Patents

Literature

34results about How to "Lightweight with" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light energy conservation insulating concrete

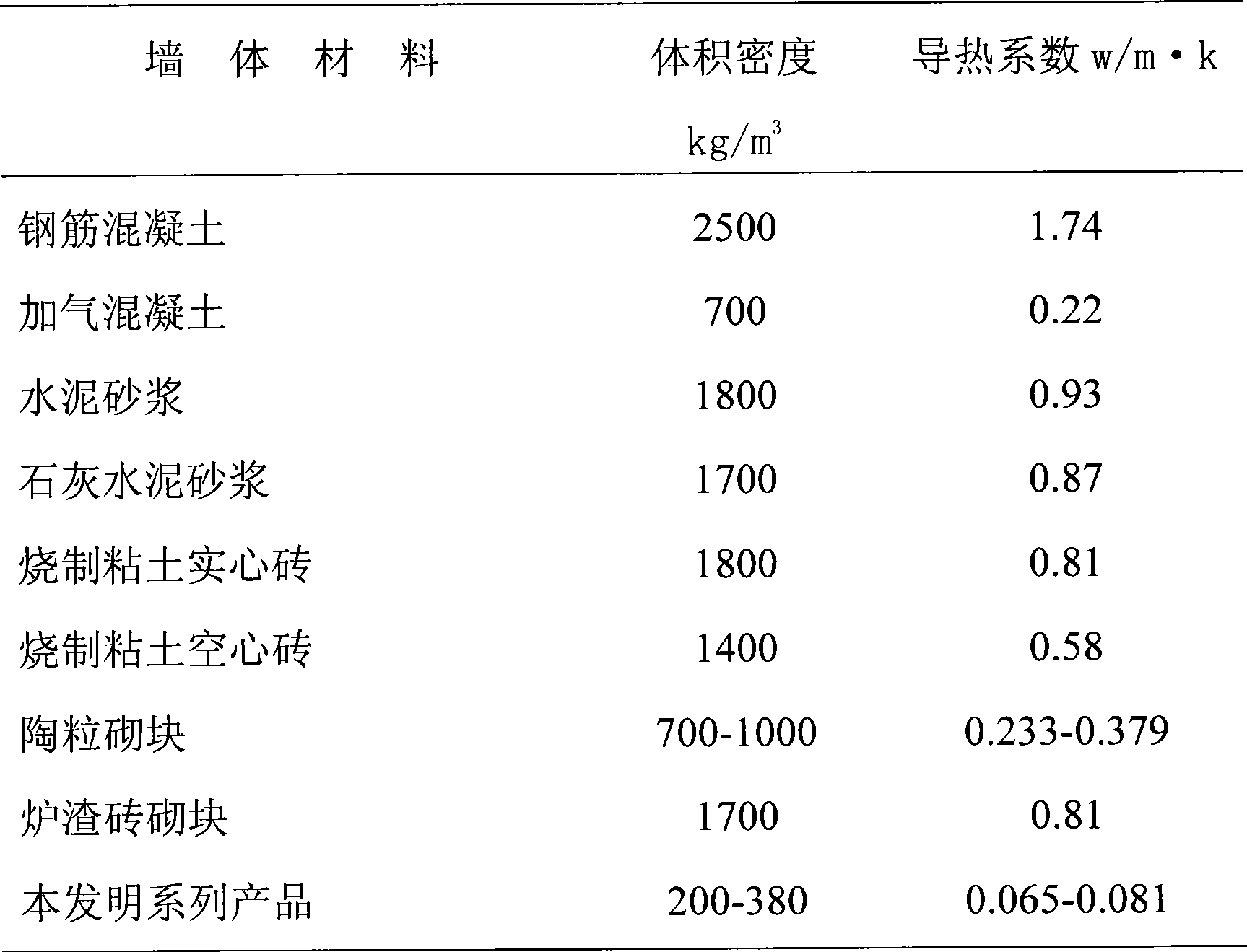

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Method for preparing ceramsite by using Xianfeng diatomite

InactiveCN102515822AEasy to operateIncrease contentCeramicwareExpanded clay aggregateUltimate tensile strength

The invention discloses a method for preparing ceramsite by using Xianfeng diatomite. The method comprises steps of: crushing a naturally dried raw material Xianfeng diatomite; mixing the raw material with water in a ratio of 100:60-70 and stirring uniformly; air-drying the mixture to a water content of 40-50%; moulding; air-drying naturally; and finally sintering to obtain high strength diatomite ceramsite. The method of the invention is simply operated, has good effect; and the ceramsite prepared by the method has good strength, reduced water absorption, strong durability and wide application scope.

Owner:KUNMING UNIV OF SCI & TECH

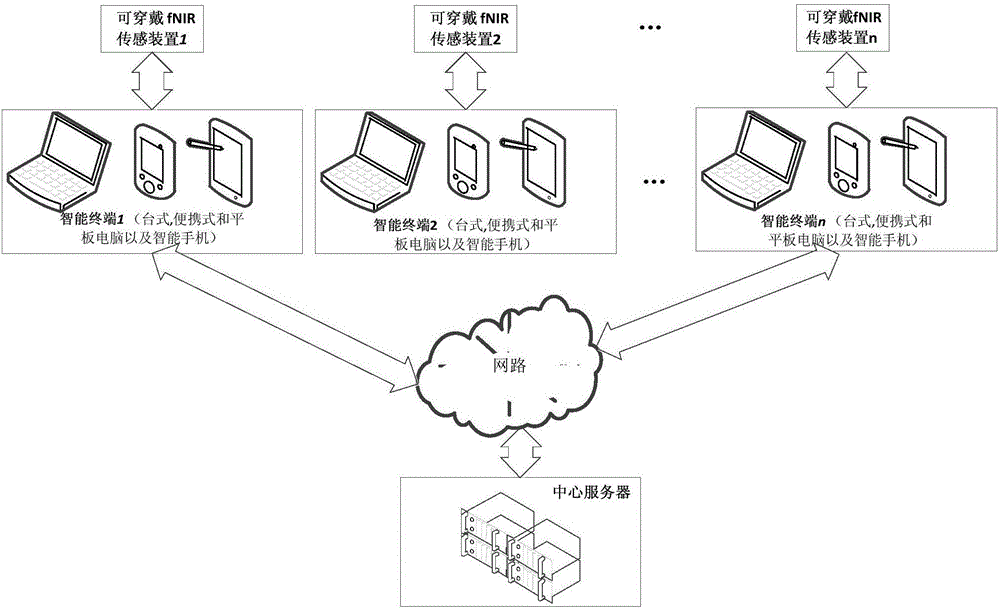

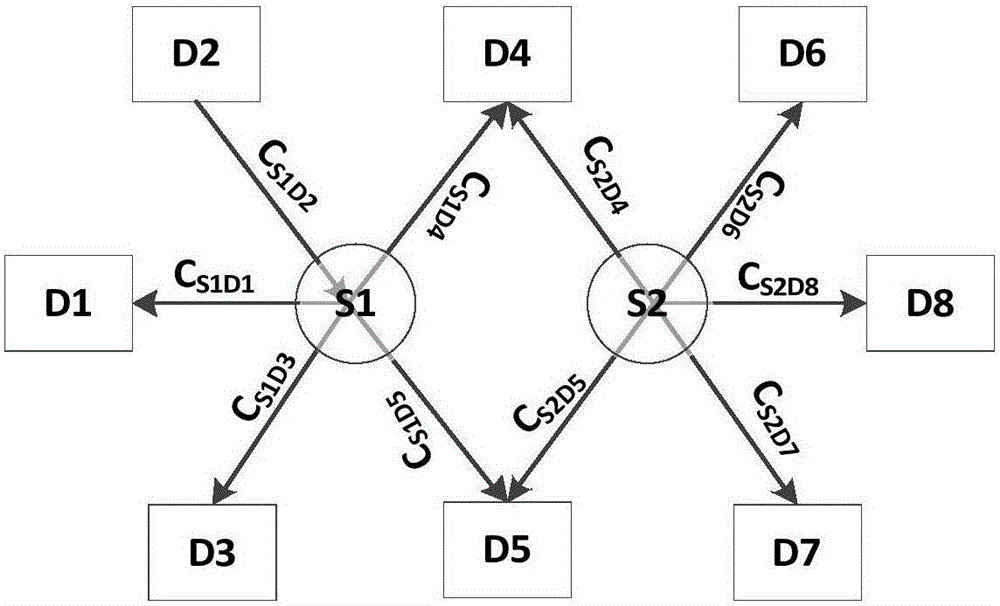

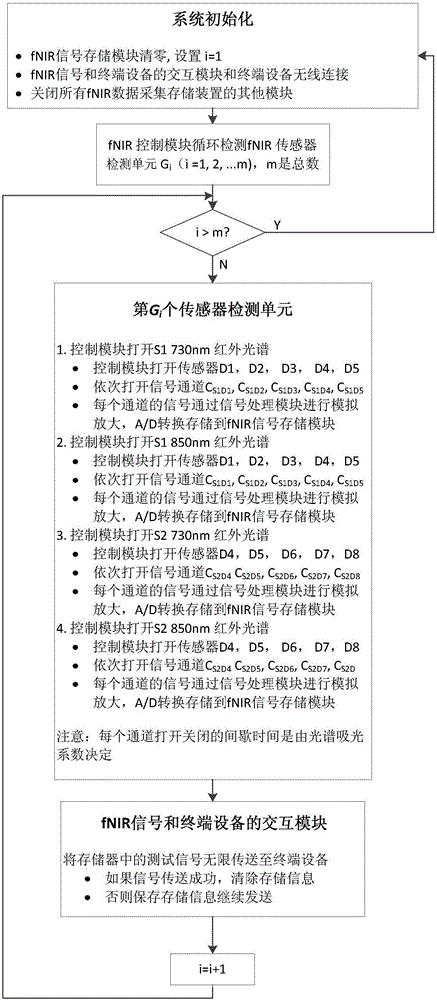

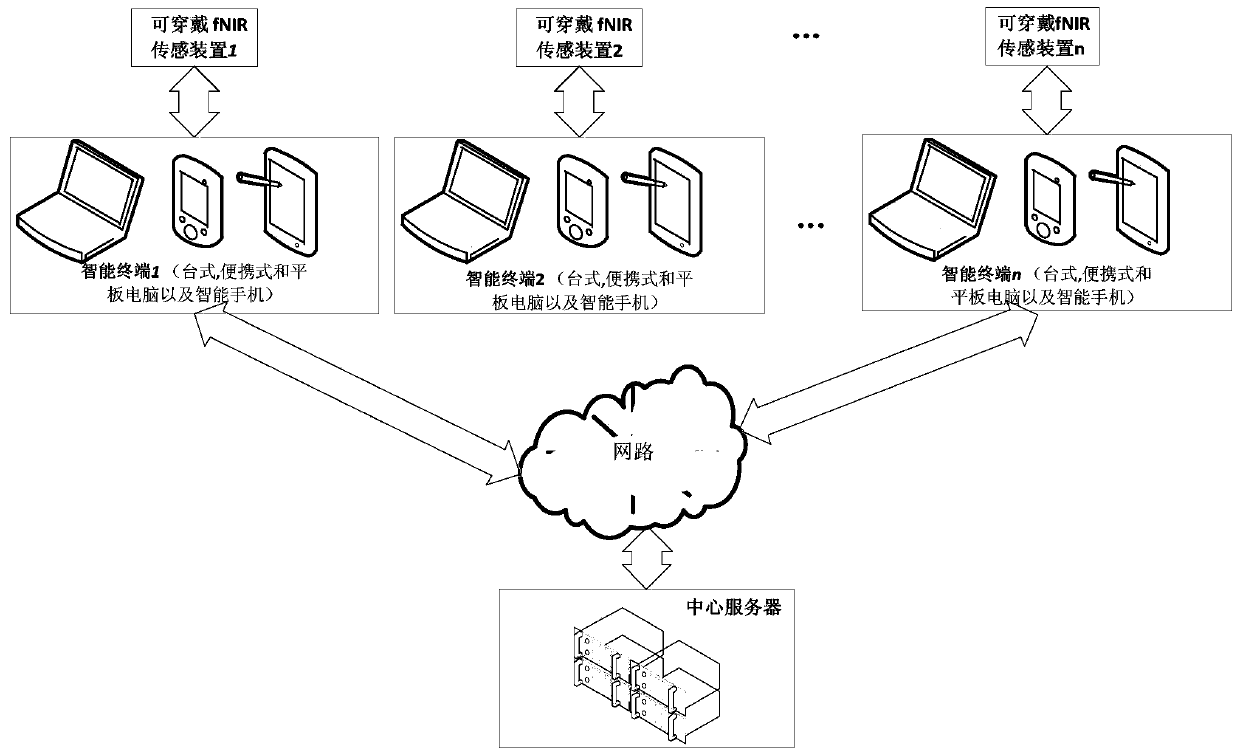

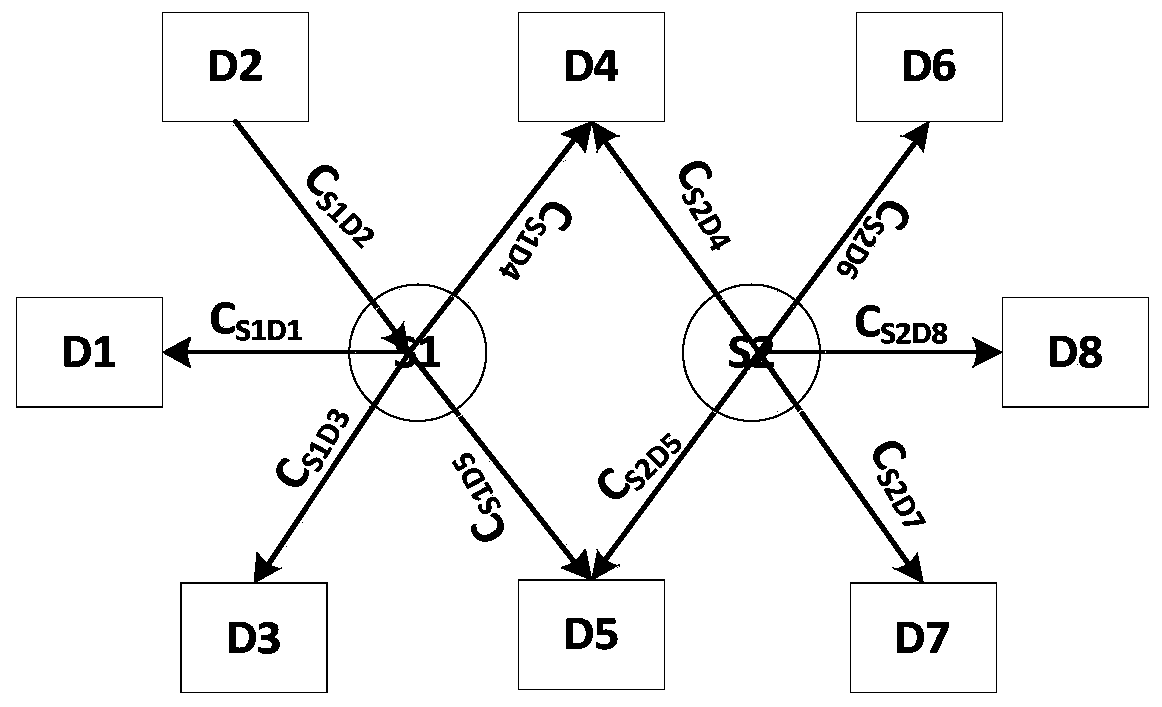

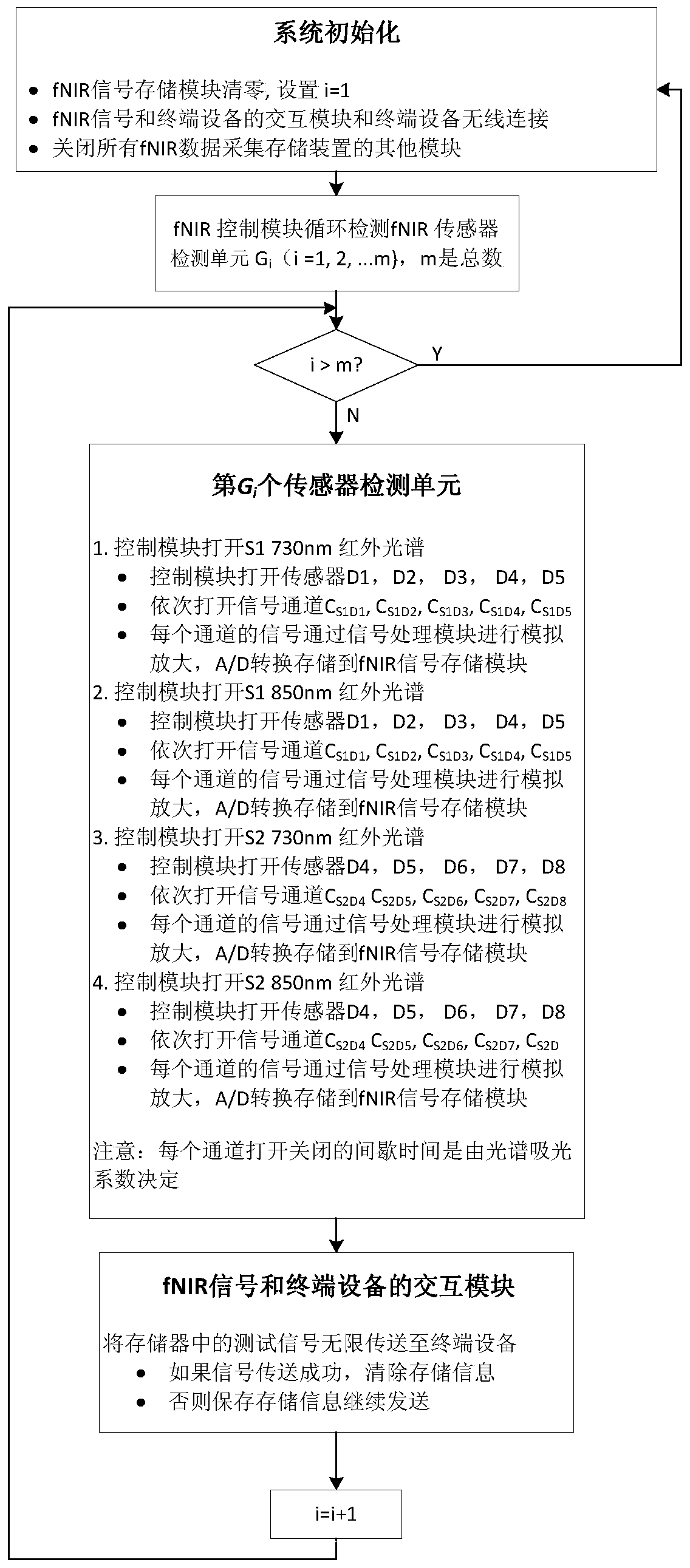

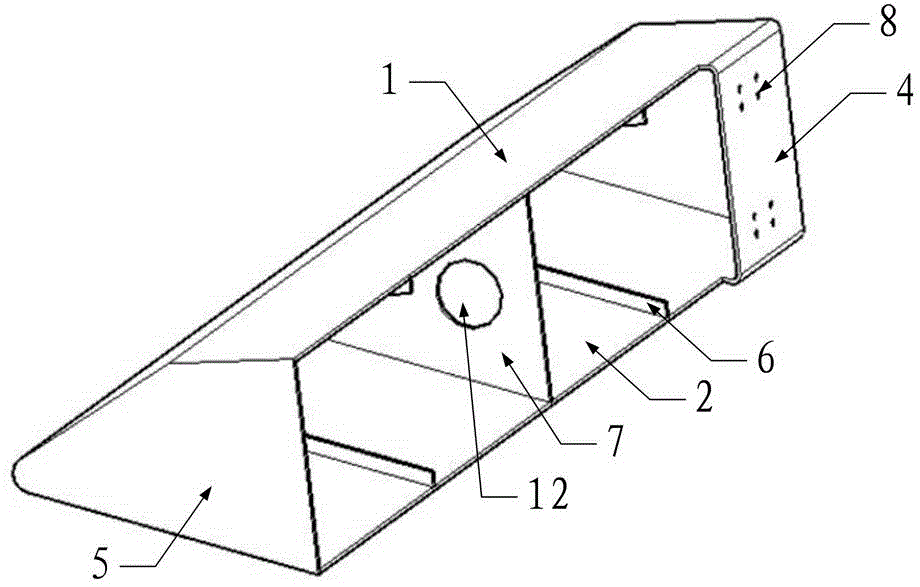

System and method for concentration detection and training based on functional near infrared spectrum technologies

InactiveCN106805985ARegulatory intelligenceSensitive Accurate Response MappingSensorsPsychotechnic devicesSignal onTerminal equipment

The invention discloses a system and method for concentration detection and training based on functional near infrared spectrum technologies. The system comprises a wearable fNIR sensing device and an intelligent terminal; a fNIR control module in the wearable fNIR sensing device controls switching-on, switching-off and spectral wavelength of a signal emission source in a fNIR signal emission module, switching-on and switching-off of a sensor in a fNIR signal collection module as well as opening and closing of signal channels, and near infrared spectrum signals on each signal channel under different spectrum lengths are collected cyclically and transmitted to the intelligent terminal; and the terminal equipment uses a built-in concentration analysis module to transform the near infrared spectrum signals into hemoglobin content information in real time and then quantify the information into a concentration index.

Owner:魏伟

Ceramsite concrete light-weight partition board and preparation method thereof

InactiveCN101691794ALightweight withLightweight partition wall panels, which have soundproofing propertiesConstruction materialSolid waste managementSlagCement board

The invention provides a ceramsite concrete light-weight partition board and a preparation method thereof. The partition board is characterized by comprising the following components in weight ratio: 58-75% of ceramsite, 13-21% of cement, 10-21% of slag and 0.5-1.7% of water reducing agent. The partition board solves the problem that such partition boards widely used in the buildings at present as strengthened plant fiber boards, aerated cement boards, slag and flyash boards, flyash, gravel and cement boards, gypsum boards and the like have high water absorption, short lives, low overall structural strength and low anti-impact and anti-bending loads, are liable to aging, cracking and deforming with heat and cold, can not be nailed, drilled and transversely and longitudinally threaded and the like, and is suitable for serving as a non-bearing partition board in the buildings.

Owner:吴跃平 +1

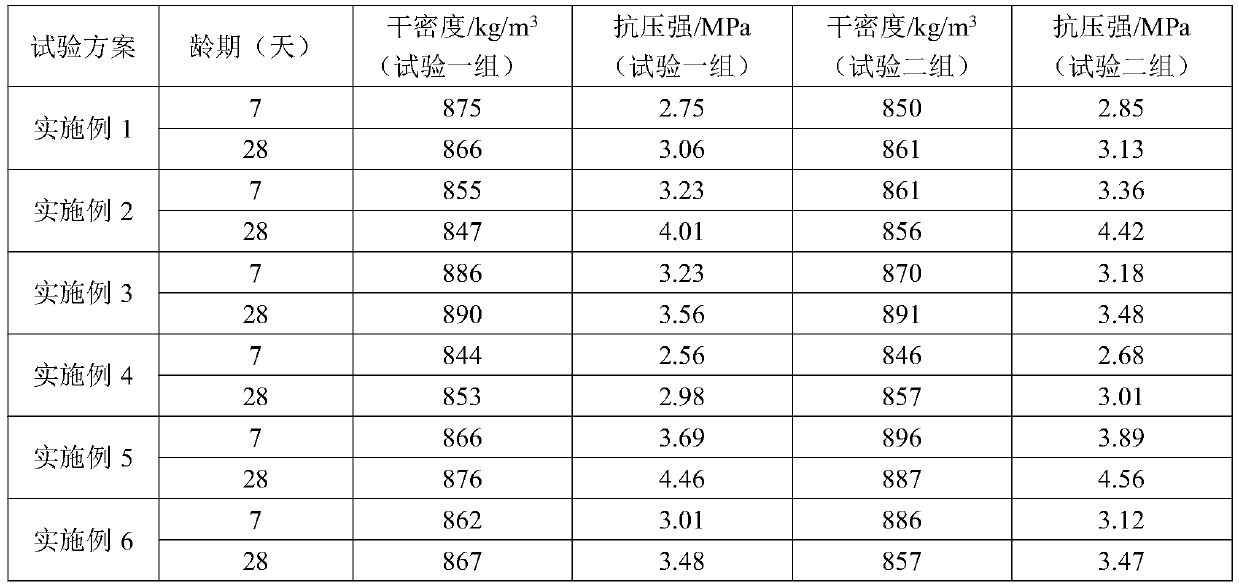

Preparation for concrete ceramsite wallboard

The invention provides preparation for a concrete ceramsite wallboard. The concrete ceramsite wallboard is characterized by being prepared through the following steps: (1) material selection: a step of weighing materials according to a proportion; (2) stirring: a step of placing the materials weighed in proportion into a stirrer, adding water, and carrying out stirring for 2 to 3 minutes; (3) manufacturing: a step of placing a steel wire mesh at the bottom part of a mould, pouring stirred concrete into the mould, carrying out vibration treatment by using a plate vibrator until a cement paste of concrete is vibrated out, then placing a steel wire mesh onto the mould, continuing performing vibration by using the plate vibrator, and carrying out levelling; and (4) demoulding: a step of controlling the proper time of demoulding, and carrying out demoulding according to environment temperature and demoulding operation regulations. The concrete ceramsite wallboard provided by the invention solves the problems on high water absorption rate, easy aging, easy cracking and deformation of partition boards like plant fiber reinforced boards, and is applicable to being used as a non-load bearing partition board in construction.

Owner:顾杨子

Lightweight ceramisite concrete external wallboard and preparation method thereof

InactiveCN101705731ALightweight withLightweight exterior wall panels, which have sound insulation withConstruction materialBrickAnti freezing

The invention provides a lightweight ceramisite concrete external wallboard and a preparation method thereof. The external wallboard is characterized by comprising the following components in percentage by weight: 58-75% of ceramisite, 13-21% of cement, 11-21% of medium sand, 0.13-0.92% of waterproof agents, 0.098-0.69% of water reducing agents and 0.065-1.15% of anti-freezing agents. The lightweight ceramisite concrete external wallboard solves the problem that the aerated cement bricks, slag and coal ash bricks, coal ash, stone and cement bricks, which are widely used in the non-bearing external walls in the buildings at present, feature high water absorption, easy cracking and dropping of plastering ceramic tiles and stones, low whole structure strength, low anti-impact and anti-kink load and the like, and is suitable for being used in the buildings.

Owner:吴跃平 +1

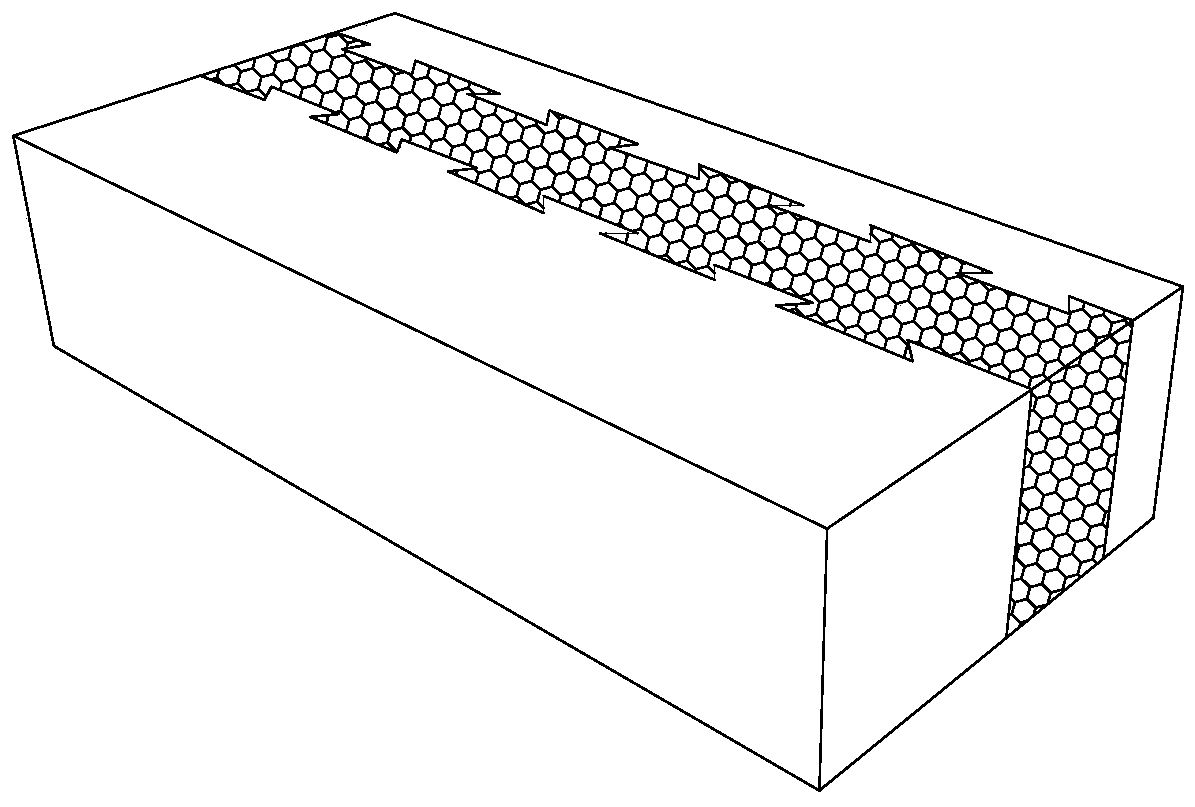

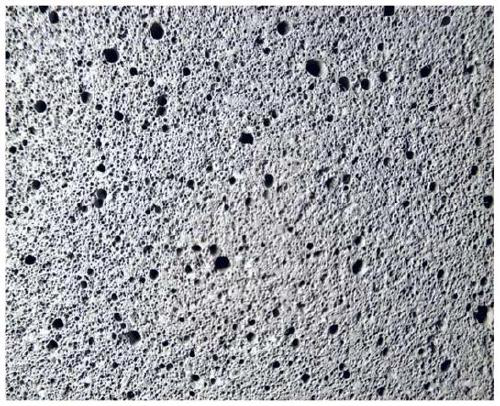

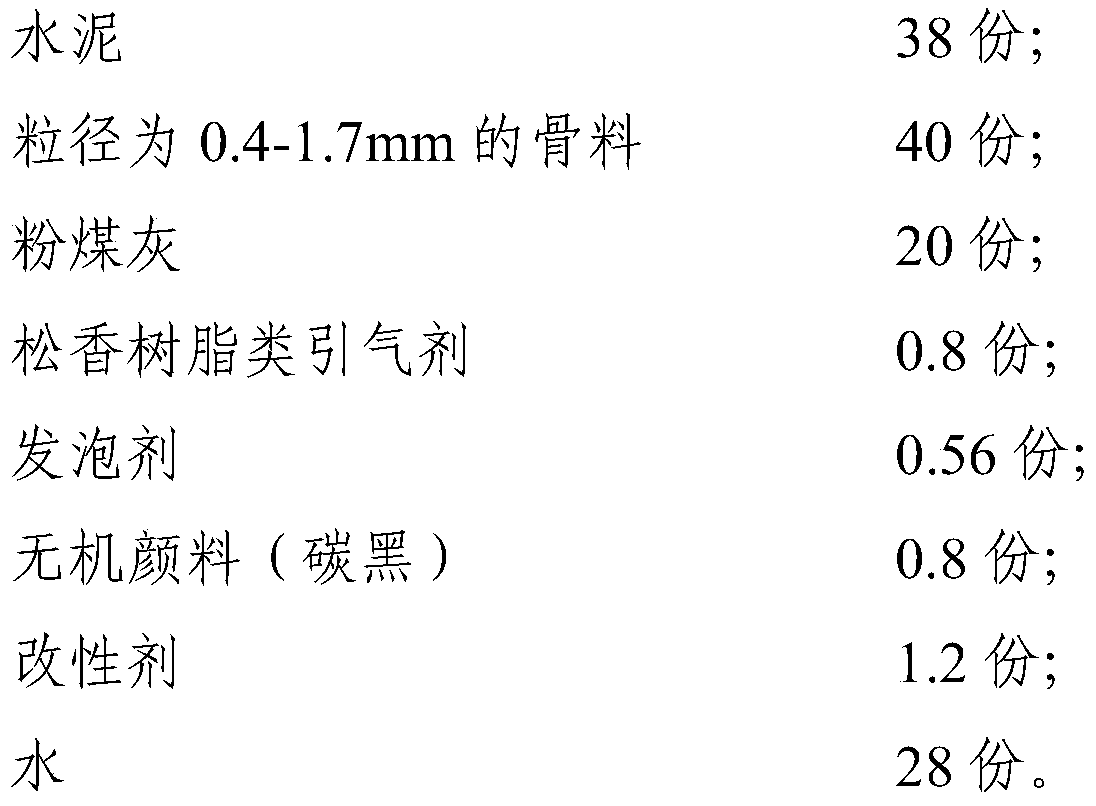

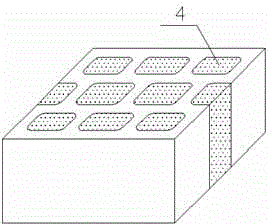

Scoria-imitated light heat-preservation composite building block and processing method thereof

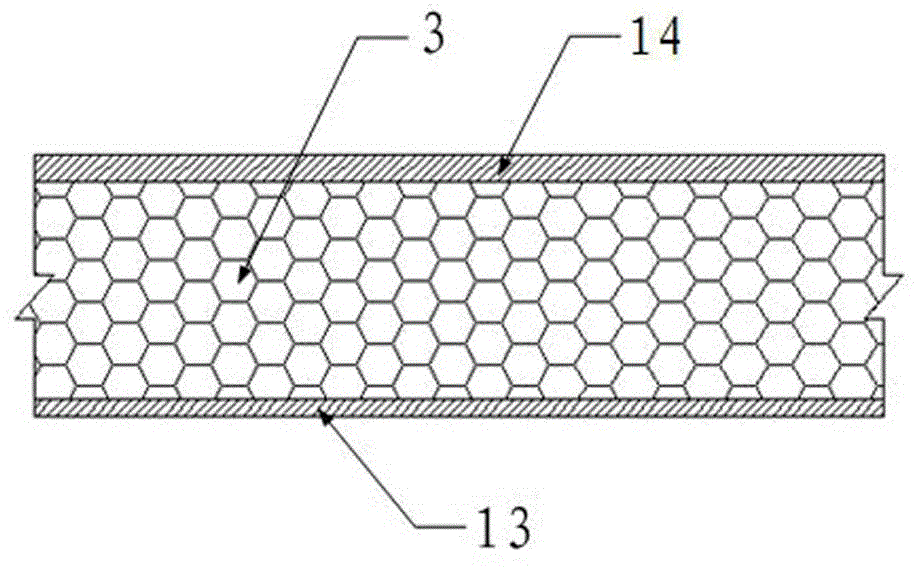

InactiveCN110372275AHigh strengthGood insulation performanceConstruction materialCeramicwareOptoelectronicsPore diameter

The invention provides a scoria-imitated light heat-preservation composite building block and a processing method thereof. The scoria-imitated light heat-preservation composite building block comprises two independent and mutually-parallel light porous concrete matrixes and a heat-preservation core layer arranged between the two light porous concrete matrixes in a clamped mode, each light porous concrete matrix is of a natural-scoria-imitated structure prepared through a chemical foaming-curing process and provided with irregular pores in a distributed mode, and each light porous concrete matrix is prepared from the raw materials: cement, aggregate, an active admixture, a foaming agent and an air entraining agent; and the processing method comprises the steps that the heat-preservation core layer is fixedly arranged in a pouring mold, then the raw materials of the light porous concrete matrixes are evenly mixed according to the ratio and then injected, demolding is conducted after chemical foaming, and the scoria-imitated light heat-preservation composite building block is obtained through curing, surface processing and drying. The scoria-imitated light heat-preservation compositebuilding block is prepared through the chemical foaming-curing process, meanwhile by combining adjusting of the pore size and pore diameter distribution, the surface of the scoria-imitated light heat-preservation composite building block has a unique and realistic natural-scoria-imitating effect; and the scoria-imitated light heat-preservation composite building block is light, high in strength, good in heat-preservation performance, excellent in comprehensive performance and wide in actual application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Lightweight ceramisite concrete external wallboard and preparation method thereof

The invention provides a lightweight ceramisite concrete external wallboard and a preparation method thereof. The external wallboard is characterized by comprising the following components in percentage by weight: 58-75% of ceramisite, 13-21% of cement, 11-21% of slag, 0.13-0.92% of waterproof agents, 0.098-0.69% of water reducing agents and 0.065-1.15% of anti-freezing agents. The lightweight ceramisite concrete external wallboard solves the problem that the aerated cement bricks, slag and coal ash bricks, coal ash, stone and cement bricks, which are widely used in the non-bearing external walls in the buildings at present, feature high water absorption, easy cracking and dropping of plastering ceramic tiles and stones, low whole structure strength, low anti-impact and anti-kink load and the like, and is suitable for being used in the buildings.

Owner:吴跃平 +1

Light aggregate concrete heat insulating plate

InactiveCN1978375ALightweight withHas high strengthConstruction materialSolid waste managementSlagPortland cement

This invention relates to a new type of heat-insulating boards of light aggregate concrete, in which, 0.16m3-0.19m3 slag of 1-3mm grains, 0.12-0.14m3 of 3-5mm slag, 0.30.3-0.33m3 of 8-15mm, 0.06m3-0.08m3 rubbles of 1-3mm, 0.04-0.06m3 rubbles of 3-5mm and 0.14-0.16m3 rubbles of 8-15mm are watered and ready to be used, then 0.65m3-0.75m3 expanded perlite grains, 30-50kg first level fly ash and 120-180 kg ordinary Portland cement are put in a mixer to be mixed then to be pressed in a die.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

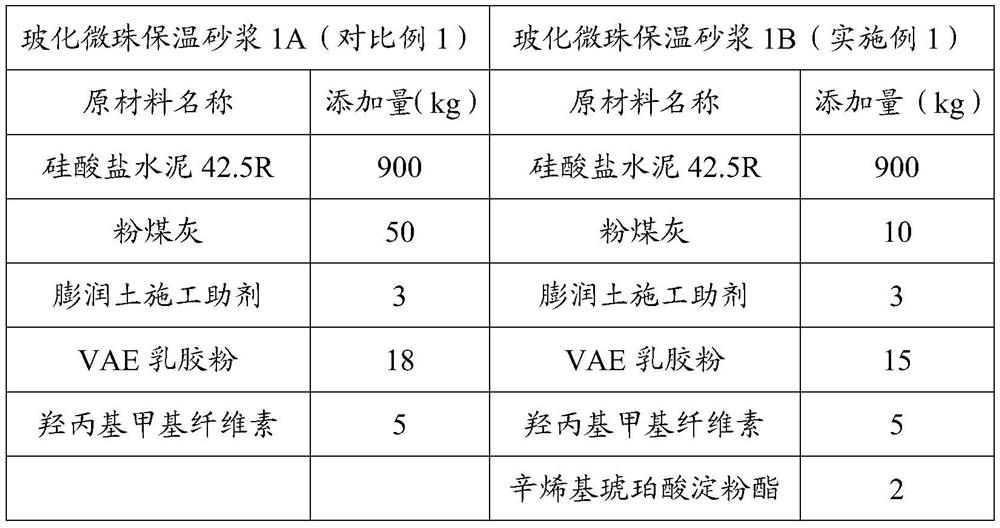

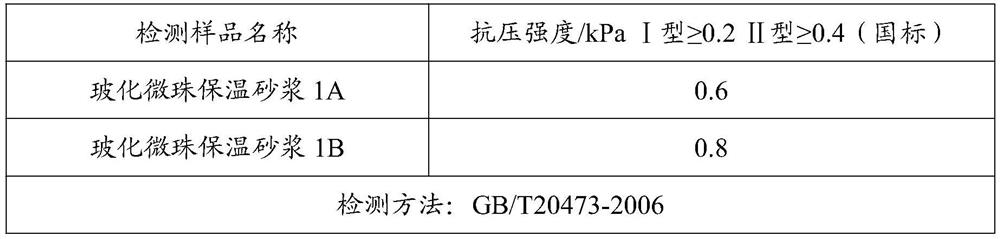

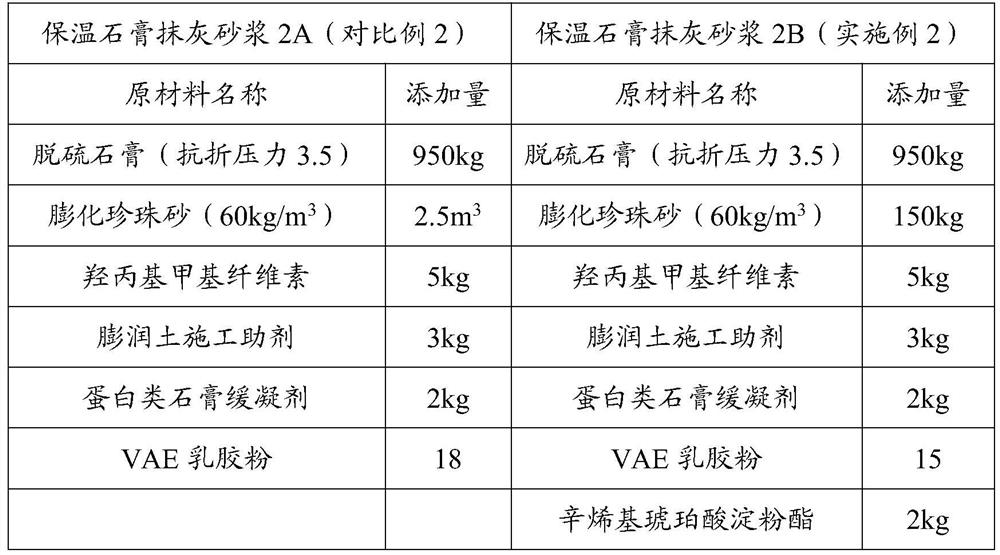

Application of starch octenyl succinate, building mortar, putty and tile glue

The invention provides an application of octenyl succinic acid modified starch in building mortar, putty or tile glue. According to the invention, starch octenyl succinate is added into cement-based mortar (thermal insulation mortar, bonding mortar, anti-crack mortar and cement mortar for plastering an inner wall), gypsum-based mortar (thermal insulation gypsum plastering mortar, gypsum mortar for plastering a bottom layer of the inner wall or gypsum mortar for plastering a surface layer of the inner wall), cement-gypsum mixed mortar building mortar ( lightweight mixed mortar for interior wall bottom layer plastering, cement main material-based self-leveling mixed mortar or gypsum main material-based self-leveling mixed mortar), cement-based putty (exterior wall waterproof putty or cement-based interior wall putty (N-type)), gypsum-based putty (sound-absorbing gypsum putty for interior wall surface layer plastering, gypsum interior wall putty (Y-type), gypsum interior wall putty (N-type) or ash-calcium-based interior wall putty (N-type)) or tile adhesive, so the building mortar, the putty or the tile adhesive is ensured to have the properties of light weight, sound absorption, impression and the like, and meanwhile, the building mortar, the putty or the tile adhesive is ensured to have high strength.

Owner:中象新材料(大连)有限公司

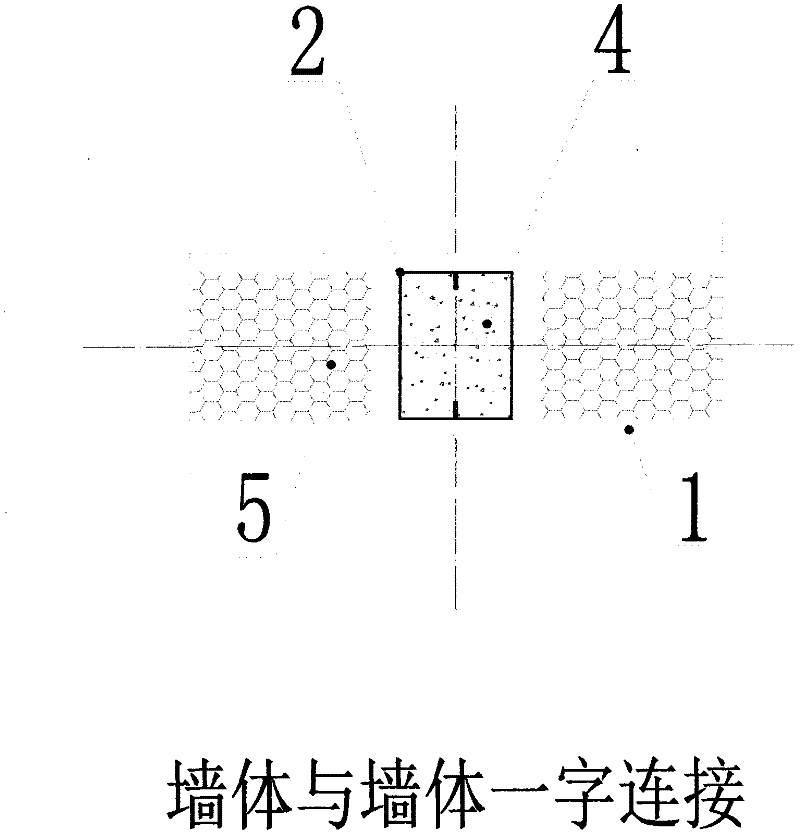

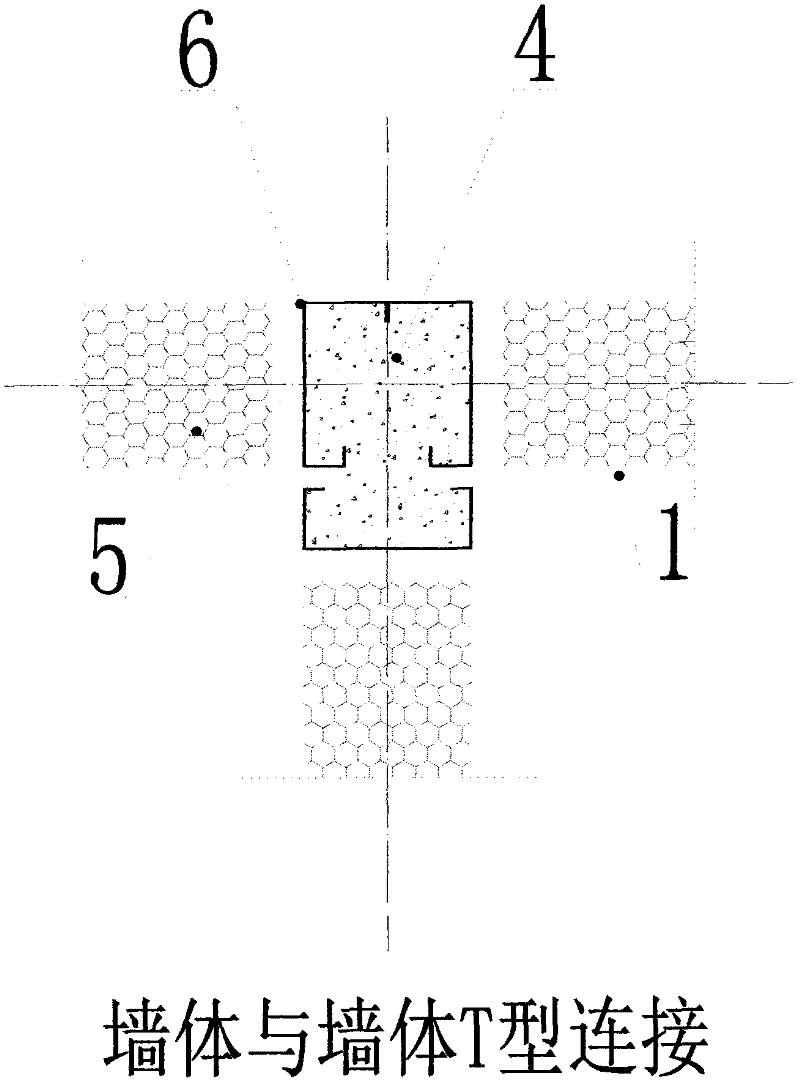

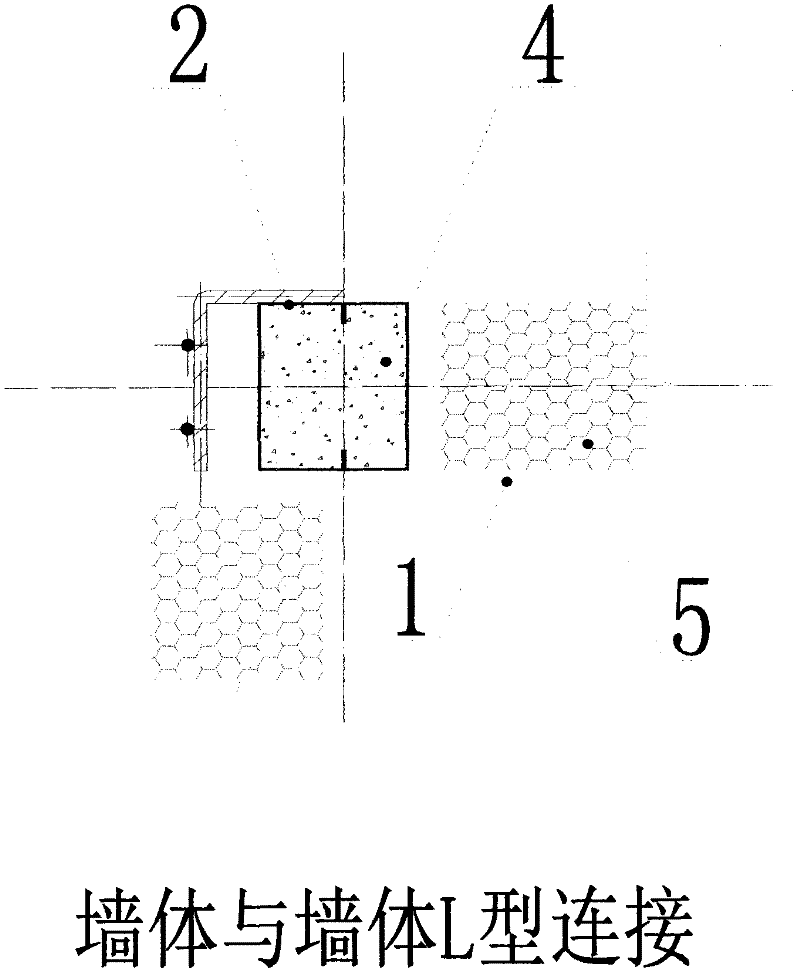

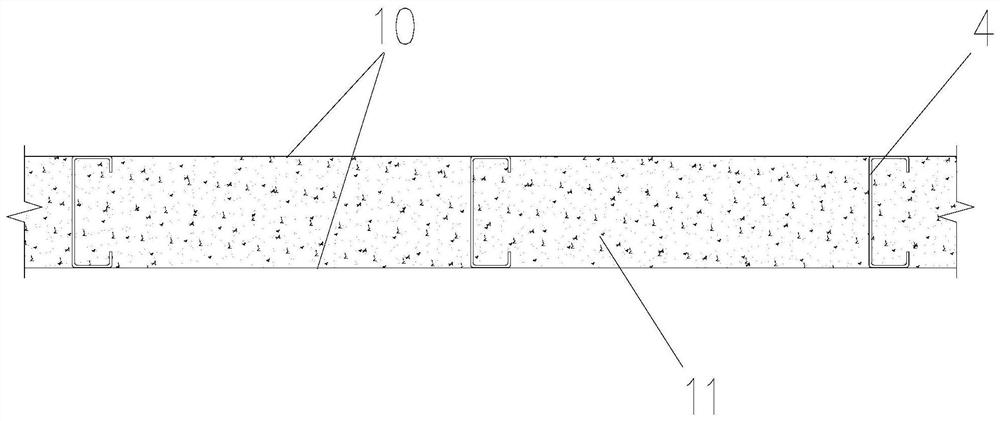

Cast-in-place concrete core column ring beam house manufactured by light composite board and assembling method

InactiveCN102493595AStrong carrying capacityGood self-supporting functionRoof covering using slabs/sheetsSpecial buildingThermal insulationSteel tube

The invention discloses a light composite board which can overcome the defects in the prior art, a cast-in-place concrete core column ring beam house manufactured by the light composite board and an assembling method. In the light composite board manufacturing process, structural steels are arranged around a board to form a keel. Composite boards are aligned in a construction field, joints among boards are caulked and smeared by polymer mortar so as to form a sealed space on the junction of two boards by the structural steels, and a ring beam U-shaped slot faces upwards. On the construction site, polymer fine stone concrete is poured into the space to form a core column and a wall body so as to assemble the house. The system is stressed clearly and reasonably and can be calculated according to a steel tube concrete structure. The cast-in-place concrete core column ring beam house manufactured by the light composite board has the characteristics of light weight, high strength, earthquake and wind resistance, thermal insulation, heat protection, water and leakage resistance, varied decoration and the like and can be quickly installed.

Owner:孙四海

Lightweight ceramisite concrete external wallboard and preparation method thereof

The invention provides a lightweight ceramisite concrete external wallboard and a preparation method thereof. The external wallboard is characterized by comprising the following components in percentage by weight: 34.5-43% of coarse ceramisite (phi0.5-1.0cm), 6.9-17.2% of medium ceramisite (phi0.3-0.5cm), 13.8-25.8% (below phi0.3cm), 13-21% of cement, 0.13-0.92% of waterproof agents, 0.098-0.69% of water reducing agents and 0.065-1.15% of anti-freezing agents. The lightweight ceramisite concrete external wallboard solves the problem that the aerated cement bricks, slag and coal ash bricks, coal ash, stone and cement bricks, which are widely used in the non-bearing external walls in the buildings at present, feature high water absorption, easy cracking and dropping of plastering ceramic tiles and stones, low whole structure strength, low anti-impact and anti-kink load and the like, and is suitable for being used in the buildings.

Owner:吴跃平 +1

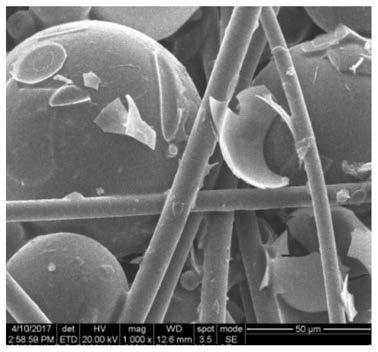

Pressure-resistant and weather-resistant light material containing loofah sponge and used for vehicle covering and preparation method

InactiveCN105200667AImprove stress resistanceEasy to carryFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsWeather resistanceSodium carboxymethylcellulose

The invention discloses a pressure-resistant and weather-resistant light material containing loofah sponge and used for vehicle covering and a preparation method. The light material comprises raw materials in parts by weight as follows: 100-200 parts of nano loofah sponge fiber, 40-80 parts of nano lotus leaf fiber, 30-50 parts of polypropylene staple fiber, 20-40 parts of sodium hydroxide, 3-7 parts of ultraviolet ray absorption polyester, 1-5 parts of a brominated flame retardant, 4-6 parts of nano hollow glass beads, 60-80 parts of epoxy resin, 5-7 parts of a coupling agent, 4-8 parts of phenyl silicone oil, 2-4 parts of carboxymethyl cellulose sodium, 70-80 parts of polystyrene, 15-25 parts of hydrochloric acid, 12-20 parts of ethanol and an appropriate amount of deionized water. An epoxy resin material is prepared from the low-density and light loofah sponge fiber with high toughness, high pressure resistance and high fracture resistance in cooperation with weather-proof materials such as ultraviolet ray absorption polyester, the brominated flame retardant, the nano hollow glass beads and the like; the pressure-resistant and weather-resistant light material has the advantages of lightweight, pressure resistance, weather resistance, convenience in carrying and use and the like; the hydrophobic lotus leaf fiber is adopted for graft modification of the loofah sponge fiber, and hydrophobicity is realized; the polypropylene staple fiber is adopted for graft modification of the loofah sponge fiber, and the fracture resistance of the material is realized.

Owner:FOSHAN LANTU TECH CO LTD

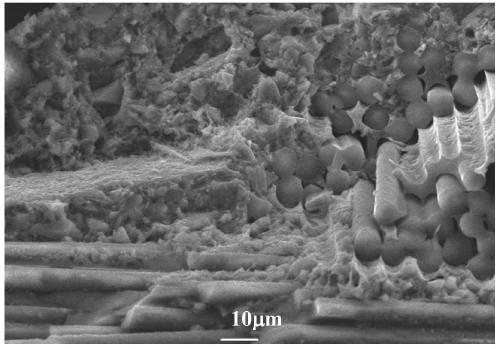

An ablation-resistant lightweight heat-proof and heat-insulating integrated composite material and its preparation method

ActiveCN109968757BLightweight withImproves ablation resistanceLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

Owner:NAT UNIV OF DEFENSE TECH

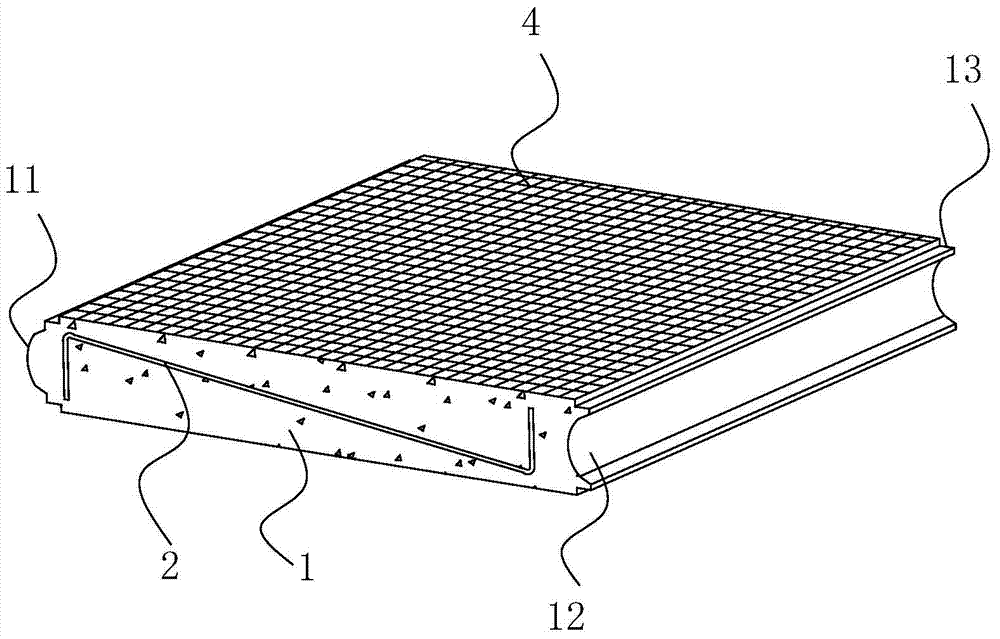

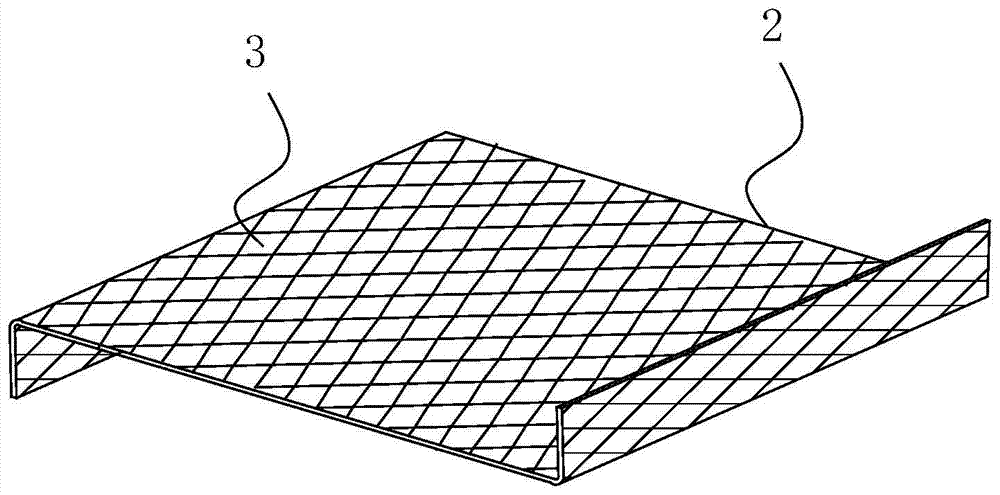

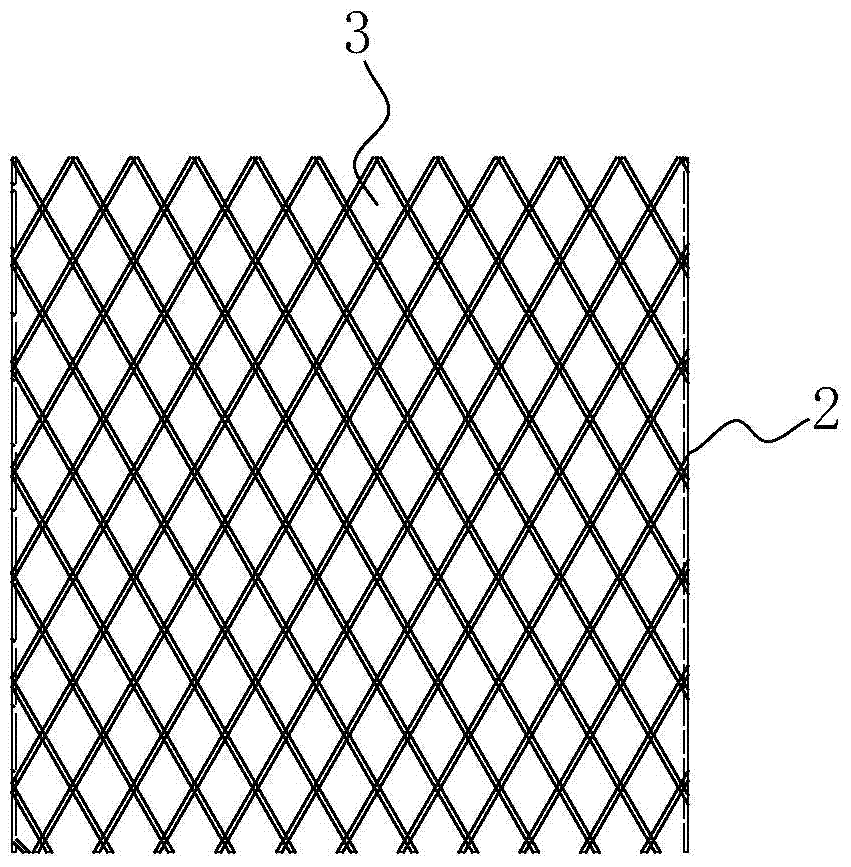

Prefabricated anti-folding lightweight partition board

ActiveCN104453079BIncrease the force sectionImprove bending resistanceConstruction materialWire rodEngineering

The invention relates to building walls, in particular to a prefabricated, lightweight partition board. The purpose is to provide an assembled partition wall panel with light weight, excellent bending resistance and bending resistance, the partition wall panel includes a panel body, and a support net is arranged in the panel body; the support net is formed by connecting wires, and the length of the wires is The projection of the direction on the board surface is oblique. The wire can be polymer material or steel bar. The so-called oblique arrangement in the length direction of the wires can be implemented in various ways. A supporting net is laid in the panel, and the wires of the supporting net are arranged obliquely, that is, deviate from the vertical direction and the horizontal direction of the wall. Therefore, all the wires can share the bending force on the board. And after the wires are arranged obliquely, the stressed section of the wires is significantly larger than that when they are arranged vertically. Therefore, under the condition that the wire consumption is equal, the partition wall panel adopting the support net of the present patent can obviously increase the bending resistance and bending resistance of the panel body.

Owner:重庆市臻成建材有限公司 +1

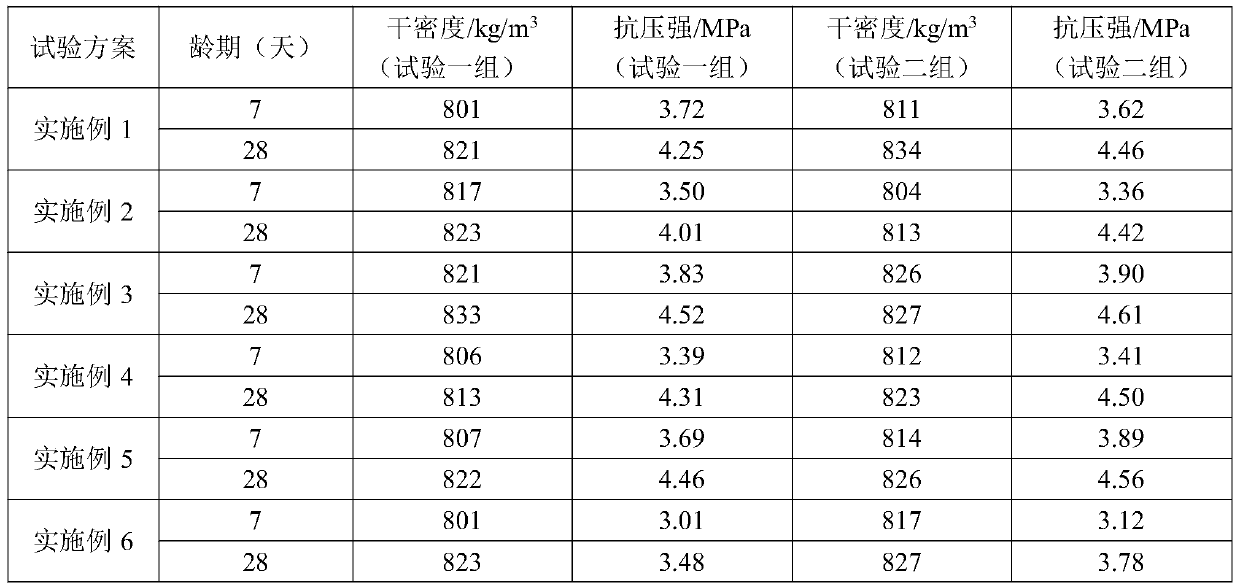

Building muck lightweight building block and preparation method thereof

The invention relates to a civil construction material, in particular to a construction muck lightweight building block, which is characterized in that the construction muck lightweight building blockis prepared from the following components in parts by weight on a dry basis: 50 to 80 parts of construction muck, 15 to 25 parts of cement, 10 to 20 parts of mineral powder, 10 to 20 parts of gypsumand 10 to 20 parts of ultrafine stone powder; and the volume of the polyphenyl granules is calculated according to the setting of the dry density of the lightweight building block, and the dry densitycan be 600kg / m<3>-1200kg / m<3>. According to the building muck lightweight building block, the building block for construction is prepared by taking construction muck and waste recycled materials as raw materials, so that the construction waste soil can be recycled, secondary treatment is avoided, and the main purposes of reducing the cost, saving resources and protecting the environment are achieved; and the construction waste soil accumulated around a construction site can be effectively consumed, the cost is saved, and a new way for treating the waste soil is provided.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

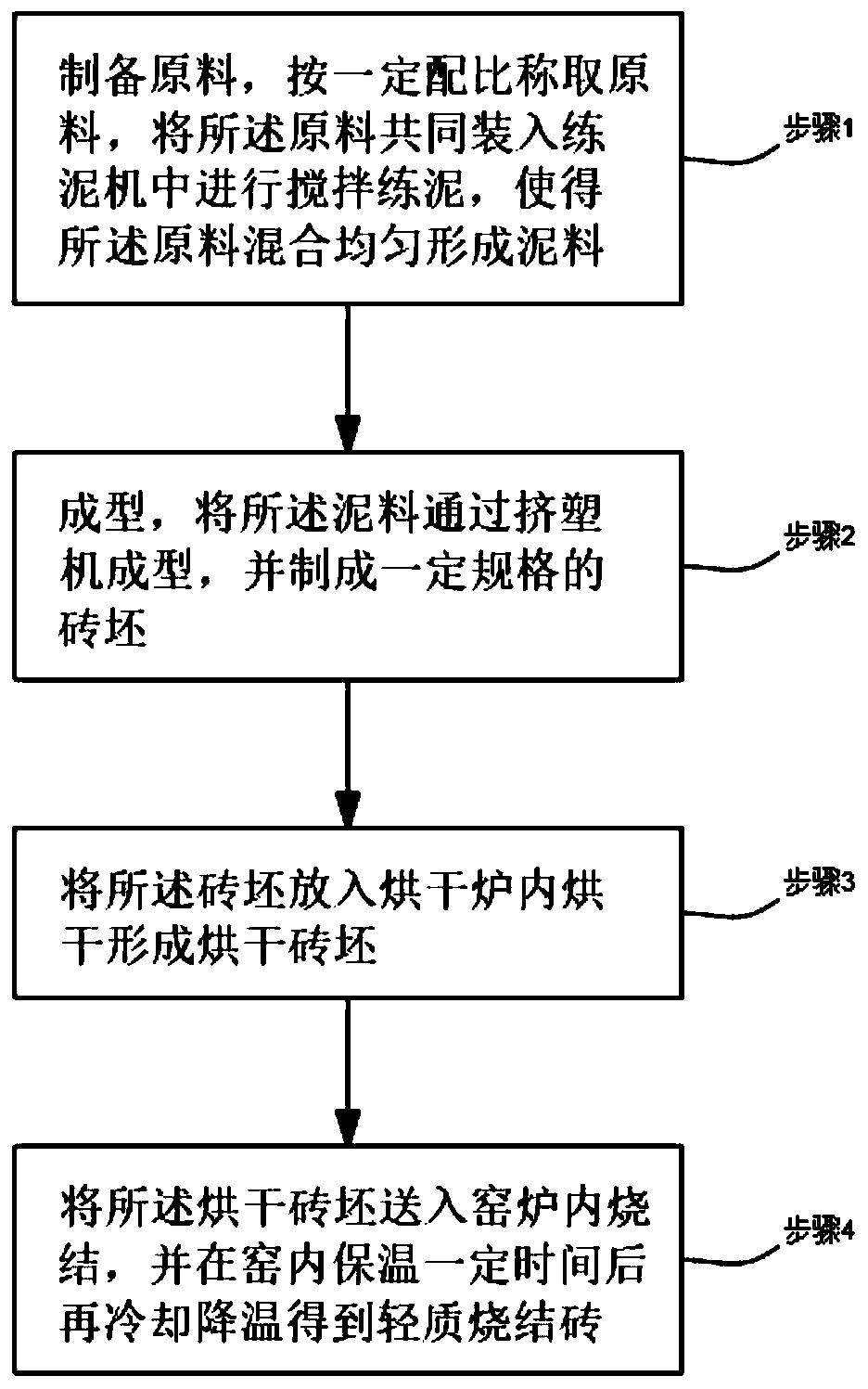

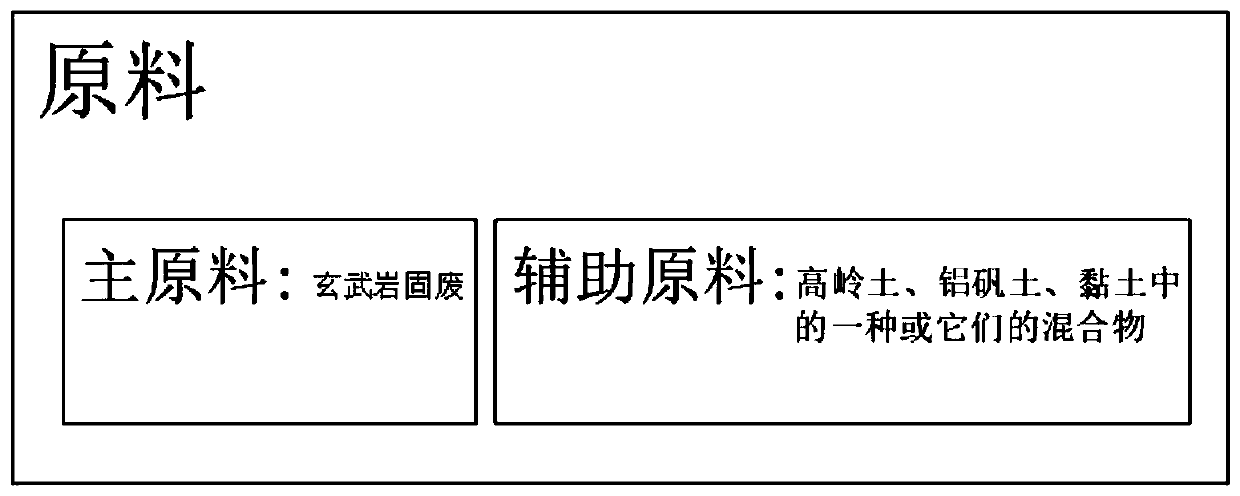

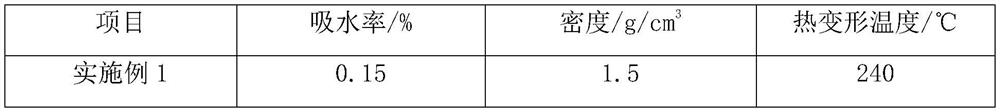

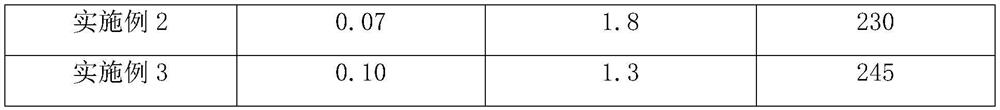

Method for preparing light sintered brick from basalt solid waste

PendingCN111410512AHigh hardnessImprove stress resistanceCeramic materials productionCeramicwareBrickKiln

The invention relates to the technical field of preparation of light sintered bricks, in particular to a method for preparing a light sintered brick from basalt solid waste. The method comprises the steps of: weighing the raw materials according to a certain proportion; putting the raw materials into a pug mill together for stirring and pugging; uniformly mixing the raw materials to form pug; molding the pug through a plastic extruding machine; preparing a green brick with a certain specification; putting the green brick into a drying furnace for drying to form a dried green brick; sending thedried brick blank into a kiln for sintering; keeping the temperature in the kiln for a certain time, and then performing cooling to obtain the light sintered brick. Basalt solid waste is used as a main raw material for preparation; the proportion of the basalt solid waste is more than 70%; heavy metal in basalt solid waste is solidified through high-temperature sintering, resource and harmless utilization of the waste is achieved, natural mineral resources are saved, environmental protection and improvement are facilitated, and the prepared light sintered brick belongs to an inorganic heat preservation material and has the advantages of being light, high in strength, resistant to corrosion, free of aging and the like.

Owner:上海艺热实业有限公司

Sheet molding compound and preparation method thereof

PendingCN114426767AImprove structural strengthGood mechanical propertiesSolid waste managementFirming agentBasalt fiber

The invention relates to the field of high polymer materials, and particularly discloses a sheet molding compound and a preparation method thereof. The sheet molding compound is prepared from the following raw materials in parts by weight: 80 to 100 parts of polyurethane resin, 85 to 100 parts of basalt fiber, 25 to 40 parts of hollow glass beads, 30 to 45 parts of expanded microspheres, 4 to 6.5 parts of a thickening agent, 2.5 to 8 parts of a release agent, 10 to 16 parts of a low-shrinkage additive and 0.5 to 2.2 parts of a curing agent, the preparation method comprises the following steps: S1, weighing the polyurethane resin, the hollow glass beads and the expanded microspheres, mixing and stirring to prepare a primary mixture; s2, weighing a thickening agent, a release agent, a low-shrinkage additive and a curing agent, adding into the primary mixture, and uniformly mixing and stirring to obtain a mixture; and S3, mixing the mixture with basalt fibers, and carrying out compression molding and standing shaping to obtain a finished product. Therefore, the sheet molding compound has the advantages of good mechanical property, good insulating property and good plasticity at the same time.

Owner:青岛东远新材料科技有限公司

Concentration detection and training system and method based on functional near-infrared spectroscopy

InactiveCN106805985BRegulatory intelligenceSensitive Accurate Response MappingSensorsPsychotechnic devicesSignal onTerminal equipment

The invention discloses a system and method for concentration detection and training based on functional near infrared spectrum technologies. The system comprises a wearable fNIR sensing device and an intelligent terminal; a fNIR control module in the wearable fNIR sensing device controls switching-on, switching-off and spectral wavelength of a signal emission source in a fNIR signal emission module, switching-on and switching-off of a sensor in a fNIR signal collection module as well as opening and closing of signal channels, and near infrared spectrum signals on each signal channel under different spectrum lengths are collected cyclically and transmitted to the intelligent terminal; and the terminal equipment uses a built-in concentration analysis module to transform the near infrared spectrum signals into hemoglobin content information in real time and then quantify the information into a concentration index.

Owner:魏伟

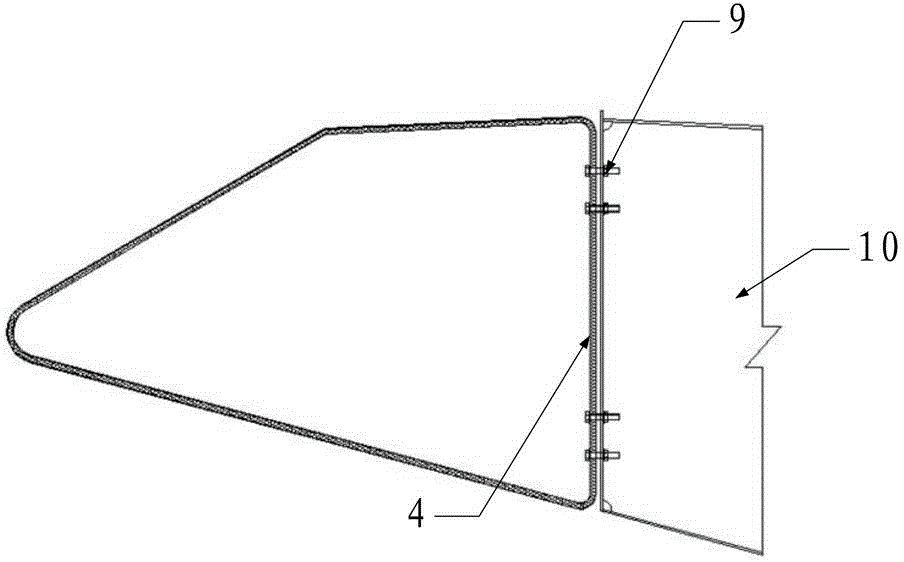

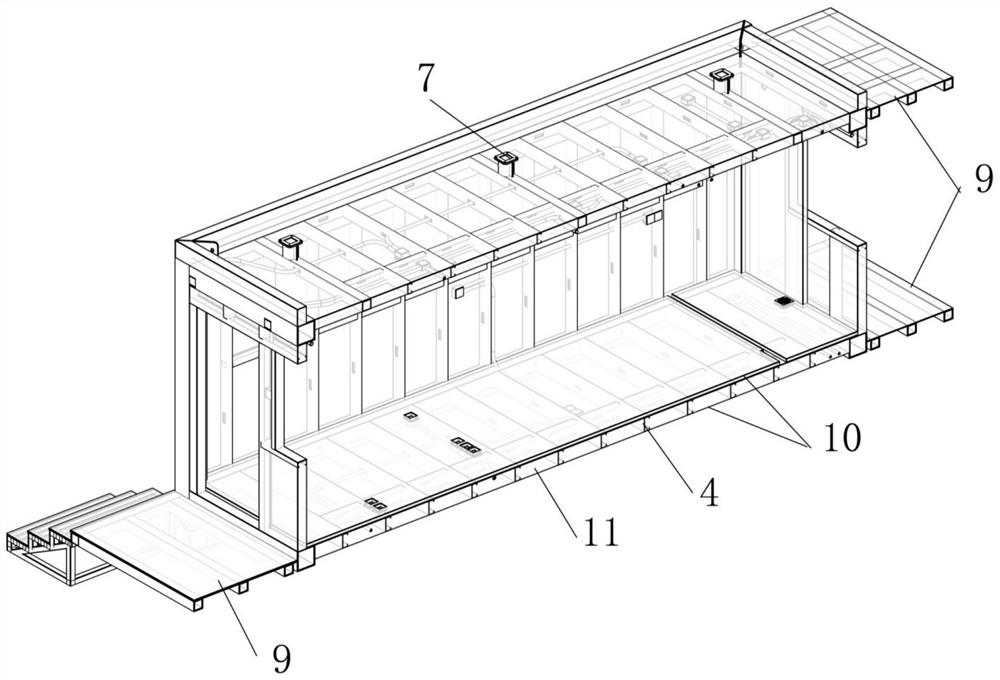

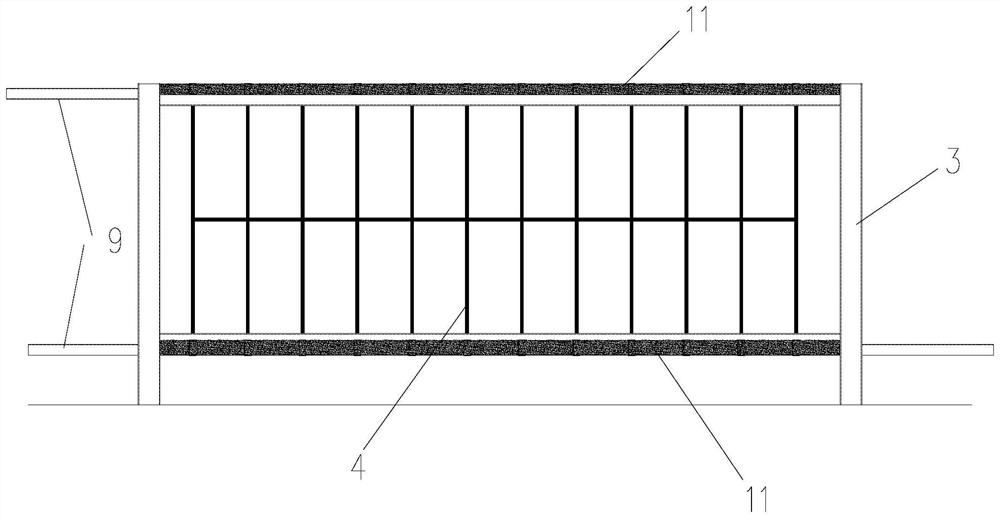

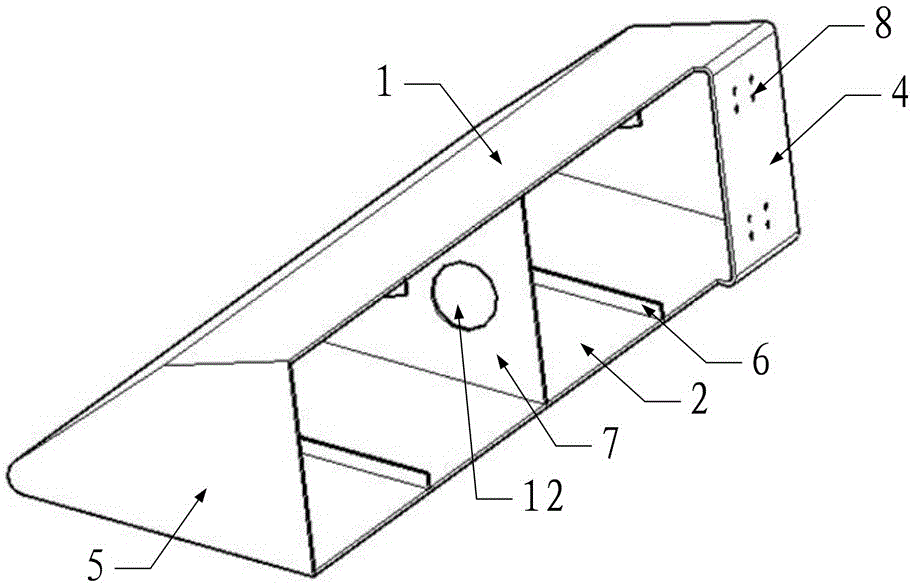

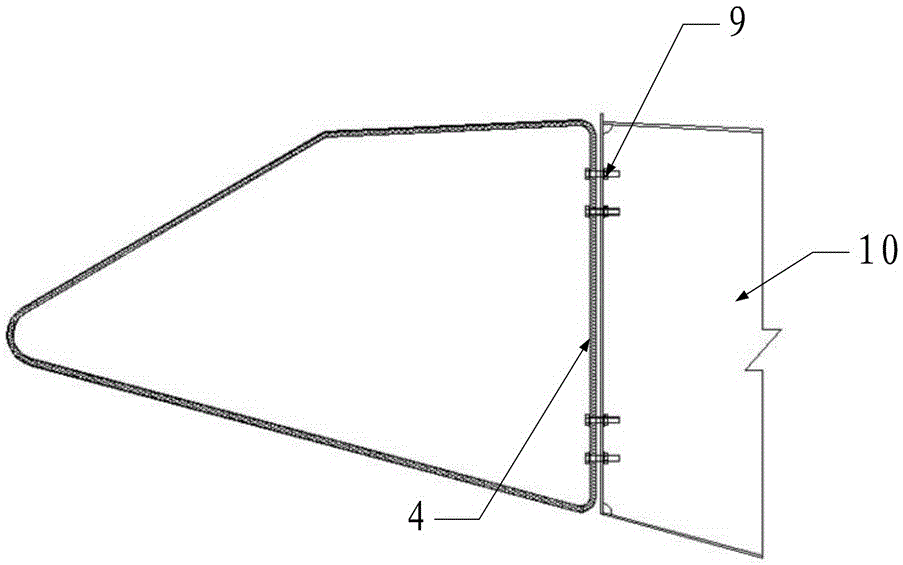

Air guide device and manufacturing and assembling method thereof

ActiveCN104631306AIncrease stiffnessMeet the force requirementsBridge structural detailsFiber-reinforced compositeUltimate tensile strength

The invention discloses an air guide device and a manufacturing and assembling method of the air guide device. The air guide device comprises at least one air guide section, each air guide section comprises an air guide section body composed of a top plate and a bottom plate, reinforcement ribs are arranged inside the air guide section bodies, and each of the top plates, the bottom plates and the reinforcement ribs is made of a fiber reinforcement composite material inner layer and a fiber reinforcement composite material outer layer. The manufacturing and assembling method includes the steps that (1), the fiber reinforcement composite material inner layers, the fiber reinforcement composite material outer layers and light sandwich layers are manufactured and used for forming the top plate, the bottom plate and the reinforcement rib, so that one air guide section is formed; (2), the preset number of air guide sections are manufactured and connected with a main beam of a bridge through bolts, and the air guide sections are connected through bolts. The air guide device has the advantages of being light, high in strength and corrosion performance and easy to connect with the main beam, and the manufacturing and assembling method is simple and convenient to implement.

Owner:长沙绘通工程咨询有限公司

A steel skeleton foam concrete composite structure unit house

ActiveCN110924533BImprove carrying capacityImprove integrityBuilding constructionsFoam concreteFire protection

The invention discloses a steel frame foam concrete composite structure unit house, which comprises 4 equal-length X-axis square tubes, 4 equal-length Y-axis square tubes and 4 equal-length Z-axis square tubes passing through 8 coordinates. A right-angled cuboid three-dimensional frame formed by connecting nodes, and any four square tubes are connected in turn to form a rectangular frame. The inner cavity of the rectangular frame is provided with a dragon skeleton fixedly connected to the rectangular frame; the lower ends of the four Z-axis square tubes pass through the The adjustment mechanism is connected with a support, and the adjustment mechanism is used to adjust the distance between the Z-axis square tube and the corresponding support; the inner and outer surfaces of the rectangular frame are fixed with panels that seal the inner cavity of the rectangular frame, and each inner cavity is filled with Foam concrete, wires and water pipes are pre-embedded in at least one cavity of a right-angled quadrilateral frame. The unit house has high integrity, is convenient for consignment, does not need to build a special foundation, and can quickly adjust the level of the mobile room; and the functions of heat preservation, sound insulation, waterproof and anti-seepage, and fire prevention have been greatly improved.

Owner:HUNAN CONSTR ENG GRP COR +1

Low shrinkage unsaturated polyester resin/concrete composite board and preparation method

Low-shrinkage unsaturated polyester resin / concrete composite plate and its preparation method, 30-35 parts of aluminate cement, 10-20 parts of natural aggregate, 20-30 parts of resin aggregate, 40-45 parts of glass microspheres; preparation method As follows: first mix unsaturated polyester resin, nano-silver antibacterial agent, filler, low-shrinkage agent, diluent, and initiator to prepare resin aggregate, and mix it with natural aggregate and glass beads evenly, and then pour it into the mold Spread a layer of cement slurry and glass fiber mesh Ⅰ, then spread the aggregate mixture on the glass fiber mesh Ⅰ, spread the glass fiber mesh Ⅱ after spreading, and then pour the remaining cement slurry on the glass fiber mesh Ⅱ , demoulding after standing for 24 hours, the light-weight low-shrinkage unsaturated polyester resin / concrete composite board can be obtained; Electrical insulation can guarantee the safety performance of use.

Owner:PUYANG SHENGYUAN ENERGY TECH

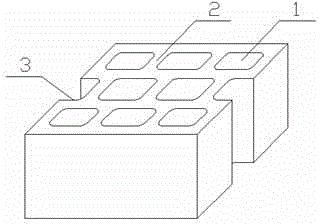

A large amount of fly ash composite self-insulating block and its preparation method

InactiveCN102979240BLight weightReduce in quantityConstruction materialSolid waste managementPolymer scienceThermal insulation

The invention discloses a large-dosage coal ash composite self-insulation building block and a preparation method thereof. The building block comprises a rectangular building block body on which multiple through holes are formed through extrusion, wherein semi-open through holes are symmetrically formed on two sides of the rectangular building block body; a thermal insulation material mixed by rice hull, silicate cement and 901 glue according to mass percentage is filled in the semi-open through holes and the multiple through holes; and the thermal insulation material is compacted, flattened, naturally cured to prepare the building block. The coal ash, coal ash ceramsite, rice hull, other industrial and agricultural wastes and light materials serve as main components, and a self-insulation function can be realized. The building block has the volume density of 676-704kg / m<3>, so that the capacity of the building block is greatly reduced, and the building deadweight and construction cost are reduced. The comprehensive dosage of the coal ash is more than 70 percent, the resources are fully utilized, and waste materials are changed into valuable materials. The building block are few in holes and rows and easy to form, and the damage rate in the processing, transport and construction process is low.

Owner:CHINA UNIV OF MINING & TECH

Waste concrete lightweight building block and preparation method thereof

The invention relates to the field of geotechnical engineering, and relates to a waste concrete light building block which comprises the components in parts by weight based on dry basis based on 100 parts of raw materials: 40-60 parts of waste concrete powder, 10-40 parts of waste brick powder, 15-25 parts of cement and 10-25 parts of clay. The volume of polyphenyl granules is calculated accordingto the setting of dry density, and the dry density is designed to be 600 kg / m<3>-1200 kg / m<3>. Main raw materials are waste concrete powder, waste brick powder, clay and the like; due to the utilization of the waste concrete and the waste bricks, the generation of construction waste can be greatly reduced, the recycling of resources is realized, the environmental protection is facilitated, a large amount of manpower and material resources are saved, the cyclic utilization of the resources is realized, and the strategic requirements of sustainable development in China are met.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

Air guiding device and its manufacturing and assembling method

ActiveCN104631306BIncrease stiffnessMeet the force requirementsBridge structural detailsEngineeringFiber-reinforced composite

The invention discloses an air guide device and a manufacturing and assembling method of the air guide device. The air guide device comprises at least one air guide section, each air guide section comprises an air guide section body composed of a top plate and a bottom plate, reinforcement ribs are arranged inside the air guide section bodies, and each of the top plates, the bottom plates and the reinforcement ribs is made of a fiber reinforcement composite material inner layer and a fiber reinforcement composite material outer layer. The manufacturing and assembling method includes the steps that (1), the fiber reinforcement composite material inner layers, the fiber reinforcement composite material outer layers and light sandwich layers are manufactured and used for forming the top plate, the bottom plate and the reinforcement rib, so that one air guide section is formed; (2), the preset number of air guide sections are manufactured and connected with a main beam of a bridge through bolts, and the air guide sections are connected through bolts. The air guide device has the advantages of being light, high in strength and corrosion performance and easy to connect with the main beam, and the manufacturing and assembling method is simple and convenient to implement.

Owner:长沙绘通工程咨询有限公司

Lightweight concrete exterior wallboard

InactiveCN107963836ALightweight withLightweight exterior wall panels, which have sound insulation withCeramic shaping apparatusSlagExpanded clay aggregate

A lightweight concrete exterior wall panel, which is characterized in that its composition is coarse ceramsite (φ0.5‑1.0cm), medium ceramsite (φ0.3‑0.5cm), ceramsite powder (less than φ0.3cm) , cement, waterproofing agent, water-reducing agent, antifreeze; its composition ratio is (by weight) coarse ceramsite (φ0.5‑1.0cm) 34.5‑43%, medium ceramsite (φ0.3‑0.5cm) 6.9‑ 17.2%, ceramsite powder (below φ0.3cm) 13.8‑25.8%, cement 13‑21%, waterproofing agent 0.13‑0.92%, water reducing agent 0.098‑0.69%, antifreeze agent 0.065‑1.15%. It solves the problems of high water absorption rate, easy cracking and falling off of pasted tiles and low overall structural strength of steamed cement bricks, slag fly ash bricks, fly ash gravel cement bricks, etc. Impact resistance, low bending load and other issues, suitable for use in construction.

Owner:刘成其

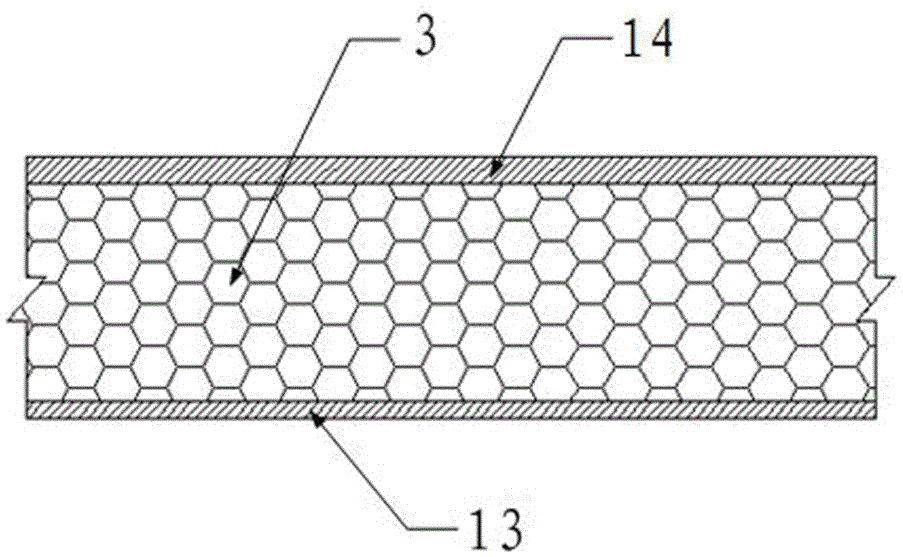

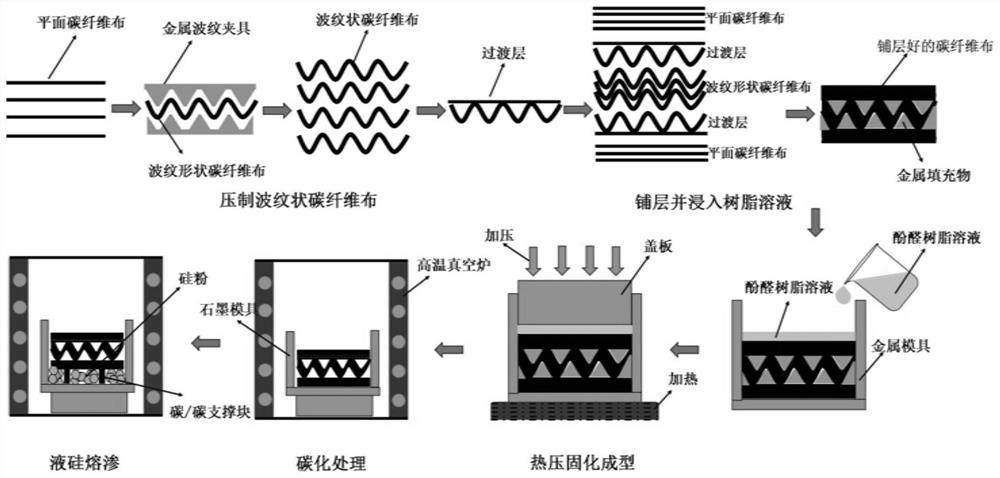

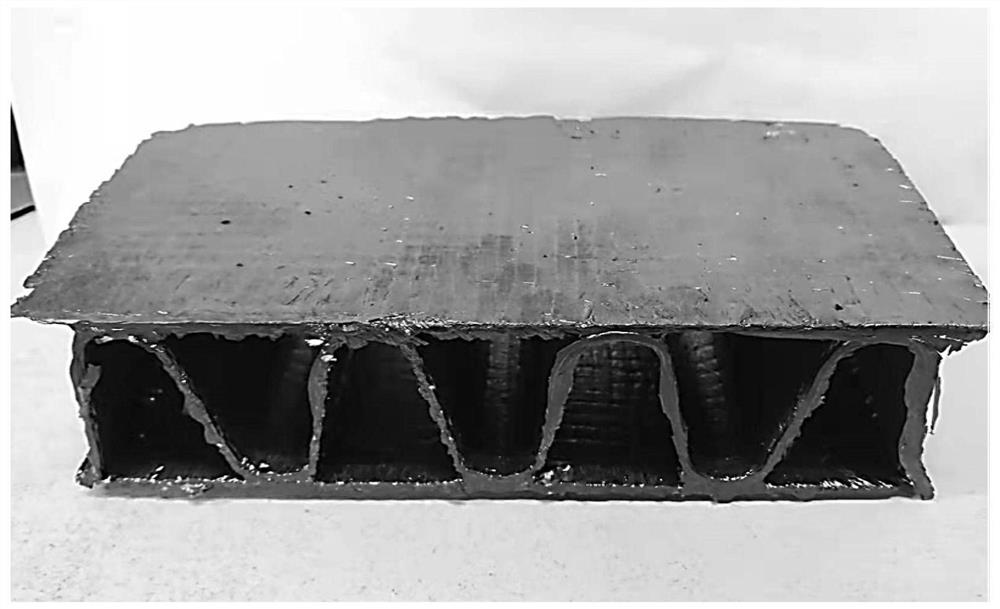

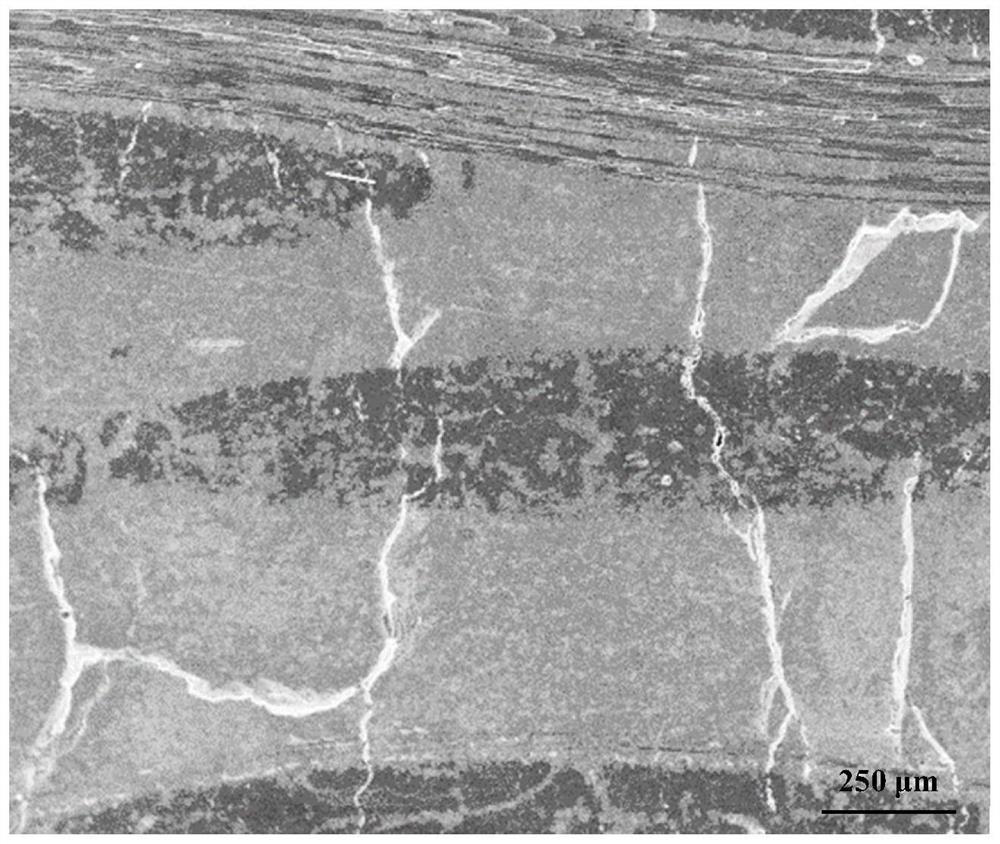

Preparation method of carbon fiber reinforced silicon carbide ceramic matrix composite corrugated sandwich plate

The invention relates to the technical field of preparation of thermal protection materials, in particular to a preparation method of a carbon fiber reinforced silicon carbide ceramic matrix composite corrugated sandwich board. The preparation method comprises the following steps: (1) pressing corrugated carbon fiber cloth; (2) laying and immersing in a resin solution; (3) hot-pressing, curing and molding; (4) carbonization treatment; and (5) liquid silicon infiltration. The carbon fiber reinforced silicon carbide ceramic-based composite material corrugated sandwich plate prepared by the invention has the excellent properties of light weight, high strength, heat insulation, ablation resistance and the like, can reduce the weight of a thermal protection system when being applied to the thermal protection system of a hypersonic aircraft, and solves the problems that the aircraft consumes oil seriously and cannot fly for a long time due to the thermal protection weight.

Owner:XIAN TECH UNIV

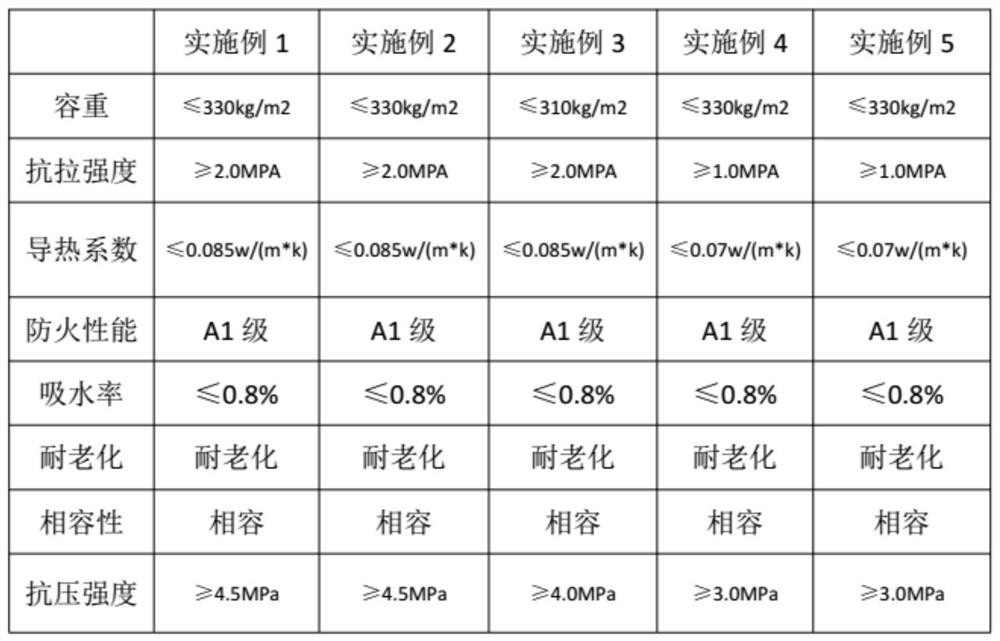

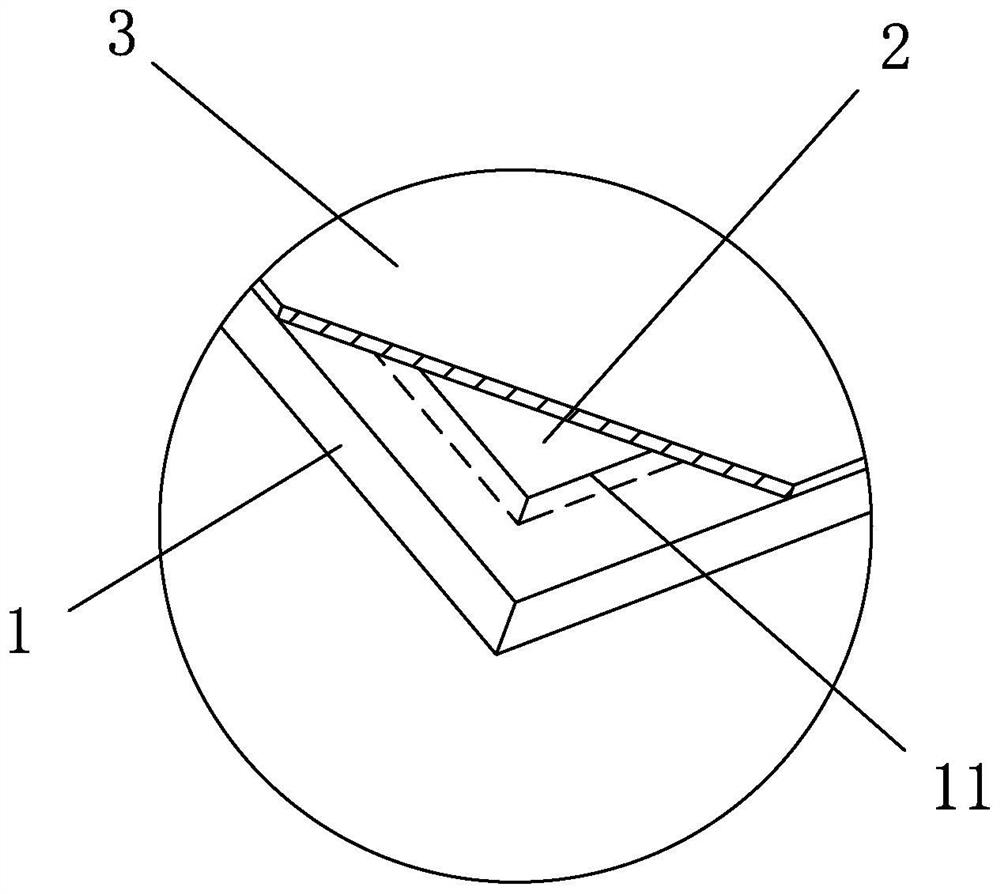

Lightweight thermal insulation decoration panel and preparation method thereof

PendingCN114809500ASolve the problem of poor sound insulationLightweight withCovering/liningsFlooringInsulation layerThermal insulation

The invention relates to a light heat preservation decoration panel which sequentially comprises a heat preservation layer, a sound insulation layer and a decoration layer from the inner side to the outer side, the heat preservation layer, the sound insulation layer and the decoration layer are integrally connected, a notch is formed in the outer side of the heat preservation layer, the sound insulation layer is filled and formed in the notch, and the heat preservation layer and the sound insulation layer comprise flush outer side end faces. The decorative layer is formed and attached to the outer side end face, the heat preservation layer is made of a light porous ceramic material, the sound insulation layer is made of a nano aluminum-magnesium sound insulation material, and the decorative layer is a glaze surface. In addition, the invention further provides a preparation method of the light heat preservation decoration panel, and the preparation method comprises the steps of manufacturing the heat preservation layer, manufacturing the sound insulation layer, manufacturing the decoration layer and the like. The technical scheme of the invention has the technical effects of light weight, heat preservation, fire prevention, water prevention, high strength, sound insulation and aging resistance with a decorative surface.

Owner:温州海螺孚瓯科技有限公司

A light-weight concrete exterior wall panel

InactiveCN106630779ALightweight withLightweight exterior wall panels, which have sound insulation withSlagShock resistance

A light-weight concrete exterior wall panel is disclosed. The panel is characterized in that components of the panel include coarse ceramsite (with Phi being 0.5-1.0 cm), middle-size ceramsite (with Phi being 0.3-0.5 cm), ceramsite powder (with Phi being 0.3 cm or below), cement, a waterproof agent, a water reducer and an antifreezing agent; and the components include 34.5-43% of the coarse ceramsite (with Phi being 0.5-1.0 cm), 6.9-17.2% of the middle-size ceramsite (with Phi being 0.3-0.5 cm), 13.8-25.8% of the ceramsite powder (with Phi being 0.3 cm or below), 13-21% of the cement, 0.13-0.92% of the waterproof agent, 0.098-0.69% of the water reducer and 0.065-1.15% of the antifreezing agent. The panel overcomes a problem that aerated cement bricks, slag-fly ash bricks, fly ash-broken stone-cement bricks, and the like which are widely used in nonbearing exterior walls of buildings at present have disadvantages of high water absorption rates, liable cracking and shedding of adhered tiles and stone materials, low overall structural intensity, low shock resistance, low flexural load, and the like, and is suitable for application in buildings.

Owner:顾杨子

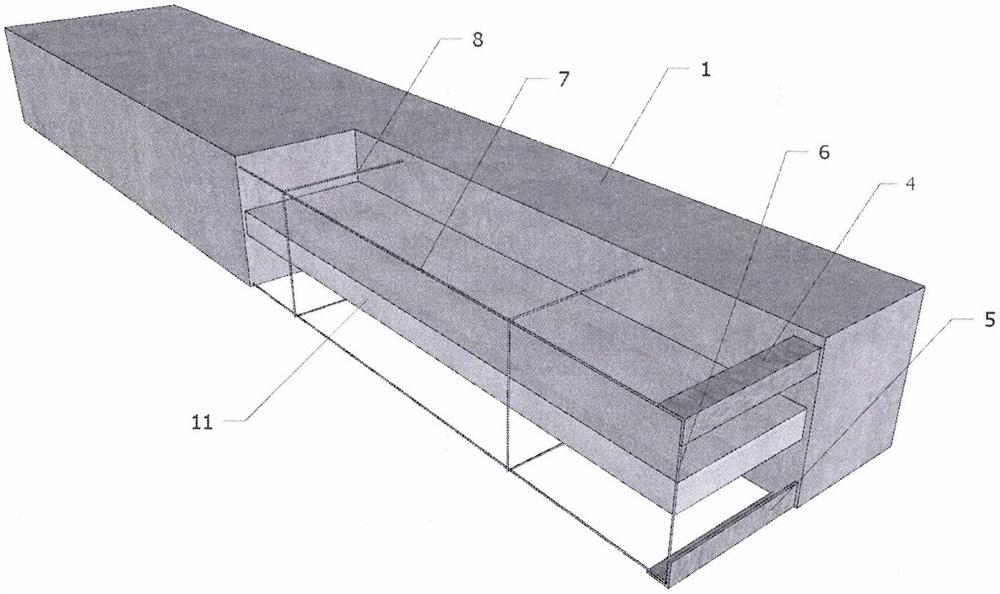

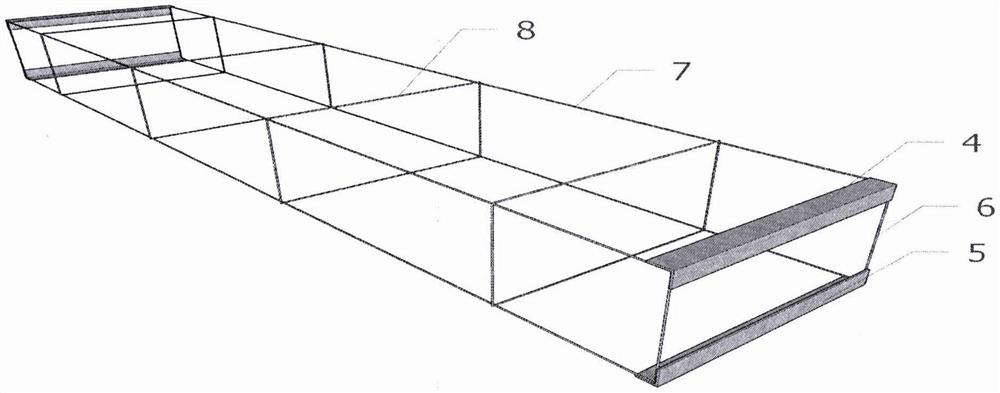

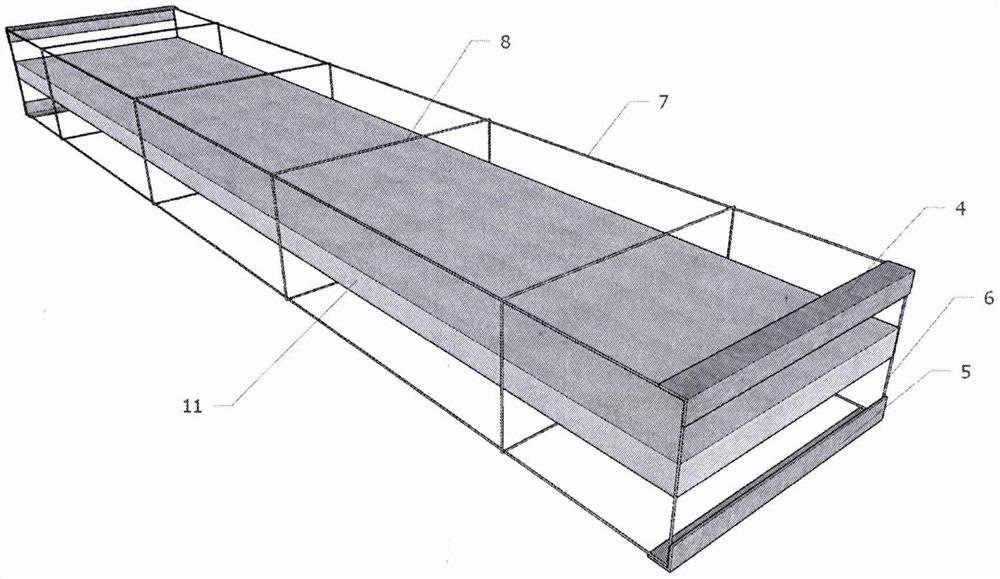

Ultrathin light self-thermal-insulation floor slab

PendingCN111997248ALightweight withThermal insulation hasFloorsCeramic shaping apparatusFoam concreteFloor slab

The invention relates to an ultrathin light self-thermal-insulation floor slab. The ultrathin light self-thermal-insulation floor slab is composed of a light foam concrete edge 1, a floor slab angle steel rebar hollow net rack 2, angle steel rebar frames 3, upper angle steel bars 4, lower angle steel bars 5, angle steel connecting rebars 6, an angle rebar frame 3, longitudinal thick rebars 7, thinrebars 8, transverse four-edge annular thin rebar rings 9 and a heat preservation panel 10. The two ends of the upper angle steel bar 4 and the two ends of the lower angle steel bar 5 are welded intoangle steel rebar frames 3 through two angle steel connecting rebars 6, the four corners of the two angle steel rebar frames 3 are welded through four longitudinal thick rebars 7, and a plurality ofthin rebars 8 are welded between the longitudinal thick rebars 7 to form a plurality of annular thin rebar rings 9; the four-side annular thin rebar rings 9, the longitudinal thick rebars 7 and the floor angle steel rebar frames 3 form the floor angle steel rebar hollow net rack 2, and after the heat preservation panel 10 is inserted into the net rack 2, light foam concrete is poured on the periphery of the heat preservation board 10 to form a floor slab. The floor slab has the advantages of being precast in a floor factory, ultra-thin, light, capable of preserving heat and insulating heat, rapid to install on site and the like.

Owner:王奕忱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com