Soft magnetic ferrite material and preparation process thereof

A technology of soft magnetic ferrite and magnetic flux density, applied in the direction of magnetism of inorganic materials, can solve the problems of limiting the miniaturization of electronic devices, low saturation magnetic flux density, high magnetic loss, etc., to achieve mass production and improve resistivity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

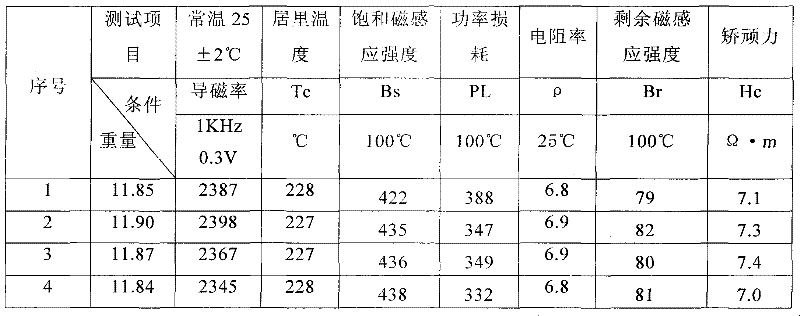

Examples

Embodiment 1

[0036] A soft ferrite material, the composition and molar ratio are: 55mol Fe 2 o 3 , 39mol Mn 3 o 4 , 6mol ZnO, 0.15mol SnO 2 , a total of 0.1 to 0.15mol of Nb 2 o 5 , V 2 o 5 .

[0037] The preparation method of above-mentioned soft magnetic ferrite material is as follows:

[0038] 1) the main material Fe 2 o 3 , Mn 3 o 4 , ZnO and additive SnO 2 Carry out wet mixing for the first time according to the molar ratio;

[0039] 2) The above-mentioned mixed materials are granulated with a spray dryer, and then pre-fired in a rotary kiln through a rotary kiln. The magnetization of the fired material is well controlled at 3A*m 2 Within / kg;

[0040] 3) Carry out the second wet sand milling of the pre-burned material: add the additive 2Nb according to the above ratio 2 o 3 , V 2 o 5 ; The average particle size after wet pulverization is 0.9-1.0 microns, so that the sintered Bs has room for improvement;

[0041] 4) Add PVA glue with a concentration of 8% to 12% t...

Embodiment 2

[0044] A soft magnetic ferrite material, the composition and molar ratio are: 52mol Fe 2 o 3 , 40mol of Mn 3 o 4 , 8mol of ZnO, 0.1mol of CaCO 3 , a total of 0.12mol of CaCO 3 、 Ta 2 o 5 , SnO 2 , 0.006mol of ZrO 2 .

[0045] The preparation method of above-mentioned soft magnetic ferrite material is as follows:

[0046] 1) the main material Fe 2 o 3 , Mn 3 o 4 , ZnO and additive CaCO3 The first wet mixing is carried out according to the molar ratio.

[0047] 2) The above-mentioned mixed materials are granulated with a spray dryer, and then pre-fired in a rotary kiln through a rotary kiln. The magnetization of the fired material is well controlled at 3A*m 2 / kg or less.

[0048] 3) Carry out the second wet sand milling of the pre-burned material: add the additive CaCO according to the above ratio 3 、 Ta 2 o 5 , SnO 2 and ZrO 2 , the ZrO 2 The addition of Bs can further reduce the loss of materials and increase the saturation magnetic flux density; the ave...

Embodiment 3

[0052] A soft magnetic ferrite material, the composition and molar ratio are: 53mol Fe 2 O, 40mol of Mn 3 o 4 , 7mol of ZnO, 0.1mol of V 2 o 5 , a total of 0.13mol of Ta 2 o 5 , SnO 2 , V 2 o 5 , 0.025mol of ZrO 2 .

[0053] The preparation method of above-mentioned soft magnetic ferrite material is as follows:

[0054] 1) the main material Fe 2 o 3 , Mn 3 o 4 , ZnO and additive V 2 o 5 The first wet mixing is carried out according to the molar ratio.

[0055] 2) The above-mentioned mixed materials are granulated with a spray dryer, and then pre-fired in a rotary kiln through a rotary kiln. The magnetization of the fired material is well controlled at 3A*m 2 / kg or less.

[0056] 3) The pre-burned material is subjected to the second wet sand milling: add the additive Ta according to the above ratio 2 o 5 , SnO 2 , V 2 o 5 and ZrO 2 , the ZrO 2 The addition of Bs can further reduce the loss of materials and increase the saturation magnetic flux density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com