Patents

Literature

52results about How to "Less loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

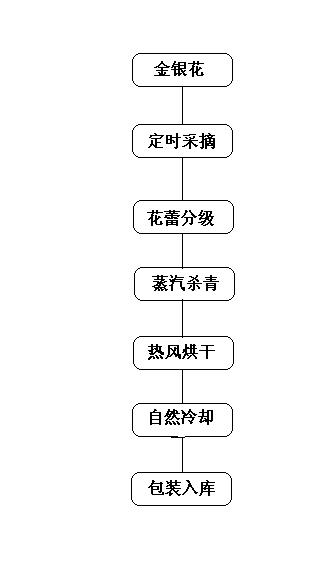

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

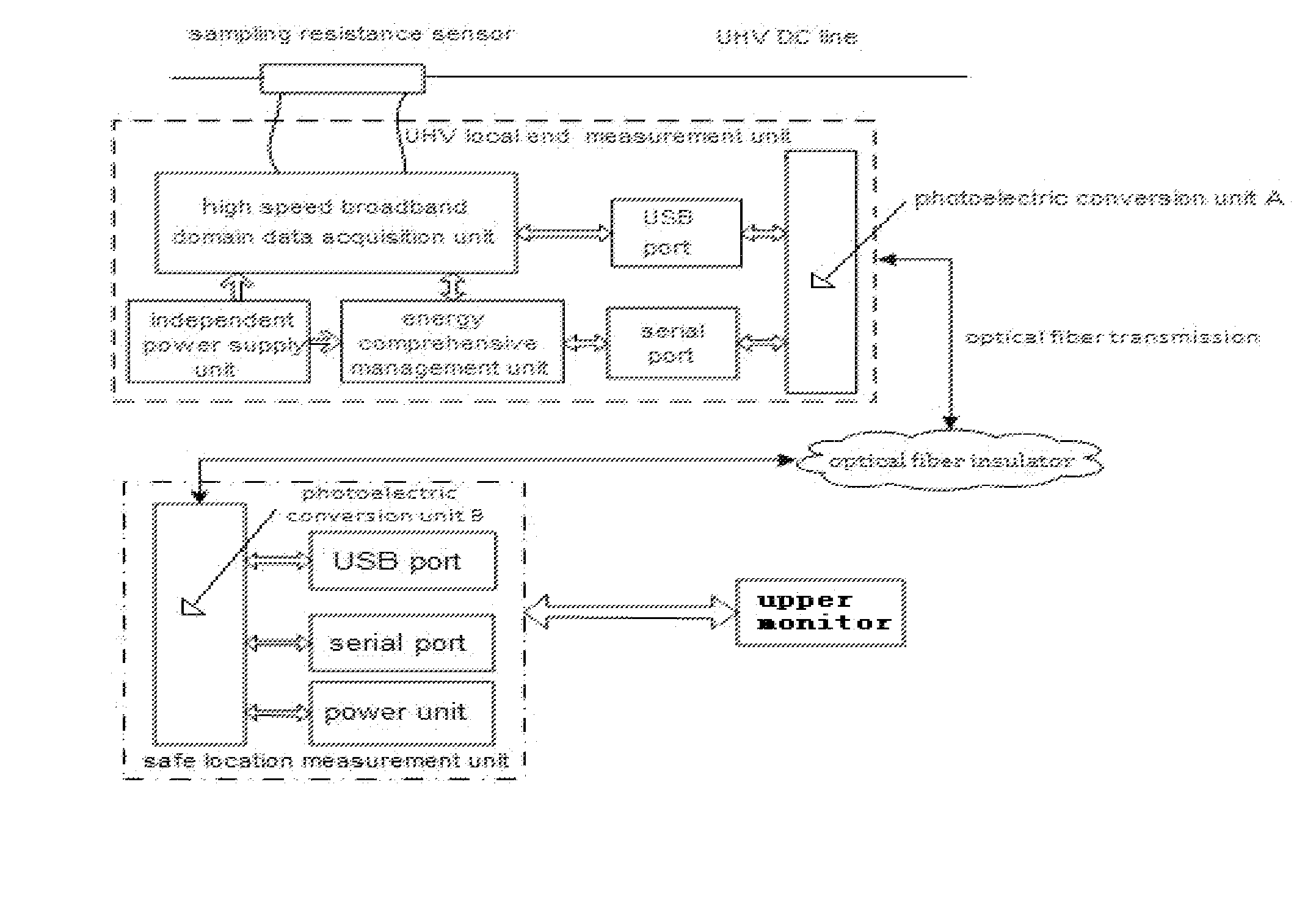

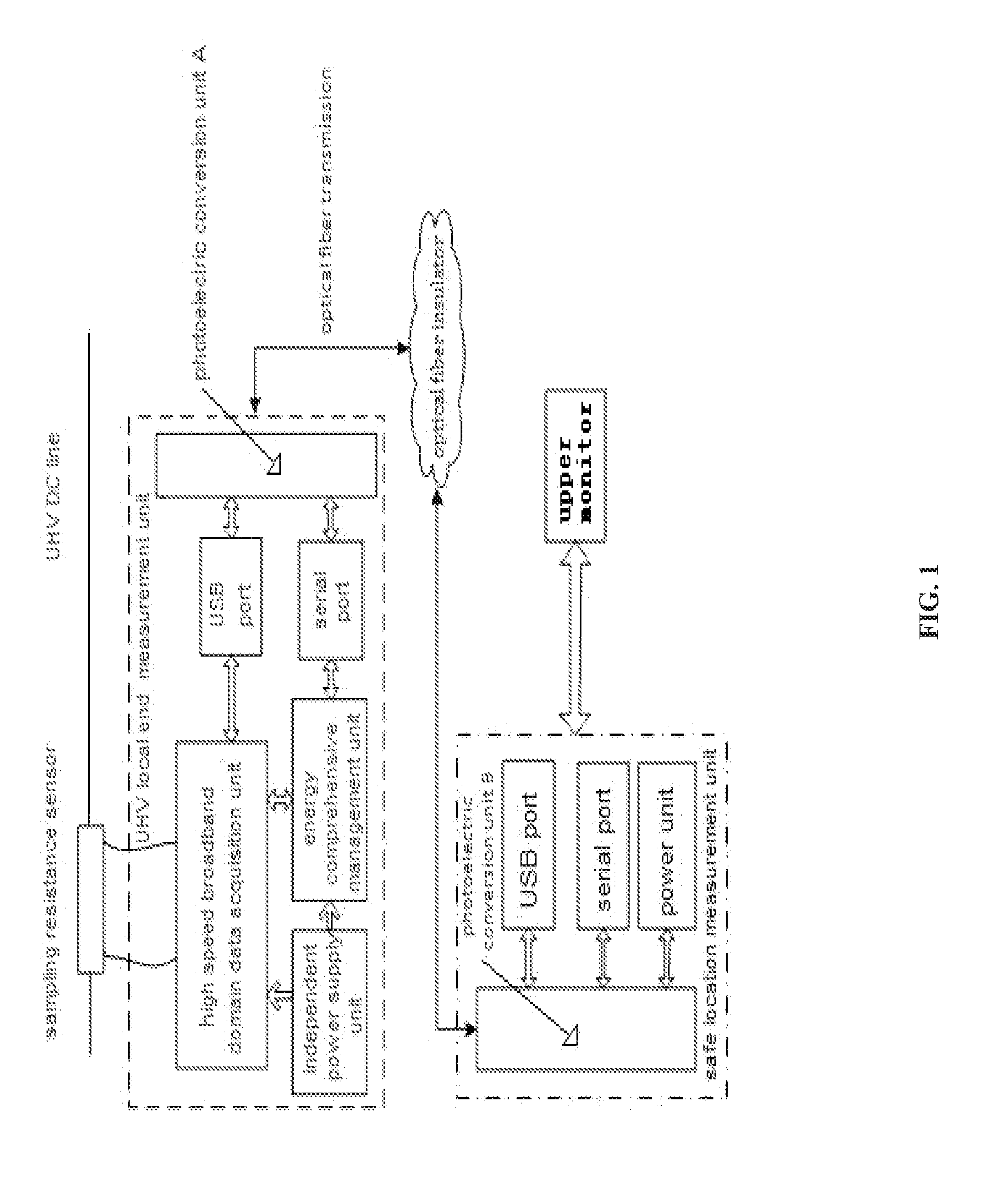

High-voltage direct current broad frequency-domain corona current measurement system

InactiveUS20150362536A1Wide rangeImprove abilitiesResistance/reactance/impedenceElectrical measurement instrument detailsStable statusHigh-voltage direct current

The present invention provides a kind of high voltage direct current broadband domain corona current measurement system, including the sampling resistance sensor, the UHV local end measurement unit, the optical fiber transmission unit, the safe location measurement unit and the upper monitor; The sampling resistance sensor samples the corona current signal of the HVDC line, and converts the corona current signal to the voltage signal, the UHV local end measurement unit collects the voltage signal, and obtains the optical signal by photoelectric conversion, the optical signal transforms to the safe location measurement unit by the optical fiber transmission unit, the safe location measurement unit converts the optical signal to the voltage signal, the host computer performs processing, storing and displaying with the voltage signal. The present invention has a wide range of measuring frequency, strong ability of anti-electromagnetic interference and other advantages, also can running in long-term stable status under the condition of the UHV DC and all kinds of bad natures, this provides effective technological means for further research on the character of the UHVDC corona.

Owner:YUAN HAIWEN +2

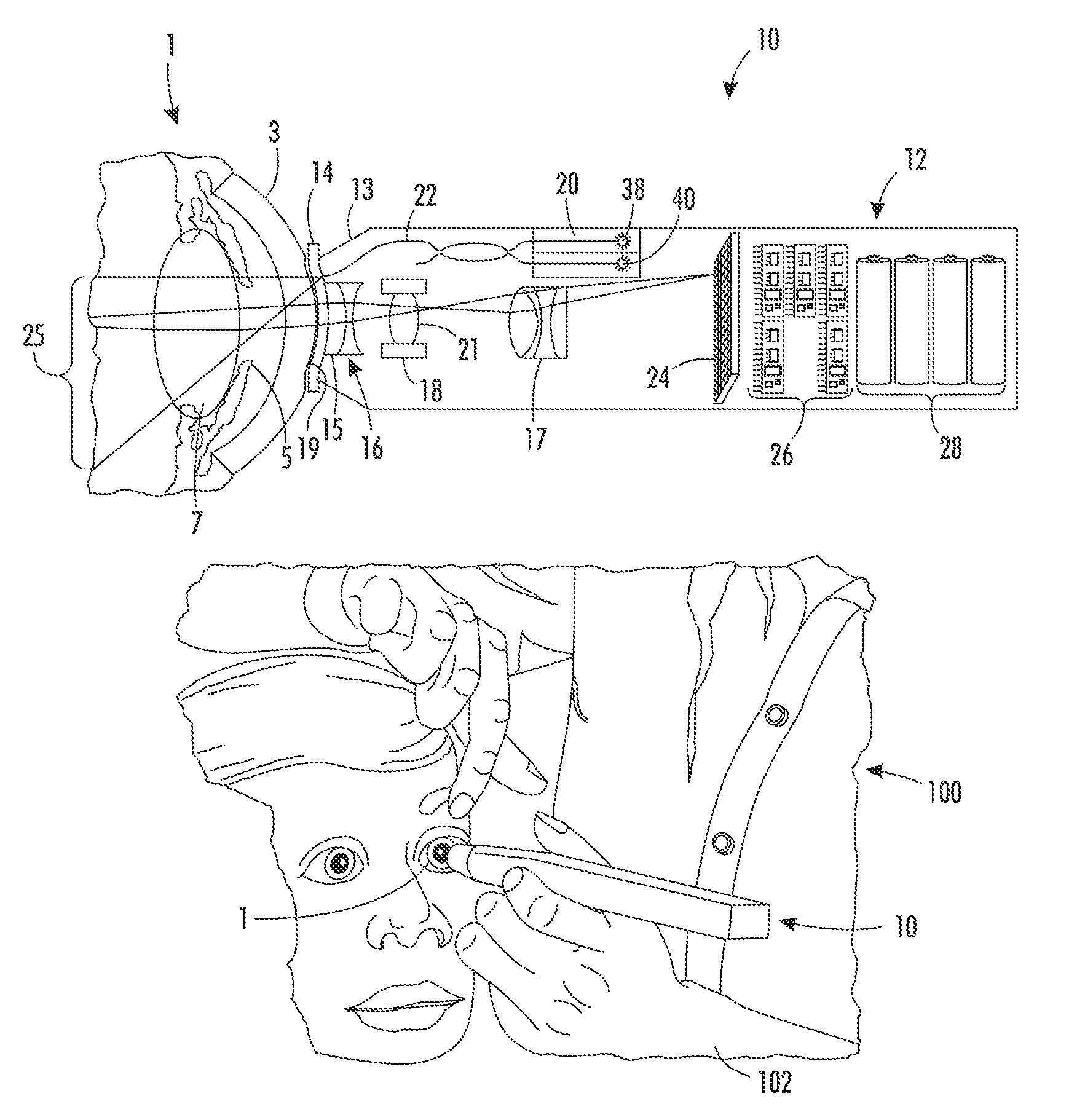

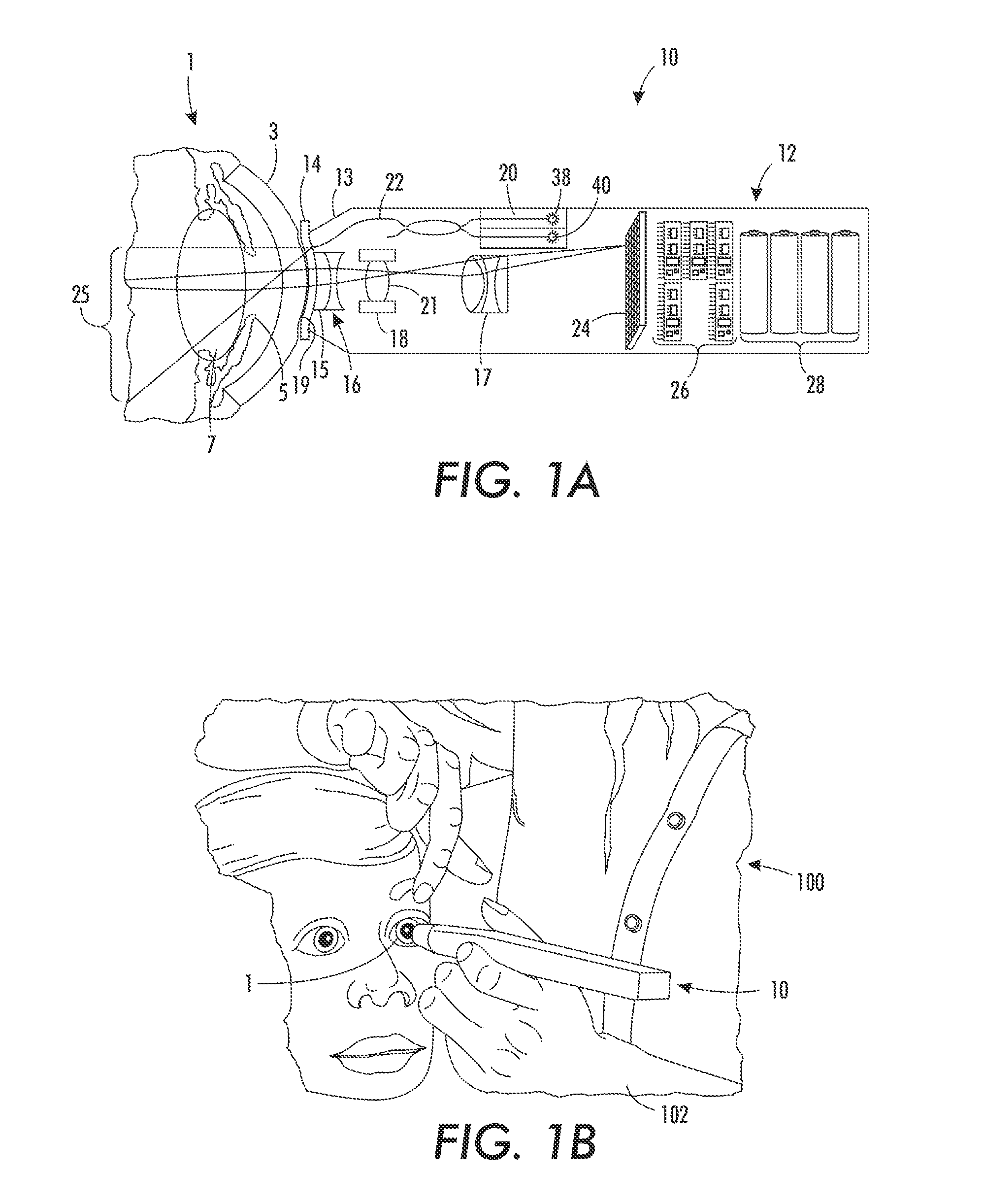

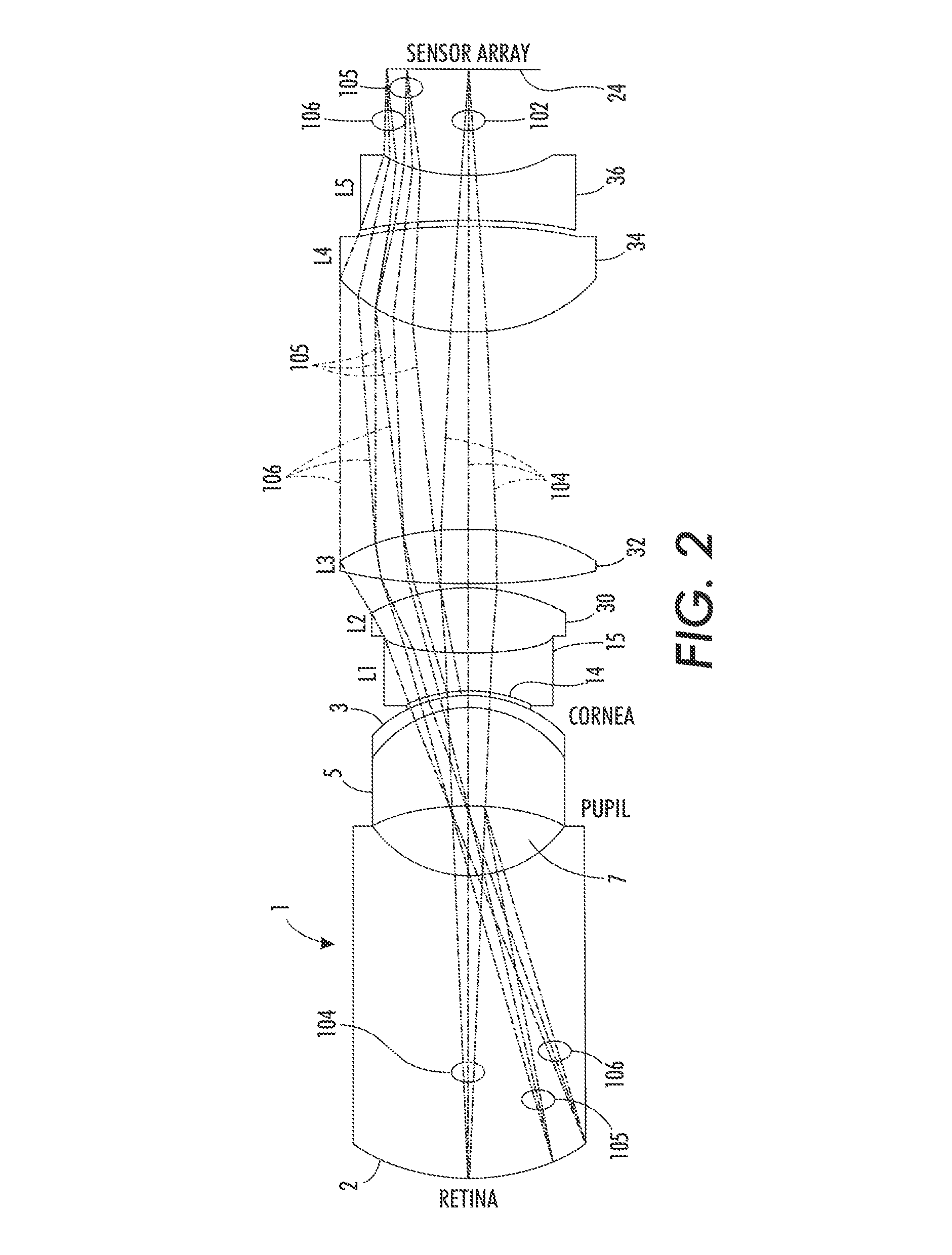

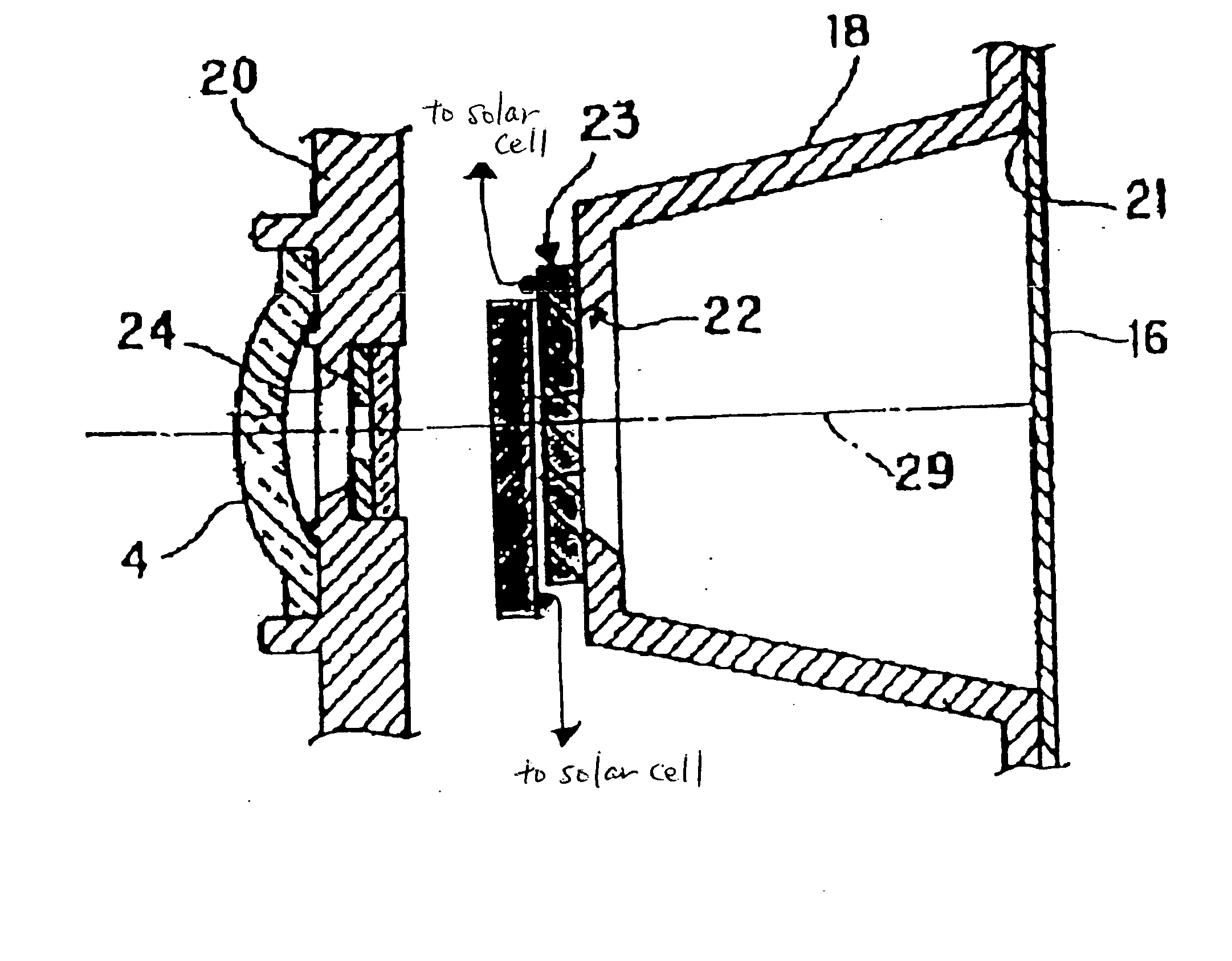

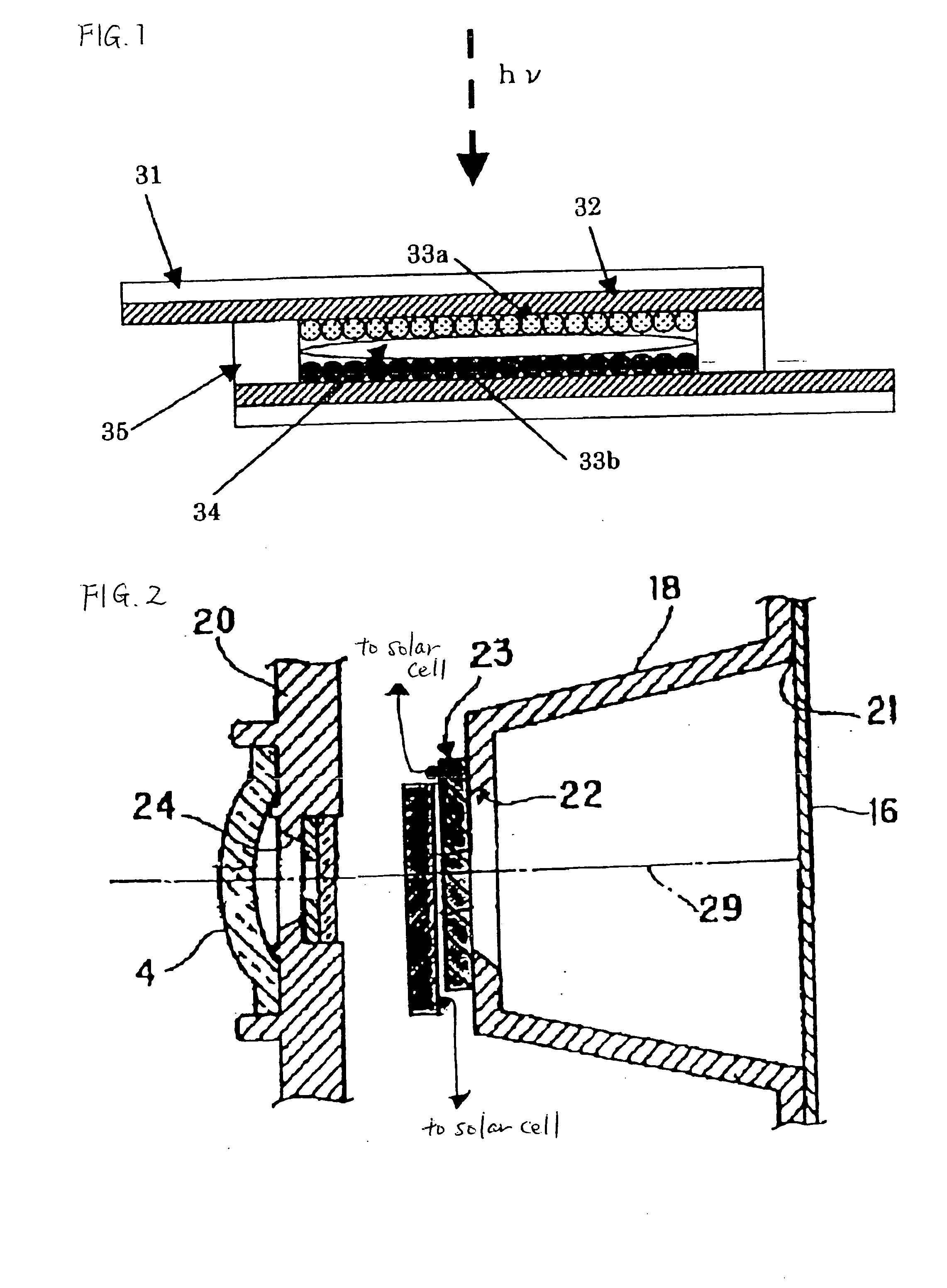

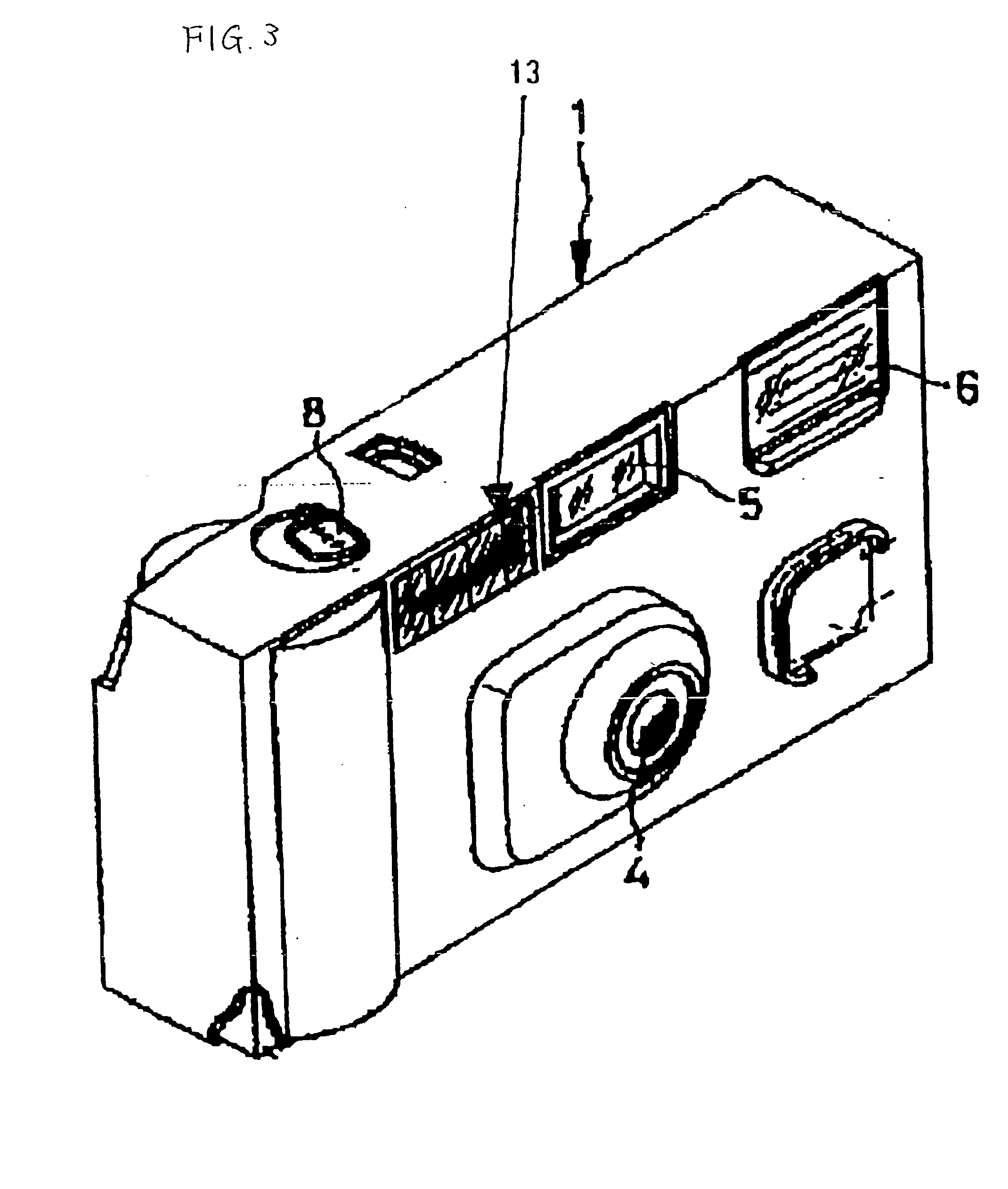

Portable fundus camera

ActiveUS8836778B2Speed flowEconomically beneficialUltrasonic/sonic/infrasonic diagnosticsAcquiring/recognising eyesFundus cameraHand held

A portable hand-held camera for imaging the fundus of an eye, the camera comprising a housing comprising an internal cavity terminating at a forward housing end, a forward lens, and a light source configured to direct light from locations distributed around the perimeter of the forward lens forwardly out of the housing end. In other embodiment, a portable hand-held camera for imaging the fundus of an eye includes optics configured to focus light reflected back from the fundus onto an image receptor, with the optics being capable of varying the field of view among differing portions of the fundus. Methods to ensure unique image identification and storage are described.

Owner:LUMETRICS

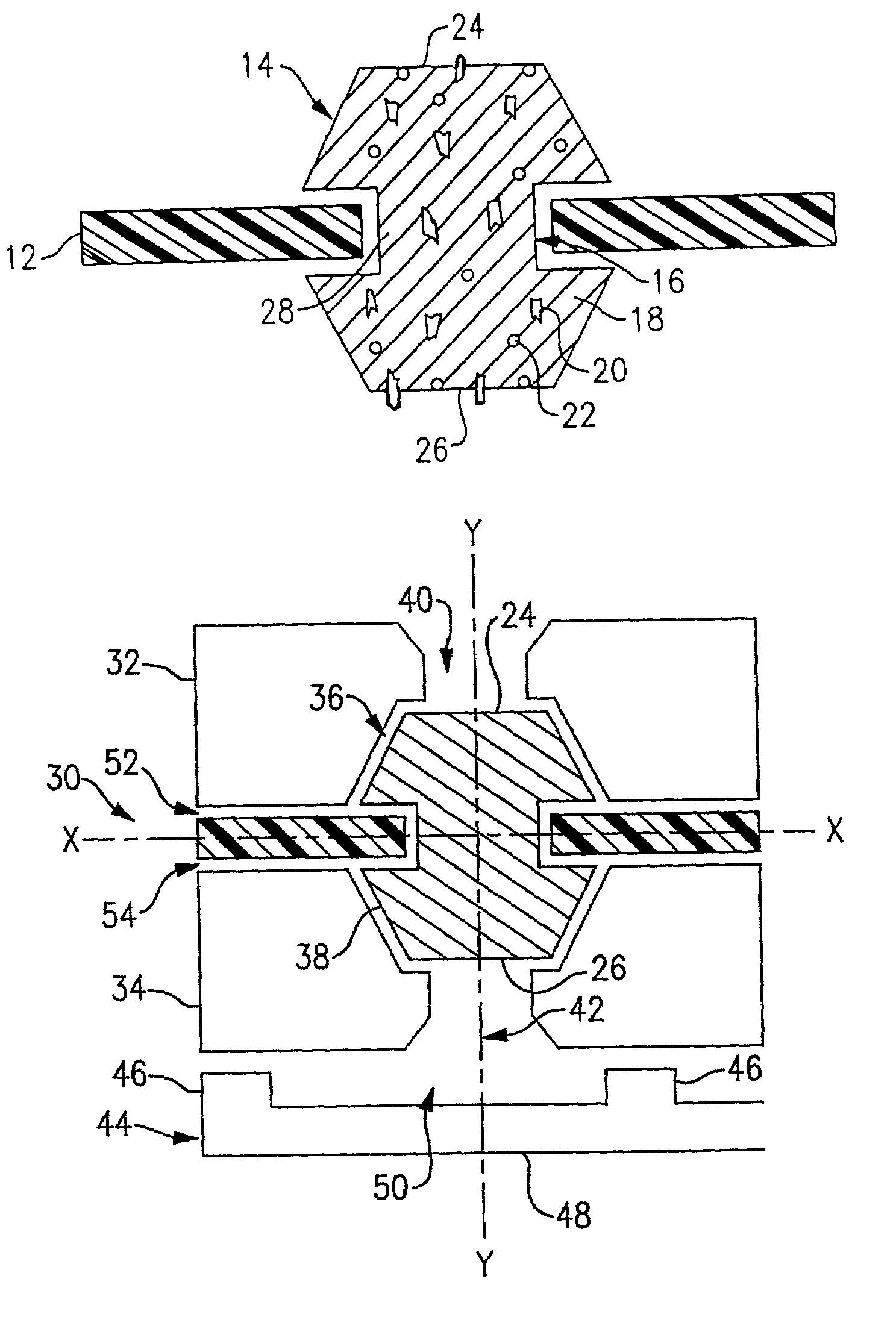

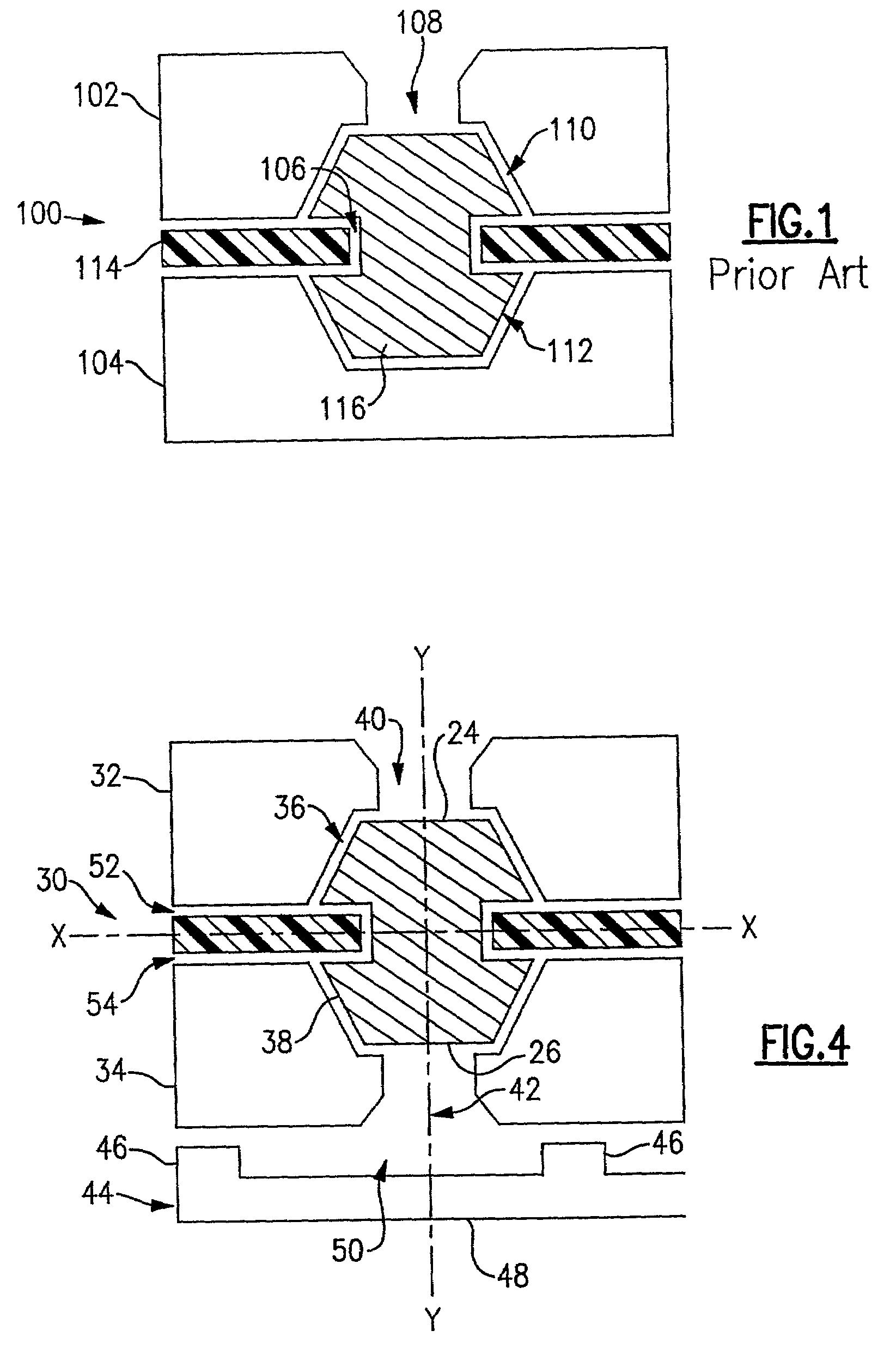

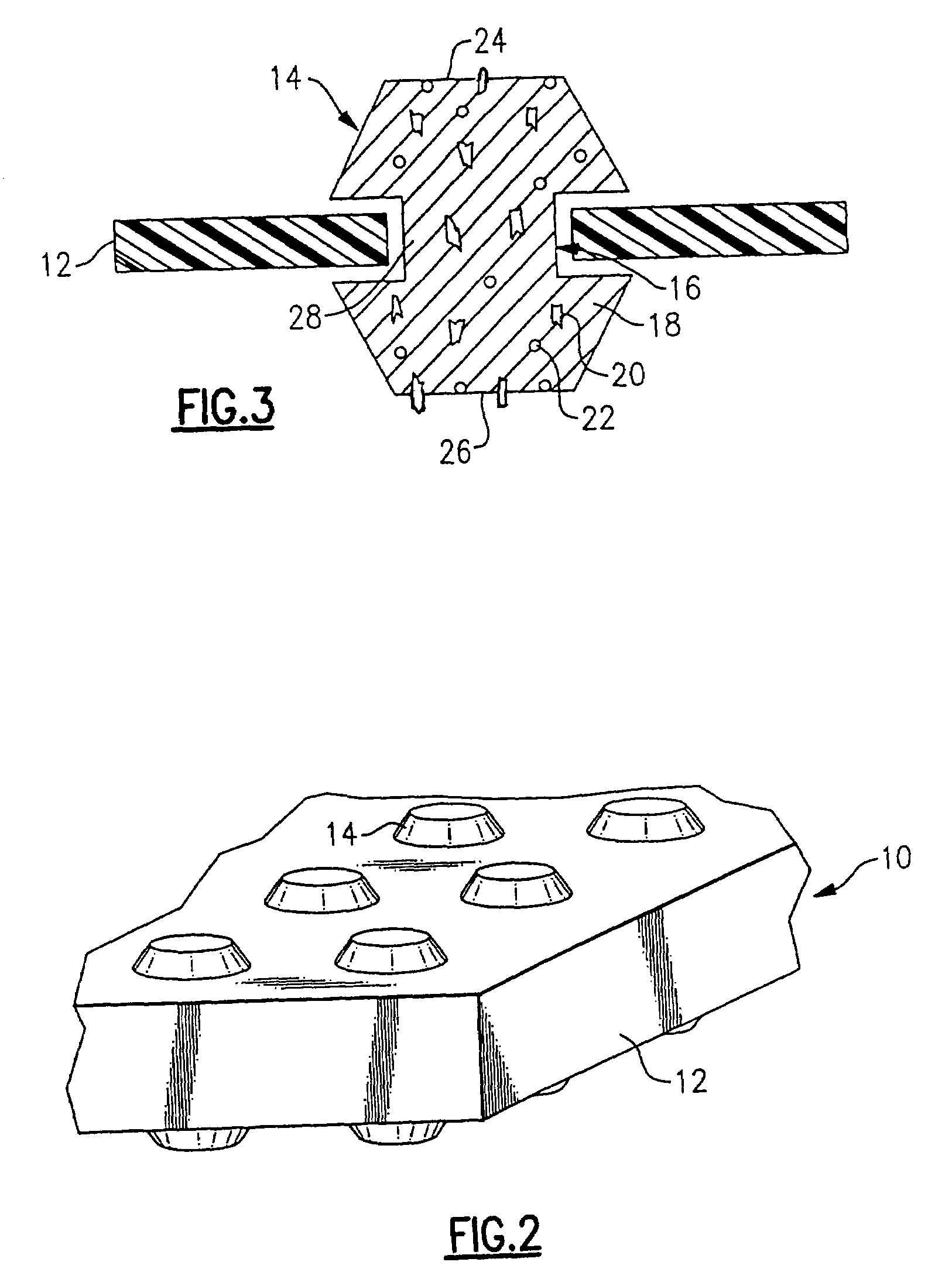

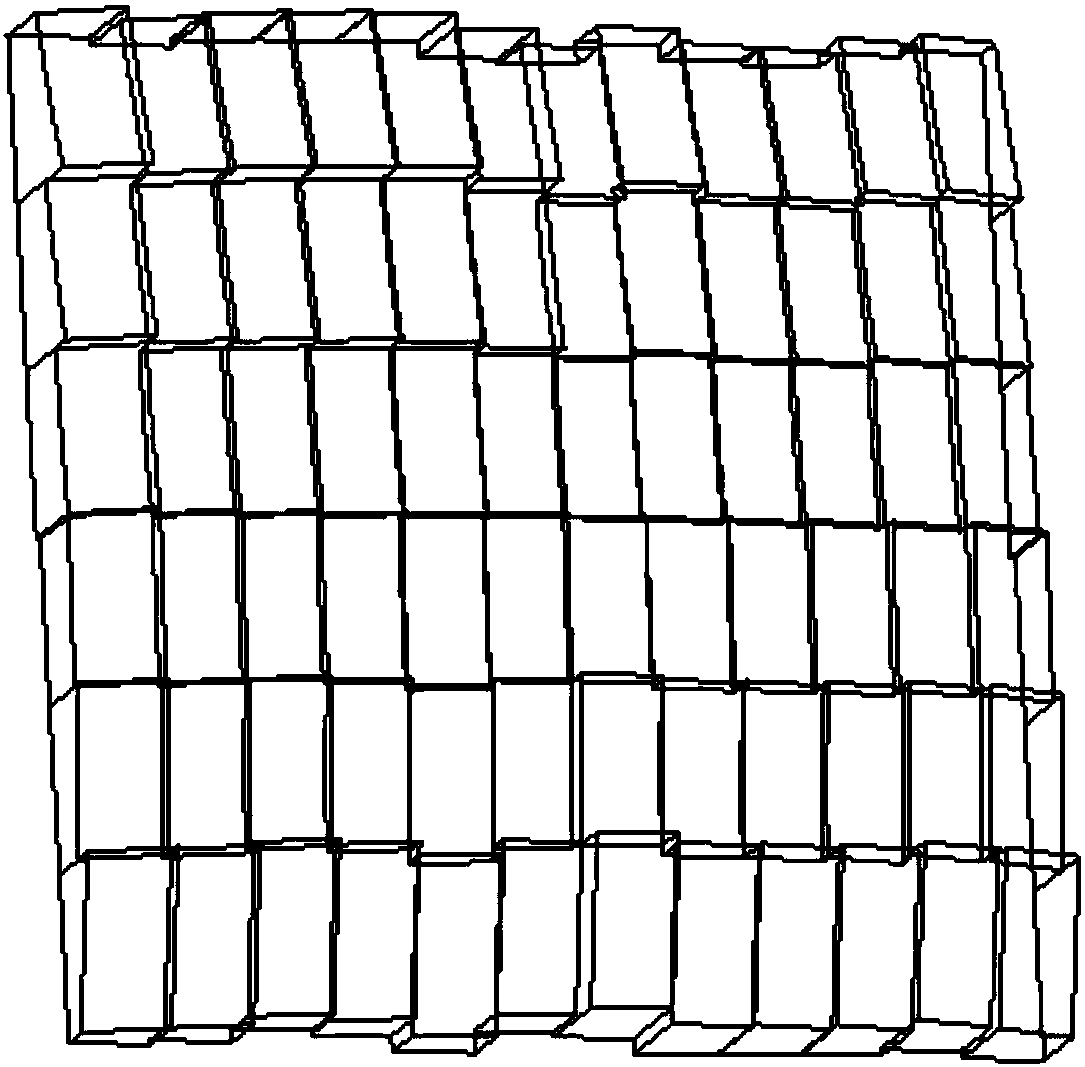

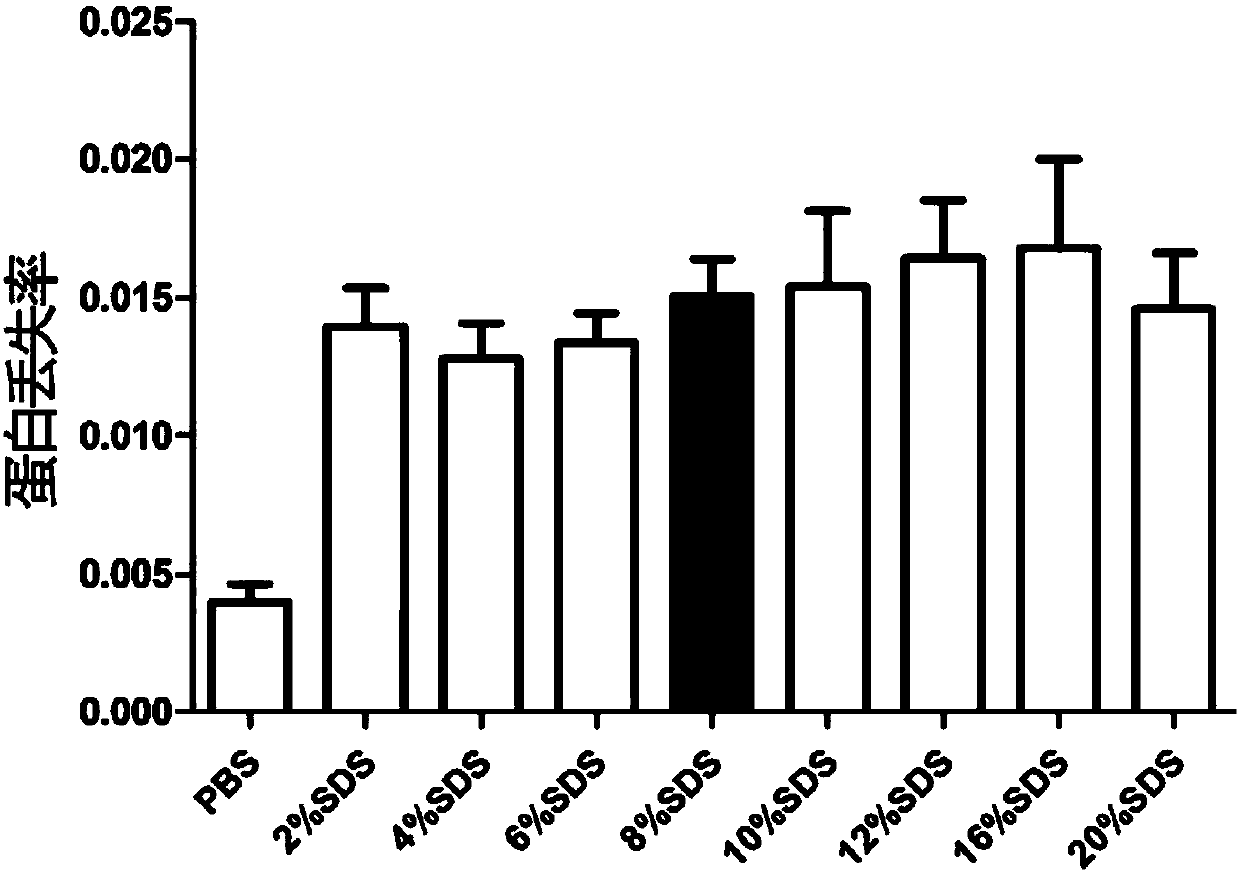

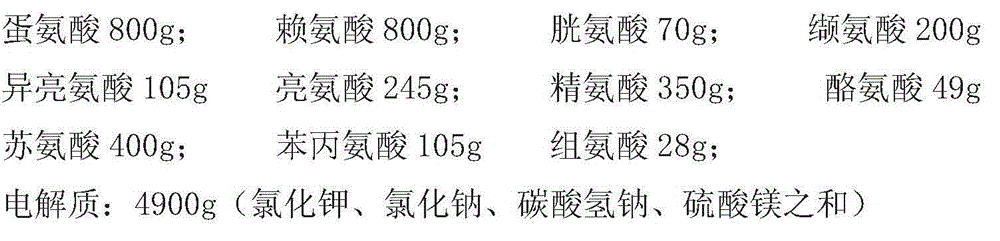

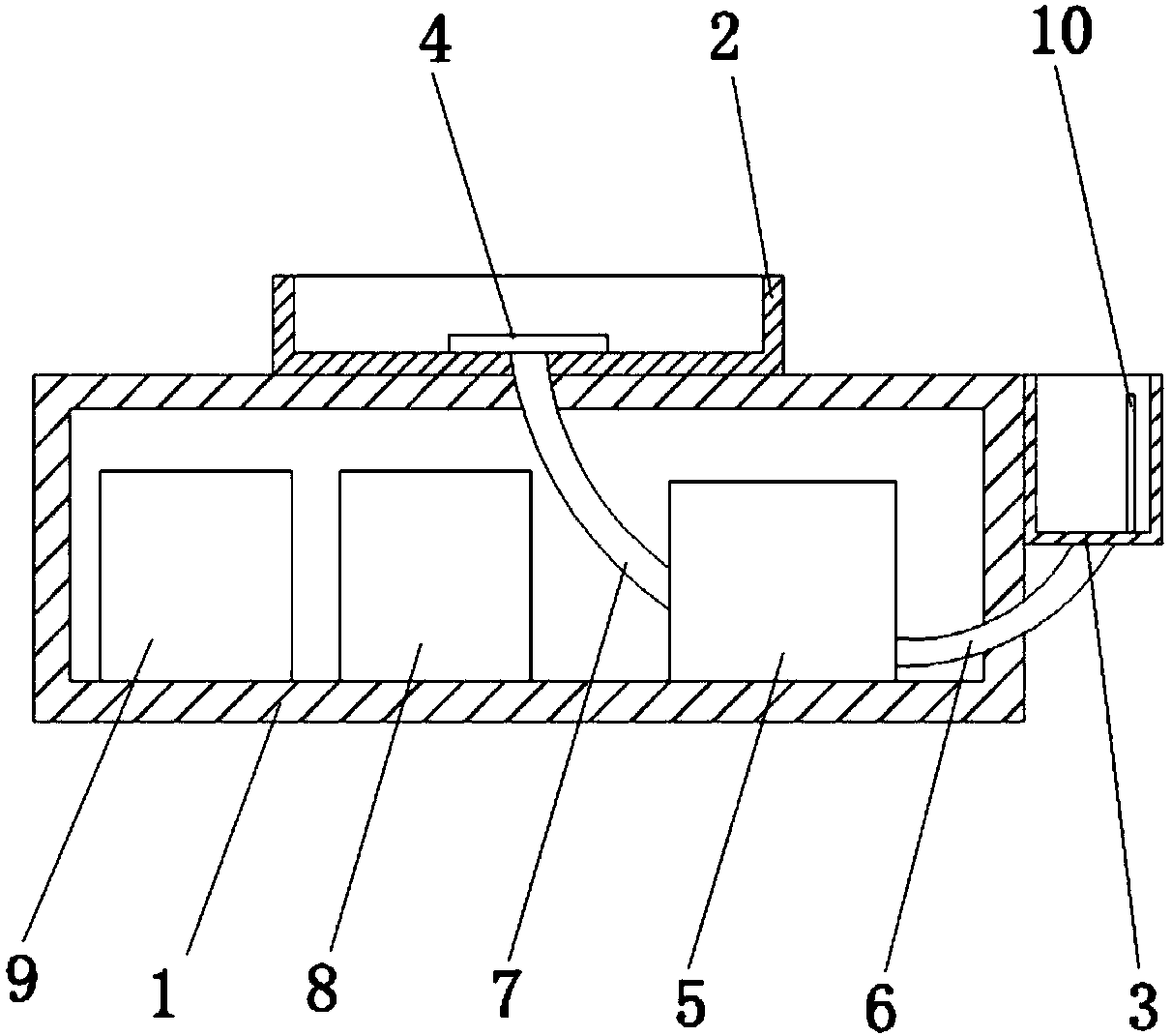

Particle distribution interposer and method of manufacture thereof

InactiveUS7083436B2Improved conductive particle distributionLess flashingSemiconductor/solid-state device detailsPrinted circuit aspectsElastomerThermoplastic

An interposer comprising a non-conductive carrier sheet with a pre-arranged pattern of conductive interconnect members positioned therethrough and formed from an elastomeric thermoplastic with suspended spherical and non-spherical conductive particles. The non-spherical conductive particles of the present invention are positioned substantially perpendicularly to and partially through the contact faces of the interconnect member, thereby resulting in higher conductivity and efficiency. The interposer is formed by a mold comprising two sections with first and second sets of vias formed in the first and second mold sections, respectively, which permit the injected elastomer mixture to flow completely through the mold cavity and thereby aligns the non-spherical conductive particles. The exit side of the mold is further contacted by support posts of a separable mold interface creating a network of vent passages for venting of air and the elastomer mixture, resulting in less pressure within the mold and less mold flash.

Owner:IBM CORP

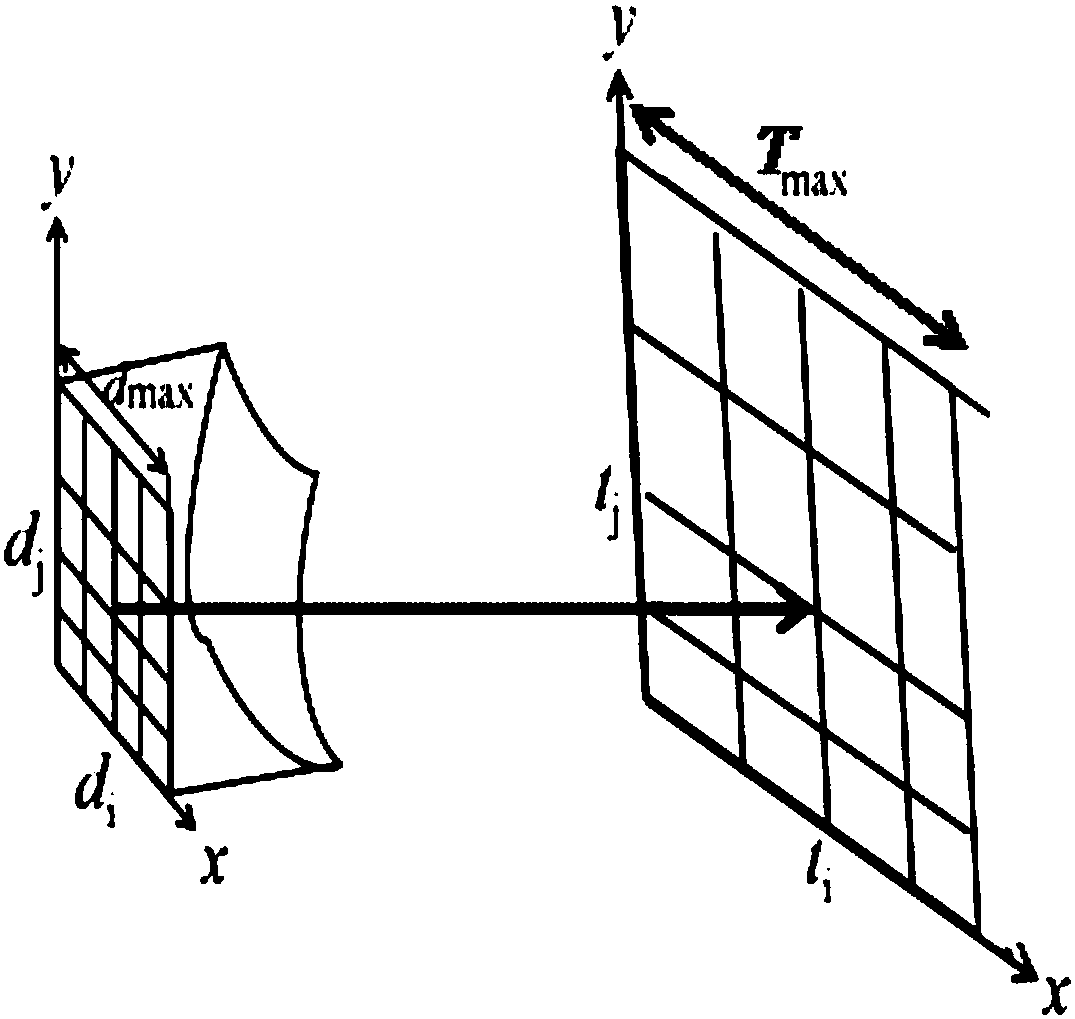

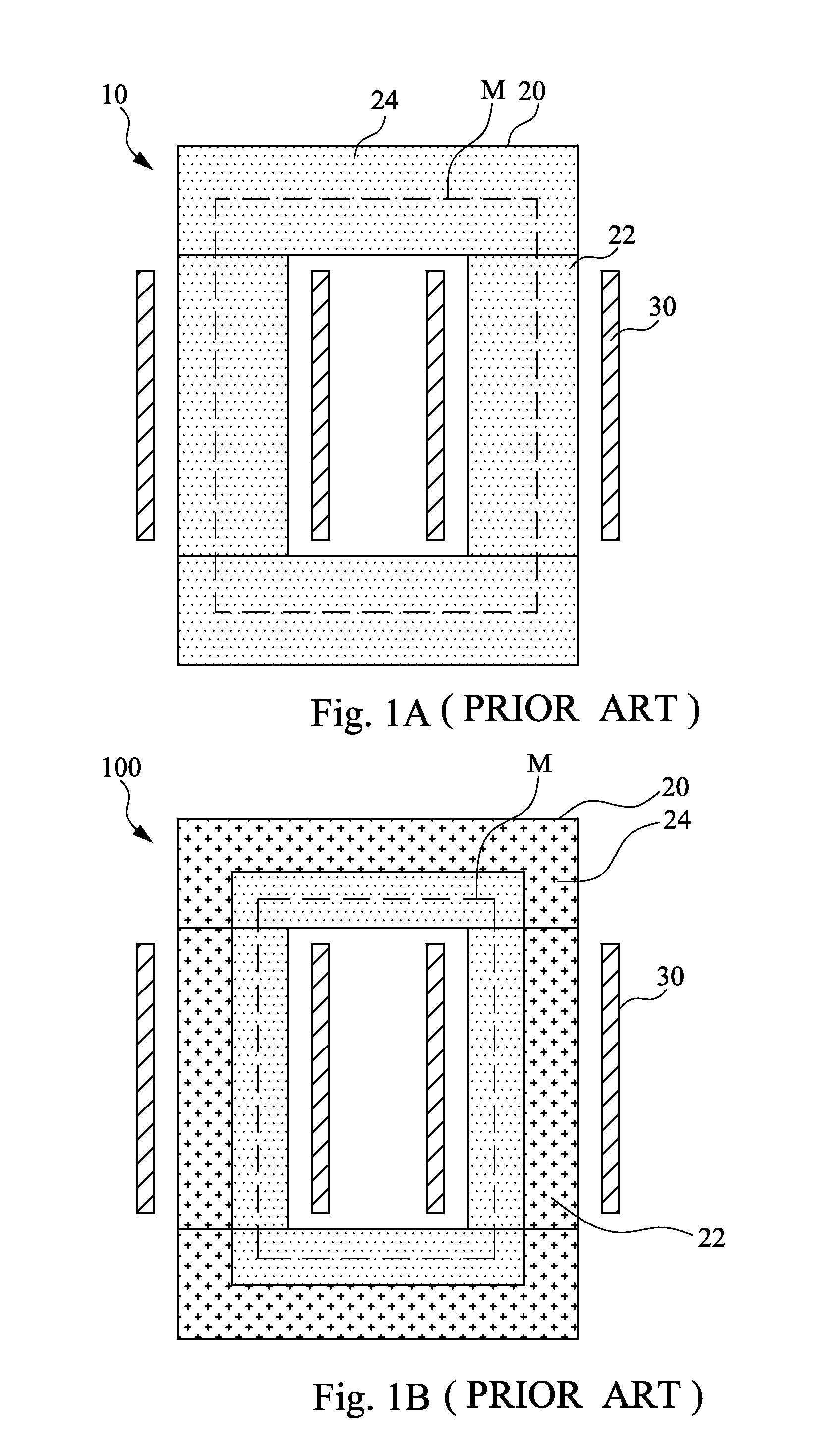

Uniform light element for DMD digital photolithography system and design method thereof

InactiveCN107942520AGood dodging effectBreak the cyclePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMicro lens array

The present invention provides a uniform light element for a DMD digital photolithography system and a design method thereof, belonging to the field of digital photolithography technology. The methodcomprises more than one sub lens, each sub lens is one square with a length-width ratio of 1:2, the front surface of each sub lens is a plane, and the rear surface of each sub lens is a free curved surface. The uniform light element for the DMD digital photolithography system and the design method thereof are high in utilization rate of luminous energy, good in uniform light effect, small in sizeand convenient to integrate, can perform individual design of each sub lens, employ a mode of random arrangement of area sizes and positions, break periodicity of a traditional microlens array and greatly improve the uniform light effect of a coherent source.

Owner:NORTHEAST NORMAL UNIVERSITY

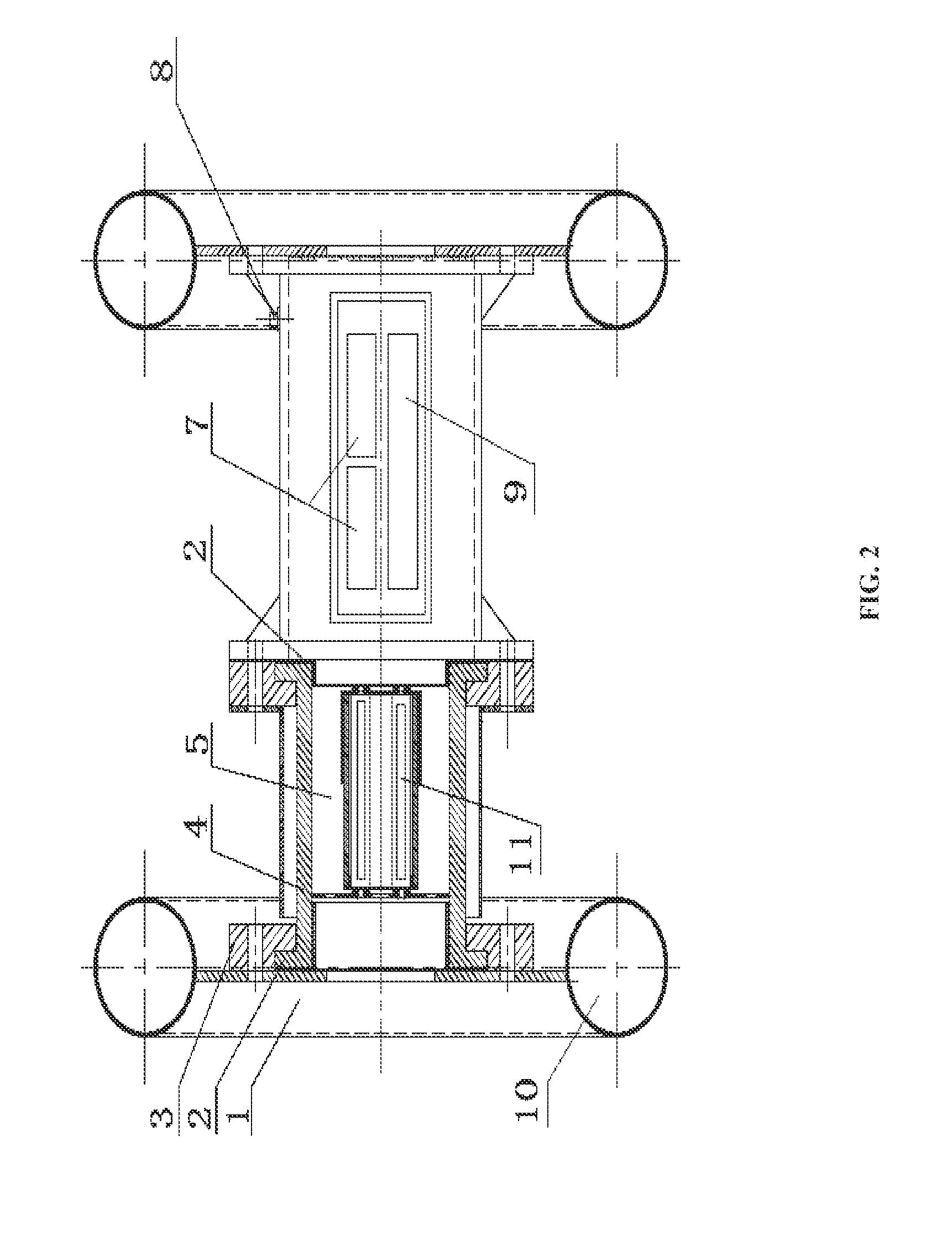

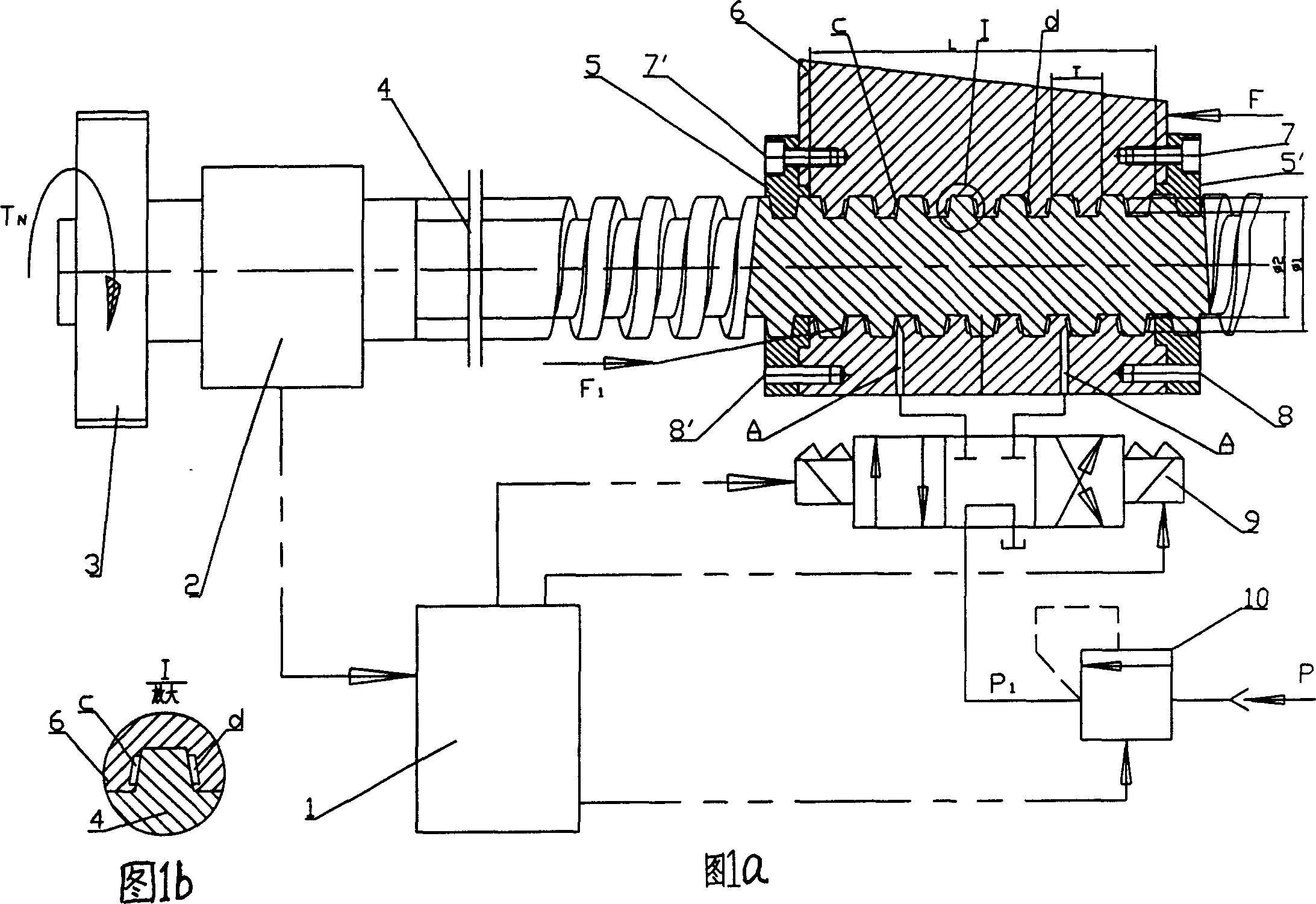

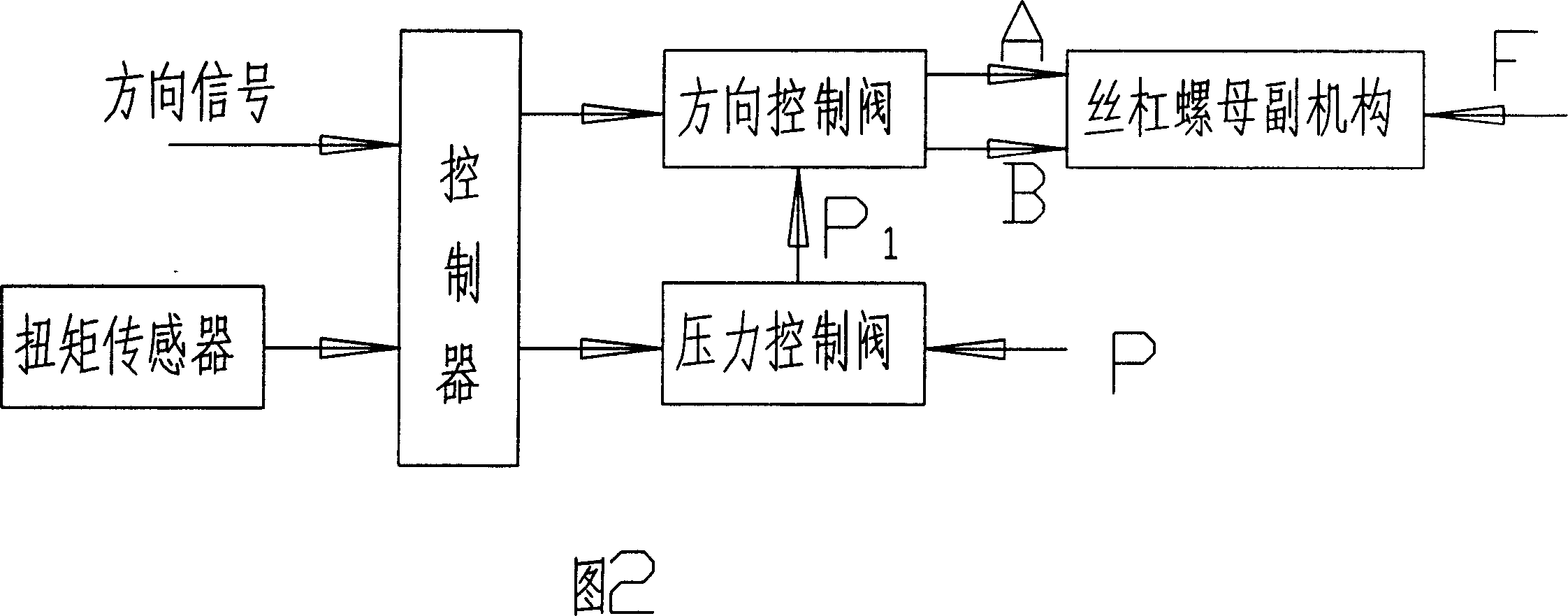

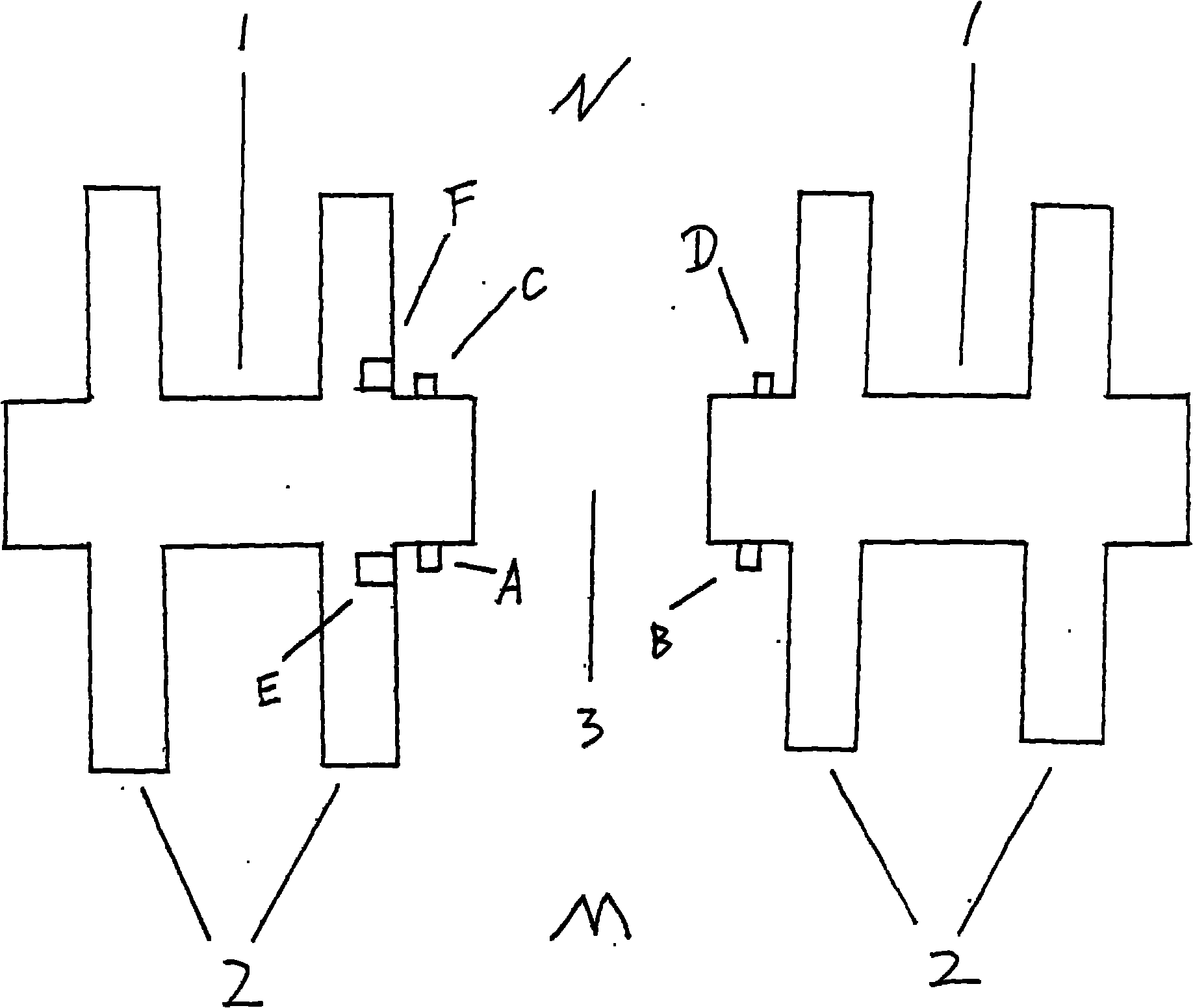

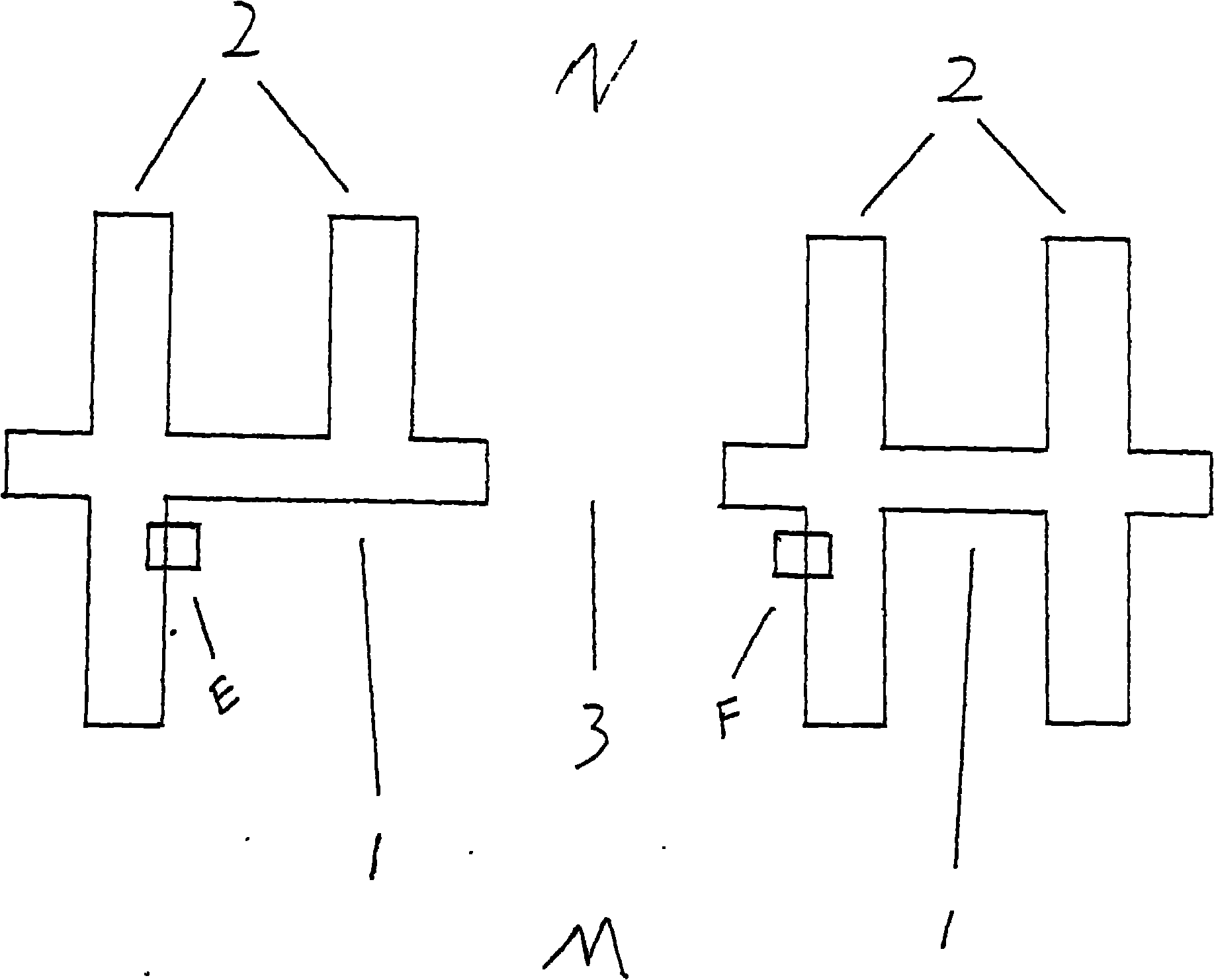

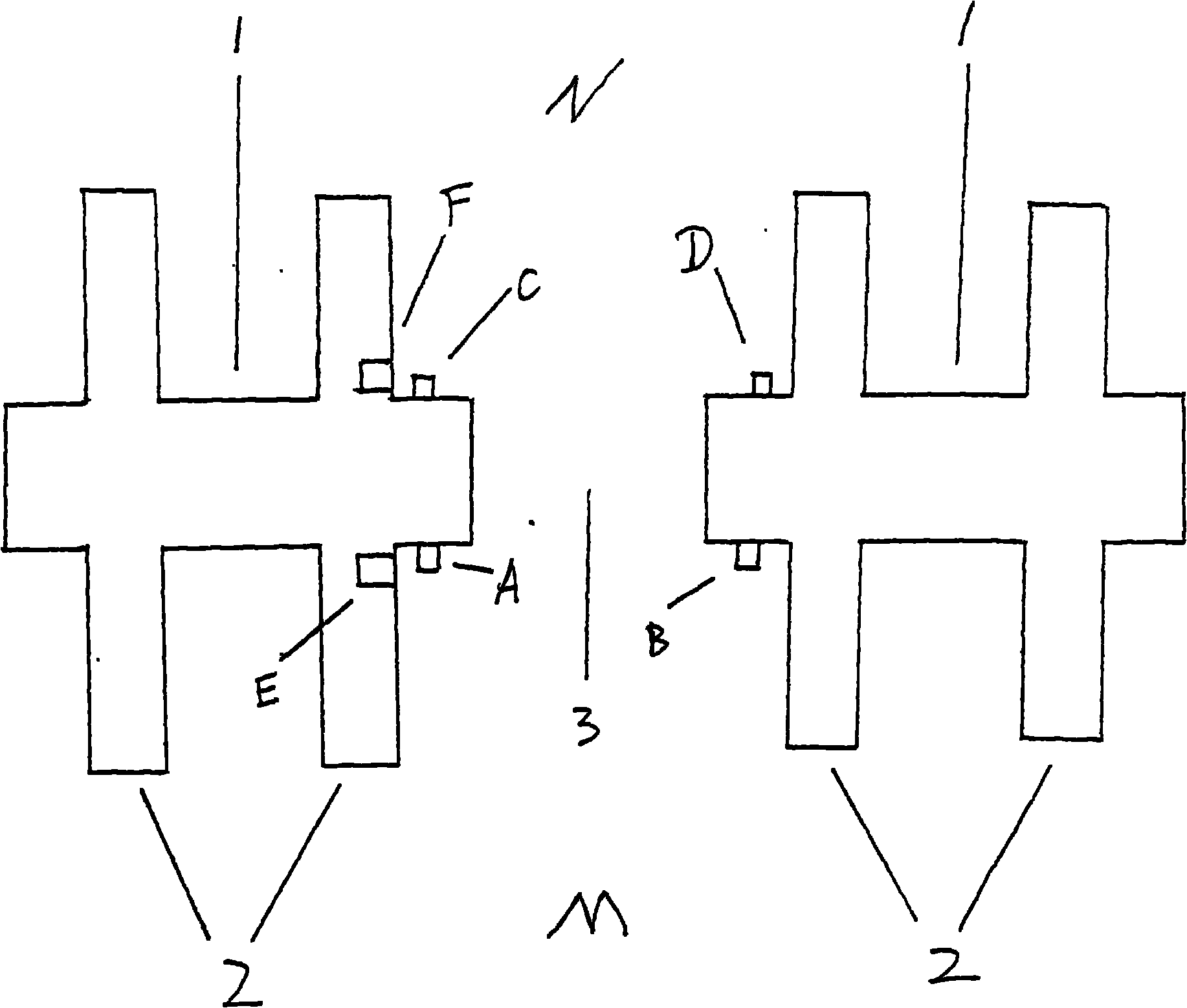

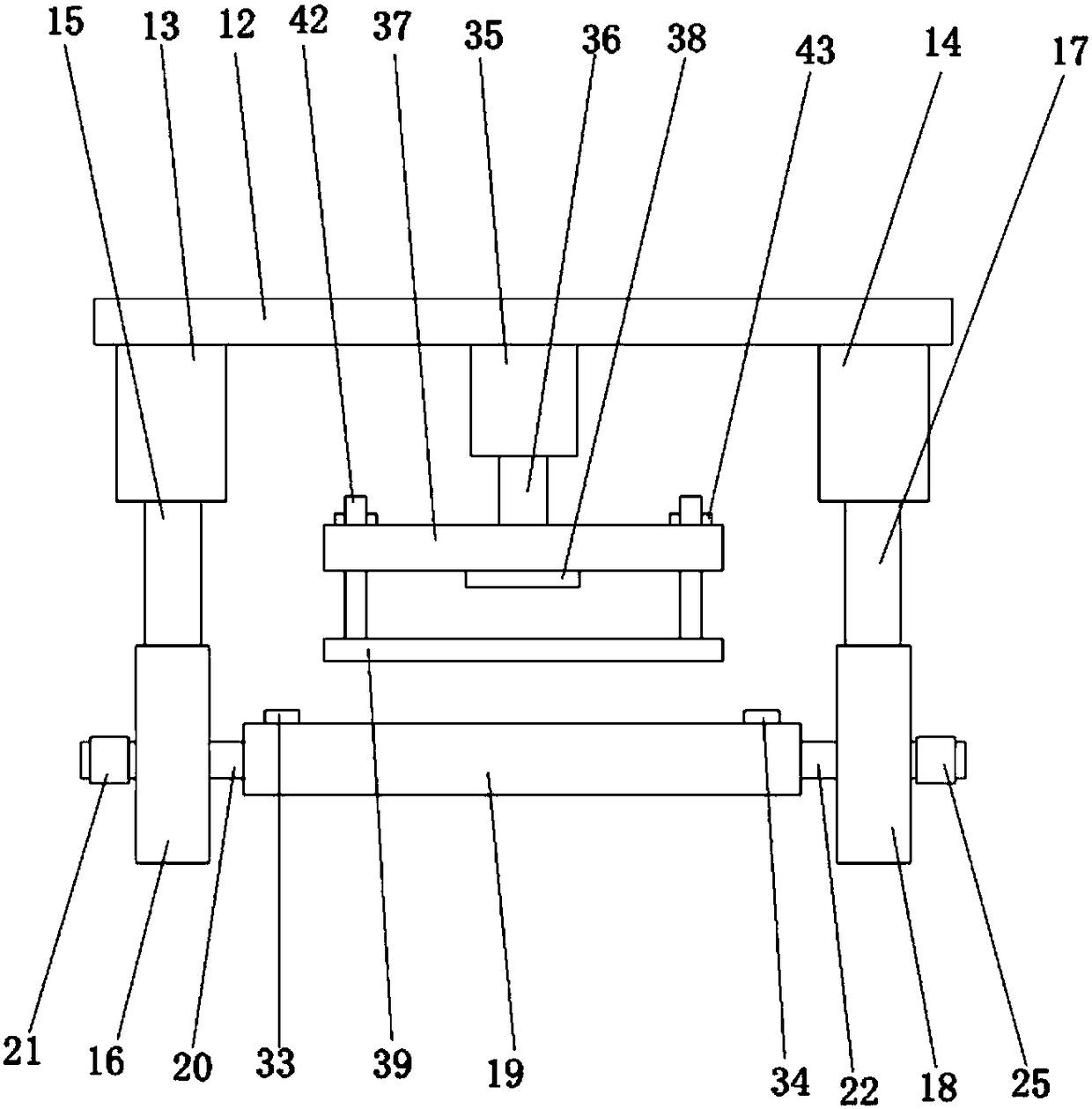

Lead screw nut pair transmission control device and method, nut subassembly processing method

InactiveCN101059165AReduce rigid contact pressureWon't breakGearingGear lubrication/coolingTorque sensorHydraulic control

Lead-screw nut vice transmission control device and the method and the processing method of nut components, the torque sensor in hydraulic control device of control device changes the torque transmitted by lead-screw into signals and transmits the signals to controller, the controller sends the oil duct reversing control signals on the three-position four-way magnetic reversing solenoid valve, the controller controls the output mouth pressure of pressure control valve which is transmitted on the side surface contacted with nut and lead-screw through two pipelines, the screw thread two sides of nut is opened with two spiral oil-storing grooves which are sealed and formed by two end covers of nut two ends and the surface contacted with nut and lead-screw; the control method is: the controller controls the output mouth pressure of pressure control valve to make it is less than or equal with 8TN / ((phi12-phi22)L), the processing method is: first assembling the nut and two end covers into one unit, processing screw thread on the inner hole surface of nut and two end covers, then processing two spiral oil-storing grooves on the screw thread two sides of nut, last assembling the nut and two end covers into one unit.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Optical density-changing element, optical element and photographic unit

InactiveUS20050058445A1Expand rangeImprove performanceNanoopticsExposure controlMolecular physicsAnode

To provide an optical density-changing element which has excellent properties that it can be brought into a colored state by applying only a low voltage, that it shows a rapid response speed and becomes completely colorless when restored to a bleached state from the colored state, and which can undergo a change in optical density in response to an applied voltage, the optical density-changing element includes, on each of an anode and a cathode, a material capable of at least one of donating and accepting an electron and, as a result of at least one of donating and accepting the electron, undergoing a change in absorption spectrum in a visible region and a material undergoing substantially no change in absorption spectrum in the visible region, with potentials of these materials satisfying a specific relation defined in the specification.

Owner:FUJIFILM HLDG CORP +1

Testicle sperm freeze-storage and revival method

The invention discloses a cooling storage and resuscitation method of testicle sperm, which is characterized by the following: taking the exhausting cytoplasmic transparent tape as carrier; loading the biopsy testicle sperm in the sealed transparent tape; reducing the sperm loss; improving the sperm recovery ratio by 70 percent; aspirating the sperm under the microscopic operation in the ICSI directly; improving the flexibility of non-sperm patient to receive the auxiliary fertility treatment.

Owner:ZHEJIANG UNIV

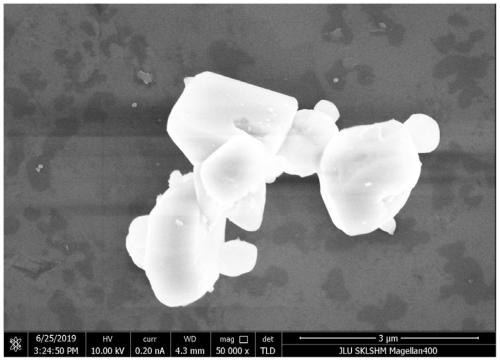

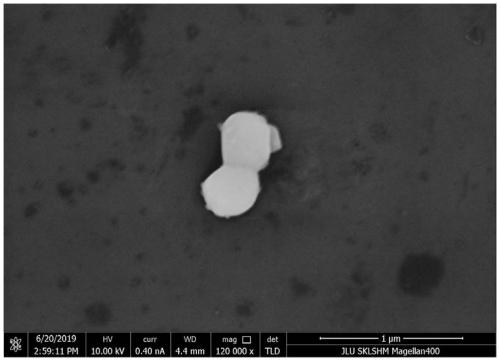

Hydroxyl copper chloride material and synthesizing method thereof

The invention discloses a hydroxyl copper chloride material and a synthesizing method, and belongs to the field of preparation of IB race hydroxyl chloride materials. The preparation method includes the steps that with copper chloride crystal particles and copper oxide powder being raw materials, firstly, the raw materials are mixed and then ground for two hours; then, at the temperature of 100-180 DEG C, sealed heating is conducted for 12 hours, and after reaction is ended, the raw materials are cooled to have room temperature, and then are ground for 30 minutes-1 hour; the processes of heating, cooling and grinding are repeated 3-4 times, so that hydroxyl copper chloride Cu(OH)Cl powder which is dark green is obtained. The prepared product is the compound Cu(OH)Cl composed of copper, hydroxyl and chlorine which are measured according to the proportion of 1:1:1, and is monoclinic system crystals, wherein the space group is P21 / a; the particle size of the crystals is 0.7-1.5 micrometers. The preparation method has the advantages of being simple and easy to implement and realizing a high crystallinity degree, a high yield of products, small losses, high purity and low costs for reactants.

Owner:JILIN UNIV

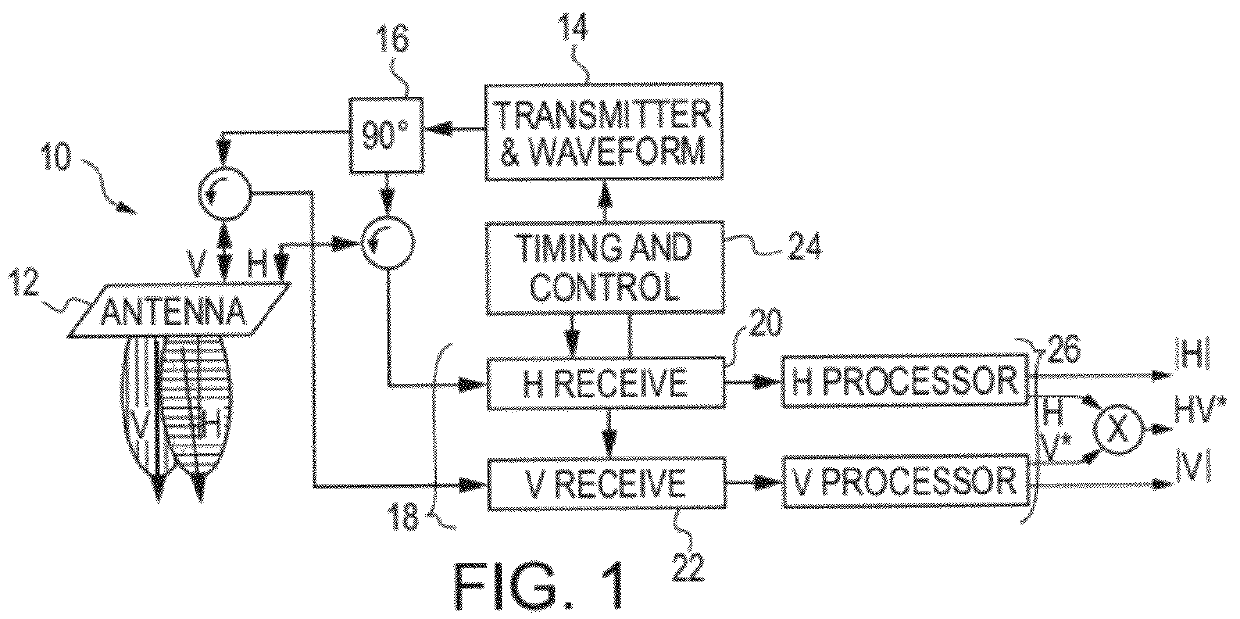

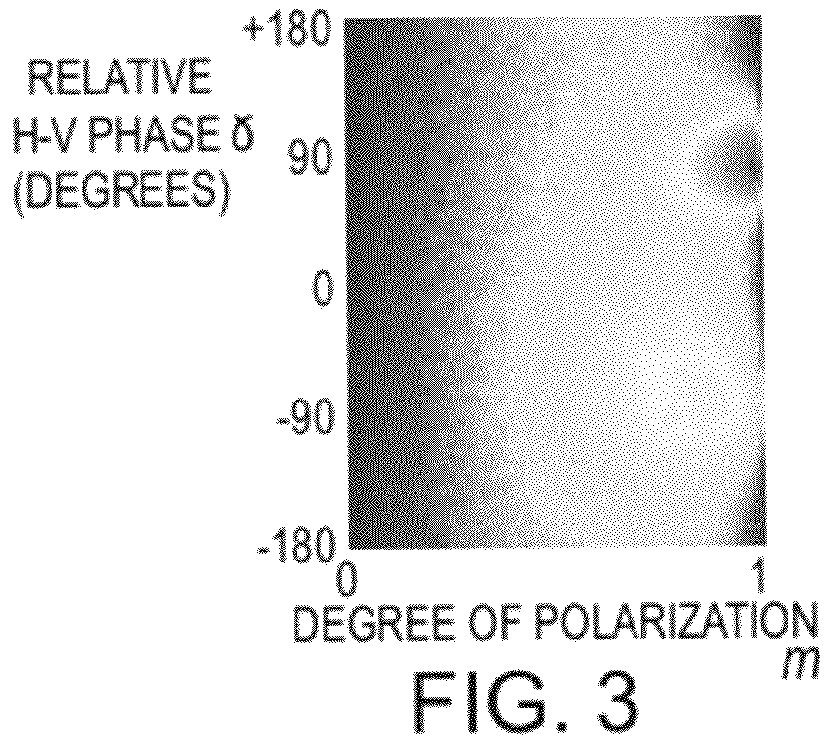

Synthetic aperture radar hybrid-quadrature-polarity method and architecture for obtaining the stokes parameters of radar backscatter

ActiveUS8258996B2Minimizing sensitivitySimple systemRadio wave reradiation/reflectionComplex amplitudeSynthetic aperture radar

A synthetic aperture radar hybrid-quadrature-polarity method and architecture comprising transmitting both left and right circular polarizations (by alternately driving, at the minimum (Nyquist) sampling rate, orthogonal linear feeds simultaneously by two identical waveforms, + / −90° out of phase), and receiving two orthogonal linear polarizations, coherently. Once calibrated, the single-look complex amplitude data are sufficient to form all Stokes parameters, which fully characterize the radar backscatter.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

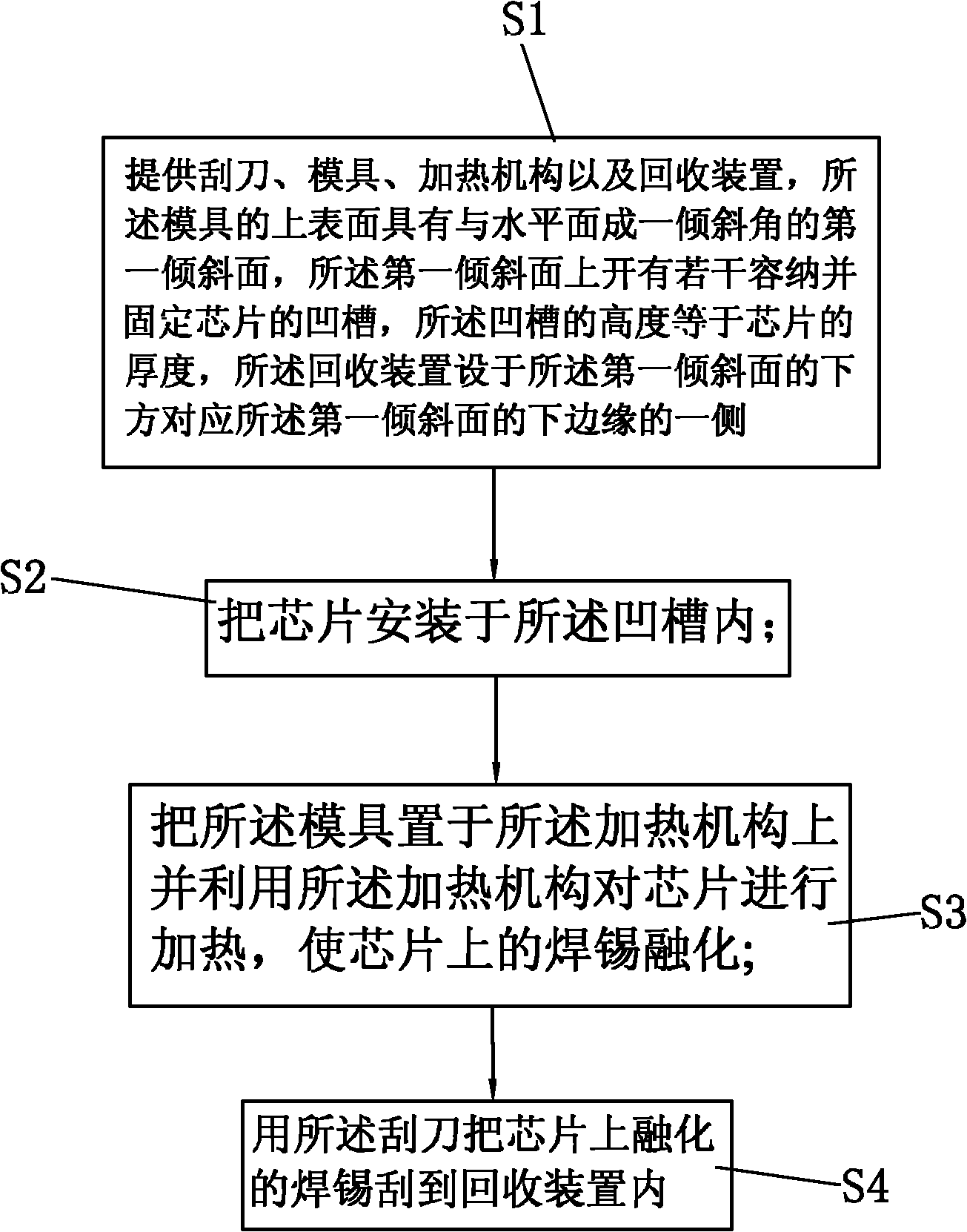

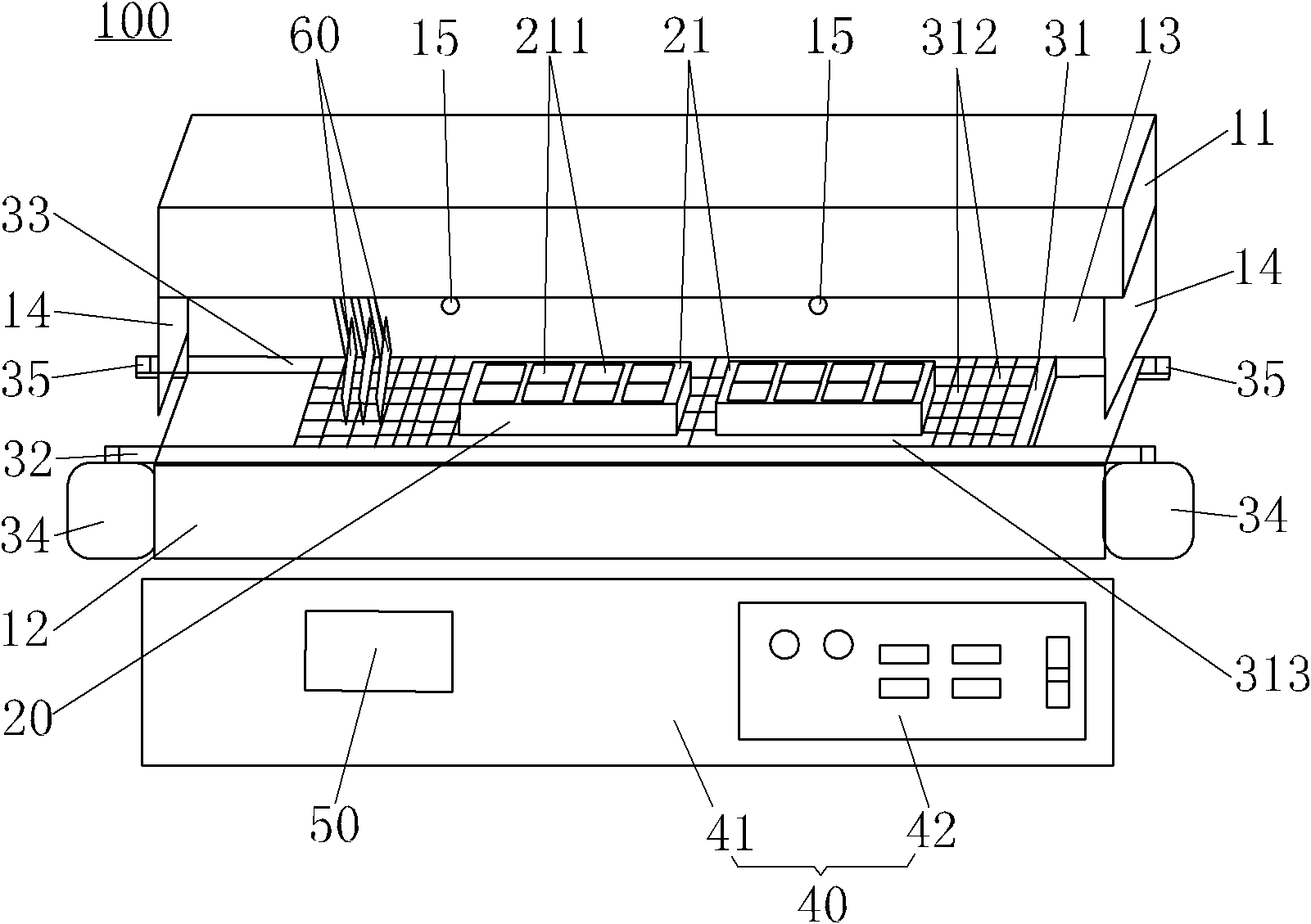

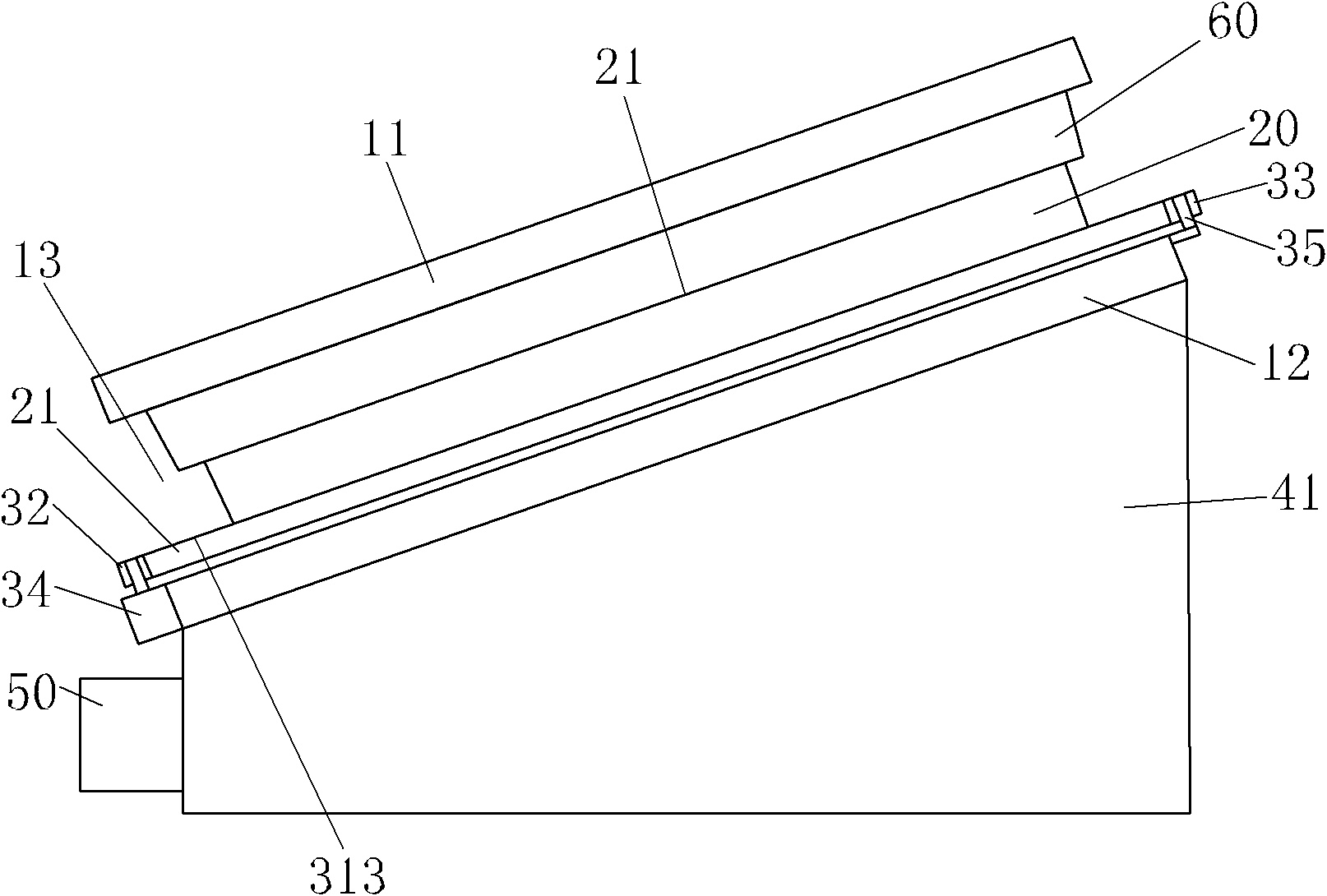

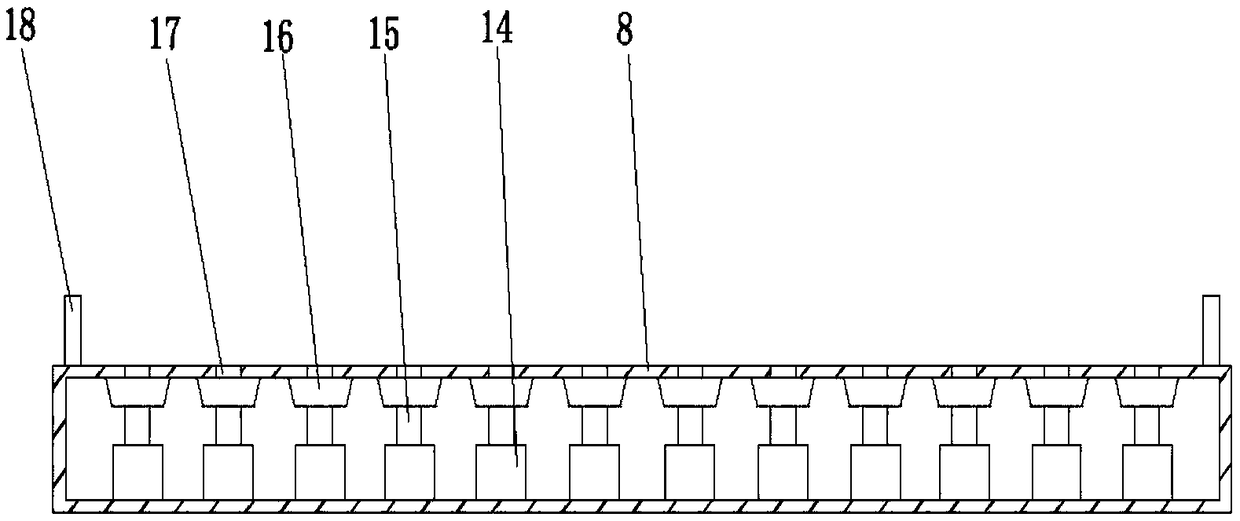

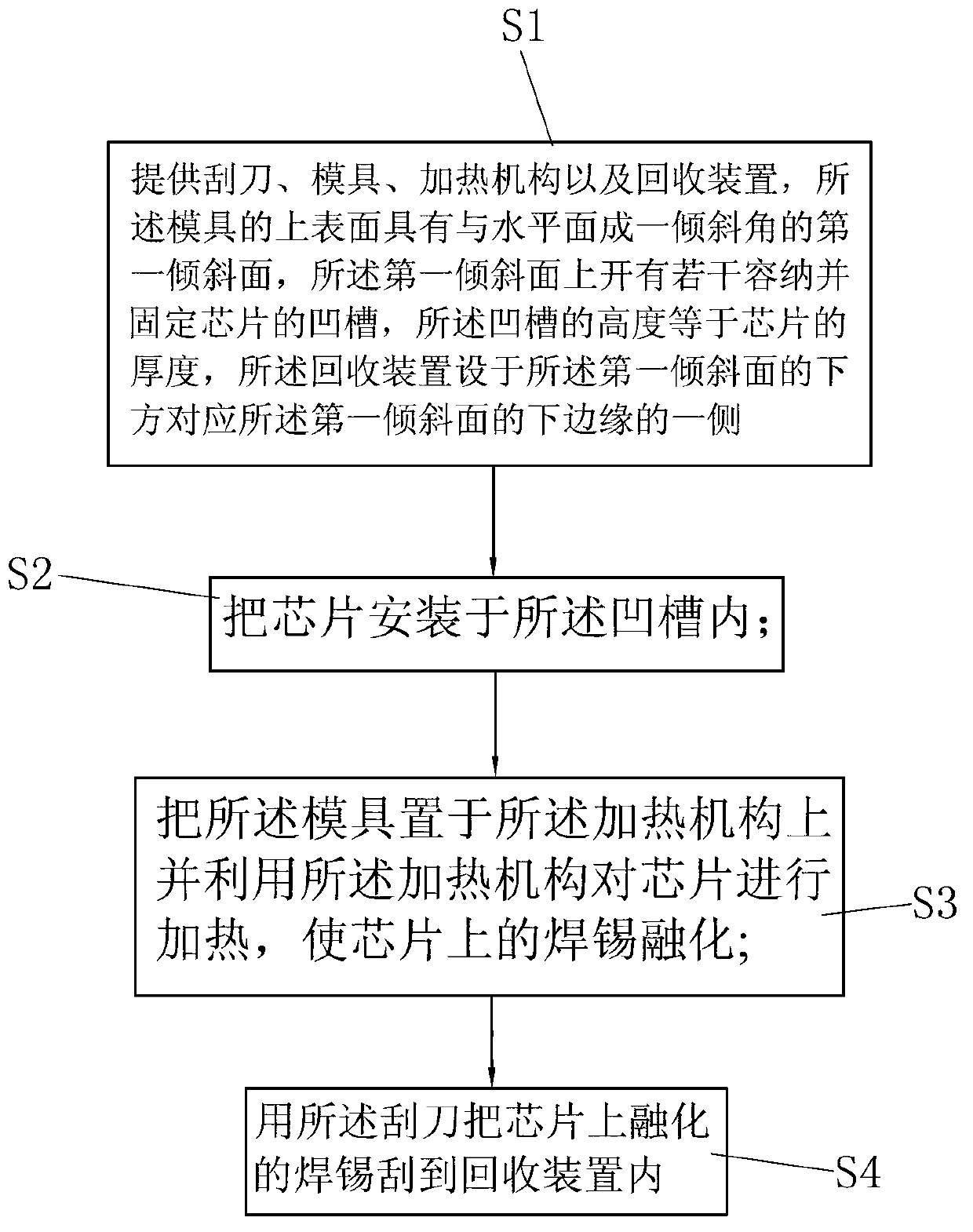

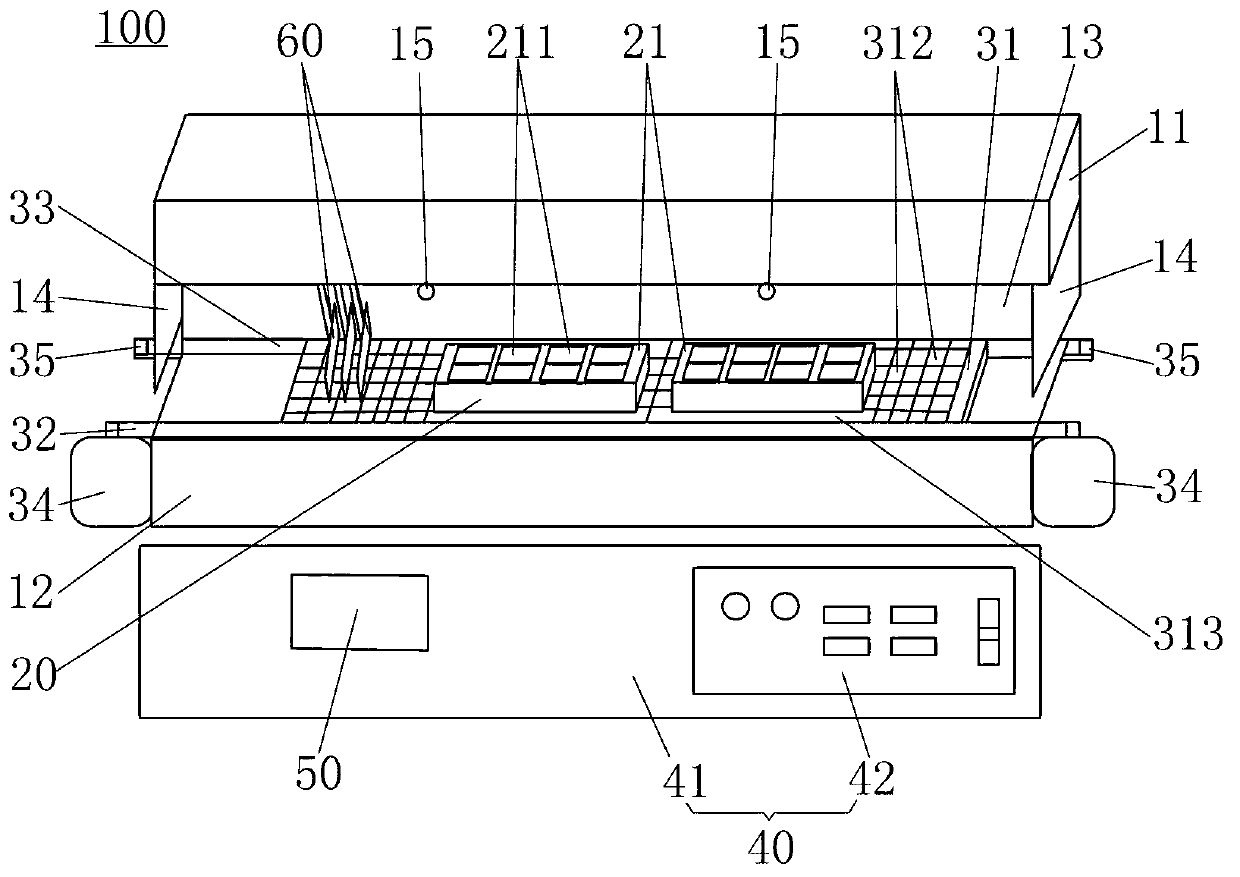

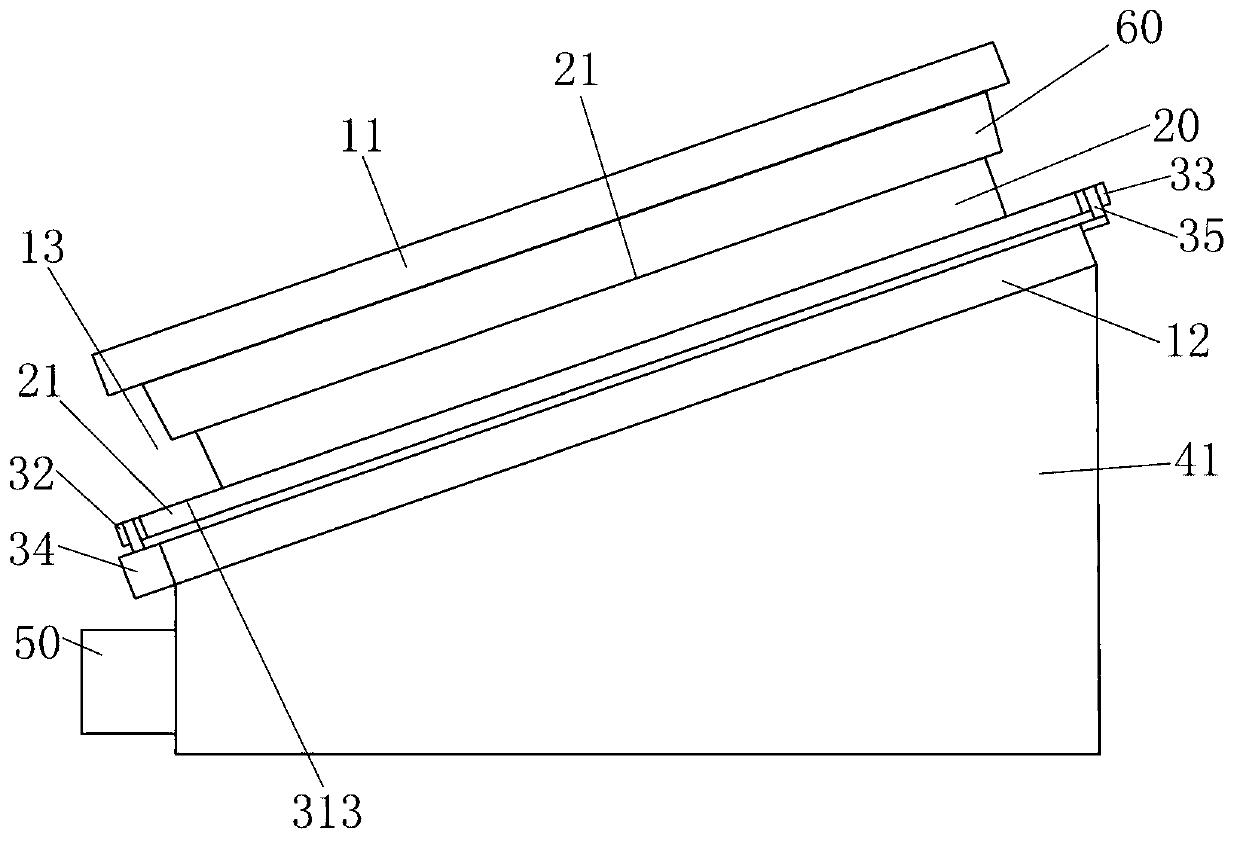

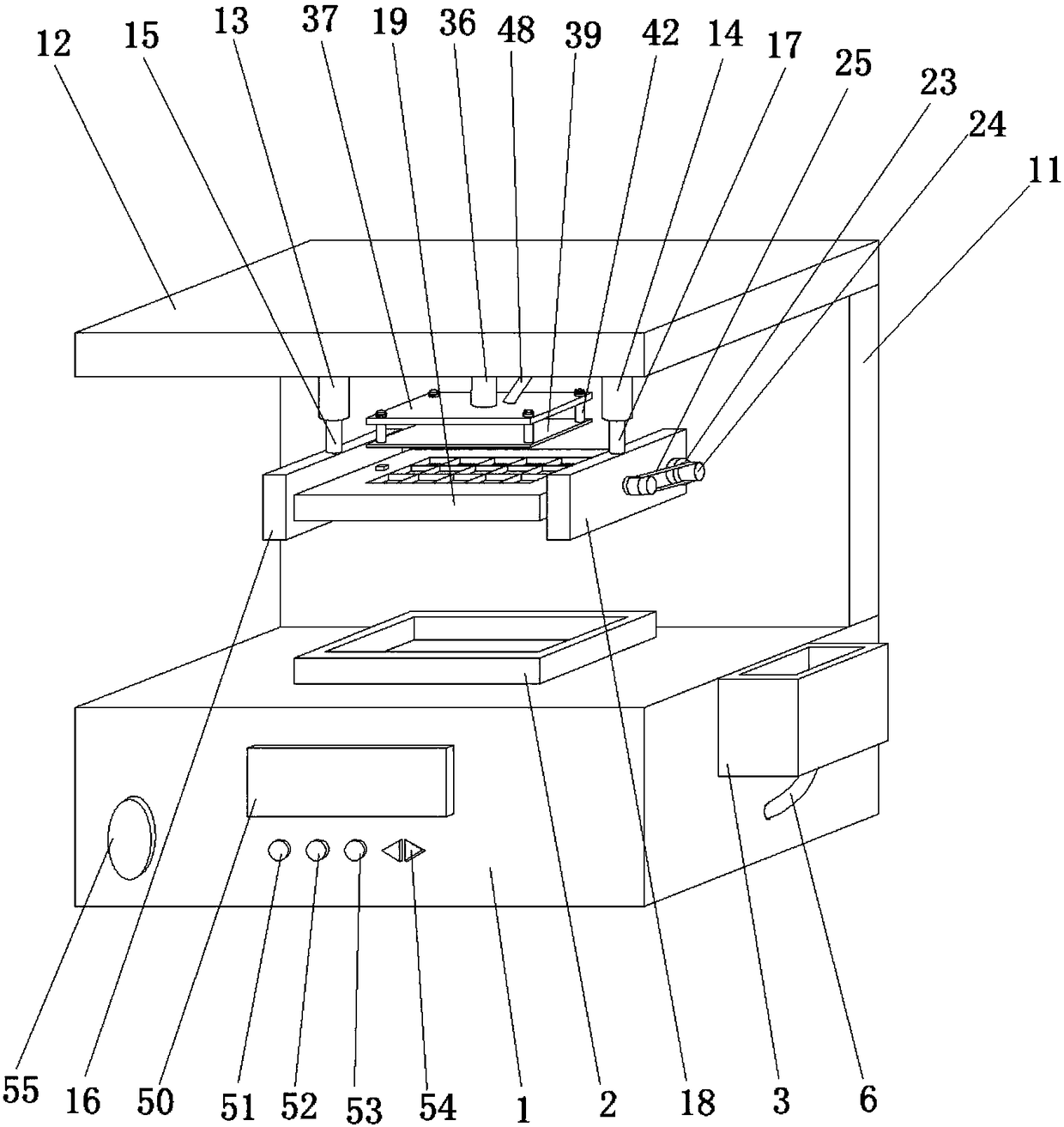

Detinning processing method of chip and chip detinning machine applying method

The invention discloses a detinning processing method of a chip, and the method comprises the following steps: providing a scraper, a die, a heating mechanism and a recovery device, wherein a first inclined plane which forms an inclination angle with the horizontal plane is arranged on the upper surface of the die, a plurality of grooves for accommodating and fixing chips are formed on the first inclined plane, the height of each groove is equivalent to the thickness of each chip, and the recovery device is arranged on one side corresponding to the lower edge of the first inclined plane belowa conveying mechanism; arranging the chips in the grooves; placing the die on the heating mechanism, and utilizing the heating mechanism to heat the chips so as to melt soldering tin on the chips; and utilizing the scraper to scrape the soldering tin on the chips into the recovery device. In the method, the scraper is utilized for scraping off the molten soldering tin form the chips, the soldering tin can stably slide into the recovery device along the wall of the scraper, the loss of the soldering tin is low, and the recovery rate is high; and furthermore, the plurality of the grooves are arranged on the die, the plurality of the chips can be scraped according to needs, and the tin scraping efficiency is high. In addition, the invention further provides a chip detinning machine applying the detinning processing method of the chip.

Owner:何光宁

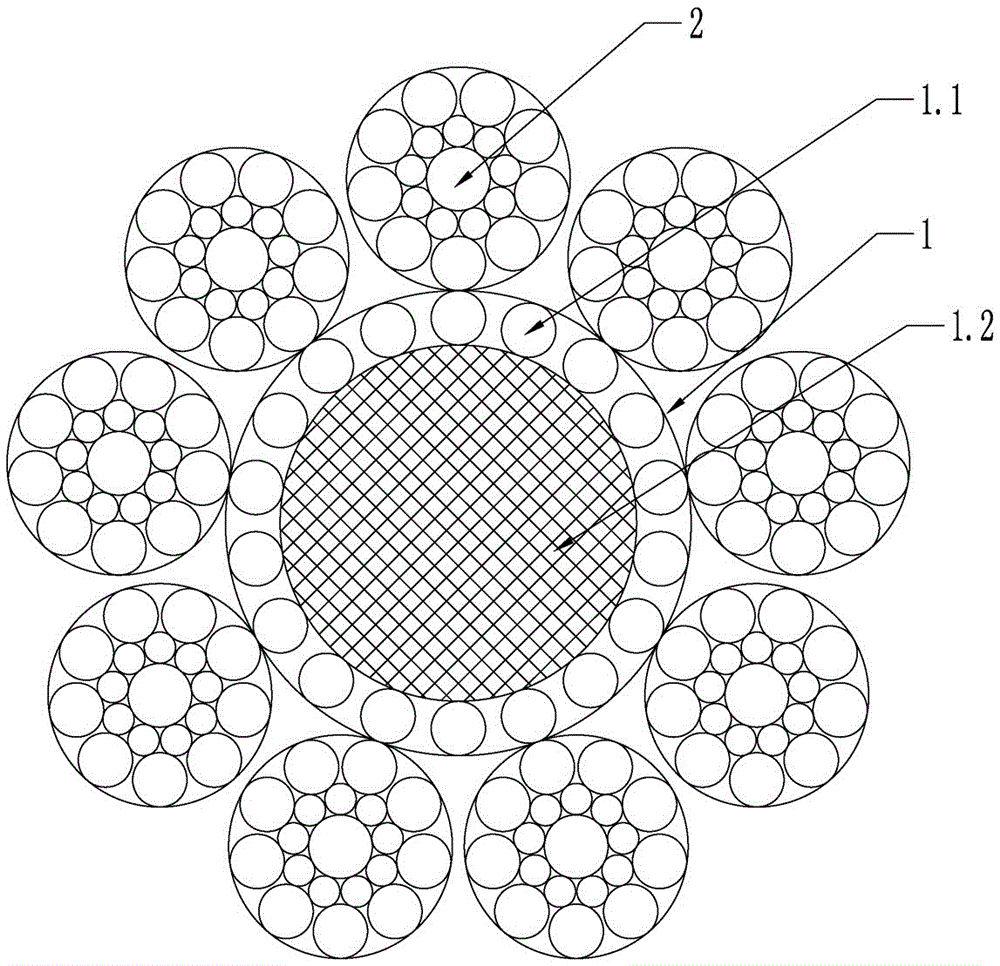

Steel wire rope with single-stranded compound core for elevator

InactiveCN105064105ALittle change in elongationImprove fatigue lifeElevatorsTextile cablesSingle strandZinc

The invention relates to a steel wire rope with a single-stranded compound core for an elevator. The steel wire rope with the single-stranded compound core for the elevator is characterized by comprising the single-stranded compound rope core and outer strands, and the outer side of the single-stranded compound rope core is wrapped with six to nine outer strands; the single-stranded compound rope core comprises ten to thirty-six outer wound steel wires and a fiber core, and the surface of each outer wound steel wire is plated with a layer of pure zinc or zinc-aluminum alloy. The steel wire rope with the single-stranded compound core for the elevator has the advantages that the corrosion resistance and the abrasion resistance are better, and the use requirements of medium and high speed elevators can be met.

Owner:FASTEN HONGSHENG GRP CO LTD

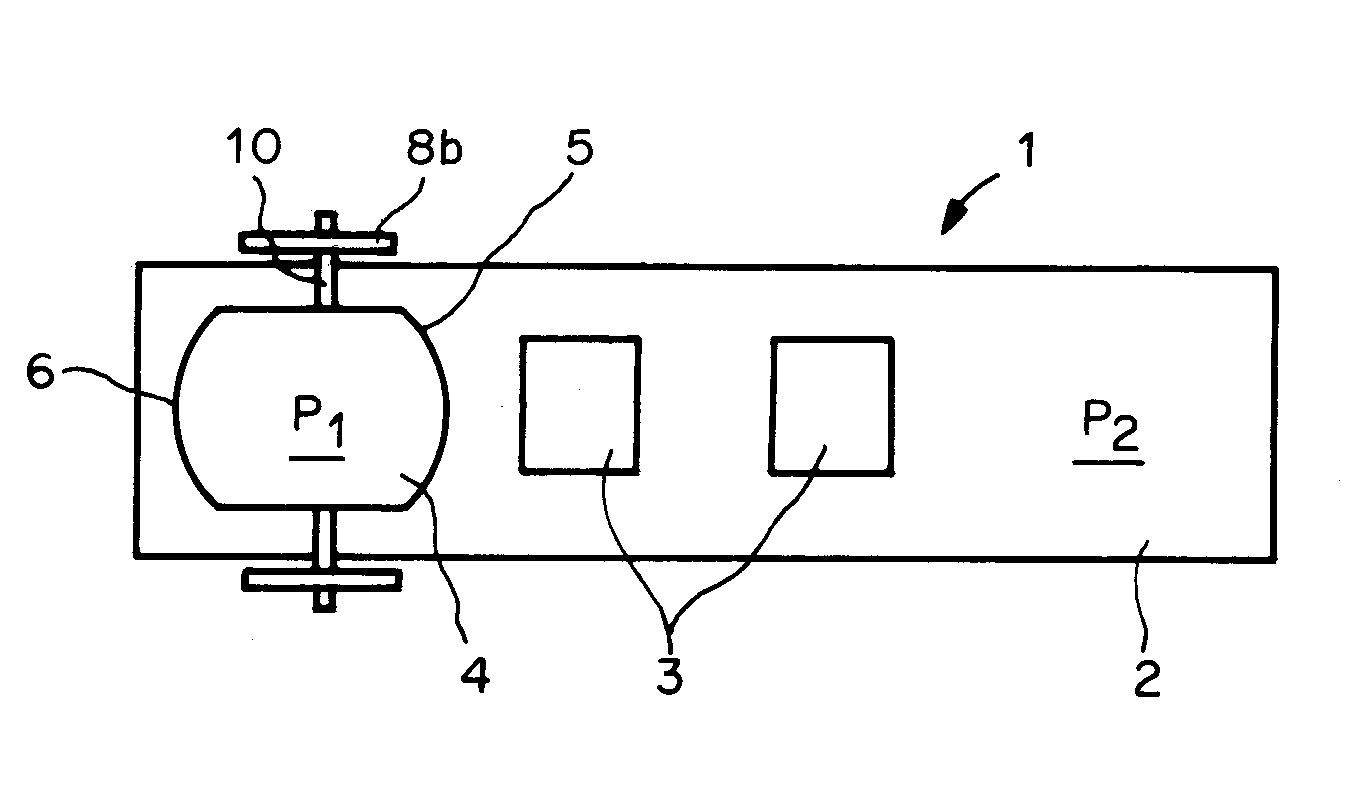

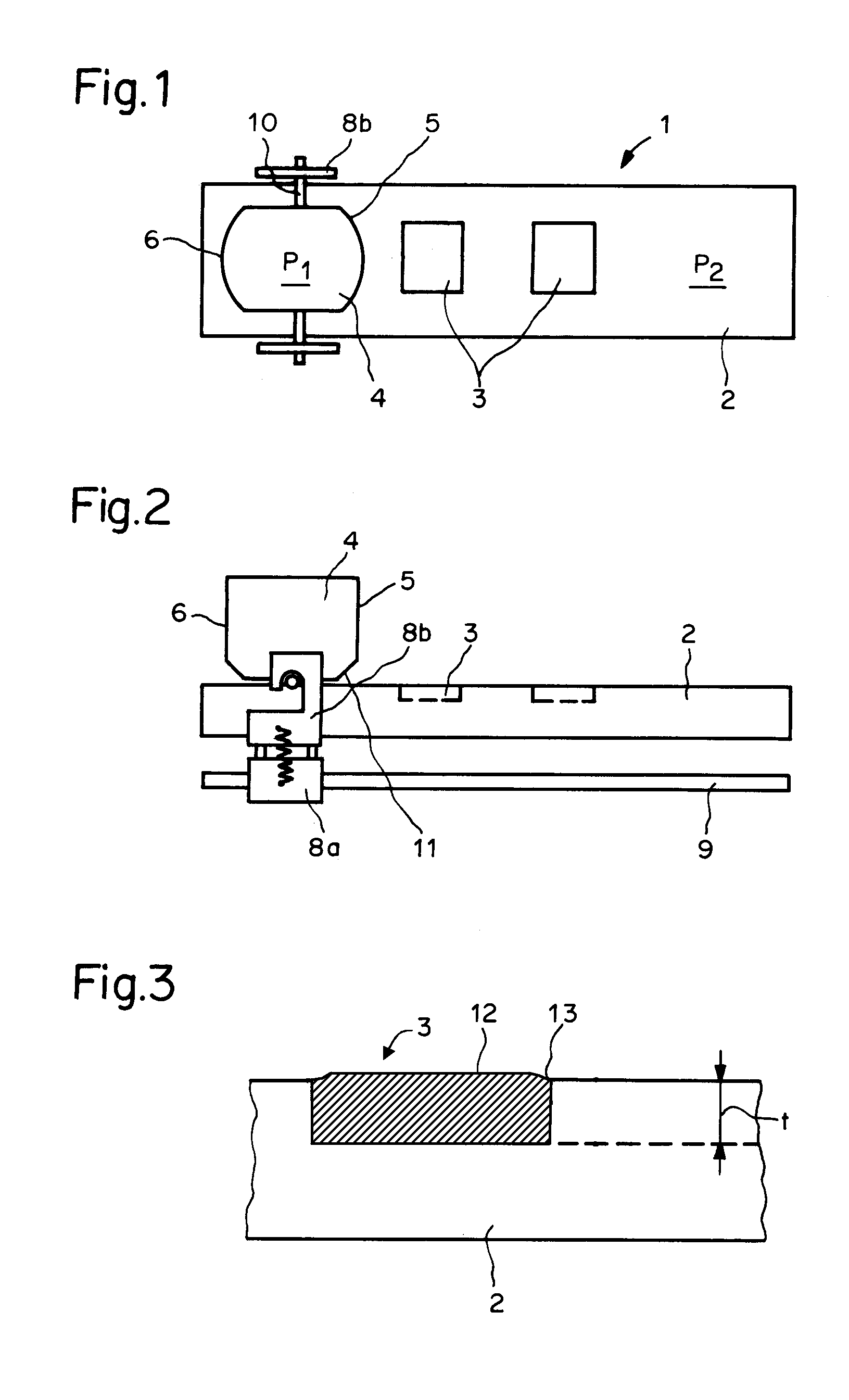

Method And Device For Wetting The Bumps Of A Semiconductor Chip With Soldering Flux

InactiveUS20100019018A1Less lossSolid-state devicesSemiconductor/solid-state device manufacturingSolderingEngineering

The present invention relates to a method and a device for wetting the bumps of a semiconductor chip with a soldering flux, in which a container, which accommodates the soldering flux and is open on the bottom, and a base plate, which contains at least one cavity, are moved back-and-forth in relation to one another on one side of the cavity to the other side of the cavity. The viewed in the movement direction front wall of the container is lifted up during the relative movement, so that it is located at a distance above the base plate. The distance is somewhat greater than the height difference by which the soldering flux projects above the level of the surface of the base plate. This measure has the effect that the front wall of the container does not convey any soldering flux onto the base plate, which has caused the loss of this soldering flux until now.

Owner:BAUMANN DAMIAN +2

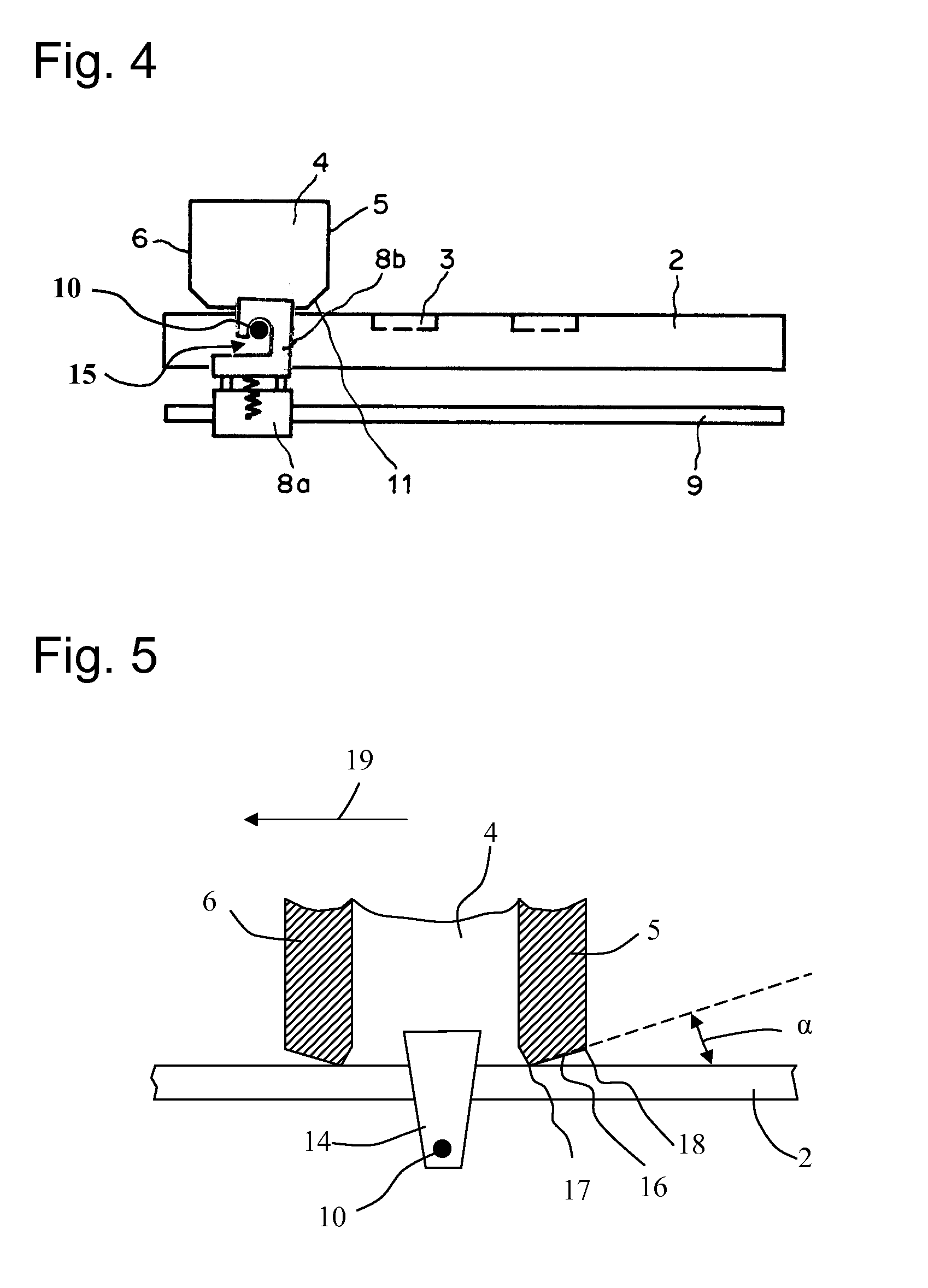

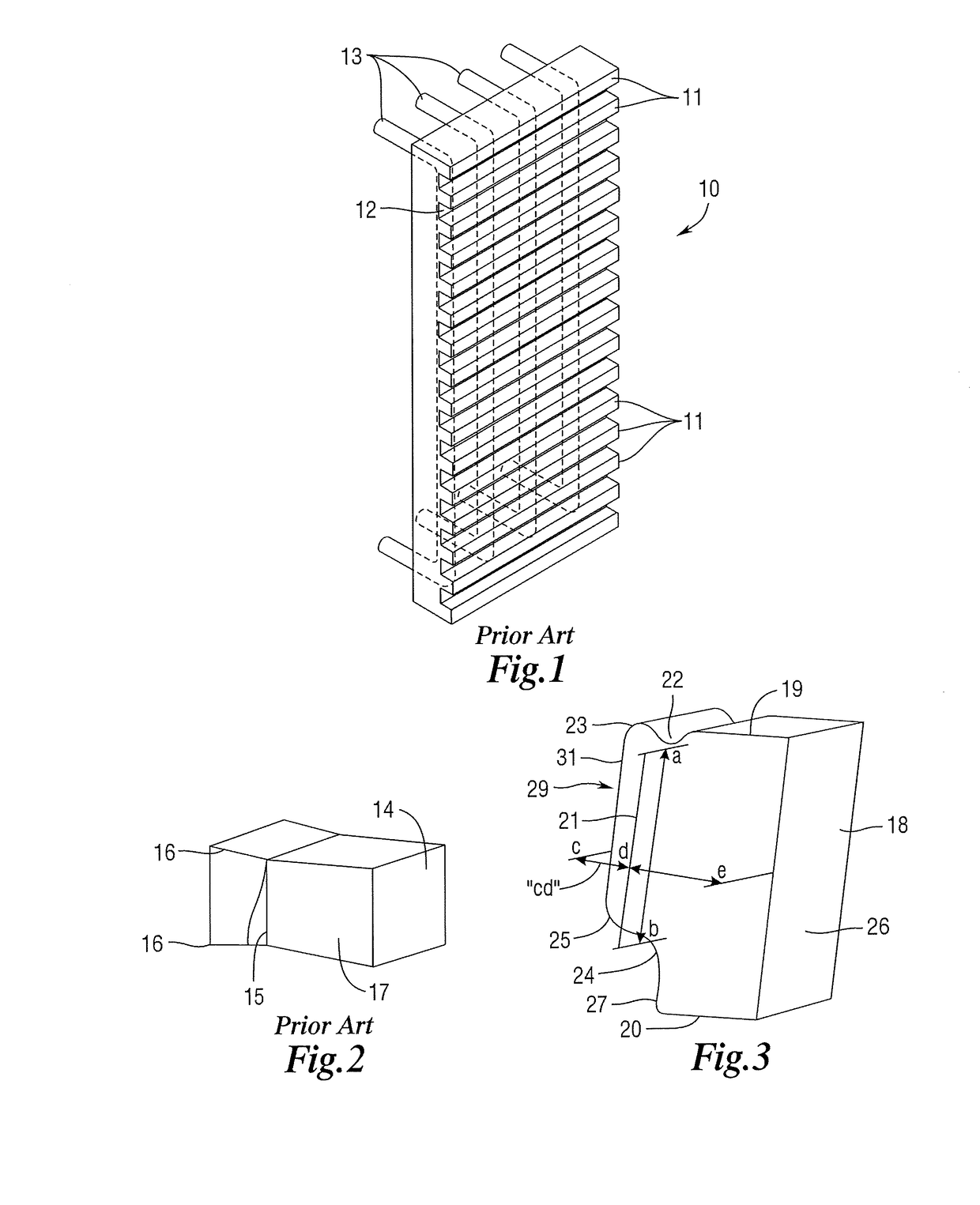

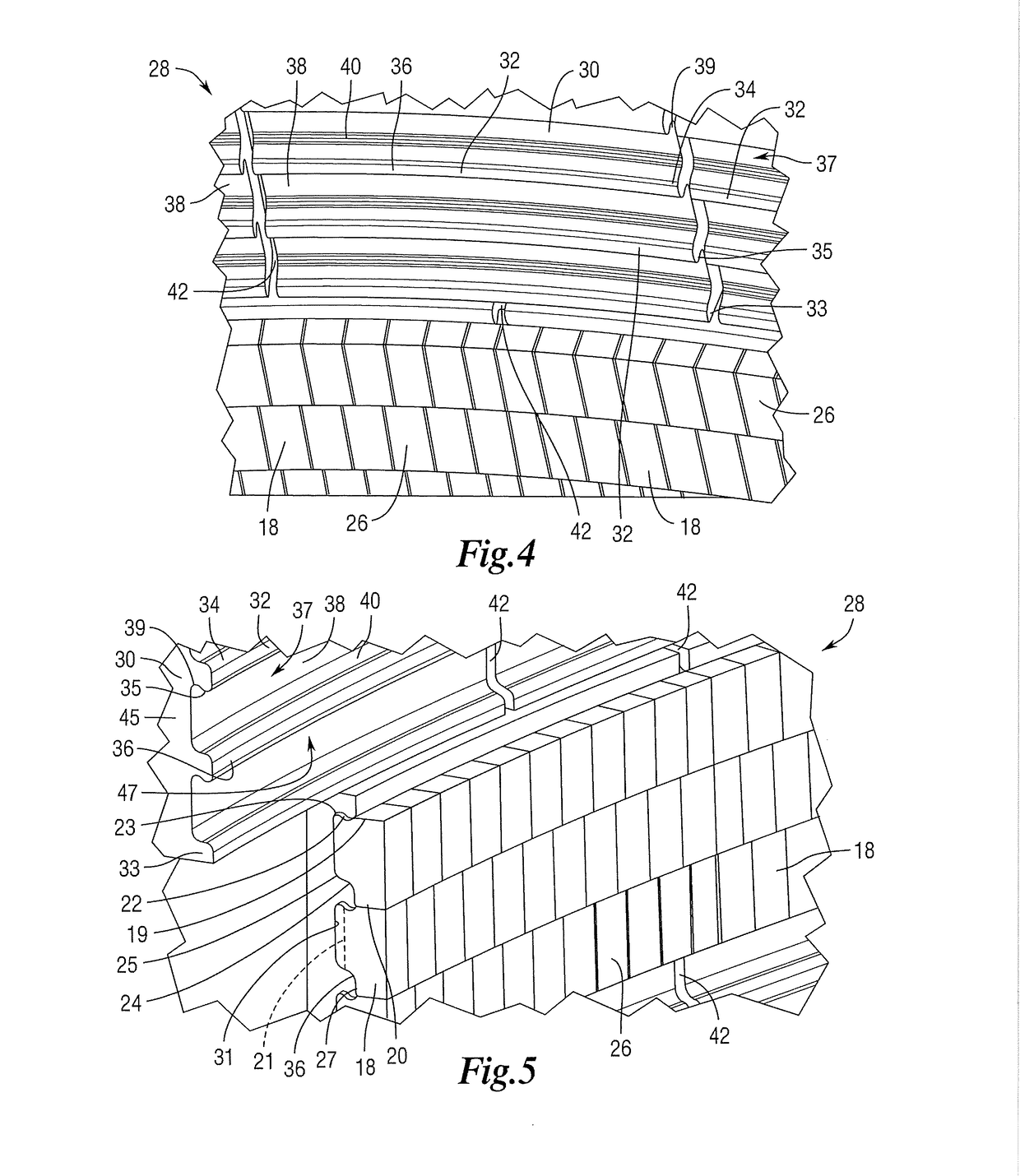

Magnetic core and magnetic component using the same

ActiveUS20140320255A1CharacteristicLess lossTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic coreMagnetic flux

A magnetic core and a magnetic component using the same are disclosed. The magnetic core has a first magnetic material and a non-uniform filling section in connection; also, the magnetic core has a magnetic flux direction, for which the non-uniform filling section perpendicular to the magnetic flux direction contains at least two kinds of magnetic material. Comparing to a conventional uniform-filling magnetic core, the non-uniform filling section within the magnetic component of the magnetic core can provide higher initial inductance and better DC-bias characteristics; this improved magnetic component can provide higher inductance in specific mandatory loads, or less efficiency loss in a condition of the same inductance provided.

Owner:DELTA ELECTRONICS INC

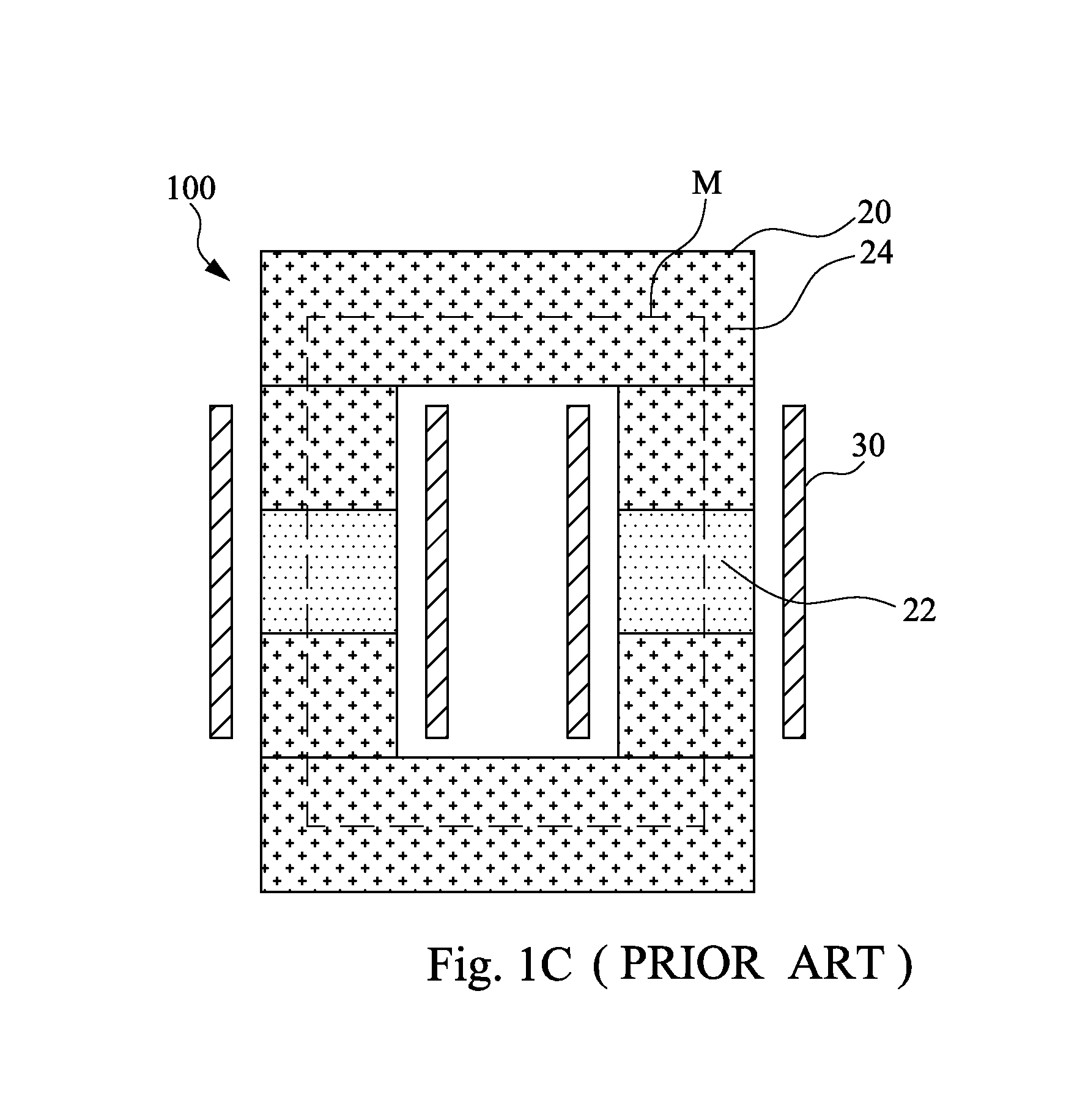

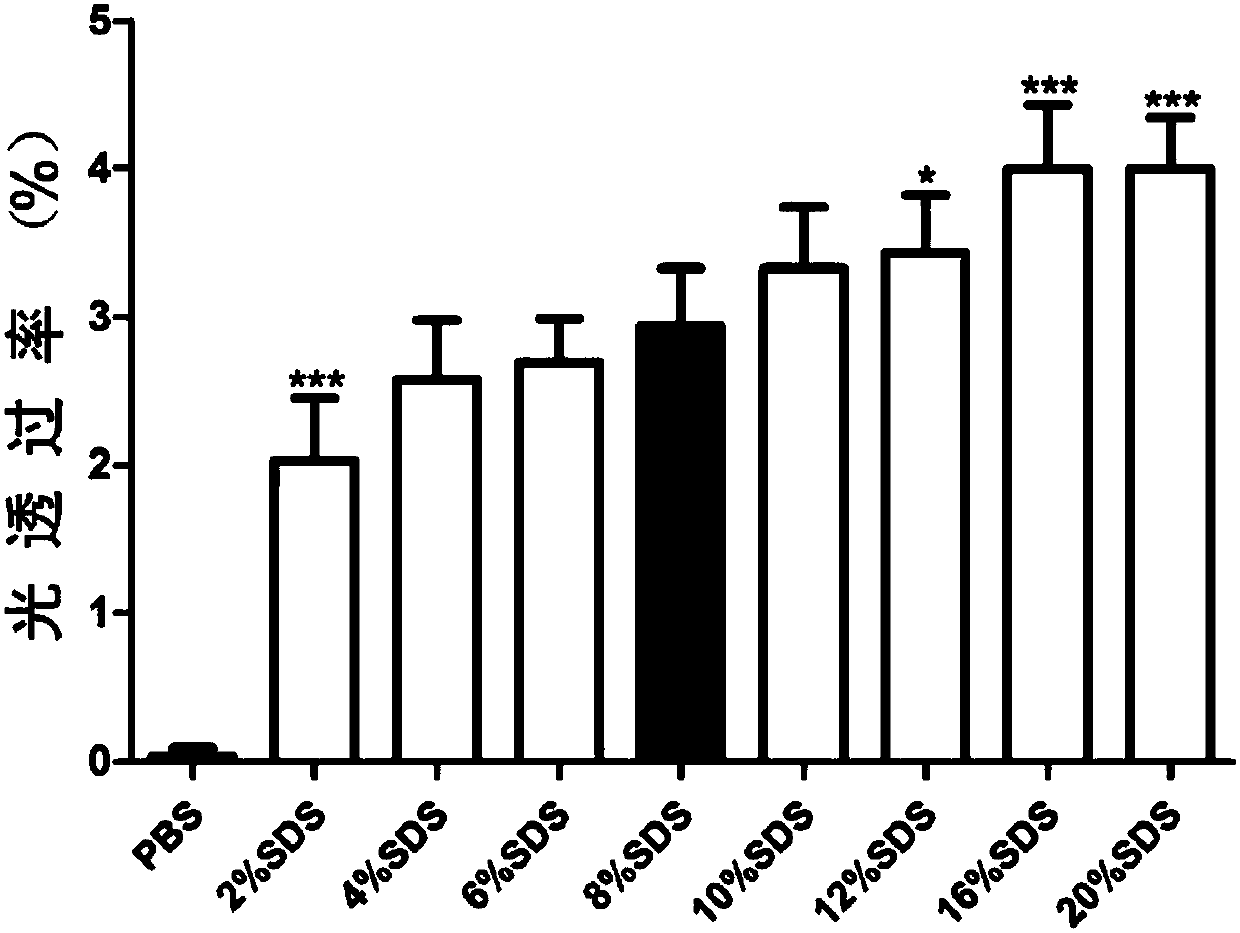

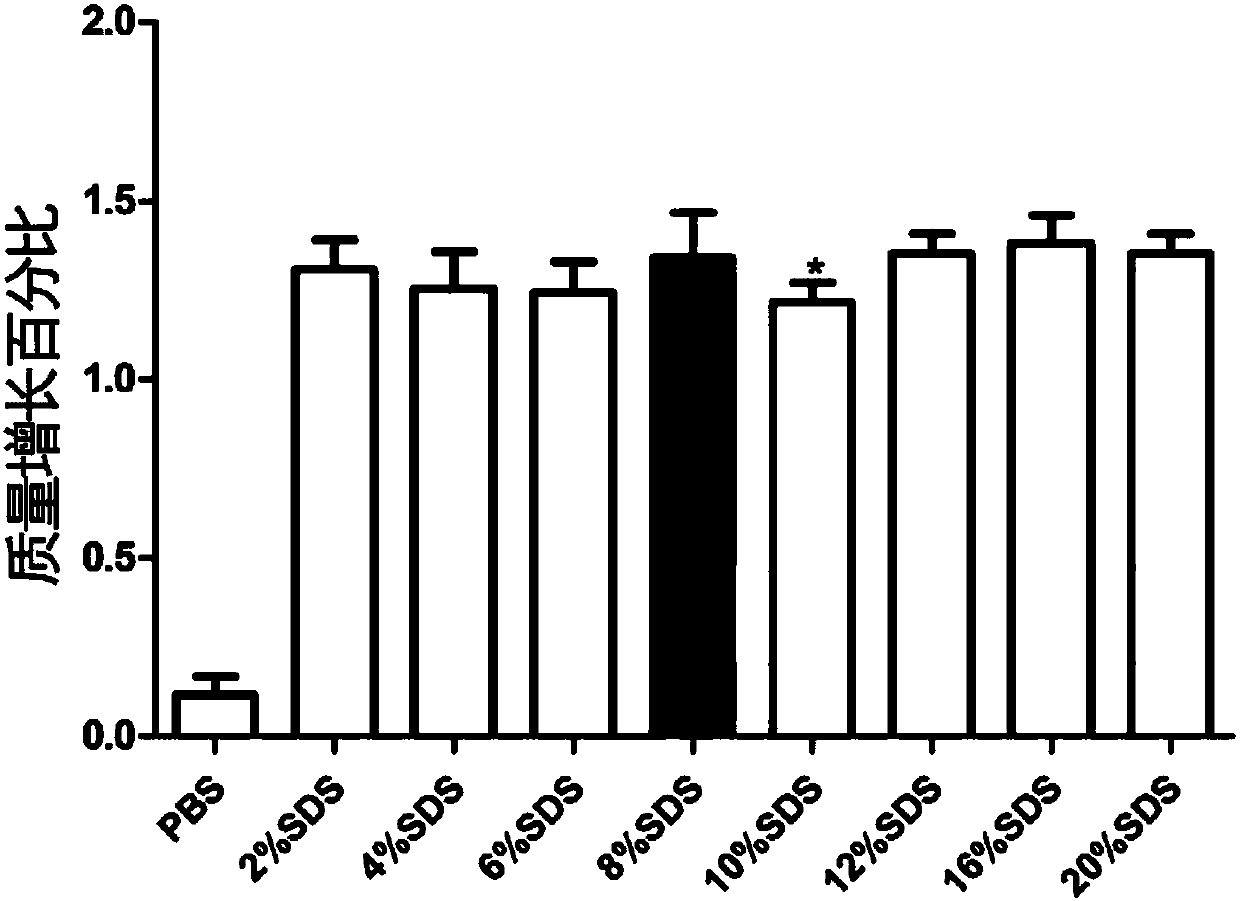

Tissue vitrification liquid SUT and preparation and application thereof

InactiveCN107621462ALow costReduce difficultyWithdrawing sample devicesTransmissivity measurementsVitrificationCardiac muscle

An embodiment of the invention relates to a tissue vitrification liquid SUT, which mainly comprises SDS, urea and TritonX-100. The invention further relates to a preparation and application of the tissue vitrification liquid SUT. The tissue vitrification liquid SUT provided in the embodiment is reduced in preparation cost and difficulty, is improved in vitrification effect, and has a cardiac muscle vitrification degree superior than that of some vitrification liquids in the prior art.

Owner:王志伟

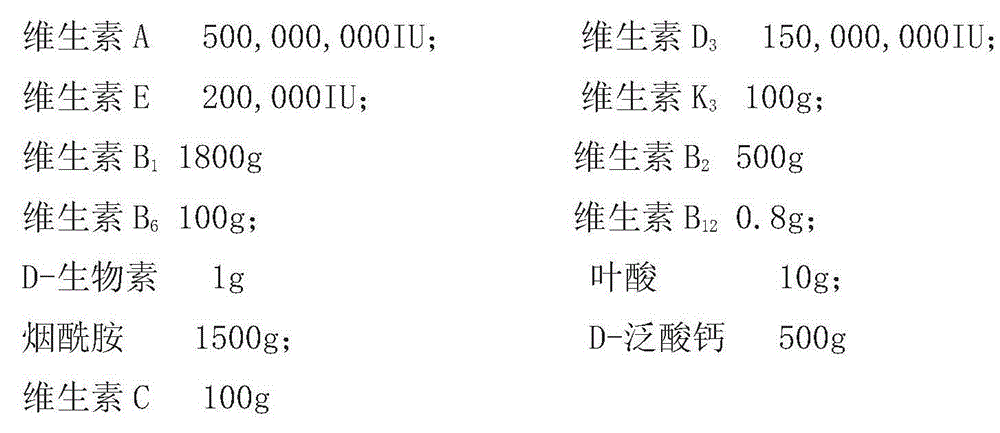

Soluble premixed feed additives for improving poultry egg laying performance and preparation method thereof

The invention discloses soluble premixed feed additives for improving poultry egg laying performance and a preparation method thereof. The additives are yellow solid powder, are a combination of pure nutrients, and include 13 types of vitamins, 7 types of trace elements, 11 types of amino acids, specially-designed electrolyte and oligosaccharide; the additives are designed according to the physiological metabolism and nutritional requirement characteristics of poultry in the egg laying period at the high-stress state, and selected raw materials are all water-soluble substances and can be added in a water-drinking mode and a material-stirring mode so that the rapid compensating and adjustment balancing effects can be achieved. By means of the additives, indexes of egg laying performance such as the egg laying number, egg shell color, hardness and egg shape index of poultry are kept in a good level, and the additives can be all absorbed by organisms and are free of residues and environment pollution.

Owner:SHANGHAI FRONTAN ANIMAL HEALTH

Ecological method for transporting high-density earthworm

The invention relates to an ecological method for transporting earthworm with high density. The invention employs clean water sponge as carrier. Firstly putting sponge into black plastic bag, then putting earthworm into black bag, packing the bag, and putting it into shipping box. The invention solves problem of transporting commercial earthworm and strain earthworm under high density for long distance, improves earthworm survival rate and reduces transportation cost.

Owner:河南省科学院河南省发展计划委员会地理研究所

Stave with external manifold

InactiveUS20180149429A1Operation moreLess lossManufacturing convertersFurnace cooling arrangementsEngineeringCooling fluid

A stave comprising a housing, an inner cooling fluid circuit comprising a cooling fluid inlet, a cooling fluid outlet and one or more cooling fluid pipes housed within, or cooling fluid passageways defined by, the housing, wherein each cooling fluid pipe and / or passageway is in direct or indirect fluid communication with the cooling fluid inlet and the cooling fluid outlet; and a manifold, integral with or disposed on or in the housing, that provides support for installation of the stave on a furnace shell; wherein the manifold has one or more inlet pipes, or defines one or more inlet passageways, for providing cooling fluid to the cooling fluid inlet of the cooling fluid circuit of the housing; and wherein the manifold has one or more outlet pipes, or defines one or more outlet passageways, for receiving cooling fluid from the cooling fluid outlet of the cooling fluid circuit of the housing.

Owner:BERRY METAL

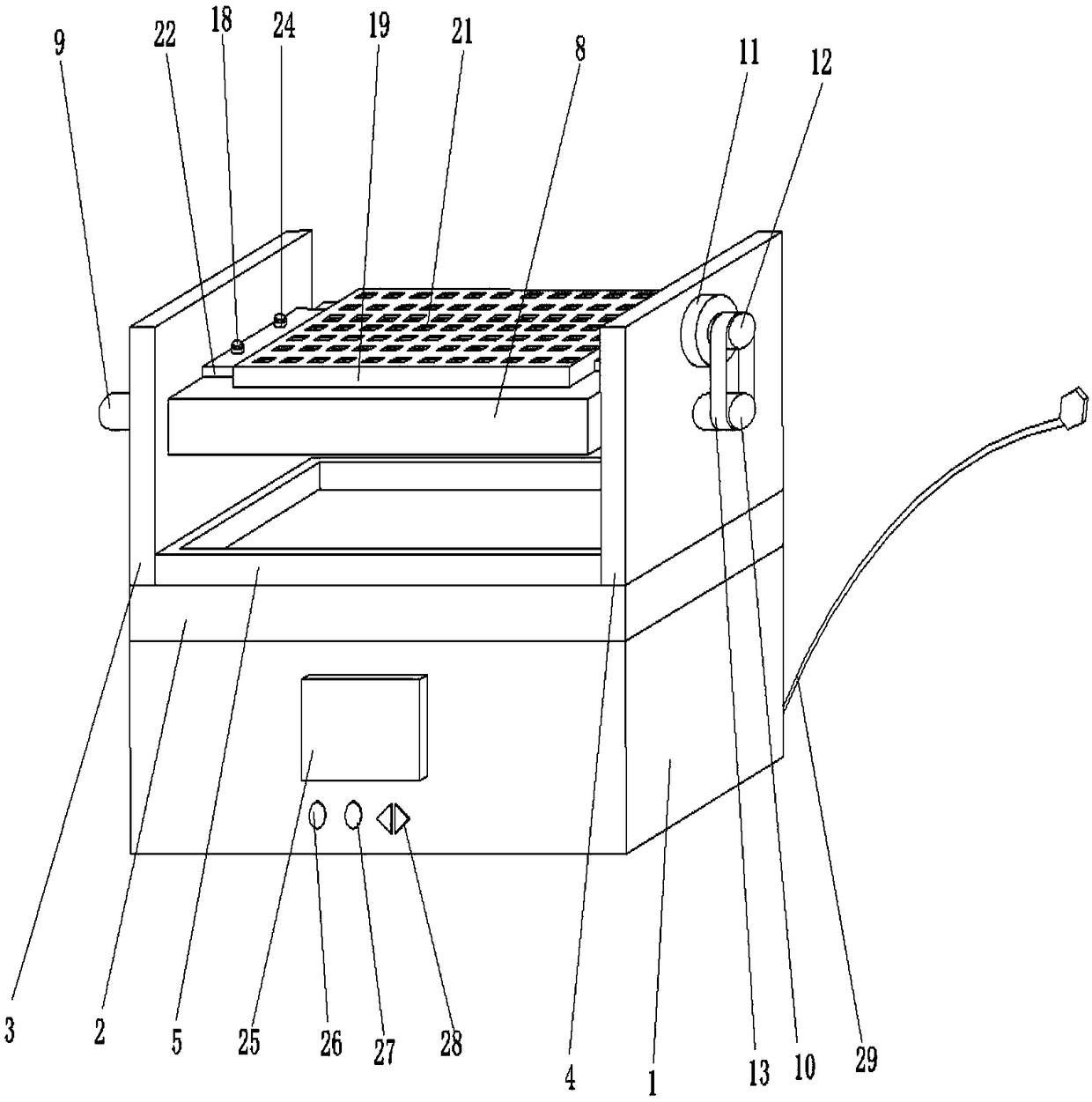

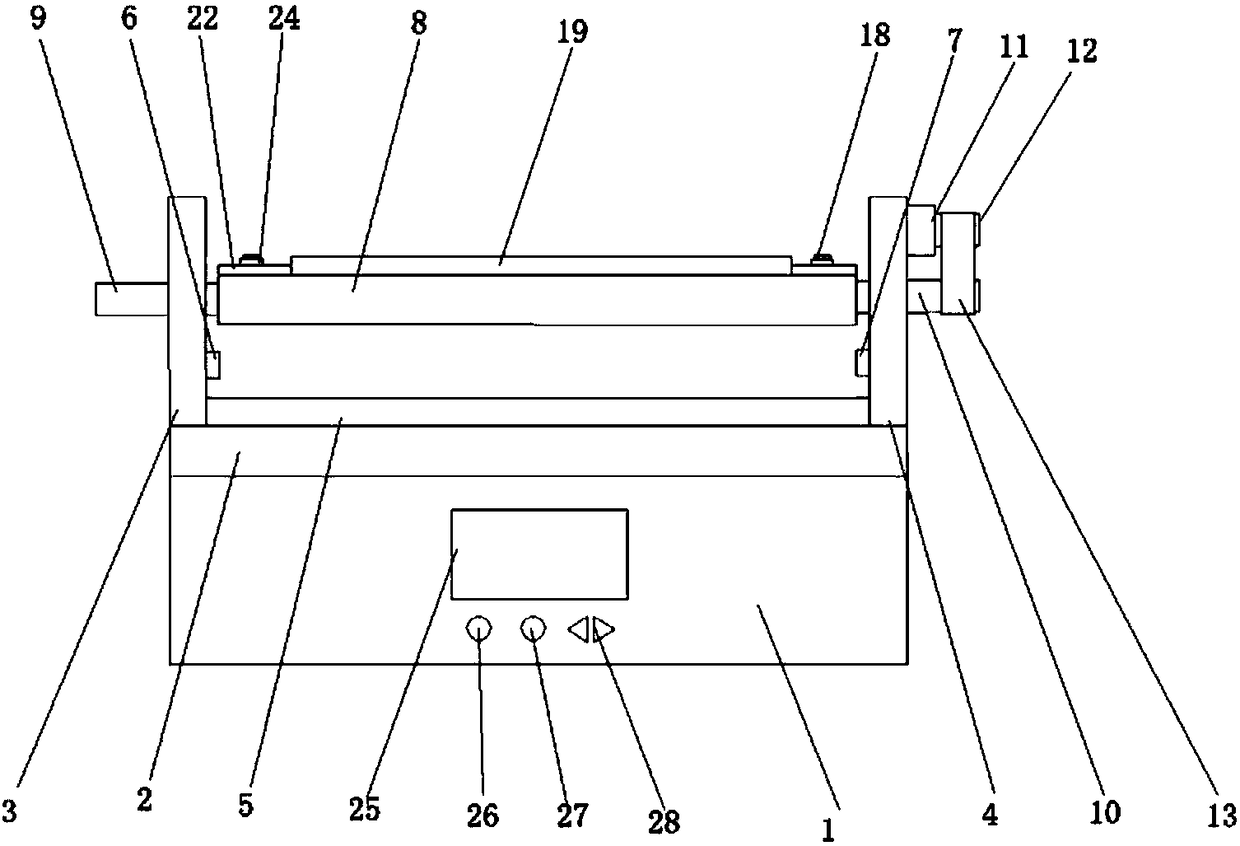

Weightless chip tin remover

InactiveCN108380995ATin removal achievedMeet the needs of batch tin removalSoldering apparatusLiquid stateElectric machinery

The invention provides a weightless chip tin remover which comprises a device body, wherein the device body comprises a control console; a heating plate is arranged at the top of the control console;a heater is arranged in the heating plate; a first supporting plate and a second supporting plate are arranged at the top of the heating plate; the first supporting plate is positioned on one side ofthe heating plate; the second supporting plate is positioned on the other side of the heating plate; and a recovery box is arranged between the first supporting plate and the second supporting plate.The weightless chip tin remover provided by the invention has the beneficial effects that an adsorption table and a chip carrier plate are turned over through a driving motor, so that chips in the chip carrier plate can get close to the heating surface of the heating plate and can be heated by the heater according to the preset temperature, original soldering tin on the surfaces of the chips can be molten to achieve the liquid state, as well as the soldering tin in the liquid state can be separated from the surfaces of the chips under the action of weightlessness and then can drop into the recovery box below the chips; accordingly, the low loss of the soldering tin and the high recovery rate can be achieved; and the chips in batch can be subjected to tin removal and the high tin removal efficiency can be achieved.

Owner:HUZHOU HUINENG ELECTROMECHANICAL TECH CO LTD

A series of anti-wave design for seaports or harbours

The invention provides a series of anti-wave device for a seaport or a harbour. Firstly, an anti-wave wall is constructed at positions of the seaport or the harbour, the anti-wave wall encloses the seaport or the harbour where ships are anchored. Reinforcing and supporting structures are provided on the anti-wave along two directions perpendicular to the central axis of the wall to resist strong stormy waves and allow the anti-wall not to be pushed down by the strong stormy waves. One outlet and one inlet for ships passing through are provided on the anti-wave wall, or, one opening is provided on the anti-wave wall and is taking the roles of the outlet and the inlet, width of the opening needs to be wider. Secondly, when a strong stormy wave is coming and ships are anchored, the outlet and inlet of the anti-wave wall are blocked by wave-breaking facilities. The wave-breaking facility is composed of a plurality of overlapped fine-mesh nets. The width of the wave-breaking facility is wider than the outlet and inlet of the anti-wave wall, when the tide falls, the bottom edge of the wave-breaking facility may be about 20 meters below the water surface, when the tide rises, the top edge of the wave-breaking facility may be about 10 meters above the water surface. Such anti-wave wall and wave-breaking facility can effectively break the impulsive force and energy of stormy waves. Certain facilities need to be constructed outside the anti-wave wall, which allows ships arriving late to avoid risk. All the facilities which are contacting with seawater are required to be able to resist seawater corrosion.

Owner:赵彦杰

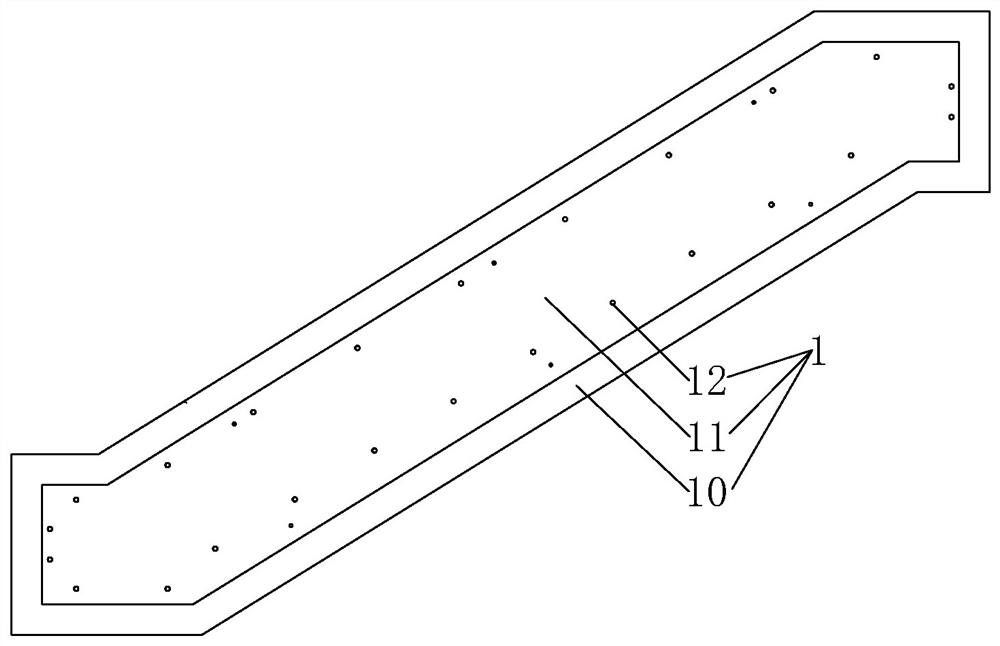

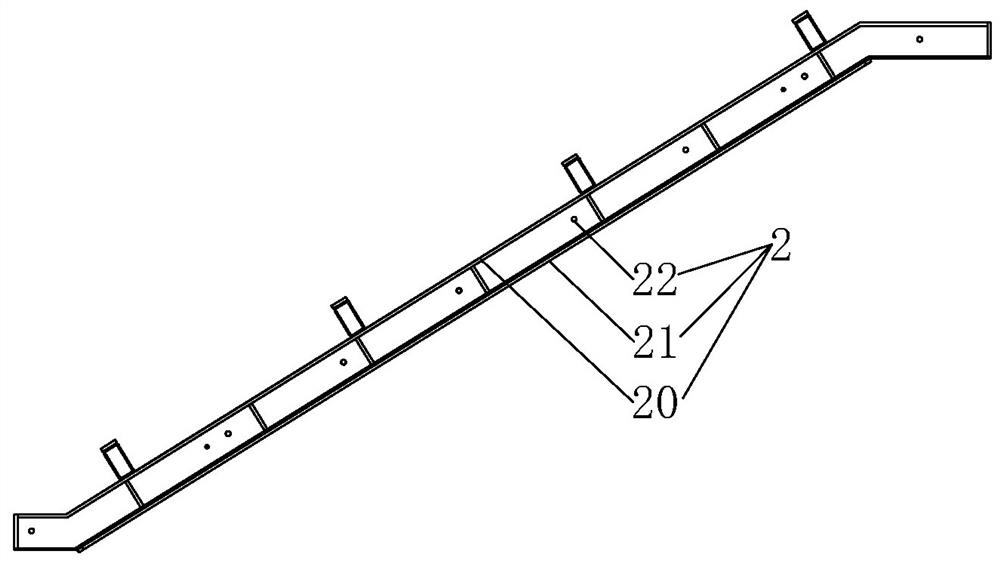

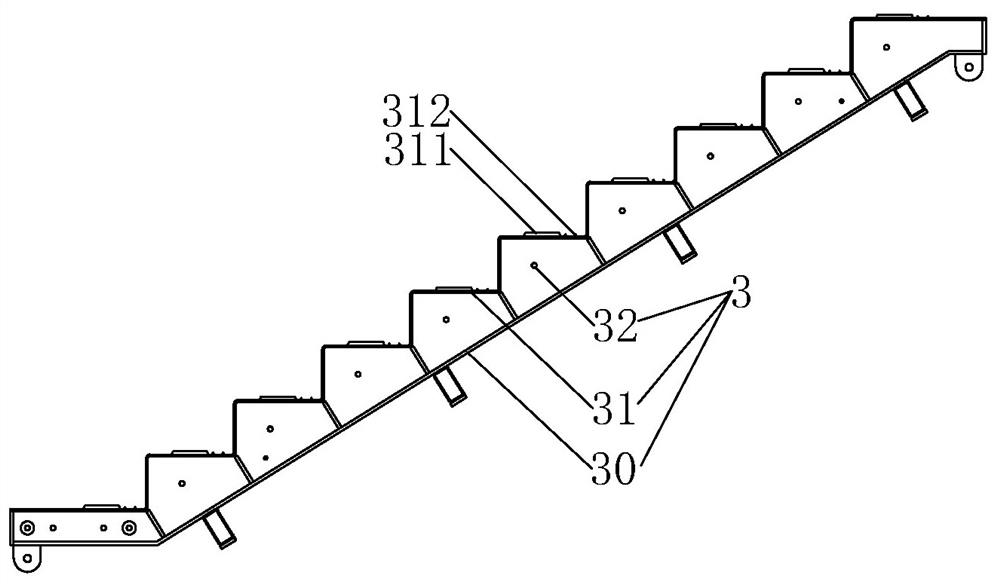

Concrete stair manufacturing mold, concrete stair manufacturing method and concrete stair

InactiveCN112659334AAvoid damageDoes not affect the demoulding operationMouldsMechanical engineeringMold removal

The invention discloses a concrete stair manufacturing mold. The concrete stair manufacturing mold comprises a first mold part used for forming a ceramic tile pasting surface of a concrete stair prefabricated part, a mold connecting surface of the first mold part is provided with a rough surface forming part, and the rough surface forming part is provided with a demolding angle. The concrete stair manufacturing mold is suitable for manufacturing the concrete stair prefabricated part with a surface suitable for sticking ceramic tiles. The invention discloses a concrete stair manufacturing method. The concrete stair manufacturing method comprises the steps that the first mold part with the rough surface forming part on the mold connecting surface is used for forming the ceramic tile pasting surface of the concrete stair prefabricated part, and the rough surface forming part is provided with the demolding angle. The method is suitable for sticking ceramic tiles when being used for manufacturing concrete stair prefabricated parts. According to the concrete stair manufactured through the concrete stair manufacturing method, the surface suitable for pasting ceramic tiles is formed on the surface, needing ceramic tile pasting, of the concrete stair prefabricated part.

Owner:河南省第一建设集团荥阳装配式建筑有限公司

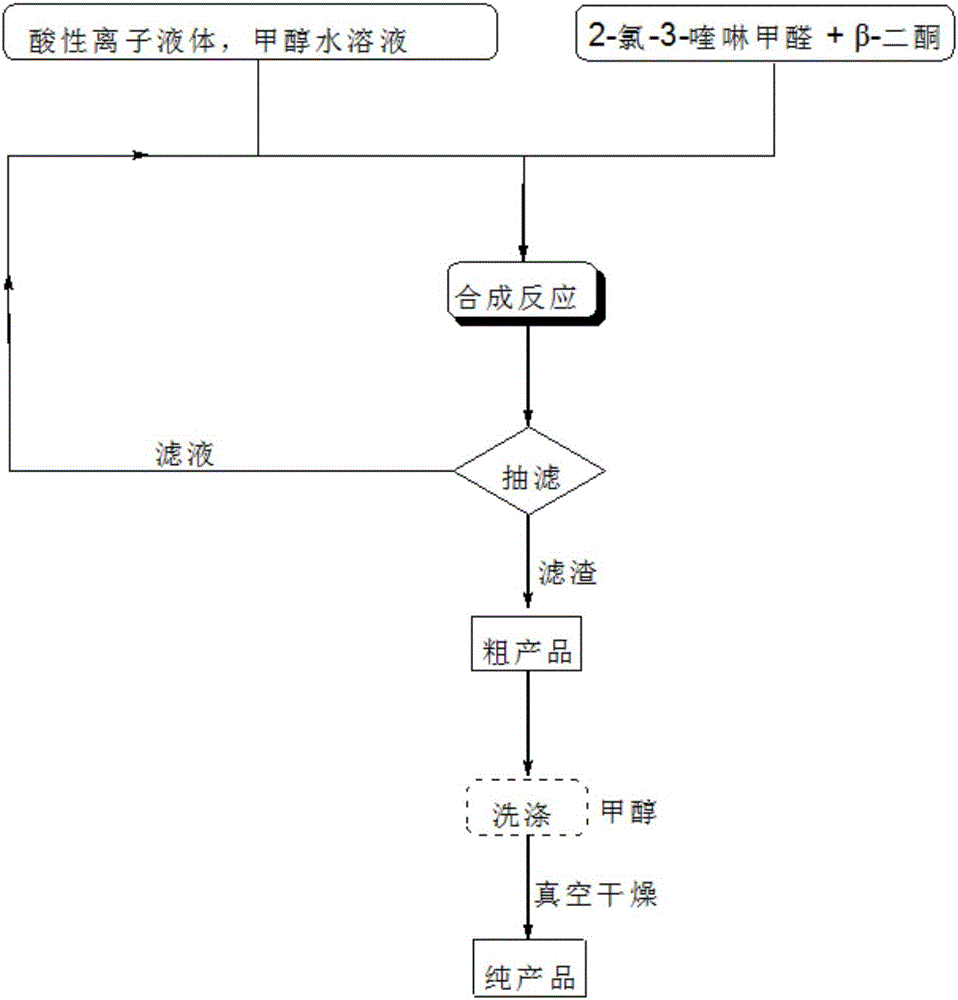

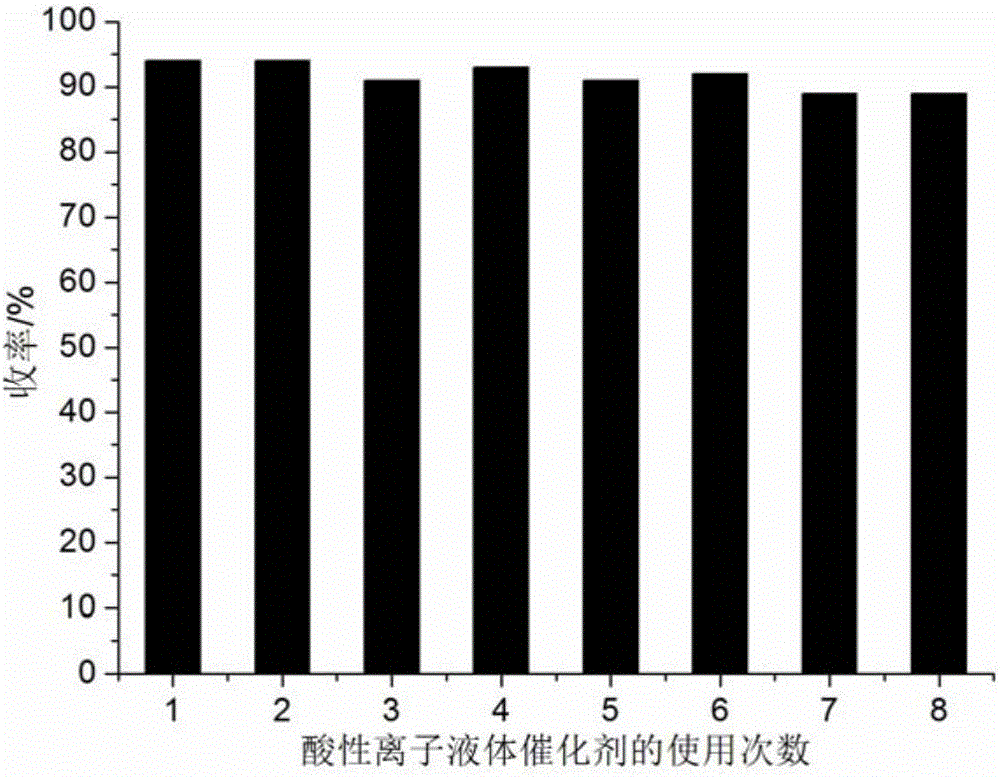

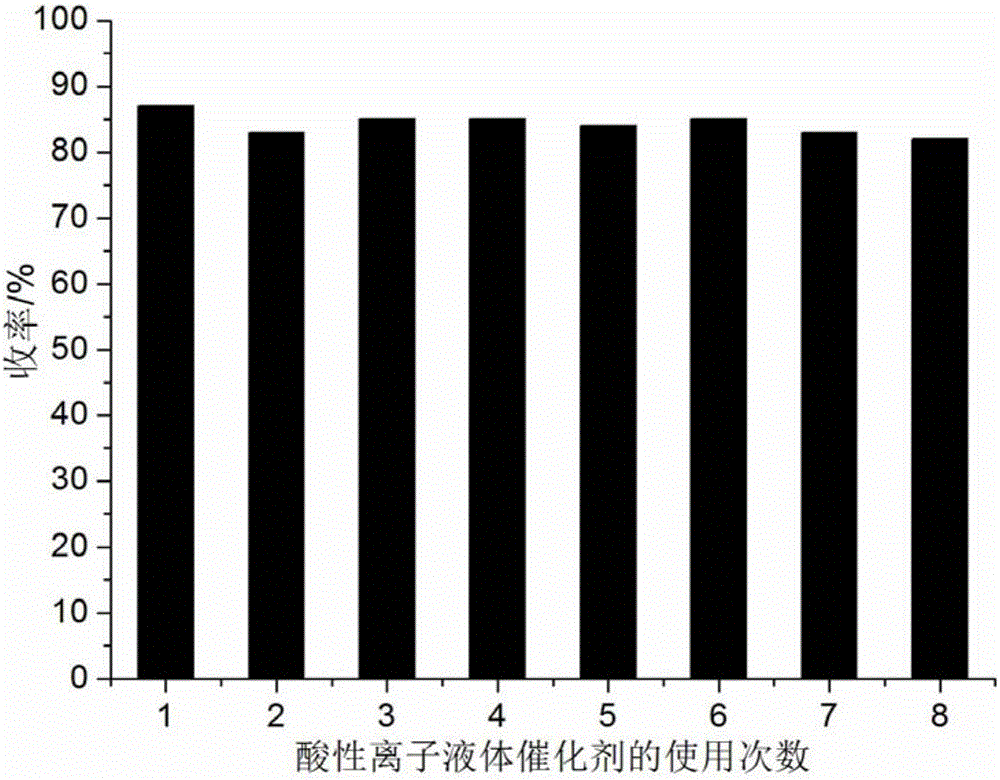

Quinoline derivative, synthesis method of derivative and catalyst for synthesis

ActiveCN106334578AHigh catalytic activityReduce usageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisSynthesis methods

The invention discloses a quinoline derivative, a synthesis method of the derivative and a catalyst for synthesis, and belongs to the technical field of organic chemical synthesis. The molar ratio of 2-chloro-3-quinoline formaldehyde and beta-dione in synthesis reaction is 1:1, the molar amount of an acidic ionic liquid catalyst is 6-12% of the used 2-chloro-3-quinoline formaldehyde, the volume amount of a reaction solvent methanol aqueous solution in ml is 7-10 times of the molar amount of the 2-chloro-3-quinoline formaldehyde in mmol, the reflux reaction time is 7-15 min, cooling is performed to room temperature after the reaction is finished, suction filtration is performed, and the filter residues are washed with methanol and vacuum-dried to obtain the quinoline derivative. Compared with synthetic methods using other catalysts, the method has low use amount of the catalyst, reusability without treatment, high raw material utilization rate, simple and convenient operation of the whole synthesis process and the like, and is advantageous for large-scale industrial application.

Owner:东港智科产业园有限公司

Production method of original-taste honeysuckle tea

The invention relates to a production method of original-taste honeysuckle tea and belongs to the technical field of tea processing. The method includes: using chitosan to prepare chitosan fixing syrup, mixing preprocessed honeysuckle with the chitosan fixing syrup and deionized water to allow the honeysuckle to be evenly dispersed in the chitosan fixing syrup; subjecting the honeysuckle to heating, heat preservation, filtering and washing, natural airing and the like after the honeysuckle is evenly dispersed, and performing vacuum freeze drying on the collected honeysuckle to obtain the original-taste honeysuckle tea. The production method has the advantages that the honeysuckle tea is emerald green, the shape of the honeysuckle tea is like fresh honeysuckle and complete, nutrient content loss is reduced, and the drinking value and appearance quality of the honeysuckle tea can be increased greatly; the honeysuckle tea has effects of clearing away heat and toxic materials, diminishing inflammation and sterilizing and lowering blood pressure; the production method is simple in procedure and low in cost.

Owner:JIANGSU JINYU ENVIRONMENTAL ENG

Detinning processing method of chip and chip detinning machine applying method

The invention discloses a detinning processing method of a chip, and the method comprises the following steps: providing a scraper, a die, a heating mechanism and a recovery device, wherein a first inclined plane which forms an inclination angle with the horizontal plane is arranged on the upper surface of the die, a plurality of grooves for accommodating and fixing chips are formed on the first inclined plane, the height of each groove is equivalent to the thickness of each chip, and the recovery device is arranged on one side corresponding to the lower edge of the first inclined plane belowa conveying mechanism; arranging the chips in the grooves; placing the die on the heating mechanism, and utilizing the heating mechanism to heat the chips so as to melt soldering tin on the chips; and utilizing the scraper to scrape the soldering tin on the chips into the recovery device. In the method, the scraper is utilized for scraping off the molten soldering tin form the chips, the soldering tin can stably slide into the recovery device along the wall of the scraper, the loss of the soldering tin is low, and the recovery rate is high; and furthermore, the plurality of the grooves are arranged on the die, the plurality of the chips can be scraped according to needs, and the tin scraping efficiency is high. In addition, the invention further provides a chip detinning machine applying the detinning processing method of the chip.

Owner:何光宁

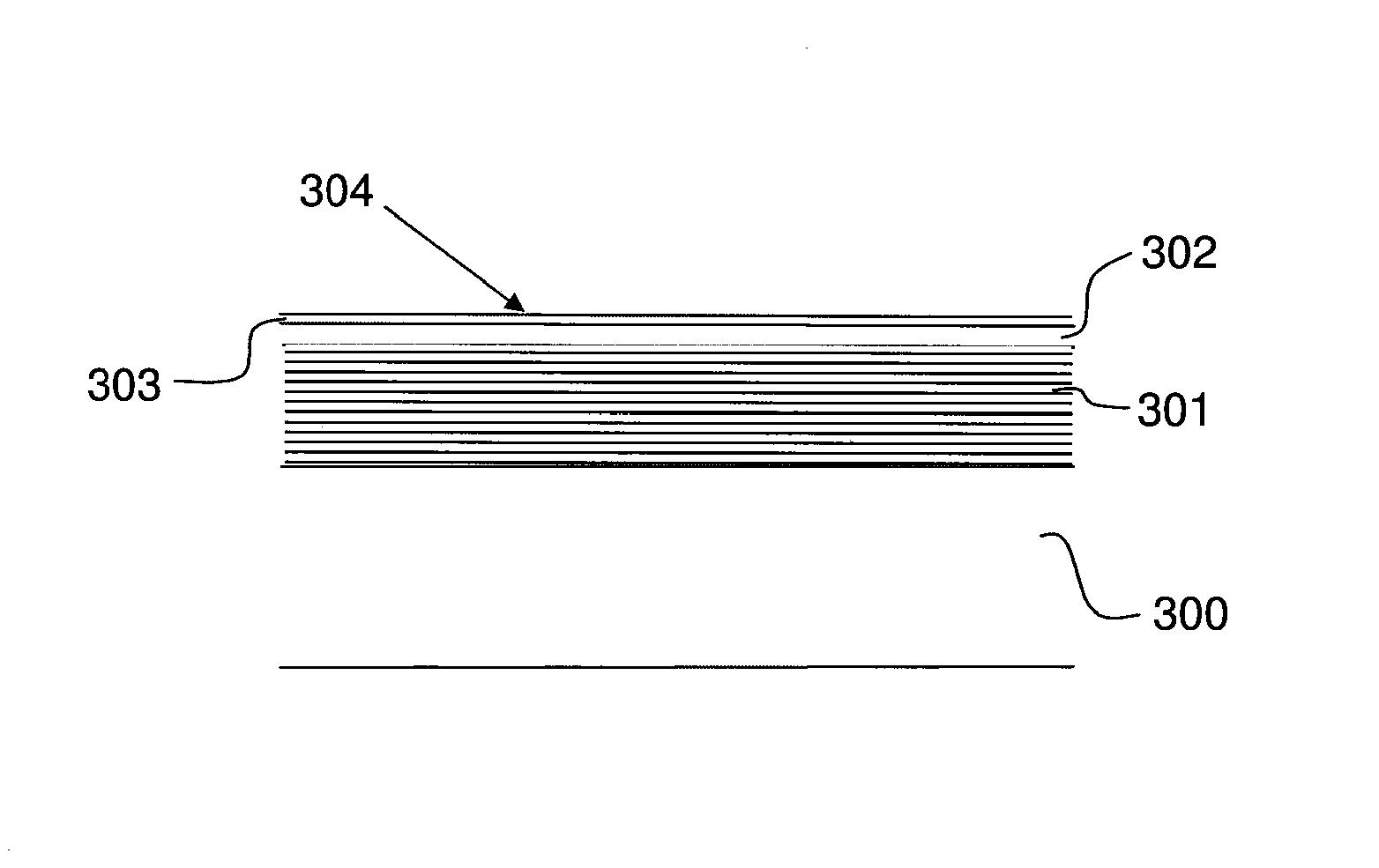

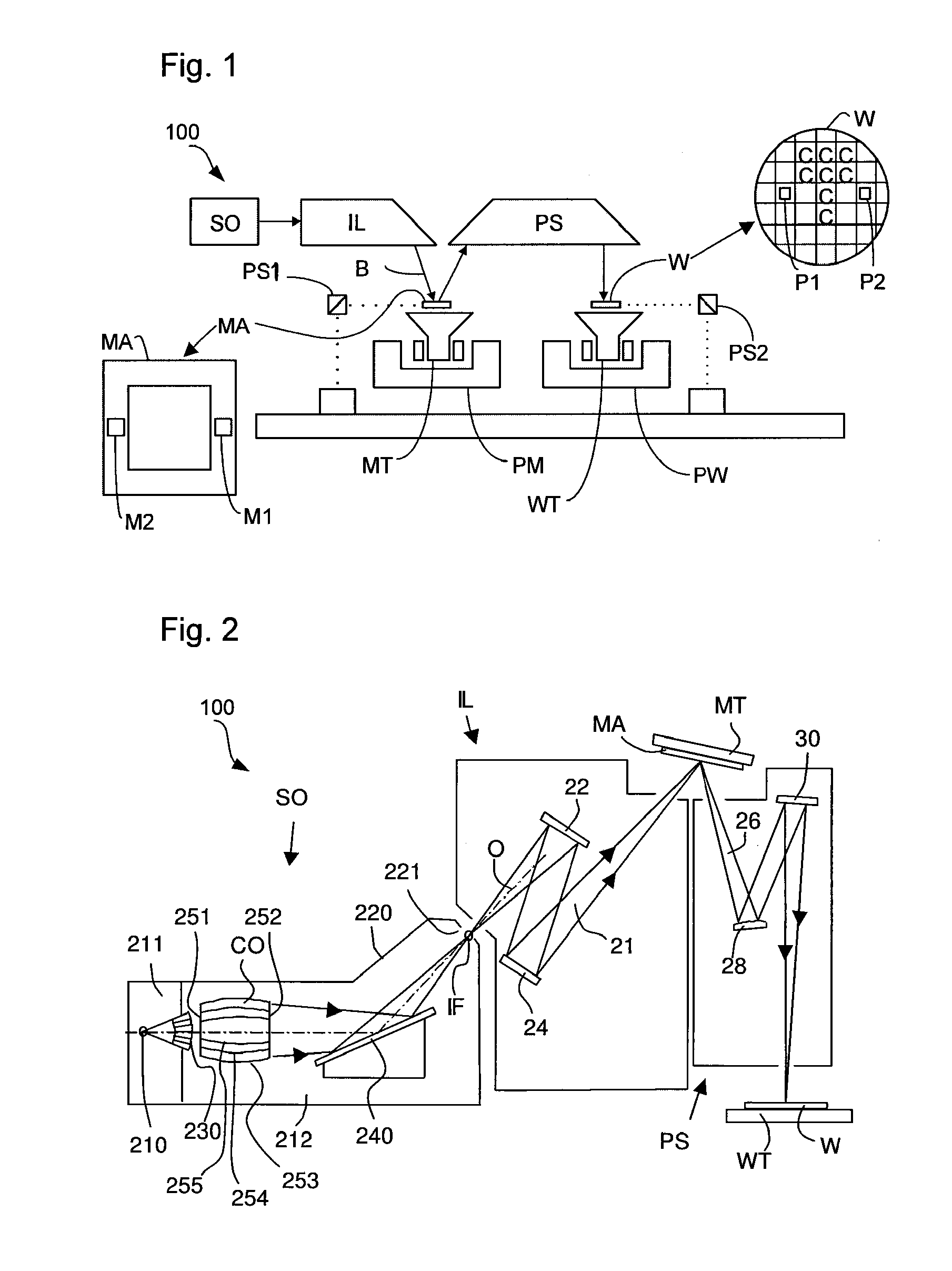

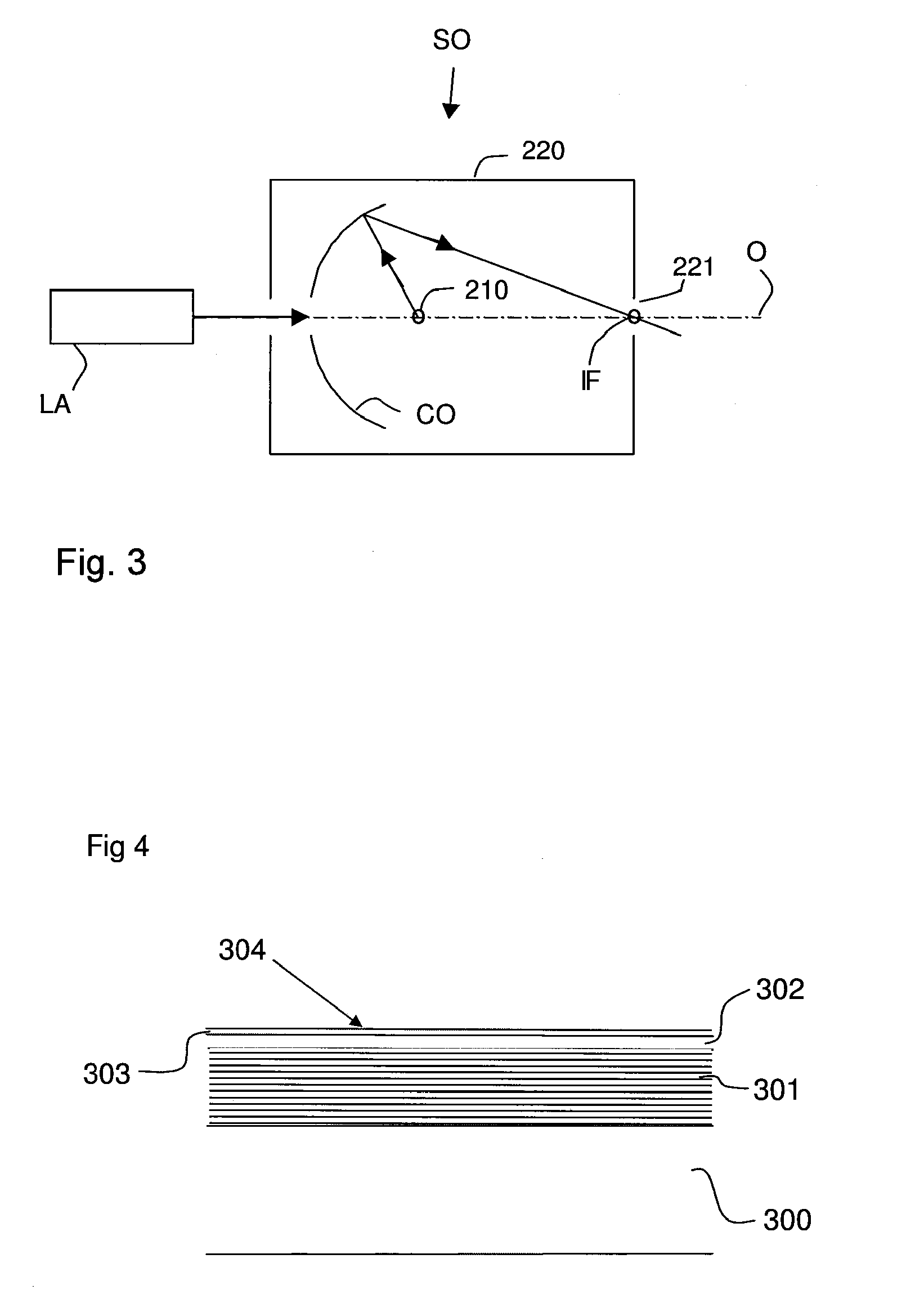

Reflective optical components for lithographic apparatus and device manufacturing method

A reflective optical component is configured to reflect EUV radiation. The reflective optical component has a reflective layer with a bimetal cap layer of differing first and second metals selected to ensure that the outer surface of the cap layer is substantially unreactive or non-adsorptive to sulfur. The bimetal cap layer may be an alloy of the two metals or may consist of a base layer of the first metal deposited on the reflective layer and a surface layer of the second metal on the base layer. The interaction of the two metals may lead to modification of the bonding energy to the outer face of the cap layer of sulfur-containing molecules such as SO2 so that sulfur adsorption, which leads to loss of reflectivity, is reduced or eliminated.

Owner:ASML NETHERLANDS BV

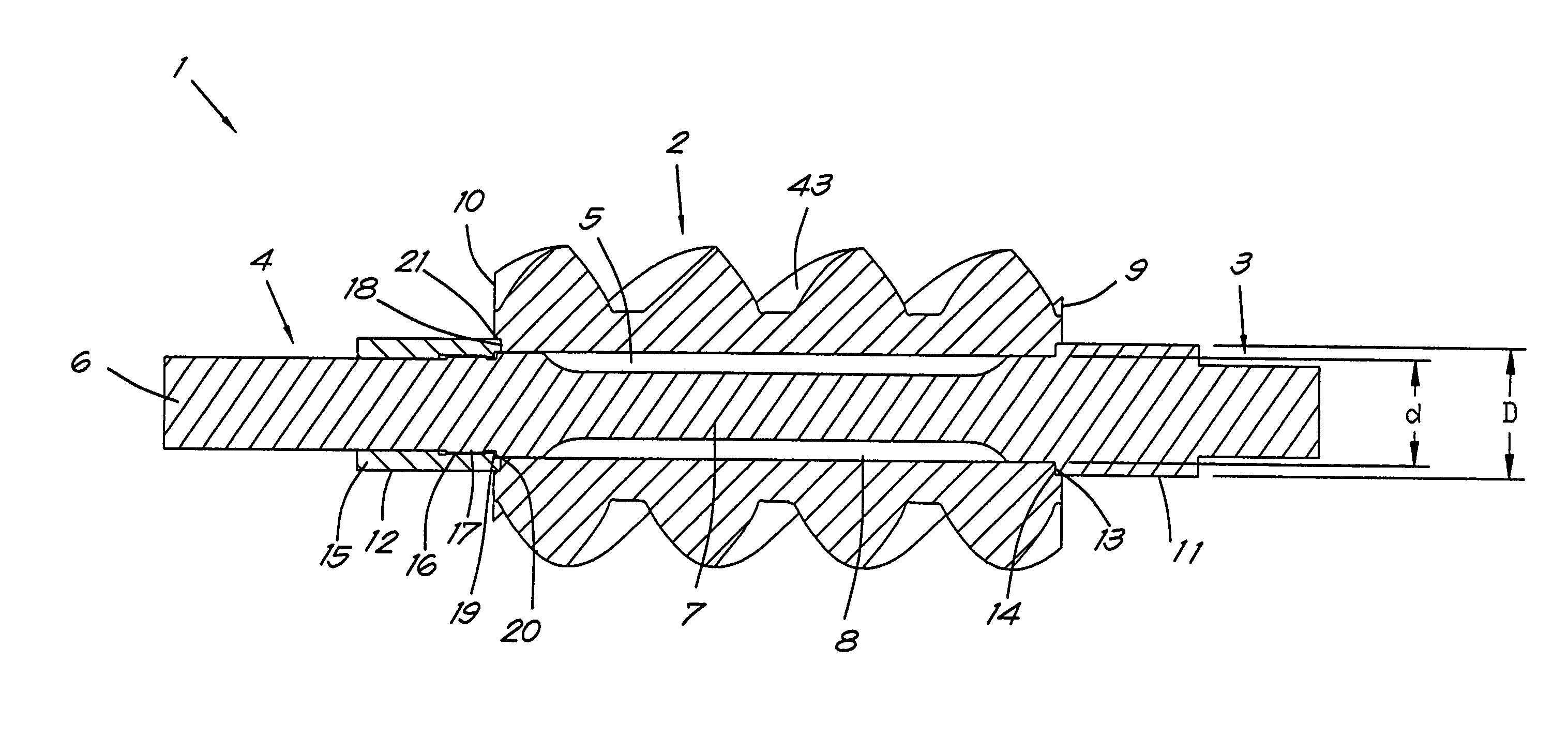

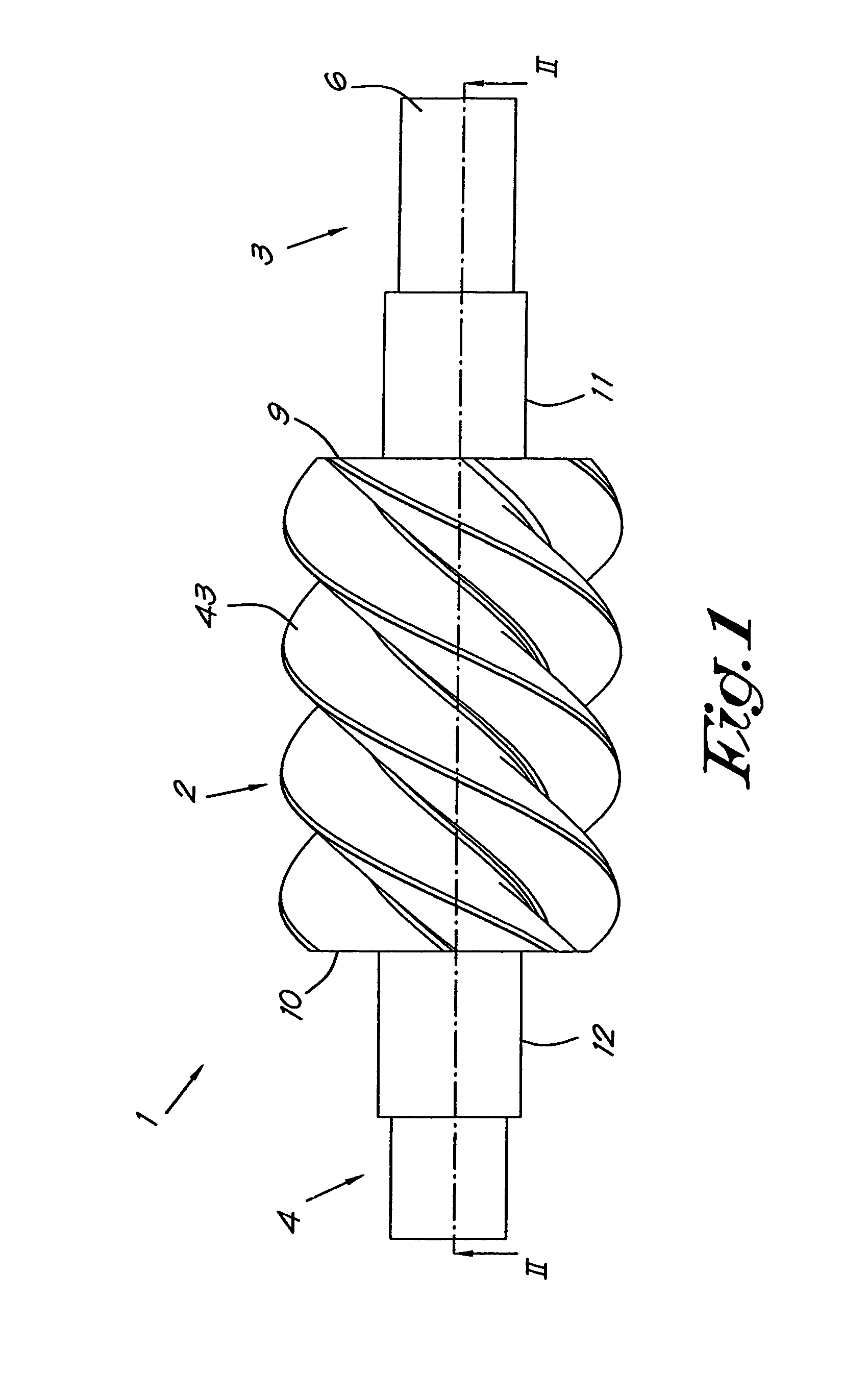

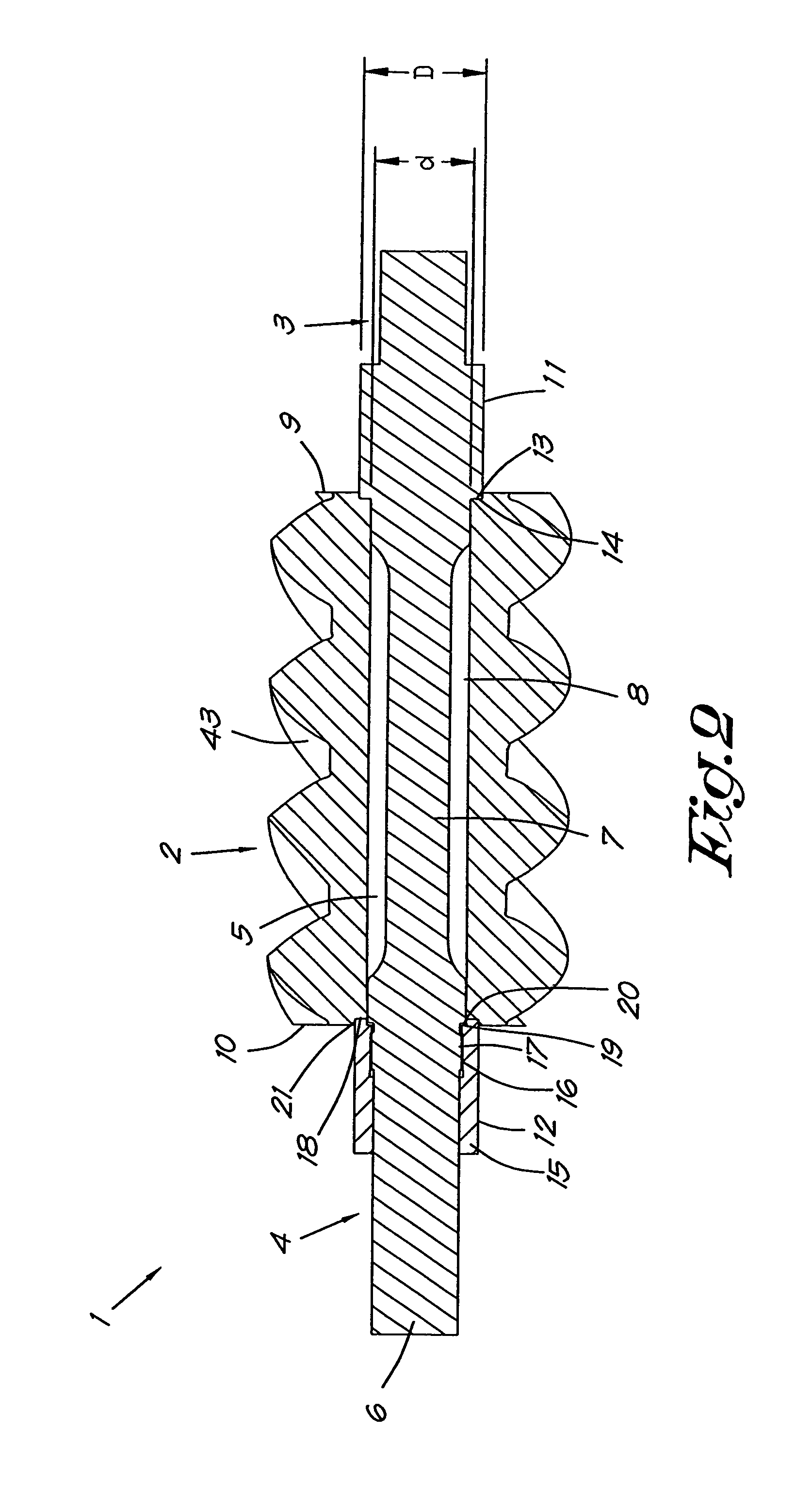

Rotor for a screw compressor

ActiveUS8876505B2Less lossReduce lossesEngine of arcuate-engagement typeOscillating piston enginesRotary-screw compressorEngineering

Owner:ATLAS COPCO AIRPOWER NV

Rapid tin planting device for BGA chip

InactiveCN108493140AEasy to assemble and disassembleLarge amount of tin removalSemiconductor/solid-state device manufacturingLiquid tankSoldering

The invention provides a rapid tin planting device for a BGA chip. The rapid tin planting device comprises a device body, wherein the device body comprises a control table, wherein a tin stripping liquid tank is arranged on one side of the control table. A to-be-tin-planted chip is positioned by virtue of the positioning slot and is firmly adsorbed by virtue of a vacuum pump, a first rotating motor and a second rotating motor cooperatively work to overturn an operation table downwards, the operation table is put down by a first linear motor and a second linear motor to enable the chip to be close to a first spraying head in a waste liquid tank, tin stripping liquid in the tin stripping liquid tank is extracted by virtue of a first water pump so as to remove soldered tin on the chip, the operation table is rotated to be restored, a corresponding tin planting net is fixed under a mounting plate, is put down to the to-be-tin-planted chip by a third linear motor, a soldering aid in a soldering aid tank is extracted by virtue of a second water pump, is sprayed to the tin planting net and then flows to soldering disc of the to-be-tin-planted chip through soldering holes in the tin planting net, and then the to-be-tin-planted chip is filled with tin paste to be heated.

Owner:HUZHOU HUINENG ELECTROMECHANICAL TECH CO LTD

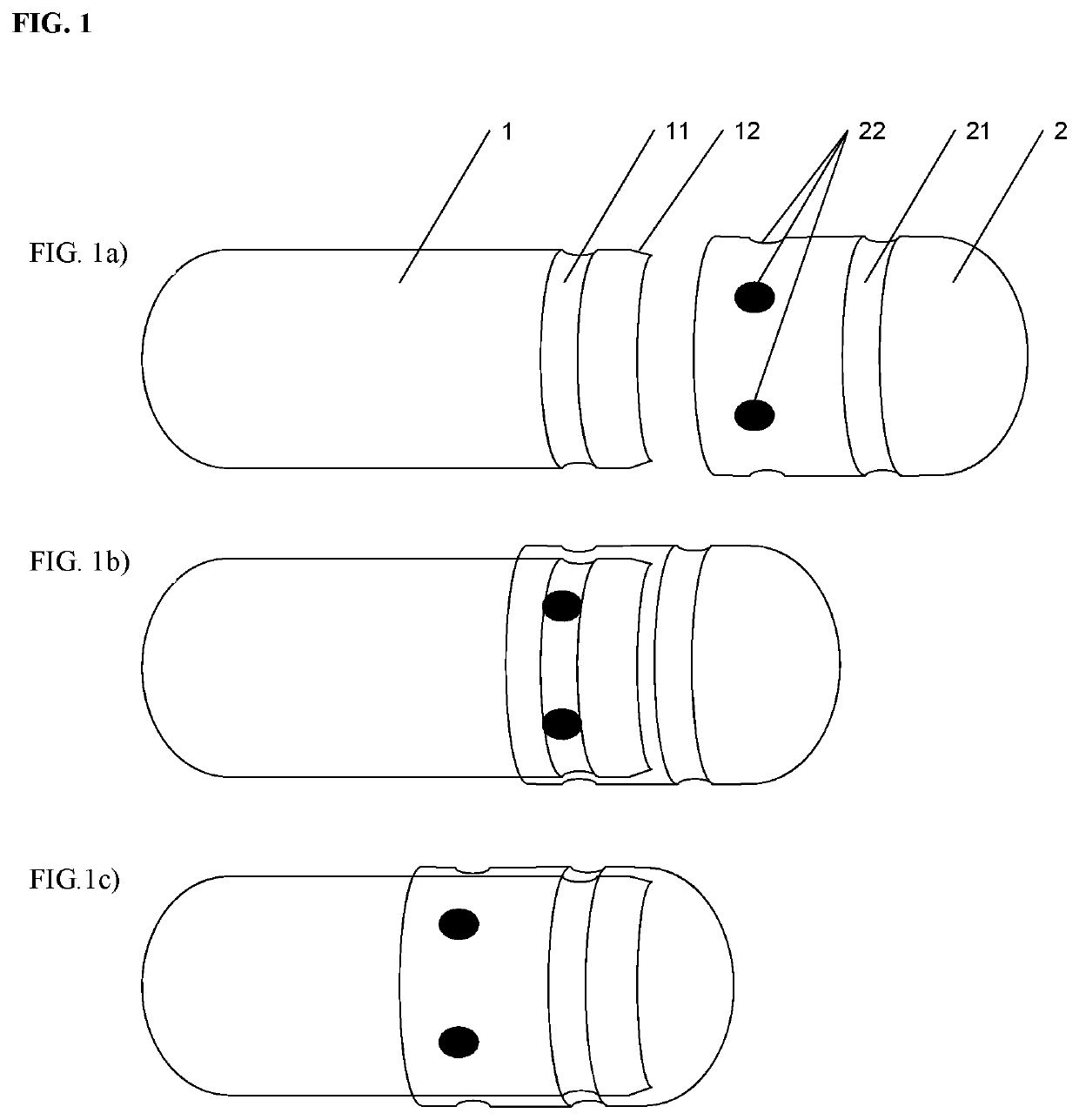

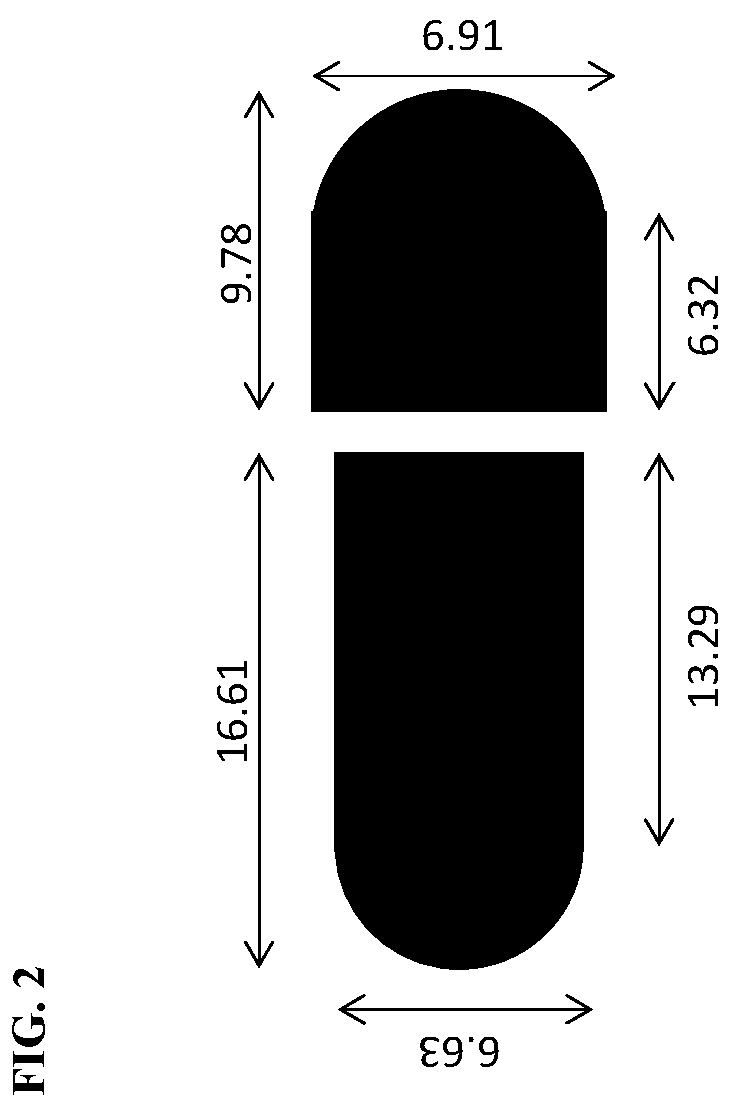

Process for preparing a coated hard shell capsule

PendingUS20210361585A1Less lossSufficient mechanical stabilityPharmaceutical non-active ingredientsCapsule deliveryPolymer chemistryPolymer coating

A process prepares a polymer-coated hard shell capsule, suitable as container for pharmaceutical or nutraceutical biologically active ingredients. The hard shell capsule can include a body and a cap. In the closed state, the cap overlaps the body either in a pre-locked state or in a final-locked state. The hard shell capsule can be provided in the pre-locked state and spray-coated with a coating solution, suspension, or dispersion that includes a polymer or a mixture of polymers to create a coating layer which covers the outer surface of the hard shell capsule in the pre-locked state.

Owner:EVONIK OPERATIONS GMBH

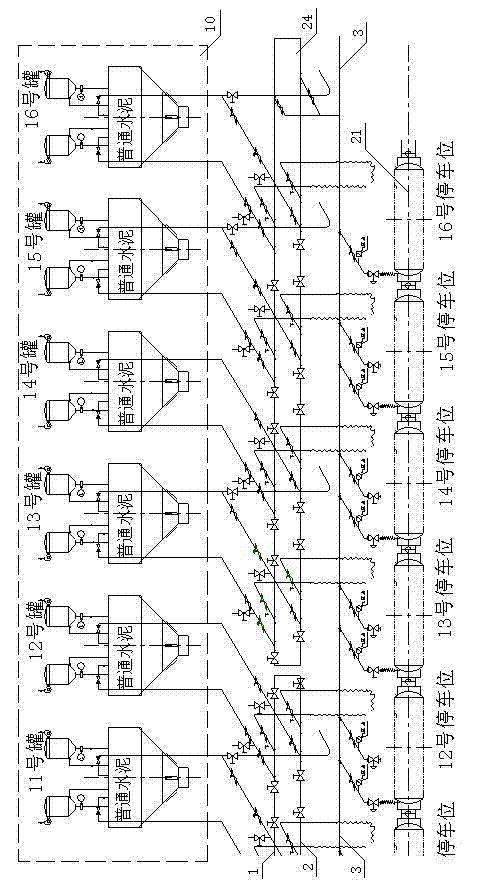

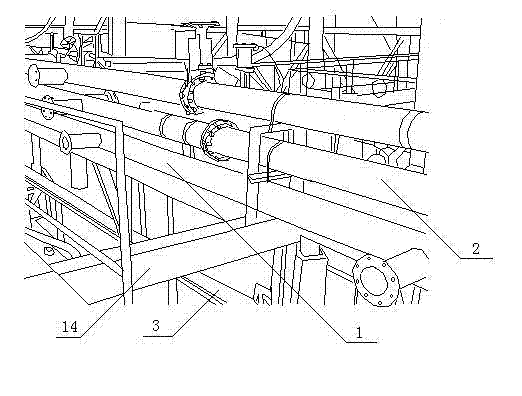

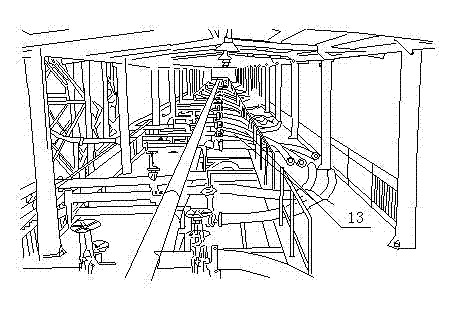

Loose-packed gel material parallel ash-unloading system

The invention relates to the technical field of transportation, in particular to a loose-packed gel material parallel ash-unloading system for transfer management of a loose-packed gel material in large hydropower station construction. The system comprises 1) a loose-packed gel material storage tank, 2) a main pipeline system, 3) an ash unloading branch pipe, 4) an ash loading branch pipe, and 5) a warehouse side unloading port. According to the loose-packed gel material loading system, an advanced computer remote management mode is adopted, and the routine work in the conventional loose-packed gel material loading system is changed from an optional manual mode into a normalized computer work mode, which means the revolution of the working mode. According to the loose-packed gel material loading system of the hydropower station, unattended or less-attended operation is realized in a unique way, the work load of maintenance staff is lightened, and the maintenance level is improved. The capability of the loose-packed gel material loading system of a gel material transfer station is greatly improved, and the requirements on peak annual loose-packed gel materials of hydropower stations at all levels are met.

Owner:中国水利水电第四工程局有限公司第六分局

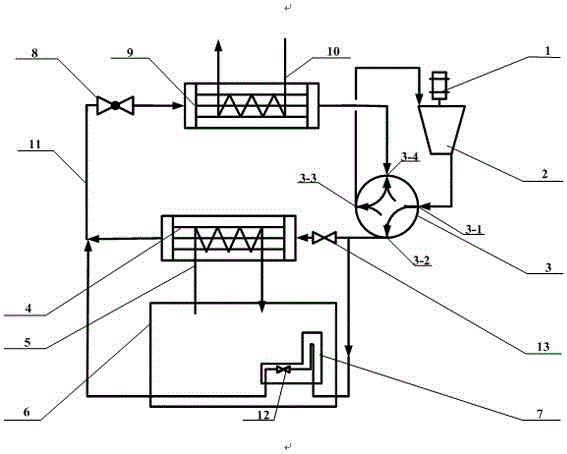

Vehicular air conditioning system and working method thereof

InactiveCN105691146AFeel comfortableNo hot feelingAir-treating devicesSeat heating/ventillating devicesCold winterThermal force

The invention discloses a vehicular air conditioning system and a working method thereof, and belongs to the field of energy sources, power and the like. The system is characterized in that a vapor compression thermodynamic reverse cycle used for the system is used for adjusting the temperature of air in a compartment, and is further used for directly adjusting the temperature of seats. The system is particularly used for an electric vehicle without available waste heat, and under an extreme air temperature environmental condition, the temperature of air in the compartment is closer to the environment temperature only on the basis of seat temperature adjustment. The system is particularly suitable for air conditioning during vehicle running in severe cold winter and extremely hot summer. Compared with a conventional method for conditioning air only, the method is high in comfort, and the energy consumption can be adjusted according to the quantity of passengers, so that the system is more energy-saving and efficient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com