Patents

Literature

237 results about "Rotation test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing a group of head gimbal assemblies

InactiveUS7363697B1Electrical transducersDisposition/mounting of recording headsRotation testBiomedical engineering

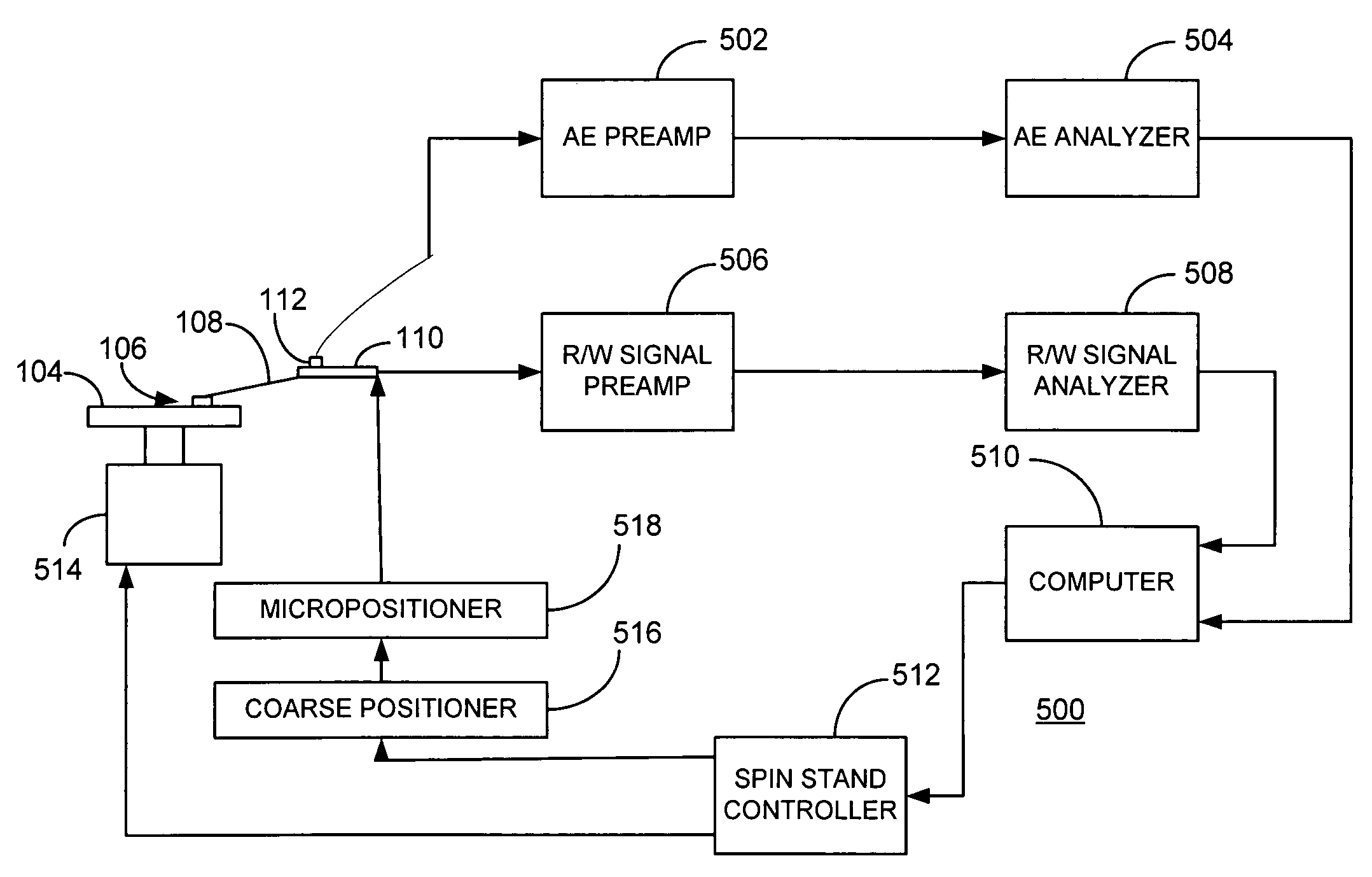

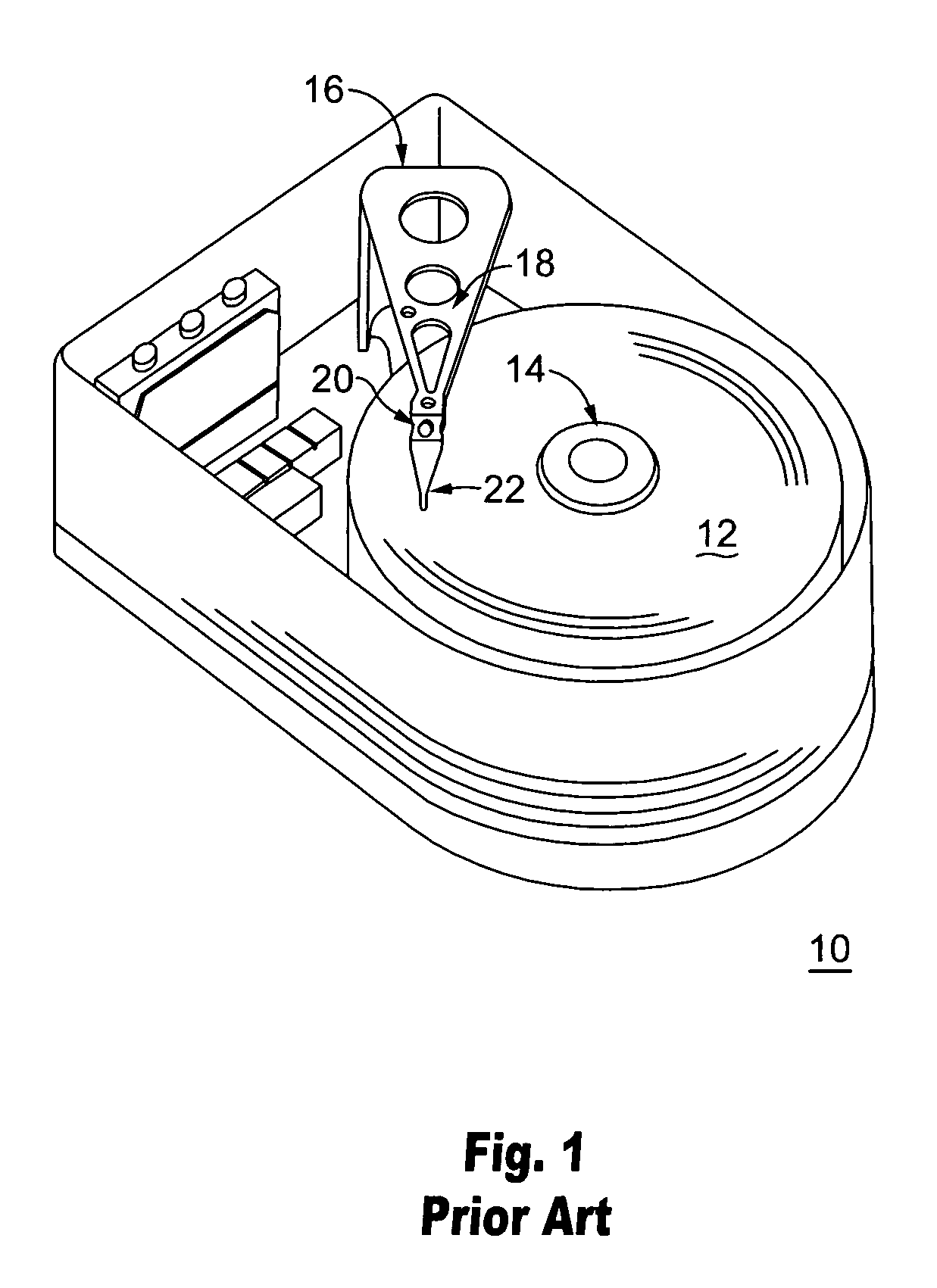

A system and method for the production level screening of low flying magnetic heads in the manufacture of disk drive head disk assemblies (HDAs) is disclosed. A test disk is provided and has a plurality of bumps extending from at least one surface thereof. The test disk is rotated to fly a head of a head gimbal assembly selected from the group adjacent the surface of the test disk. An interaction of the head with one or more of the plurality of bumps may be sensed and the head gimbal assembly may be screened out from the group in response to the sensing of the interaction.

Owner:WESTERN DIGITAL TECH INC

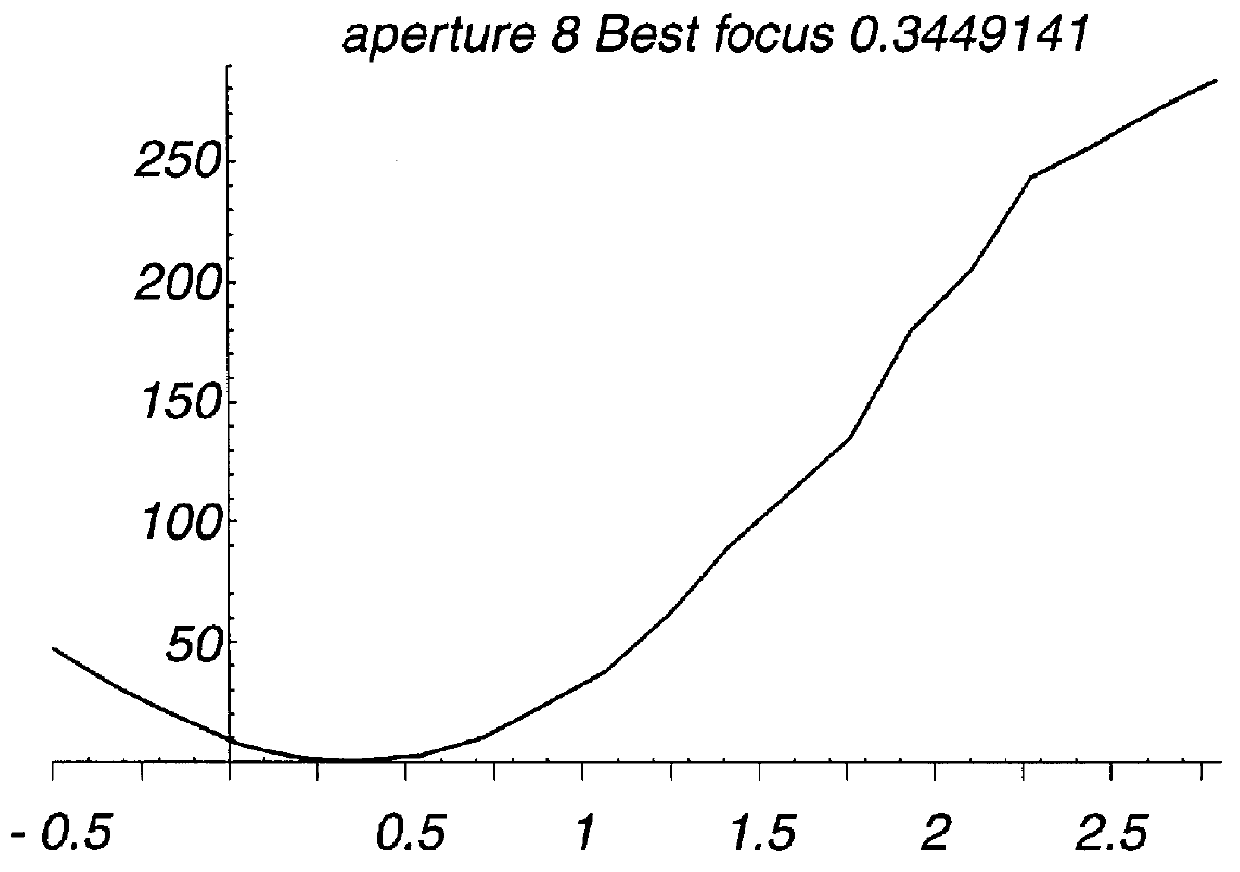

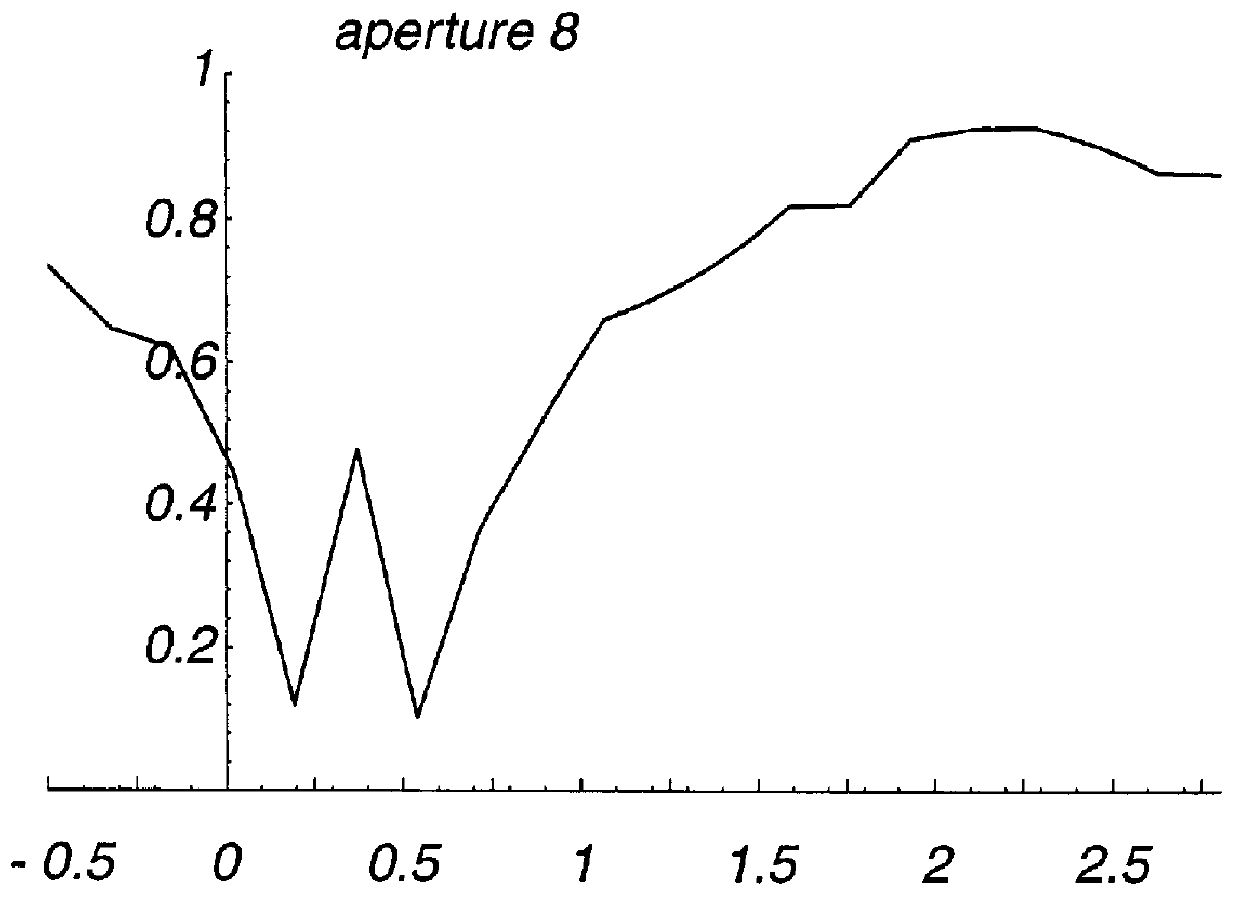

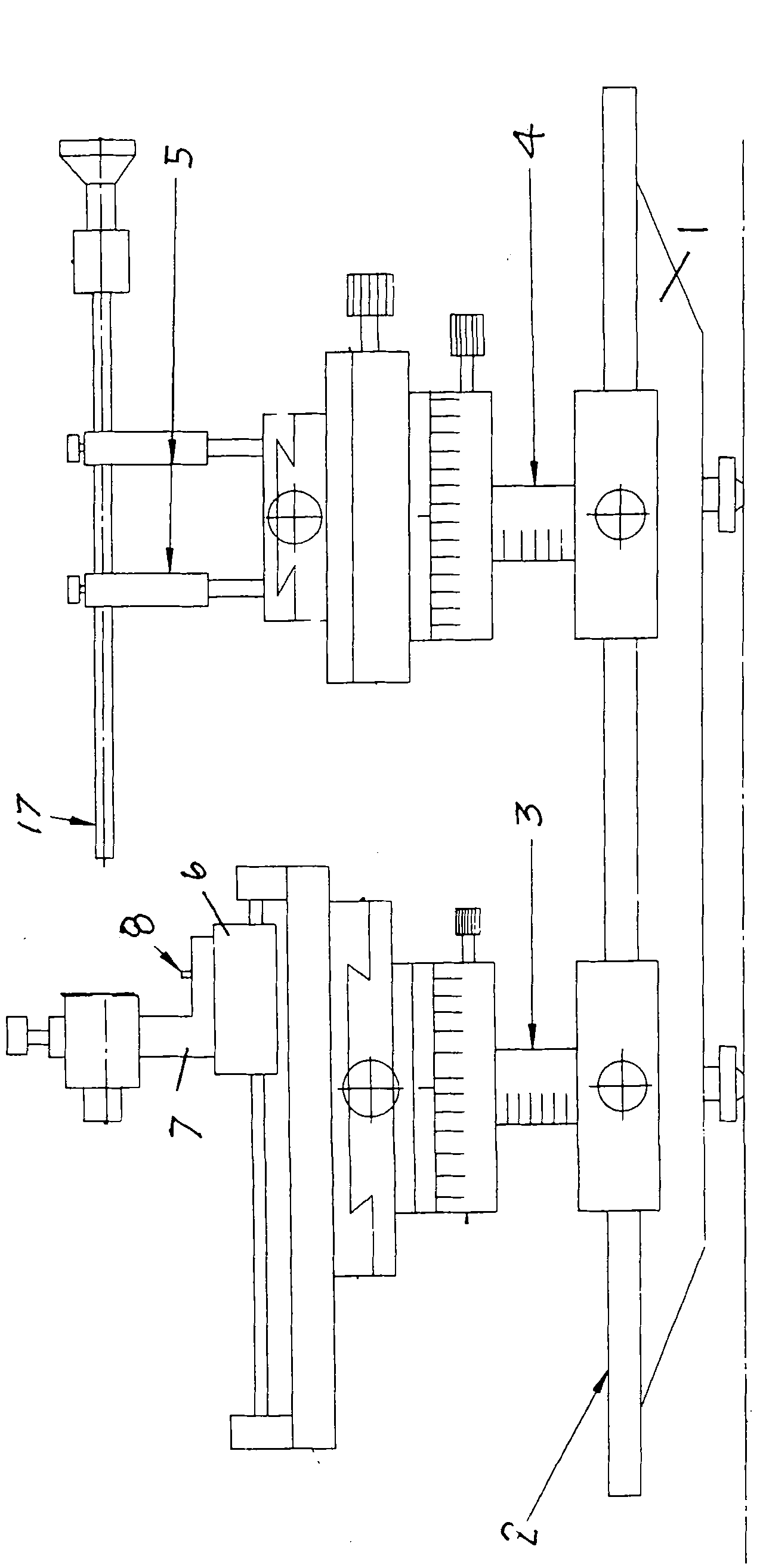

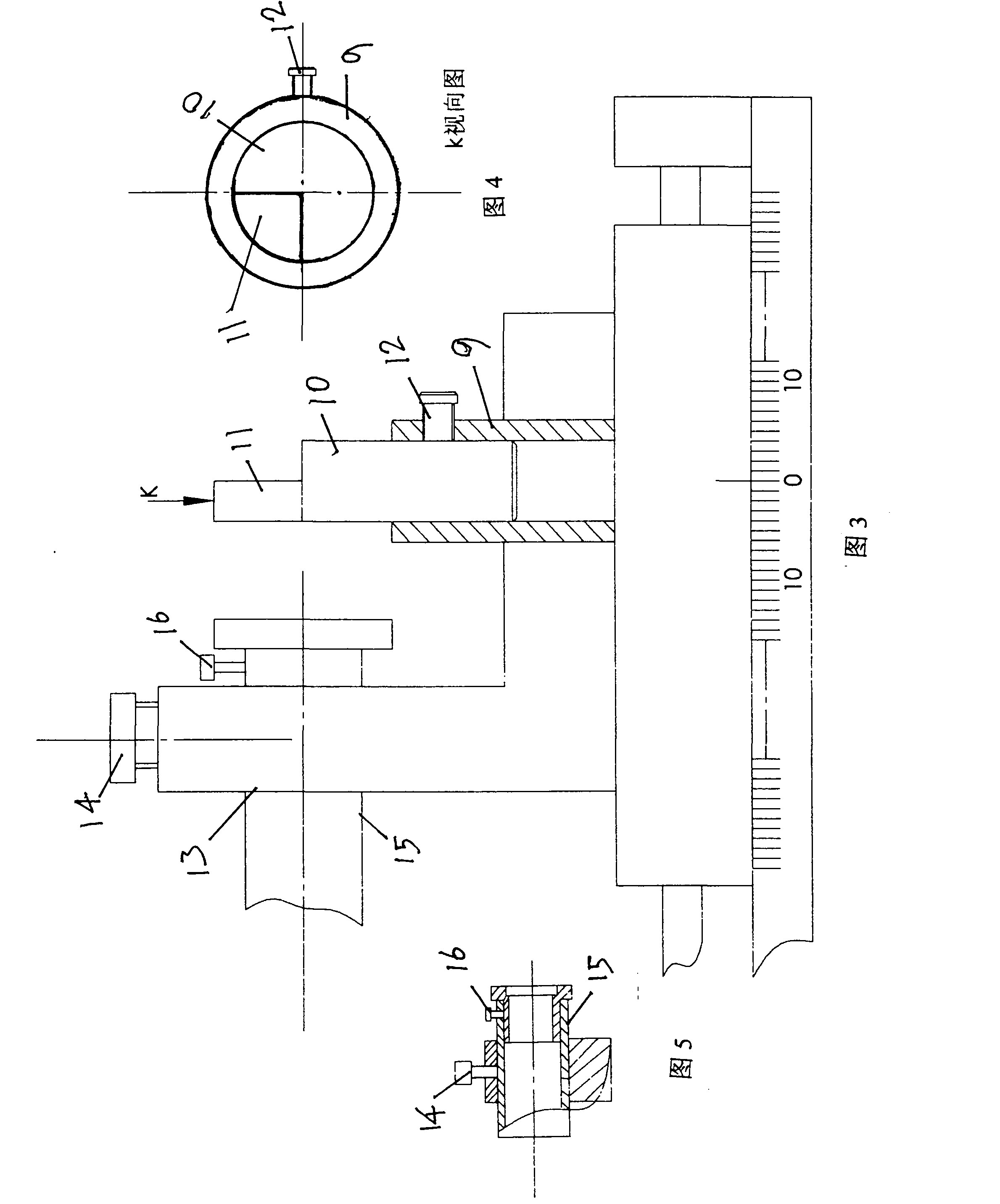

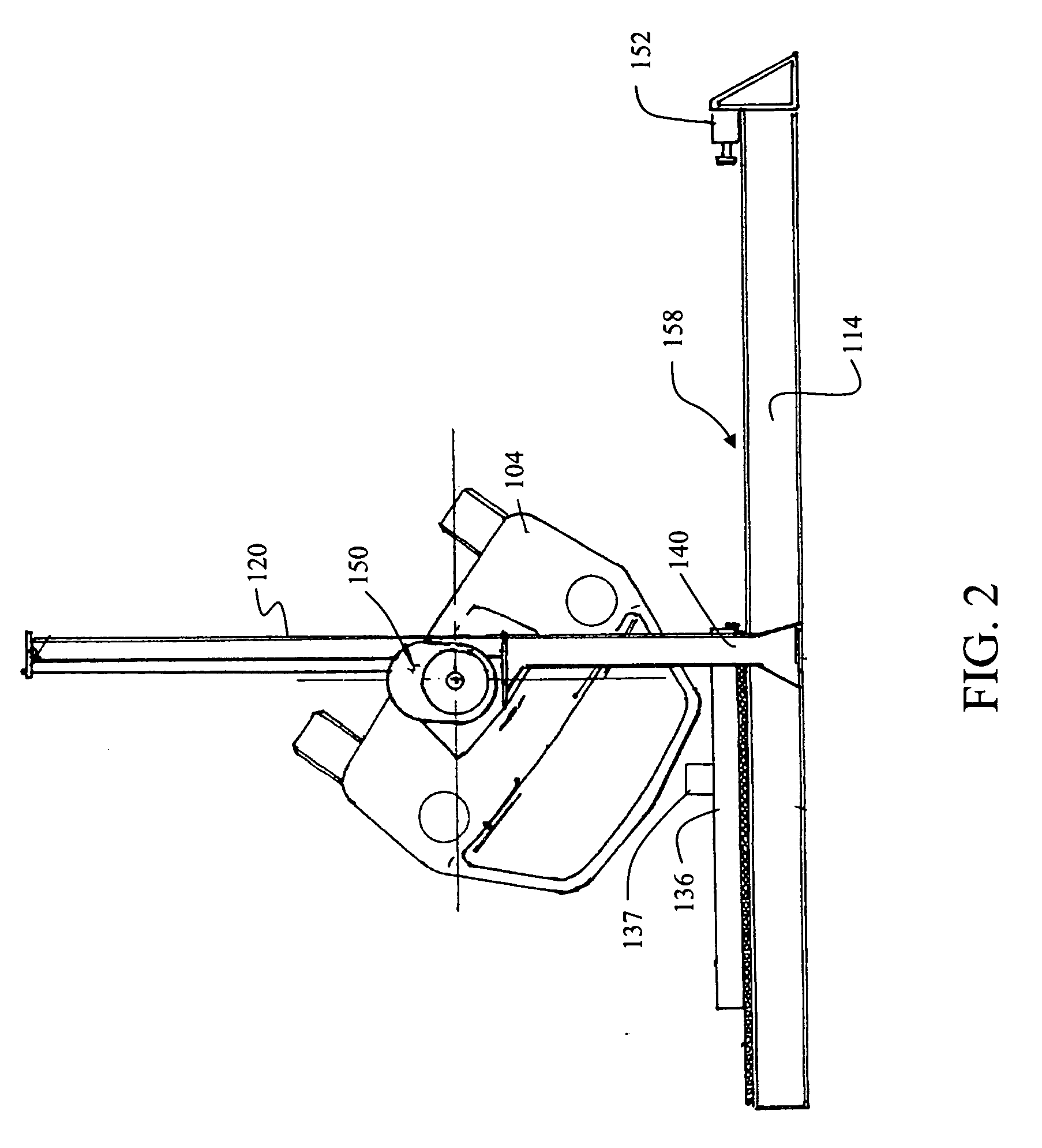

Image quality mapper for progressive eyeglasses

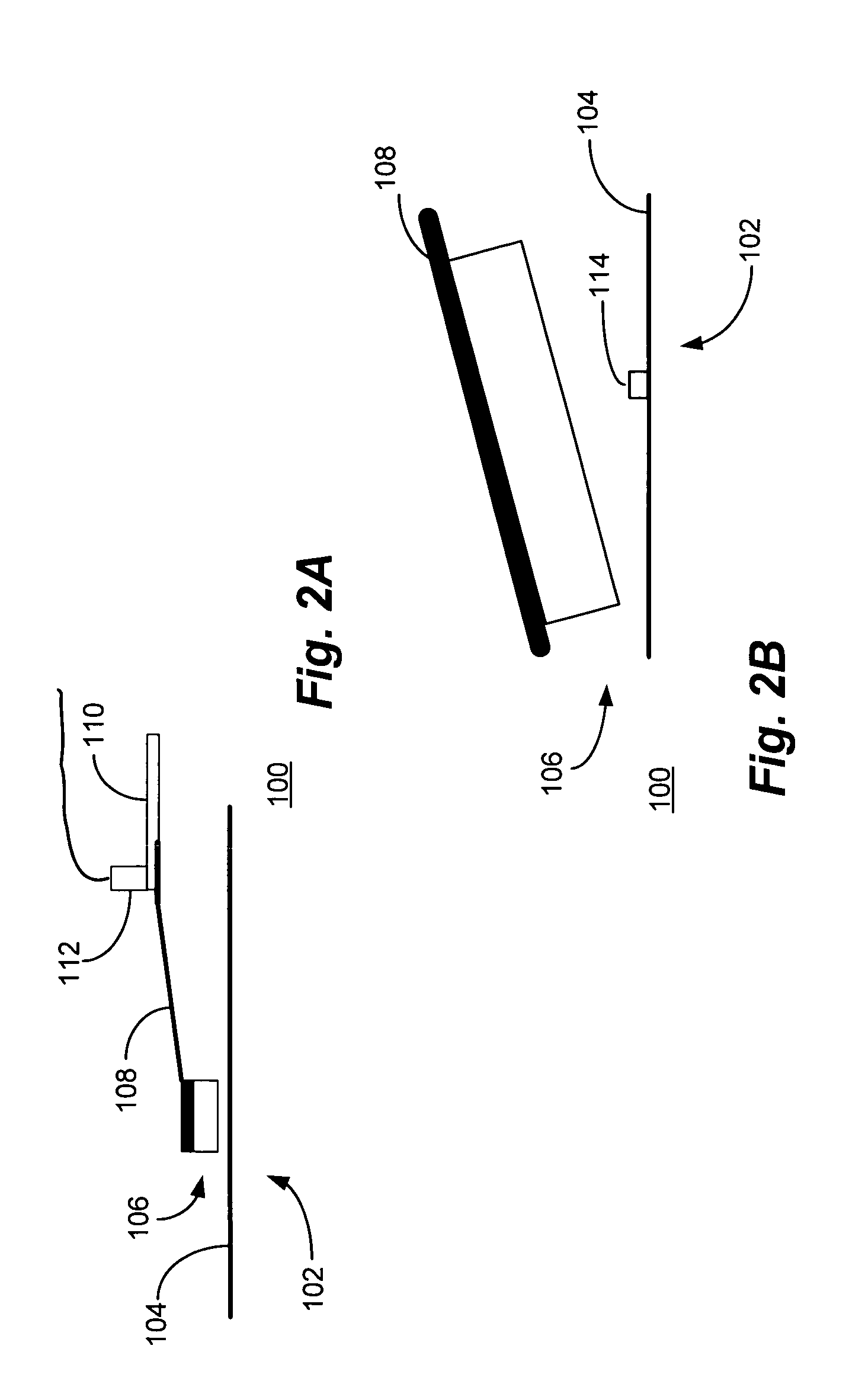

An instrument and method for optical testing of an eyeglass lens, including progressive addition lenses, to obtain image quality measurements includes an illumination system for presenting a beam of light to a test lens, a test lens positioning system for rotating the test lens so that different areas on the lens are illuminated, a zoom lens for focusing the beam at a constant effective focal length, a detection system for recording and measuring image quality of the test lens, and an alignment boom for conveying the zoom lens and the detection system such that the optical axis remains aligned with the beam existing the test lens. The instrument is fully automated and capable of obtaining measurements of the power, astigmatism, prism and modulation transfer function at various locations on the surface of the lens.

Owner:ESSILOR INT CIE GEN DOPTIQUE

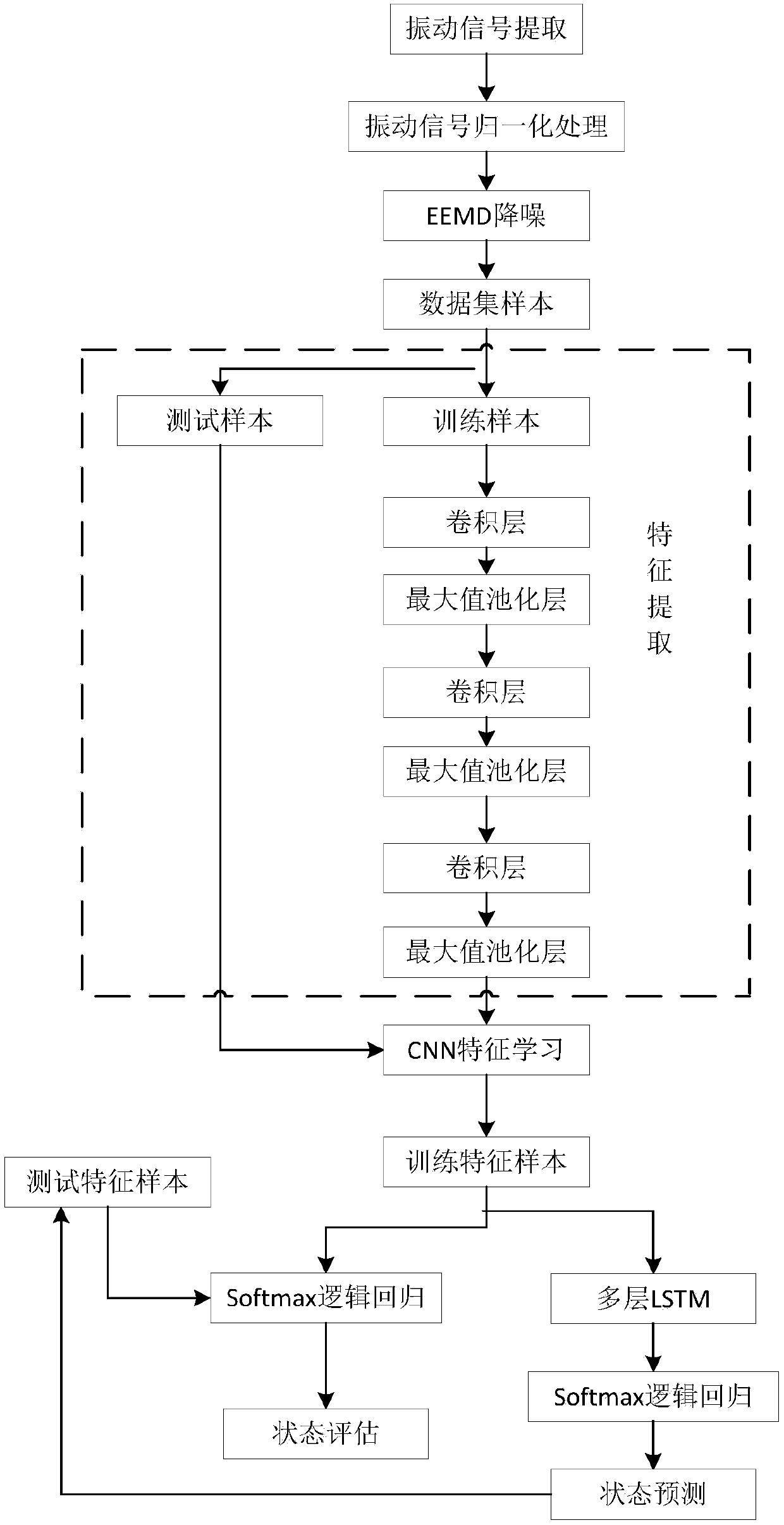

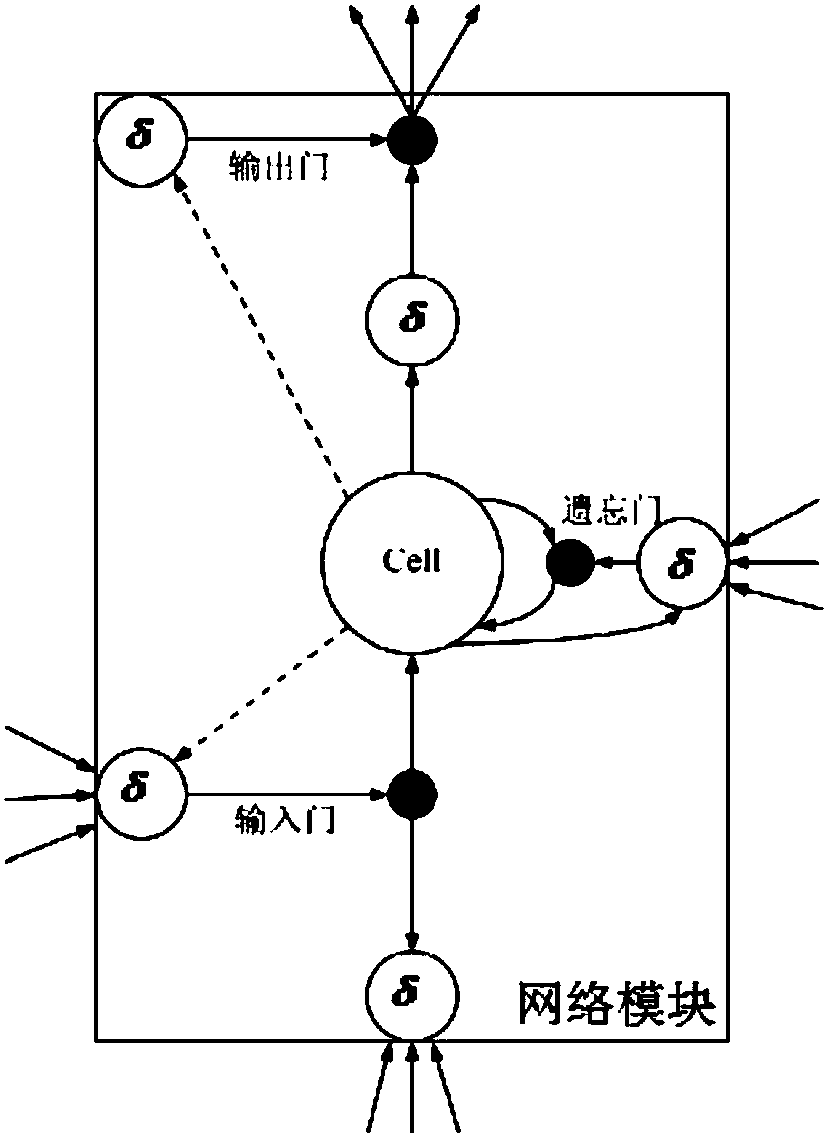

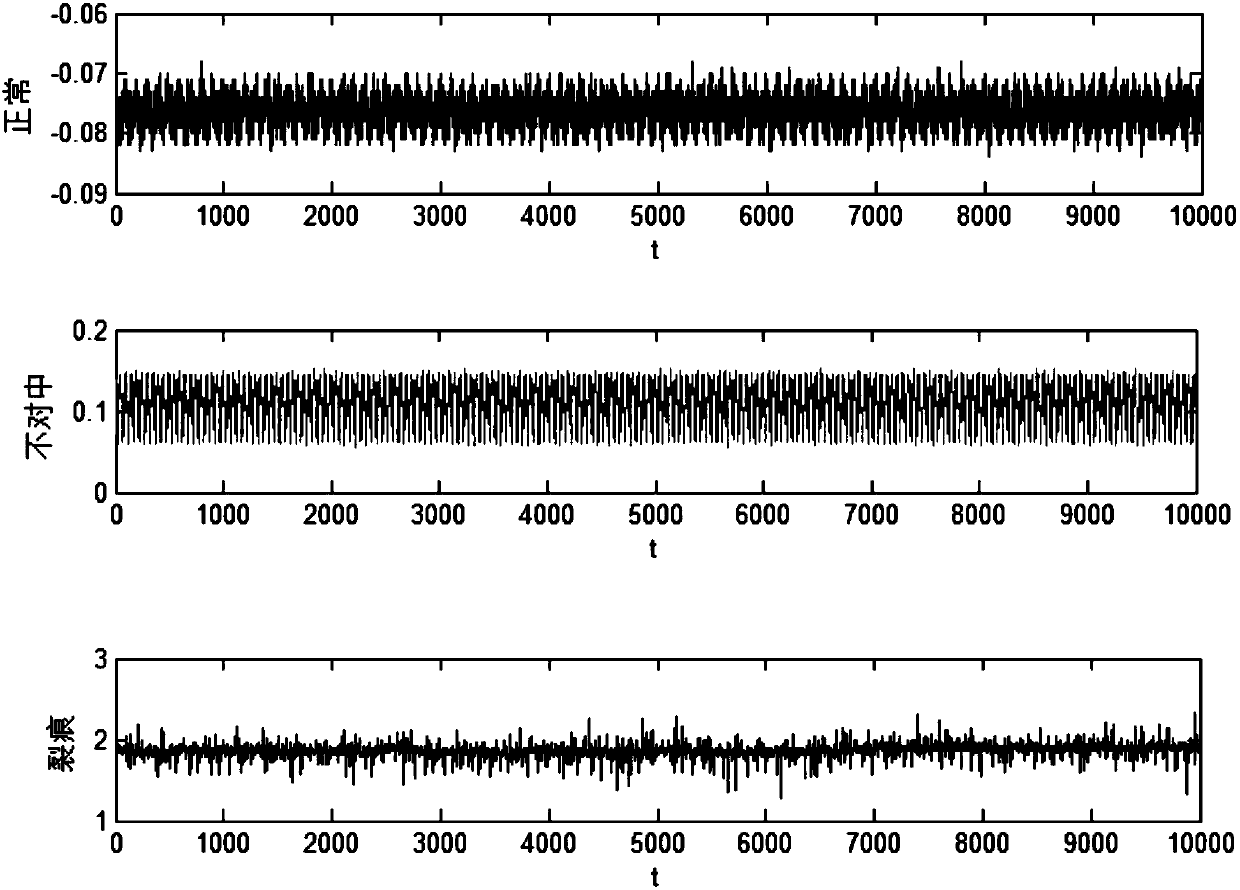

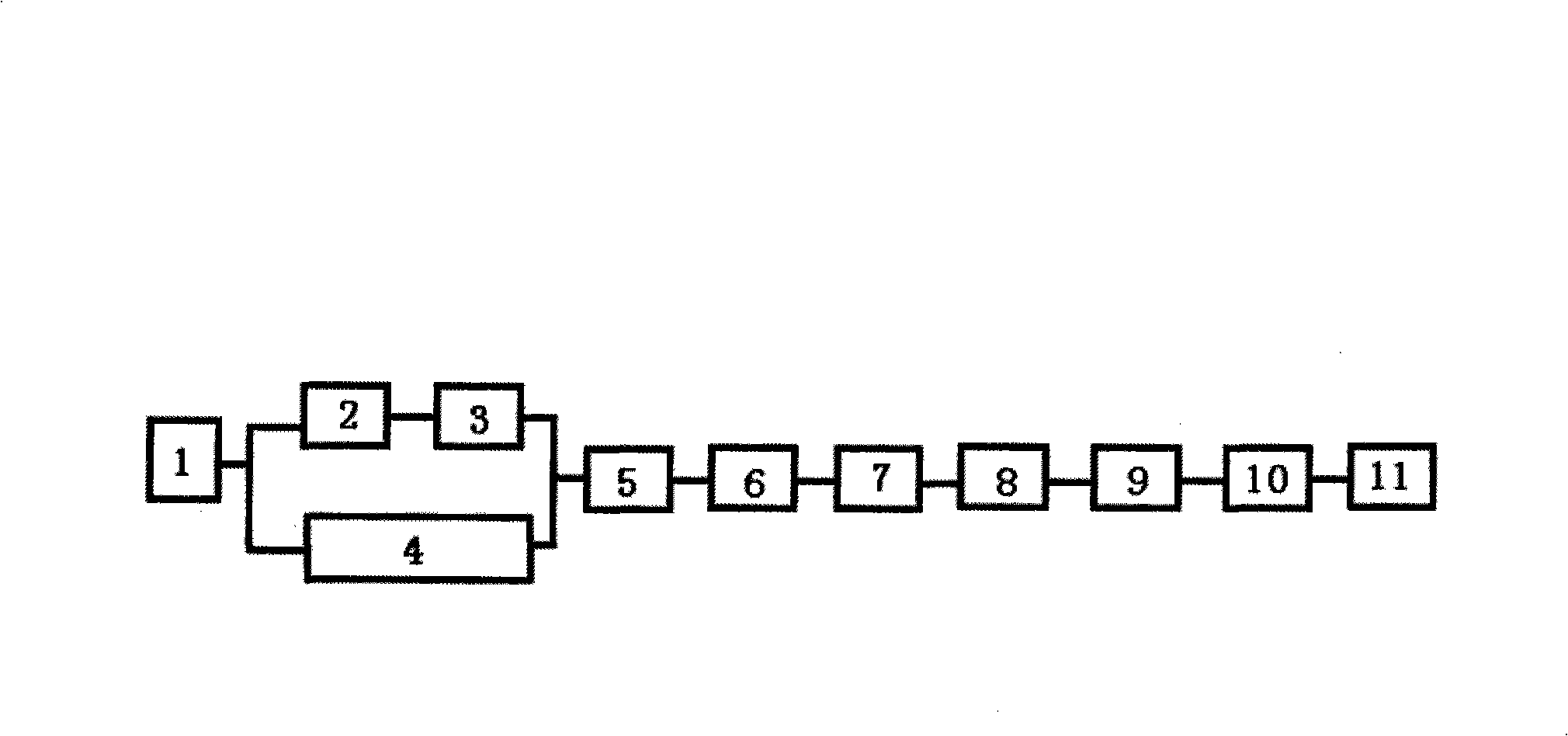

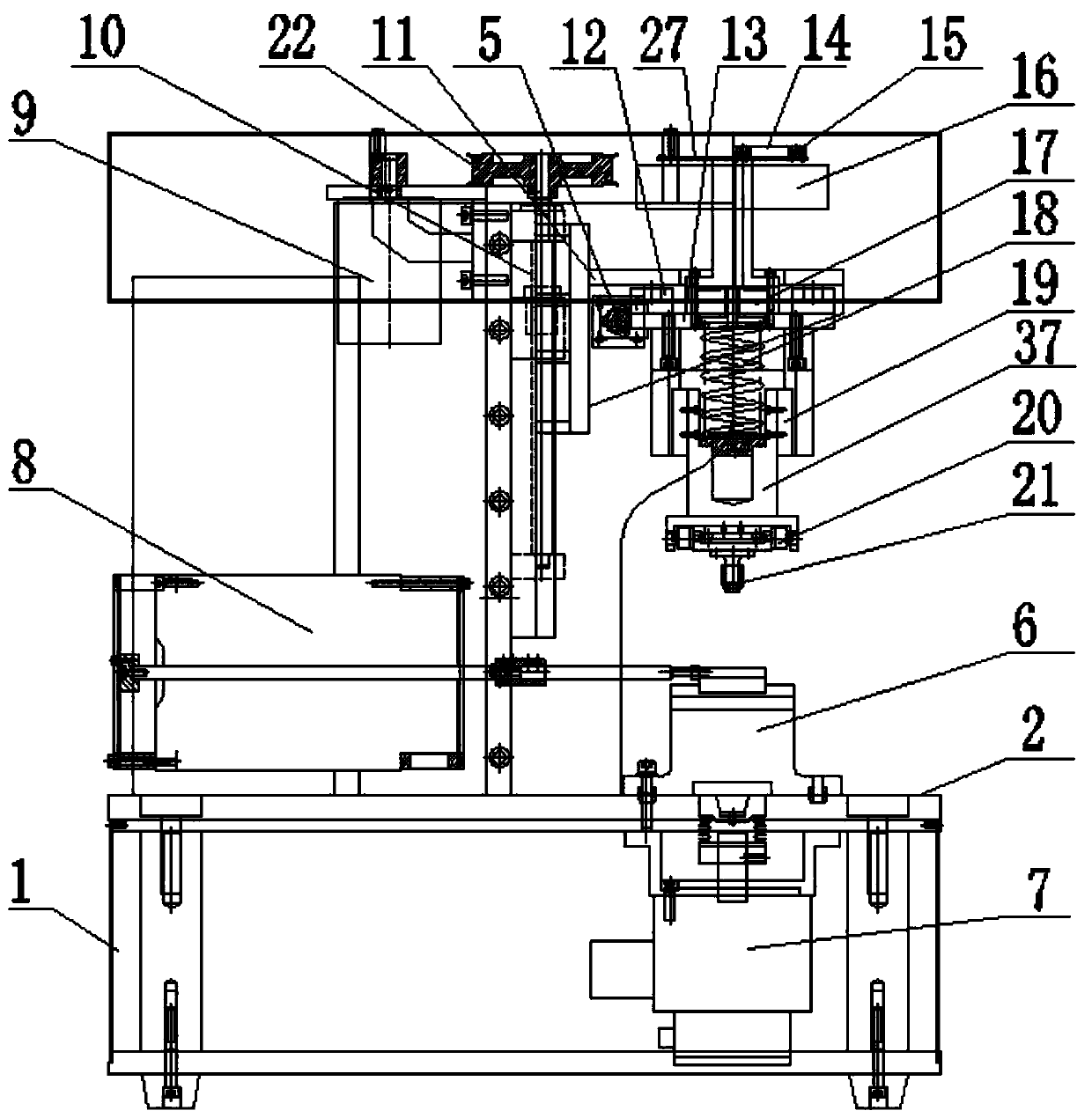

State recognition and prediction method for spindle characteristic test bench based on deep learning

ActiveCN108344564AStrong characteristicImprove generalization abilityMachine bearings testingCharacter and pattern recognitionDecompositionRotation test

The invention relates to a state recognition and prediction method for a spindle characteristic test bench based on deep learning, which comprises the steps of collecting vibration signals in the operating process of the spindle characteristic test bench, performing normalization processing on the vibration signals, performing noise reduction processing on the normalized vibration signals by adopting EEMD (Ensemble Empirical Mode Decomposition) to obtain IMF components, and reconstructing the obtained IMF components to form restored signals; enabling the restored signals to serve as input samples of a CNN, performing feature extraction on the restored signals to obtain feature vectors, carrying out CNN feature learning on the feature vectors to obtain training feature samples; coding timeinformation for the training feature samples through a multi-layer LSTM (Long Short Term Memory), carrying out classification through Softmax logistic regression to obtain prediction feature samples,and realizing prediction for the operating state; and performing Softmax logistic regression through the training feature samples and the prediction feature samples, carrying out classification on a logistic regression layer so as to judge the fault type of a rotor rotation test bench system, and realizing state recognition. The state recognition and prediction method has fast response performanceand tracking performance.

Owner:BEIJING INFORMATION SCI & TECH UNIV

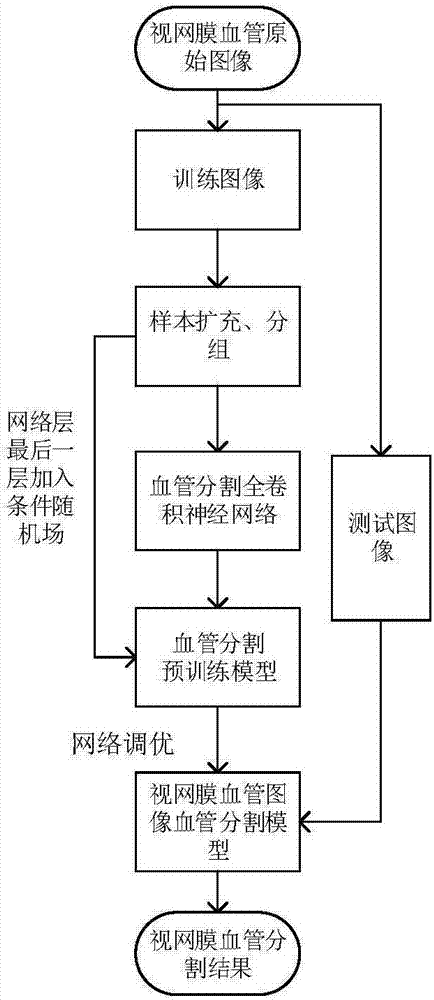

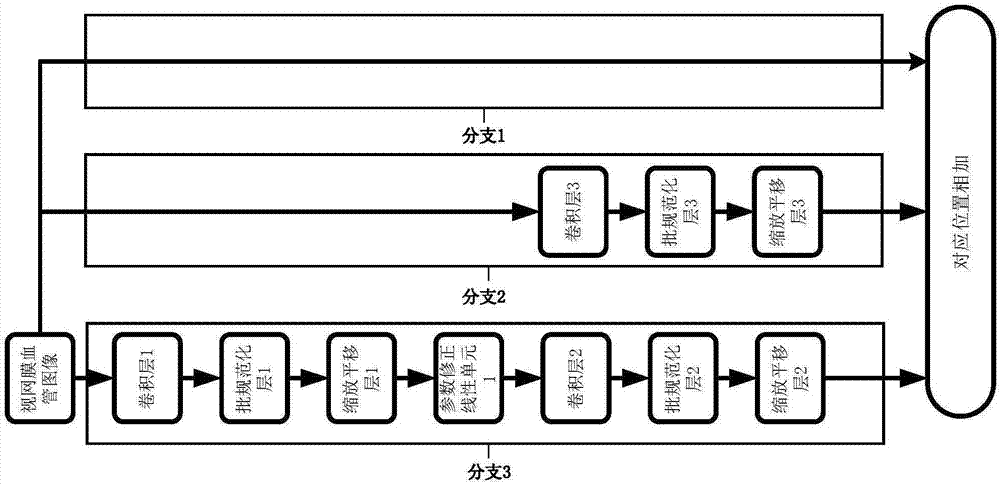

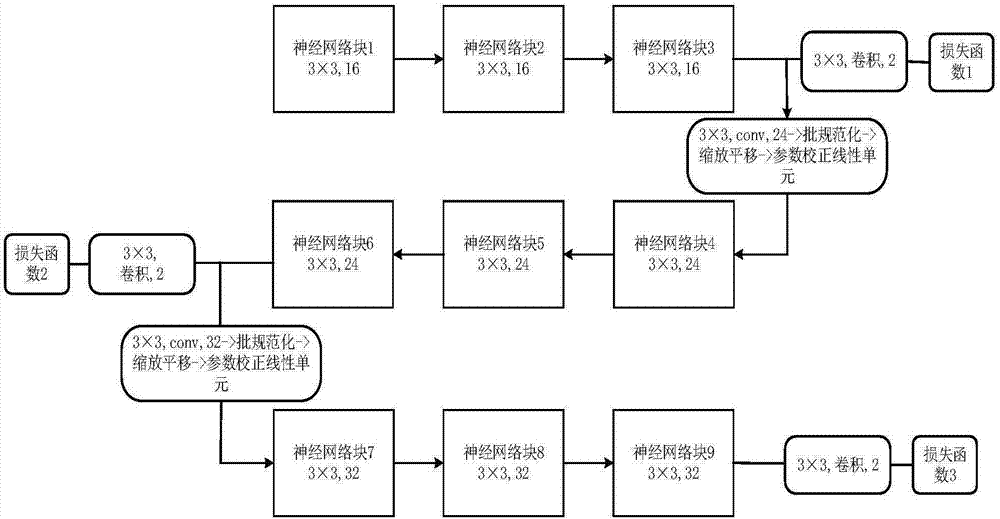

Retinal blood vessel segmentation method based on deep-learning adaptive weight

ActiveCN107292887AFast convergenceEliminate class imbalance problemsImage enhancementImage analysisConditional random fieldRetinal blood vessels

The invention discloses a retinal blood vessel segmentation method based on the deep-learning adaptive weight, comprising: performing sample expansion on retinal blood vessel images and grouping the samples; constructing a full-convolution neural network for blood vessel segmentation; pre-training the network through the training samples; performing the global adaptive weight segmentation on the retinal blood vessel images; obtaining the initial model parameters for retinal blood vessel segmentation; adding a conditional random field layer to the last network layer and optimizing the network; using the rotation test method to input the testing samples to the network; and obtaining the retinal blood vessel segmentation result. The blood vessel segmentation full-convolution neural network structure and the adaptive weight method proposed by the invention can realize the human-eye level image segmentation and can test on two internationally published retinal image databases DRIVE and CHASE_DB1 with the average accuracy of 96.00 % and 95.17% respectively, both higher than the latest algorithm.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

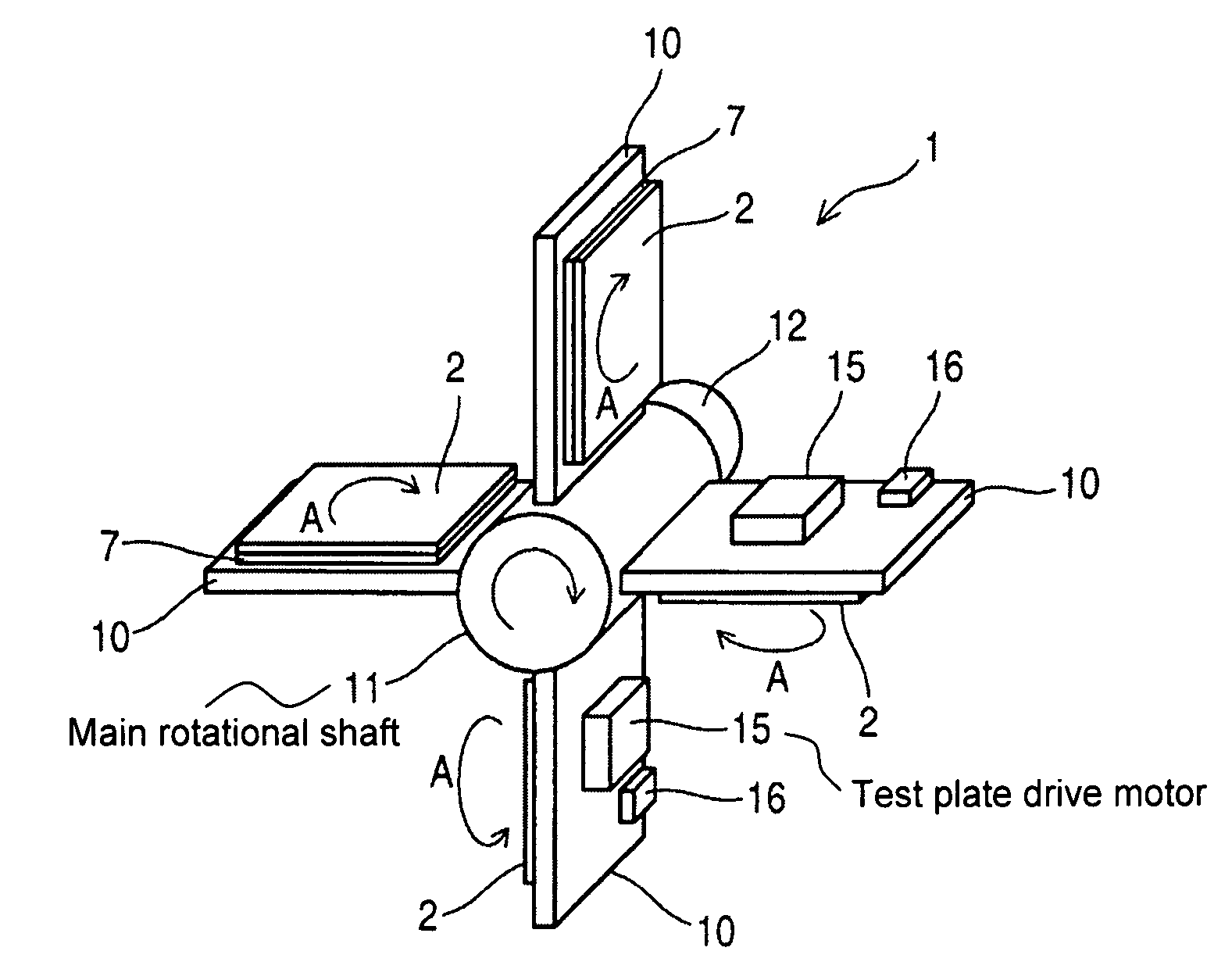

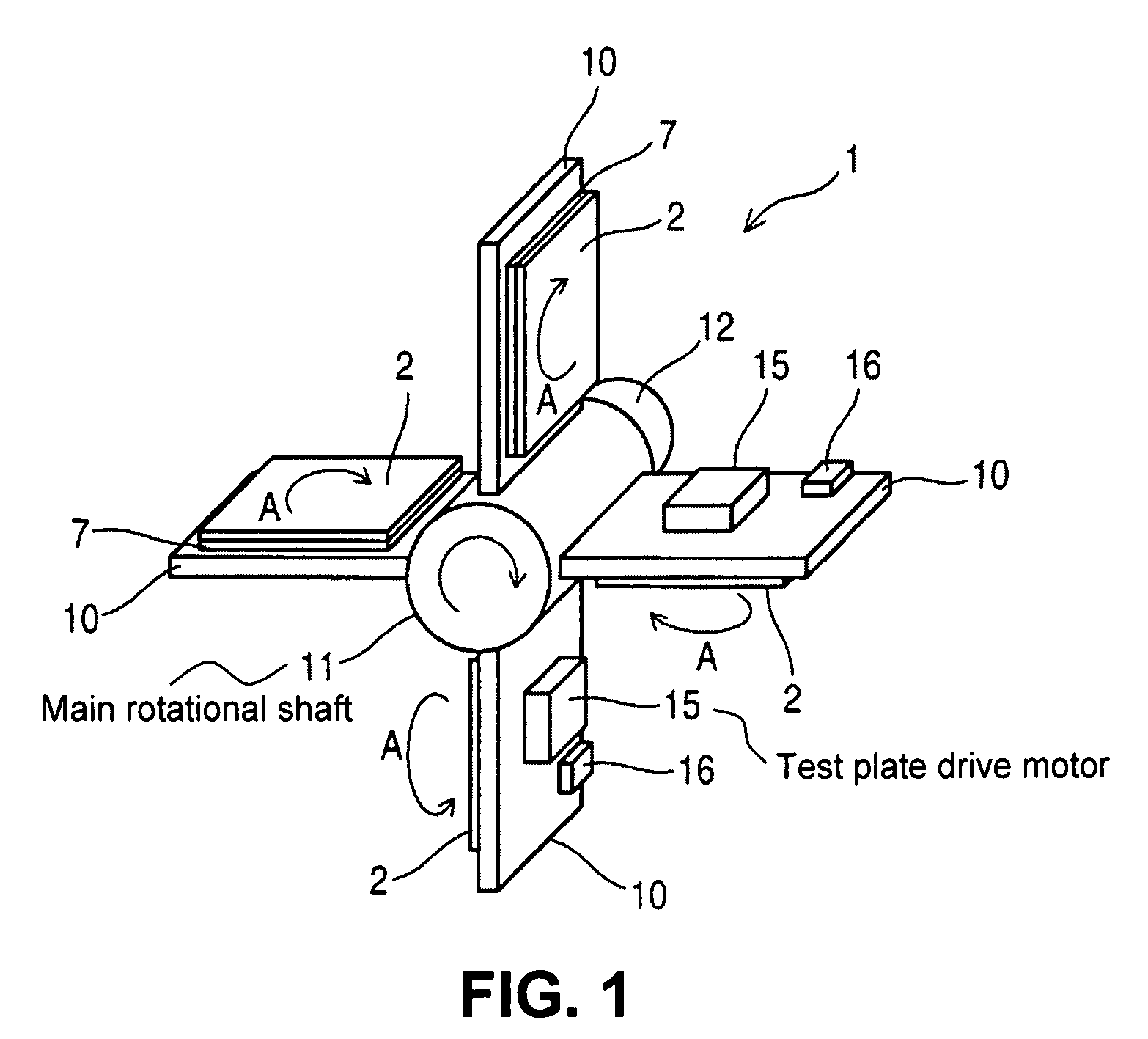

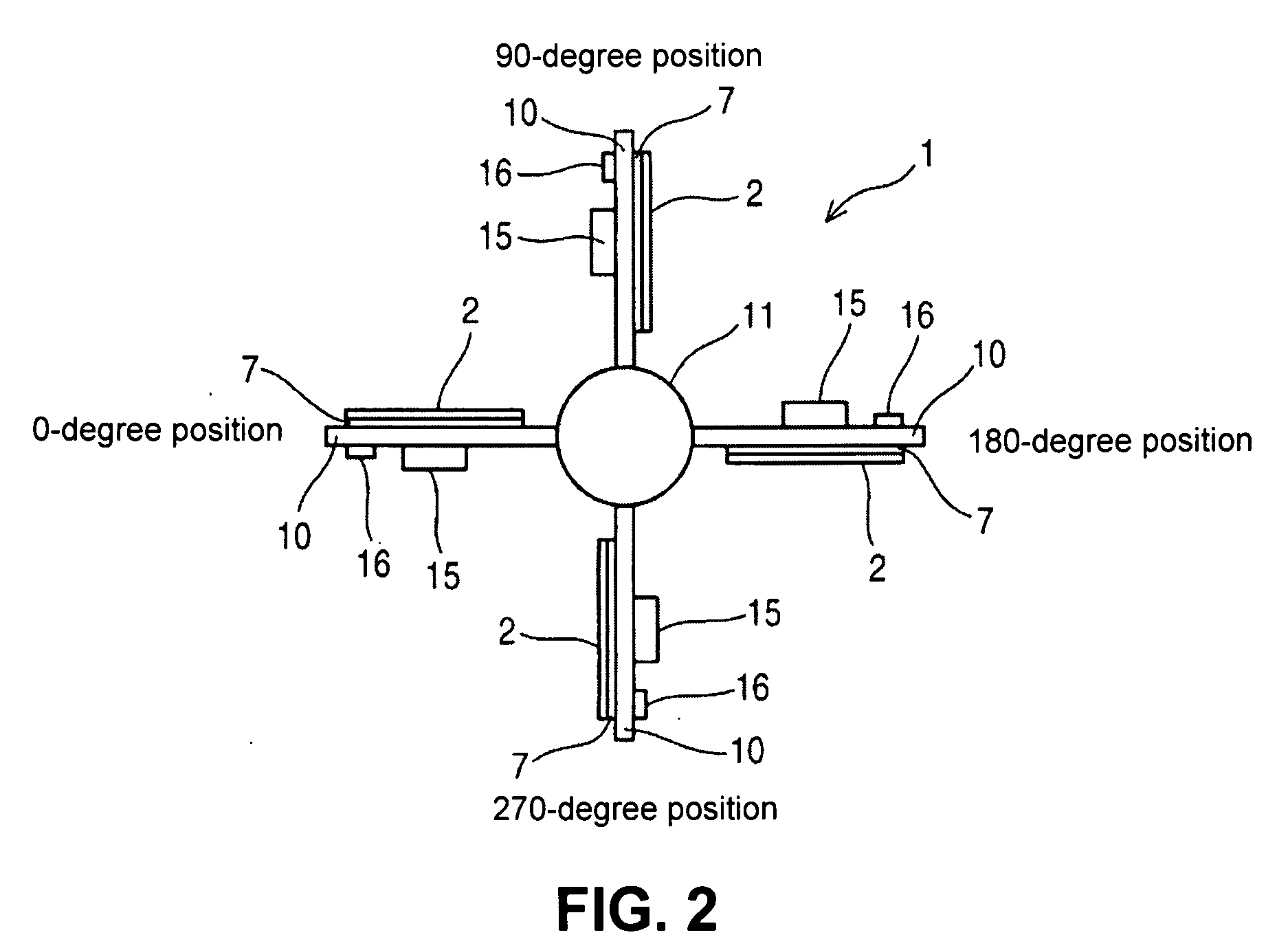

Three-axial acceleration sensor inspection device and method of inspecting three-axial acceleration sensor

InactiveUS20070277586A1Small sizeImprove inspection efficiencyAcceleration measurement using interia forcesTesting/calibration of speed/acceleration/shock measurement devicesRotation testEngineering

A three-axial acceleration sensor inspection device is provided for inspecting a three-axial acceleration sensor that detects acceleration components in three axes crossing perpendicularly with each other and outputs acceleration component signals. The three-axial acceleration sensor inspection device includes a test plate for mounting the three-axial acceleration sensor thereon; a supporting plate for supporting and rotating the test plate; a main rotational shaft for rotating the supporting plate. The supporting plate is arranged radially around the main rotational shaft along a radius direction of the main rotational shaft, and is disposed at each of at least four locations with an equal angular interval along a circumferential direction of the main rotational shaft.

Owner:LAPIS SEMICON CO LTD

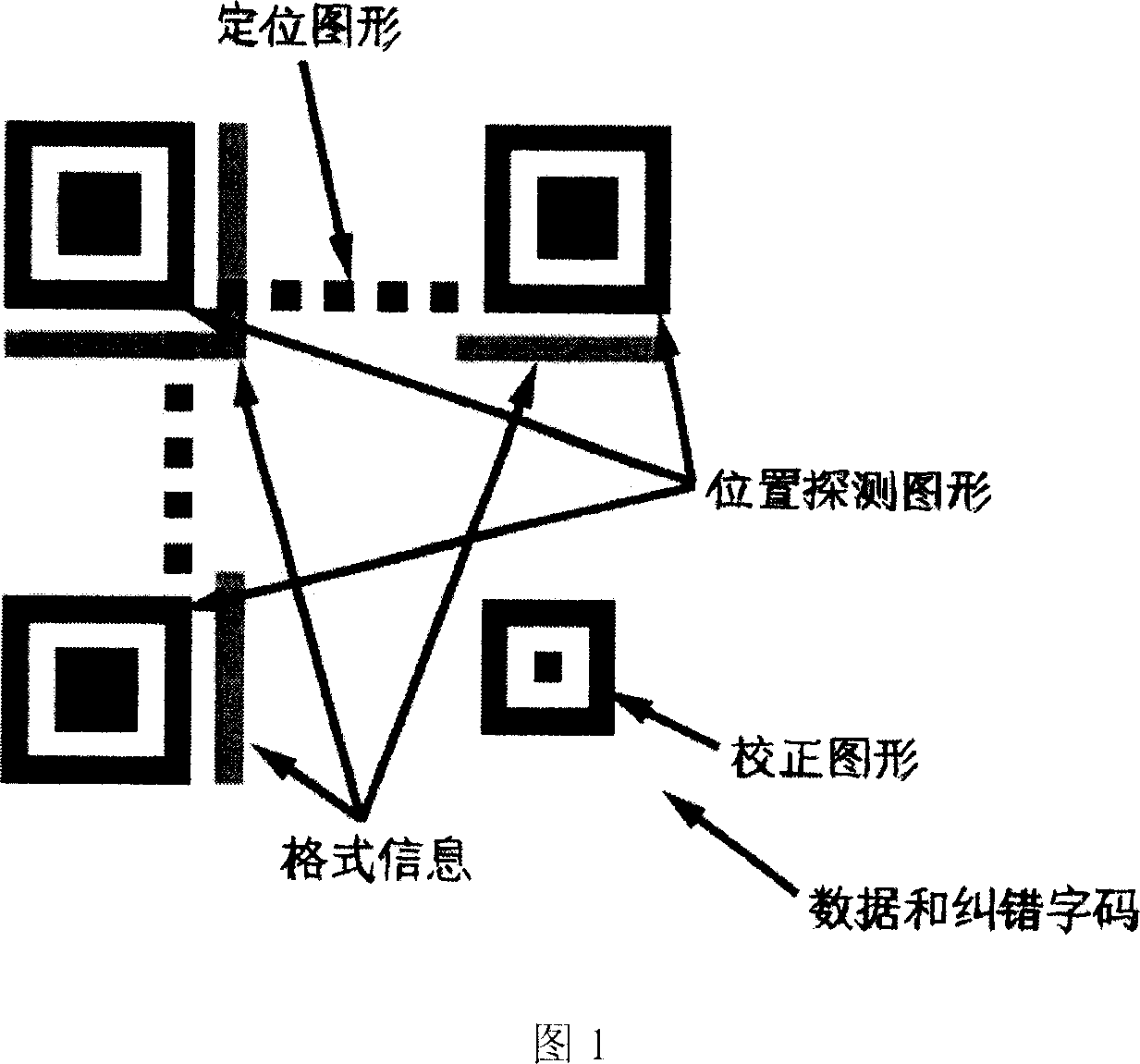

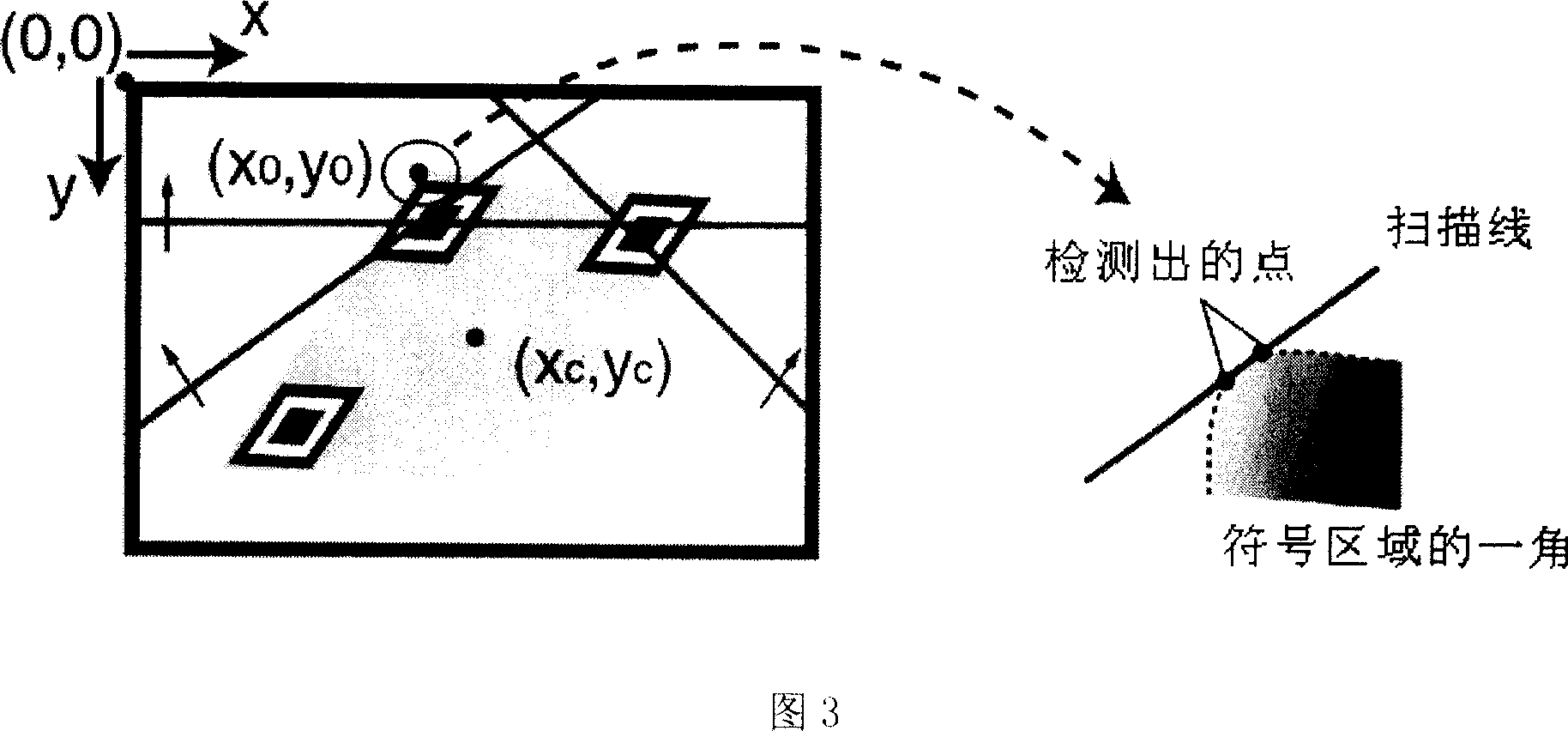

Precise location method of QR code image symbol region at complex background

This invention relates to accurate position method under complex background of QR codes image area, which comprises the following steps: a, adopting self-adapting valve binary method to filter focus out effect and fringe information of each module and keep central information; b, finding out the said QR codes image outline through outer fringe an finding out all position detection image according to detected image characteristics; c, processing rotation test on the said image to determine their normal QR codes image relative position; d, determining its QR code image area according to the said position detection image.

Owner:FUJIAN RONGJI SOFTWARE

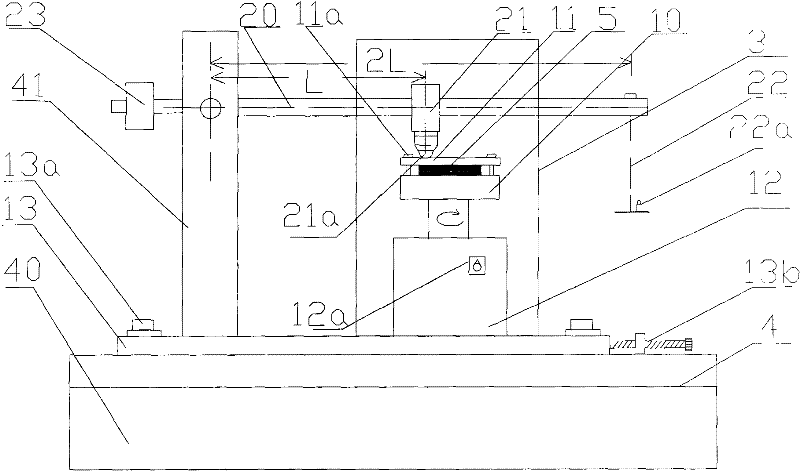

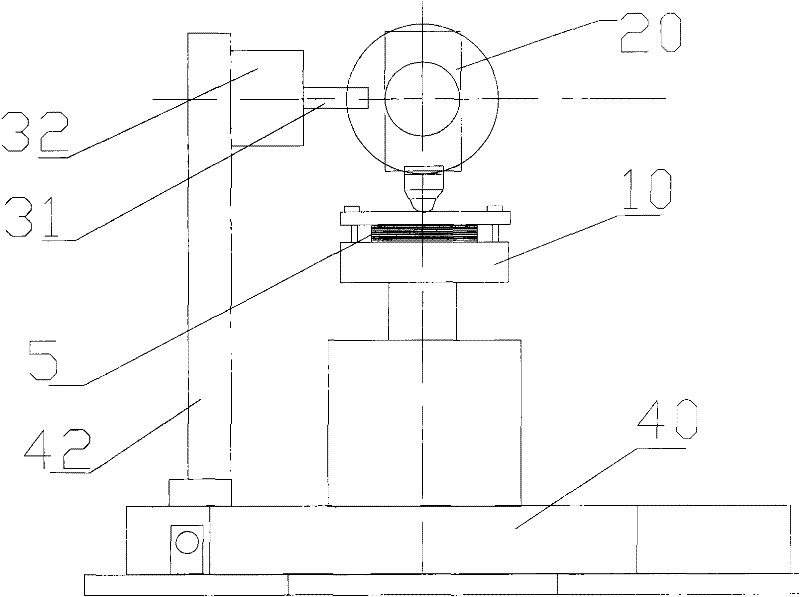

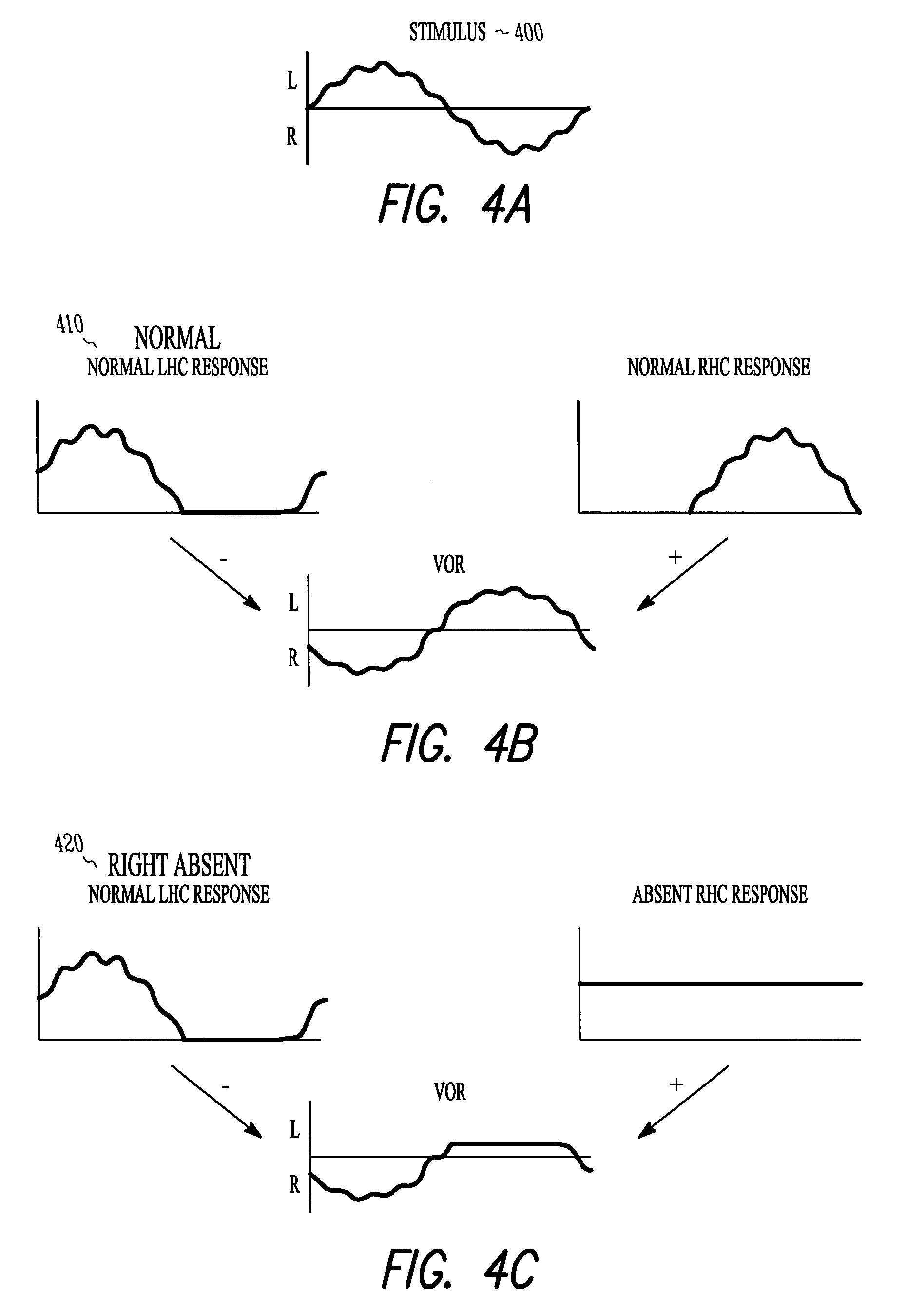

Instrument for testing friction and wear performance of coating

InactiveCN102128758AAccurate surface friction and wear propertiesReduce volumeInvestigating abrasion/wear resistanceLow loadTest sample

The invention discloses an instrument for testing friction and wear performance of a coating. The instrument comprises a rotary test board, a loading friction beam, a friction detector and a frame. Through the rotary test board, the loading friction beam and the friction detector, the friction track and frictional force data of a tested sample are obtained, and accurate surface friction and wear performance data of a coating sample are obtained by calculating in combination with data parameters such as pressure, rotating speed and the like. The instrument has the advantages of small size, low load, high measuring accuracy and high stability, and is particularly suitable for detecting the friction and wear performance of a coating product.

Owner:文晓斌

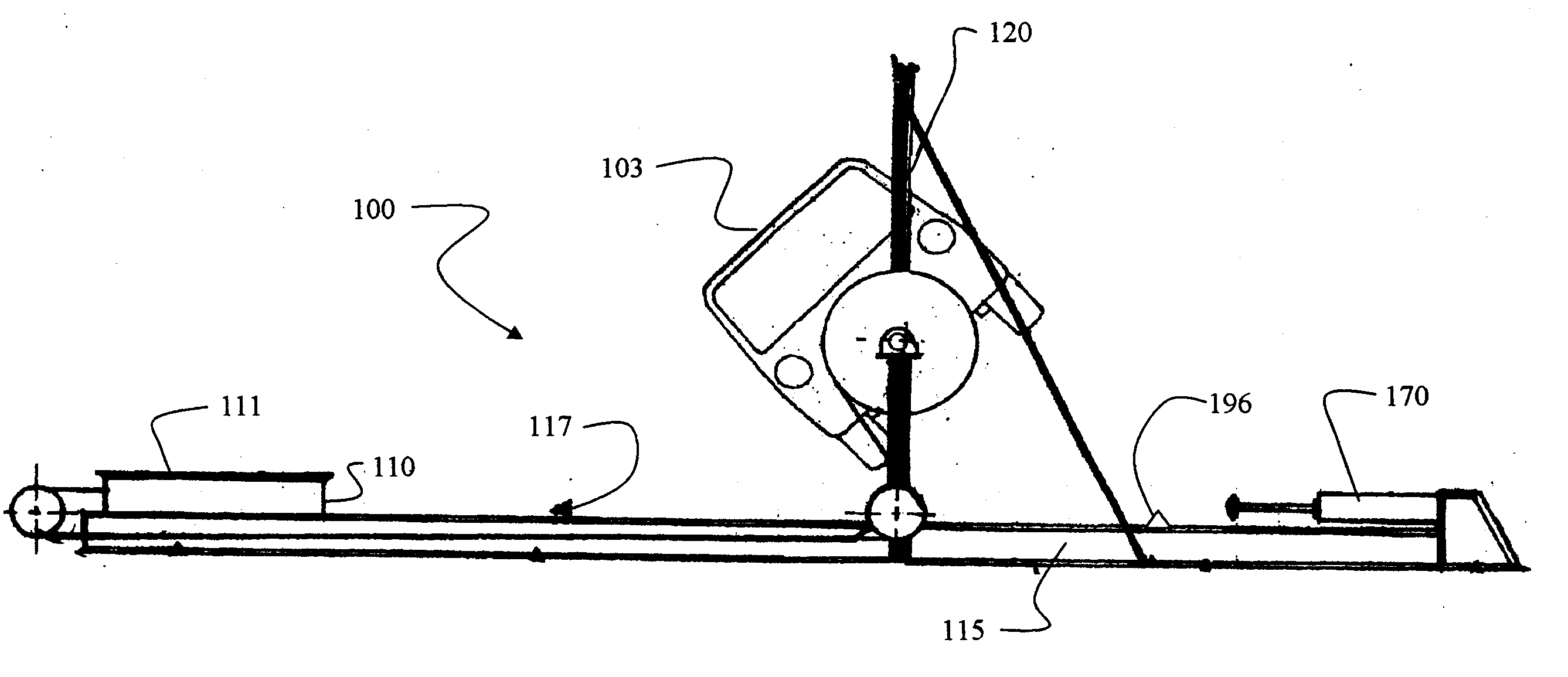

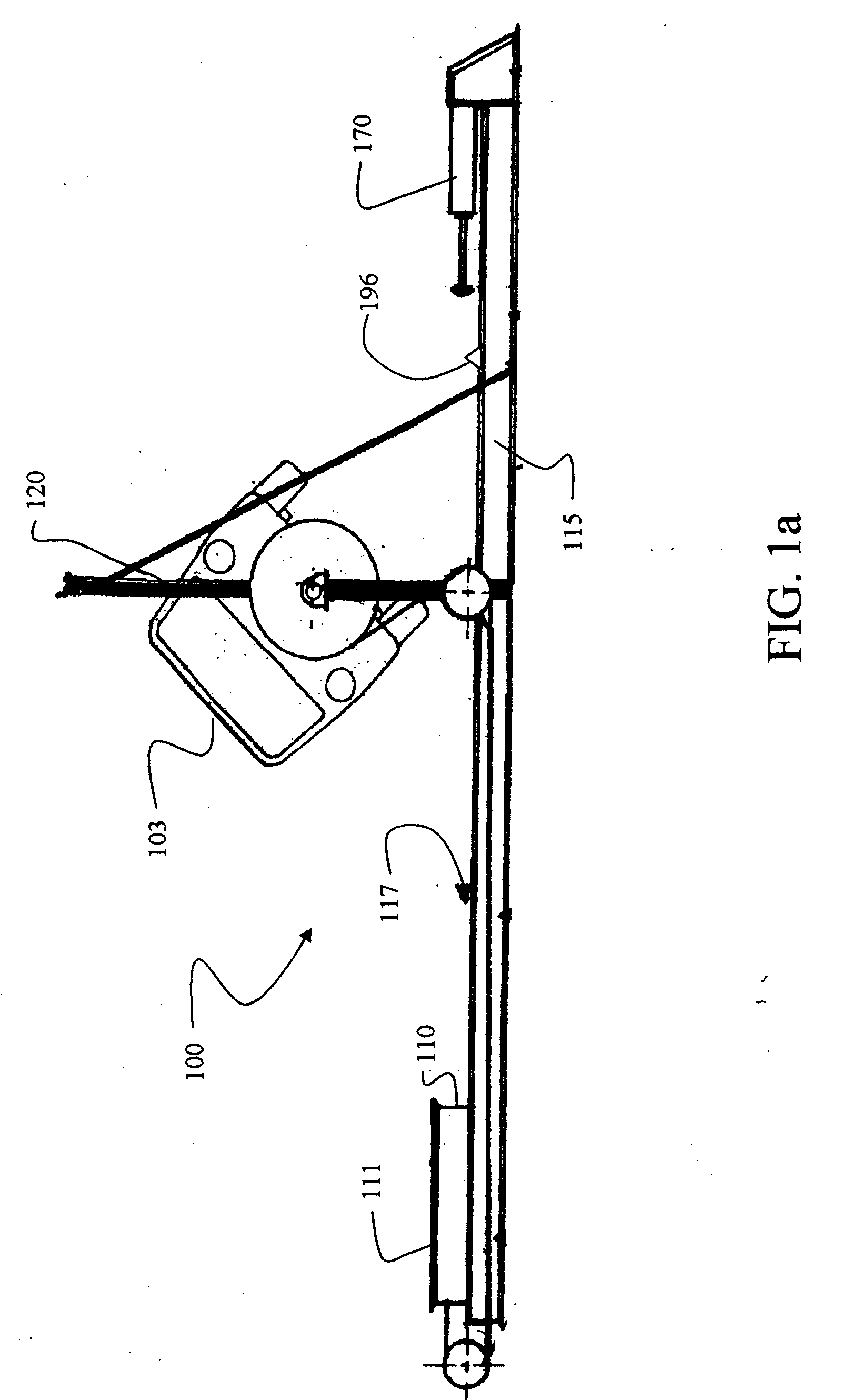

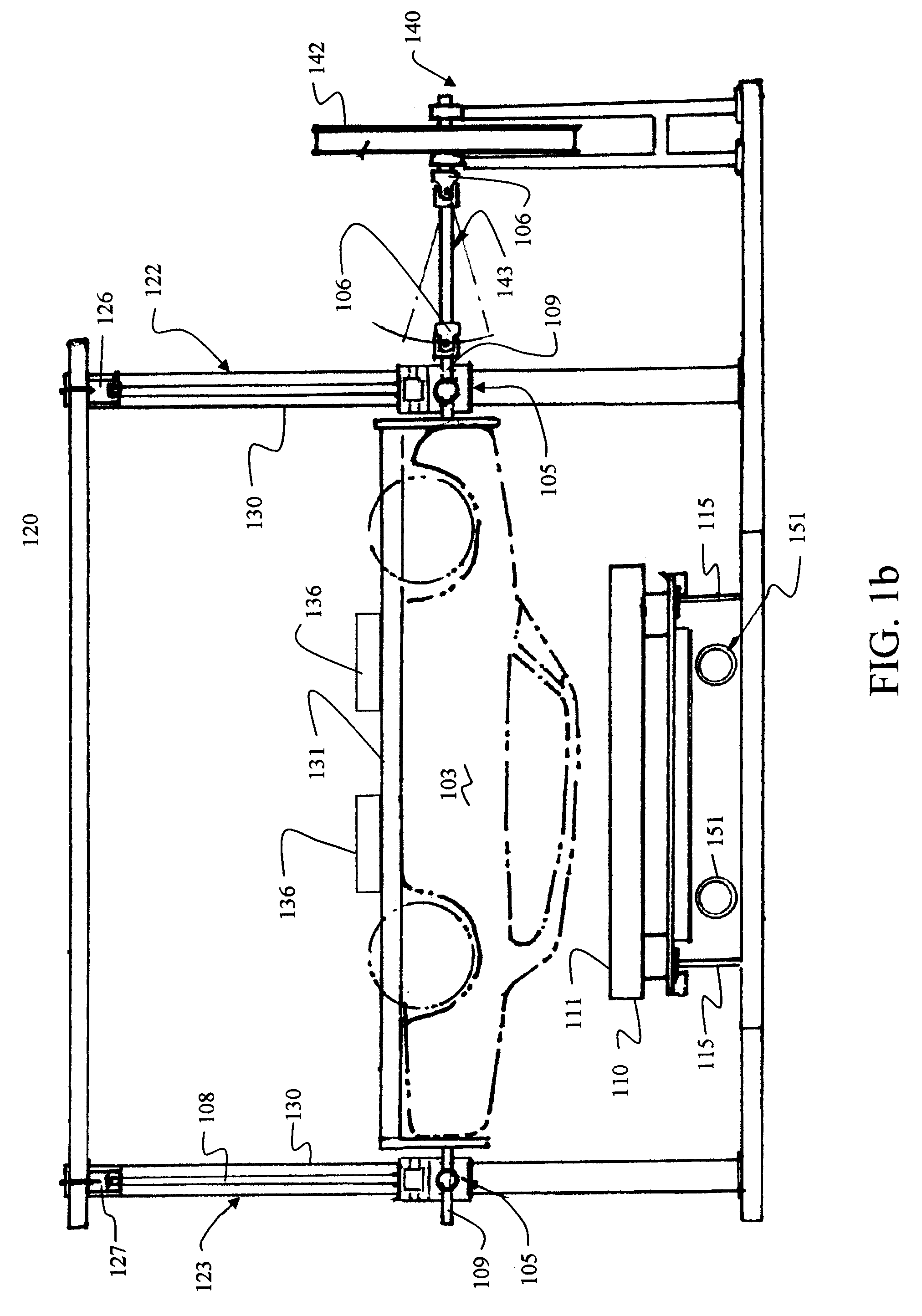

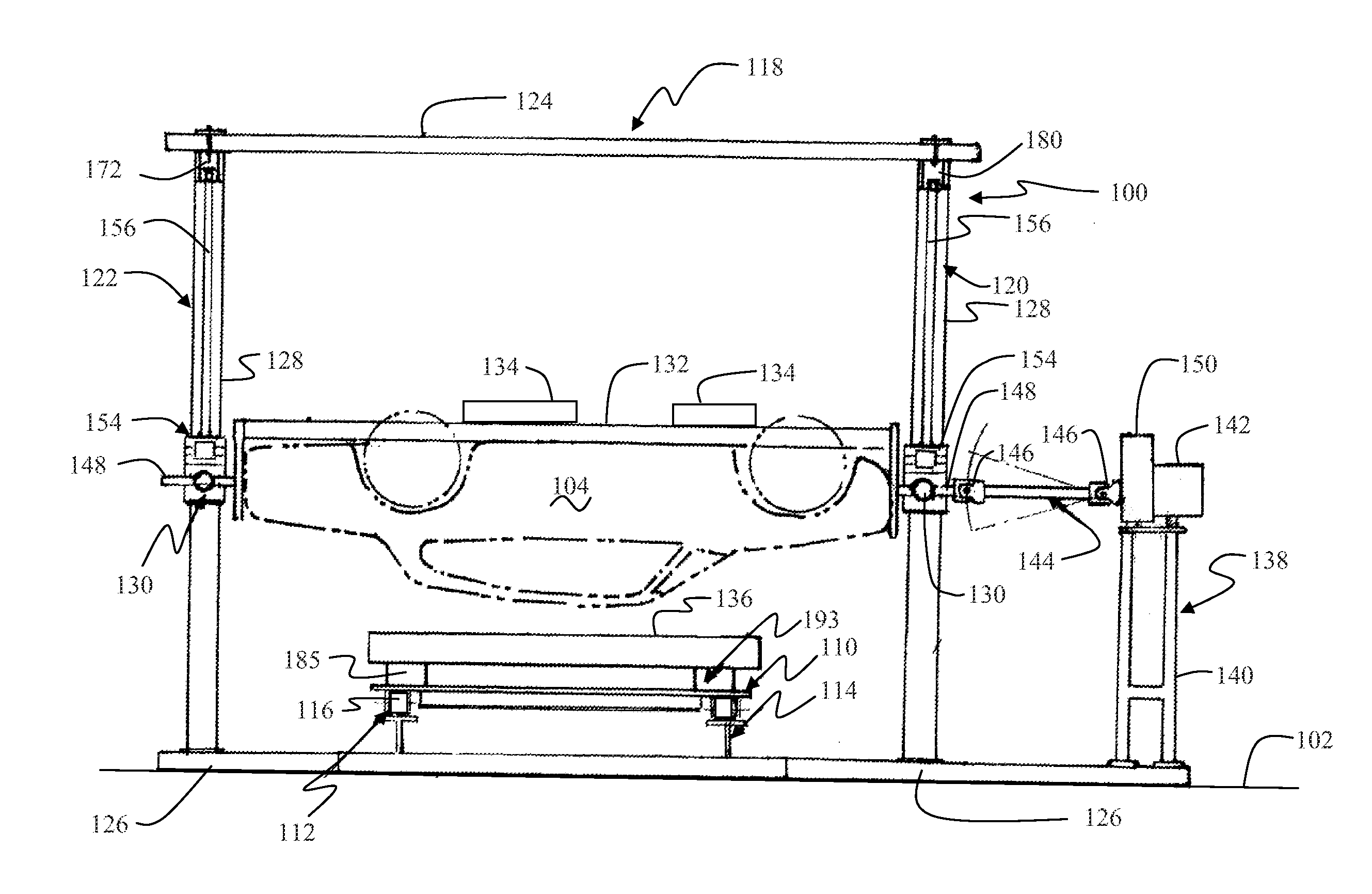

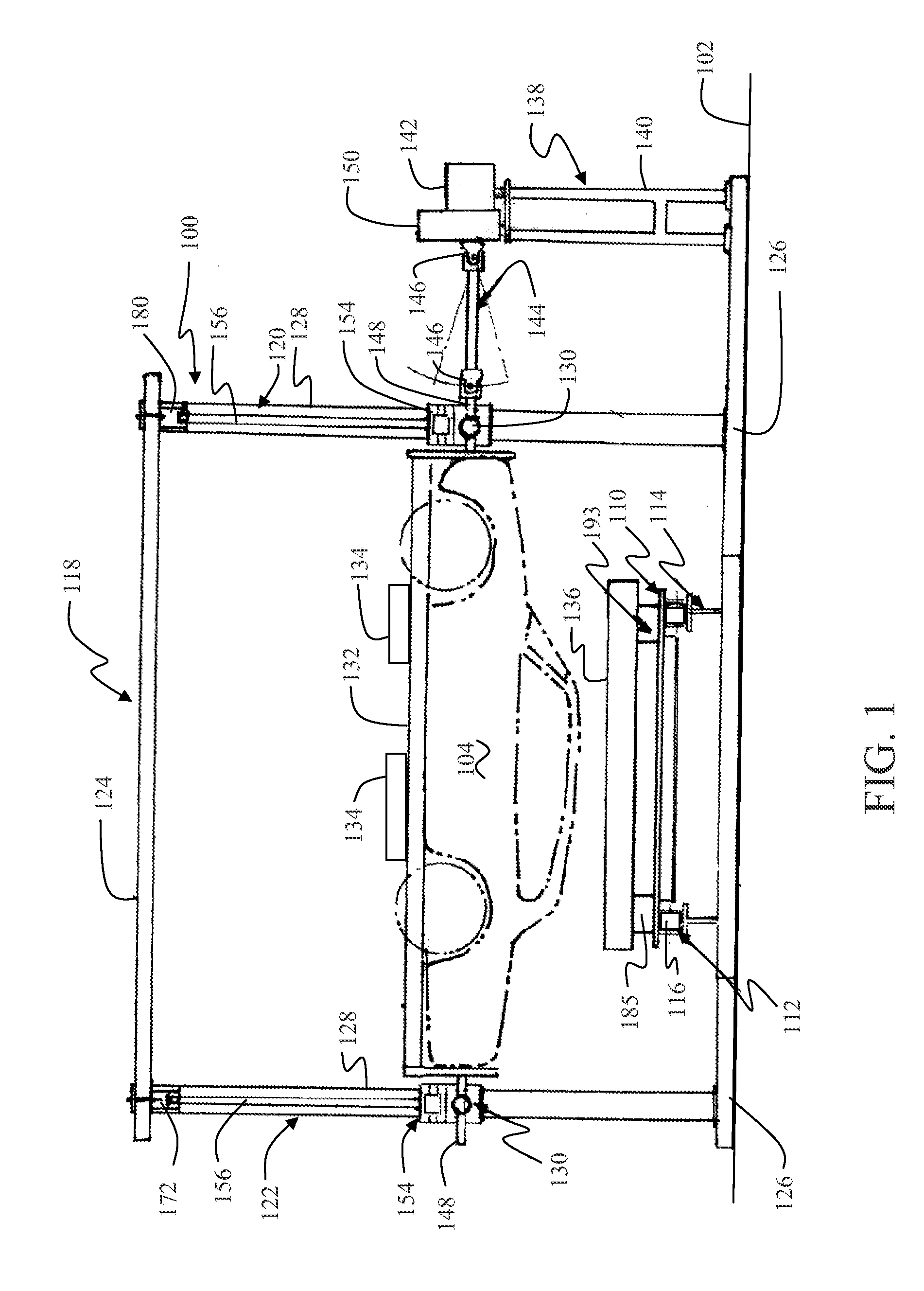

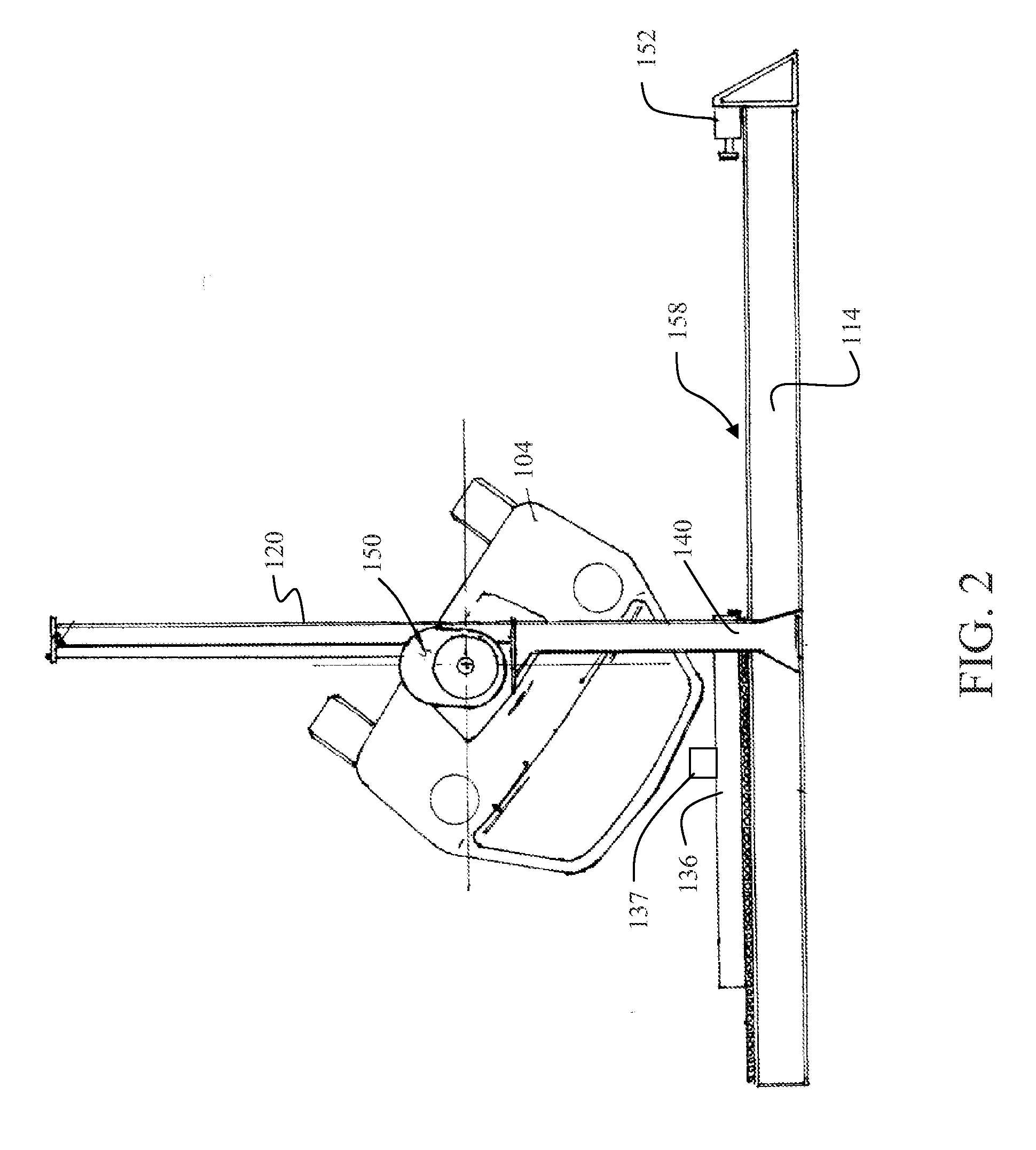

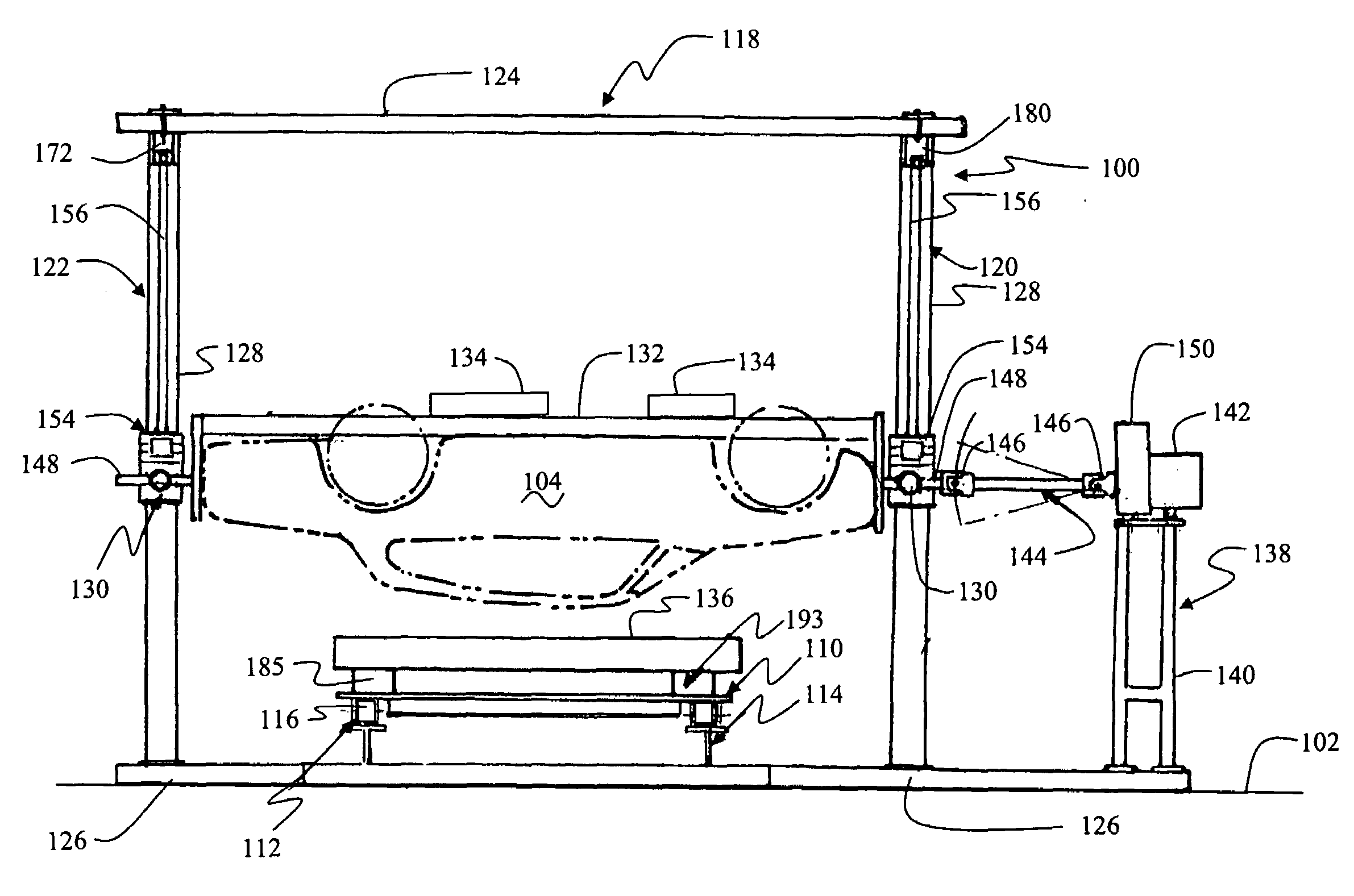

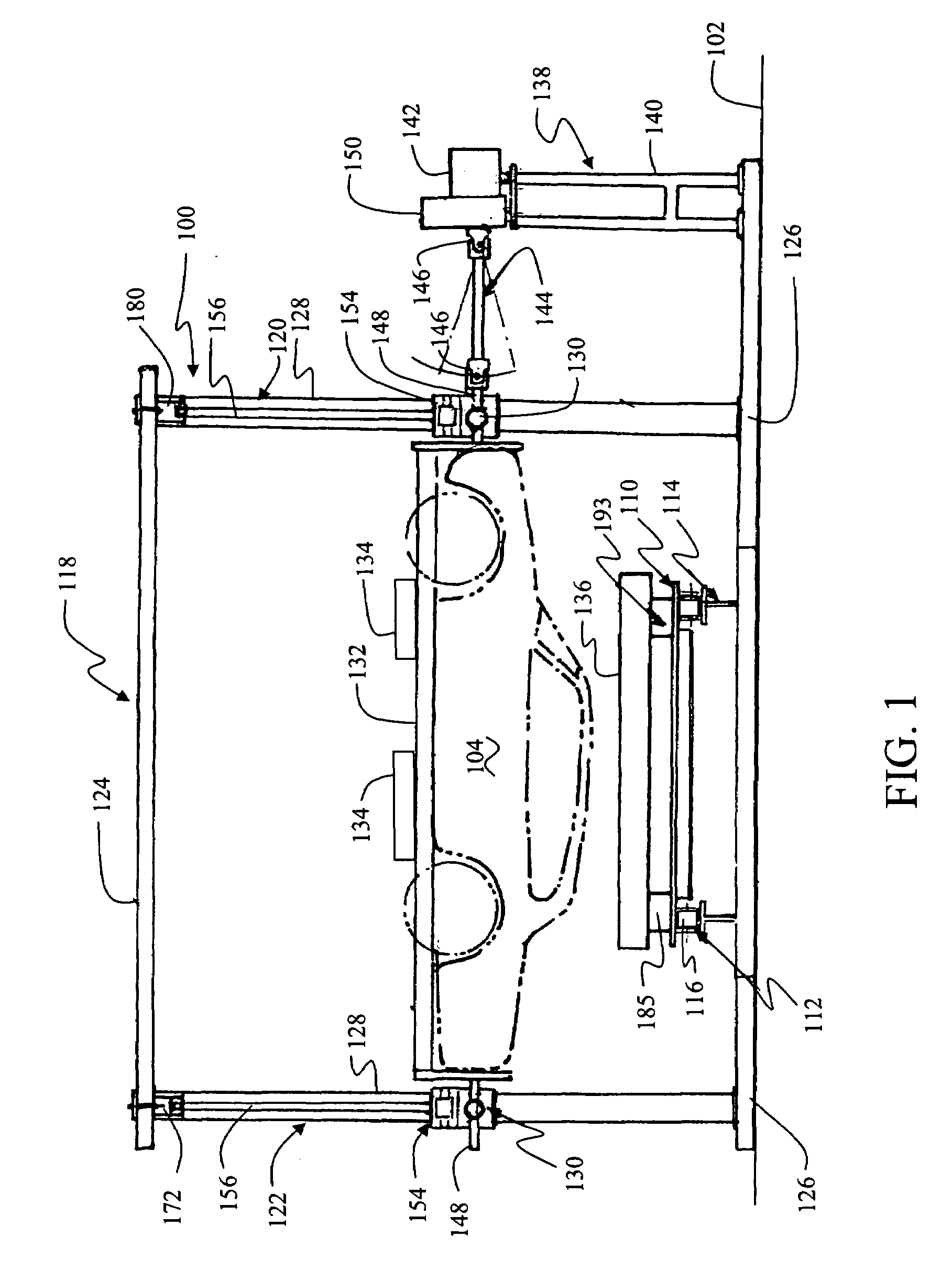

Vehicle Rollover Test Fixture

InactiveUS20060278026A1Avoid damageLimiting further damageWeather/light/corrosion resistanceAcceleration measurementRolloverDrop impact

A test fixture for rollover crash testing of a test vehicle onto a moving surface employs a cradle to support and rotate the test vehicle. A vertical support structure to positions and releasably holds the cradle. A moving sled having a contact surface is carried by a guide extending beneath the structure and the cradle fixture. The cradle is rotated and released from the structure responsive to a sensor for contact within a drop impact zone on the contact surface of the moving sled. Vertical motion of the cradle is then arrested to prevent further damage to the test vehicle or the test structure.

Owner:SAFETY TESTING INT

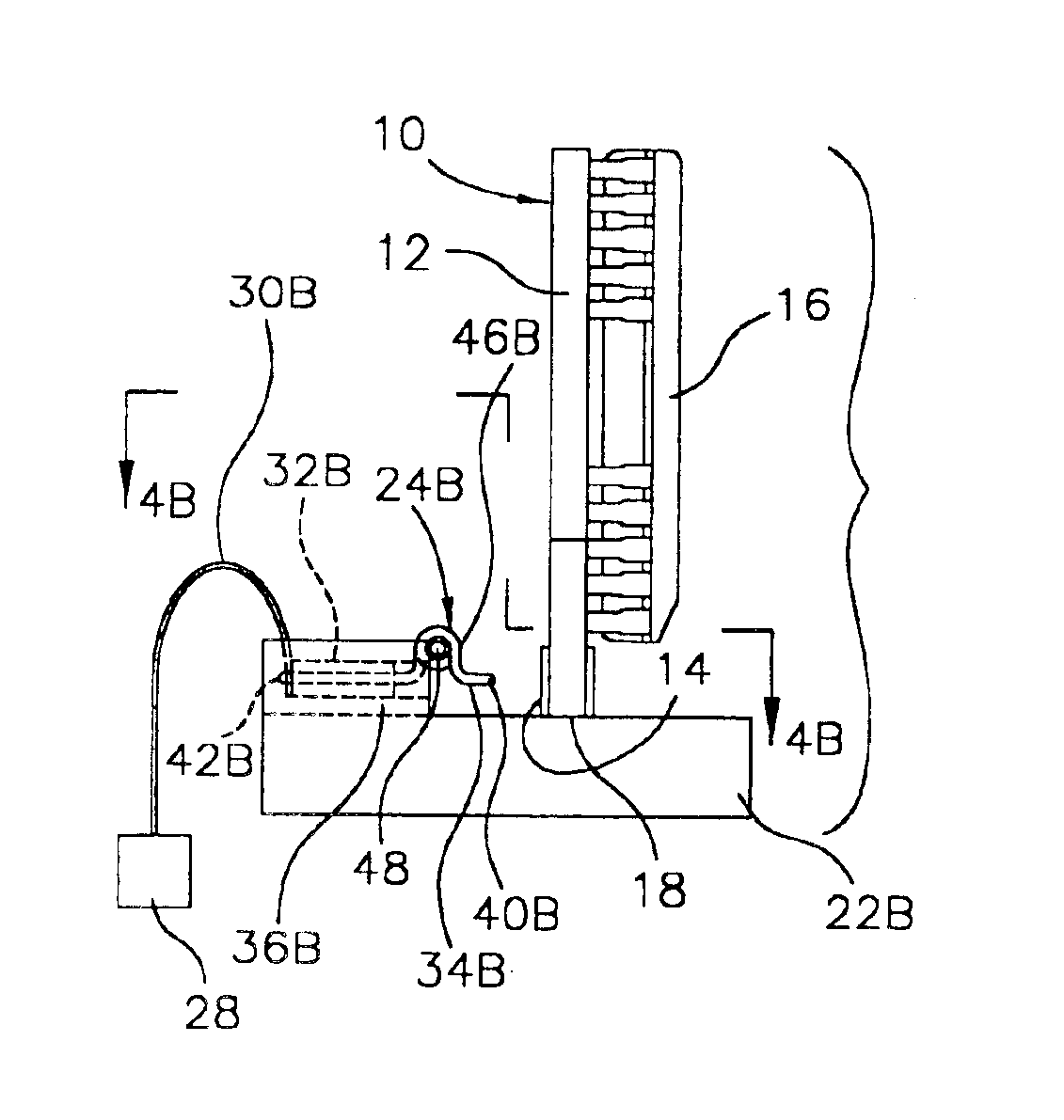

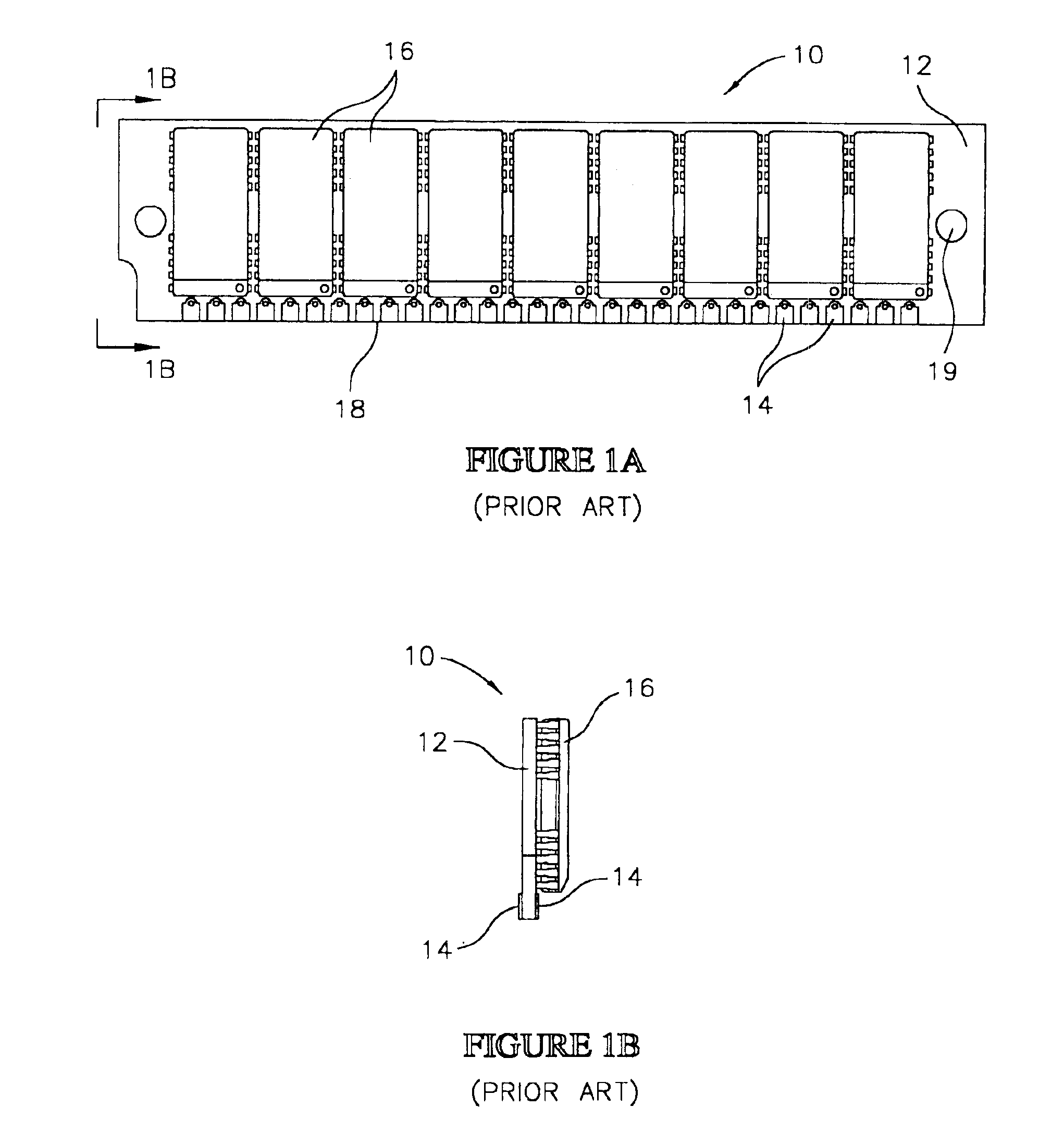

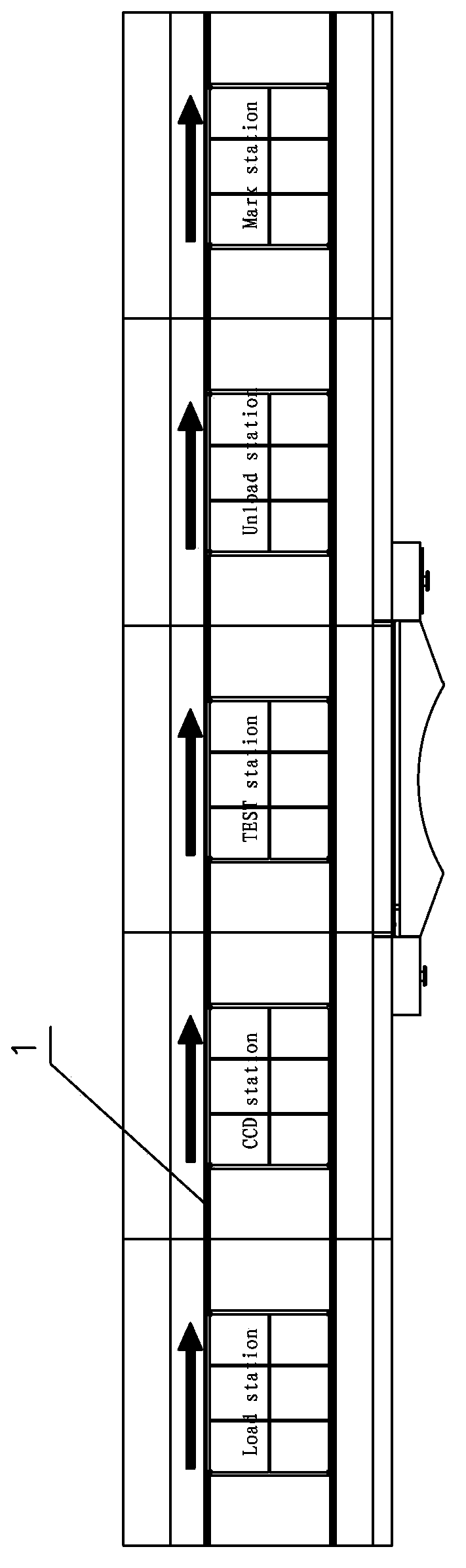

Test system and test contactor for electronic modules

InactiveUS6888364B2Easy to keepElectronic circuit testingMeasurement instrument housingElectricityFlexible circuits

A pass through test system for testing an electronic module includes an interface board, and test contactors movably mounted to the interface board for electrically engaging terminal contacts on the module with a zero insertion force on the modules. The interface board is configured for mounting to an automated or manual pass through test handler in electrical communication with test circuitry. In a first embodiment the interface board includes test pads in electrical communication with the test circuitry, and rotatable test contactors having spring contacts configured to simultaneously engage the test pads and the terminal contacts on the module. In a second embodiment the interface board includes test pads in electrical communication with the test circuitry, and slidable test contactors having beam leads configured to simultaneously engage the test pads and the terminal contacts on the module. In a third embodiment the test contactors are slidably mounted to the interface board, and include coiled spring contacts in electrical communication with a flex circuit. A test method includes the steps of: providing the test contactors, electrically engaging the terminal contacts on the module with a zero insertion force using the test contactors, and then applying test signals through the test contactors and the terminal contacts to the module.

Owner:MICRON TECH INC

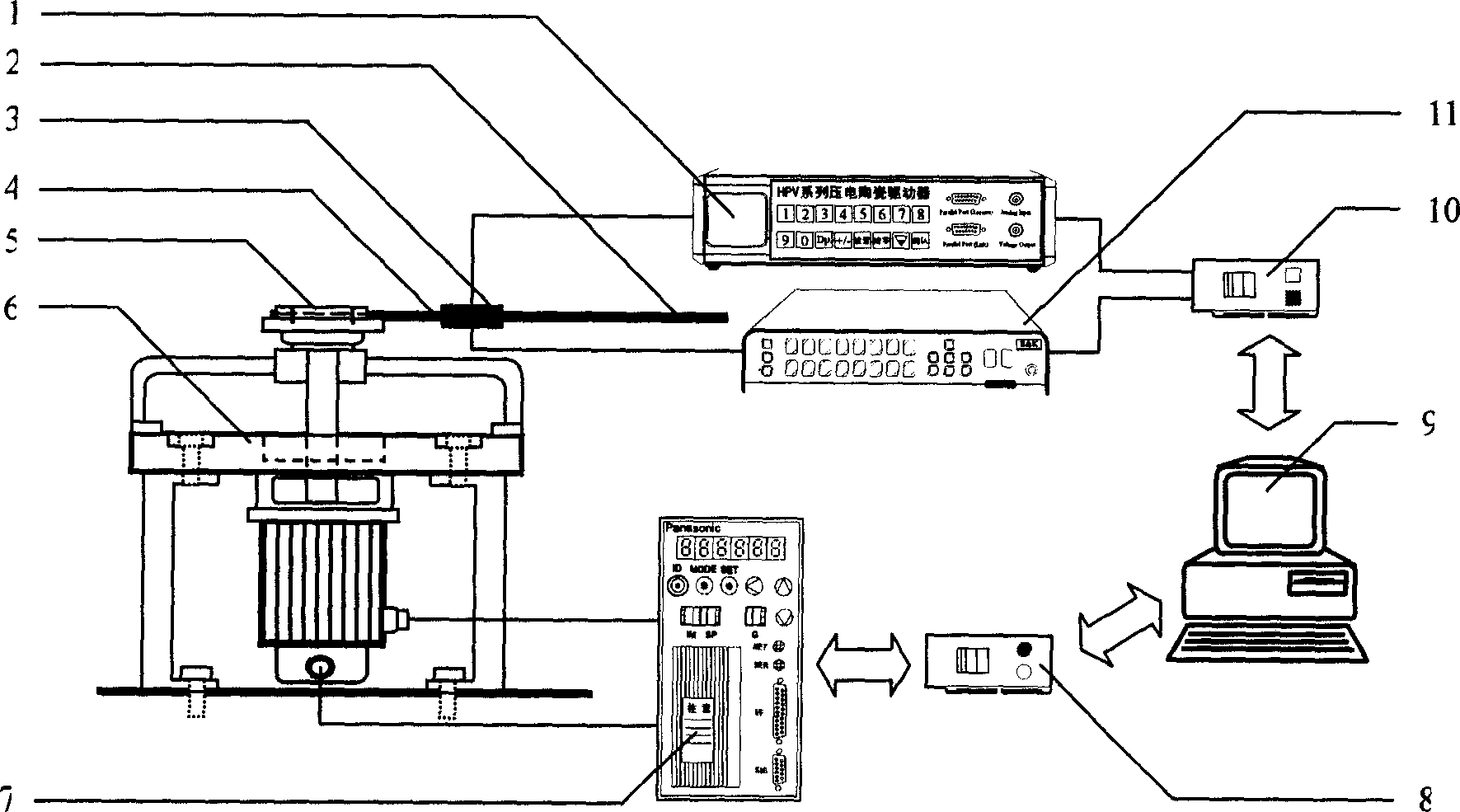

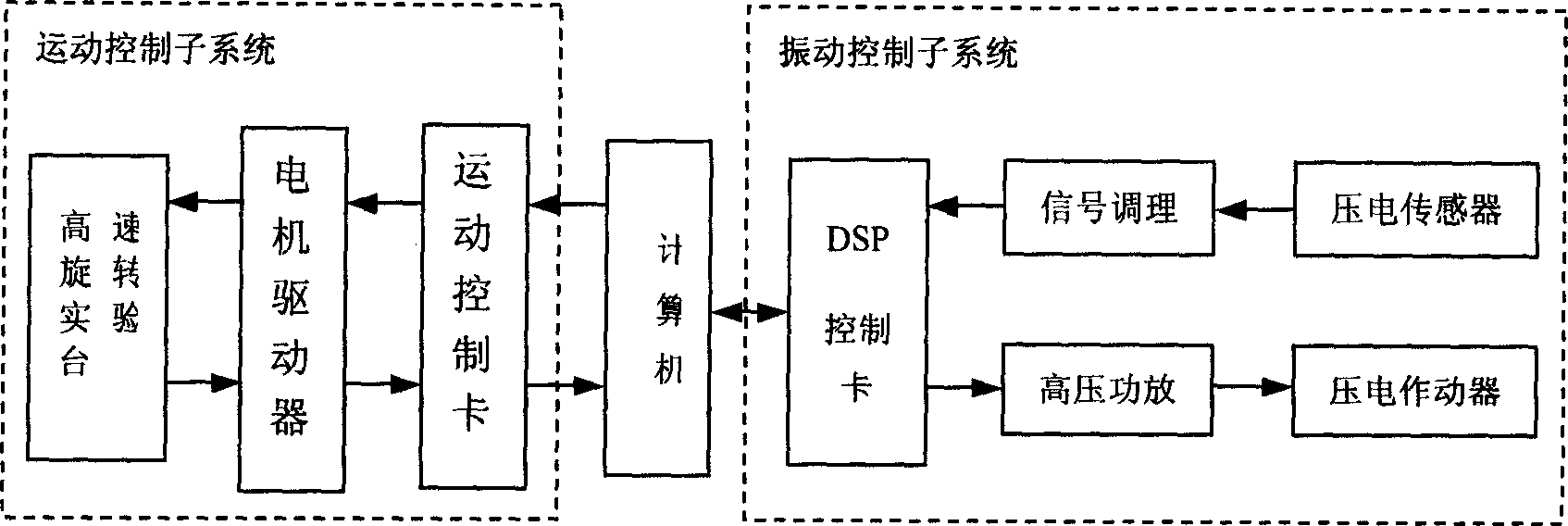

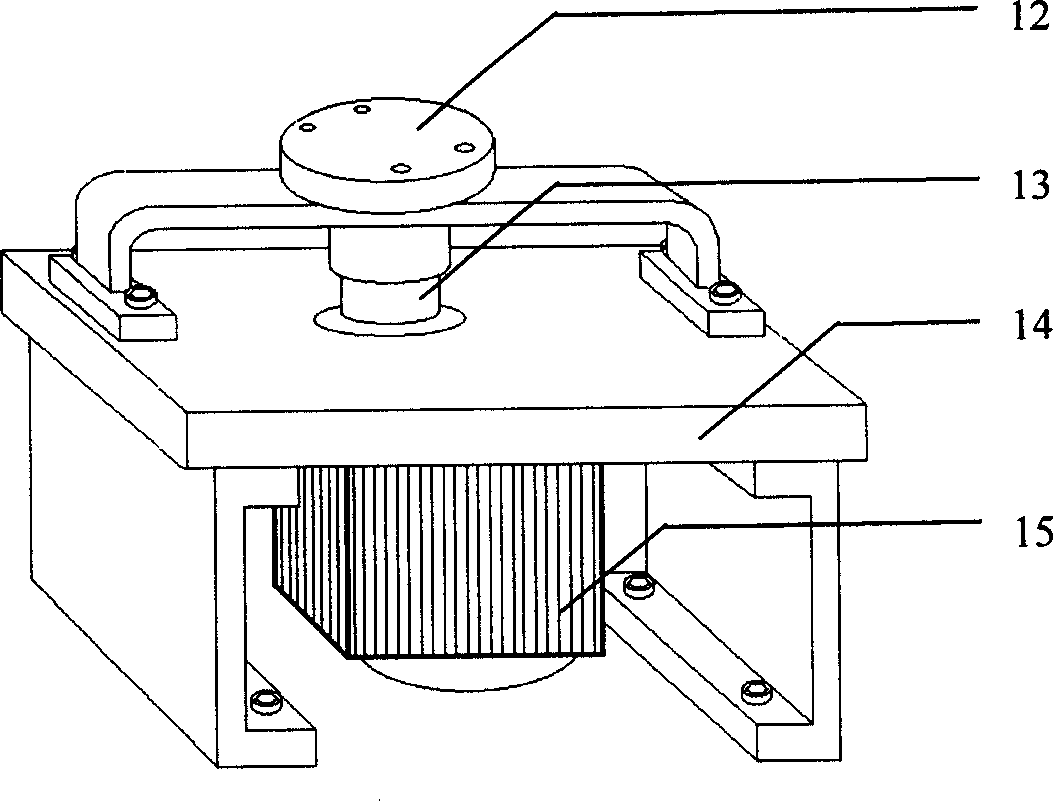

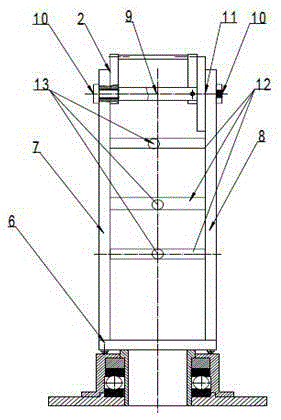

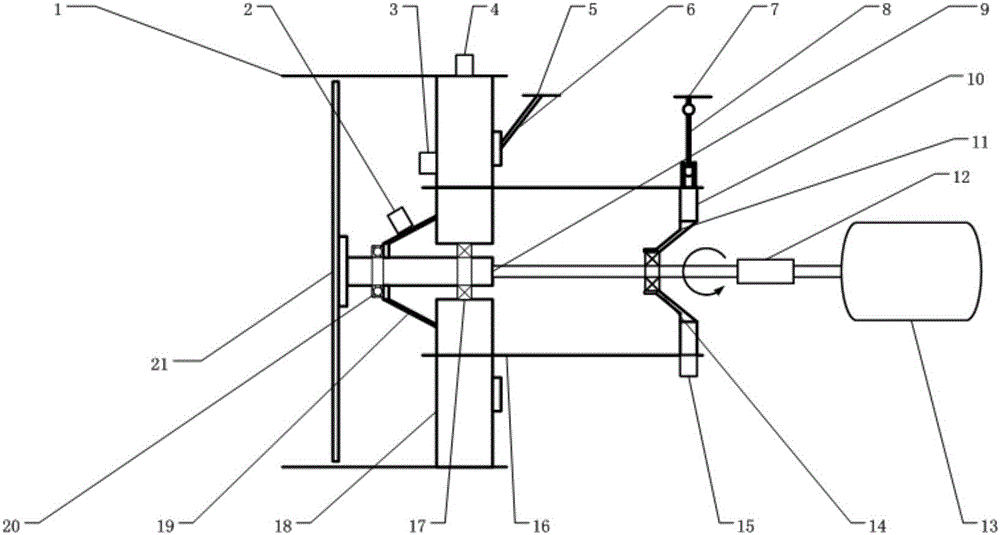

Motion control and vibration control experimental system for flexible cantilever beam in noninertial system

It is a non-inertial frame flexible cantilever beam movement control and vibration control test system, wherein, its aluminium beam is attached with piezo-sensor and piezo-actuator which are fixed on the high-speed rotation test bench though clamper. The analog output end of DSP control card is connected with analog input end of high-pressure power amplifier. The voltage output of high-pressure power amplifier is connected with electrode of piezo-actuator. The piezo-sensor electrode is connected with the analog input end of DSP control card through signal adjusting amplifier. The coder of motor driver is connected with the high-speed rotation test bench. The DSP control card and motor movement control card are plugged in the IO extension tank of computer.

Owner:SHANGHAI JIAO TONG UNIV

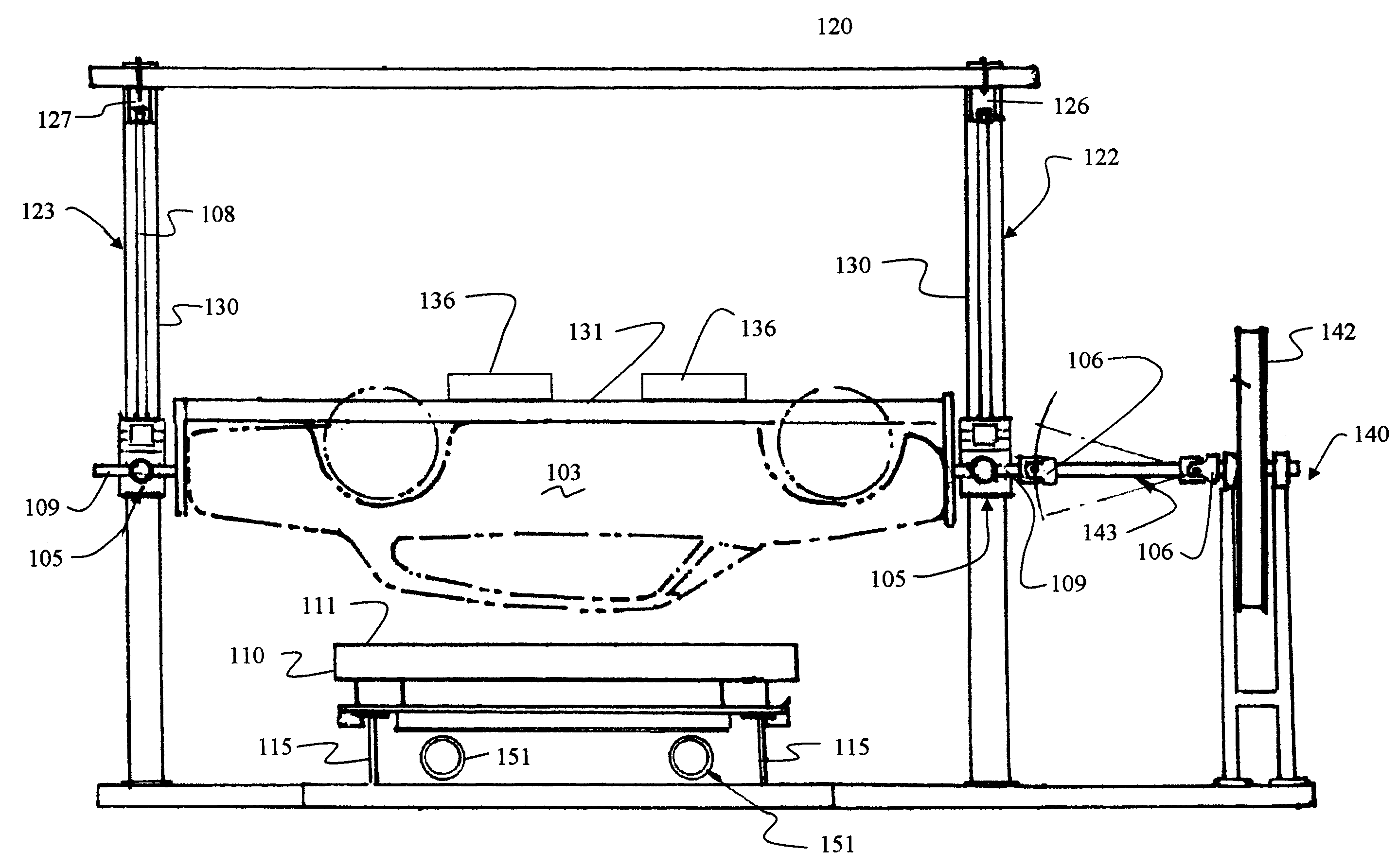

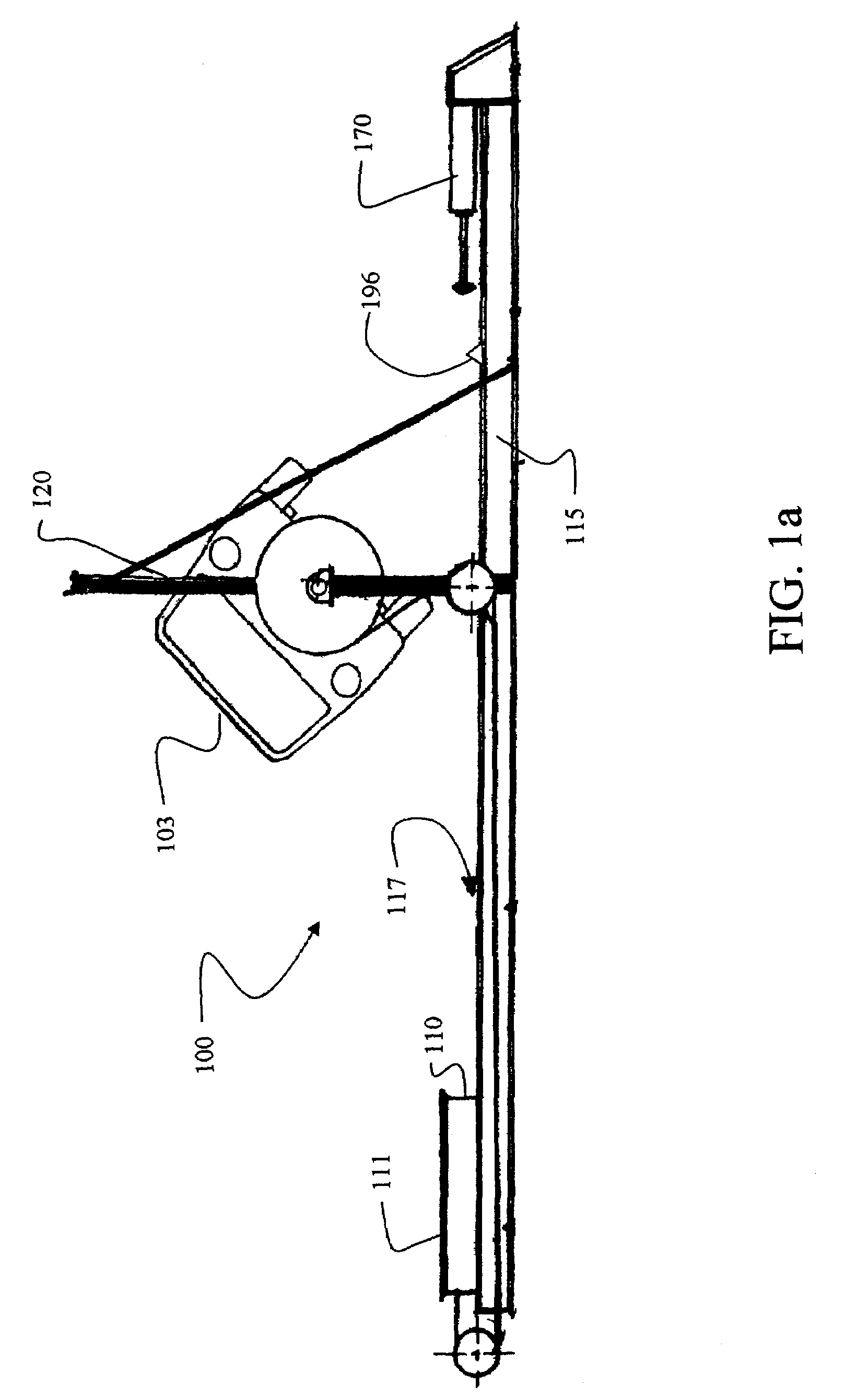

Vehicle rollover test fixture

InactiveUS7373801B2Avoid damageLimiting further damageWeather/light/corrosion resistanceAcceleration measurementRolloverDrop impact

A test fixture for rollover crash testing of a test vehicle onto a moving surface employs a cradle to support and rotate the test vehicle. A vertical support structure to positions and releasably holds the cradle. A moving sled having a contact surface is carried by a guide extending beneath the structure and the cradle fixture. The cradle is rotated and released from the structure responsive to a sensor for contact within a drop impact zone on the contact surface of the moving sled. Vertical motion of the cradle is then arrested to prevent further damage to the test vehicle or the test structure.

Owner:SAFETY TESTING INT

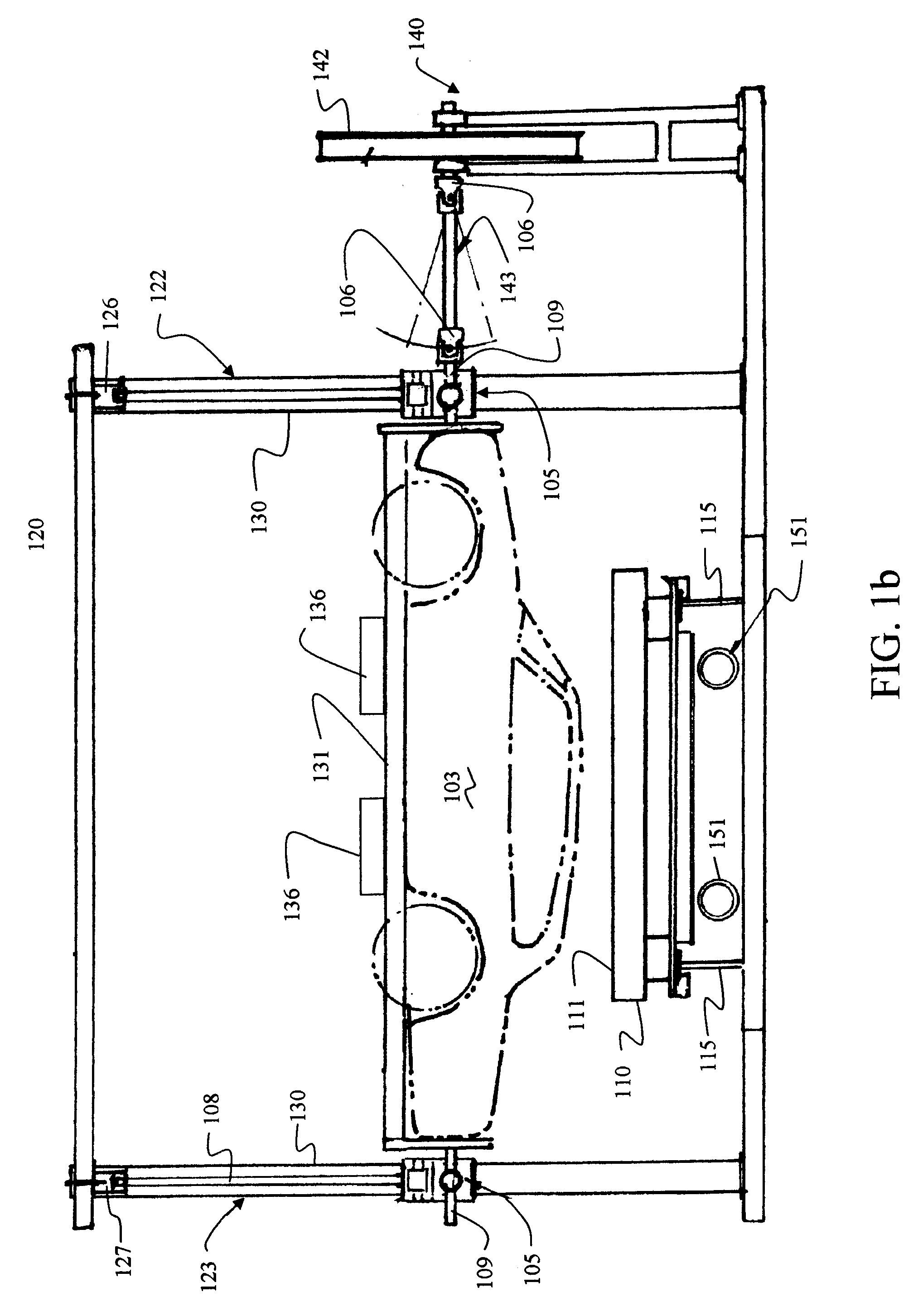

Vehicle rollover test fixture

A test fixture for rollover crash testing of a test vehicle onto a movable sled surface employs a cradle to support and rotate the test vehicle. A suspension assembly is attached to each end of the cradle for vertically supporting and dropping the cradle. A gantry has a cross beam supported by a first telescoping column for support of a first of the suspension assemblies and translationally supported by a second telescoping column for support of a second of the suspension assemblies to position and releasably hold the suspension assembly. Roll control arms rotate the cradle and a trigger assembly releases the cradle and test vehicle from the cross beam for contact within a drop impact zone on the contact surface of the sled. A brake assembly then arrests vertical motion of the cradle.

Owner:SAFETY TESTING INT

Ignition driving system of high-overload test device used for solid-propellant rocket engine

The invention discloses an ignition driving system of a high-overload test device used for a solid-propellant rocket engine, relates to an ignition driving system used for a solid-propellant rocket engine experimental apparatus and in particular to an ignition driving system used for a solid-propellant rocket engine under the high-overload rotation test condition, and belongs to the field of aerospace. The ignition driving system comprises a long-distance integrated console, an ignition power supply control module, a test controller, a relay driving module, a solid-propellant rocket engine and an ignition tool, wherein the relay driving module is fixed on a noseplate on the central axis plane of a rotary test bench, and the axial line between the relay moving contact C and the relay stationary contact D in the relay driving module is tangent to a rotary table top. The ignition driving system can reduce or eliminate the adverse effect of radial centrifugal inertia and tangential acceleration impact on the relay driving module in the ignition power supply loop under the high-overload test condition. The ignition driving system has high dynamic operating precision and can be used for reliably and safely carrying out a continuous ignition test on solid-propellant rocket engines under high-overload rotary conditions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

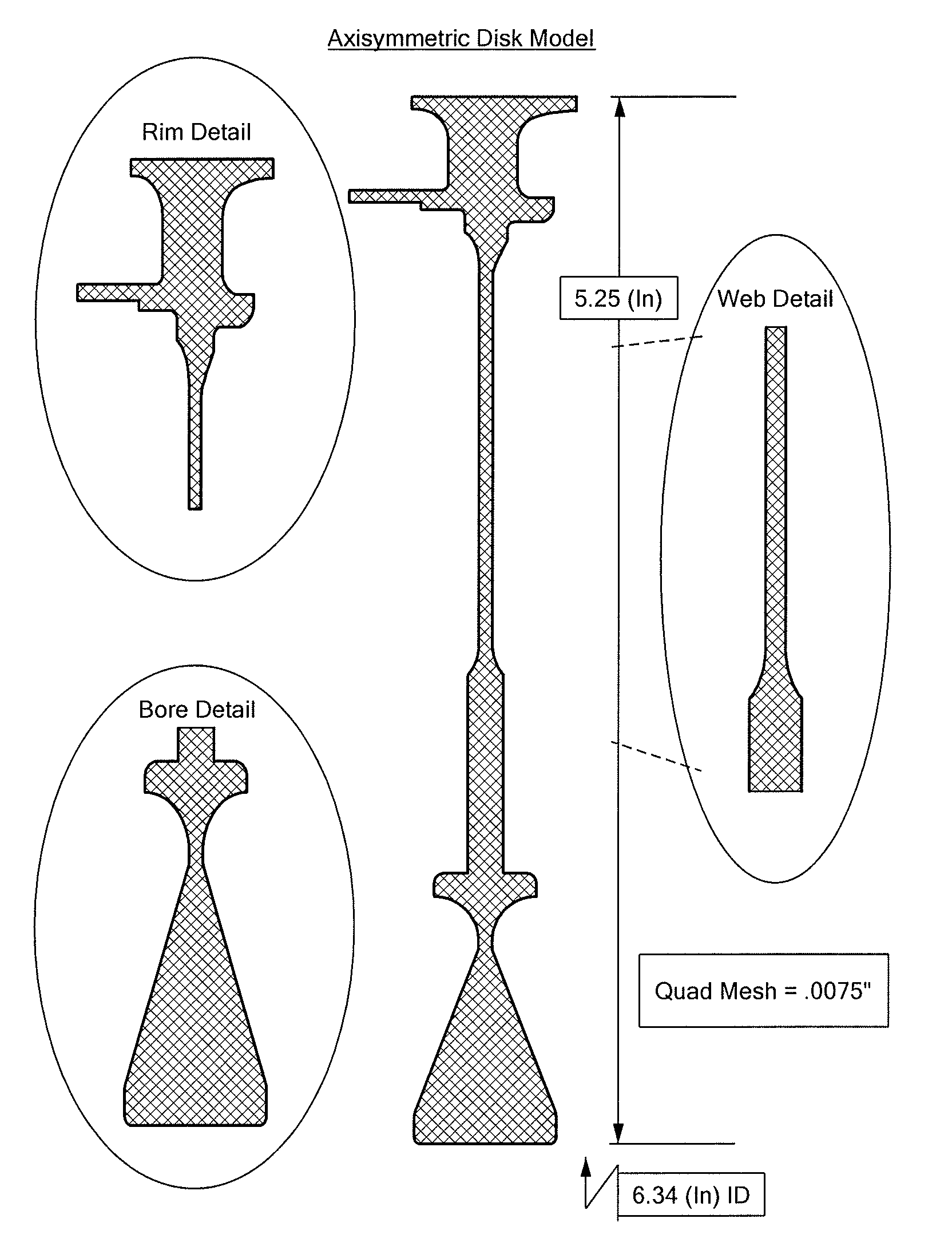

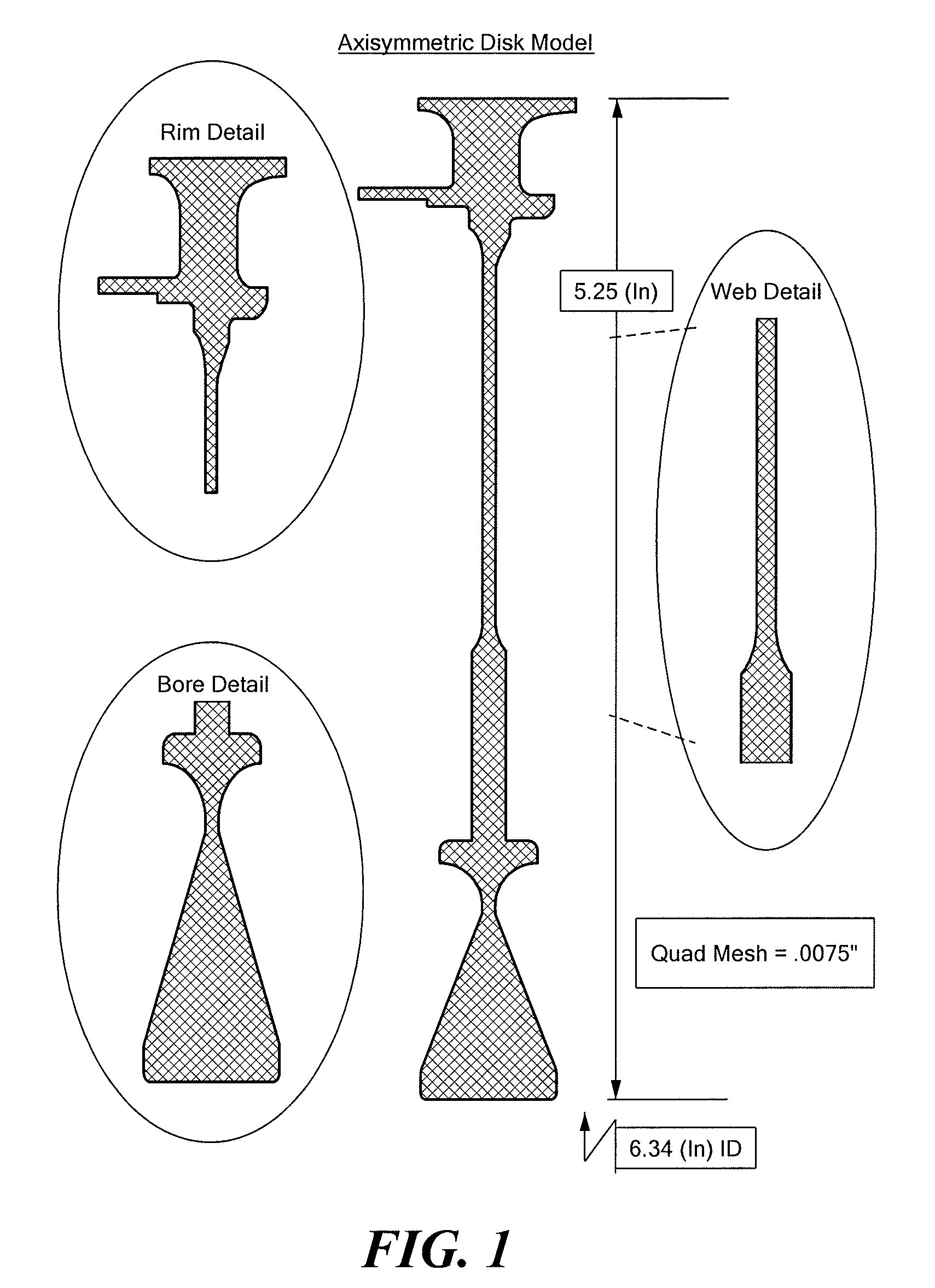

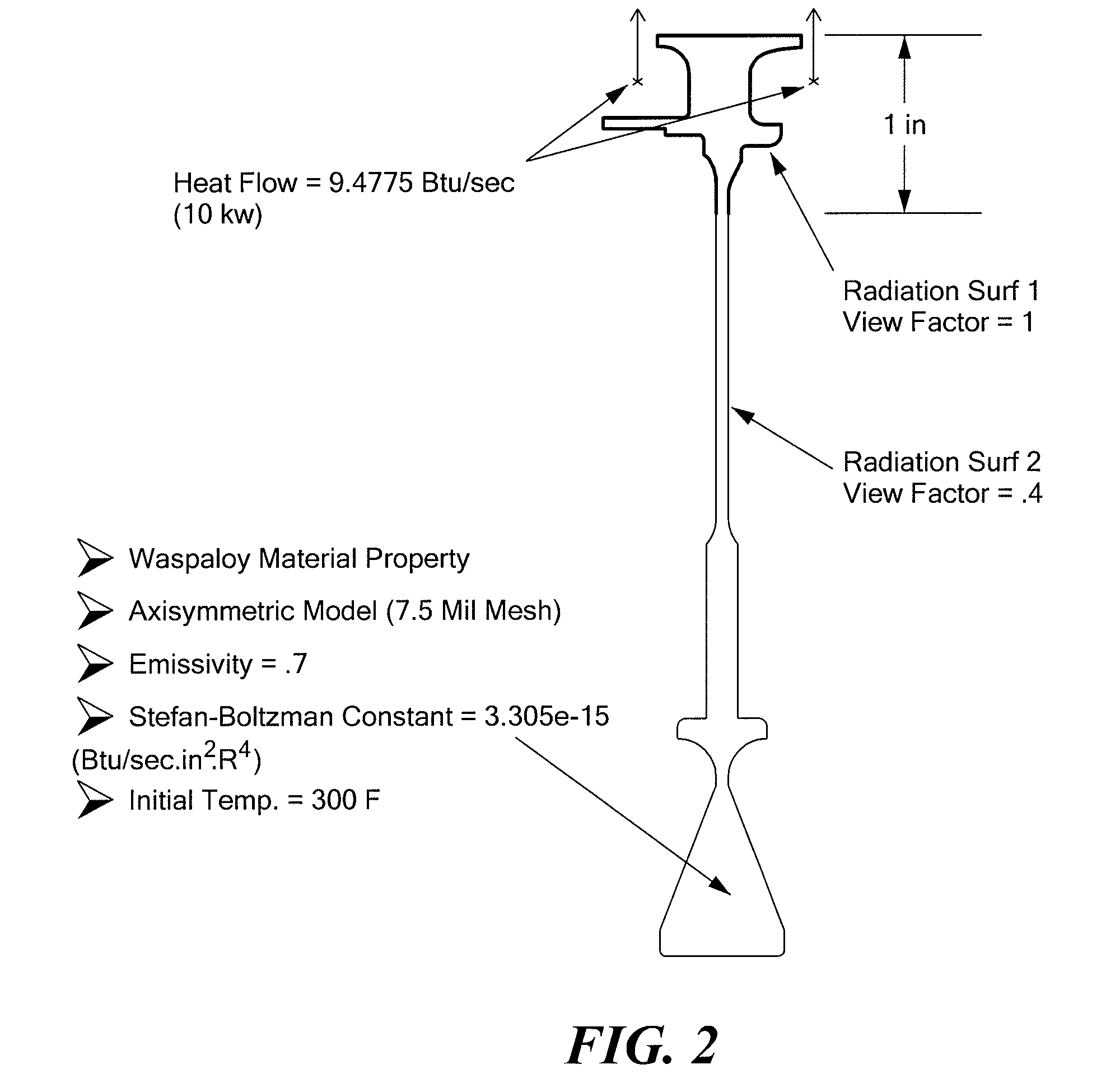

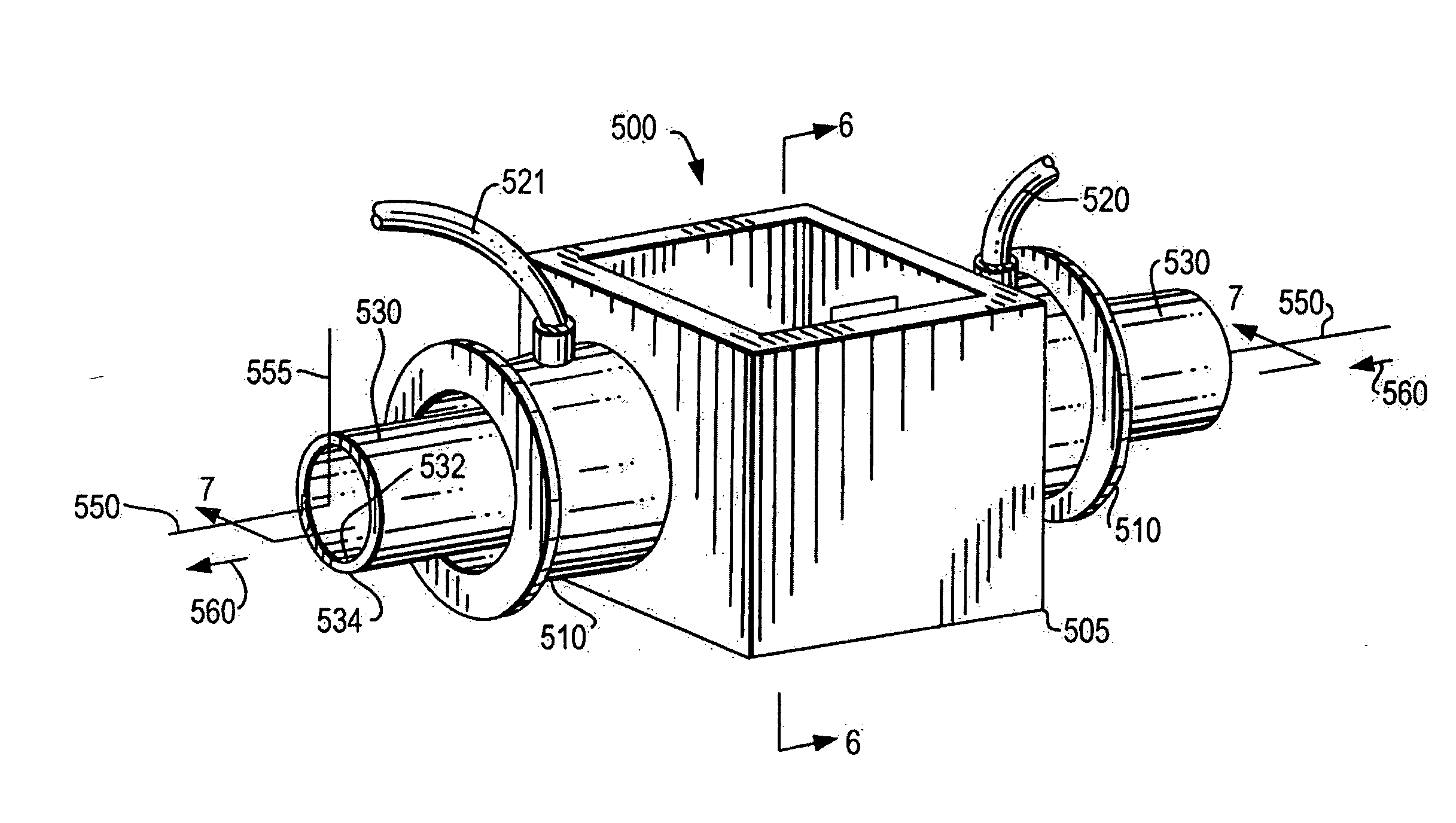

Systems and methods for producing thermal mechanical fatigue on gas turbine rotors in a spin test environment

InactiveUS20090316748A1Limit stray thermal radiationImprove heating efficiencyThermometer detailsMachine part testingRotation testEngineering

A test facility includes a heat source to thermally load a test object being mechanically loaded by rotation imposed by a spin test rig. The heat source can be a quartz lamp controlled to provide a thermal load with a differing phase than the mechanical load. Testing cycles can be run for the test object, with impingement cooling permitting the removal of the thermal load between cycles. The test facility emulates operating conditions in a gas turbine engine to impose realistic thermal and mechanical fatigue stress on the test component.

Owner:SCHENCK USA CORP

CBN grinding wheel of low temperature vitrified bond and preparation technique thereof

A CBN grinding wheel of a low-temperature ceramic bond consists of a bond, auxiliary materials, an abrasive layer and a transition layer. The components and the proportion of the bond are 48-60% of SiO2, 25-37% of Al2O3, 5-10% of Na2O and 3-7% of Li2O; the components and the proportion of the abrasive layer are 23-40% of CBN and 23-40% of SiC, 20.3-29.8% of the bond, 0.1-0.3% of dextrin powder and 0.1-0.2% of walnut powder; and the components and the proportion of the transition layer are 64-76% of the SiC, 21.9-32.9% of the bond and 0.1-0.2% of the dextrin powder. By adopting the technical processes of mixing materials, molding a blank of the abrasive layer by compression, sintering the blank of the abrasive layer, configuring, determining and processing the dimension of matrix bond, bonding the abrasive layer with the matrix, carrying out rotation test, trimming the external circle and end face of the abrasive layer, inspecting the abrasive layer of the grinding wheel, carrying out dynamic balancing, processing the appearance, and the like, and by reducing the firing temperature of the ceramic bond, the problem that burning loss happens easily due to oxidation of the abrasive is solved, and the strength of the product is improved.

Owner:沈阳中科超硬磨具磨削研究所

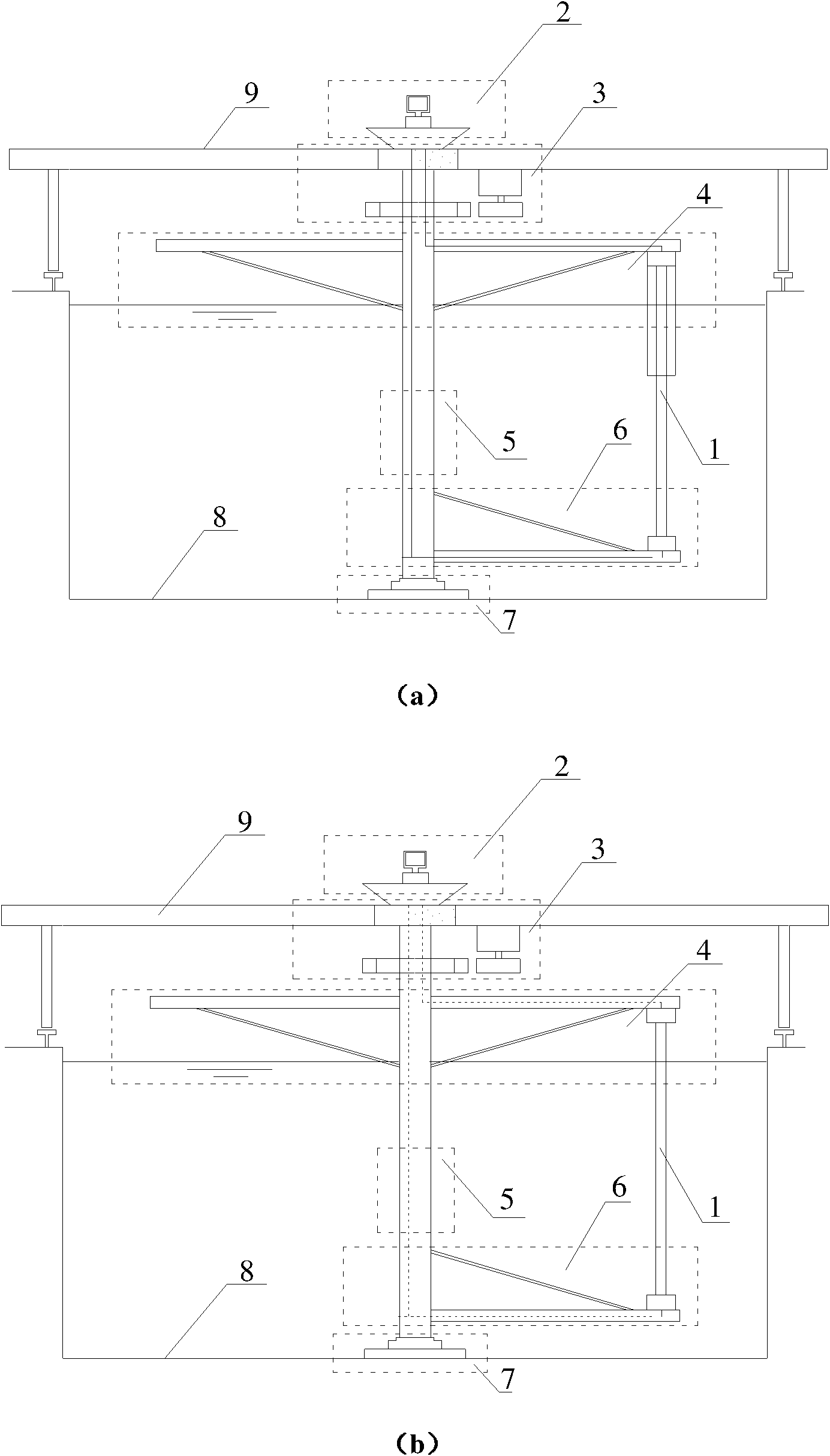

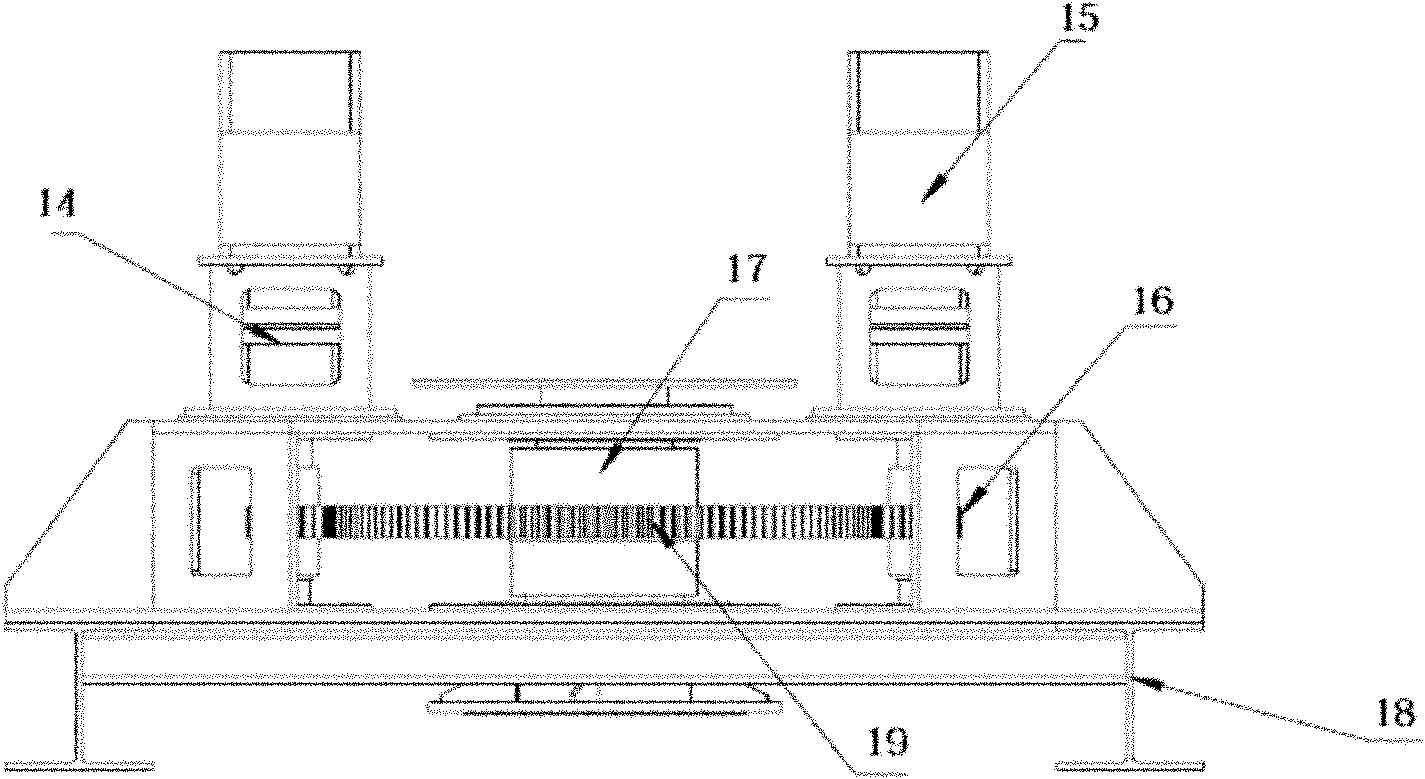

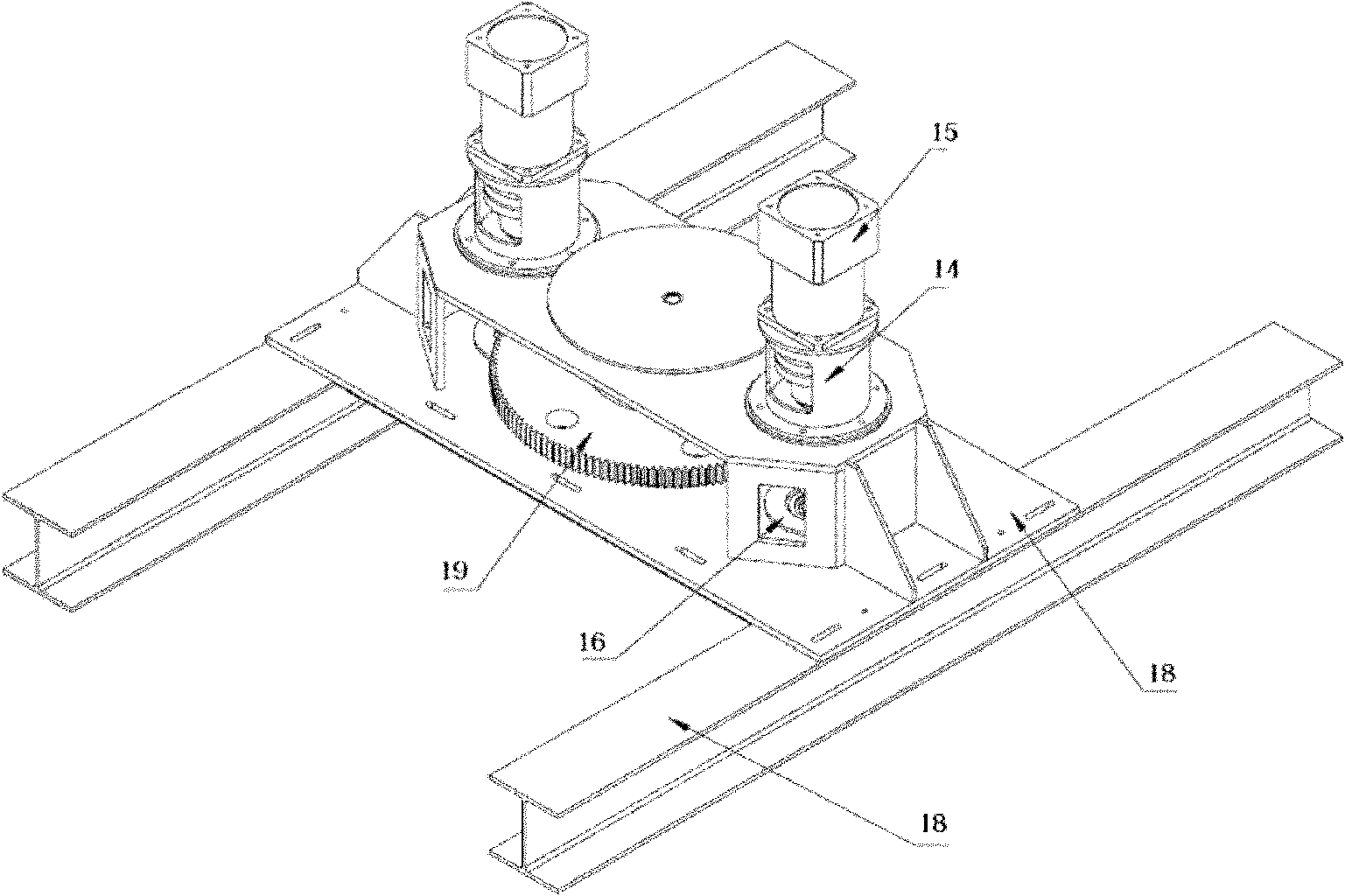

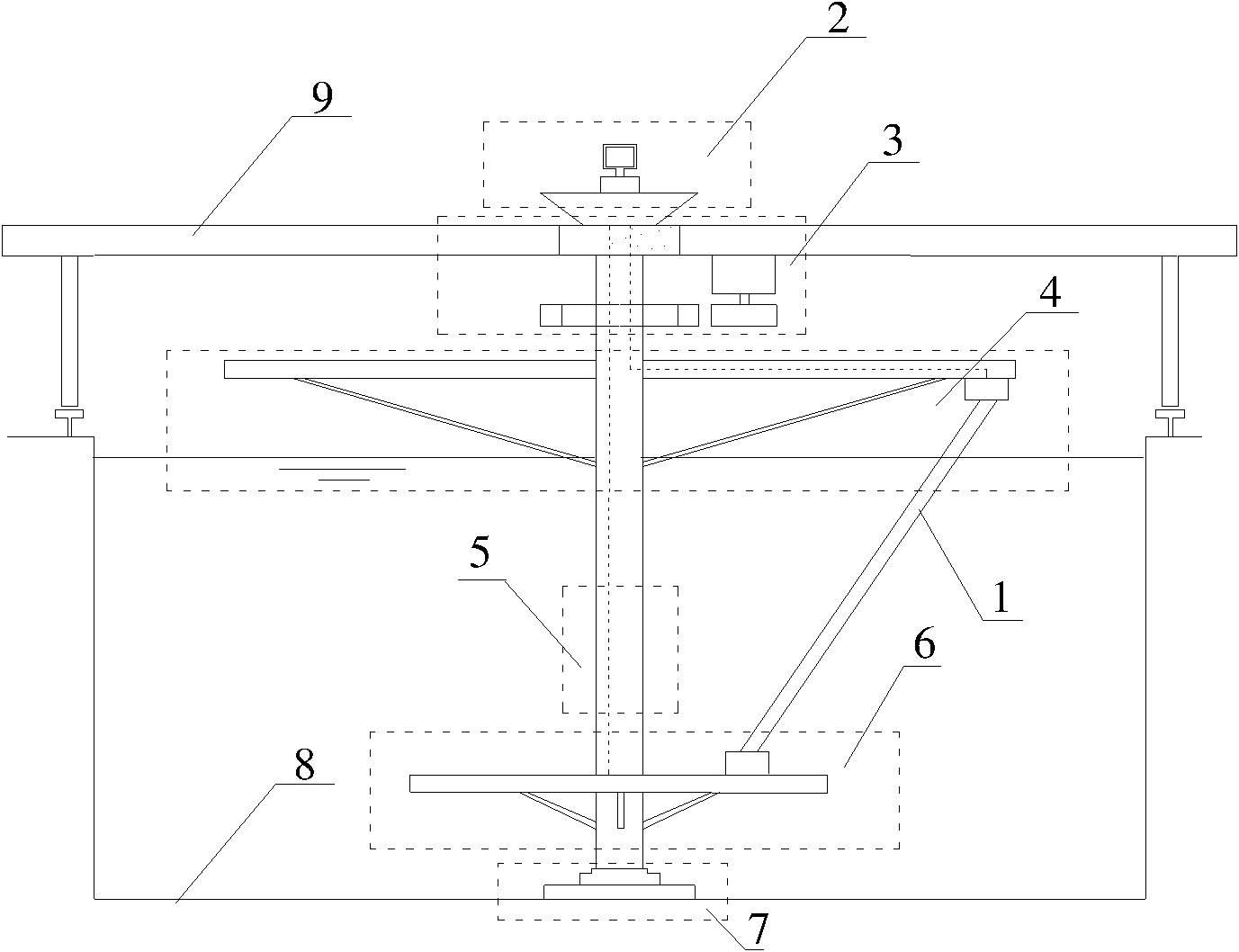

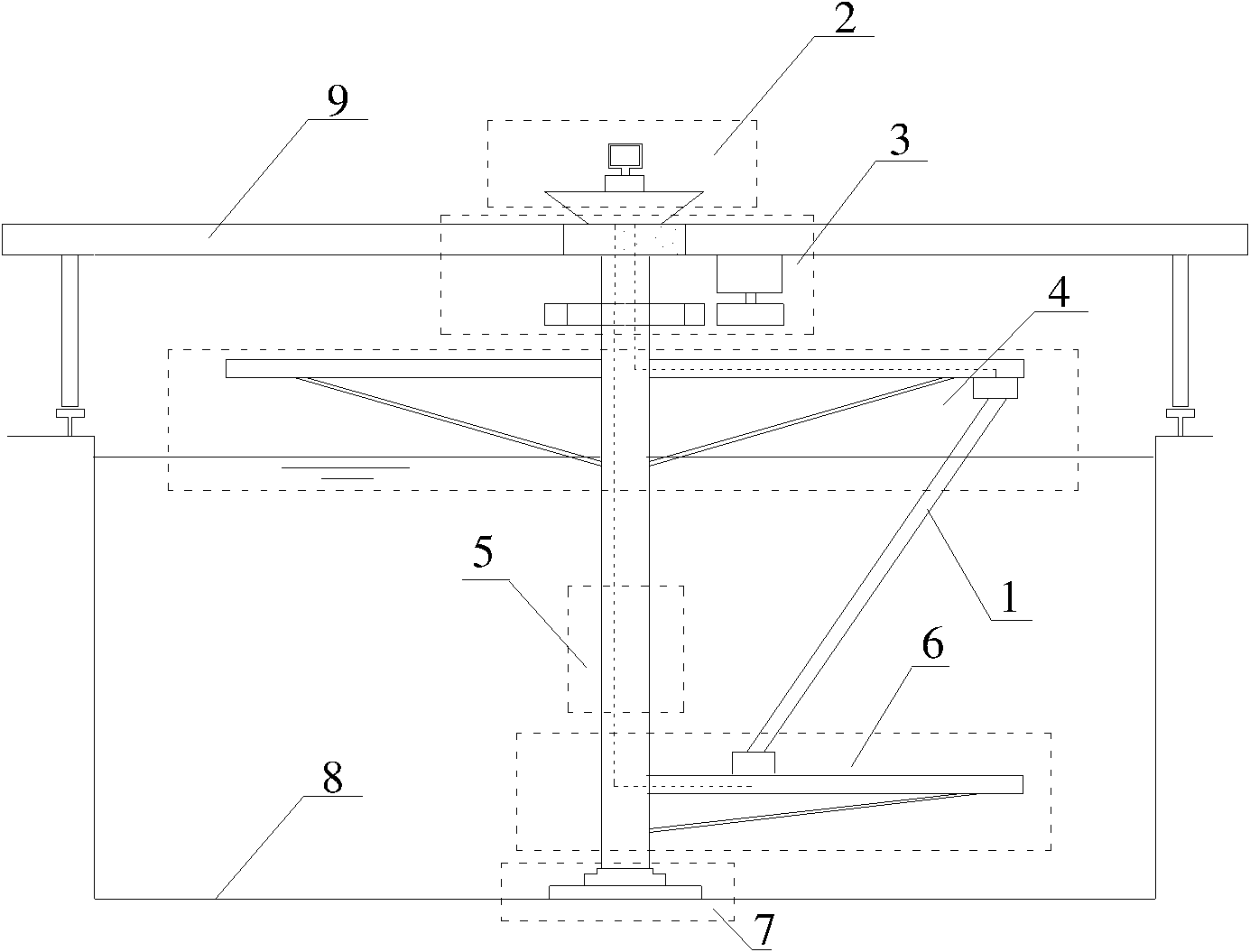

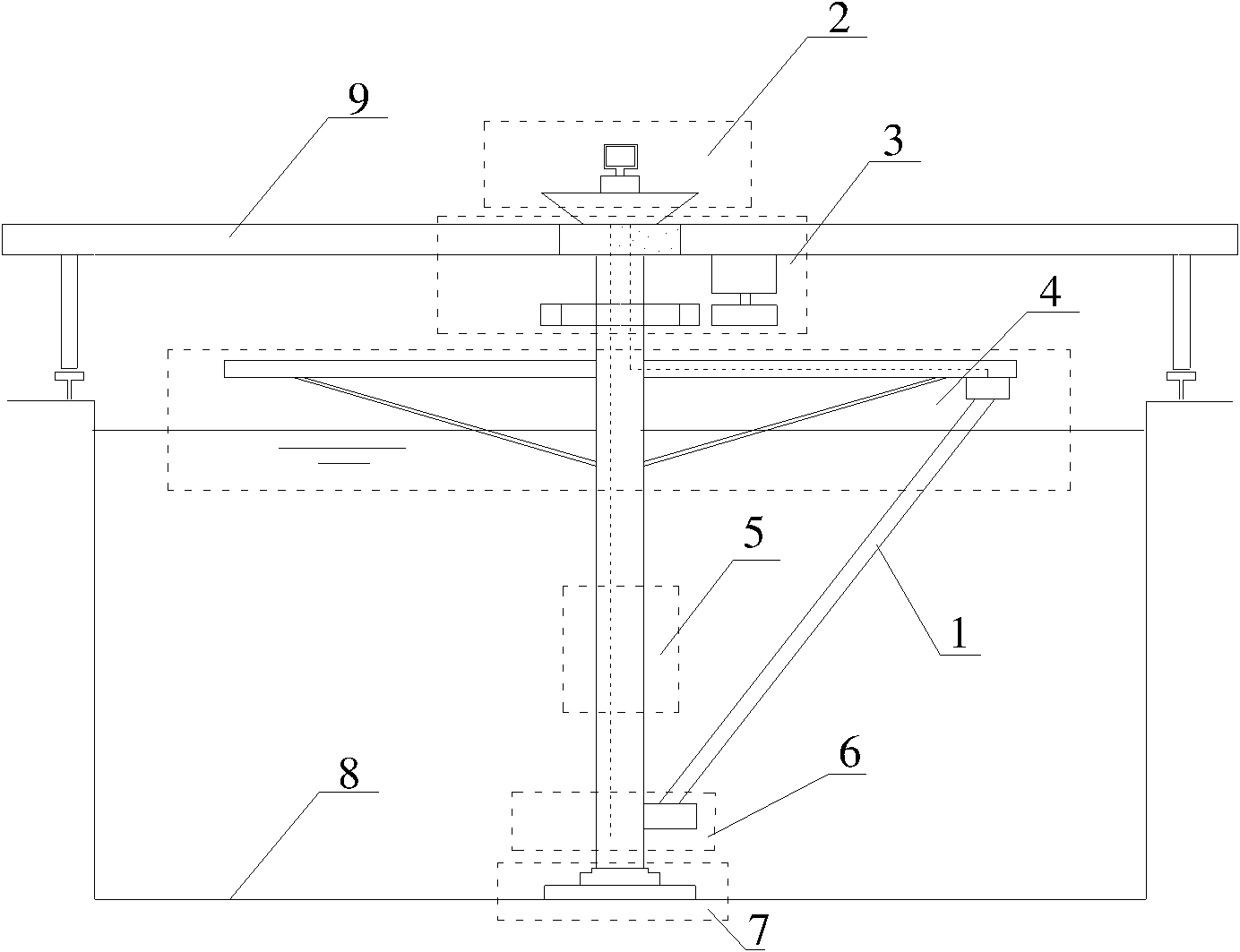

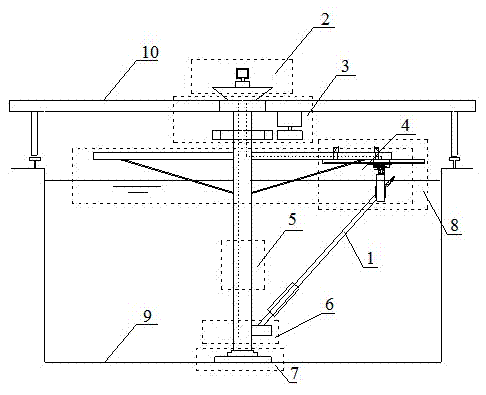

Device for testing vortex-excited oscillation and rotation of vertical riser pipe under uniform flow and stepped uniform flow

ActiveCN102053001ARealize vortex induced vibration testImprove accuracyVibration testingRotation testEngineering

Owner:SHANGHAI JIAO TONG UNIV

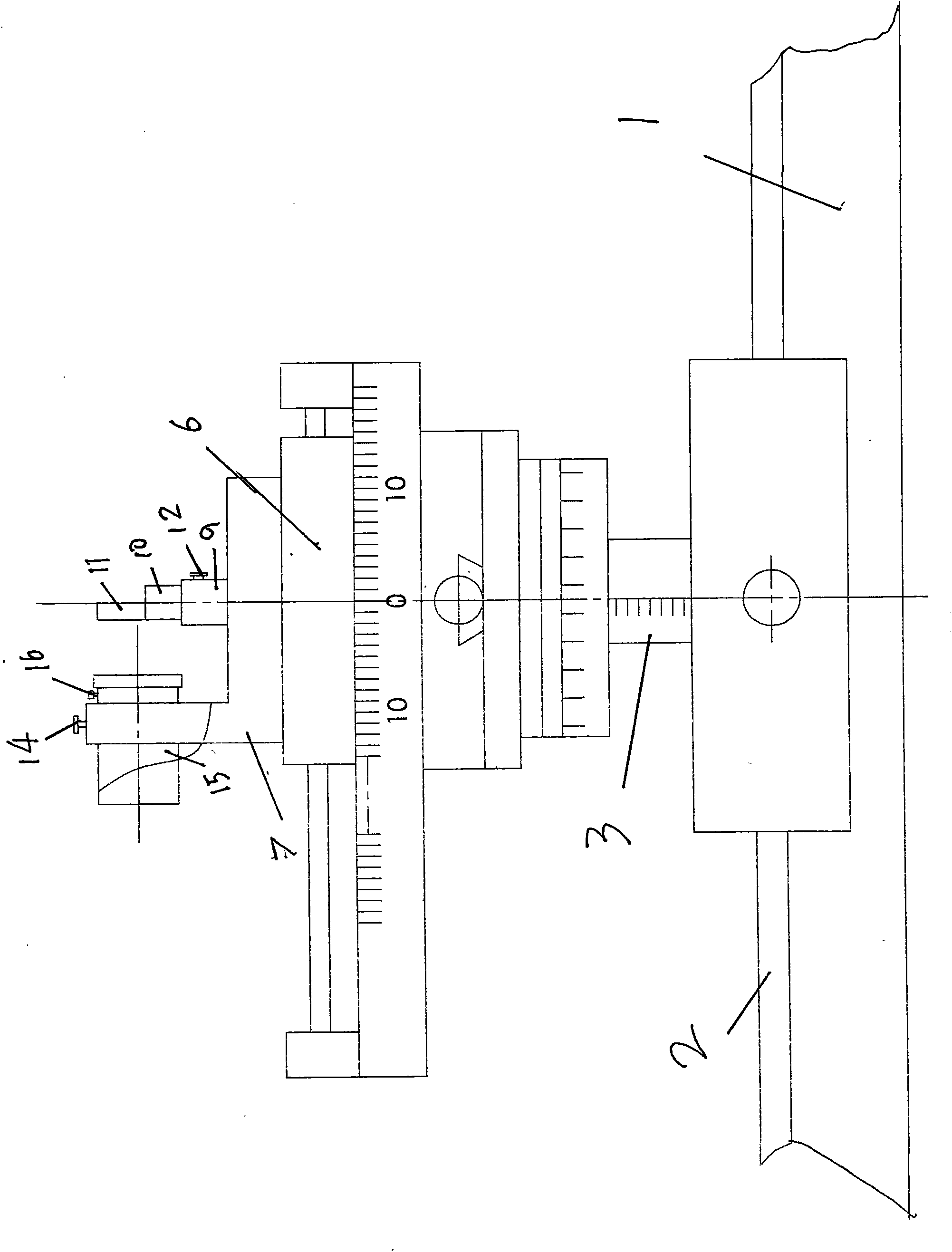

Rotary testing device for vortex-induced vibration for oblique riser under shear current

ActiveCN102053000ARealize vortex induced vibration testImprove accuracyVibration testingRotation testEngineering

The invention relates to a rotary testing device for vortex-induced vibration for an oblique riser under shear current, belonging to the technical field of ocean engineering. The rotary testing device comprises a riser model mechanism, a measurement and analysis system platform module, a driving module, a top cantilever module, a cylinder shaft segmentation module, a bottom riser fixing module and a bottom supporting module, wherein the riser model mechanism is fixedly arranged between the top cantilever module and the bottom riser fixing module; the cylinder shaft segmentation module is vertically arranged in an ocean engineering deepwater basin and respectively connected with the bottom supporting module, the driving module, the top cantilever module and the bottom riser fixing module; the bottom supporting module is fixedly arranged on a lifting bottom; the driving module is connected with the cylinder shaft segmentation module and outputs power; both ends of the top cantilever module are connected with the driving module or the cylinder shaft segmentation module and the cylinder shaft segmentation module; and the measurement and analysis system platform module is connected with the riser model mechanism, the top cantilever module and the bottom riser fixing module. The invention can simulate risers of actual sizes and shear current fields.

Owner:SHANGHAI JIAO TONG UNIV

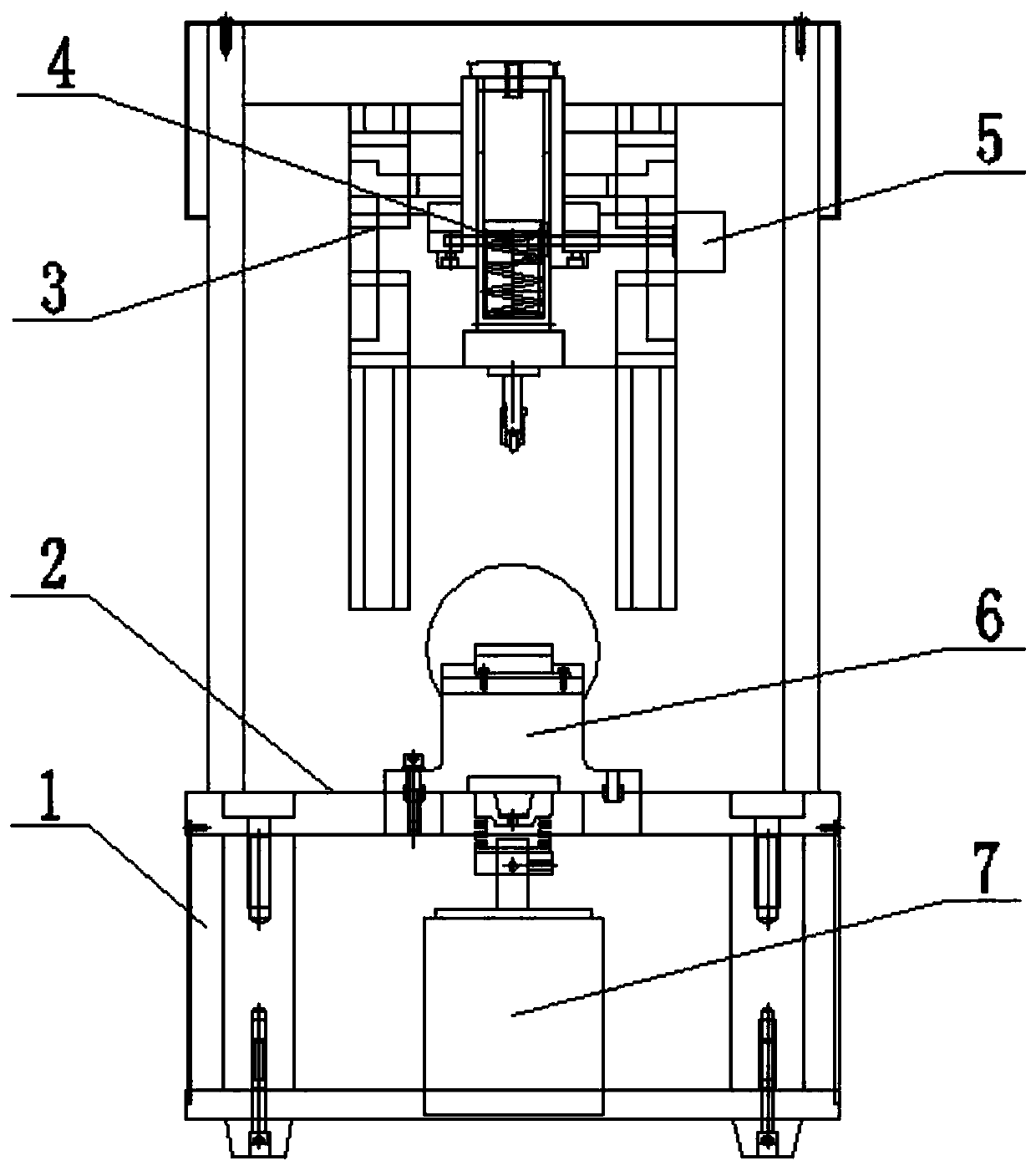

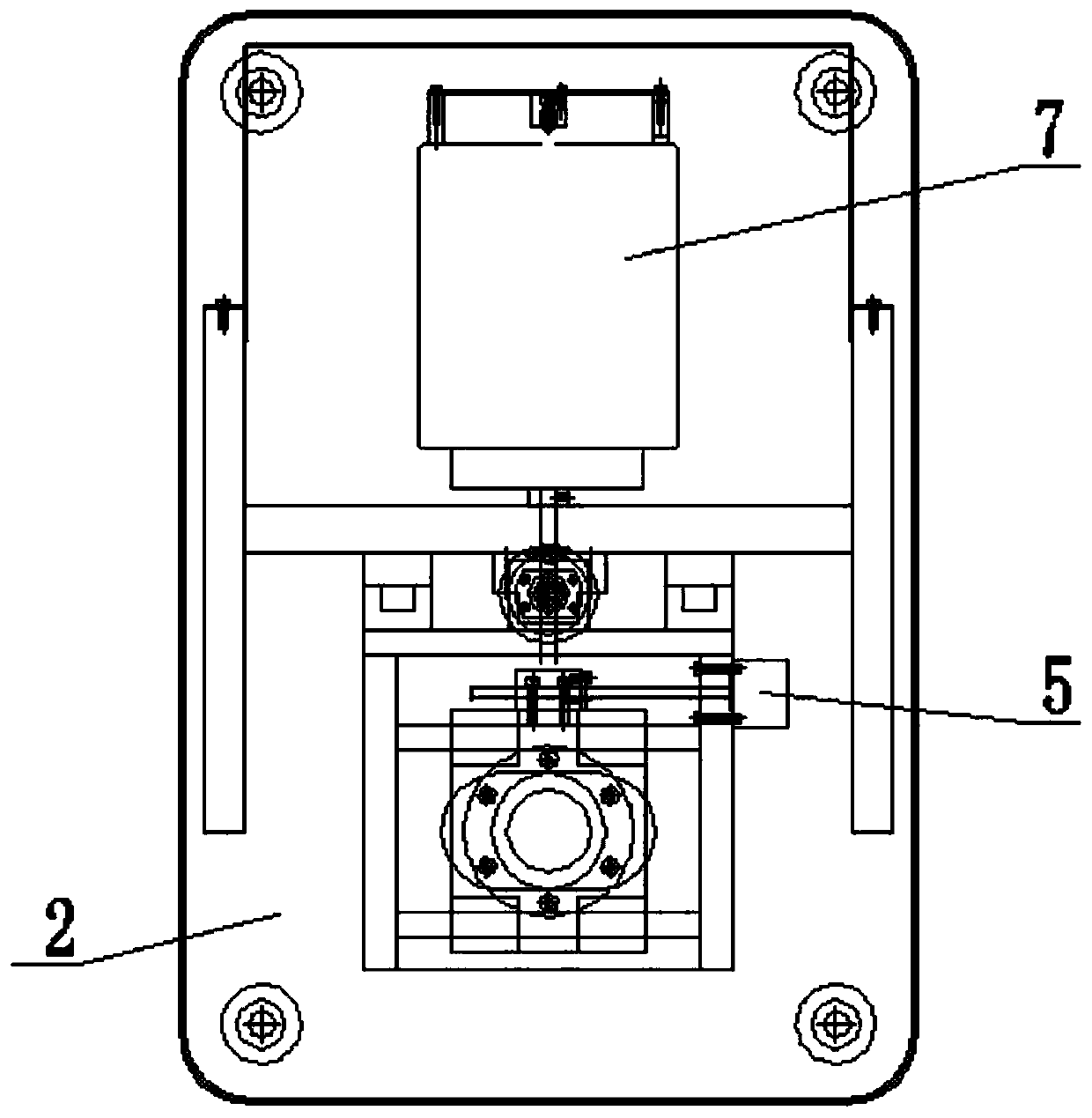

Rotary reciprocating frictional wear testing machine

PendingCN110530752AHigh precisionPrecise frequency controlInvestigating abrasion/wear resistanceWear testingReciprocating motion

The invention discloses a rotary reciprocating frictional wear testing machine which comprises a rack provided with a rack workbench, a rotation test device, a linear reciprocating test device, a testforce loading mechanism and a sample clamping module. The rotation test device comprises a rotation driving motor. The rotary driving motor is vertically arranged in the rack and is positioned at a lower part of the rack workbench. The linear reciprocating test device comprises a reciprocating motion linear motor which is a voice coil motor. The reciprocating motion linear motor is horizontally arranged on the rack, an axis of the reciprocating motion linear motor perpendicularly intersects with an axis of the rotary driving motor, the sample clamping module is detachably mounted on the rackworkbench and is coaxial with the axis of the rotary driving motor. The test force loading mechanism comprises a lifting mechanism and a force application mechanism, the lifting mechanism is arrangedon the rack, the force application mechanism comprises a force application shaft, a measurement sensor connected to the force application shaft and an upper sample clamp connected to a lower end of the force application shaft, and the force application mechanism is connected to the lifting mechanism.

Owner:济南益华摩擦学测试技术有限公司

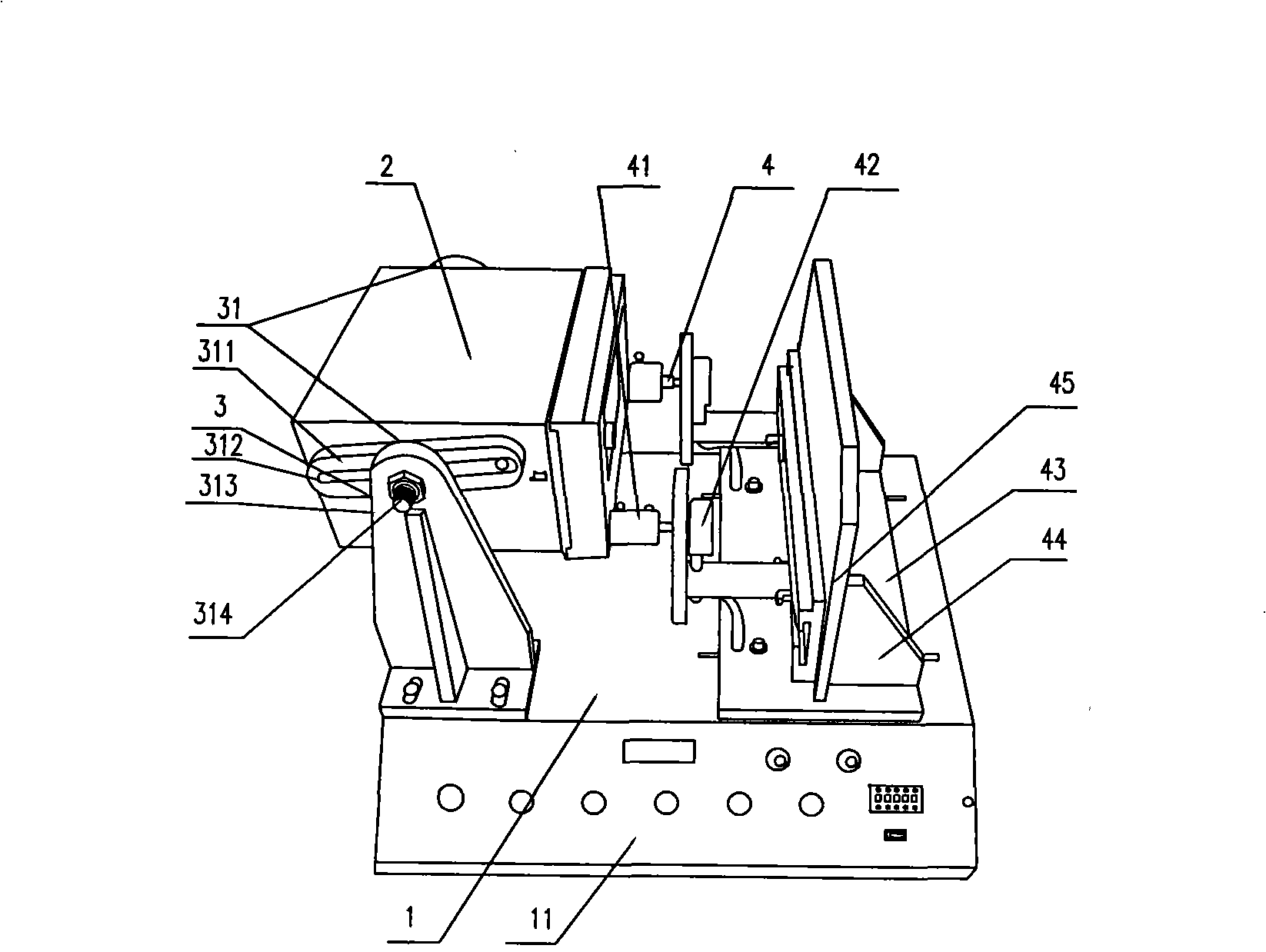

Turn knob potentiometer rotating life-span tester

InactiveCN101339219AEasy to operateAdjustable turning forceElectrical testingElectricityTester device

The invention discloses a rotation life test instrument of a knob potentiometer and is characterized in that: the instrument comprises a test platform and an embedded controller. A positioning mechanism used for fixing an object to be tested is arranged on the platform. Periphery of the positioning mechanism is arranged with a knob driving gear which is fixed on a chassis with an adjustable position and connected with the controller. The instrument can simulate hand rotation so as to test the service life of the knob potentiometer. The instrument is simple in structure, convenient and simple in operation, precise and reliable in test with good popularization value.

Owner:GUANGDONG COAGENT ELECTRONICS SCI & TECH

Rigidity test restraining device of car frame

The invention provides a rigidity test restraining device of a car frame and a corresponding restraining method thereof. When the rigidity of the car frame is tested by the method, the car frame is formed to be a simply supported beam structure during testing the bending rigidity and reversing rigidity, thus releasing three rotation degrees of freedom and necessary translation degrees of freedom at corresponding restraining positions; through the restraining device, the three rotation degrees of freedom at the corresponding restraining positions are released on the car frame through a ball hinge structure; and the translation degrees of freedom at the corresponding restraining positions are released through a sliding block structure. The restraining method of a car frame restraining bending and rotation test provided according to the minimum restraining theory is close to the actual condition of the car frame. Simultaneously, the test is carried out on an independent car frame, therefore, the restraining device is simple in structure and mounting method, thereby completely meeting the requirements of testing accuracy and reliability.

Owner:JIANGSU UNIV

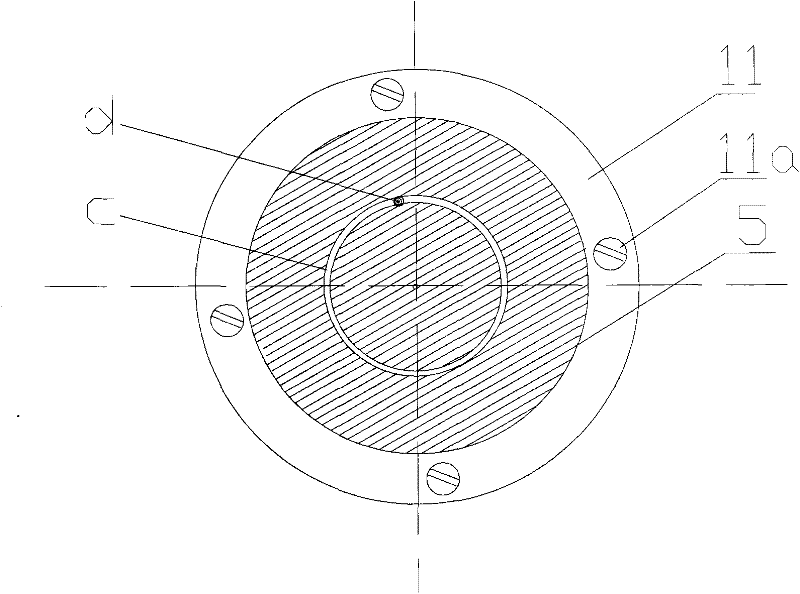

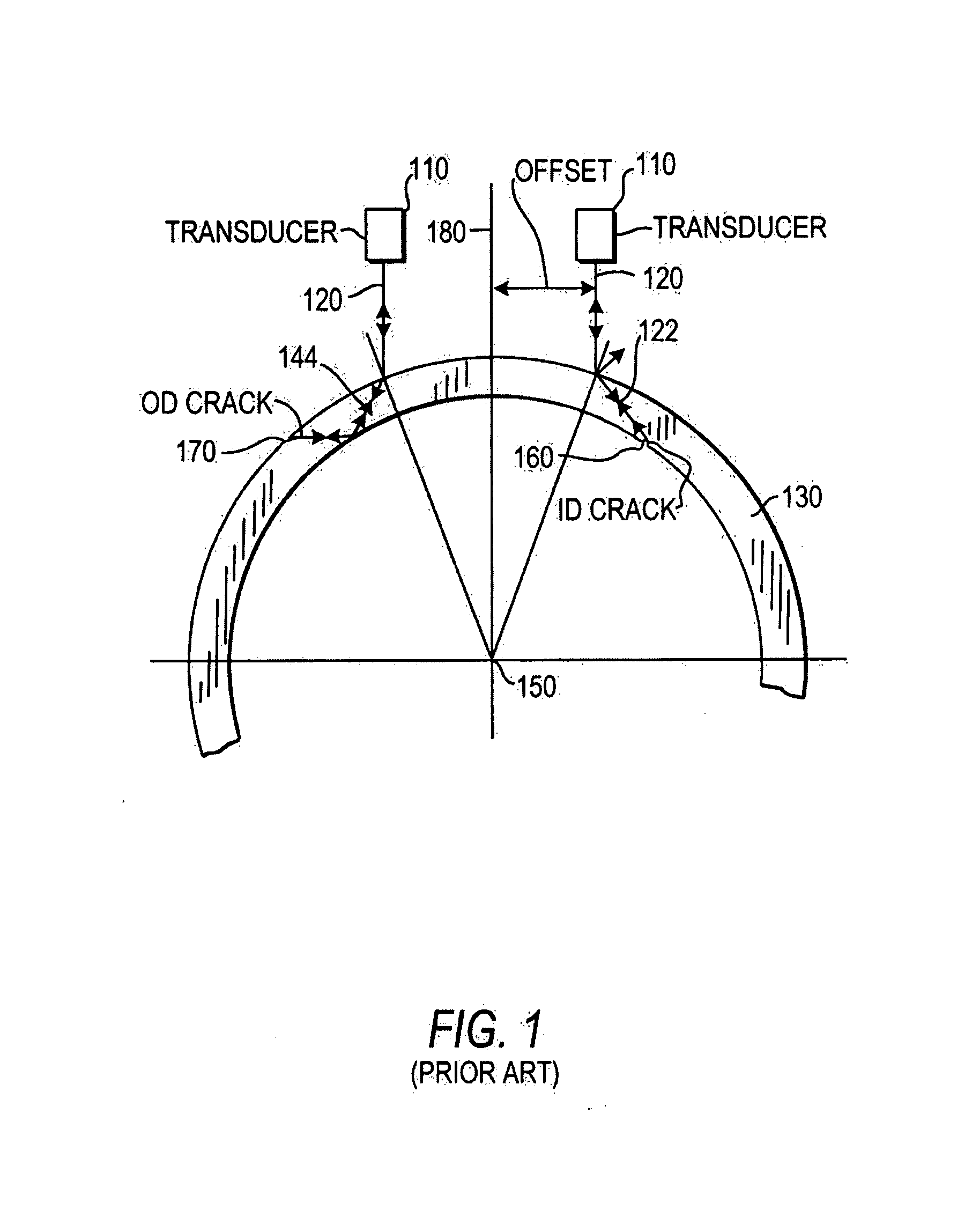

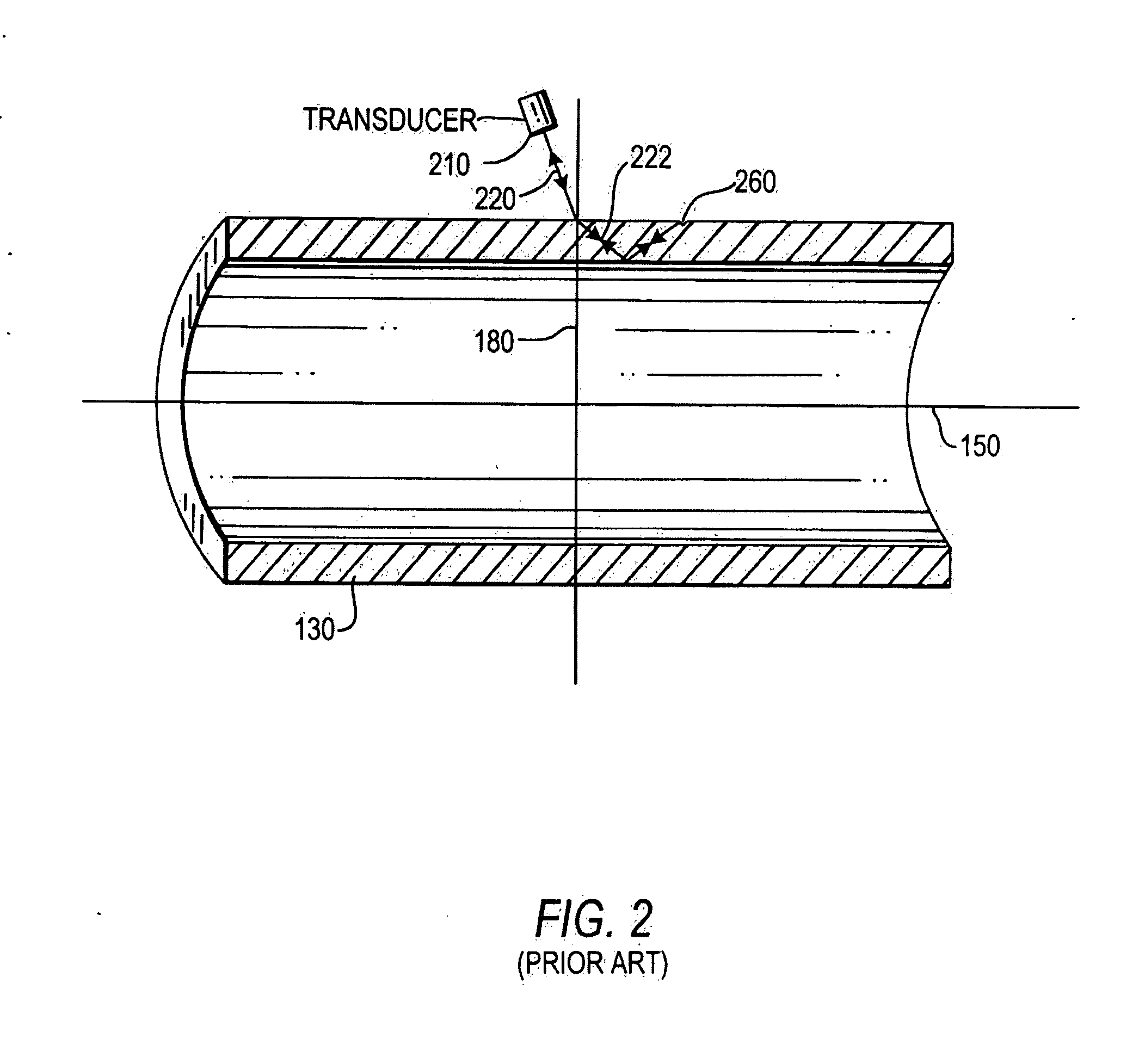

Oblique flaw detection using ultrasonic transducers

ActiveUS20080289424A1Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansTransducerRotation test

Ultrasonic transducers and methods for detecting oblique flaws in cylindrically-shaped objects using pulse-echo testing are provided. By mounting one or more transducers on a rotary tester for testing manufactured objects such as tubes and bars, offsetting each transducer horizontally from its position if it were to emit a beam that is perpendicular to the object's outer surface, and actuating the transducer so as to emit an angled beam, oblique surface flaws and internal flaws may be reliably detected without reducing inspection speed, significantly adding to transducer cross-talk, or requiring significant additional hardware or processing.

Owner:MAGNETIC ANALYSIS

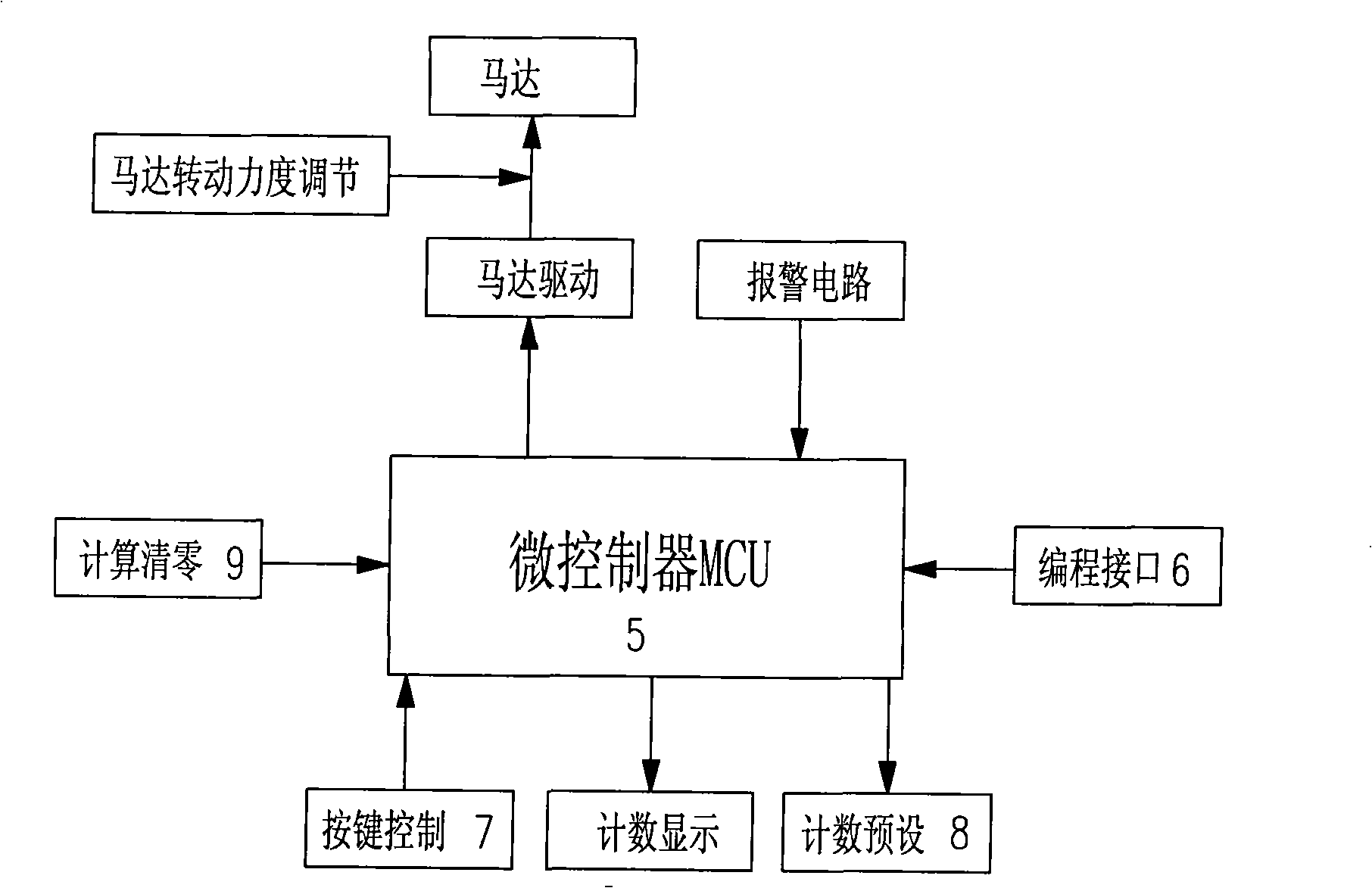

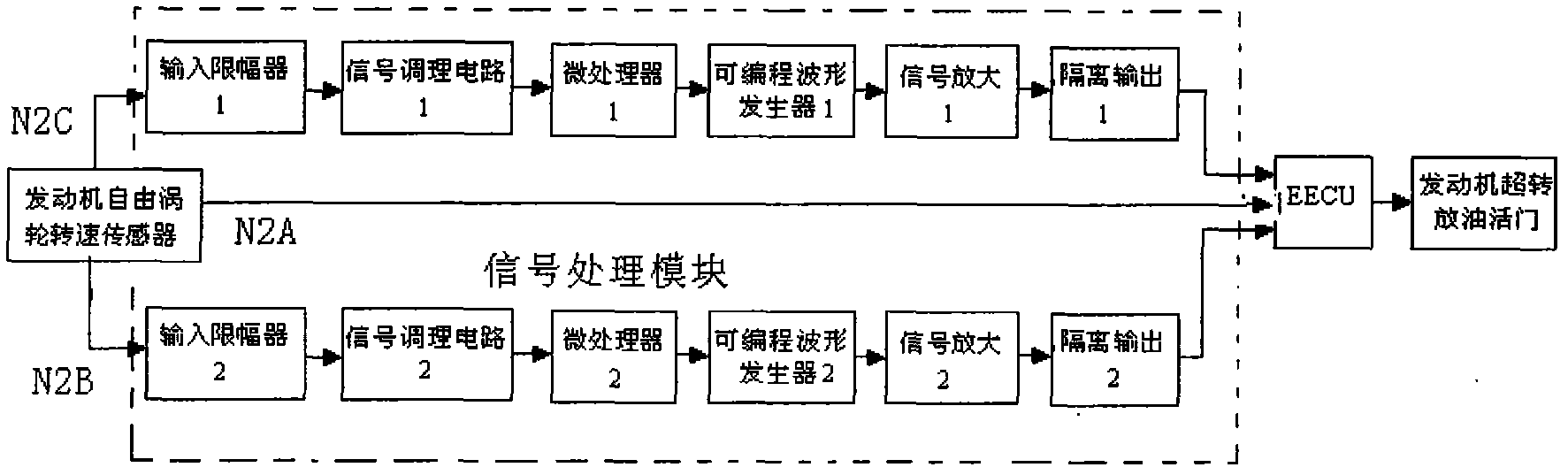

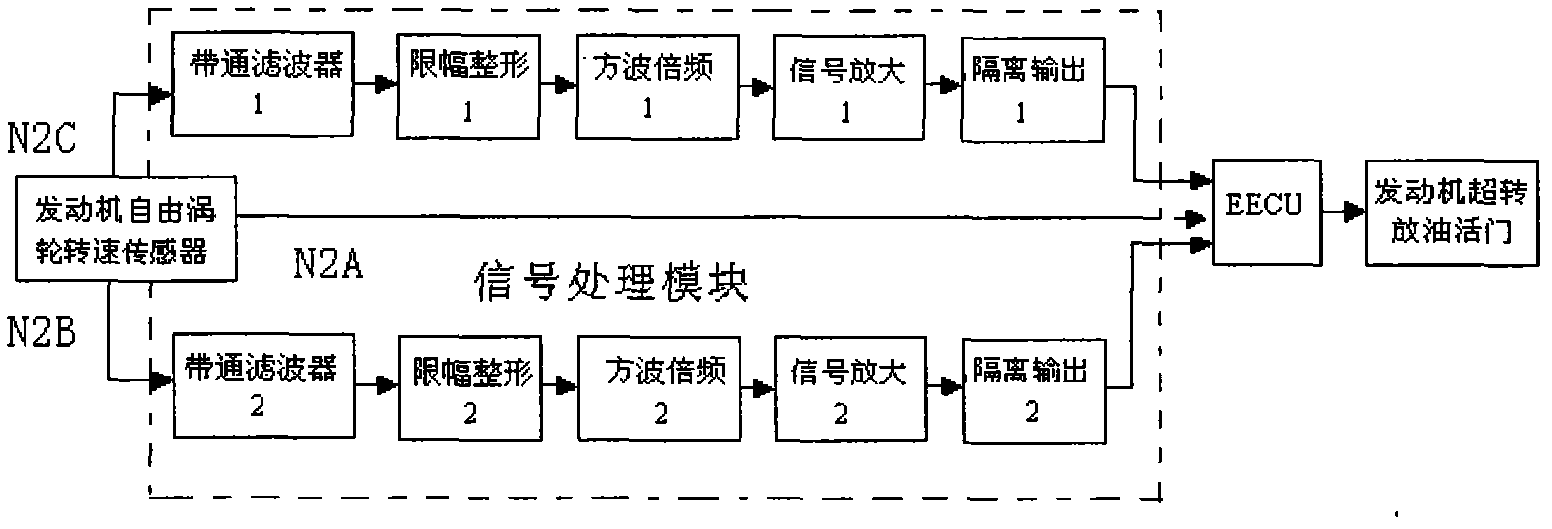

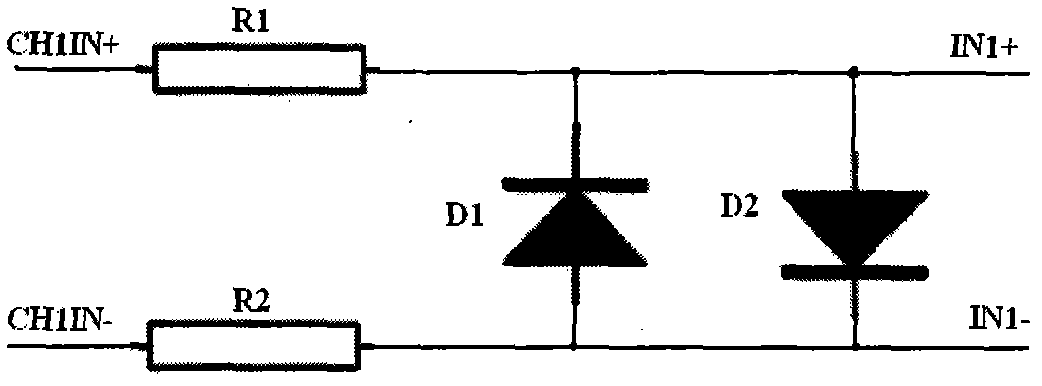

Over-rotation test system for electrical-adjustable bi-motored helicopter turbo shaft engine

InactiveCN102147333AEasy to useImprove performanceEngine testingElectricitySignal conditioning circuits

The invention relates to the technical field of engine experiments, in particular to the technical field of helicopter engine over-rotation experiments. The system comprises an engine free turbine speed sensor, a signal processing module, an electronic engine controller and an engine over-rotation fuel bleed valve, wherein the signal processing module comprises two identical sub-circuits, each ofwhich consists of an input limiter, a signal conditioning circuit, a microprocessor, a programmable waveform generator, a signal amplifier and an isolating output end; a rotating speed signal collected by the engine free turbine speed sensor is processed by the signal processing module and is then output to the electronic engine controller; the electronic engine controller controls the turn-on / turn-off of the engine over-rotation fuel bleed valve by analyzing the signal. The test system is simple in use, and has reliable performance and good effect.

Owner:中航通用飞机有限责任公司

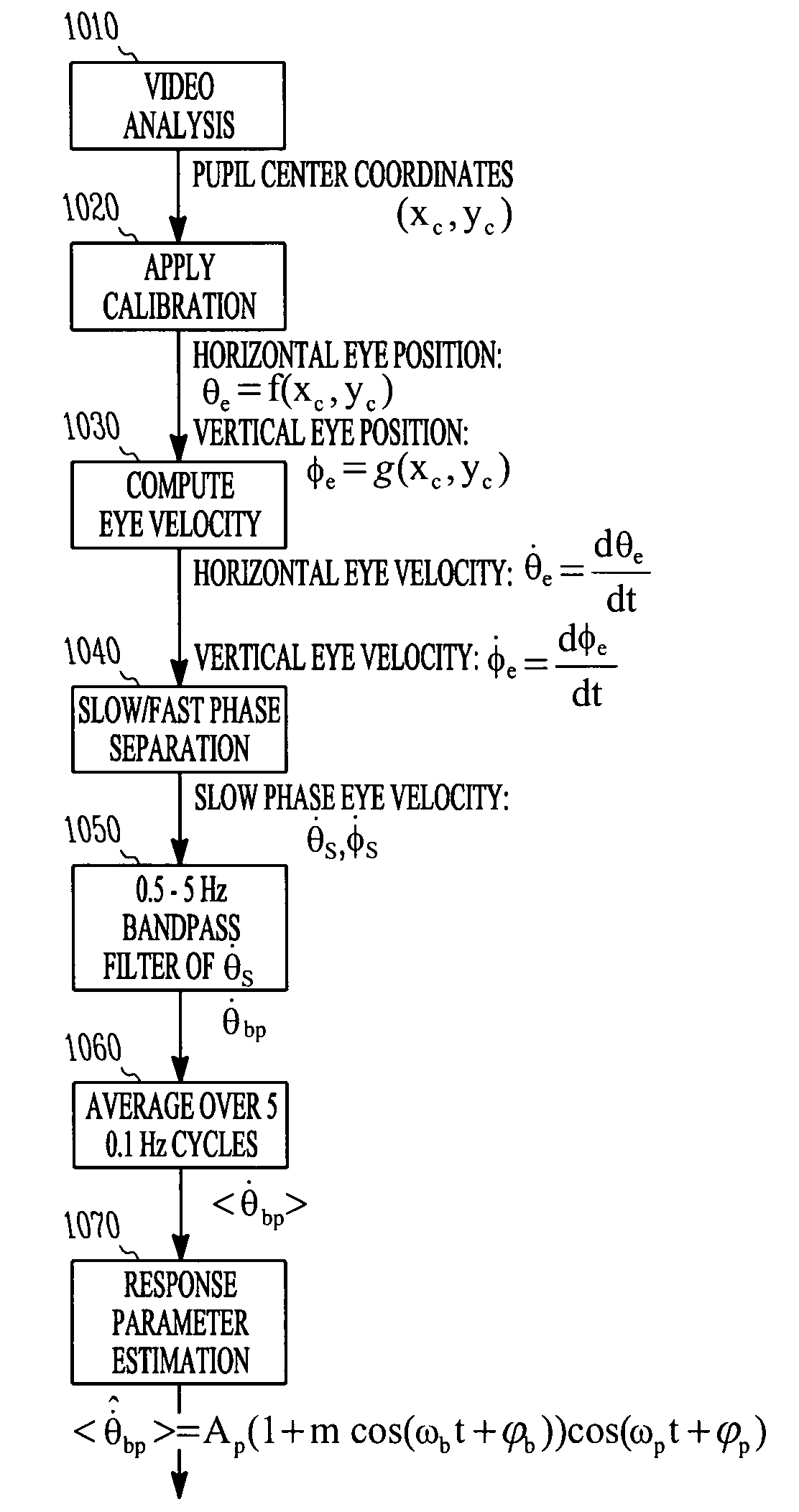

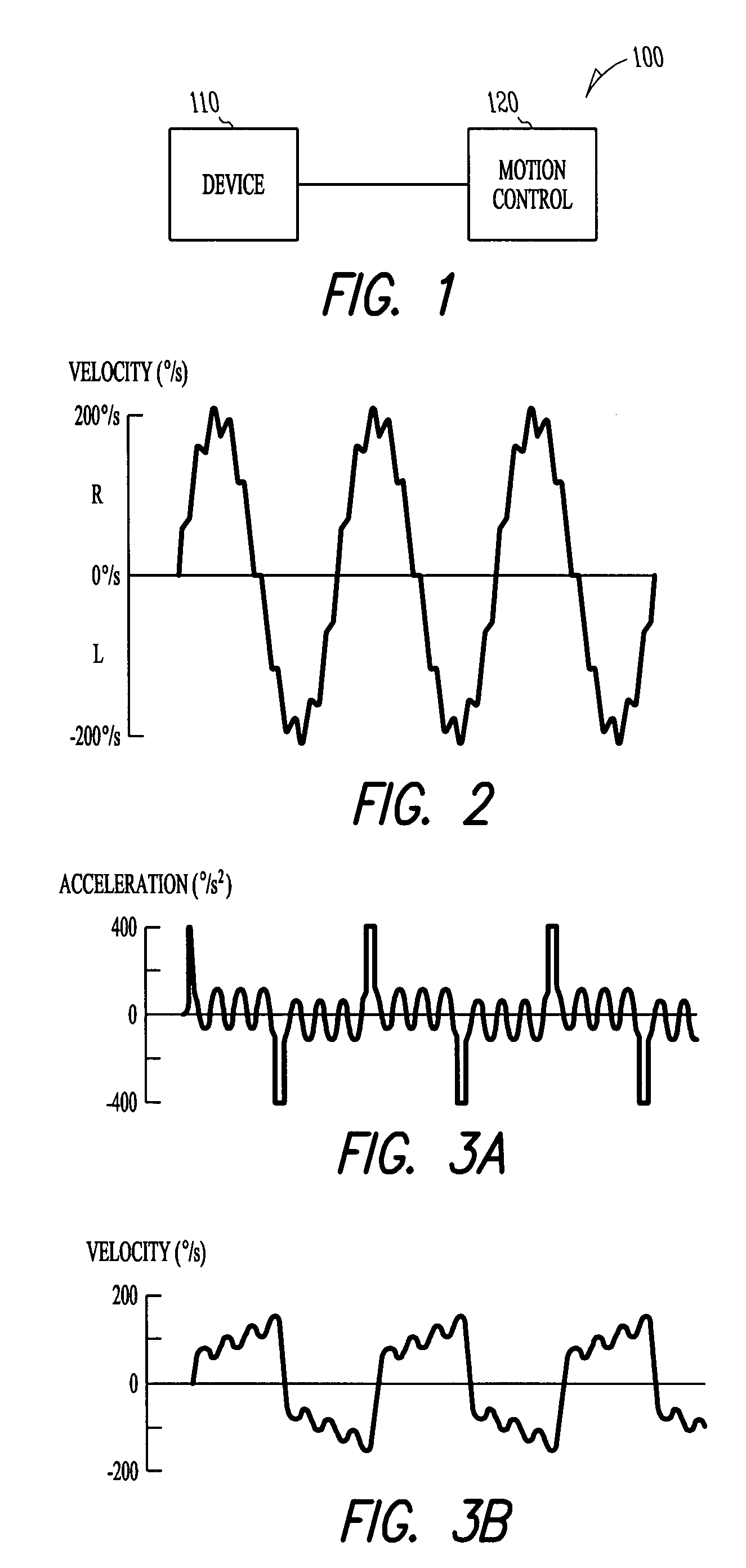

Bias-probe rotation test of vestibular function

Apparatus and methods for rotation test stimulus and analysis methods overcome many of the limitations of traditional clinical tests of peripheral vestibular function. An embodiment includes a rotational stimuli applied to the rotational motion for testing that includes two separate components, a bias component and a probe component. The bias component for rotational motion is designed to temporarily turn off vestibular responses in one ear while the responsiveness in the opposite ear is simultaneously evaluated using the probe component of the stimulus. Responses from application of these stimuli are analyzed by isolating and separating the bias response from the probe response. The bias and probe component responses are parameterized by applying curve fits of mathematical functions to the isolated bias and probe component responses. These parameters characterize the patient's vestibular function.

Owner:OREGON HEALTH & SCI UNIV

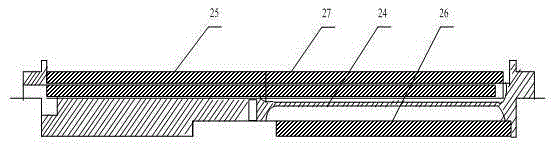

Face angle testing device of rotary tool

A face angle testing device of a rotary tool comprises a well deviation calibration table frame, a rotary testing table frame, an orientation calibration table frame, a power supply module, a microcomputer module, a slip ring wire and an emergency brake; a rotary tool face angle testing and control system is installed on the rotary testing table frame and is driven to rotate by a direct-current deceleration motor on the rotary testing table frame, then the rotary testing table frame is fixed to the well deviation calibration table frame, and finally the well deviation calibration table frame is fixed to the orientation calibration table frame; and power is supplied to the whole rotary testing table frame by the power supply module through the slip ring wire, and after collected signals such as well deviation, orientation, the rotation speed and the tool face angle are regulated by the rotary tool face angle testing and control system, the signals are transmitted to the microcomputer module through the slip ring wire, so that data and control communication between the rotary testing table frame and the externally-connected microcomputer module is achieved. The face angle testing device of the rotary tool supplies powerful technical guarantee to the processes of accurate measuring, measured influence factor analyzing and accurate control achieving of the rotary tool face angle system under the rotary working condition.

Owner:中石化石油工程技术服务有限公司 +3

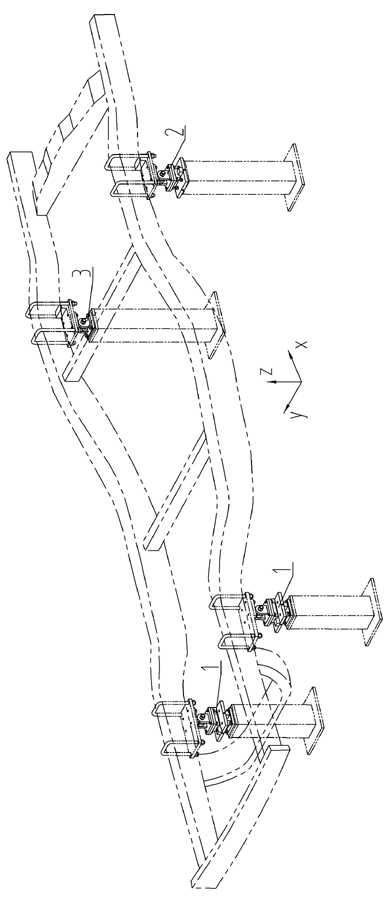

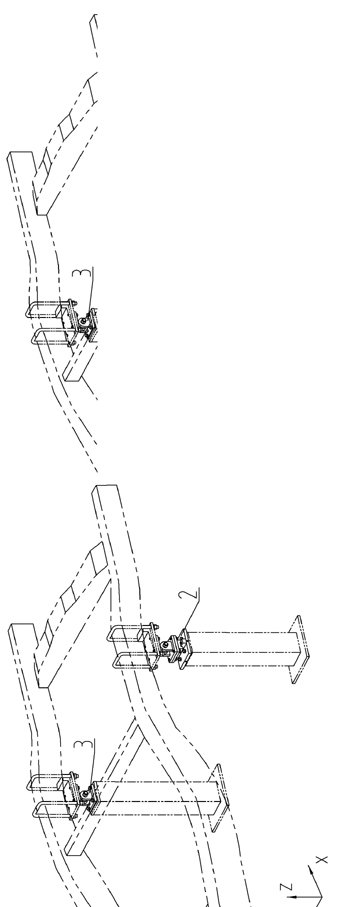

Vortex induced vibration rotation testing device of inclined vertical pipe with movable top part under step shear flow

ActiveCN102410920ARealize vortex induced vibration testImprove accuracyVibration testingRotation testEngineering

The invention provides a vortex induced vibration rotation testing device of an inclined vertical pipe with a movable top end under a step shear flow, belongs to the technical field of marine engineering. The vortex induced vibration rotation testing device comprises a vertical pipe model mechanism, a measurement analysis system platform module, a driving module, a top cantilever module, a cylinder shaft section module, a bottom vertical pipe fixing module, a bottom supporting module and an oscillation module; the vertical pipe model mechanism is fixed between the oscillation module and the bottom vertical pipe fixing module, the oscillation module is fixed on the top cantilever module, the driving module is respectively connected with the cylinder shaft section module and the top cantilever module, the left and right ends of the top cantilever module are respectively connected with the cylinder shaft section module, the measurement analysis system platform module is respectively connected with the vertical pipe model, the top cantilever module, the oscillation module and the bottom vertical pipe fixing module. The testing device provided by the invention can simulate the verticalpipe step shear flow field and vertical pipe top platform movement in an actual size.

Owner:SHANGHAI JIAO TONG UNIV

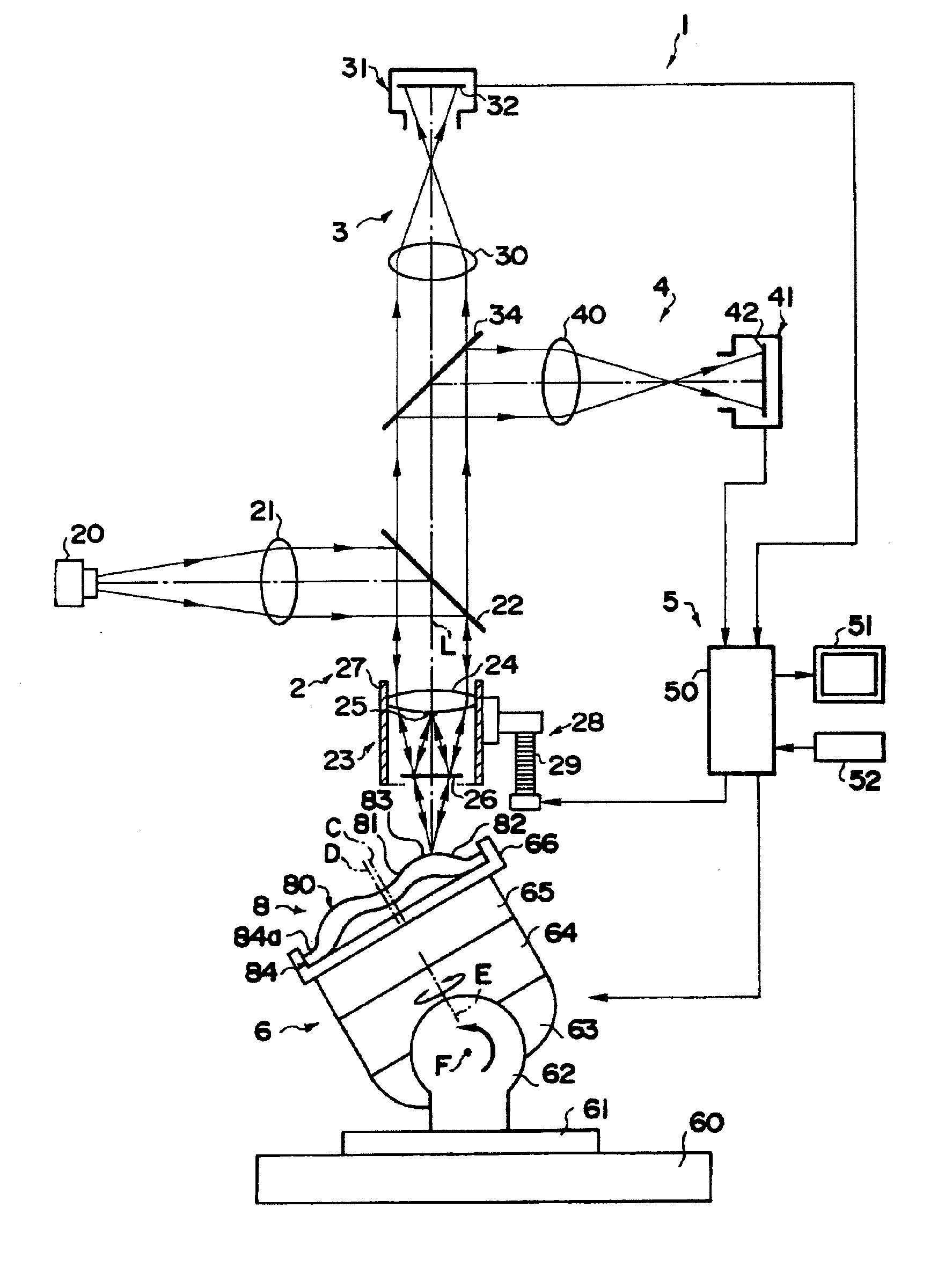

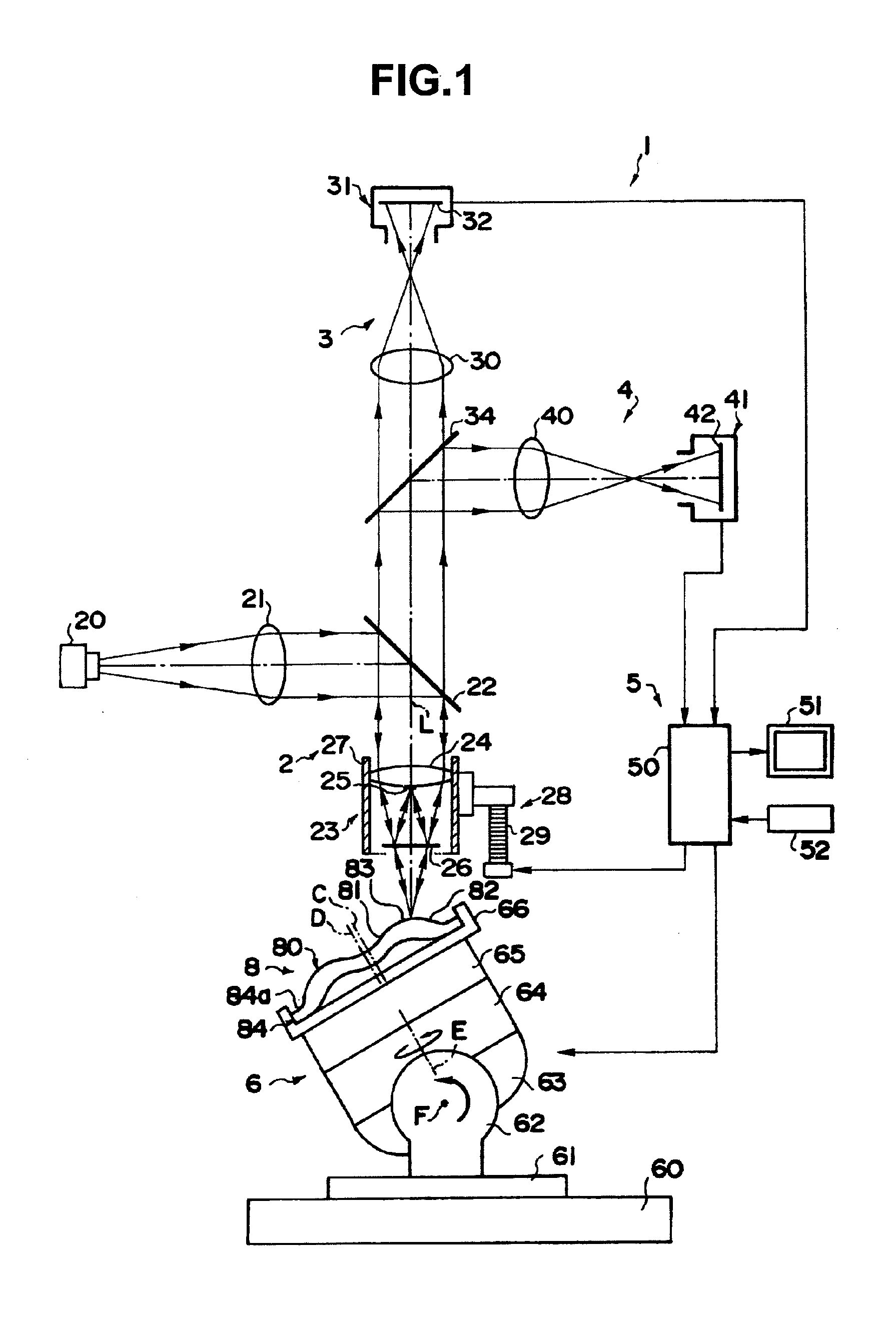

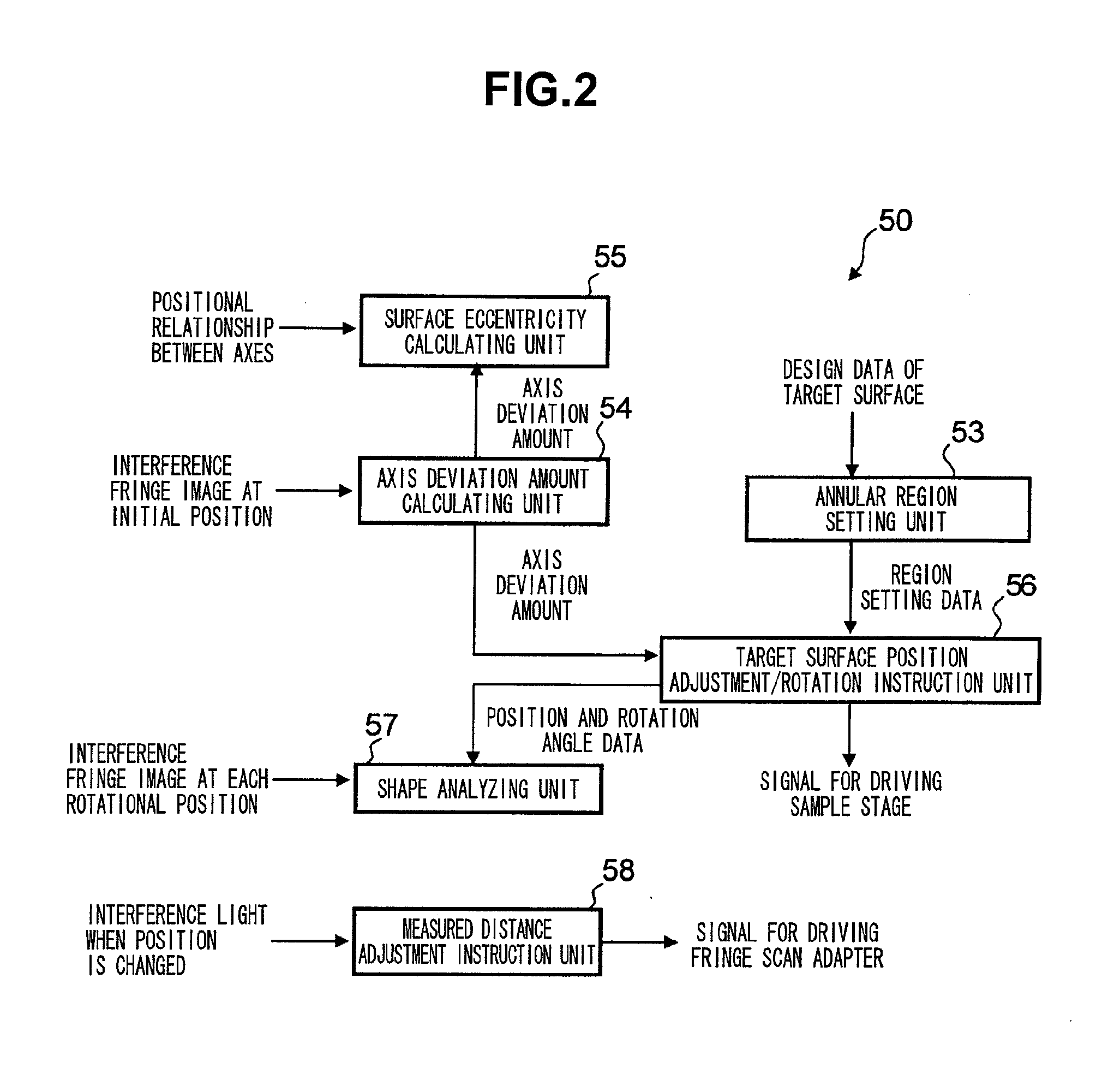

Optical wave interference measuring apparatus

InactiveUS20100097619A1Complex shapeNarrow regionUsing optical meansGeometric properties/aberration measurementMeasurement deviceOptical axis

The relative position of a test surface is sequentially changed from a reference position where a surface central axis is aligned with a measurement optical axis such that the measurement optical axis is sequentially moved to a plurality of annular regions obtained by dividing the test surface in a diametric direction. The test surface is rotated on a rotation axis whenever the relative position is changed. Measurement light that travels while being converged by a Mirau objective interference optical system is radiated to the rotating test surface, and a one-dimensional image sensor captures interference fringes at each of a plurality of rotational positions. The shape information of each annular region is calculated on the basis of the captured interference fringes at each rotational position, and the shape information is connected to calculate the shape information of the entire measurement region.

Owner:FUJI PHOTO OPTICAL CO LTD

Medical rigid endoscope detection equipment

The invention provides medical rigid endoscope detection equipment. An endoscope holder is arranged on one X-Y-Z three-dimensional moving and spinning test floor which is arranged on a guide rail of an optical test floor; and a locating device and a testing device frame are arranged on an uppermost platform of the other X-Y-Z three-dimensional moving and spinning test floor. The center of the locating device is coincide with the spinning axis of the test floor, a testing device frame installing hole is arranged in a 90-DEG bent-board perpendicular plate, and a fastening bolt is arranged on the 90-DEG bent-board perpendicular plate. The front end of the testing device frame can be provided with testing devices of a resolution plate lens cone, an illuminometer measuring head, an equal spectrum diffuse reflection screen, a collimator, a diffuse transmission screen, a diaphragm and the like in a replacing manner. The medical rigid endoscope detection equipment can be used for testing all measuring technical data contents of a rigid endoscope of a medical endoscope, partial optical properties and testing methods thereof in national standardYY0068-2008 in a once-clamped rigid endoscope, is convenient for use and rapid in testing, and accords with all testing accuracy requirements.

Owner:TIANJIN WEITAIKE OPTICAL TECH DEV

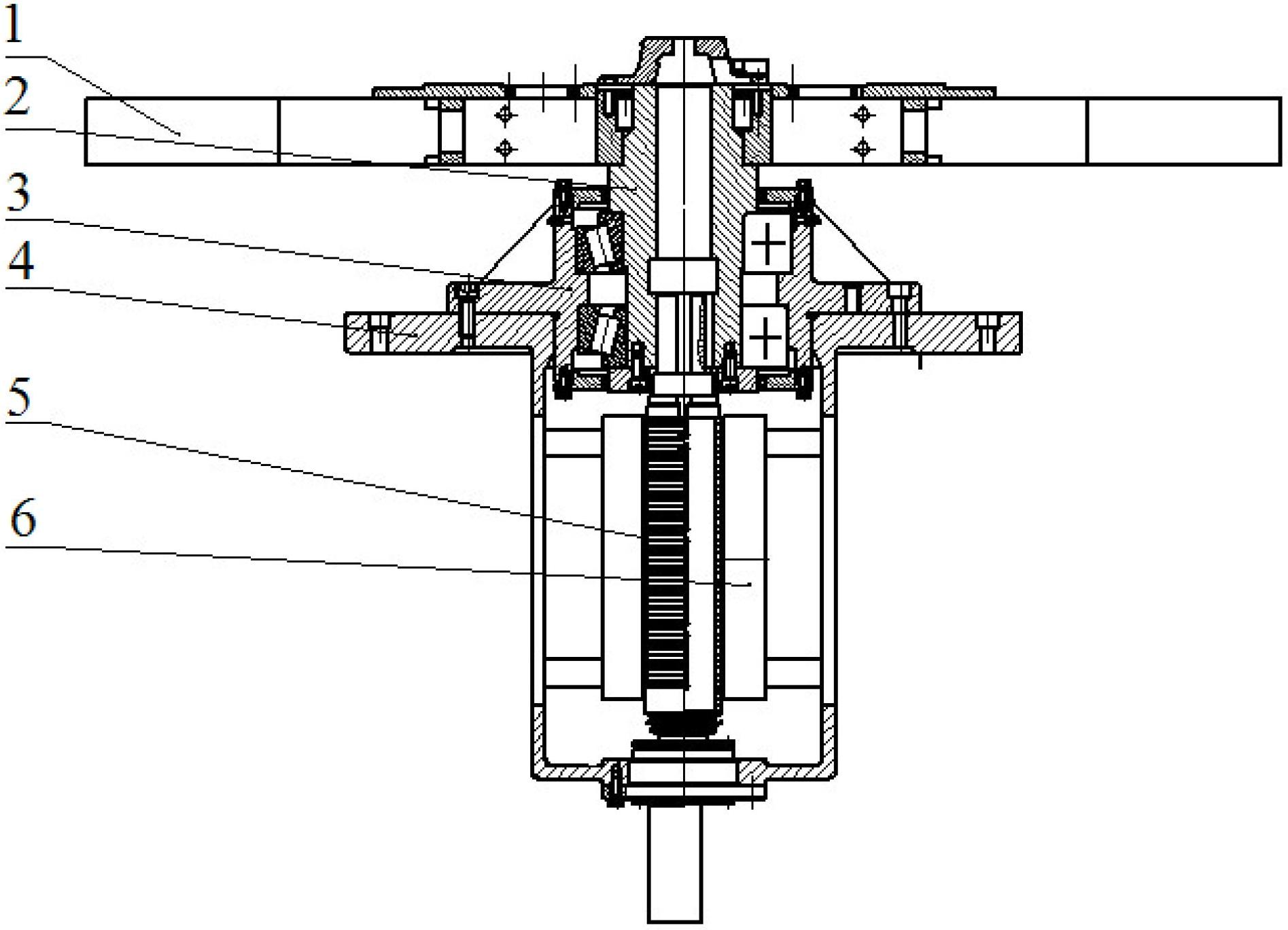

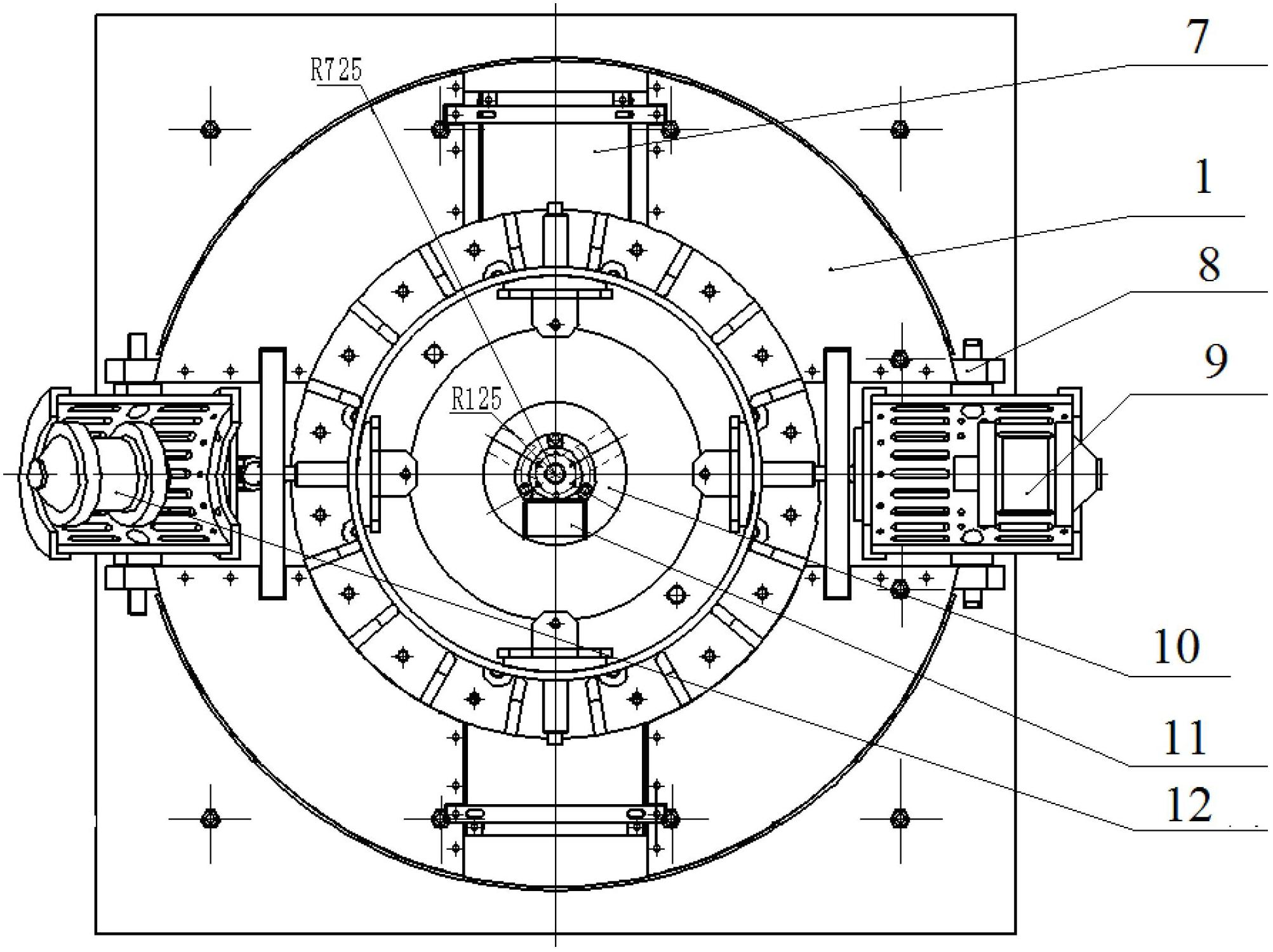

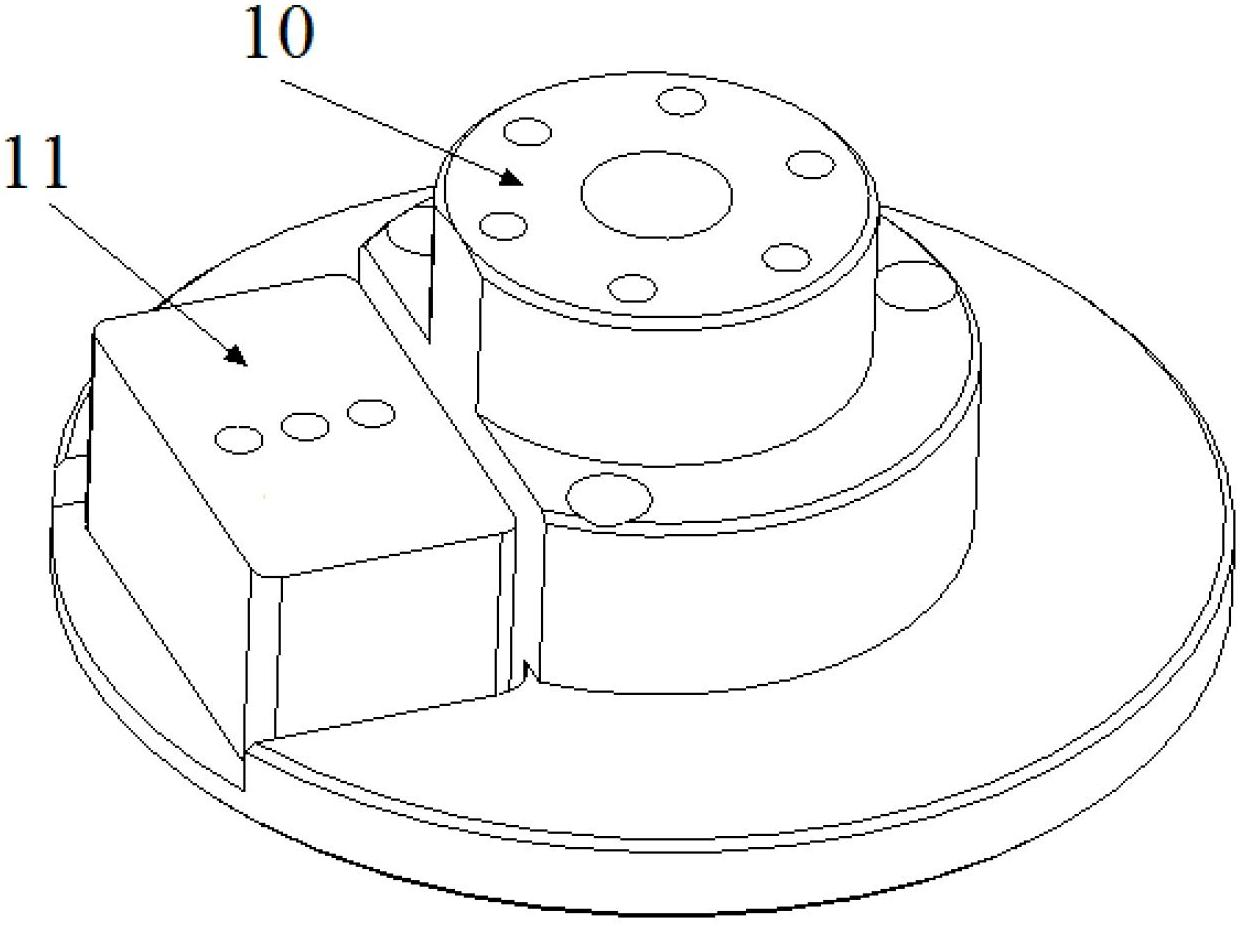

Sub-scale simulated aero-engine rotation test device

The invention discloses a sub-scale simulated aero-engine rotation test device which comprises simulated casings, a simulated support plate, a simulated rotor shaft, a simulated blade disc, a simulated drum, a front fulcrum bearing, a middle fulcrum bearing, a rear fulcrum bearing and simulated front and rear mounting sections. The sub-scale simulated aero-engine rotation test device is driven by a motor to rotate through a set of breaking shaft protection devices. The simulated casings are connected via mounting side bolts. The simulated support plate is in welded connection with the simulated casings. The simulated blade disc is connected with a mounting plate and a shaft via bolts. The simulated drum is connected with the simulated support plate via bolts. The simulated front mounting section is connected with a rigid mounting base via bolts and a suspend rod. The simulated rear mounting section is connected with the rigid mounting base via bolts and a hinge. The various components of the sub-scale simulated aero-engine rotation test device can be disassembled and assembled to meet the needs of different tests.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Vehicle rollover test fixture

InactiveUS20080307855A1Avoid damageLimiting further damageVehicle testingAcceleration measurementRolloverDrop impact

A test fixture for rollover crash testing of a test vehicle onto a moving surface employs a cradle to support and rotate the test vehicle. A vertical support structure to position and releasably holds the cradle. A moving sled having a contact surface and is carried by a guide extending beneath the structure and the cradle fixture. The cradle is rotated and released from the structure responsive to a sensor for contact within a drop impact zone on the contact surface of the moving sled. Vertical motion of the cradle is then arrested to prevent further damage to the test vehicle or the test structure.

Owner:SAFETY TESTING INT

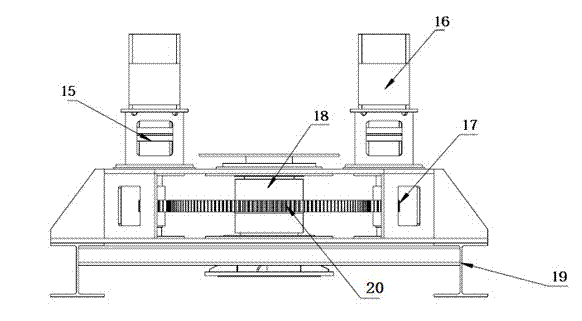

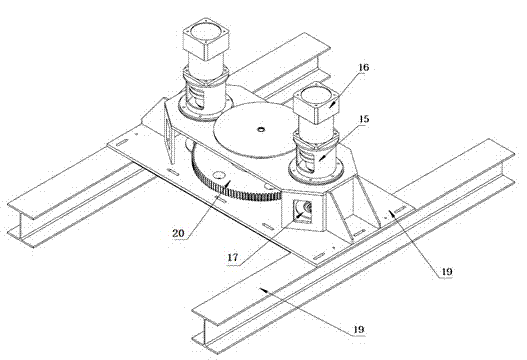

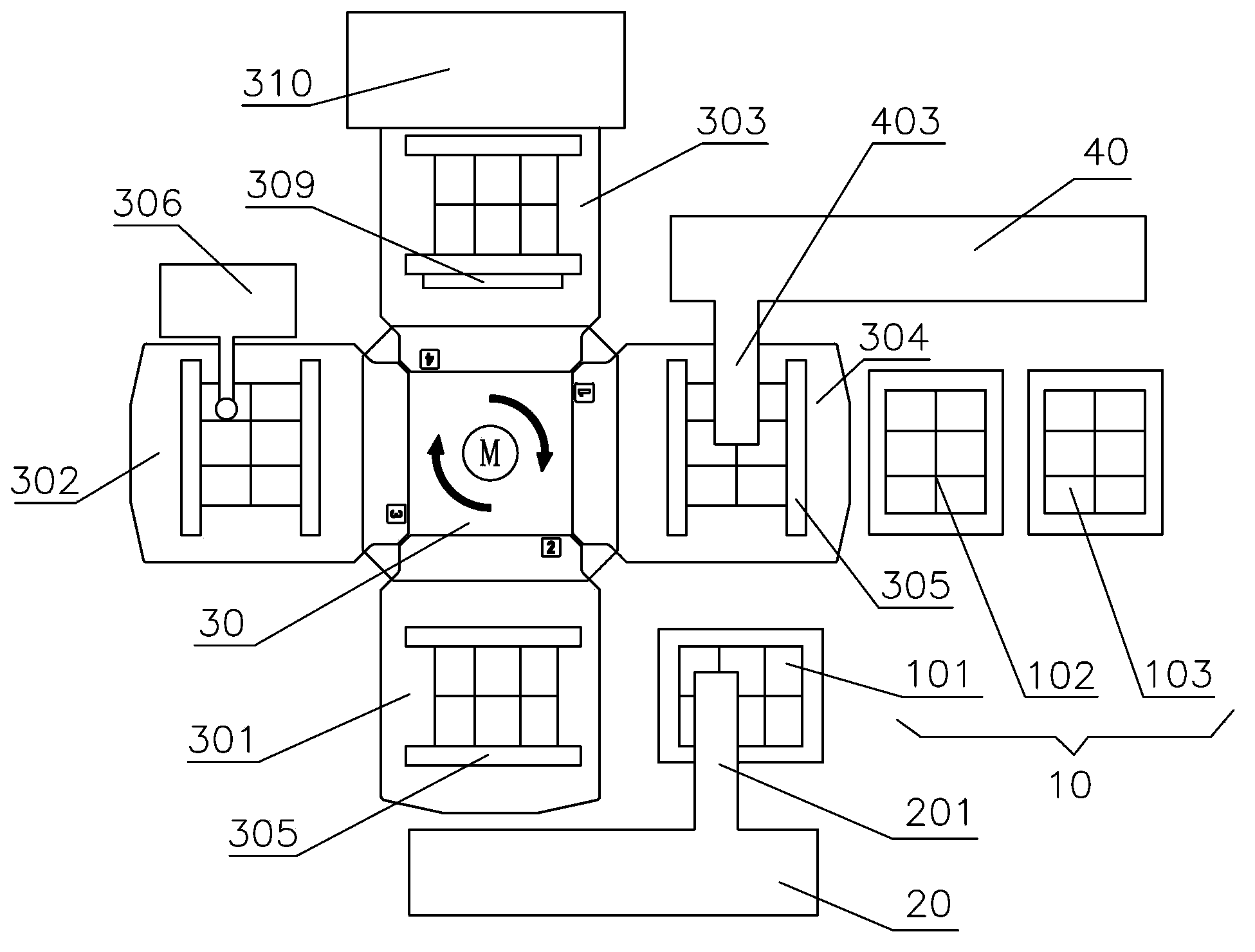

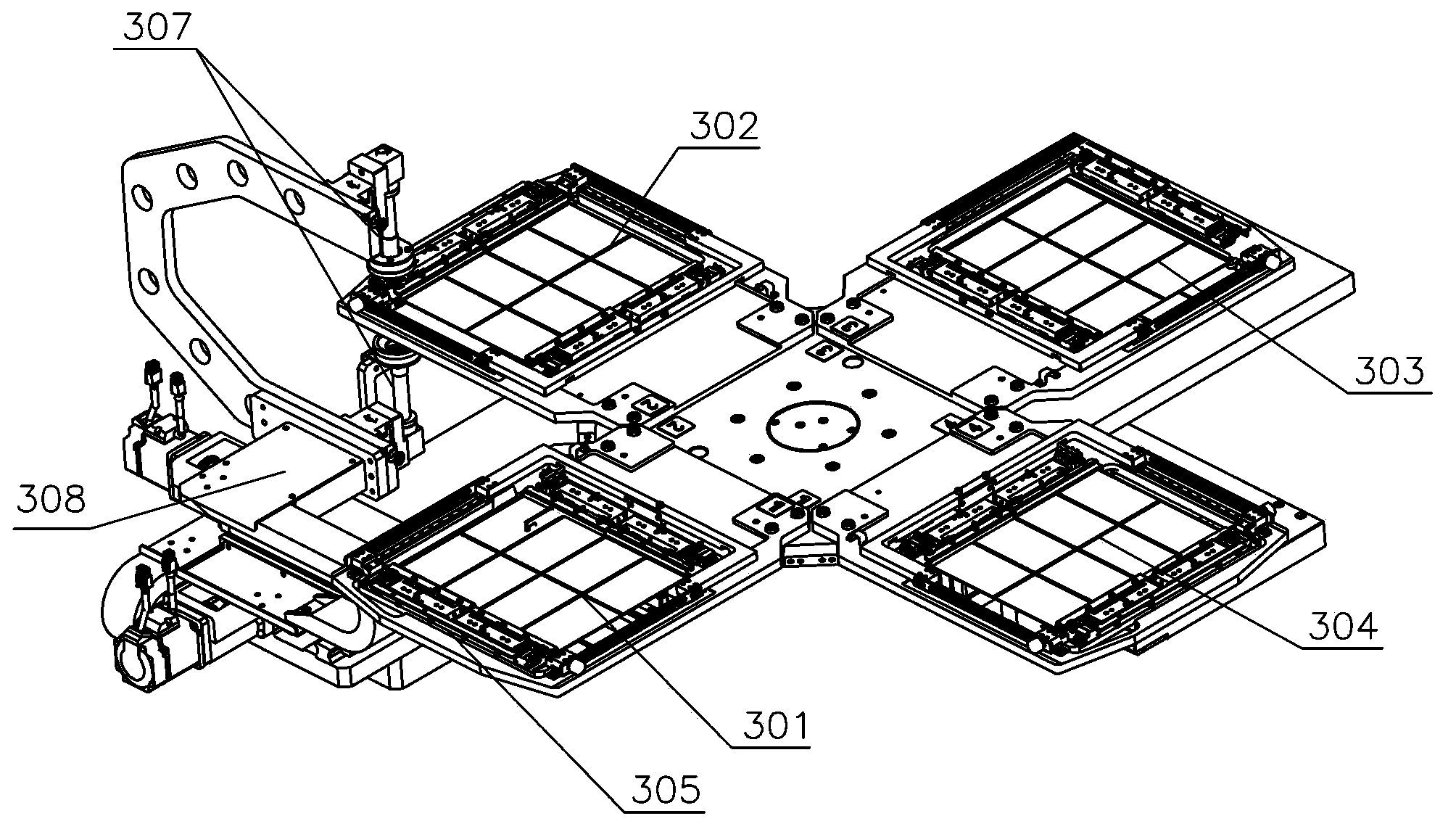

Four-station parallel testing device and method

ActiveCN103674949AHigh precisionImprove stabilityMaterial analysis by optical meansRotation testEngineering

The invention discloses a four-station parallel testing device and a method and relates to the technical field of printed circuit board (PCB) test. The four-station parallel testing device comprises a PCB material table, a feeding mechanism, a rotary test bed, a material taking mechanism and a data processing center, wherein the data processing center is respectively connected with the feeding mechanism, the rotary test bed and the material taking mechanism and is used for controlling operations among the mechanisms. According to the rotary testing device and the method, independent operation is realized among the stations, and the testing accuracy is greatly improved. Moreover, the position of the PCB is fixed during each process, the testing stability is improved.

Owner:SHENZHEN MASONE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com