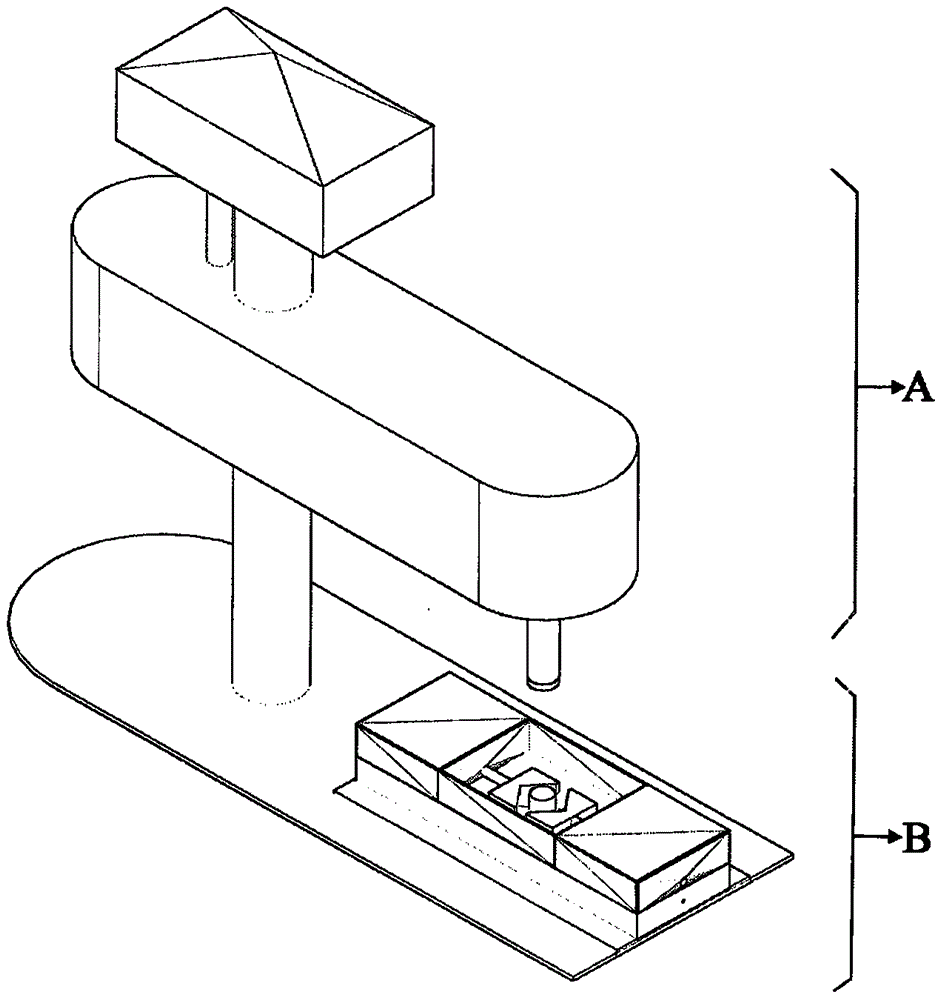

Automatic rock sample fixing device for indoor rock core drilling machine

A coring machine and rock sample technology, applied in the direction of sampling devices, etc., can solve the problems of uncontrollable clamping force, damage to the rock to be processed, and cumbersome operation, so as to improve the success rate, improve work efficiency, and simplify the test steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

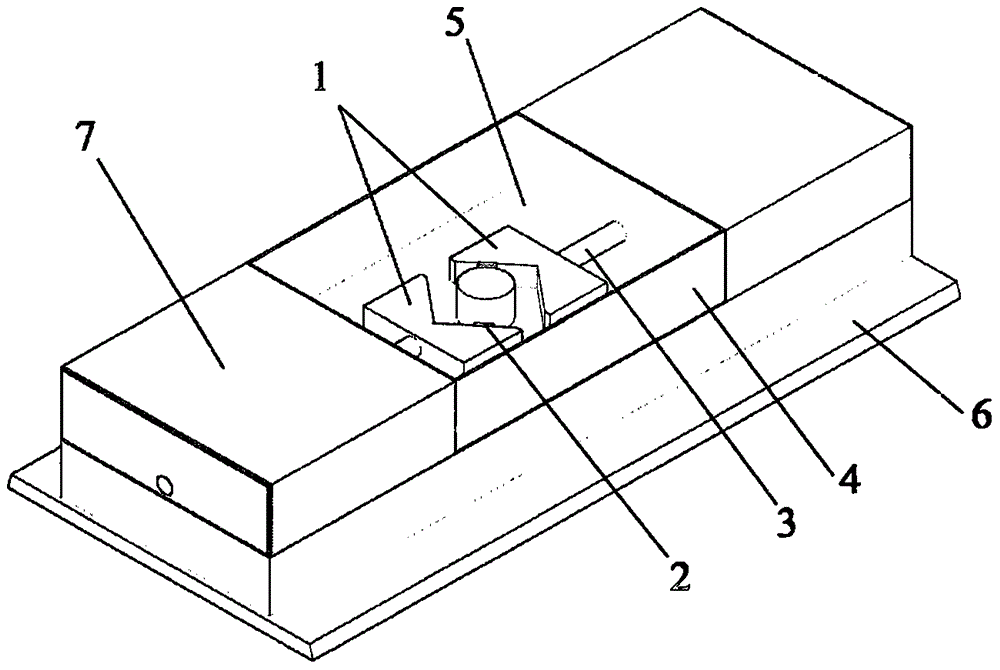

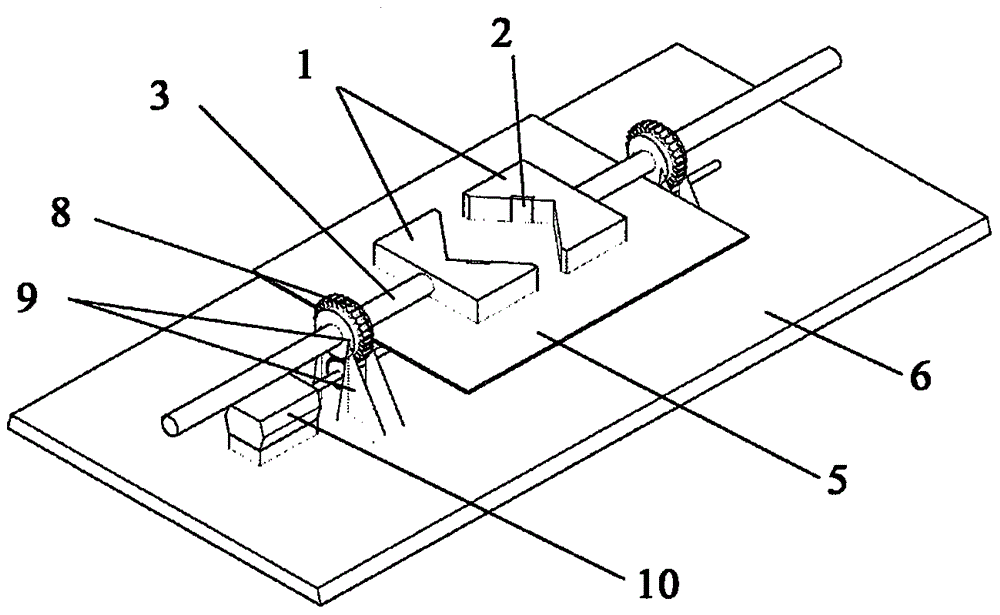

[0030] The invention is an automatic rock sample clamping device for indoor rock core machine. The function mainly relates to the automatic clamping and fixing of rock samples. It can be directly installed on existing rock core drilling rigs to realize the processing of rock samples. Automatic fixation, with the drill bit drive motor, lifting system, frame and foundation of the coring instrument, automatically complete the drilling of various soft and hard cores. The operation is as follows:

[0031] Place the rock sample in the center of the two V-shaped clamps, select the fixed rock sample on the control panel and input the clamping force. Driven by the motor, the screws of the two V-shaped clamps rotate synchronously to push the two clamps to move relative to each other until the rock sample is clamped. Tight: The clamping pressure is sensed by the pressure sensors installed on the two V-shaped clamps. When the clamping pressure increases to the set value, the motor is cut off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com