Fermented dairy product and preparation method and raw material composition thereof, lactobacillus plantarum application

A technology for fermented dairy products and raw material compositions, applied in dairy products, applications, milk preparations and other directions, can solve the problems of difficult fermentation preparation, inability to grow, slow growth of Lactobacillus plantarum, etc., and achieves expansion of species and balance of intestinal bacteria. Group, the effect of relieving lactose intolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw material composition of fermented dairy products: fresh milk 82%, Guangming Dairy Co., Ltd., protein 3.0%, fat 3.1%; tomato juice 10%; white sugar 7%; pectin 0.2%; modified starch 0.5%; plantaractobacillus 10% 6 cfu / mL.

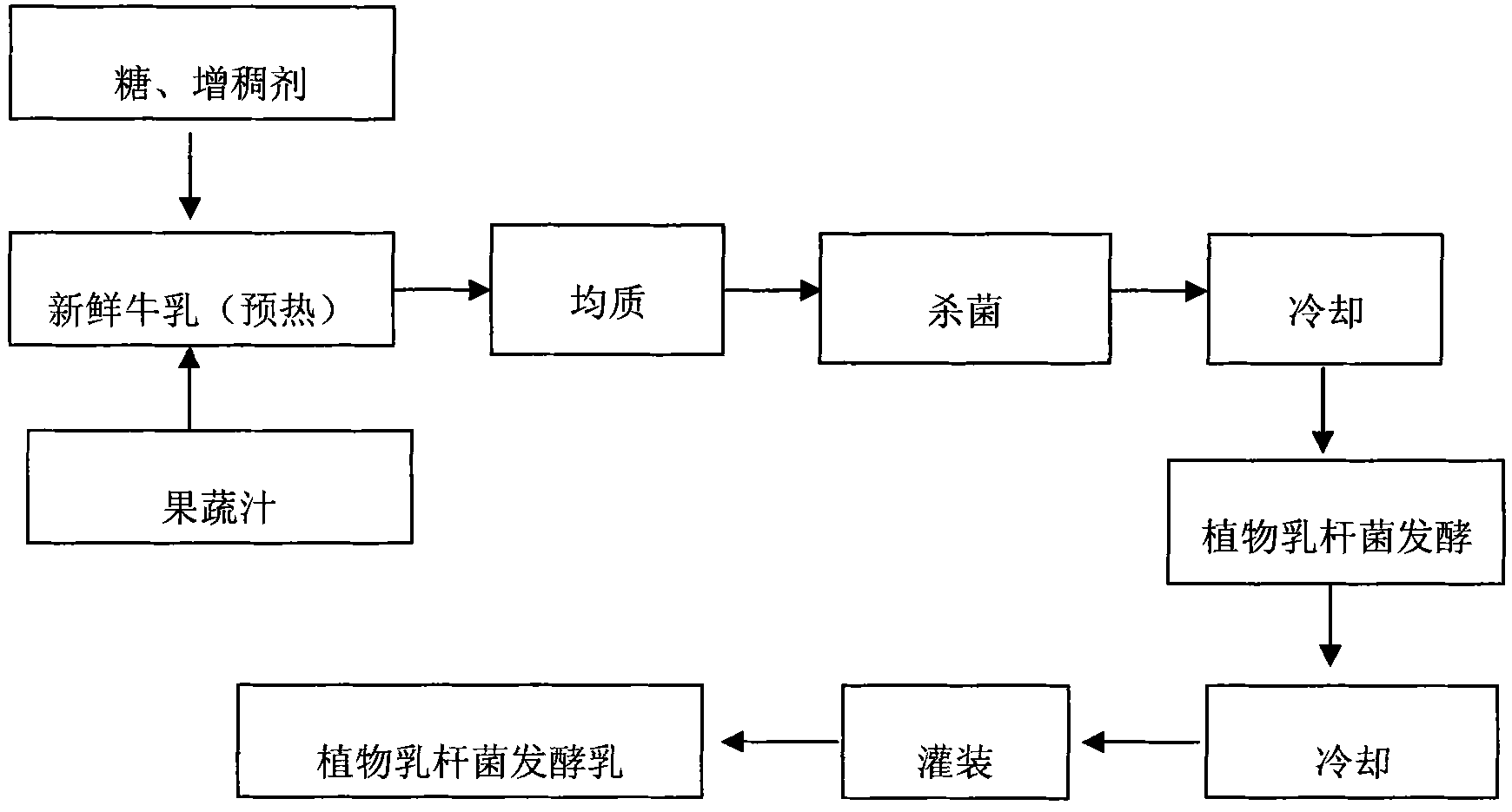

[0046] Preparation method of fermented milk: heat fresh milk to 40-50°C, mix with white sugar, pectin, modified starch and tomato juice at high speed; preheat to 60-65°C, homogenize at 20MPa; sterilize at 90-95°C 5min; cool to 30~42℃, inoculate Lactobacillus plantarum 10 6 cfu / mL, heat preservation and fermentation for 6-8 hours; turn over the tank when pH=4.5, then cool to 10-20°C; fill at 10-20°C; store in cold storage (4-10°C).

[0047] When the fermented milk is stored at 4-10°C, the shelf life is 25 days. Lactobacillus plantarum was greater than 3×10 at the initial stage of storage 8 cfu / mL, Lactobacillus plantarum is greater than 2×10 at the end of the shelf life 7 cfu / mL.

Embodiment 2

[0049] Raw material composition of fermented dairy products: 87% of fresh milk, Guangming Dairy Co., Ltd., 3.0% of protein, 3.1% of fat; 5% of tomato juice; 7% of white sugar; 0.15% of pectin; 0.2% of gelatin; 0.4% of modified starch; Lactobacillus plantarum 10 6 cfu / mL, Bifidobacterium 10 6 cfu / mL.

[0050] Preparation method of fermented milk: heat fresh milk to 40-50°C, mix with white sugar, pectin, gelatin, modified starch and tomato juice at high speed; preheat to 60-65°C, homogenize at 20MPa; 90-95°C Sterilize for 5 minutes; cool to 30-42°C, inoculate Lactobacillus plantarum 10 6 cfu / mL, heat preservation and fermentation for 5-7 hours; turn over the tank when pH=4.5, then cool to 10-20°C; fill at 10-20°C; store in cold storage (4-10°C).

[0051] The shelf life of fermented milk is 30 days when stored at 4-10°C. Lactobacillus plantarum was greater than 1×10 in the initial stage of storage 8 cfu / mL, Lactobacillus plantarum is greater than 5×10 at the end of the shelf...

Embodiment 3

[0053] Raw material composition of fermented dairy products: reconstituted milk 27%, skimmed milk powder (New Zealand Fonterra Group) and water are reconstituted at a mass ratio of 1:7, protein in skimmed milk powder is 34%; fructose syrup 3%; white granulated sugar 12%; water 57.66%; Pectin 0.3%; Flavor 0.04%; Lactobacillus plantarum 10 6 cfu / mL.

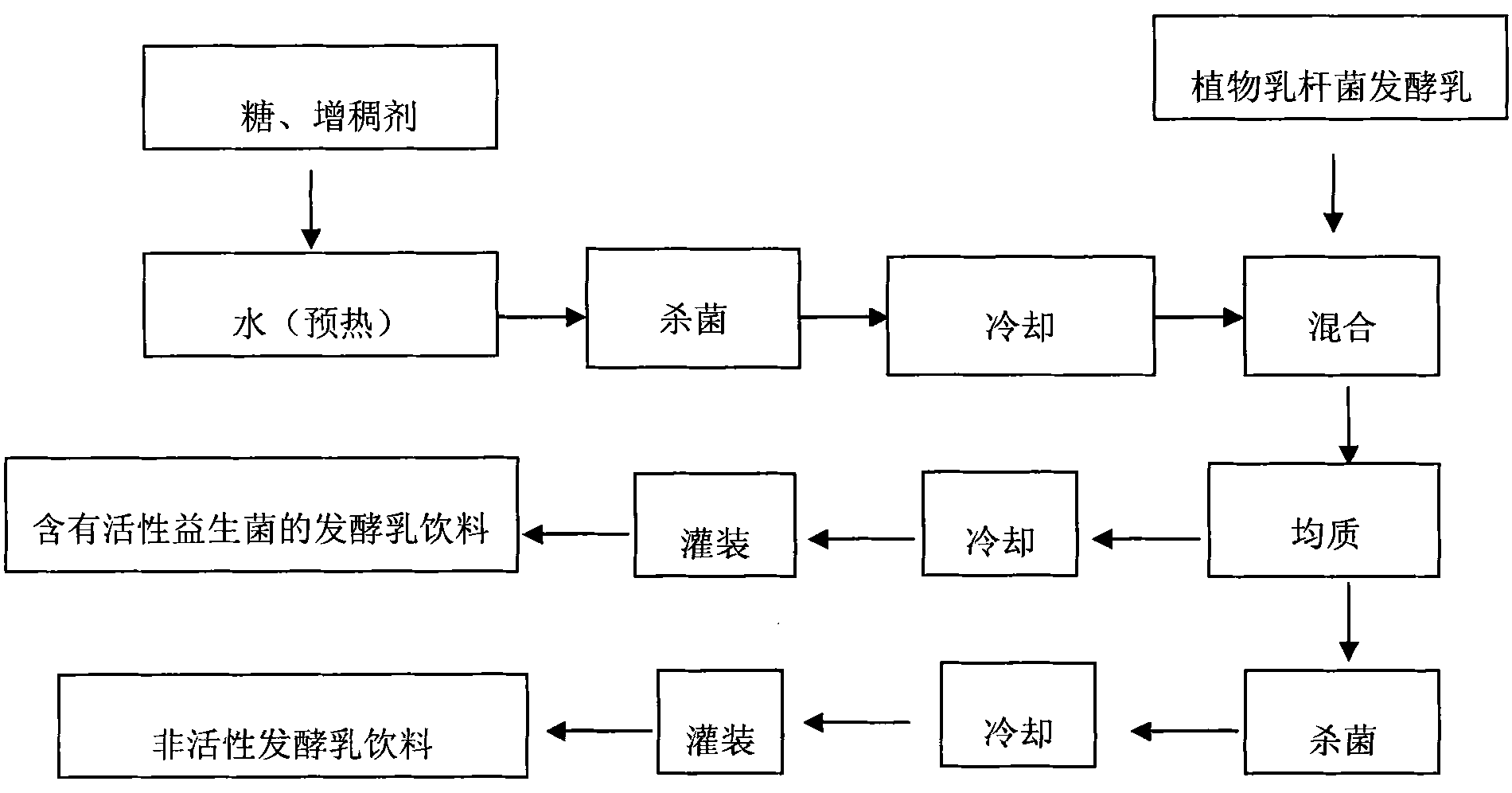

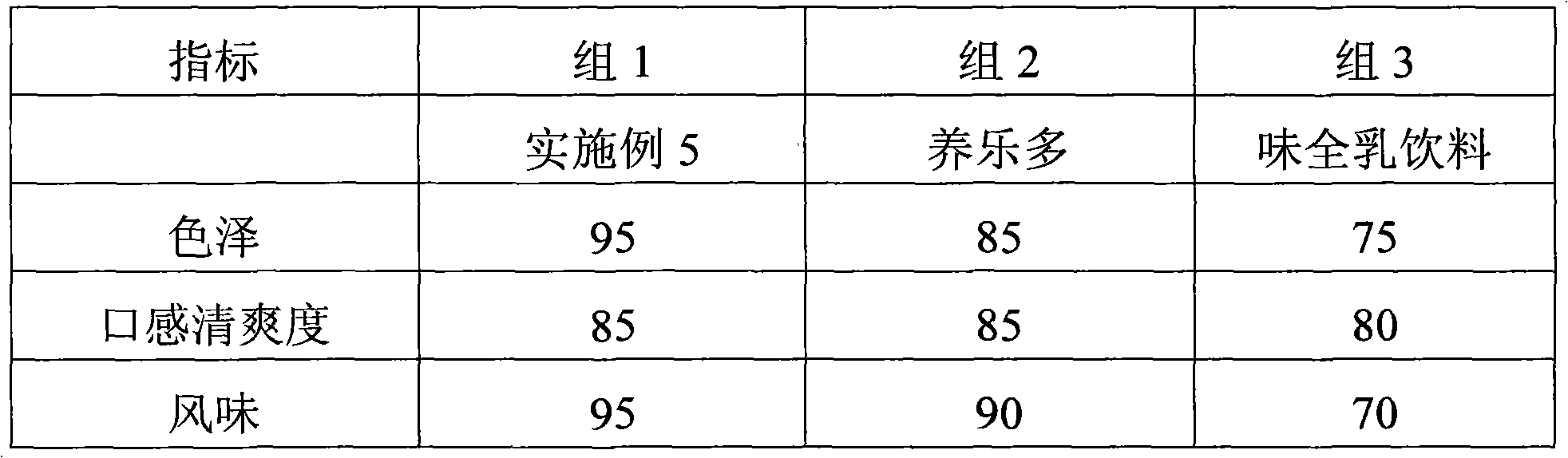

[0054] The preparation method of the fermented milk beverage containing active probiotics: heating reconstituted milk to 40-50°C, adding fructose syrup; preheating to 60-65°C, homogenizing at 20MPa; sterilizing at 90-95°C for 90 minutes; 30~42℃, inoculate Lactobacillus plantarum 10 6 cfu / mL, heat-preserved and fermented for 72 hours; turn over the tank when pH=4.4, and then cool to 10-20°C to obtain pre-fermented milk; mix white sugar, water, thickener, sterilize (90-95°C, 5min), After cooling to 10-20°C, mix it with the above-mentioned pre-fermented milk in proportion, homogenize at 20MPa, add essence when filling at 10-20°C; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com