Patents

Literature

505results about How to "Reduce the degree of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

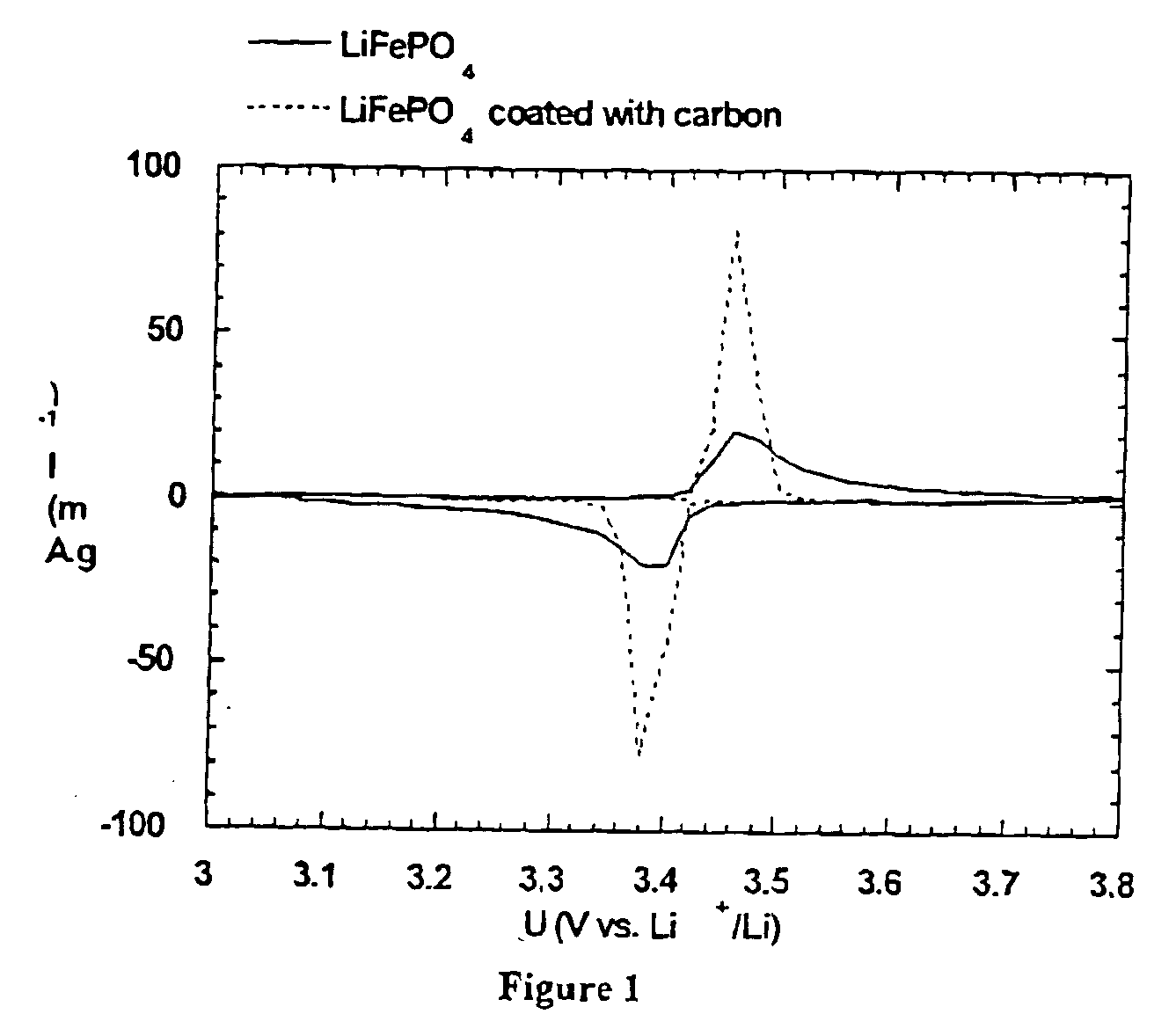

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

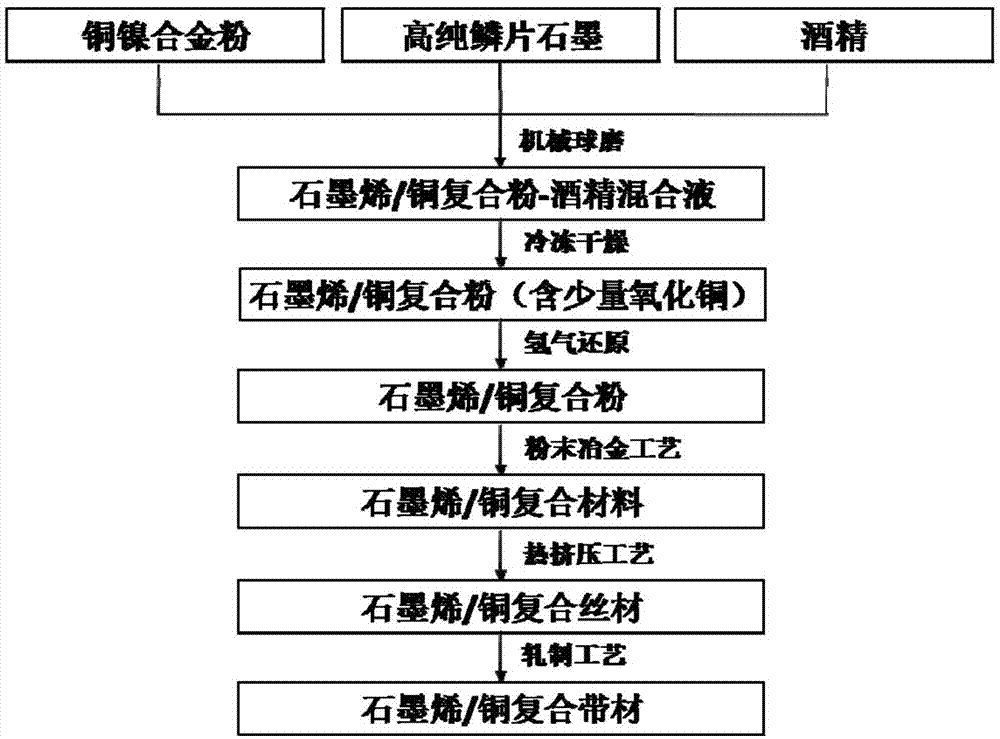

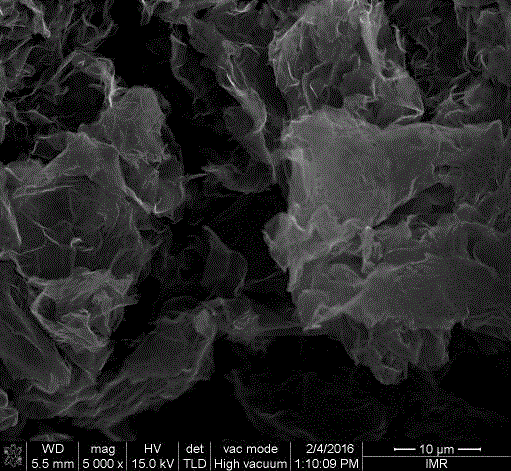

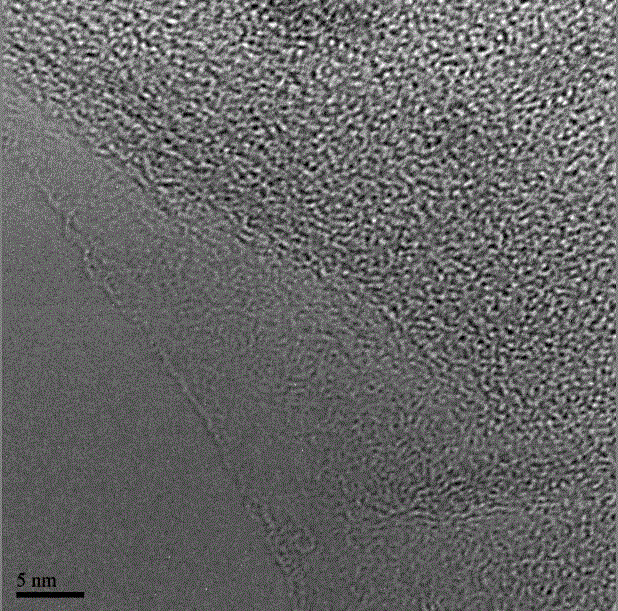

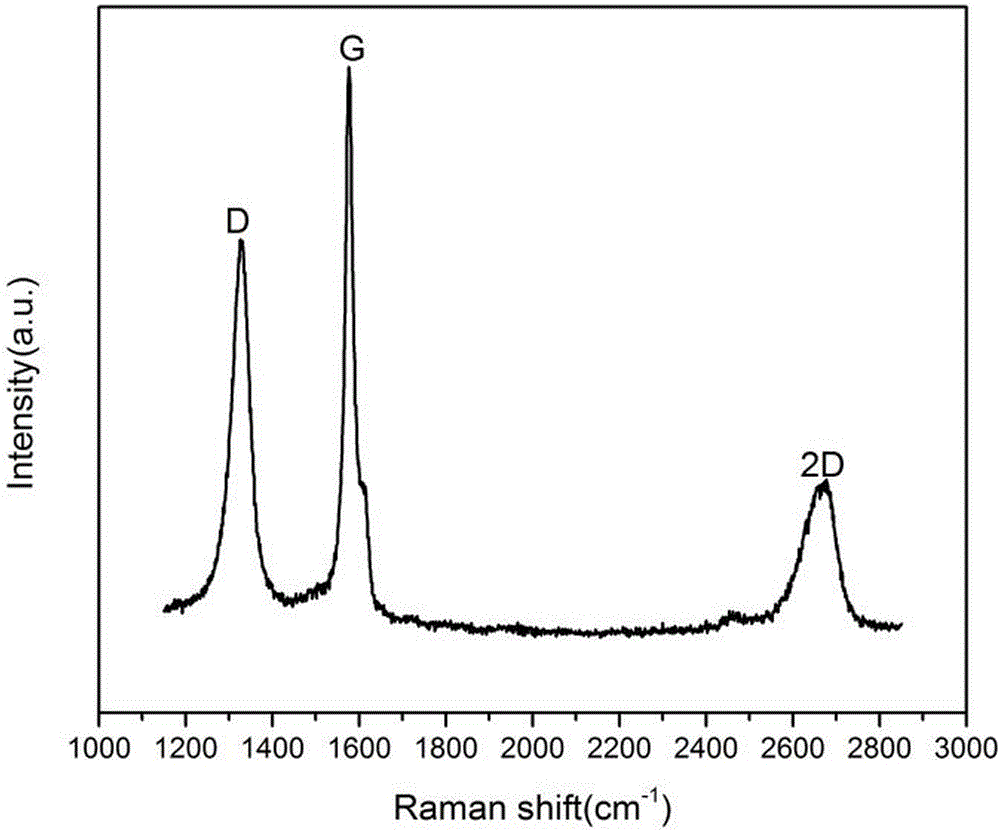

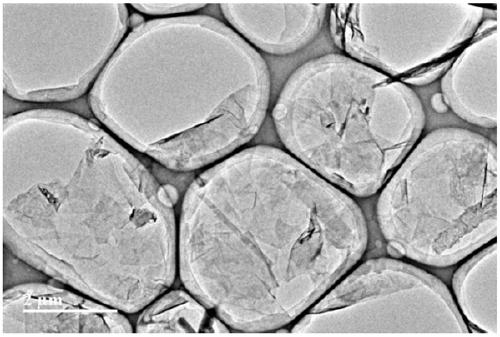

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

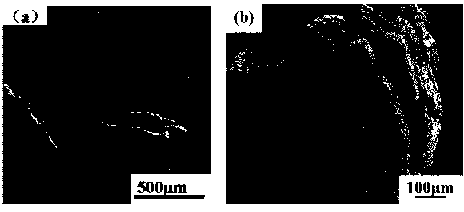

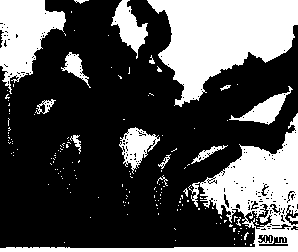

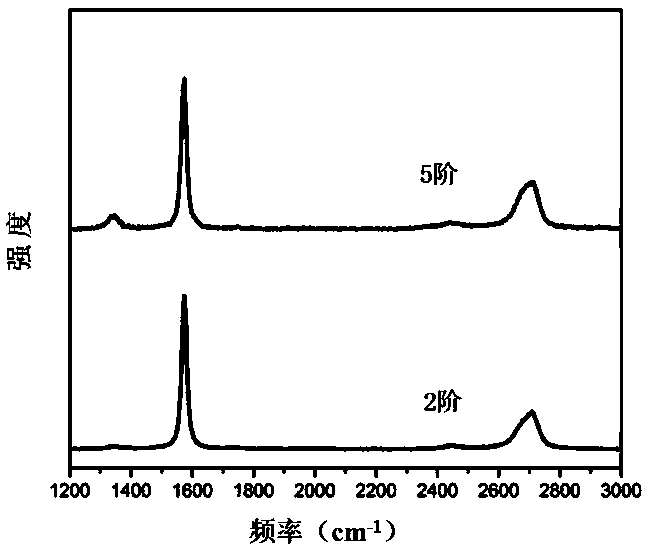

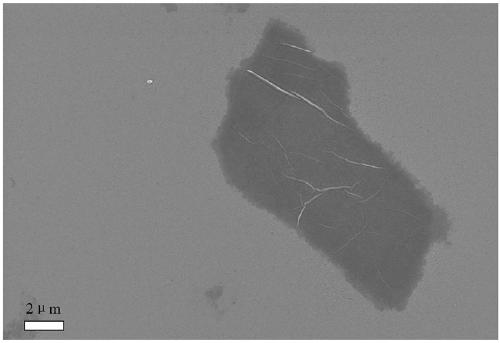

Method for preparing large-size high-quality graphene with controllable number of layers

The invention discloses a method for preparing large-size high-quality graphene with controllable number of layers, wherein graphite powder or flake graphite is mainly adopted as a raw material. The method specifically comprises the steps of intercalating the graphite raw material by virtue of an intercalating agent to initially weaken the intercalation interaction force and obtain different orders of graphite intercalation compounds (GICs); soaking the GICs in an appropriate expander, and then under the case that an auxiliary agent is added or not, enabling the intercalation materials to be quickly reacted with the expander to release a gases to obtain highly expanded wormlike graphene aggregate and further to cause the distances among graphene lamellar layers to be increased; and after certain processing, peeling, and then repeatedly centrifuging and dispersing to obtain a graphene dispersion with different numbers of layers. According to the method disclosed by the invention, the intercalation-expansion-peeling process is involved, raw materials are cheap, the reaction process is simple and easily controlled, and the number of layers of graphene is precisely controlled; the obtained graphene lamellar layers have the advantages of few defects, large size, high conductivity, high yield and the like, the large-scale industrial production is easily implemented, and the problems of high cost, low productivity, poor quality, small size, uncontrollable number of layers and the like in an existing graphene preparation technology are solved.

Owner:安徽百特新材料科技有限公司

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene. The method comprises the following steps: 1, intercalating and expanding graphite paper by adopting graphite paper as a positive electrode and an aqueous intercalator solution as an electrolyte to obtain expanded graphite; 2, filtering and washing the expanded graphite, and carrying out ultrasonic peeling treatment on the expanded graphite to obtain a flocculent graphene slurry; and 3, filtering the graphene slurry, and drying the graphene slurry through adopting a microwave vacuum drier to obtain fluffy graphene powder. The electrochemical method solves the problem of use of heavy metal-containing reagents, strong acids, strong oxidants and expensive organic liquids in the graphene preparation process in the prior art, and has the advantages of simple preparation technology, low energy consumption and low cost.

Owner:DEYANG CARBONENE TECH

Low-cost high-strength anti-fatigue nonflammable wrought magnesium alloy and preparation method thereof

ActiveCN105779834AHigh strengthMeeting the Urgent Need for High-Performance MaterialsRare-earth elementChemical composition

The present invention discloses a low-cost high-strength anti-fatigue nonflammable wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following chemical components in percentage by mass: 2.0-6.0% of Al, 1.5-4.0% of Ca, 0.2-0.8% of Mn, 0.1-0.8% of rare earth (RE), and the balance Mg and trace inevitable impurities, wherein the RE is one or more of cheap rare earth elements of La, Pr, Ce and Nd, and the content of the cheap rare earth is not zero simultaneously. The magnesium alloy provided by the present invention will meet the urgent need of users for high-performance materials, and the application of the magnesium alloy to magnesium alloy products, for example, load-bearing structural parts of aerospace, vehicles, rail trains and so on, structural parts of medical treatment, welfare and outdoor sport equipment, and parts (e.g., compressor scroll pans) having certain requirements for heat resistance and fatigue performance, is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

Polymer coated vitamin E liposome and preparation method thereof

InactiveCN101780041AReduce the degree of oxidationHigh biological potencyPowder deliveryOrganic active ingredientsPolymer scienceFreeze-drying

The invention relates to a polymer coated vitamin E liposome and a preparation method thereof. The preparation method of the invention comprises the following steps: preparing a vitamin E liposome suspension; adding a polymer into the suspension for coating to obtain a polymer coated vitamin E liposome suspension; obtaining a polymer coated vitamin E proliposome solid powder by spray drying or freeze drying; and before use, adding a proper amount of distilled water as required to obtain the polymer coated vitamin E liposome suspension with the entrapment rate of 82-94%. The polymer coated vitamin E liposome of the invention can obviously reduce the degree of oxidation of vitamin E, reduce the percolation rate, delay the release of the vitamin E in vivo, prolong the cycling time in vivo, and be prepared into the coated type proliposome solid powder which can be more conveniently packed, stored, transported and used.

Owner:NANCHANG UNIV

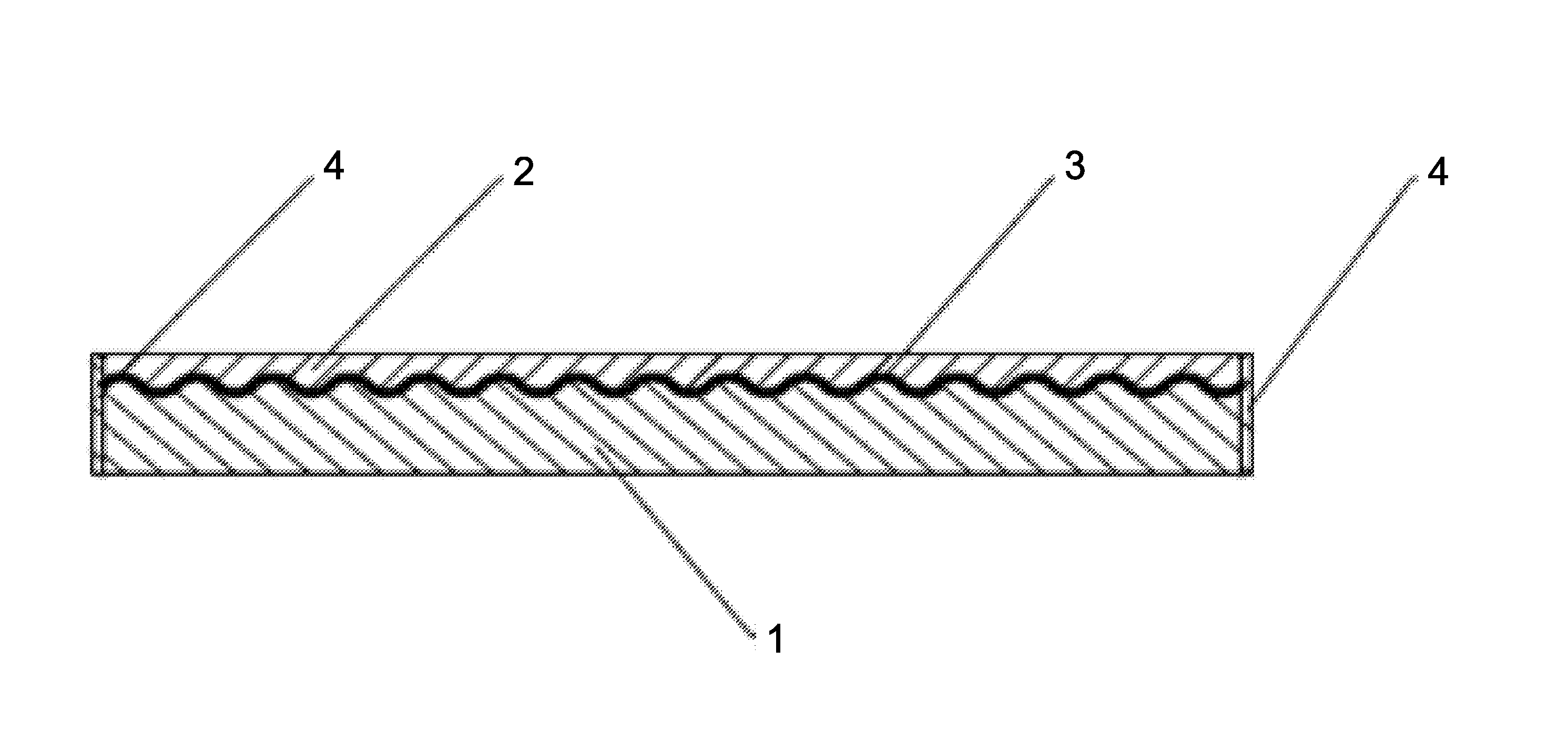

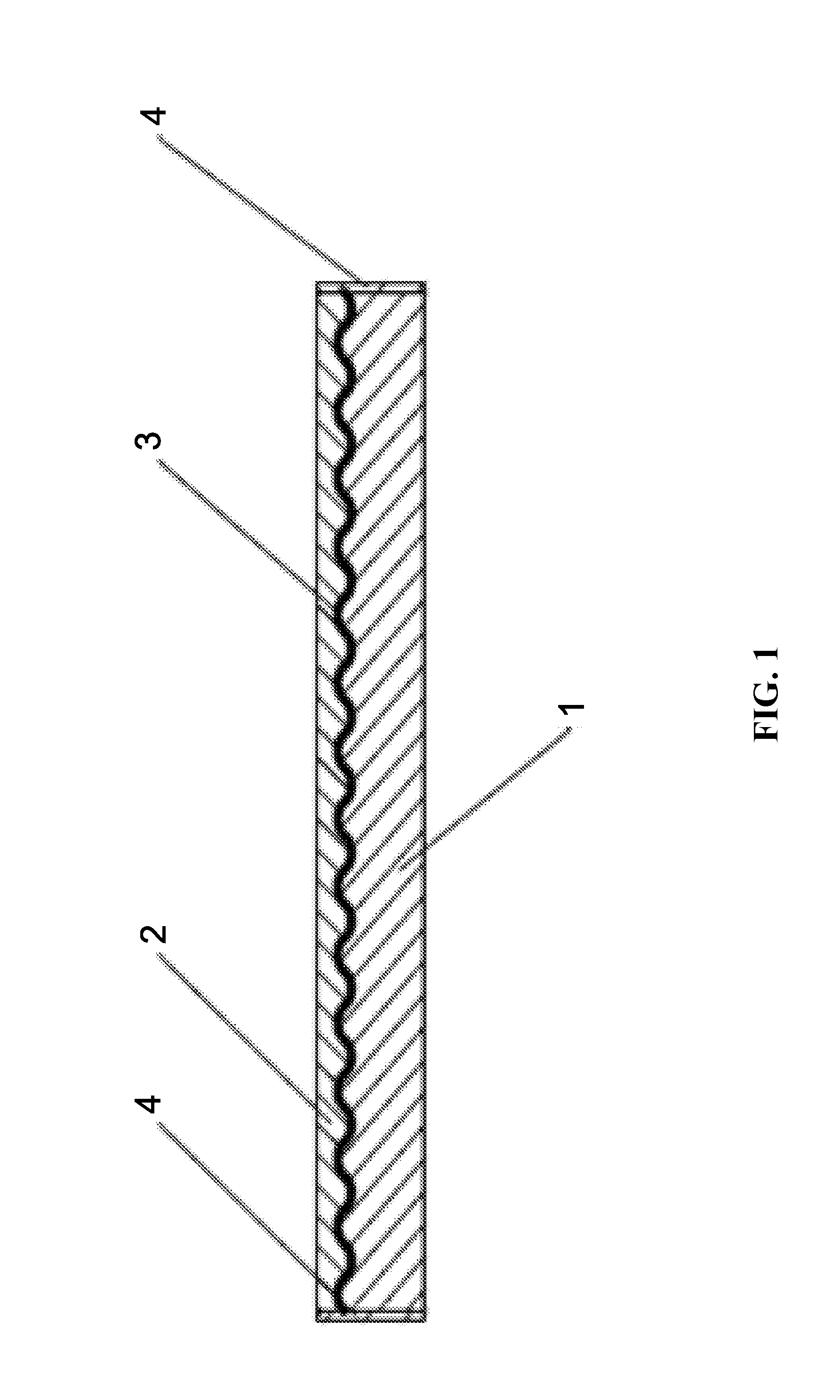

Aluminium brazing sheet material

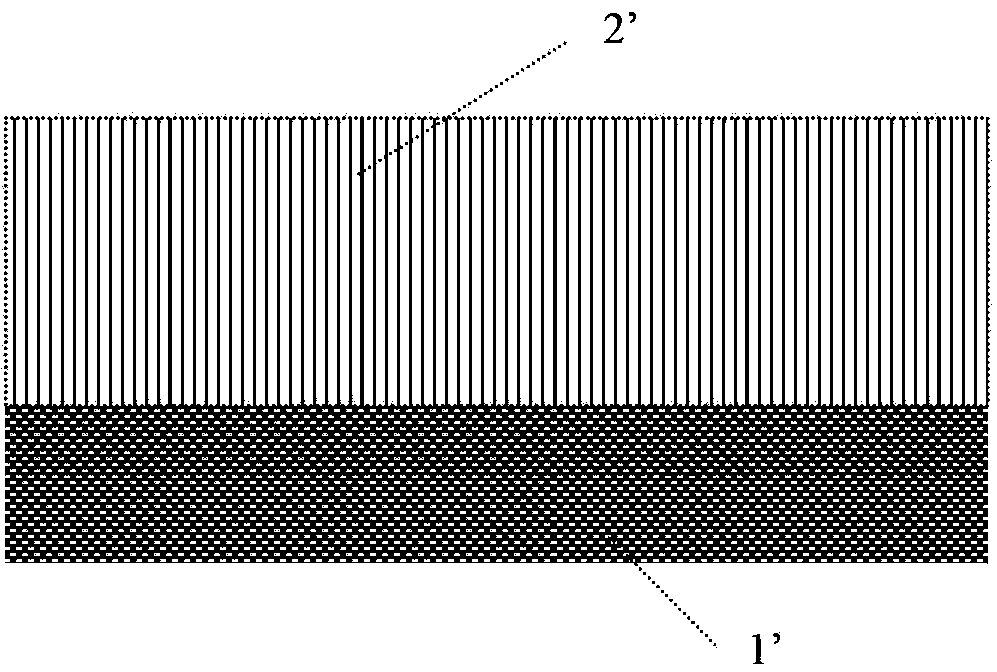

ActiveUS20110111254A1Lower capability requirementsGood brazingElectron beam welding apparatusWelding/cutting media/materialsAlloyAluminium

A brazing sheet material for CAB brazing without applying flux. The brazing sheet material including an aluminum core alloy layer provided with a first brazing clad layer material on one or both sides of the aluminum core layer and at least one second brazing clad layer material positioned between the aluminum core alloy layer and the first braze clad layer material. The second brazing clad layer material is an Al—Si alloy brazing material having 5% to 20% Si and 0.01% to 3% Mg, and the first brazing clad layer material is an Al—Si alloy brazing material having 2% to 14% Si and less than 0.4% Mg. Also disclosed is a brazed assembly manufactured in a brazing operation.

Owner:NOVELIS KOBLENZ GMBH

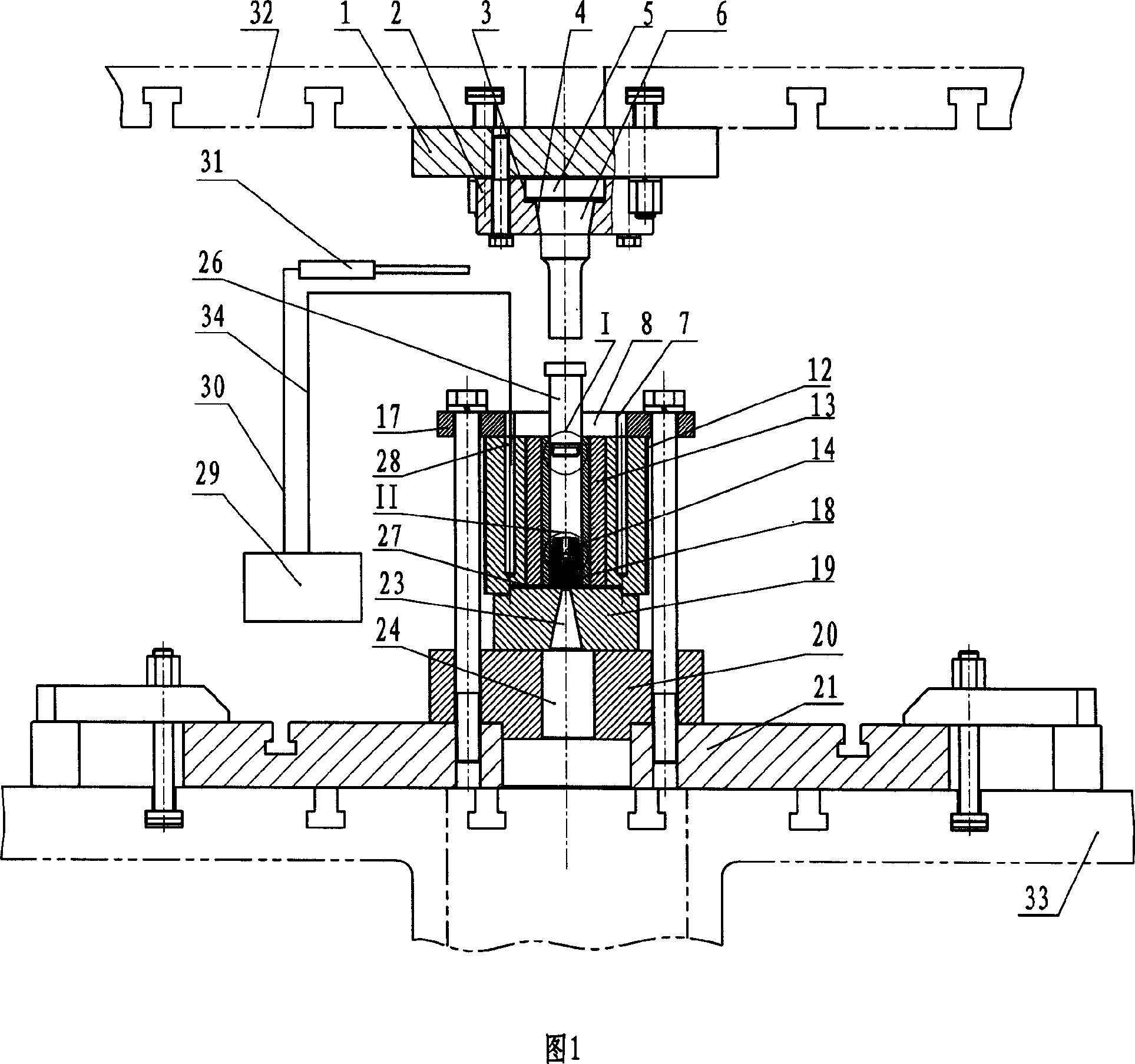

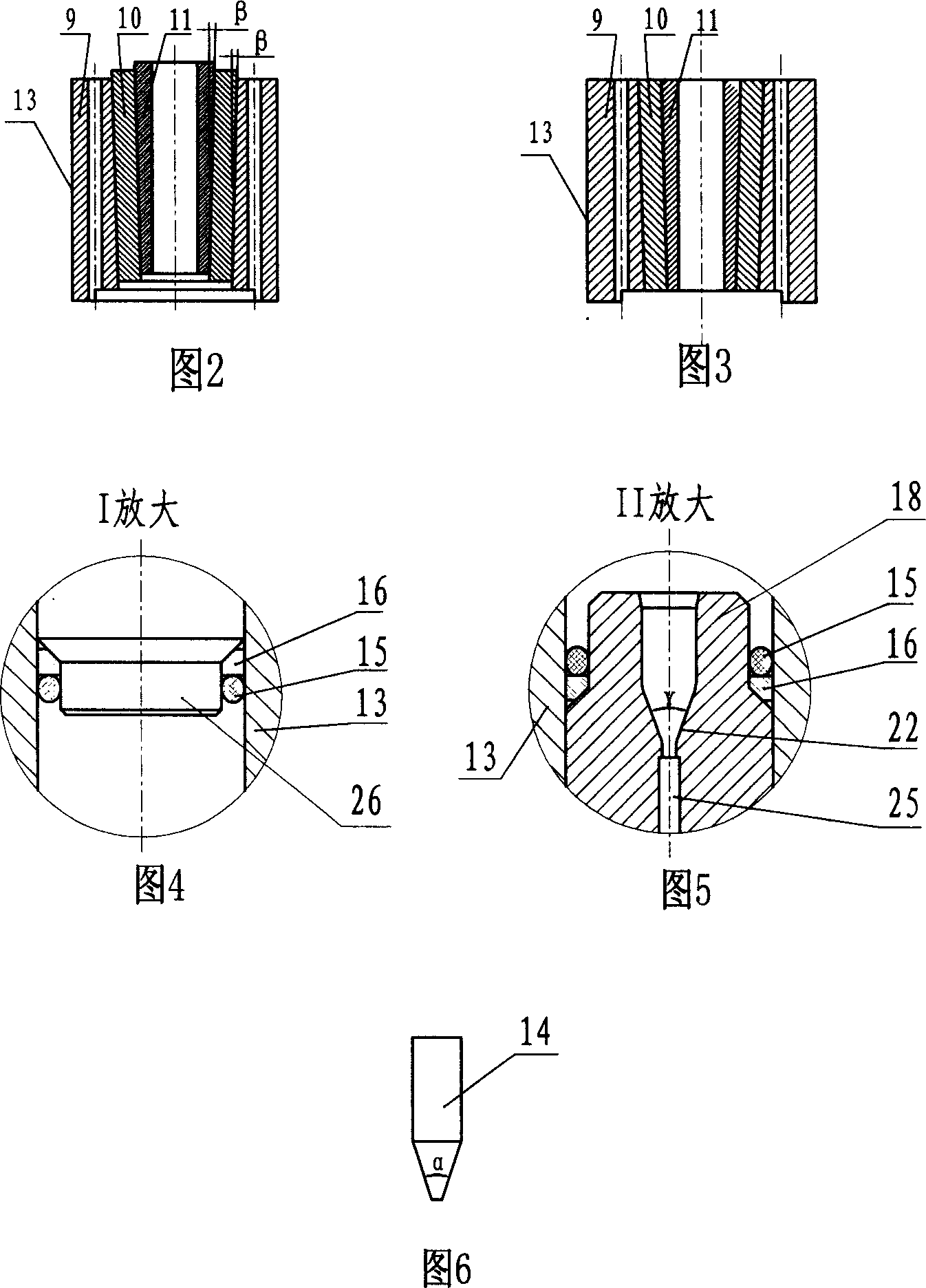

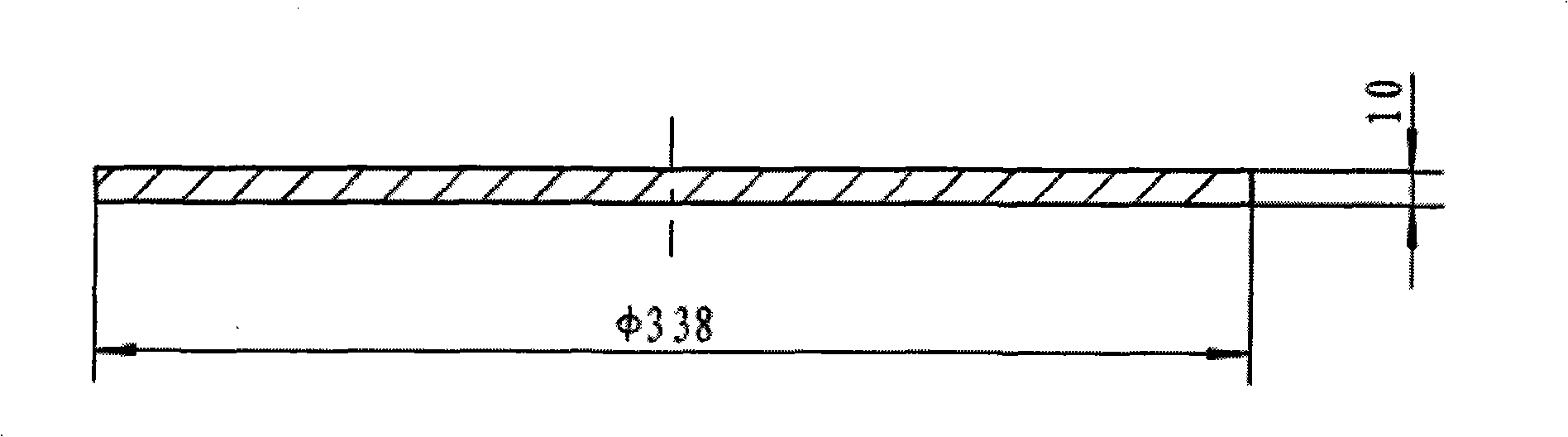

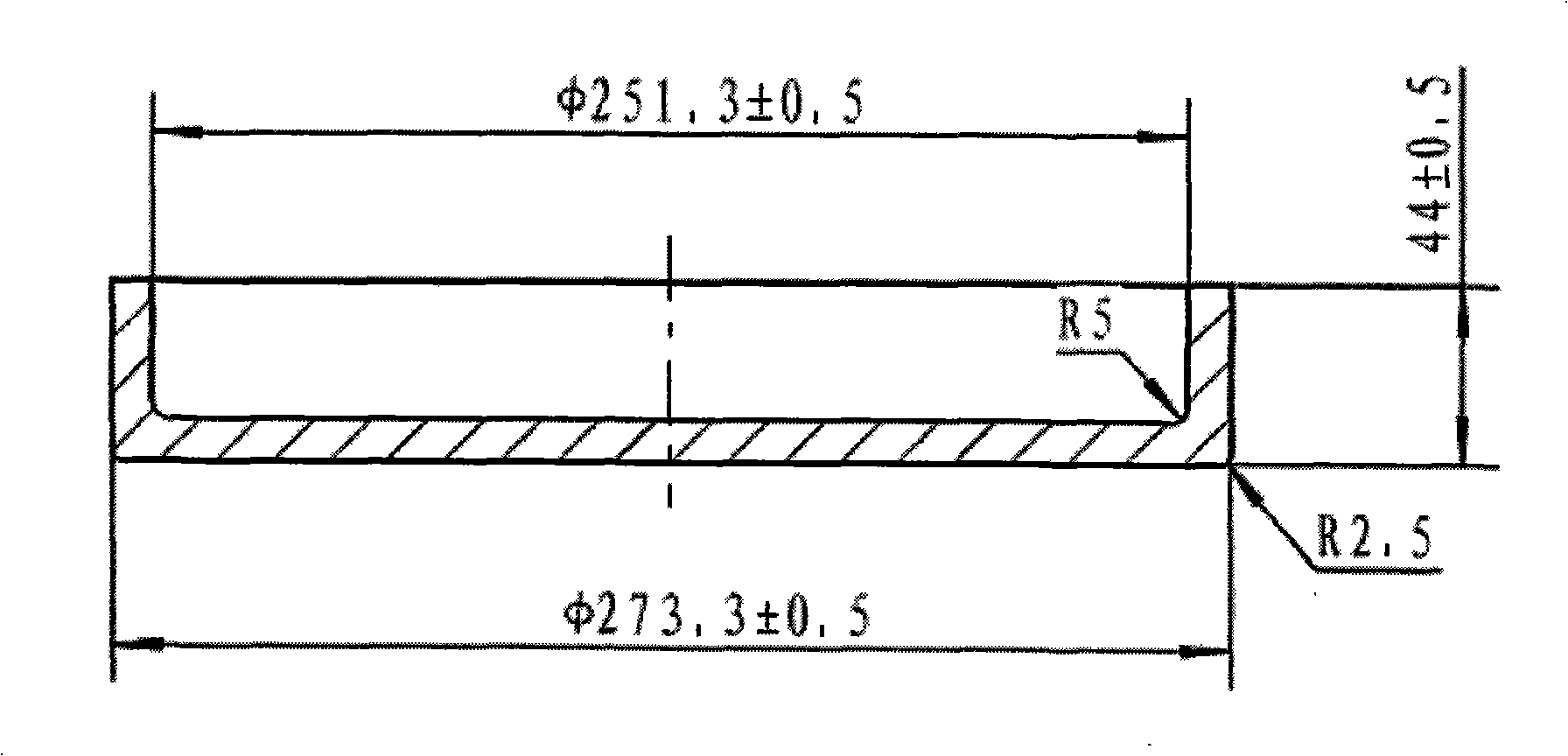

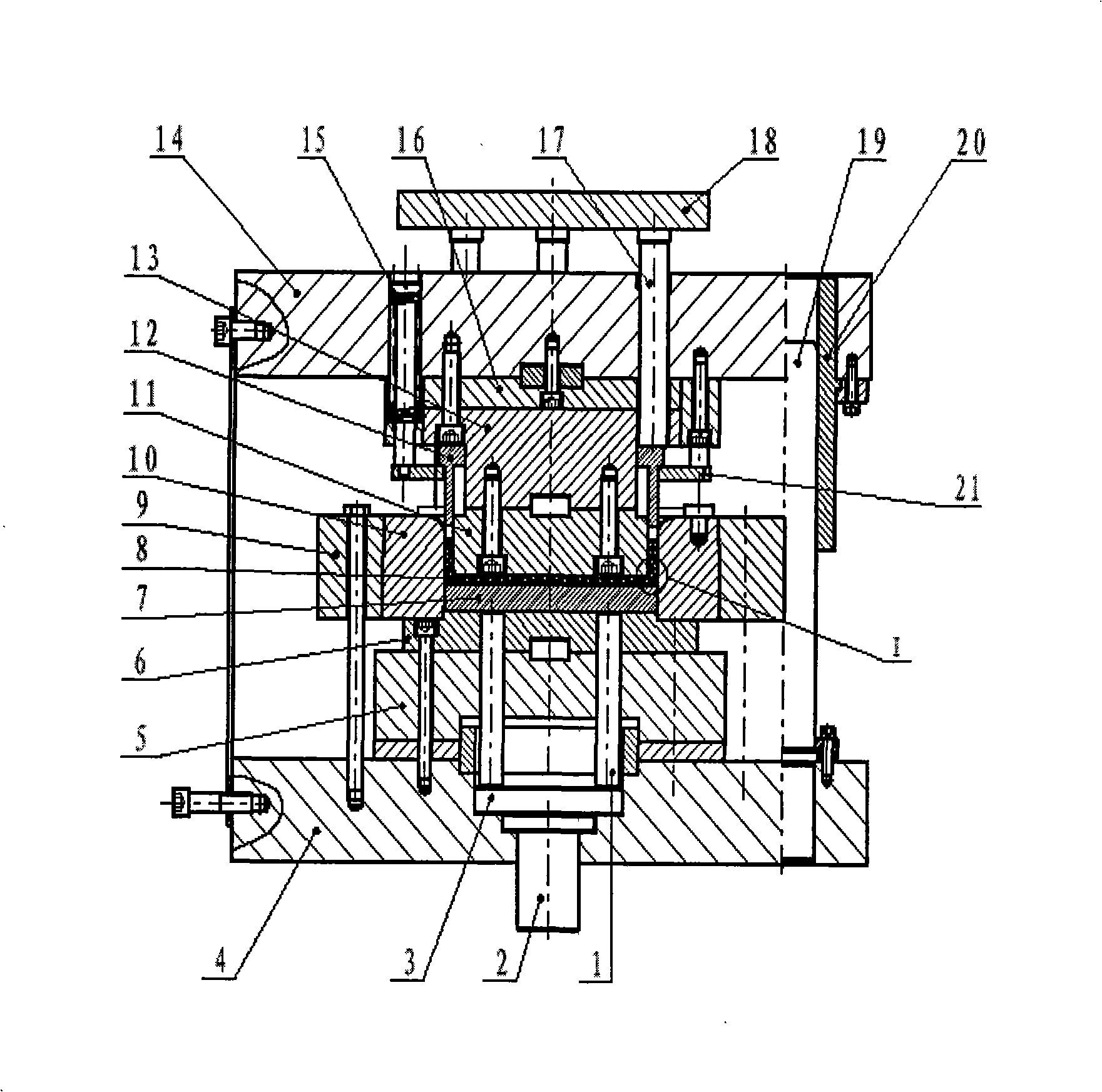

Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

InactiveCN101015841ASpeed up heat dissipationSlow down heat dissipationExtrusion diesExtrusion control devicesTemperature controlPhysical property

The invention relates to a hydraulic extruding method for producing magnesium alloy wire or rod, and relative specific extruding mould, which can avoid crack and high cost or the like. The inventive method comprises that processing magnesium alloy blank, coating lubricant, and heating with era oil, heating hydraulic extruding mould and controlling temperature, arranging magnesium alloy blank, filling era oil, arranging movable convex mould, pressurizing and extruding. The inventive mould comprises a movable convex mould (26), under a convex mould (6) and coaxial with the convex mould (6), wherein the lower end of the convex mould (26) is through a convex mould through hole (8) at the middle of a convex mould press plate (17) to be mounted on the upper part of an extruding barrel (13), and the extruding barrel (13) is a multilayer cold press extruding one. The invention can obtain better physical property and surface quality, or the like.

Owner:HARBIN INST OF TECH

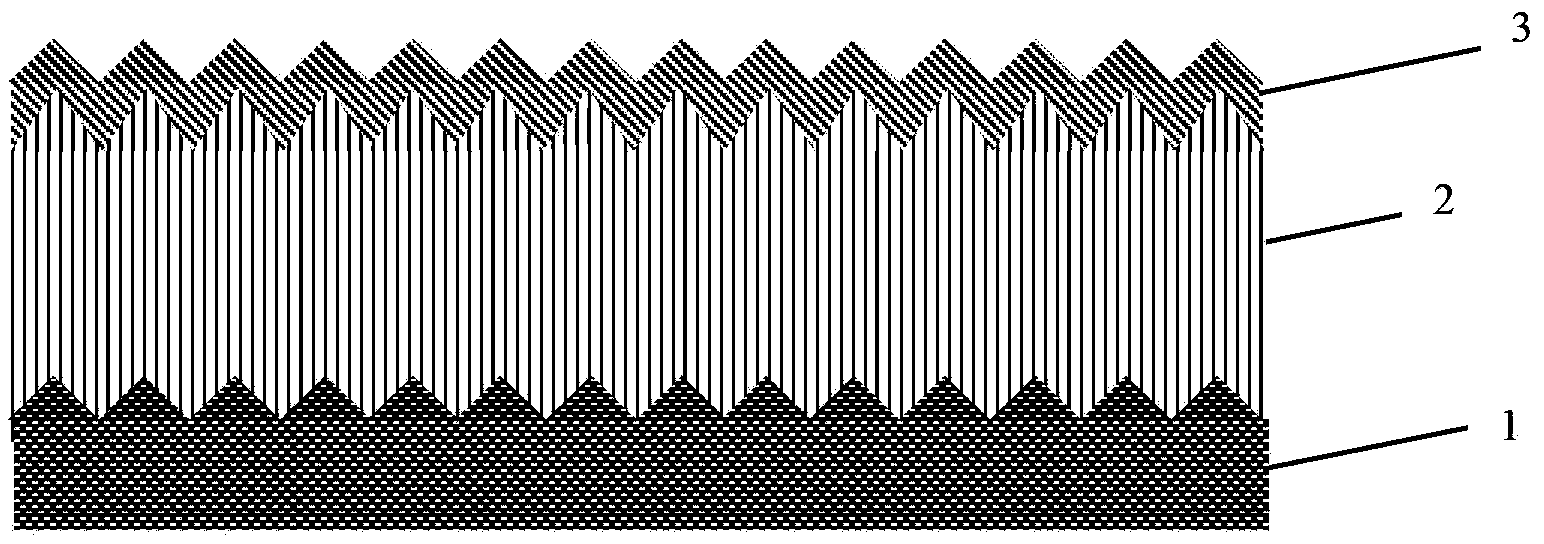

Zr-Co-Re thin film getter provided with protection layer, and preparation method thereof

InactiveCN103849835AIncrease speedIncrease inspiratory capacityVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

The invention relates to a Zr-Co-Re thin film getter provided with a protection layer, and a preparation method thereof. The Zr-Co-Re thin film getter is composed of a getter layer and the protection layer; main components of the getter layer are Zr, Co, and one or more selected form rare earth elements La, Ce, Pr, and Nd; and main component of the protection layer is Ni. Pulsed laser deposition film plating is adopted, and deposition of the double-layer structured thin film getter containing the protection layer and the getter layer on texture monocrystalline silicon is carried out. The texture substrate is capable of increasing effective area of the getter thin film, and so that inspiratory flow rate and inspiratory capacity are increased. The surface of the getter layer is plated with a Ni protection layer; Ni is capable of realizing dissociation of hydrogen, and increasing absorption amount of hydrogen; and the Ni protection layer is capable of inhibiting absorption of oxygen and reducing activation temperature. Activation of the Zr-Co-Re thin film getter can be realized in roasting processes at a temperature of 180 to 350 DEG C; after roasting, the Zr-Co-Re thin film getter possesses excellent inspiration performance at room temperature, can be used for internal gas residue removing of high vacuum microelectronic devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

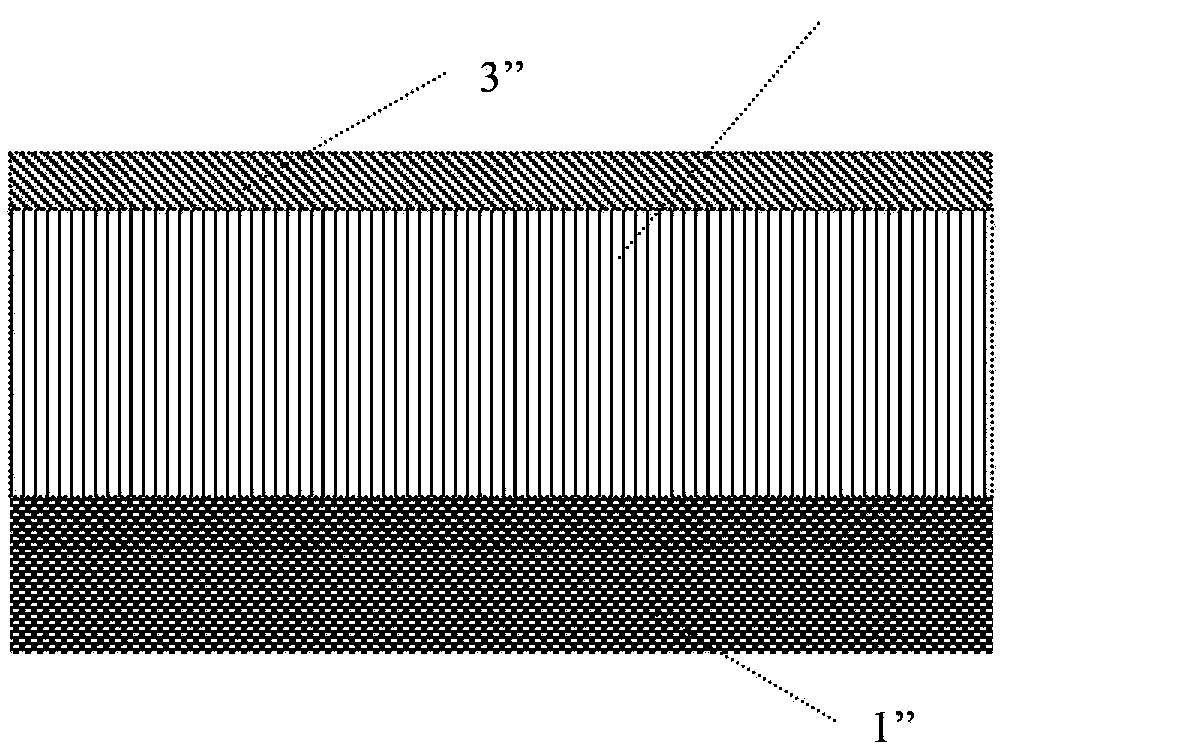

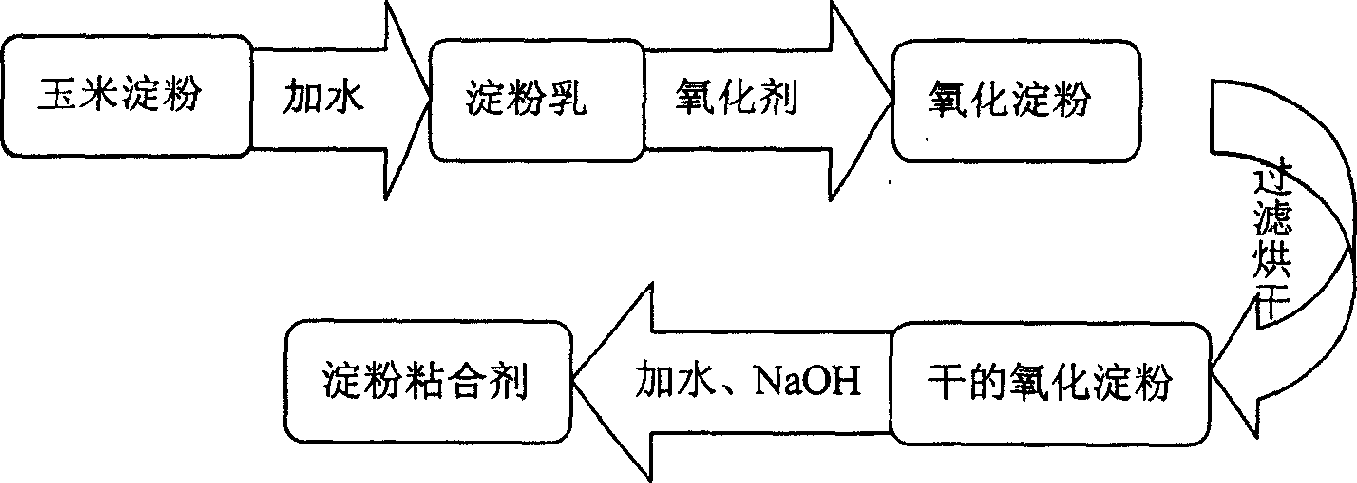

Method for preparing rapid-dry corn starch adhesive

InactiveCN1528849AHigh bonding strengthFast bond strengthStarch adhesivesSodium BentonitePolymer science

The invention discloses a manufacturing method for dry core starch adhesives, the method uses new catalyst Fe2+, reduces the use quantity of oxidant to 5%A, reduces the reaction time to 30 minutes, and produces a kind of cheap and high adhesives starch adhesives. The method adds in modified bentonite or natrium group bentonite whose weight is 30% of dried starch as the fillers before adding in NaOH, it enhances the drying speed greatly. The adhesives can be dried quickly, it doesn't counter tide, high rigidity. The cost is reduced greatly, the dry speed is enhabced greatly.

Owner:XI AN JIAOTONG UNIV

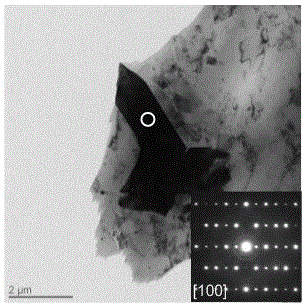

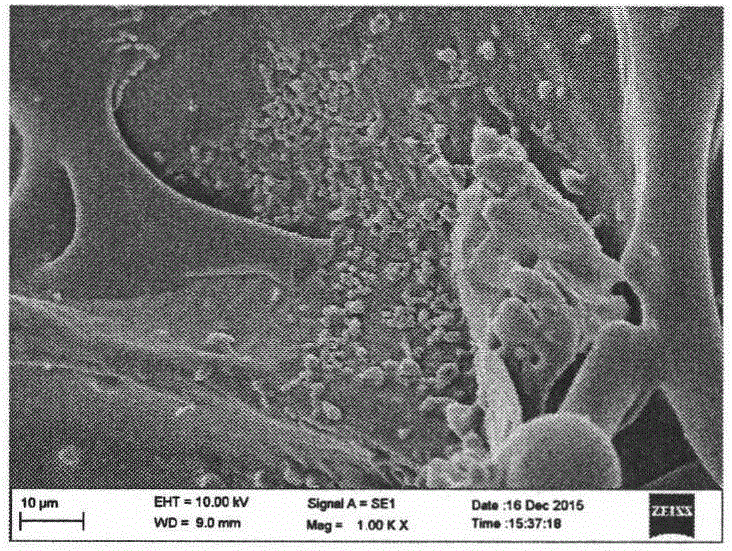

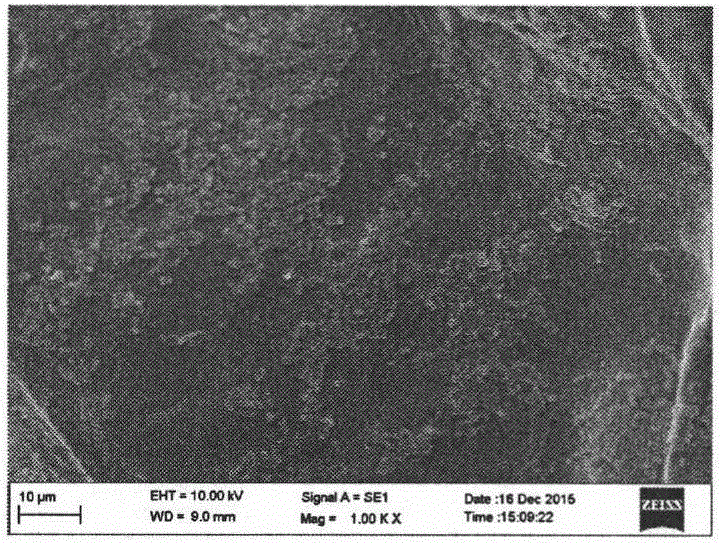

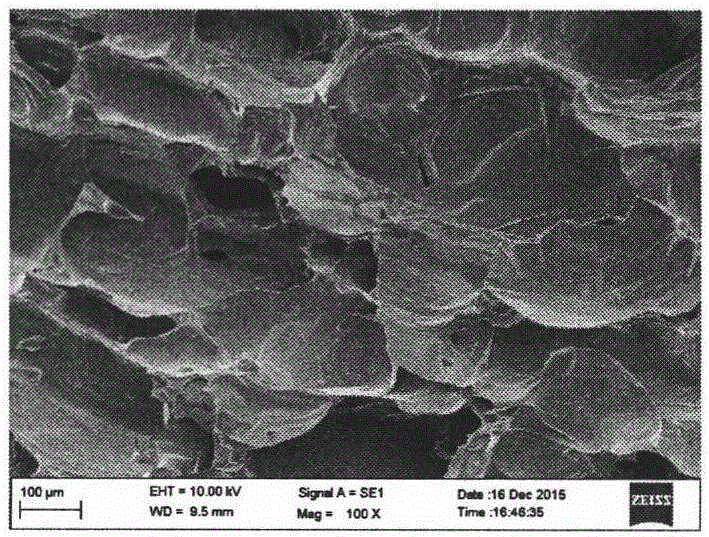

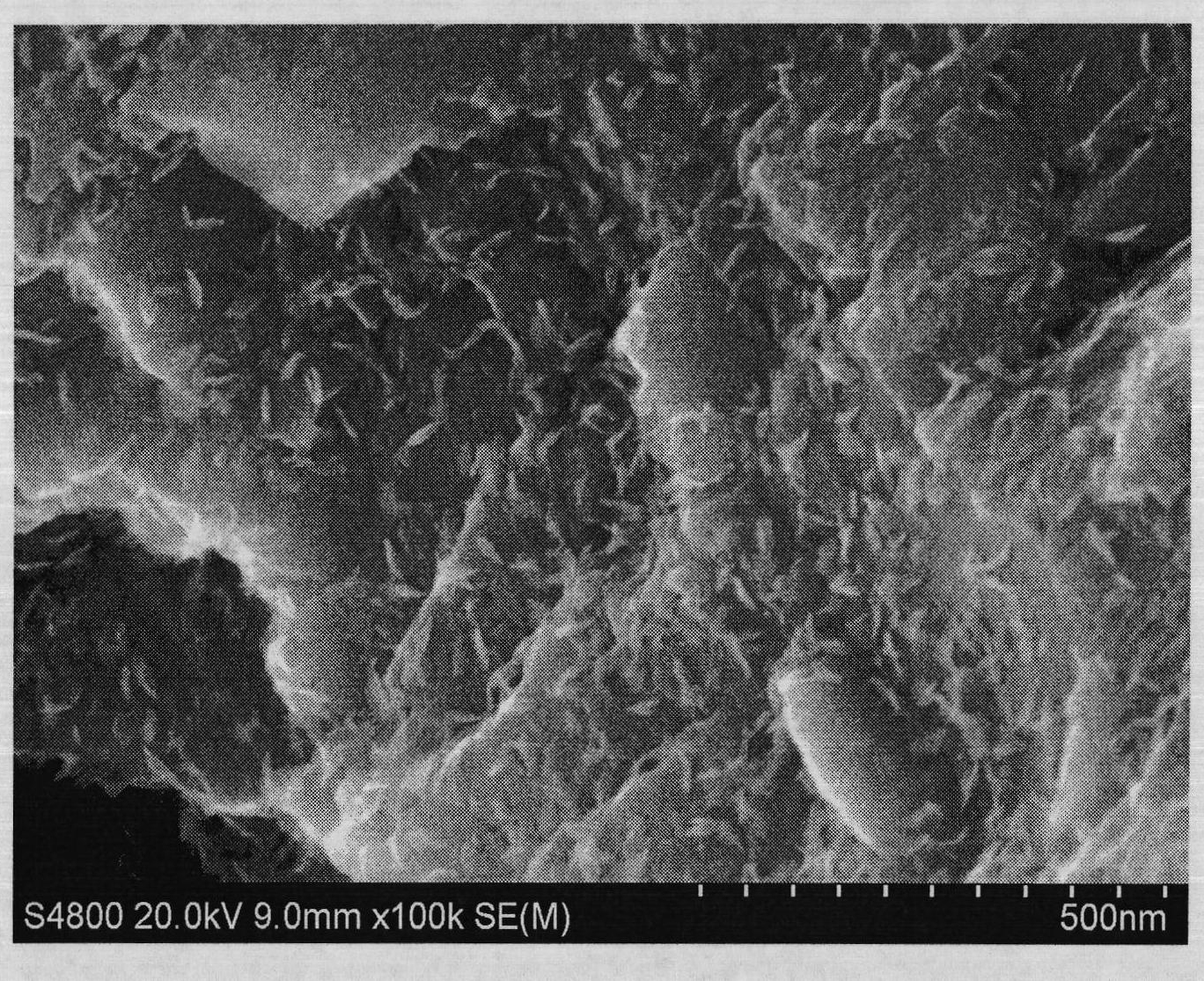

Nano hard alloy material containing spherical face-centered cubic structure cobalt powder and preparation process thereof

The invention provides a nano hard alloy material containing spherical face-centered cubic structure cobalt powder and a preparation process thereof and belongs to the technical field of hard alloy preparation. The method comprises the steps of using 12-14 wt.% of the spherical face-centered cubic structure cobalt powder with the average grain diameter in a range of 200-300nm, 65-70 wt.% of tungsten carbide with the average grain diameter in a range of 200-300nm, 16-23 wt.% of tungsten carbide-titanium carbide-vanadium carbide-tantalum carbide-chromium carbide solid solution powder with the average grain diameter in a range of 300-400nm and a proper amount of an active and surface dispersing agent, and combining with airtight inert gases to protect high-speed ball milling, spray drying and overpressure sintering, so that sintering bodies are compact to the maximum extent, grain growth is restrained, the high-temperature performance of an alloy is optimized, and finally the high-hardness high-strength hard alloy material is obtained. The process is optimal in technology, easy to operate and applicable to industrial production.

Owner:重庆金锐新材料技术研究院有限公司

Lycium ruthenicum beverage and preparation method thereof

InactiveCN103960727AEasy to keepReduce the effects of oxidationFood ingredient functionsFood preparationFlavorLiver and kidney

The invention discloses a lycium ruthenicum beverage and a preparation method thereof and provides a beverage prepared by taking dried lycium ruthenicum fruit powder as a main raw material and a preparation method thereof. The lycium ruthenicum beverage is composed of following raw materials by weight percent: 0.1%-7% of the dried lycium ruthenicum fruit powder, 0.05%-3% of guar gum, 0.2%-7% of CMC-Na (Carboxyl Methyl Cellulose-Na), 0.05%-3% of xanthan gum, 3%-15% of erythritol, 0.006%-0.6% of stevioside, 0.01%-0.8% of citric acid, 0.01%-0.4% of sodium citrate, 0.01%-1.5% of tea polyphenol and the balance being water. The beverage is prepared by taking the dried lycium ruthenicum fruit powder as the main raw material; reasonable compatibility and synergistic effects of all the components are utilized and the color of a product is amaranth; the lycium ruthenicum beverage has a unique flavor, no astringent and mellow mouth feel, and has the effects of nourishing liver and kidney, replenishing vital essence to improve eyesight and nourishing blood, enhancing the immunity of people, beautifying, resisting oxidization, decaying aging, resisting fatigues, lowering blood pressure and lowering blood sugar.

Owner:TIANJIN UNIV OF COMMERCE

Colored liquid metal and manufacturing method thereof

ActiveCN105220013AGood coloring effectImprove conductivityAdditive manufacturing apparatusLiquid metalElectron

The invention provides colored liquid metal and a manufacturing method thereof. A colored liquid metal raw material comprises a liquid metal body, pigment and / or nanometer conductive particles. The colored liquid metal can be presented in various specific colors while achieving electrical conduction. Firstly, the colored liquid metal has good electrical conductivity of liquid metal and rich colors of the pigment, an approach to color printed electronics can be opened up, and the aesthetic property and experience of the printed electronics can be remarkably promoted; meanwhile, the oxidation resistance and rust-proof property of traditional liquid metal are improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

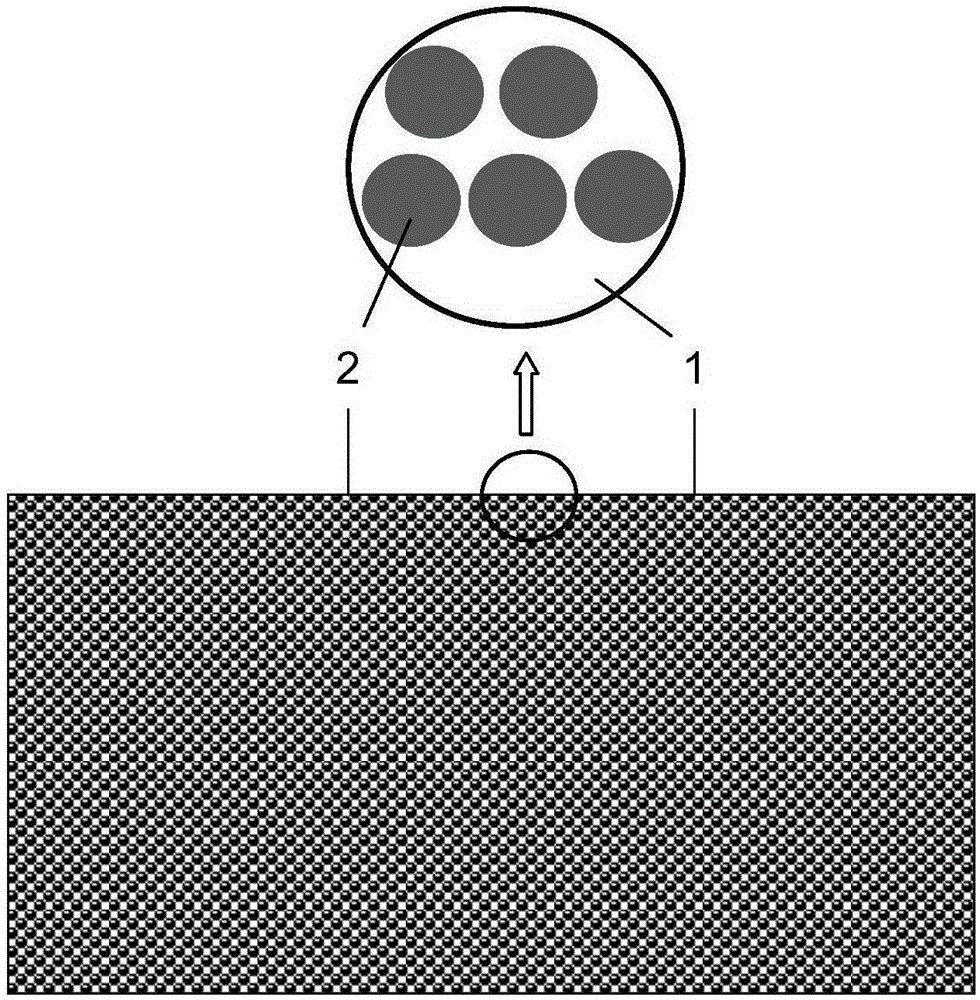

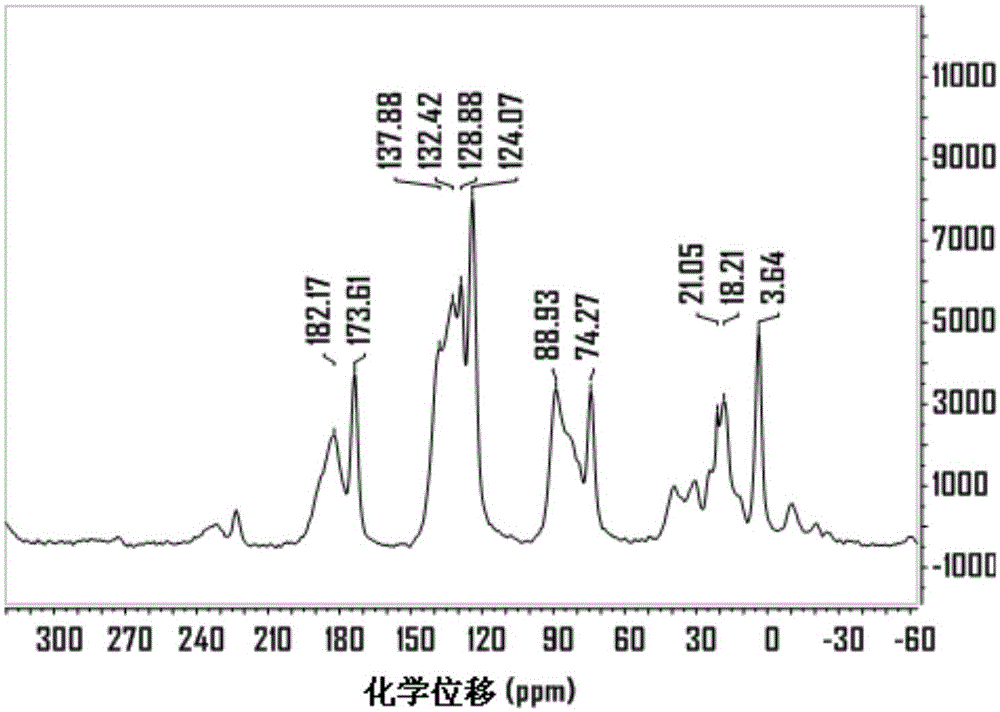

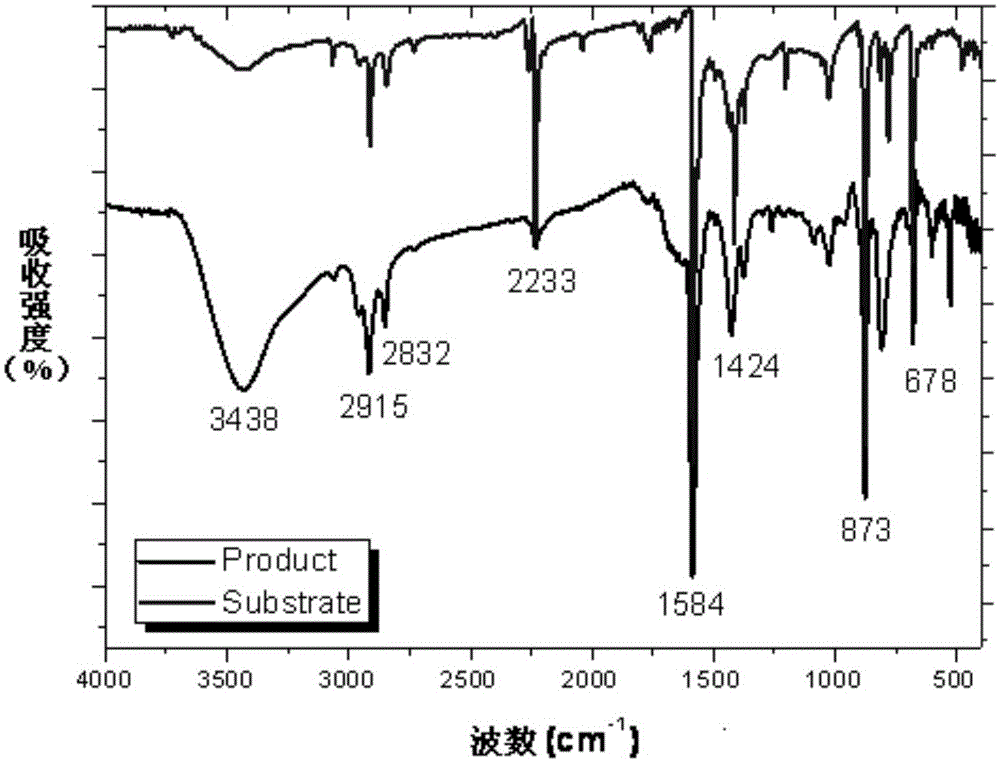

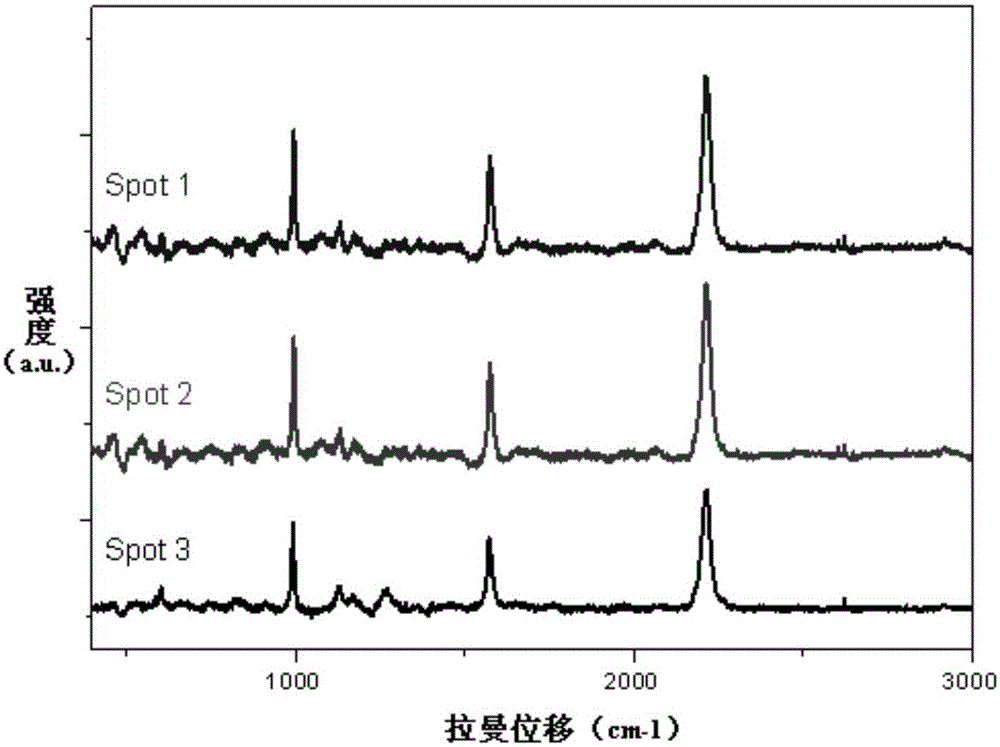

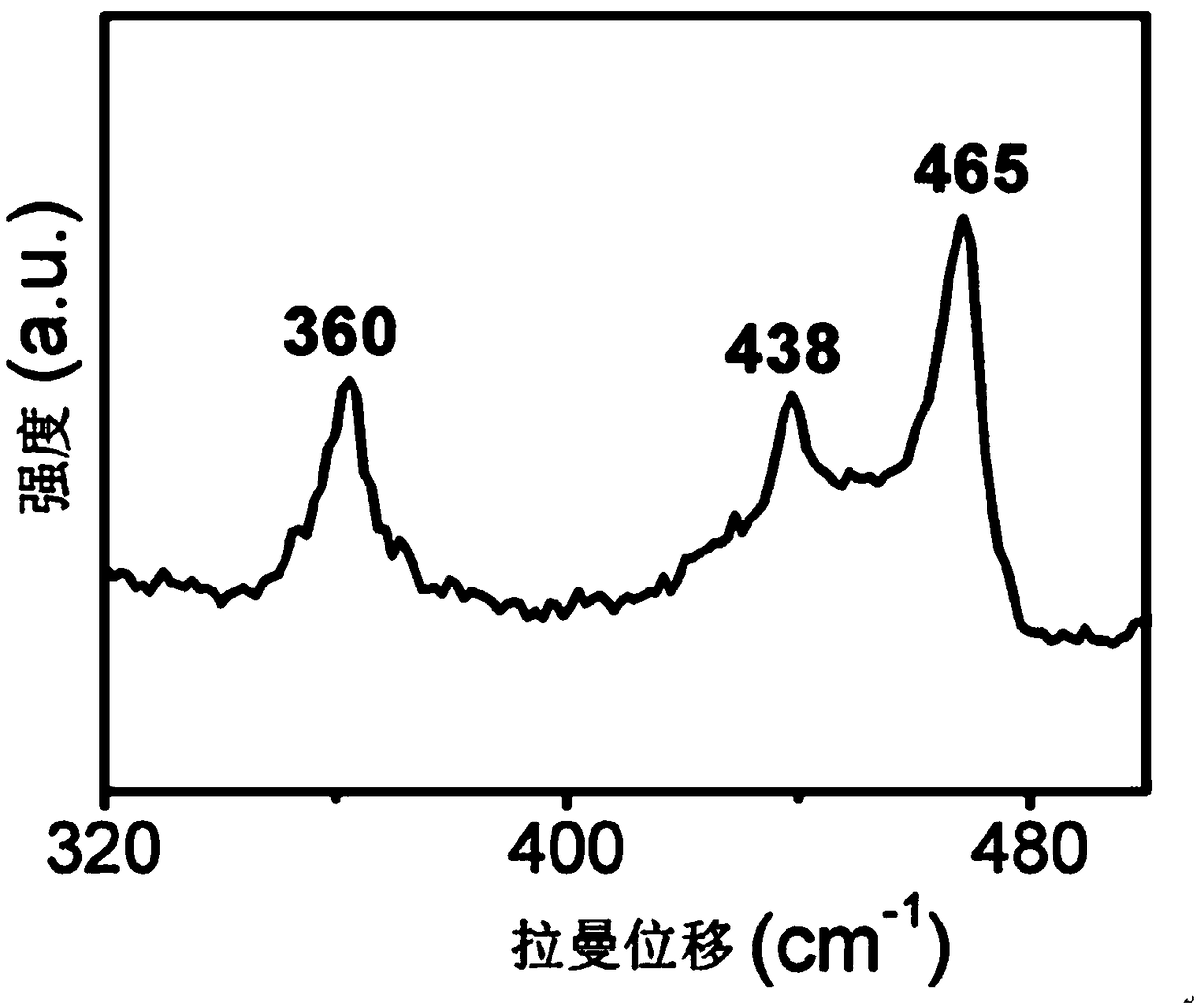

Preparation method of graphdiyne

ActiveCN105016962APromote formationEasy to assembleHydrocarbonsHydrocarbon preparationVacuum pumpingNitrogen

The invention relates to a preparation method of graphdiyne. The preparation method comprises that 1, in a nitrogen or argon protective atmosphere, a reaction substrate 1,3,5-tripropargylbenzene and a catalyst are put into a reaction container, a solvent is added into the reaction container to dissolve the materials in the reaction container, and the solution undergoes a heating reaction, 2, in the reaction process in the step 1, the solution is subjected to vacuum pumping process multiple times so that a reaction side product 2-butyne is removed and a solvent is supplied to make up for a loss of the solvent, and 3, after the reaction, the reaction product is purified so that the product graphdiyne is obtained. Compared with the prior art, the preparation method has simple processes. The prepared graphdiyne has the uniform surface and a low oxidation degree and can stably exist in air.

Owner:SHANGHAI NORMAL UNIVERSITY

Probiotics enriched crisp apple products and preparation method thereof

The present invention discloses probiotics enriched crisp apple products and a preparation method thereof, and belongs to the technical field of agricultural product processing. Apples are used as raw materials, the apples are washed, the washed apples are blanched, a vacuum soaking method is used to enrich probiotics into apple tissues, and then a vacuum freeze-drying and vacuum microwave combined drying method is used to prepare the probiotics enriched crisp apple products. The method comprises the following steps: (1) raw material washing and blanching; (2) probiotic soaking liquid preparing; (3) vacuum soaking; and (4) vacuum freeze-drying and vacuum microwave combined drying. The prepared probiotics enriched fruit and vegetable crisp products are mellow in fruit fragrance, and crisp and tasty. The viable probiotic number can be maintained at 10<7> CFU / g at 25 DEG C for 90 days or more. The preparation method avoids the two major defects of high cholesterol risk of the probiotic fermented milk products and the non-consumption of lactose intolerant population, and the products combine health care and leisure, and have broad market prospects.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

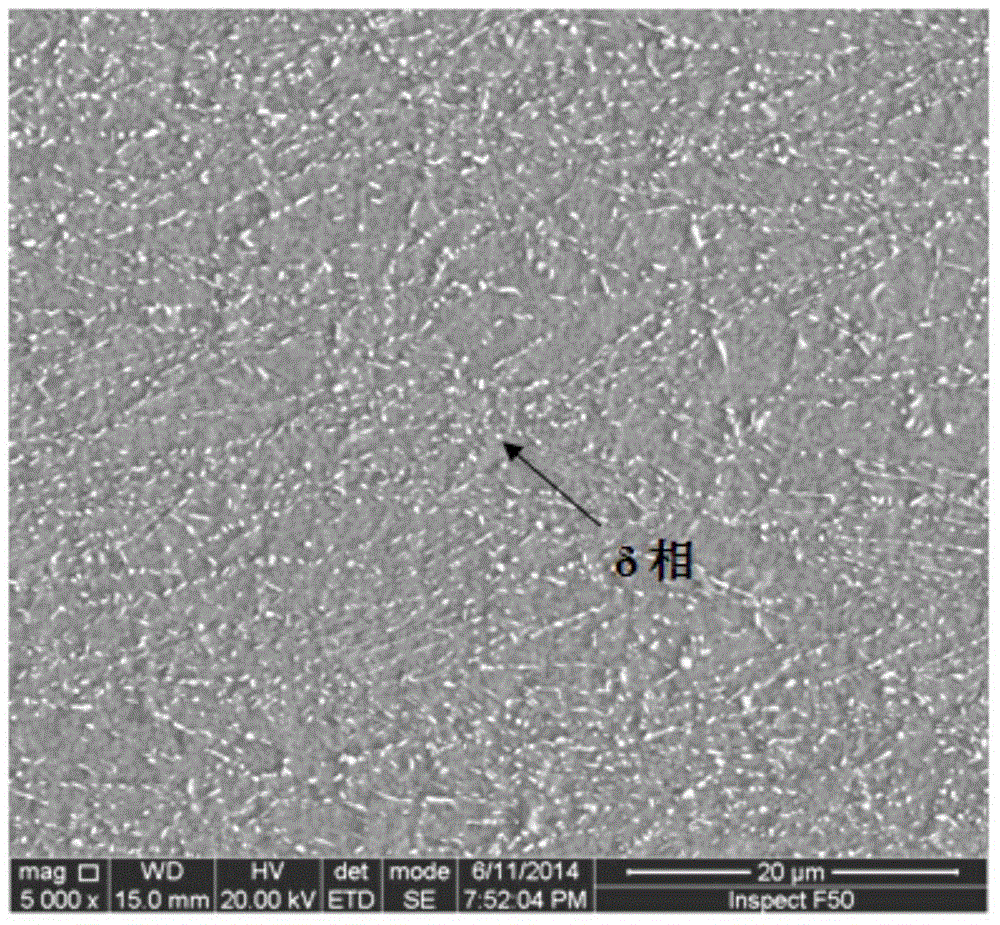

Granular delta-phase uniformly distributed GH4169 alloy preparation method

The invention relates to a granular delta-phase uniformly distributed GH4169 alloy preparation method and belongs to the technical field of preparation of high-temperature alloy materials. On the basis of combination of cold deformation and heat treatment processes, the method includes GH4169 alloy cold deformation and heat treatment. Firstly, plate blanks are subjected to cold rolling deformation more than 30% after solid solution and quickly cooled under vacuum argon shielding after heat preservation at 985+ / 5 DEG C for 1h; secondly, the plate blanks are subjected to standard double aging treatment; finally, granular delta phases uniformly distributed in grains and at grain boundaries of GH4169 alloy are acquired. Therefore, GH4169 alloy strength is improved, and crack growth rate of the GH4169 alloy is decreased to acquire better fatigue performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing black phosphorus nanosheets

InactiveCN109019540AControl the degree of expansionControlled diffusionMaterial nanotechnologyPhosphorus preparationOrganic solventPower flow

The invention discloses a method for preparing black phosphorus nanosheets. The method comprises the following steps: (1) assembling black phosphorus used as an electrode and an organic solvent containing an intercalating agent, used as an electrolyte, in order to form an H-shaped electrolytic cell; (2) applying a current or voltage between the electrodes to intercalate and expand the black phosphorus; (3) filtering and washing the treated black phosphorus obtained in step (2), and carrying out ultrasonic vibration treatment on the treated black phosphorus in an organic solvent; and (4) centrifuging the obtained solution, and collecting the obtained supernatant to obtain a uniform-size black phosphorus nanosheet dispersion. The black phosphorus nanosheets stripped by the method have a thickness of 2-100 nm and a lateral dimension of 10 nm to 50 [mu]m. The method solves the problem of difficult control of the thickness and the lateral dimension of the black phosphorus nanosheets duringthe preparation of the black phosphorus nanosheets in the prior art, also solves the problem of too long time in traditional black phosphorus nanosheet preparation methods, and has the advantages of simple preparation process, low energy consumption, low cost, and realization of large-scale production.

Owner:深圳市中科墨磷科技有限公司

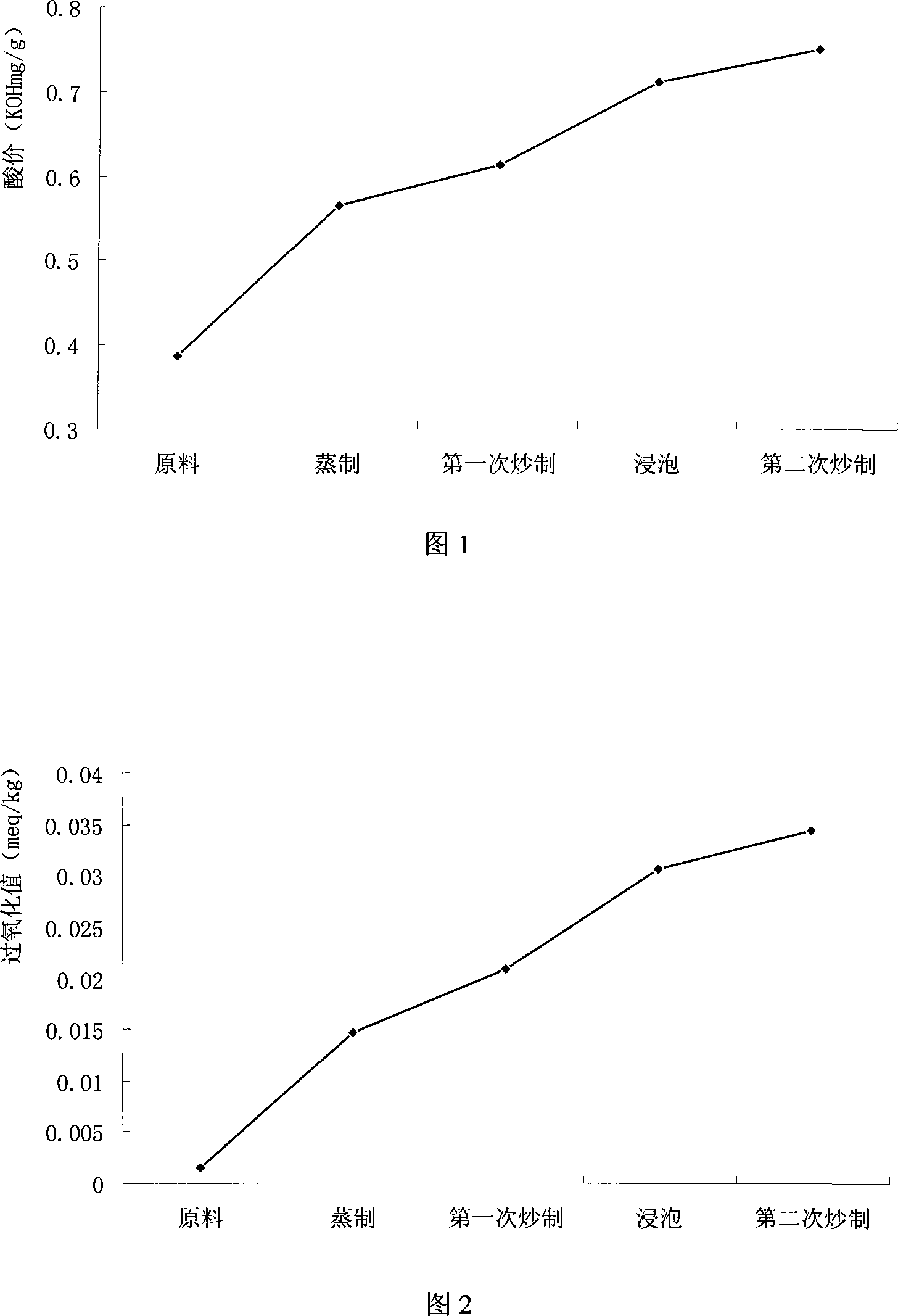

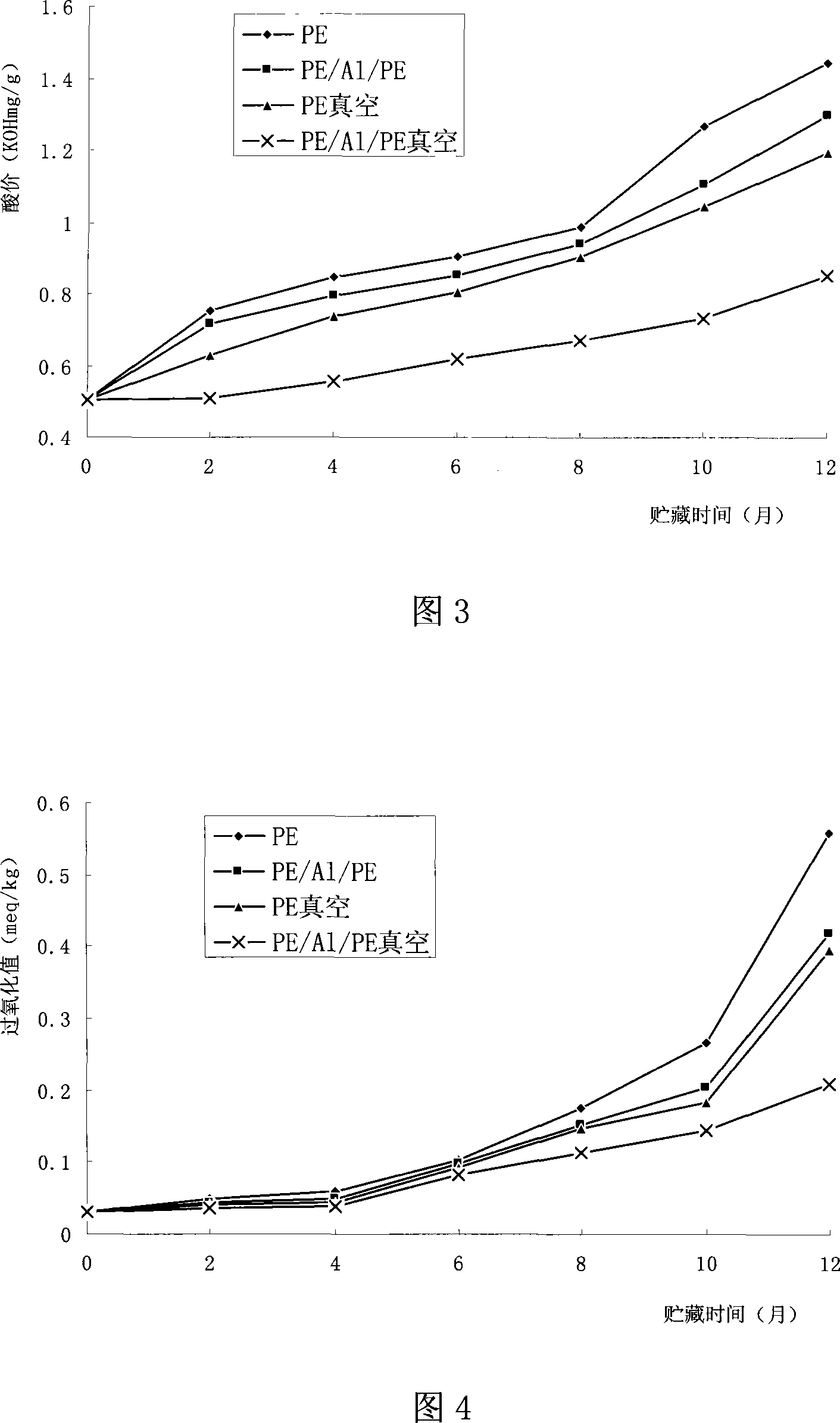

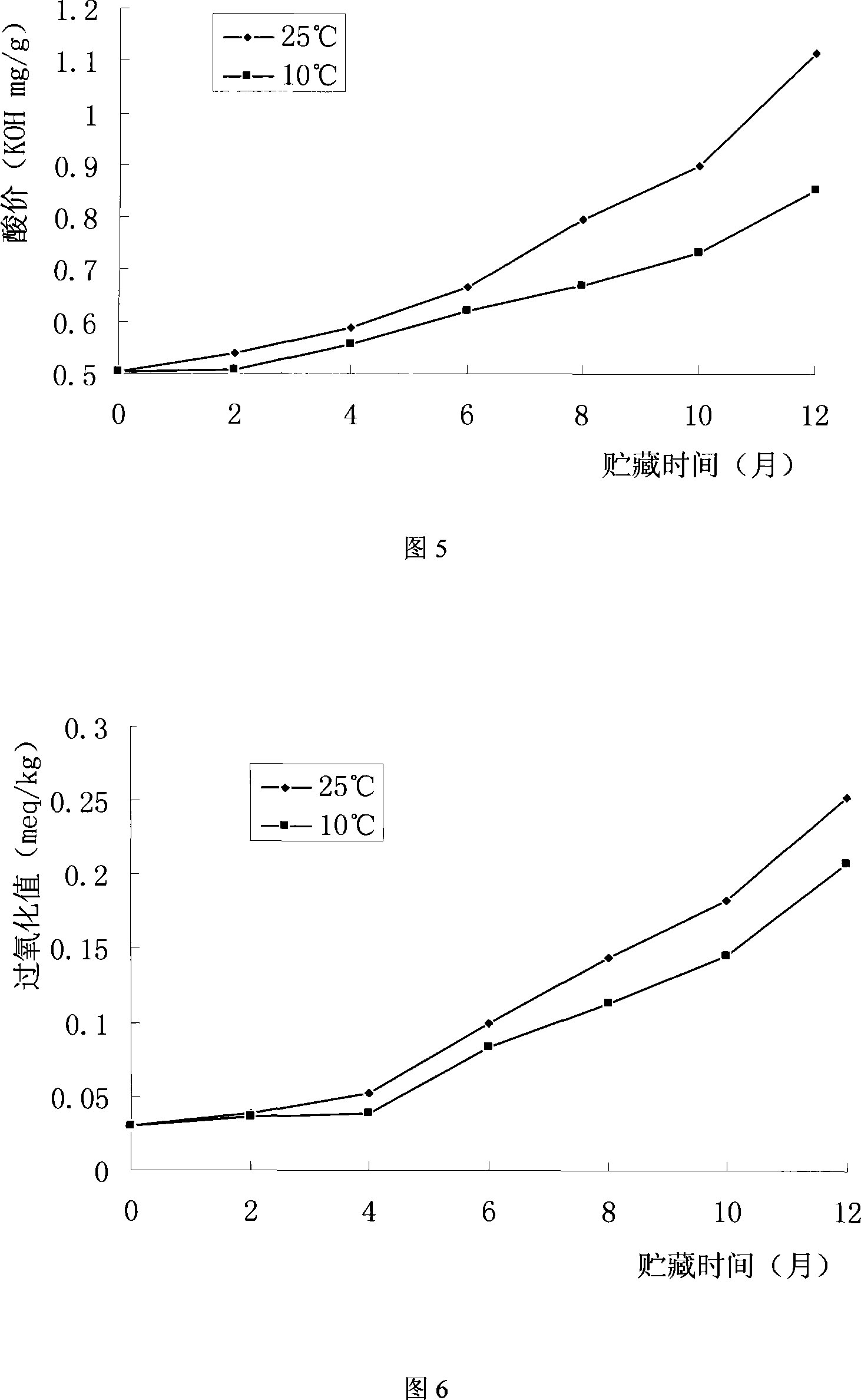

Method for processing, packing and storing hickory

ActiveCN101243892AReduce high temperature timeReduce the degree of oxidationFruit and vegetables preservationFood preparationFlavorHydrolysis

The invention discloses processing, packaging and storage methods of pecans, and belongs to the technical field of processing and storage of nut foods. The method includes: (1) preparation of raw materials; (2) preparation of seasoning liquid; (3) steaming, frying and seasoning of raw materials; (4) composite film, iron-based deoxidizer, vacuum packaging; (5) bagging The product is directly marketed or stored in a warehouse at 7-13°C until the end of the storage period. This method greatly improves the steaming and soaking process of the traditional method, is low in cost, simple and easy to implement, and has a significant effect on inhibiting the hydrolytic rancidity and oxidative rancidity of hickory oil, so that the shelf life of its products is changed from 4 to 4 times that of the traditional method. -6 months extended to 10-12 months, all physical and chemical indicators have reached industry standards. This method is suitable for popularization and application by hickory processing factories and large sellers.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

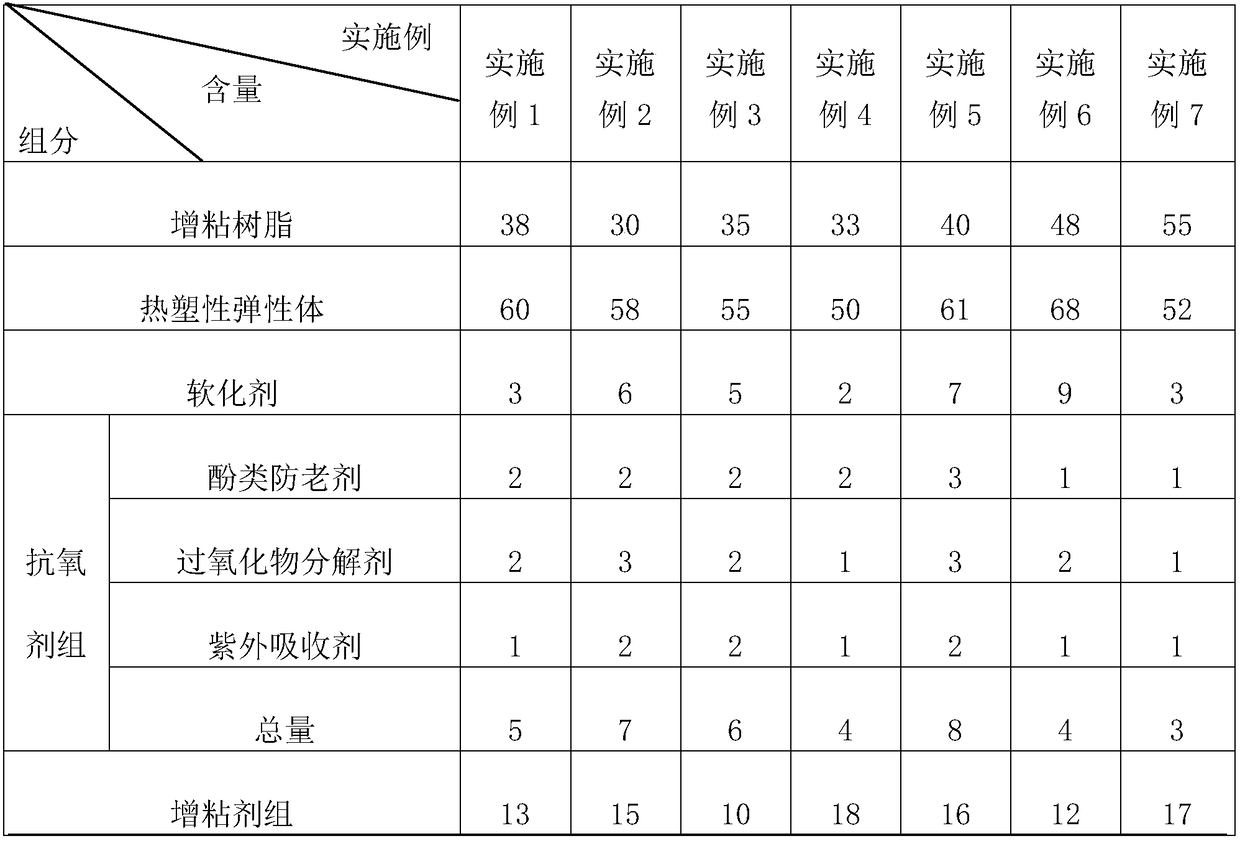

Anti-oxidation medical hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN108587532AImprove adhesionNo stimulationNon-macromolecular adhesive additivesMacromolecular adhesive additivesMicrocrystalline waxIrritation

The invention discloses an anti-oxidation medical hot-melt pressure-sensitive adhesive and a preparation method thereof. The anti-oxidation medical hot-melt pressure-sensitive adhesive comprises the following components: tackifying resin, a thermoplastic elastomer, a softening agent, an antioxidant group and a tackifier group, wherein the tackifying resin is hydrogenated petroleum resin, the thermoplastic elastomer is SBS / SIS, the antioxidant group comprises a phenolic anti-aging agent, a peroxide decomposing agent and an ultraviolet absorbent, and the tackifier group comprises at least one selected from rosin modified resin, terpene resin, a maleic anhydride grafted compatilizer, microcrystalline wax, dicyclohexyl phthalate and polyisobutene. According to the invention, harm is not causedto skins during peeling while the adhesive force of the product is further improved, and all the components are nontoxic and harmless, have no irritation to the skins, and have low allergenicity. Inaddition, the oxidation resistance of the product is greatly improved, the application range of the product is expanded, and the bonding reliability is further ensured.

Owner:浙江精华科技有限公司

Aluminium brazing sheet material

ActiveUS8455110B2Lower capability requirementsGood brazingWelding/cutting media/materialsThin material handlingAlloyAluminium

A brazing sheet material for CAB brazing without applying flux. The brazing sheet material including an aluminum core alloy layer provided with a first brazing clad layer material on one or both sides of the aluminum core layer and at least one second brazing clad layer material positioned between the aluminum core alloy layer and the first braze clad layer material. The second brazing clad layer material is an Al—Si alloy brazing material having 5% to 20% Si and 0.01% to 3% Mg, and the first brazing clad layer material is an Al—Si alloy brazing material having 2% to 14% Si and less than 0.4% Mg. Also disclosed is a brazed assembly manufactured in a brazing operation.

Owner:NOVELIS KOBLENZ GMBH

Method for extracting astaxanthin from haematococcus pluvialis

The invention belongs to the technical field of medicines, and relates to a method for extracting astaxanthin from haematococcus pluvialis. The method comprises the steps of culturing a seed stock solution in a glass apparatus with a drainage system, and carrying out later amplification culture of the haematococcus pluvialis and accumulation culture of the astaxanthin after 10-15 d; centrifuging a culture in an exponential growth period of seed culture; and inoculating cell clusters in a BBM basal medium to obtain a primary culture. The later accumulation culture of the astaxanthin is amplification culture by using a breathable plastic bag type simple device provided by the invention. In the accumulation stage, a stress culturing method is adopted to obtain a lab-scale test haematococcus pluvialis culture; and haematococcus pluvialis powder is obtained by spray drying. According to a preparation technology that extracts astaxanthin from the haematococcus pluvialis by adopting an ultrasonic cell disruption assisted mixed solvent extraction method, the haematococcus pluvialis powder is added in an organic solvent to carry out ultrasonic cell disruption, and then the astaxanthin is obtained by the steps of reflux extraction in a water bath, suction filtration, filtrate merging and concentration. Compared with a conventional direct extraction method, the method provided by the invention saves extraction time, and increases astaxanthin yield.

Owner:SHENYANG PHARMA UNIVERSITY

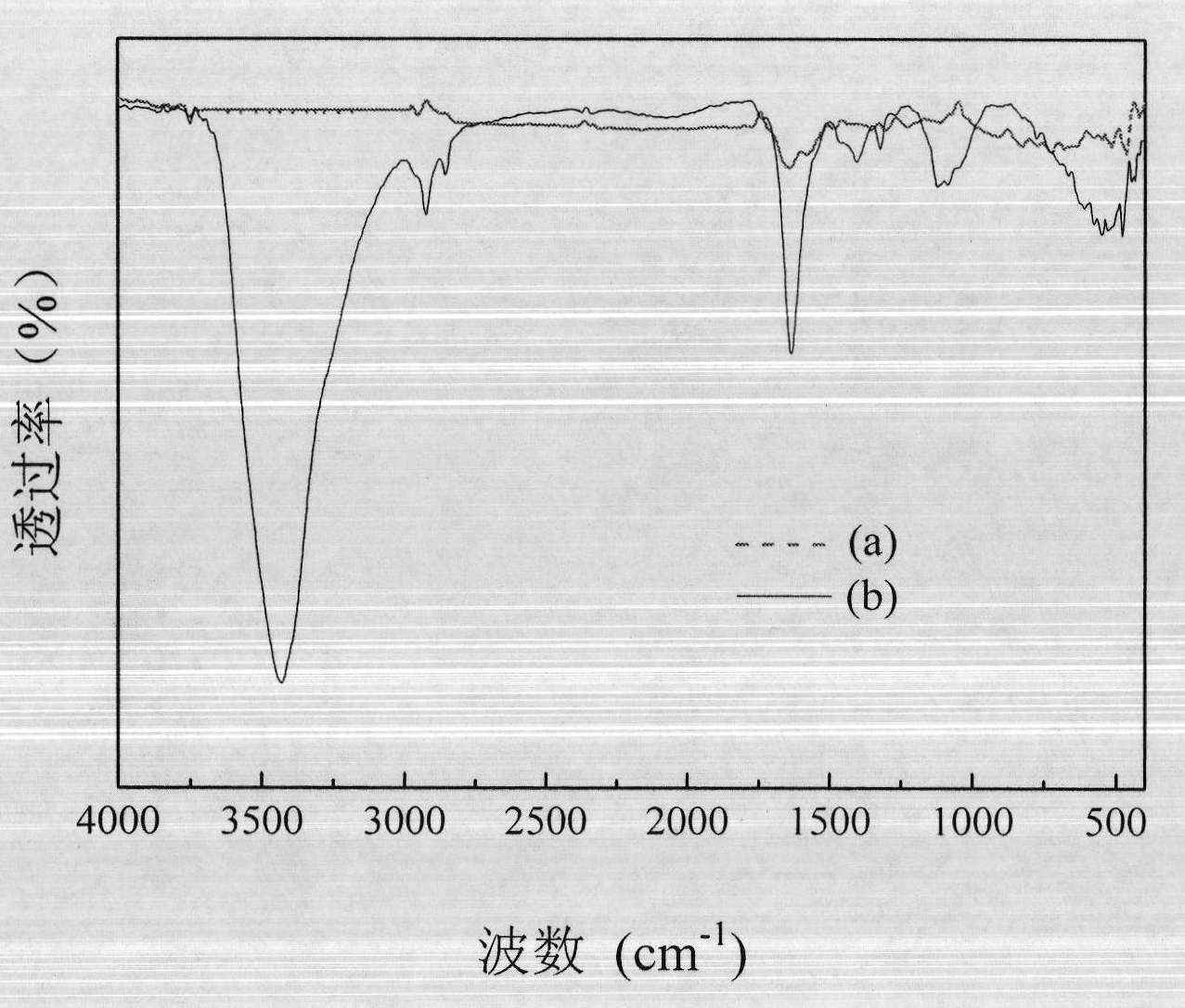

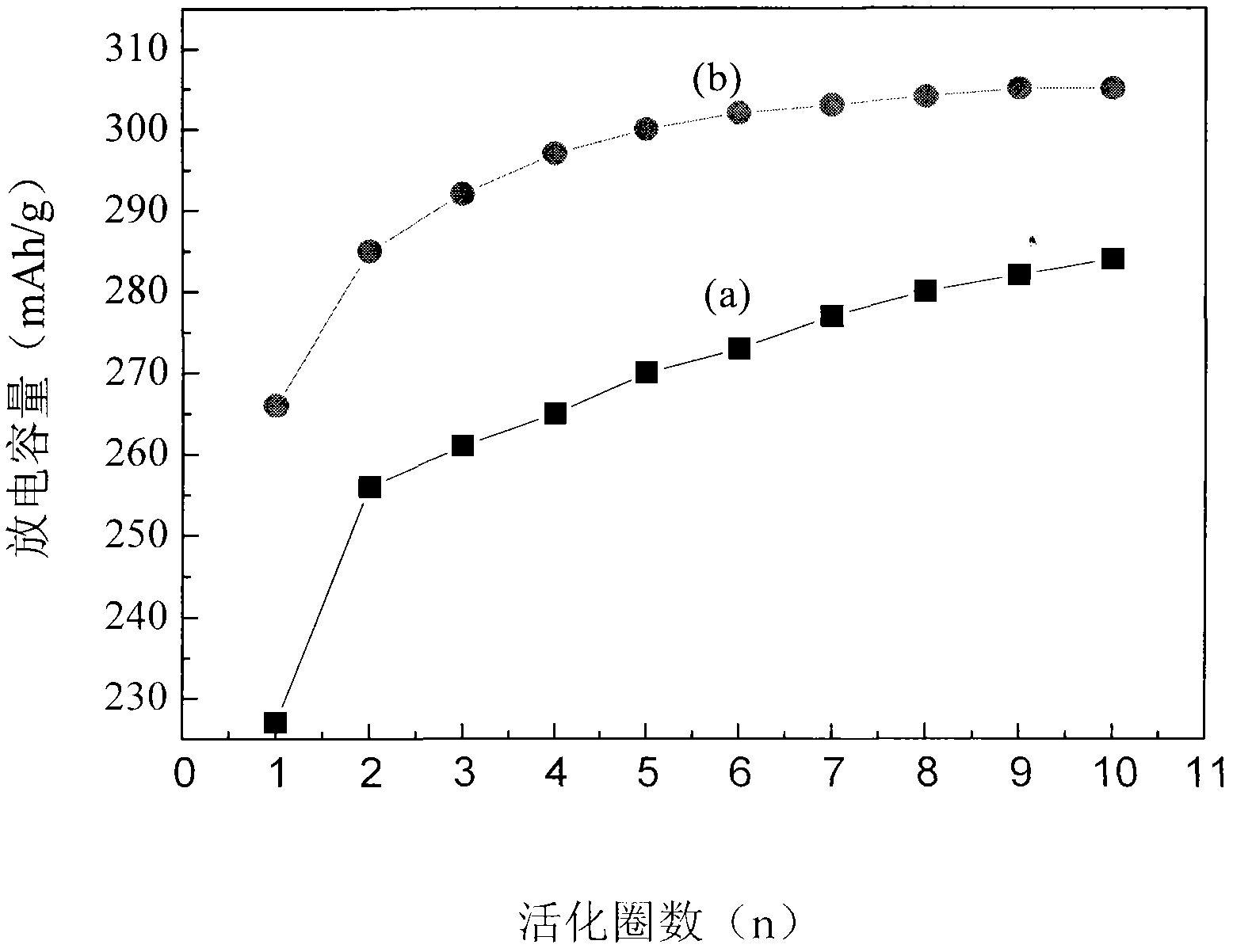

Method for Improving the Electrochemical Performance of Hydrogen Storage Alloy Powder Using Electropolymerized Polyaniline

ActiveCN102274965AEasy to operateReduce manufacturing costCell electrodesElectrophoretic coatingsElectrochemistryCorrosion

The invention relates to a method for improving the electrochemical performance of hydrogen storage alloy powder by utilizing electropolymerization polyaniline, and belongs to the technical field of the surface treatment of hydrogen storage alloy. The method comprises the following steps of: putting hydrogen storage alloy powder of which the granularity is between 100 and 400 meshes into mixed solution containing phenylamine and protonic acid in a certain ratio, and stirring uniformly at a speed of between 50 and 100 revolutions / minute, wherein the mass ratio of the hydrogen storage alloy powder to the mixed solution is 10 / 100-100 / 100; and applying direct-current voltage of between 1 and 2 V for 0.5 to 5 minutes by taking the hydrogen storage alloy powder as an anode and graphite as a cathode, so that the phenylamine performs electro-deposition polymerization reaction on the surface of the hydrogen storage alloy powder to form a polyaniline membrane layer. In the method, a polyanilinewrapped membrane with electrical conductivity and corrosion resistance is formed on surfaces of hydrogen storage alloy powder particles to improve the hydrogen storage capacity, high-multiplying power discharging performance and cyclic stability of the hydrogen storage alloy. The method has the characteristics of simplicity of operation, low production cost, obvious improvement effect and the like.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD +1

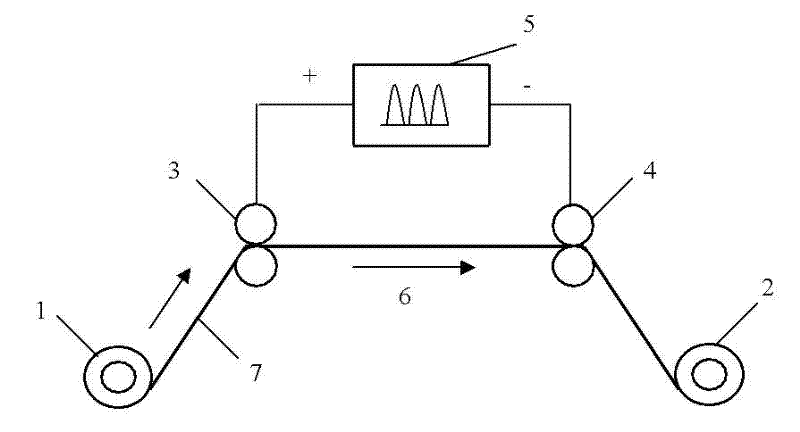

Method for promoting growth of GOSS textures of silicon steel strips by using pulse current

InactiveCN102212671AReduce the degree of oxidationShort initial recrystallization timeFurnace typesHeat treatment furnacesAir atmosphereElectricity

The invention discloses a method for promoting growth of GOSS textures of silicon steel strips by using pulse current. The method comprises the following steps of: conveying the silicon steel strips at the speed of 2 to 10 meters per minute under the drive of a conveying device; and guiding the pulse current of a pulse power supply to a moving silicon steel strip electrifying zone through a pair of electric contact devices, and performing electric stimulation treatment on the silicon steel strip electrifying zone in air atmosphere to promote the generation of a large amount of GOSS textures in the primary re-crystallization process, wherein the silicon steel strips are in a high magnetic induction cold-rolled state, the thickness of the silicon steel strips is 0.1 to 0.5 millimeter, the width of the silicon steel strips is 10 to 150 millimeters and the silicon content of the silicon steel strips is 0.5 to 6.5 percent. Compared with the traditional thermal treatment furnace annealing treatment process, the method has the advantages of low energy consumption, high production efficiency and low production cost, and the GOSS textures in the primary re-crystallization process have manycomponents. By electron back-scattered diffraction (EBSD) detection, the GOSS texture content of the silicon steel strips treated by adopting electric stimulation of the pulse current reaches 15 to 25 percent.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Self-changing gearbox flywheel bracket tray deep-drawing hammer down forming process and mould

InactiveCN101402128AHigh strengthImprove deformation resistanceForging hammersForging/hammering/pressing machinesAutomatic transmissionMetallic materials

The invention discloses a method and a die for warm deep drawing and upsetting of automatic transmission flywheel pallet, and belongs to a method and a die for plastic forming of metal materials. The invention solves the problems that the prior process and die for cold stamp forming can form small pallet like parts by using only low-strength, high-plasticity carbon thin steel plate as blank materials and a process and a die for forming large pallet like parts by using No. 45 medium carbon thick steel plate with high strength and low plasticity as blank materials are not available, and is used for forging automatic transmission flywheel pallet for cars. The forming process of the invention comprises a heating step and a forming step and has the advantages of short and reasonable process flow and stability. The die of the invention comprises a deep drawing lower die, an ejecting device, a deep drawing and upsetting upper die and a guiding device, and has the advantages of reasonable structure, convenient manufacture, installation and use, reliable operation, long service life and capacity of forming flywheel pallet castings with high surface finish quality. The method and die require only one time of heating and a die set and can operate once for all, thereby improving production efficiency and forging quality of the castings.

Owner:湖北天轮机械有限公司 +1

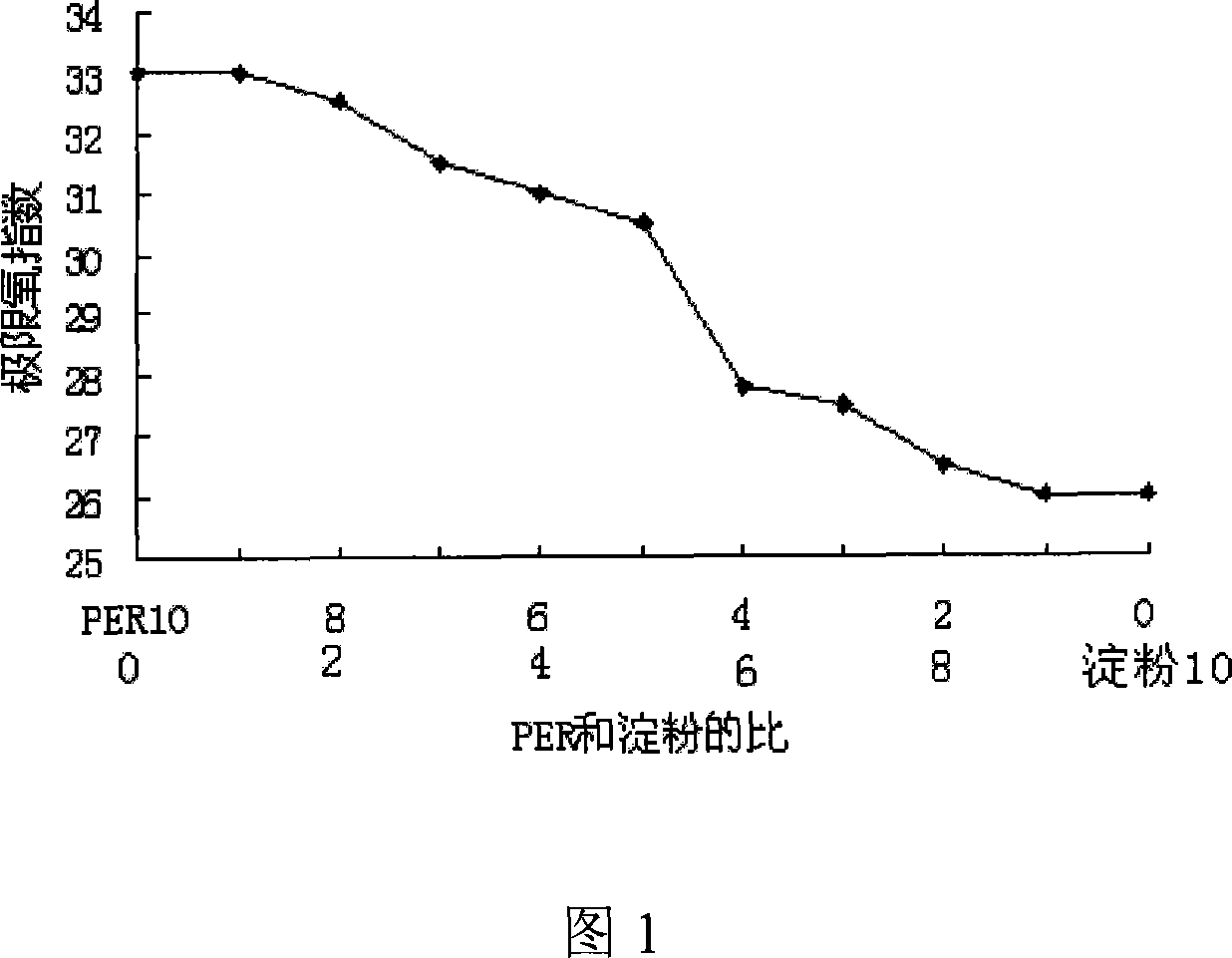

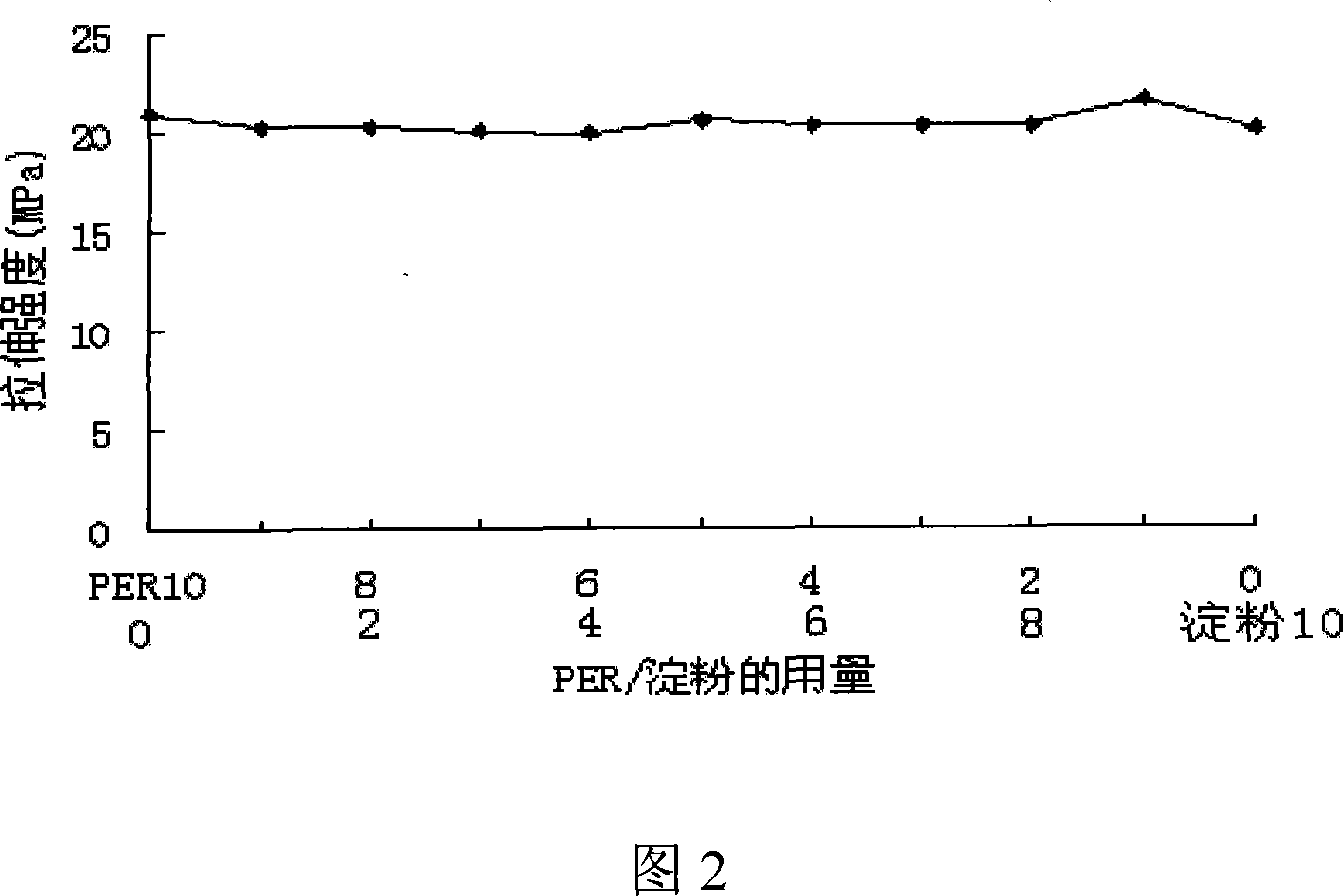

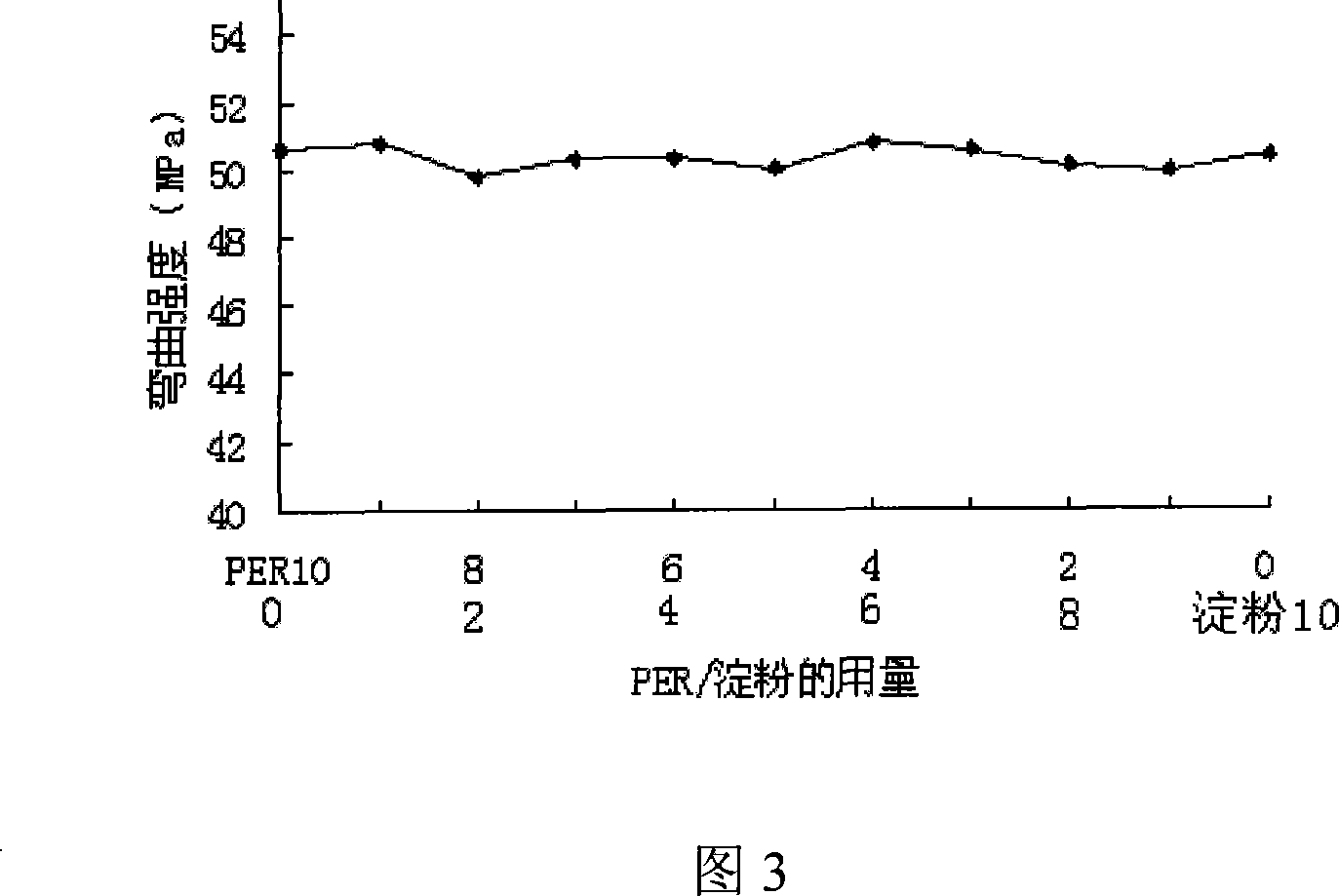

Non-bittern expanding flame-proof material and method for making same

InactiveCN101134830ARaise the maximum thermogravimetric rate temperatureIncrease the residual rate of thermogravimetric lossFireproof paintsHalogenPolypropylene

The present invention relates to one kind of no-halogen expanding fire retardant material and its preparation process. The no-halogen expanding fire retardant material consists of polypropylene and expanding fire retardant in 30-50 wt% of polypropylene. It is prepared through melting and rolling polypropylene at 160-170 deg.c, adding expanding fire retardant and additive and mixing for 8-15 min, hot pressing at 15 MPa and 180 deg.c for 2-5 min and cooling to set. The no-halogen expanding fire retardant material of the present invention has excellent fire retardant effect and high mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH

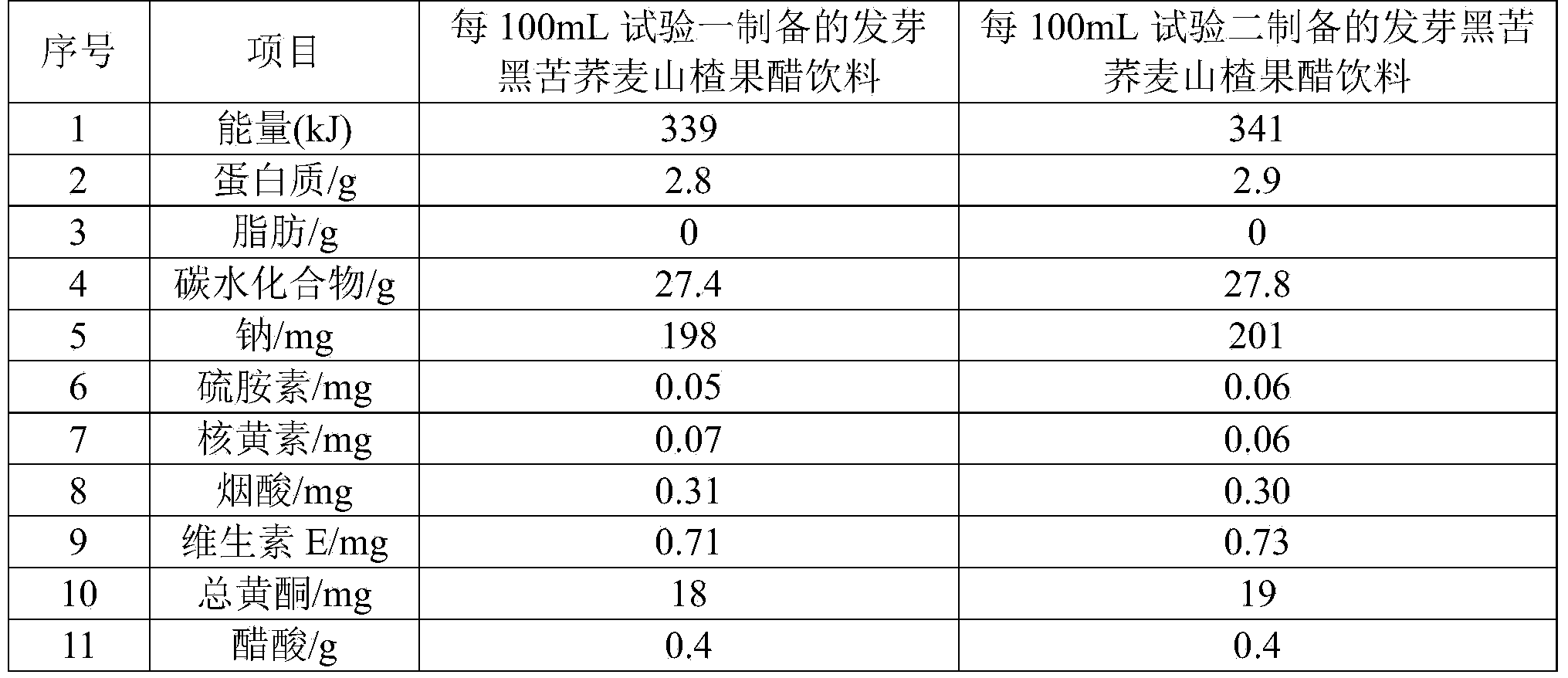

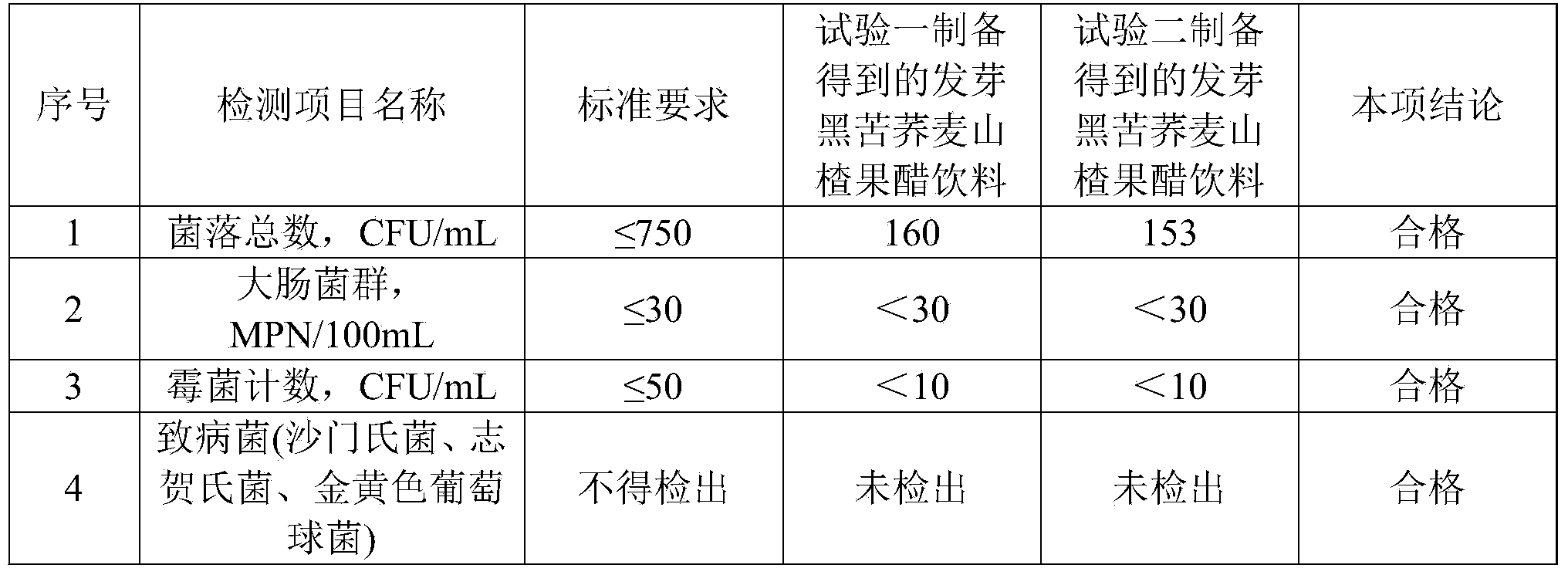

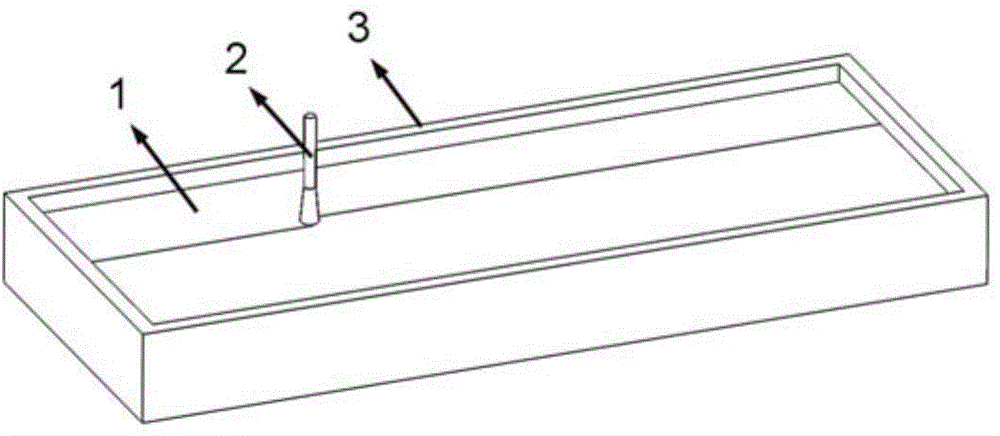

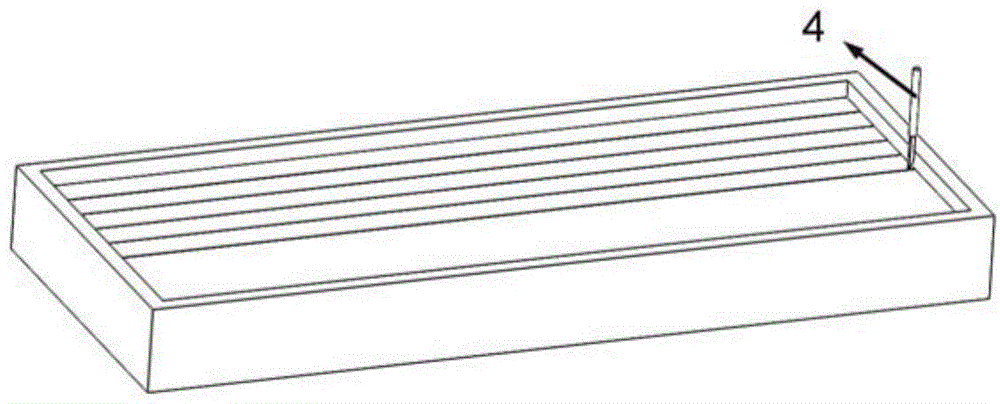

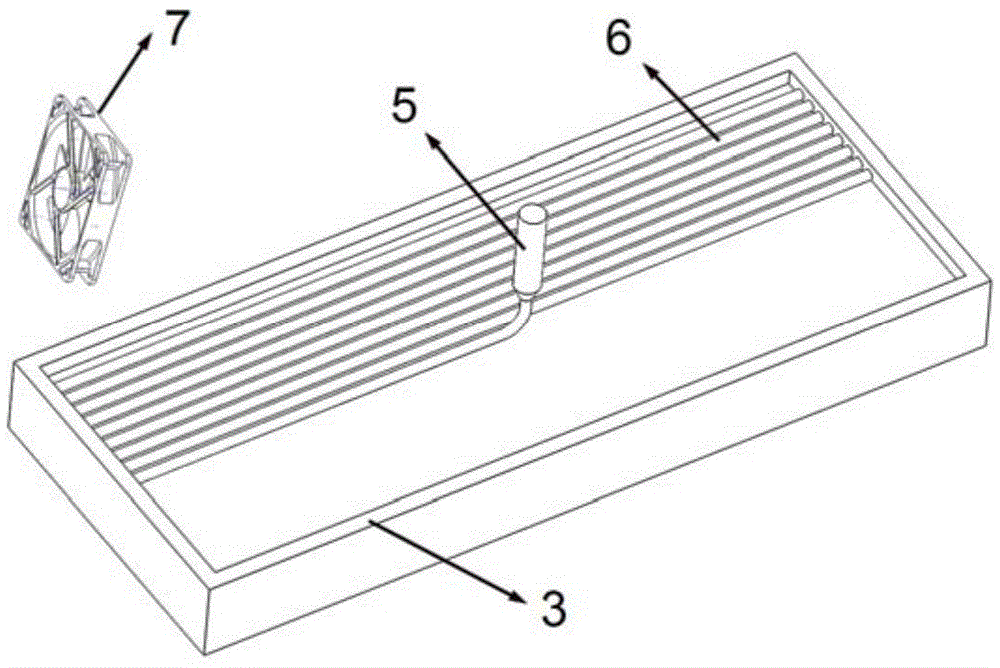

Method for preparing germinated black tartary buckwheat and hawthorn fruit vinegar beverage

InactiveCN103734836AImprove germination rateHigh content of target ingredientsVinegar preparationFood preparationFlavorPolygonum fagopyrum

The invention discloses a method for preparing a germinated black tartary buckwheat and hawthorn fruit vinegar beverage, and relates to the method for preparing beverages. The invention aims to solve the problems of the current method for preparing fruit vinegar beverages as follows: the functional ingredients seriously lose, the production cycle is long, the energy consumption is large, and the sensory flavor of product is not good enough. The method comprises the following steps: 1, screening; 2, cleaning; 3, soaking seeds; 4, germinating; 5, liquefying; 6, saccharifying uncooked materials; 7, preprocessing hawthorns; 8, squeezing juice; 9, conducting alcoholic fermentation; 10, conducting acetic fermentation; 11, mixing; 12, fining and clarifying; 13, sterilizing to obtain the germinated black tartary buckwheat and hawthorn fruit vinegar beverage. The method is mainly used for preparing the germinated black tartary buckwheat and hawthorn fruit vinegar beverage.

Owner:程健博

Low-melting-point metal wire for 3D printing and manufacturing method thereof

ActiveCN104889397AReduce manufacturing costChange mechanicsMaterial nanotechnologyIndiumNanoparticle

The invention belongs to the field of 3D printing, and provides a low-melting-point metal wire for 3D printing. The metal wire comprises raw materials of a gallium-based alloy or a bismuth-based alloy or an indium-based alloy; and a manufacturing method of the metal wire comprises the following steps that (1) the raw materials are respectively weighed and put in a container, are put in a vacuum constant-temperature tank for constant-temperature treatment, and are taken out and stirred to prepare metal ink, or the prepared metal ink is mixed and stirred with nanometer particles or nonmetal small particles to prepare nanometer particle or nonmetal particle contained metal ink; and (2) the metal ink is sprayed on a basal plate to form a sheet and the sheet is cut into a strip to obtain the metal wire, or the metal ink is extruded onto the basal plate or wound on a rolling shaft and is cooled to obtain the metal wire. The low-melting-point metal wire is largely reduced in manufacturing cost, and is largely reduced in oxidation degree compared with metal powder; the low-melting-point metal wire can be conveniently applied to a household portable 3D printer with low cost; and printed products are convenient to be recycled.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Meat curing agent and processing method of conditioned meat

InactiveCN105410718AReduce the degree of oxidationReduce hardnessFood scienceFrozen storageAdditive ingredient

The invention provides a meat curing agent which is capable of making the meat product high in meat tenderness and yield rate. In parts by weight, per 100 parts of the meat curing agent comprises the following ingredients: 1-3 parts of shrimp sauce, 0.001-0.01 parts of paprika red, 2-10 parts of corn starch, 0.1-0.5 part of seasonings and water accounting for all the remaining parts. The seasonings include anises, barks of Japanese cinnamon, fennels, gingers, garlic and green onions of the same parts by weight. The invention further provides a processing method of conditioned meat which is capable of making the meat product high in meat tenderness and yield rate. The beneficial effects of the processing method are as follows: the pork and the meat curing agent disclosed by the invention are mixed according to a certain ratio, then low-temperature vacuum intermittent rolling and kneading and ultrasonic treatment are performed, so that the indexes all satisfies relative national standards; the product is high in meat tenderness and yield rate (the yield rate can be as high as 152%) as well as long in shelf life; the product meets commercial sales requirements in overall sensory acceptability even after one year frozen storage at 18 DEG C below zero; moreover, the product is relatively low in lipid oxidation degree and free of oil-burning smell.

Owner:FUJIAN YAMING FOOD

Method for preparing seasoning material by enzymolysis of trash fish and fish oil

InactiveCN1965701AReduce the degree of oxidationEasy to separateEdible oils/fatsFood preparationChemistryEnzyme

The invention relates to a method for using cheap fish enzyme to prepare flavouring material and fish oil, wherein said method comprises that: washing and breaking cheap fish into meat slurry; adding water at same mass, mixing into uniform fish slurry; putting it into enzymolysis pot, increasing temperature to 50-65Deg. C, adding 1000u / g-3000u / g excision protein enzyme and 1000u / g-3000u / g interior protein enzyme, mixing and enzymolyzing to liquidize the fish slurry; foaming at the bottom of pot, exhausting the air at upper part, increasing temperature to 85-90Deg. C when the enzymolysis is end, holding temperature for 15-30min to disinfect the enzyme; discharging fish skeleton and fish oil from the pot bottom, the left liquid is the final product. The invention can avoid forming emulsion layer abundant with fat and protein composite, with high protein utilization.

Owner:SOUTH CHINA UNIV OF TECH

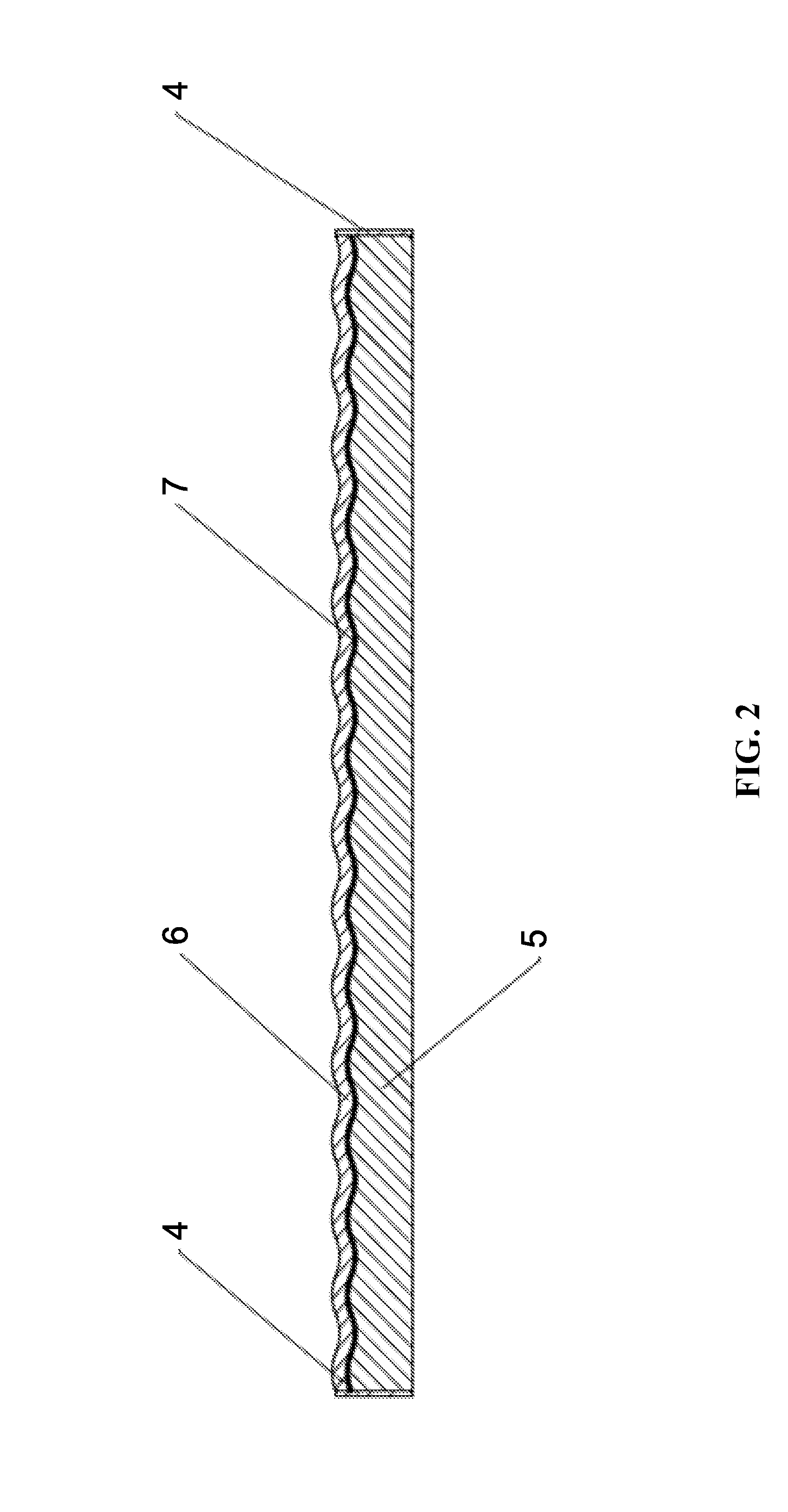

Method for preparing metal composite plate strip by rolling

ActiveUS20160271674A1Eliminate differenceIncrease bonding strengthArc welding apparatusMetal rolling arrangementsMetalMaterials science

A method for preparing a metal composite plate / strip by rolling, comprises the following steps: 1) respectively rolling the composite surfaces of a base plate and a cladding plate to obtain the base plate corrugation and the cladding plate corrugation for mating with each other; 2) cleaning the composite surfaces of the base plate and the cladding plate to expose the metal matrixes; 3) sequentially laminating the base plate and the cladding plate so that the base plate corrugation on the base plate and cladding plate corrugation on the cladding plate mate with each other, compacting, and performing welding sealing treatment to obtain a composite plate slab; 4) rolling the qualified composite plate after inspection by using a compositing machine to a desirable thickness, to obtain a composite plate / strip.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com