Multiple-factor accelerated aging test device for composite material electric pole

A composite material, accelerated aging technology, applied in measurement devices, analytical materials, instruments, etc., can solve problems such as wind deflection, galloping, aging, accelerated materials, etc., to achieve the effect of simplifying experimental operation, comprehensive testing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

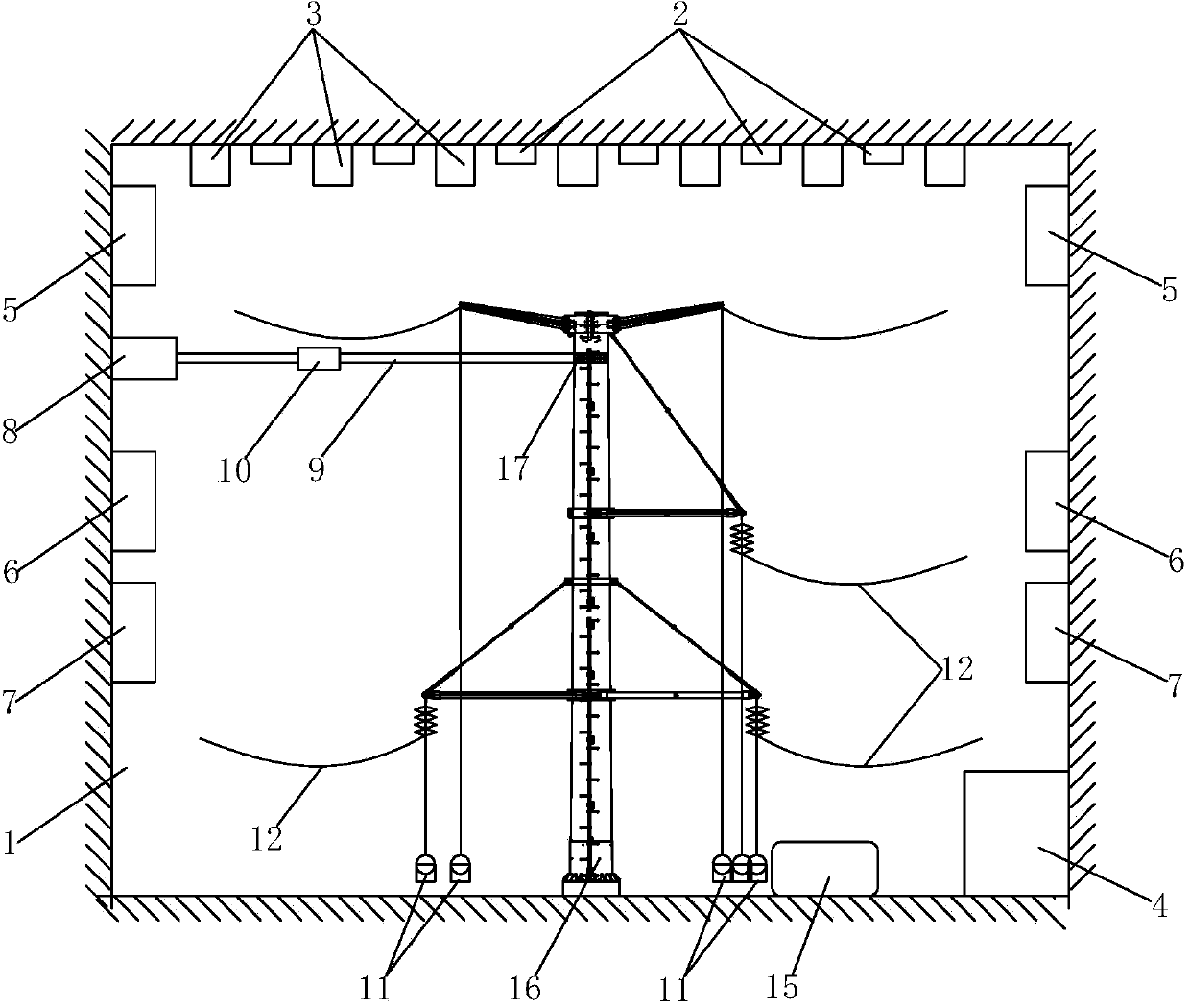

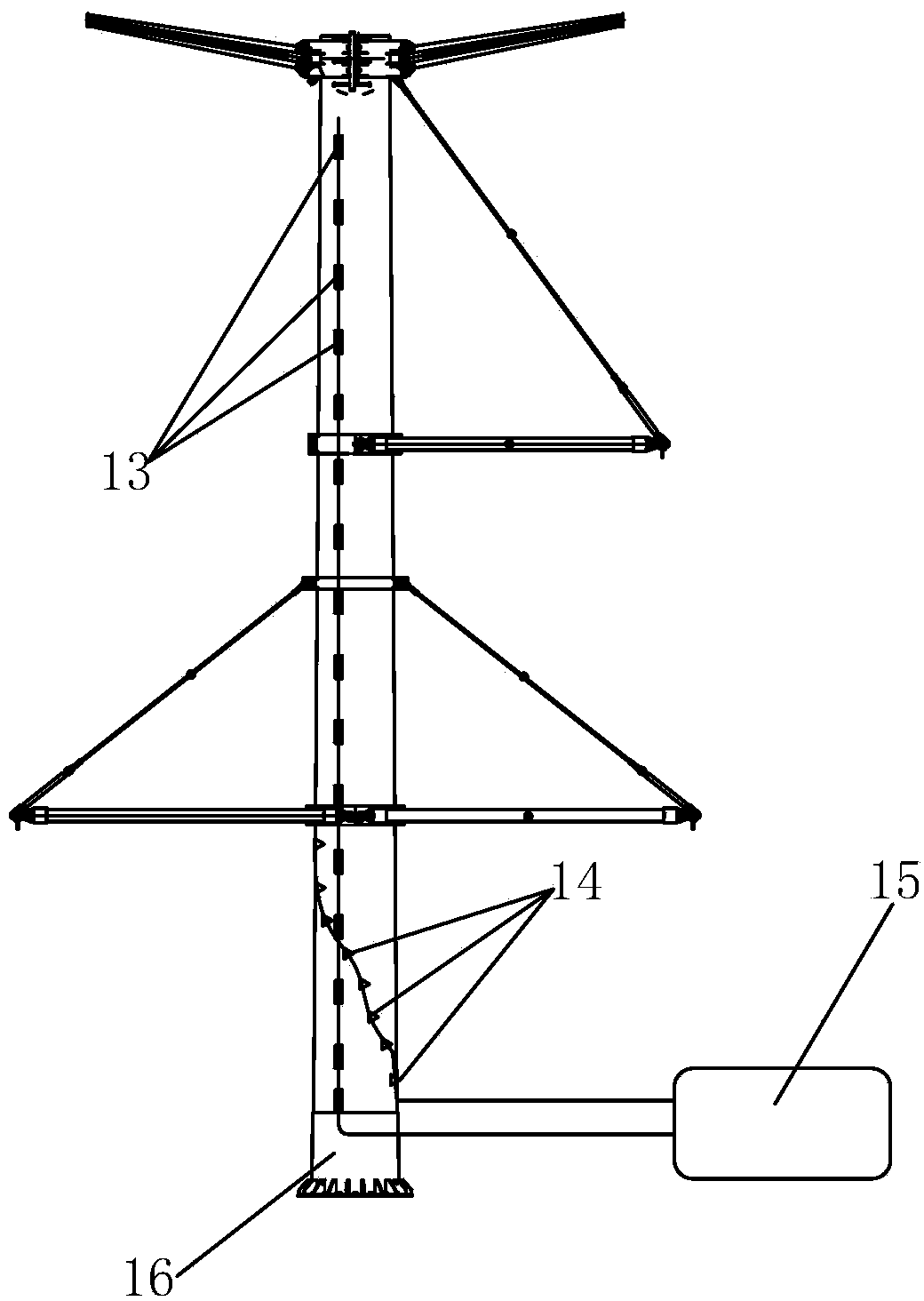

[0021] Such as figure 1 As shown, this embodiment discloses a multi-factor accelerated aging experiment device for composite poles, including an aging laboratory 1, and the top surface of the aging laboratory 1 is respectively provided with a water nozzle 2 for simulating a rainwater environment and a water nozzle for simulating a rainwater environment. Cooperate with the acid-base salt sprayer 3 of the water nozzle 2 to simulate the acid rain environment, the side wall of the aging laboratory 1 is respectively provided with an ozone generator 5 for simulating the ozone environment, an ultraviolet lamp 6 for simulating the ultraviolet radiation environment and a A high and low temperature humid heater 7 simulating an alternating high and low temperature environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com