Patents

Literature

250results about How to "High biological potency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power having nutrition of paddy, bean, fruit, vegetables and tea with the functions of equalizing the nutrition, losing weight and reducing blood sugar

ActiveCN101116510ABalanced nutritionHave weight lossPre-extraction tea treatmentMetabolism disorderFiberGlucose polymers

The present invention provides a low-lipid, high-fiber, balanced-nutritional, instant-taking and instant-resolving powder made from all natural components including corn, bean, flower, vegetable, fruit, tea and bi-usage plants for both food and medication. The nutritional powder provided by the present invention has not only the functions to balance the nutrition, but also the effect to decrease the body weight, lower the blood glucose, and effectively prevent and treat the diabetes.

Owner:湖南湘泉药业股份有限公司

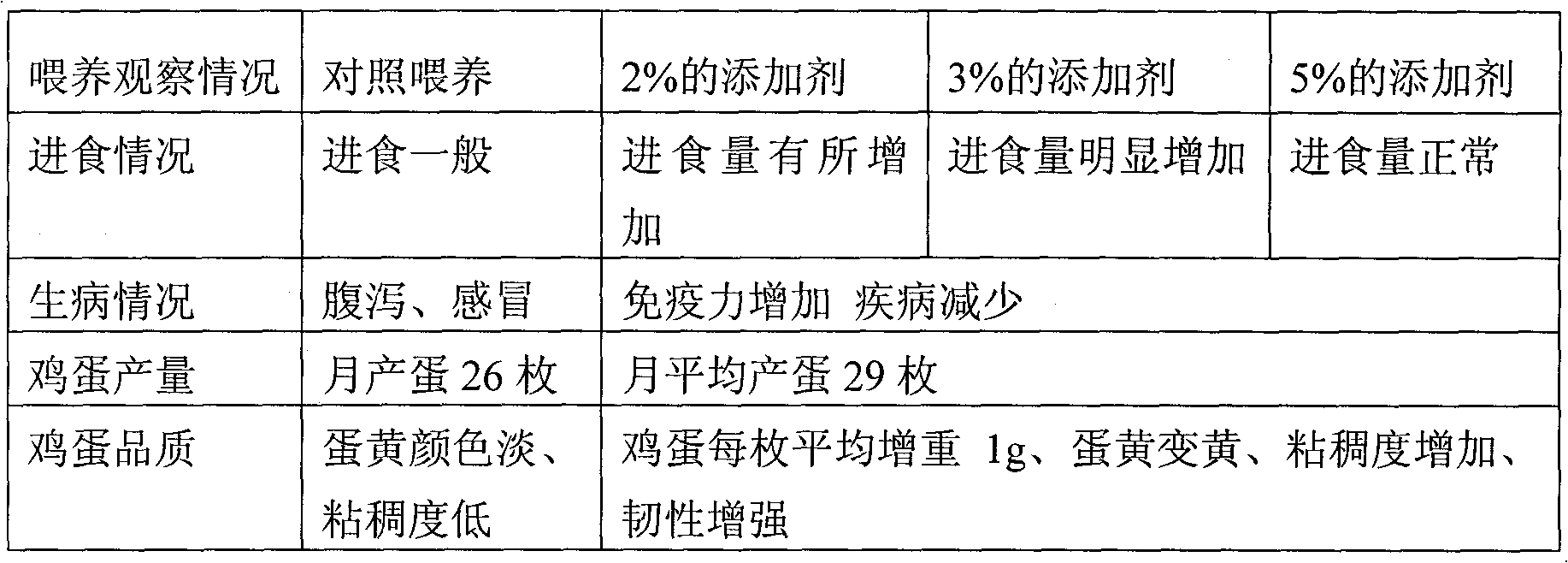

Method for producing high-micro-element egg

InactiveCN101194673AImprove developmentGood for healthAnimal feeding stuffTrace elementLycium barbarum fruit

The invention relates to a method for preparing high trace element eggs, which is characterized in that a chinese herbal medicine composition is added into an usual chicken feed. The proportioning by weight of each component of the chinese herbal medicine composition is that astragalus are 9-12 parts, dodder is 9-12 parts, angelica is 6-9 parts, wolfberry fruitis 6.9 parts, and fleece-flower root is 6-9 parts. Three kinds of agents which are powder or agent or dry paste are capable of being made. The content of trace elements of the produced eggs is greatly improved, simultaneously, the performance of the eggs are further improved, and the body immunity is increased. The invention has the advantages of simple operation, no toxicity, and low cost and the like.

Owner:青岛苏氏生态养殖有限公司

Low-salinity cultivating litopenaeus vannamei additive premixture

ActiveCN101099541AIncrease profitPromote growthMetabolism disorderClimate change adaptationBiotechnologyLow salinity

The present invention belongs to the field of aquaculture feed technology, in particular, it relates to an additive premixed material for low-salinity culture of Fanna prawn. Said additive premixed material is composed of vitamin complex and compound mineral matter. Said additive premixed material can be added into prawn feed, and said feed can raise immunity of prawn, and can promote quick growth of prawn, its conversion rate is high and its feed coefficient is 0.9-1.3.

Owner:湖南粤海饲料有限公司

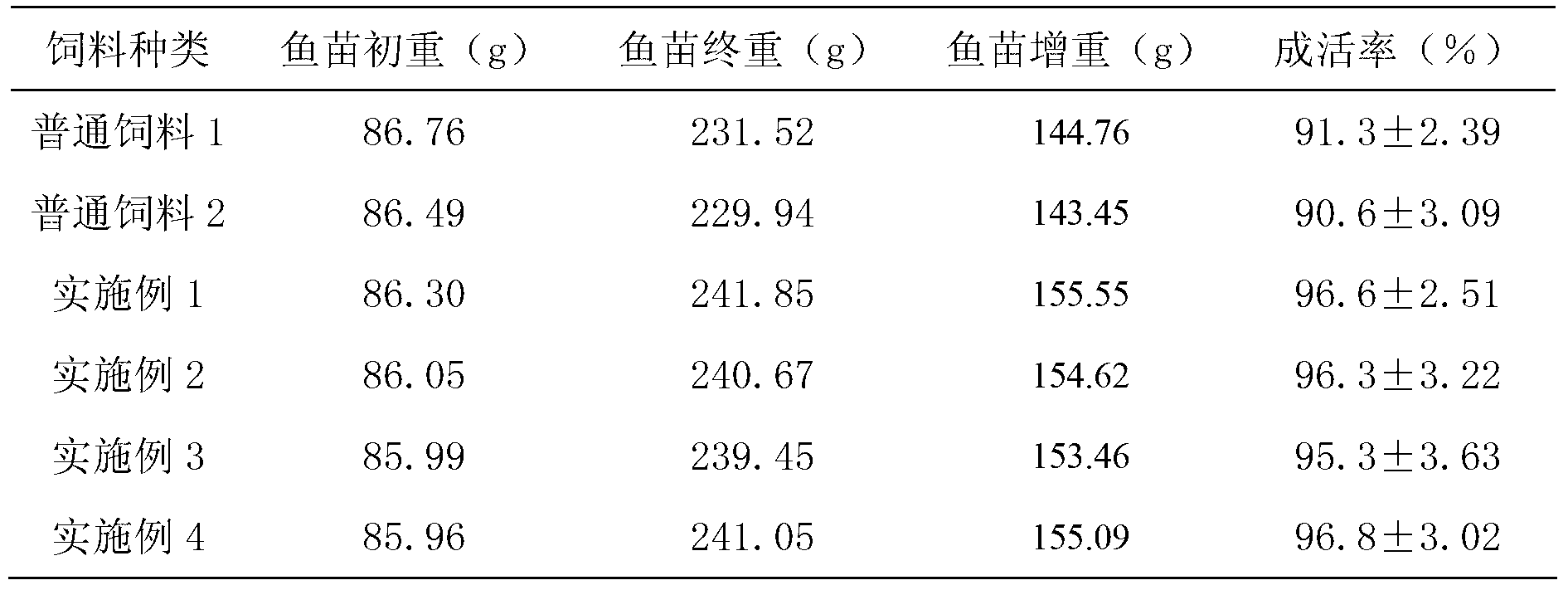

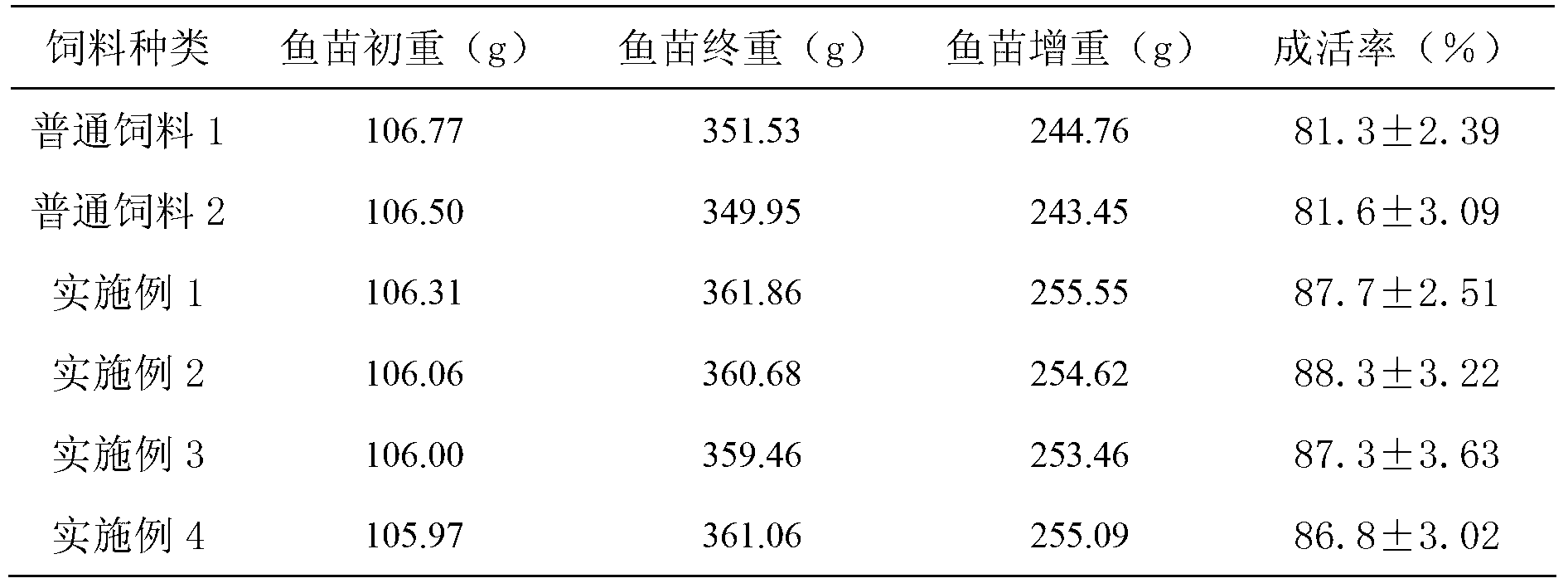

Health-care fodder for freshwater fish

InactiveCN103271249APromote healthy growthHigh biological potencyAnimal feeding stuffHazardous substanceIntestinal microorganisms

The invention discloses health-care fodder for freshwater fish. The health-care fodder is mainly prepared by raw materials in percentage by weight as follows: 14%-35% of soybean meal, 1%-5% of fish meal, 15%-45% of miscellaneous meal, 5%-10% of corn distiller dried grains with solubles, 20%-35% of wheat meal, 2%-5% of fish oil and 1.0%-1.4% of a health-care additive, wherein the health-care additive is a mixture of vitamin, mineral, immunity polyhexose, probiotics and a complex enzyme preparation agent. According to nutritional requirements of freshwater fish, plant protein is taken as a main protein source, and the biological value of fodder protein is increased by adjusting balance of amino acid; and simultaneously, the immunity polyhexose, the probiotics, the complex enzyme preparation agent and the like are added, so that the utilization rate of the fodder is increased, antinutritional factors are passivated, enteric microflorae of the freshwater fish are adjusted, the immunity of the freshwater fish is enhanced, contents of hazardous substances in excrement are reduced, water pollution caused by the excrement and undigested fodder in the excrement is reduced, the freshwater fish can healthily grow, and economic benefits for culturing the freshwater fish are increased.

Owner:BAIYANG INVESTMENT GRP INC

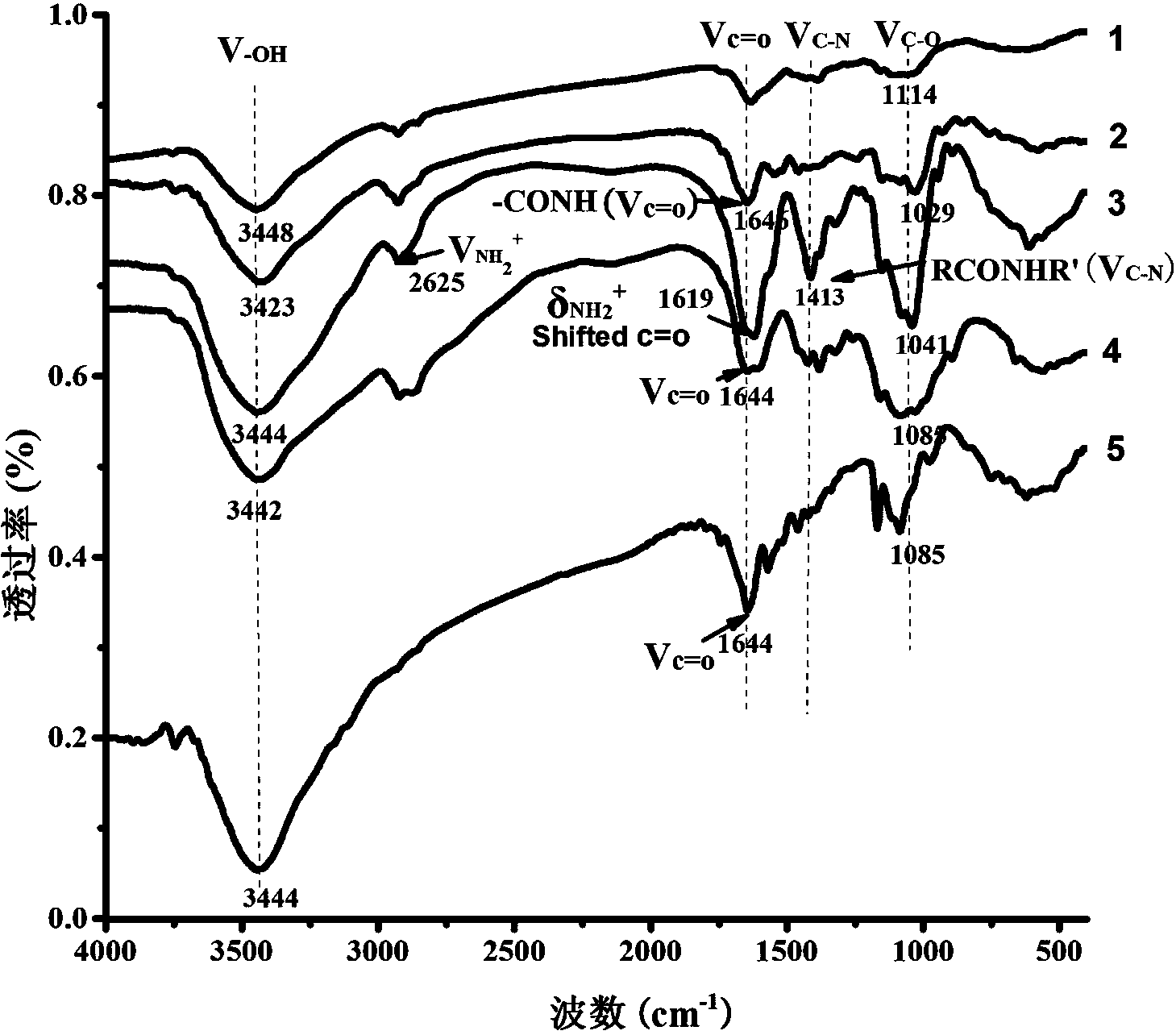

Polymer coated vitamin E liposome and preparation method thereof

InactiveCN101780041AReduce the degree of oxidationHigh biological potencyPowder deliveryOrganic active ingredientsPolymer scienceFreeze-drying

The invention relates to a polymer coated vitamin E liposome and a preparation method thereof. The preparation method of the invention comprises the following steps: preparing a vitamin E liposome suspension; adding a polymer into the suspension for coating to obtain a polymer coated vitamin E liposome suspension; obtaining a polymer coated vitamin E proliposome solid powder by spray drying or freeze drying; and before use, adding a proper amount of distilled water as required to obtain the polymer coated vitamin E liposome suspension with the entrapment rate of 82-94%. The polymer coated vitamin E liposome of the invention can obviously reduce the degree of oxidation of vitamin E, reduce the percolation rate, delay the release of the vitamin E in vivo, prolong the cycling time in vivo, and be prepared into the coated type proliposome solid powder which can be more conveniently packed, stored, transported and used.

Owner:NANCHANG UNIV

Feedstuff additive premix compound for Eriocheir sinensis

ActiveCN101411403AStable sourceNutritional diversityClimate change adaptationAnimal feeding stuffTrace element compositionVitamin K2

The invention relates to the technical field of aquaculture feedstuff. Premix material consists of composite vitamin and composite microelement according to the mass ratio of 5 to 10:15 to 20, wherein the composite vitamin consists of vitamin A, vitamin D, vitamin E, vitamin K3, vitamin B1, vitamin B2, vitamin B6, vitamin B12, nicotinic acid, calcium pantothenate, folic acid, biotin, inositol, vitamin C, beta-glucan, garlicin, DMPT, astaxanthin, topaz, antioxidant, mildew inhibitor and wheat middlings; and the composite microelement consists of ferric citrate, zinc sulfate, magnesium sulfate, methionine, potassium iodate, manganese sulfate, copper sulfate, sodium selenite, potassium chloride, choline chloride, betaine and zeolite. The invention has stable raw material sources and complete nutrition. A cultivated object grows rapidly with a high feedstuff conversion rate and good cultivating benefits. Compared with crabs eating other feedstuff sources such as rough fish, corn, bean pulp, and the like, the quality of Chinese mitten crab is improved. The invention relates to the feedstuff additive premix material for the Chinese mitten crab.

Owner:GUANGDONG EVERGREEN FEED INDAL

Coptis chinensis total alkaloid extracting technique

InactiveCN101269132ALow costEasy to processAntibacterial agentsAntimycoticsSide effectResource utilization

The invention relates to the extraction technology of a rhizoma coptidis total alkaloid and the process flow is as follows: raw materials (rhizoma coptidis or coptis fibrous roots or coptis leaves), pulverization (Coptis fibrous roots or coptis leaves need no pulverizing.), addition of right amount of sulphuric acid of 0.01 to 10 percent for soaking, heated extraction for four times, preconcentration, sediment of sodium chloride and high-valencied metal salt, filtration, drying and products of rhizoma coptidis total alkaloid. The main active ingredients for the product are berberine, coptisine, jateorrhizine, palmatine, epiberberine and other active coptis ingredients, the content of rhizoma coptidis total alkaloid is over 20 percent, wherein, the content of berberine is over 10 percent. The product adopts coptis fibrous roots and so on as raw materials to extract rhizoma coptidis total alkaloid, which is different from the traditional extraction of berberine. The extraction technology improves the pure quotient of the product and particularly eliminates cold-natured ingredients of toxic and side effect through the operating procedure of impurity eliminating, thereby improving the product quality. Besides the traditionally-utilized berberine, the product still contains a large quantity of other active coptis ingredients such as coptisine, jateorrhizine, palmatine, epiberberine and so on. The product has a higher utilization rate of resources and a higher security of products, and the effective function and action of rhizoma coptidis can be brought into a better play.

Owner:SOUTHWEST UNIV

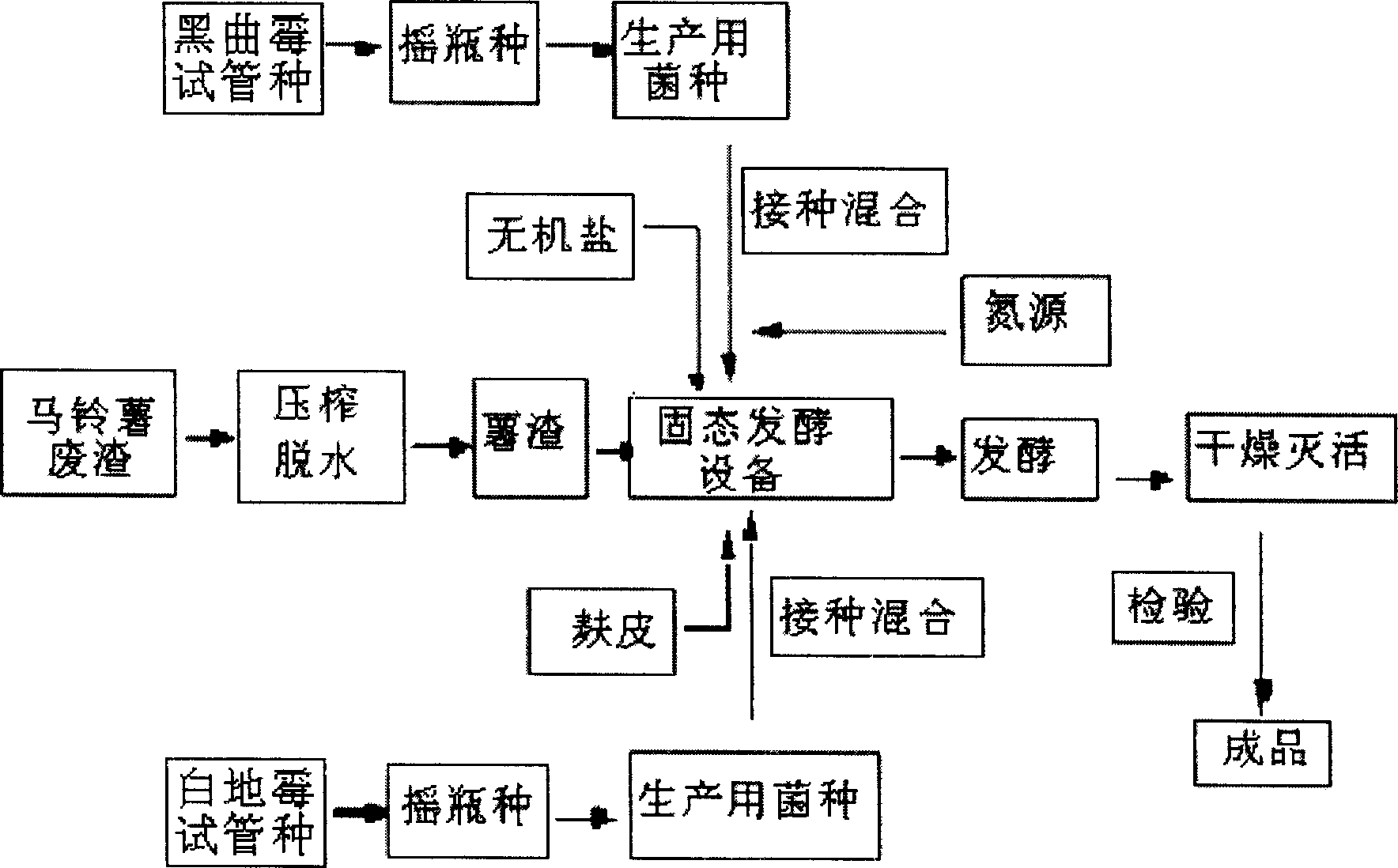

Method for preparing protein feed by solid fermenting potato slag

ActiveCN1899079ALow degree of mechanizationLess investmentAnimal feeding stuffVegetable proteins working-upMetabolitePotato starch

The present invention is protein feed and its preparation process with potato slag. Protein feed is prepared with waste potato slag from starch production, and through squeezing to dewater, adding certain amount of supplementary material, inoculating certain amount of microbe seed and solid fermentation. The said preparation process is simple, and has high yield, low investment, low power consumption and other advantages. Thus obtained feed product has the fermented product, including microbe, metabolite and substrate utilized fully, and possesses the active components maintained, high amino acid content and high nutritious value.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

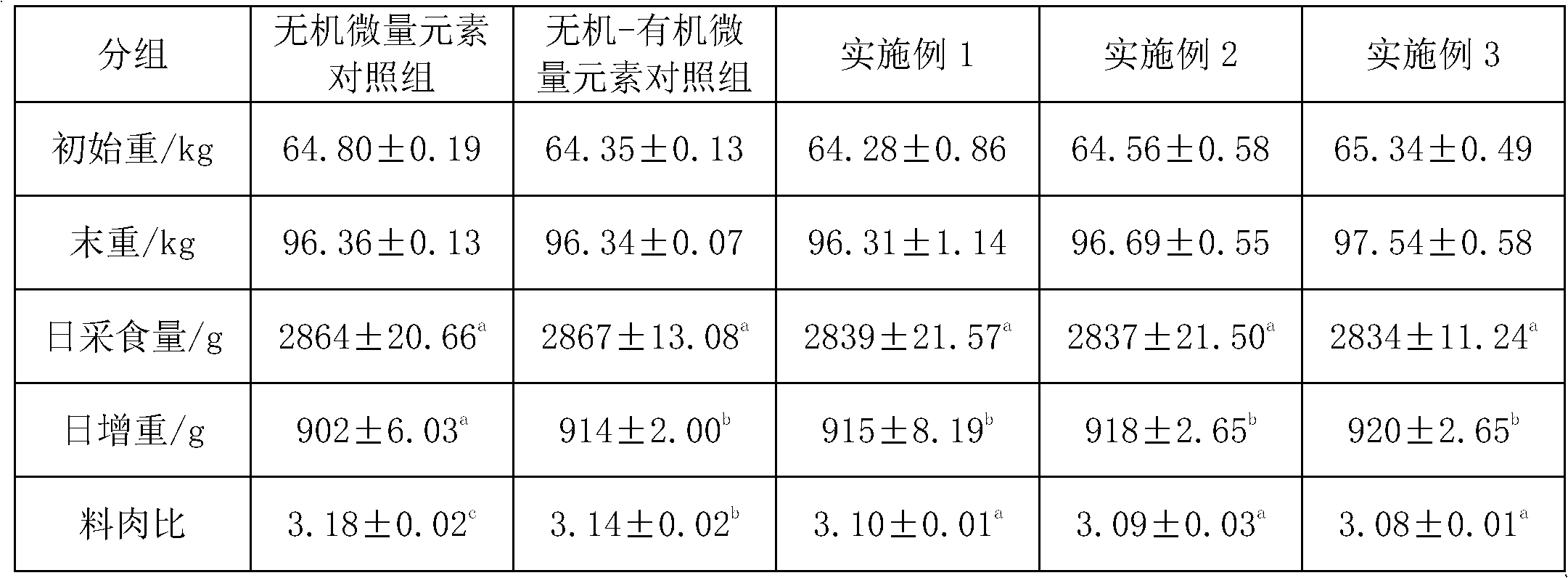

Composite premix for pigs

ActiveCN102726618AImprove immunityImprove survival rateAnimal feeding stuffPig farmsEcological environment

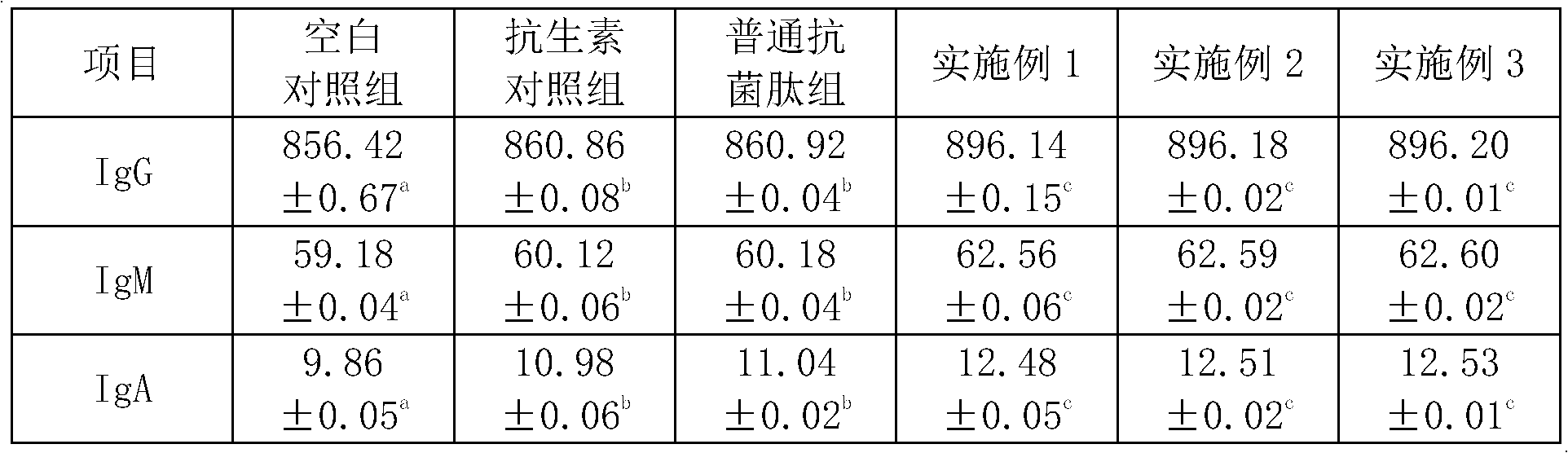

The invention discloses a composite premix for pigs and belongs to the technical field of feeds. The composite premix for pigs comprises a carrier, mineral matters, composite vitamin, amino acid, an anti-oxidant, phytase, antibacterial peptide and phytosterol. The mineral matters comprise trace element mineral matter and constant element mineral matter. The composite premix for pigs contains no antibiotic but antibacterial peptide and phytosterol. The trace elements adopted in the invention are mainly organic trace elements. Weighed according to a ratio, components of the composite premix forpigs can perform a synergistic effect, so as to avoid the antagonistic effect, raise utilization rate of additives such as trace elements for live pigs, save limited resources of inorganic mineral feeds, substantially improve the ecological environment around a pig farm, simultaneously reduce deposition of the trace elements in pigs, raise the quality of pork and guarantee the health of consumers.

Owner:CHENGDU CENTURY INVESTMENT

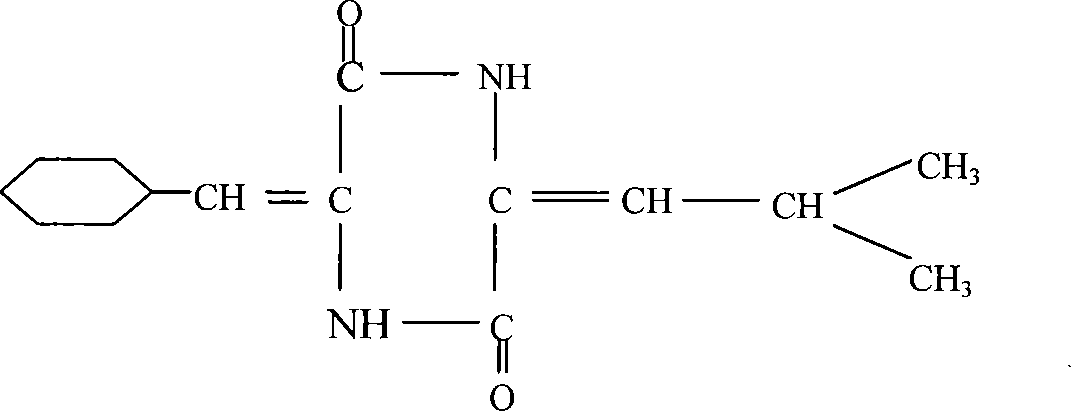

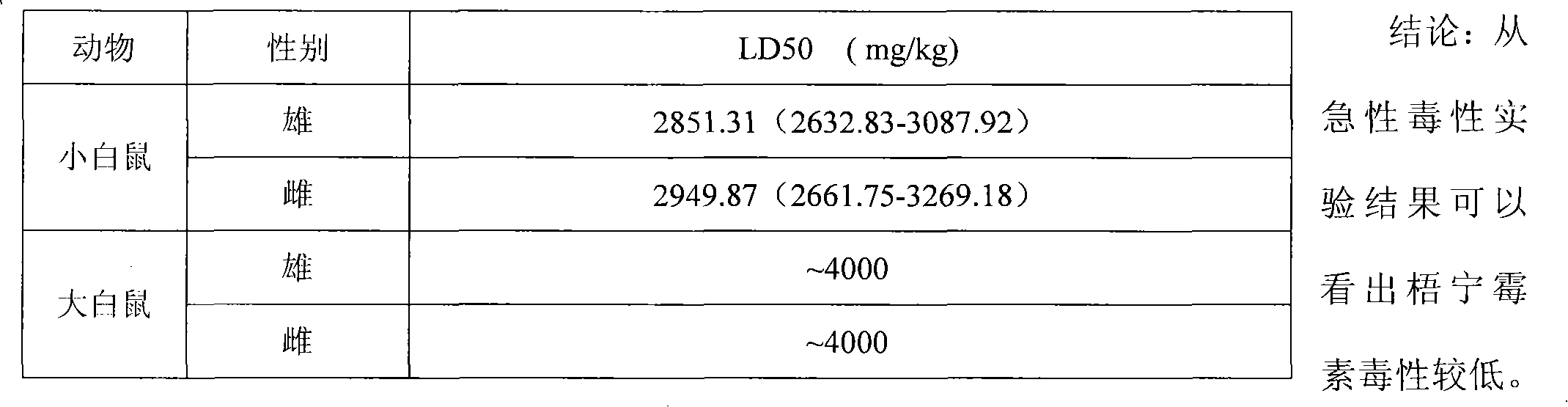

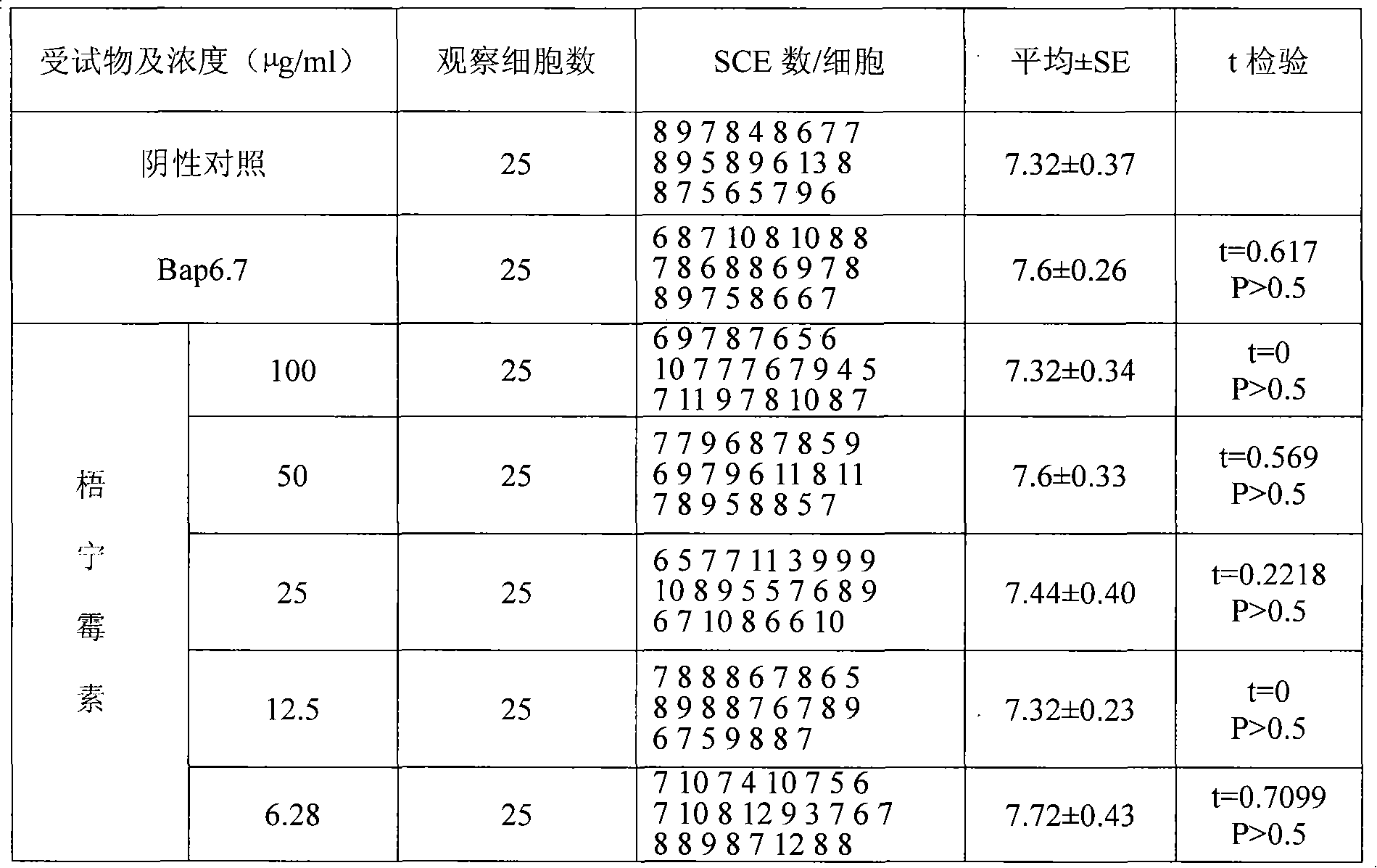

Method for preparing biopesticide tetramycin and application

ActiveCN101633941AImprove efficiencyLower resistanceBiocideMicroorganism based processesDiseaseAlternaria

The invention discloses a method for preparing biopesticide tetramycin from Streptomyces ahygroscopicus subsp.Wuzhouensis n.subsp, and application of a product prepared by the method in preventing and controlling diseases such as apple alternaria leaf spots and the like. The tetramycin prepared by the method improves the biological potency of the tetramycin (the biological potency of fermentation liquor is improved by 15.5 percent after 0.3 to 0.5 percent of normal propyl alcohol is added.), can prolong the quality guarantee period, improves the effect of preventing and controlling apple canker to over 95 percent, has good effect of preventing and controlling the diseases such as the apple alternaria leaf spots, tomato gray mold and the like, has effect of inhibiting yeast, gram-negative and gram positive bacteria, fungi (comprising fungal pathogens) and the like, has wide adaptability, and belongs to the environment-friendly biopesticide.

Owner:辽宁微科生物工程有限公司

Extraction method of high-purity coptis total alkaloid

ActiveCN103393780ALow costEasy to processMetabolism disorderCardiovascular disorderCoptisineCalcium hydroxide

The invention relates to an extraction method of high-purity coptis total alkaloid, which comprises the following steps: preparing a raw material (coptis or coptis fibril or coptis ash), pulverizing (not required if the raw material is coptis fibril or coptis ash), immersing in 0.1-5% sulfuric acid, heating and extracting four times, filtering, neutralizing with calcium oxide (or calcium hydroxide), filtering, washing the precipitate, preconcentrating, regulating the acid, precipitating with sodium chloride, filtering, recovering alkaloid from the mother liquor, and drying the precipitate to obtain the coptis total alkaloid product. The main active components of the product are coptis effective components, such as berberine, coptisine, palmatine, epiberberine, jateorhizine and the like; the coptis total alkaloid content is more than 50%; and the berberine content is more than 25%. The product provided by the invention has favorable actions of lowering blood sugar and blood fat, losing weight and the like, and is an ideal raw material for treating diabetes and cardiovascular diseases.

Owner:重庆伊士腾生物科技有限公司

Coarse grain noodles

ActiveCN103766752AHigh biological potencyReasonable ratioYeast food ingredientsFood ingredient functionsMillet flourDietary fibres

The invention relates to coarse grain noodles which comprise the following raw materials in parts by weight: 80-100 parts of flour, 2-5 parts of corn powder, 1-3 parts of peanut powder, 1-3 parts of millet powder, 5-8 parts of mashed pumpkin, 0.5-2 parts of yeast powder and 0.3-0.8 part of guar gum. The invention also relates to a preparation method of coarse grain noodles. In the invention, the raw materials of the coarse grain noodles are fermented, and the overall nutritional value of the coarse grain noodles is increased; as functional noodles, the coarse grain noodles provided by the invention are rich in dietary fibers easy to digest and absorb as well as other nutrient substances.

Owner:ANHUI YANZHIFANG FOOD

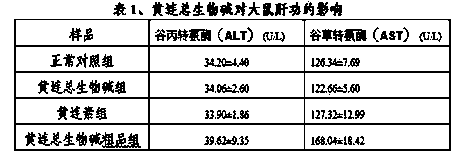

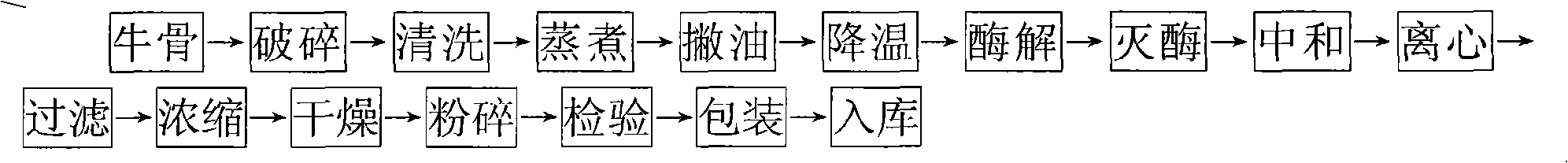

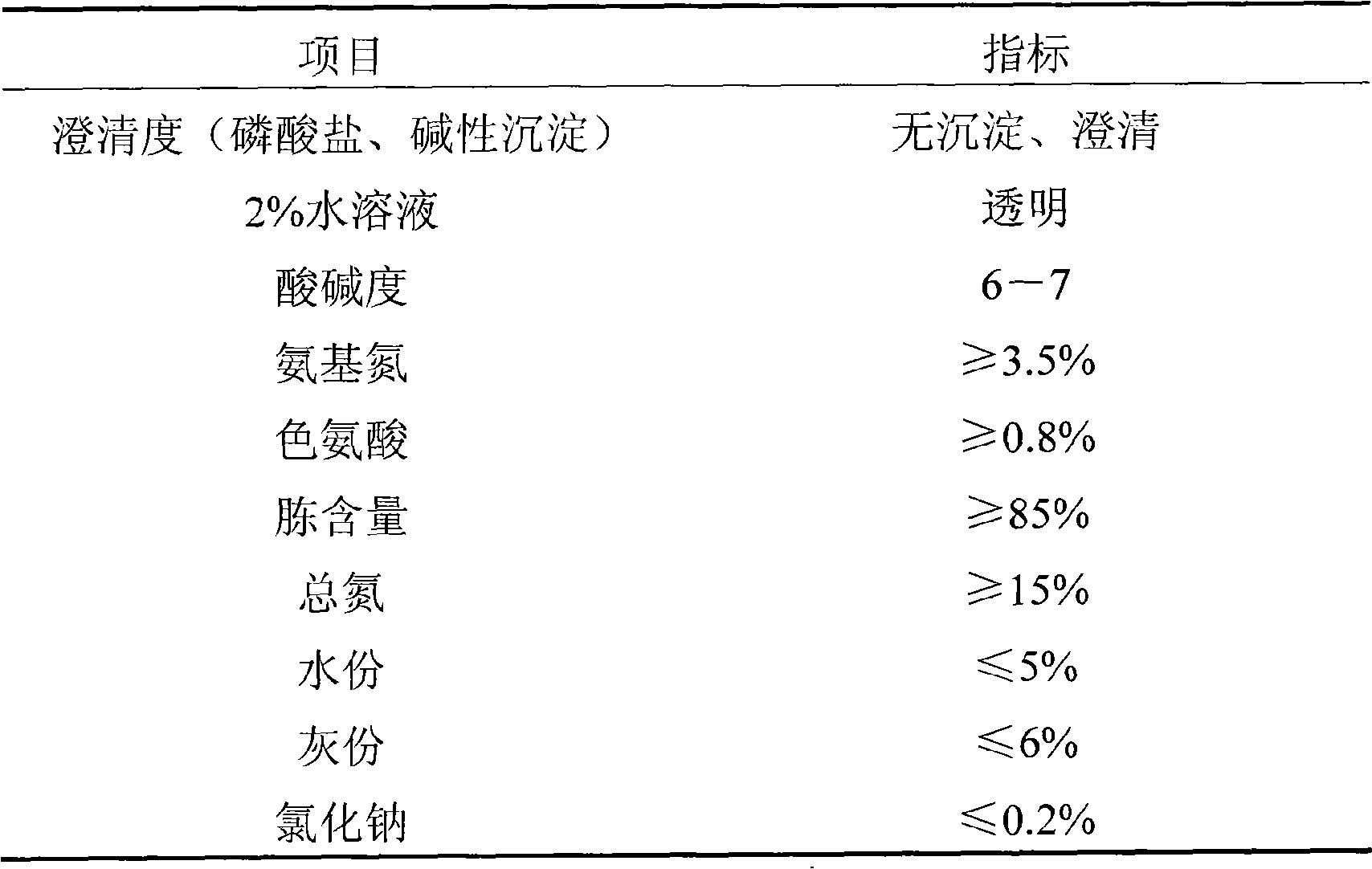

Method for producing bovine-bone peptone by enzyme technology

InactiveCN101538601ATake advantage ofHigh yieldPeptide preparation methodsFermentationTotal nitrogenPre treatment

The invention discloses a method for producing bovine-bone peptone by enzyme technology, which belongs to the technical field of bioengineering. The method comprises the steps of pretreating fresh bovine bones and then adding enzyme for enzymolysis. The method has the advantages of advanced technique, reasonable process route, thorough enzymolysis, sufficient raw-material utilization, high yield of peptone products, good quality, high amino nitrogen content, high total nitrogen content, plentiful species of amino acid, proper proportion and high biological potency, and reaches reagent-grade product standards. The method takes the bovine bones as raw materials, changes waste into valuables, improves the utilization ratio of the bovine bones in China, reduces environmental pollution, drives the development of the livestock breeding industry and other industries, and remarkably improves the comprehensive benefit of farming and animal husbandry industrialization.

Owner:BEIJING KEWEIHUA FOOD ENG TECH

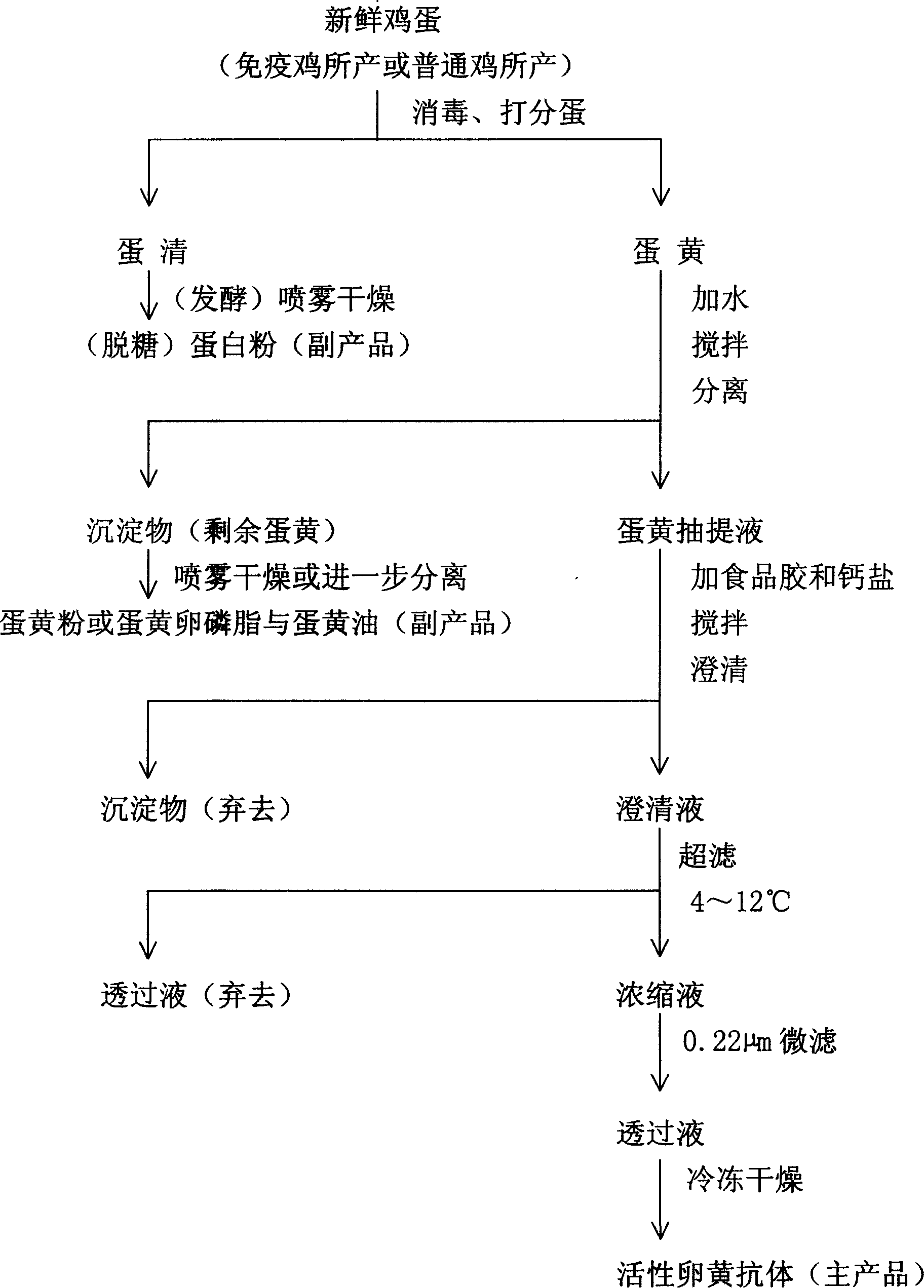

Process for preparing yelk antibody with high bioactivity

ActiveCN1844144AHigh biological potencyImprove biological activityEgg immunoglobulinsImmunoglobulins against bacteriaYolkDrug biological activity

This invention is preparation procedure of the yolk antibody of high biological activity, belonging to the field of bioproduct and industrialized isolation technique. In this invention, we adopt the natural macromolecule gel high -extractive technique and hyperfiltration to extract the yolk-antibody of high biological activity from yolk at an industrialized level, annual output is upto 10 ton. the yolk-antibody content is about 30%-50%, meanwhile we could obtain some by-products like albumen powder, yolk powder, egg oil, vitellin and so on. In the invention high technology like bioimmunology and membrane separation is adopted. The invention is high-tech, high-usage, highly-automated and typical of green food and environmental-friendly.

Owner:NANTONG KANGDE BIOLOGICAL PROD

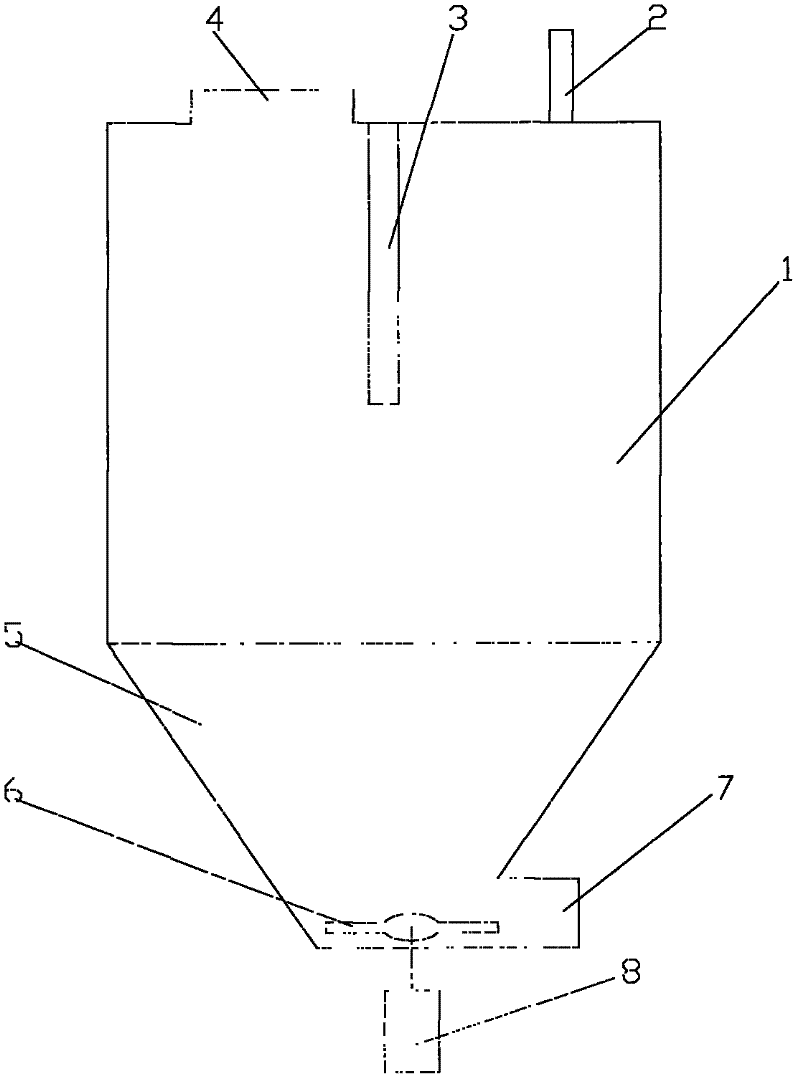

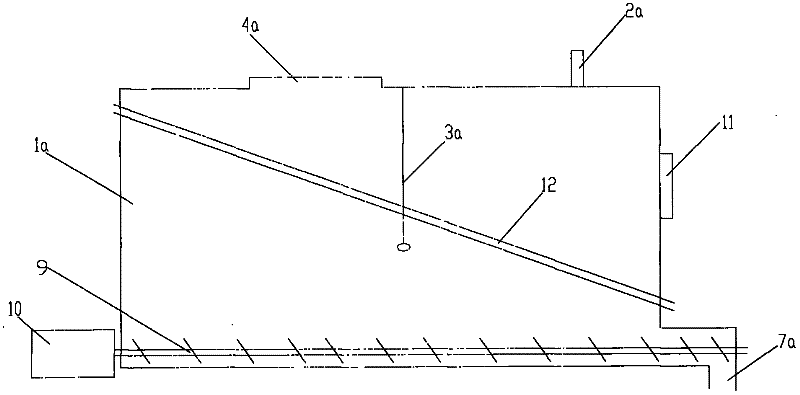

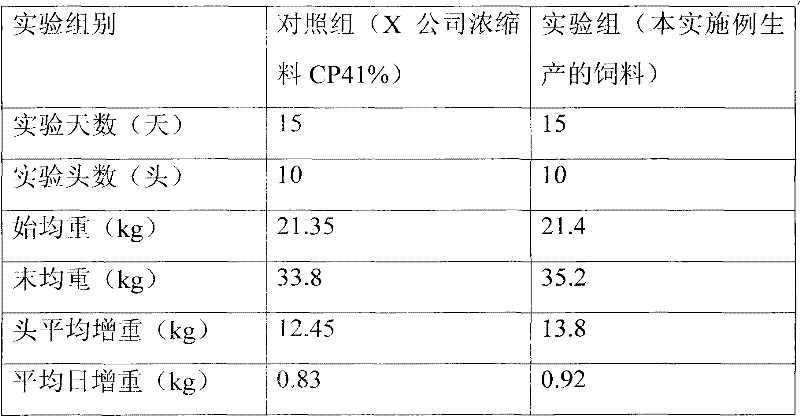

Production method, using method and production equipment of high-activity nonreactive feed

The invention discloses a production method, a using method and production equipment of high-activity nonreactive feed. Raw materials of the feed comprise a concentrate feed raw material and a companion feed raw material. The feed is obtained through fermentation by adopting a reasonable raw material formula and a proportion thereof; the produced fermentation feed has low cost, is good for marketcirculation, also does not contain any harmful additive agent which affects the health of human beings, and has higher utilization ratio by adopting the specific proportion when the feed is used for raising pigs; harmful substances in intestinal canals of animals are absorbed and utilized by beneficial fungi, comprehensive nutritious substance can be provided for animals, and the balance of microbiota in the gastrointestinal tract of piglets is regulated, which plays roles of diarrhea prevention as well as harmful fungi inhibition and killing in the intestinal canal; the immunity of animals is strengthened; the occurrence of disease is reduced; and the cultivation cost is lowered, thus healthy and safe animal products are produced to protect the health of human beings.

Owner:云南轩瑜生物科技有限公司

Method for extracting plant flavone compounds by enzymatic process

InactiveCN101967137AGood curative effectIncrease added valueOrganic chemistryGinkgophyta medical ingredientsBiotechnologyAlcohol

The invention relates to a method for extracting plant flavone compounds by an enzymatic process, which comprises the following steps: (1) lixiviating, wherein enzymolysis water extraction is carried out once, and alcohol extraction is carried out twice; (2) purifying on the columns; (3) and processing the analytic solution to obtain the plant flavone compound product. Under the guidance of biotechnology theory, natural product chemical theory and technology and international drug test standard, the invention formulates an experimental scheme for production, and determines proper enzymatic process extraction technique and flavone glycoside biotransformation technique, thereby obtaining the product with high biological value. The invention determines to compound multiple enzyme preparations, optimizes the optimal transformation conditions and enhances the flavone biotransformation efficiency. The invention formulates a technical scheme of adsorption with macroporous absorbent resin to be used in industrial production, thereby increasing the content of aglycon flavones in the product.

Owner:天津市食品加工工程中心

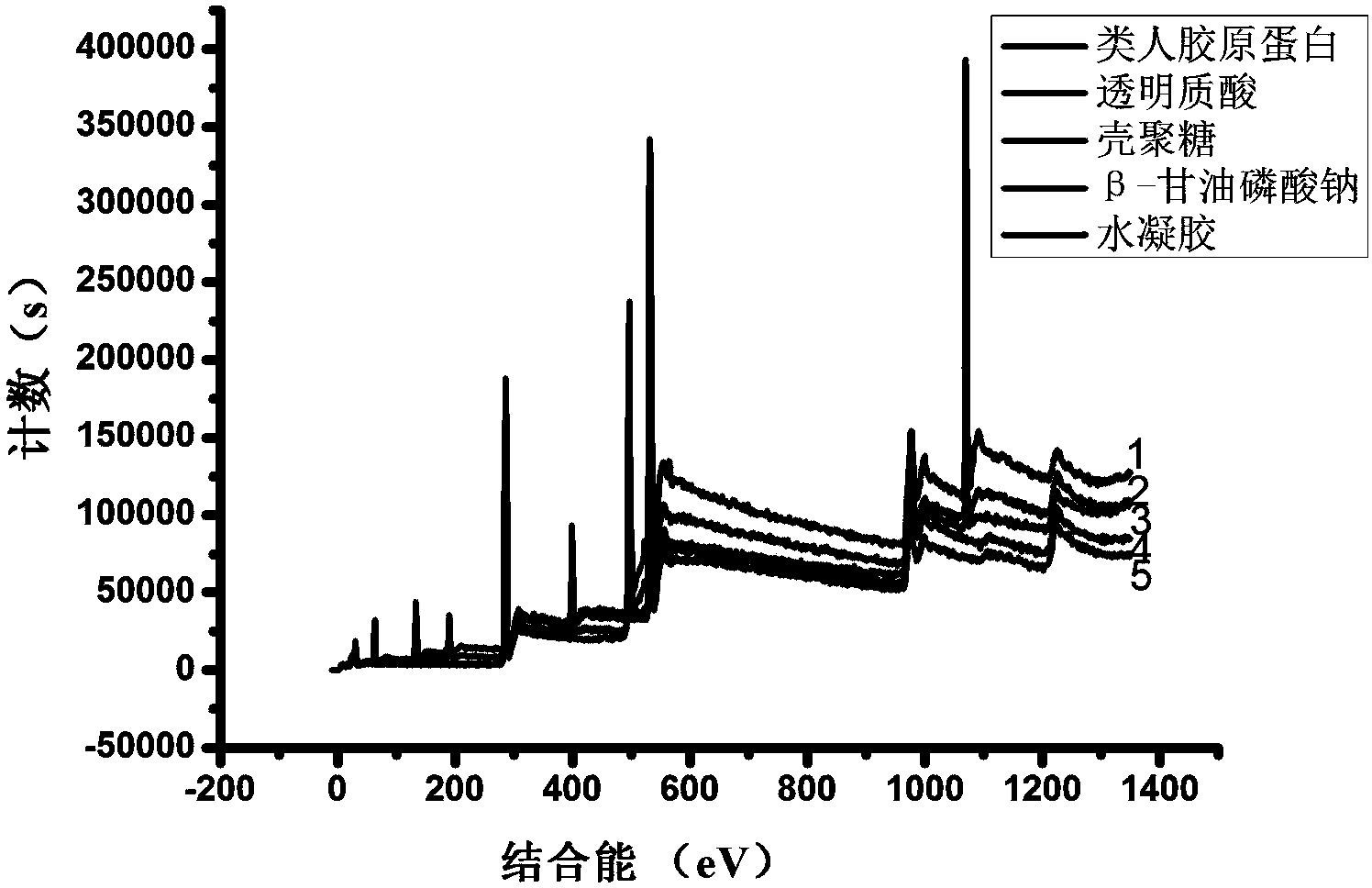

Hydrogel used as skin filling material and preparation method thereof

InactiveCN103755981AGood stabilityHigh biological potencyProsthesisSilicone resinBiomedical engineering

The invention relates to a hydrogel used as a skin filling material and a preparation method thereof. Skin filling materials such as white wax, silicon resin, a saline water bag, and silica gel have defects of generating chronic inflammation, lump, and tissue damage to tissues, are poor in biocompatibility, and are incapable of meeting the recovering requirement. The preparation method comprises the steps: adding a chitosan solution in a human-like collagen protein solution, stirring for reacting, adding a hyaluronic acid solution, stirring for reacting, adding a crosslinking agent, and stirring for reacting; and heating by adopting a constant-temperature water bath to prepare the hydrogel, wherein a human-like collagen protein is produced by a genetically engineered bacterium BL21 high-density fermentation. The hydrogel provided by the invention is prepared by adopting two methods of self-assembling and physical / chemical crosslinking, and has the advantages of better stability and high biological value, is capable of preventing trauma of surgical operation and reducing patient pain, thereby actually realizing the advantage of skin filling.

Owner:NORTHWEST UNIV

Protein feed stuff and processing method thereof

InactiveCN1788598AIncrease payGuaranteed Bioactive IngredientsAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The biotechnological process of producing polypeptide and protein feed is superior to traditional fish meal producing process, which has high protein loss rate, high power consumption, high cost, serious pollution and other demerits. The present invention produces polypeptide paste, polypeptide powder, protein paste or protein powder with fresh low value fishes and shrimp and aquatic animal leftover and through the process including the steps of eliminating impurity, steam to eliminate fat, oil-water separation, crushing, sterilizing, enzymolysis, inactivating enzyme, concentration, drying and others. The present invention has the advantages of high protein content in the products, high bioavailability, no environmental pollution, low power consumption, etc. The products have the effects of promoting animal growth, regulating immunity, preventing and treating diseases, etc. and are used mainly in raising animal and as nitrogen source for biological culture.

Owner:韩福山

Eucommia ulmoides feed additive and preparation method and application thereof

InactiveCN101785528AExtensive sources of raw materialsEasy to prepareAnimal feeding stuffEUCOMMIA ULMOIDES LEAFLivestock

The invention discloses an eucommia ulmoides feed additive, a preparation method and an application thereof. The eucommia ulmoides feed additive is prepared from eucommia ulmoides leaf fine powder and hawthorn fruit powder according to the mass ratio of 8:1-2.5. The eucommia ulmoides feed additive provided by the invention has wide raw material sources, convenient and concise preparation and safeand reliable application, can be used in producing and feeding of green and pollution-free livestock, has high animal absorption and utilization rate, promotes growth, improves feeding environment, is favor of growth of livestock, enhances immunity of the livestock, increases product quality of the livestock and has wide adaptability.

Owner:XIAN WATSON BIOLOGY TECH

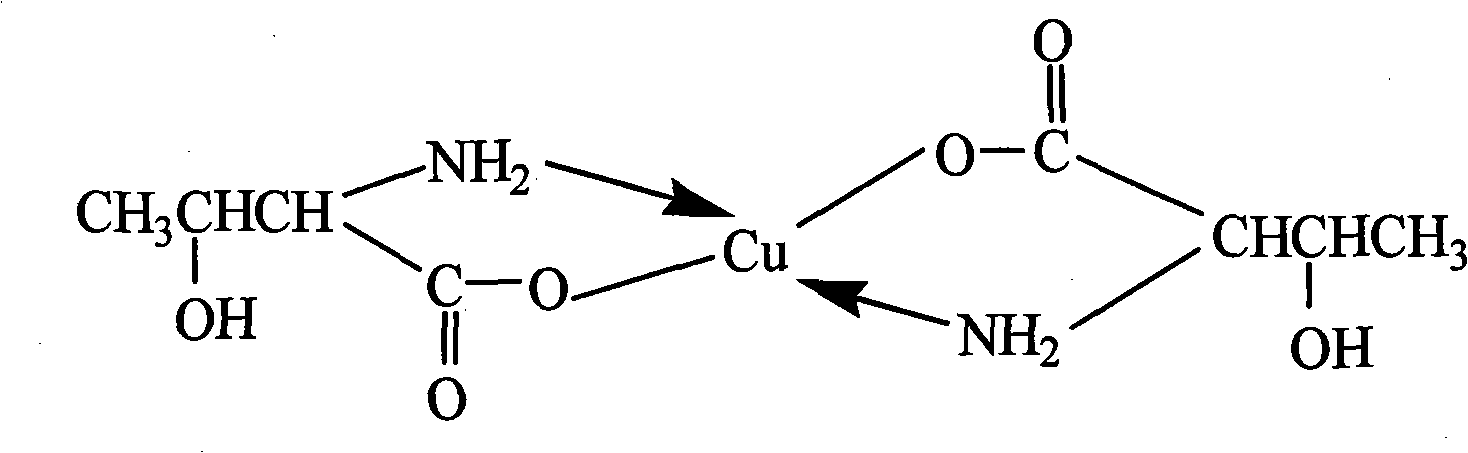

Method for preparing DL-threonine chelated copper serving as feed additive

InactiveCN101838214AHigh yieldRaw materials are easy to getOrganic compound preparationAnimal feeding stuffGlycineFood additive

The invention discloses a method for preparing DL-threonine chelated copper serving as a feed additive. The invention adopts a technical scheme of taking aminoacetic acid as raw material, allowing aminoacetic acid to react with basic copper carbonate to form glycine chelated copper and allowing glycine chelated copper to react with acetaldehyde to form DL-threonine chelated copper. Compared with the conventional method for preparing threonine chelated copper, the method of the invention has the following outstanding advantages that: 1) as threonine and threonine chelated copper are prepared from aminoacetic acid, the method is readily available in raw material, needs no threonine and is low in cost; 2) as the feed additive amino-acid chelated copper does not need separation, and DL-threonine copper is directly utilized, so over 50 percent of cost is reduced; and 3) the preparation of the DL-threonine chelated copper is performed at normal temperature under normal pressure and is short in reaction route, little in equipment investment and convenient for industrial production.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Method for producing glucose bulk drug for injection by using rice

ActiveCN102703547AHigh biological potencyImprove saccharification puritySugar derivativesFermentationIon exchangeChemistry

The invention provides a method for producing a glucose bulk drug for injection by using rice. The method comprises the following steps of: soaking and defibrination, size mixing, liquefaction and slag removal, saccharification, primary decoloration and filtration, secondary decoloration and filtration, ion exchange, concentration and refining, primary crystallization, primary centrifugation, sugar solution, sugar concentration and decoloration, secondary sugar boiling and crystallization, secondary centrifugation, drying, packaging and the like. The method has the following advantages: (1), a two-time crystallization process is adopted, the quality is high, and a filtration speed is quick; (2), the problem that a raw material for producing an injection glucose in the south does not existis solved by using the rice as the raw material, and the blank of the production of a crystalline glucose in the south is filled; (3), the crystalline glucose produced by using the rice as the raw material has low-irritability in absorption property and is high in biological value; and (4), a breeding fermentation problem in a production procedure is solved successfully, the sugar concentration and the filtration are added, the quality of a finished product is greatly improved, and the clarity and the filtration speed of the product are guaranteed. The continuous feed and the continuous discharge can be carried out; the crystallization and fermentation contamination is stopped; the quality can be guaranteed; and the continuous production is guaranteed.

Owner:北京佳沃臻诚科技有限公司

Nutrients additive for biological feed of livestock and fowls and its preparing process

InactiveCN1372816AIncrease profitPromote growthFood processingAnimal feeding stuffBiotechnologyOrganism

A nutritive bio-additive for feed of livestock and fowls contains fermented product of lysine, bacillus and photosynthetic bacteria, bean cake, plant starch and trace elements. Its advantages are high biological effect-cost ratio, high effect on decomposing harmful substances in animal body, and rich methionine and somatic protein for high immunity.

Owner:广西化工生物技术研究所有限责任公司

Polypeptide chelate calcium preparation and preparation method thereof

ActiveCN104920782AImprove stabilityImprove absorption rateProtein composition from eggsUltrafiltrationChemistry

The invention relates to poultry egg shell membrane polypeptide chelate calcium and a preparation method thereof. The method comprises the following steps: using poultry egg processing scraps, namely egg shells, as raw materials; performing pretreatment, shell membrane separation by a mechanical method, egg shell ultramicro grinding and two-step egg membrane hydrolysis on the raw materials so as to obtain polypeptide; performing centrifugation and ultrafiltration on egg membrane hydrolysate so as to obtain polypeptide of which the molecular weight is smaller than or equal to 5000Da, and performing nano-filtration and desalination; mixing ultramicro egg shell powder with the polypeptide with the mass ratio of the ultramicro egg shell powder to the polypeptide to be 1:1-1:3; controlling definite temperature and time for performing chelation; and finally performing purification with ethanol of 90%-95%, and performing freeze drying so as to obtain the polypeptide chelate calcium. The polypeptide chelate calcium disclosed by the invention uses two kinds of natural substances of the poultry egg processing scraps, namely the egg shells and egg membranes, as the raw materials, the obtained polypeptide chelate calcium is safe and natural, the resource utilization of the poultry egg processing scraps, namely the egg shells and the egg membranes is realized, and the waste of resources is reduced.

Owner:SICHUAN UNIV

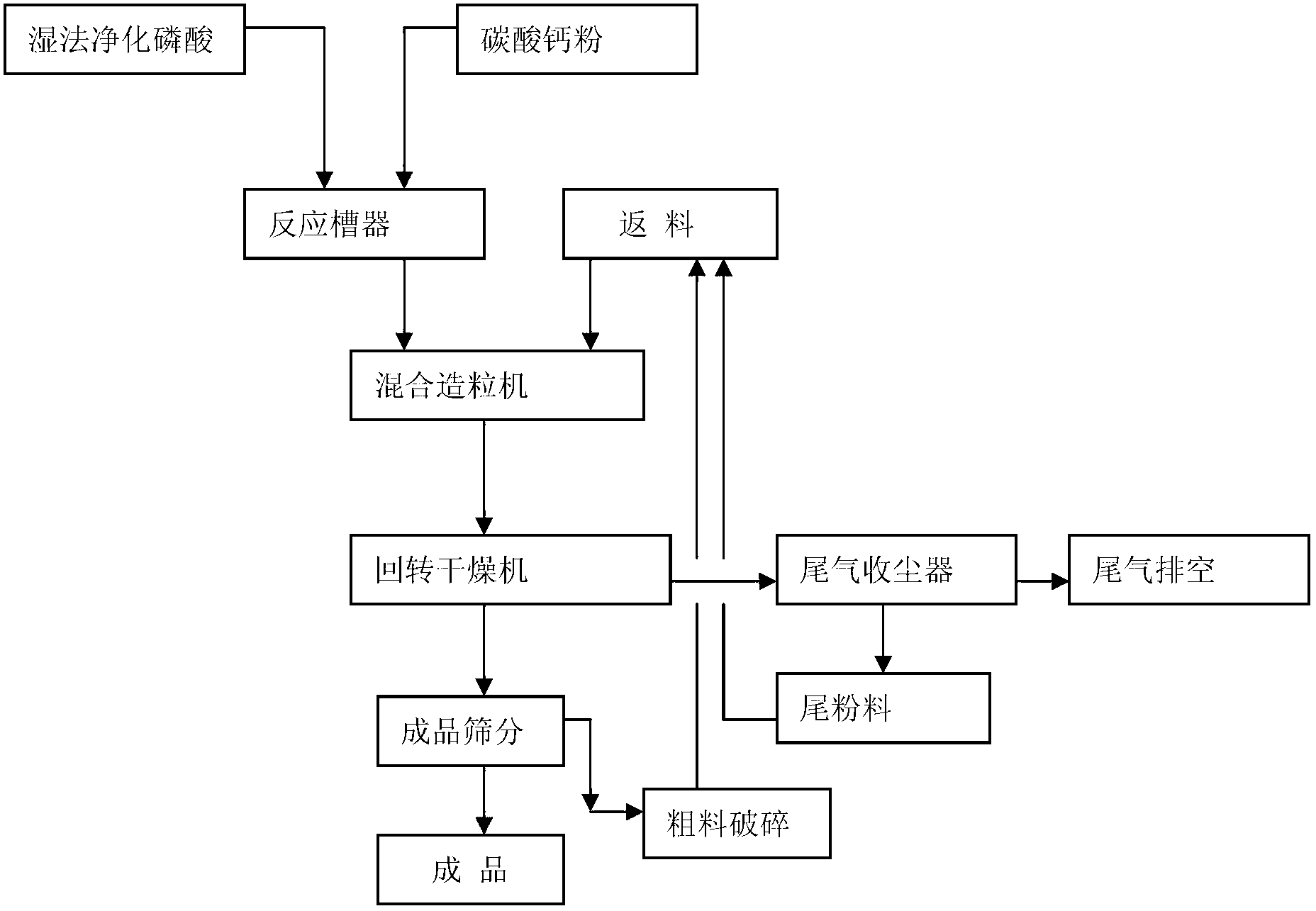

Production method of feed-grade granular calcium hydrogen phosphate III-type product

ActiveCN102701171ALow grade requirementsHigh biological potencyAnimal feeding stuffPhosphorus compoundsPhosphoric acidMonocalcium phosphate

The invention relates to a production method of a feed-grade granular calcium hydrogen phosphate III-type product, which comprises the following steps of: mixing strong phosphoric acid with 30-50 wt% of phosphorus pentoxide and a calcium-containing compound according to the Ca / P ratio of 0.75-0.85 in a reactor at high rotating speed greater than and equal to 450 RPM for reaction, continuously feeding produced mixed slurry containing calcium hydrogen phosphate and monocalcium phosphate together with a return material into a mixing granulator for granulation, and feeding a produced feed-grade granular calcium hydrogen phosphate III-type moisture semi-finished product into a drying machine for drying; and screening a dried finished product output by the drying machine to obtain the calcium hydrogen phosphate III-type product, and crushing tailings remained after screening and returning the crushed tailings to the mixing and granulation steps as the return material. With the production method, the feed-grade granular calcium hydrogen phosphate III-type product is directly synthesized in one-step reaction, the production method has low grade requirement for raw materials, short production process flow and high phosphorus utilization rate, and no white fertilizer or waste water is produced; and the granular product does not cake and has good flowability, and the biological value of animals is high.

Owner:SINOCHEM YUNLONG

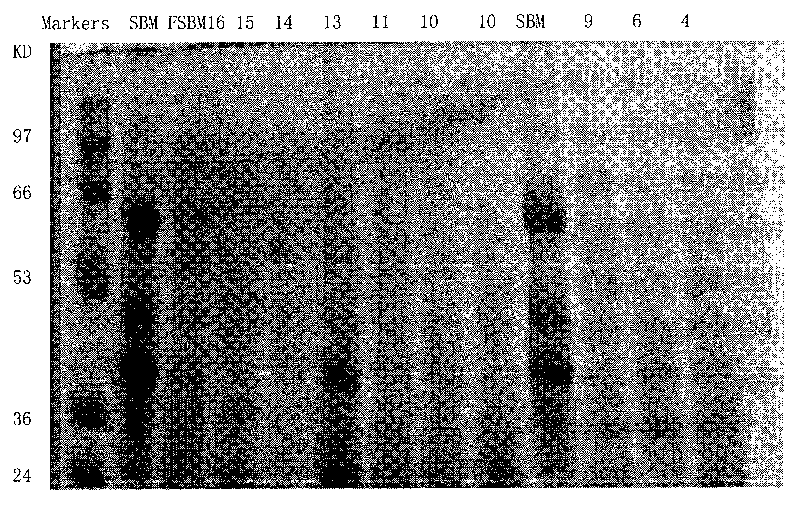

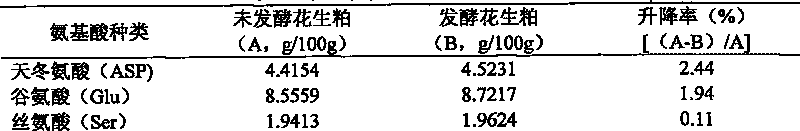

Fermentation process for improving amino acid and protein contents in peanut meal

InactiveCN101692865AHigh biological potencyEfficient degradationAnimal feeding stuffPeanut mealAmino acid

The invention discloses a fermentation process for improving amino acid and protein contents in peanut meal, which comprises the steps of respectively conducting enrichment culture to Bacillus subtilis, Lactobacillus casei and Candida utilis to lead the viable counts of the three funguses to respectively reach more than 1012cfu / mL, 109cfu / mL and 109cfu / mL, then simultaneously inoculating the three fungus suspensions into wet peanut meal according to the weight ratio of 1-5:100, conducting mixed fermentation at 28-40 DEG C, turning over every 4-8h, achieving fermentation end after 24-72h, then crushing to 20-60 meshes, and then conducting hot air current drying, thus obtaining the fermented peanut meal with the water content being below 12 percent. The fermented peanut meal has high protein content and biological value, does not contain aflatoxin, and can enhance resistance of animal intestine, prevent and treat indigestion, and effectively adjust microecological balance.

Owner:SOUTH CHINA UNIV OF TECH

Chinese herbal medicine feed additive with pine needle flavor for fattening lambs

InactiveCN101623053AImprove absorption and utilizationIncrease assimilationFood processingAnimal feeding stuffAnimal scienceFood flavor

The invention relates to Chinese herbal medicine feed additive with pine needle flavor for fattening lambs, which can realize rapid fattening of the lambs under prior feeding conditions. The feed additive is prepared by the steps of mixing and crashing pine needles, dried orange peels and tuckahoe powders and adopting molasses, and the like as carriers for adsorbing, and can be added into feed for usage. The invention improves meat quality, flavor, mutton system water power, and meat tenderness at the same time of prompting the nutrient digestibility ratio of the lamb feed and improving the return interest of the feed according to digestion functions.

Owner:山西全生现代农业发展有限公司

Chinese herbal medicine feed additive with astragalus root flavor for fattening lambs

InactiveCN101623054AImprove absorption and utilizationIncrease assimilationAnimal feeding stuffAnimal scienceFood flavor

The invention relates to Chinese herbal medicine feed additive with astragalus root flavor for fattening lambs, which can realize rapid fattening of the lambs under prior feeding conditions. The feed additive is prepared by adopting the steps of mixing and crashing astragalus root, hawthorn, white paeony root and selfheal, and adopting molasses, and the like as carriers for adsorbing, and can be added into feed for usage. The invention improves meat quality, flavor, mutton system water power, and meat tenderness at the same time of prompting the nutrient digestibility ratio of the lamb feed and improving the return interest of the feed according to digestion functions.

Owner:山西全生现代农业发展有限公司

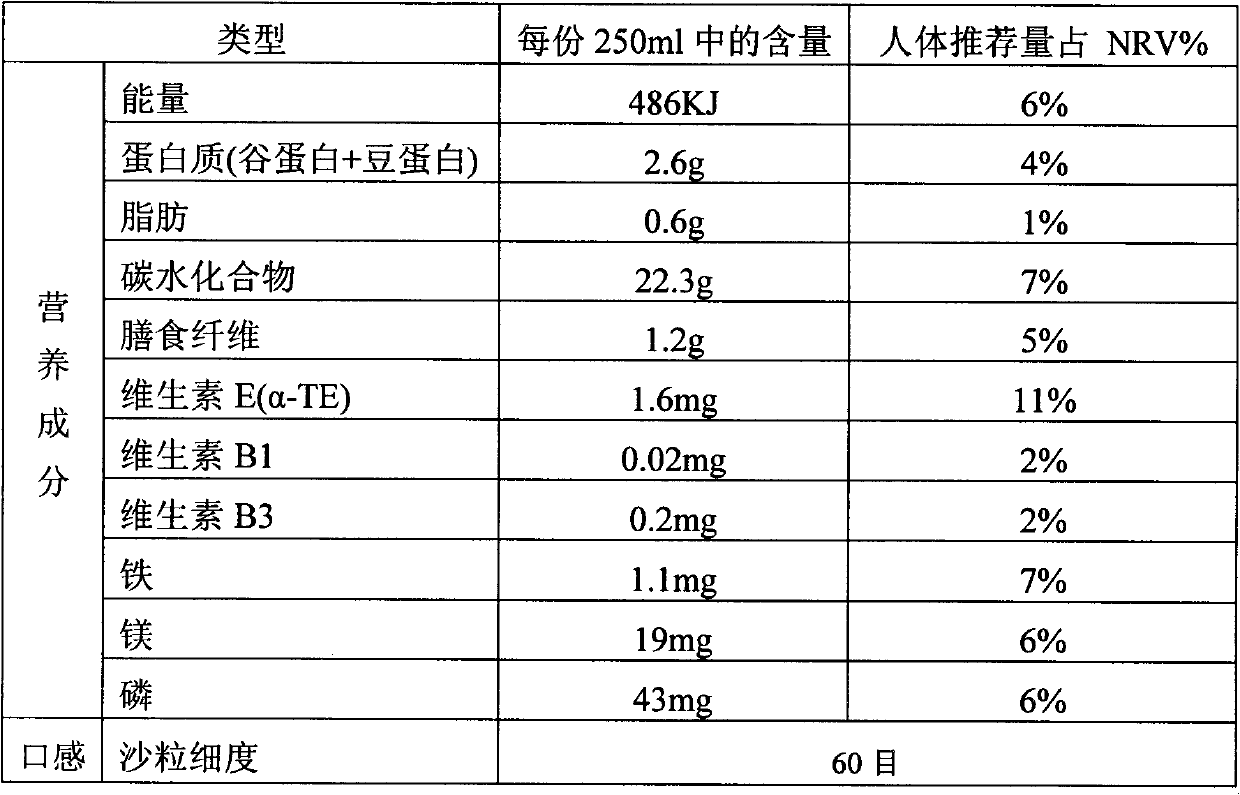

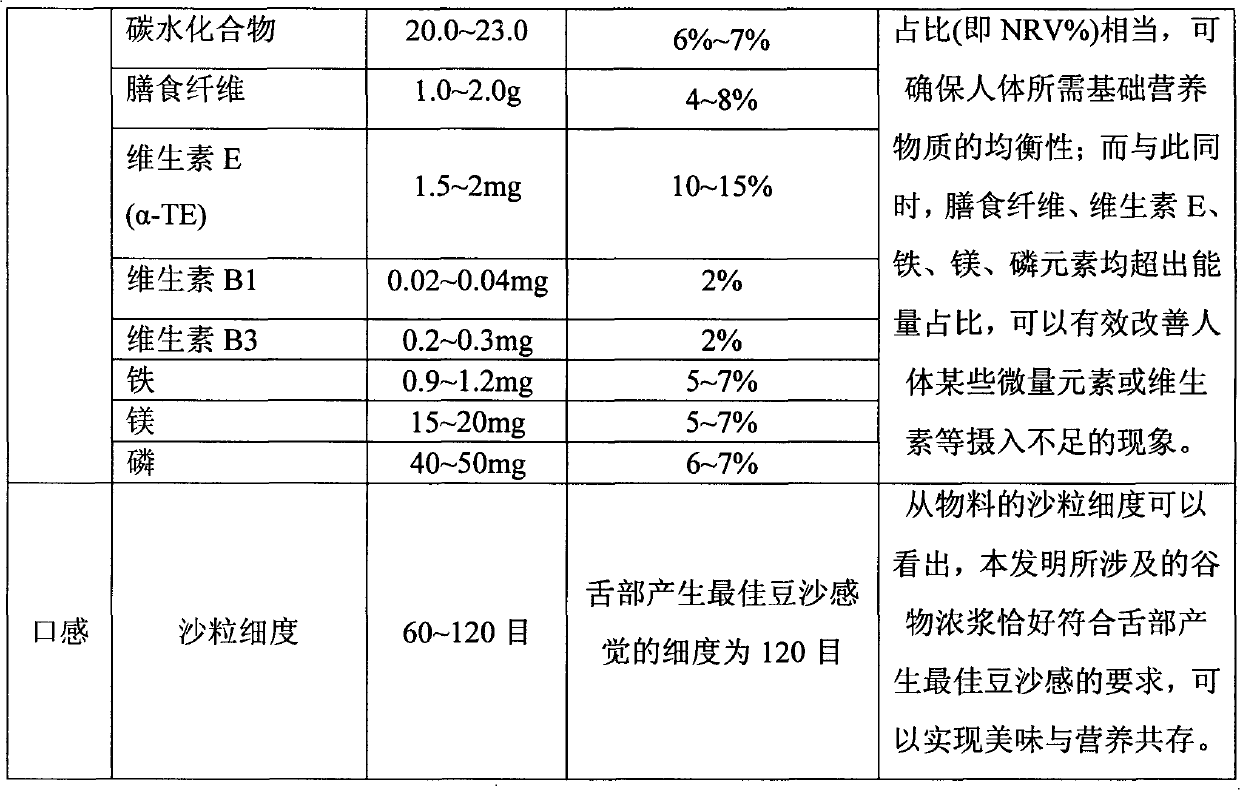

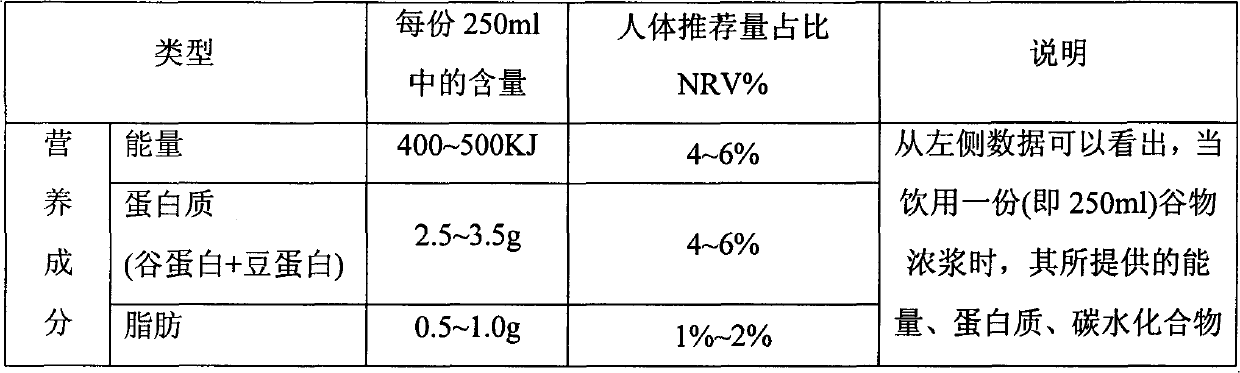

Red bean paste grain concentrated pulp and preparation method thereof

The invention relates to a red bean paste grain concentrated pulp non-alcohol drink and a preparation method thereof. The grain concentrated pulp drink is prepared from the following raw materials: red beans, black beans, dry cowpeas, white sugar, maltodextrin, non-dairy creamer, compound stabilizer and water. The preparation method of the grain concentrated pulp comprises: preparing a grain concentrate; preparing an auxiliary concentrate; blending; sterilizing; and finally, obtaining the red bean paste grain concentrated pulp non-alcohol drink which has a strong bean paste flavor, offers a full and smooth mouthfeel, contains rich dietary fibers, and has long-lasting stability.

Owner:山东朝能福瑞达生物科技有限公司

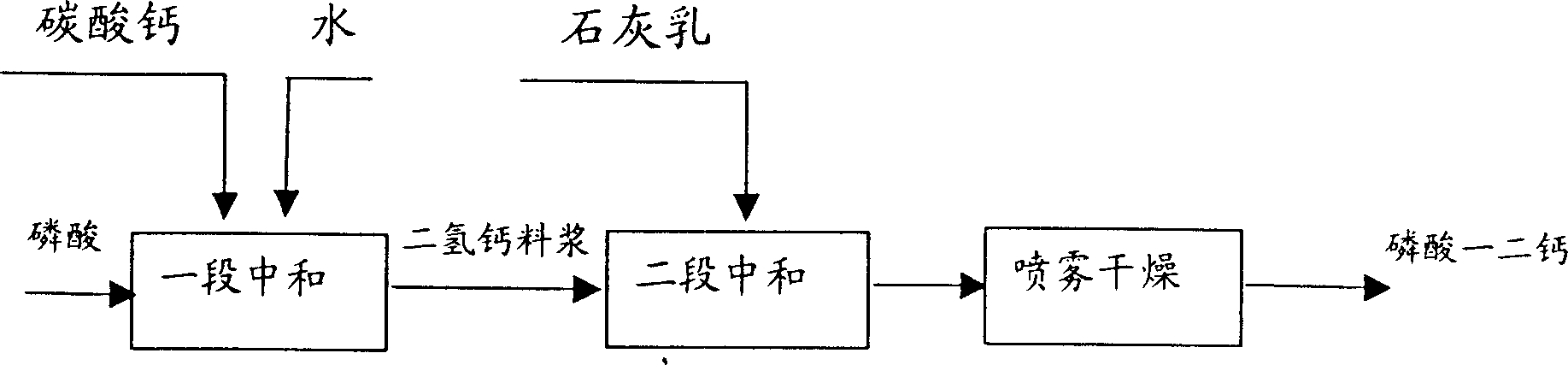

Method for producing feed grade dicalcium phosphate

InactiveCN1857997AIncrease profitReduce manufacturing costAccessory food factorsPhosphorus compoundsCalcium phosphate productO-Phosphoric Acid

The process of producing feed grade calcium phosphate features that the calcium phosphate producing process includes the first liquid phase neutralizing reaction between dilute phosphoric acid and calcium containing compound in the reactor to produce calcium dihydrogen phosphate slurry, the subsequent adding calcium containing compound for the second liquid phase neutralizing reaction to produce mixture slurry of calcium hydrogen phosphate and calcium dihydrogen phosphate, and the spray drying of the slurry to obtain the calcium phosphate product. The production process has no produced white fertilizer and waste water, high phosphorus utilization rate, low production cost, less environmental pollution and well preservation of crystalline water resulting in high biological potency.

Owner:四川川恒控股集团股份有限公司

Process for biological enzyme extraction of grape seed polypeptide protein

The invention relates to a plant protein extraction process technology, that is, a process for extracting grape seed polypeptide protein by biological enzyme method. The grape seed is used as a raw material, crushed, softened with water, hydrolyzed with endo-cut slightly acidic cellulase and papain mixed enzyme, exo-cut rice koji enzyme hydrolyzed, separated, concentrated and dusted to obtain powdery grape seed polypeptide protein. It has the characteristics of no peculiar taste, high protein extraction rate, low production cost, and maximum protection of raw materials without loss of nutrition during processing.

Owner:通化腾龙生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com