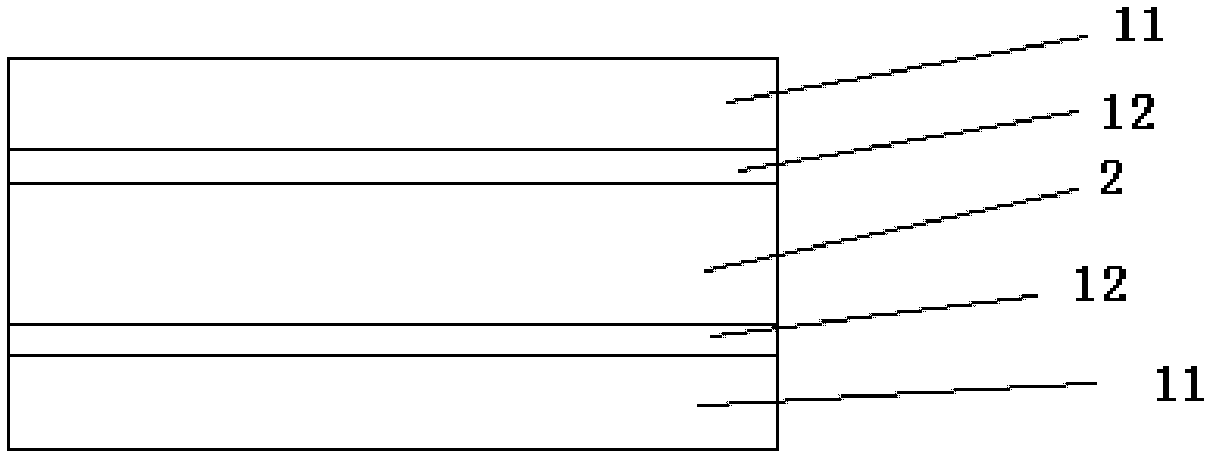

Light-weight and high-strength plastic steel sandwich board and its making method

A sandwich panel and plastic-steel technology, which is applied in the fields of architectural decoration and transportation, can solve the problems of lack of heat insulation, high density of metal plates, and lack of fire resistance, etc., and achieve light weight, simple equipment, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 200 parts of polypropylene pellets as thermoplastic matrix material, 600 parts of glass fiber (alkali-free) yarn as reinforcement material, 10 parts of antioxidant 1010, 20 parts of antioxidant 168 as antioxidant, 10 parts of organosilane A -151 is a coupling agent, 1 part of UV-531 is a light stabilizer, 150 parts of decabromodiphenyl ether is a flame retardant, and 10 parts of calcium stearate is an auxiliary agent.

[0045] Mix the above materials in a high mixer for 2 to 5 minutes except for the glass fiber, and then extrude through the extruder at 180 to 200 ° C. During the extrusion process, the molten thermoplastic melt is dipped and stretched 600 parts of non-alkali glass fiber yarns are rolled and cooled to form a prepreg tape. The thickness of the prepreg tape is about 0.23mm. During the molding process, the PET release plastic, PET non-woven fabric, and prepreg tape are laid in three layers in the lower mold in sequence, and the PET release plastic is p...

Embodiment 2

[0048] Take 530 parts of polypropylene pellets as thermoplastic matrix material, 450 parts of glass fiber (alkali-free) cloth as reinforcing material, 1 part of antioxidant 1076, 1 part of organosilane A-174 as coupling agent, 3 parts of UV-327 It is a light stabilizer, 10 parts of chlorinated paraffin 70 is a flame retardant, and 5 parts of calcium stearate is an auxiliary agent.

[0049] Mix the above materials in a high mixer for 2 to 3 minutes except for the glass fiber, and then extrude through the extruder at 180 to 200 ° C. During the extrusion process, the molten thermoplastic melt is dipped and stretched 450 parts of non-alkali glass fiber cloth, which is rolled and cooled to form a prepreg tape. The thickness of the prepreg tape is about 0.29mm. During the molding process, lay PET release plastics, PET non-woven fabrics, and 5 layers of prepreg tapes in the lower mold in sequence, and arrange them alternately along the fiber direction and vertical fiber direction, P...

Embodiment 3

[0052] Take 430 parts of polycarbonate pellets as thermoplastic matrix material, 450 parts of carbon fiber cloth as reinforcing material, 1 part of antioxidant 1010, 5 parts of antioxidant 1076, 10 parts of antioxidant 168 as antioxidant, take 20 Part A-187 is the coupling agent, 3 parts of UV-9 is the light stabilizer, and 80 parts of tetrabromobisphenol A is the flame retardant.

[0053] Put the above materials except carbon fiber into a high mixer and mix them for 2-3 minutes, then extrude them through an extruder at 250-260°C. 450 parts of carbon fiber cloth are rolled and cooled to form a prepreg tape, and the thickness of the prepreg tape is 0.43mm. During the molding process, put PET release plastic, PET non-woven fabric, 7 layers of prepreg tape, PET release plastic in the lower mold in sequence, put the upper mold, and send the laid materials into the hot press Carry out hot pressing, the hot pressing temperature is 250-260°C, the hot pressing pressure is 2MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com