Patents

Literature

469 results about "Sandwich board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sandwich board is a type of advertisement composed of two boards (holding a message or graphic) and being either...

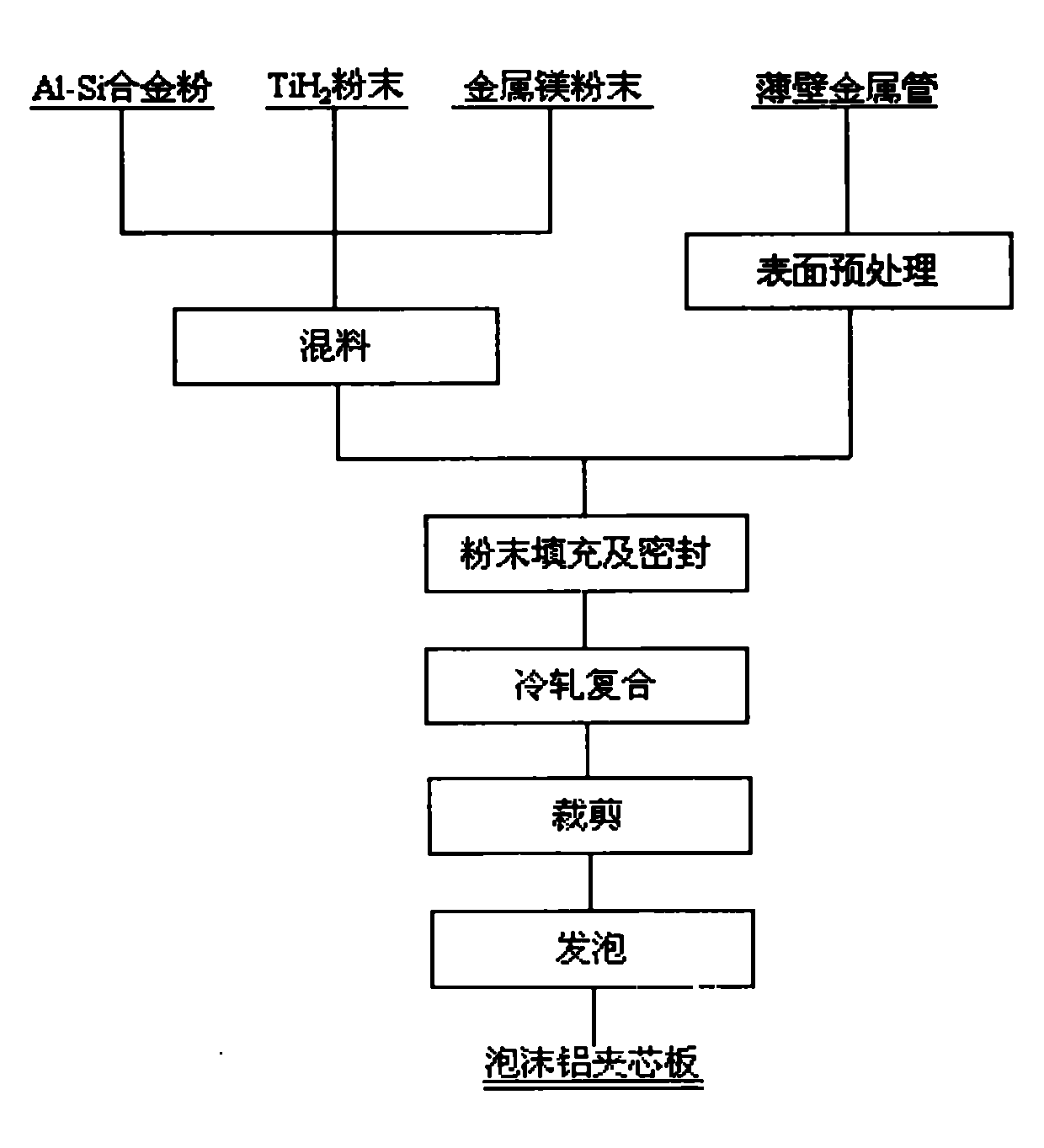

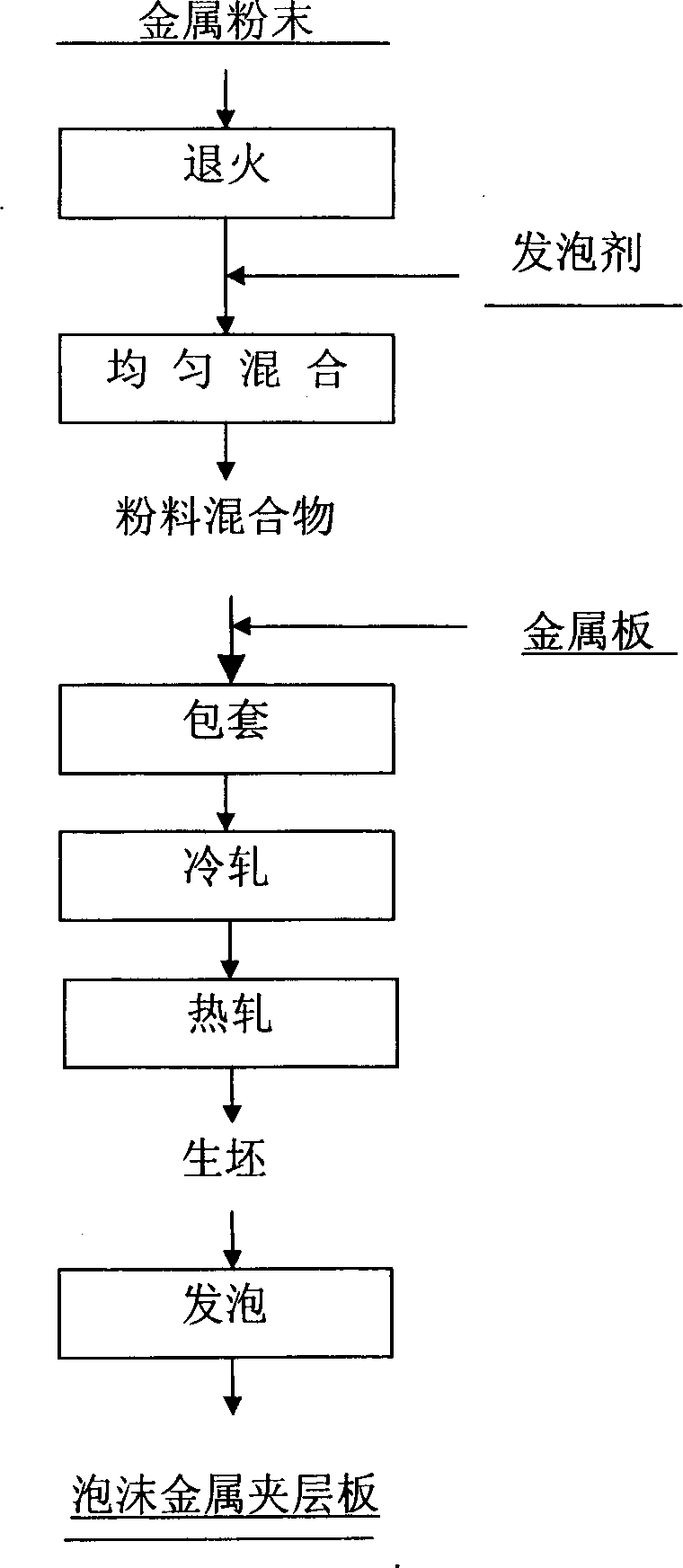

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

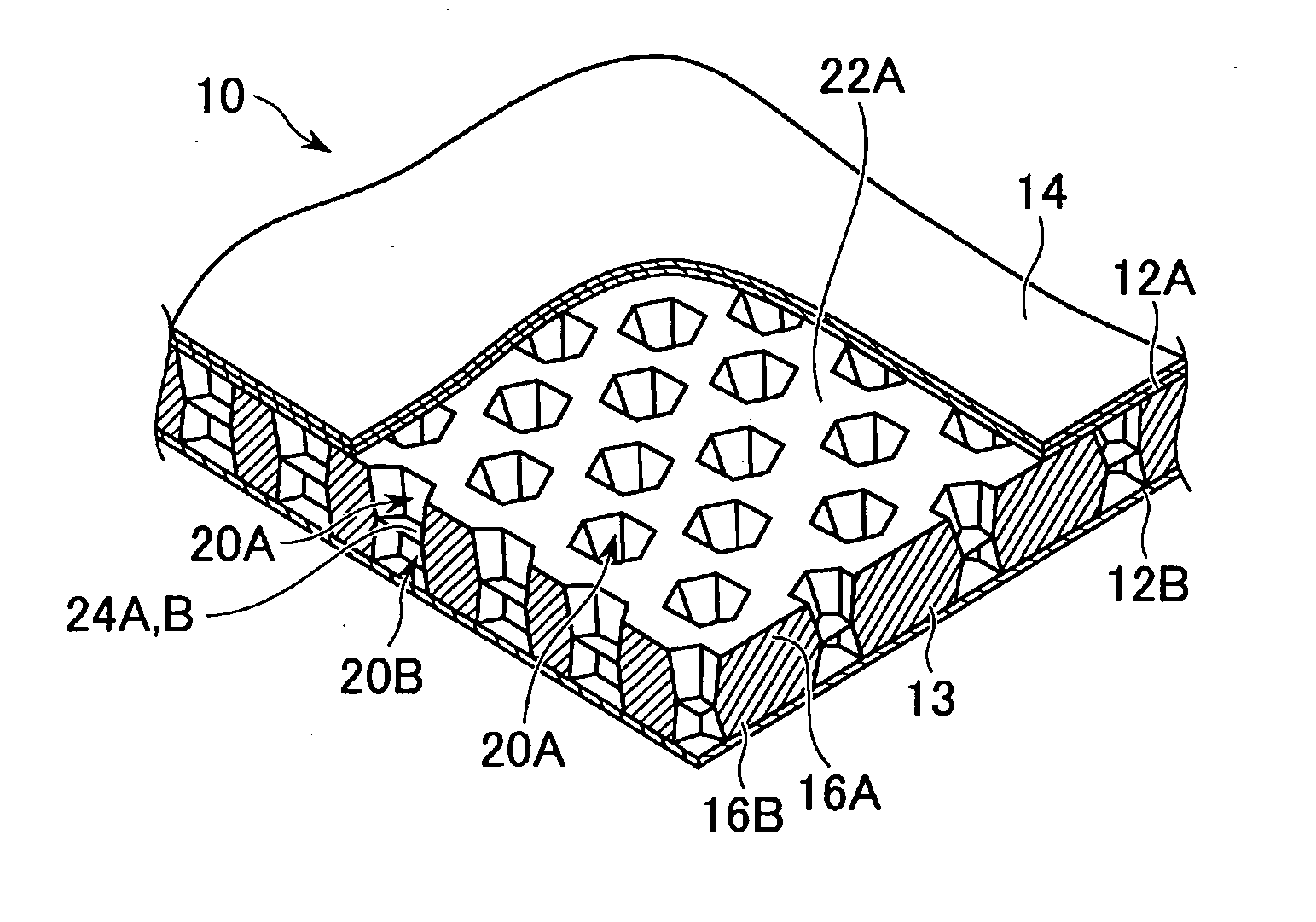

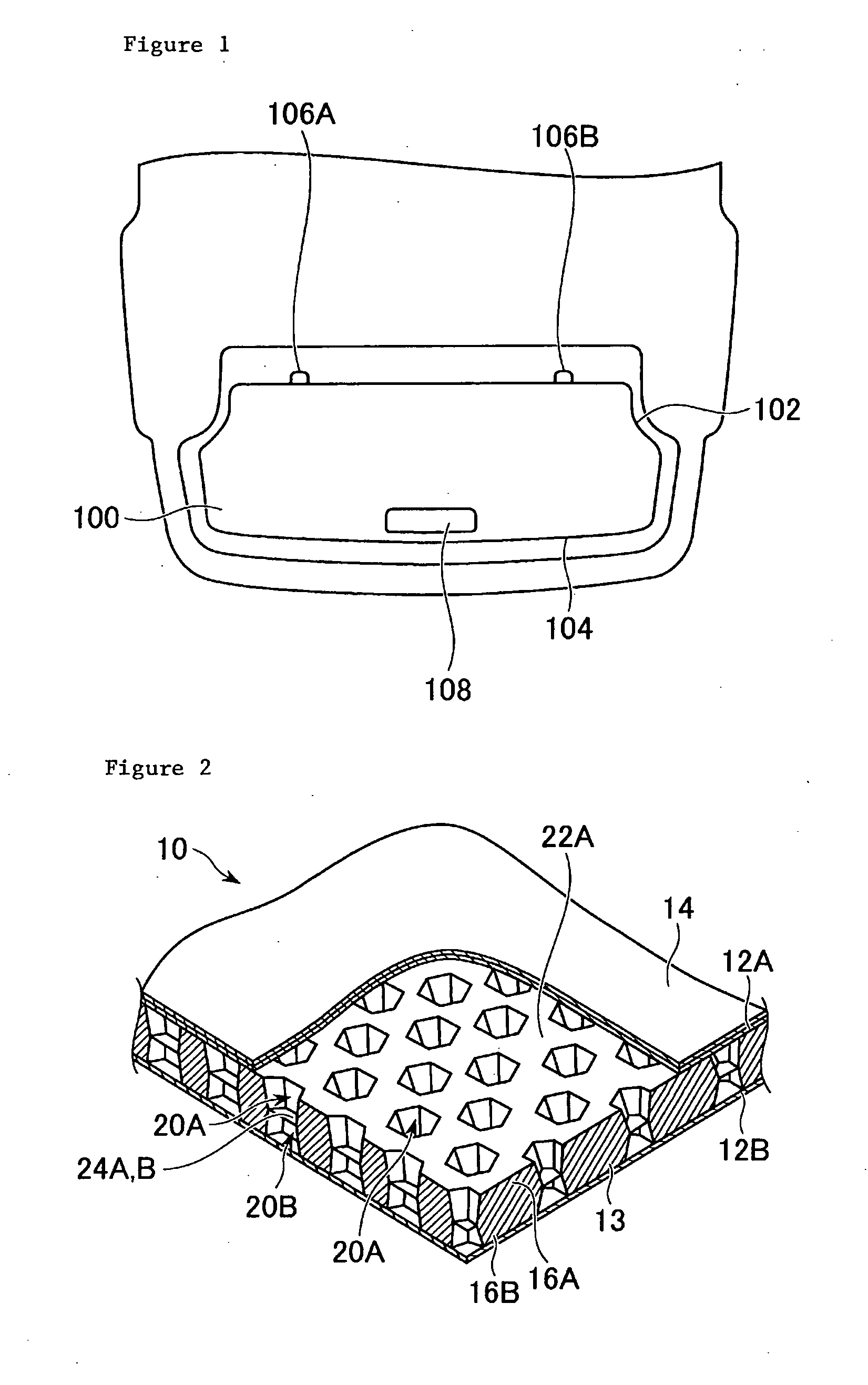

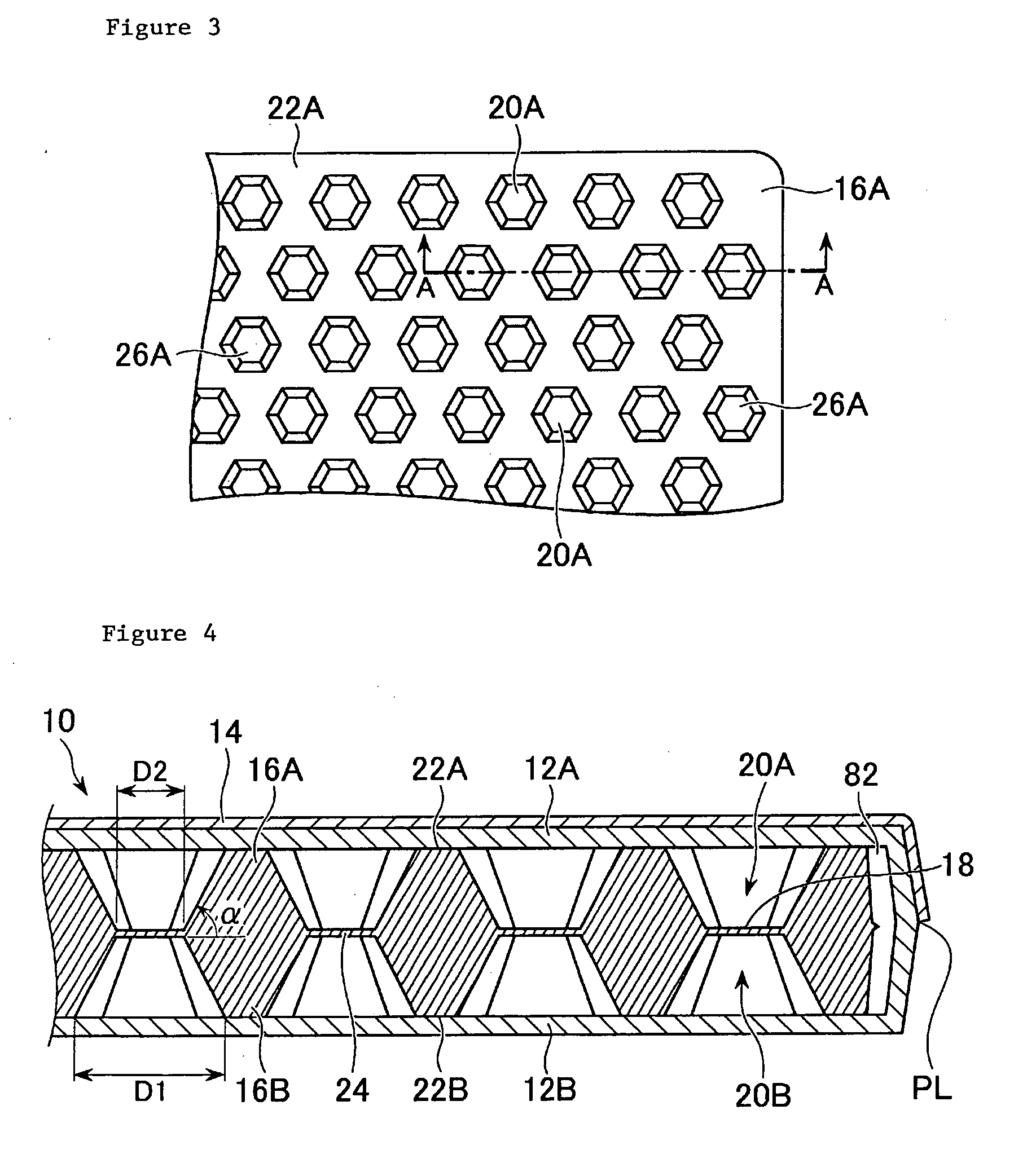

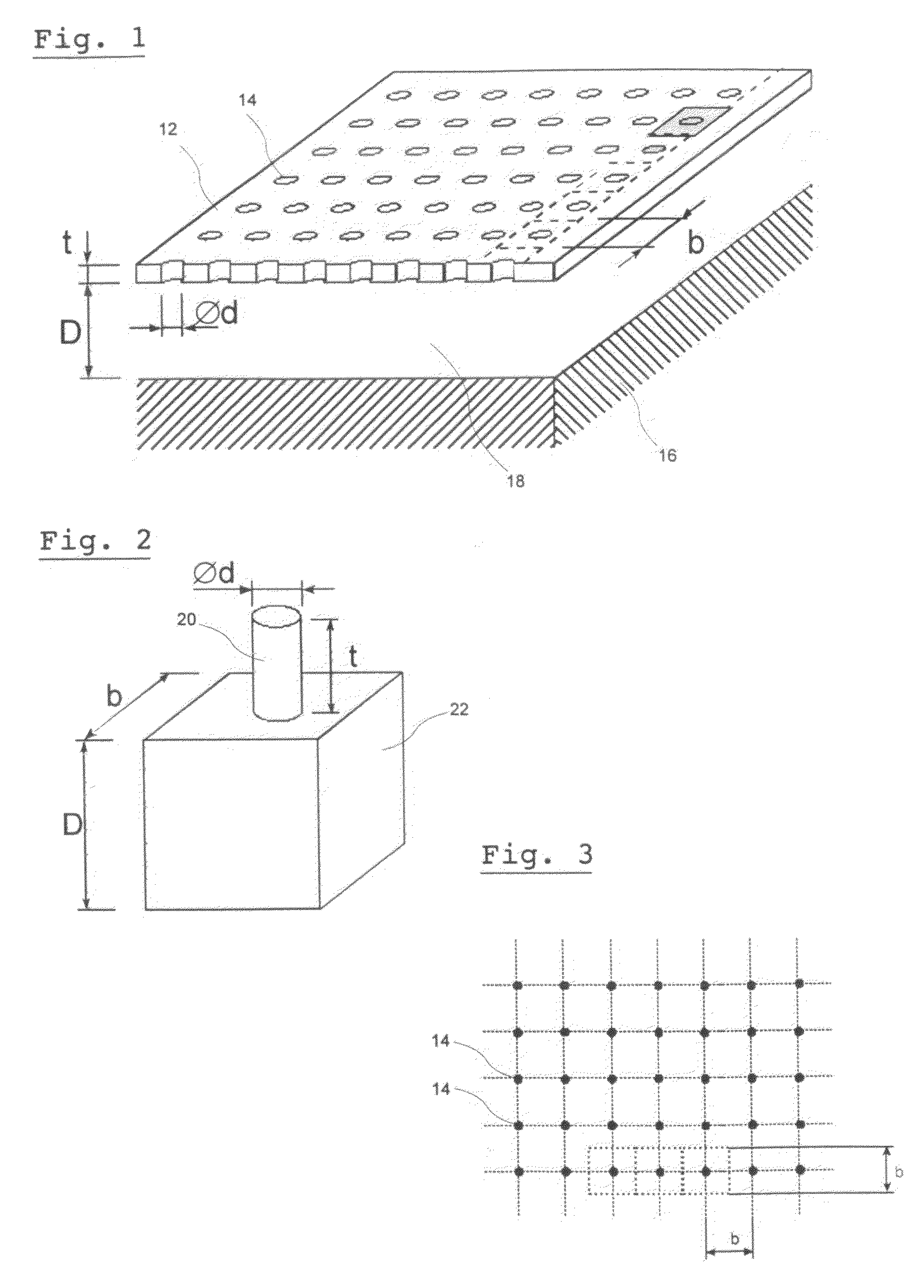

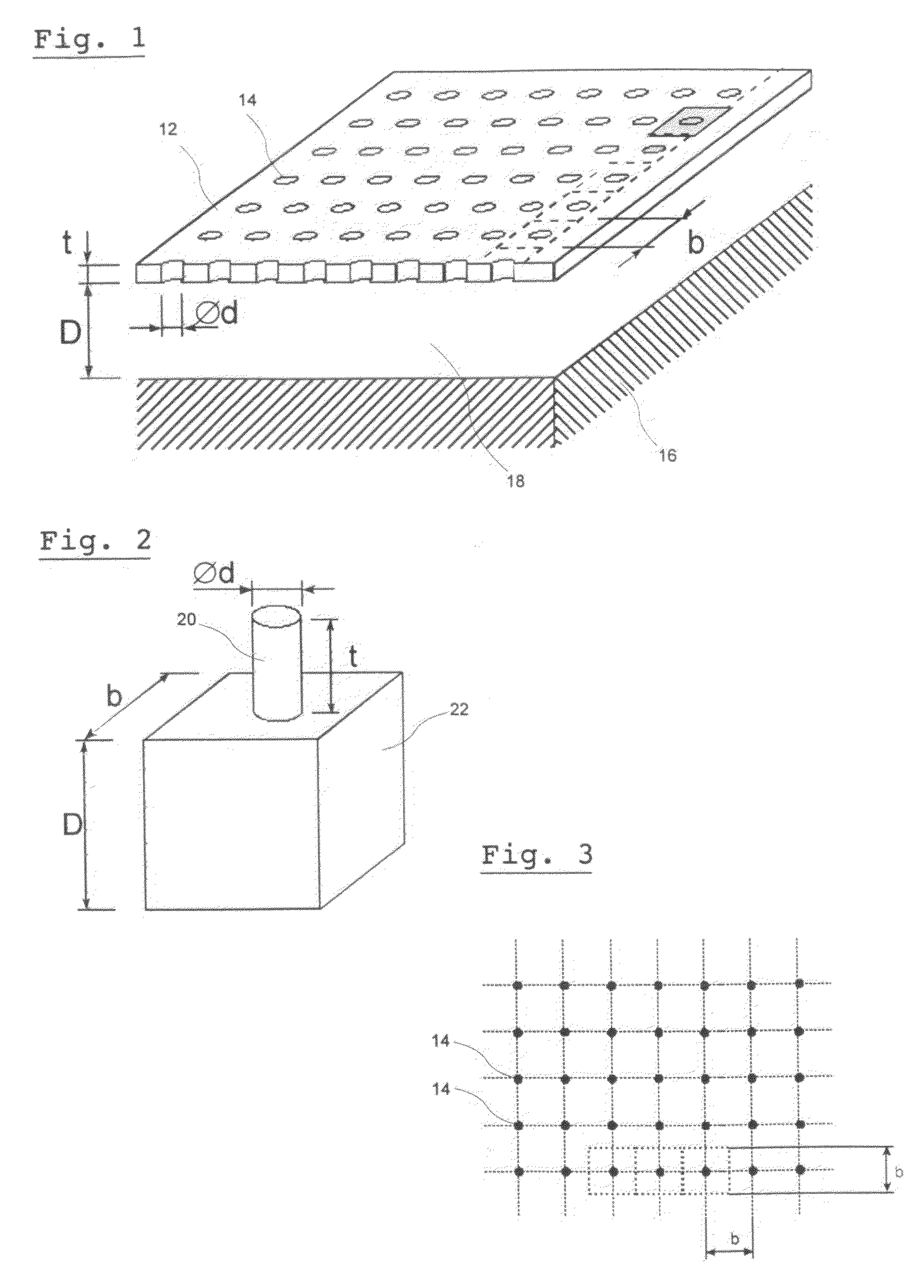

Core material for sandwich panel, method of molding core material for sandwich panel, sandwich panel, and method of molding sandwich panel

ActiveUS20110135862A1High strengthLabelling non-rigid containersLayered productsSandwich boardEngineering

An object of the present invention is to provide a core member for a sandwich panel and a method of forming the core member for the sandwich panel which are capable of attaining a desired profile, a desired pattern on its surface, and a desired inner structure in accordance with an application of the sandwich panel. According to an aspect of the invention, there is provided a thermoplastic resin core member interposed between two resin skin sheets comprising a closed hollow portion located to be inside of a desired position in accordance with an application of the sandwiched panel, and it is formed by clamping parison of a molten thermoplastic resin positioned to be between two split molds so as to exhibit a desired profile and / or a surface shape, two surfaces against each of which the molten parison is pressed to form an adhesive surface on which the corresponding resin skin sheet is formed.

Owner:KYORAKU CO LTD

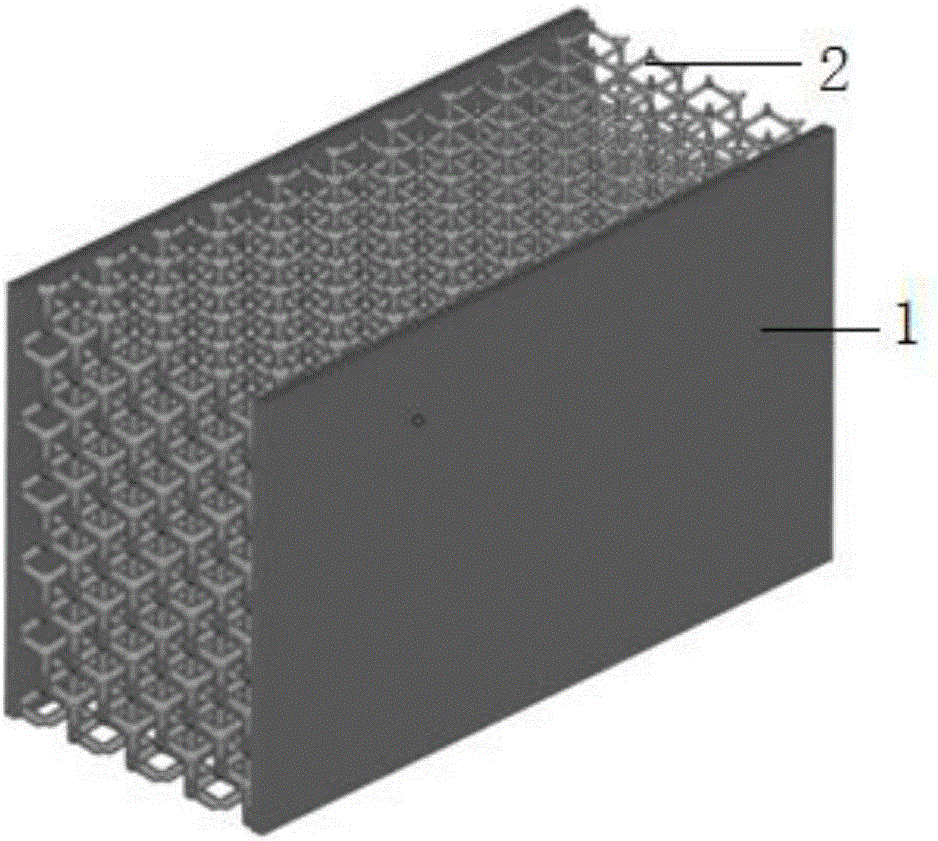

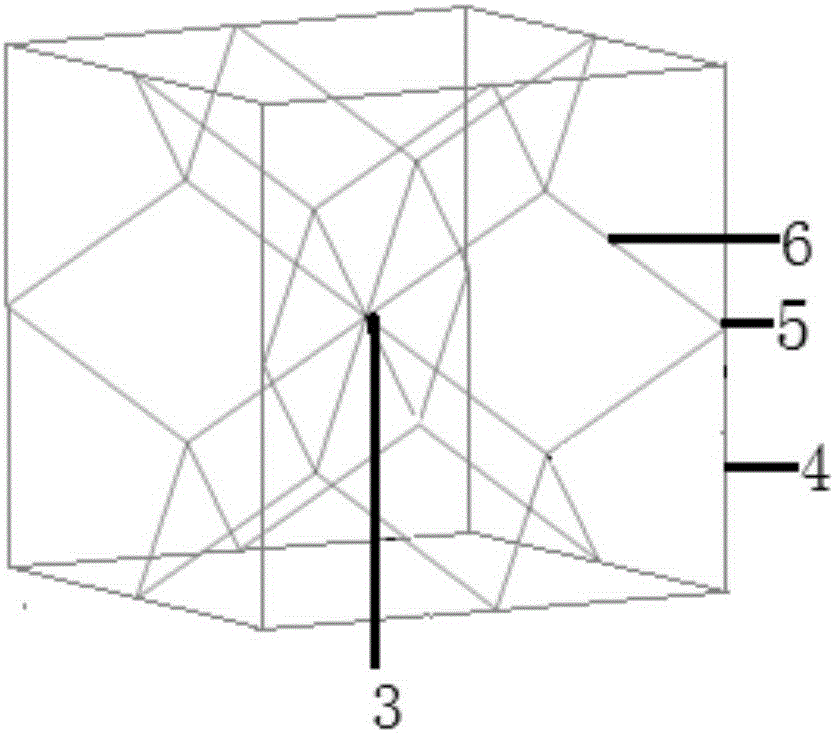

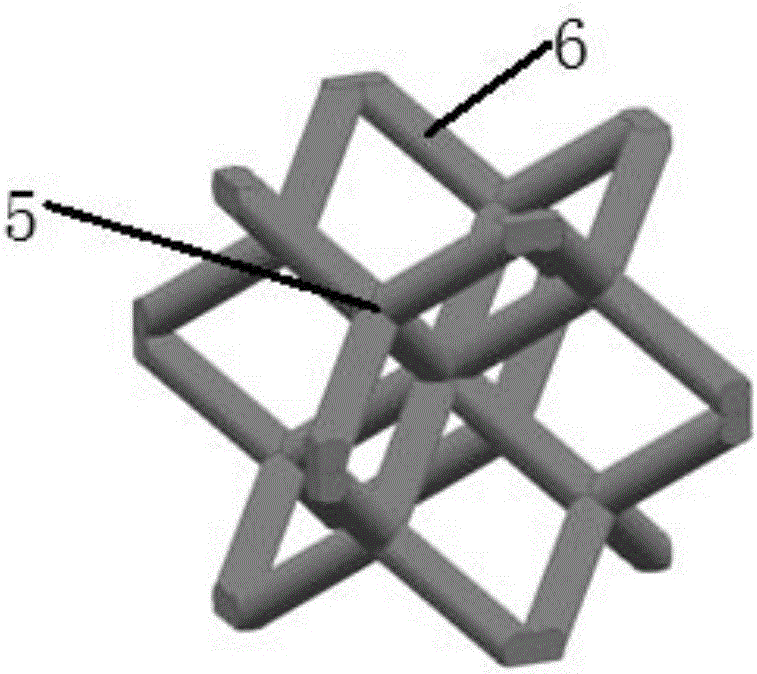

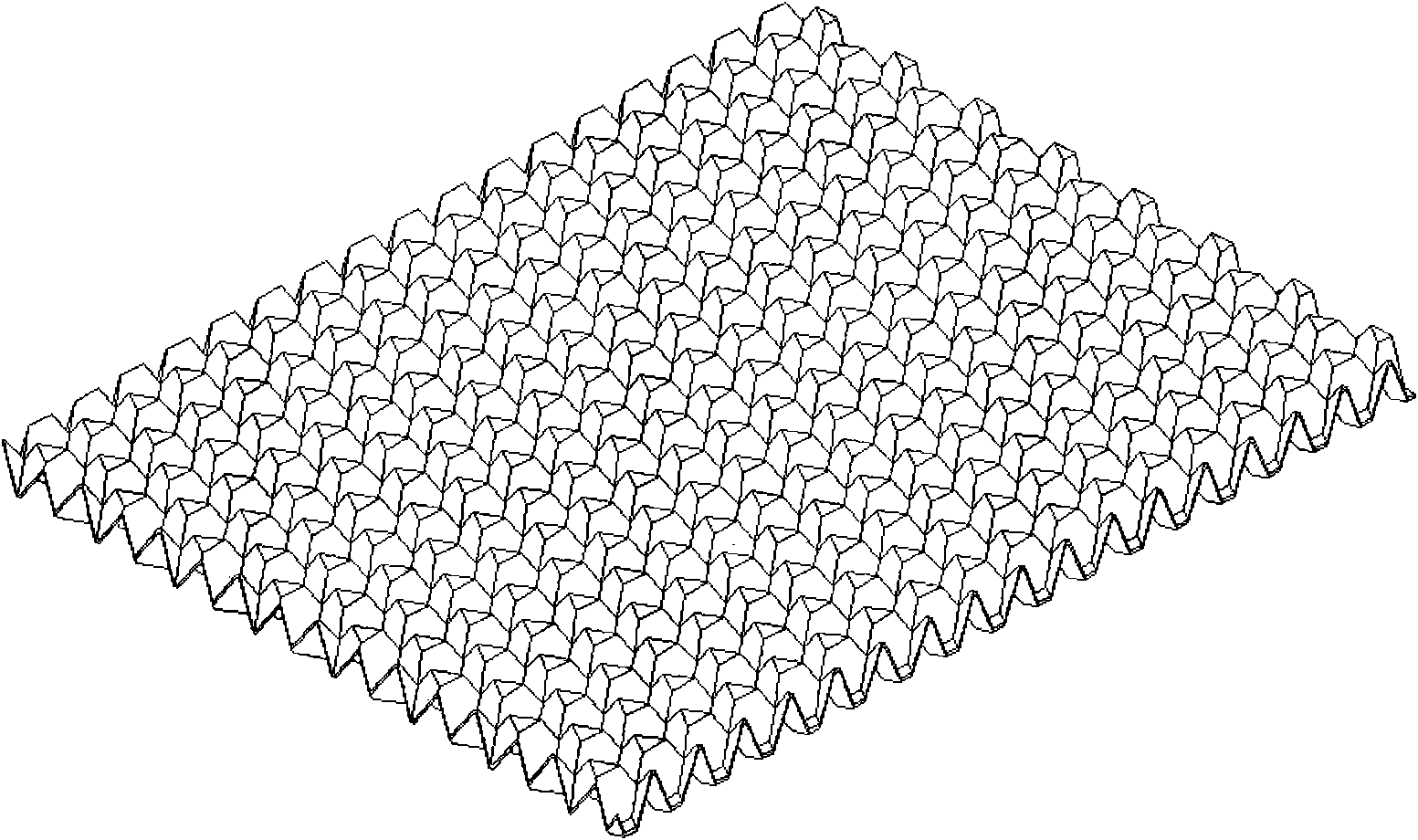

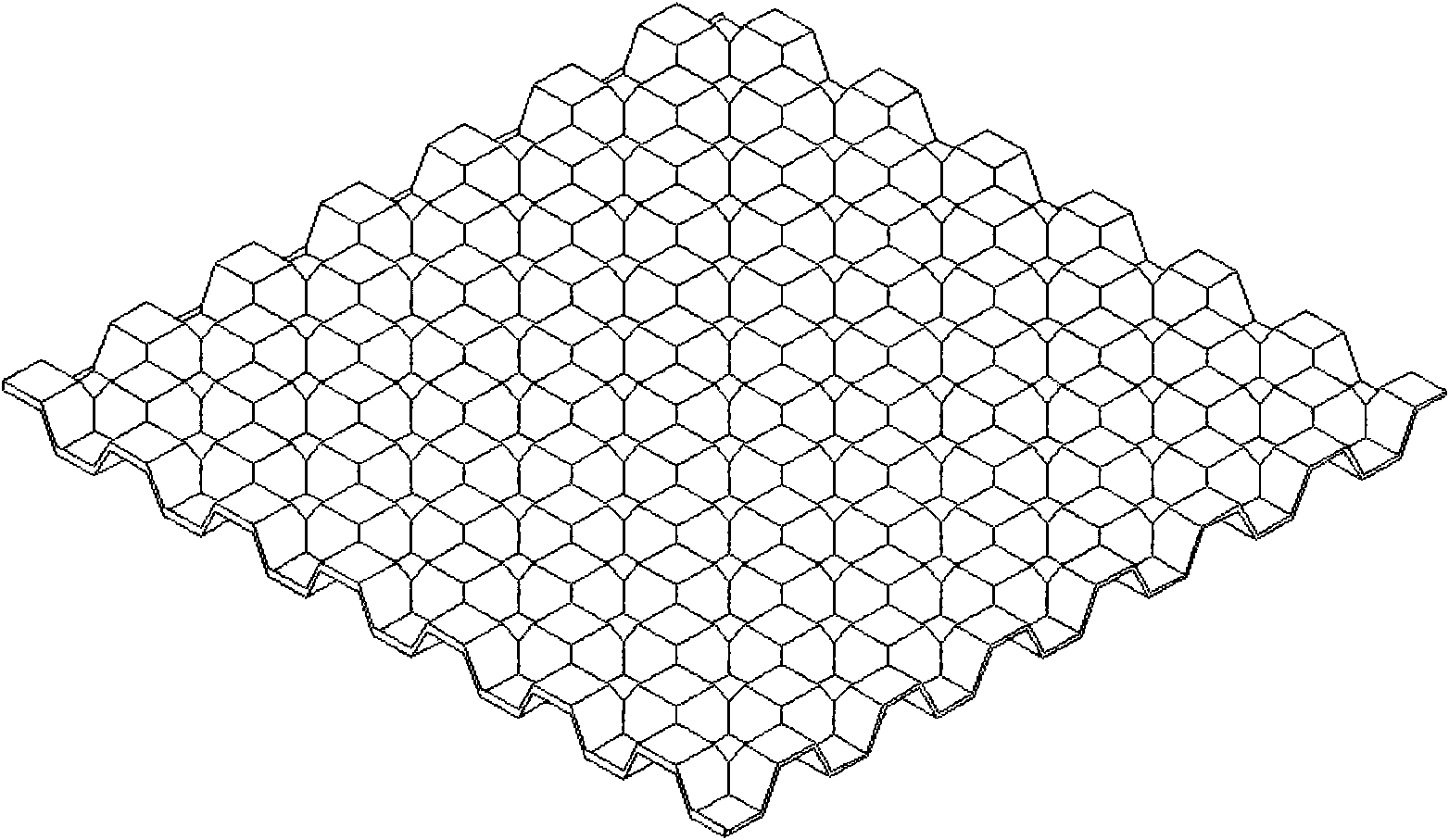

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

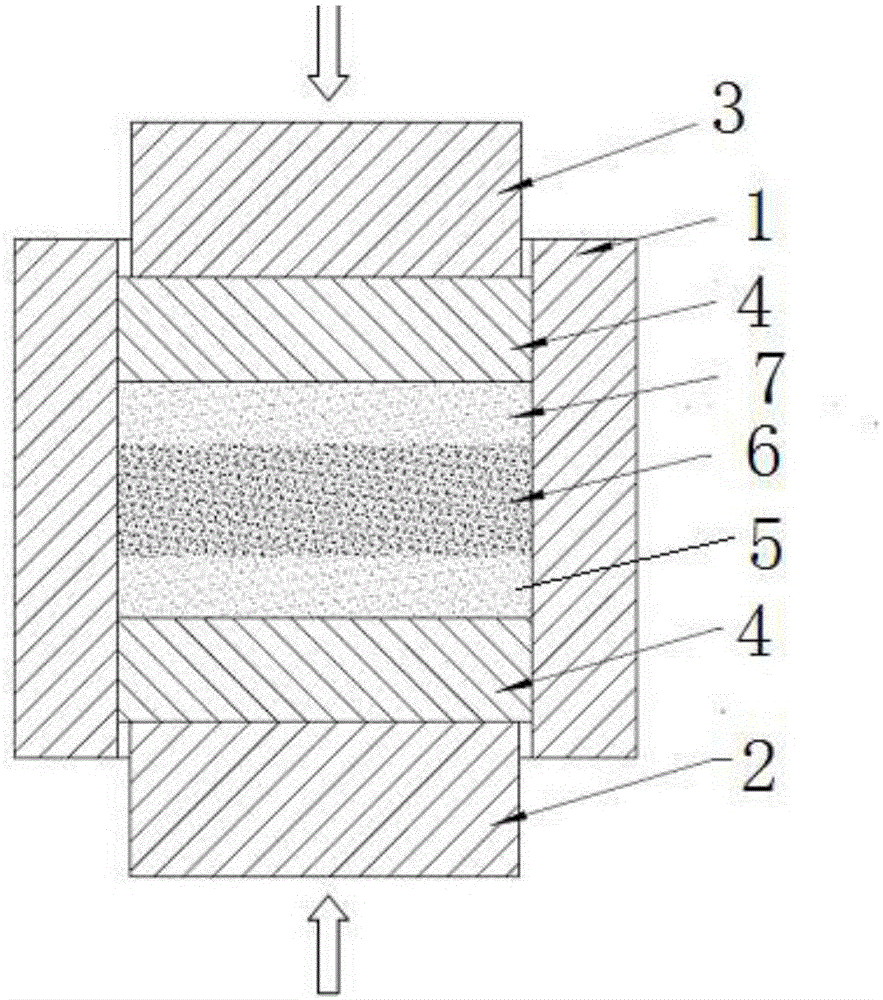

Novel foam-filled honeycomb sandwich board

InactiveCN101850638ARapid Foaming and CuringFoam curing is simple and convenientSynthetic resin layered productsBody shapeComposite construction

The invention discloses a novel foam-filled honeycomb sandwich board, the structure of which comprises a pyramidal honeycomb core, rigid polyurethane foam and panels clamping both sides of the rigid polyurethane foam. Mould pressing, rolling and other methods are utilized to process a whole board / sheet into a latticed supporting body-shaped core board as the pyramidal honeycomb core with a series of staggered concave-convex truncated pyramids on both sides, a V-shaped groove can be formed at the joint between the slanted arrises of neighboring raised truncated pyramids, so that the notches of the truncated pyramids on the core board are communicated with one another, moreover, the vertex of each truncated pyramid body is a small plane, so that the panels on both sides can be conveniently bonded, and the rigid polyurethane foam plastic is filled in the clearance of the pyramidal honeycomb core between the panels on both sides. The produced novel foam-filled honeycomb sandwich board has all the advantages of the honeycomb sandwich board and the foam sandwich board, and is a novel composite-structured board with the advantages of reasonable structure, excellent performance, light weight, high strength and simple and easy production technique, which can be widely applied in various fields such as aeronautics and aerospace, vehicles, ships, furniture and buildings.

Owner:王韬

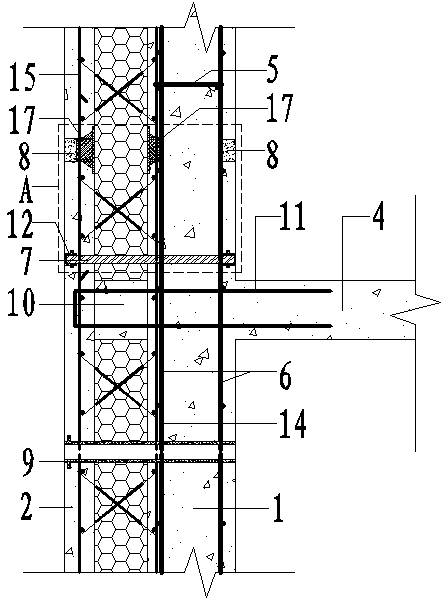

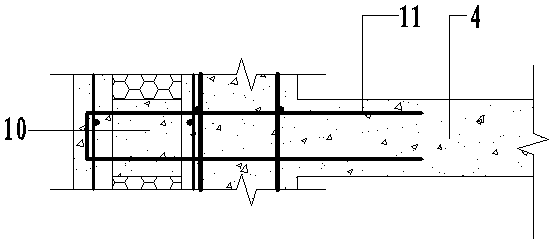

Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

ActiveCN103195193AGuaranteed section sizeSolving Linear Thermal Bridge ProblemsWallsBuilding material handlingFloor slabSandwich board

The invention relates to a structure and a construction method of a cast-in-style welded steel frame composite concrete shear wall. The structure comprises an indoor concrete layer, an outdoor concrete layer and a wire frame insulation sandwich board. The wire frane insulation sandwich board is coated between the indoor concrete layer and the outdoor concrete layer. At least two rectangular and groove-typed cantilever holes are arranged at the top of the sandwich board, and each cantilever hole is provided with a U-shaped cantilever anchor bar which penetrates through the sandwich board and a floor slab to be fixedly connected with the floor slab. The construction method includes site preparation work, binding of load-bearing steel bars of a wall body and edge member steel bars, custom processing of the sandwich boards, installation of the sandwich boards, pavement of template positioning pieces and wall bushings, fixation of water and electric pipes inside the wall body, binding of ordinary blocks on both sides of the wall body steel bars, erecting of the templates, pouring of the concrete, removing of the templates and concrete curing. Since a series of composite wall construction methods are adopted, problems existing in the prior art are solved, and a composite heat preservation technology is improved.

Owner:石家庄晶达建筑体系有限公司

Method for preparing metal honeycomb core and honeycomb sandwich board

ActiveCN103009013ANo pollution in the processOvercome the shortcomings of large performance impactSoldering apparatusLaminationSandwich boardHoneycomb

The invention discloses a method for preparing a metal honeycomb core and honeycomb sandwich board. Aluminum, stainless steel and copper honeycomb core and honeycomb boards are prepared by using a brazing filler metal brazing method; according to the invention, a prepared product joint can form a metallurgical structure, which can be secondarily welded, can be machined and is featured with light weight, high strength, large rigidity, good stability, heat and sound insulation properties and no pollution; and the defect that the performance of an adhesive greatly influences the traditional adhesive honeycomb board honeycomb core is overcome; the mechanical property of the metal honeycomb core and honeycomb sandwich board is far higher than that of an adhesive material; moreover, a preparation process and operation means are simpler; all the performances are obviously improved; and the method for preparing the metal honeycomb core and honeycomb sandwich board, disclosed by the invention, is suitable for industrial production.

Owner:QINGDAO TAIHONG TRACK EQUIP

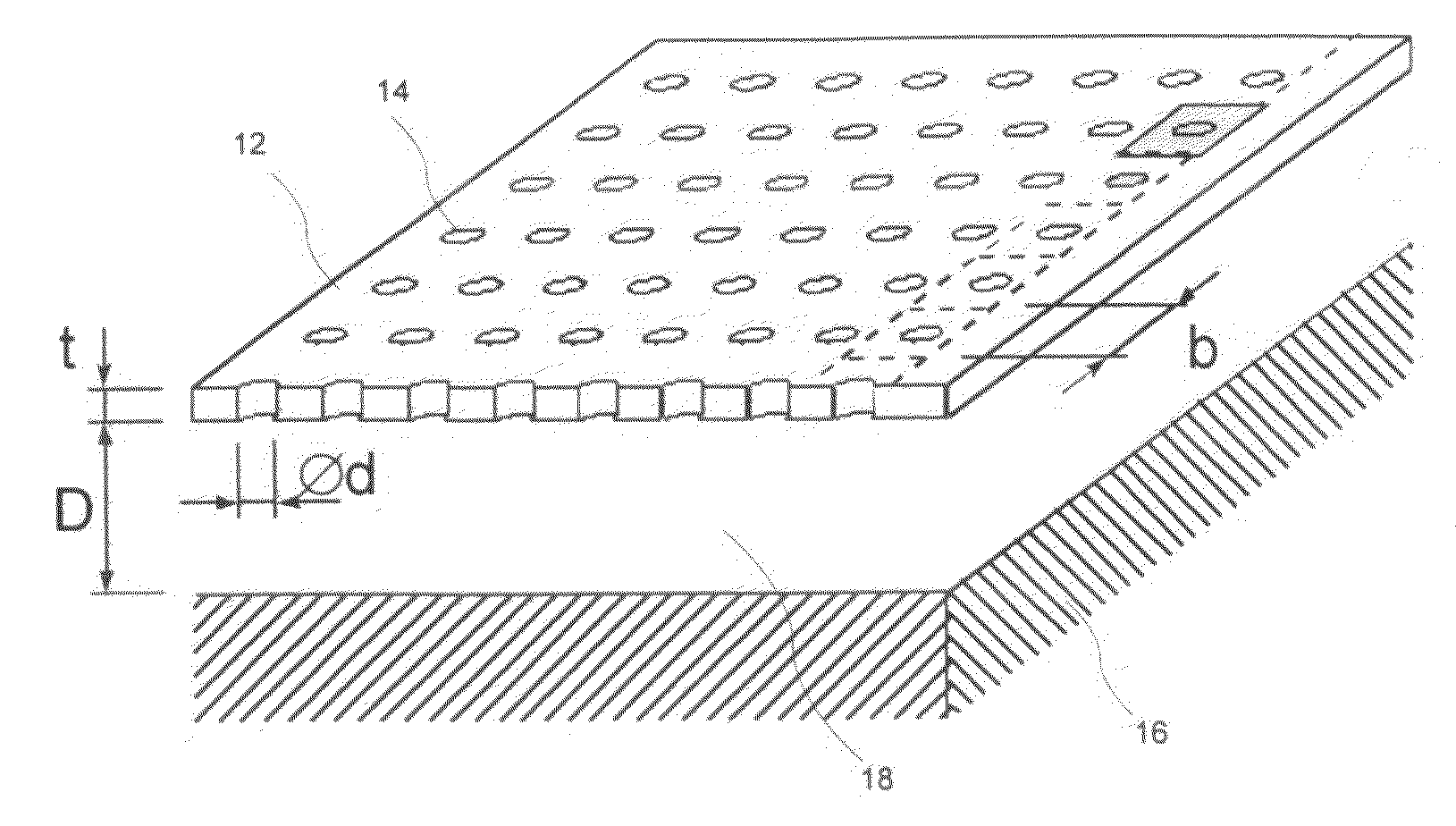

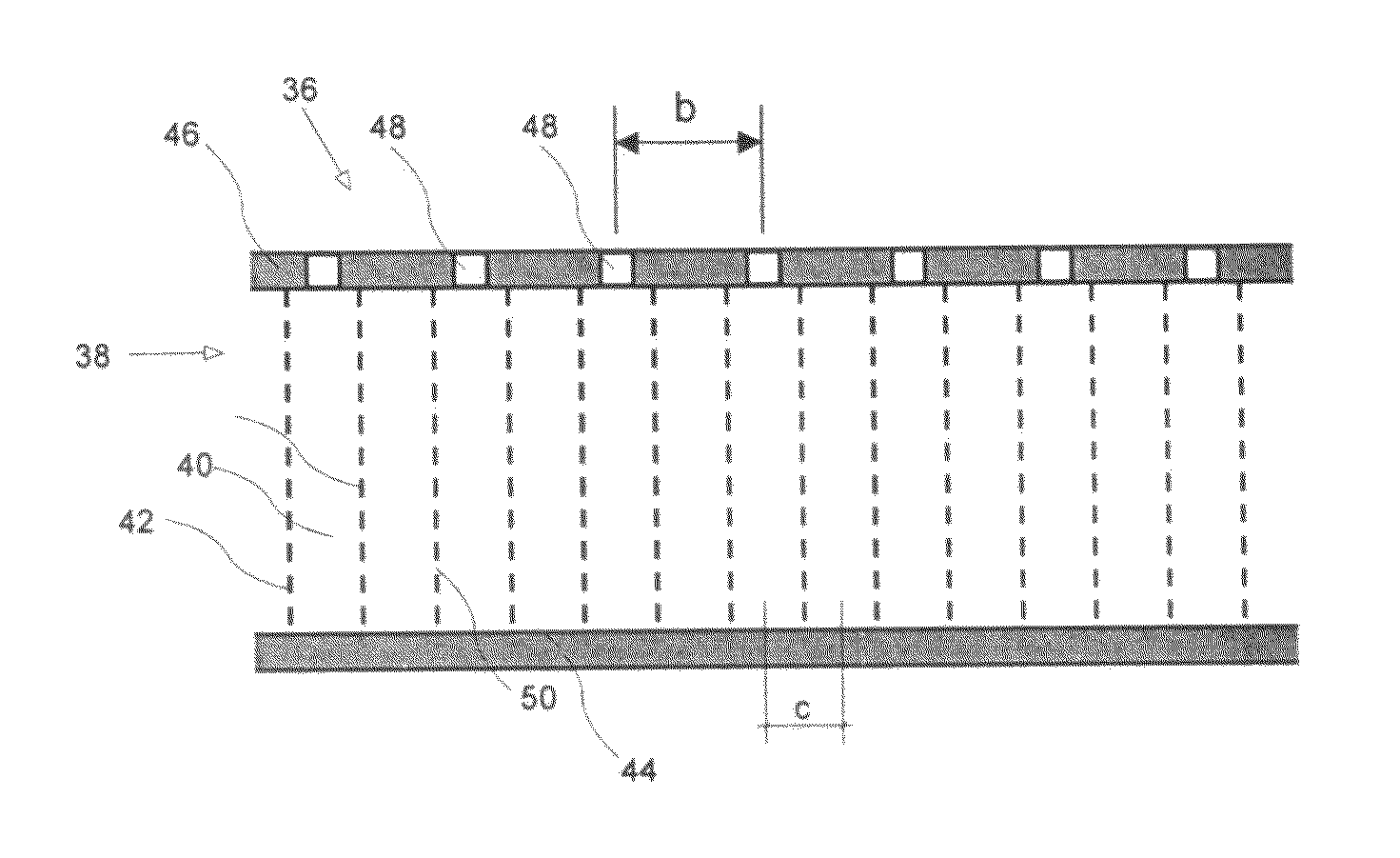

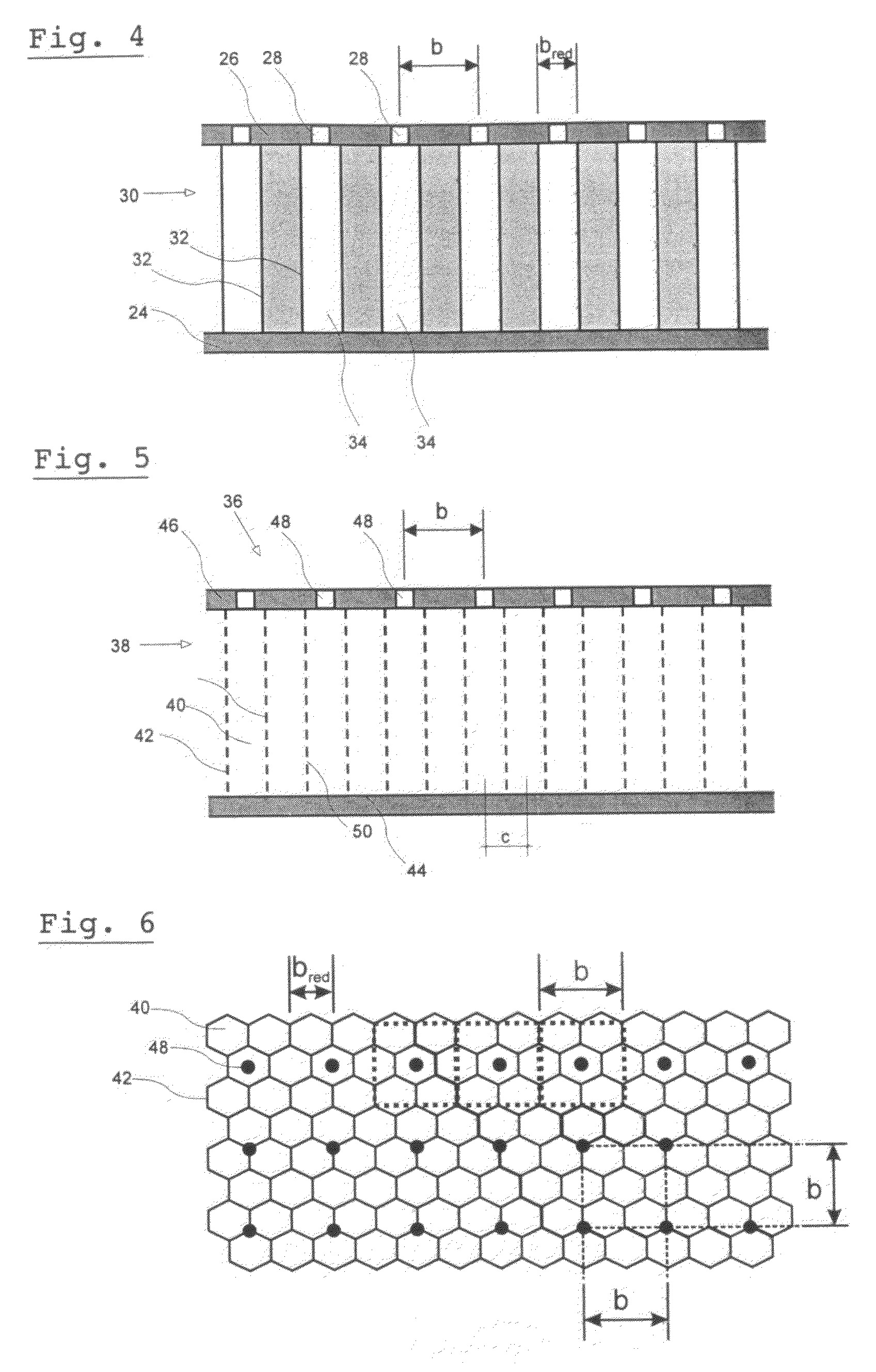

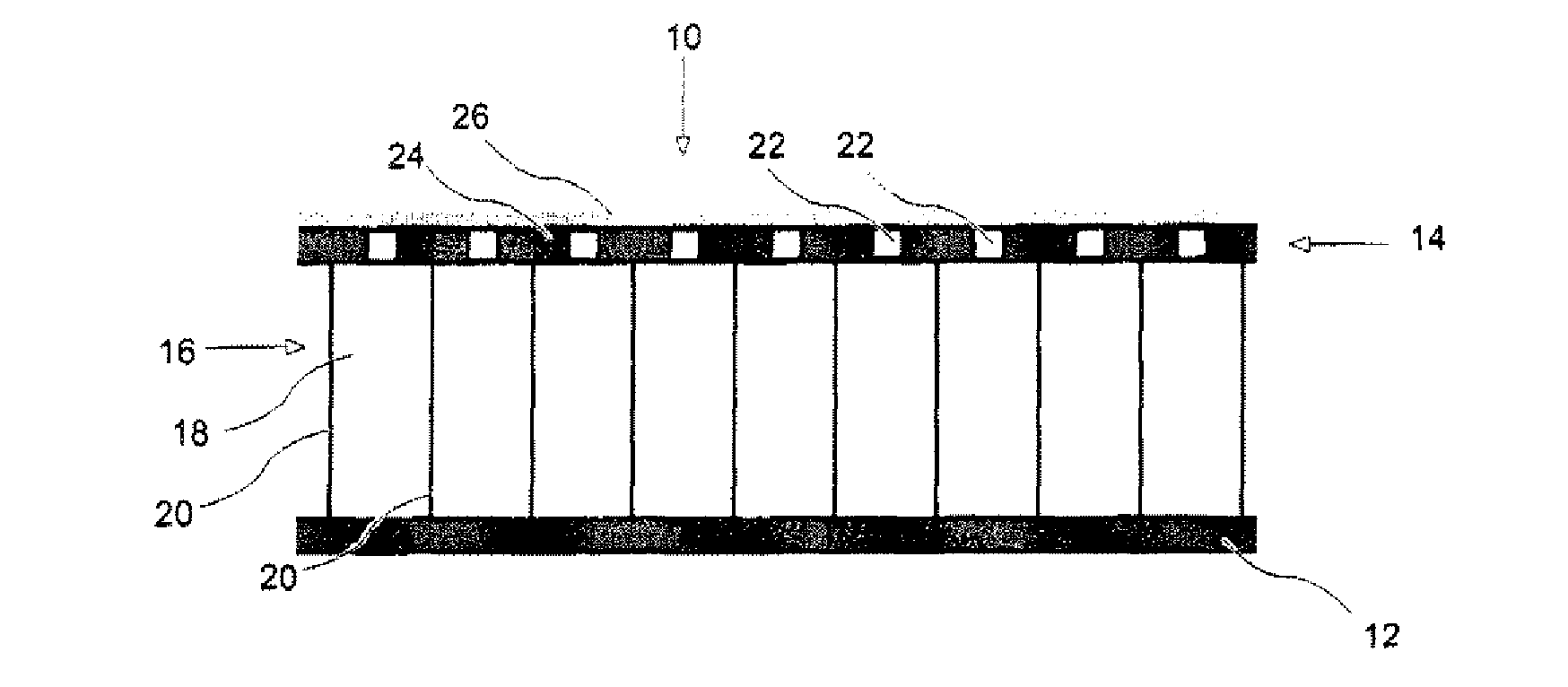

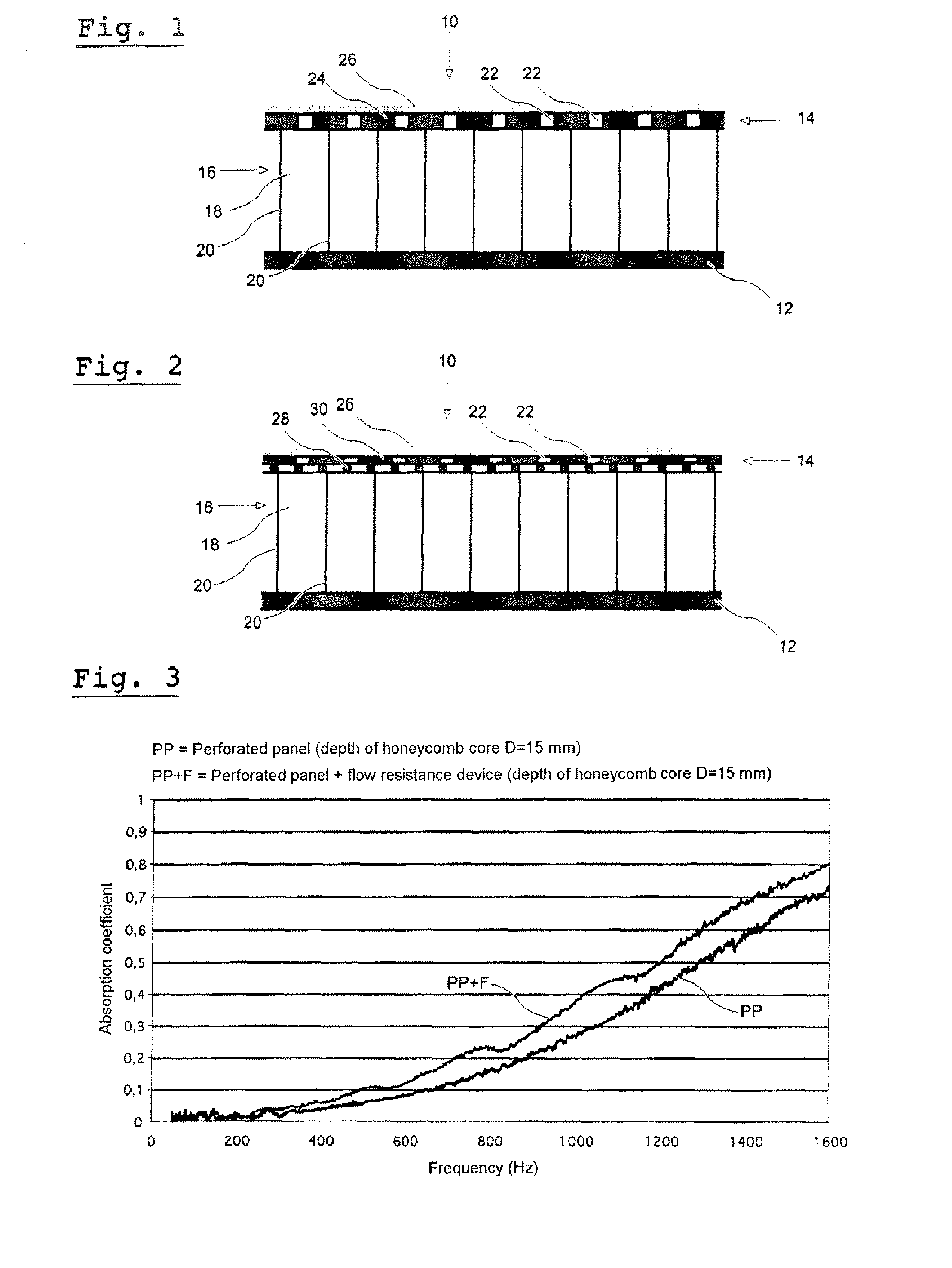

Sandwiich panel for sound absorption

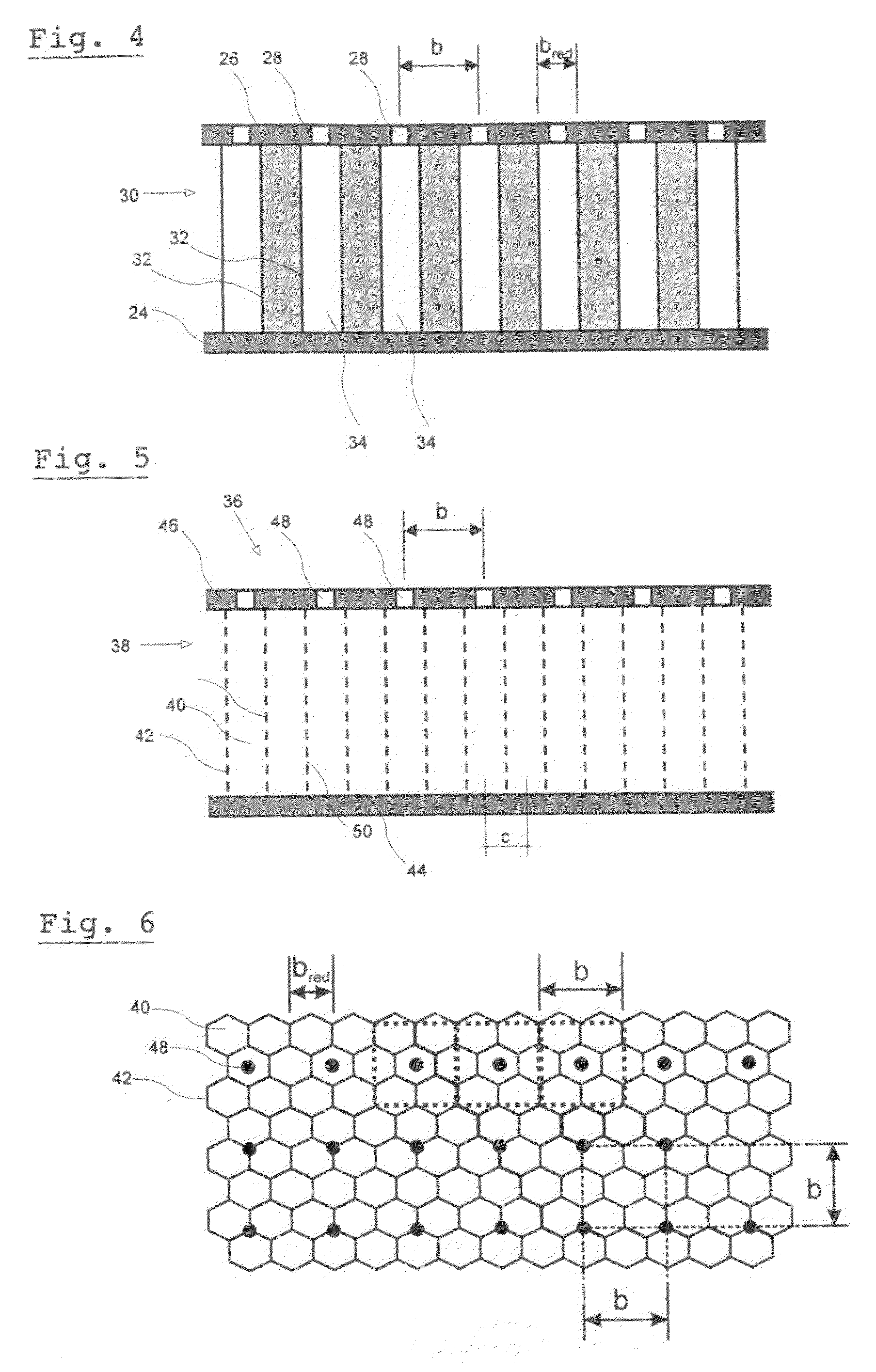

ActiveUS20090166127A1Large space volumeReduce weightPump componentsBlade accessoriesSandwich boardEngineering

An aircraft cabin panel for sound absorption, with a sandwich construction, comprising a core layer that comprises a plurality of tube-like or honeycomb-like cells that extend in an open manner across the thickness of the core layer and that are separated from each other by cell walls and that are uniform in design. A first cover layer faces away from the sound field, as well as a second cover layer that faces towards the sound field and that comprises a plurality of perforation holes and adjacent cells are interconnected by way of apertures in the cell walls. The perforation of the second cover layer comprises a distance (b) between holes, which distance exceeds the opening width (c) of the cells of the core layer, wherein the first cover layer is closed and wherein the cell walls comprise a perforation so that they are acoustically transparent in the direction parallel to the cover layers.

Owner:AIRBUS OPERATIONS GMBH

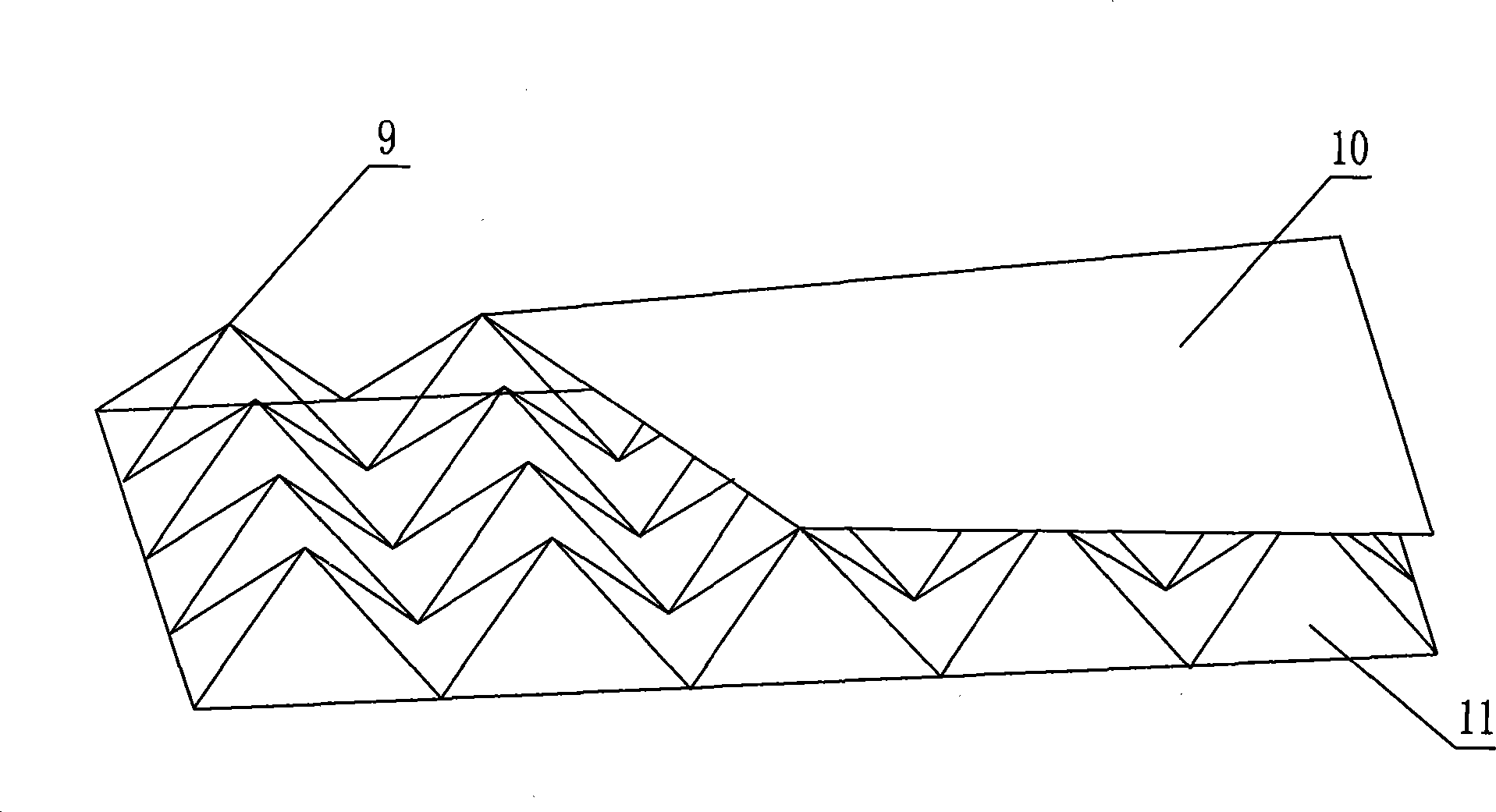

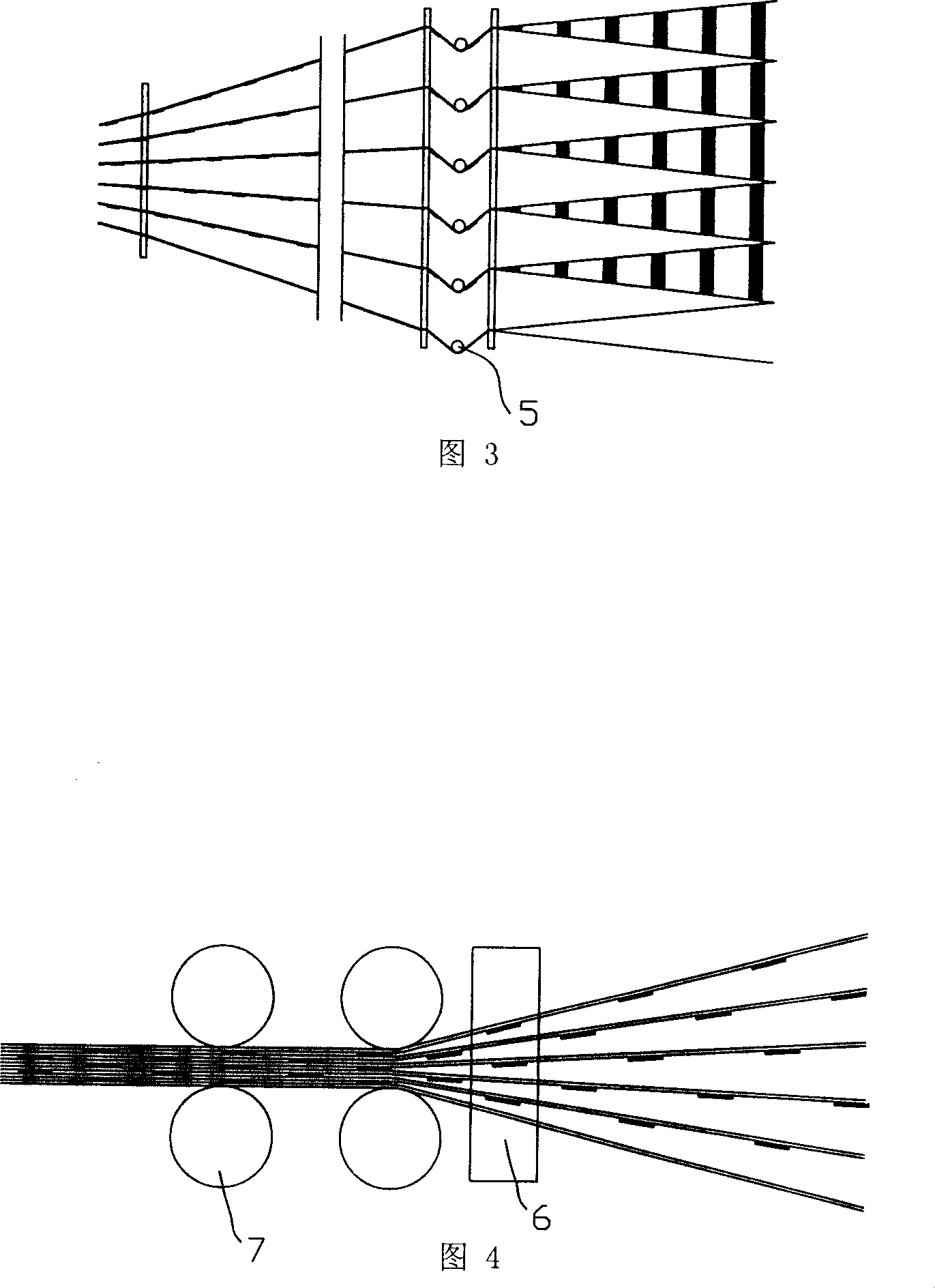

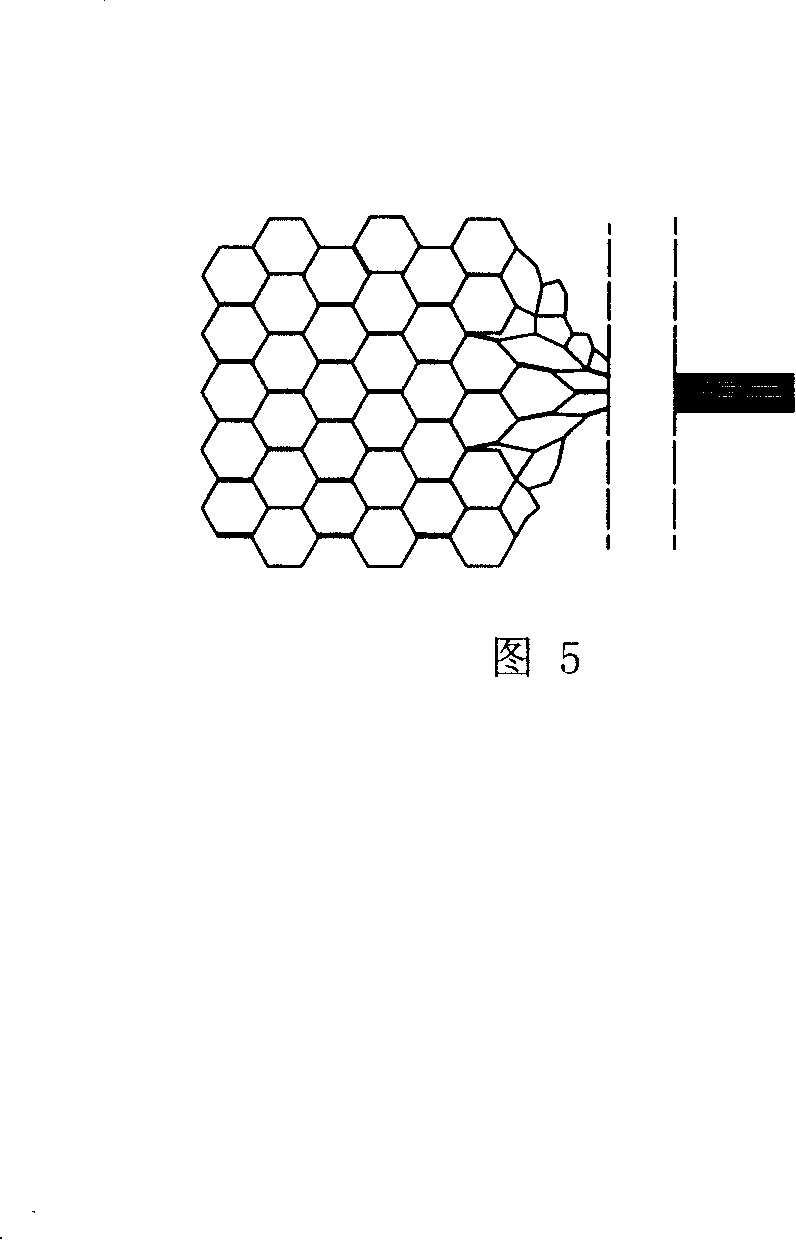

Fibre reinforcement pyramid shape dot matrix sandwich board and preparation thereof

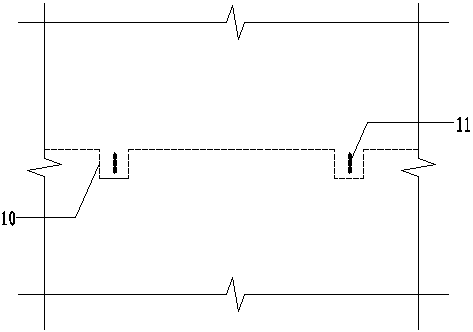

The invention discloses a fiber reinforced lattice laminboard in the shape of a pyramid and its preparation method, and relates to a fiber laminboard and its preparation method. The invention overcomes the difficult of forming to the lattice laminboard and the problem of that materials limits to metal materials. A plurality of the pyramid lattice pillars (9) are positioned between the upper plate(10) and the lower plate (11) obliquely and longitudinally, the upper head face of the pyramid lattice pillar(9) connects with the lower plane of the upper plate (10), and the lower head face of the pyramid lattice pillar(9) connects with the upper plane of the lower plate (11). Methods are (1) designing a mould, (2) assembling the mould, (3) spreading the upper plate (10)of fiber and the lower plate (11) which are prepared to immerse into material, (4) injecting the epoxy resin into the pyramid lattice pillar hole (10), (5) solidifying on a hydrostatic press by pressure and heat, then the fiber reinforced pyramid lattice laminboard is made. The composite material lattice laminboard of the invention has great specific tenacity, greater specific stiffness, simple process.

Owner:HARBIN INST OF TECH

Easy parking finder

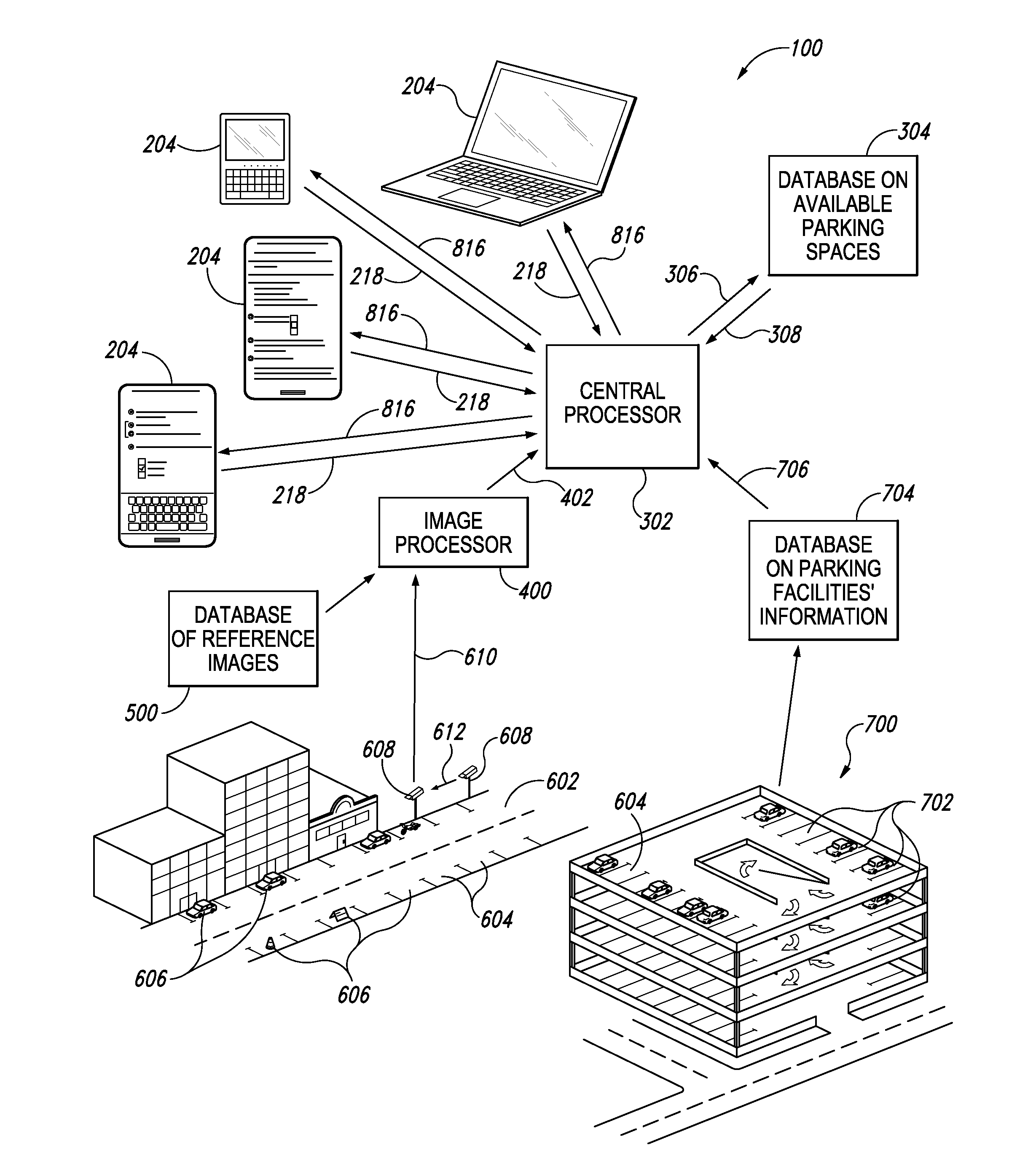

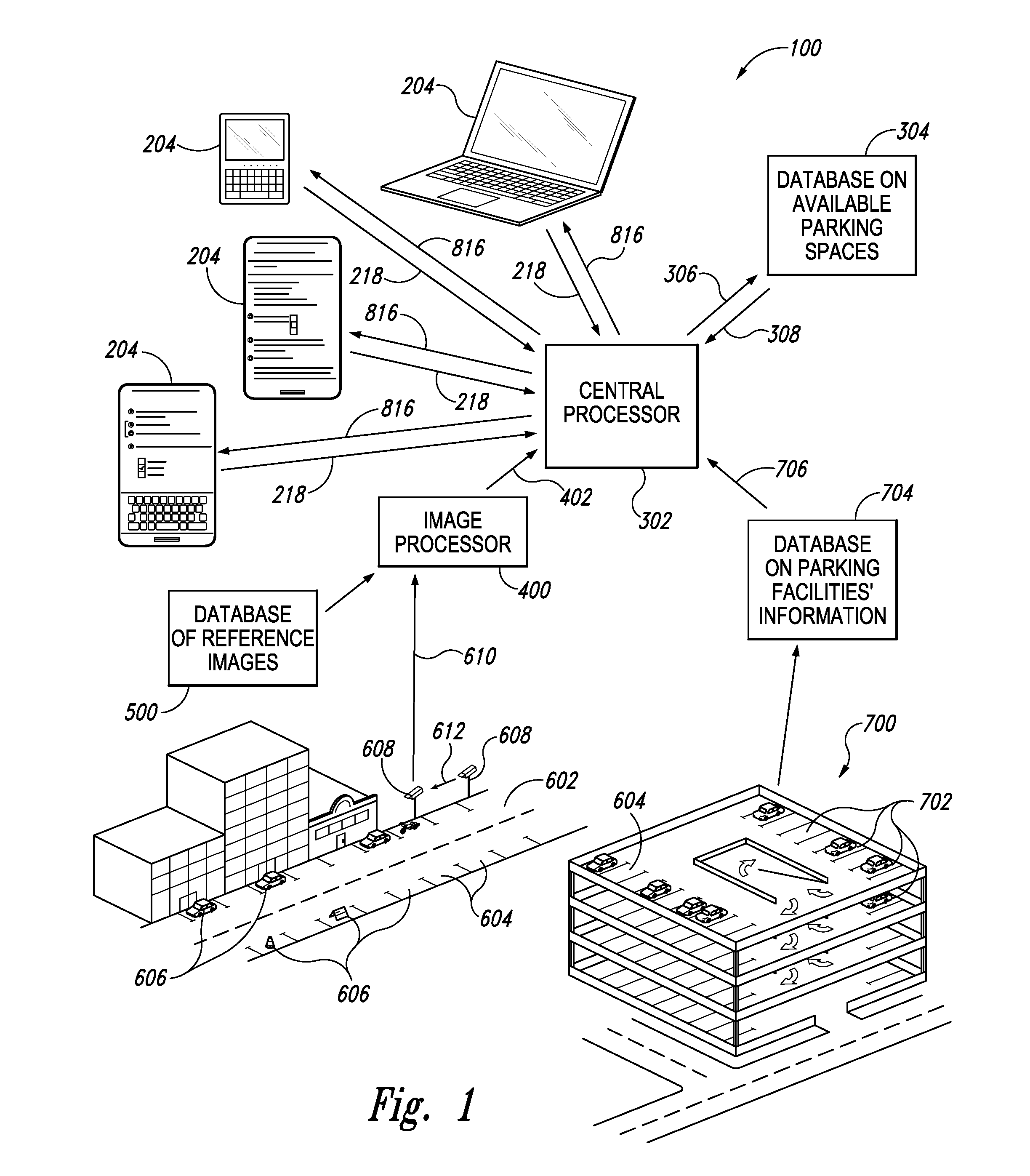

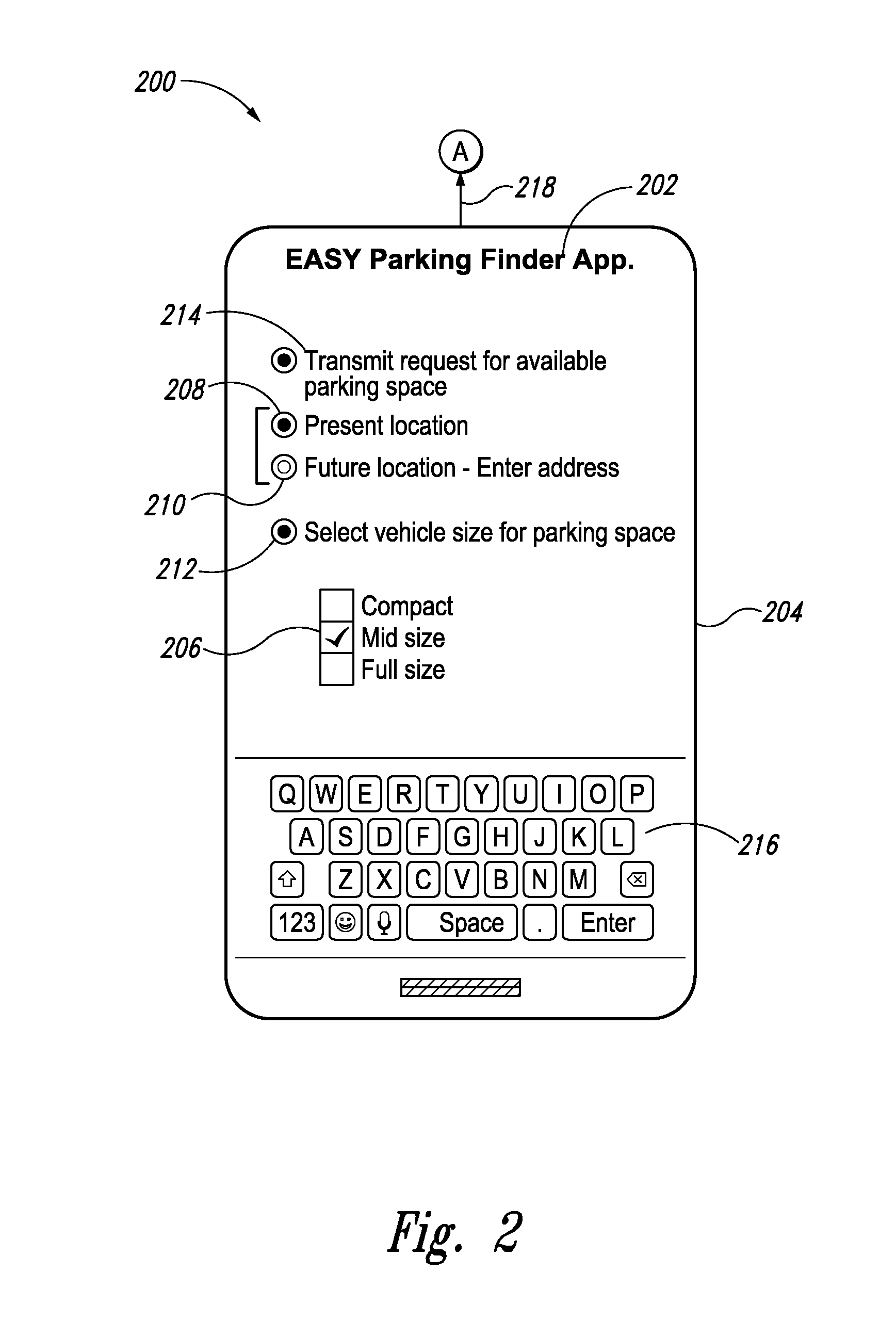

A driver uses a mobile phone application to transmit a request to a central processor for information on available parking spaces, accommodating a specific size car, close to her present location or a future location.An image processor processes real time images from linked cameras overlooking parking spaces, comparing them with reference images of unoccupied parking spaces, vehicles including automobiles, bicycles and motorcycles, a no parking sign sandwich board and a traffic cone. The image processor sends the information on available parking spaces to the central processor.The central processor saves image processor information and information on available parking spaces, parking fee and advertising promotions from parking facilities on a database and transmits a response to the driver's request.The mobile phone application displays and audio broadcasts the response. The driver pays a fee and reserves an available parking space to exclude it from responses to other requests.

Owner:NAKHJAVANI OMID B

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

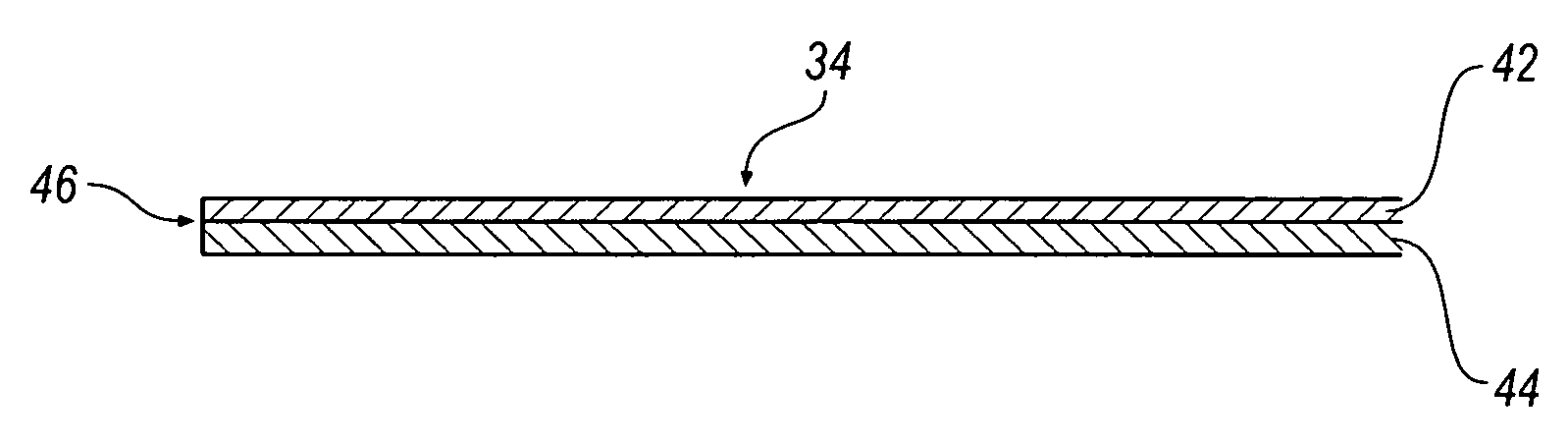

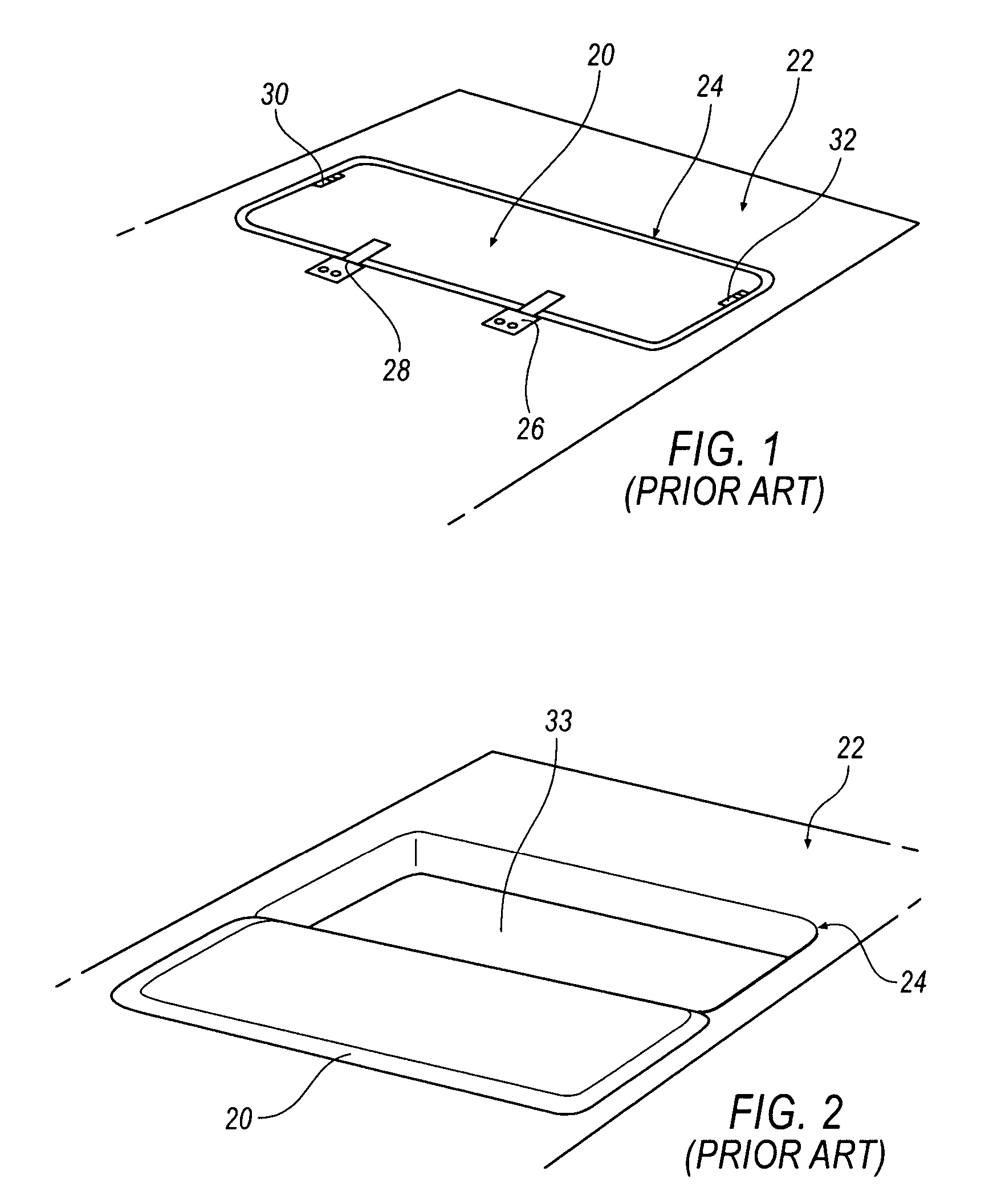

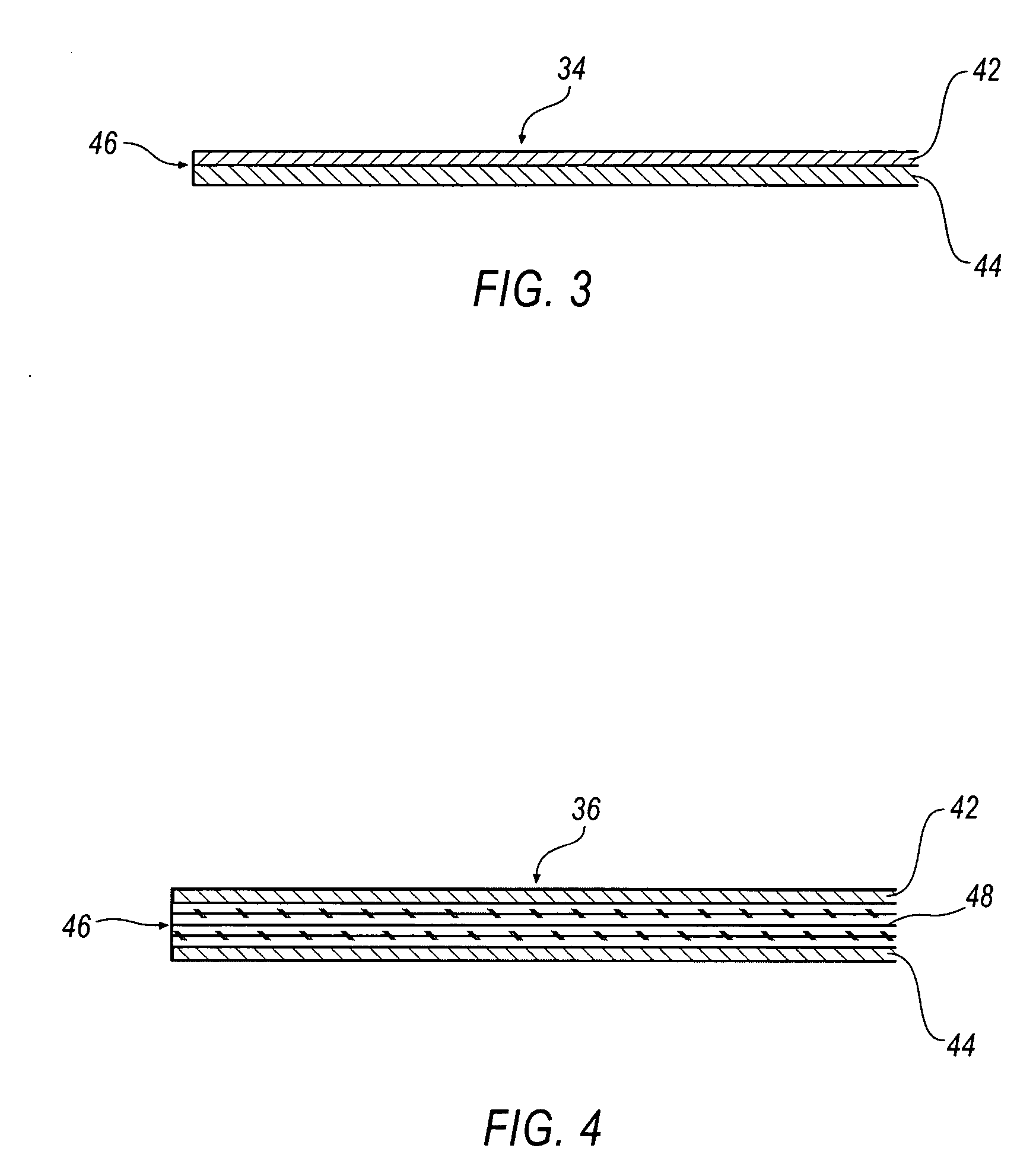

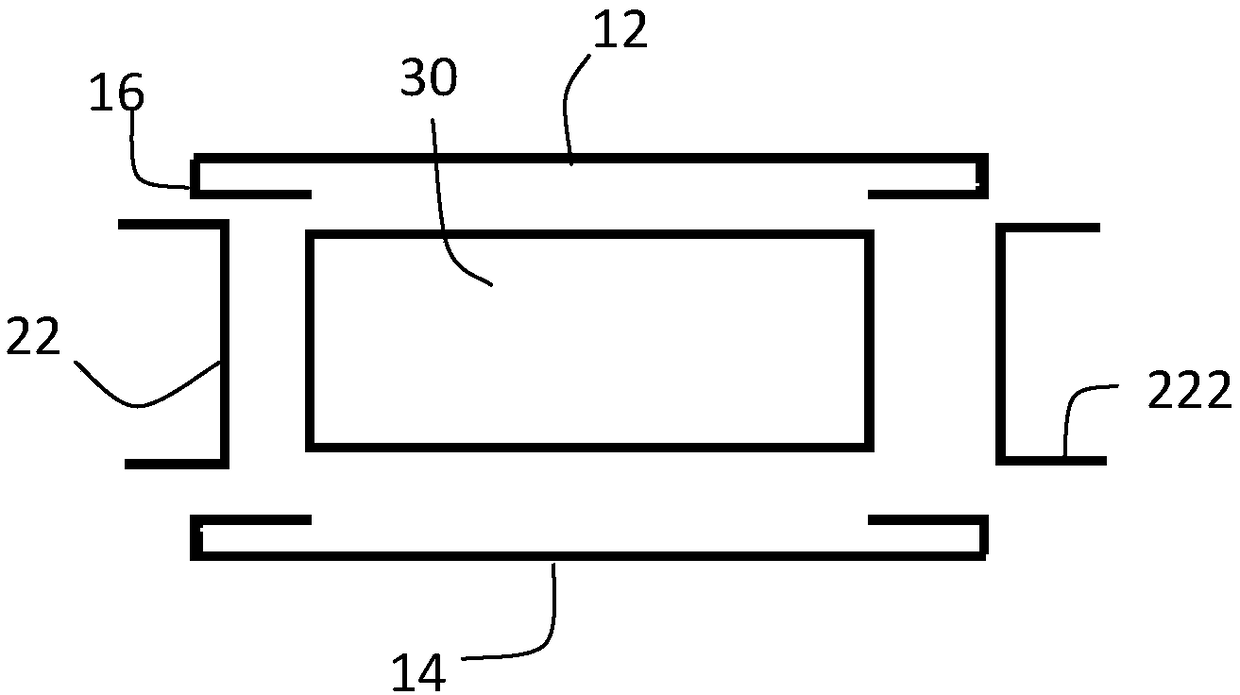

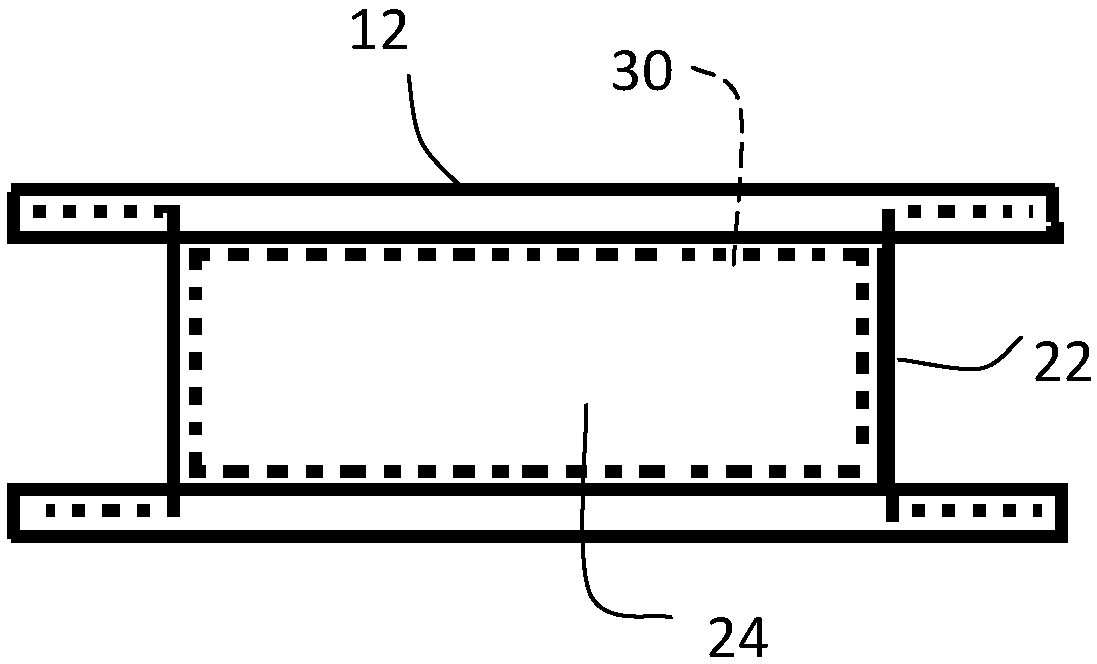

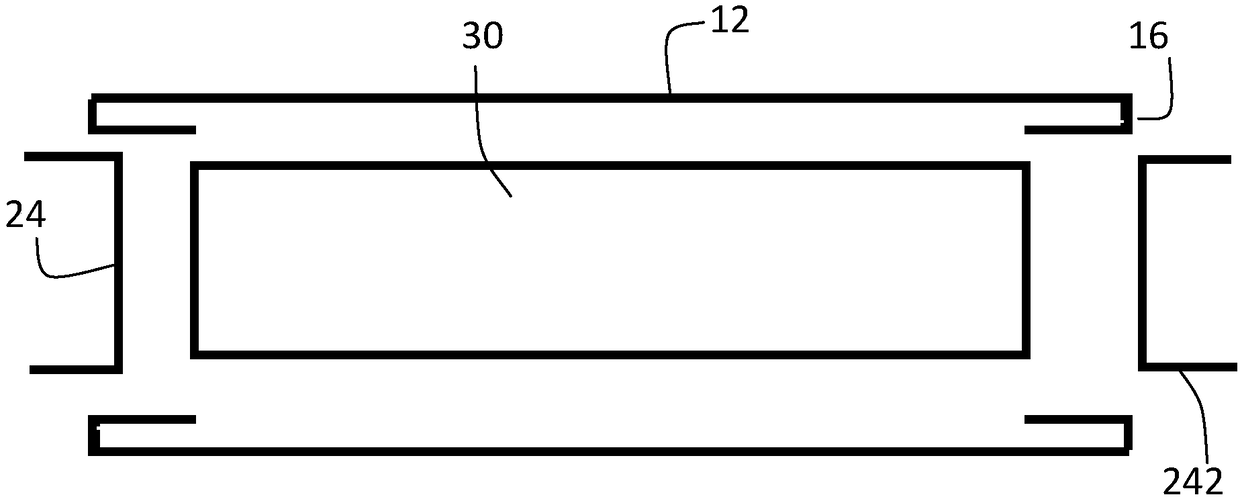

Sandwich panel and method of manufacturing same

InactiveUS20060008609A1Improve reliabilityImprove fit and finish of the panelCellulosic plastic layered productsPaper/cardboard layered productsSandwich boardPressboard

A sandwich panel having a pair of skins and an intermediate substrate secured between the two skins creating a structural panel. The skins may be a pressboard material and a covering material may be applied to the skins forming an exterior surface. Selectively, the skins may be covered with a material. Further, an edge member may be provided that is engaged around the peripheral edge of the intermediate substrate. The edge member may include an engaging member and the engaging member may include anti-reverse fins. The edge member may also trap the covering material. A method of manufacturing a sandwich panel for an automobile where two skins of predetermined size and shape are provided. The two skins are attached to each other forming a structural panel. An intermediate substrate may be provided and attached between the skins. Further, an edge member may be provided and attached to the periphery of the structural panel.

Owner:GRUPO ANTOLIN NORTH AMERICA

Sandwich panel for sound absorption

ActiveUS7743884B2Large space volumeReduce weightPump componentsFuselage insulationSandwich boardEngineering

Owner:AIRBUS OPERATIONS GMBH

Light-weight and high-strength thermoplastic composite material sandwich board and production method thereof

InactiveCN103568396ALight in massLightweight and high-strength qualitySynthetic resin layered productsLaminationSandwich boardHoneycomb

The invention relates to a light-weight and high-strength thermoplastic composite material sandwich board and a production method thereof. The light-weight and high-strength thermoplastic composite material sandwich board comprises two panels and a sandwich layer, wherein the sandwich layer is fixedly arranged between the two panels. The preparation method comprises the following steps: putting the sandwich layer between the two panels; and sticking the two panels on the front and rear faces of the sandwich layer by a thermoplastic glue film through a hot pressing process and a cold pressing process to produce the thermoplastic composite material sandwich board. The panels are continuous fiber enhanced thermoplastic composite material boards and the sandwich layer is made of a honeycomb aluminum material. Compared with the prior art, the thermoplastic composite material sandwich board has the advantages of light weight, high strength, heat preservation, fireproof prevention, moisture prevention, corrosion prevention and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

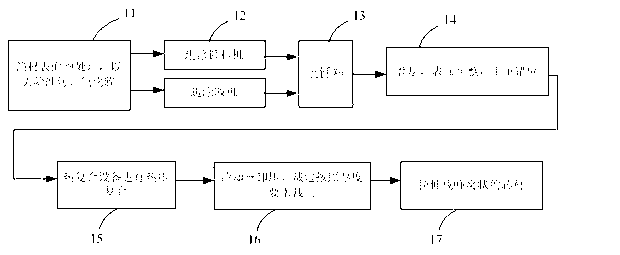

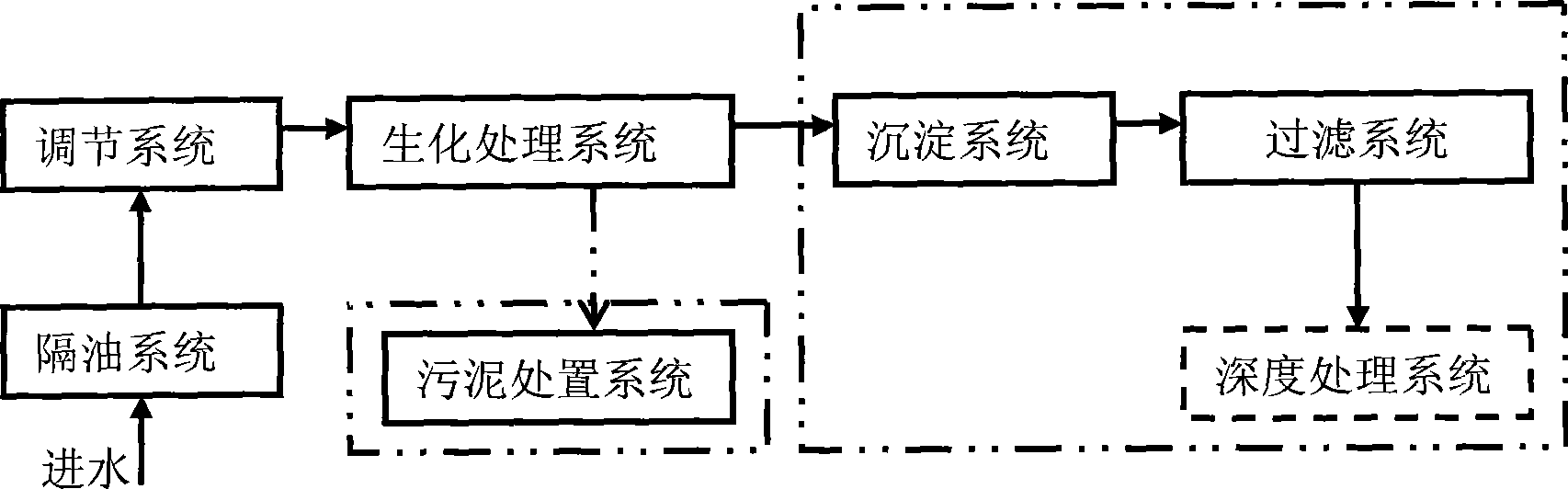

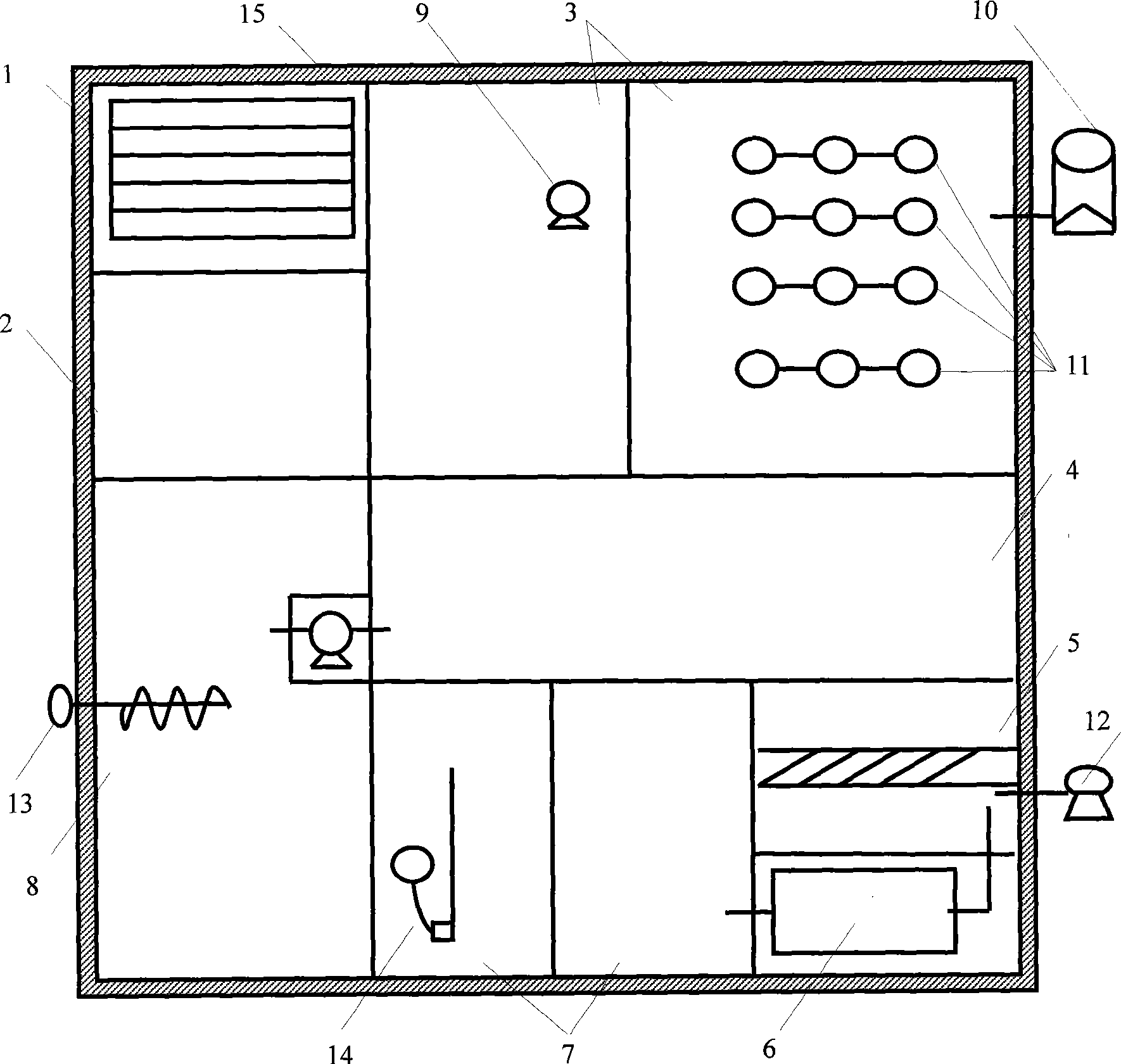

Apparatus for integrated treatment and comprehensive utilization of wastewater and use thereof

InactiveCN101462816AImpact treatmentAvoid cloggingBio-organic fraction processingFatty/oily/floating substances removal devicesSludgeSandwich board

The invention relates to a wastewater integrated treatment and comprehensive utilization device and application thereof. A method for the wastewater integrated treatment and comprehensive utilization comprises the following steps: firstly leading the wastewater into an oil interceptor tank and then into an equalizing tank; leading the wastewater after neutralization regulation into a biochemical treatment tank where a sump pump and an aeration device are arranged; leading the wastewater after the biochemical treatment into a sedimentation tank; leading the sedimentated wastewater into a filter tank with built-in filler for the filtration treatment of the wastewater; arranging a back flushing device or filtering material regeneration device beside the filter tank; leading the water outputted from the filter device into an advanced treatment tank to obtain the reclaimed water up to the standards; leading the reclaimed water into a reclaimed water tank where a liquid level controller is arranged for controlling the liquid level; and lifting the rest sludge in the sedimentation tank to a sludge drying compost tank, and carrying out the moderate temperature and high temperature composting of the rest sludge through a temperature controlled heating device. The integrated device is enveloped by an insulating layer formed by polyurethane sandwich boards. The invention provides an integrated device which has the advantages of modularized unit structure, high treatment efficiency, strong self control, wide adaptability, less investment and convenient motion and transportation.

Owner:ZHEJIANG UNIV

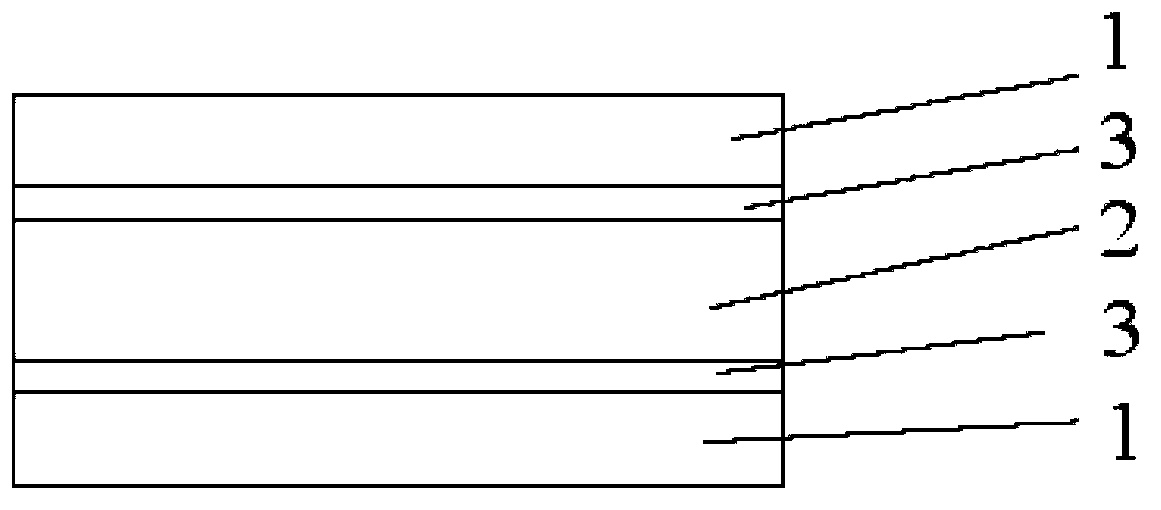

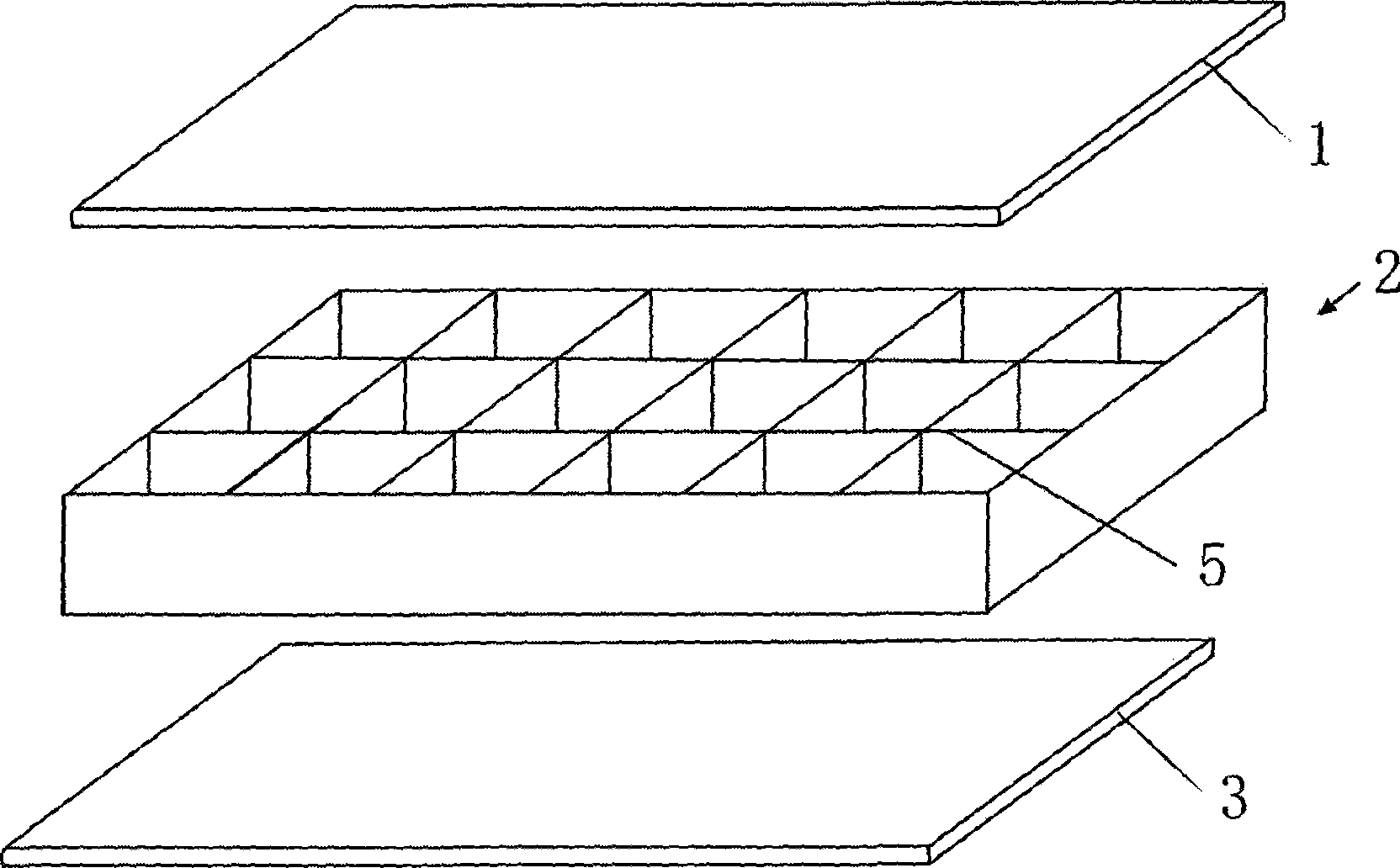

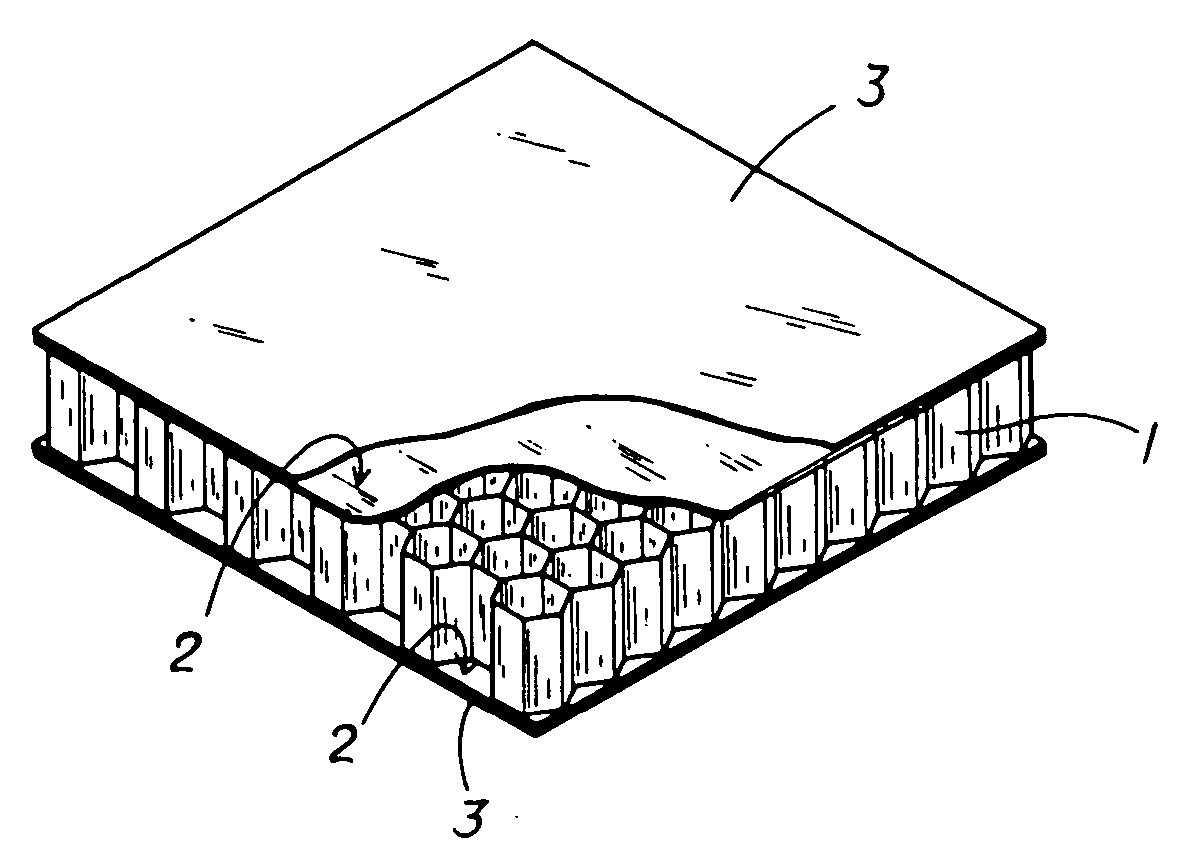

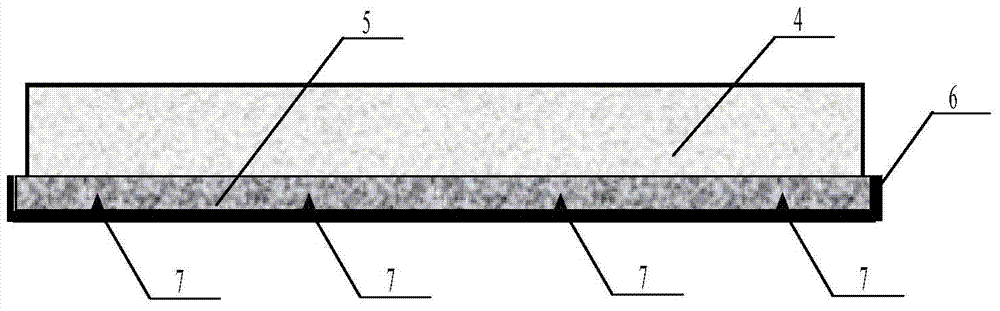

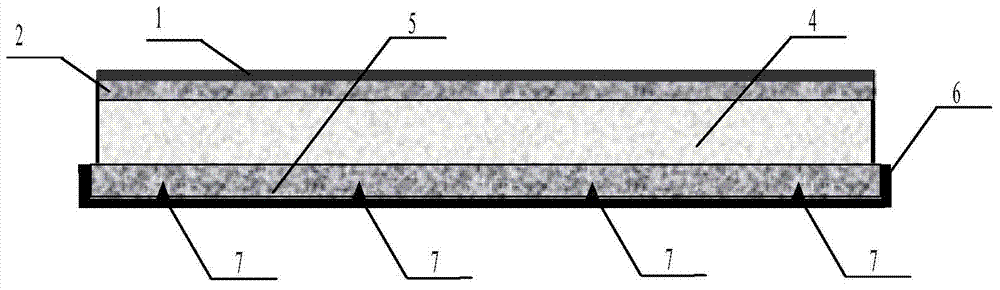

Wood sandwich board

InactiveCN101417450AImprove insulation effectReduce usageWood veneer joiningWood layered productsSandwich likeInter layer

The invention discloses a wood sandwich panel, comprising a board layer one (1), a sandwich layer (2) and a board layer two (3) which are inter-layer stuck and laminated into a whole; the sandwich layer (2) comprises a wood structure framework (5) and filling agents filled in the wood structure framework (5); the wood structure framework (5) is crisscross and uniformly distributed in the sandwich layer; the board layer one (1) and the board layer two (3) can adopt reconstituted decorative veneer or other boards. By introducing the wood elements to the production of the sandwich panels, the invention increases the decorative effect, expands the use ranges of the sandwich panel to meet the requirements of high-grade decoration; in addition, the panel is high in strength, stable, solid, good in sound insulation effect, light as well as massive and has good thermal insulation performance, so the panel can be widely applied for partition, floors, doors, interior wall decoration and repairs of ceilings and roofs and is suitable for high-grade places such as hotels, airports, exhibition centers, villas, and the like.

Owner:庄启程 +2

Preparation of foamed metal sandwich board using clad rolling method

InactiveCN1410200AHigh bonding strengthEquipment condition is simpleAuxillary arrangementsMetal rolling arrangementsFoaming agentSandwich board

A process for preparing sandwich plate of foam metal by wrapping-rolling method includes such steps as proportioning metal powder and foaming agent and controlling their granularity, mixing them, wrapping the mixture under stirring to uniformity, cold rolling, hot rolling for compactness, and foaming. Its advantages are simple apparatus and high binding strength between foamed core and metal plate and specific rigidity. It can be used to damp sound and vibration and insulate heat.

Owner:KUNMING UNIV OF SCI & TECH

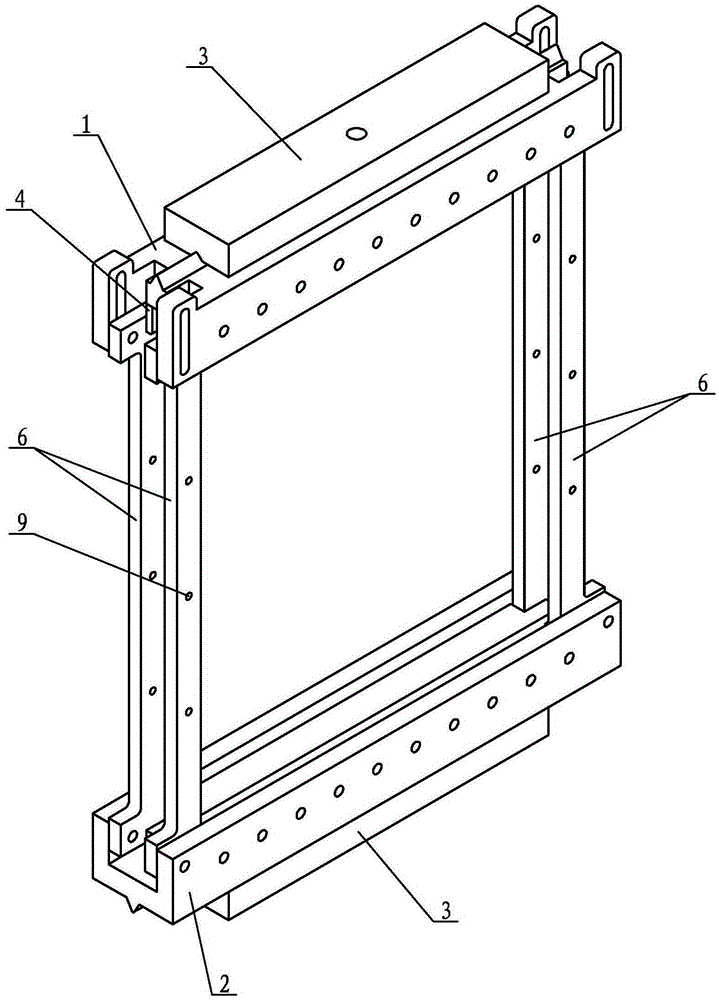

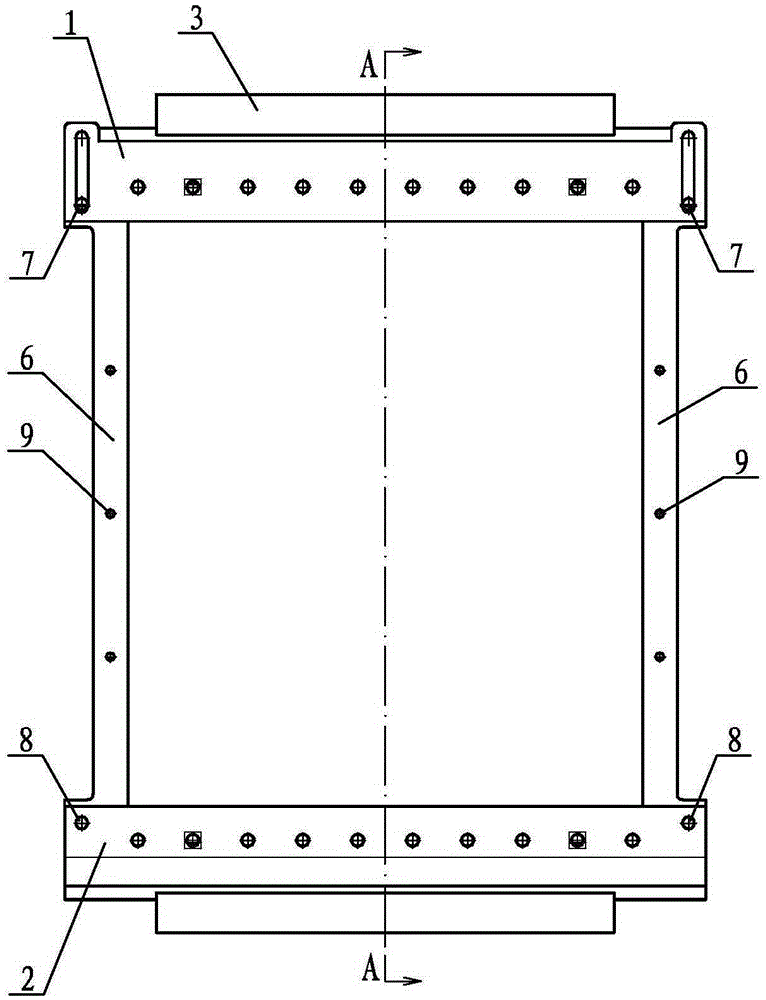

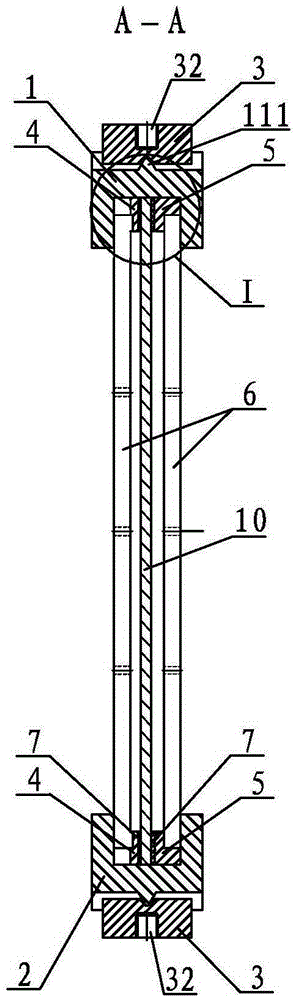

Assembly clamper for sandwich structure board lateral compression test

ActiveCN105241751AGuaranteed internal and external symmetry of strainEasy to assembleStrength propertiesSandwich boardLateral compression

The invention relates to an assembly clamper for sandwich structure board lateral compression test. In the prior art, when the large-size and non-symmetrical sandwich board is subjected to the lateral compression performance test, the centering of the compression center is difficult, and the deflection is high. A purpose of the present invention is to solve the problems in the prior art. According to the assembly clamper, an upper clamping head and a lower clamping head are arranged in an upper-lower manner, the deep groove of the upper clamping head and the U-shaped groove of the lower clamping head are oppositely arranged, four vertical position limiting plates are arranged between the upper clamping head and the lower clamping head in a rectangular manner, the upper ends of each vertical position limiting plate are positioned inside the deep groove, the lower ends of each vertical position limiting plate are positioned inside the U-shaped groove, the upper ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the lower ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the two universal pad blocks are oppositely arranged in an upper-lower manner, the two adjustment pad blocks are oppositely arranged in an upper-lower manner, two end plates are respectively arranged on the upper end and the lower end of the upper clamping head and the lower clamping head, and the upper cone column on the upper clamping head and the lower cone column on the lower clamping head are respectively embedded into the corresponding V-shaped grooves. The assembly clamper of the present invention is used for the sandwich structure board lateral compression test.

Owner:HARBIN INST OF TECH

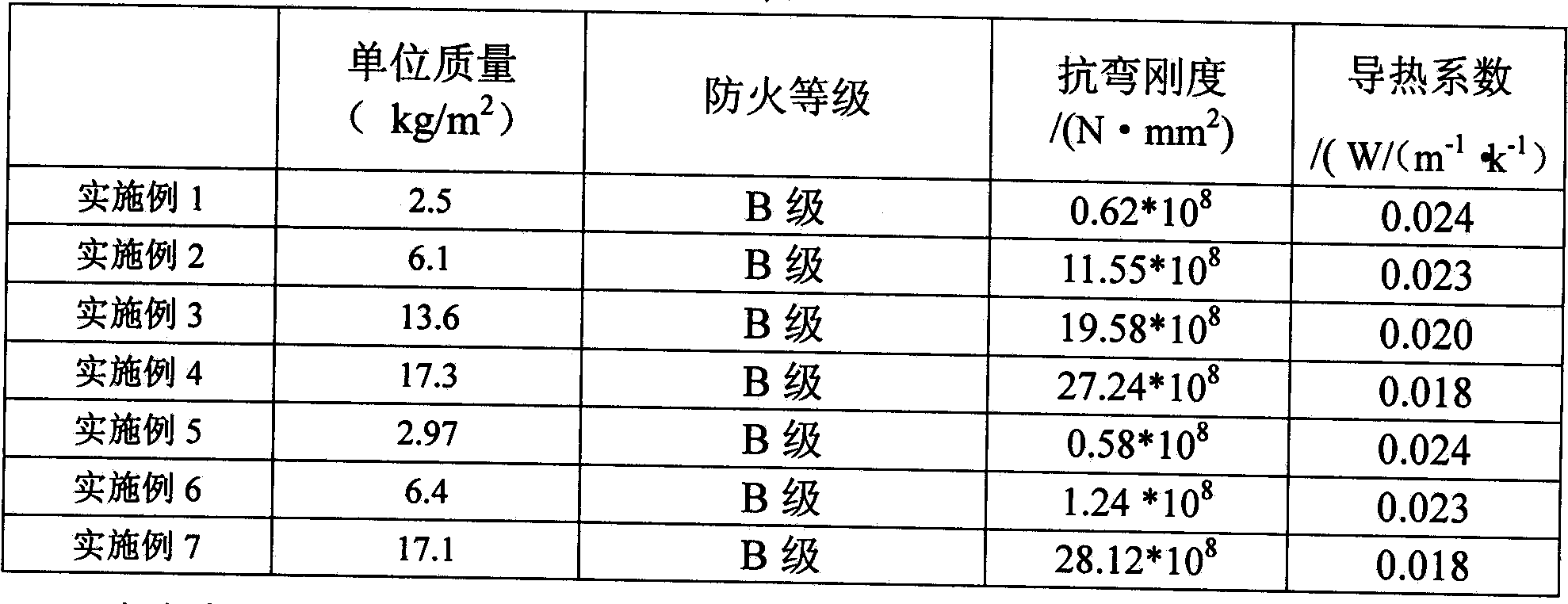

Fireproofing and heat-insulating adhesive

ActiveCN109021837AEasy to prepareReduce investmentNon-macromolecular adhesive additivesClimate change adaptationCombustionSandwich board

The invention discloses a fireproofing and heat-insulating adhesive. The fireproofing and heat-insulating adhesive comprises, 100 parts of a saturated magnesium sulfate solution, 100 parts of magnesium oxide, 100-500 parts of water, 0.05-20 parts of a curing modifier, 0.05-40 parts of a waterproof modifier, 10-70 parts of a flame retardant and 0.5-50 parts of a flame retardant synergist. The fireproofing and heat-insulating adhesive is used for the fireproof coating modification of a polystyrene foam board, so the fireproofing and heat-insulating adhesive penetrates into the polystyrene foam board in order to achieve the purpose of uniform coating modification. A color steel sandwich board produced from the polystyrene fireproofing and thermal-insulating board has the advantages of high bending strength, high compressive strength, good tolerance, good combustion performance, and no collapse in fire scenes.

Owner:应急管理部四川消防研究所

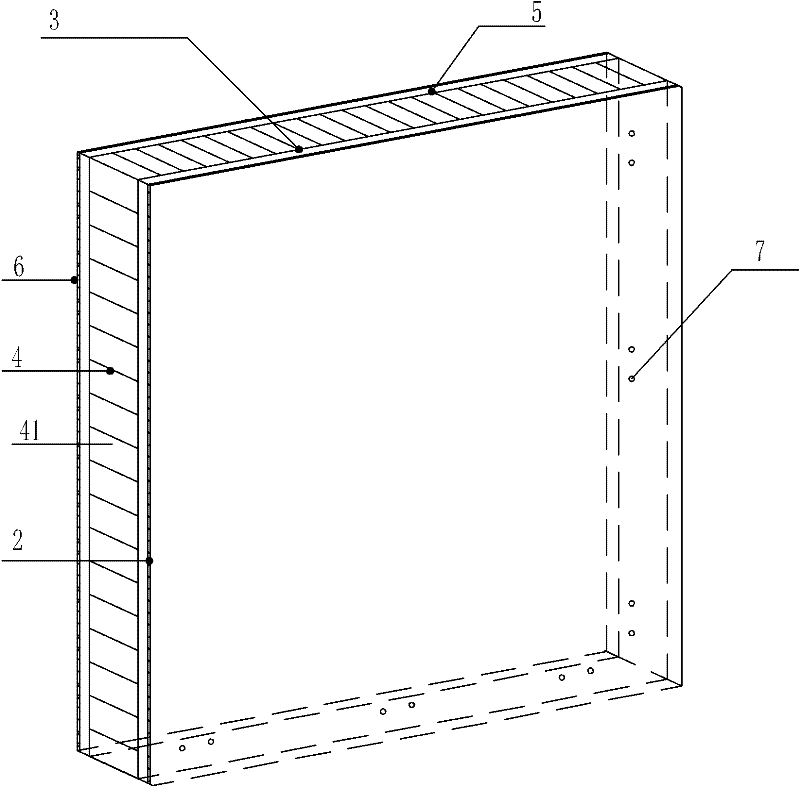

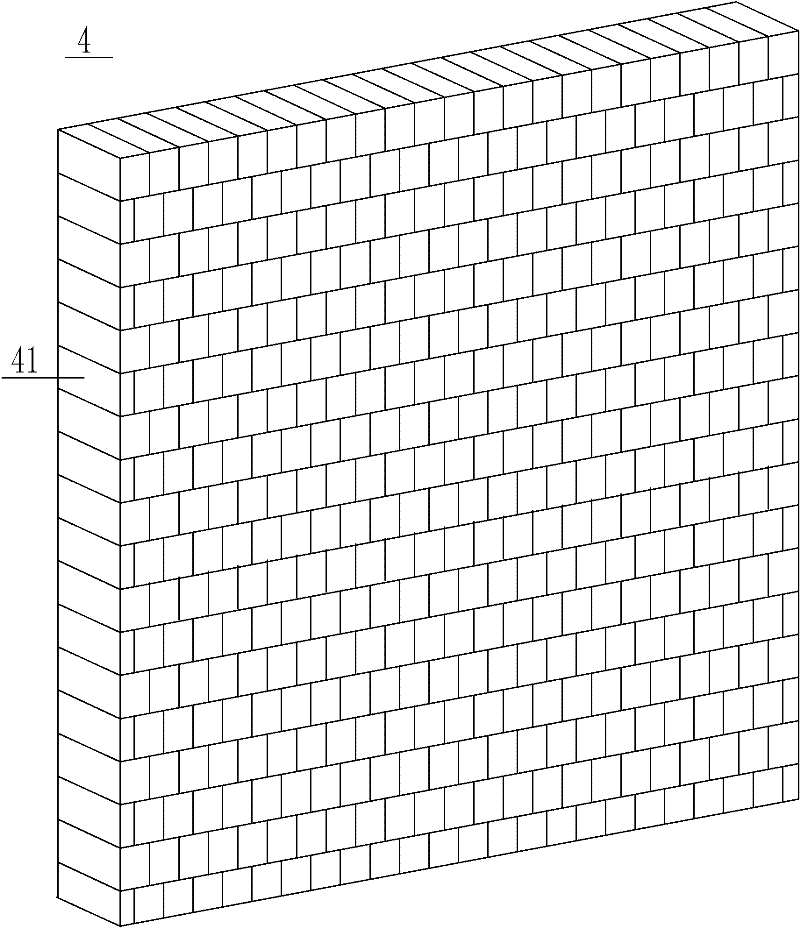

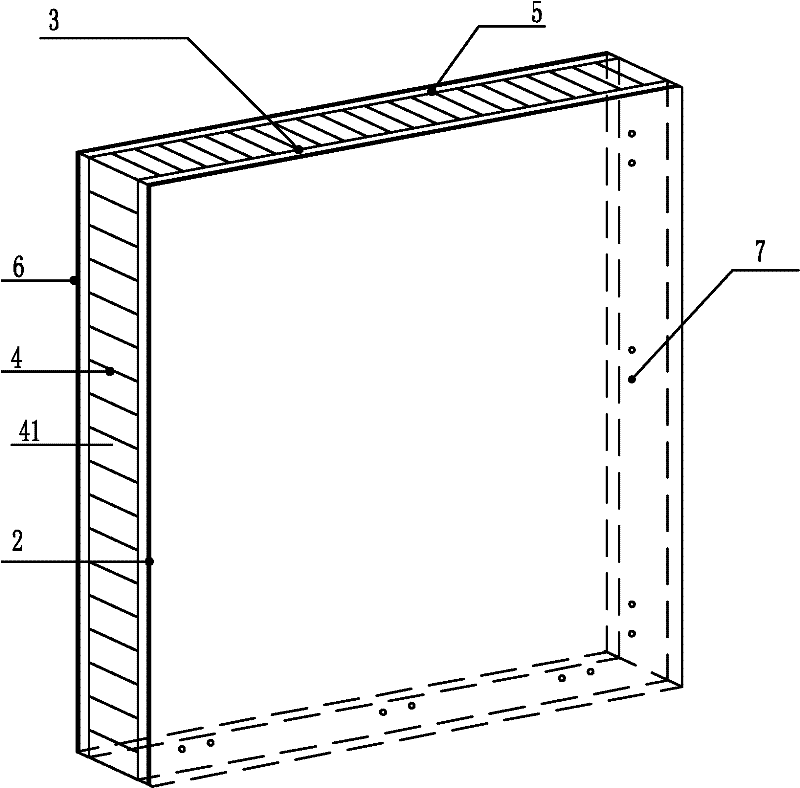

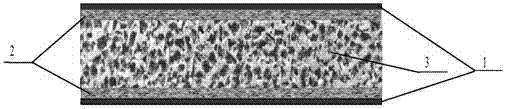

Rock wool sandwich composite board, and preparation method and application thereof

ActiveCN102304968ASolve the collapseSolve the strength problemLamination ancillary operationsCovering/liningsFiberSurface layer

The invention relates to a rock wool sandwich composite board, and a preparation method and application thereof. The rock wool sandwich board sequentially comprises a surface layer (2), a sandwich layer (4) and a back layer (6), wherein one face of the sandwich layer (4) is fixedly connected with the surface layer (2) through a first bonding layer (3) and the other face of the sandwich layer (4) is fixedly connected with the back layer (6) through a second bonding layer (5); the sandwich layer (4) consists of rock wool stripes (41) which are arranged in a staggered manner; one face of each rock wool stripe is fixedly connected with the surface layer (2) through the first bonding layer and the other face of the each rock wool stripe is fixedly connected with the back layer (6) through the second bonding layer (5); and fibers of the rock wool stripes (41) are vertical to the surface layer (2) and the back layer (6). By the rock wool sandwich composite board, the phenomenon of collapse and fall, caused by damp and debonding, of rock wool can be avoided; by adopting a good bonding formula, a welding process and a screw fixing mode are not required; the obtained product has high strength and high flatness and hardly becomes damp and falls off; furthermore, the shortcomings of low fireproof performance of the conventional composite board and low heat preservation performance of the rock wool can be overcome at one time.

Owner:蔡伯中

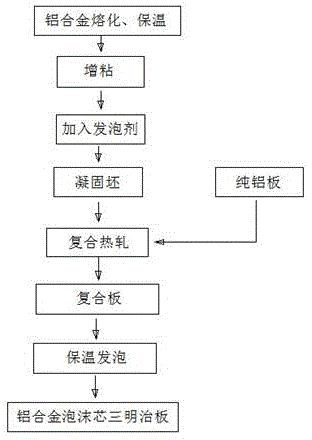

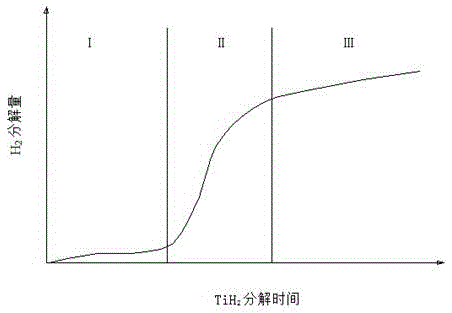

Preparation method of sandwich board with aluminium alloy foam core

InactiveCN105642671ASimple processProcess is easy to controlMetal rolling arrangementsFoaming agentSandwich board

The invention provides a preparation method of a sandwich board with an aluminium alloy foam core and belongs to the field of porous metal materials. According to the method, an aluminium alloy is melted, kept at the temperature and tackified, a foaming agent TiH2 subjected to pre-oxidation treatment is added to tackified aluminium alloy melt for stirring dispersion, after TiH2-containing tackified aluminium alloy melt is cooled and solidified, a solidified blank is obtained, a pure aluminium board and the solidified blank are subjected to composite hot-rolling, a composite board with the surface being a pure aluminium layer and the core being an aluminium alloy foamable precursor is obtained, then the composite board is heated to the temperature 10-30 DEG C higher than that of an aluminium alloy liquid phase line for heat-insulating foaming, and the sandwich board with the surface being a pure aluminium layer and the core being aluminium alloy foam is obtained after a foamed body is cooled.

Owner:KUNMING UNIV OF SCI & TECH

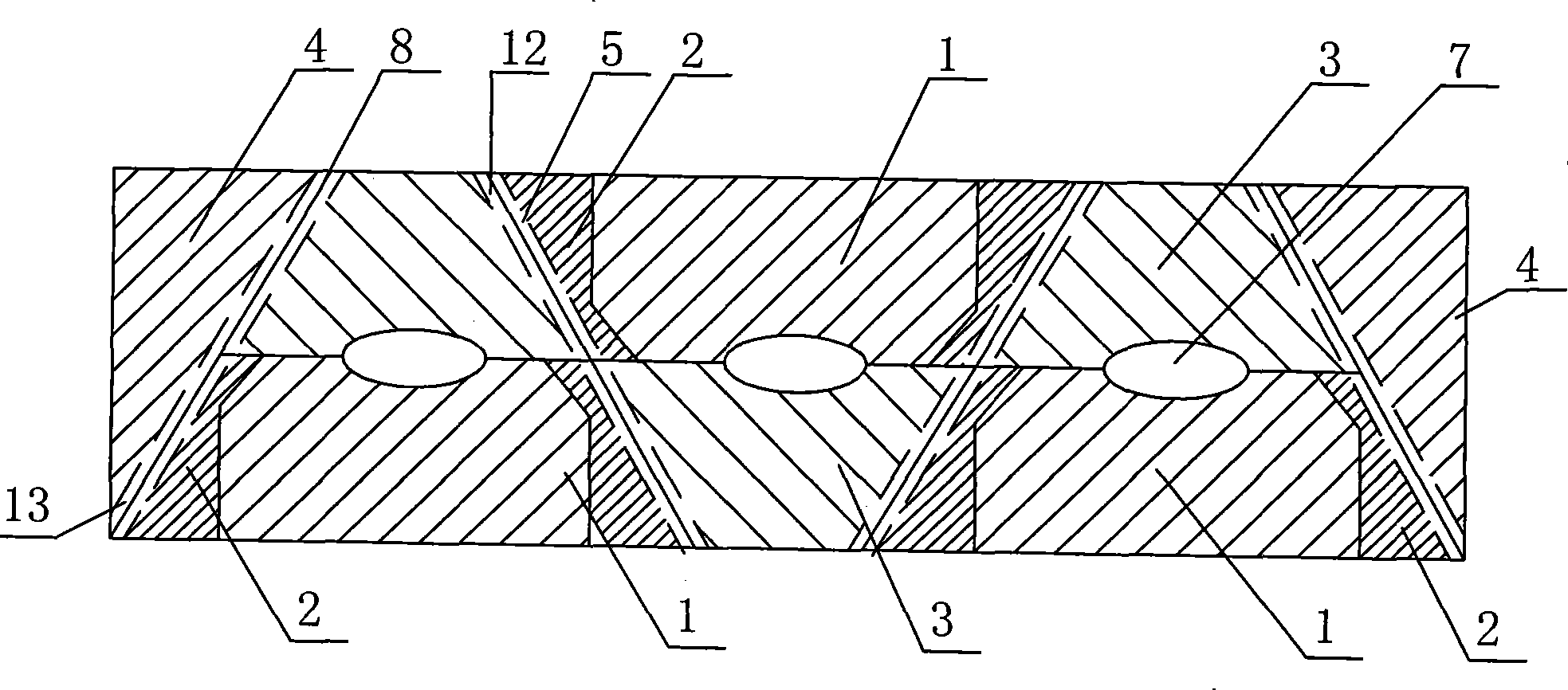

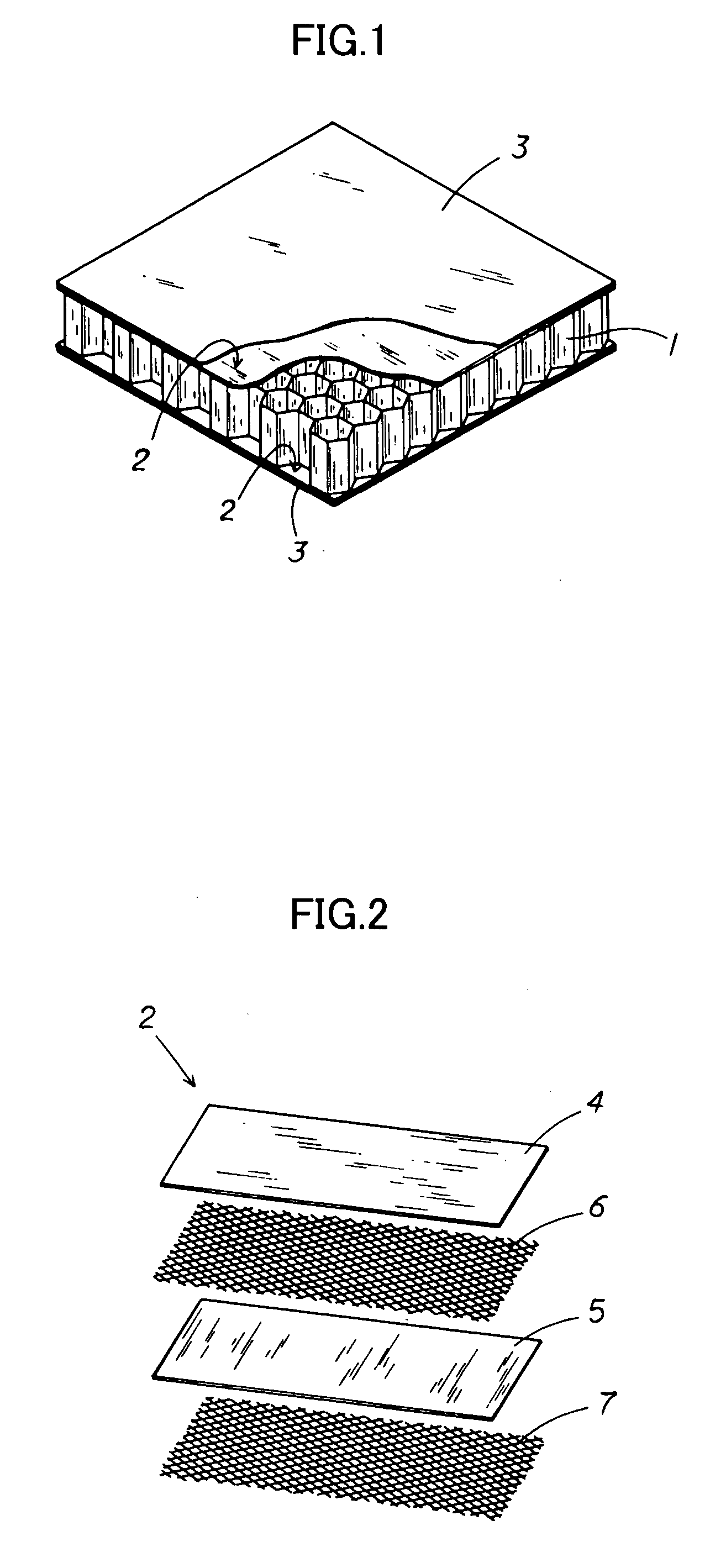

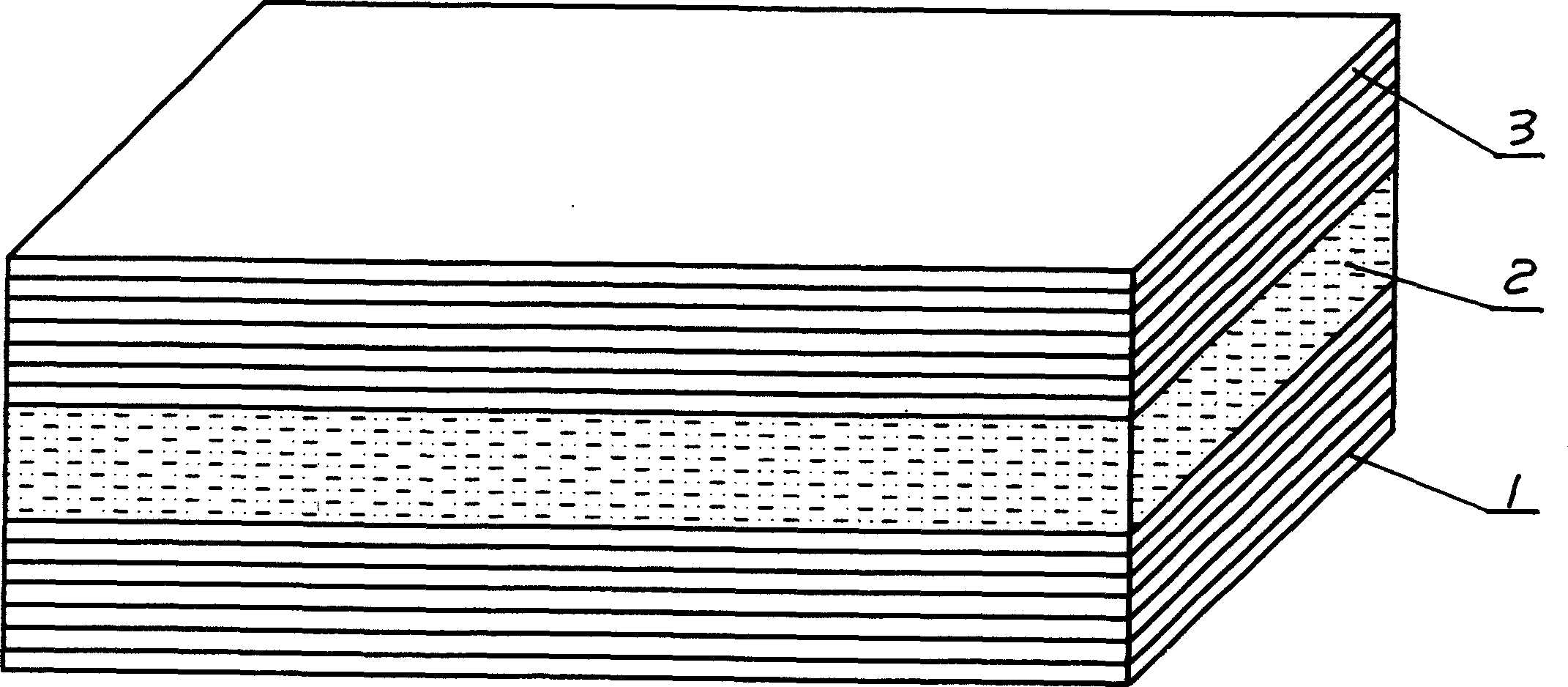

Sandwich panel

ActiveUS20080131645A1Improve practicalityReduce weightSynthetic resin layered productsBuilding componentsFiberSandwich board

A sandwich panel that has excellent practicality as an inner wall material used in aircraft, for example, whereby the abovementioned requirements of flexural strength, peel strength, and in-plane shear strength can be satisfied while having reduced weight. A sandwich panel in which a middle material 2 and a surface material 3 that are each formed by laminating a plurality of fiber bodies are laminated from inside to outside on the upper and lower surfaces of a hollow columnar core 1, wherein the middle material 2 is composed of a set of unidireactional fiber bodies 4, 5 whose fibers are aligned in one direction, fibers in a first unidireactional fiber body 4 are in a direction that is substantially parallel to an edge of the sandwich panel, fibers in a second unidireactional fiber body 5 are in a direction that is substantially orthogonal to an edge of the sandwich panel, and bonding layers 6, 7 having a resin content ratio of 50% or higher are provided between the unidireactional fiber bodies 4, 5 and between the hollow columnar core 1 and an inside unidireactional fiber body 5.

Owner:JAMCO +1

Sandwich panel for sound absorption

InactiveUS20090173572A1Reduce weightLarge space volumeSound proofingSound producing devicesSandwich boardEngineering

An aircraft cabin panel for sound absorption, with a core layer that comprises a plurality of cells that extend in an open manner across the thickness of the core layer and that are separated from each other by cell walls, and with a first cover layer that faces away from the sound field, as well as a second cover layer that faces towards the sound field and that comprises a plurality of perforation holes. The second cover layer is multi-layered and apart from a layer with the perforation also comprises a second layer that acts as a flow resistance device. The second layer is arranged on the outside, and visually closes off the perforation, and the outer layer comprises an air-permeable woven fabric.

Owner:AIRBUS OPERATIONS GMBH

Baseboard plywood of high-intensity composite container

InactiveCN1583526AReduce material requirementsAbundant resourcesFlexible coversWrappersFiberBaseboard

A high-strength ply-board as the bottom plate of container is composed of two surface boards made of hard wood, sandwich board which is medium-density fibroboard or shaving board, and long boards between surface board and sandwich board.

Owner:河南黄河林业股份有限公司

Polymer/foam aluminum integrated composite sandwich board

The invention provides a polymer / foam aluminum integrated composite sandwich board. According to the polymer / foam aluminum integrated composite sandwich board, a foam aluminum core layer is arranged in the middle of the sandwich board and polymer / foam aluminum composite layers are arranged on upper and lower faces of the sandwich board; a five-layered structure with pure polymer protection surface layers are arranged on upper and lower surface layers. A preparation method of the polymer / foam aluminum integrated composite sandwich board comprises the following steps: washing a foam aluminum board to remove oil; drying for later use; preparing a polymer into fluid and injecting the fluid into a mould; arranging a plurality of thimbles for controlling the thickness of pure polymers on the surface layers at the bottom of the mould, wherein the height of the mould is equal to the sum of the thicknesses of the pure polymer surface layers and the thicknesses of the polymer / foam aluminum composite layers; then, slowly placing a treated foam aluminum board to be used into the mould, curing and de-molding; cutting surplus polyurethane on the edge; and overturning the board and repeating the preparation process. The polymer / foam aluminum integrated composite sandwich board is simple in process, low in cost, high in operability and good in integrity; a problem of cracking releasing of an interface between a core material and a panel and a surface corrosion problem are avoided.

Owner:YANSHAN UNIV

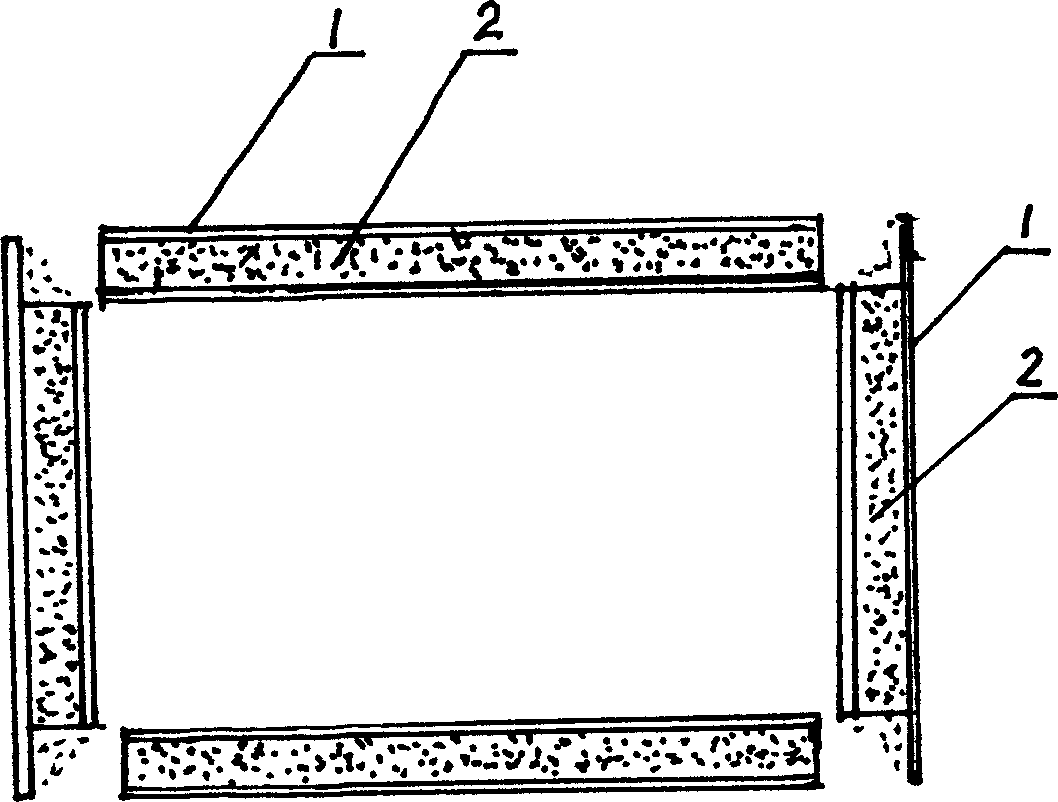

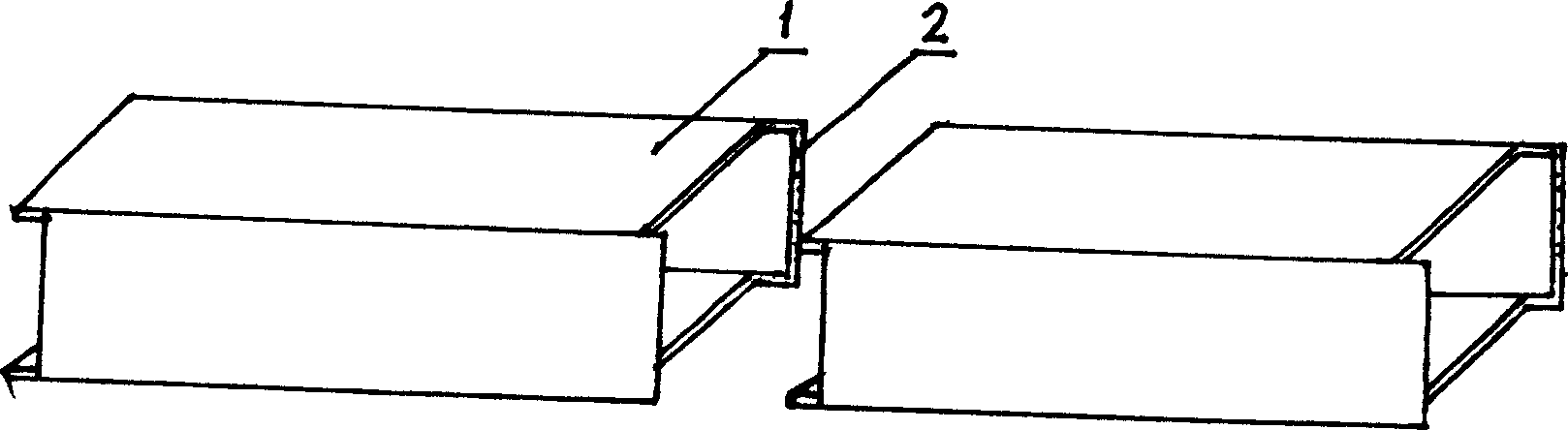

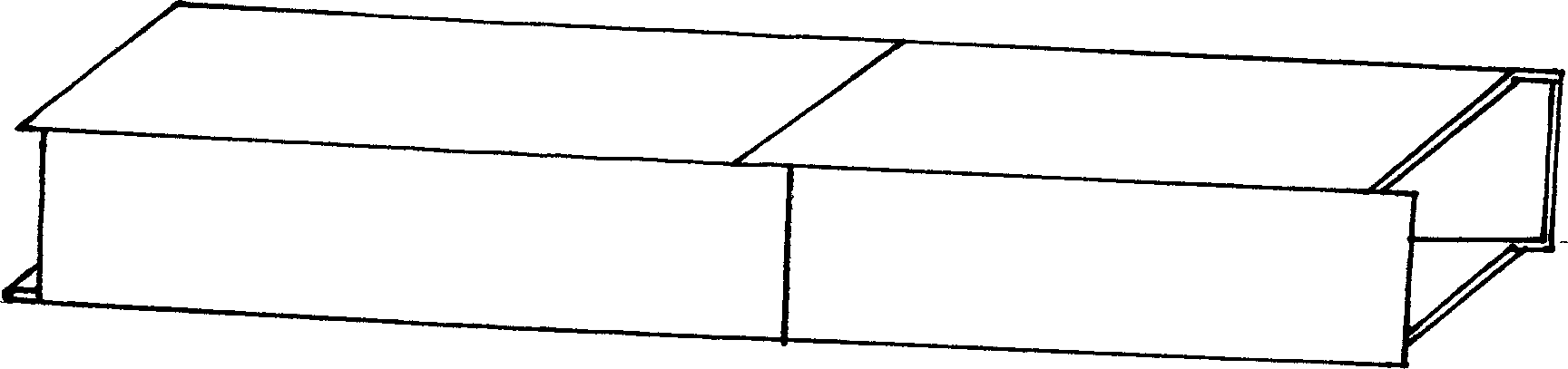

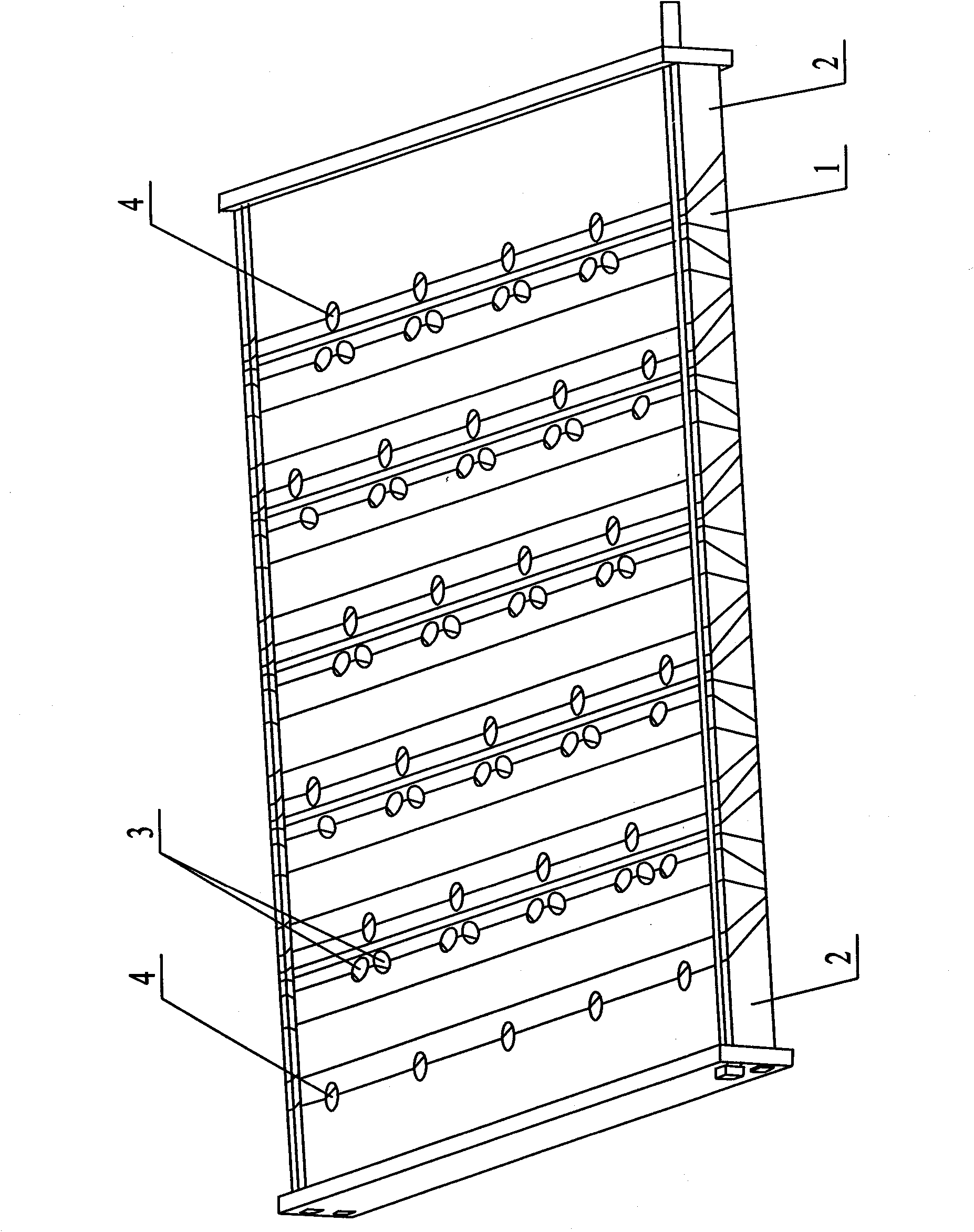

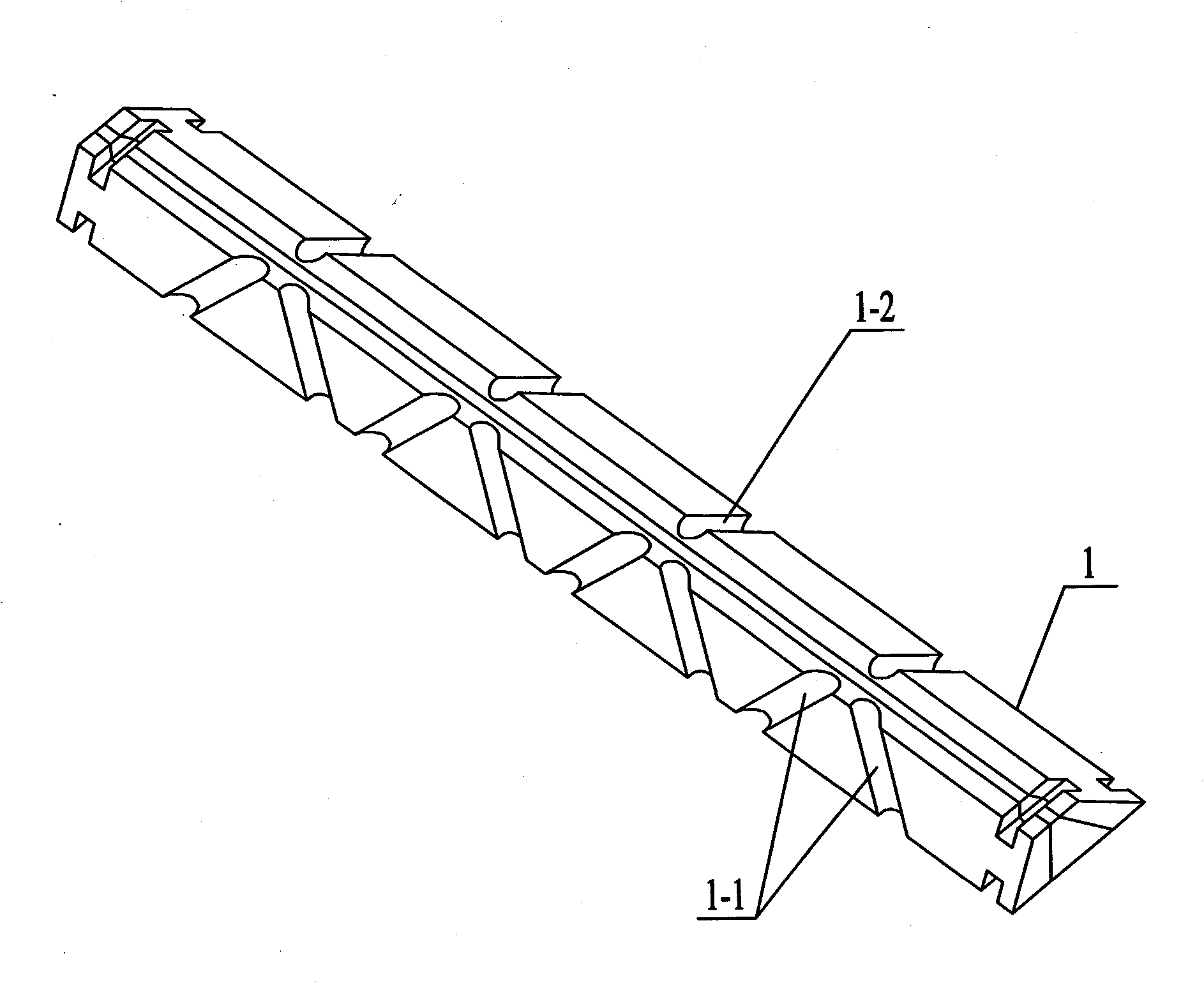

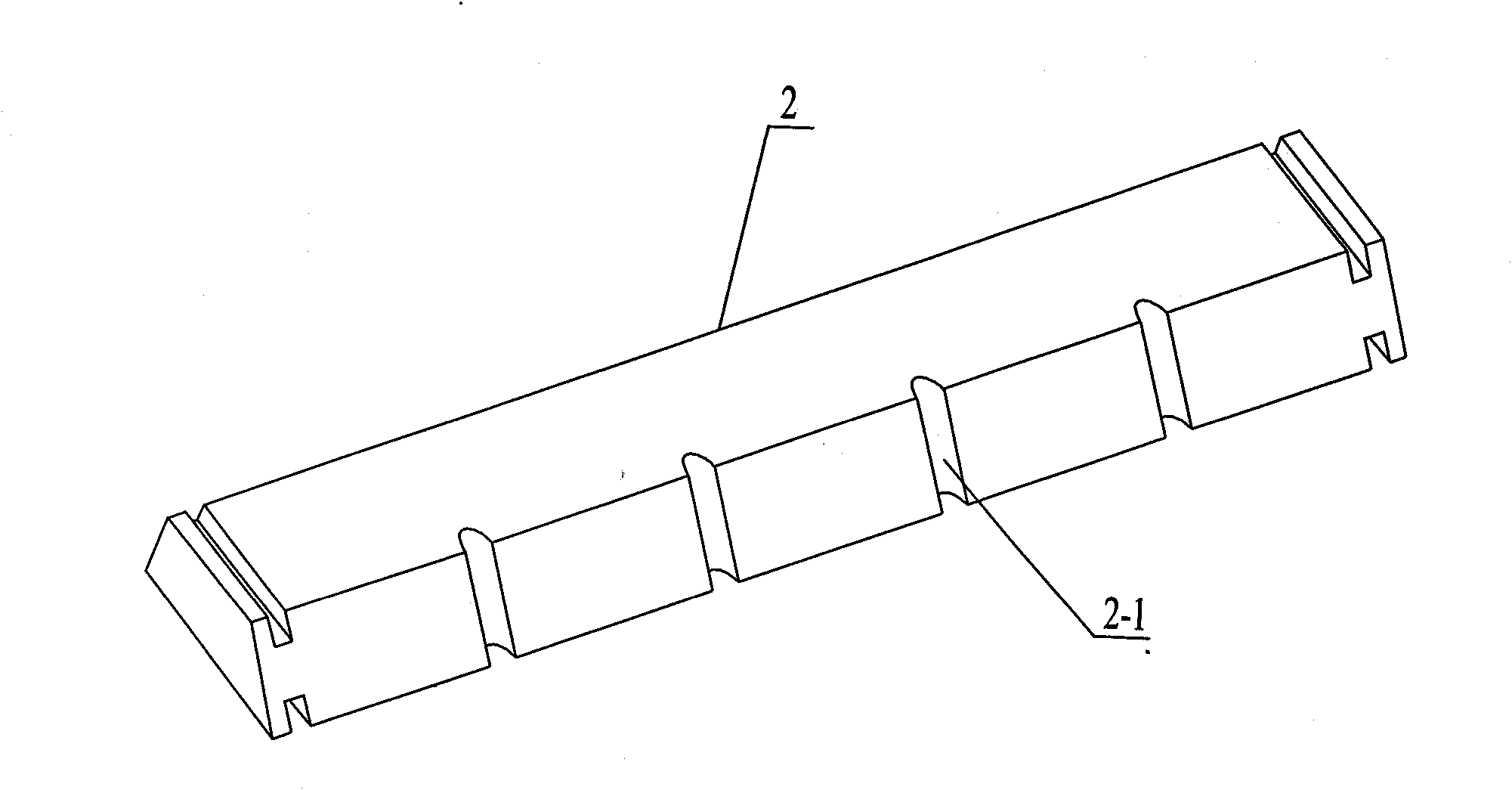

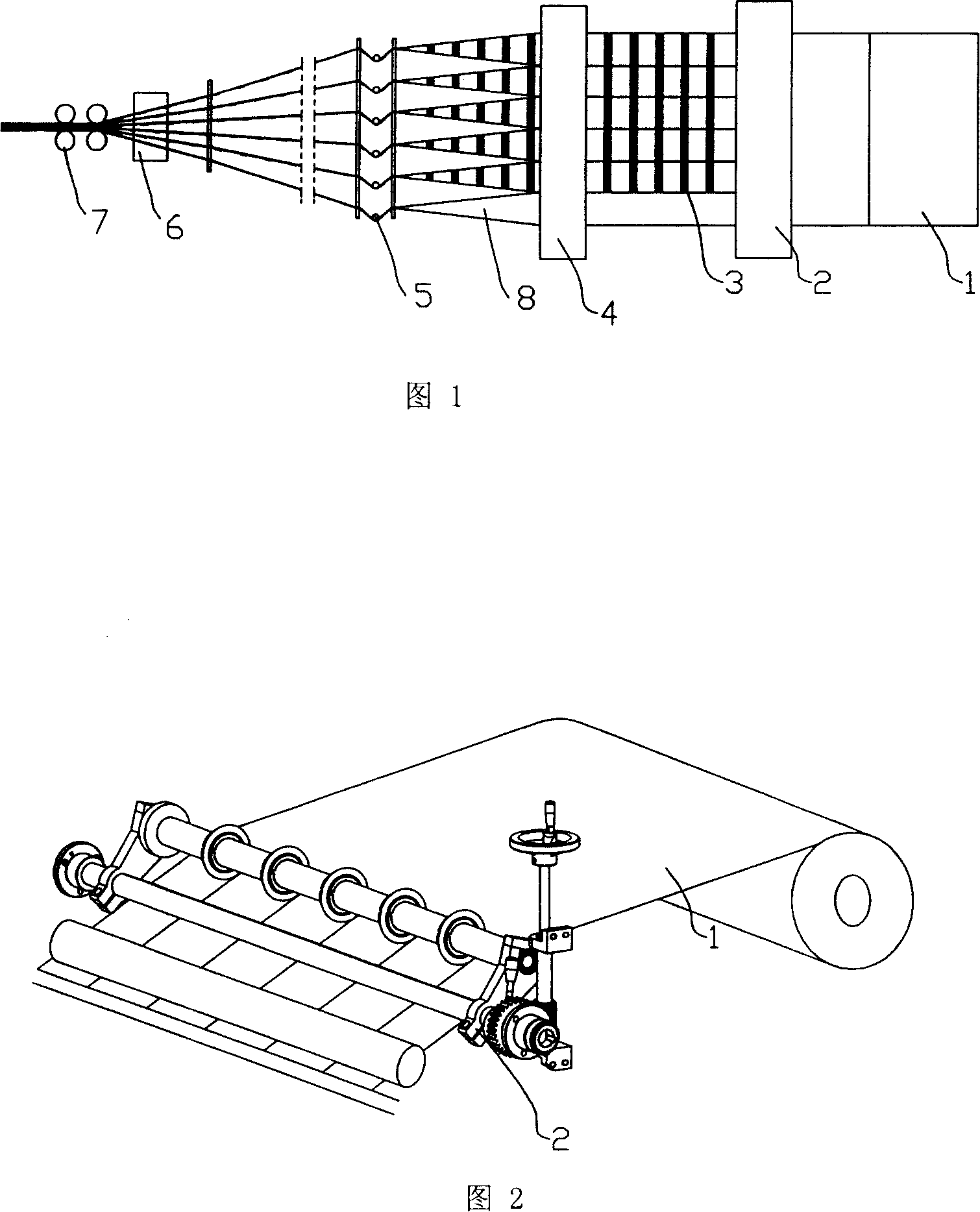

Method for prducing and connecting ventilation pipe

InactiveCN1458436AHigh bonding strengthLow costLighting and heating apparatusSpace heating and ventilation detailsSandwich boardFastener

The making and connecting process of ventilation pipe with foamed fireproof sandwiched board as base board includes assembling, adhering and connecting. The foamed fireproof sandwiched board is processed to possess stepped adhered surface to increase the contact area and thus the adhering strength. The ventilation pipe sections are connected via their staggered upper and lower boards and right and left boards, and this can omit metal fastening parts, lower cost, facilitate in-situ construction and raise installation efficiency.

Owner:支亮

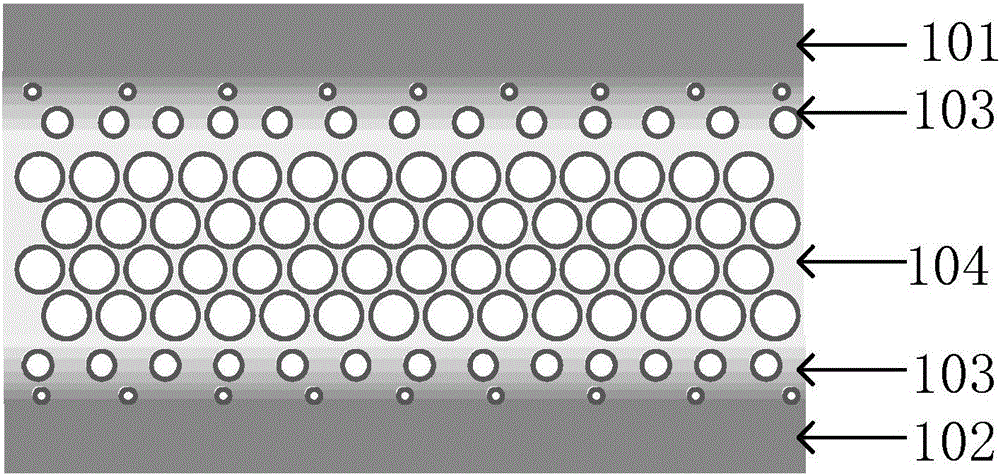

Preparation method of hollow circular-tube tetrahedral full-composite lattice sandwich board

The invention provides a preparation method of a hollow circular-tube tetrahedral full-composite lattice sandwich board, and relates to the tetrahedral full-composite lattice sandwich board and the preparation method thereof. The preparation method solves the problem that the existing preparation process is not applicable to preparing the hollow circular-tube tetrahedral composite lattice sandwich board. The preparation method comprises the following steps: preparing and treating a die; pre-forming a composite hollow circular tube: rolling prepreg or winding fiber bundles with the prepreg or the fiber bundles soaked with resin on the outer wall of a thermal expansion core model, and then filling the manufactured fiber column with the thermal expansion core model into a mounting hole of a rigidly assembled die; laying the unidirectional fiber prepreg on the upper surface and the lower surface of the rigidly assembled die, splitting the fiber column at outer side of the rigidly assembled die, and then embedding the split fiber columns into the unidirectional fiber prepreg; heating, pressurizing and curing the rigidly assembled die; demoulding; and finally splicing a sandwich structure in which a panel is provided with circular holes with a composite panel. The preparation method of the invention is used for preparing the tetrahedral full-composite lattice sandwich board.

Owner:HARBIN INST OF TECH

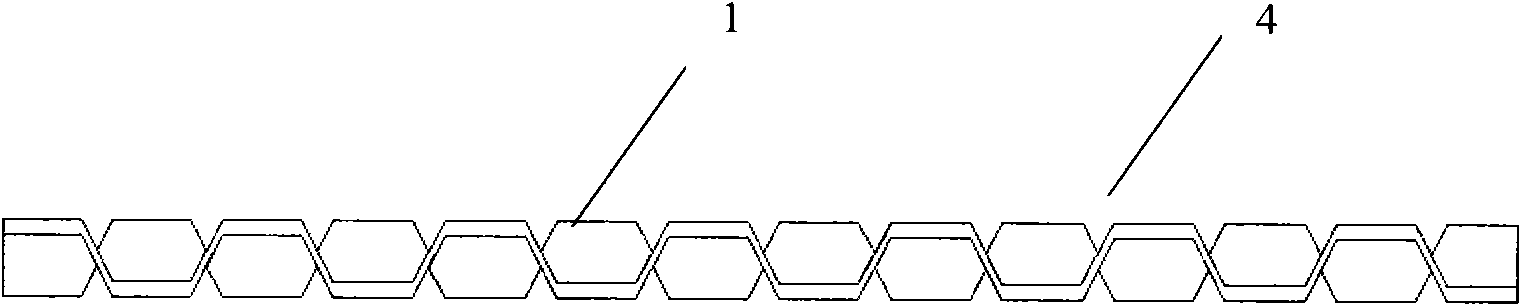

Honeycomb core made in mechanized production and method for producing sandwich board by using said honeycomb core

InactiveCN101112804ARealize mechanized productionIncrease productivityPaper/cardboard articlesSandwich boardHoneycomb

The invention discloses a method for machining producing honeycomb core and producing the honeycomb plate by the honeycomb core. The invention is characterized in that 1) a piece material with one surface provided with a transverse strip-shaped glue is prepared and is cut into a plurality of fine strips with uniform width by the mechanism; 2) the mechanism is adopted to pull ahead and to converge the fine strips made in the step 1); when the fine strips are overlapped, the strip-shaped glues on the two adjacent fine strips are mutually staggered; 3) the fine strips ahead and overlapped together is taken through a heating device for heating the strip-shaped glue on the fine strips by the heating device; the adjacent fine strips are bound together after the strip-shaped glue in the fine strips is subject to the head, thus producing the honeycomb products. All the process steps of the production method can be continuously produced by the mechanism, the length of the obtained products is not restricted; the invention is easy to be operated and does not have high technical requirement. Furthermore, the invention also discloses a honeycomb plate production method which causes the production method of continuous production of the honeycomb plates is implemented.

Owner:FOSHAN CITY DEBAO PRINTING MACHINERY

Aluminum foam sandwich plate with gradient interface and manufacturing method thereof

The invention discloses an aluminum foam sandwich plate with a gradient interface and a manufacturing method thereof, which belong to the technical field of porous metallic materials and laminar composite materials. The manufacturing method comprises the steps of firstly, uniformly mixing aluminite powder or aluminum alloy powder and foaming agent titanium hydride powder to obtain mixed powder; then sequentially filling lower panel alloy powder, the mixed powder and upper panel alloy powder into a steel mold, wherein the three powder is distributed in a layered way; then putting the steel mold into a hot press machine so as to be hot-press densified to obtain a foamable sandwich plate prefabricated member; and finally heating and foaming the prefabricated member to obtain the foam sandwich plate with the gradient interface. According to the method, the densification of the aluminum foam prefabricated member and a compounding process of aluminum foam and panels are completed at the same time within one working procedure, so that the process flow is short, and the manufacturing cost is low; commercially available metal sheets have no need to be used, so that a material selection range and a design space are wide; and the aluminum foam sandwich plate with the gradient interface prepared through the invention is hopefully applied widely in the fields of automobiles, rail trains, buildings, electronics and national defense and military industry.

Owner:有研金属复材技术有限公司

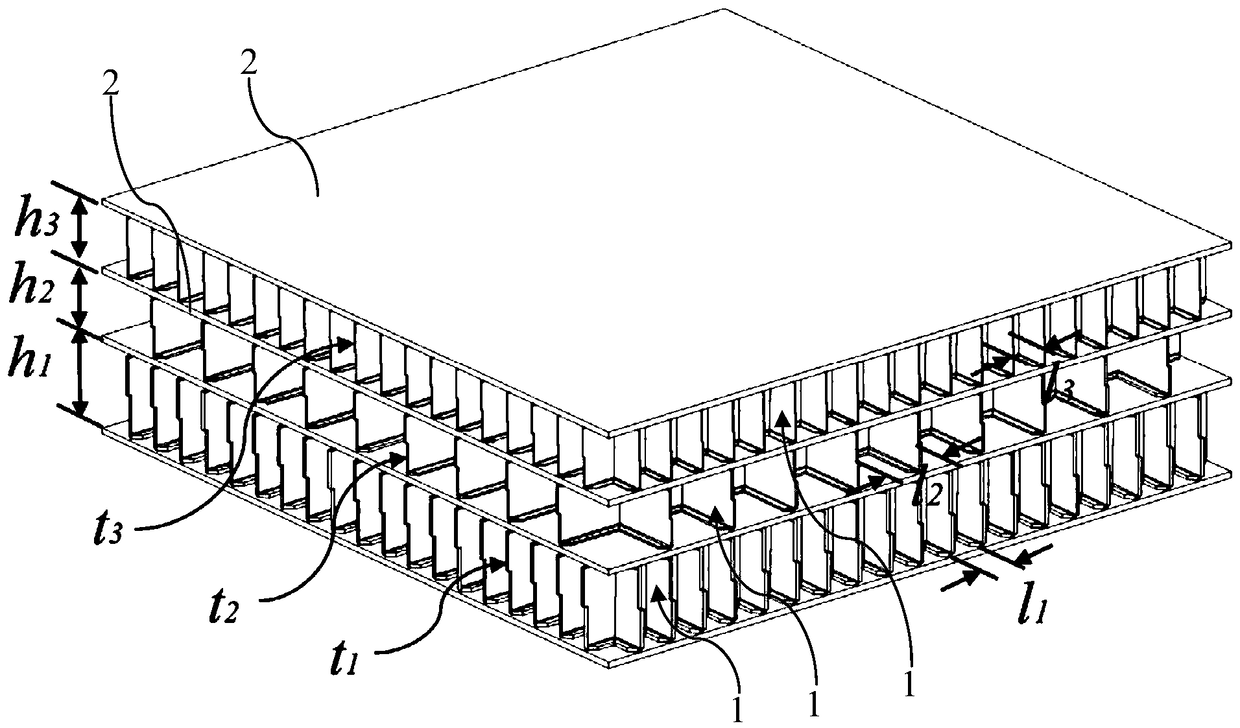

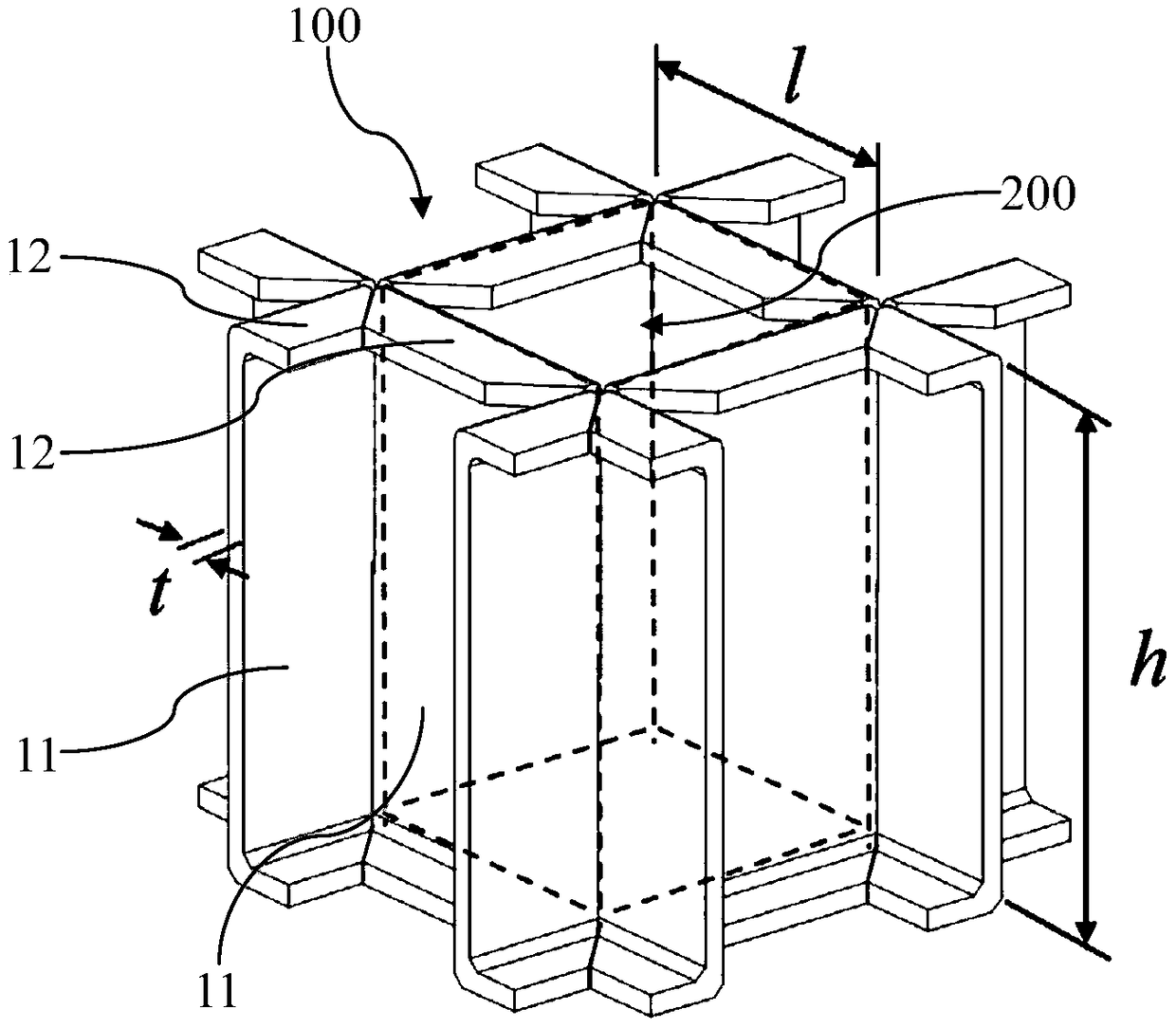

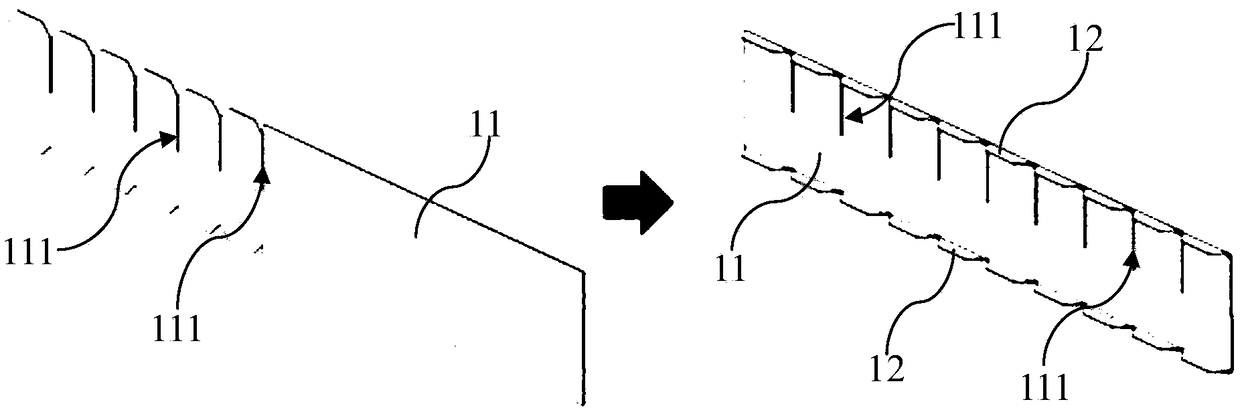

Functional gradient honeycomb sandwich board and manufacturing method thereof

InactiveCN108773111ASimple structureReduce manufacturing costLayered productsSandwich boardHoneycomb

The invention belongs to the technical field of porous materials and particularly relates to a functional gradient honeycomb sandwich board and a manufacturing method thereof. The functional gradienthoneycomb sandwich board comprises at least two honeycomb sandwich layers; all the honeycomb sandwich layers are stacked and connected and are respectively provided with a plurality of unit cell bodies which are distributed and connected in a triangular-array manner; all the unit cell bodies have hollow holes and the cross sections are rectangular; all the unit cell bodies positioned at the same honeycomb sandwich layer are same in structure and material, and all the unit cell bodies positioned at the adjacent honeycomb sandwich layers are different in structure and / or material. The functionalgradient honeycomb sandwich board disclosed by the invention has the beneficial effects that prediction and control for the energy-absorbing effect can be realized, the functional gradient honeycombsandwich board has the advantages unmatched in other various porous materials in the safety field of passive protection; meanwhile, the unit cell bodies at all the honeycomb sandwich layers are controlled in size and uniform in tissue, and the structural morphology is diversified, so that the mechanical property of the whole functional gradient honeycomb sandwich board in the vertical direction shows stable functional gradient characteristic.

Owner:SHENZHEN INST OF ADVANCED TECH

Fire-proof thermal insulation sandwich board mounting component for ceiling and mounting method thereof

InactiveCN102747785ASignificantly decorativeSignificant energy savingCovering/liningsClimate change adaptationVertical planeFire protection

The invention provides a rockwool sandwich board or phenol formaldehyde resin sandwich board mounting component special for a building ceiling or an inverted vertical plane of a building, reaching fire protection level A, and a mounting method thereof to achieve the effects of quick mounting, safety and firmness aiming at the defects existing in the prior art. The fire-proof thermal insulation sandwich board mounting component for ceiling comprises a rockwool sandwich board or phenol formaldehyde resin sandwich board, a bonding agent, special adhesive mortar, an anchoring part, an expansion bolt, a polyurethane foam joint filling agent, fiber glass grid cloth, anti-crack mortar and elastic plaster. Safety, firmness and obvious decorative, thermal insulation and energy conservation effects are achieved by mounting the fire-proof thermal insulation sandwich board of the ceiling or the inverted vertical plane using the method provided by the invention. Compared with other methods, the mounting cost is low and the mounting is quick and convenient.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com