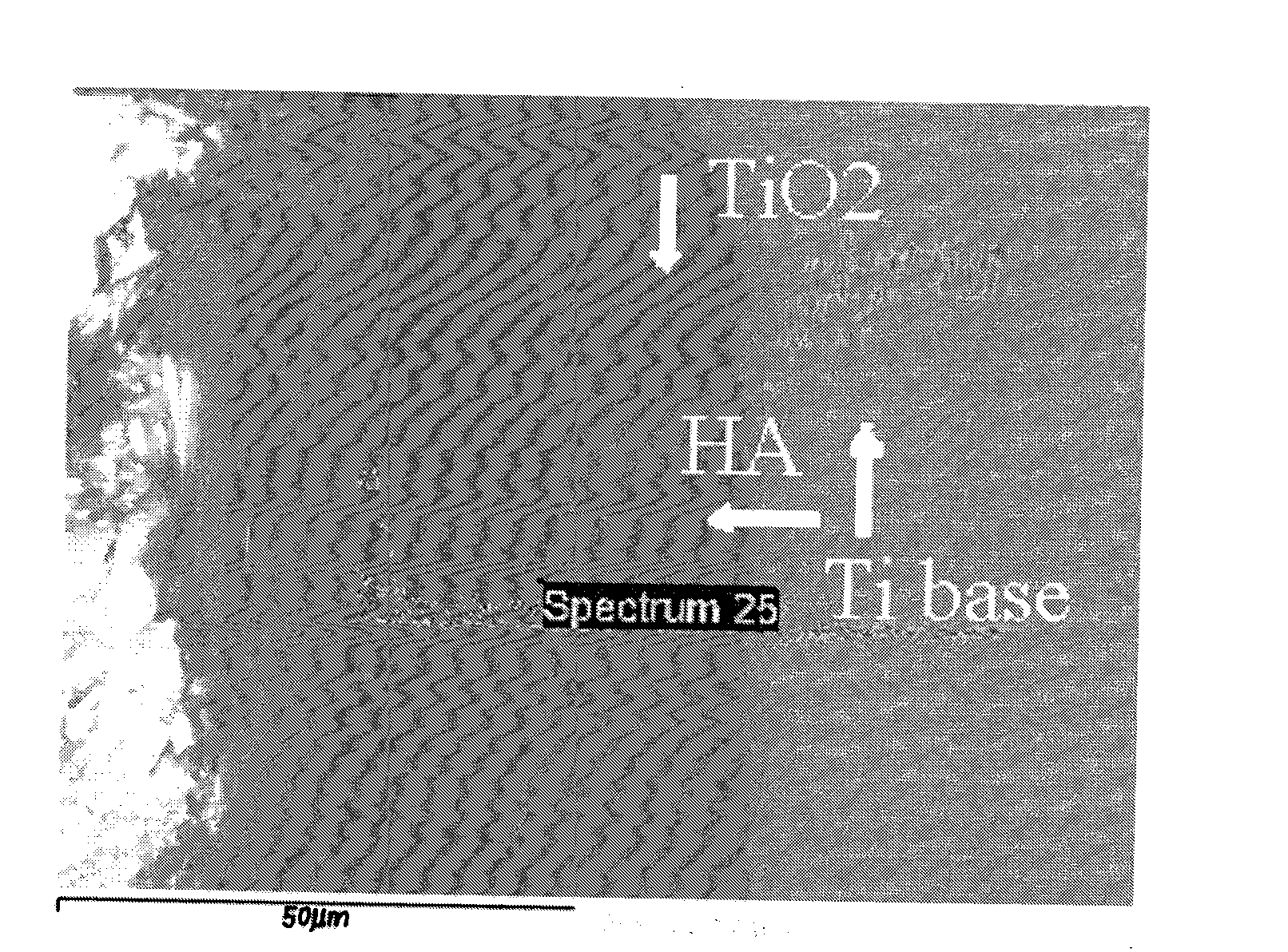

Preparation method of hydroxylapatite/titanic oxide composite biological coatings

A technology of hydroxyapatite and titanium dioxide, which is applied in coatings, medical science, prostheses, etc., can solve the problems of large particles, poor dispersion, and difficult control of coating uniformity, and achieve high component purity and component uniformity Good, the effect of improving chemical and physical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of hydroxyapatite sol, that is, HA sol: triethyl phosphate [(C 2 h 5 O) 3PO] was added to absolute ethanol and diluted according to the molar concentration of triethyl phosphate at 2 mol / L; the pure water with 2.7 times the molar weight of triethyl phosphate was slowly added dropwise to the above diluent for hydrolysis, and a magnetic stirrer was used to Stir vigorously for 24 hours; dry the calcium nitrate at a temperature of 165°C for 36 hours, seal it, and cool it; prepare the calcium nitrate ethanol solution with the dried calcium nitrate at 2mol / L; mix the calcium nitrate ethanol solution with the hydrolyzed triethyl phosphate The esters were mixed in a molar ratio of 5:3, stirred for 3 hours, and aged for 40 hours.

[0036] TiO 2 Preparation of sol: Mix and stir the butyl titanate and ethylene glycol methyl ether solution at a molar ratio of 1:20 for 25 minutes; the molar ratio of ethyl acetoacetate to butyl titanate is 1:5, Then add ethyl acet...

Embodiment 2

[0041] Preparation of HA sol: triethyl phosphate [(C 2 h 5 O) 3 PO] was added to absolute ethanol and diluted according to the molar concentration of triethyl phosphate at 2 mol / L; the pure water with 2.7 times the molar weight of triethyl phosphate was slowly added dropwise to the above diluent for hydrolysis, and a magnetic stirrer was used to Stir vigorously for 24 hours; dry the calcium nitrate at a temperature of 175°C for 32 hours, seal it, and cool it; prepare the calcium nitrate ethanol solution from the dried calcium nitrate at 2mol / L; mix the calcium nitrate ethanol solution with the hydrolyzed triethyl phosphate Mix at a molar ratio of 5:3, stir for 3 hours, and age for 40 hours.

[0042] Preparation of titanium dioxide sol: Mix butyl titanate and ethylene glycol methyl ether solution at a molar ratio of 1:20, and stir for 25 minutes with a magnetic stirrer; the molar ratio of ethyl acetoacetate to butyl titanate is 1:5 , then add ethyl acetoacetate for chelation...

Embodiment 3

[0047] HA sol 0 preparation 0: triethyl phosphate [(C 2 h 5 O) 3 PO] was added to absolute ethanol and diluted according to the molar concentration of triethyl phosphate at 2 mol / L; the pure water with 2.7 times the molar weight of triethyl phosphate was slowly added dropwise to the above diluent for hydrolysis, and a magnetic stirrer was used to Stir vigorously for 28 hours; dry the calcium nitrate at 185°C for 28 hours, seal it, and cool it; prepare the calcium nitrate ethanol solution with 2 mol / L of the dried calcium nitrate; mix the calcium nitrate ethanol solution with the hydrolyzed triethyl phosphate Mixed at a ratio of 5:3, stirred for 3h, and aged for 40h.

[0048] Titanium dioxide sol preparation: mix butyl titanate and ethylene glycol methyl ether solution at a molar concentration ratio of 1:20, stir with a magnetic stirrer for 25 minutes, and then set the molar ratio of ethyl acetoacetate to butyl titanate to 1 : 5, add ethyl acetoacetate for chelation, stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com