Patents

Literature

167results about How to "Good composition uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

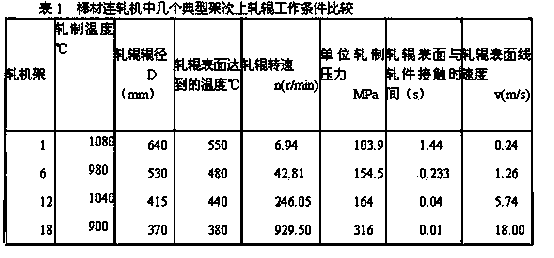

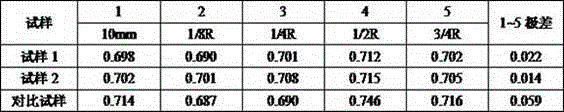

Dynamic soft reduction technologies for bloom continuous casting of heavy rail

The invention discloses a process of continuous casting dynamic with less reduction heavy rail steel cogged ingot, the process is applied in the continuous casting of high carbon steel cogged ingot, which can not only evidently alleviate center segregation, center porosity, center line shrinkage, center crack and so on defects and prevent the casting ingot center crack, middle crack and so on underbead crack, but also can improve component homogenization of rail rolled by the casting ingot, stabilize and improve mechanical property and functional performance of the rail and reach technical requirements of the high speed rail. The technical measure as follows: controlling continuous casting pulling rate and molten steel temperature of the heavy rail steel, the continuous casting pulling rate is 0.60-0.80m / min, the molten steel superheating temperature is 15-40 DEG C; adopting even and assuasive control mode in the secondary cooling zone, the continuous casting ratio water amount is 0.25-0.30L / kg, the casting ingot surface temperature on the area with less reduction is 900-1020 DEG C; the reduction is controlled on the area with less reduction, the casting ingot solidification rate on the area with less reduction fs=30%-100%, total reduction is 1.6-7.0 mm.

Owner:PANZHIHUA IRON AND STEEL

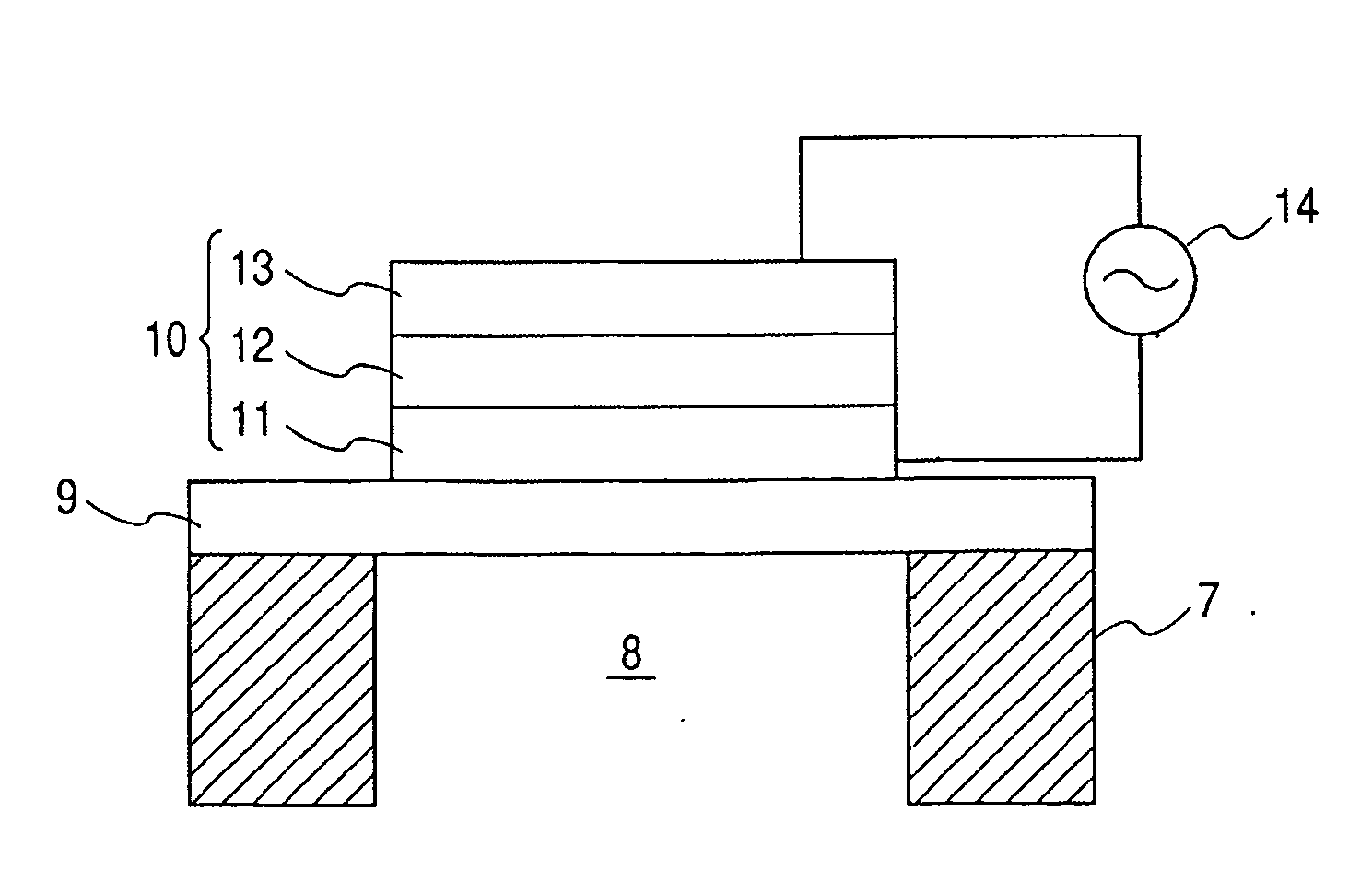

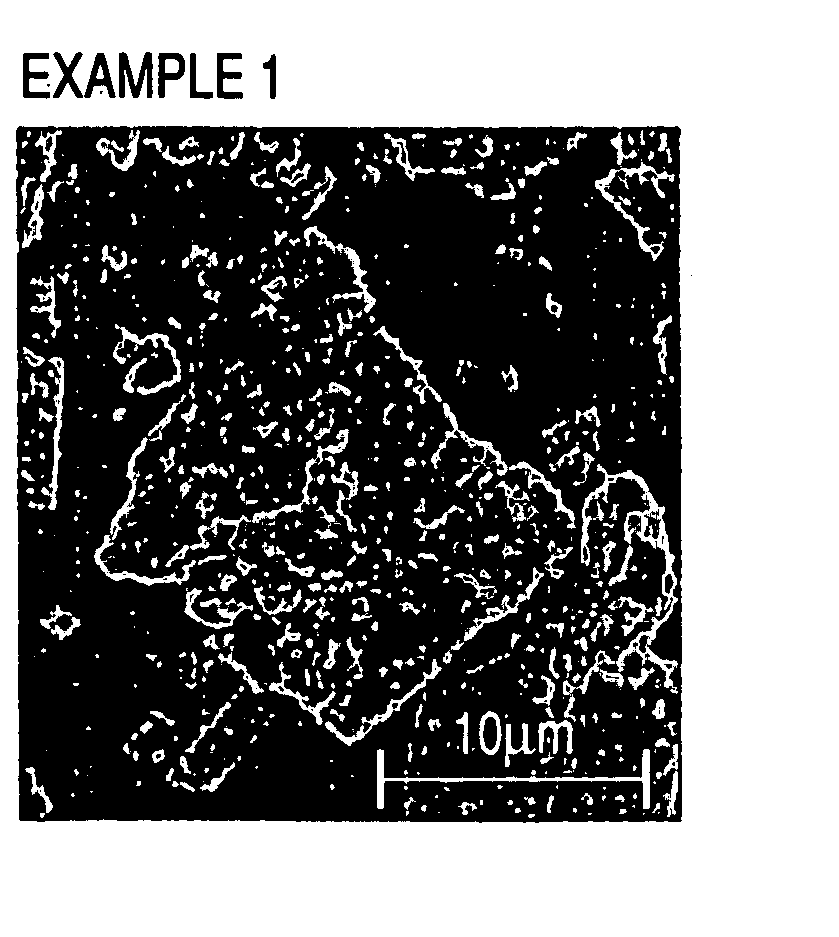

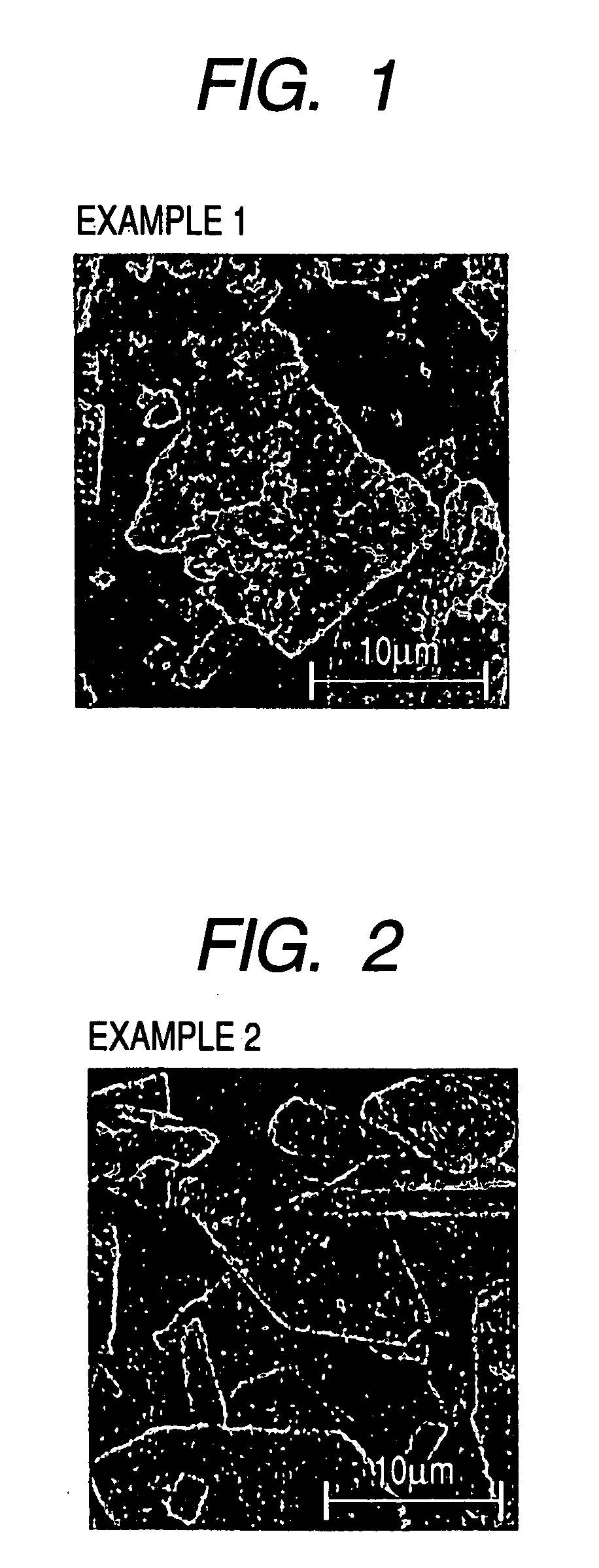

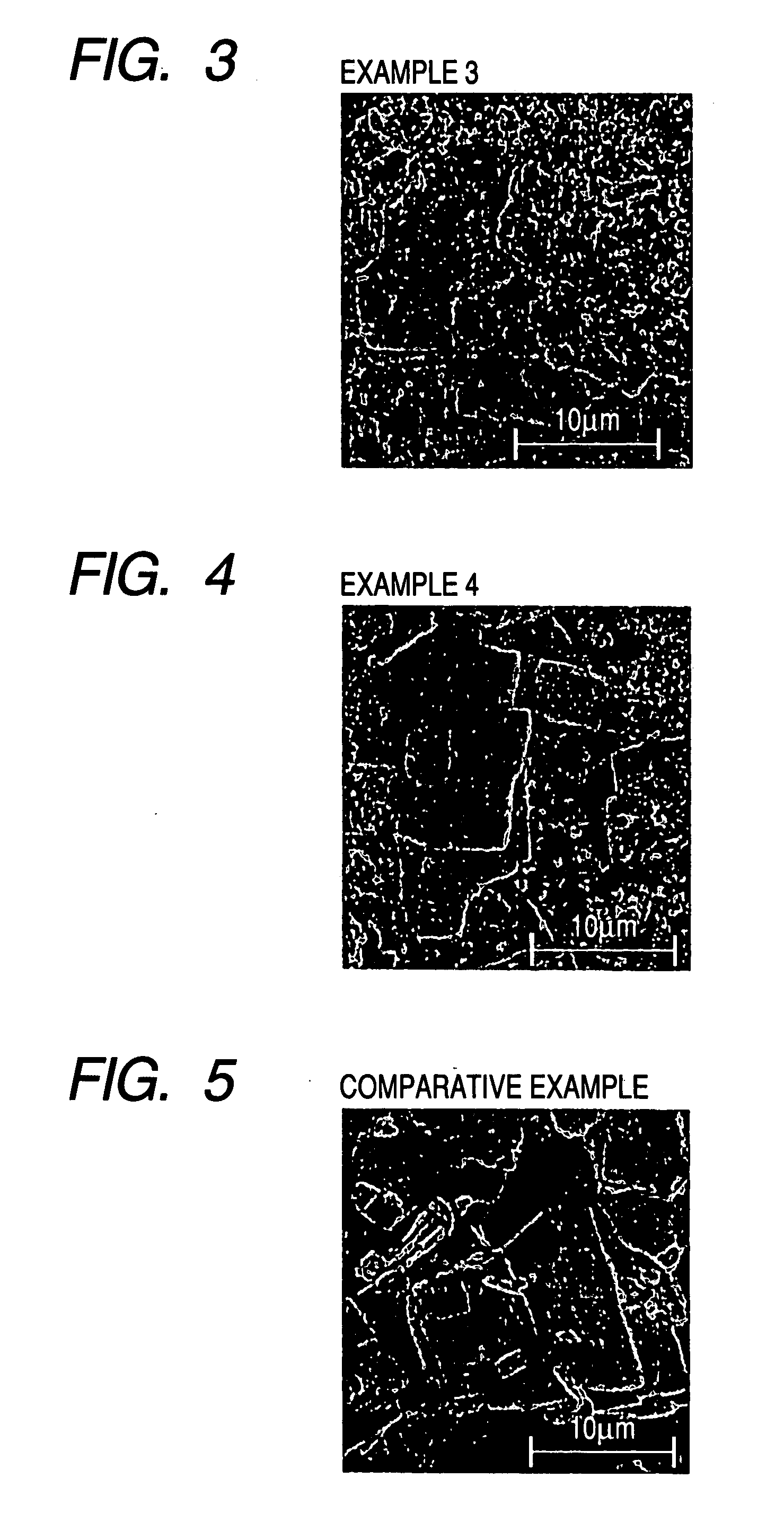

Piezoelectric thin film, method of manufacturing piezoelectric thin film, piezoelectric element, and ink jet recording head

ActiveUS20070097182A1Good composition uniformityLarge constantPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyOptoelectronicsTitanium

There is disclosed a piezoelectric thin film having less non-uniform portion and holding satisfactory piezoelectric characteristics, a method of manufacturing the film, a piezoelectric element using the piezoelectric thin film, and an ink jet system recording head using the piezoelectric element. In the piezoelectric thin film of perovskite crystals formed on a substrate by a sol-gel process and represented by a general formula Pb(1-x)Lax(ZryTi1-y)O3 (where 0≦x<1, 0.05≦y≦1), a film thickness of the thin film is 1000 nm or more and 4000 nm or less, and a difference between a maximum value and a minimum value of y in an arbitrary portion of the thin film is 0.05 or less.

Owner:CANON KK +1

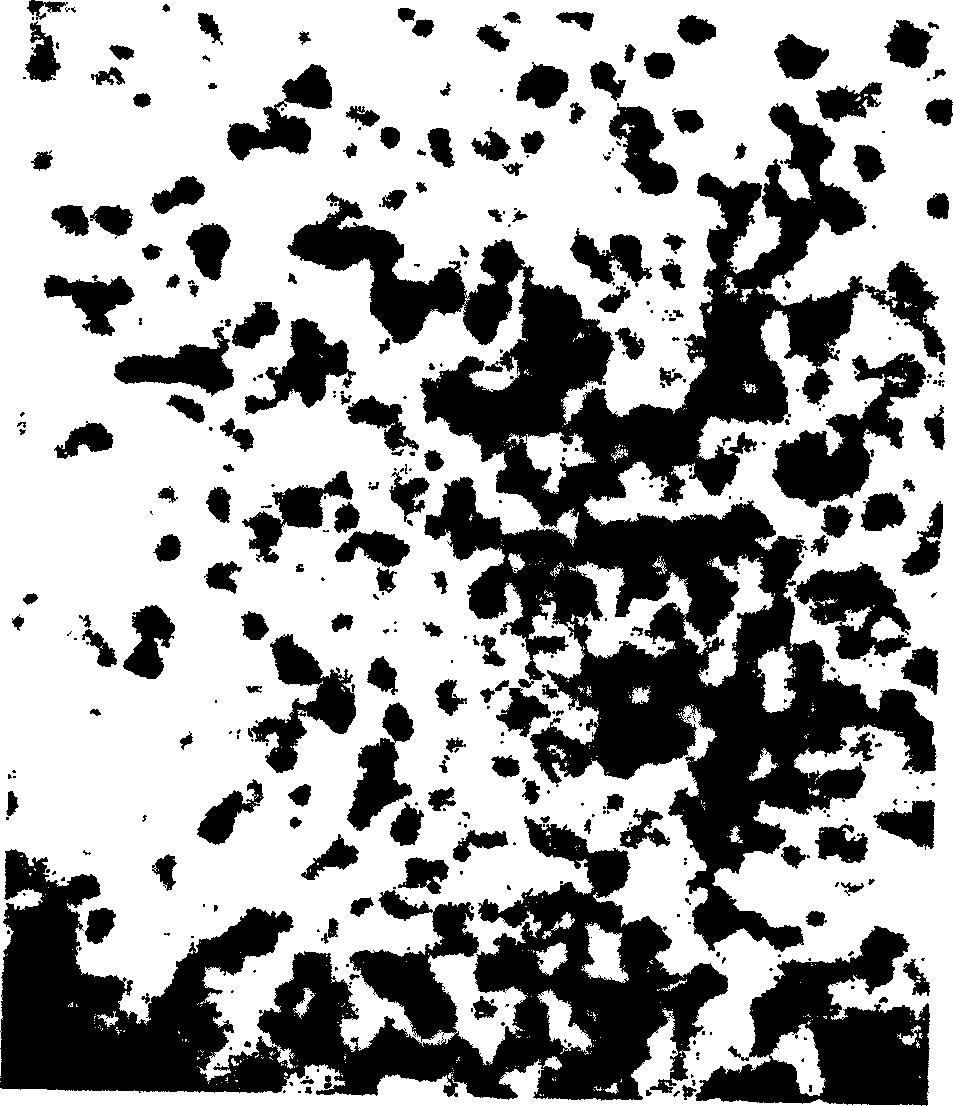

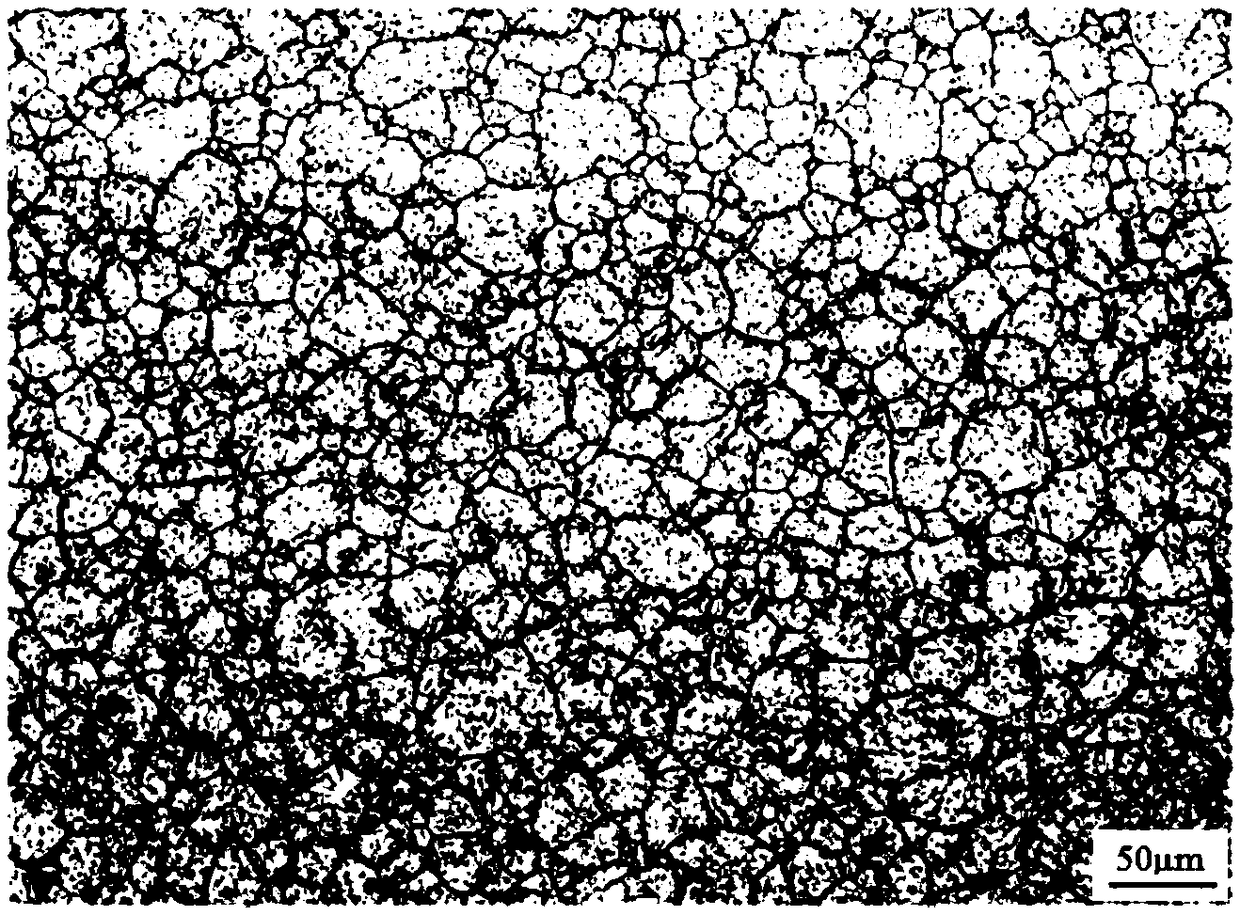

RE-containing prealloy powder

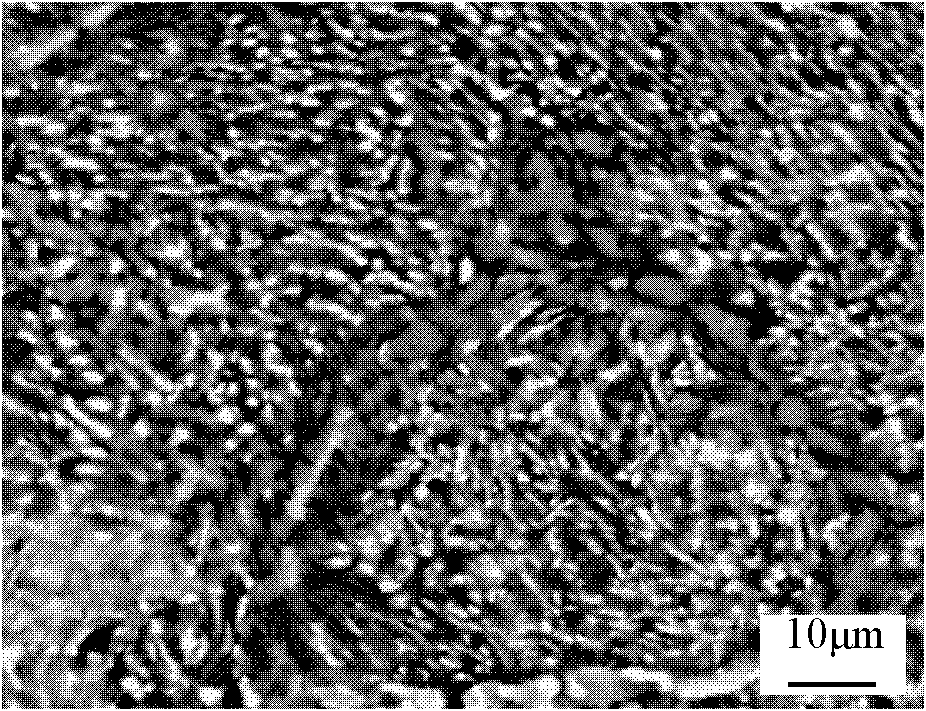

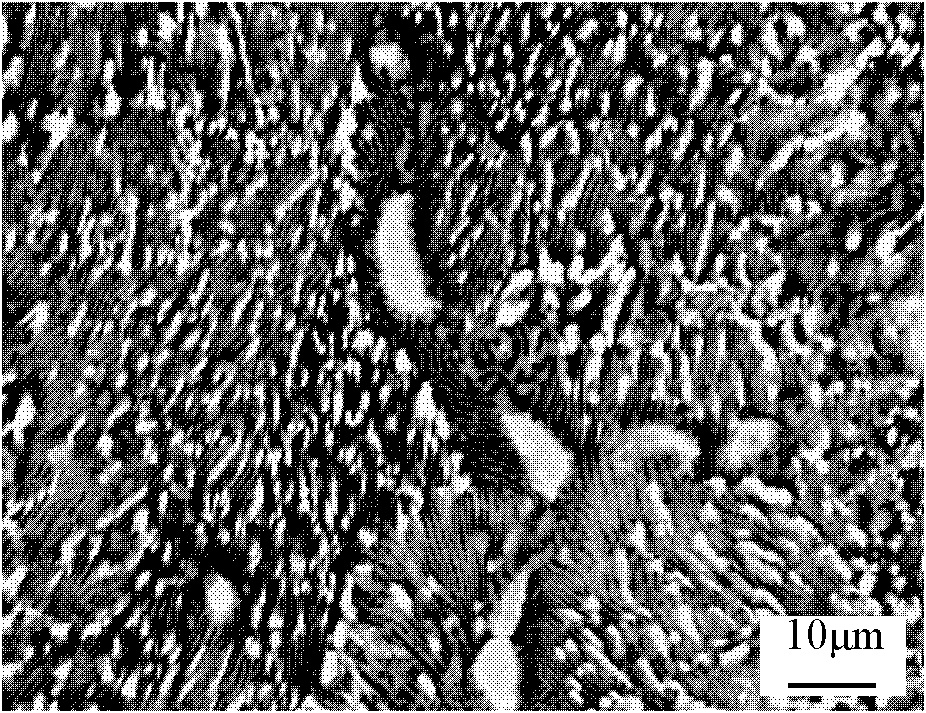

ActiveCN1986116AGood composition uniformitySufficient sintering reactivityRare-earth elementScanning electron microscope

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

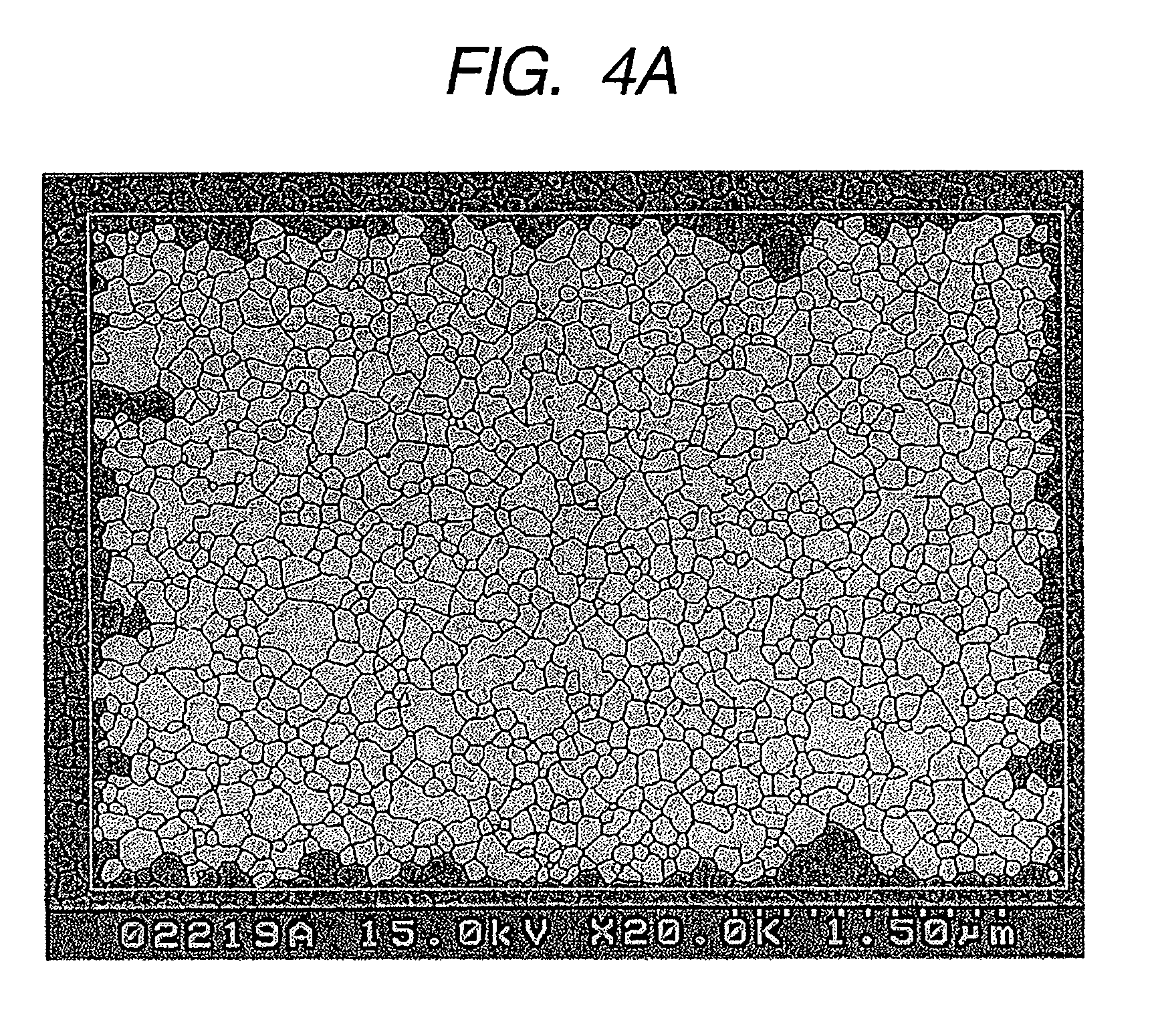

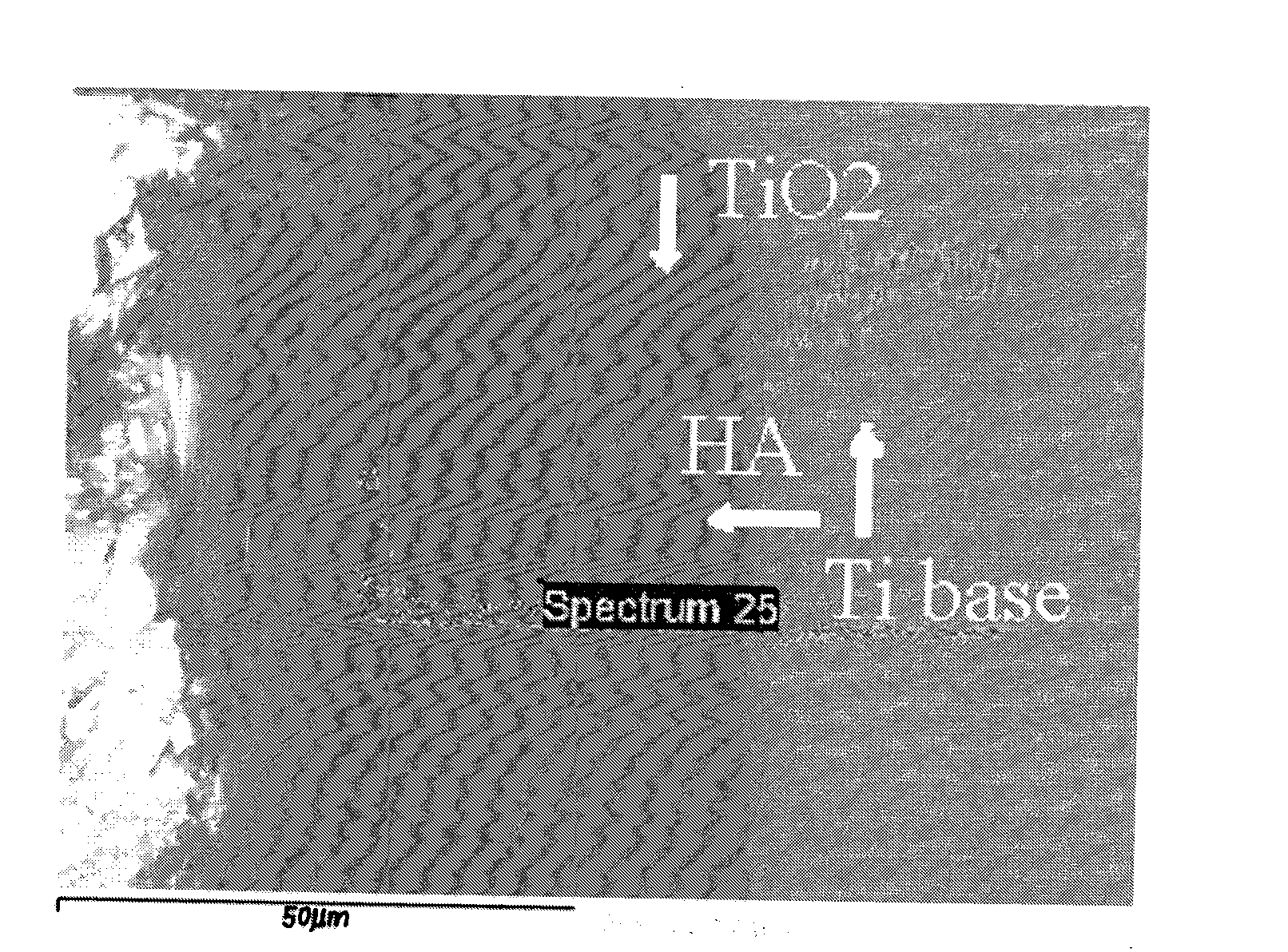

Preparation method of hydroxylapatite/titanic oxide composite biological coatings

The invention provides a method for preparing a hydroxyapatite / titanium dioxide composite bioactive coating on the surfaces of medical metals such as a titanium alloy, and the like, and belongs to the technical field of the preparation of bioactive coatings on the surface of the titanium alloy. The composite coating is prepared by preparing precursor sols of HA and TiO2 respectively, then mixing the precursor sols of the HA and the TiO2, and performing aging, coating, drying and heat treatment. The coating has high bioactivity, low cost of preparation technology, and high bonding strength with a matrix, is applicable to the preparation of surface coatings of various complicated geometric structures, and can be used for surface modification of surgical implants such as artificial hip joints and dental implants as well as orthopedic instrument products.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Sintered flux utilized in automatic submerged arc welding with multiple wires in high speed

InactiveCN1415454AGood composition uniformityImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaWeld seamSoldering process

A sintering welding wire for the multi-wire high-speed autoamtic hidden arc welding contains MgO (19-28 mass%), CaF2 (12-18%), ZrO2 (8-15%), Al2O3 (18-24%), SiO2 (17-25%), CaO (7-13%), RE (0-7%), MnO (0-5%), TiO2 (0-5%), Na2O+K2O (2-5%), S (0-0.05%), and P (0-0.06%). Its advantages are stable arc, beautiful welded seam, and high welding speed (1.5-2 m / m).

Owner:YANSHAN UNIV

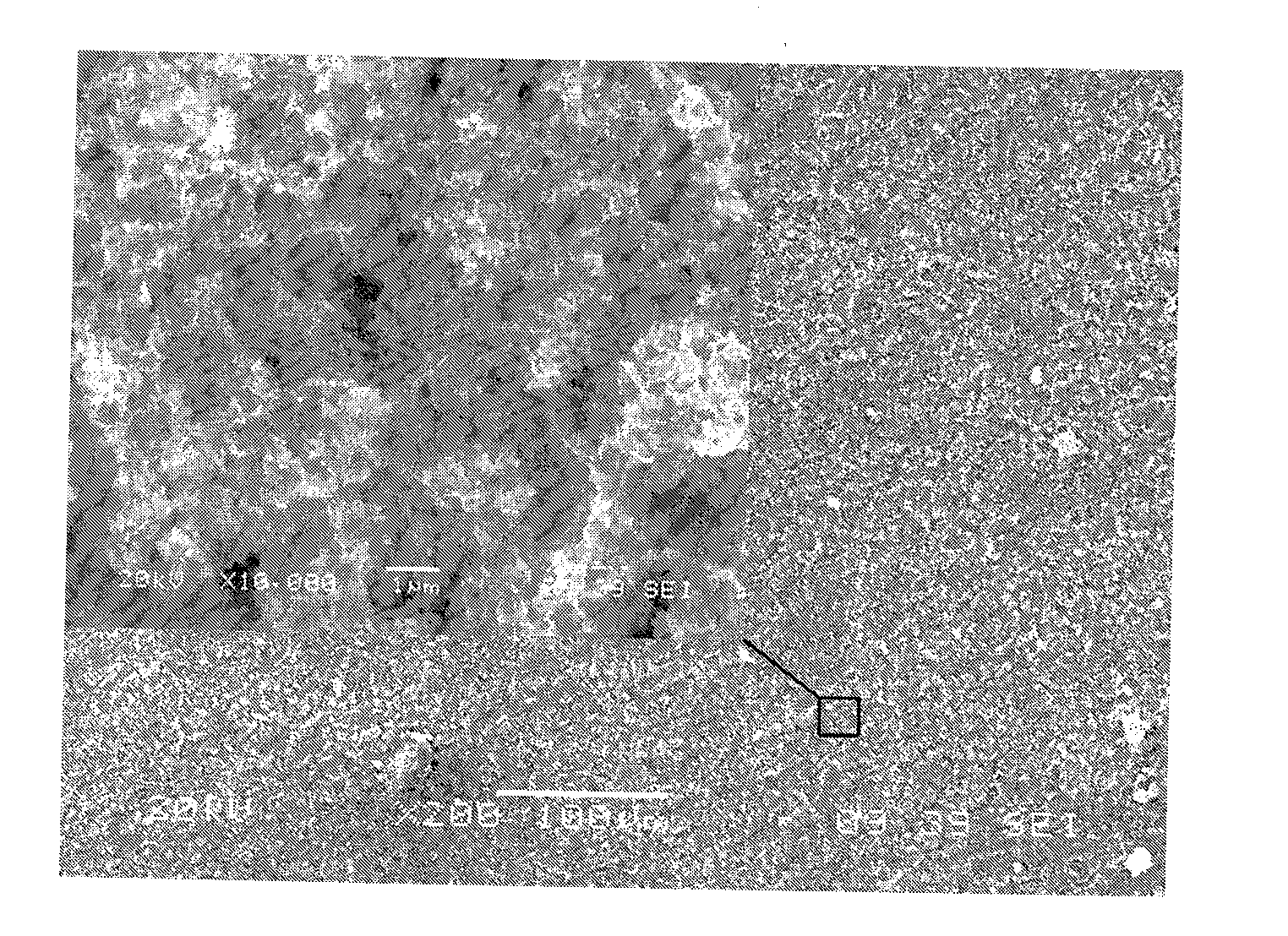

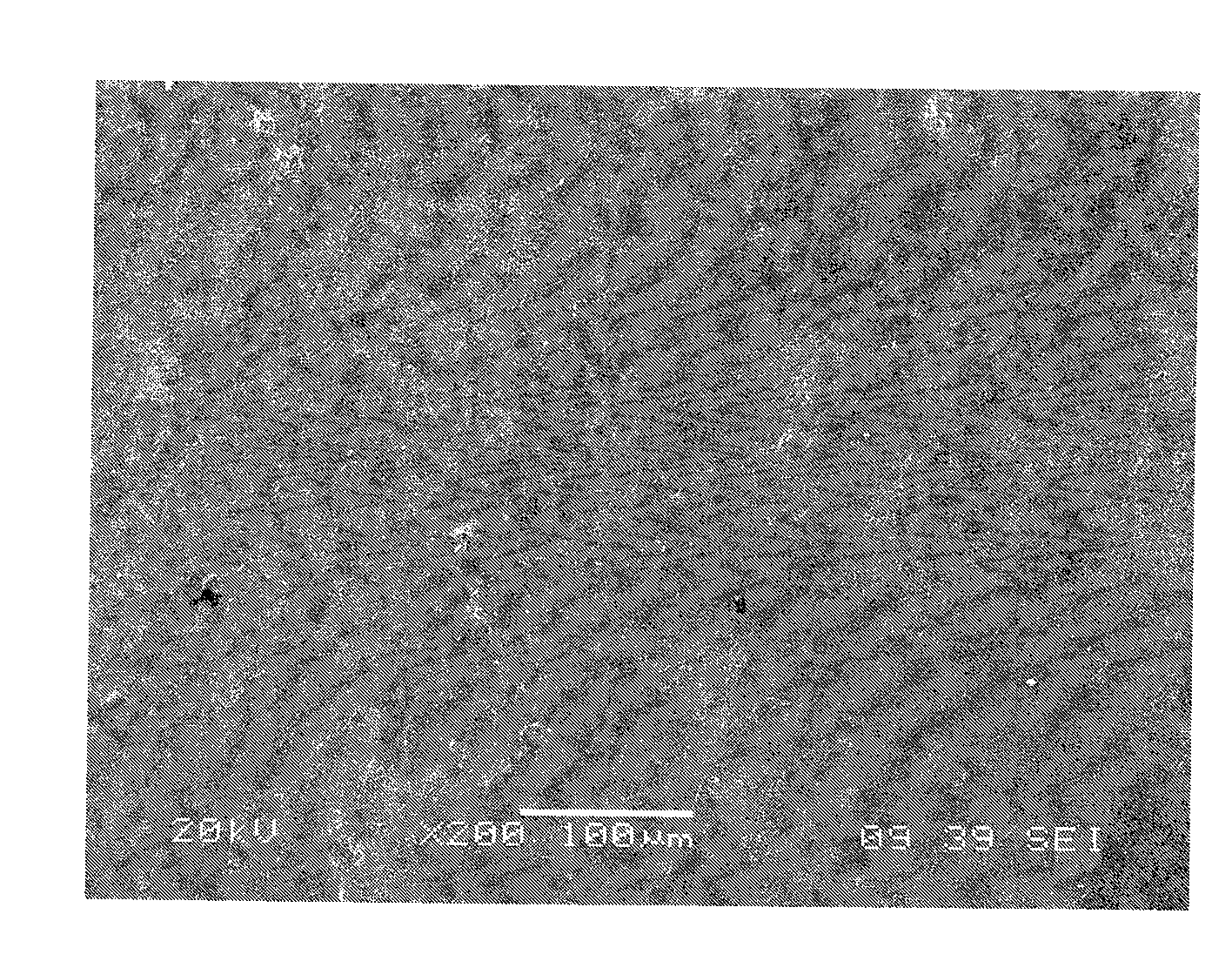

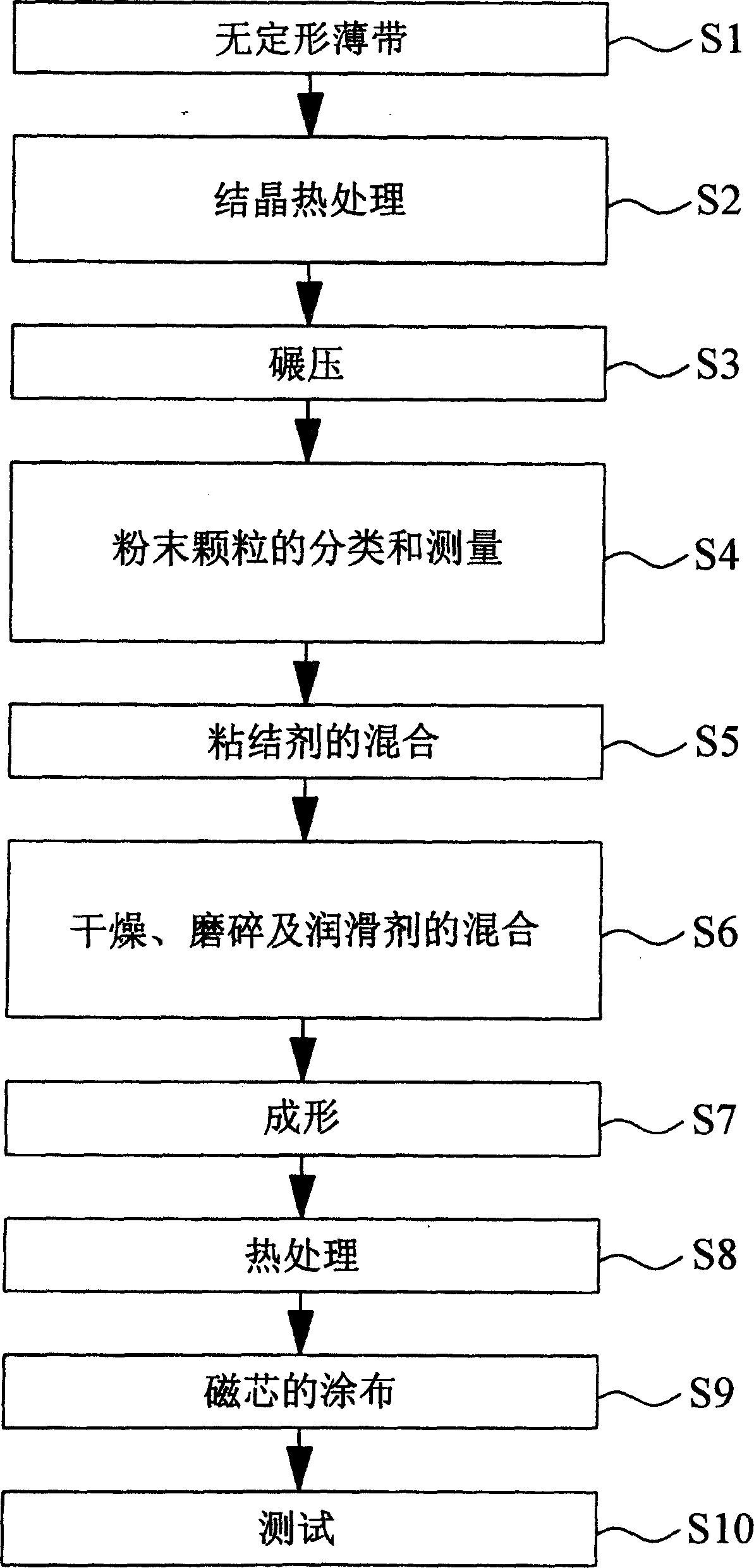

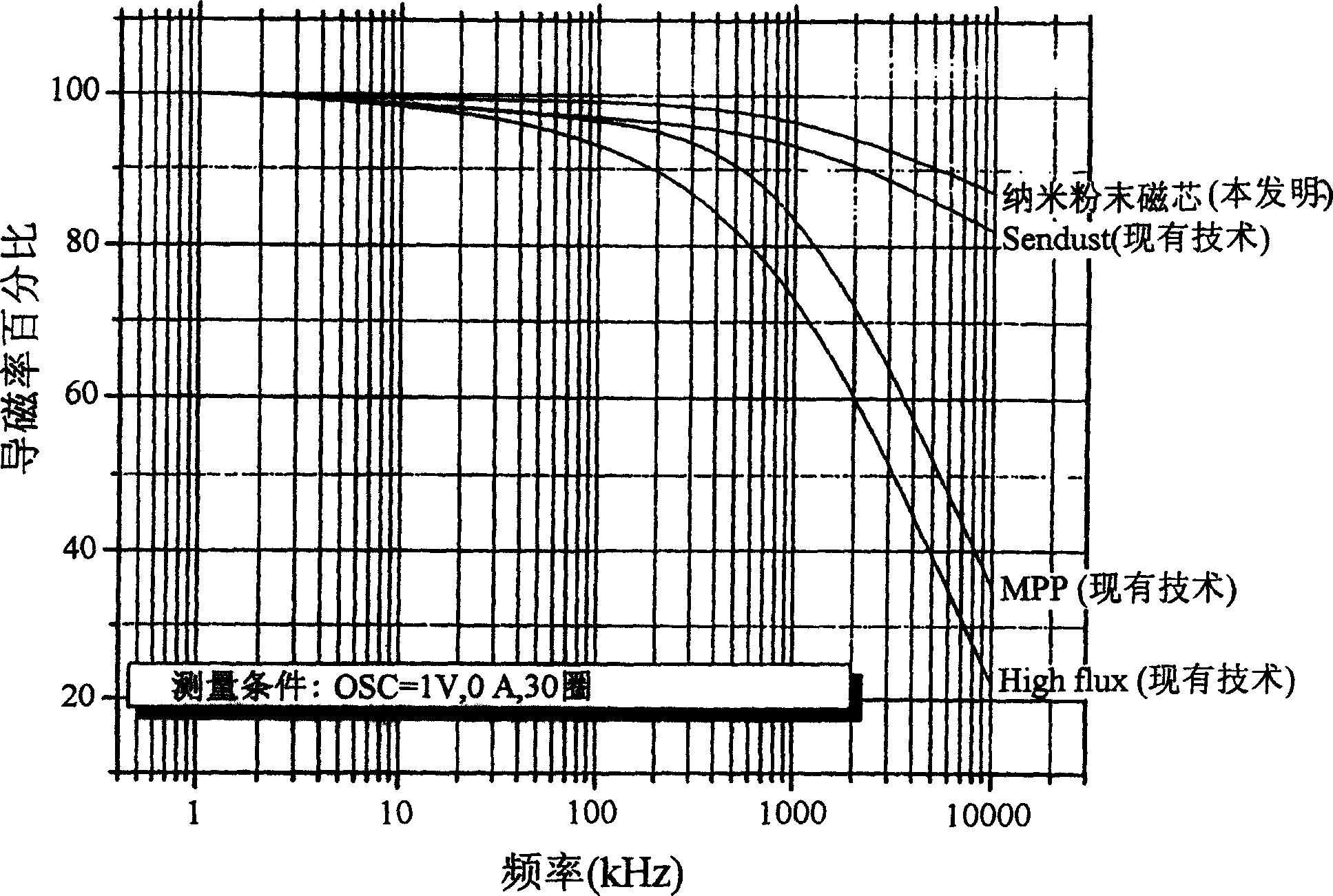

Method for making nano-scale metal powder and method for making high-frequency soft magnetic core using same

InactiveCN1579682AImprove economyReduce lossNanostructure manufactureTransportation and packagingMetal powderAmorphous metal

A method for making a nano-scale amorphous soft magnetic powders obtained by thermally processing and crystallizing amorphous ribbons produced using a rapid solidification process (RSP) and crushing the same. The amorphous soft magnetic core having an excellent high-frequency characteristic is obtained by performing a preliminary thermal treatment of Fe-based amorphous metal ribbons produced by using RSP to then be converted into nano-scale grain metal ribbons, crushing the metal ribbons to thereby obtain nano-scale grain metal powders, classifying the nano-scale grain metal powders to then be mixed into a distribution of powder particles having an optimal uniform composition, mixing the mixed powder with a binder, and then forming a core, and annealing the formed core to then coat the core with an insulating resin.

Owner:AMOXIANSI ELECTRONICS & ELECTRICAL CO LTD

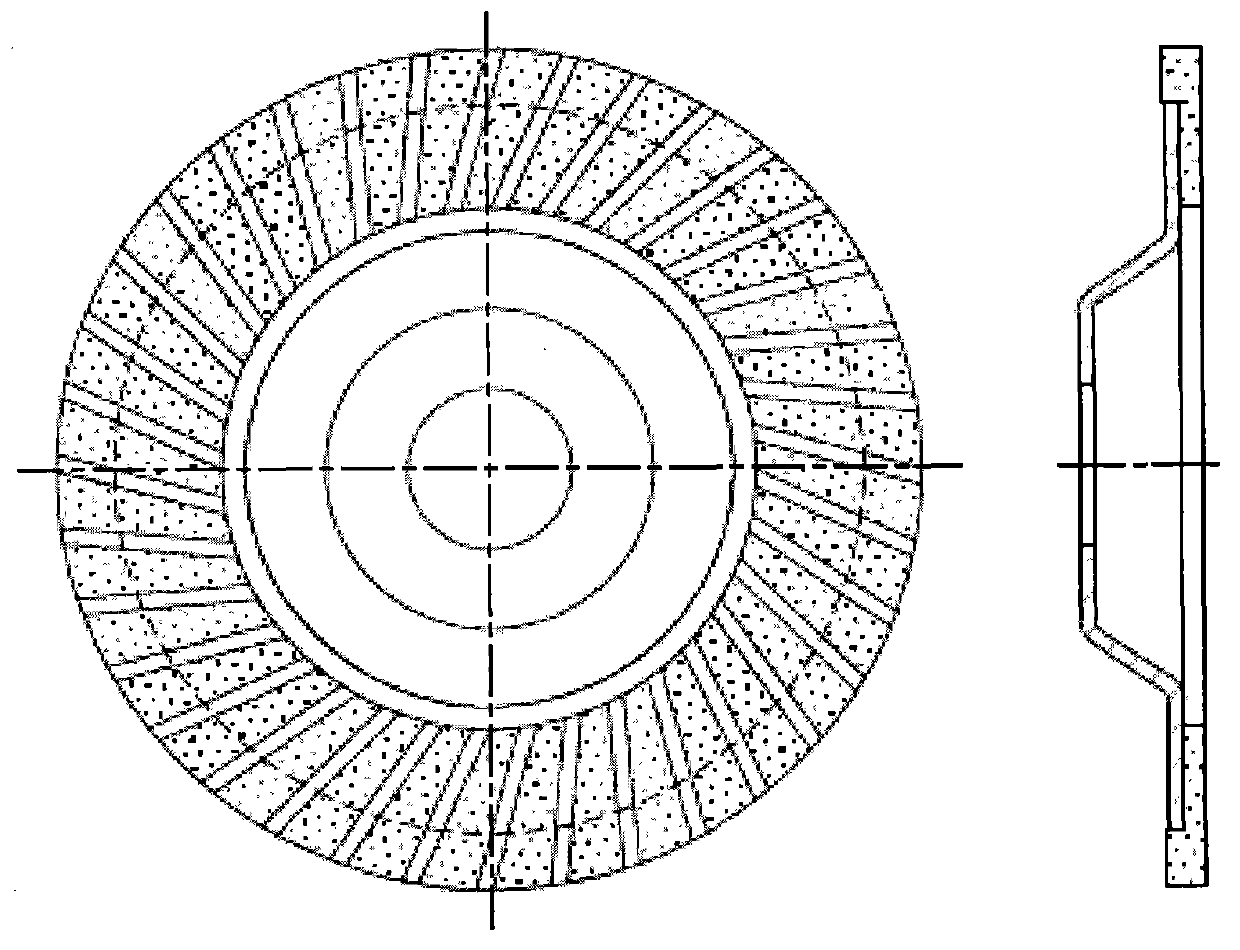

Preparation method for diamond cutting grinding piece

The invention relates to a preparation method for a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a 65Mn steel substrate, and corrugated water channels are formed in the surface of the diamond cutting grinding piece body. The preparation method for the diamond cutting grinding piece comprises the steps of material mixture, substrate machining, compression forming, sintering and edge forming. The diamond cutting grinding piece produced through the preparation method for the diamond cutting grinding piece has the cutting effect and the grinding effect, and is safe and reliable in performance, simple and reasonable in structure, low in manufacturing cost, flexible in operation, good in sharpness of products and good in chip-removal performance.

Owner:JIANGSU FENGTAI TOOLS

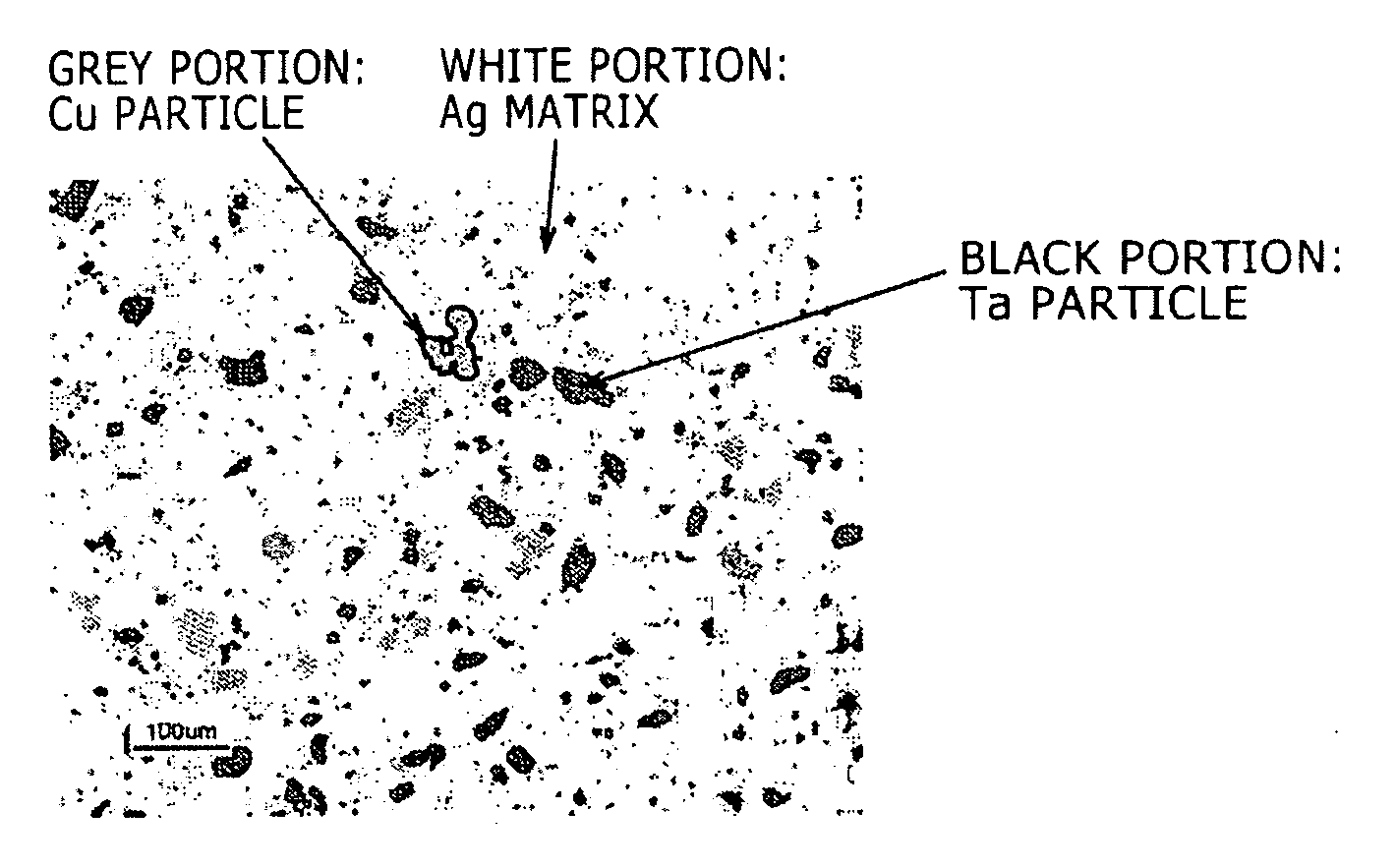

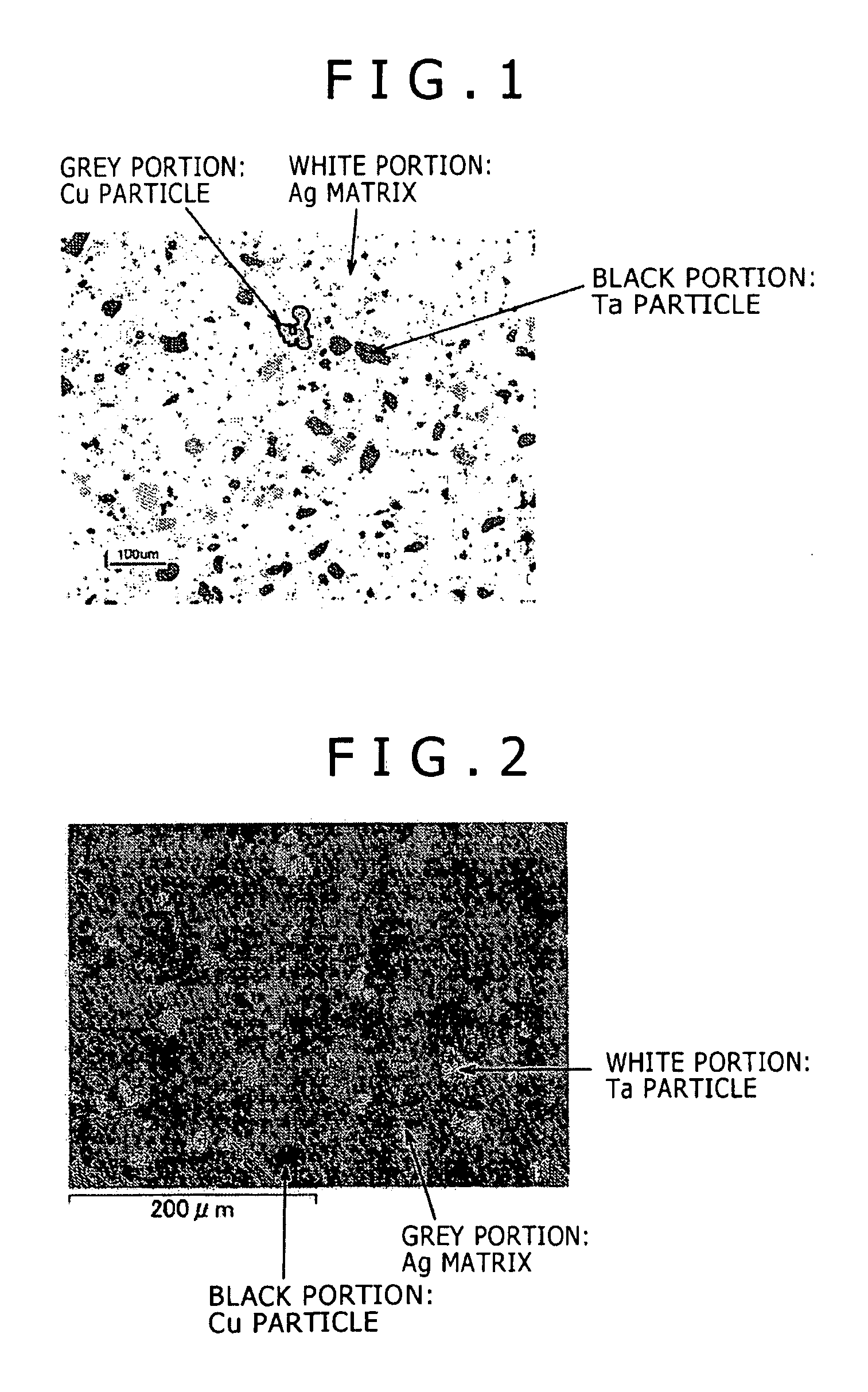

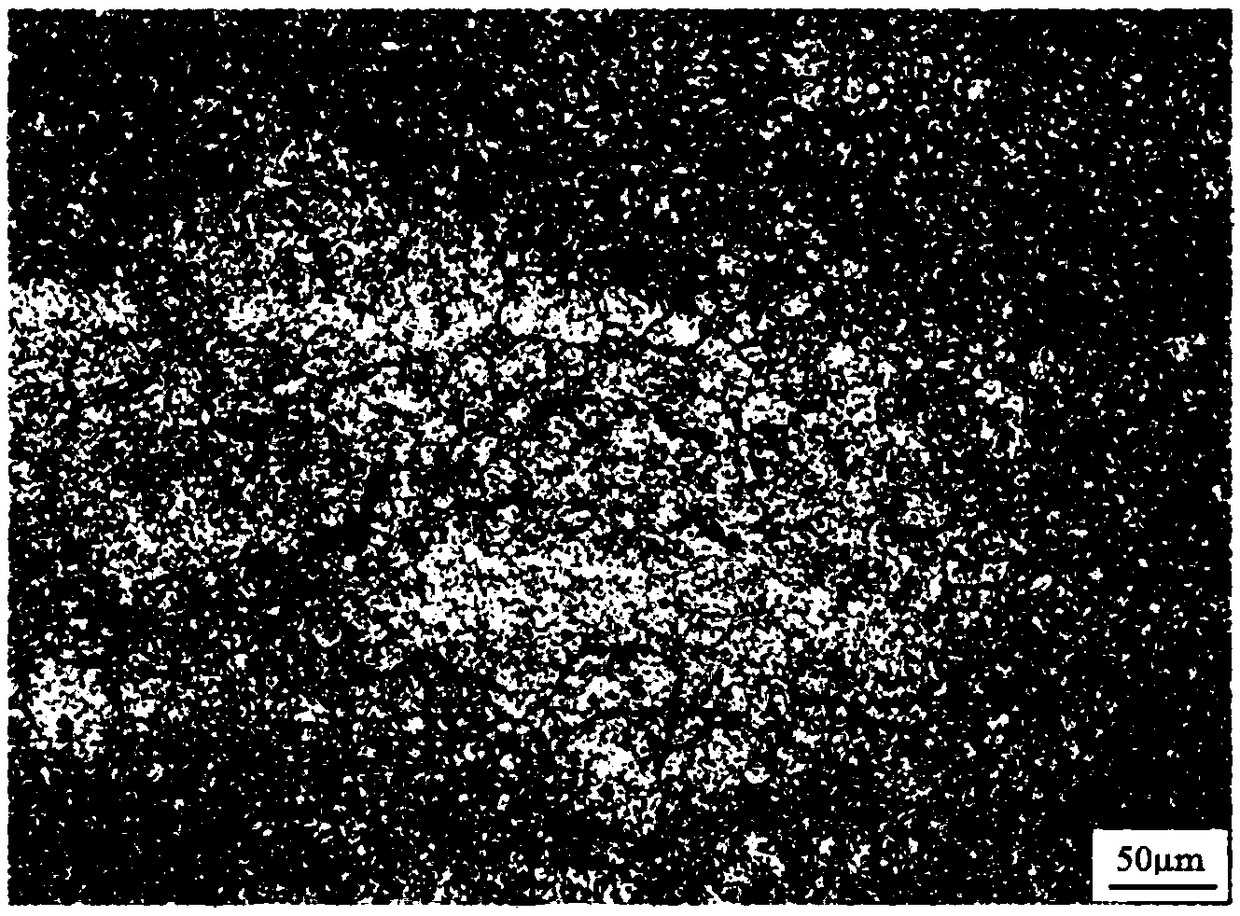

Ag base alloy sputtering target and method for manufacturing the same

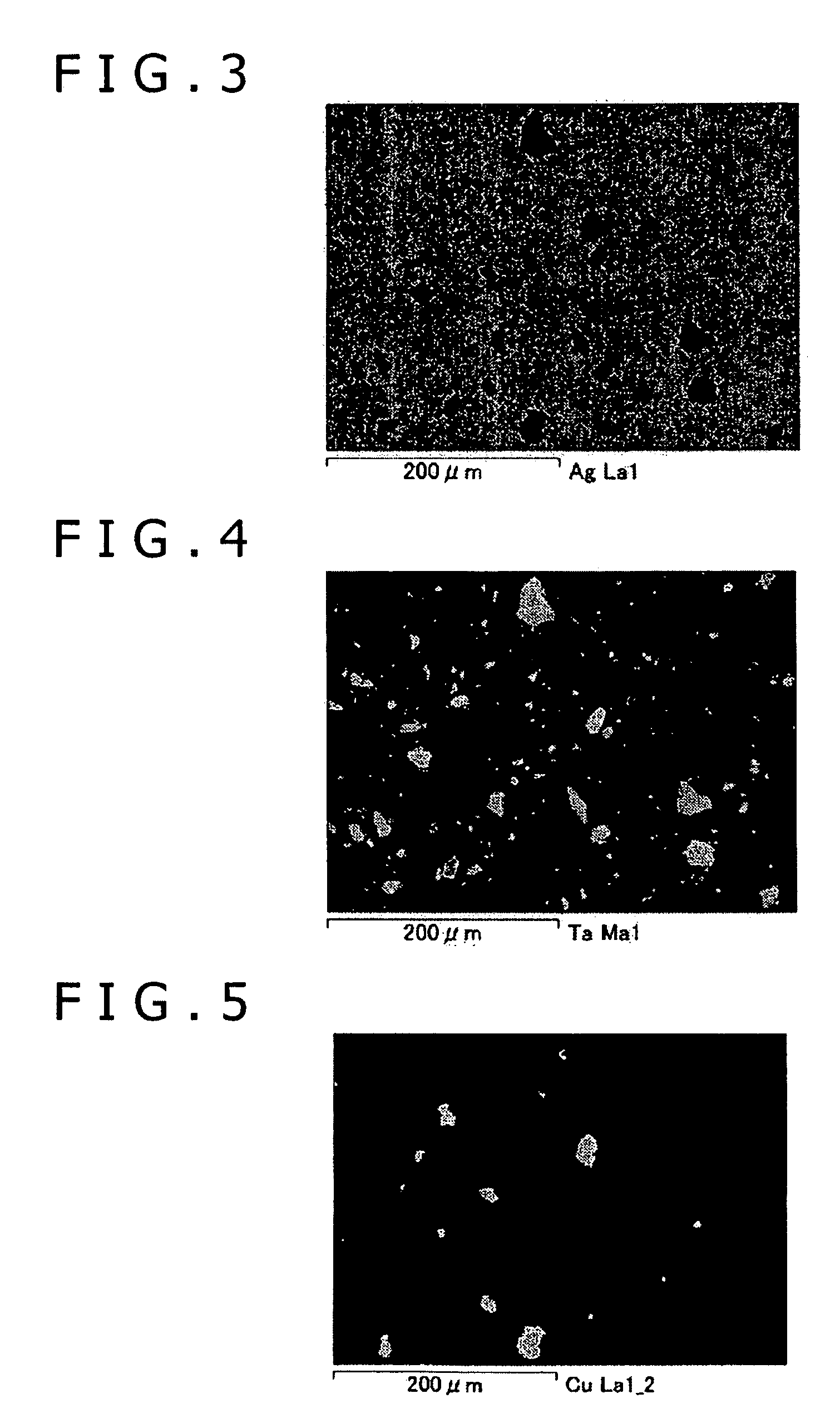

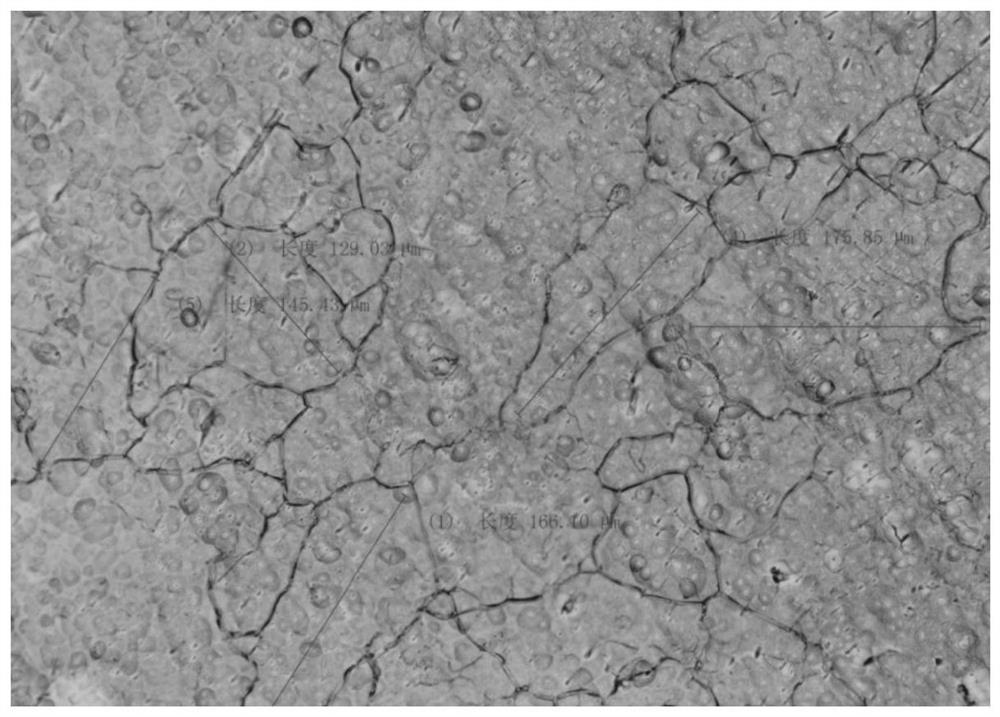

InactiveUS20090057140A1Good composition uniformityImprove featuresCellsVacuum evaporation coatingAlloyEquivalent weight

A sputtering target made of an Ag base alloy containing 0.6 to 10.5 atomic % Ta and 2 to 13 atomic % Cu, is characterized in that: when the sputtering surface of the sputtering target is image-analyzed,(1) the ratio of the total area of Ta particles having a circle equivalent diameter of from 10 μm or more to 50 μm or less, to the total area of all Ta particles, is 60% or more, and the average distance between the centers of gravity of Ta particles is from 10 μm or more to 50 μm or less; and(2) the ratio of the total area of Cu particles having a circle equivalent diameter of from 10 μm or more to 50 μm or less, to the total area of all Cu particles, is 70% or more, and the average distance between the centers of gravity is from 60 μm or more to 120 μm or less.

Owner:KOBELCO RES INST

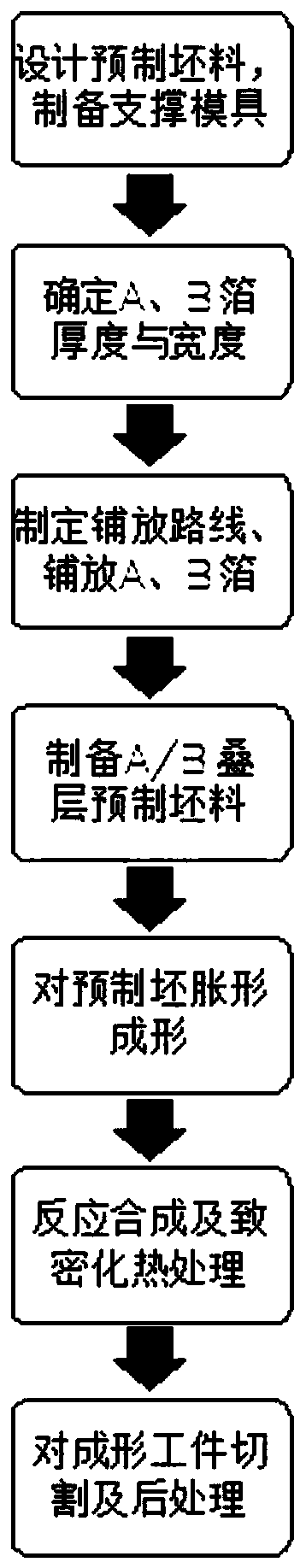

Integrated manufacturing method of high-temperature-resistant thin-wall component by laying metal foil strips for blank making

ActiveCN111168407AComplex structureUniform wall thicknessShaping toolsOther manufacturing equipments/toolsMetal foilMechanical engineering

The invention discloses an integrated manufacturing method for a high-temperature-resistant thin-wall component by laying metal foil strips for blank making. The method comprises the steps of designing a prefabricated blank; preparing a supporting mold; determining the thickness of the foil strips; determining the width of the foil strips; formulating a laying process; laying the foil strips A andthe foil strips B; preparing the AB laminated prefabricated blank; performing bulging forming on the prefabricated blank; performing reaction synthesis and densification treatment on the bulged component; performing subsequent treatment on the thin-walled component and the like. According to the method, the thin-wall integrally-prefabricated blank which is complex in structure, uniform in wall thickness and similar to a final part in shape can be obtained by continuously laying the metal foil strips with proper widths, the thin-wall prefabricated blank does not need to be welded, the problemthat the comprehensive performance of a welding area is weak when a laminated plate blank is firstly prepared and then roll-welded into a cylinder blank at present is solved, meanwhile, the deformation during subsequent bulging is reduced, and the defects of local bulging, thinning and cracking, undercut at the parting position in the mold closing process or wrinkling caused by uneven distributionof materials in all areas are avoided.

Owner:DALIAN UNIV OF TECH

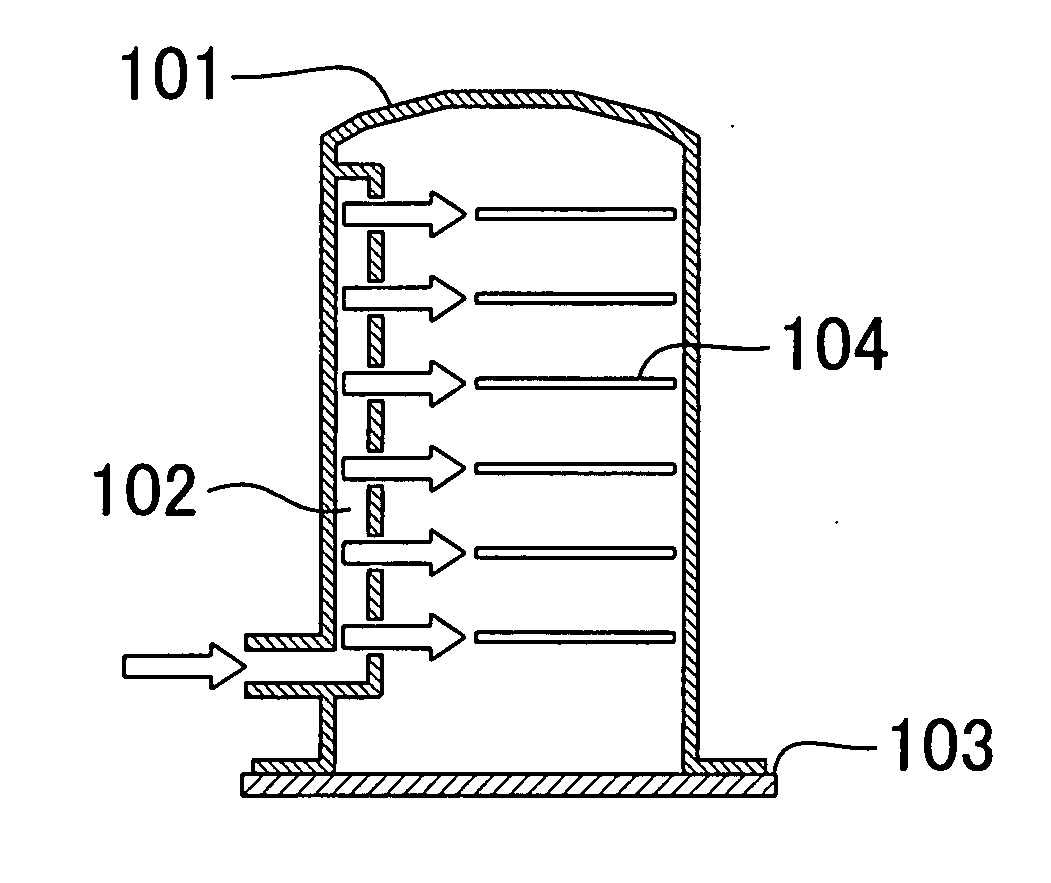

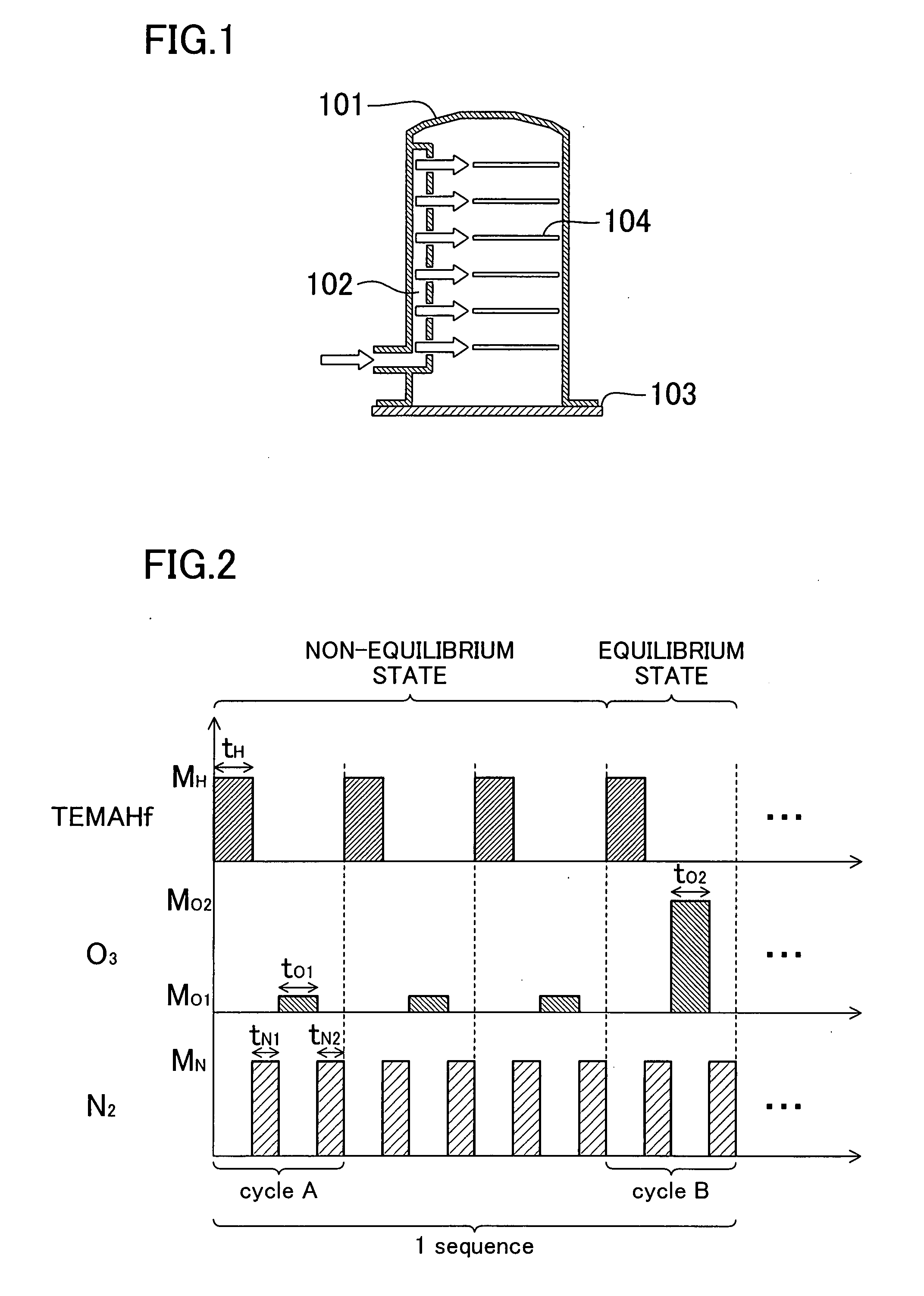

Insulating film formation method, semiconductor device, and substrate processing apparatus

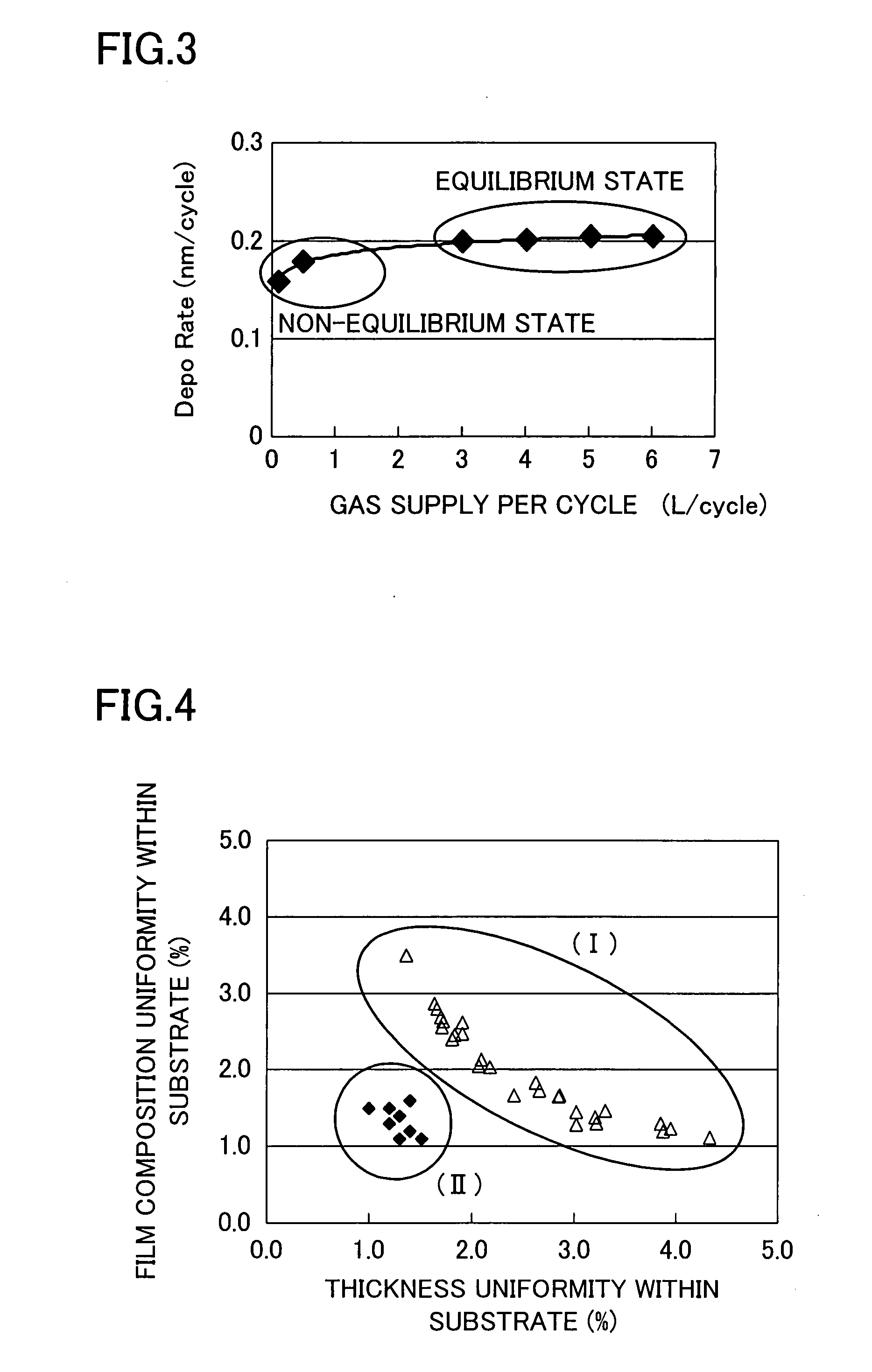

ActiveUS20080026251A1Improve thickness uniformityReduce variationPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialPhysical chemistry

In an insulating film formation method, a cycle A in which O3 at a low flow rate is supplied onto a substrate and then O3 supplied is allowed to react with Hf on the substrate in a non-equilibrium state to form a hafnium oxide film is carried out M times (M≧1), and a cycle B in which O3 at a high flow rate is supplied onto the substrate and then O3 supplied is allowed to react with Hf on the substrate in an equilibrium state to form a hafnium oxide film is carried out N times (N≧1). These insulating film formation cycles are defined as one sequence. This sequence is repeated until a desired thickness is obtained, thereby forming a target insulating film.

Owner:PANNOVA SEMIC

Spherical nickel-rhenium alloy powder and preparation method and application thereof

InactiveCN107008916AGood composition uniformitySpeed up evaporationTransportation and packagingMetal-working apparatusRheniumSpray Granulation

The invention discloses a preparation method of spherical nickel-rhenium alloy powder. The preparation method comprises the following steps that dissolving and mixing are carried out; reducing is carried out after atomizing or dynamic drying is carried out, and precursor powder is obtained; and reducing, slurry preparation, spray granulation and balling forming are carried out. According to the aim, the preparation method of the spherical nickel-rhenium alloy powder is provided, the problems that an existing low-rhenium alloy is uneven in ingredient, rhenium-containing elements can hardly be introduced into a base material, multicomponent ingredient controllability is poor, and the preparation process is complex are solved, a balling process is creatively used two times, and the spherical powder is obtained well and fast in a saving manner. The powder obtained through the method can be directly applied to wear-resisting anti-corrosive coatings, thermal spraying, 3D printing and powder metallurgy parts, and powder raw materials do not need to be additionally matched.

Owner:湖南元极新材料有限公司

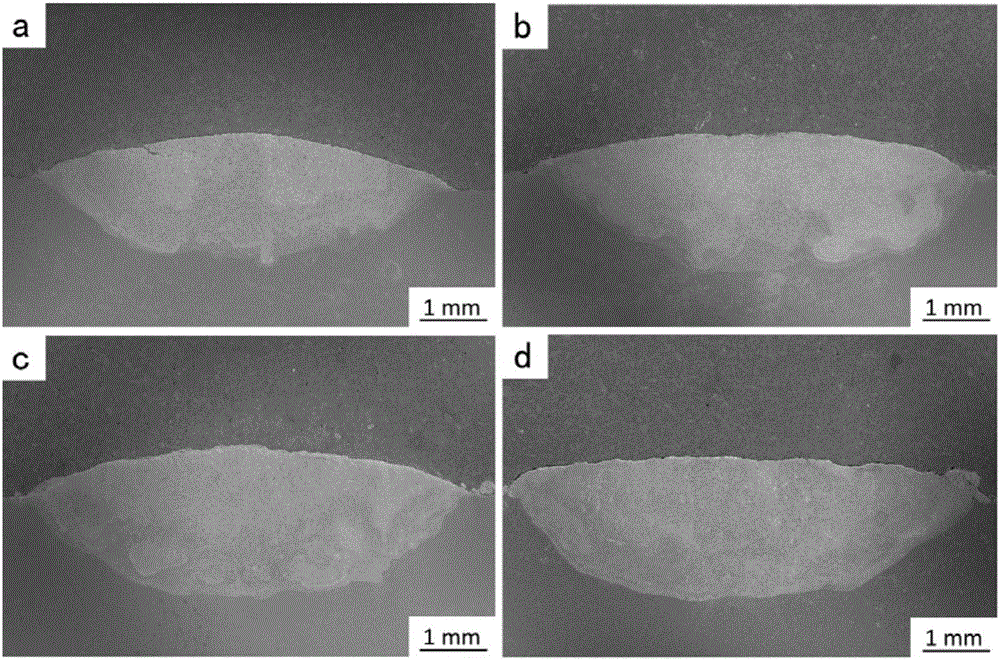

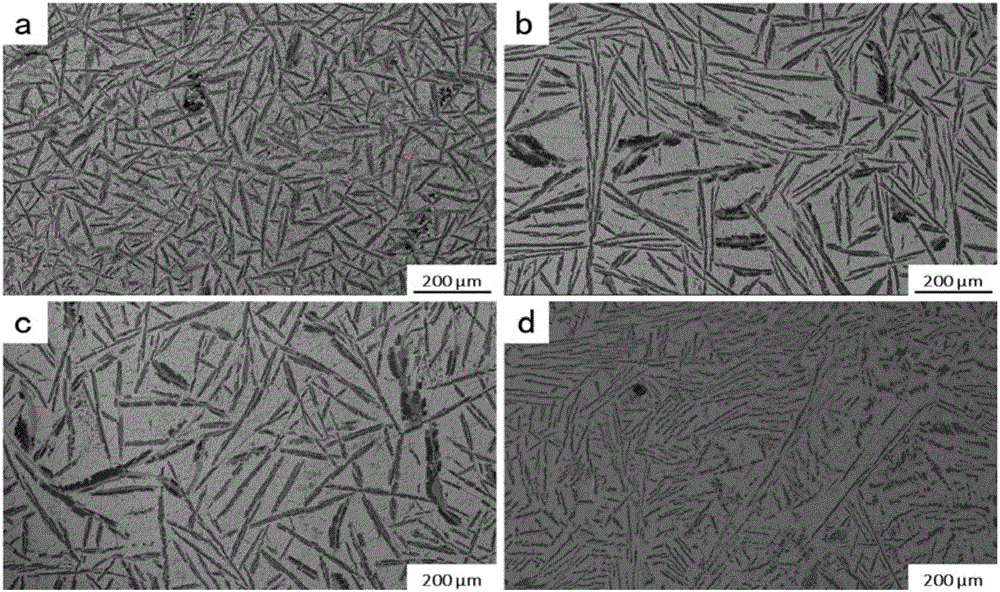

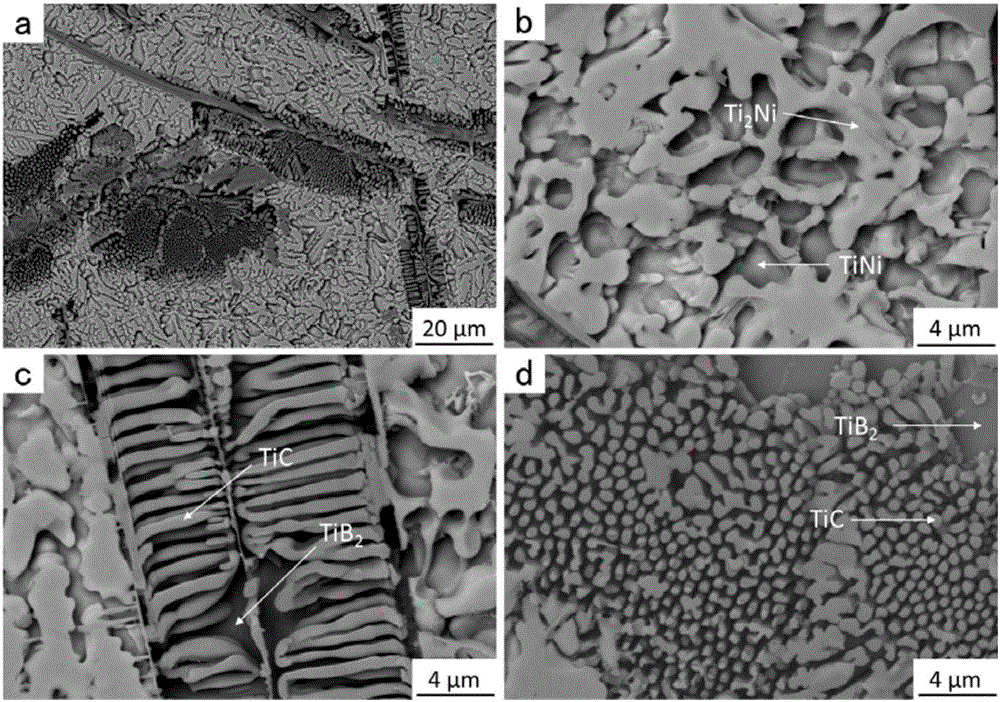

Laser cladding method for titanium alloy

InactiveCN105937035APrecise thickness controlHigh densityMetallic material coating processesCarbideTitanium alloy

The invention relates to a laser cladding method for a titanium alloy. The laser cladding method includes the following steps that firstly, a nickel-based alloy and carbide ceramics are ground into powder and then stirred and mixed, and mixed powder is obtained for standby application; secondly, a titanium alloy Ti6Al4V substrate is coated with a layer of bonding agent, then the mixed powder obtained in the first step is added, tabletting is conducted, and a preset coating is formed; and thirdly, the titanium alloy Ti6Al4V substrate containing the preset coating is heated to 100 DEG C to 800 DEG C, the temperature is kept for 10 min to 30 min, then laser cladding is conducted under the condition that the temperature is not changed, and the titanium alloy which has the low cracking sensibility and is coated with the coating is obtained. Compared with the prior art, the manufactured composite coating is uniform in structure and has the lower cracking sensibility. The laser cladding method can be applied to modification of titanium alloy parts serving on aerospace vehicles and navigation ships under the wear working condition and anti-acid pumps and anti-acid valve titanium alloy components.

Owner:SHANGHAI UNIV OF ENG SCI

Extruding technology of aluminum alloy profile

InactiveCN107931343AGood composition uniformityImprove mechanical propertiesExtrusion control devicesFiberIngot

The invention discloses an extrusion process of an aluminum alloy profile, belongs to the technical field of aluminum profile preparation, and aims to ensure the uniformity of the structure and composition of the bar. The invention includes aluminum ingot heating, mold heating, ingot tube heating, extrusion, quenching, artificial aging, straightening and length determination. The invention is conducive to the formation of the microstructure of the material, which is dominated by fiber grains and a very small amount of recrystallized structure. After a certain amount of tensile deformation, uniform and consistent grain structures are formed in various parts of the profile, and the rational design of the post-processing method is added. , to obtain aluminum profiles with good uniformity in structure and composition, so that the aluminum profiles have better comprehensive mechanical properties. The tensile strength of the aluminum profiles can reach more than 600Mpa, and the elongation after breaking can reach more than 15%.

Owner:朱旭

Prealloyed carcass powder

The invention relates to pre-alloyed tire body powder and belongs to the technical field of powdery metallurgical material. The pre-alloyed tire body powder is used for solving the problem that the prior metal or pre-alloyed tire body powder has relatively low mechanical performance or overhigh sintering temperature. The powder consists of the following raw materials by weight percentage: 50 to 70 percent of Fe, 10 to 20 percent of Co, 10 to 20 percent of Cu, 1 to 5 percent of Ni, 1 to 5 percent of Sn, 1 to 3 percent of P and 5 to 10 percent of WC. Through repeated testing, proper mixing compositions are obtained; Fe, Co and Cu are adopted as basic compositions and are added with Ni, Sn, P, WC and other elements according to the mixture ratio to prepare the pre-alloyed tire body powder through the prior powder preparation technology. With the proper content and synergistic action of each added element, the pre-alloyed tire body powder has excellent composition evenness and enough activity of sintering reaction, simultaneously improves the performance of a sinter cake and particularly has remarkable improvement on rigidity, bending strength, wearing resistance, holding force to diamond and other aspects.

Owner:BOSUN TOOLS CO LTD

Hot-rolled steel plate for ultra-wide thick-wall X80-grade pipeline and production method of hot-rolled steel plate

ActiveCN109957713AGuaranteed toughnessSuitable for solderabilityFurnace typesHeat treatment furnacesThick wallYield ratio

The invention discloses a hot-rolled steel plate for an ultra-wide thick-wall X80-grade pipeline and a production method of the hot-rolled steel plate. The steel plate comprises the following components: 0.03%-0.05% of C, 0.16%-0.28% of Si, 1.50%-1.75% of Mn, 0.05%-0.08% of Nb, 0.012%-0.025% of Ti, 0.10%-0.25% of Cr, 0.01%-0.04% of V, smaller than or equal to 0.19% of Mo, smaller than or equal to0.20% of Ni, smaller than or equal to 0.14% of Cu, smaller than or equal to 0.020% of Al, smaller than or equal to 0.013% of P, smaller than or equal to 0.0015% of S, 0.0005%-0.0020% of O, 0.001%-0.004% of N, 0.0010%-0.0045% of Ca, 0.40%-0.65% of Mo+Ni+Cr+Cu, and the balance of iron and inevitable impurities, wherein Ca / S is larger than or equal to 1.6. The rough rolling starting temperatureis 1070-1150 DEG C, and the finish rolling starting temperature is 820-860 DEG C. The final rolling temperature is 760-780 DEG C, and the cooling temperature is 730-770 DEG C. The width of the steelplate is larger than 4000 mm, and the thickness of the steel plate is larger than 25 mm. The steel plate is good in low-temperature toughness and low in yield ratio.

Owner:ANGANG STEEL CO LTD

Steelmaking method of microalloy steel with added vanadium nitride alloy in steel

InactiveCN102220454AEasy accessReduce oxidationProcess efficiency improvementSteelmakingCarbonization

The invention provides a steelmaking method of microalloy steel with added vanadium nitride alloy in the steel, and the method is characterized in that during steel making, when molten steel poured into a ladle accounts for 20-40% of the steel tapping amount, a packaging block of a vanadium nitride alloy additive which is specially sealed and packaged is thrown into the ladle, and residual moltensteel is poured into the ladle; the vanadium nitride alloy additive is a mixture of vanadium nitride alloy powder and 0-10% of aluminium powder or aluminium particles, and is sealed and packaged intoa packaging block by a packaging bag; the packaging bag comprises an outer layer of paper-based packing paper with sufficient strength, and a lining of a single-layer or double-layer airproof plasticfilm; the vanadium nitride alloy powder is directly prepared by the following steps: mixing vanadium compound powder and carbon powder to obtain a mixed powder raw material, adding the powder raw material into a preparation furnace, introducing ammonia gas or nitrogen into the preparation furnace, and allowing the raw material to perform pre-reduction, carbonization and nitridation reactions. Compared with existing steelmaking methods of microalloy steel, the invention can effectively increase recovery rates of vanadium and nitrogen, and improve steel quality.

Owner:蔡惜辉

Novel large-current-carrying heat-resistant aluminum alloy wire and preparation method thereof

InactiveCN106521250ASolve the shortcomings of low solid solubility, limited heat resistance and low strengthImprove heat resistanceSingle bars/rods/wires/strips conductorsConductive materialContinuous useFriction stir processing

The invention provides a novel large-current-carrying heat-resistant aluminum alloy wire and a preparation method thereof. The aluminum alloy wire is composed of elements such as Se, Ru, Zr, Sc, Ni and Si, the Vickers hardness of the aluminum alloy wire at the room temperature is no less than 70 HV, the extension strength of the aluminum alloy wire at the room temperature is no lower than 200 Mpa, the elongation is no less than 10%, the electric conductivity at 20 DEG C is no lower than 58% that of IACS, and the continuous use temperature is no lower than 165 DEG C. According to the method, the wire is obtained through processing by steps such as smelting, casting, rolling, friction stirring processing, slicing, overlaying, extruding, drawing and heat treatment, and finally the wire with good physical and chemical properties is obtained. The aluminum alloy wire adopts common industrial grade aluminum ingots as raw materials for production, compared with the prior art, the product properties of higher electric conductivity, higher strength and better heat resistance can be obtained, and the wire has good development prospects.

Owner:HEFEI UNIV OF TECH

Method for preparing diamond blade by using special metal bond

ActiveCN102189260AGood composition uniformitySufficient sintering reactivityStone-like material working toolsHigh densityMetal powder

The invention discloses a method for preparing a diamond blade by using a special metal bond. The method comprises the following steps of: (1) weighing the following raw materials in percentage by mass: 10-15% of pre-alloying powder, 22-30% of Cu, 3-12% of Sn, 25-40% of Fe, 10-15% of TFe, 3-6% of Zn, 5-10% of W, 1-3% of Mn and 0.1-0.2% of PFe, fully mixing and ball-milling the raw materials in a mechanical mixer, wherein the pre-alloying powder comprises the following materials in percentage by mass: 45-55% of Fe, 5-10% of Ni, 25-35% of Cu and 5-10% of Co; (2) mixing the metal powder prepared in the step (1) with diamond; (3) adding a forming agent, mixing uniformly and air drying; (4) cold pressing; (5) performing hot pressed sintering to obtain a high-density thin sheet; and (6) grinding the thin sheet to finally obtain the blade. The method for preparing the blade by using the special metal bond has the advantages of low sintering temperature and short sintering time, and the prepared blade has long service life and good sharpness, therefore, the use cost of the blade is greatly reduced.

Owner:南通江海港建设工程有限公司

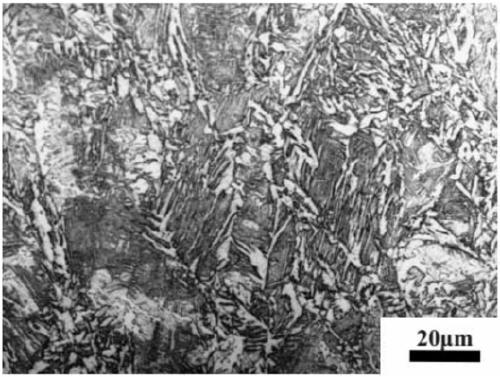

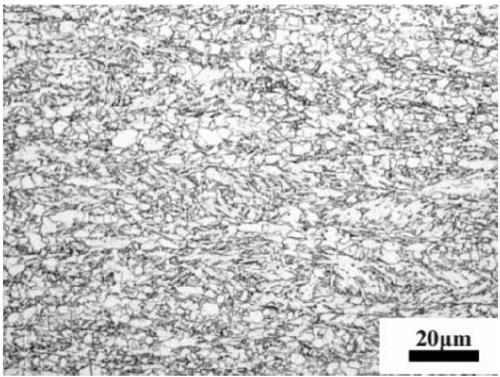

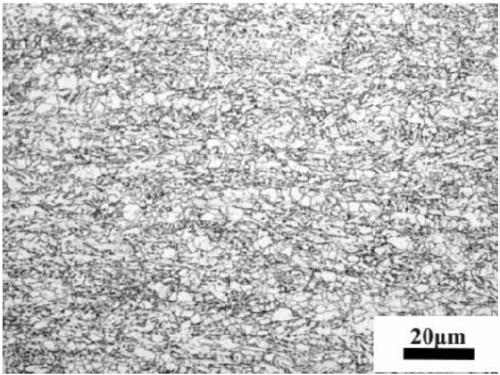

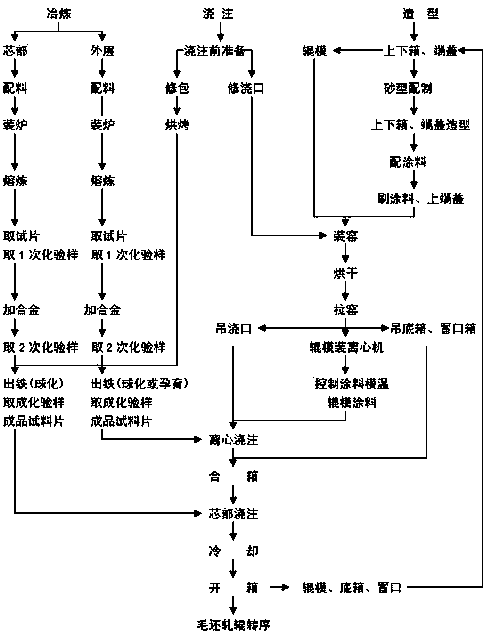

Manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls

ActiveCN103691903AThe solidification temperature range is smallGood composition uniformityMulti elementMaterial selection

The invention relates to a manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls, and belongs to the technical field of metallurgical rolls. The technical scheme includes that eutectic compositions are selected as materials of a roll working layer, and besides five elements of C, Mn, Si, P and S commonly existing in steel, not less then five alloying elements of Cr, W, Mo, V, Nb, Ti, Al, Cu, B and Mg need to be added into the roll materials to form a multi-element alloying state; carbon content of the roll materials is controlled to be 1.3%-2.8% in mass percent. The manufacturing process is small in solidification temperature range of the eutectic compositions, and particularly suitable for obtaining high-quality castings under the circumstance that feeding conditions are insufficient; the castings are crystallized simultaneously, and optimal in composition uniformity, concentrated cavity shrinkage is formed, metallic yield by casting moulding is high; the metal is solidified at the same time, and casting stress in the process of solidification is minimum; the eutectic compositions in alloy are lowest in melting point, and smelting cost is also low; liquid of the eutectic compositions is best in fluidity; castability is improved, and abrasion resistance and heat resistance are taken into consideration.

Owner:朝阳联强轧辊有限公司

Anisotropically shaped powder, related manufacturing method, and method of manufacturing crystal oriented ceramics

InactiveUS20080066496A1High densityGood orientationTantalum compoundsGlass shaping apparatusCrystal planeCeramic

An anisotropically shaped powder composed of oriented grains with a specific crystal plane {100} of each crystal grain being oriented, a related manufacturing method and a method of manufacturing a crystal oriented ceramics using such an anisotropically shaped powder are disclosed. The anisotropically shaped powder includes a principal component of an isotropic perovskite-based pentavalent metal acid alkali compound represented by a general formula (1): (KaNa1−a)(Nb1−bTab)O3 (wherein 0≦a≦0.8 and 0.02≦b≦0.4). In manufacturing the anisotropically shaped powder, a bismuth-layer-like perovskite-based compound of a specific composition is acid treated; a source of K or the like is added to the resulting acid-treated substance; and the resulting mixture is heated.

Owner:DENSO CORP

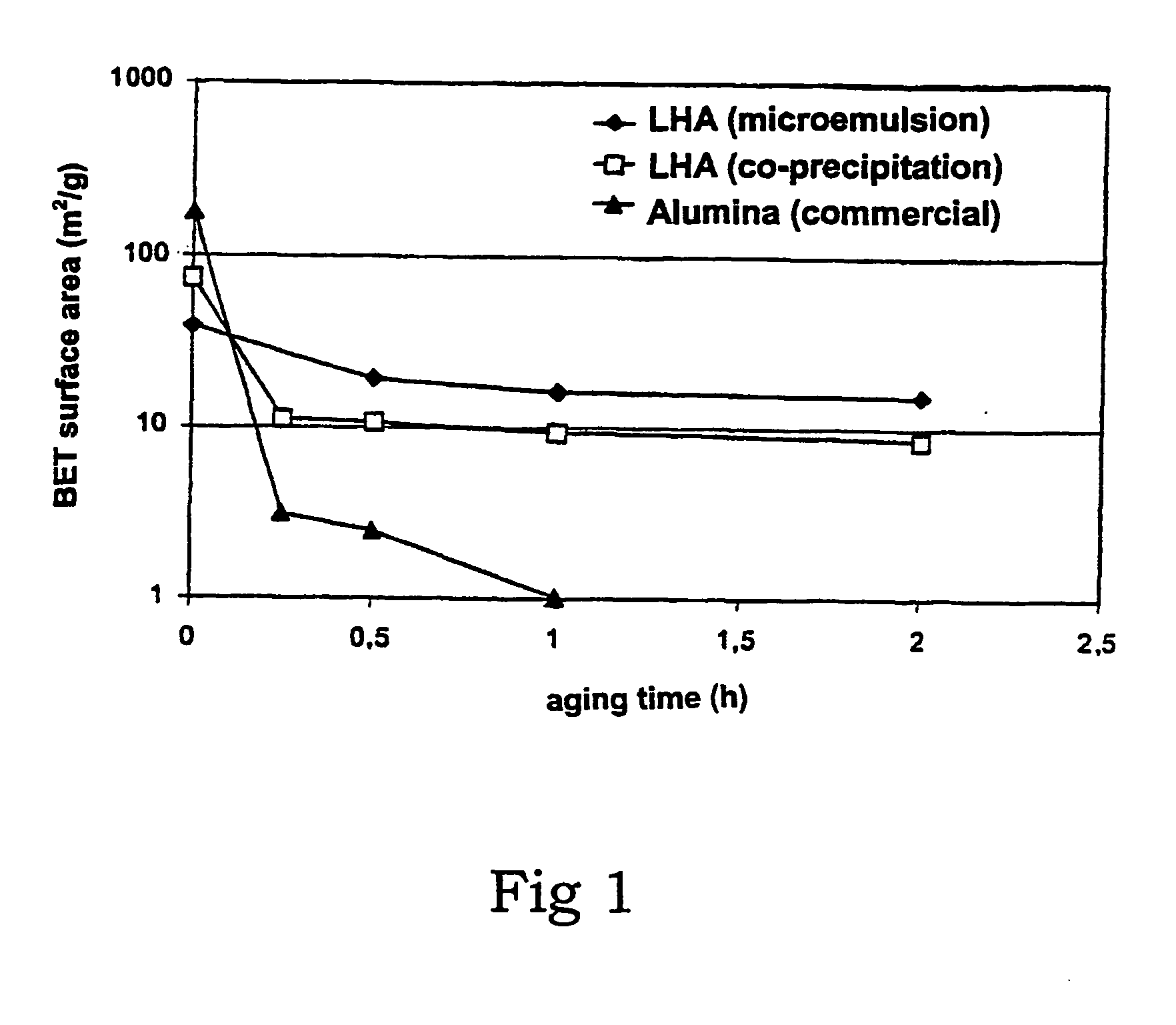

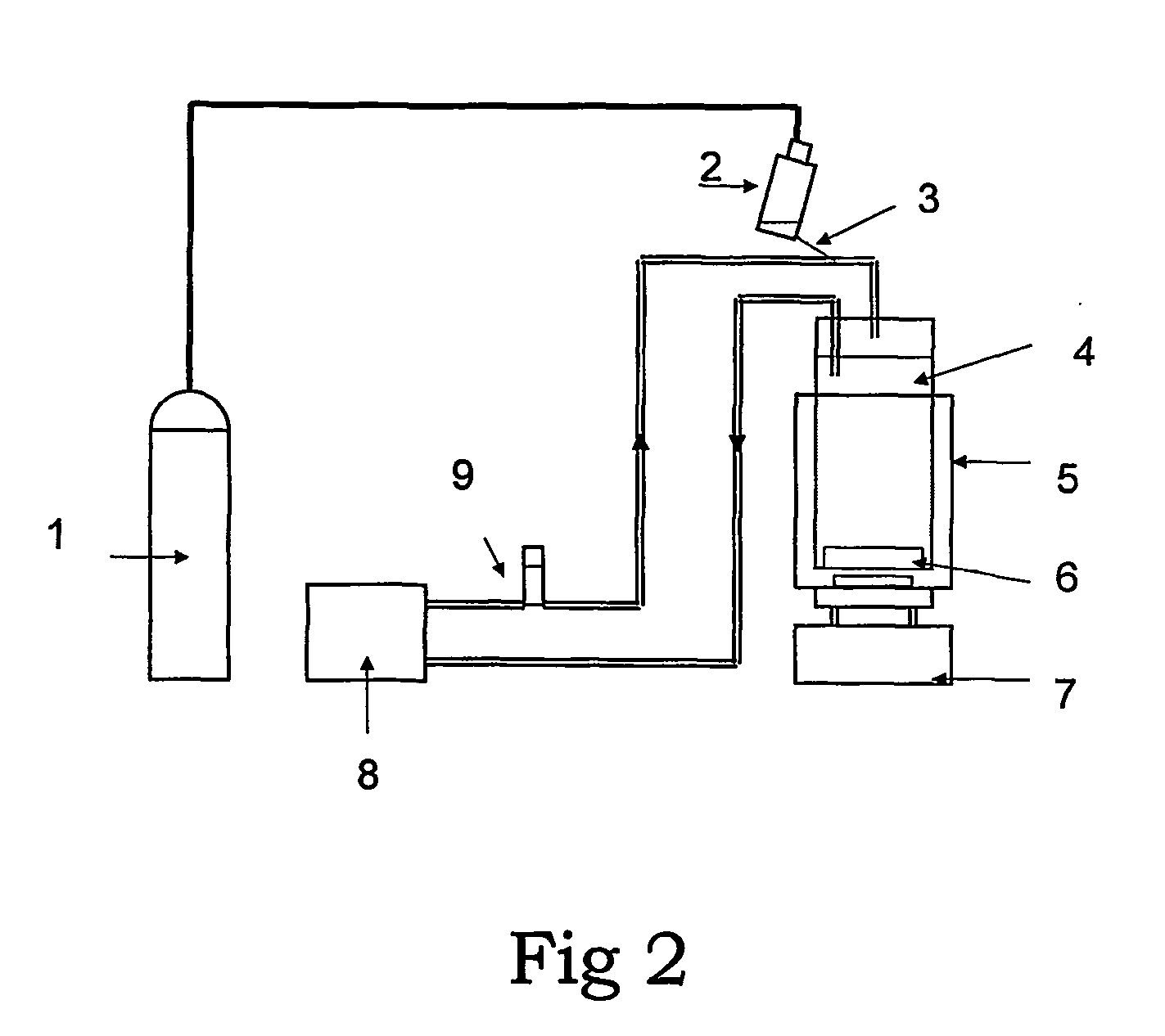

Sintering resistant catalyst material and a method for the preparation thereof

InactiveUS20040208819A1Easy to evaporateReduce materialGranulation by liquid drop formationCatalyst activation/preparationAlkaline earth metalRare earth

Preparation of sintering resistant hexaaluminates, AAl11O18, wherein A is an alka-line earth or rare earth metal, and more particularly lanthanum, by a combination of sol-gel and microemulsion techniques using a water soluble salt of A, and a method of forming spherical pellets thereof are disclosed.

Owner:ECAPS

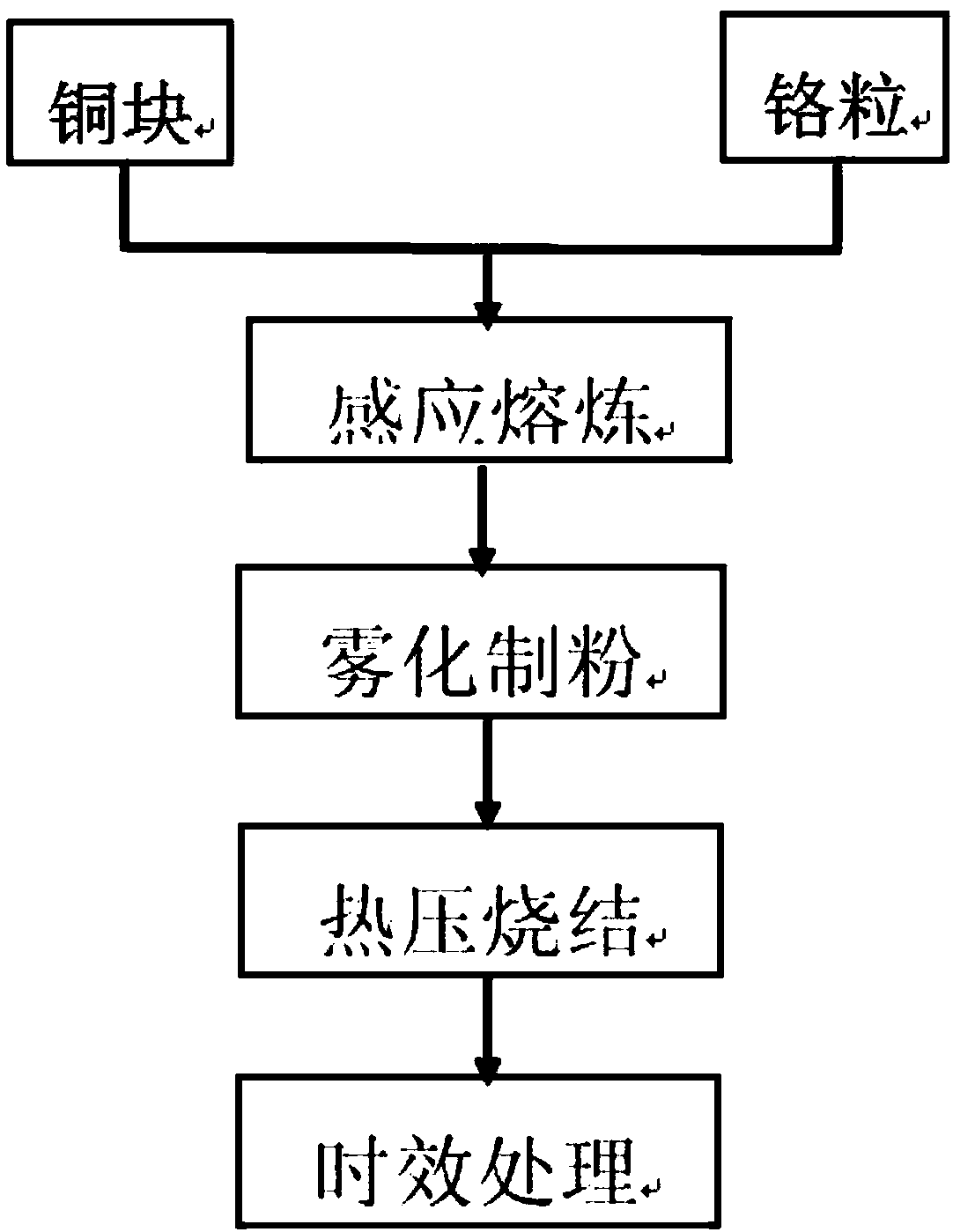

Preparation method of aging-enhanced copper-chromium alloy

InactiveCN107604200AReduce the amount of impuritiesGood alloy composition uniformitySolid solubilityNitrogen gas

The invention discloses a preparation method of an aging-enhanced copper-chromium alloy. The preparation method comprises the following steps that 1, vacuum induction melting is carried out by adopting nitrogen as a protective gas; 2, powder is prepared through atomization by using a ring hole limiting type atomizer; 3, screening is carried out on the atomized alloy powder according to different particle sizes; and 4, hot pressed sintering and aging treatment are carried out in the alloy powder with a certain particle size to obtain the copper-chromium alloy. According to the preparation method of the copper-chromium alloy, the solid solubility of chromium in copper is improved; compared with an alloy prepared through a mechanical ball milling method, the alloy is better in component uniformity; the copper-chromium alloy prepared through gas atomization has fine grain structures and relatively high degree of supersaturation of chromium, and the obtained alloy sample has high conductivity and strength; and phases precipitated from the alloy powder obtained after sintering are small in size and large in number, and the alloy powder can be used for materials of high-energy electric conduction elastic devices and electrical contacts in the aerospace field.

Owner:XIAN UNIV OF TECH

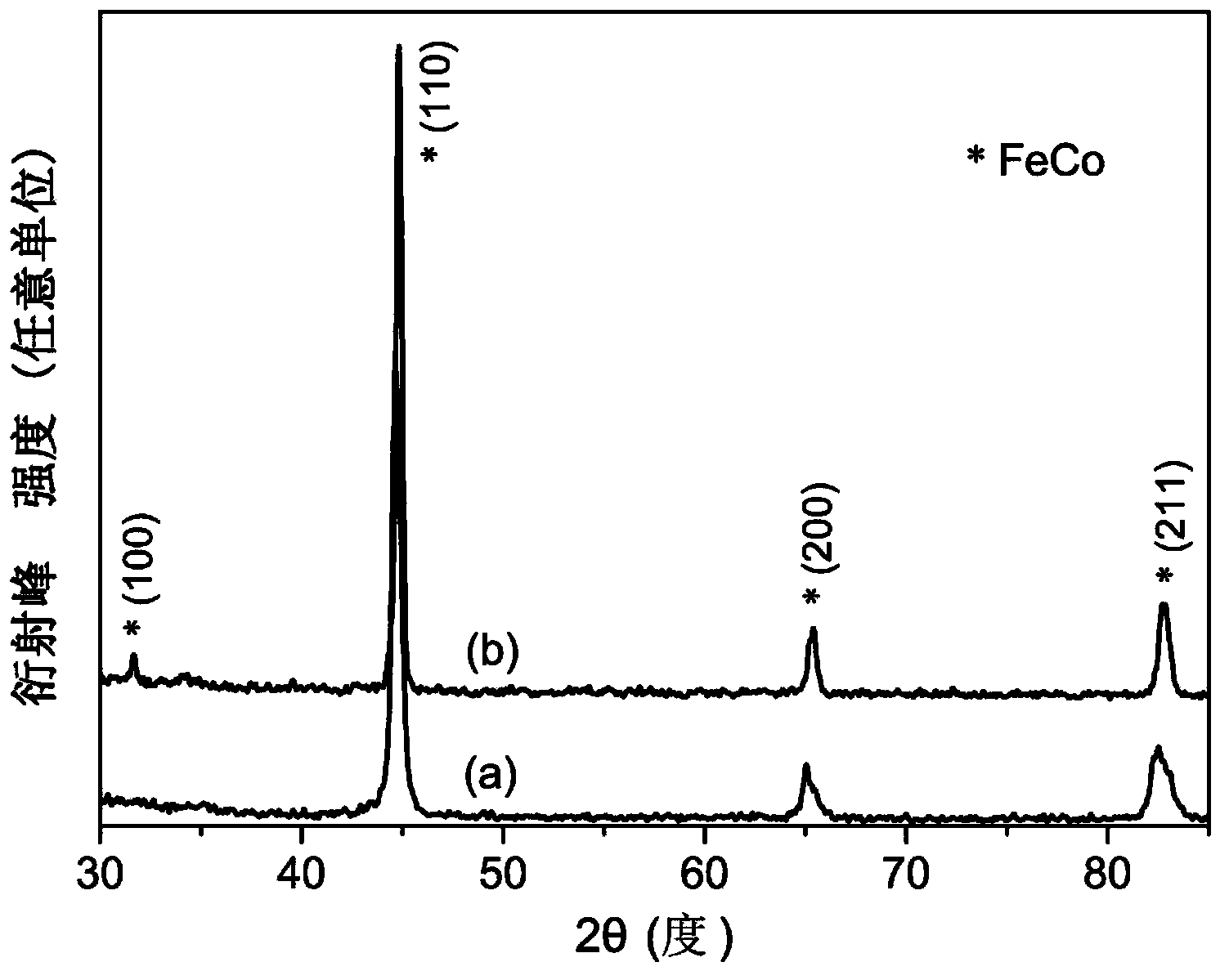

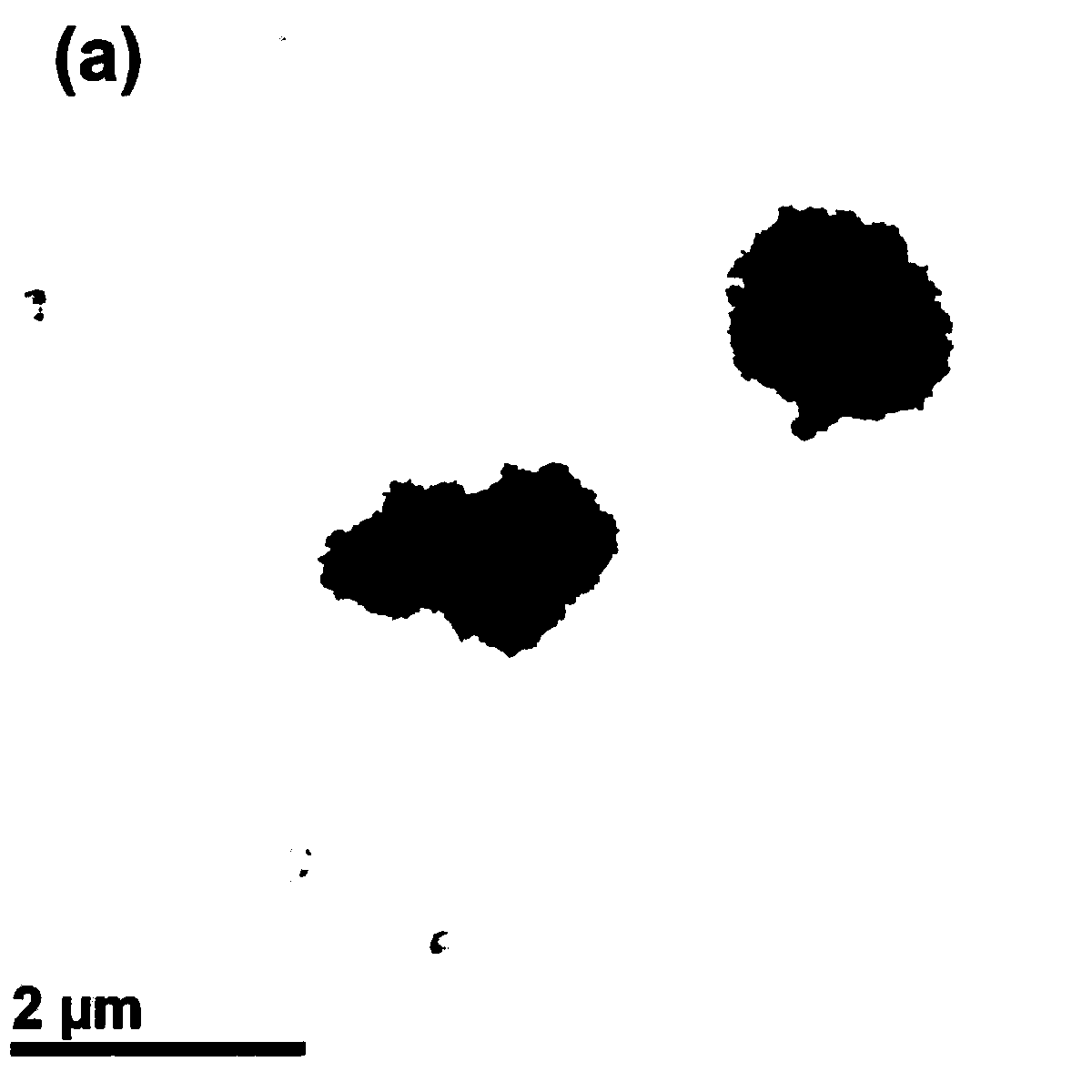

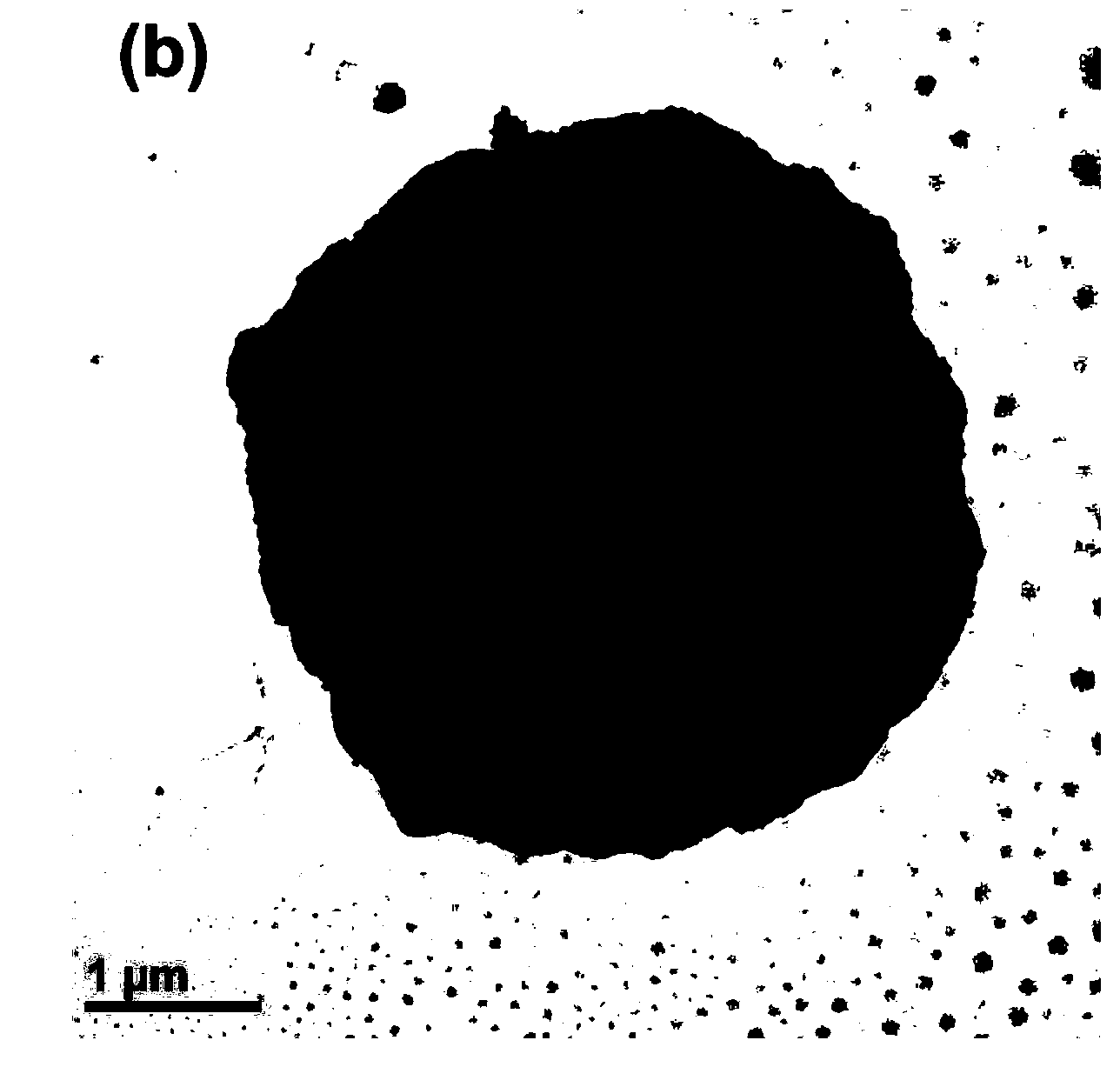

Preparation method for micrometer-particle-diameter FeCo particles

ActiveCN103406545AHigh purityGood composition uniformityInorganic material magnetismChemical reactionReaction temperature

The invention discloses a preparation method for micrometer-particle-diameter FeCo particles, and belongs to the technical field of preparation of magnetic materials. By controlling a microemulsion chemical reaction process, reduction reaction is carried out on ferrous iron elements and cobaltous elements through hydrazine hydrate, and by adjusting and controlling reaction temperature and time, the micrometer-particle-diameter FeCo particles are synthesized directly. The micrometer-particle-diameter FeCo particles prepared through the chemical method are high in purity, are uniform in content and structure, can be used for preparing high-performance Fe-Co-radical composite soft magnetic materials, and are suitable for preparing a large-power soft magnetic element which is complex in shape, small and multifunctional. The preparation method for the micrometer-particle-diameter FeCo particles has the advantages of being abundant in raw material source, simple in process, small in consumption of recourses of water and electricity, environmentally friendly, suitable for industrialized production and the like. The preparation method for the micrometer-particle-diameter FeCo particles widens the search and application range of the chemical preparation process in the field of metal and alloy, and has great scientific significance for developing the new preparation technology of the high-performance soft magnetic materials.

Owner:北京中磁新材科技有限公司

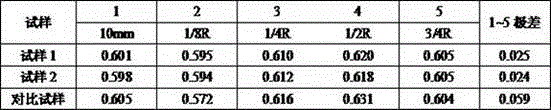

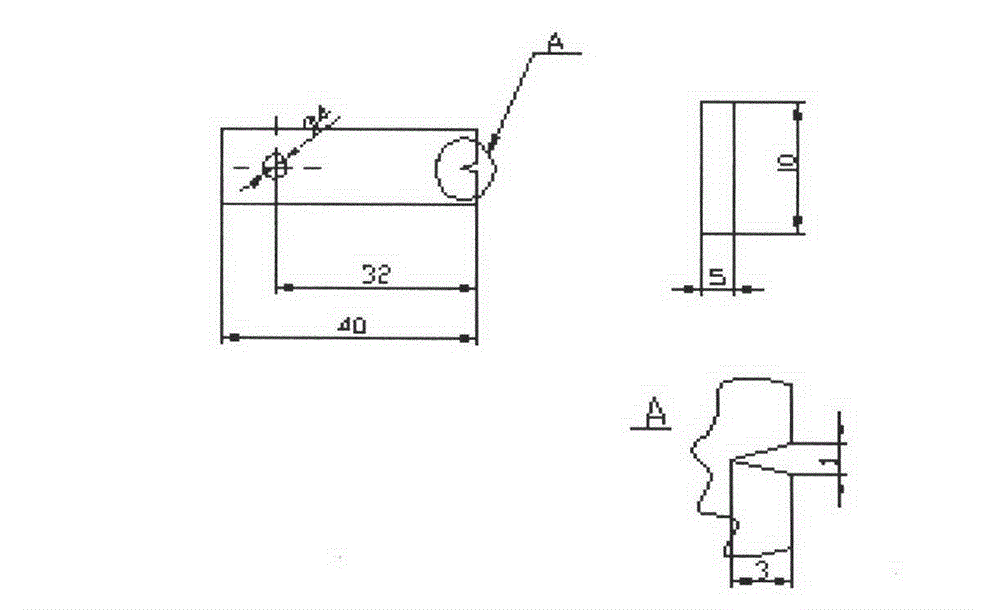

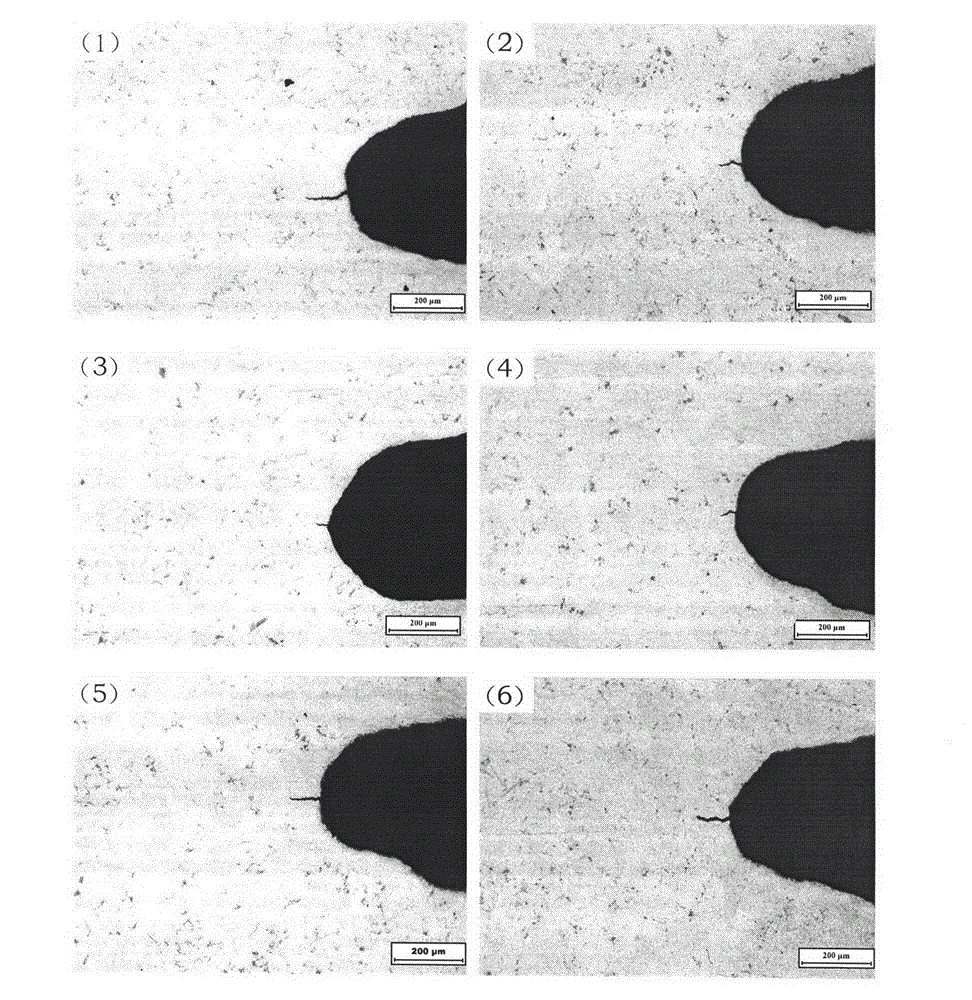

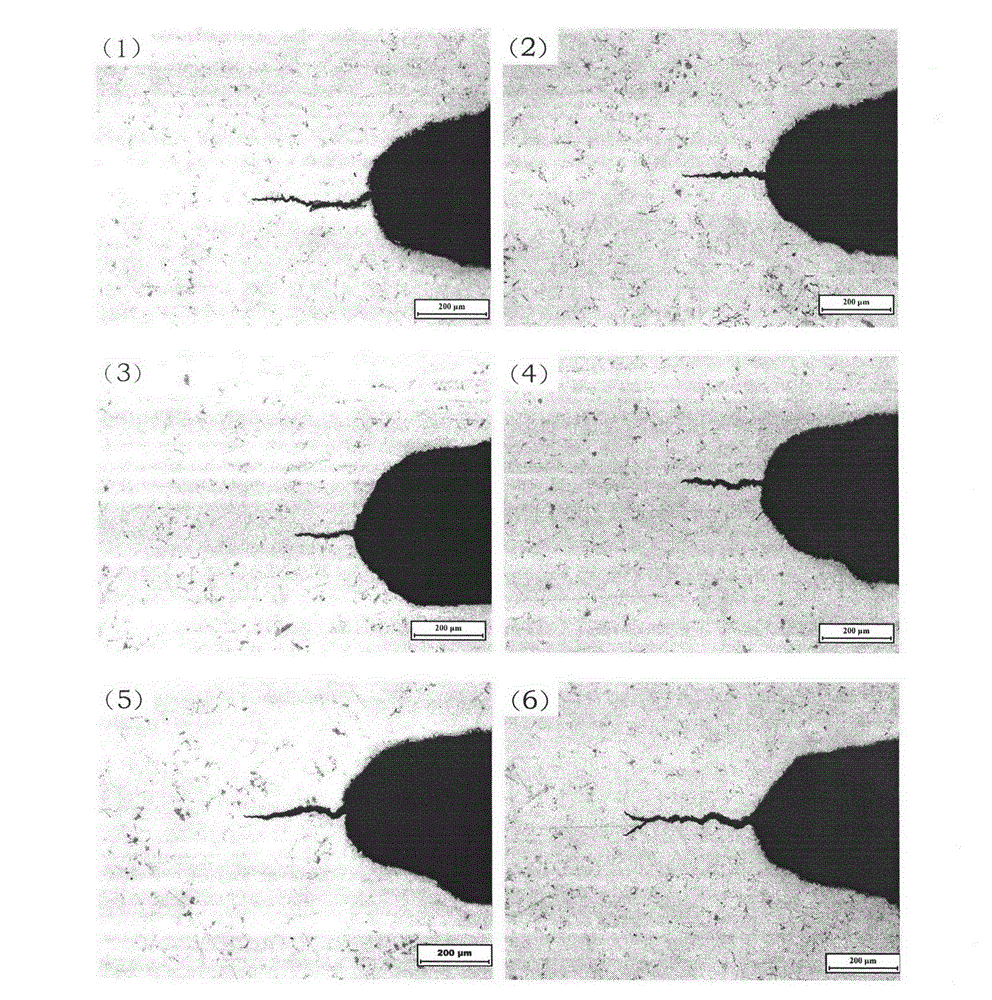

Carbon segregation control method for continuous casting round billet for vehicle wheel

InactiveCN106583676AControl composition uniformityReduce chemical composition deviationChemical compositionHigh carbon

The invention discloses a carbon segregation control method for a continuous casting round billet for a vehicle wheel. The carbon segregation control method includes the following steps that the floating range of the content of chemical components of steel and the corresponding target content of the components is reduced; the superheat degree of molten steel during casting is reduced; and various compound stirring manners are adopted for stirring while casting is conducted. It can be known from the method that the difference value range of the practical content of the chemical components in molten steel and the target content is reduced, deviation of the chemical components of molten steel in the last melt and the next melt in the continuous casting process can be reduced, and therefore the chemical components of tundish melting in 80% or more of the melts can be basically the same, the actual content of C, the actual content of Si, the actual content of Mn, the actual content of Cr and the actual content of V are controlled in the corresponding range of the target content + / - 0.01%, and component evenness on the cross section of the medium-and-high-carbon wheel steel continuous casting round billet can be better controlled.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Aluminum-scandium alloy sputtering target material and preparation method thereof

PendingCN110527956ASolve difficultySolve the problem of low scandium contentVacuum evaporation coatingSputtering coatingLevitationIngot

The invention discloses an aluminum-scandium alloy sputtering target material and a preparation method thereof, and belongs to the technical field of high-performance aluminum-scandium alloy target materials. In the aluminum-scandium alloy target material, the content of scandium is 5 at%-50 at%, and the balance is aluminum. The preparation method comprises the following steps of 1, preparing materials; 2, smelting and casting ingots; 3, calcining or rolling; 4, sampling and detecting; 5, milling and cleaning; 6, carrying out vacuum packing. According to the present invention, the aluminum-scandium alloy target material is prepared through a vacuum induction levitation melting furnace and a rapid casting and rapid condensation technology, and the thickness of the prepared aluminum-scandiumalloy target material is 2-35 mm, the density is 99.9%, the scandium content is 5-50 at%, and the balance is the aluminum element. The preparation method is easy to operate, the alloy is uniform, theutilization rate of the expensive metal scandium is high, and the industrial application is facilitated. The characteristics of good component uniformity and good subsequent machinability satisfy therequirements of the semiconductors and the sputtering target materials in the special fields, and the defects in the prior art are overcome.

Owner:何午琳

Heat treatment technology for improving tissue uniformity of H13 hot working die forged steel

The invention discloses a heat treatment technology for improving the tissue uniformity of H13 hot working die forged steel. The technology comprises following steps: loading forged H13 steel into a heating furnace, wherein the heating temperature is 860 to 880 DEG C, cooling the H13 steel in the air to the room temperature; then loading the forged steel into the heating furnace, heating to a temperature of 1030 to 1050 DEG C, cooling the forged steel to a temperature of 300 to 400 DEG C in the air; filling the forged steel into the heating furnace for a third time, heating to a temperature of1080 to 1100 DEG C, cooling the forged steel to a room temperature in the air; filling the forged steel into the heating furnace for a fourth time, heating to a temperature of 870 to 890 DEG C, maintaining the temperature for 4 to 6 hours, cooling to a temperature of 720 to 740 DEG C, maintaining the temperature for 6 to 8 hours, secondarily cooling to a temperature not higher than 500 DEG C, taking out the forged steel out of the heating furnace, and cooling the forged steel in the air. Compared with a conventional forging stock annealing treatment, the horizontal impact energy is not less than 12J; the ratio of horizontal impact energy to vertical impact energy is not less than 0.8; the size of grains in tissues is uniform; the mixed crystal tissue is avoided, banded segregation is reduced or eliminated; and horizontal impact toughness and isotropy are enhanced.

Owner:HEBEI IRON AND STEEL

Preparation method of high-strength and high-tenacity nodular cast iron

ActiveCN108624806AGood composition uniformityImprove uniformityProcess efficiency improvementDuctile ironImpurity

The invention discloses a preparation method of high-strength and high-tenacity nodular cast iron. The high-strength and high-tenacity nodular cast iron is prepared from, by mass, 3.6%-3.8% of C, 3.5%-3.8% of Si, 0.4%-0.6% of Mn, 0.01%-0.04% of Sn, 0.4%-0.6% of Ni, 0.3%-0.4% of Ti, 0.04%-0.01% of Sb, 0.02%-0.04% of RE, 0.16%-0.2% of P, no more than 0.02% of S, and the balance Fe and inevitable impurities. The tensile strength of the nodular cast iron is 1050-1180 MPa, the yield strength of the nodular cast iron is 780-820 MPa, the ductility of the nodular cast iron is 15%-16%, the nodularity of the nodular cast iron is 95%, and all properties of the nodular cast iron are excellent.

Owner:佛山市高明康得球铁有限公司

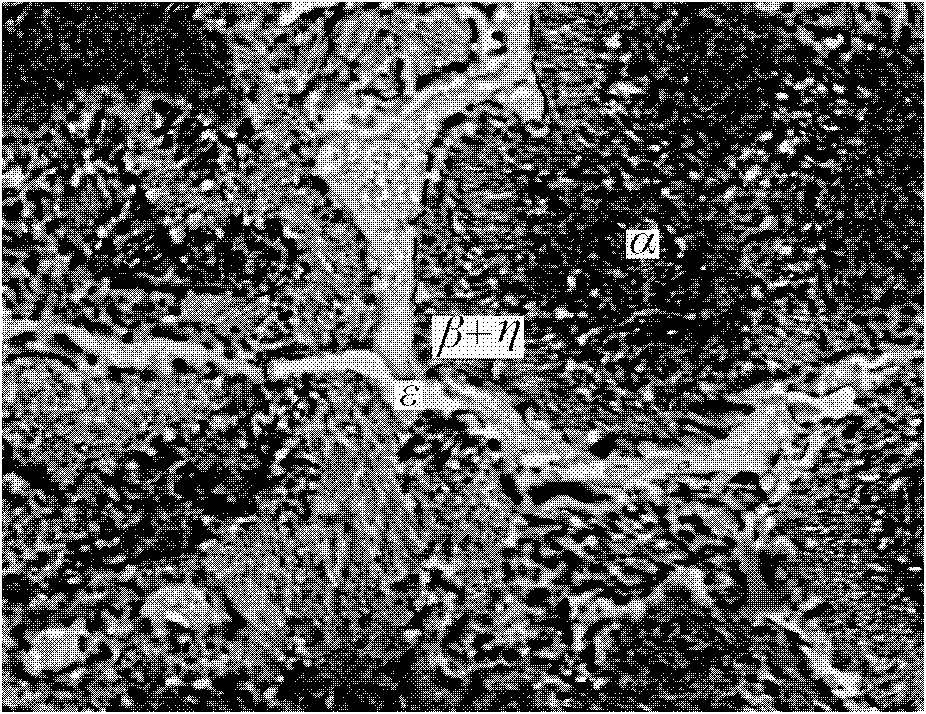

Multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property

ActiveCN102719705AImprove plasticityImprove thermal fatigue resistanceThermal fatigueMedium frequency

A multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property belongs to the technical field of zinc-aluminium alloy preparation and is characterized in that No.A00 industrial aluminium ingots, No.0 zinc ingots, electrolytic copper, composite modifier (including 20 to 30 percent of Ni, 15 to 25 percent of Ti, 5 to 15 percent of Mn, 5 to 15 percent of Cr, 5 to 10 percent of Si, 5 to 10 percent of Ce, 5 to 10 percent of La, 1 to 6 percent of Y, 1 to 6 percent of Nb, 1 to 6 percent of V and the balance of aluminium) and pure magnesium are adopted as materials. Calculated according to percentage by weight, 27 to 29 percent of Al, 2 to 2.5 percent of Cu (added in the form of aluminium-copper master alloy containing 50 percent of copper), 0 to 1.2 percent of composite modifier, 0.01 to 0.02 percent of Mg and the balance of Zn are weighed and then smelted in a medium-frequency induction smelting furnace. An ordinary metal mold is adopted to cast round rod-shaped billets, the round bar-shaped billets are machined into test bars which come up to national standard, and thermal fatigue samples are then taken from the billets.

Owner:SHENZHEN MINGLIDA PRECISION MACHINERY

Homogenization heat treatment method of as-cast zinc-aluminum alloy material

The invention discloses a homogenization heat treatment method of an as-cast zinc-aluminum alloy material, which comprises: performing the homogenization heat treatment of a cast ingot which comprises 25.0 to 28.0 weight percent of Al, 2.0 to 2.5 weight percent of Cu, 0.015 to 0.020 weight percent of Mg, less than 0.07 weight percent of Fe, less than 0.04 weight percent of Pb, less than 0.003 weight percent of Cd, less than 0.002 weight percent of Sn and the balance of Zn at a heating temperature of 330 to 360 DEG C, keeping the temperature for 8 to 24 hours and cooling the cast ingot with the furnace. In the invention, the technical method is simple; the operation is convenient; the uniformity of the structural constituents of the zinc-aluminum alloy casting is improved effectively, and the plasticity and size stability of the zinc-aluminum alloy casting are improved; by improving the solid solution degree of the Cu element in a substrate, the size and performance stability of the material are improved; the dendritic segregation and unbalance eutectic phase are improved to a maximum degree, the uniformity of the material structure is improved and the plasticity of the alloy is improved; and the method is suitable for industrial production, and can improve the mechanical performance of the as-cast aluminum alloy and expand the application range of the as-cast aluminum alloy.

Owner:CENT SOUTH UNIV +1

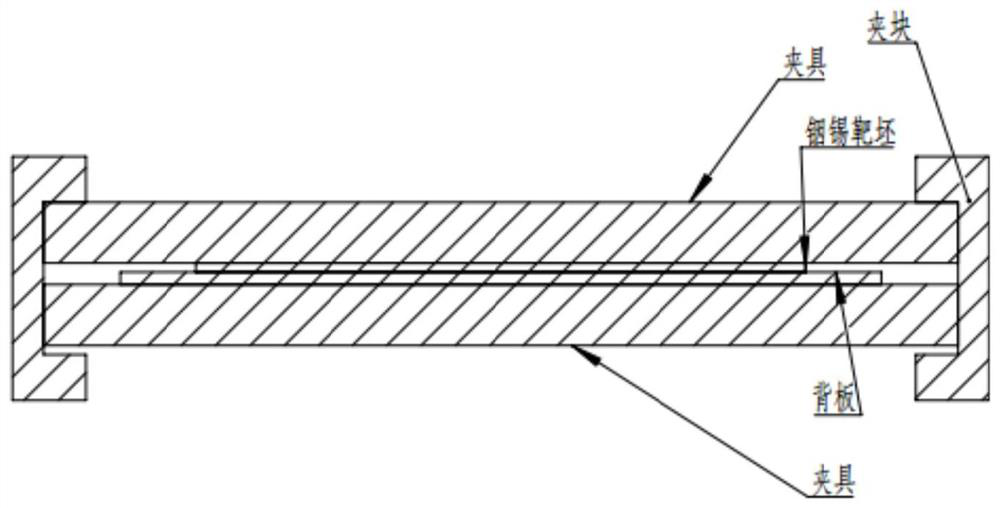

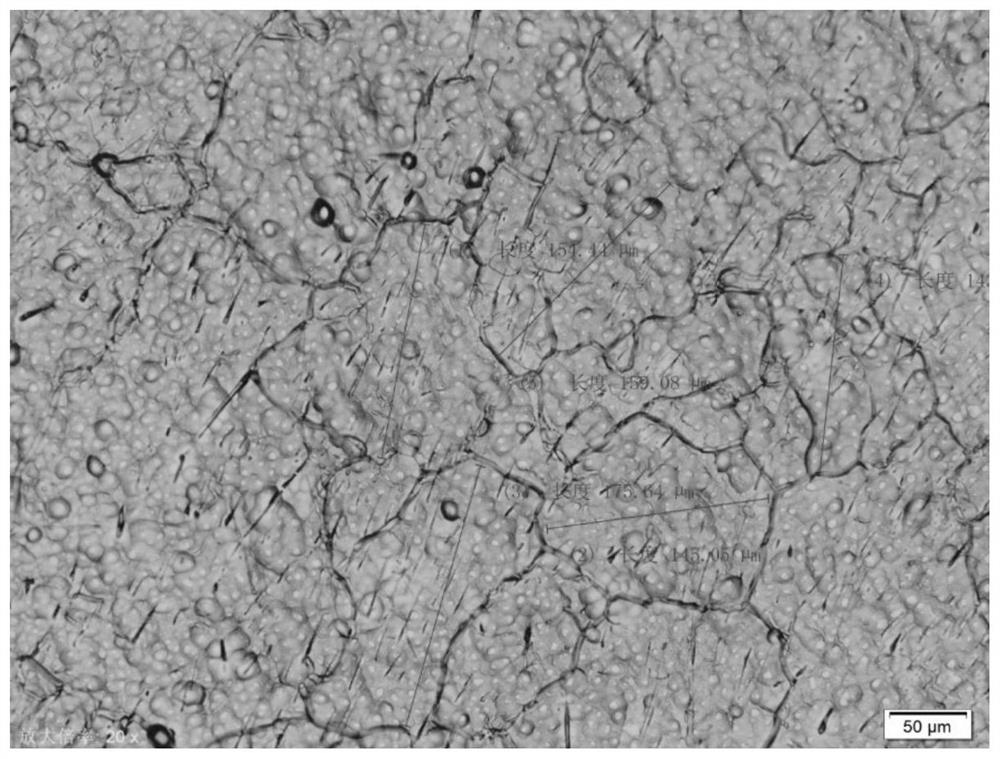

Indium-tin alloy target material and preparation method thereof

ActiveCN111809152AHigh puritySmall granularityVacuum evaporation coatingFoundry mouldsIndiumCrucible

The invention discloses a preparation method of an indium-tin alloy target material. The preparation method specifically comprises the following steps that metal indium and metal tin are put into a crucible, heated to be melted, and stirred until the melt components are uniform; the melt is subjected to casting and molding to obtain an indium-tin alloy cast ingot; the indium-tin alloy ingot is rolled to obtain an indium-tin alloy blank; the indium tin alloy blank is machined into a rough target blank with the thickness larger than the target size, and the binding face of the rough target blankis machined to be smooth; and a matched back plate and the rough target blank are heated and subjected to heat preservation at the temperature lower than the critical melting point of the rough target blank, then the back plate and the rough target blank are attached and clamped and gradually cooled to the room temperature, and after binding is qualified, the rough target blank is machined to thetarget size. By means of the method, the indium-tin target materials can be rapidly produced in batches, no melting medium exists between the target blank and the back plate, the target blank is highin purity, uniform in grain size and small in granularity, the average granularity ranges from 100 micrometers to 150 micrometers, the component uniformity is good, the indium-tin component deviationis smaller than + / -0.5%, and the sputtering effect is good.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com