Nickel zinc ferrite magnetic shielding inductor product and manufacturing method thereof

A nickel-zinc ferrite and inductor technology, used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of low saturation magnetic flux density and poor temperature characteristics, and improve the resistance to DC superposition. The ability to improve the anti-interference ability, the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Fe as the main component of the present invention 2 o 3 , NiO, ZnO, CuO according to the ratio set in the table below,

[0028] material name

[0029] Vibrate and mix the prepared main component raw materials with a vibrating ball mill for 15 minutes, and then pre-calcine their mixture in the air for 3 hours. The pre-burned material is mixed and pulverized with a ball mill (12 hours). During the pulverization process, the ratio of the material to water is 1: 2 by weight; after the pulverization is completed, it is dried, and the concentration is 10% polyvinyl alcohol is added during drying. Solution, the addition ratio is calculated as 11% of the total material weight according to the polyvinyl alcohol solution; after adding polyvinyl alcohol, it is made into a powder, and the full-automatic rotary press is used at 2t / cm 2 Under the pressure of high pressure, the powder is pressed into a rod-shaped magnetic core and a square cap-shaped magnetic core blank wi...

Embodiment 2

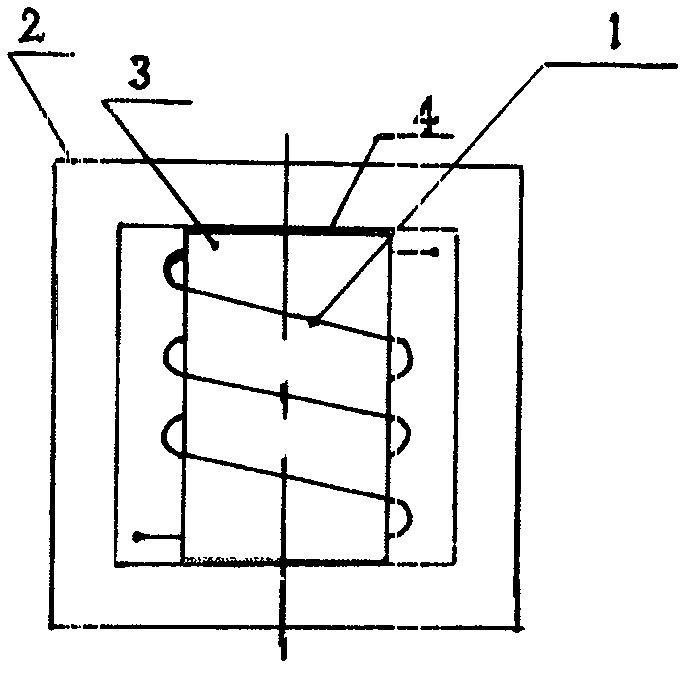

[0031] With the nickel-zinc ferrite material obtained by the present invention at 2t / cm 2 The cap-shaped magnetic core and the rod-shaped magnetic core blank are respectively formed under pressure. The shapes of these two kinds of magnetic core blanks are shown in the appendix figure 1 , sintering the obtained blank in air at 1160° C. for 3 hours to obtain a rod-shaped magnetic core 3 and a cap-shaped magnetic core 2 .

[0032] as attached figure 1 As shown, use a winding machine to wind the Φ0.8mm enameled wire into an air-core coil 1 with an inner diameter of 3mm, and the number of winding turns is 5 turns. The coil 1 is fixed on the rod-shaped magnetic core 3 with an adhesive 4 to ensure that the coil is stable. The position is in the center of the rod-shaped magnetic core; the rod-shaped magnetic core 3 with the coil 1 is fixed in the cap-shaped magnetic core 2 with an adhesive to obtain a magnetically shielded inductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com