Patents

Literature

426 results about "Fermented milk products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fermented milk products, also known as cultured dairy foods, cultured dairy products, or cultured milk products, are dairy foods that have been fermented with lactic acid bacteria such as Lactobacillus, Lactococcus, and Leuconostoc. The fermentation process increases the shelf life of the product while enhancing its taste and improving the digestibility of its milk. There is evidence that fermented milk products have been produced since around 10,000 BC. A range of different Lactobacilli strains has been grown in laboratories allowing for many cultured milk products with different flavors and characteristics.

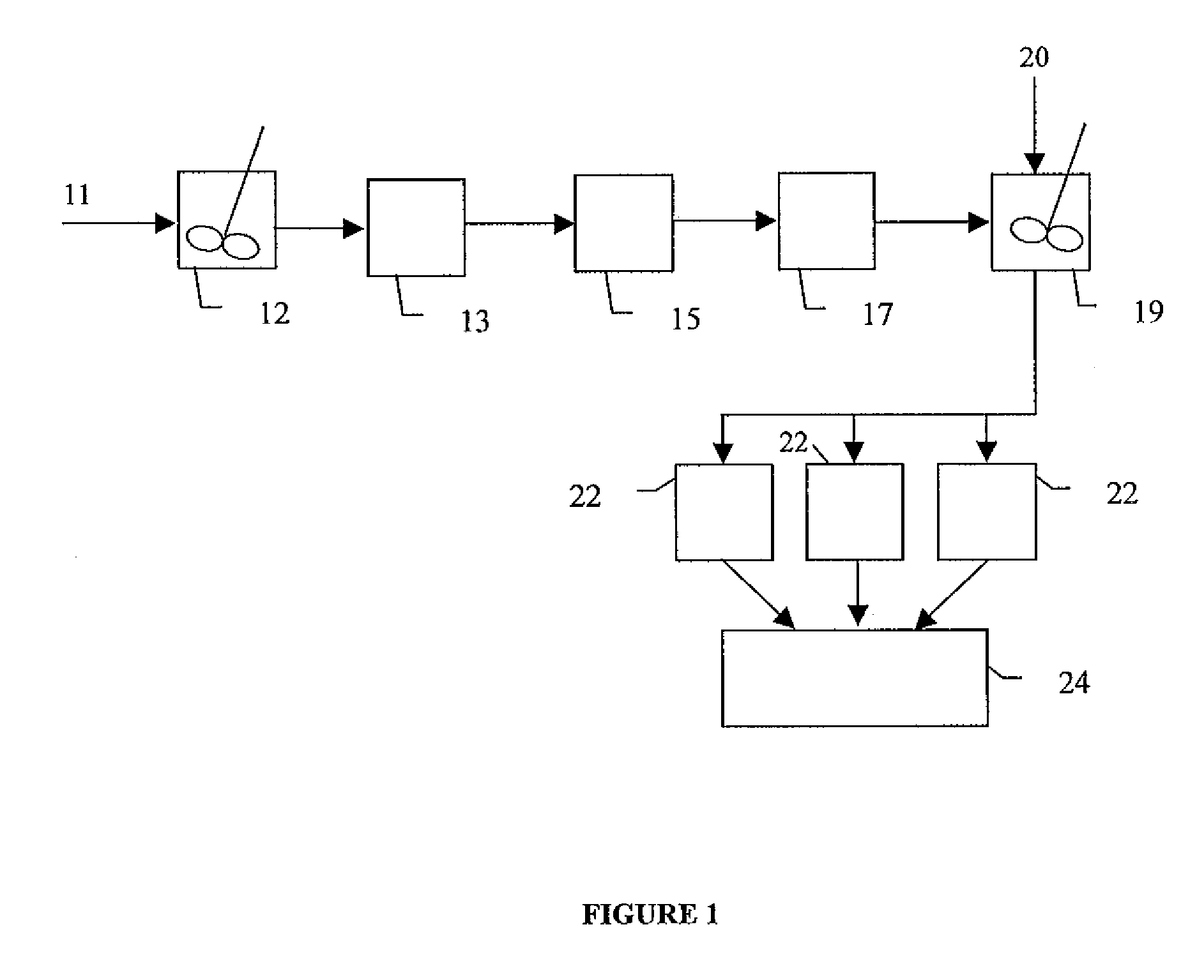

Method for continuous production of fermented dairy products

The invention provides continuous methods for preparing a fermented dairy product, the methods including steps of fermenting a dairy base with agitation while measuring the viscosity change of the fermentation mixture until an initial fermented dairy base having a target viscosity is achieved. The initial fermented dairy base is then preferably further fermented to a final fermented dairy base without agitation.

Owner:GENERAL MILLS INC

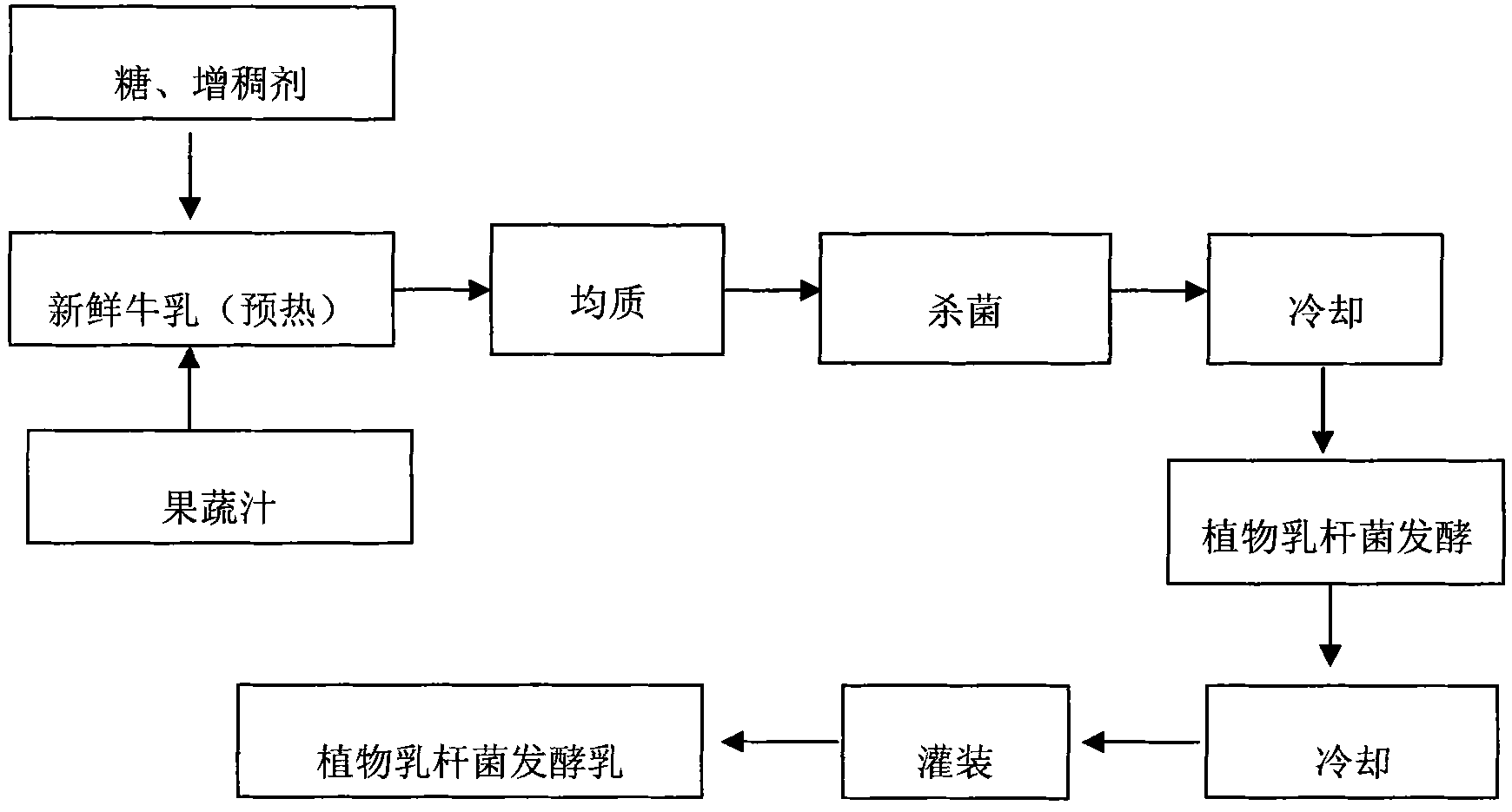

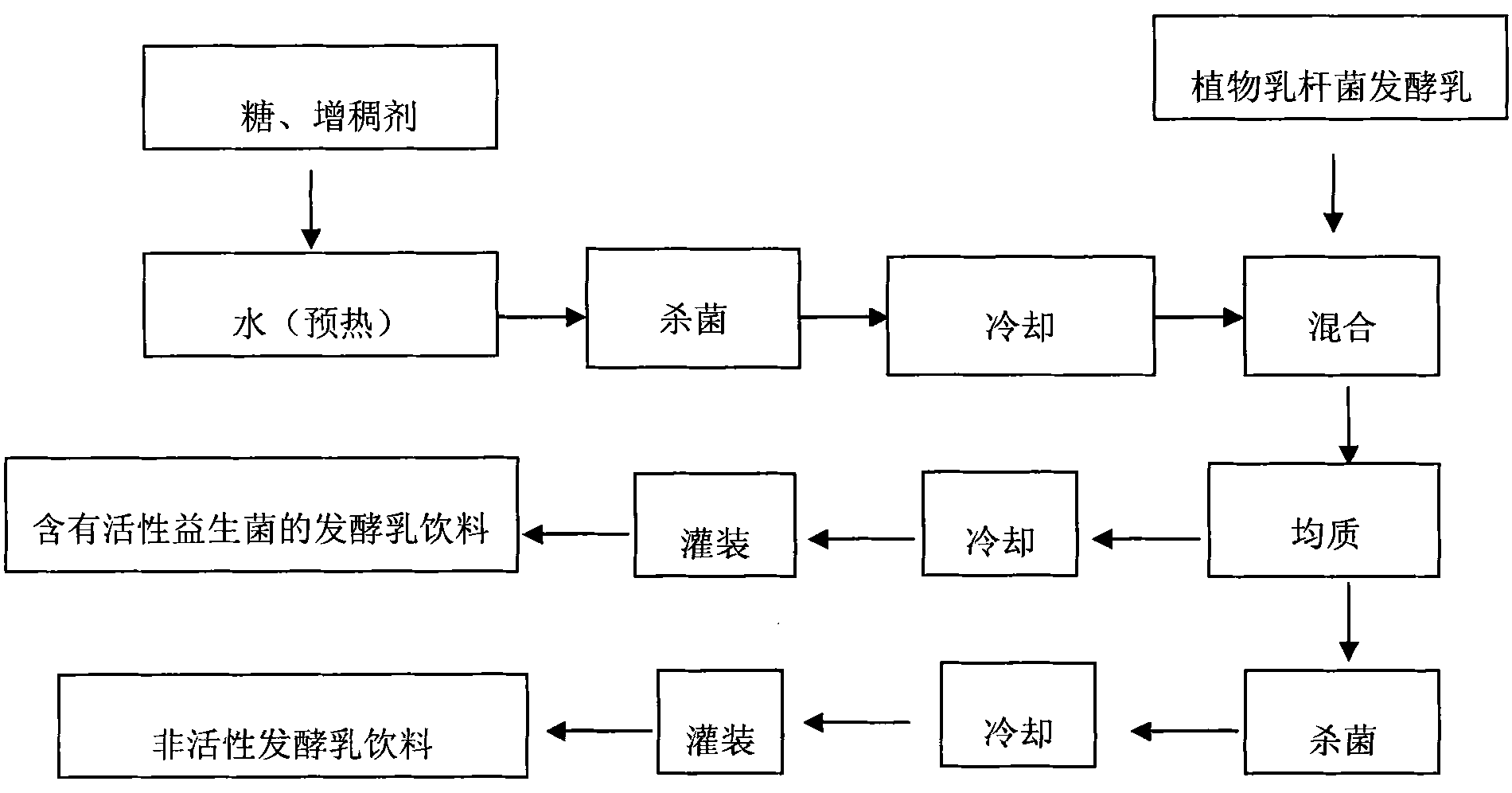

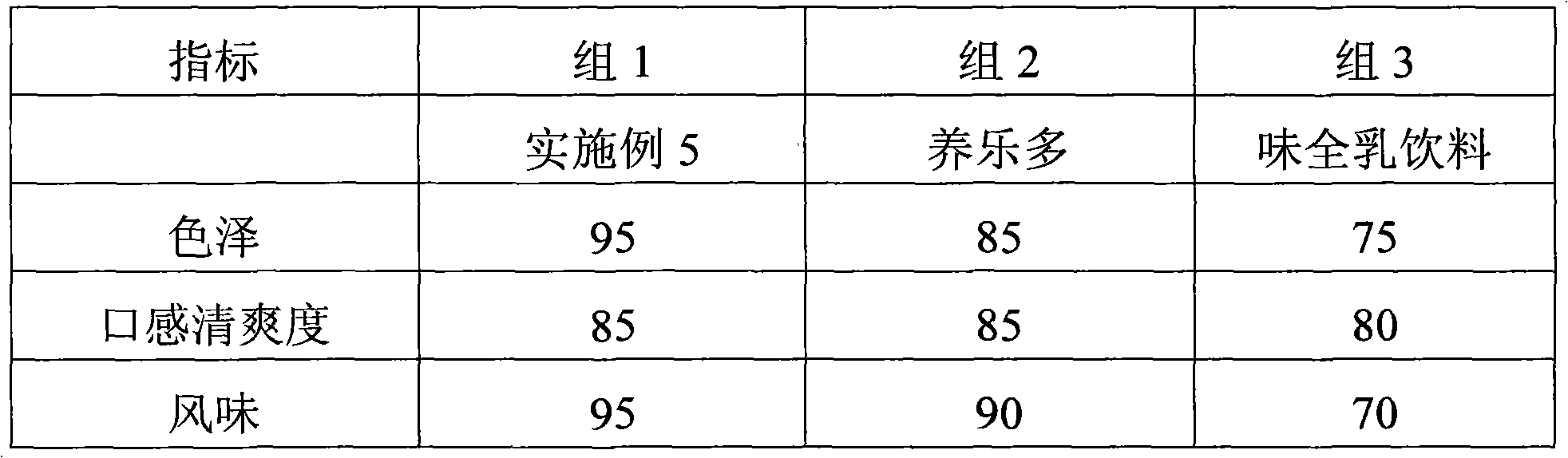

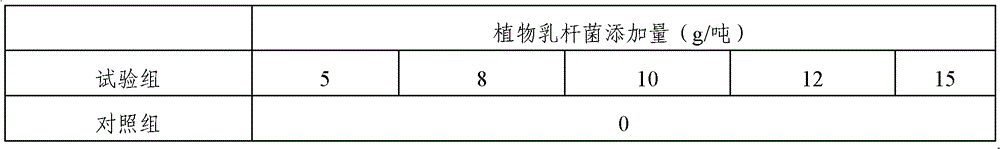

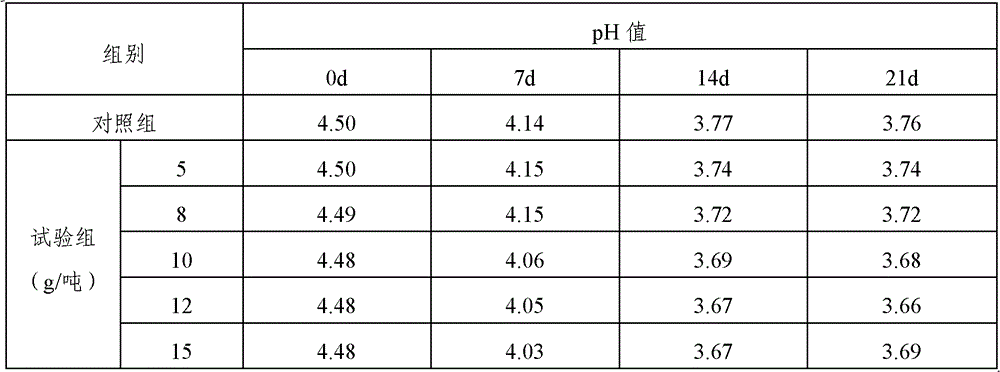

Fermented dairy product and preparation method and raw material composition thereof, lactobacillus plantarum application

InactiveCN102100252AIncrease varietyChange the status quo that cannot be applied in fermented dairy productsMilk preparationFlavorMetabolite

The invention discloses a raw material composition of a fermented dairy product, which comprises a milk raw material and a zymocyte strain; the milk raw material comprises the following compositions: animal milk, fruit and vegetable juice and a thickening agent; and the zymocyte strain is at least lactobacillus plantarum. The invention also discloses a method for preparing the fermented dairy product by the raw material composition of the fermented dairy product and the prepared fermented dairy product. The invention overcomes the defects in the prior art that lactobacillus plantarum grows slowly or can not grow in animal milk and can not be fermented to prepare dairy products; and the fermented dairy product provided by the invention contains lactobacillus plantarum and metabolites thereof, so the product facilitates the balance of intestinal microecology, is helpful to enhance body immunity, and has good flavor and mouthfeel. The invention further widens the application range of lactobacillus plantarum.

Owner:BRIGHT DAIRY & FOOD CO LTD

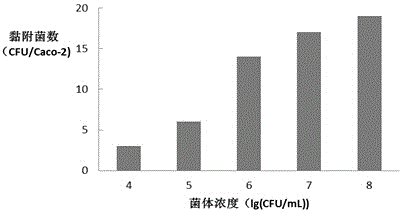

Lactobacillus plantarum CCFM8724 and application thereof

ActiveCN102533618AWith acidityWith fragranceAntibacterial agentsMilk preparationBiotechnologySoybean product

The invention relates to lactobacillus plantarum CCFM8724 and application thereof. The lactobacillus plantarum CCFM8724 has ability of suppressing growth of campylobacter jejuni in vitro, good resistance to acid and cholate and good adhesive ability to intestinal epithelial cells, and can control the campylobacter jejuni adhering to the intestinal epithelial cells so as to suppress growth of the campylobacter jejuni in chicken. The lactobacillus plantarum CCFM8724 can be used for preparing a medicinal composition for suppressing campylobacter jejuni; a fermentation agent containing the strain of lactobacillus plantarum CCFM8724 can be used for producing fermented dairy products, fermented bean products, fermented fruit / vegetable products and silage; the fermentation agent enables the products to obtain certain acidity and particular flavor; and meanwhile, the product preserving time is prolonged, and the nutritional value, digestibility and safety of the products are improved.

Owner:JIANGNAN UNIV

Fermented milk product and use thereof

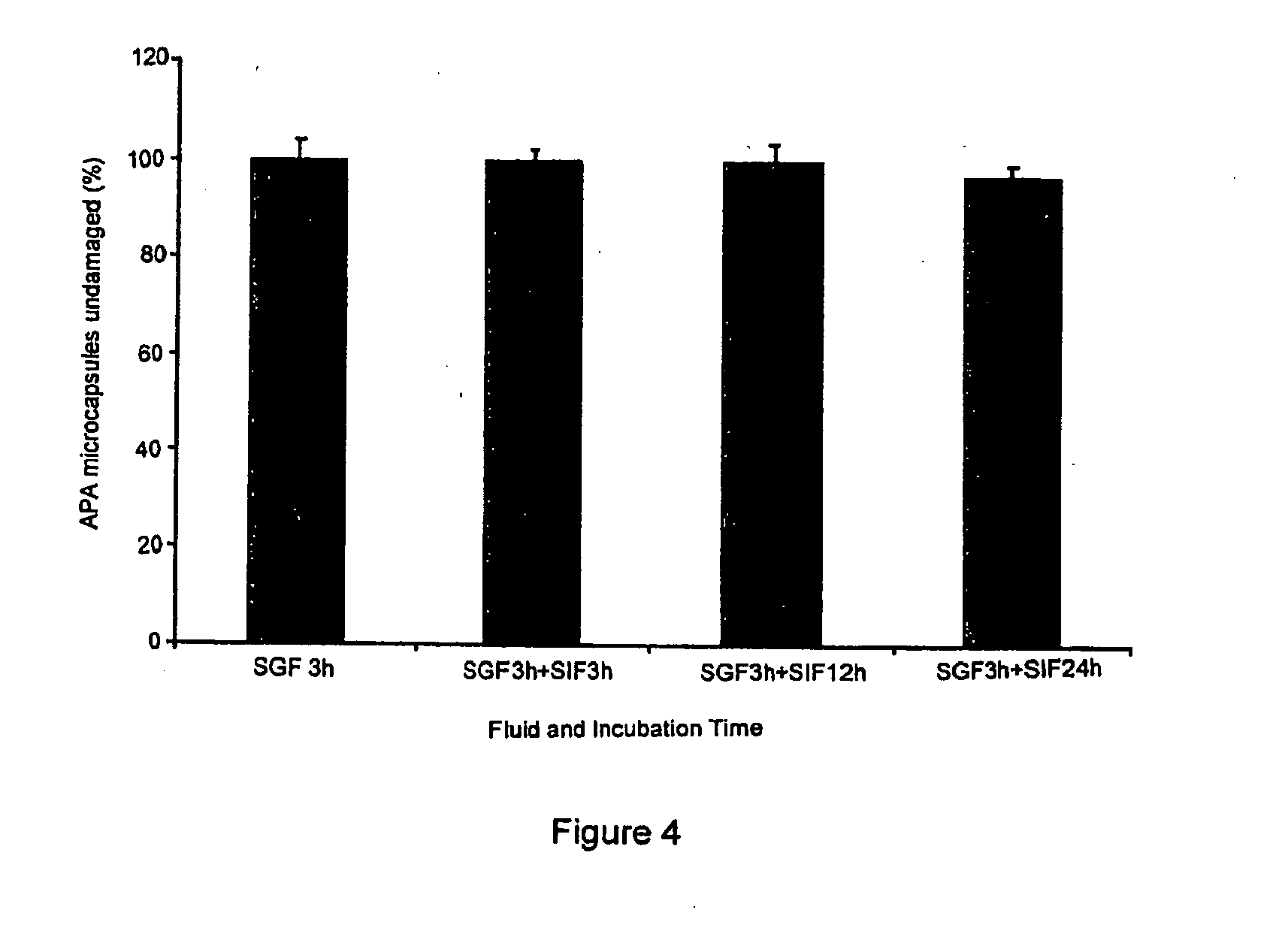

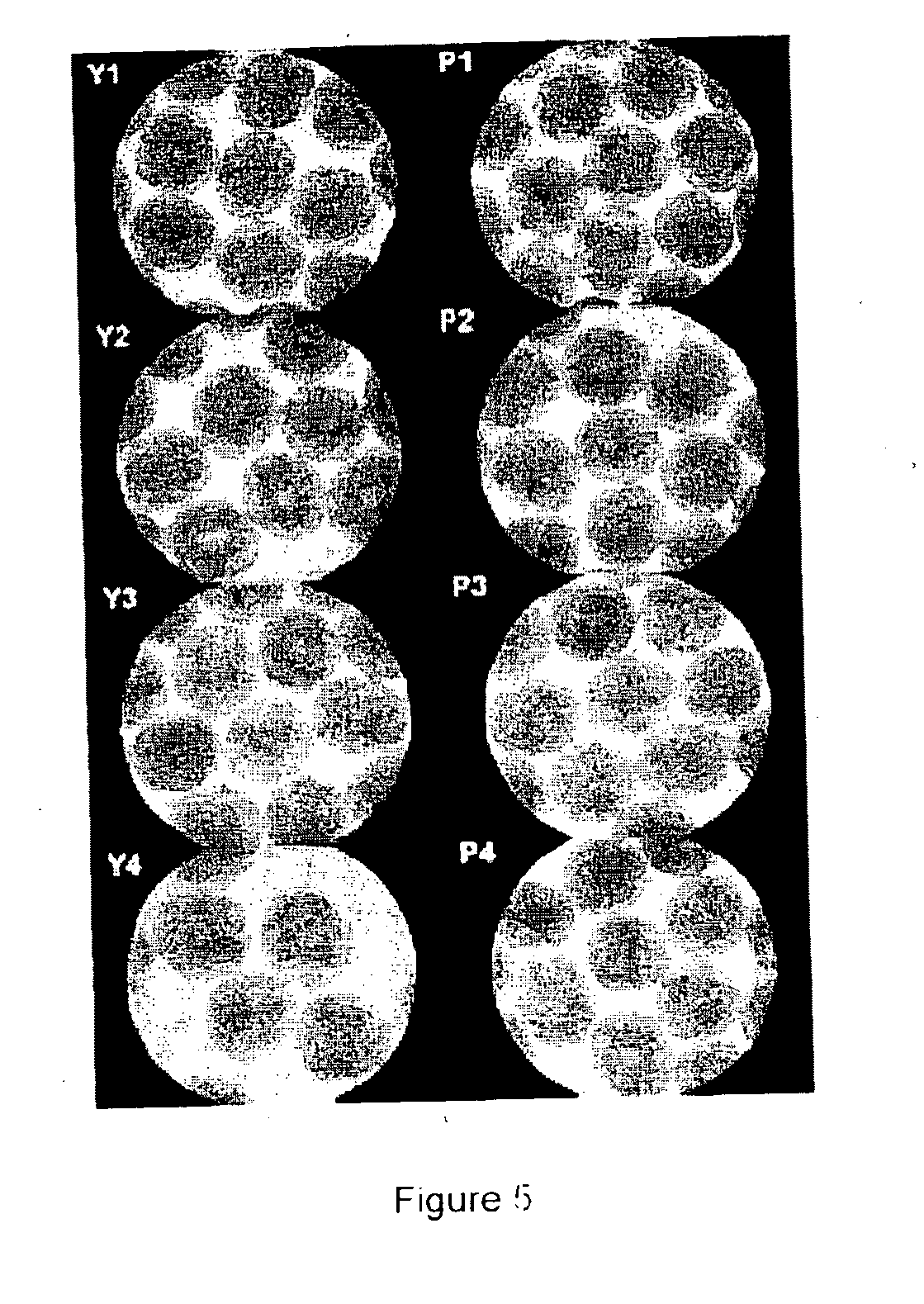

InactiveUS20100028449A1Improve mechanical stabilityEnhance cell viabilityPowder deliveryBiocideMedical treatmentDisease cause

The present invention relates to an oral formulation comprising a microcapsule containing bacteria and a fermented milk carrier. There is also provided a method of medical treatment of an inflammatory gastrointestinal disease or disorder in a subject in need thereof, comprising detecting the presence of inflammatory gastrointestinal disease or disorder in the subject, wherein if inflammatory gastrointestinal disease or disorder is detected, then administering the formulation of the present invention to the subject.

Owner:MCGILL UNIV

High-fiber dairy product

A process for producing a fermented dairy product supplemented with fiber, especially a purified digestion resistant fiber such as maltodextrin, inulin or oligofructose. This process takes advantage of the naturally acidic nature and enzymatic properties of fermented milk products such as yogurt and specific mixing and blending steps which produce a product having a superior organoleptic and textural properties. A fermented dairy product supplemented with at least 1-5% fiber, especially, a purified digestion-resistant fiber such as maltodextrin, inulin or oligofructose.

Owner:DANNON COMPANY INC THE

Flavored yogurt products and methods of making same

InactiveUS20060068075A1Reduced activityNot adversely microbial stabilityMilk preparationOther dairy technologyWater activityLactic acid fermentation

The invention provides fermented dairy products composed of fermented dairy base containing active cultures and a low water activity sweet brown base component admixed within the fermented dairy base. Further, the invention provides methods for preparing fermented dairy products including steps of fermenting a dairy base by lactic fermentation to a pH of 4.7 to 5.3 to provide a fermented dairy base; cooling the fermented dairy base; admixing a sweet brown base component with the fermented dairy base to form a sweet brown flavored fermented dairy product; and packaging the sweet brown flavored fermented dairy product. Methods of formulating yogurt compositions are also described.

Owner:GENERAL MILLS INC

Low-carbohydrate dairy product

InactiveUS20060057247A1Less lactoseLess other sugarMilk preparationOther dairy technologyViscosityOrganoleptic

A process for producing a low-carbohydrate dairy product comprising producing a low carbohydrate fermented dairy product, especially a fermented dairy product produced using ultrafiltered milk, a low carbohydrate or low glycemic sweetener, and a fruit preparation. This process takes advantage of the naturally acidic nature and enzymatic properties of yogurt-like product and specific mixing steps which produce a product having a suitable viscosity, pH and other organoleptic properties. A low carbohydrate dairy product, such as a fermented dairy product having less than 4.9% carbohydrate.

Owner:DANNON COMPANY INC THE

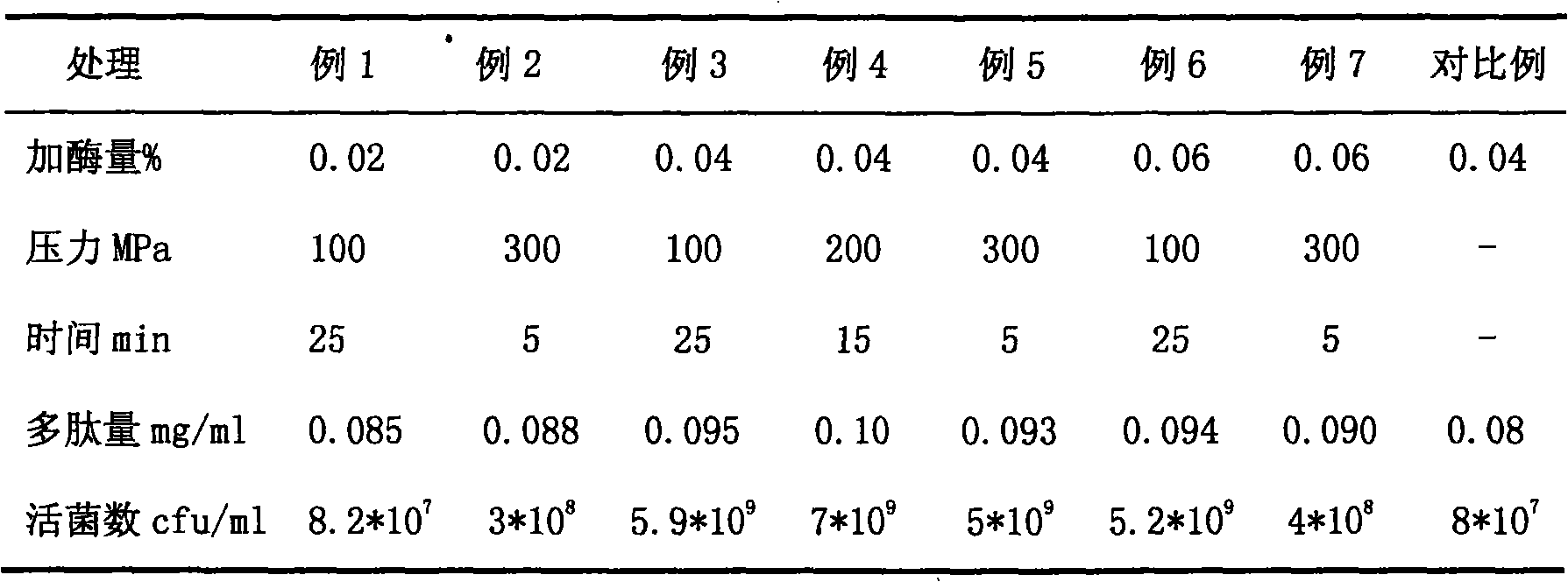

Functional soy peptide fermented milk and preparation method thereof

InactiveCN101642221AHigh dissolution rateExtended shelf lifeCheese manufactureFood preparationSlurrySoya bean

The invention provides functional soy peptide fermented milk and a preparation method thereof and relates to a manufacturing method of fermented dairy products in the field of food processing. The method is carried out according to the following steps: (1) the preparation of fermented base stock; (2) the preparation of mother cultures; (3) synchronous enzymolysis and fermentation; (4) blending and homogenizing; (5) ultrahigh pressure sterilization and filling; by adopting the steps, a finished product is obtained. The method adopts protease and lactic acid bacteria synchronous-enzymolysis fermentation technology, and ultrasonic waves are adopted to process slurry-residue mixture which is ground, so as to increase the dissolving-out rate of the protein and prepare acidity soy-bean milk by ultrahigh pressure and non-heat processing. The product taste is coordinated without enzymolysis odour; the enzymolysis fermentation time can shorten to 2-4h, and the production cost is low. The ultrahigh pressure processing can remarkably improve the product taste; the method can keep and produce new functional peptide, the lactic acid bacteria is inhibited to ferment continuously, and a certain micro-organism viable counts are kept; the shelf life of the acidity soy-bean milk is prolonged, so as to prevent the acid milk from being whey-separated owning to continuous increasing of acidity; inaddition, the product can be stored and marketed at normal temperature.

Owner:JIANGSU UNIV

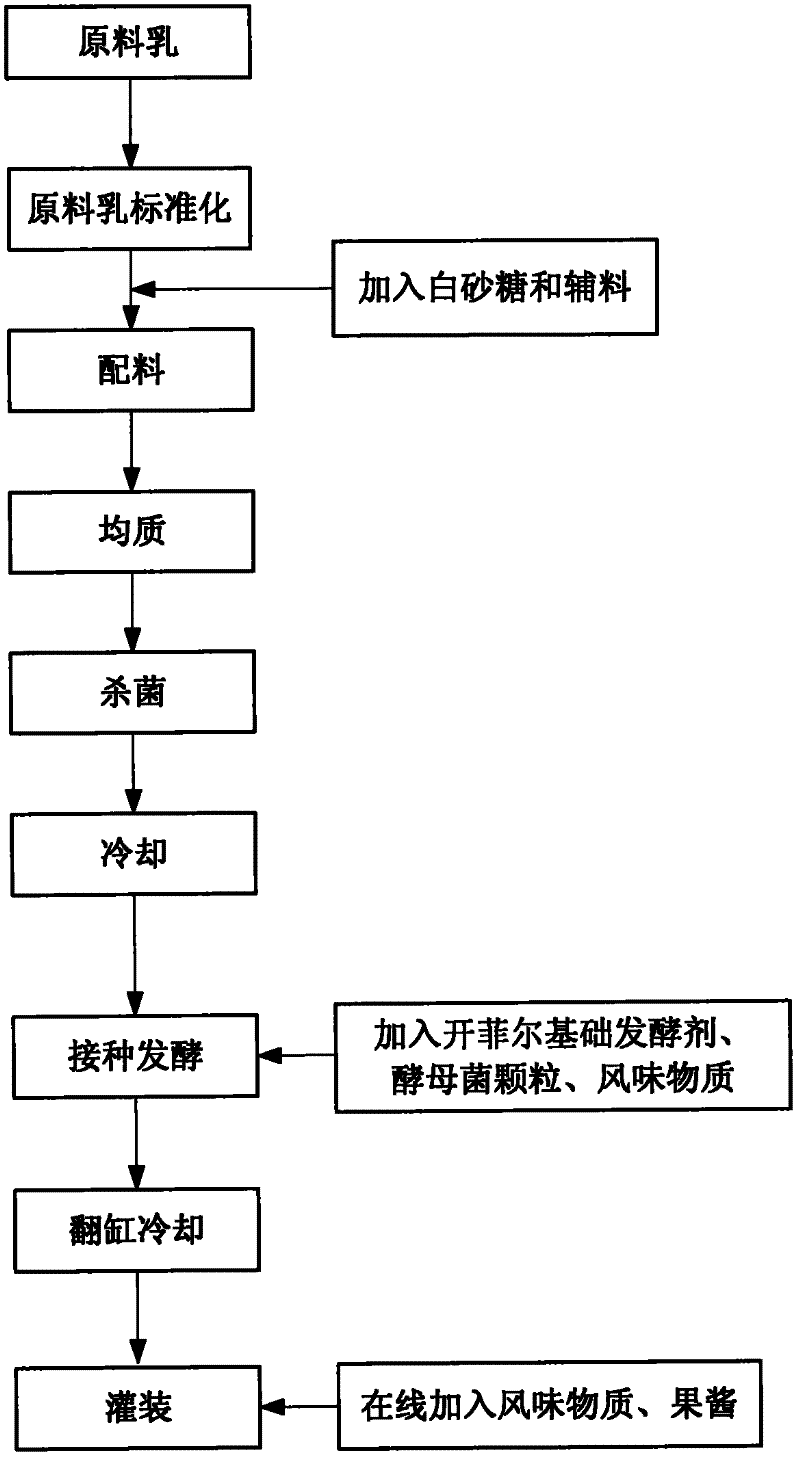

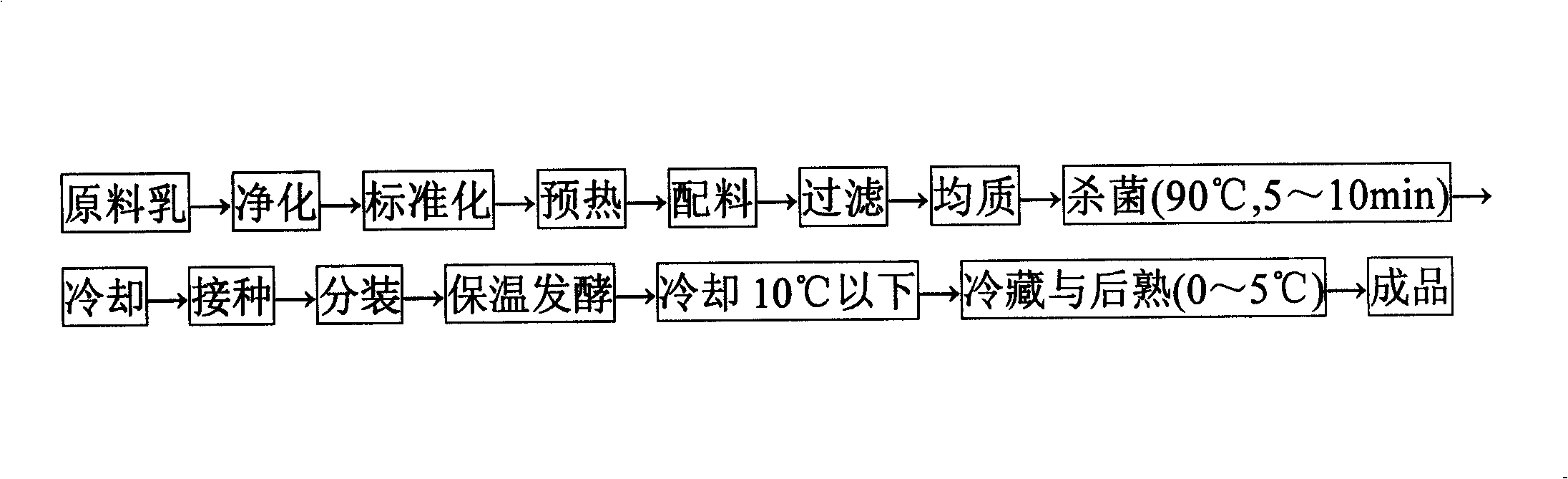

Kefir fermented dairy product and preparation process thereof

The invention discloses a preparation process of a Kefir fermented dairy product. The preparation process comprises the following steps of: 1, homogenizing the mixed liquid of raw material milk with the protein content of 2.5-3.5% and white granulated sugar and sterilizing; 2, cooling and inoculating Kefir base leaven KM-01 and yeast grains into the mixed liquid and fermenting at 25-35 DEG C to obtain fermented milk at the end of the fermentation, wherein 0.02-0.1g of Kefir base leaven KM-01 and 0-0.1g of yeast grains are used relative to every one kilogram of the total raw material; and 3, turning over raw materials in a jar, cooling, filling and sealing and after-ripening. The invention also discloses a Kefir fermented dairy product prepared by the preparation process. Through adoption the preparation process disclosed by the invention, the traditional preparation process is greatly simplified and the controllability of the preparation process is improved remarkably. The Kefir fermented dairy product has good taste and meets the taste requirement of Chinese people; the taste of the fermented dairy product can be changed through controlling the parameters of the preparation process and different consumption demands of consumers on the fermented dairy product can be met.

Owner:BRIGHT DAIRY & FOOD

Lactobacillus plantarum and preparation method thereof for high-density culture and freeze-drying bacteria powder

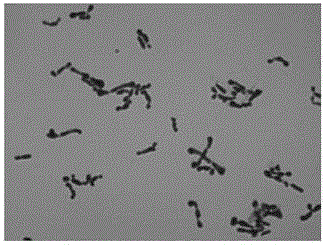

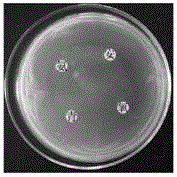

InactiveCN102864096AStrong toleranceIncrease vitalityBacteriaMicroorganism based processesFreeze-dryingAgglutination

The invention discloses a lactobacillus plantarum and a preparation method thereof for high-density culture and freeze-drying bacteria powder, and has the technical scheme that the lactobacillus plantarum (Lactobacillus plantarum P8) is probiotics separated from the traditional fermentation milk product (yoghurt) of the Urat Middle Banner of Inner Mongolia Bayan Nur. The probiotics has the characteristics of artificial gastric juice and artificial digestive juice tolerance, cholate tolerance, intestinal agglutination action and common pathogenic entero bacteria inhibition. The bacterial strain of the bacteria is collected in the China general microbiological culture collection center with the collection number of CGMCC (China general microbiological culture collection center) No. 5468 on 18th, Nov., 2011.

Owner:北京和美科盛生物技术有限公司

Lactobacillus plantarum capable of lowering cholesterol

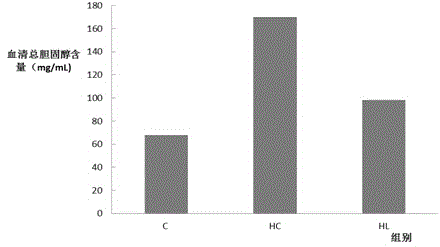

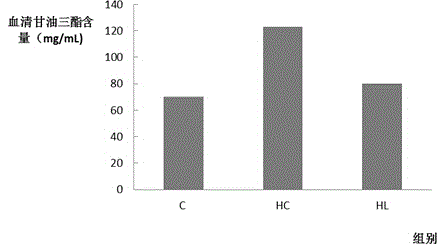

ActiveCN104073455AGood artificial gastric juiceImprove toleranceMilk preparationBacteriaGeneticsLow-density lipoprotein

The invention discloses lactobacillus plantarum capable of lowering cholesterol. The lactobacillus plantarum is separated from the traditional fermented yak yoghourt of the Qinghai-Tibet Plateau, and the collection number is CGMCC No.9017. The lactobacillus plantarum can remarkably lower the contents of total cholesterol, triglyceride and low-density lipoprotein, and can be used for preparing fermented diary products, health-care foods and medicines.

Owner:哈尔滨美华生物技术股份有限公司

Anti-listerial mixed culture and method for producing cheese

ActiveUS20130011516A1Highly effective against ListeriaGreat tasteMilk preparationBacteriaMixed cultureBiotechnology

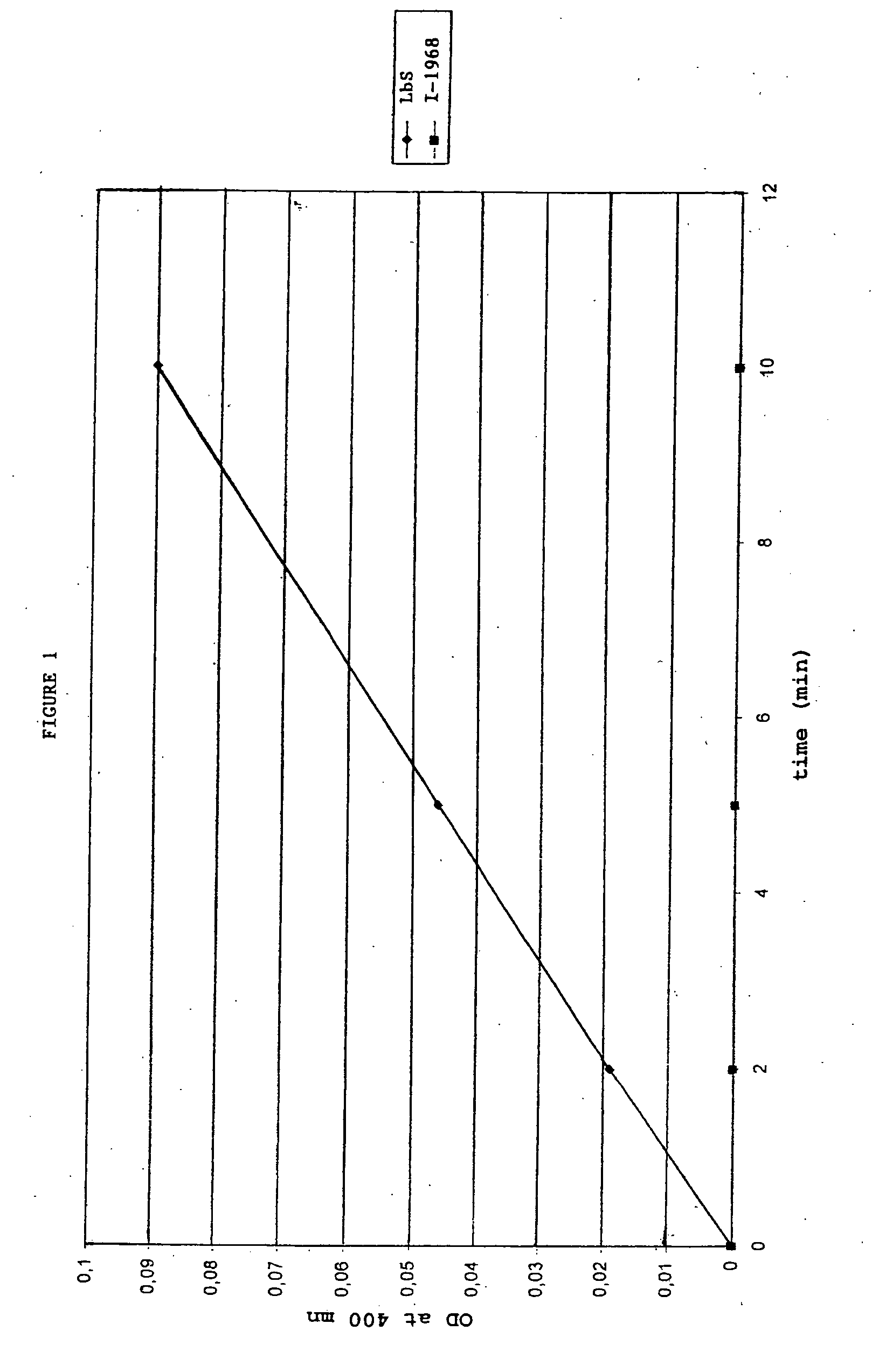

The present invention discloses a method for producing a fermented dairy product, preferably cheese, comprising inoculating milk with lactic acid bacteria capable of producing a Class IIa type bacteriocin; and lactic acid bacteria capable of producing a Class I type bacteriocin.

Owner:CSK FOOD ENRICHMENT

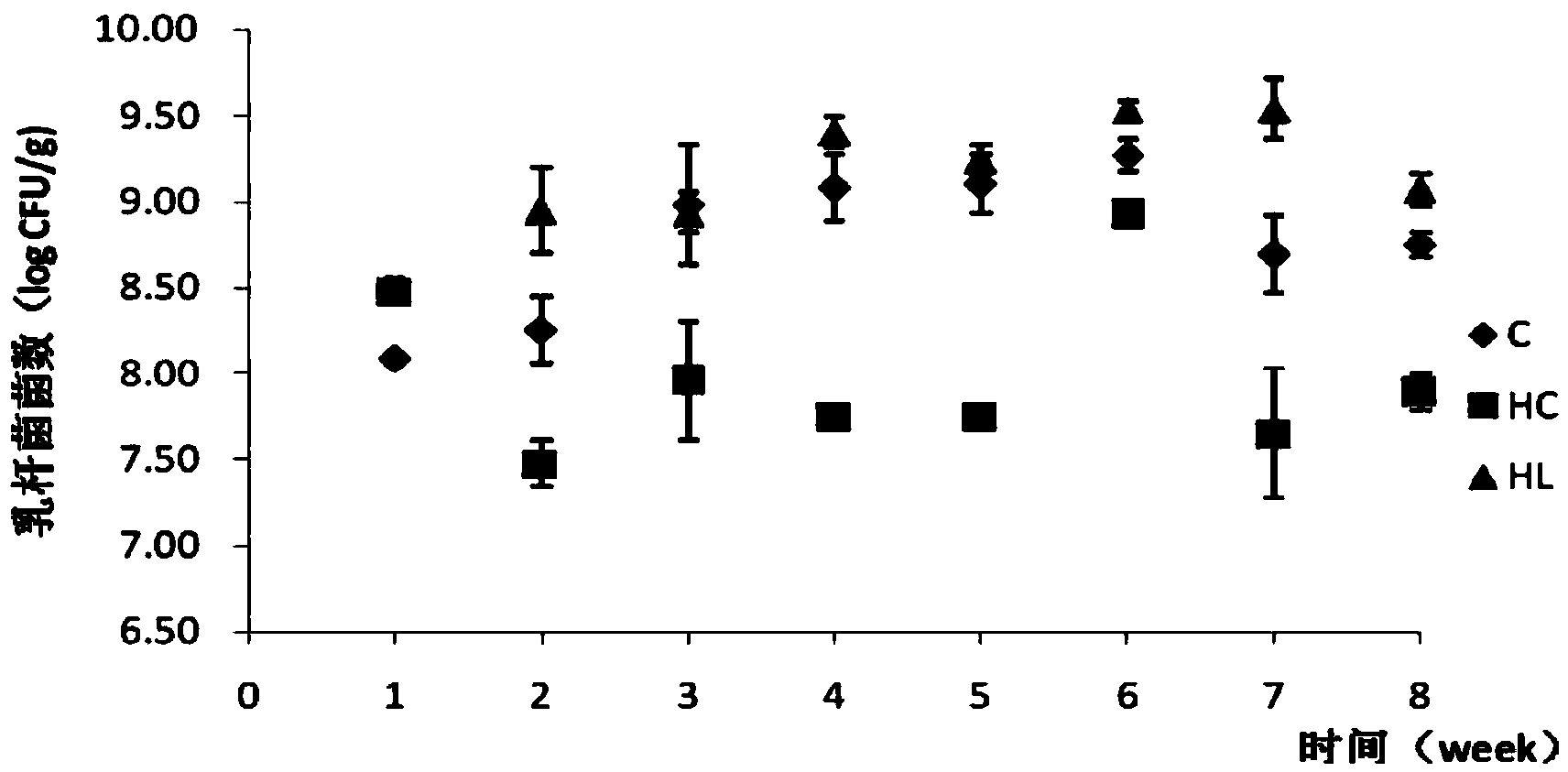

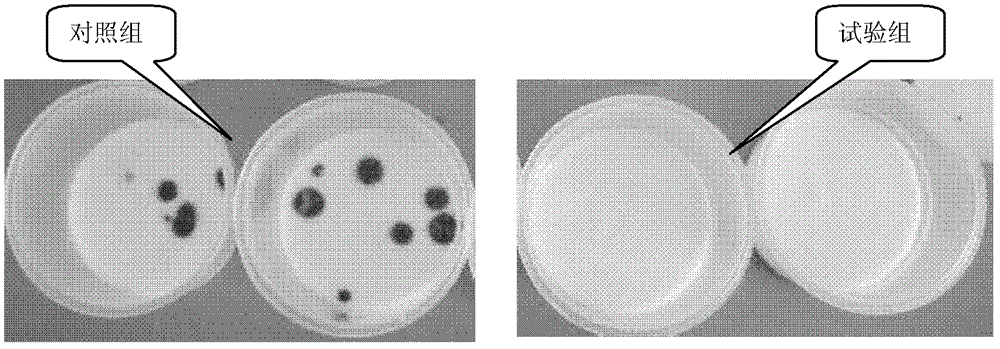

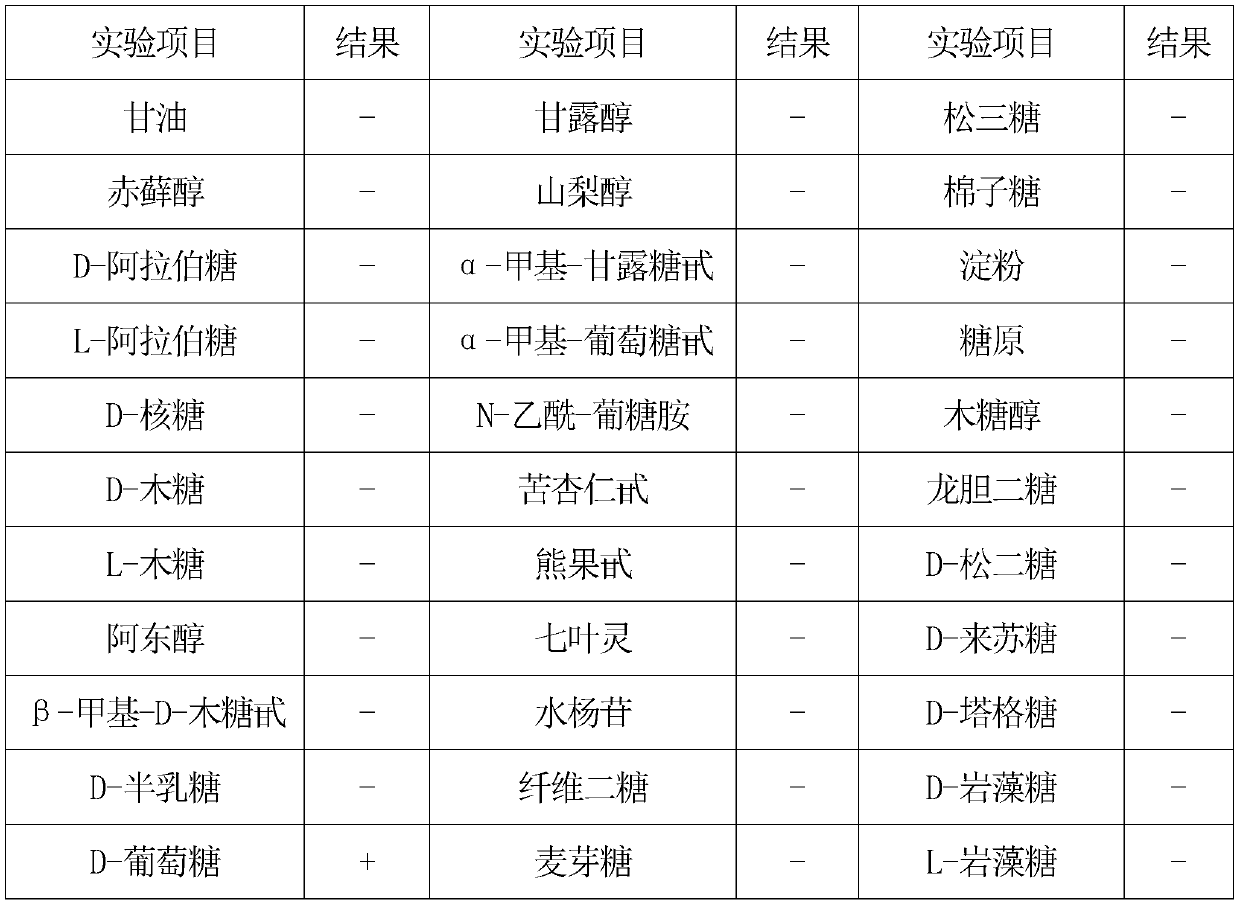

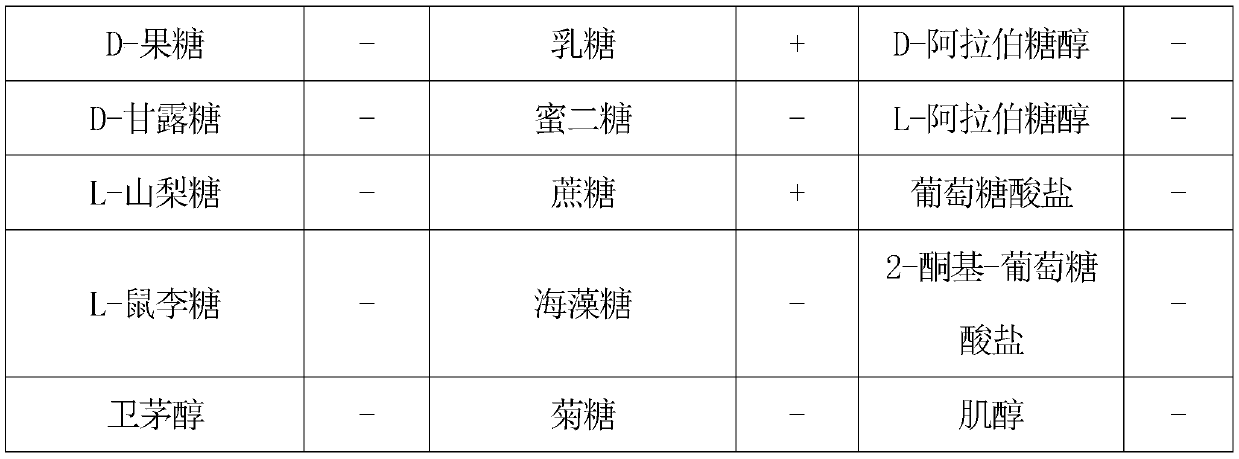

Lactobacillus plantarum PY-1 and use method of lactobacillus plantarum PY 1 in fermentation of dairy products

ActiveCN102747009AGood probiotic propertiesImprove acid resistanceMilk preparationBacteriaMicrobiological cultureSaccharomyces

The invention relates to a strain of lactobacillus plantarum PY-1. A technical scheme of the present invention is that: the lactobacillus plantarum PY-1 is a strain of probiotic bacteria, wherein the probiotic bacteria is prepared by carrying out separation on sour milk samples handmade by herdsman families, and has effects of inhibition of mould and yeast. The lactobacillus plantarum PY-1 is preserved in the China General Microbiological Culture Collection Center (CGMCC) on October 28, 2011, and a preservation number is CGMCC No.5358. The present invention further discloses a method for application of the lactobacillus plantarum PY-1 in fermentation of dairy products.

Owner:BEIJING SCITOP BIO TECH CO LTD

Coconut yogurt and preparing method thereof

ActiveCN105028649APrevent browningMeet stability requirementsMilk preparationHigh-fructose corn syrupDietary fiber

The invention relates to a preparing method for coconut yogurt and coconut yogurt prepared through the method, and belongs to the technical field of fermented milk product processing. The preparing method for the coconut yogurt comprises the main steps that 3-5 g / L of whey protein powder, 1-2 g / L of modified dietary fiber, 0.4-0.8 g / L of acetylated distarch phosphate, 0.1-0.2 g / L of pectin, 1-4 g / L of fructooligosaccharide, 6-10 g / L of high fructose corn syrup and 70-90 g / L of white granulated sugar are dissolved in raw milk, mixed uniformly, then sterilized for 300 s at the temperature of 95 DEG C, cooled to 41 DEG C-43 DEG C, inoculated with ready-to-use starters such as Hansen YF-L904 and Danisco YM-C LYO, and fermented until acidity reaches over 70 degree T, in the mixing process, coconut syrup and / or coconut powder / or coconut jam containing pulp are / is added, and / or in the filling process, the coconut jam is added online. The problems that in the preparing process, coconuts are prone to browning, and the yogurt is prone to being contaminated by infectious microbes in the fermenting process are solved.

Owner:河北新希望天香乳业有限公司

Lactobacillus plantarum L01 having cholesterol degrading function and application thereof

InactiveCN104818230AImprove toleranceImprove immunityMilk preparationBacteriaBiotechnologyCell adhesion

The invention discloses lactobacillus plantarum L01 which is assigned the accession number CCTCC No.M2014568, and also provides an application of the lactobacillus plantarum L01 in degradation of cholesterol and preparation of a fermented dairy product capable of degrading the cholesterol. The invention has following advantageous effects: the lactobacillus plantarum L01, which is obtained through separation and screening from traditional pickled vegetables, is sourced from traditional foods so that the lactobacillus plantarum L01 is excellent in safety and meanwhile is excellent in acid resistance, cholate resistance and cell adhesion and has a certain effect of maintaining enteric microorganism colony balance. The lactobacillus plantarum L01 can be used for preparing the fermented dairy product, is strong in cholesterol degrading function, can effectively reduce serum cholesterol and can enhance body immunity.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

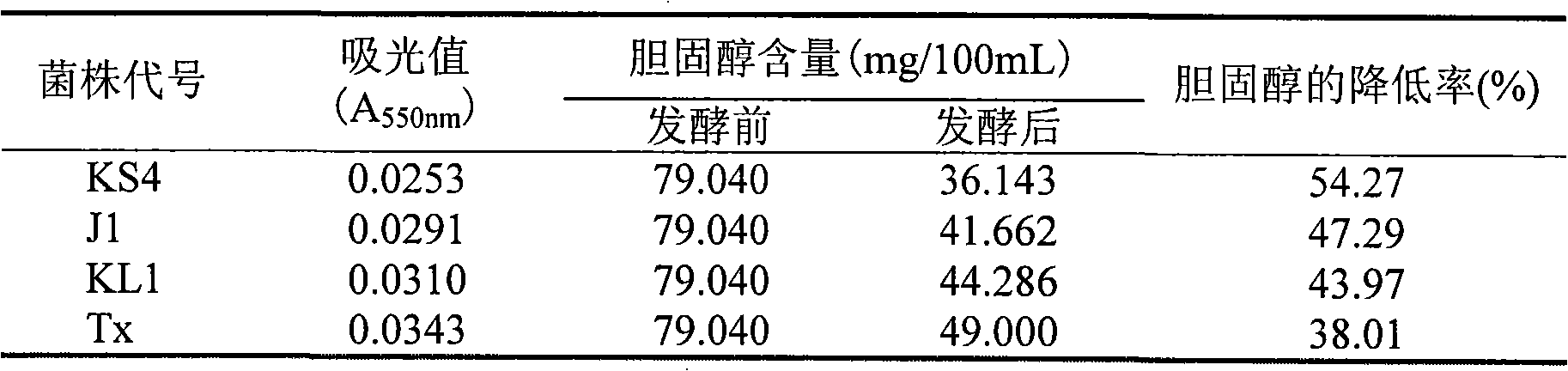

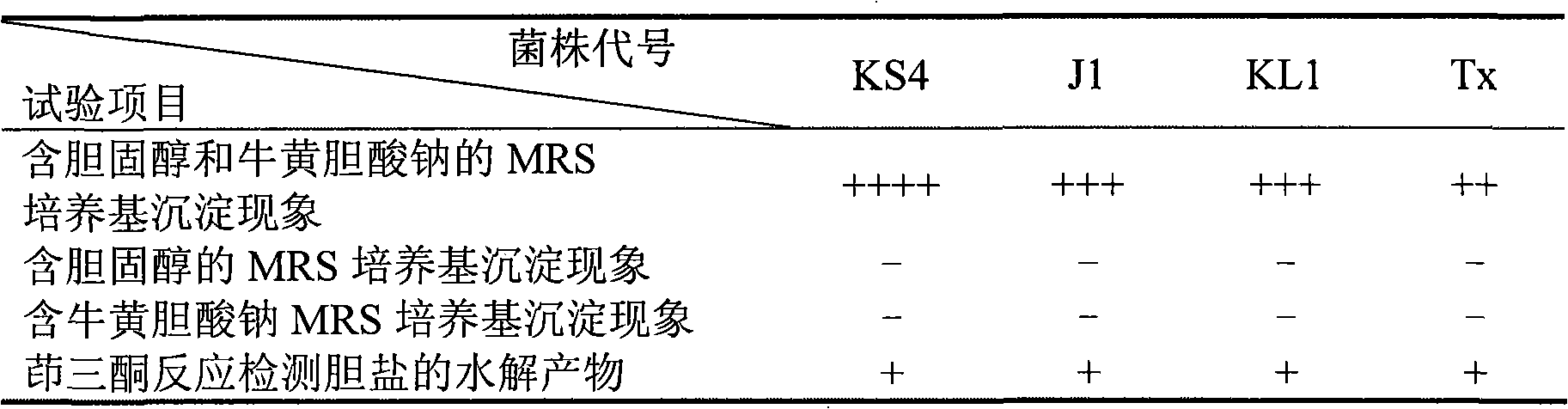

Four kinds of lactobacillus for generating bilesalt hydrolase and extracellular polysaccharide and functionality yoghourt production technique thereof

ActiveCN101331900AImprove stabilityImproved rheological propertiesMilk preparationPhenolsFermented milk products

The invention belongs to a production technology of four lactobacillus producing bile salt hydrolase and extracellular polysaccharide as well as functional yoghurt production technology. The technology is adaptable to the production of functional yoghurt and microbial ecological agents in fermented dairy products for lowering cholesterol. The technology adopts high throughput screening technique and an ortho-phthalaldehyde method to obtain bacterial strains which can efficiently reduce the cholesterol, to get the bacterial strains which can produce the bile salt hydrolase with high yield by an Oxford cup method and to gain the bacterial strains which can produce the extracellular polysaccharide with high yield by a phenol-sulfuric acid method. All the four kinds of screened lactobacillus have excellent fermentation performance. The yogurt with fine quality is prepared by lactobacillus casei KL1 (CGMCC No1809) and J1 (CGMCC No1808), which have the bile salt hydrolase with high efficiency in lowering the cholesterol as well as high yield and the extracellular polysaccharide, lactococcus lactis subsp.lactis KS4 (CGMCC No1807) and streptococcus thermophilus Tx(CGMCC No1810), therefore, the yogurt not only has the function of lowering serum cholesterol, but also utilizes the extracellular polysaccharide produced by thalli to replace stabilizer, thus solving the separating problem of yogurt whey. The technology has simple fermentation process in producing the functional yoghurt, low fermentation cycle and lower cost, so the technology is suitable for industrialized production in large scale.

Owner:BEIJING UNIV OF AGRI

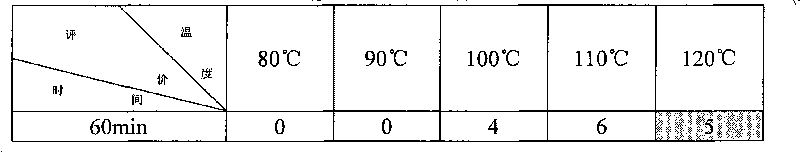

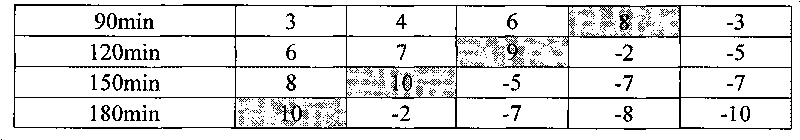

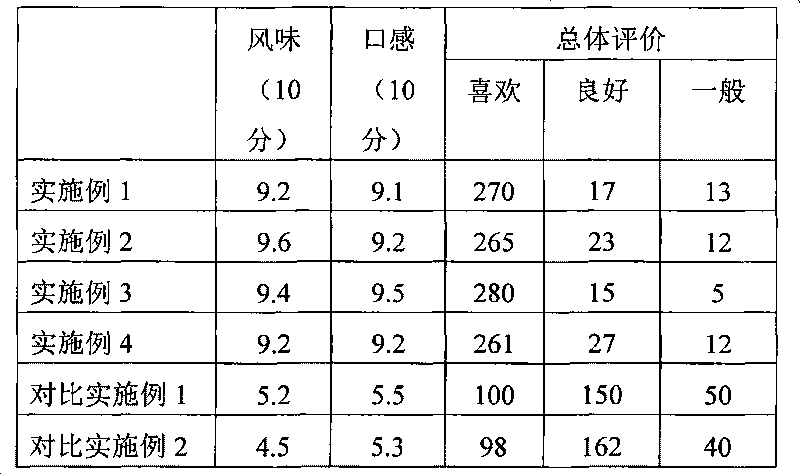

Method for preparing fermented dairy products with unique flavor

The invention relates to the field of producing dairy products, more specifically to a method for preparing fermented dairy products with unique flavor. The method for preparing fermented dairy products with unique flavor comprises the steps of adding reducing sugar to milk and heating the obtained product at 90 to 121 DEG C for 1 to 3 hours to perform Maillard reaction. The method has the advantages of overcoming technical prejudice against the Maillard reaction, utilizing the Maillard reaction from a novel perspective so as to improve the flavor and taste of fermented dairy products, givingmilk unique flavor and rich aroma through the Maillard reaction and preserving the nutritional value of milk by designing process parameters.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Domestic direct yoghourt ferment and preparation method thereof

The invention relates to the food technology field, in particular to a domestic DVS yoghurt starter culture and a preparation method thereof. The invention discloses a domestic DVS yoghurt starter culture which is freeze-dried powder prepared from a composition containing a protective agent and probiotics. The domestic DVS yoghurt starter culture is characterized in that the proportion by weight of the protective agent and the probiotics in the composition is equal to 1.0:0.1-100, wherein, the protective agent consists of the following components (proportion by weight): 0.1 percent to 5.0 percent of sodium glutamate, 0.1 percent to 8.0 percent of milk sugar, 0.1 percent to 2 percent of antioxidant, 1 percent to 30 percent of milk powder, 800.1 percent to 5.0 percent of glycerin or tween and water as the rest. The domestic DVS yoghurt starter culture disclosed by the invention has strong fermentation activity and 5.0 multiplied by 10<6> cfu / g to 5.0 multiplied by 10<10> cfu / g of viable count, can be inoculated directly when producing acidophilus milk or fermented dairy products without intermediate succesive transfer culture and being convenient for use, and can promote the specialization, socialization, standardization and unification of the production of the acidophilus milk and other fermented dairy products and improve the quality of the fermented dairy products, thereby guaranteeing the interest and health of consumers.

Owner:BIOGROWING CO LTD

Probiotics enriched crisp apple products and preparation method thereof

The present invention discloses probiotics enriched crisp apple products and a preparation method thereof, and belongs to the technical field of agricultural product processing. Apples are used as raw materials, the apples are washed, the washed apples are blanched, a vacuum soaking method is used to enrich probiotics into apple tissues, and then a vacuum freeze-drying and vacuum microwave combined drying method is used to prepare the probiotics enriched crisp apple products. The method comprises the following steps: (1) raw material washing and blanching; (2) probiotic soaking liquid preparing; (3) vacuum soaking; and (4) vacuum freeze-drying and vacuum microwave combined drying. The prepared probiotics enriched fruit and vegetable crisp products are mellow in fruit fragrance, and crisp and tasty. The viable probiotic number can be maintained at 10<7> CFU / g at 25 DEG C for 90 days or more. The preparation method avoids the two major defects of high cholesterol risk of the probiotic fermented milk products and the non-consumption of lactose intolerant population, and the products combine health care and leisure, and have broad market prospects.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

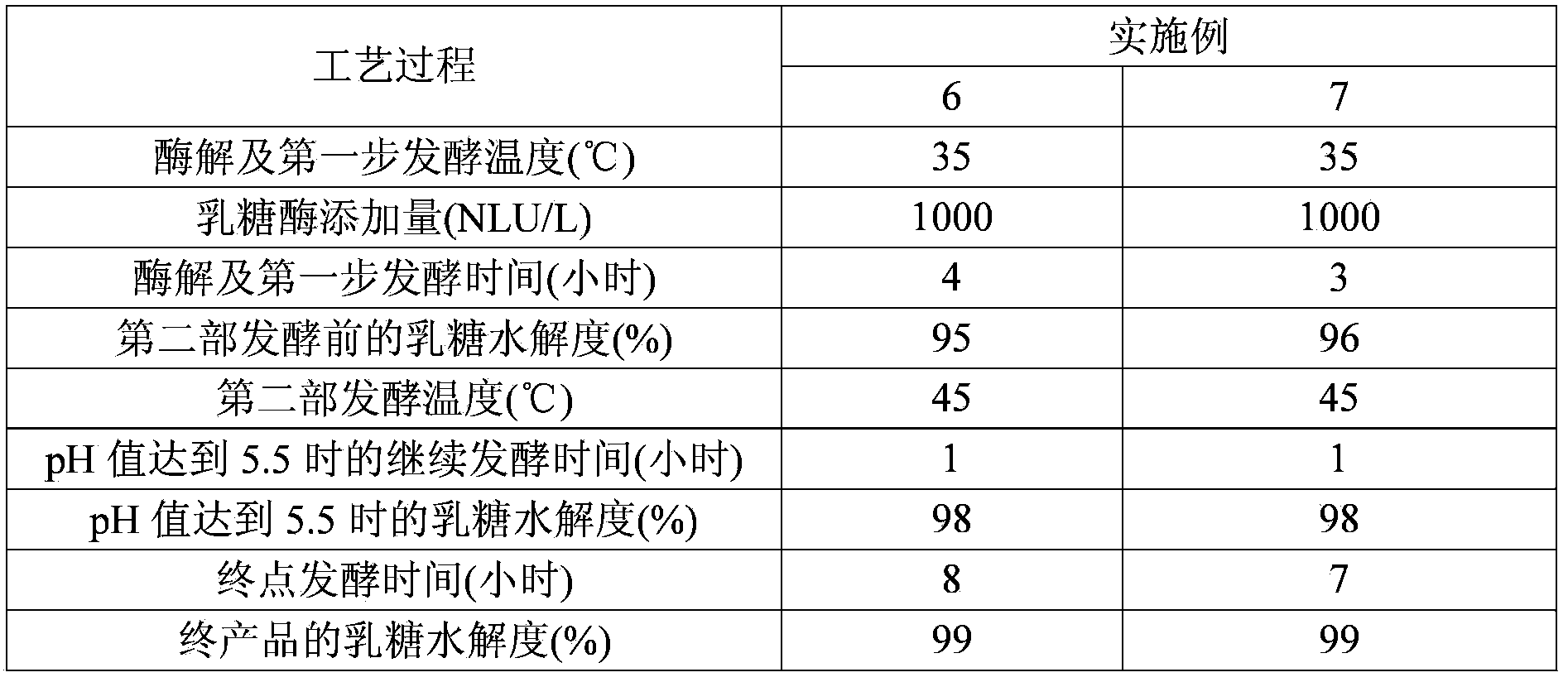

Preparation method of lactose-free fermented dairy product

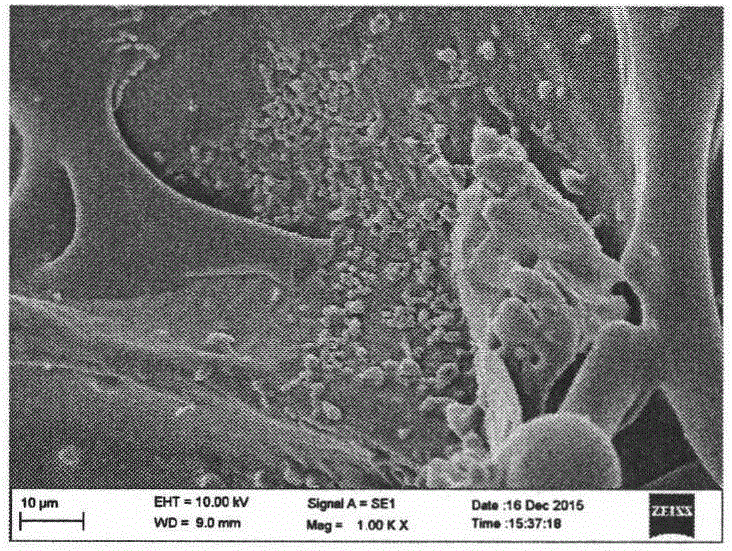

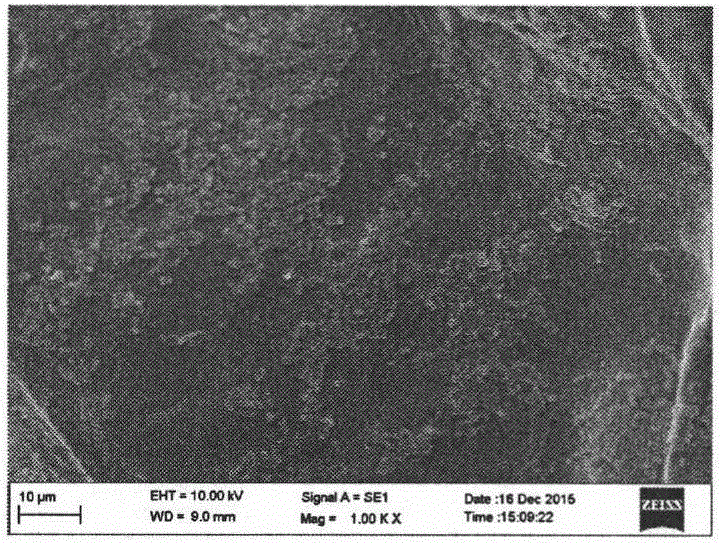

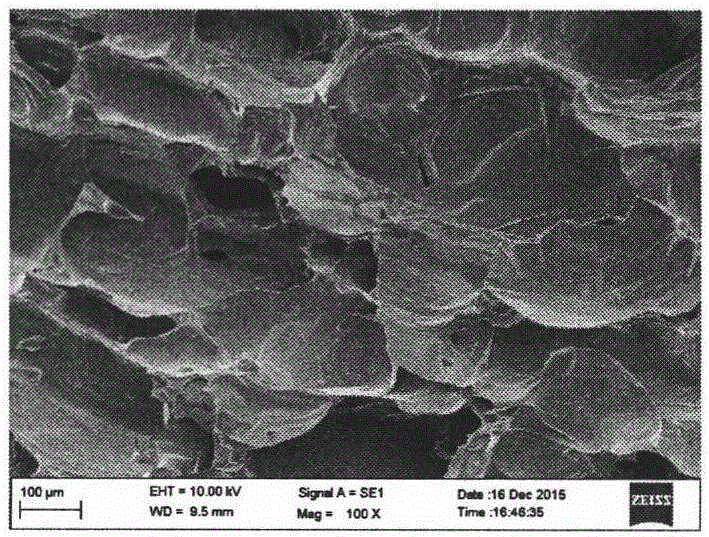

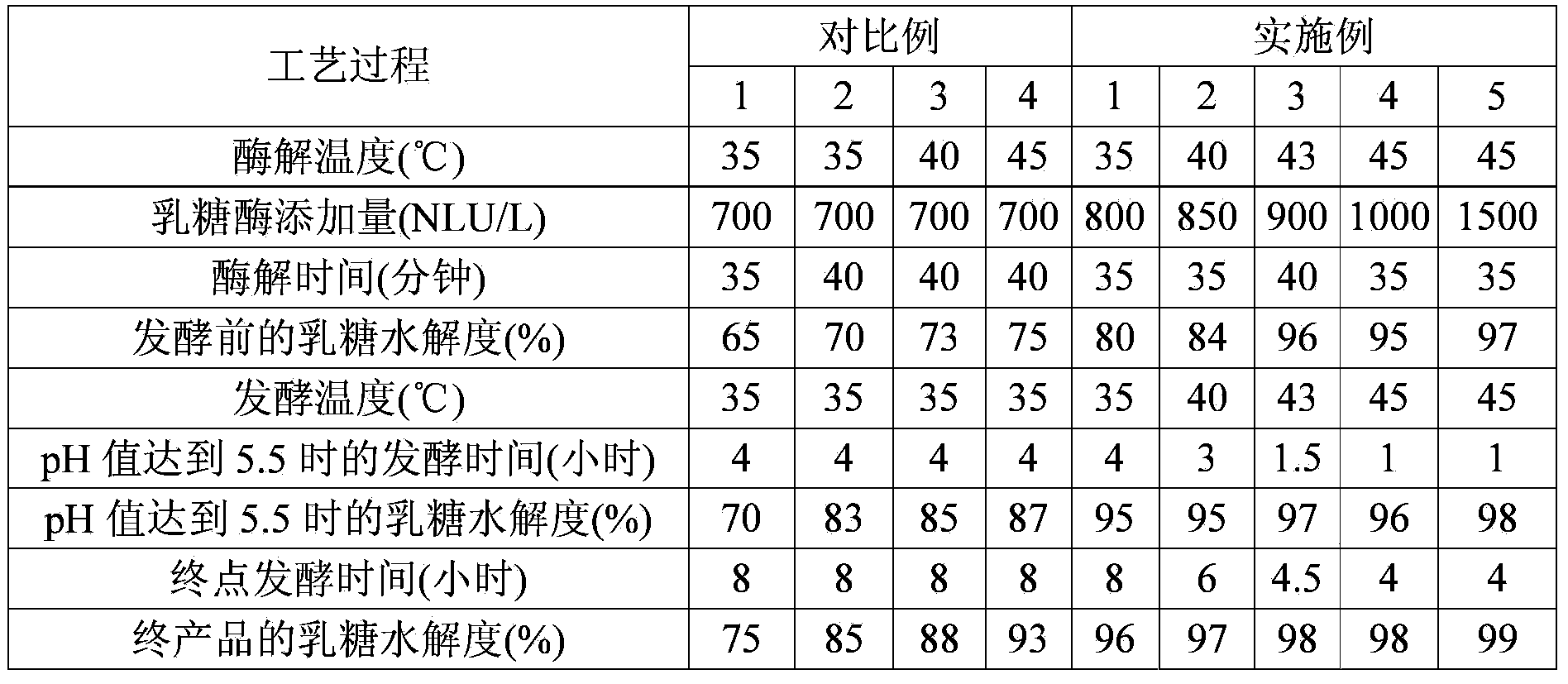

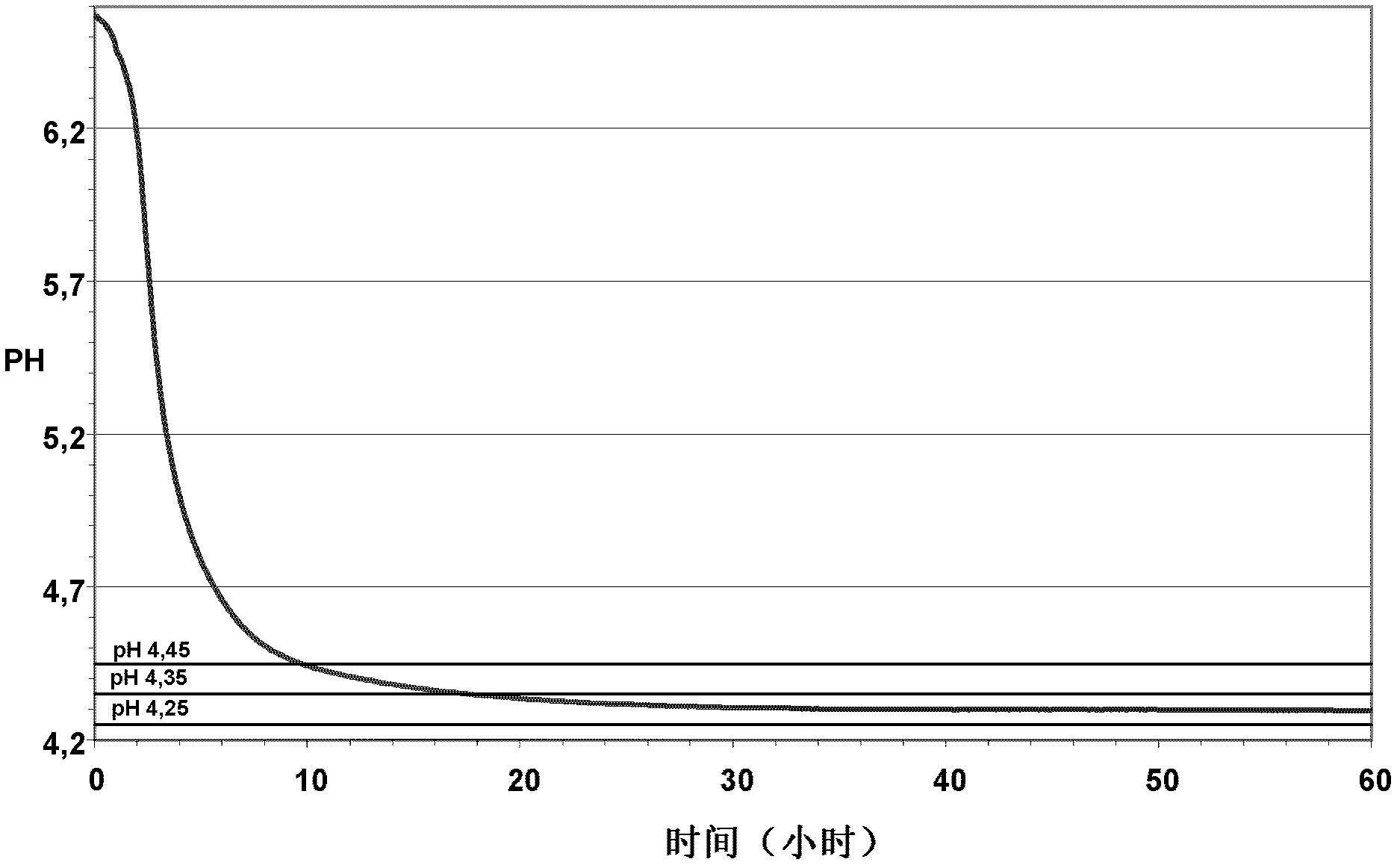

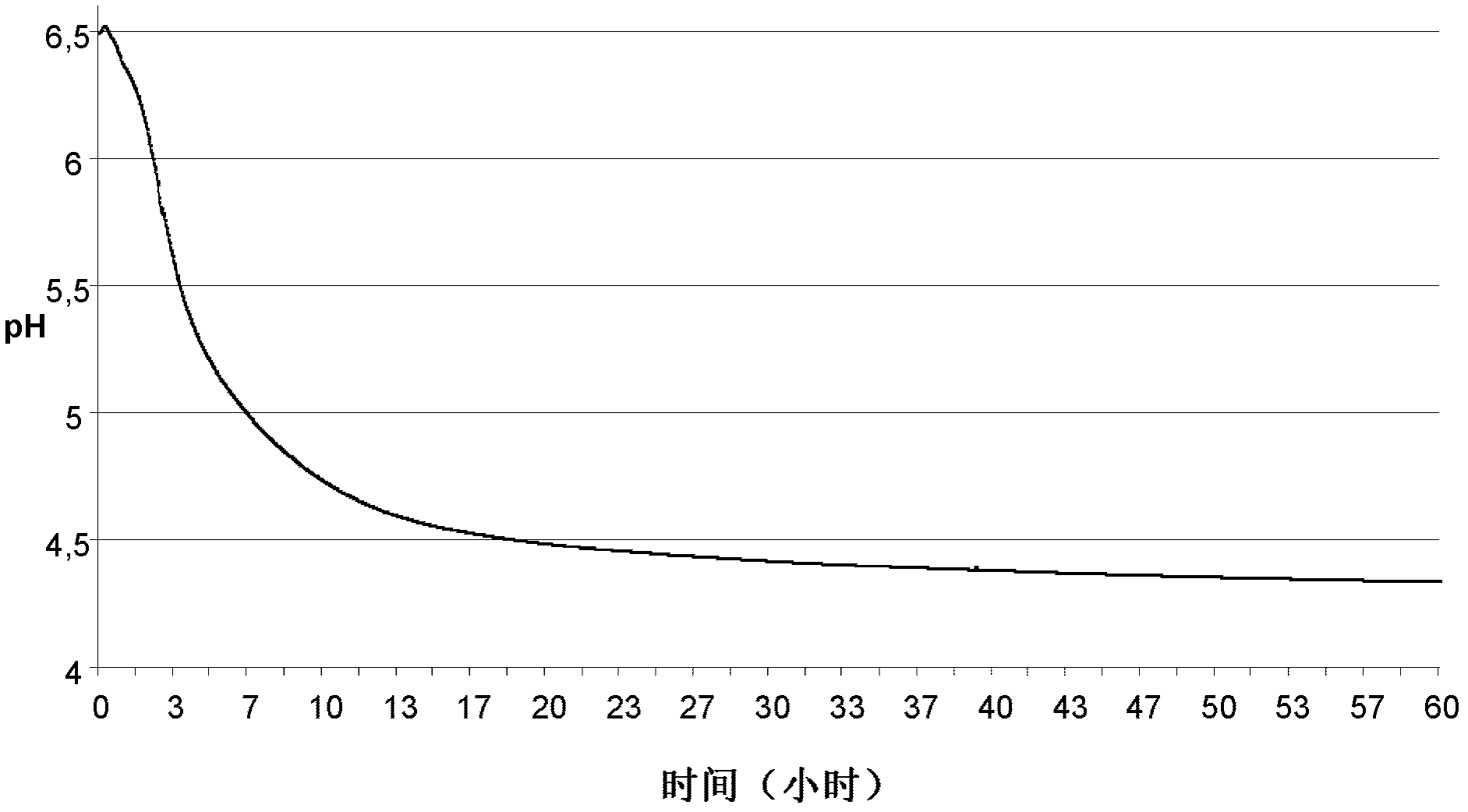

The invention provides a preparation method of a lactose-free fermented dairy product. The method comprises the following steps: blending, homogenizing, sterilizing, carrying out enzyme-hydrolyzing, fermenting, filling and refrigerating all the raw materials in sequence to obtain the lactose-free fermented dairy product, wherein the enzymatic hydrolysis and fermentation steps comprise the following processes: adding lactase at the temperature of 35-40 DEG C, hydrolyzing till the degree of hydrolysis is above 80 percent, and then adding stains; or adding lactase at the temperature of 41-45 DEG C, hydrolyzing till the degree of hydrolysis is above 95 percent, and then adding stains; fermenting till the pH value of feed liquid is 5.5, starting to inactivate the lactose and ending the fermentation when the pH value of the feed liquid is 4.3-4.5; or adding lactose and medium temperature strains at the temperature of 30-35 DEG C, fermenting till the pH value of feed liquid is 5.5, then rising the temperature to 40-45 DEG C and adding thermophilic stains, and ending the fermentation when the pH value of the feed liquid is 4.3-4.5. The preparation method has the benefit that through addition of the lactose and improvement of a fermented milk preparation process, the lactose-free fermented dairy product can be effectively prepared and obtained.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

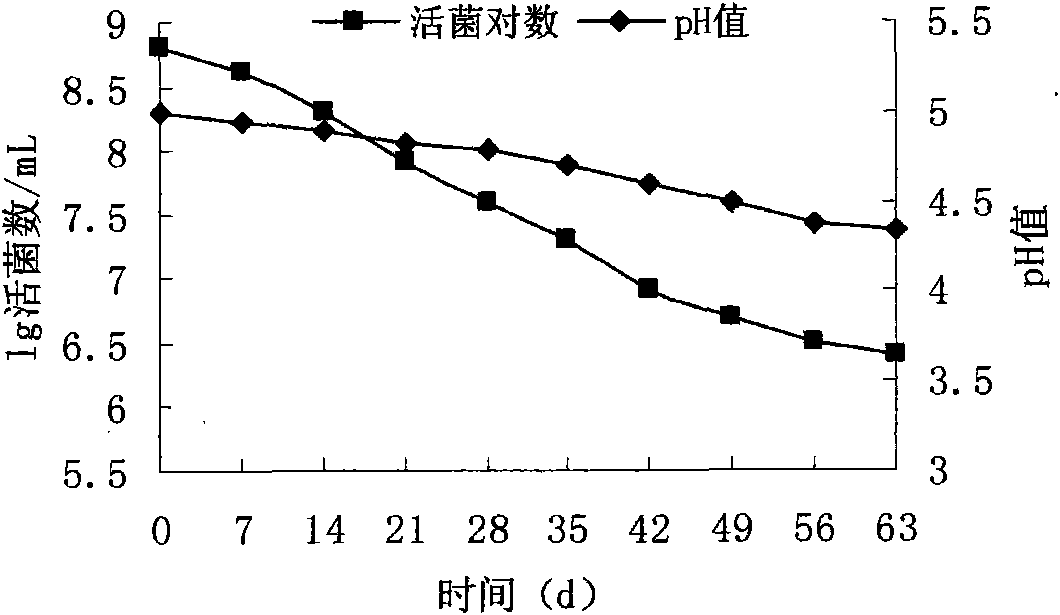

Lactobacillus rhamnosus grx19 and its application

The invention relates to lactobacillus rhamnosus grx19 and its application. The collection number of the lactobacillus rhamnosus grx19 is CGMCC No.5519. The stain can be used to produce live bacteria lactobacillus beverages with long shelf-life and fermented dairy products. Lactobacillus rhamnosus grx19 is taken as culture starter alone or in combination with other lactic acid bacterias and then live bacteria lactobacillus beverages and fermented dairy products are prepared according to routine methods. After heat treatment at the temperature of 70-75 DEG C for 15-20 seconds, by the adoption of aseptic filling or sanitary filling, live bacteria lactobacillus beverages and fermented dairy products sold at room temperature can be produced.

Owner:YANGZHOU UNIV

High-density culture method for lactic acid bacteria

ActiveCN102191202ARaw materials are easy to getBacteriaMicroorganism based processesBiotechnologyCulture mediums

The invention relates to a high-density culture method for lactic acid bacteria. The method comprises the following steps of: activating the lactic acid bacteria in a basic culture medium to obtain two generations; and inoculating the two generations according to the inoculation quantity of 1 percent to a fermentation culture medium to ferment at the temperature of between 35 and 38 DEG C for 20 to 24 hours so as to obtain high-density lactic acid bacteria fermenting liquid, wherein the fermentation culture medium consists of 0.5 to 1.5 percent of soy peptide, 3 to 5 percent of composite fruit and vegetable juice and the balance of raw milk. In the culture method, the raw materials of the fermentation culture medium are easy to obtain; other substances are not added in the culture process, so the method is simple and practicable; the viable bacterium number of the lactic acid bacteria in the fermenting liquid can reach 8.9*10<10> to 2.7*10<11> cfu / mL; and the lactic acid bacteria can serve as base materials of probiotic fermented milk and fermented milk beverage and can be directly used for producing other fermented milk products.

Owner:JUNLEBAO DAIRY GRP CO LTD

Fragrant pig derived cholesterol-assimilating and oxygen-resistant bifidobacterium BZll

Provided is fragrant pig derived cholesterol-assimilating and oxygen-resistant bifidobacterium BZll. The fragrant pig derived cholesterol-assimilating and oxygen-resistant bifidobacterium BZll is Bifidobacterium animalis subsp.Lactis, the pure culture of the fragrant pig derived cholesterol-assimilating and oxygen-resistant bifidobacterium BZll is preserved at the China General Micro-biological Culture Collection Center (CGMCC), China Microbial Culture Preservation Management Committee, the address is Institute of Microbiology, Institution No.3 China Academy of Science, Western Beichen Road No.1 in Chaoyang District of Beijing in China, the postal code is 100101, the preservation number is CGMCC NO.10224, and the Bifidobacterium animalis subsp.Lactis BZll is called for short. The Bifidobacterium animalis subsp.Lactis BZll is high in cholesterol-assimilating capacity, acid resistance and cholate resistance, good in oxygen resisting performance, has probiotic property and can serve as probiotics to be added into a fermentative milk product to produce a functional food, bifidobacterium culture resources are enriched, and development of bifidobacterium health-care products is facilitated.

Owner:奈安制药(中国)有限公司

Preparation method and application of weakly post-acidified yogurt compound fermentation agent, and corresponding yogurt

The present invention discloses a preparation method and an application of a weakly post-acidified yogurt compound fermentation agent, and corresponding yogurt. The fermentation agent is prepared by mixing four bacterium powders of streptococcus thermophilus JMCC16, streptococcus thermophilus JMCC0019, streptococcus thermophilus JMCC0022 and lactobacillus bulgaricus subsp. JMCC0018 at bacterium number of 1,000:(1-10,000):(1-1,000):(1-100), and after a weakly post-acidified treatment, the weakly post-acidified yogurt compound fermentation agent JLB-1510 is obtained. The prepared yogurt compoundfermentation agent is applied in fresh cow milk / reconstituted milk for fermentation to prepare weakly post-acidified yogurt. The four bacterium powders are all excellent strains isolated from traditional fermented dairy products in China, and scientific and reasonable in a ratio. Lactic acid and aroma substances produced by using lactose are utilized, so that the fermented yogurt is sour, sweet and tasty. Besides, the weakly post-acidified yogurt compound fermentation agent overcomes a problem that during existing yogurt transportation process, yogurt post-acidification caused by an imperfectcold chain affects product mouthfeel and state. The compound fermentation agent JLB-1510 is applicable to all yogurt and can effectively control post-acidification when further applied in yogurt fermentation.

Owner:JUNLEBAO DAIRY GRP CO LTD

Exopolysaccharides-producing lactobacillus plantarum for adsorbing monophthalate effectively

The invention relates to the biotechnical field, particularly relates to the field of production and development of functional lactic acid bacteria, more particularly relates to exopolysaccharides-producing lactobacillus plantarum for adsorbing monophthalate effectively. The strain number of the exopolysaccharides-producing lactobacillus plantarum for adsorbing monophthalate effectively is RS20D, and the exopolysaccharides-producing lactobacillus plantarum for adsorbing monophthalate effectively is registered and preserved in China General Microbiological Culture Collection Center (CGMCC) with the preservation number of CGMCC No.13272 and the preservation date of November 14, 2016. The lactobacillus plantarum RS20D provided by the invention is functional lactic acid bacteria which has acid resistance, grows well in an environmental condition of pH 3.0-9.0, and particularly has the characteristic of adsorbing monophthalate and producing exopolysaccharides, for example, the lactobacillus plantarum RS20D is developed to a health-care food or drug which is taken for a long time to improve intestinal flora, and the damage of a phthalate plasticizer on a human body is reduced; or, the lactobacillus plantarum RS20D is input to a fermenting diary product or a cheese product, so that the sensory characteristic of the product can be improved.

Owner:SICHUAN AGRI UNIV

Process for manufacturing of a fermented dairy product

InactiveCN102695421AGuaranteed fermentation temperatureMilk preparationOther dairy technologyLactic acid bacteriumFermentation

The present invention relates to a process for manufacturing fermented dairy products, in particular stirred milk products. The invention concerns a process for the manufacture of a fermented dairy product without any cooling step for stopping fermentation due to the use of a weakly post-acidifying lactic bacterium culture as a starter.

Owner:YOPLAIT FRANCE +1

Mutant lactobacillus bulgaricus strains free from beta-galactosidase activity

InactiveUS20050196388A1Increase capacityReduced post-acidificationBiocideMilk preparationBiotechnologyBeta-galactosidase activity

The invention concerns mutant L. bulgaricus strains bearing a nonsense mutation, in at least one of the sequences coding for the lactose operon, and free from β-galactosidase activity, and lactic starters comprising these strains. The strains and starters can be used to obtain fermented milk products from glucose-added milk.

Owner:DANONE

Acid sensitivity lactobacillus bulgaricus strain and usage thereof

InactiveCN101586087ASolve the defect of short shelf lifeReduce manufacturing costMilk preparationBacteriaStability studyFruit juice

The invention provides an acid sensitivity lactobacillus bulgaricus strain and the usage thereof, belonging to the biological engineering technology field. An acid sensitivity strain L.B-FM-6 which is a lactobacillus delbrueckii subsp. bulgaricus is separated and screened in the research of the natural dairy ferment-tibet kefir. The research on the storage stability of the fermented dairy product, fermented juice and the fermented vegetable juice which are fermented by the combination of the strain L.B-FM-6 and other microbial strains solves the defects of short shelf life of the active lactobacillus drink and displays the superiority of the strains in fermenting the dairy product and the juice.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

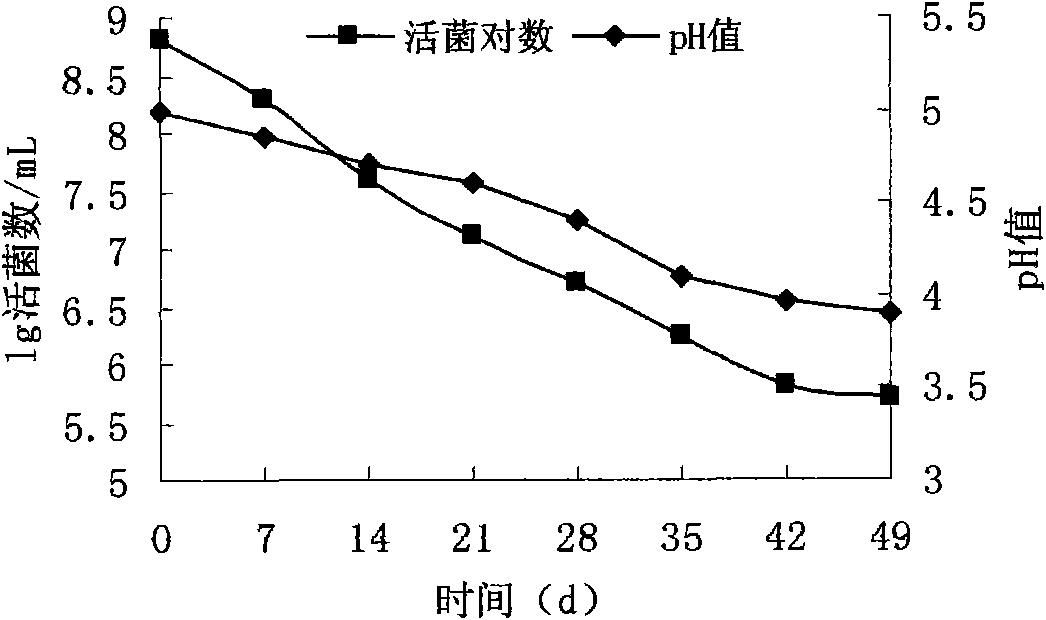

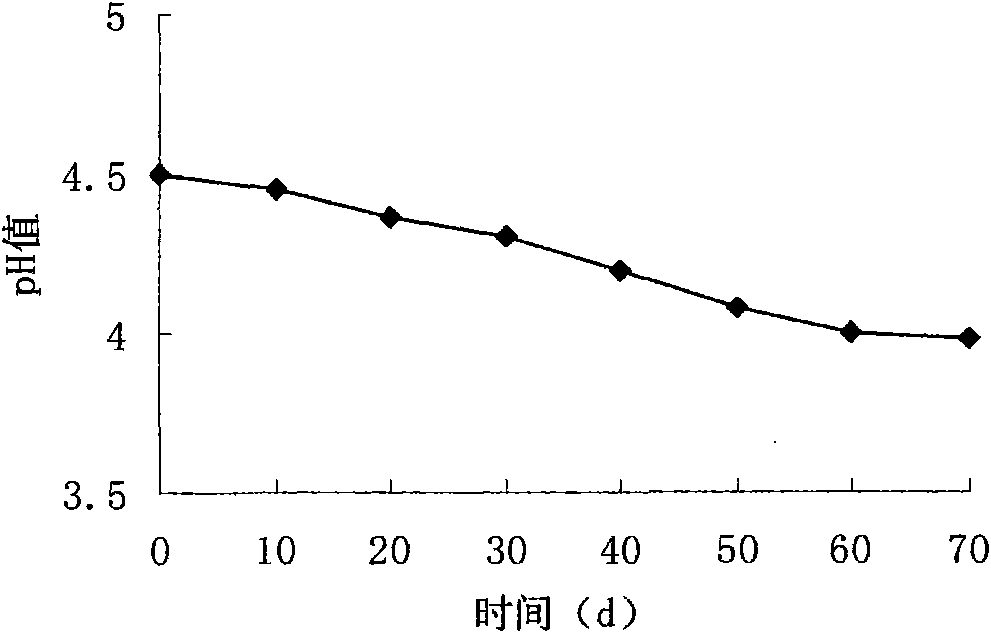

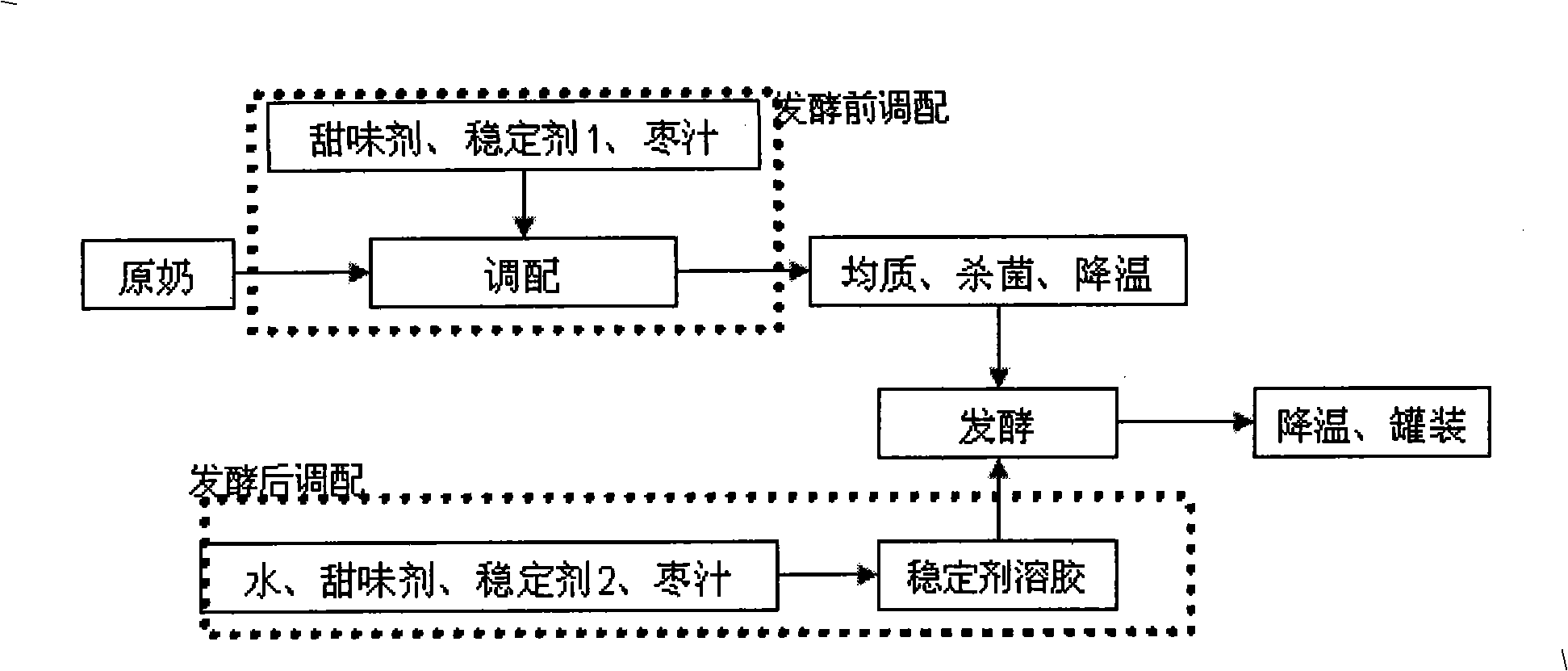

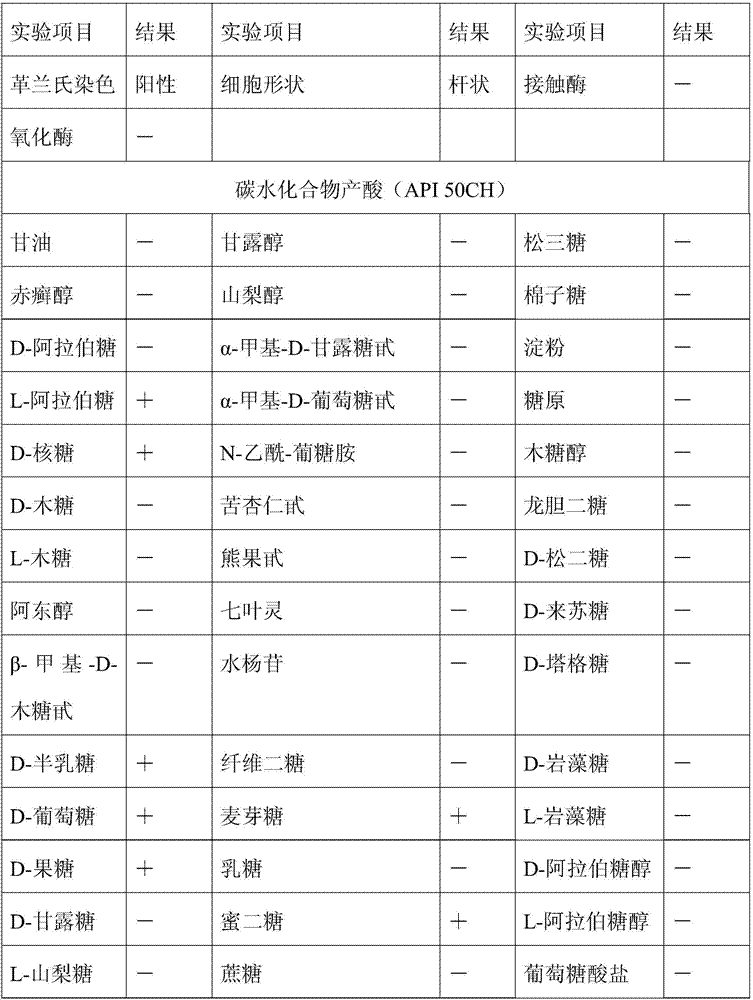

Red date fermentation dairy food and method for making same

InactiveCN101326932AMake up for the defect of single flavorHas nutritional and health valueMilk preparationFood preparationDairy foodsAdditive ingredient

The invention relates to a red-date fermented milk product and a preparation method thereof. The product contains the ingredients of raw milk, fermentation agent, stabilizer added prior to fermentation and or stabilizer added after fermentation as well as sweeting agent and / or water. The product also contains jujube juice. According to the mixture ratio, the product contains 300-950 proportions of the raw milk, 1-500 proportions of the jujube juice,1-100 proportions of the sweeting agent and 0-700 proportions of the water; the raw materials are achieved by blending, homogenizing,sterilizing, cooling and fermentation. The fermented milk prepared bu the invention has the flavor of red date, and the fermented milk is more favorable to nourishment and healthcare.

Owner:JUNLEBAO DAIRY GRP CO LTD

Lactobacillus caucasus JMCC0101 with antioxidant function, and screening method and application thereof

ActiveCN107058161AImprove antioxidant capacityImprove anti-aging effectMilk preparationBacteriaMicroorganismFlavor

The invention relates to a lactobacillus caucasus JMCC0101 with an antioxidant function. The lactobacillus caucasus JMCC0101 is a probiotic separated and screened from a traditional fermented milk product in Dali in Yunnan Province in China; the bacterial strain is preserved at the General Microbiology Center of the China Committee for Culture Collection of Microorganisms with the preservation number of CGMCC No.11772. The lactobacillus caucasus JMCC0101 is finally screened through experiments such as sample collection, enrichment, separation, purification and identification in sequence. The lactobacillus caucasus JMCC0101 has very good acid and bile salt tolerant characteristic and antioxidant ability, good survival property, weak acid property and a fermentation flavor. The lactobacillus caucasus JMCC0101 is applied to preparation of probiotic powder or lactic acid bacteria beverage.

Owner:JUNLEBAO DAIRY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com