Patents

Literature

72 results about "Circumferential strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Circumferential strain is highest at the apex and lowest at the base (a basal-to-apical gradient). Circumferential strain is lowest in the basal segments of the inferior, posterior, and lateral wall and highest at the apex. Circumferential strain is higher than longitudinal strain.

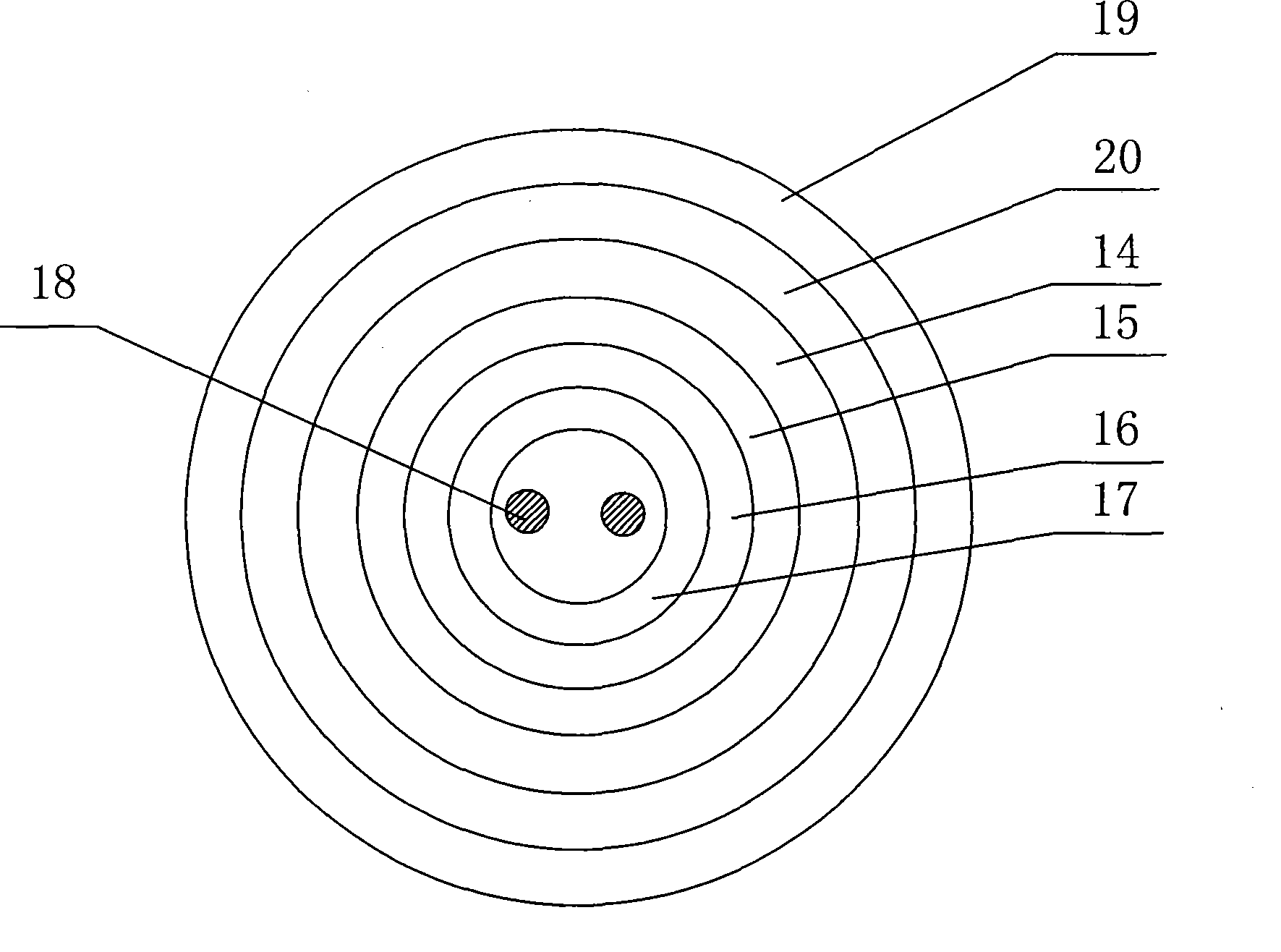

Cardiac motion tracking using cine harmonic phase (HARP) magnetic resonance imaging

InactiveUS6892089B1High speedAccurate operationSurgeryDiagnostic recording/measuringCircumferential strainFourier transform on finite groups

The present invention relates to a method of measuring motion of an object such as a heart by magnetic resonance imaging. A pulse sequence is applied to spatially modulate a region of interest of the object and at least one first spectral peak is acquired from the Fourier domain of the spatially modulated object. The inverse Fourier transform information of the acquired first spectral-peaks is computed and a computed first harmonic phase image is determined from each spectral peak. The process is repeated to create a second harmonic phase image from each second spectral peak and the strain is determined from the first and second harmonic phase images. In a preferred embodiment, the method is employed to determine strain within the myocardium and to determine change in position of a point at two different times which may result in an increased distance or reduced distance. The method may be employed to determine the path of motion of a point through a sequence of tag images depicting movement of the heart. The method may be employed to determine circumferential strain and radial strain.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

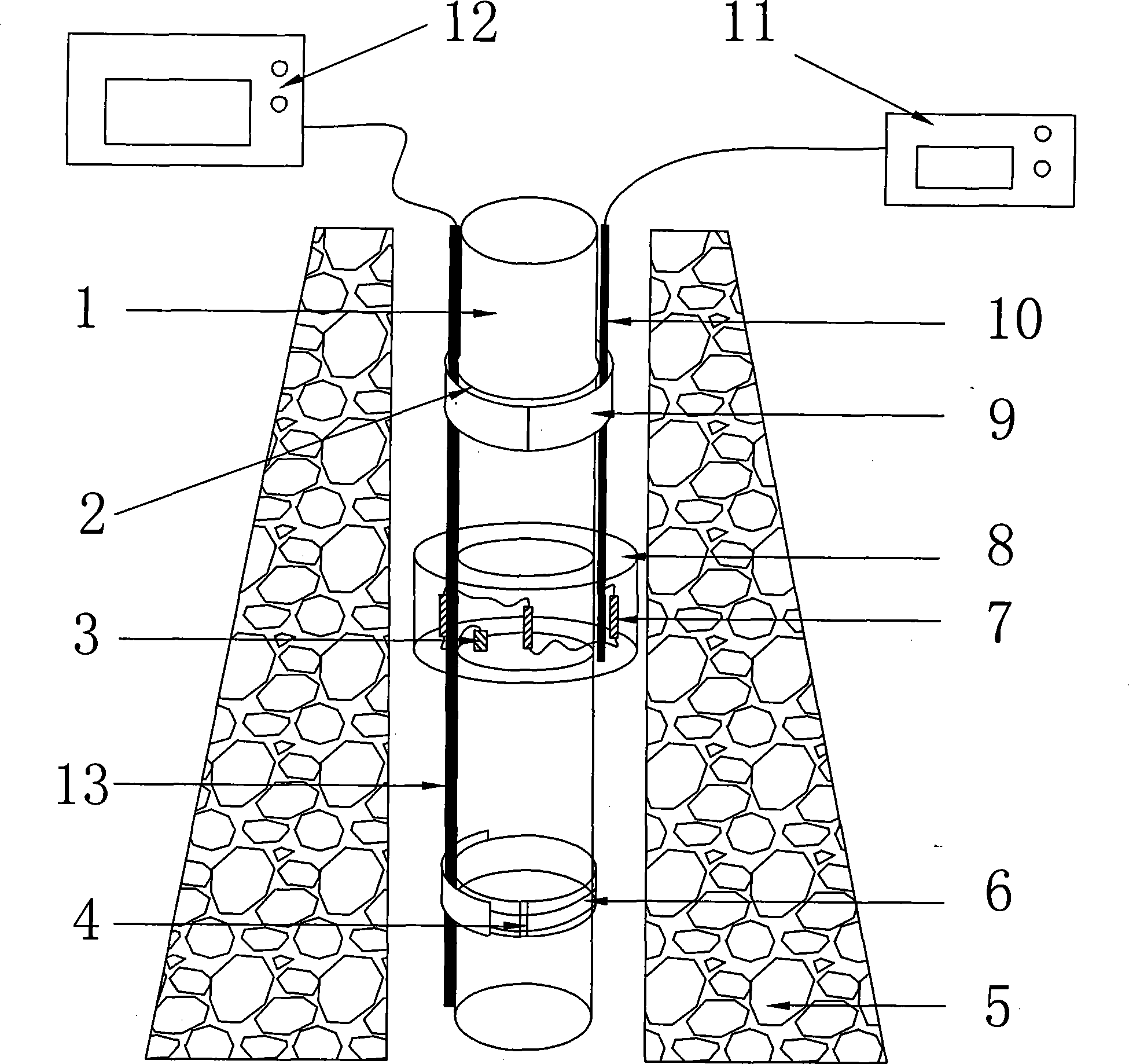

Method for monitoring downhole casing strain by using optical fibre sensor

InactiveCN101397904ARealize full well section monitoringAccurate measurementSurveyConstructionsGratingCircumferential strain

The invention relates to a method for monitoring the stress of a casing in a well by applying optical-fiber sensors, which mainly solves the problem that the existing research field of the casing erosion of an oil field and oil-water well does not have a direct method for monitoring the stress loading process of the casing in the well and the morphological characters of the casing erosion. The method is characterized in that: optical-fiber grating sensors are circumferentially arranged along the outer surface of the casing; a ground optical-fiber grating demodulation instrument connected with the optical-fiber grating sensors is utilized to monitor the circumferential strain Epsilon Theta of the casing and obtain the circumferential strain data of the casing; meanwhile, Brilliouin optical-fiber sensors are axially arranged along the outer surface of the casing; a ground Brilliouin optical-fiber demodulation instrument connected with the Brilliouin optical-fiber sensors is utilized to monitor the axial strain Epsilon Z of the casing and obtain the axial stain data of the casing; and the obtained circumferential strain Epsilon Theta and the axial strain Epsilon Z of the casing are utilized to obtain the stress of the outer layer of the casing in the well according to a ground stress explanation model. The method is characterized by being capable of permanently monitoring the deformation of the casing and obtaining corresponding stratum pressure under the condition without knowing the casing erosion and the stratum pressure.

Owner:DAQING OILFIELD CO LTD

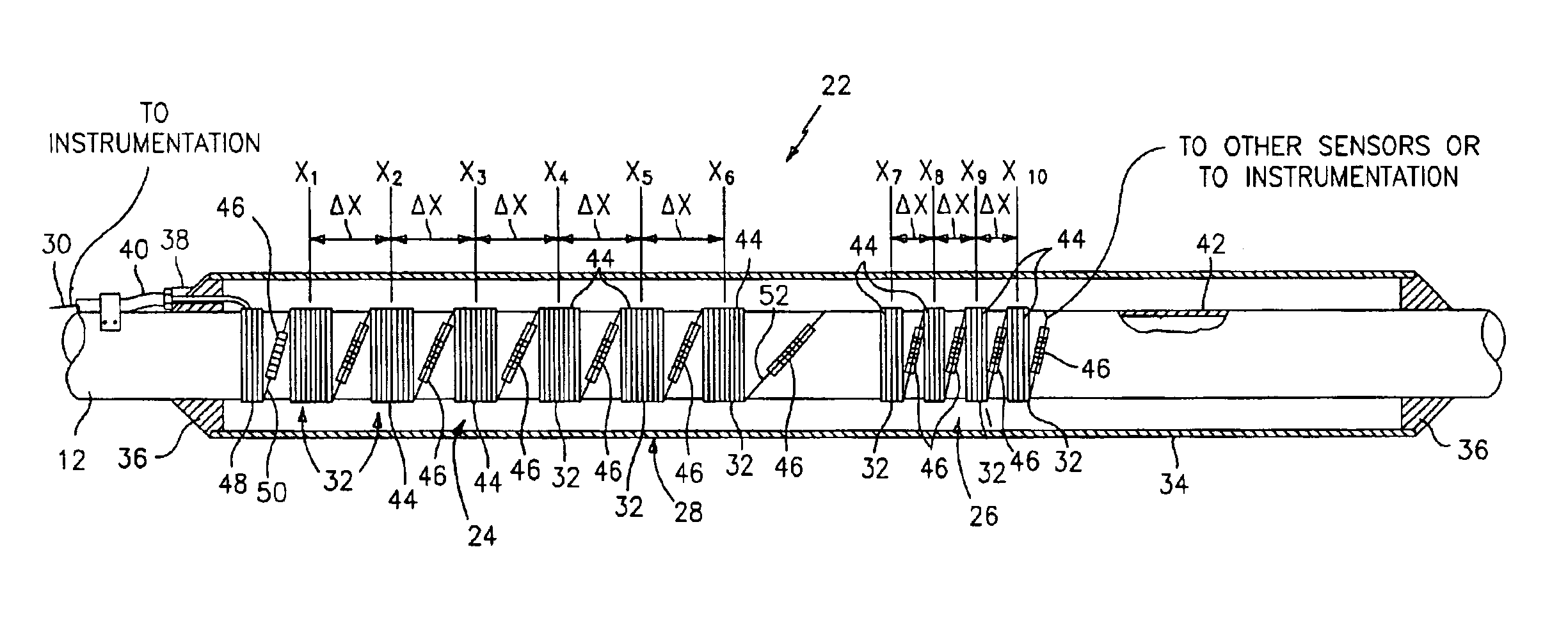

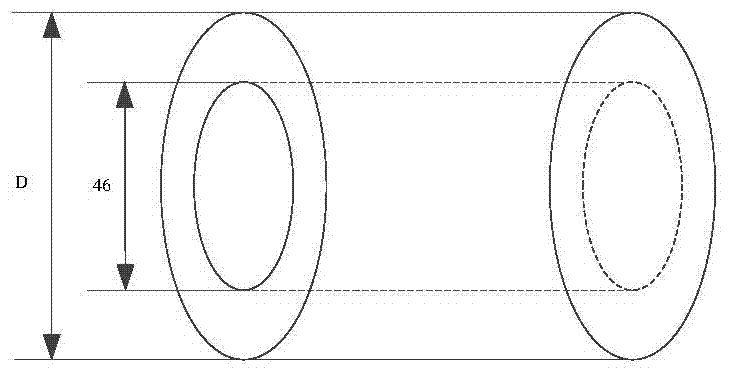

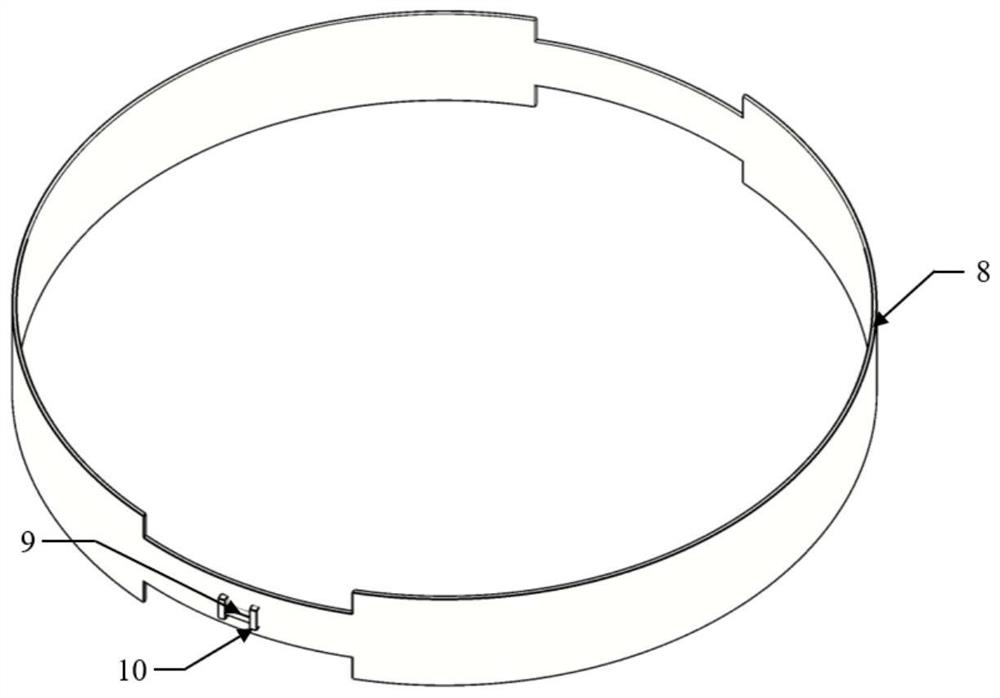

Circumferential strain attenuator

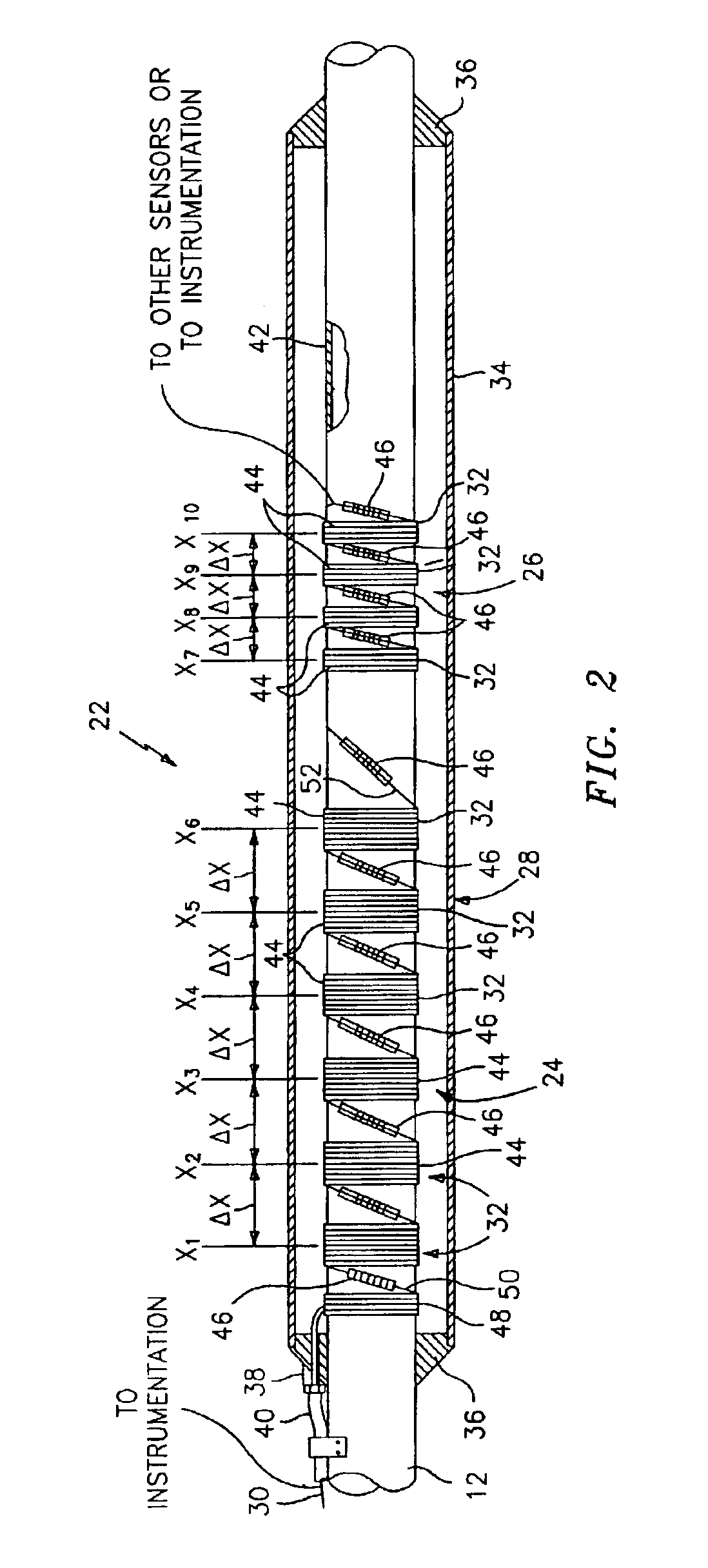

InactiveUS6868737B2Reduce gainWide rangeSubsonic/sonic/ultrasonic wave measurementForce measurement by measuring optical property variationCircumferential strainEngineering

An apparatus for varying the gain of a fiber optic sensor that non-intrusively senses the strain response of a pipe is provided. The apparatus includes a circumferential strain attenuator that has an annular land portion that mechanically couples the attenuator to the pipe. An annular web extends coaxially from the land portion and has a reduced cross sectional area relative to the land, and an annular mandrel portion extends coaxially from the web portion and forms a gap between the pipe and the mandrel. The fiber optic sensor is wound on the circumferential strain attenuator. The web and mandrel cooperate to reduce the strain response of the fiber optic sensor relative to the strain response of the pipe.

Owner:WEATHERFORD TECH HLDG LLC

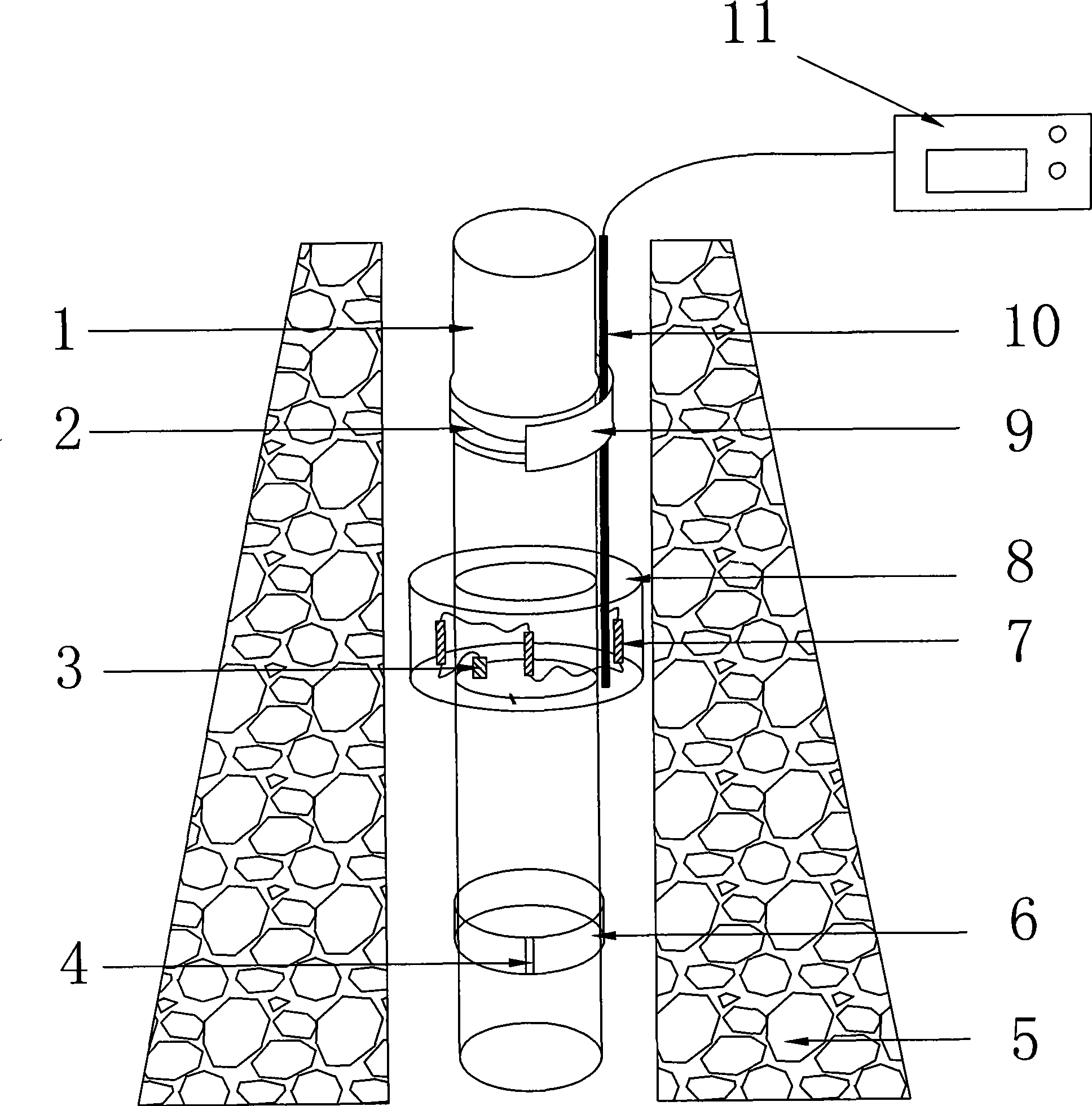

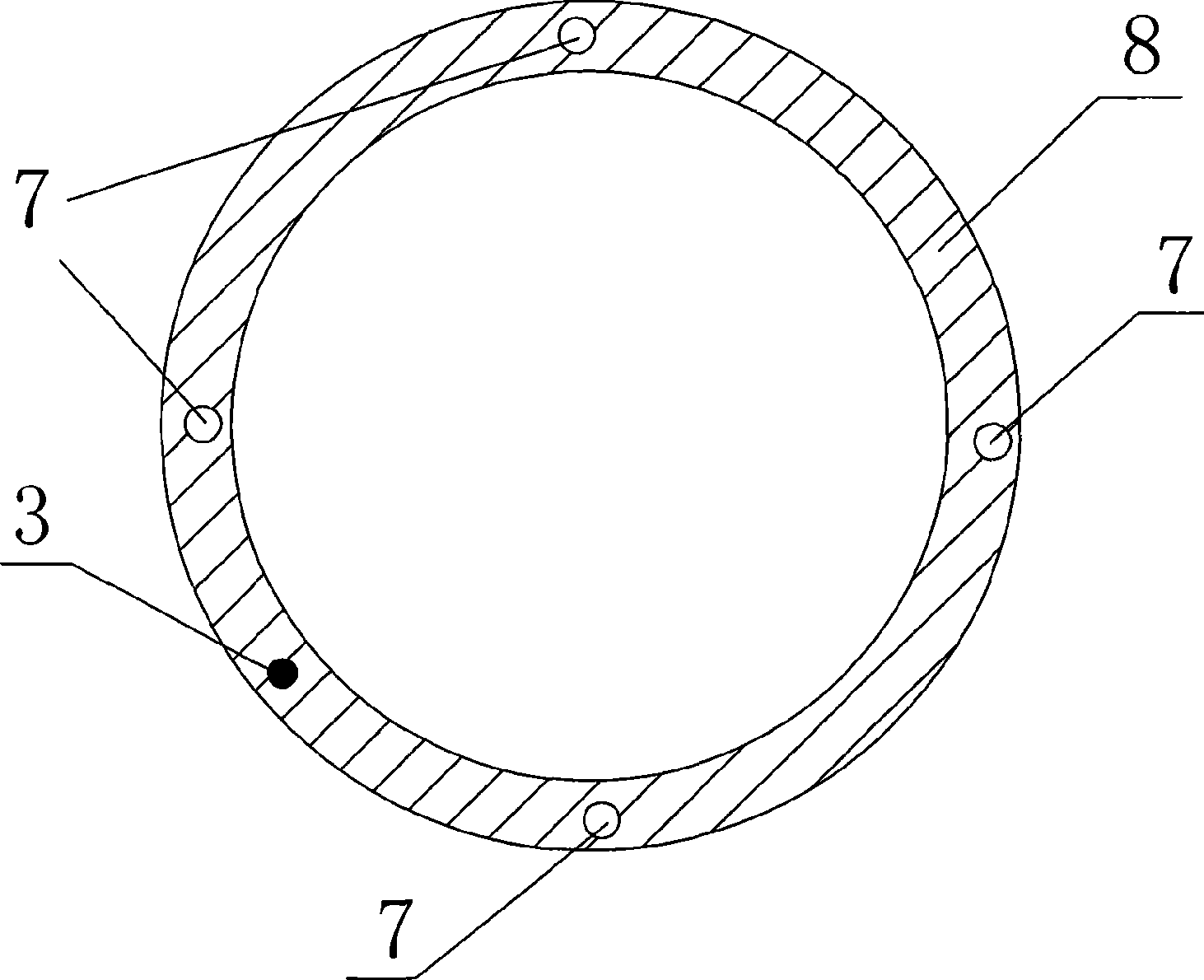

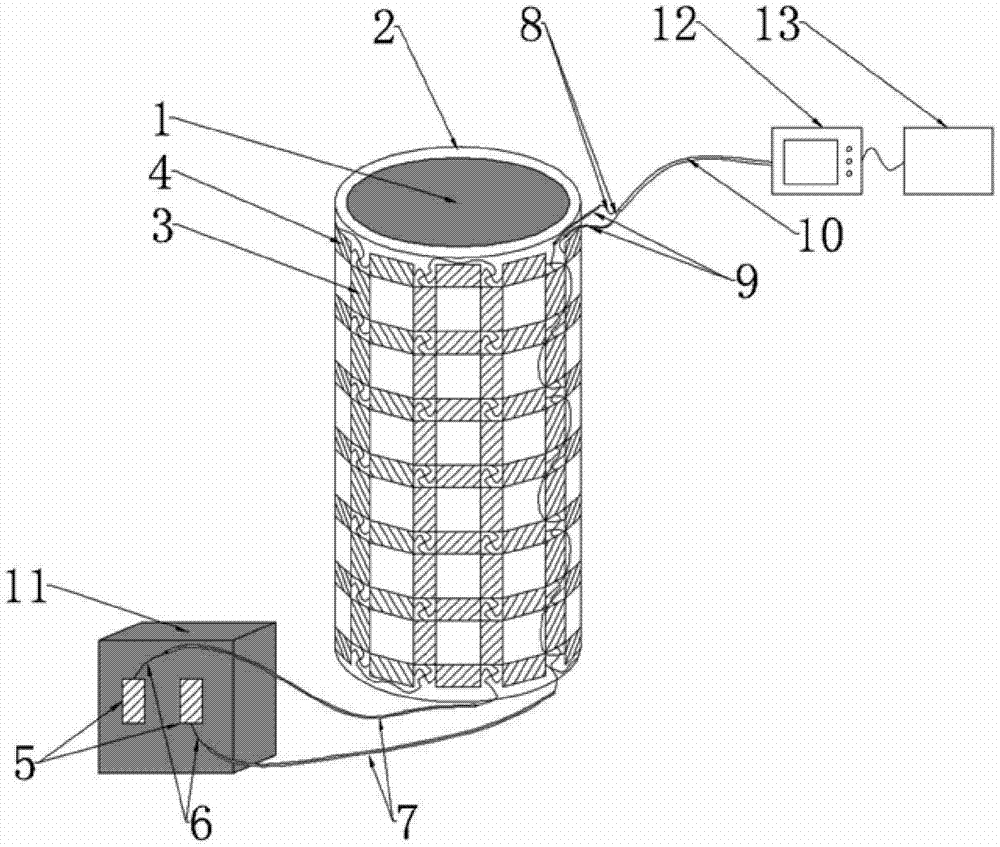

Method for monitoring sleeve circumferential strain by using optical fibre grating sensor

InactiveCN101397903AGuaranteed stabilityOvercoming the limitations of susceptibility to electromagnetic interferenceSurveyUsing optical meansGratingEngineering

The invention relates to a method for monitoring the circumferential strain of a casing by applying optical-fiber grating sensors, which mainly solves the problem that an electric-resistance strain gauge adopted of the current technology for monitoring the circumferential deformation of the casing is easy to be affected by electromagnetism in a well and corrosion, thus causing a measured circumferential strain signal of the casing to be inaccurate. The method is characterized in that: the optical-fiber grating sensors are arranged outside the casing along the circumferential direction of the casing, wherein, a plurality of optical-fiber grating sensors are evenly arranged around the casing; sections of adjacent intervals form a certain angle; an optical-fiber temperature compensating sensor is arranged in a position at a corresponding distance away from the group of sensors; the optical-fiber grating sensors are applied to monitoring the circumferential deformation and stress status of the casing within certain ranges; meanwhile, the temperature compensating sensor is applied to serving the temperature compensation and temperature monitoring in the well of the strain sensor; the sensors transmit underground signals to the ground by a transmission optical cable; and the signals can be transformed into the circumferential strain information of the casing after a demodulation instrument obtains the signals and carries out secondary treatment. The method is characterized by not being affected by the underground electromagnetism.

Owner:DAQING OILFIELD CO LTD

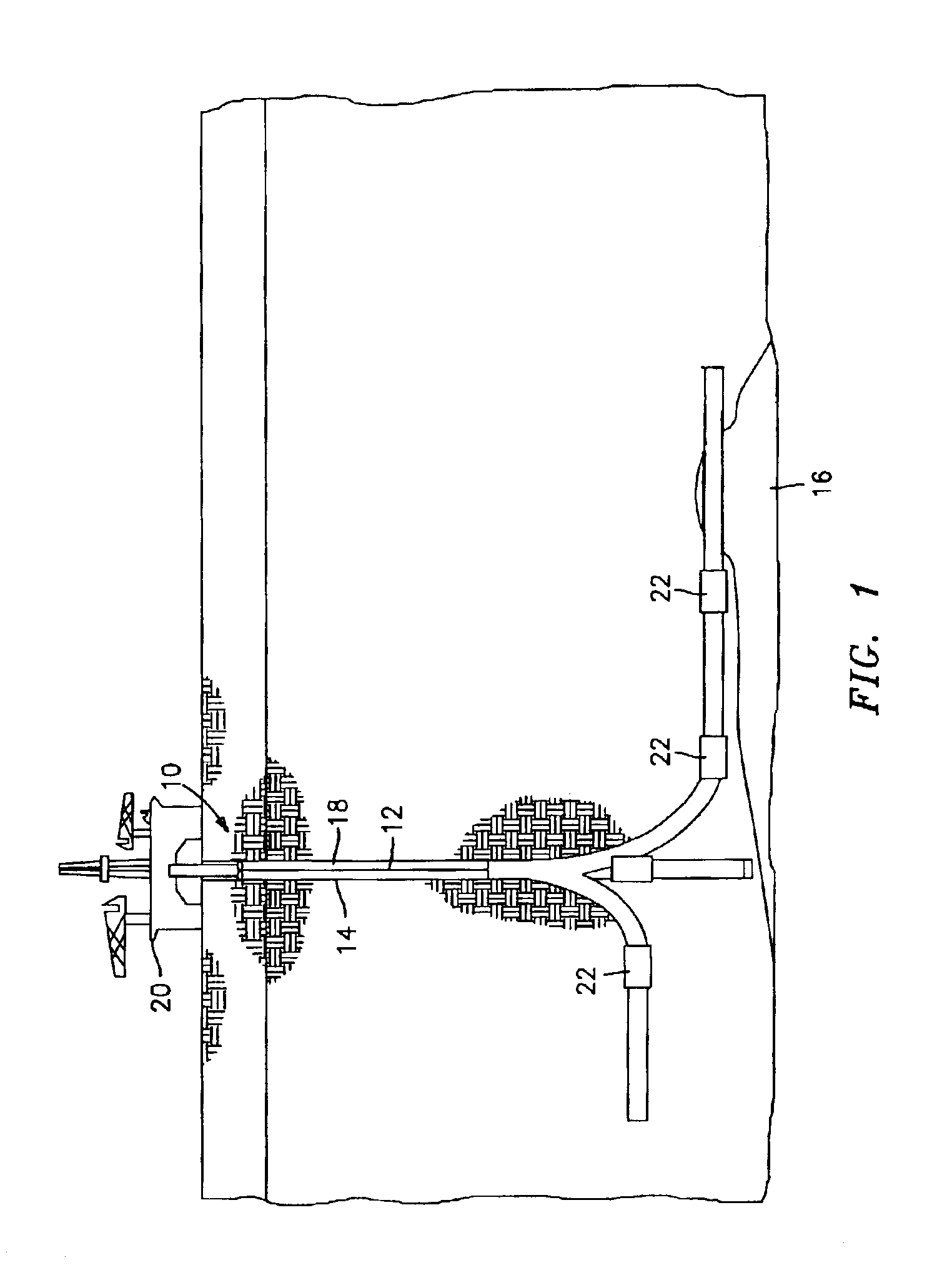

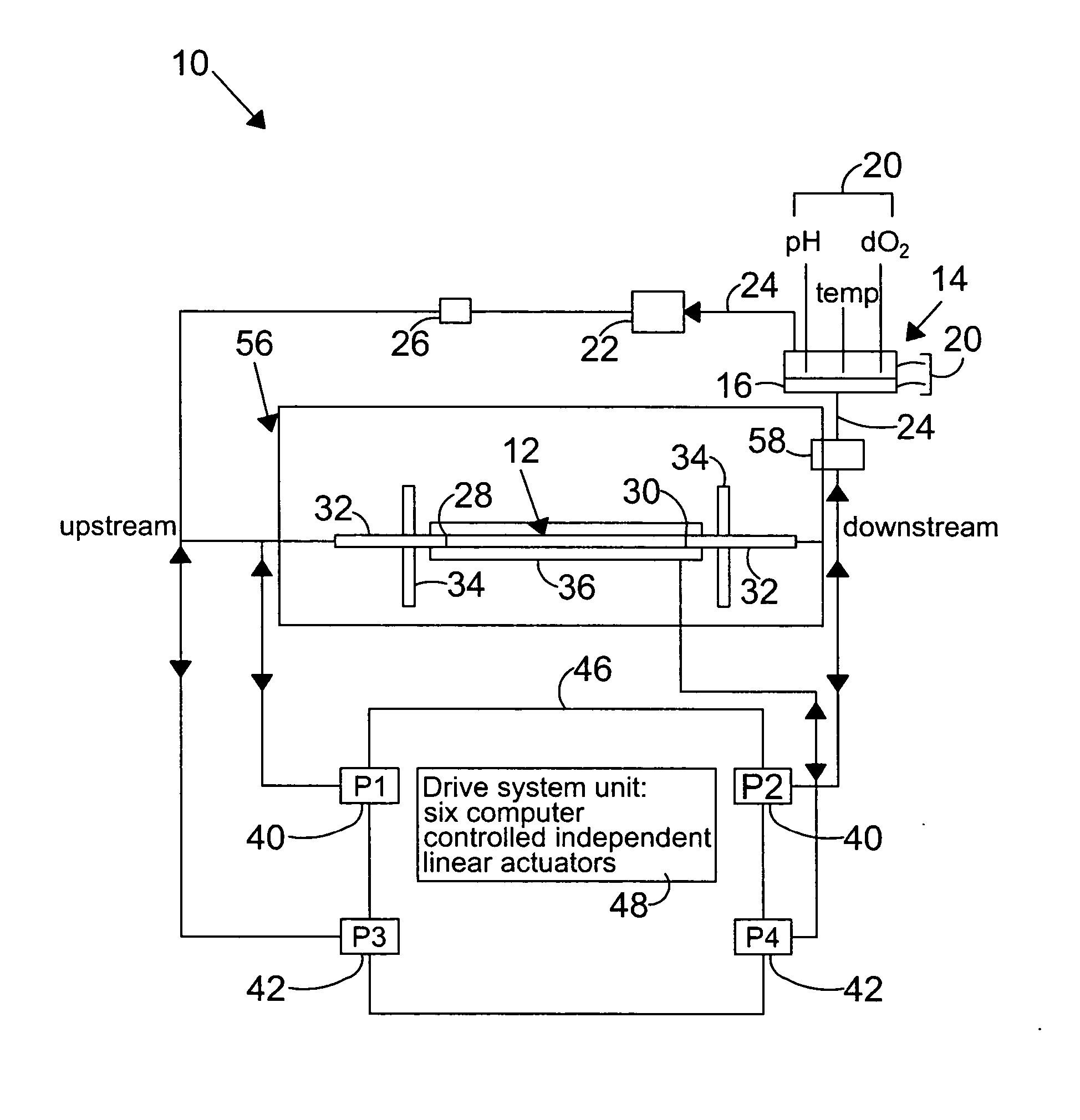

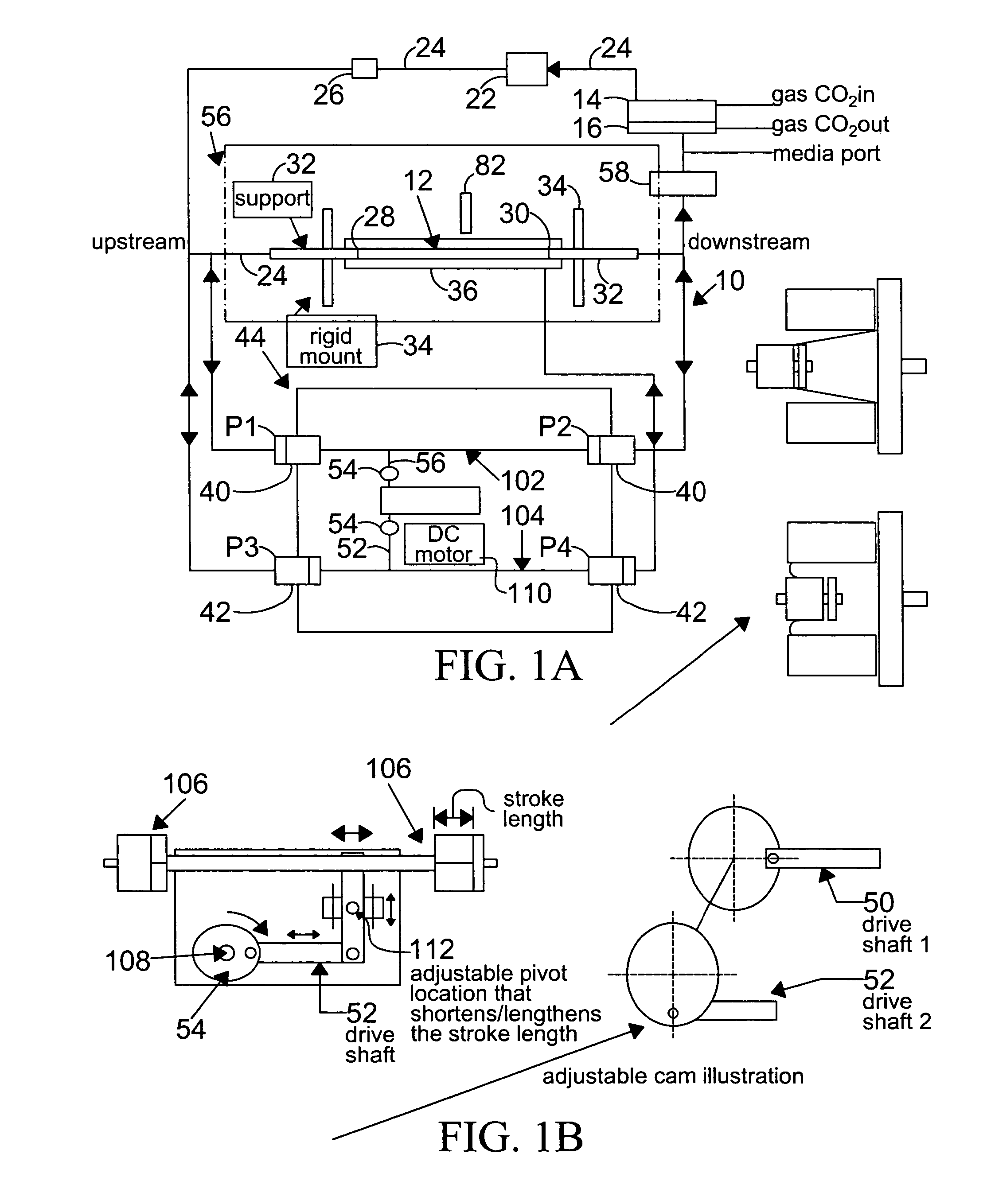

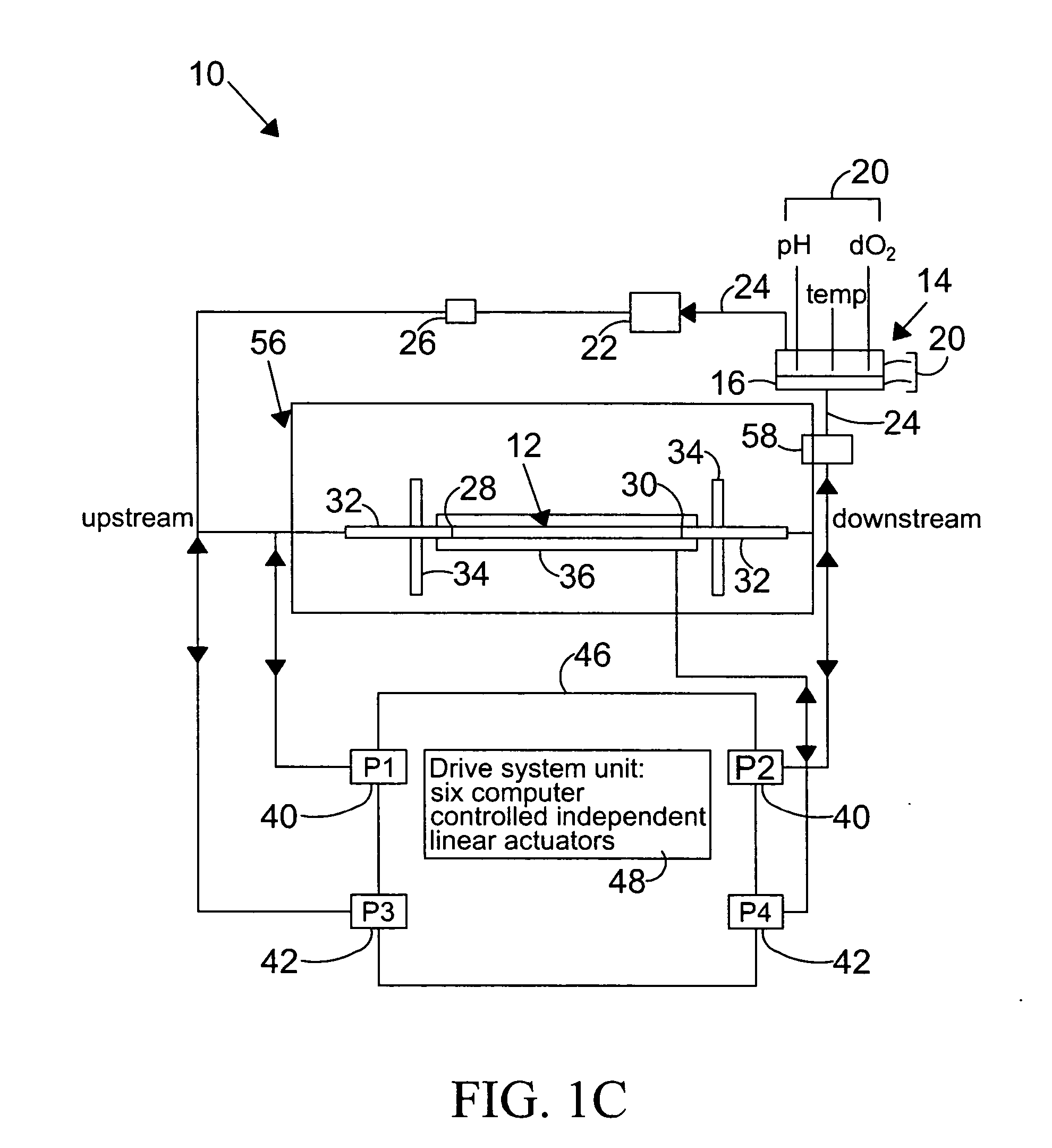

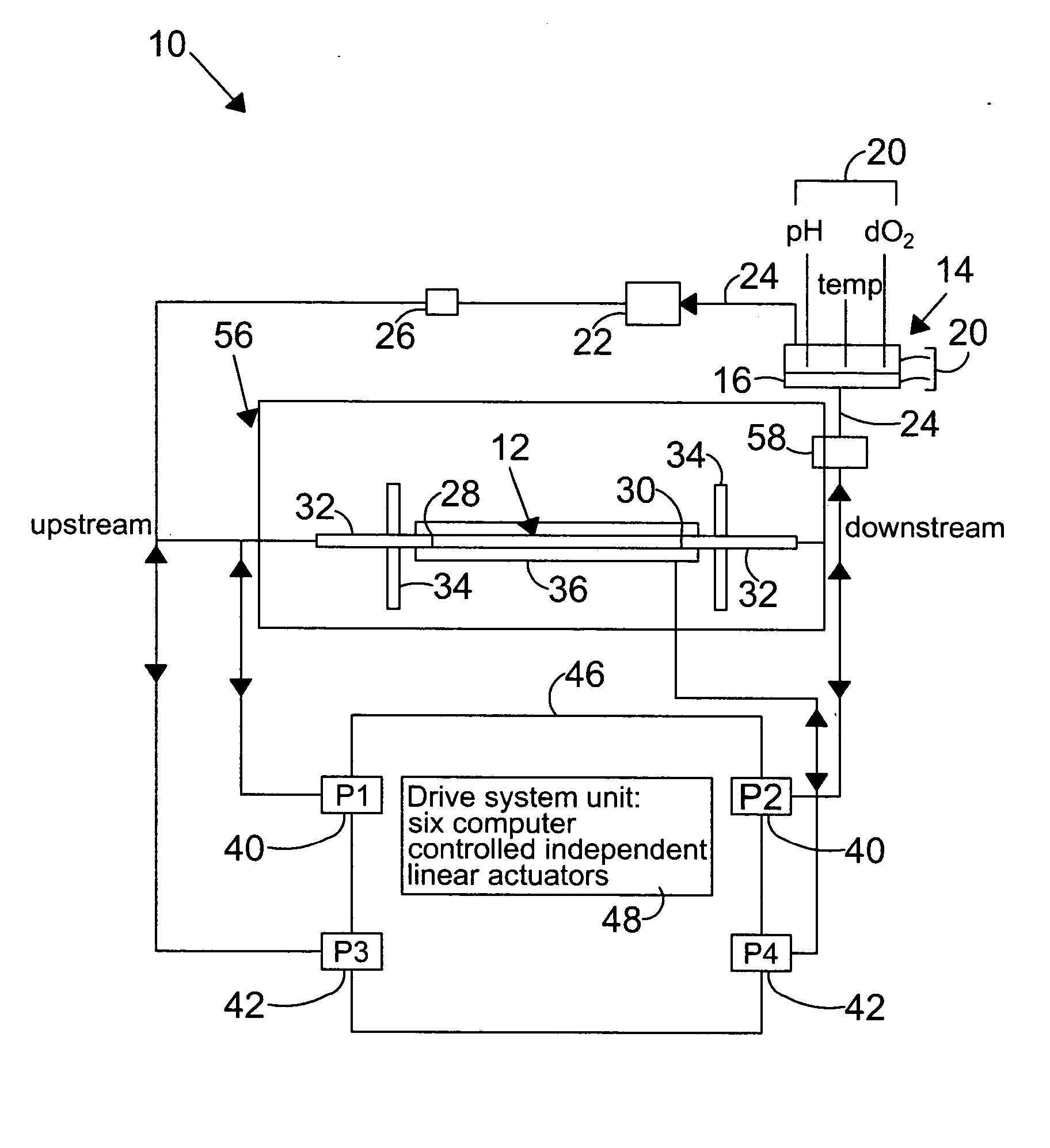

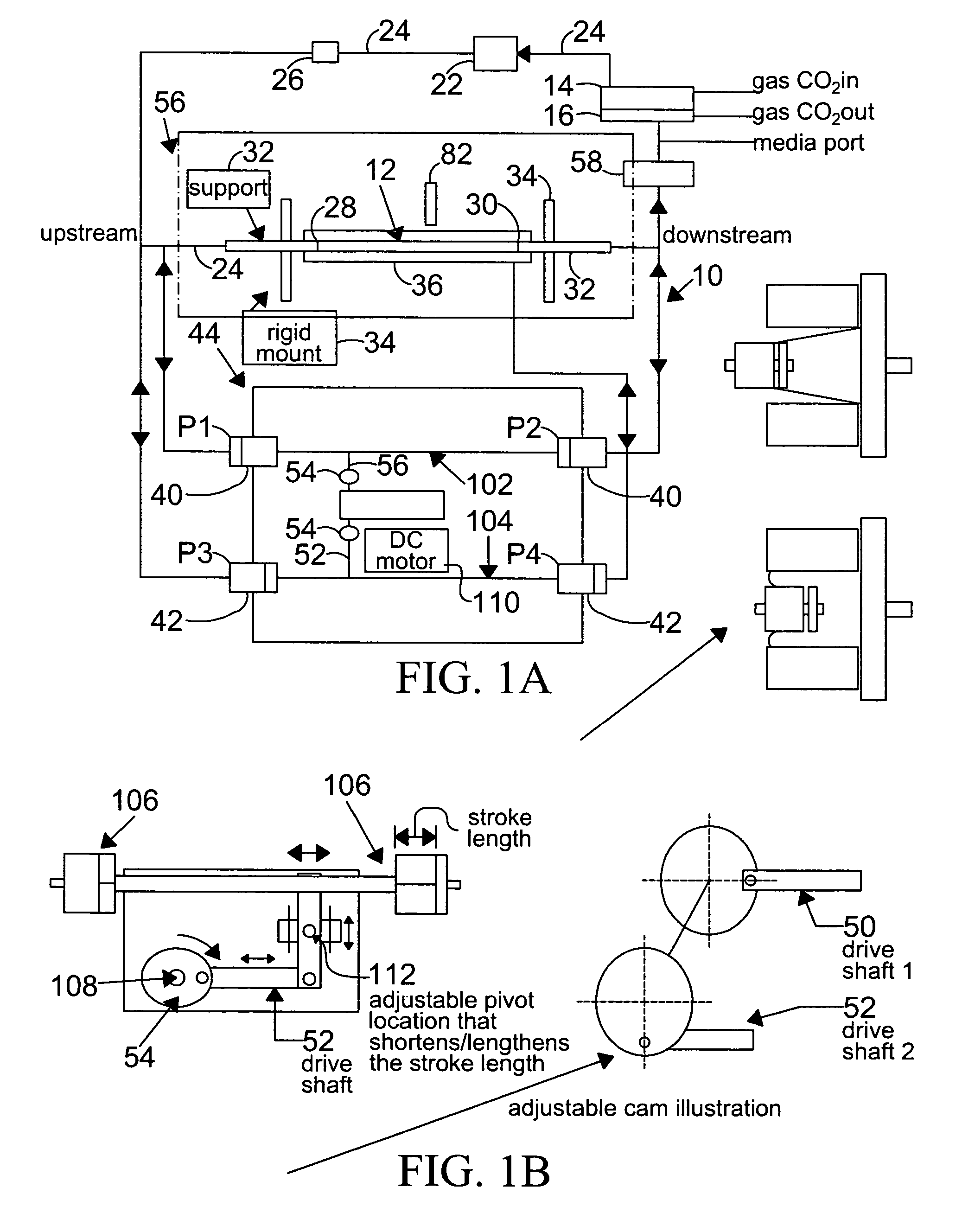

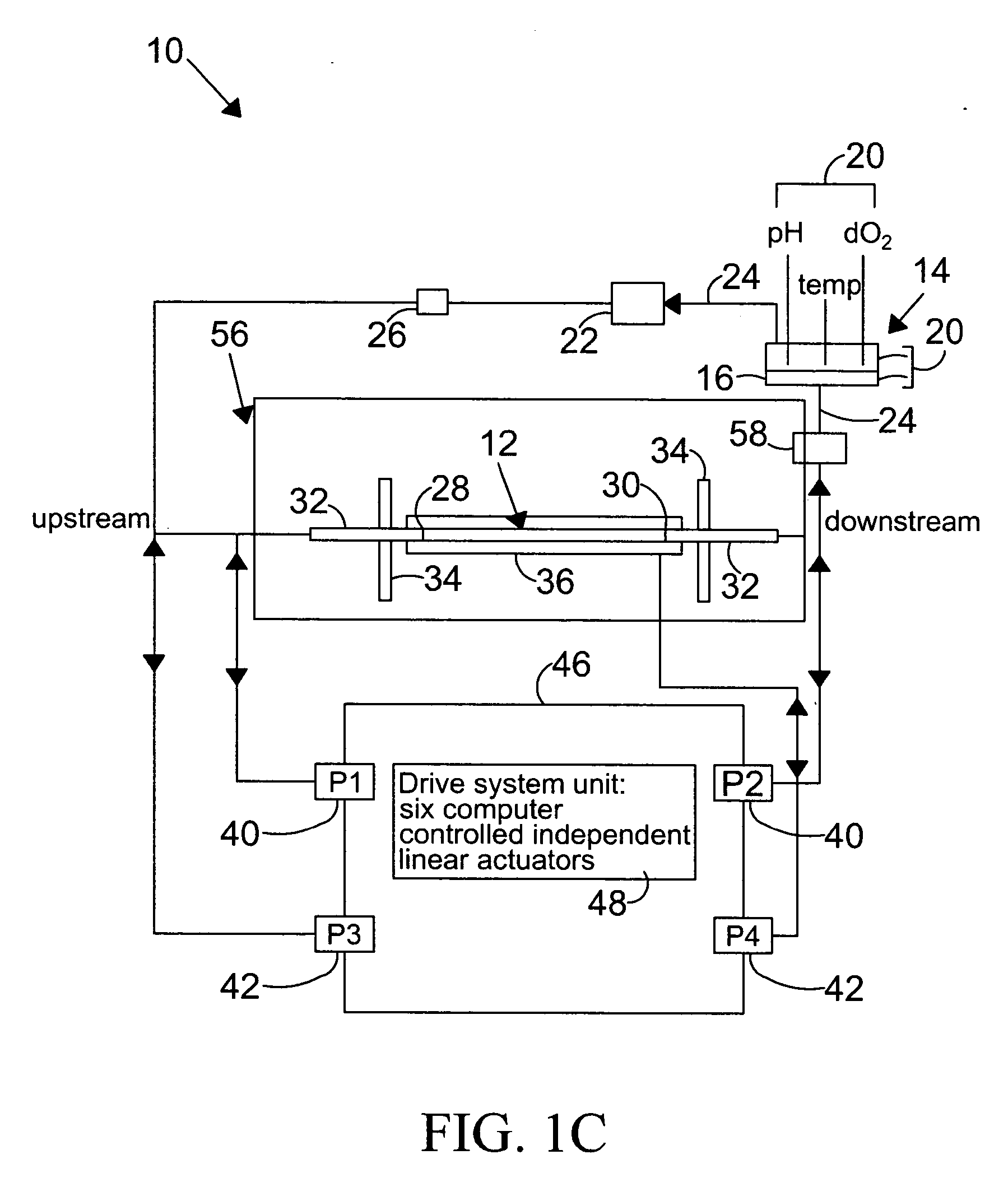

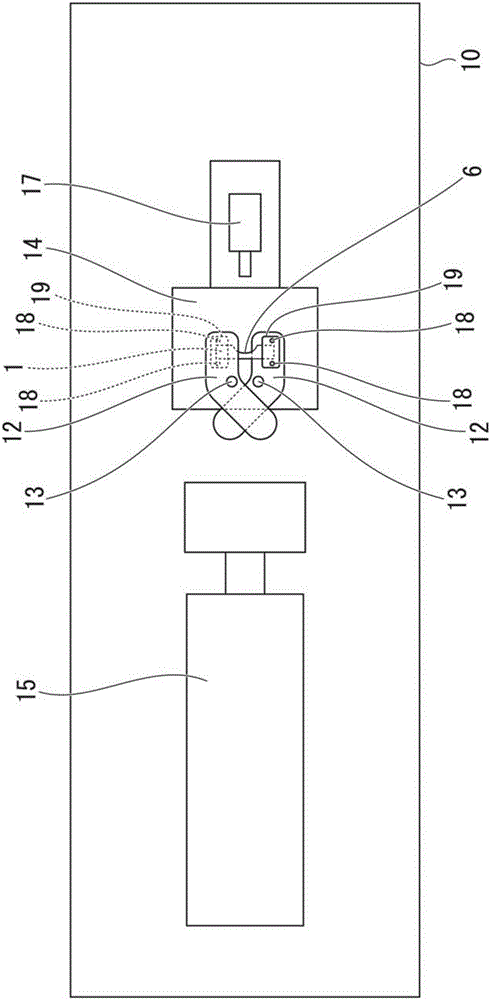

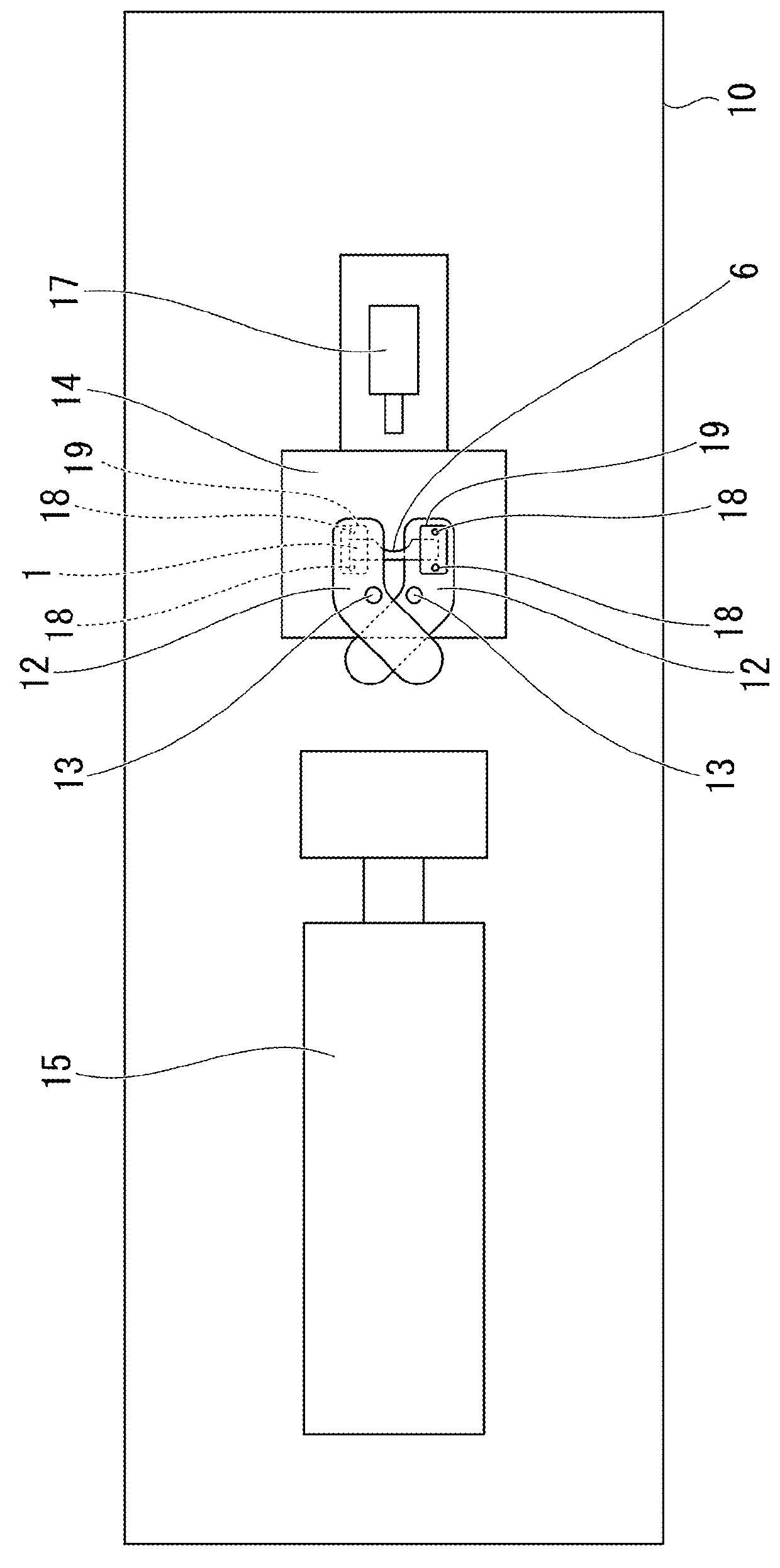

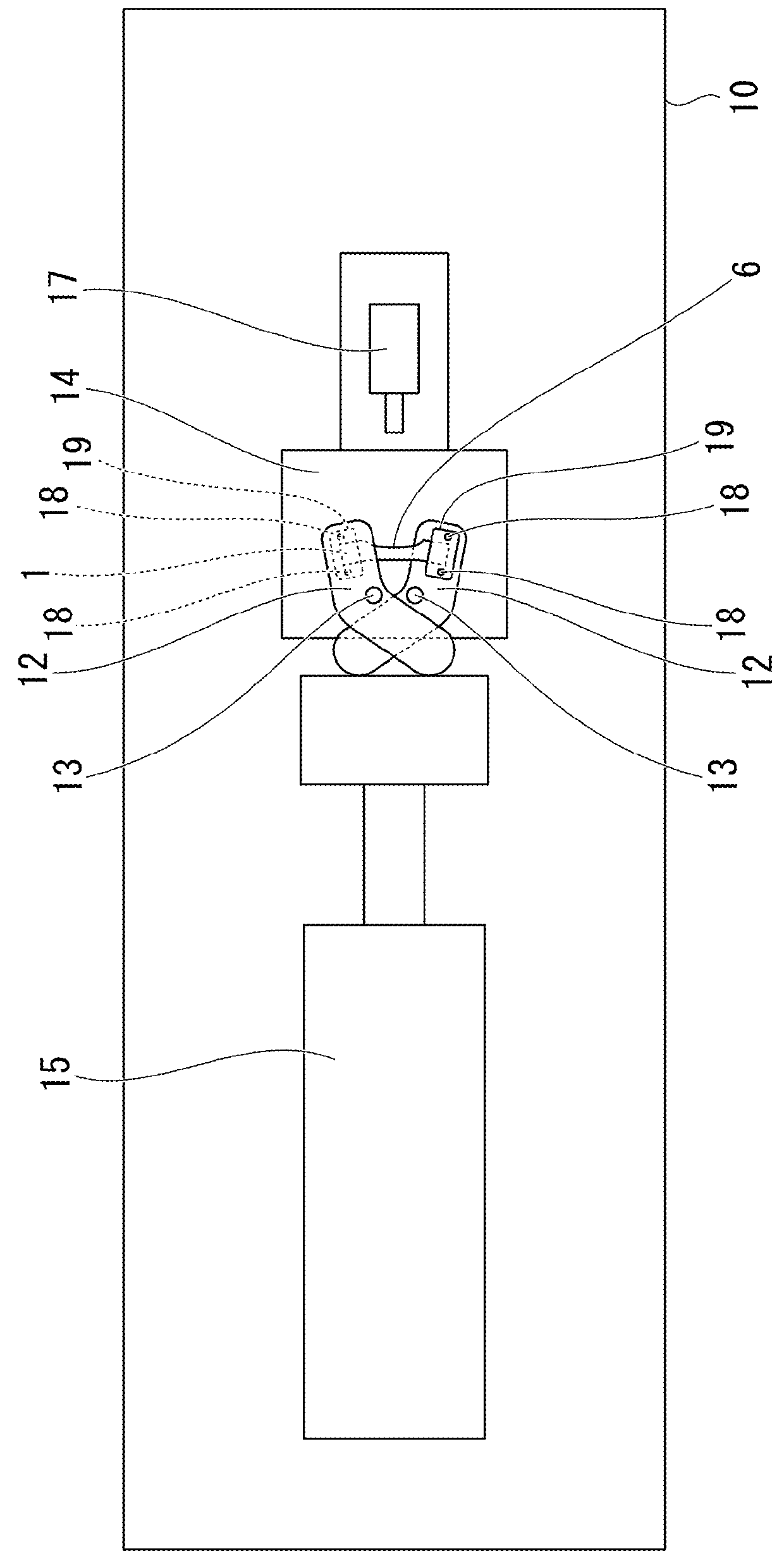

System and method to simulate hemodynamics

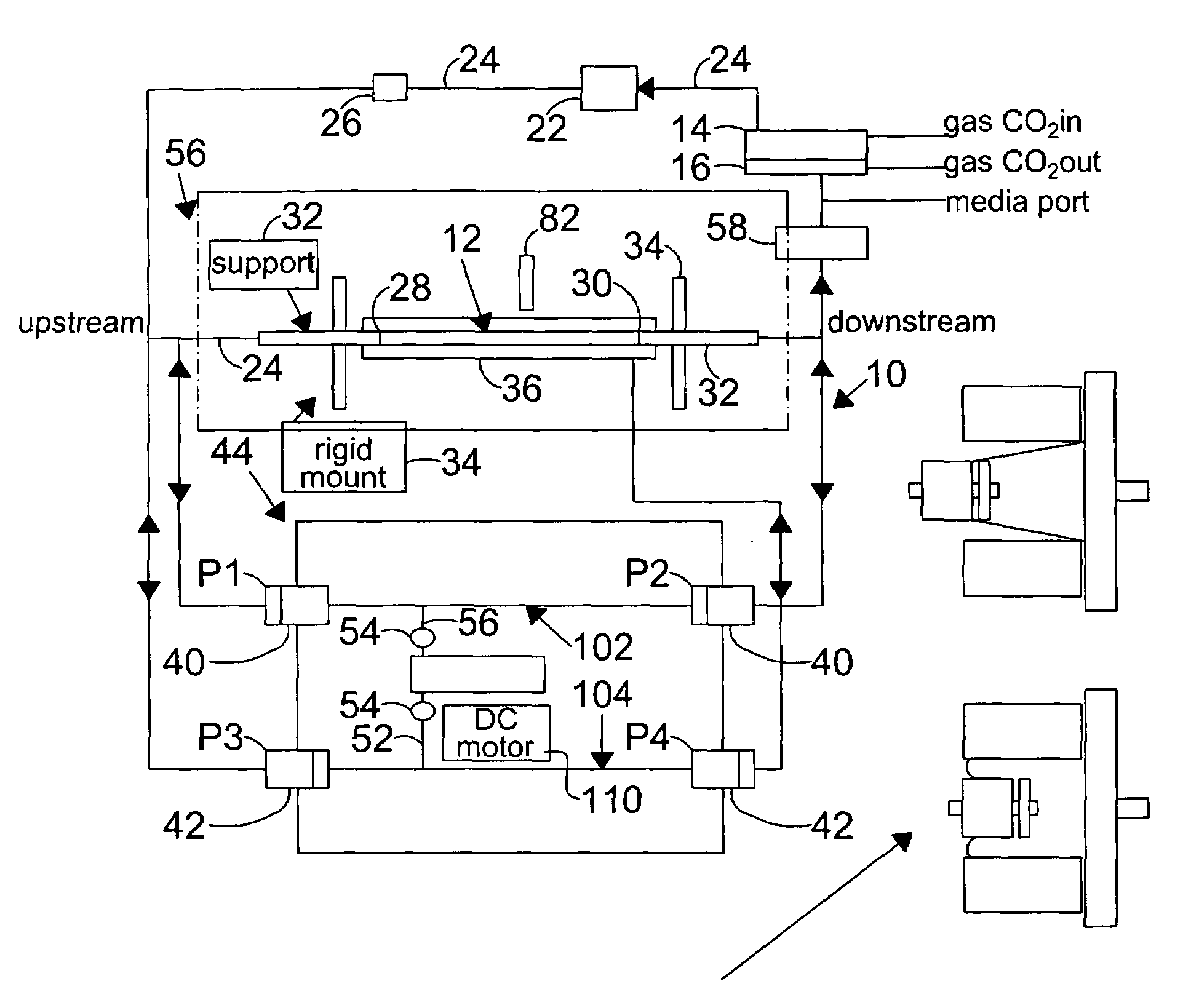

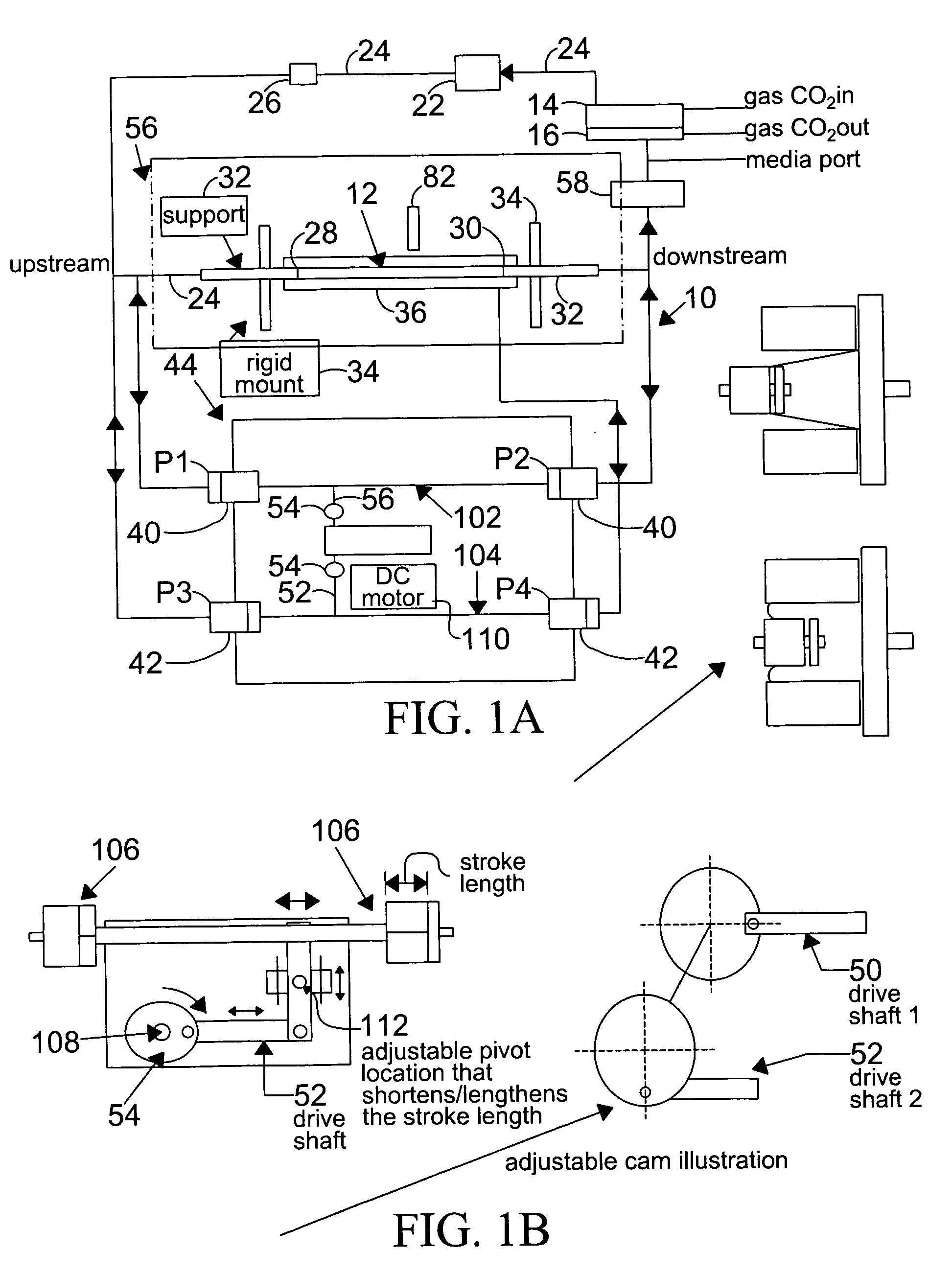

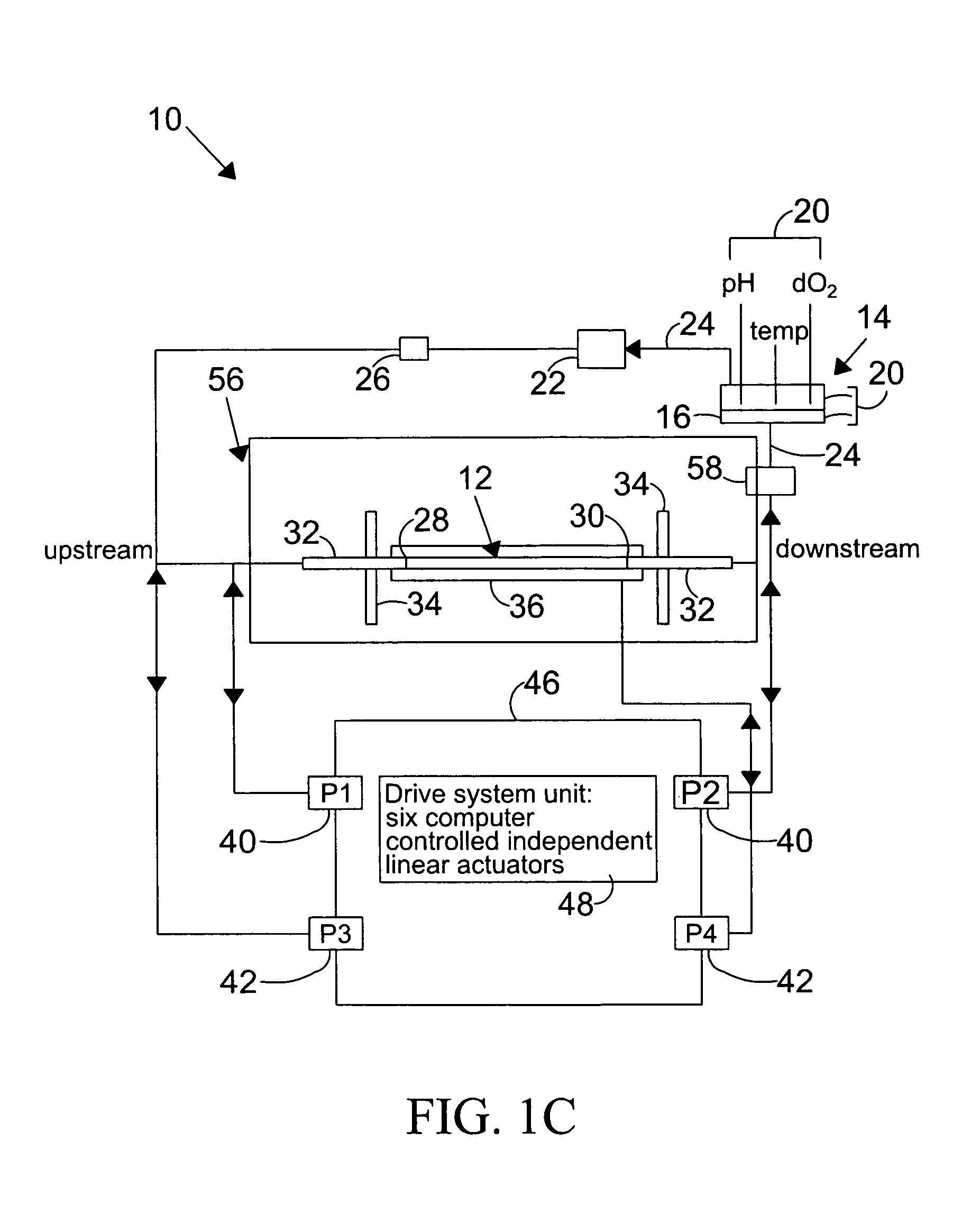

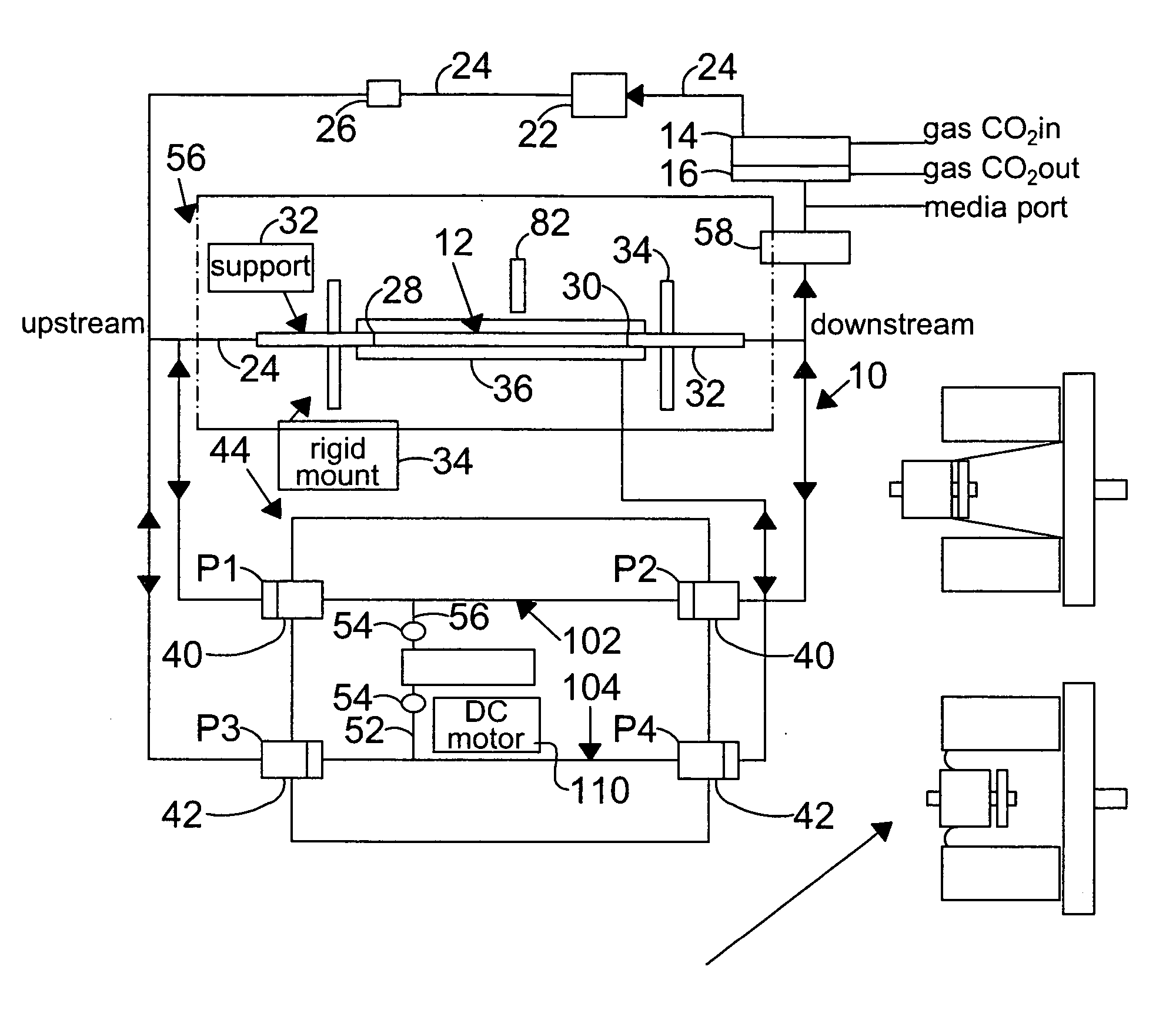

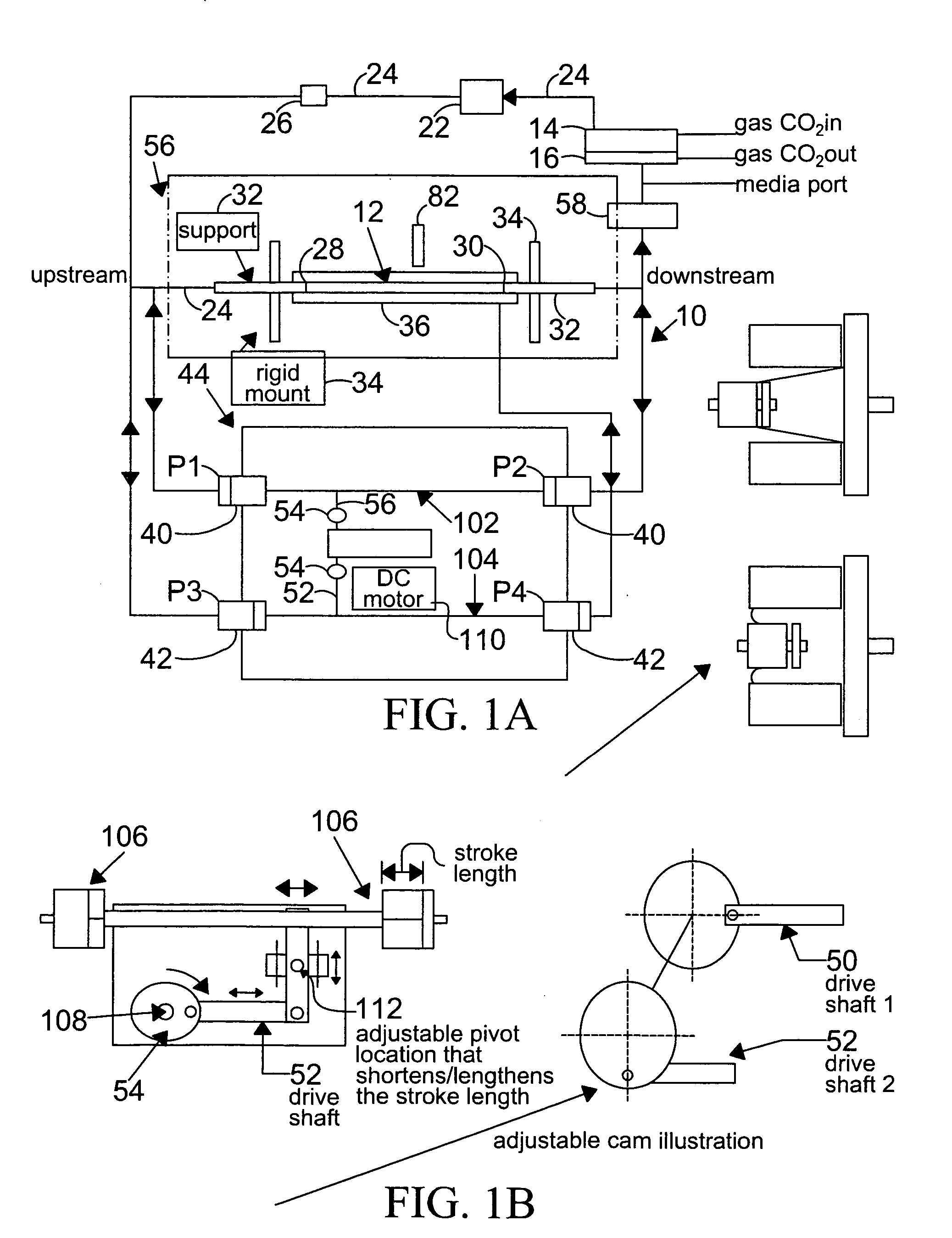

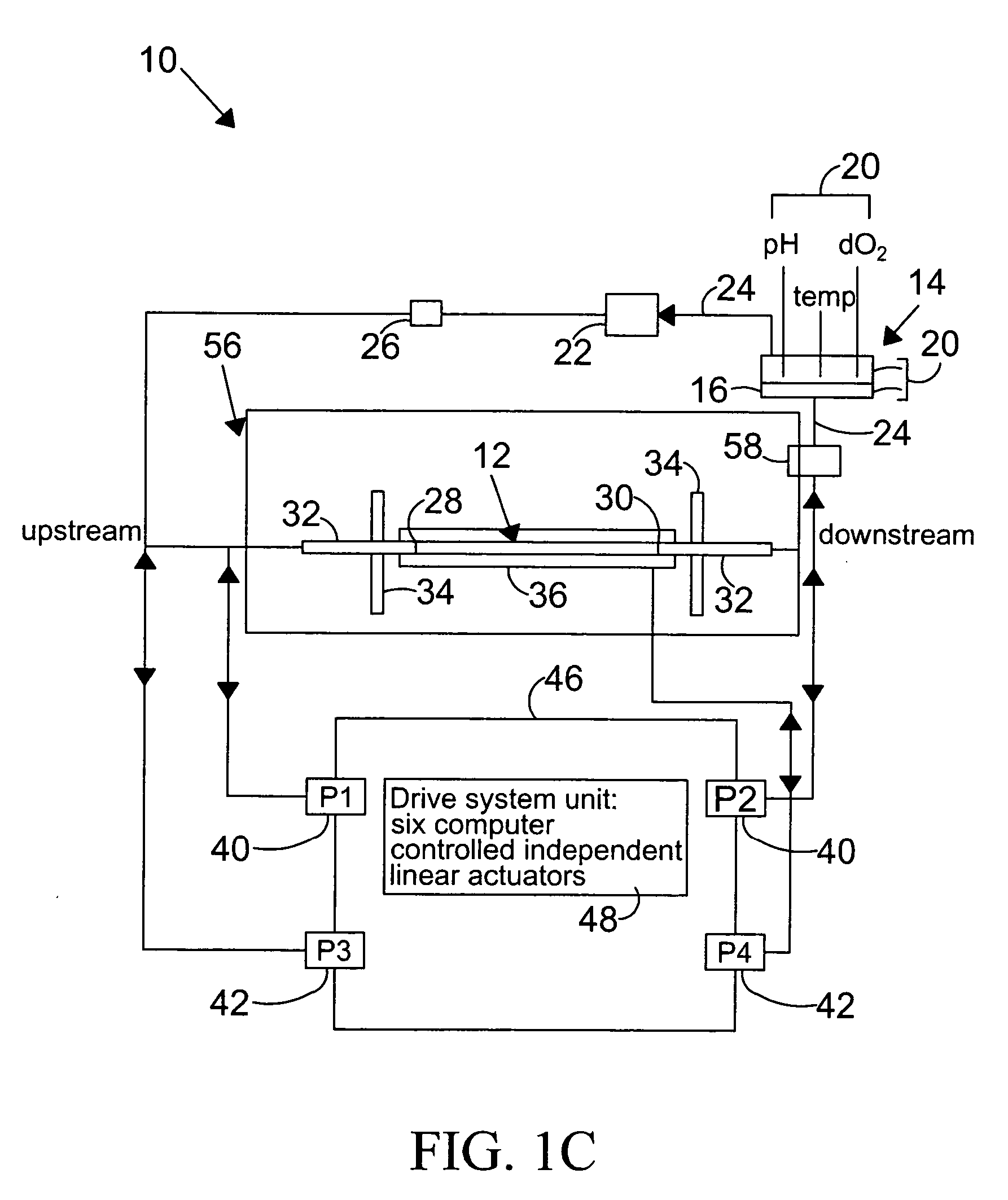

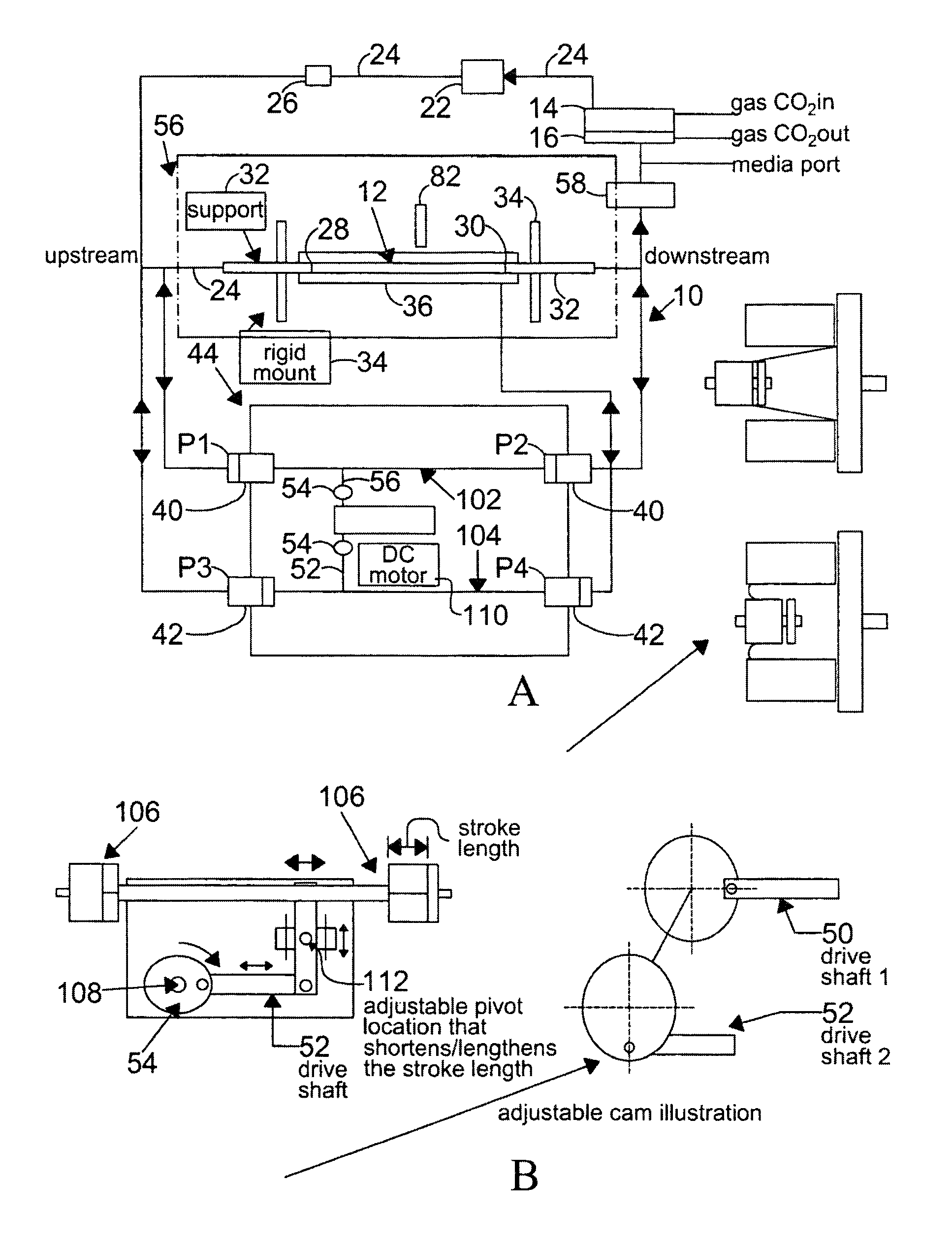

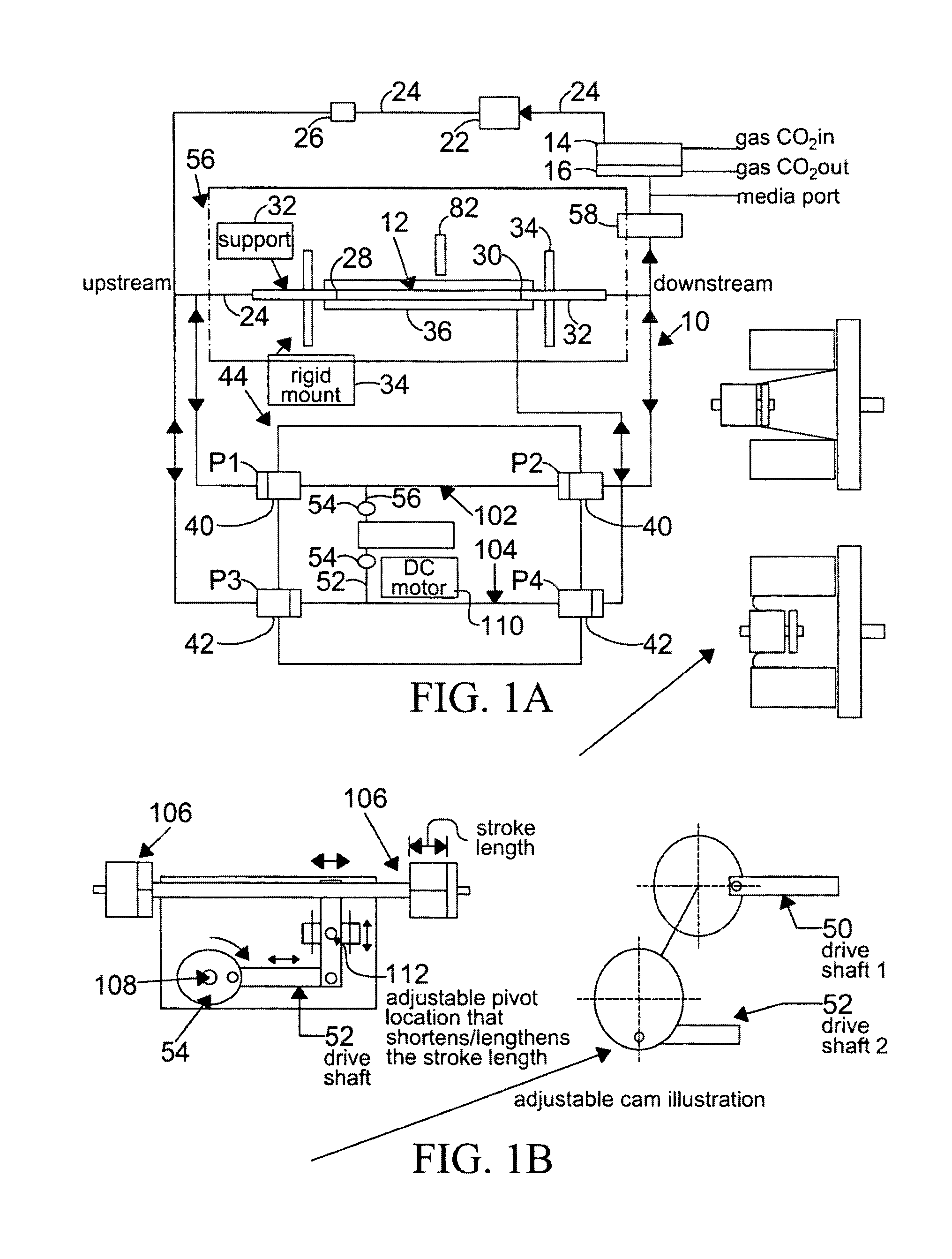

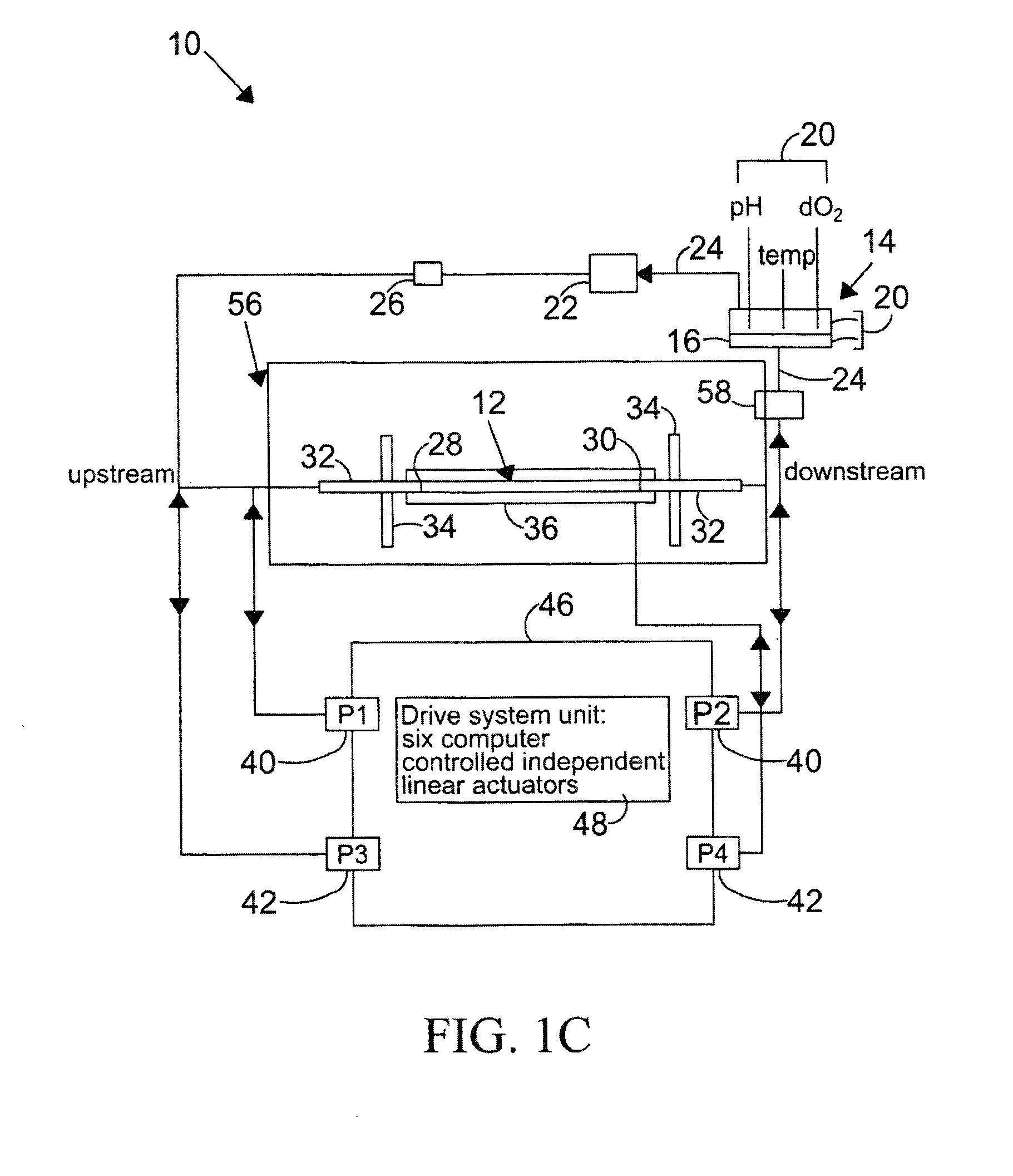

InactiveUS7063942B2Independent controlBioreactor/fermenter combinationsBiological substance pretreatmentsWall shearDrive shaft

A system for hemodynamic simulation comprises a vessel having properties of a blood vessel, a reservoir containing a quantity of fluid, tubing connecting the vessel and reservoir, and at least one pump for circulating the fluid within the system. Fluid can be tissue culture medium or blood analog fluid, and the vessel may include mammalian cells attached to its inside. A drive system, comprising two reciprocating drive shafts that are coupled by a cam, enables the uncoupling of pulsatile flow and pulsatile pressure to provide independent control over wall shear stress and circumferential strain. The shaft drives two pumps that are 180 degrees out-of-phase and are connected upstream and downstream of the vessel, and effect this uncoupling.

Owner:VICTOR KRSTEC +1

System and method to simulate hemodynamics

InactiveUS20060210959A1Independent controlBioreactor/fermenter combinationsBiological substance pretreatmentsWall shearDrive shaft

A system for hemodynamic simulation comprises a vessel having properties of a blood vessel, a reservoir containing a quantity of fluid, tubing connecting the vessel and reservoir, and at least one pump for circulating the fluid within the system. Fluid can be tissue culture medium or blood analog fluid, and the vessel may include mammalian cells attached to its inside. A drive system, comprising two reciprocating drive shafts that are coupled by a cam, enables the uncoupling of pulsatile flow and pulsatile pressure to provide independent control over wall shear stress and circumferential strain. The shaft drives two pumps that are 180 degrees out-of-phase and are connected upstream and downstream of the vessel, and effect this uncoupling.

Owner:DANCU MICHAEL B

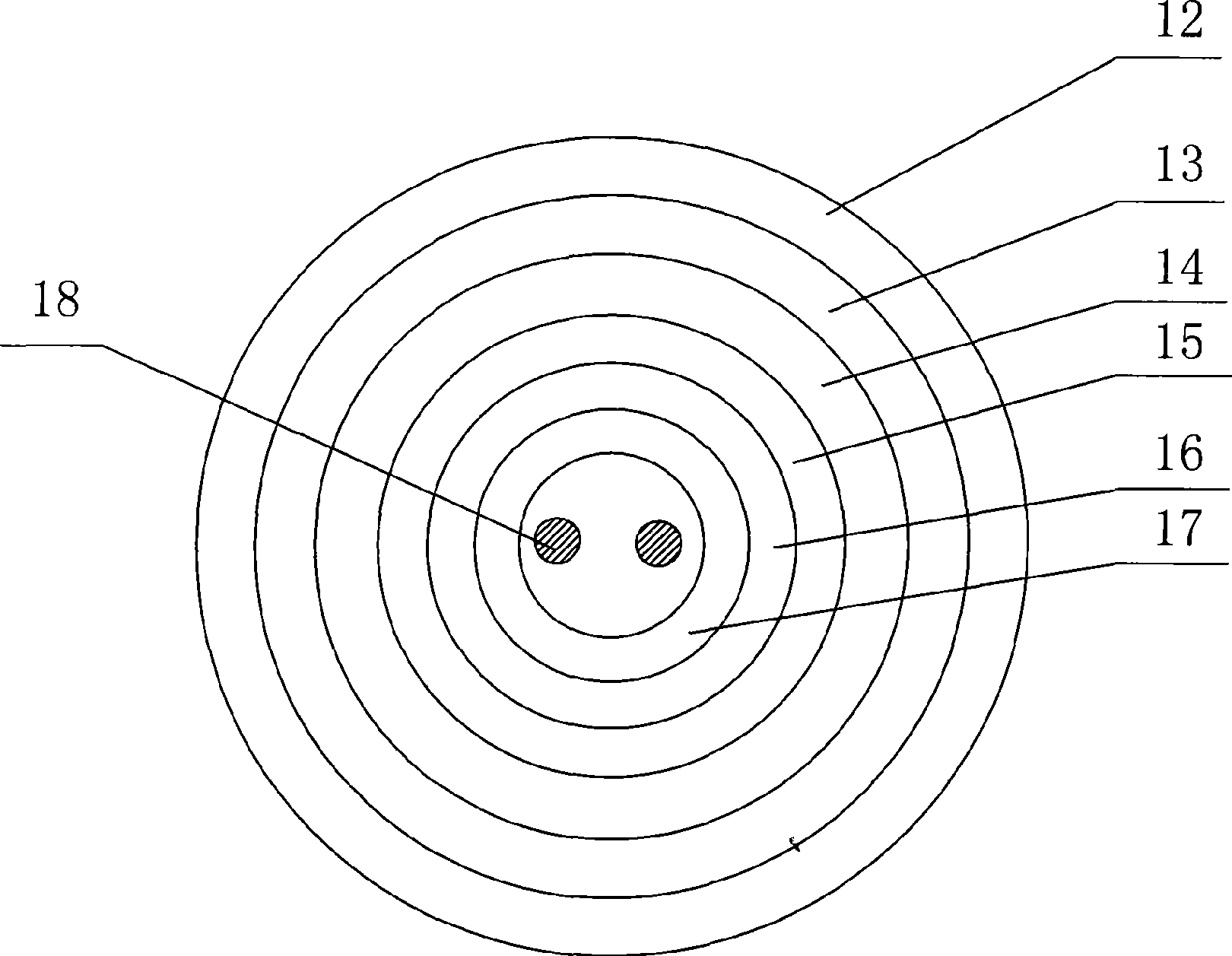

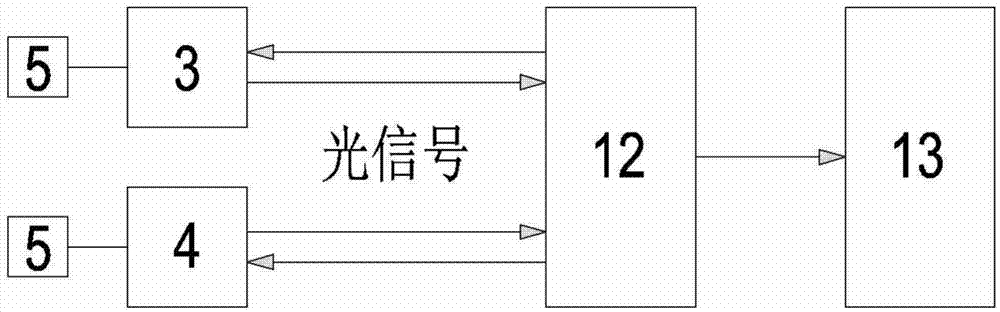

Method for measuring and calculating circumferential strain of rock sample by utilizing distributed-type optical fiber grating sensing network

InactiveCN104748694AHoop strain objectivePrecise local strain monitoringUsing optical meansGratingCircumferential strain

The invention discloses a method for measuring and calculating circumferential strain of a rock sample by utilizing a distributed-type optical fiber grating sensing network. The method includes: arranging two sets of optical fiber grating sensors which are in series connection on a rubber sleeve coated on the outer surface of the rock sample at an interval along the peripheral direction and the axial direction of the rock sample in a staggered mesh form to form the optical fiber grating sensing network to measure and calculate local strain of each point in the circumferential direction of the rock sample; enabling each optical fiber grating sensor to be serially connected with one temperature compensation sensor to finally acquire circumferential strain of the rock sample and a circumferential deformation diagram of the rock sample at each transient time. Distributed mesh type sensor layout is utilized, so that accurate local strain monitoring of the circumferential surface of the rock sample can be realized while circumferential deformation diagram of the rock sample at a certain transient moment is acquired, knowing of deformation features of the rock sample at each stage of an experiment is facilitated, and circumferential strain features of the rock sample can be reflected more objectively.

Owner:HOHAI UNIV

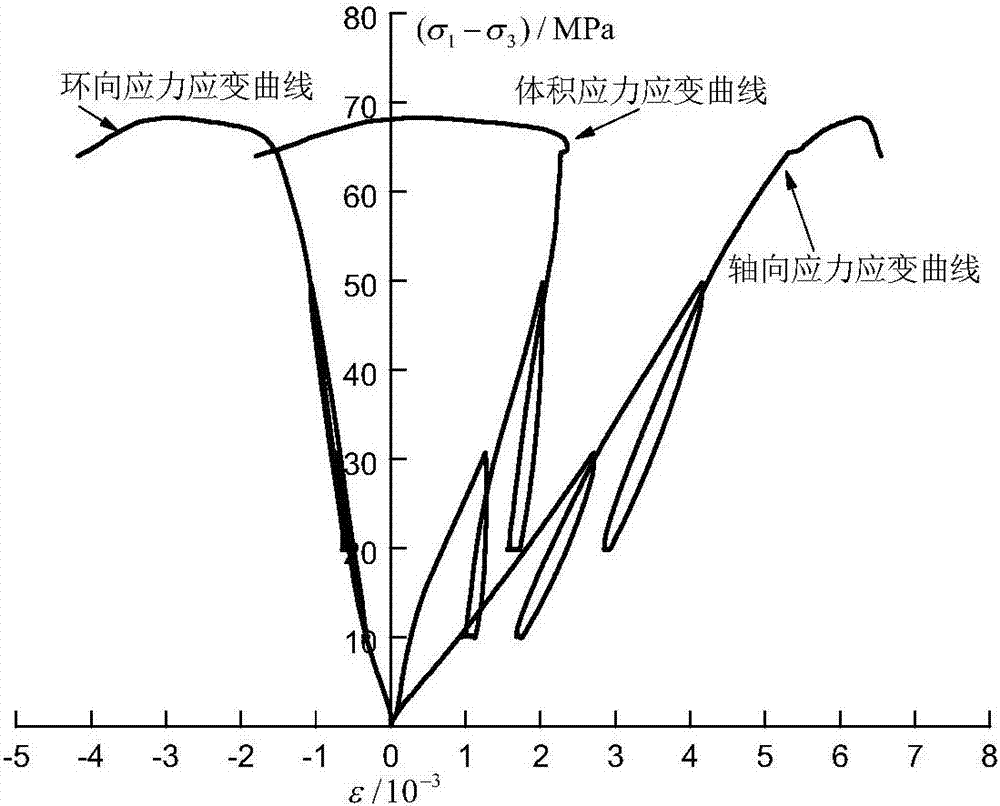

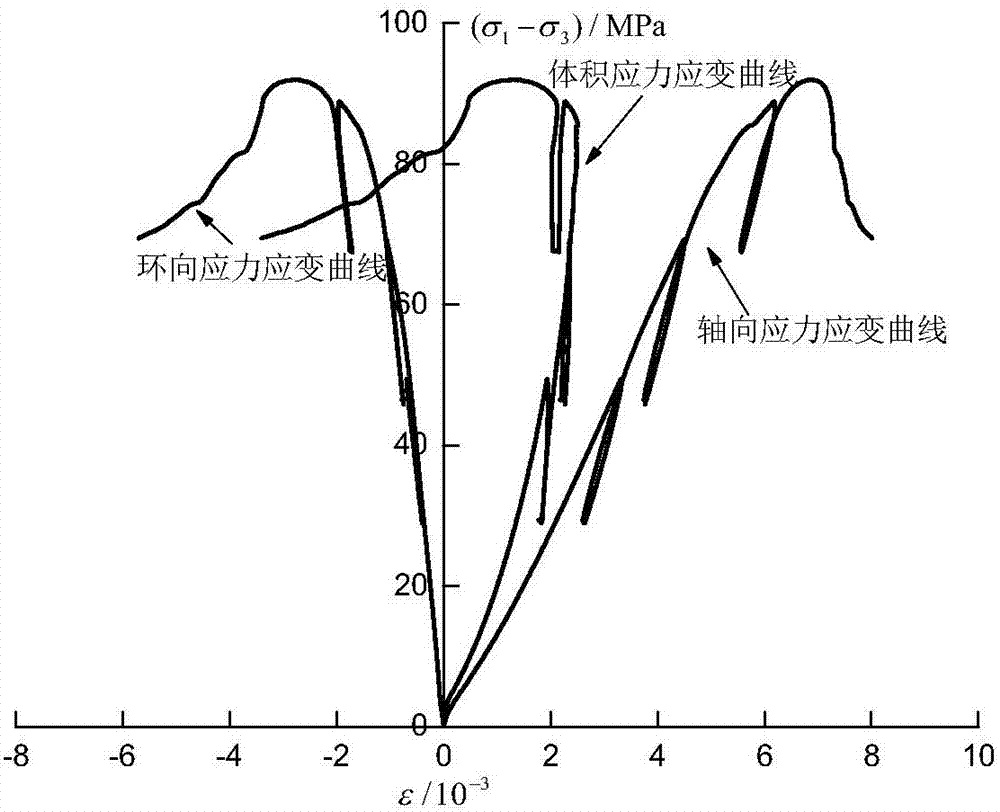

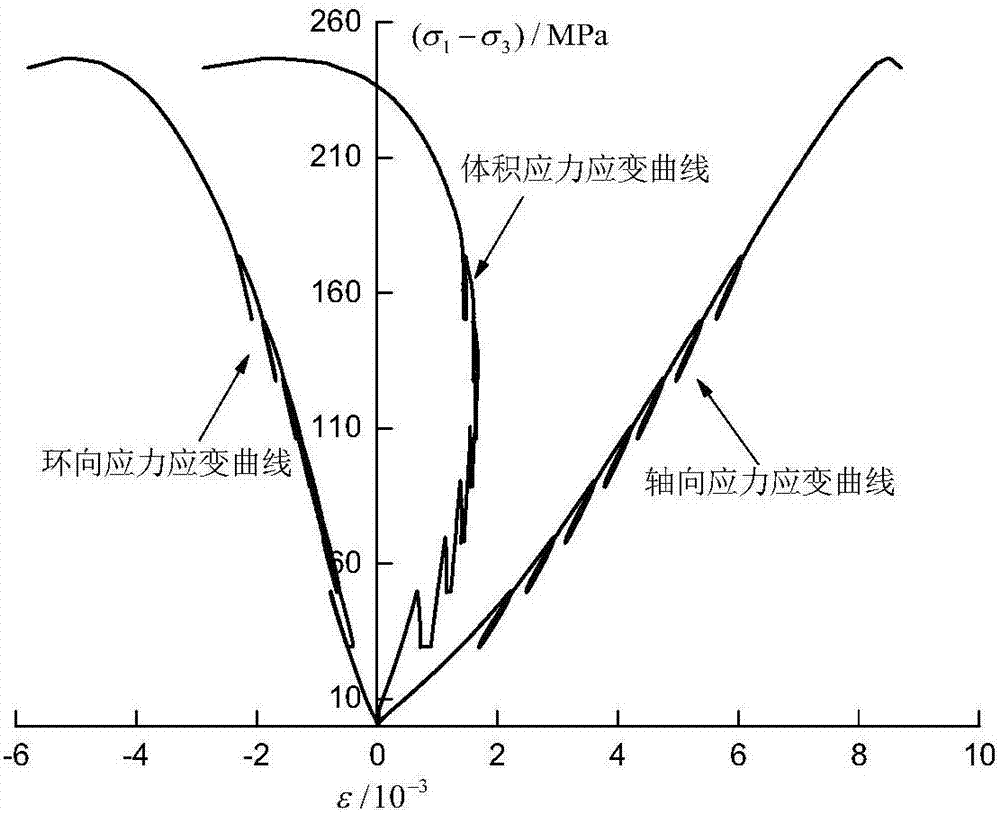

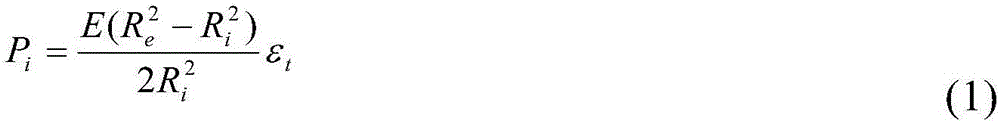

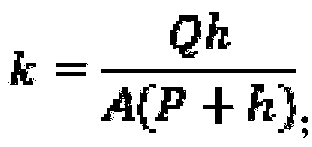

Method for determining effective stress coefficients of rock

ActiveCN107084886AImprove calculation accuracyThe effective stress coefficient is accurate and reliableMaterial strength using tensile/compressive forcesPermeability/surface area analysisCircumferential strainTest sample

The invention discloses a method for determining effective stress coefficients of a rock. The method comprises the steps of preparing a rock test sample and measuring and recording the size of the rock sample; loading the rock sample into a pressure chamber of a triaxial servometer, loading confining pressure to a predetermined value, keeping the confining pressure, constantly loading bias, loading the bias to a set value, unloading, keeping the bias and the confining pressure constant and loading pore water pressure; repeating the previous step and loading the bias until the rock sample is destroyed; drawing a relation curve of bias increments and axial / circumferential strain increment under different confining pressure and carrying out data fitting on the curve to obtain an effective elastic modulus E1 and poisson ratio v31 related to bias grades; and calculating an axial effective stress coefficient and a circumferential effective stress coefficient of the rock sample through a formula. The effective stress coefficients obtained through the method are accurate and reliable, and can be applied to numerical calculation of seepage and stress coupling in practical engineering, the calculation accuracy is greatly improved and the analysis error is reduced.

Owner:HOHAI UNIV

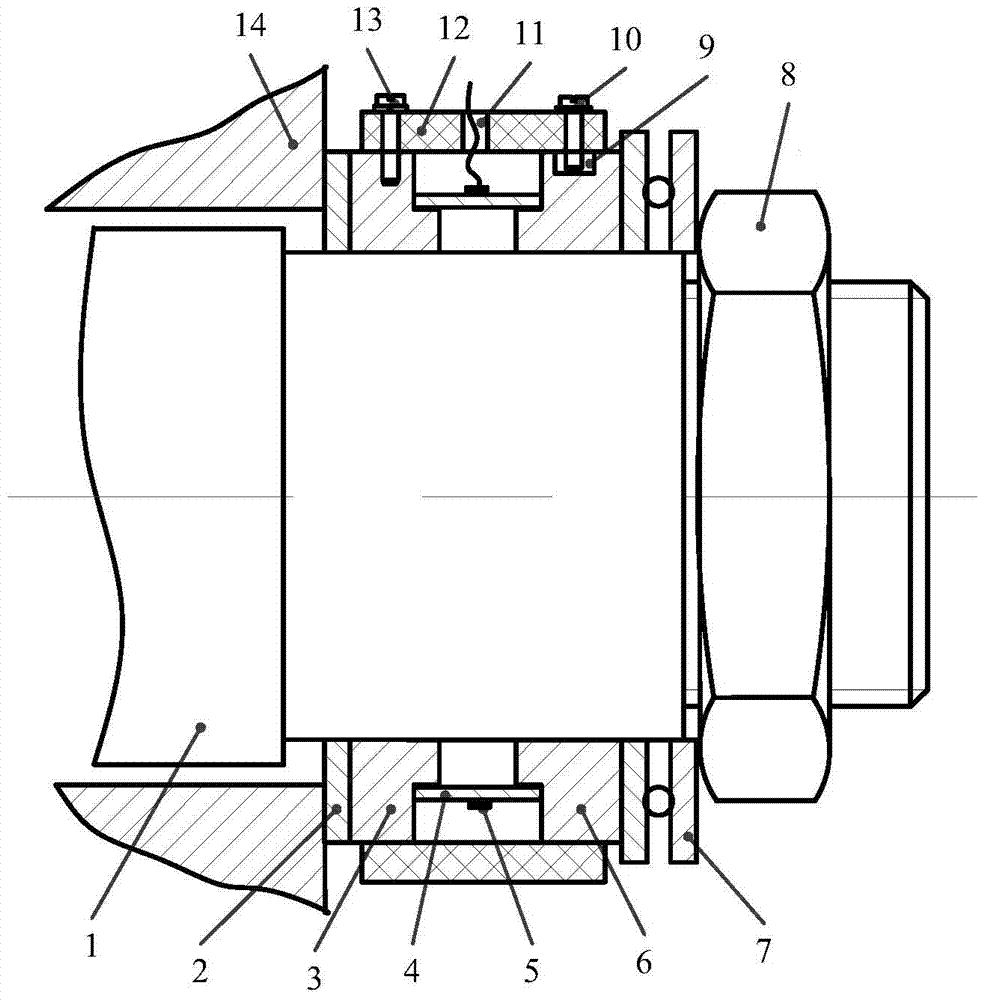

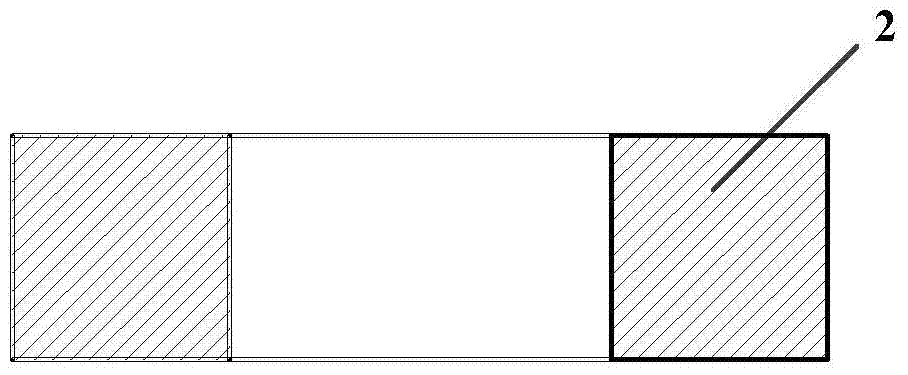

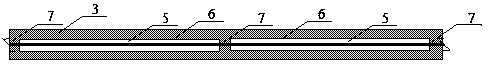

Axial pre-tightening force sensor

InactiveCN103592062AClear principleWide range of axial preloadForce measurementAxial displacementBall bearing

The invention relates to an axial pre-tightening force sensor. The axial pre-tightening force sensor comprises a regulating gasket 2, a left end cover 3, an elastic sensitive element 4, a strain gage 5, a right end cover 6, a thrust ball bearing 7, an axial hole groove 9, a right bolt 10, a fairlead 11, a package shell 12 and a left bolt 13. The regulating gasket is used for regulating the axial position of the sensor on a shaft, the left end cover and the right end cover support the elastic sensitive element through bosses, the elastic sensitive element generates axial strain because of bearing axial force, and the axial force can be measured through the resistance strain effect and a measuring circuit. The axial hole groove 9 in the right end cover 6 of the sensor is matched with the right bolt 10 to be used for preventing the elastic sensitive element from generating circumferential strain in a pre-tightening process, axial displacement of the right end cover 6 and axial strain of the elastic sensitive element 4 are allowed, and the thrust ball bearing is used for insulating circumferential twisting force generated when the pre-tightening force is exerted so that the axial twisting force can be prevented from being transmitted to the elastic sensitive element 4.

Owner:NANJING UNIV OF SCI & TECH

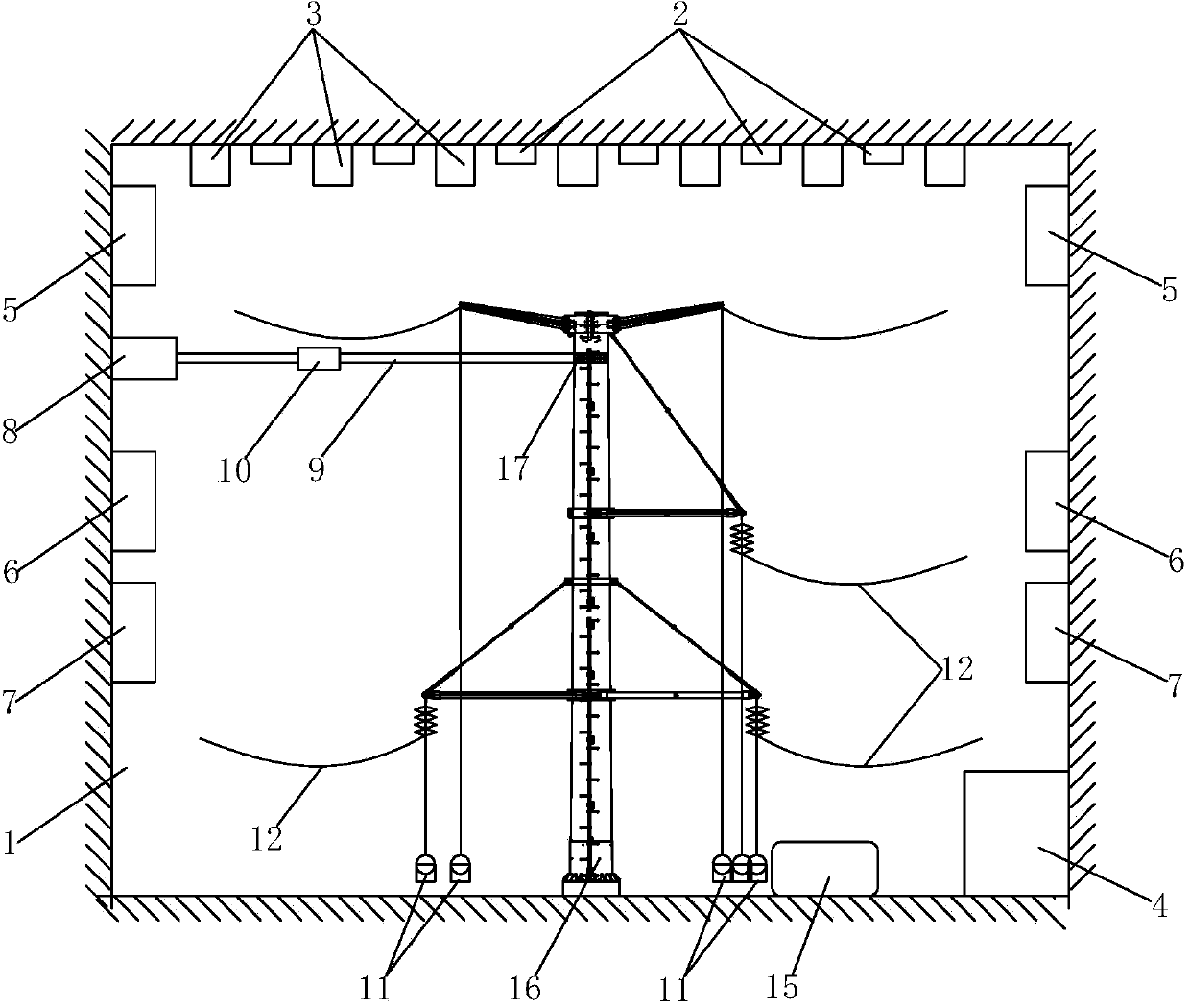

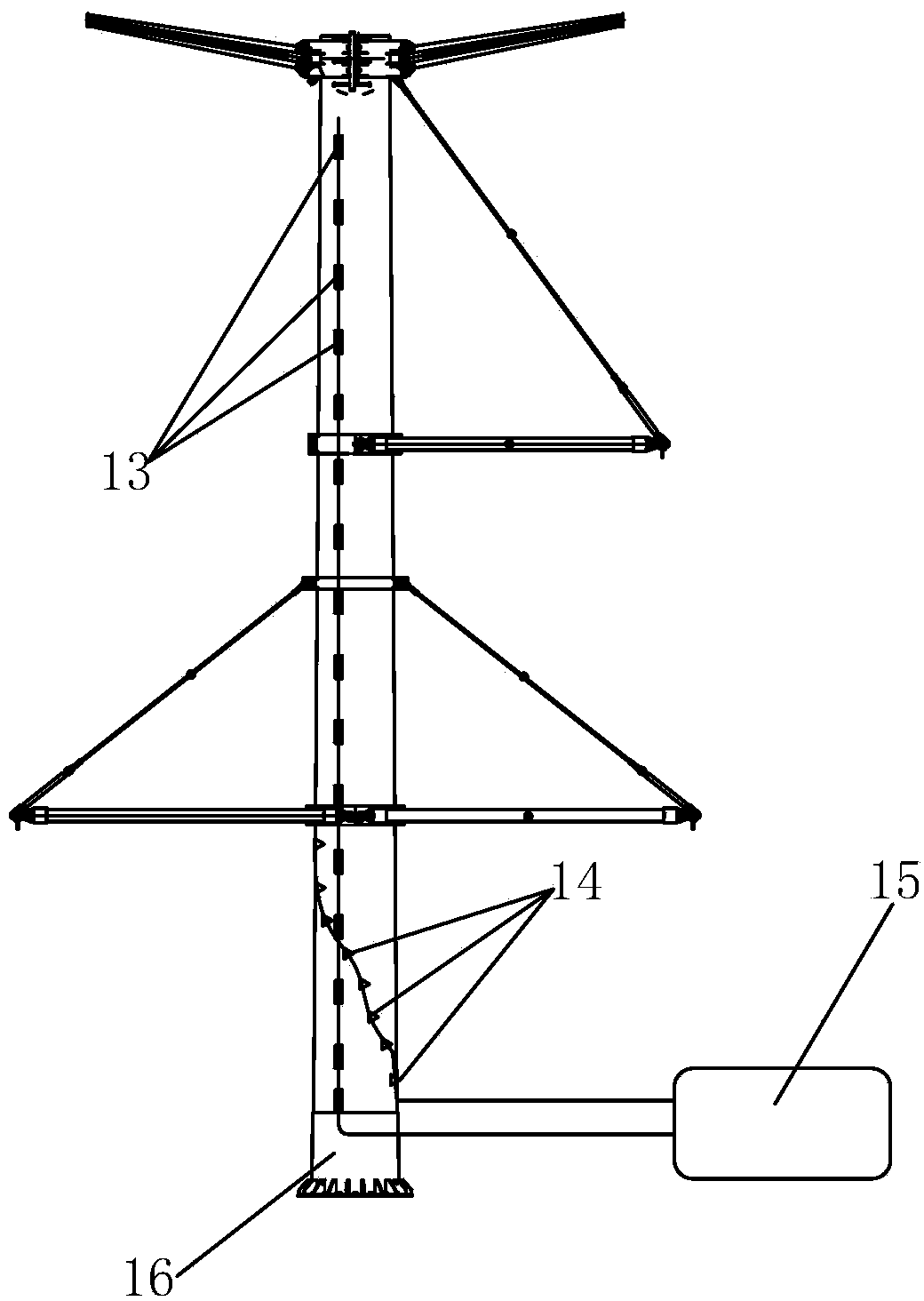

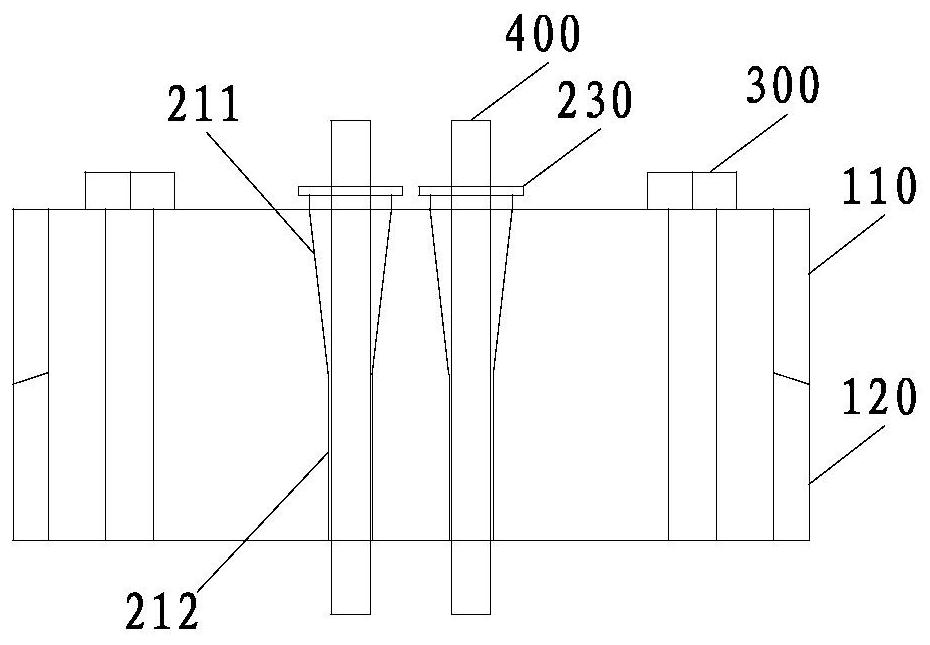

Multiple-factor accelerated aging test device for composite material electric pole

ActiveCN104198358ATest performanceSimple structureWeather/light/corrosion resistanceGratingUltraviolet

The invention discloses a multiple-factor accelerated aging test device for a composite material electric pole. The multiple-factor accelerated aging test device comprises an aging test room, wherein water nozzles and acid, alkali and salt atomizers are arranged on the roof surface of the aging test room; ozone generators, ultraviolet lamps, high-temperature and low-temperature humidity-heat devices, and a tensile machine are arranged on the side walls of the aging test room respectively; the action end of the tensile machine is connected with a traction rod which is provided with a force meter; corresponding to the composite material electric pole to be tested, weights, leads, longitudinal strain gratings, circumferential strain gratings, and a signal detection processor which is electrically connected with the force meter, the longitudinal strain gratings and the circumferential strain gratings respectively, are arranged inside the aging test room. By the cooperation of the water nozzles, the acid, alkali and salt atomizers, the ozone generators, the ultraviolet lamps, the high-temperature and low-temperature humidity-heat devices, the tensile machine, the weights and the leads, various natural environments can be simulated comprehensively, so that the performance of the composite material electric pole can be thoughtfully and correctly tested. The accelerated aging test device is applicable to testing of pole towers.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

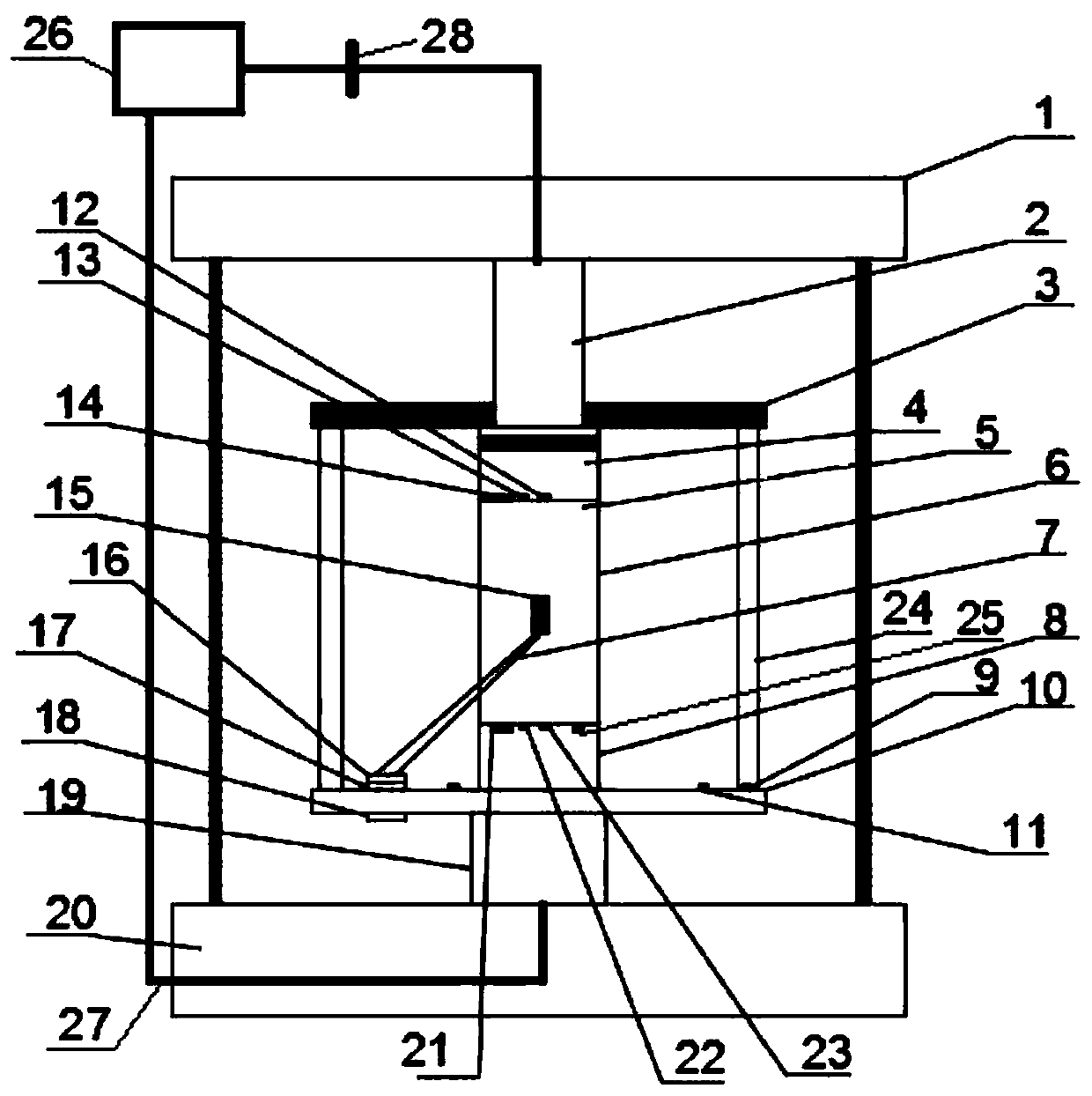

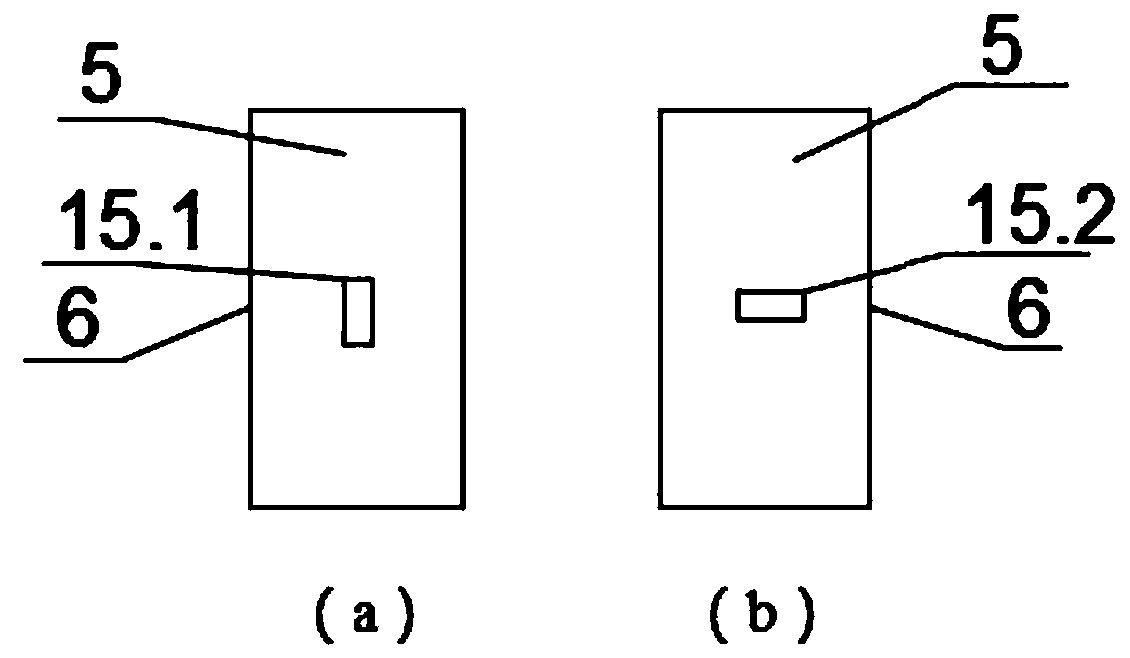

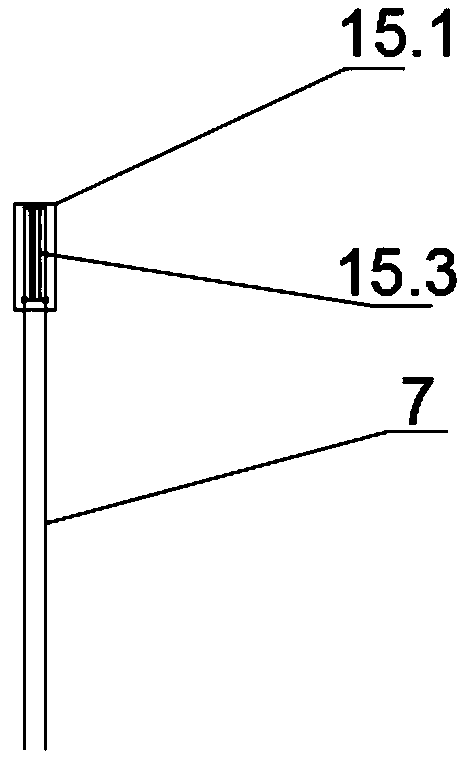

Forming explosive friction testing system and testing method thereof

The invention discloses a forming explosive friction testing system and a testing method thereof. The forming explosive friction testing system comprises a supporting frame, a mounting component fixedly connected with the supporting frame, a drop speed loading component above the mounting component and a pressurizing component under the mounting component; a to-be-measured explosive piece is fixed by the mounting component. The forming explosive friction testing system further comprises a static charge amplifier electrically connected with a pressure sensor, a circumferential strain gauge arranged in the circumferential direction of a friction sleeve and a high-speed photographic instrument testing component for obtaining the friction velocity between the to-be-measured explosive piece and the sleeve wall of the friction sleeve; the static charge amplifier is connected with an oscilloscope; the circumferential strain gauge is connected with the static strain gauge through an electric bridge and is merged into an intelligent terminal through the static strain gauge. The testing system can detect the radial pressure change and realize the friction coefficient detection under different speed and pressure conditions through the drop speed loading component and the pressurizing component, so that the quantitative analysis on the effect of external friction conditions on friction coefficients under the conditions of high pressure and high speed is realized, and the application scope and the numerical simulation accuracy of the friction testing system are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

System and method to simulate hemodynamics

InactiveUS20060223049A1Independent controlBioreactor/fermenter combinationsBiological substance pretreatmentsWall shearDrive shaft

A system for hemodynamic simulation comprises a vessel having properties of a blood vessel, a reservoir containing a quantity of fluid, tubing connecting the vessel and reservoir, and at least one pump for circulating the fluid within the system. Fluid can be tissue culture medium or blood analog fluid, and the vessel may include mammalian cells attached to its inside. A drive system, comprising two reciprocating drive shafts that are coupled by a cam, enables the uncoupling of pulsatile flow and pulsatile pressure to provide independent control over wall shear stress and circumferential strain. The shaft drives two pumps that are 180 degrees out-of-phase and are connected upstream and downstream of the vessel, and effect this uncoupling.

Owner:DANCU MICHAEL B

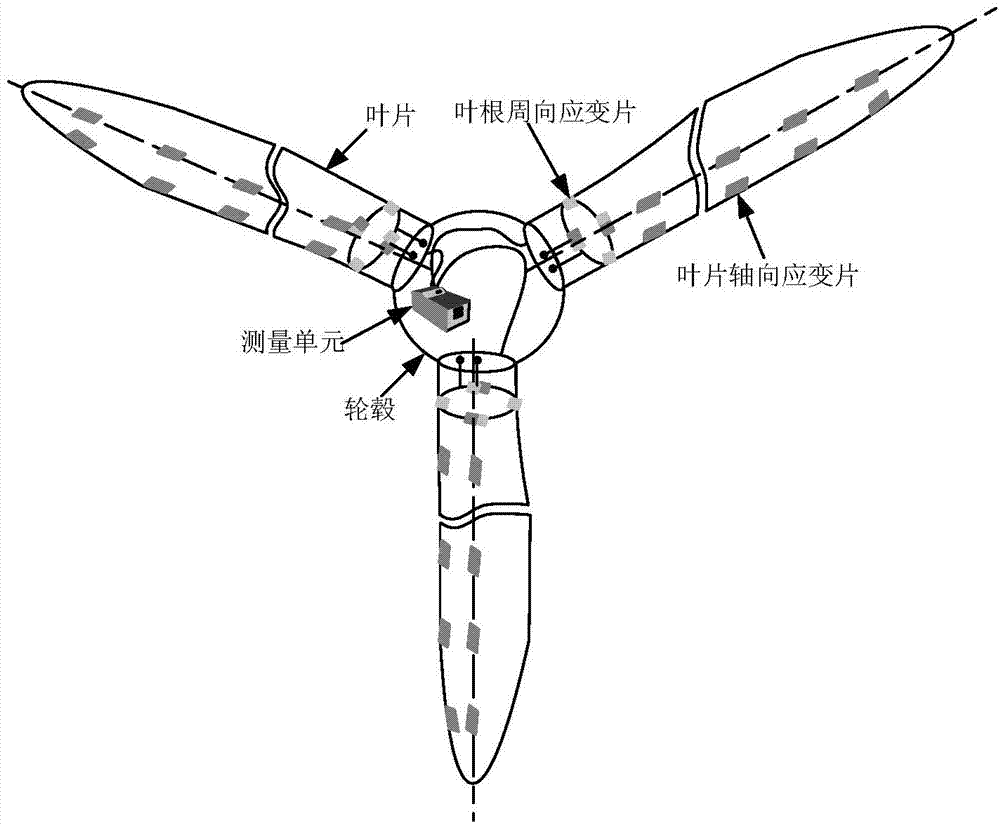

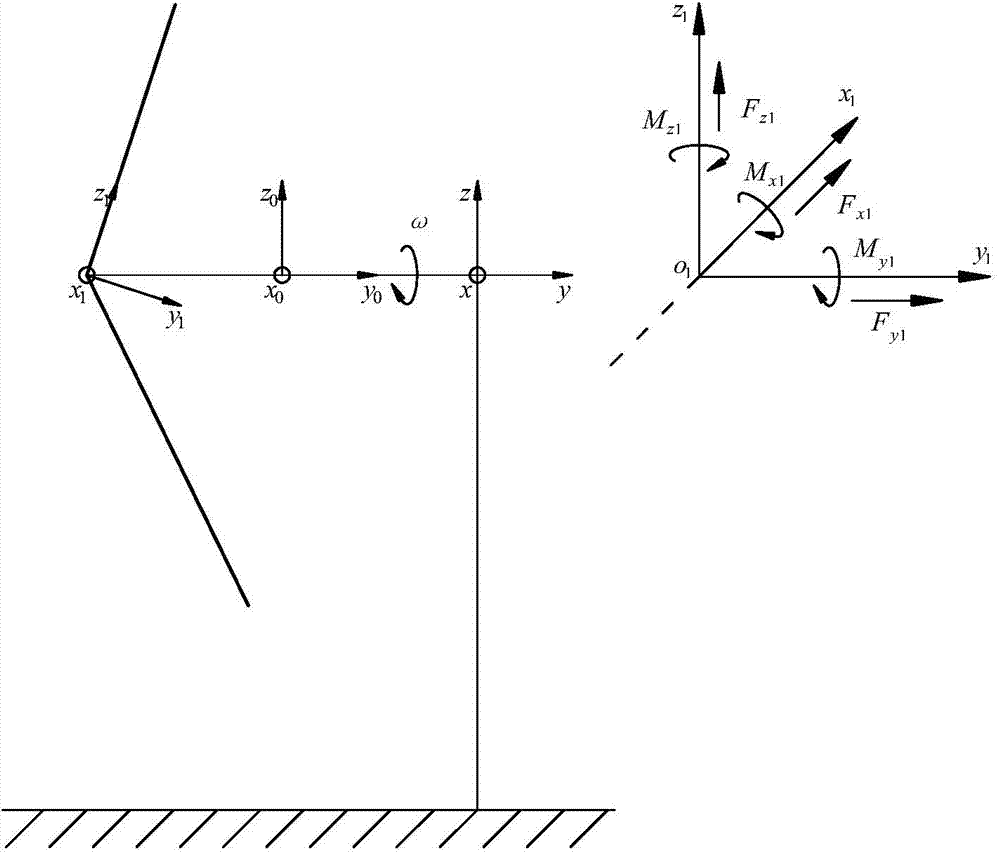

Online identification method for multiple loads on blades of large wind power generation set

ActiveCN104732060AOnline identification is quickOnline identification is accurateSpecial data processing applicationsCorrection algorithmEngineering

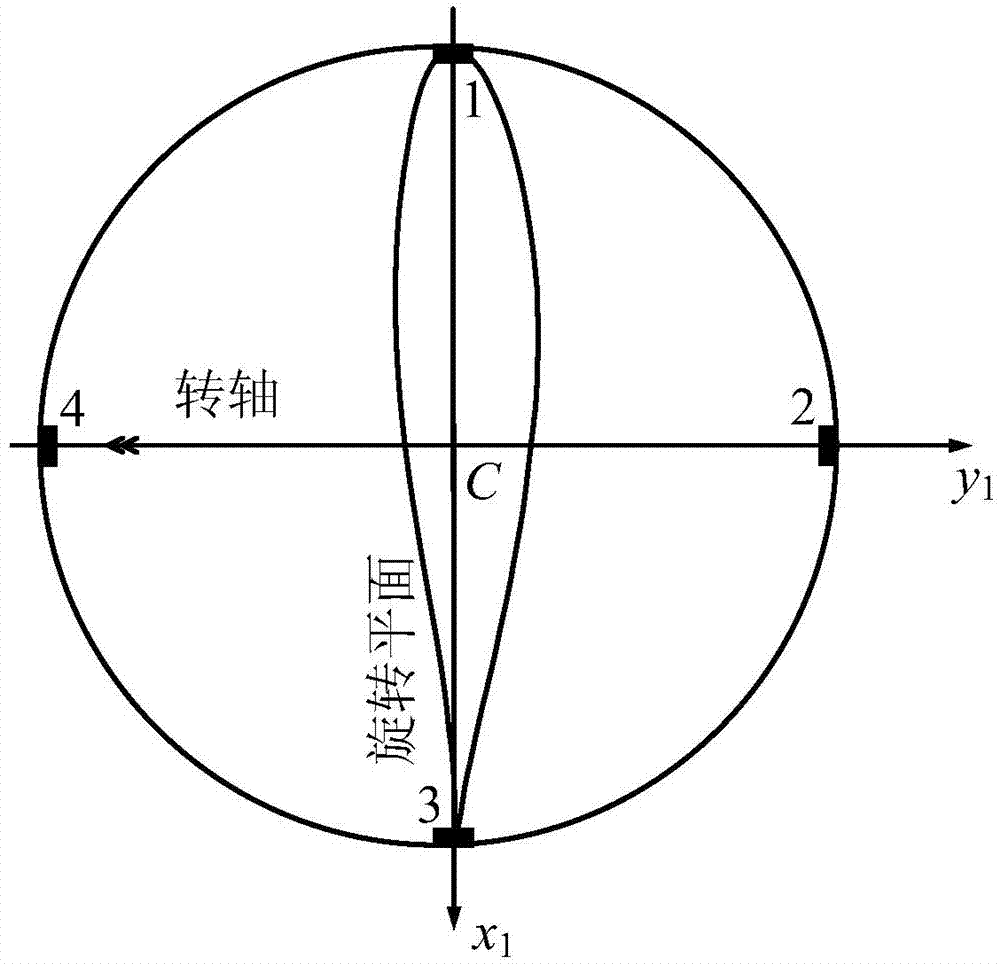

The invention discloses an online identification method for multiple loads on blades of a large wind power generation set. The method includes following steps that 1, the transformation relation between coordinate systems of the large wind power generation set is set; 2, the arrangement mode of blade root circumferential strain gages and blade axial strain gages is determined; 3, a data processing algorithm is adopted for decomposing the multiple loads on the blades; 4, an outline deformation correction algorithm is adopted for correcting the loads. By means of the method, the multiple loads such as gravitational loads, centrifugal force loads, inertial loads and complex aerodynamic loads can be effectively extracted and identified on line, the information of gravity, centrifugal force, inertia force, aerodynamic force and the like can be extracted from measured data, a computer is adopted for performing real-time computing on the computing algorithms, rapid and accurate online identification of the multiple loads on the large blades is performed, and it is guaranteed that the large wind power generation set operates safely and reliably in the service cycle.

Owner:HUNAN UNIV OF SCI & TECH

System and method to simulate hemodynamics

InactiveUS20140127795A1Independent controlBioreactor/fermenter combinationsBiological substance pretreatmentsWall shearCircumferential strain

A system for hemodynamic simulation comprises a vessel having properties of a blood vessel, a reservoir containing a quantity of fluid, tubing connecting the vessel and reservoir, and at least one pump for circulating the fluid within the system. Fluid can be tissue culture medium or blood analog fluid, and the vessel may include mammalian cells attached to its inside. A drive system, comprising two reciprocating drive shafts that are coupled by a cam, enables the uncoupling of pulsatile flow and pulsatile pressure to provide independent control over wall shear stress and circumferential strain. The shaft drives two pumps that are 180 degrees out-of-phase and are connected upstream and downstream of the vessel, and effect this uncoupling.

Owner:DANCU MICHAEL B +1

System and method to simulate hemodynamics

InactiveUS20060223047A1Independent controlBioreactor/fermenter combinationsBiological substance pretreatmentsWall shearDrive shaft

Owner:DANCU MICHAEL B

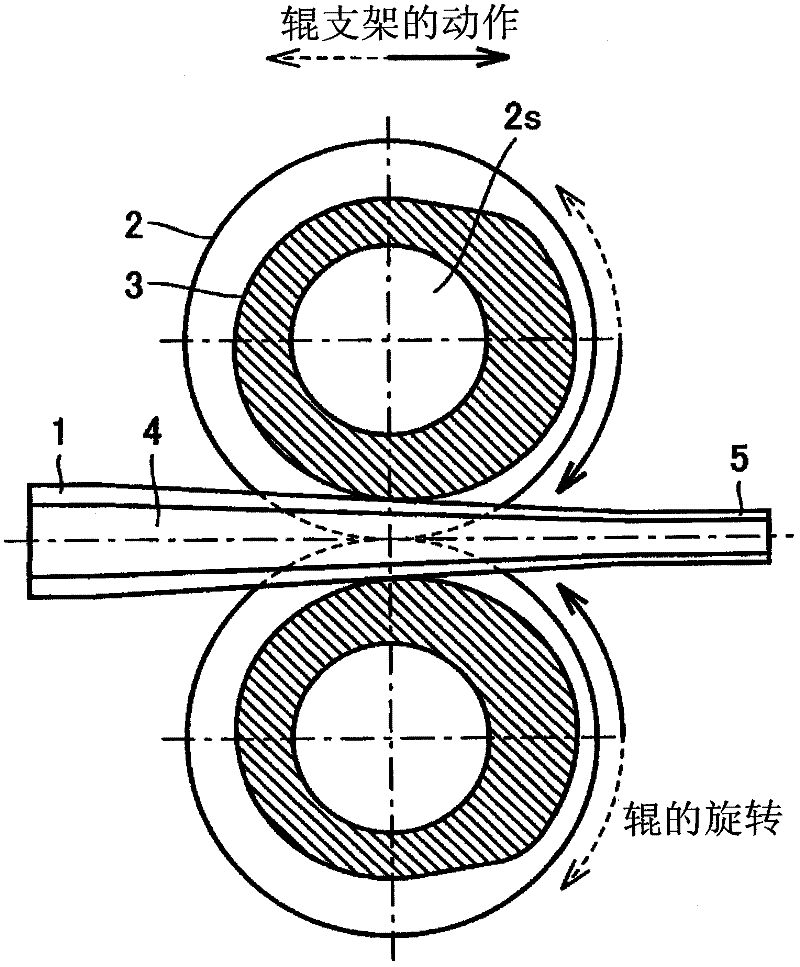

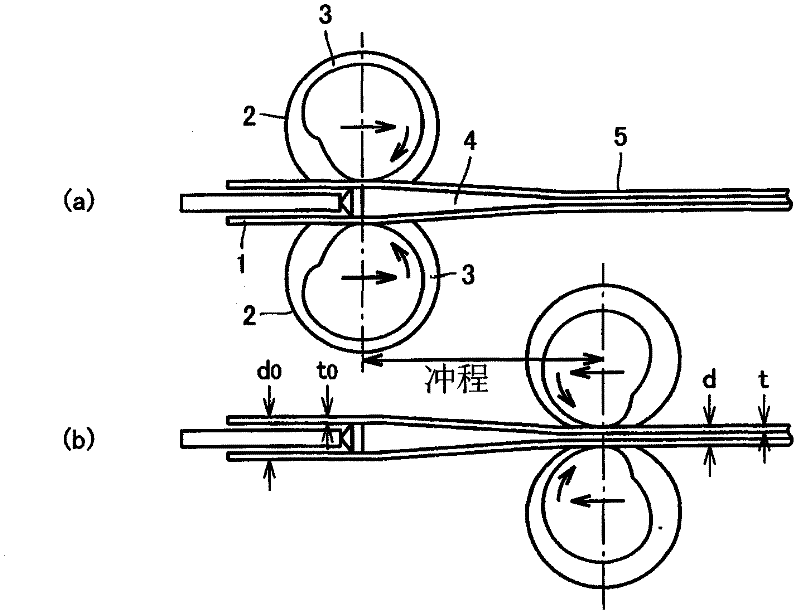

Process for production of seamless metal pipe by cold rolling

InactiveCN102245320AImprove qualitySuppression of inner surface wrinkle defectsMetal rolling arrangementsWrinkle skinCircumferential strain

In cold-rolling a seamless metal pipe by means of a cold pilger mill, too great an outer-diameter reduction as compared with wall thickness reduction creates too great a circumferential strain on the flange sides to result in too great a circumferential compressive stress, whereby wrinkles occur on the inner surface of the pipe. Further, the wrinkles are folded on the groove bottom sides to create cold shut folds. Repetition of these phenomena causes flaws on the inner surface. Unlike a tube stock produced by an extrusion process, a tube stock produced by a Mannesmann-mandrel process has, on the inner surface, wrinkles which have occurred during the sizing (using a stretch reducer or a sizer), and the wrinkles are further encouraged by cold-rolling. Therefore, attention must be paid to this problem. In view of these facts, the ratio of outer-diameter reduction to wall thickness reduction in cold-rolling using a cold pilger mill is adjusted to 1 / 2 or below, whereby the occurrence of flaws on the inner surface is prevented in the cold rolling, and a high-quality seamless metal pipe having few flaws on the inner surface can be obtained.

Owner:NIPPON STEEL CORP

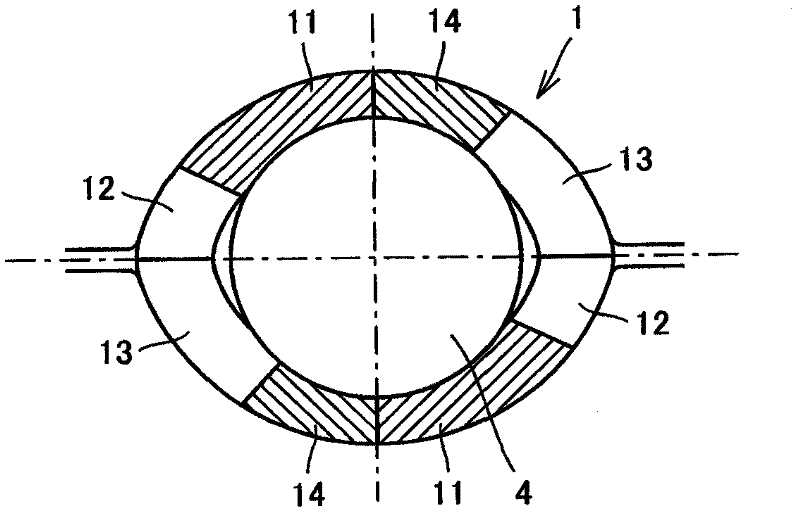

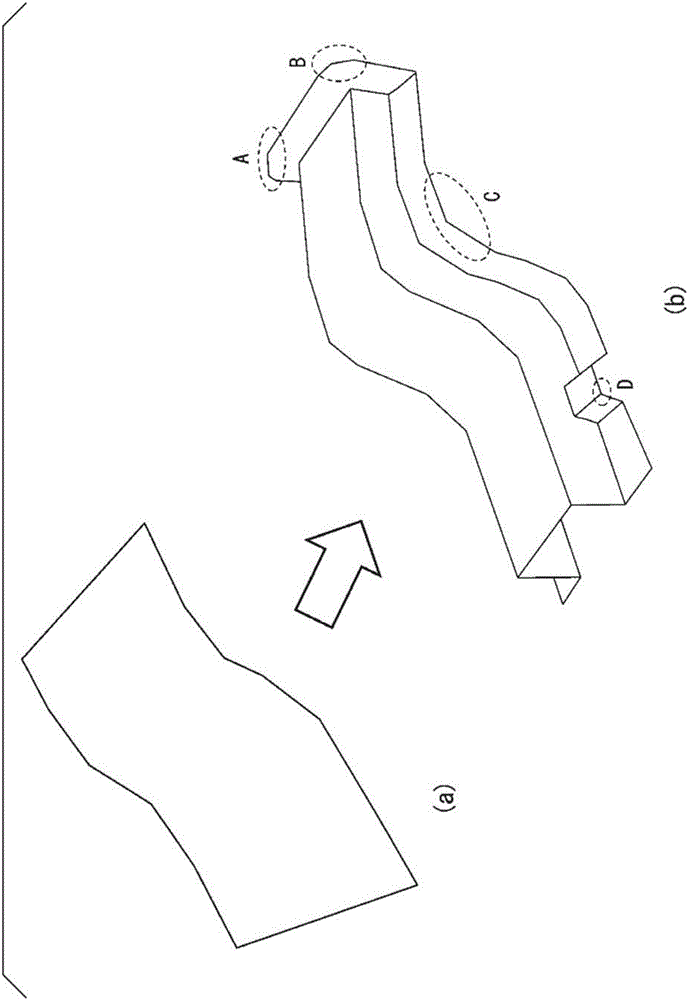

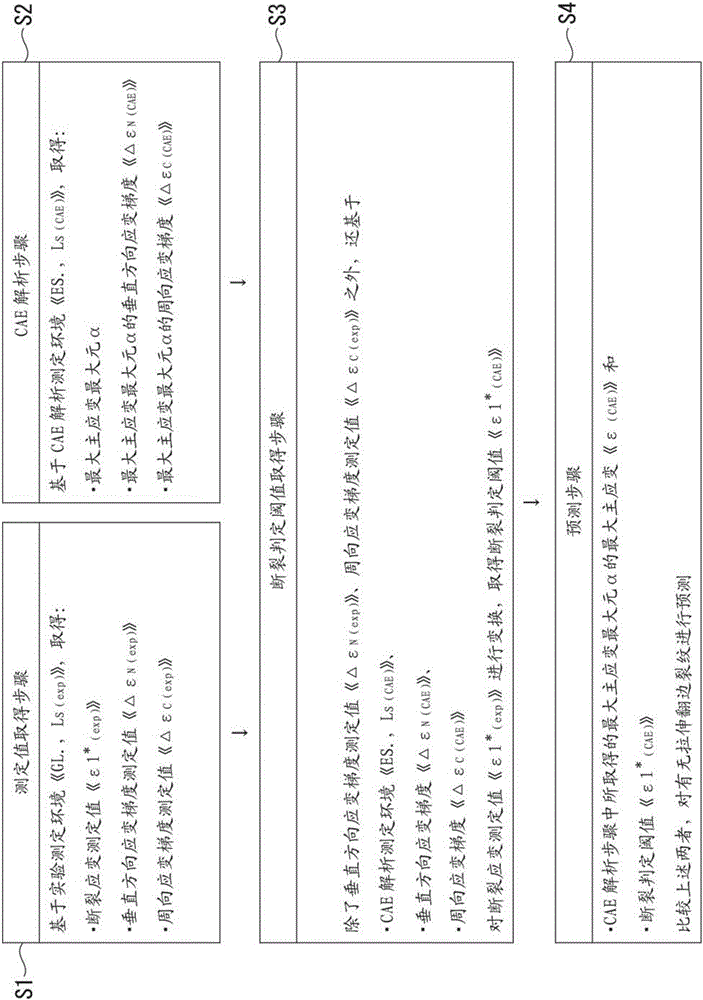

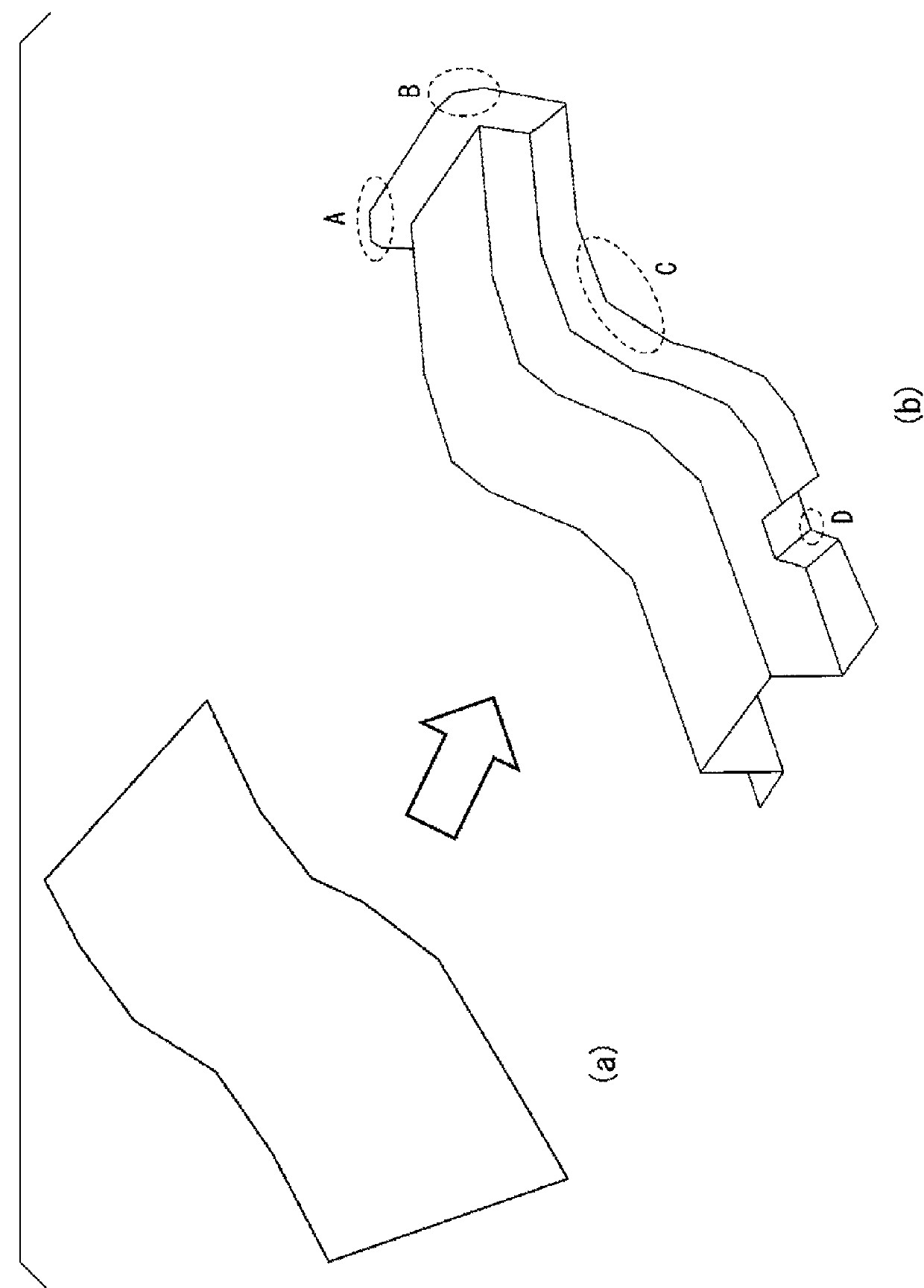

Stretch-flange crack prediction method, stretch-flange crack prediction device, computer program, and recording medium

ActiveCN106470776AAccurate predictionDesign optimisation/simulationAerodynamics improvementCircumferential strainEngineering

This stretch-flange crack prediction method for predicting occurrence of stretch-flange cracking at a flange end part when stretch-flange forming is performed on a plastic plate, wherein the method is provided with: a measured value acquisition step (S1) for acquiring a breaking strain measurement, vertical strain gradient measurement, and a circumferential strain gradient measurement for each of a plurality of plate-shape specimens; a CAE analysis step (S2) for acquiring a largest maximum principal strain element in which the maximum strain is the largest, the vertical strain gradient of the largest maximum principal strain element, and the circumferential strain gradient of the largest maximum principal strain element; a breakage determination threshold value acquisition step (S3) for converting the breaking strain measurement to acquire a breakage determination threshold value; and a prediction step (S4) for predicting the occurrence of a stretch-flange cracking when the maximum principal strain is equal to or greater than the breakage determination threshold value.

Owner:NIPPON STEEL CORP

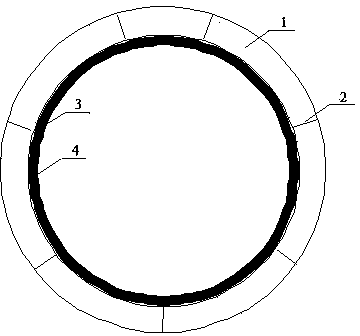

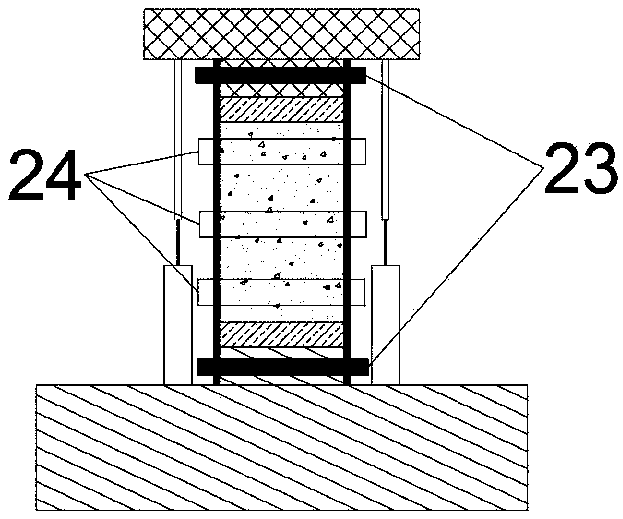

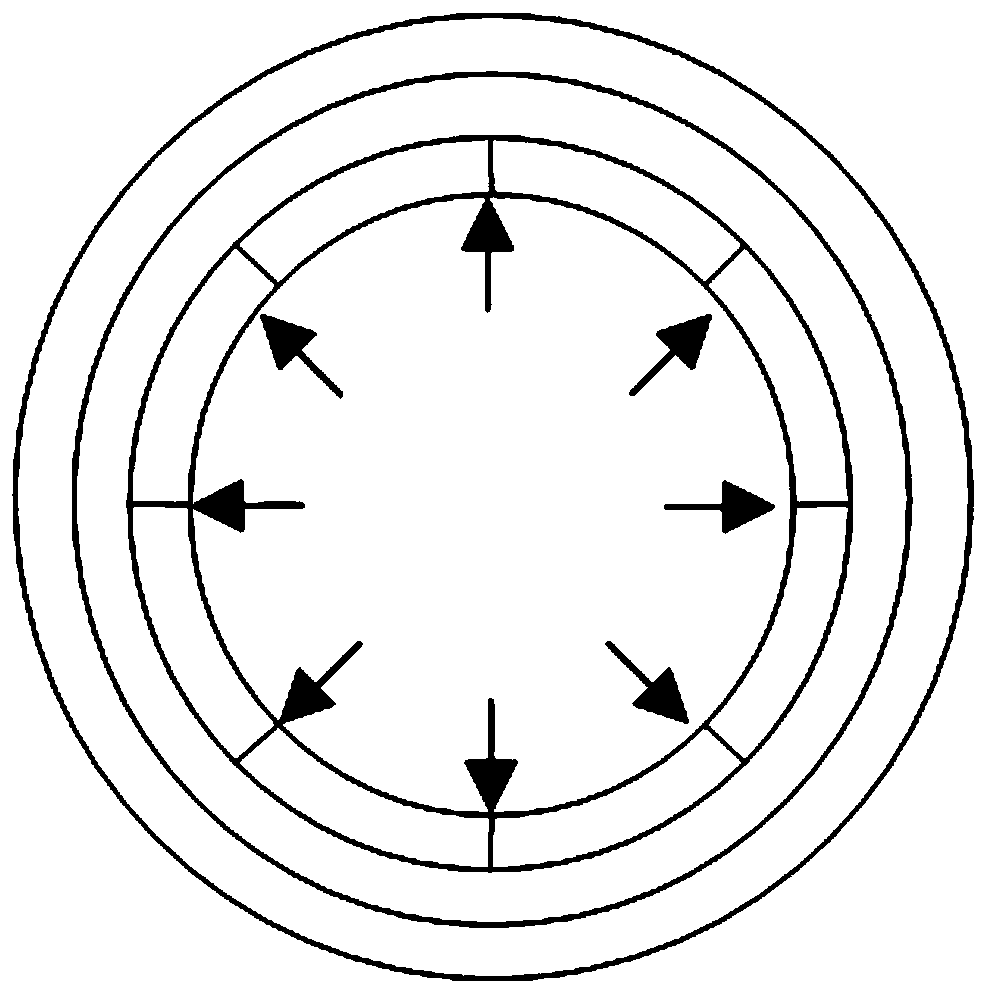

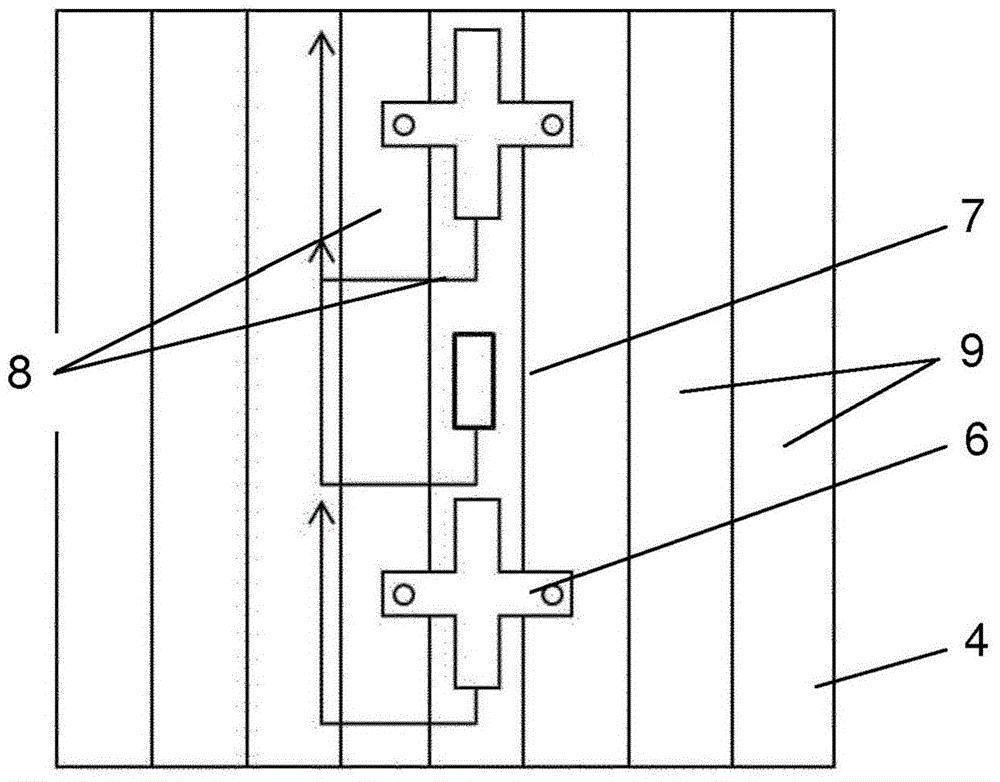

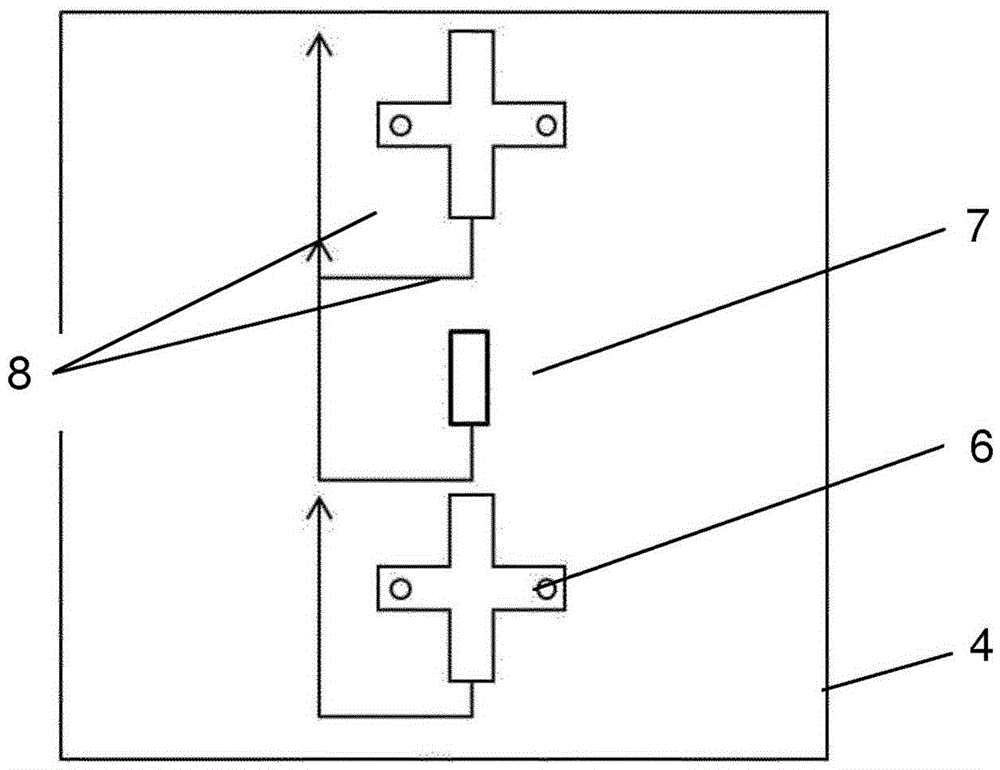

Circumferential intelligentized reinforcement structure and method of shield tunnel

ActiveCN104389621ATo achieve reinforcementRealize monitoringMining devicesUnderground chambersCircumferential strainEngineering

The invention discloses a circumferential intelligentized reinforcement structure and method of a shield tunnel. A reinforcing and monitoring integrated structure is formed through intelligent fiber composite ribs with built-in distributed optical fiber sensors, circumferentially arranged along the inner side surface of the tunnel. The method comprises the following steps: bonding intelligent FRP (fiber reinforced plastic) ribs with the inner side of the tunnel through bonding materials to form a structure layer with good mechanical property; calculating the circumferential convergence of the structure by monitored circumferential strain, and judging the performance change of the reinforced structure. According to the circumferential intelligentized reinforcement structure and method, facilities are simple, the engineering construction is convenient, the difficult problem of reinforcing and monitoring integration of the conventional shield tunnel can be solved, the market competitiveness is high, and large-scale popularization is facilitated.

Owner:SOUTHEAST UNIV +2

Stretch flange crack prediction method, stretch flange crack prediction apparatus, computer program, and recording medium

ActiveUS20180107772A1Accurate predictionDesign optimisation/simulationAerodynamics improvementCircumferential strainEngineering

A stretch flange crack prediction method of predicting initiation of stretch flange cracks that occurs in a flange end section during stretch flange forming of a deformable sheet, includes: a measurement value acquisition process of acquiring, for each of a plurality of sheet-shaped test pieces, a fracture strain measurement value, a normal strain gradient measurement value, and a circumferential strain gradient measurement value; a CAE analysis process of acquiring a maximum major strain maximum element having a highest maximum major strain, a normal strain gradient of the maximum major strain maximum element, and a circumferential strain gradient of the maximum major strain maximum element; a fracture determination threshold acquisition process of acquiring a fracture determination threshold by converting the fracture strain measurement value; and a prediction process of predicting that stretch flange cracks will be initiated, when the maximum major strain is equal to or higher than the fracture determination threshold.

Owner:NIPPON STEEL CORP

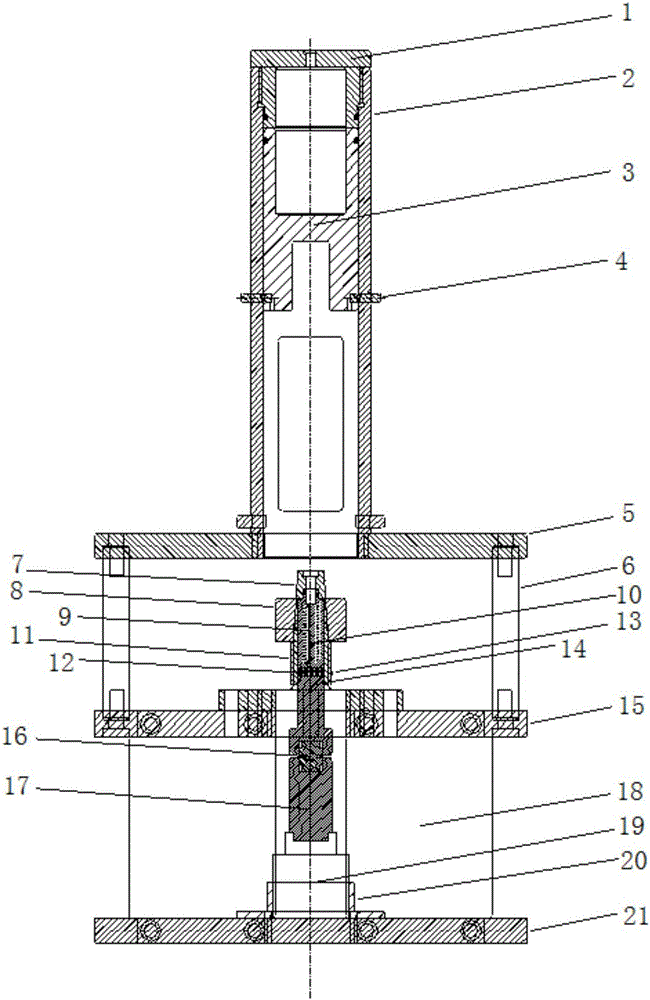

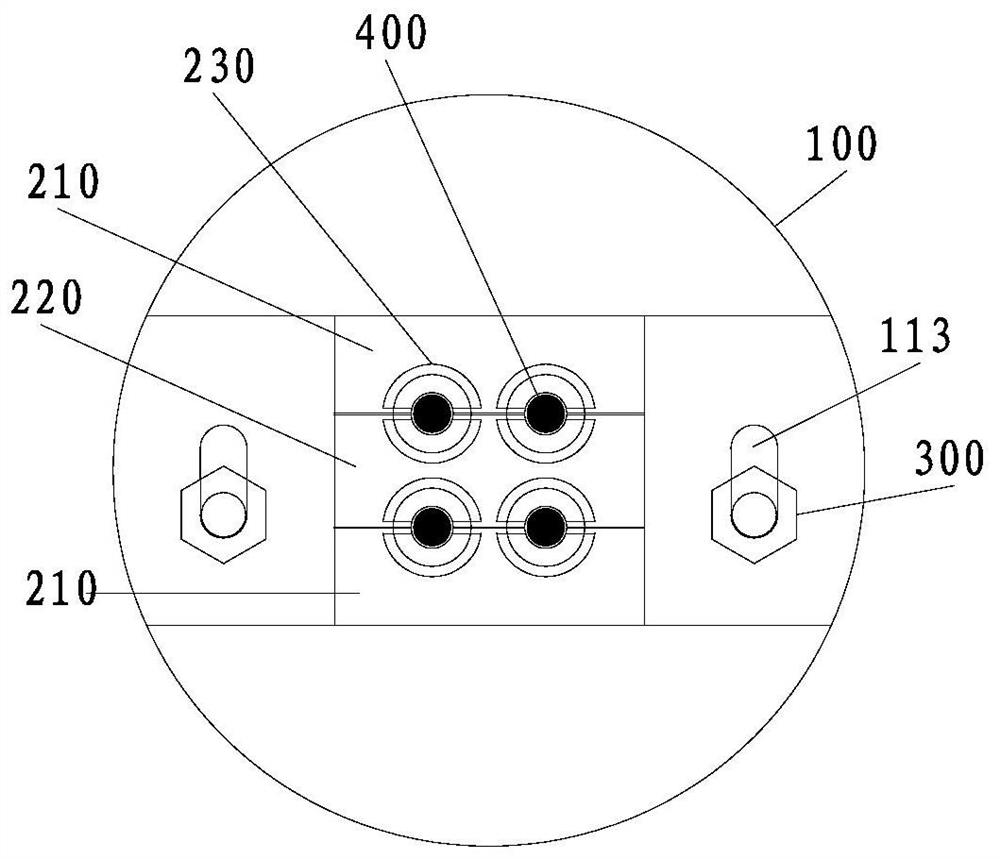

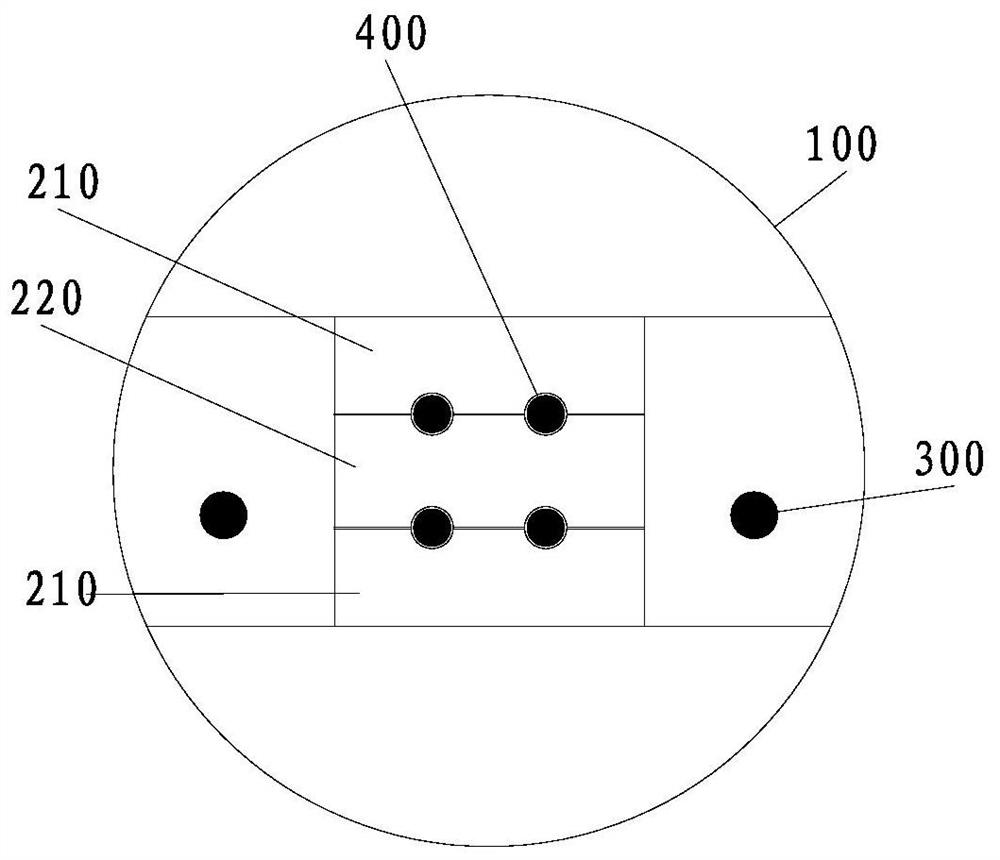

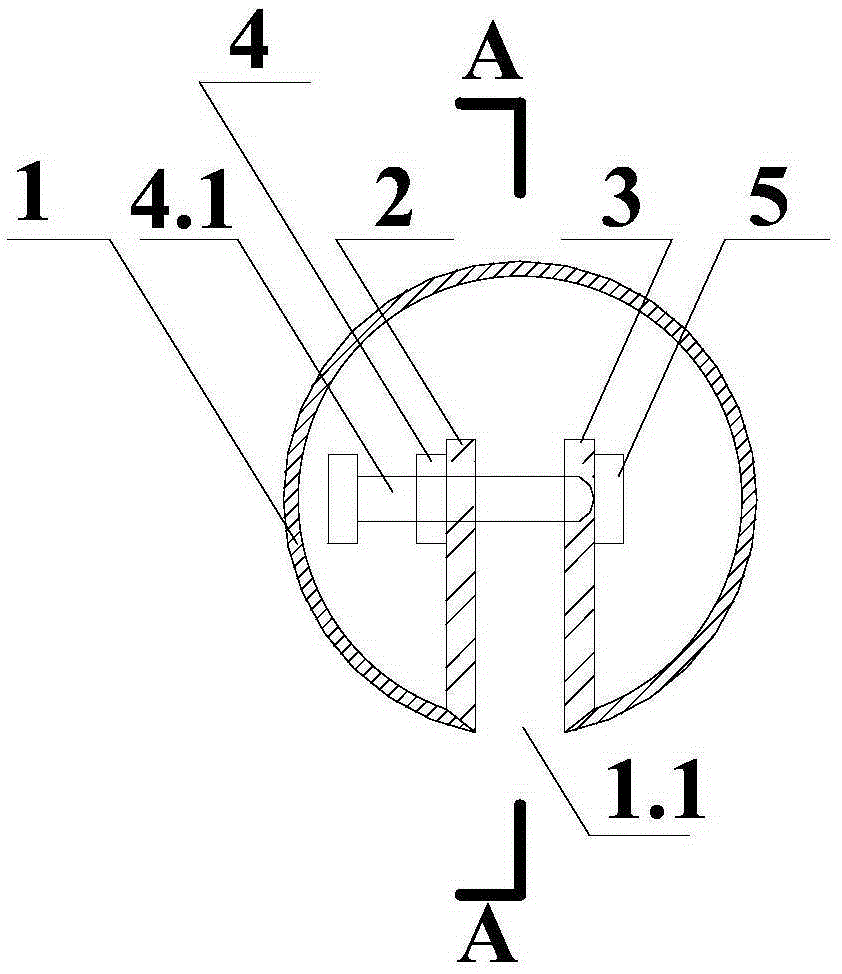

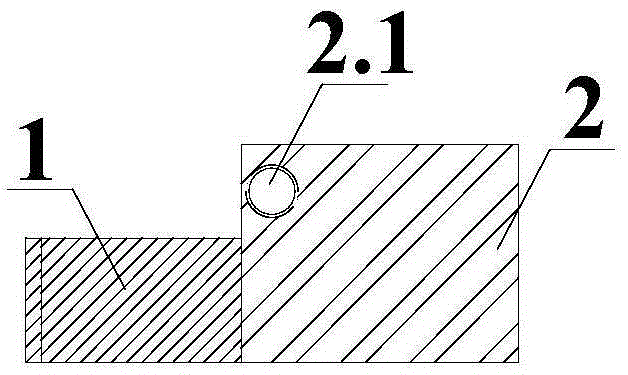

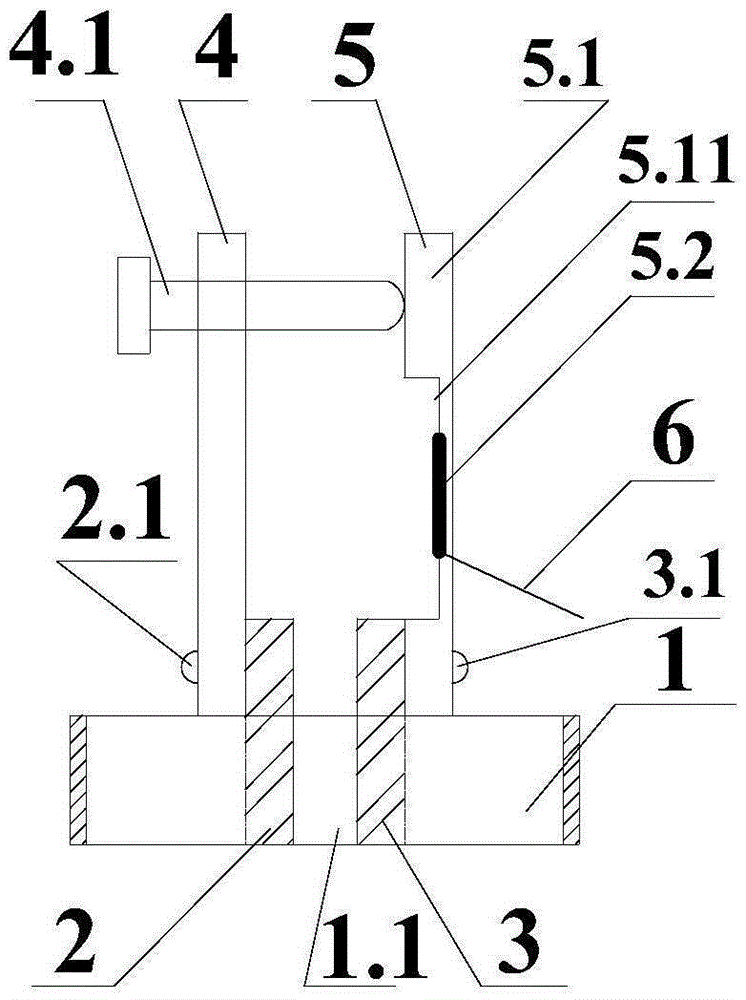

Intelligent anchorage device and method for testing axial force of anchor rod by using intelligent anchorage device

PendingCN112378555ALow priceLow costForce measurementBulkheads/pilesCircumferential strainClassical mechanics

The invention relates to an intelligent anchorage device, which comprises anchor rings and a split type anchorage device body used for clamping an anchor rod steel strand, wherein the anchor rings comprise a first anchor ring and a second anchor ring, the first anchor ring and the second anchor ring are locked together through a connecting piece, an anchorage device mounting groove used for mounting the split type anchorage device body is defined by the first anchor ring and the second anchor ring, the intelligent anchorage device further comprises a strain gauges used for sensing the circumferential strains of the anchor rings, compensation gauges used for compensating strain difference caused by temperature, and a data collector, and the strain gauges are connected to the data collectorthrough conducting wires, and are fixed to the outer walls of the anchor rings in the circumferential directions of the anchor rings. The invention further provides a method for testing the axial force of an anchor rod by adopting the intelligent anchorage device. The intelligent anchorage device has the advantages of being simple in structure, convenient to operate and high in measurement precision.

Owner:HUAQIAO UNIVERSITY

Circumferential strain gauge for inner wall of circular hole

InactiveCN105403141AZoom in and outHigh sensitivityElectrical/magnetic solid deformation measurementCircumferential strainArchitectural engineering

Disclosed in the invention is a circumferential strain gauge for an inner wall of a circular hole. The circumferential strain gauge comprises a rigid ring; and an opening is formed in the rigid ring. A first support and a second support that are arranged in parallel are arranged in the rigid ring; and one end of each of the first support and the second support is fixed at the opening. In addition, the circumferential strain gauge also includes a first steel plate and a strain sensor; the strain sensor consists of a second steel plate and a resistor plate; a groove is formed in the second steel plate and the resistor plate is attached to the bottom of the groove; and a cable connected with the resistor plate is led out from a circular hole. One end of the first steel plate is fixedly connected with the other end of the first support; and the other end of the first steel plate is provided with a screw penetrating the first steel plate. The end of the screw is abutted against one end of the second steel plate; and the other end of the second steel plate is fixed at the other end of the second support. The first steel plate and the second steel plate are arranged horizontally. The provided circumferential strain gauge has advantages of reasonable design, simple structure, and high sensitivity and stability and is suitable for strain measurement of an inner hole.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

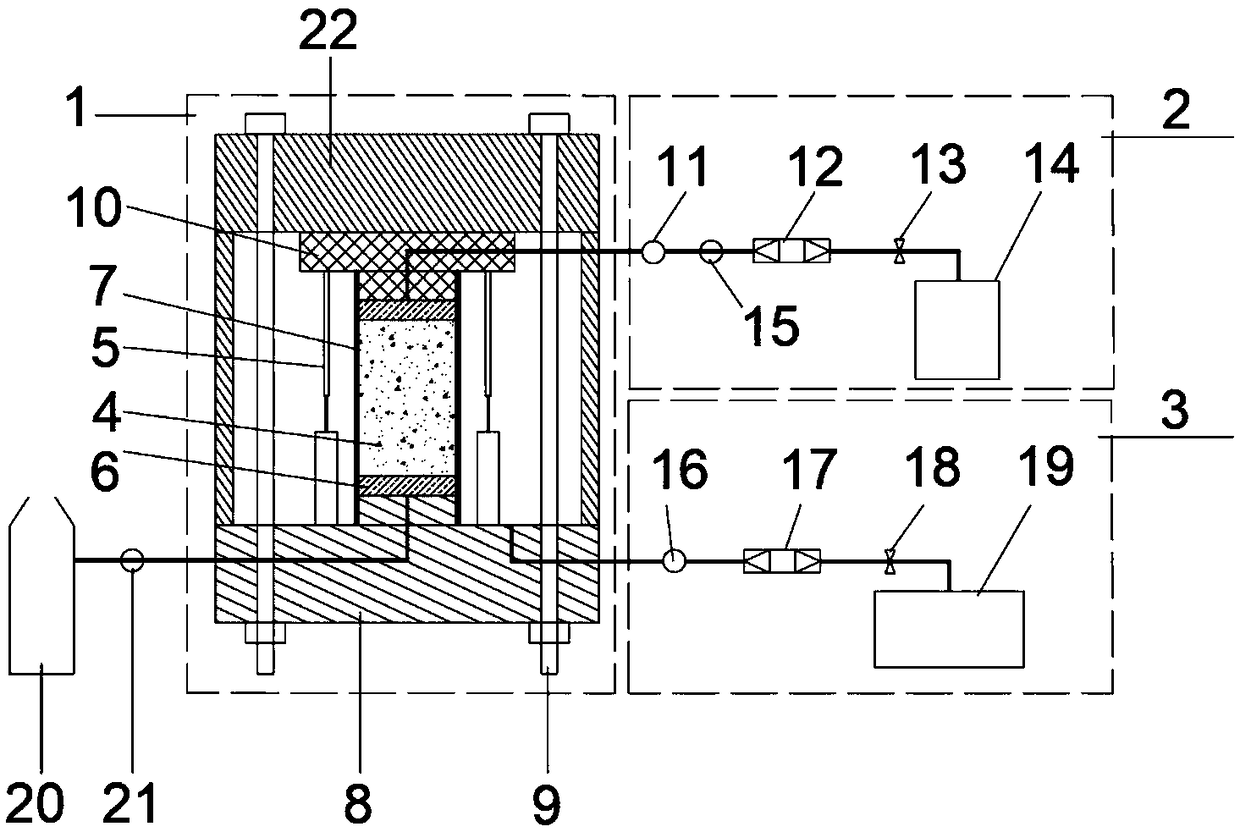

Dynamic tri-axial experiment device and method measuring dynamic strain of hydrate deposit of natural gas

PendingCN109752256AReal and effective simulationEasy to operateMaterial strength using tensile/compressive forcesCircumferential strainHydraulic pump

The invention discloses a dynamic tri-axial experiment device and method measuring dynamic strain of hydrate deposit of natural gas. The device comprises a cylinder, an upper end cover and a lower endcover, a sample table, an upper press head and a lower press head, wherein the lower press head supports a sample, the upper press head is connected with a hydraulic pump station, the sample is dynamically loaded by vibrating the upper press head, the upper press head and the lower press head are respectively provided with a sound wave receiving device and a sound wave emitting device, the lowerpress head is further provided with an electrode, the lower end cover is provided with a lower end cover male adapter, two ends of the lower end cover male adapter are respectively connected with a strain sheet female adapter and a lower end cover female adapter, a rubber sleeve sleeved around the sample is provided with a strain sheet, and strain data measured by the strain sheet is transferred to the strain sheet female adapter, the lower end cover male adapter and the lower end cover female adapter in sequence, and is transmitted out through the lower end cover female adapter. The dynamic tri-axial experiment device has a simple structure, is easy to operate, has high reliability, and can accurately measure axial strain and circumferential strain of hydrate deposit of natural gas.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Rock-soil material penetration deformation testing method under complex stress state and test device

InactiveCN109142070AAccurately characterize seepage deformationLoad accuratelyMaterial strength using tensile/compressive forcesPermeability/surface area analysisOsmotic coefficientEngineering

The invention discloses a rock-soil material penetration deformation testing method under complex stress state and test device. The test method comprises those steps as follows: fabricate the cylindrical sample, measure and record the sample size; consequently, the sample is placed inside the pressure chamber which is fully closed, and the confining pressure is loaded up to the target value and kept the same controlled by servo. Afterwards, the servo controls the multi-stage osmotic loading pressure and record the water flow volume, axial deformation and circumferential deformation of sample when the osmosis passes through the sample with times so as to determine the changes on osmotic coefficient, axial strain and the circumferential strain of sample, which reflects the osmosis deformation status of sample. It is repeated that the confining pressure and osmosis pressure are loaded which is controlled by servo to achieve the osmosis deformation status of rock-soil material under complex stress state. The test device comprises pressure chamber, confining pressure servo loading system and osmotic pressure servo loading system. The sample is fixed inside the pressure chamber and arranged with an axial strain gauge. The upper part, the middle part and the lower part of the sample are respectively provided with a circumferential strain gauge.

Owner:HOHAI UNIV

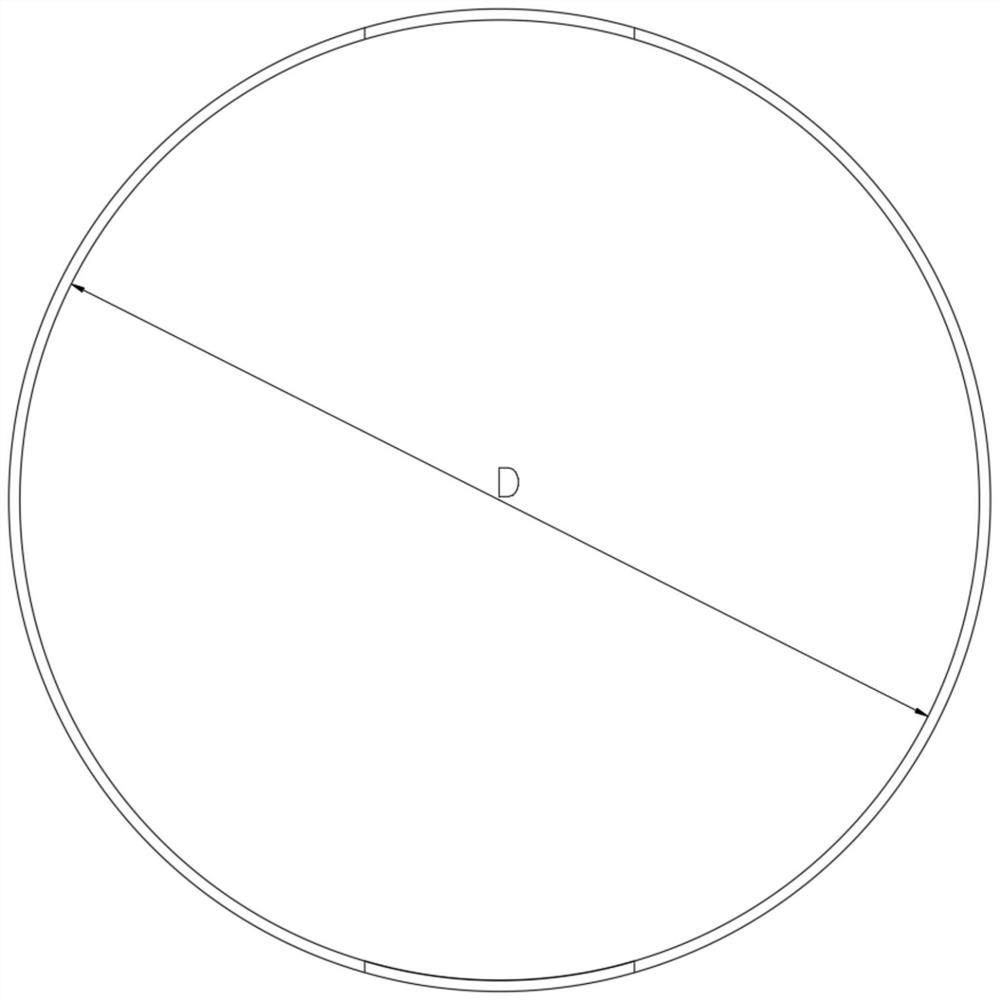

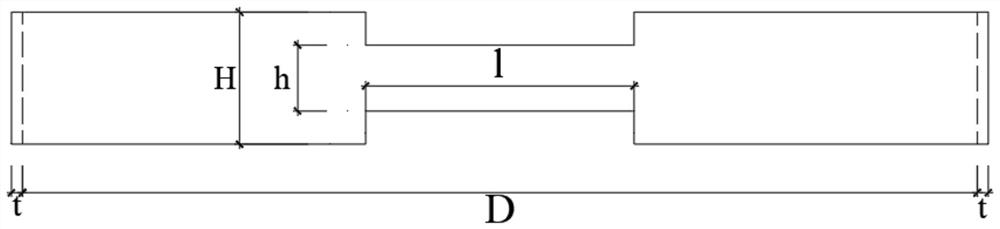

Test device and test method for measuring circumferential tensile property of composite material pipe for structural engineering

PendingCN113252453AMeasuring hoop tensile propertiesAccurate measurementMaterial strength using tensile/compressive forcesCircumferential strainEngineering

The invention relates to a test device for measuring the circumferential tensile property of a composite material pipe for structural engineering. The test device comprises two tensioning arc-shaped steel blocks, two fixed arc-shaped steel blocks, four screw rods, a connecting node, two connecting pieces, two supporting rods, a traction mechanism, an axial strain gauge and an annular strain gauge, the four screw rods are fixed with the connecting joints; the connecting pieces are in threaded connection with the fixed arc-shaped steel blocks, the connecting pieces are in threaded connection with the screw rods, and the two connecting pieces are arranged in a straight line shape; the supporting rods are in threaded connection with the screw rods, the supporting rods abut against the inner side faces of the tensioning arc-shaped steel blocks, and the two supporting rods are arranged in a straight line shape; the traction mechanism is detachably connected with the two tensioning arc-shaped steel blocks; and the axial strain gauge and the circumferential strain gauge are arranged on the outer surface of the annular sample. The invention also relates to a test method for measuring the circumferential tensile property of the composite material pipe for structural engineering. The method is high in measurement precision and high in universality, and belongs to the technical field of structural material performance detection in civil engineering.

Owner:SOUTH CHINA AGRI UNIV

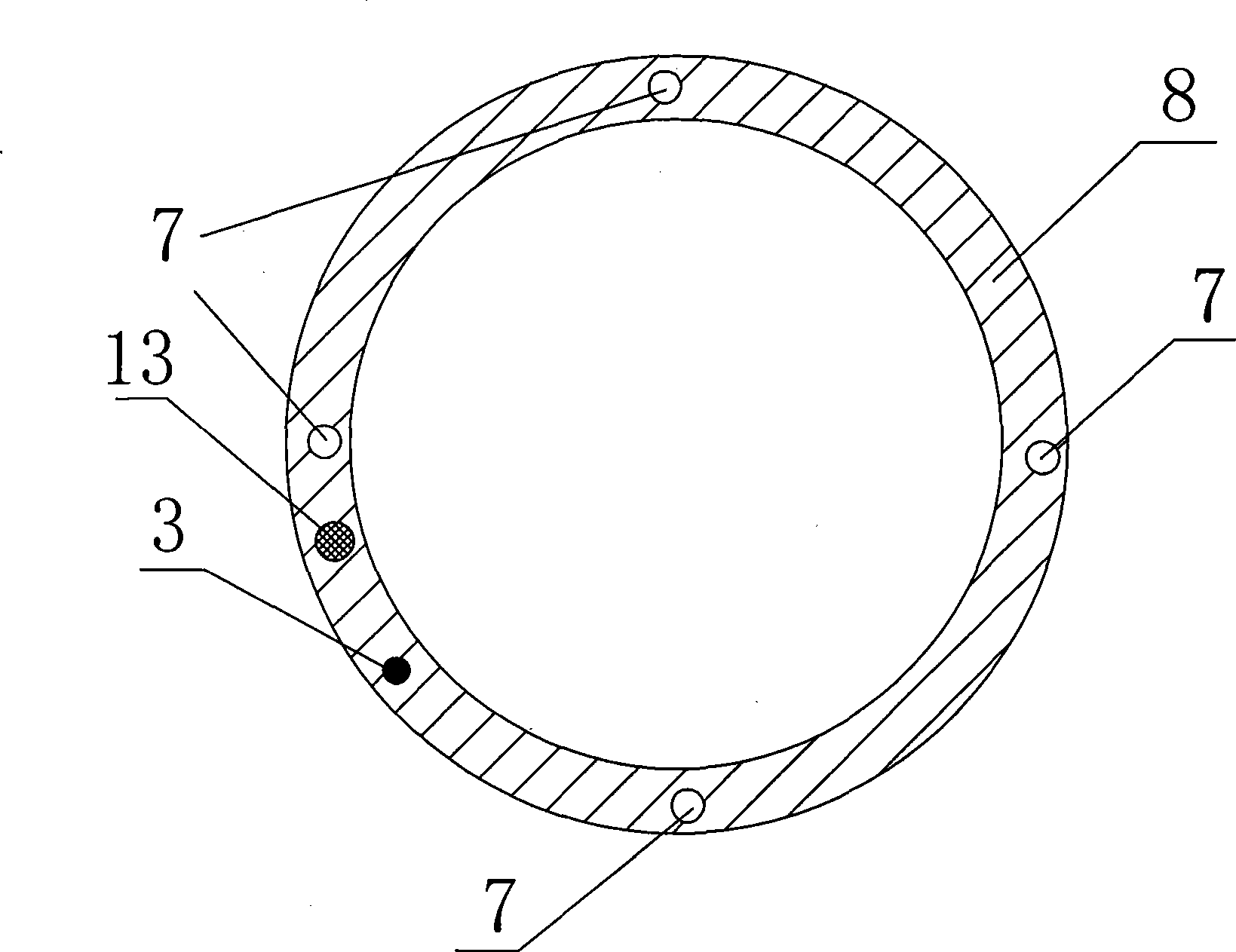

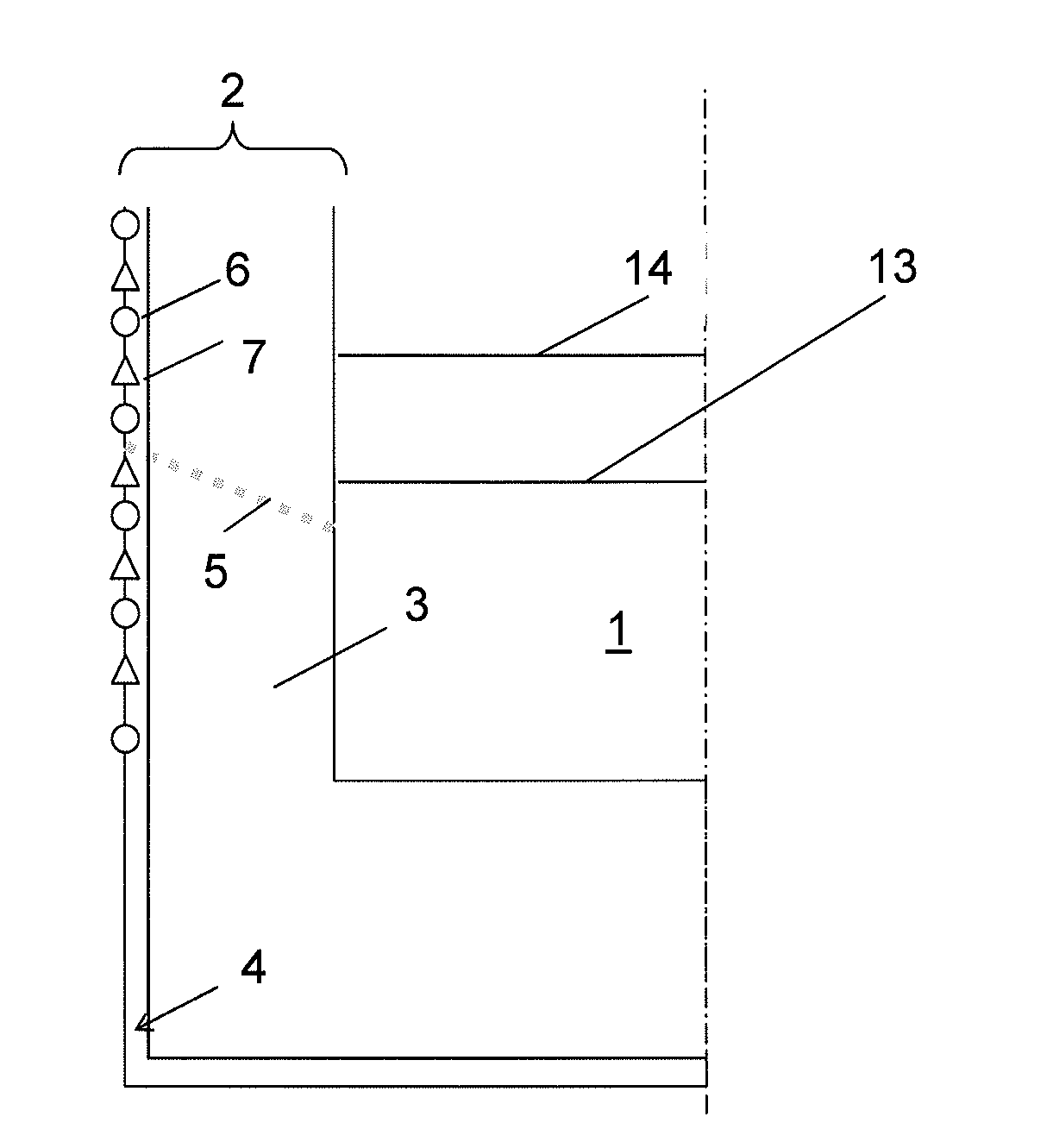

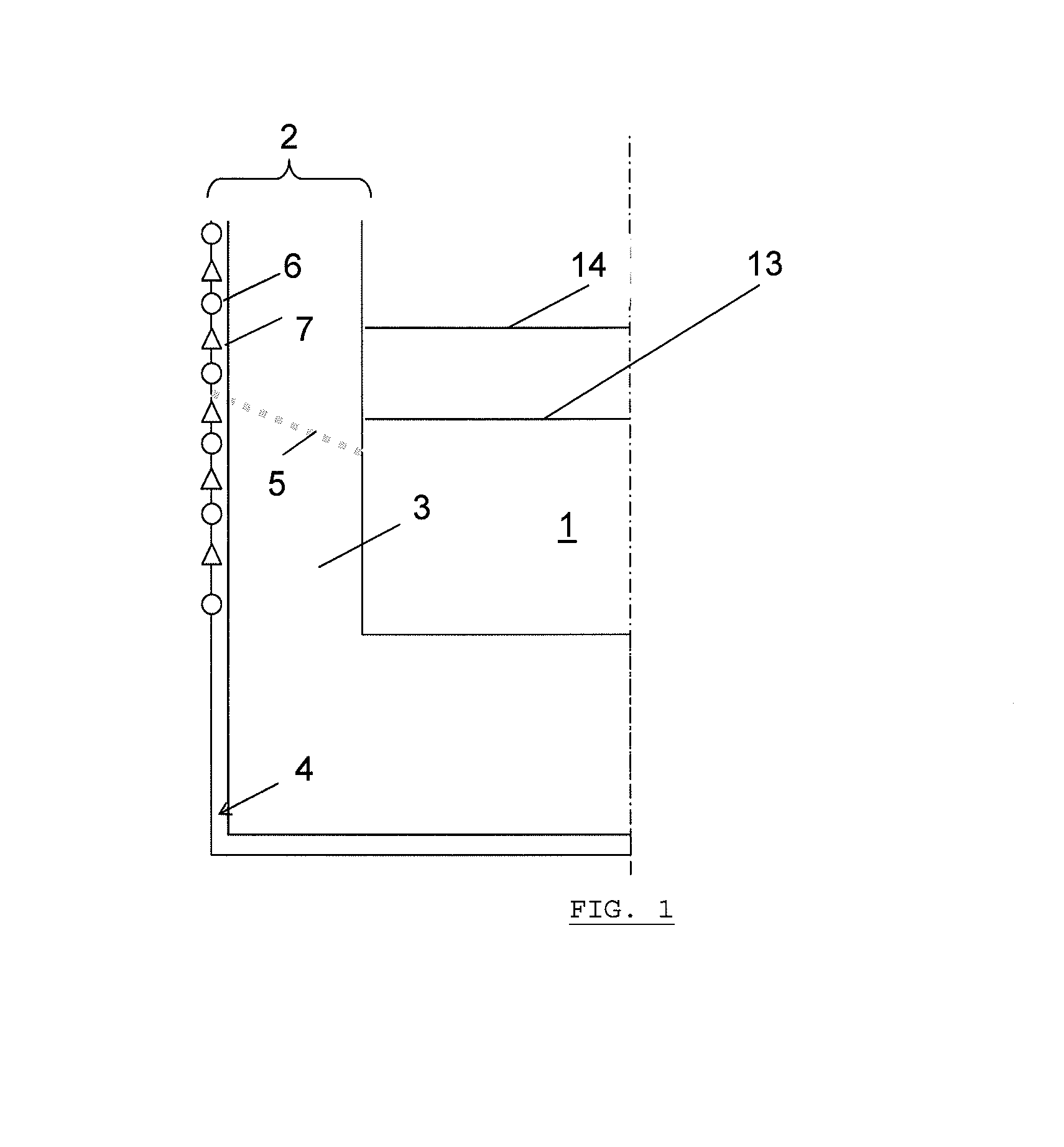

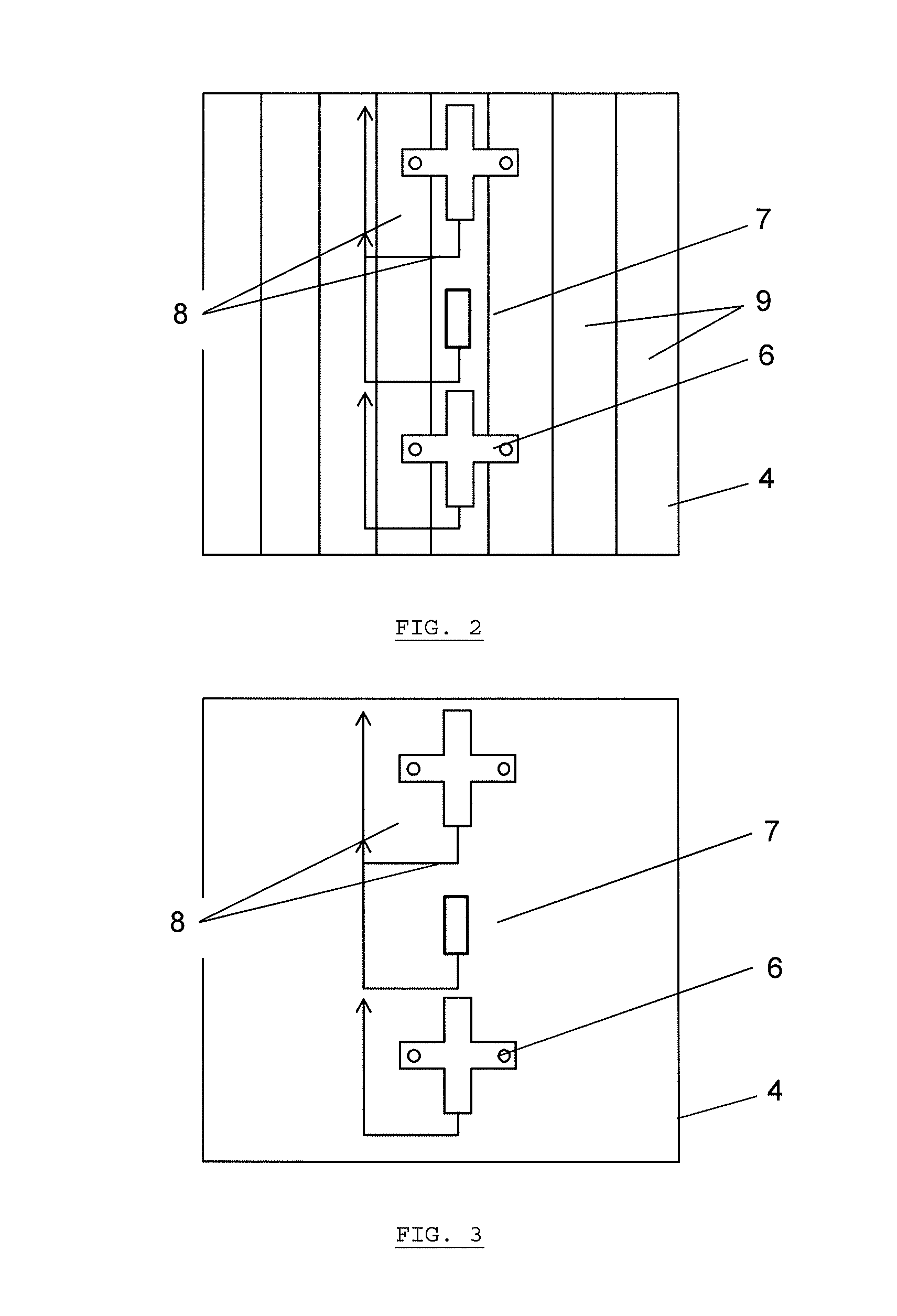

Method and Device for Measuring Levels of Cast Iron and Slag in a Blast Furnace

ActiveUS20150218667A1Easy and rapid installation and possible replacementLow costFurnace componentsBlast furnace detailsCircumferential strainSlag

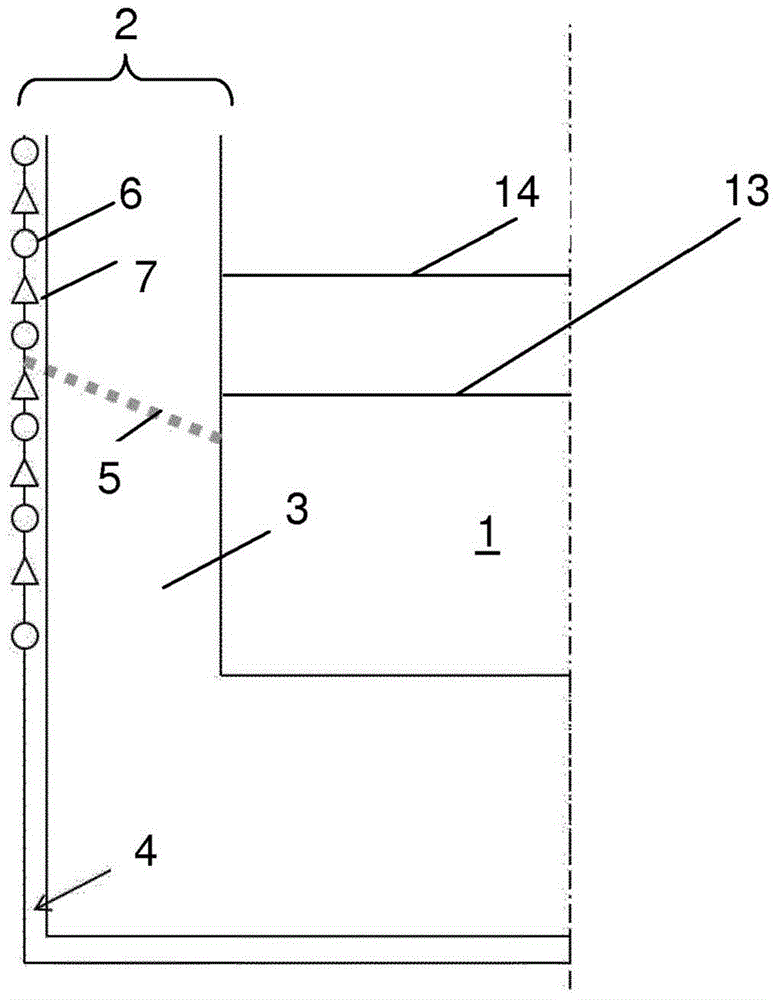

The present invention relates to a method for measuring the liquid-metal surface level (13) and the slag surface level (14) in the crucible (1) of a metallurgical shaft furnace comprising the following steps: measuring, at one or more points on the external wall (2) of the crucible, the following variables: the circumferential strain in said external wall (2) by means of a number of strain-gauge sensors (6) fixed to the armour (4) of the external wall (2) of the crucible; and the temperature of said external wall (2) by means of one or more temperature sensors (7) fixed to the armour (4) of the external wall (2) of the crucible; introducing said variables measured at a number of points on the external wall of the crucible into the general equation governing circumferential strain, the solution of which is analytical, and which contains two unknowns, the liquid metal level and the overall liquid metal / slag level, considering set parameters; and solving said equation and obtaining an analytical solution giving the liquid metal surface level (13) and the slag surface level (14) in the crucible (1).

Owner:CENT DE RECH METALLURGIQUES CENT VOOR RES IN DE METALLURGIE

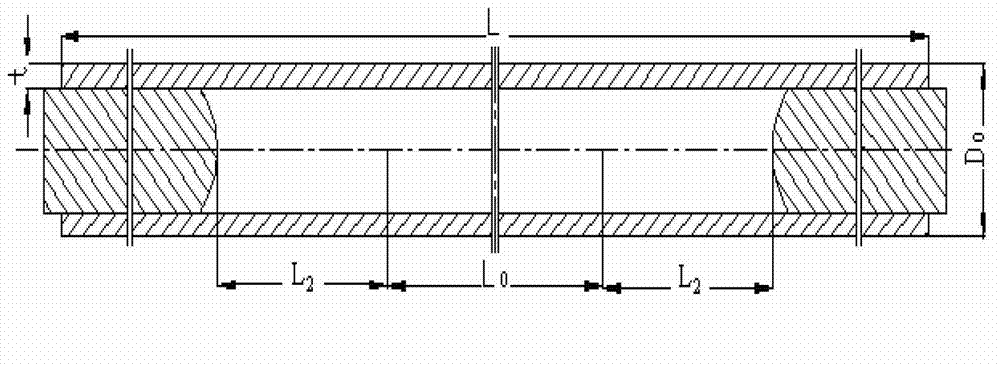

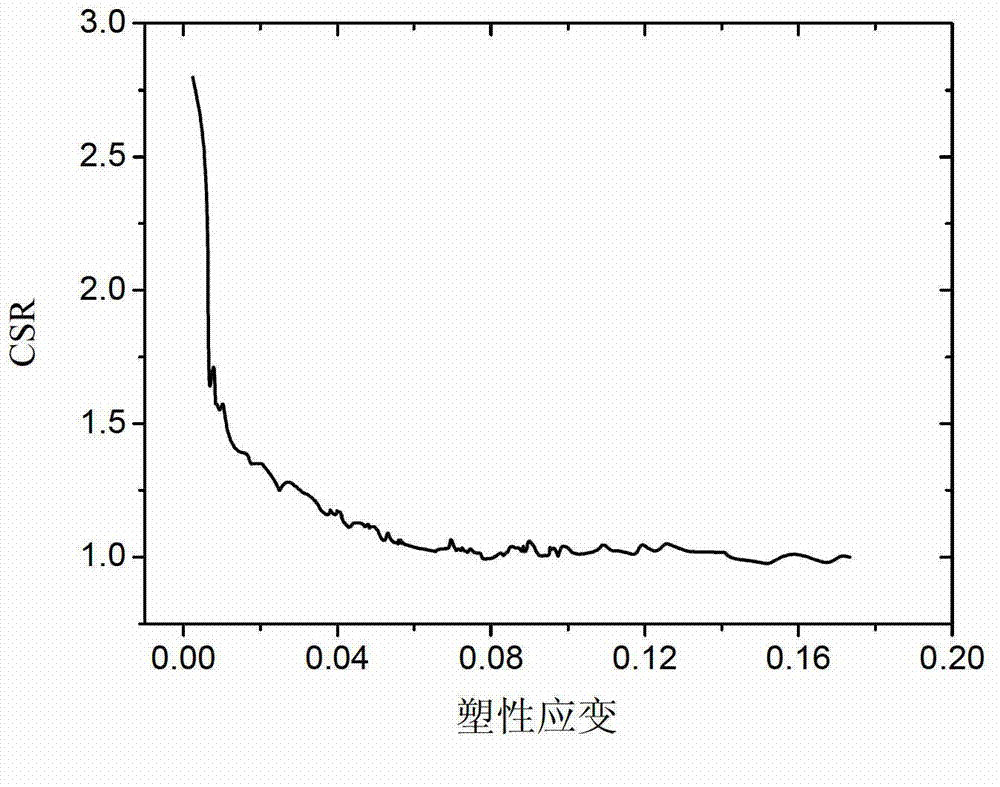

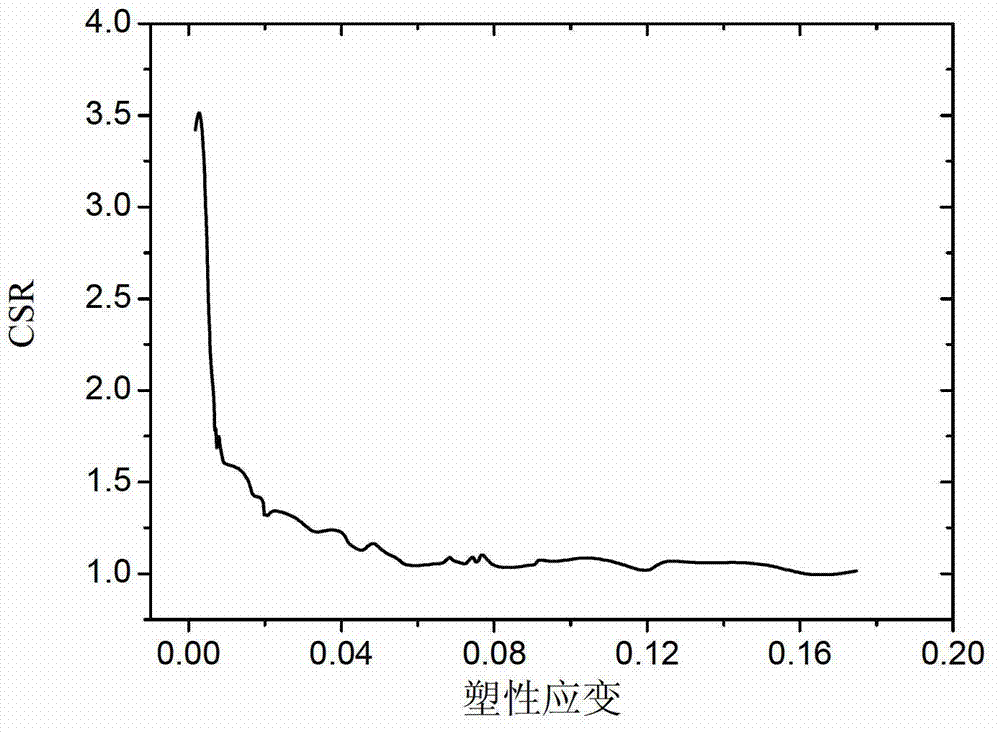

Method for obtaining shrinkage strain ratio in continuous change of titanium alloy tube

ActiveCN103115817AHigh precisionAccurately Obtain Shrinkage Strain RatioMaterial strength using tensile/compressive forcesCcd cameraTensile testing

The invention discloses a method for obtaining a shrinkage strain ratio in continuous change of a titanium alloy tube. A tube test sample is machined according to the size of a metal tube test sample in GB / T228-2002. A tensile test is carried out on a tensile test machine in a set tensile speed. The changes of the circumferential strain and the axial strain of the tube test sample in the tensile process are both precisely obtained through a CCD (Charge Coupled Device) camera. The circumferential strain and axial strain values of the tube test sample are precisely measured by using the camera in the one-way tensile process, and are subjected to elastic corrosion so as to accurately obtain the shrinkage stain ratio of the titanium alloy tube under a large plasticity deformation condition in the tensile process through formulas; and moreover the shrinkage strain ratio of the titanium alloy tube is decreased, that is, in the primary deformation period of the tube test sample, the shrinkage stain ratio is decreased dramatically, however, in later deformation, the decrease tendency of the shrinkage stain ratio is gradually reduced, and the decrease tendency of the shrinkage stain ratio in later deformation is gradually stable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

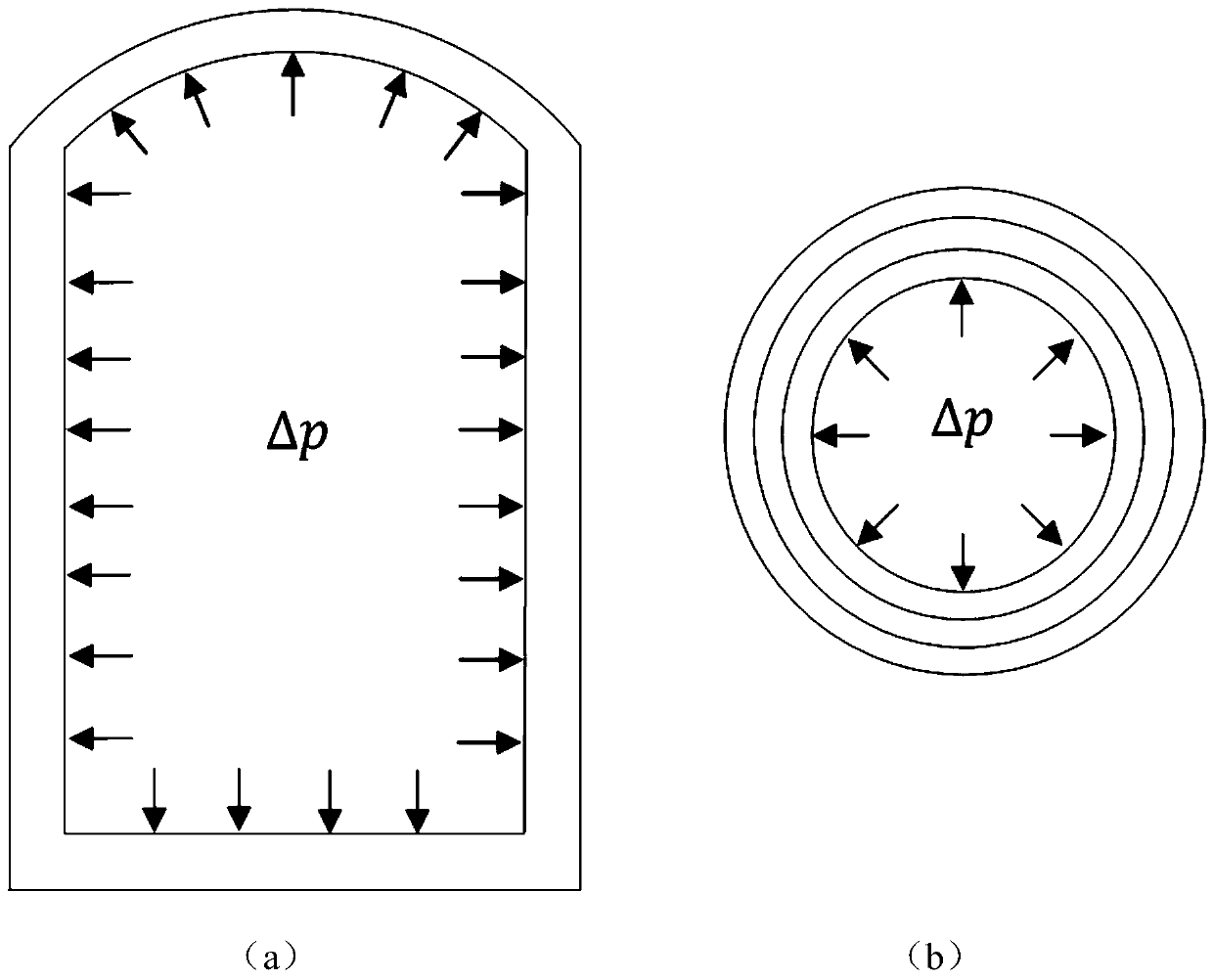

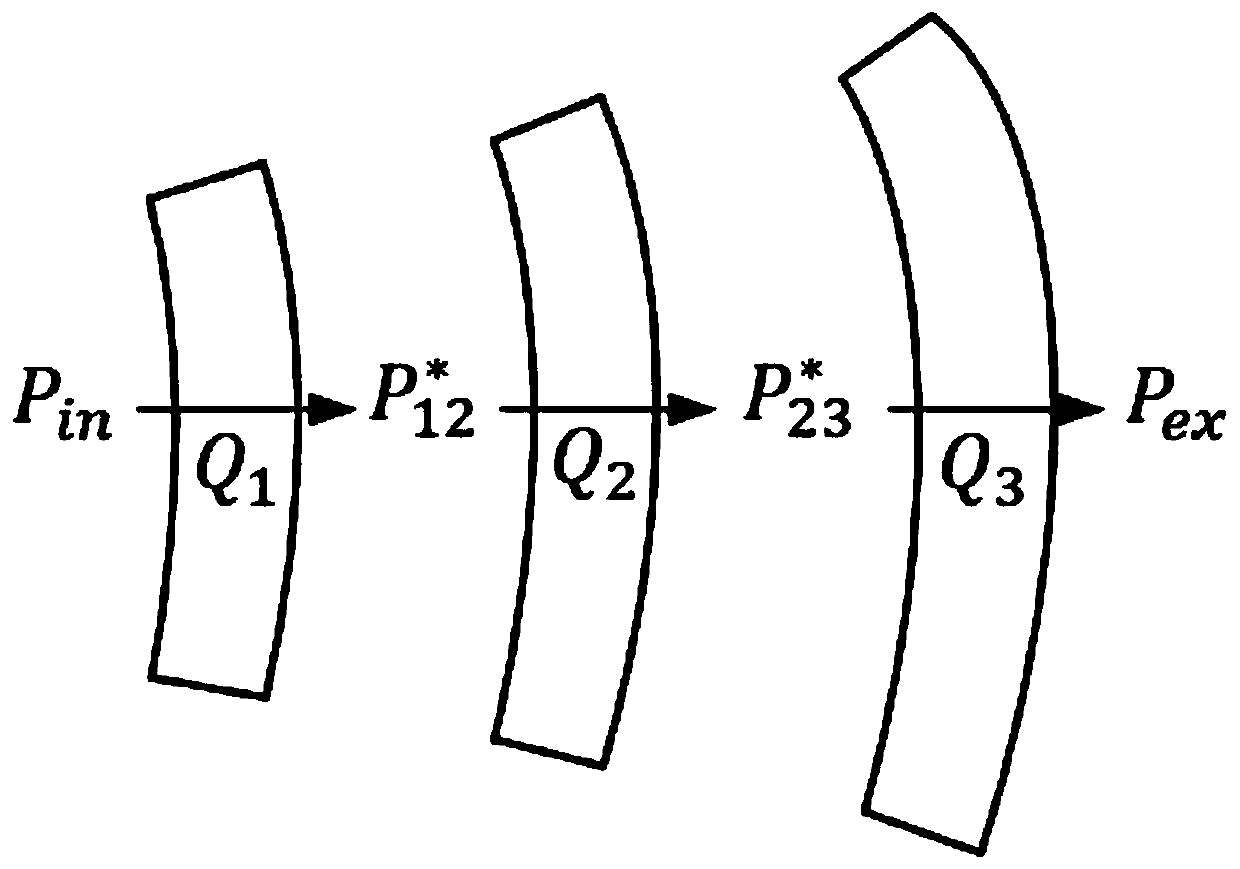

Method for quickly evaluating leakage rate of multi-layer pressure-bearing shell based on flow conservation theorem

ActiveCN111189594AQuickly assess leak ratesQuickly assess gas leak ratesMeasurement of fluid loss/gain rateInternal pressureCircumferential strain

The invention discloses a method for quickly evaluating the leakage rate of a multilayer pressure-bearing shell based on a flow conservation theorem, and belongs to the field of evaluation of the leakage rate of a damaged pressure-bearing structure. The main principle of the method is as follows: based on an ideal elastic-plastic constitutive, considering the cracking process and the failure mechanism of the multilayer pressure-bearing shell, quickly estimating the circumferential strain distribution of each layer of shell, and estimating the circumferential crack opening on the basis of exceeding the tensile limit strain of the material; and based on the flow conservation theorem, calculating the overall leakage rate of the shell structure with inconsistent cracking degree of each layer.According to the method, the cracking condition of the multi-layer pressure-bearing shell under the action of the internal pressure of a serious accident can be estimated, and the gas leakage rate ofthe multi-layer shell walls with different cracking degrees can be quickly estimated.

Owner:DALIAN UNIV OF TECH

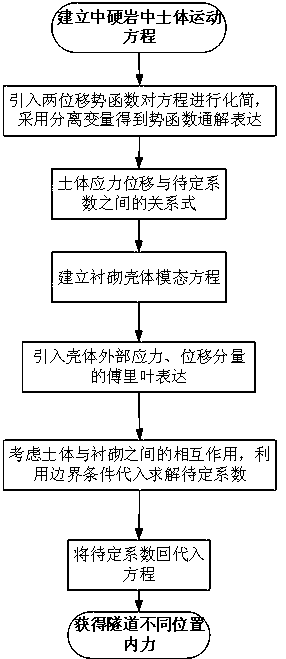

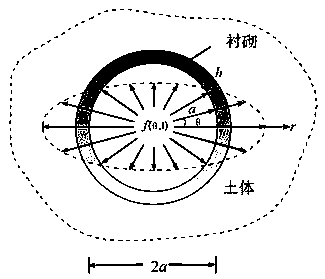

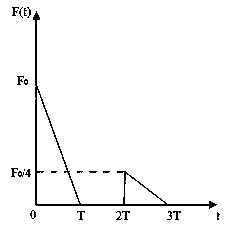

A method for calculating deformation and stress of tunnel under non-uniform explosion load

ActiveCN109101744ADeformation Accurate CalculationAccurately calculate stress magnitudeGeometric CADComplex mathematical operationsCircumferential strainGoverning equation

A method for calculating deformation and stress of tunnel under non-uniform explosion load comprises the following steps: it is assumed that non-uniform explosion load exist in an infinite medium-hard rock tunnel, the tunnel model is simplified as a rock mass-plane strain model of single-layer lining; according to the elastic wave theory, the governing equation of rock mass is established, and the constitutive equation and constitutive relation of rock mass are deduced to make the transient load, circumferential strain and shear strain change with a formula(shown in the specification). The potential function is introduced to decouple the equilibrium equation of rock mass. The modal equation of a shell in polar coordinates is established, and the relationship between stress and displacement of lining is obtained. The boundary conditions are introduced to solve the undetermined coefficients, and the Internal force solution in tunnel-rock mass is obtained.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method and device for measuring levels of cast-iron and slag in a blast furnace

InactiveCN104823028AEasy to installLow costFurnace componentsManufacturing convertersSlagCircumferential strain

The present invention relates to a method for measuring the liquid-metal surface level (13) and the slag surface level (14) in the crucible (1) of a metallurgical shaft furnace comprising the following steps: measuring, at one or more points on the external wall (2) of the crucible, the following variables: the circumferential strain in said external wall (2) by means of a number of strain-gauge sensors (6) fixed to the armour (4) of the external wall (2) of the crucible; and the temperature of said external wall (2) by means of one or more temperature sensors (7) fixed to the armour (4) of the external wall (2) of the crucible; introducing said variables measured at a number of points on the external wall of the crucible into the general equation governing circumferential strain, the solution of which is analytical, and which contains two unknowns, the liquid metal level and the overall liquid metal / slag level, considering set parameters; and solving said equation and obtaining an analytical solution giving the liquid metal surface level (13) and the slag surface level (14) in the crucible (1).

Owner:CENT DE RECH METALLURGIQUES CENT VOOR RES IN DE METALLURGIE

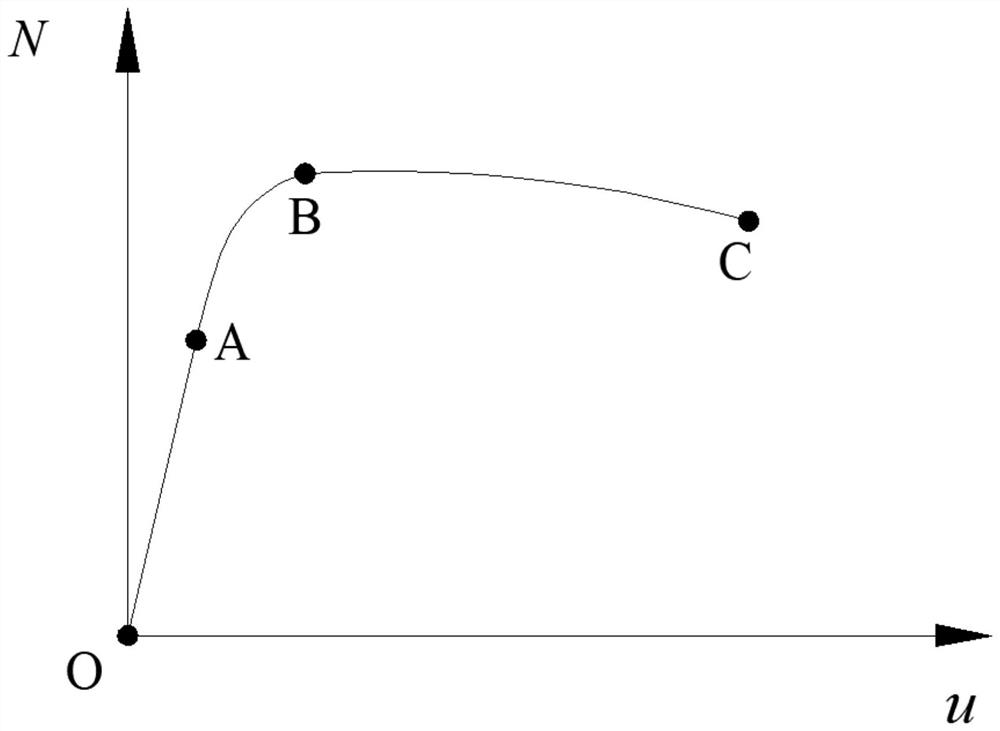

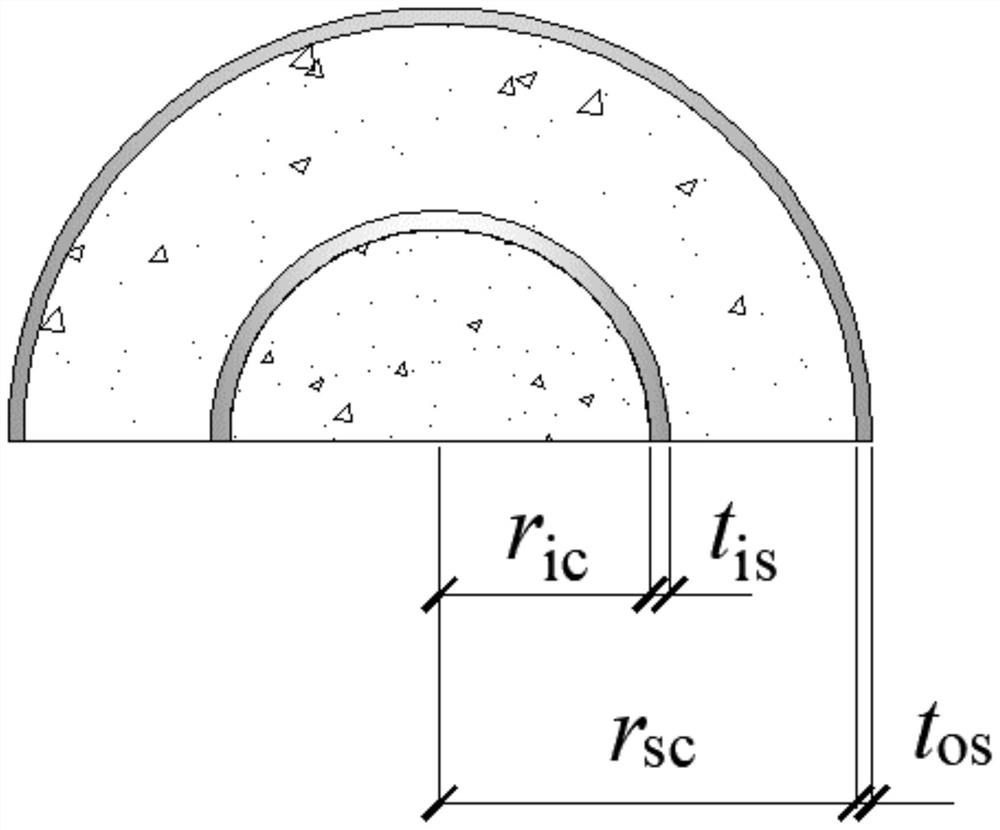

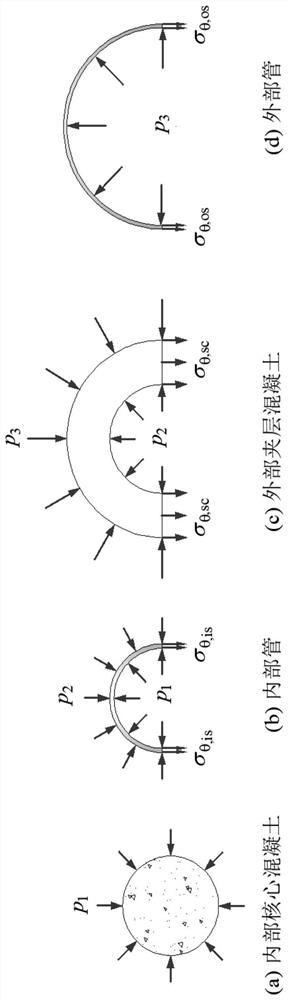

Method and system for calculating extrusion stress of isotropic double-pipe concrete column

The invention provides a method and system for calculating extrusion stress of an isotropic double-pipe concrete column, and the method comprises the steps: 1, obtaining calculation parameters of a double-pipe concrete column, including the Poisson's ratio and elastic modulus of internal core concrete and external interlayer concrete, and the Poisson's ratio, elastic modulus, inner diameter and wall thickness of an internal pipe and an external pipe; 2, establishing an extrusion stress relationship among all parts of the double-pipe concrete column; 3, substituting calculation parameters into the step 2 to obtain the extrusion stress between the parts; 4, based on the calculation parameters and the result obtained through solving in the step 3, obtaining the annular and radial strain of the inner core concrete, the annular stress and the annular strain of the inner pipe, the radial and annular stress of the outer interlayer concrete changing along the thickness and the radial and annular strain of the outer interlayer concrete changing along the thickness, the circumferential strain of the inner side and the outer side of the outer interlayer concrete and the circumferential stress and the circumferential strain of the outer pipe.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com