Patents

Literature

90 results about "Material Name" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The non-unique textual identification of a material in a specified context.

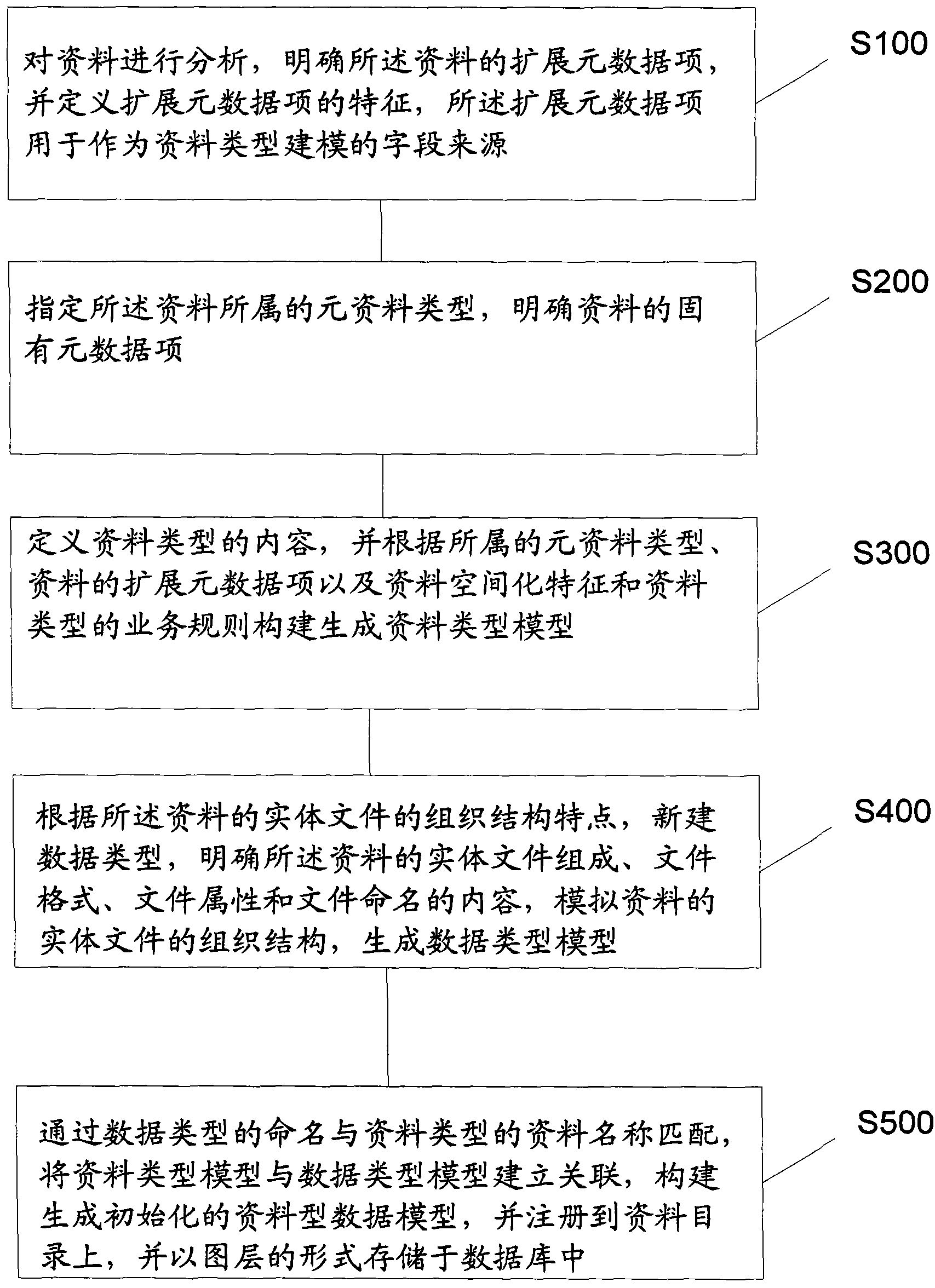

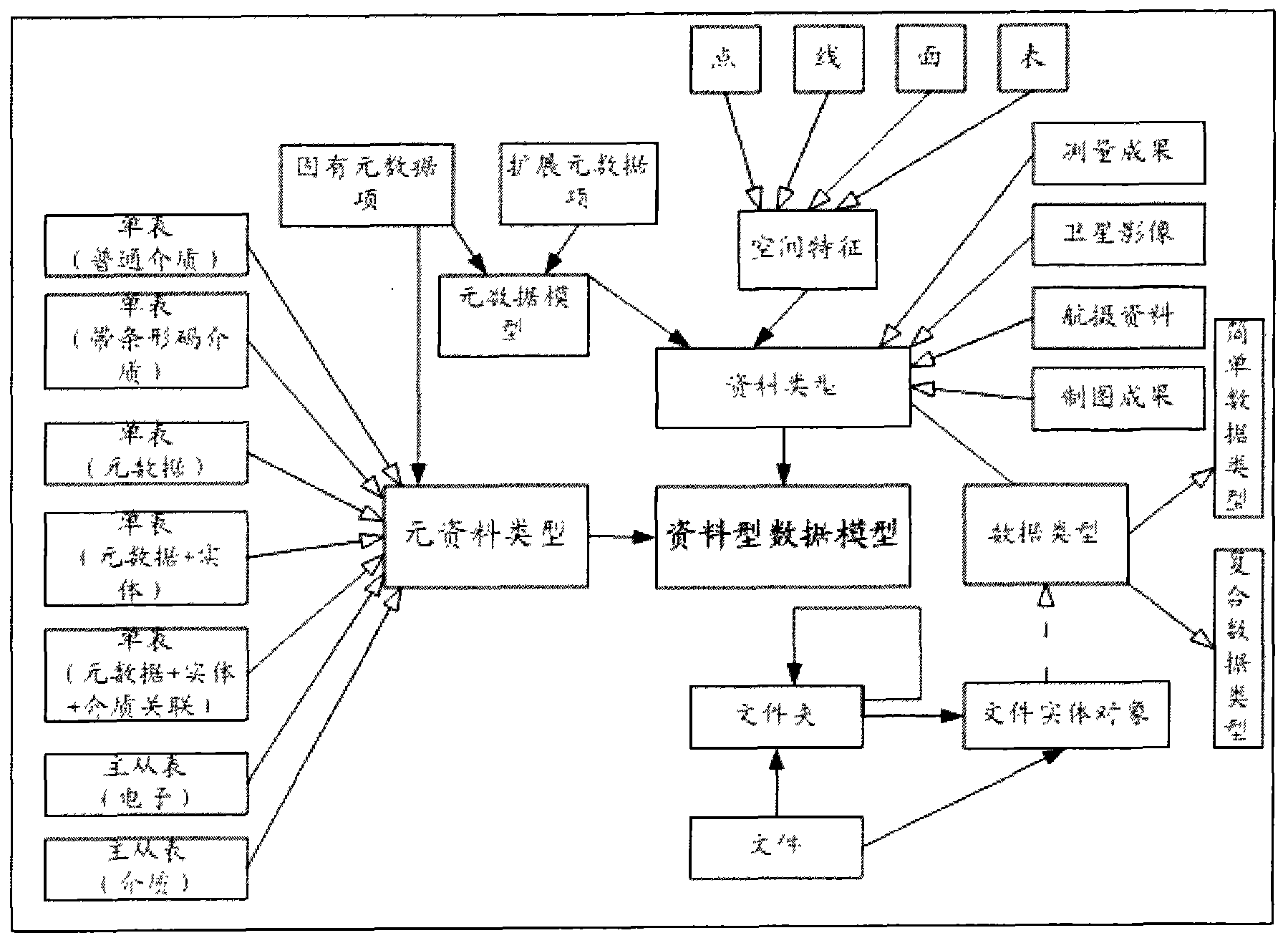

Material data modeling processing method

ActiveCN103886004ARapid expansionQuick buildSpecial data processing applicationsMaterial typeData modeling

The invention discloses a material data modeling processing method. The method includes: designating meta-material types of material and specifying inherent metadata items of the material; specifying extended metadata items of the material, and defining features of the extended metadata items; defining material type contents, and building a material type model according to the meta-material types, the extended metadata items of the material, spatial features of the material and business rules of the material type; generating a data type model according to structure features of a solid file of the material; correlating the material type model to the data type model by matching names of data types and material names of the material types, building an initial material data model, and storing the model in a database. The inherent metadata items and the extended metadata items are used as field sources for material type modeling. According to the method, the material types and the corresponding data types are classified and modeled by modeling, and data processing is more reasonable, more direct, faster and clearer.

Owner:BEIJING GEOWAY SOFTWARE

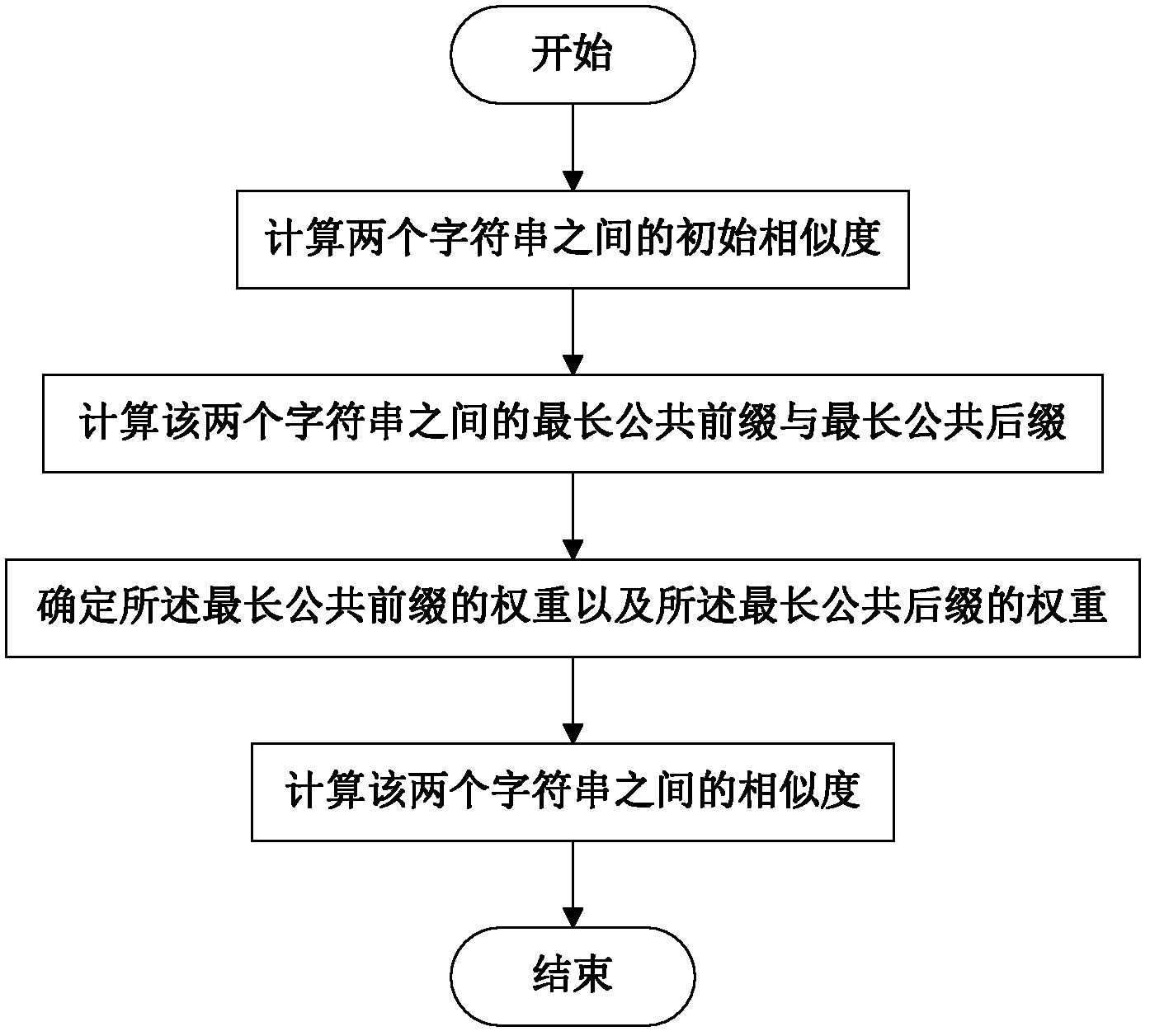

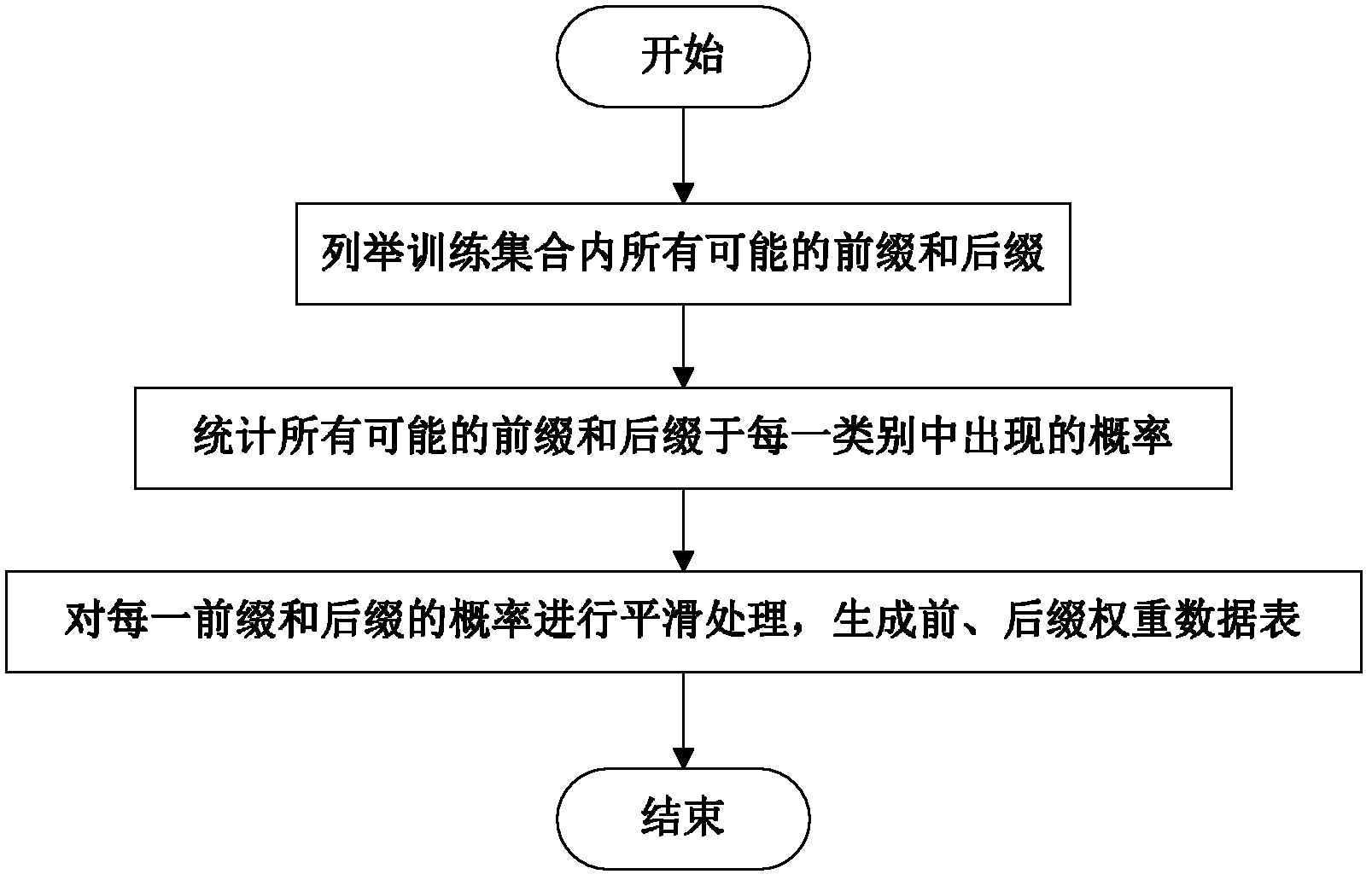

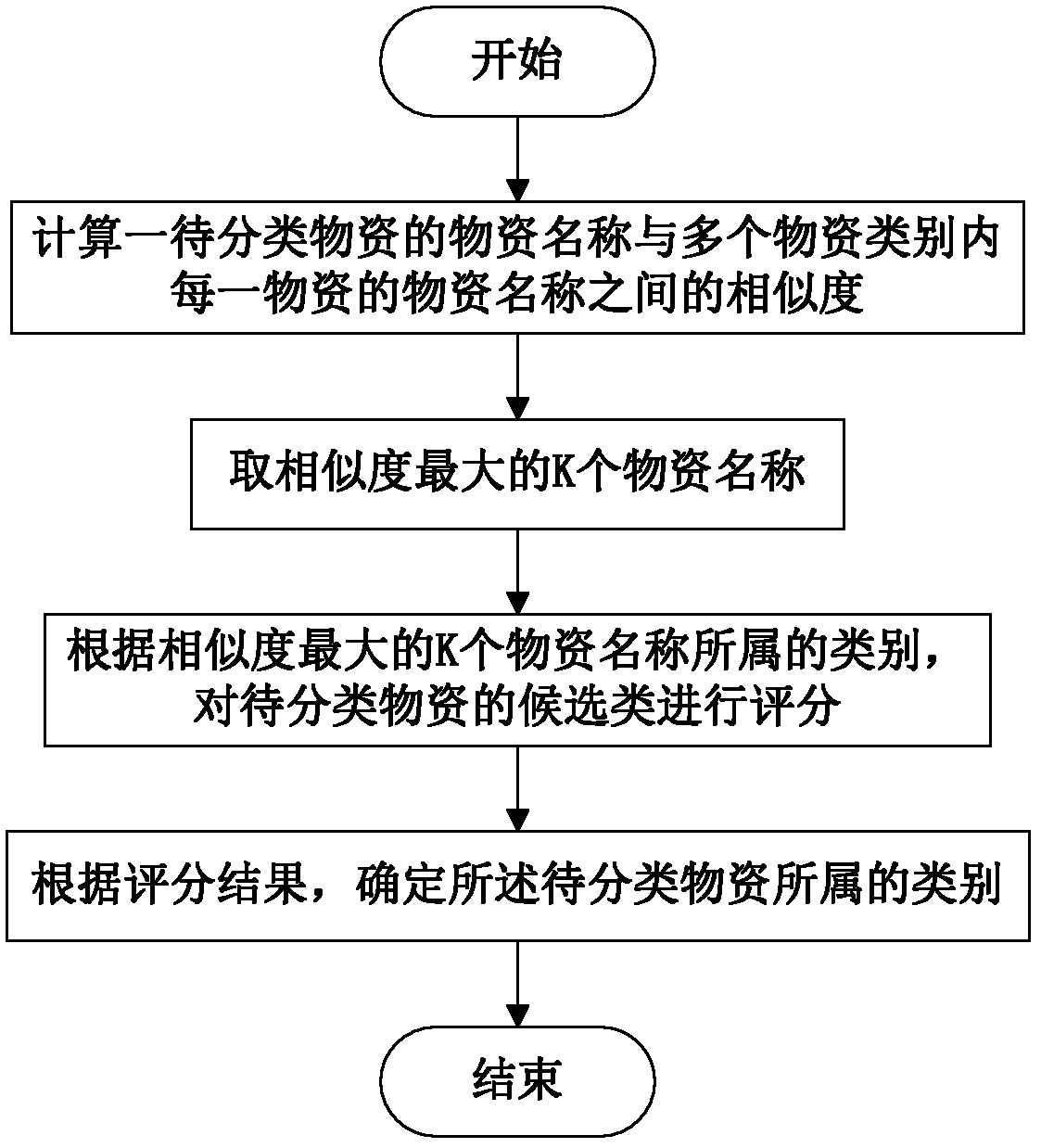

Method and device for calculating character string similarity and material classification method and device

ActiveCN102298632AImprove accuracyHigh similaritySpecial data processing applicationsMaterial classificationChinese characters

The invention discloses a character string similarity calculation method and device as well as a material classification method and device. The similarity calculation method includes: calculating the initial similarity between the character string X and the character string di; obtaining the character string X and the character string di; The longest common prefix and the longest common suffix between di; determine the weight of the longest common prefix and the weight of the longest common suffix; and calculate the similarity between the string X and the string di. Through the above technical scheme, aiming at the characteristics of Chinese material names, the present invention provides a method for calculating the similarity of Chinese character strings oriented to material classification (that is, the dynamic weight method (DynamicWeight)), which can dynamically estimate the material name characters The weight of the prefix and suffix of the string makes the material names of the same category have a higher similarity, which improves the accuracy of automatic material classification.

Owner:CHNA ENERGY INVESTMENT CORP LTD

Peony fragrant bead and preparation method thereof

InactiveCN104189935AImprove symptoms of dysmenorrheaAvoid coldAntipyreticAnalgesicsThuja sutchuenensisPeach blossom

The invention discloses a peony fragrant bead and a preparation method thereof. The peony fragrant bead is composed of the following compositions in parts by weight: 21-25 parts of jasminum sambac flower, 22-26 parts of rose, 23-24 parts of flos puerariae, 23-25 parts of hibiscus mutabilis flower, 24-26 parts of lotus, 26-27 parts of lilium brownii flower, 25-26 parts of peach blossom, 24-25 parts of wintersweet flower, 23-24 parts of sweet osmanthus, 21-22 parts of calendula officinalis, 21-24 parts of carnation, 24-27 parts of hibiscus sabdariffa, 22-25 parts of honeysuckle flower, 23-26 parts of lavender, 9-11 parts of aquilaria wood, 23-25 parts of Laoshan sandalwood, 65-75 parts of bulnesia sarmientoi, 35-39 parts of thuja sutchuenensis, 9-11 parts of a wood material named as Tianmu by the inventor, 18-20 parts of larix potaninii, 22-24 parts of dendrobium nobile, 9-11 parts of benzoin, 12-15 parts of amber fragrance, 10-13 parts of frankincense, 9-10.5 parts of clove and 40-45 parts of peony.

Owner:洛阳珍绿牡丹科技有限公司

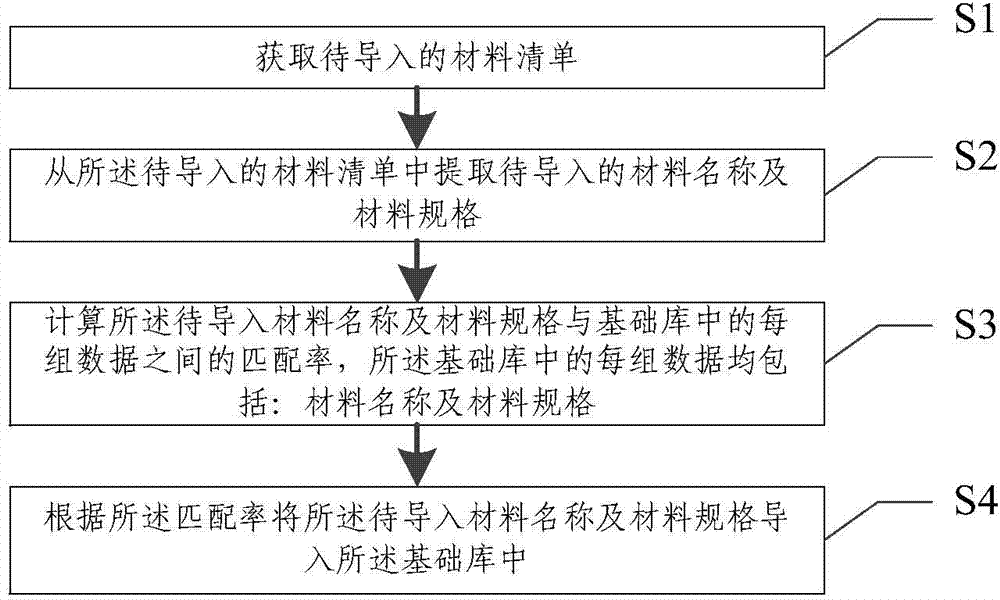

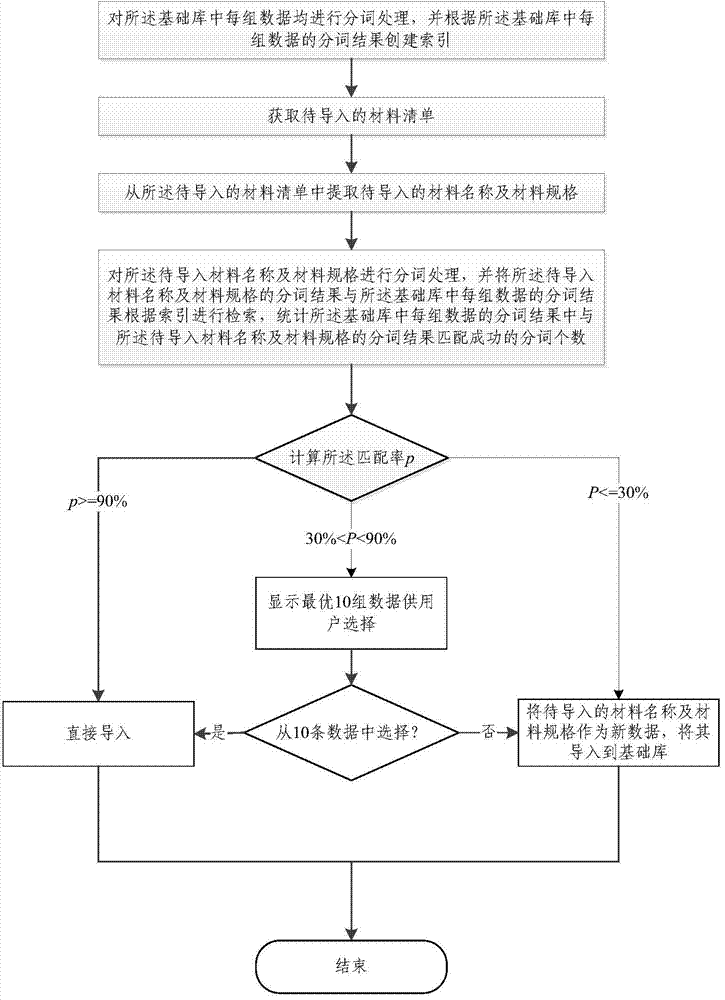

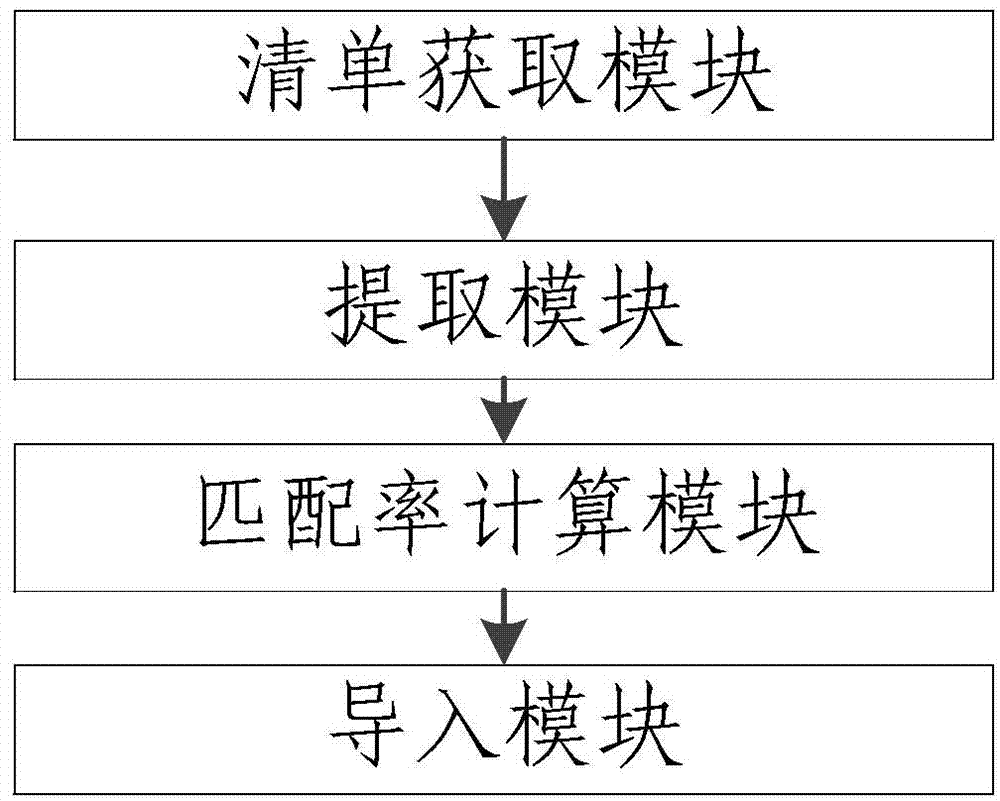

Data importing method and system based on data matching

ActiveCN103761249AImprove entry efficiencyReduce error rateSpecial data processing applicationsData matchingComputer science

The invention discloses a data importing method and a data importing system based on data matching and relates to the technical field of data matching. The data importing method includes: step 1, obtaining a list of materials to be imported; step 2, extracting the names and the sizes of the materials to be imported from the list of materials to be imported; step 3, calculating the matching rate between the names and sizes of the materials to be imported and each group of data in a basic library, wherein each group of data in the basic library comprises the material name and the material size; step 4, importing the names and sizes of the materials to be imported to the basic library according to the matching rate. The data importing method and the data importing system based on data matching enable the data importing efficiency to be improved and enable the error rate to be lowered through calculating the matching rate and importing the names and sizes of the materials to be imported to the basic library according to the matching rate.

Owner:BEIJING FOREVER TECH

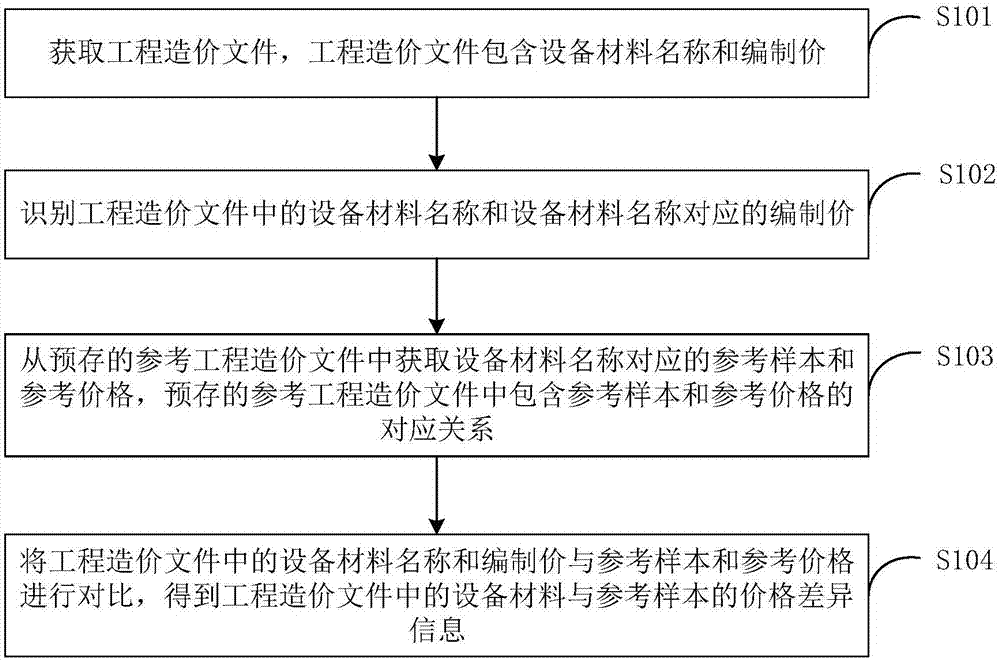

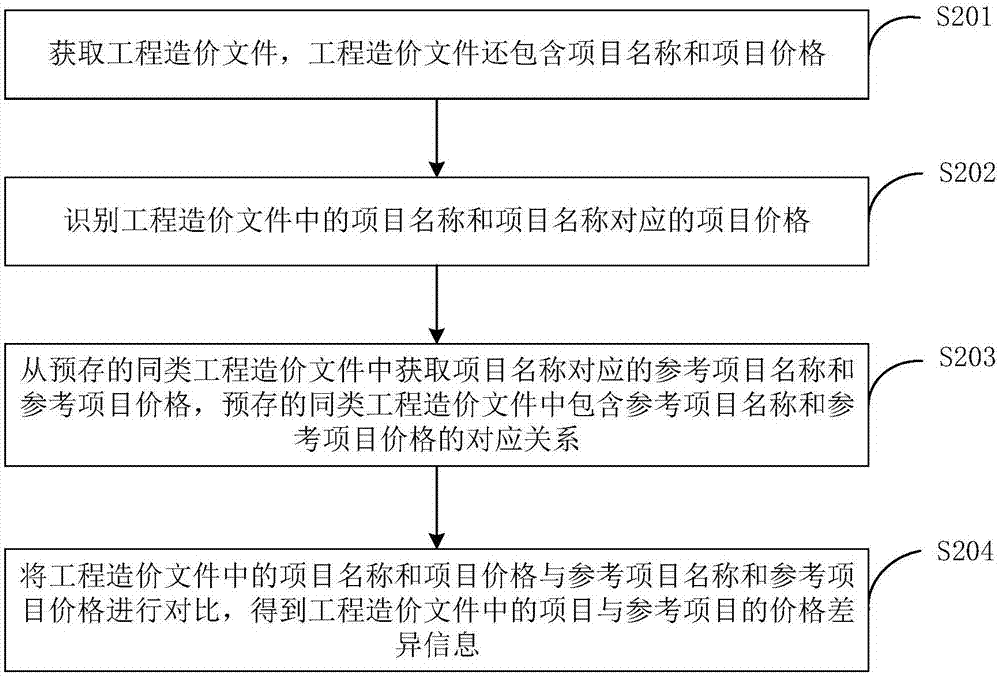

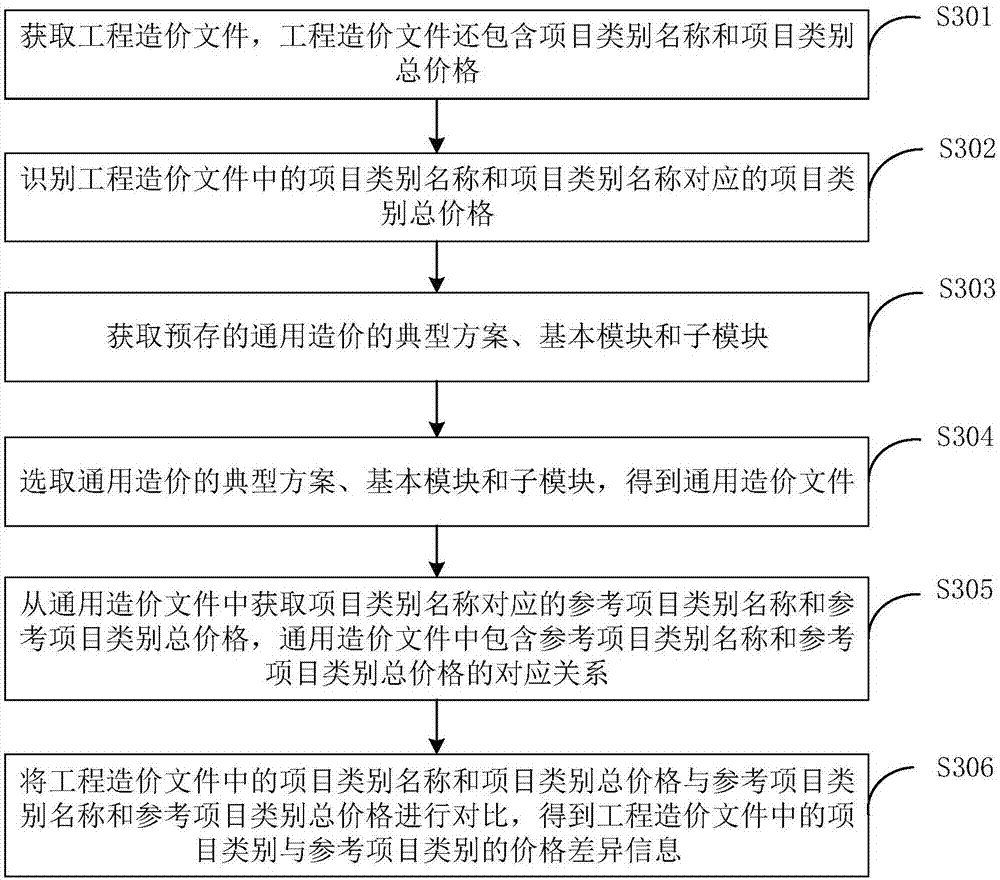

Control method for cost analysis of electric power engineering and system

InactiveCN107491907ARealize automatic comparative analysisSolve management inefficienciesResourcesMarketingReference samplePower engineering

The present invention is applicable to the technical field of electric power engineering, and discloses a method and system for analyzing and controlling electric power engineering cost. The method includes: obtaining a project cost file; identifying the equipment material name in the project cost file and the preparation price corresponding to the equipment material name; Obtain the reference sample and reference price corresponding to the equipment material name from the pre-stored reference project cost file; compare the equipment material name and compilation price in the project cost file with the reference sample and reference price, and obtain the equipment material and reference price in the project cost file Refer to the price difference information of the sample. The embodiment of the present invention can effectively solve the problem of low efficiency of electric power project management caused by the heavy workload and high error rate of the method in the prior art relying on manual operation for power project cost analysis and control, and can realize automatic comparative analysis between project cost files , reduce the workload, and improve the efficiency of cost preparation and review.

Owner:STATE GRID CORP OF CHINA +2

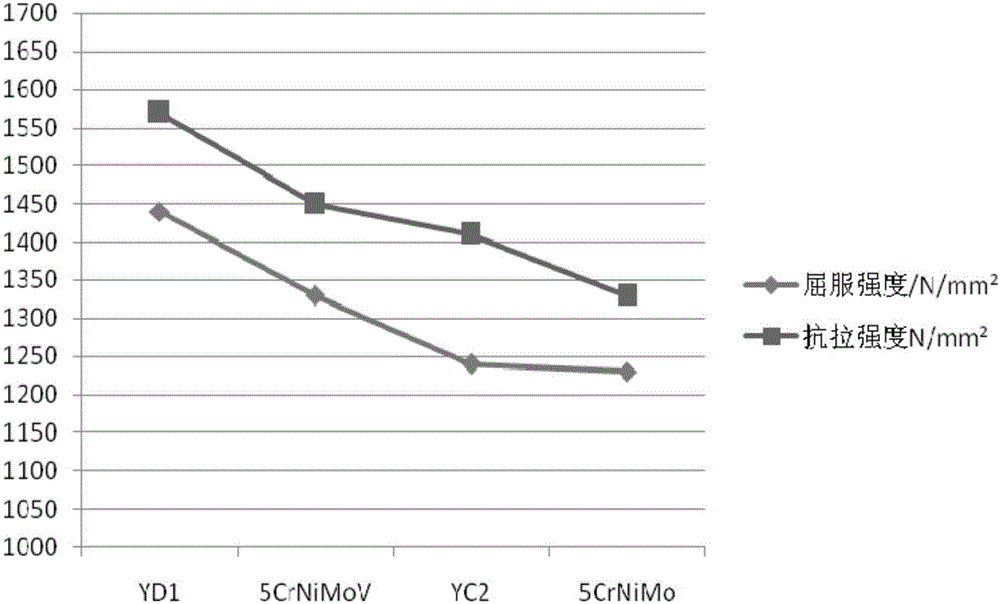

Cr1-series hot work die steel and heat treatment method thereof

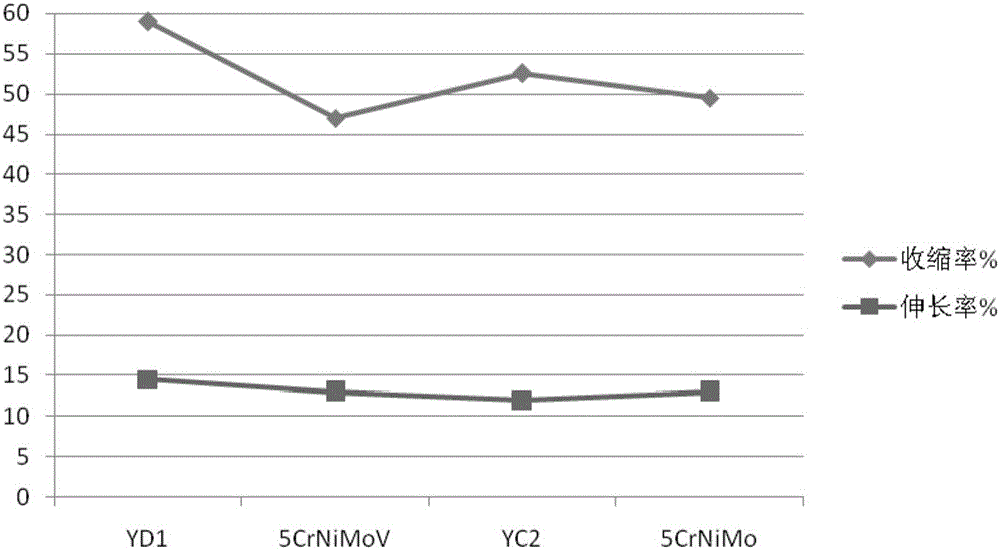

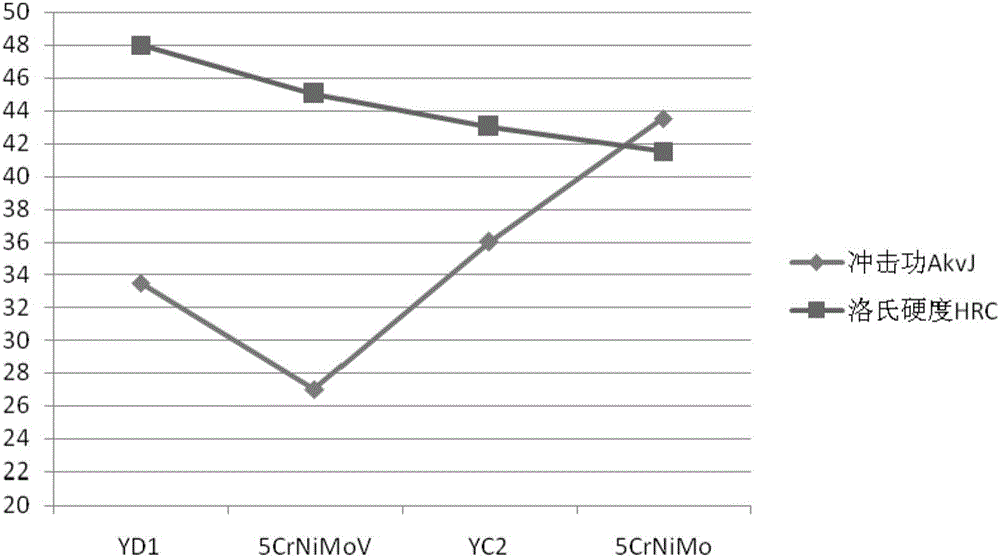

The invention provides Cr1-series hot work die steel. The Cr1-series hot work die steel is characterized by comprising, by weight, 0.40%-0.48% of C, 0.17%-0.40% of Si, 0.80%-1.20% of Mn, 0-0.020% of P, 0-0.010% of S, 0.80%-1.60% of Cr, 1.00%-1.70% of Ni, 0.80%-1.60% of Mo, 0.05%-0.30% of V, 0.010%-0.050% of Al, 0.02%-0.20% of Nb and the balance Fe. According to the chemical component formula of the novel Cr1-series hot work die steel, the material name is YD1. Compared with existing Cr1-series (5CrNiMo and 5CrNiMoV) hot work die steel, the YD1-series die steel reduces the content of carbon, the contents of the Mn and Cr are increased, the content of the Mo is greatly increased, the content of the Ni is slightly decreased, and the Nb element and Al element are added. Hence, high-temperature strength and creep resistance are improved, and toughness is also improved.

Owner:YINGKOU SPECIAL STEEL FORGING

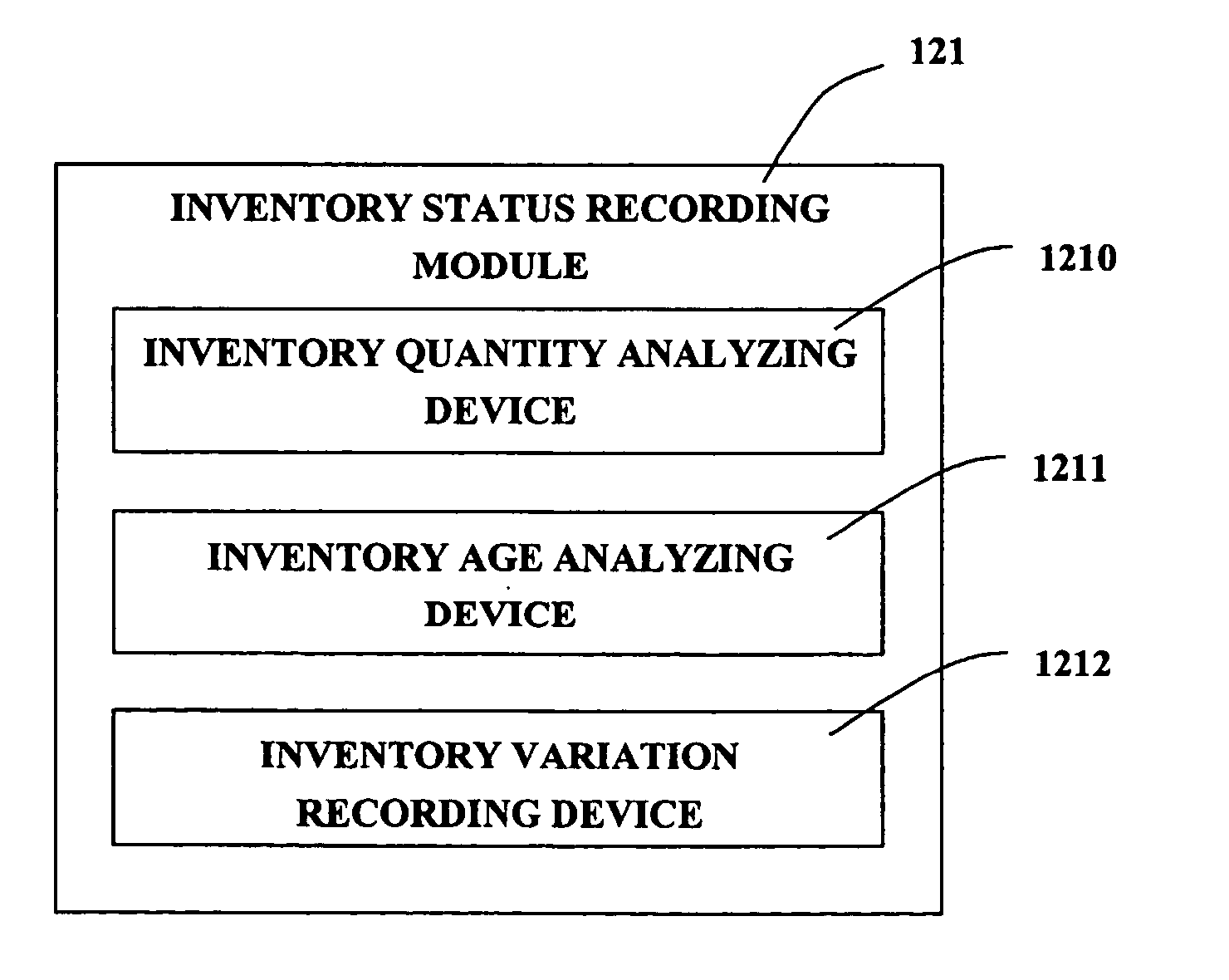

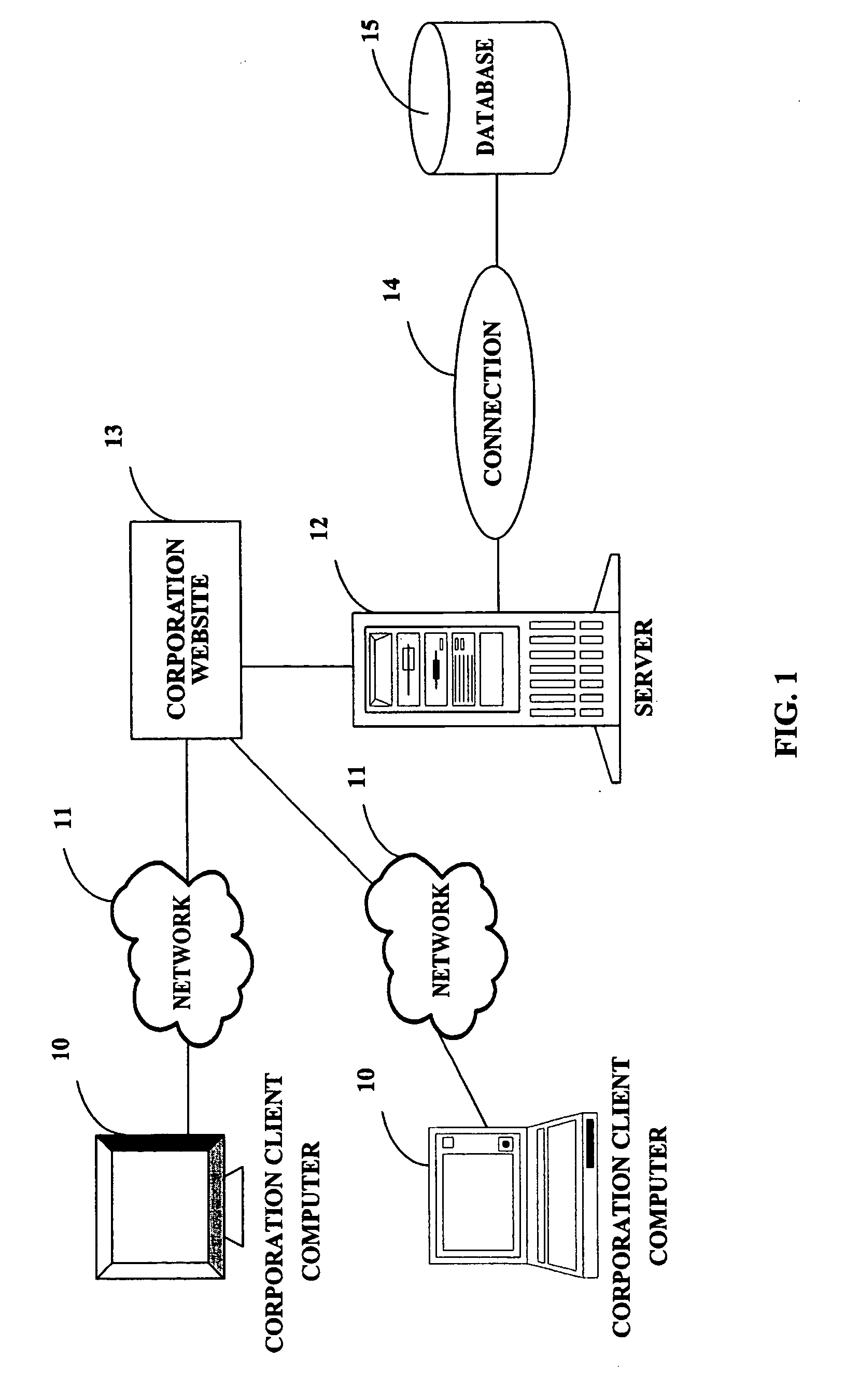

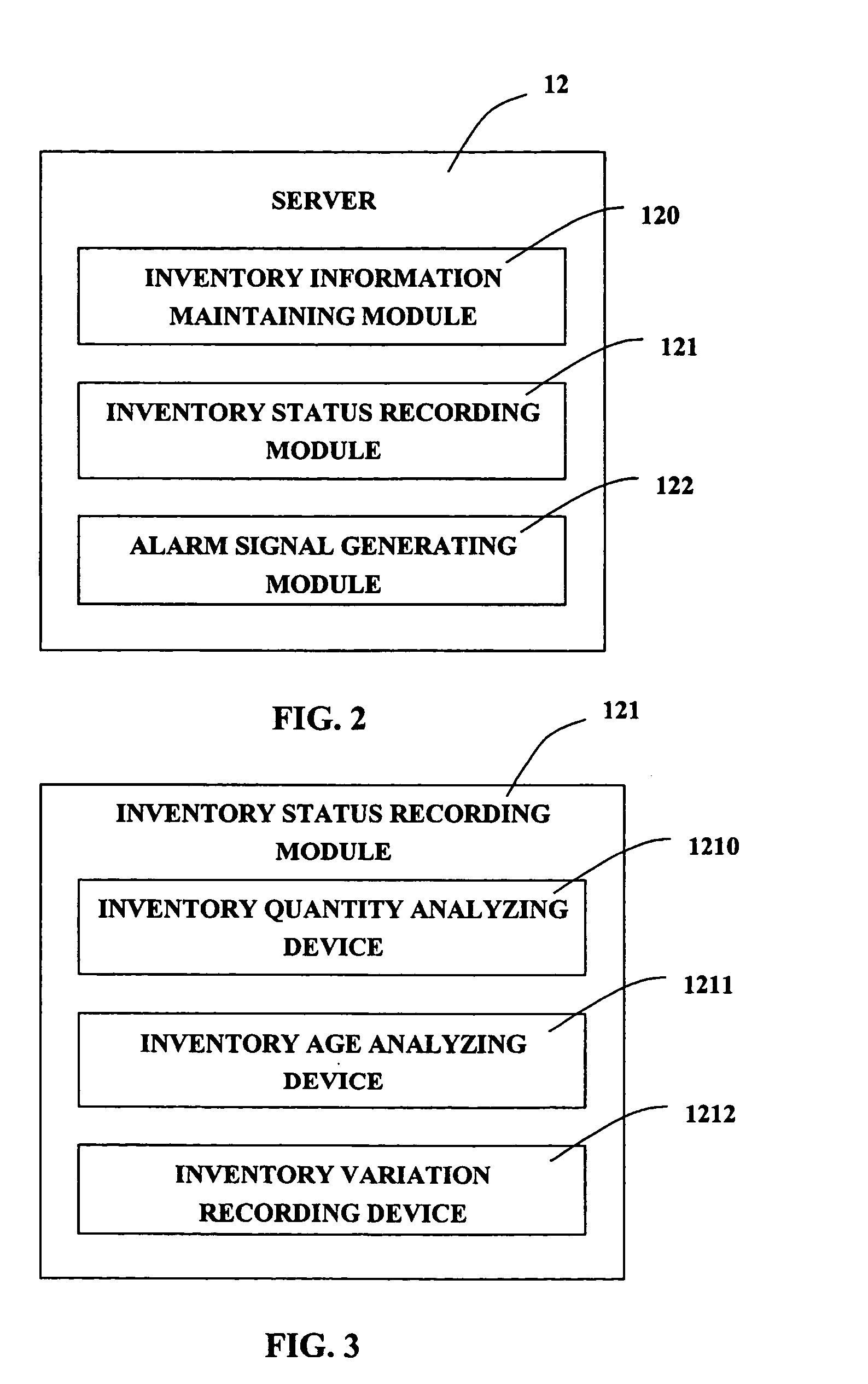

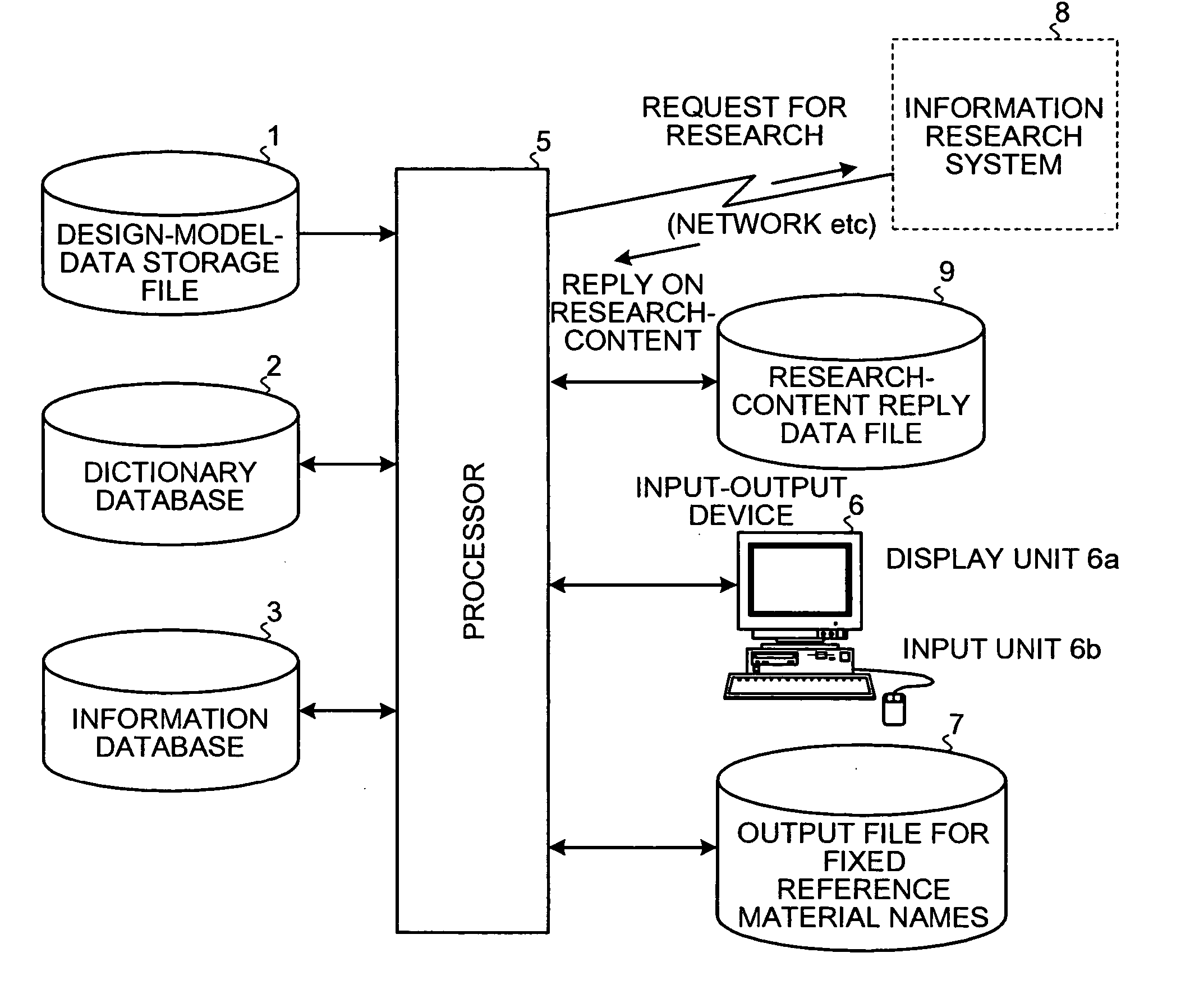

Inventory management system and method including real-time alarms

An inventory management system includes a plurality of corporation client computers (10), a corporation website (13), a server (12), and a database (15). Each corporation client computer provides an interactive user interface for user to perform inventory management. The corporation website is connected to the server, and provides an operating platform for inventory management. The server includes a plurality of function modules for timely managing inventory information, in order to control procurement operations and automatically generate alarm signals when inventory abnormalities occur. The database stores inventory information including material names, material quantities, storage locations, serial numbers for the storage locations, inventory ages, and names of suppliers. A related inventory management method is also disclosed.

Owner:HON HAI PRECISION IND CO LTD

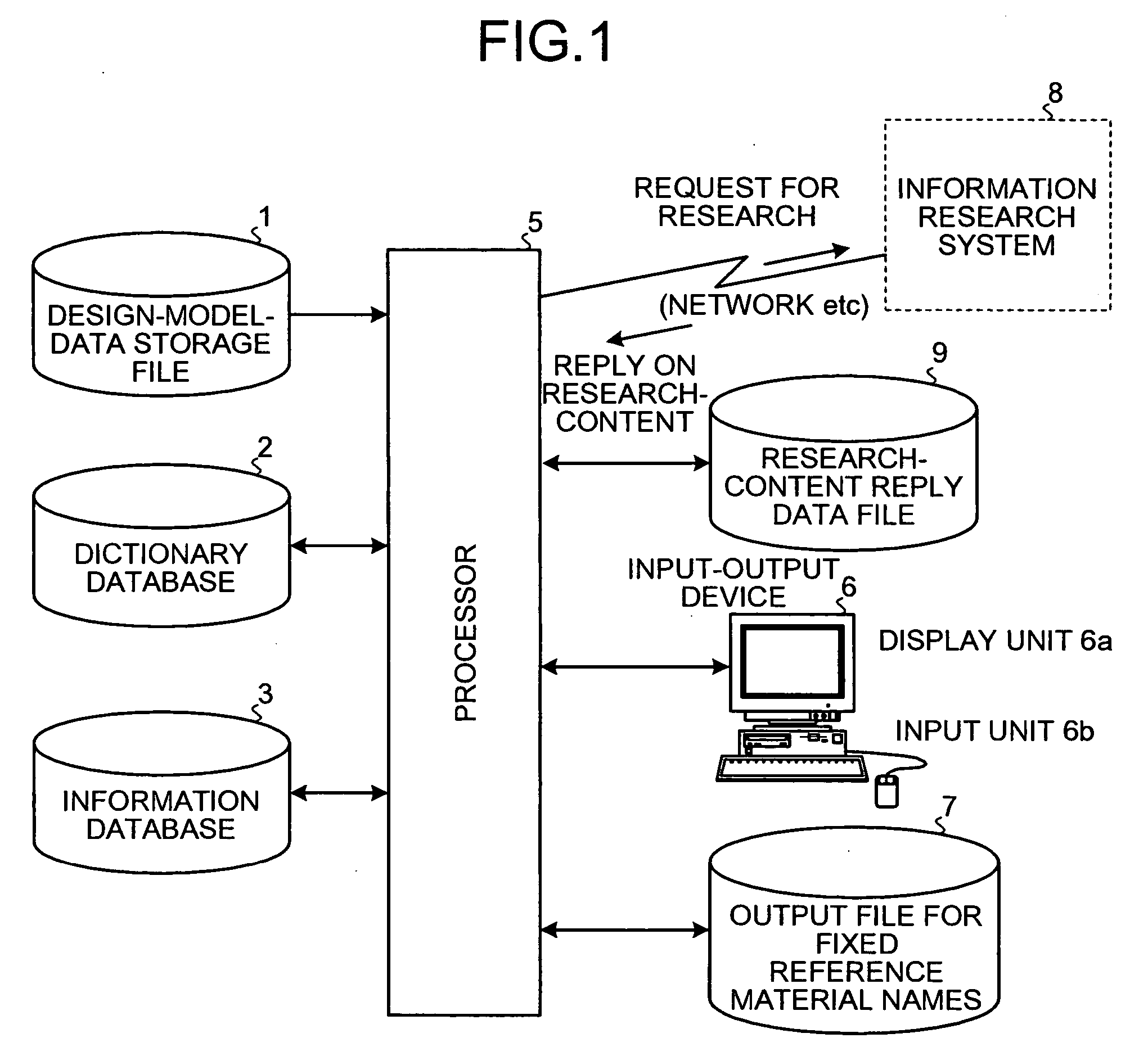

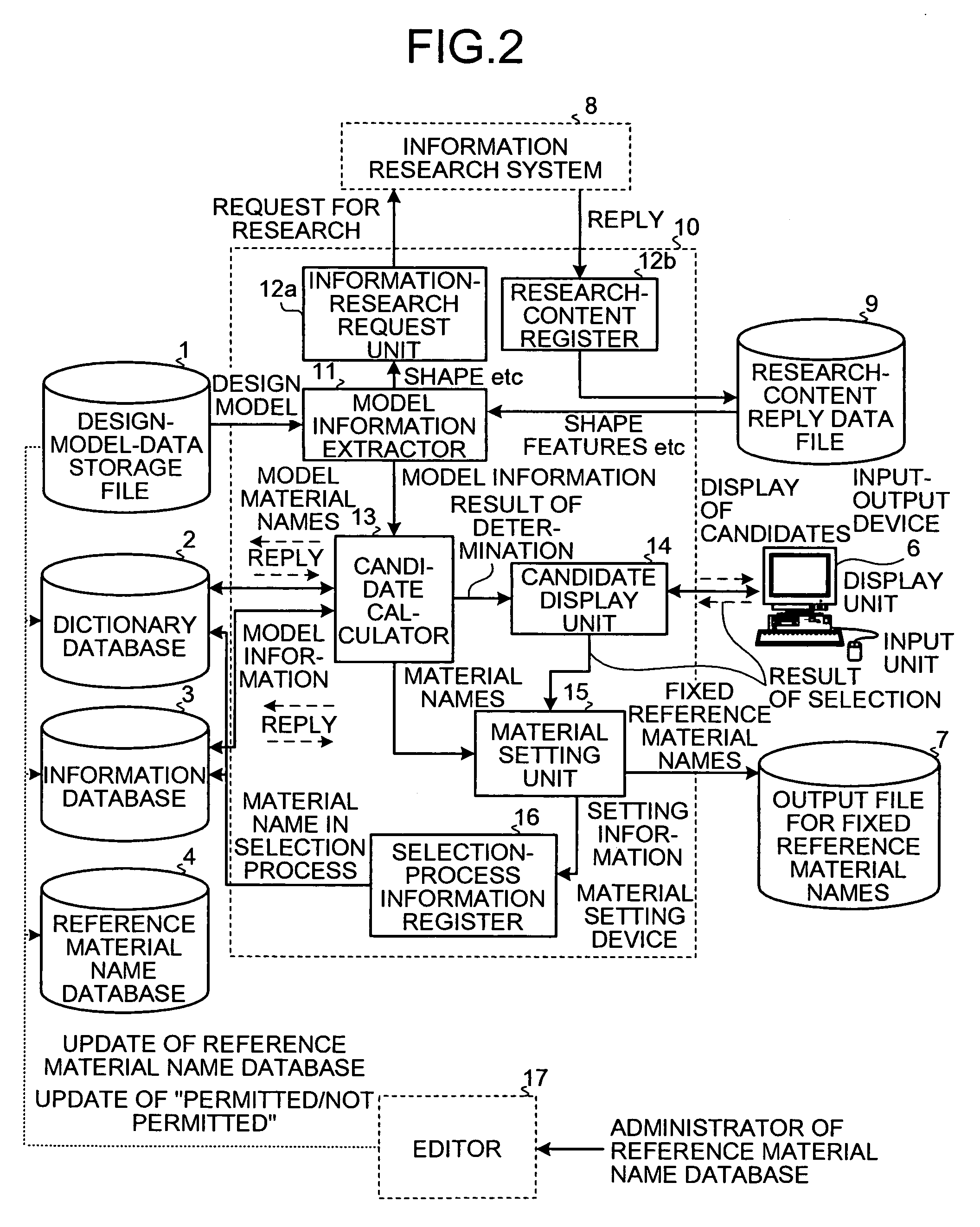

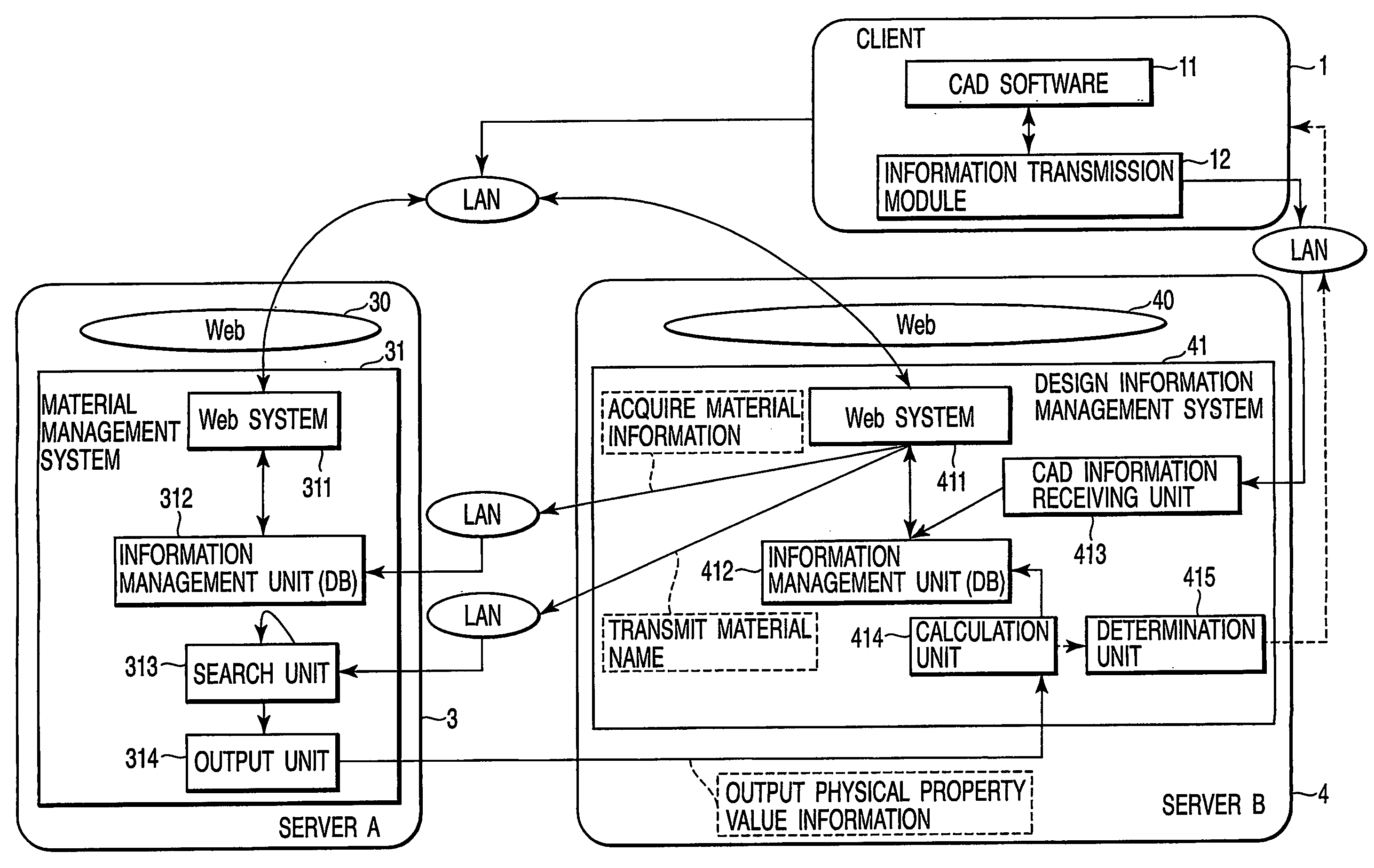

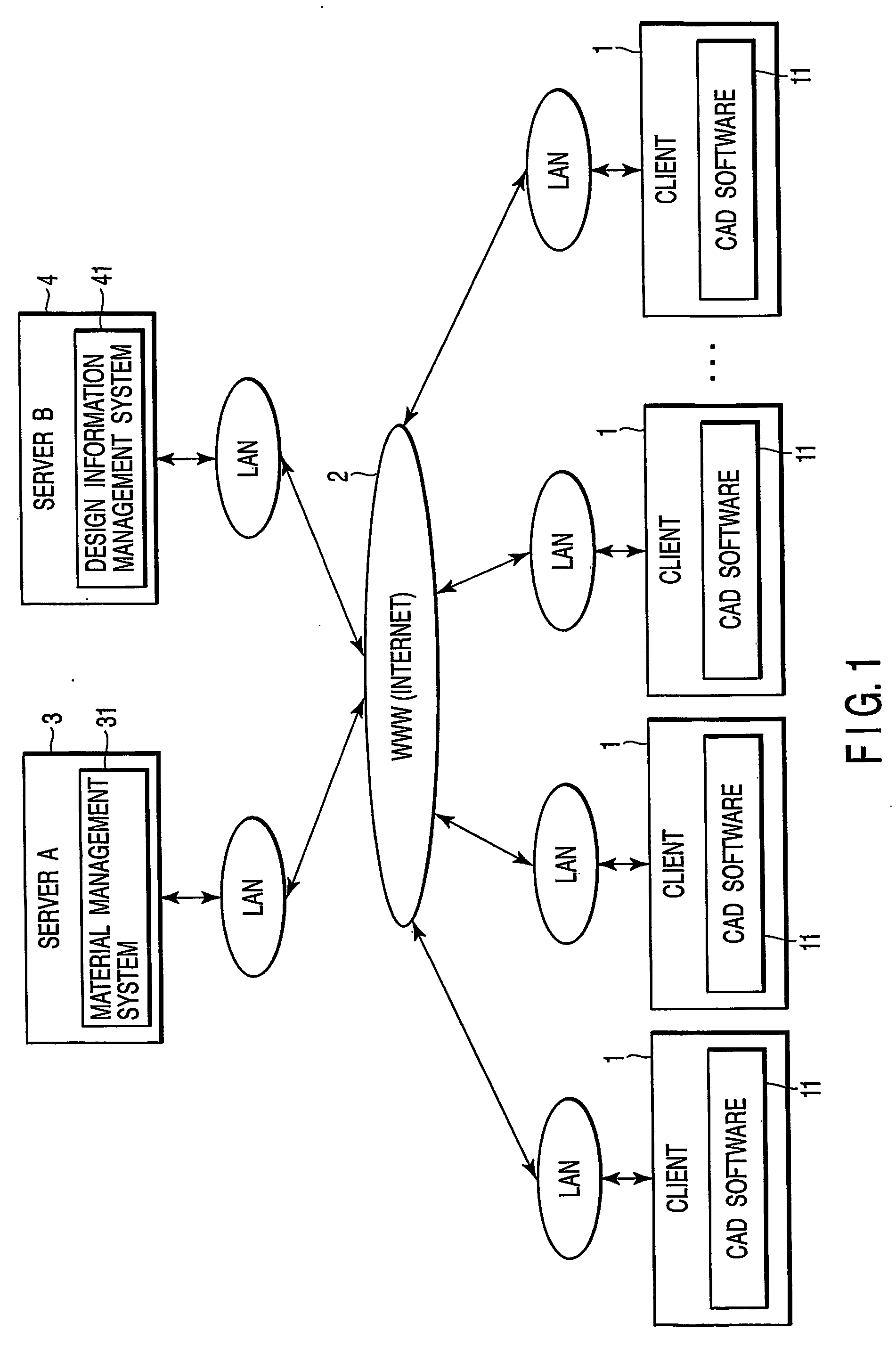

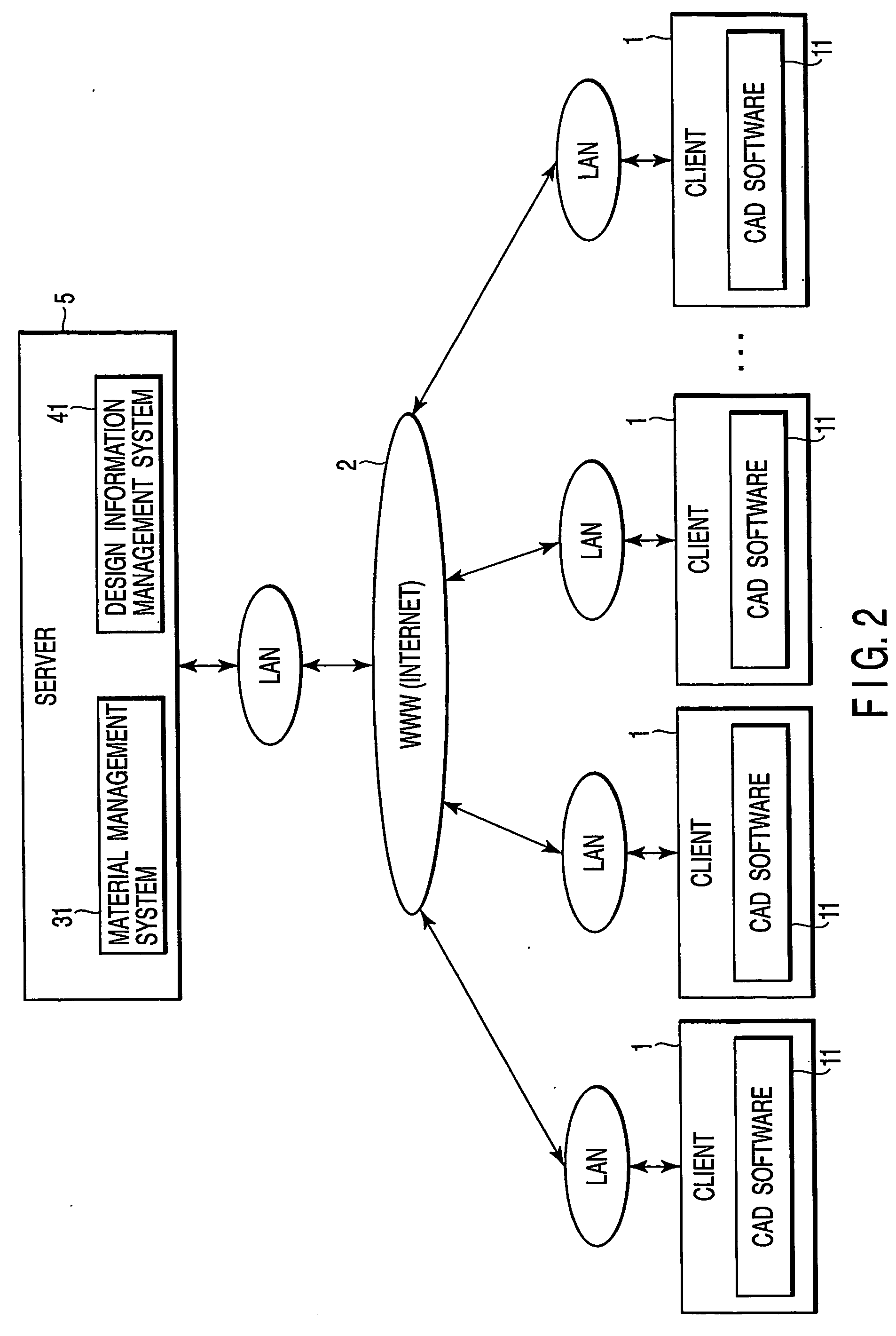

Device and method for supporting material name setting, and computer product

InactiveUS20060195419A1Solve problemsComputer aided designSpecial data processing applicationsMaterial NameDatabase

A material name and attribute information are extracted from design data, and a reference material name corresponding to the material name is searched for from a dictionary database. When a desired search result is obtained, the search result is output. When a desired reference material name is not obtained, candidates of the reference material name having the attribute information are searched in an information database, and priorities are assigned to candidates obtained through the search, to display the candidates. A user selects a reference material name from the candidates displayed based on the priorities. The processes of selecting the material name and the reference material name selected are registered in the dictionary database and the information database.

Owner:FUJITSU LTD

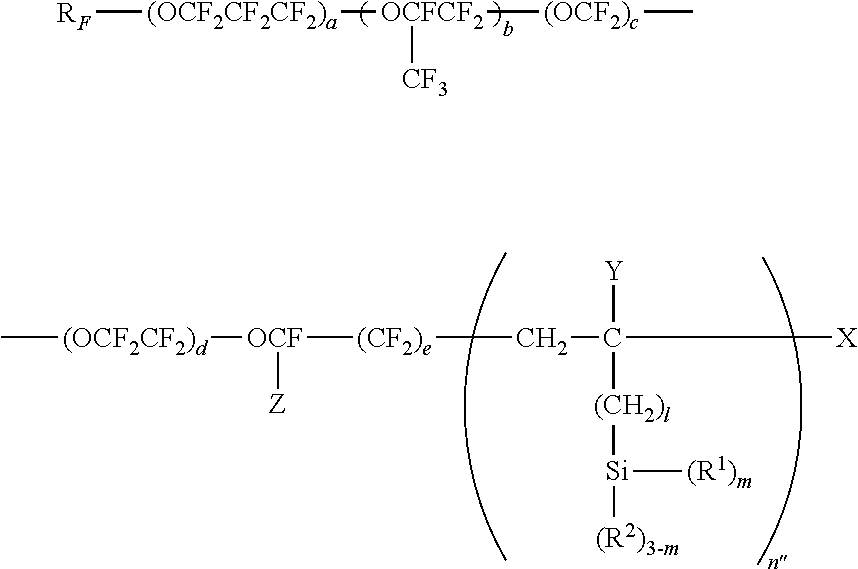

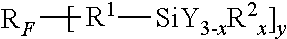

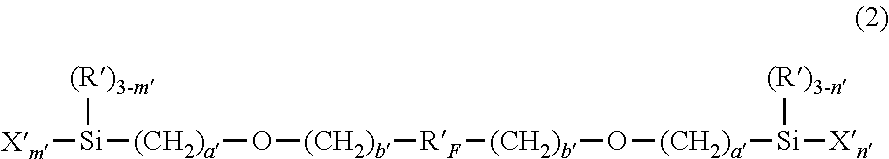

Method for the Production of an Optical Article with Improved Anti-Fouling Properties

ActiveUS20150361279A1Lower surface energyAntifouling/underwater paintsSynthetic resin layered productsSilanesFluoride

Method for the manufacture of an optical article comprising the following steps:—providing a substrate having two main faces and bearing —OH functions on at least one of its faces,—successively exposing in this order one face of the substrate bearing —OH functions to at least 3 distinct materials named M1, M2, M3 and optionally material M4 in a vacuum chamber under conditions resulting in the deposit of those materials on the surface of the substrate, and wherein:—M1 is a substituted silane comprising at least one function X1 directly bonded to a Si atom of the substituted silane, wherein the Si—X1 group is capable of forming a covalent bond with a OH group of the substrate, X1 being preferably a hydrolysable group (such a —NH2 group) or a —OH group directly bonded to the silicon atom and comprising at least one fluorine containing group,—M2 is a substituted silane of number average molecular weight inferior or equal to 900 g / mol comprising at least one function X2 directly bonded to a silicon atom of said substituted silane wherein the Si—X2 group is capable of forming a covalent bond with a —OH group of the substrate and / or a covalent bond with M1, X2 being preferably a hydrolysable group (such a —NH2 group) or a OH group and at least one hydrophobic or oleophobic group, or at least one hydrophilic group,—Wherein M1 has a weight average molecular weight higher than M2 and the difference between M1 and M2 weight average molecular weights is equal to or higher than 600 g / mol, preferably equal to or higher than 900 g / mol.—M3 is a metal fluoride,—Optional M4 is a non fluorinated metal oxide or metal hydroxide.

Owner:ESSILOR INT CIE GEN DOPTIQUE

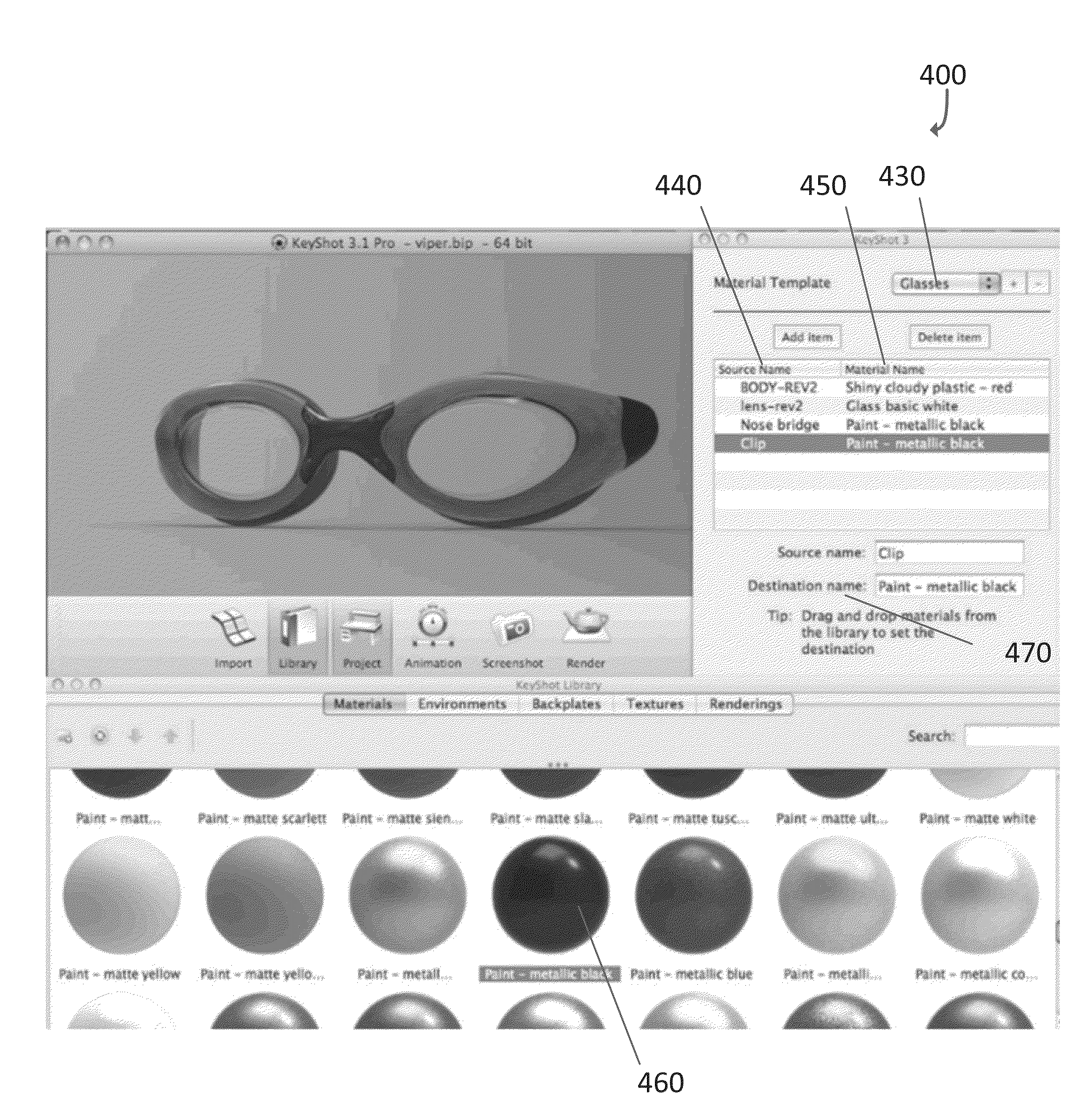

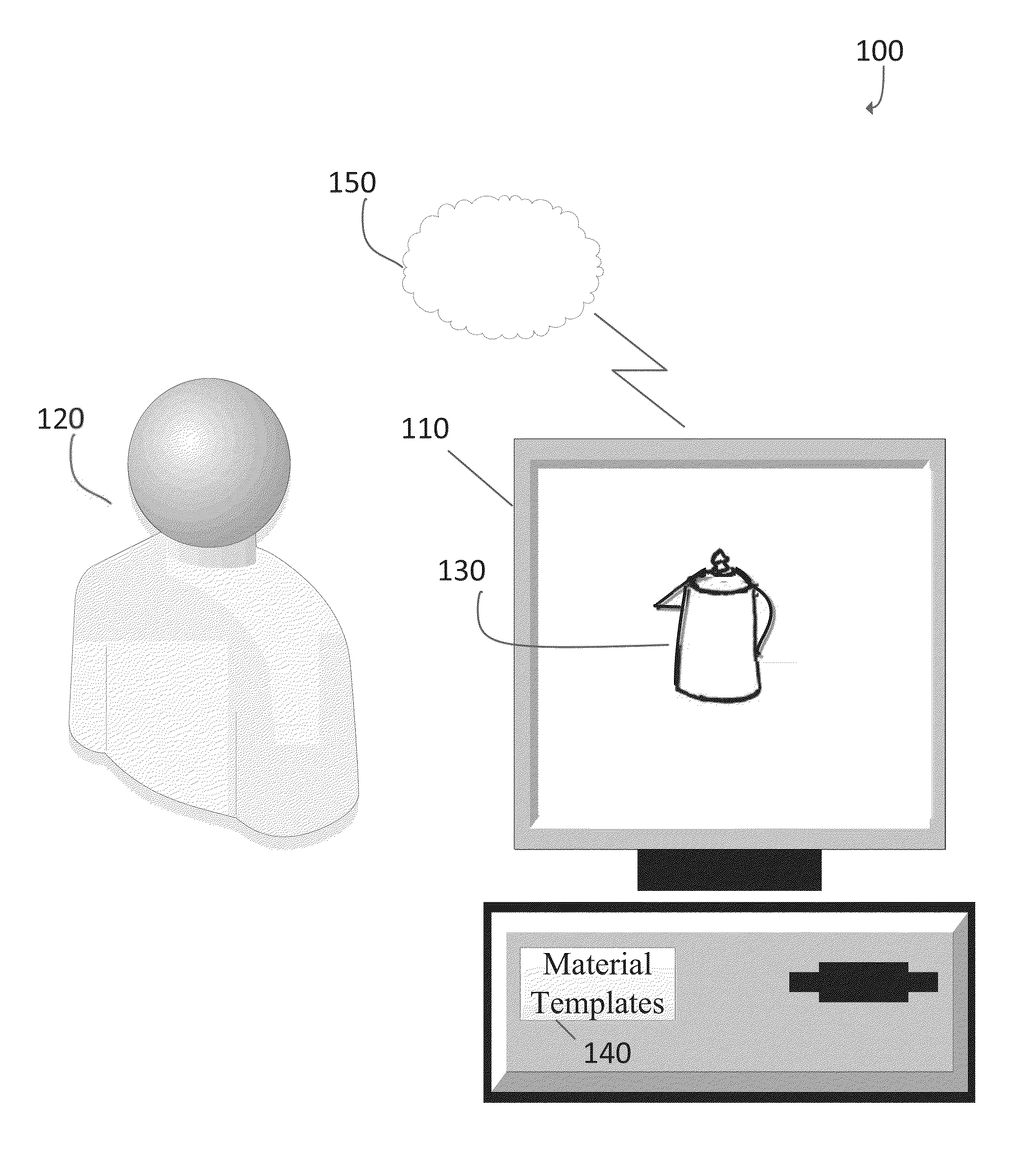

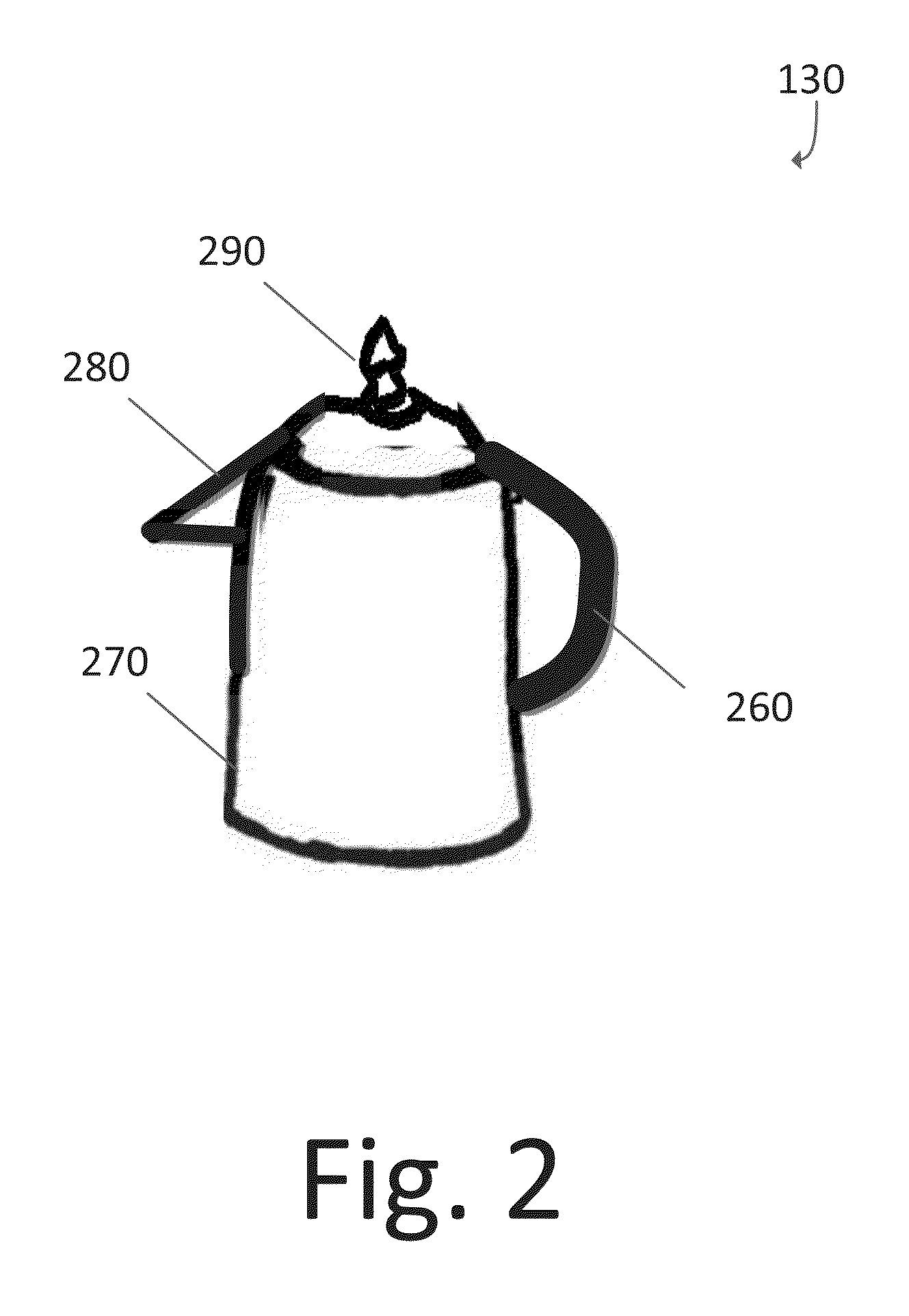

Material templates for automatic assignment of materials to a 3D cad model

ActiveUS20130231768A1More accuracyTedious and time-consumeGeometric CADTotal factory controlComputer scienceMaterial Name

The present invention relates to a system, method, and apparatus that include a novel way of automatically assigning materials to 3D CAD models. A predefined material template specifies that a particular part or material name is assigned to a particular material such that all instances of the particular part name are assigned or modified automatically by the material template. By having a consistent naming convention for the parts in the CAD file, this material assignment can be performed automatically when the CAD file is imported or viewed.

Owner:LUXION INC

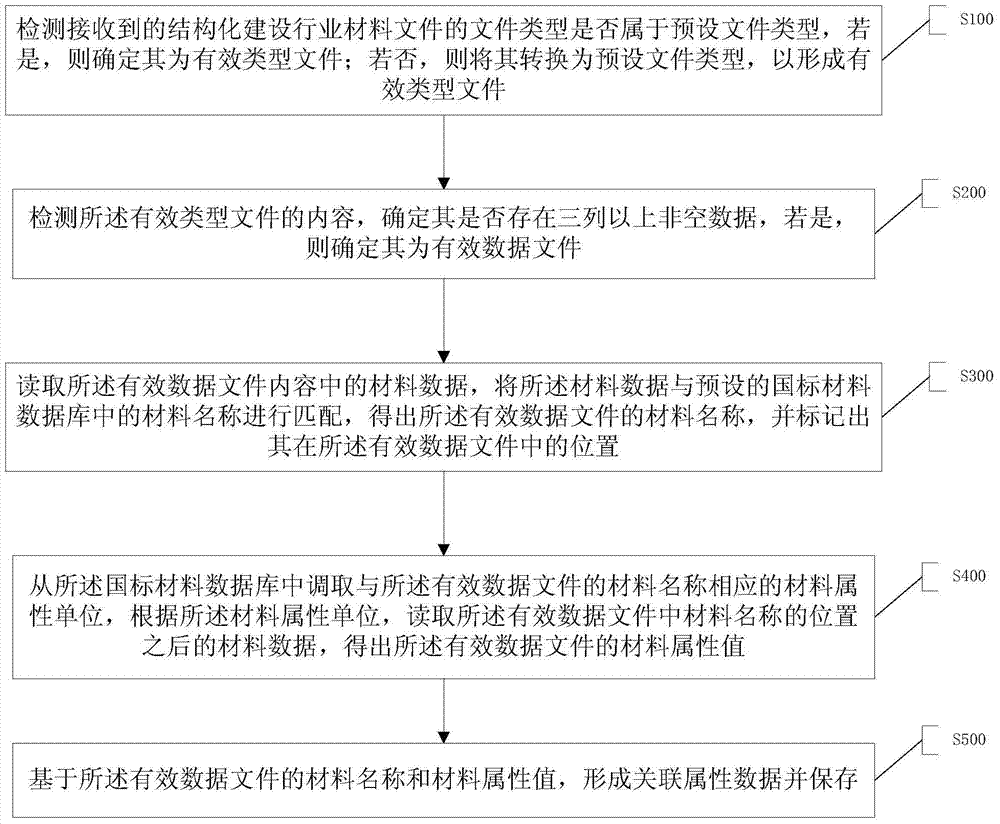

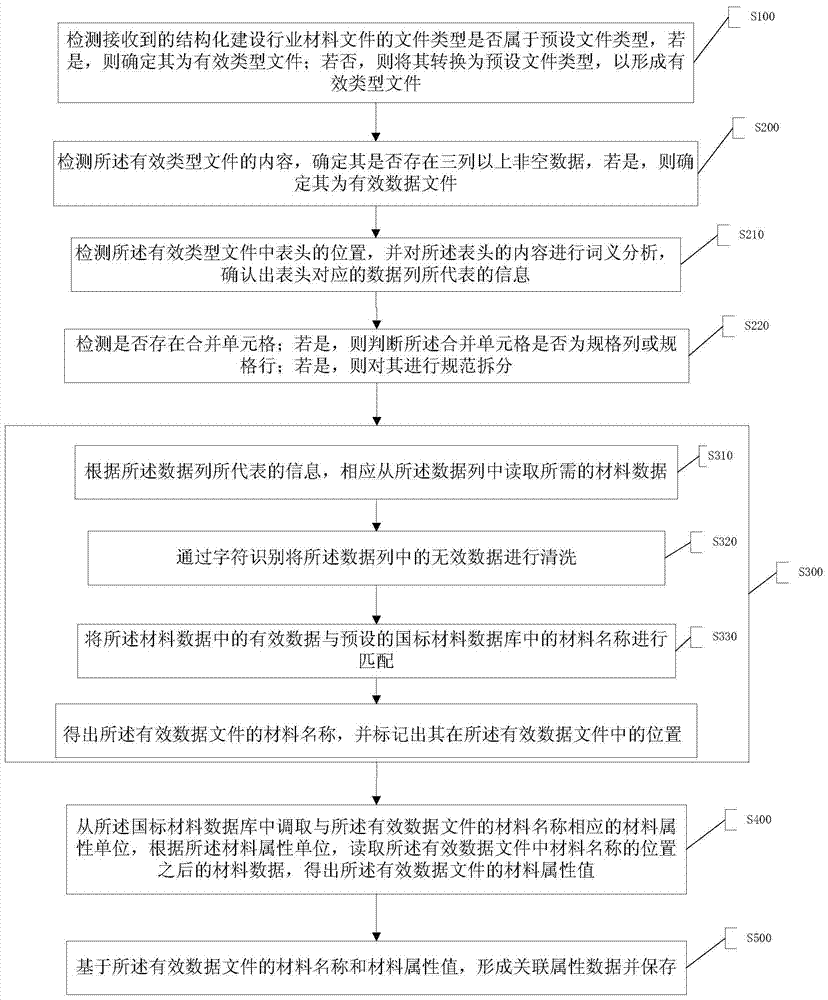

Identity management method for material files and material data of structure construction industry

ActiveCN104715359AAchieve accurate identificationImprove recognition efficiencyOffice automationOperational costsData file

The invention relates to an identity management method for material files and material data of the structure construction industry. According to the method, file type detection and conversion are performed on the material files of the structure construction industry, and effective type files are determined, so that the obtained files can be processed according to a unified way; the effective type files are detected, and effective data files are determined, so that efficiency of subsequent identity and management is improved; material names and material attribute values of the effective data files are identified from the effective data files by utilizing a preset national standard material database, so that accurate identity of the material data is realized; associate attribute data is formed by the material names and the material attribute values, subsequent query and use are facilitated, and the efficiency and accuracy of query and use are improved favorably. According to the identity management method, the identity and management of the material files and material data are finished automatically without relying on manual operation too much, the work efficiency can be improved greatly, and the operation cost is obviously lowered.

Owner:广东中建普联科技股份有限公司

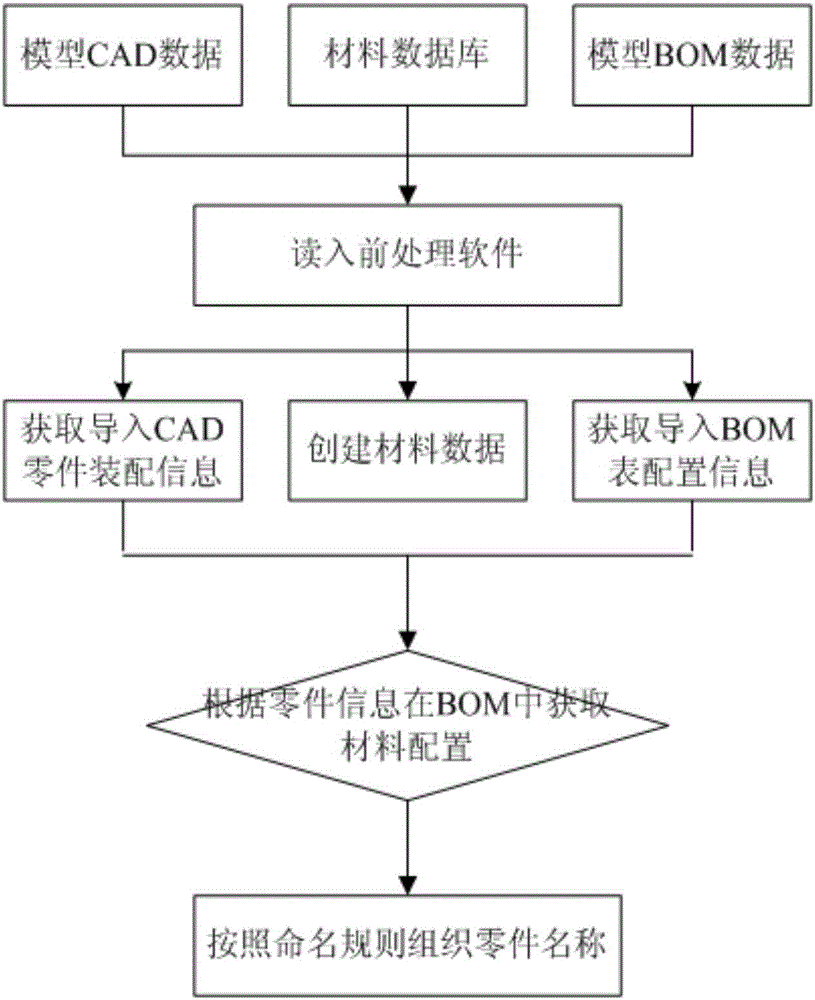

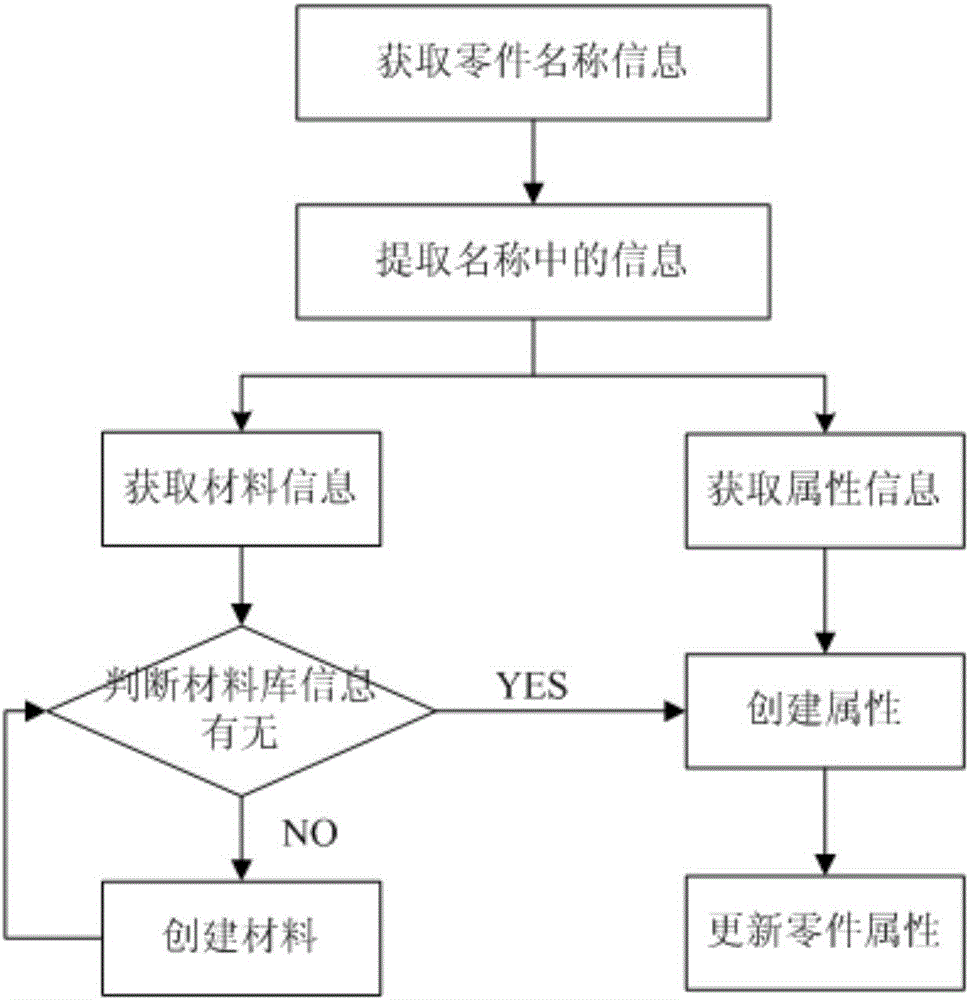

Modeling method for structural finite element model

InactiveCN106682336AShorten the production cycleEmbodies the theory of computational mechanicsDesign optimisation/simulationSpecial data processing applicationsElement modelModel method

The invention relates to the field of computer simulation technologies and especially relates to a modeling method for a structural finite element model. The method comprises the steps that data is normalized; an organization manner of geometric models input into universal pre-processing is arranged, and computer assistant design CAD parts are named according to the rule that each part name is composed of three part including a part name, a material name and attribute information; model part attributes are updated; and according to the name manner of the model part names at the first step as well as the information contained in the part names, the information in the part names can be obtained, and corresponding materials and attributes can be established. According to the invention, a finite element simulation method is used, so analysis and prediction can be conducted in advance before actual processing of the parts; the parts does not need separate manual processing; modeling processes are optimized; simulation efficiency is increased; production duration of the parts is reduced; and production cost is reduced.

Owner:上海波客实业有限公司

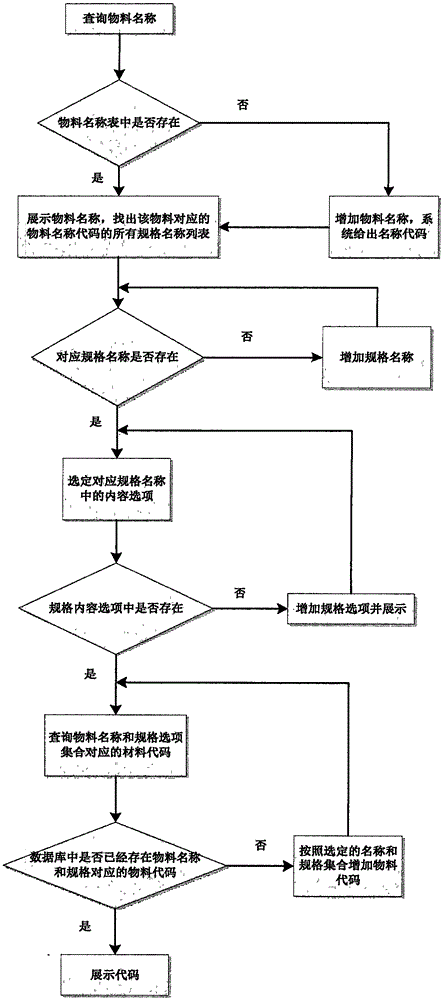

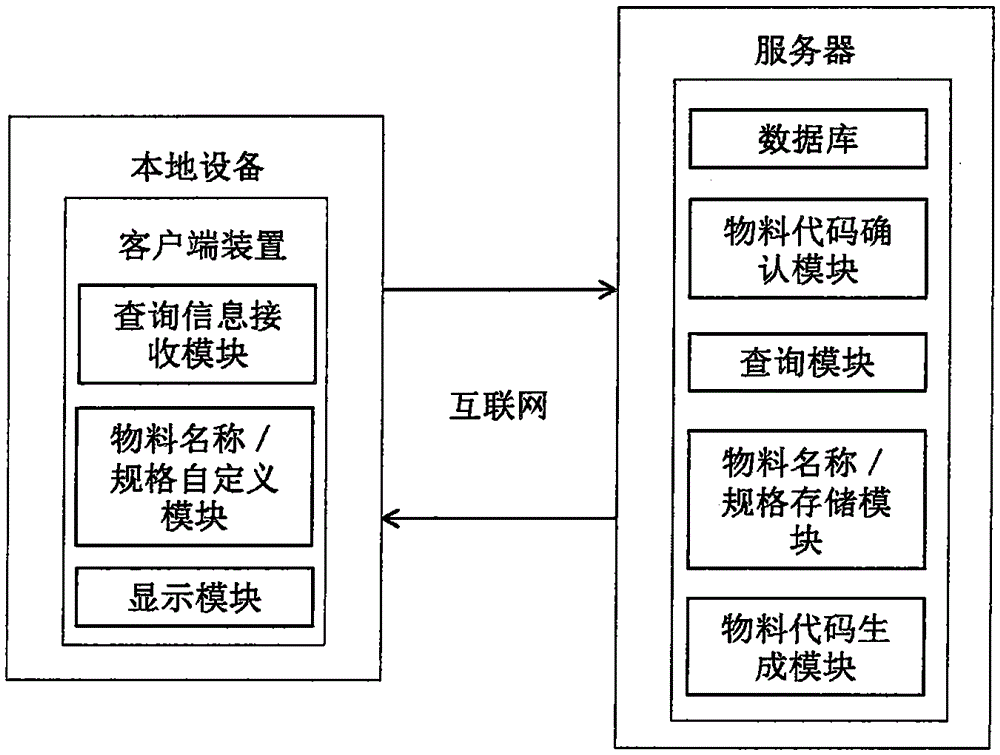

Universal material code writing method suitable for enterprise material management

The invention discloses a universal material code writing method suitable for enterprise material management. The method comprises the steps of performing a query by using material names and material specifications, and querying whether the material names and the material specifications are all existent in a database or not according to the material names and the material specifications input by a user; when the database does not store the material names and / or the material specifications, self-defining the material names and / or the material specifications and corresponding material name codes and / or material specification codes by the user, and returning the self-defined material names and / or material specifications and corresponding material name codes and / or material specification codes to the database for performing storage; and combining the material name codes with the material specification codes to obtain material codes. Through the method, the user can add the material codes in the database when the material codes need to be used, so that the technical problems of heavy work, low efficiency and definition solidification of conventional material code pre-definition are avoided.

Owner:魏毅 +1

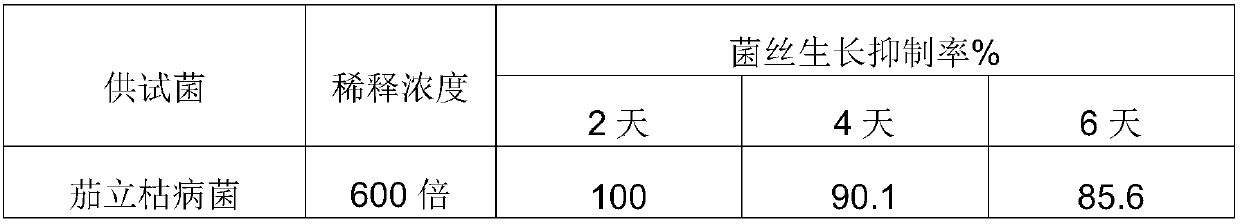

A botanical fungicide and a preparing method thereof

A botanical fungicide and a preparing method thereof are disclosed. The fungicide includes 5-10 parts of matrine, 8-15 parts of an alcohol extract of sisal hemp leaves, 1-5 parts of a material named as Chinese characters 'Xiaochaihujian' by the inventor, 1-5 parts of arecoline and 10-20 parts of a water extract of artemisia annua. The matrine, the alcohol extract of sisal hemp leaves, the 'Xiaochaihujian', the arecoline, and the water extract of artemisia annua are composited into the efficient wide-spectrum nontoxic fungicide. The fungicide has good antagonistic effects on a plurality of germs, and has advantages of a high efficiency, a low cost, capability of being environmentally friendly, difficult generation of drug resistance, and no harm to humans and livestock.

Owner:HAINAN UNIVERSITY

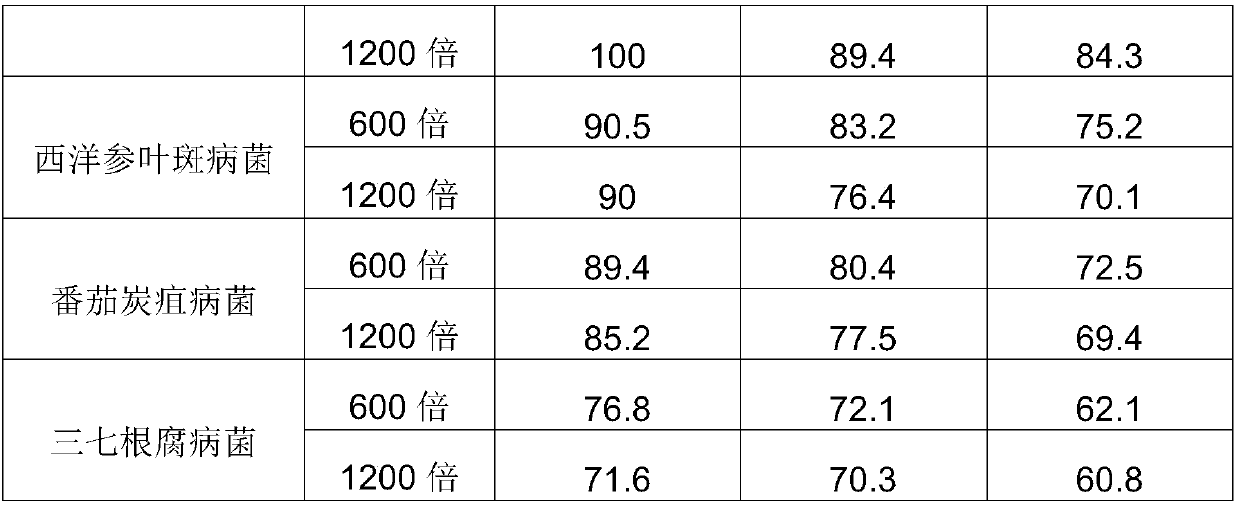

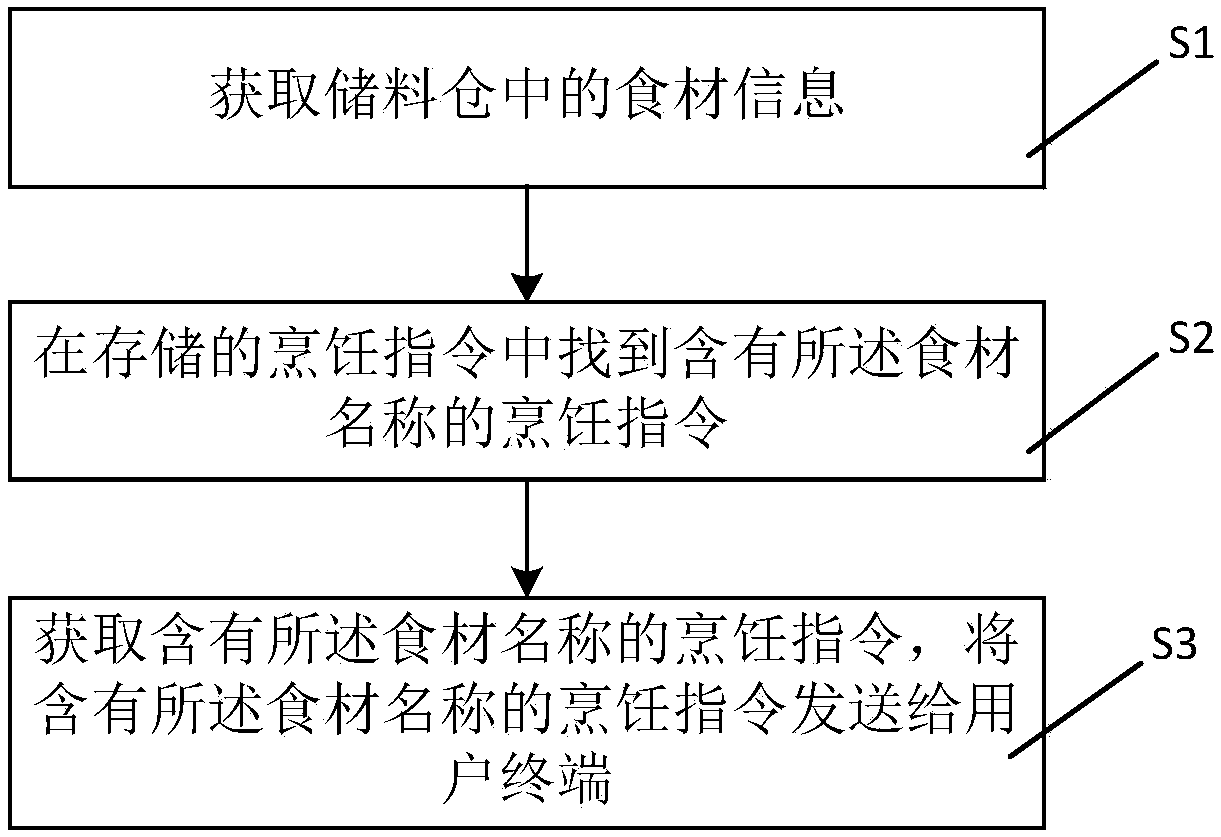

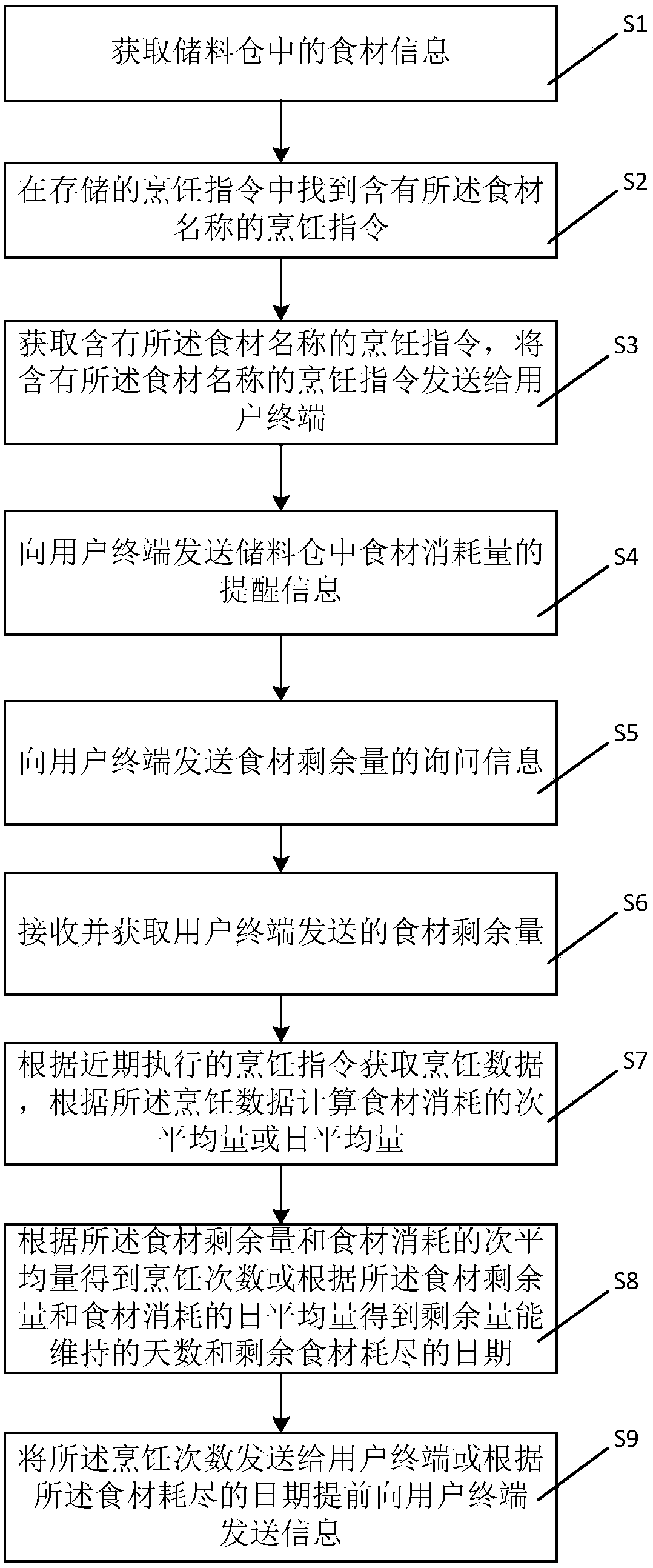

Intelligent electric rice cooker, cooking command recommending method of intelligent electric rice cooker, and medium

The invention discloses a cooking command recommending method of an intelligent electric rice cooker. The intelligent electric rice cooker includes a plurality of storage bins. The cooking command recommending method includes the following steps: acquiring the food material information in the storage bins, wherein the foot material information includes the food material names; finding cooking commands containing the food material names in the stored cooking commands; and acquiring the cooking commands containing the food material names, and sending the cooking commands containing the food material names to a user terminal. The cooking command recommending method of the intelligent electric rice cooker has the advantages of intelligently searching the matched cooking commands correspondingto the foot material names from the food materials stored in the storage bins according to the food materials stored in the storage bins, and recommending the selectable cooking commands to the user terminal, thus being convenient to enable the user to know the food material situation in the storage bins, and reasonably selecting the cooking commands according to the food material situation.

Owner:重庆羽狐科技有限公司

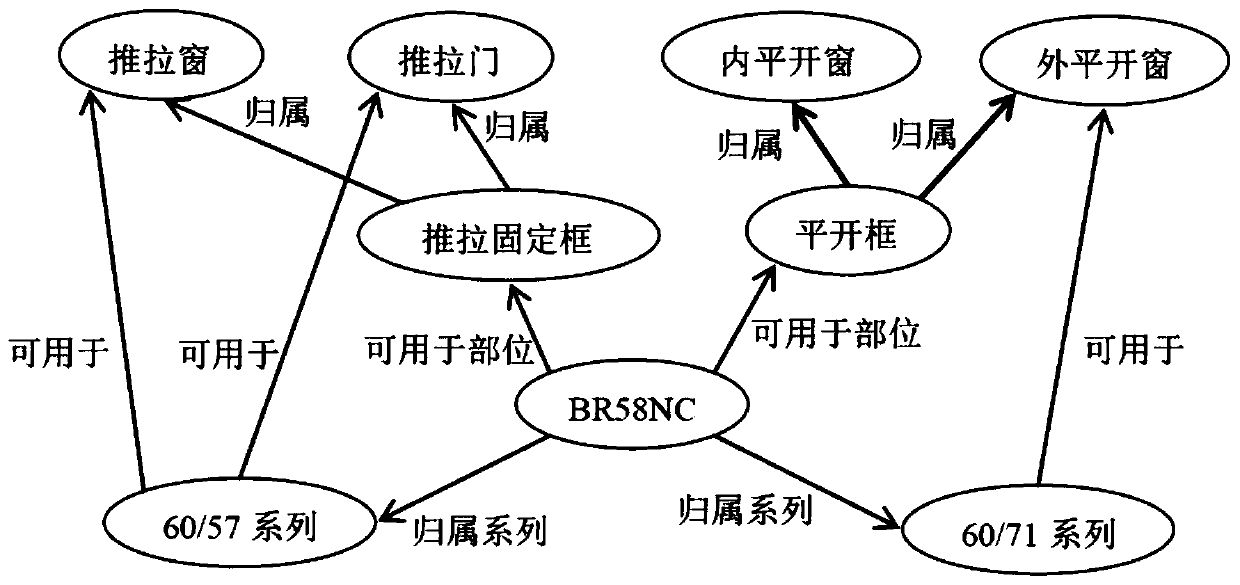

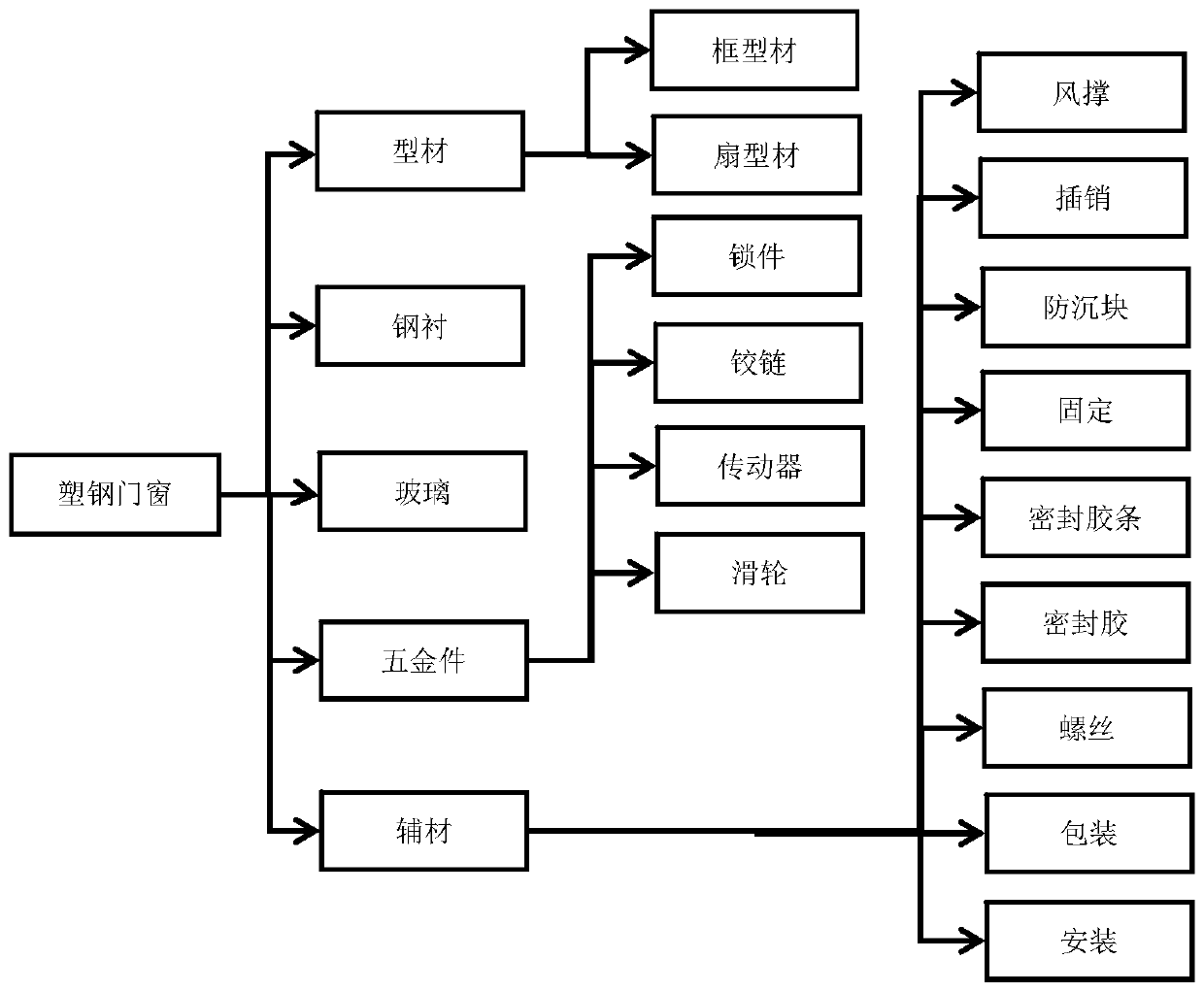

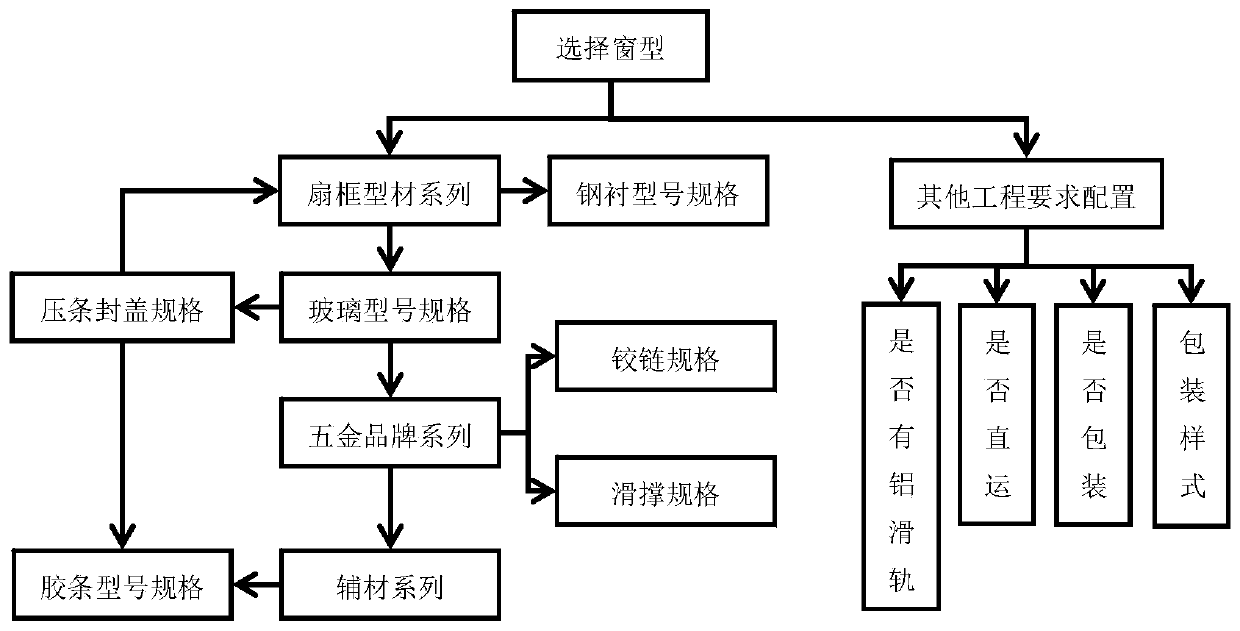

Door and window customization material information rapid configuration method, system and device and medium

ActiveCN110334939AOptimize the configuration processImprove maintenance efficiencyBuying/selling/leasing transactionsResourcesSoftware engineeringKnowledge graph

The invention discloses a door and window customized material information rapid configuration method, system and device and a medium. The method comprises: constructing a knowledge graph for all typesof doors and windows in a unified mode; analyzing each part of the door and window in the knowledge graph, and then constructing an incidence relation constraint model; receiving an input query statement, and searching a corresponding query result from the knowledge graph; outputting the query result as a to-be-configured material name; and a configuration step: receiving the input configurationinformation about the to-be-configured material, and completing the configuration of the door and window material information.

Owner:UNIV OF JINAN

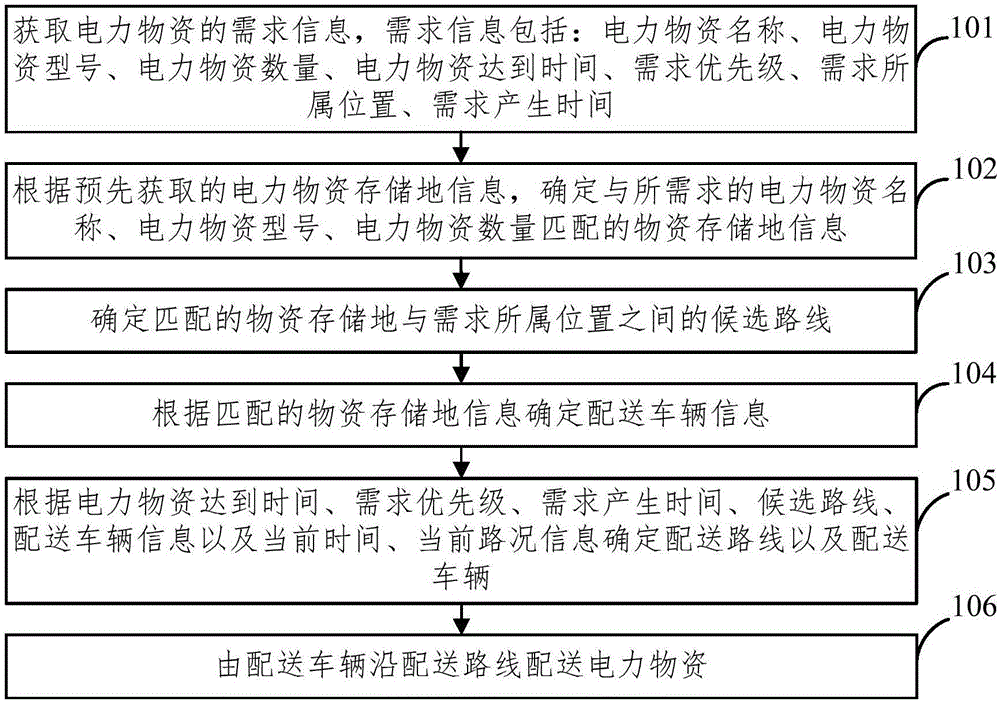

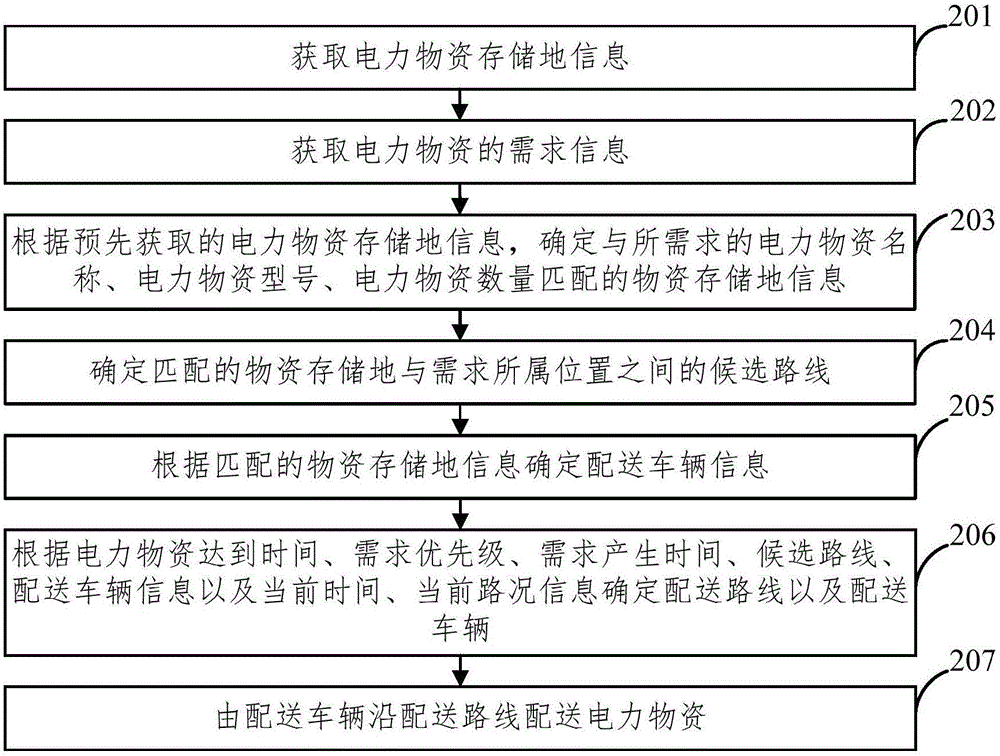

Power material dispensing method

InactiveCN106408234AConvenience guaranteedLogisticsInformation technology support systemElectric power systemEngineering

The invention discloses a power material dispensing method and belongs to the technical field of power systems. The method includes the steps of obtaining demand information of power materials, determining the material storage place information matching with the power material names, models and quantities according to the power material storage place information obtained in advance, determining candidate paths between the matched material storage places and demanding positions, determining the dispensing vehicle information according to the matched material storage place information, determining the dispensing path and dispensing vehicles according to the power material arriving time, demanding priority, demand generation time, the candidate paths, dispensing vehicle information and current time and current road condition information, and the dispensing vehicles dispensing the power materials along the dispensing path. The dispensing path and dispensing vehicles are determined according to the power material demanding information, matched material storage place information, the candidate paths, the dispensing vehicle information and current time and current road condition information to ensure optimal dispensing path and dispensing vehicles.

Owner:STATE GRID CORP OF CHINA +1

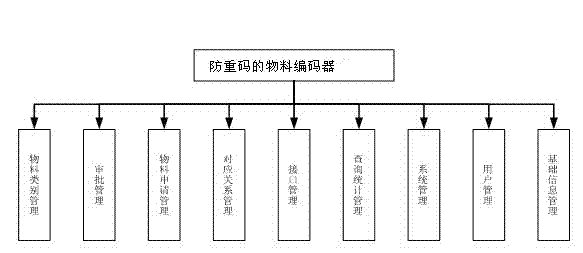

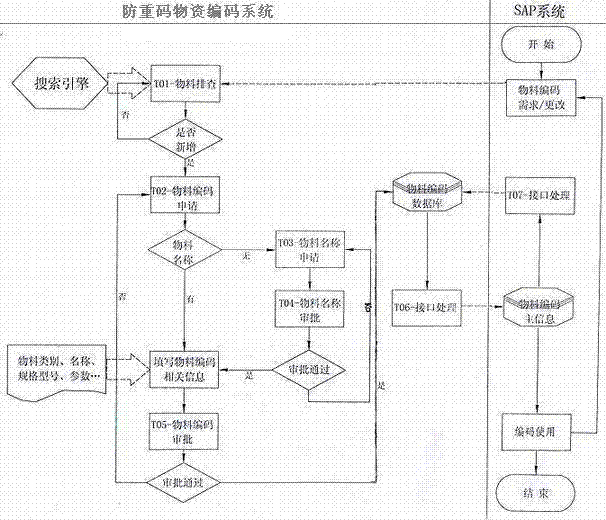

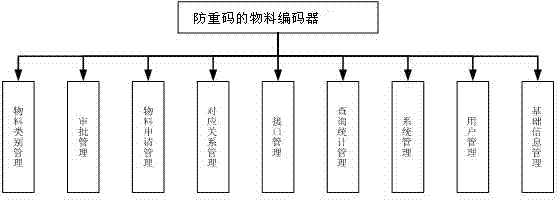

Anti-coincident-code material encoder

InactiveCN102446300AAvoid duplicationImprove management levelInstrumentsSystems managementLibrary science

The invention relates to an anti-coincident-code material encoder, which belongs to the technical field of material purchase and inventory information management. According to the technical scheme, the material encoder comprises the following functional modules: (1) a material category management module for managing size and name classification data related to a material; (2) an approval management module for providing management on approval operation of application of a material name and a material code; (3) a material application management module for providing application function of the material name and the material code for a code applicant; (4) a correspondence management module for maintaining various correspondences in a handling process of material code application; (5) an interface management module; (6) a query statistical management module; (7) a system management module for configuring various necessary parameters for system running; (8) a basic information management module; and (9) a user management module. The material encoder has the beneficial effects of performing information management on the material, avoiding coincident code of the material, improving management level, reducing overstock and lowering cost.

Owner:TANGSHAN IRON & STEEL GROUP +1

Material templates for automatic assignment of materials to a 3D CAD model

ActiveUS9043007B2Tedious and time-consumeQuick changeGeometric CADTotal factory controlComputer scienceMaterial Name

The present invention relates to a system, method, and apparatus that include a novel way of automatically assigning materials to 3D CAD models. A predefined material template specifies that a particular part or material name is assigned to a particular material such that all instances of the particular part name are assigned or modified automatically by the material template. By having a consistent naming convention for the parts in the CAD file, this material assignment can be performed automatically when the CAD file is imported or viewed.

Owner:LUXION INC

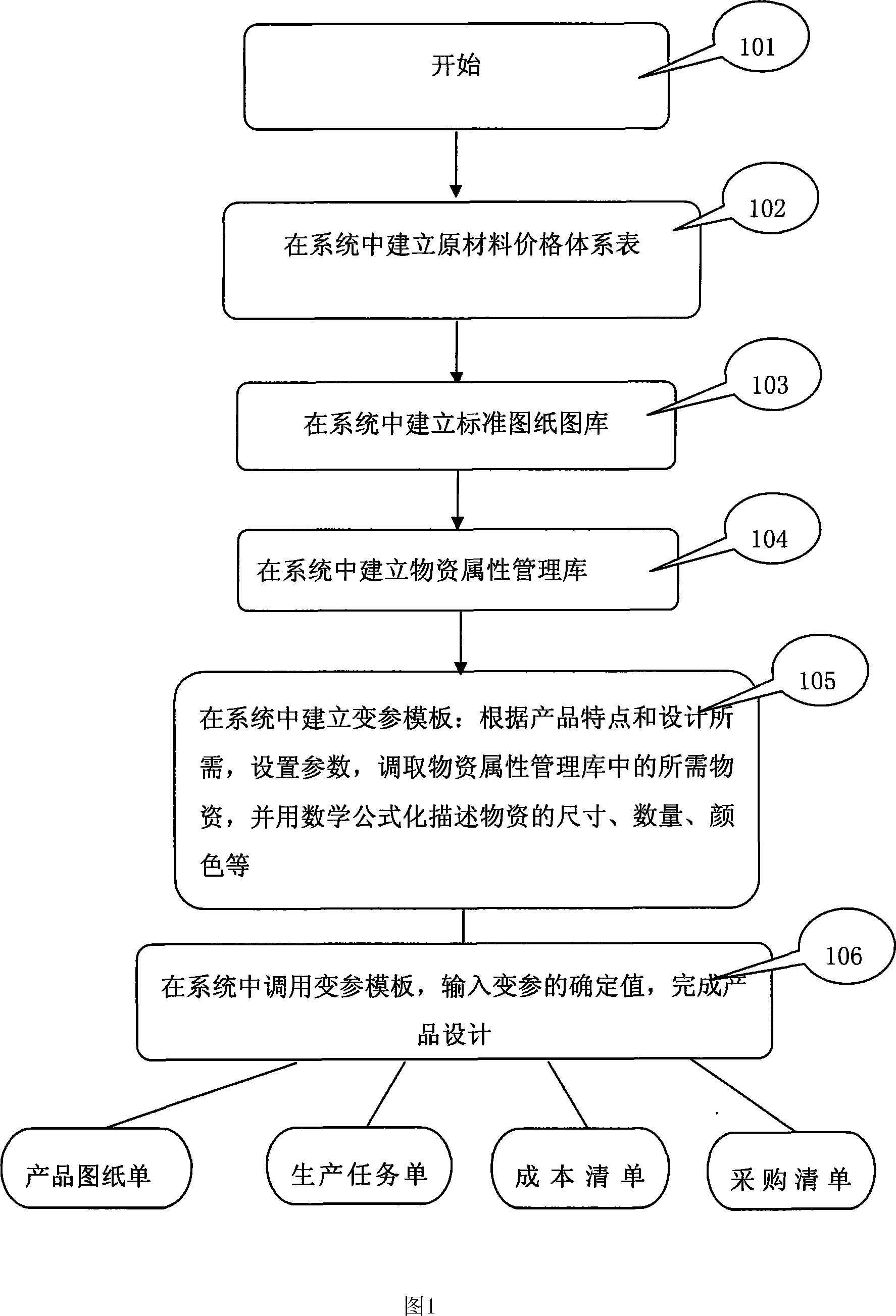

Method for parametrizing goods shelf product design

This invention provides to a kind of parameter type shelf product design method, includes the following steps: builds material price system table in the system; builds standard drawing gallery, included the drawing information of each material, distributes to different material drawing number, builds material attribute manage bank, included material drawing number, material name, stock next process flow direction, material price and process cost, the said material attribute has variable parameter; builds variable module in the system: sets the parameter according to the product's character and the design request, takes the material in the said material attribute manage bank, describes the size, amount, color and other information of the material requested; gets the variable module, inputs the variable parameter's define value, finishes the design of the product, and build the shelf product drawing, the produce task list, the cost list and the stock list. The method can leave out a lot of simple repeated jobs, it is fast, correct, convenience and utility.

Owner:南京音飞货架有限公司

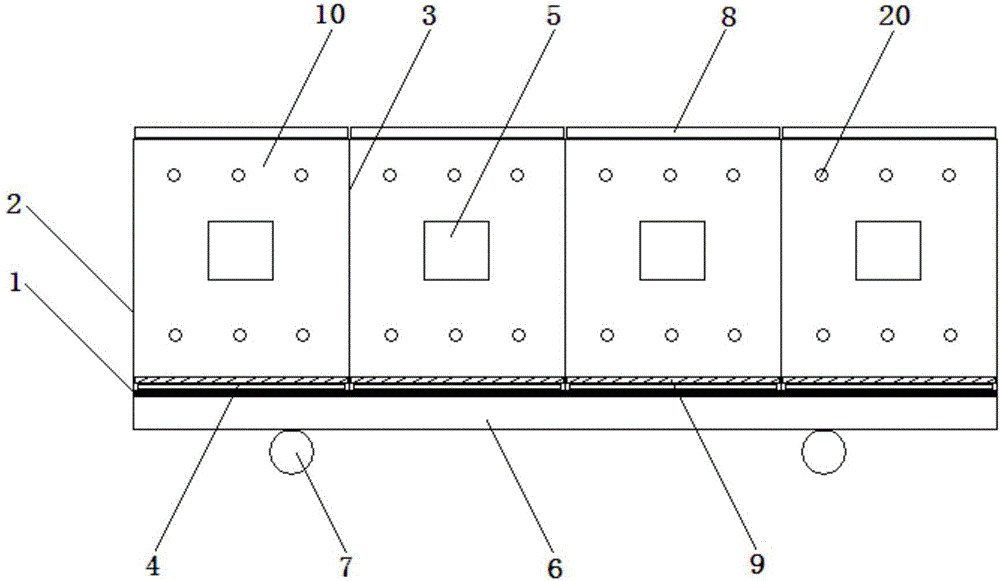

Automobile part storage cabinet

InactiveCN106005850AEfficient managementAvoid miscalculationsStorage devicesDisplay deviceEngineering

The invention discloses an automobile part storage cabinet which comprises a bottom plate, hoarding plates perpendicularly arranged at the periphery of the bottom plate and a plurality of partition plates perpendicularly arranged on the bottom plate, wherein by virtue of the plurality of the partition plates, a hollow accommodating cavity defined by the hoarding plates and the bottom plate is divided into a plurality of storage accommodating cavities used for storing automobile parts; a weighing sensor and a display are separately arranged on the bottom plate and the hoarding plates, which correspond to each accommodating cavity; each weighing sensor is connected to the corresponding display through a micro processor; and each micro processor is used for displaying material name and a material number on the display by calculating the material number according to the material name and unit weight of each storage accommodating cavity. The invention provides the automobile part storage cabinet which is compact in structure, convenient to dismount, easy to manufacture, safe and reliable, and strong in practicability; and the automobile part storage cabinet realizes efficient management on automobile parts, avoids occurrence of phenomena such as miscounting or counting missing, is strong in intuition and is convenient for looking up.

Owner:KUNSHAN YIBANGTAI AUTO PART MFG CO LTD

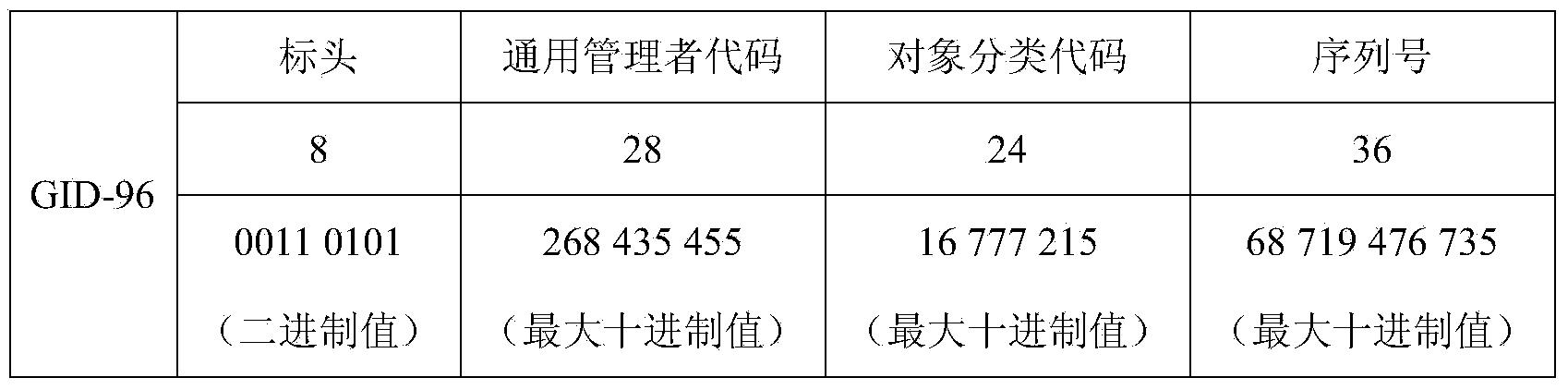

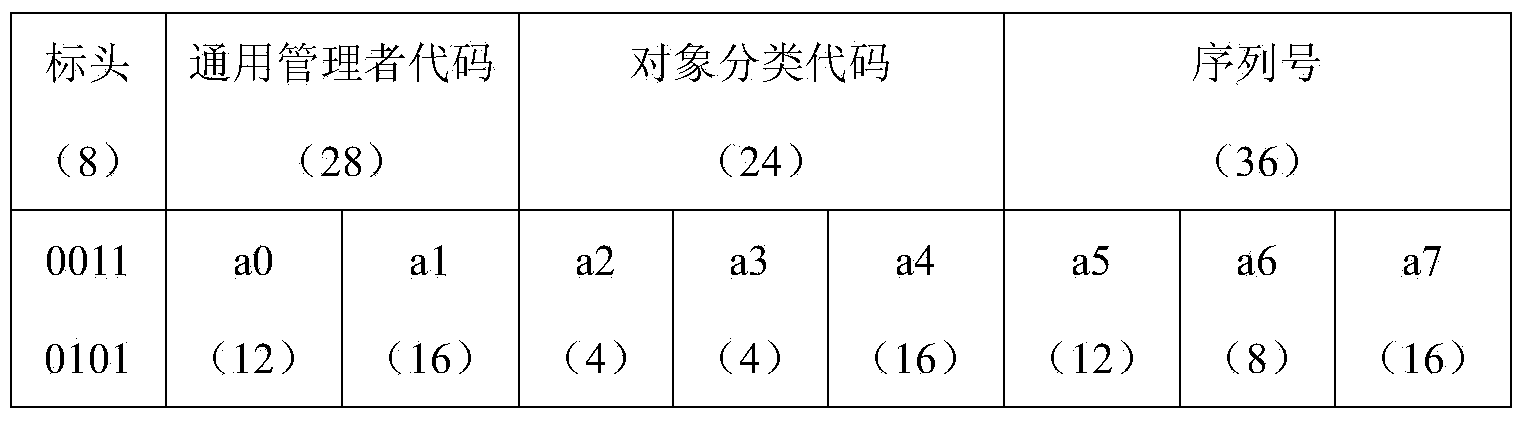

Storing and tracing method for plantation management information of TCM (Traditional Chinese Medicine) decoction pieces

InactiveCN103810567APromote innovationResourcesRecord carriers used with machinesPlant factoryComputer terminal

The invention discloses a storing and tracing method for the plantation management information of TCM (Traditional Chinese Medicine) decoction pieces. The method comprises the steps of obtaining the plantation management information of the TCM decoction pieces; storing the plantation management information of the TCM decoction pieces through RFID (Radio Frequency Identification Devices) radio frequency tags, wherein the radio frequency tags comprise the following fields: the identification field of medicinal material planting factories, the identification field of medicinal materials, the identification field of medicinal material planting fields, the identification field of medicinal material planting dates and the identification field of medicinal material names; scanning the RFID radio frequency tags by a mobile terminal, and reading the plantation management information. According to the storing and tracing method for the plantation management information of the decoction pieces provided by the invention, on the basis of an EPC (Electronic Product Code) coding standard specification stipulated by GS1, RFID (Radio Frequency Identification Devices) is applied to a TCM decoction pieces plantation process in a pioneering way, so that the method is better in innovation.

Owner:NANJING HAICHANG CHINESE MEDICINE GRPCO LTD +1

Universal material code writing method suitable for enterprise material management

The invention discloses a universal material code writing method suitable for enterprise material management. The method comprises the steps of performing a query by using material names and material specifications, and querying whether the material names and the material specifications are all existent in a database or not according to the material names and the material specifications input by a user; when the database does not store the material names and / or the material specifications, self-defining the material names and / or the material specifications and corresponding material name codes and / or material specification codes by the user, and returning the self-defined material names and / or material specifications and corresponding material name codes and / or material specification codes to the database for performing storage; and combining the material name codes with the material specification codes to obtain material codes. Through the method, the user can add the material codes in the database when the material codes need to be used, so that the technical problems of heavy work, low efficiency and definition solidification of conventional material code pre-definition are avoided.

Owner:魏毅 +1

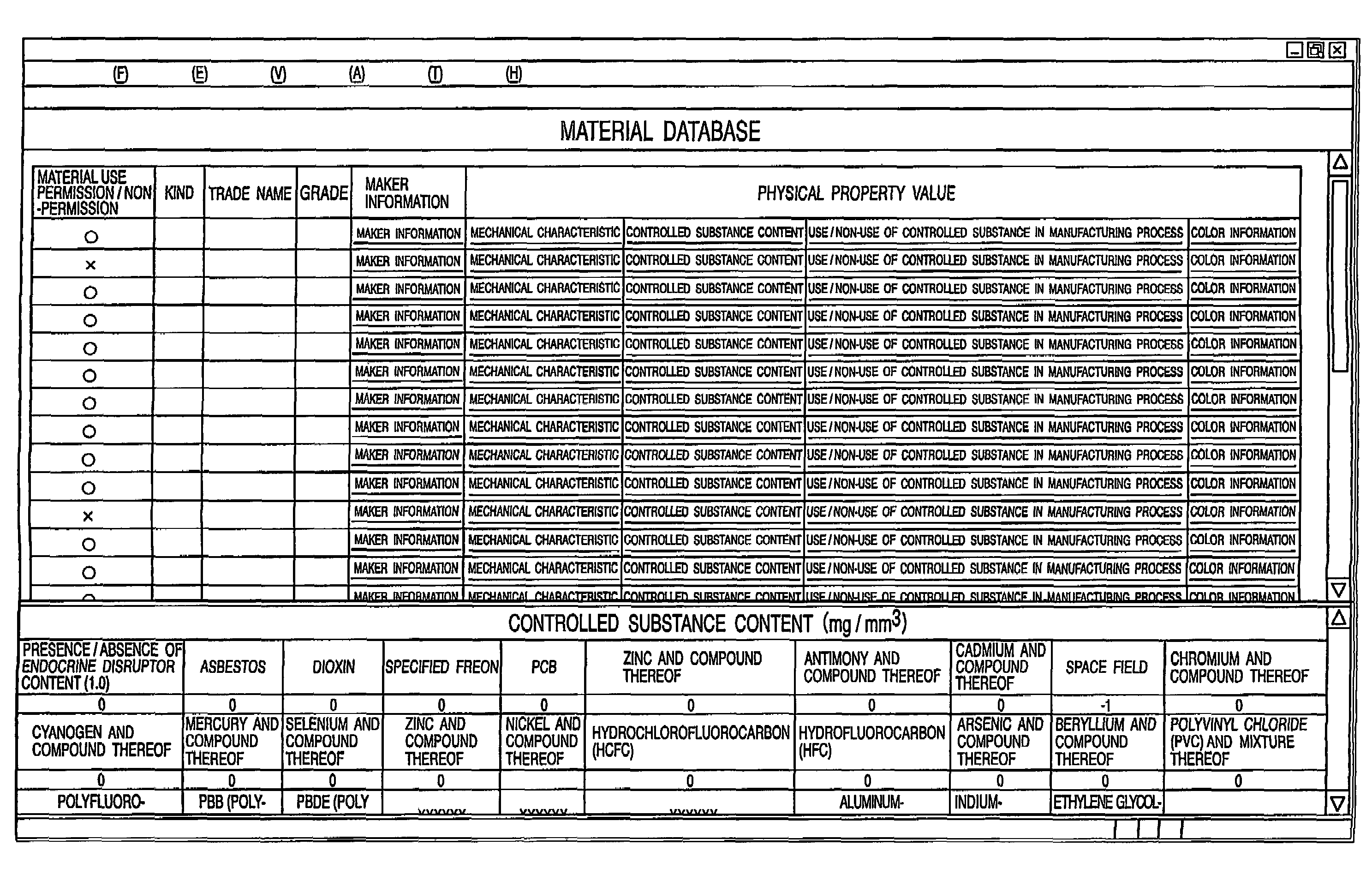

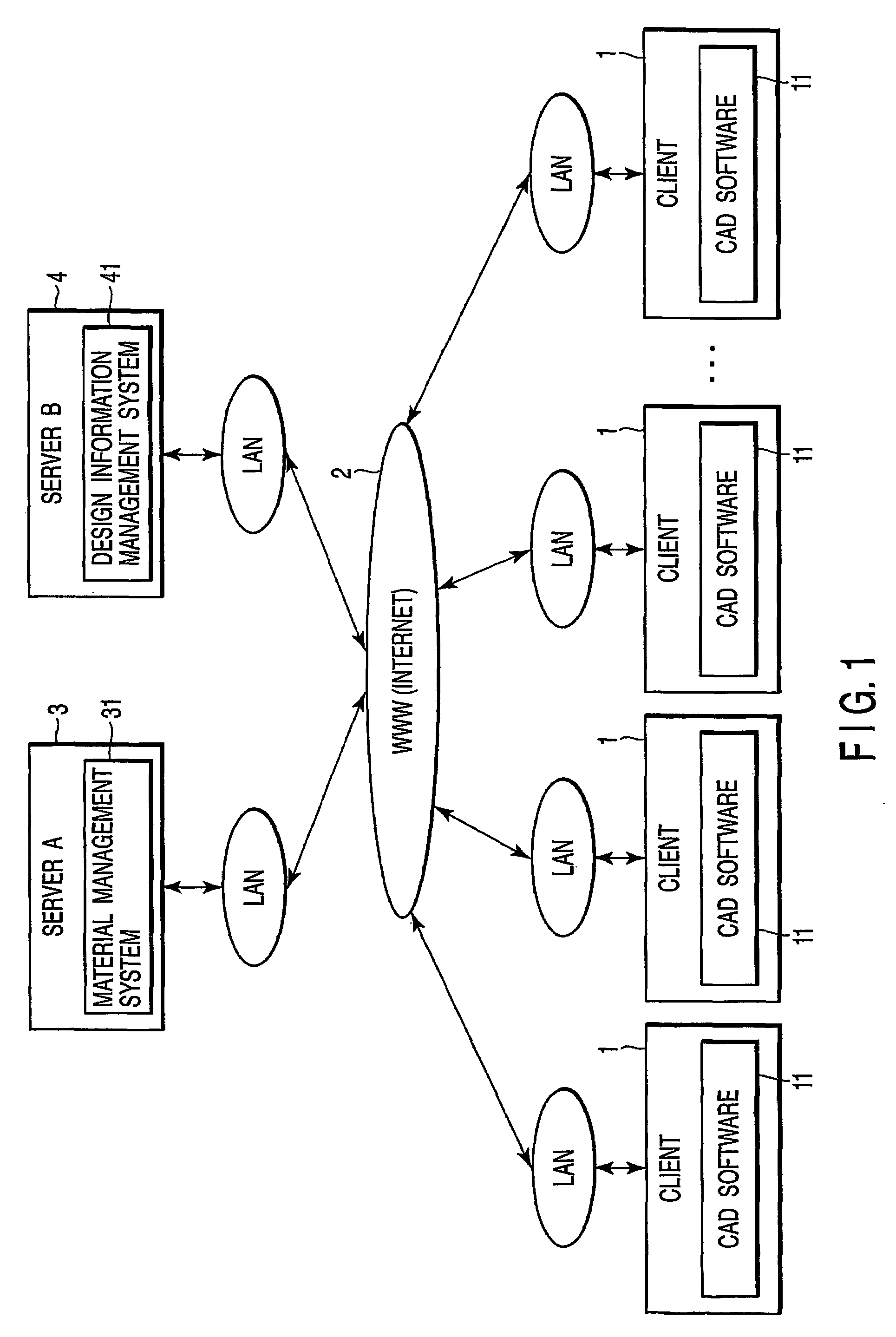

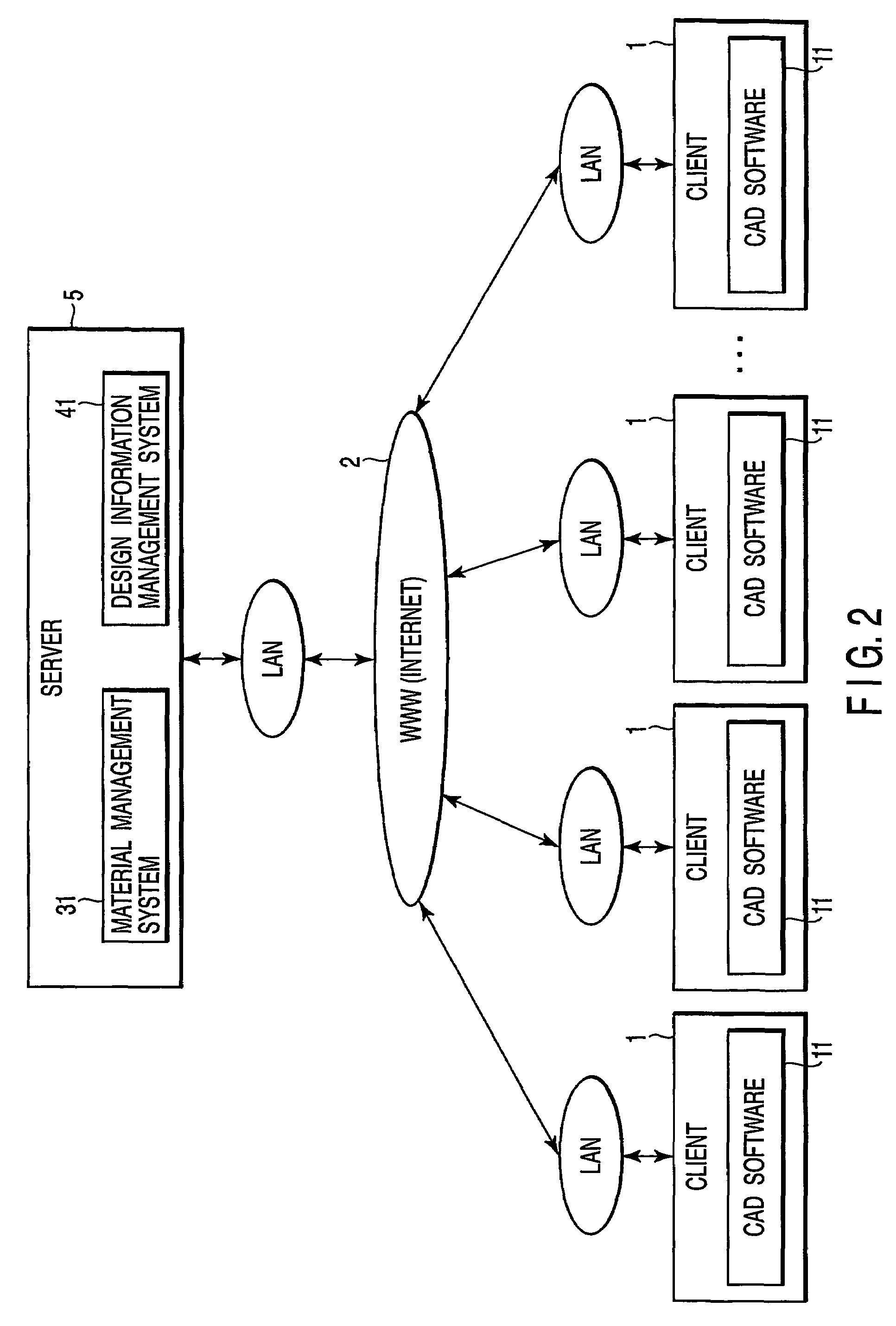

Design supporting system for supporting component design

InactiveUS20060142883A1Analogue computers for chemical processesForecastingSupporting systemDesign support system

A design supporting system includes a unit that acquires, from a component design supporting program which is executed in a client terminal, component design information including volume information indicative of a volume of a designed component, a unit that generates list information that is indicative of a list of names of usable materials for the component classification corresponding to the designed component, and sends the list information to the client terminal, an acquisition unit that acquires, from the material database, controlled substance information corresponding to the material name that is selected from the list information by the client terminal, a unit that calculates a content of the controlled substance that is included in the designed component when the material of the selected material name is applied to the designed component, and a unit that outputs the calculated content of the controlled substance as evaluation information of the designed component.

Owner:KK TOSHIBA

An archaized brick

The invention discloses an archaized brick and belongs to the technical field of ceramic bricks. A blank of the archaized brick is prepared from 21% by weight of bauxite, 7% by weight of magnesian soil, 6% by weight of bentonite, 11% by weight of a material named as a Chinese character 'Tingqiansha' by the inventor, 18% by weight of a material named as a Chinese character 'Tailisha' by the inventor, 12% by weight of a material named as a Chinese character 'Ruichangtu' by the inventor, 15% by weight of mica and 10% by weight of a material named as a Chinese character 'Hushatou' by the inventor. According to firing temperature of the archaized brick, surface temperature is 860-1015 DEG C and bottom temperature is 960-1010 DEG C in a front temperature zone, surface temperature is 1035-1128 DEG C and bottom temperature is 1025-1120 DEG C in a middle temperature zone, and surface temperature is 1125-1200 DEG C and bottom temperature is 1130-1205 DEG C in a high-temperature zone. By adjusting blank components and ratios of the archaized brick, archaized bricks with different specifications can be fired in a same kiln, thus avoiding building of a plurality of kilns and reducing investment. The archaized brick is advantaged by good color and lustre, high hardness, low water absorption, high wear resistance, and the like. Firing quality of the archaized brick is greatly improved.

Owner:湖北兴成建陶股份有限公司

Design supporting system for supporting component design

InactiveUS7340315B2Digital data processing detailsAnalogue computers for chemical processesSupporting systemDesign support system

A design supporting system includes a unit that acquires, from a component design supporting program which is executed in a client terminal, component design information including volume information indicative of a volume of a designed component, a unit that generates list information that is indicative of a list of names of usable materials for the component classification corresponding to the designed component, and sends the list information to the client terminal, an acquisition unit that acquires, from the material database, controlled substance information corresponding to the material name that is selected from the list information by the client terminal, a unit that calculates a content of the controlled substance that is included in the designed component when the material of the selected material name is applied to the designed component, and a unit that outputs the calculated content of the controlled substance as evaluation information of the designed component.

Owner:KK TOSHIBA

Salted flour-mixed hot pepper and preparation method thereof

ActiveCN108740891AHas antibacterial and bactericidal effectsAvoid breedingFood preservationFood ingredient as taste affecting agentChinese charactersMetabolite

The invention discloses salted flour-mixed hot pepper and a preparation method thereof and relates to the technical field of food processing. The salted flour-mixed hot pepper includes 25-30 jin of hot pepper, 60 jin of corn flour, about 0.5 jin of garlic, about 0.5 jin of ginger, and 5-10 jin of enzyme. The enzyme is prepared from 25-35 parts of bitter gourd, 20-30 parts of Chinese water chestnut, 5-10 parts by weight of aloe, 1-2 parts by weight of a material named as Chinese characters 'Hanbiwen' by the inventor, 1-5 parts by weight of oligosaccharide, 1-5 parts by weight of honey and 5-15parts by weight of composite microbe powder. Addition of table salt to a high salt concentration is not needed in a fermentation process, and rich metabolites are generated through functions of the composite microbe powder, and therefore, a fermented finished product is safe, healthy, and pure and rich in fragrance.

Owner:BAOKANG BADOU FOODSTUFF

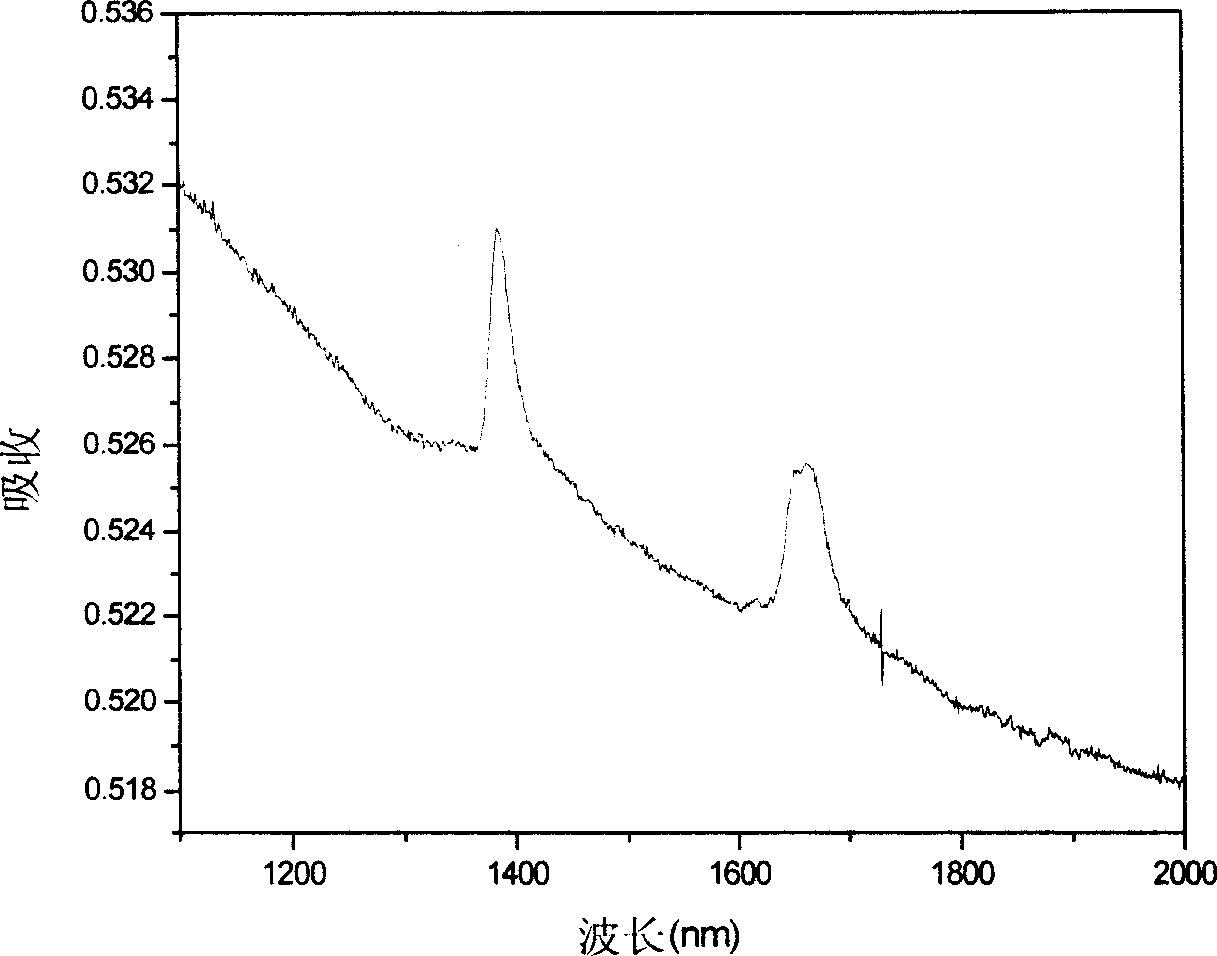

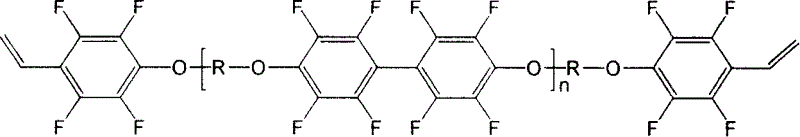

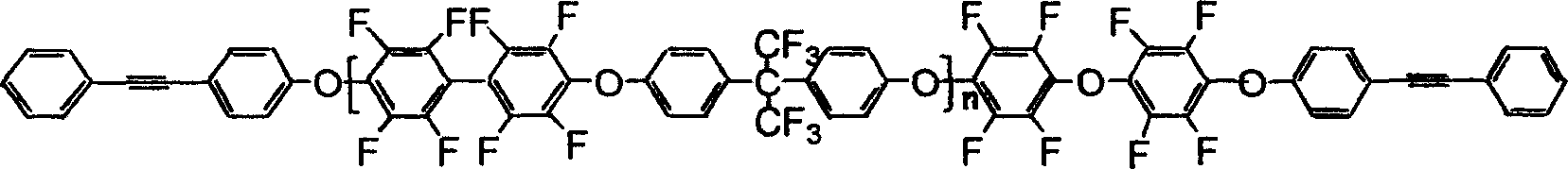

Preparation of photosensitive fluorine-containing poly(aryl ether) materials and use thereof

The invention relates to a method for preparing the light-sensitive fluorine-containing polyarylether materials, which belongs to the field of polymer material and its preparation. The material names pentafluorostyrene terminated fluorine-containing polyarylether. The preparation process comprises: using the bisphenol monomers such as 3F-PH or (and) 6F-PH to finish the bisphenol salt process, then reacting with pentafluorostyrene in 10-25 min to finish the two steps condensation synthetic process, adding decafluorobiphenyl to react to 10-25 min, then getting through cooling filtration, boiling filtration and drying to get a linear polymer or random copolymer, thermal or ultraviolet crosslinking to get a thermosetting material in the crosslinking process. The degree of crosslinking of the said line polyarylether terminated using pentafluorostyrene is controlled by polymeric feed weight ratio and the exposure time. The product in the invention has the characteristic of high heat stability, low optical loss and low dielectric constant.

Owner:JILIN UNIV

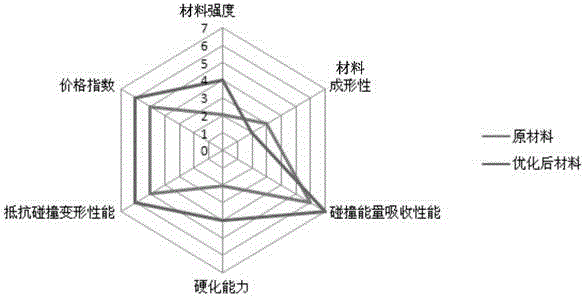

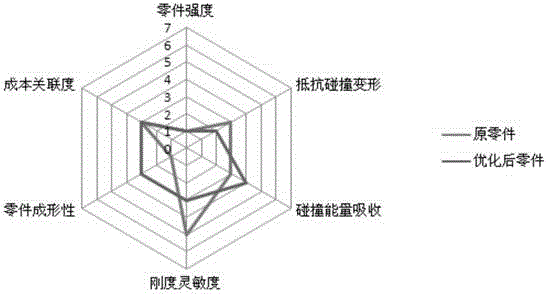

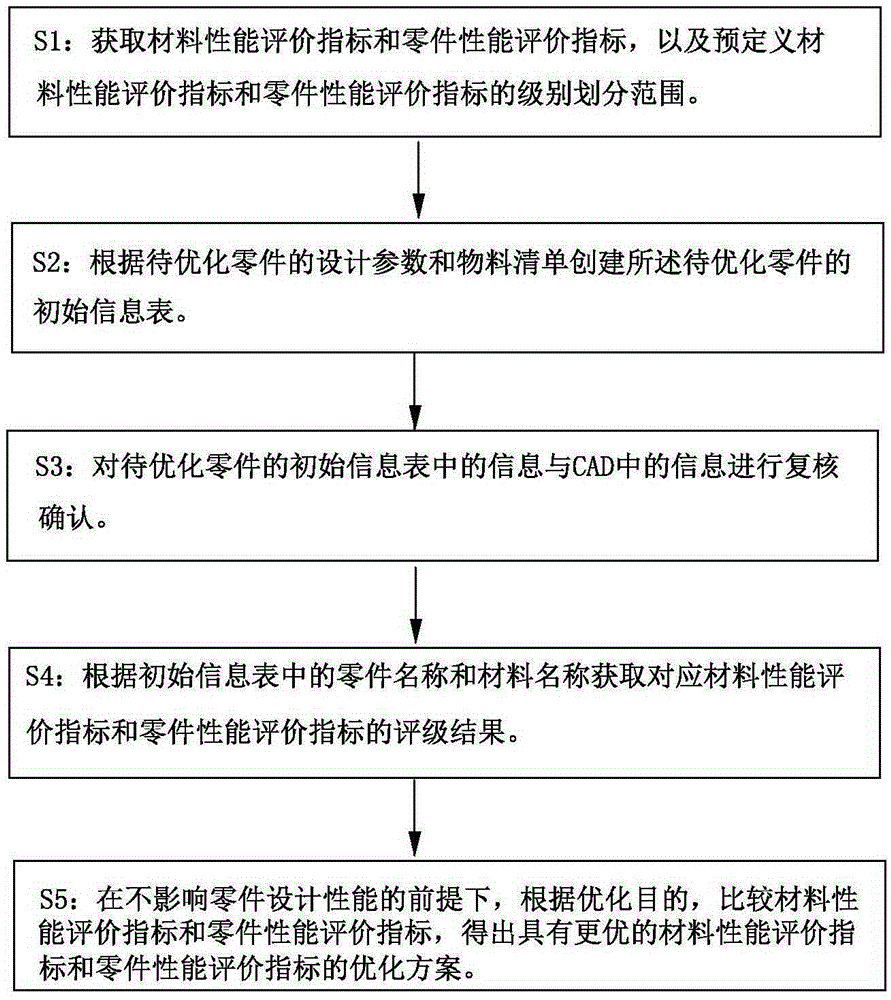

Optimization method and optimization system for automobile body material

The invention provides an optimization method for an automobile body material. The optimization method for the automobile body material comprises the steps of obtaining material performance evaluation index and part performance evaluation index, and pre-defining a rank division range of the material performance evaluation index and the part performance evaluation index; establishing an initial information sheet of to-be-optimized parts according to design parameters and a material list of the to-be-optimized parts, wherein the initial information sheet comprises part names and material names; obtaining a grading result corresponding to the material performance evaluation index and the part performance evaluation index according to the part names and the material names in the initial information sheet; and comparing the material performance evaluation index and the part performance evaluation index according to an optimization target under the premise of not influencing design performance of the parts so as to obtain an optimization scheme with better material performance evaluation index and the part performance evaluation index. The invention also provides a selection and evaluation apparatus for the automobile body material, wherein the selection and evaluation apparatus comprises a pre-defining module, an initial information establishing module, a rank grading module and a screening module.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

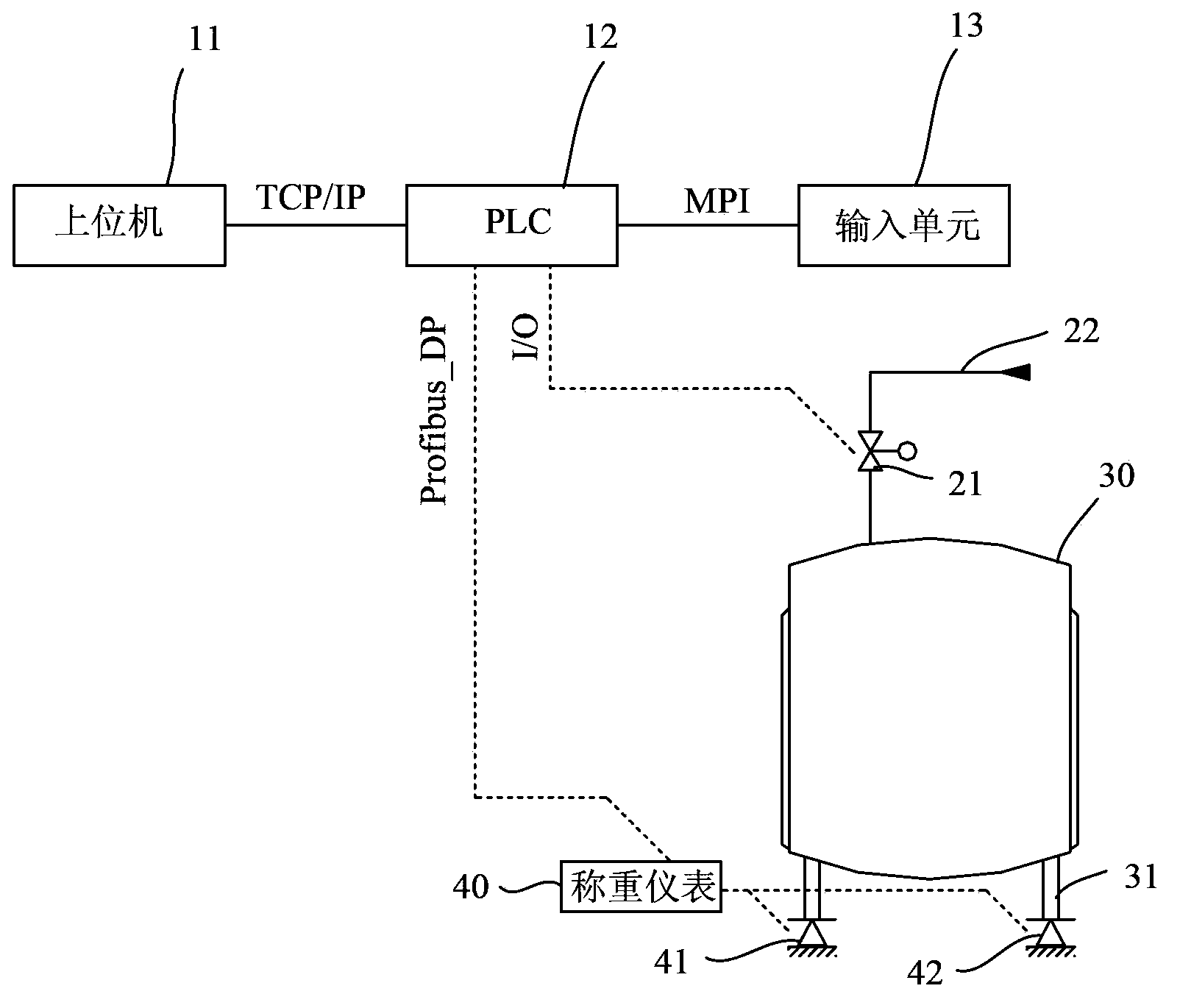

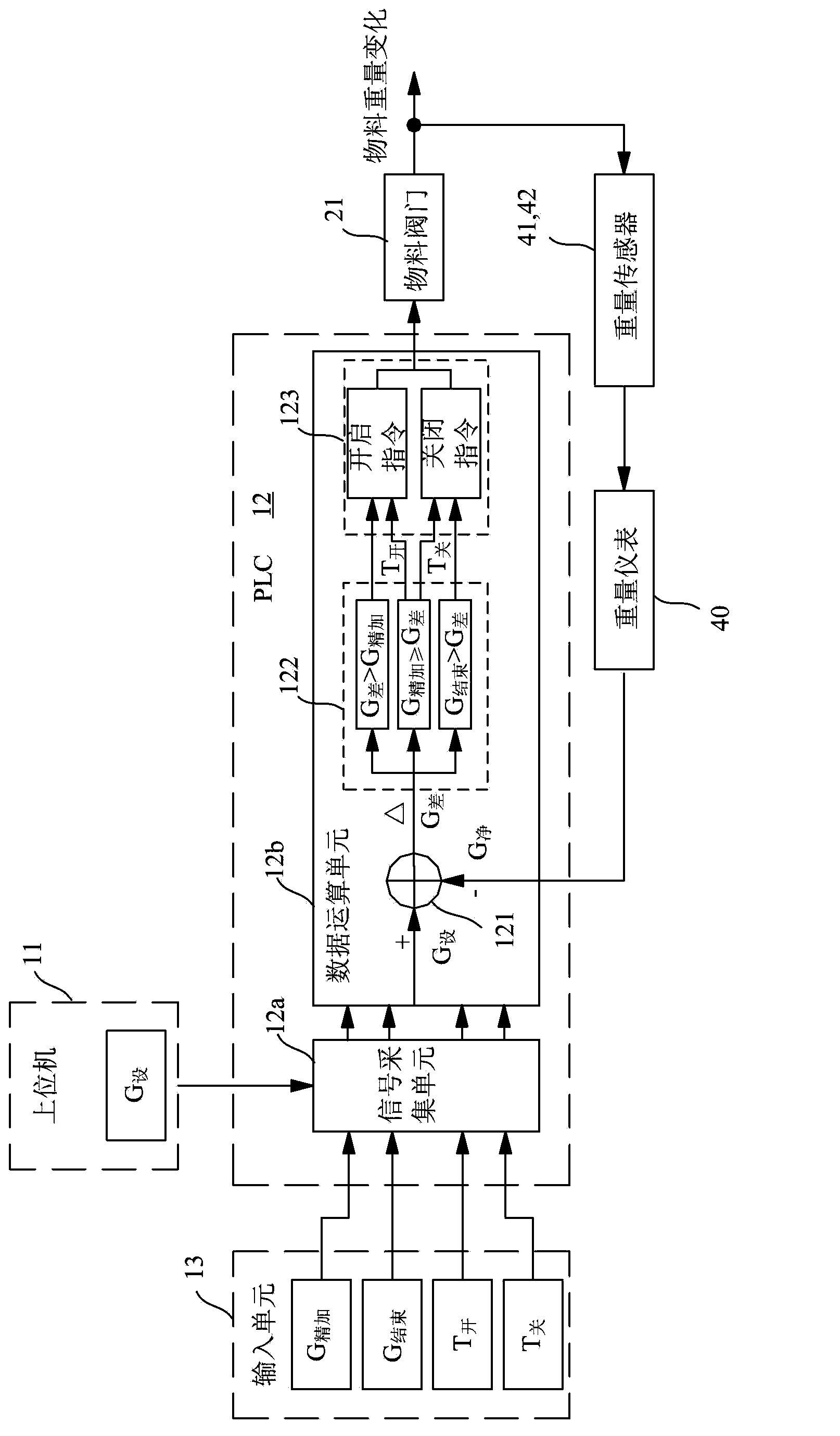

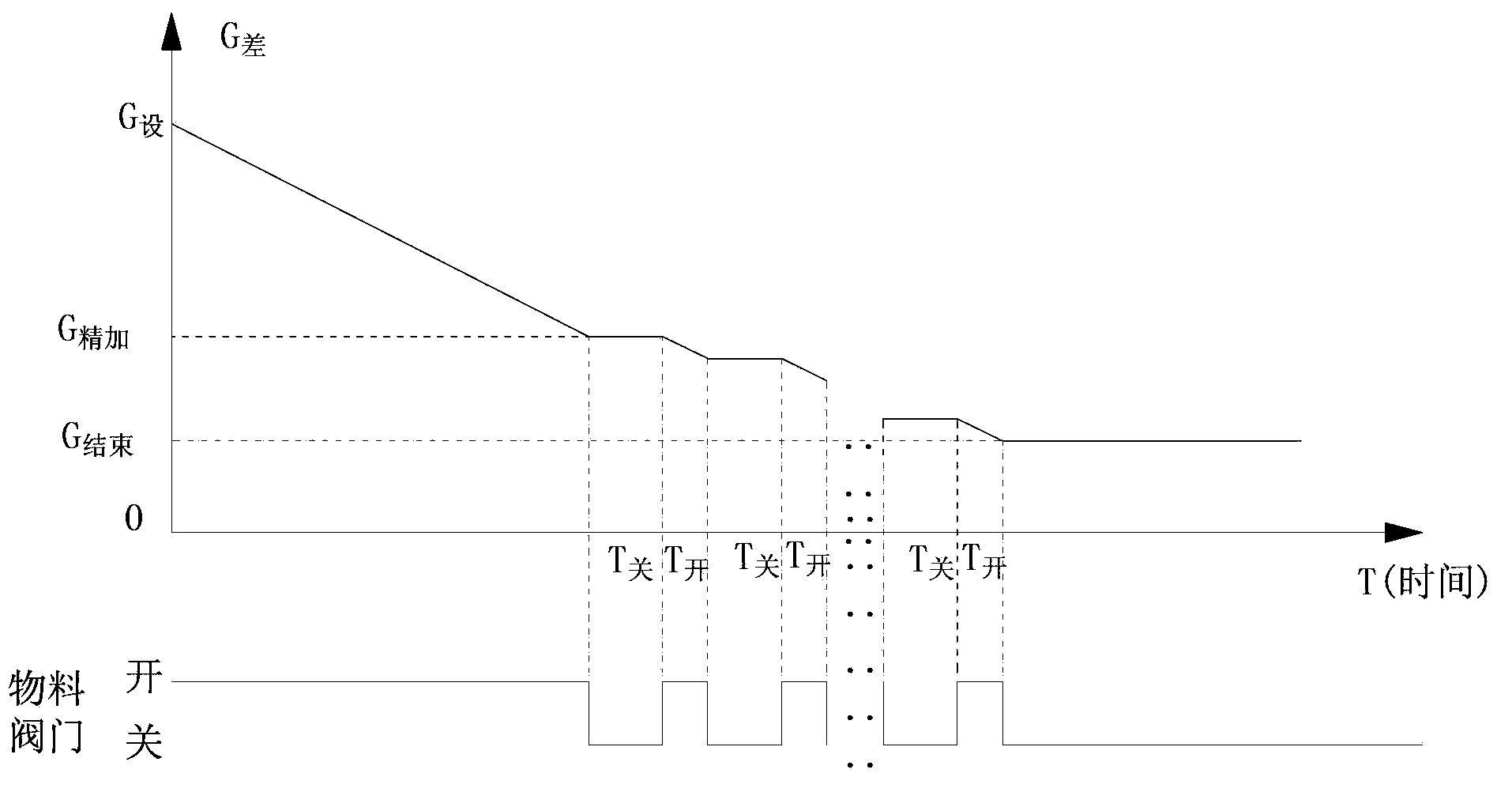

Automatic control method and device for stirring pot material feeding

ActiveCN103894100AAutomatic feedingAutomatic feed controlMixer accessoriesProgramme control in sequence/logic controllersAutomatic controlMechanical engineering

The invention relates to an automatic control method and a device for stirring pot material feeding. The method comprises the following steps: receiving a material name and a set material feeding amount; continuously opening a material valve leading to a stirring pot to feed a material to the stirring pot; continuously detecting the difference valve between an actual material feeding amount and the set material feeding amount; when the difference valve reaches a precise feeding start threshold value, intermittently turning on the material valve to continue to feed the material to the stirring pot; and when the difference valve reaches a feeding-off start threshold value, turning off the material valve to stop feeding the material to the stirring pot;.

Owner:SHANGHAI LIGHT IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com