IDC socket strain relief cap rework tool

a technology of strain relief cap and idc socket, which is applied in the direction of contact members penetrating/cutting insulation/cable strands, electrical appliances, fastening/insulating connecting parts, etc., can solve the problem of not being able to adapt to large pin array connectors, and achieve the effect of easy removal of large pin arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

up to this point is identical to that of copending application COLE 1-2-32-52-21 mailed to the USPTO on Nov. 17, 1999 and assigned to the assignee of this disclosure.

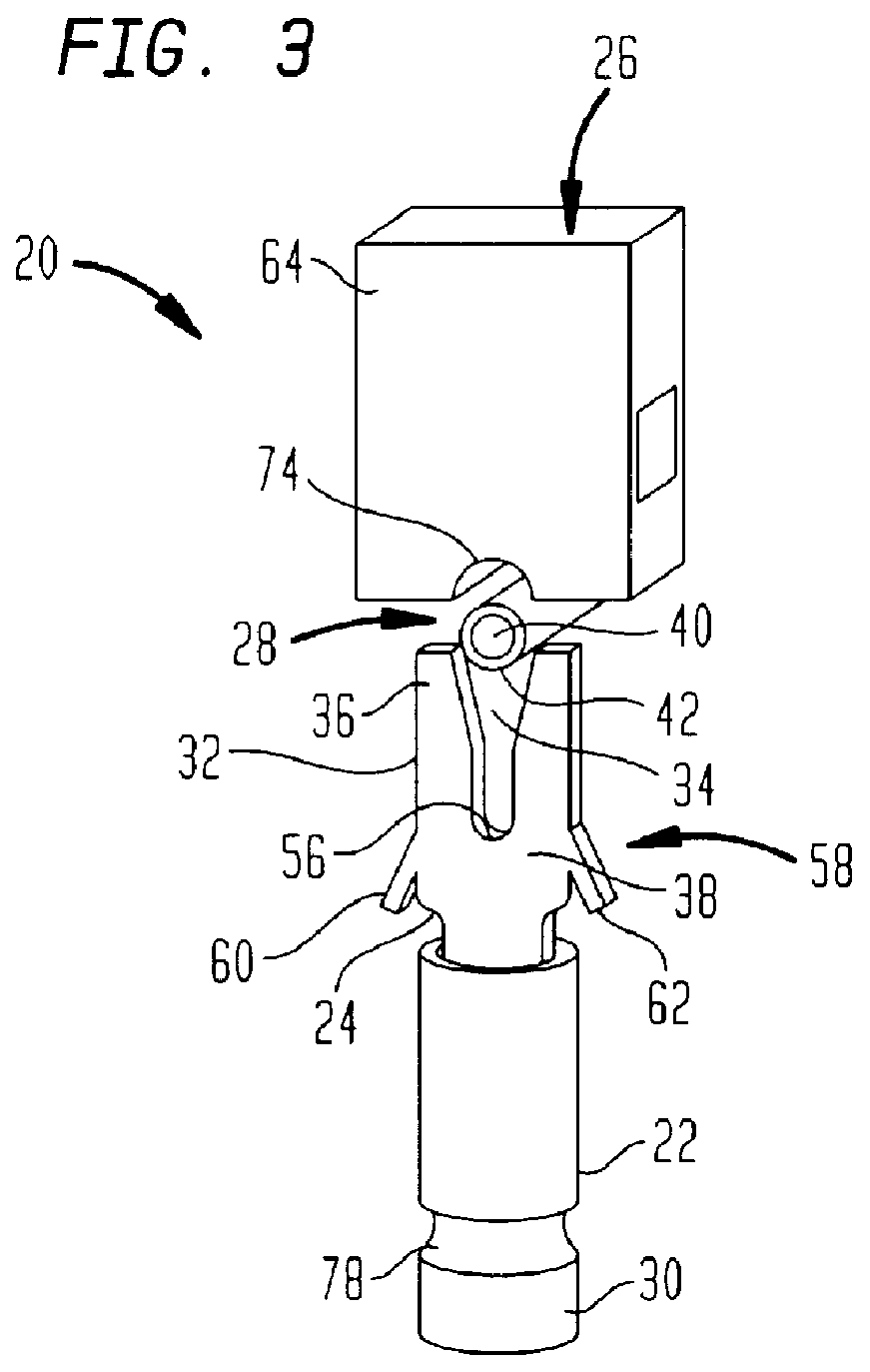

FIGS. 5 and 6 illustrate an IDC relief cap removal tool 78 having a head portion 80 supporting a center section 82 flanked by a pair or movable arms 84 and 86. Center section 82 has a width (W) that is equal to or greater than the width of the relief cap 26 as illustrated in FIG. 5. Arms 84 and 86 terminate or have thereon a pair of tangs 88 and 90 that are configured to fit within locking window 70 and 72 as illustrated in greater detail in FIGS. 7, 8 and 9.

In its normal condition, relief cap removal tool 78 may have its arms 84 and 86 biased outwardly as illustrated in FIG. 6. Force, for example a hand grip, exerted along lines 92 and 94 is used to move arms 84 and 86 into contact with center section 82 as illustrated in FIG. 5.

When relief cap removal tool 78 is located relative to a strain relief cap 26 as illustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com