Patents

Literature

8501 results about "Mold removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

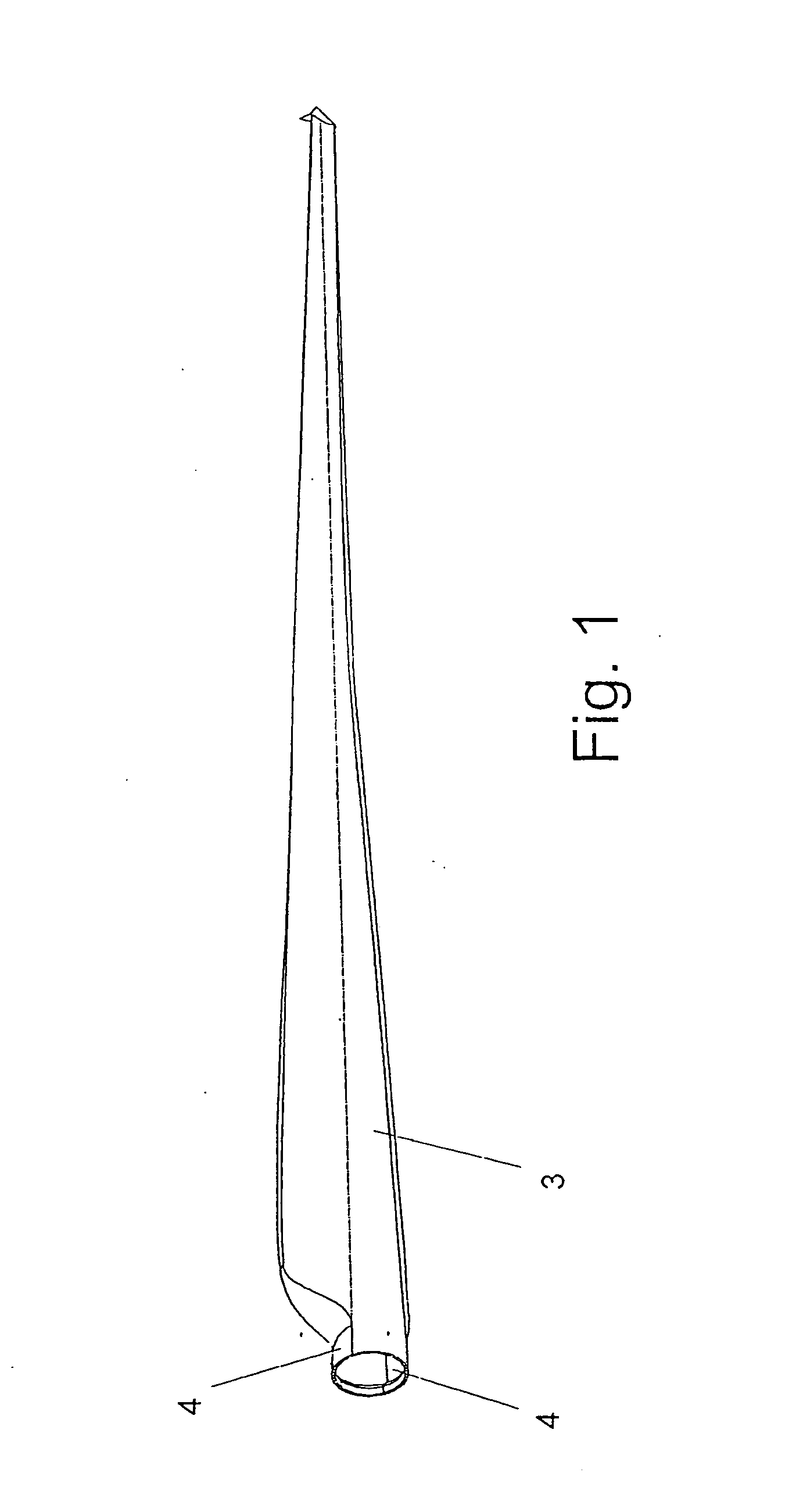

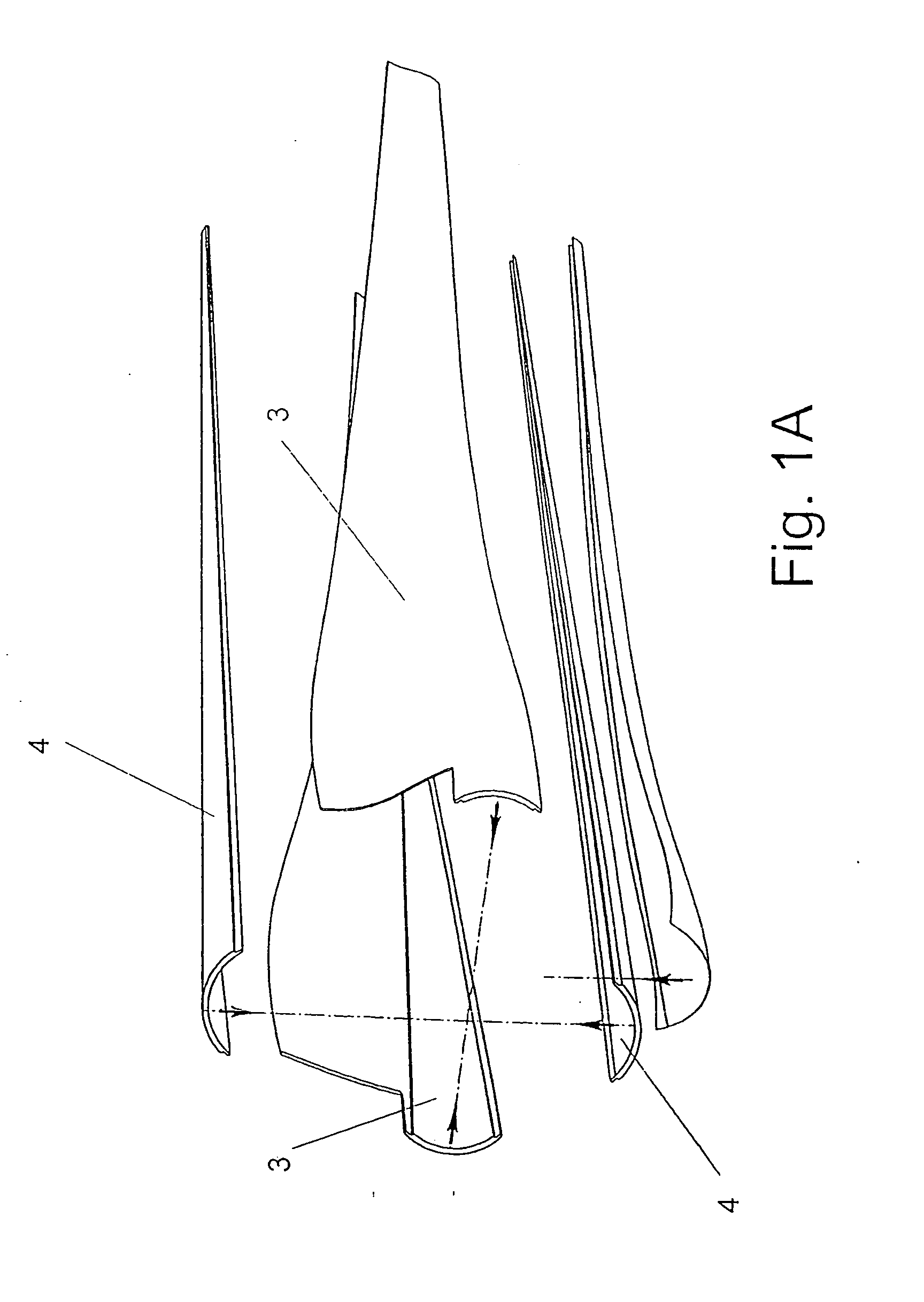

Method of making a part of large dimensions out of composite material

InactiveUS6264877B1Avoid disadvantagesRisk of pollutionFinal product manufactureLaminationGlass fiberFiber

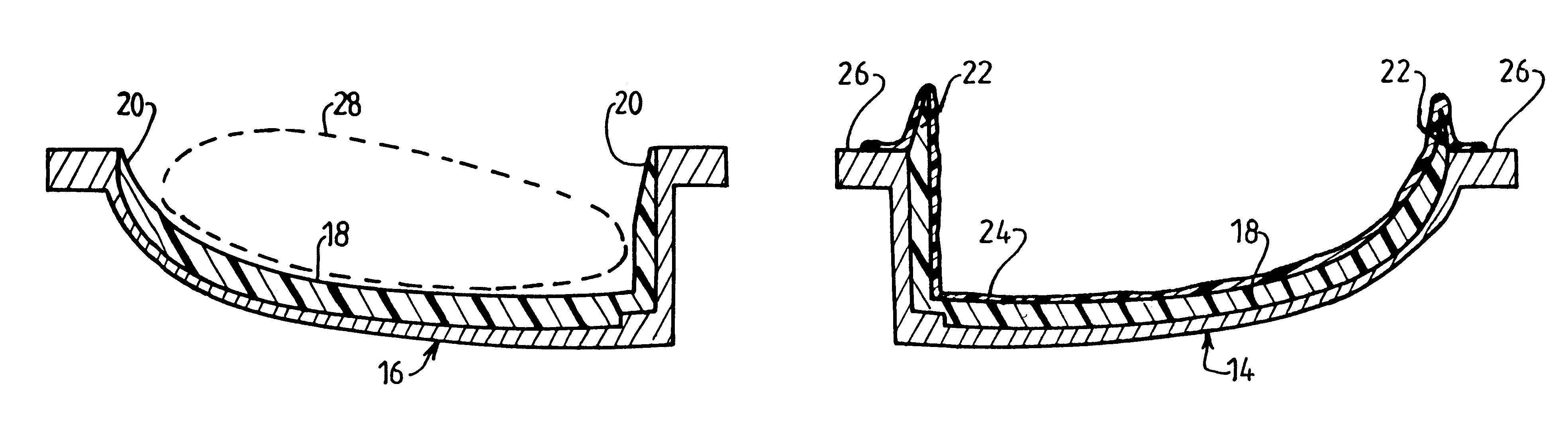

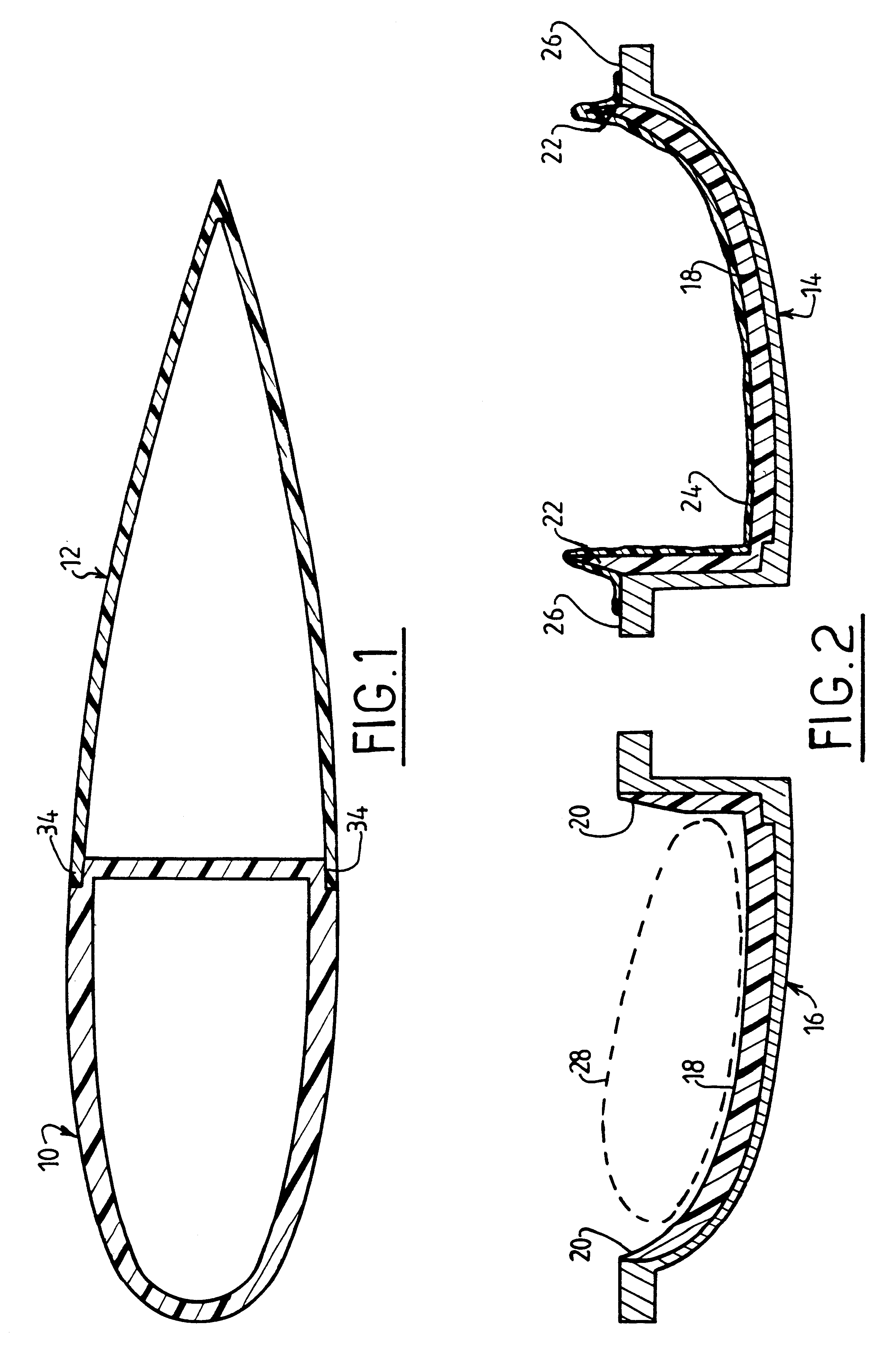

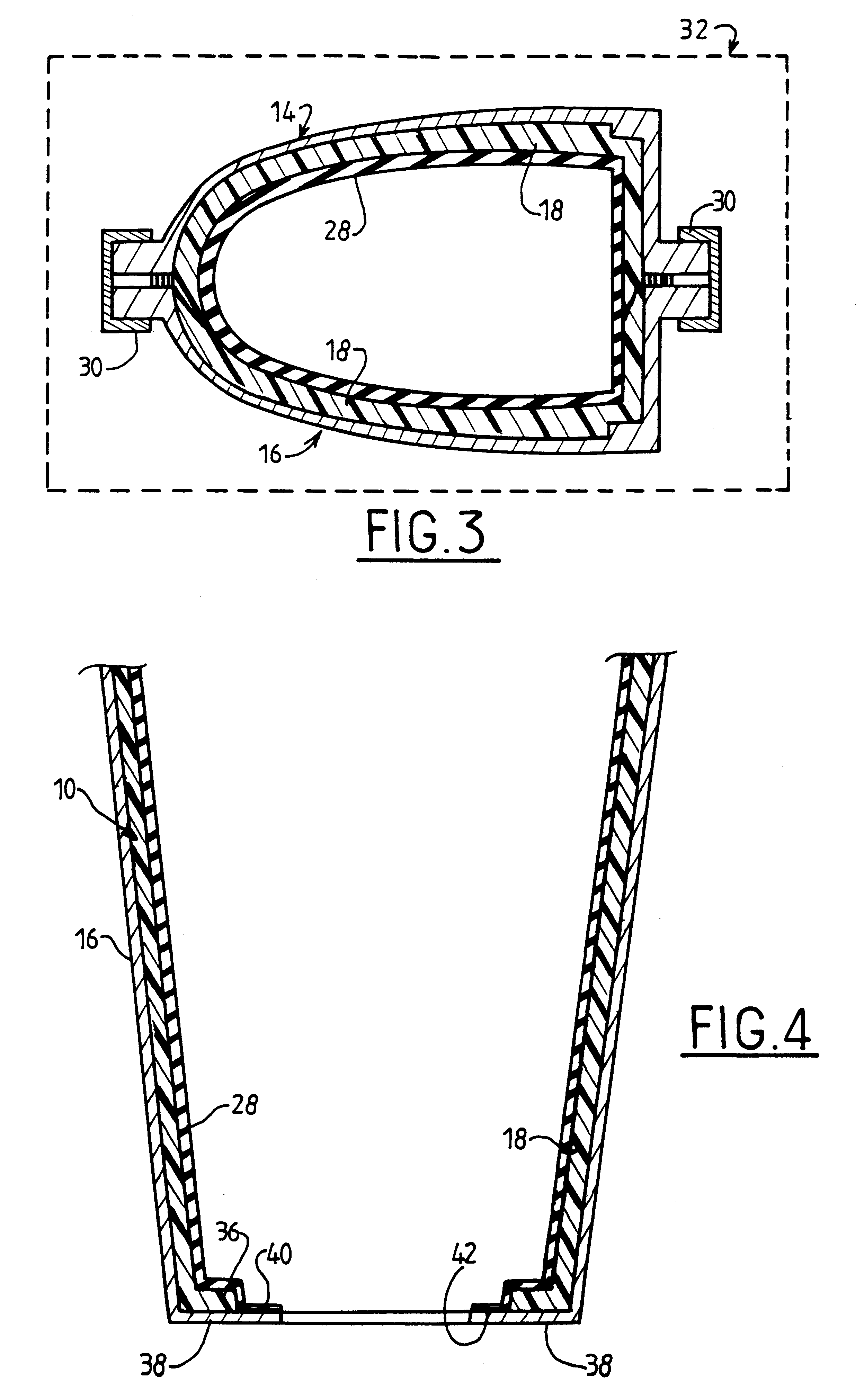

A method of making a composite material part, in particular a wind turbine blade of great length, consists in placing a thickness of a cloth made up of threads comprising a mixture of polypropylene threads or fibers and of glass fibers or threads in two mold portions having the shape of the part that is to be made, placing an inflatable envelope on the cloth inside one of the mold portions, in closing the mold, in placing it in an enclosure fed with hot gas under pressure to melt the polypropylene of the cloth, thereby embedding the glass fibers or threads, then in allowing it to cool, and in unmolding.

Owner:ALTERNATIVES ENERGIES

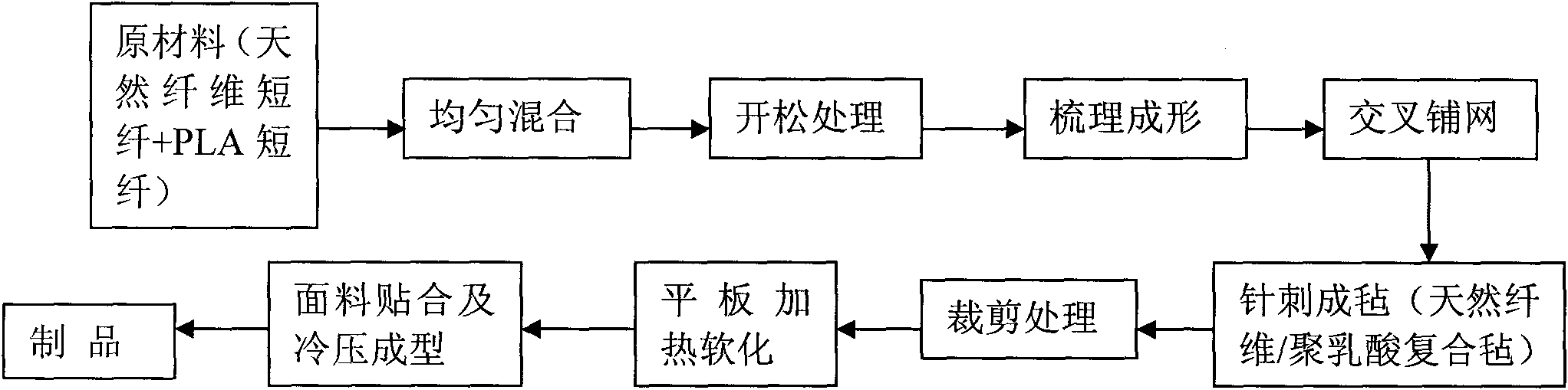

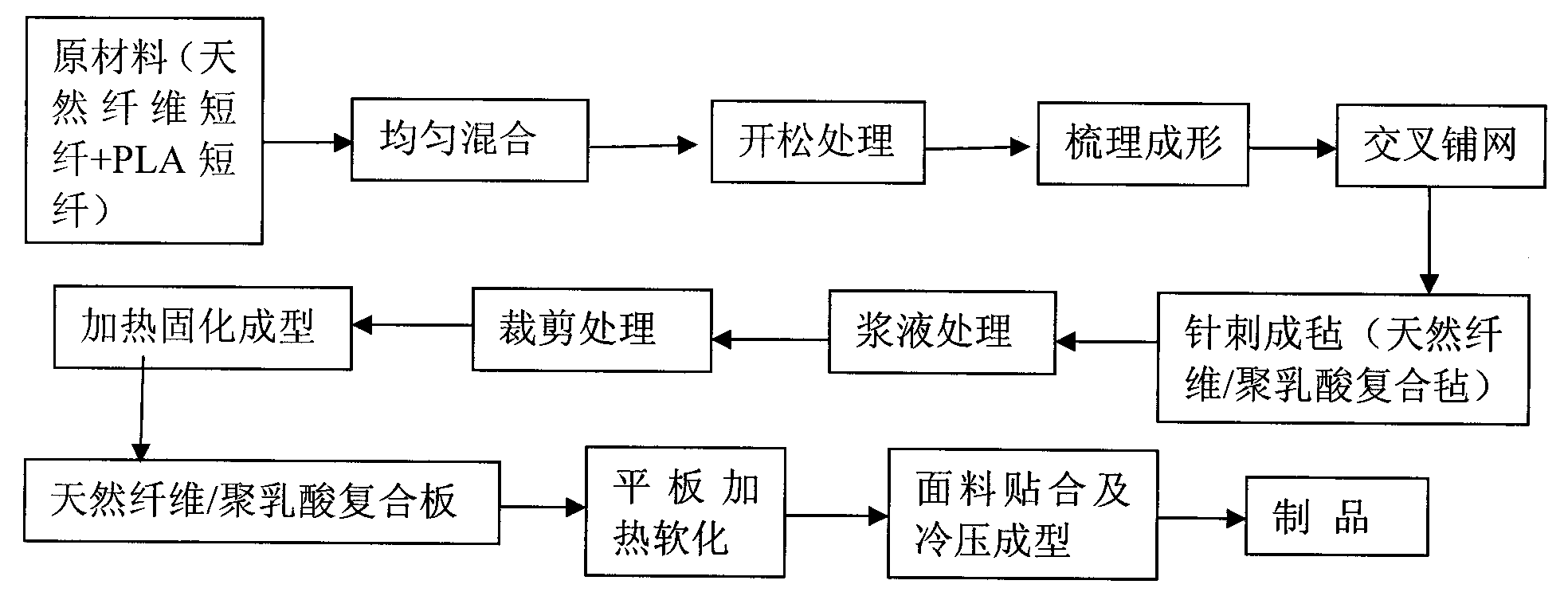

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

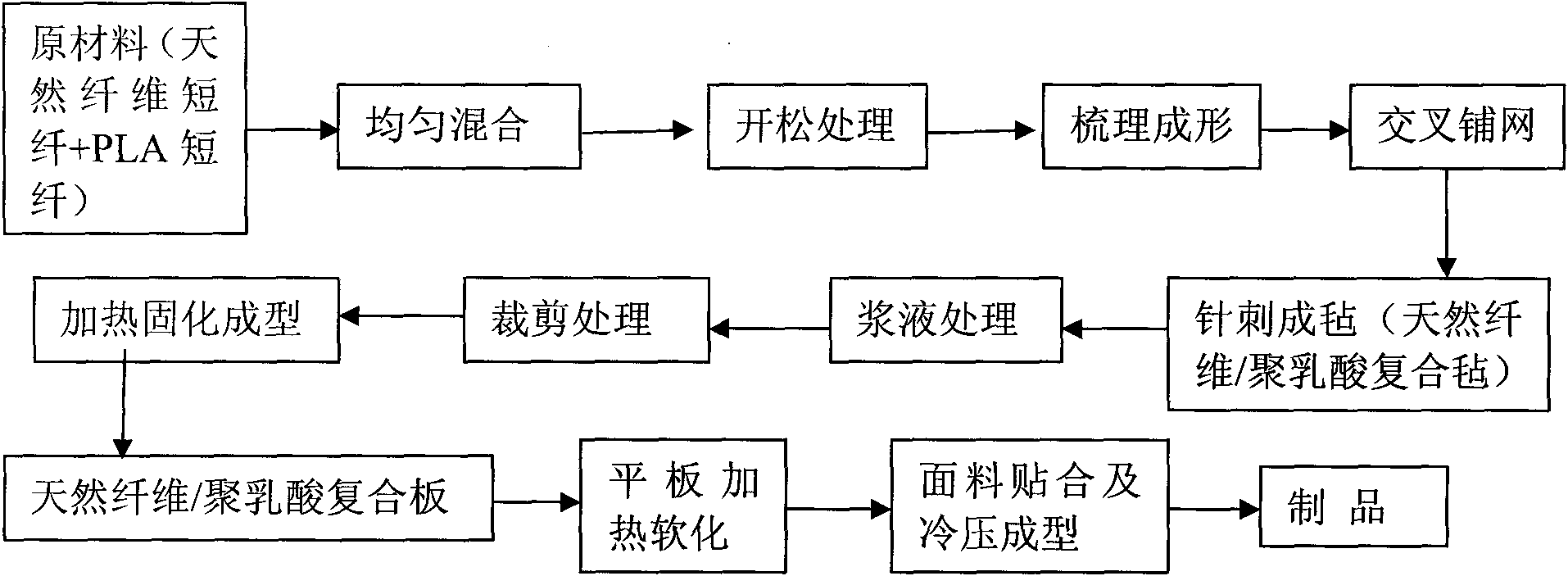

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

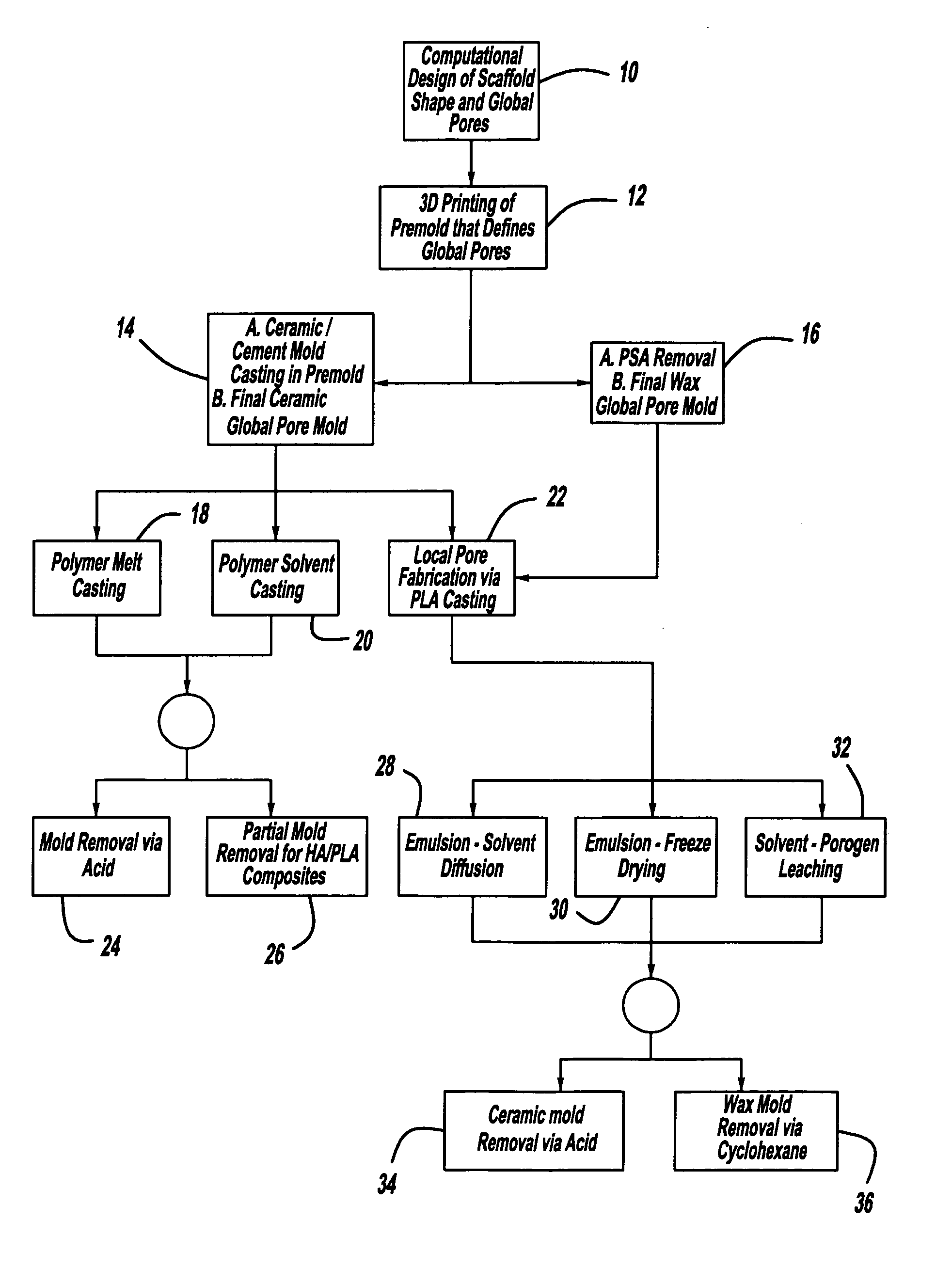

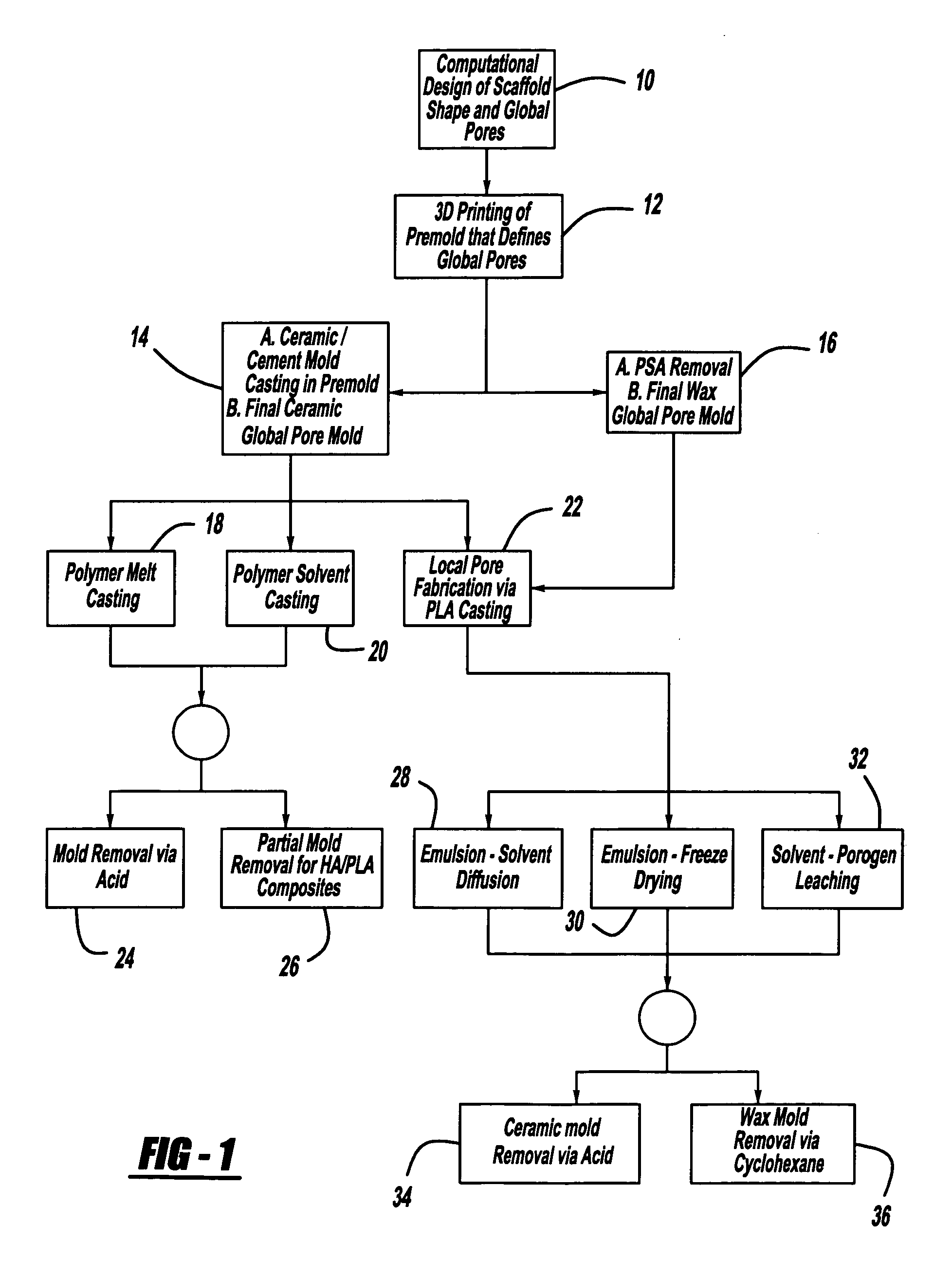

Controlled local/global and micro/macro-porous 3D plastic, polymer and ceramic/cement composite scaffold fabrication and applications thereof

InactiveUS7087200B2Easy to controlImprove interconnectivityMouldsJoint implantsManufacturing technologyFree form

An indirect solid free form scaffold manufacturing technique is provided. More particularly, the present invention provides a set of molds, casting methods, mold removals, and surface modification techniques that are compatible with image-based design methods and with solvent, melt, and slurry casting of polymers and ceramics.

Owner:RGT UNIV OF MICHIGAN

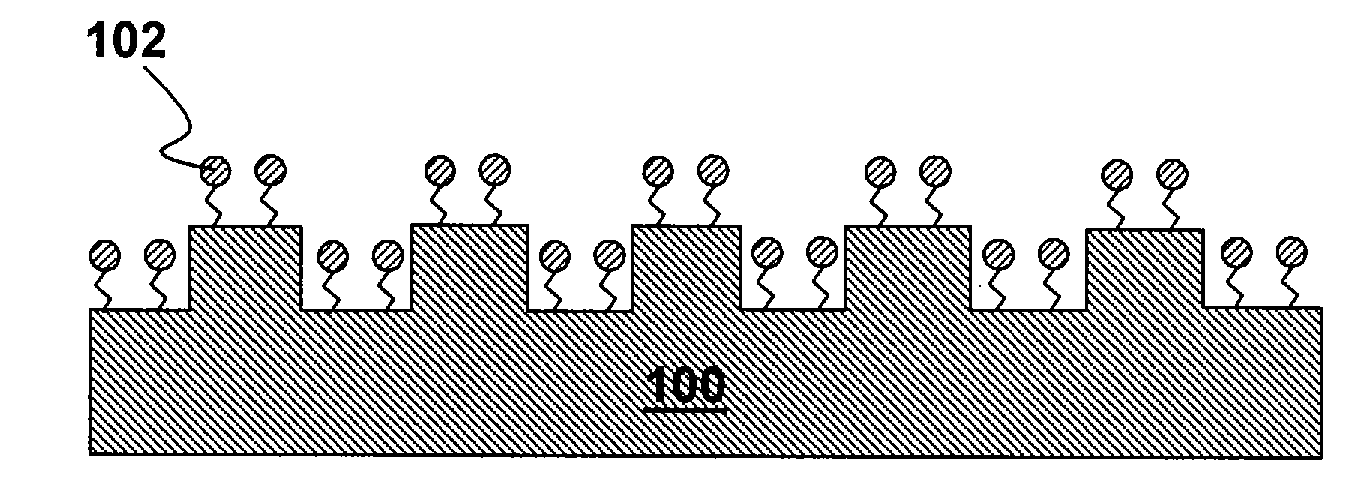

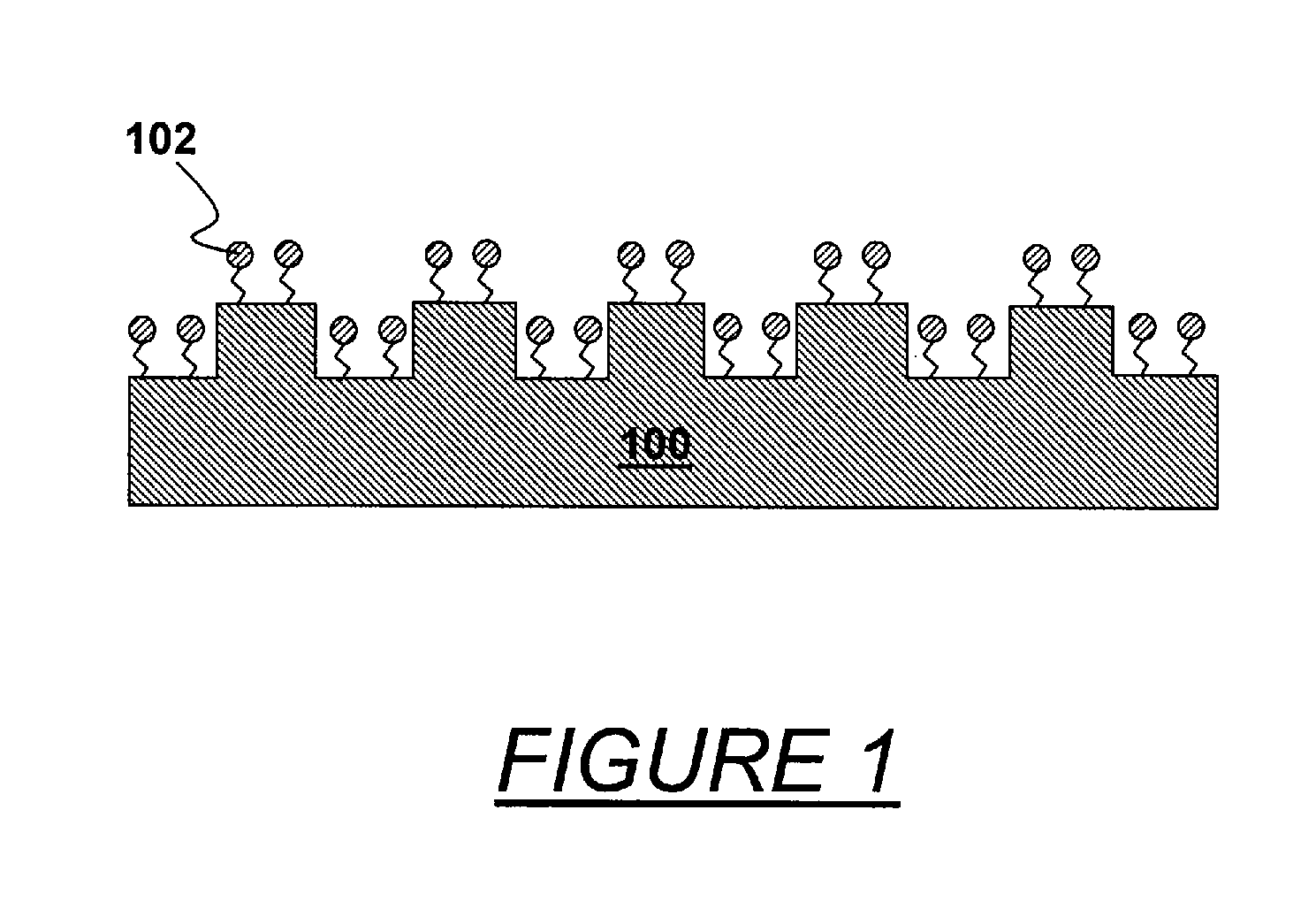

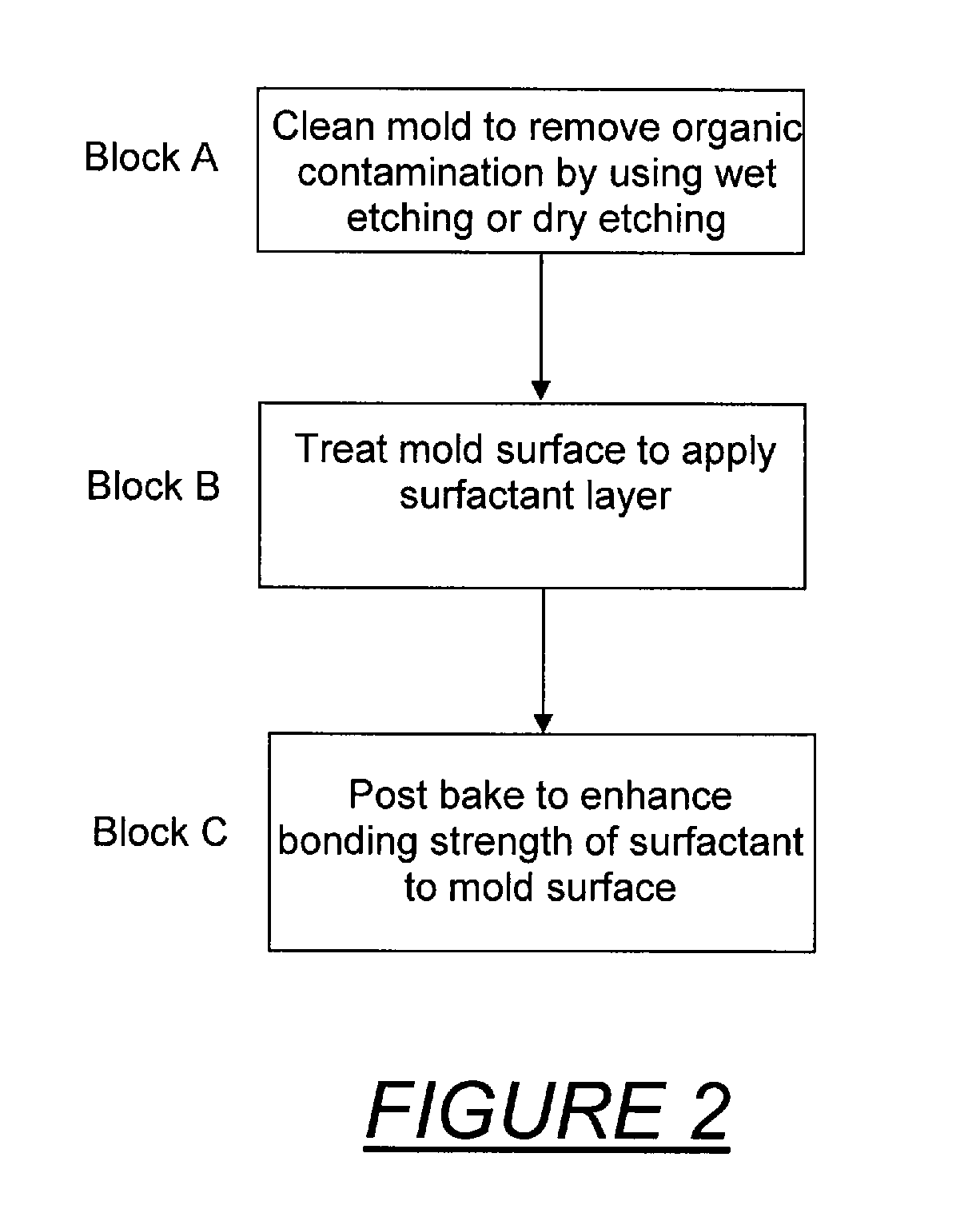

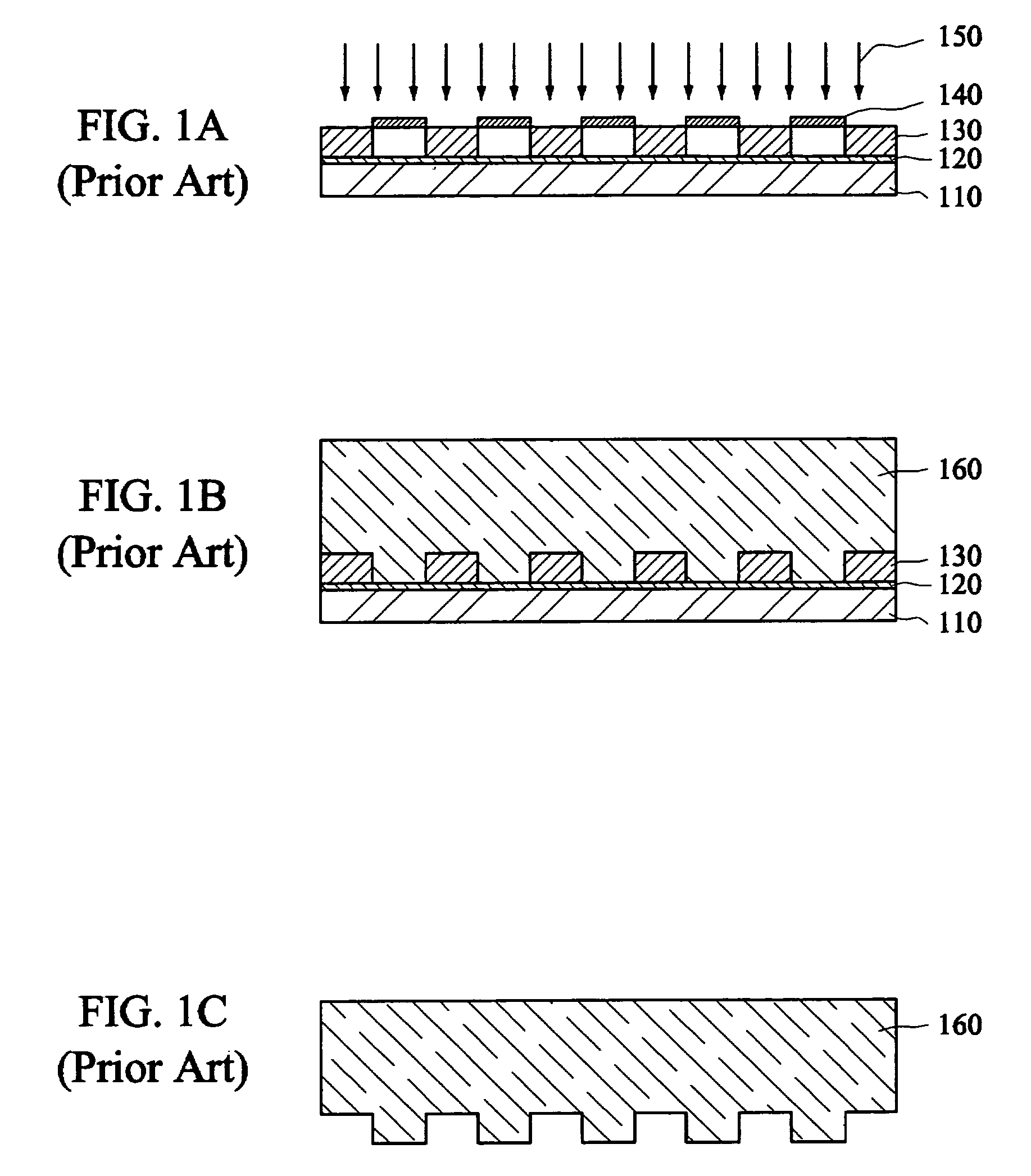

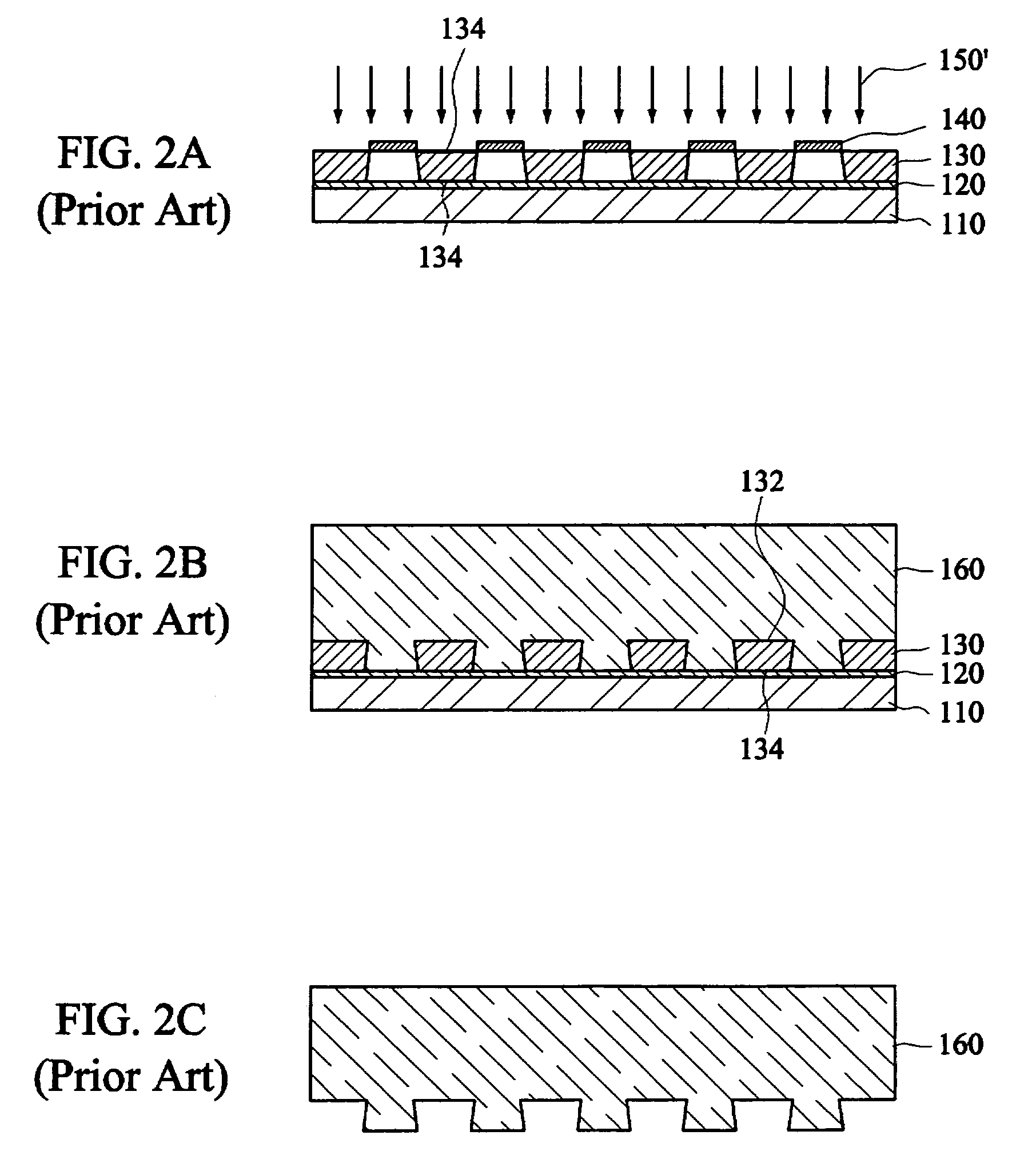

Method and apparatus to apply surface release coating for imprint mold

In imprint lithography, the mold is coated with a surface release layer for a non-sticking separation. Bonding strength of the release layer to the mold depends on the cleanness of the surface and the process of release layer deposition. In accordance with the invention, the mold is disposed in an evacuable chamber, cleaned to remove surface organic contamination and coated with the surface release layer in a chamber, all without relocation or undesired time delay. The chamber encloses a support chuck for the mold or substrate, a surface cleaner unit adjacent the support, a heating source adjacent the support, and advantageously, sensors of measuring chamber pressure, vapor partial pressure and moisture concentration. A vapor source connected to the chamber supplies release surfactant vapor. The mold is cleaned, and the cleaning is followed by vapor phase deposition of the surfactant. The mold is advantageously heated. Typical ways of cleaning include exposure to ozone or plasma ion etch. Surfactant vapor may be generated by liquid surface vaporization, liquid injection or spray vaporization. A surface adhesion promoter can be coated on the substrate by a similar method with the same apparatus.

Owner:NANONEX

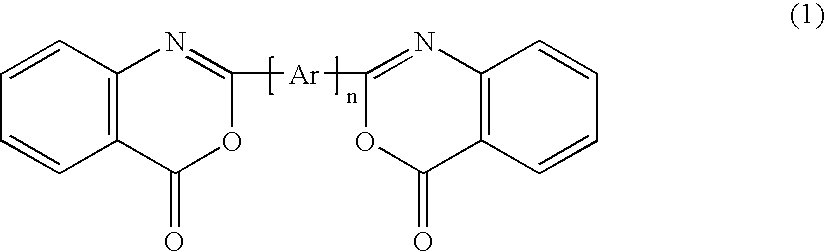

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS20040152806A1Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsAlcoholCrack resistance

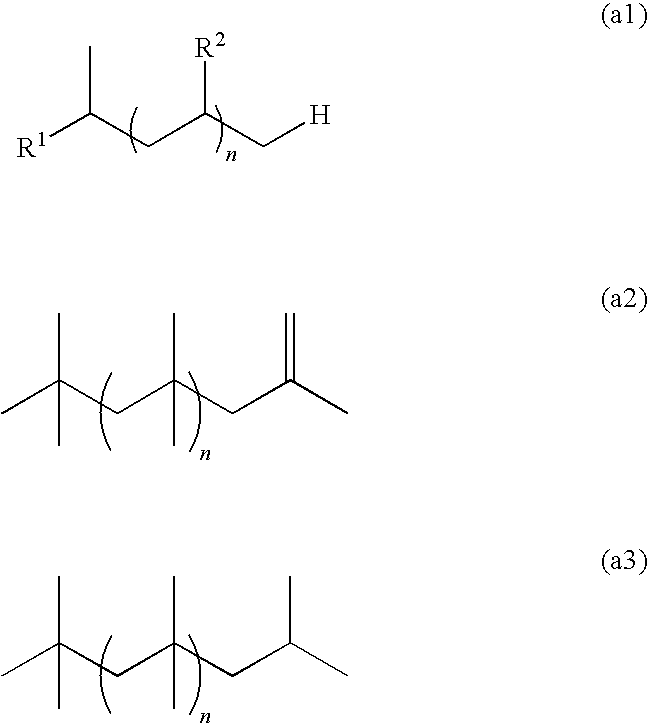

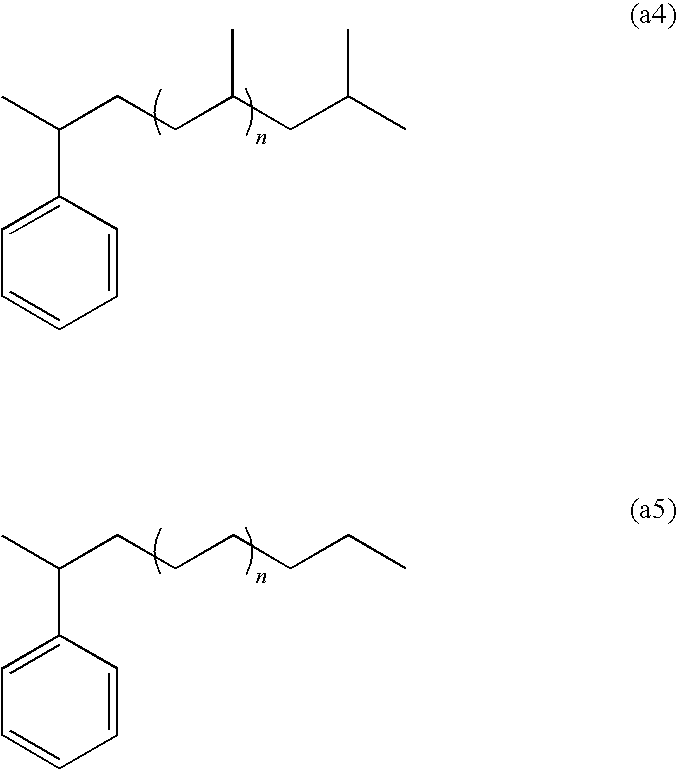

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

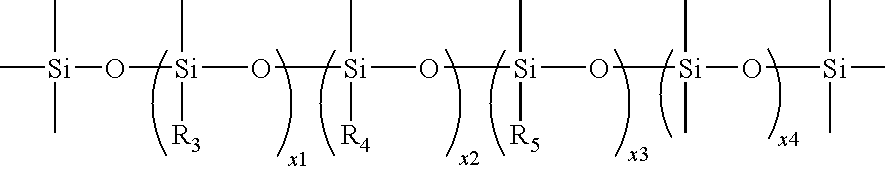

Room temperature curable water-based mold release agent for composite materials

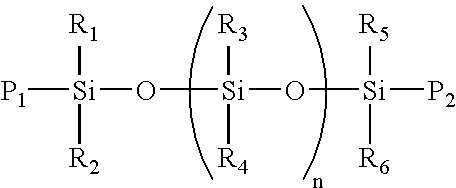

InactiveUS20060074159A1Effective regulationGroup 4/14 element organic compoundsOther chemical processesEpoxyWater based

A room temperature curable water-based mold release agent that is useful for demolding composite parts, such as epoxy and polyester based polymer materials. The mold release agent is curable at low temperatures, such as room temperature, but is thermally stable up to conventional epoxy based composite molding temperatures, e.g., greater than 200 or 280° C. The mold release agent is useful for demolding large composite parts that are cured in large ovens at high temperature when the molds themselves are prepped at room temperature before placing in the oven. The mold release agent is also useful for demolding polyester composite parts that are prepared and cured at low temperature such as room temperature.

Owner:HENKEL IP & HOLDING GMBH

Mold and method of producing the same

InactiveUS20040047938A1Easy to produceHighly precise transfer molding surfaceConfectioneryOptical articlesTransfer moldingMechanical engineering

(1) Alignment mark transfer portion(s) is / are formed on the transfer molding surface of a mold that is used for press-molding a optical element fixing member and having alignment marks; (2) alignment mark(s) is / are formed on the mold material by dry-etching, and the mold material is worked using the alignment mark(s) as a reference to form the transfer molding surface constituted by a plurality of transfer patterns, in order to obtain a mold for press-molding; and (3) the transfer patterns are formed by dry-etching, or a transfer molding bare surface for transfer patterns is formed by dry-etching and a mold release film is formed thereon to reflect the shape of the transfer molding base surface, in order to obtain a mold for press-molding.

Owner:KOSUGA HIROYUKI +1

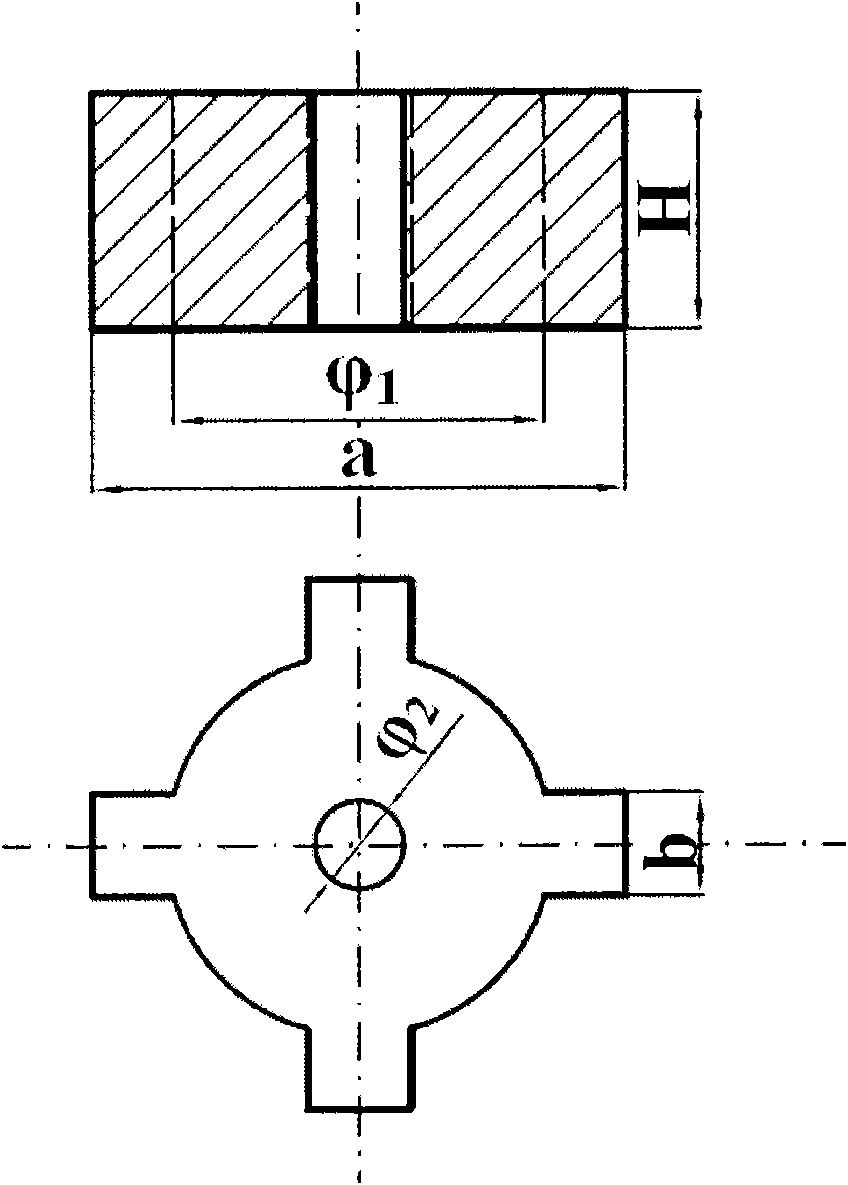

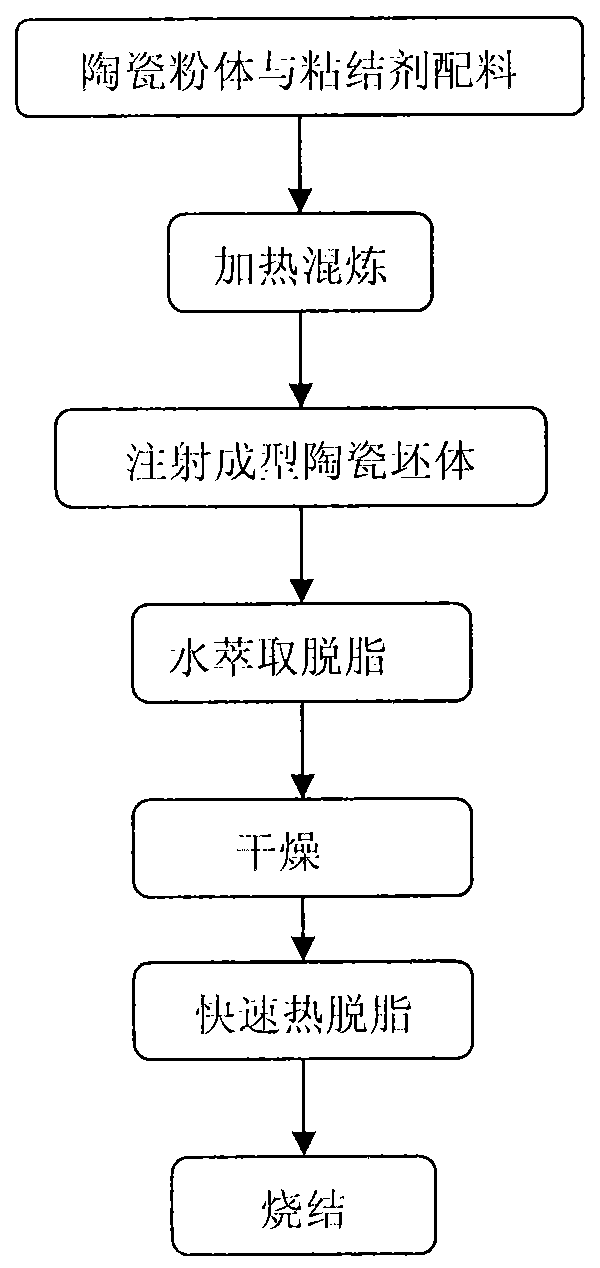

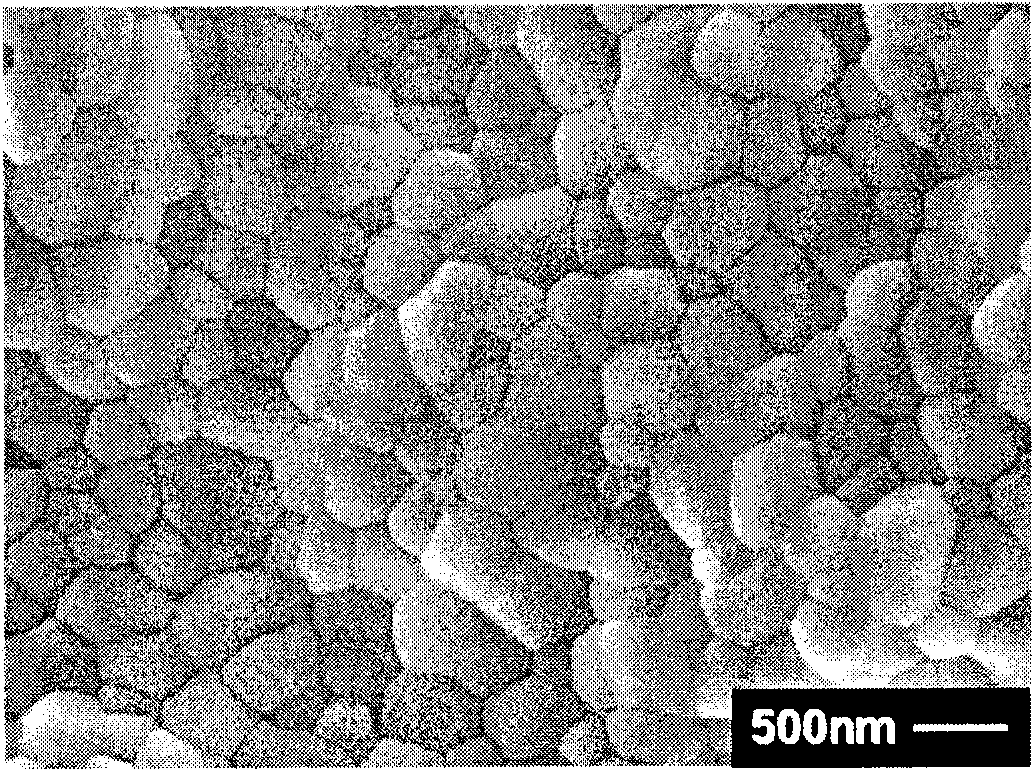

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

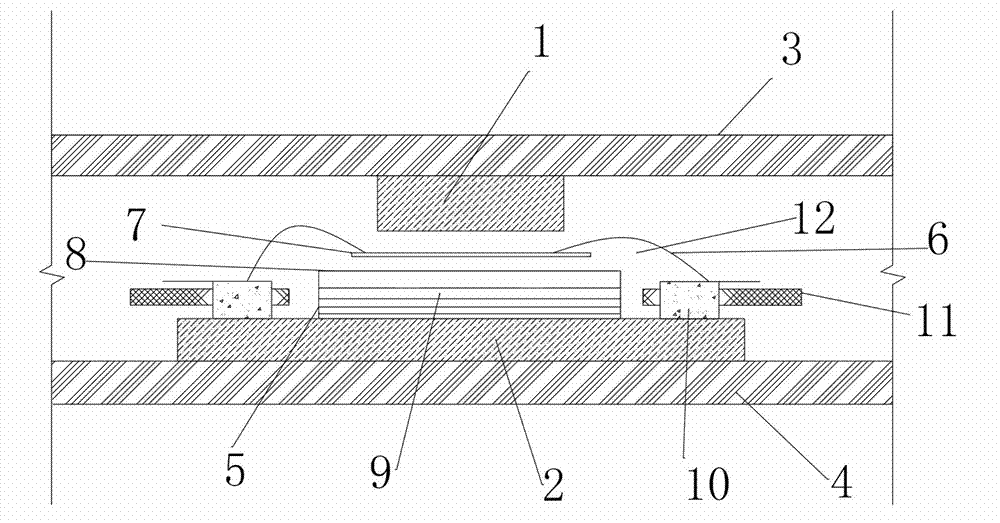

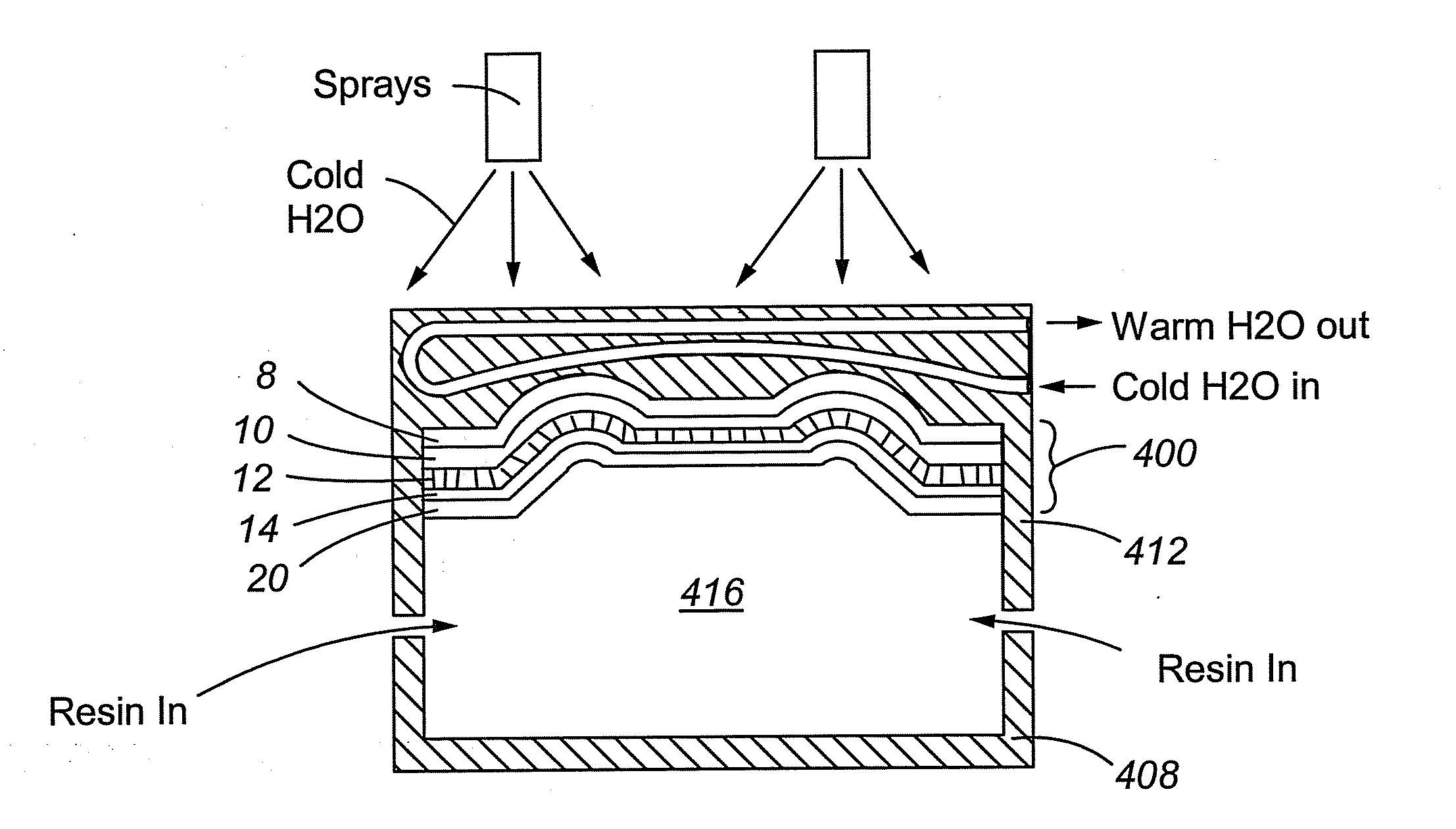

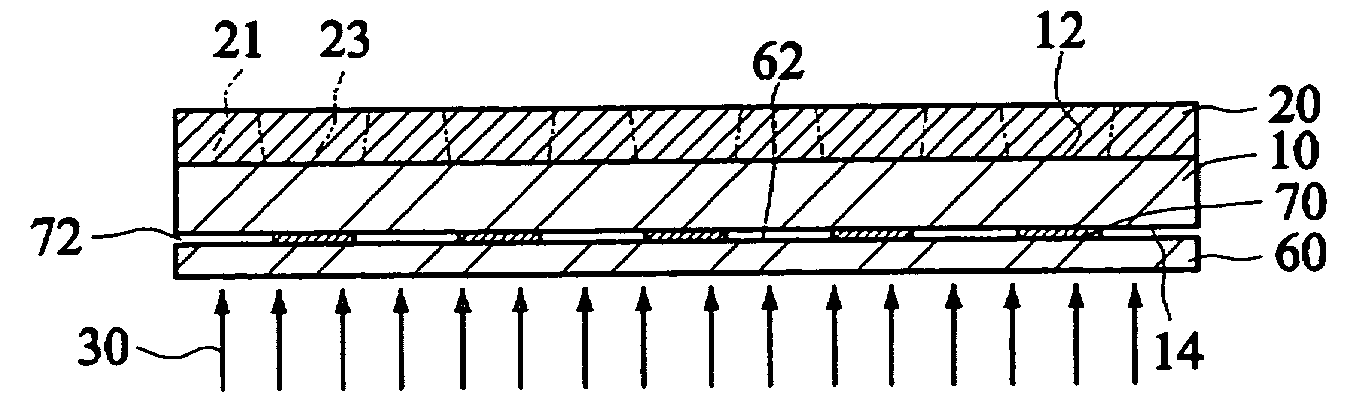

Vacuum assisted molding system of composite and molding method of composite

The invention discloses a vacuum assisted molding system of a composite, which comprises an open shaping mold comprising an upper mold and a lower mold, wherein a vacuum bag-pressing system is connected on the lower mold in a sealing manner; and a mold-pressing heating system is connected outside the mold. The invention also discloses a method for shaping a composite article by vacuum assisted molding, which comprises the following steps: preparing the open shaping mold and placing a prepreg on the lower mold, paving an isolating film, a piece of mold releasing cloth, and a breathable felt in turns, connecting a vacuum bag film in a sealing manner, and communicating a formed vacuum bag-pressing cavity with a vacuum pump; connecting the upper mold and the lower mold to the mold-pressing heating system; assembling the upper mold and the lower mold under a condition of keeping a vacuum bag pressing status, molding and pressing the prepreg by the mold-pressing heating system and heating the upper mold and the lower mold at the same time, and carrying out curing treatment after reaching a curing temperature; and after finishing the curing reaction, molding to obtain the composite article. According to the invention, the process cost is low, the generality is high, the consumption of auxiliary materials is little, and the use performance of the product can be improved.

Owner:NAT UNIV OF DEFENSE TECH

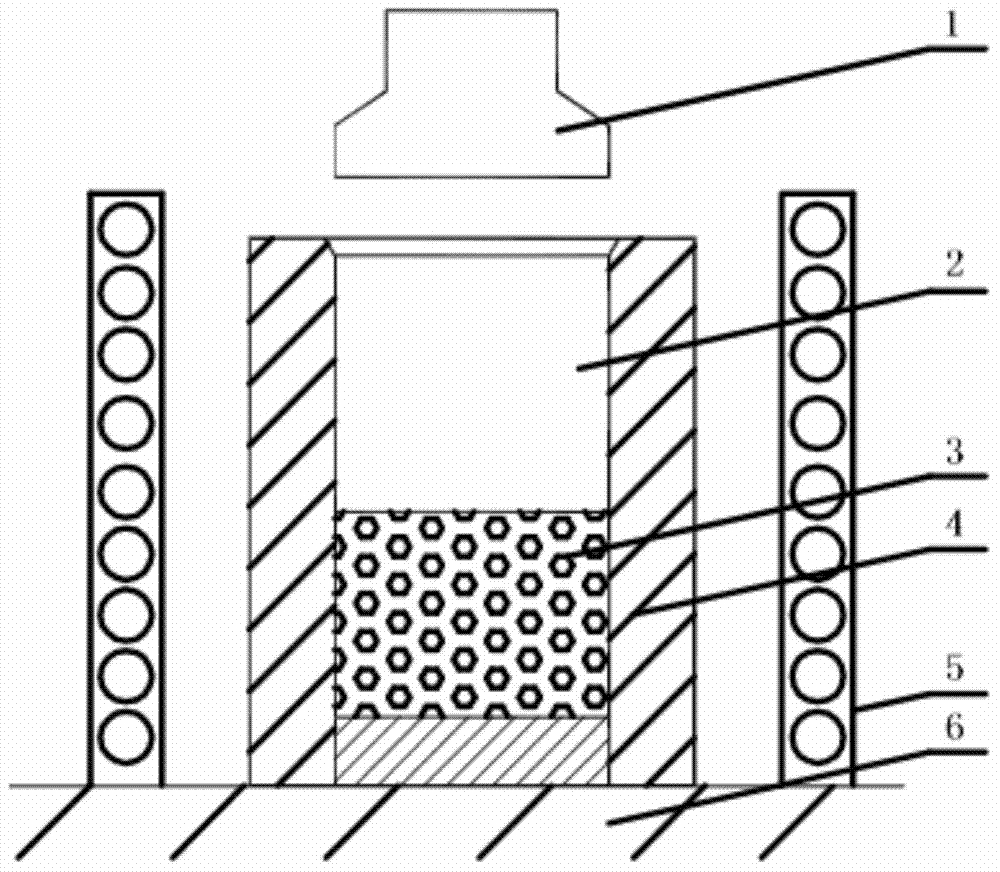

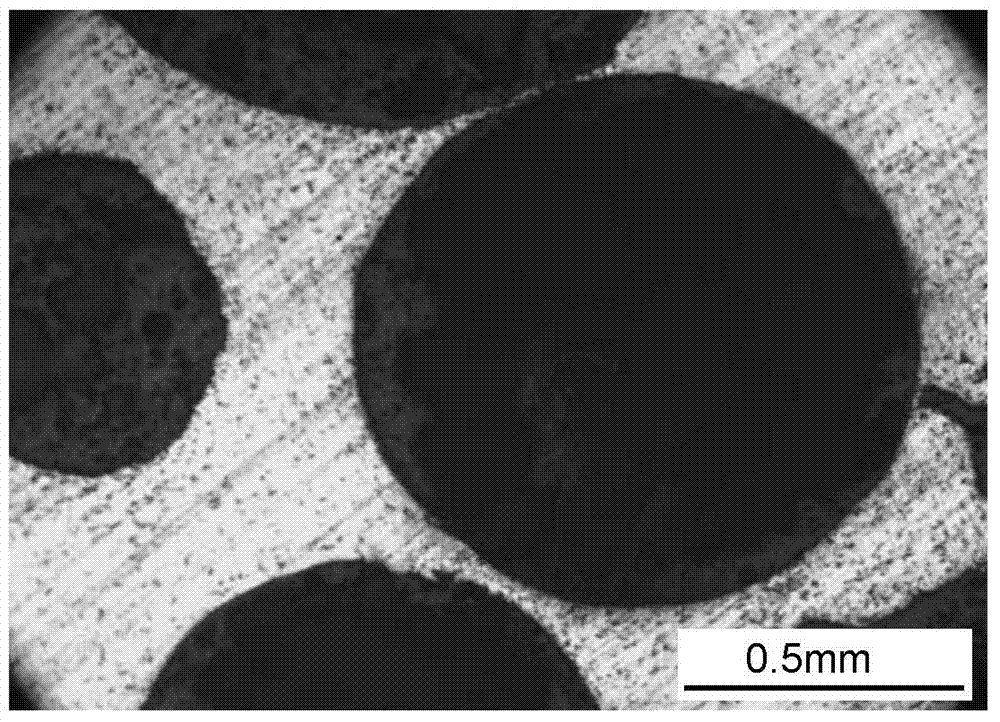

Preparation method for Al2O3 hollow sphere/aluminum porous composite material

ActiveCN103614586AImprove mechanical propertiesAdjustable sizeMold removalAluminum matrix composites

The invention provides a preparation method for an Al2O3 hollow sphere / aluminum porous composite material, relates to a preparation method for an aluminum-based porous composite material, which solves the problems that the strength of a traditional foam aluminum material is low, the process conditions are harsh and the cost is high in an existing preparation method. The preparation method 1 comprises the following steps: step 1. filling an Al2O3 hollow sphere; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and carrying out de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The preparation method 2 comprises the following steps: step 1. mixing the Al2O3 hollow spheres with different grain diameters and filling; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The Al2O3 hollow sphere / aluminum porous composite material is prepared by immersing aluminum or aluminum alloy into a gap between Al2O3 hollow ball prefabricated blocks; porous structure characterizes of the Al2O3 hollow spheres are maintained and a strengthening mechanism of the aluminum-based composite material is introduced, so that the mechanical properties of materials are improved. According to the preparation method, the operation is convenient, the cost is low, the process is simple, and the production cost is reduced.

Owner:HARBIN INST OF TECH

Ablation-resistant lightweight heatproof integrated composite material with thermal insulation function and preparation method thereof

ActiveCN109968757ALightweight withImproves ablation resistanceLamination ancillary operationsSynthetic resin layered productsFiberHeat flux

Provided is an ablation-resistant lightweight integrated composite material with a thermal insulation function. The composite material is of a sandwich structure, the middle layer adopts a chopped fiber as a reinforcing body, phenolic resin as a substrate and hollow microbeads as thermal insulation fillers, upper and lower surface layers are bonded to each other by a fiber cloth pre-impregnation material, and the three layers are cured to improve the bearing capacity and the anti-scouring capacity. The preparation method of the composite material comprises eight steps including ceramic powdertreatment, pretreatment of the chopped fiber and a fiber cloth, mixing, drying, slurry preparation, brushing or impregnation, mold filling, curing formation and demolding. The composite material can be applied to the ablation working condition of medium and low heat flux density; the composite material is formed at one time, so that the preparation cycle is short, and the cost is low; a stable ablation-resistant ceramic layer can be formed on the surface in a temperature range from 800 DEG C to 1,300 DEG C, and meanwhile, low-density fillers such as the hollow microspheres achieve a thermal insulation function. In this way, the integrated thermal insulation function under the conditions of medium and low heat flux density and oxidation is achieved.

Owner:NAT UNIV OF DEFENSE TECH

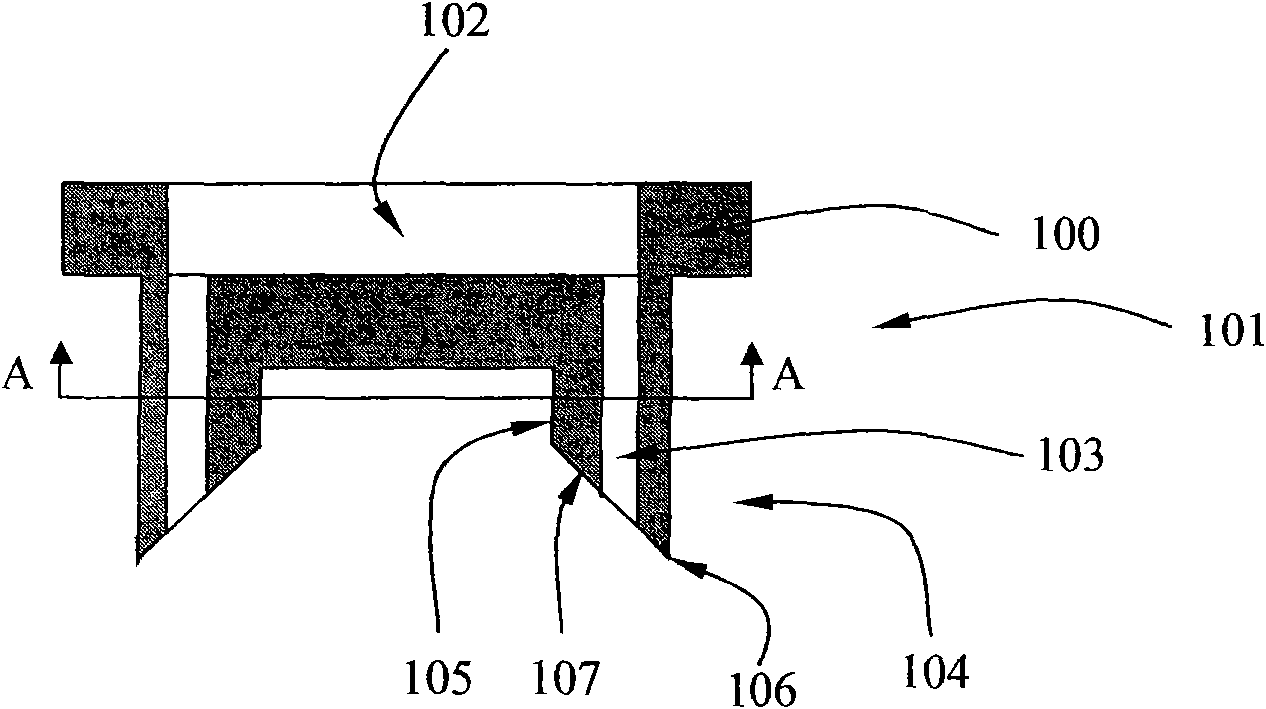

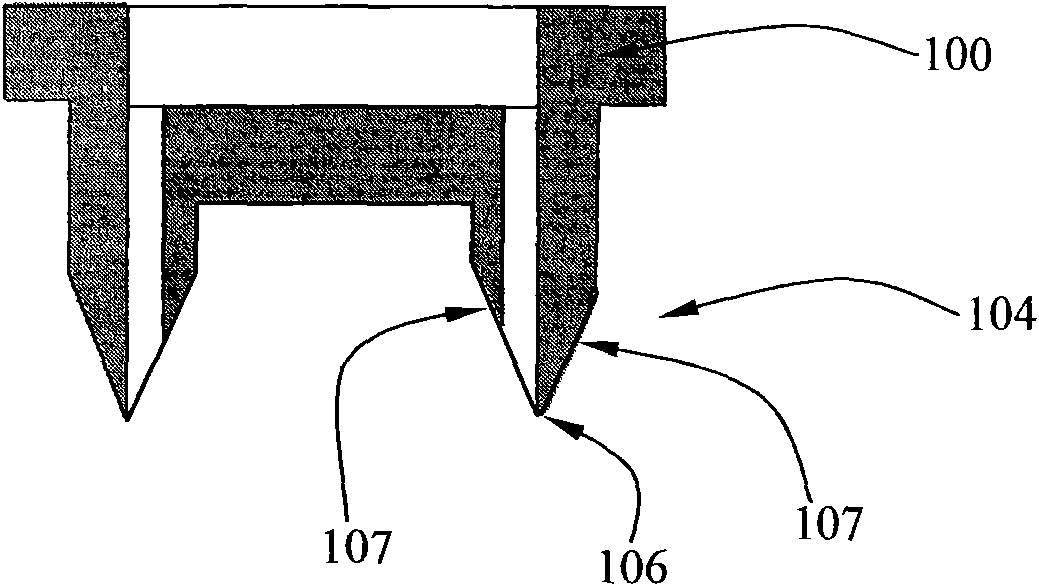

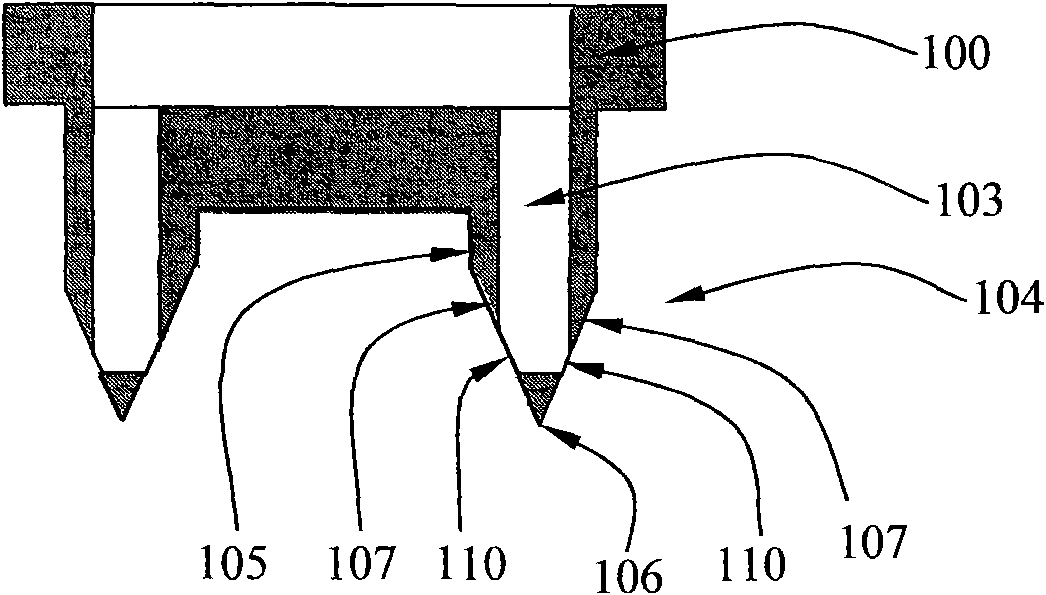

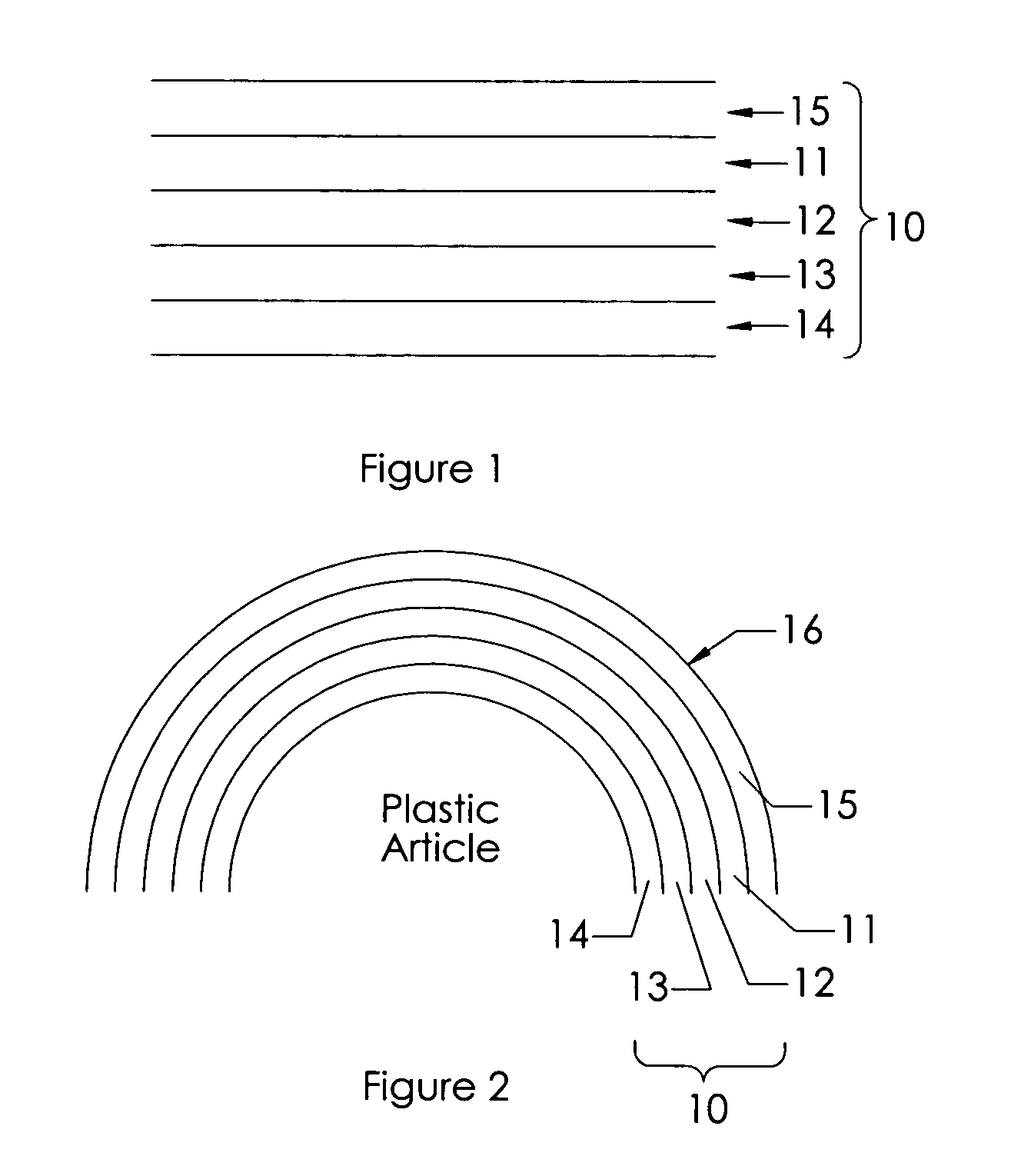

Microneedles array, die casting method for manufacturing microneedle array and die for manufacturing microneedle array

ActiveCN101856538AReduce manufacturing costLow priceMicroneedlesMedical devicesMetallic materialsDie casting

The invention provides a microneedles array, a method for manufacturing the microneedles array and a die for manufacturing the microneedles array. The microneedles array comprises a base and a plurality of microneedles which are integrated with the base, wherein a liquid storage cavity is arranged in the base, and each microneedle are provided with micro-pinholes which are communicated with the liquid storage cavity; the microneedles array is made of plastics, composite materials, and ceramics or metal materials by injection molding; and each microneedle has at least one inclined surface which is inclined towards the central line of the microneedle, and the outlet of each micro-pinhole is positioned on at least one inclined surface, so that the end of the outlet of the microneedle forms a pinnacle part. The die specialized for the invention comprises an upper die, a middle die and a lower die, wherein the middle die and the lower die are provided with cavities for forming the microneedles; and the upper die and the middle die are provided with grooves for forming the base. The three-plate die of the invention can be used for conveniently manufacturing the microneedles array with the pinnacles. Since the stripping process in the injection molding method is carried out step by step, the method has the advantages of small die drawing resistance and low manufacturing cost.

Owner:THE HONG KONG POLYTECHNIC UNIV

Heat moldable flock transfer with heat resistant, reusable release sheet and methods of making same

InactiveUS20080006968A1Avoid heat damageReduce operating costsLiquid surface applicatorsDecorative surface effectsFiberPolymer science

A method of decorating a molded article is provided in which a mold insert, the mold insert, comprising a plurality of flock fibers, a heat resistant release sheet, a release adhesive, a permanent adhesive layer, and a forming film is thermoformed. During thermoforming, the heat resistant release sheet is positioned between a surface of a forming mold and the flock fibers to protect the flock fibers from overheating.

Owner:HIGH VOLTAGE GRAPHICS

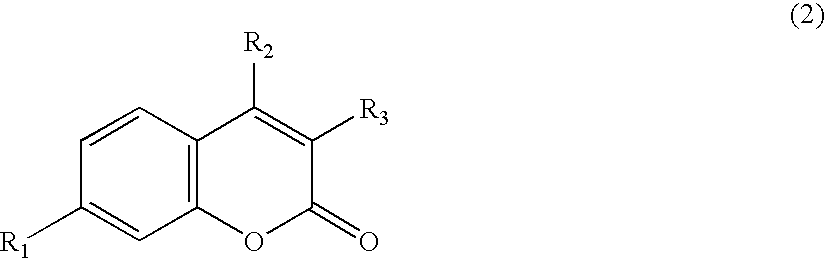

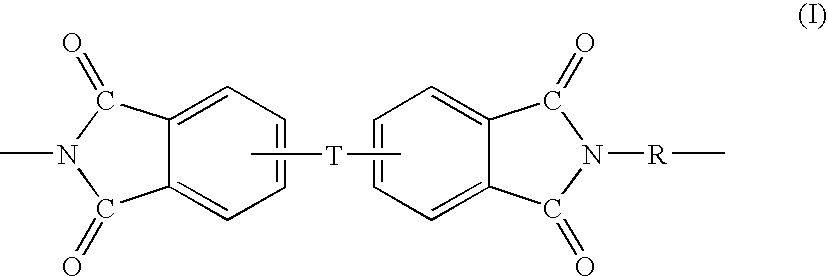

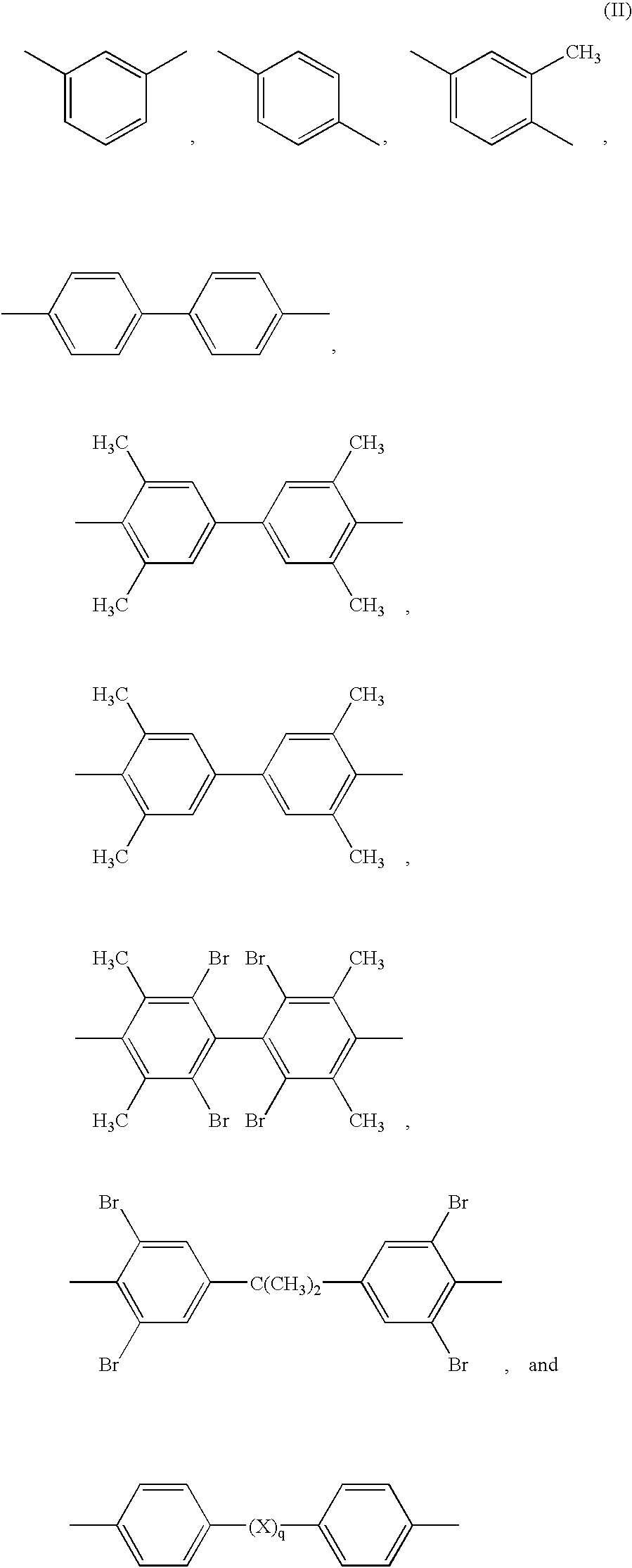

Composition for imprints, pattern and patterning method

InactiveUS20100009137A1Hardly worsening mold transferabilitySolve the real problemDecorative surface effectsLayered productsMonomerLubricant

A lubricant-containing composition for imprints comprising a polymerizable monomer and a photopolymerization initiator in combination or a resin component is excellent in patternability and mold releasability. The composition can form a pattern having a small line edge roughness after etching.

Owner:FUJIFILM CORP

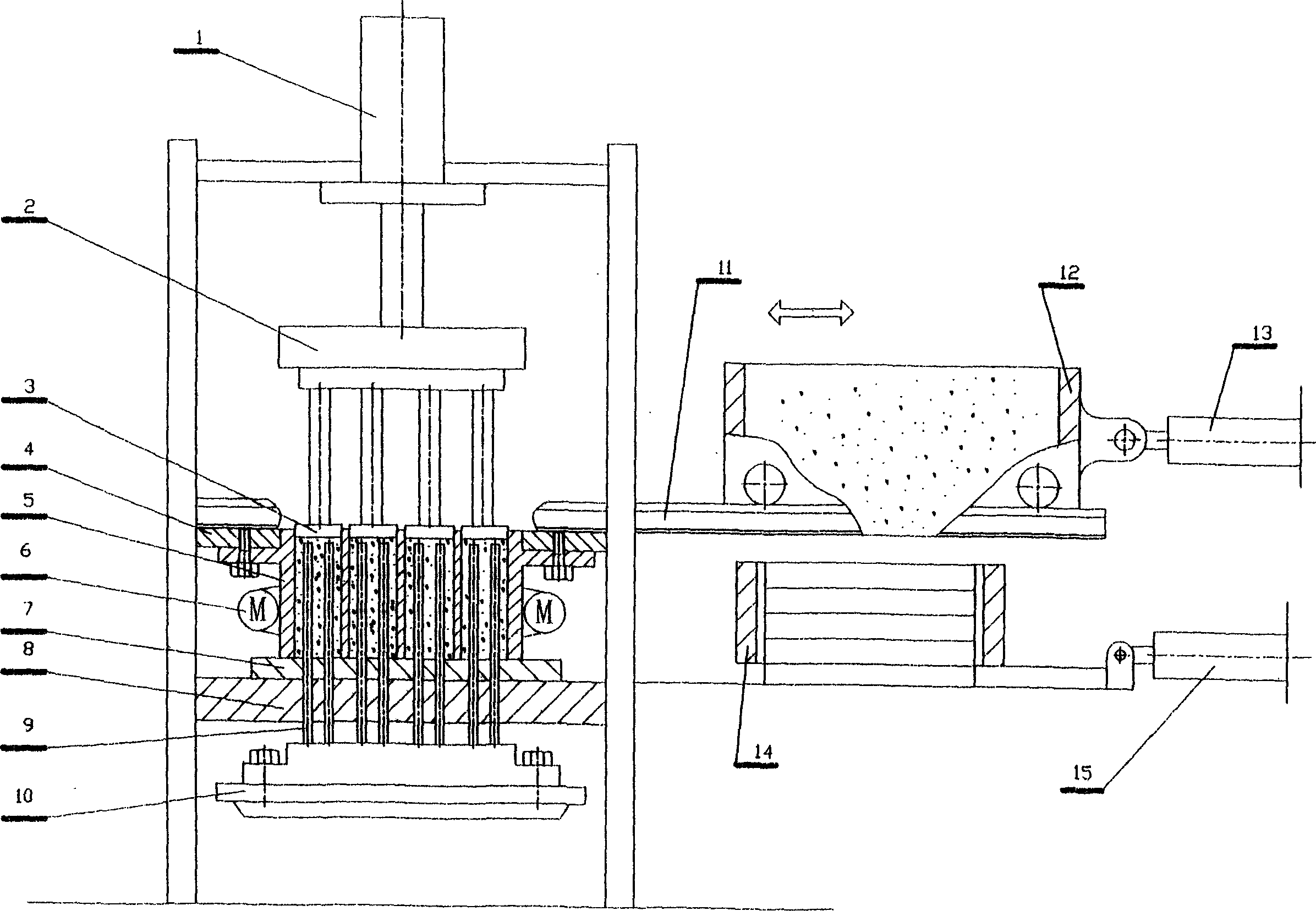

Automatic shaping method and equipment for load-bearing hollow brick

InactiveCN1657251ALiberate labor intensitySpeed up the flowDischarging arrangementMouldsBrickEngineering

A method for automatically shaping the load-bearing hollow brick includes such steps as preparing concrete, stirring, filling in mould, inserting core mould while vibrating, hydraulic pressing, and demoulding. Its apparatus is composed of electric power control box, control mechanism, motor, concrete preparing system, shaping system, feeding unit, and discharging unit.

Owner:广西金瓯建材机械有限公司

Preparation technique of waste residue composite light-weight thermal-insulation wallboard

ActiveCN102863189ALow costCost enoughSolid waste managementCeramic shaping apparatusAggregate (composite)Engineering

The invention discloses a preparation technique of a waste residue composite light-weight thermal-insulation wallboard, which comprises the following steps: preparing a waste residue base material; preparing a composite admixture A; preparing waste residue light-weight aggregate; preparing a composite admixture B; preparing a wallboard blank material; preparing a wallboard blank; putting the wallboard blank in a curing chamber, and curing in a 75-80 DEG C saturated steam environment for 4-5 hours; and when the difference between inside temperature and outside temperature of the curing chamber is 25-40 DEG C, putting the wallboard blank outside the chamber, and demolding to obtain the waste residue composite light-weight thermal-insulation wallboard. According to the preparation method disclosed by the invention, the wallboard blank can be cured and demolded within 8.5-12 hours, and the demolded wallboard can be immediately put into engineering use, thereby shortening the processing cycle, and preparing the high-strength favorable-water-resistance light-weight wallboard under the conditions of changing wastes into valuable substances and using low production cost. The wallboard can be widely used in various types of construction engineering.

Owner:杜世永

Feed for lambs

InactiveCN102524550AMeet nutritional needsMeet energy supplyFood processingAnimal feeding stuffMycotoxinAnimal science

Owner:李健

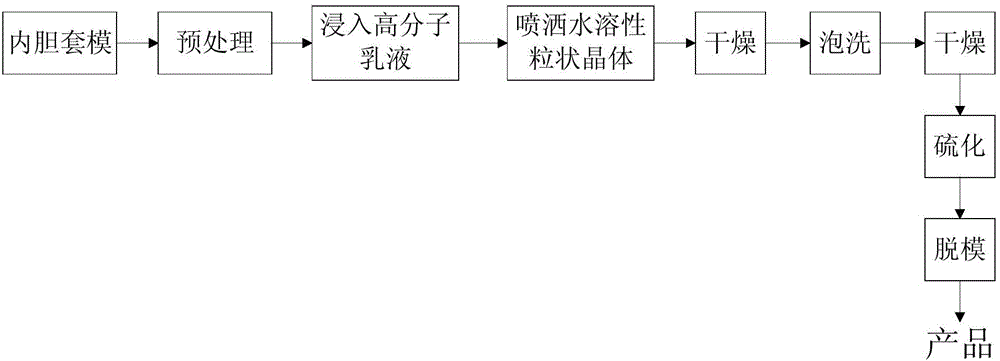

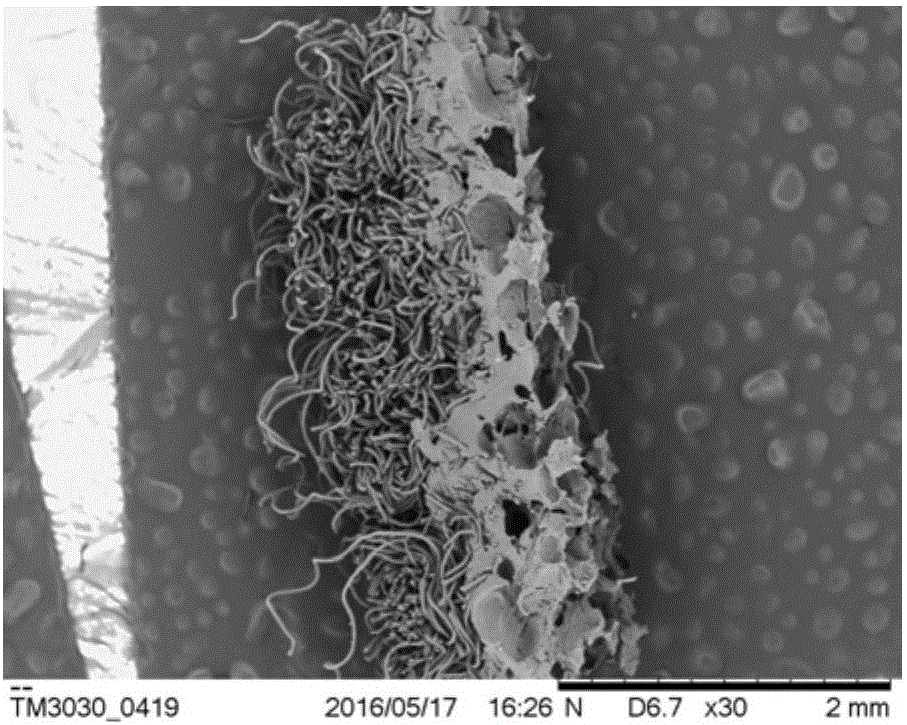

Anti-slip breathable operating gloves and preparation method thereof

ActiveCN106072923AGood anti-skid effectGood air permeabilityGlovesProtective garmentPre treatmentEmulsion

The invention provides a pair of anti-slip breathable operating gloves and a preparation method thereof. The preparation method comprises the steps that 1, macromolecular emulsion is prepared; 2, a mold is sleeved with an inner container of each glove, the inner container of each glove is immersed into the prepared macromolecular emulsion to form a macromolecular coating after pretreatment; 3, water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, then drying treatment is performed, and the water-soluble granular crystals on the surface of the unsolidified macromolecular coating are dissolved with water; 4, the inner containers of the gloves treated in the step 3 are subjected to coating drying, vulcanization and demoulding treatment to obtain glove products. The macromolecular coating is formed on the inner container of each glove, the water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, the water-soluble granular crystals are dissolved with water after the macromolecular coating solidifies, accordingly a large amount of micropores are formed on the macromolecular coating so as to form a concave-convex structure, and the gloves have an excellent anti-slip effect, good breathability, softness and abrasion resistance.

Owner:WONDERGRIP CHINA CO LTD

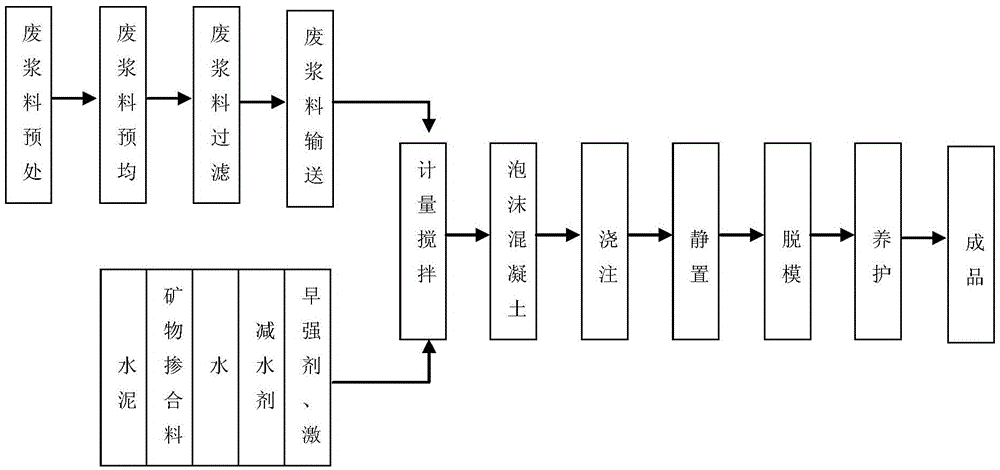

Waste slurry recycling and reusing technology of concrete mixing station

InactiveCN105645800AIncrease profitRealize comprehensive recyclingSolid waste managementCeramicwarePre treatmentLand resources

The invention discloses a waste slurry recycling and reusing technology of a concrete mixing station. The waste slurry recycling and reusing technology of the concrete mixing station comprises the following steps: firstly pre-treating waste slurry of the concrete mixing station, and maintaining the activity of a cementing material in the waste slurry; then conveying the waste slurry from a settling pond to a pre-homogenizing pond, adding water and stirring for carrying out waste slurry pre-homogenization; filtering the obtained homogenous waste slurry through a filter screen, and conveying the homogenous waste slurry to a burdening and stirring tank; metering and stirring cement, a mineral admixture, water, a water reducing agent, an early strength agent and an exciting agent according to a proportion to prepare concrete slurry, conveying the obtained concrete slurry to a foaming machine to prepare foam concrete, pouring the foam concrete in a mold, standing, demoulding, and maintaining, thus obtaining a regenerated foam concrete product with the dry density level of 600 to 800 kg / m<3>. According to the waste slurry recycling and reusing technology disclosed by the invention, the problems of waste of land resources, environment pollution and increment of running cost of the concrete mixing station due to backfilling of the waste slurry of the concrete mixing station can be solved, qualified regenerative products can be generated, and the waste slurry recycling and reusing technology is suitable for being popularized and applied.

Owner:中建西部建设西南有限公司

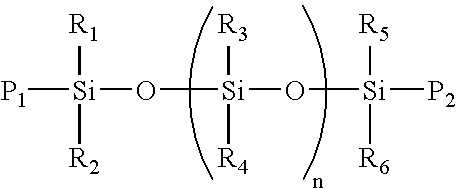

Composition for release layer of in-mold decoration

InactiveUS20050255314A1Synthetic resin layered productsLaminationEngineeringElectrical and Electronics engineering

This invention relates to a composition suitable for the formation of a release layer in an in-mold decoration or thermal transfer printing process.

Owner:WANG FEI +6

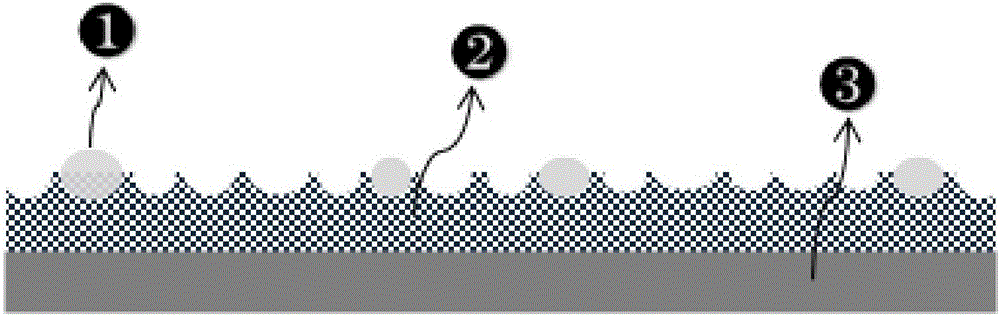

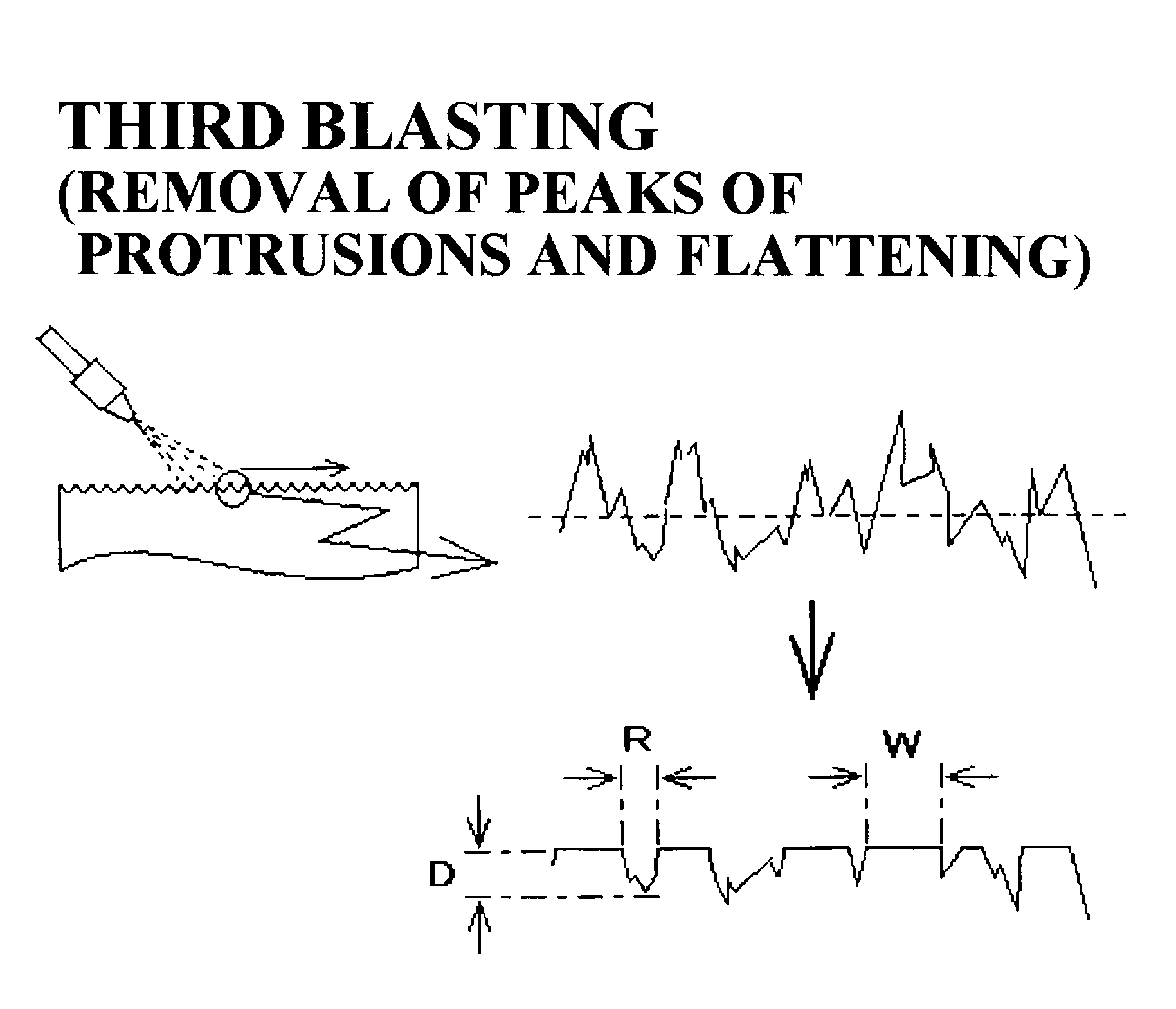

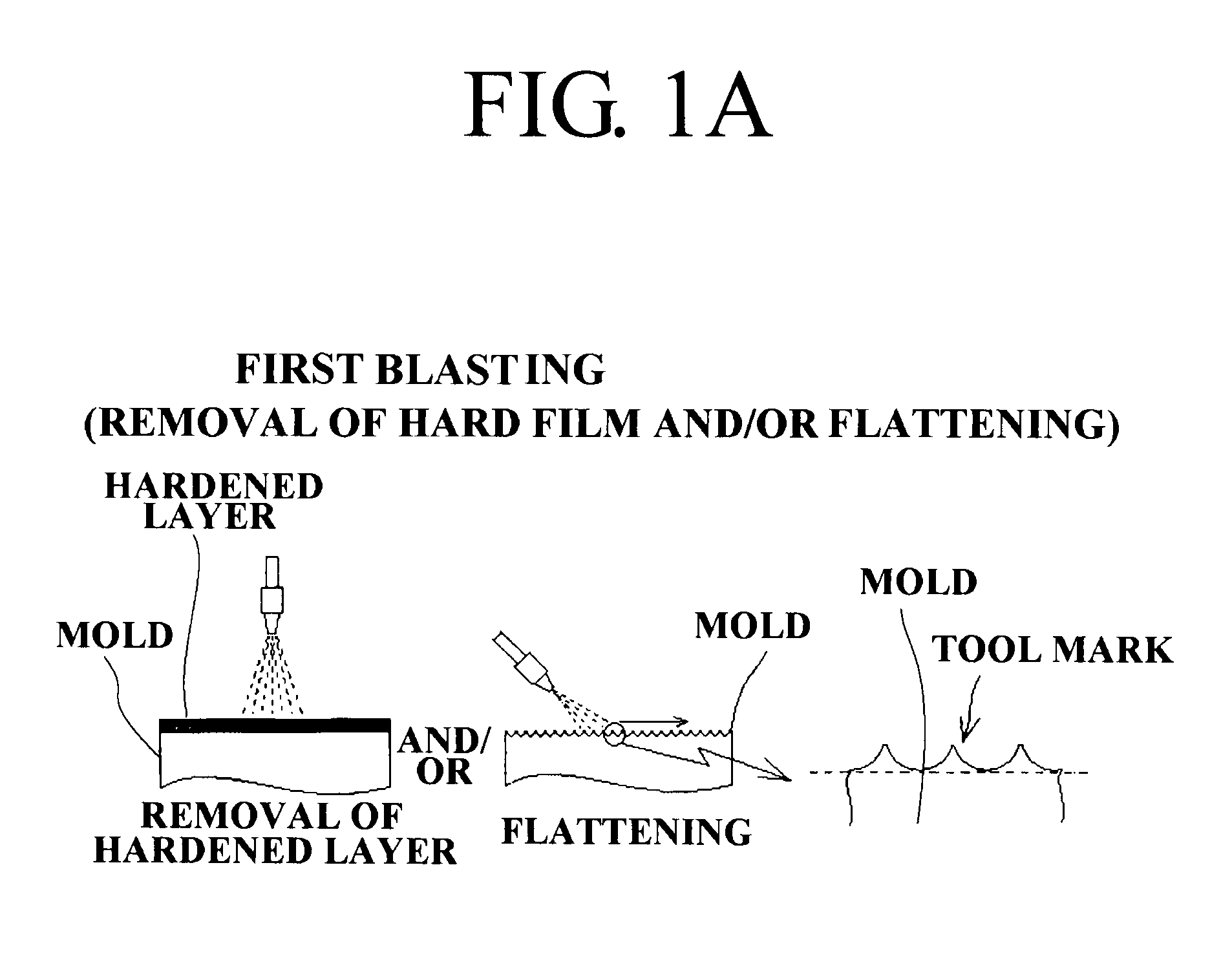

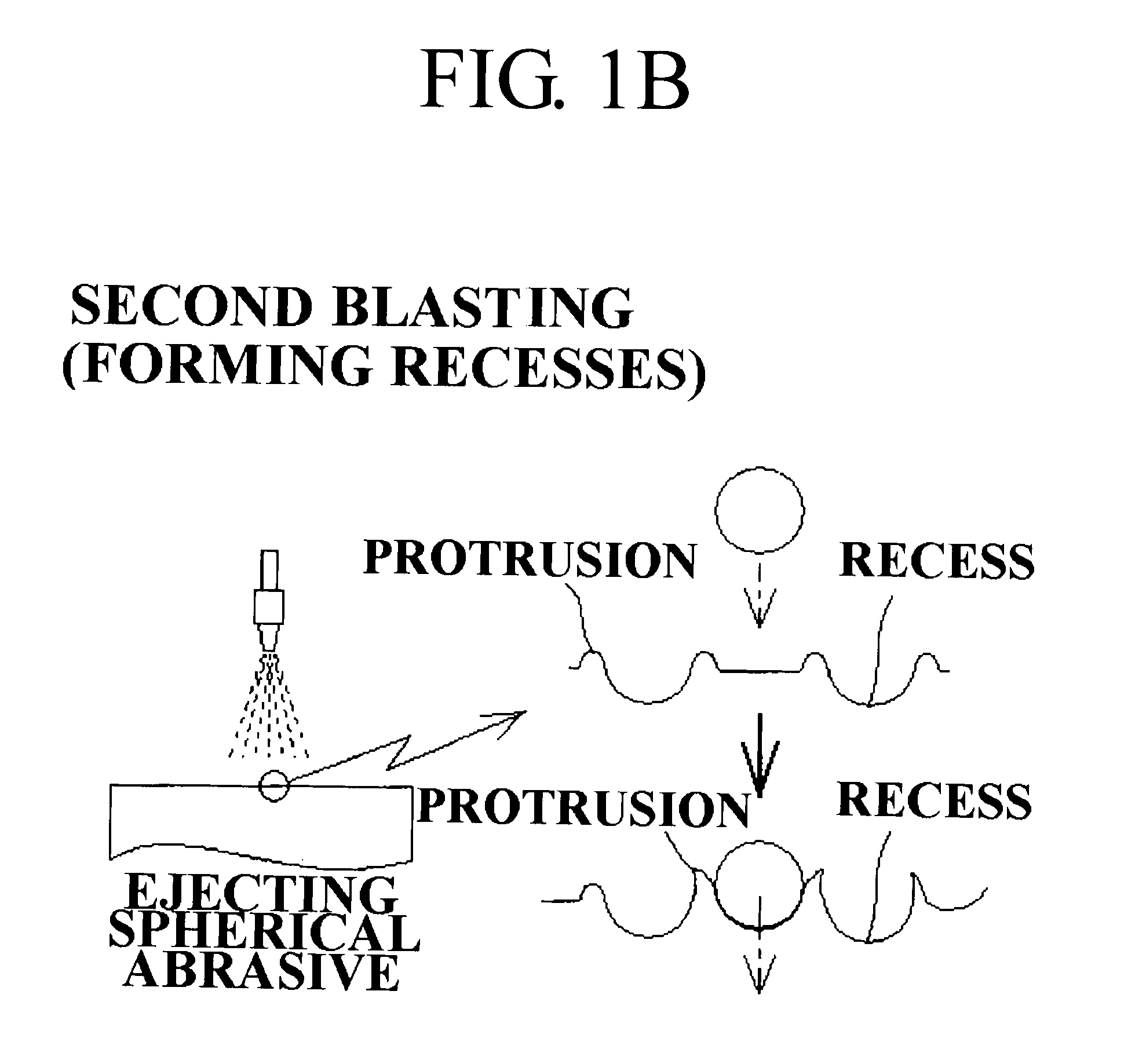

Method of treating surface of mold and mold having surface treated by said method

ActiveUS20120043044A1Good release effectEasy procedureFoundry mouldsFoundry coresElastomerAbrasive blasting

Provided is a method of treating a surface of a mold to achieve good demoldability and capable of preventing wearing of the mold by avoiding load concentration on one part of the surface of the mold. After a first blasting is performed on the surface of the mold to remove a hardened layer produced on the surface and / or to adjust the surface roughness, a second blasting is performed to create fine irregularities on the surface. Then, an elastic abrasive in which abrasive grains are carried on an elastic body, or a plate-like abrasive having a planar shape with a maximum length that is 1.5 to 100 times the thickness thereof, is ejected onto the surface of the mold at an inclined ejection angle such that the abrasive is caused to slide along the mold surface to flatten peaks of the irregularities created on the mold surface.

Owner:FUJI MFG CO LTD

System and method for manufacturing concrete blocks

A system and method for manufacturing an uncured concrete block using the dry-cast manufacturing process includes a mold box having a pair of side walls, a pair of side plates, an open top side and an open bottom side defining a mold cavity. One or more end liners are disposed within the mold cavity and are selectively shiftable within the mold cavity with hydraulic cylinders between a first position and a second position. The end liners can be provided with a three-dimensional textured face to impart a decorative face to a side surface of the concrete block formed in the mold or can also provide blocks with a tapered face when disposed in the second position while the mold is filled with concrete. Before the block is stripped from the mold, the end liners are returned to the first position, so that the side surfaces are not damaged as the block is released.

Owner:MARSHALL CONCRETE

Method of manufacturing a LIGA mold by backside exposure

InactiveUS20060275711A1Low costPhotomechanical exposure apparatusMicrolithography exposure apparatusLIGAThermal compression

A method of manufacturing a LIGA mold by backside exposure includes the steps of: disposing a mask layer at a side of a first substrate, wherein the first substrate is transparent to a predetermined light source and has a front side and a backside; forming a photoresist layer on the front side of the first substrate; providing the predetermined light source to illuminate the backside of the first substrate so as to expose the photoresist layer to form an exposed portion and an unexposed portion; removing the unexposed portion to form a patterned structure on the photoresist layer; forming a metal layer on the patterned structure of the photoresist layer and the first substrate; and removing the photoresist layer and the first substrate to remain the metal layer as the LIGA mold, which is good in a de-molding procedure of a hot embossing process.

Owner:NATIONAL TSING HUA UNIVERSITY

Polyetherimide composition, method, and article

InactiveUS6753365B2Good release effectSpeed up the flowWater/sewage treatment by flocculation/precipitationImidePolymer science

A composition useful in the manufacturing of plastic cookware includes a polyetherimide resin and an acidic additive selected from the group consisting of aliphatic carboxylic acids having a vapor pressure less than one atmosphere at 300° C., aromatic carboxylic acids having a vapor pressure less than one atmosphere at 300° C., and combinations comprising at least one of the foregoing acidic additives. In one embodiment, the composition further comprises an additional resin, such as a polyester resin. The acidic additive is effective in improving the mold release and increasing the melt flow of the composition. Articles including the composition and a method for preparing the composition are also described.

Owner:SHPP GLOBAL TECH BV

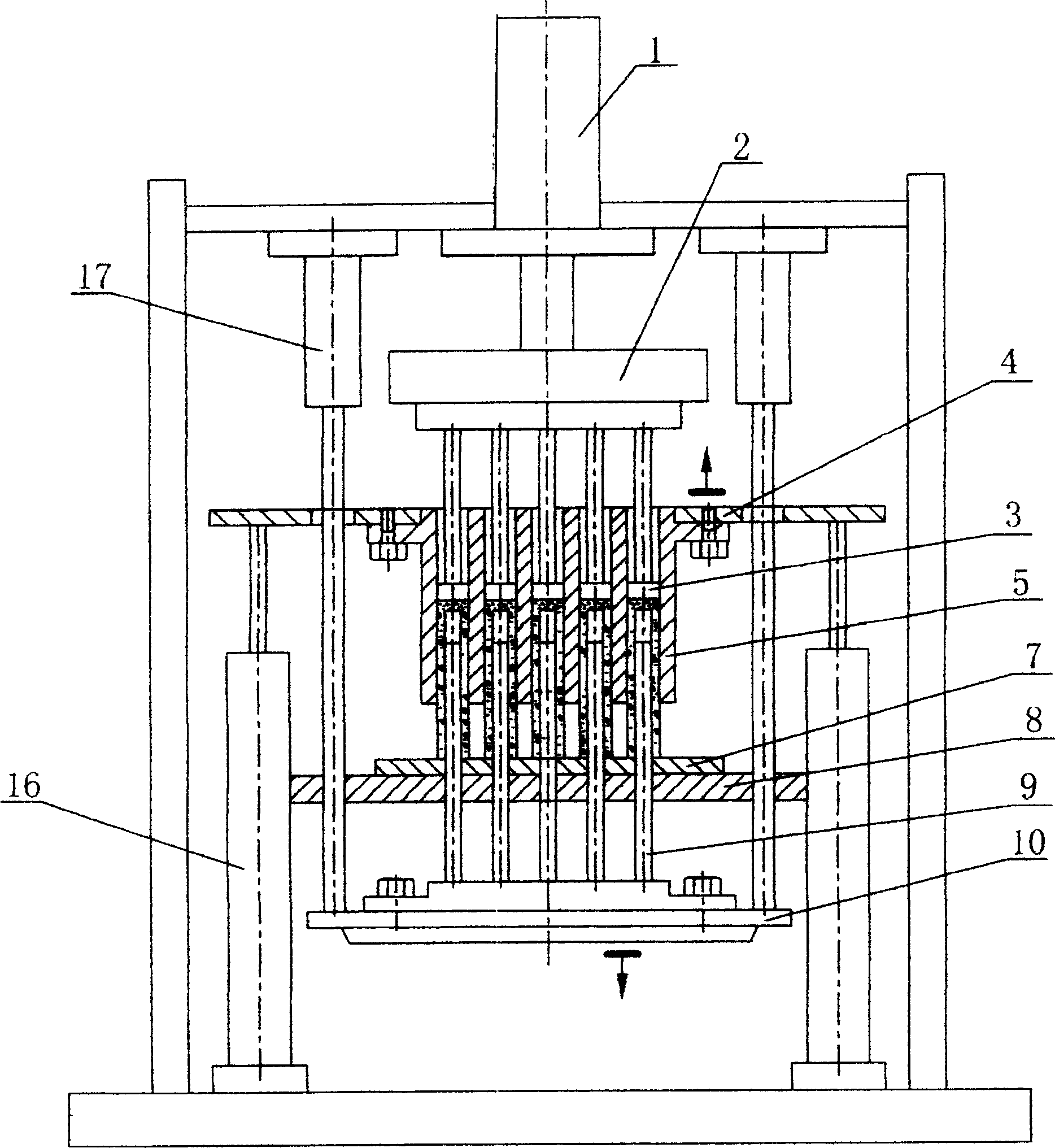

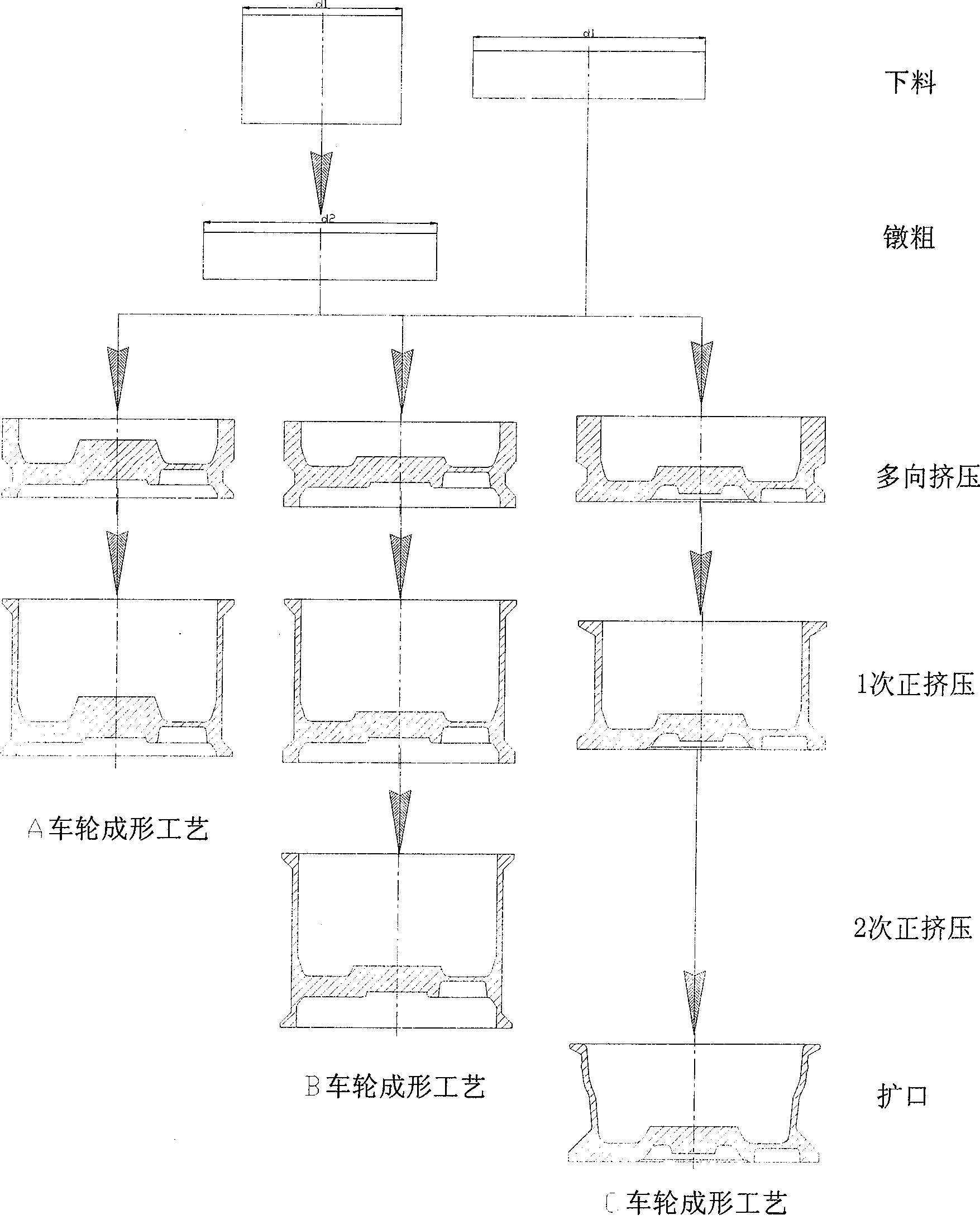

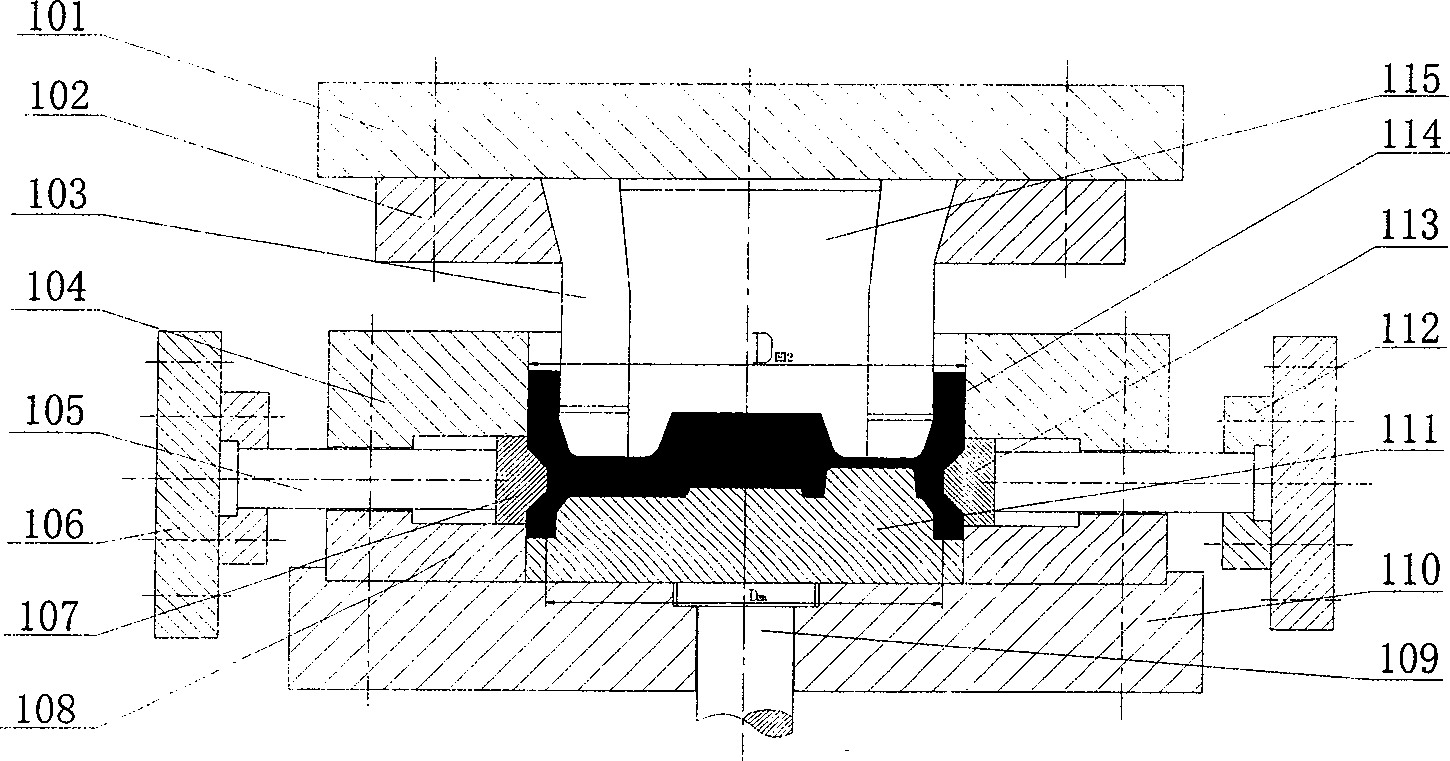

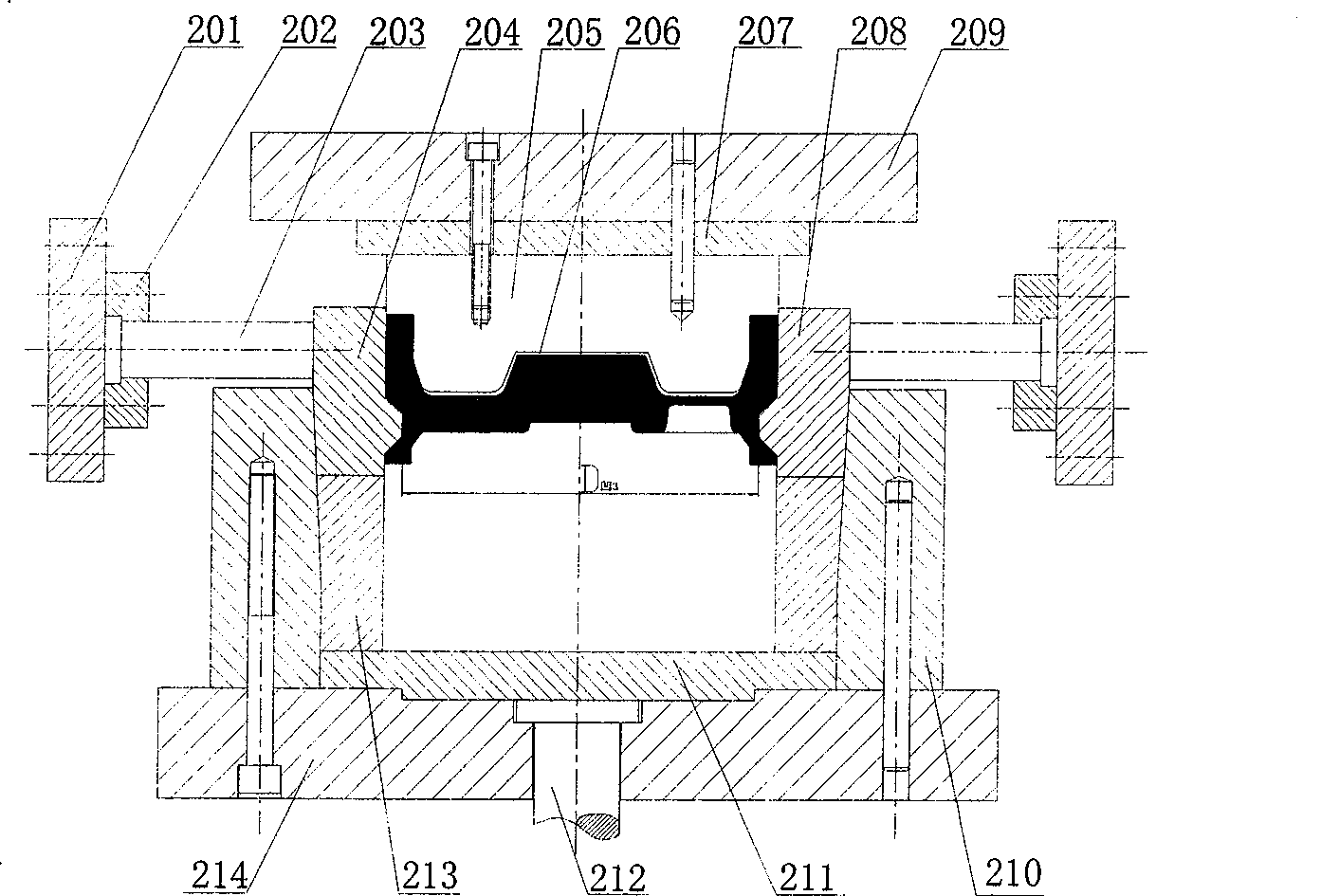

Multiway shaping method of magnesium alloy wheel and mold

InactiveCN101474642ASubstantiveEliminate intermediate machining processesExtrusion diesAxial pressurePressure.drive

The invention belongs to a magnesium alloy wheel multi-directional forming method and a die. The method is characterized by comprising the working procedures of blanking, upsetting, multi-directional extrusion, forward extrusion, flaring, heat treatment, machining and surface treatment, in the working procedures of the multi-directional extrusion, the forward extrusion and the flaring, axial pressure is applied to an axial male die so as to complete the forming of a magnesium alloy wheel, and lateral pressure drives a lateral male die to be connected with a split female die so as to complete the clamping and splitting of the split female die. The method solves the problems of forming and demoulding of a round wheel with small middle part and two large ends, has the advantages of simplifying the technical processes, improving the production efficiency, preventing the generation of burr flash, having high forming precision and the like.

Owner:ZHONGBEI UNIV

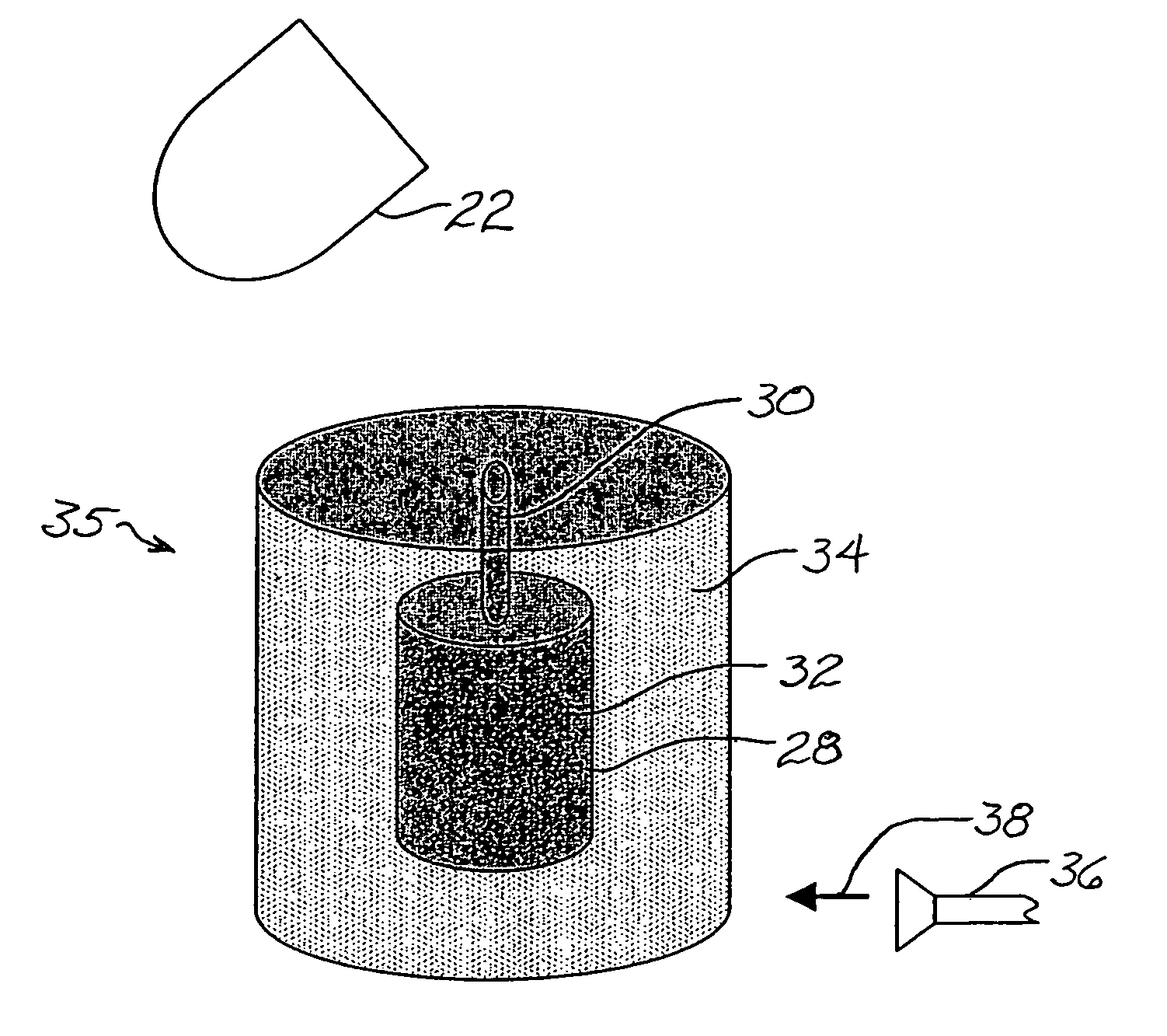

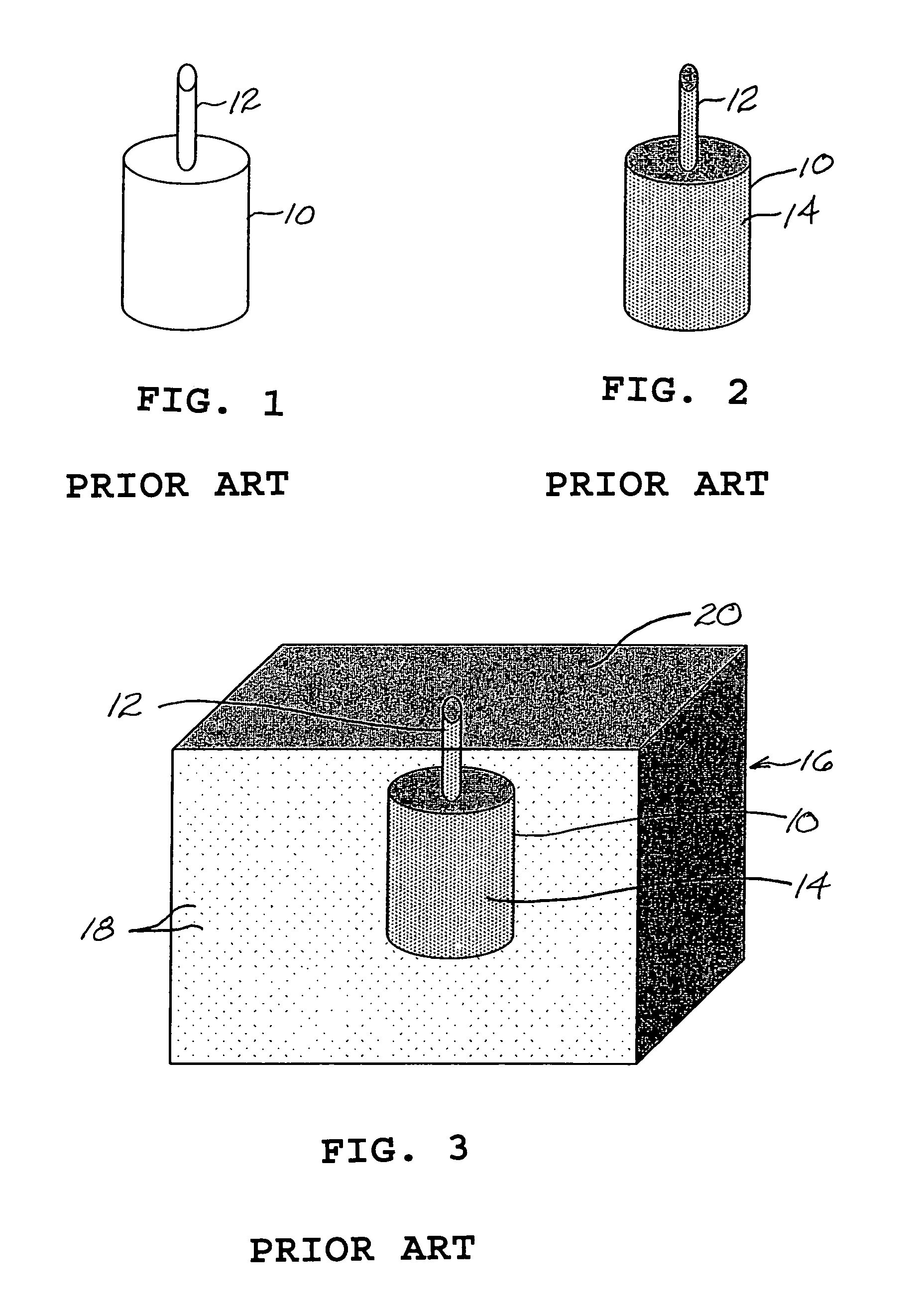

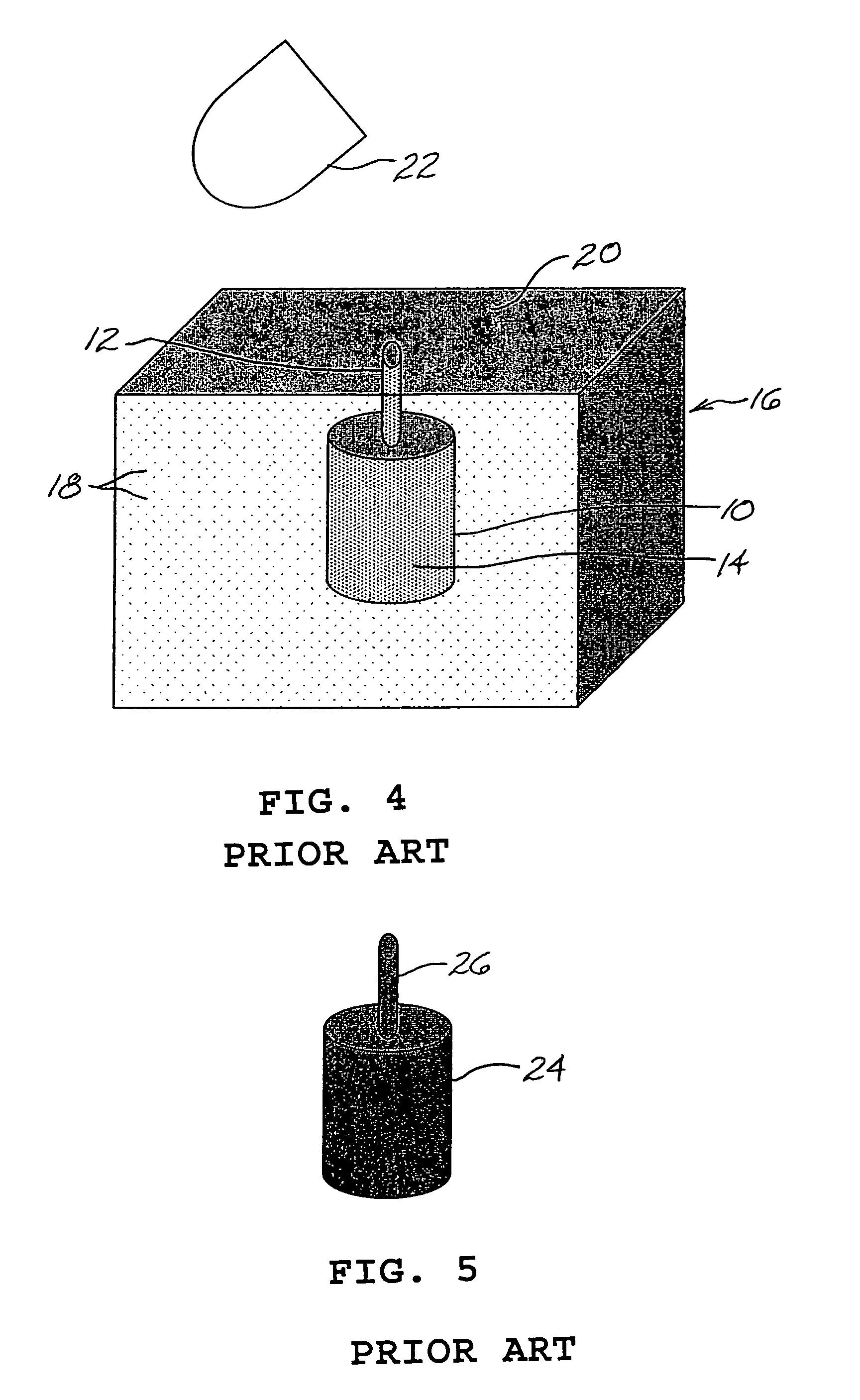

Lost pattern mold removal casting method and apparatus

A method and apparatus for the lost pattern casting of metals is disclosed. In the method, a pattern is formed from a material and a mold is formed around at least a portion of the pattern. The mold includes a particulate material and a binder. The pattern is removed from the mold and molten metal is delivered into the mold. The mold is contacted with the solvent and the molten metal is cooled such that it at least partially solidifies to form a casting. The step of cooling includes contacting a shell of solidifying metal around the molten metal with the solvent. An apparatus is also disclosed.

Owner:ALOTECH LTD

Preparation method of SQRTM forming process carbon fiber grating based on water-soluble core

InactiveCN106853694ASolve the demoulding problemReduce manufacturing costDomestic articlesAviationFiber

The invention relates to a method for preparing a carbon fiber grid based on the SQRTM molding process of a water-soluble core. The method first prepares a grid core with a soluble material, and lays carbon fiber prepreg on it, and adopts SQRTM molding The process is to solidify the part, and in the later stage, the water-soluble mandrel is dissolved by tap water under a certain pressure, and the grille part is obtained by demoulding. This method solves the demoulding problem of complex parts with high curvature of the grid. The SQRTM process adopted, combined with the prepreg process and liquid RTM molding technology, effectively reduces the manufacturing cost and guarantees The high performance requirements of the parts are met. This invention can provide a feasible solution for composite aviation complex curvature parts.

Owner:HENGSHEN

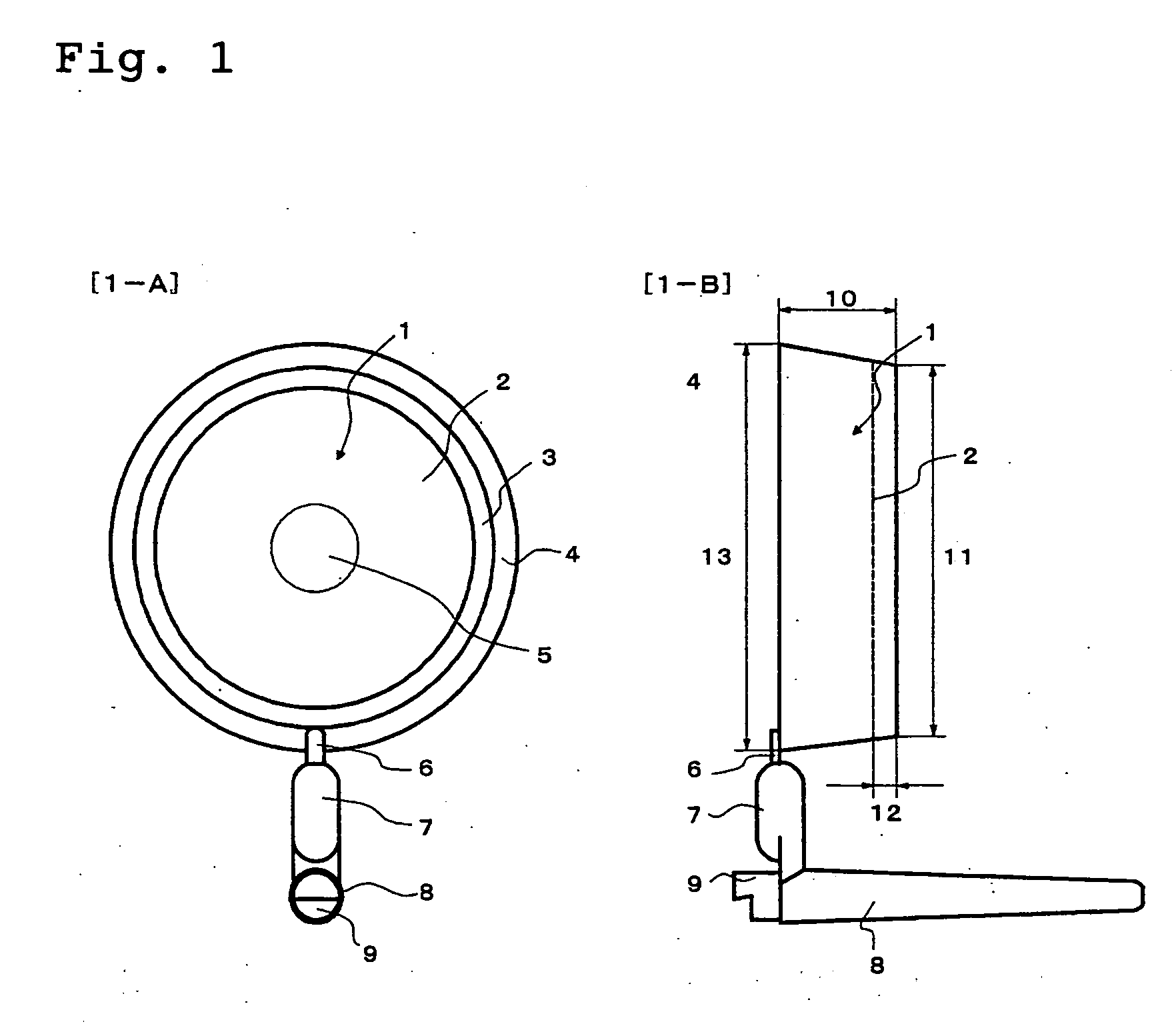

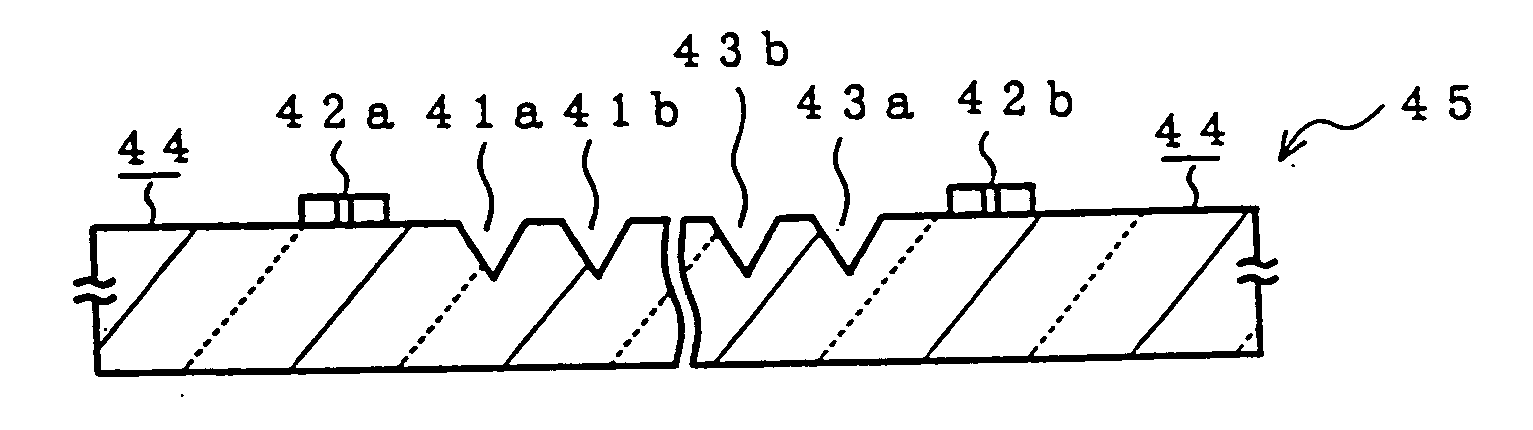

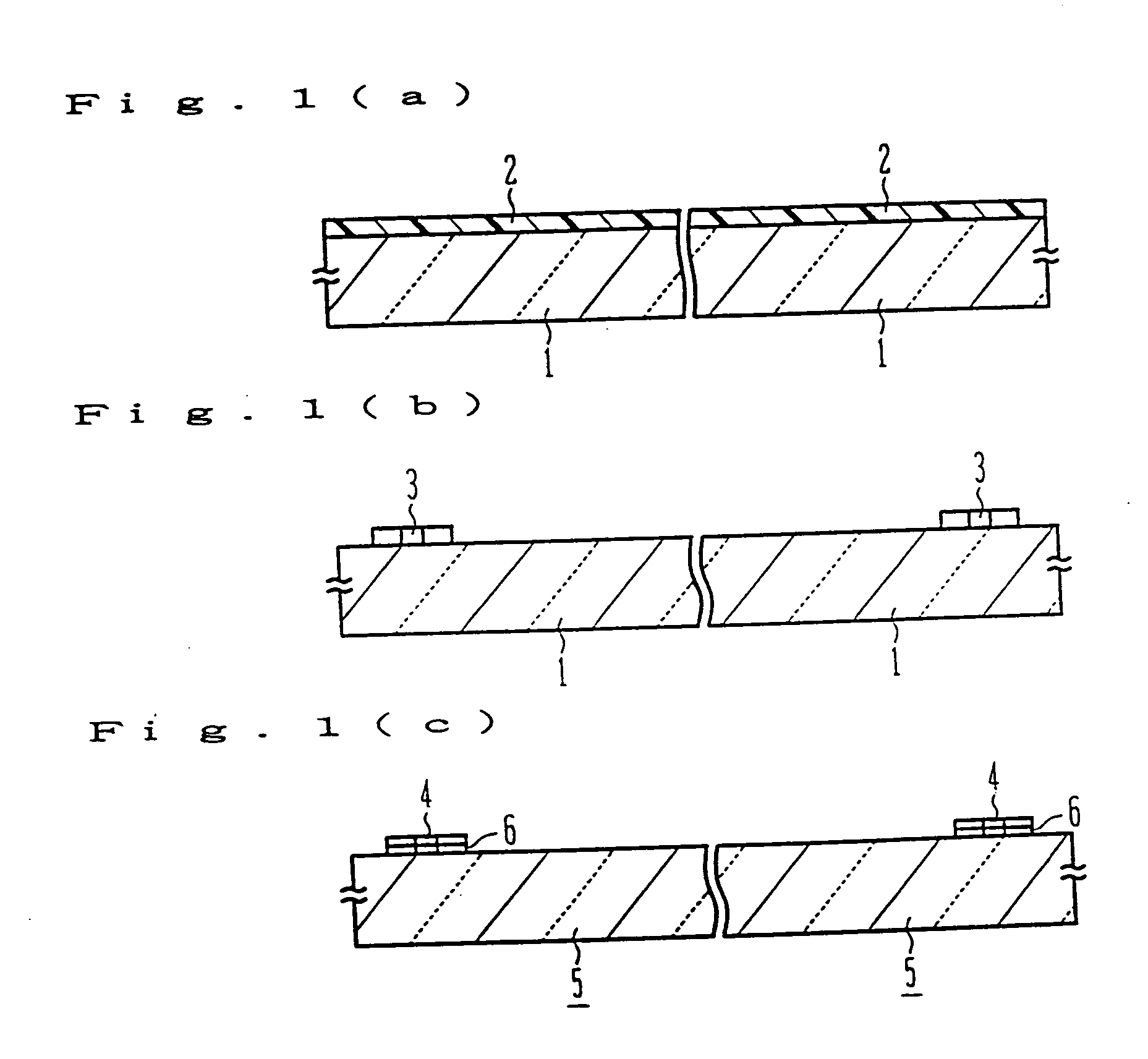

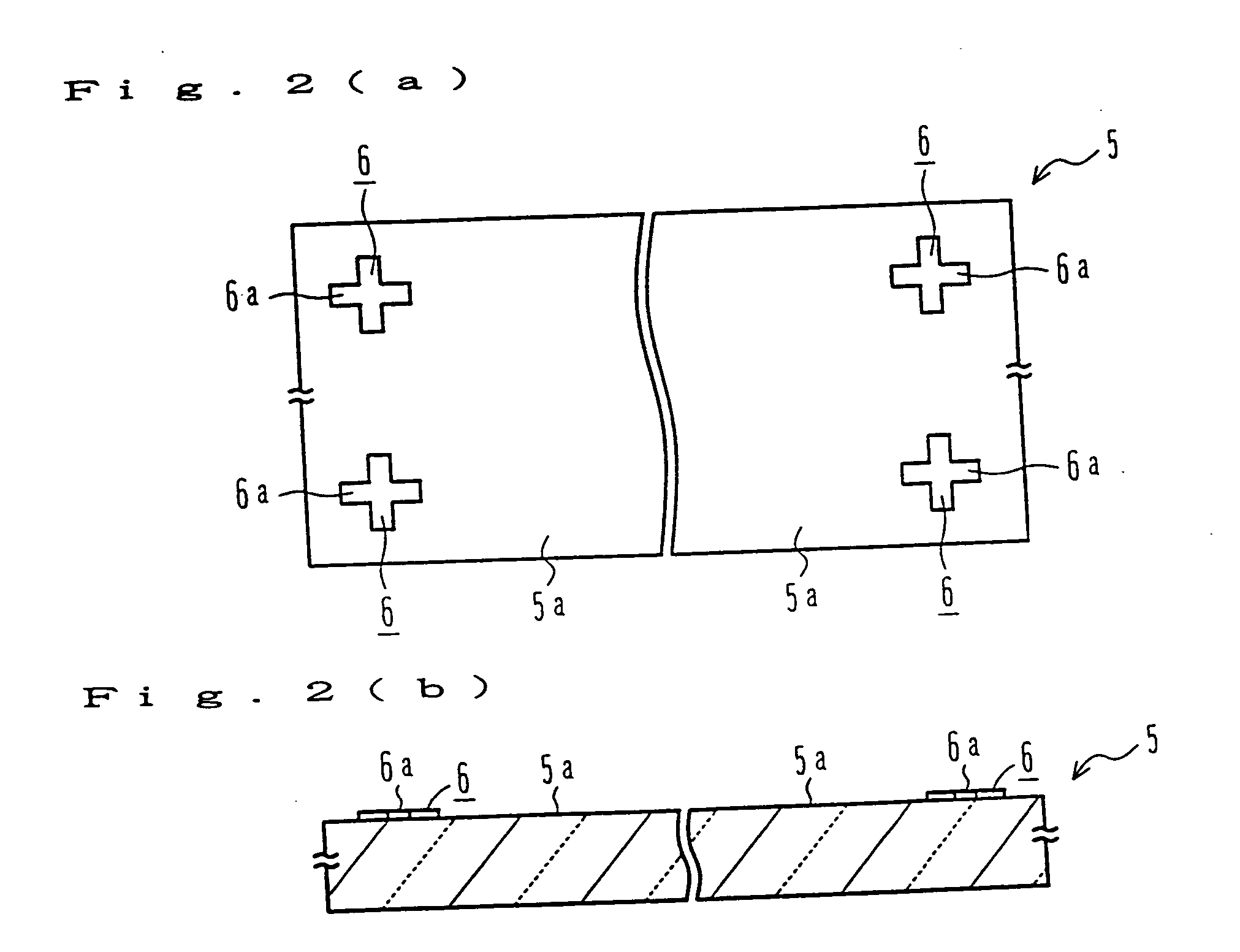

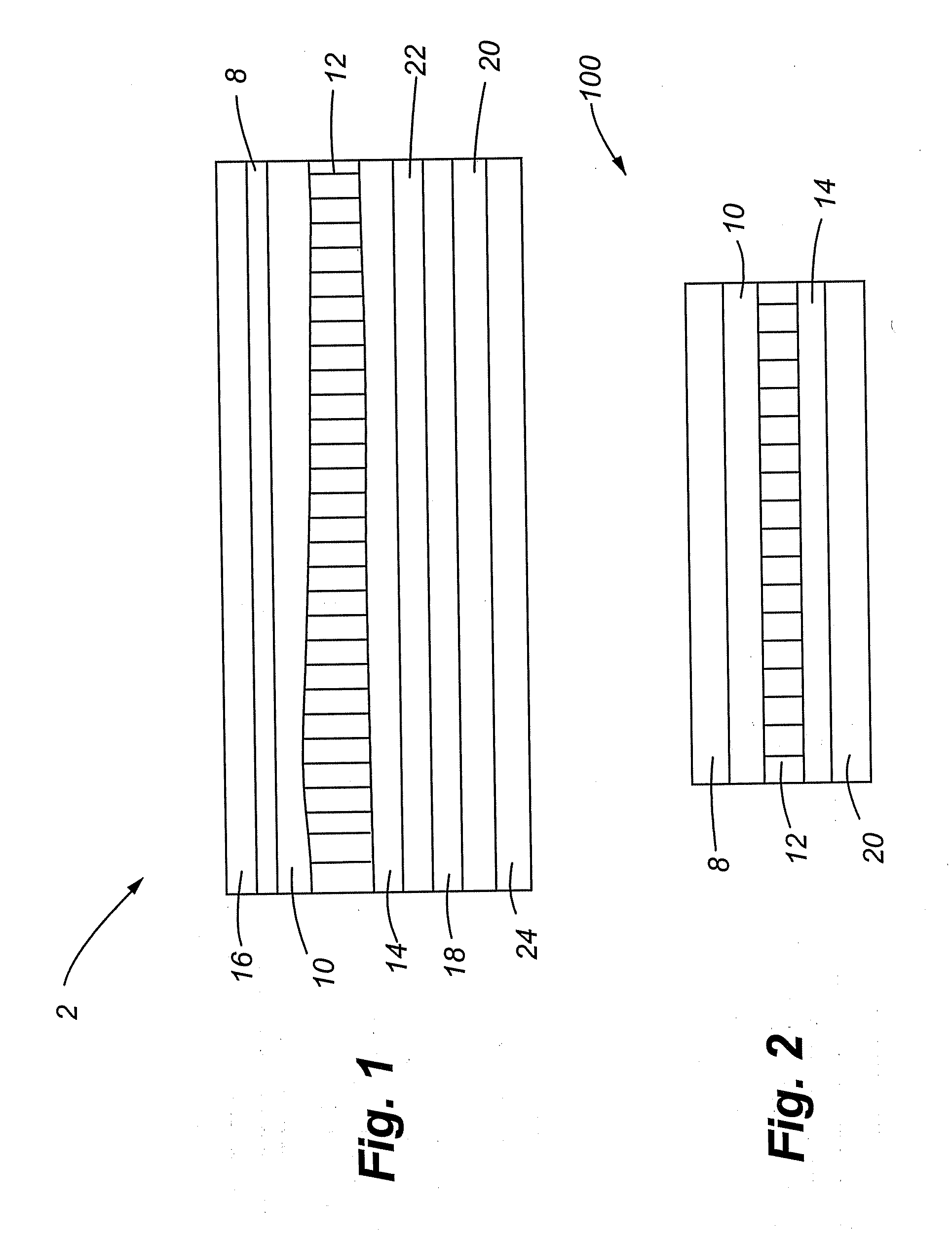

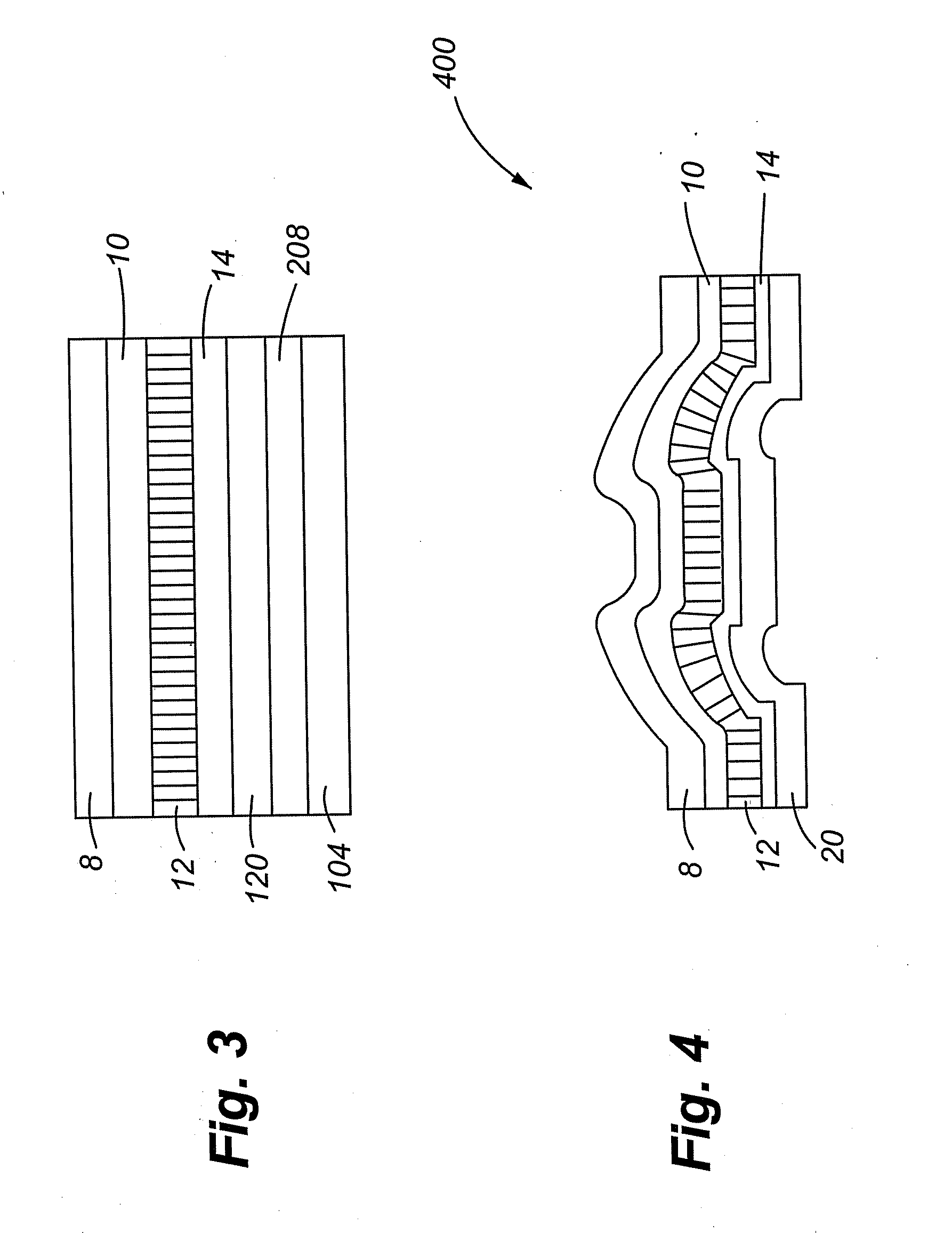

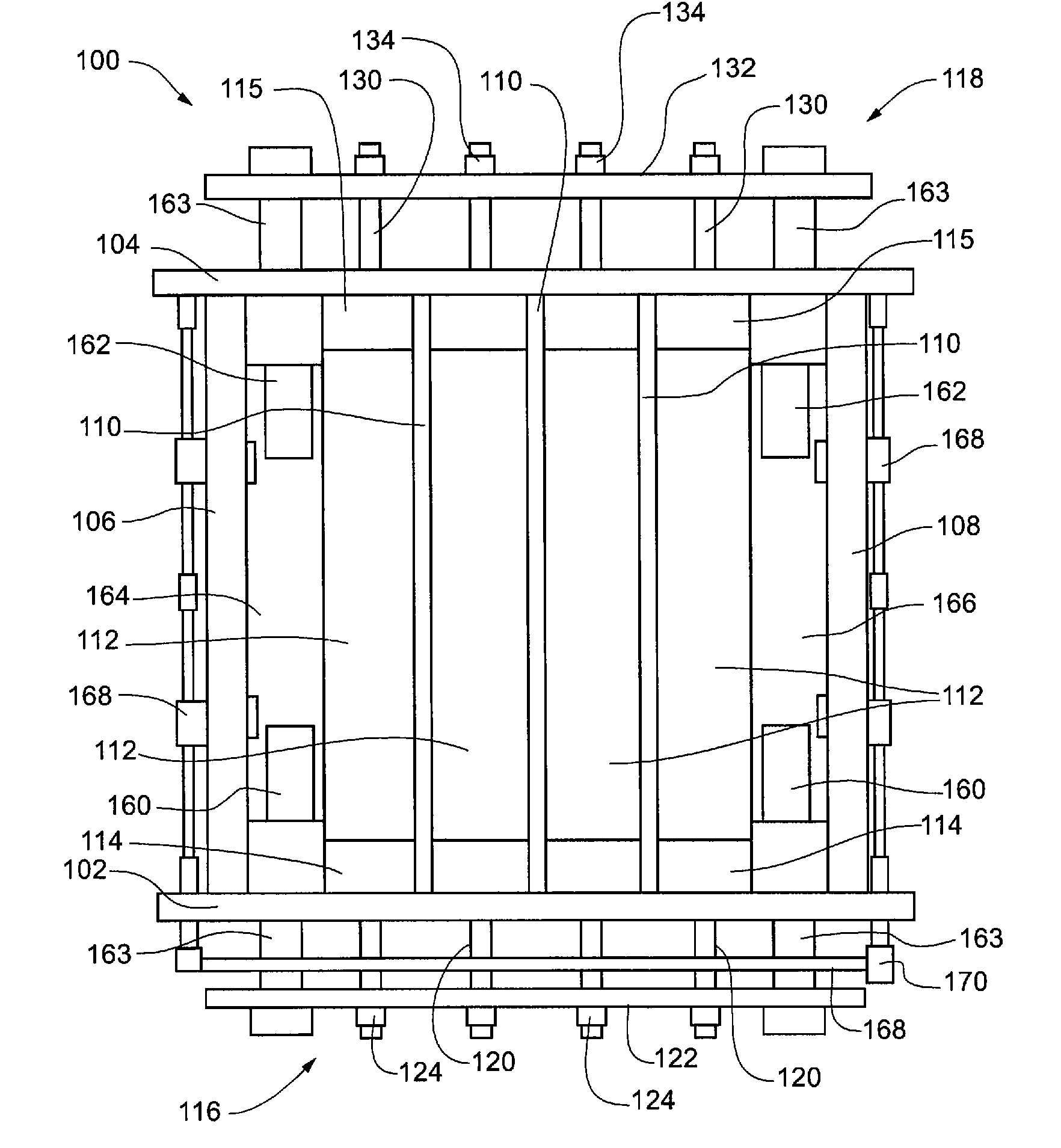

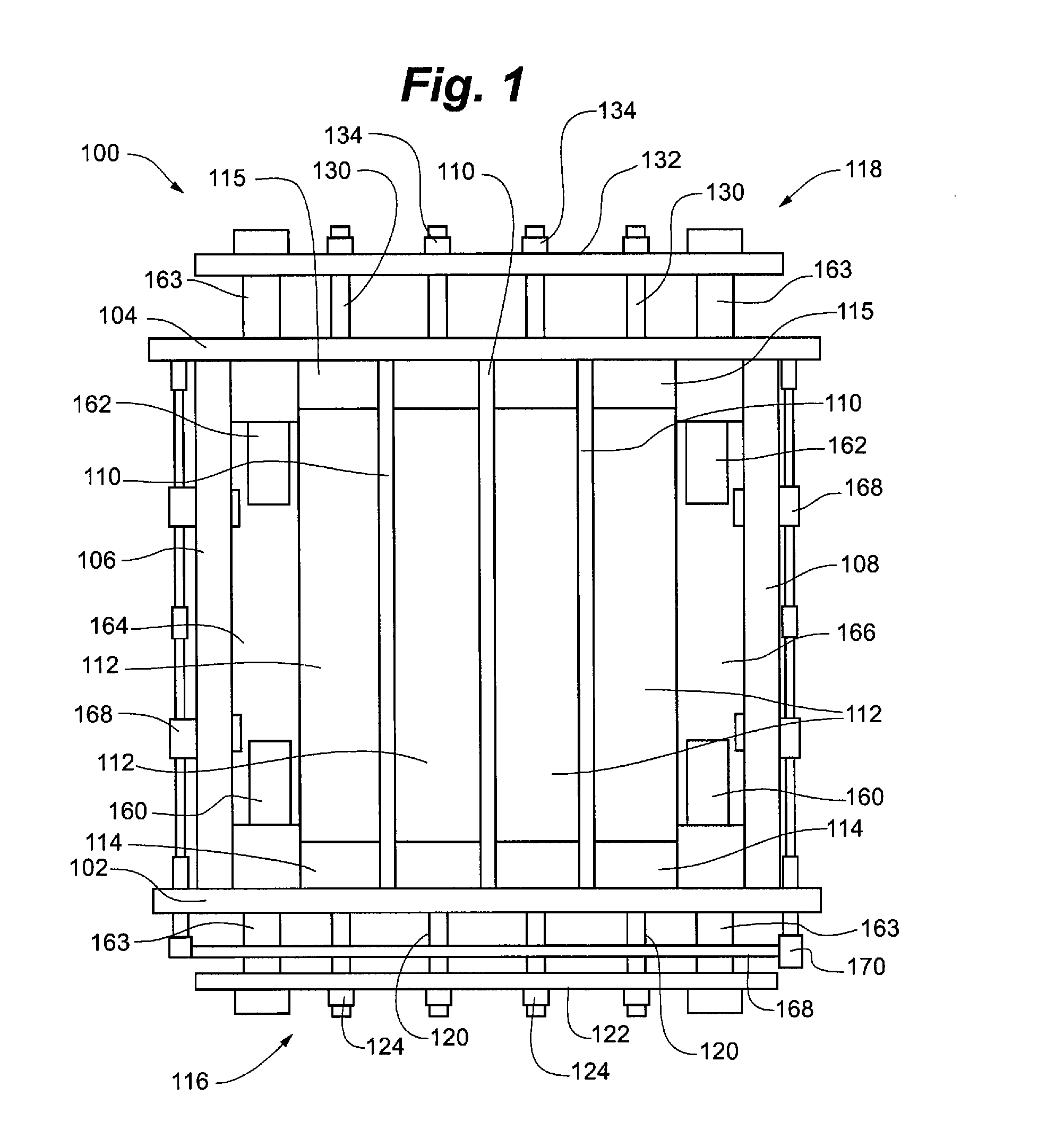

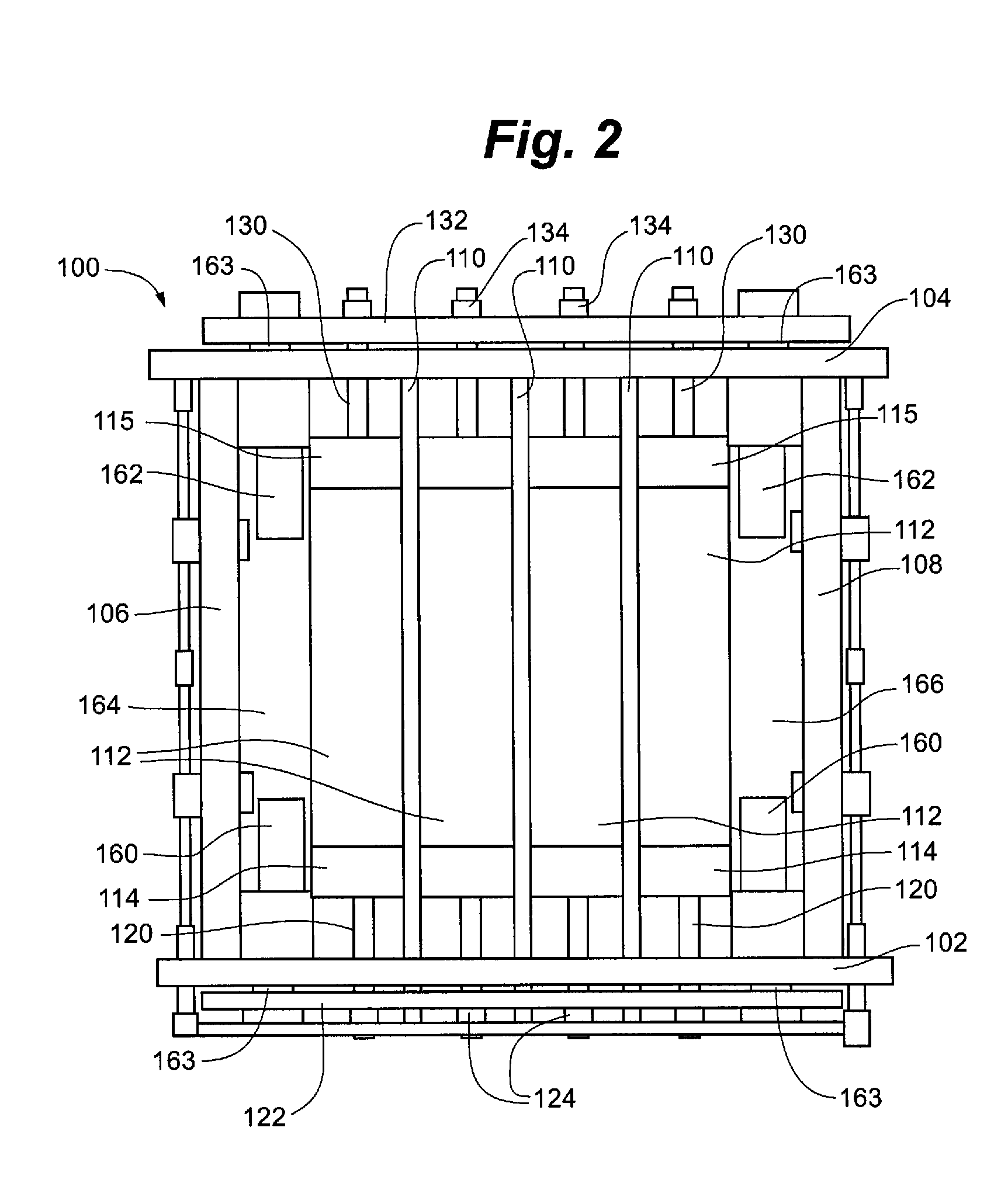

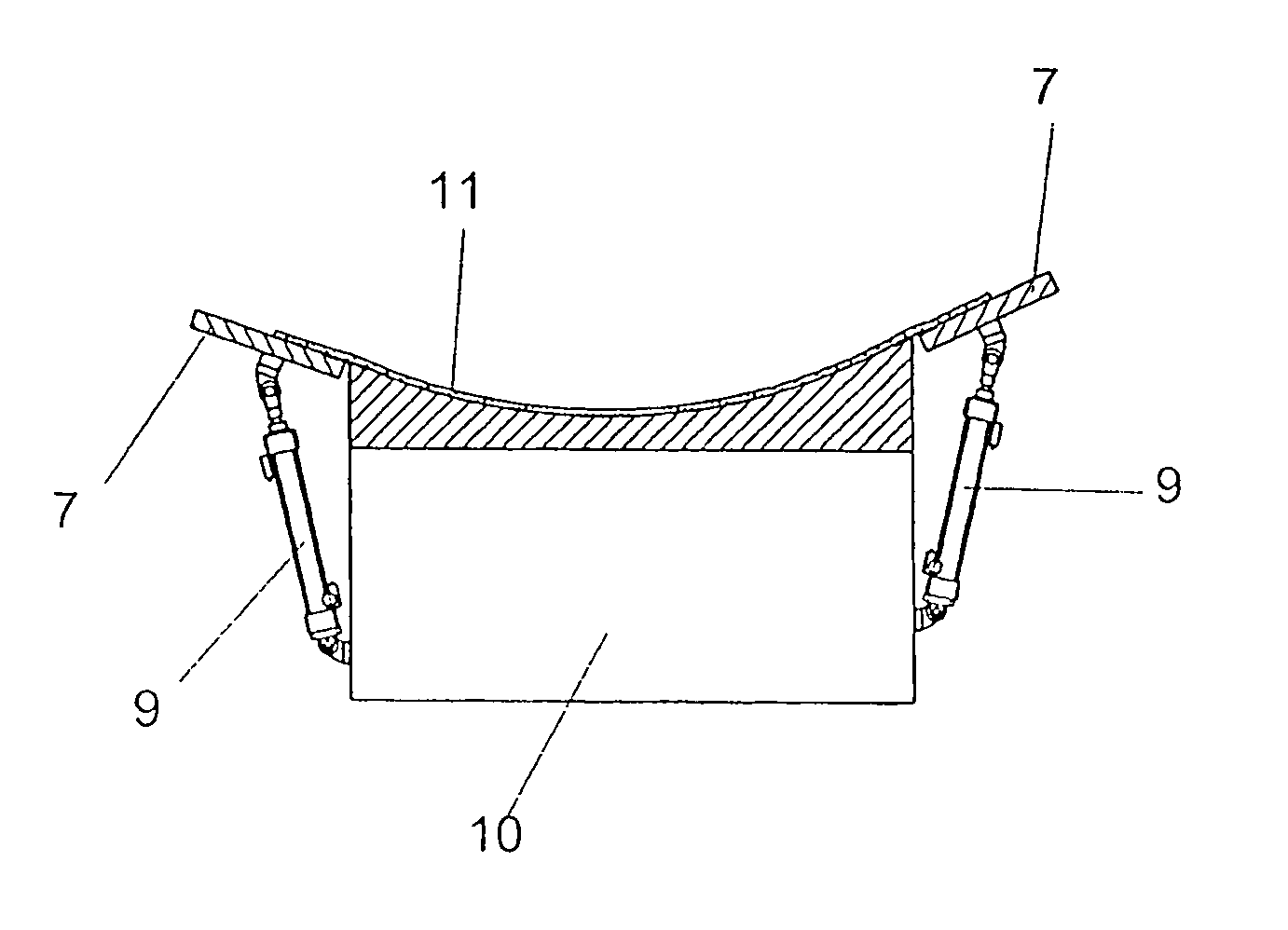

Jig for manufacturing components of aerodynes and wing turbines and manufacturing process for these components

InactiveUS20100024215A1Easy to manufacturePrecise arrangementFinal product manufactureMetal-working apparatusHinge angleEngineering

The invention relates to a jig for manufacturing components of aerodynes and wind turbines and a manufacturing process for these components, the jig comprising a base (10), on which at least one rigid part (7) like a flange is arranged in the upper edge of at least one of the sides, which rigid part is connected to the base (10) through an elastic hinge (8), which can driven to pivot between a raised closed position and a lowered open position, for the molding and demolding of the components to be manufactured by means of incorporating fiber strip layers on the surface that they determine between the base (10) and the flange or flanges (7).

Owner:TORRES MARTINEZ MANUEL

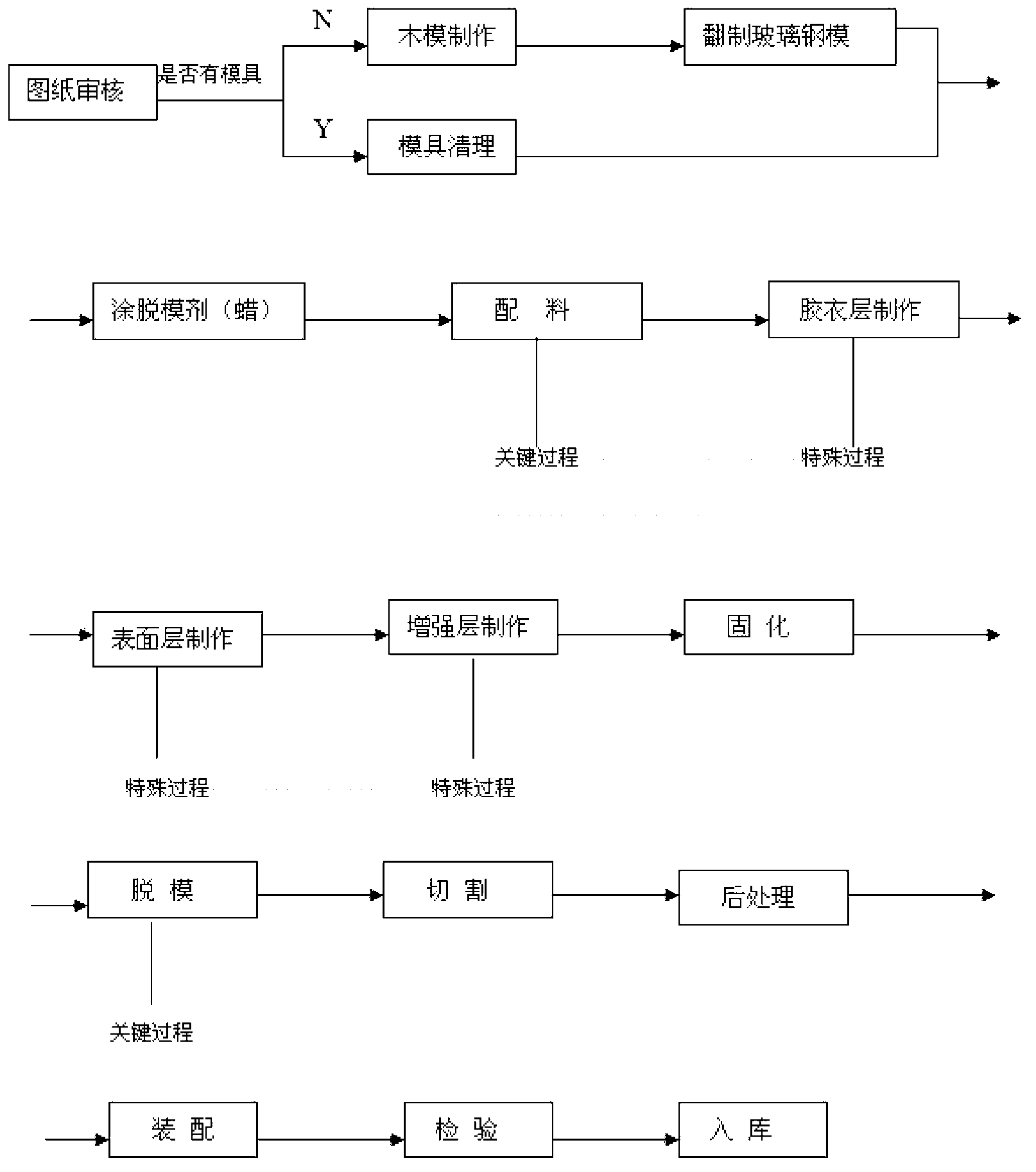

Production technology for glass reinforced plastic hand washer and face washing cabinet

ActiveCN102837346AReduce manufacturing costShorten the production cycleWood working apparatusEngineeringPutty

The invention discloses a production technology for a glass reinforced plastic hand washer and a face washing cabinet. A method comprising the steps of split pasting, cutting, polishing and then assembling is mainly adopted. The production technology comprises the following steps: (1) manufacturing a hand washer / face washing cabinet wood mould: firstly selecting materials, dividing the product into three parts, namely, a hand washer / face washing cabinet platform, a vertical surface and a check surface, according to the dimension of the product, respectively manufacturing the wood mould, coating putty and polishing; (2) manufacturing a glass reinforced plastic mould: coating release agent and gel coat, and then pasting; (3) treating the surface of the glass reinforced plastic mould: performing water sand grinding and surface polishing; (4) pasting; (5) de-molding; and (6) cutting and assembling. The production technology is low in production cost and shorter in production period. The produced glass reinforced plastic hand washer and face washing cabinet are highly polished.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com