Patents

Literature

291 results about "Shear flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term shear flow is used in solid mechanics as well as in fluid dynamics.

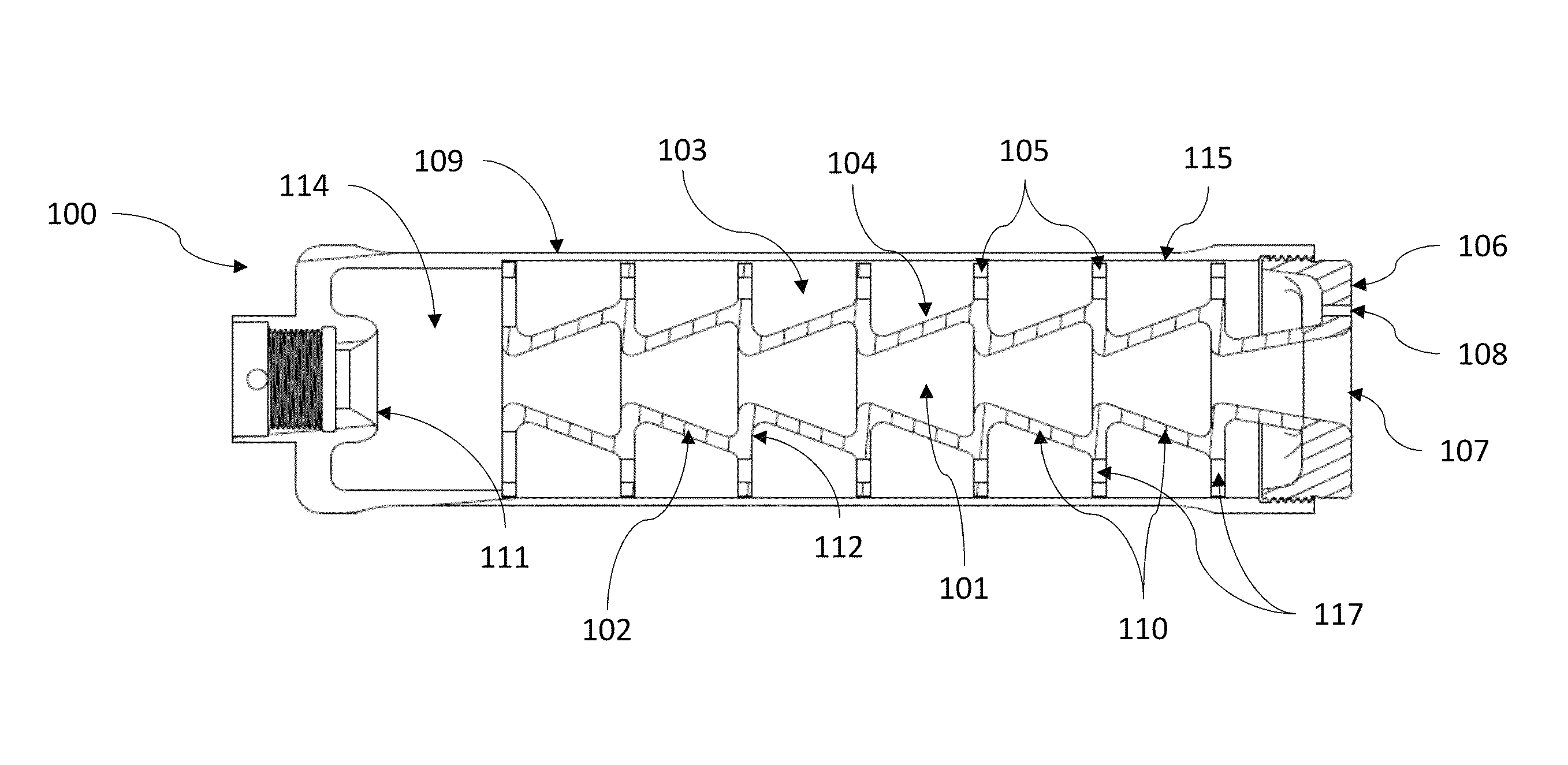

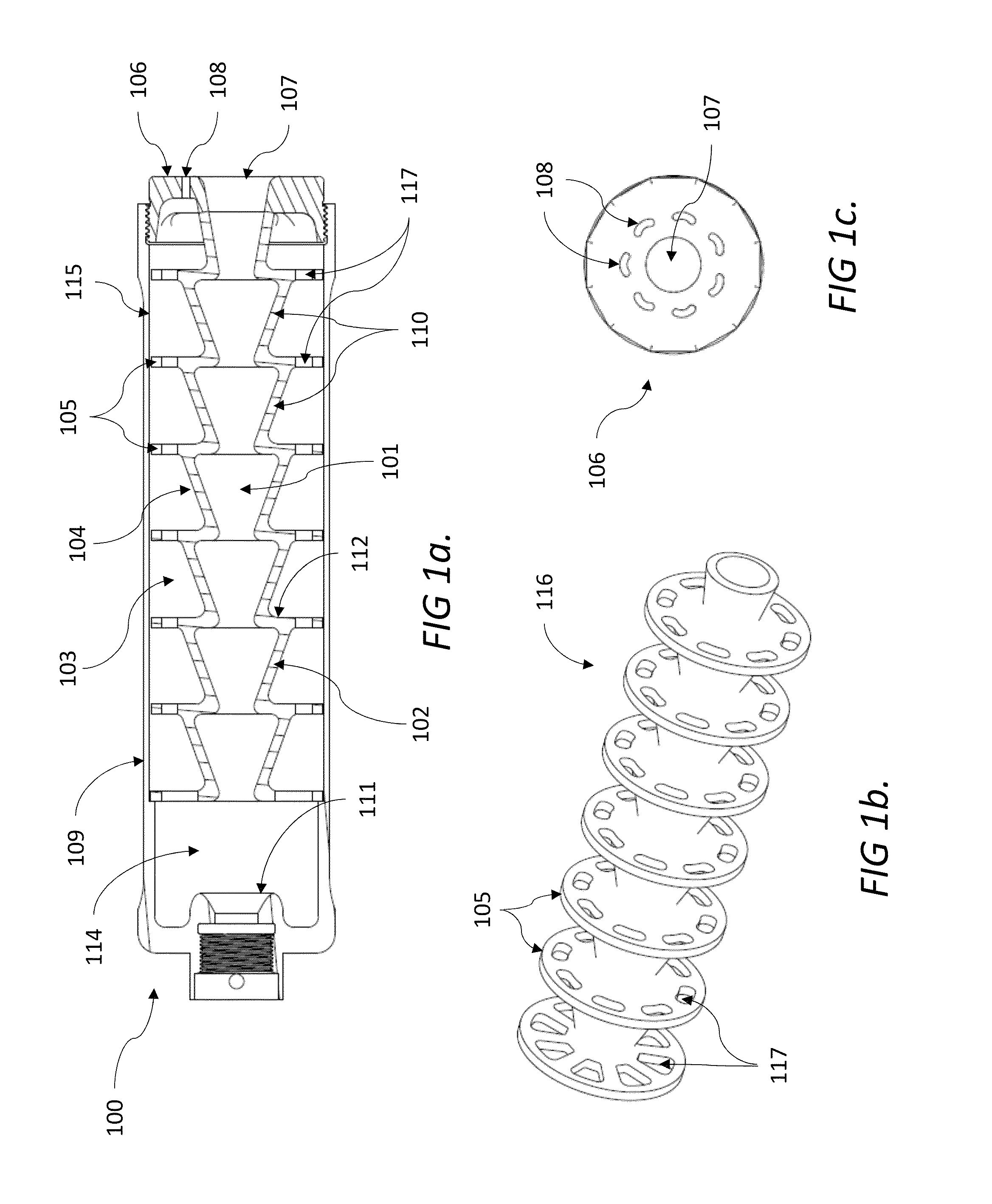

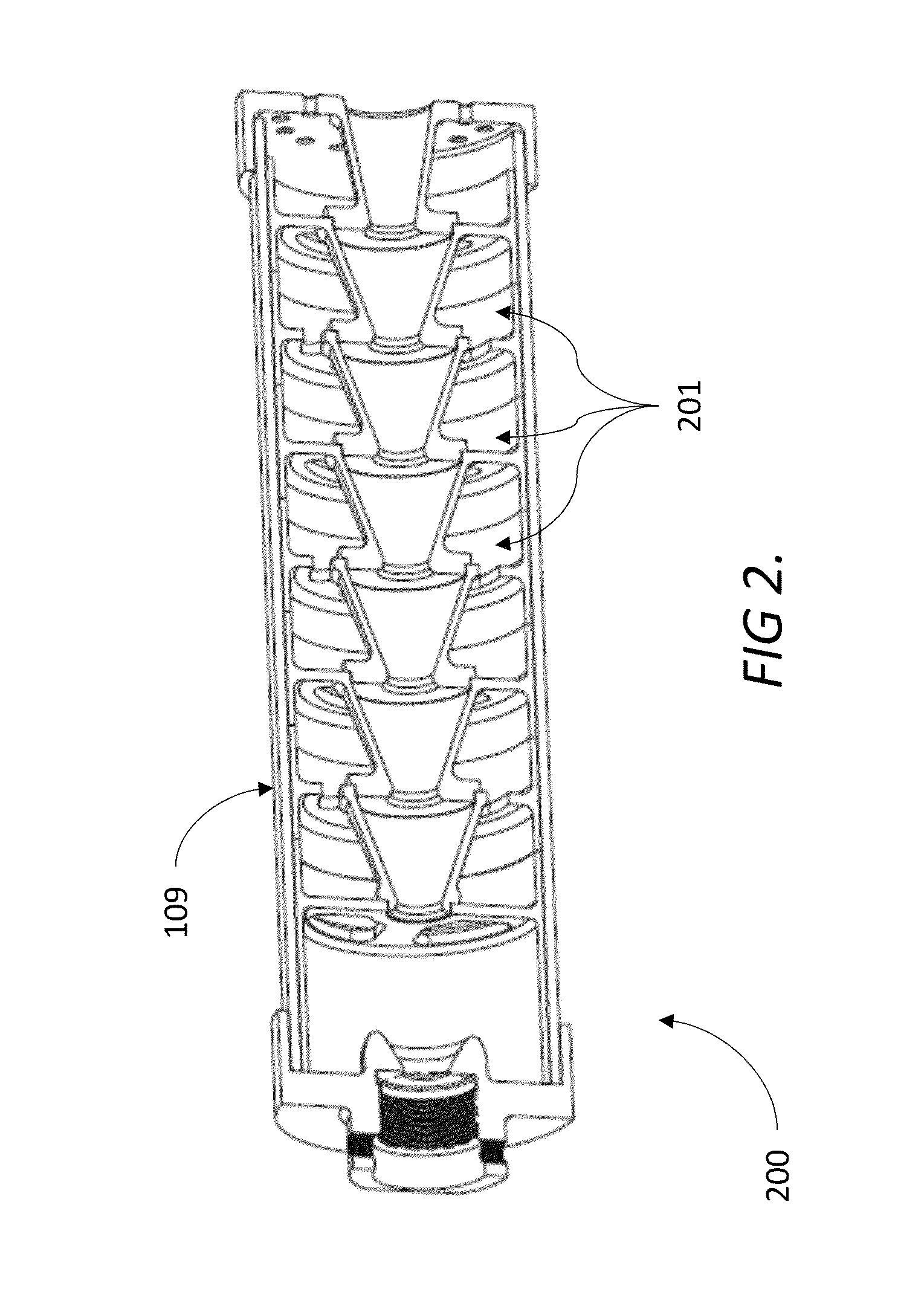

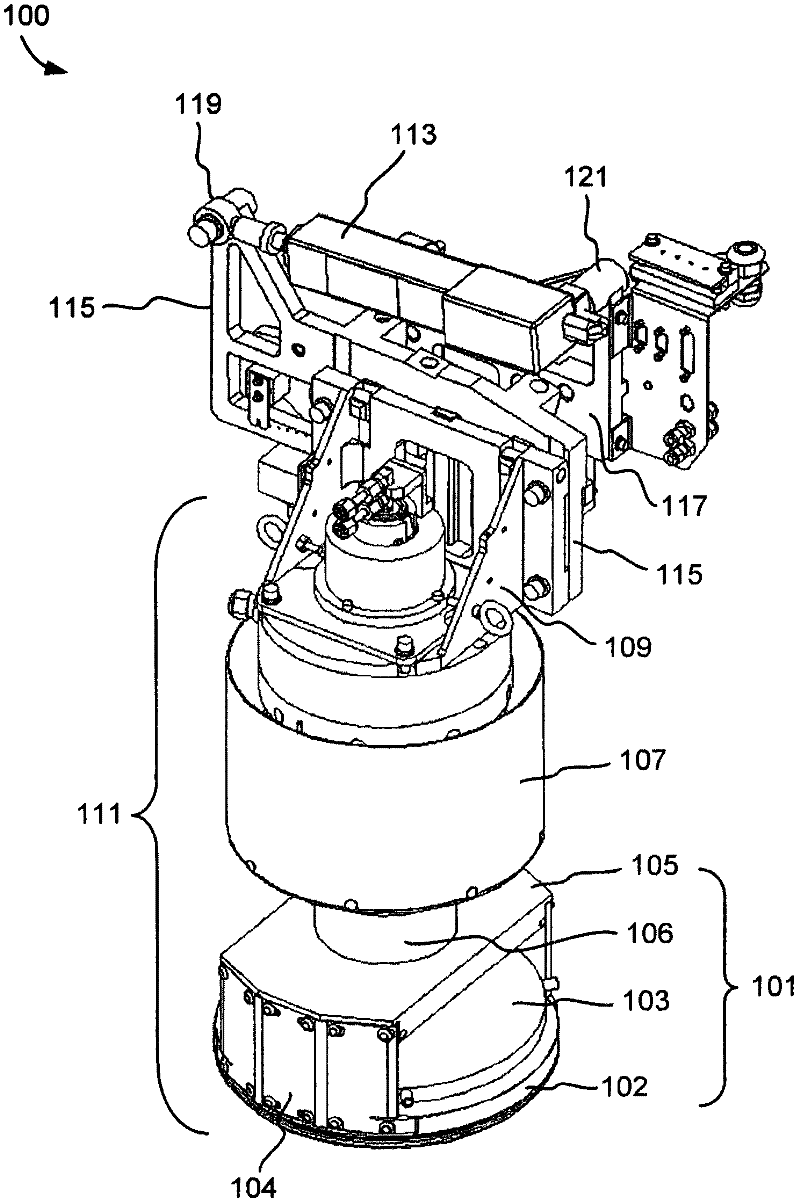

Automatic weapon suppressor

ActiveUS9347727B1Reduce heat transferLow internal surface areaWeapon componentsSuppressorEngineering

A suppressor for rapid fire weapons designed to rapidly bleed down the weapon pressure and thereby minimizing gas blowback to the operator and to the weapon's gas operating system; while also creating a shear gas flow about the exiting bullet's gas flow to mask the flash thereof. The suppressor is configured within a generally cylindrical housing, having: (1) a central core of unported K-baffles located about a central bulletway; (2) a bypass located between the cylindrical housing and the unported K-baffled central core—providing a generally forward subsonic high gas flow area to an endcap closing the cylindrical housing; (3) said endcap having a series of vent ports for the bypass, which also create a shear flow about the centrally exiting bullet; and (4) wherein the series of unported K-baffles are spaced away from the weapon's bore end to allow the propellant gasses to expand into the bypass.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

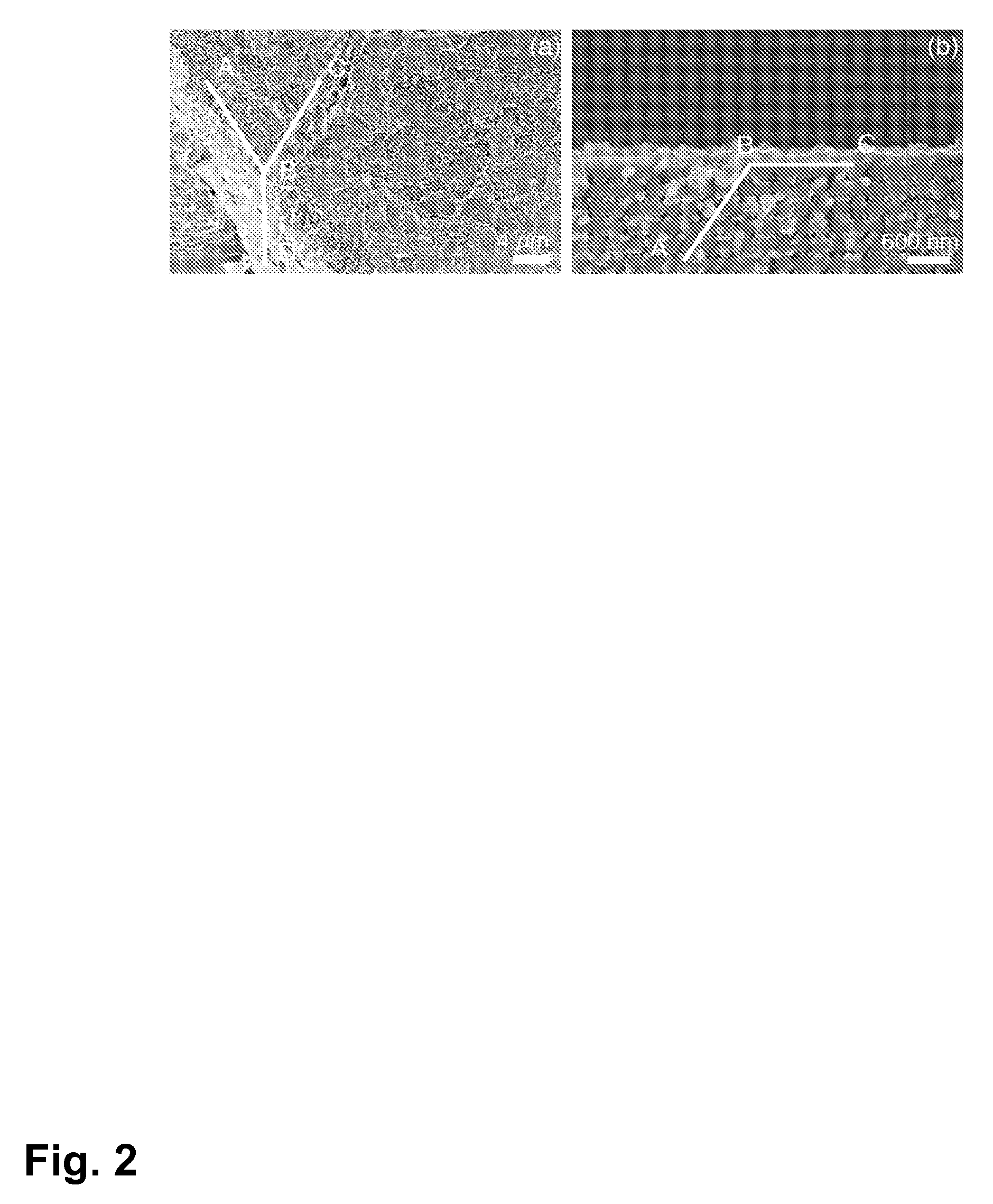

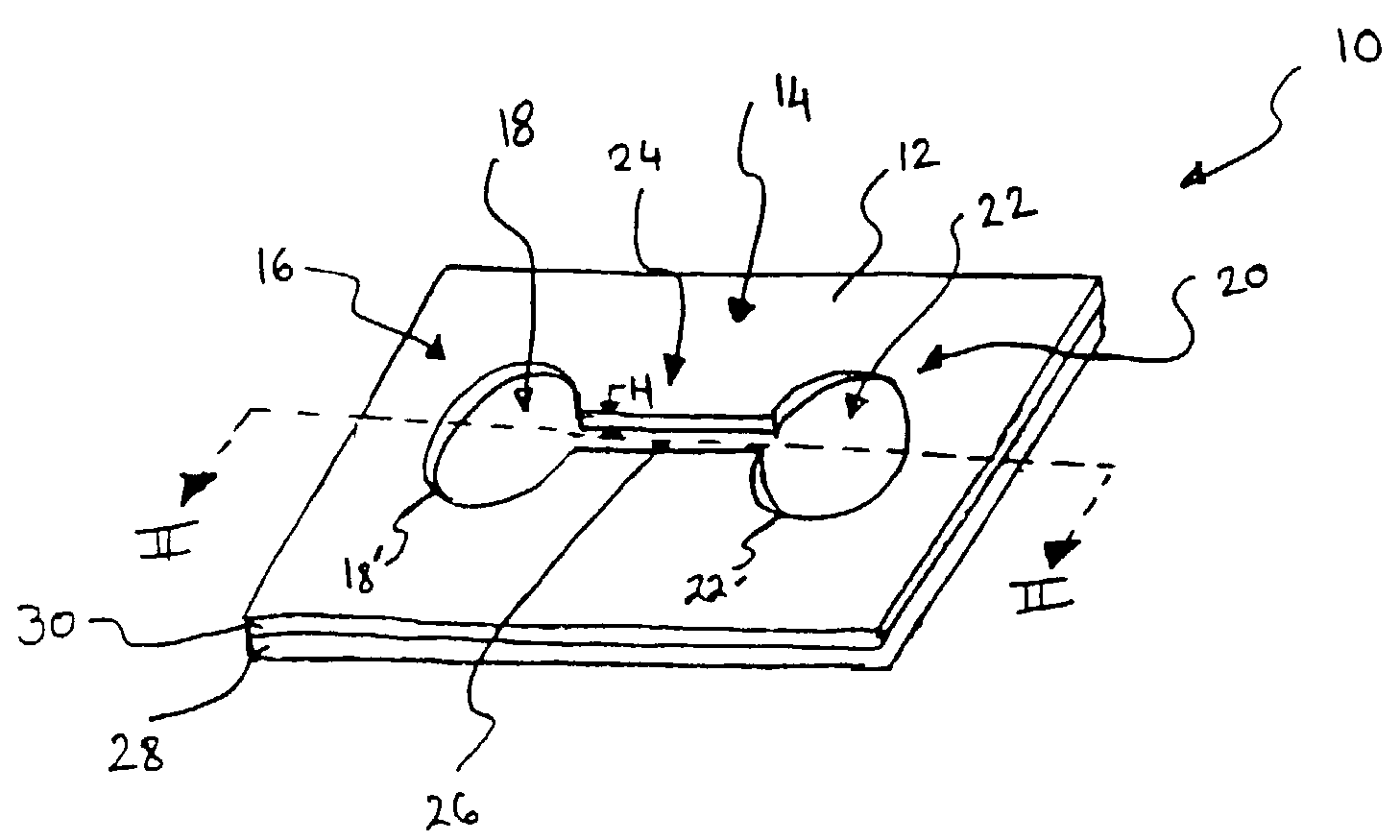

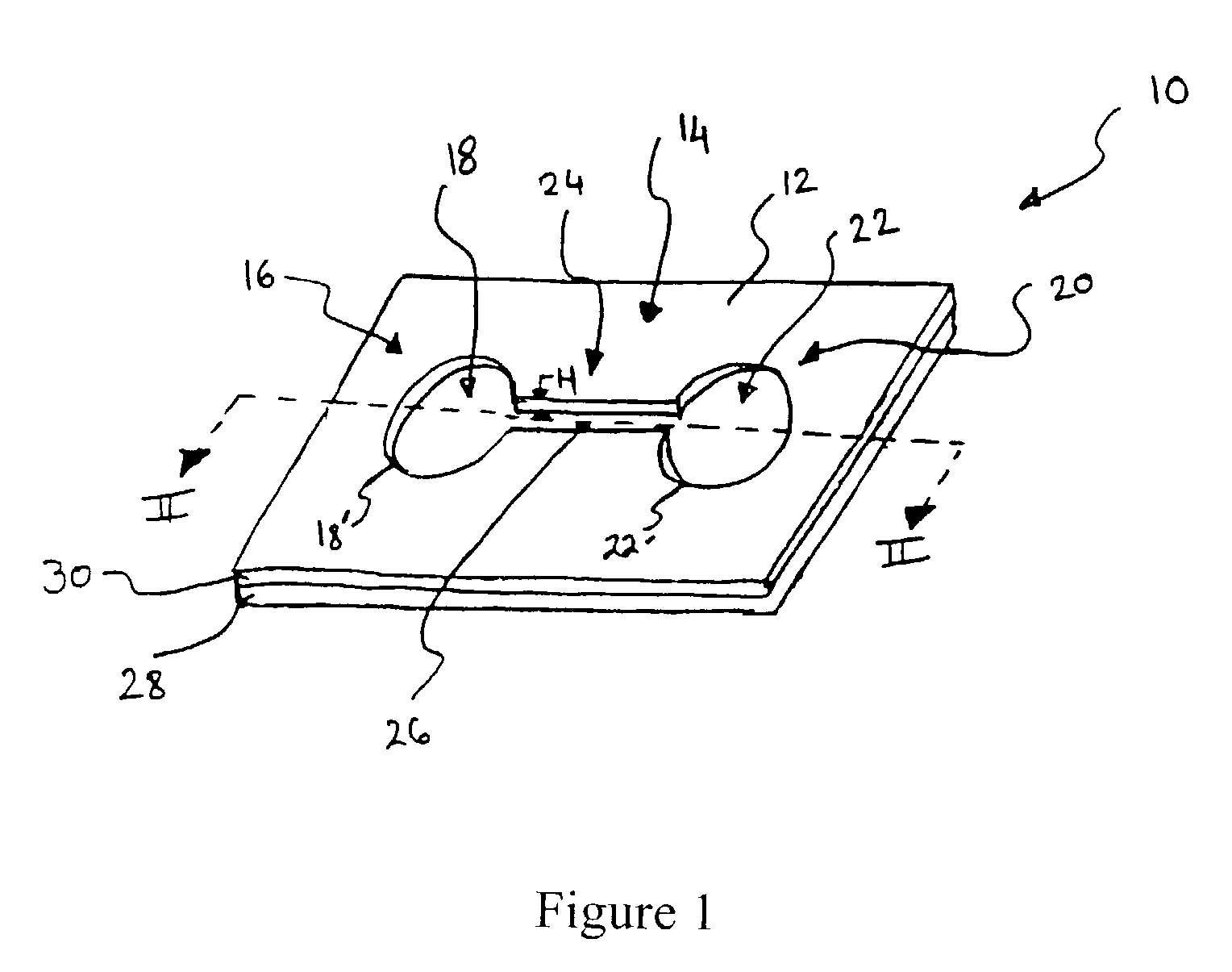

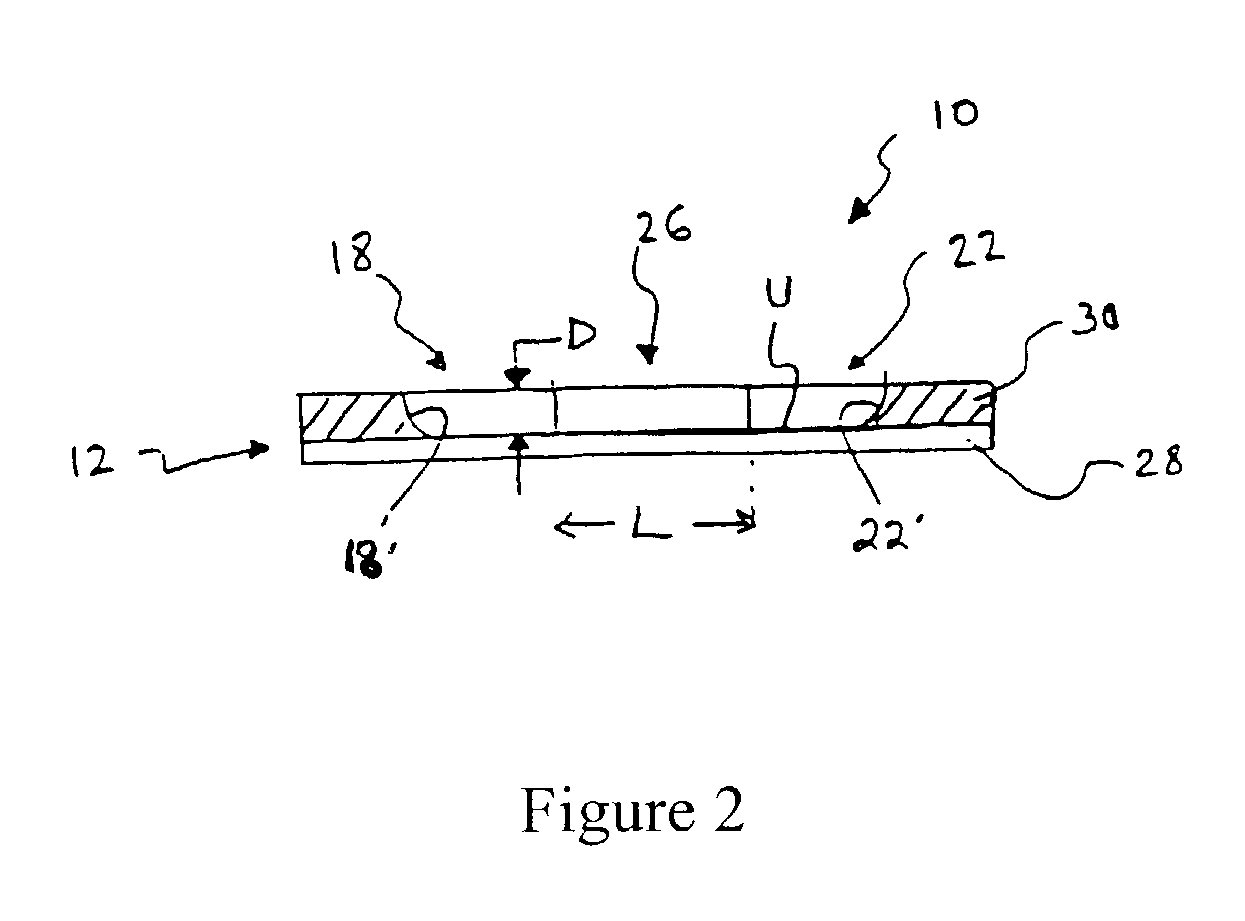

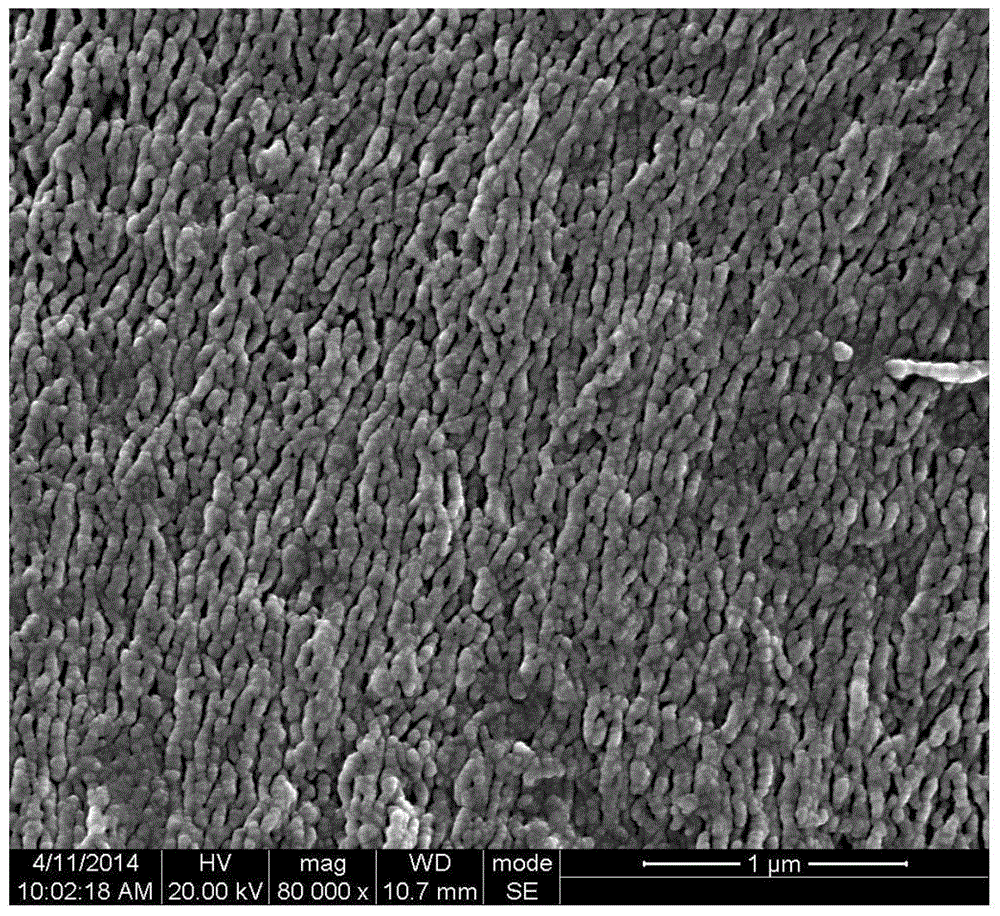

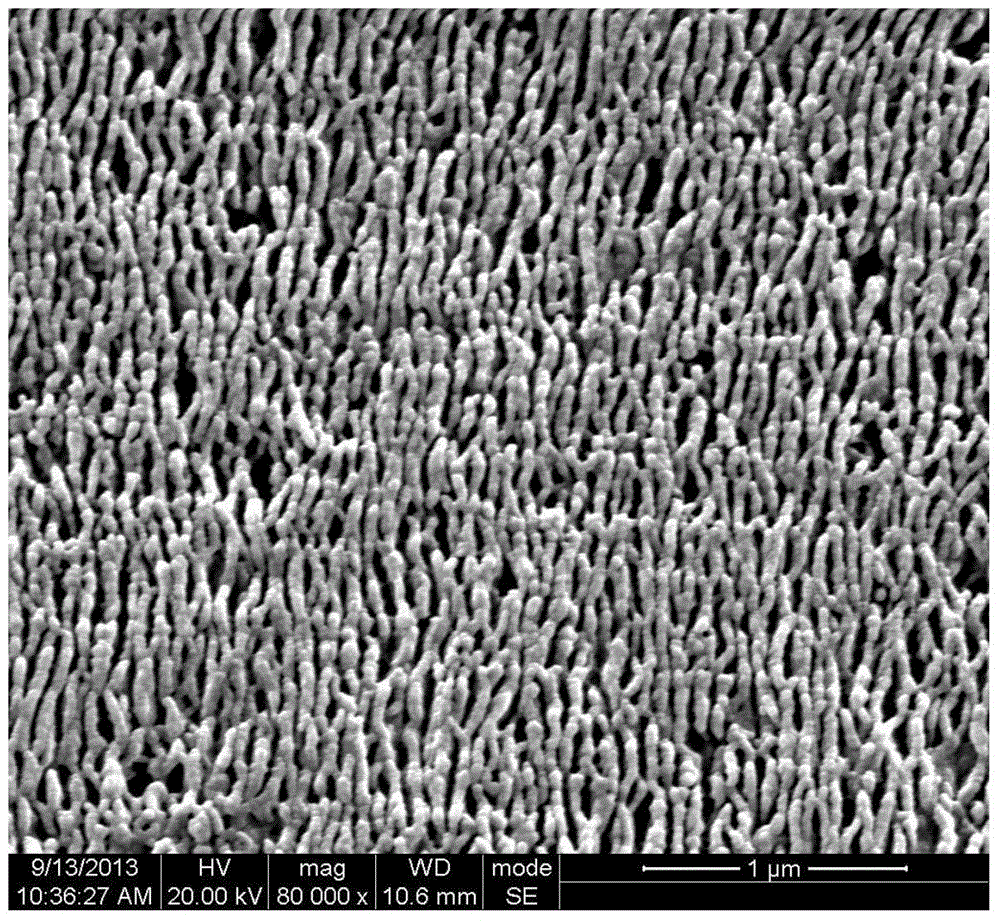

Layered aligned polymer structures and methods of making same

InactiveUS7048963B2Monocomponent protein artificial filamentPharmaceutical containersPolymer scienceControl manner

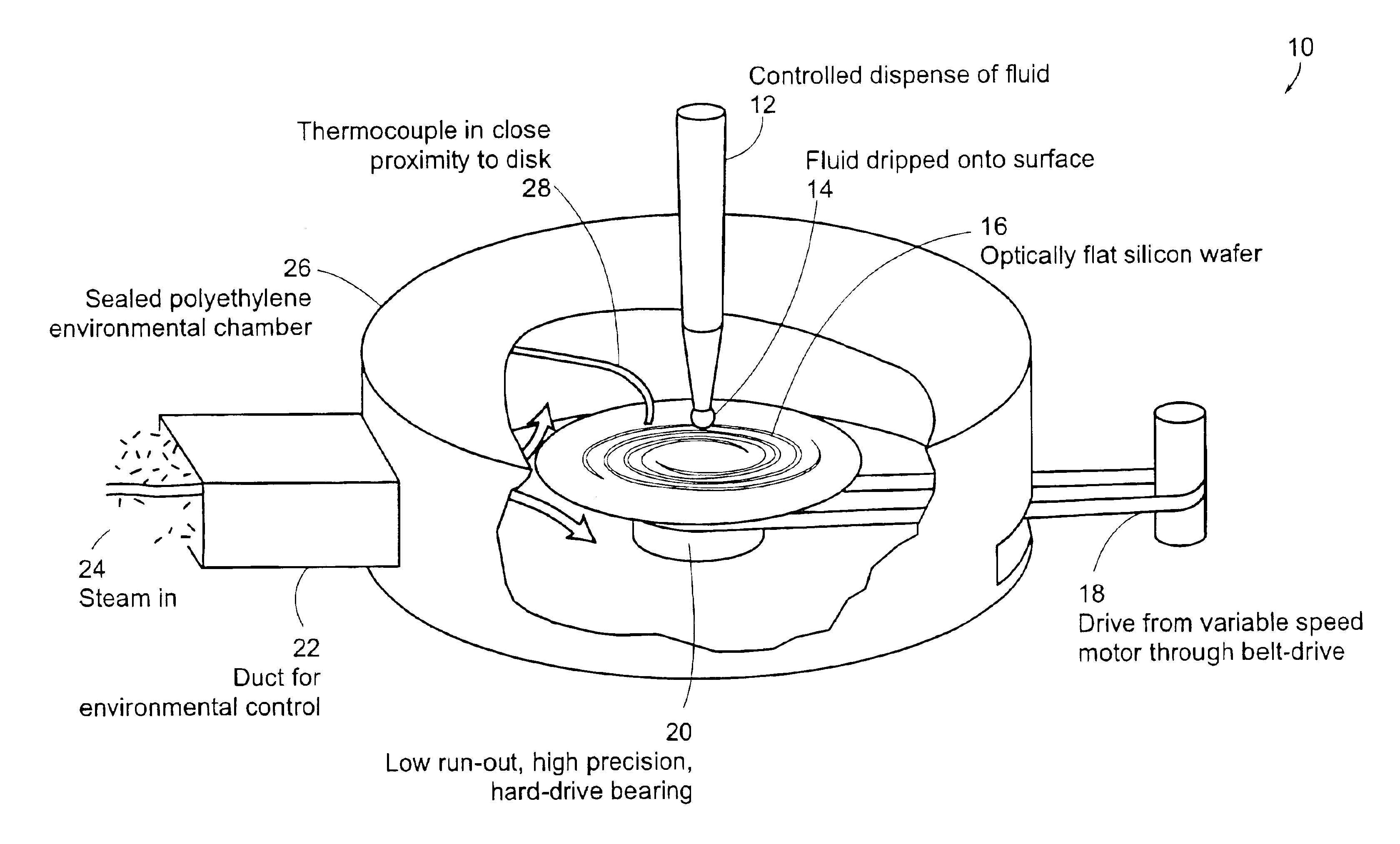

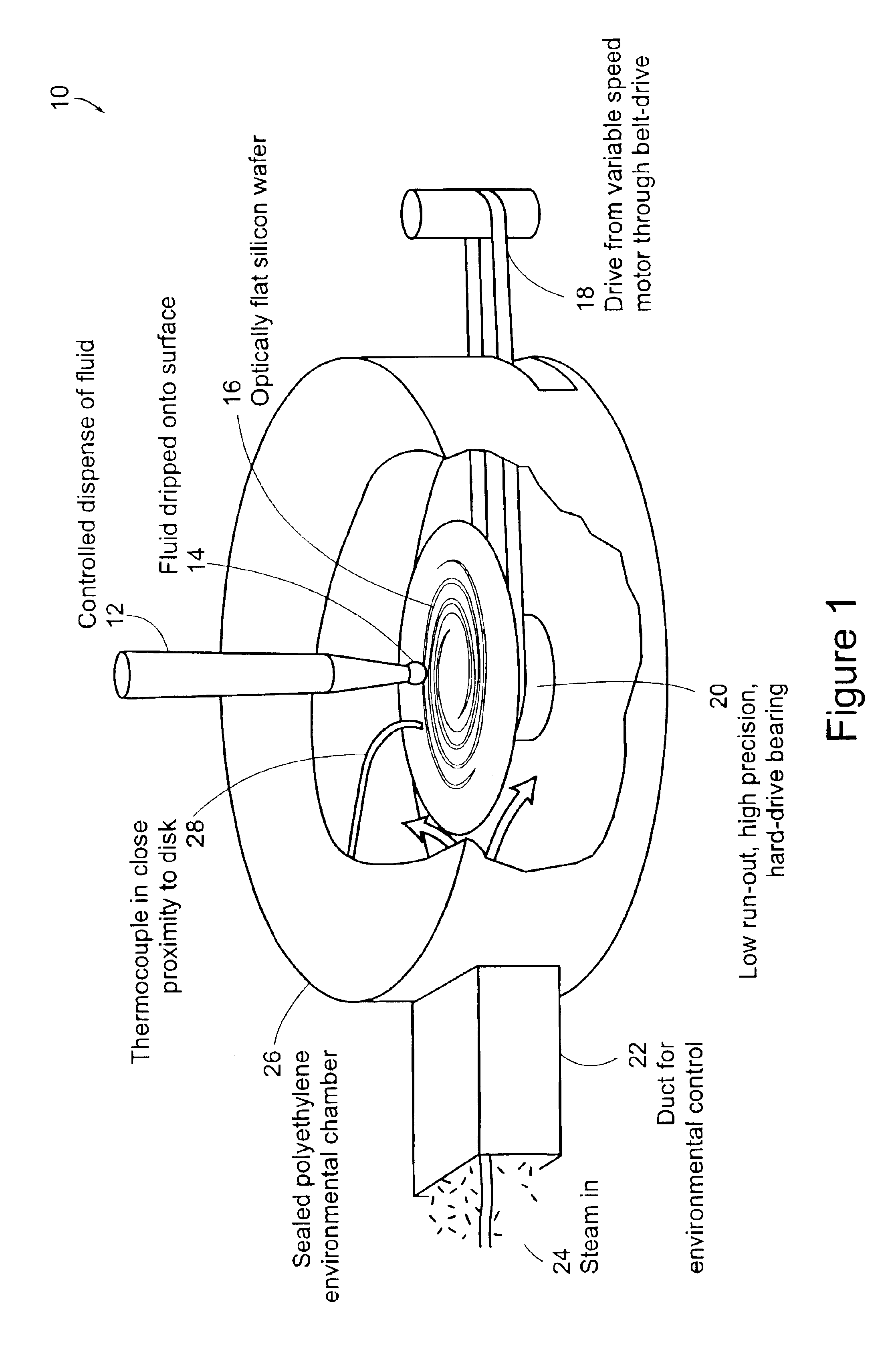

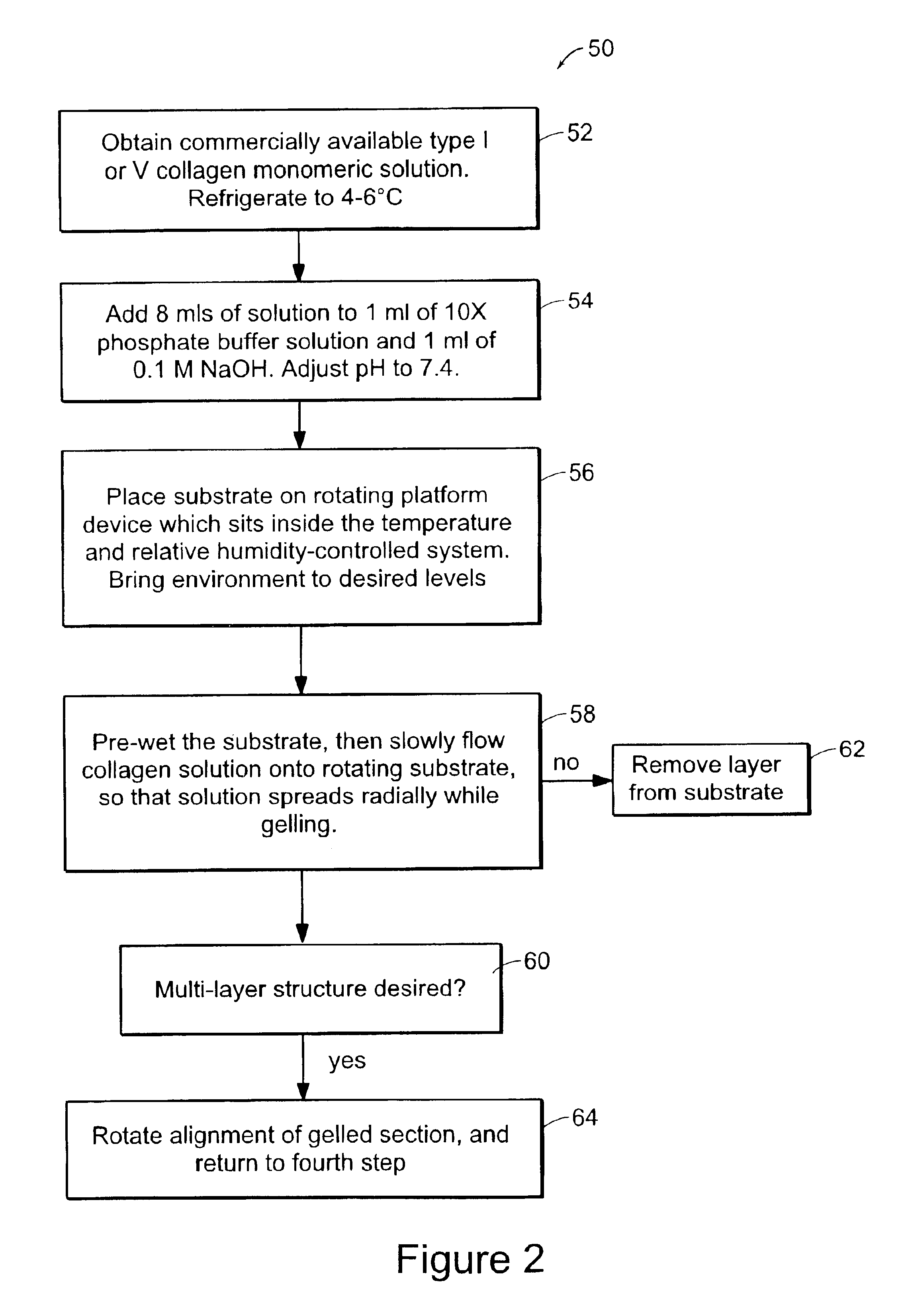

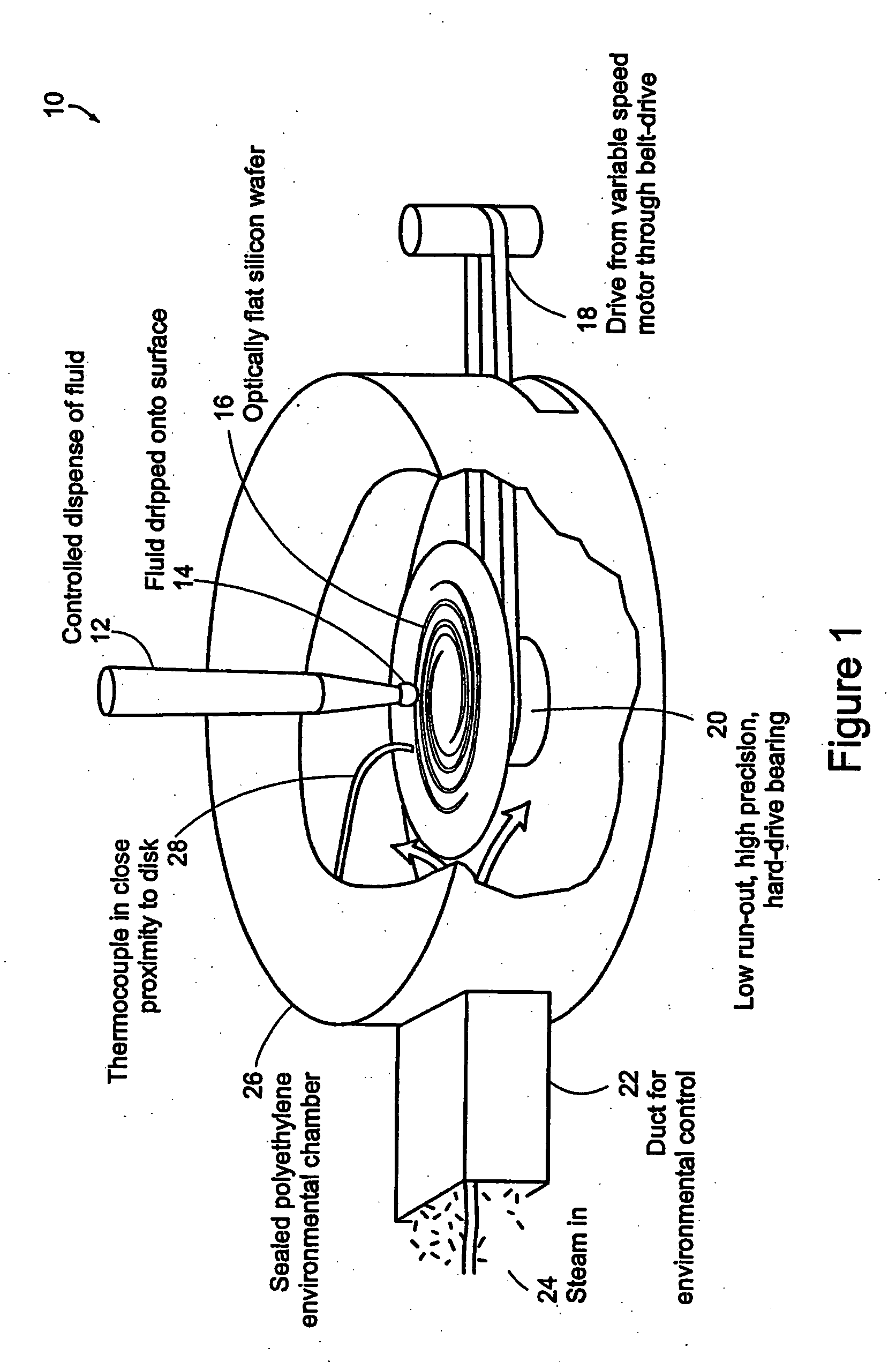

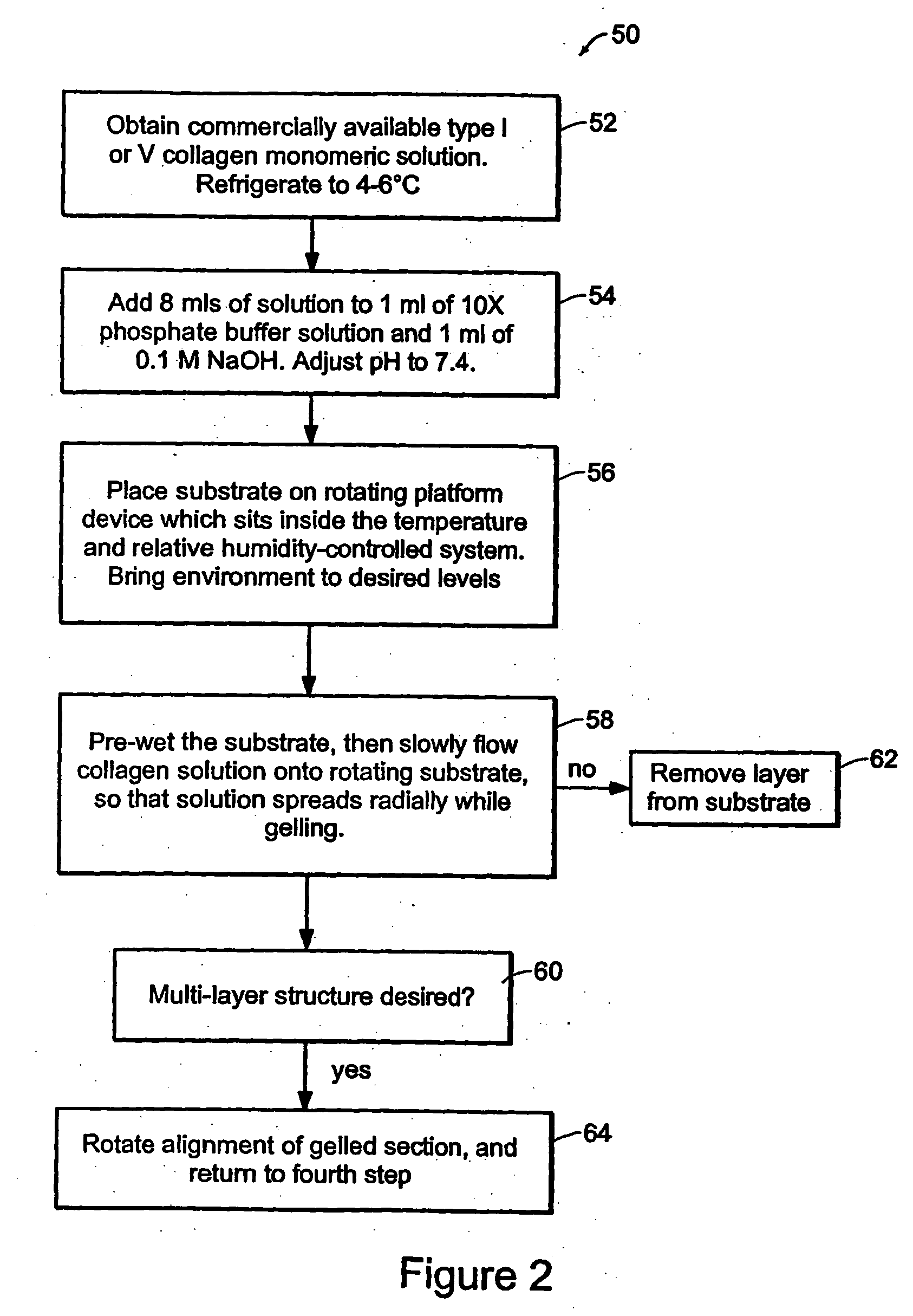

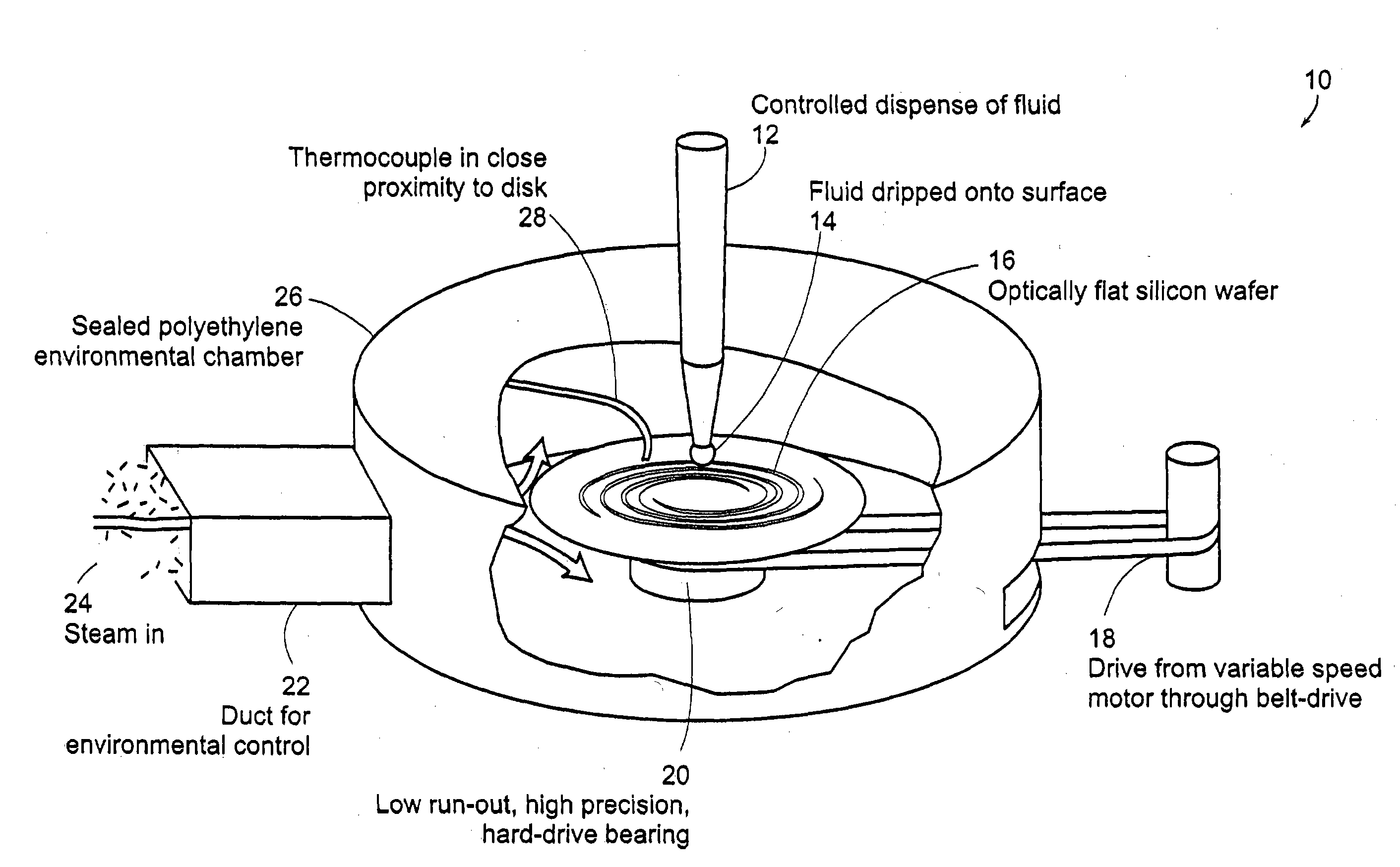

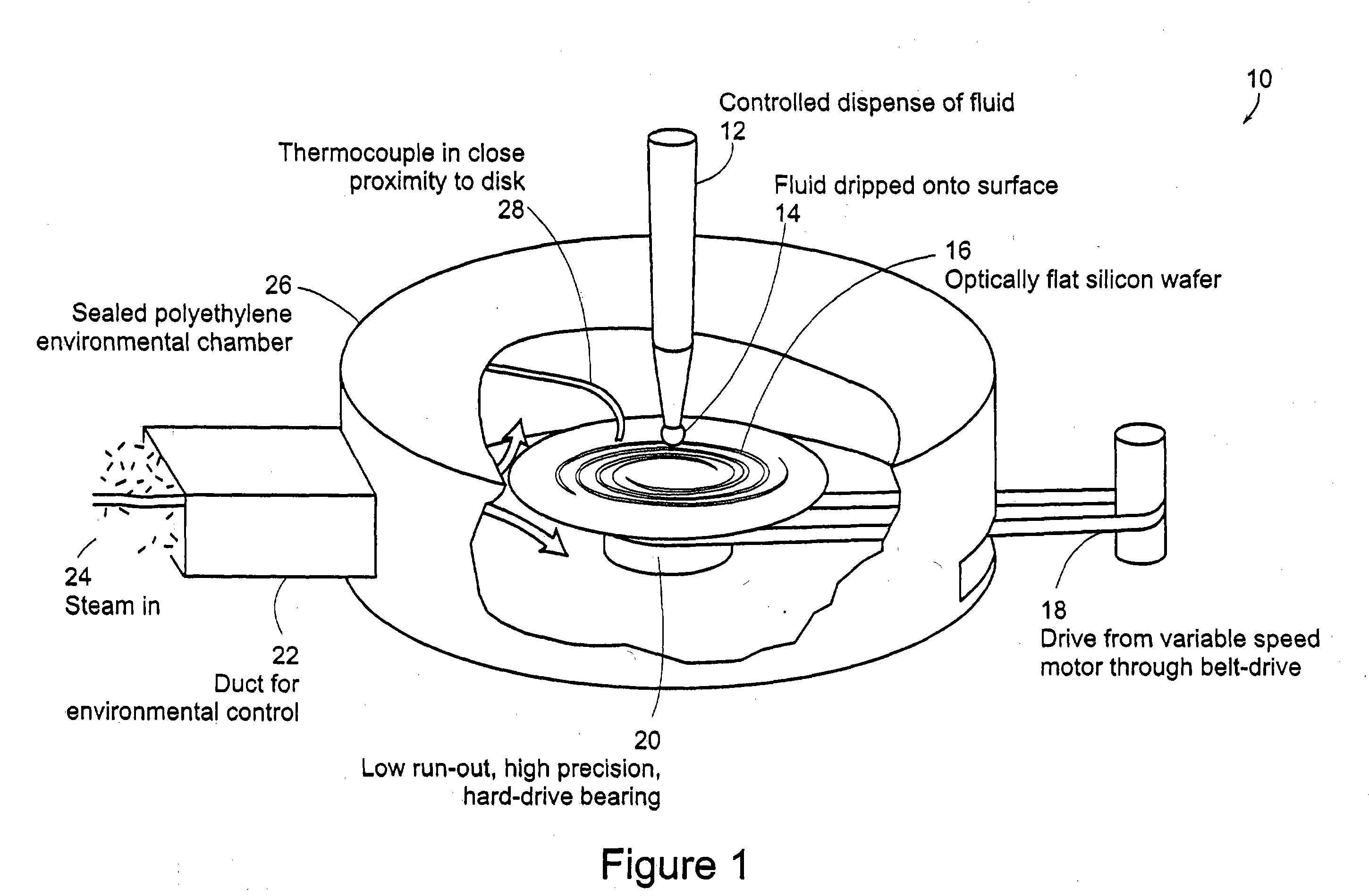

This invention includes a method of producing a thin, oriented layer of polymer material. The material is preferably produced by the method of introducing a shearing flow to a free surface in a predominantly monomeric solution of the self-assembling polymer sub-units, and inducing polymerization or growth of the monomer while in this shearing flow. The system for forming the oriented layer of material provides relative movement between a delivery system and the substrate on or over which the material is deposited. The rate of flow of the material from the delivery system and the relative velocity between the deposition surface and the material as it is delivered to the surface are controlled to properly orient the material at the desired thickness. These rates can be adjusted to vary the properties of the film in a controlled manner. Preferred embodiments include either angular or linear relative movement between the delivery system and the substrate.

Owner:PTS SPA +1

Layered aligned polymer structures and methods of making same

InactiveUS20060159722A1Promote wettingPromote aggregationMonocomponent protein artificial filamentFilament/thread formingPolymer scienceCell-Extracellular Matrix

Owner:CAMBRIDGE POLYMER GROUP

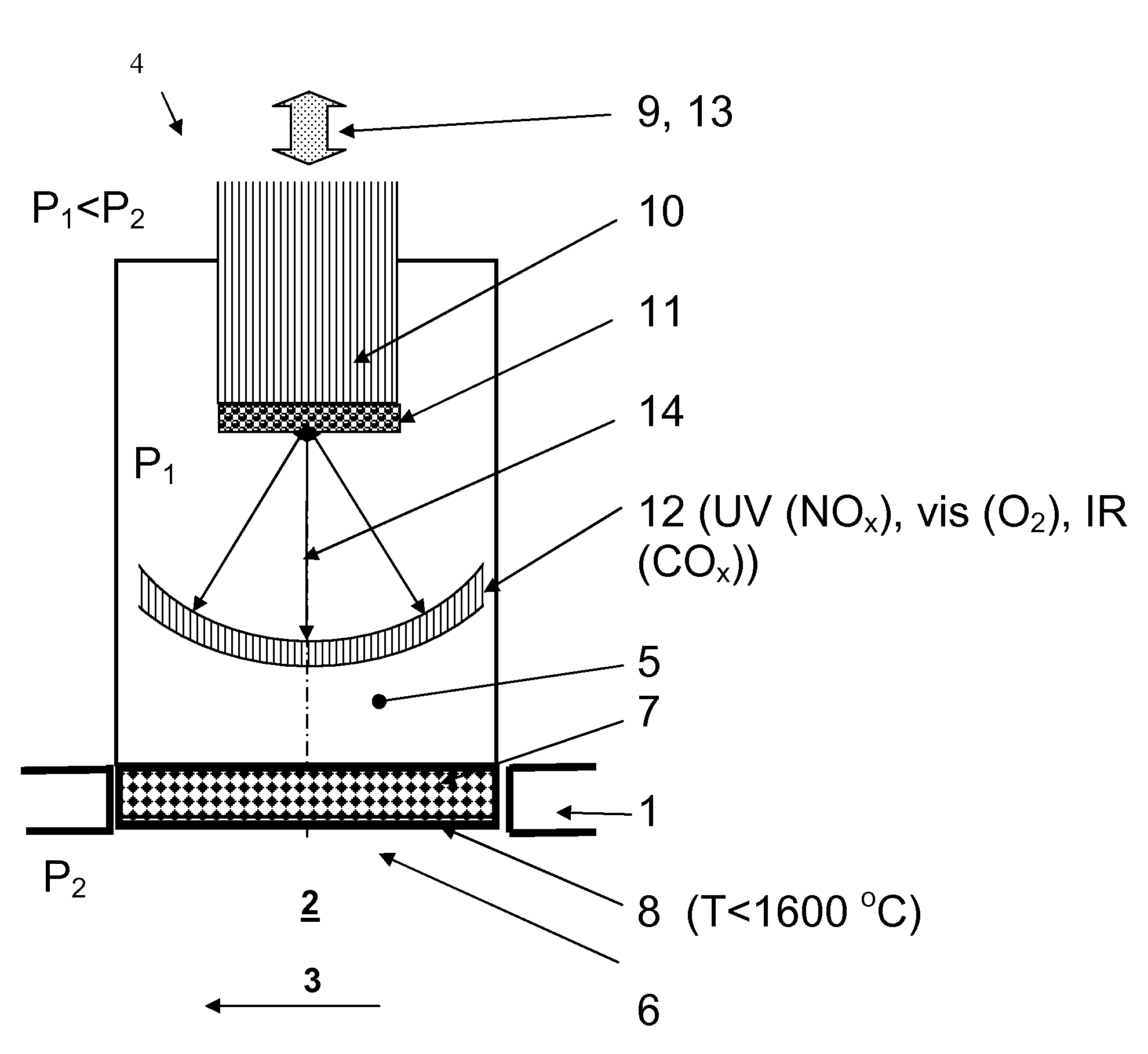

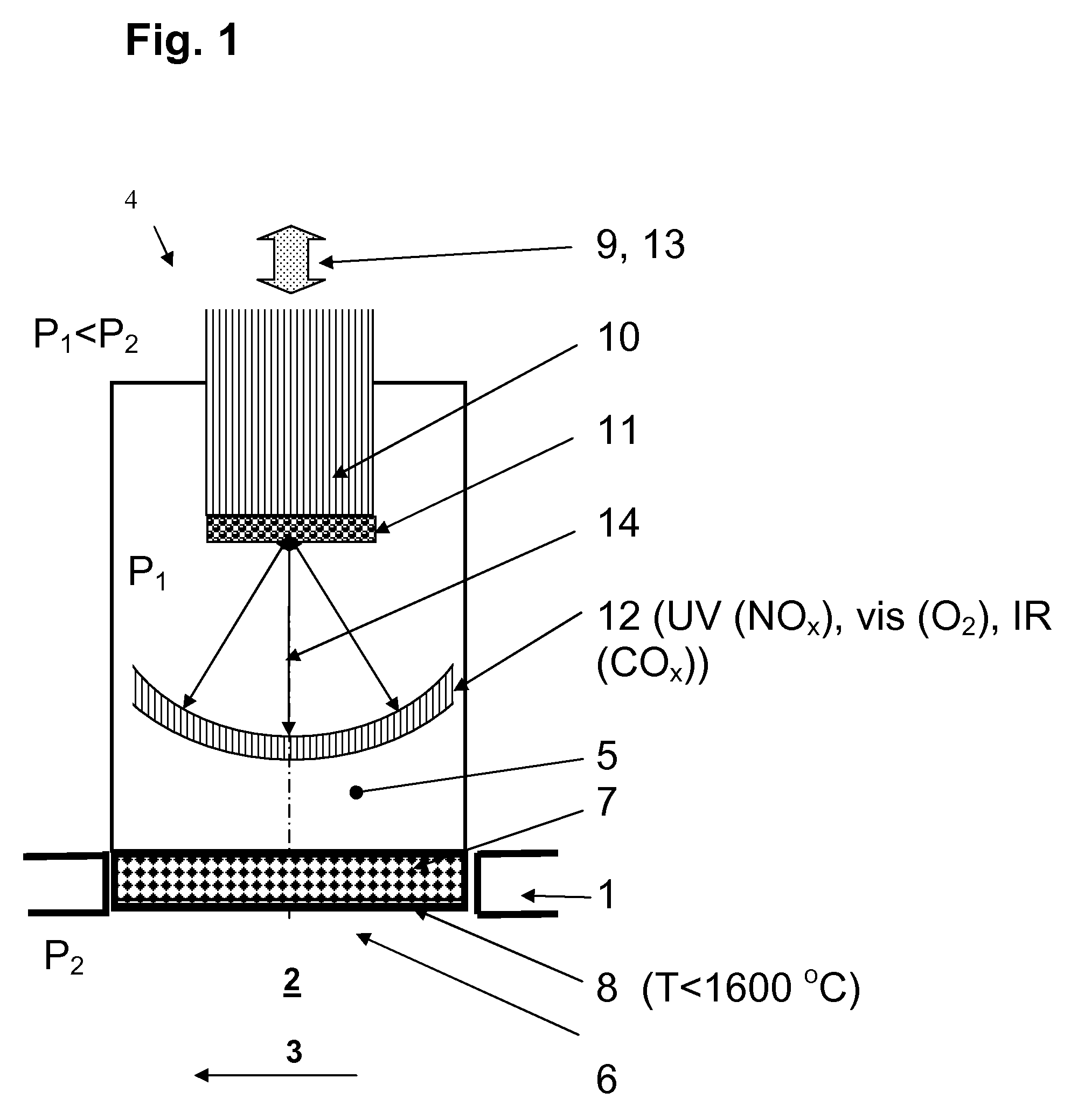

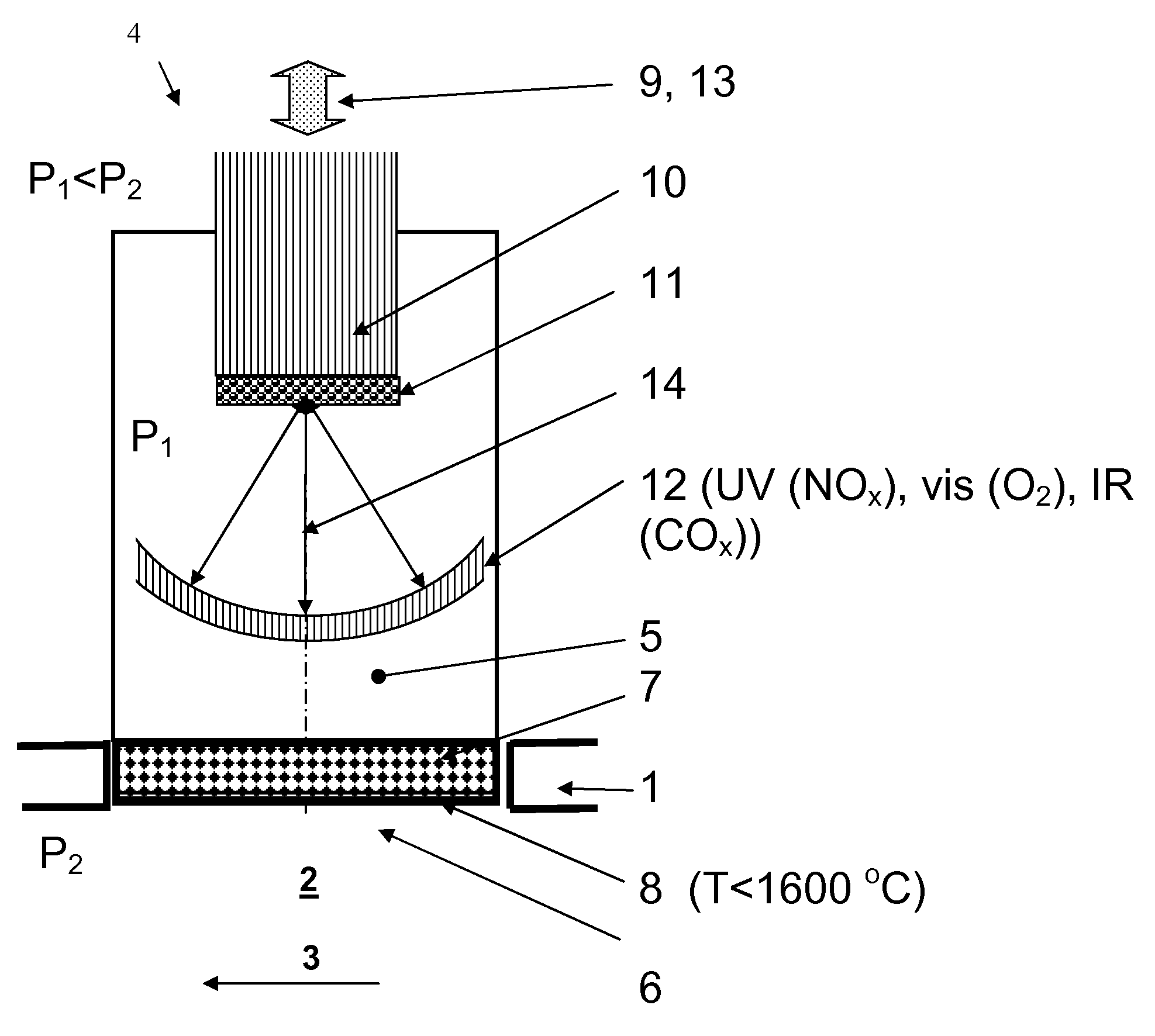

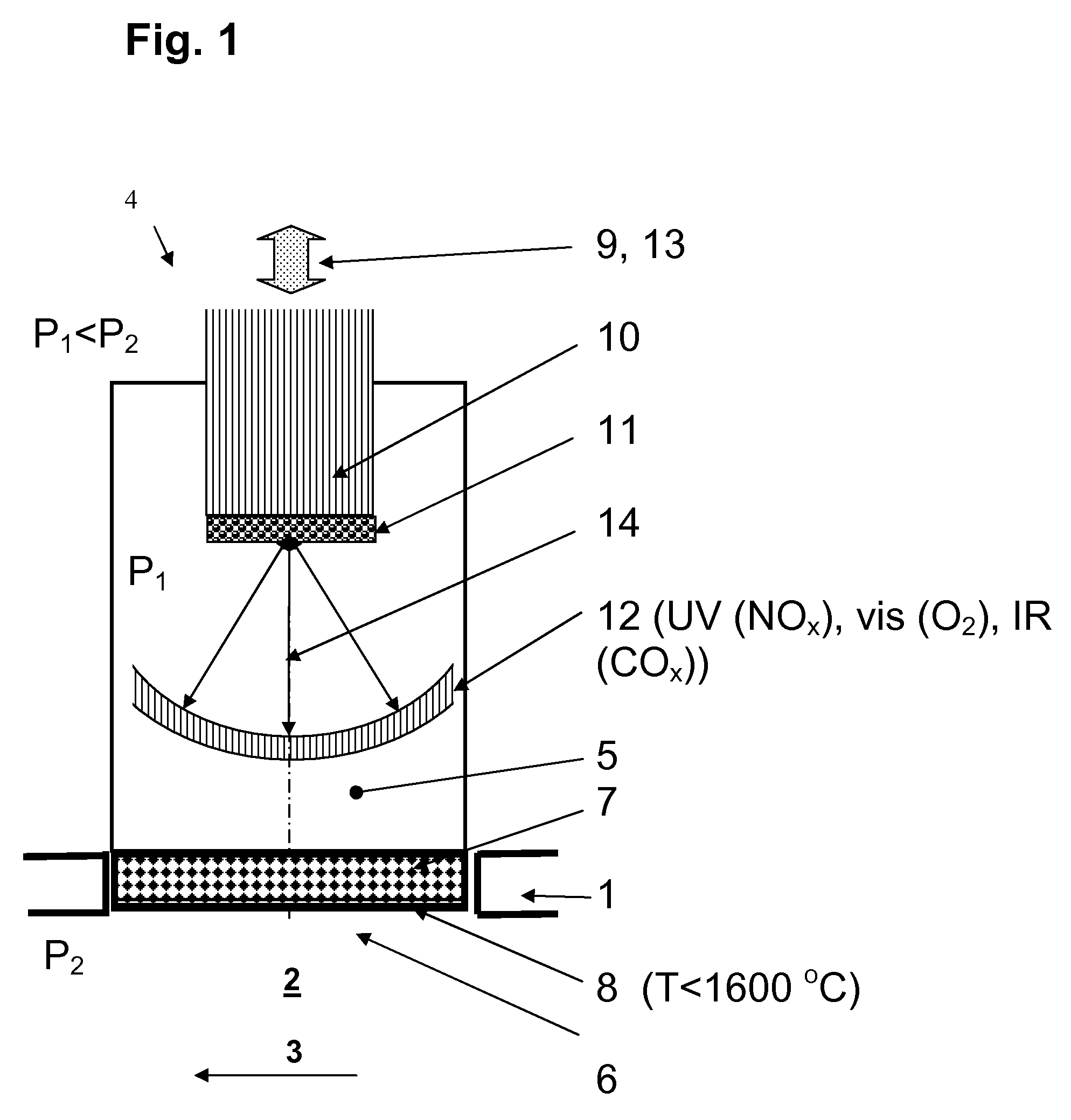

Optical sensor device for local analysis of a combustion process in a combustor of a thermal power plant

InactiveUS7650050B2Easy constructionInexpensive to fabricatePhotometryMaterial analysis by optical meansCombustorEngineering

Owner:ANSALDO ENERGIA IP UK LTD

Layered aligned polymer structures and methods of making same

InactiveUS20050019488A1Increase spacingImprove adhesionMonocomponent protein artificial filamentPharmaceutical containersPolymer scienceCell-Extracellular Matrix

This invention includes a method of producing a nanostructured artificial template comprising more than one thin, oriented layer of polymer material. The material is preferably produced by the method of introducing a shearing flow to a free surface in a predominantly monomeric solution of the self-assembling polymer sub-units, and inducing polymerization or growth of the monomer while in this shearing flow. The system for forming the oriented layer of material provides relative movement between a delivery system and the substrate on or over which the material is deposited. The rate of flow of the material from the delivery system and the relative velocity between the deposition surface and the material as it is delivered to the surface are controlled to properly orient the material at the desired thickness. These rates can be adjusted to vary the properties of the film in a controlled manner. Preferred embodiments include either angular or linear relative movement between the delivery system and the substrate. The nanostructured artificial template is useful for inducing the production of a templated extracellular matrix by a population of cells.

Owner:CAMBRIDGE POLYMER GROUP

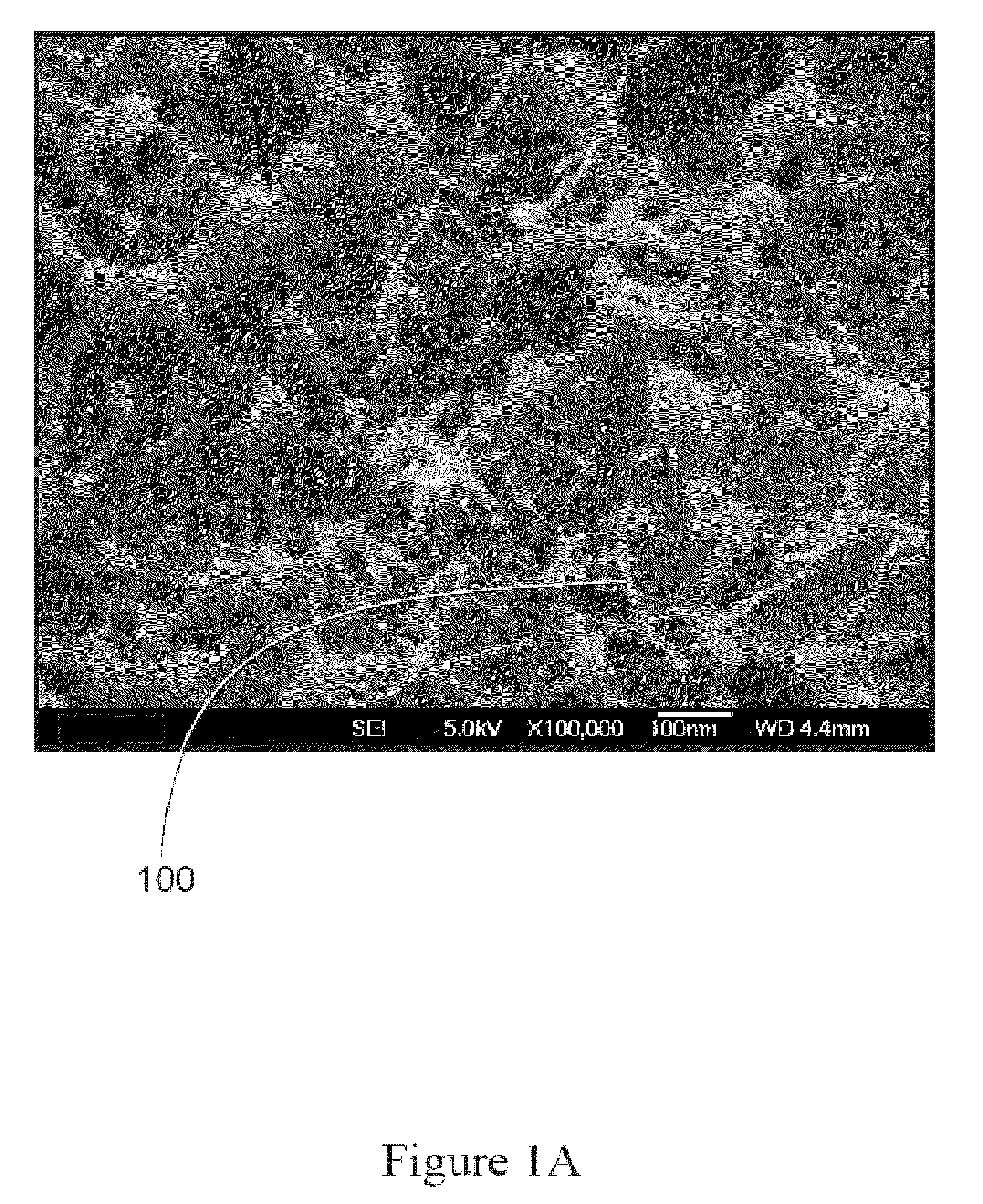

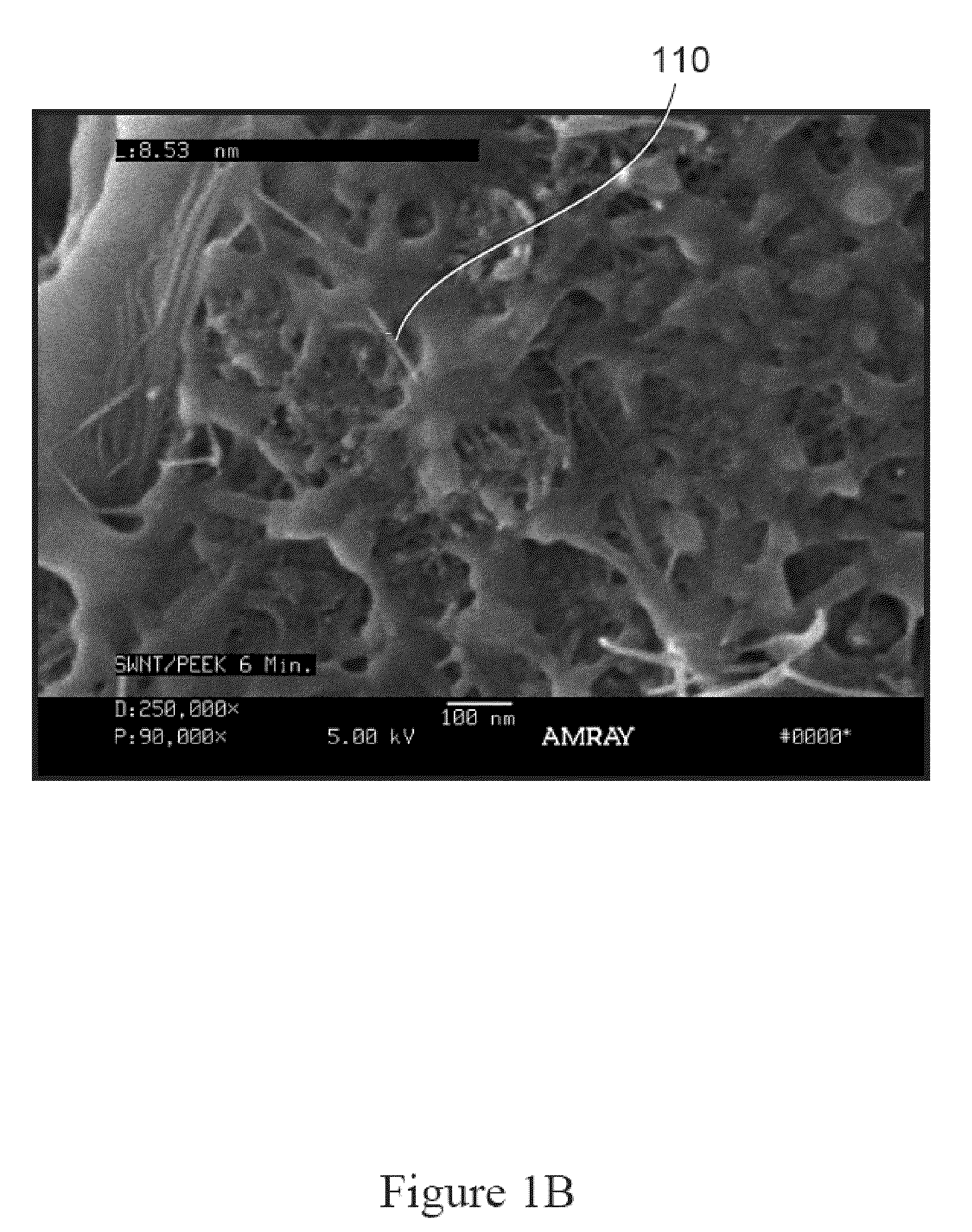

Nanotube Polymer Composite Composition and Methods of Making

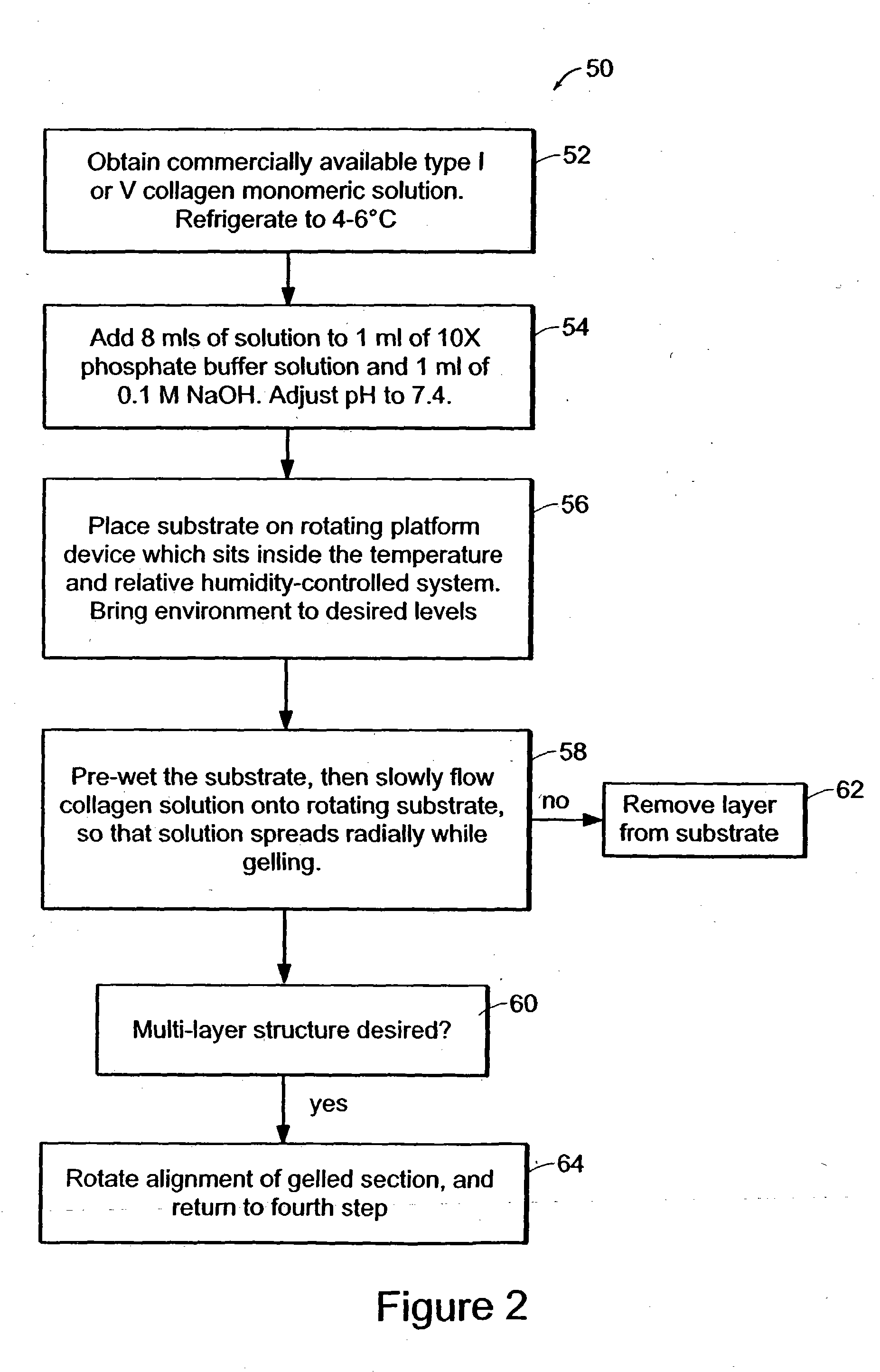

InactiveUS20100267883A1LessReduce loadMaterial nanotechnologySpecial tyresShell moldingPolymer composites

Embodiments of the invention include compositions comprising a polymer an amount of nanotubes extrusion compounded together. The amount of the nanotubes dispersed in the polymer forms a composition with a storage modulus G′ that does not increase further extrusion compounding of the composition. Extrusion compounded compositions of conductive nanotubes and polymer can be molded into electrically dissipative articles whose resistivity decreases with decreasing shear flow in the molding process.

Owner:ENTEGRIS INC

Optical Sensor Device for Local Analysis of a Combustion Process in a Combustor of a Thermal Power Plant

InactiveUS20070133921A1Easy constructionInexpensive to fabricatePhotometryMaterial analysis by optical meansCombustorEngineering

An optical sensor device for local analysis of a combustion process in a combustor of a thermal power plant, in particular a gas turbine plant, includes at least one wavelength selective optical element exposed directly or indirectly to hot combustion gases being produced by said combustion process, the optical element including an array of nano- and / or microcrystalline fibres which are created by shear flow crystallization.

Owner:ANSALDO ENERGIA IP UK LTD

Control of electrolyte hydrodynamics for efficient mass transfer during electroplating

Owner:NOVELLUS SYSTEMS

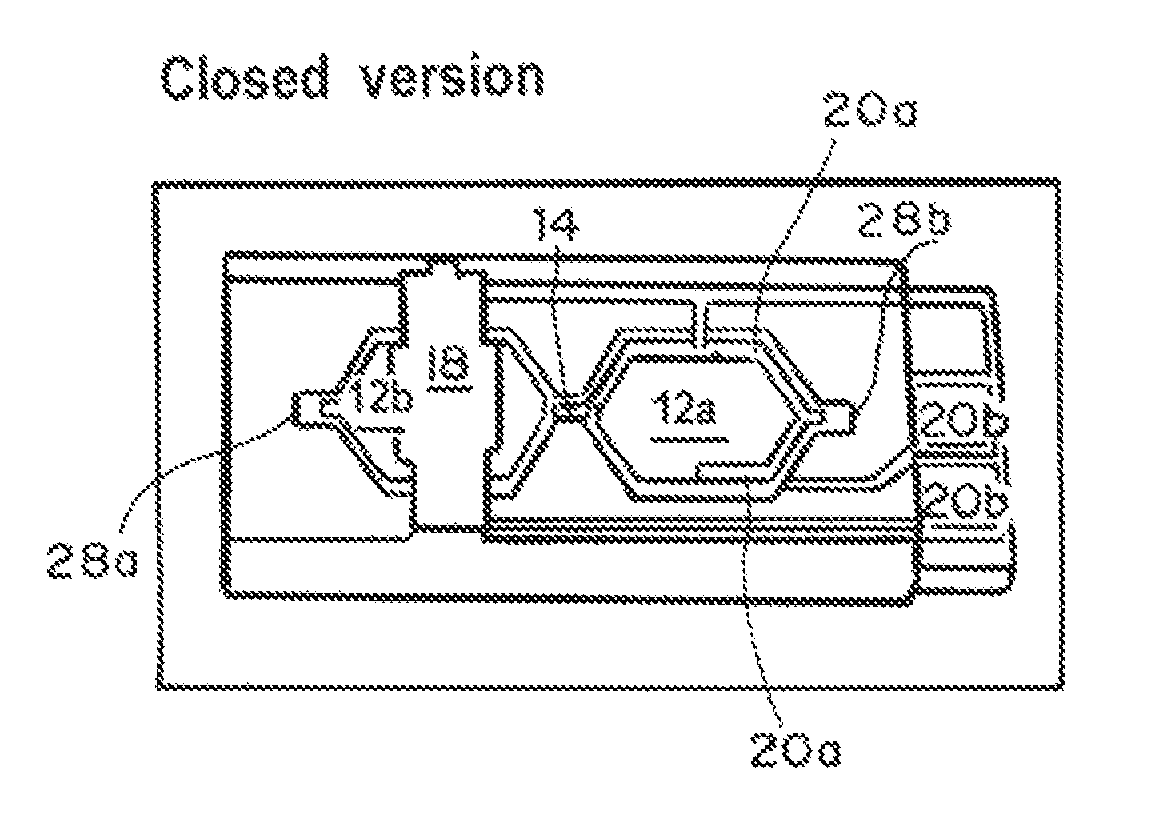

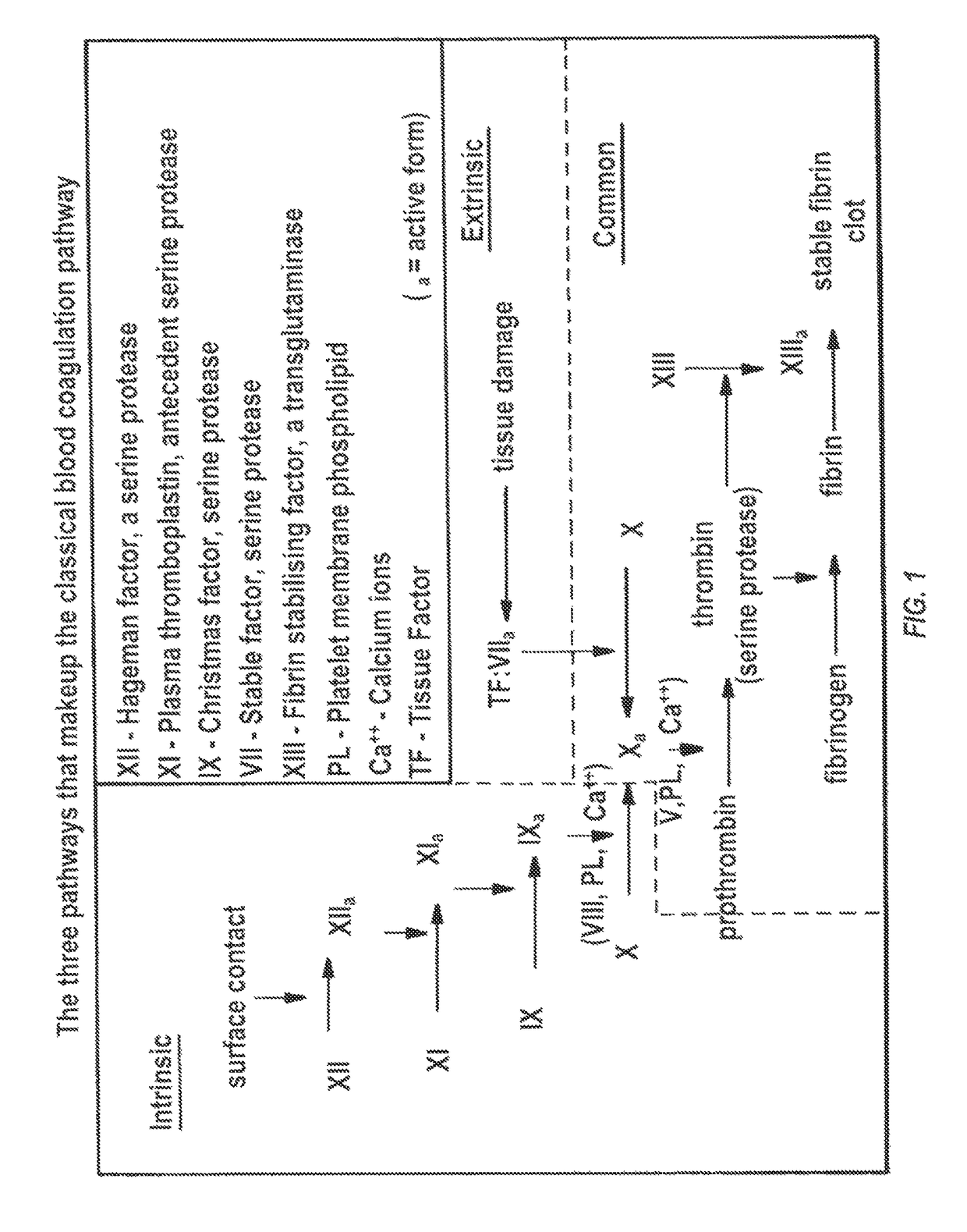

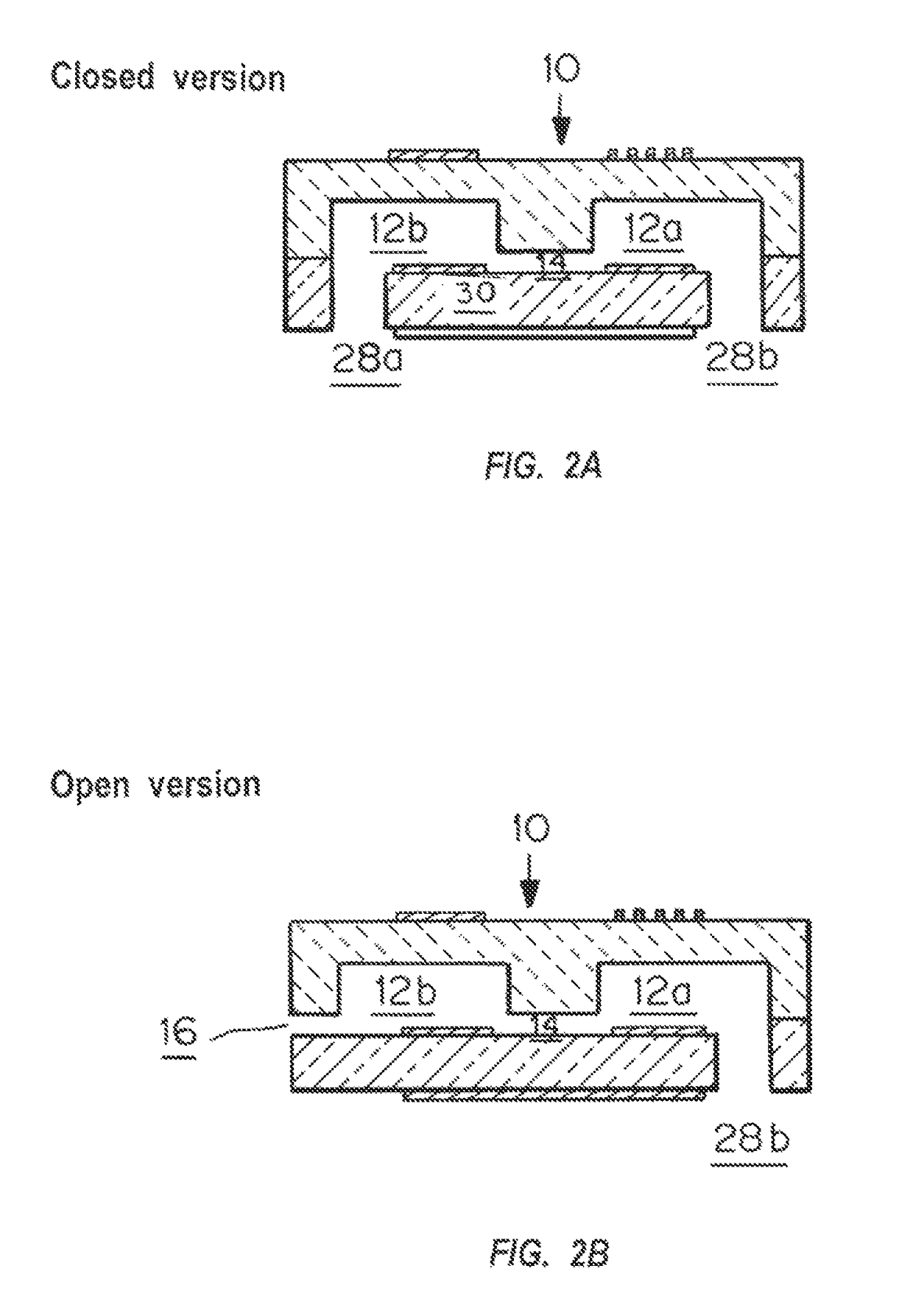

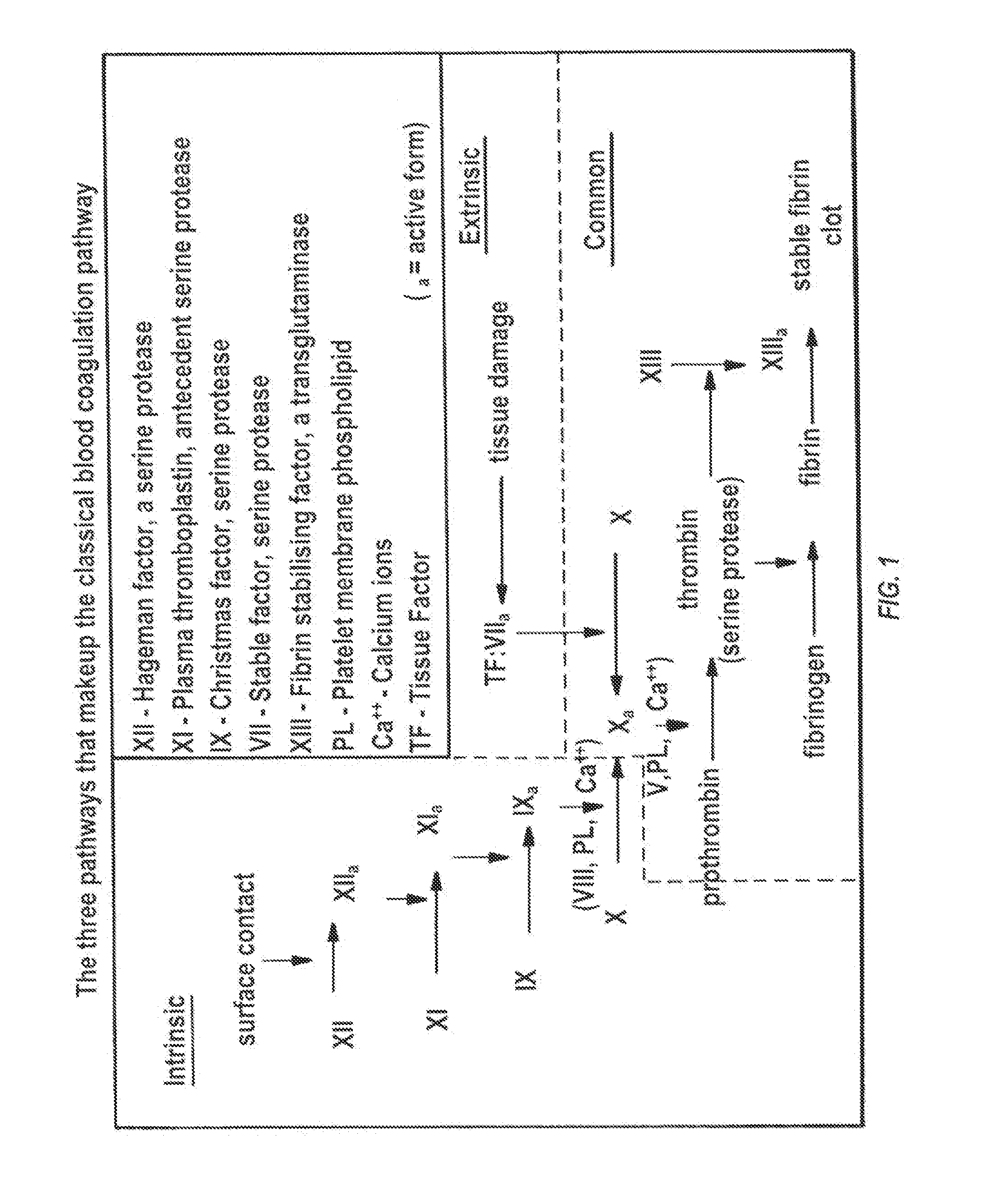

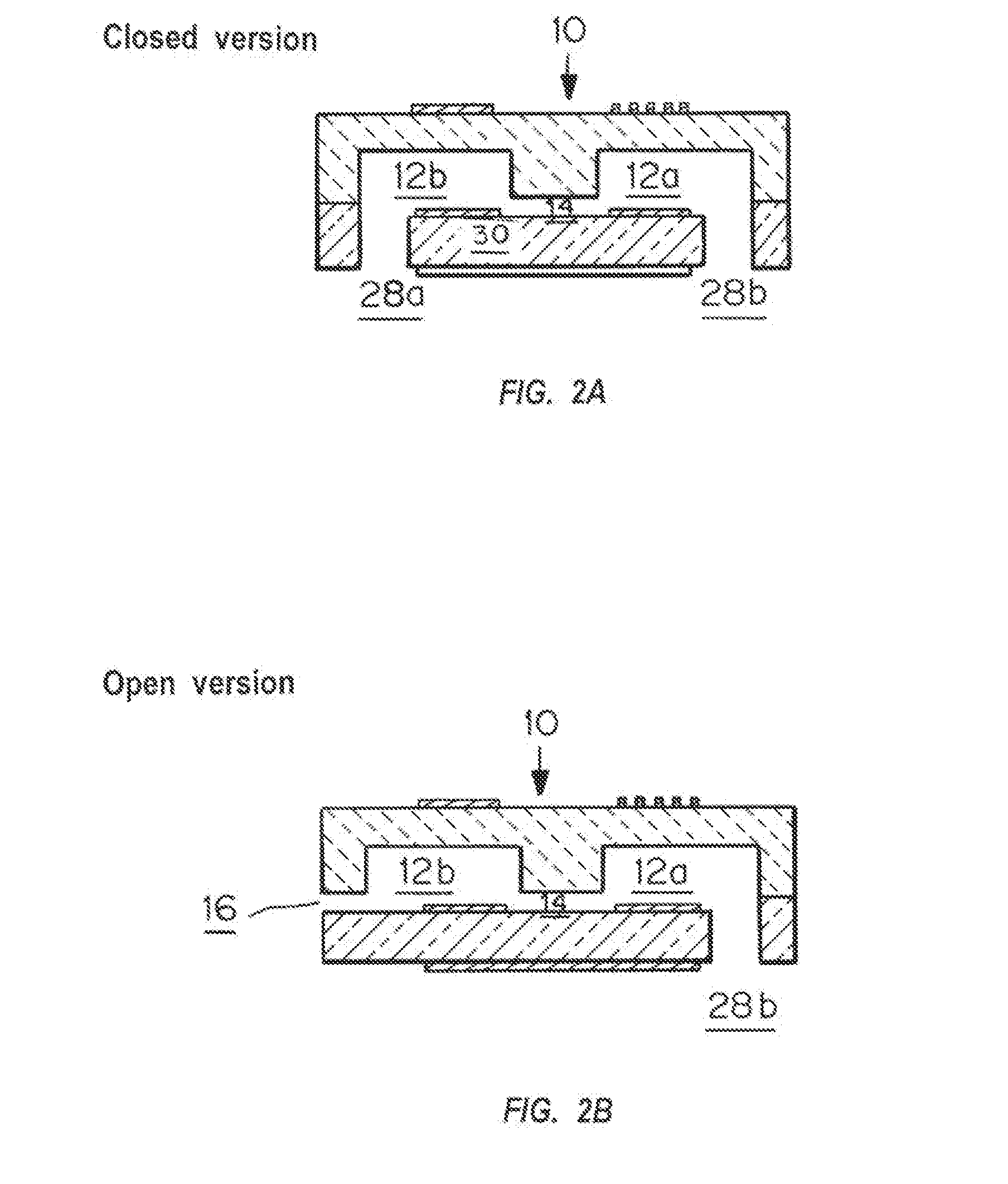

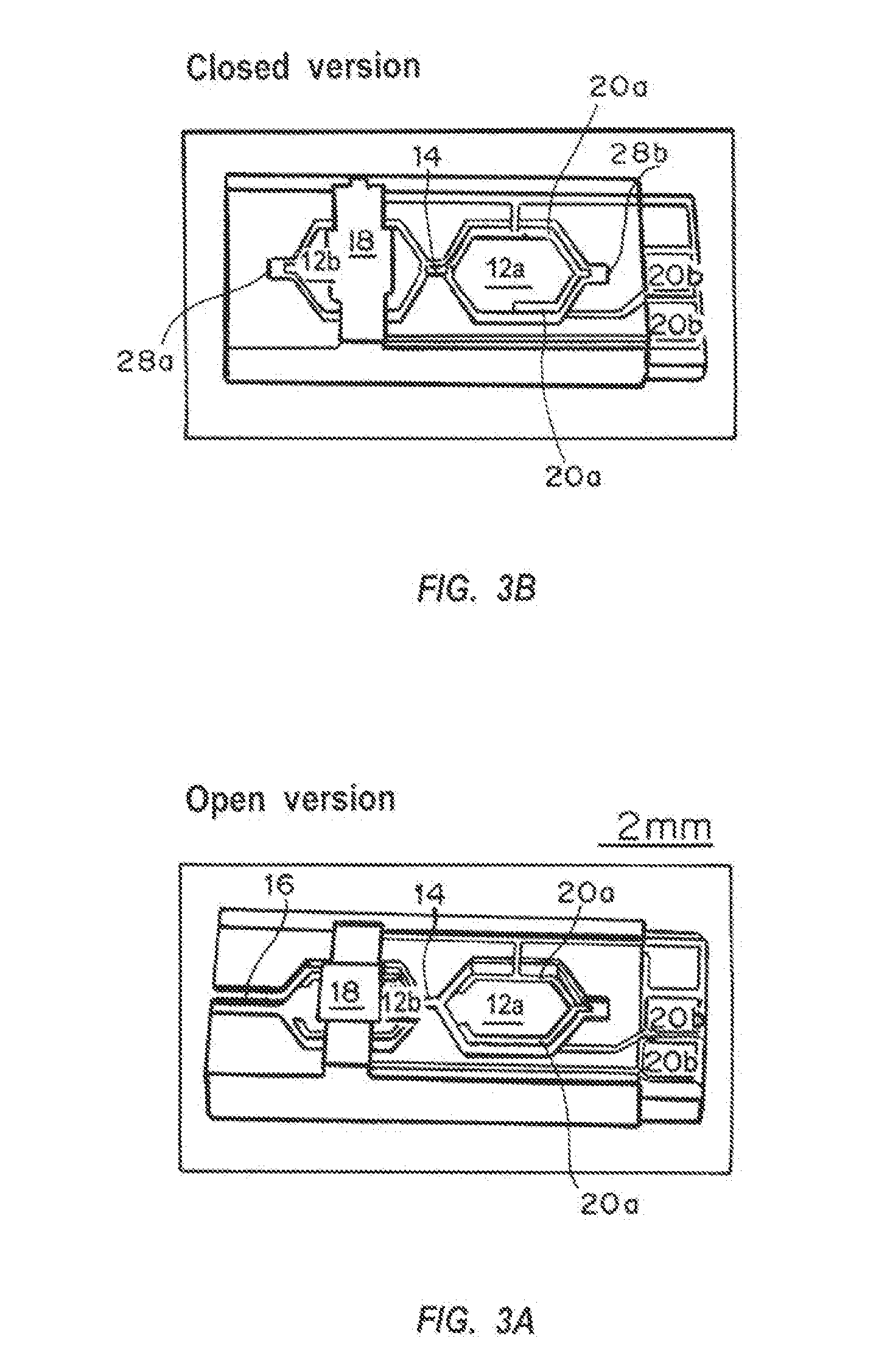

Microfluidic chip-based, universal coagulation assay

ActiveUS9910053B2Ensures comparabilityEnsure repeatabilityLaboratory glasswaresBiological testingPoint of careShear flow

Owner:PEROSPHERE TECH INC

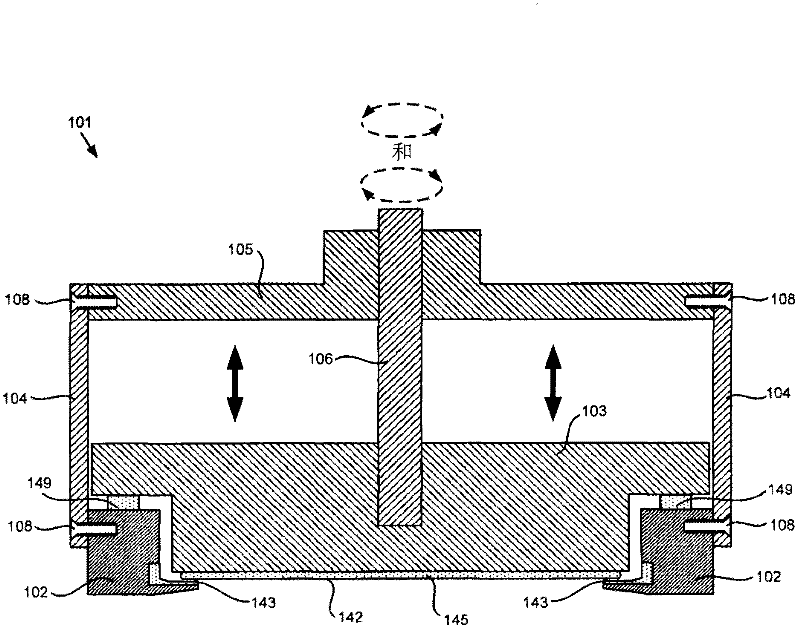

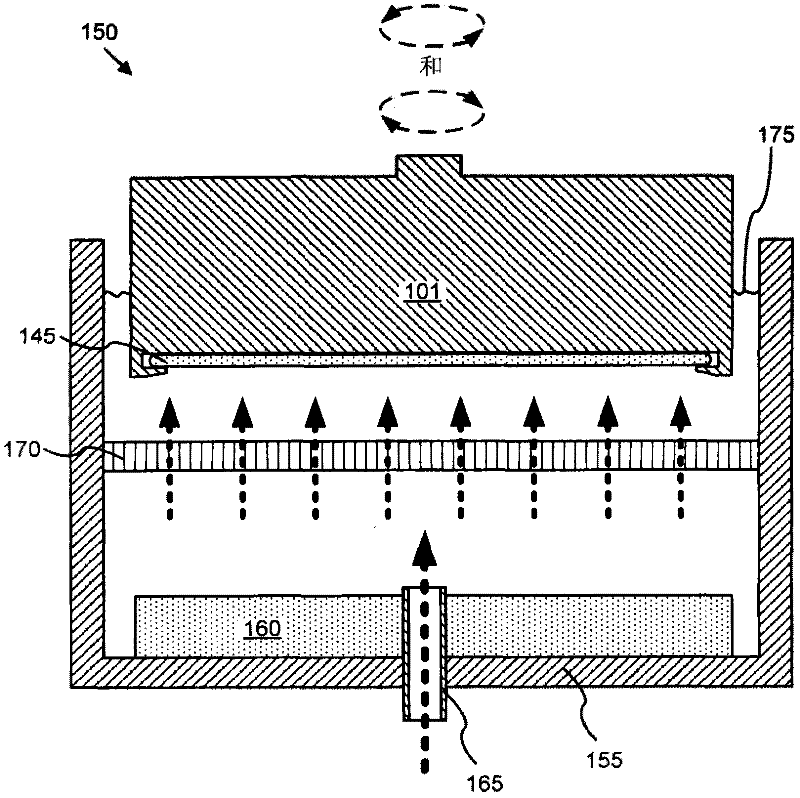

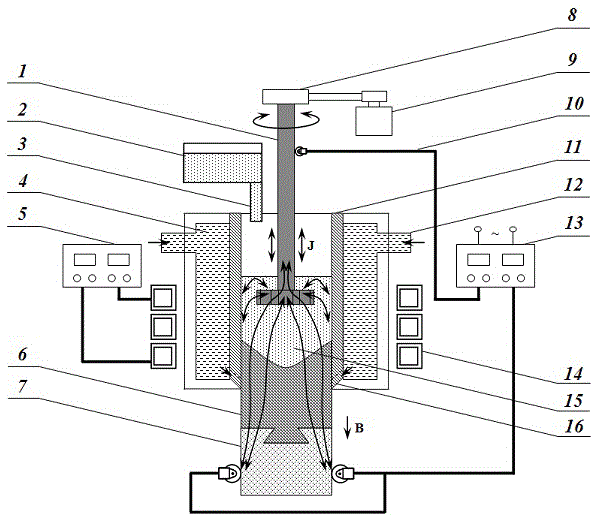

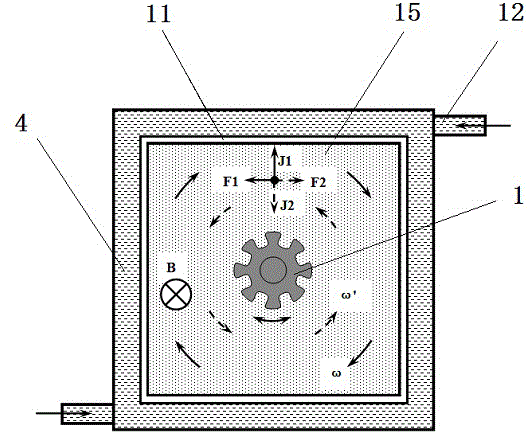

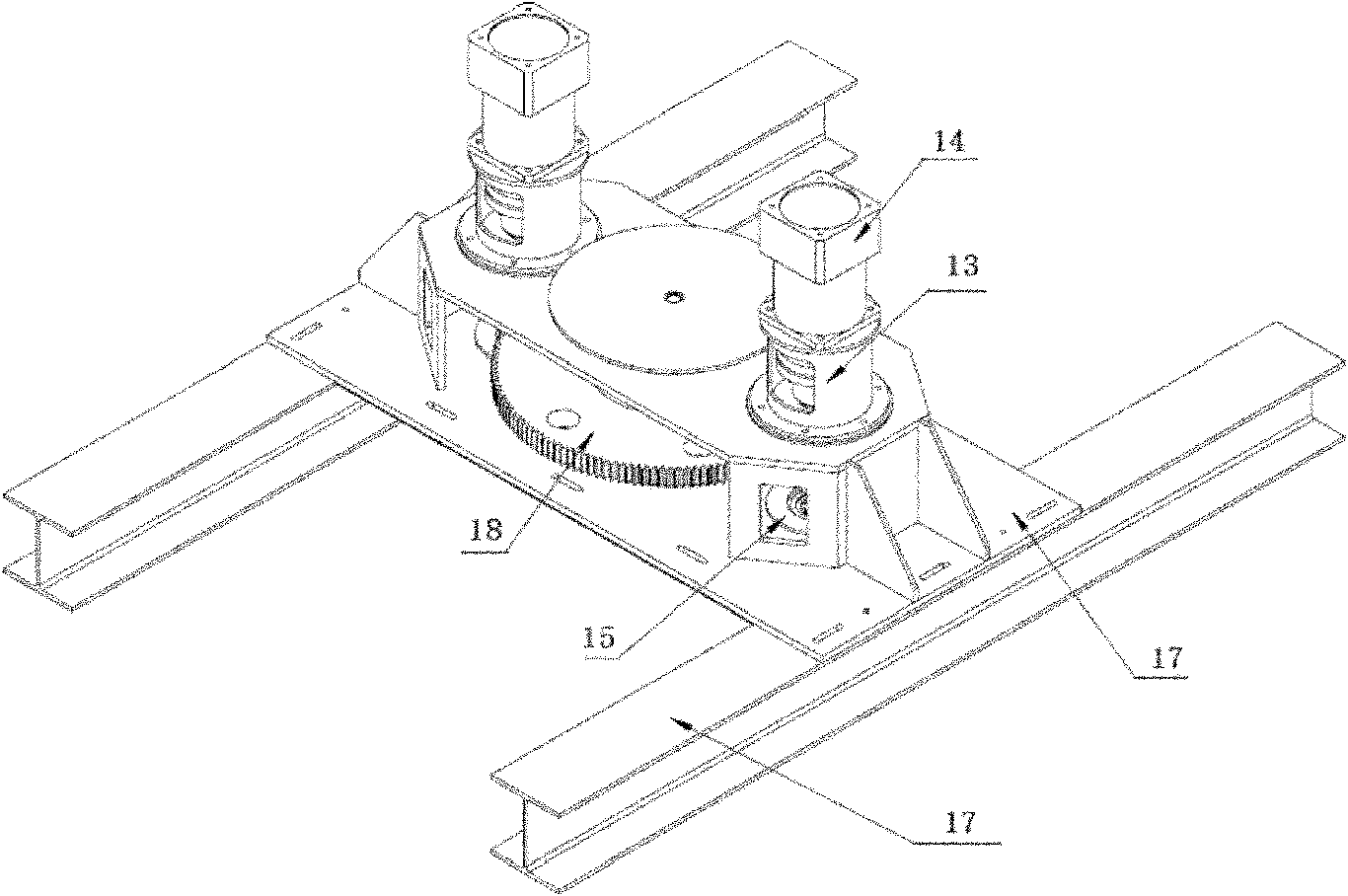

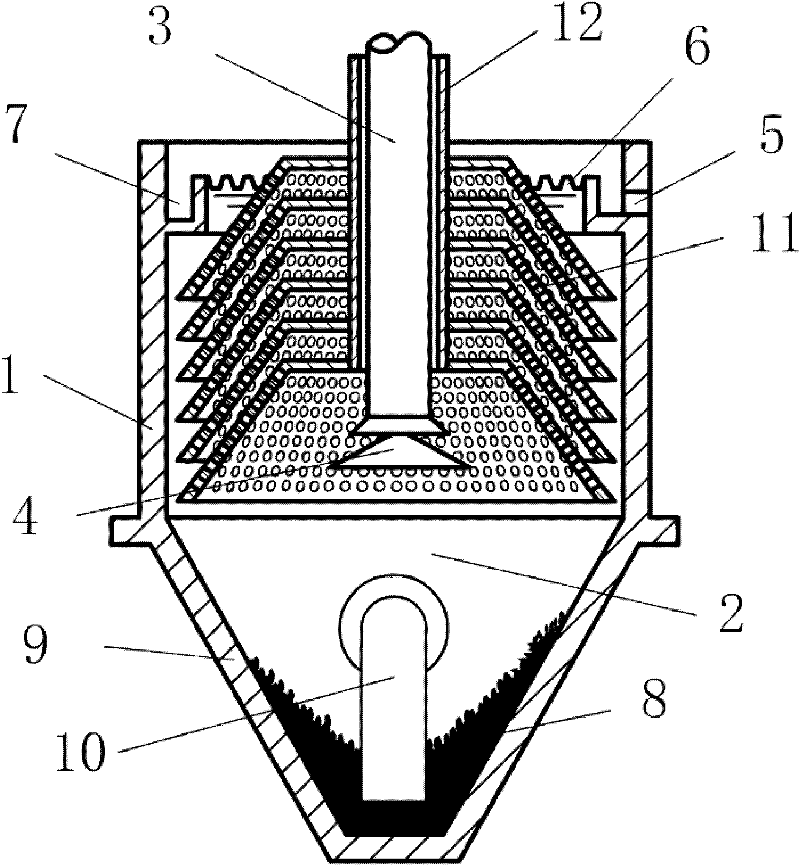

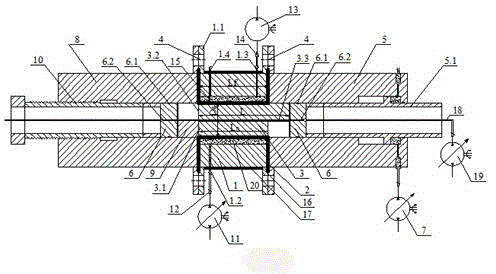

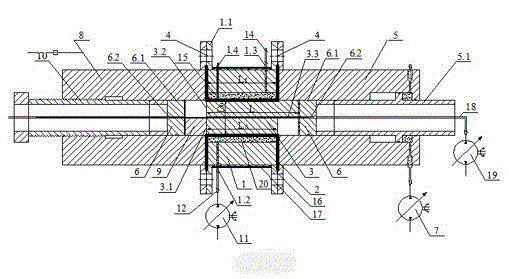

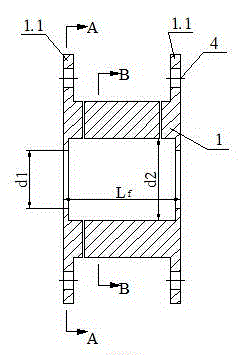

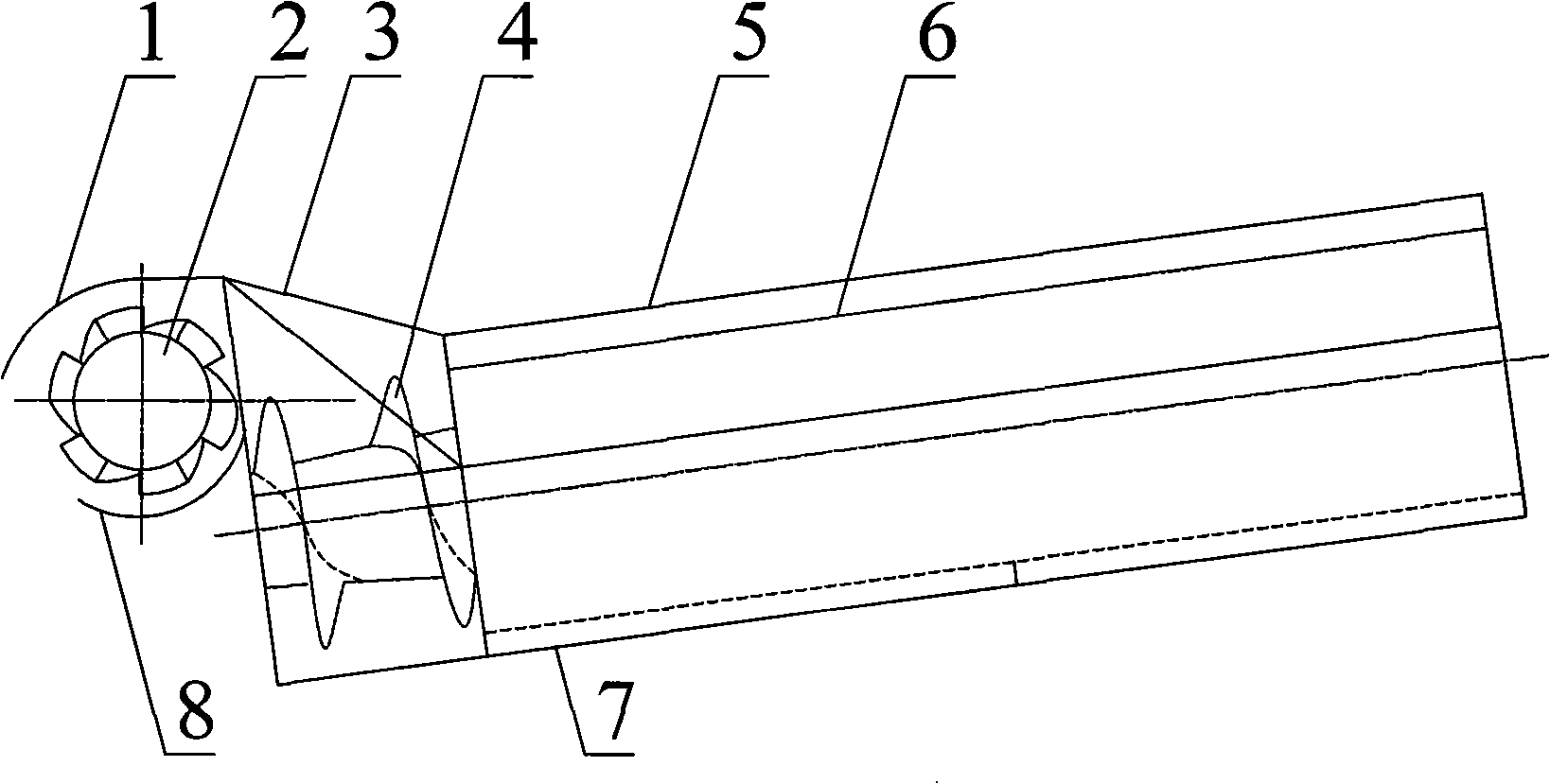

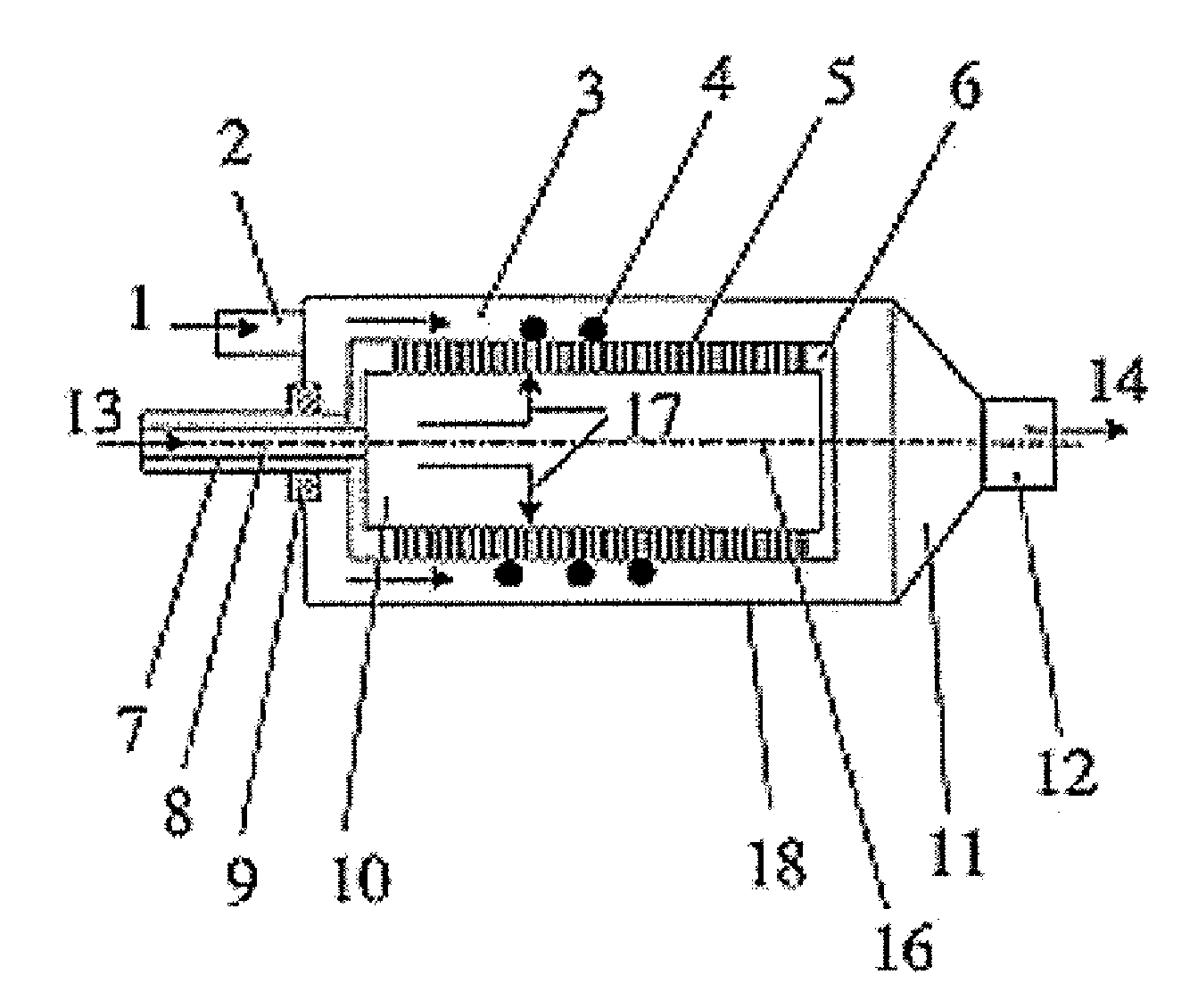

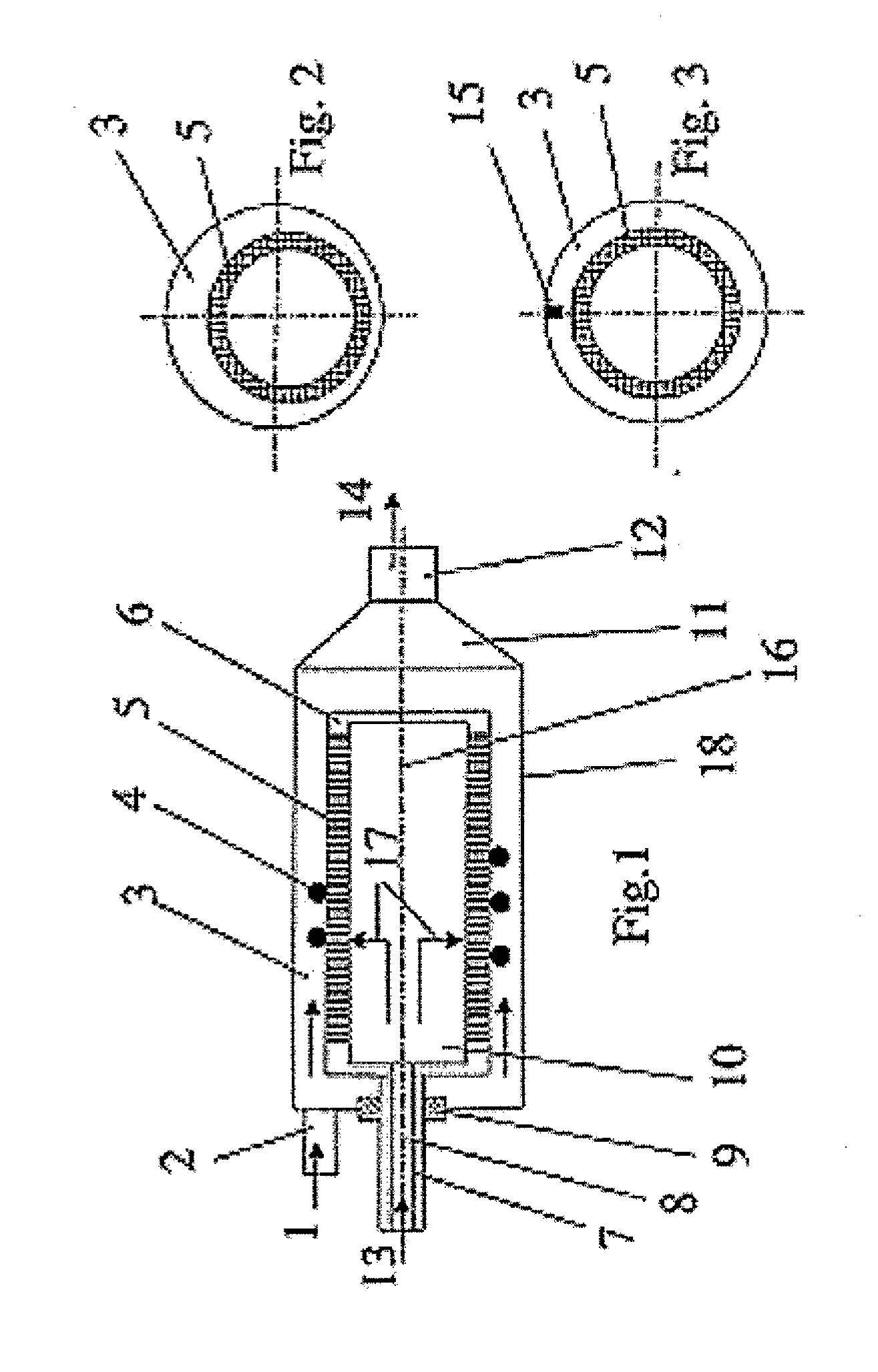

Continuous steel casting process and device with function of electromagnetic excitation compound mechanical stirring

The invention discloses a continuous steel casting process with a function of electromagnetic excitation compound mechanical stirring. According to the process, when alloy melt solidifies, microscopic and macroscopic strong shear flows are generated to break dendritic crystal by the electromagnetic excitation compound mechanical stirring technology, and accordingly, solidification structure refinement, full-equiaxed crystallization and solute segregation reduction are achieved, and alloy properties are improved. The invention further provides a continuous steel casting device mainly comprising a crystallizer, a rotor stirring paddle, a wheel, a program control motor, a magnetic field generator, a coil, and a voltage-regulating frequency-modulating alternating current source. The microscopic flows generated by electromagnetic excitation and macroscopic flows generated by mechanical stirring form complex chaotic flows which form strong shear flows to brake the dendritic crystal, crystal nucleus proliferation is prompted, temperature gradient is reduced, and ultrafine full-equiaxed crystal structure is achieved; meanwhile, segregation of alloy elements is significantly reduced or completely suppressed. The continuous steel casting process and method has the advantages that the energy consumption is significantly lower than that of conventional electromagnetic stirring and energy conservation is significantly effective.

Owner:新兴发展集团有限公司

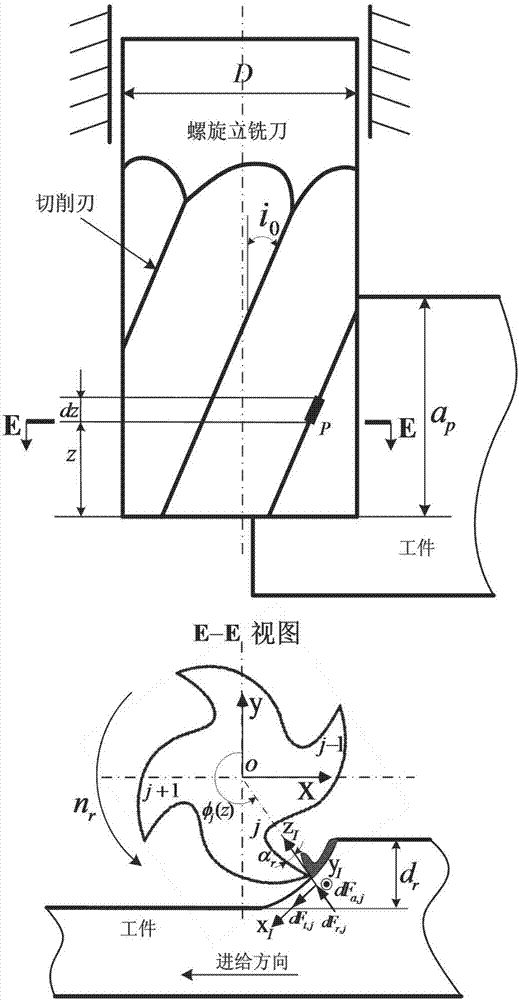

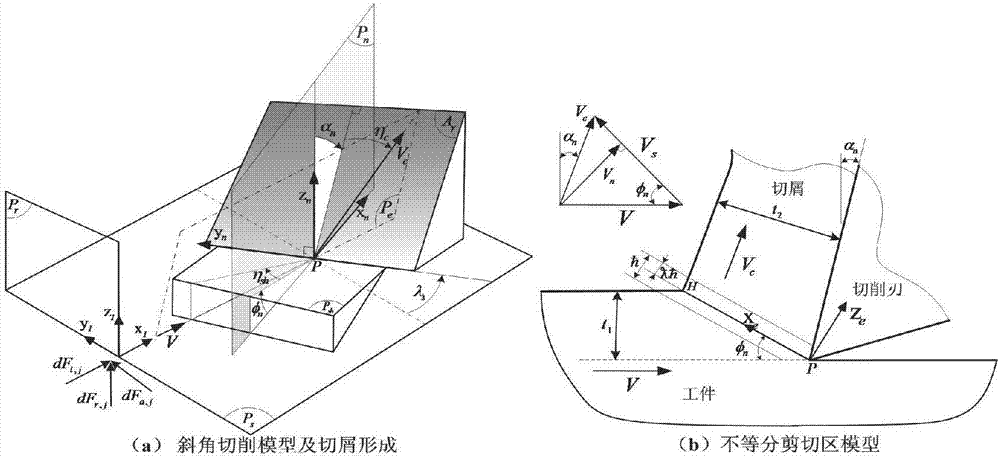

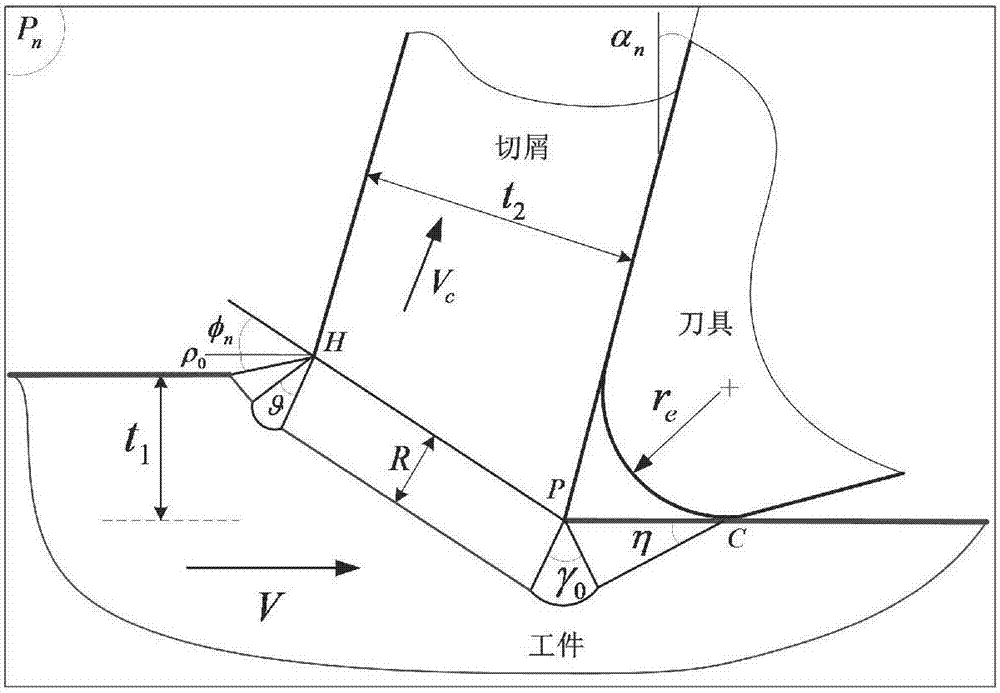

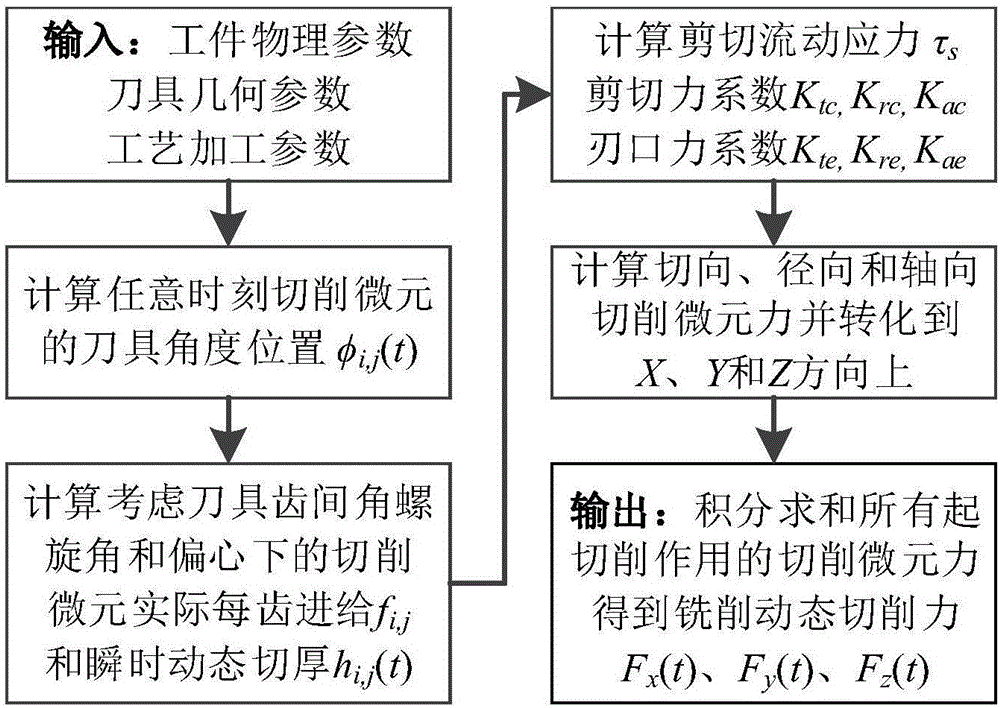

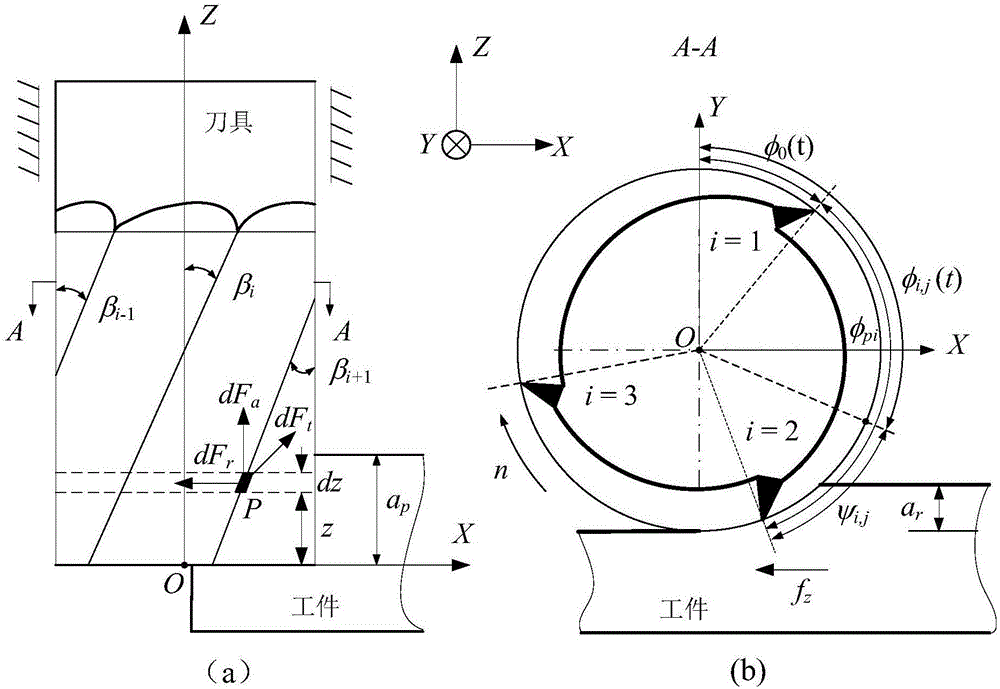

Analyzing and modelling method of milling force of flat spiral end milling cutter

InactiveCN107330138ACutting Force PredictionImprove accuracyDesign optimisation/simulationSpecial data processing applicationsFlow stressModel method

The invention relates to an analyzing and modelling method of milling force of a flat spiral end milling cutter. According to the method, workpiece material characteristics, cutter geometry, cutting conditions and milling modes serve as model input parameters, consideration is given to the influence on the cutting force by a cutter cutting edge radius, a variable sliding friction coefficient and cutter bounce, shear flow stress is calculated through a Johnson-Cook constitutive model in a model, each cutting edge of the milling cutter is scattered into multiple microelements in the cutter axis direction, the cutting characteristic of each microelement is equivalent to an inclined cutting process, cutting force exerted on each cutting microelement is obtained through an analytical model of inclined cutting force, then cutting force of all the cutting microelement is superposed, and a milling force value of the milling cutter is obtained. According to the analyzing and modelling method of the milling force of the flat spiral end milling cutter, cutting mechanism, relevant stress, strain and a strain rate in the cutting process and the distribution situation of the temperature can be reflected truly, the milling force can be quickly predicted only by inputting the cutting conditions and workpiece characteristic parameters, and the method is high in accuracy and rapidity.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

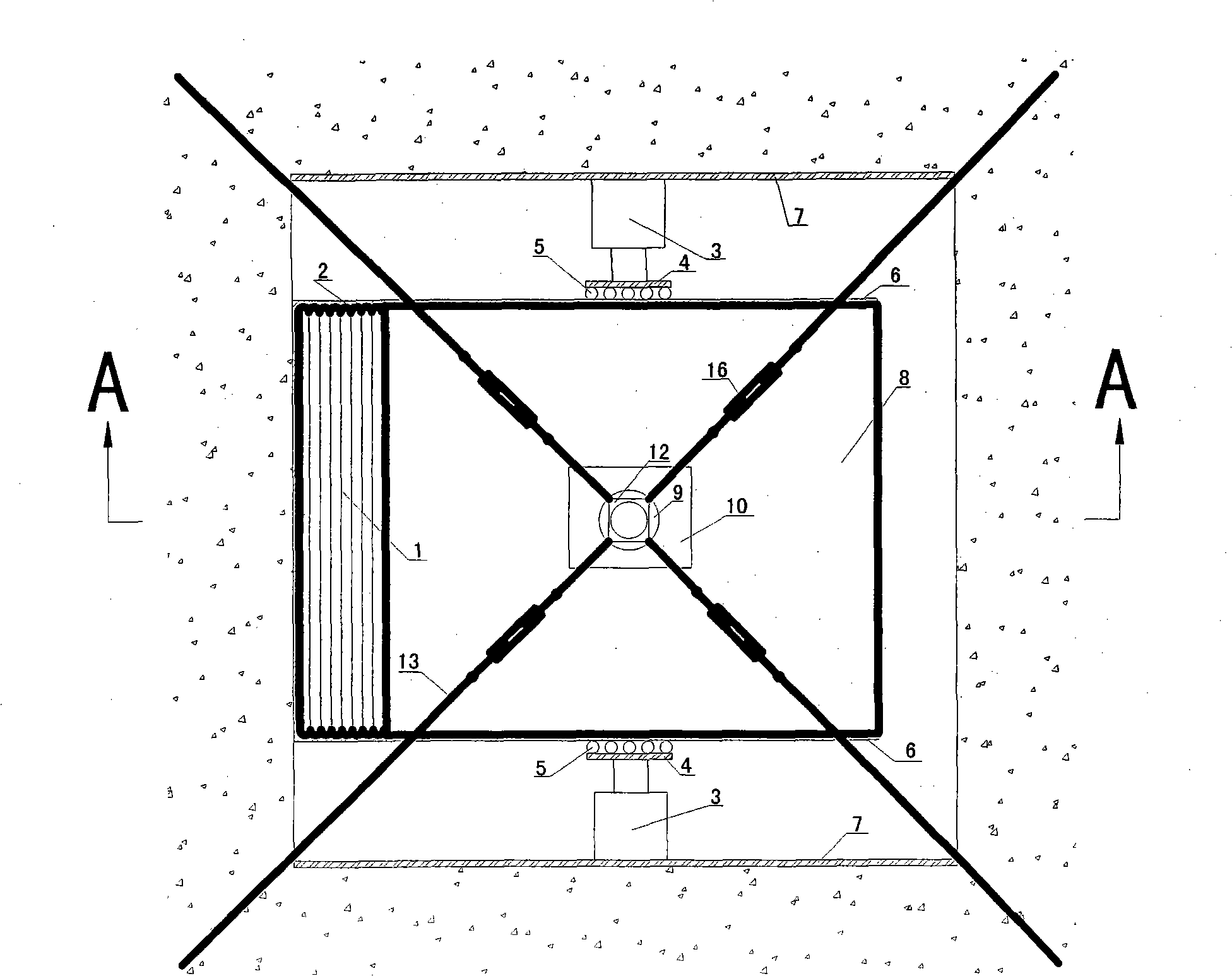

Airbag type soil-rock mixture in-situ compression shear test device

InactiveCN101592576AImprove data result distortionMaterial strength using steady shearing forcesNormal loadEngineering

The invention provides a special soil-rock mixture in-situ compression shear test device, which is characterized in that: according to the high anisotropy and discontinuity of a soil-rock mixture, shear load is applied onto a sample under variable normal load to obtain the shearing resistance property of the soil-rock mixture and the shearing plane of the soil-rock mixture can be formed freely. The shear load is applied by a method of soft loading, namely, a method of high pressure airbag pressurization. The device can actually reflect the forming process of the shearing plane in the soil-rock mixture and effectively improve the situation that the rigid application of the shear load leads to data results distortion. The device can perform shear tests of the soil-stone mixture and obtains test results highly reflecting actual situations.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

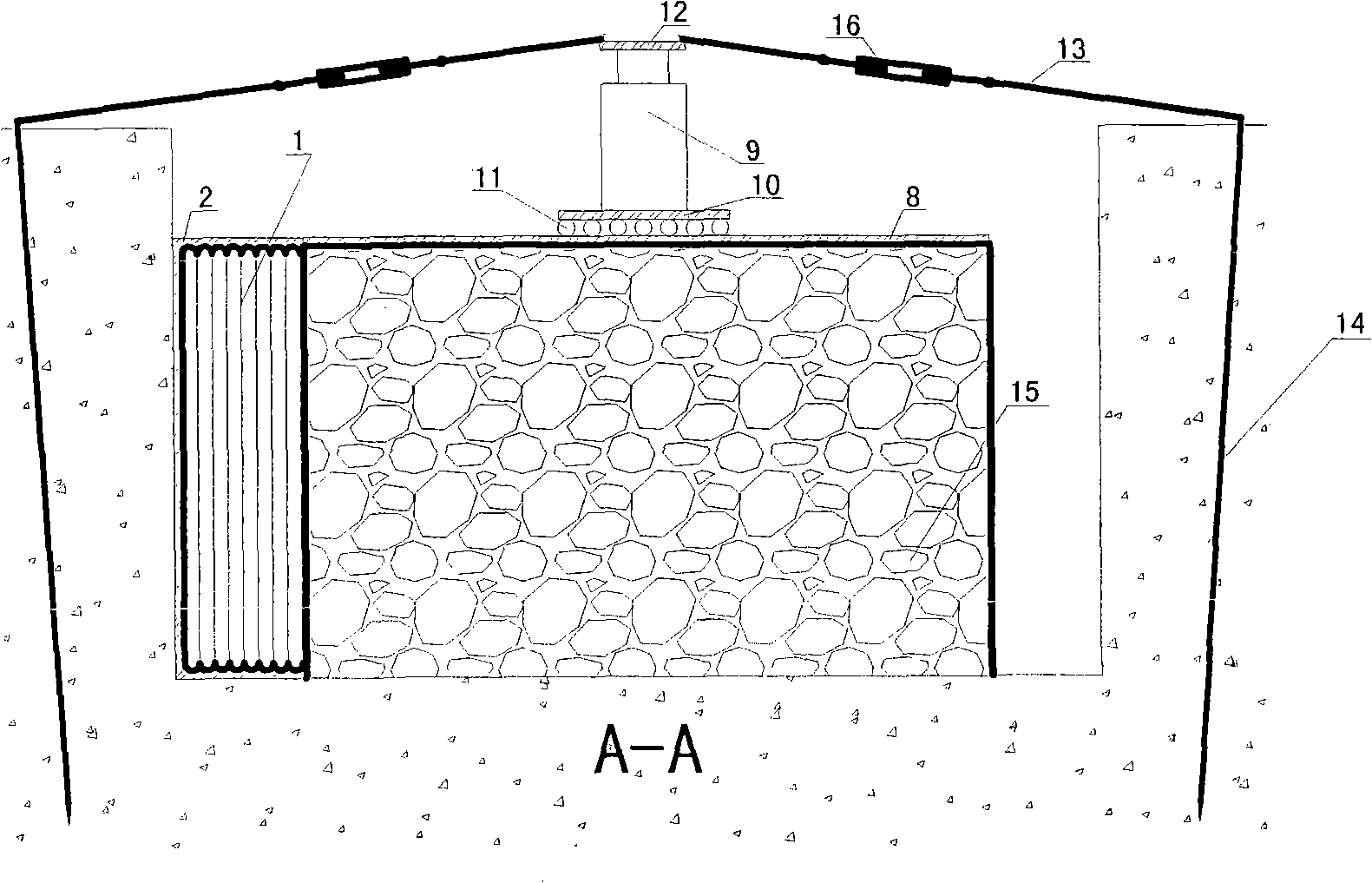

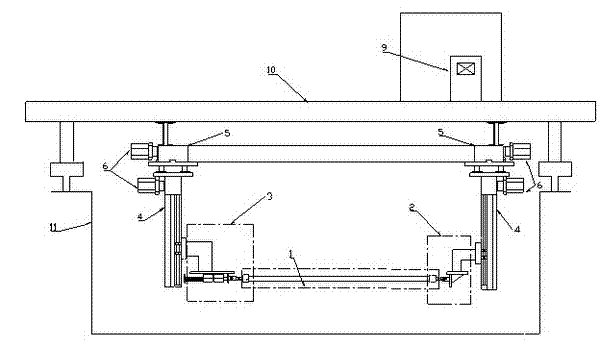

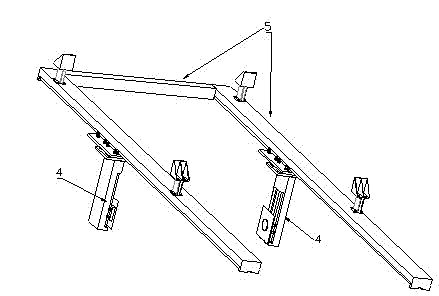

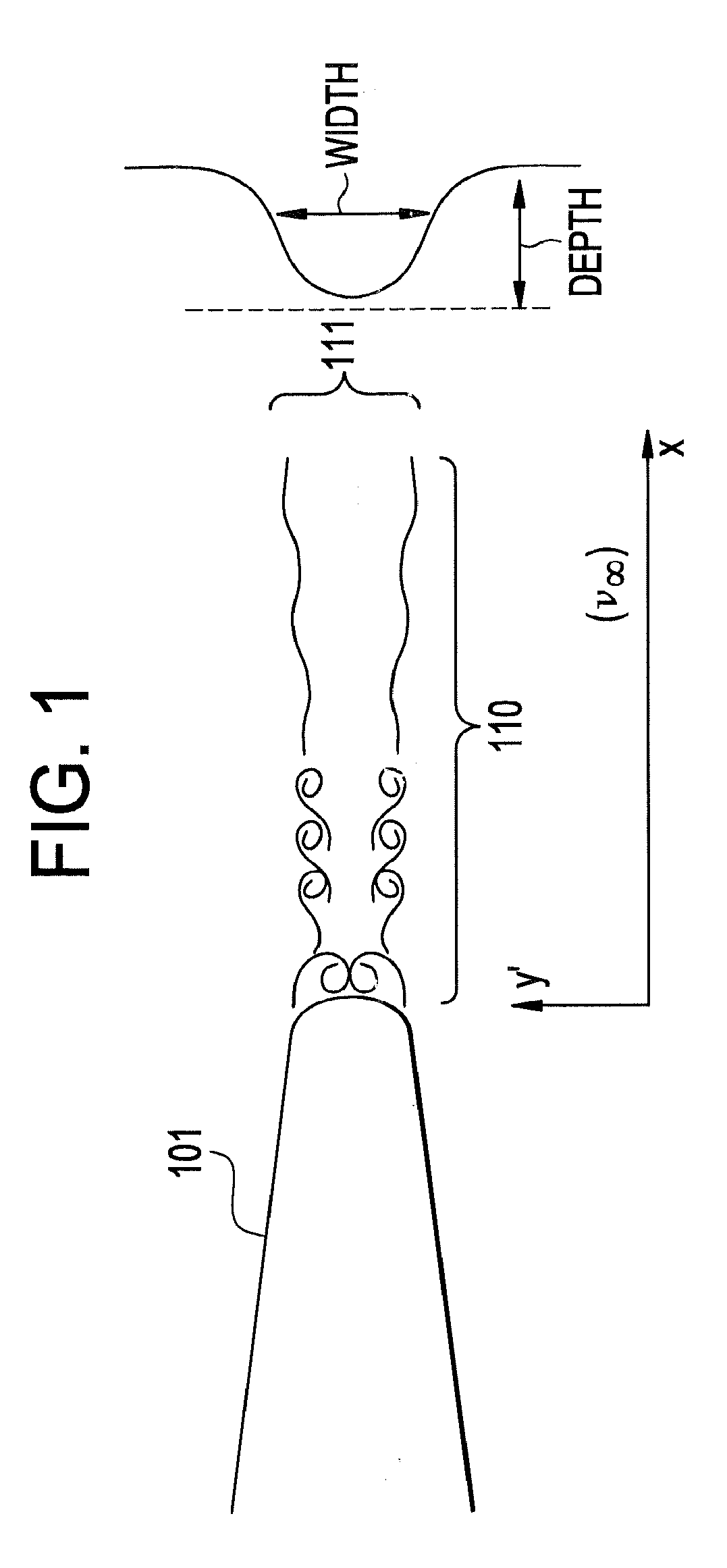

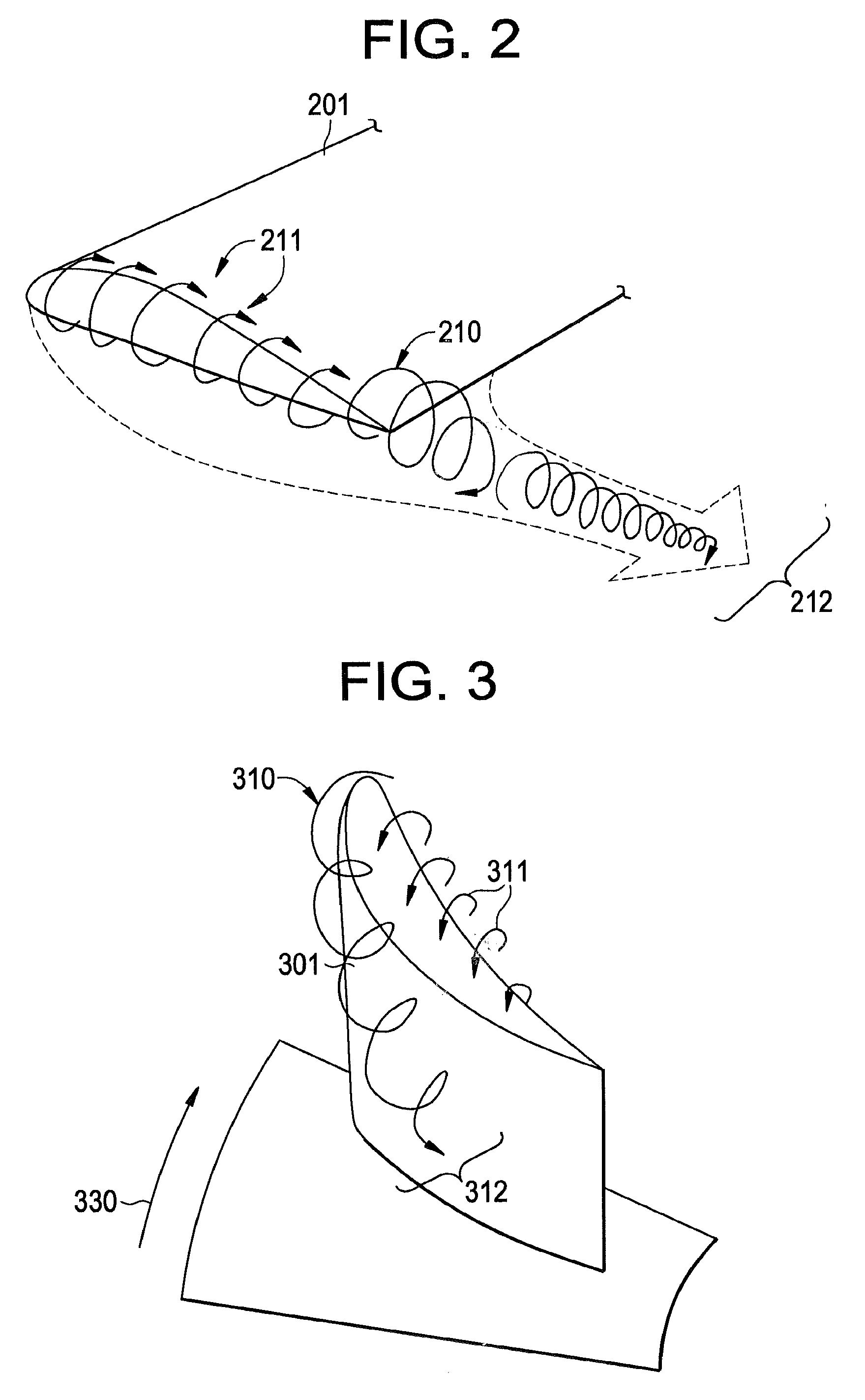

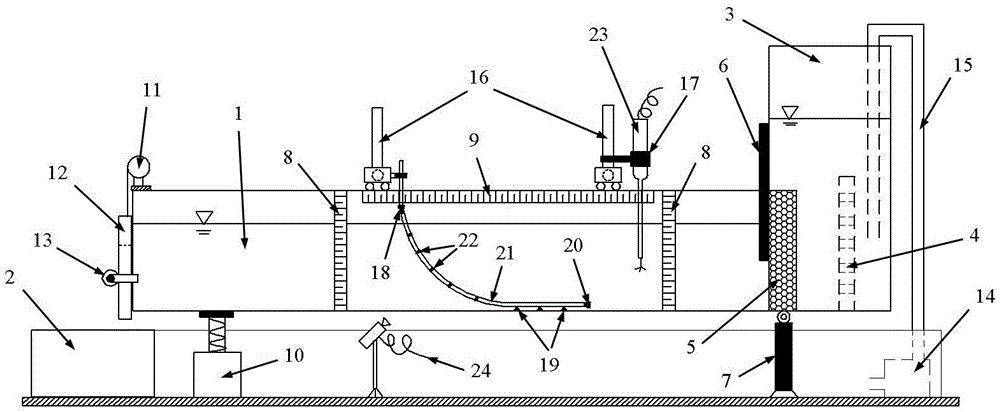

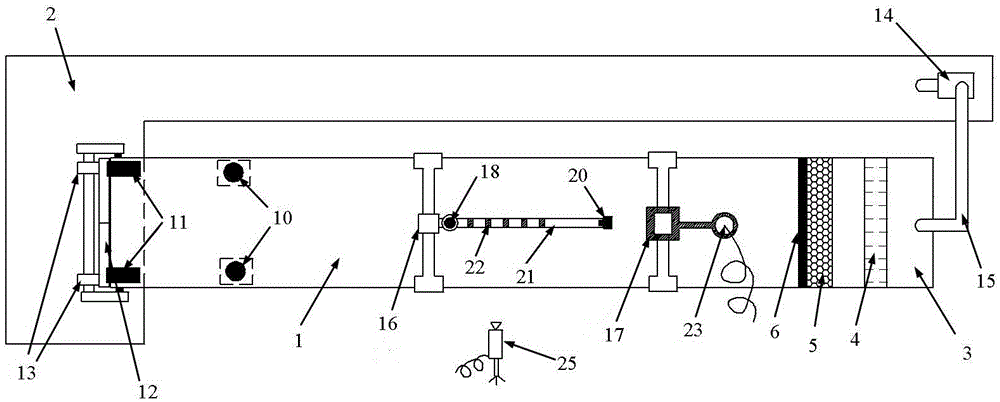

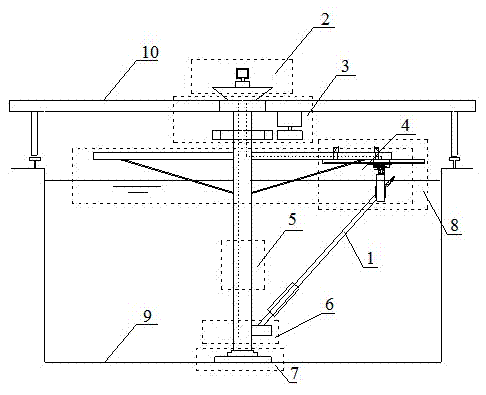

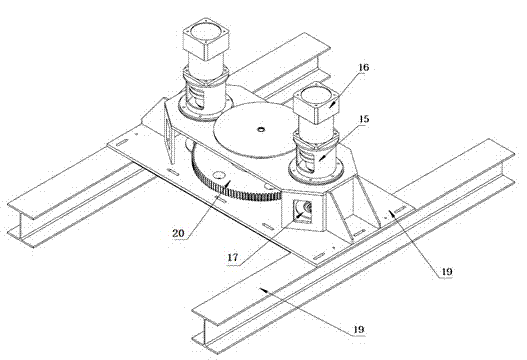

Vortex-induced vibration test device for stand pipe under bidirectional shear flow and bidirectional ladder shear flow

ActiveCN102109405ARealize vortex induced vibration testImprove accuracyHydrodynamic testingVibration testingComputer moduleEngineering

The invention relates to a vortex-induced vibration test device for a stand pipe under the bidirectional shear flow and the bidirectional ladder shear flow, and belongs to the technical field of marine engineering. The vortex-induced vibration test device comprises a stand pipe model mechanism, a measurement and analysis system platform module, a drive module, a top cantilever module, a cylinder shaft segmentation module and a bottom supporting module, wherein the fixed end of the stand pipe model mechanism is suspended and fixed below the top cantilever module; the cylinder shaft segmentation module is perpendicularly placed in a marine engineering deep pool and is respectively and perpendicularly connected with the bottom supporting module, the drive module and the top cantilever module; the bottom supporting module is fixedly arranged on the lifting bottom of the marine engineering deep pool; the drive module is respectively connected with the cylinder shaft segmentation module and the top cantilever module and is used for outputting power; the left end and the right end of the top cantilever module are respectively connected with the cylinder shaft segmentation module; and the measurement and analysis system platform module is respectively connected with the stand pipe model, the top cantilever module and the bottom cantilever module. The vortex-induced vibration test device is convenient to install, update and change, and meets different functional requirements.

Owner:SHANGHAI JIAO TONG UNIV

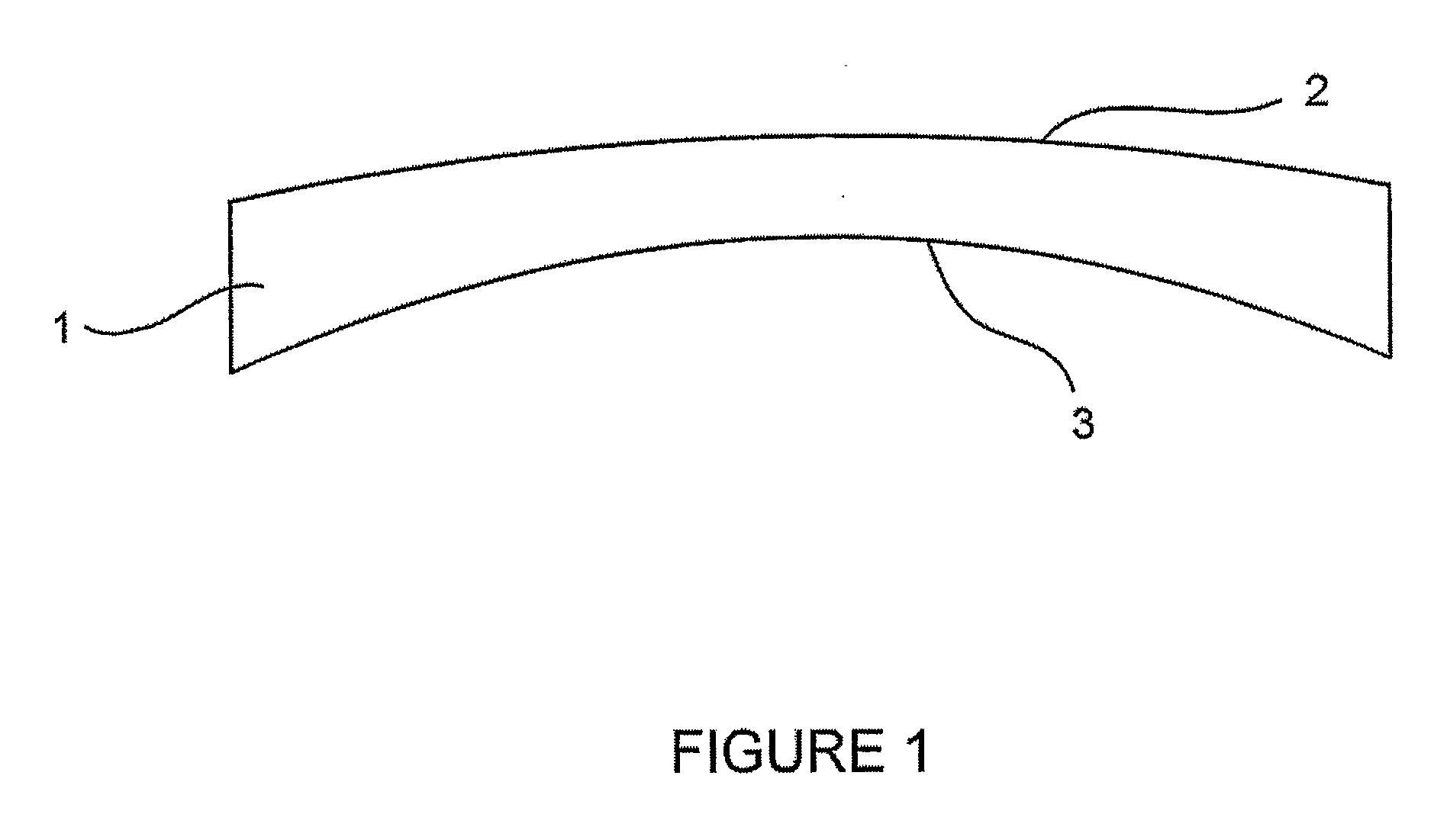

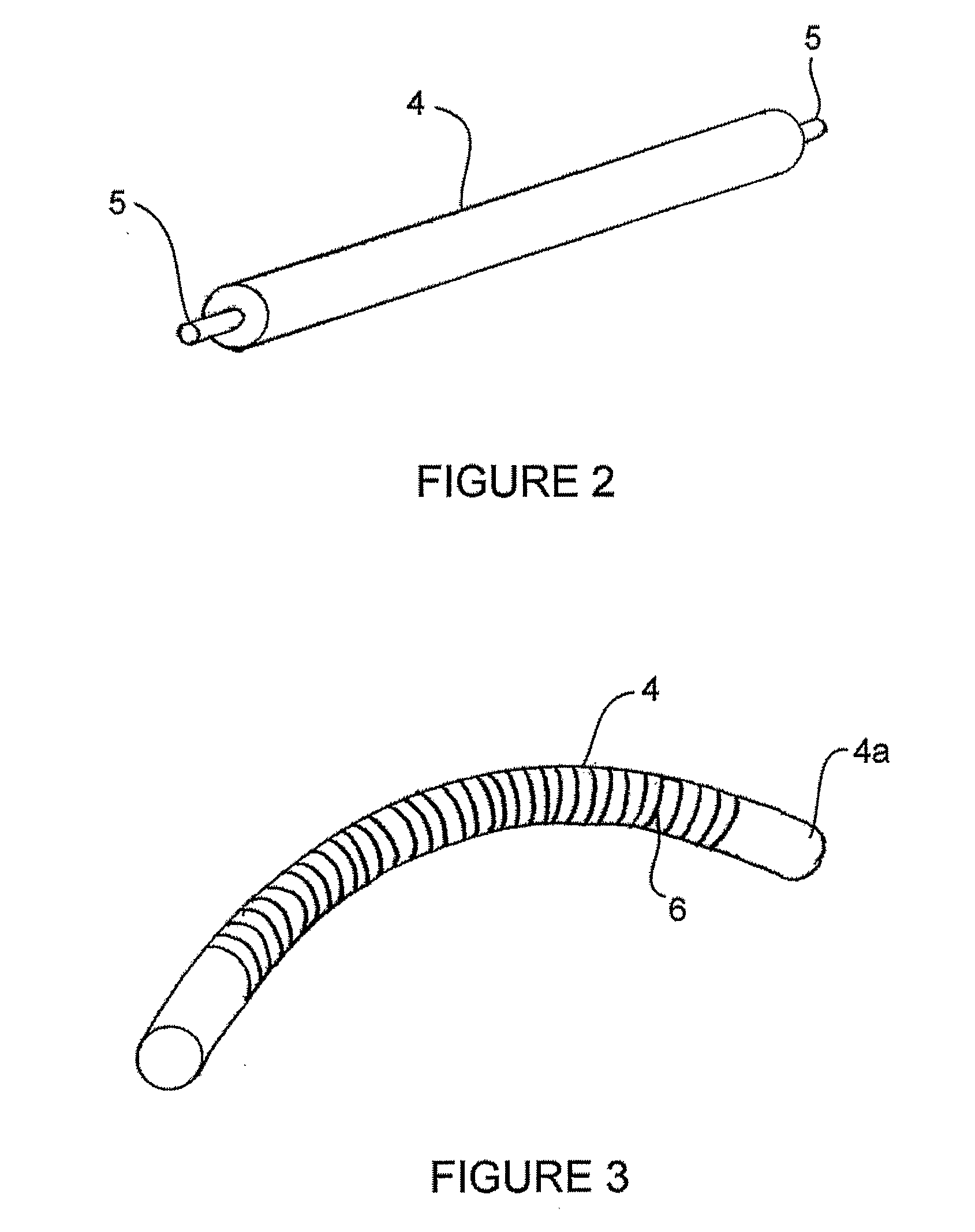

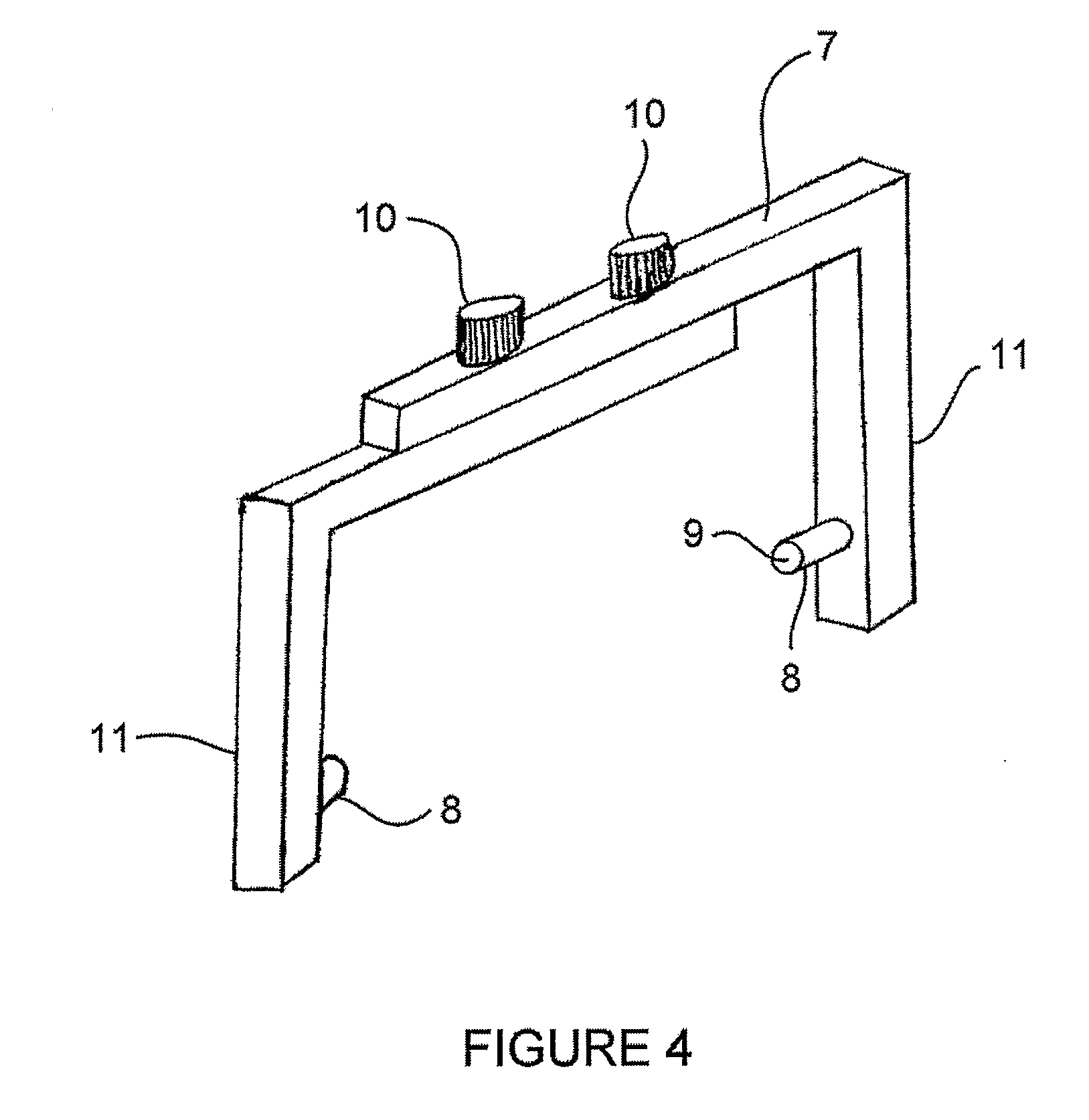

Methods for coating curved surfaces with a polarizing liquid

Methods and apparatuses for coating at least a portion of a curved surface of a lens with a polarizing liquid are disclosed throughout the specification. For example, there is provided a method comprising providing a lens having a curved surface, and applying a polarizing liquid to at least a portion of the curved surface by shear flow with a flexible apparatus. Other methods are included. Apparatuses include ophthalmic lenses having polarized coatings formed according to any of the disclosed methods.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Vortex-induced vibration simulation test device for deep sea riser model with movable top end under uniform flow

The invention provides a vortex-induced vibration rotary test device for an oblique riser with movable top under shear flow. The test device comprises a deep sea riser module, a top support module, a bottom support module, two vertical track modules, a horizontal track module, four motor modules, four fairing modules and a measurement analysis control module, wherein the two vertical track modules are connected with the bottom of the horizontal track module, the top support module and the bottom support module respectively; the horizontal track module is connected with the tops of the two vertical track modules; the two ends of the deep sea riser module are connected with the top support module and the bottom support module respectively; and the measurement analysis control module is connected with the deep sea riser module, the top support module and the bottom support module. According to the test device, vortex-induced vibration of a large-sized riser model under the influence of asea platform can be simulated by fully utilizing the vertical track modules and the horizontal track module; and the test device is very convenient to install and detach.

Owner:SHANGHAI JIAO TONG UNIV

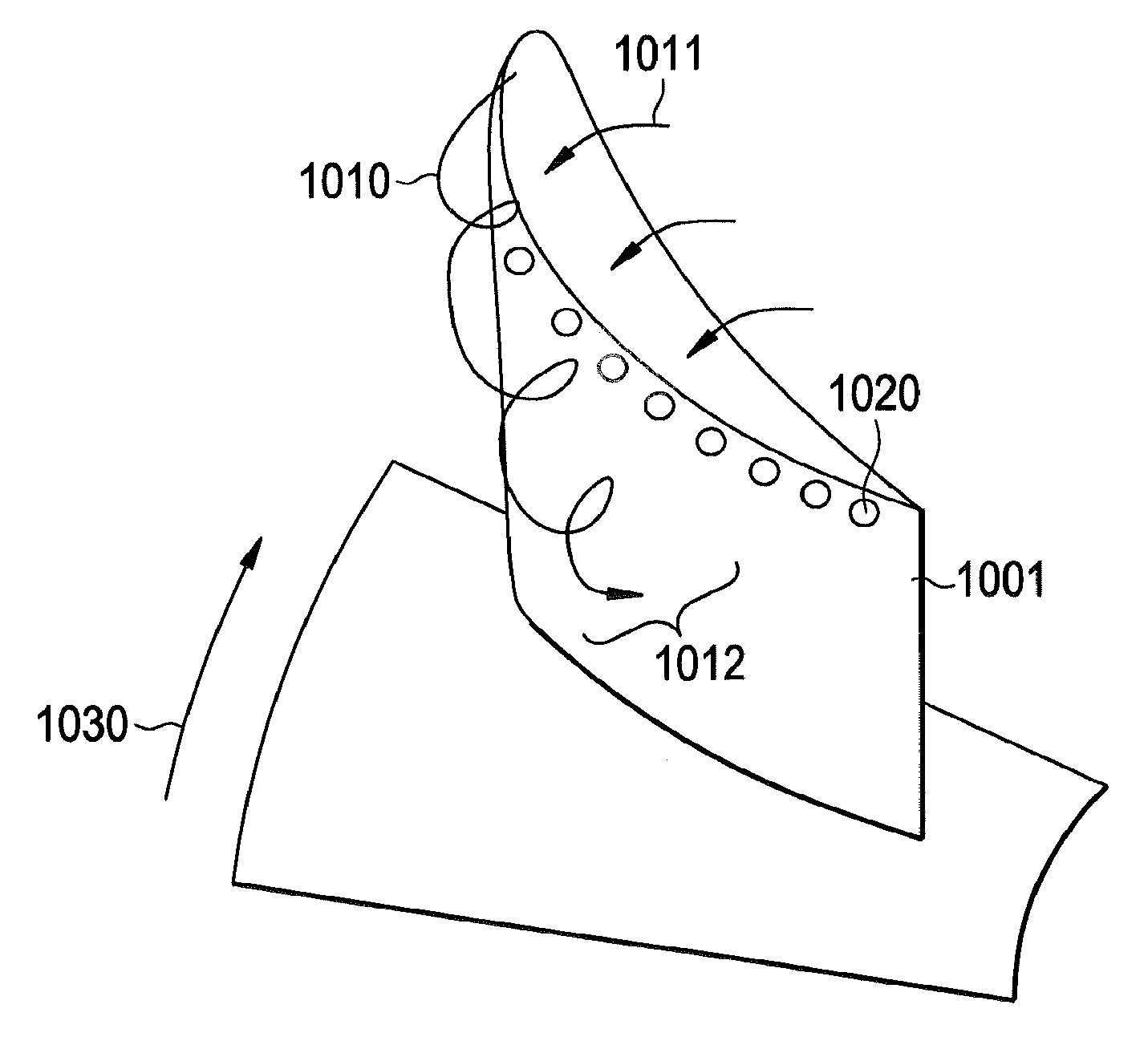

Reduction of Tip Vortex and Wake Interaction Effects in Energy and Propulsion Systems

An airfoil includes a plasma actuation surface integrated onto the airfoil surface. On the airfoil, the plasma actuation surface is configured to provide high-frequency plasma actuation along the plasma actuation surface such that excitation of the vortex flow or shear flow mitigates the vortex flow or the shear flow associated with the airfoil.

Owner:GENERAL ELECTRIC CO

Microfluidic chip-based, universal coagulation assay

ActiveUS20160069913A1Easy doseEnsures comparabilityBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careShear flow

A microfluidic, chip-based assay device has been developed for measuring physical properties of an analyte (particularly, whole blood or whole blood derivatives). The technologies can be applied to measure clotting times of whole blood or blood derivatives, determine the effects of anticoagulant drugs on the kinetics of clotting / coagulation, as well as evaluate the effect of anticoagulant reversal agents. These technologies can additionally be used to optimize the dosage of anticoagulation drugs and / or their reversal agents. The assay is independent of the presence of anticoagulant; clotting is activated by exposure of the blood sample in the device to a glass (or other negatively charged material such as oxidized silicon) surface, which activates the intrinsic pathway and can be further hastened by the application of shear flow across the activating materials surface. The absence of chemical activating agents and highly controlled and reproducible micro-environment yields a point of care universal clotting assay.

Owner:PEROSPHERE TECH INC

Device and method for monitoring leukocyte migration

A device for monitoring leukocyte migration is provided. The device generally includes a plurality of chambers, each chamber including a channel in which leukocyte migration mediators or endothelial cells are disposed therein. The device is fabricated in the footprint of a standard microtiter plate. The invention also provides a method of using the device to monitor leukocyte migration in the presence of physiological shear flow and therefore simulate physiological conditions of a blood vessel in vivo. The invention further provides a method of using the device to high-throughput screen a plurality of test agents.

Owner:SURFACE LOGIX INC

Sewage filter

InactiveCN102228759AImprove purification efficiencySS reductionFiltration separationSedimentation settling tanksFlocculationWater flow

The invention provides a sewage filter, which synthesizes a shallow tank theory, a dynamic coagulation theory, an accelerated coagulation theory and an inclined plate technology, effectively solves the problem of easiness in blockage of the traditional inclined plate. The sewage filter is used for subdividing raw motion water through by using filter masks and a plurality of through hole structures; and the raw water forms stable eddies at rear edges of plate holes of filter mask bodies. Under the entrainment action of the eddies, non-fluidic substances in the raw water are collected at centers of the eddies and get in continuous contact and collision with one another in eddy cores to undergo a flocculation reaction, and slides down along the mask bodies under the gravity action to settle into a mud collecting hopper, so that the purposes of removing suspended substances in the raw water and cleaning a water body are achieved. The sewage filter can rotate around an axis of a rotating shaft; and a strongly turbulent shear flow is formed through left and right repeated quick rotation to scour an inclined plate at a high speed and to clean deposits and blockages very conveniently.

Owner:韦志锋 +1

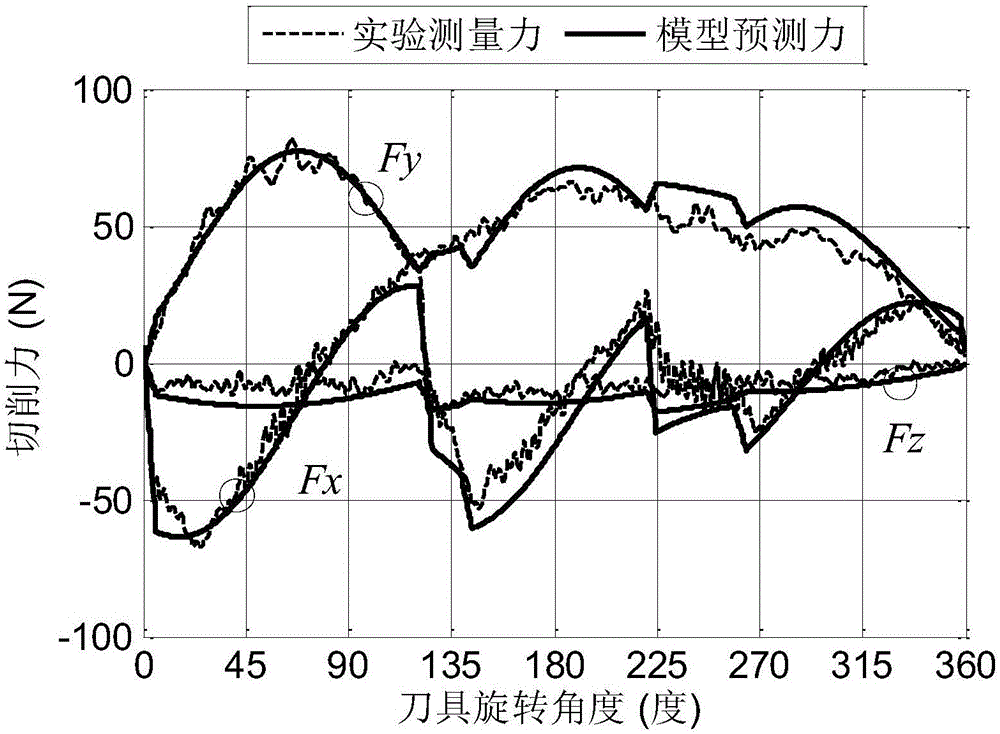

Cutting force prediction method considering tooth spacing angles, helical angles and eccentricity of cutter

ActiveCN106808320AAvoid problems requiring retest calibrationLow costMeasurement/indication equipmentsHelical scanAngular degrees

The invention belongs to the technical field related to cutting force prediction in a metal machining process, and discloses a cutting force prediction method considering tooth spacing angles, helical angles and eccentricity of a cutter. The method comprises the following steps: (1) determining physical parameters of a workpiece, geometrical parameters of the cutter and machining parameters of a process; (2) dividing the cutting area of the cutter into multiple sections of cutting micro-units, and calculating cutter angle positions of the cutting micro-units at any moment, wherein the cutter operates in the cutting area; (3) calculating actual each tooth feed and instantaneous dynamic cut thickness of the cutting micro-units; (4) calculating shear flow stress, a shear force coefficient and a cutting edge force coefficient; (5) calculating cutting micro-unit force of the cutting micro-units in the tangential, radial and axial directions of the cutter, and transforming the micro-unit force to the X, Y and Z axes of a machine tool coordinate system via a Cartesian coordinate system; and (6) summing integrals of all the cutting micro-unit force achieving a cutting effect on each cutting edge to obtain three-dimensional dynamic cutting force at any moment.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for testing vortex-induced vibration of suspended flexible standpipe based on open channel experiment water tank

InactiveCN105157943AMeet the vortex induced vibration testMeet the experimental needsVibration testingWater flowHigh speed video

The invention relates to a method for testing the vortex-induced vibration of a suspended flexible standpipe based on an open channel experiment water tank. The method employs the open channel experiment water tank and comprises the following steps of: (1) placing an experiment standpipe; (2) constructing a water flow environment of the open channel experiment water tank; (3) placing a testing instrument; (4) testing the velocity profile of a shear flow; and (5) testing the vibration response of the flexible standpipe. The water tank bottom slope, the water flow, the water depth, the velocity profile of the shear flow, the flexible standpipe material and size can be adjusted according to an experiment requirement. The method captures the vibration displacement of a mark point on the flexible standpipe by using two high-speed video cameras so as to achieve non-intervention interference-free flexible standpipe vibration testing under a shear flow velocity profile condition.

Owner:SOUTHWEST PETROLEUM UNIV

Measurement method for large-displacement shear-flow of rock under high temperature and high pressure

ActiveCN104596907AGuaranteed measurementEasy to measurePermeability/surface area analysisTest sampleShear flow

The invention discloses a measurement method for the large-displacement shear-flow of rock under a high temperature and a high pressure, relates to a rock mechanics test method, and solves the technical problem that measurement for the large-displacement shear-flow of rock under high temperature and high pressure cannot be carried out by the existing method. According to the measurement method disclosed by the invention, high-temperature-resistant rubber is arranged in a pressure kettle with two open ends in a sleeving manner, two semi-cylindrical rock test samples with the same section shape and dimensions and different lengths are combined and then placed into a high-temperature-resistant rubber sleeve, a pressure transfer medium fills up the space between the outer wall of the rubber sleeve and the inner wall of the pressure kettle, heating and confining pressure applying devices are configured for the pressure kettle, a pore pressure applying device is configured for an axial pressing cylinder, a pore fluid flows out through a crack surface in the middle of the combined rock test sample, and flow characteristics in a rock shear process under the high temperature and the high pressure are obtained by measuring the flow speed of the pore fluid flowing out from an axial fixed cylinder. The measurement method disclosed by the invention has the advantages of being reasonable in structure, simple in operation method, and easy to realize the measurement for the large-displacement shear-flow of the rock under high temperature and high pressure.

Owner:TAIYUAN UNIV OF TECH

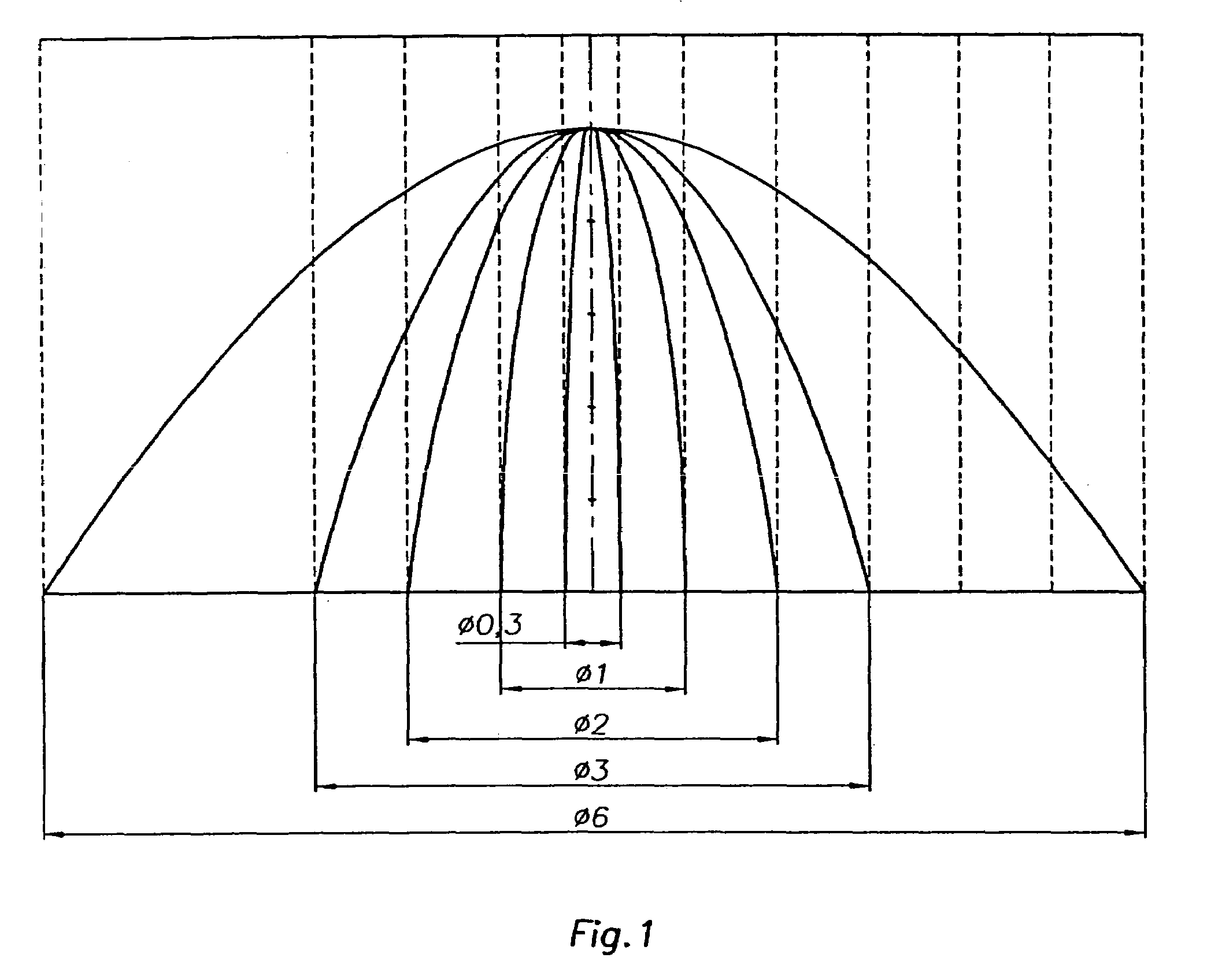

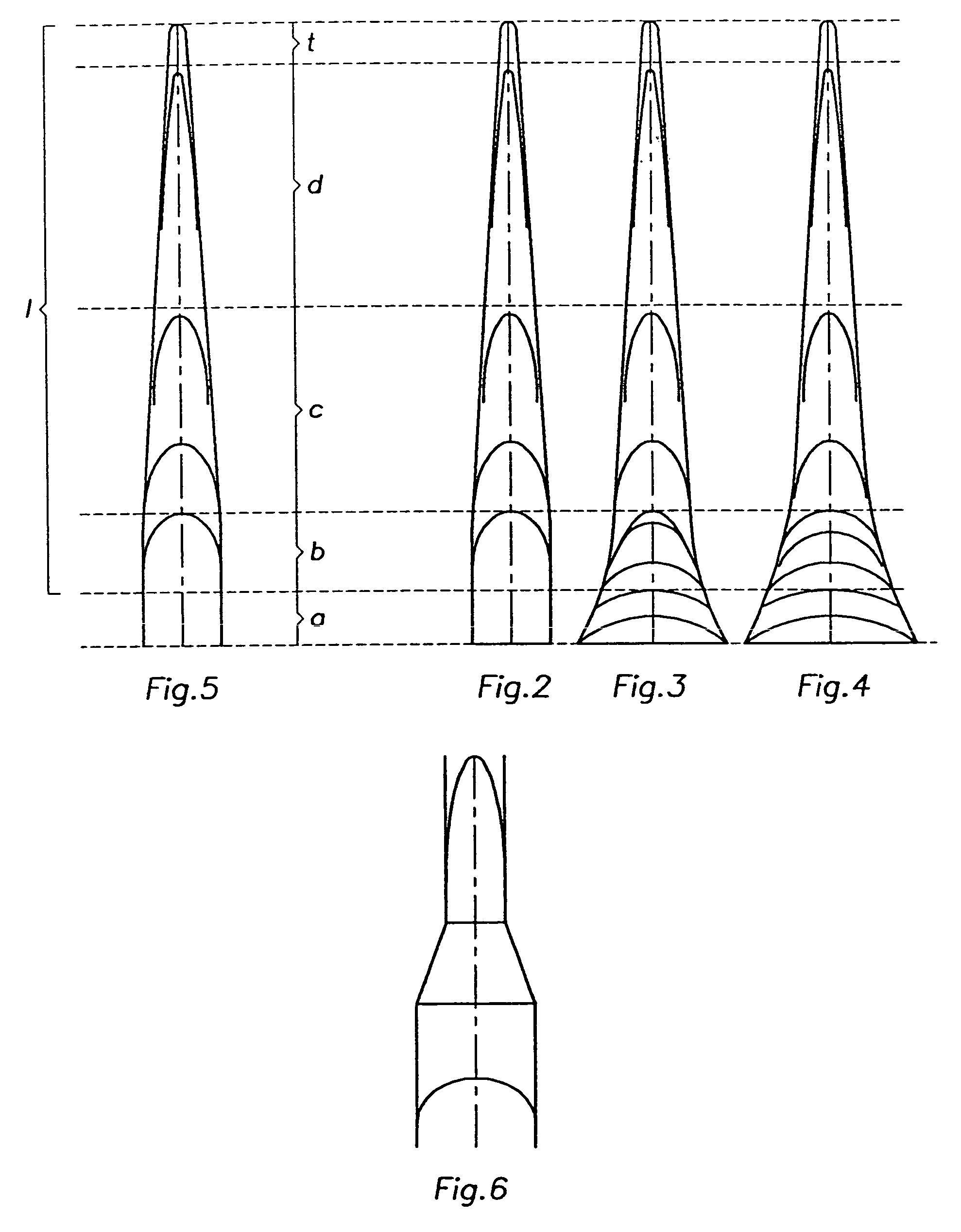

Method and device of the production of brushes

In a method for producing a bristle from thermoplastic polymers through injection molding, the molten polymer mass is injected under pressure into a bristle-molding channel of predetermined length having a predetermined cross-section along this length and the channel is vented during injection molding. To produce injection-molded bristles with excellent bending behavior, the magnitude of the injection pressure is adjusted in dependence on the cross-sectional extension of the bristle-molding channel such that a shear flow is generated with high core speed in the center of the molten polymer mass flow and large shearing effect due to wall friction of the molten polymer mass under distinct longitudinal orientation of the polymer molecules at least in the region of the molten polymer mass close to the wall, which is maintained along the channel wherein the channel is simultaneously vented along its length to support maintenance of the shear flow. A device for carrying out the method is also described.

Owner:GEKA

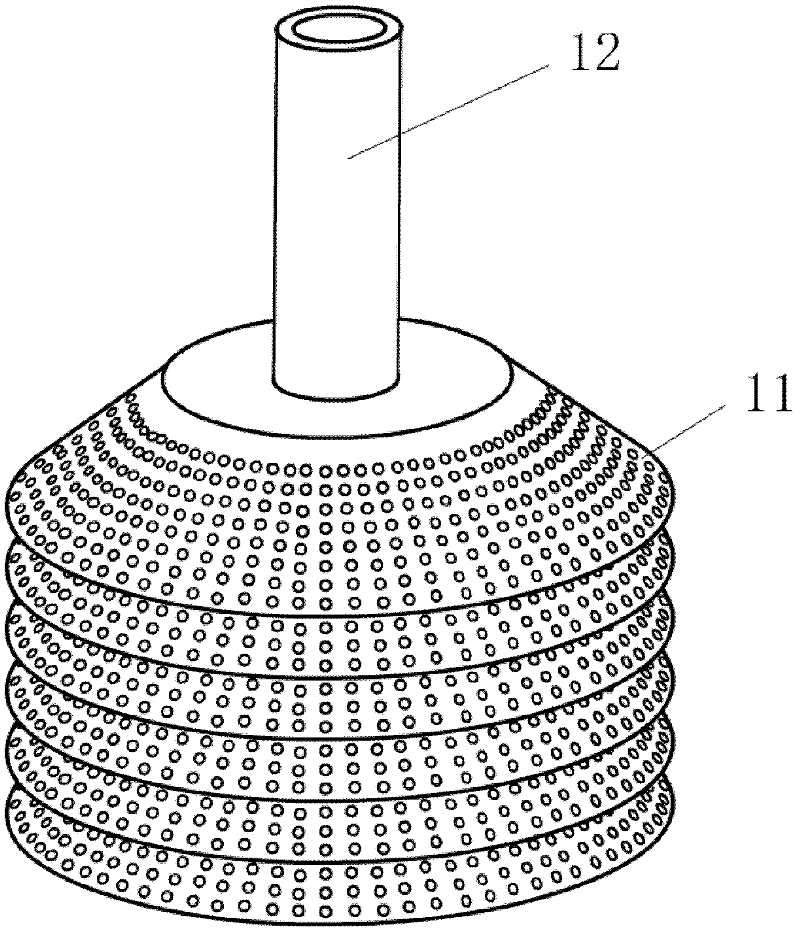

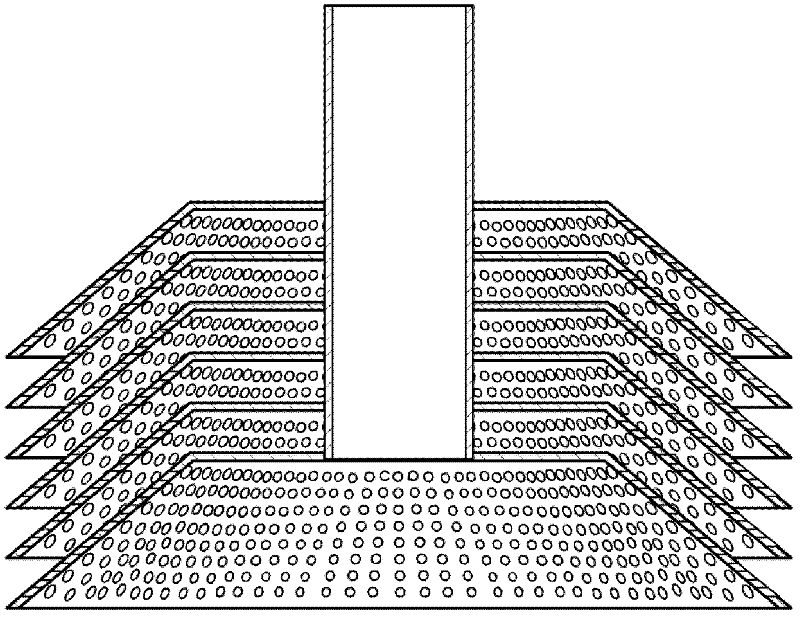

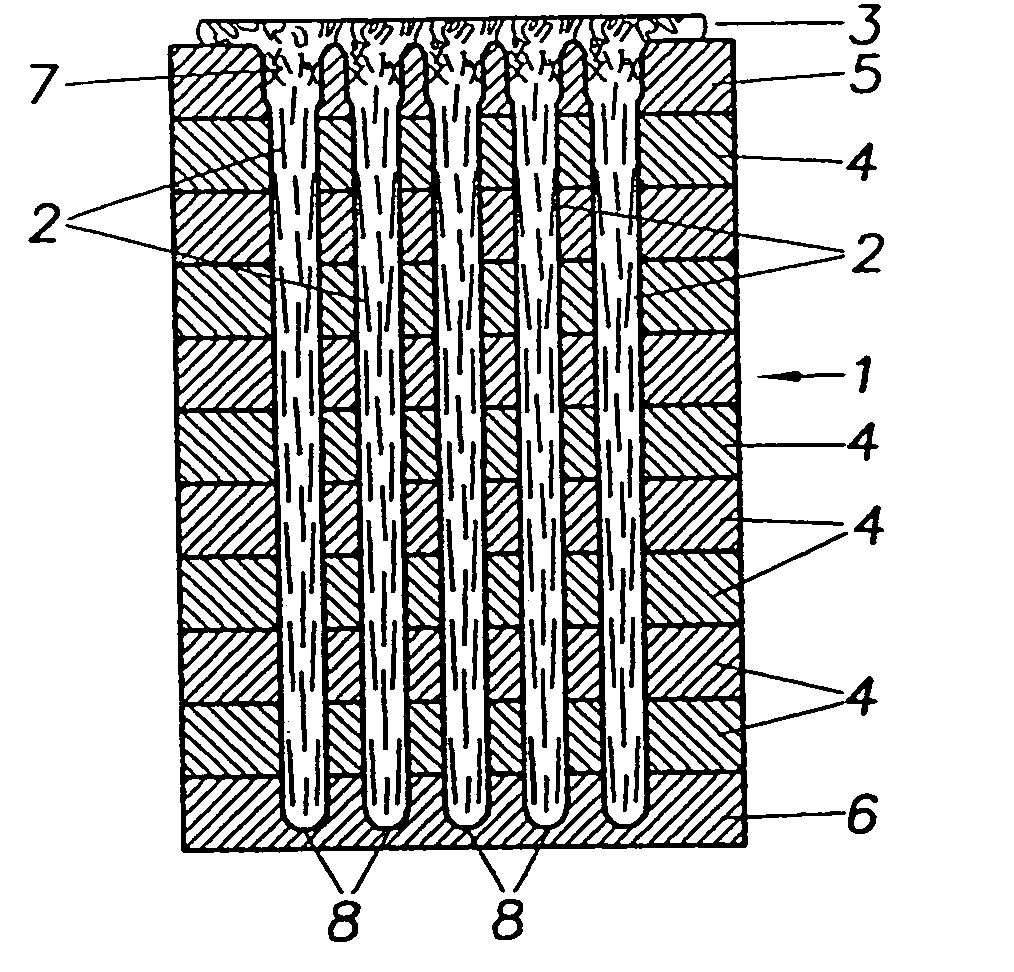

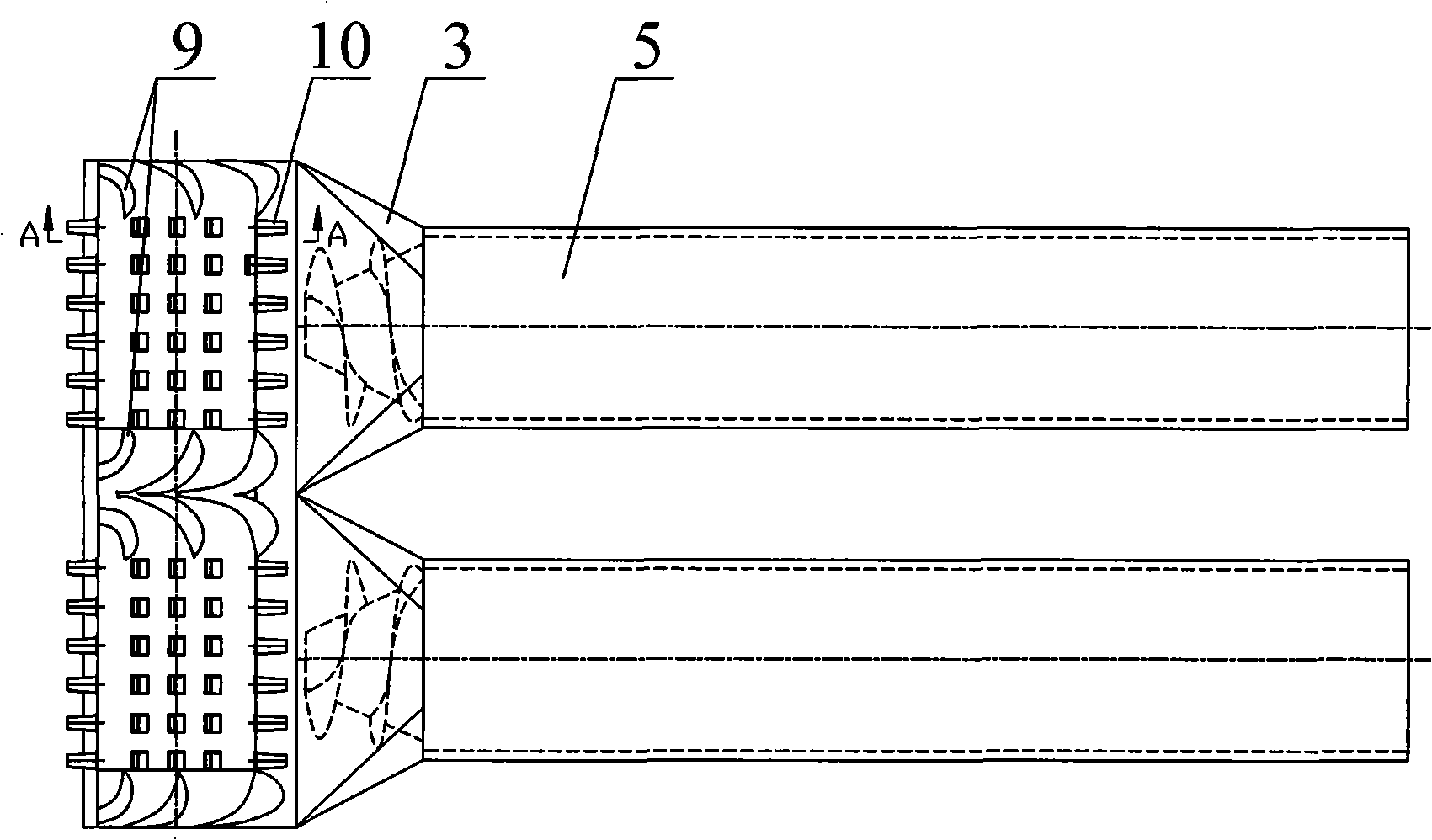

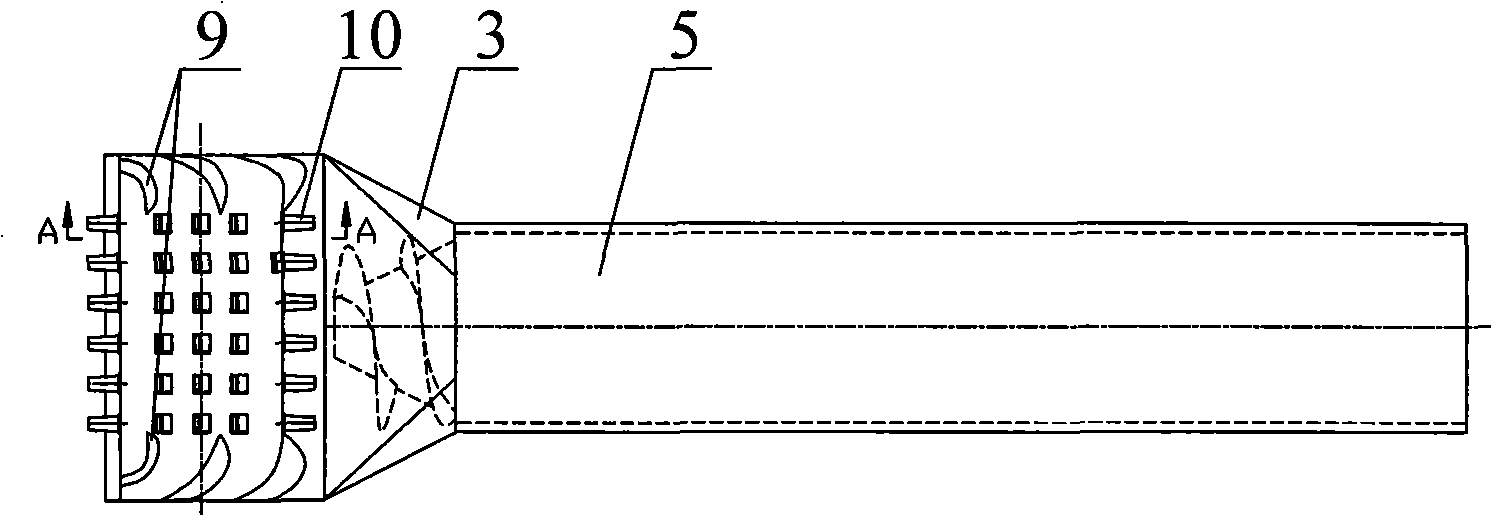

Longitudinally axial flow threshing and separating installation

The invention relates to a longitudinal axial flow threshing and separating unit which comprises an auxiliary feeding threshing unit and a longitudinal axial flow threshing and separating unit; the auxiliary feeding threshing unit consists of an auxiliary feeding threshing cylinder 2, an upper cover plate 1 and a punching concave plate 8. The longitudinal axial flow threshing and separating unit consists of a dome 3, a feeding auger 4, a top cover 5, a longitudinal axial flow threshing and separating cylinder 6 and a separating concave plate 7. The longitudinal axial flow threshing and separating unit integrates the functions of the shear flow threshing unit and the auxiliary feeding device of a traditional longitudinal axial flow threshing and separating unit, is applicable to crops with quite large feed quantity, has the advantages of even and smooth feeding, low price, simple structure and small size, and is easier to be deployed on medium- and small-sized harvesters accepted by most markets of our country.

Owner:JIANGSU UNIV

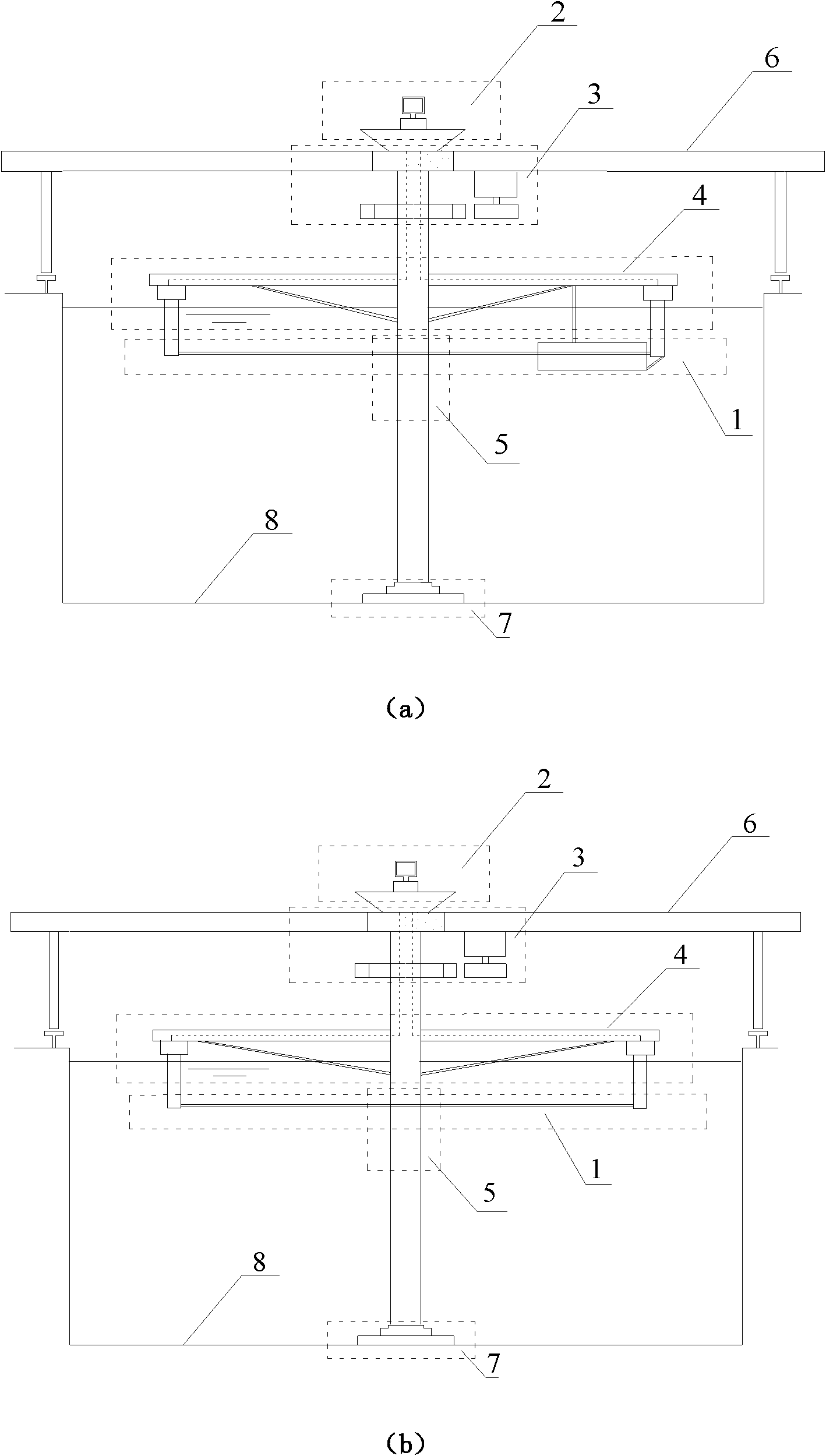

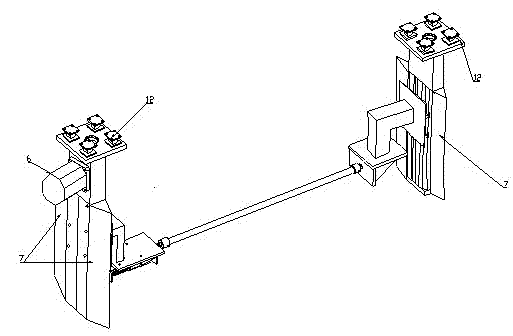

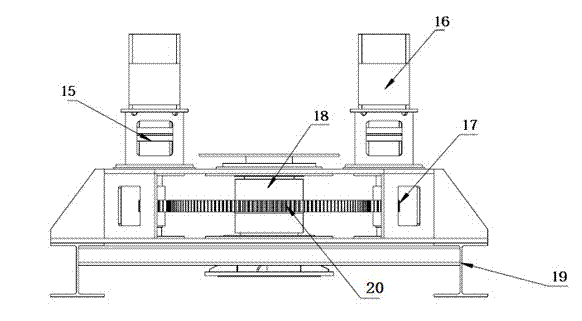

Vortex induced vibration rotation testing device of inclined vertical pipe with movable top part under step shear flow

ActiveCN102410920ARealize vortex induced vibration testImprove accuracyVibration testingRotation testEngineering

The invention provides a vortex induced vibration rotation testing device of an inclined vertical pipe with a movable top end under a step shear flow, belongs to the technical field of marine engineering. The vortex induced vibration rotation testing device comprises a vertical pipe model mechanism, a measurement analysis system platform module, a driving module, a top cantilever module, a cylinder shaft section module, a bottom vertical pipe fixing module, a bottom supporting module and an oscillation module; the vertical pipe model mechanism is fixed between the oscillation module and the bottom vertical pipe fixing module, the oscillation module is fixed on the top cantilever module, the driving module is respectively connected with the cylinder shaft section module and the top cantilever module, the left and right ends of the top cantilever module are respectively connected with the cylinder shaft section module, the measurement analysis system platform module is respectively connected with the vertical pipe model, the top cantilever module, the oscillation module and the bottom vertical pipe fixing module. The testing device provided by the invention can simulate the verticalpipe step shear flow field and vertical pipe top platform movement in an actual size.

Owner:SHANGHAI JIAO TONG UNIV

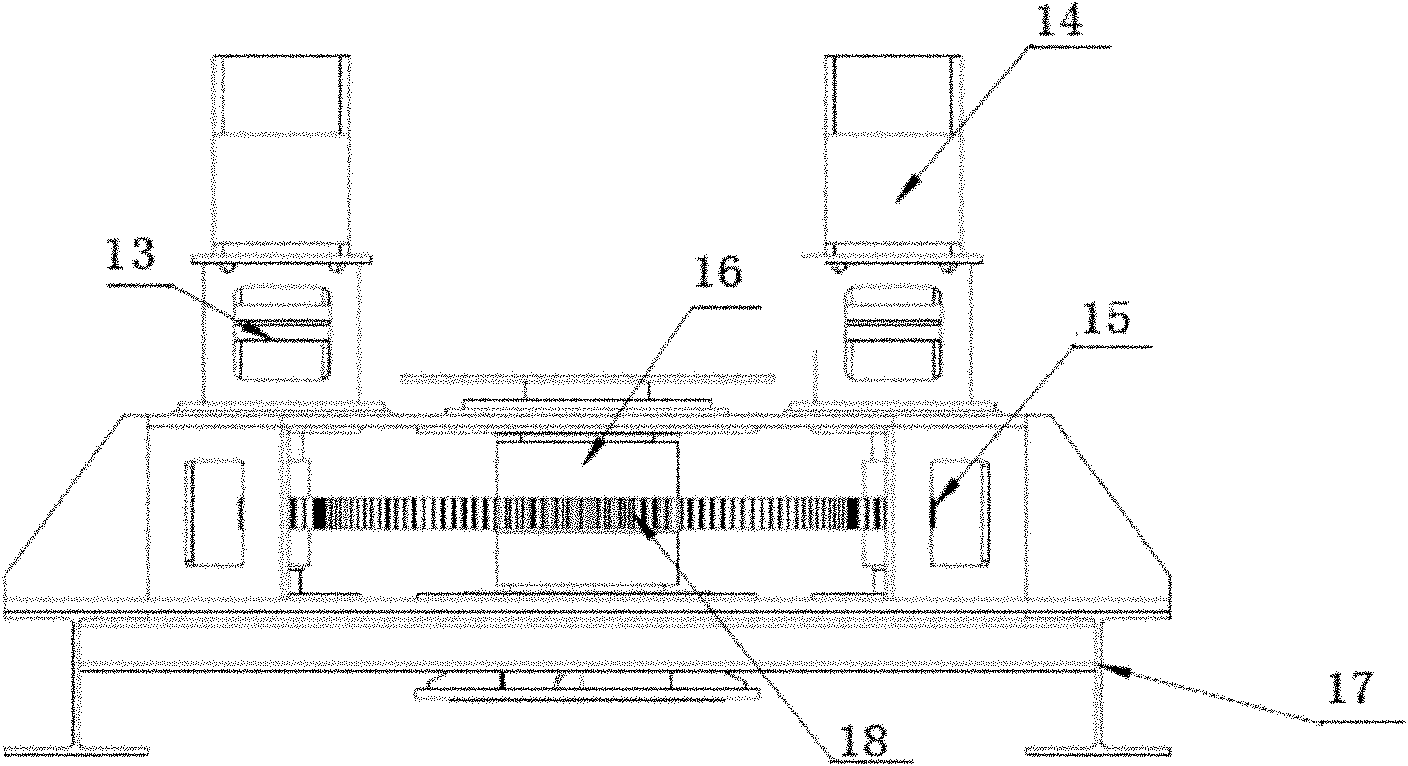

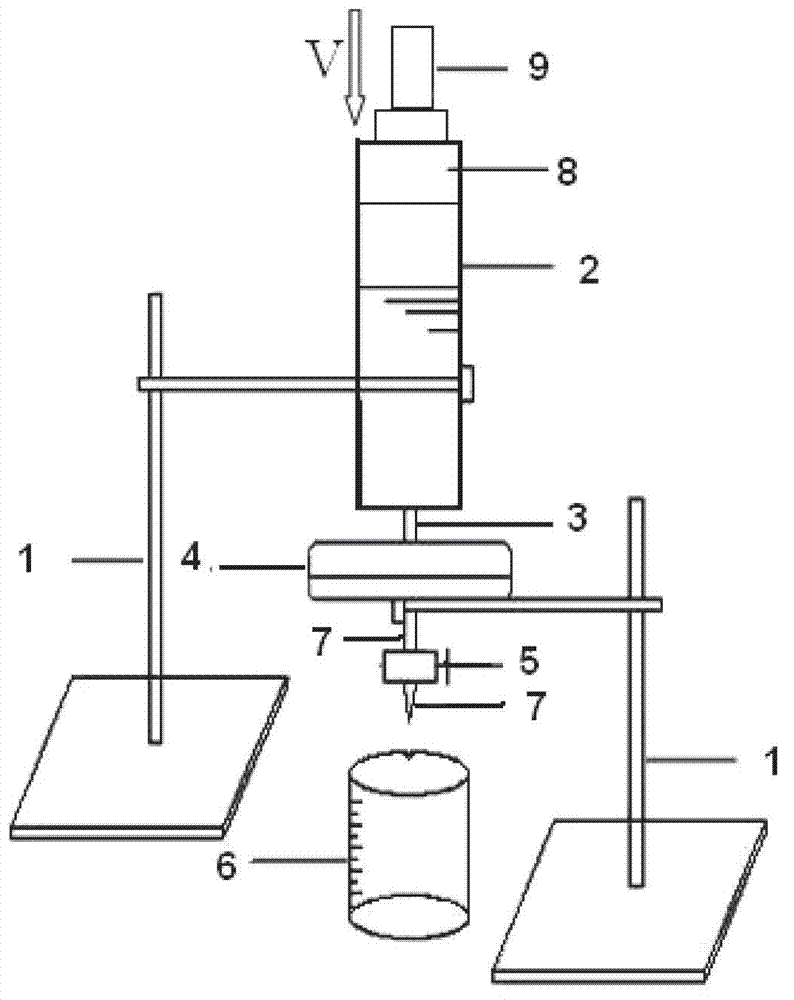

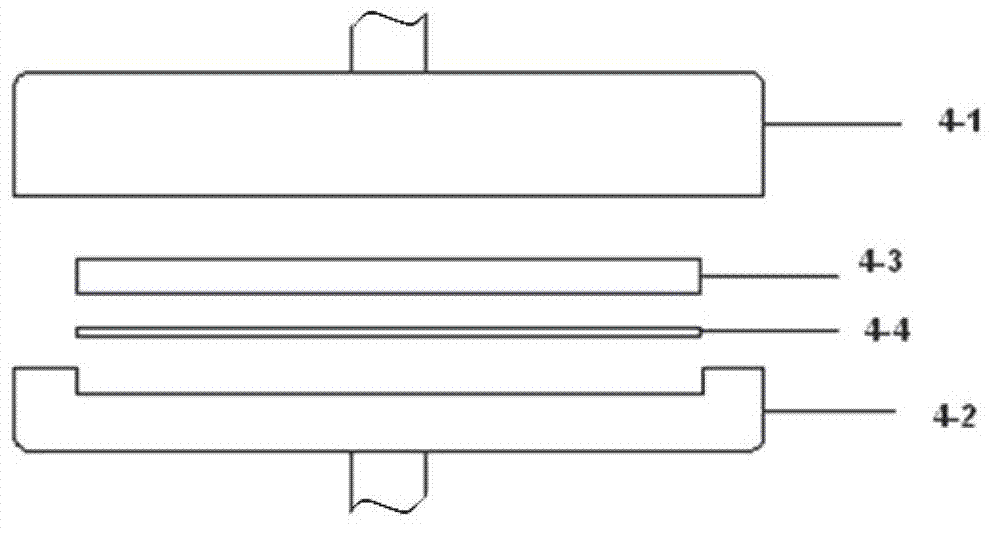

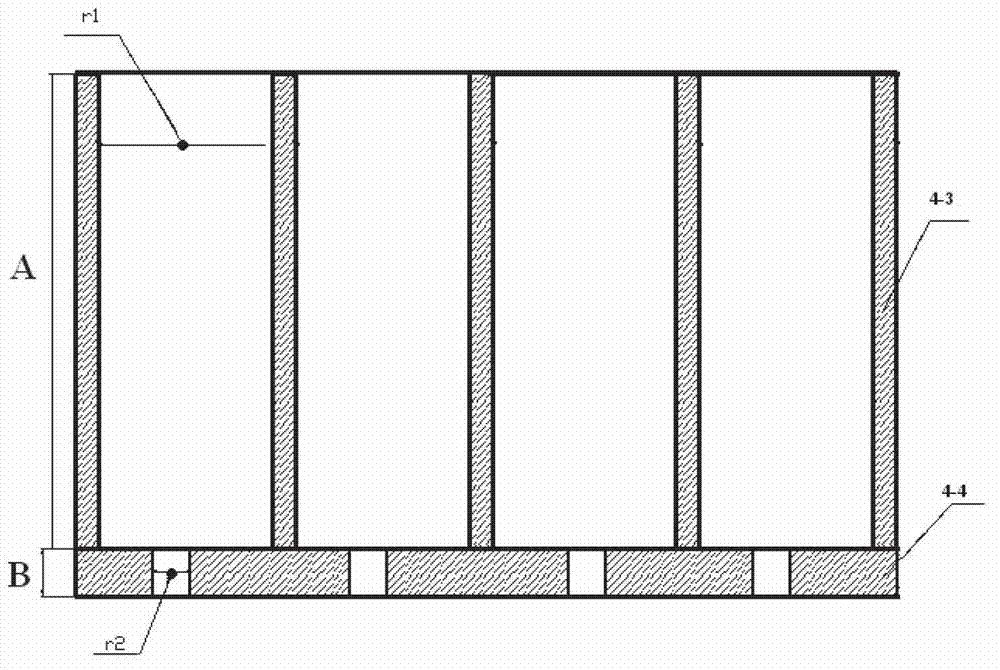

Test method for hydraulics size of shear flow polymer and test device thereof

InactiveCN102927953AAvoid lateral streamingImprove stabilityMeasurement devicesEngineeringPolymer solution

Provided are a test device and a test method for the hydraulics size of shear flow polymer. The device comprises a liquid barrel, a shear flow generator, a filter liquid collection container and a support for supporting the liquid barrel and the shear flow generator, wherein the liquid barrel is provided with a piston matched with the inner diameter of the liquid barrel, the lower end of the liquid barrel is communicated with the shear flow generator, the shear flow generator is composed of an upper chuck, a lower chuck, an upper layer filter membrane and a lower layer filter membrane, the upper layer filter membrane and the lower layer filter membrane are arranged on the lower chuck, a liquid outlet pipe is positioned at the lower portion of the lower chuck, a control valve is positioned on the liquid outlet pipe, and the filter liquid collection container is positioned under the liquid outlet pipe. The method using the test device comprises the steps of preparing polymer solution, filtering and drawing relation curve between viscosity retention rate and corresponding hole diameter of the lower layer filter membrane. When the viscosity retention is 70%, the hole radius of the corresponding lower layer filter membrane is the average hydraulics radius of the shearing rate.

Owner:SOUTHWEST PETROLEUM UNIV

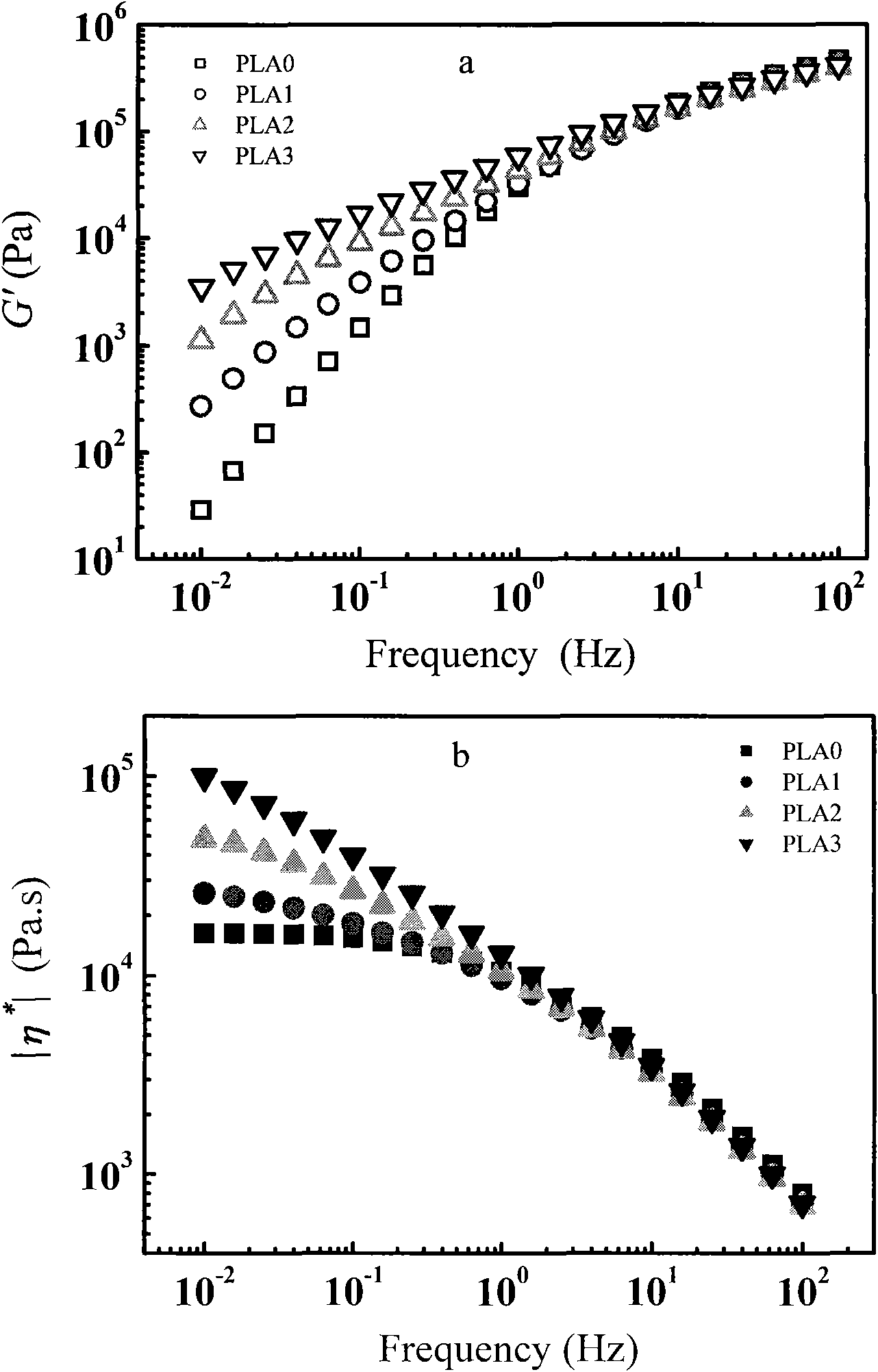

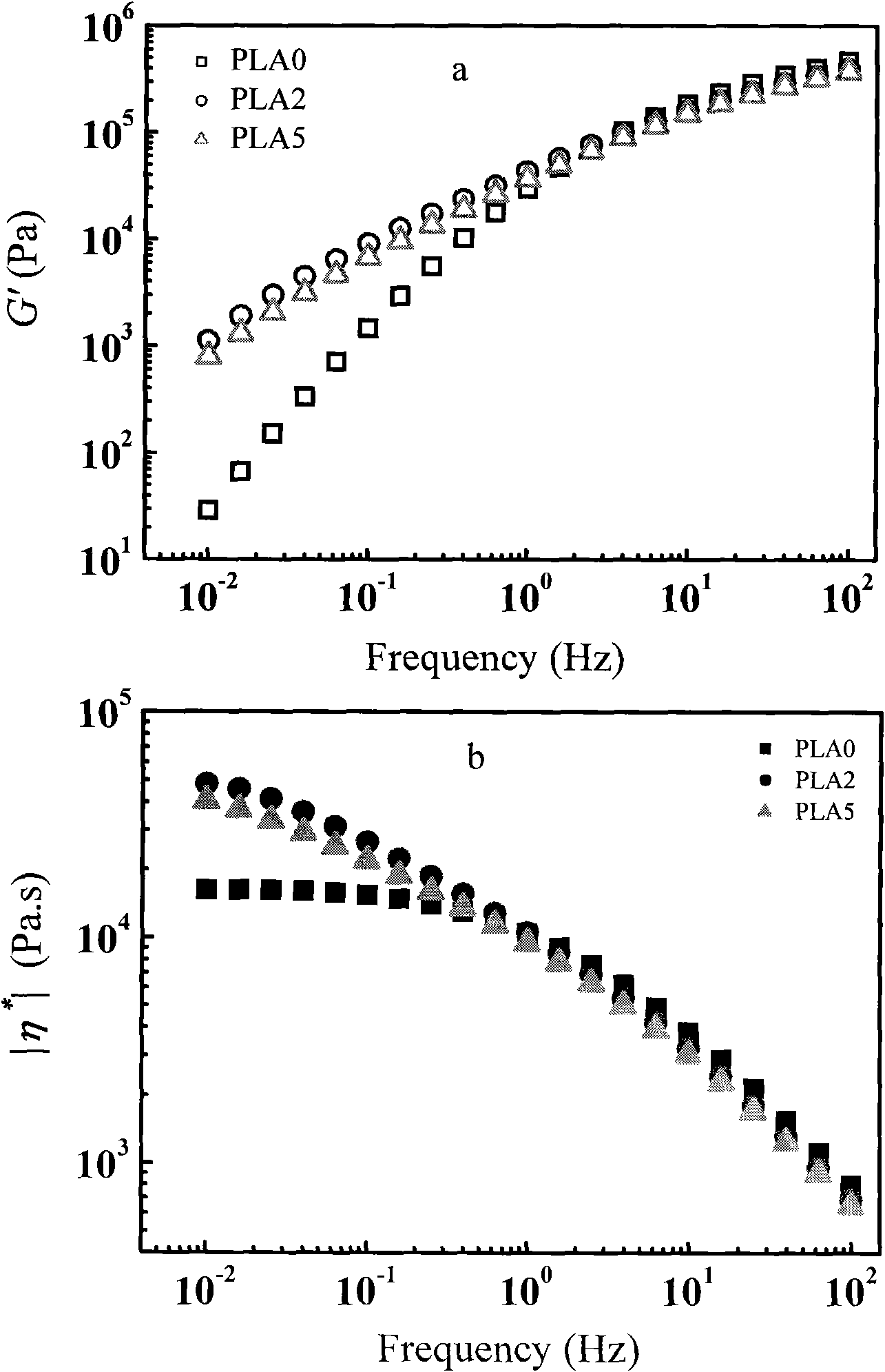

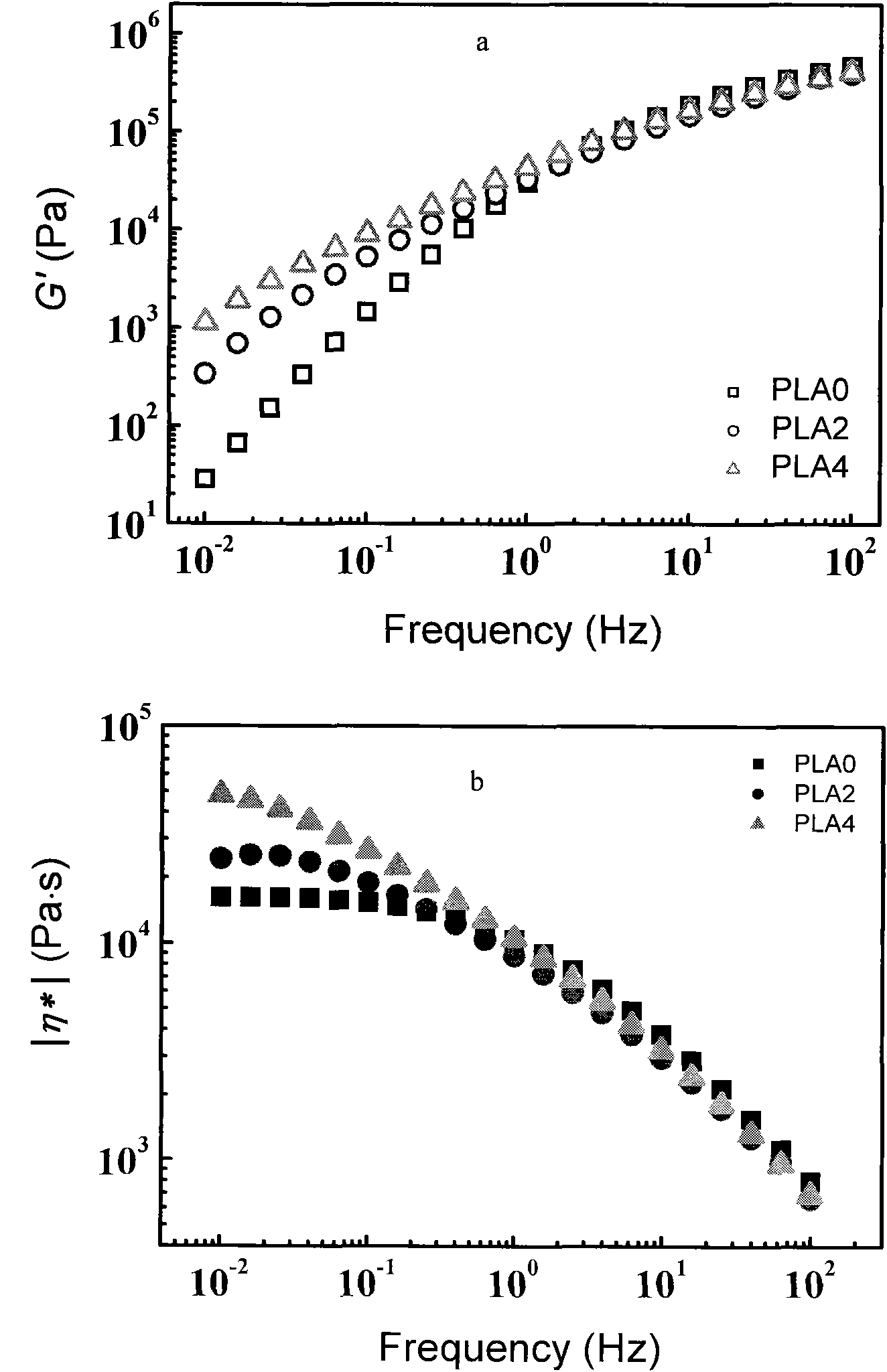

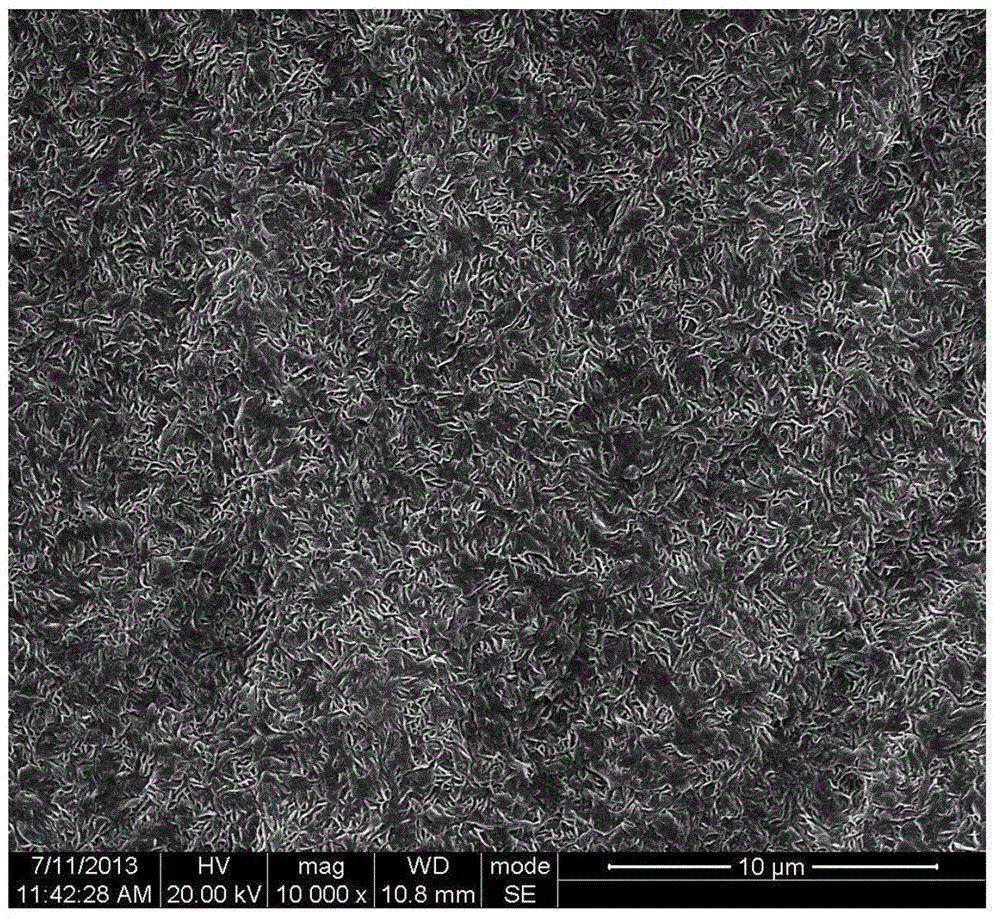

Long chain branching polylactic resin and preparation method thereof

InactiveCN101921371AImprove formation efficiencyHas strain hardening propertiesPolymer scienceZero shear viscosity

The invention discloses a long chain branching polylactic resin and a preparation method thereof. In the long chain branching polylactic resin, constitutional repeating units of a main chain and branch chains are lactic acid, wherein branch points on the main chain are tertiary carbon atoms in the lactic acid constitutional repeating units of the main chain. The preparation method comprises the steps of uniformly mixing a solution-mixed aid and a linear polylactic resin, and forming a long chain branching structure through internal melt mixing or double-screw reaction extrusion. The branch chain molecular weight Mb is larger than the entanglement molecular weight Me, the molecular weight is obviously improved, low-frequency end storage modulus G' and zero shear viscosity eta 0 are obviously improved during shear flow, the gel content is less than 1 percent, obvious strain hardening characteristic is shown during extensional flow, the requirement for secondary forming processing is met, and the tensile strength is obviously improved to 64MPa. The resin can be applied to the fields such as foaming, melt spinning and the like, and can be expansively applied to the fields such as foam packaging materials and clothing fibers.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-wear-resisting high-strength ultra-high molecular weight polyvinyl artificial articular material and preparation method thereof

InactiveCN105001486APreserve oxidation stabilityThe method is efficientTissue regenerationProsthesisPolymer scienceBoundary friction

The invention relates to a high-wear-resisting high-strength ultra-high molecular weight polyvinyl artificial articular material and a preparation method thereof. The high wear-resisting high-strength ultra-high molecular weight polyvinyl artificial articular material is prepared by melt blending and injection moulding of ultra-high molecular weight polyethylene (UHMWPE) and ultra-low molecular weight polyethylene (ULMWPE). The preparation method comprises the following steps of 1 irradiation-crosslinking UHMWPE preparation; 2 crosslinking UHMWPE / ULMWPE blend preparation; 3 vibrating-shearing injection moulding. According to the high-wear-resisting high-strength ultra-high molecular weight polyvinyl artificial articular material and the preparation method thereof, the wear-resisting performance of the UHMWPE is improved greatly by using the irradiation crosslinking technology, the melt viscosity of the crosslinking UHMWPE is reduced greatly by adding minute quantity of ULMWPE, and the melt machinability of the crosslinking UHMWPE is guaranteed; in the pressure maintaining stage of injection moulding, shearing flow field is introduced, a large number of reinforcing orientation lamella structures are induced to be generated, the mechanical performance of the material is improved greatly, residual free radical caused by irradiation in the UHMWPE is removed effectively, the oxidation stability of the material is improved, and the material is suitable for be used as boundary friction material of an artificial joint and is especially suitable for total knee prosthesis with higher demand of mechanical performance.

Owner:安徽瑞琦塑胶科技有限公司

Method for Gentle Mechanical Generation of Finely Dispersed Micro-/Nano-Emulsions with Narrow Particle Size Distribution and Device for Carrying Out Said Method

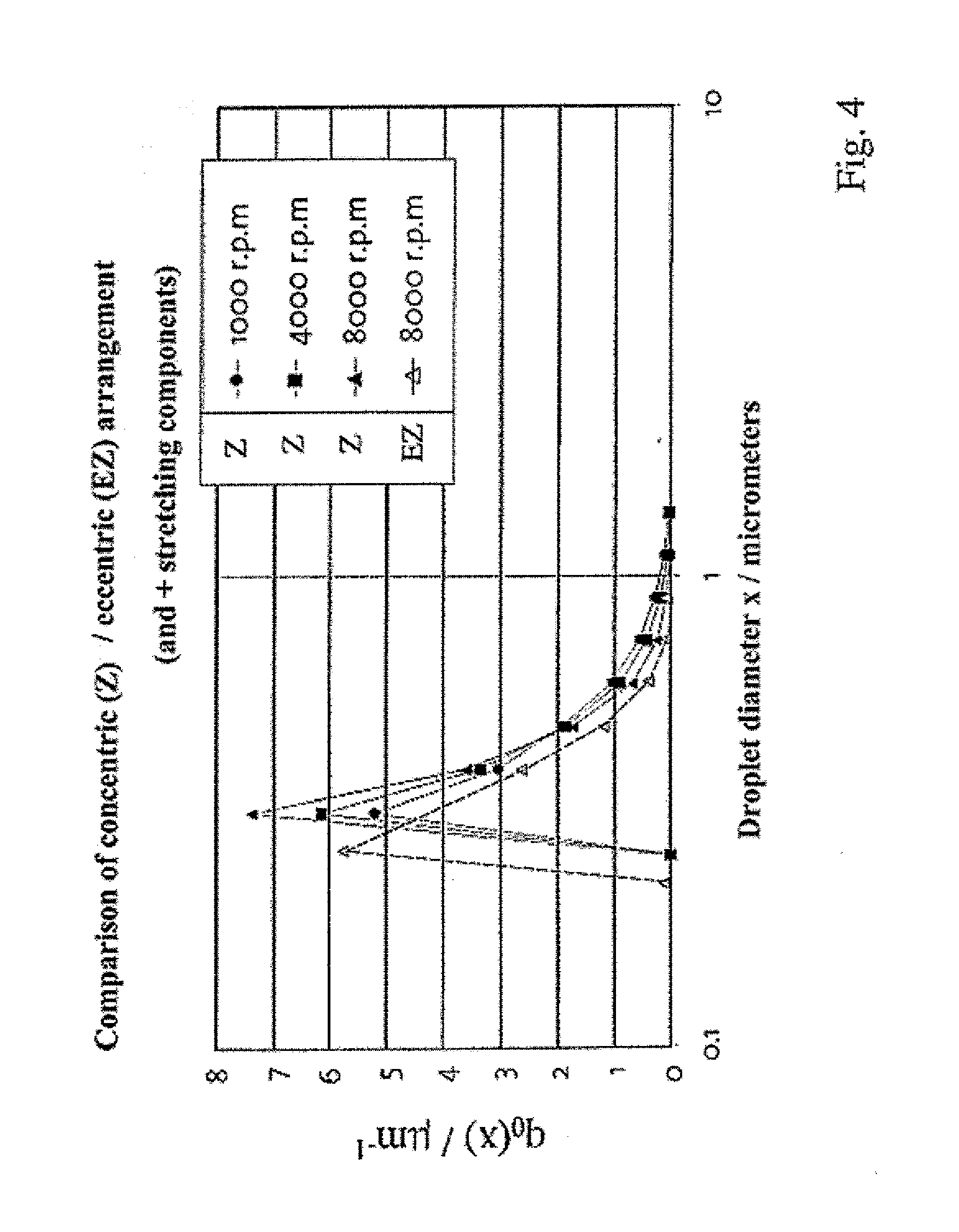

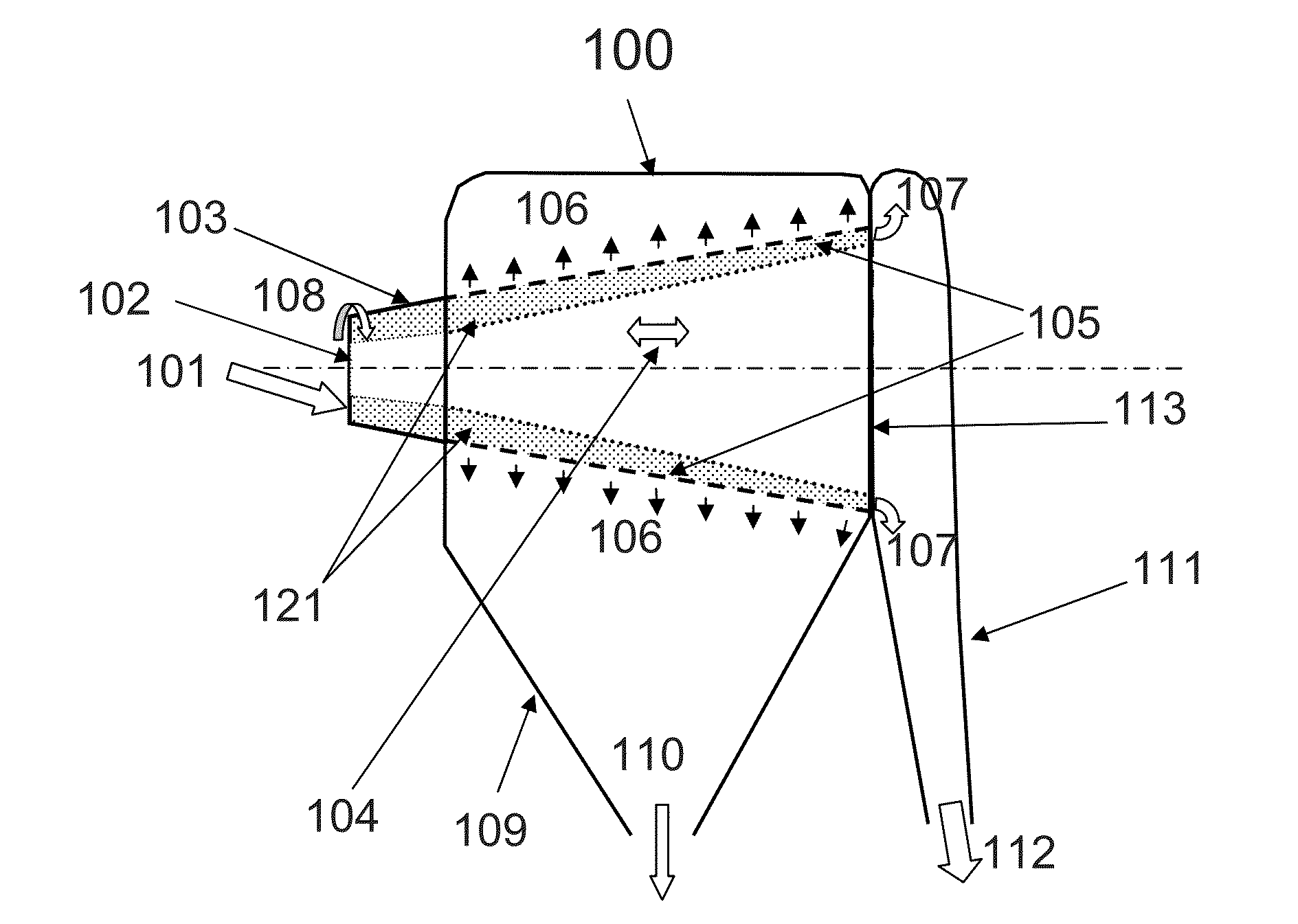

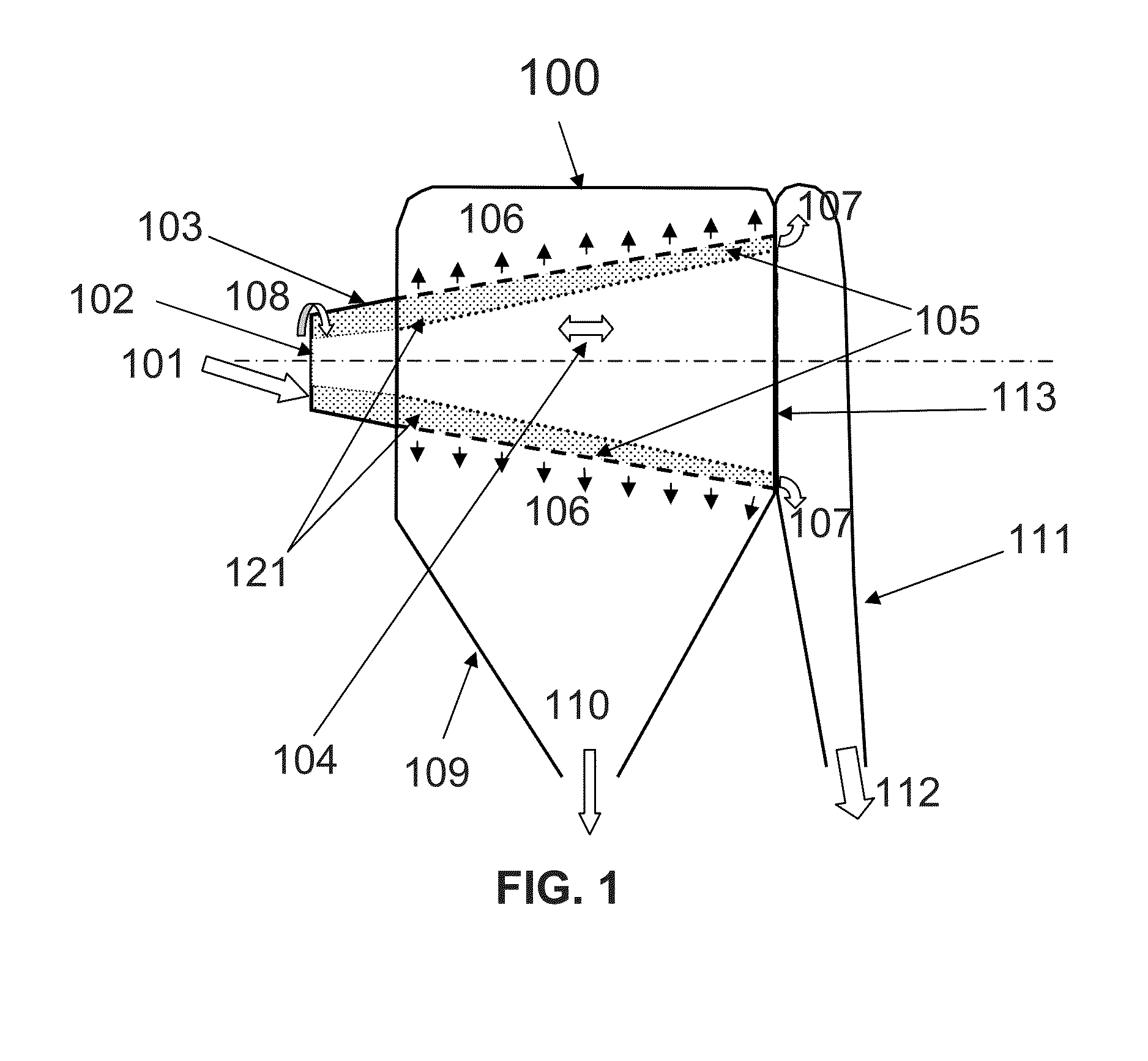

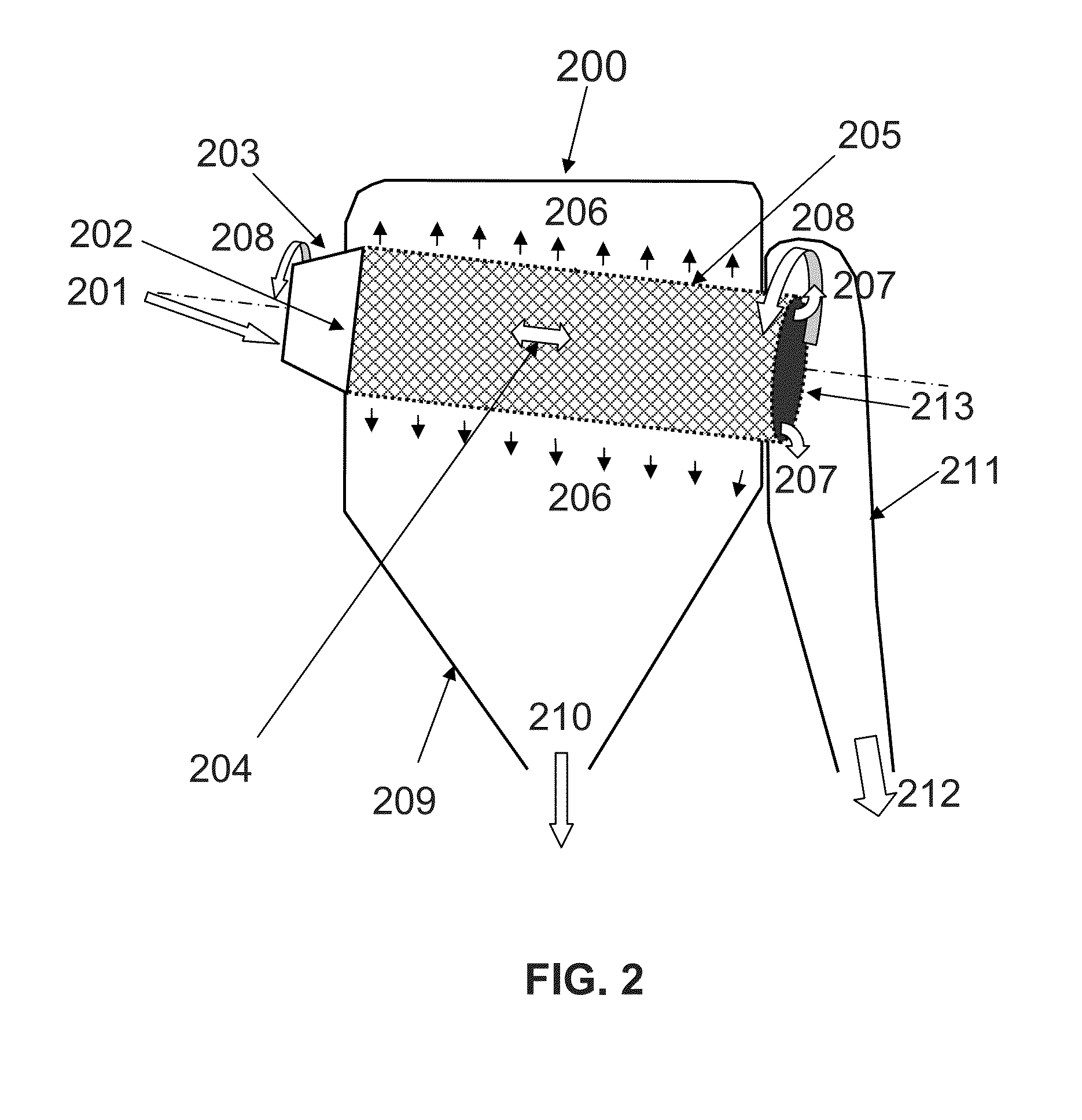

InactiveUS20110038901A1Effective dispersionReduce mechanical stressCosmetic preparationsPowder deliveryMembrane surfaceShear flow

This invention relates to a method for the mechanically protective production of finely dispersed micro- / nanoemulsions with narrow droplet size distribution, whereby drops are produced on the surface of a membrane or of a filter fabric, and the drops are detached from the membrane or filter fabric surface by motion of the membrane or of the filter fabric in a first immiscible liquid phase in which pronounced stretching flow components in particular, besides shear flow components, bring about the detachment of the drops formed on the membrane surface especially efficiently and protectively. The invention also relates to a device for implementing the method according to the invention with a membrane or filter unit that is positioned to move, in particular to be able to rotate, in a housing with a gap that may be eccentric toward the inner wall of the housing and / or provided with flow baffles that produce stretching flow components.

Owner:ETH ZURICH INSTITUT FUR LEBENSMITTELWISSENSCHAFT +3

Centrifugal Size-Separation Sieve for Granular Materials

A centrifugal sieve and method utilizes centrifugal force in rapidly-rotated cylindrical or conical screens as the primary body force contributing to size segregation. Within the centrifugal acceleration field, vibration and / or shearing flows are induced to facilitate size segregation and eventual separation of the fines from the coarse material. Inside a rotating cylindrical or conical screen, a separately-rotated screw auger blade can be used to transport material along the rotating cylinder or conical wall and to induce shearing in the material.

Owner:WALTON OTIS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com