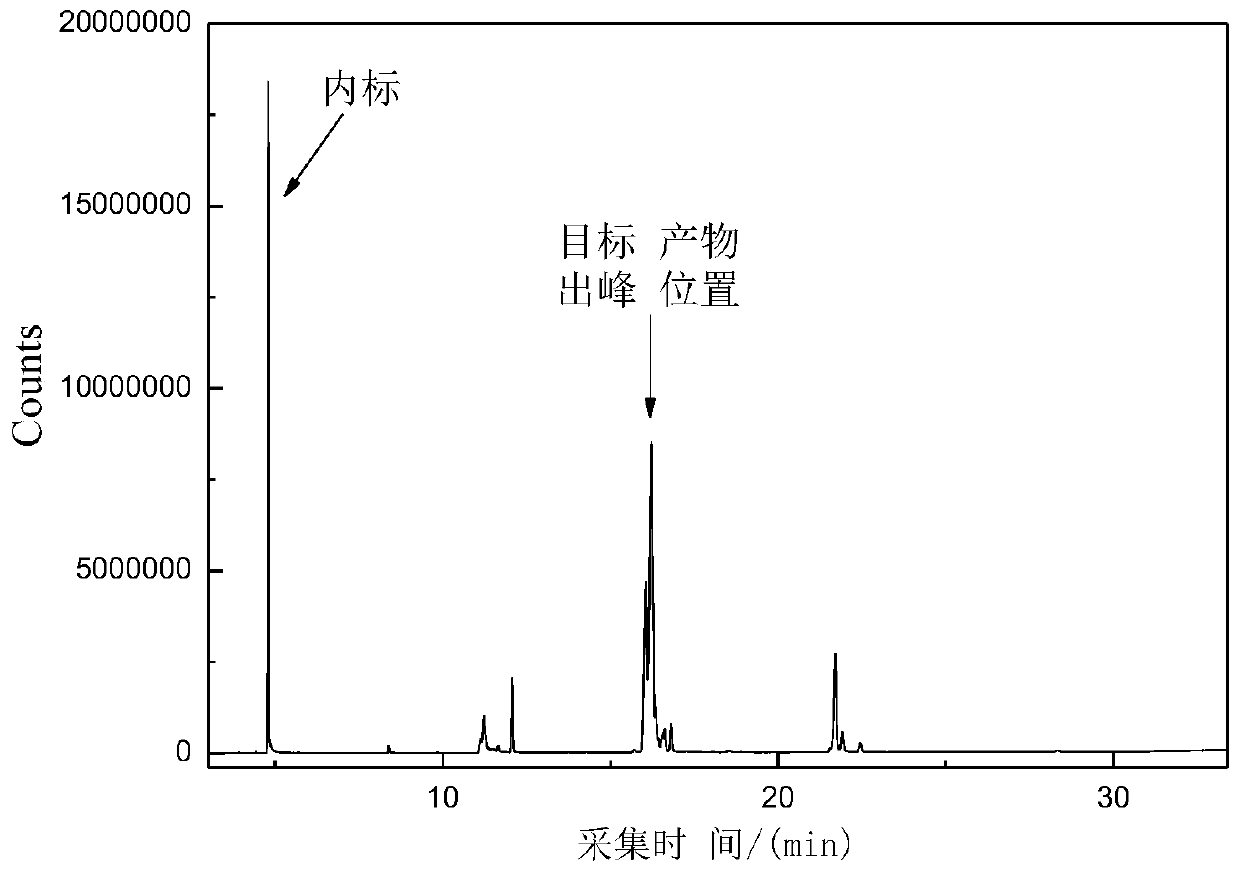

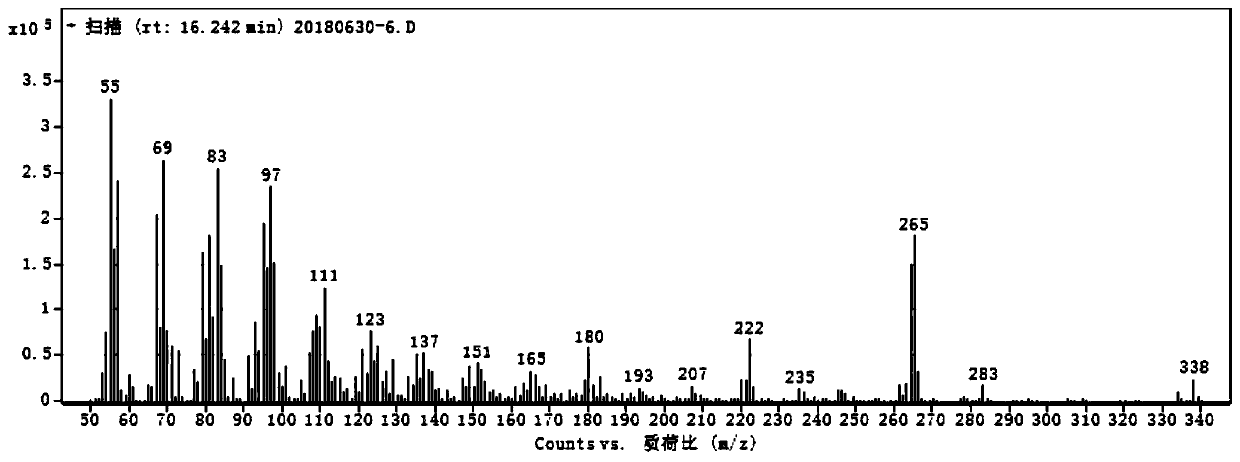

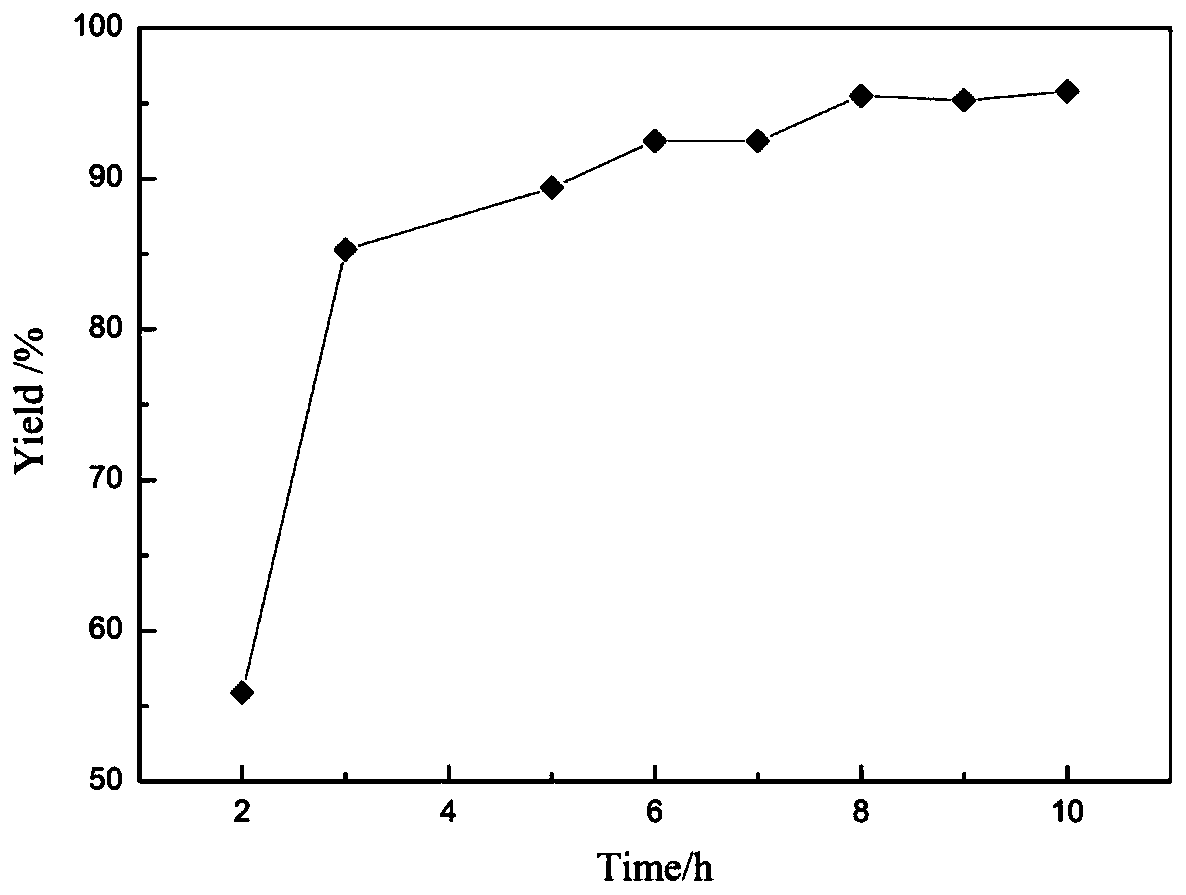

A kind of preparation method of palbociclib

The invention belongs to the field of pharmaceutical and chemical engineering, and particularly relates to a preparation method of palbociclib. 2-acetyl-2-butenoic acid methyl ester, malononitrile and a guanidino compound III are reacted together according to an ultrasonic-microwave assisted synthesis method, and a compound IV is rapidly obtained with a high yield; then, sodium nitrite and hypophosphorous acid are subjected to a deamination reduction reaction to generate a compound V; then, the compound V and cyclopentane halide are subjected to a coupled reaction under the action of a catalyst to generate a compound VI; finally, a dehydrogenation reaction is conducted under the action of a catalyst TPND to obtain the palbociclib. The method has the advantages that reaction conditions are mild, the technological process is simple and reasonable, reaction time is short, aftertreatment is easy, product quality is high, and the yield is high.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

Heterogeneous catalysis pretreatment method of Carlin type refractory gold ore

InactiveCN104342549AImprove leaching rateImprove oxidation capacityProcess efficiency improvementPretreatment methodRefractory

The invention discloses a heterogeneous catalysis pretreatment method of a Carlin type refractory gold ore. The method comprises the following steps: (1) pre-crushing the ore; and (2) treating the crushed ore with a chemical heterogeneous catalysis pre-oxidization process under an aeration condition by adopting an alkaline reagent, an oxidant and a composite dispersant so as to obtain pretreated ore. The pretreatment method disclosed by the invention can be used for oxidizing sulfur in the Carlin type refractory gold ore so that coated gold existing in the form of sulfide can be exposed, and thus the leaching rate of the gold is increased.

Owner:厦门紫金矿冶技术有限公司

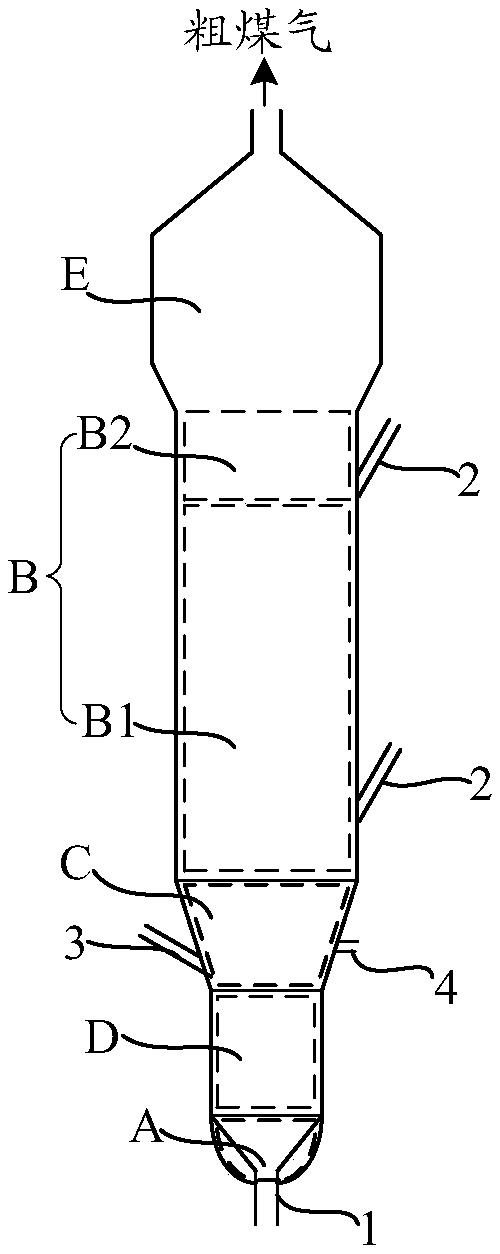

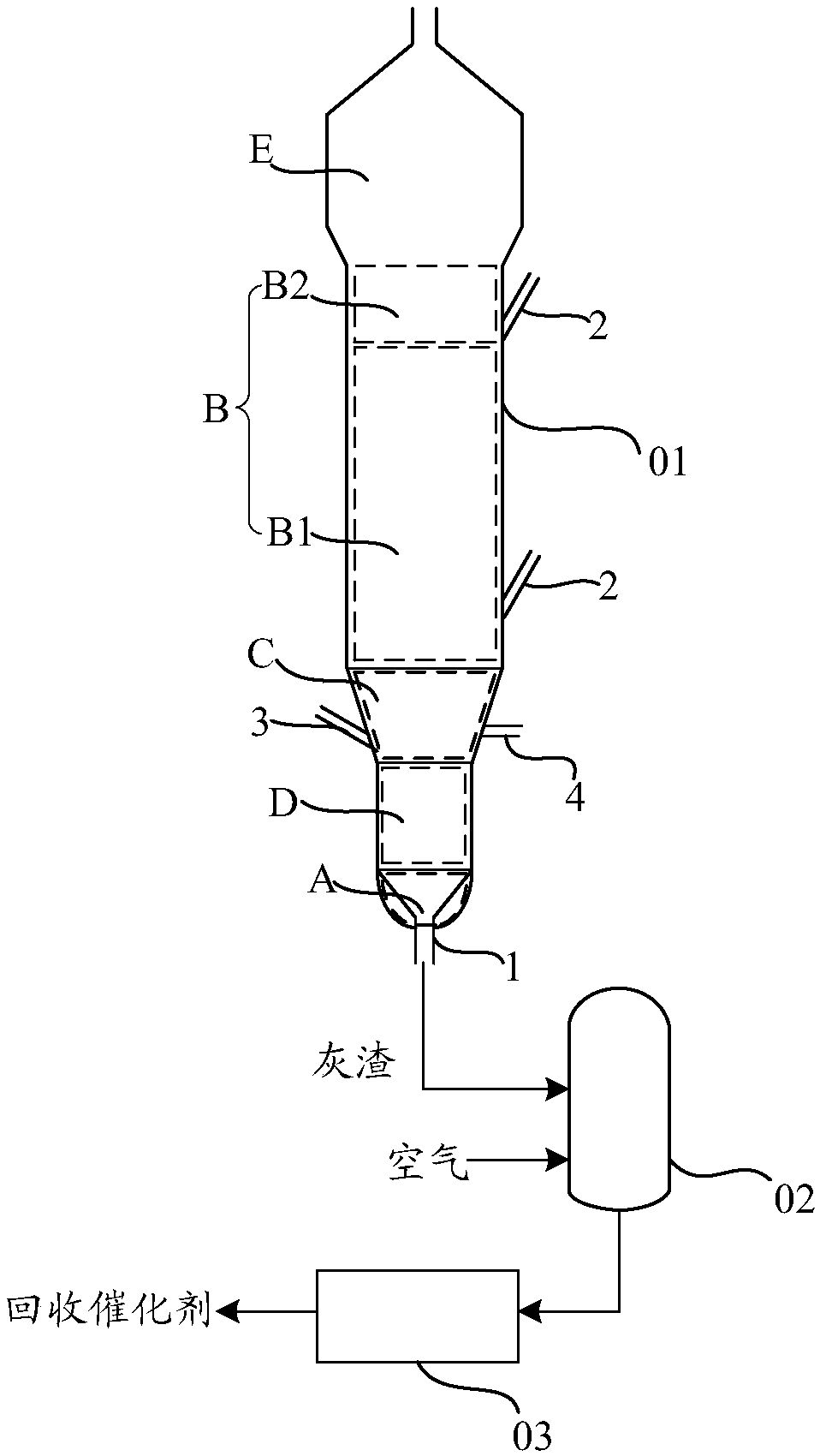

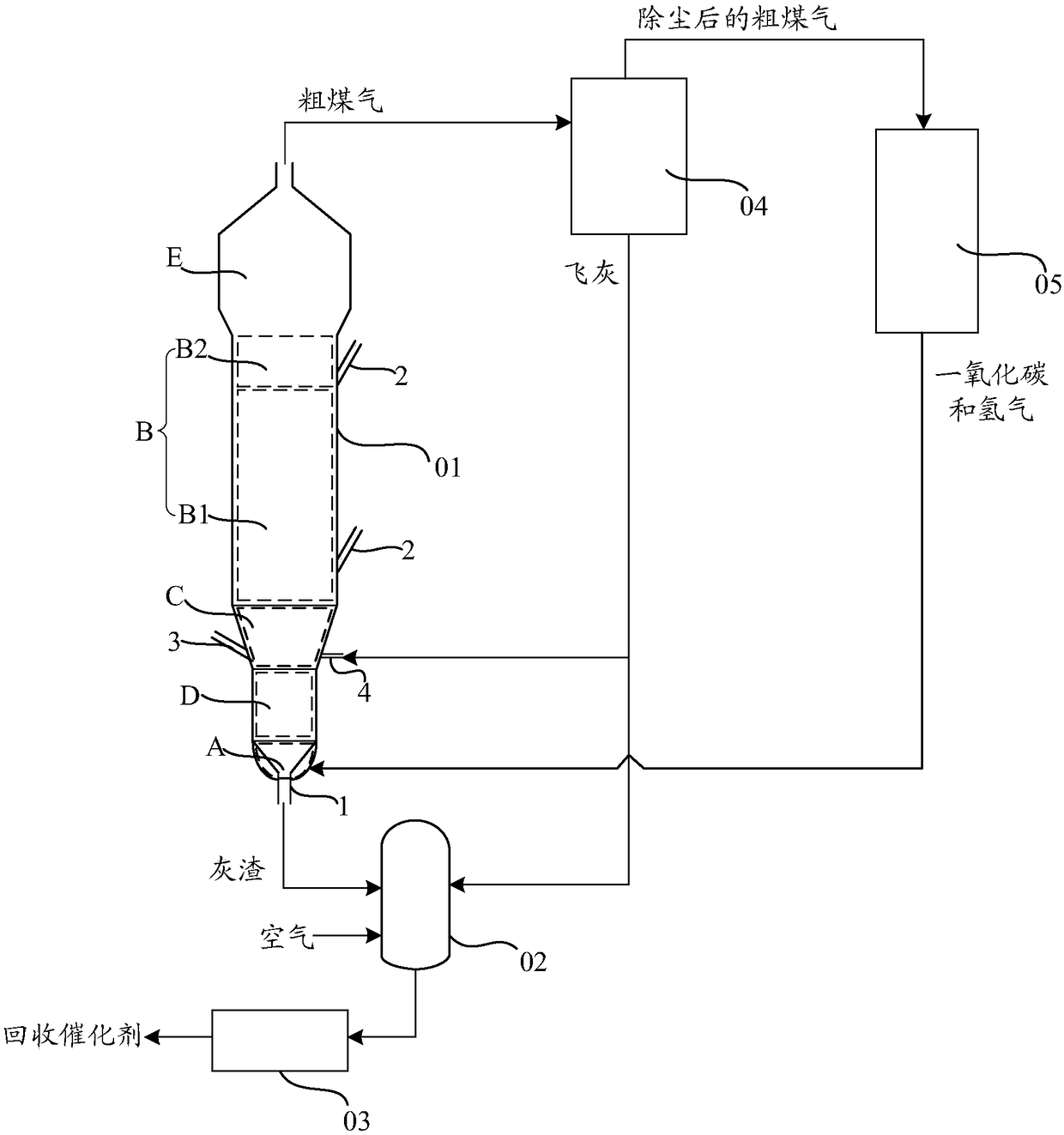

Fluidized bed gasifier, coal gasification system and method

InactiveCN108179032AHigh yieldStable furnace temperatureGasification processes detailsGranular/pulverulent flues gasificationSyngasFluidized bed gasifier

The invention relates to the technical field of coal gasification, in particular to a fluidized bed gasifier, a coal gasification system and a method, can satisfy the heat requirement of overall reaction in the furnace, have no need for introducing oxygen burning coal to provide heat, lower the risk of easy slagging in the gasifier due to introduction of oxygen, at the same time can promote forward overall reaction in the furnace, have no need for returning substantial synthesis gas to the furnace to increase the methane yield, and lower the risk of inhibition on overall reaction in the furnace caused by return of synthesis gas to the furnace. According to the fluidized bed gasifier, the bottom is a gas distribution plate area, a fluidized bed reaction area is disposed above the gas distribution plate area, a variable diameter section with a gradually enlarging inner diameter from the bottom up is disposed between the fluidized bed reaction area and the gas distribution plate area, thebottom of the fluidized bed gasifier is equipped with deslagging port, the side wall of the fluidized bed gasifier corresponding to the fluidized bed reaction area is equipped with coal inlets, and the lower part of the variable diameter section is equipped with a carbon carrier inlet.

Owner:ENN SCI & TECH DEV

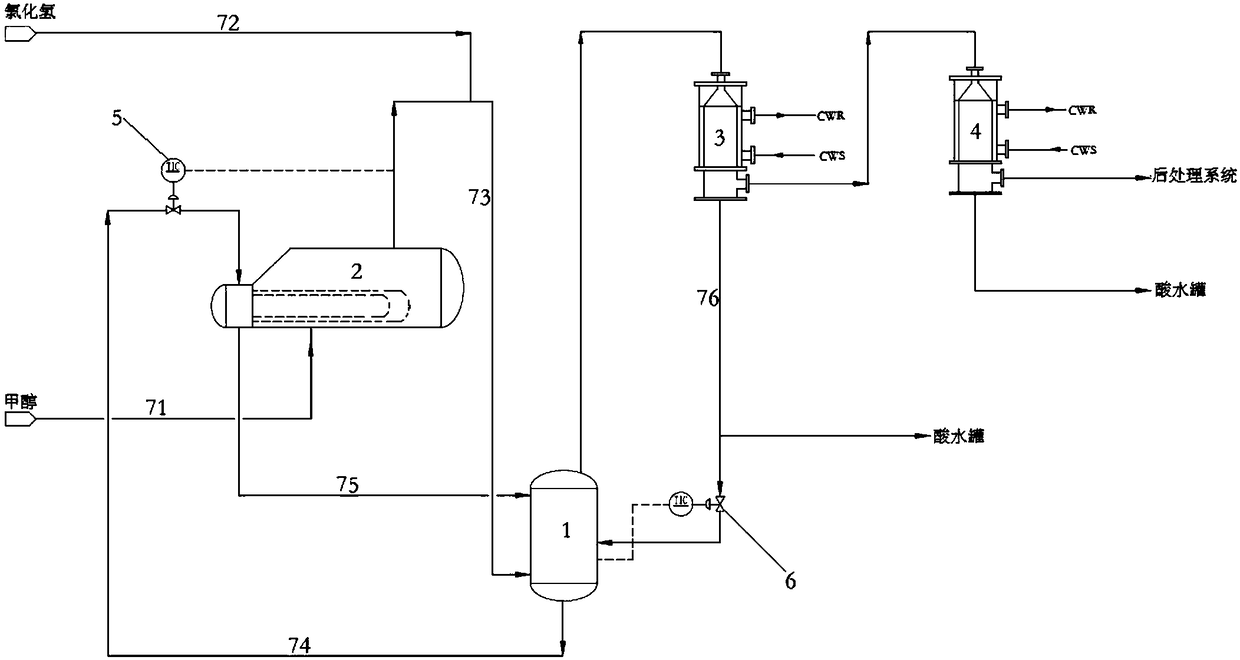

Energy-saving methane chloride production system and method

ActiveCN108409526AEffective recovery of heatTake advantage ofHalogenated hydrocarbon separation/purificationHeat flowGas phase

The invention discloses an energy-saving methane chloride production method. The method includes: liquid raw material methanol is heated in a methanol vaporizer, and the methanol is mixed with hydrogen chloride and then enters a reaction kettle through a gas-phase inlet in the lower portion of the reaction kettle; the kettle-bottom produced liquid of the reaction kettle is used as the heating medium of the methanol vaporizer, and the kettle-bottom produced liquid is subjected to heat exchanging through the methanol vaporizer and circulated to a liquid-phase inlet in the upper portion of the reaction kettle; liquid and gas are in continuous countercurrent contact on a tower plate or filler in the reaction kettle; high-temperature mixed gas in the reaction kettle escapes from the top of thereaction kettle, and the gas is cooled by a first condenser and a second condenser and then conveyed to a purification system. The invention further discloses an energy-saving production system used for achieving the method above. The method has the advantages that heat flow produced at the bottom of the reaction kettle and the raw material methanol are subjected to heat exchanging in the methanolvaporizer, the heat carried by the high-temperature heat flow is recycled effectively, reaction heat is utilized sufficiently, all steam needed by methanol preheating and vaporization is saved, and an evident energy saving effect is achieved.

Owner:SEDIN NINGBO ENG

Production integrated system of leptospermum scoparium couperose skin mitigating extract composition, leptospermum scoparium couperose skin mitigating extract composition and preparation method thereof

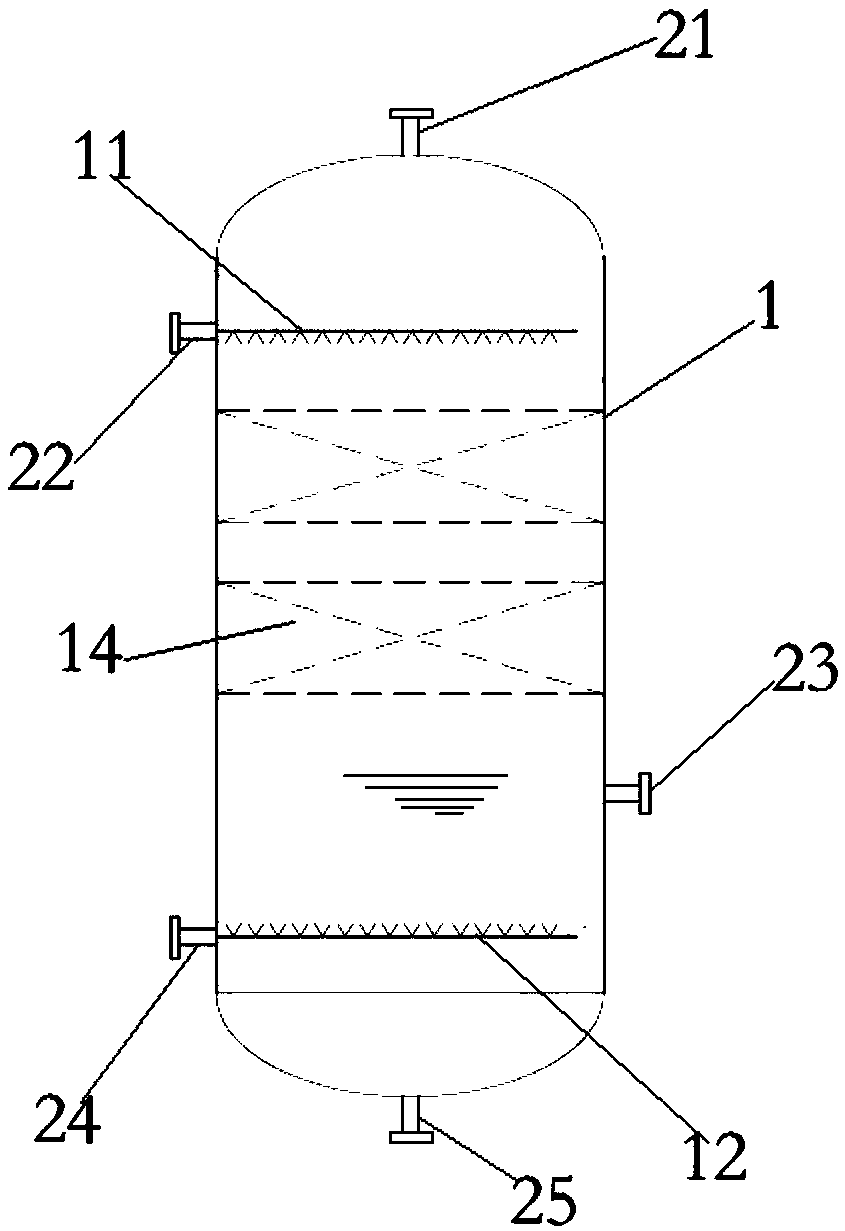

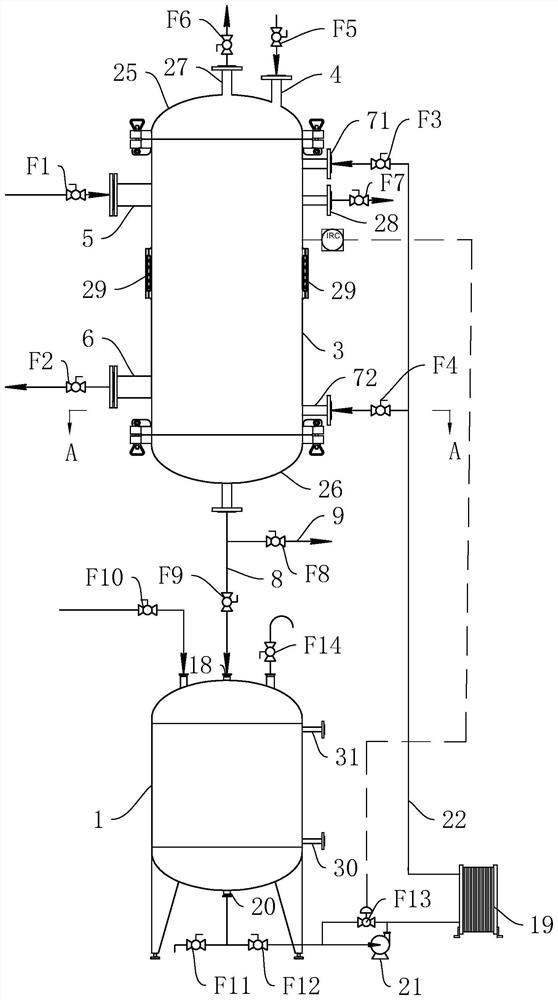

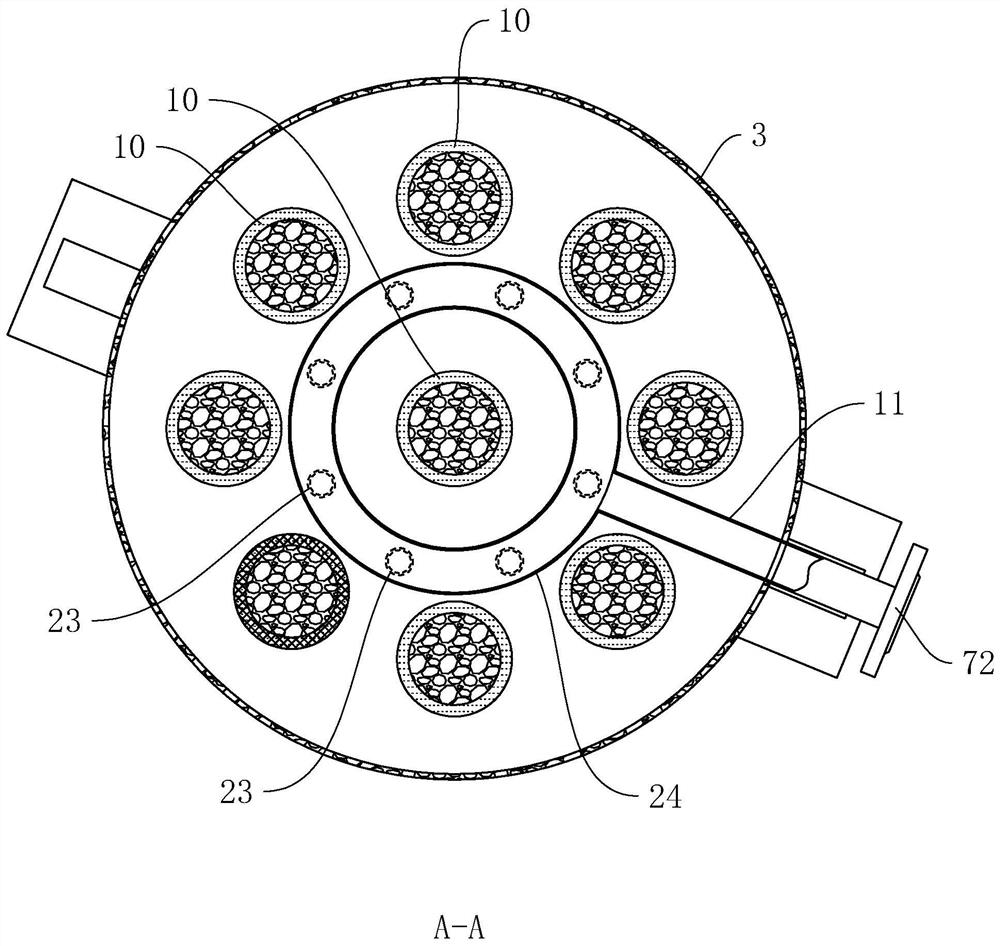

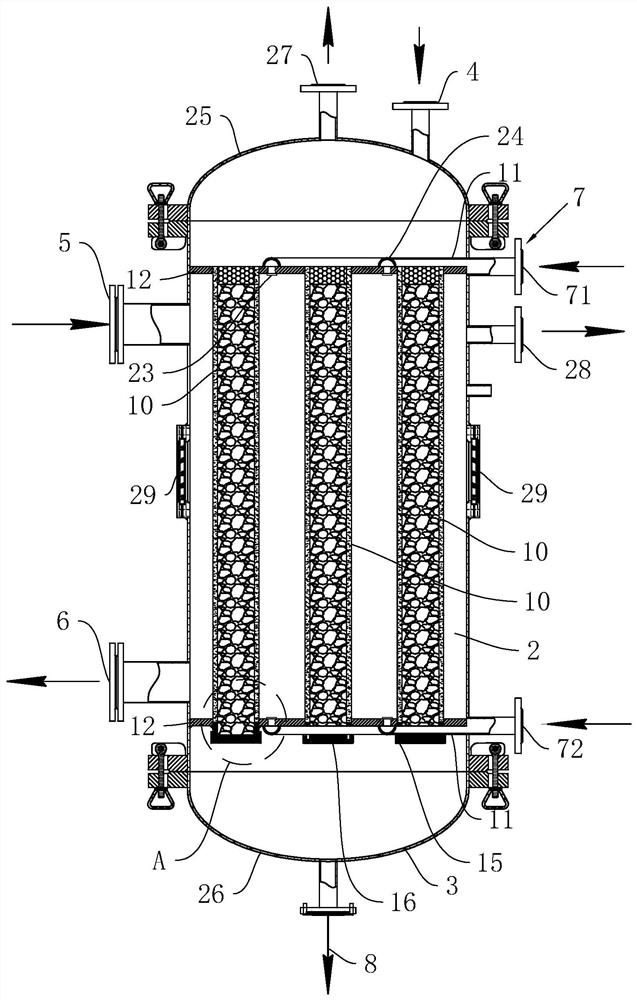

ActiveCN113634011ASolve the disadvantages of large residual active ingredientsPromote positive progressCosmetic preparationsToilet preparationsBiotechnologyMedicinal herbs

The invention relates to the technical field of daily chemicals, and particularly discloses a production integrated system of a leptospermum scoparium couperose skin mitigating extract composition, the leptospermum scoparium couperose skin mitigating extract composition and a preparation method thereof. The production integrated system comprises an extraction tank, a liquid storage tank and a heat exchanger. The extraction tank is an integrated pressurized extraction tank used for extracting, separating and integrating alkaloid active components. According to the application, through circulating extraction in which convection extraction under pressure, filtration and adsorption are synchronously carried out, the defects of low preparation efficiency, long-time heating oxidation of active matters in a solution, irritation of residual alcohol solvent to skin and large residual effective components of medicinal materials in the extraction process in the preparation of a leptospermum scoparium couperose skin mitigating extract composition through a traditional process are overcome.

Owner:伽能生物科技(上海)有限公司

Novel hydrogen production method and hydrogen production system

ActiveCN106629592AImprove conversion rateHigh yieldGas treatmentDispersed particle separationIron powderGas phase

The invention provides a hydrogen production method. The method comprises the steps of enabling feed gas to enter a pyrolysis reactor in presence of iron powder so as to have reaction, and then separating reaction effluent to obtain a gas phase material and a solid phase material; enabling the gas phase material to enter a sulfur catcher for recovering elemental sulfur, and then enabling the gas phase material without the elemental sulfur to enter a desulfurization device and react with an absorbent to obtain hydrogen-rich gas and rich absorbing liquid; enabling the rich absorbing liquid to enter a regeneration tower to obtain a regenerated absorbent and desorbed gas; sending the solid phase material into a magnetic field separator, and separating to obtain ferrous sulfide and the iron powder. The invention also provides a hydrogen production system. After the hydrogen production method and the hydrogen production system are adopted, the decomposition rate of H2S is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing biodiesel by utilizing oil plant

ActiveCN103396883AHigh yieldEasy to synthesizeFatty acid esterificationBiofuelsTrans esterificationOil and grease

The invention belongs to the chemical field of bio oil, and in particular relates to a method for preparing biodiesel by utilizing oil plants. The invention discloses a method for preparing biological diesel by utilizing oil plants. The method utilizes the seeds oil plants as raw materials; an oil extraction solvent and a transesterification solvent form a double liquid phase mixed solvent; and in the presence of a solid base catalyst, the double liquid phase mixed solvent in different volumes is refilled for grease extraction and a transesterification reaction. The invention mainly solves the problem that one step synthesis of biodiesel by double liquid phase mixed solvent in the prior art has disadvantages of inhibition on the synthesis of biodiesel by reaction raw materials and inability to increasing yield, and provides a high-efficiency and high-yield method for synthesis of biodiesel.

Owner:黄耀江

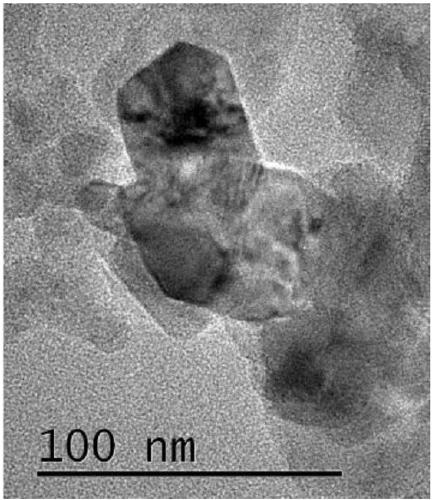

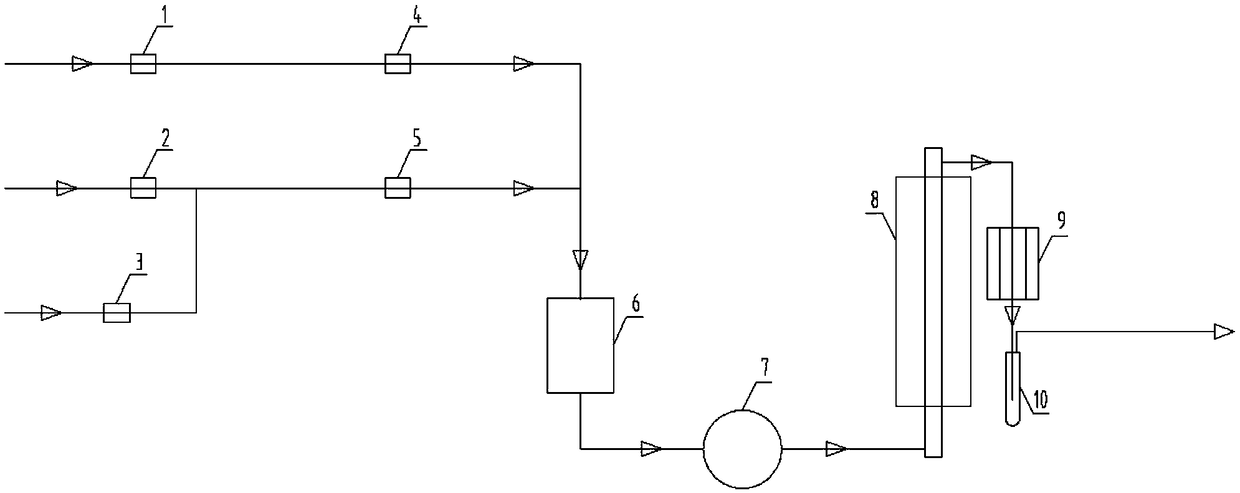

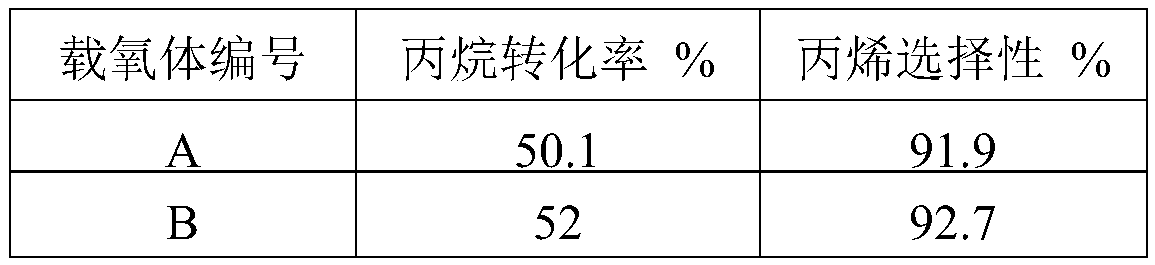

Preparation method of oxygen carrier for producing propylene through propane chemical-looping dehydrogenation

ActiveCN109482174AImprove wear resistanceSimple processCatalystsHydrocarbon preparation catalystsLithium oxideActive component

The invention belongs to the technical field of preparation of oxygen carriers, and relates to a preparation method of an oxygen carrier for producing propylene through propane chemical-looping dehydrogenation. The preparation method includes dipping aluminium oxide into precursor aqueous solution containing manganese to obtain an aluminum oxide oxygen carrier, loading a certain quantity of manganese-base active component, adding in clay and a binder into the oxygen carrier to improve wear resistance of the oxygen carrier, further, loading lithium oxide active component to the carrier so as toobtain oxygen carrier particles for producing propylene through propane chemical-looping dehydrogenation. The preparation method is simple in process; the oxygen carrier cannot cause environmental pollution in preparation and recycling process; the prepared oxygen carrier has high dehydrogenation activity, high propane conversion rate and high prpylene selectivity.

Owner:QINGDAO UNIV OF SCI & TECH

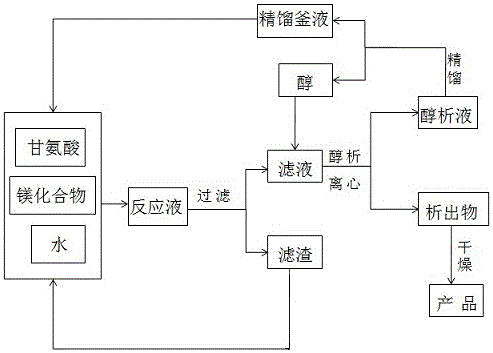

Preparation method of magnesium glycinate chelate

InactiveCN106478438APromote absorptionShort reaction timeOrganic compound preparationAmino-carboxyl compound preparationGlycineAlcohol

The invention discloses a preparation method of a magnesium glycinate chelate. The preparation method comprises the following steps: (1) synthesis reaction: adding glycine, a magnesium compound and water into a reaction kettle according to a ratio, stirring and mixing the raw materials, heating the mixture to a reaction temperature, allowing the mixture to react for a period of time to obtain a reaction solution, (2) purification of the product: filtering the reaction liquid at a certain temperature to obtain a filtrate and a filter residue; carrying out alcohol precipitation treatment on the filtrate, allowing the filtrate to stand for a period of time, and then centrifugally separating the filtrate to obtain alcohol precipitation solution and precipitate; drying the precipitate to obtain the magnesium glycinate chelate product; (3) post-treatment: rectifying the alcohol precipitation solution, and reusing the alcohol obtained after rectification to the alcohol precipitation treatment step; and returning the distillation residue after rectification and the filter residue to the reaction kettle for reuse. The invention provides the preparation method of the magnesium glycinate chelate without interference ions, and three wastes are prevented.

Owner:HEBEI DONGHUA JIHENG CHEM

Method for catalyzed synthesis of butyl oleate with oleic acid-based ionic liquid microemulsion

ActiveCN109912413AReduce the impactHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateTetrafluoroborate

The invention discloses a method for catalyzed synthesis of butyl oleate with an oleic acid-based ionic liquid microemulsion. The method comprises the following steps: (1) at 25-35 DEG C, uniformly mixing a surfactant with an imidazole disulfate ionic liquid so as to obtain a surfactant mixed solution, further uniformly mixing with oleic acid and n-butyl alcohol, finally adding an imidazole fluoborate ionic liquid, and stirring so as to obtain an oleic acid-based ionic liquid microemulsion; (2) putting the oleic acid-based ionic liquid microemulsion of the step (1) into a nitrogen atmosphere,heating, stirring to carry out reactions, separating, and purifying, thereby obtaining butyl oleate. The reaction process is gentle in condition, no conventional toxic organic solvent (such as cyclohexane and methylbenzene) except reactants is used, the idea of green and environment protection can be met, the product can be easily separated, and the product is light yellow or golden yellow and ishigh in yield.

Owner:SOUTH CHINA UNIV OF TECH

Carbide slag modifier for circulating fluidized bed boiler desulfurization, modified carbide slag and preparation method thereof

PendingCN110813070APromote positive progressImprove desulfurization efficiencyGas treatmentDispersed particle separationPtru catalystFluidized bed

The invention relates to the field of circulating fluidized bed desulfurization, in particular to a carbide slag modifier for circulating fluidized bed boiler desulfurization, modified carbide slag and a preparation method thereof. The carbide slag modifier for circulating fluidized bed boiler desulfurization comprises the following components in percentage by mass: 1-35% of a binder, 1-35% of a dispersing agent and the balance a cerium-containing rare earth catalyst. By adopting the carbide slag modifier for circulating fluidized bed boiler desulfurization and the modified carbide slag provided by the invention, the defect caused by application of carbide slag in circulating fluidized bed boiler desulfurization in the past can be avoided, the desulfurization efficiency is relatively high,resource secondary utilization is realized, the efficiency of the circulating fluidized bed boiler is improved, and the abrasion of heating surface pipes is reduced; and compared with the traditionalcirculating fluidized bed boiler combustion desulfurizer limestone, the advantage is that the desulfurization treatment cost is reduced.

Owner:SHENHUA SHENDONG POWER +1

Co-based MOFs-heteroatom doped porous carbon catalyst for oxygen reduction and preparation method thereof

InactiveCN111185218AImprove electrocatalytic activityImprove electron supply capabilityCatalyst activation/preparationPtru catalystPorous carbon

The invention relates to the technical field of oxygen reduction catalysts, and discloses a Co-based MOFs-heteroatom doped porous carbon catalyst for oxygen reduction and a preparation method thereof.The catalyst comprises the following formula raw materials: Fe-based MOFs, 1-hydroxyethane 1,1-diphosphonic acid, chitosan, glycine, an esterification catalyst, a composite base catalyst and a condensing agent. According to the catalyst and the method, N / P co-doping enables a carbon material to form rich pore channels and a large number of mesoporous structures; the formation of active sites andmedium transmission of oxygen reduction reaction are facilitated; the core-shell nanostructure of a cobalt compound coated with a porous carbon material has a richer morphological structure, so that the catalyst has better mass transfer performance; the cobalt compound formed after the cobalt-based MOFs with the nanometer structure are calcined is uniformly loaded into the pore channels of the porous carbon material, the graphitization degree of the carbon material is improved with the cobalt compound, the electrical conductivity of the carbon material is increased, and the forward oxygen reduction reaction is promoted.

Owner:朱旭烈

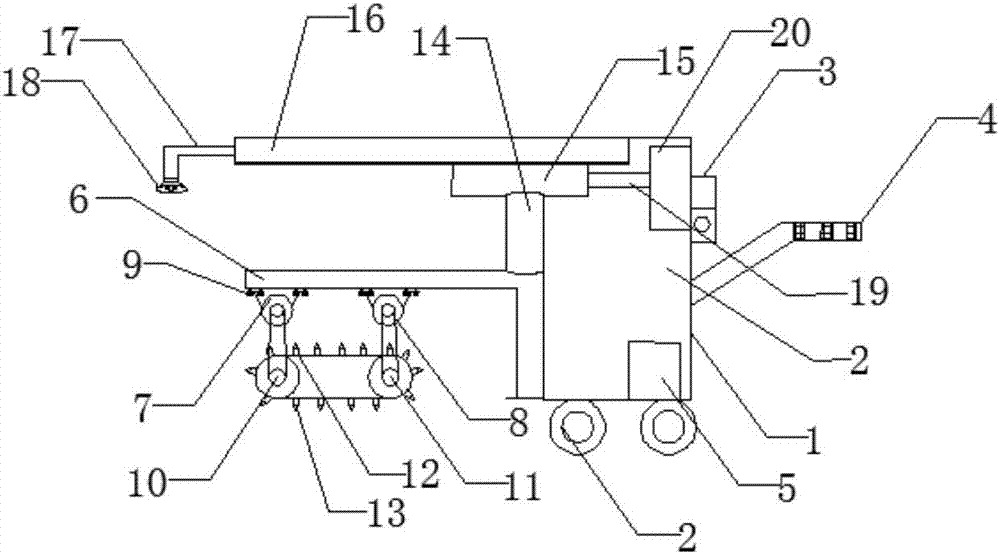

Agricultural ditching device

InactiveCN107254867AEasy to adjustPromote positive progressSoil drainageSoil-shifting machines/dredgersElectric machineryAgricultural engineering

The invention discloses an agricultural ditching device, which comprises a body, a universal wheel is provided at the bottom of the body, a control panel and a push rod are threadedly connected to one side of the body, the control panel is located at the top of the push rod, and the inner wall side of the bottom of the body is threaded with a storage battery. Connect, and the other side of the inner wall at the bottom is fixedly welded to the bottom of the "L" frame column, and one side of the inner wall at the top of the "L" frame column is connected to the top of the forward motor and the top of the reverse motor through screws. The present invention is equipped with the first hydraulic machine and the second hydraulic machine, which is convenient for people to operate the control panel to adjust the height of the tool and the ground and to adjust the tool to the designated area where ditching is required, and is provided with a forward-rotating motor and a reverse-rotating motor to facilitate farmland ditching The device performs forward and reverse excavation operations on the ditch, and is equipped with LED lights, which can help people to carry out ditching operations in dimly lit environments.

Owner:安仁信和科技有限公司

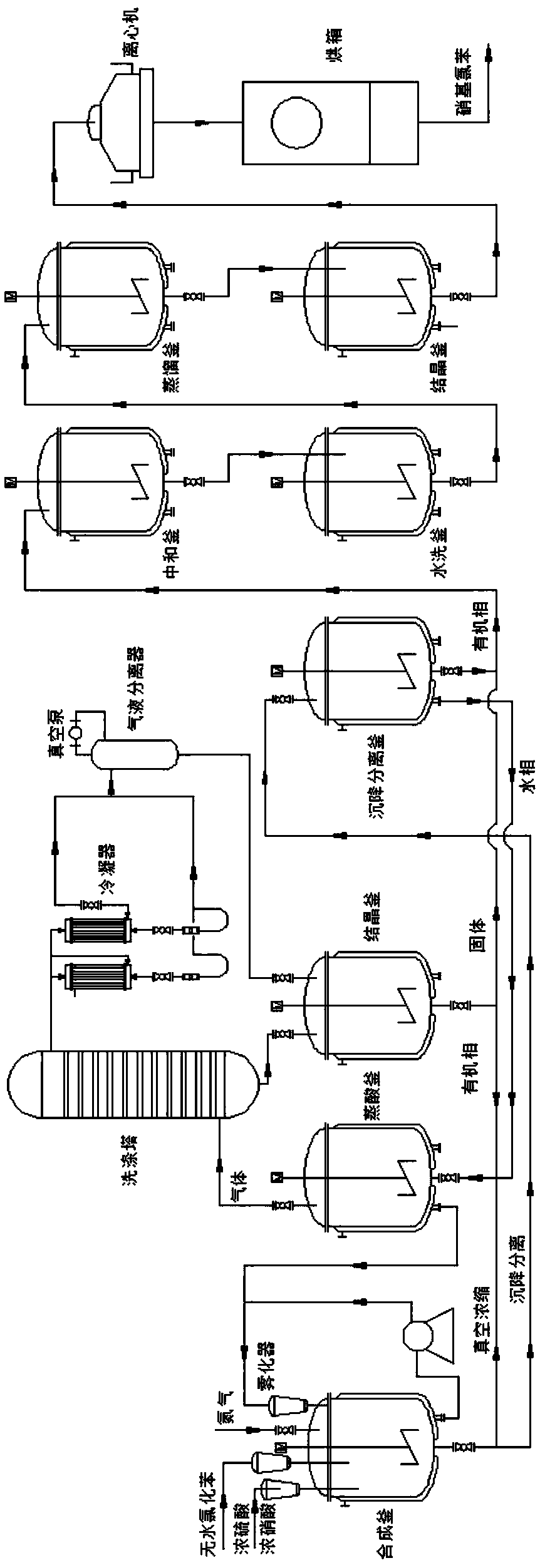

Method of preparing nitrochlorobenzene by adopting vacuum concentration process

InactiveCN109096116ALower synthesis costPromote positive progressOrganic compound preparationNitro compound preparationNitrophenol productPollution

The invention discloses a method of preparing nitrochlorobenzene by adopting a vacuum concentration process. The production method specifically comprises the following steps: carrying out a reaction on Chlorobenzene and nitric acid under the action of sulfuric acid to generate a nitrochlorobenzene mixture; settling and separating the nitrochlorobenzene mixture; concentrating waste sulfuric acid generated by nitrification in vacuum to be applied mechanically; neutralizing, washing and distilling the acidic nitrochlorobenzene mixture; drying the neutral nitrochlorobenzene mixture to remove chlorobenzene and water and the like, and obtaining a coarse product nitrochlorobenzene mixture; and then separating p-nitrophenol and o-nitrophenol products and meta-position oil rich in m-nitrochlorobenzene and high boiling point organic matter waste liquor by means of a multi-time crystallizing separating method. The nitrified waste acid is concentrated and dehydrated in vacuum, so that the concentration of sulfuric acid exceeds 80%, the sulfuric acid and nitric acid are prepared to a mixed acid to be recycled, the economical benefit is improved and the purity of the product is improved. In theproduction process of the nitrochlorobenzene, the waste acid and the high boiling point organic matter waste liquor are recycled, the green, environmentally-friendly and pollution-free theory is met,and the economical benefit and practicality are reflected.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

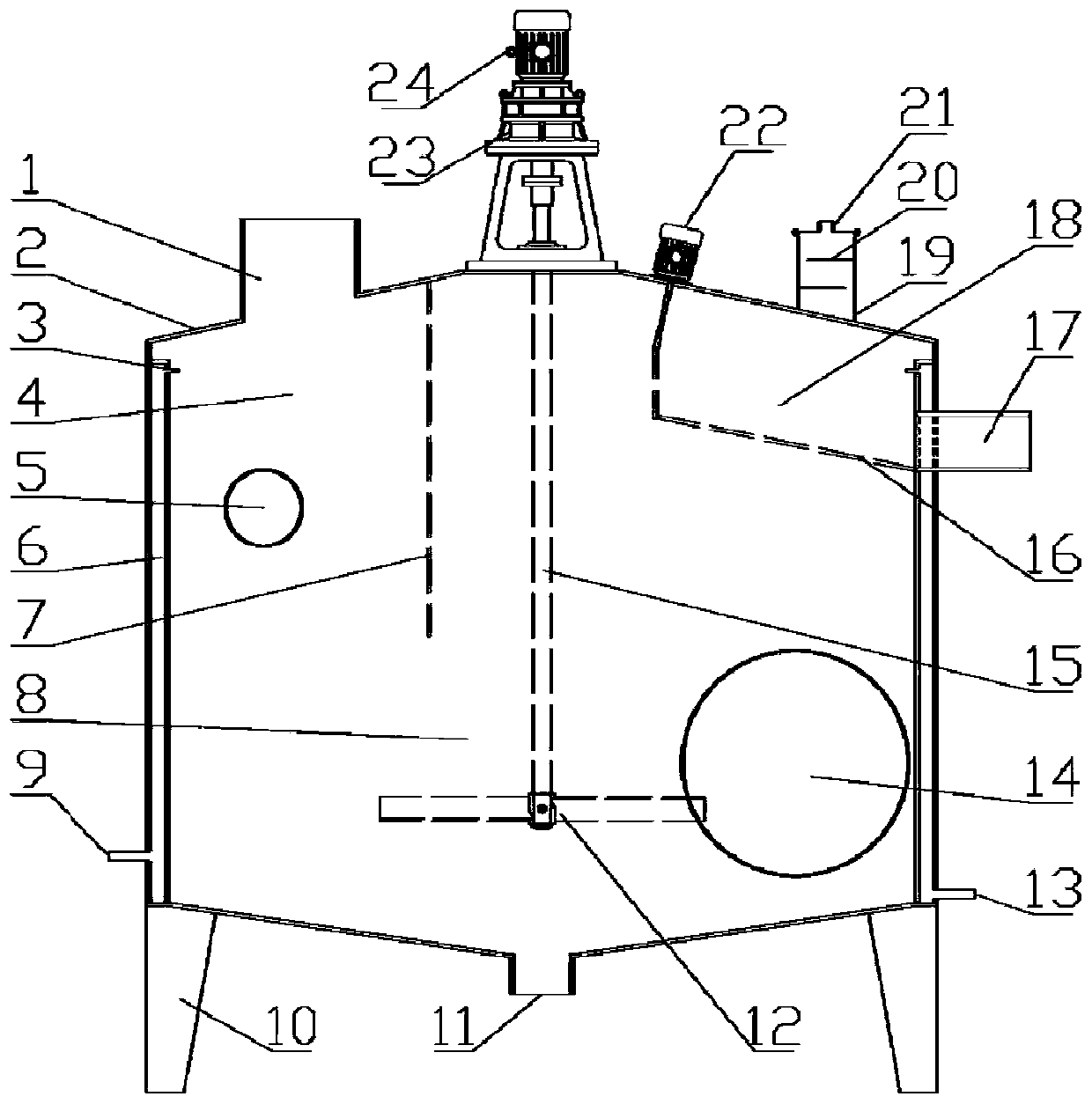

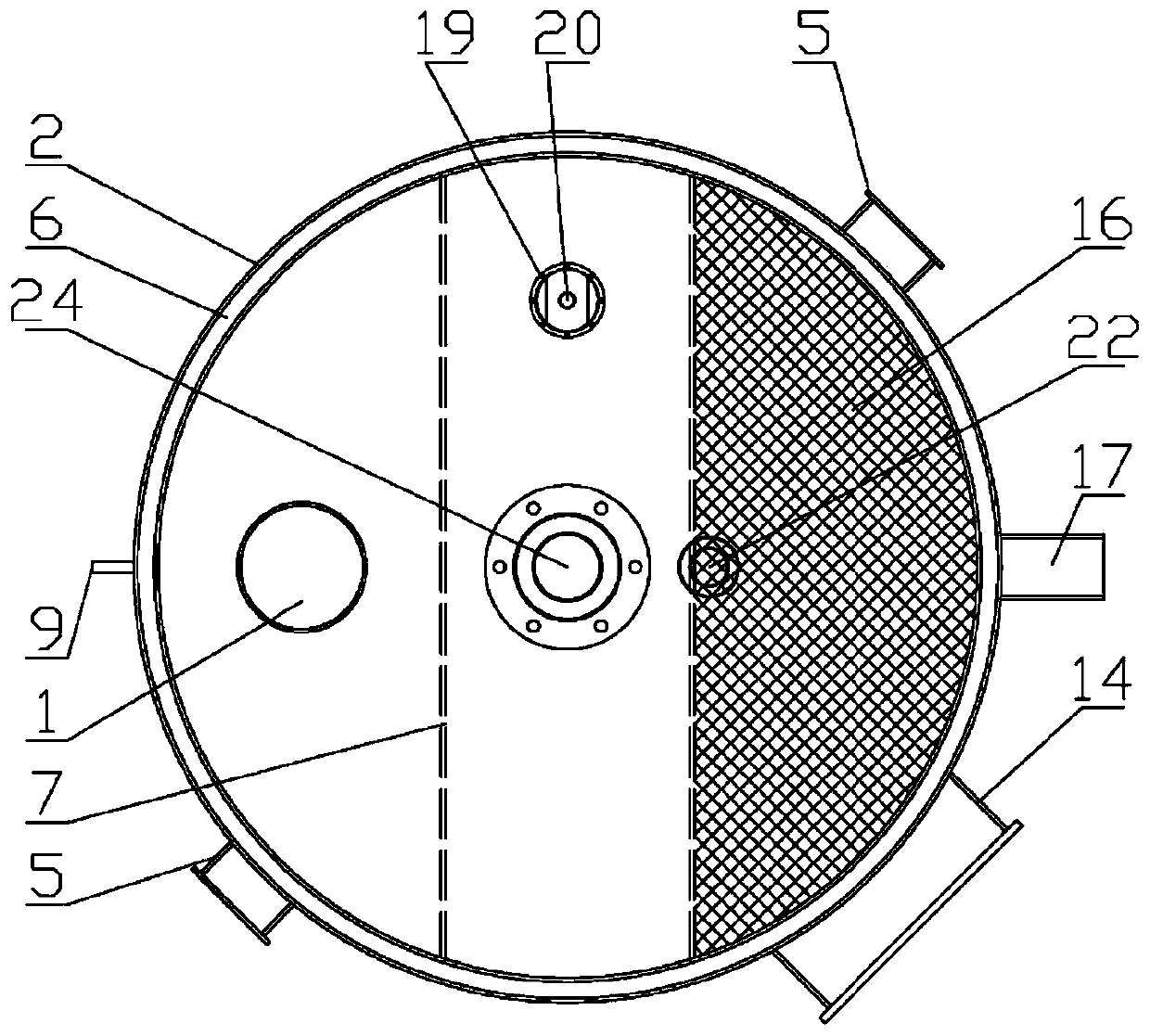

Efficient lime slaking and deslagging device

The invention discloses an efficient lime slaking and deslagging device. The efficient lime slaking and deslagging device comprises a tank body, wherein the tank body is fixedly mounted on a support;the top of the tank body is provided with a stirring device, a lime feeding hole and an exhaust hole; the stirring device is positioned at the center of the tank body; the exhaust port is positioned in one side far away from the lime feeding hole; a water cooling wall is arranged on the side wall of the tank body; a water inlet connected with an external water source is formed in the lower part ofthe water cooling wall; a water outlet communicated with the interior of the tank body is formed in the upper portion of the water cooling wall; a slurry overflowing opening is formed in the upper portion of the side wall, away from the lime feeding hole, of the tank body; the water outlet is higher than the slurry overflowing opening; a filter screen is arranged on the slurry feeding side of theslurry overflowing opening and provided with a vibration motor; and a slag discharging opening is formed in the bottom of the tank body. The efficient lime slaking and deslagging device can prevent impurities and lime which does not react completely from caking and overflowing out of the tank body, guarantees discharging quality, realizes cooling in the tank body while providing water for a limeslaking reaction, and promotes forward progression of the lime slaking reaction.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com