Patents

Literature

156results about How to "Automate assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

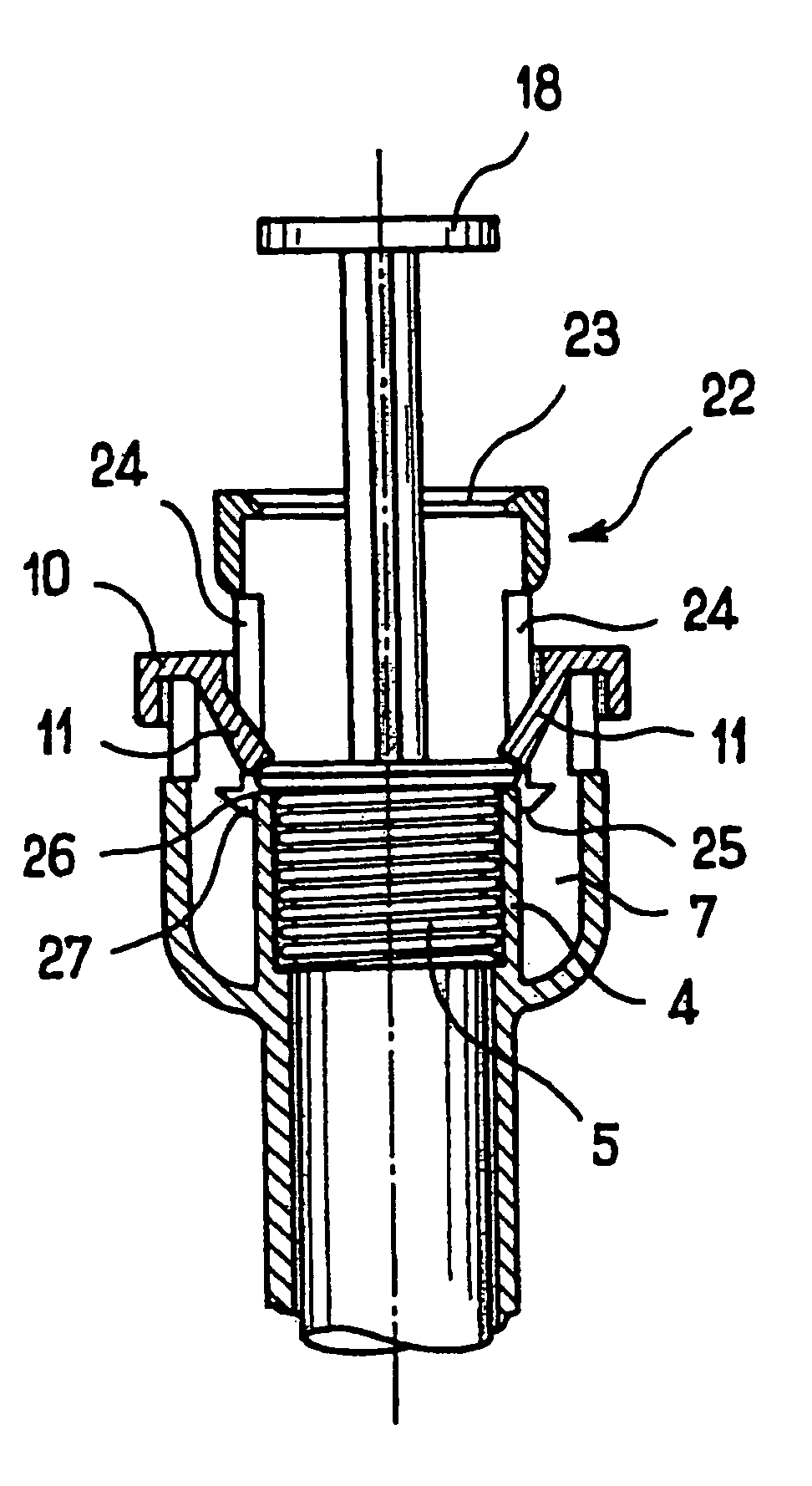

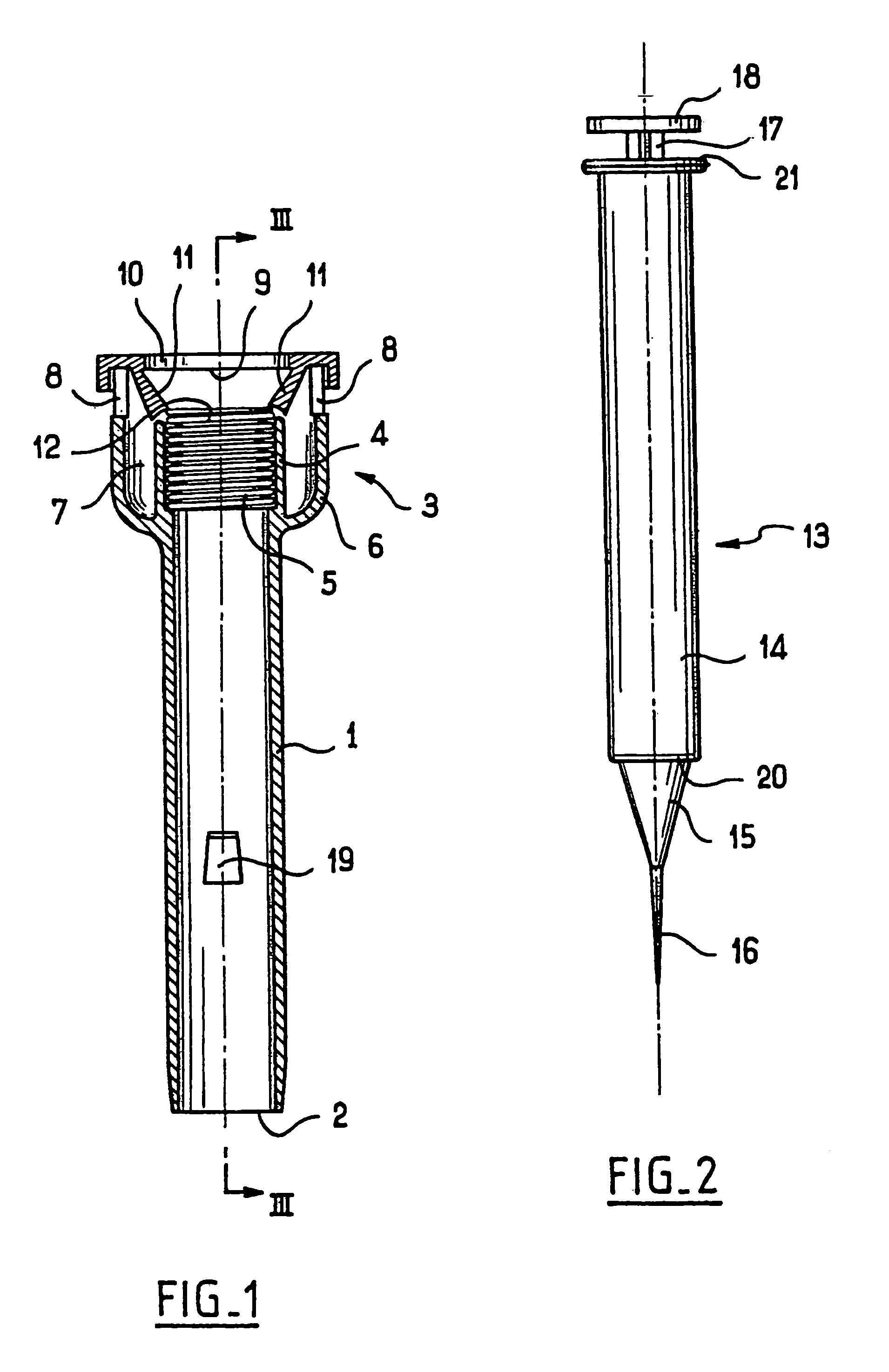

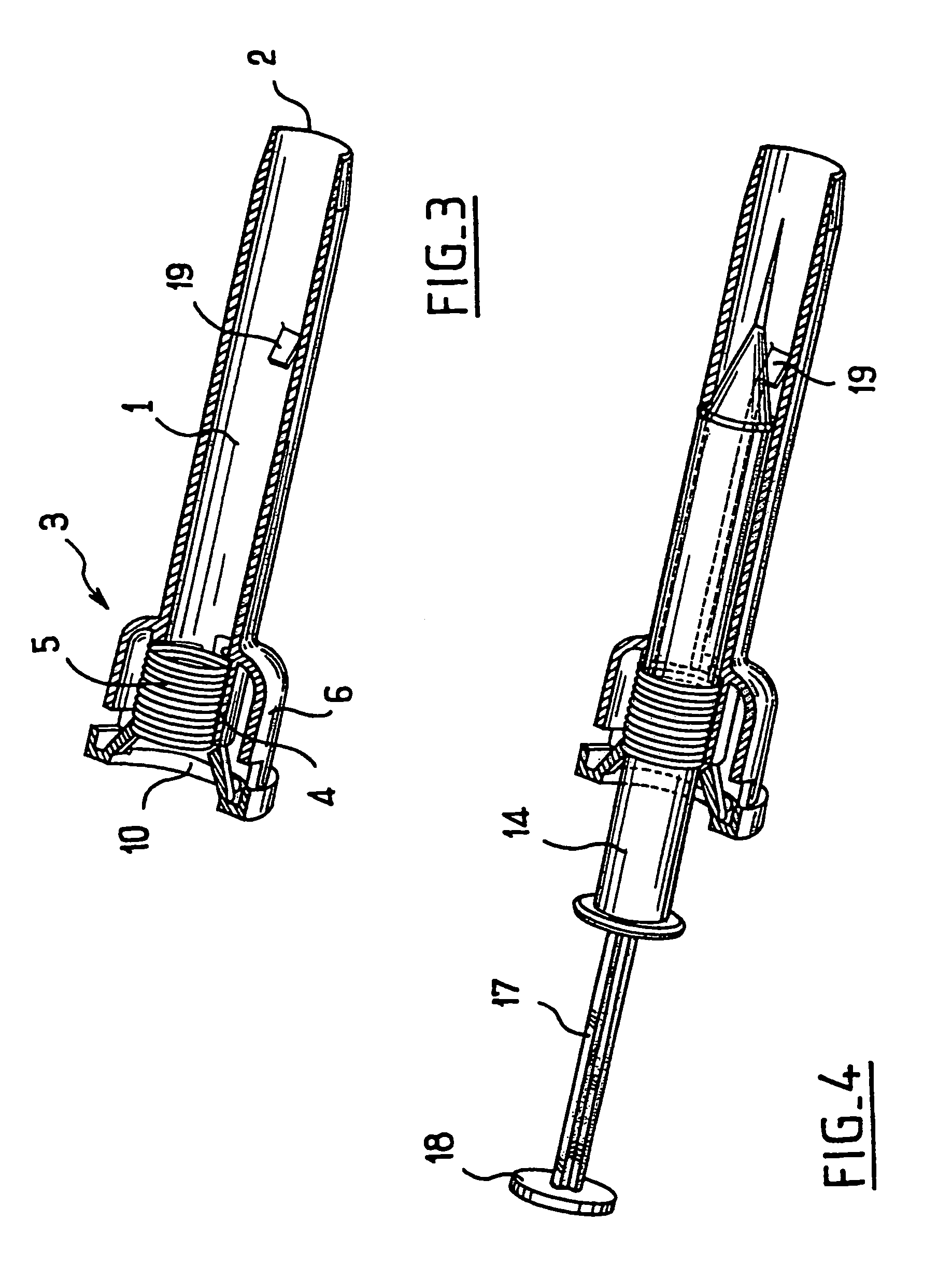

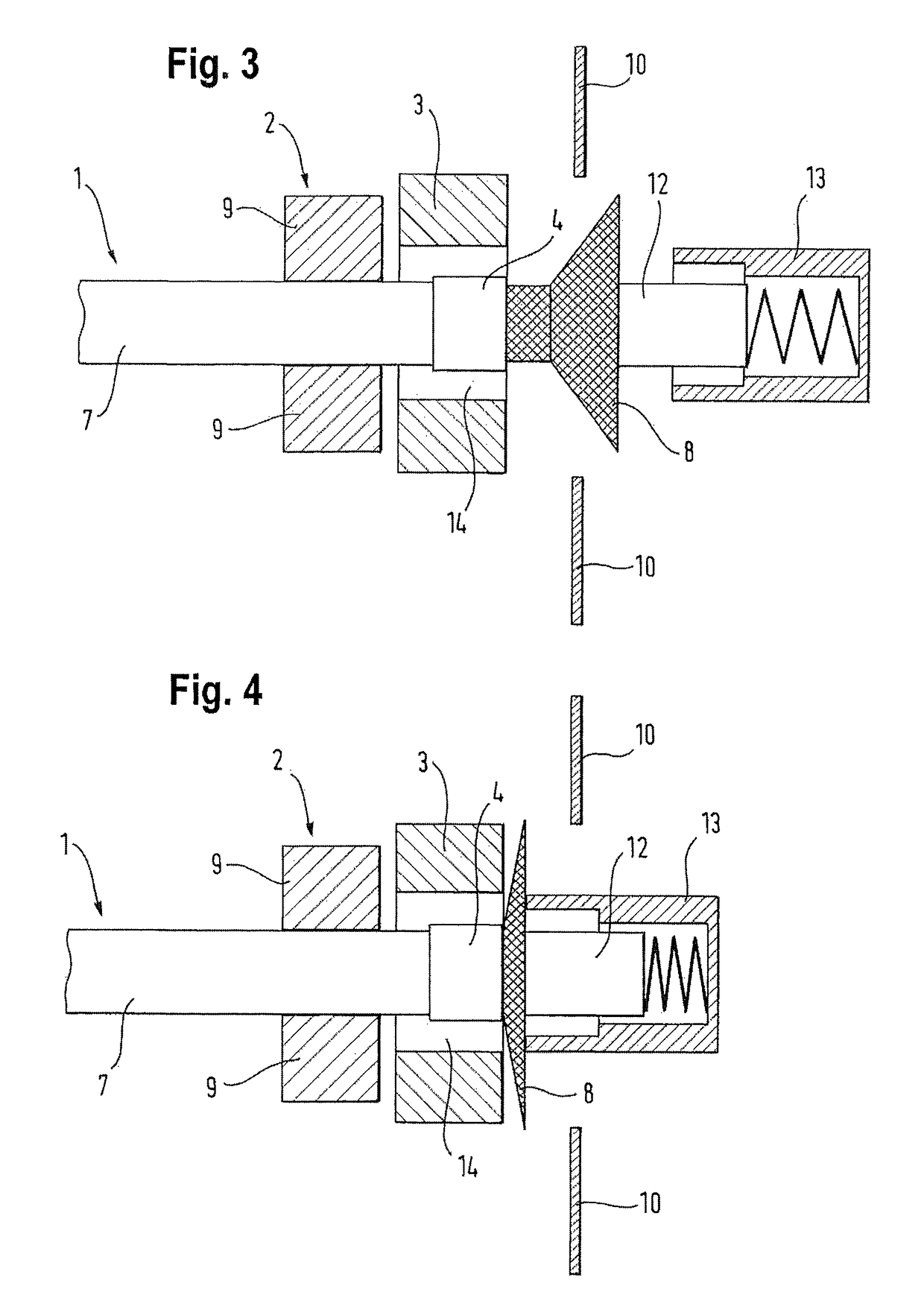

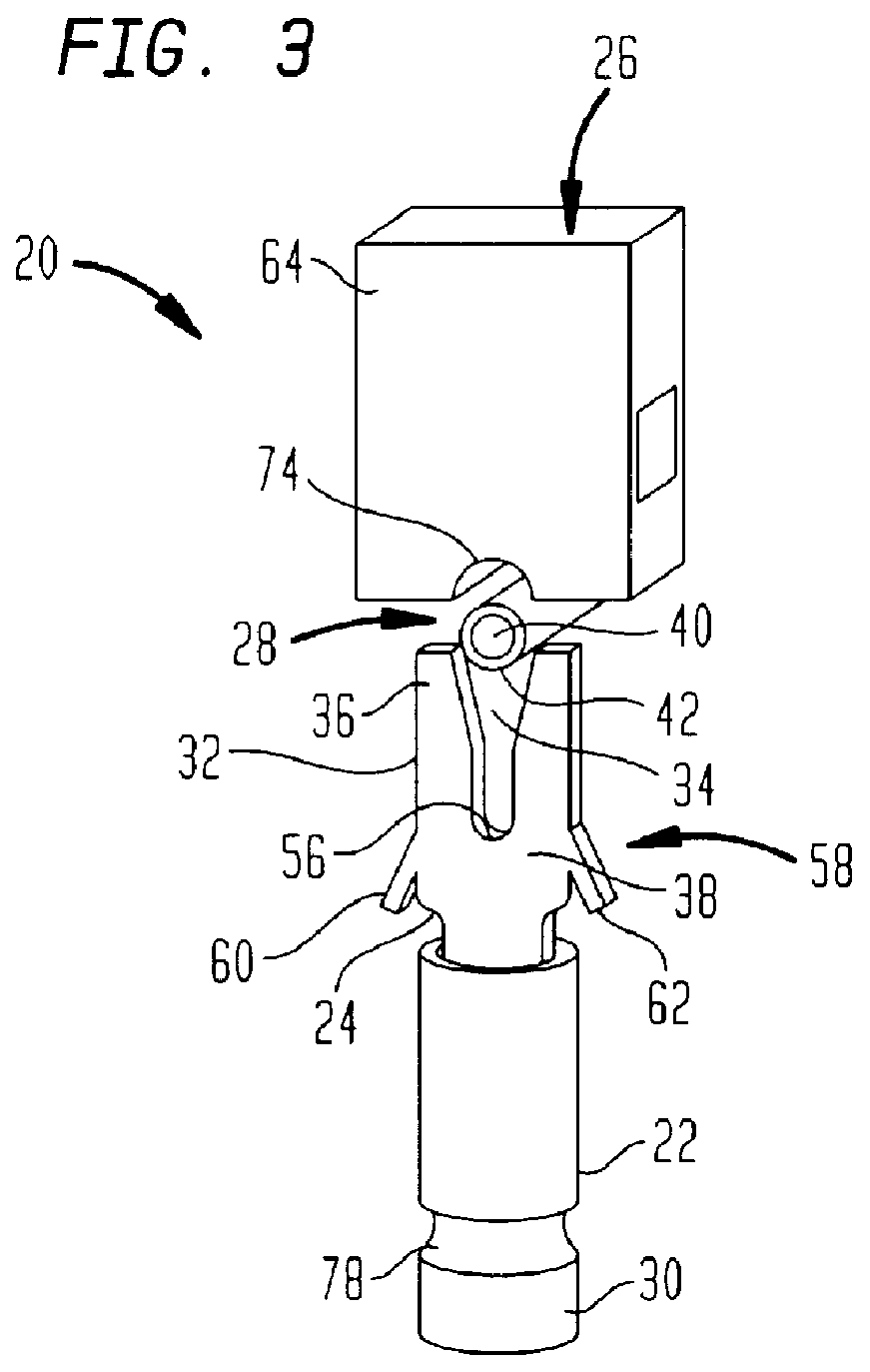

Safety device for an injection syringe

A safety device for a syringe constituted by a body, a needle carrier mounted at one end of the body, a piston that is axially movable in the body, and a piston plunger projecting from the body at its end opposite from the needle carrier and suitable for pushing the piston inside the body towards the needle carrier, the device comprising a sheath in which the syringe body can slide axially between an injection position in which the needle carrier is flush with one end of the sheath and a safe position in which the needle carrier is retracted into the sheath, a helical spring which is axially compressed when the syringe body is in the injection position, said spring then exerting on said body a force tending to cause it to slide into the safe position, retention means for retaining the syringe body in the injection position, and a release mechanism for releasing the retention means acting on said retention means when the piston plunger of the syringe has pushed the piston inside the body into the vicinity of the needle carrier, wherein the retention means for retaining the body of the syringe in the injection position in the sheath are constituted by at least one radially-movable resilient tab extending substantially longitudinally relative to the sheath and arranged to hold the spring in the compressed state even when the syringe body is not in the sheath.

Owner:NEMERA LA VERPILLIERE SAS

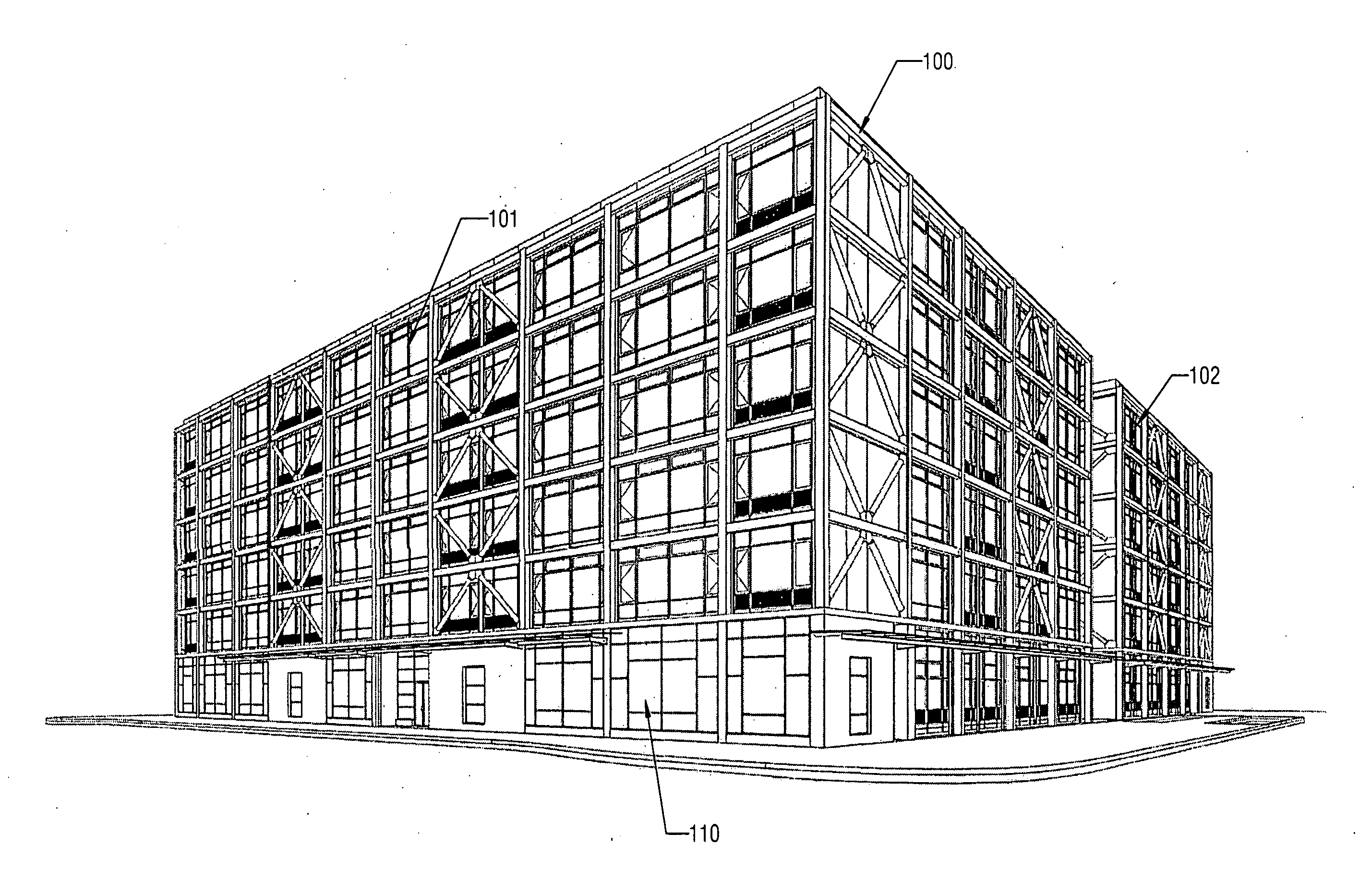

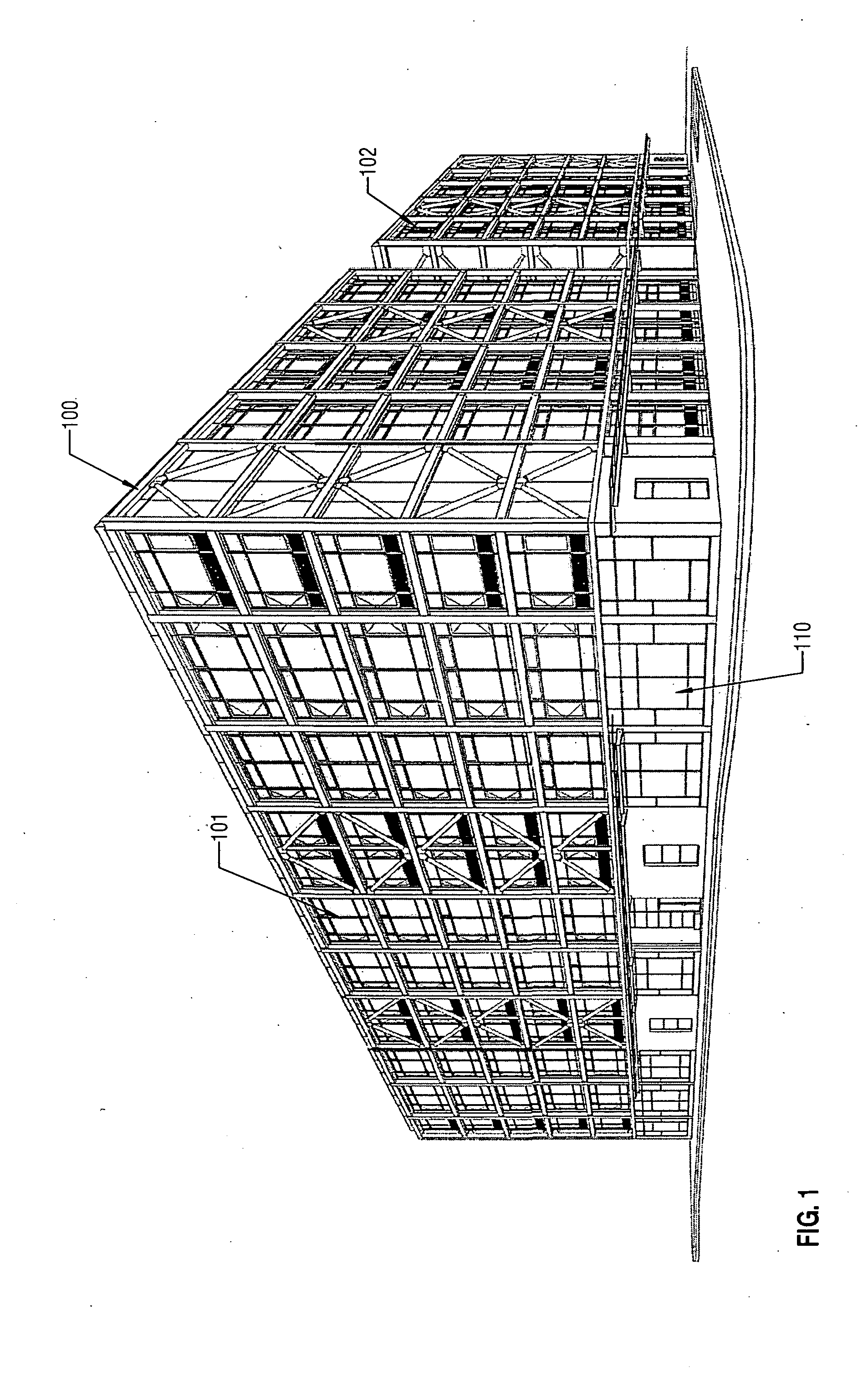

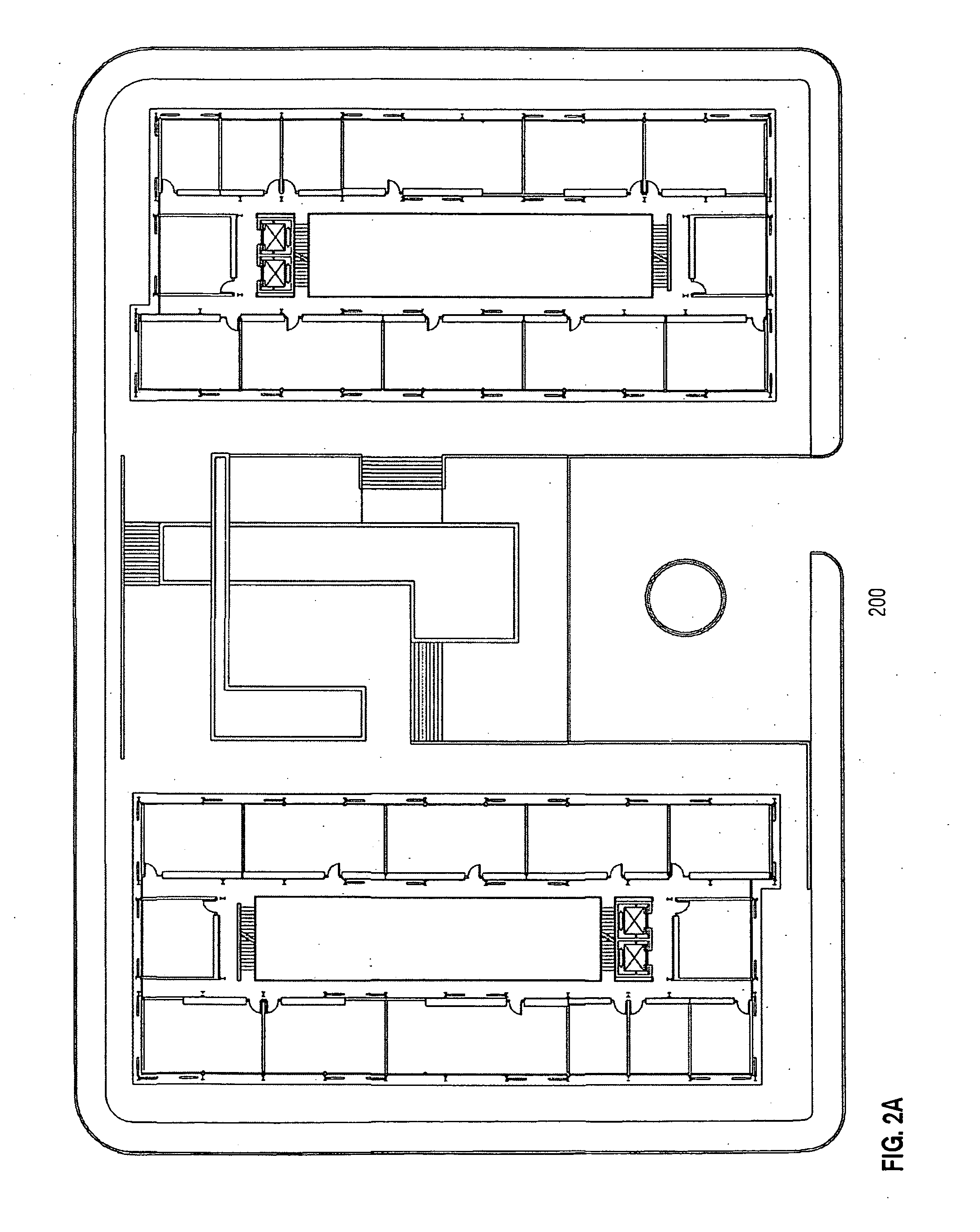

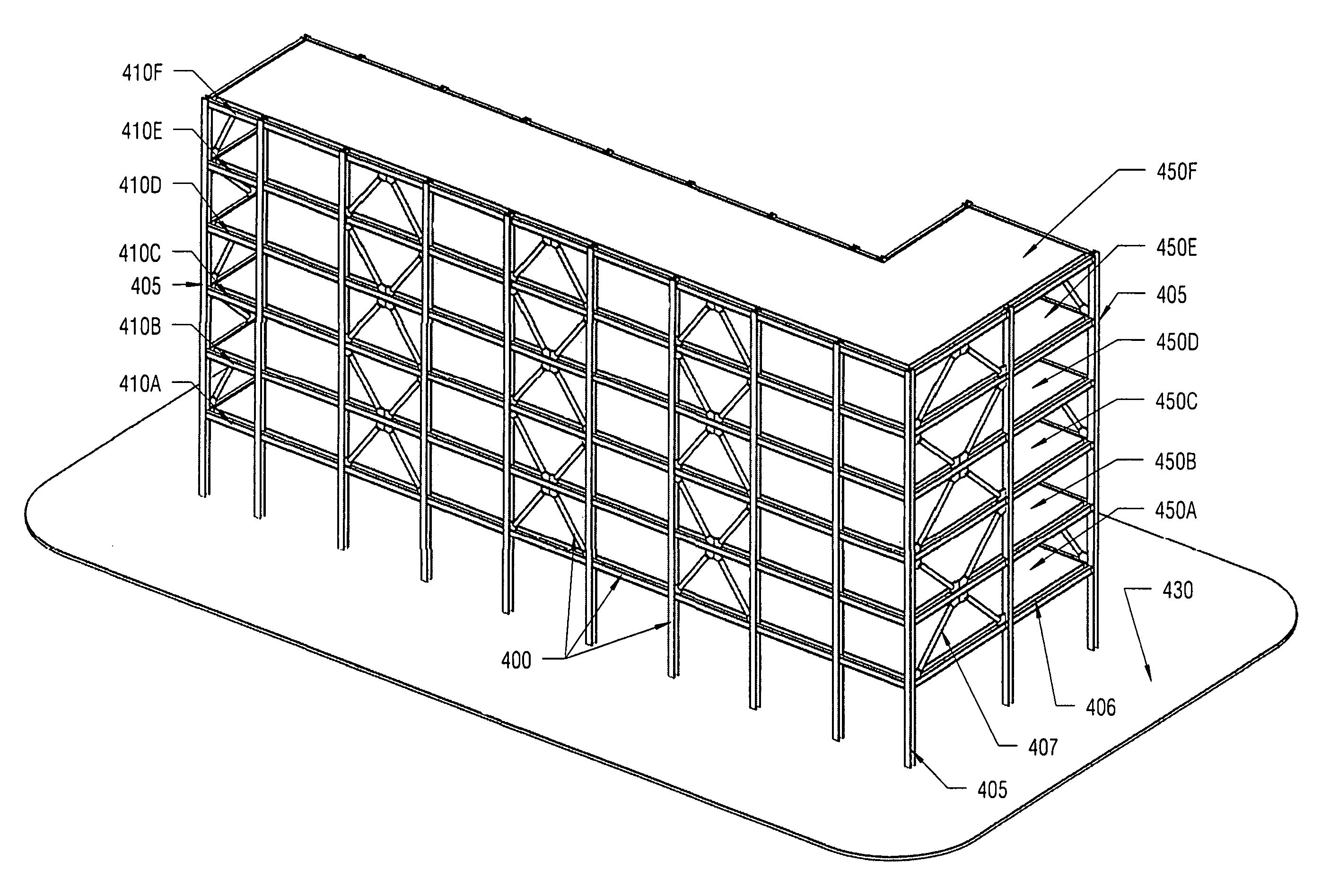

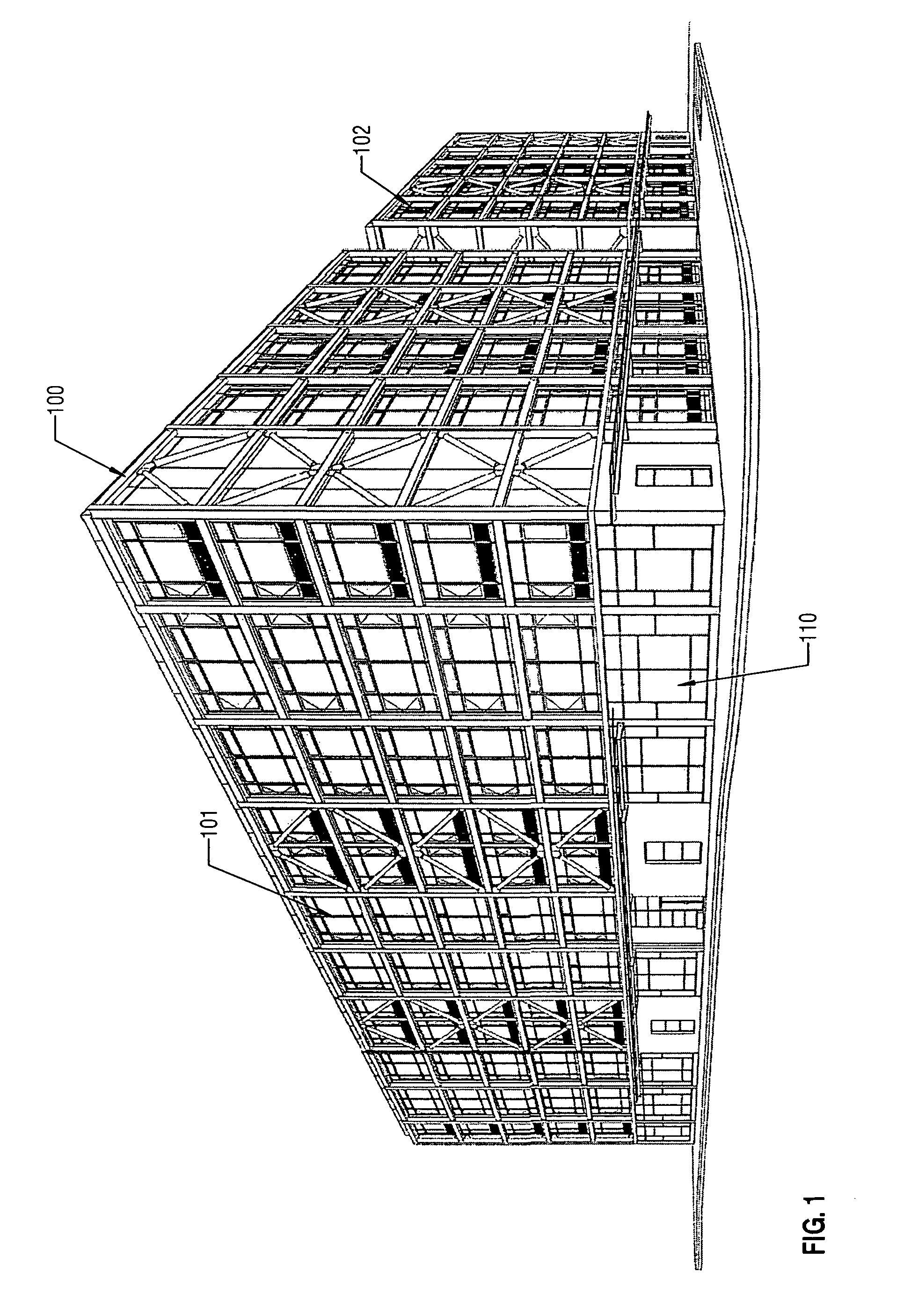

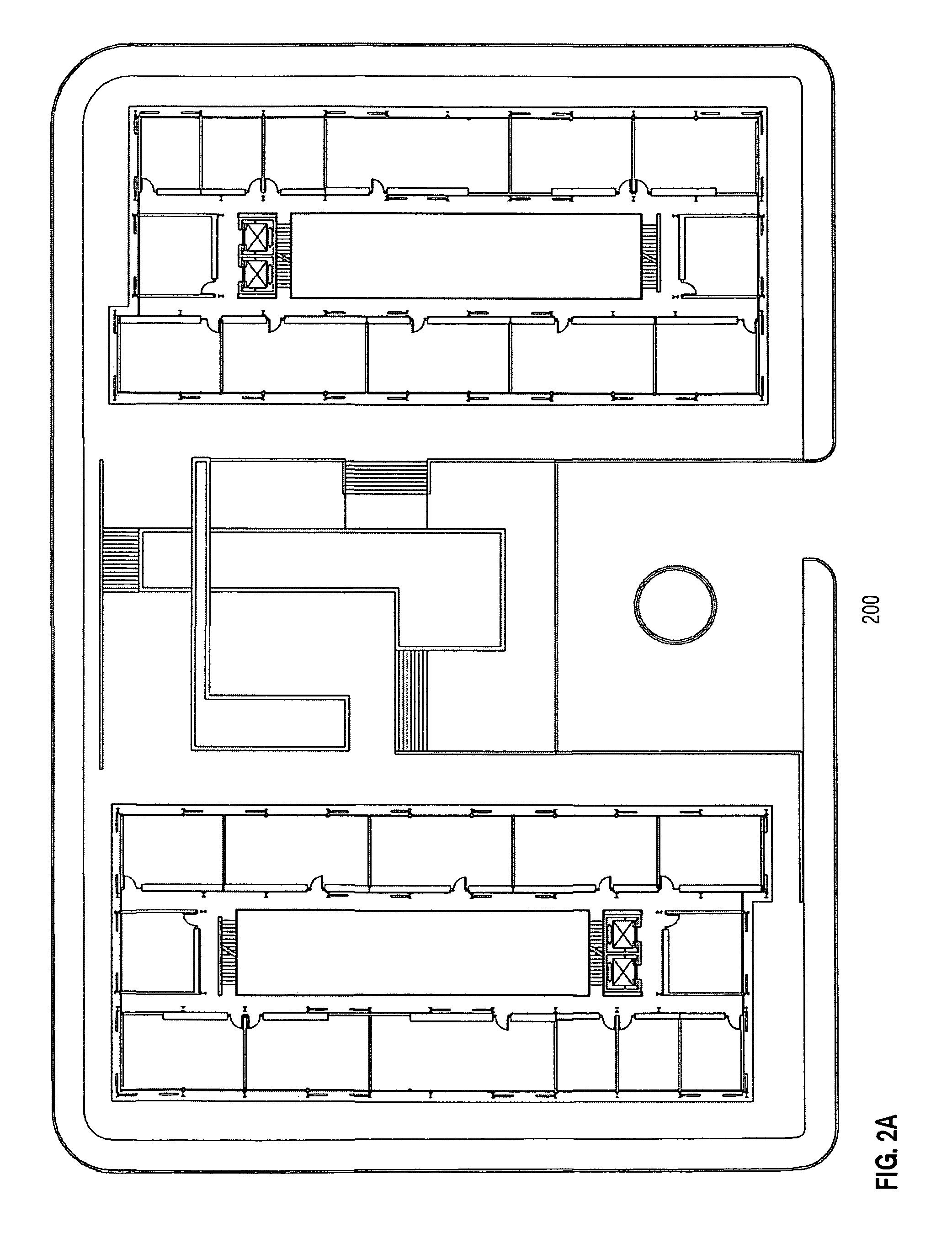

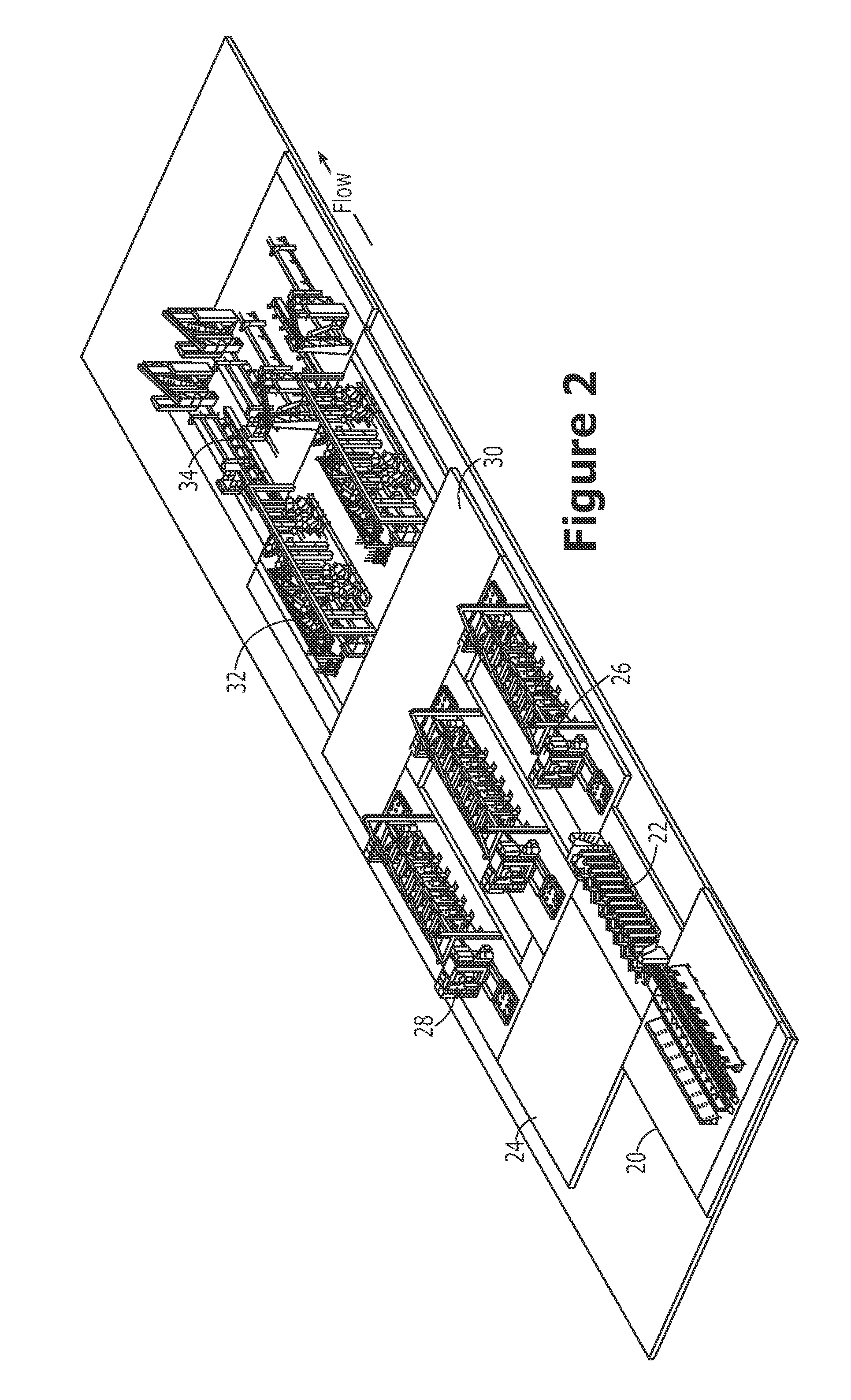

Lift-slab construction system and method for constructing multi-story buildings using pre-manufactured structures

ActiveUS20130067832A1Efficient and quick installation methodEliminates potential unsafeCovering/liningsWallsDesign planIntelligent design

The present invention integrates the use of pre-manufactured structures with minimal on-site installation and lift-slab construction to achieve the construction of multi-story buildings. The pre-manufactured structures are designed to be readily integrated with both horizontal and vertically adjacent building components, including lift-slab components, so that multiple building stories may be readily and securely stacked, one on top of the other. The present invention advantageously permits top- down lift-slab construction for multi-story buildings. The present invention also provides for the development of flexible design plans for institutional, residential, office and other types of buildings. The present invention advantageously provides for easier, more efficient, faster, cheaper, safer, higher quality and more consistent, environmentally advantaged, energy-efficient, easier to maintain, intelligently designed, and customizable multi-story building construction.

Owner:INNOVATIVE BUILDING TECH

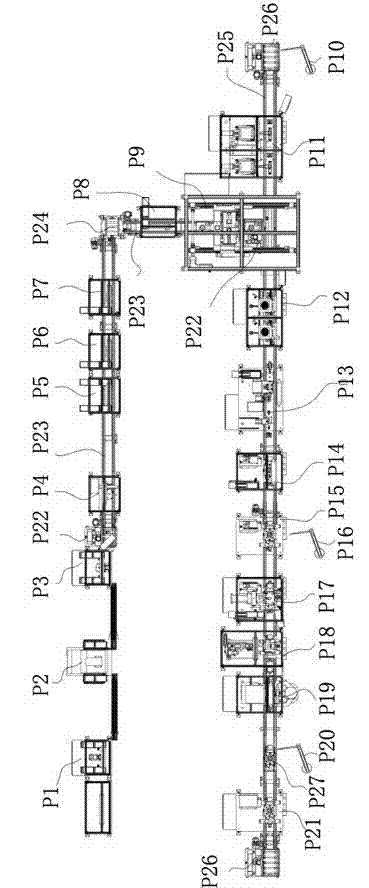

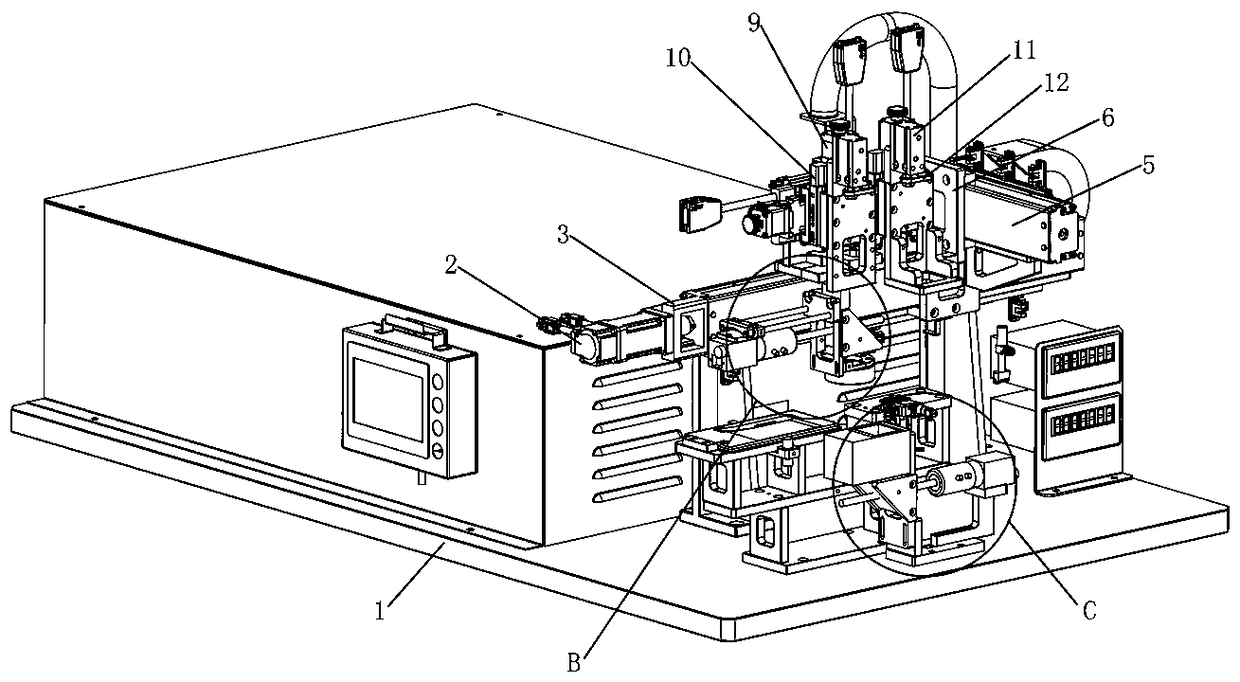

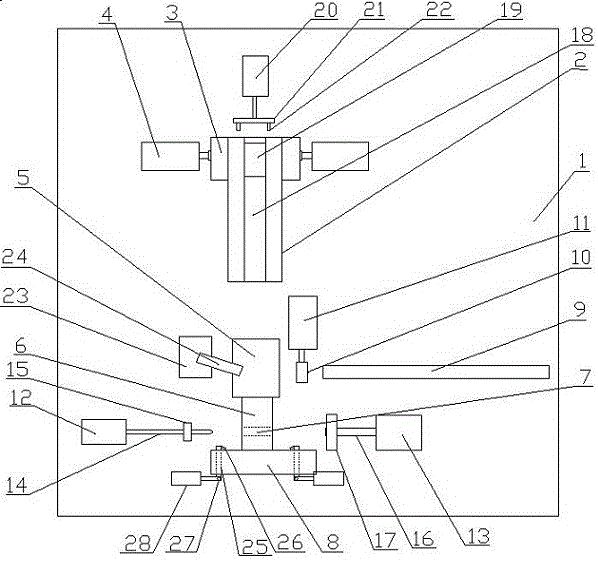

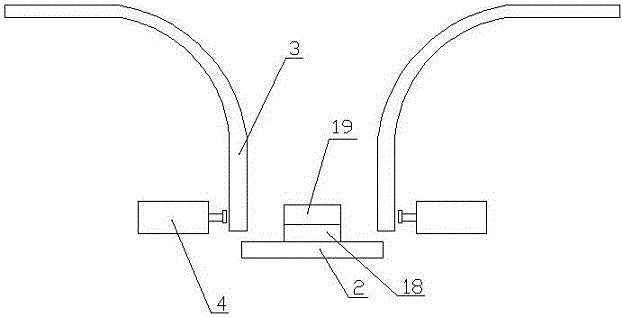

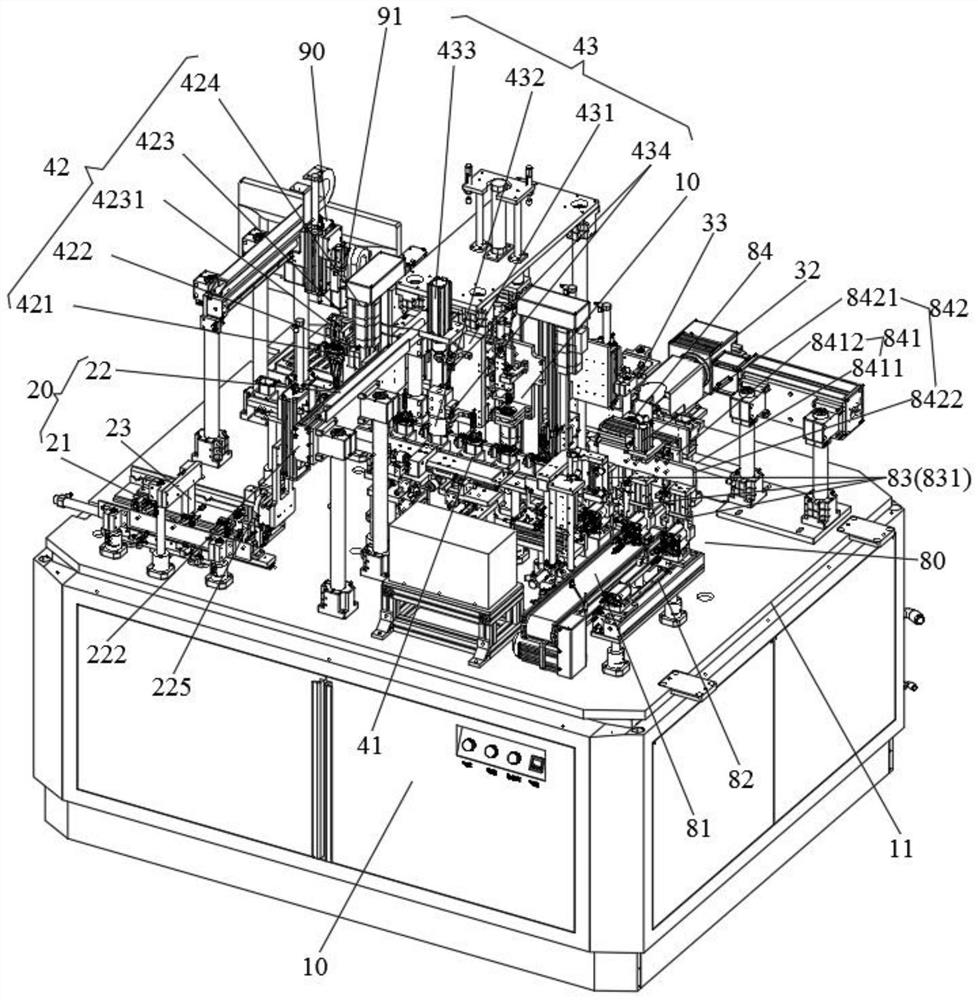

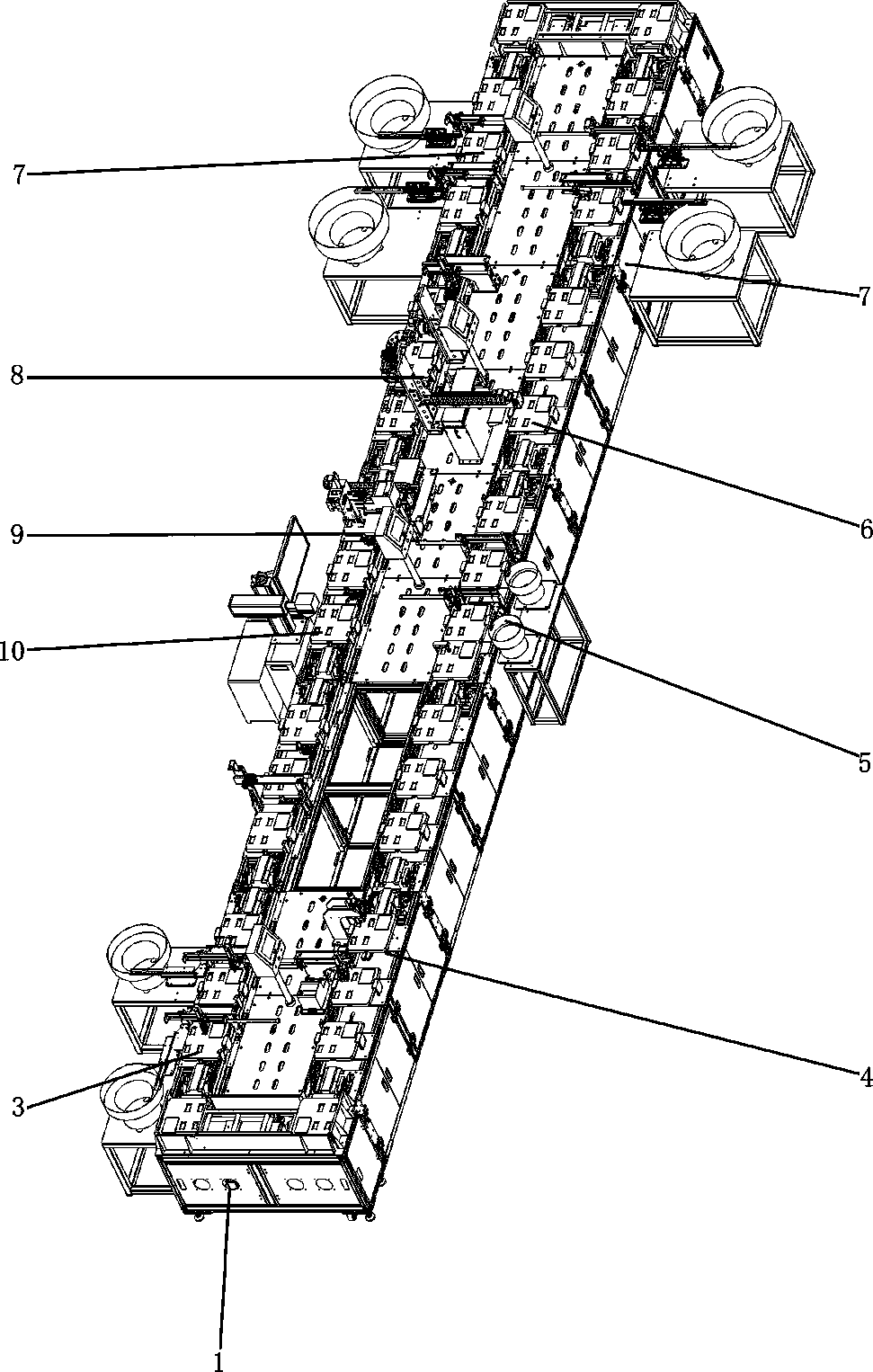

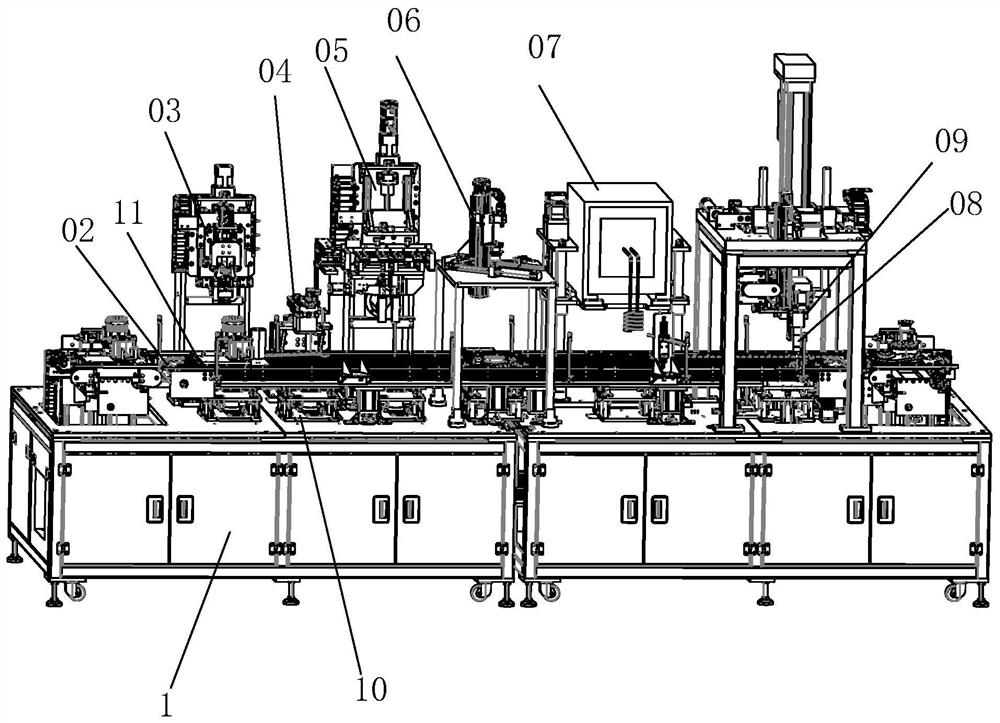

Intelligent assembly testing production line of hydraulic plunger pump

ActiveCN102922282ARealize automatic cycle transportationImprove work efficiencyAssembly machinesAssembly lineManufacturing line

The invention discloses an intelligent assembly testing production line of a hydraulic plunger pump. The intelligent assembly testing production line of the hydraulic plunger pump is characterized by comprising a branch line assembly line and a main line assembly line, wherein the branch line assembly line comprises a branch line conveyer line and assembly tables which are orderly arranged on the branch line conveyer line, and the main line assembly line comprises a main line conveyer line and assembly tables which are orderly arranged on the main line conveyer line. Compared with the prior art, the intelligent assembly testing production line of the hydraulic plunger pump has the following advantages and effects that the structure design is more reasonable; automatic transportation of a workpiece is achieved; automatic detection and automatic assembly are achieved; a computer is adopted to measure and control; the systematization and the datamation of the assembly lines are achieved; the data of an accepted product and an rejected product can be traced; the production efficiency is improved; the labor intensity is reduced; the labor cost is reduced; the production efficiency is improved, and assembly and production of 2-3 similar standardized products can be achieved.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

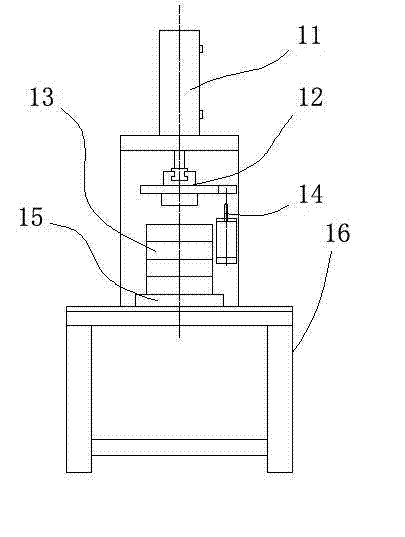

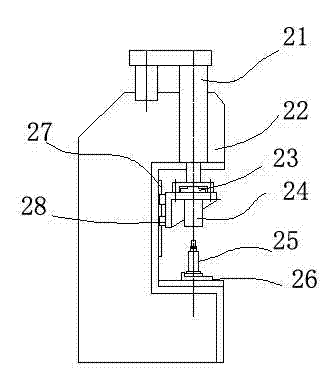

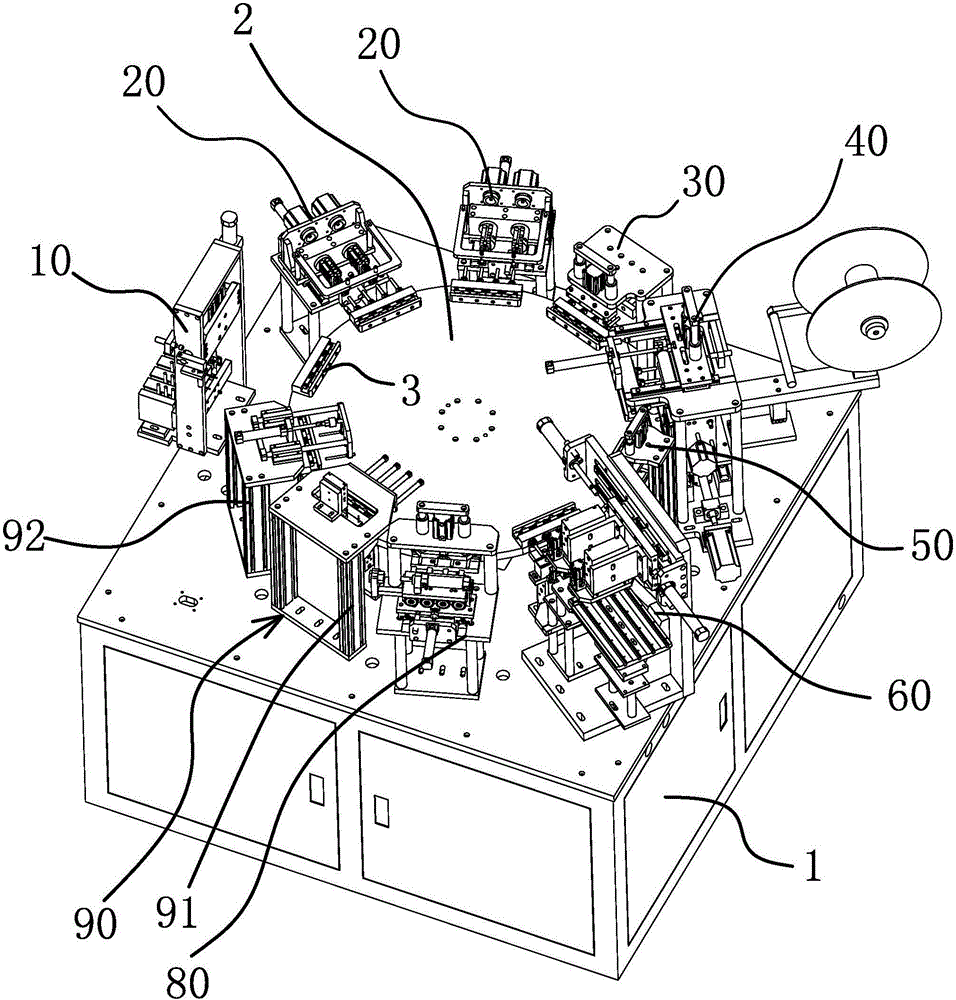

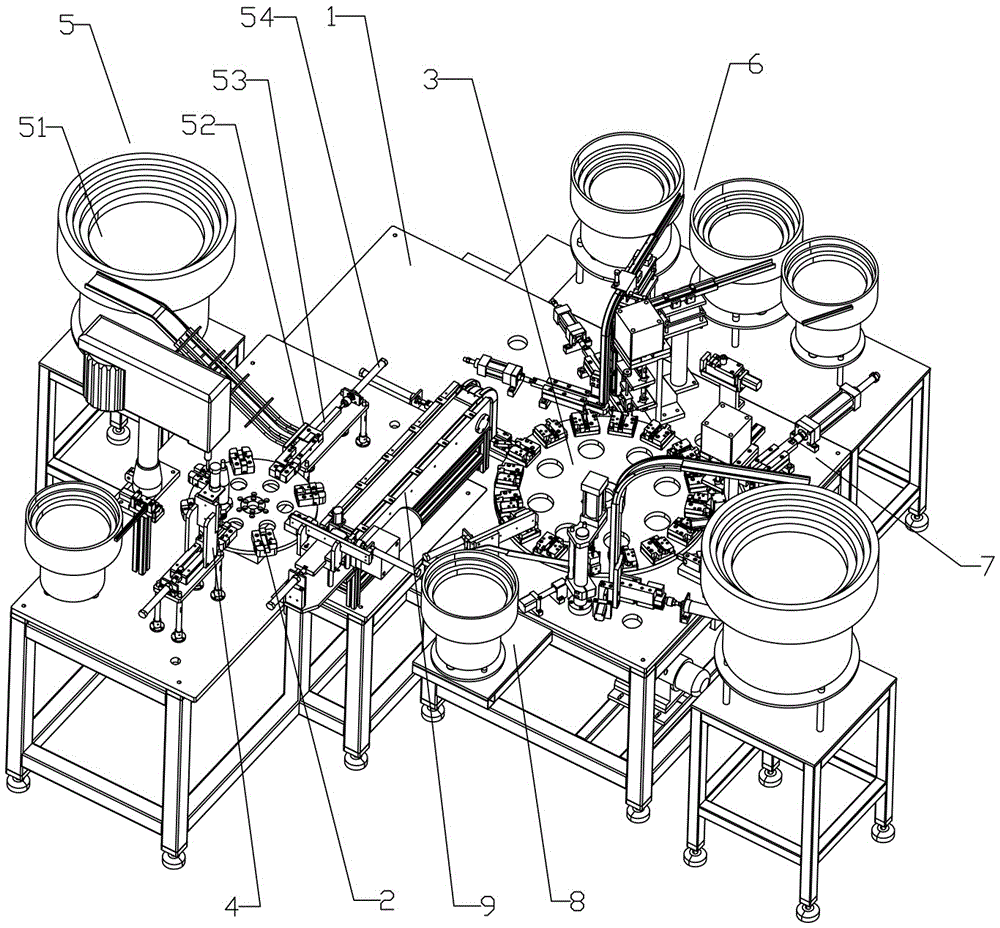

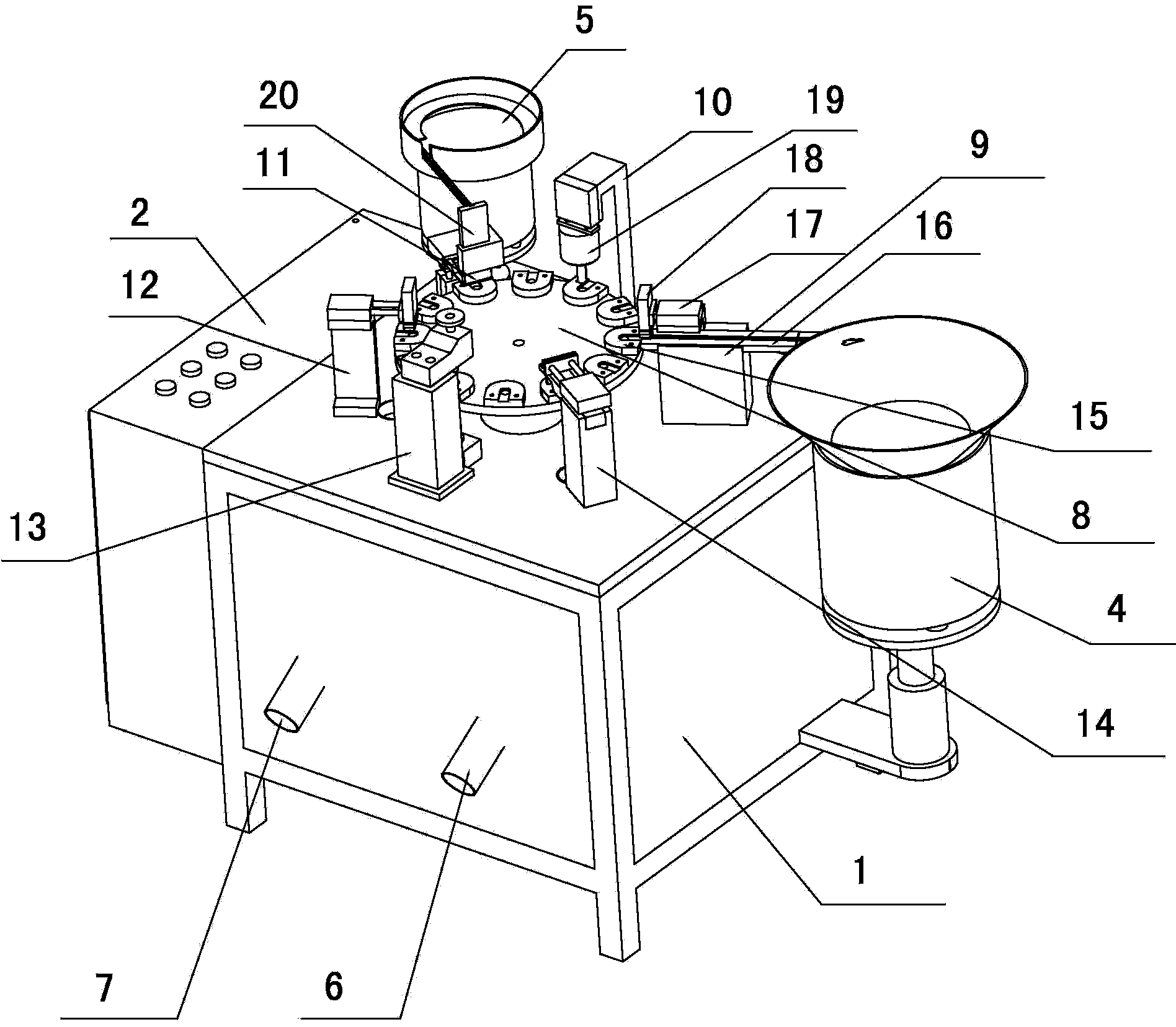

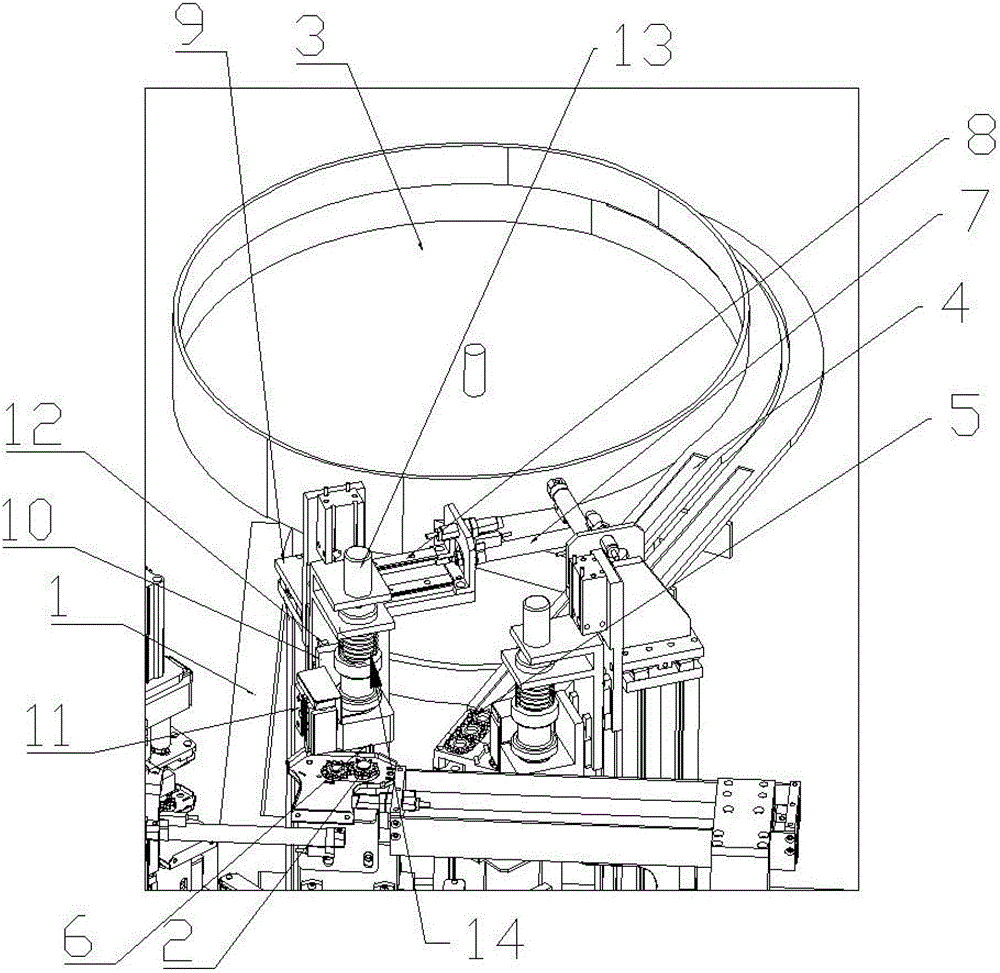

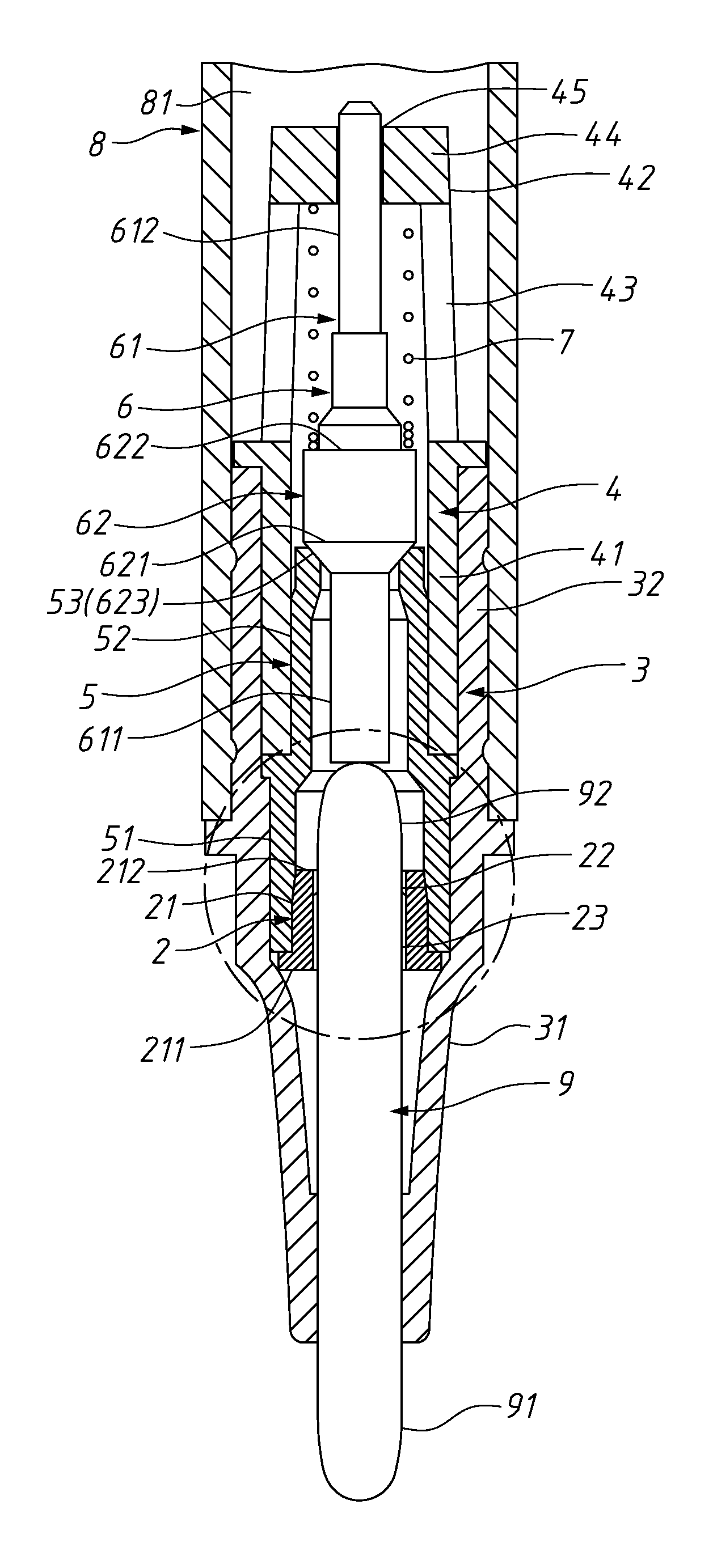

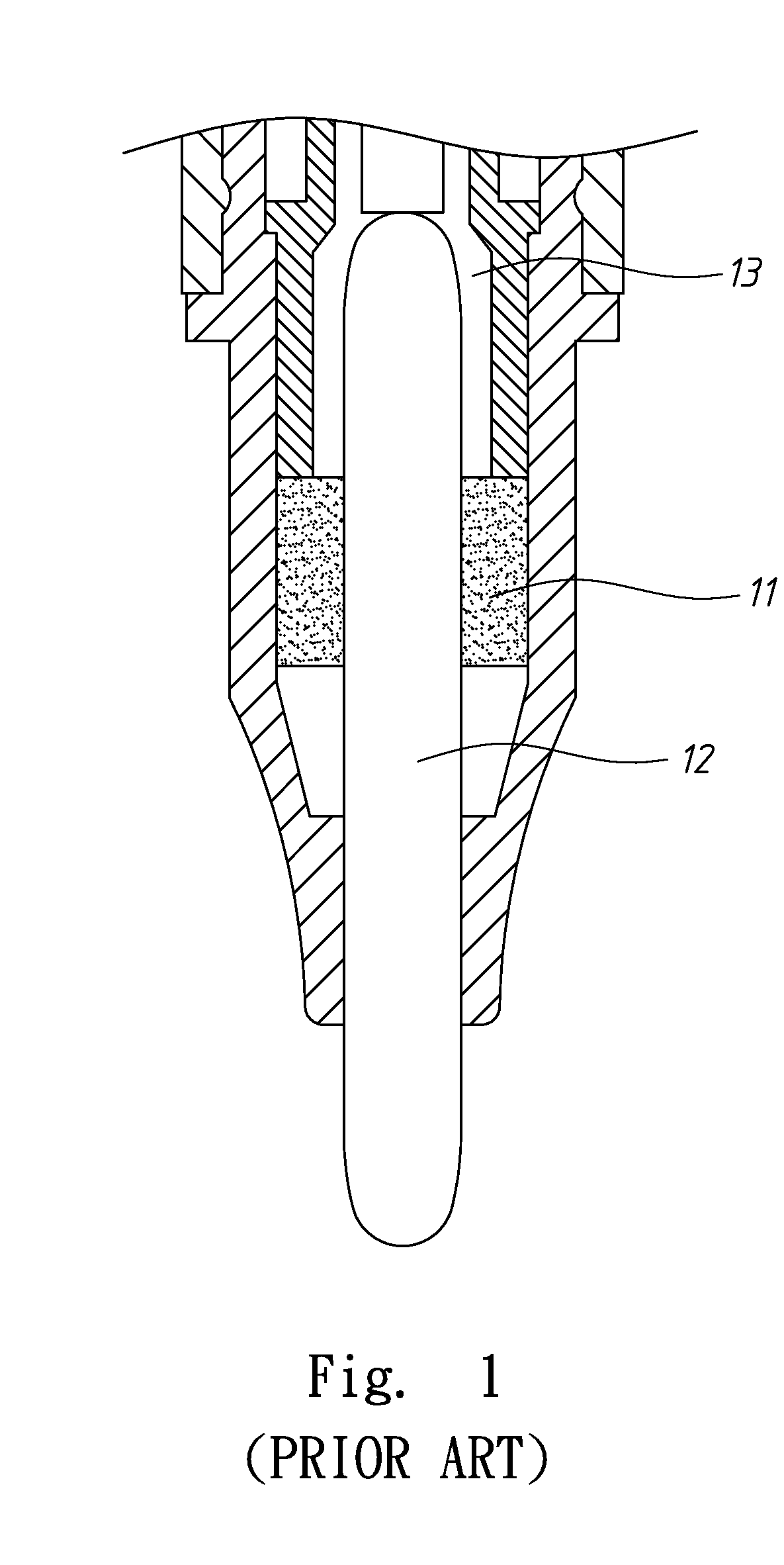

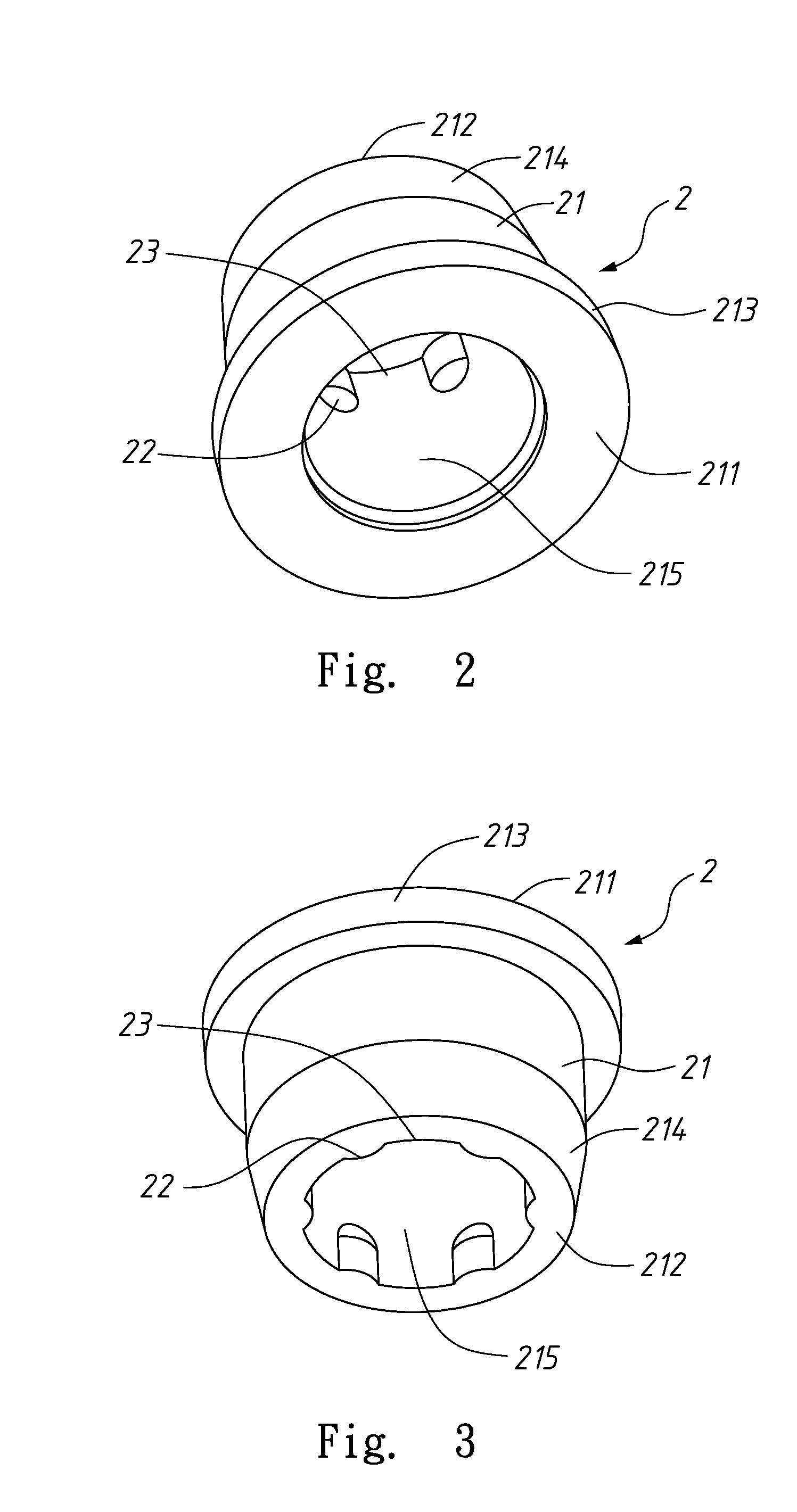

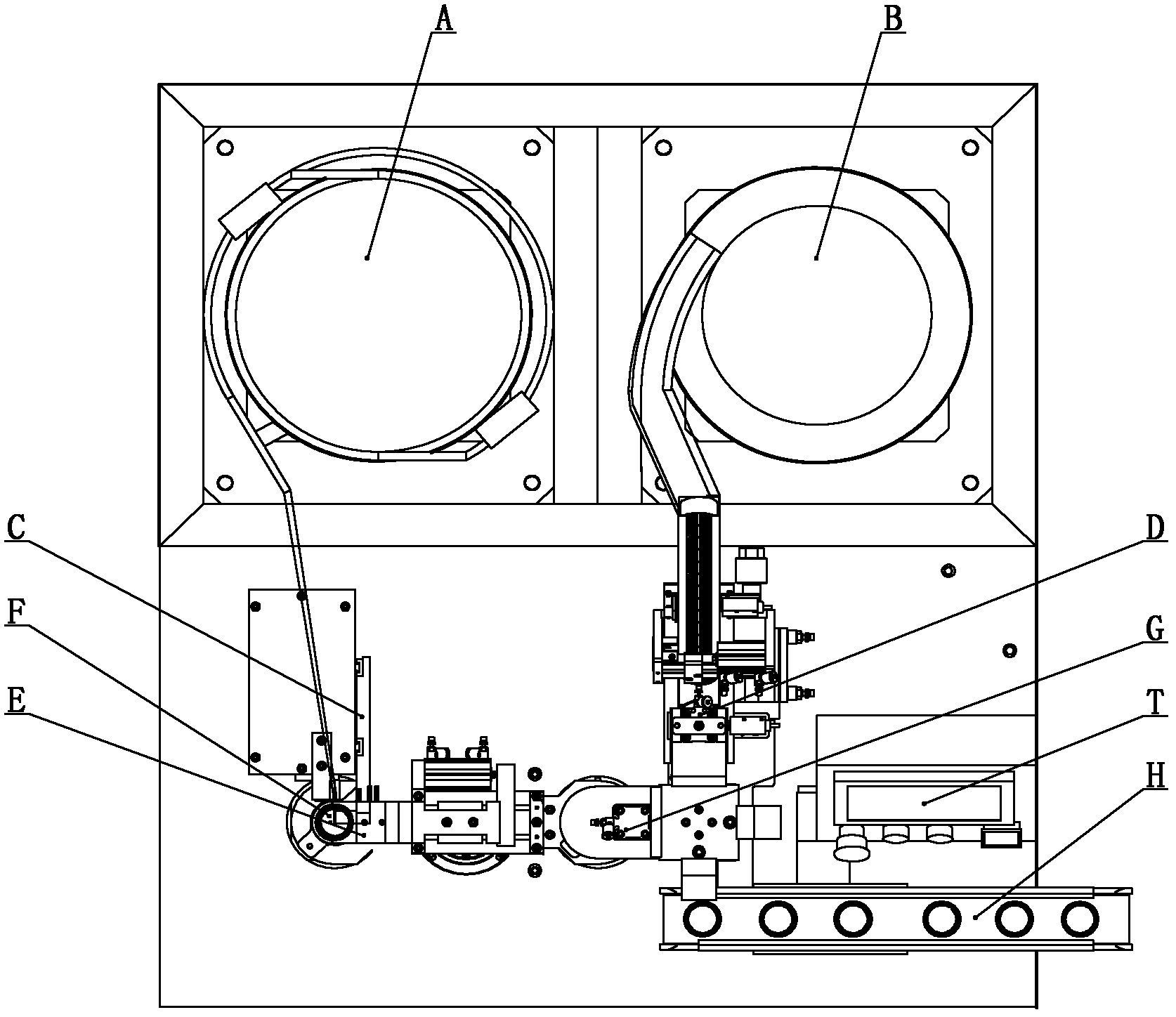

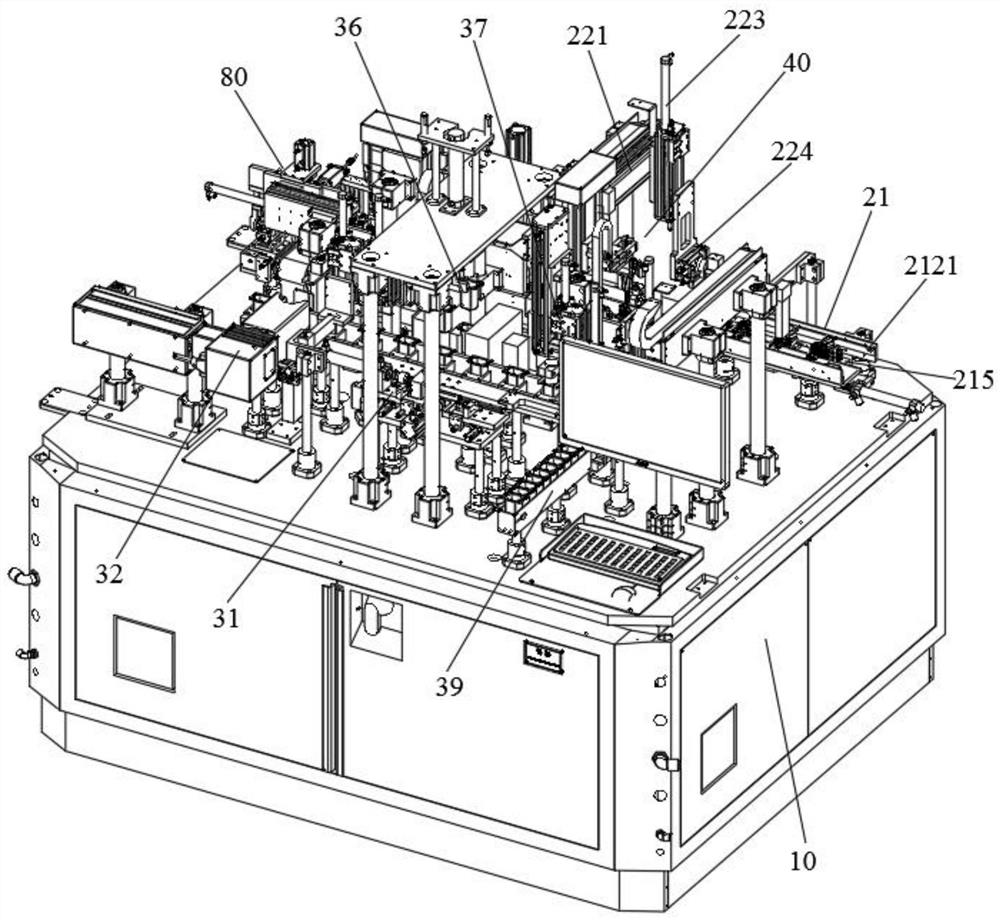

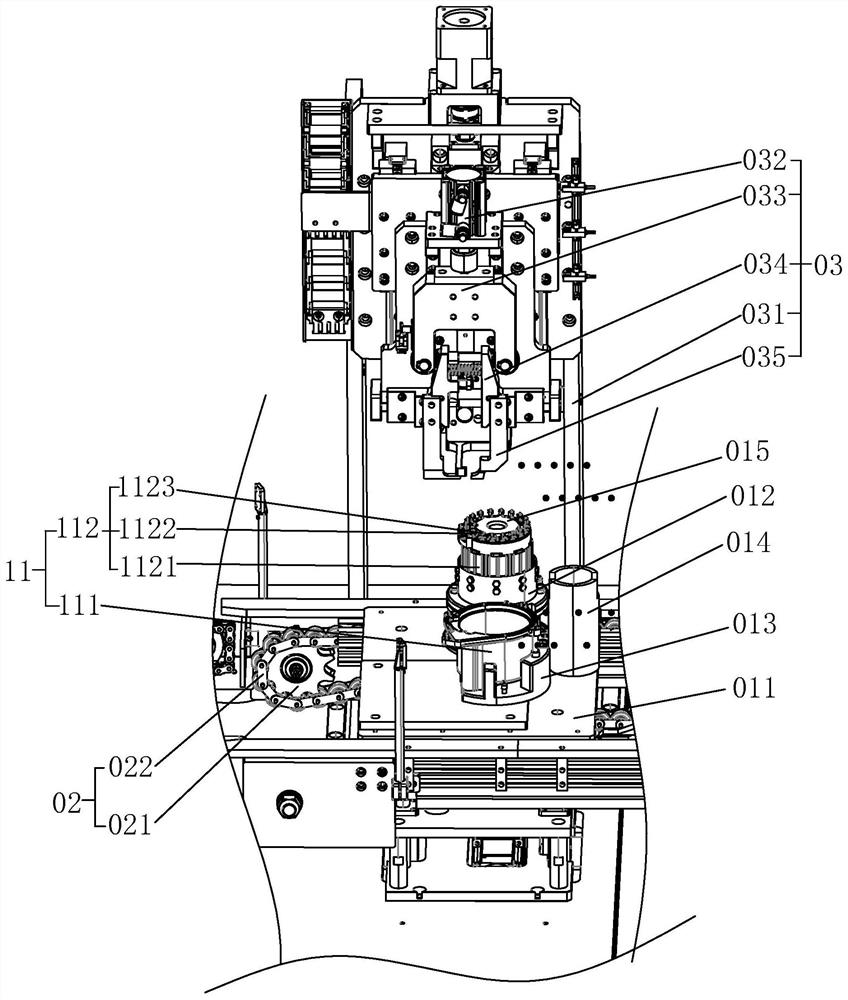

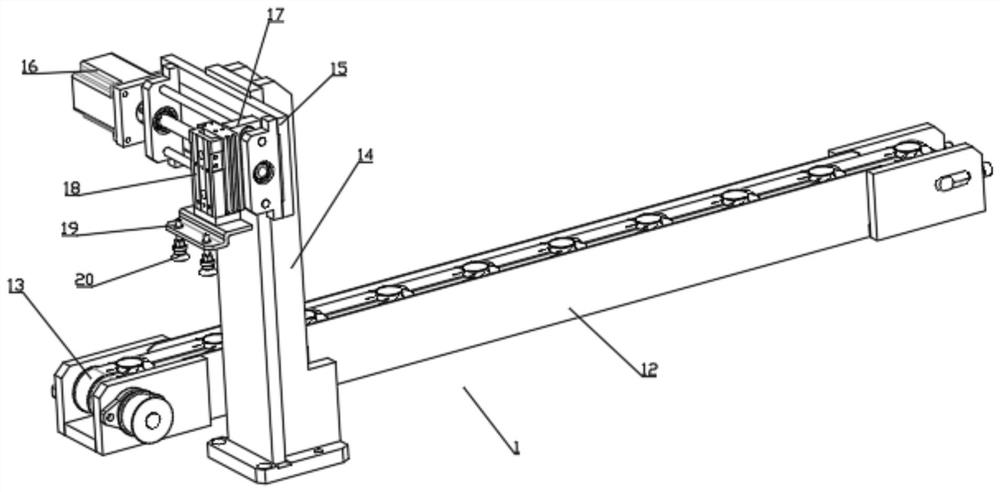

Assembling device of plastic needle assembly of infusion apparatus

ActiveCN105108492AAutomate assemblyIncrease productivityAssembly machinesMetal working apparatusPunchingAssembly machine

The invention provides an assembling device of a plastic needle assembly of an infusion apparatus, and belongs to the technical field of infusion apparatus assembling machines. The technical problem that a plastic needle assembly cannot be automatically assembled in the prior art, so that efficiency is low is solved. The assembling device comprises a machine frame. The machine frame is provided with an index plate which can rotate around the axis of the index plate relative to the machine frame in the horizontal direction. A clamp for positioning a plastic needle body is fixed to the edge of the index plate. An upper film station fixed to the machine frame and used for assembling a filter film on an exhaust hole in the plastic needle body is arranged on the periphery of the index plate. The upper film station comprises an upper film support. A film punching assembly is fixed to the middle of the upper film station. A feeding tray used for conveying filer film paper is fixed to the rear portion of the upper film support. According to the assembling device, automatic plastic needle assembling can be achieved, and therefore production efficiency is improved; meanwhile, manual contact is avoided, and the hygiene level is improved.

Owner:浙江东美智能设备有限公司

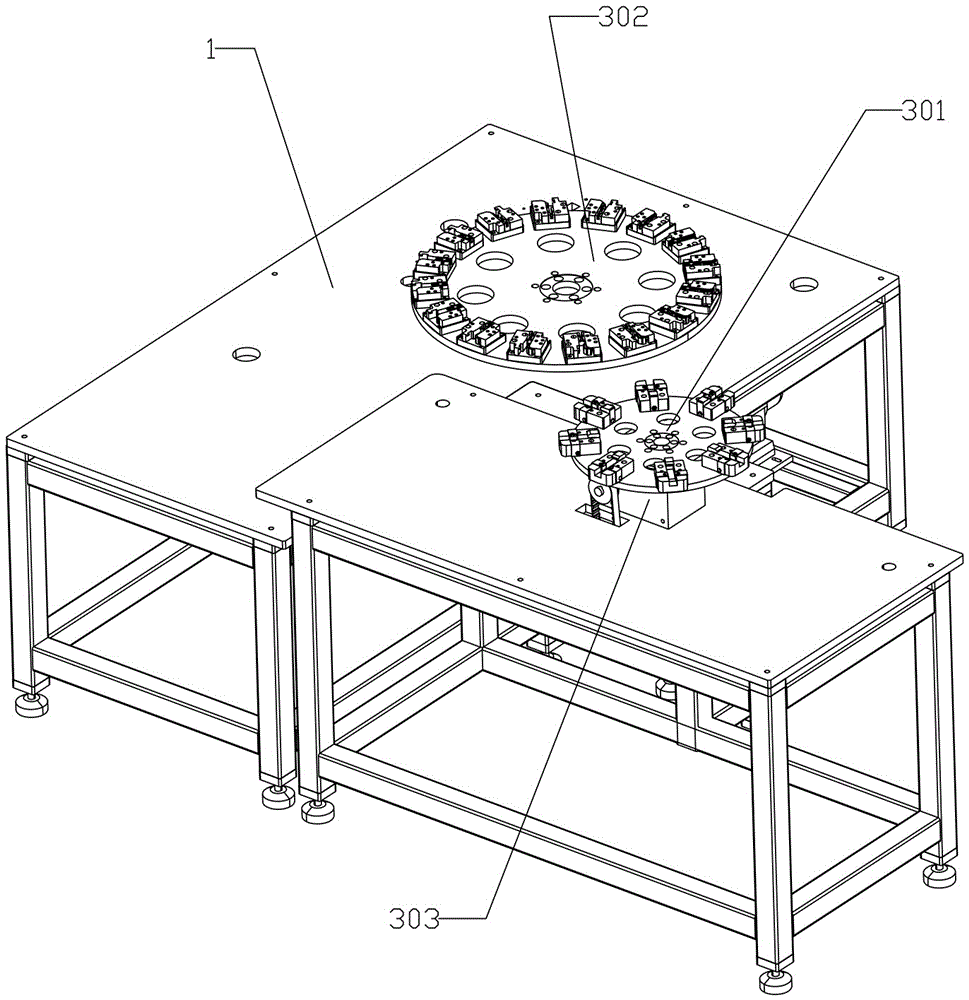

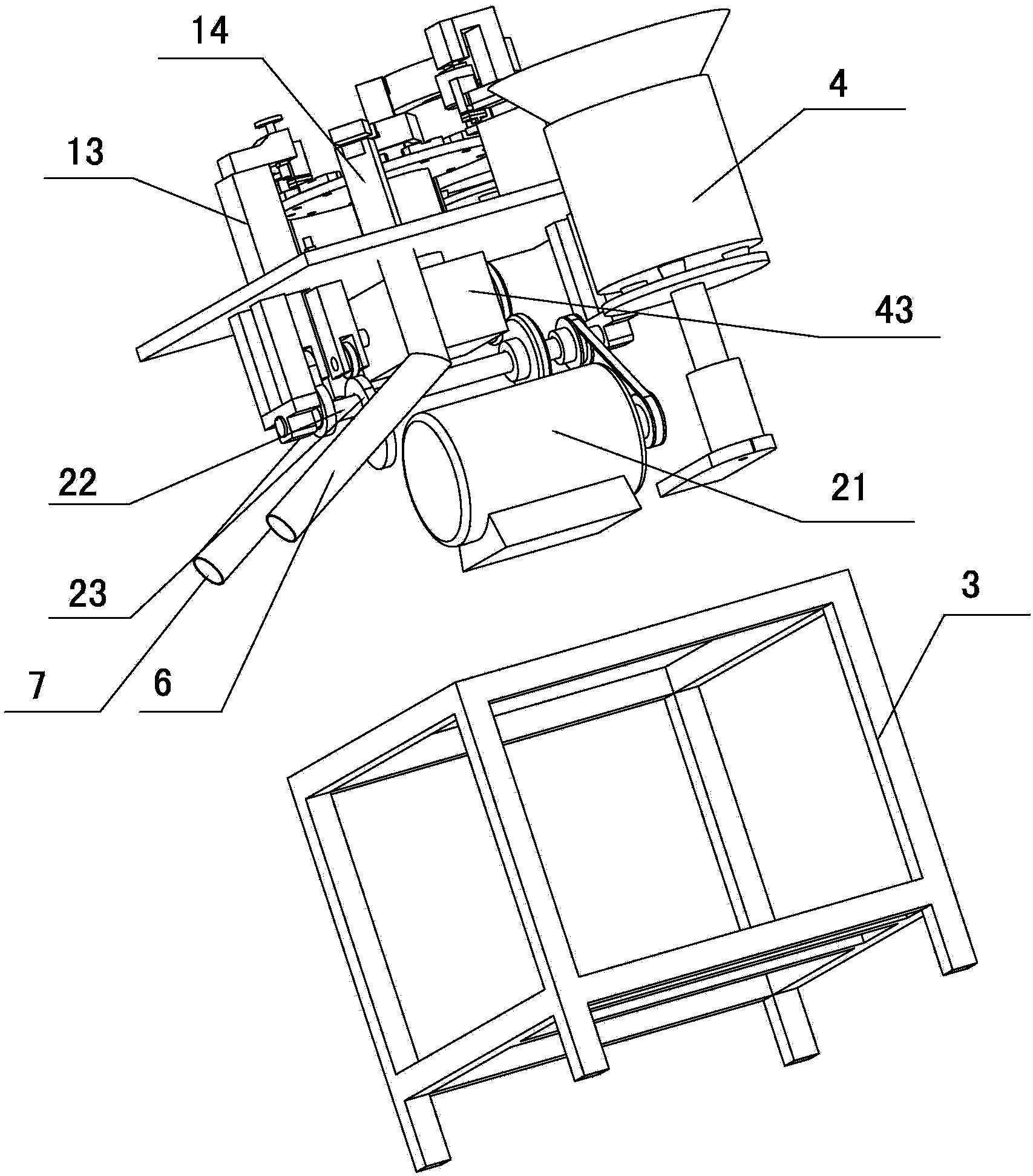

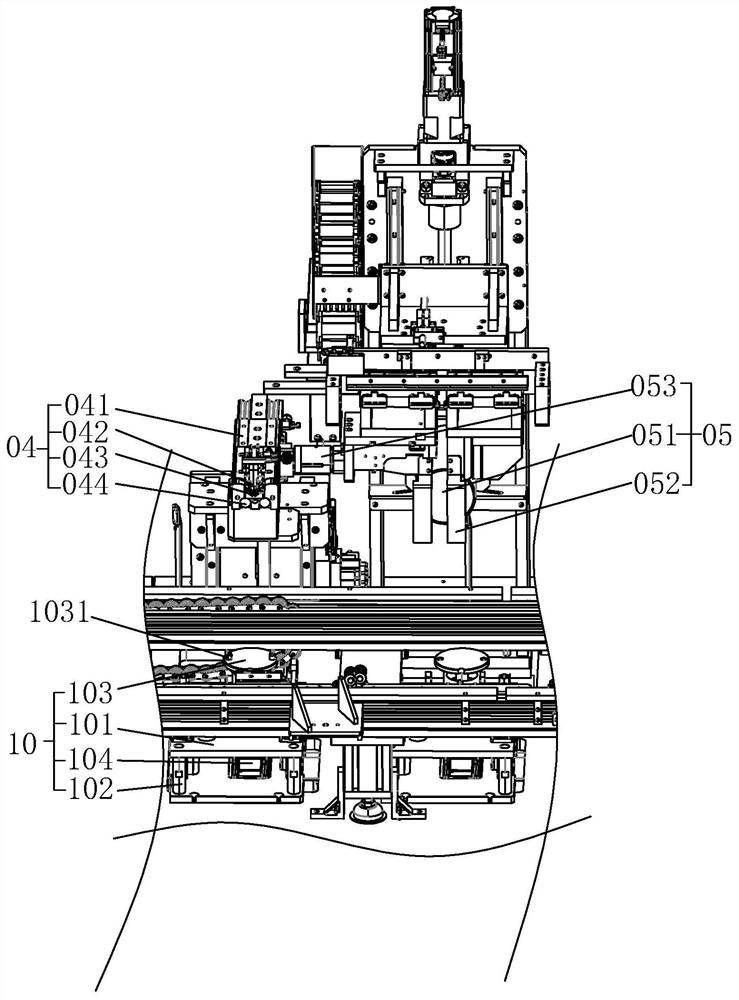

Automatic hinge assembly equipment

InactiveCN105522381AHigh degree of automationImprove stabilityPrecision positioning equipmentAssembly machinesTorsion springAutomation

The invention discloses automatic hinge assembly equipment. The automatic hinge assembly equipment comprises a frame, and is characterized in that the frame is provided with a rotating transmission mechanism with an assembly station, and a screw screwing mechanism, an adjusting block assembly mechanism, a torsion spring rocking rod assembly mechanism, a crank assembly mechanism and a hinge cup assembly mechanism arranged around the rotating transmission mechanism in sequence. The automatic hinge assembly equipment is high in stability and automation degree.

Owner:QINGYUAN SACA PRECISION MFG CO LTD

Slab construction system and method for constructing multi-story buildings using pre-manufactured structures

ActiveUS9493940B2Reduce material wasteReduce energy costsCovering/liningsWallsDesign planArchitectural engineering

The present invention integrates the use of pre-manufactured structures with minimal on-site installation and lift-slab construction to achieve the construction of multi-story buildings. The pre-manufactured structures are designed to be readily integrated with both horizontal and vertically adjacent building components, including lift-slab components, so that multiple building stories may be readily and securely stacked, one on top of the other. The present invention advantageously permits top-down lift-slab construction for multi-story buildings. The present invention also provides for the development of flexible design plans for institutional, residential, office and other types of buildings. The present invention advantageously provides for easier, more efficient, faster, cheaper, safer, higher quality and more consistent, environmentally advantaged, energy-efficient, easier to maintain, intelligently designed, and customizable multi-story building construction.

Owner:INNOVATIVE BUILDING TECH

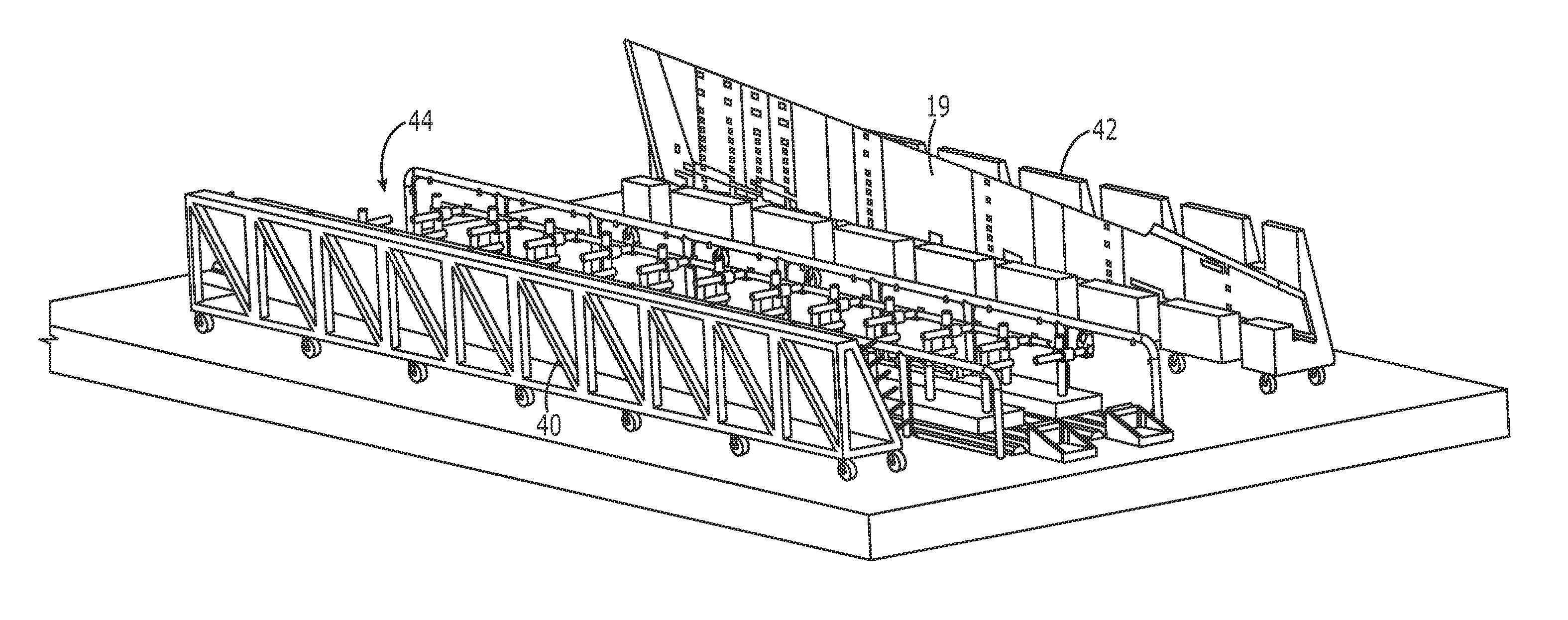

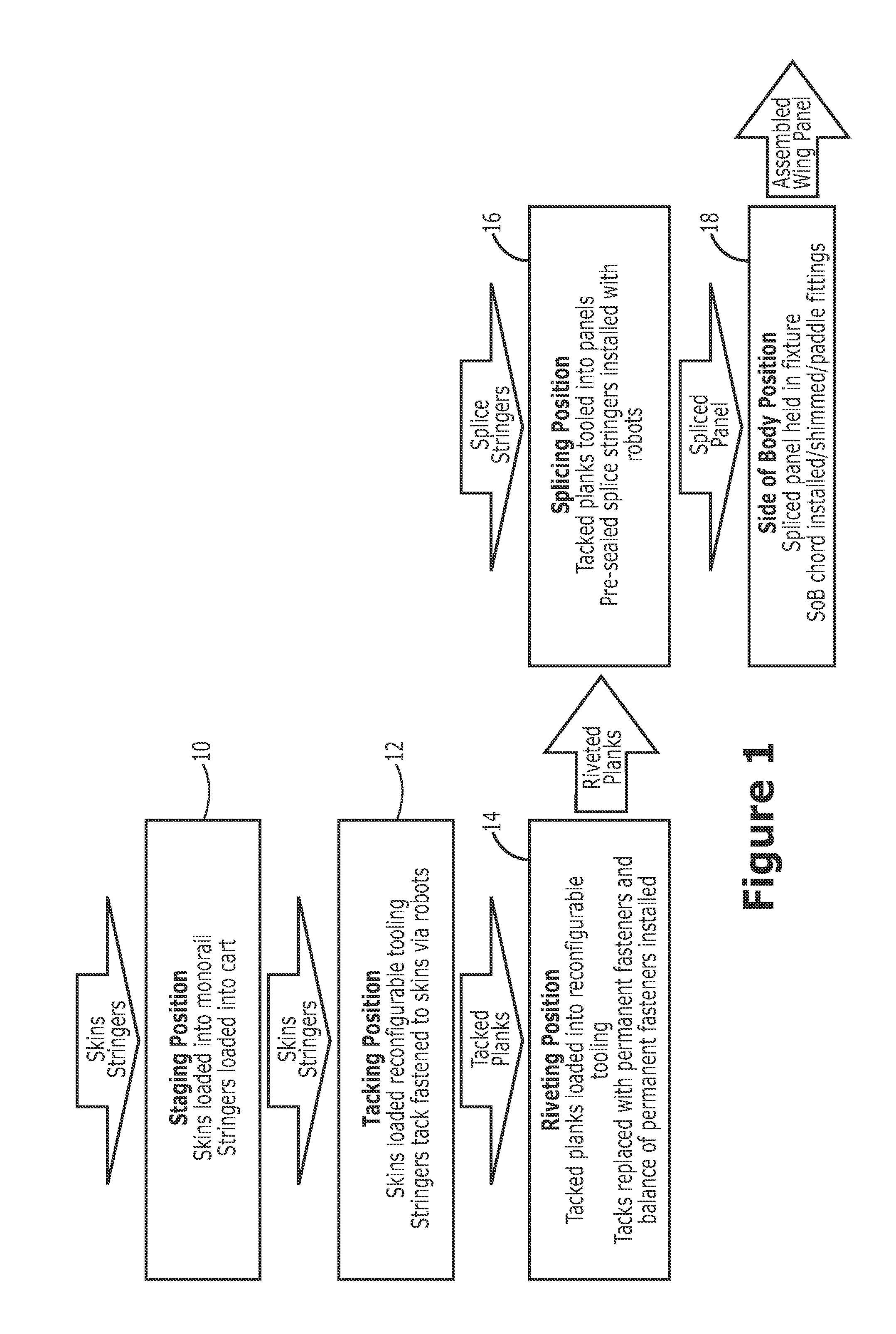

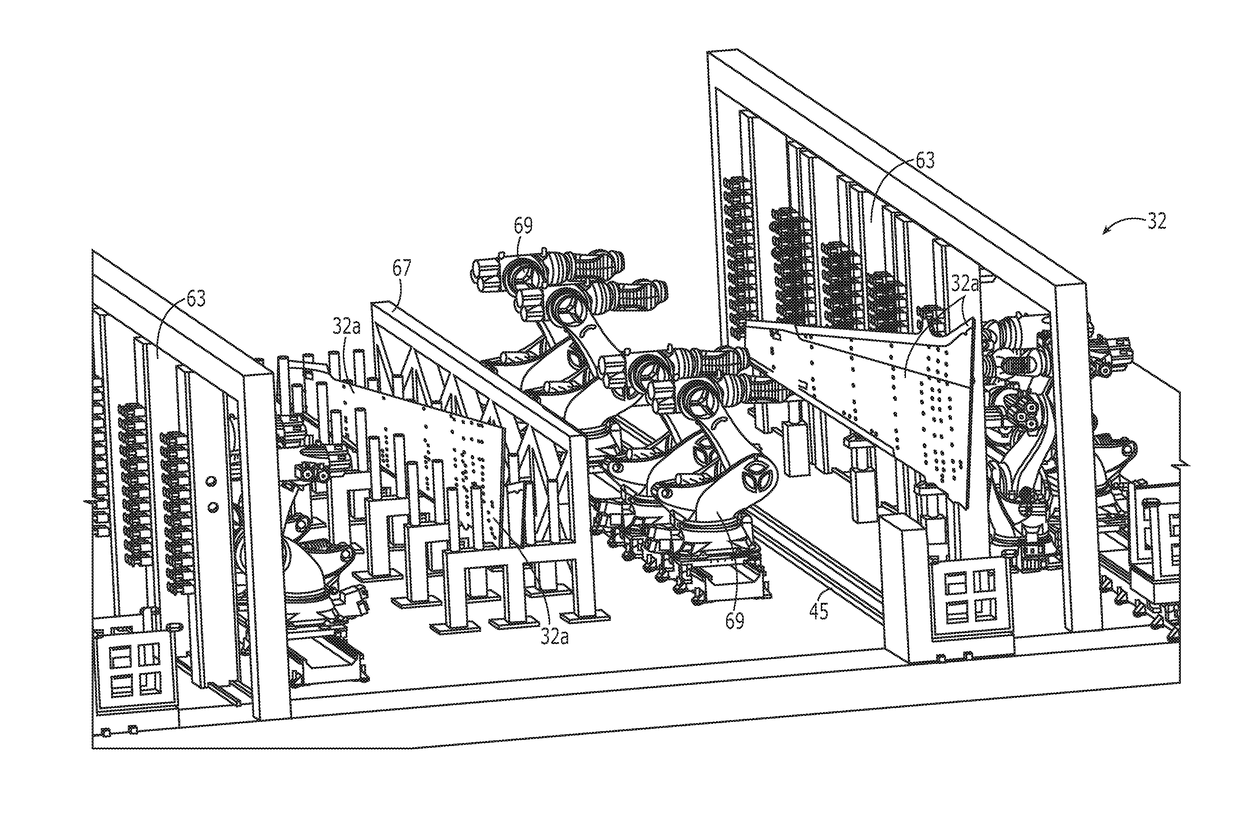

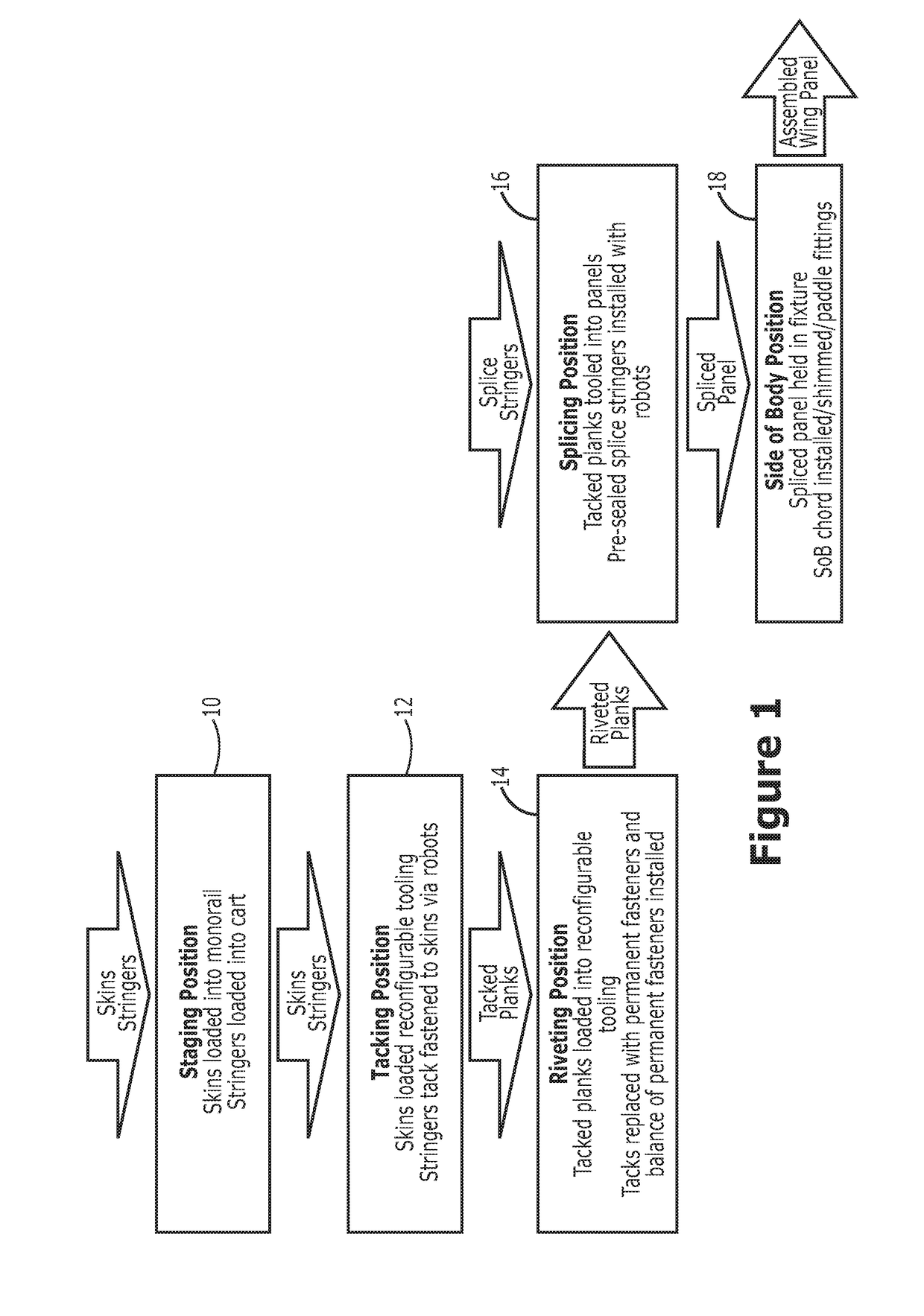

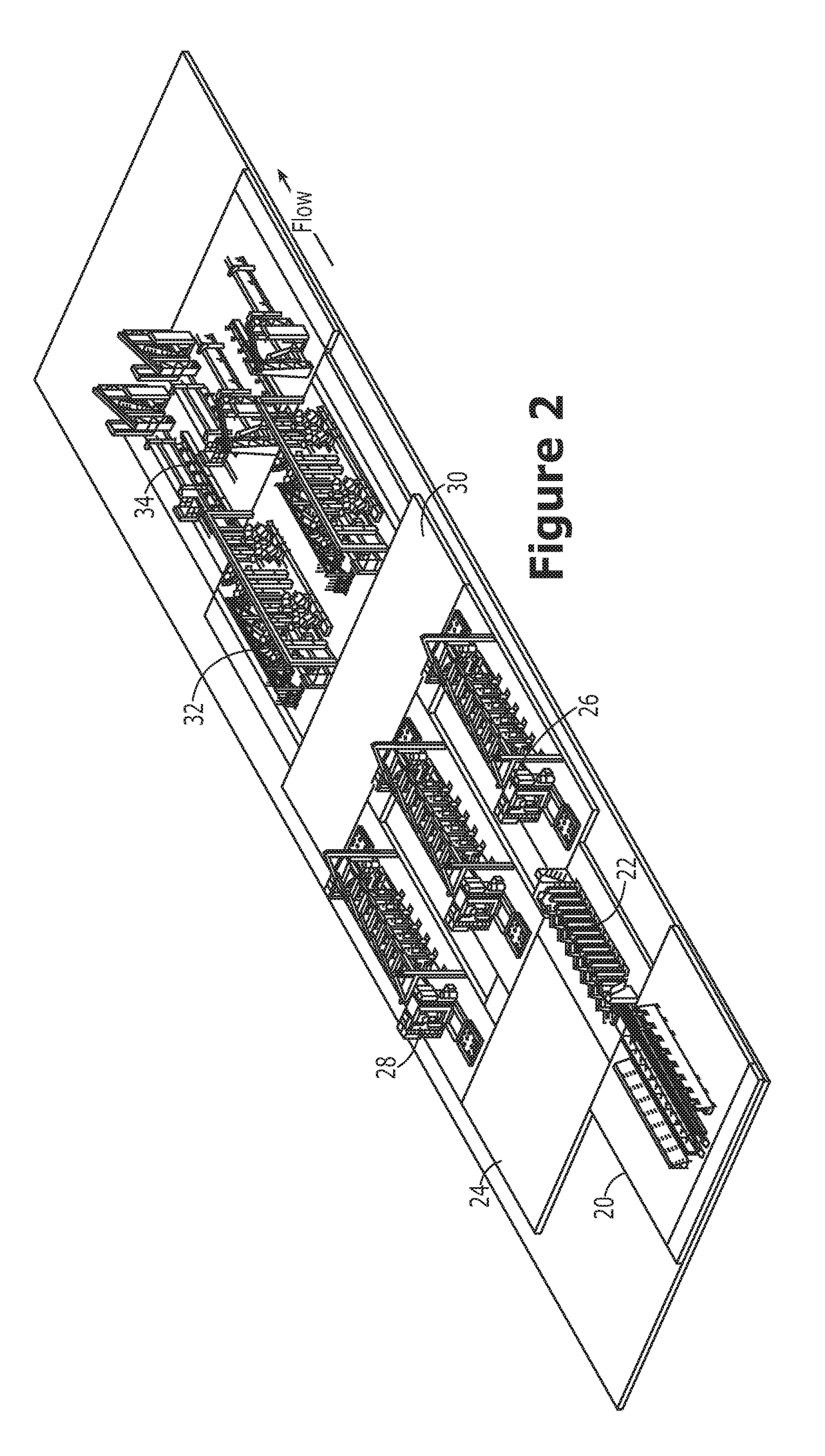

System and method for manufacturing a wing panel

ActiveUS20140090252A1Automate assemblyFast preparationAssembly machinesAircraft assemblyEngineeringTissue skin

A system and method are provided to automate the assembly of a wing panel, such as utilized by commercial aircraft. In the context of a system, a tacking cell is provided that is configured to tack one or more stringers to a skin plank. The system also includes a riveting cell configured to receive a tacked plank from the tacking cell and to rivet the one or more stringers to the skin plank. The system also includes a splicing cell configured to receive a plurality of riveted planks from the riveting cell and to attach one or more splice stringers to the plurality of riveted planks. Further, the system includes a side of body cell configured to receive a spliced panel from the splicing cell and to attach a side of body chord thereto to produce a wing panel.

Owner:THE BOEING CO

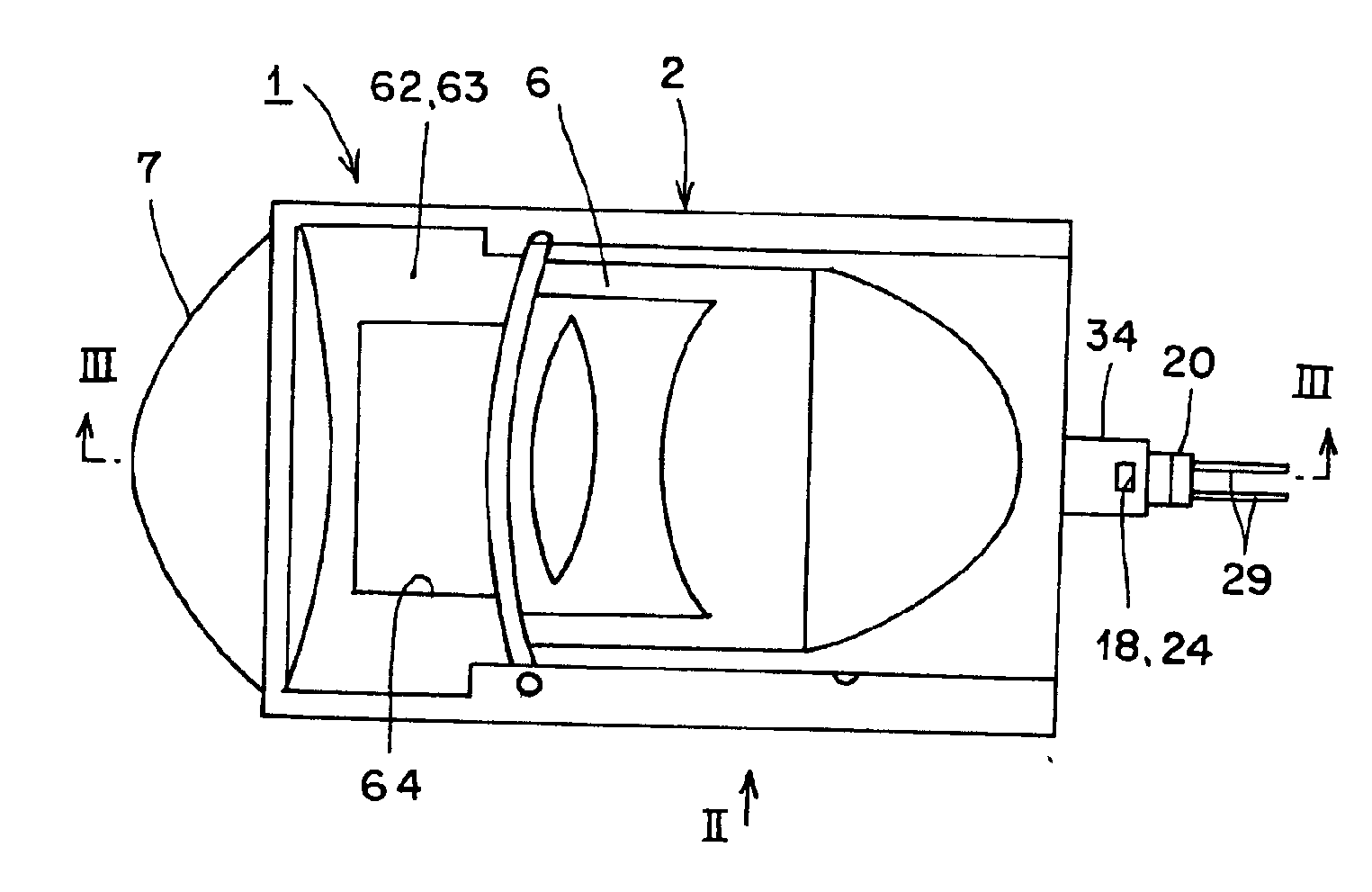

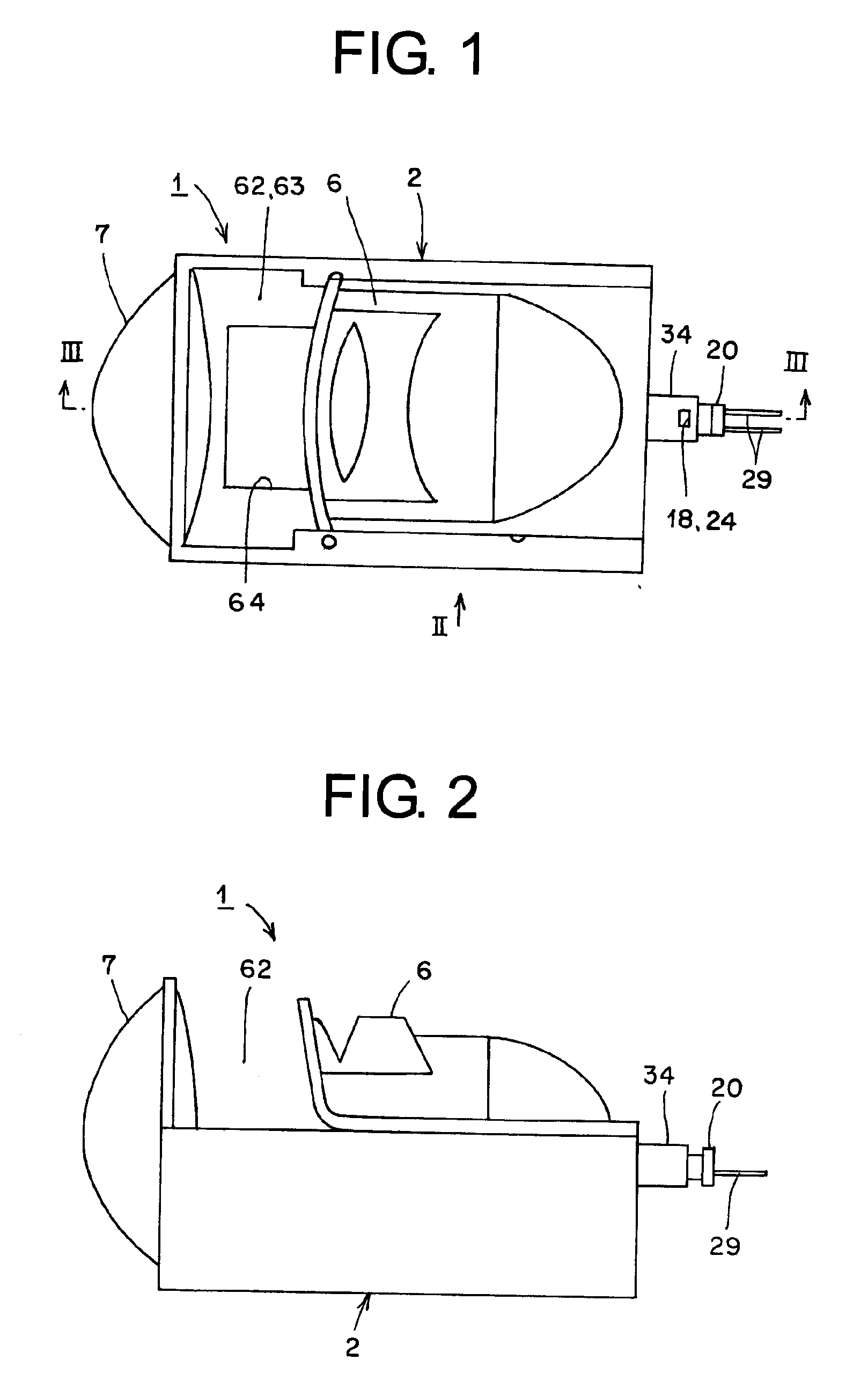

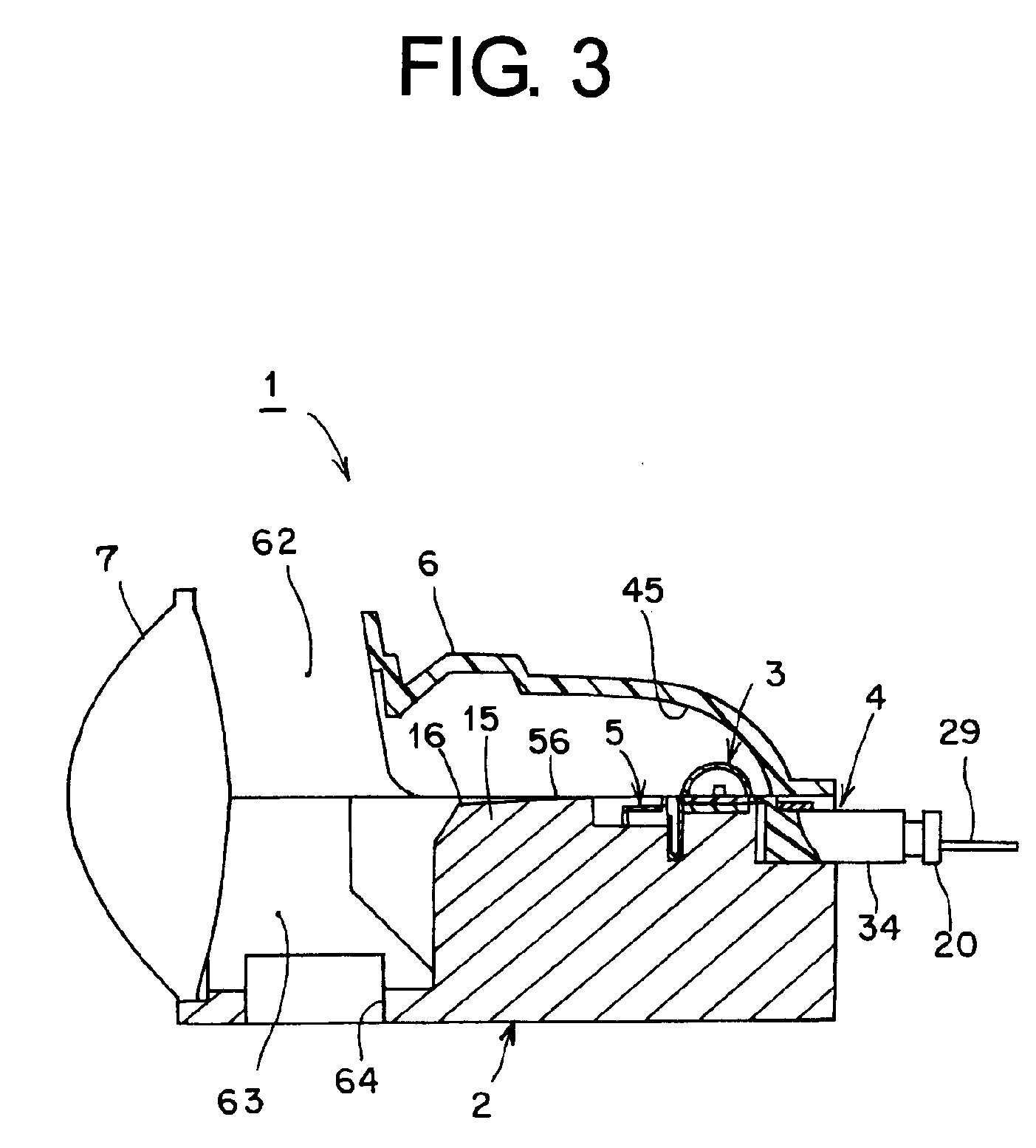

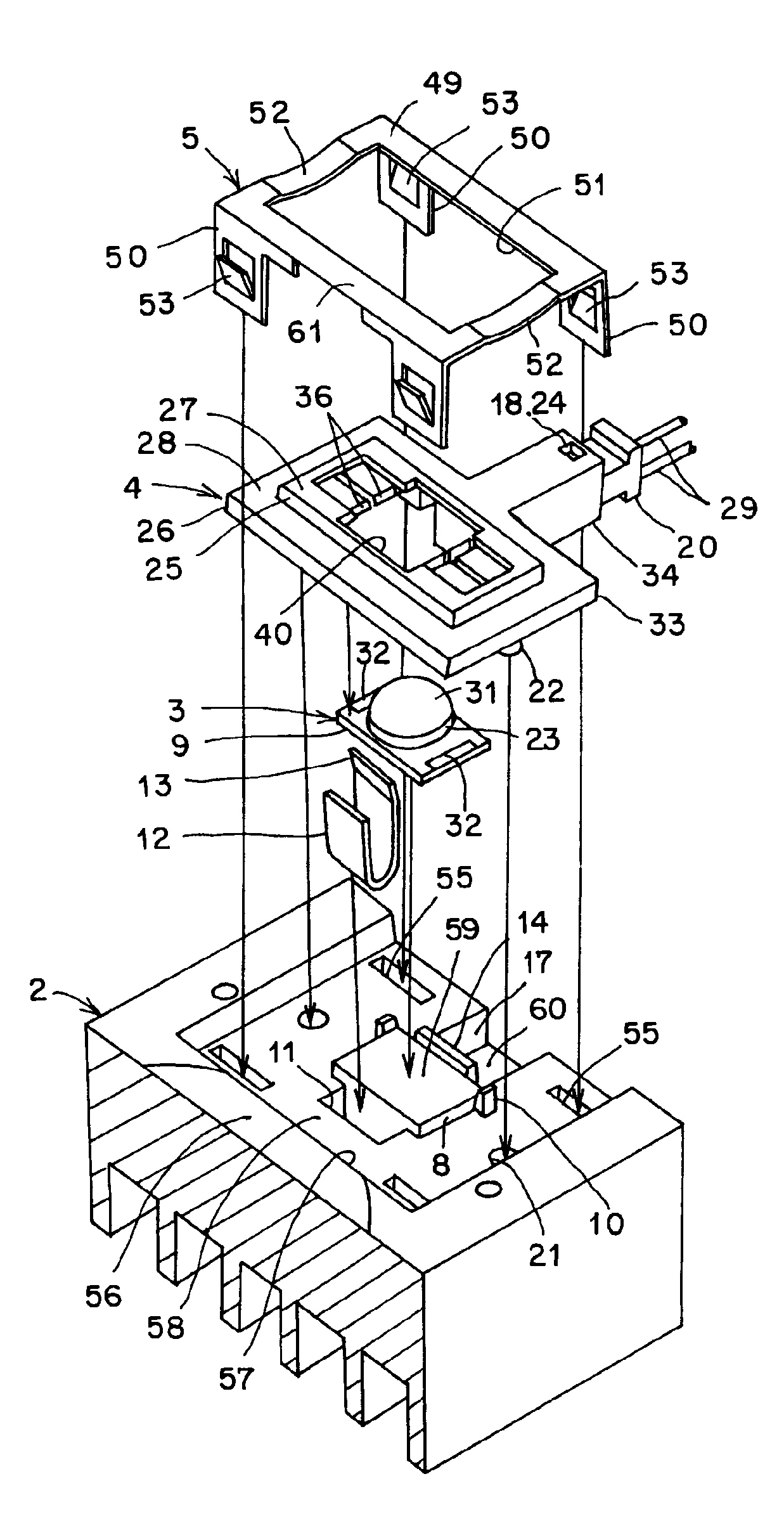

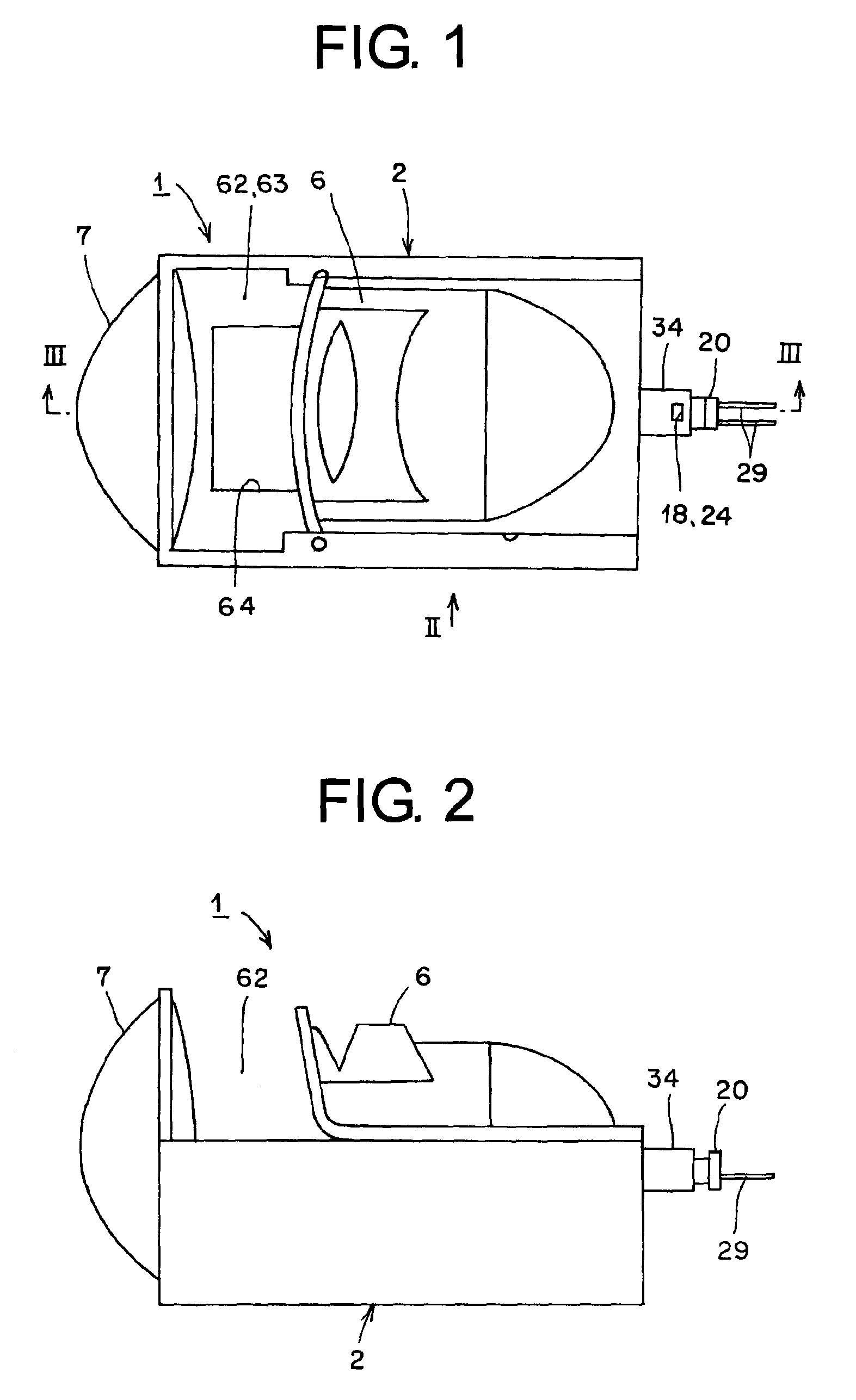

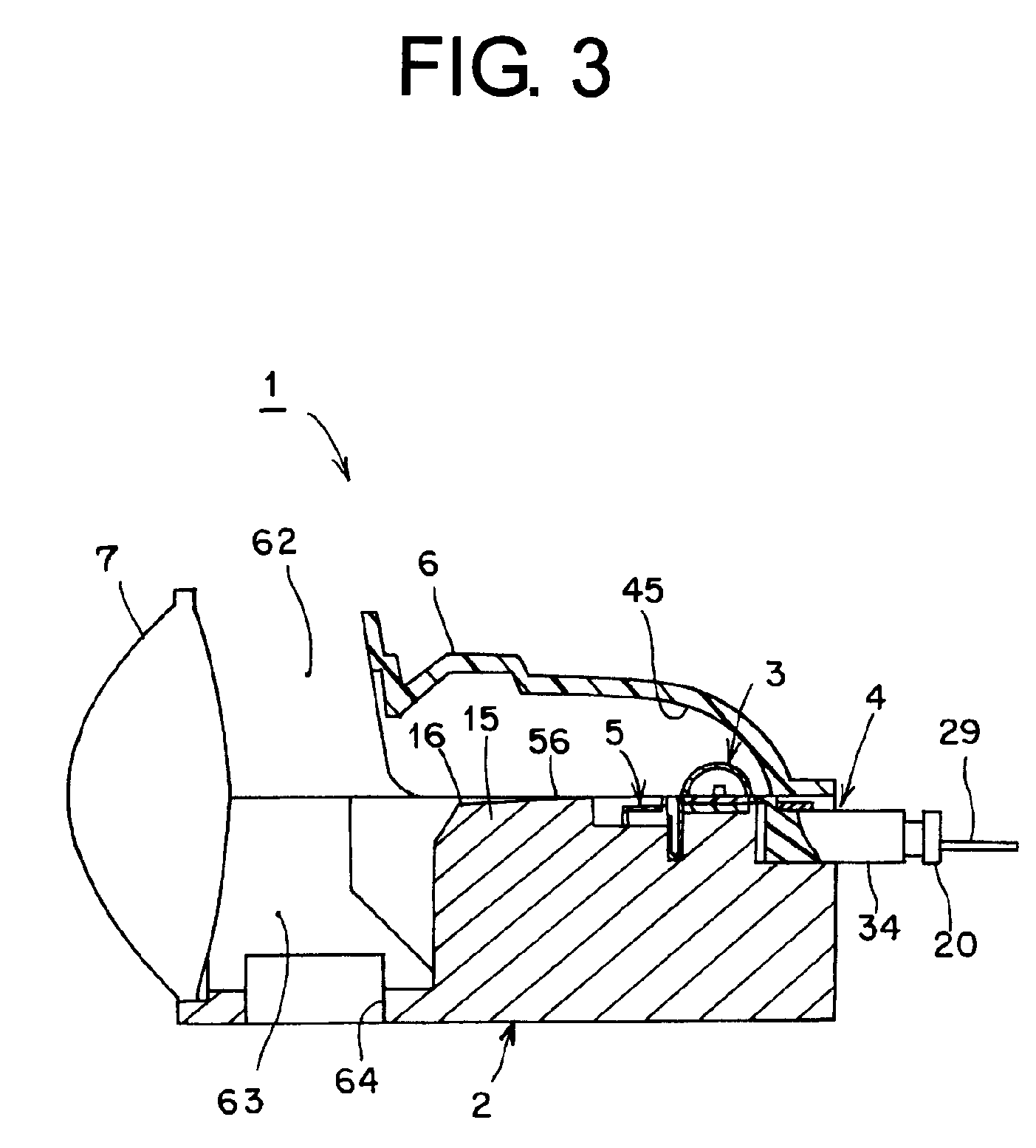

Vehicle lighting device

InactiveUS20100067251A1Improve workabilityAutomate assemblyVehicle headlampsLighting support devicesEffect lightEngineering

A vehicle lighting device includes: a heat sink member; a semiconductor-type light source directly placed on a top face of the heat sink member; a power-feeding holder which is set on the semiconductor-type light source and the heat sink member, for holding the semiconductor-type light source at the side of the heat sink member and feeding a power current to the semiconductor-type light source; and a fixing member which is covered on the power-feeding holder and fixed to the heat sink member, for fixing the power-feeding holder to the heat sink member and sandwiching and fixing the semiconductor-type light source between the power-feeding holder and the heat sink member. As a result, this vehicle light device improves workability of assembling components.

Owner:ICHIKOH IND LTD

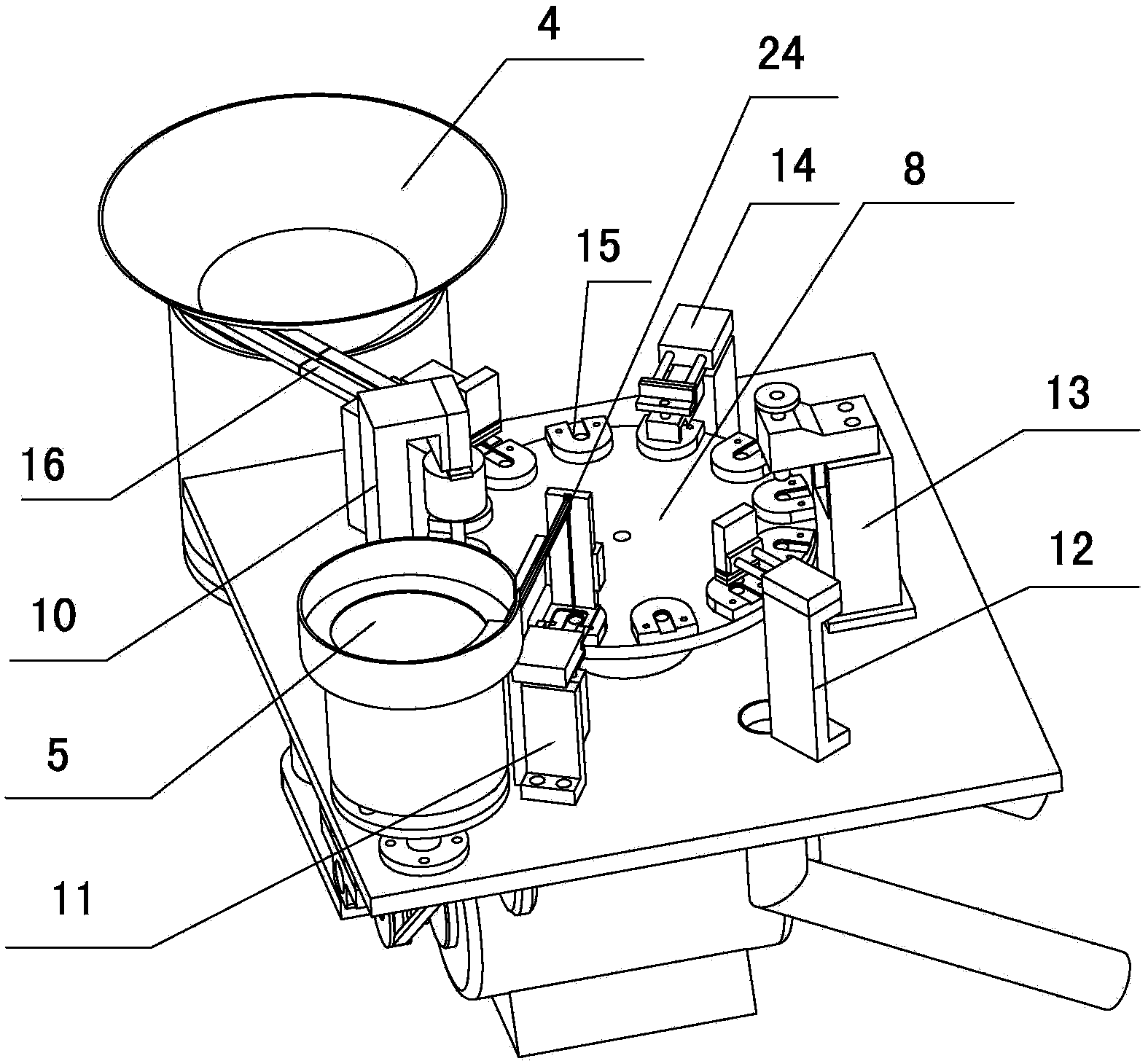

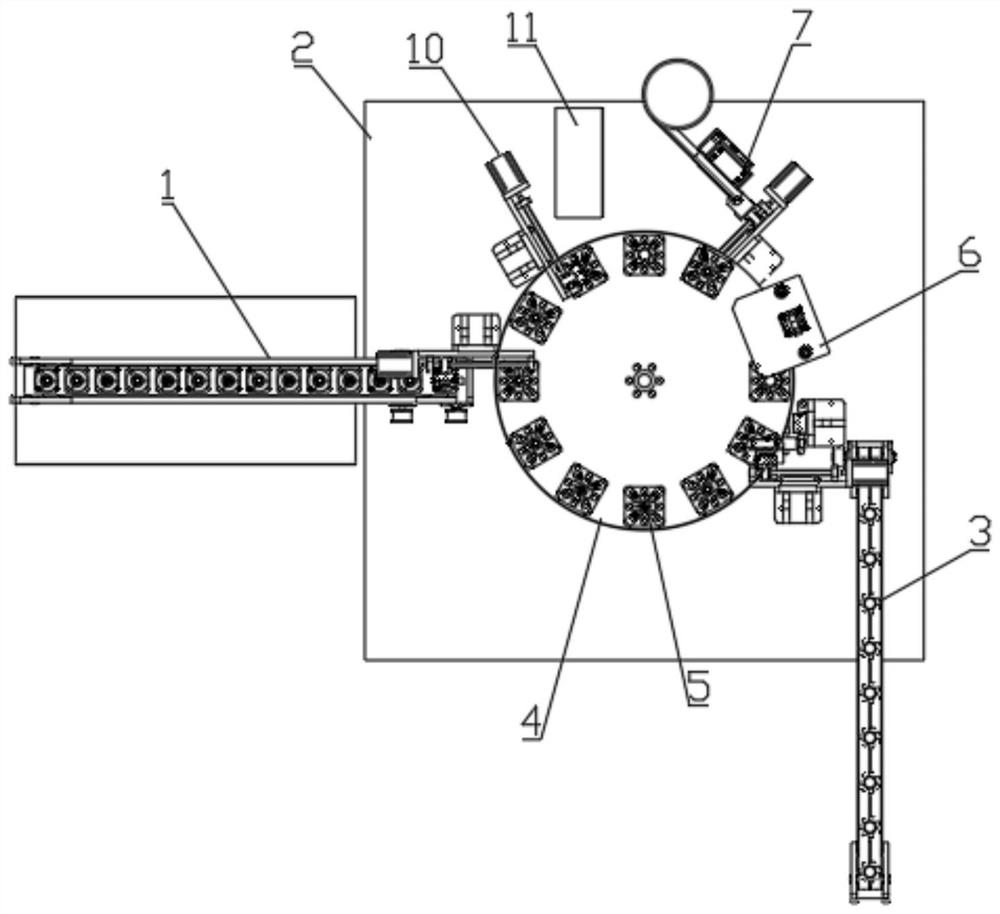

Automatic stub threading equipment for copper clip buttons

InactiveCN104337092AIncrease productivityReduce manufacturing costClothes making applicancesEngineeringCopper

The invention discloses automatic stud threading equipment for copper clip buttons. The equipment comprises a machine case, an electric control box, a working platform, a button vibration disc, a stub vibration disc, a rotary plate, a button feeding device, a button direction adjusting device, a stub feeding device, a press-fitting device and a material returning device, wherein the electric control box is mounted on the machine case; the working platform is mounted above the machine case; the rotary plate is mounted on the working platform; a driving device is used for driving the rotary plate to rotate; more than one jig is mounted on the periphery of the rotary plate; the button feeding device, the button direction adjusting device, the stub feeding device, the press-fitting device and the material returning device are mounted on the working platform in the manner of surrounding the rotary plate at a time by taking the driving direction of the rotary plate as the direction respectively; the button feeding device is arranged corresponding to the outlet of the button vibration disc; the stub feeding device is arranged corresponding to the outlet of the stub vibration disc. The equipment can automatically realize conveying, mounting and stamping of stubs, and completely realizes automatic assembling of the copper clip buttons, so that the production efficiency is greatly improved, and the production cost is reduced.

Owner:深圳市联星服装辅料有限公司

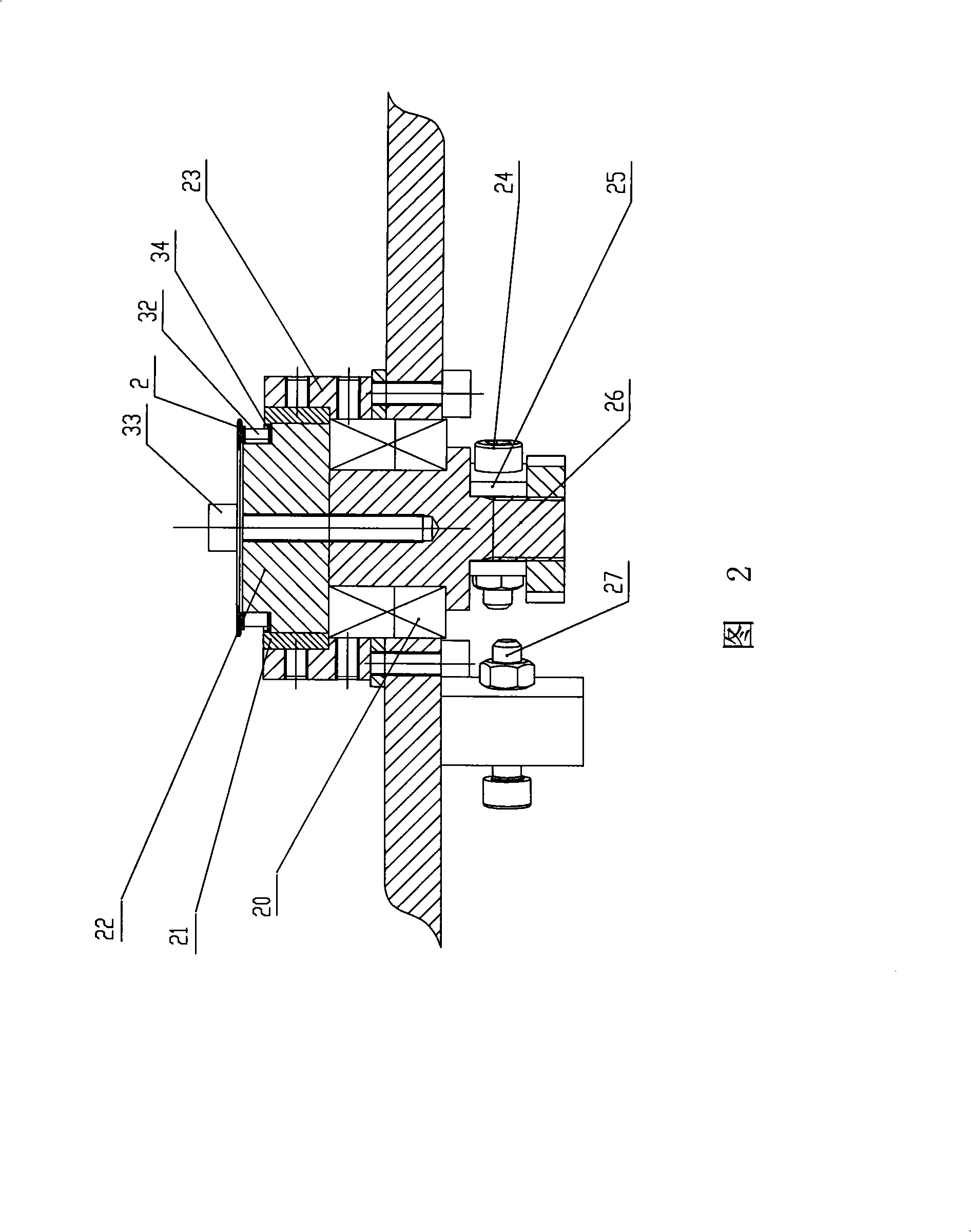

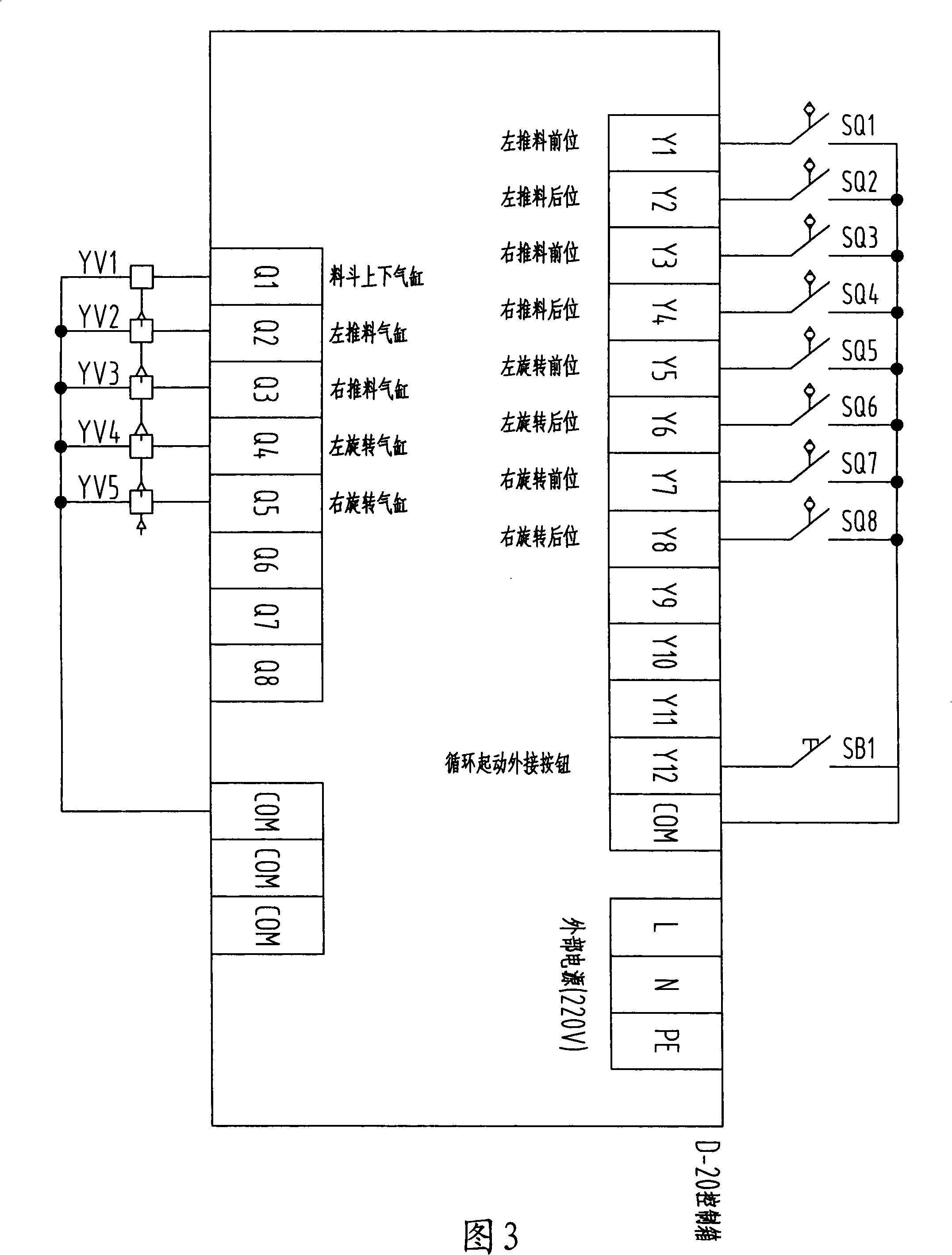

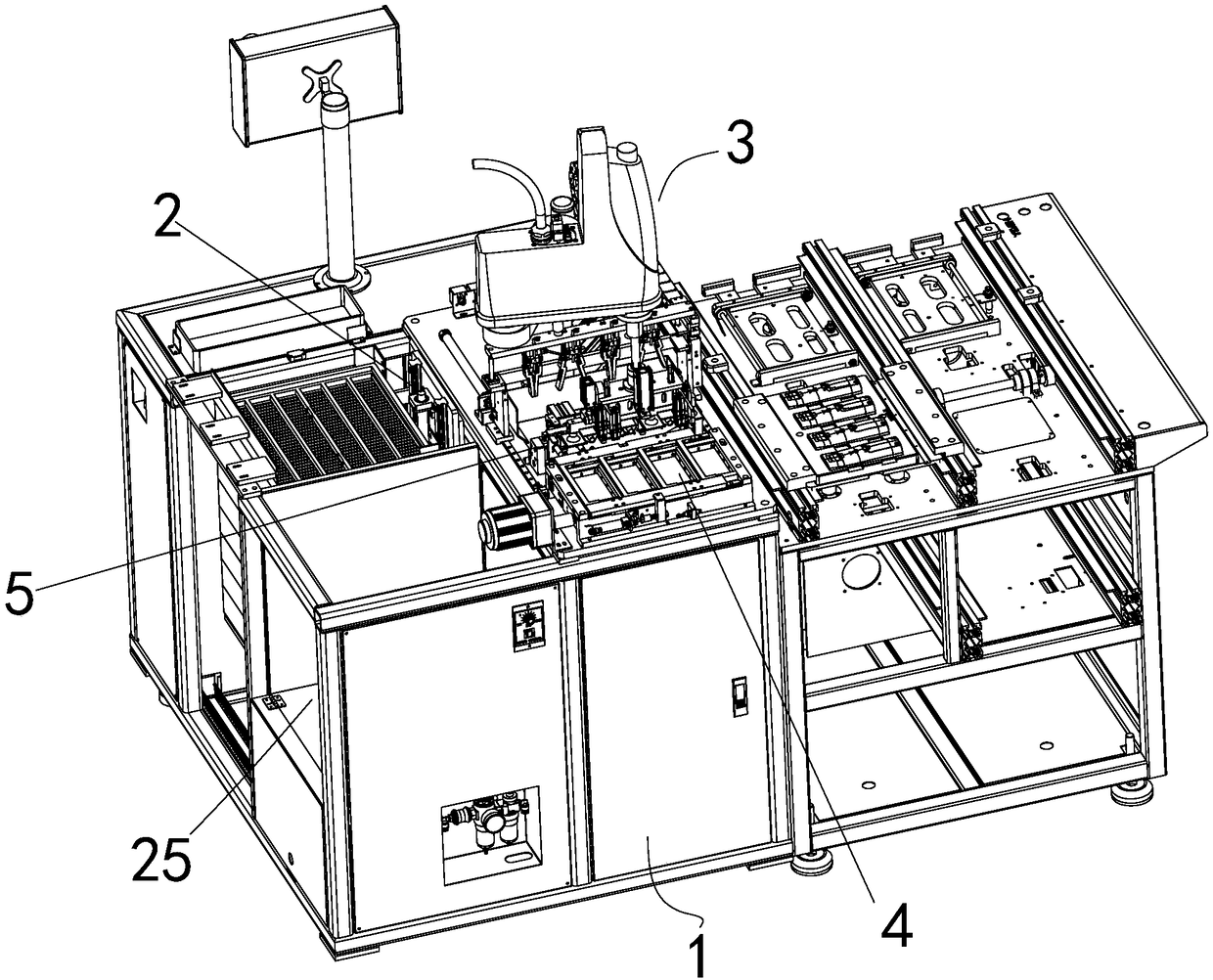

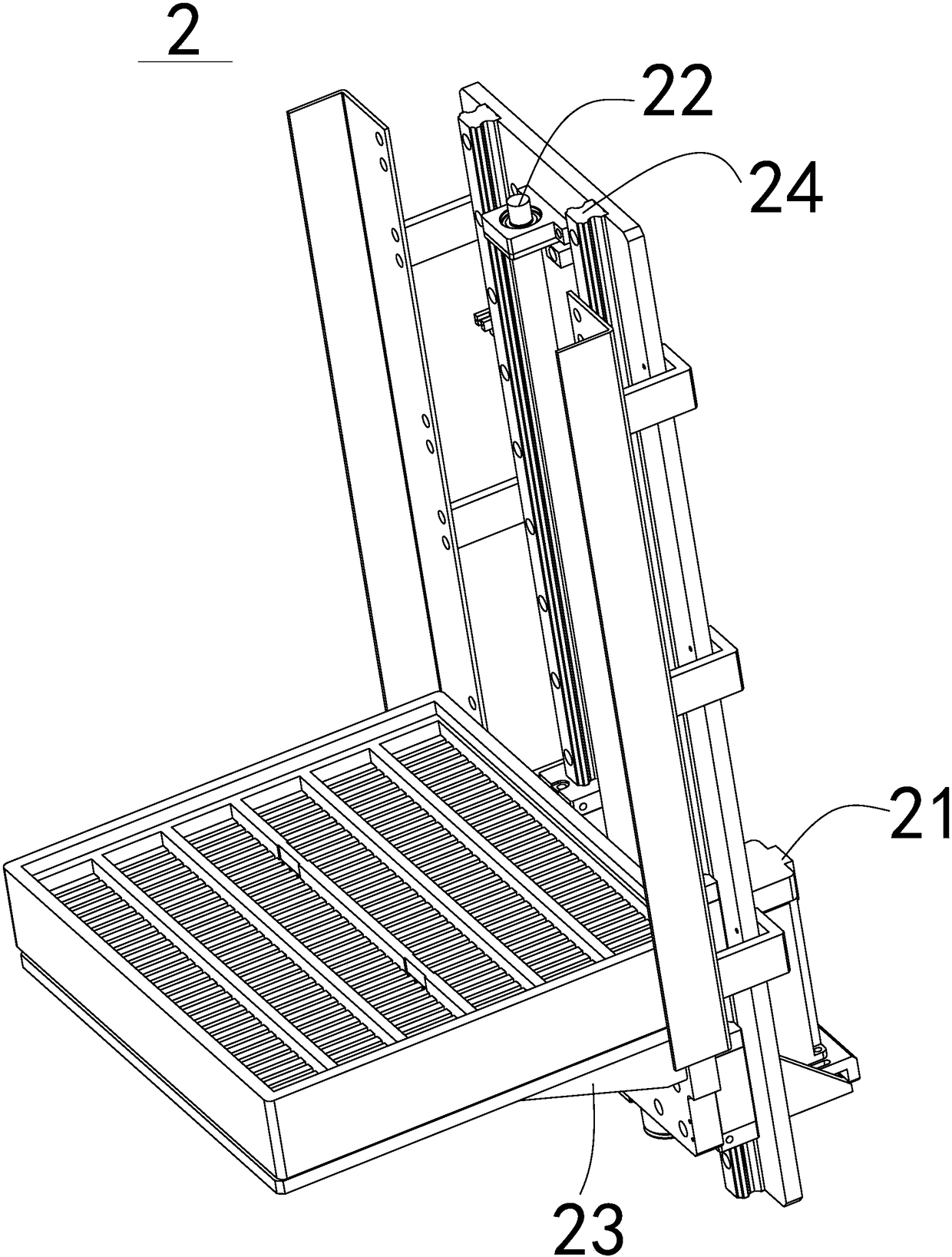

Semi-automatic roller loading machine of one-way bearing

InactiveCN101315103AAutomate assemblyImprove assembly efficiencyBearing componentsBearingsSolenoid valveSemi automatic

The invention relates to the assembly of a unidirectional bearing, which comprises a unidirectional bearing semiautomatic roller loading machine capable of automatically conducting suction, delivery, feeding, discharging and loading of rollers and rotation of a holder at an angle. Two round pneumatic roller storage disks capable of automatically orienting and delivering rollers are arranged inside a workpiece basket positioned on one side of a rectangular workbench, a rectangular vertical controller is arranged on the other side of the rectangular workbench, a PLC chip is equipped inside the controller for controlling the operation of the unidirectional bearing semiautomatic roller loading machine by programming the PLC chip, two completely same holder mechanisms are arranged at the front end of the rectangular workbench for manually placing a holder into a serrated holder seat; two completely same transposition mechanisms are arranged below the holder mechanisms for controlling the powering on sequence of five solenoid valves via the PLC in the controller, so as to press the rollers in the roller storage disks into a material guide pipe and wait for the action of a rolling pushing machine; and when the rolling pushing machine pushes a first roller into a pocket hole of the holder, the transposition mechanisms start to operate by the steps of rotating an angle in accordance with a predetermined angle, waiting for the pushing of a second roller, and repeating and stopping until the pocket hole of the holder is full of rollers, and then the holder is removed and a holder not filled with rollers is loaded to start the next round roller loading operation by pressing a loop start button on a controller panel. The inventive assembly has the advantages of easy assembly of the unidirectional bearing and high assembly efficiency.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

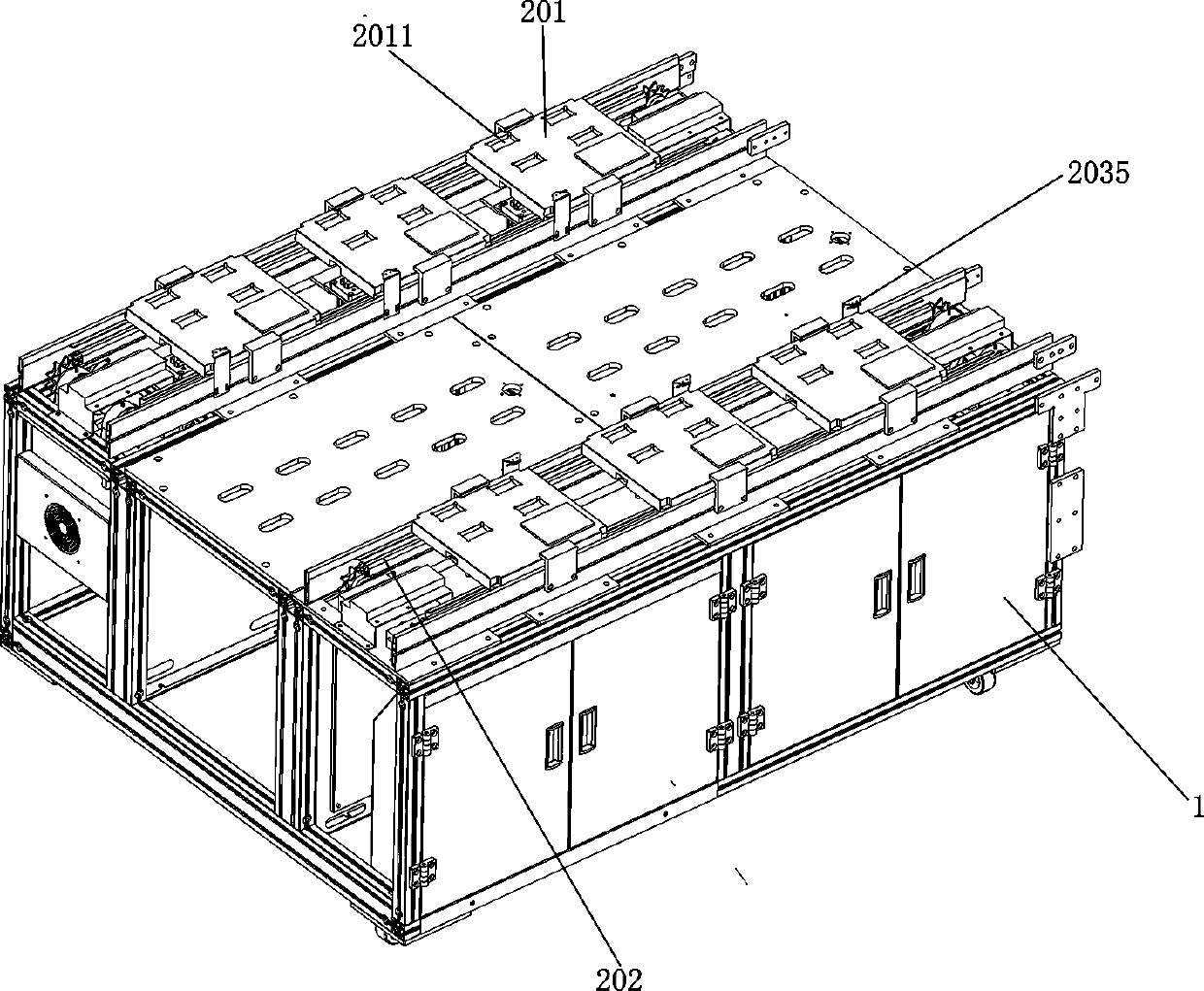

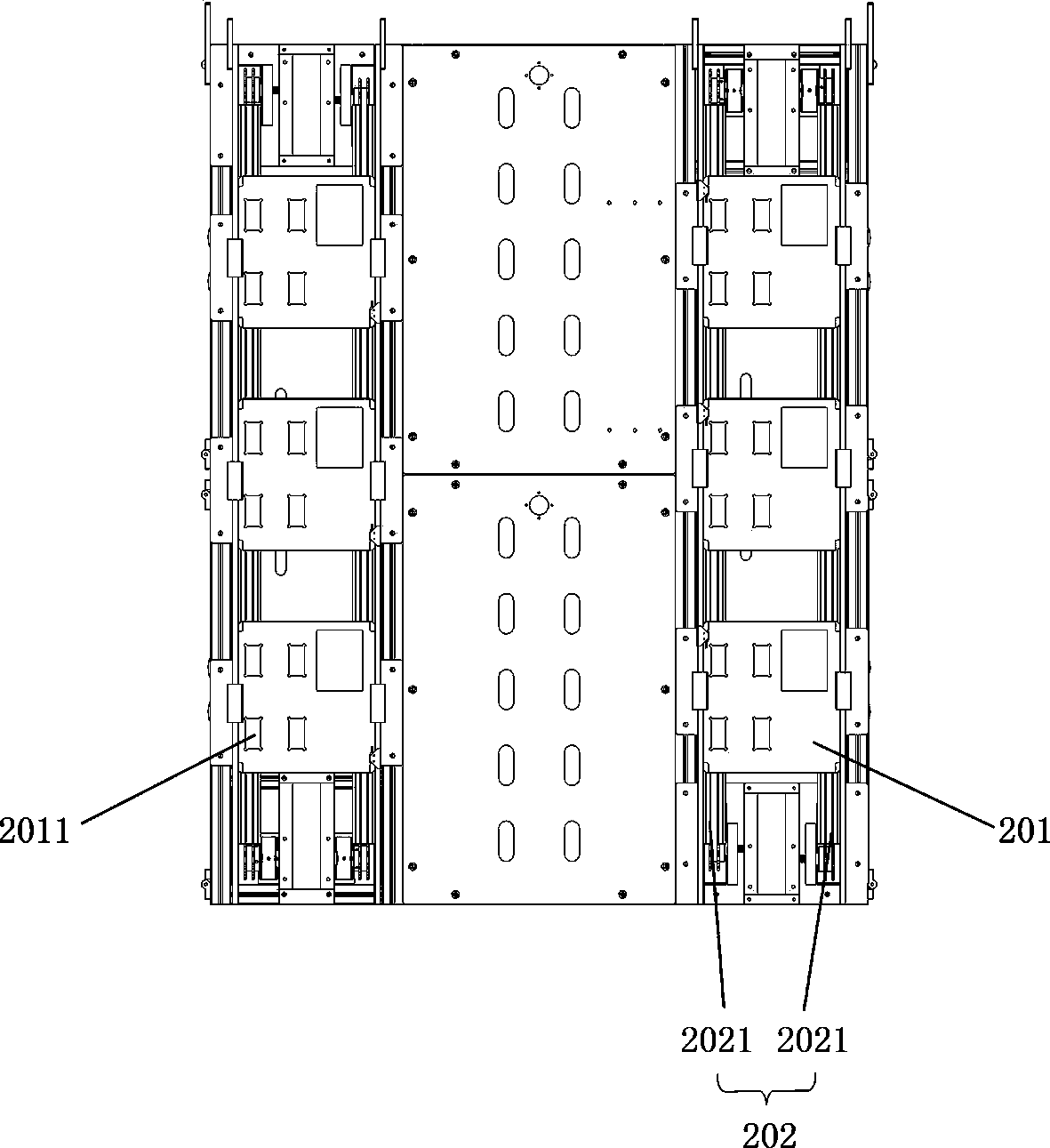

LCD screen film stripping equipment and LCD screen film stripping method

ActiveCN109421973AAutomatic material loadingFor automatic positioningArticle unpackingMaterial consumptionElectrical and Electronics engineering

The invention discloses LCD screen film stripping equipment and an LCD screen film stripping method. The LCD screen film stripping equipment comprises a rack, a feeding device used for conveying materials automatically, a taking and placing device used for taking and placing LCD screens and transporting the LCD screens, a positioning device used for positioning the LCD screens, and a film stripping device used for stripping protective film of the LCD screens off. The feeding device, the taking and placing device, the positioning device and the film stripping device are all mounted on the rack.According to the LCD screen film stripping equipment, operation including feeding, positioning, film stripping and assembling of the LCD screens can be automatically achieved through cooperation of all the devices, adhesive tape in the same position can be repeatedly used within the scope of viscidity through cooperation of an adhesive tape rotating assembly and a film clamping assembly, if the viscidity is insufficient, the adhesive tape is replaced with a new segment of adhesive tape through an adhesive tape rotating motor, and material consumption and cost in the production process are greatly reduced.

Owner:HIMIT (SHENZHEN) TECH CO LTD

System and method for manufacturing a wing panel

ActiveUS20170144779A1Automate assemblyFast preparationAssembly machinesAircraft assemblyEngineeringFace sheet

A system and method are provided to automate the assembly of a wing panel, such as utilized by commercial aircraft. In the context of a system, a tacking cell is provided that is configured to tack one or more stringers to a skin plank. The system also includes a riveting cell configured to receive a tacked plank from the tacking cell and to rivet the one or more stringers to the skin plank. The system also includes a splicing cell configured to receive a plurality of riveted planks from the riveting cell and to attach one or more splice stringers to the plurality of riveted planks. Further, the system includes a side of body cell configured to receive a spliced panel from the splicing cell and to attach a side of body chord thereto to produce a wing panel.

Owner:THE BOEING CO

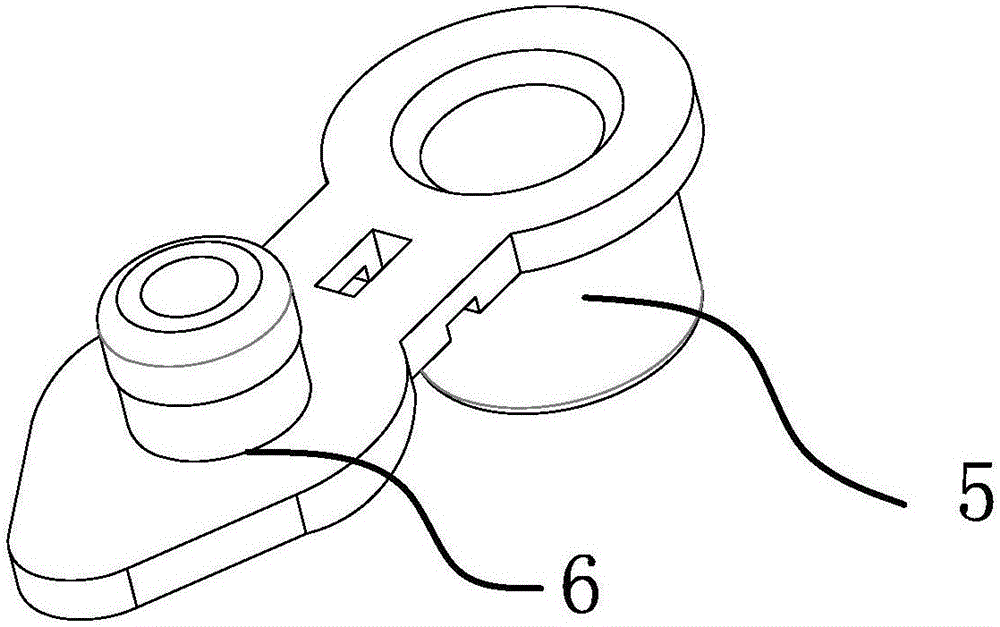

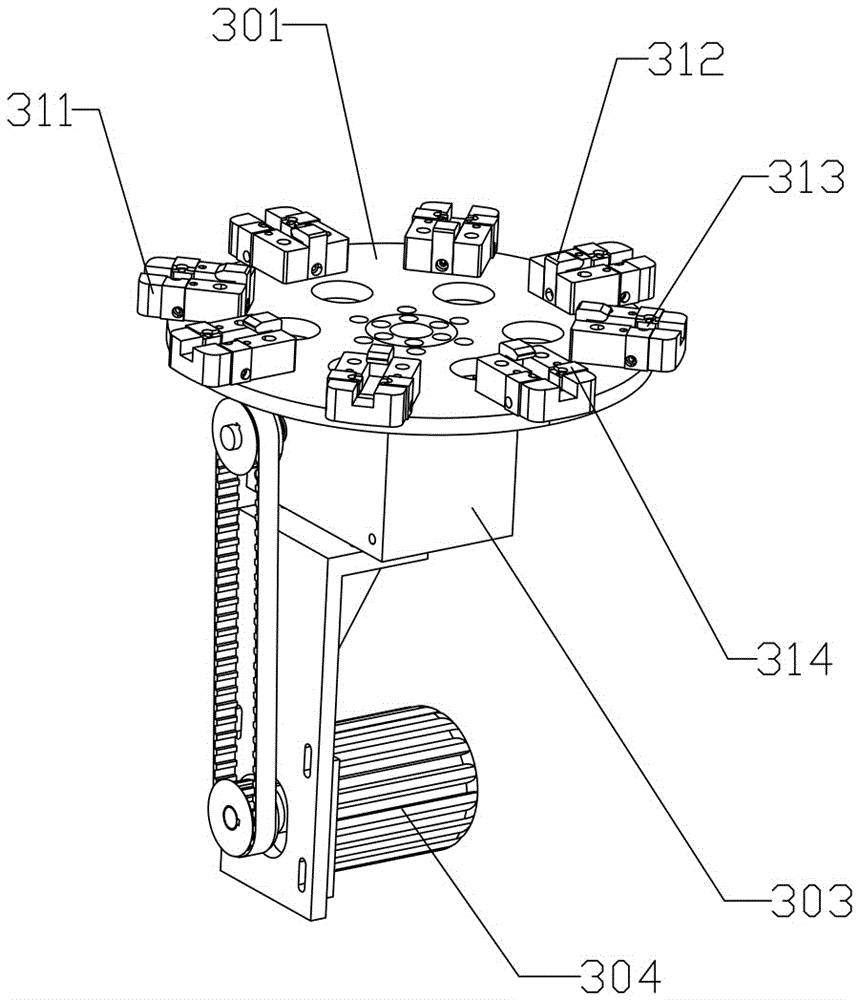

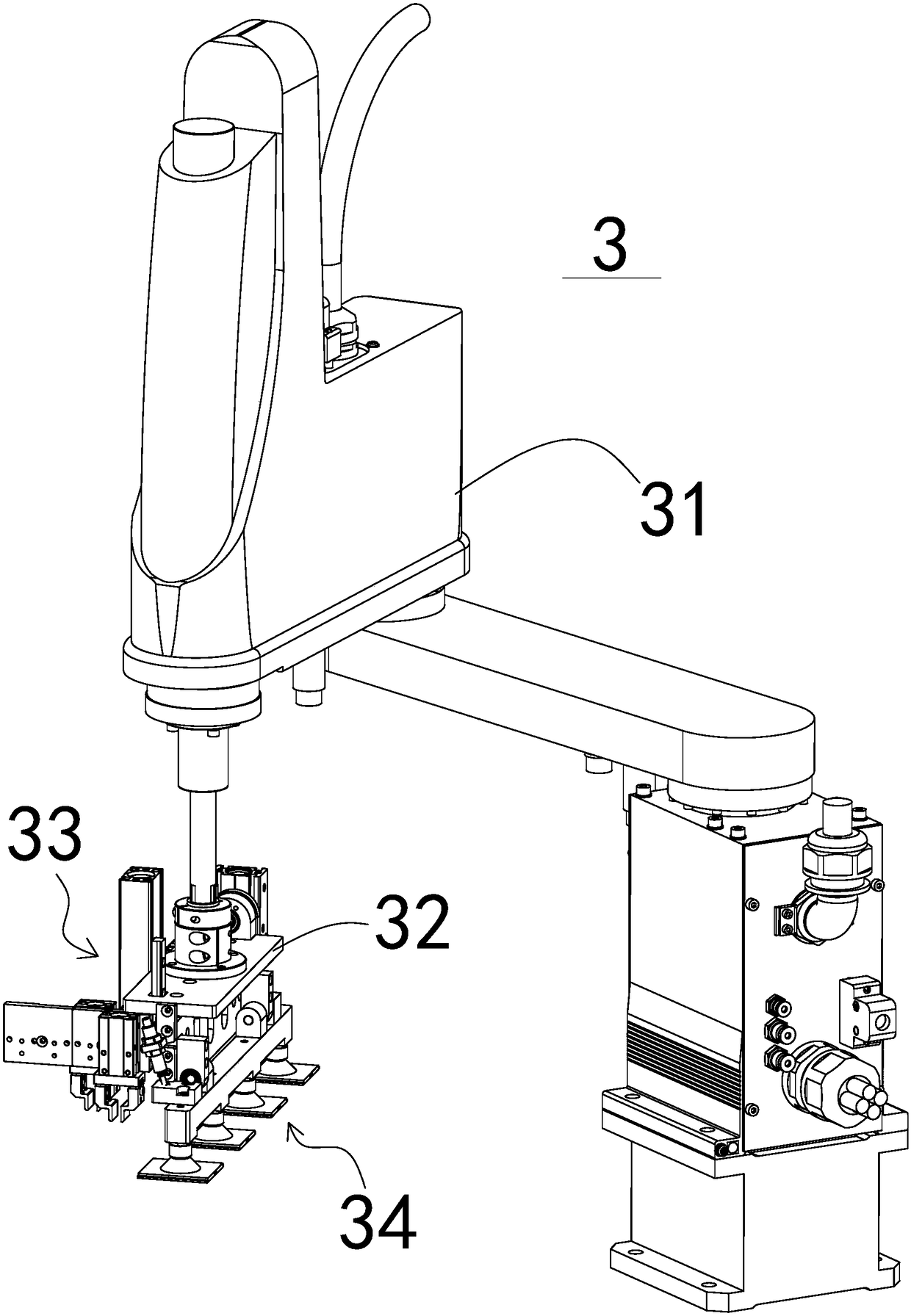

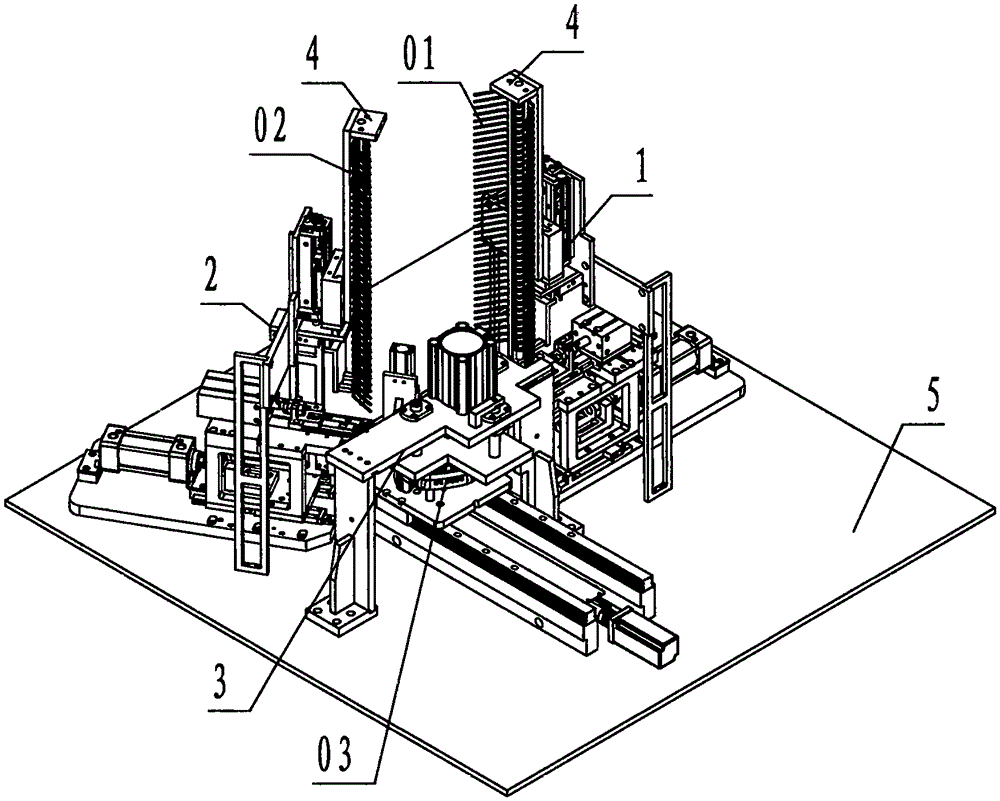

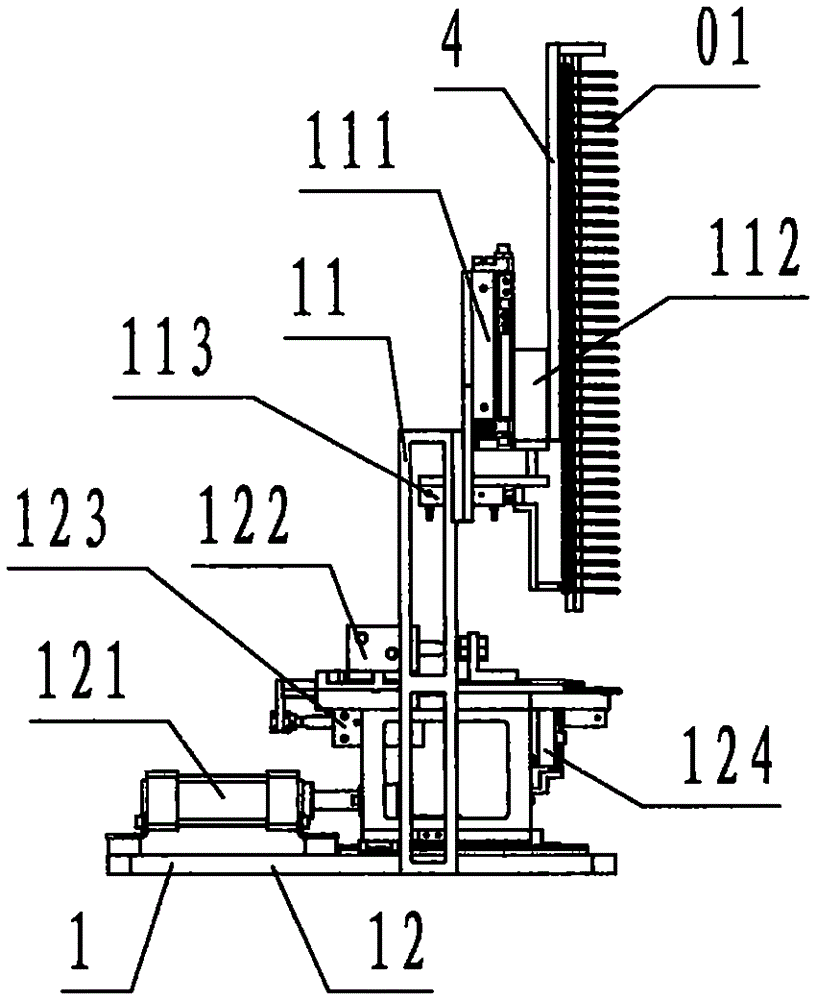

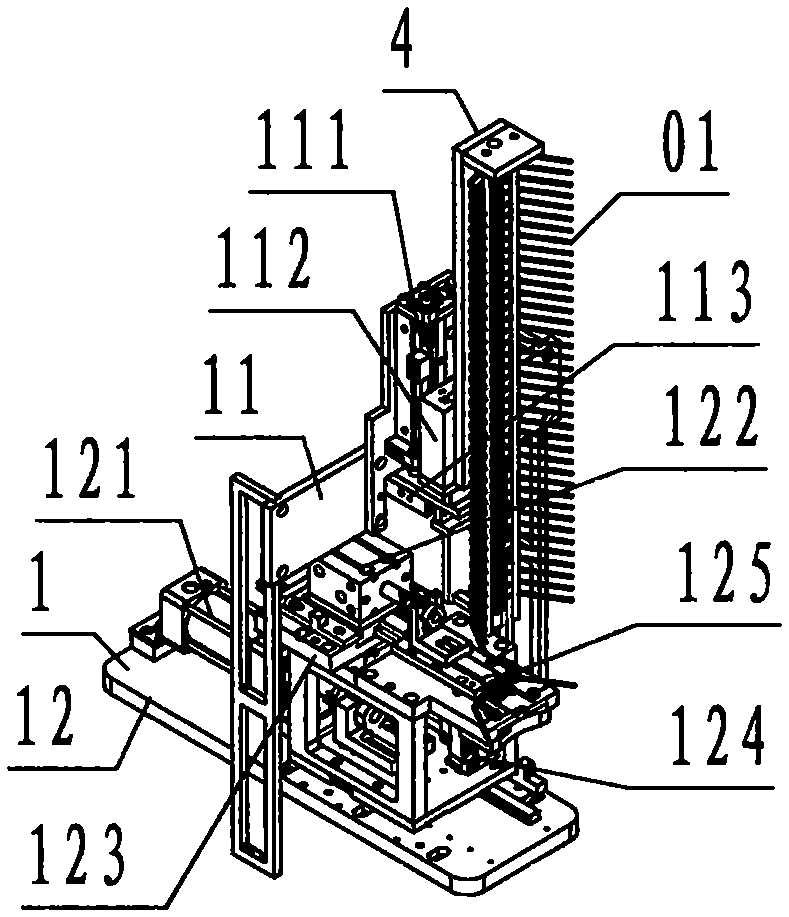

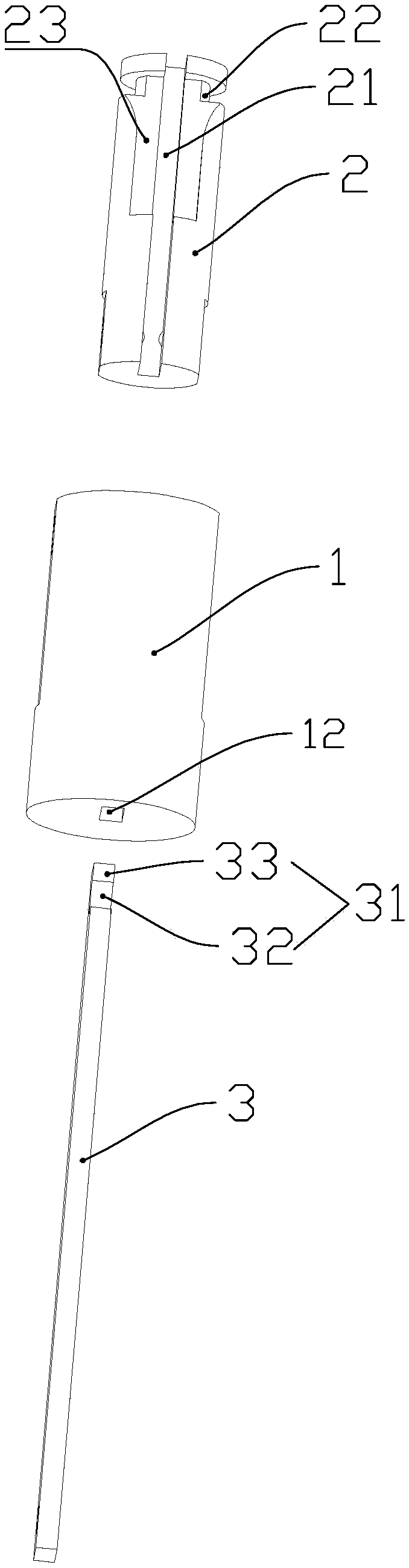

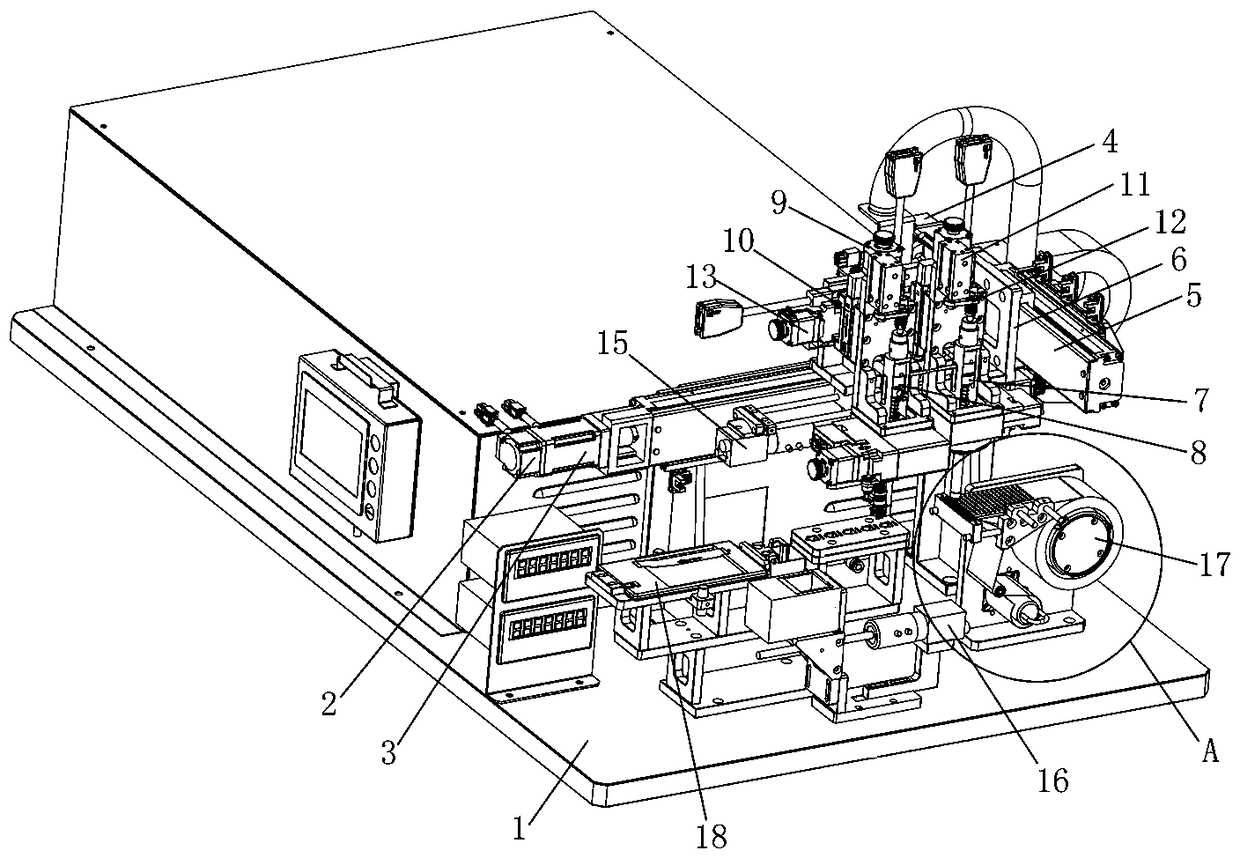

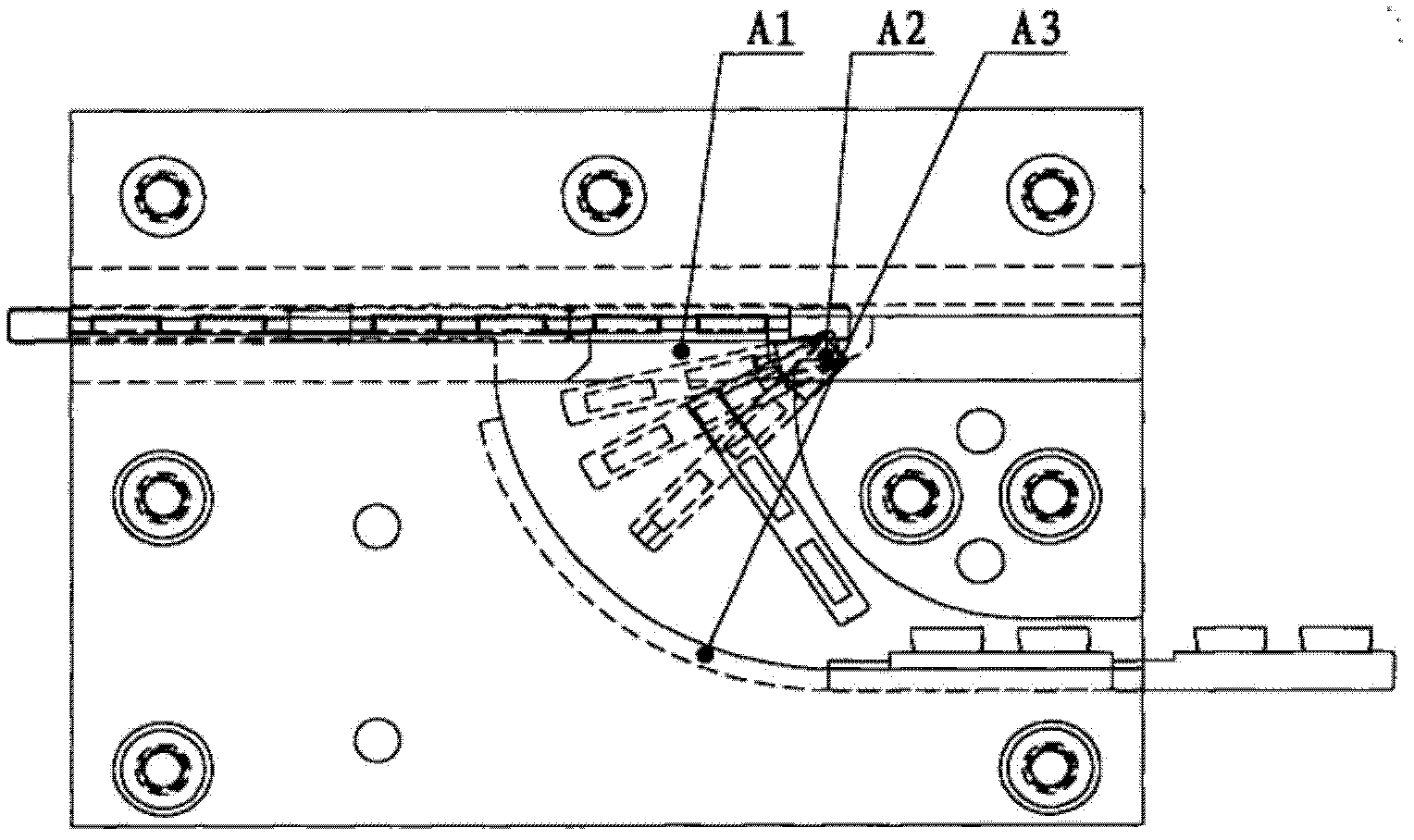

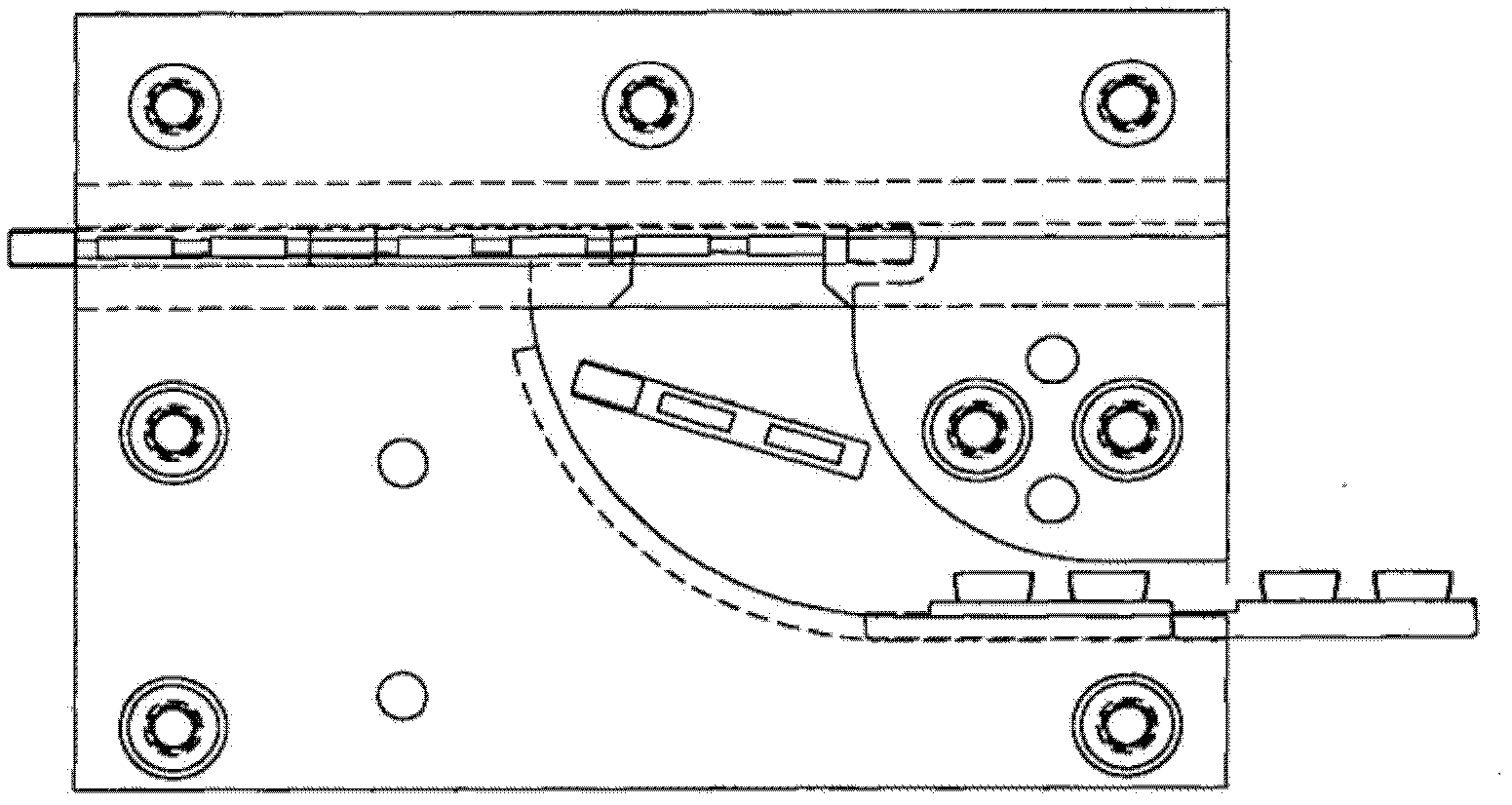

Integrated unit for automatically assembling torsion springs

ActiveCN105345443AAutomate assemblyReduce work intensityMetal working apparatusIntegrated circuitTorsion spring

The invention discloses an integrated unit for automatically assembling torsion springs. The integrated unit comprises an A torsion spring feeder (1), a B torsion spring feeder (2), a pressure spring unit (3), torsion spring clips (4) and a base plate (5). When the integrated unit consisting of the mechanisms works, torsion springs are supplied by the torsion spring clips; a torsion spring A and a torsion spring B are respectively fed to corresponding mounting positions by virtue of the A torsion spring feeder and the B torsion spring feeder; an airbag seat is fed to a set position by virtue of the pressure spring unit, and the torsion spring A and the torsion spring B are pressed into the airbag seat. According to the technical scheme, the plurality of torsion spring clips are arranged for repetitive use, so that only the torsion spring A and the torsion spring B are required to be manually fed into the torsion spring clips respectively, and the torsion spring clips without the torsion springs are timely replaced correspondingly, and therefore, torsion spring assembly can be continuously carried out; and the torsion spring assembly for an automotive airbag seat achieves the purposes of relieving working strength, improving efficiency, reducing labor, reducing cost and improving quality.

Owner:NINGBO SHUANGLIN MOULD CO LTD

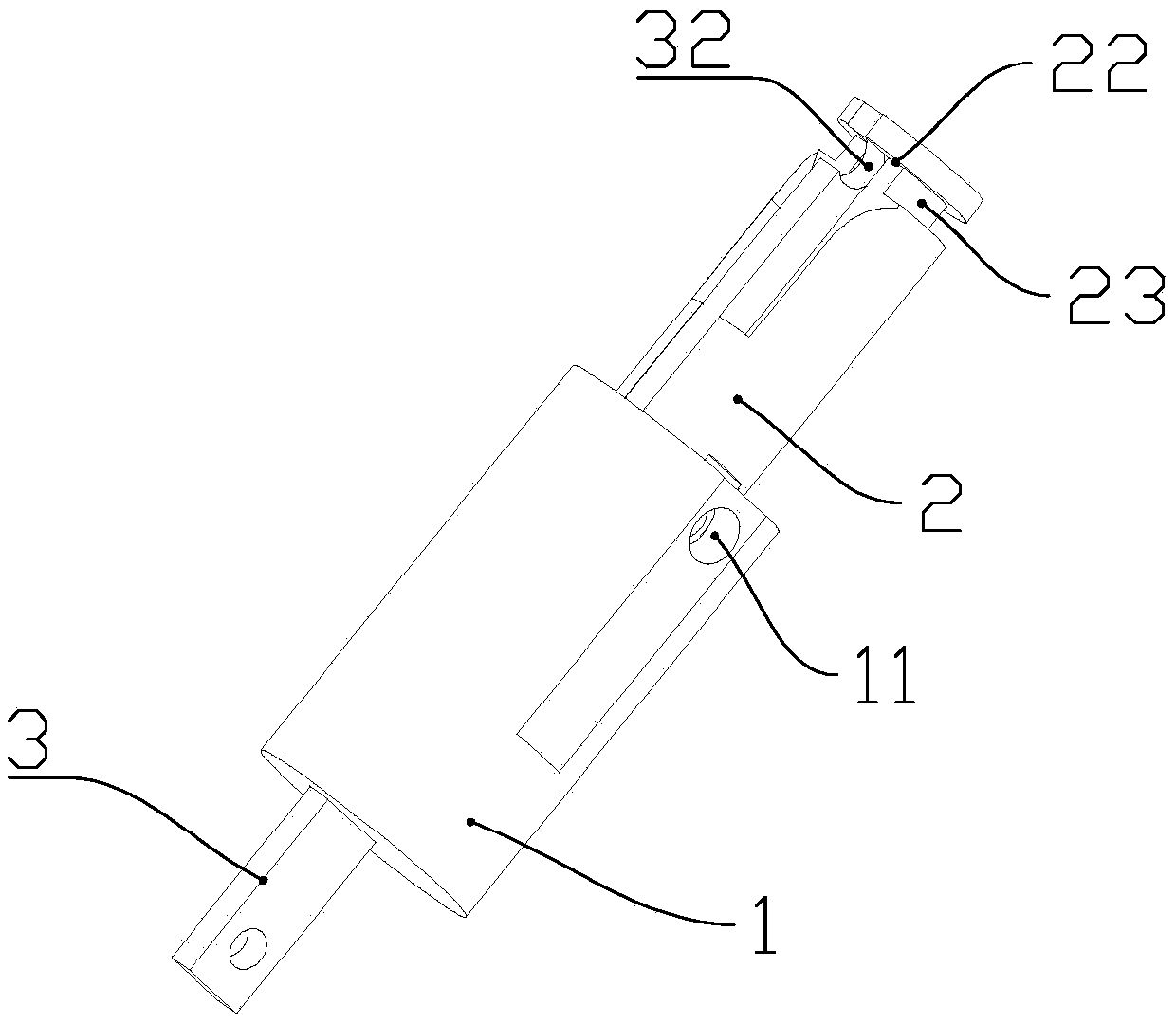

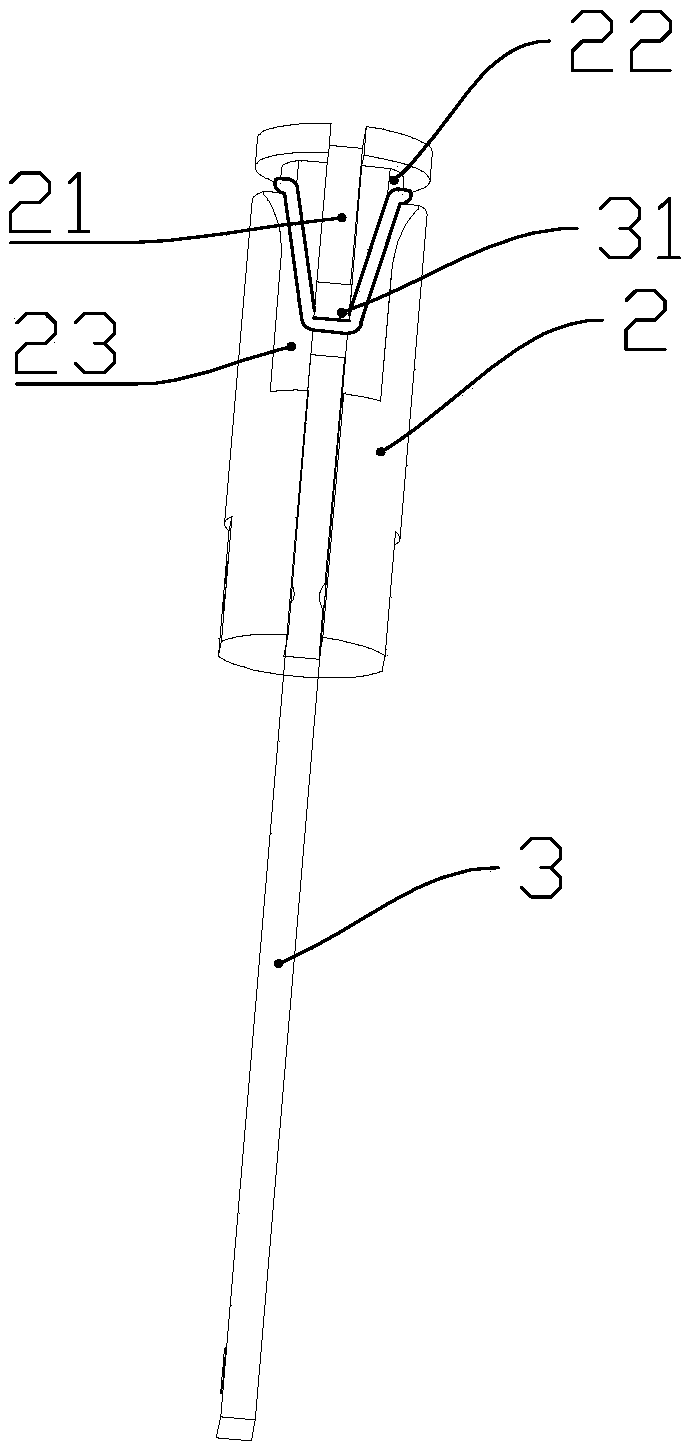

Mounting device of hole seal ring and assembly machine of hole seal ring

PendingCN109676342AOutstanding and Beneficial Technical EffectsEasy to fastenMetal working apparatusEngineeringTransfer mechanism

The invention belongs to the field of seal ring mounting instruments, and particularly relates to a mounting device of a hole seal ring and an assembly machine of the hole seal ring. The mounting device comprises a main body, and an axial through hole is formed in the main body; a pull rod is movably arranged on the axial through hole; a clamping groove used for arranging the seal ring in a sleeving manner is formed in the main body; and a hook used for hooking the seal ring is arranged on the pull rod. The assembly machine of the hole seal ring comprises a rack, and a feeding mechanism used for seal ring feeding, a loading mechanism used for mounting the seal ring, a transfer mechanism used for transferring workpieces, and a discharge mechanism used for discharging the workpieces, which are mounted on the rack, wherein the mounting device used for hole seal ring filling is mounted on the loading mechanism.

Owner:TAIZHOU KEJIE AUTOMATION EQUIP CO LTD

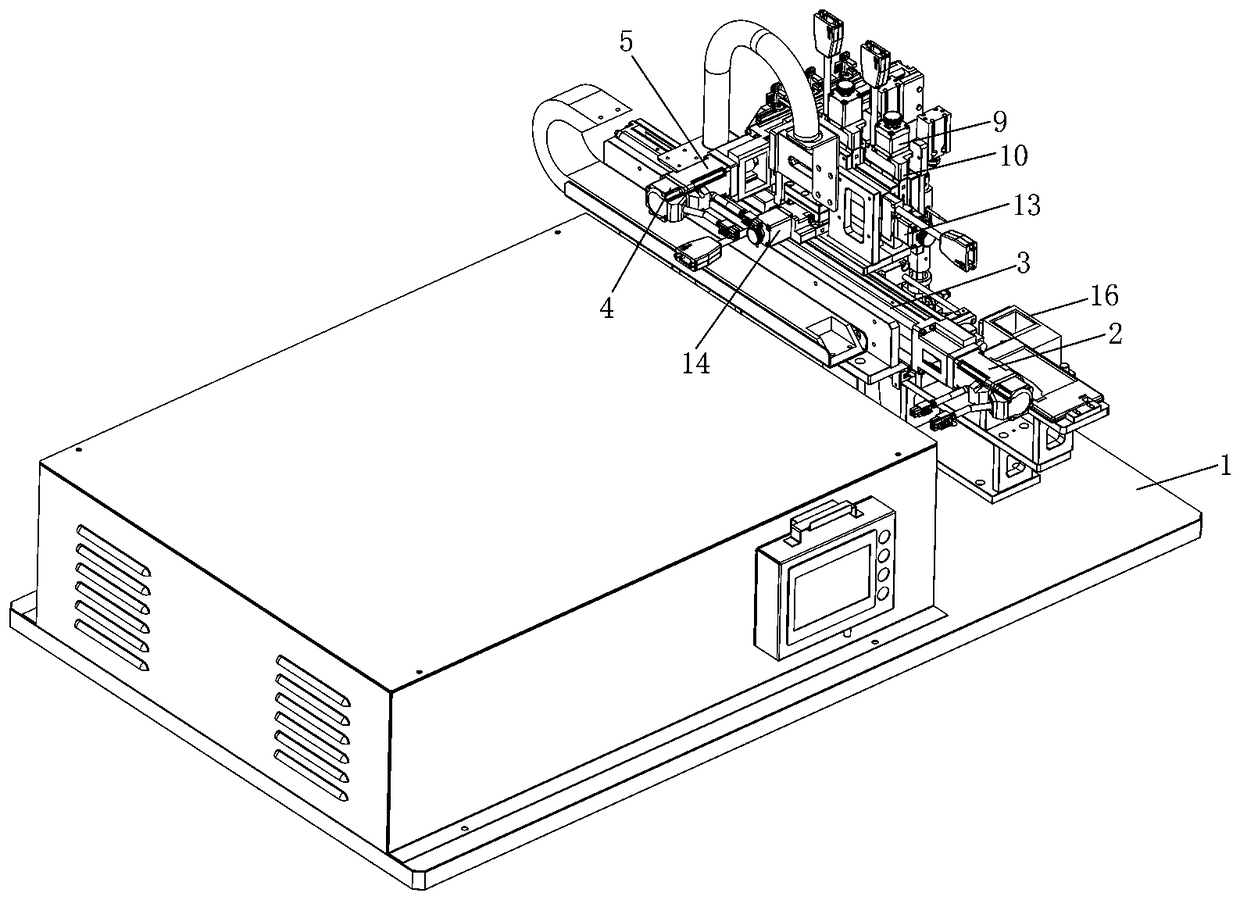

Device for processing an end of a cable

ActiveUS9906005B2Low costAutomate assemblyApparatus for removing/armouring cablesCutting forceBiomedical engineering

A method for the automated processing of an end of a cable, which has an inner part and a sleeve surrounding the inner part, wherein one section of the sleeve is radially widened. The radially widened section of the sleeve is severed by the exertion of an axial cutting force in one region. A device suitable for implementing this method for the radial widening of a section of the sleeve and a cutting device having a first cutting body and a second cutting body, which can be moved toward each other in the axial direction with respect to the cable end and, as a result, sever the radially widened section of the sleeve in one region.

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG

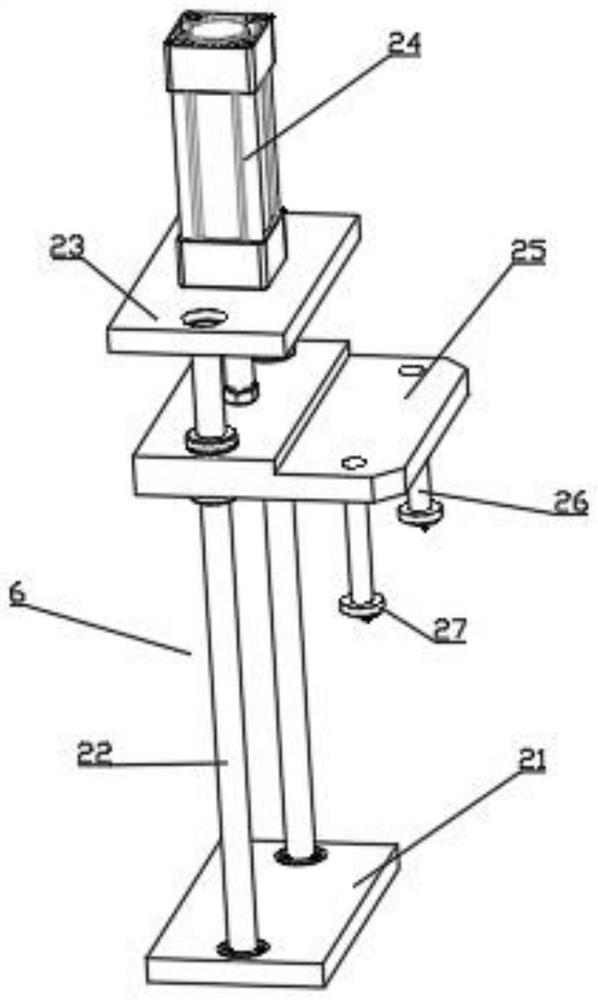

Automatic assembly machine for gears

InactiveCN103143911AAutomate assemblyIncrease productivityMetal working apparatusGear wheelEngineering

The invention belongs to the field of automatic assembly for workpieces, and particularly relates to an automatic assembly machine for gears. The automatic assembly machine comprises a machine seat, wherein a working platform is arranged on the machine seat; a clamping device used for clamping shafts is arranged on the working platform; a vibration feeder used for accommodating gears is arranged on a side surface of the working platform; an assembly device which can assemble gears automatically is arranged on the working platform; the assembly device and the vibration feeder are connected through a guide groove; the assembly device comprises a transverse extension mechanism and a longitudinal extension mechanism; a rotary electromagnetic mechanism is arranged at one end part of the longitudinal extension mechanism, and the longitudinal extension mechanism is fixed on the transverse extension mechanism; and a magnetic claw is arranged at one end part of the rotary electromagnetic mechanism. The automatic assembly machine for gears has the advantages that gears can be assembled automatically on shafts, and the production efficiency and the production quality are improved.

Owner:CHANGZHOU SHULE KITCHEN UTENSILS

Automatic electronic product assembling device and assembling manipulator thereof

PendingCN108323155AAutomate assemblyEfficient assemblyElectrical componentsEngineeringElectronic component

The invention discloses an automatic electronic product assembling device and an assembling manipulator thereof. The assembling device comprises a driving mechanism, a slide seat, two fine tuning mechanisms, a CCD mechanism, a feeding mechanism and first and second assembling manipulators; the driving mechanism is arranged on a workbench, and comprises a horizontal assembly, and a vertical assembly and two elevating assemblies connected to the horizontal assembly; the slide seat is connected with the output end of the vertical assembly; the slide seat is provided with two installation stations; the two fine tuning mechanisms are arranged in the two installation stations of the slide seat respectively; the two elevating assemblies are arranged in the two installation stations of the slide seat respectively; the first and second assembling manipulators are arranged in the external sides of the elevating assemblies respectively, and connected to the output ends of the elevating assembliesrespectively; and each CCD mechanism comprises an upper CCD assembly and a lower CCD assembly. According to the invention, materials are aligned with product assembly portions accurately, the assembling precision is high, and different electronic components are assembled.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Ink feeder for felt-tip ink pen

ActiveUS20100247224A1Easy to introduceEasy to moveLiquid surface applicatorsInk reservoir pensEngineeringMechanical engineering

Owner:LION PENCIL

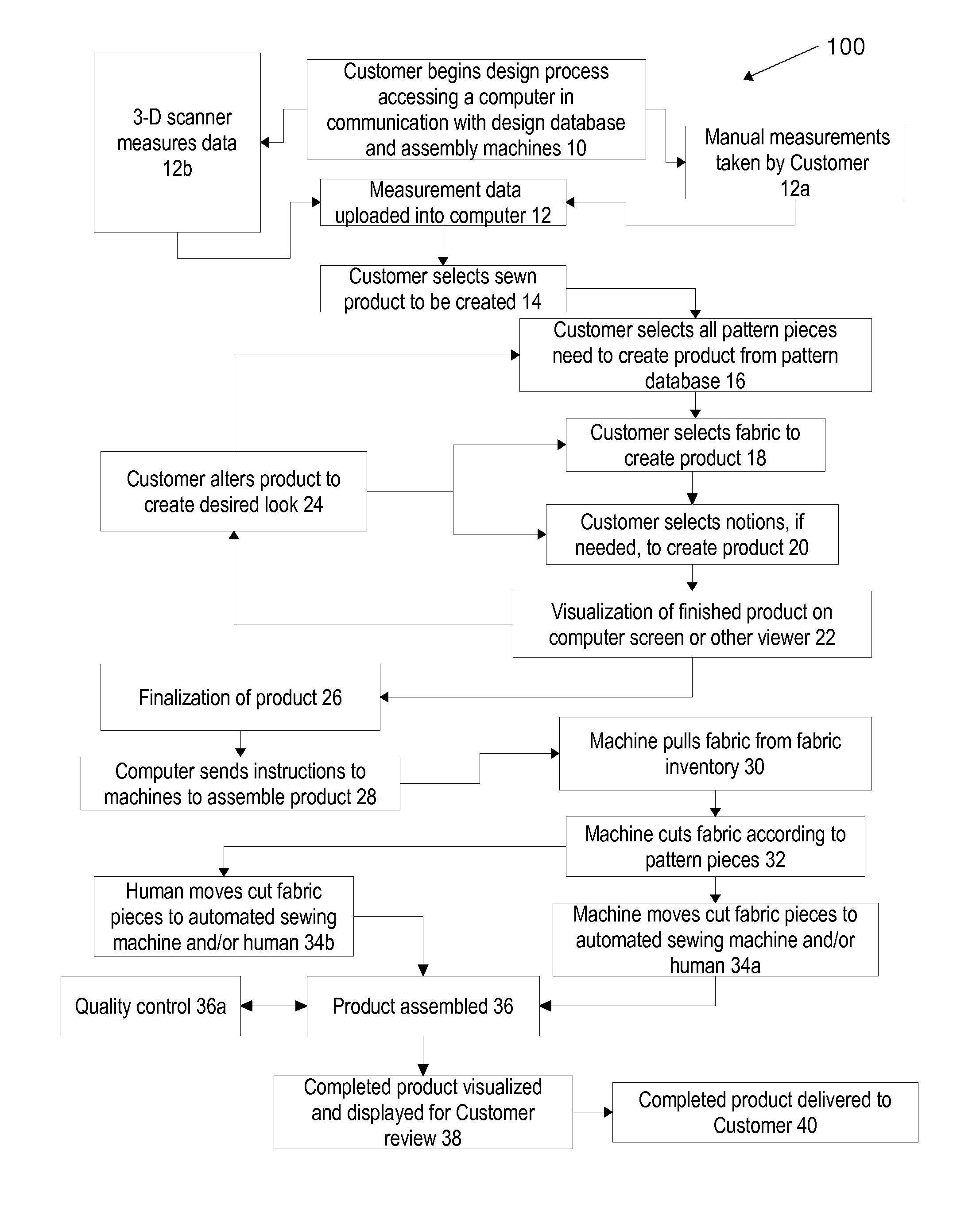

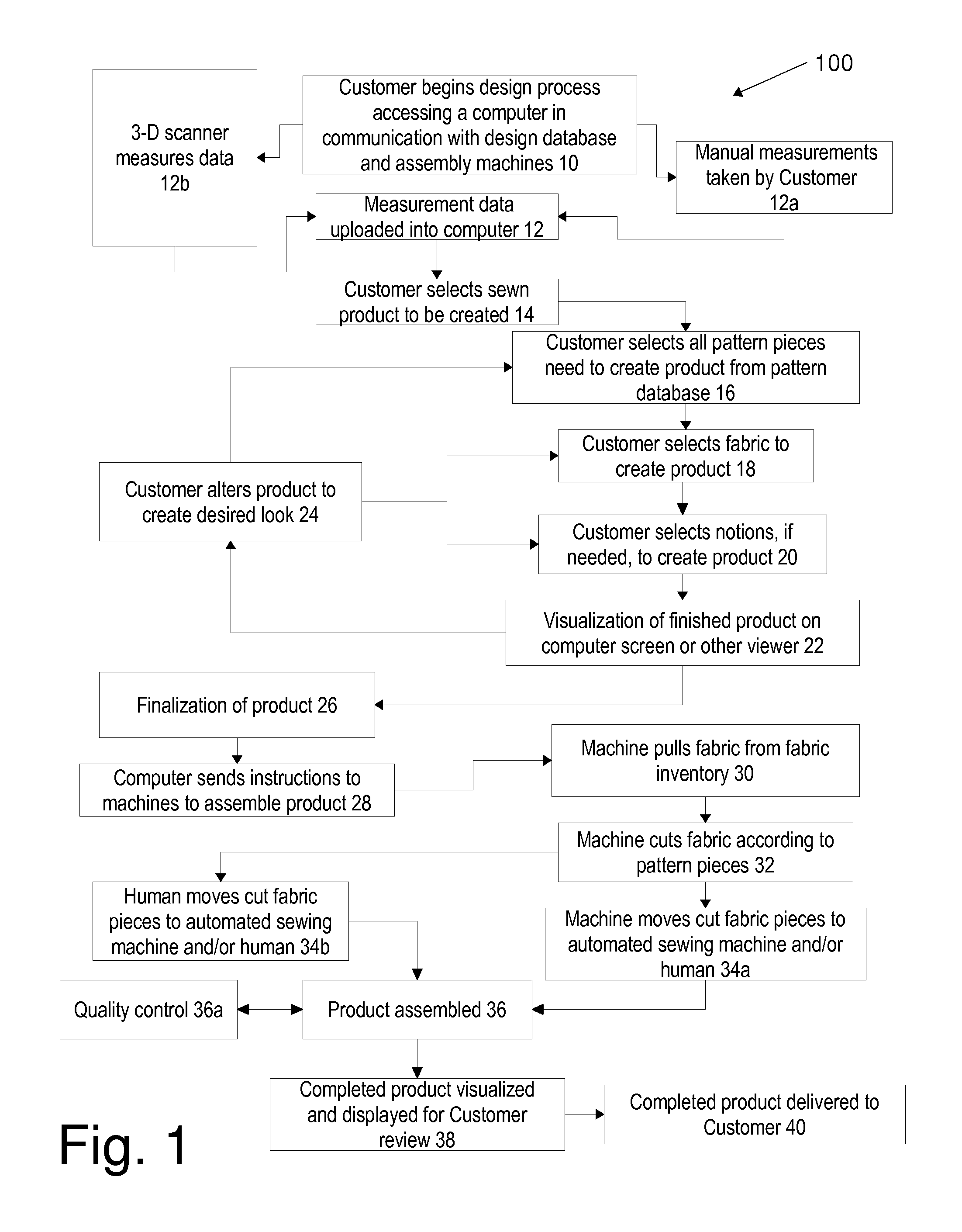

Method for Automated Design and Assembly of Customized Apparel and Other Sewn Products

InactiveUS20150332366A1Automate assemblyAutomated designBuying/selling/leasing transactionsComputer scienceData library

A method of designing and assembling customized garments and other sewn items using a plurality of automated machines in communication with a computer, a viewing device, and a pattern database. A customer uploads measurements into a computer, and designs the desired garment or other sewn item by selecting patterns from a database, fabrics and notions. A virtual finished item is then displayed on a viewing device. The customer finalizes the design, and the garment or sewn item is then assembled according to instructions provided by the customer, the instructions sent directly from the computer to the plurality of automated machines. Human involvement in the assembly process is minimized, with the majority or all of the steps being performed automatically by the plurality of machines.

Owner:GINOCCHI SHARON L

Automatic assembling device for automobile door hinge

InactiveCN105921964AAutomate assemblyIncrease productivityVehicle componentsMetal working apparatusEngineeringMechanical engineering

Owner:FENGYE TIMS WUHU AUTO PARTS CO LTD

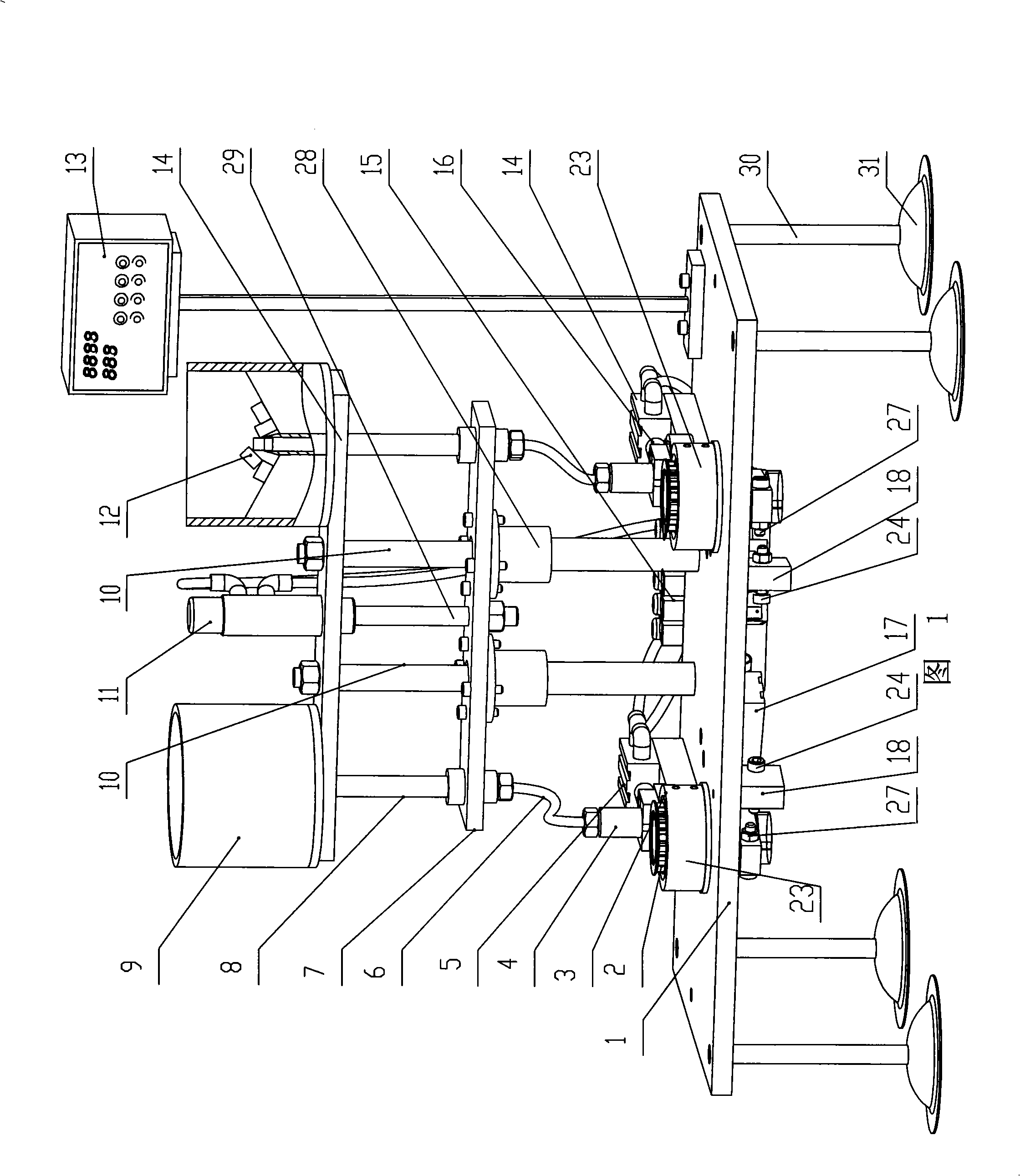

Full-automatic commutator bar assembly machine of rubber sleeve commutator

InactiveCN102496830AAutomate assemblyReduce management costsCommutators manufactureMechanical equipmentOutput device

The invention provides a full-automatic commutator bar assembly machine of a rubber sleeve commutator. The machine comprises a commutator bar part screening vibration feeder, a rubber sleeve part screening vibration feeder, a commutator bar inserting device, a rubber sleeve loading device, a rubber sleeve heating device, an indexing transfer device, a finished product clamping device and a finished product output device. In the technical scheme provided by the invention, manual operation is replaced by the work of mechanical equipment, the benefit and yield of the assembly worker post in the commutator (motor commutator) industry are met, automatic commutator assembly is realized, the working efficiency is greatly improved, the commutator insertion is simplified due to the mechanical operation, the whole manufacturing level is ensured, and the benefits of the product are increased naturally; and moreover, since the manual operation is replaced by mechanical equipment, the labor amount in enterprises is reduced, the cost investment of the enterprises is lowered, the fund is saved, and the administrative cost of the post is lowered therewith.

Owner:WENZHOU K Q B W AUTOMATIC EQUIP

Motor assembling equipment and assembling method thereof

PendingCN113300548AReduce manual laborIncrease productivityManufacturing dynamo-electric machinesMetal working apparatusMotor shaftVirtual position

The invention discloses motor assembling equipment and an assembling method thereof. The equipment comprises a rack, an armature feeding mechanism, an iron shell conveying and detecting mechanism, an assembling mechanism used for assembling an armature and an iron shell, an axon virtual position detecting mechanism used for performing axon virtual position detection on a motor shaft, a bent core testing mechanism used for detecting the radial run-out amount of the motor shaft during operation, a discharging mechanism used for distributing good products and defective products, and a workbench for mounting each mechanism is arranged on the rack. The armature feeding mechanism and the iron shell conveying and detecting mechanism are respectively connected with the assembling mechanism; the axon clearance detection mechanism and the bent core testing mechanism are sequentially located between the assembling mechanism and the discharging mechanism. Therefore, all the mechanisms are integrated on the rack to form the motor assembling equipment. According to the equipment, automatic feeding, assembling and detection of each link of the armature and the iron shell are realized, so that the assembly of the motor is fully automatic, a large amount of manual labor is reduced, the production efficiency of products is improved, and meanwhile, the qualification rate of the products is improved.

Owner:深圳市合利士智能装备有限公司

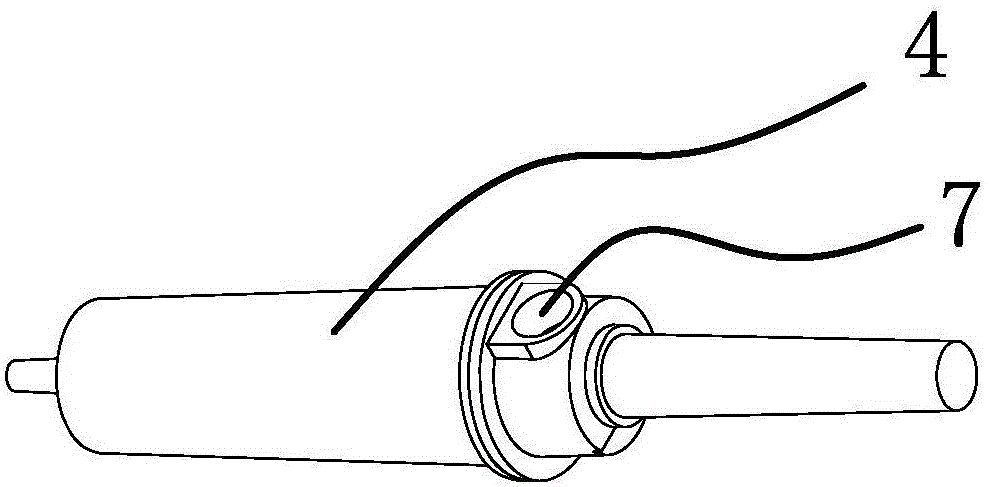

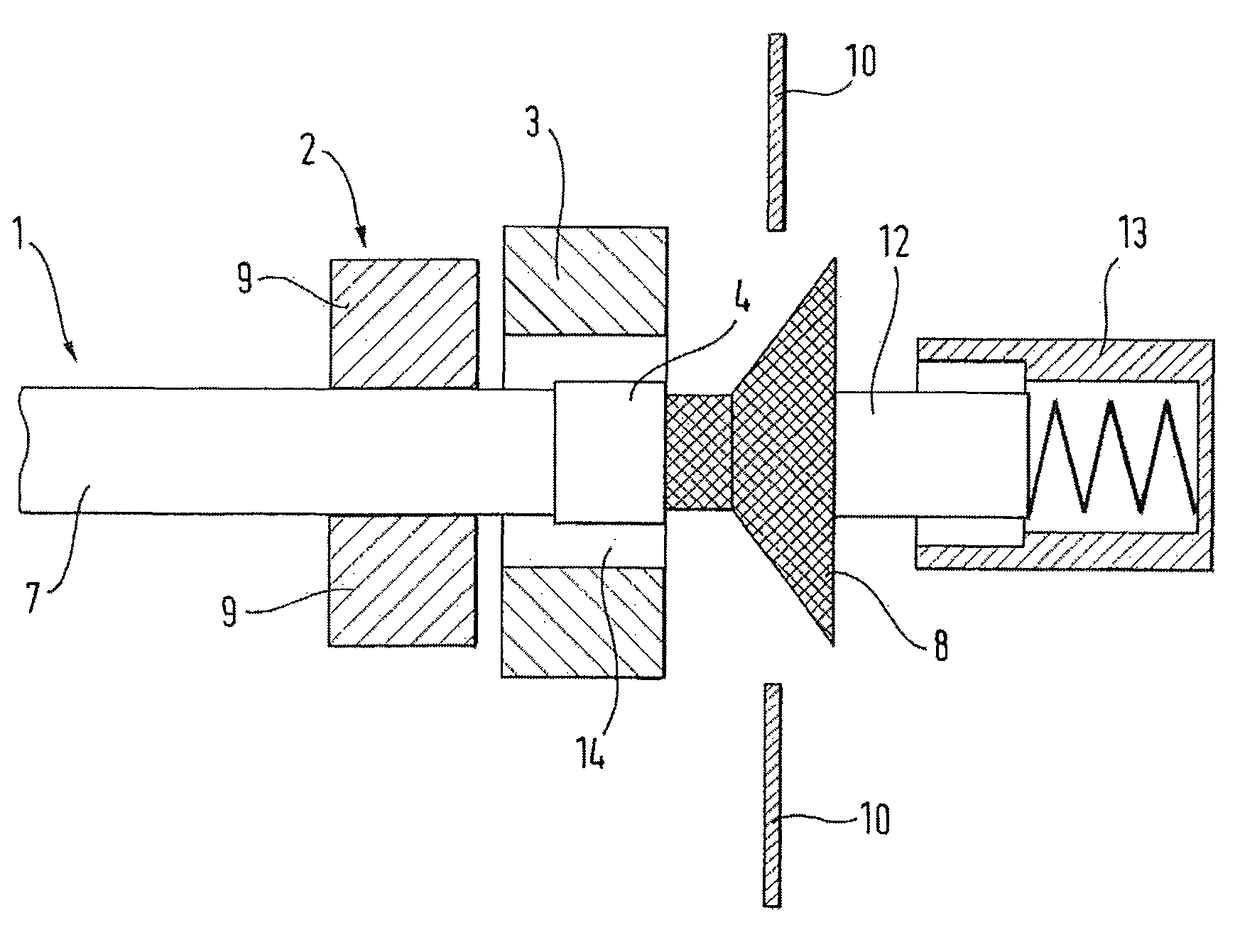

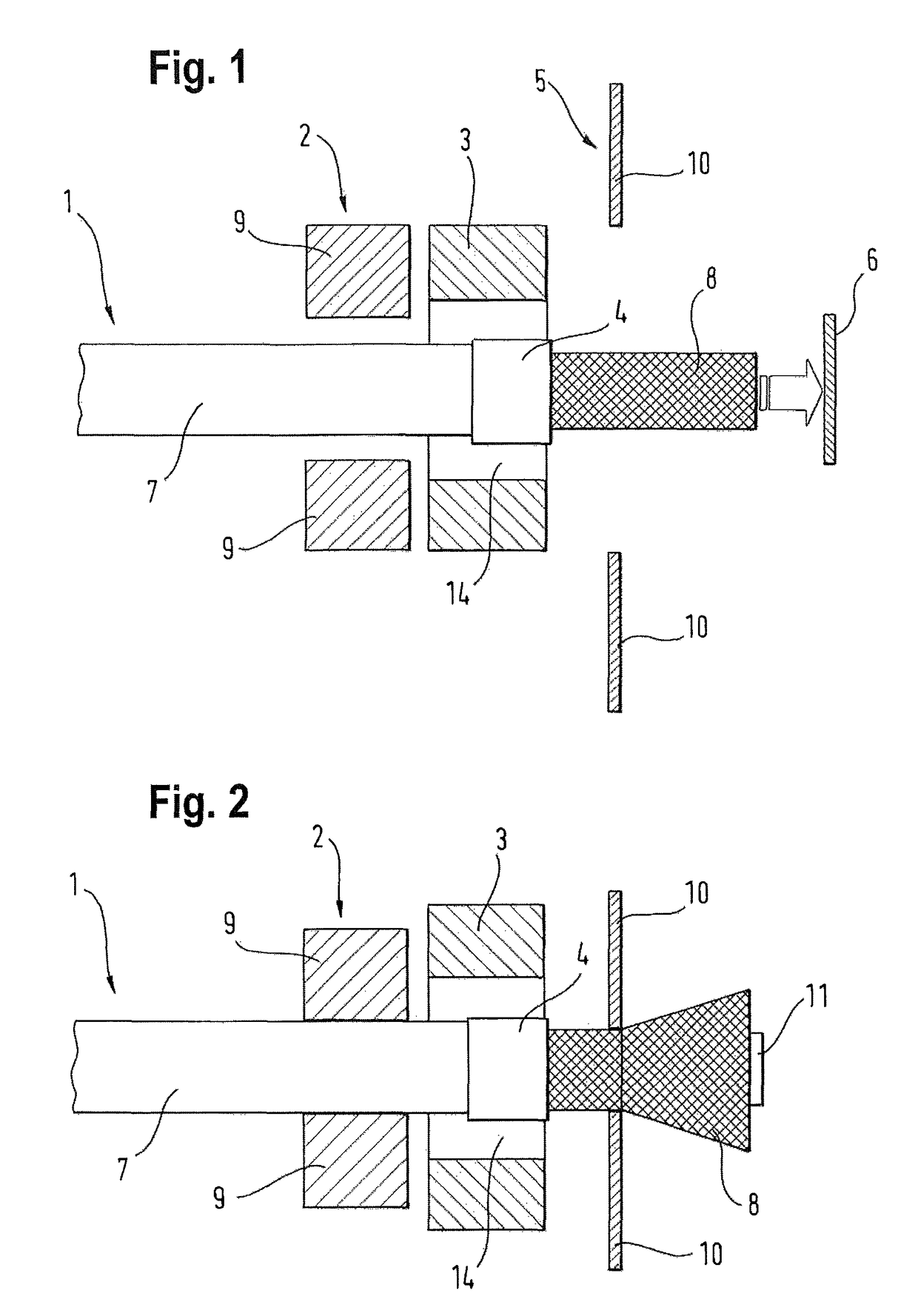

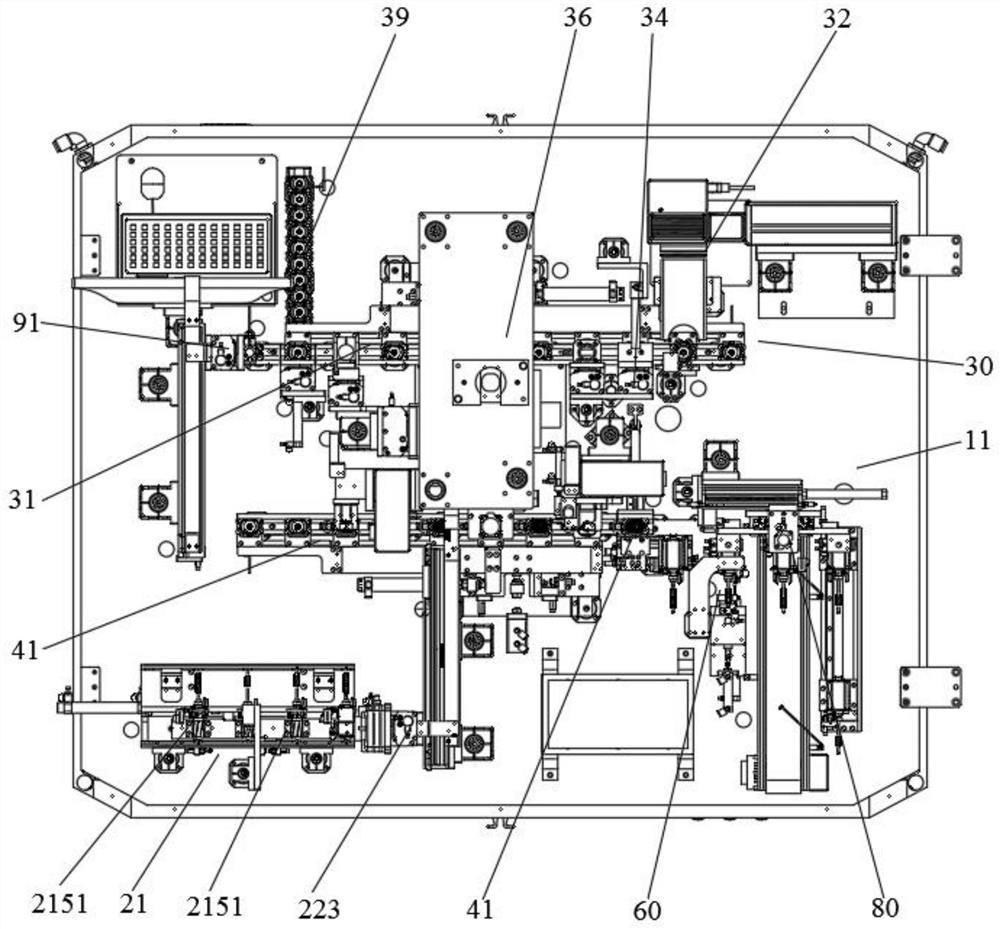

Tool and method for assembling metal parts

InactiveCN101155660APrecise positioningAutomate assemblyOhmic-resistance heatingVehicle componentsAbutmentEngineering

A tool (1) for assembling a part (2) made of a ferromagnetic material with a part (3) made of a paramagnetic material comprises a first tool part (4) provided with a first abutment (5) and a first electromagnetic coil (6). The inventive tool also comprises a second part (7) provided with a second abutment (8), wherein sad second part (7) is mechanically assembled with the first part (4) in such a way that the first and second abutments (5, 8) are selectively approachable or remotable with respect to each other, the first electromagnetic coil (6) is used for generating an electromagnetic flux which enables the paramagnetic part (3) to be pushed towards the second abutment (8) and / or the ferromagnetic part (2) to be attracted thereto when said part(s) (2, 3) is / are placed between the first and second abutments (5, 8).

Owner:RENAULT SA

Vehicle lighting device

InactiveUS8277100B2Improve workabilityAutomate assemblyVehicle headlampsPoint-like light sourceEffect lightEngineering

A vehicle lighting device includes: a heat sink member; a semiconductor-type light source directly placed on a top face of the heat sink member; a power-feeding holder which is set on the semiconductor-type light source and the heat sink member, for holding the semiconductor-type light source at the side of the heat sink member and feeding a power current to the semiconductor-type light source; and a fixing member which is covered on the power-feeding holder and fixed to the heat sink member, for fixing the power-feeding holder to the heat sink member and sandwiching and fixing the semiconductor-type light source between the power-feeding holder and the heat sink member. As a result, this vehicle light device improves workability of assembling components.

Owner:ICHIKOH IND LTD

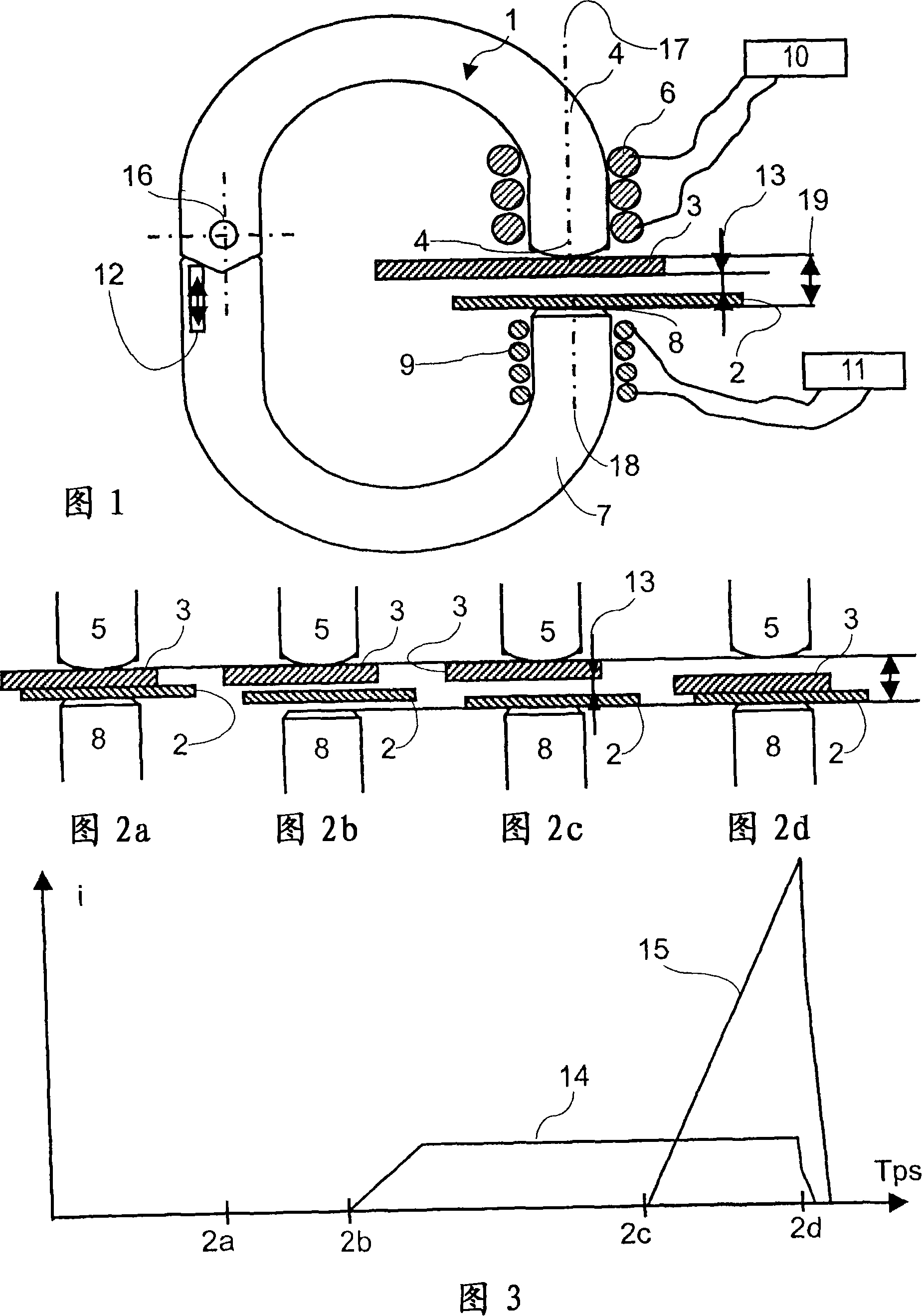

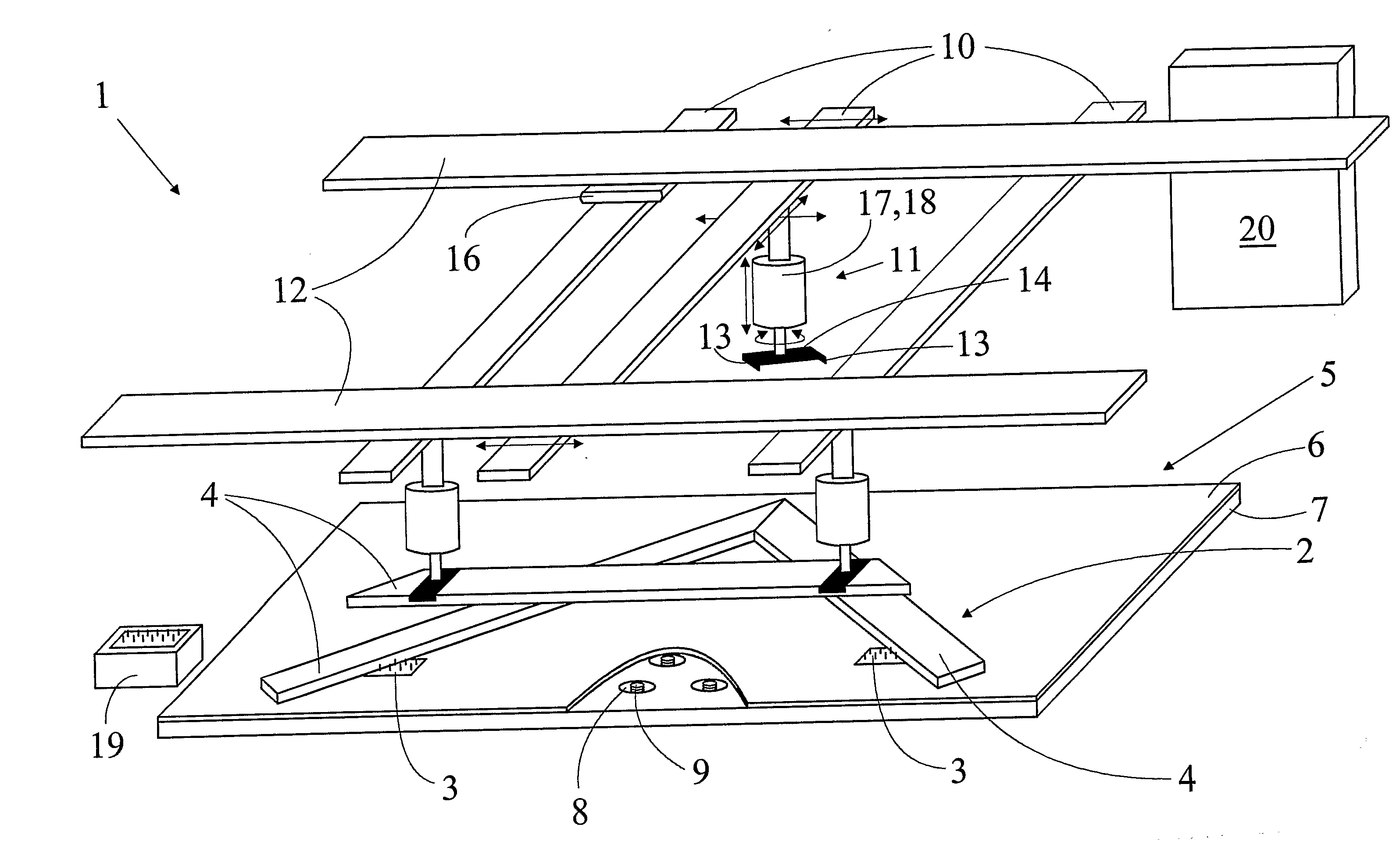

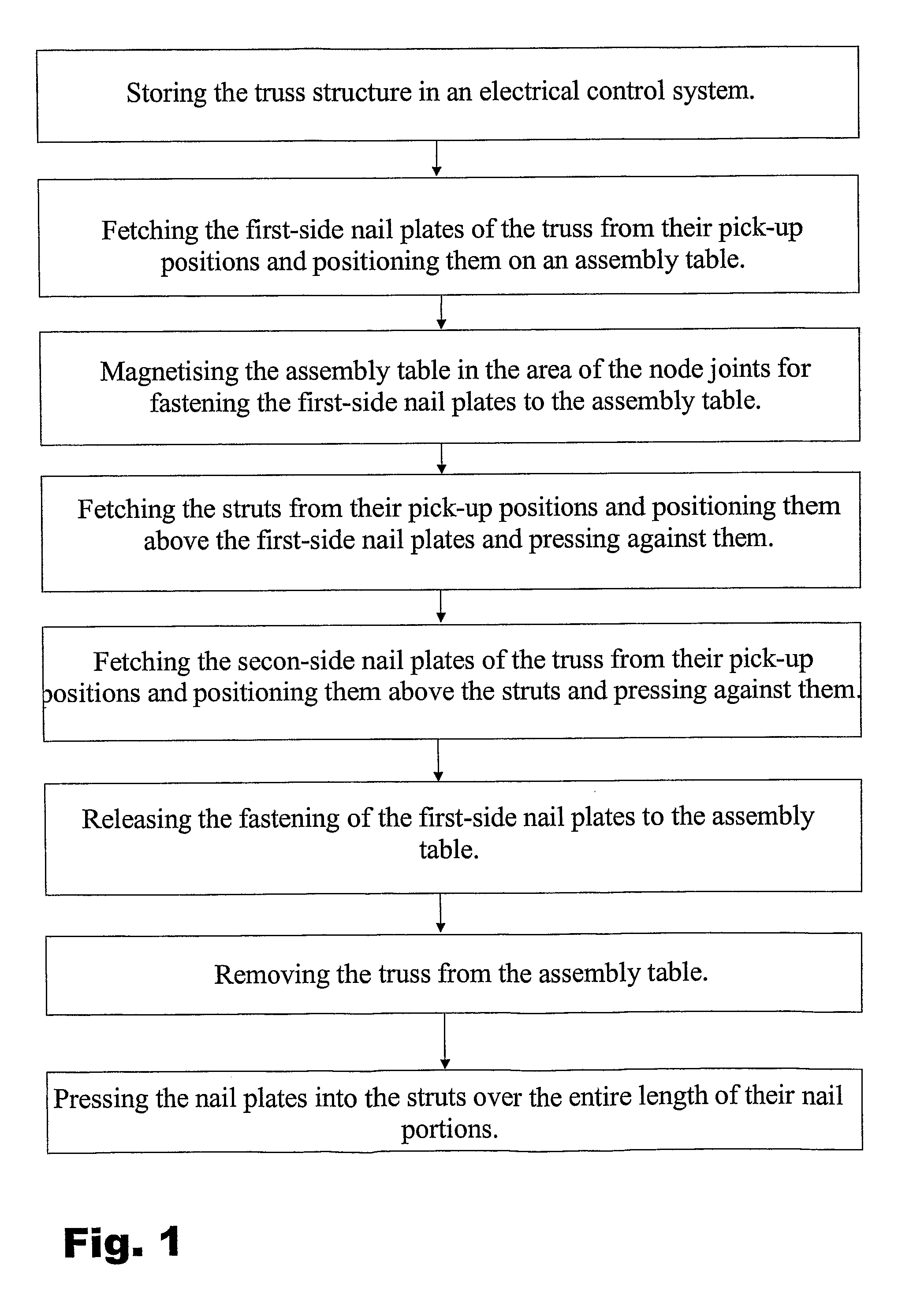

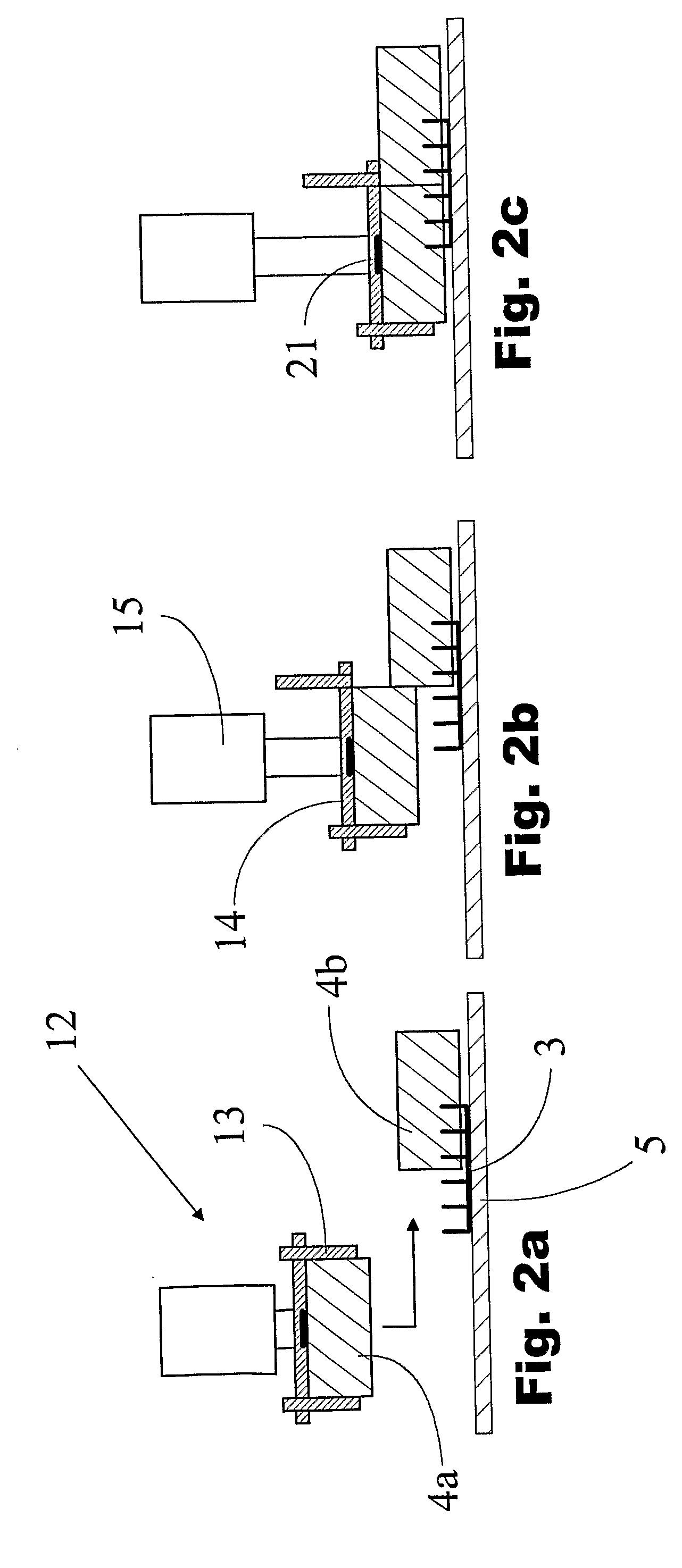

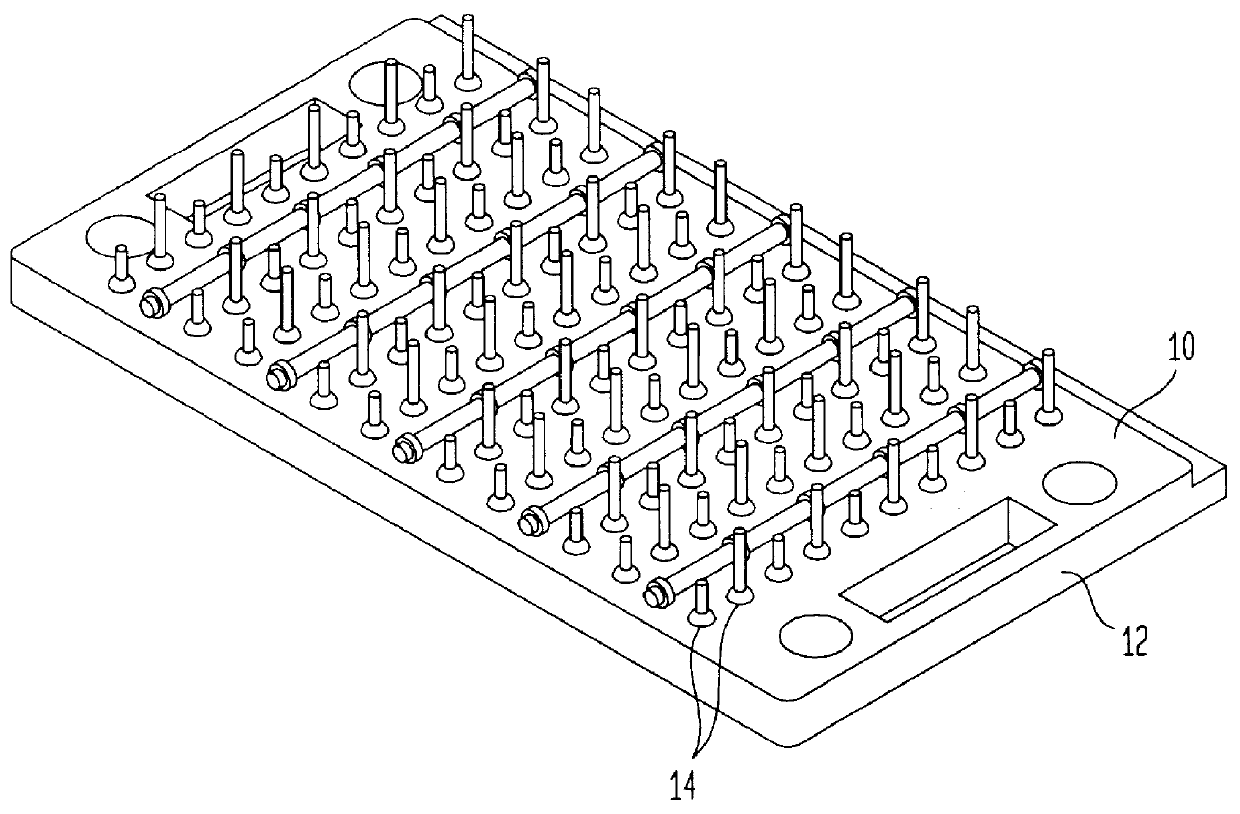

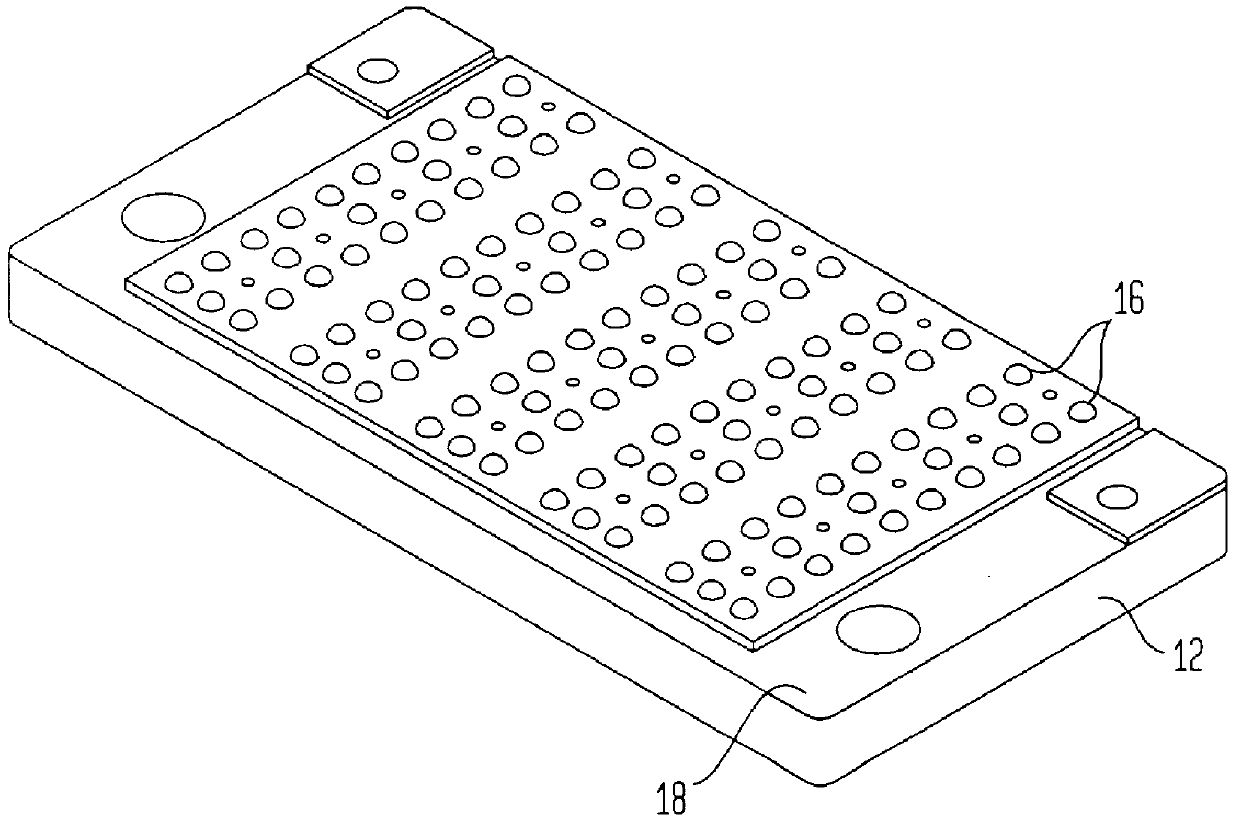

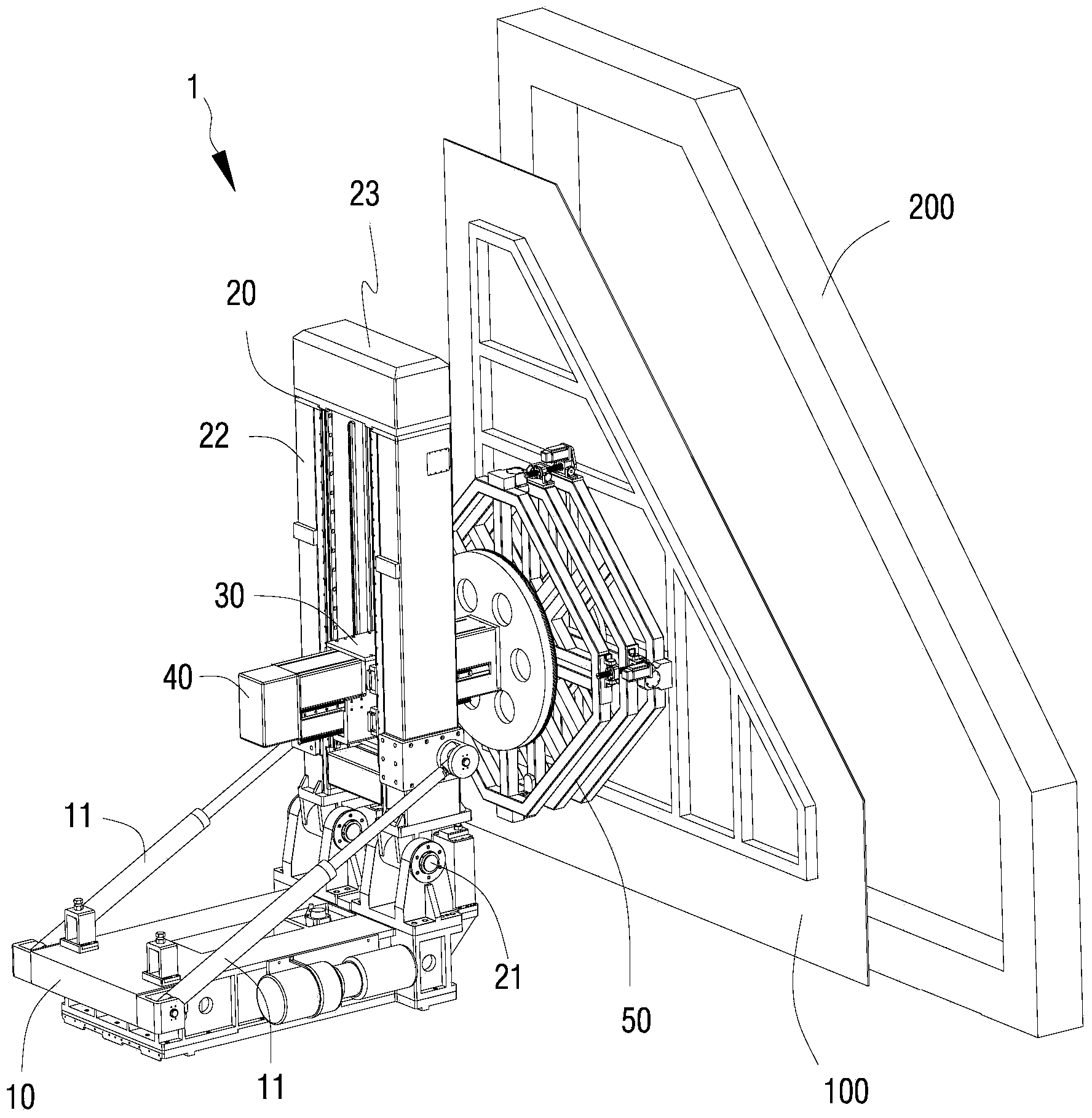

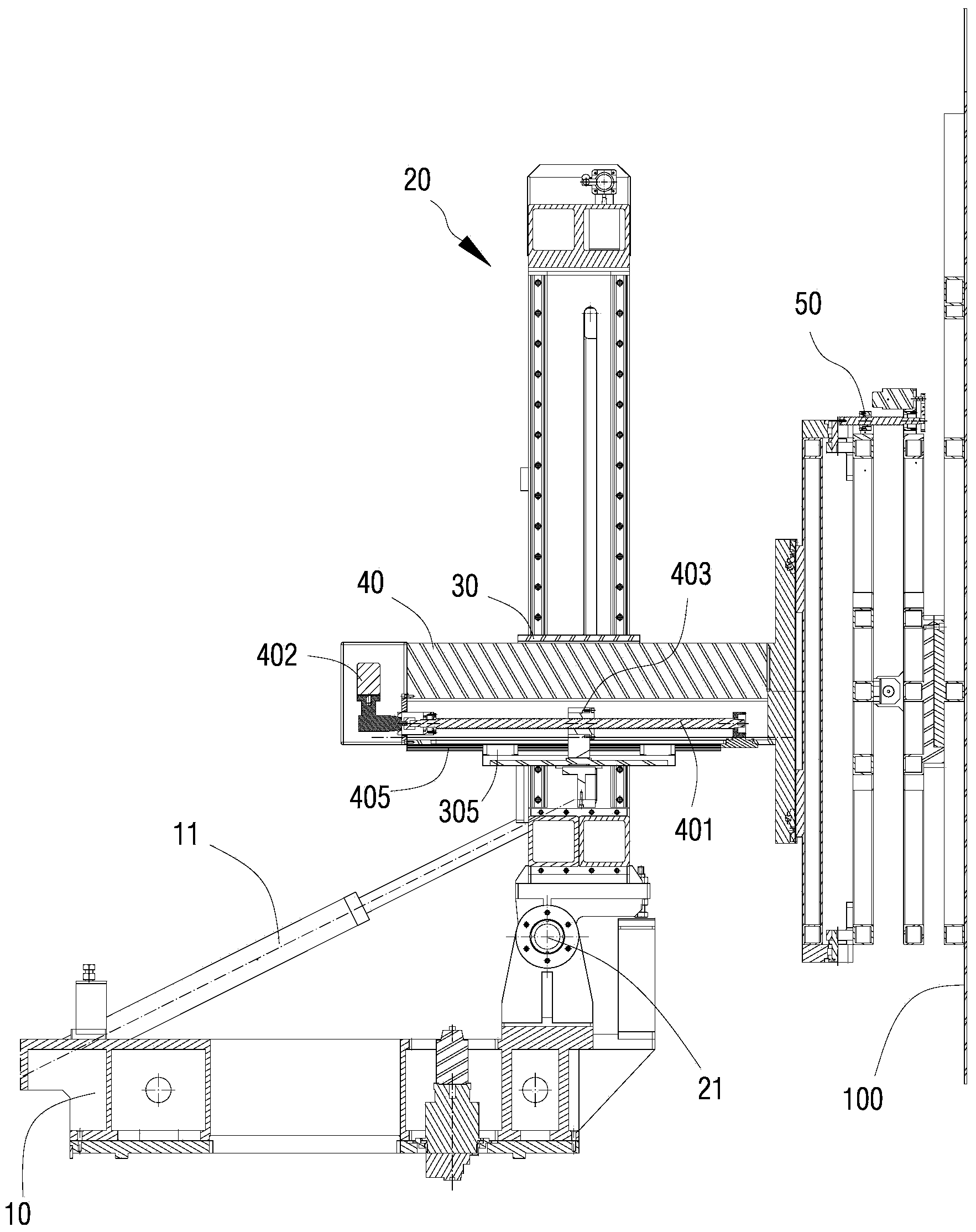

Method and Apparatus For Manufactring a Nail Plate Truss Without Setting

InactiveUS20080313994A1Improve effectivenessSufficient speed and positioning precisionStapling toolsBuilding repairsEngineeringMarine engineering

A method and an apparatus for the manufacture of a nail plate truss (2) without setting, said nail plate truss including first-side nail plates (3) of the truss, second-side nail plates (3) of the nail plate truss, and struts (4) joined together by nail plates. According to the inventive method, the structure of the truss is stored in an electric control system (20), and the nail plates (3) and struts (4) for a truss are brought into their positions required by the truss structure onto a horizontal assembly table (5), as controlled by an electric control system, using handling members (11) separate from the assembly table, the parts (3, 4) of the truss being positioned into their positions based directly on positioning of the handling member (11) transporting them.

Owner:LINEARTEC

IDC socket strain relief cap rework tool

InactiveUS6149453AEasy to disassembleAutomate assemblyContact members penetrating/cutting insulation/cable strandsFastening/insulating connecting partsEngineeringElectric wire

A tool to remove an insulation displacement contact (IDC) strain relief cap that interconnects a wire with an electrical contact. The electrical contact has a bifurcated end to engage and retain a wire and is engageable with the strain relief cap to secure The wire. Means in the form of tabs are provided on the electrical contact to releaseably retain the electrical contact and the strain relief cap together with the wire whereby the electrical contact, wire, and strain relief cap may be moved as a single unit. The tool has tangs to engage the tabs and move them out of engagement with the relief cap while gripping the relief cap for removal from the electrical contact.

Owner:LUCENT TECH INC

Assembly production line for toy remote control

ActiveCN111055119AReduce manufacturing costAutomate assemblyAssembly machinesProcessing accuracyAssembly line

The invention discloses an assembly production line of a toy remote control. The assembly production line includes a machine frame and a toy remote control assembly line. The toy remote control assembly line includes a conveying positioning device, a rocker mounting device, a nut mounting device, a switch antenna pedestal mounting device, a tin coating device, a handle mounting device, a remote control cover closing device and a screw tightening device. The conveying positioning device includes pallets, a conveying mechanism and a plurality of positioning mechanisms, and the positioning mechanisms are arranged in the direction of conveying the pallets by the conveying mechanism. The pallets are conveyed by the conveying mechanism to the rocker mounting device, the nut mounting device, theswitch antenna pedestal mounting device, the tin coating device, the handle mounting device, the remote control cover closing device and the screw tightening device in sequence, and are positioned bythe corresponding positioning mechanism when arrive. The assembly production line of the toy remote control can automatically and continuously assemble various parts of the toy remote control, the production efficiency is high, the processing accuracy is high, and the production cost is effectively reduced.

Owner:GUANGDONG QISHIDA INTELLIGENT TECH CO LTD

Full-automatic motor stator assembly production line

ActiveCN111817511AAutomate assemblyIncrease productivityLiquid surface applicatorsOther manufacturing equipments/toolsElectric machineCopper wire

The invention discloses a full-automatic motor stator assembly production line, and belongs to the technical field of motor production. The production line comprises a rack, and a carrying plate usedfor carrying a motor shell and a motor stator is connected to the rack in a sliding mode. A positioning mandrel used for fixing the motor stator is inserted into the carrying plate; and the rack is further connected with a driving assembly for driving the carrying plate to move. A pre-shaping assembly, a wire cutting assembly used for cutting off redundant copper wires, a welding assembly, a corepulling assembly, a heating assembly, a gluing assembly and an assembling assembly are sequentially arranged in the sliding direction of the carrying plate. The pre-shaping assembly, the wire shearingassembly, the welding assembly, the core pulling assembly, the heating assembly, the gluing assembly and the assembling assembly are all connected with the rack, and the effect of improving the production efficiency is achieved.

Owner:天津德科智控股份有限公司

Electric vehicle battery quick assembling equipment and working method thereof

ActiveCN112894333ASimple structureRealize automatic fixationFinal product manufactureAssembly machinesElectric-vehicle batteryElectrical battery

The invention discloses electric vehicle battery quick assembling equipment. The electric vehicle battery quick assembling equipment comprises a first feeding mechanism, a machining table, a second feeding mechanism, a rotating disc, a fixing base, a pressing mechanism, a fixed connecting mechanism and a discharging mechanism; the rotating disc is arranged in the middle of the top face of the machining table through a driving motor, the first feeding mechanism, the second feeding mechanism, the pressing mechanism, the fixed connecting mechanism and the discharging mechanism are annularly arranged along the rotating disc, and the first feeding mechanism, the second feeding mechanism, the pressing mechanism, the fixed connecting mechanism and the discharging mechanism are all installed on the machining table; and the first feeding mechanism and the second feeding mechanism are the same in structure, and each of the first feeding mechanism and the second feeding mechanism comprises a first clamping assembly and a conveying assembly. According to the electric vehicle battery quick assembling equipment and a working method thereof, batteries of different sizes can be assembled, automatic assembling can also be achieved, and the electric vehicle battery assembling efficiency is greatly improved.

Owner:东莞赛普若斯科技有限公司

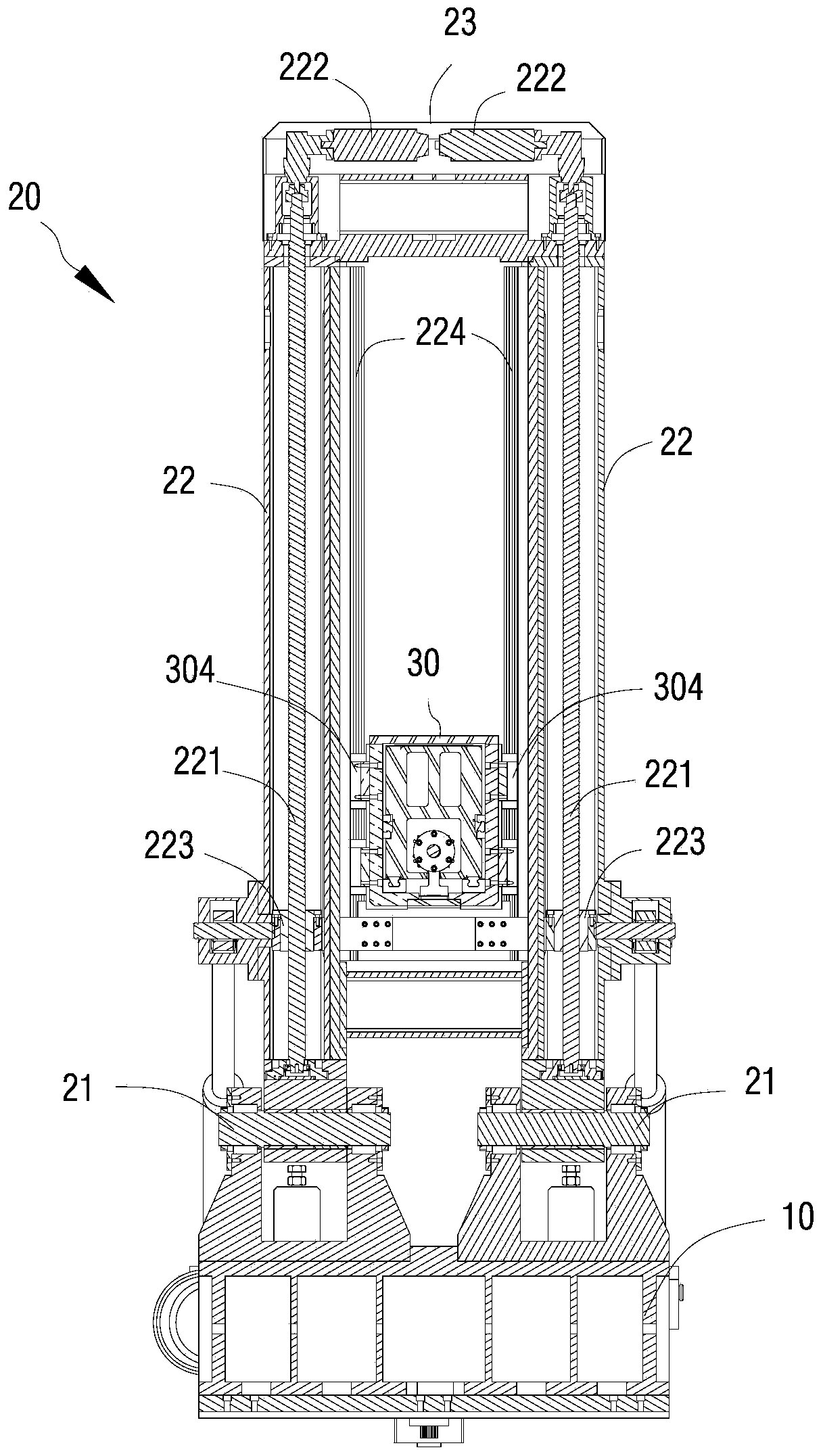

Device for enabling wall plates of wings to be automatically assembled onto and disassembled from frame

The invention discloses a device for enabling wall plates of wings to be automatically assembled onto and disassembled from a frame. The device comprises a base, a door-frame-shaped turning guide rail hinged to the base, a horizontally-moving frame arranged between two frame guide rails of the turning guide rail, an telescopic guide rail arranged in the horizontally-moving frame, and a swing posture adjusting assembly arranged at the tail end of the telescopic guide rail, wherein the wall plates of the wings can be arranged on the swing posture adjusting assembly. According to the device for enabling the wall plates of the wings to be automatically assembled onto and disassembled from the frame, the problem of enabling the wall plates of the wings to be assembled onto and disassembled from the frame in the wing assembly process can be solved, the wing assembly automation is achieved, and the wing wall plate assembly operation such as rapid positioning of the wings, automatic adjustment of the postures of the wings and accurate attaching of the wings can be achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com