Concrete stair manufacturing mold, concrete stair manufacturing method and concrete stair

A production method and concrete technology, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of reducing the structural strength of concrete stairs, wasting concrete materials, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

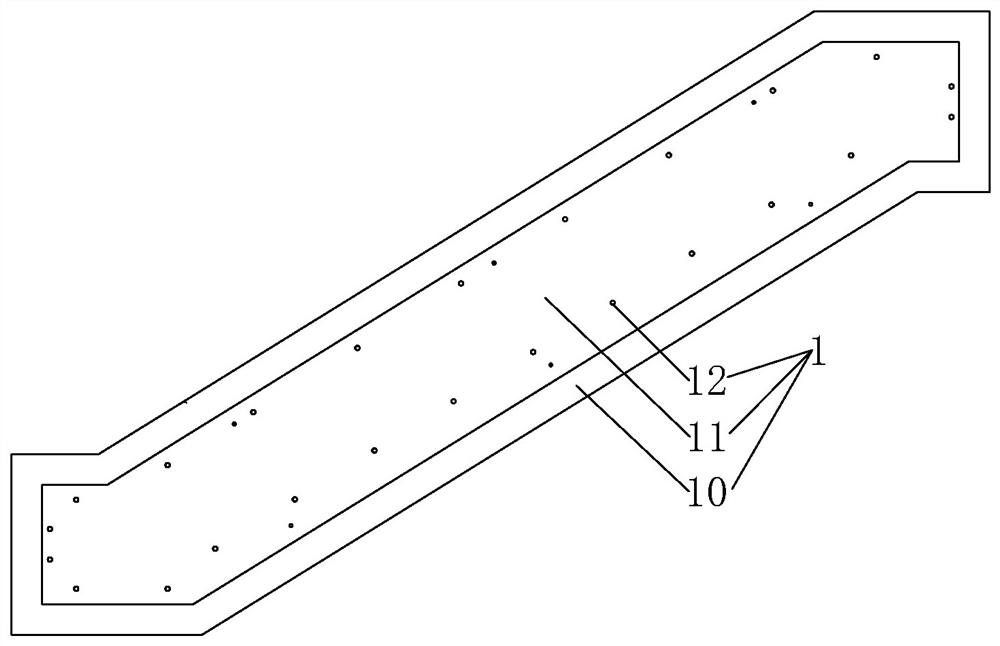

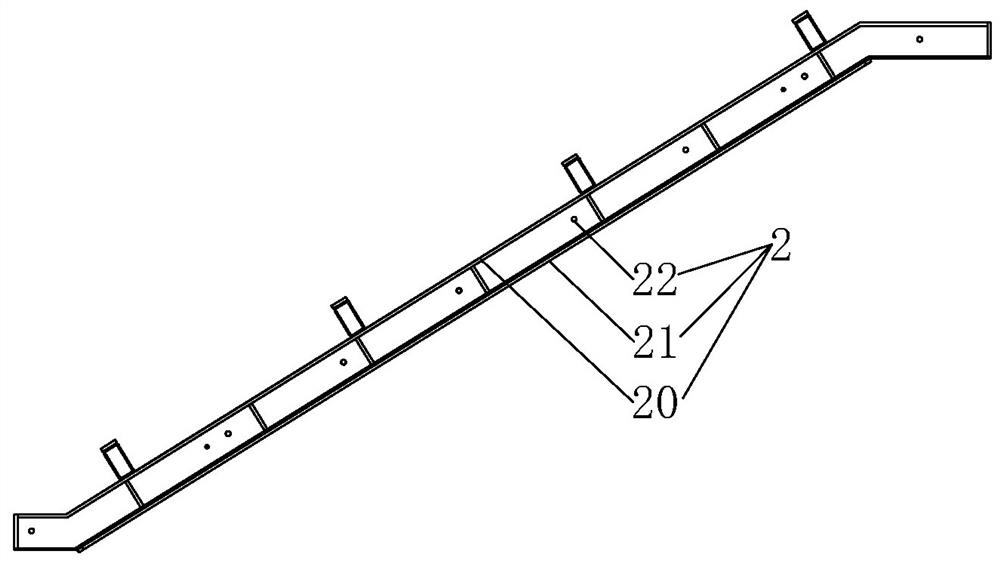

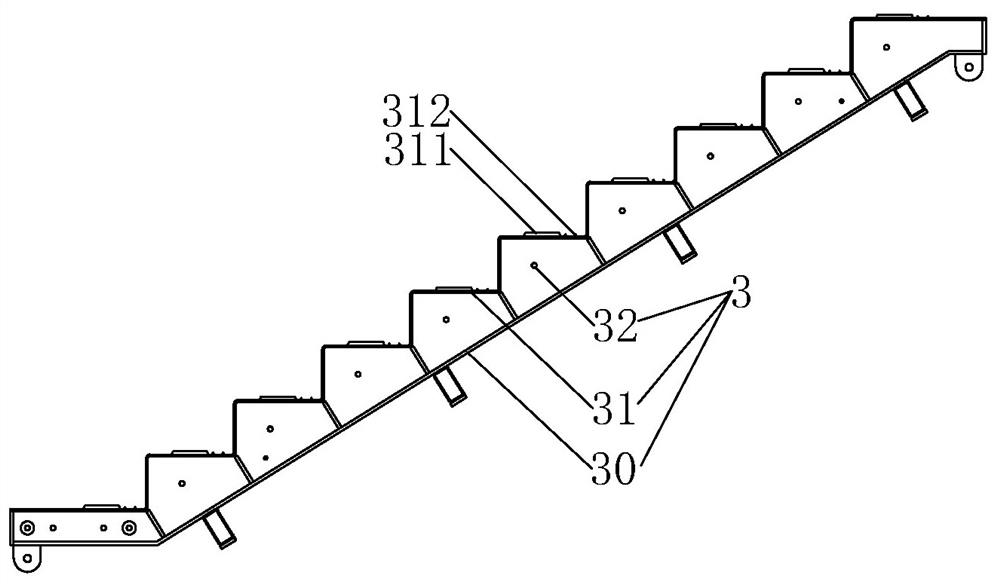

[0050] Embodiment 1: A mold for making concrete stairs, including a bottom form 1 for forming the side of the concrete stairs, a first side form 2 for forming the lower side of the concrete stairs, and a second side form 3 for forming the upper side of the concrete stairs . A third side form 5 for forming the lower end face of the concrete stairs, a fourth side form 4 for forming the upper end face of the concrete stairs, and a top form 6 for forming the sides of the concrete stairs.

[0051] The bottom mold 1 includes a bottom mold fixing frame 10 and a bottom mold 11 which are fixedly connected, and the bottom mold fixing frame 10 is provided with mold clamping positioning holes 12 .

[0052] The first side mold 2 includes a first side mold fixing frame 20 and a first side mold part 21 which are fixedly connected, and the first side mold fixing bracket 20 is provided with mold clamping positioning holes 22 .

[0053] The second side mold 3 includes a second side mold fixing ...

Embodiment 2

[0065] Embodiment 2: a kind of concrete staircase manufacturing method, comprising:

[0066] For the mold closing steps of the mold for making concrete stairs, see Figure 1-10 The mold for making concrete stairs includes a bottom form 1 for forming the side of the concrete stairs, a first side form 2 for forming the lower side of the concrete stairs, a second side form 3 for forming the upper side of the concrete stairs, and a second side form 3 for forming the concrete stairs. The third side form 5 of the lower end face, the fourth side form 4 for forming the upper end face of the concrete stairs and the top form 6 for forming the side of the concrete stairs, the second side form 3 includes the tile paste for forming the prefabricated concrete stairs The first mold part on the surface, the first mold part is used to form part or all of the mold joint surface of the second side mold, the mold joint surface of the first mold part is provided with a rough surface forming part, ...

Embodiment 3

[0073] Embodiment 3: a kind of concrete staircase manufacturing method, comprises the following steps:

[0074] (1) BIM intelligent processing and collision inspection, get the quantity, specification and size of steel bars, and check whether the steel bars interfere;

[0075] (2) Rebar processing and blanking, the steel bar table obtained through BIM intelligent processing is transmitted to the reinforcement processing background for blanking;

[0076] (3) Steel bar binding, the processed steel bars are bound manually, involving binding of several characters, binding of end stirrups, binding of board wall stirrups, etc.;

[0077] (4) template cleaning and spraying release agent, the cleaning part includes the cleaning of side molds and bottom molds, so that there is no residue on the surface of the template, and the release agent is brushed until it becomes fine water droplets;

[0078] (5) Assemble the side forms, and use bolts to connect and fix the side forms together

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com