Automatic control method and device for stirring pot material feeding

An automatic control device and stirring pot technology, applied in the direction of mixer accessories, electrical program control, chemical instruments and methods, etc., can solve the problems of manual weighing errors, wrong feeding, etc., and achieve the effect of precise feeding control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

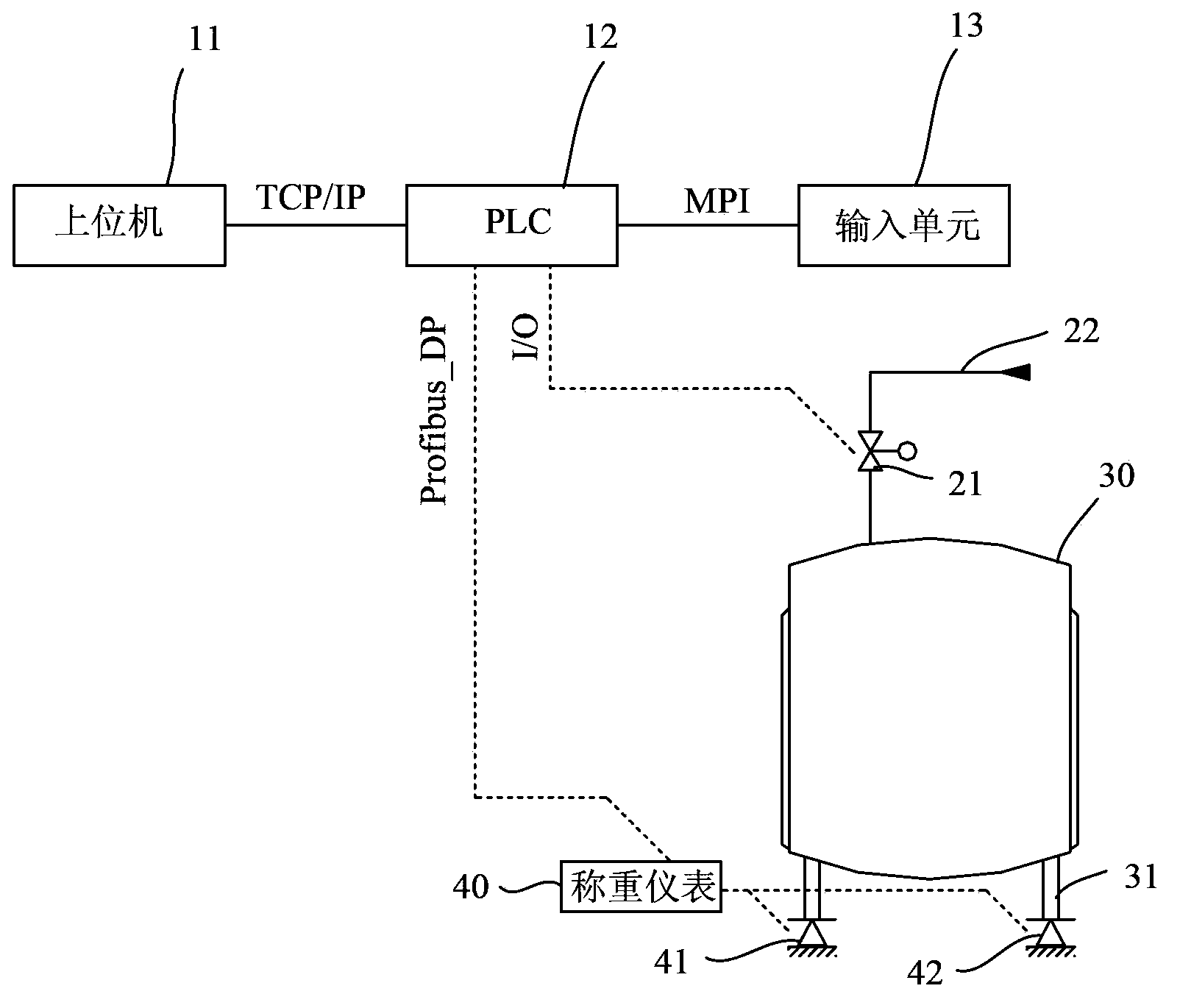

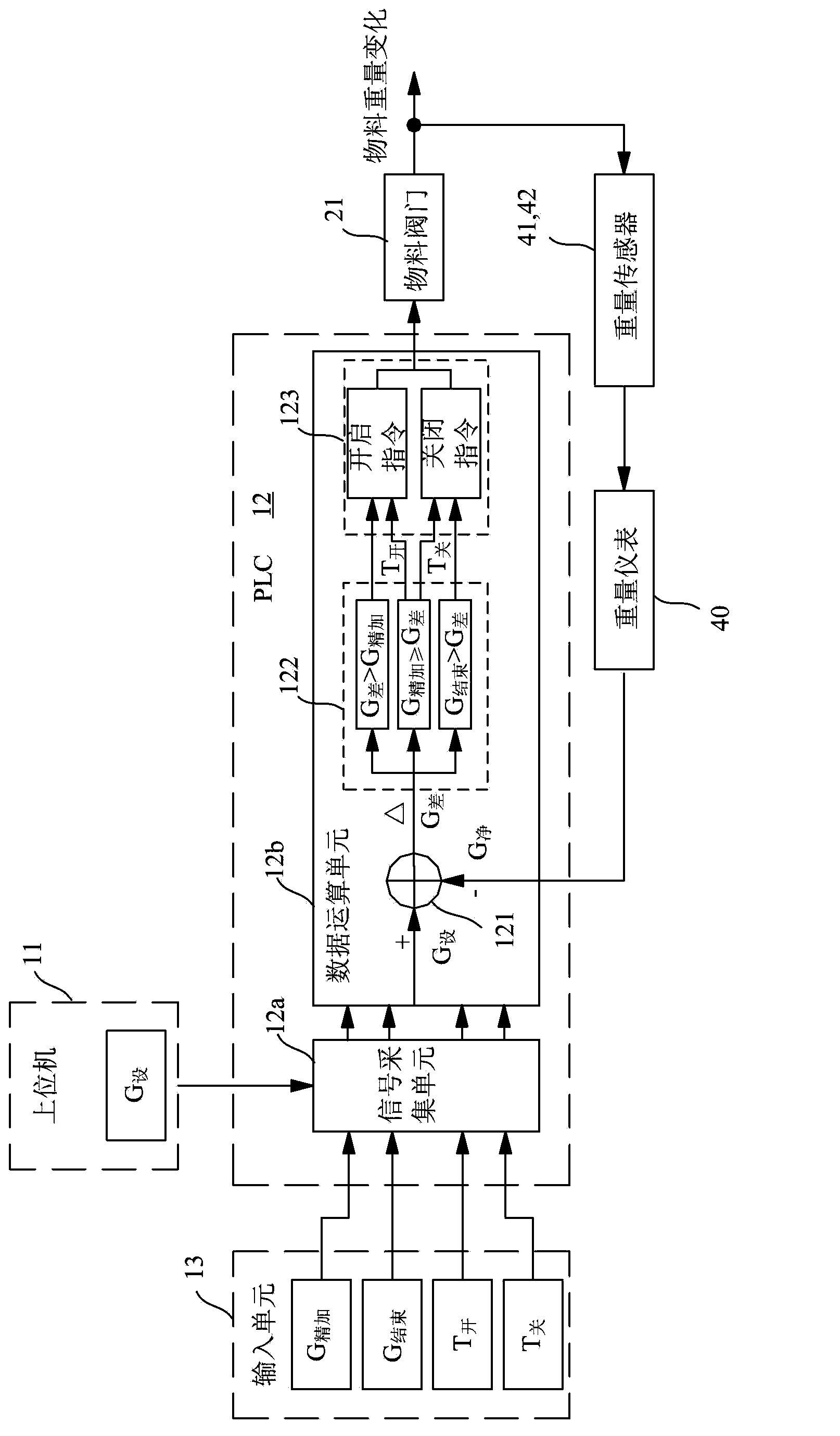

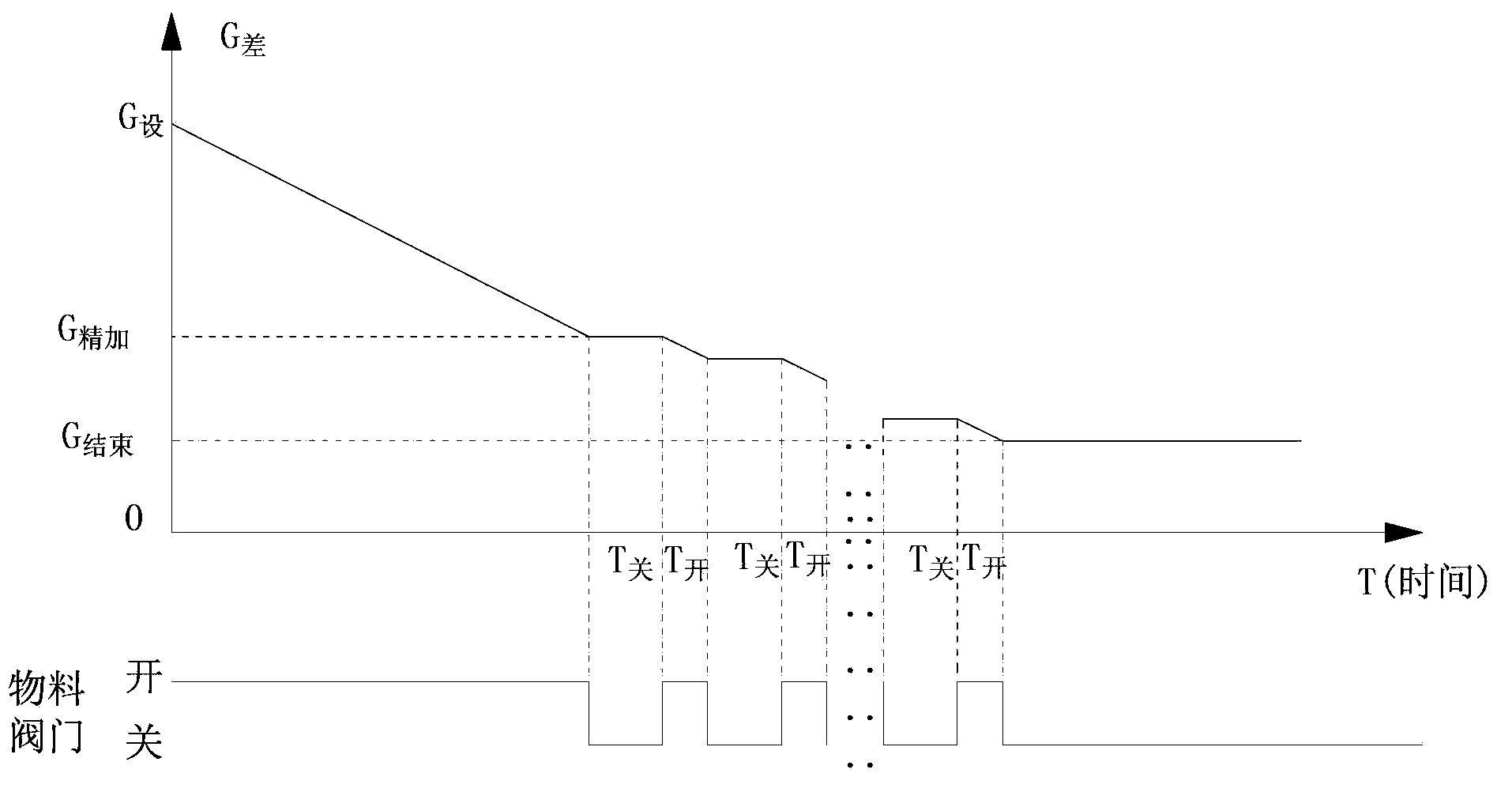

[0020] figure 1 A schematic diagram of a material delivery system for a stirring pot according to an embodiment of the present invention is shown. refer to figure 1 As shown, the material feeding system includes a host computer 11 , a programmable logic controller (PLC) 12 , an input unit 13 , a material valve 21 , weighing sensors 41 , 42 and a weighing instrument 40 . The host computer 11 is used as a delivery window for a production order. On the host computer 11, the name of the material to be dropped and the amount of material to be put in can be input and set, and this parameter will be passed to the PLC12. The PLC 12 and the upper computer 11 can be connected through an Ethernet network cable, and communicate based on the TCP / IP protocol. The input unit 13 is used to receive various process control parameters input by the operator, and input them to the PLC 12 . In one embodiment, the input unit 13 can be a touch screen. The input unit 13 and the PLC 12 can be conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com