Patents

Literature

209results about How to "Realize automatic fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste metal treatment equipment

ActiveCN106945334ARealize automatic controlImprove work efficiencySolid waste disposalPressesCompression deviceEngineering

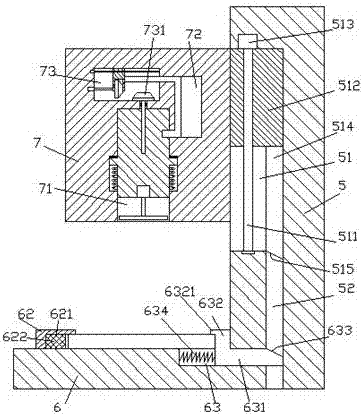

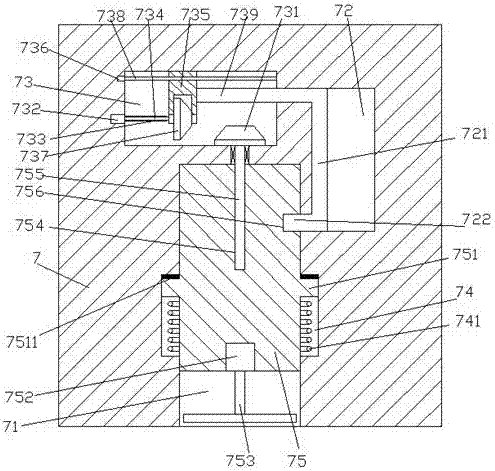

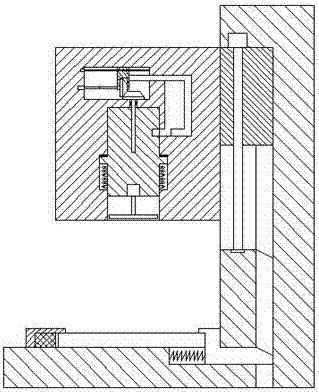

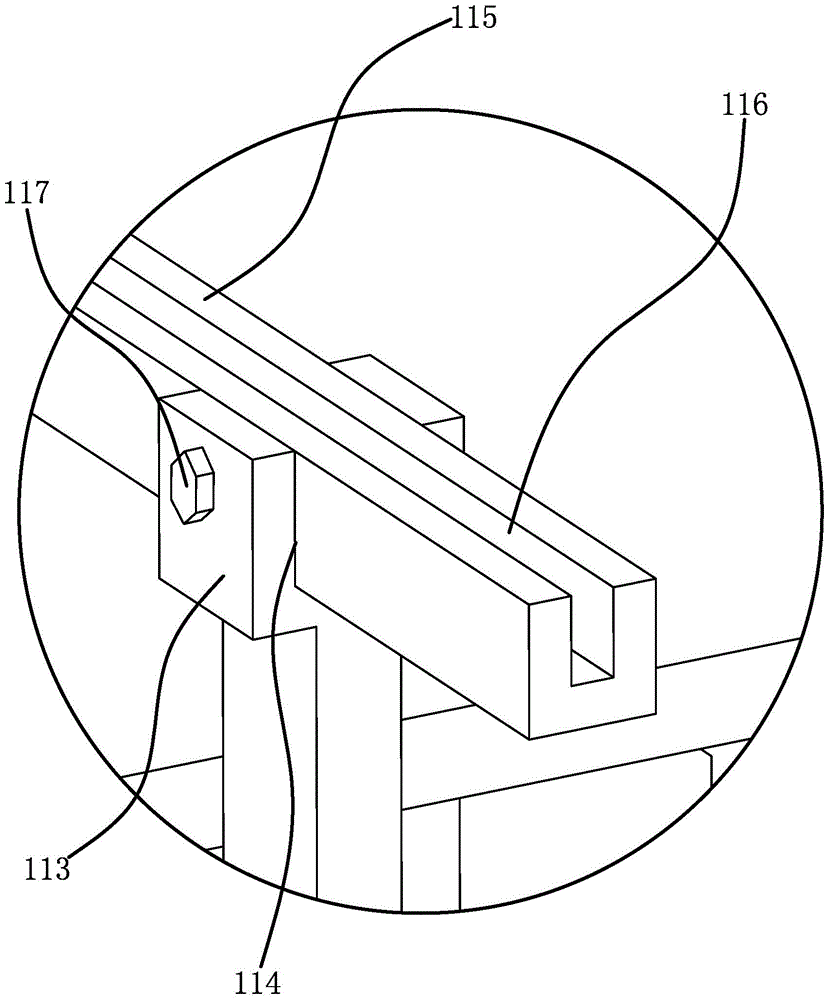

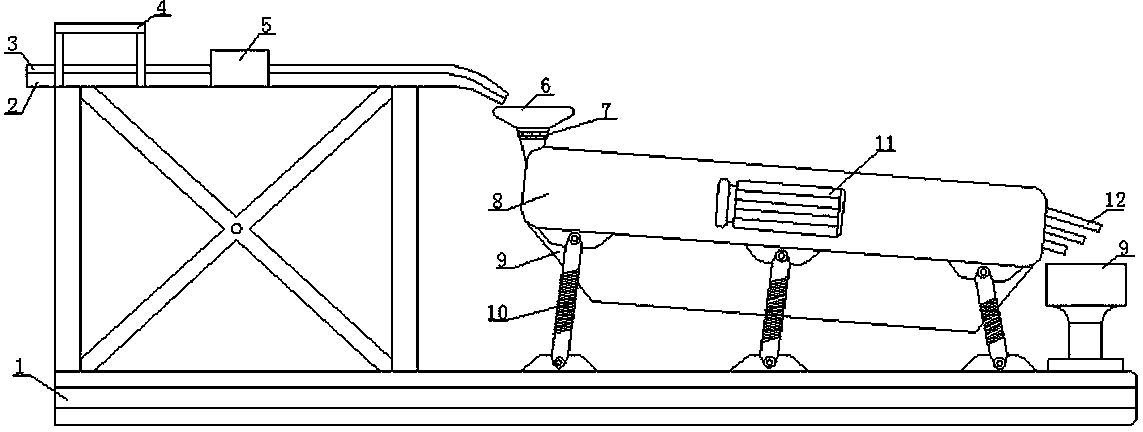

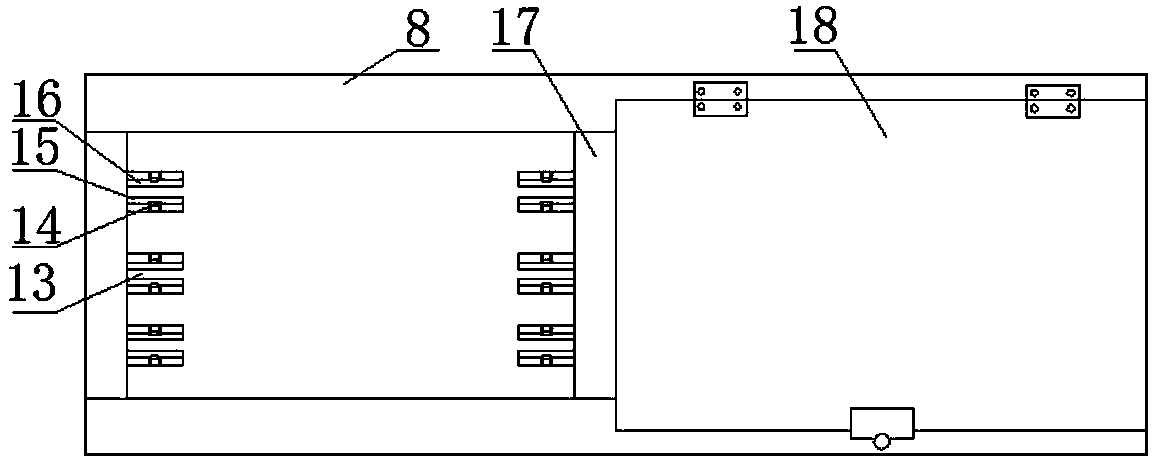

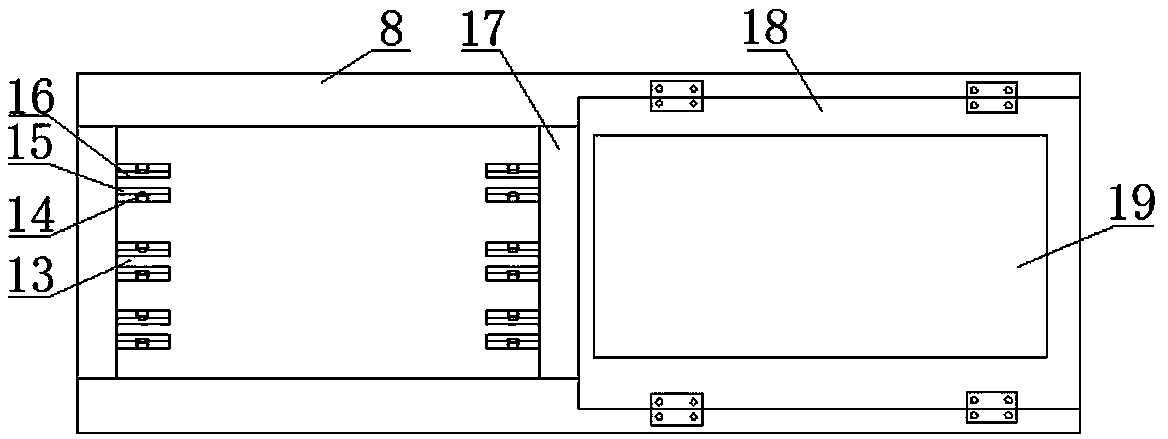

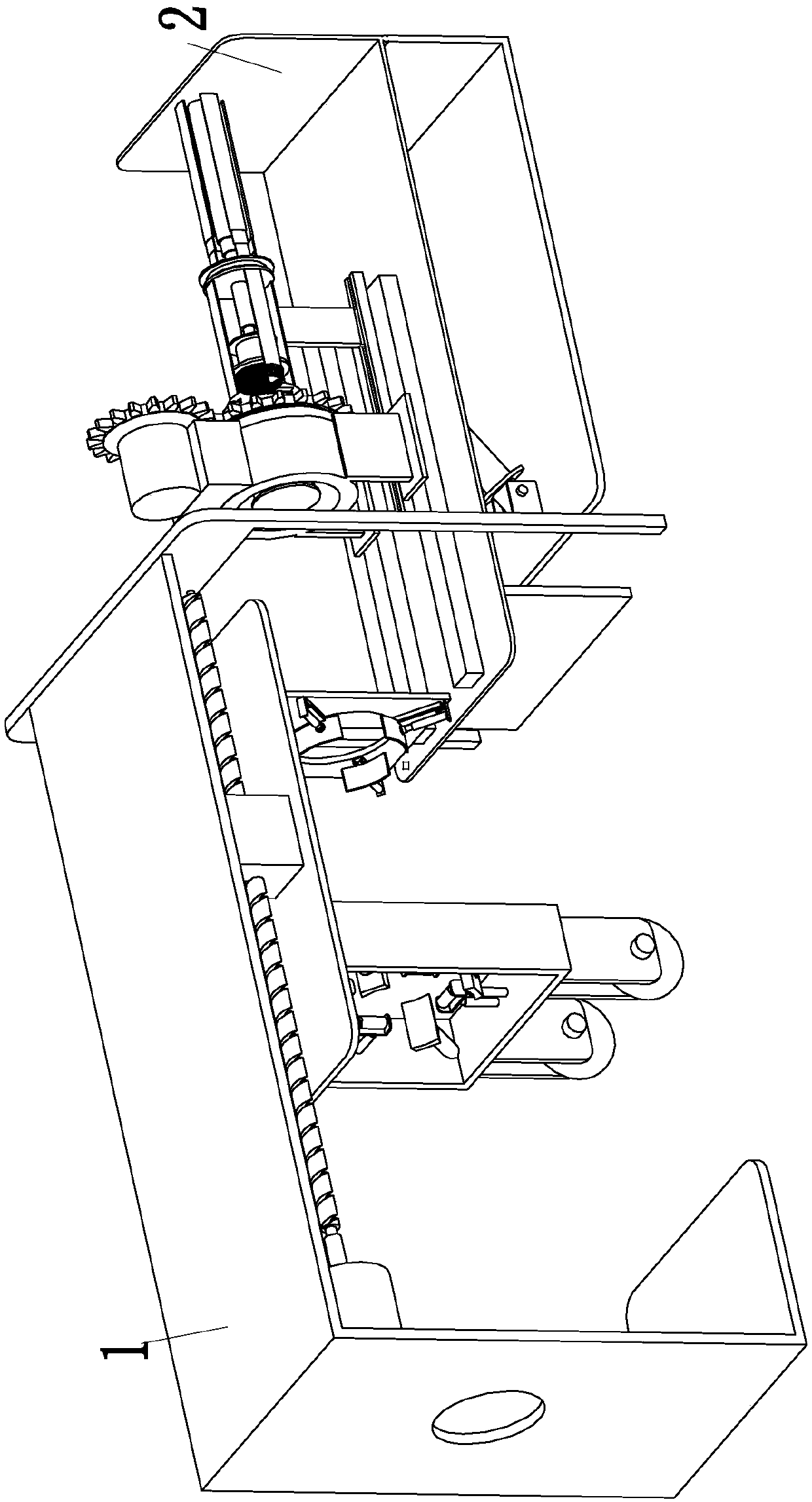

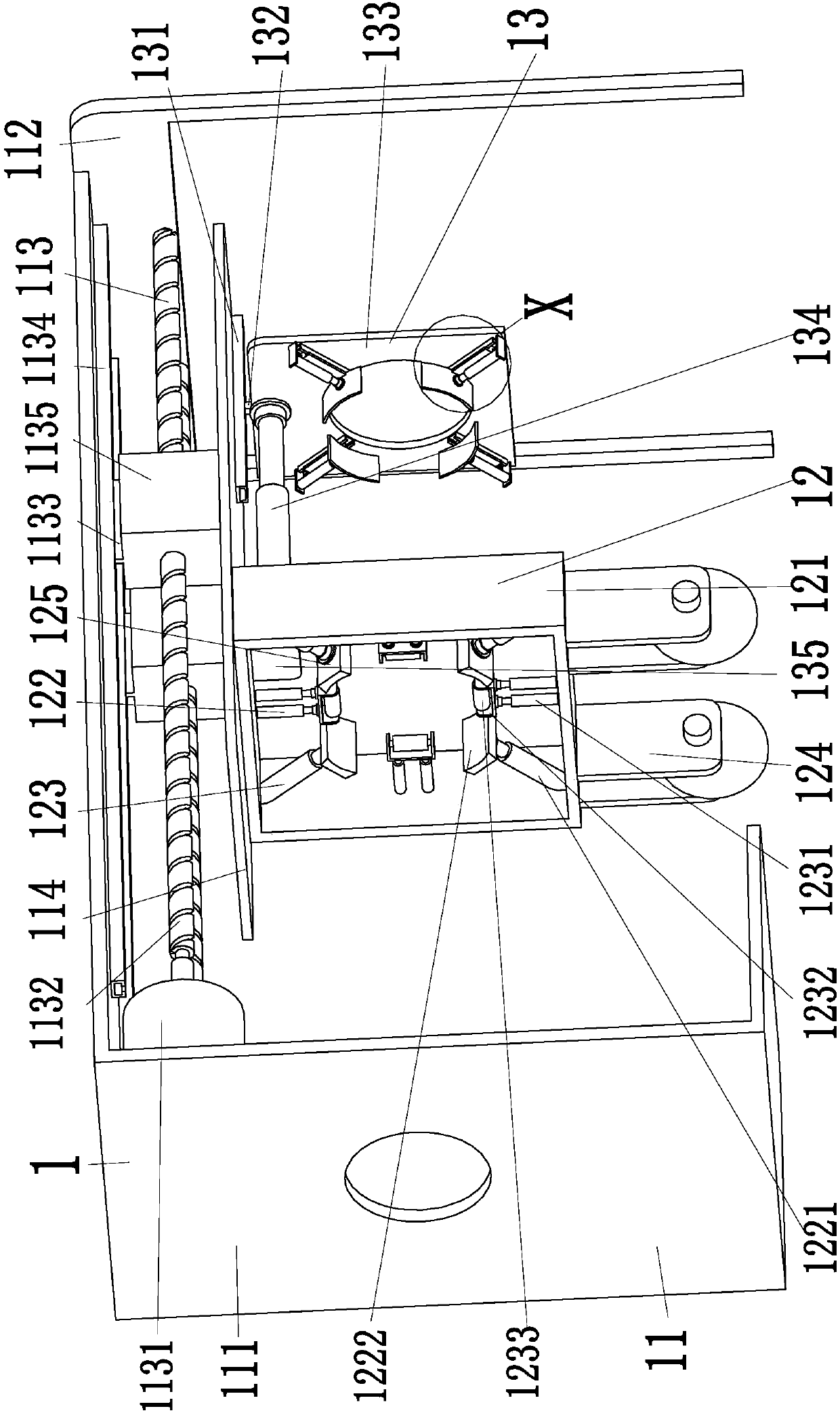

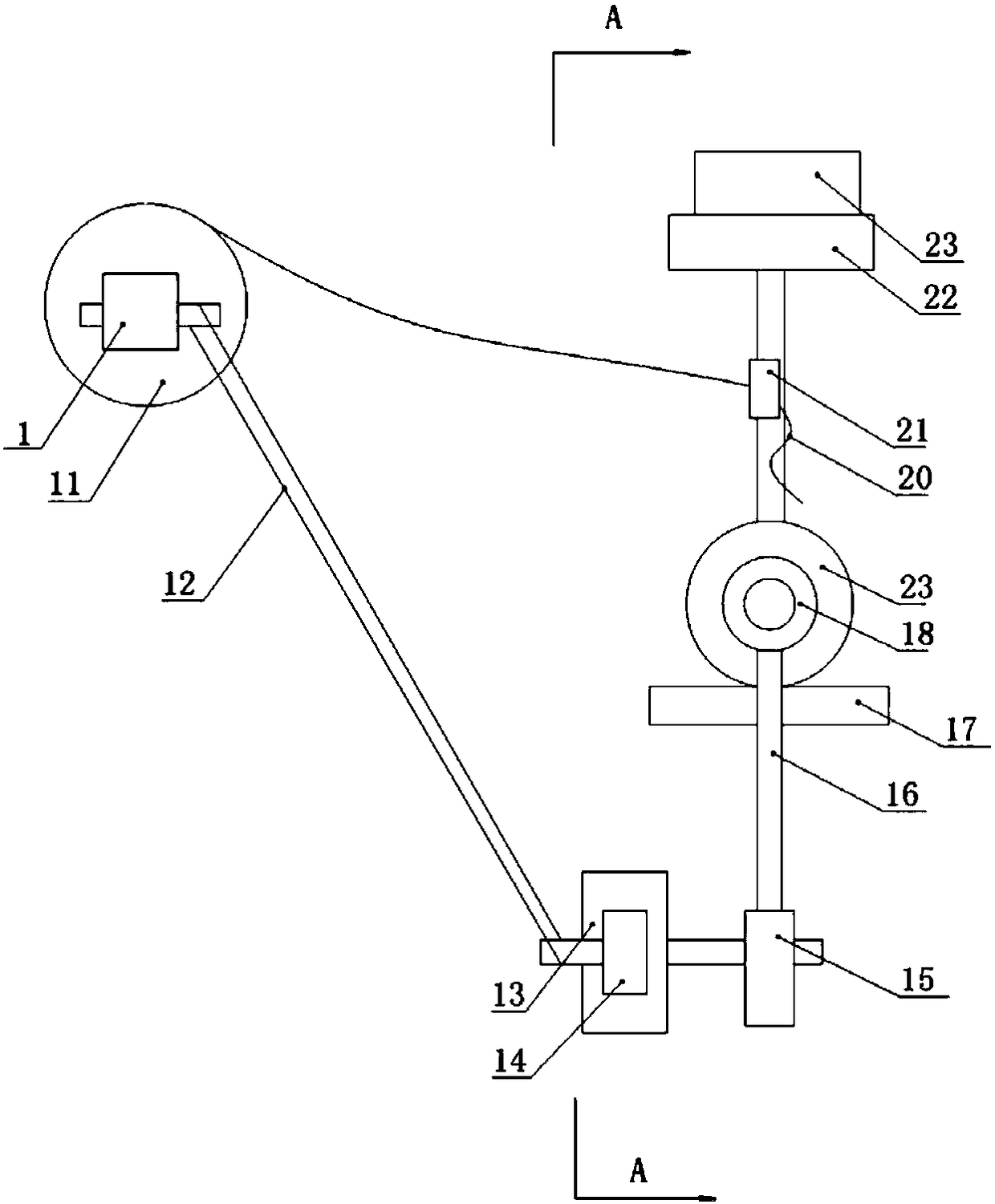

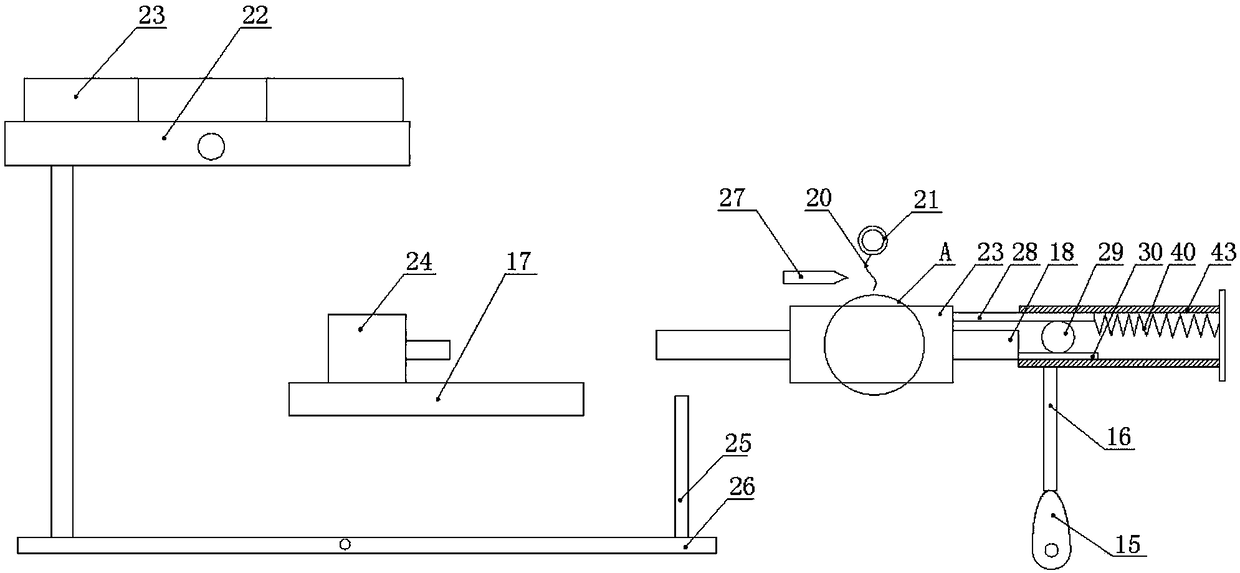

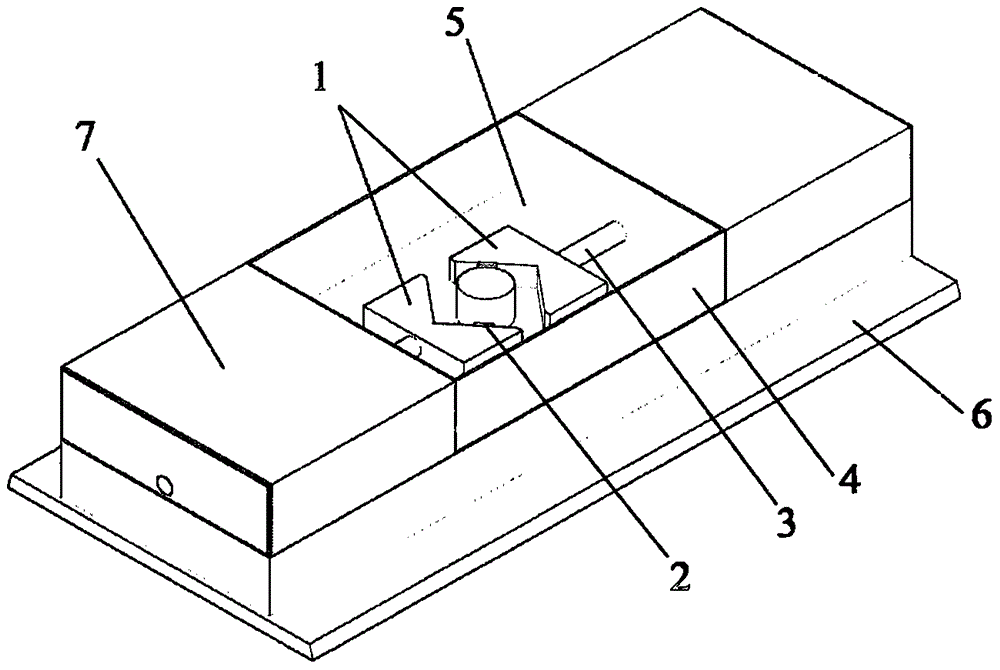

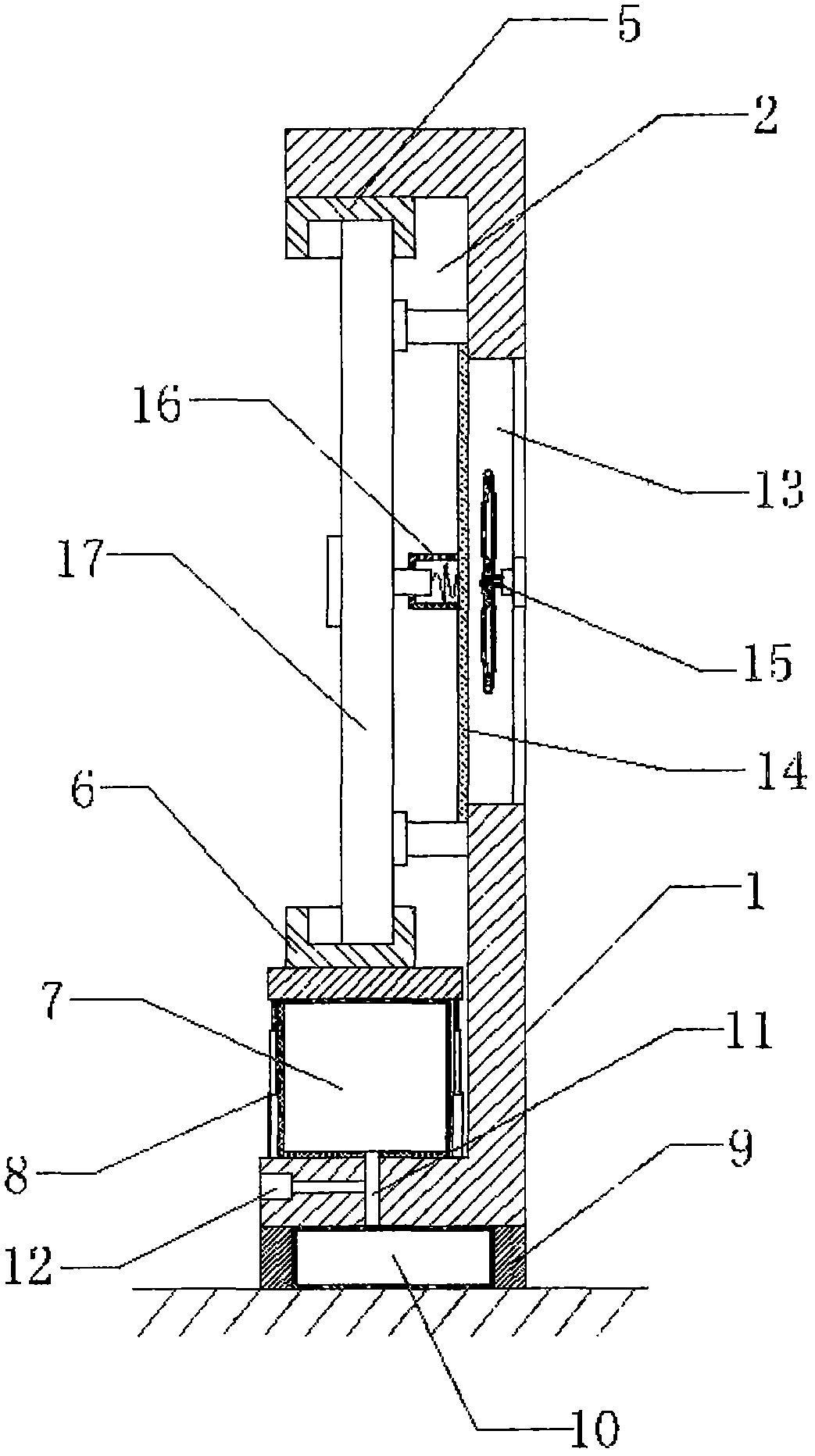

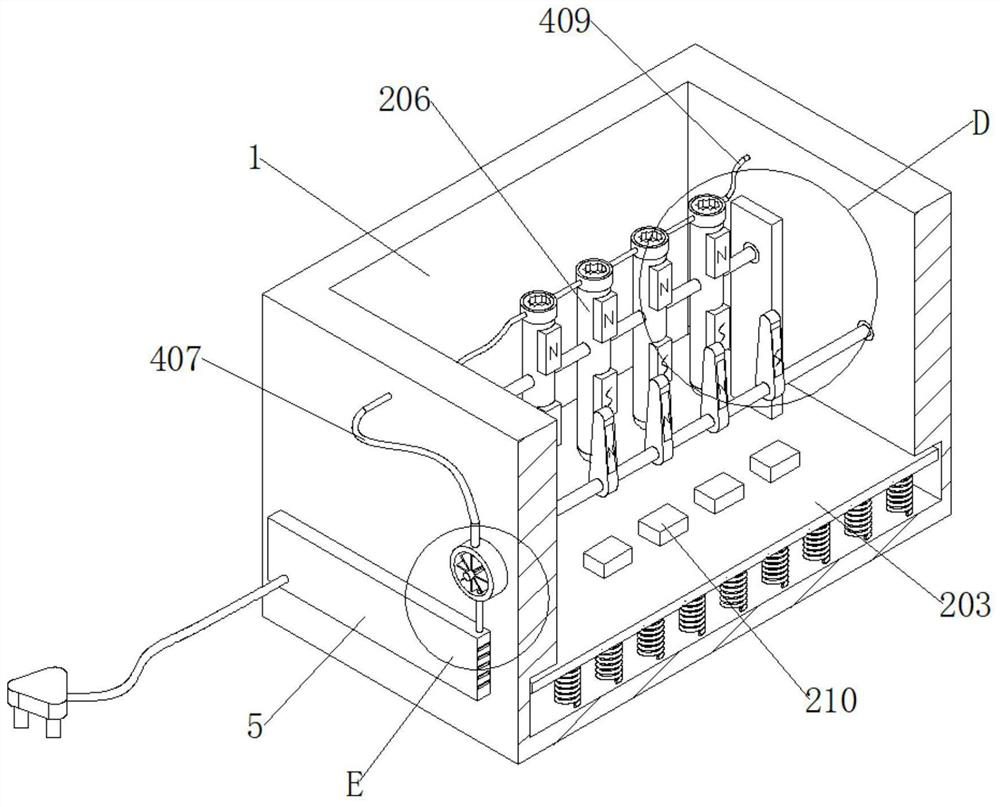

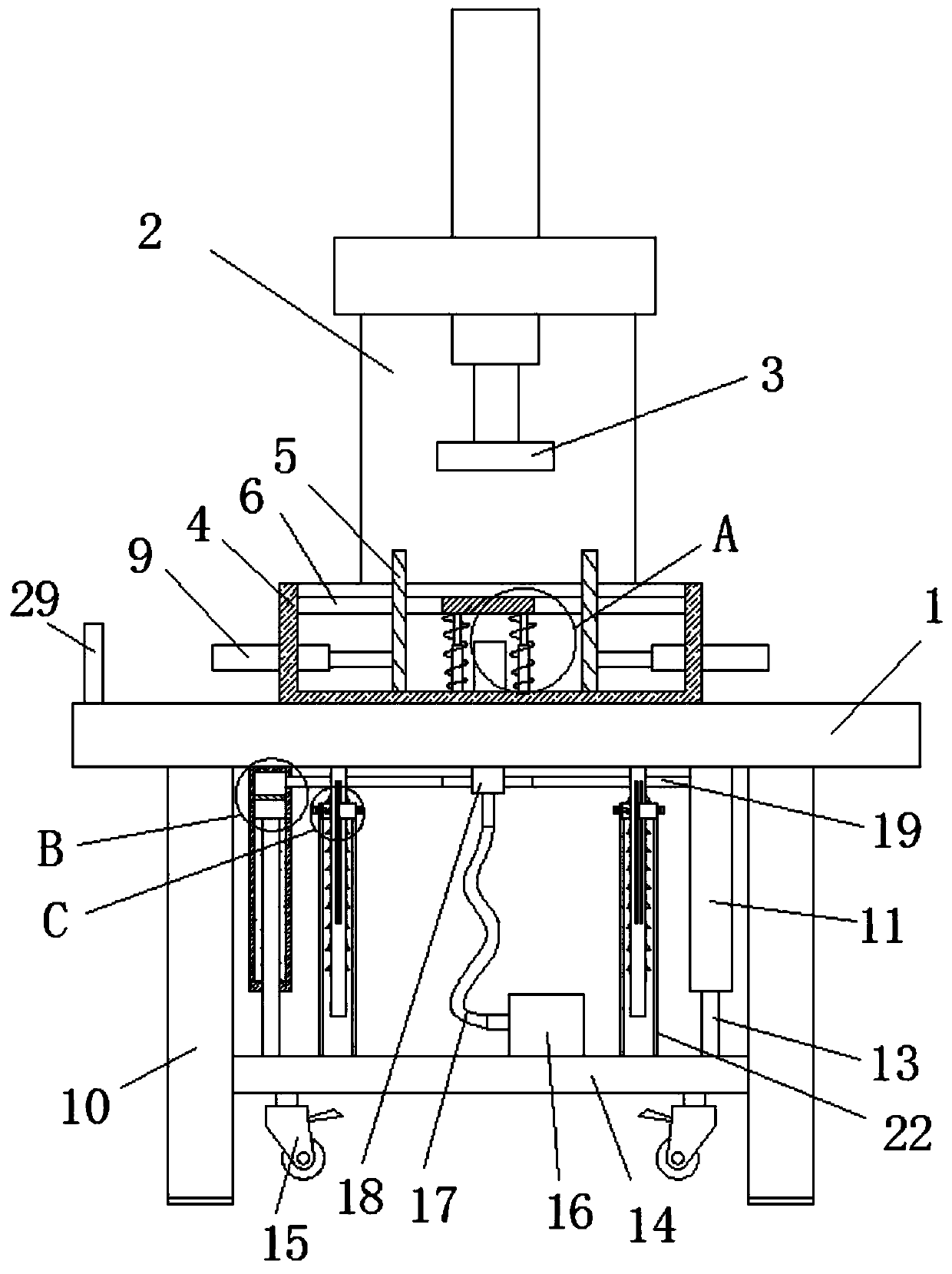

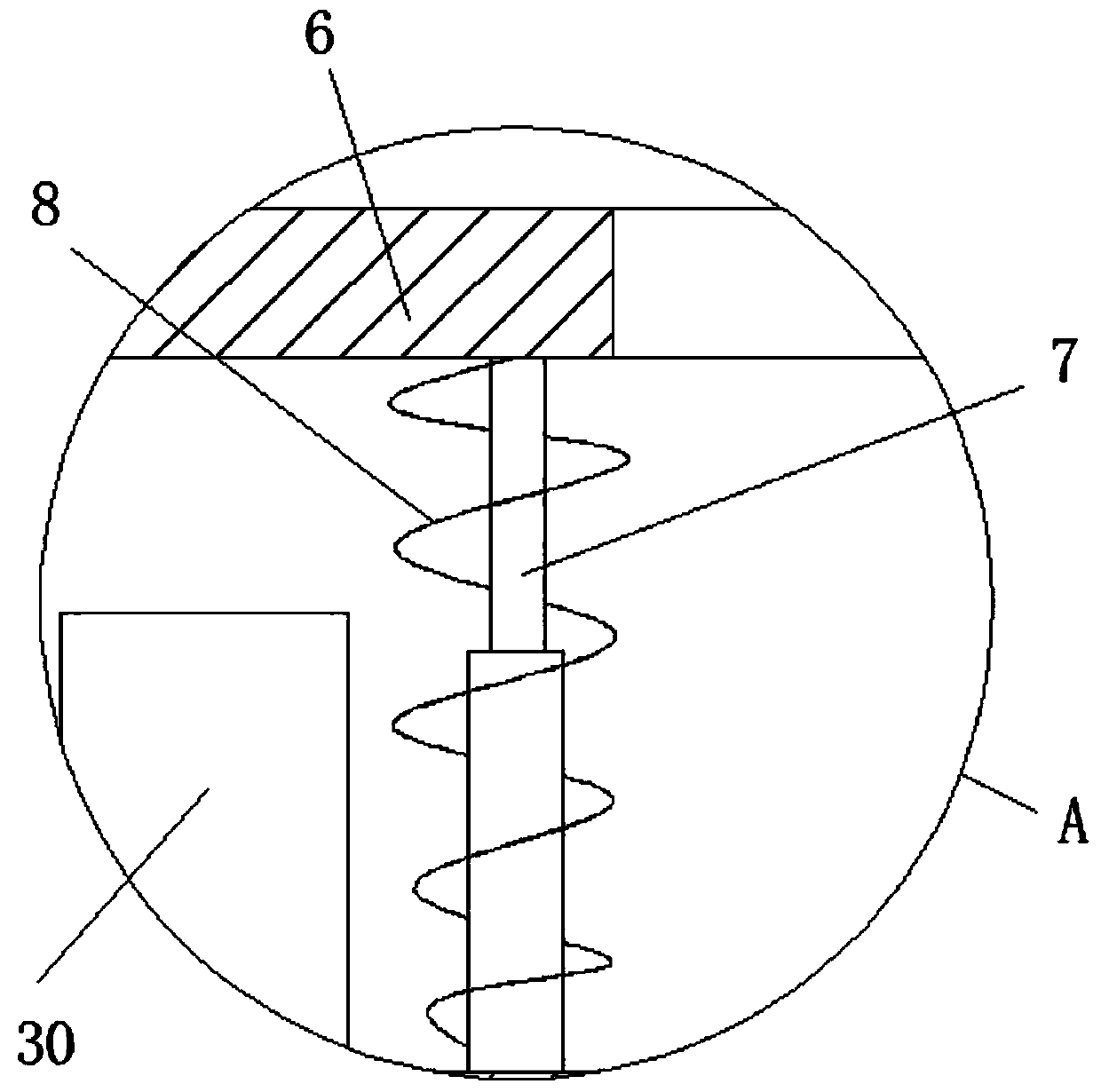

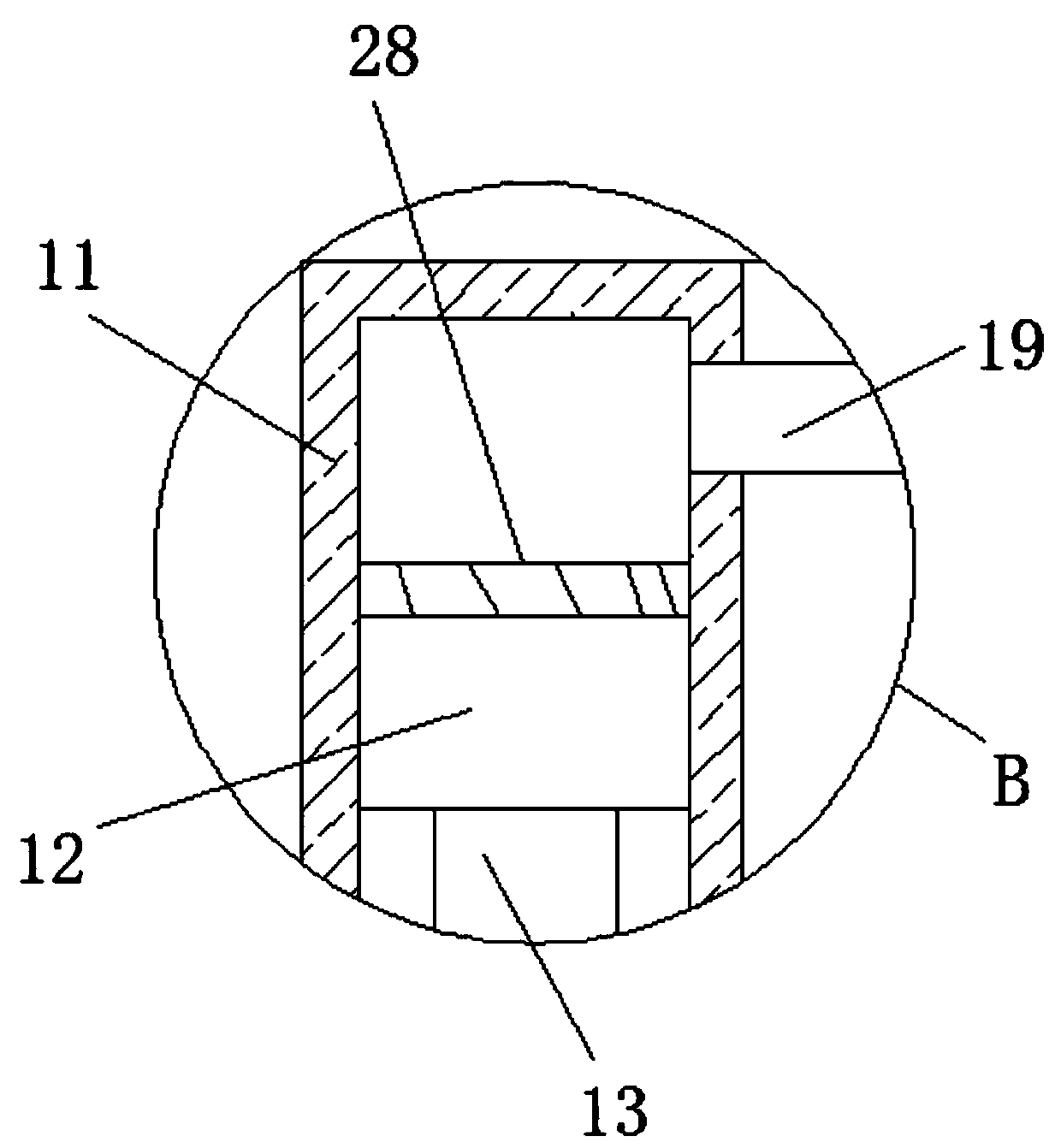

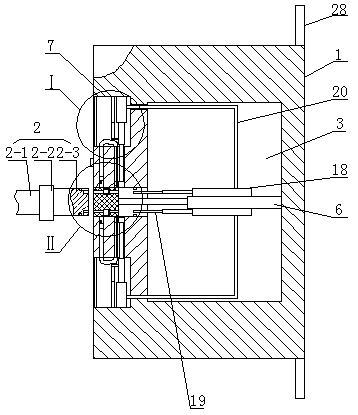

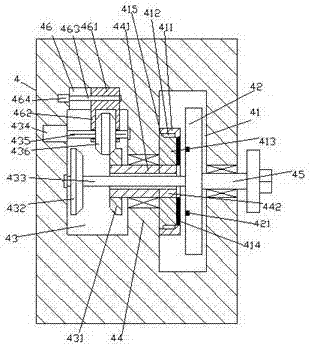

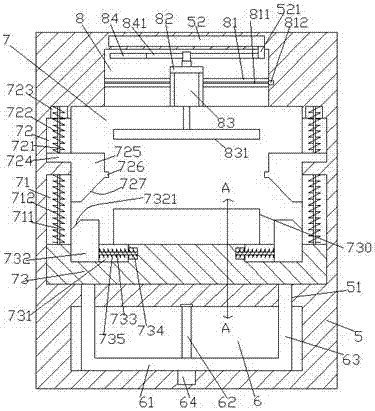

The invention discloses waste metal treatment equipment. The waste metal treatment equipment comprises a frame body composed of a working platform and a pillar body and a compression device arranged in the frame body; the end face of the bottom of the compression device is internally provided with a compression sliding transport slot, the position, above the compression sliding transport slot, of the compression device is internally provided with a transmission cavity, the position, on the right side of the top of the compression sliding transport slot, of the compression device is internally provided with a locking cavity extending upwards, and the extending portion segment at the top of the locking cavity is located on the right side of the transmission cavity; the inner side wall of the compression sliding transport slot is provided with a guide slot, the compression sliding transport slot is internally connected with a compression sliding transport block in a sliding transport fit manner, the end face of the top of the compression sliding transport block is internally provided with a spiral hole, and the spiral hole is internally in fit connection with a spiral rod; and the guide slot is internally provided with a protruded block, the side, close to the compression sliding transport block, of the protruded block is fixedly connected with the compression sliding transport block, and the right side end face of the compression sliding transport block above the protruded block is internally provided with a locking slot. The waste metal treatment equipment is simple in structure, convenient to operate and high in work efficiency and safety, and quality is improved.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

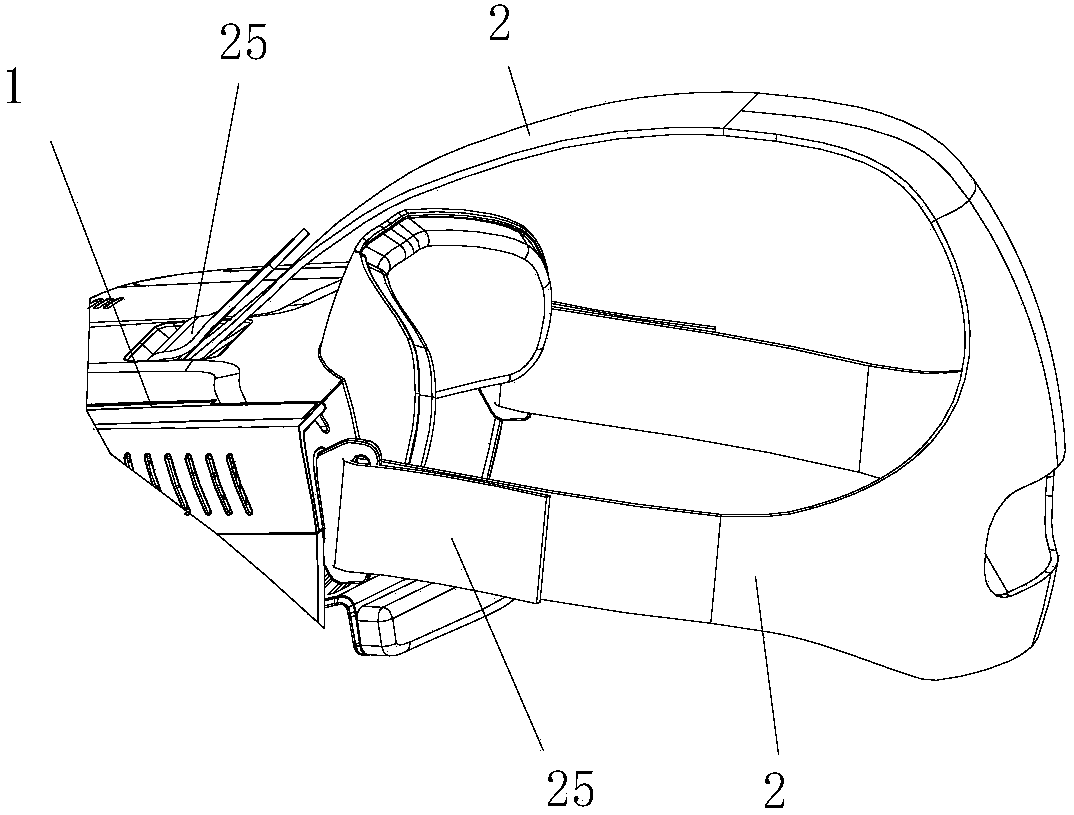

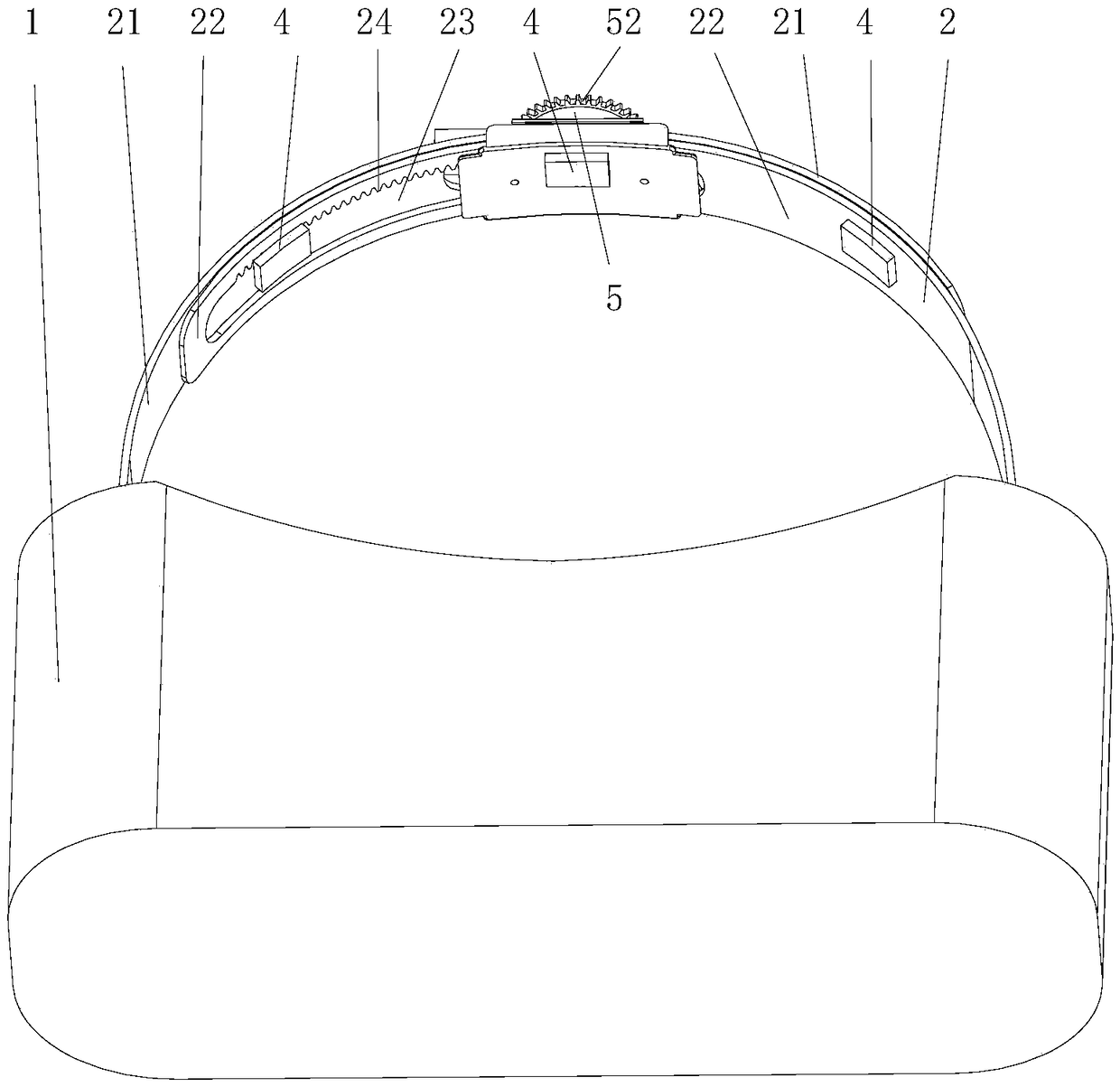

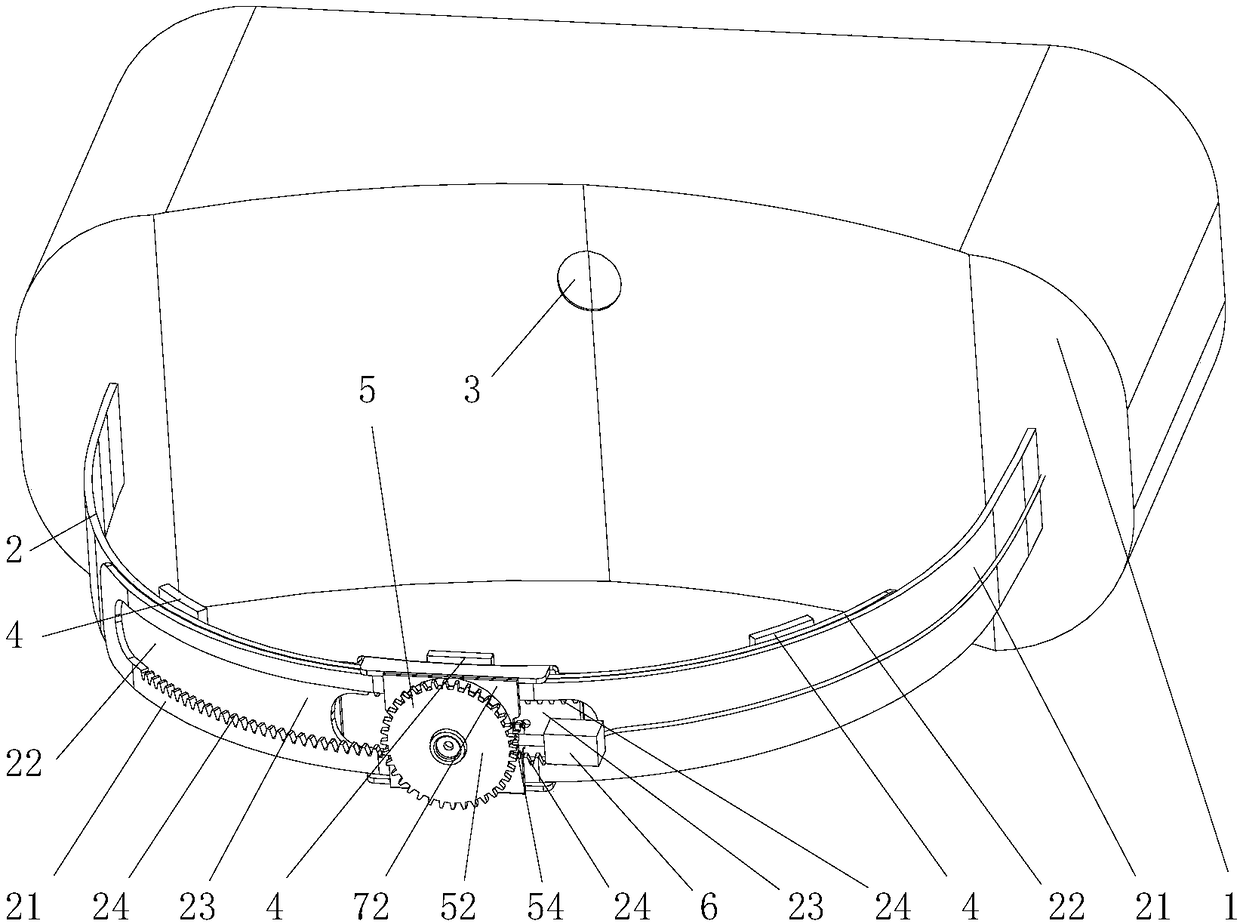

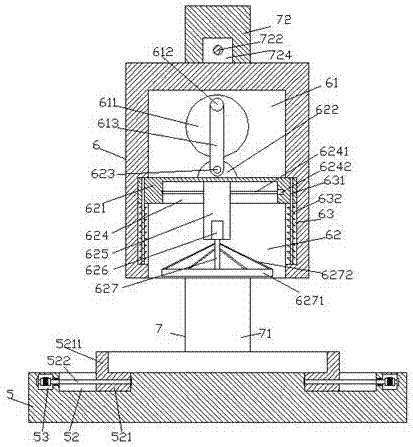

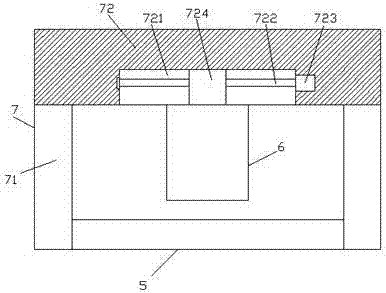

Headset display equipment and bandage adjusting method thereof

The invention belongs to the technical field of electronic products, and discloses headset display equipment and a bandage adjusting method thereof. Usually, the headset display equipment in the priorart is manually adjusted by an elastic type bandage or a bandage with Velcros. The headset display equipment comprises an equipment body, a bandage, a proximity sensor, a pressure sensor, a transmission assembly and a motor, wherein the bandage is connected with the equipment body; the proximity sensor and the pressure sensor are respectively electrically connected with the motor; the bandage isconfigured to retract or expand corresponding to the equipment body under the driving of the motor. The headset display equipment provided by the invention has the advantage that when a user uses theheadset display equipment, the headset display equipment is automatically fixed with the user.

Owner:GEER TECH CO LTD

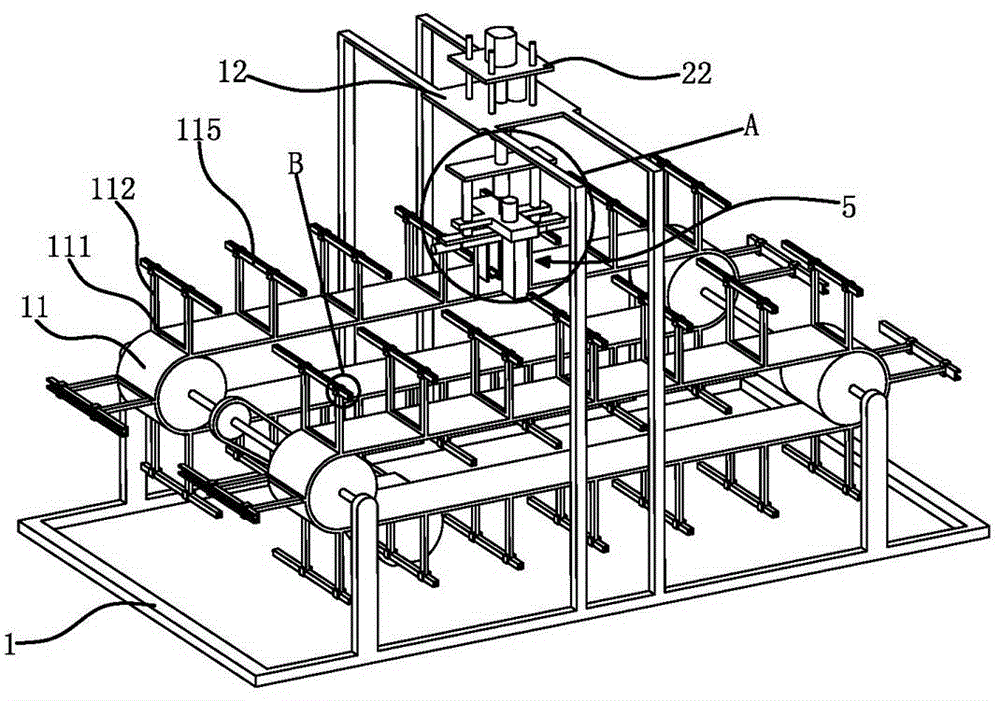

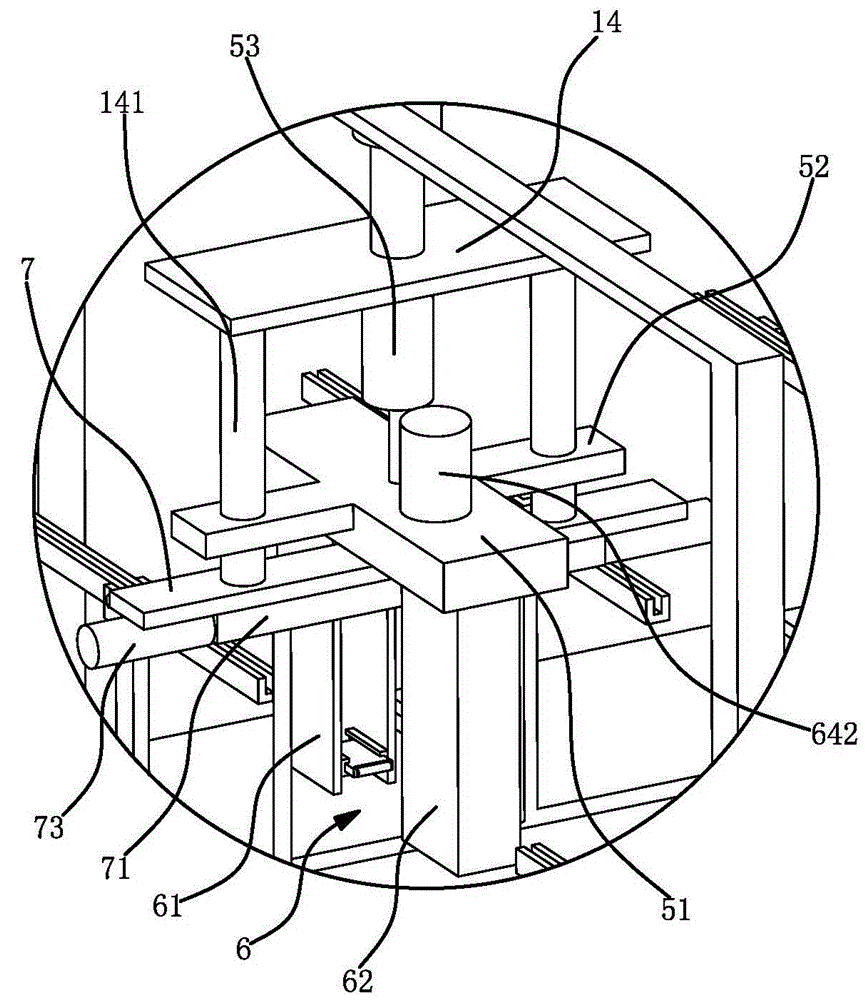

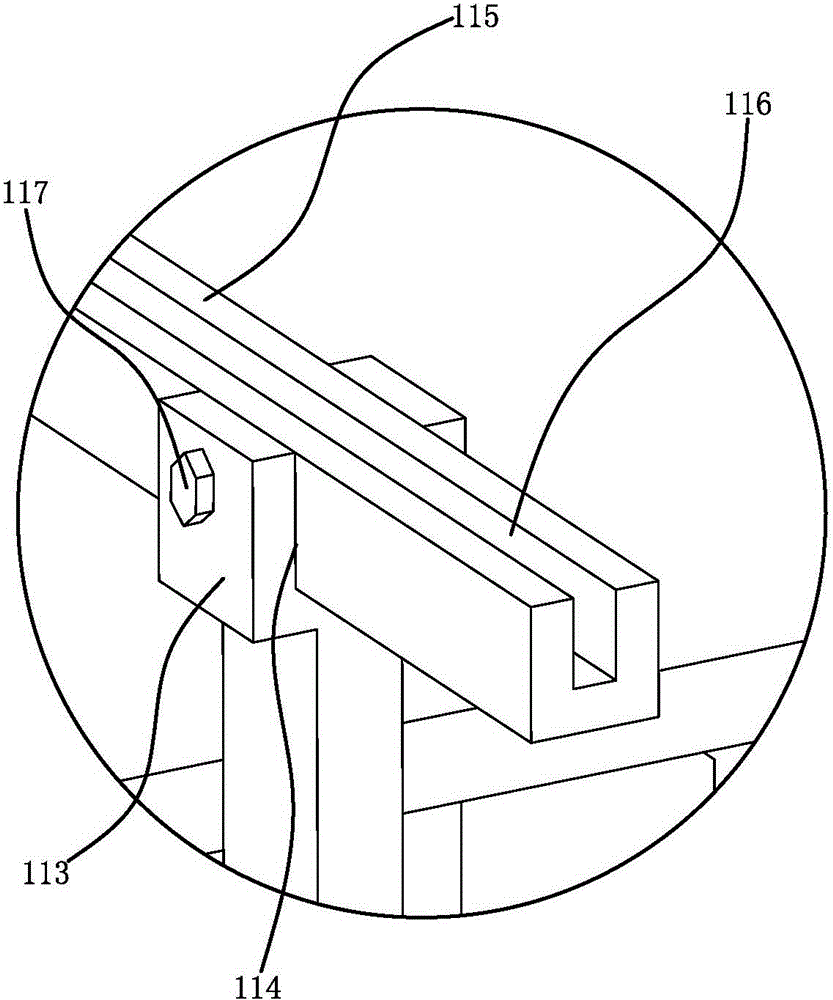

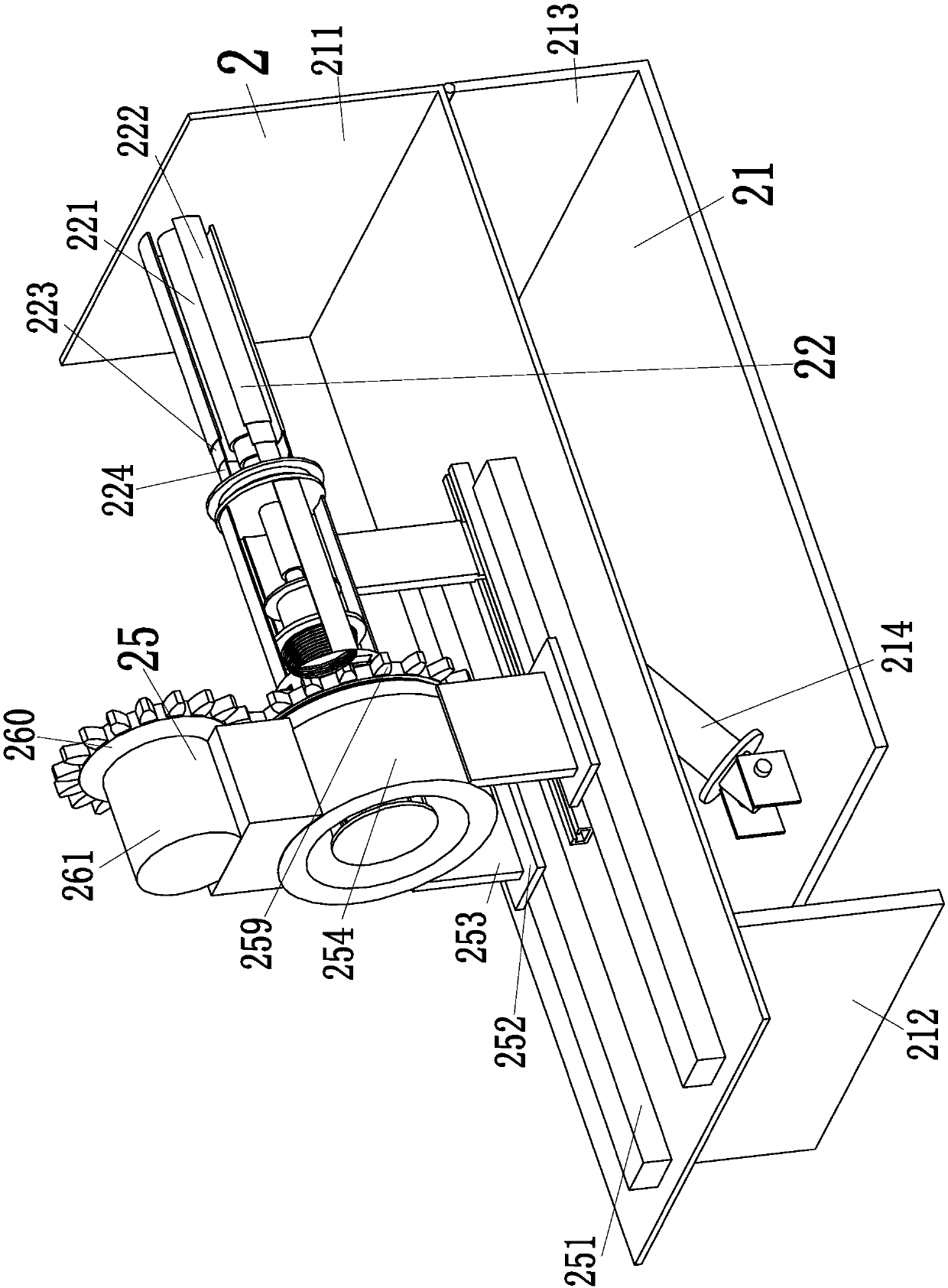

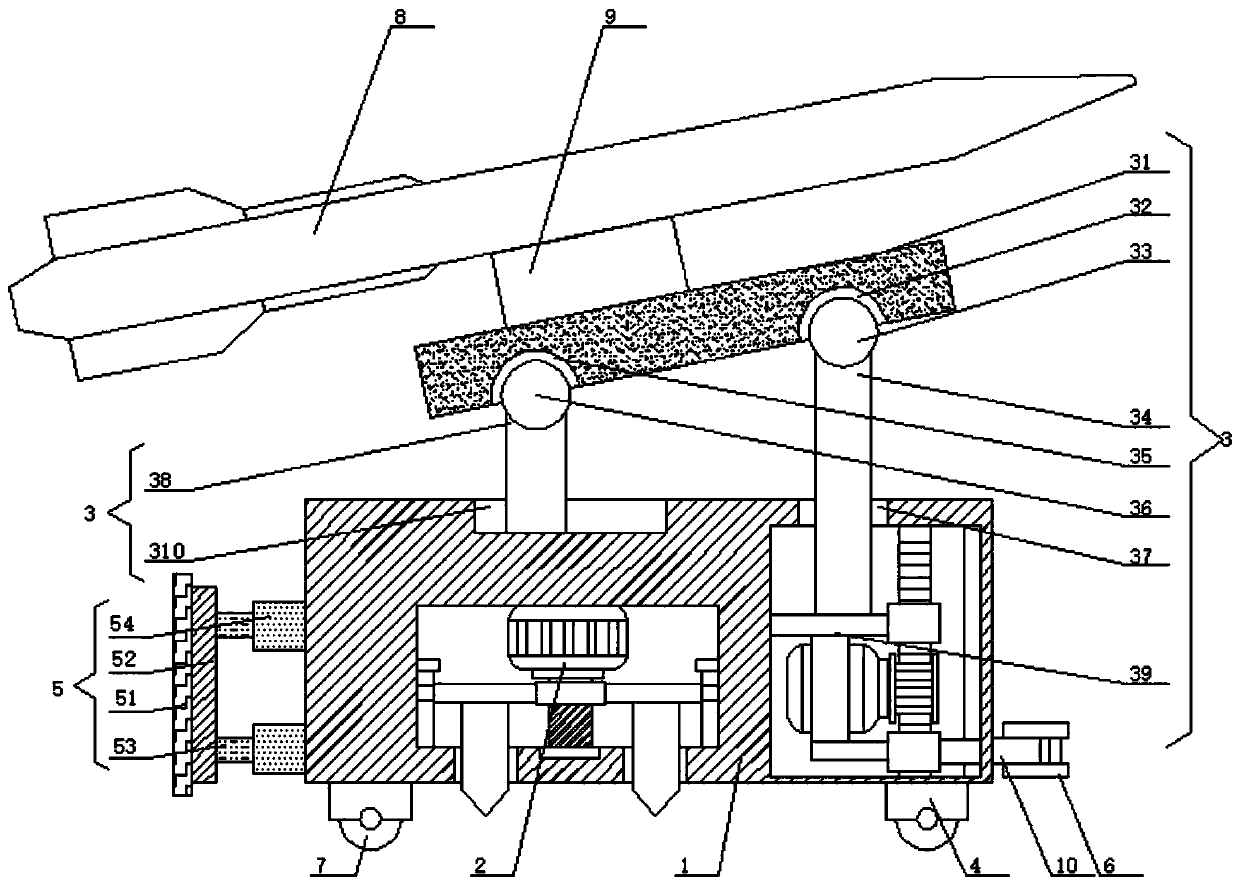

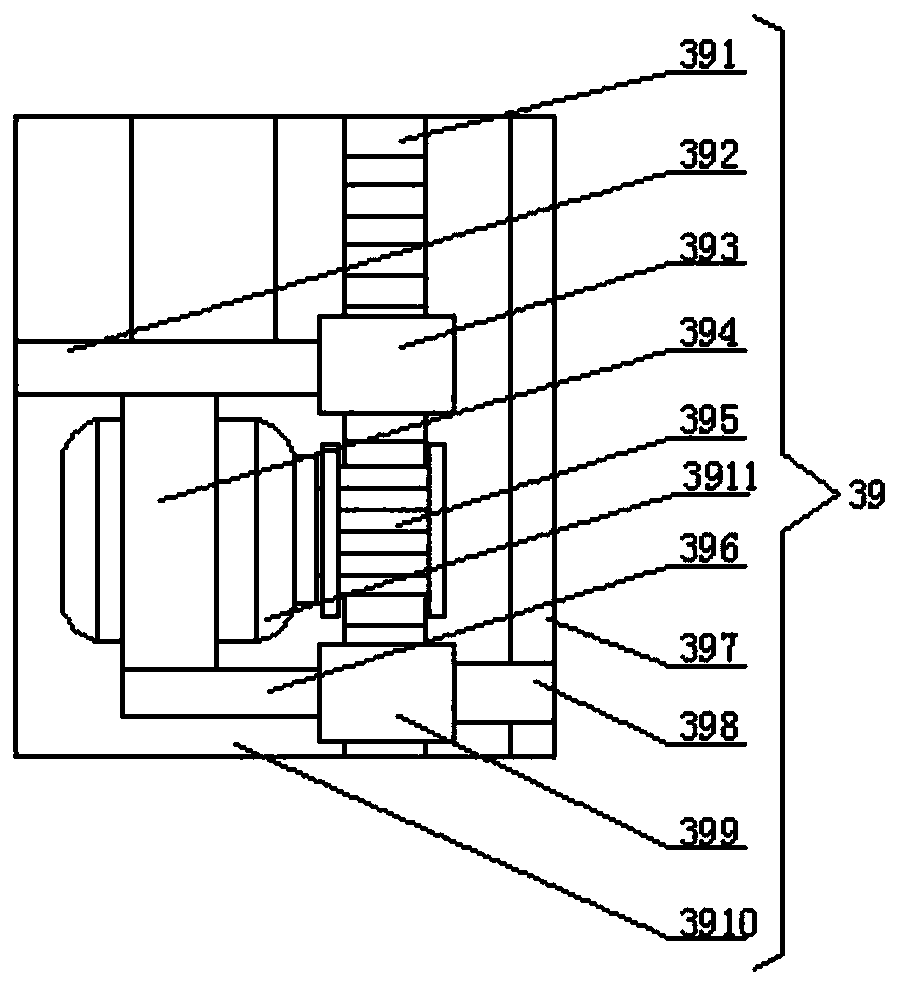

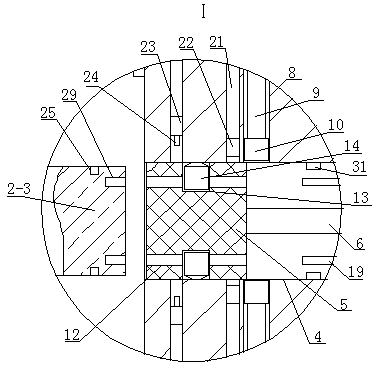

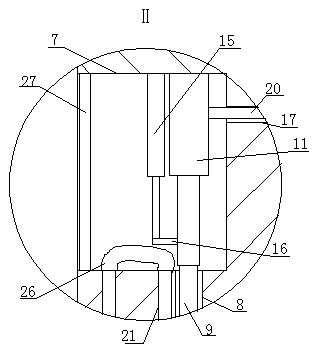

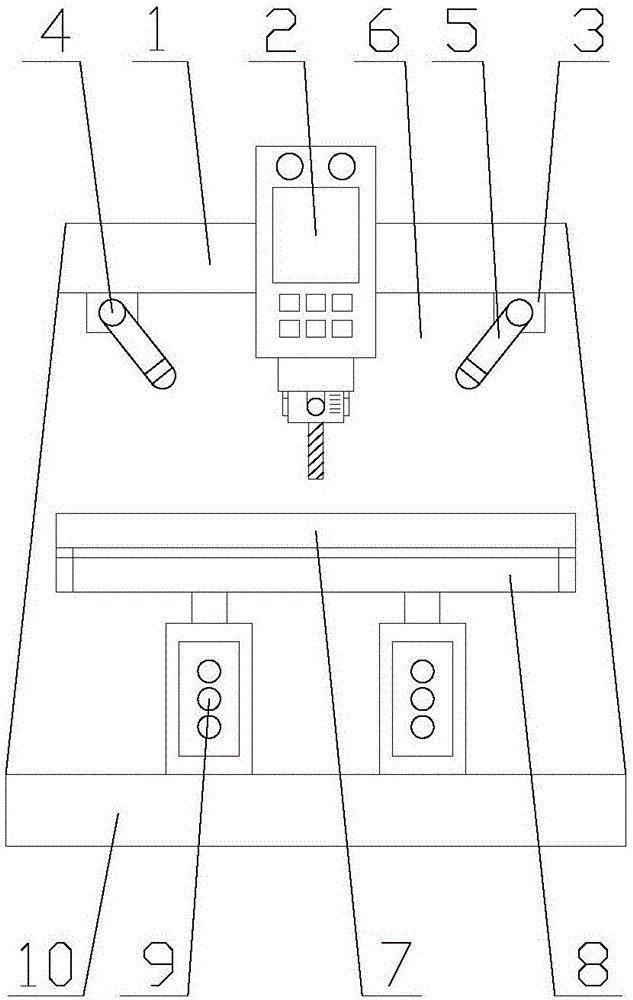

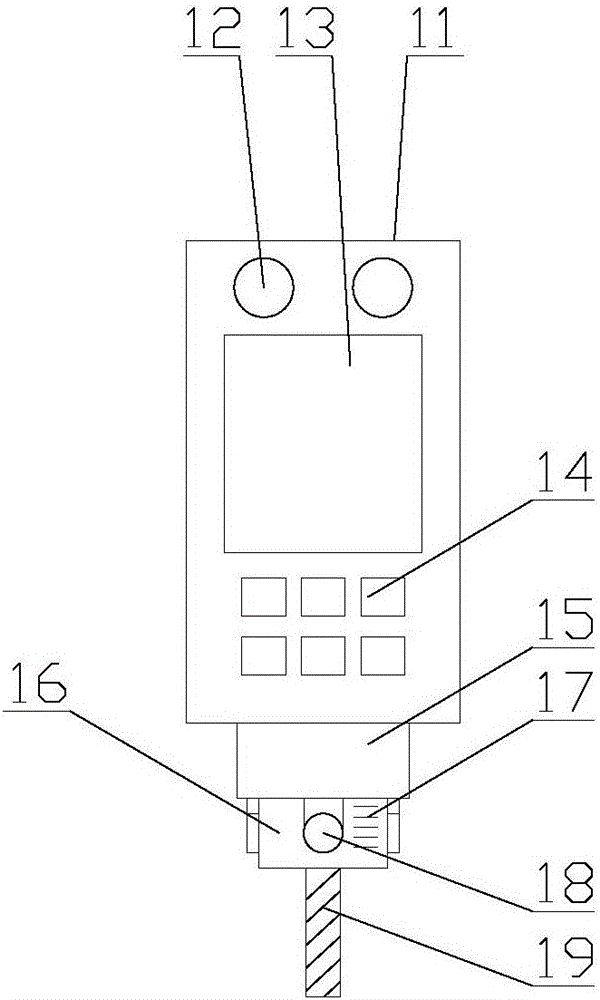

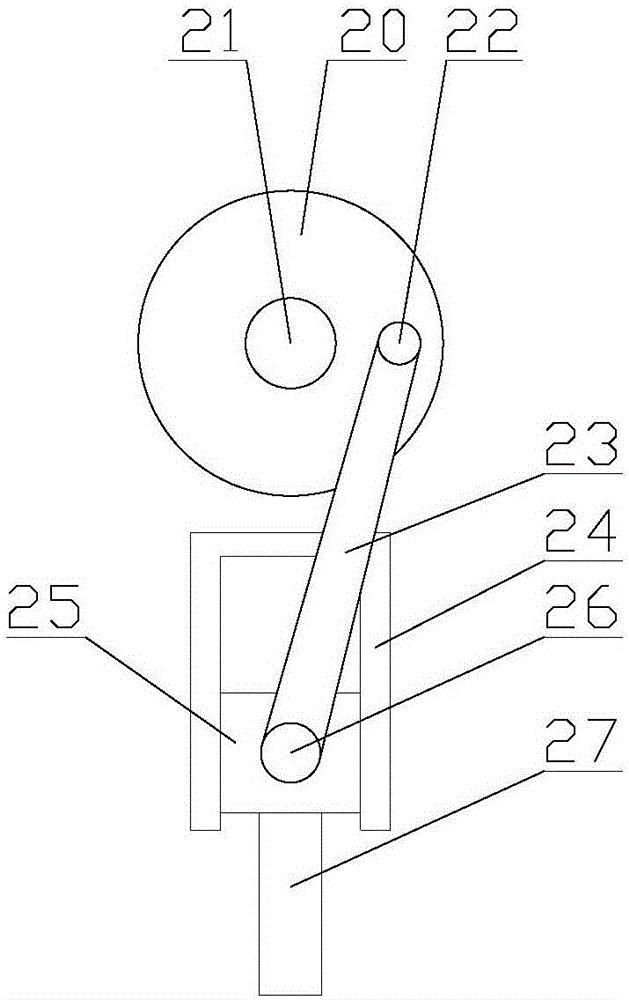

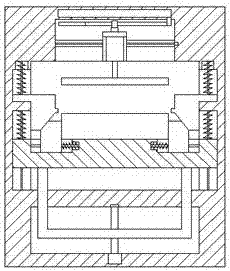

Garbage treatment device

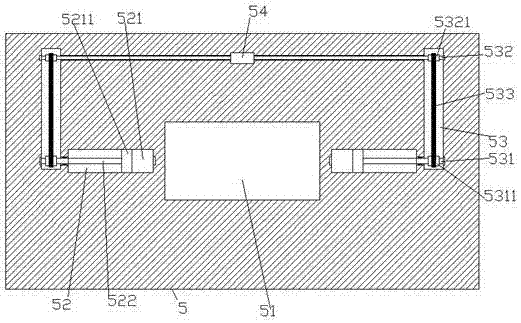

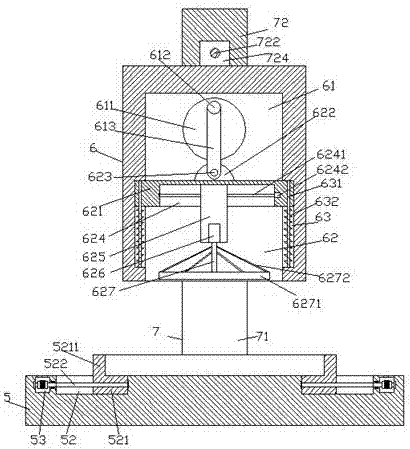

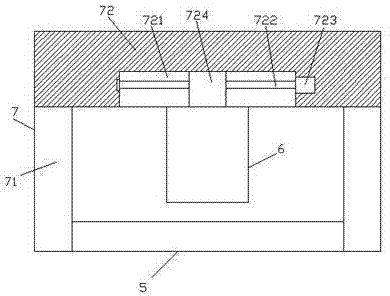

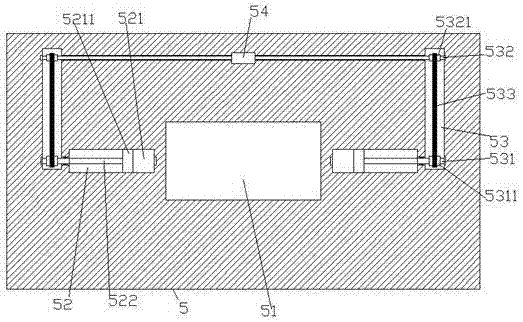

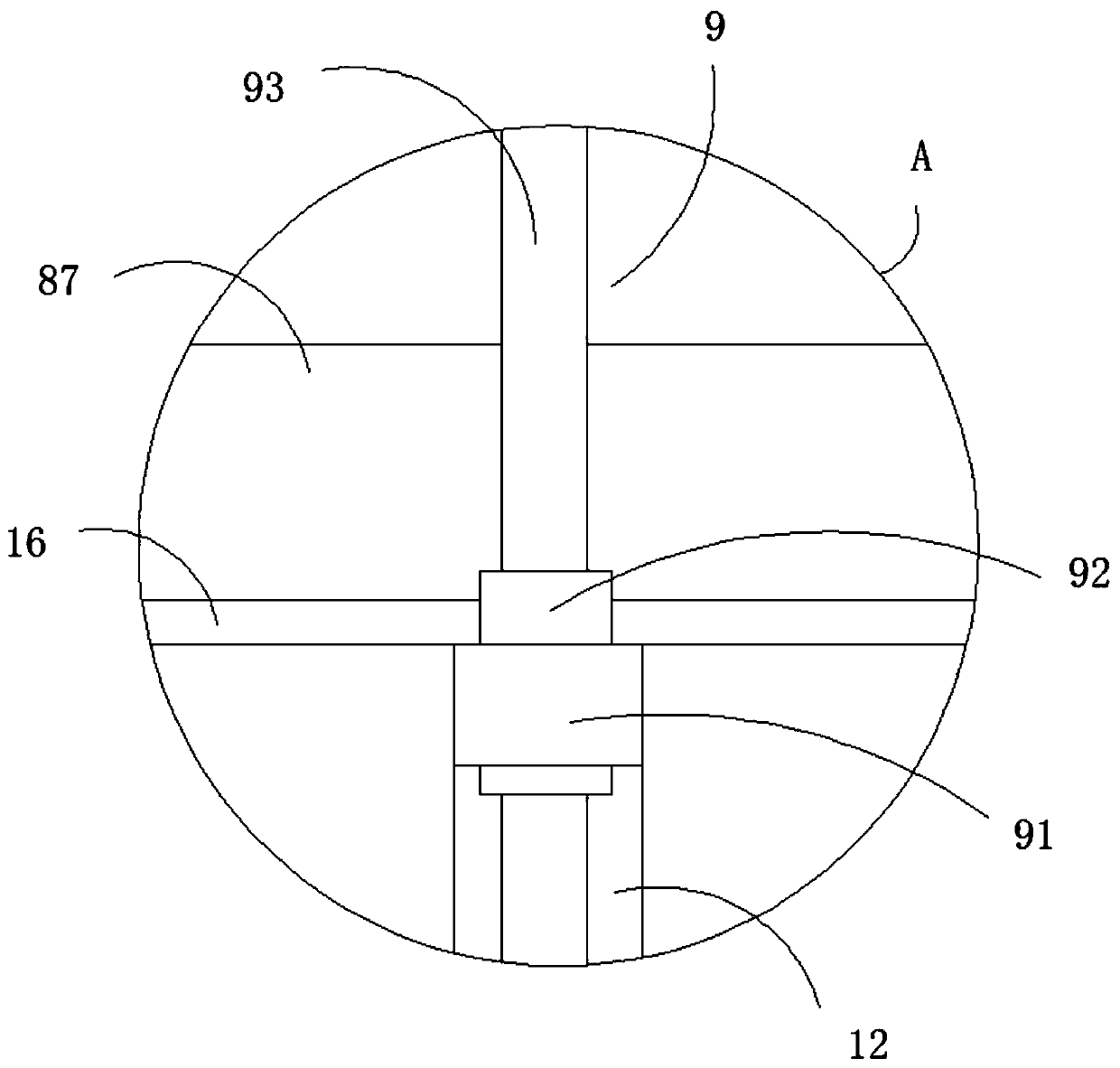

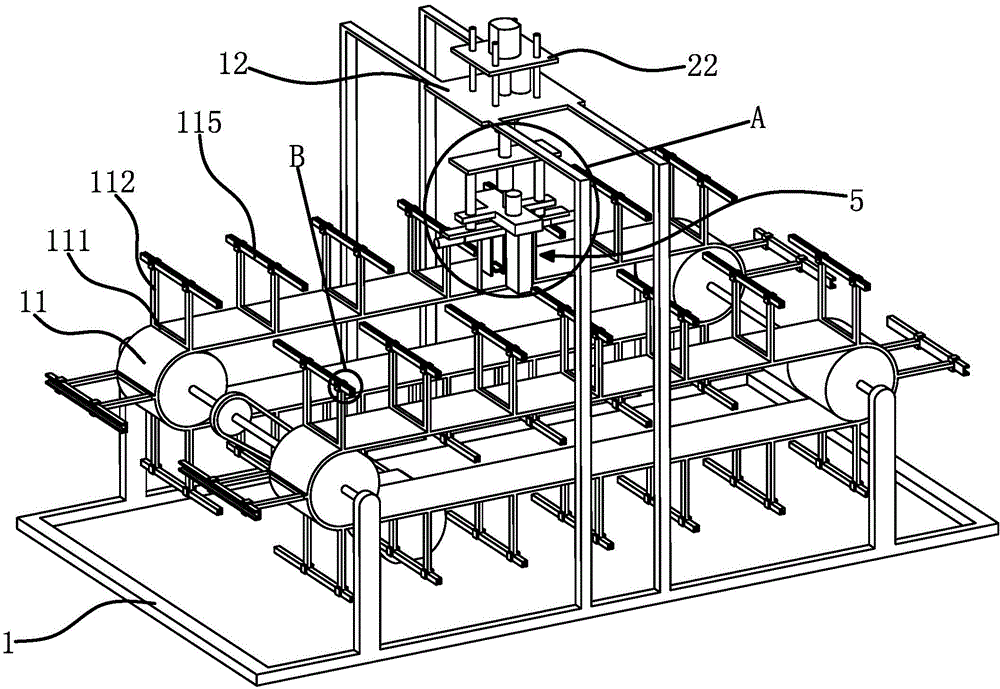

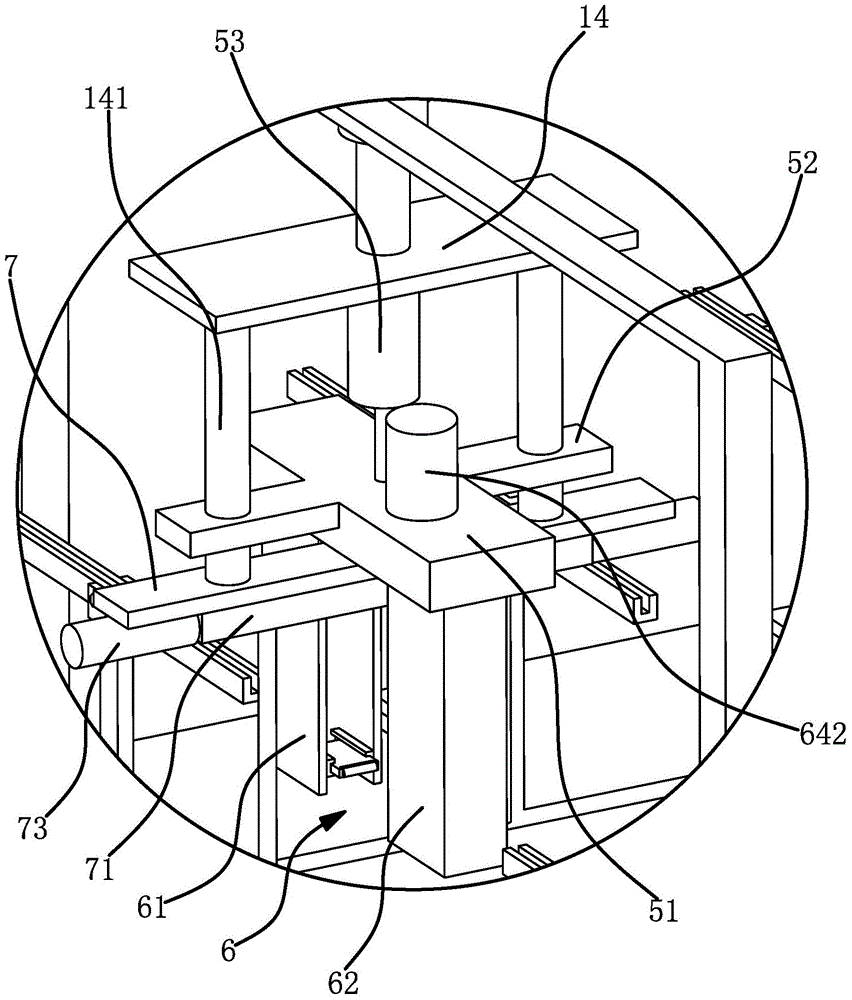

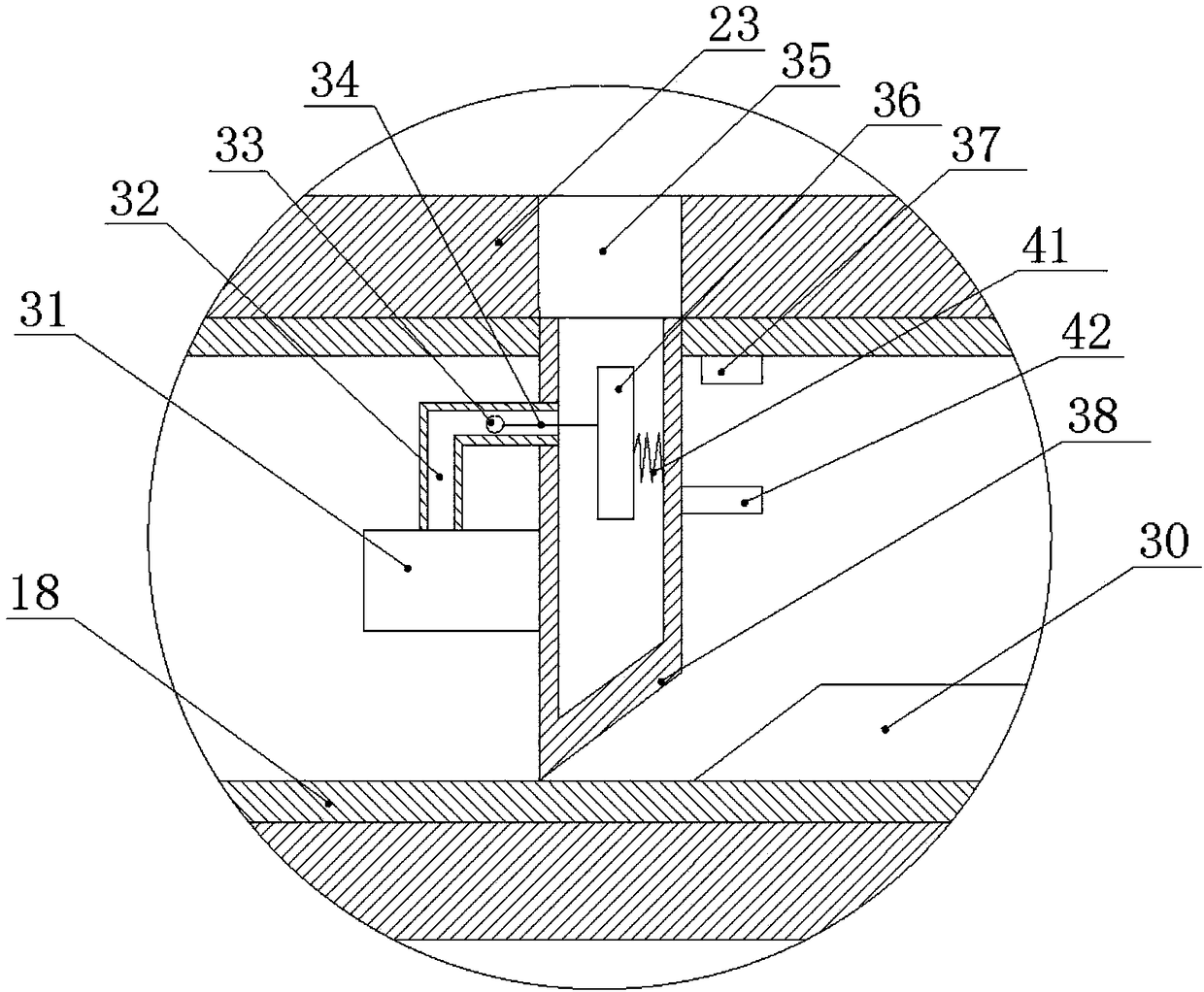

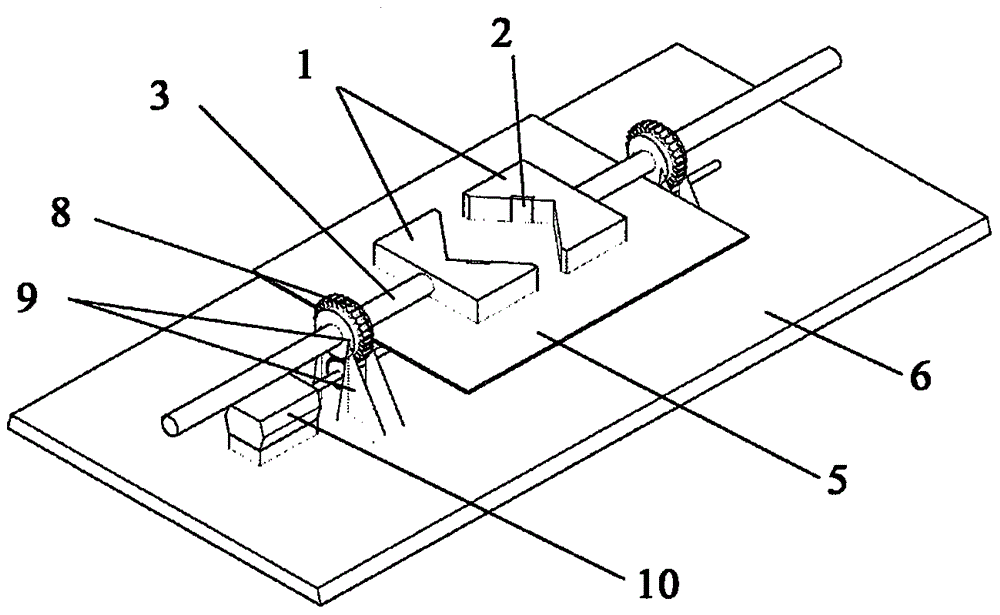

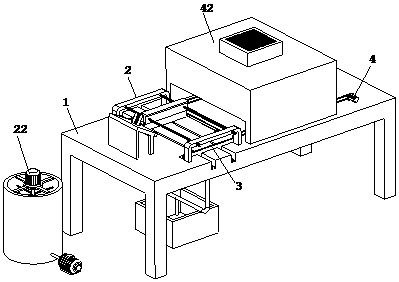

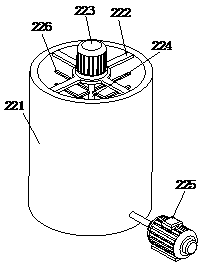

ActiveCN107053736AImprove compression efficiencyRealize automatic fixationPressesCompression deviceOpen cavity

The invention discloses a garbage treatment device. The garbage treatment device comprises a stand, a compression device and a bracket; the bracket comprises support columns equally arranged front and back, and a beam column fixed between the tops of the support columns; the stand is arranged between the bottoms of the support columns below the beam column; a first chute for extending front and back is formed in the bottom surface of the beam column; a first spiral rod for extending front and back is arranged in the first chute, and is spirally matched and connected with a first slide block; the bottom of the first slide block is fixedly connected with the top end of the compression device; a conduction cavity is formed in the compression device; an opening cavity communicates with the bottom of the conduction cavity; and a turntable is arranged on the back side wall of the compression device. The garbage compression device is simple in structure, reasonable in design and low in manufacturing and maintenance costs, can realize zoned garbage compression to achieve convenient to operate, can realize automatic extension compression to achieve excellent compression effect, and can realize automatic garbage fixation to improve the compression stability.

Owner:TONGLING JINSHIDAI TECH CO LTD

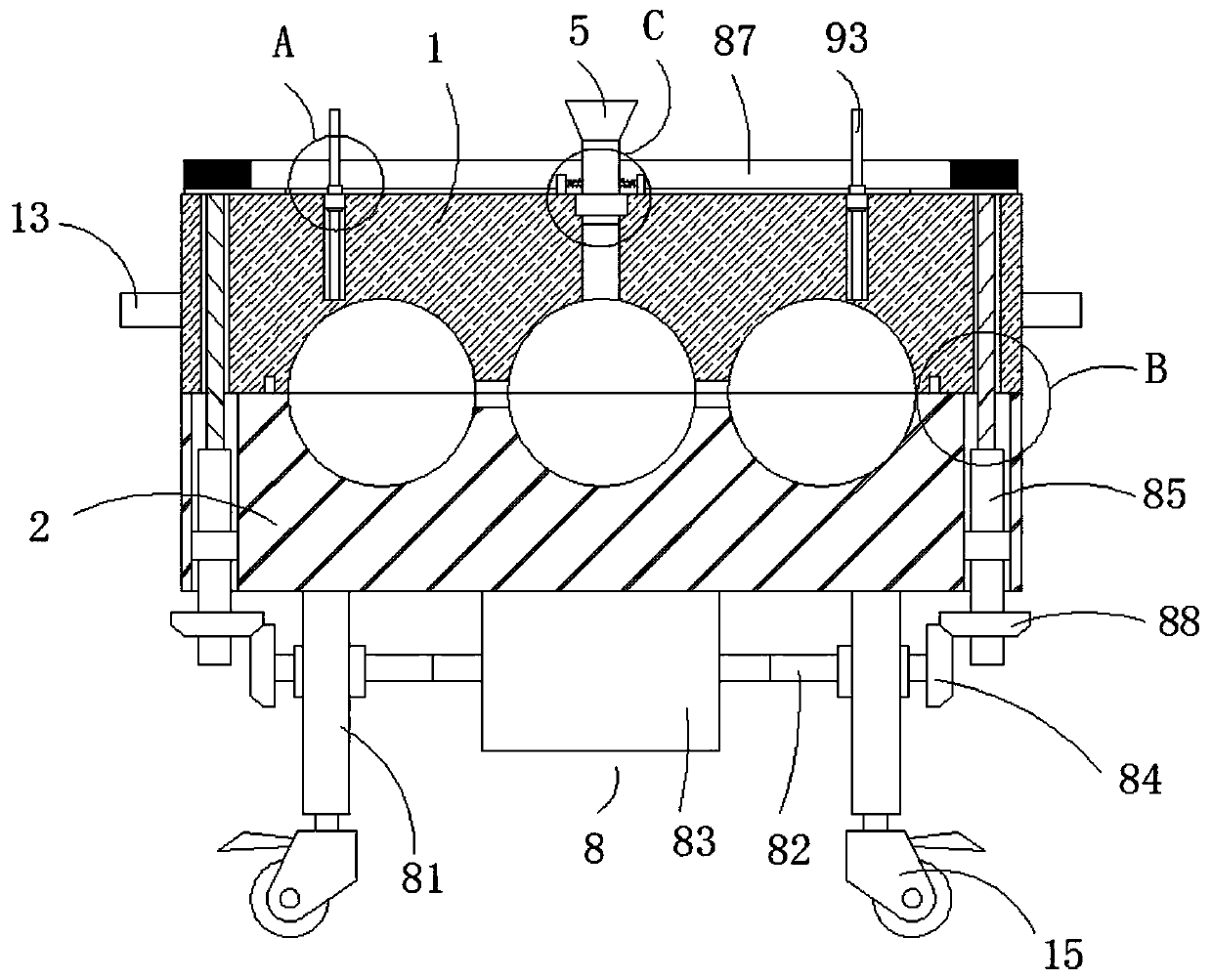

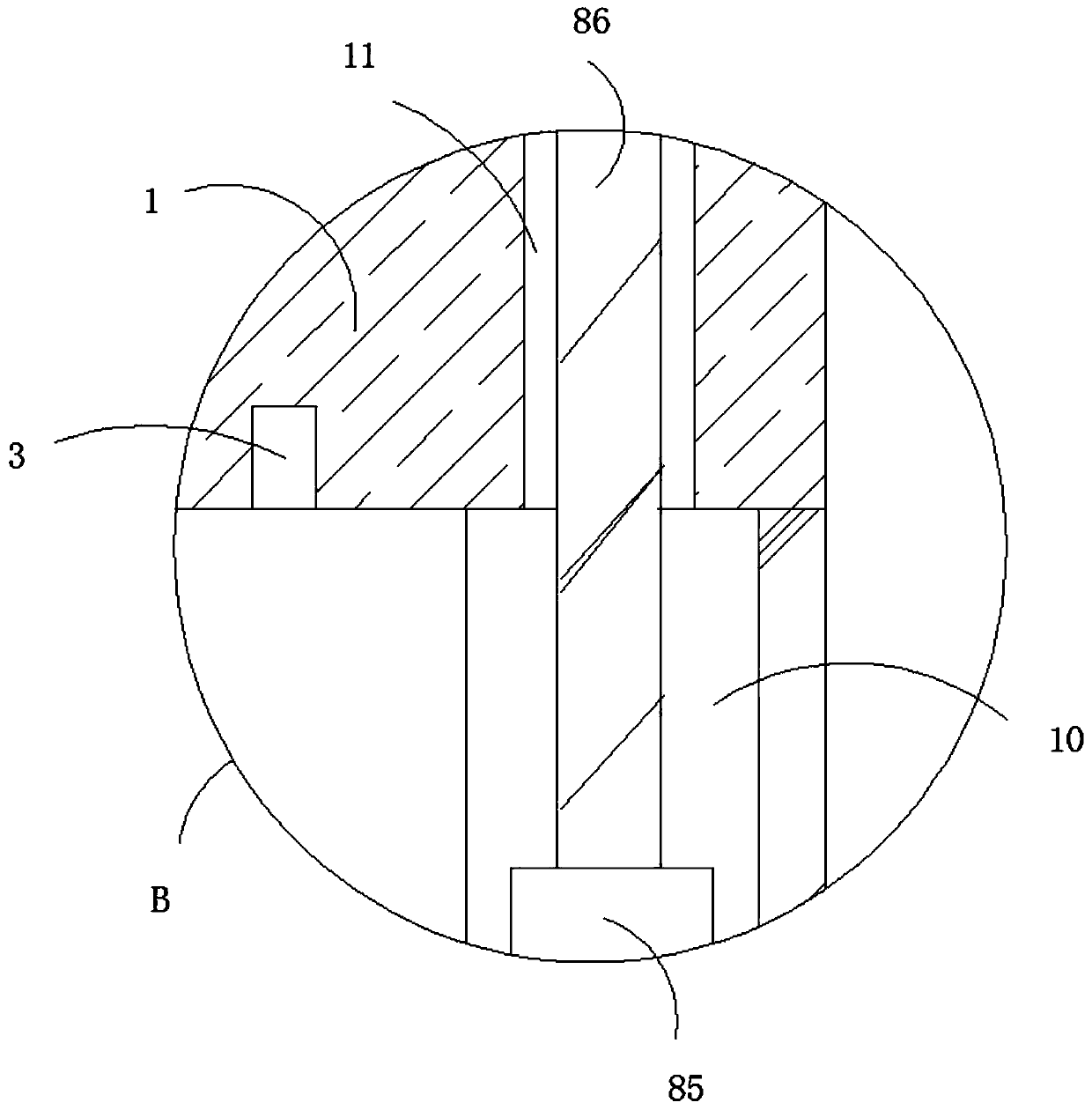

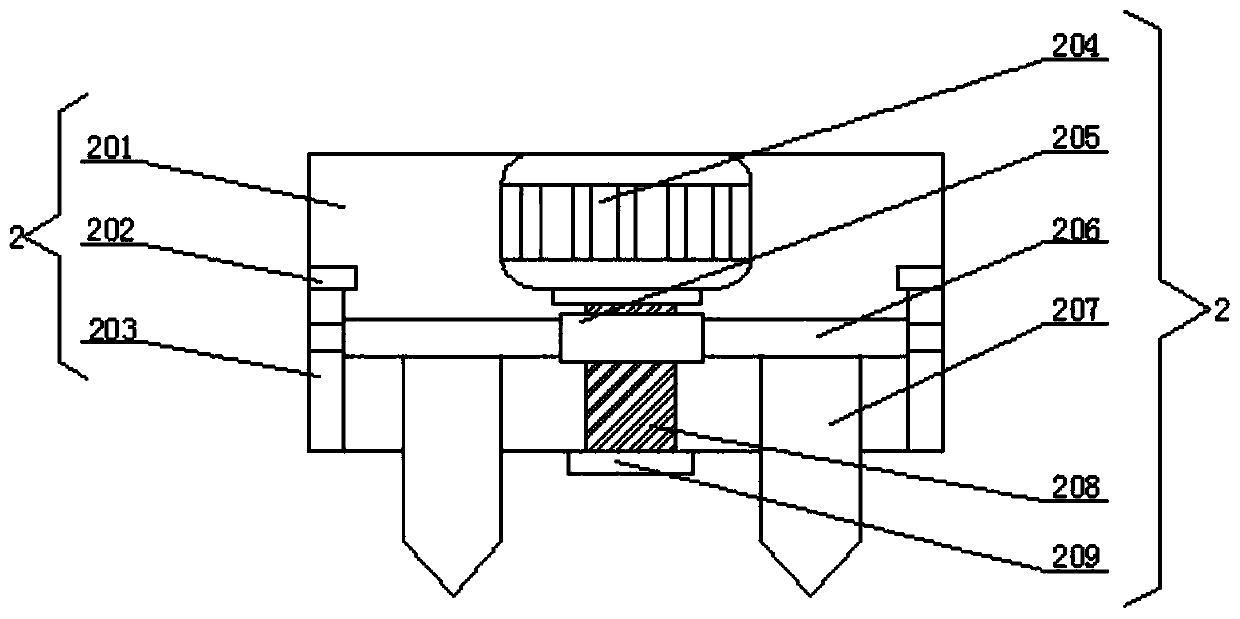

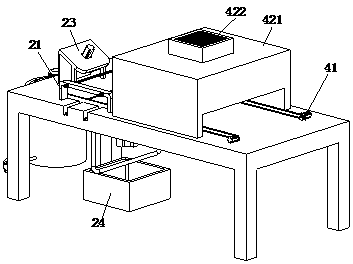

Garbage compression treatment device

InactiveCN107053737AImprove compression efficiencyAchieve fixationPressesCompression deviceOpen cavity

The invention discloses a garbage compression treatment device. The garbage compression treatment device comprises a stand, a compression device and a bracket; the bracket comprises support columns equally arranged front and back, and a beam column fixed between the tops of the support columns; the stand is arranged between the bottoms of the support columns below the beam column; a first chute for extending front and back is formed in the bottom surface of the beam column; a first spiral rod for extending front and back is arranged in the first chute, and is spirally matched and connected with a first slide block; the bottom of the first slide block is fixedly connected with the top end of the compression device; a conduction cavity is formed in the compression device; an opening cavity communicates with the bottom of the conduction cavity; and a turntable is arranged on the back side wall of the compression device. The garbage compression treatment device is simple in structure, reasonable in design and low in manufacturing and maintenance costs, can realize zoned garbage compression to achieve convenient to operate, can realize automatic extension compression to achieve excellent compression effect, and can realize automatic garbage fixation to improve the compression stability.

Owner:温岭市兴庆机械设备有限公司

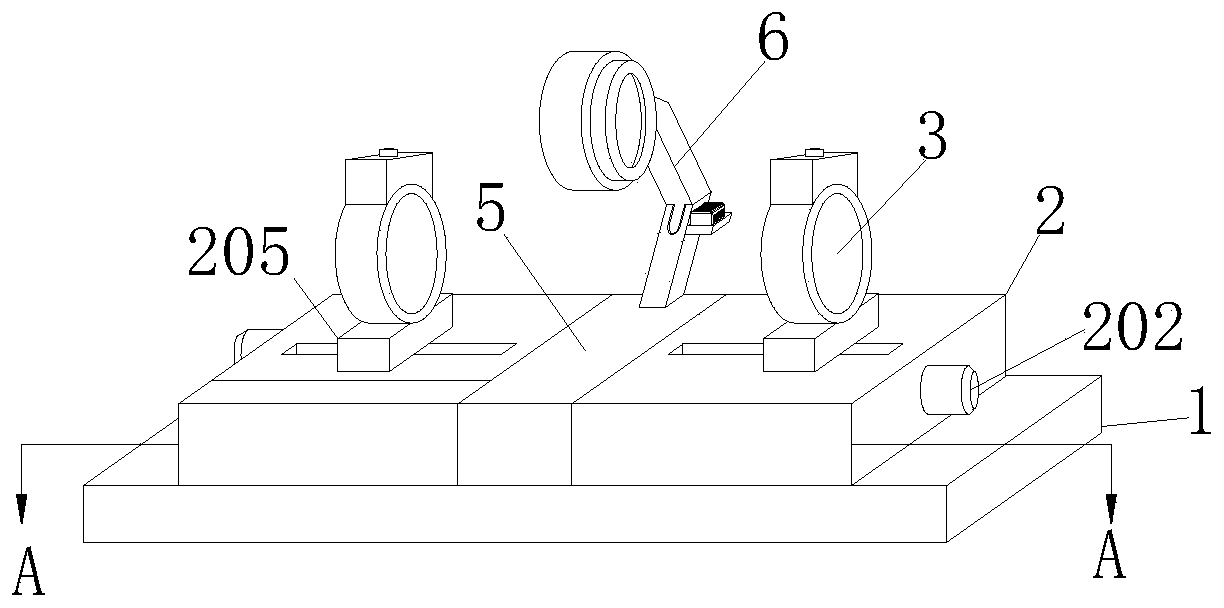

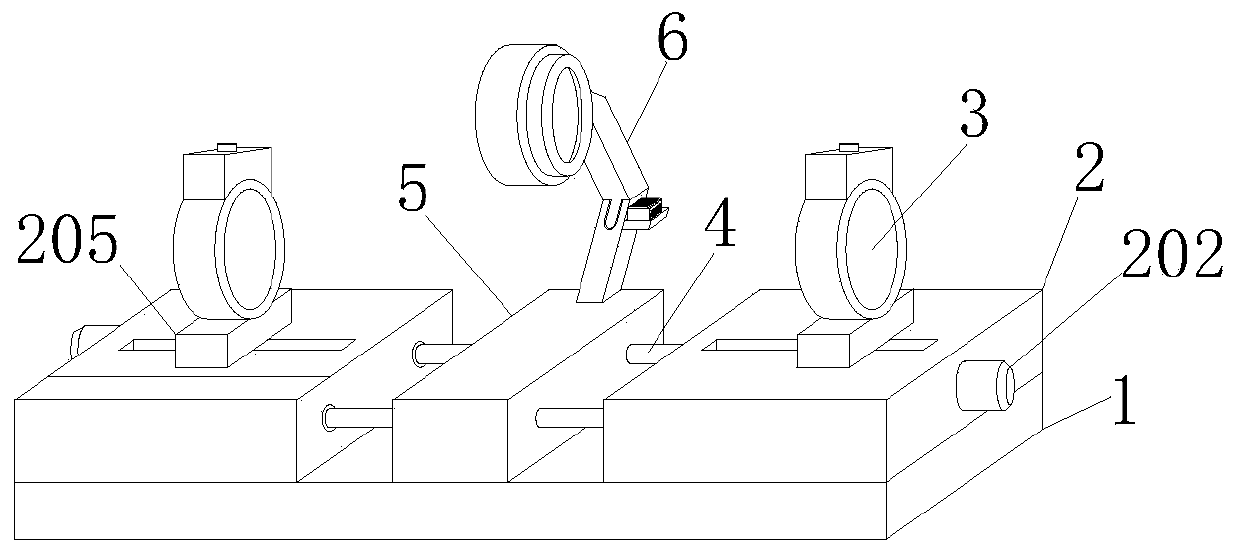

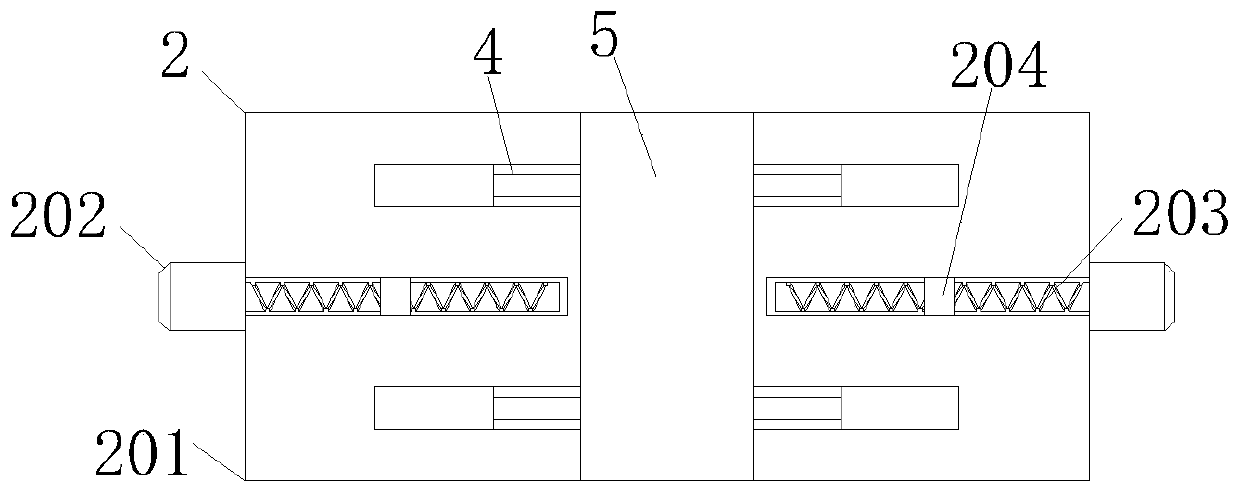

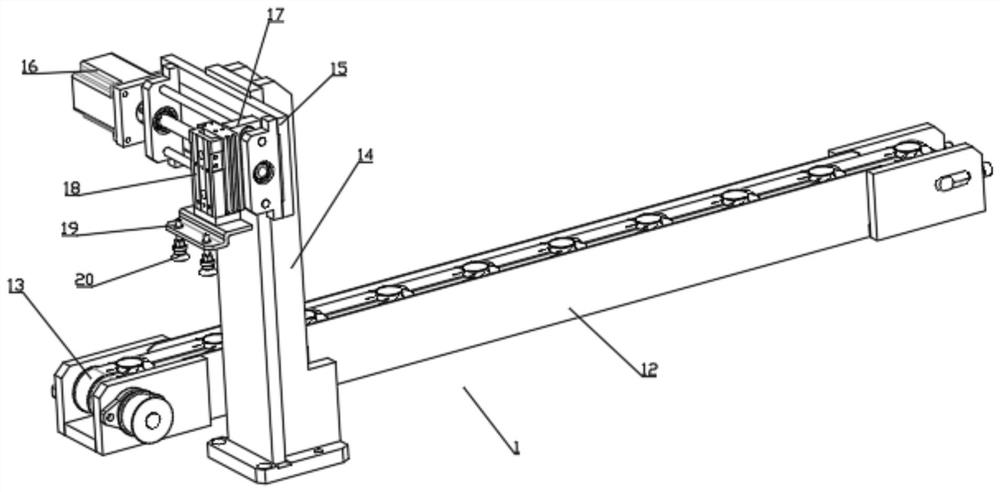

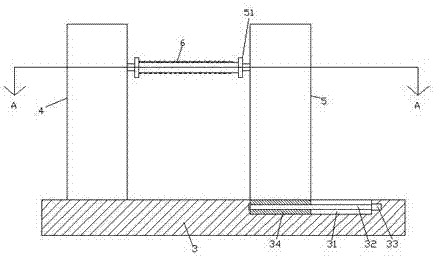

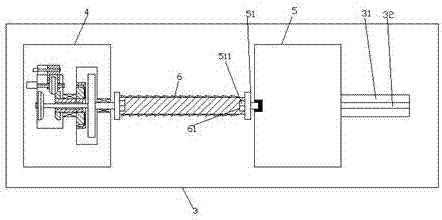

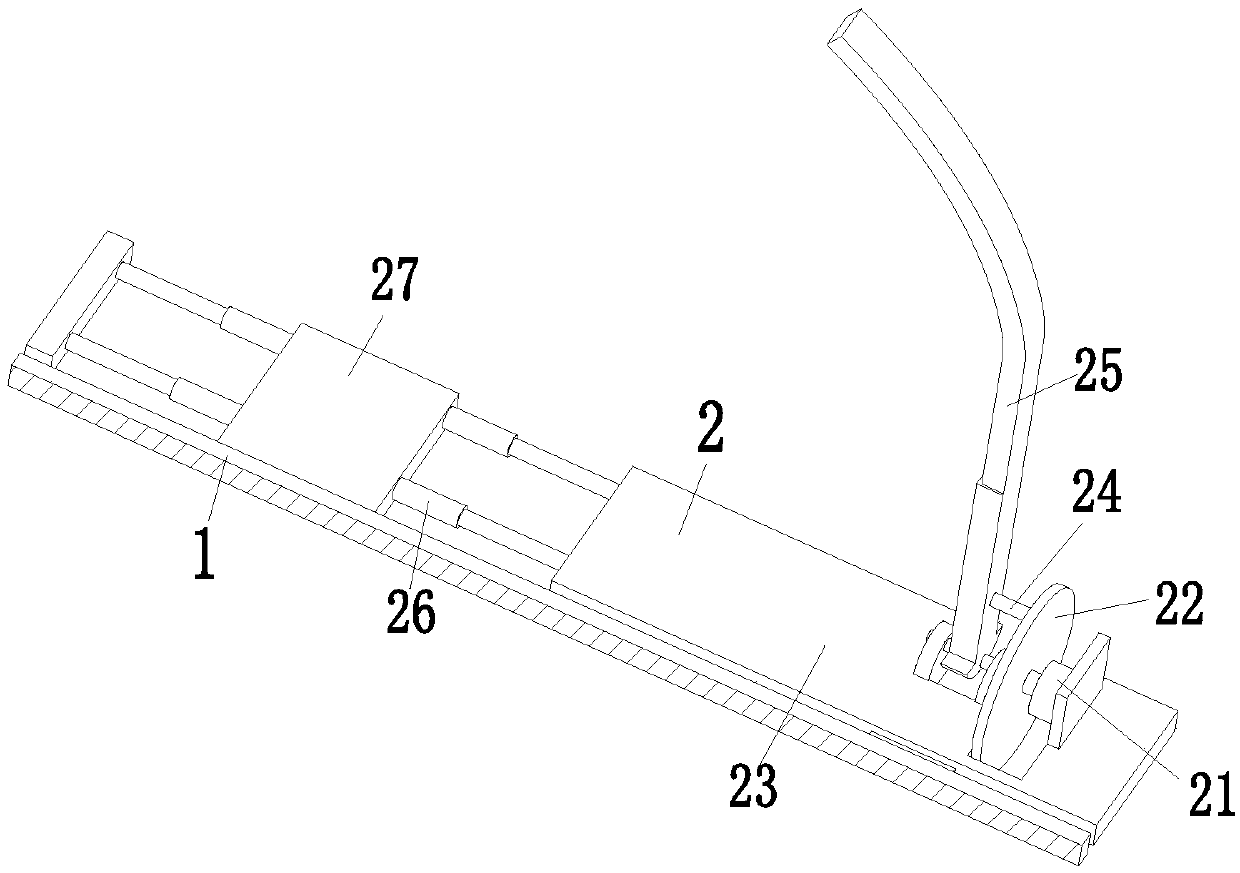

Winding binding machine for medical infusion tube

InactiveCN104015952AHigh degree of automationRealize automatic strappingBinding material applicationPaper/cardboard containersEngineeringConductor Coil

The invention provides a winding binding machine for a medical infusion tube and belongs to the technical field of medical device processing equipment. The winding binding machine for the medical infusion tube solves the problems that the existing infusion tube winding binding quality is low and efficiency is low. The winding binding machine for the medical infusion tube comprises a rack, wherein two conveyor belts are rotatably connected with the rack, a plurality of material carrying rods are respectively fixedly connected on the two conveyor belts, the rack is fixedly connected with one working platform, the working platform is connected with a main shaft in a sliding way along the vertical direction, a driving mechanism I and a driving mechanism II are arranged on the working platform, the main shaft is fixedly connected with a mainboard, the mainboard is connected with two winding rods, each material carrying rod is provided with a clamping mechanism, the mainboard is connected with a binding main body, and a binding device is arranged on the binding main body. The winding binding machine for the medical infusion tube can automatically wind the medical infusion tube and then automatically bind the medical infusion tube after winding, automation degree is high, and production efficiency is improved.

Owner:杨丽华

Combined steel ball casting mold

InactiveCN110303118AImprove casting efficiencyFast connectionFoundry mouldsFoundry coresSteel ballCasting mold

The invention relates to the technical field of molds, and discloses a combined steel ball casting mold. The casting mold comprises an upper mold and a lower mold, wherein a connecting frame is fixedly connected to the upper surface of the lower mold, and a connecting groove matched with the connecting frame is formed in the upper surface of the upper mold; a T-shaped pouring channel is formed inthe upper surface of the upper mold, a pouring bucket is movably connected to the inner wall of the T-shaped pouring channel, and two connecting mechanisms which are symmetrically distributed are fixedly connected to the outer wall of the pouring bucket; and a fixing block is fixedly connected to the upper surface of the upper mold, a fixing mechanism is fixedly connected to the lower surface of the lower mold, two first circular through holes which are symmetrically distributed are formed in the lower surface of the lower mold, and two second circular through holes which are symmetrically distributed are formed in the upper surface of the upper mold. The combined steel ball casting mold has the advantages of time saving and labor saving, simple and quick in connection and fixation betweenthe upper mold and the lower mold, the labor intensity of workers is reduced, the mold cooling speed is increased, and the steel ball casting efficiency is improved.

Owner:徐州国隆电力配件铸造有限公司

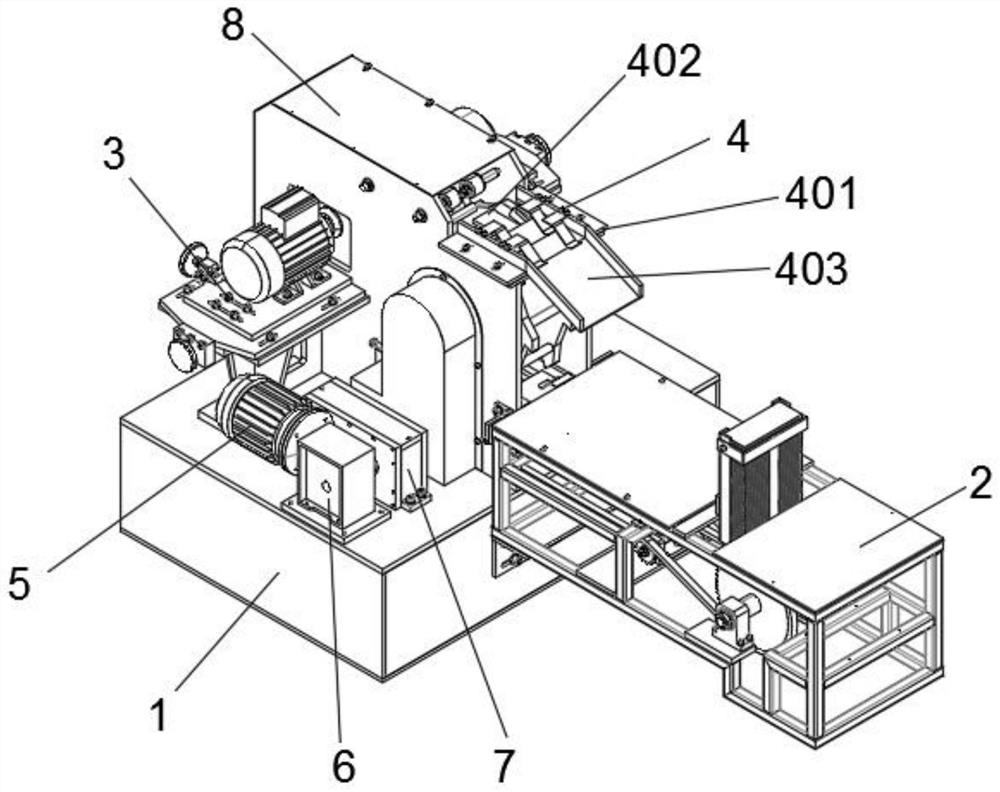

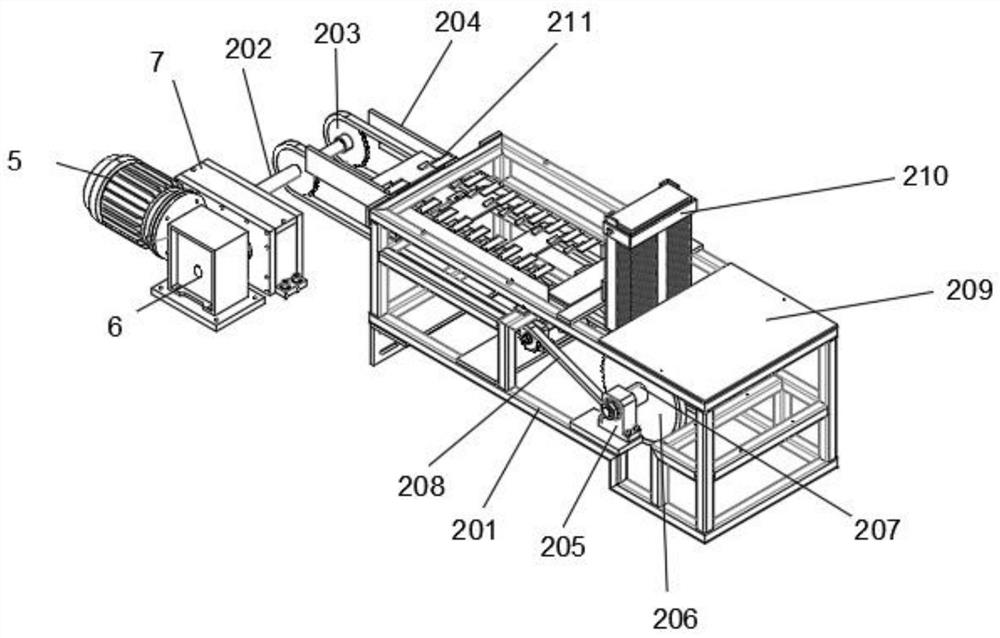

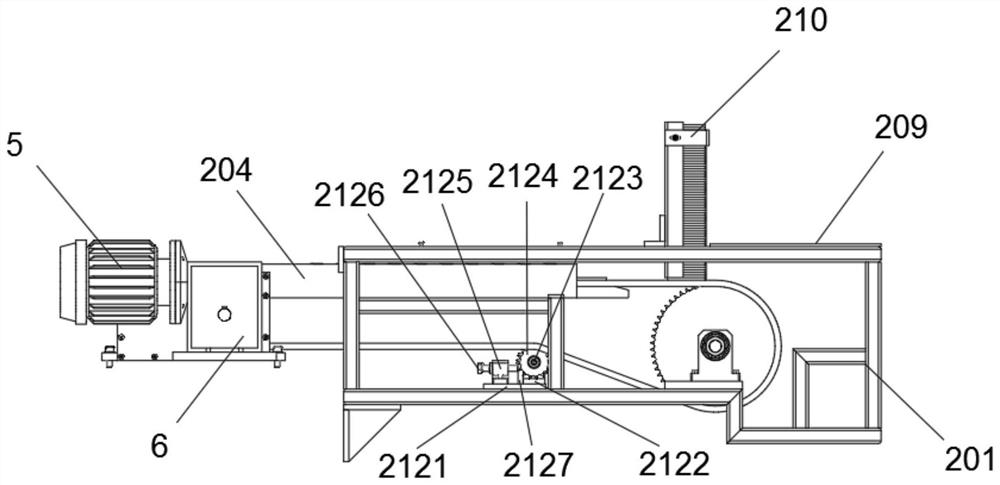

Winding and strapping machine for medical infusion tube

InactiveCN104085554AHigh degree of automationIncrease productivityBinding material applicationBundling machine detailsEngineeringMedical equipment

The invention provides a winding and strapping machine for a medical infusion tube, and belongs to the technical field of processing equipment of medical equipment. The winding and strapping machine solves the problems that an existing infusion tube is low in winding and strapping quality and efficiency. The winding and strapping machine for the medical infusion tube comprises a rack. The rack is connected with two conveying belts in a rotating mode, each conveying belt is fixedly connected with multiple material supporting rods, the rack is fixedly connected with a working table, the working table is connected with a main shaft in a sliding mode in the vertical direction and provided with a first driving mechanism and a second driving mechanism, the main shaft is fixedly connected with a main plate which is connected with two winding rods, a clamping mechanism is arranged on the material supporting rods, the main plate is connected with a strapping body, and the strapping body is provided with a strapping device. The winding and strapping machine for the medical infusion tube can wind the infusion tube automatically and strap the infusion tube automatically after the infusion tube is wound, is high in automation degree and improves production efficiency.

Owner:郭嘉川

Clean production process of jasmine tea

The invention discloses a clean production process of jasmine tea. The process mainly comprises the steps of curing fresh flowers, scenting, cleaning, holding out of scented flowers, baking, conveying while vibrating, and packaging. The jasmine tea prepared by adopting the process is long-lasting in aroma, fresh, rich and mellow in taste and clear, and yellow and bright in color of soup. The fresh flowers are cured, scented and cleaned on an operation platform, so that the cleanness of the jasmine tea can be ensured and the grade of the jasmine tea can not be influenced.

Owner:四川省炒花甘露茗茶有限公司

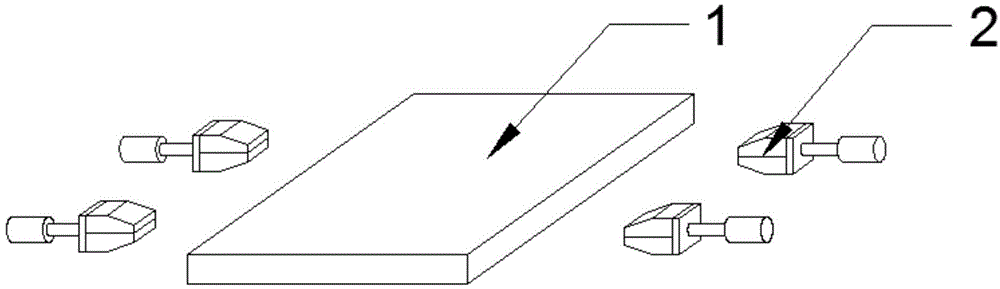

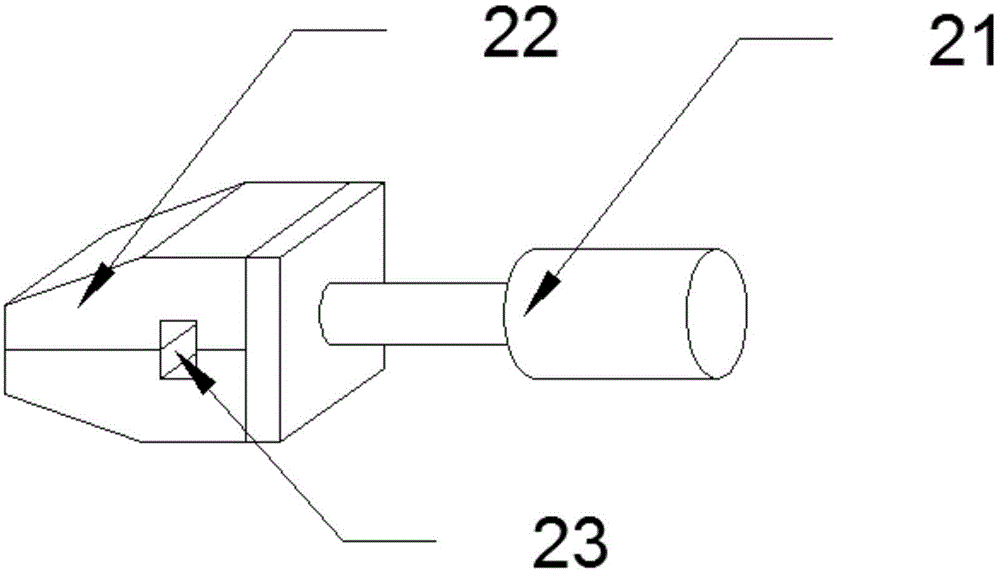

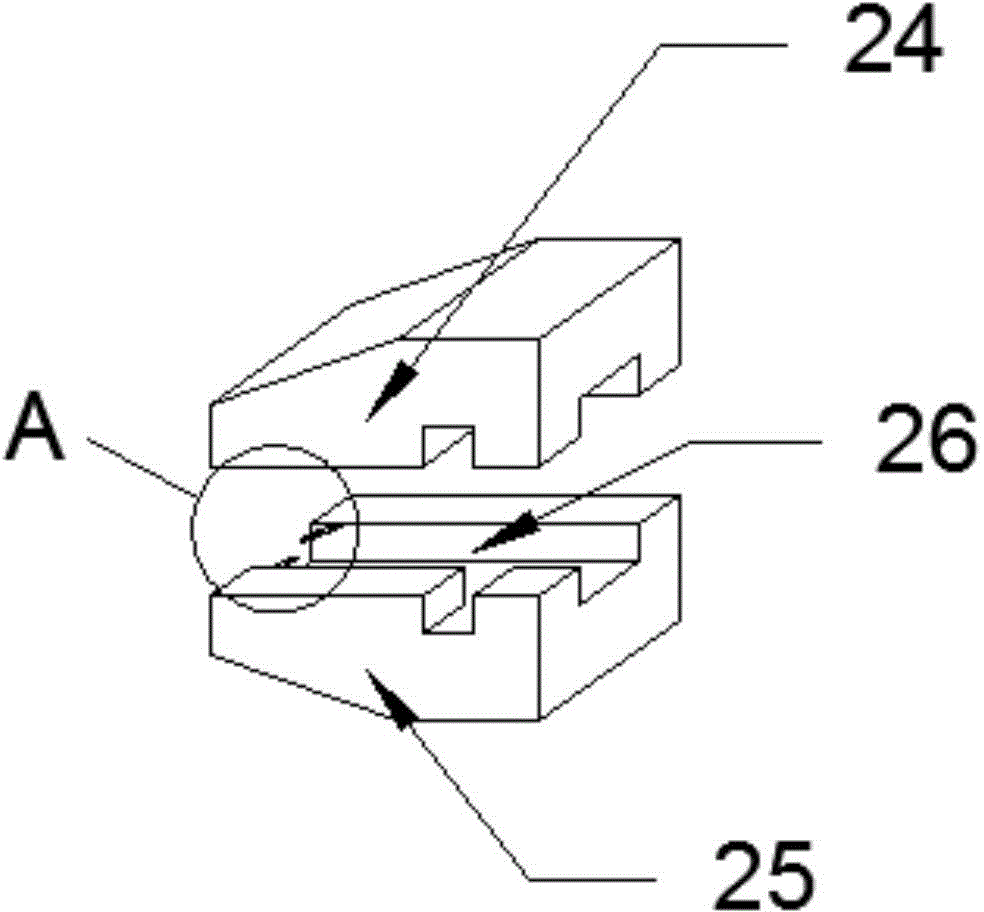

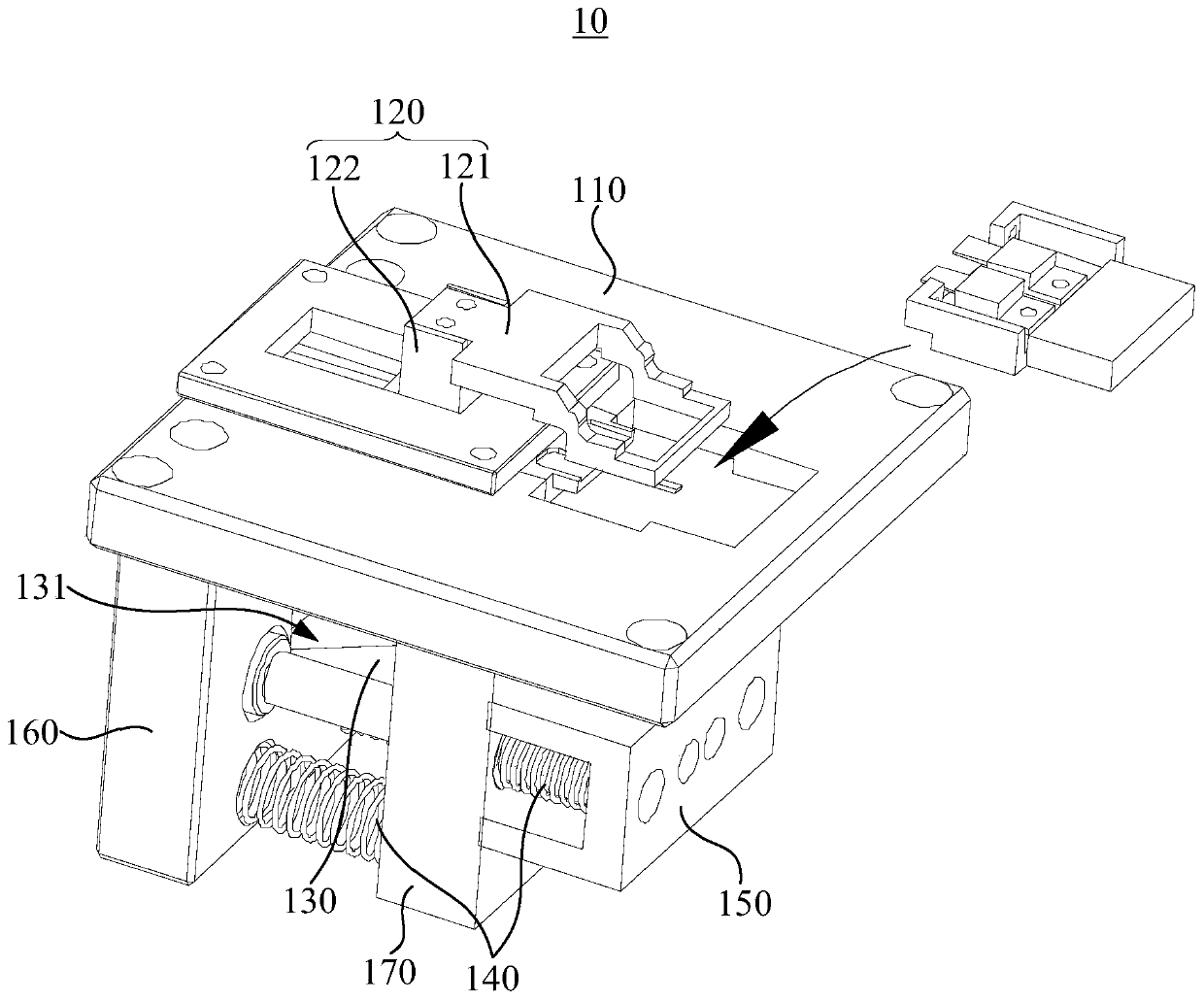

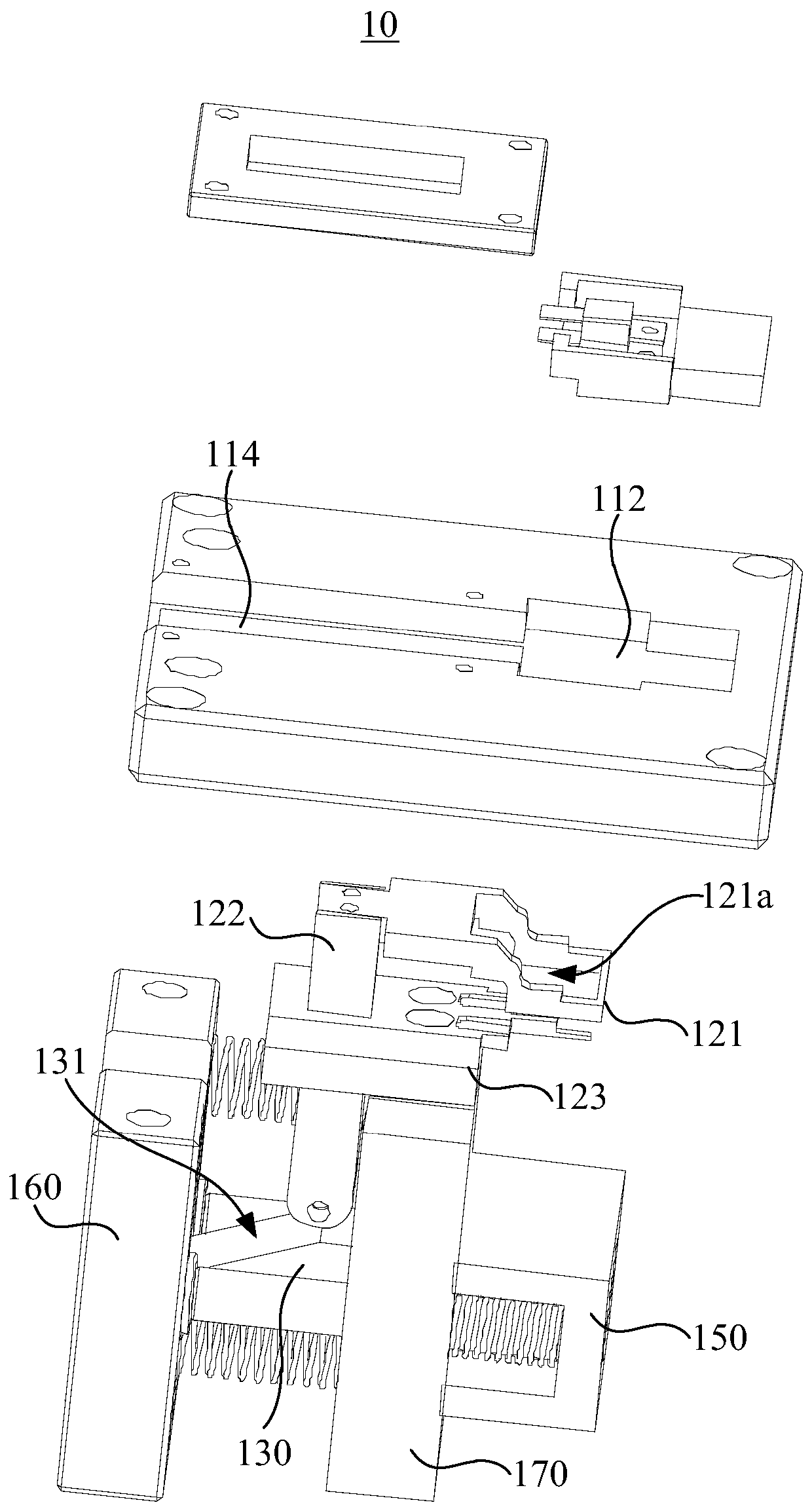

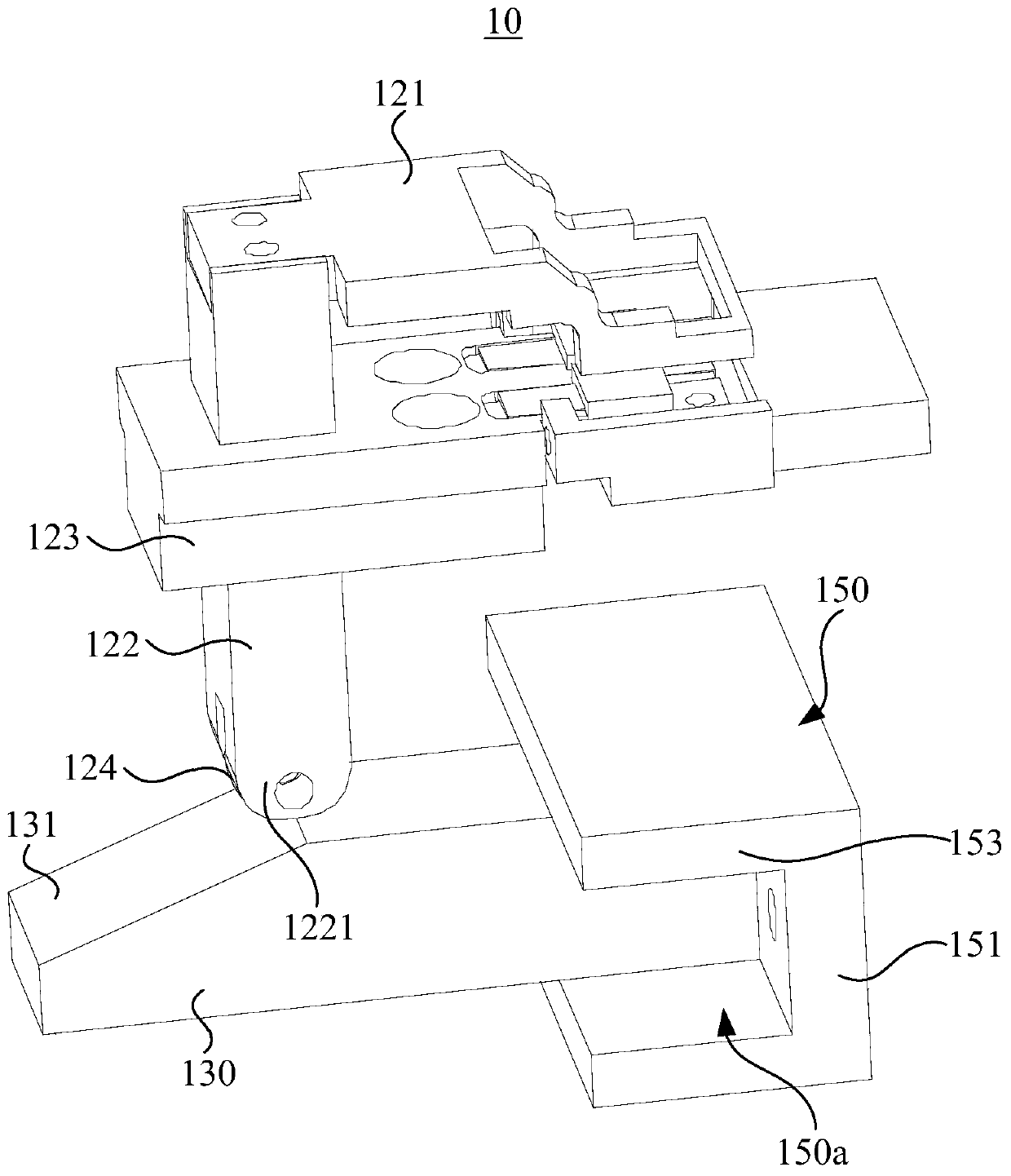

Fixing device of printed circuit board and frame

ActiveCN104582461ARealize automatic fixationAchieve fixationElectrical componentsEngineeringPrinted circuit board

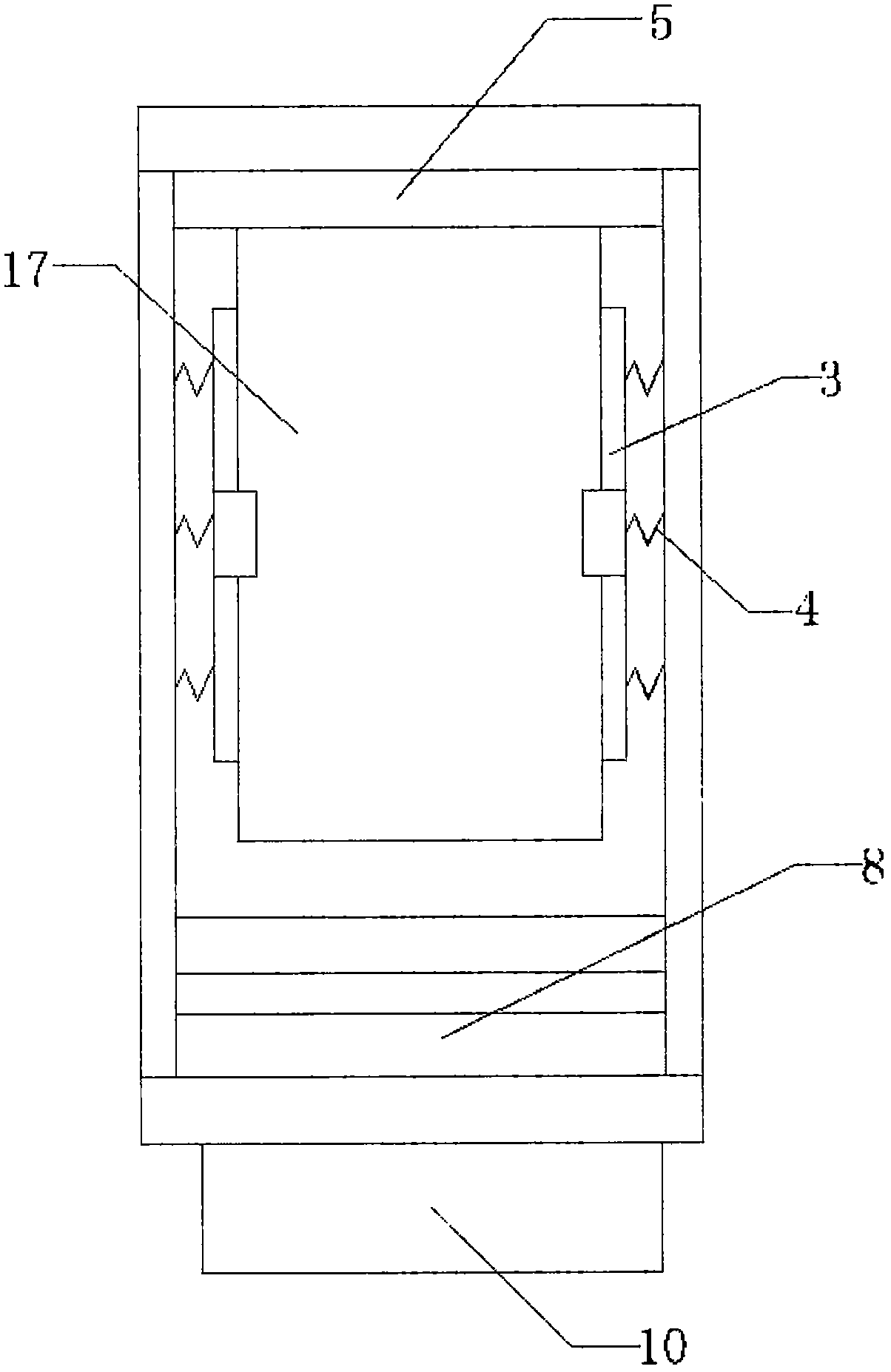

The invention relates to a fixing device of a printed circuit board and a frame. The fixing device comprises a rack, a horizontal platform is arranged on the rack, the left side and the right side of the platform are both provided with at least one telescopic clamping mechanism, the top view of the platform is rectangular, the width of the platform is smaller than that of the printed circuit board, the length of the platform is larger than that of the printed circuit board, and when the telescopic clamping mechanisms are in a stretching state, the top ends of the telescopic clamping mechanisms are matched with the printed circuit board and the frame on the platform. The circuit board and the frame are placed on the platform, clamps are driven by the telescopic clamping mechanisms to clamp the frame and the printed circuit board, therefore, the frame and the printed circuit board are fixed, automatic fixing of the frame and the printed circuit board is achieved, and compared with an existing mode of manually clamping the frame and the printed circuit board, the yield and efficiency of the mode of automatically clamping the frame and the printed circuit board are higher.

Owner:ZHUHAI JIAYI ELECTRONICS

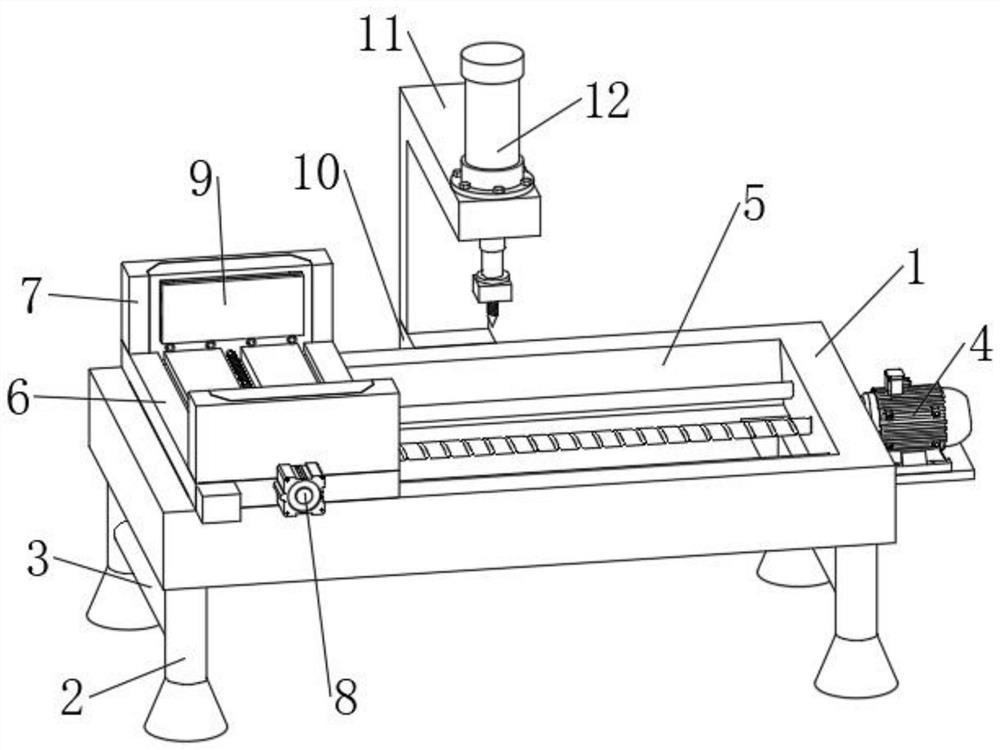

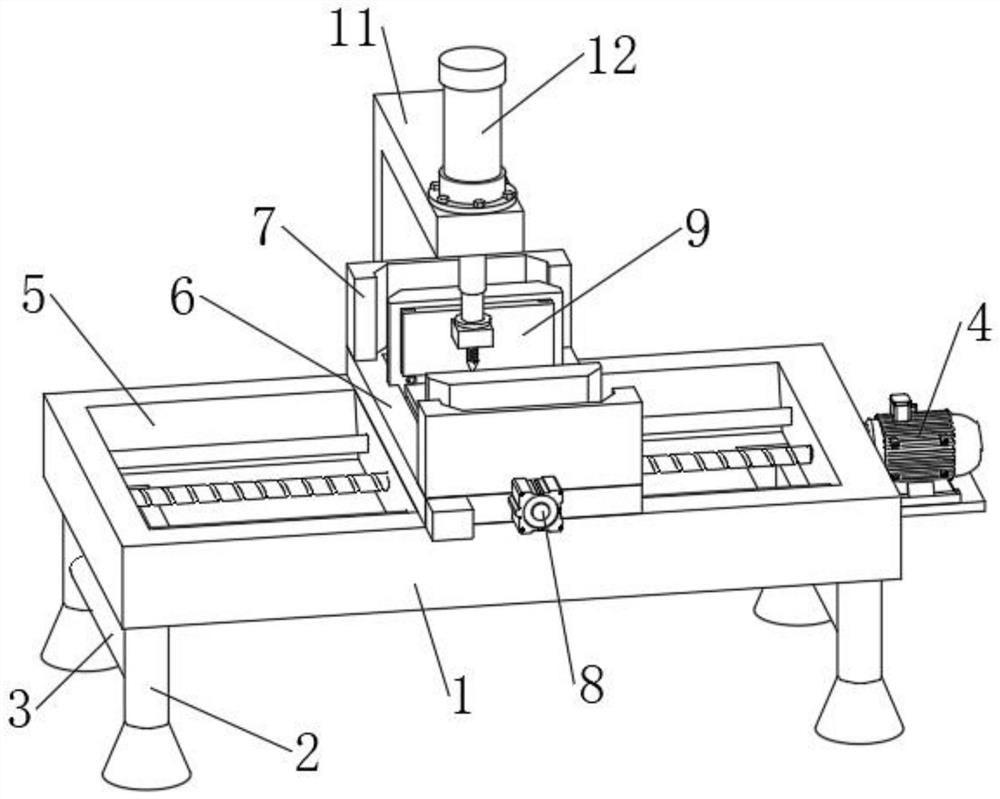

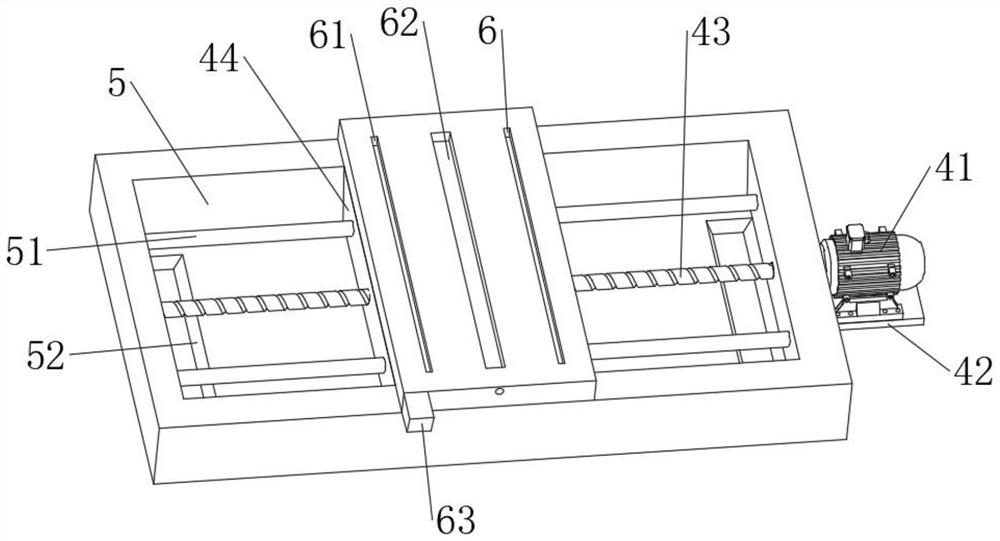

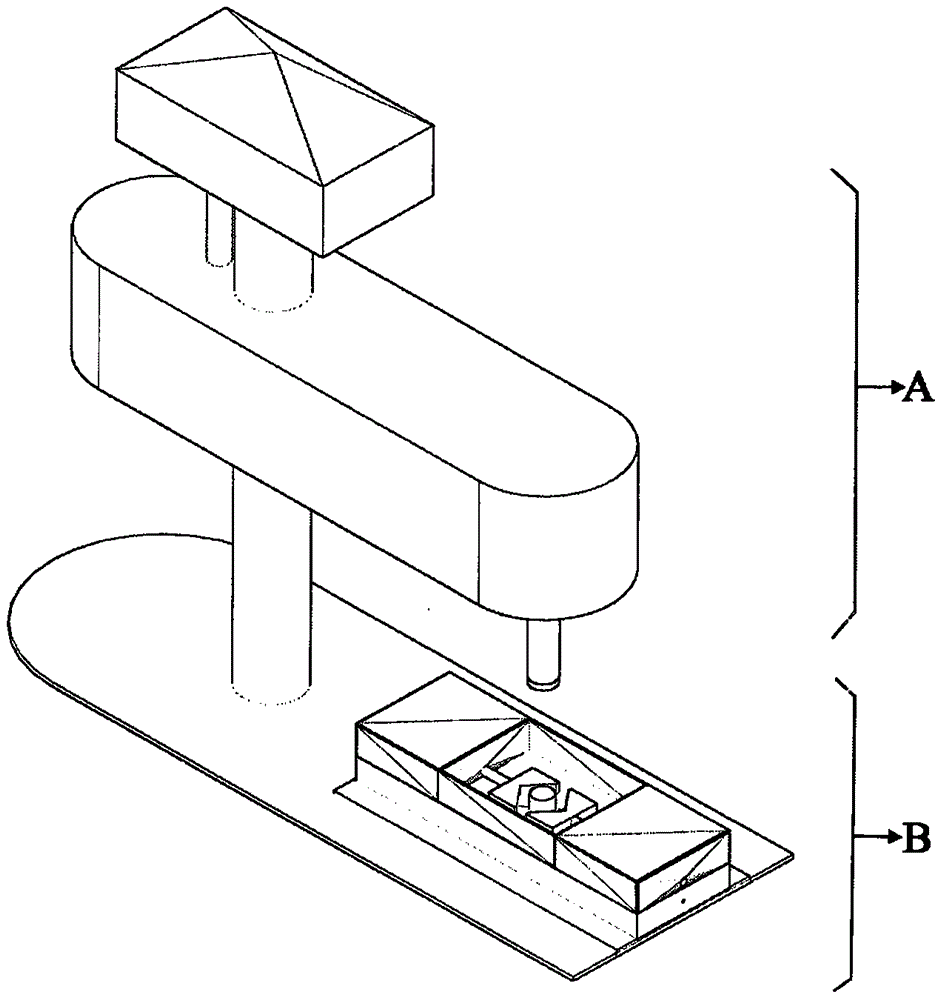

Automatic bidirectional clamping drilling machine

PendingCN112247626ARealize automatic clampingRealize automatic fixationMeasurement/indication equipmentsFeeding apparatusEngineeringWorkbench

The invention discloses an automatic bidirectional clamping drilling machine. The automatic bidirectional clamping drilling machine comprises a workbench. Two supporting legs are fixedly installed oneach the left portion of the lower end of the workbench and the right portion of the lower end of the workbench, a reinforcing rod is fixedly connected between the every two corresponding supporting legs jointly, a first installing groove is formed in the upper end of the workbench, and a moving mechanism is arranged at the right end of the workbench. A containing table is arranged at the upper end of the workbench, vertical plates are fixedly installed at the front portion and the rear portion of the upper end of the containing table, a clamping mechanism is arranged at the front end of the containing table, automatic stopping mechanisms are arranged at the ends, close to each other, of the two vertical plates, and a connecting block is fixedly installed in the middle of the rear end of the workbench. An L-shaped arm is fixedly installed at the rear portion of the upper end of the connecting block, a drilling mechanism is arranged at the upper end of the L-shaped arm, and the drillingmechanism extends to the position above the first installing groove. The automatic bidirectional clamping drilling machine is compact in structure, capable of automatically clamping and fixing a workpiece, high in drilling precision, high in practicability and convenient to use.

Owner:谢东

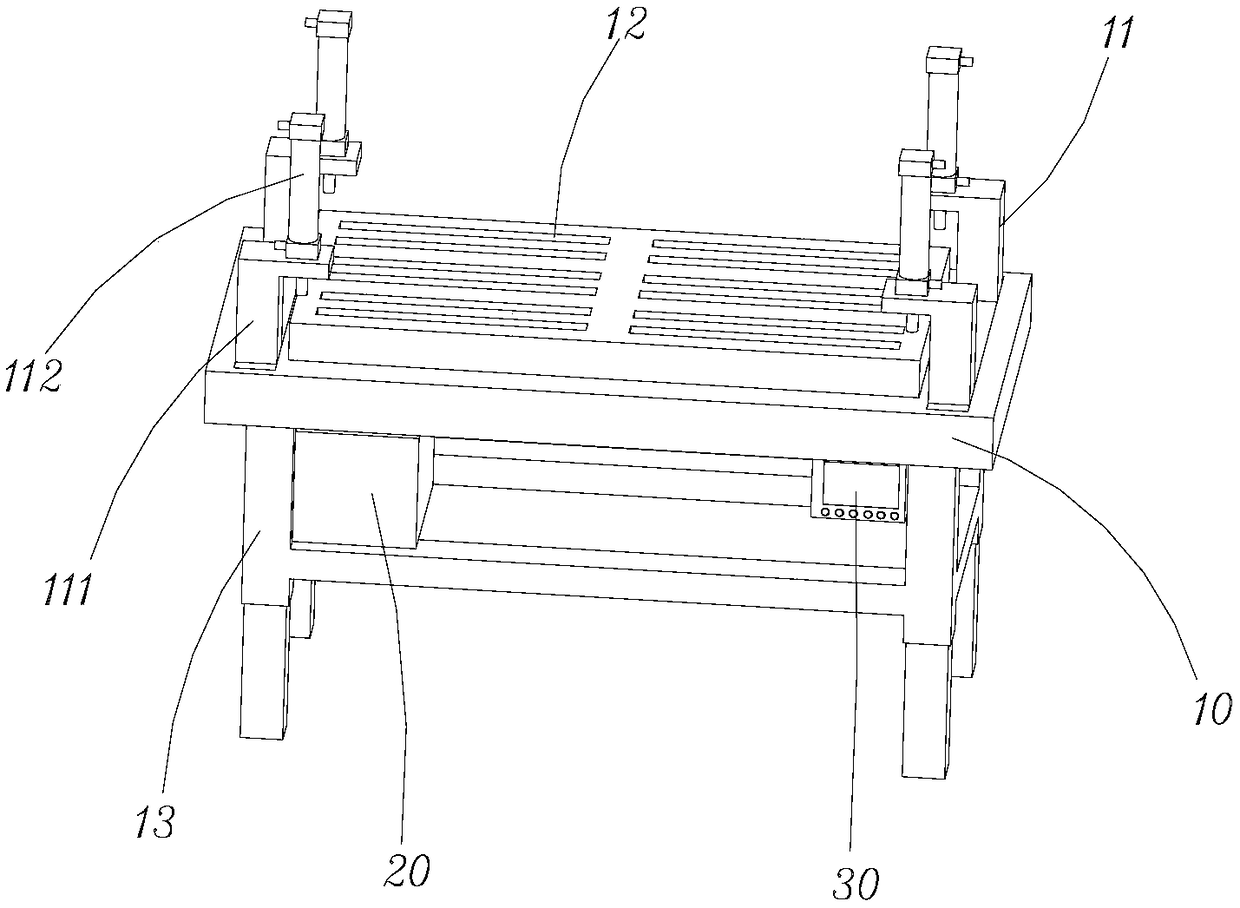

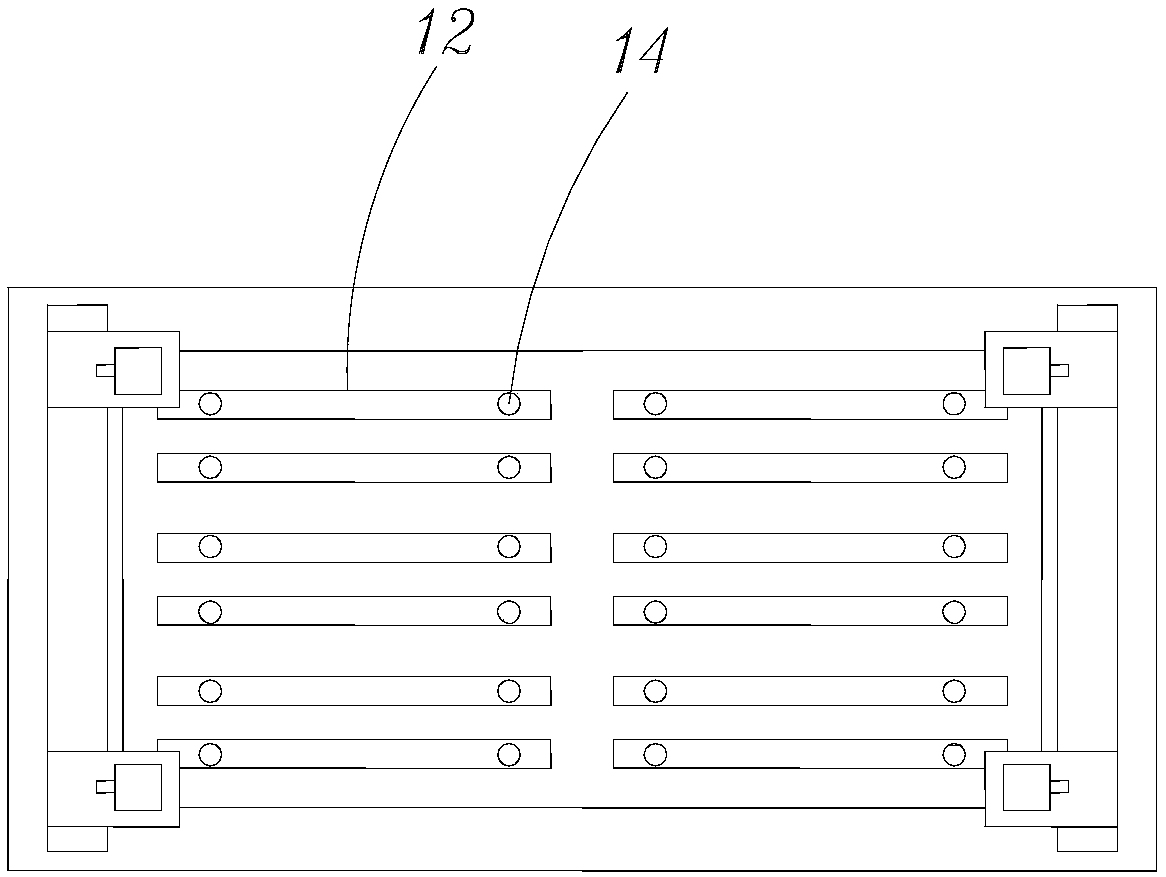

Clamping table for plate machining

InactiveCN108296842ARealize automatic fixationPrevent overflowWork clamping meansWork holdersAir pumpEngineering

The invention provides a clamping table for plate machining. The clamping table for plate machining comprises a worktable, an air extracting pump, a controller, and a tightening device and an air guide groove on the worktable; when plates are fixed in machining, the plates are only needed to place on the worktable; through connection between an air inlet end of the air extracting pump and the airguide groove, air of the air guide groove is extracted, and the plates are fixedly sucked on the worktable; meanwhile, an air outlet end of the air extracting pump is connected with a cylinder on thetightening device for fixedly tightening the plates again to realize no-bolt automatic fixation of plates to be machined, so that materials are flat on a carving machine without arching and displacing; meanwhile, through self suction of a vacuum sucking table, dust generated in the machining process can be sucked away, so that splashing of the dust can be effectively prevented, and the health of operators is protected; and materials to be machined are fixed through suction, so that mounting and taking are more convenient, the working efficiency is improved, and the labor cost is reduced.

Owner:FOSHAN SHANGLIFENG DECORATION MATERIALS CO LTD

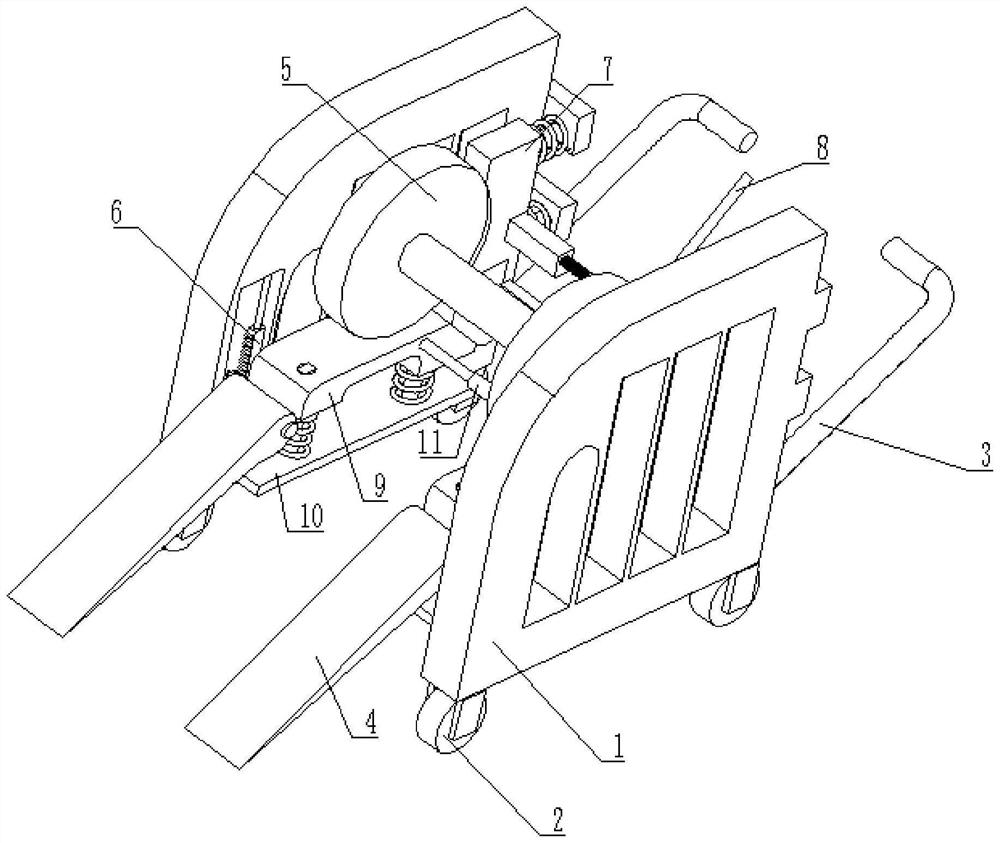

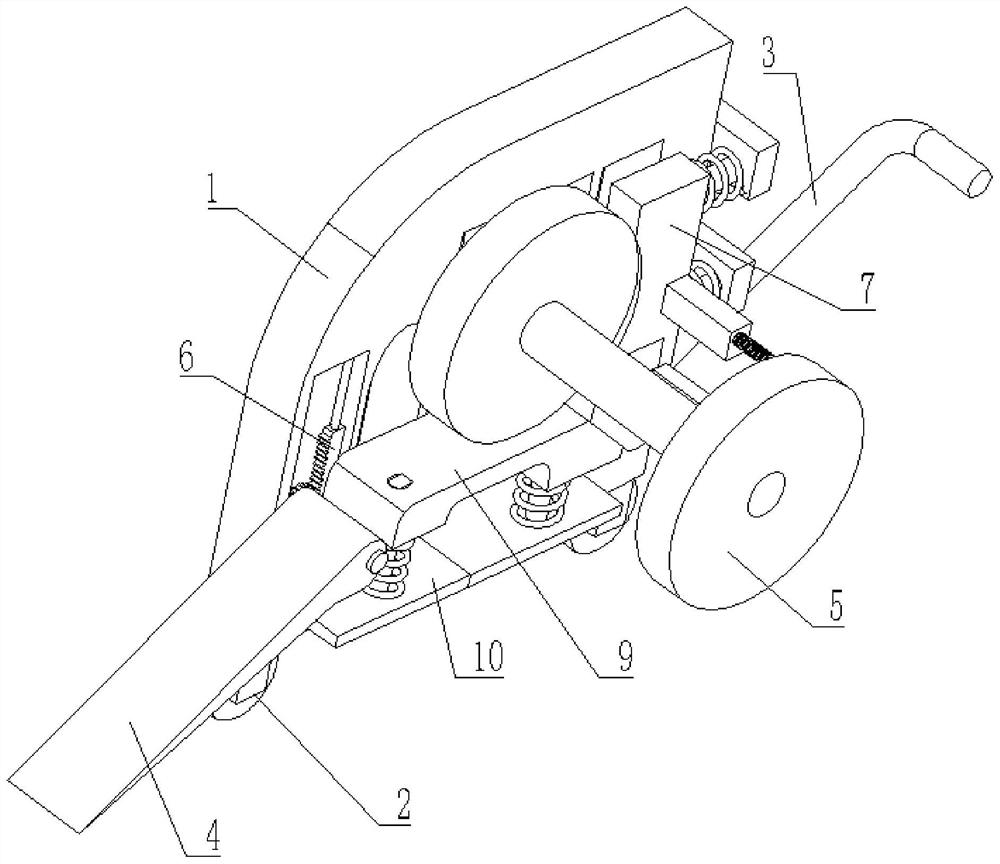

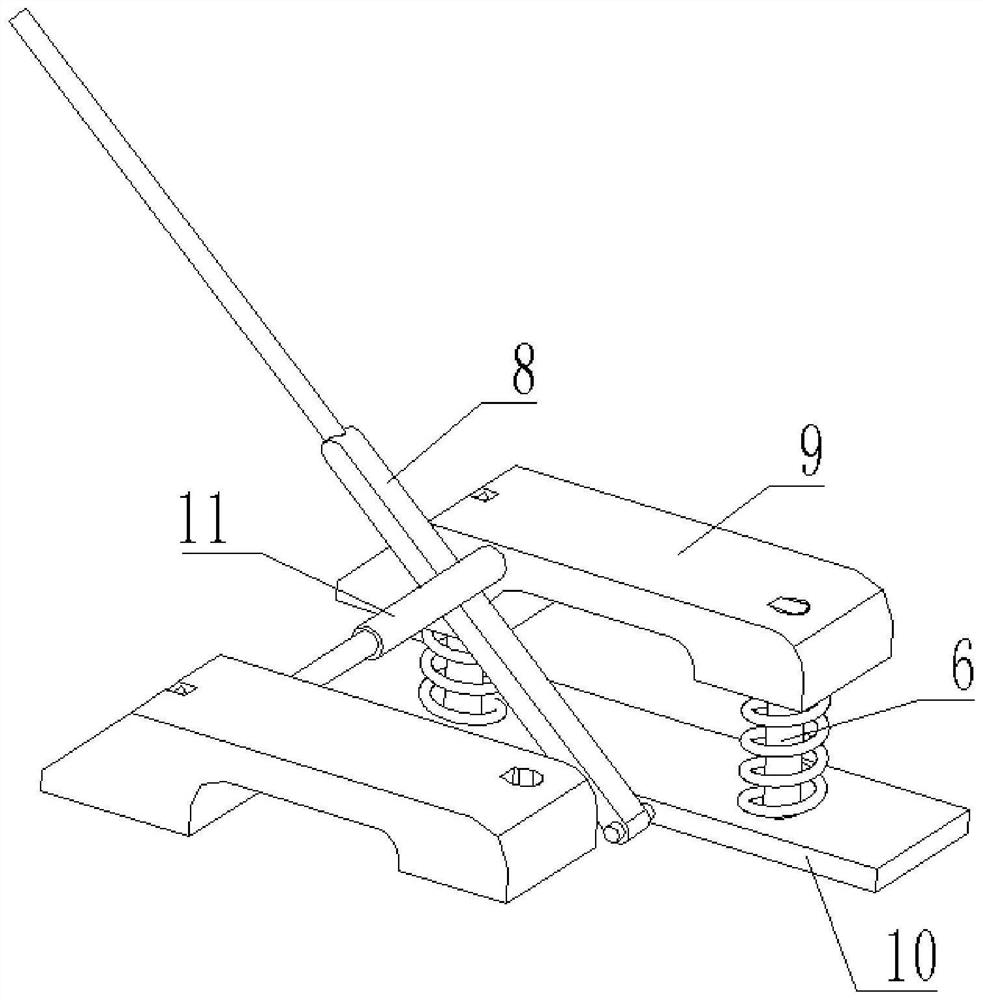

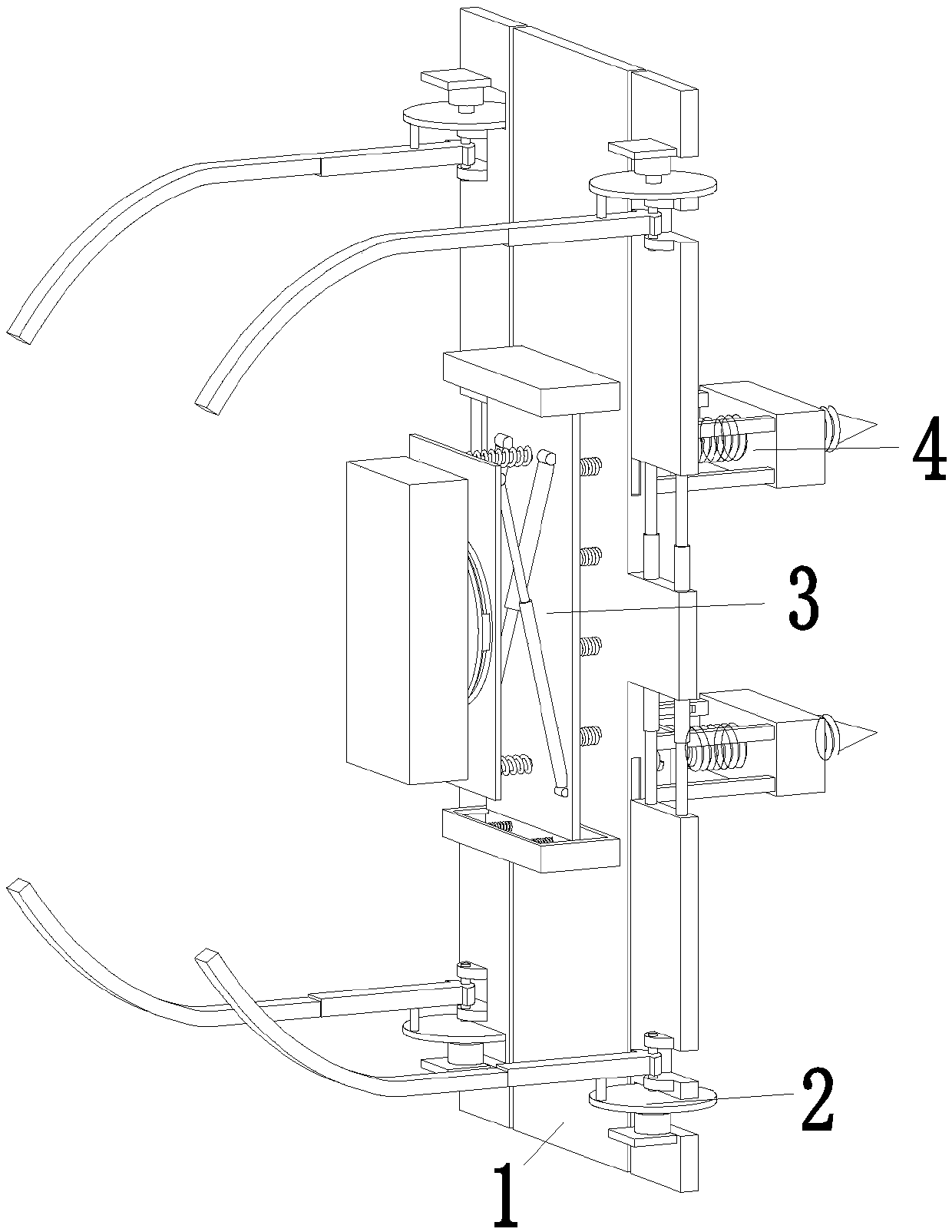

Automatic fixing and cutting robot for building water supplying and draining PPR pipe

InactiveCN107718122ARealize automatic fixationEnsure safetyMetal working apparatusEngineeringWater supply

The invention relates to an automatic fixing and cutting robot for building water supply and drainage PPR pipes, comprising a fixing device and a cutting device, and the fixing device is located directly in front of the cutting device. The invention can solve the problem that in the existing process of cutting the PPR water pipe, personnel are required to fix the position and then use the cutting equipment to cut the outer wall of the PPR water pipe. The process is cumbersome and complicated. The flatness affects the later work progress. During the cutting process, it is easy to cut the PPR water pipe crooked, so that the ends of the PPR water pipe are not flush, and improper cutting can easily cause personal injury and cause safety hazards. The PPR water pipe falls off. After the cutting is completed, the personnel need to fix the PPR water pipe to be cut again to find the cutting position for cutting. The process is cumbersome, and the cutting position cannot be accurately found, which is time-consuming, labor-intensive and low-efficiency problems.

Owner:倪菊莲

Winding machine for spinning

ActiveCN108502629AQuality assuranceReduce the amount of manual laborFilament handlingWinding machineEngineering

The invention relates to the technical field of textile processing and manufacturing, in particular to a winding machine for spinning. The winding machine for spinning comprises a machine frame, a feeding mechanism, a discharging mechanism and a hollow spline shaft are arranged on the machine frame, a feeding roller parallel to the spline shaft is arranged above one side of the spline shaft, and the spline shaft can be in spline connection with a winding roller. A first hollow wedge rod is arranged in the spline shaft in a sliding mode, a driving mechanism is arranged on one side of the firstwedge rod, one side of the first wedge rod communicates with an air extracting pump, the other side of the first wedge rod is connected with a supporting rod, a switch is arranged above the supportingrod and can abut against the supporting rod, and the switch is electrically connected with the air extracting pump. A pressing plate is arranged in the first wedge rod in a sliding mode, one side ofthe pressing plate is connected with a rolling ball, the rolling ball is arranged in an air pipe of the air extracting pump in a sliding mode, a first spring is connected between the other side of thepressing plate and the first wedge rod, a through hole capable of allowing the first wedge rod to penetrate therein is formed in the winding roller, a thread ring is arranged above the through hole,and a cutter is arranged on one side of thread ring. By means of the winding machine for spinning, the problem of low winding efficiency in the prior art can be solved.

Owner:NINGBO WENZE TEXTILE CO LTD

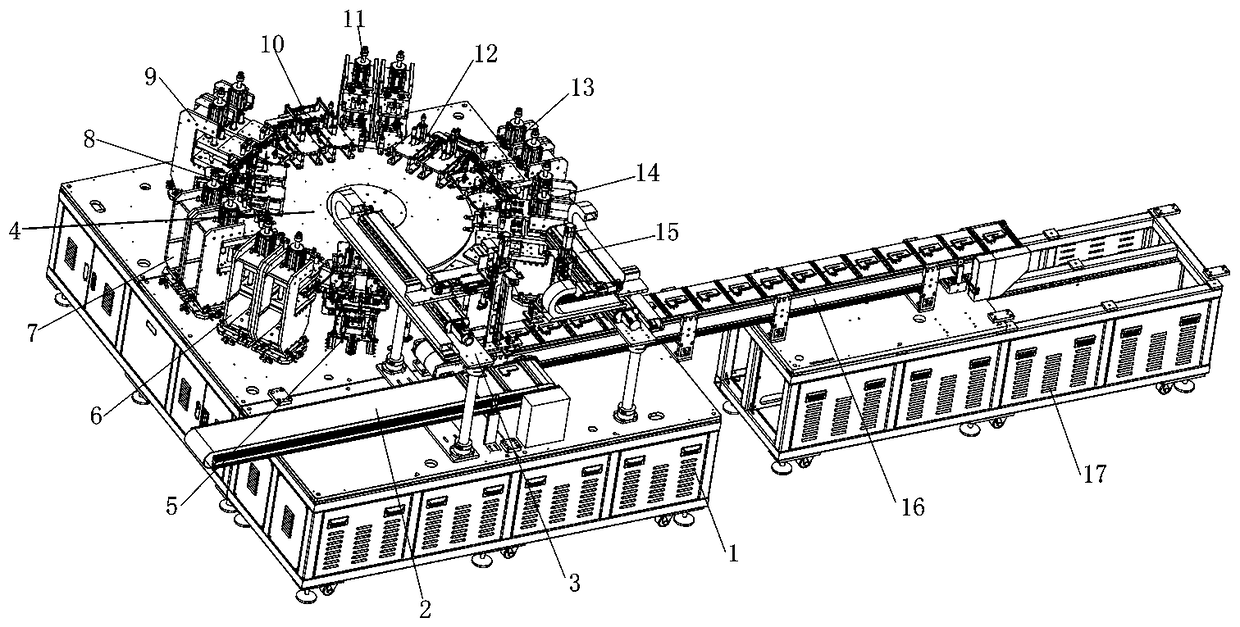

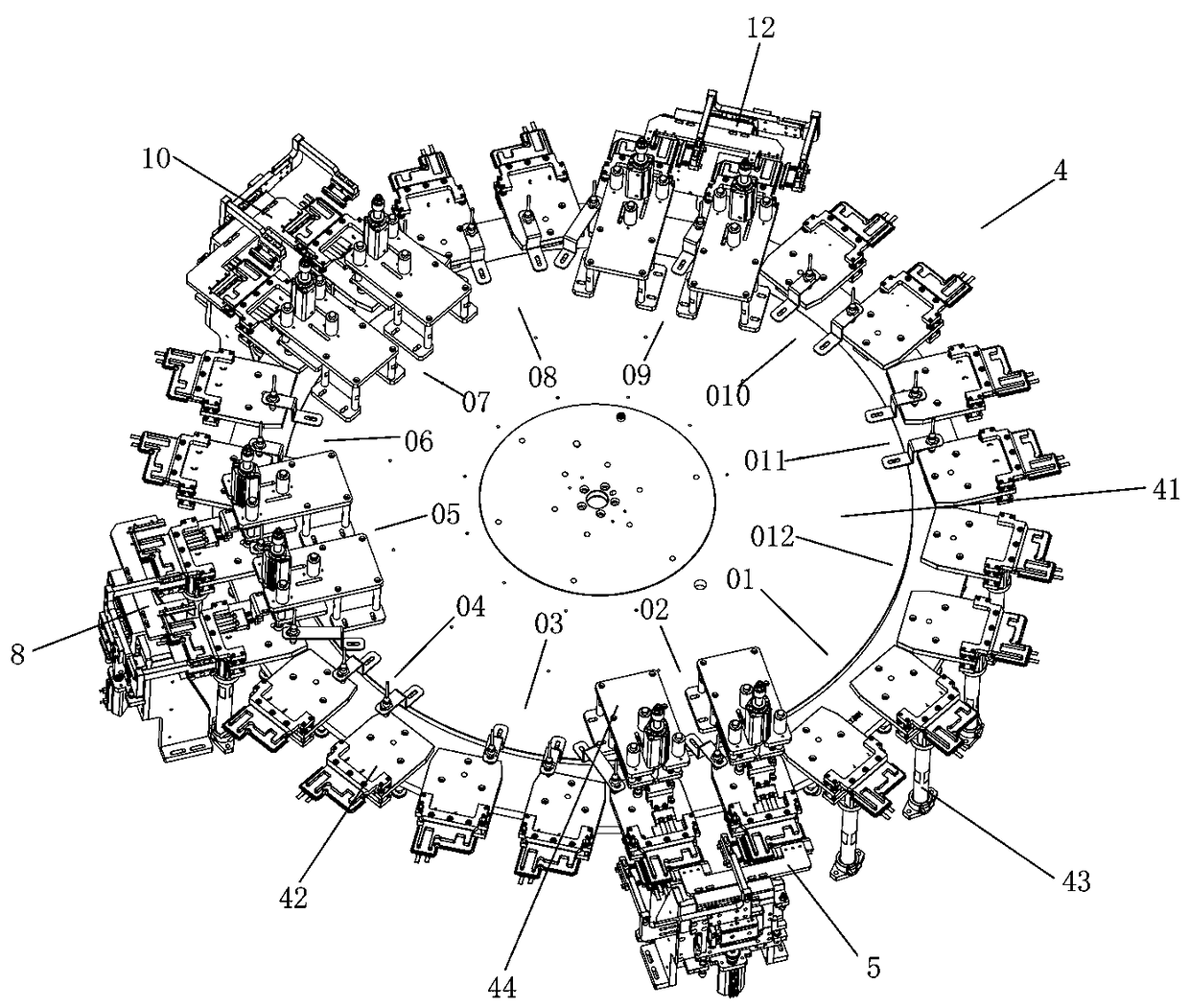

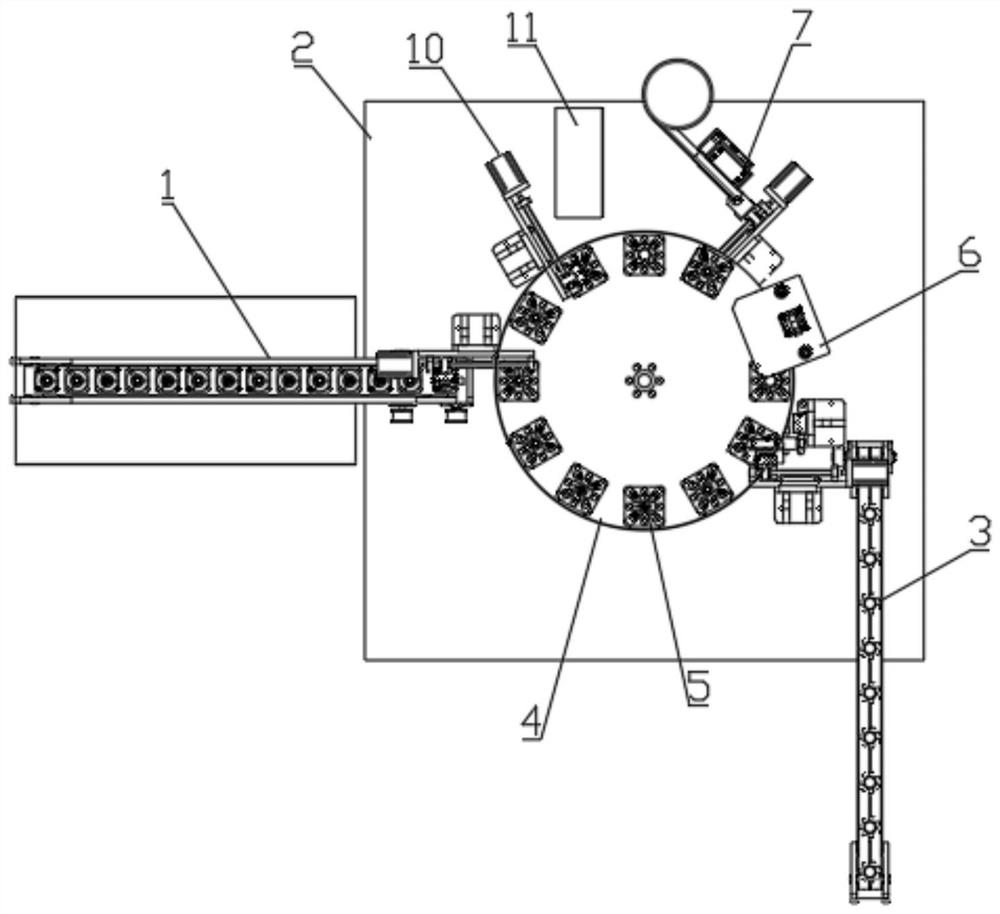

Automatic film cutting line for battery

PendingCN108199074ARealize automatic fixationRealize automatic handlingFinal product manufactureSecondary cells manufactureProduction lineOccupancy rate

The invention discloses an automatic film cutting line for a battery. The automatic film cutting line for the battery comprises a feeding belt, a feeding mechanism, a rotating disc mechanism, a firstpositioning mechanism, a first hot pressing mechanism, a first film cutting mechanism, a second positioning mechanism, a second film cutting mechanism, a third positioning mechanism, a third film cutting mechanism, a fourth positioning mechanism, a fourth film cutting mechanism, a second hot pressing mechanism, a discharging mechanism and a discharging belt, and the feeding belt and the discharging belt are arranged on the first machine frame and a second machine fame respectively; the rotating disc mechanism is arranged on the first machine frame; the feeding mechanism, the first positioningmechanism, the first hot pressing mechanism, the first film cutting mechanism, the second positioning mechanism, the second film cutting mechanism, the third positioning mechanism, the third film cutting mechanism, the fourth positioning mechanism, the fourth film cutting mechanism, the second hot pressing mechanism and the discharging mechanism are correspondingly arranged on the outer side of arotating disc. According to the automatic film cutting line for the battery, the space occupancy rate of the production line is effectively reduced, and automatic fixation of the battery, automatic joining between battery fixation and feeding and discharging and automatic positioning before battery film cutting are achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Automatic welding device for municipal water supply and drainage thermoplastic pipe

InactiveCN110154413AHot melt not requiredRealize automatic fixationNon-rotating vibration suppressionTubular articlesThermoplasticEngineering

The invention discloses an automatic welding device for a municipal water supply and drainage thermoplastics pipe. The automatic welding device comprises a bearing plate and two sliding devices, wherein the two sliding devices are slidably connected to the upper end of the bearing plate, the two sliding devices are connected with the upper end of the bearing plate in a sliding mode, and used for adjusting the relative distance between the two sliding devices; and the sliding devices are connected with clamping devices, the sliding devices are used for adjusting the distance between the two clamping devices, a fixing block is fixedly connected to the middle of the bearing plate, a welding device capable of automatically adjusting the position is fixedly connected to the upper end of the fixing block, the two sides of the fixing block are fixedly connected with sliding parts in the sliding devices through first stretchable parts. A water pipe is automatically locked through the clampingdevices, so that the automatic fixing is realized, meanwhile, by controlling the welding device, automatic adjustment of the whole welding device and hot melting of the water pipe can be realized, then the hot melting, separating and butting joint of the water pipe are realized through adjustment of the sliding devices, labor is saved, manual operation is not needed all the time, and high automation is realized.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Power cable transferring device

The invention relates to the technical field of cables, in particular to a power cable transferring device. The power cable transferring device comprises a machine frame, wherein moving wheels are fixedly connected to the bottom of the machine frame; a push handle is fixedly connected to the right side of the machine frame; a bearing plate is connected to the inner wall of the machine frame in a sliding manner; a fixed plate is fixedly connected to the inner wall of the machine frame; a self-immobilizing mechanism is arranged at the bottom of the bearing plate; a cable tray is arranged on theupper surface of the bearing plate; and a clamping mechanism is arranged on the right side of the bearing plate. The power cable transferring device disclosed by the invention can be lowered because the device is affected by the gravity of the cable tray through the bearing plate while a rotary gear can drive charging plates to be rotated and rolled up, so that the situation of interference between the two charging plates is avoided in a moving process of the whole device, and a good place can be given, and thus, automatic immobilization of the device in a cable transferring process can be realized preferably, manual binding and mounting are not needed, the labor intensity is reduced, and the stability of the device in the moving process is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Automatic rock sample fixing device for indoor rock core drilling machine

InactiveCN105784412AAchieve fixationAchieve releaseWithdrawing sample devicesRock coreStructure of the Earth

The invention relates to an automatic rock sample fixing device for an indoor rock core drilling machine.The device is composed of a clamping chamber and a driving system.A pair of V-shaped clamps, pressure sensors and screw rods are arranged in the clamping chamber.The driving system composed of the pair of screw rods, a gear and the clamping chamber is used for driving the two V-shaped clamps to move, and a rock sample to be processed is fixed and loosened; the inner side of each V-shaped clamp is provided with one pressure sensor, and the pressure sensors are used for sensing clamping pressure and controlling rock sample controlling pressure and adapt to various soft and hard rock samples.The automatic rock sample fixing device can be installed on the existing indoor rock core drilling machine, and has the advantages of being simple in structure, convenient to operate and applicable to automatically fixing various soft and hard rock samples.According to the automatic rock sample fixing device, experiment steps can be simplified, the rock core drilling survival rate is improved to a certain degree, rock core preparation time is effectively saved, and working efficiency is improved.

Owner:SUN YAT SEN UNIV

Locking screw fixing device

PendingCN109877747AAchieve fixationRealize automatic fixationWork holdersMetal working apparatusEngineeringRestoring force

The invention relates to a locking screw fixing device. The device comprises a fixed plate, a pressing holding assembly, a driving part, a moving sliding base and an elastic part; a mounting positionis arranged on the fixed plate, and is used for mounting and fixing of a workpiece, the pressing holding assembly comprises a positioning block and a supporting rod, one end of the supporting rod is fixedly connected to the positioning block, the positioning block hangs above the mounting position, and is close to or away from the mounting position along with moving of the supporting rod, the moving sliding base is in transmission connection to the driving part, the end, away from the positioning block, of the supporting rod is in abut joint with the moving sliding base, the moving sliding base is provided with a slope, when the driving part drives the moving sliding base to move, the supporting rod moves along the slope to move towards the top end of the slope, and the positioning block is away from the mounting position; the elastic part is used for providing restoring force for resetting of the moving sliding base, in the resetting process of the moving sliding base, the supportingrod moves to the bottom end of the slope along the slope, and the positioning block moves in the direction close to the mounting position. Two parts are fixed through the positioning block, and threeor more parts can be easily fixed.

Owner:SHENZHEN BESTEK TECH CO LTD

Angle-changeable fixing device based on missile launching

The invention discloses an angle-changeable fixing device based on missile launching, and relates to the technical field of missiles. The fixing device comprises a fixing pedestal, and the four corners of the bottom surface of the fixing pedestal are each fixedly connected with a support block; a wheel is fixedly hinged with the bottom end of each support block through a hinge pin, and the fixingpedestal is internally provided with a fixing structure; and the right inner side of the fixing pedestal is provided with a regulation structure. According to the angle-changeable fixing device basedon missile launching, through arrangement of a towing rod and a towing ring, a user connects a towing vehicle with the towing ring conveniently, so that a launcher is moved through the towing vehicle,and manual movement of the launcher is avoided; the fixing device is convenient and efficient; through arrangement of the fixing structure and the regulation structure, automatic fixation of the launcher can be achieved effectively; thus, the situation that the launcher topples due to recoil force of a missile during launching and consequently the launching of the missile is failed is avoided; and the fixing device facilitates regulation of the launching angle of the missile overall.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Cutting device for wooden furniture processing and using method thereof

InactiveCN111791307AArrange neatlyRealize automatic feeding processFeeding devicesCircular sawsWood plankIndustrial engineering

The invention discloses a cutting device for wooden furniture processing and a using method thereof. The cutting device comprises a base, a timber conveying device, a timber cutting device, a discharging device, a first rotating motor, a gearbox, a power transmission device, a cutting protective cover and a cleaning device; the timber conveying device is arranged on one side of the base and fixedly connected with the side wall of the base, the timber cutting device is fixedly connected to the top of the base, and the cleaning device is arranged inside the base; a timber conveying frame is matched with a synchronous belt, so that the cutting device can automatically convey wood boards, a timber conveying wheel and a conveying wheel connecting roller are arranged, timbers are pressed and fixed by using a belt, and the timber conveying wheel automatically conveys the timbers to a cutting position to complete cutting. The effect that the timber cutting device automatically completes feeding cutting and discharging work is achieved, in addition, the cleaning device is arranged in the base, production environment pollution caused by inconvenience or untimely wood chip cleaning in the production process is avoided, the labor intensity of workers is greatly relieved through the whole device, the production cost is reduced, and meanwhile the working efficiency is improved.

Owner:安徽宏润工艺品有限公司

Airbag type computer mainboard fixing frame

The invention discloses an airbag type computer mainboard fixing frame. The fixing frame comprises a host frame; the host frame is provided with a square accommodation cavity used for accommodating acomputer mainboard; elastic clamping components for limiting transverse displacement of the computer mainboard are arranged on two side walls of the square accommodation cavity; an upper clamping block is arranged on the upper wall of the square accommodation cavity; a lower sliding block is arranged at the lower part of the square accommodation cavity; the two sides of the lower sliding block arein sliding fit with sliding rails arranged on the two side walls of the square accommodation cavity; an airbag type pushing assembly fixedly connected with the lower sliding block is arranged at thelower end of the lower sliding block; the airbag type pushing assembly comprises an upper airbag and two opposite telescopic plates; a square supporting part which protrudes downwards is arranged at the lower end of the host frame; and a lower airbag connected with the upper airbag is arranged in the square supporting part. When the host frame is vertically placed, the lower airbag is extruded bythe host frame and the ground to fill the upper airbag with air, so that the degree of freedom of the computer mainboard is limited.

Owner:浙江民安信息技术有限公司

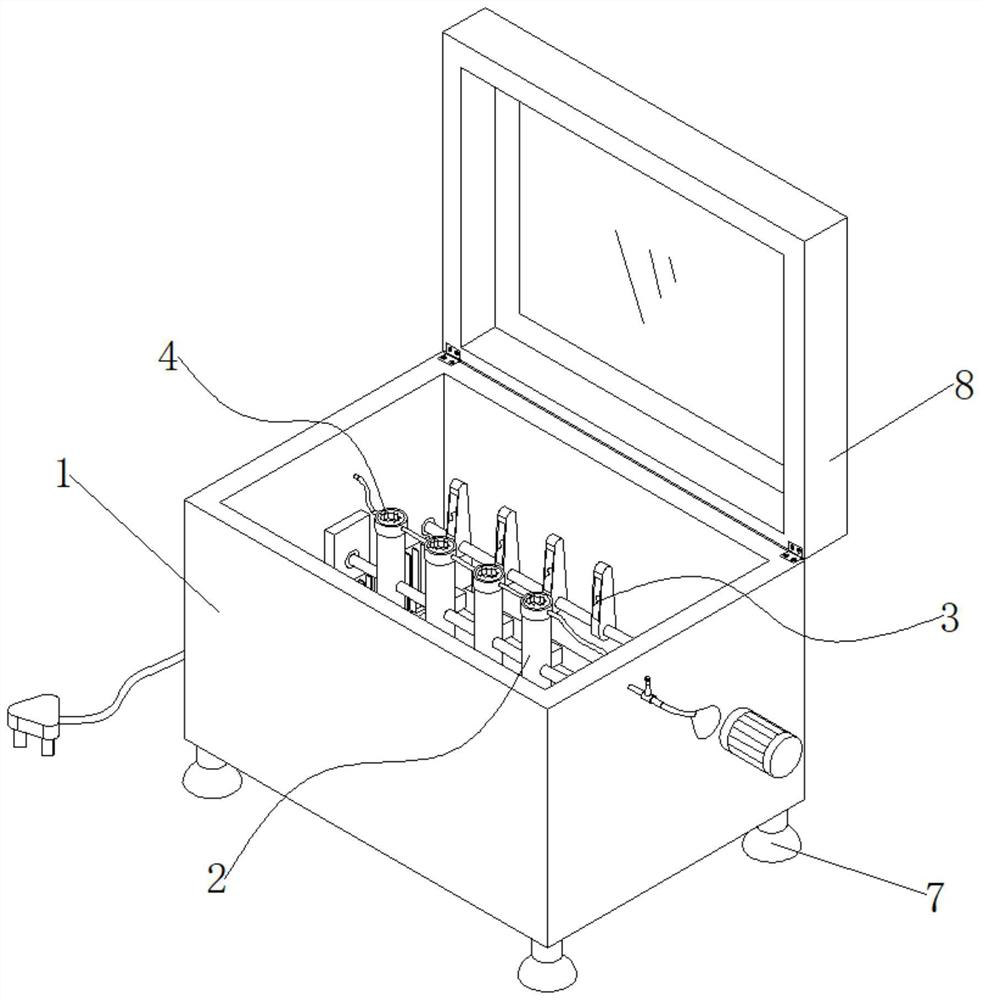

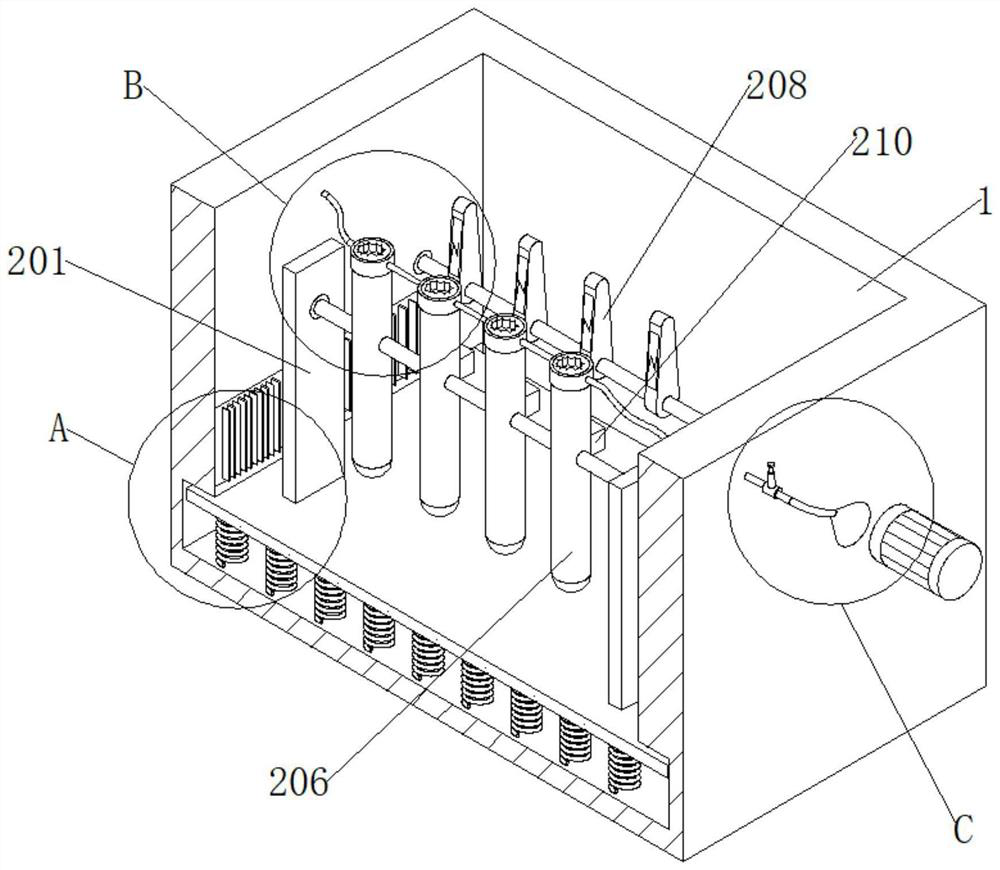

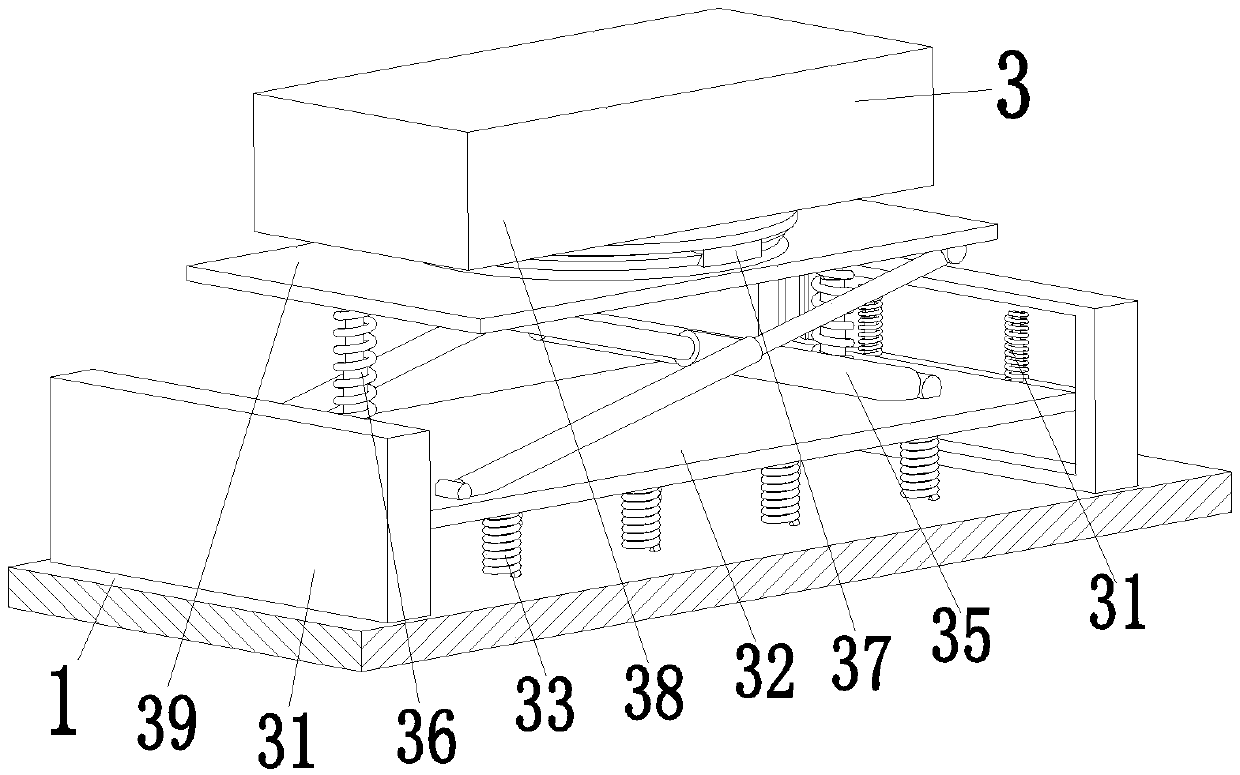

Test tube oscillation equipment for hospital clinical laboratory

ActiveCN113617269AAutomatic reciprocating tiltingRealize reciprocating tiltingShaking/oscillating/vibrating mixersMixer accessoriesStructural engineeringTest tube

The invention relates to test tube oscillation equipment for a hospital clinical laboratory. The test tube oscillation equipment comprises a mounting box, and a test tube up-down oscillation assembly and a tilting oscillation assembly are arranged on the inner wall of the bottom of the mounting box in a linkage mode; the test tube up-down oscillation assembly comprises a bottom groove, the bottom groove is formed in the inner wall of the bottom of the mounting box, springs are distributed and fixed to the inner wall of the bottom of the bottom groove, a bottom plate is arranged on the inner wall, located above the springs, of the bottom groove, mounting frames are symmetrically fixed to the outer wall of one side of the top of the bottom plate, and a mounting shaft is rotationally connected to the inner wall of the top between the mounting frames; test tube sleeves are distributed and embedded on the outer wall of the mounting shaft; the test tubes can be placed through the test tube up-and-down oscillation assembly, the test tubes can be driven to oscillate in the up-and-down direction, the test tube up-and-down oscillation assembly and the tilting oscillation assembly are linked, and the test tubes can be subjected to tilting oscillation in a linkage mode in the up-and-down oscillation process. Tilting oscillation realizes the traditional simulation of manually swinging the test tube by hand, so that the oscillation mixing effect of the reagent is improved.

Owner:WUXI NO 5 PEOPLES HOSPITAL

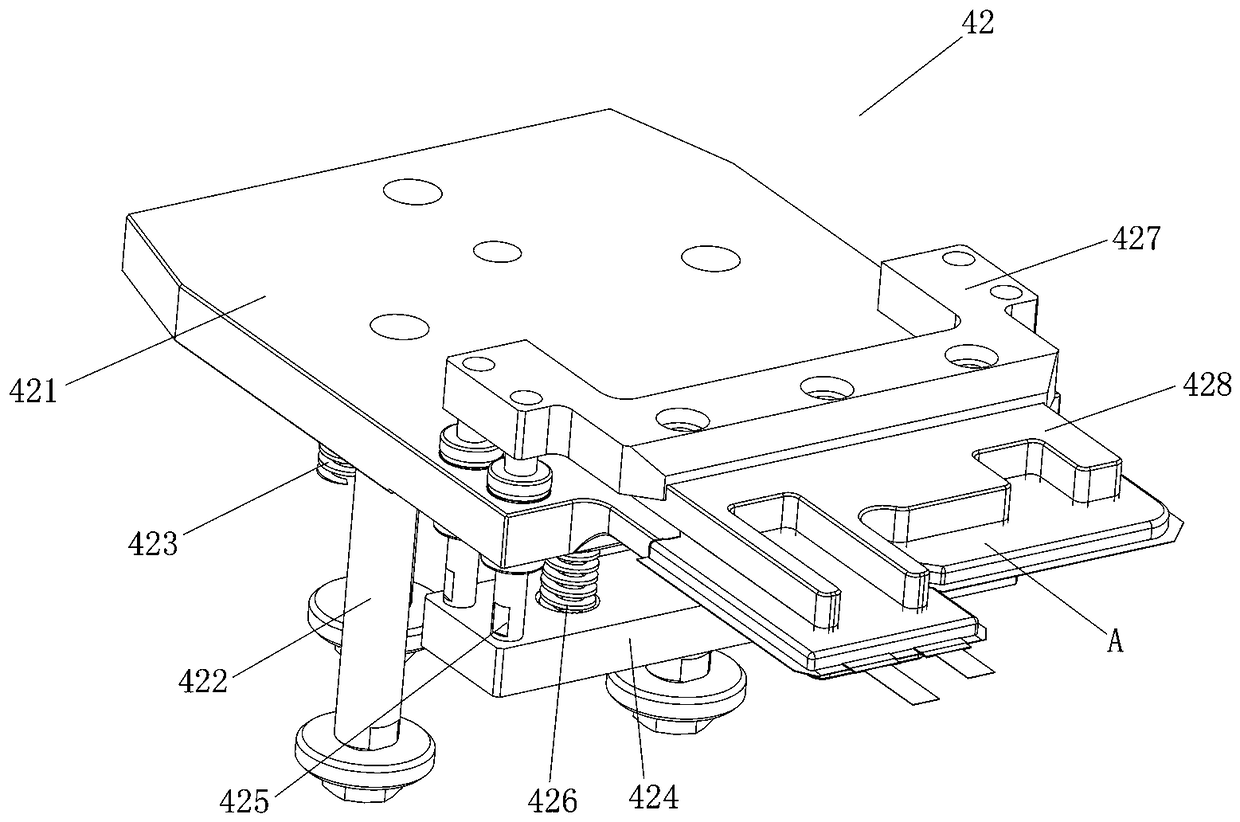

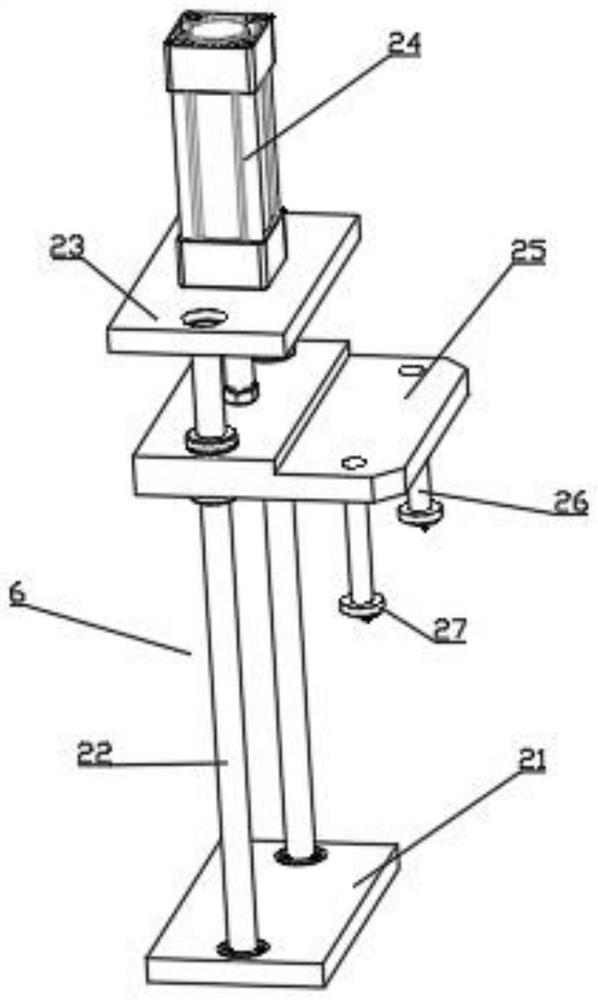

Electric vehicle battery quick assembling equipment and working method thereof

ActiveCN112894333ASimple structureRealize automatic fixationFinal product manufactureAssembly machinesElectric-vehicle batteryElectrical battery

The invention discloses electric vehicle battery quick assembling equipment. The electric vehicle battery quick assembling equipment comprises a first feeding mechanism, a machining table, a second feeding mechanism, a rotating disc, a fixing base, a pressing mechanism, a fixed connecting mechanism and a discharging mechanism; the rotating disc is arranged in the middle of the top face of the machining table through a driving motor, the first feeding mechanism, the second feeding mechanism, the pressing mechanism, the fixed connecting mechanism and the discharging mechanism are annularly arranged along the rotating disc, and the first feeding mechanism, the second feeding mechanism, the pressing mechanism, the fixed connecting mechanism and the discharging mechanism are all installed on the machining table; and the first feeding mechanism and the second feeding mechanism are the same in structure, and each of the first feeding mechanism and the second feeding mechanism comprises a first clamping assembly and a conveying assembly. According to the electric vehicle battery quick assembling equipment and a working method thereof, batteries of different sizes can be assembled, automatic assembling can also be achieved, and the electric vehicle battery assembling efficiency is greatly improved.

Owner:东莞赛普若斯科技有限公司

Shell embossing device for electronic product production

The invention relates to the technical field of electronic product production equipment, and discloses a shell embossing device for electronic product production. The device comprises a workbench andan embossing device body, wherein the output end of the embossing device body is fixedly connected with an embossing head through a bolt; the upper surface of the workbench is fixedly connected with afixing frame; the inner wall of the bottom end of the fixing frame is slidably connected with symmetrically distributed clamping plates; the outer walls of the two clamping plates are sleeved with astorage plate together; openings matched with the clamping plates are formed in the two side walls of the storage plate; a plurality of telescopic rods are fixedly connected to the lower surface of the storage plate; and the bottom ends of the multiple telescopic rods are fixedly connected with the inner wall of the bottom end of the fixing frame. According to the shell embossing device, a shell can be automatically fixed with less time and labor, so that the labor intensity of workers is relieved, the embossing efficiency of the shell of an electronic product is improved, the moving efficiency of the embossing device for electronic product production can be effectively improved, less time and labor are needed in the moving process, and accordingly the waste of labor is avoided.

Owner:马鞍山小古精密机电科技有限公司

New energy electric vehicle safety charging device

ActiveCN108944540ASimple and compact structureEasy to installElectric vehicle charging technologyVehicular energy storageElectric vehicleAutomobile safety

A new energy electric vehicle safety charging device includes a housing of a charging device and a charging gun head, acavity is arrange inside the shell, the center of A left end face of that house is provided with a square hole, A square slider is arranged in the square hole, the square slider is of slightly deformable material, the right end of the square slider is fixedly connected with the right wall of the cavity through an elastic telescopic rod, grooves are symmetrically formed on the upper and lower sides of the square hole on the left end face of the shell, the inner upper and lowersides of the square hole are symmetrically formed with first through holes, and vertical rods are arranged in the first through holes. As the new energy electric vehicle safety charging device is simple and small in structure, is easy to install, is ingenious in design, can ensure the safety of electric vehicle when charging; When the charging device is not charged, the square hole responsible forplugging and charging of the charging device can be automatically sealed to prevent dust and other impurities from enter the inside of the device, so as to ensure the cleanness of the inside of the device, prevent dust deposited on the internal power supply parts from affecting the stability of the electric connection during charging, and thus ensuring the safety of charging.

Owner:临沭县益兴供汽维修服务有限公司

Stirring-type water cup

ActiveCN107048971AImprove stabilityImprove work efficiencyStrainersEngineeringMechanical engineering

Owner:永康市顾得工贸股份有限公司

Solar cell processing and cleaning equipment

ActiveCN110491810AAffect cleaning operationsRealize automatic fixationFinal product manufactureSemiconductor/solid-state device manufacturingCell processingCells panel

The invention discloses solar cell processing and cleaning equipment, and belongs to the technical field of cell processing. The equipment comprises a workbench, a cleaning assembly, a fixing assemblyand a drying assembly. The cleaning assembly comprises a sweeping part, a mixing part, a cleaning part and a collecting part. The sweeping part is arranged at the top of the fixing assembly, the mixing part is arranged beside the workbench, the cleaning part is arranged at the top of the workbench, the collecting part is arranged below the workbench, the drying assembly comprises a moving part and a drying part, the drying part is arranged at the top of the workbench, and the moving part is arranged at the top of the workbench. The two rotating motors work to drive the two rotating lead screws to rotate on the two fixing frames; the two rotating lead screws rotate to drive the moving plate to move, the moving plate moves to drive the sweeping plate to move, the sweeping plate moves to drive the sweeping brush to sweep residues on the cell panel, after sweeping is conducted, the residues on the cell panel can be cleaned easily, and it is guaranteed that the cell panel is cleaned cleanly.

Owner:江苏悦阳光伏科技有限公司

Milling machine with temperature protection function for industrial production

ActiveCN106270670AImprove practicalityImprove reliabilityMeasurement/indication equipmentsMilling machinesDrive wheelElectric machinery

The invention relates to a milling machine with a temperature protection function for industrial production. The milling machine comprises a machine body, a cross beam arranged above the machine body, a base arranged below the machine body, a processing mechanism, a temperature measurement mechanism and an orientation control mechanism. In the milling machine with the temperature protection function for the industrial production, a driving wheel is driven to rotate through a first driving shaft, and then, a transmission rod pulls a transmission sliding block to move in a guide rail, so that a connecting rod can be used for pulling a fixing block, and a cutter bar can be stretched into a main shaft. In addition, since the internal diameter of an installation groove in the main shaft is gradually reduced along a cutter bar loading direction, the automatic fixing of the cutter bar can be realized so as to improve the reliability and the practicality of the milling machine. In addition, a steering motor is used for controlling the measurement angle of an infrared thermodetector through a rotation shaft to guarantee that accurate measurement can be realized for tool bits of different models so as to improve the reliability and the practicality of the milling machine.

Owner:安徽鹏睿智能科技有限公司

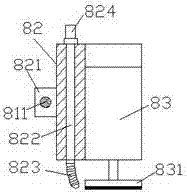

Waste treatment equipment

ActiveCN106976268ALimit the maximum push slip distanceLimit push slip distanceShaping pressTransverse grooveVolumetric Mass Density

The invention discloses waste treatment equipment which comprises a main body. An extruding cavity is formed in the main body; a regulating cavity is formed in the position, on the lower portion of the extruding cavity, in the main body; a transverse groove is formed in the inner top wall of the extruding cavity in a left and right extending mode; a sliding block is arranged in the transverse groove; an extruding power device is fixedly arranged on the end face of the front side of the sliding block; the bottom of the extruding power device is provided with an extruding head which stretches into the extruding cavity and is rotatably connected with the extruding cavity in a matched mode; first guiding grooves and second guiding grooves formed in the upper portions of the first guiding grooves are formed in the inner side faces of the left side and the right side of the extruding cavity correspondingly; first guiding rods are arranged in the first guiding grooves in an up and down extending mode; and first square grooves are formed in the inner top walls of the second guiding grooves. The waste treatment equipment is simple in structure, waste can be extruded into waste blocks with different sizes and different densities according to different requirements, the size is reduced, the landfill space is saved, the deodorization effect is good, the requirement of extrusion work of the waste in waste boxes with different specifications is met, self fixation can be achieved, and the working efficiency is high.

Owner:天长市天香源粮油食品有限公司

Rapid-mounting portable base station

PendingCN109525906AQuick installation and fixingAdjustable angleMachine supportsWireless communicationEngineeringBase station

The invention relates to a rapid-mounting portable base station. The base station comprises a mounting side plate, fixing devices, an angle adjusting device, and drilling devices. The fixing devices are symmetrically mounted on the outer end surface of the mounting side plate. Chutes are symmetrically arranged on the outer end of the mounting side plate. The angle adjusting device is mounted on the central left end surface of the mounting side plate. The drilling devices are mounted on the right end surface of the mounting side plate. The rapid-mounting portable base station can solve the problems that the existing portable base station cannot be rapidly mounted and fixed, cannot be suspended and fixed at the upper end of the dead tree, and cannot adjust the angle of the base station. Thefunctions of automatic fixation and portability can be realized. And the base station of the invention has advantages that the base station can be rapidly mounted and fixed, can be suspended and fixedat the upper end of the dead tree, and can adjust the angle of the base station.

Owner:XIAN HUAYUN TIANCHENG COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com