Small-displacement reciprocating rolling friction abrasion test device

A rolling friction and wear test technology, applied in the direction of measuring devices, test wear resistance, instruments, etc., can solve the problems of inability to simulate test research, inconvenient microscopic analysis of microscope, etc., and achieve simple and convenient operation, convenient wear mechanism analysis and research, The effect of high accuracy of motion displacement amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

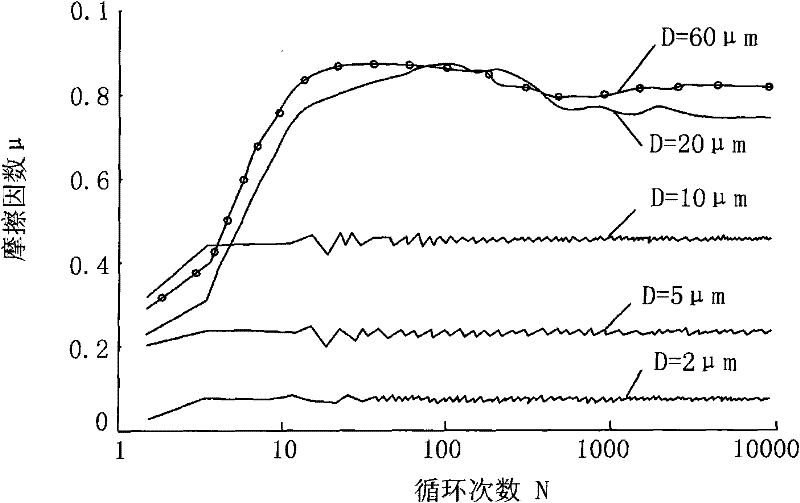

Examples

Embodiment Construction

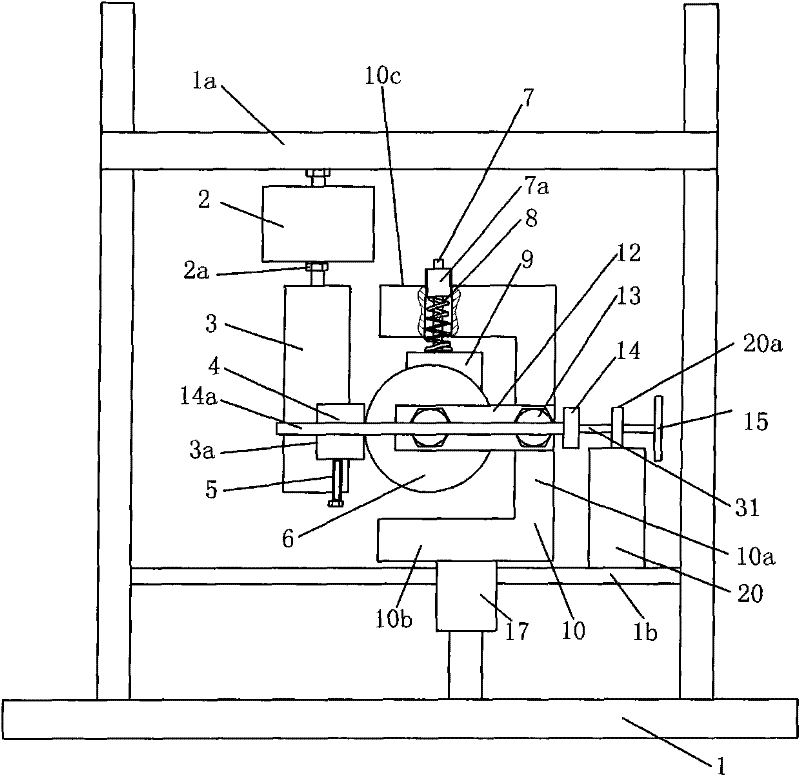

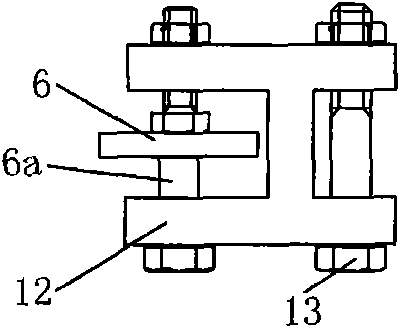

[0035] figure 1 , figure 2 Shown, a kind of embodiment that the present invention adopts is: a kind of small displacement reciprocating rolling friction and wear test device, comprises computer data acquisition and control system, hydraulic friction testing machine 1, the plane testing machine installed on hydraulic friction testing machine 1 Sample clamp 3 and rolling sample clamp 12.

[0036] The upper end of the plane sample holder 3 of this example is spliced with the connector 2a at the lower end of the tangential force sensor 2, and the upper end of the tangential force sensor 2 is connected with the beam 1a of the hydraulic friction testing machine 1;

[0037] The rolling sample clamp 12 is located on the right side of the plane sample clamp 3, and is fixed on the column 10a of the clamp support frame 10, and the bottom plate 10b of the clamp support frame 10 is connected to the hydraulic piston 17 of the hydraulic friction testing machine 1;

[0038] The normal forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com