NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method

An alloy and thin-walled technology, which is applied in the field of precision forming of intermetallic compound thin-walled pipe fittings, can solve problems such as many defects in superplastic forming, difficult pipe rolling process, and complicated welded pipe process, so as to achieve good composition uniformity and improve dimensional accuracy , The effect of the safety of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] An integrated method for forming and controlling NiAl alloy thin-walled pipe fittings, comprising the following steps:

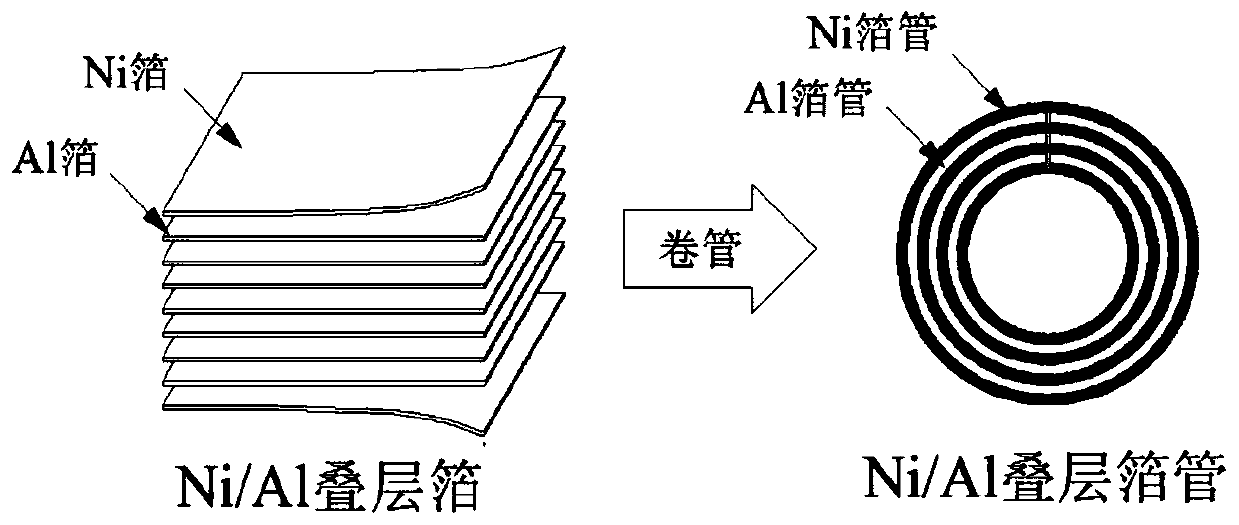

[0066] (1) According to the atomic number ratio of Ni atoms and Al atoms in NiAl alloy, calculate the thickness ratio of Ni foil and Al foil; polish Ni foil and Al foil with fine sandpaper, and then put it into acetone solution for ultrasonic Wash, then soak in distilled water for 1 min, take it out and dry it with cold air to obtain pretreated Ni foil and pretreated Al foil; the specific calculation process of the thickness ratio of Ni foil and Al foil is:

[0067] N=n×N A (1); Wherein, N represents number of atoms, and n represents the amount of substance, N A represents Avogadro's number;

[0068] m=n * M (II), wherein, m represents quality, and n represents the amount of substance, and M represents the molar mass of substance;

[0069] h=m / (ρ S) (III), wherein, h represents height, m represents quality, ρ represents density, and S represents ...

Embodiment 2

[0076] An integrated method for forming and controlling NiAl alloy thin-walled pipe fittings, comprising the following steps:

[0077] (1) same as embodiment 1;

[0078] (2) Alternately stack several pretreated Ni foils and several pretreated Al foils to obtain Ni / Al laminated foil; Insert the metal shaft tube inside, and apply boron nitride solder resist between the Ni / Al laminated foil tube and the metal shaft tube, and put the Ni / Al laminated foil tube and the metal shaft tube into the cylindrical cavity mold as a whole The temperature of the expansion joint is 400°C, the gas pressure of the expansion joint is 20MPa, and the expansion joint time is 0.5h; then the Ni / Al laminated foil tube and the metal shaft tube are taken out as a whole, and the internal Take out the metal shaft tube;

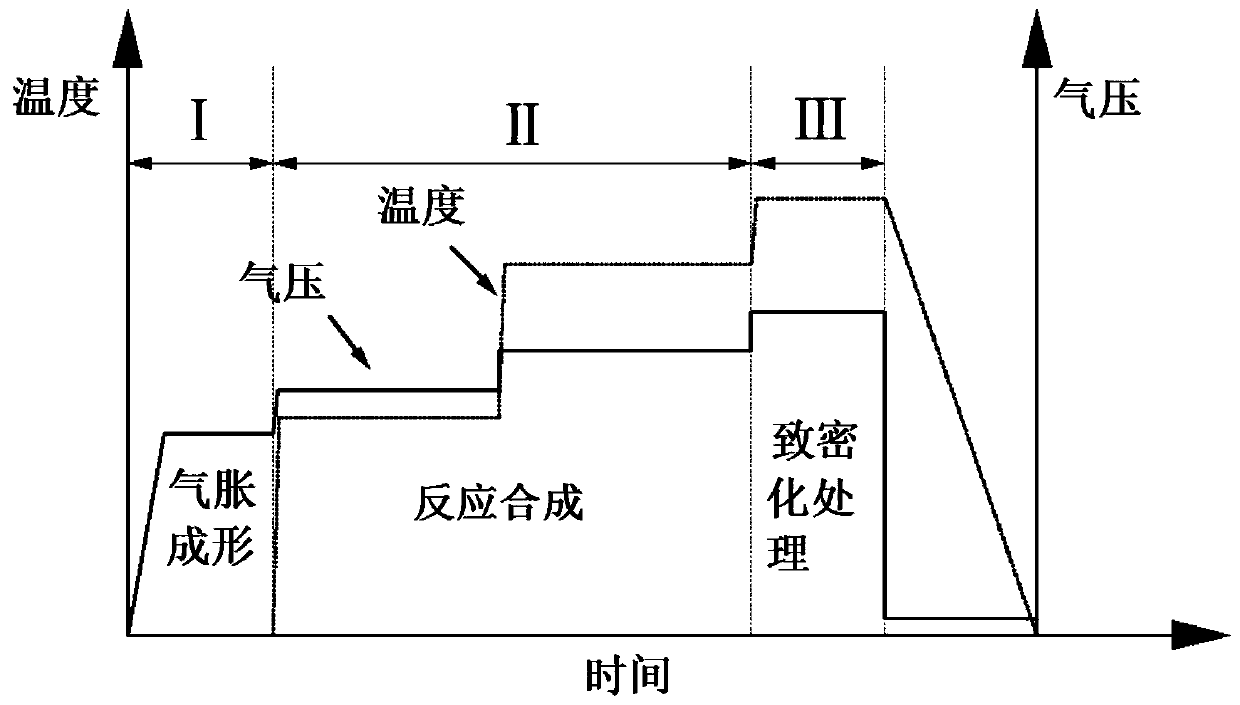

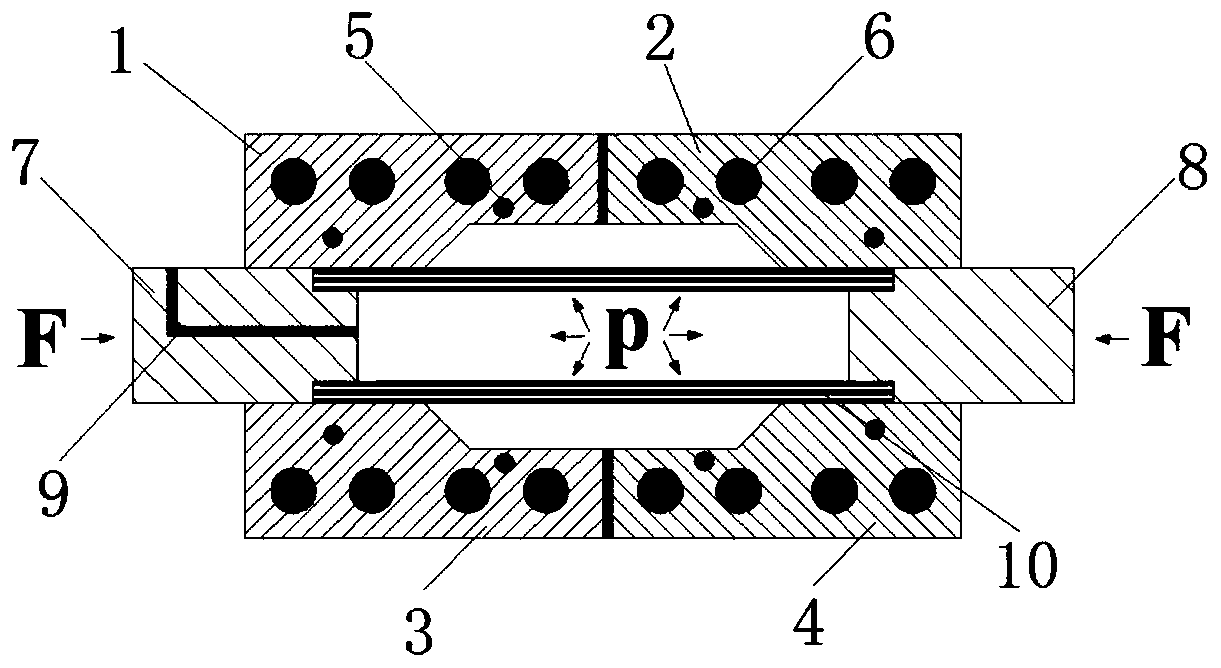

[0079] (3) The Ni / Al laminated foil tube is placed in the inflation forming mold, and the inflation forming mold is heated to 400°C for inflation forming. The pressure required for the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com