Four-station parallel testing device and method

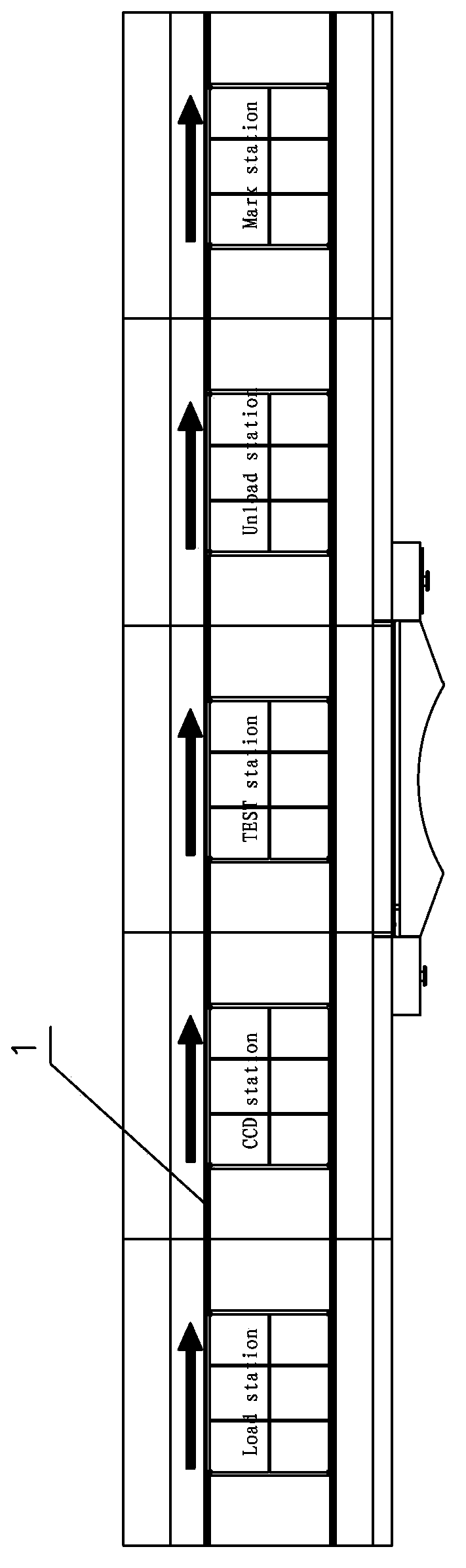

A testing device and a four-station technology are applied to measuring devices, material analysis through optical means, instruments, etc., which can solve problems such as unfixed positions for photographing and testing, long equipment footprints, and different benchmarks, etc., to achieve Improve stability and test efficiency, reduce floor space, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

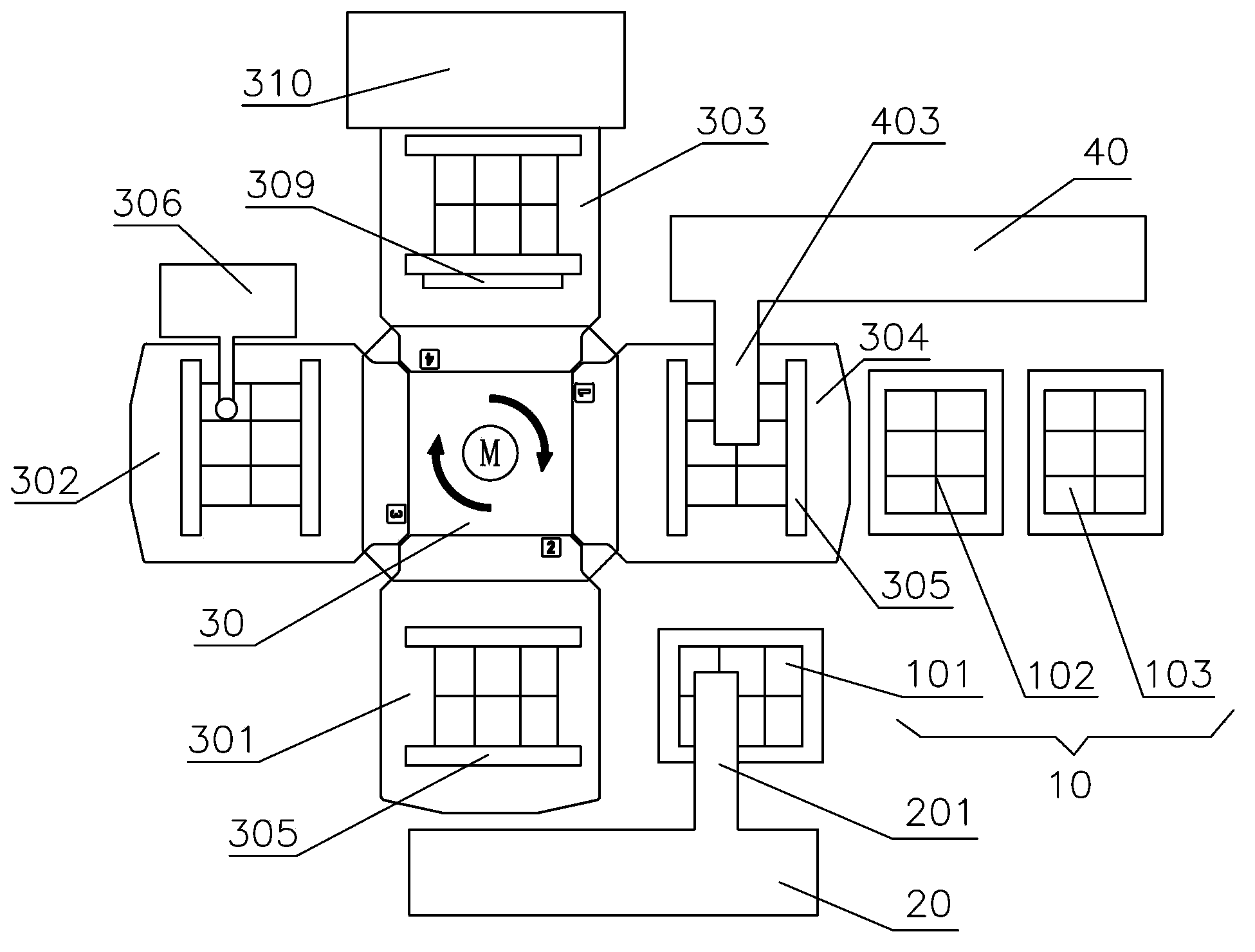

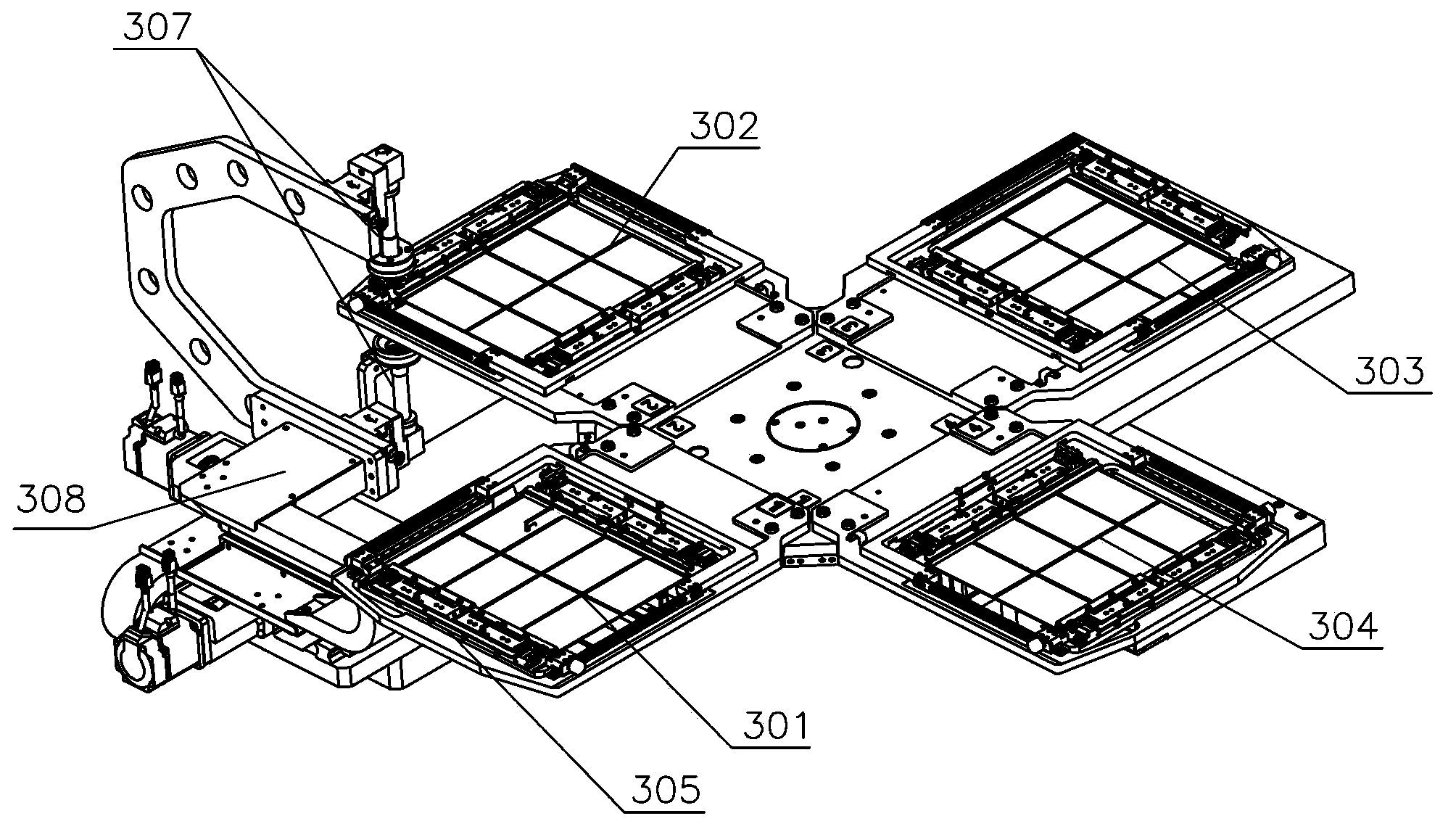

[0026] refer to figure 2 As shown, the present invention discloses a four-station parallel testing device for testing PCB boards, the testing device comprising:

[0027] A PCB material table 10, the PCB material table 10 is provided with three areas: a PCB board placement area 101 to be tested, a pass area (PASS) 102 and a failure area (FAIL) 103, which are respectively used to prevent the PCB board to be tested, Qualified PCB boards and unqualified PCB boards;

[0028] A feeding mechanism 20, which is installed next to the PCB board placement area 101 to be tested, consists of a movable water balance arm 201, a lifting cylinder located at the end of the horizontal cross arm 201, and a cylinder connected to the lifting cylinder The vacuum nozzle on the rod (the lifting cylinder and the vacuum nozzle are not marked in the figure);

[0029] A rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com