Fermentation process for improving amino acid and protein contents in peanut meal

A technology of protein content and fermentation method, which is applied in the field of solid-state fermentation of peanut meal, can solve problems such as high cost and complicated process, and achieve the effects of low cost, increased biological potency, and improved biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

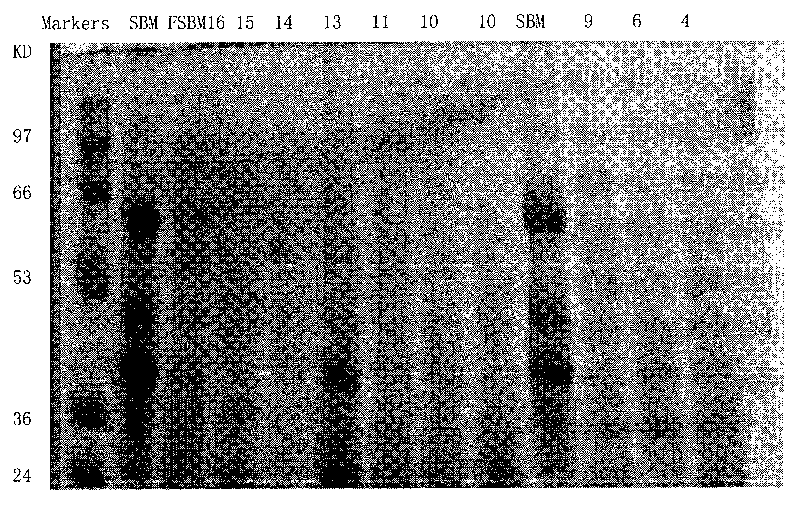

Image

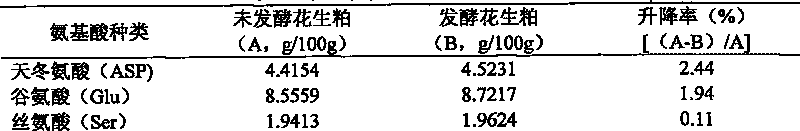

Examples

Embodiment 1

[0021] In the first step, Bacillus subtilis (No. CICC 20018, Bacillus subtilis 20018, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027), Lactobacillus casei rhamnosin sub species (No. CICC 6013, Lactobacillus casei subsp.rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) and Candida utilis (No. CICC 31188, Candida utilis 31188, preserved by China Industrial Microorganism Culture Collection and Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) The freeze-dried powders of the three bacteria were placed in different liquid media, of which Bacillus subtilis Place broth liquid medium (beef extract 5g / L, peptone 39g / L, glucose 1g / L, sodium chloride 5g / L, pH is 7.2), Lactobacillus casei is placed in MRS liquid m...

Embodiment 2

[0034] In the first step, Bacillus subtilis (No. CICC 20018, Bacillus subtilis 20018, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027), Lactobacillus casei rhamnosin sub species (No. CICC 6013, Lactobacillus casei subsp.rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) and Candida utilis (No. CICC 31188, Candida utilis 31188, preserved by China Industrial Microorganism Culture Collection and Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) and other three types of bacteria were placed in different liquid culture media {Bacillus subtilis Place broth liquid medium (beef extract 5g / L, peptone 39g / L, glucose 1g / L, sodium chloride 5g / L, pH is 7.2), Lactobacillus casei is placed in MRS liquid medium (by de M...

Embodiment 3

[0043] In the first step, Bacillus subtilis (No. CICC 20018, Bacillus subtilis 20018, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027), Lactobacillus casei rhamnosin sub species (No. CICC 6013, Lactobacillus casei subsp.rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) and Candida utilis (No. CICC 31188, Candida utilis 31188, preserved by China Industrial Microorganism Culture Collection and Management Center, address: No. 32, Xiaoyun Road, Chaoyang District, Beijing, Zip Code: 100027) and other three types of bacteria were placed in different liquid culture media {Bacillus subtilis Place broth liquid medium (beef extract 5g / L, peptone 39g / L, glucose 1g / L, sodium chloride 5g / L, pH is 7.2), Lactobacillus casei is placed in MRS liquid medium (by de M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com