Longitudinally axial flow threshing and separating installation

A threshing separation and threshing device technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of large volume and power consumption, easy blockage of crops, complex structure, etc., and achieve less impurities and high removal rate. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

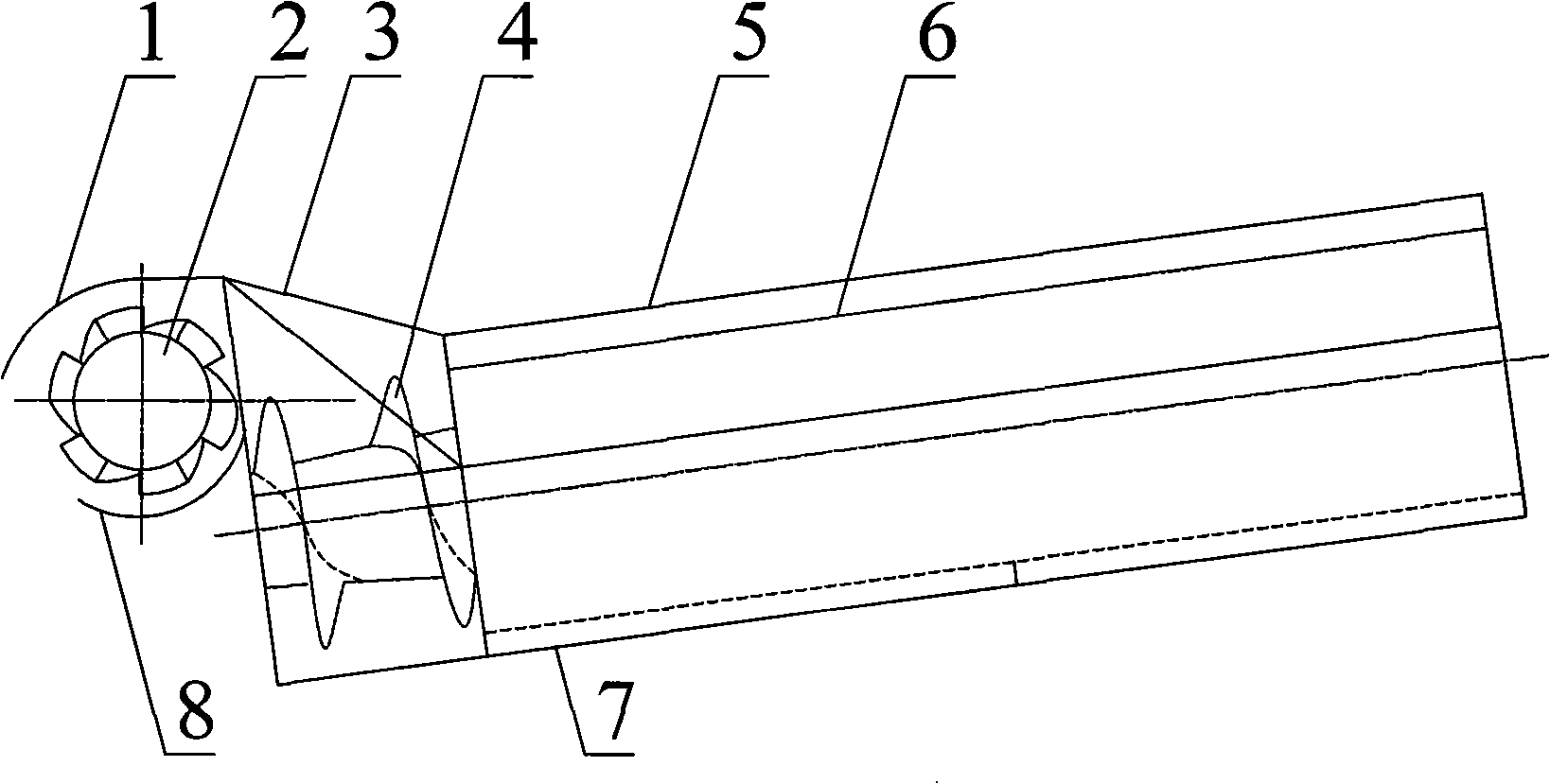

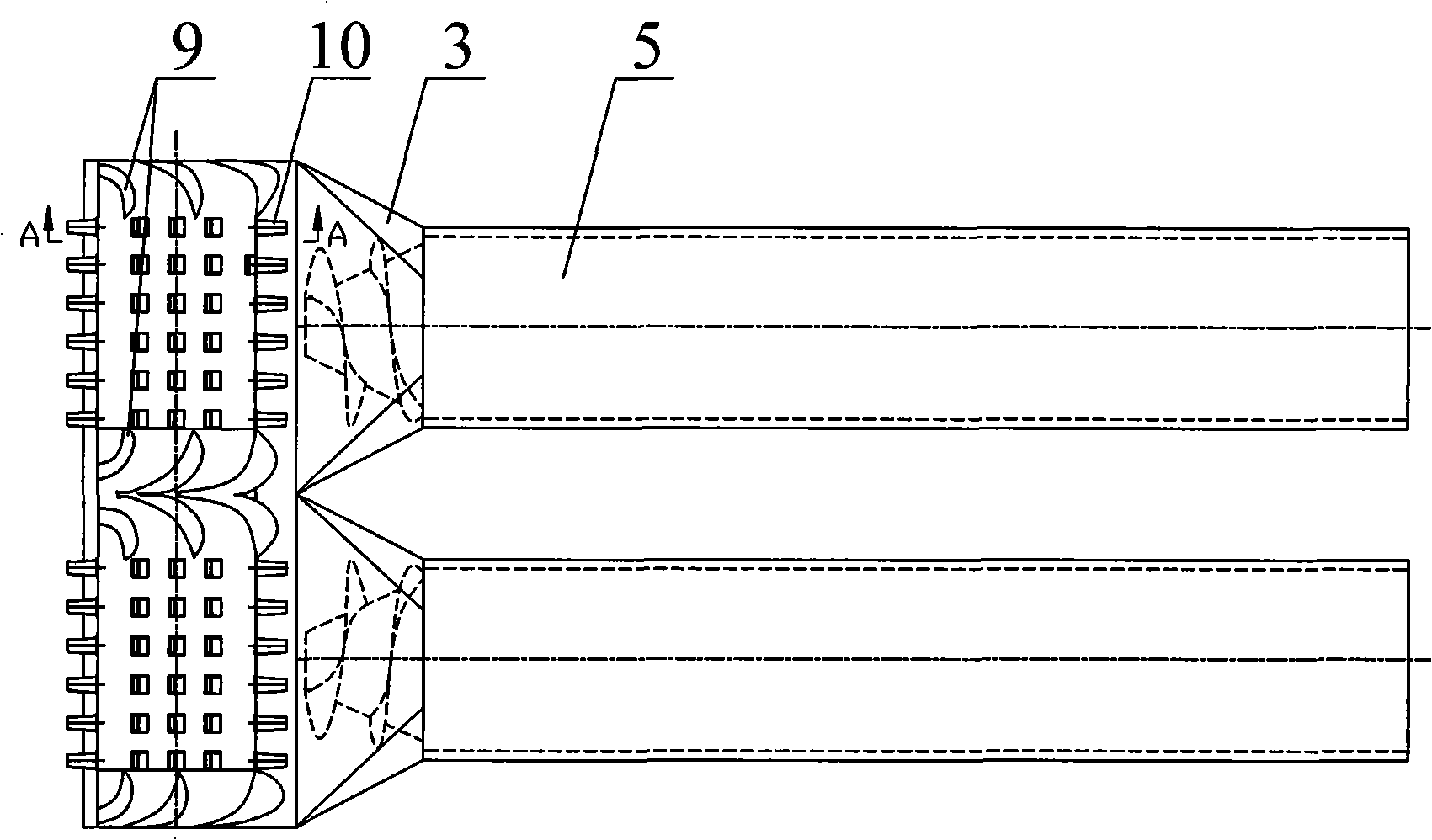

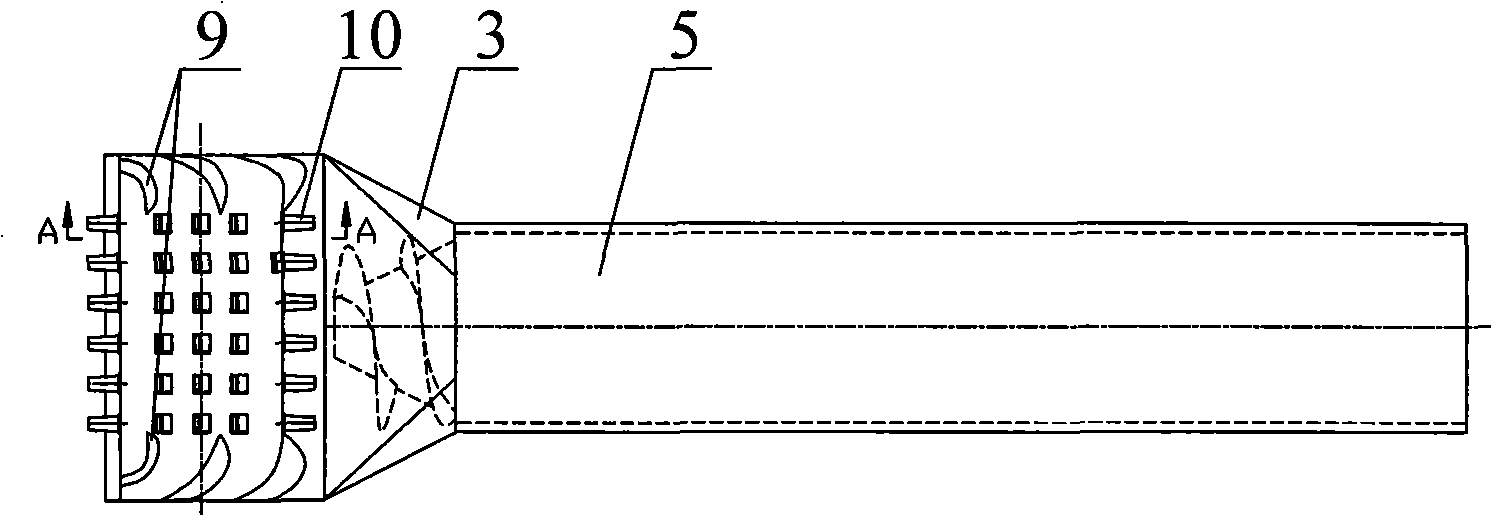

[0019] combine Figure 1-Figure 6 , the present invention is a kind of vertical axial flow threshing separation device used on combine harvester, including auxiliary feeding threshing device and longitudinal axial flow threshing separation device, auxiliary feeding threshing device is composed of auxiliary feeding threshing drum 2, upper cover plate 1 and punching concave plate 8 to form. The vertical axial flow threshing and separating device is composed of a shroud 3 , a feeding screw 4 , a top cover 5 , a longitudinal axial flow threshing and separating drum 6 and a separating concave plate 7 .

[0020] The auxiliary feeding threshing drum 2 adopts a composite structure of helical blade 9 and trapezoidal plate teeth 10. The upper part of the auxiliary feeding threshing drum 2 is equipped with an upper cover plate 1, and the lower part is equipped with a punching concave plate 8. The auxiliary feeding threshing drum 2 is equipped with 4-8 sets of trapezoidal plate teeth 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com