Microslip testing platform for friction liner of elevator

A friction pad and test platform technology, applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of single test parameters, single parameters, and frequent occurrence of slight slippage, and achieve various test parameters and real-time accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings.

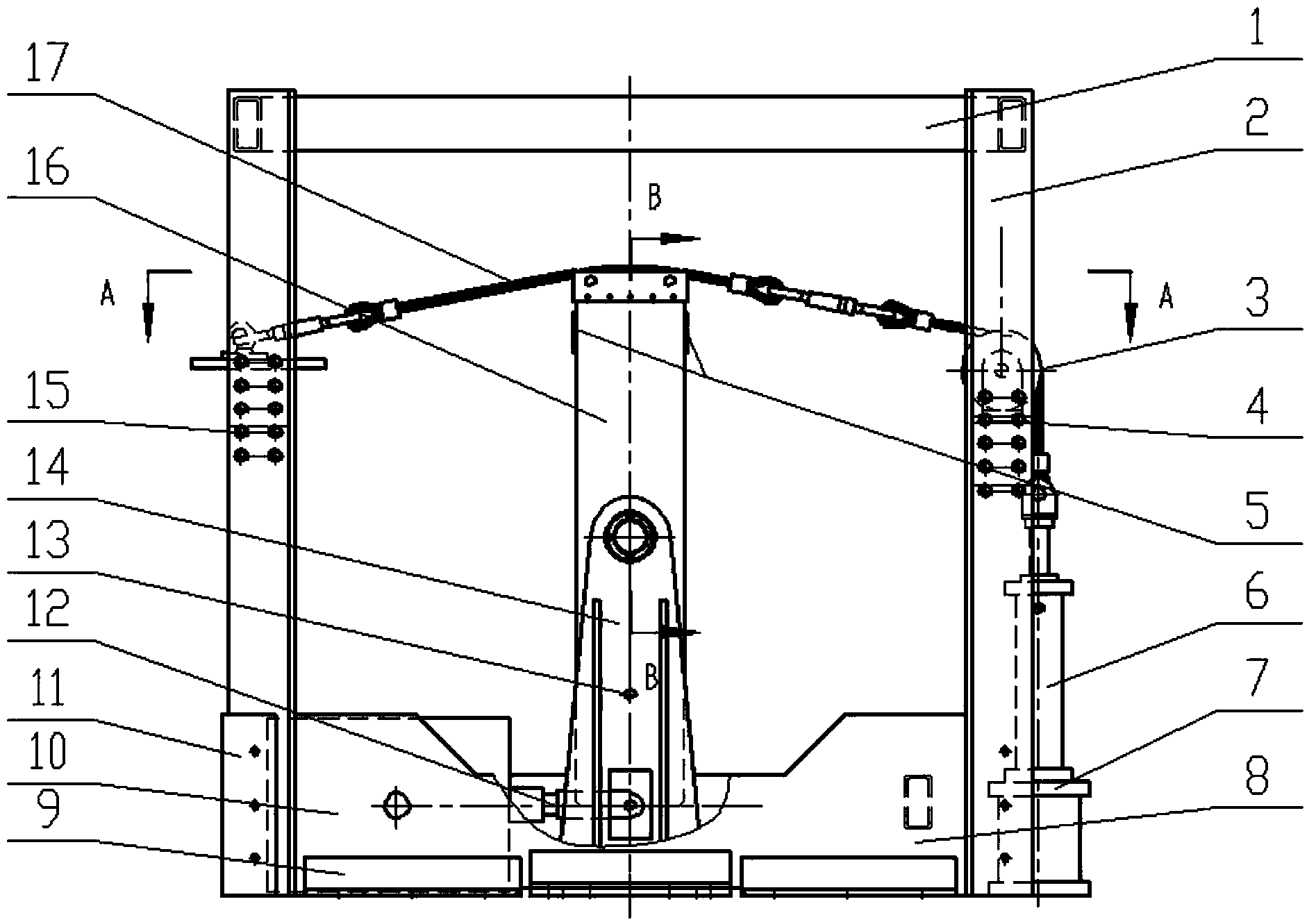

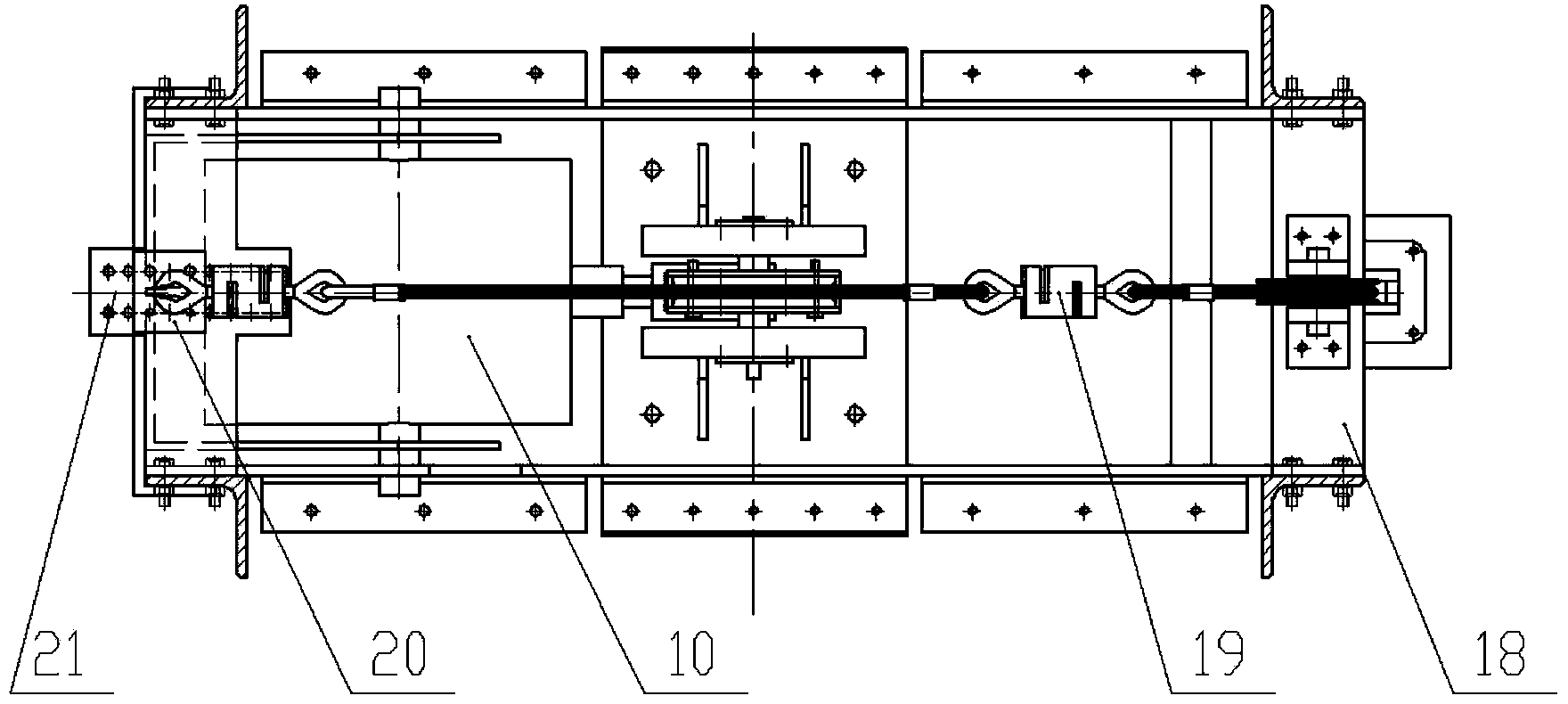

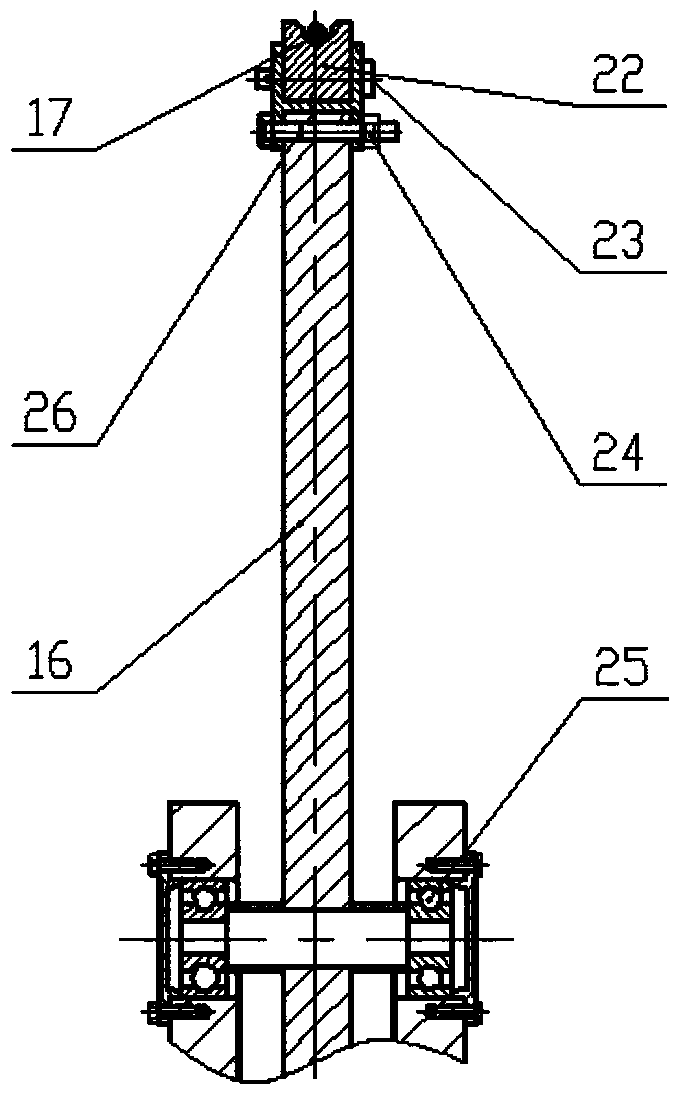

[0016] like Figures 1 to 3 As shown, the micro-slip test platform of the hoist friction lining of the present invention includes a support stand, a loading system, a power system and a measurement system.

[0017] The support platform includes a bottom beam 8, which is fixed by a fixed angle steel 9, and a support column 2 is welded at both ends of the bottom beam 8, and the top beam 1 is welded to the upper end of the support column 2, and a row of vertical columns is arranged on the support column 2 along the vertical direction. The fixing hole, the pulley bracket 18 and the adjustment bracket 2 are respectively fixed with the support column 2 by the first adjustment bolt 4 and the second adjustment bolt 15, and the pulley bracket 18 and the adjustment bracket can be adjusted respectively by the first adjustment bolt 4 and the second adjustment bolt 15 2 Position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com