Patents

Literature

509 results about "Friction test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

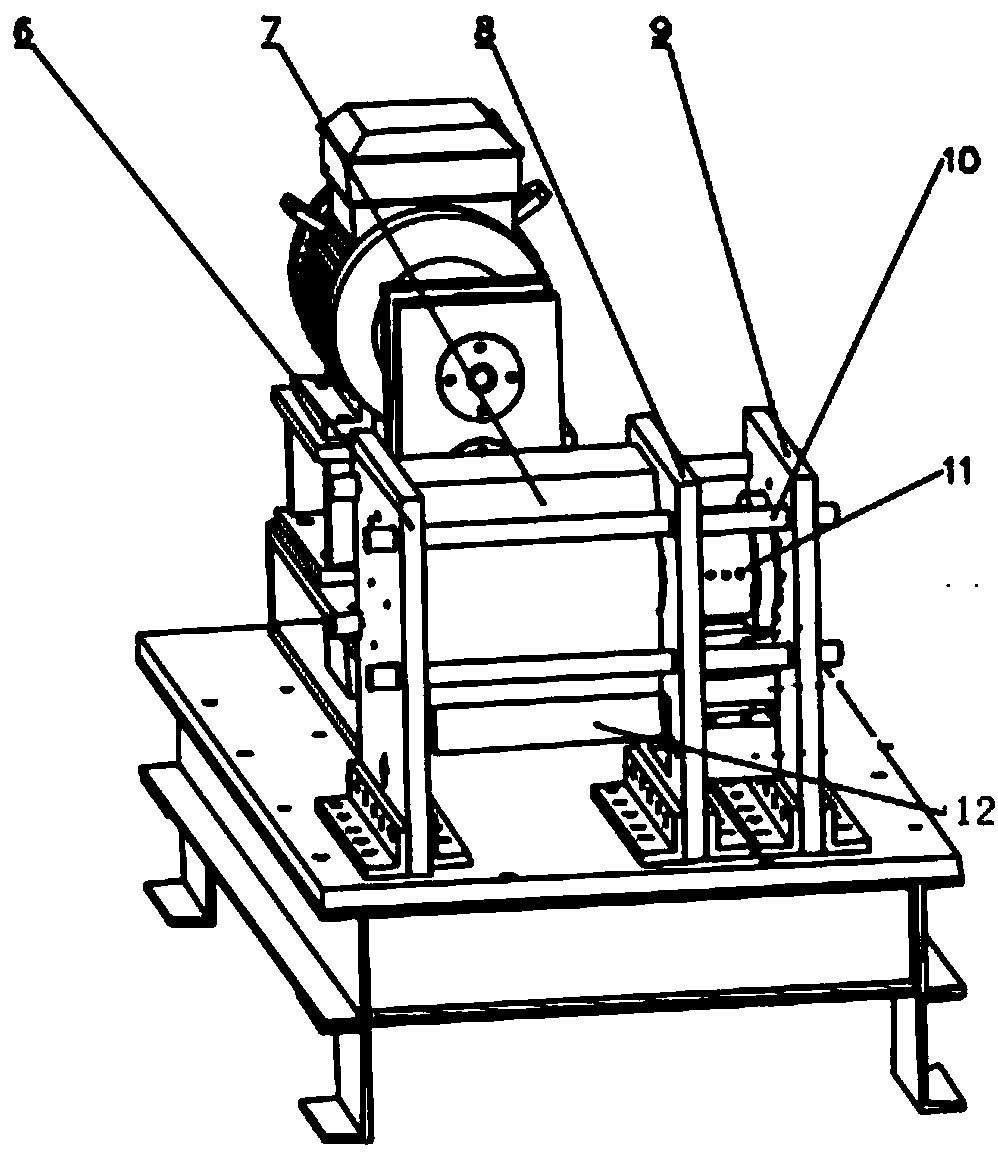

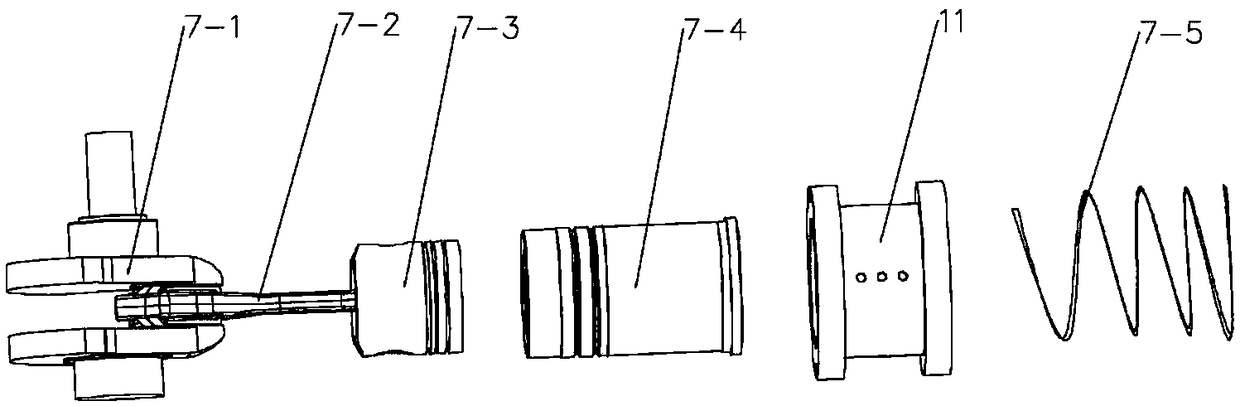

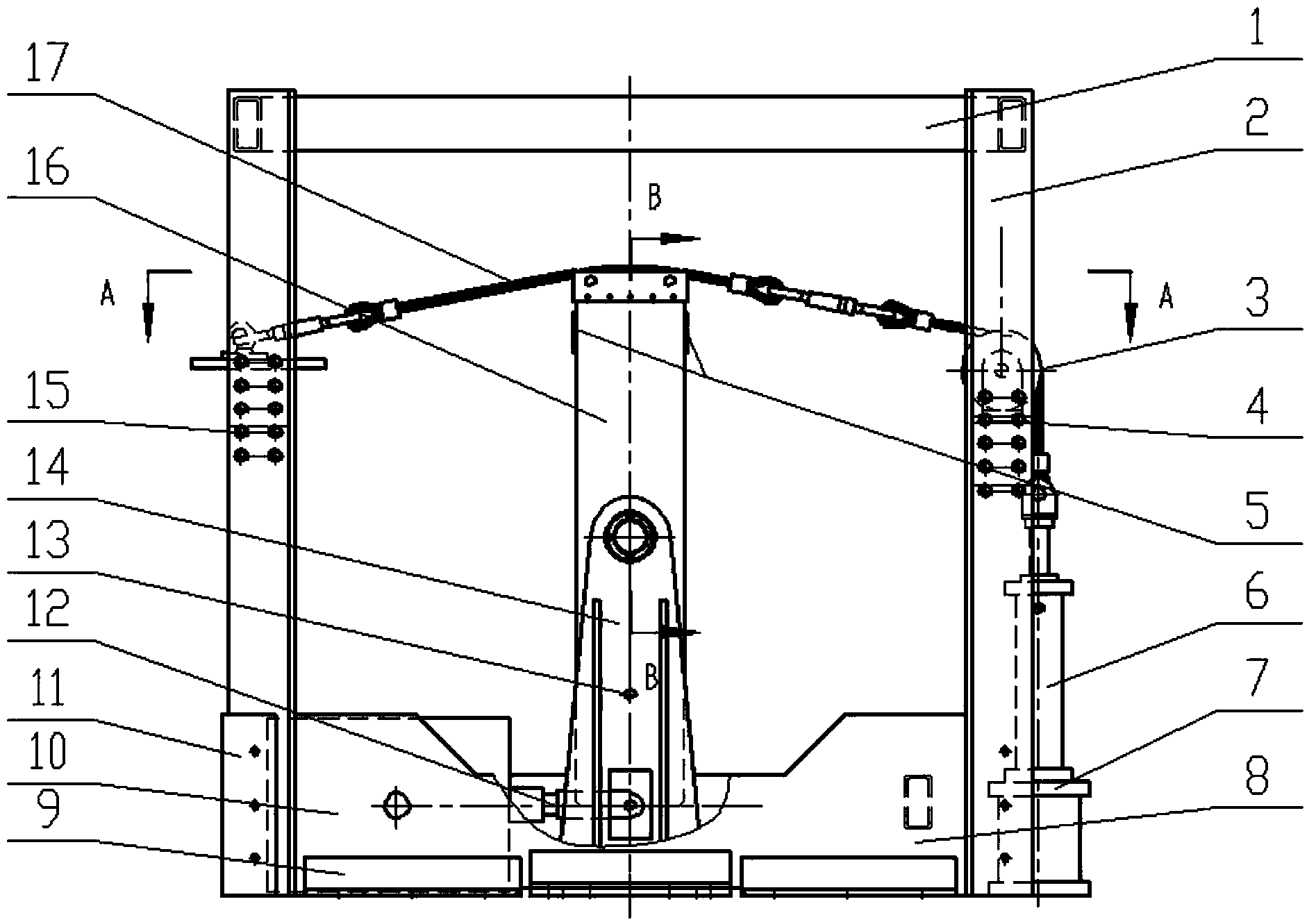

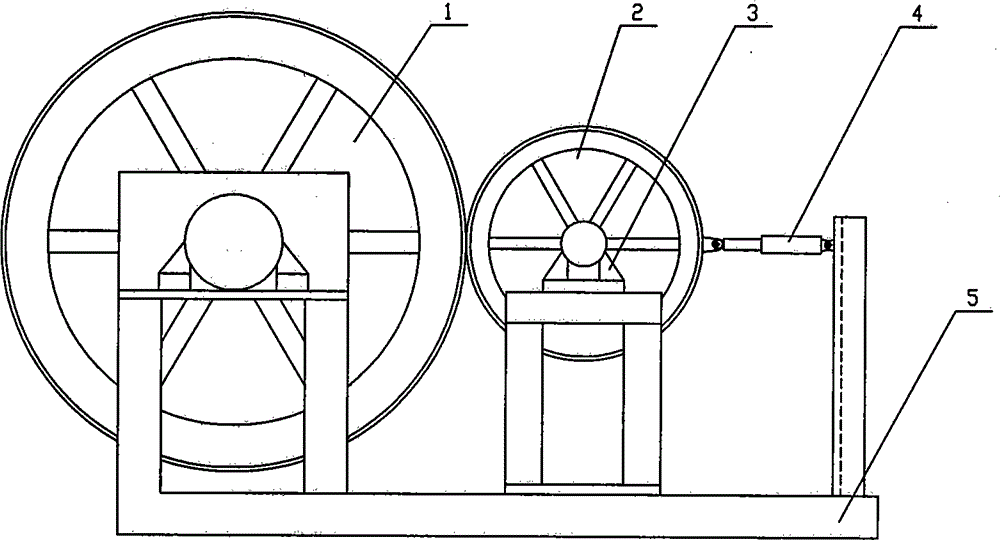

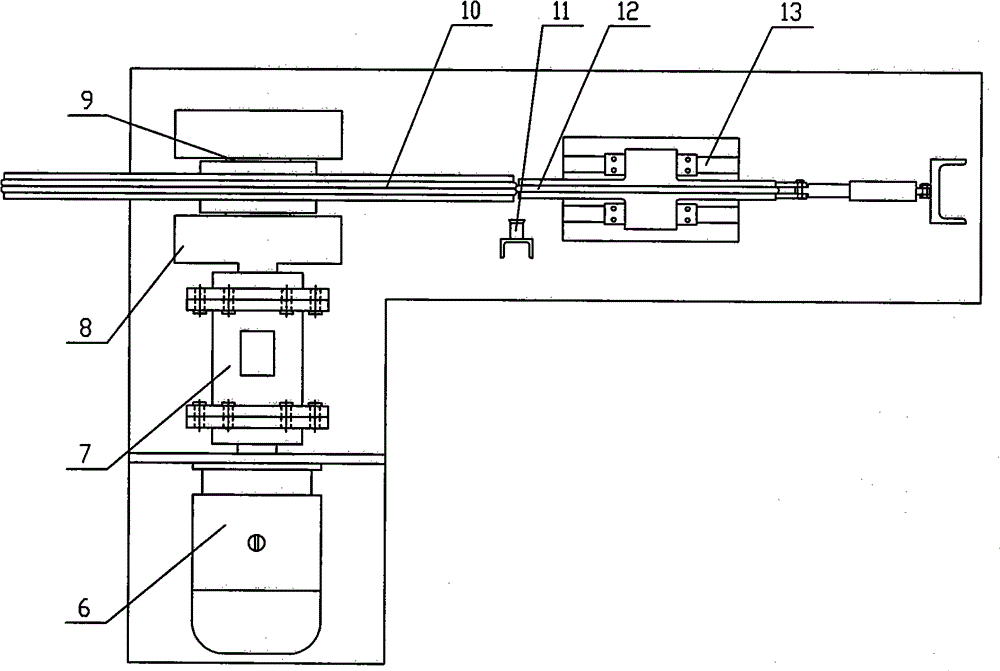

A friction test device and test method for screw drilling tool rotor coating

ActiveCN105092401BTest data availableAccurate data supportInvestigating abrasion/wear resistanceElectric machineEngineering

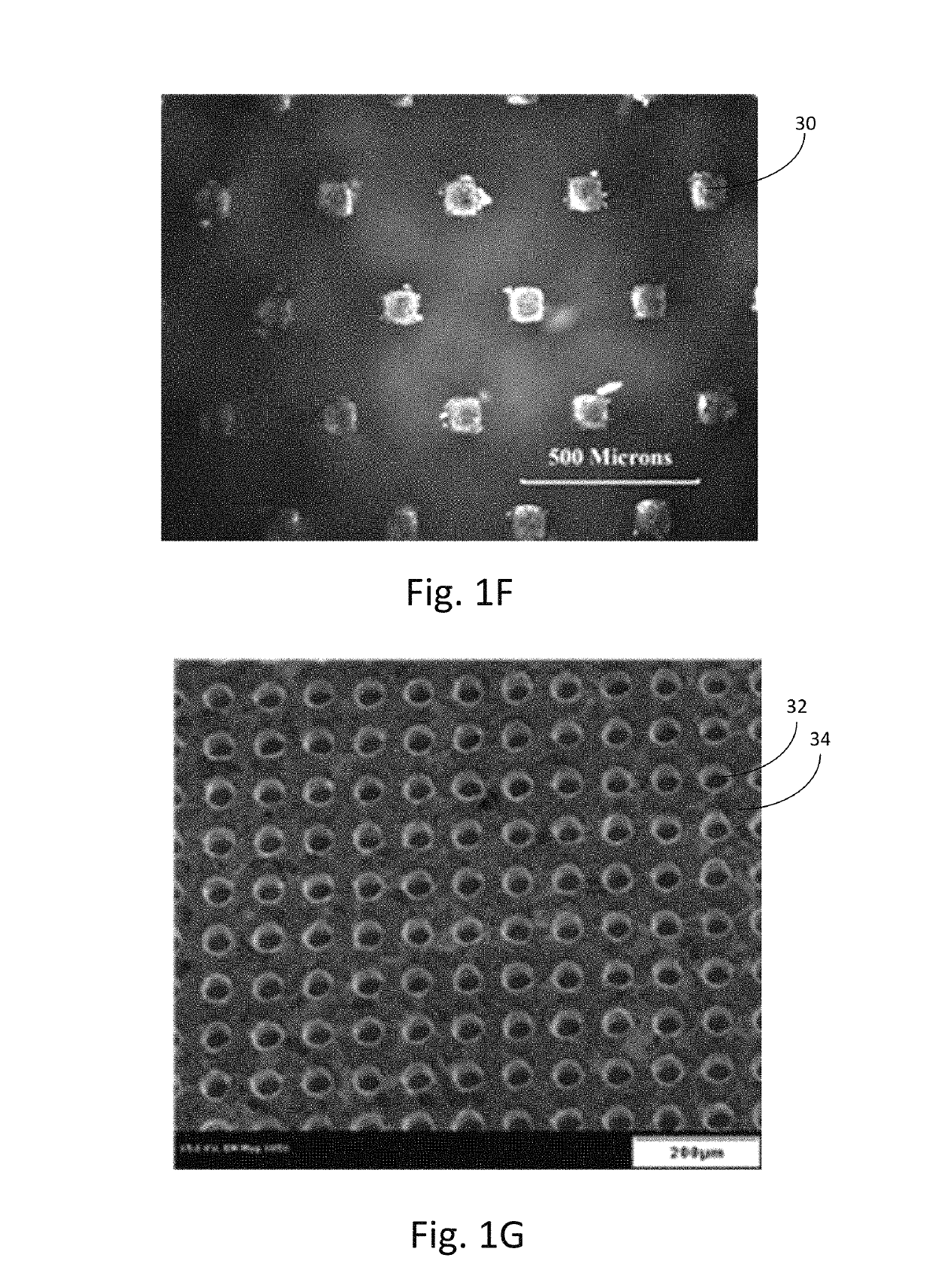

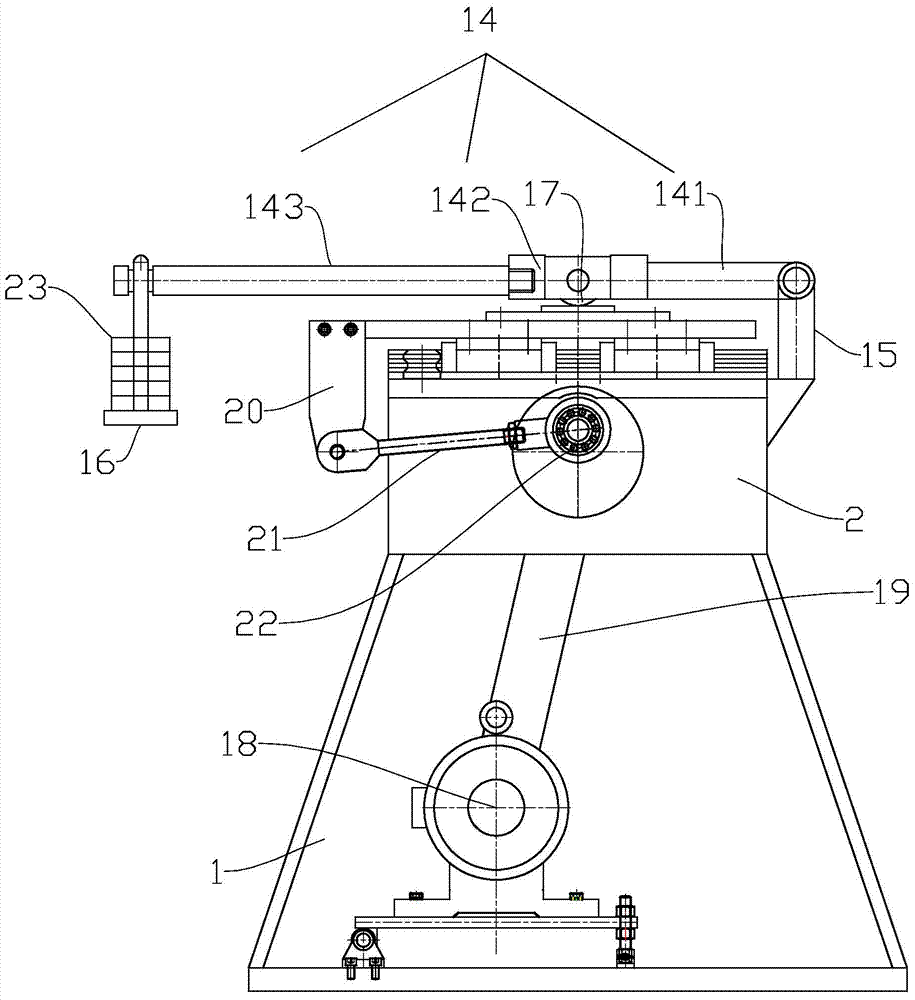

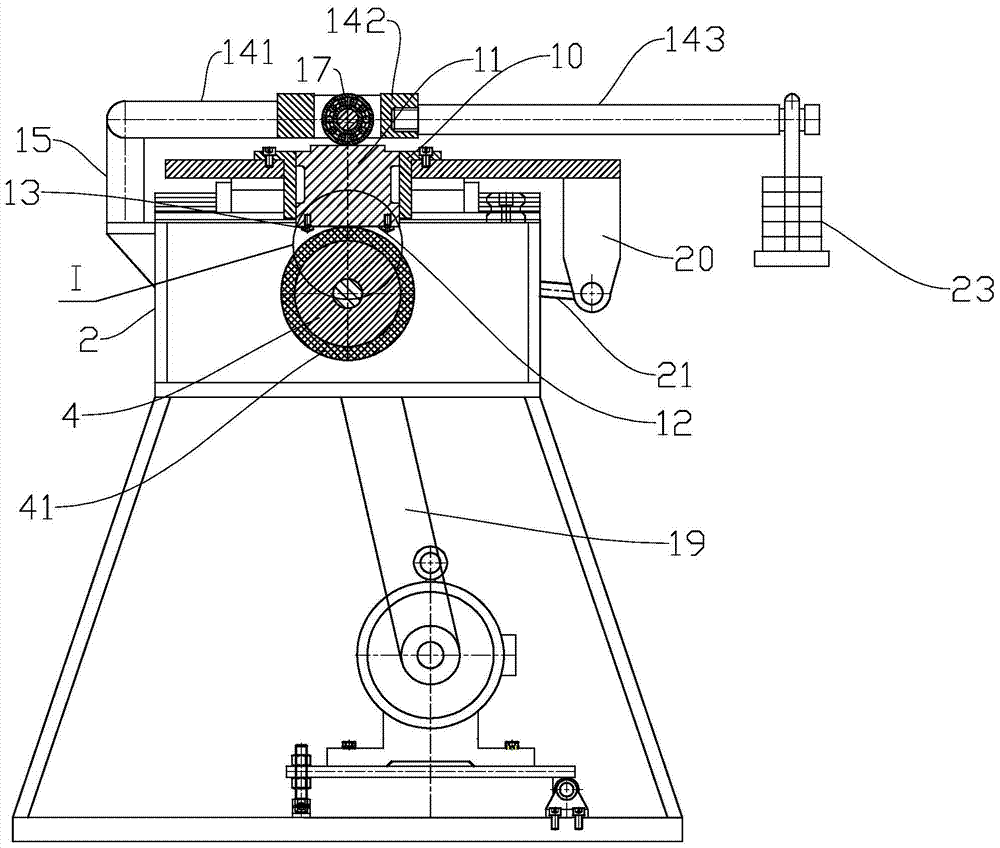

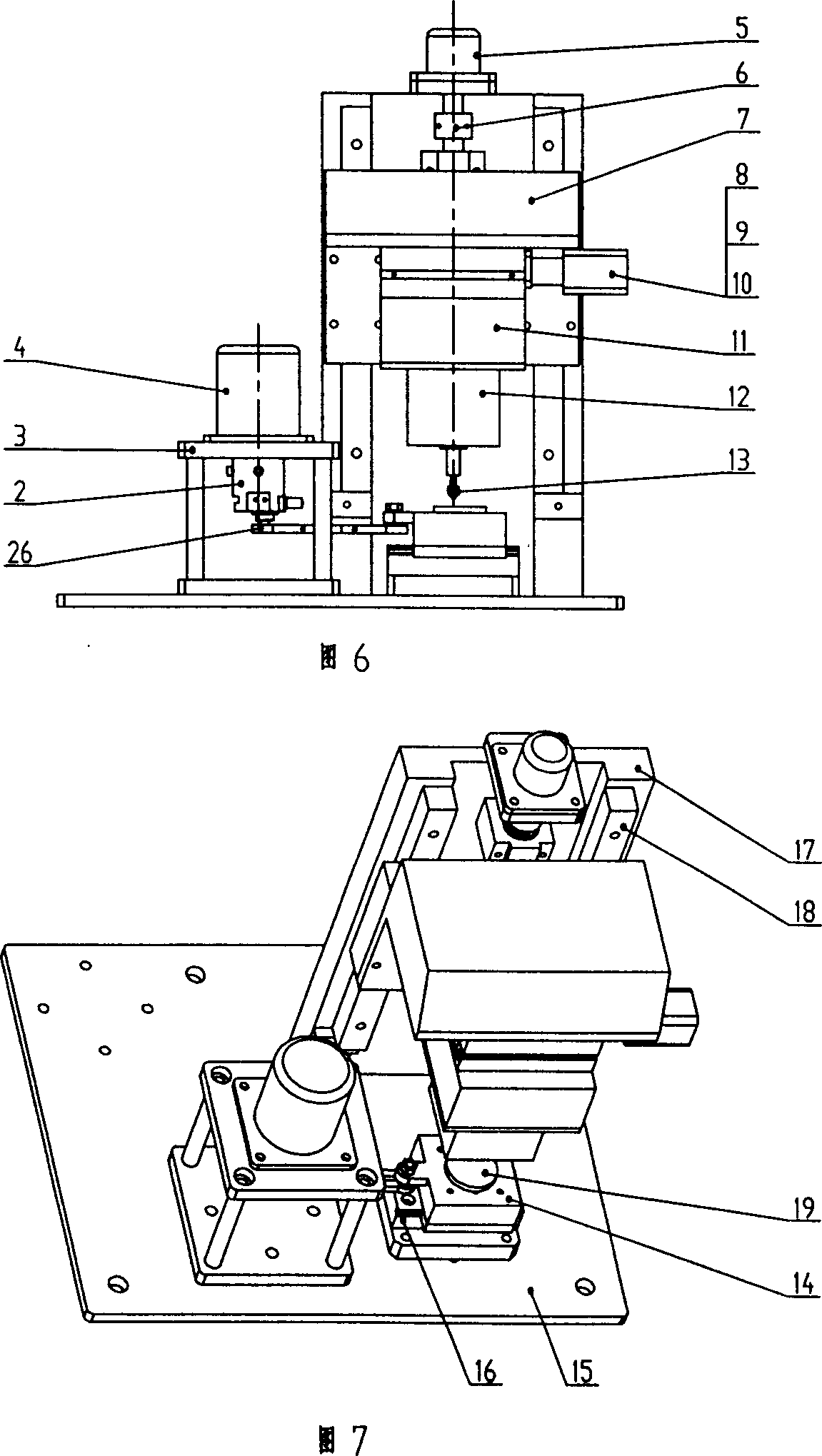

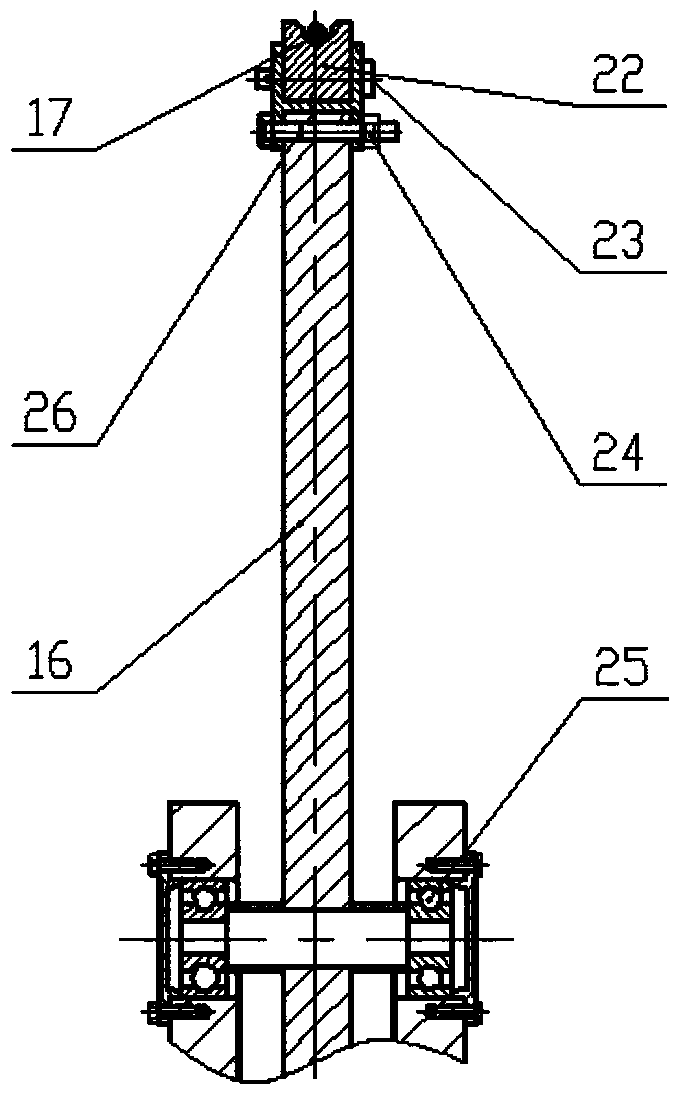

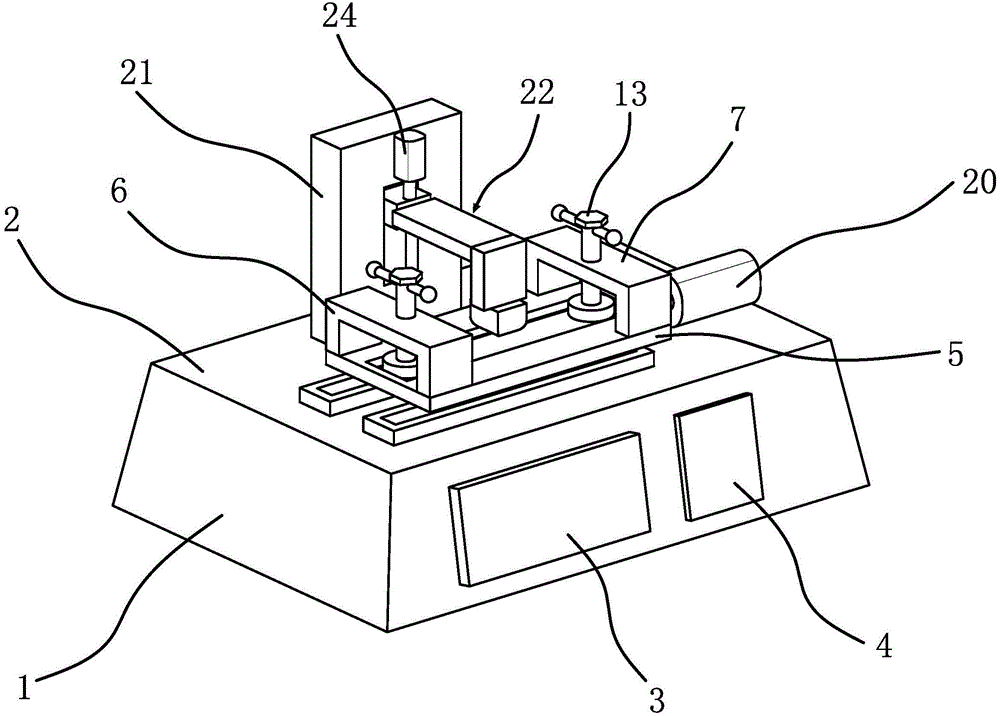

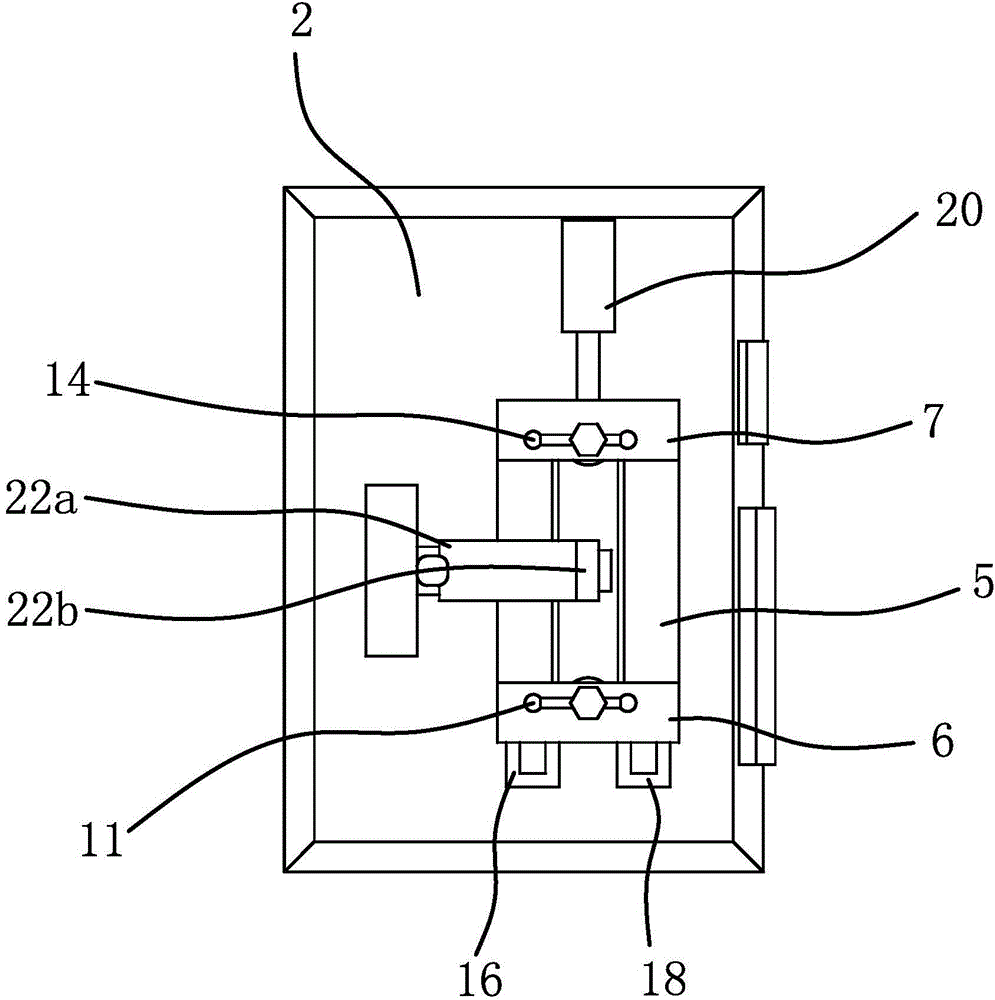

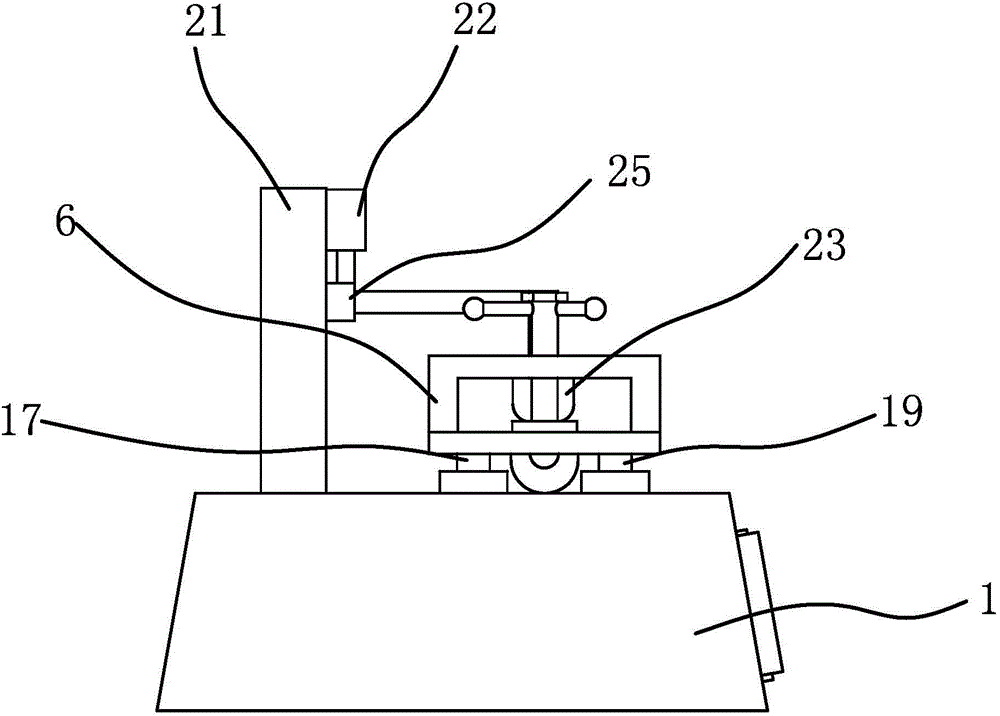

The invention discloses a screw rd drilling tool rotor cladding layer friction test device and a screw rod drilling tool rotor cladding layer friction test method. The device comprises a rack, a box, a grinding wheel assembly, a linear rail assembly, a rectilinear motion assembly, a pressurizing assembly, a speed reducing machine with a motor, and a rectilinear motion assembly driving mechanism. Mud liquid is added in the box; a main shaft of the grinding wheel assembly penetrates through the box; a plurality of grinding wheels are fixedly arranged on the main shaft; at least lower parts of the grinding wheels are positioned in the box; two linear rails of the linear rail assembly are fixed at two sides of the box and are vertical to the main shaft; a base part of the rectilinear motion assembly runs on the linear rails; a pressing block limiting device is arranged on the base part; pressing blocks in the pressurizing assembly are arranged in pressing block installation holes in the pressing block limiting device; the bottom surface of each pressing block clamps a test piece; each pressing block is loaded by a lever mechanism and a pressure applying roller; the speed reducing machine drives the main shaft to rotate by a belt transmission mechanism; the main shaft rotates to drive the rectilinear motion assembly to run by a cam mechanism and a connection rod. Test data are relatively desirable, so that a relatively accurate data support is provided for study on a wear-resisting property of a cladding layer.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

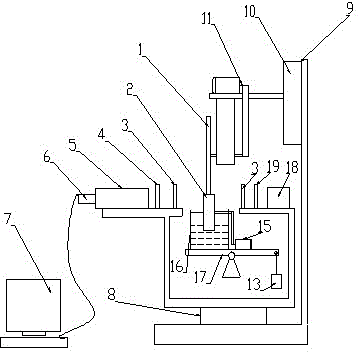

Multifunctional micro friction wear testing machine

InactiveCN101017129AGreat driving forceLess exerciseUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceWear testing

This invention relates to one multi-function micro friction test machine, which comprises drive device, move device connected to the drive one and load and measurement device on the move device and lift bench of the measurement device, wherein, it uses hanging spring board and connection bar are hinged with drive device and move device to make the slide bench generate one small range reverse line move under bar push with constant vibration range and small error; it uses motor to drive connection bar push slide to generate large vibration reverse line move.

Owner:CHINA UNIV OF MINING & TECH

Roadway friction tester and method

InactiveUS6840098B2Simple and reliable processProvide real-timeUsing mechanical meansRoads maintainenceTester deviceRoad surface

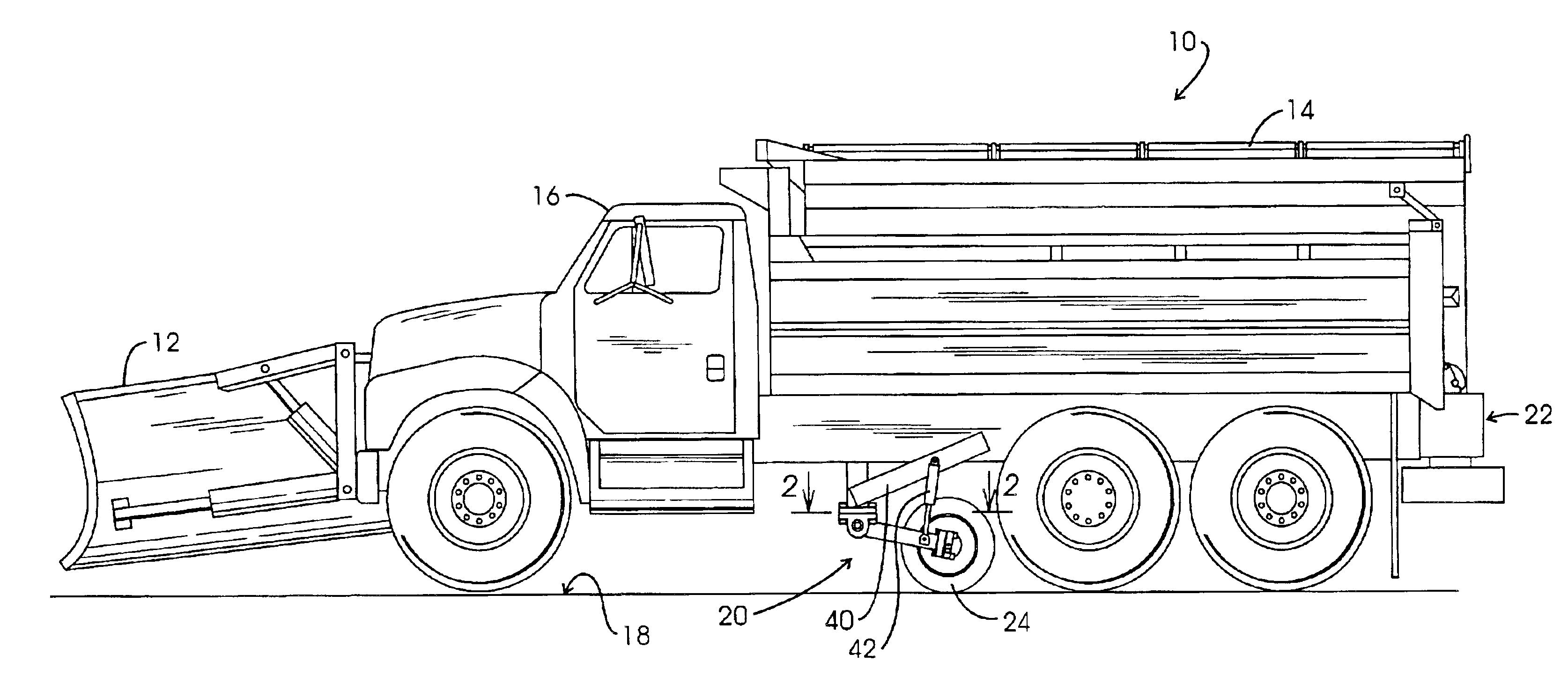

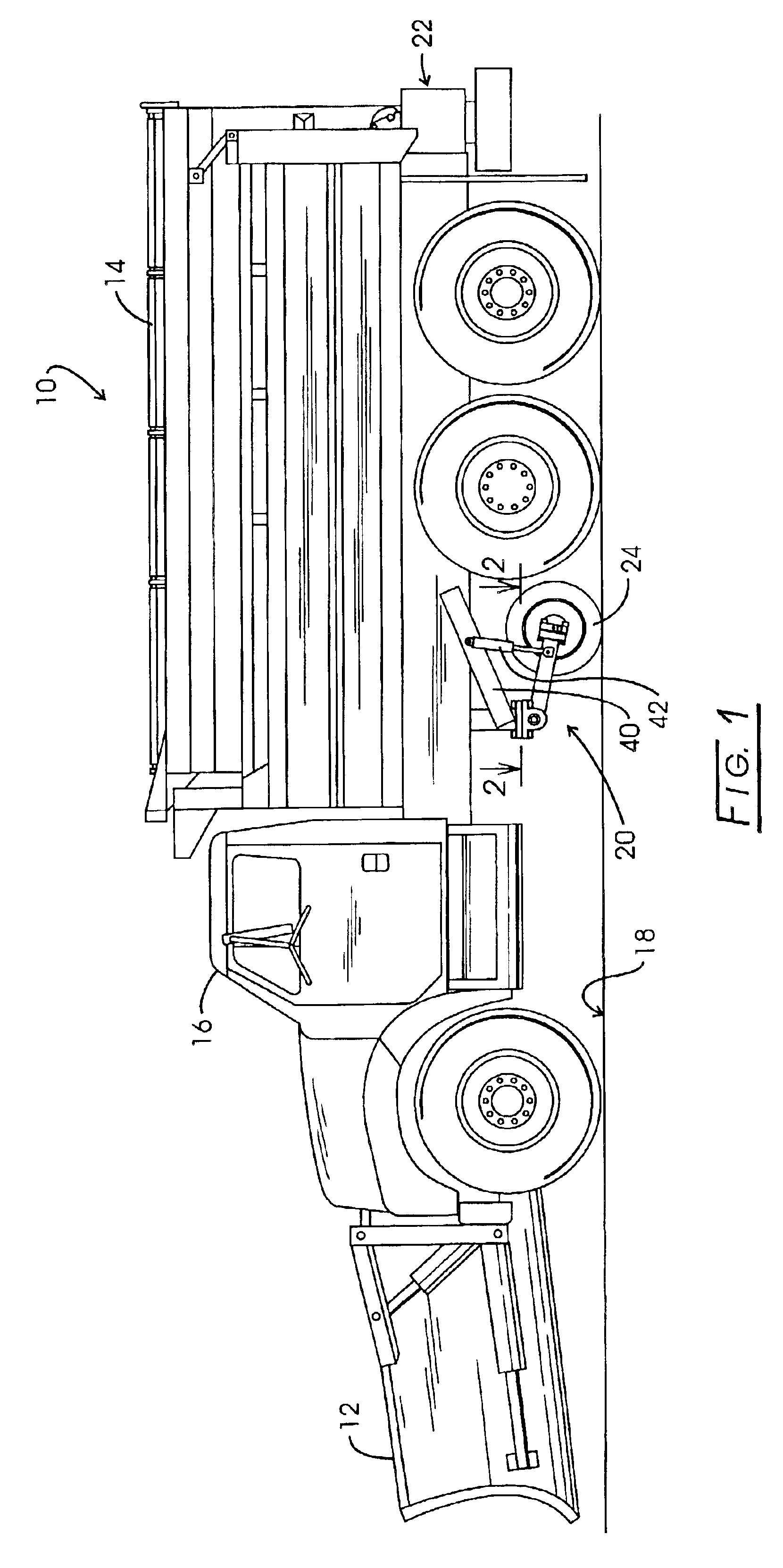

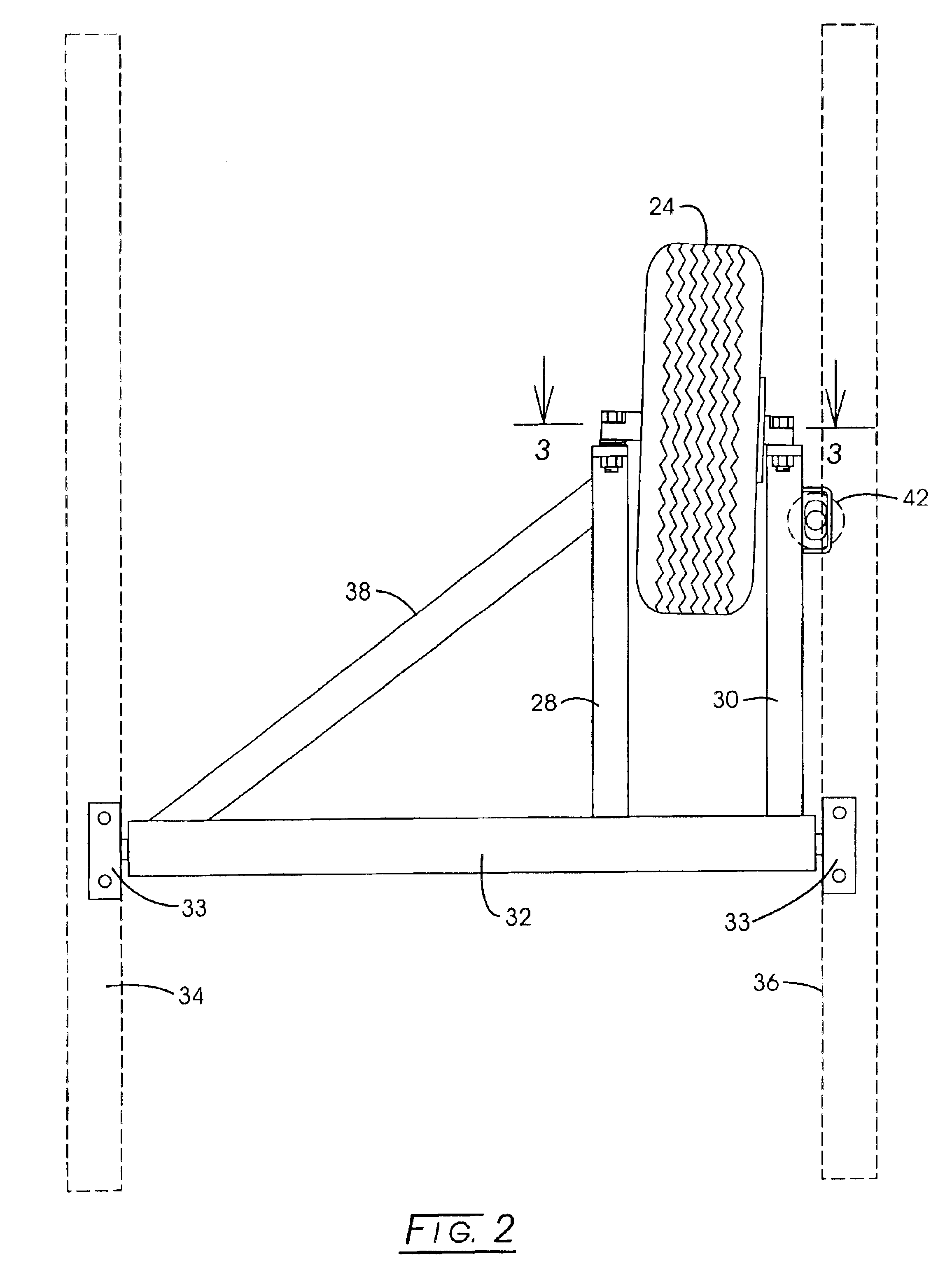

A method for measuring road surface friction of a road surface uses a vehicle that moves across the road surface. An auxiliary independent wheel is interposed between the vehicle and the road surface. The auxiliary wheel is freely rotatable by movement of the vehicle and is toed in (skewed) with respect to a direction of travel of the vehicle so as to create an axial force on the auxiliary wheel. The axial force on the auxiliary wheel is isolated and measured while the vehicle moves across the road surface. The measured axial force is correlated with the road surface friction.

Owner:HALLIDAY DONALD R

Two-dimensional micro-force measuring sensors

A transducer is featured as fixing one end of suspension arm and another end set with frictional head, forming both of vertical and horizontal bent beam by elastic body and sticking foil gauge on the elastic body to make it full bridge circuit. In frictional test, strain deformation of horizontal bent beam is caused by normal load and strain deformation of vertical one is caused by only frictional force so the load and frictional force can be measured out through strain detection.

Owner:SHANGHAI JIAO TONG UNIV

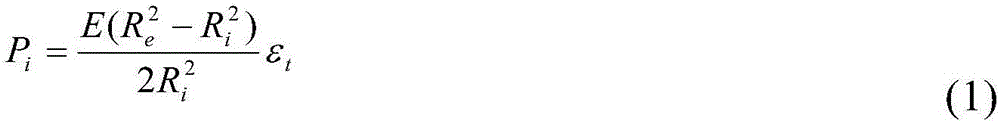

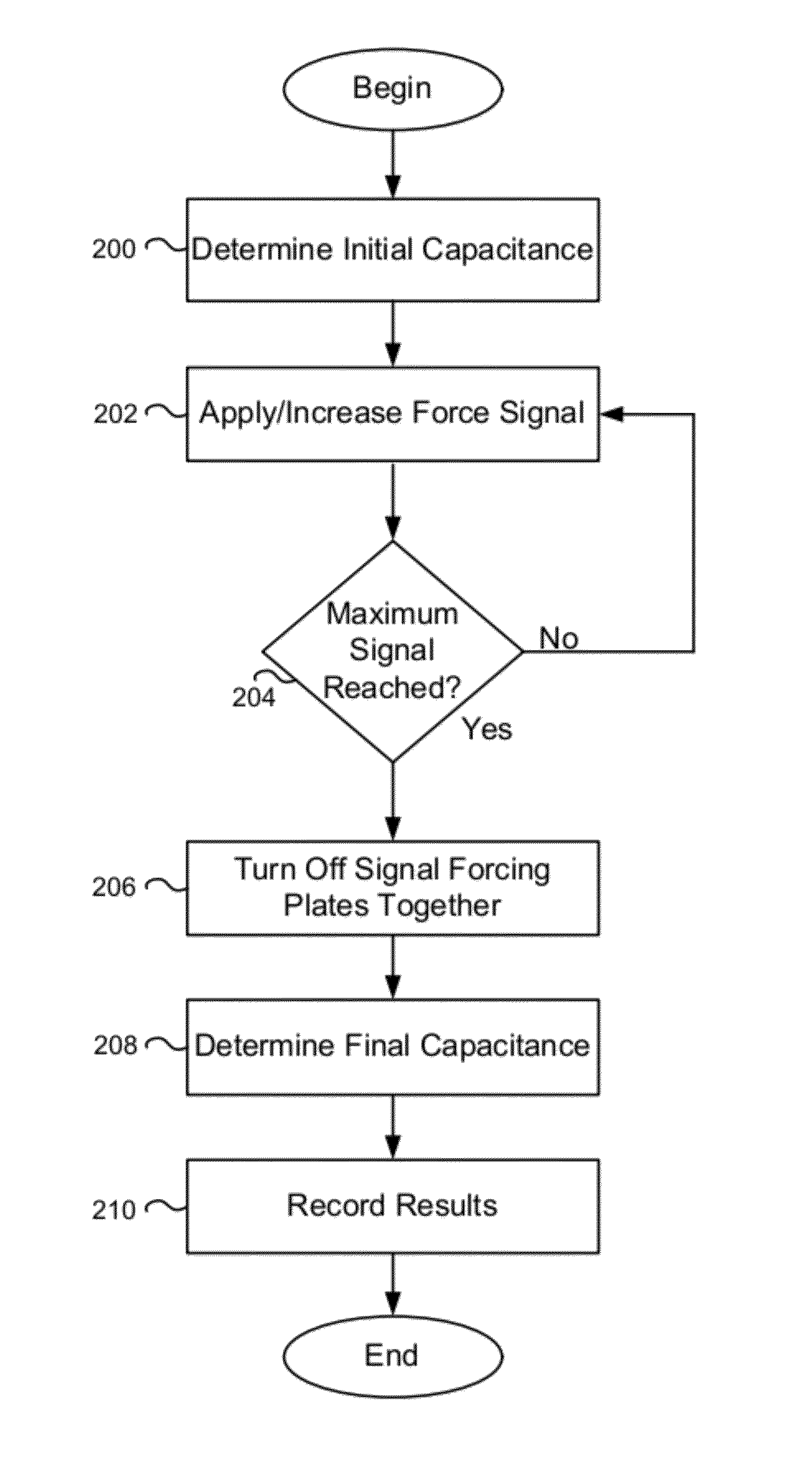

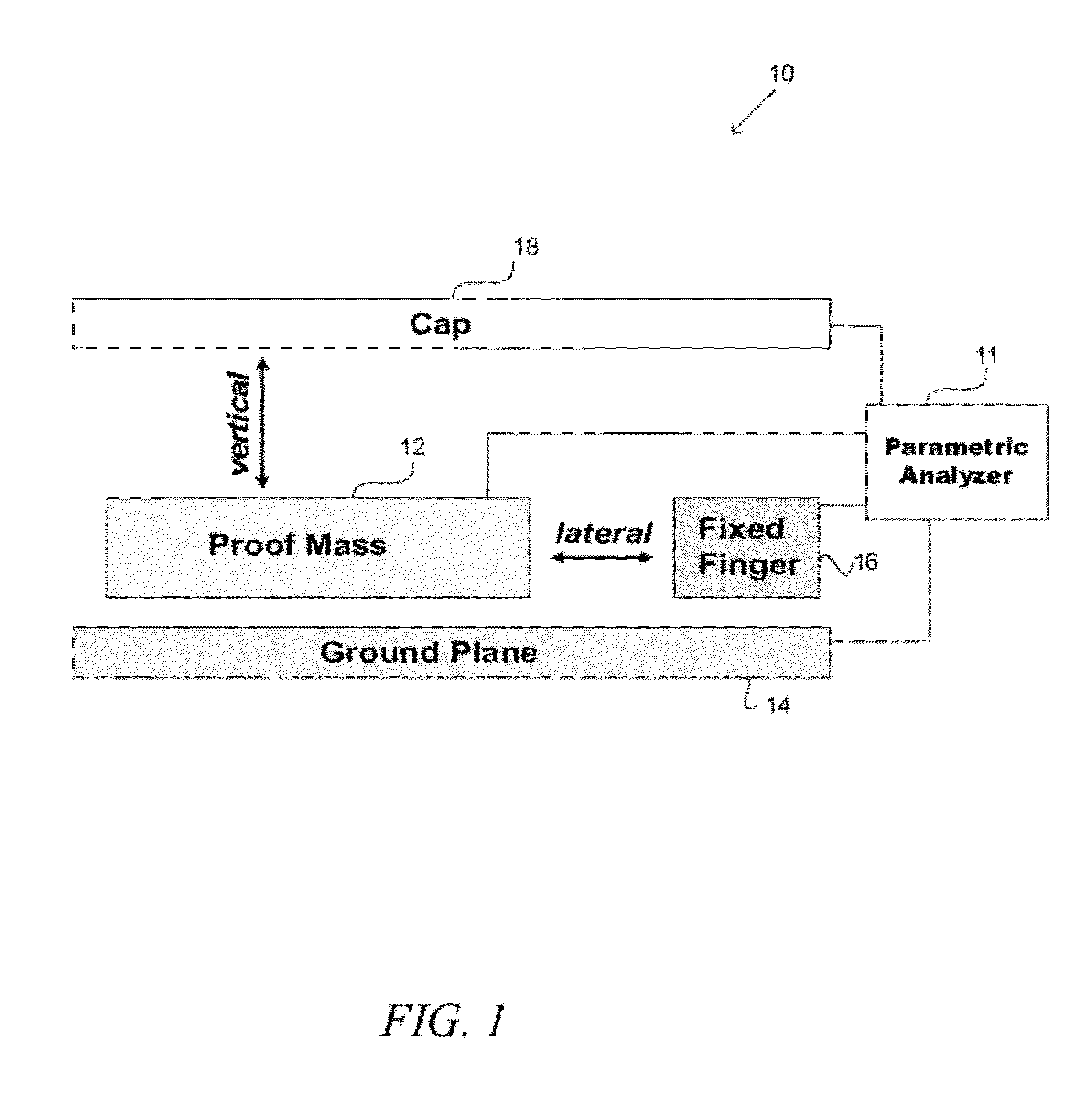

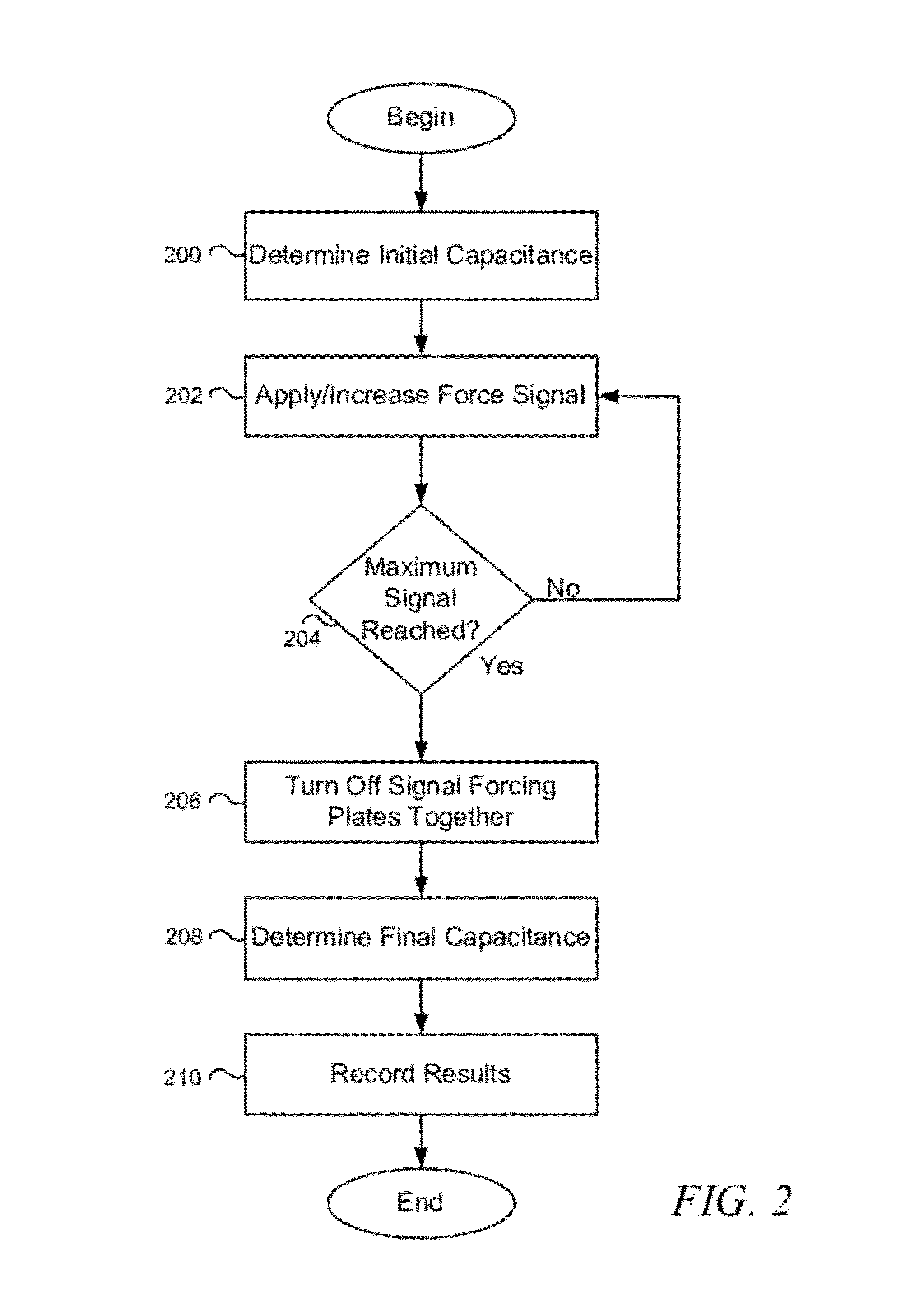

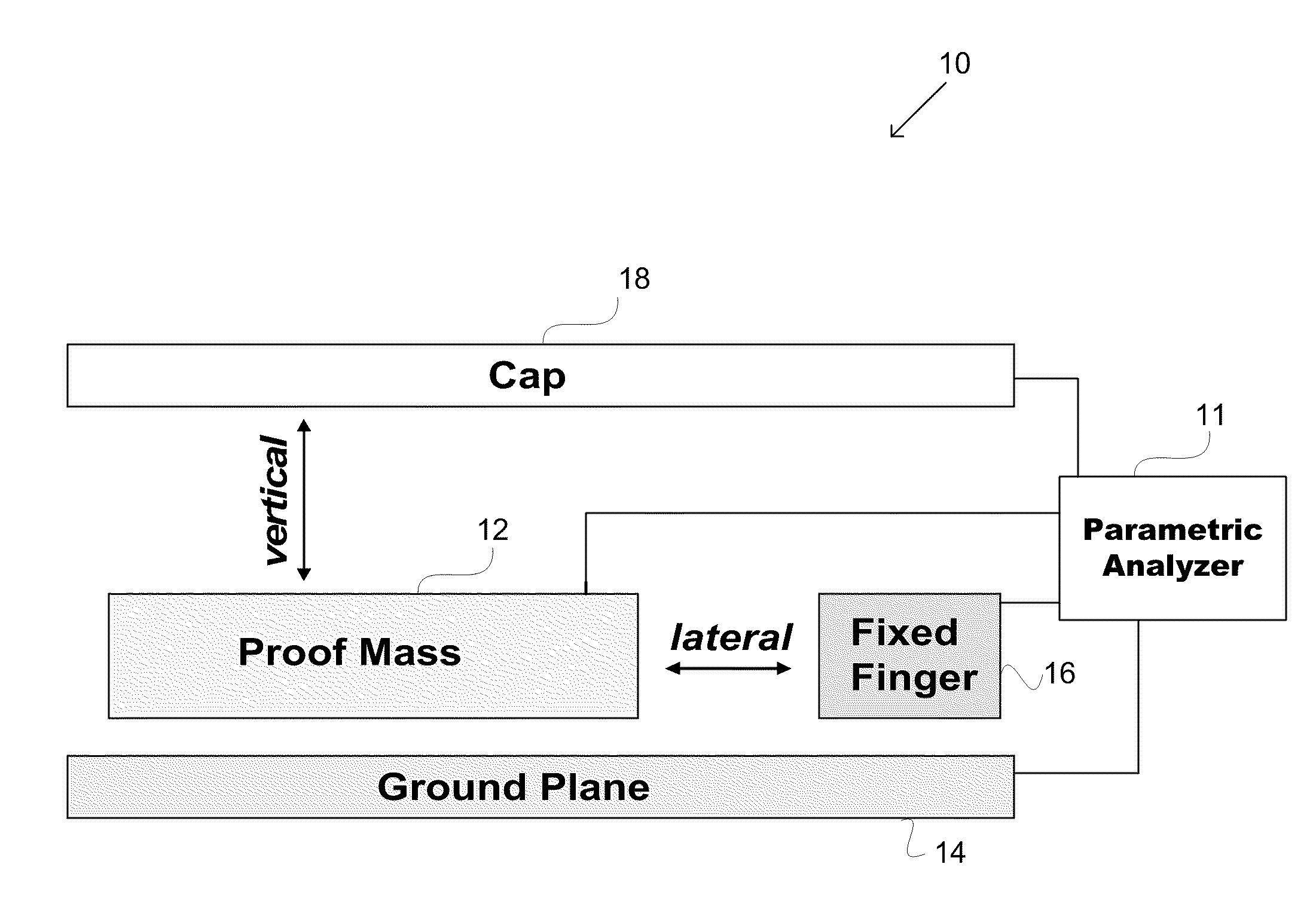

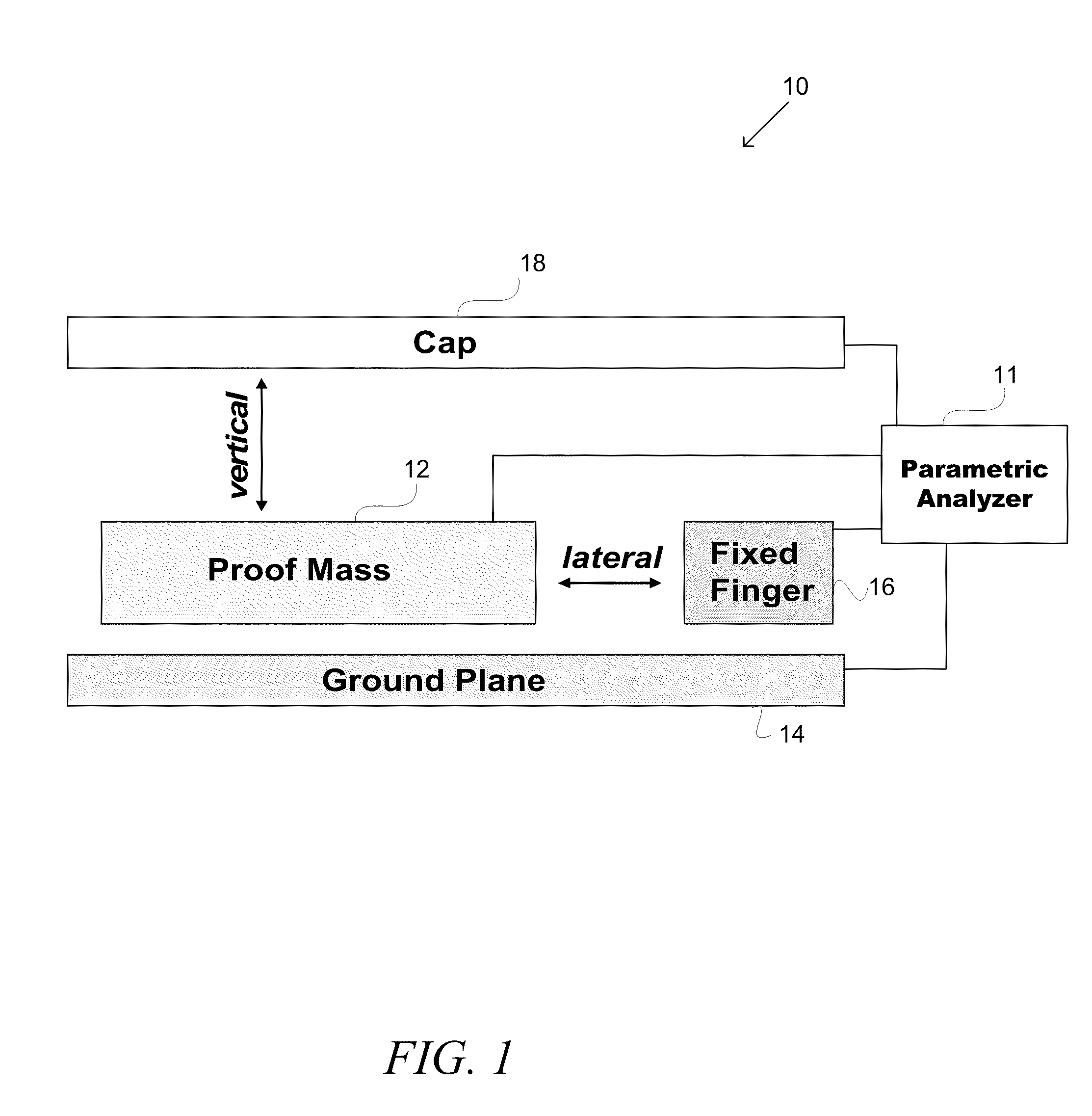

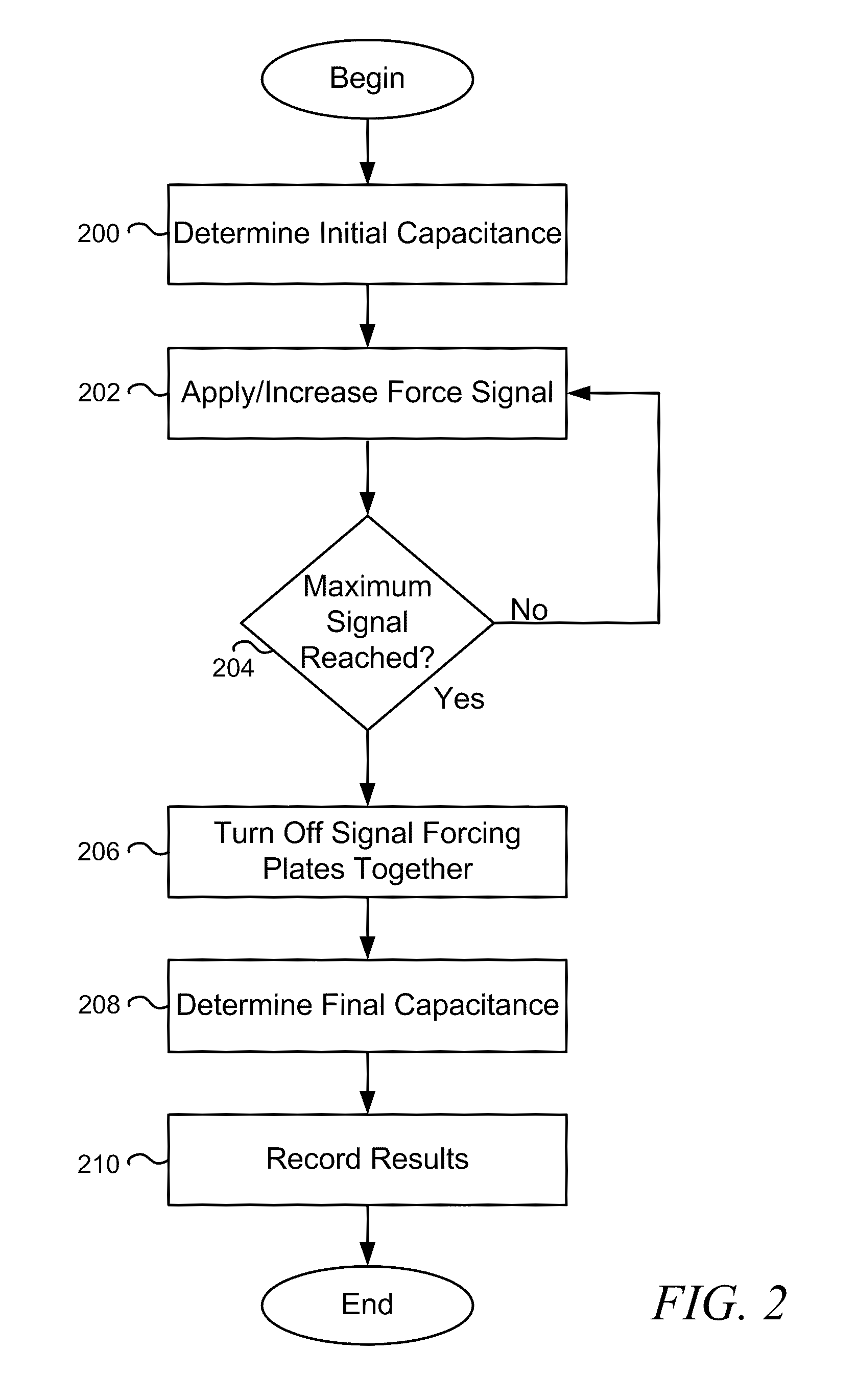

MEMS Stiction Testing Apparatus and Method

ActiveUS20090320557A1Attenuation of electrical signalSolution value is not highTesting dielectric strengthUsing mechanical meansElectricityStiction

A MEMS stiction testing method applies a first electrical signal to a MEMS device having two opposing surfaces to cause the two opposing surfaces to make physical contact. The two opposing surfaces produce a second electrical signal when in physical contact. The method then substantially mitigates the first electrical signal after detecting that the second electrical signal has reached a prescribed maximum value.

Owner:ANALOG DEVICES INC

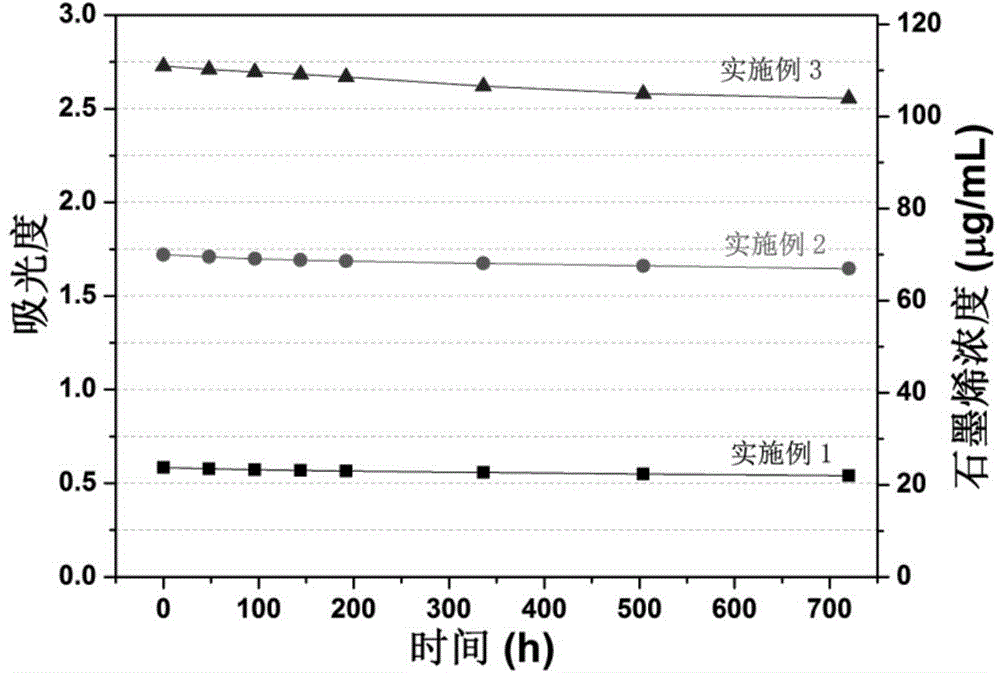

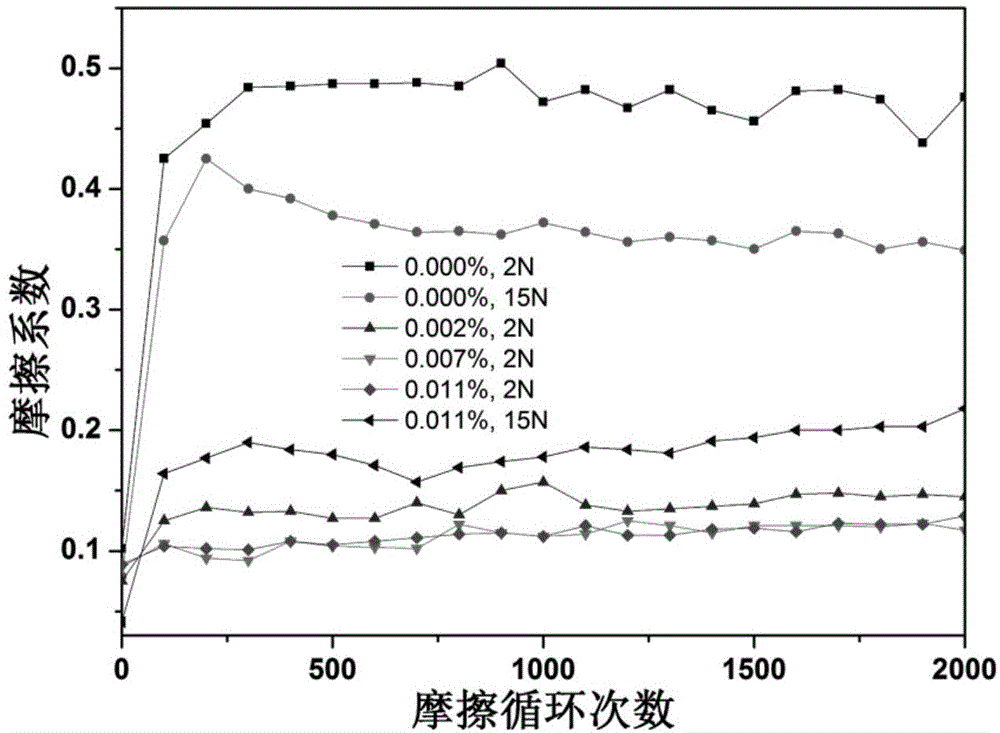

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

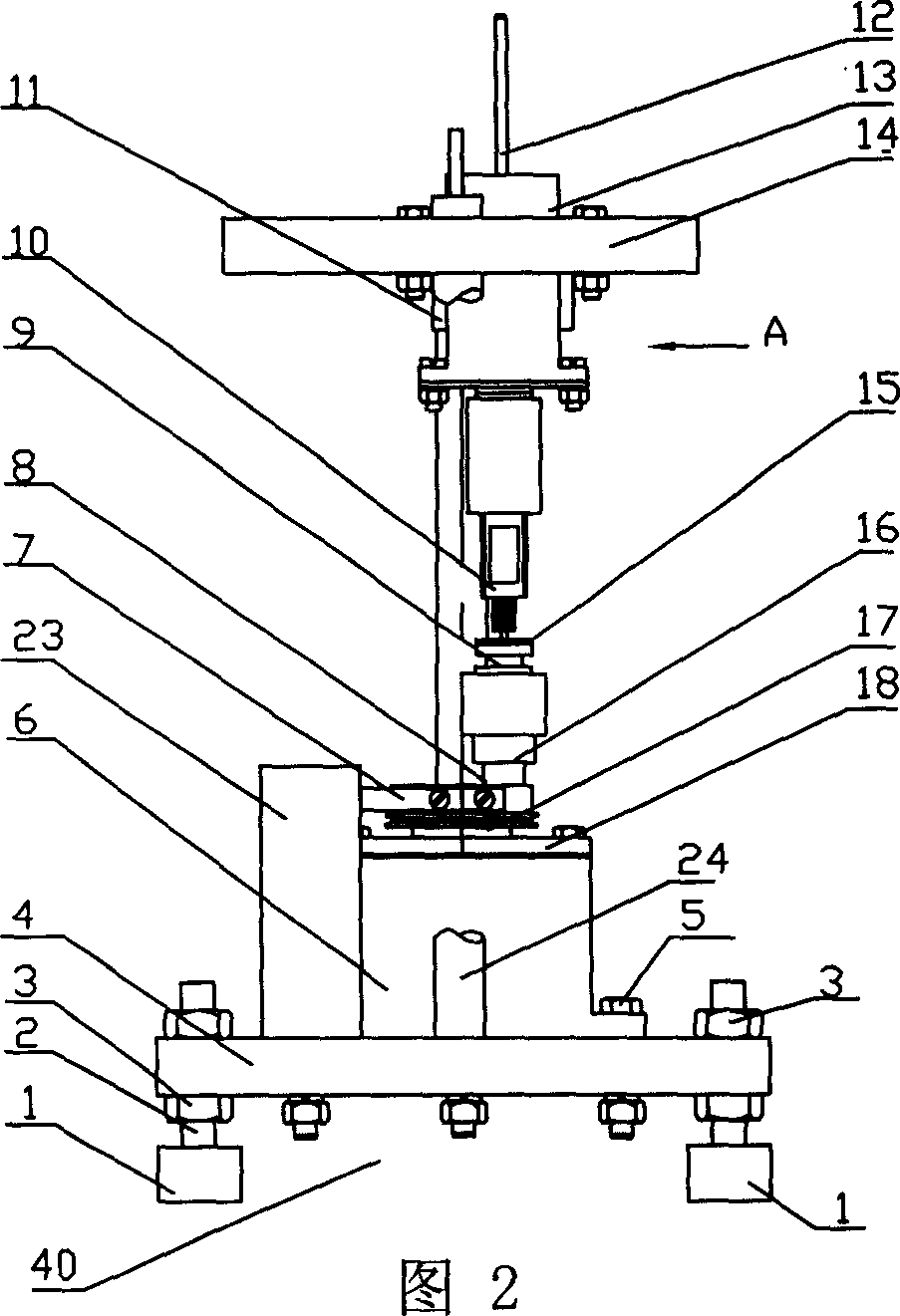

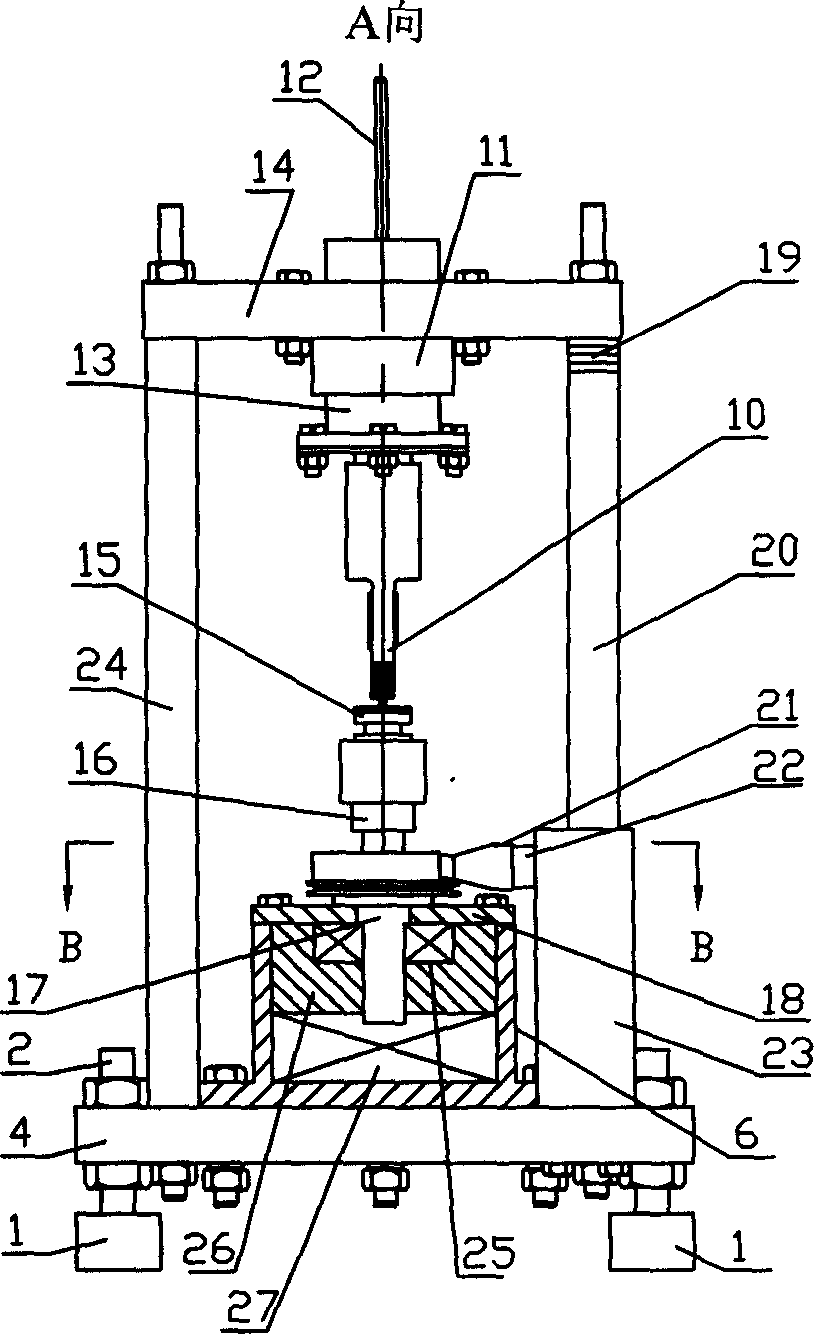

High-frequency high-specific pressure long-stroke temperature-controllable reciprocating friction test device

InactiveCN102175599ARealize measurementHigh frequencyUsing mechanical meansMaterial analysisReciprocating motionEngineering

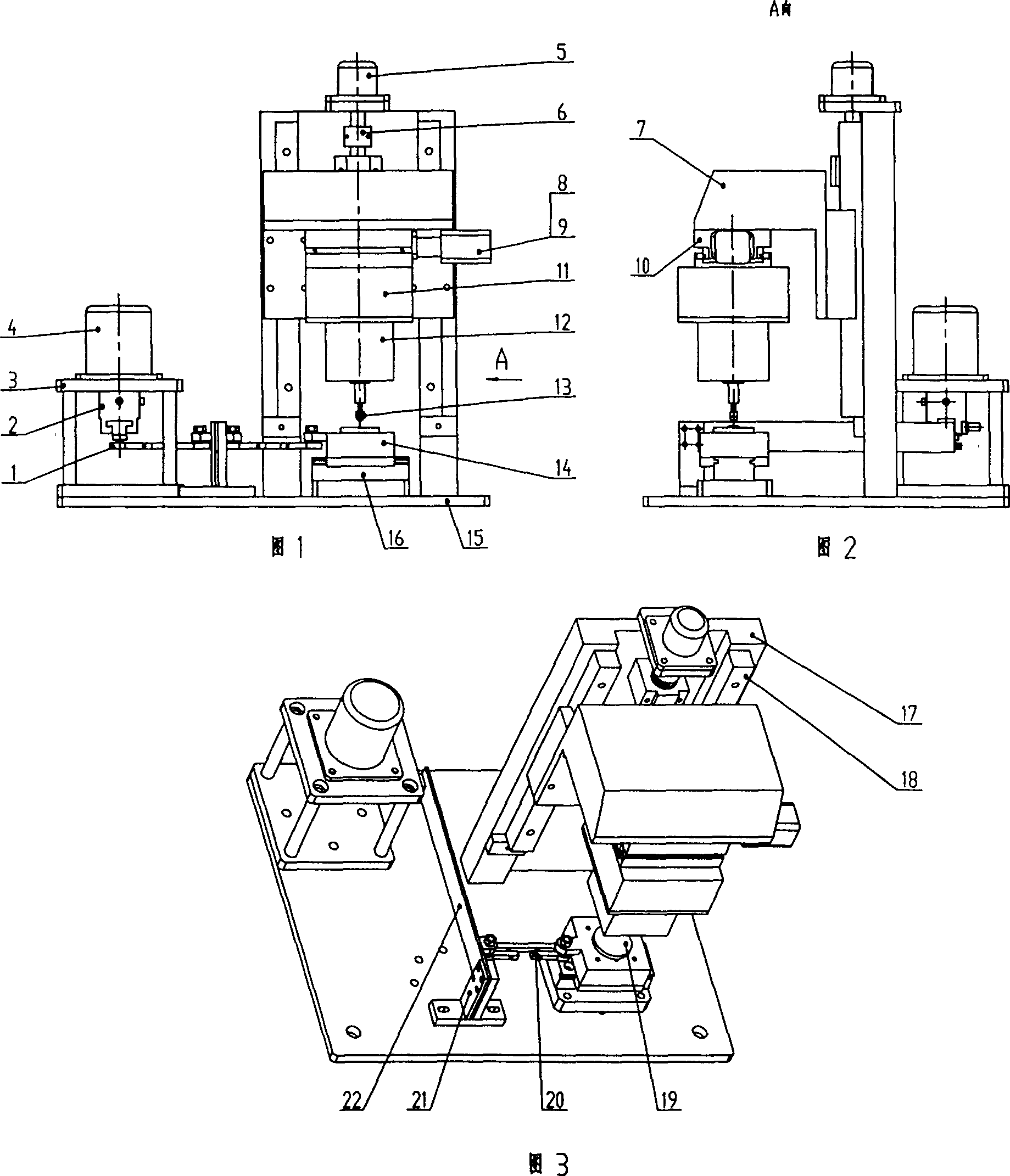

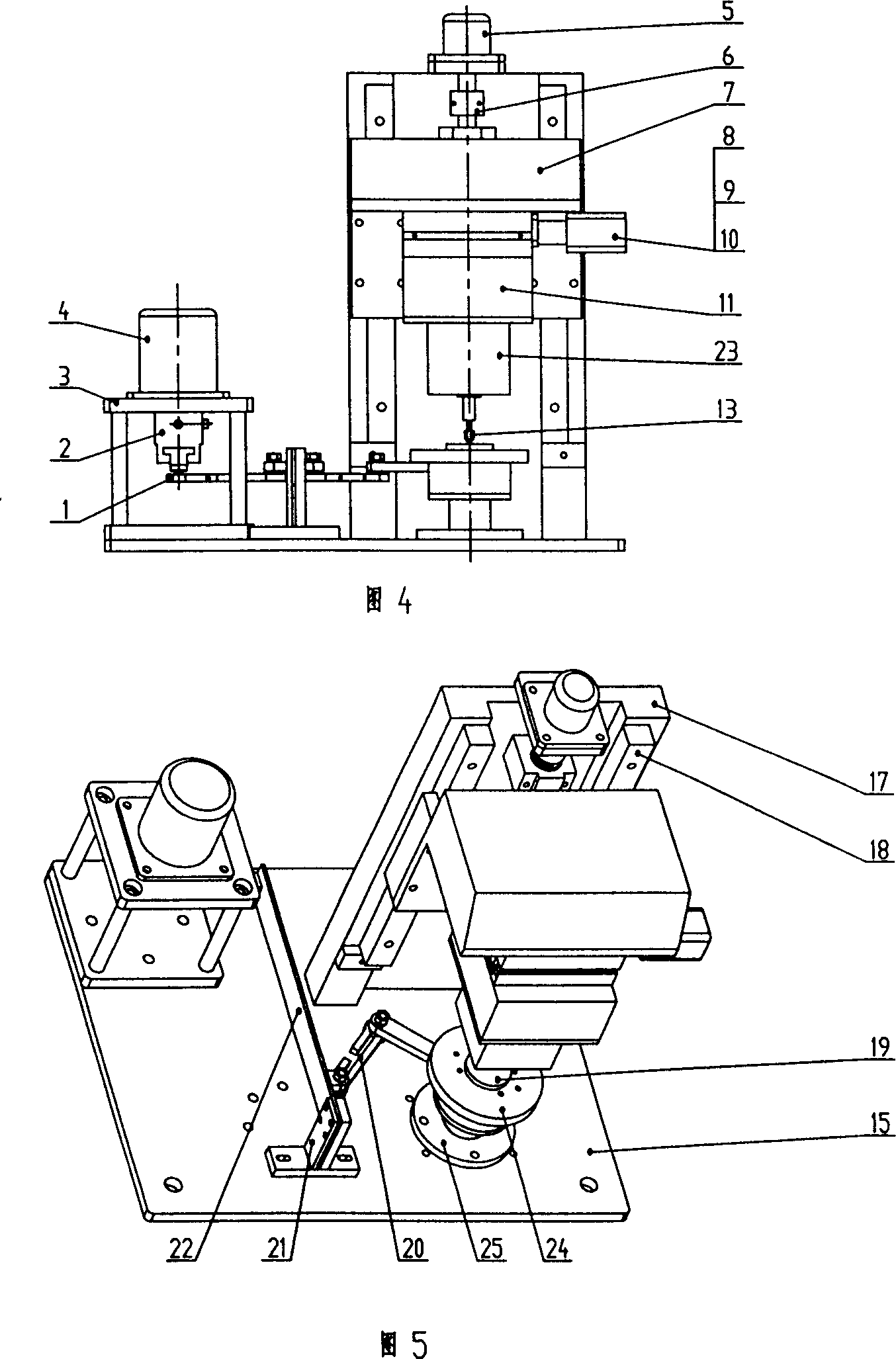

The invention discloses a high-frequency high-specific pressure long-stroke temperature-controllable reciprocating friction test device. The high-frequency high-specific pressure long-stroke temperature-controllable reciprocating friction test device is characterized in that a tested unit comprises an upper test piece and a lower test piece which are arranged in a splitting way, wherein the lower test piece is supported on a roll ball; the upper test piece and a pressure transmitting piece are arranged in a reverse T shape; a mating test piece positioned between the upper test piece and the lower test piece is in surface contact with the upper test piece and the lower test piece; a reciprocating motion driving unit is a crank-slider mechanism driven by a motor; a loading unit is a loading lever capable of carrying out multilevel incremental loading; and a friction coefficient measuring unit is a force sensor taking the lower test piece as a tested piece. In the invention, the reciprocating motion frequency can reach 40 Hz, the reciprocating motion stroke can reach 115 millimeters and the contact surface specific pressure can reach 40 MPa; the measurement of the friction coefficients and the real-time temperature of parts can be realized; and the ultimate loads of the parts can be measured.

Owner:HEFEI UNIV OF TECH

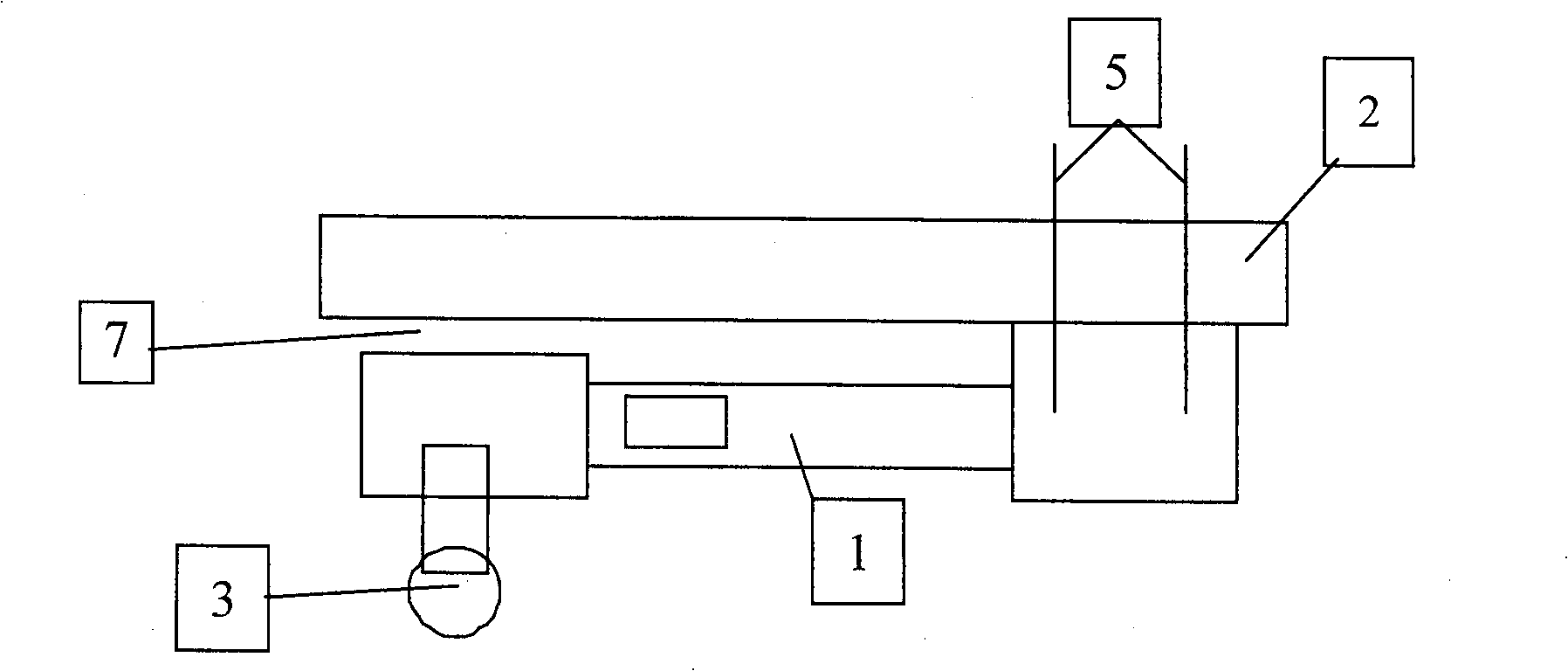

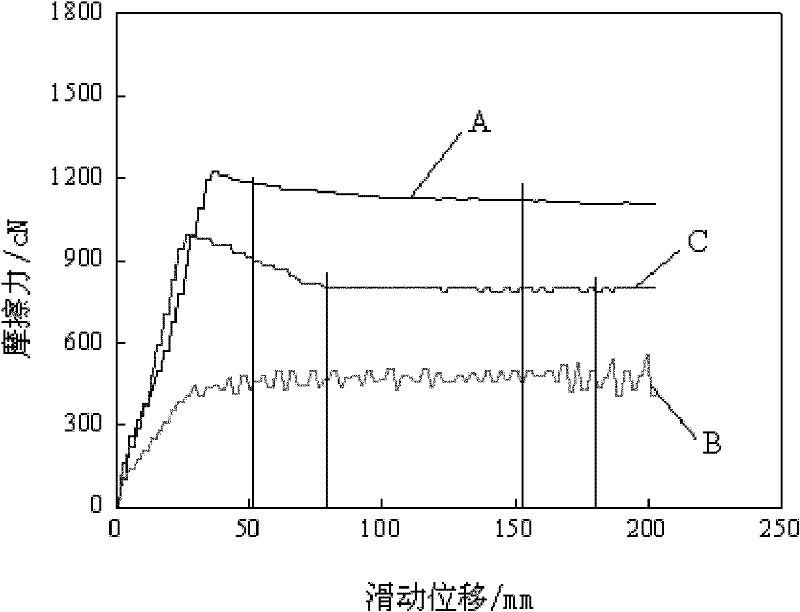

Device and method for detecting frictional performance between fabric and skin

InactiveCN102175600AGuaranteed breadthGuaranteed accuracyUsing mechanical meansMaterial analysisBiomedical engineeringFriction test

The invention relates to a device and a method for detecting frictional performance between a fabric and skin. The detection device comprises a friction device, a signal acquisition device and a mechanism driving and controlling device, wherein the friction device comprises a friction bracket and a friction base; a support is arranged on two sides of the friction bracket respectively; a clamp is arranged on the support; a guide roller is arranged in front of the support; a tension clamp is arranged below the guide roller; and a clamping device is arranged above the support. The detection method comprises the following steps of: (1) infiltrating a fabric sample; (2) airing the infiltrated fabric sample for different time to obtain a fabric sample with different wetting degrees; (3) calibrating the wetting degree of the fabric sample at various points of time through a relative airing time method; (4) performing a friction test on the fabric sample by utilizing the device; and (5) formulating different friction indexes according to characteristics of various friction curves. The device and the method can quantitatively measure the frictional performance between the fabric and the skin under dry condition and various wet conditions.

Owner:DONGHUA UNIV

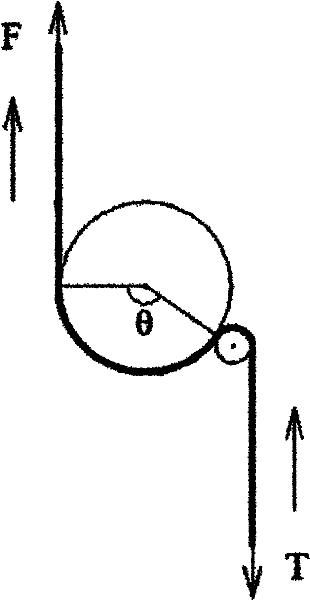

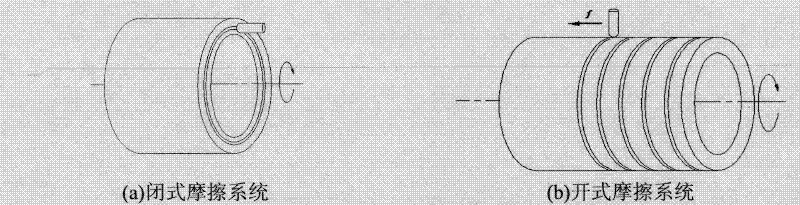

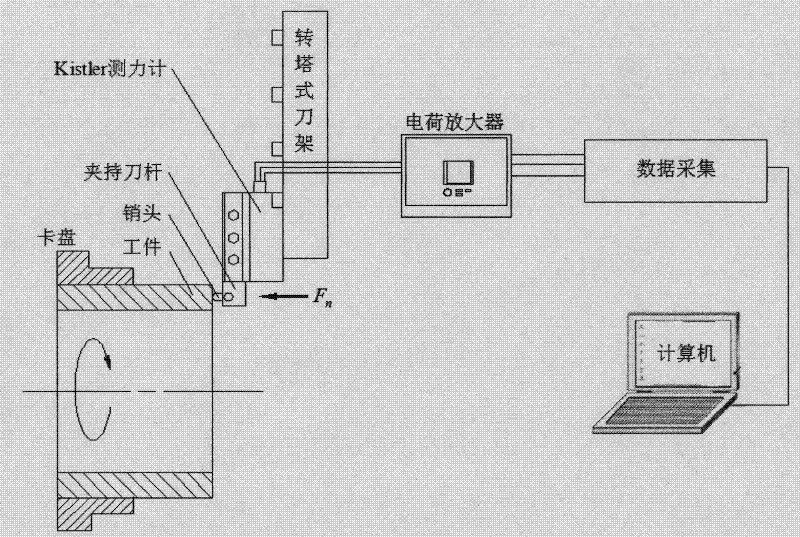

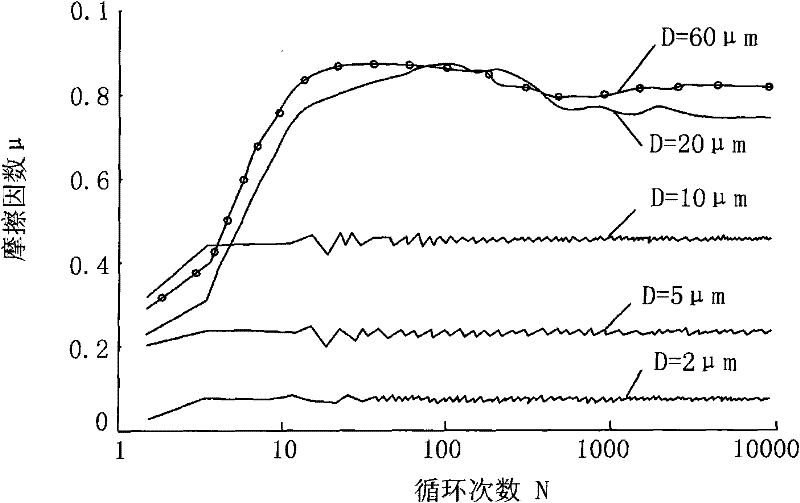

Method for testing cutting and bonding friction characteristics with point-contact opened-closed type pin-disc friction system

The invention relates to a method for testing cutting and bonding friction characteristics with a point-contact opened-closed type pin-disc friction system which is structured by a friction test platform transformed by a lathe. Aiming at the research requirements on the cutting friction problem and through the design of a pin-disc structure and the combination of lathe space motion trail, an opened-closed type system can be structured, and the cutting friction under an extreme working condition can be simulated; and an acting force of a contact interface can be measured by utilizing a Kistler piezoelectric force meter, a tangential force component caused by material elasticplastic deformation can be removed by combining a finite element simulation method, and thus a bonding friction factor can be obtained. The method disclosed by the invention is mainly used for testing and analyzing the friction characteristic of cutters in the cutting process. A main body of equipment is common equipment in a manufacturing laboratory, and has the advantages of good rigidity, simple structure, easy implementation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Small-displacement reciprocating rolling friction abrasion test device

InactiveCN101750259AAuthentic, reliable and effective simulationAuthentic, reliable and effective analysisInvestigating abrasion/wear resistanceRolling resistanceTangential force

The invention relates to a small-displacement reciprocating rolling friction abrasion test device. A plane sample clamp is fixedly connected below a cross beam of a hydraulic friction test machine by a tangential force sensor; a rolling sample clamp is positioned at the right side of the plane sample clamp and is fixed on a vertical column of a support frame; a bottom plate of the clamp support frame is connected on a hydraulic piston of the hydraulic friction test machine; the right side of the clamp support frame is provided with a normal force; a screw at the right side of the normal force sensor is connected on a support nut by threads, and the end part of the screw is connected with a rotating disc; the support nut is fixed on a work platform surface of the hydraulic friction test machine by a support seat; and a U-shaped connecting piece at the left side of the normal force sensor is sheathed on the vertical column of the clamp support frame. The small-displacement reciprocating rolling friction abrasion test device can simulate the friction abrasion between a plane sample and a rolling body more really and reliably, is convenient to microscopically analyze the test result, and has high degree of automation, simple and convenient operation, high accuracy of control and test and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

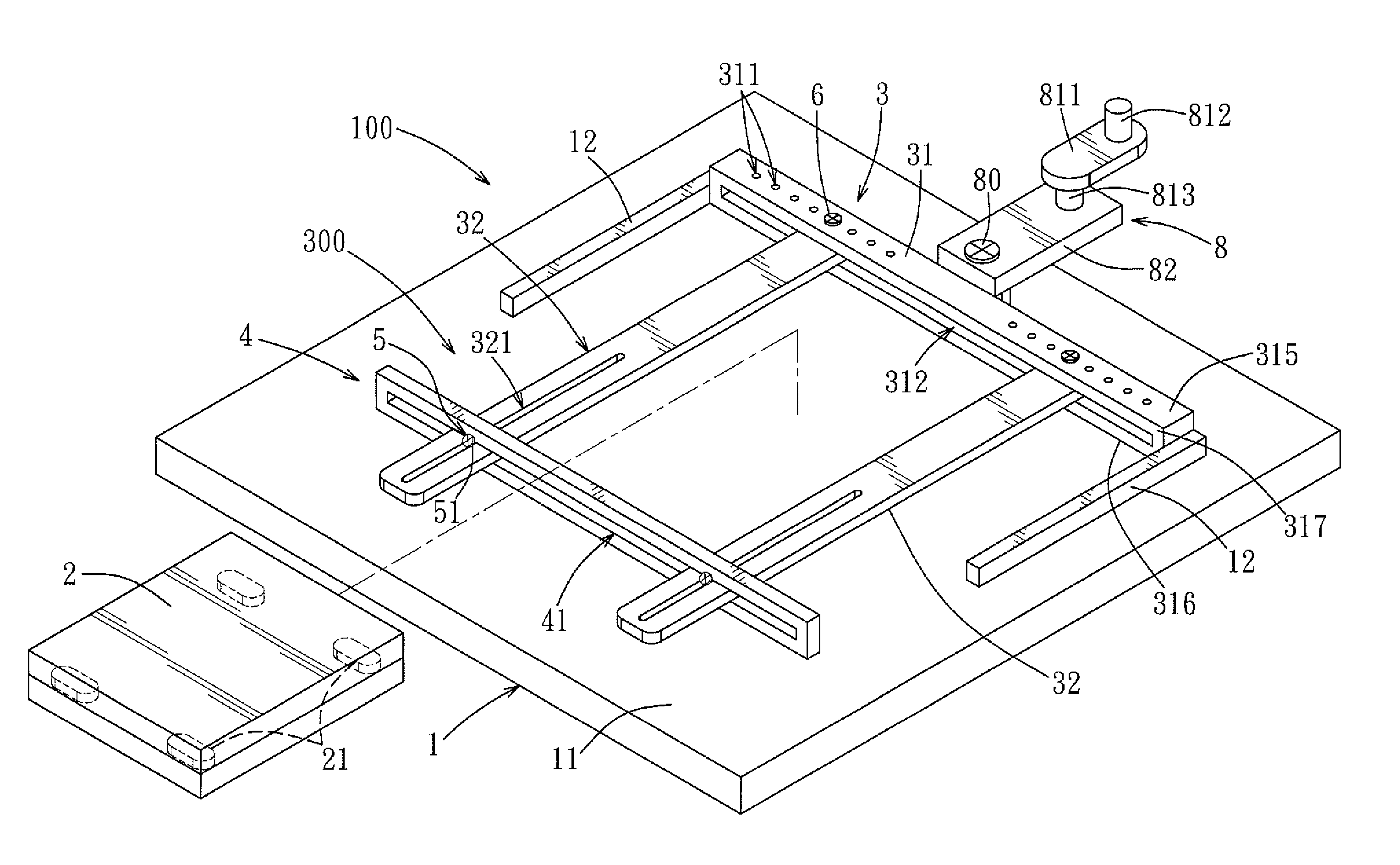

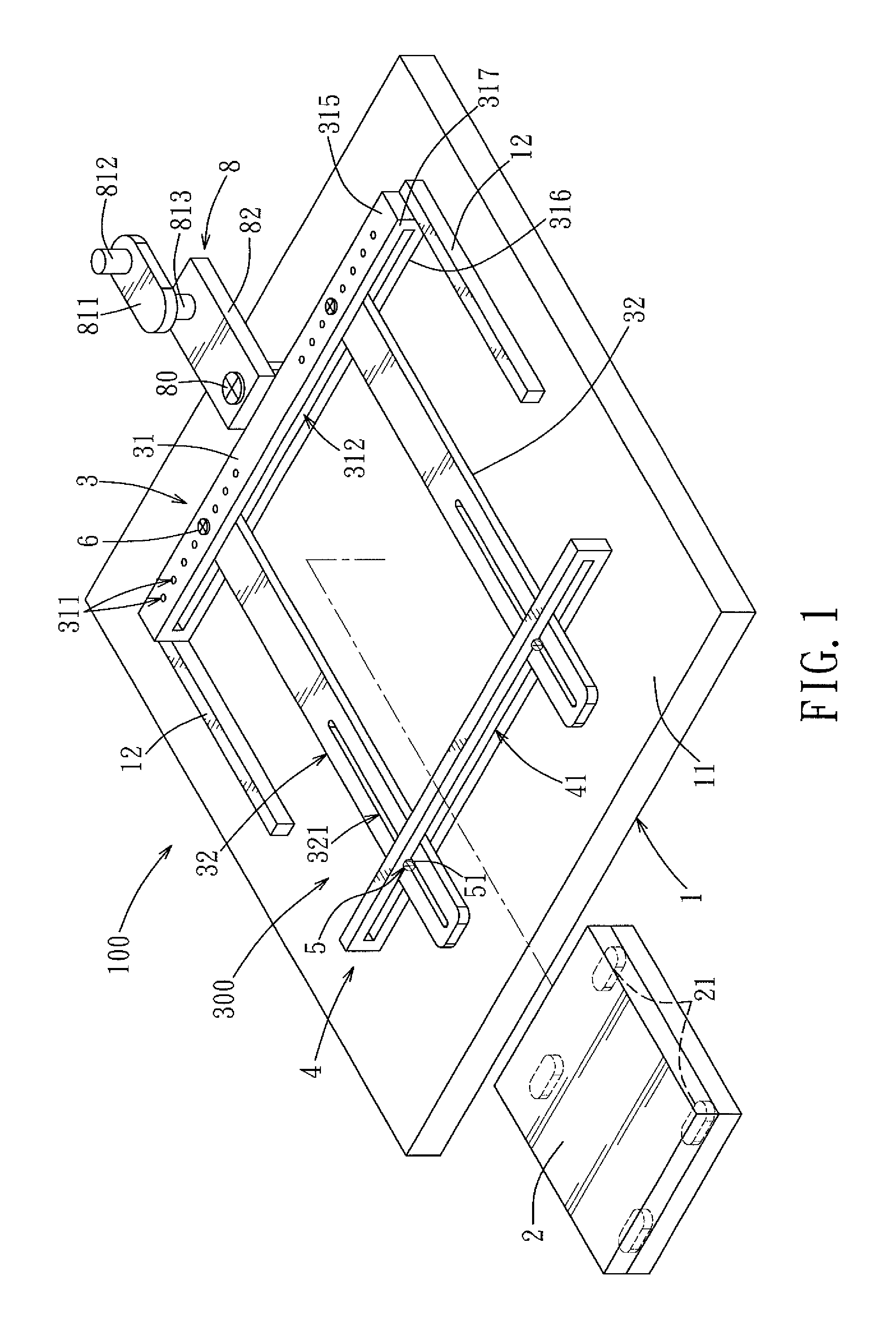

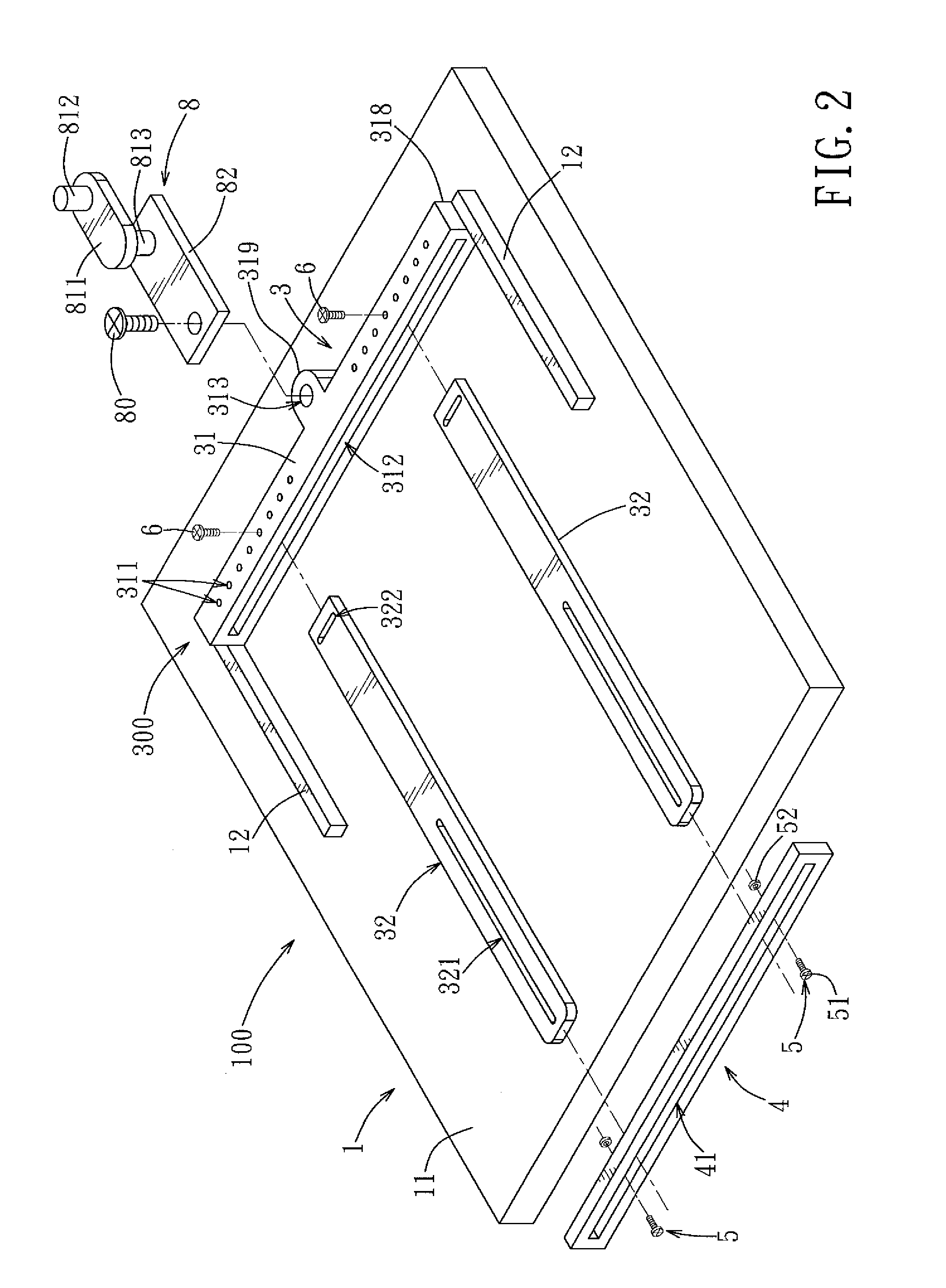

Clamping jig, a friction testing device having the clamping jig, and friction test method

InactiveUS20120192616A1Improve accuracyImprove reliabilityWork holdersUsing mechanical meansLateral extensionEngineering

A clamping jig for clamping a test object includes a first clamping member extending in a left-right direction, two second clamping members connected to and extending transversely of the first clamping member and spaced apart from each other in the left-right direction, and a third clamping member connected to and extending transversely of the second clamping members. The third clamping member is movable along the second clamping members in a front-rear direction to adjust a distance between the first and third clamping members. The first, second, and third clamping members are adapted to clamp therebetween the test object.

Owner:WISTRON CORP

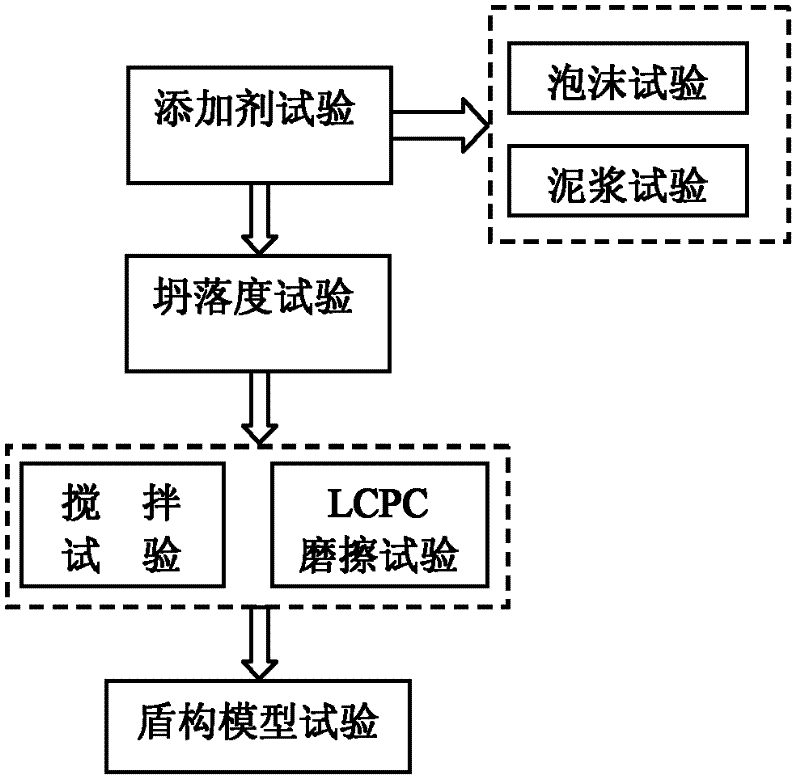

Complete earth pressure balance shield construction soil mass improvement test method

InactiveCN102359925AFast constructionThe design of test operation steps is scientific and reasonableFlow propertiesEarth material testingSoil scienceSoil mass

The present invention discloses a complete earth pressure balance shield construction soil mass improvement test method, and belongs to the technical field of the tunnel construction. According to the present invention, a set of test methods for evaluating commonly-used additives in the shield construction and performances of the improved soil mass are designed; a foam test and a mud test are adopted to prepare and evaluate the performances of the additives; a slump test, a stirring test, a friction test, and an earth pressure tank model test are adopted to evaluate the performances of the improved soil mass, and study the fluidity, the vicidity, the friction performance, the permeability and the force transmission performance of the improved soil mass, determine the performance evaluation standard of the improved soil mass, and provide an additive proportion optimizing scheme for the earth pressure balance shield construction. With the set of the test methods and the process, the performances of the additives and the improved soil mass can be comprehensively evaluated; the test scheme is scientific and reasonable; the applicable soil mass of the test method has wide types; the test effect is significant; the test method and the evaluation standard are provided for effectively and economically adopting the additives for improving the soil mass in the earth pressure balance shield construction in different stratums.

Owner:BEIJING UNIV OF TECH

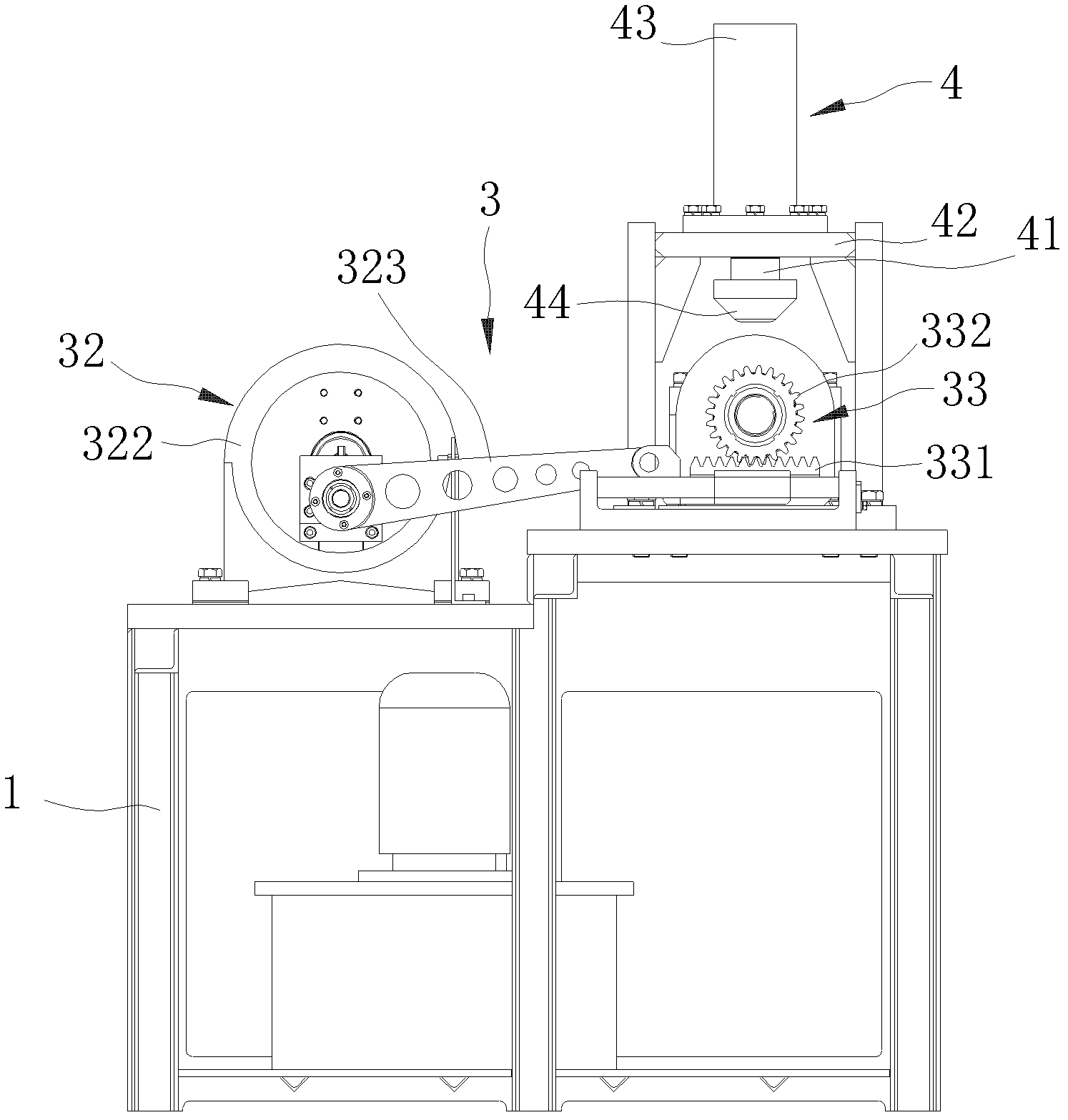

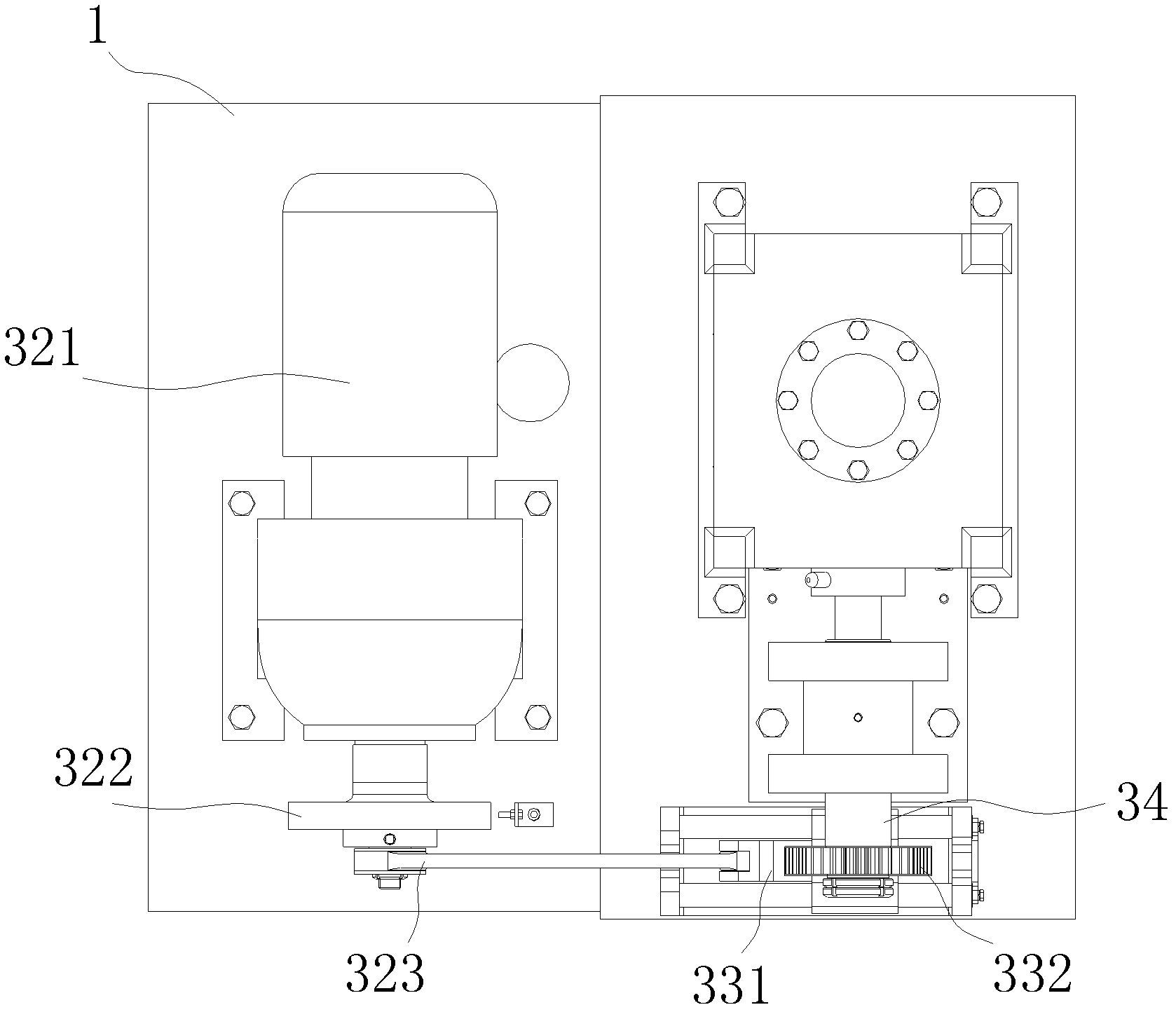

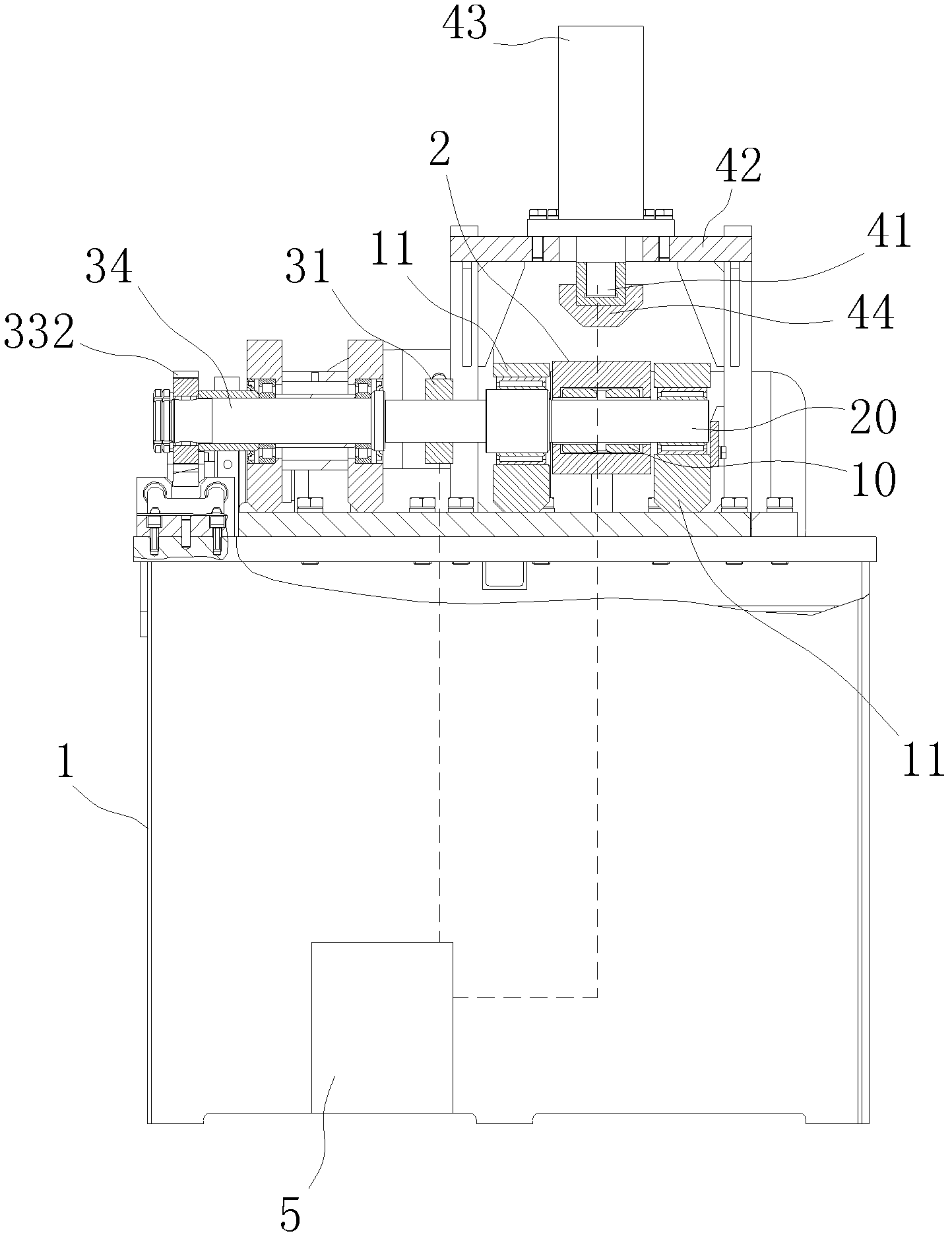

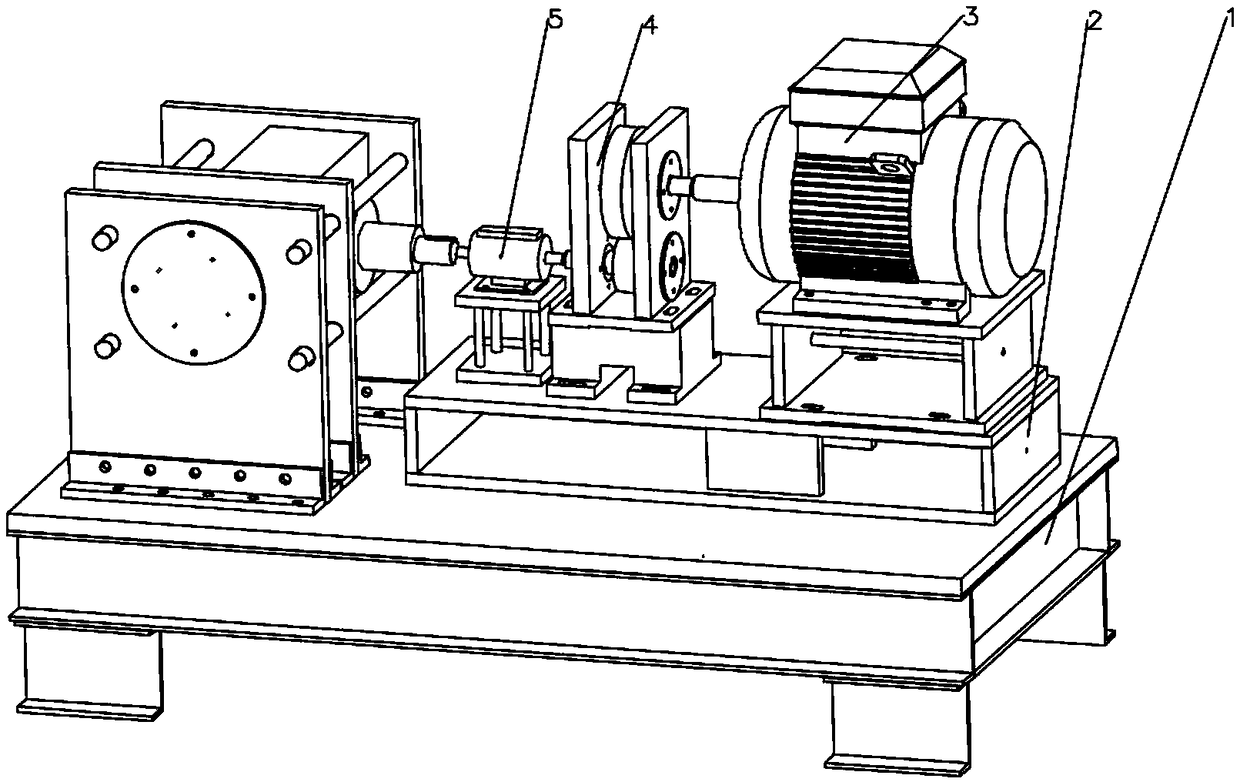

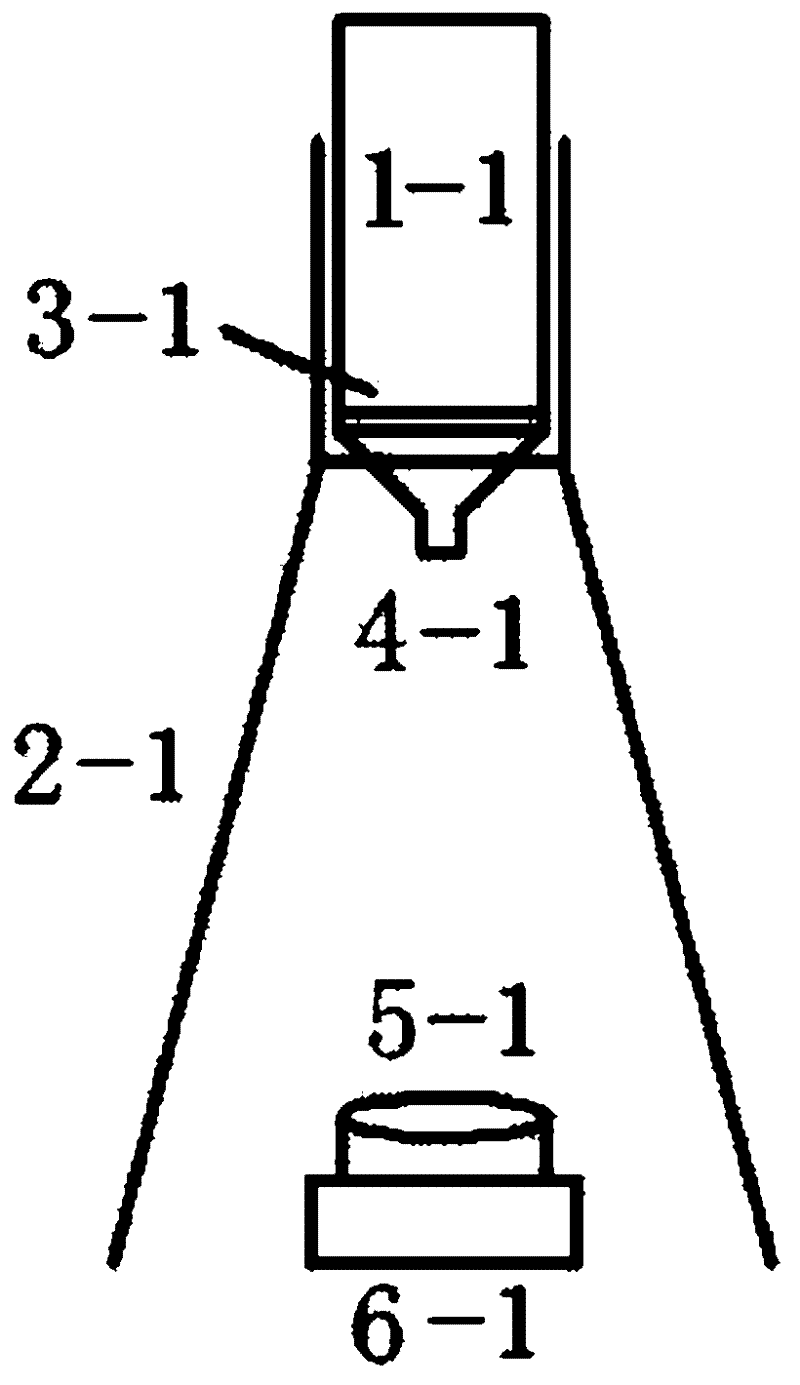

Microslip testing platform for friction liner of elevator

InactiveCN103940733AAccurate measurementImprove working conditionsUsing mechanical meansMaterial analysisHydraulic cylinderEngineering

The invention relates to a microslip testing platform for a friction liner of an elevator. The microslip testing platform comprises a support rack, a loading system, a power system and a measurement system, wherein the support rack comprises a bottom beam; the two ends of the bottom beam are respectively provided with a support stand column; each support stand column is provided with a pulley bracket and an adjusting bracket; a fixed pulley is arranged on each pulley bracket; a fixed hook is arranged on each adjusting bracket; a bearing seat is arranged in the middle of the bottom beam; the middle part of a swing rod is articulated on the bearing seat by a bearing; the upper end of the swing rod is provided with a liner which is provided with an arc-shaped groove; the loading system comprises a steel wire rope set up on the arc-shaped groove of the liner; one end of the steel wire rope is connected with the fixed hooks, and the other end of the steel wire rope is connected with a piston rod of a hydraulic cylinder after winding the fixed pulleys; the power system comprises a vibration exciter; the vibration exciter is articulated with the lower end of the swing rod by a connecting rod; the measurement system comprises a tension sensor and a strain gauge. The microslip testing platform is capable of simulating the actual working conditions of the friction type elevator, and a microslip friction test with variable frequency, variable amplitude, variable load and variable radian can be realized.

Owner:CHINA UNIV OF MINING & TECH

Abrasion resistant test machine for cattle leather

InactiveCN104819905AAchieve fixationRealize reciprocating motionUsing mechanical meansInvestigating abrasion/wear resistanceHeifer calfSoftware engineering

Belonging to the technical field of test equipment, the invention provides an abrasion resistant test machine for cattle leather, and solves the problem that abrasion resistant test cannot be carried out on cattle leather effectively in the prior art. The abrasion resistant test machine for cattle leather consists of a machine body and a workbench. The workbench is provided with a clamping mechanism, the clamping mechanism comprises a mounting panel, a clamping block 1 and a clamping block 2. The mounting panel is provided with a mounting groove, in which a heating piece is fixed. The clamping block 1 is provided with an adjustment hole 1, a positioning bolt 1 is disposed in the adjustment hole 1, the lower end of the positioning bolt 1 is equipped with a positioning block 1, the clamping block 2 is provided with an adjustment hole 2, a positioning bolt 2 is disposed in the adjustment hole 2, the lower end of the positioning bolt 2 is provided with a positioning block 2, a slide rail 1 and a slide rail 2 are fixed on the workbench, the slide rail 1 and slide rail 2 are equipped with a sliding block 1 and a sliding block 2. The workbench is provided with a driving mechanism and a friction test device. The abrasion resistant test machine for cattle leather provided by the invention has the advantage that it can carry out abrasion resistant test on cattle leather more efficiently.

Owner:浙江富邦汽车内饰科技有限公司

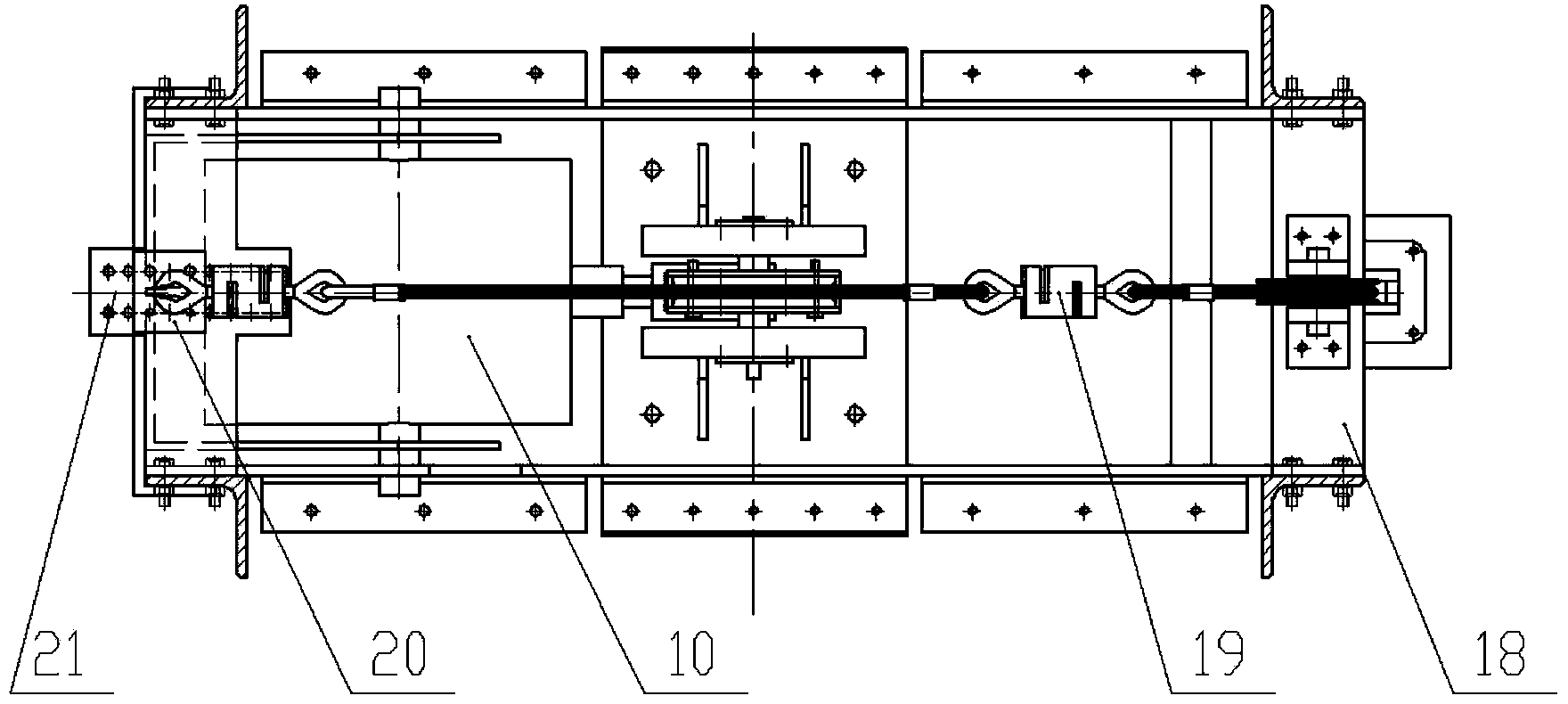

Impact friction test system for winding hoisting rope of kilometer deep shaft

InactiveCN104677816AImprove friction conditionsCompactUsing mechanical meansMaterial analysisContact pressureElectric machinery

Owner:CHINA UNIV OF MINING & TECH

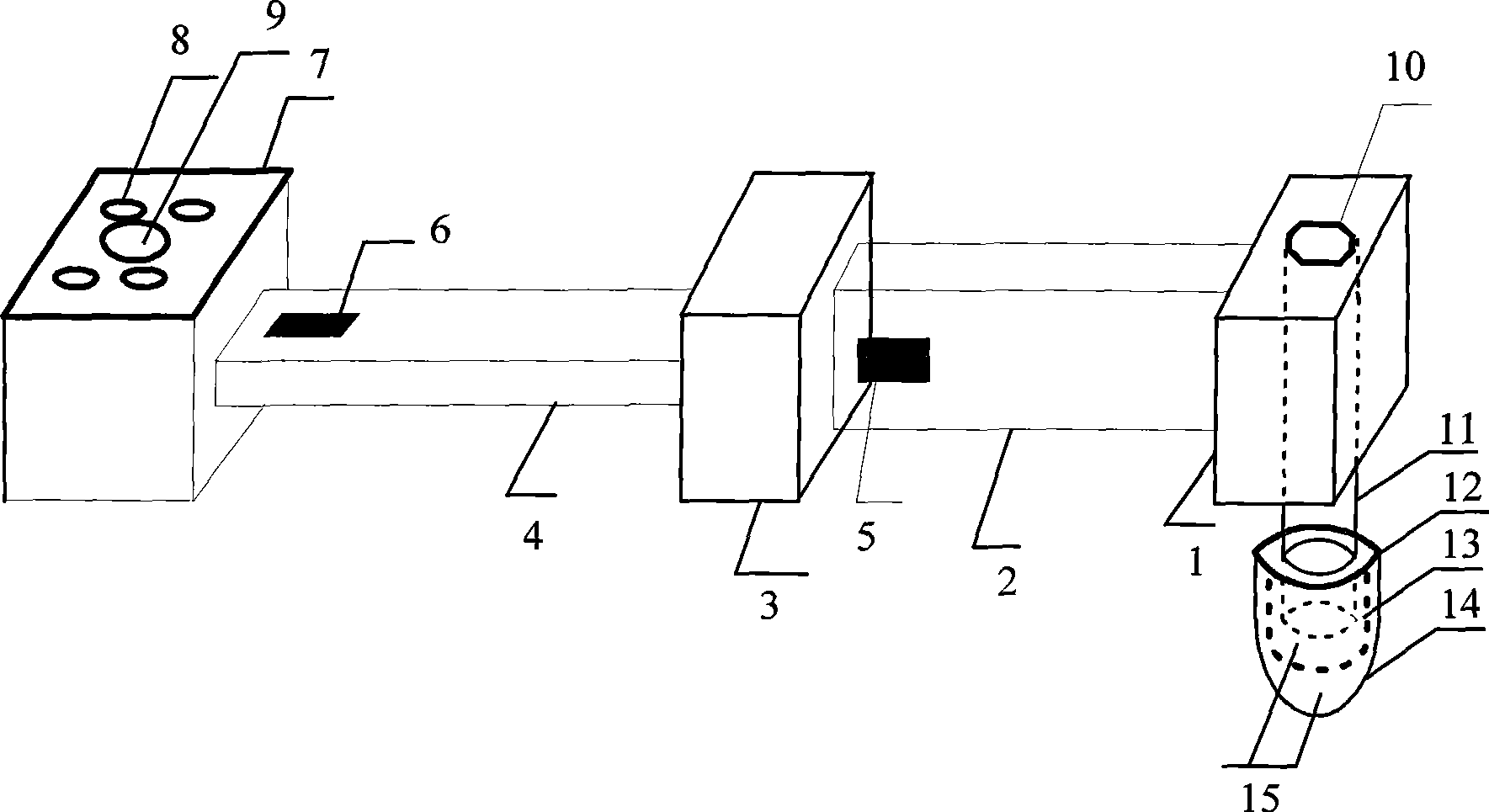

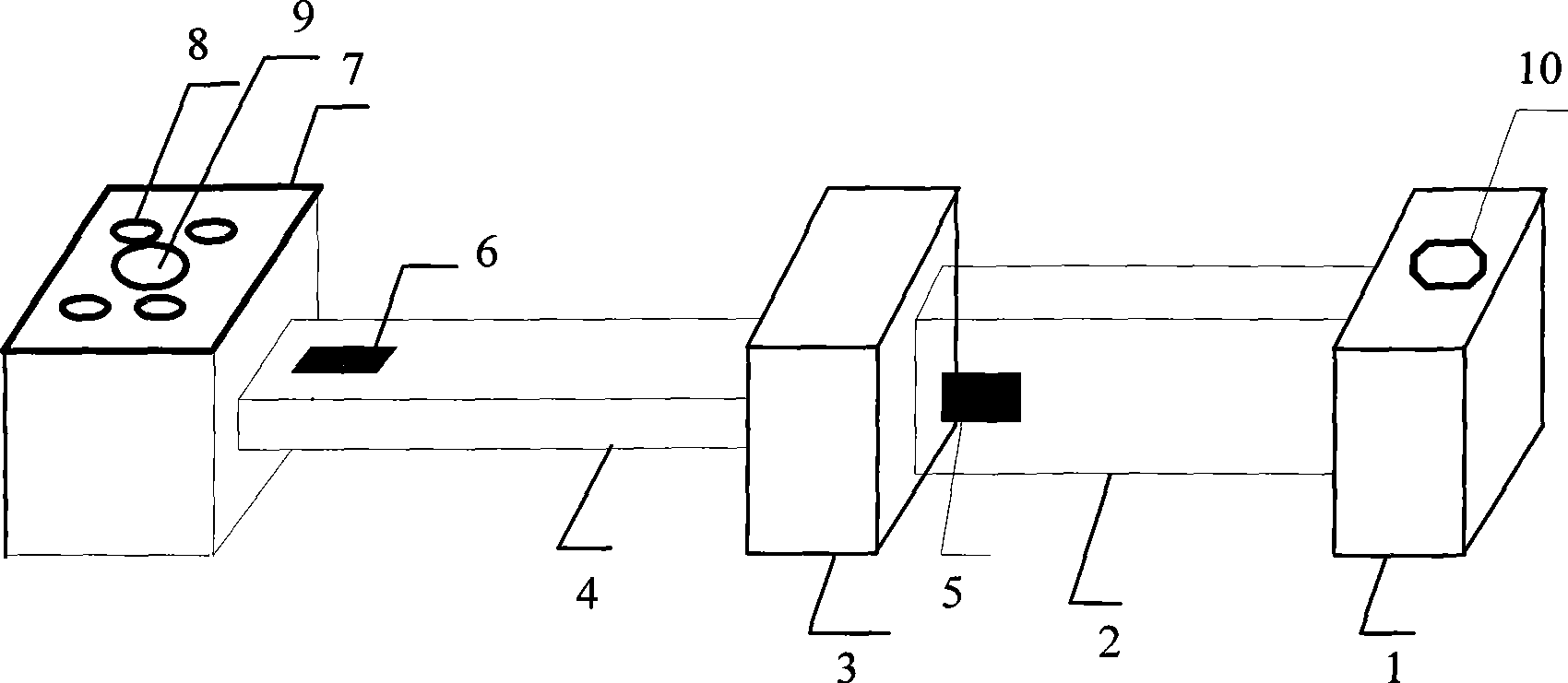

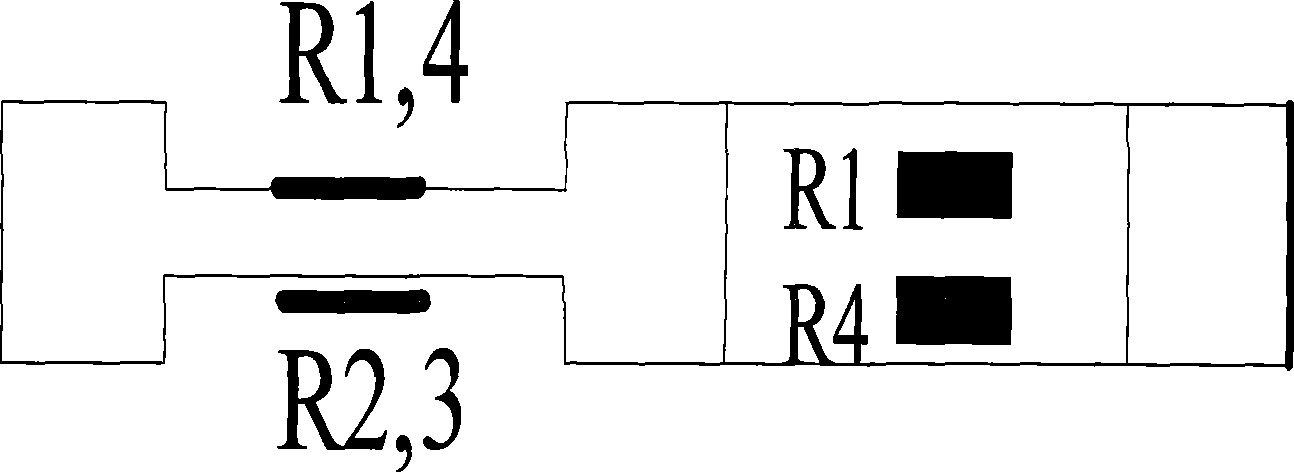

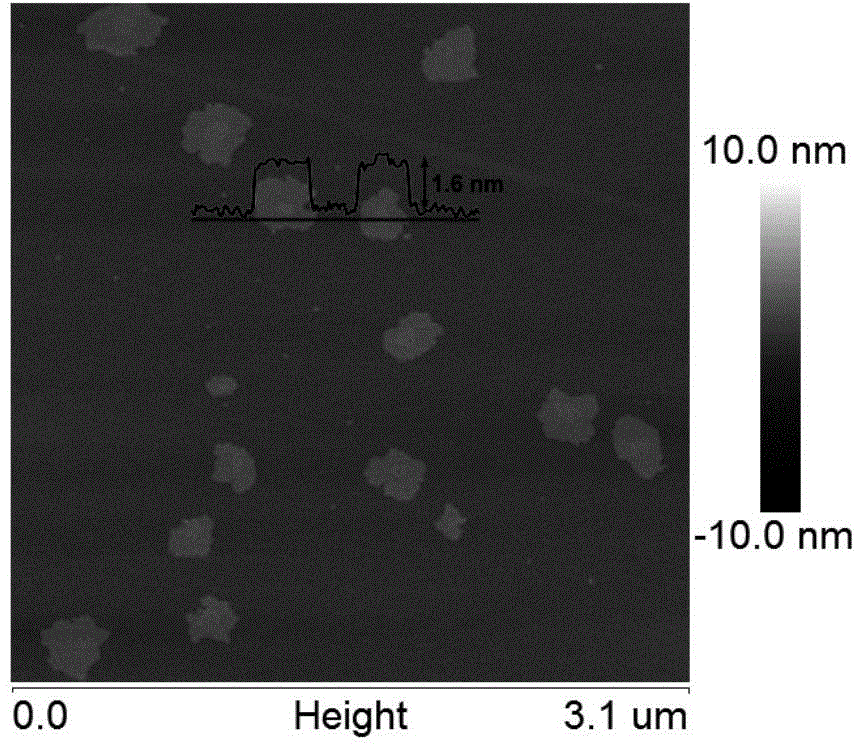

Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m

The present invention provides a film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m. The film system structure comprises a ZnS substrate and a color separation film system, and the color separation film system is made of three film materials; the number of the film layers is 51, wherein the first layer and the 51th layer are oxidation zirconium film layer, the even layers from the second layer to the 50th layer are ytterbium fluoride film layers and the odd layers from the second layer to the 50th layer are zinc sulfide film layers. The transmittance is smaller than 2% with the waveband from 0.5 to 0.8 [Mu]m; the transmittance is smaller than 1% with the laser waveband of 1.064 [Mu]m; and the transmittance is larger than 95% with the medium wave infrared band from 3.7 to 4.8 [Mu]m. The film system structure is small in the number of layers, small in thickness, low in plating difficulty, good in technology repeatability, high in obtained film firmness and good in spectral property, is able to satisfy the use requirement of multi-waveband co-window optoelectronic system and the work requirement in the condition of the inclination with 45 degrees, and stand against the environment tests such as high and low temperature storage, temperature impact and the like, the adhesion test and the moderate friction test.

Owner:西安应用光学研究所

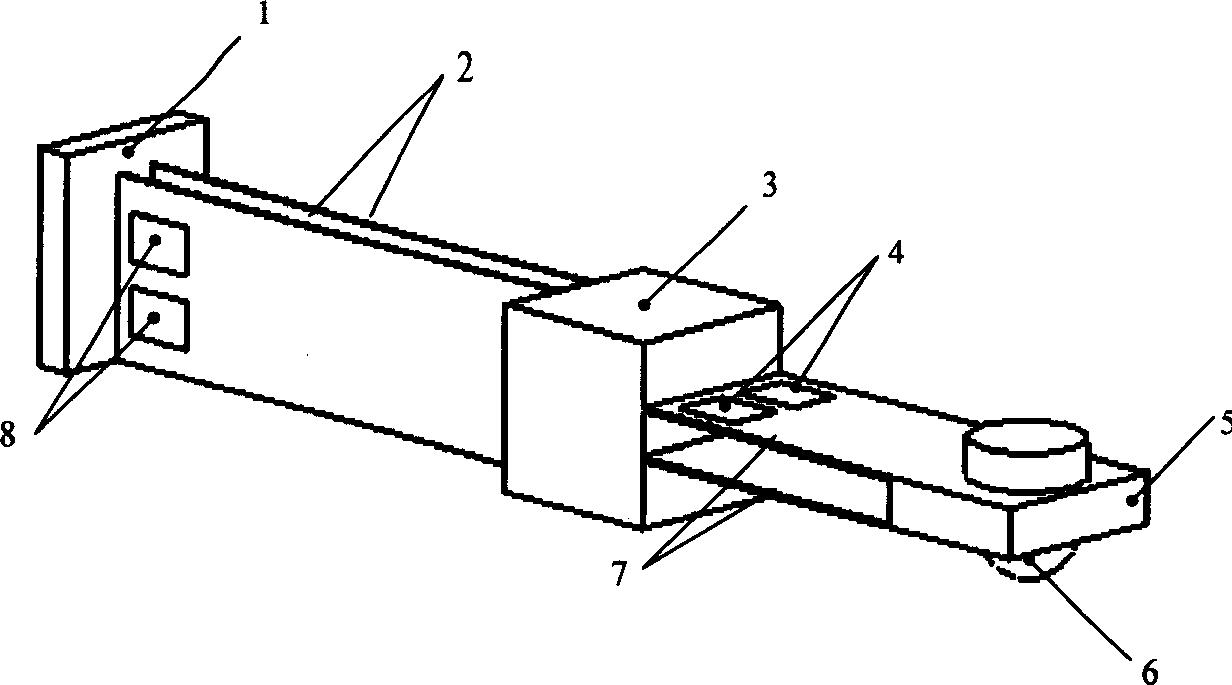

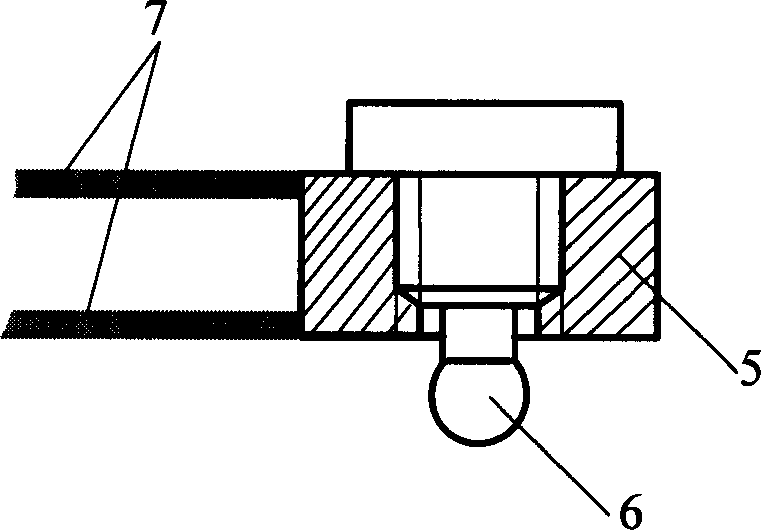

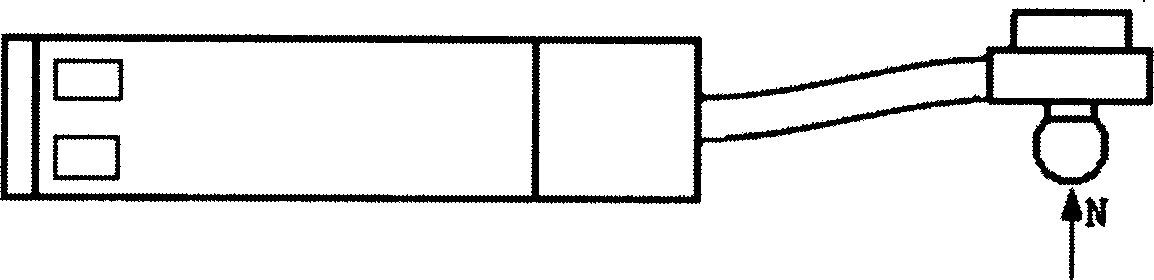

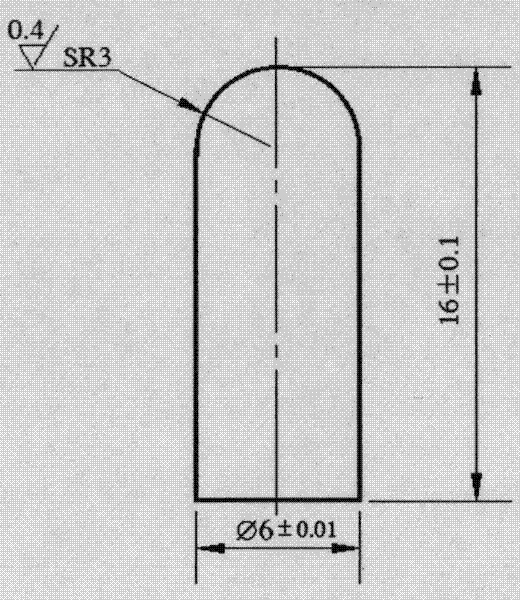

Bionic sensor for testing dynamic friction of fabric

InactiveCN101520406ASimple structureEasy to installForce measurementUsing mechanical meansFiberElastomer

The invention provides a bionic sensor for testing dynamic friction of fabric. The sensor consists of a friction head embedded with a PVDF film and a cantilever structure of a thin girder elastomer; and the cantilever structure is symmetrical according to the axes which are vertical with each other. The sensor comprises the PVDF film, an acrylic resin solidified body connecting rod, an acetate fiber film, vulcanized rubber, a vertical type strain girder, a horizontal type strain girder, a pedestal, a connecting girder and another connecting girder. The bionic sensor of the invention has simple structure, convenient mounting, large integrated rigidity, high inherent frequency and sensitivity of each direction of two-dimensional force, can be used for the friction test of fabric tactility evaluation and has rotary and reciprocating sliding flexibility.

Owner:DONGHUA UNIV

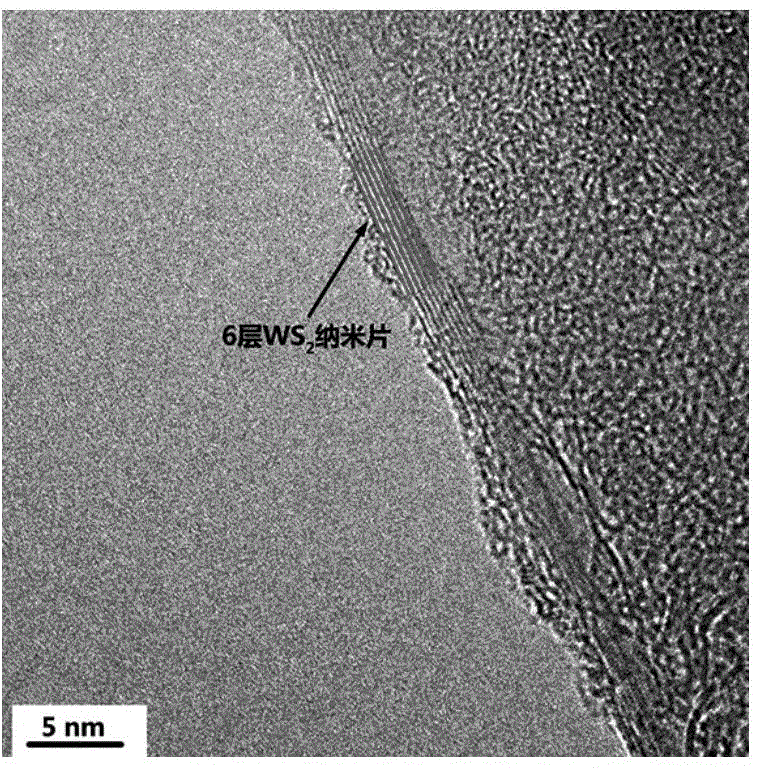

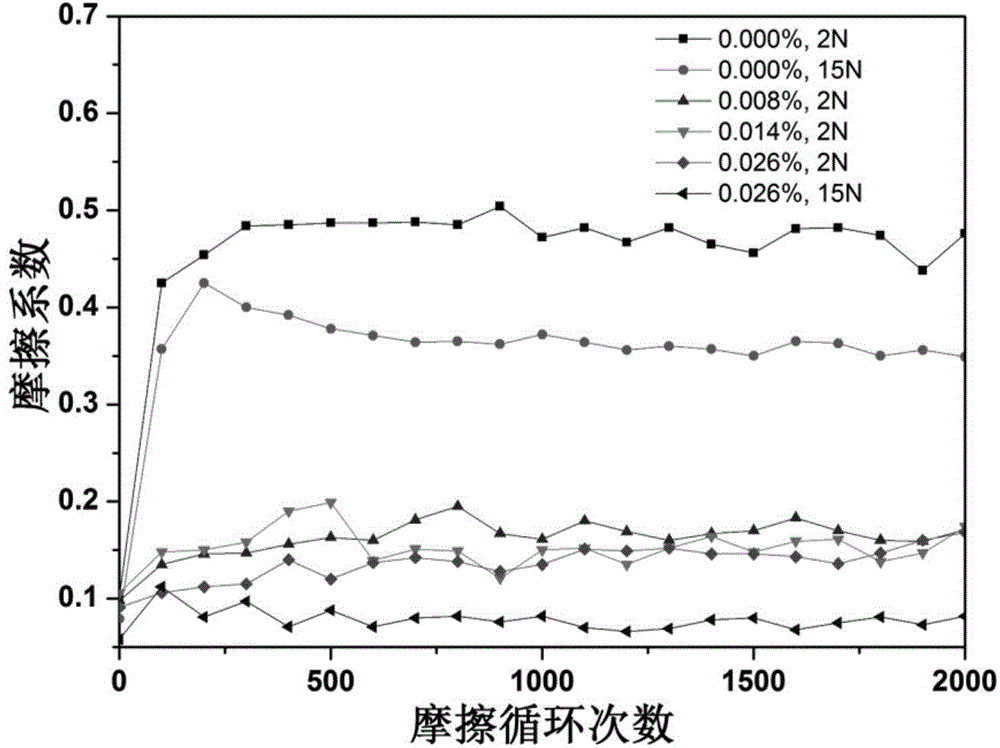

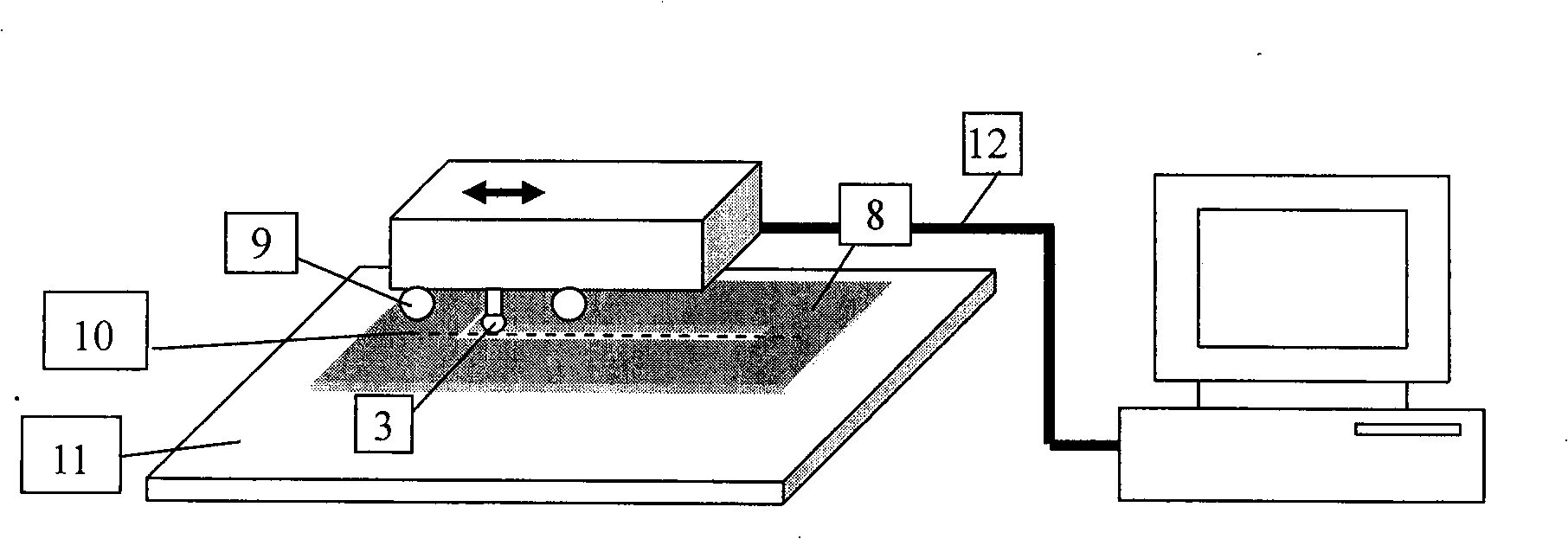

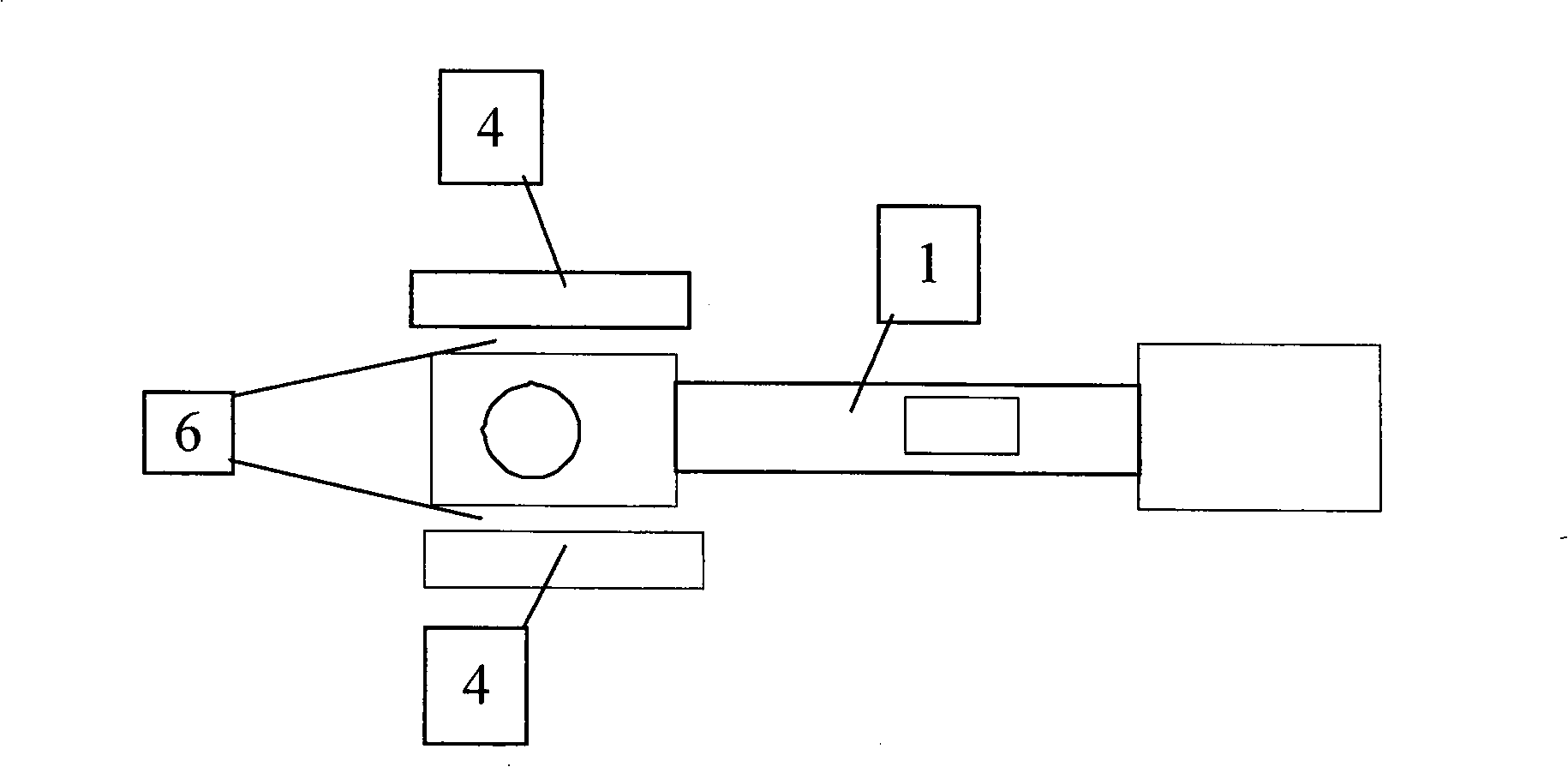

Method for preparing tungsten disulfide nanosheet water-based lubricating agent in situ

The invention discloses a method for preparing a tungsten disulfide nanosheet water-based lubricating agent in situ. The method comprises the following six steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing tungsten disulfide powder in the liquid; 3, performing ultrasonic cavitation treatment on the tungsten disulfide dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing tungsten disulfide nanosheets prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the tungsten disulfide nanosheets is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the tungsten disulfide nanosheets, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property and high machinability of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

Portable system and method for measuring friction coefficient

The invention relates to a portable system and a method for measuring friction coefficient, belonging to the technical field of the measurement of the friction coefficient. The method comprises the following steps: adopting a force sensor to synchronously measure a normal force and a friction force of a friction measuring head passing a measuring surface and displaying the normal force and the friction force in real time; coating septum materials on a front section and a rear section a distance away from the measured surface, dividing the measured surface into a first septum material section, a measuring surface section which is not coated by septum material and is to be measured and a second septum material section along a motion trail direction of the friction measuring head, and causing the obvious change of the friction force and the normal force because the obvious difference of height differences or materials is formed on the measured surface; and calculating speed under the condition that the speed is unchangeable on the distance by considering the continuity of motion speed and the short distance of the measured surface. The method can be used for measuring the friction coefficient of large-scale workpieces, irregular surfaces and biological surfaces and can realize the portability of equipment.

Owner:戴振东 +1

Measuring method and measuring device of elastohydrodynamic lubrication line contact pressure based on photoelasticity

ActiveCN103063355AReal-time measurementReal-time display of pressure distributionFluid pressure measurement by optical meansPhotoelasticityImage resolution

The utility model discloses a measuring method and a measuring device of elastohydrodynamic lubrication line contact pressure based on photoelasticity. According to the measuring method of the elastohydrodynamic lubrication line contact pressure based on the photoelasticity, a friction test sample of elastohydrodynamic lubrication is made of transparent photoelasticity materials, a friction area is irradiated by polarized light, the friction area is observed in an amplified mode through a microscope in the direction of a light source after a polarizing film is detected, photoelasticity strips appear in a friction pair in the contact area irradiated by the polarized light, oil film pressure in the contact area can be displayed and measured in real time after calculating and marking, and resolution ratio of the pressure is determined by the amplification ability of the microscope which is used and the resolution ratio of a camera. The measuring device of the elastohydrodynamic lubrication line contact pressure based on the photoelasticity comprises a collimation light source, a polarizer, the friction contact area, an analyzer, a stereoscopic microscope and an imaging recording device in sequence in the light path direction. According to the measuring method and the measuring device of the elastohydrodynamic lubrication line contact pressure based on the photoelasticity, distribution of pressure in the elastohydrodynamic lubrication line contact area can be measured with high resolution ratio and in real time.

Owner:SOUTH CHINA UNIV OF TECH

Wobble bearing type friction test device and method

InactiveCN102519724AStable pressure loadRealize stepless pressure regulationMachine bearings testingTorque sensorFriction test

Owner:SANY HEAVY MACHINERY

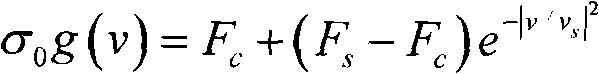

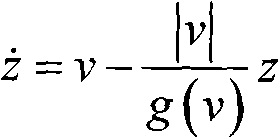

System for accurately testing friction damping

ActiveCN101907557AWith frictionWith displacementForce measurementUsing mechanical meansAutomatic controlDrive motor

The invention discloses a system for accurately testing friction damping. The system comprises a piston, a damping sealing member, a sleeve, a piston rod, force sensors, a cutting sleeve coupler, a displacement sensor, a driving motor, a measurement control platform, an experiment table body and a sleeve centering adjusting rod. The piston, the damping sealing member and the sleeve are matched together to simulate a moving part structure of a liquid rocket valve, and then are assembled together with the experiment tale body and the sleeve centering adjusting rod to form an experiment table of friction testing system; the piston is in rigid connection with the driving motor through the piston rod and the cutting sleeve coupler; the force sensors at two ends of the sleeve and the displacement sensor of the driving motor are connected with the measurement control platform; and the driving motor is connected with the measurement control platform to form a control test bed of the friction testing system. The system provides a valve piston friction structure for simulating reality, adopts a driving mode combining direct driving and macro-micro motions, and has the advantages of automatic control, high control accuracy, high reciprocating frequency, large motion stroke, high dynamic frictional force measurement accuracy and the like.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

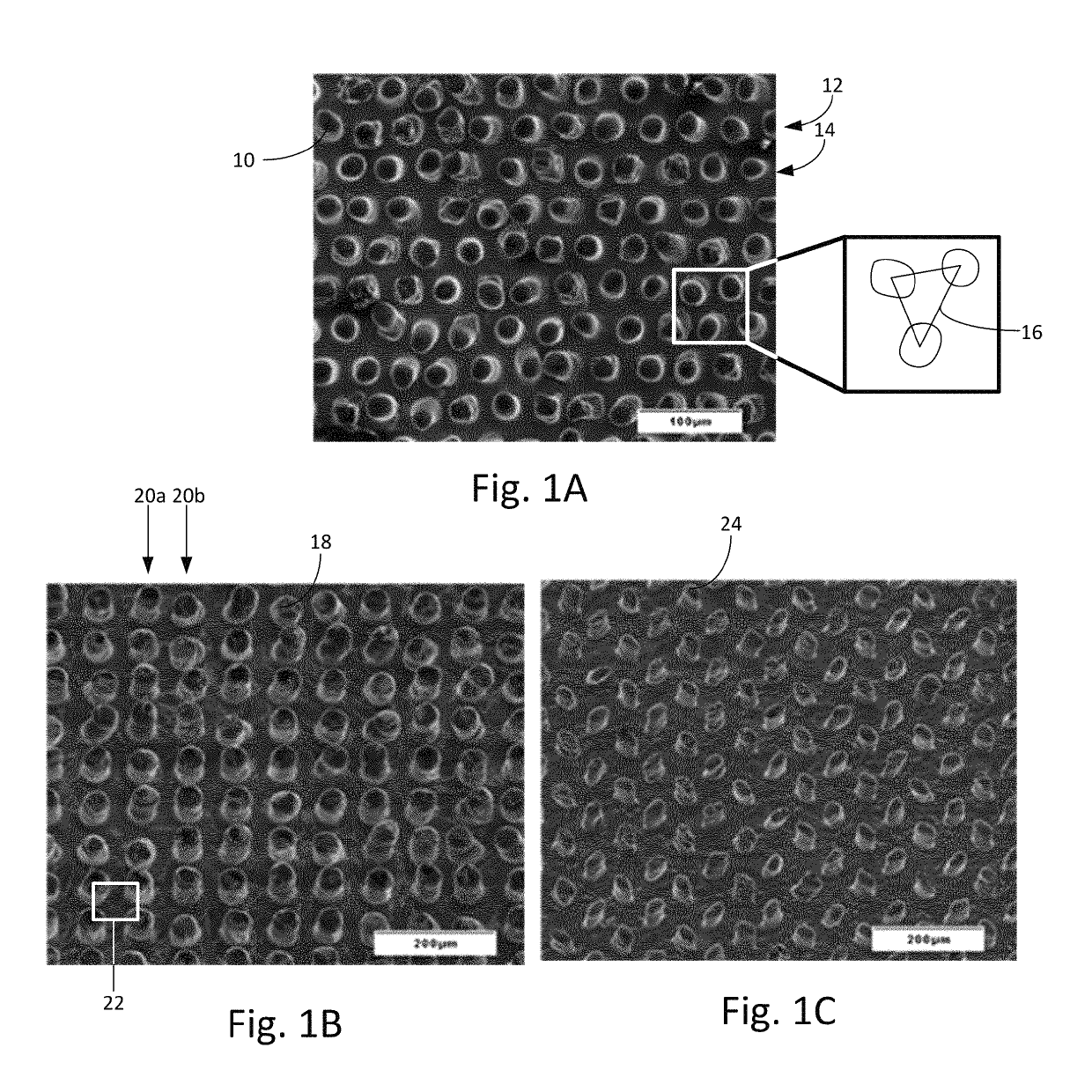

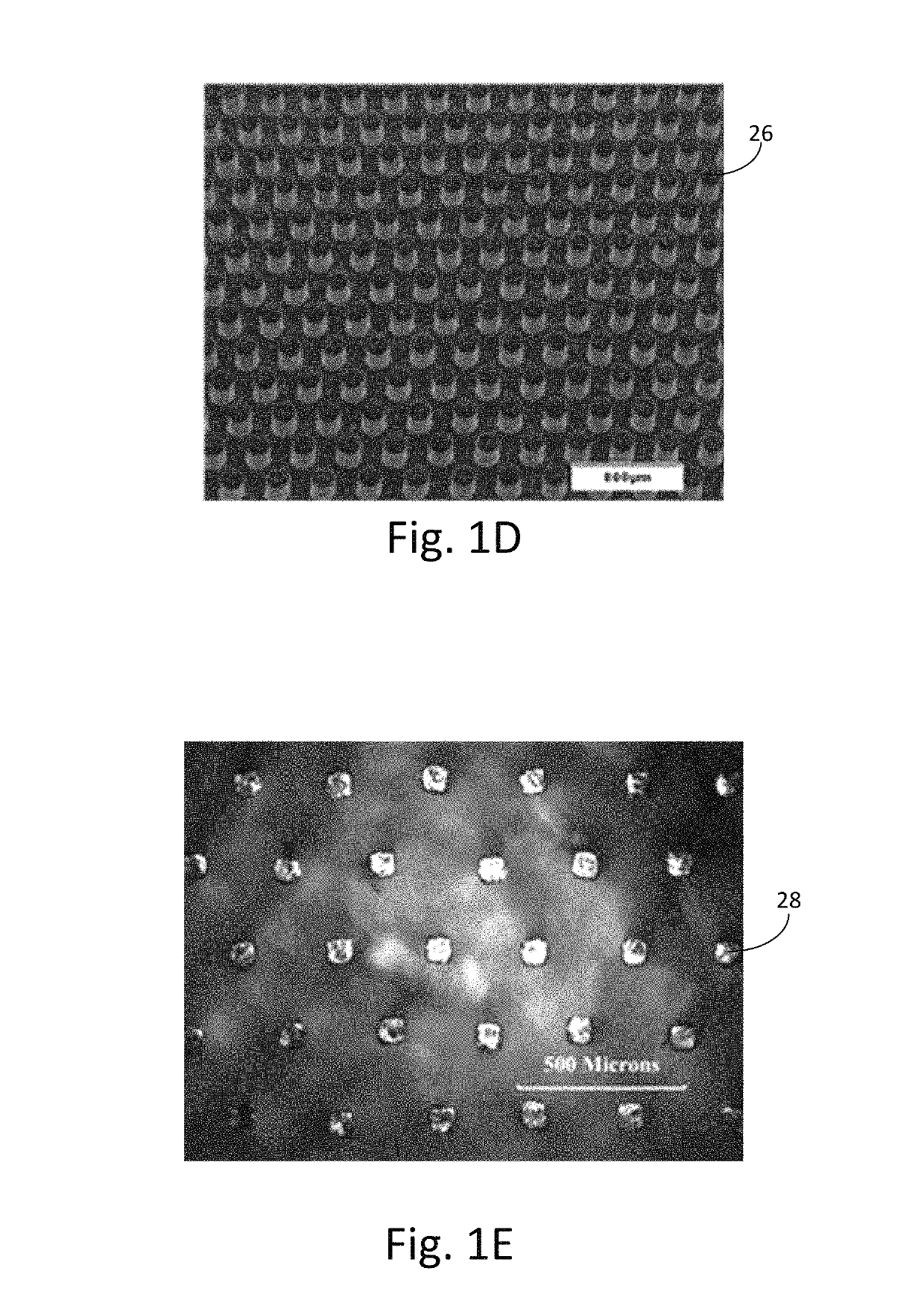

Microstructure arrangement for gripping low coefficient of friction materials

A microstructure arrangement for gripping low coefficient material comprising: a substrate disposed on a gripping surface; a set of pillars disposed on the substrate; and, wherein the set of pillars have the physical property of a grip force in excess of 50.0N with a contact area of 25% or less as determined by the friction testing method. A first set of pillars can be disposed on the substrate having a cross section area in the range of 100 μm2 to 160,000 μm2, height relative to the substrate in the range of 10 μm to 400 μm, and a pitch determined from the center of the pillars, in the range of 20 μm to 1000 μm; and a secondary set of pillars disposed on the first set of pillars having a cross section area less than that of the pillars in the first set of pillars.

Owner:HOOWAKI

Forming explosive friction testing system and testing method thereof

The invention discloses a forming explosive friction testing system and a testing method thereof. The forming explosive friction testing system comprises a supporting frame, a mounting component fixedly connected with the supporting frame, a drop speed loading component above the mounting component and a pressurizing component under the mounting component; a to-be-measured explosive piece is fixed by the mounting component. The forming explosive friction testing system further comprises a static charge amplifier electrically connected with a pressure sensor, a circumferential strain gauge arranged in the circumferential direction of a friction sleeve and a high-speed photographic instrument testing component for obtaining the friction velocity between the to-be-measured explosive piece and the sleeve wall of the friction sleeve; the static charge amplifier is connected with an oscilloscope; the circumferential strain gauge is connected with the static strain gauge through an electric bridge and is merged into an intelligent terminal through the static strain gauge. The testing system can detect the radial pressure change and realize the friction coefficient detection under different speed and pressure conditions through the drop speed loading component and the pressurizing component, so that the quantitative analysis on the effect of external friction conditions on friction coefficients under the conditions of high pressure and high speed is realized, and the application scope and the numerical simulation accuracy of the friction testing system are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

MEMS stiction testing apparatus and method

A MEMS stiction testing method applies a first electrical signal to a MEMS device having two opposing surfaces to cause the two opposing surfaces to make physical contact. The two opposing surfaces produce a second electrical signal when in physical contact. The method then substantially mitigates the first electrical signal after detecting that the second electrical signal has reached a prescribed maximum value.

Owner:ANALOG DEVICES INC

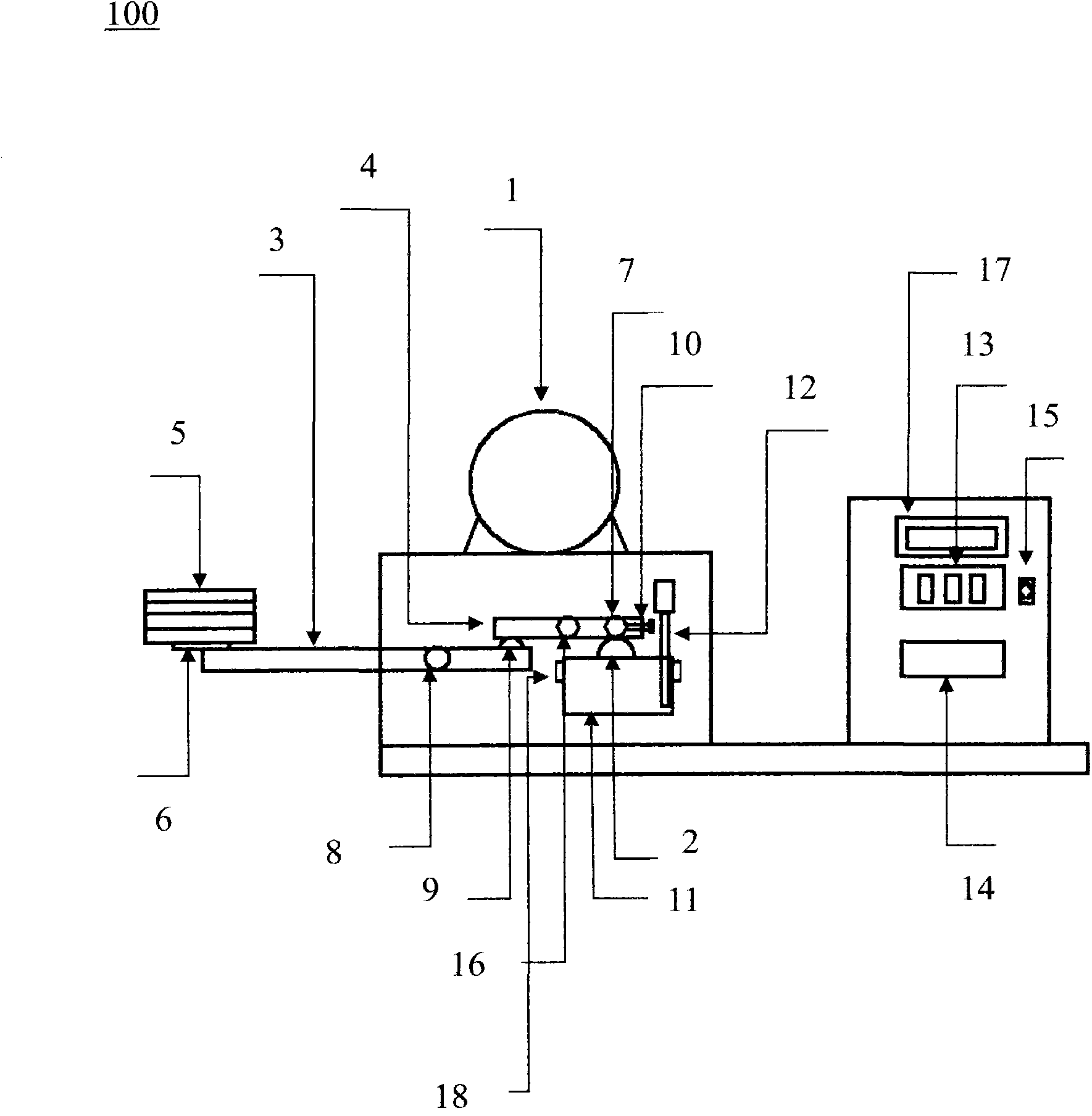

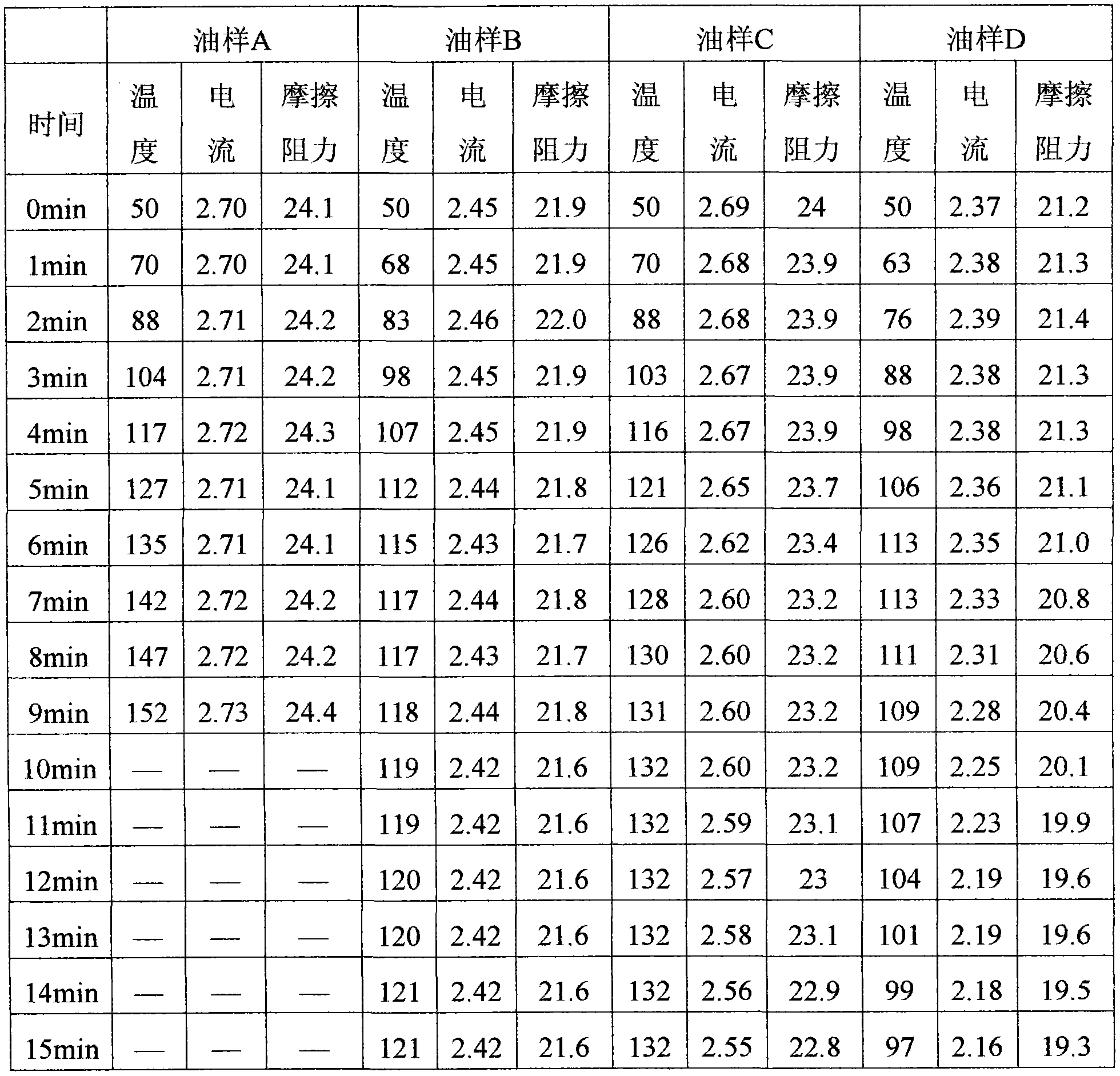

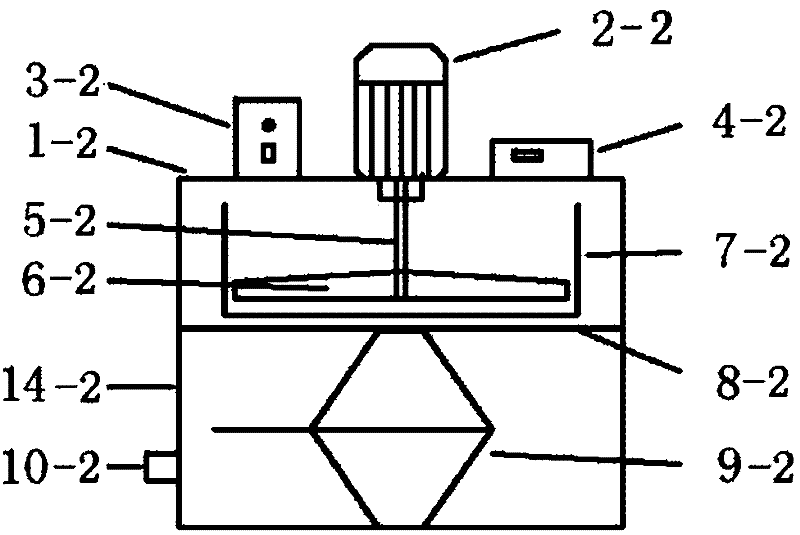

Method for testing and evaluating antifriction abrasion resistance of lubricating oil by utilizing friction test machine

ActiveCN103901184AIntuitive anti-friction and anti-wear propertiesIntuitive judgment of anti-friction and anti-wear propertiesUsing mechanical meansMaterial testing goodsPower flowEngineering

The invention relates to a method for testing and evaluating antifriction abrasion resistance of lubricating oil by utilizing a friction test machine. The method comprises the following steps of arranging a lubricating oil sample into an oil storage box so as to enable a rotating friction wheel to be in surface contact with a fixed friction wheel under the condition that the rotating friction wheel is immersed in the lubricating oil sample, thus producing the slide friction; measuring the temperature of the lubricating oil sample by utilizing a temperature sensor at a plurality of preset discrete time points; measuring power supply current of a motor by utilizing a current measuring device; calculating and displaying friction resistance (f) by utilizing a friction resistance calculating and displaying unit, wherein the calculation formula is as follows: f=UI / rc, wherein f is the friction resistance, U is the power supply voltage, I is the power supply current, r is the rotation speed of the rotating friction wheel, and c is the perimeter of the rotating friction wheel; evaluating and / or comparing the antifriction abrasion resistance of the lubricating oil sample according to the measured temperature, current and friction resistance.

Owner:北京雅士科莱恩石油化工有限公司

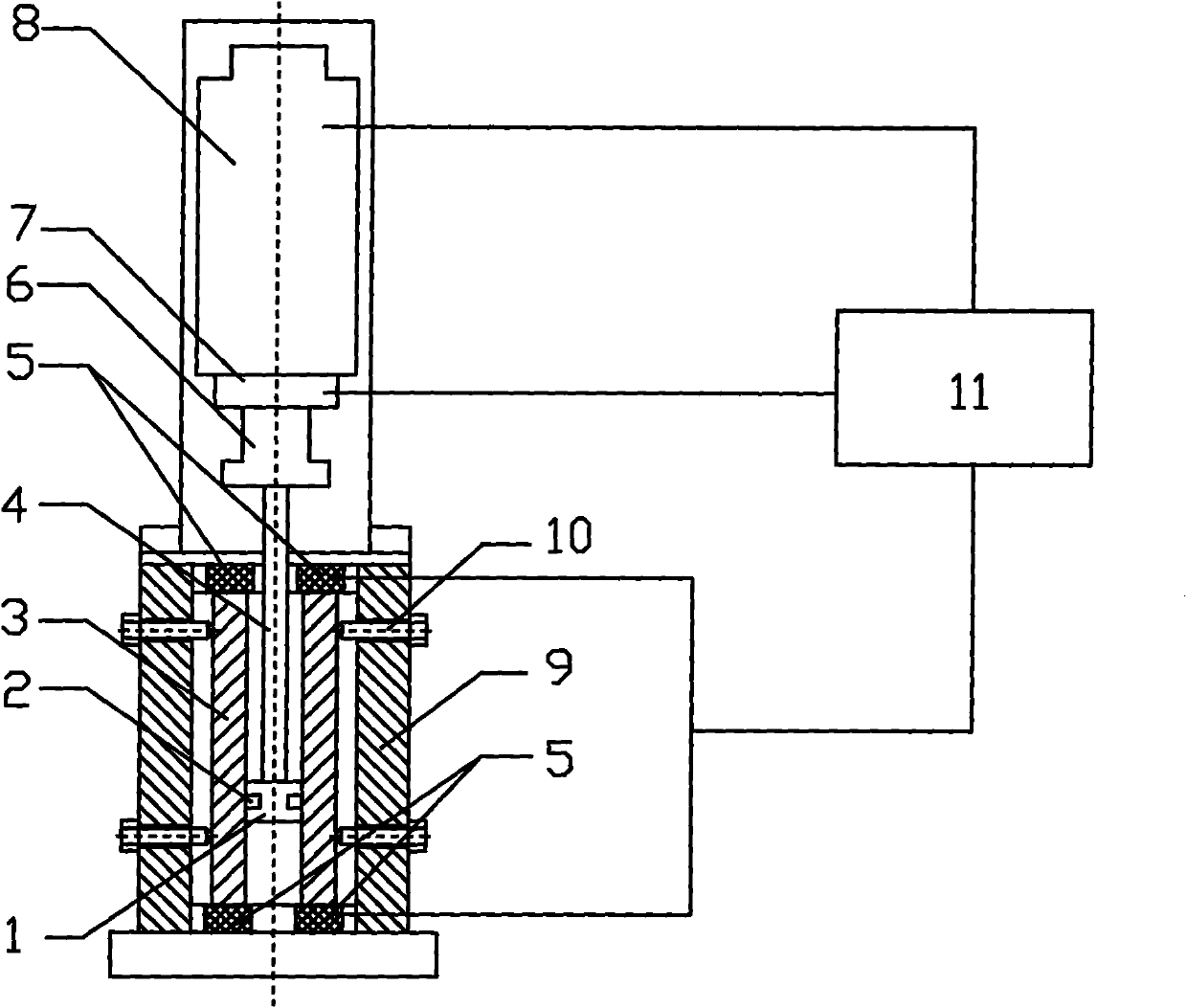

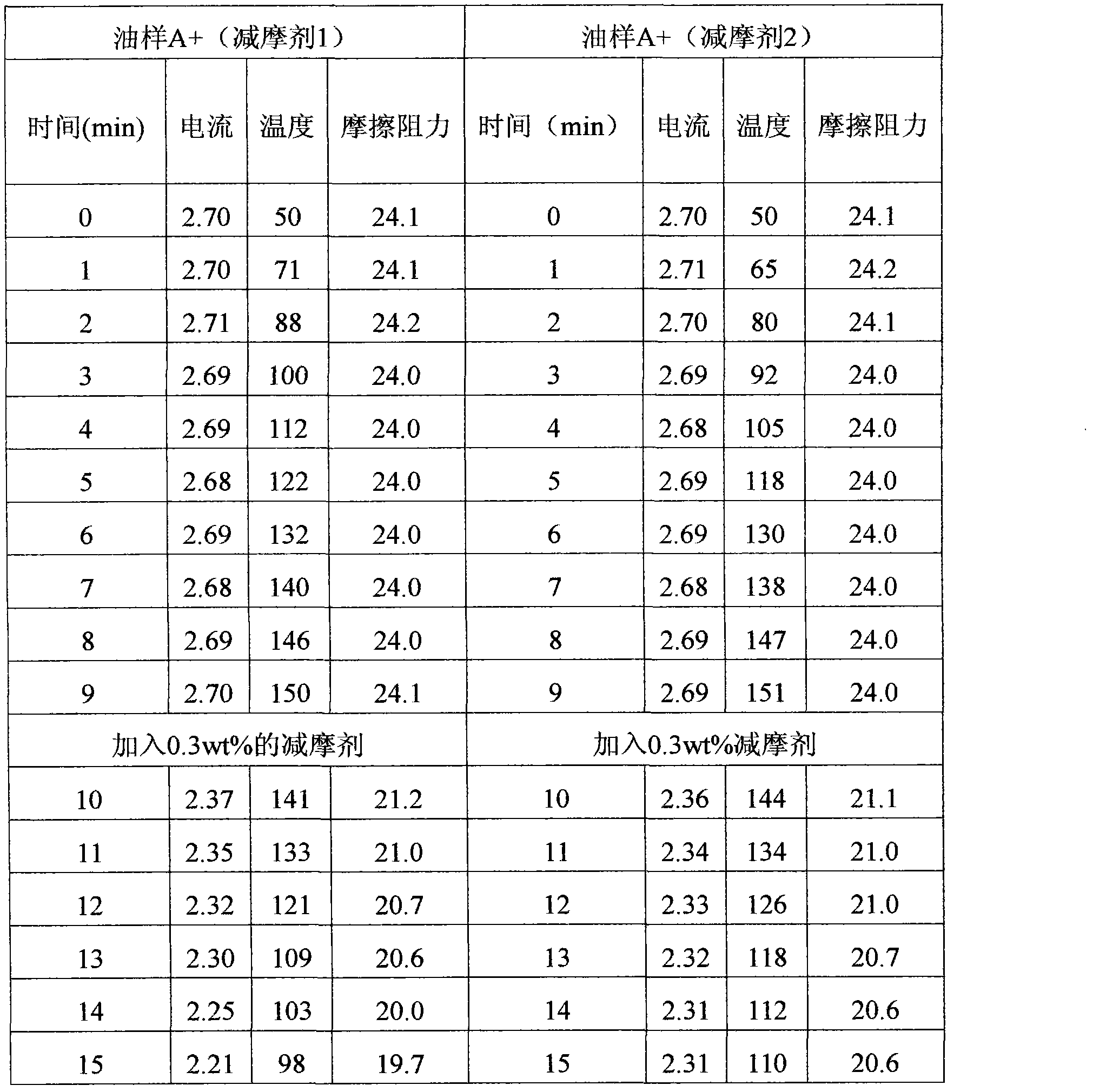

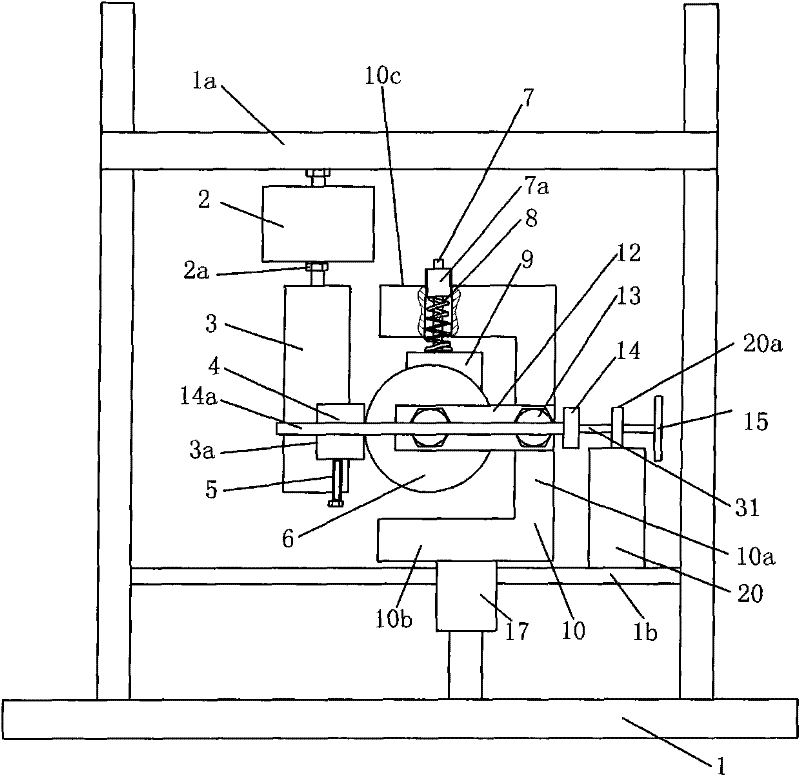

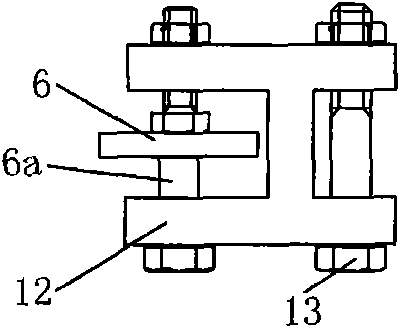

Ultrasonic micro driving friction test system

InactiveCN1580737AEasy to operateImprove performancePiezoelectric/electrostriction/magnetostriction machinesUsing mechanical meansPilot systemEngineering

This ultrasonic mini-driven friction tester comprises the electric charge amplifier, which is connected, with the electric charge ampifier and terminal block (60) by wire, and the terminal block is connected with mini-computer by the wire. This invention can equivalently imitate driven procession of rotator on which certain opposite point with the ultrasonic electric motor's stator be stirred friction materials, and can survey between the different friction materials instantaneous microcosmic condition mini, normal pressure and friction force in real time, then can gain the different friction materials on the instantaneous microcosmic condition the friction coefficient. It can study the ultrasonic electric motor intrinsic features on the different friction materials, such as the driven voltage and temperature exchange how the influence ultrasonic electric motor's instantaneous microcosmic condition fricative driven function.

Owner:HARBIN INST OF TECH

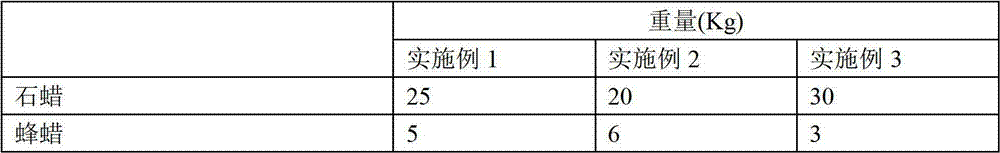

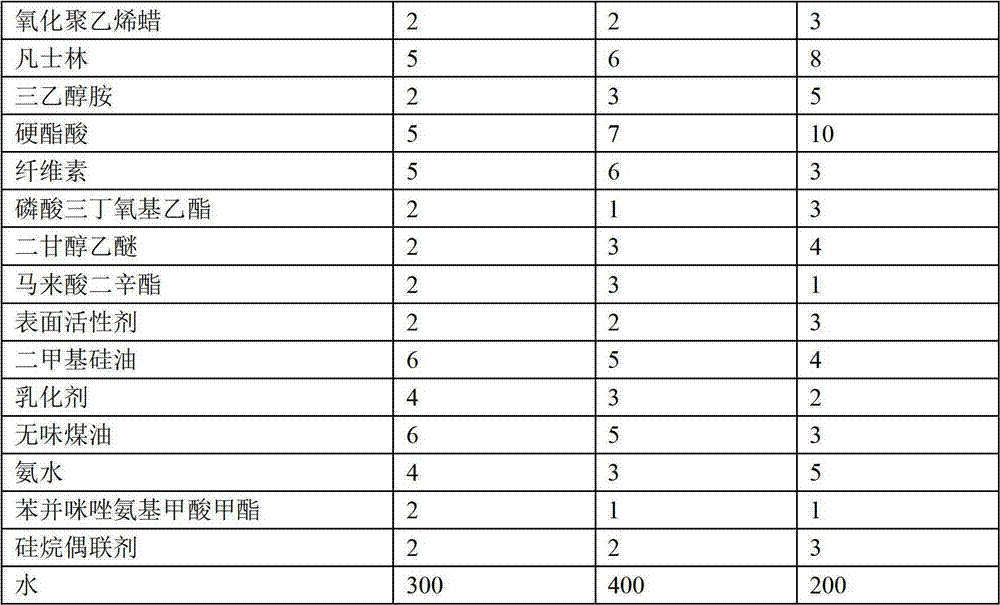

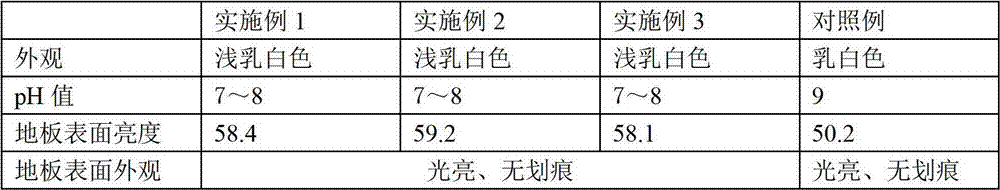

High-durability floor wax

The invention provides high-durability floor wax, and belongs to the technical field of a furniture cleaning agent. The high-durability floor wax comprises the following raw materials by weight: 20 to 30 parts of wax, 3 to 6 parts of beewax, 2 to 3 parts of oxidized polyethlene wax, 5 to 8 parts of Vaseline, 2 to 5 parts of triethanolamine, 5 to 10 parts of stearic acid, 3 to 7 parts of cellulose, 1 to 3 parts of butoxy triethyl phosphate, 2 to 4 parts of diglycol diethyl ether, 1 to 3 parts of dioctyl maleate, 2 to 3 parts of surface active agent, 4 to 6 parts of simethicone, 2 to 4 parts of emulsifying agent, 3 to 6 parts of odorless kerosene, 3 to 5 parts of ammonia water, 1 to 2 parts of benzimidazole methyl carbamate, 2 to 3 parts of silane coupling agent and 200 to 400 parts of water. With the adoption of the floor wax provided by the invention, the glossiness of the surface of a floor can be effectively improved, scratches can be shielded, and the damage of the friction on the floor surface to the floor can be effectively prevented; and after being subjected to a friction test, the floor wax also has high brightness and has no scratch.

Owner:盐城创咏新能源投资有限公司

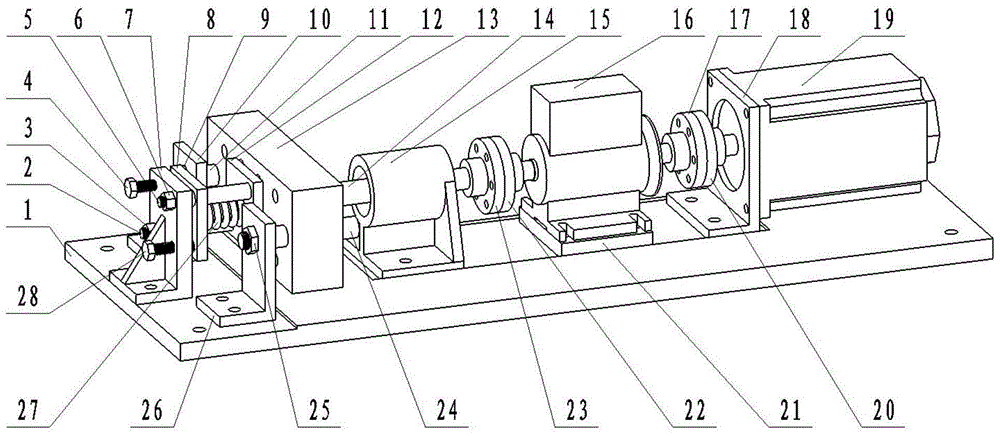

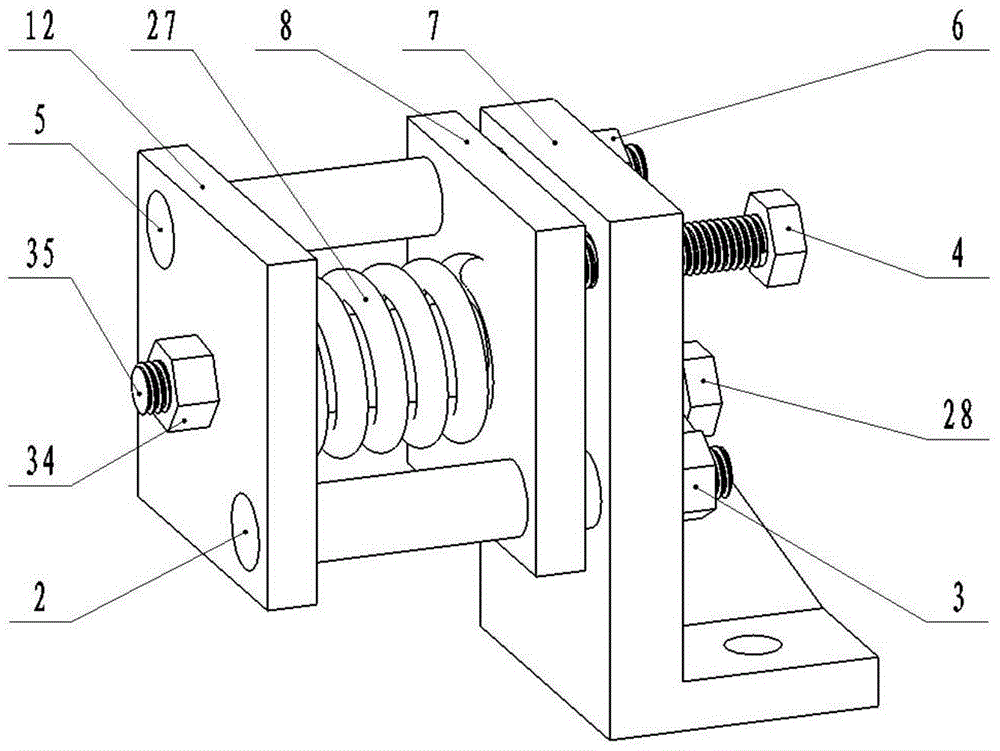

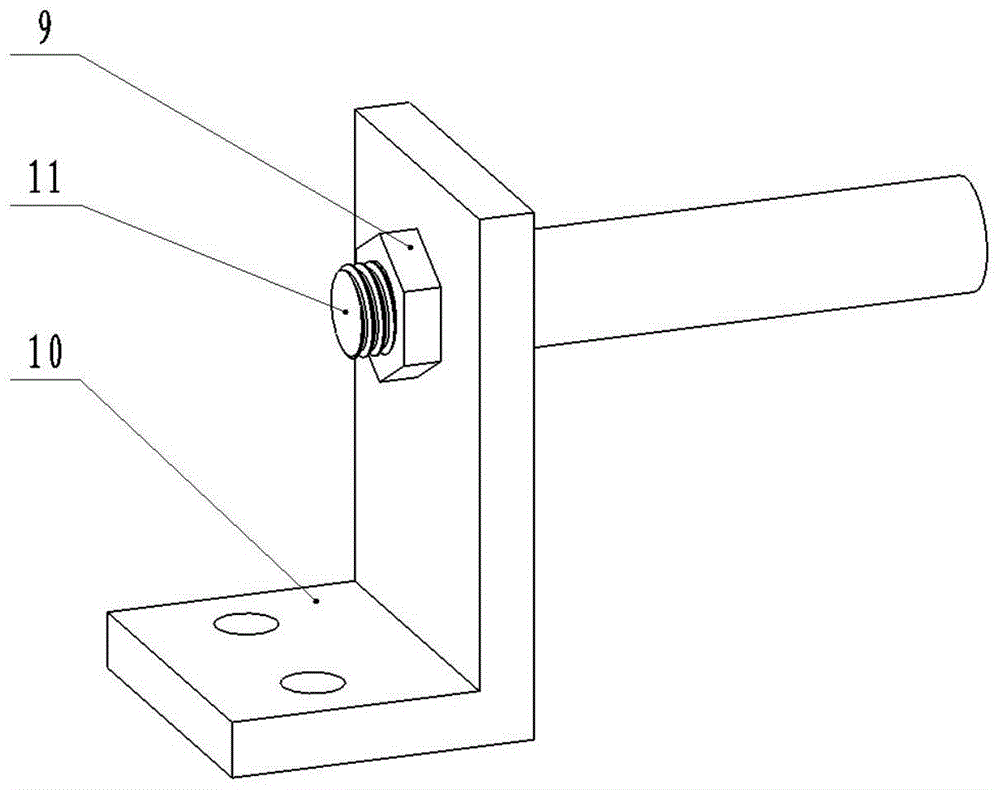

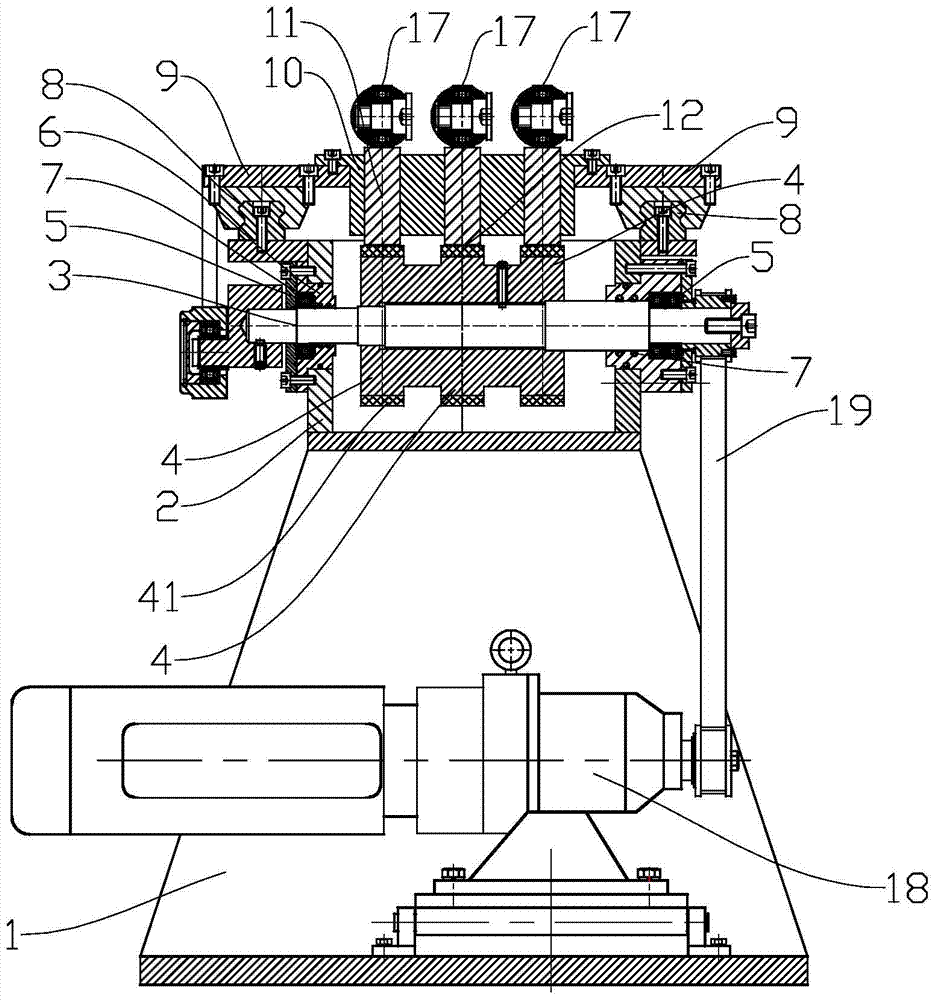

Frictional wear characteristic test device and method for joint curved junction surfaces

InactiveCN105067467AIncrease profitSimple structureInvestigating abrasion/wear resistanceSupporting systemTest fixture

The invention relates to a frictional wear characteristic test device and method for joint curved junction surfaces. The test device comprises a friction test device body and a signal collecting, analyzing and processing system. The friction test device body is composed of a loading system, a test junction surface system, a guiding and supporting system, a signal detecting system and a supporting power system. Structural design with variable loads is adopted in a frictional wear characteristic test for the joint curved junction surfaces, a sensor detects torque signals in the rotating process to obtain frictional wear characteristics of the joint curved junction surfaces, and the test device is suitable for comparing and researching the frictional wear characteristics of the joint curved junction surfaces of different materials. As exchangeable parts to be tested are adopted, the frictional wear characteristics of the joint curved junction surfaces of the different materials can be measured through one test table, the use ratio of the test table is increased, the magnitude of loading force can be obtained visually, and the test device has great guiding significance in testing the frictional wear characteristics of the joint curved junction surfaces in engineering practice.

Owner:BEIJING UNIV OF TECH

Multifunctional piston-cylinder sleeve system friction-wear experiment testing machine

PendingCN108362598AAccurate friction and wearOvercoming Measurement LimitationsInvestigating abrasion/wear resistanceWear testingPiston ring

The invention discloses a multifunctional piston-cylinder sleeve system friction-wear experiment testing machine and belongs to the field of mechanical friction-wear test. In order to solve the problems that the conventional friction test machine cannot truly reflect the friction-wear state of the piston-cylinder sleeve system during actual work, and has low friction force measuring precision, themultifunctional piston-cylinder sleeve system friction-wear experiment testing machine performs high-precision simulation on pressure, temperature, vibration and the like of the actual working conditions of an engine by taking a speed-regulating motor as driving and adopting the following simple open type structure: a special suspended type cylinder sleeve, a linear bearing type piston skirt part, a cylinder pressure simulating mechanism, a piston ring radial force elastic adjustment mechanism and the like, under the condition of non-real-machine ignition and combustion, performs piston-cylinder sleeve system friction-wear test, performs high-precision measurement on the friction force, and avoids the influence on the experimental test by high temperature and vibration of a real engine. In addition, the test machine can perform the related friction-wear experiment of a plunger piston type air compressor.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000011.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000012.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka.patsnap.com/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000021.PNG)