Patents

Literature

226results about How to "Increase specification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

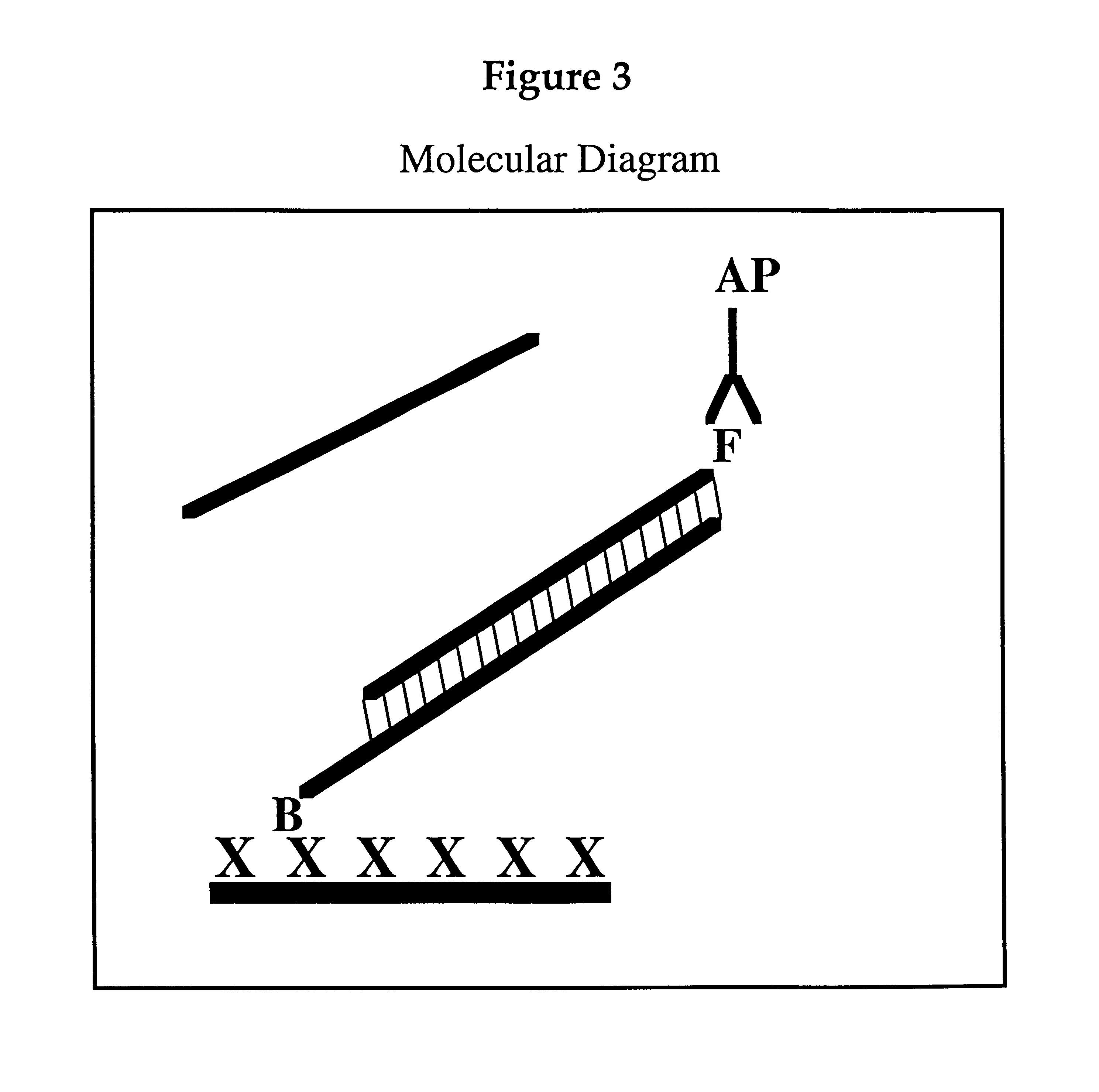

Methods for suppressing the binding of detectable probes to non-target sequences in hybridization assays

InactiveUS6110676AIncrease assayEasy to addSugar derivativesPeptide/protein ingredientsNucleic Acid ProbesTrue positive rate

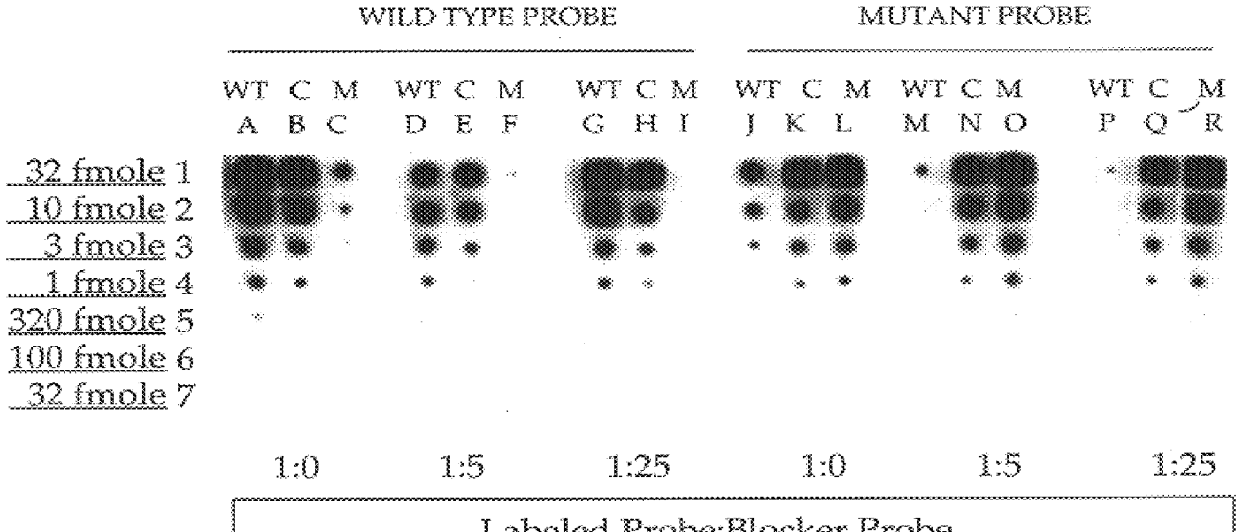

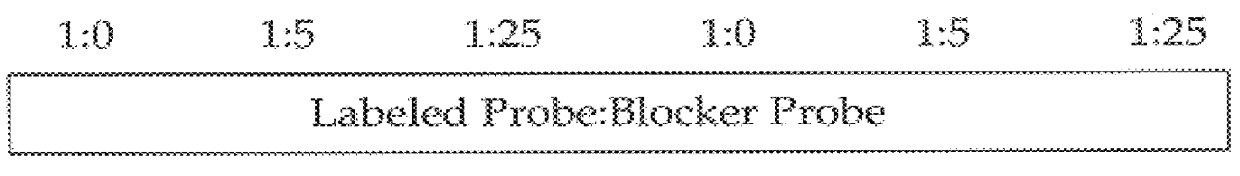

This invention relates to methods, kits and compositions suitable for the improved detection, analysis and quantitation of nucleic acid target sequences using probe based hybridization assays. The invention is more specifically directed to methods, kits and compositions suitable for suppressing the binding of detectable nucleic acid probes or detectable PNA probes to non-target nucleic acid sequences in an assay for a target nucleic acid sequence to thereby improve the reliability, sensitivity and specificity of the assay. The methods, kits and compositions of this invention are particularly well suited to the detection and analysis of nucleic acid point mutations.

Owner:APPL BIOSYSTEMS INC +1

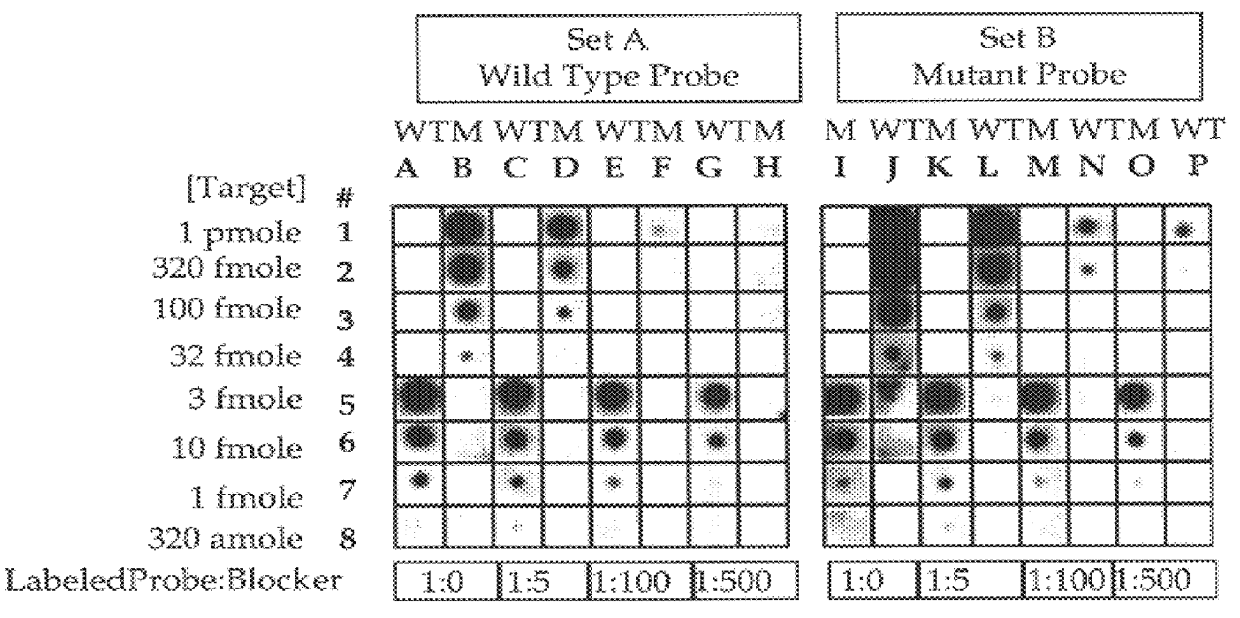

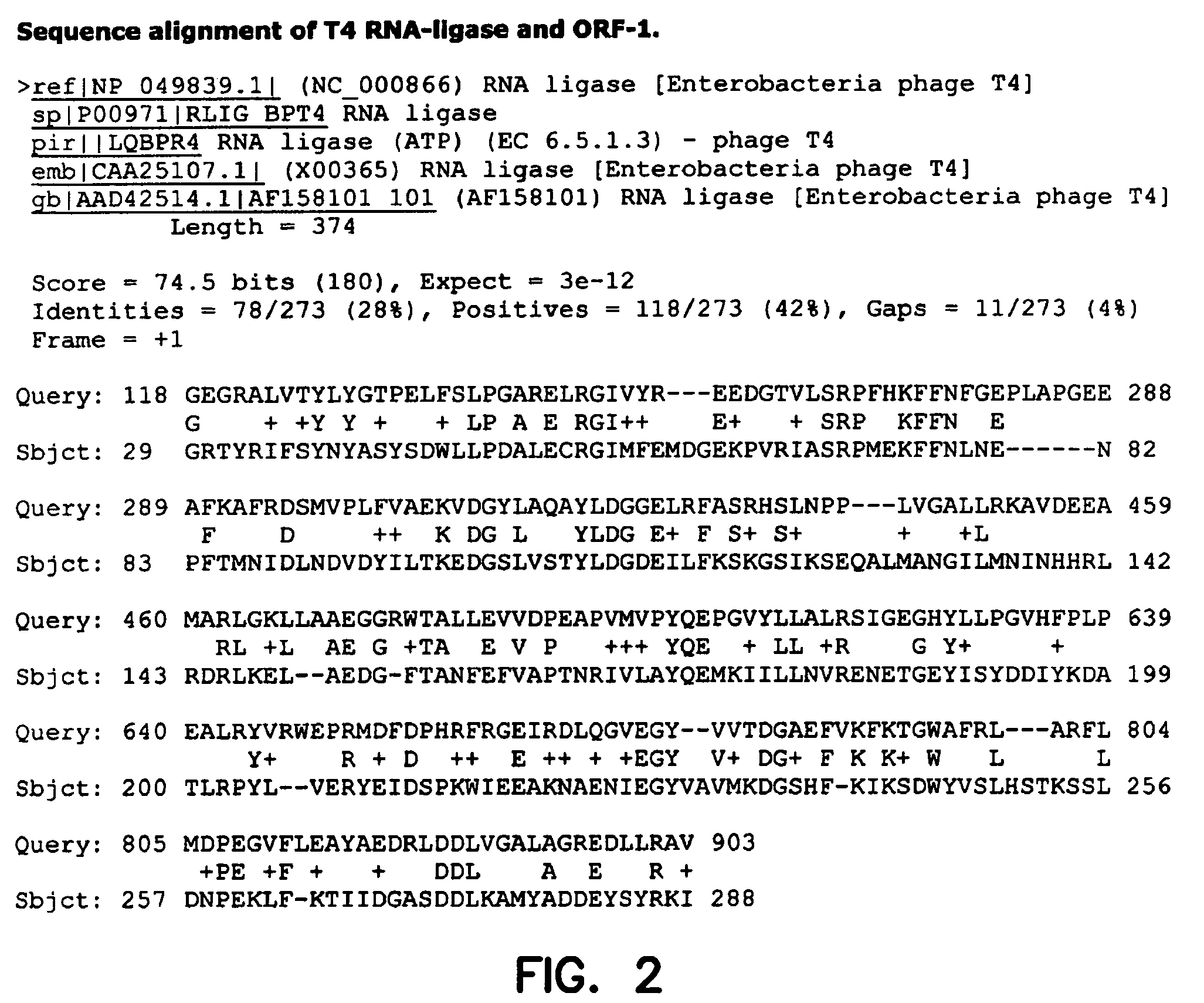

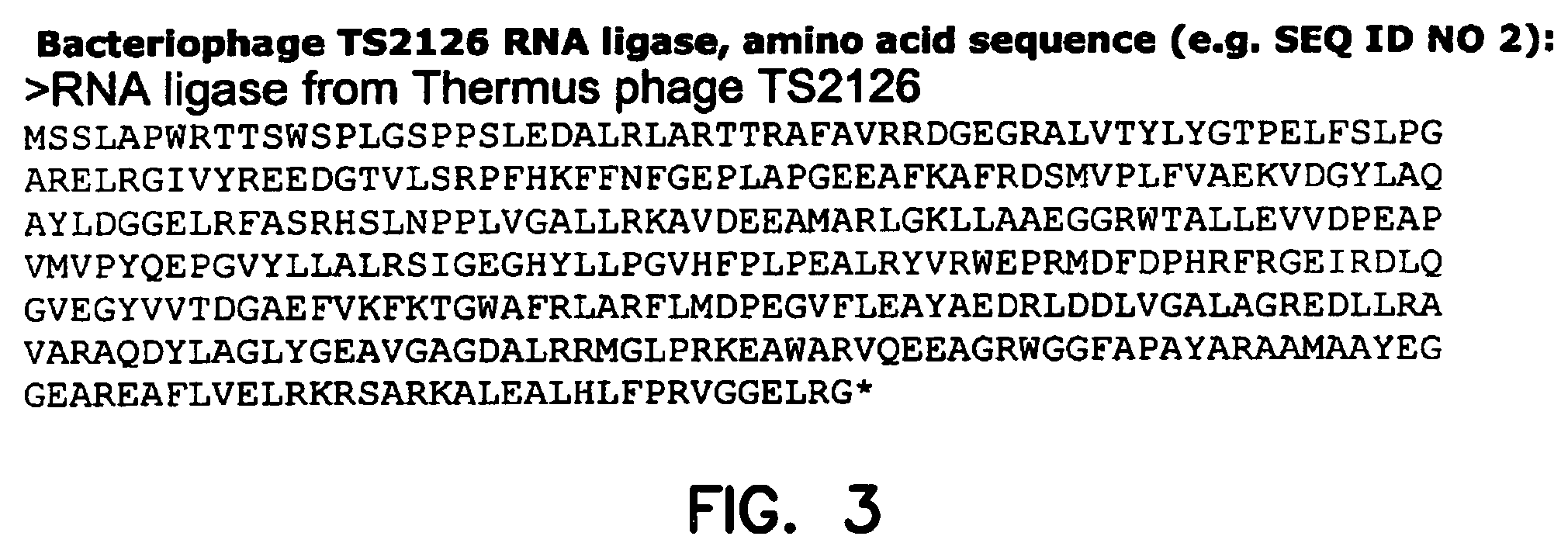

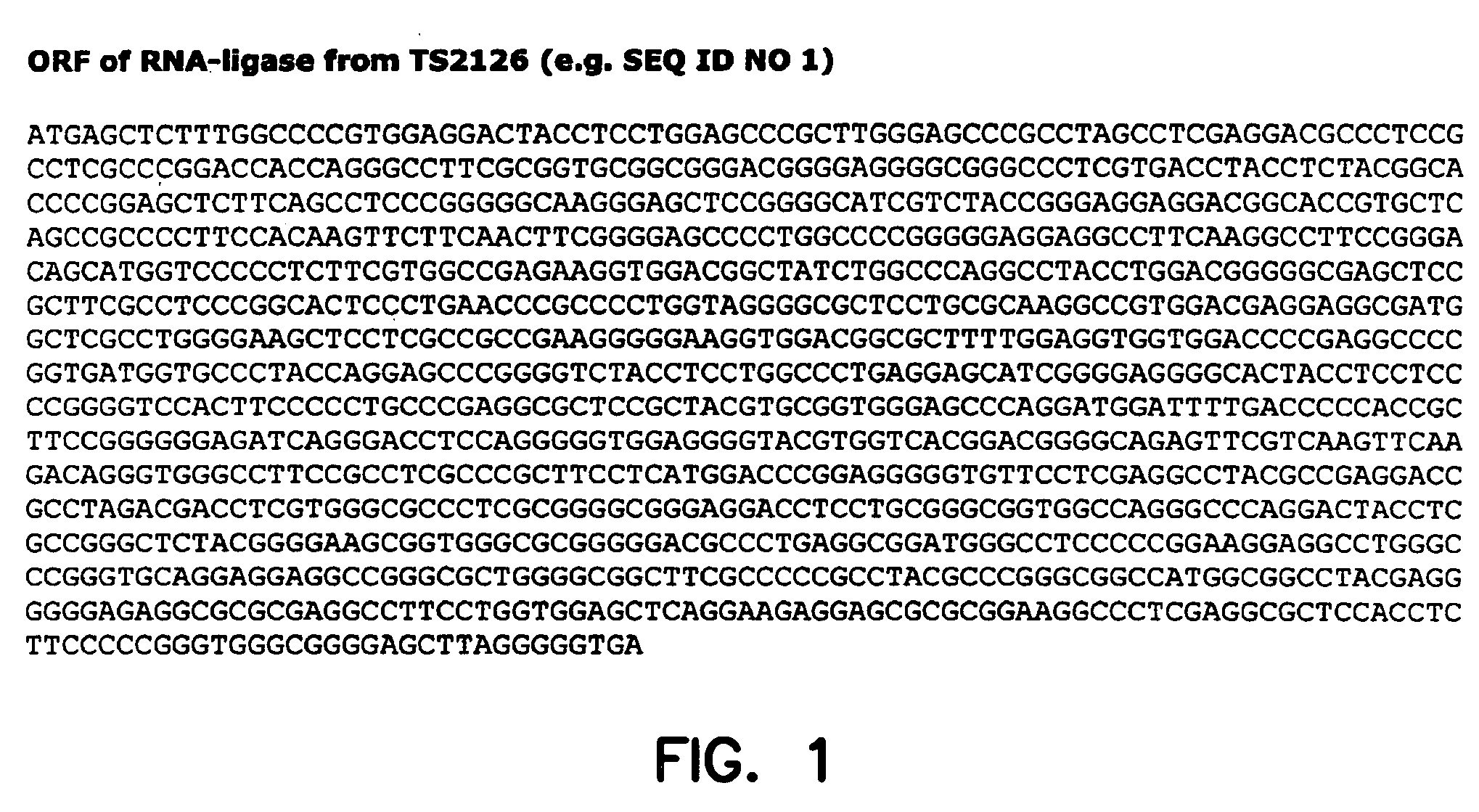

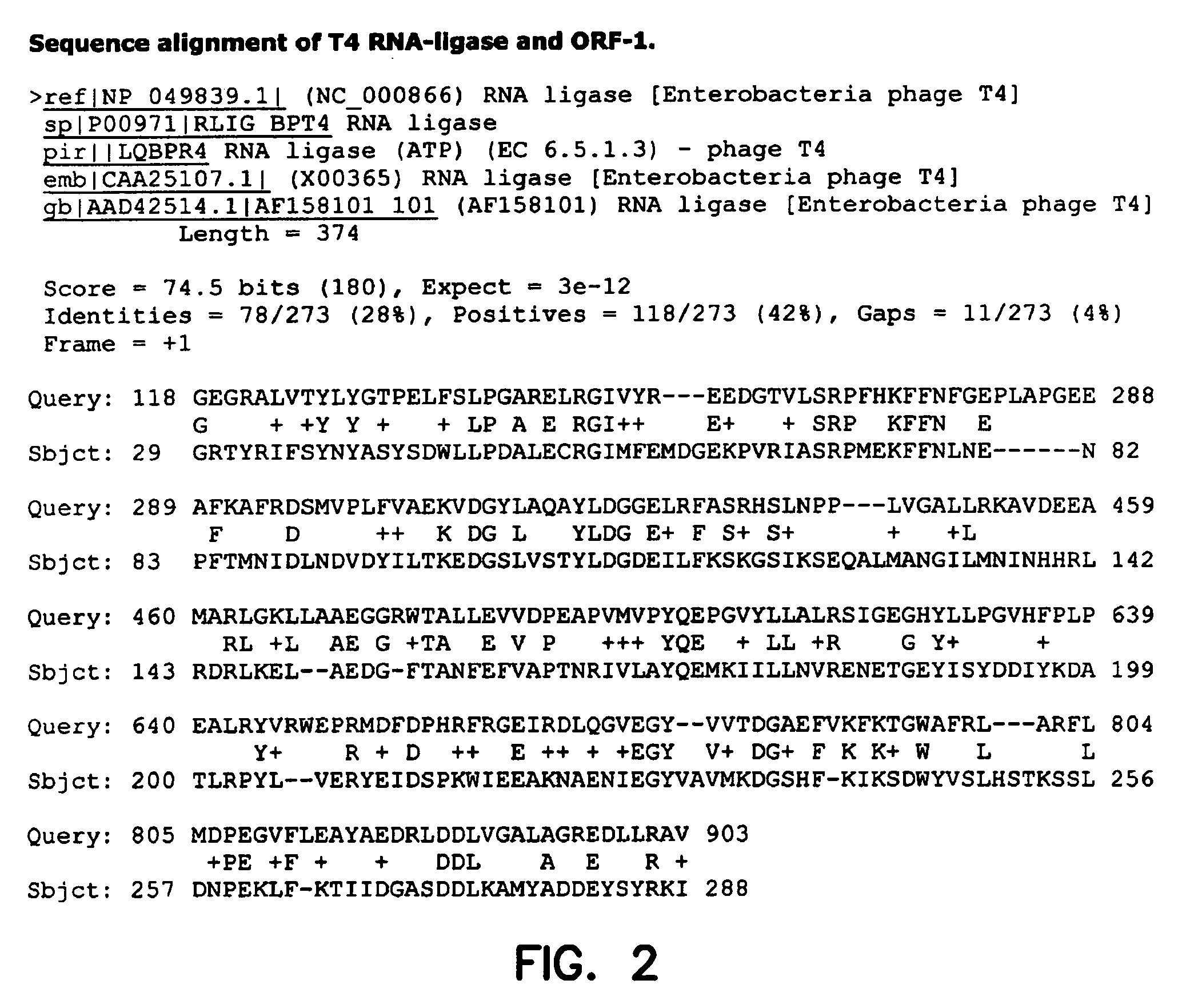

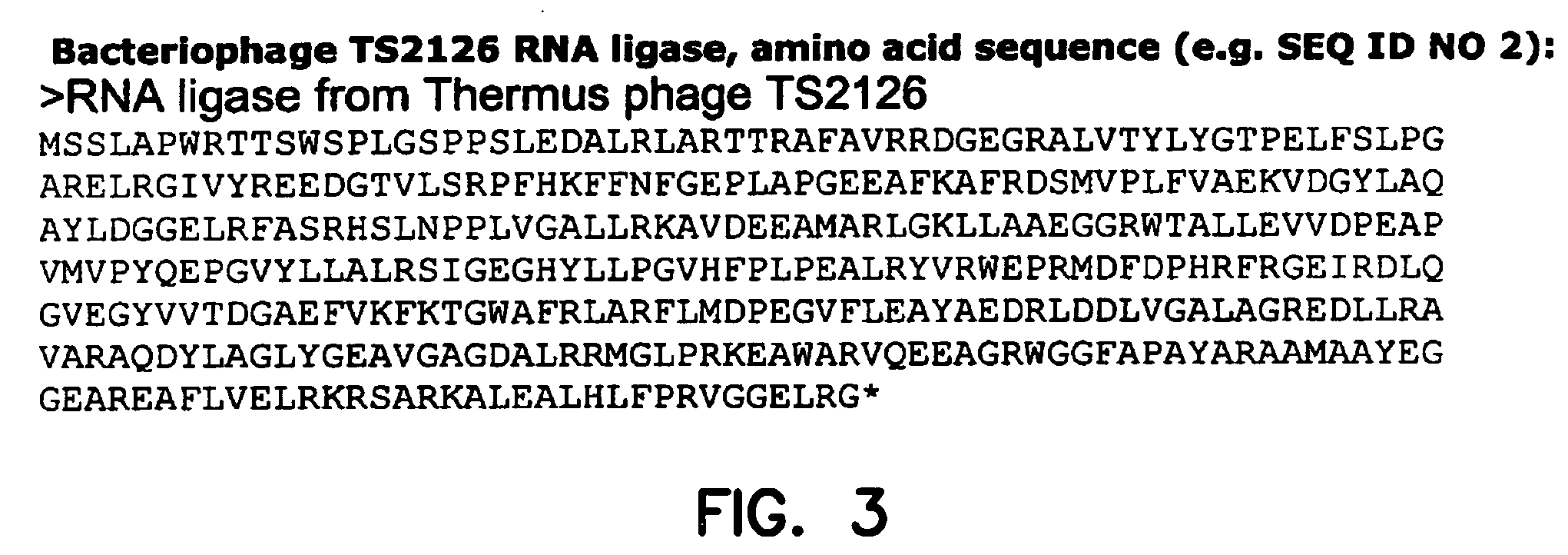

Thermostable RNA ligase from thermus phage

InactiveUS7303901B2Improve stabilityIncrease rangeSugar derivativesBacteriaGenus ThermusOpen reading frame

An RNA ligase derived from bacteriophage TS2126 which infects Thermus scotoductus, nucleic acids comprising nucleotide sequences of open reading frame (ORF) and polypeptides encoded by the nucleic acids, are described.

Owner:ILLUMINA INC

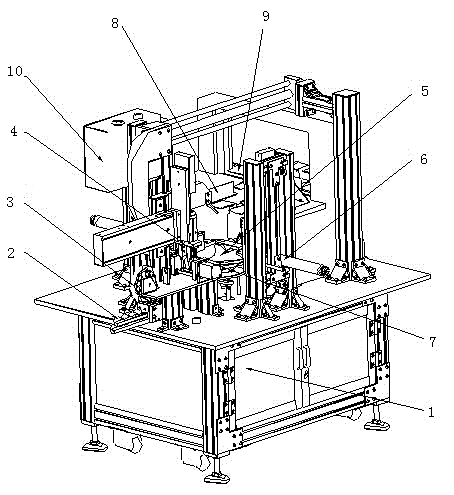

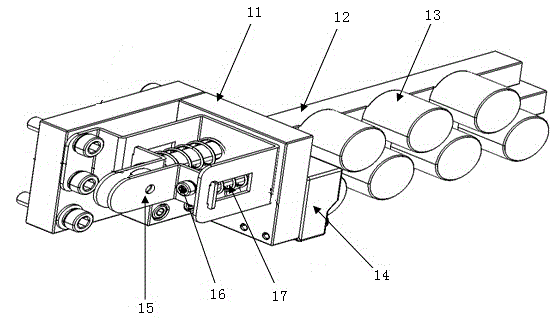

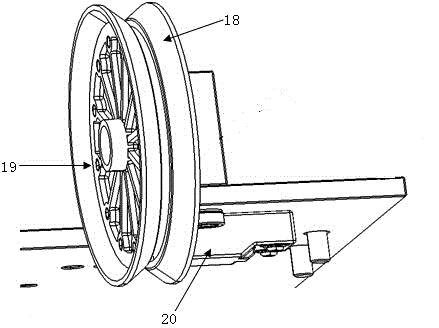

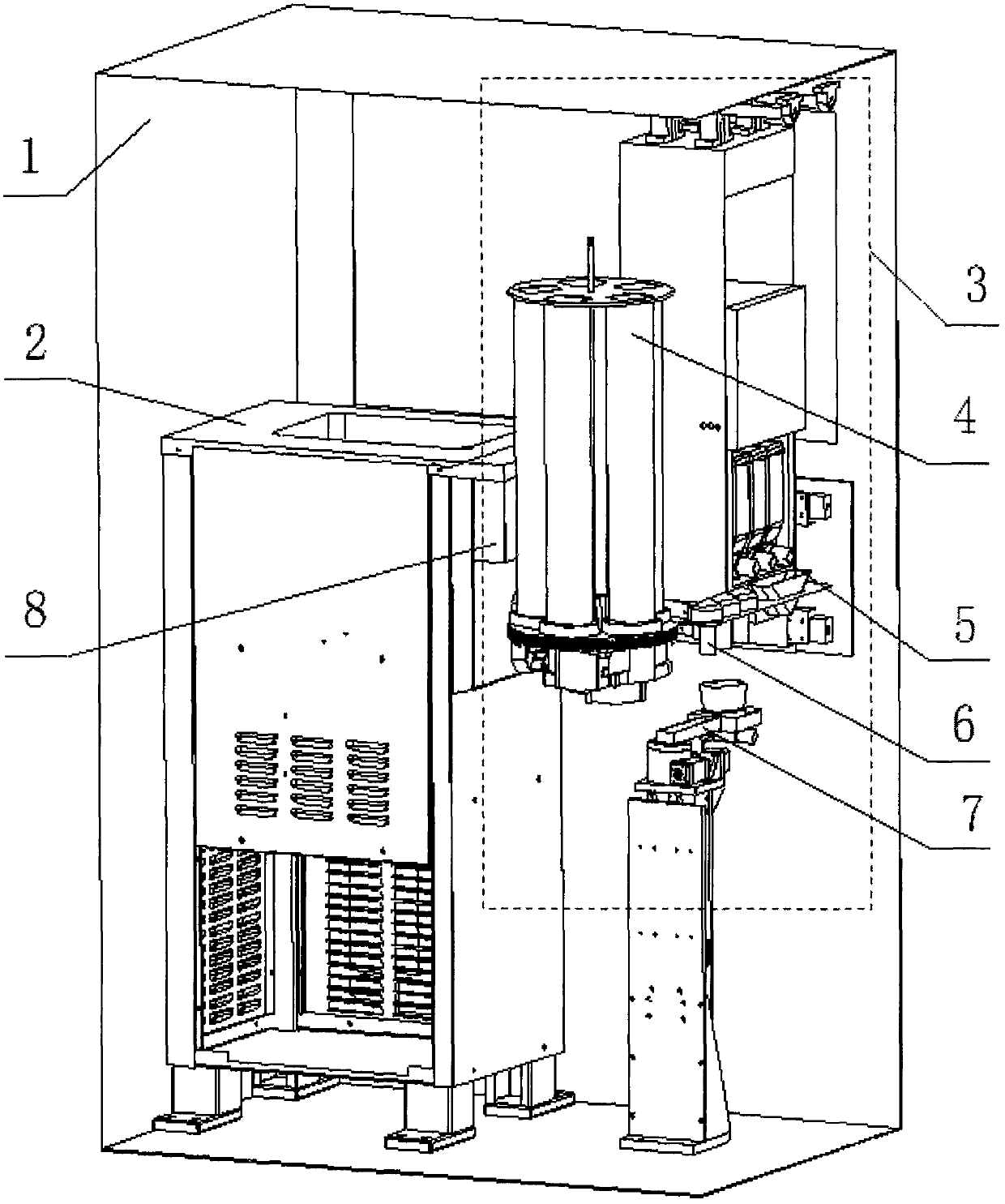

Winding machine

The invention provides a winding machine. According to the technical scheme, the winding machine comprises a wire arranging device, a meter counting device, a wire shearing device, a wire sending device, a wire winding device, a wire taking device, a wire pushing device, a bundling device and a display control device, all of which are installed on a rack. Automatic length metering, automatic shearing, automatic winding and automatic bundling can be achieved, operators only need to conduct operation such as wire replacing and simple fault removing, the production efficiency is greatly improved, and the consistency of winding shapes is ensured.

Owner:WUXI SHENGJING ELECTRONICS TECH CO LTD

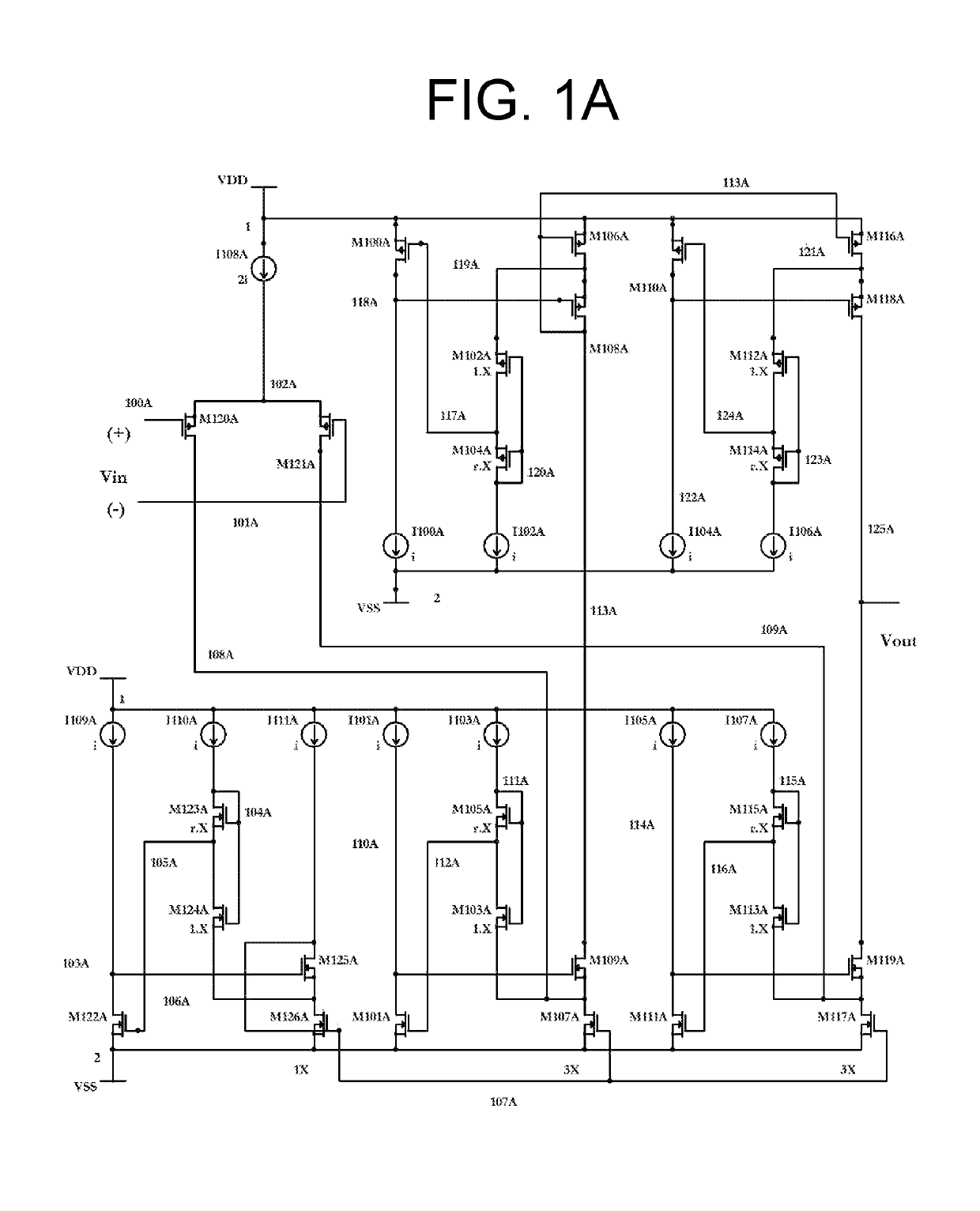

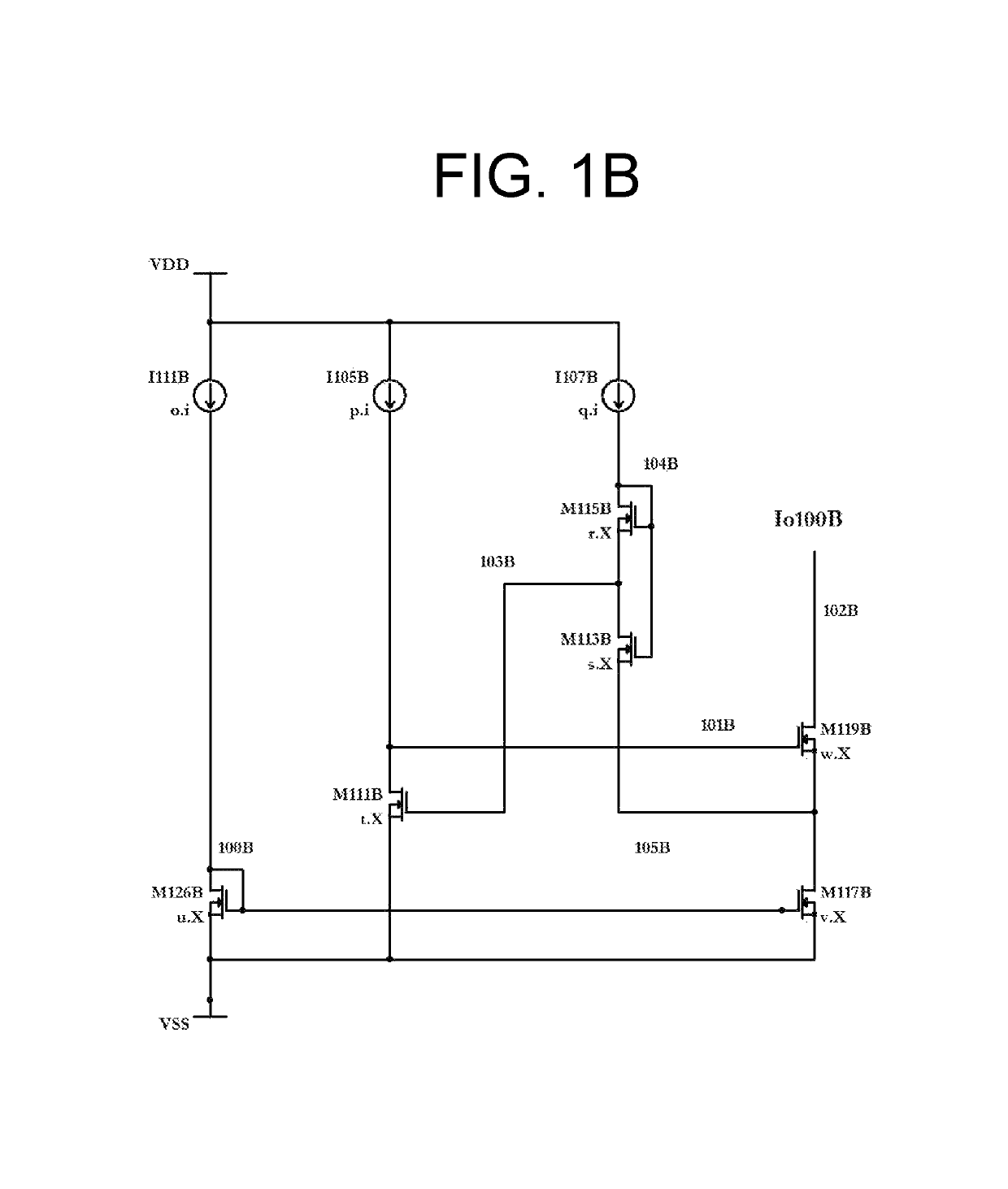

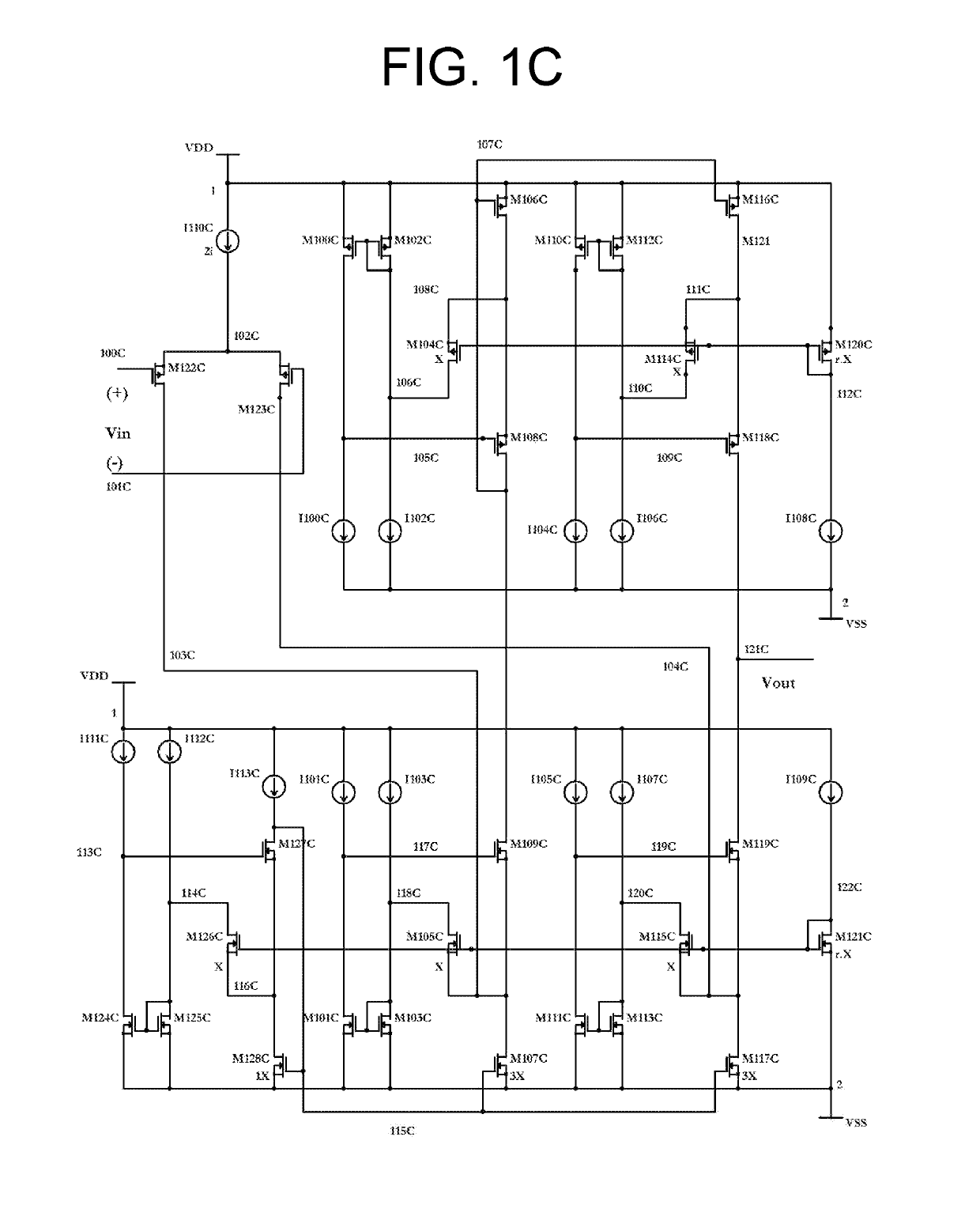

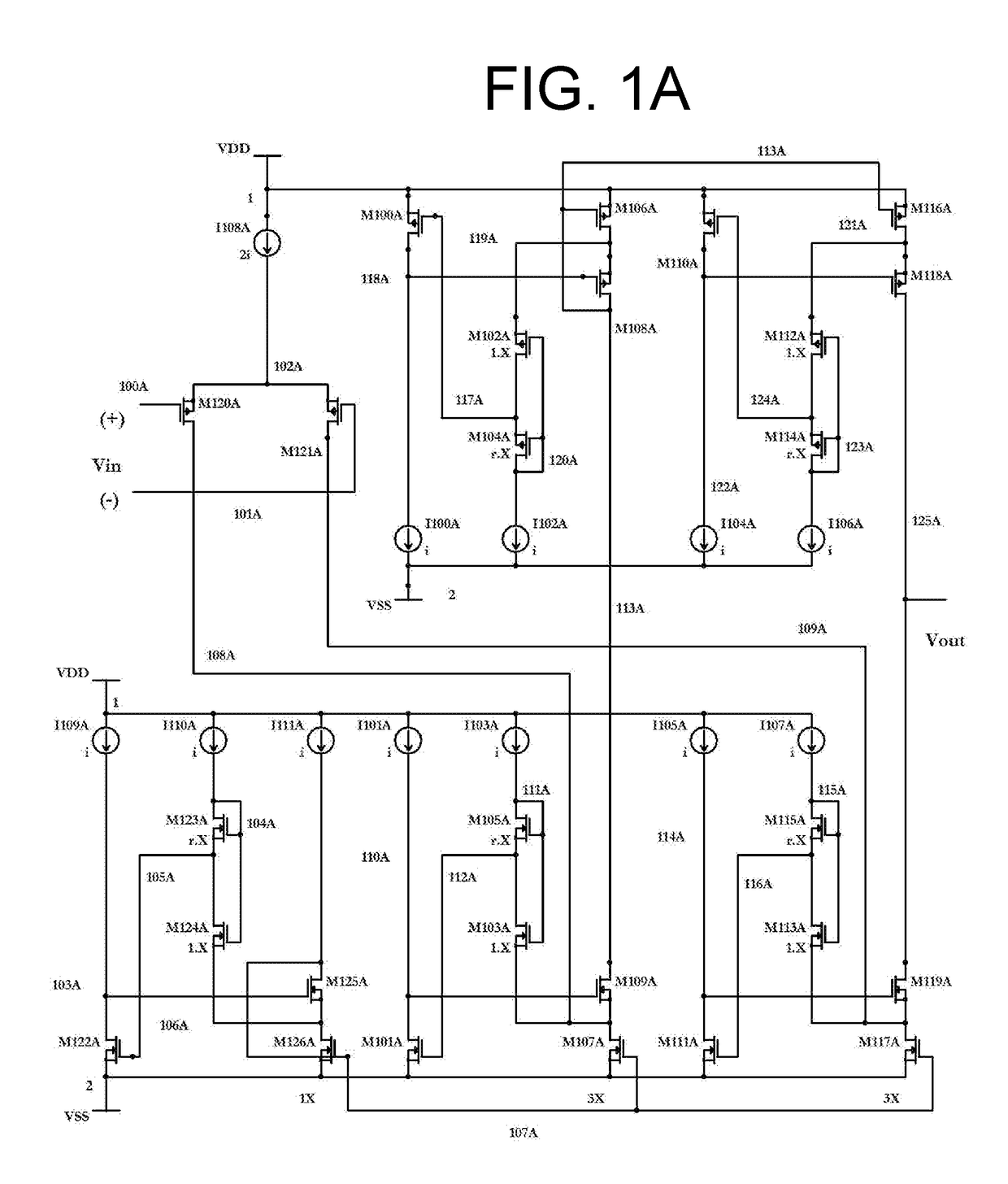

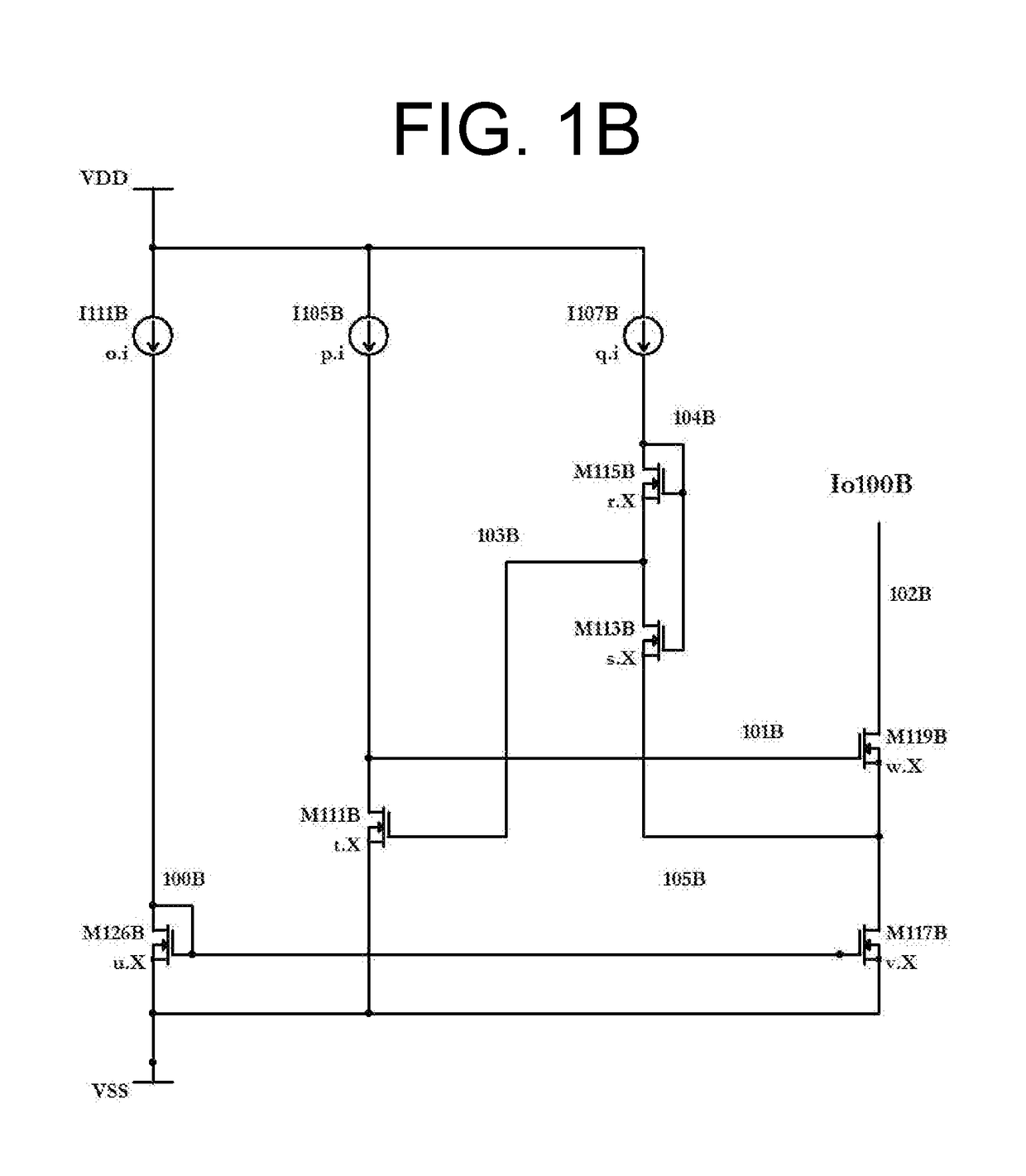

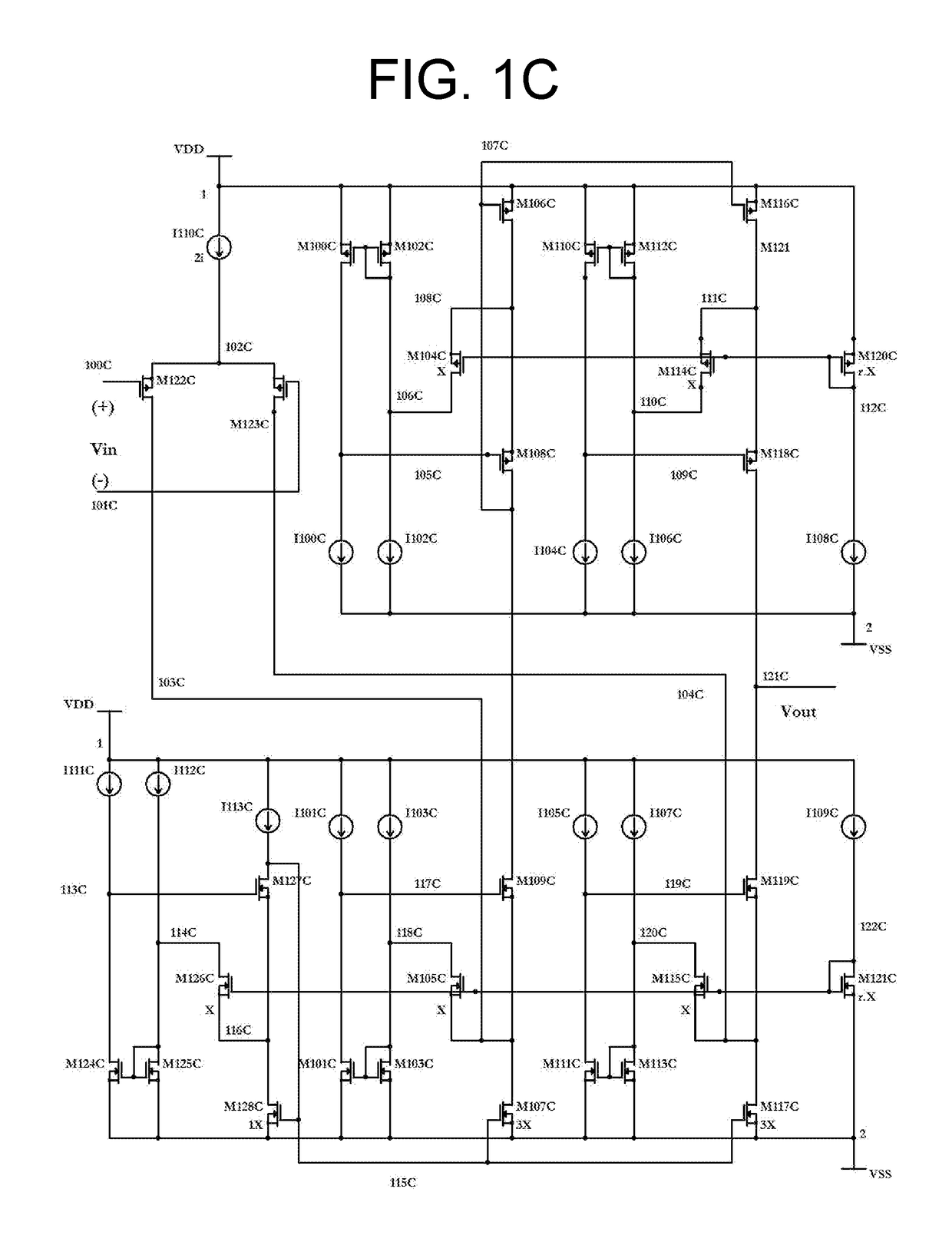

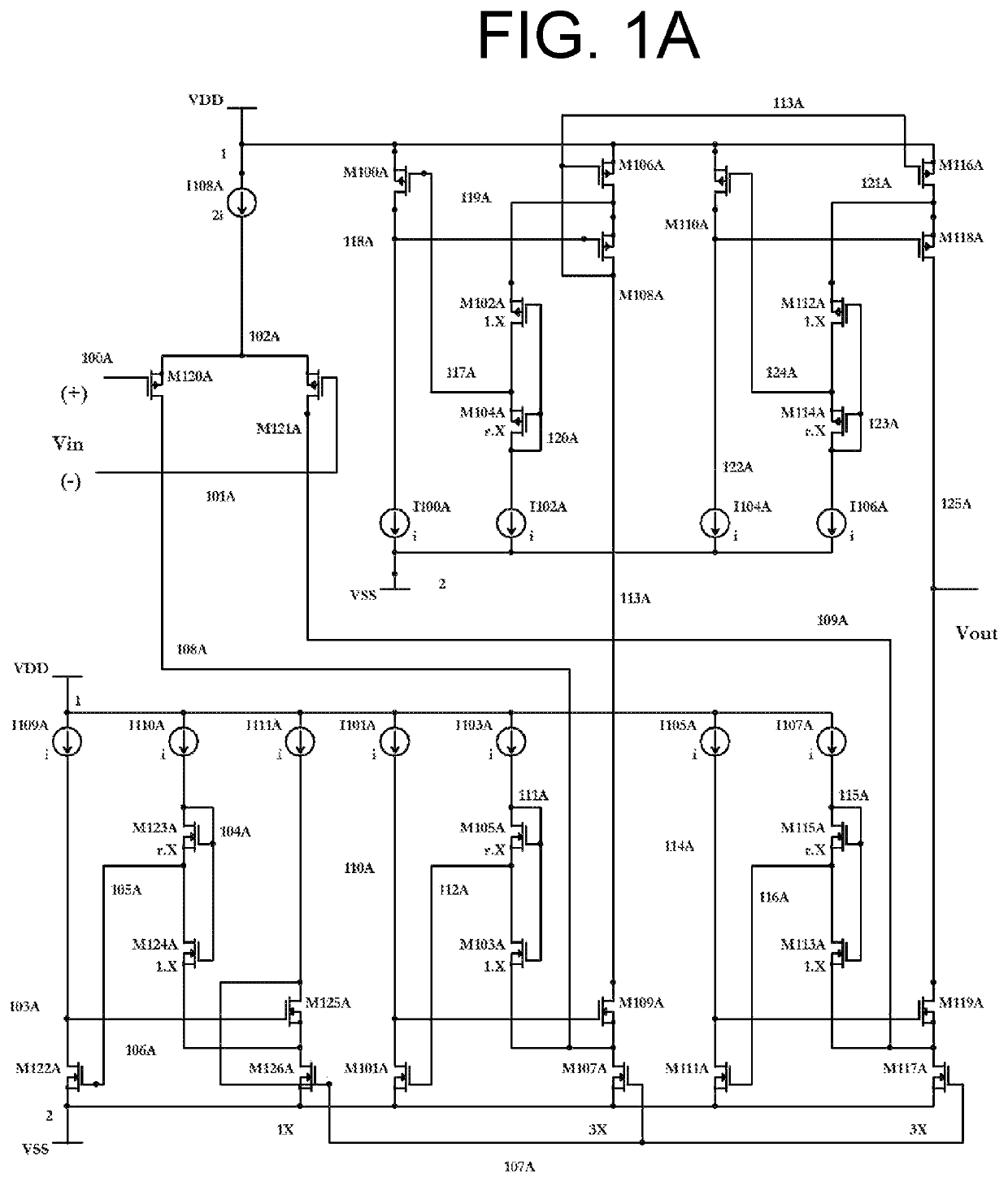

Low noise amplifier running fast at ultra low currents

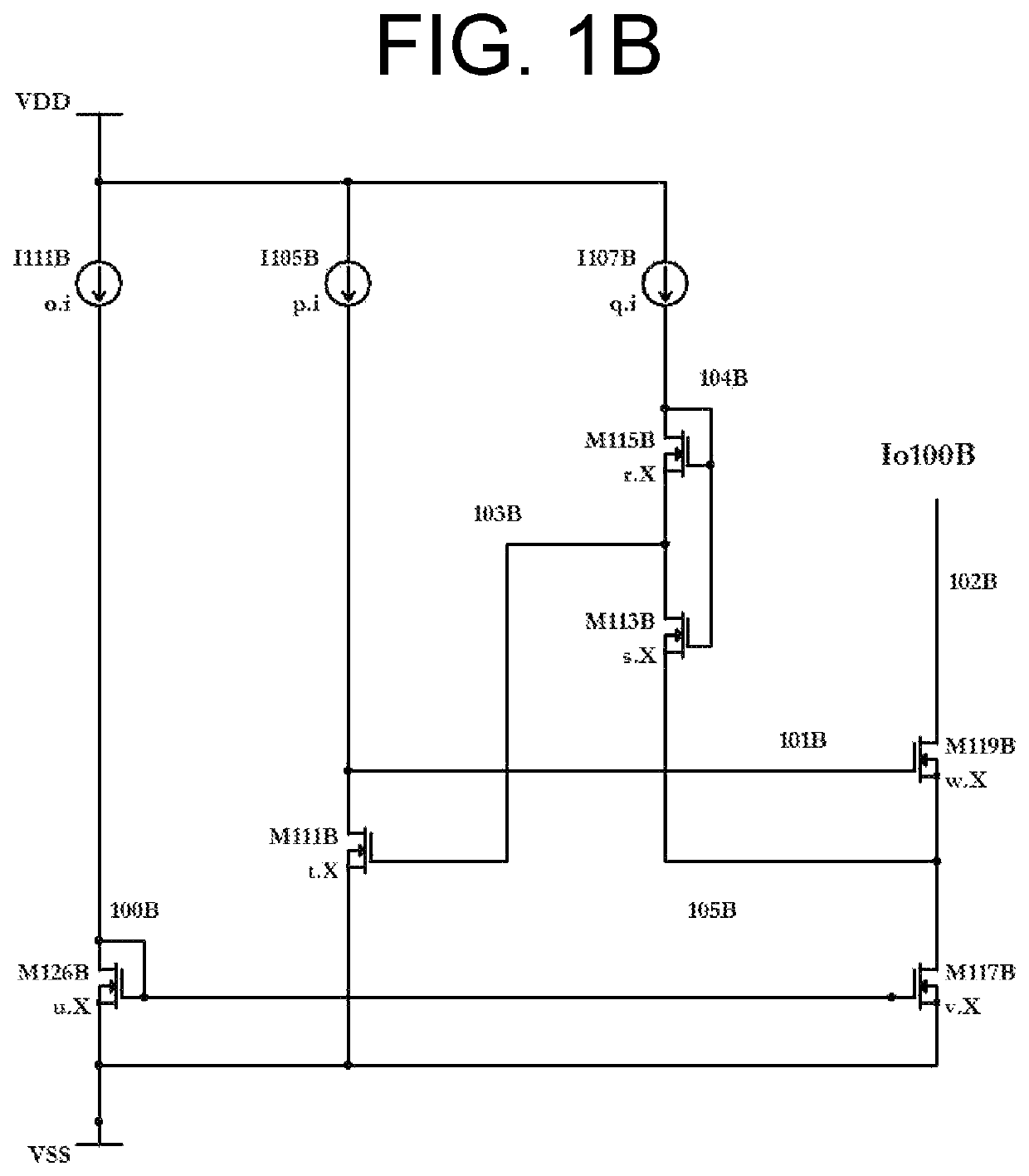

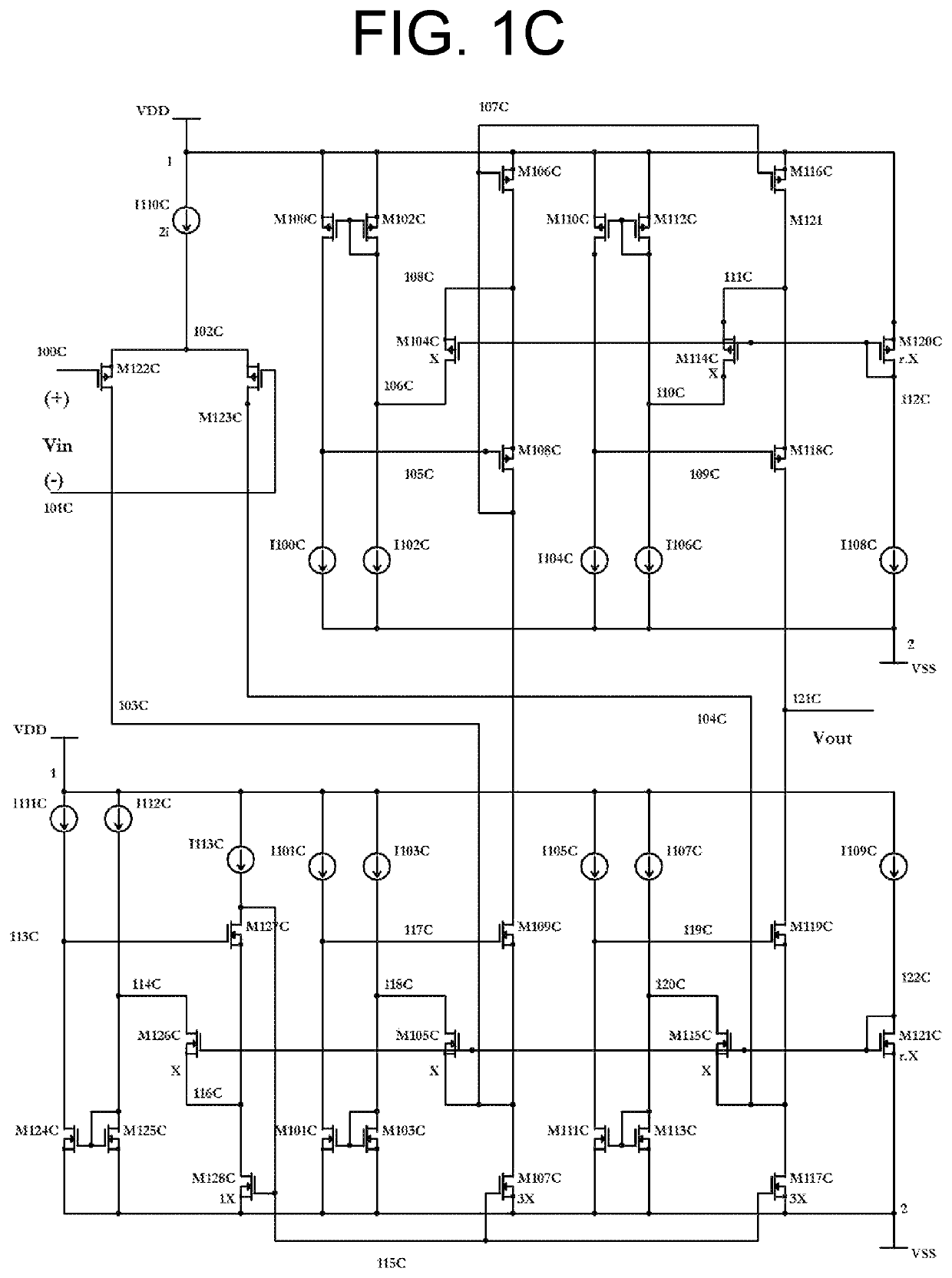

ActiveUS10491167B1Lowering minimum operating power supplyReduce offsetAmplifier modifications to reduce noise influenceGain controlAudio power amplifierSlew rate

Methods, circuits, and apparatuses are disclosed that provide a buffer amplifier with lower output noise by narrow banding the amplifier. To reinvigorate the speed of the narrow-banded amplifier, a boost-on signal is initiated. The boost-on signal dynamically and rapidly injects a substantial current into the amplifier's bias current network to speed up its slew rate, when the amplifier's inputs get unbalanced when being subjected to a large transient differential input signal. Subsequently, after the amplifier regulate itself and as the amplifier's inputs approach substantial balance, a boost-off signal dynamically injects a slow and decaying current (that converges to the level of static steady-state bias current) into amplifier's bias circuitry, instead of turning off the boost current rapidly, which improves the amplifier's settling time.

Owner:FAR ALI TASDIGHI

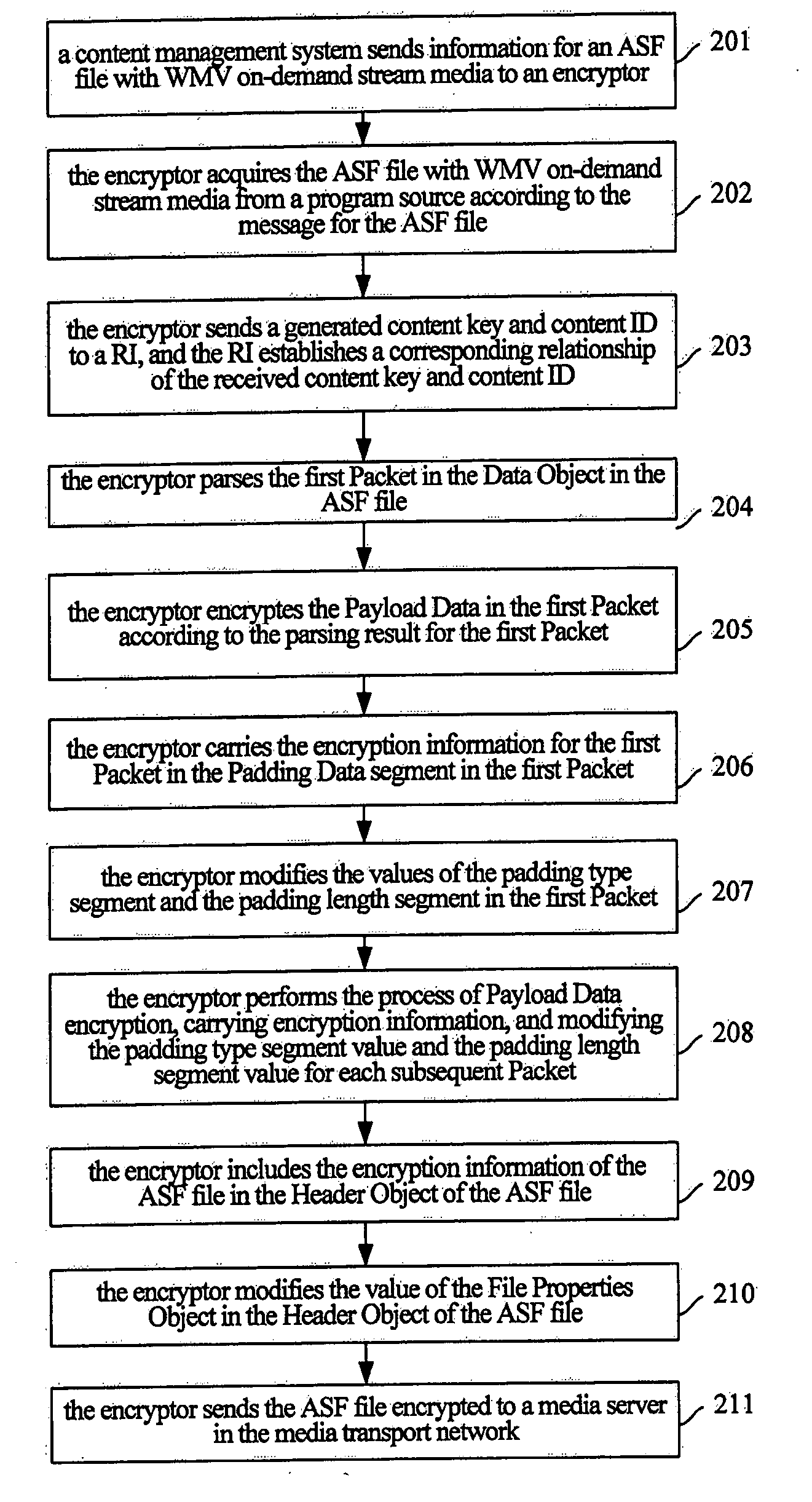

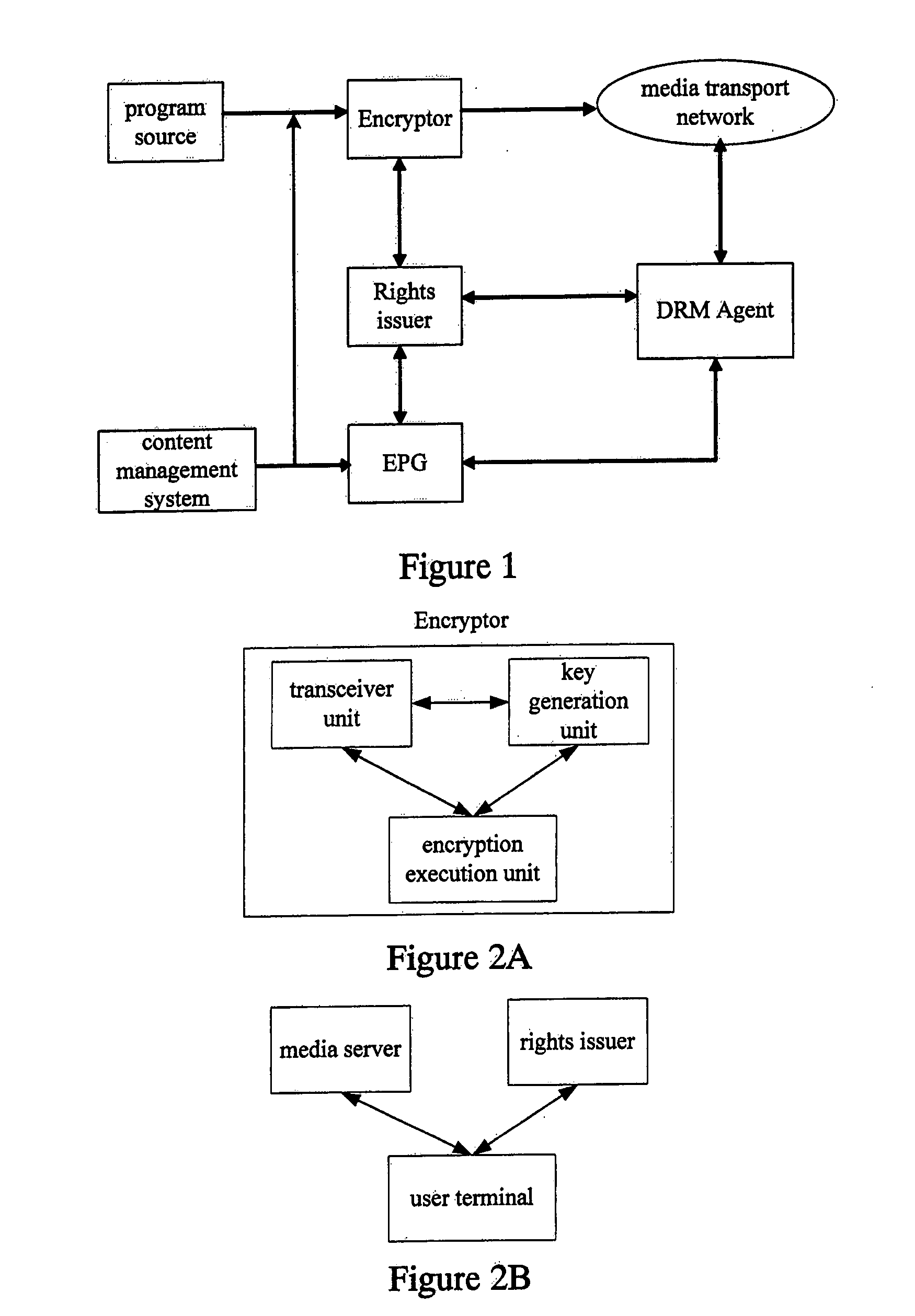

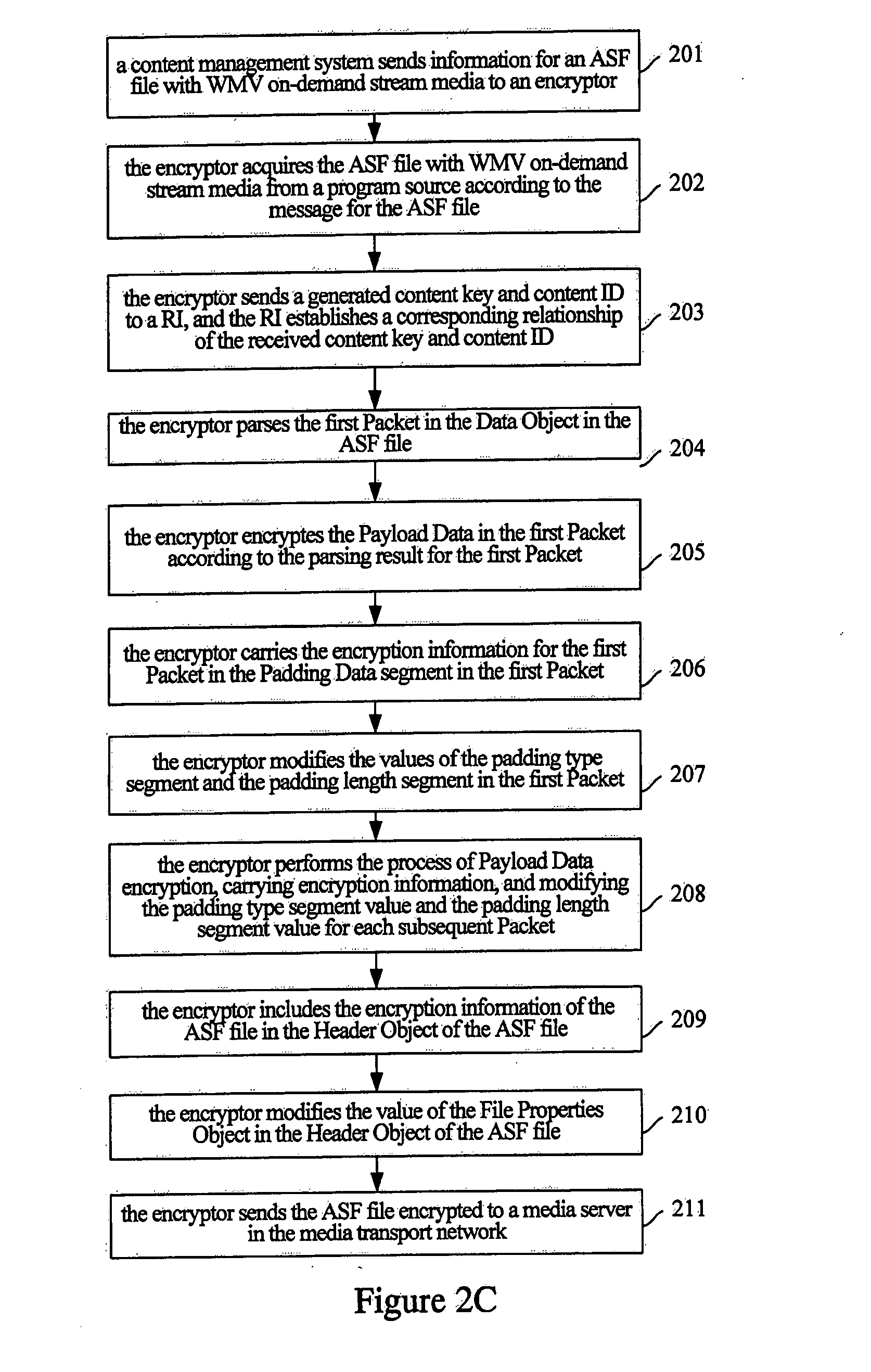

Method and system for encrypting or decrypting wmv streaming media

InactiveUS20080063195A1Quality of serviceIncrease choiceSecret communicationTelevision systemsThe InternetEncryption

Methods for encrypting or decrypting WMV streaming media are disclosed. The encrypting includes: acquiring WMV streaming media, generating a content key; and encrypting the WMV streaming media using the content key; the decrypting includes: acquiring WMV streaming media encrypted, encryption information and a content key; and decrypting the WMV streaming media encrypted according to the encryption information and the content key. Devices for encrypting or decrypting WMV streaming media are also disclosed. The scheme of encrypting or decrypting the WMV streaming media is enabled in a DRM system based on Open Mobile Alliance specifications and Internet Stream Media Alliance specifications, thus richly diversifying the content providers' choices on the media formats of on-demand streaming media.

Owner:HUAWEI TECH CO LTD

Thermostable RNA ligase from thermus phage

ActiveUS20050266439A1Minimal effectImprove stabilitySugar derivativesBacteriaGenus ThermusOpen reading frame

An RNA ligase derived from bacteriophage TS2126 which infects Thermus scotoductus, nucleic acids comprising nucleotide sequences of open reading frame (ORF) and polypeptides encoded by the nucleic acids, are described.

Owner:ILLUMINA INC

Ultra low power high-performance amplifier

ActiveUS10177713B1Lowering minimum operating power supplyReduce offsetPush-pull amplifiersPhase-splittersLow noiseAudio power amplifier

Methods, circuits, and apparatuses that provide Buffer Amplifier, containing Amplifiers and Buffer Drivers, one or more of the following: ultra low power Buffer Amplifier, capable of having high gain, low noise, high speed, near rail-to-rail input-output voltage span, high sink-source current drive capability for an external load, and able to operate at low power supply voltages. Methods, circuits, and apparatuses that provide regulated cascode (RGC) current mirrors (CM) capable of operating at low power supply and having wide input-output voltage spans.

Owner:FAR ALI TASDIGHI

High-immune anti-stress turtle complete feed

ActiveCN103039730AImprove survival rateImprove stress resistanceAnimal feeding stuffAnti stressVitamin C

The present invention relates to a high-immune anti-stress turtle complete feed, including a base material. The base material includes red fish meal, white fish meal, cod meal, skim fish meal, chicken meal, alpha-starch, fermented soybean meal, extruded soybean, vital gluten and yeast wall-broken meal; and further comprises by weight: 1.2-2% of calcium dihydrogen phosphate, 0.3-0.6% of choline chloride, 0.4-0.6% of glucose, 0.15-0.4% of compound probiotics, 0.1-0.2% of vitamin C, 0.2-0.3% of a compound hepatobiliary preparation, 0.2-0.3% of compound immunopotentiator, 2.5-3.5% of compound vitamins, and 5-6.5% of a compound mineral salt. By using the feed, the survival rate and anti-stress of the turtle can be significantly improved, the occurrence of white abdominal shell, leukoderma and enteritis of the turtle is reduced, specification and quality of the products are improved, and the economic efficiency is increased.

Owner:深圳市澳华集团股份有限公司

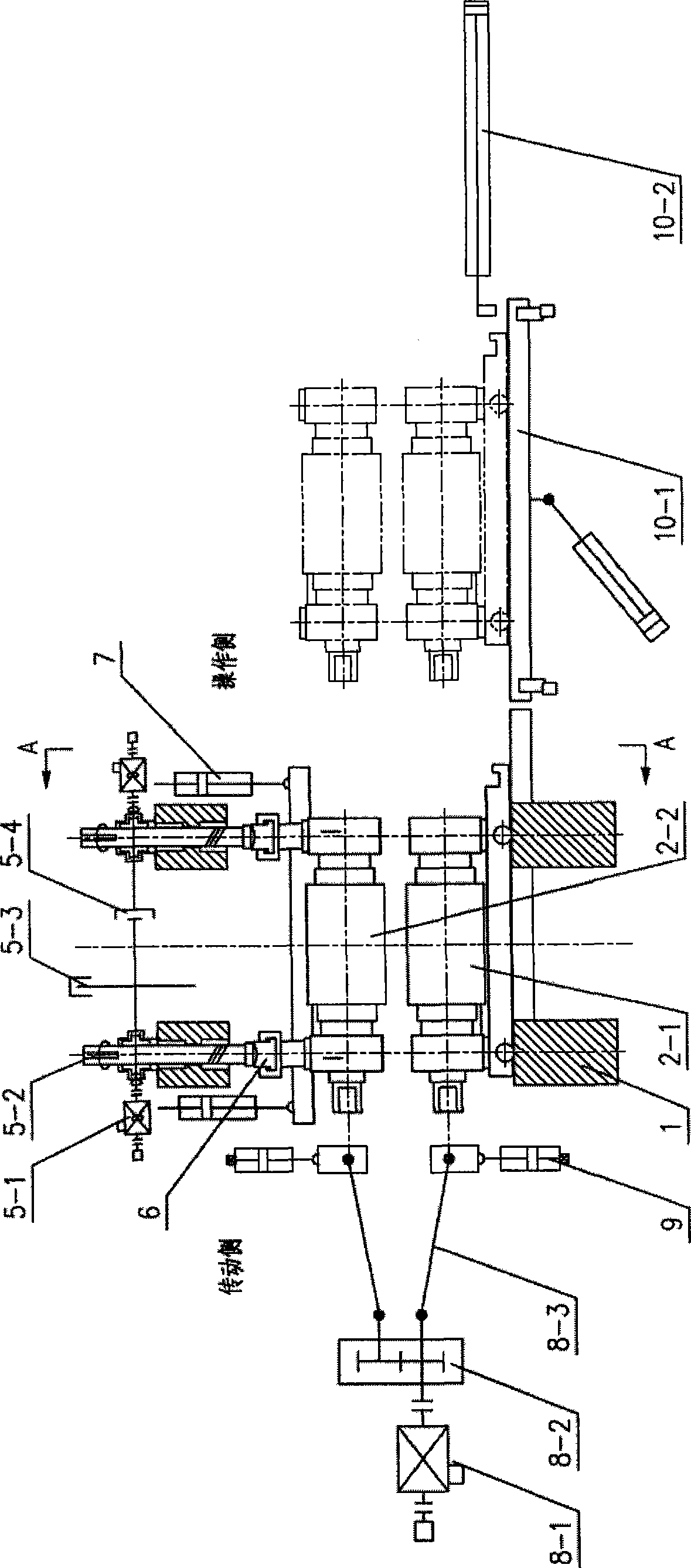

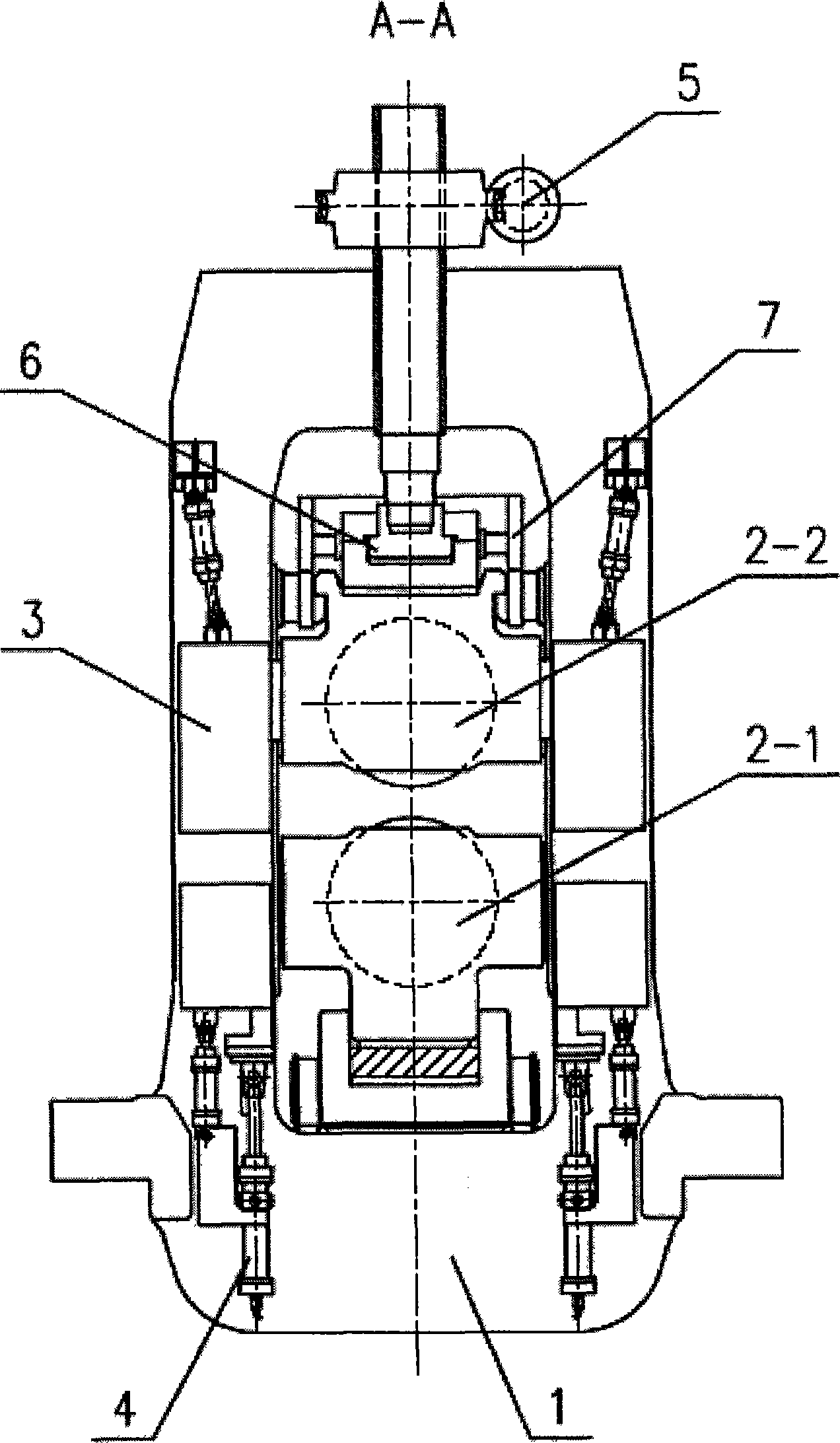

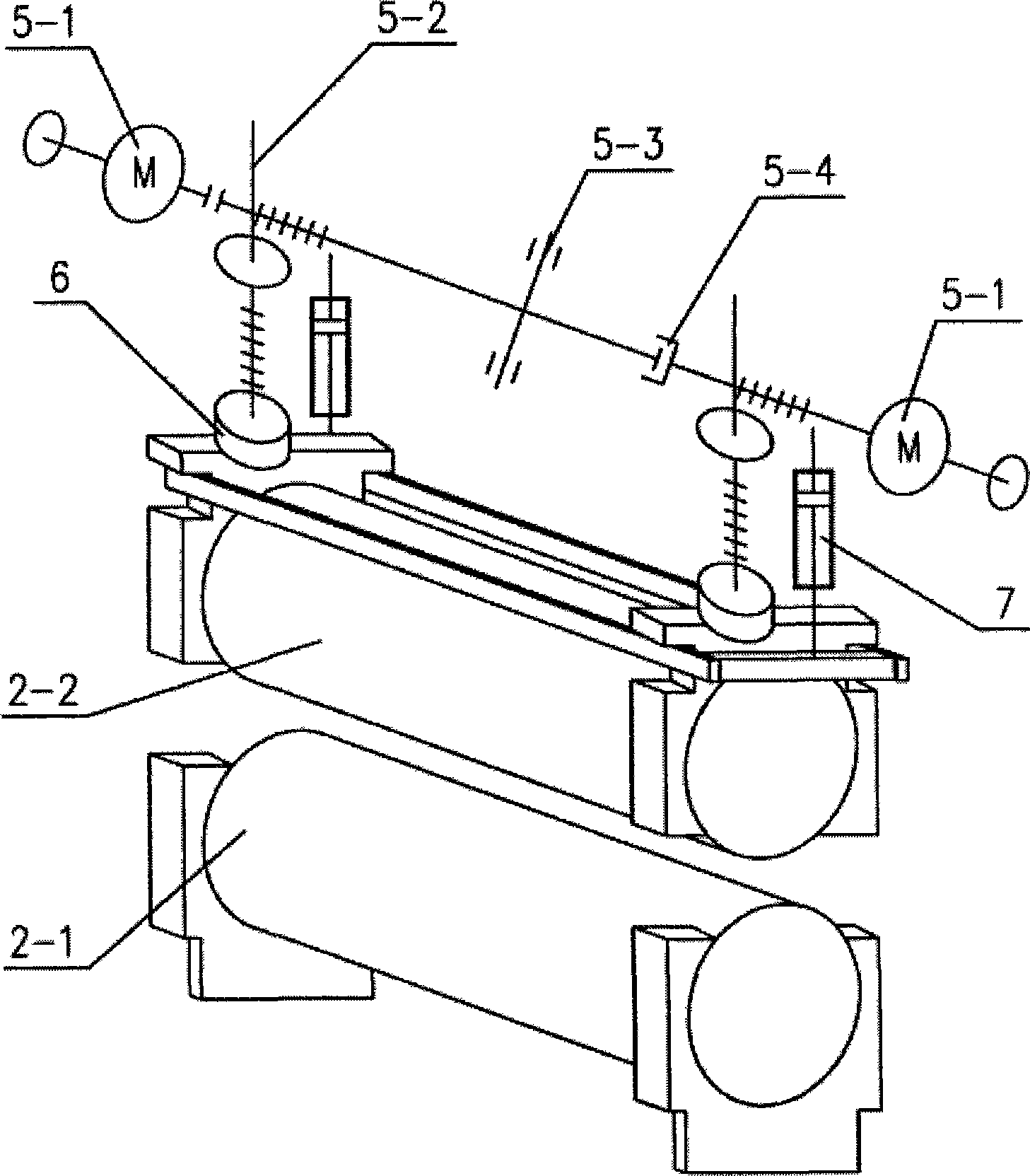

Wire rod bar blooming mill

ActiveCN101462121AAdvanced structureReduce equipment operation energy consumptionMetal rolling stand detailsRolling safety devicesEngineeringRolling mill

The invention belongs to the technical field of metallurgy machinery, and in particular relates to a linear rod cogging mill. An upper working roller and a lower working roller are driven by a main transmission device to assemble and rotate, and roller seams are adjusted up and down by driving the upper working roller to assemble through a dynamoelectric press down device. Large continuous casting square blanks are rolled into needed small square blanks through two rollers of reversible rolling mills. The cogging mill can roll the large continuous casting square blanks into the needed small square blanks, improve the product quality, promote product grades, optimize and widen product structures, and improve the continuous casting output and the product yield of the whole factory, is not limited by the specifications of upstream continuous casting blanks, and improves the forging ratio. The cogging mill can be arranged in all newly built high-speed wire machine sets or wire reformation machine sets and in particular partial prior linear rod machine sets which can be reformed by utilizing the prior rolling mill transmission devices so as to save partial investment.

Owner:CISDI HEAVY MACHINERY

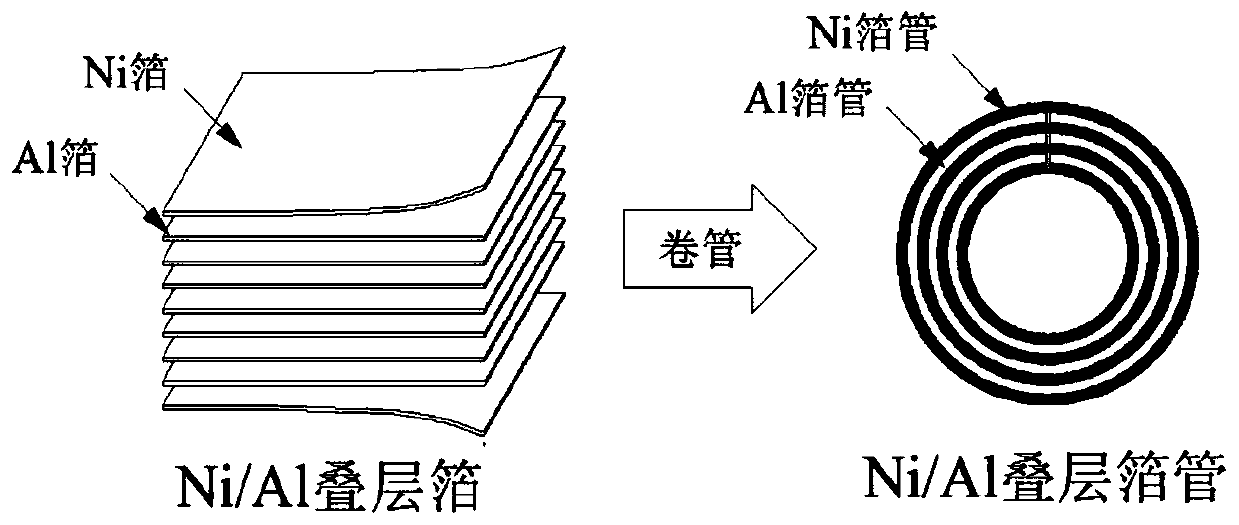

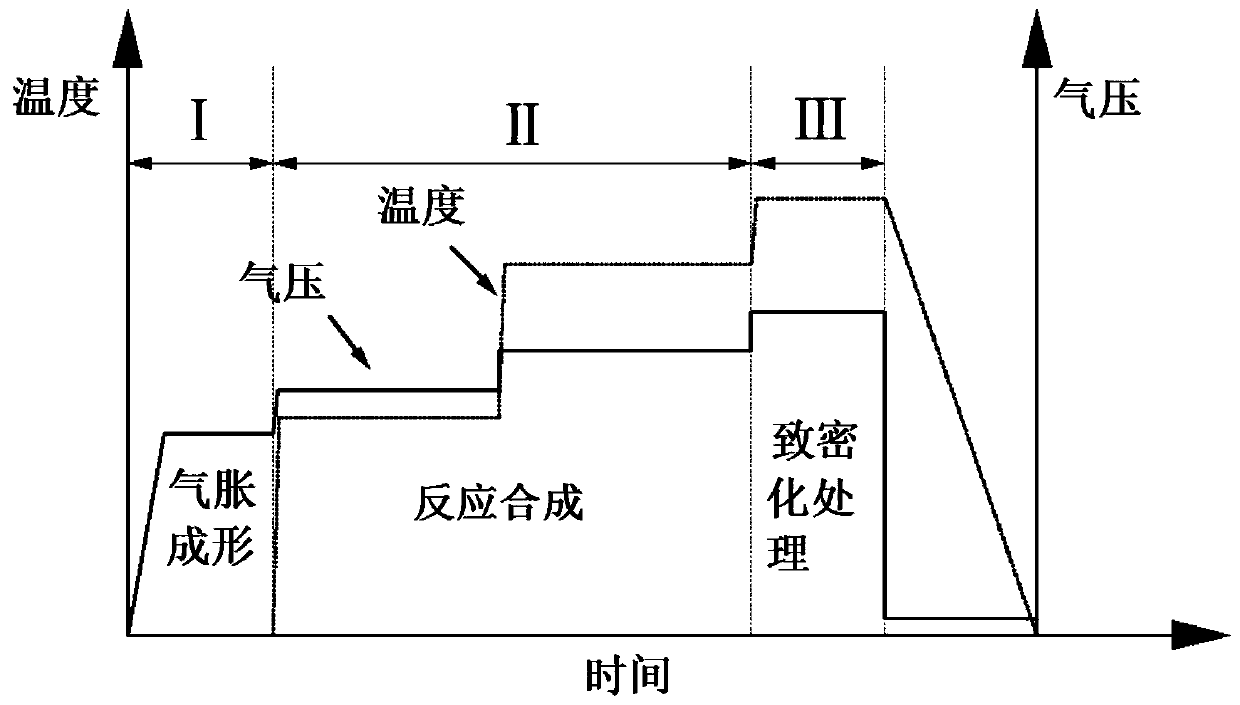

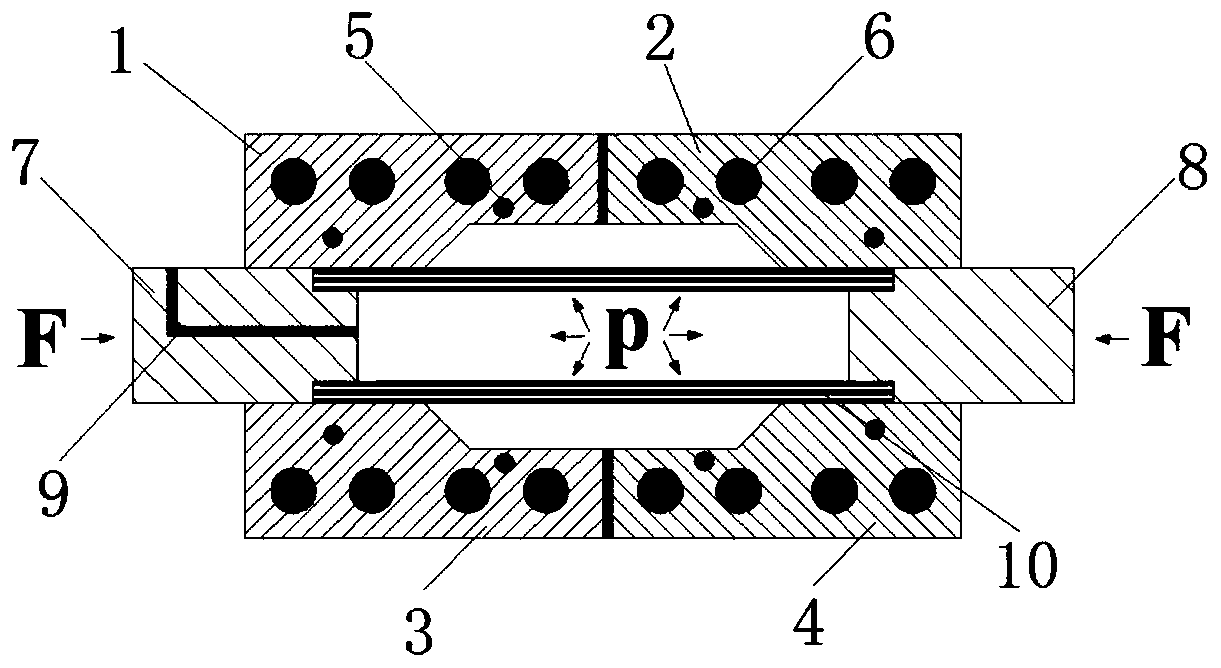

NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method

ActiveCN110142332AHigh controllability of specifications and ingredientsPreparation process safetyShaping toolsRigid pipesThin walledNial

The invention provides an NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method and belongs to the technical field of precise forming of intermetallic compound thin-walled pipe fittings. The NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method comprises the following steps that Ni foils and Al foils are alternately laminatedand coiled to obtain an Ni / Al foil an ag / l laminated foil tube; and the Ni / Al laminated foil tube is subjected to plastic forming, reaction synthesis and densification treatments in an air expansion forming die to obtain the NiAl alloy thin-walled pipe fitting. The NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method solves the problems of difficulty in controlof material flowing and tissue performance and complex procedures of existing NiAl alloy slab preparation and the thin-walled pipe fitting formed with a slab. Data of the embodiment of the inventionshows that the NiAl alloy thin-walled pipe fitting obtained by the method is high in forming rate and size precision, uniform in component distributed, good in compactness and non-defective in surface.

Owner:DALIAN UNIV OF TECH

Low voltage rail to rail high speed analog buffer and method thereof

ActiveUS10536117B1Wide input-output voltage spanReduce voltagePush-pull amplifiersPhase-splittersLow noiseLow voltage

Methods, circuits, and apparatuses that provide Buffer Amplifier, containing Amplifiers and Buffer Drivers, one or more of the following: ultra low power Buffer Amplifier, capable of having high gain, low noise, high speed, near rail-to-rail input-output voltage span, high sink-source current drive capability for an external load, and able to operate at low power supply voltages. Methods, circuits, and apparatuses that provide regulated cascode (RGC) current mirrors (CM) capable of operating at low power supply and having wide input-output voltage spans.

Owner:FAR ALI TASDIGHI

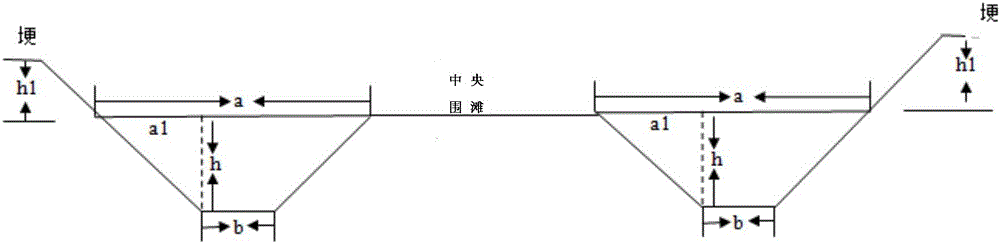

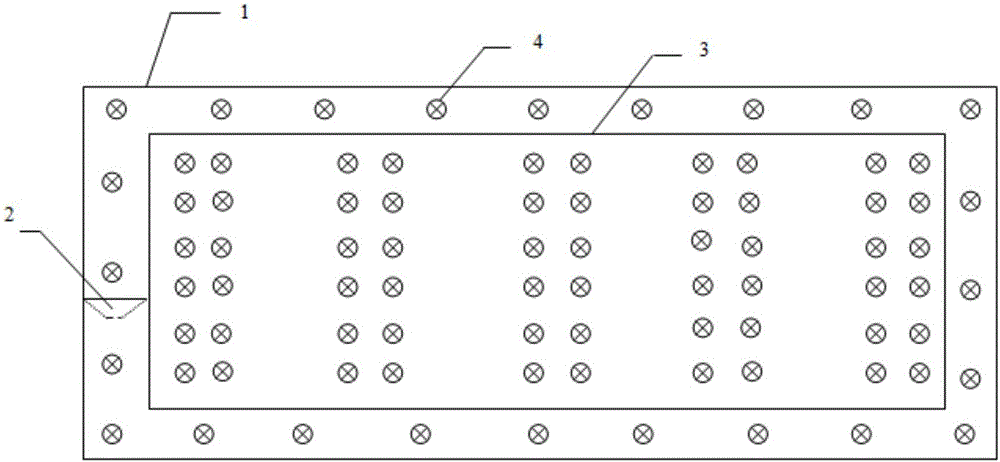

Breeding method and pond for improving commercial specification and yield of procambarus clarkii in pond

ActiveCN105994027AEasy plantingIncrease coverageClimate change adaptationPisciculture and aquariaShrimpProcambarus clarkii

The invention provides a breeding method and a pond for improving the commercial specification and the yield of procambarus clarkii in the pond. The breeding method comprises the following steps: drying the pond under the sun; putting young procambarus clarkii into the pond for the first time; performing catch rotation on commercial procambarus clarkii for the first time; putting young procambarus clarkii into the pond for the second time; performing catch rotation on commercial procambarus clarkii for the second time; and thoroughly draining water of the pond, and catching all commercial procambarus clarkii. The pond comprises a circular groove which is digged along the periphery of the pond, wherein the circular groove has an upper bottom width of 6 to 10 meters, a lower bottom width of 1 to 5 meters, a depth of 0.8 to 1 meter, a ridge height of 0.8 to 1 meter and a slope ratio of 1: 3; the area of the circular groove accounts for 20 to 30% of the total area of the pond; the a region, located at the inner side of the circular groove, of the pond is piled with a central enclosed beach; and the distance between the water level of the pond and the central enclosed beach is in a range of 10 to 70 cm. The invention has the following beneficial technical effects: by adopting the method provided by the invention, 200 to 250 kg of commercial procambarus clarkii can be harvested in two seasons, wherein the proportion of the commercial procambarus clarkii with a specification of 40 g or more reaches 60 to 70%.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

Super-pure electro-slag remelting method for super-invar alloy

ActiveCN102127652AHigh purityImprove tissue uniformityIncreasing energy efficiencyMolten stateInvar alloy

The invention discloses a super-pure electro-slag remelting method for a super-invar alloy, which comprises the following steps of: a) preparing a self-melting electrode rod, namely performing vacuum induction melting on the components of the self-melting electrode rod of the super-invar alloy: 32 to 34 weight parts of Ni, 3.5 to 5.5 weight parts of Co and 60.5 to 64.5 weight parts of Fe, and casting to obtain a round rod, namely the self-melting electrode rod for electro-slag remelting; and b) performing electro-slag remelting, namely heating slag for electro-slag remelting, which is prepared from 40 to 85 weight parts of CaF2, 10 to 30 weight parts of GaO2 and 30 to 5 weight parts of Al2O3 into a melted state, pouring into a crystallizer, descending the self-melting electrode rod into the melted slag for electro-slag remelting, ensuring that liquid drops of the melted self-melting electrode rod pass through the melted slag layer and react with the slag, recrystallizing purified steel liquid at the bottom of the crystallizer to obtain an electro-slag ingot, forging to obtain a black rod, and performing solid solution and stabilization treatment to obtain the super-invar alloy. The purity of the super-invar alloy is improved, the structure is optimized, the thermal expansion coefficient is smaller, the processability of the alloy is improved, and the yield of a product is greatly improved.

Owner:CHONGQING MATERIALS RES INST

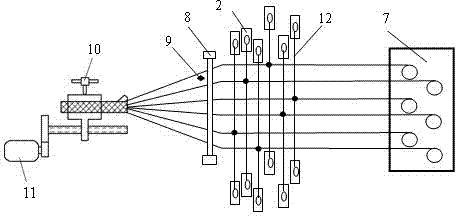

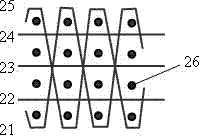

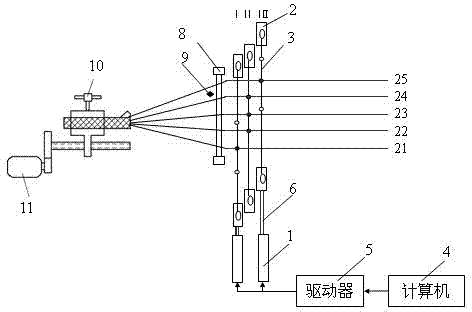

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

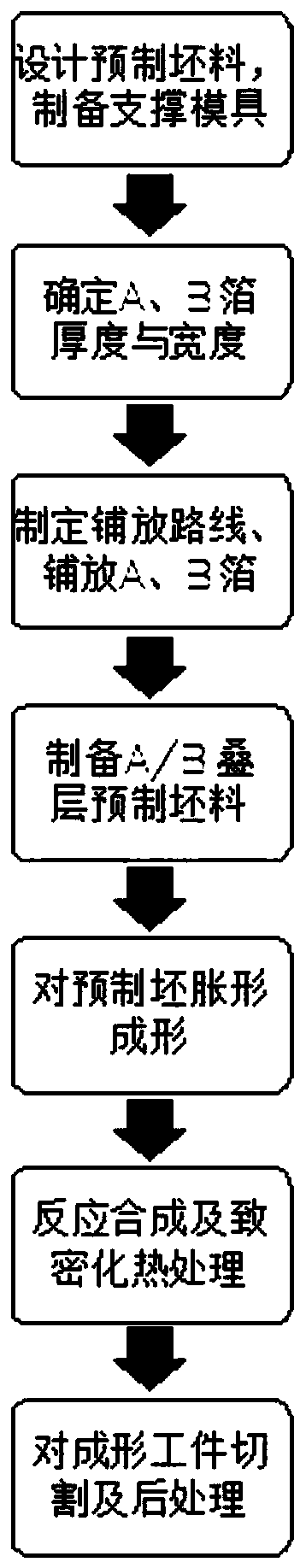

Integrated manufacturing method of high-temperature-resistant thin-wall component by laying metal foil strips for blank making

ActiveCN111168407AComplex structureUniform wall thicknessShaping toolsOther manufacturing equipments/toolsMetal foilMechanical engineering

The invention discloses an integrated manufacturing method for a high-temperature-resistant thin-wall component by laying metal foil strips for blank making. The method comprises the steps of designing a prefabricated blank; preparing a supporting mold; determining the thickness of the foil strips; determining the width of the foil strips; formulating a laying process; laying the foil strips A andthe foil strips B; preparing the AB laminated prefabricated blank; performing bulging forming on the prefabricated blank; performing reaction synthesis and densification treatment on the bulged component; performing subsequent treatment on the thin-walled component and the like. According to the method, the thin-wall integrally-prefabricated blank which is complex in structure, uniform in wall thickness and similar to a final part in shape can be obtained by continuously laying the metal foil strips with proper widths, the thin-wall prefabricated blank does not need to be welded, the problemthat the comprehensive performance of a welding area is weak when a laminated plate blank is firstly prepared and then roll-welded into a cylinder blank at present is solved, meanwhile, the deformation during subsequent bulging is reduced, and the defects of local bulging, thinning and cracking, undercut at the parting position in the mold closing process or wrinkling caused by uneven distributionof materials in all areas are avoided.

Owner:DALIAN UNIV OF TECH

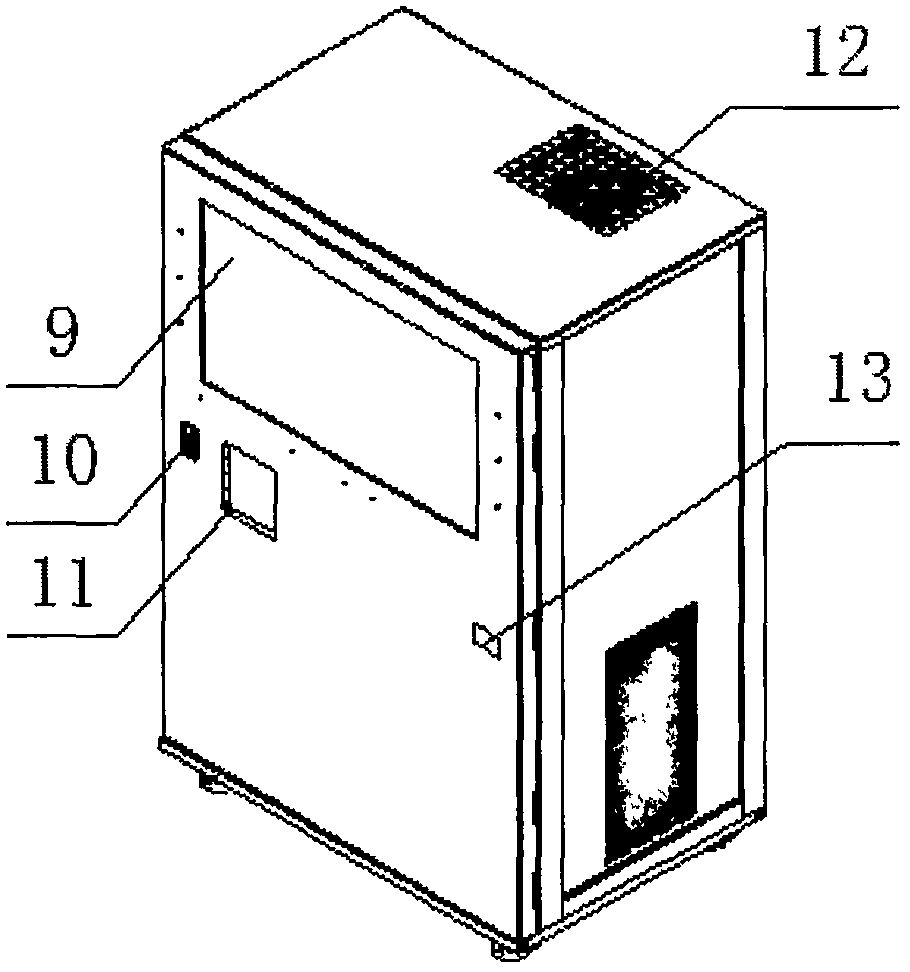

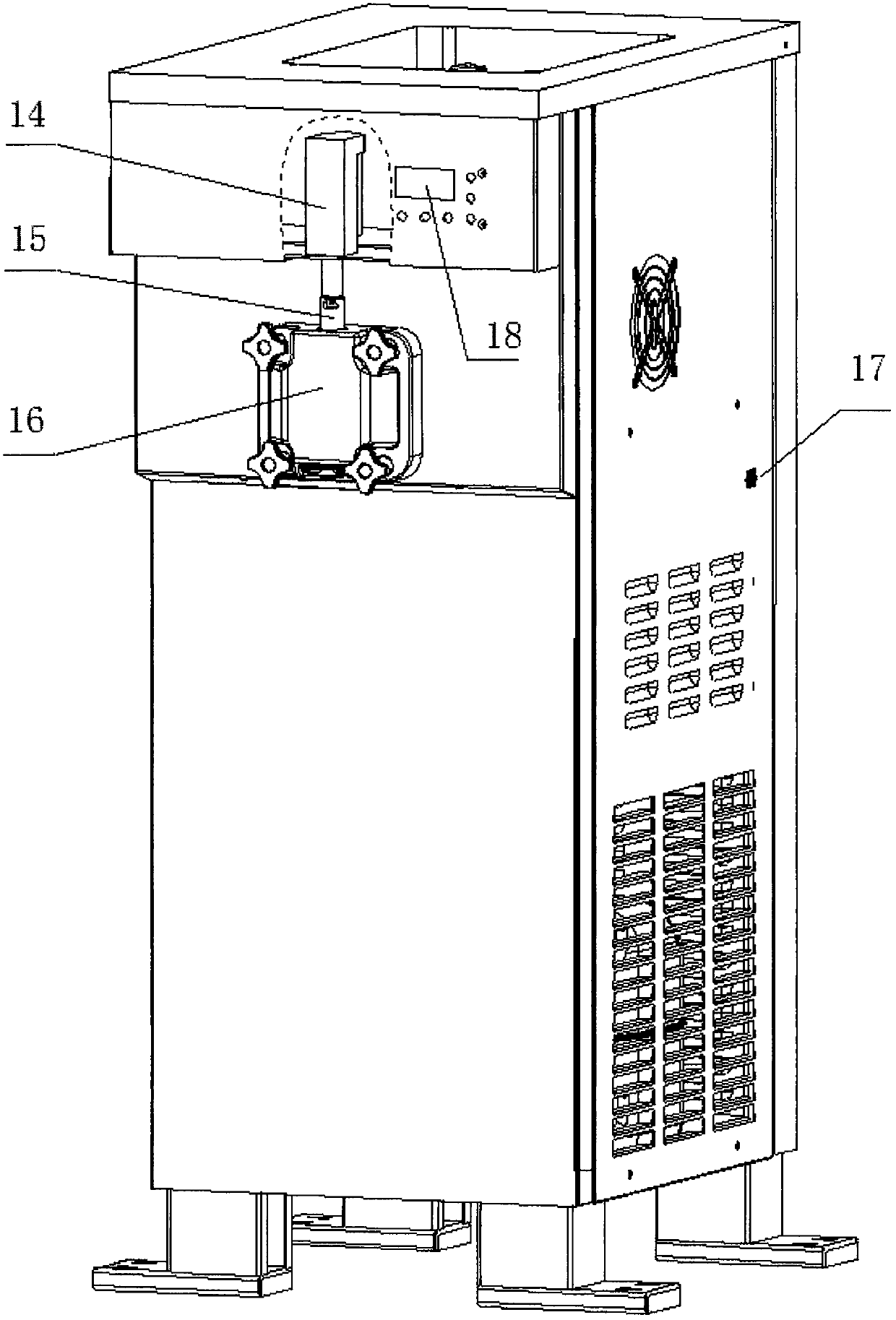

Internet-based novel intelligent ice cream machine

The invention relates to an Internet-based novel intelligent ice cream machine. The machine includes a casing module, an ice cream machine module for holding ice cream and extruding the ice cream, anautomatic selling module, a host computer interaction interface module with a purchase window, a control module and a payment module, and an interconnection and interworking module. The ice cream machine module comprises an ice cream automatic discharging mechanism; the automatic selling module comprises an automatic cup dropping mechanism, a nut adding mechanism and / or a jam adding mechanism, anda conveying mechanism; the casing module comprises a box body, and the box body is provided with a cup taking port; and the conveying mechanism sends an ice cream cup containing the ice cream to thecup taking port. A person only needs to select and pay through the host computer interaction interface module, and the ice cream machine can be automatically controlled to make the ice cream, and therefore, usage is very convenient, specifications are improved, Internet technology is applied to the industry, development can be greatly accelerated, and a prospect is better.

Owner:HUBEI POLYTECHNIC UNIV

Planting method of high-quality and high-yield root-bark of peony

InactiveCN102246650AIncrease productionQuality improvementHorticulturePesticide residueHigh yielding

The invention discloses a planting method of high-quality and high-yield root-bark of peony, comprising the steps of land selection and preparation, sowing, seedling culture, transplanting, field management, harvesting, processing, and the like. The planting method is characterized in that the yield and the quality of the root-bark of peony are improved by adopting measures of controlling the growth of an underground part and spraying foliar fertilizer. According to the planting method disclosed by the invention, by adopting a series of measures of culturing seedlings, transplanting, controlling nutrient growth, spraying foliar fertilizer, and the like, the quality of the root-bark of peony is increased, the yield is increased simultaneously and is improved by 20 percent compared with that obtained by the traditional planting method; the content of effective components is increased by over 10 percent; and the root-bark of peony has thick flesh, pink white cross section, strong aroma and export standard strip selecting rate of over 80 percent. Meanwhile, the contents of pesticide residue and heavy metal are reduced and the exported standard of medicinal materials is reached.

Owner:安徽协和成药业饮片有限公司

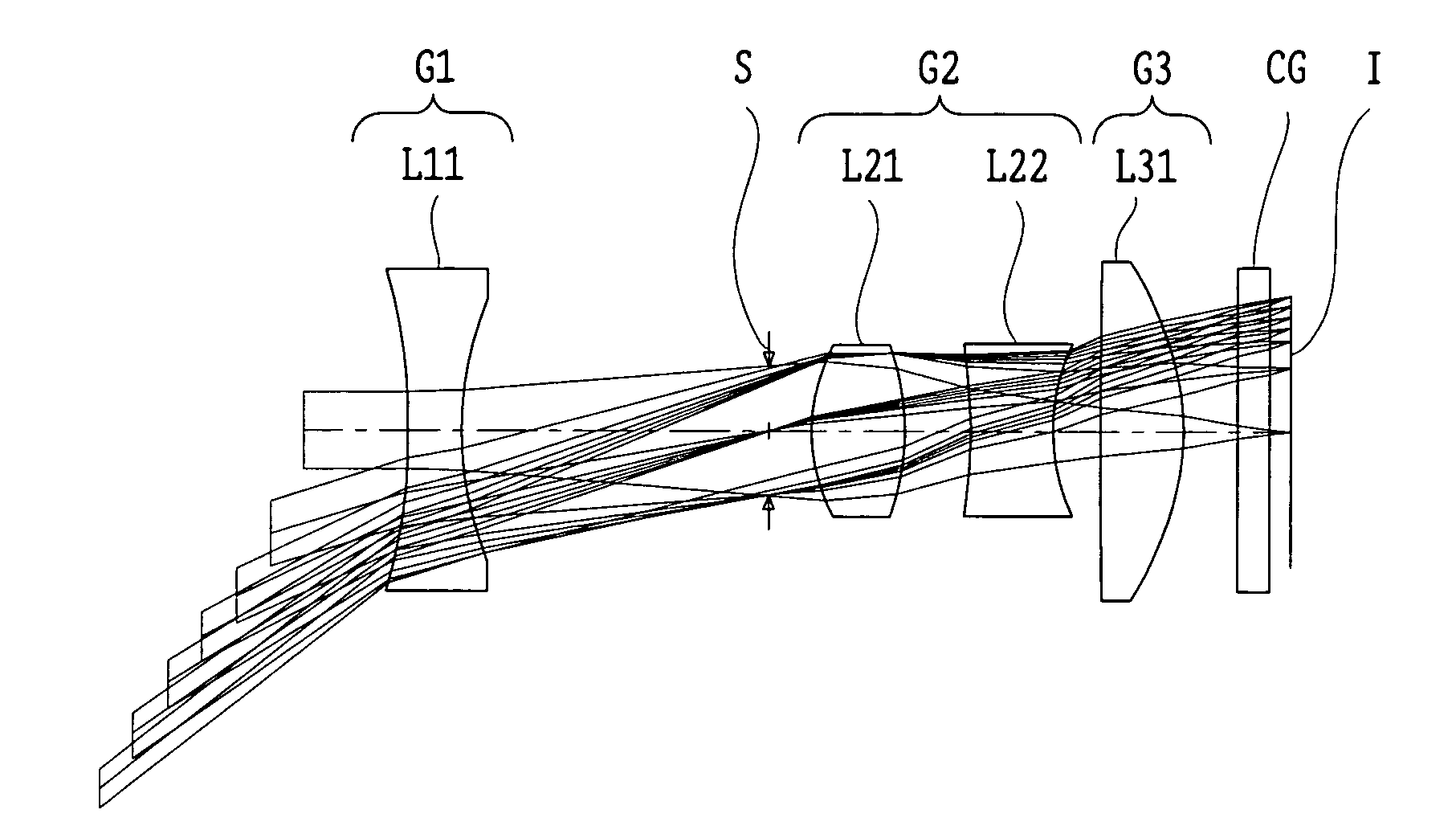

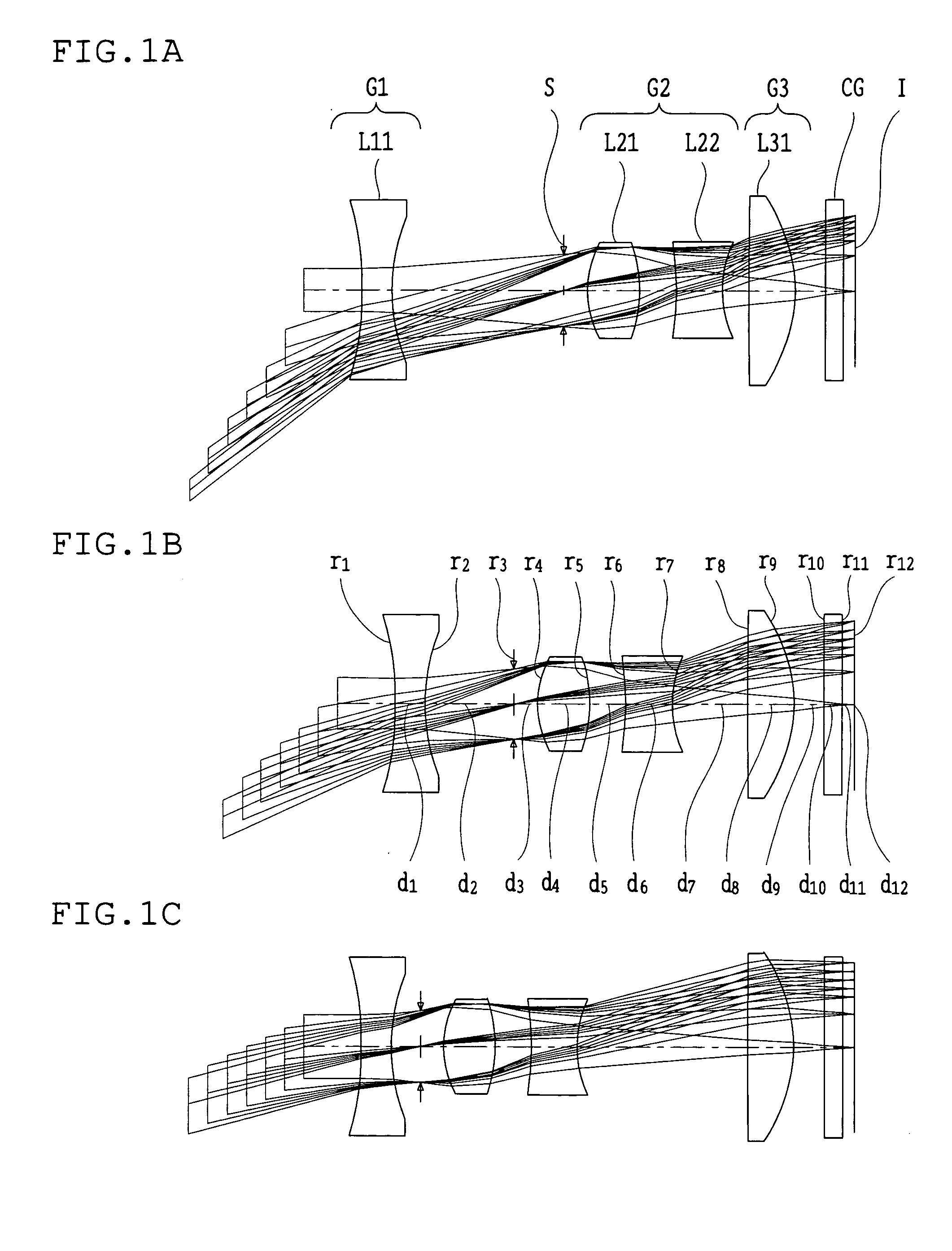

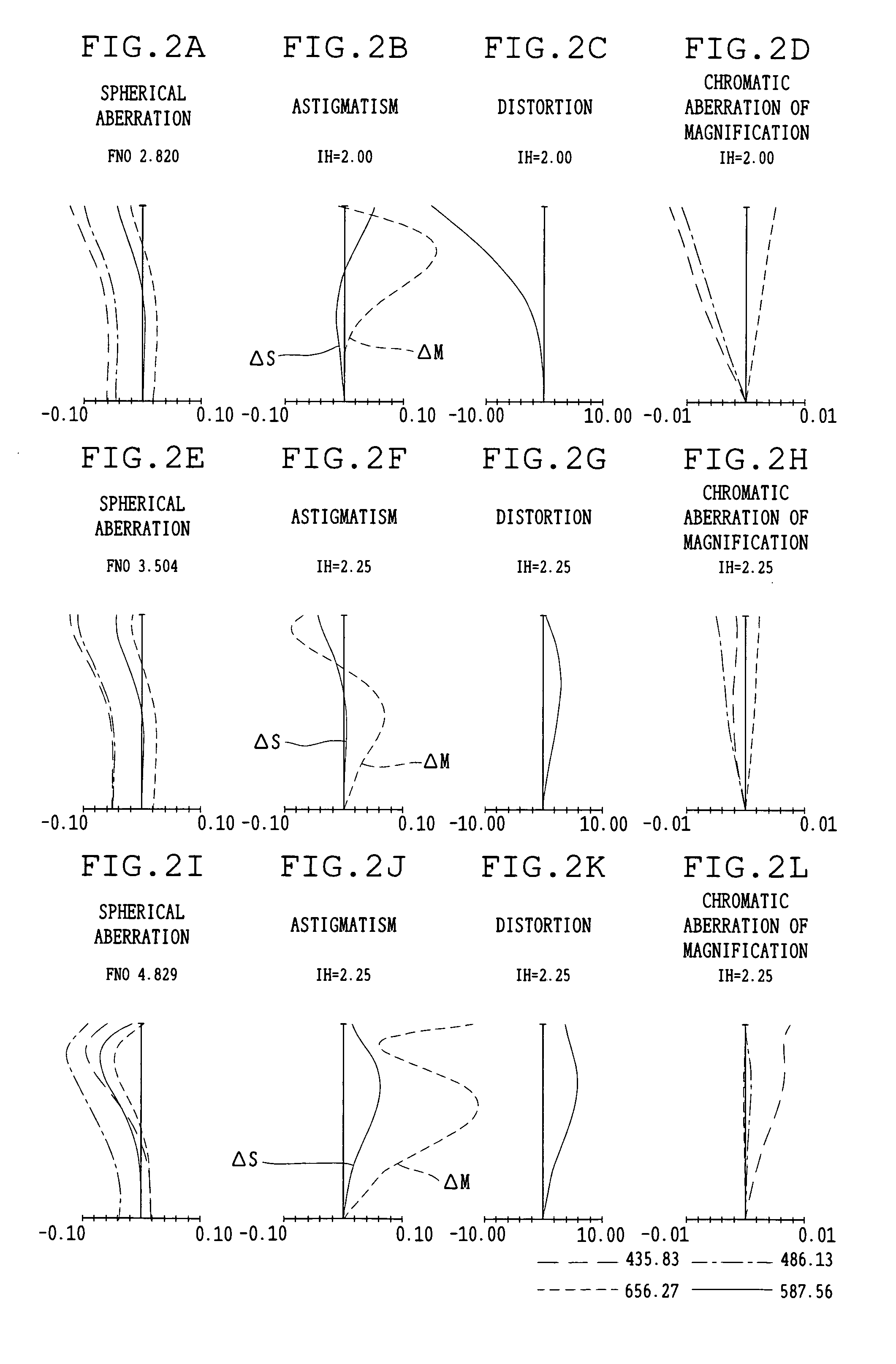

Zoom lens and electronic imaging apparatus having the same

InactiveUS20050207024A1Increase specificationLow costTelevision system detailsColor television detailsOptical axisElectronic imaging

A zoom lens includes, in order from the object side, the first lens unit consisting of one negative lens component in which a plurality of lens components are cemented to one another and the second lens unit including one negative lens component and having positive refracting power as a whole. In this case, the zoom lens satisfies the following condition: <?in-line-formulae description="In-line Formulae" end="lead"?>0.15<t1 / fw<0.6 <?in-line-formulae description="In-line Formulae" end="tail"?> where t1 is the thickness, measured along the optical axis, of the first lens unit and fw is the focal length of the entire system at the wide-angle position of the zoom lens.

Owner:OLYMPUS CORP

Brackish-water ecological cultivation technology for Yangtze-river two-year-old coilia ectenes fingerlings and exopalaemon carinicauda

ActiveCN103960173AIncrease specificationHigh outputClimate change adaptationPisciculture and aquariaExopalaemon carinicaudaGram

The invention discloses a brackish-water ecological cultivation technology for Yangtze-river two-year-old coilia ectenes fingerlings and exopalaemon carinicauda. The technology is characterized by comprising the following steps: firstly, an estuary-area earth pond and natural brackish water with an inflow salinity of 0.5-1.5% are chosen, and food organism is inoculated in the pond; secondly, an aerator is opened before fingerlings are put in the pond in winter or in early spring, wherein the stocking size of the fingerling is a total length of 10 to 20 cm, and the stocking density of the fingerlings is 500 to 600 fishes per mu; thirdly, putting the exopalaemon carinicauda into the pond, wherein the stocking density of the exopalaemon carinicauda is 6 to 12 jin per mu, and the stocking size is 200 to 280 fishes per jin; after the fingerlings and exopalaemon carinicauda are put in the pond, 1 / 3 of water is changed each month from January to June, 1 / 3 of water is changed each half month from July to September, and 1 / 3 of water is changed each month from October to December; fourthly, prawn artificial pellet feed which is adopted as exopalaemon carinicauda feed is fed 1 time per day, wherein the feeding amount is 1 to 3 percent of the weight of the exopalaemon carinicauda; finally, the fingerlings and exopalaemon carinicauda are captured with nets in winter at the temperature of 6 to 8 DEG C, wherein the specification of the captured coilia ectenes is 16 to 20 gram per fish while the specification of the exopalaemon carinicauda is 100 to 150 fishes per jin.

Owner:上海市水产研究所(上海市水产技术推广站)

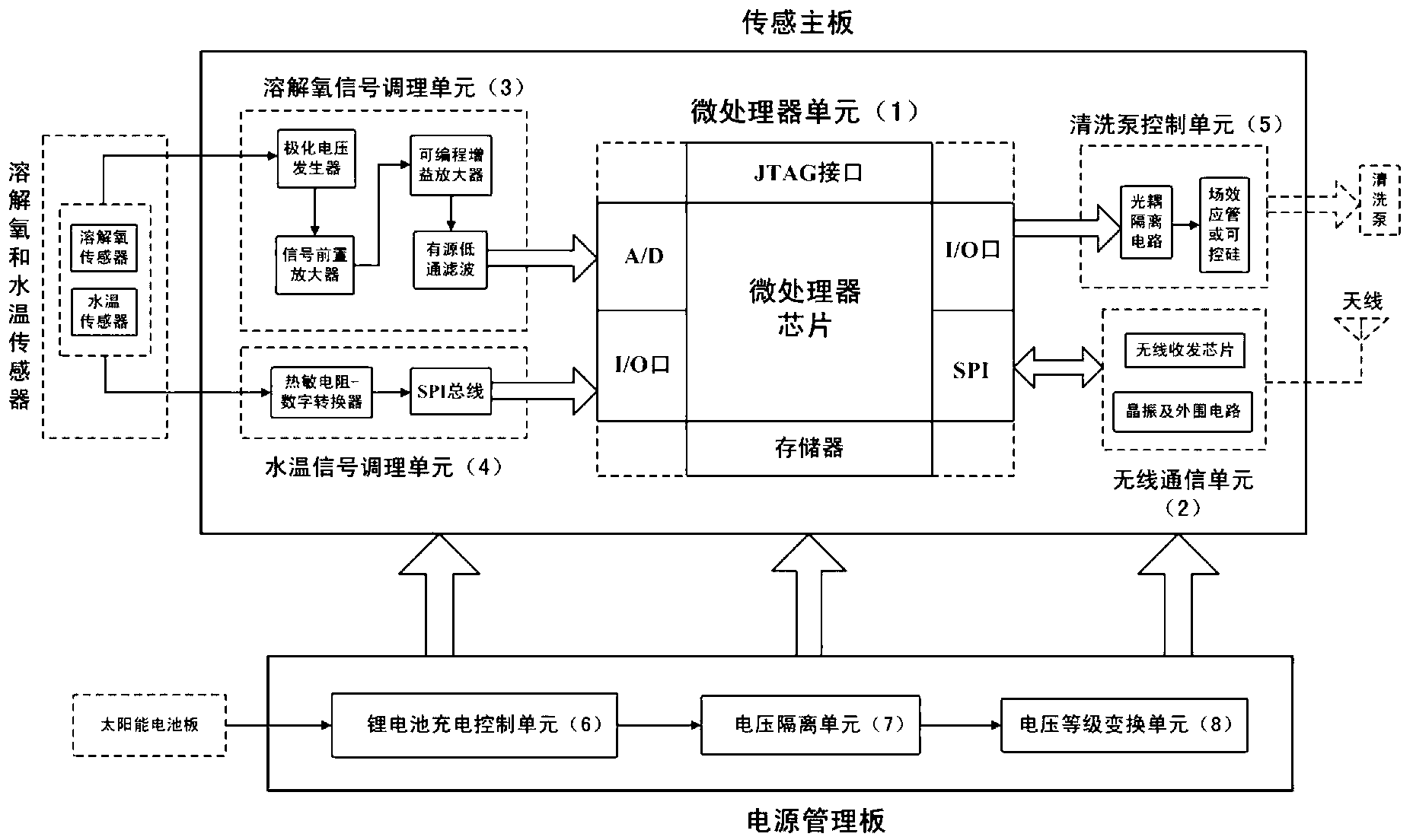

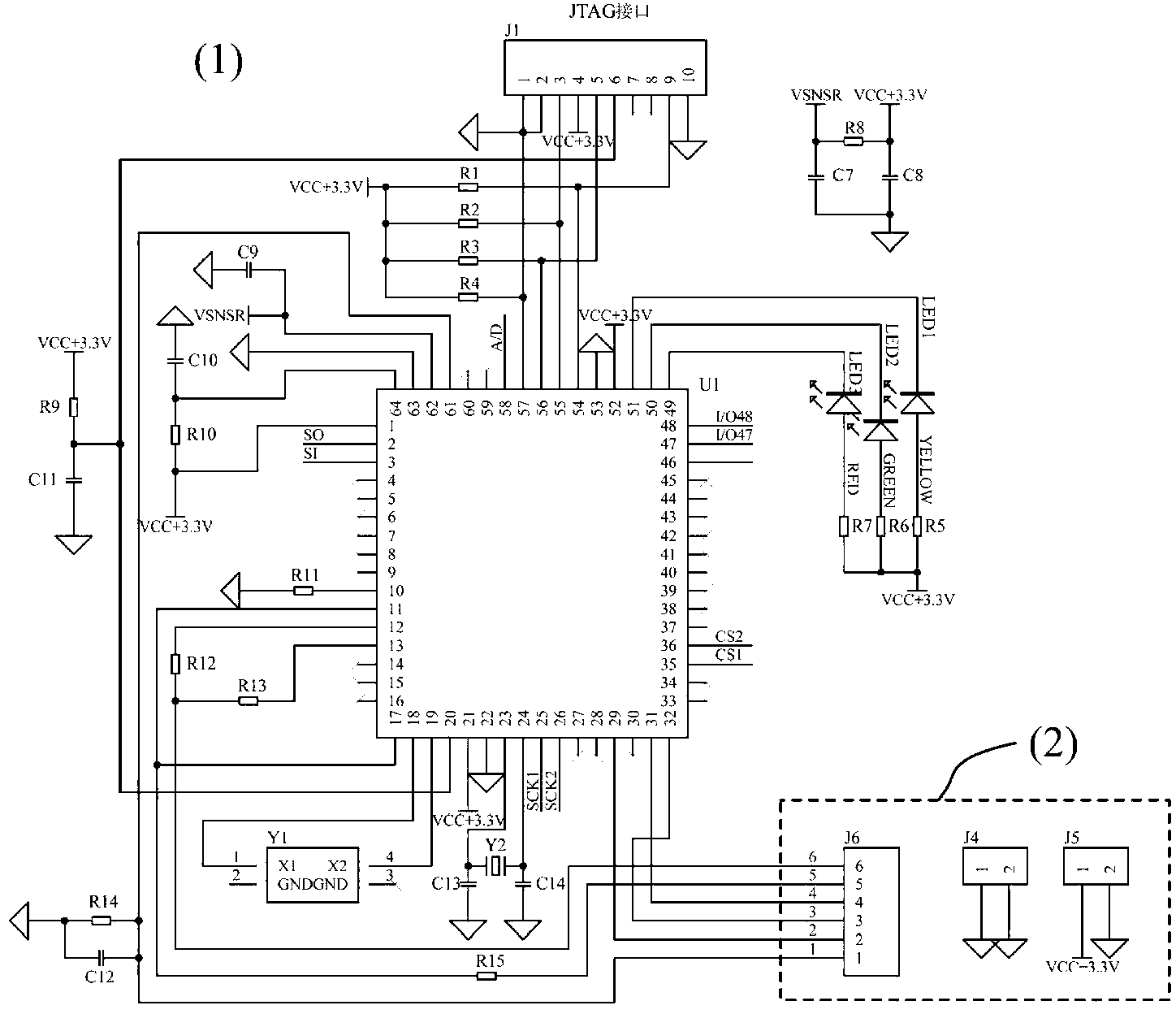

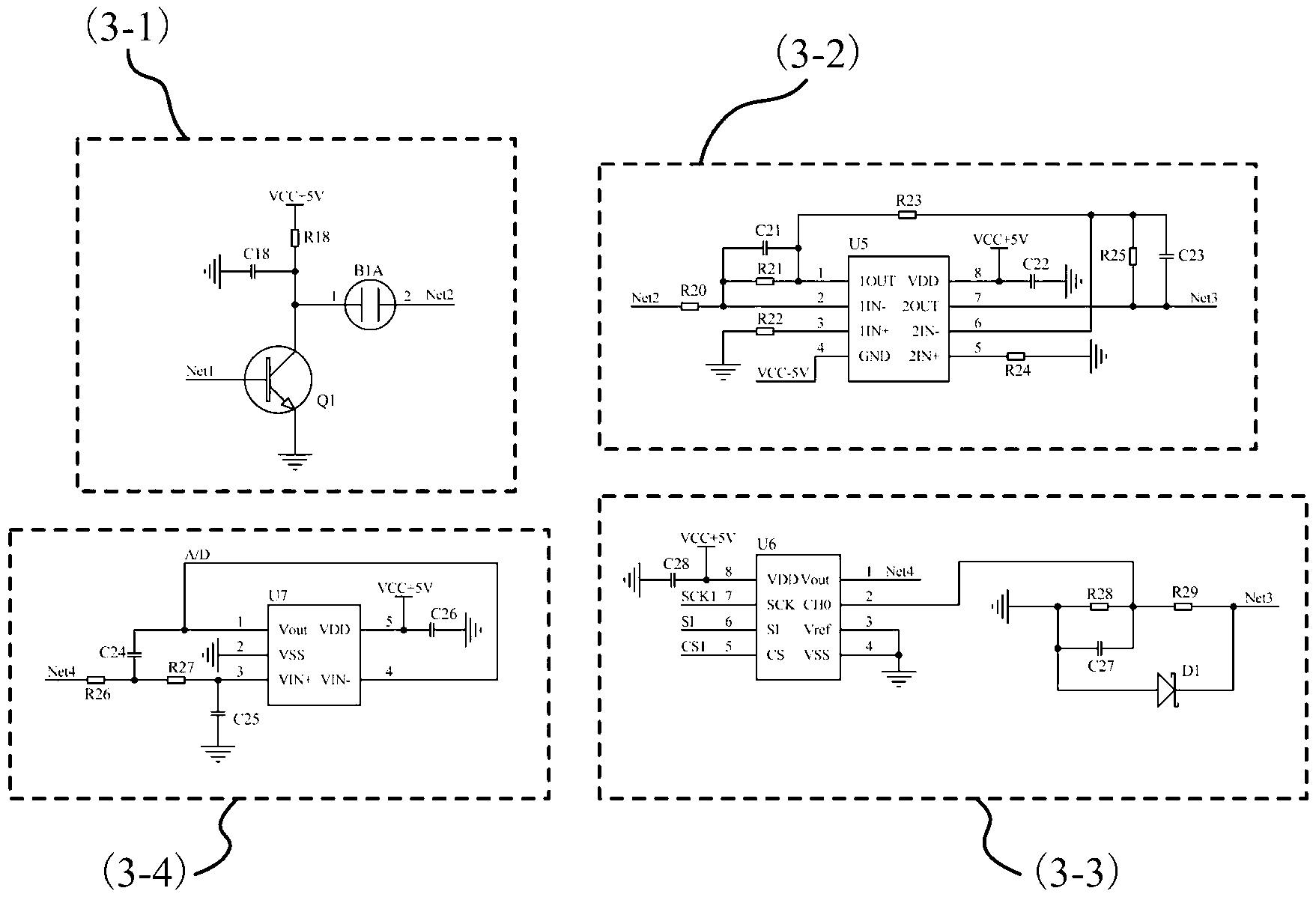

Aquaculture wireless sensor network node device and operation method

ActiveCN103326739ALow costReduce power consumptionTransmission systemsThermometers using electric/magnetic elementsWater qualityAquaculture

The invention discloses an aquaculture wireless sensor network node device and an operation method, and belongs to the technical field of water quality monitoring. The aquaculture wireless sensor network node device and the operation method are suitable for many application occasions such as water quality parameter online detection in aquaculture of Chinese mitten crabs, fish, shrimps, shellfish and the like and used for collecting parameter data of dissolved oxygen content (mg / L) and water temperature ( DEG C) in an aquaculture pond in real time online and sending the data to a wireless sensor network gateway or a wireless sensor network base station and a local terminal in a 433MHz frequency band wireless sensor network communication manner after further changing, possessing and storing the parameter data.

Owner:NANJING INAGRI SENSOR NETWORKS TECH

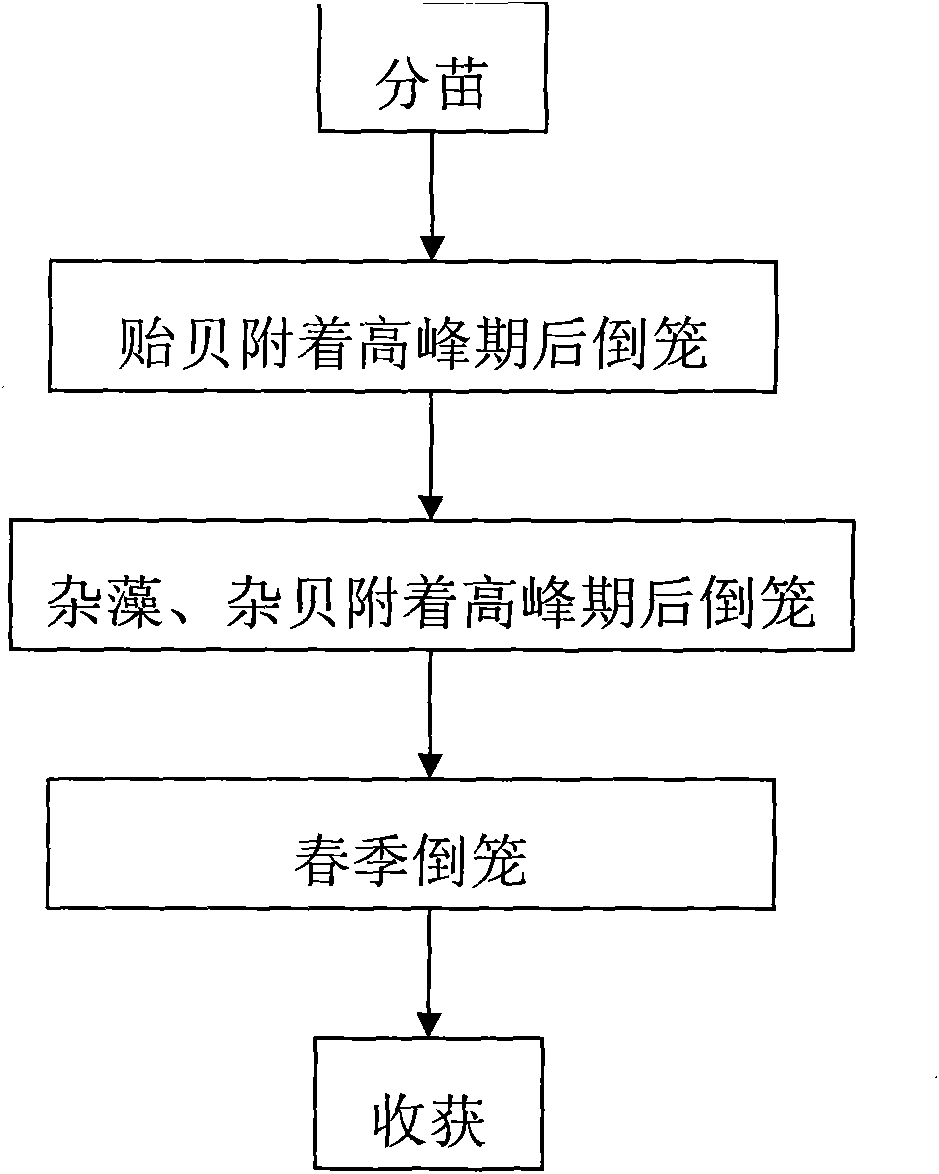

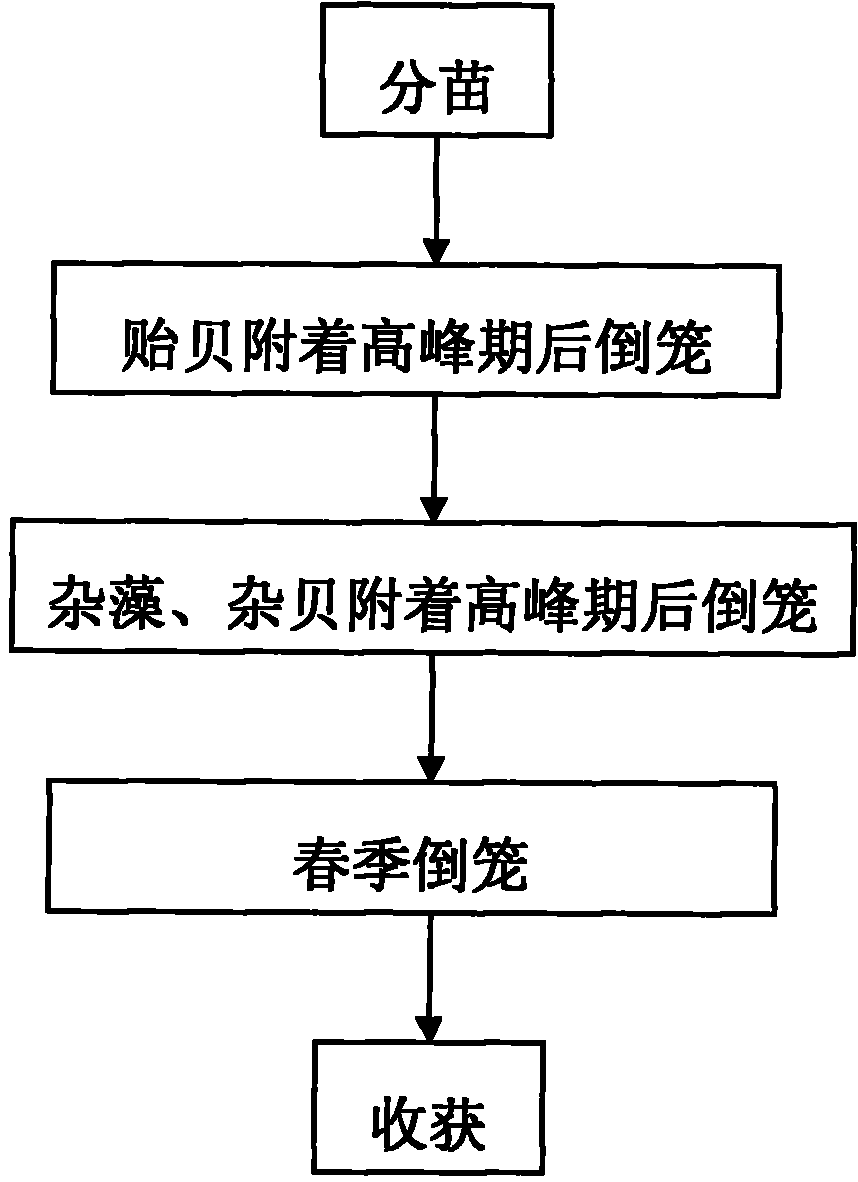

Method for culturing one-year patinopecten yesoensis

InactiveCN102100199AAvoid peak attachmentImprove survival rateClimate change adaptationPisciculture and aquariaOysterAlgae

The invention belongs to the field of aquaculture, and particularly relates to a method for culturing one-year patinopecten yesoensis. The method effectively avoids vigorous attachment periods of mussels, oysters and heterogeneous algae by one-time seedling separation and three-time cage inversion so as to improve the survival rate of seedlings; the quality and the specification of the seedlings are promoted by seedling selection; and the density is reasonably dispersed and the living space is expanded so as to facilitate the growth of the seedlings. The method is suitable for large-scale offshore culture, and has great significance for the development of the shell industry.

Owner:ZHANGZIDAO GRP

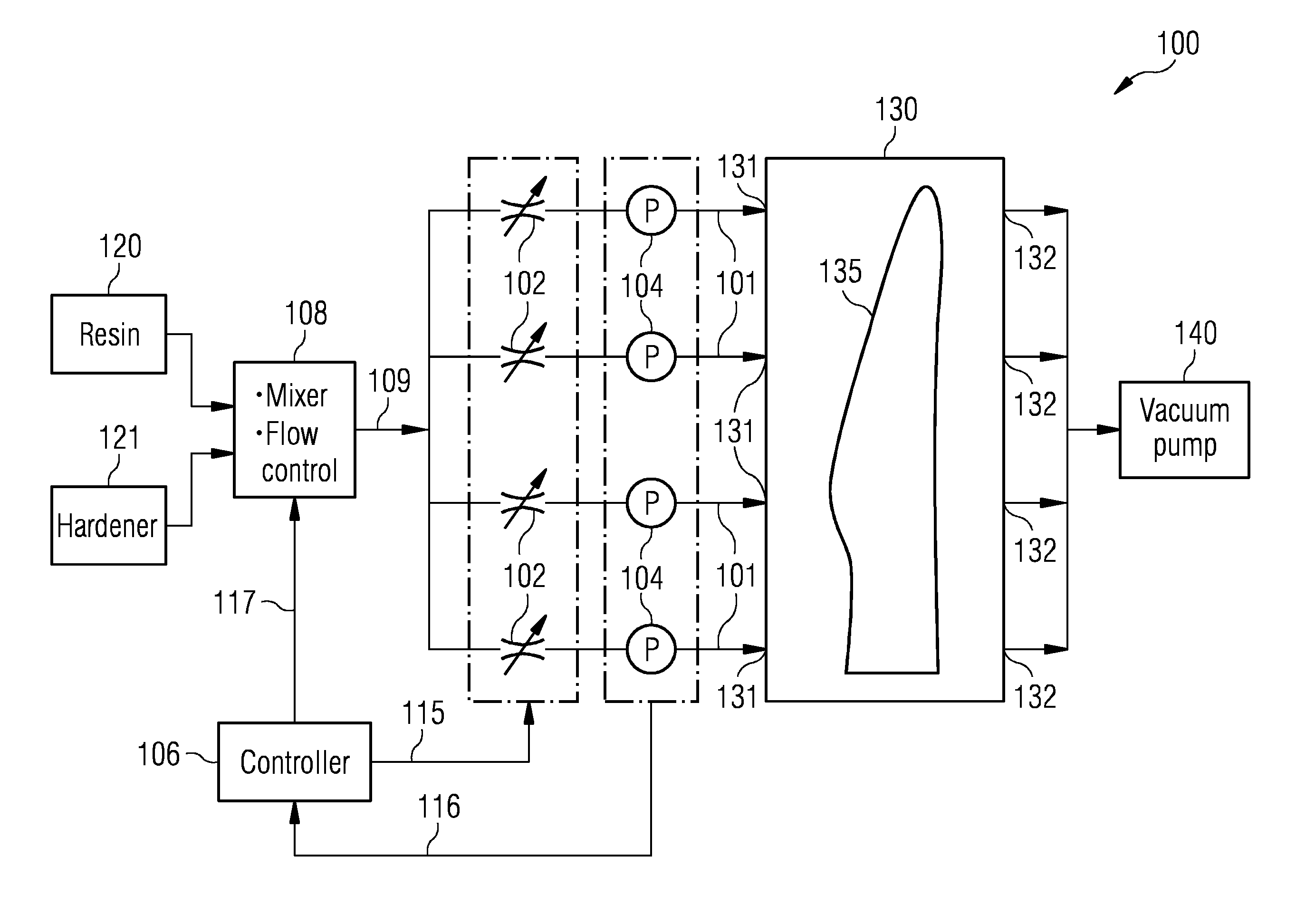

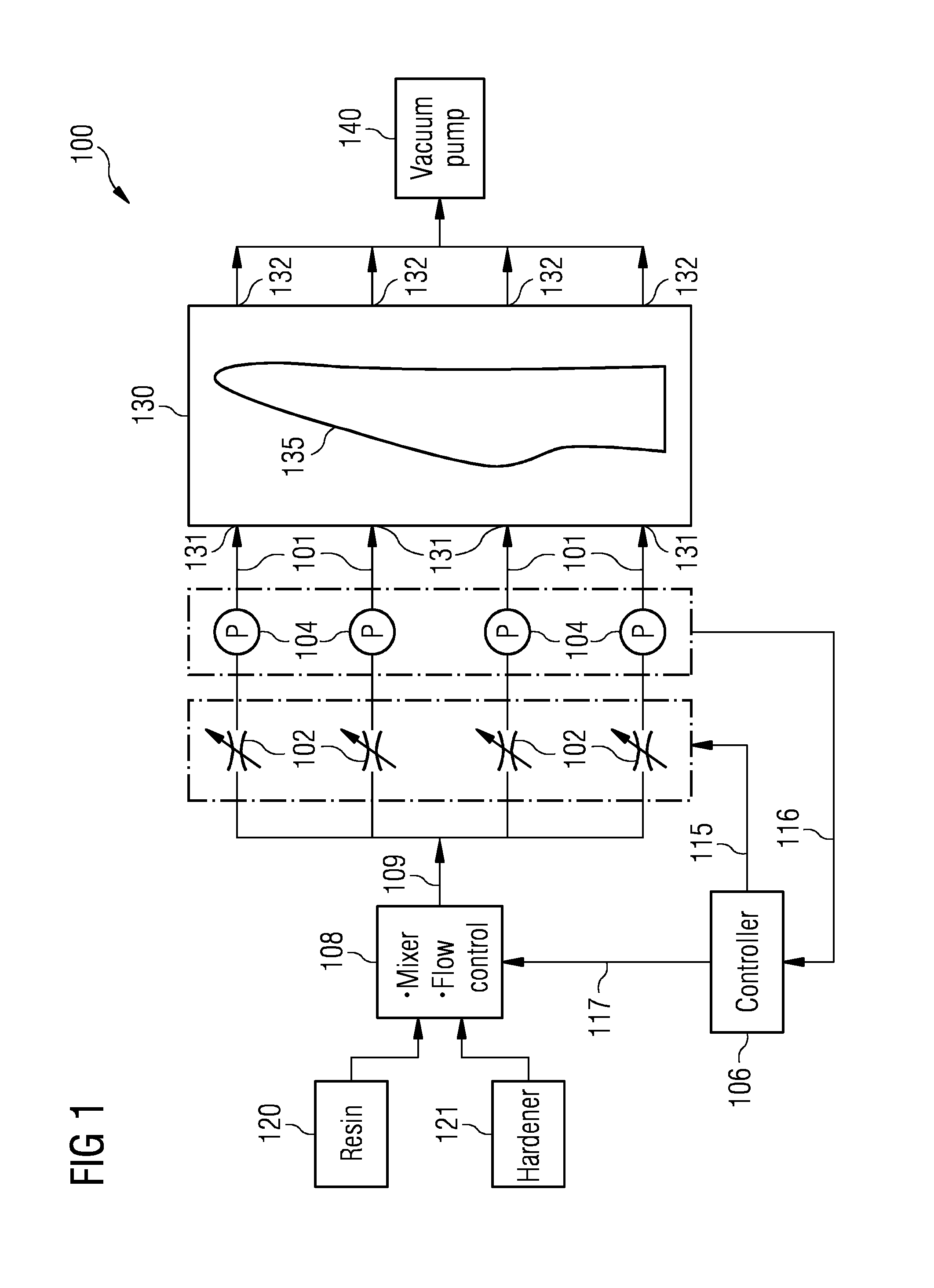

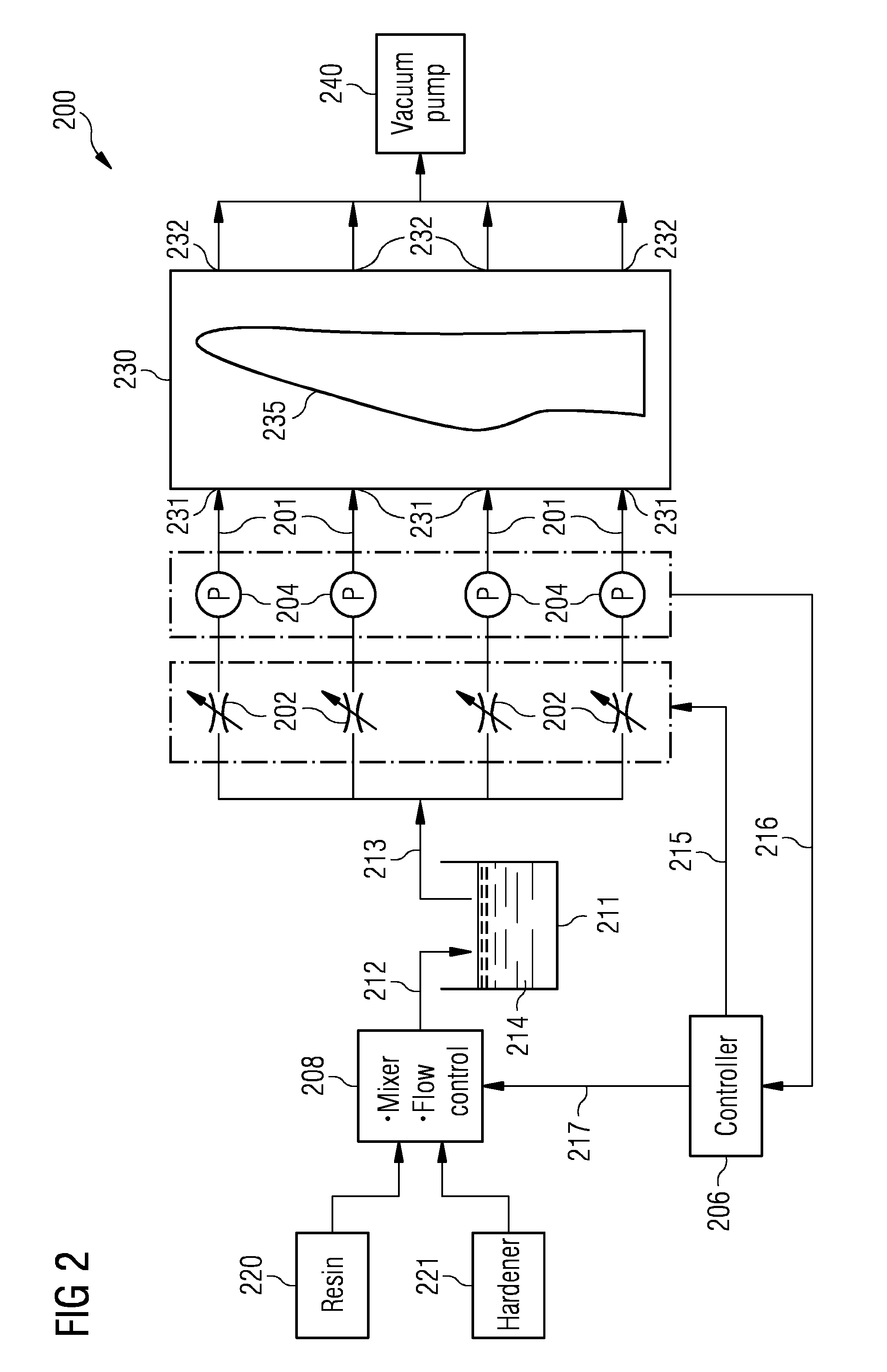

System and method for feeding a fluid to a mold for molding a reinforced composite structure

ActiveUS20140333008A1Shorten the construction periodHigh trafficFinal product manufactureFrozen sweetsTurbineMaterials science

A system and method for feeding a composite fluid to a mold for casting a reinforced composite structure, such as a rotor blade for a wind turbine are provided. The system includes a first feeding unit for feeding a first flow of composite fluid to the mold through a first mold inlet, and a second feeding unit for feeding a second flow of composite fluid to the mold through a second mold inlet. The first flow of composite fluid and the second flow of composite fluid are individually controllable.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

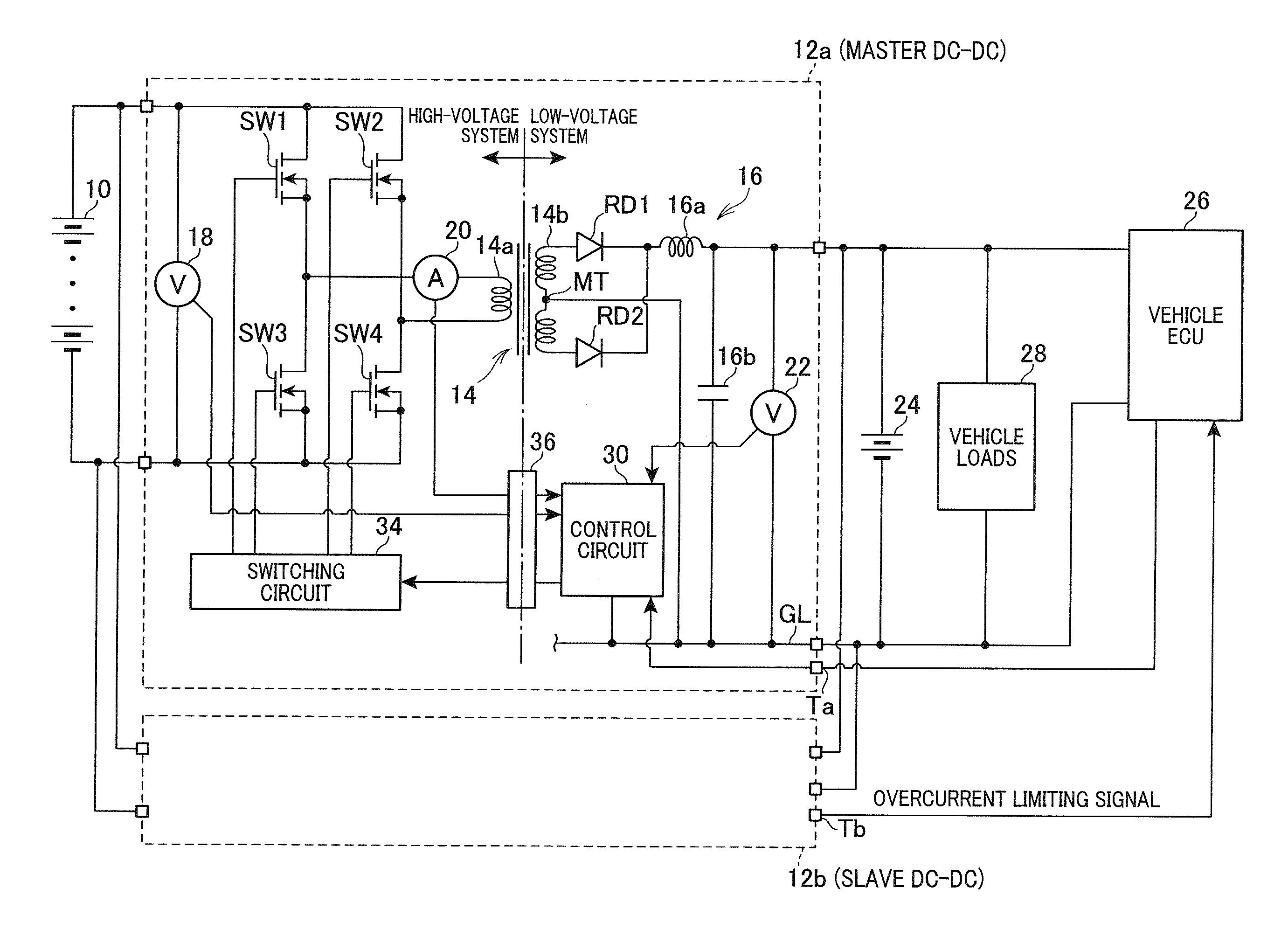

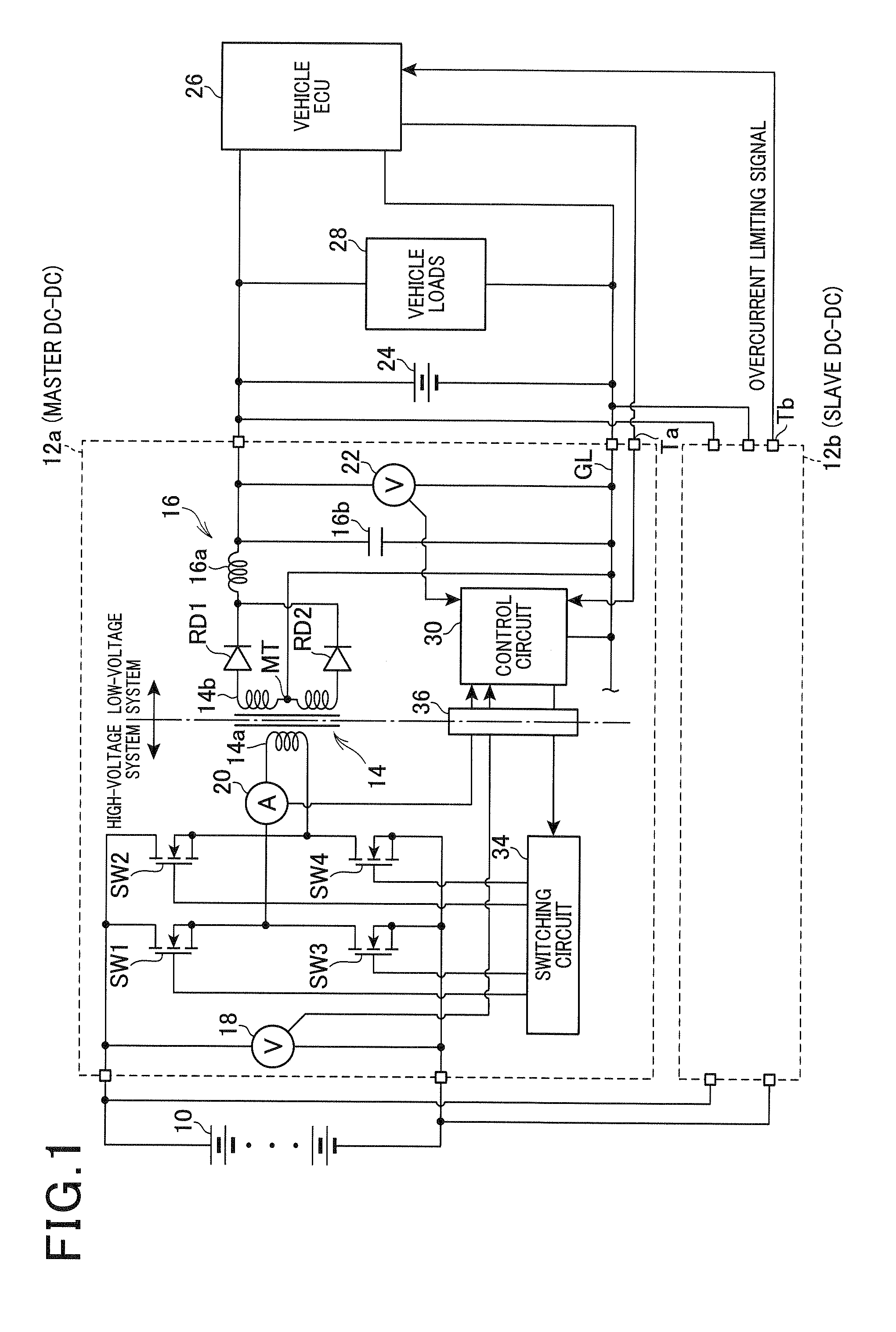

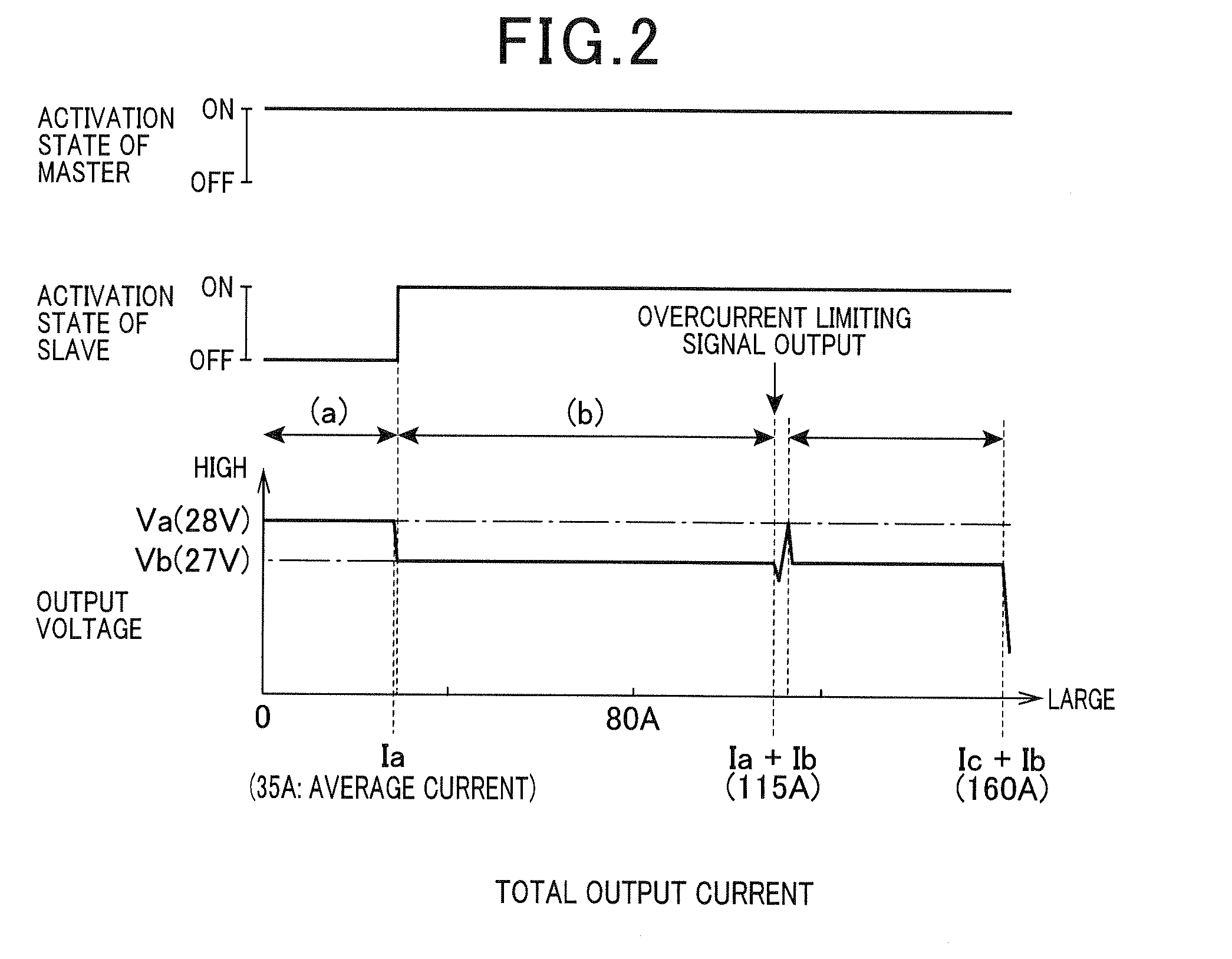

Power Supply System

ActiveUS20130099559A1Improve reliabilityImprove power supply reliabilityDc network circuit arrangementsElectric devicesDc dc converterEngineering

A power supply system includes a plurality of DC-DC converters and at least one operating unit. The DC-DC converters are connected in parallel to one another. The at least one operating unit operates the DC-DC converters such that power is supplied through the DC-DC converters to a predetermined power-supplied object. The at least one operating unit includes a voltage controller, a current limiter, and a specified value increasing unit. The voltage controller operates the DC-DC converters such that output voltages thereof are controlled to be respective target voltage. The current limiter operates the DC-DC converters such that output currents thereof are limited to respective specified value, when the output currents exceed the respective specified value. The specified value increasing unit increases the respective specified value for at least one of the DC-DC converters, when output current of the at least one of the DC-DC converters exceeds the specified value.

Owner:DENSO CORP

Mimic-ecological cultivating method for fishes, turtles and shrimps

InactiveCN102369890AIncrease production costImprove the water quality of aquacultureClimate change adaptationPisciculture and aquariaDiseaseNatural enemies

The invention discloses a mimic-ecological cultivating method for fishes, turtles and shrimps. The method comprises the following four links of creating pond conditions, reasonably stocking fries, automatically regulating water quality, and carrying out scientific cultivation and management. In the invention, a traditional consciousness that turtles are the natural enemies of shrimps, therefore, the turtles and the shrimps can not be cultivated in a mixed mode is broken up, and through cleverly using the biological links and regulating functions of cultivated breeds in the process of artificial cultivation, both the utilization rate of feeds is raised, and the diseases are reduced, thereby promoting the qualities and specifications of commercial fishes, turtles and shrimps. Meanwhile, in the invention, a characteristic that fishes, turtles and shrimps are living in different water layers is fully used, therefore, the utilization ratio of a water body in a pond is effectively improved, so that by using the technical scheme of the invention, the average annual output per mu of commercial turtles is more than 350kg, the average annual output per mu of large-size commercial freshwater shrimps is more than 40kg, and the average annual output per mu of large and medium-sized grass carps and spotted silver carps is more than 150kg. The method disclosed by the invention is universally applicable to the artificial large-scale cultivation of high-quality freshwater fishes, turtles and shrimps in the middle and lower reaches of Yangtze River.

Owner:胡政伟

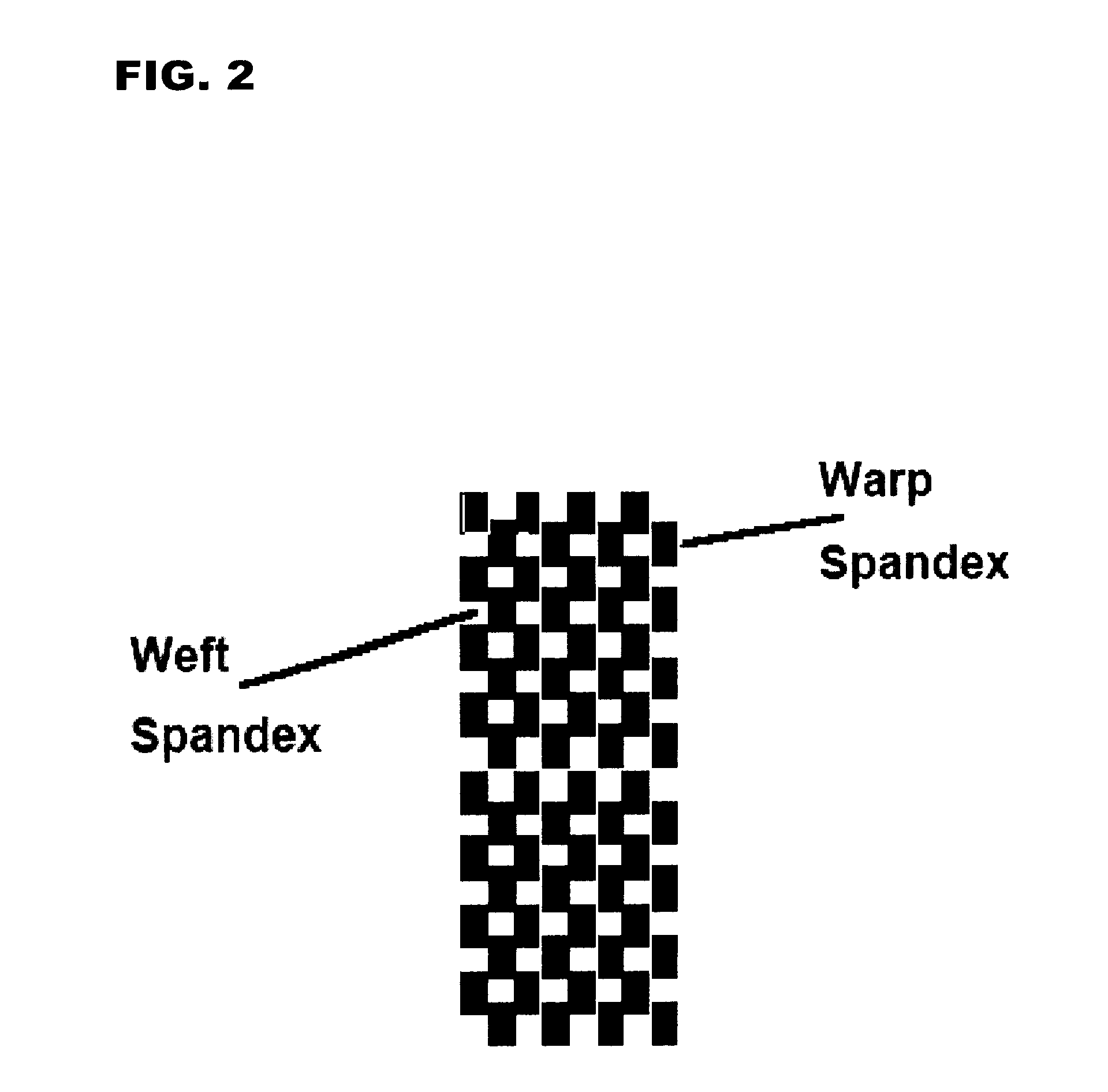

Novel Fabric Made of All Elastomeric Fiber and Its Applications

The present invention relates to a knitted fabric which adopts a novel weaving principle of changing knitting material structure to realize functions and effects which can not be achieved by ordinary fabric. The knitted fabric comprises the main component of novel woven 100 percent spandex fabric made of 100 percent spandex filament. Presently, elastic rubber pieces, rubber bands, etc., are applied to the underwear at the market for enhancing the elasticity and supporting effect. The common features is that they all have a poor elastic resilience, unstable structure, and prone to distortion and raveling. The present novel knitted fabric changes the principle of crocheting of the ordinary material of the traditional knitted fabric, adopting 100 percent spandex filament as the main material to change the elastic resilience, force, and structure stability of the traditional knitted fabric. The mutual double pulling effect of the knitted fabric in the spandex filament after crocheting is to remedy the defaults of the fabric of which the structure is deformed and the elastic resilience and the force are weakened after the fabric is elongated. Compared with the original fabric, the elastic recovery and the elastic force of the fabric are greatly increased and improved.The weaving process and the features of the novel 100 percent spandex fabric are as follows:(1) Warp yarn and weft yarn which are made of 100% spandex filament material are mutually crocheted.(2) The back weft of the spandex filament is required to pass through a filament packaging frame and a weft yarn accelerating conveyer device is provided.(3) Curling is required to be avoided. The specification of the spandex filament of which the warp yarn used required to be considered, so is the specification and constituents of the back weft made of the spandex filament.The preset novel 100% spandex fabric can completely replace the elastic woven band and rubber piece in the prior underwear to play a role of enhancing the elasticity and strength. It can also completely replace the prior common elastic woven band and rubber piece, providing good hand feel, flatness, smoothness, close fit, sound elastic resilience, comfort wear, etc. It can be widely applied to garment industry, particularly to the underwear, such as brassiere, swimwear, briefs, etc.A strap having a memory function, comprising yarns of substantially 100% spandex. The rubber band and ordinary strap applicable in the present market provide a poor elastic resilience, which would easily deform. The said strap having a memory function weaved with warp yarn made of 100% spandex and weft yarn made of 100% spandex, whose structure could be not only plain weave, but also twill or tracery. The fabric has the “memory” function by which it returns to substantially its original shape after being stretched many times it original size. It can provide excellent hand feel, good flatness, smoothness, close fit, sound elasticity, and comfortable wear when used to replace the existing ordinary elastic rubber bands. It can be widely applied in the garment industry, especially in the field of underwear such as brassiere, swimwear, briefs, lingerie, etc.The present patent for utility model discloses a laminable elastic fabric whose main components are 100% spandex elastic woven band and warp knitted shell fabric or weft knitted cloth, and the elastic fabric is formed through laminating processing. The laminated fabric currently used on the market does not have good elastic resilience and is thus easily deformed and is relatively thick. The new laminated elastic fabric of the present patent is relatively light and thin, and the elastic woven band is formed by interweaving 100% spandex warp threads and 100% spandex weft threads, and the elastic fabric is formed by laminating it to the inner side of the shell fabric. The fabric has a recovery of nearly 100% after many times of use. The fabric laminated with said woven band has the characteristics of excellent hand feel, good levelness, softness and smoothness, close fit, good elasticity, comfortable wear, etc. Meanwhile, the processing is simple, and mechanical automation and mass production can be realized, which complies with the efficiency of market economy.

Owner:BEST PACIFIC TEXTILE

Method for producing heavy caliber quartz glass pipe for IC industry by continuous melting process

InactiveCN101234844AImprove melting conditionsReasonable coordination pressureGlass forming apparatusElectric furnaceManufacturing technologyMaterials science

The invention discloses a method for manufacturing a quartz glass tube with large diameter in IC industry by a continuous melting method, which is characterized in that: high purity quartz sand is put into a continuous melting furnace and melted down through electric heating; the melted down quartz glass liquid is drawn to be the quartz glass tube with large diameter through a former , a material platform and a tube drawer; a tungsten molybdenum crucible in the continuous melting furnace has a diameter of 530mm and the height thereof is 1,600mm; a heating body tungsten rod has a diameter of 4.5mm and a length thereof is 1,100mm; the tungsten rod has 72 roots which are arranged evenly; an electric heating molybdenum electrode communicated the continuous melting furnace has electric current of 235 to 245A and the voltage thereof is 20 to 21V; the meltdown temperature is 2,200 DEG C; the diameter of the former is 340 to 350mm; the diameter of the material platform of the continuous melting furnace is 367 to 375mm; the length of a core pole in the continuous melting furnace is 1,900mm. The method for manufacturing a quartz glass tube with large diameter in IC industry by a continuous melting method improves a plurality of technology parameters in the manufacturing technology and equipments; all the technology parameters relate mutually and act synergistically so as to improve the quality and specification of the products.

Owner:徐胜利

Freshwater shrimp culturing method by comprehensively utilizing float grass and artificial shrimp nest

InactiveCN102428887AWater quality is easy to manageImprove survival rateClimate change adaptationPisciculture and aquariaWater smartweedWater quality

The invention discloses a freshwater shrimp culturing method by comprehensively utilizing float grass and an artificial shrimp nest. The culturing method comprises the steps of planting float grass, setting the artificial shrimp nest, culturing and managing and the like. By popularizing and applying the method, on the one hand, the effects of purifying the float grass and stabilizing water quality can be played to easily manage the water quality in the freshwater shrimp culturing process, on the other hand, a place for inhabitation and concealment is furthest provided to freshwater shrimp, the culture survival rate, specification and yield of freshwater shrimp are improved, and the freshwater shrimp culture benefit is remarkably improved.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

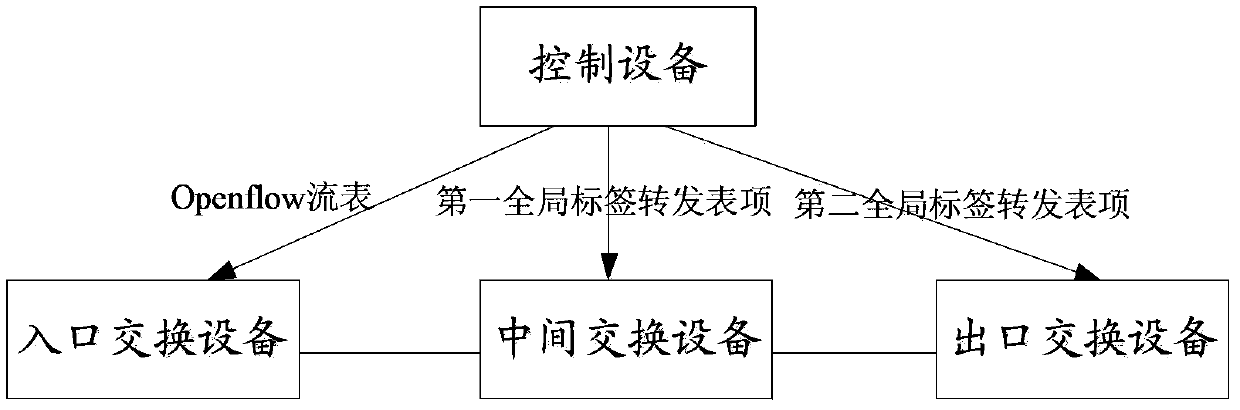

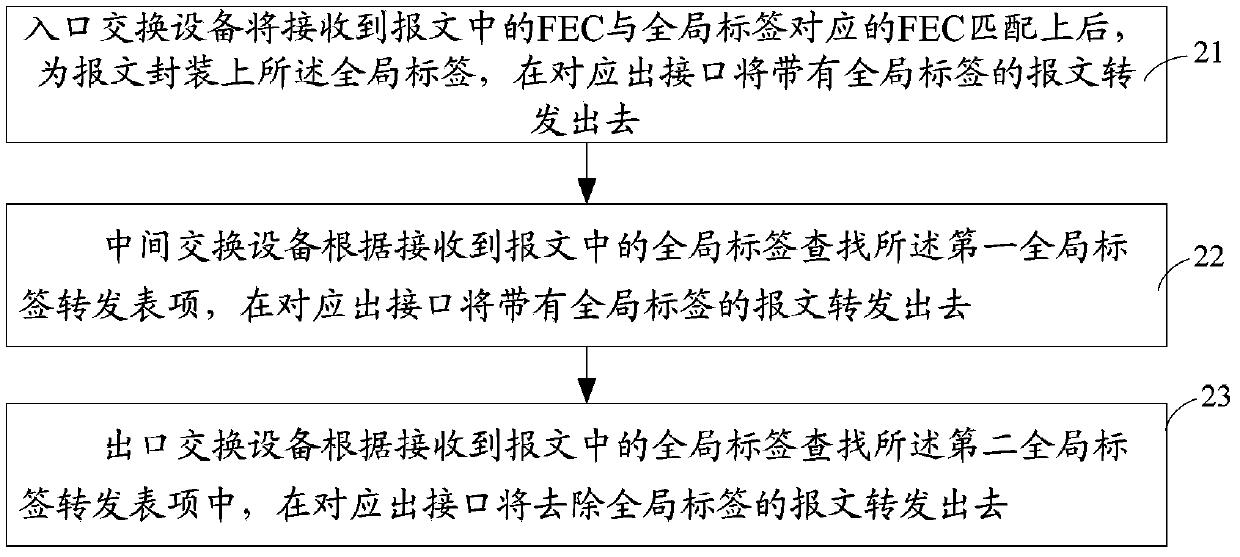

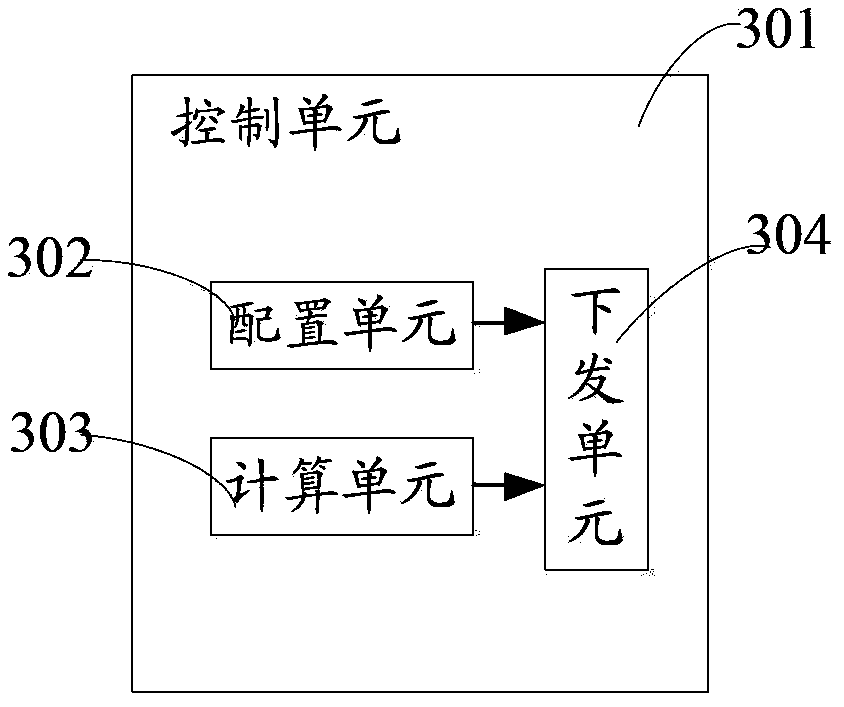

Message forwarding method and device

ActiveCN104243362AIncrease specificationImprove forwarding speedData switching networksComputer hardwareForwarding equivalence class

The invention discloses a message forwarding method. The message forwarding method is applied to an Openflow network with a control device Openflow Controller and exchange devices. The method comprises the steps that the control device assigns uniform global tags according to the forwarding equivalence class (FEC) and issues the global tags to the exchange devices, and thus the exchange devices carry out FEC matching on messages without global tags, packages the global tags on the messages and then forwards the messages out; the messages with global tags are forwarded out through global tag forwarding table items. The invention further discloses the control device and the exchange devices. By the adoption of the message forwarding method, the control device and the exchange devices, the range of specifications supported by the exchange devices can be broadened.

Owner:NEW H3C TECH CO LTD

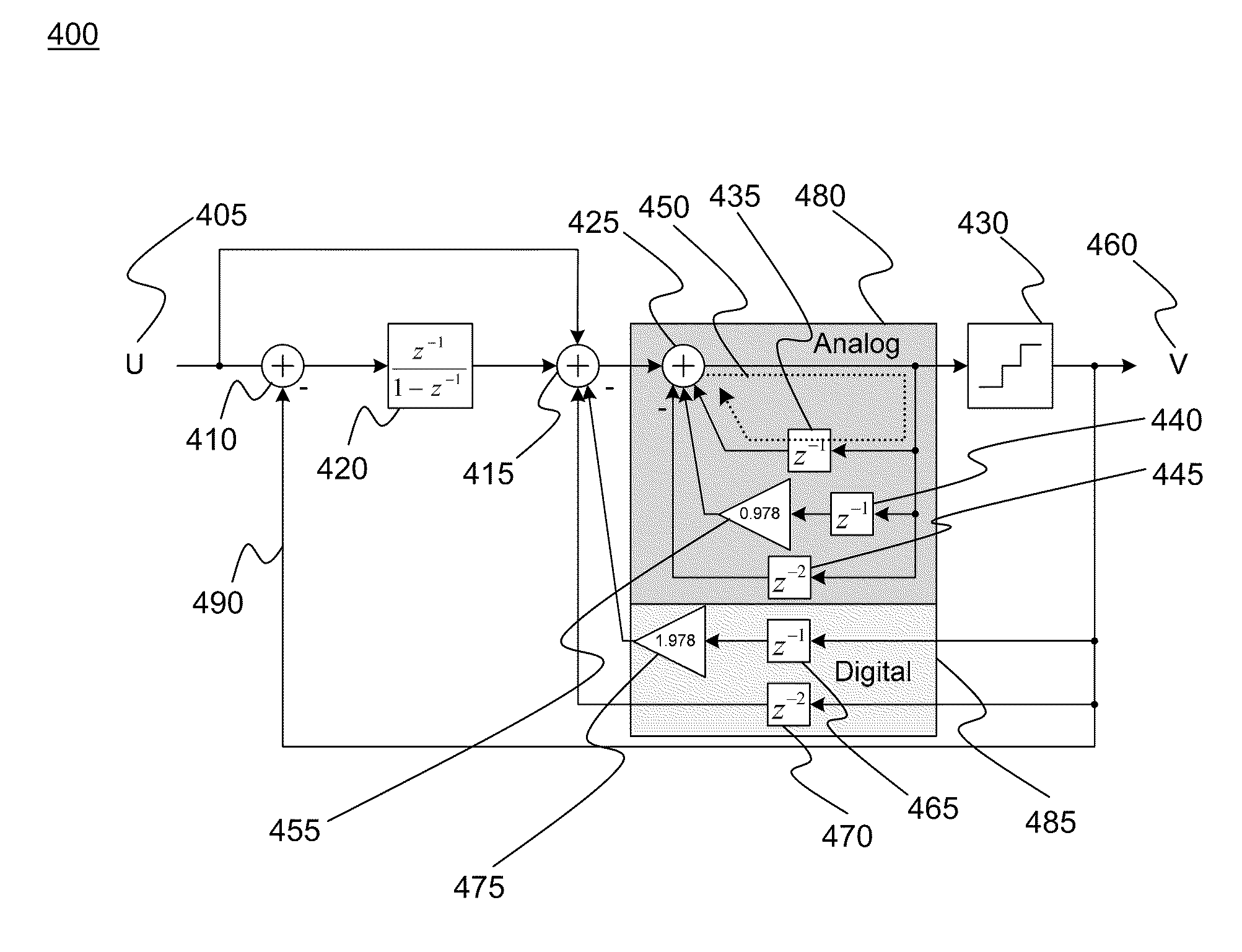

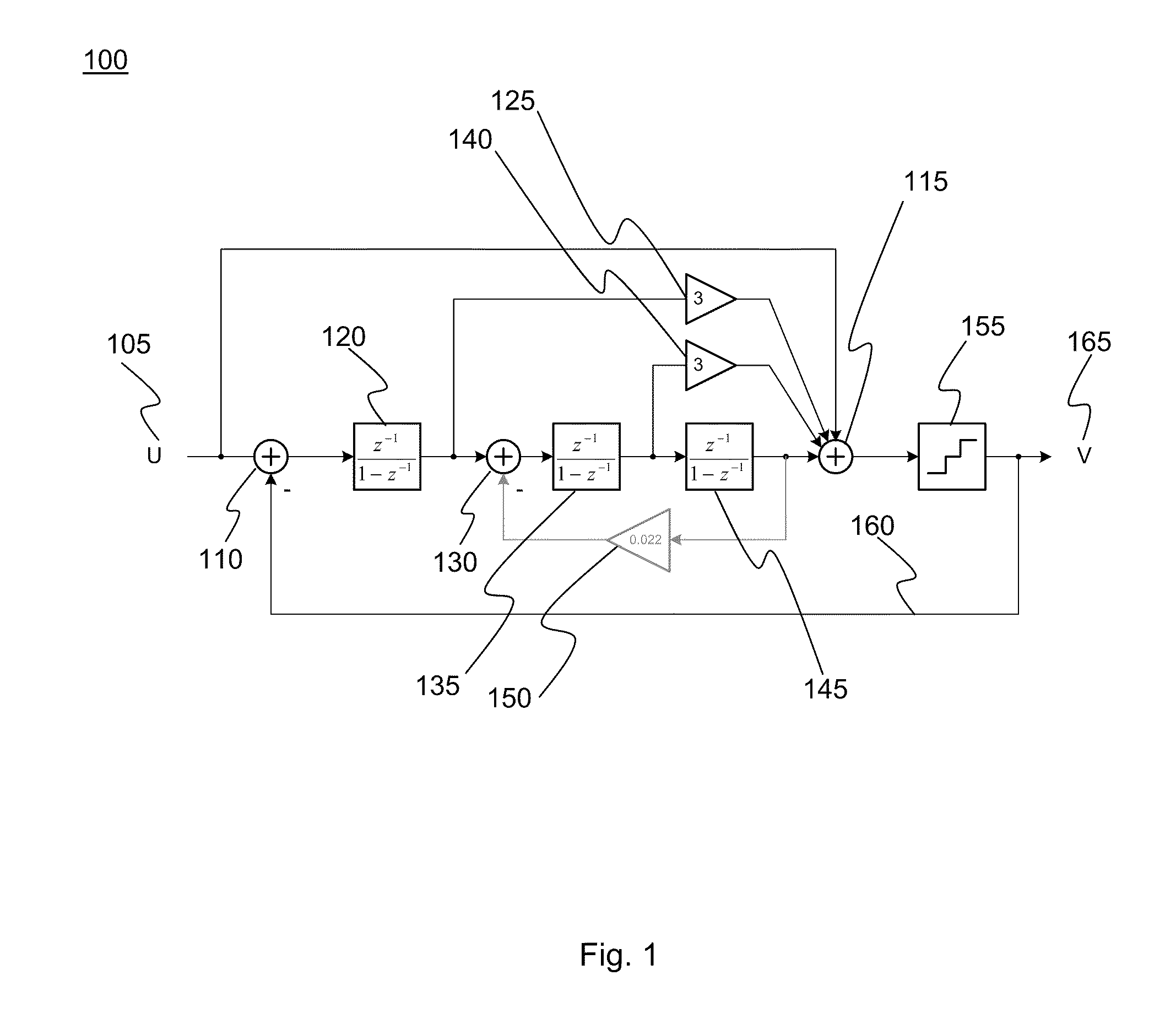

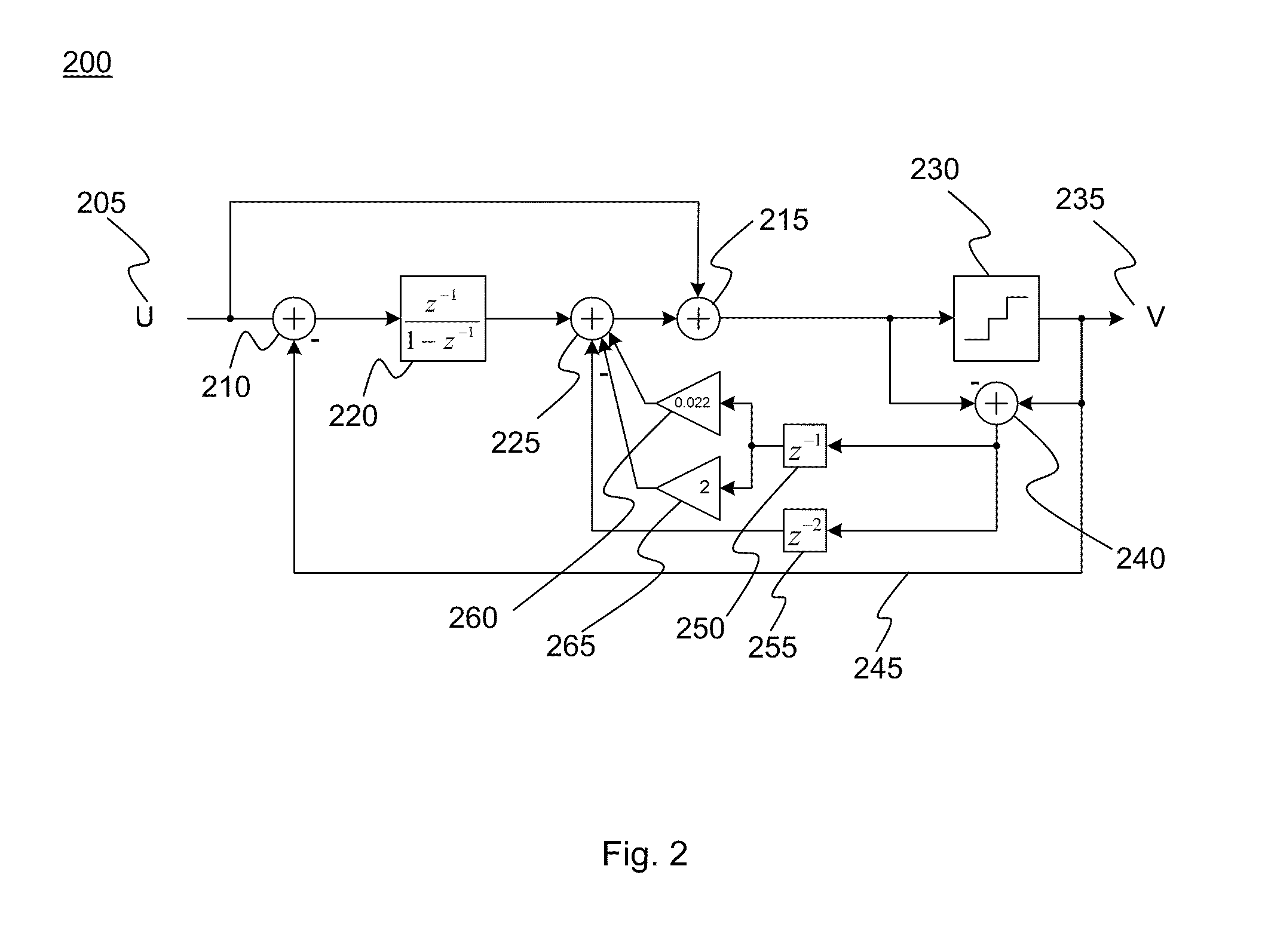

Second order noise coupling with zero optimization modulator and method

ActiveUS20110175762A1Increase specificationReduce power consumptionElectric signal transmission systemsAnalogue conversionIntegratorAudio power amplifier

A method and apparatus for a modified noise-coupled modulator using zero optimization technique is disclosed. By realizing the resonator coefficient as a part of branches other than those of the main transfer function, the problem of improving SQNR without degrading other specifications is solved. Second order noise coupling is used to implement zeros without using feedback branches going into the first integrator. Embodiments use a first-order modulator, second-order noise coupling and a resonator. It allows lower power consumption and smaller size by removing small capacitor values and gain factors and reducing the number of amplifiers.

Owner:ASAHI KASEI ELECTRONICS CO LTD

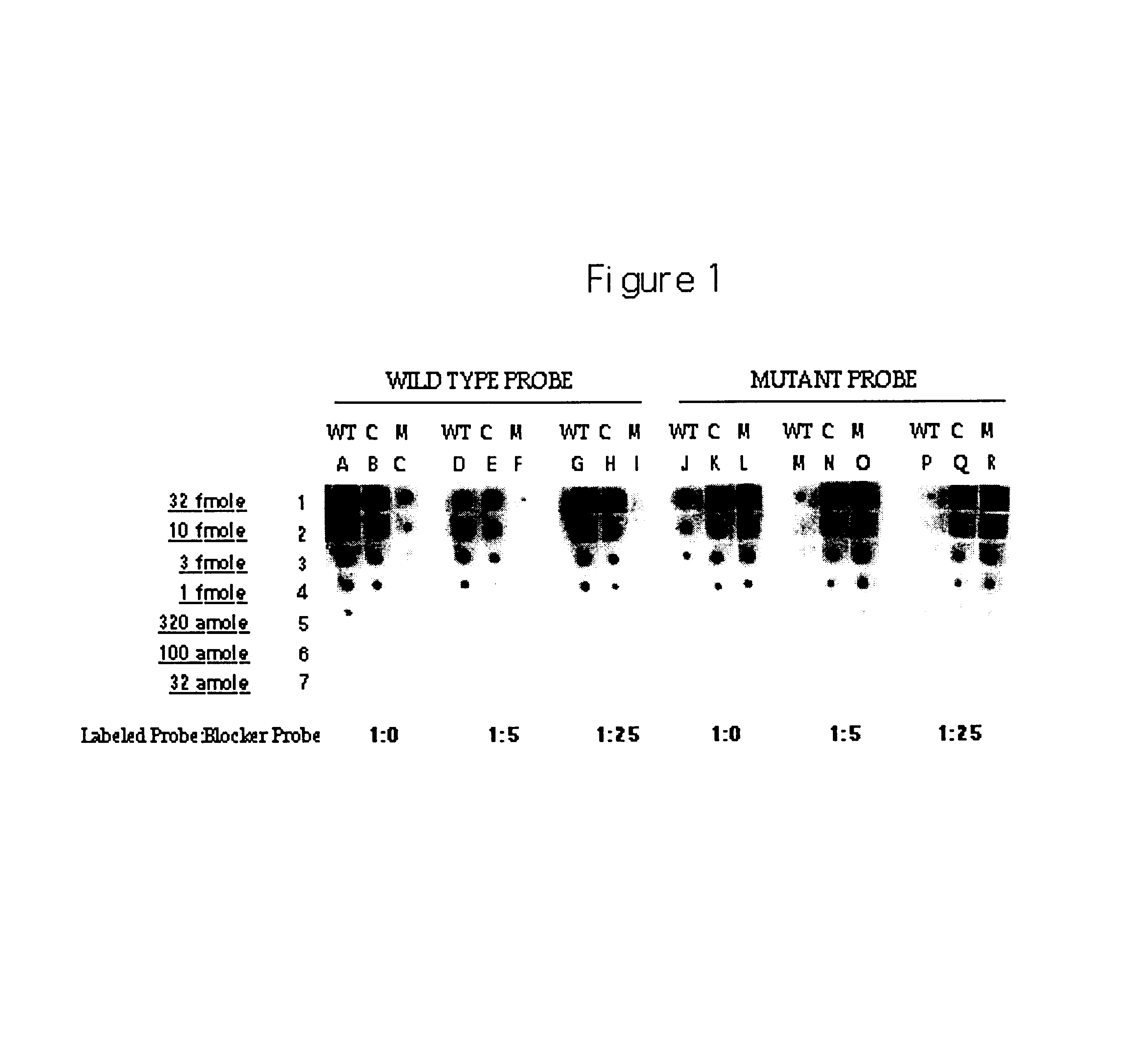

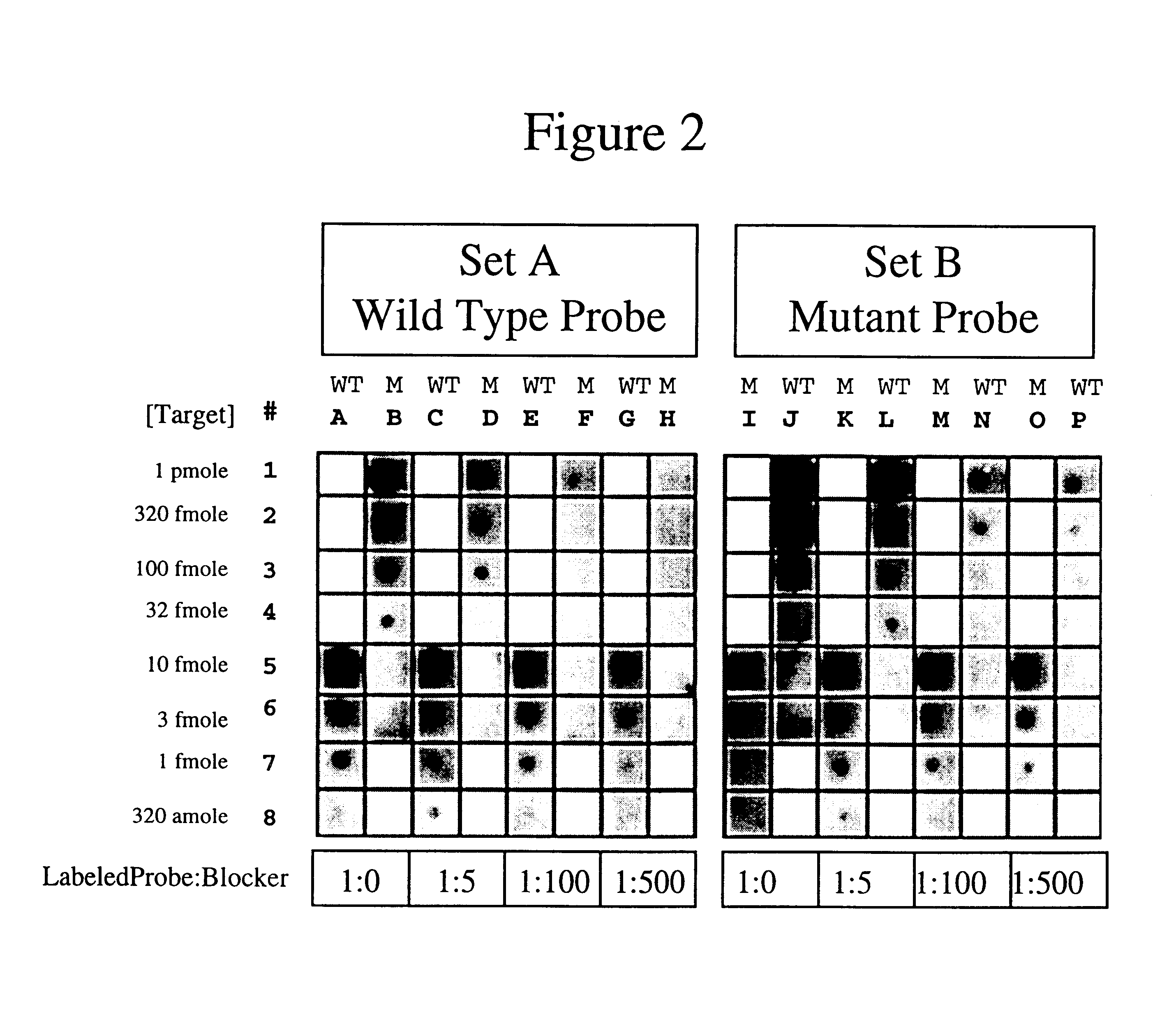

Methods, kits and compositions for suppressing the binding of detectable probes to non-target sequences in hybridization assays

InactiveUS6962778B1Sensitivity and reliability be improveImprove sequence discrimination and dynamic rangeSugar derivativesMicrobiological testing/measurementNucleic Acid ProbesMolecular biology

This invention relates to methods, kits and compositions suitable for the improved detection, analysis and quantitation of nucleic acid target sequences using probe based hybridization assays. The invention is more specifically directed to methods, kits and compositions suitable for suppressing the binding of detectable nucleic acid probes or detectable PNA probes to non-target nucleic acid sequences in an assay for a target nucleic acid sequence to thereby improve the reliability, sensitivity and specificity of the assay. The methods, kits and compositions of this invention are particularly well suited to the detection and analysis of nucleic acid point mutations.

Owner:APPL BIOSYSTEMS INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com