Preparation method of magnesium glycinate chelate

A magnesium glycinate and chelate technology, which is applied in the field of preparation of magnesium glycinate chelate, can solve problems such as adverse reactions and difficult absorption, and achieve the effects of increasing biological potency, reducing reaction time, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

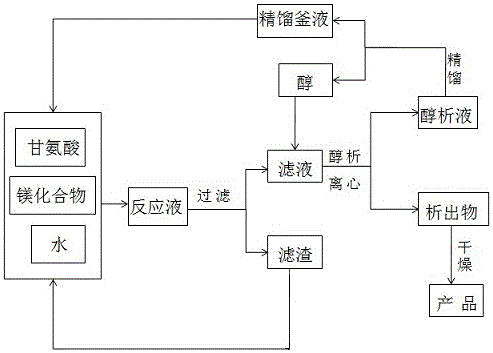

[0025] A kind of preparation method of magnesium glycinate chelate, preparation method comprises the following steps:

[0026] ①Synthesis reaction: Put glycine, magnesium compound and water into the reaction kettle according to the reaction molar ratio of 2:1.05:11.1~2:1.8:16.7, stir and mix, heat to 50~90℃, react for 1~6 hours, The reaction solution is obtained, the magnesium compound is one or more of magnesium oxide, magnesium hydroxide, magnesium acetate, magnesium carbonate, basic magnesium carbonate, and the water used is deionized water;

[0027] ②Purification of the product: filter the reaction solution at 60°-70° to obtain the filtrate and filter residue, and then carry out alcohol analysis on the filtrate. The alcohol used is any one of methanol, ethanol, ethylene glycol or propanol. The alcohol used and The volume ratio of filtrate is 1:2~1:4. ; After standing for 2 to 6 hours, centrifuge, and the speed of centrifugation is 2000 to 2500 rpm to obtain alcohol and pr...

Embodiment 1

[0031] Take 150Kg (about 2 kilomoles) of glycine, 63.8Kg (about 1.1 kilomoles) of magnesium hydroxide and 125Kg of deionized water, put the raw materials into the reaction kettle, stir and mix, heat to 80°C, and react for 4 hours to obtain the reaction liquid; filter the reaction solution while it is hot (at a temperature of 70°C) to obtain the filtrate and filter residue, then add 375 liters of ethanol to the filtrate for alcohol analysis, and after standing for 4 hours, carry out the centrifuge at a speed of 2000 rpm. Centrifuge to obtain alcohol separation liquid and precipitate, and dry the precipitate at 105° C. for 2 hours to obtain 187.2 kg of magnesium glycinate chelate product, with a yield of 97.5%. After testing, the magnesium content of the product is 11.8%. The ethanol solution was rectified at 85°C for 4 hours to obtain 367 liters of ethanol, and the remainder was rectification liquid. The ethanol was recovered and reused for alcohol analysis. The rectification li...

Embodiment 2

[0033] Take 75Kg (about 1 kilomole) of raw material glycine, 22.4Kg (about 0.56 kilomole) of magnesium oxide and 150Kg deionized water, put the raw materials into the reaction kettle, stir and mix, heat to 70°C, and react for 4 hours to obtain the reaction liquid ; Filtrate the reaction solution while it is hot (at a temperature of 60°C) to obtain the filtrate and filter residue, then add 300 liters of propanol to the filtrate for alcohol analysis, and after standing for 4 hours, proceed under the condition of a centrifuge speed of 2200 rpm Centrifuge to obtain alcohol separation liquid and precipitate, and dry the precipitate at 85° C. for 3 hours to obtain 164.2 kg of magnesium glycinate chelate product, with a yield of 85.1%. After testing, the magnesium content of the product is 9.8%. The ethanol separation liquid was rectified at 85°C for 3 hours to obtain 292 liters of propanol, and the rest was rectification still liquid. The propanol was recovered and reused for alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com