Patents

Literature

481 results about "Decabromodiphenyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decabromodiphenyl ether (also known as decaBDE, deca-BDE, DBDE, deca, decabromodiphenyl oxide, DBDPO, or bis(pentabromophenyl) ether) is a brominated flame retardant which belongs to the group of polybrominated diphenyl ethers (PBDEs).

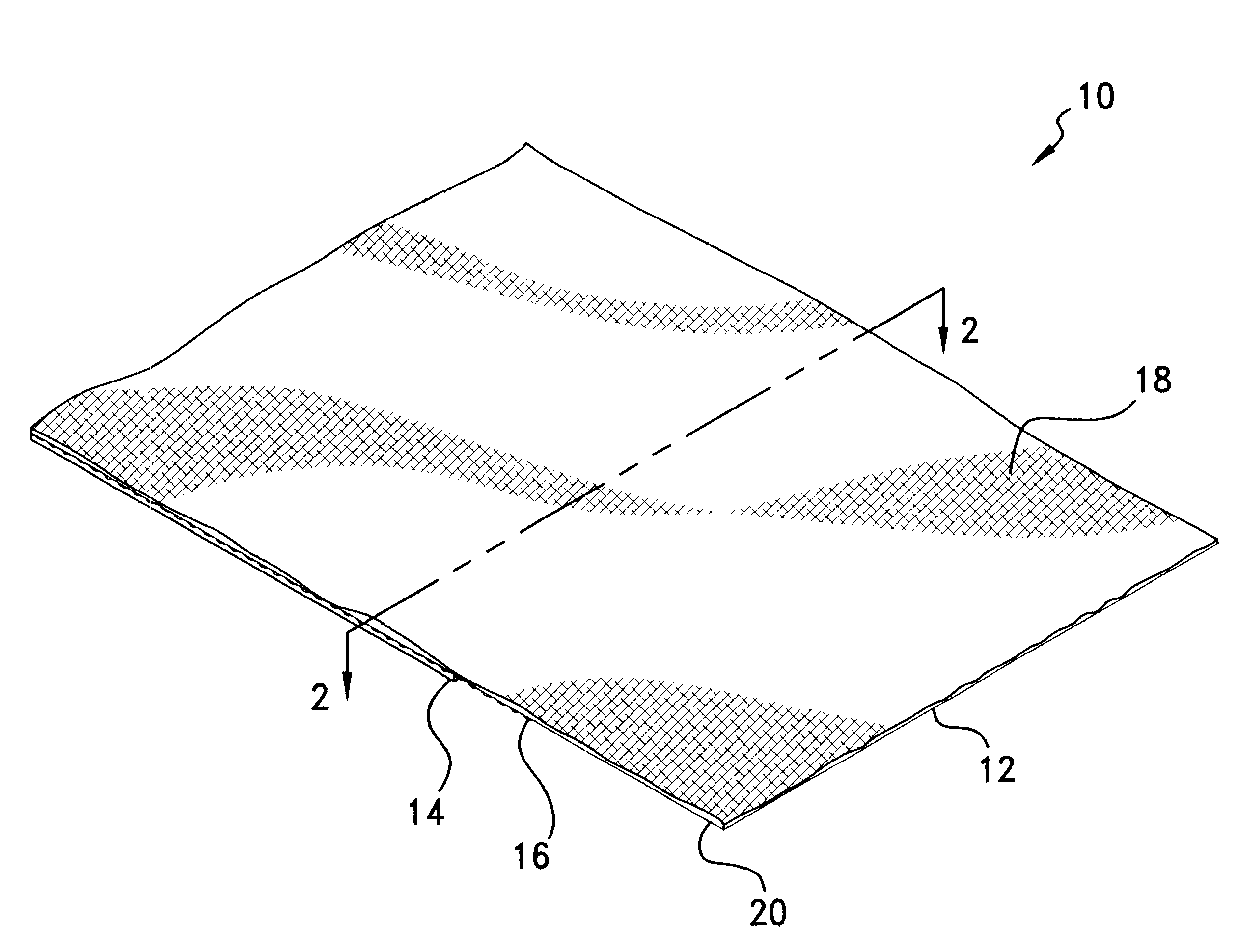

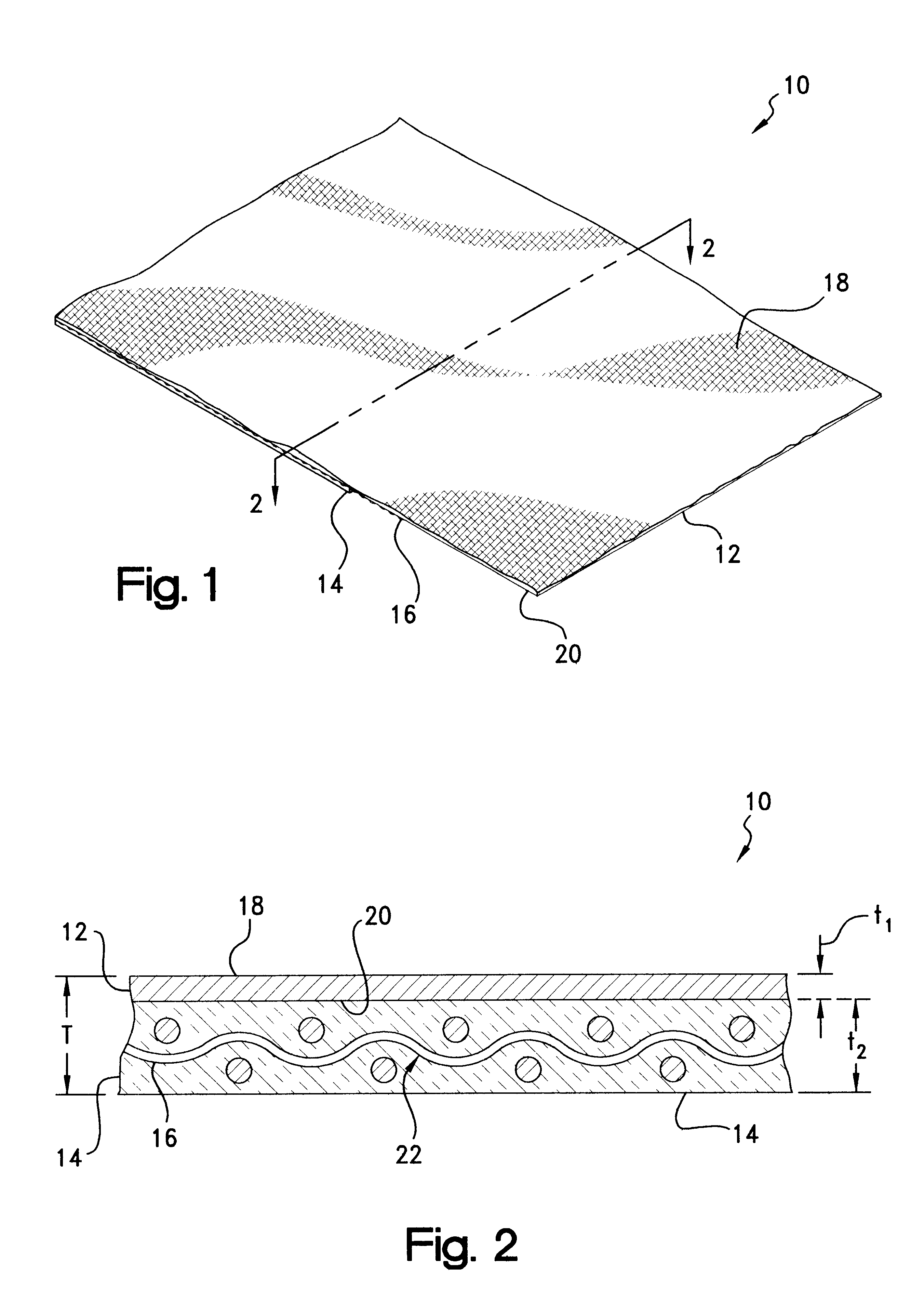

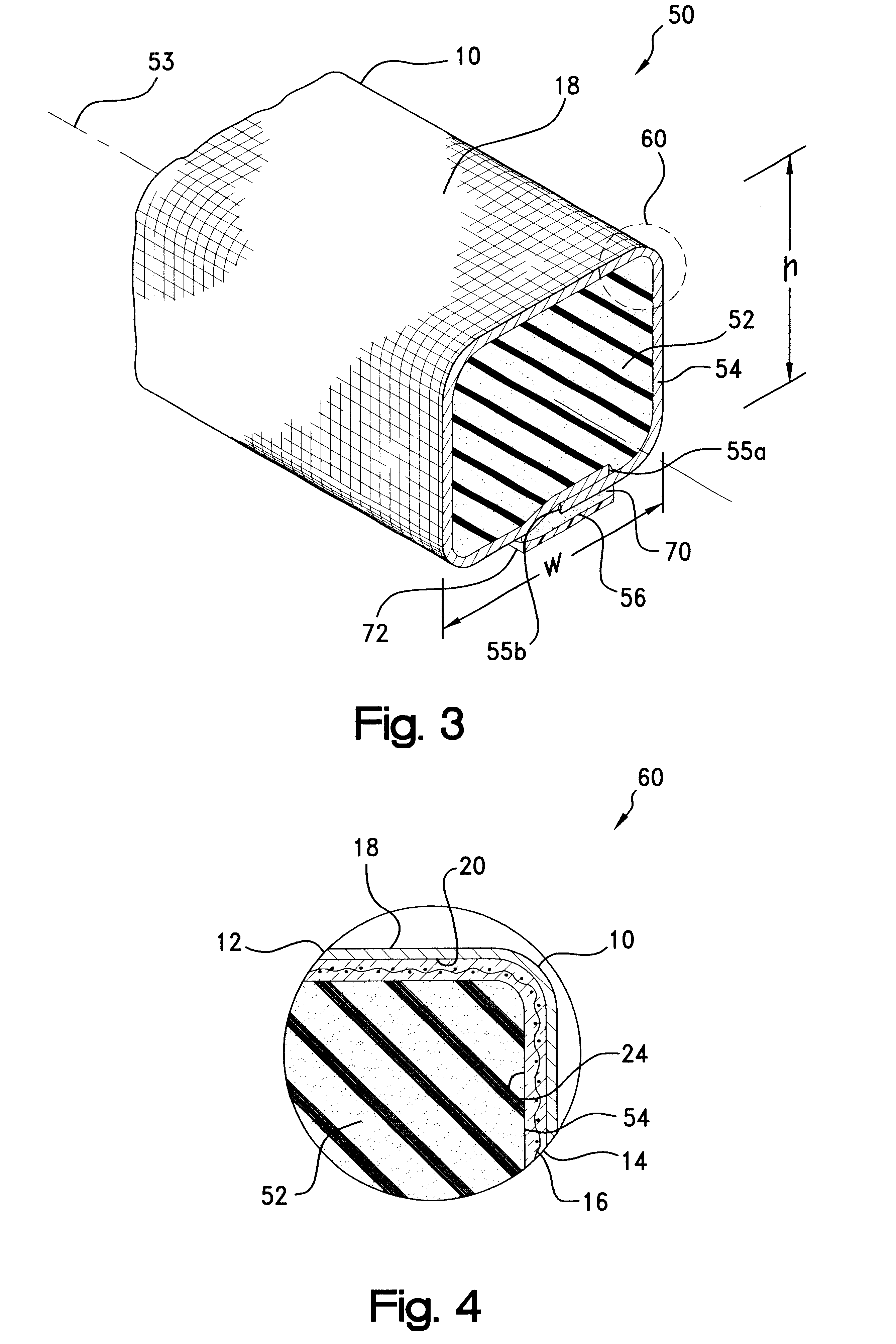

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

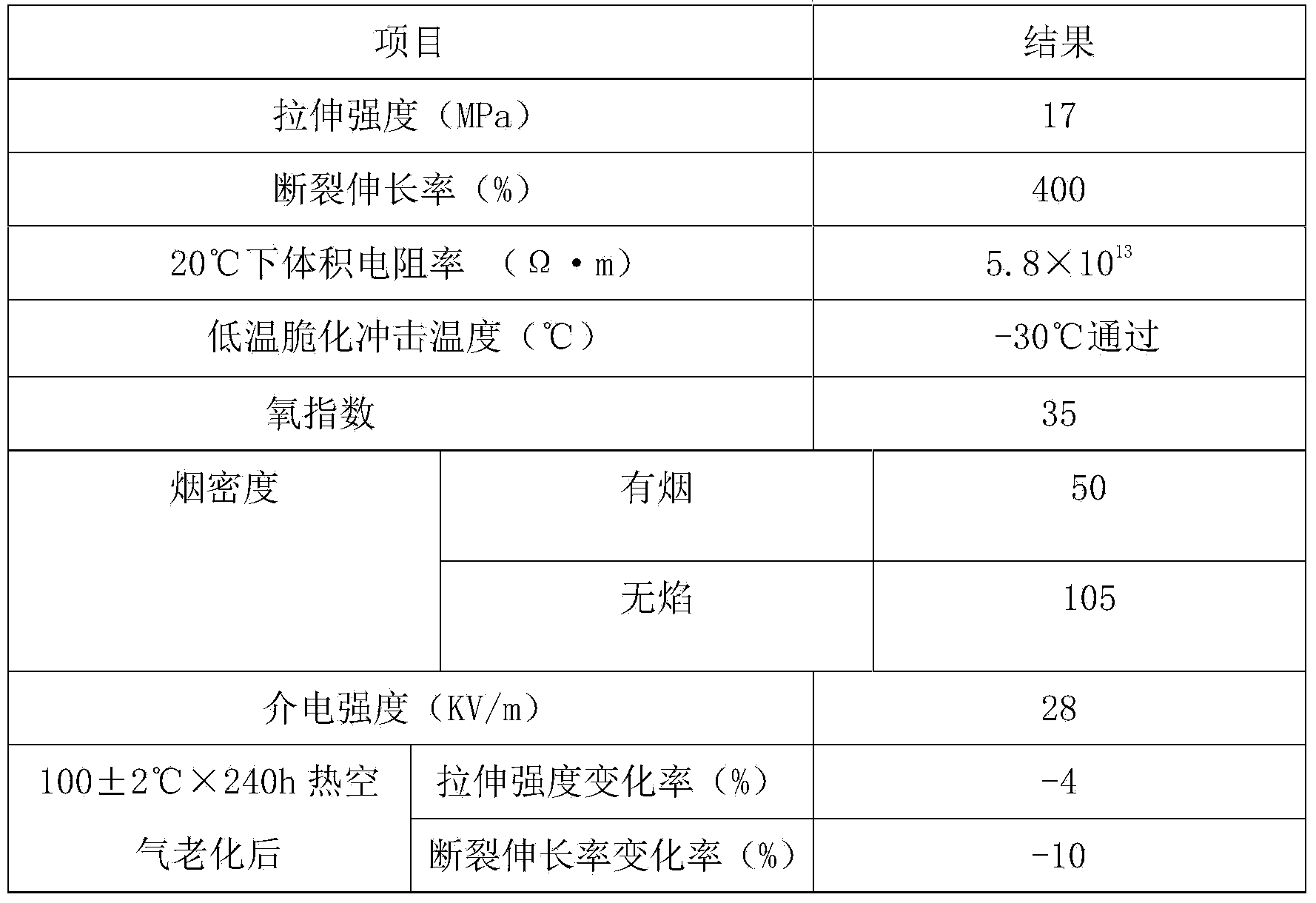

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

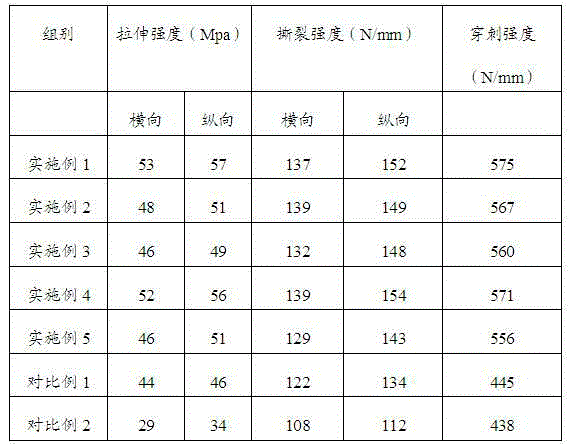

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Method for preparing fire-fighting noise rreduced, skidproof material of road surface in tunnel

ActiveCN1760279AImprove fire resistanceDoes not smoke and burnPaving detailsBuilding insulationsFiberDecabromobiphenyl ether

A fire-proof, noise-reducing and antiskid material for the pavement in tunnel is prepared through preparing flame-retarding smoke-inhibiting agent from decabromodiphenyl ether, Sb2O3, aluminium hydroxide and smoke inhibitor, preparing modified high-viscosity flame-retarding asphalt from styrene-butanediene-styrene block copolymer, activated rubber powder, stabilizer, antioxidizing agent, said flame-retarding smoke-inhibiting agent and asphalt matrix, choosing mineral material consisting of aggregate and filler, and mixing it with said modified asphalt and fibers.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

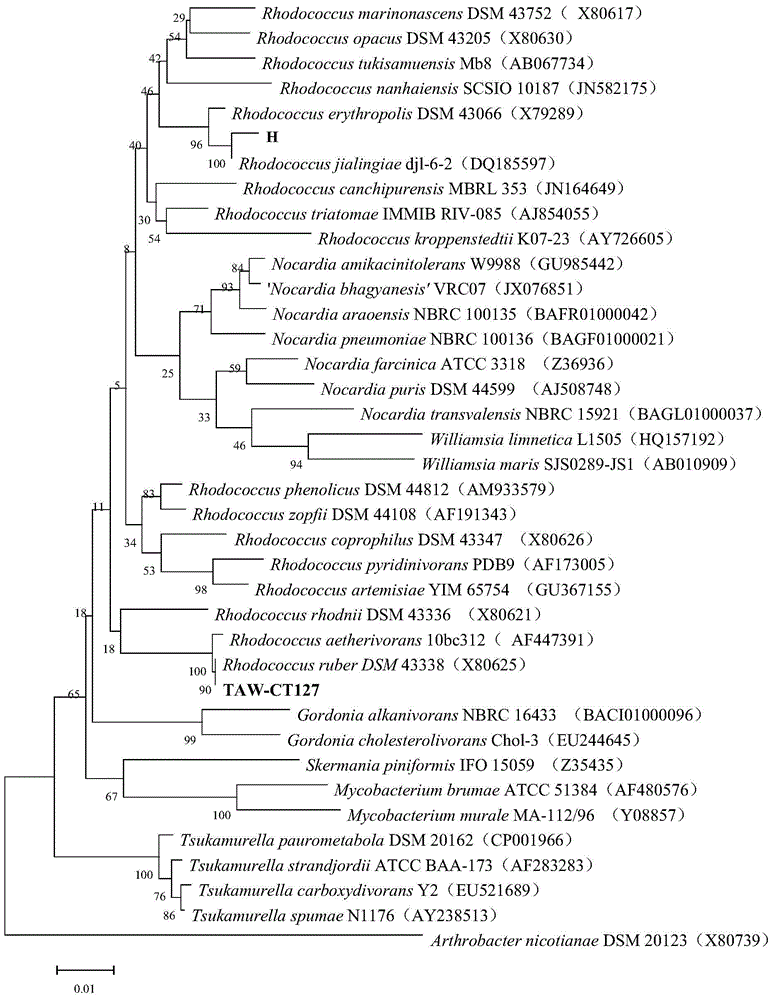

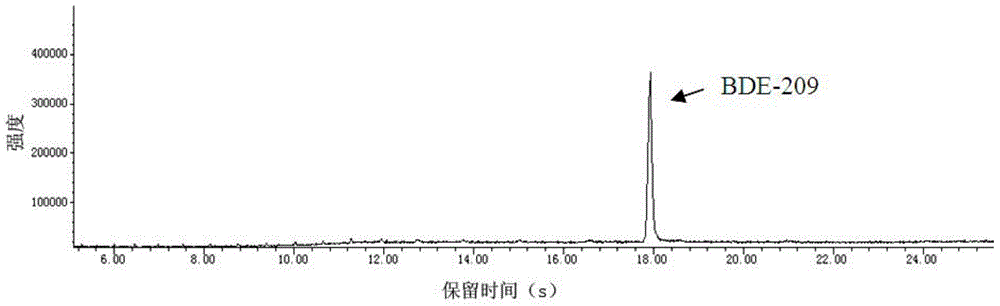

Rhodococcus ruber and application thereof in preparing decabromodiphenyl oxide degrading agent

The invention provides a Rhodococcus ruber and application thereof in preparing a decabromodiphenyl oxide degrading agent, relating to application of microbes. The collection number of the Rhodococcus ruber TAW-CT127 is CCTCC NO.M 2015212. The Rhodococcus ruber TAW-CT127 can be used in preparing the decabromodiphenyl oxide degrading agent. The decabromodiphenyl oxide is the unique carbon source in the decabromodiphenyl oxide degradation culture medium. After the Rhodococcus ruber TAW-CT127 is cultured in the degradation culture medium using decabromodiphenyl oxide as the unique carbon source at 28 DEG C under the pH value of 7.4 at the shaking table rotation frequency of 160 rpm, the degradation rate of the Rhodococcus ruber for decabromodiphenyl oxide is up to 91%.

Owner:XIAMEN UNIV

Anti-flaming antisepsis leather coating and preparation method thereof

InactiveCN105925099AImprove water resistancePrevent penetrationFireproof paintsAntifouling/underwater paintsDecabromodiphenyl etherTriterpenoid saponin

The invention discloses an anti-flaming antisepsis leather coating which is composed of, by weight, 2-3 parts of hydrous zinc borate, 1-1.5 parts of linoleic acid calcium soap, 0.1-0.2 part of triterpenoid saponin, 0.7-1 part of calcium naphthenate, 1.7-2 parts of polyvinylpyrrolidone, 0.8-1 part of polyacrylamide, 1.6-2 parts of stannous chloride, 0.1-0.13 part of triethanolamine, 190-200 parts of methyl methacrylate, 3-4 parts of lauryl sodium sulfate, 0.1-0.2 part of urotropine, 0.2-0.3 part of ammonium persulfate, 6-7 parts of a 20%-25% formaldehyde solution, 16-20 parts of zinc acetate, 4-7 parts of silver nitrate, 1-2 part of decabromodiphenyl ether and 0.4-1 part of sodium lauryl sulfate. The anti-flaming antisepsis leather coating has a good antibacterial property and excellent moisture permeability and water resistance. Leather coated with the obtained emulsion is good in antibacterial property and excellent in hygiene property.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Static conducting flame-retardant rubber for oil tank seal tape

ActiveCN101328290AMeet the requirements of static conduction and flame resistanceWith static conduction and flame retardant performanceOther chemical processesLarge containersParaffin waxPolymer science

The invention relates to a static electricity conductive flame retardant rubber for an oil tank sealing strip. The rubber takes butyronitrile rubber as a main raw material, which is mixed with stearic acid, zinc oxide, acetylene carbon black, semi reinforcing carbon black, aluminum hydroxide, decabromodiphenyl ether, antimony trioxide, chlorinated paraffin wax, antiager 4010NA, antiager A, sulfur, accelerant CZ, accelerant TMTM, coumarone and dioctyl phthalate, and the mixture undergoes the mixing by an internal rubber mixer, and the rubber is bonded on both sides of a gum dipping framework by a calender and is subject to the sulfuration to prepare the static electricity conductive flame retardant sealing strip. The surface resistance of the product is less than 3x10<8>Ohm, and the burning performance is no less than FV-1 class, the rubber of the invention meets the requirements of an steel oil tank on the static electricity conduction and the flame retardation of the rubber sealing strip.

Owner:ANQING SPECIAL RUBBER & PLASTIC PROD

Bitumen flame-proof modifier

InactiveCN101153116AImprove road performanceGood dispersionBuilding insulationsPolyolefinDecabromobiphenyl ether

The present invention discloses an asphalt flame retardant modifier which is granular. According to the weight portion, the composition is: 20 portion to 45 portion of decabromodiphenyl ether or decabromophenylethane, 15 portion to 30 portion of hydrated magnesium silicate, 5 portion to 15 portion of smoke-suppressant, 1 portion to 10 portion of fatty acid of C16-C18 as coupling agent, and 15 portion to 25 portion of polyolefin. The present invention also discloses a preparation method of the asphalt flame retardant modifier. The asphalt flame retardant modifier of the present invention has good road performances and has the characteristics of good dispersion, easy addition, security, environmental protection and so on. The present invention improves the production efficiency, has no environmental pollution in working, and less equipment corrosion. The flame retardant composition is proper; the synergic effects of a plurality of flame retardants are made full use of; the materials are directly blended and added; the present invention simplifies the production process and reduces the production cost.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Anti-cracking waterproof high-performance asphalt cable material and preparing method thereof

InactiveCN105778227AReduce injectionReduce aggregationPlastic/resin/waxes insulatorsBuilding insulationsEpoxyCrack resistance

The invention discloses an anti-cracking waterproof high-performance asphalt cable material. The cable material is prepared from, by weight, 94-96 parts of high-density polyethylene, 15-17 parts of decabromodiphenyl ether, 7-9 parts of antimonous oxide, 2-3 parts of metallocene polyethylene, 2-3 parts of nano-magnesium hydroxide, 4-5 parts of cyclohexane, 0.2-0.3 part of gamma-aminopropyl triethoxy silane, 4-6 parts of silicon carbide, 3-4 parts of zinc oxide, 2-3 parts of graphene, 9-11 parts of asphalt, 1-1.3 parts of accelerant DM, 2-3 parts of epoxy linseed oil, 10-12 parts of ethylene-vinyl acetate copolymer and 10-13 parts of absolute ethyl alcohol. By means of a series of modification, viscosity is reduced, fluidity is improved, compatibility with a base material is improved, flame retardant master batch and anti-breakdown modified master batch are added, and therefore the cable material is higher in high-temperature stability and low-temperature crack resistance, flexible, waterproof, resistant to abrasion, economical and durable and absorbs shock.

Owner:ANHUI AICS SCI & TECH GROUP

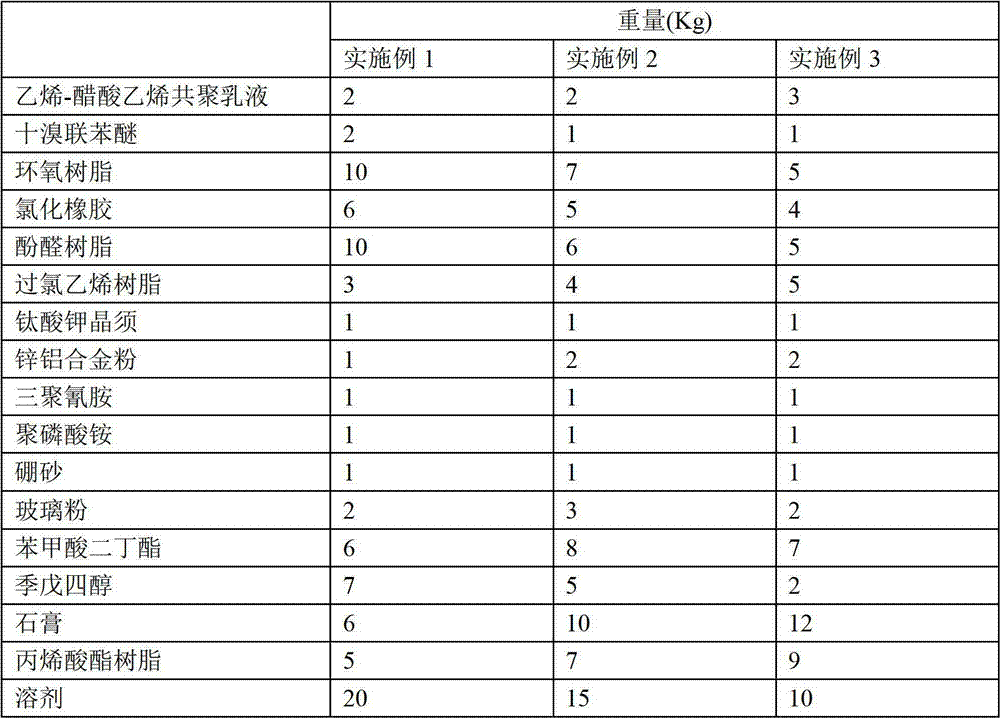

Corrosion-resistant fireproof coating

InactiveCN102850902AImprove adhesionEffective flame retardantFireproof paintsRubber derivative coatingsEpoxyDecabromodiphenyl ether

The invention provides a corrosion-resistant fireproof coating, which belongs to the technical field of coatings. The corrosion-resistant fireproof coating comprises, by weight, 2 to 3 parts of ethylene-vinyl acetate copolymer emulsion, 1 to 2 parts of decabromodiphenyl ether, 5 to 10 parts of epoxy resin, 4 to 6 parts of chlorinated rubber, 5 to 10 parts of phenolic resin, 3 to 5 parts of perchlorethylene resin, 1 part of potassium titanate whisker, 1 to 2 parts of zinc-aluminum alloy powder, 1 part of melamine, 1 part of ammonium polyphosphate, 1 part of borax, 2 to 3 parts of glass powder, 5 to 8 parts of dibutyl benzoate, 2 to 7 parts of pentaerythritol, 6 to 12 parts of gypsum, 5 to 9 parts of acrylate resin and 10 to 20 parts of a solvent. The fireproof coating provided by the invention has excellent corrosion resistance and has fire resistance in accordance with national regulations.

Owner:苏州市德莱尔建材科技有限公司

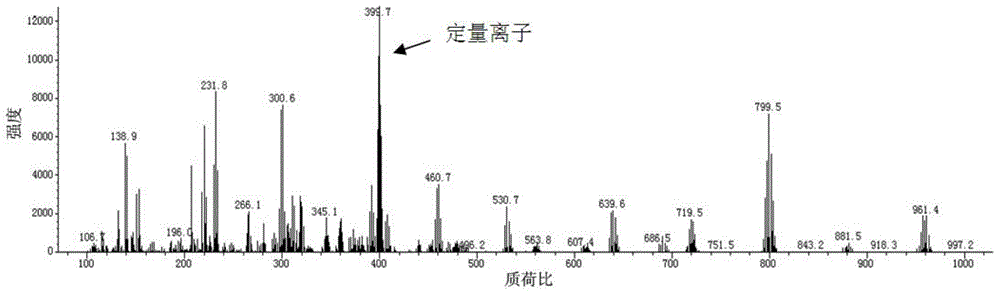

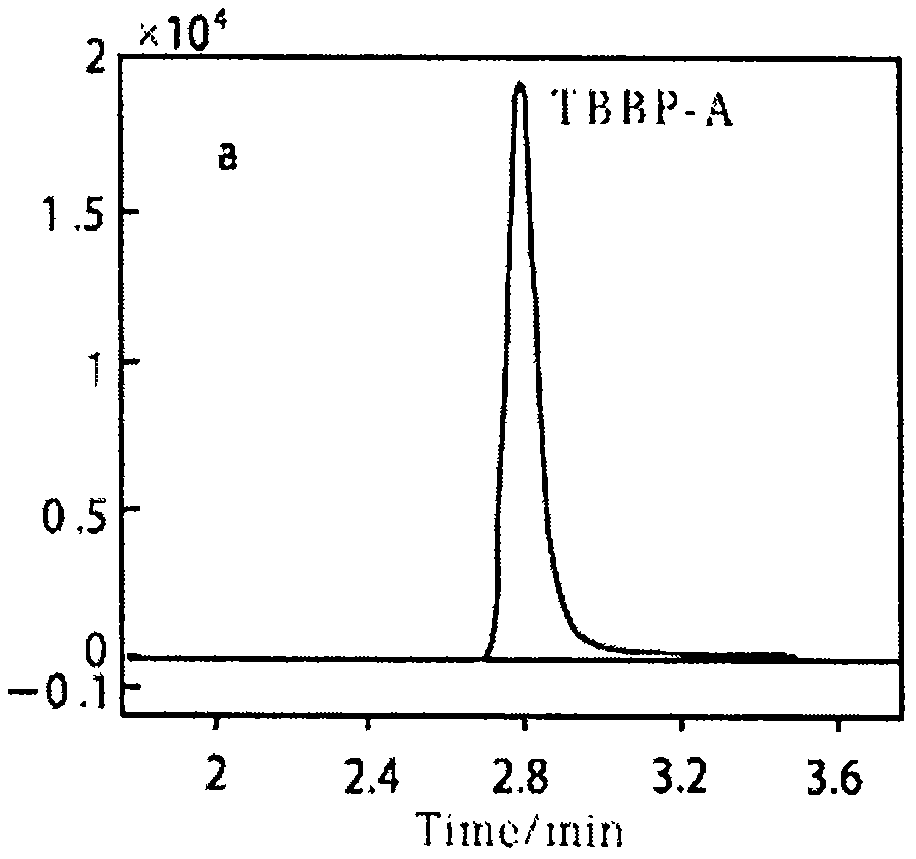

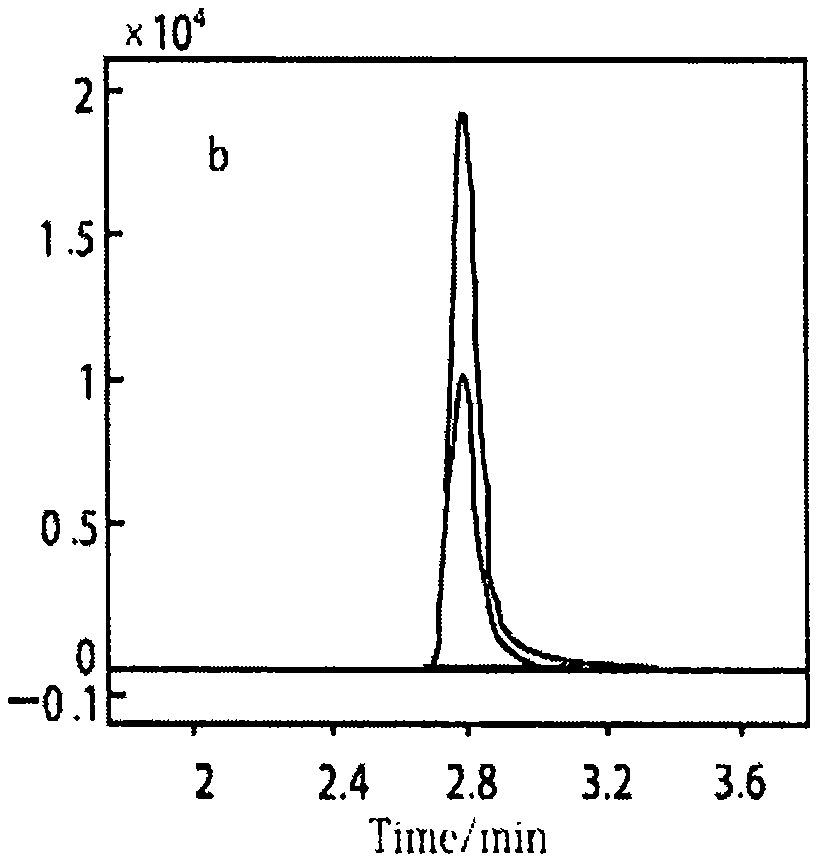

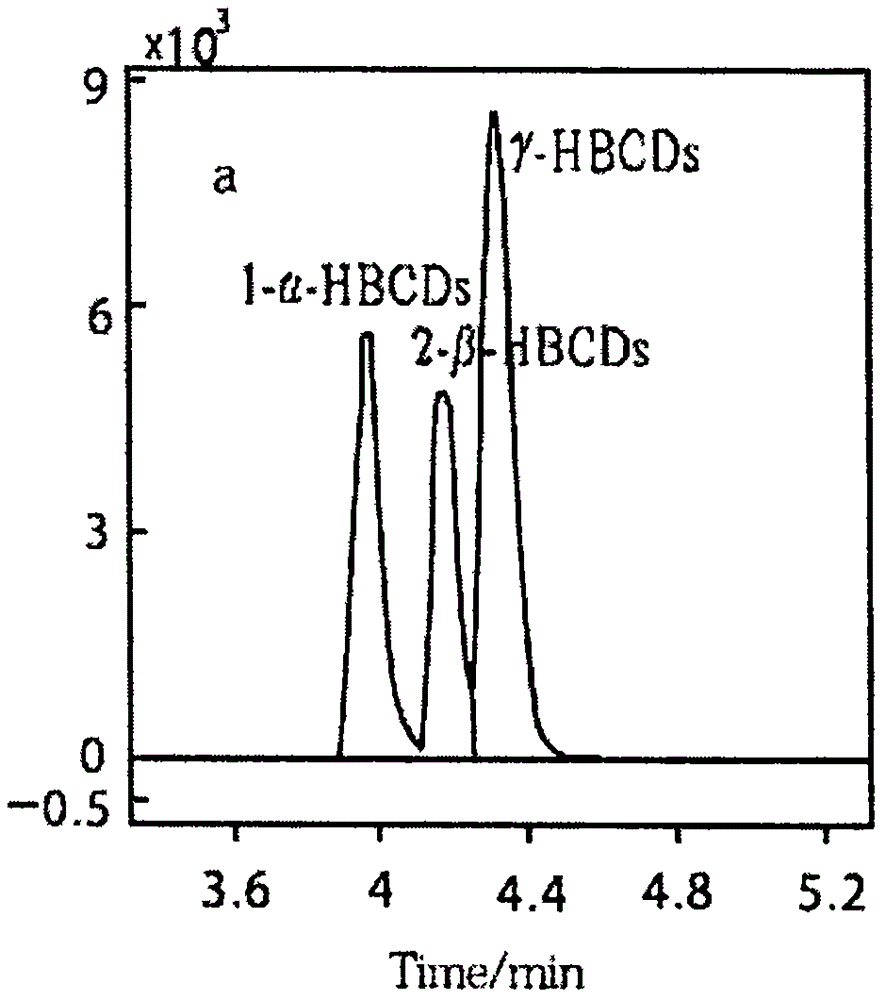

Method for detecting content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in aquatic product

ActiveCN106124643AGuaranteed accuracyGuarantee stabilityComponent separationTetrabromobisphenol ADecabromodiphenyl ether

The invention provides a method for detecting the content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in an aquatic product. The method is characterized by comprising the following steps that the content of the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product is measured by establishing accelerated solvent extraction-fast liquid chromatography-tandem mass spectrometry, an aquatic product sample needing to be detected is separated through a C18 chromatographic column, gradient elution is conducted by taking water and methyl alcohol as mobile phases, detection is conducted in a mass spectrum multi-reaction monitoring mode, the matrix standard is corrected, quantitative determination is conducted through an external standard method, and confirmation is conducted. The detection method has the advantages that operation is easy and convenient, and detection is fast and accurate; by establishing the method for simultaneously detecting the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product, physical health and life safety of consumers are guaranteed, a great practical significance is achieved for promoting sustainable and healthy development of aquatic product processing industry, and a beneficial technical reserve is provided for a food industry supervision department and a detection mechanism.

Owner:ZHOUSHAN INST FOR FOOD & DRUG CONTROL

Monocomponent PRTV anti-pollution-flashover paint and preparation method thereof

InactiveCN103923562AIncrease the pollution flashover voltage of the external insulationGuaranteed uptimeFireproof paintsPolymer scienceDecabromobiphenyl ether

The invention discloses monocomponent PRTV anti-pollution-flashover paint and a preparation method thereof. The monocomponent PRTV anti-pollution-flashover paint is composed of the following materials in parts by weight: 28-38 parts of polydimethylsiloxane, 10-19 parts of hydroxyl-terminated fluorine-containing polysiloxane, 3-5 parts of nanometer silica, 1-3 parts of a coupling agent, 0.5-1 part of a catalyst, 2-3 parts of decabromodiphenyl ether, 1-2 parts of a pigment and 40-50 parts of a solvent. The monocomponent PRTV anti-pollution-flashover paint has the beneficial effects that a fluorine material and a nanometer material are organically combined and blended with silicone rubber, silicone rubber is taken as main base rubber and fluorosilicone rubber is taken as auxiliary base rubber; and the monocomponent PRTV anti-pollution-flashover paint has the main technical advantages of being good in flame retardant effect, substantially reduced in cost.

Owner:滕州市智星电力电子工程有限公司

Courier bag material and preparation method of courier bag

InactiveCN102911429AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical field of packing materials and particularly relates to a courier bag material. The courier bag material comprises the following components: 35-45 parts of low-density polyethylene, 5-10 parts of high-density polyethylene, 50-55 parts of linear low-density polyethylene, 5-10 parts of mica, 3-7 parts of calcium carbonate, 1-9 parts of palygorskite, 1-4 parts of decabromodiphenyl ether, 1-5 parts of antimony trioxide, 1.5-2.0 parts of chlorinated polyethylene, 0.1-0.25 part of antioxidant, 0.1-2 parts of coupling agent and 0.3-0.8 part of zinc stearate. Compared with the prior art, by optimizing a formula of the courier bag material, the courier bag made of the courier bag material has the characteristics of high strength, puncture resistance, laceration resistance, and better heat resistance, wear resistance and flame retardancy, thus improving the security and practicability of the courier bag significantly and being widely applicable to various courier bags.

Owner:GUANGDONG TENGEN IND GRP CO LTD

Anticorrosive paint

The invention discloses anticorrosive paint which comprises, by mass, the following materials of 2-5 parts of allyl heptanoate, 1-4 parts of 4-methyl guaiacol, 1-2 parts of acetylacetone selenium, 4-9 parts of polyamide resin, 2-4 parts of 3-chlorine-2-carboxyl propyl trimethyl ammonium chloride, 1-3 parts of chromic chloride, 3-7 parts of vinylidene chloride, 2-5 parts of tetrabutylammonium bromide, 0.2-0.5 part of yttrium oxide, and 3-6 parts of decabromodiphenyl ether. The anticorrosive paint is not only convenient to use, easy to produce and manufacture, good in painting performance, and good in wettability for object surfaces, but also rapid in paint film drying, good in mechanical capacity, and good in acid-base resistance property, water resisting property, and resistance to organic solvent.

Owner:NANTONG HAISHUN CHEM

Flame-retardant rubber material capable of protecting high-risk chemicals and method for preparing same

ActiveCN102977478AEffective protectionSolve the problem of large polarity differenceRubber materialDecabromodiphenyl ether

The invention discloses a flame-retardant rubber material capable of protecting high-risk chemicals and a method for preparing the same, belongs to the technical field of rubber and solves the problems of single function and poor quality due to single rubber type, and difficult formation of homogeneous phase while compounding a plurality of types of rubbers of the existing rubber. The flame-retardant rubber material capable of protecting high-risk chemicals is composed of the following components according to parts by weight: 30-80 parts of chlorinated butyl rubber, 30-10 parts of butadiene styrene rubber, 40-10 parts of neoprene, 2.0 parts of sulfur, 0.8-1.2 parts of accelerant TT, 0.8-1.2 parts of accelerant DM, 30 parts of high abrasion proof carbon black, 8-15 parts of decabromodiphenyl ether, 8-20 parts of antimonous oxide, 5-15 parts of chlorcosane, 5.0 parts of zinc oxide, 2.5 parts of stearic acid and 2.0 parts of antiager D. The flame retardant rubber material effectively overcomes the shortcomings of single function and poor quality of single rubber type; the product is capable of effectively protecting high-risk chemicals and highly corrosive materials, and thus can be widely applied to effectively protecting the feet, the head and the skin.

Owner:SHANXI XINHUA CHEM +1

Bacillus subtilis and application thereof for degrading decabromodiphenyl oxide

InactiveCN101921716APromote degradationLow costBacteriaMicroorganism based processesFuranDecabromobiphenyl ether

The invention discloses bacillus subtilis DB-2 and application thereof for degrading decabromodiphenyl oxide. The bacillus subtilis is preserved in China Center for Type Culture Collection (CCTCC) on 27th November 2009 with the preservation number of CCTCC No:M 209286. The bacillus subtilis has stronger degrading ability and is capable of debrominating decabromodiphenyl oxide to generate free bromonium ions. The bacillus subtilis does not generate high-toxicity secondary pollutants of polybrominated dibenzo-p-dioxins, polybrominated dibenzo-furans, low-brominated diphenyl ether, and the like after being biodegraded, and can be used for treating the pollution of the decabromodiphenyl oxide in the environment, thereby providing a decabromodiphenyl oxide degrading bacterium with low cost and high efficiency and without secondary pollution for treating the decabromodiphenyl oxide in chemical sludge or wastewater.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

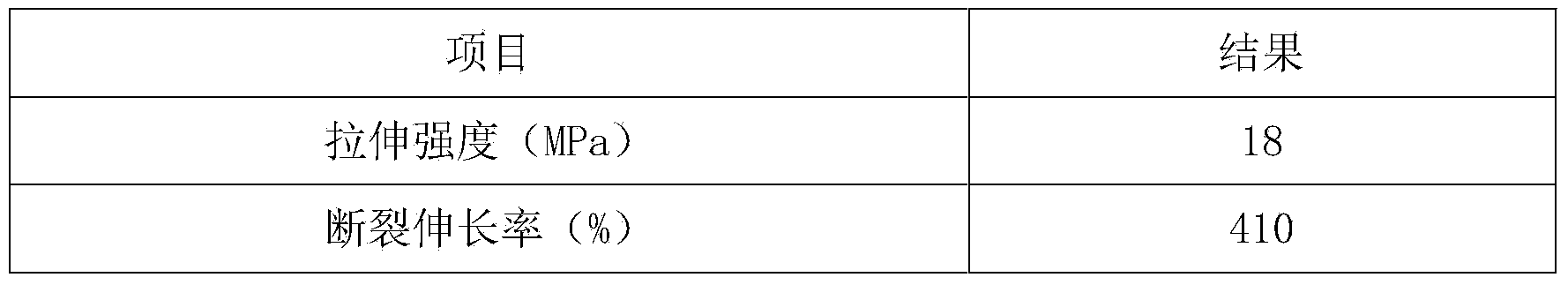

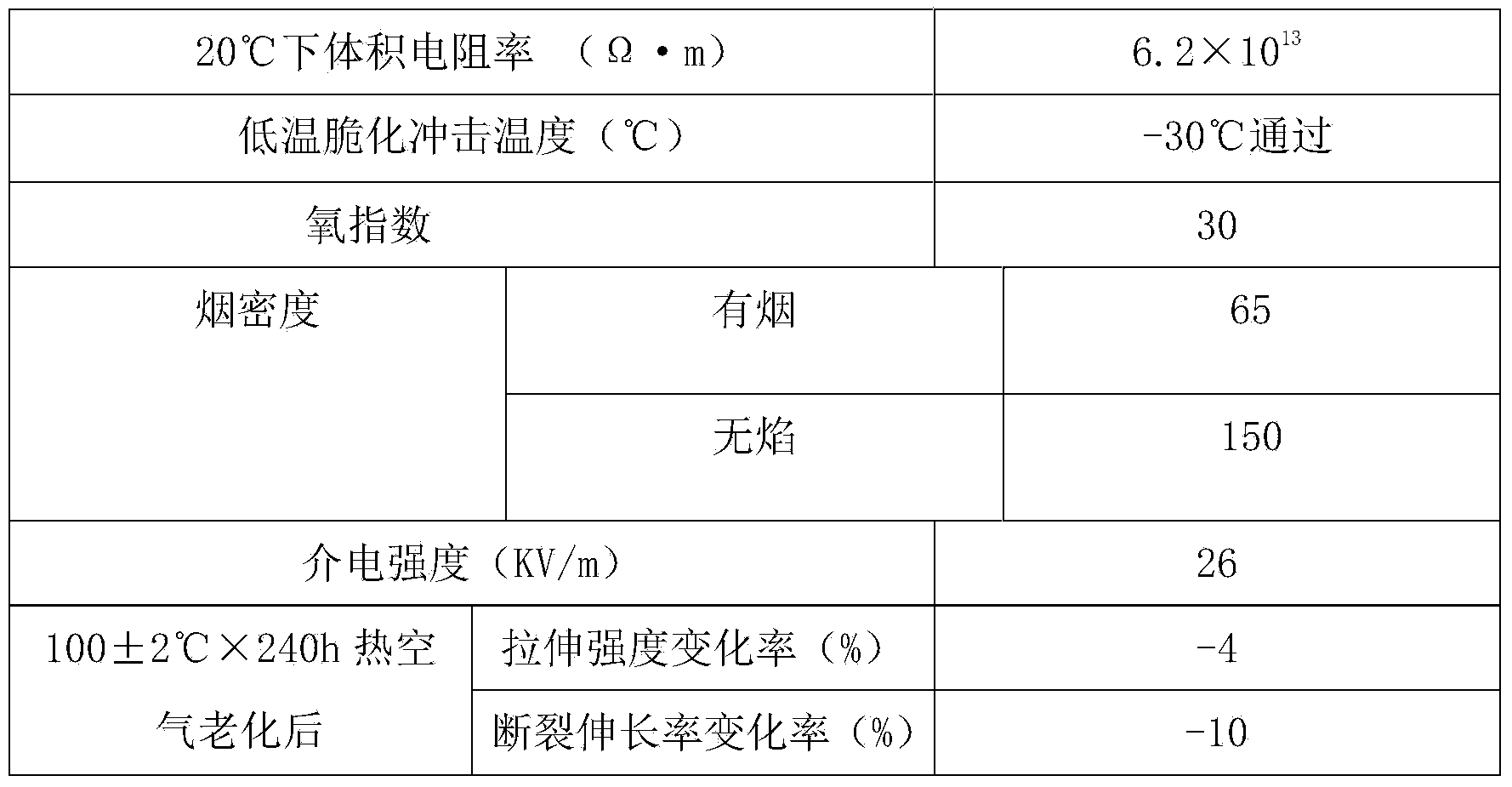

Environment-friendly cold-resistant polyvinyl chloride cable material

InactiveCN103509293AStrong impact resistanceSolve environmental problemsWear resistantDecabromodiphenyl ether

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material. The polyvinyl chloride cable material is prepared with the following components and raw materials by weight: 60-70 parts of polyvinyl chloride, 10-15 parts of polysiloxane, 8-10 parts of silicon rubber, 12-15 parts of dioctyl terephthalate, 5-10 parts of triethylene glycol di-2-ethylhexoate (triglycol dioctate), 3-5 parts of epoxy triglyceride, 8-10 parts of tributyl acetocitrate, 1-2 parts of cobalt naphthenate, 0.2-0.3 part of ethyl silicon oil, 2-5 parts of chlorinated polyethylene, 10-15 parts of aluminum hydroxide, 5-6 parts of triphenyl phosphate, 4-6 parts of decabromodiphenyl ether, 8-10 parts of light activated calcium carbonate, 5-8 parts of bentonite, 1-2 parts of zinc oxide, 1-2 parts of titanium dioxide, 5-6 parts of cinerite, 6-8 parts of highly wear-resistant carbon black, 2-3 parts of Ca-Zn compound stabilizer, 0.1-1 part of antioxidant 1076, 0.1-0.3 part of dicumyl peroxide (DCP), 0.2-0.3 part of butyl stearate, 1-2 parts of barium stearate, 0.1-0.5 part of zinc stearate, and 8-10 parts of modified filler. The cable material is of good shock resistance at low temperature and environment-protection property, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly, and bad in the shock resistance at low temperature.

Owner:东莞虎塑塑胶科技有限公司

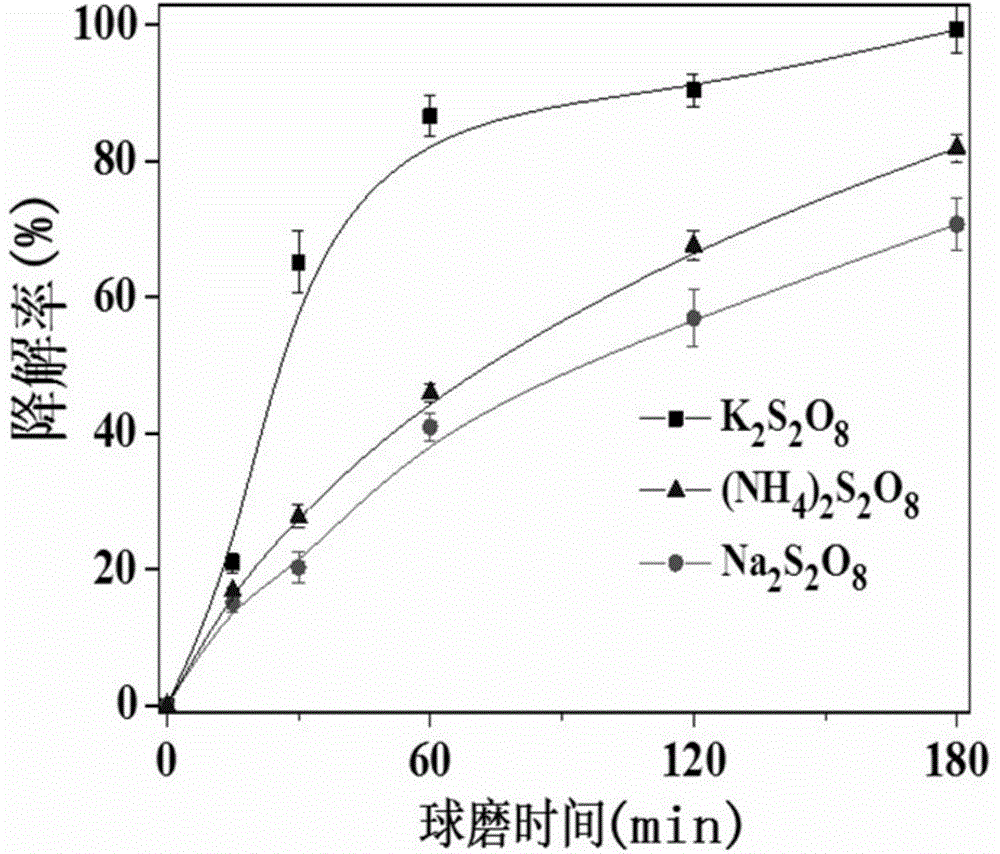

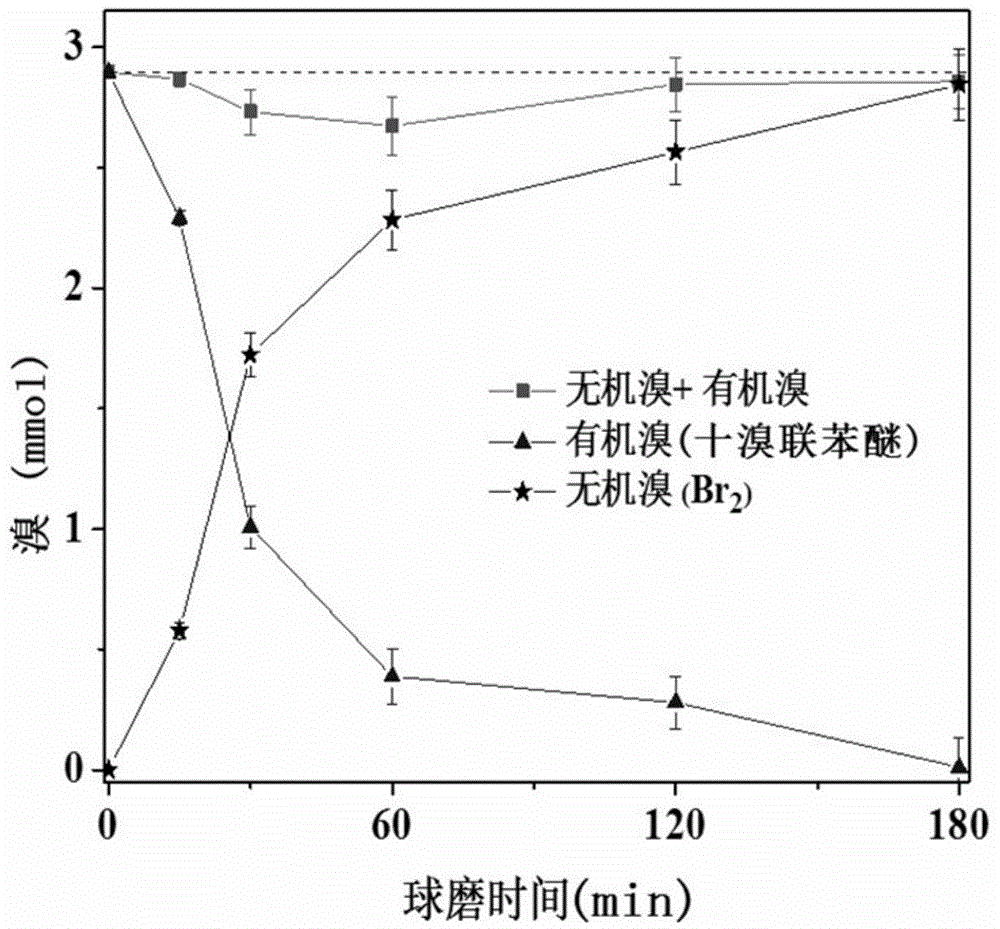

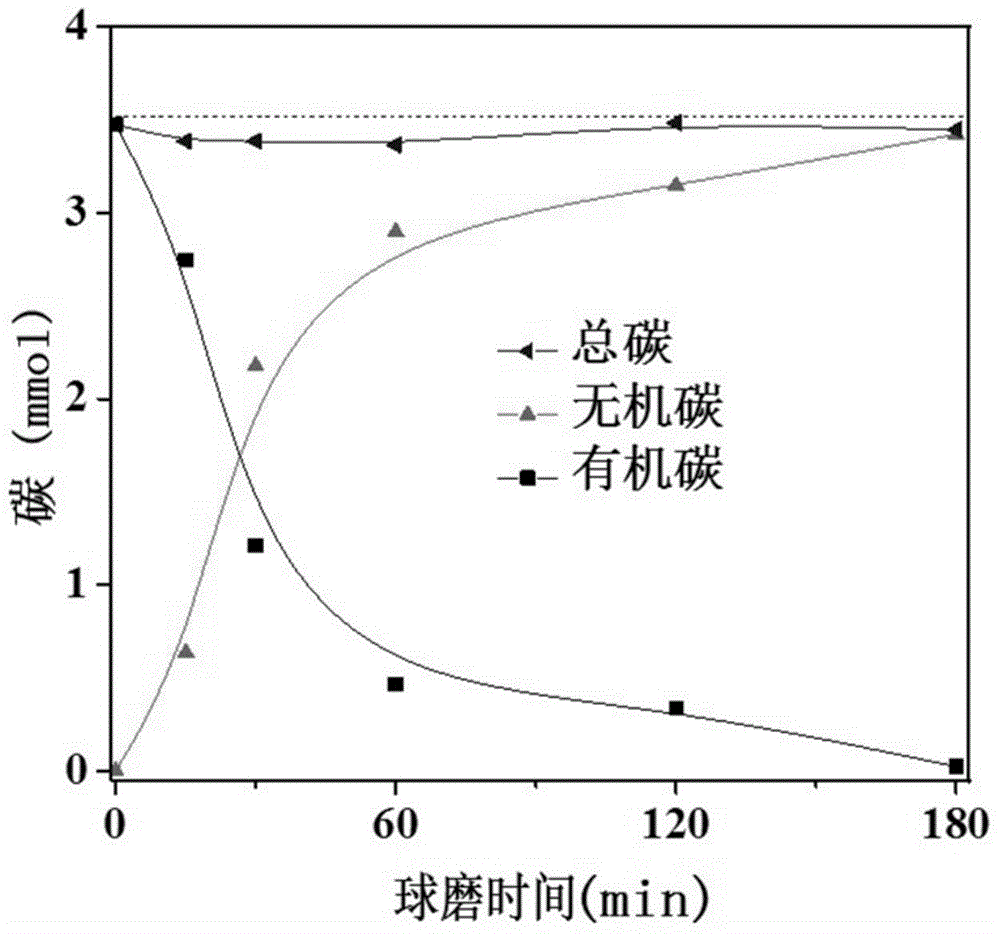

Treating method for halogenated organic solid pollutants

ActiveCN104907314ACompletely degradedComplete mineralizationSolid waste disposalTetrabromobisphenol ADecabromobiphenyl ether

The invention discloses a treating method for halogenated organic solid pollutants. The treating method comprises the following steps: mixing persulfate with the halogenated organic solid pollutants and adding the obtained mixture into a ball milling tank; and carrying out grinding by using a plurality of grinding balls with different diameters at normal temperature and normal pressure. According to the invention, the halogenated organic solid pollutants can be fully and effectively degraded at normal temperature and normal pressure through oxidation effect of free sulfate radicals on the halogenated organic solid pollutants, and degradation rates of decabromodiphenyl ether, phenyl-hexachloride and tetrabromobisphenol A all exceeds 85%.

Owner:HUAZHONG UNIV OF SCI & TECH

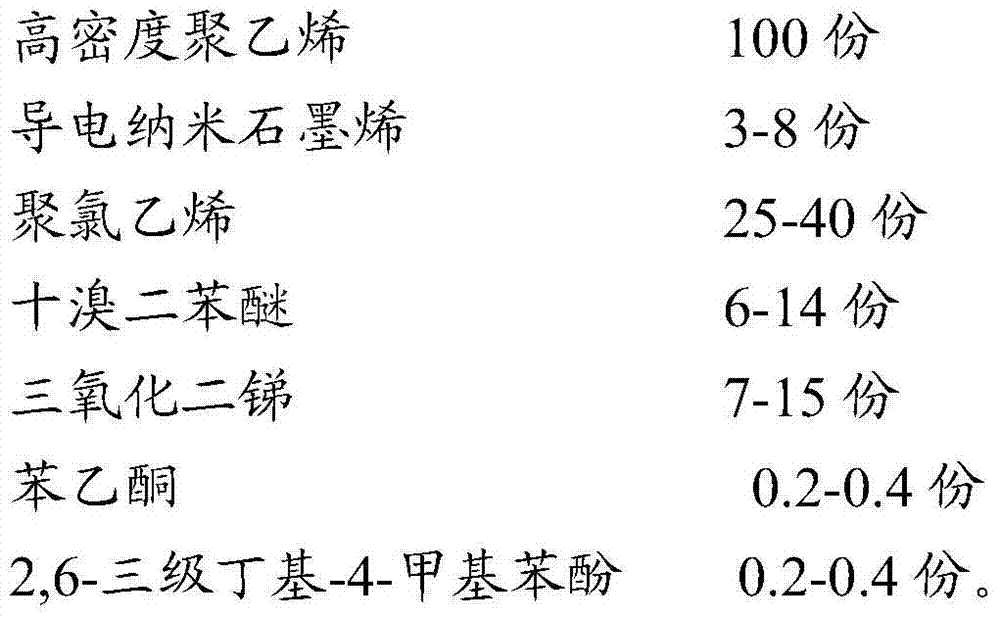

High density polyethylene pipe

InactiveCN104262740AImprove antistatic performanceImprove impact resistanceMasterbatchAntistatic agent

The invention relates to a high density polyethylene pipe. An antistatic agent, a toughener, a flame retardant, a photostabilizer and an antioxidant are added into a base material of high-density polyethylene. The manufacturing technique comprises the following steps: adding 50 parts of high-density polyethylene and additives into a high-speed mixer, carrying out extrusion granulation to prepare an antistatic high-toughness master batch, mixing the master batch with the rest of high-density polyethylene, adding into an extruder, forming the extruded material through a die orifice, cooling, pulling, and cutting to obtain the pipe which conforms to the operating requirements. The high density polyethylene pipe is prepared from the following raw materials in parts by weight: 100 parts of high-density polyethylene, 3-8 parts of conducting nano graphene, 25-40 parts of polyvinyl chloride, 6-14 parts of decabromodiphenyl oxide, 7-15 parts of antimony trioxide, 0.2-0.4 part of hypnone and 0.2-0.4 part of 2,6-tert-butyl-4-methylphenol.

Owner:王晓伟

Method for extruding ultra-high molecular weight polyethylene product with flame retardant and antistatic properties

InactiveCN101781420AInhibit migrationPromote formationFlat articlesTubular articlesPolymer scienceDecabromodiphenyl ether

The invention discloses a method for extruding an ultra-high molecular weight polyethylene product with flame retardant and antistatic properties, which is characterized by comprising the following steps: adding 100 parts of ultra-high molecular weight polyethylene resin the molecular weight of which is greater than or equal to 3800000, 15-25 parts of high-density polyethylene resin the molecular weight of which is 500000-700000, 2 parts of polyethylene wax, 1-2 parts of calcium stearate, 0.2-0.8 part of fluorine additive, 0.4 part of antioxidant, 30-35 parts of conductive carbon black powder and 30-32 parts of compound fire retardant into a single screw extruder for continuous extruding and forming, wherein the additives are kneaded in an internal mixer at 60-80 DEG C for 30-60 minutes, and then the additives and the polyethylene resin are added into the extruder. The compound fire retardant comprises decabromodiphenyl ether, antimony trioxide and ammonium polyphosphate (APP) in proportion of 10:5:1. The combination property of the product of the invention exceeds the existing coal industry standard (MT 558.1-2005), and the product is especially suitable to be used in the coal industry.

Owner:江苏联冠高新技术有限公司

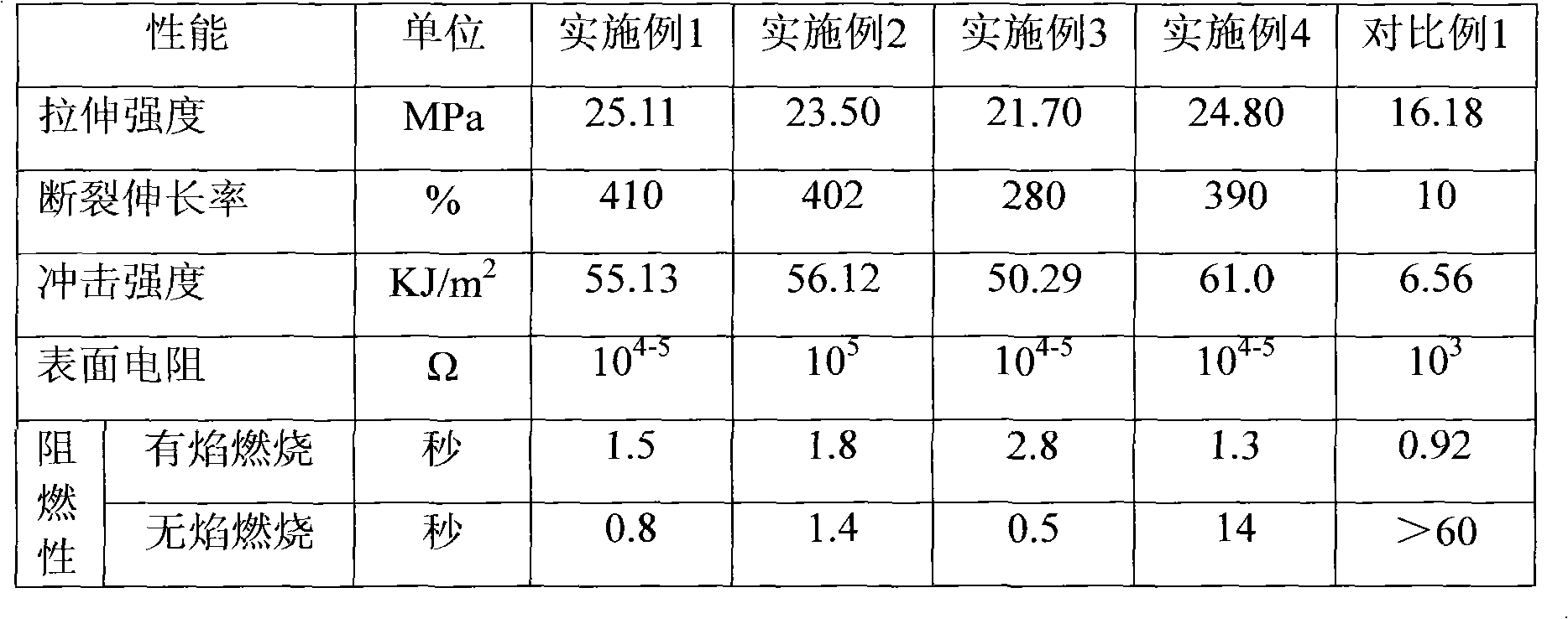

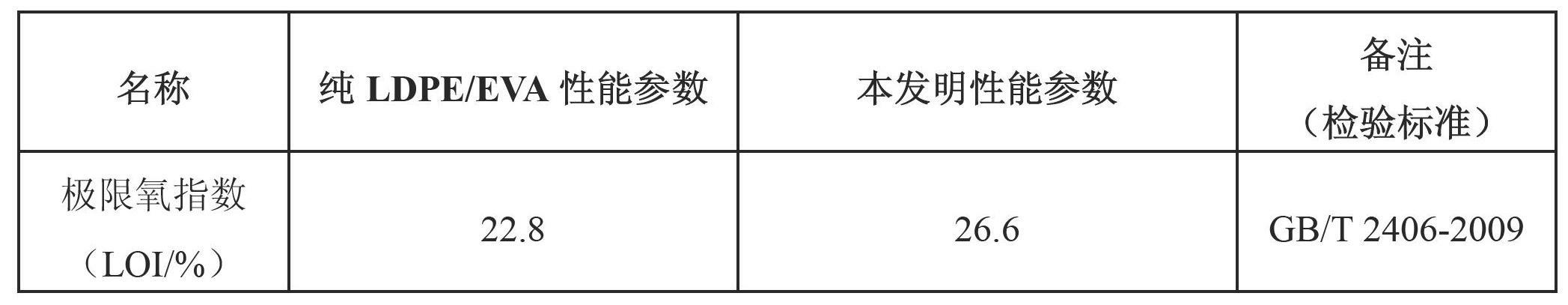

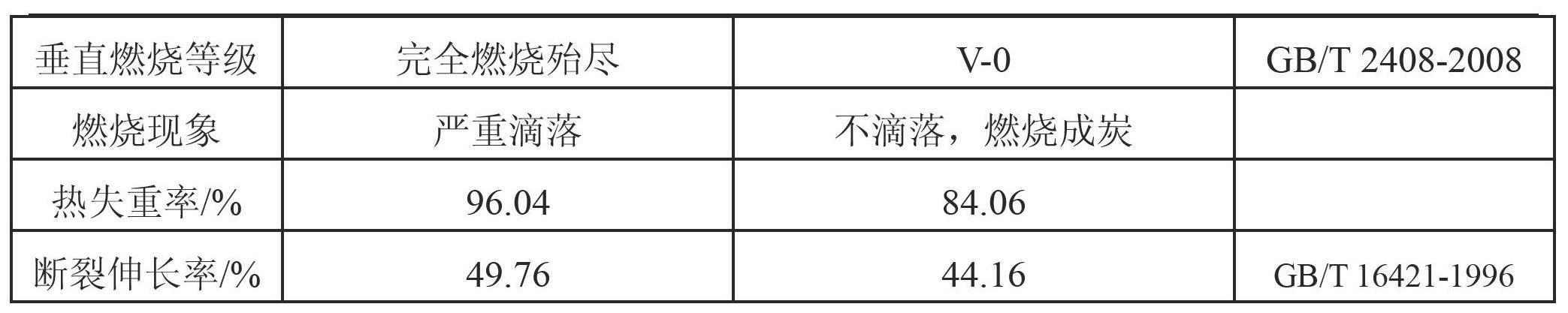

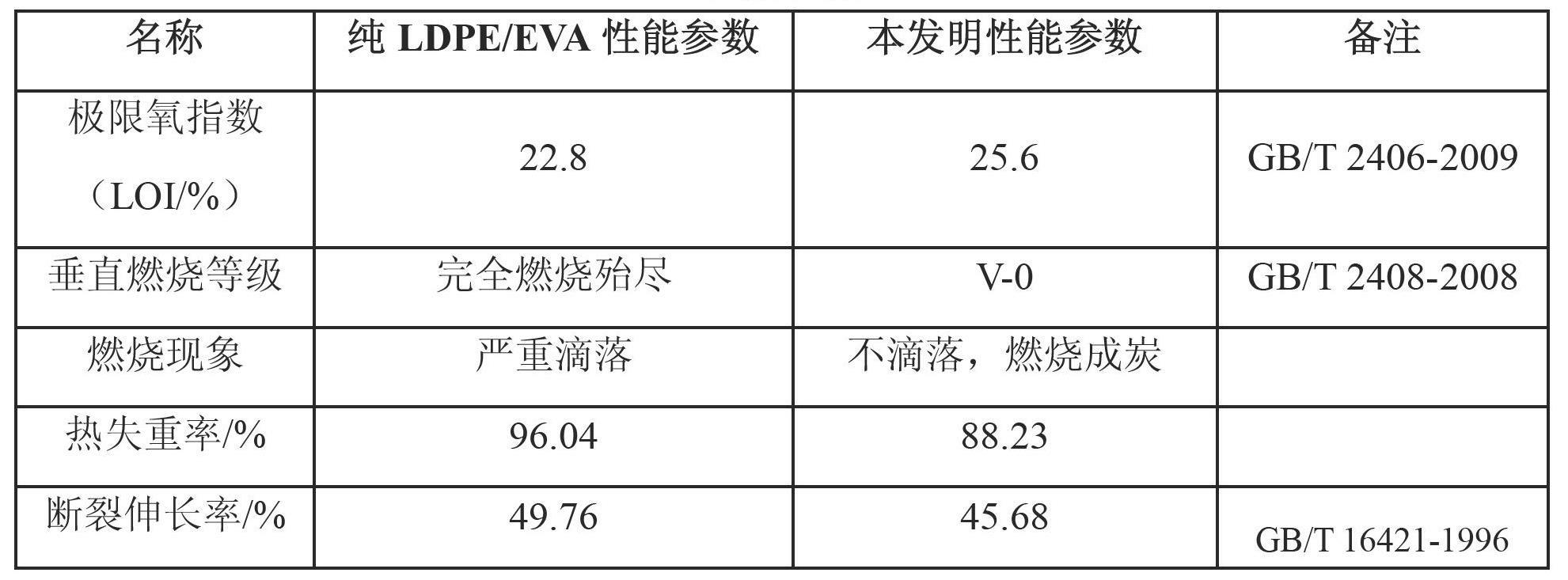

LDPE (Low-Density Polyethylene)/EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material and preparation method thereof

ActiveCN102643469ARaw materials are easy to getAbundant resourcesLow-density polyethyleneZinc borate

The invention relates to an LDPE (Low-Density Polyethylene) / EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material. The LDPE / EVA anti-flaming material comprises the following raw material compositions by weight parts: A is base resin and includes 100 parts of LDPE and EVA; B is bromine containing flame retardant and includes 10-20 parts of decabromodiphenyl ethane or decabromodiphenyl ether, C is inorganic flame retardant and includes 3-6 parts of modified antimonous oxide M-Sb2O3, 3-6 parts of talcum powder TP, 2-8 parts of zinc borate (ZB) and 2-8 parts of hydrotalcite (LDHs). The preparation method of the LDPE / EVA anti-flaming material is as follows: drying raw materials, mixing the raw materials uniformly, processing, extruding, and conducting injection molding on the raw materials to obtain the extruded anti-flaming composite material. According to the anti-flaming material and the preparation method, the advantages of the organic flame retardant, the bromine containing flame retardant and the inorganic flame retardant are combined, the using amount of the inorganic flame retardant is decreased, the limit oxygen index of the anti-flaming composite material is increased, the materials are burned into carbon directly when being burned, the dropping phenomenon can not occur, and the toxic and harmful gas can not be generated.

Owner:广西华锑科技有限公司

PET (polyethylene glycol terephthalate) fiber/mulberry bark composite sound absorbing cotton and preparation method of PET fiber/mulberry bark composite sound absorbing cotton

InactiveCN102965841AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / mulberry bark composite sound absorbing cotton, which comprises the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of mulberry bark fibers, 10 to 15 parts of emulsifying agents OP-9, 5 to 10 parts of peregal O-25, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of EVA (ethylene vinyl acetate), 15 to 20 parts of nanometer barite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl phthalate, 4 to 6 parts of decabromodiphenyl ether, 2 to 3 parts of tristearin, 1 to 2 parts of vinyltriethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dibasic lead phosphate, 0.5 to 1.5 parts of anti-ageing agents OD (octyl decyl) and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Composition of wear-resistant polyethylene pipe for underground coal mine, and preparation method of composition

InactiveCN102850637AHigh flame retardant efficiencyAdd lessRigid pipesProcedure AgentsWear resistant

The invention relates to a wear-resistant polyethylene pipe for an underground coal mine, belonging to one of polyethylene modified materials. The wear-resistant polyethylene pipe comprises the raw materials by weight percent: 2-5% of super wear-resistant carbon black, 10-20% of superconducting carbon black, 10-20% of decabromodiphenyl ether, 5-10% of antimony trioxide, 5-10% of POE, 0.5-1% of antioxidant, 2-4% of processing agent and the balance of high density polyethylene. The super wear-resistant carbon black has the required particle size of 11-15nm, the iodine absorption value of 145-152g / kg and the dibutyl phthalate (DBP) absorption value of 113-120cm<3> / 100g. The wear-resistant polyethylene pipe has the advantages that excellent flame retardant and antistatic performance is excellent, and wear resistance is high, so that the flame retardant and the antistatic performance and the mechanical property of the pipe are guaranteed not to be reduced due to dragging and friction in the processes of installation and use, and the safety factor of underground coal mine operation can be improved.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

Flame retarding anti-static plastic braiding bags

A flame-retarded and antistatic Polywoven Bag is used to solve the problem that whose average surface resistance is sharply lower than that of the national standards and is prepared by: (1) Making flame-retarded masterbatch A by mixture and plastication of the antimony oxide and the polypropylene; (2) Making flame-retarded masterbatch B by mixture and plastication of the Decabromobiphenyl ether and the polypropylene; (3) Making antistatic masterbatch by mixture and plastication of the static agent and the polypropylene; (4) Making the mixture of the flame-retarded masterbatch A, B,antistatic masterbatch and the polypropylene through the high rate agitator; (5) Making the filamentus disk through drawing it to pellicle and filamentus using the plastic machine; and (6) Surface treating using the static agent. It can be used in coal mine and chemical lines.

Owner:吴珍山

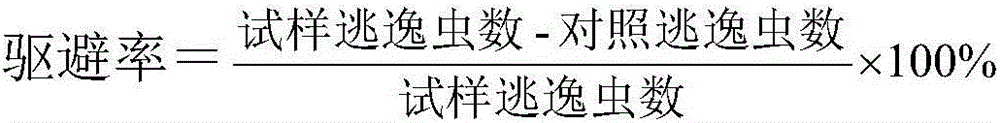

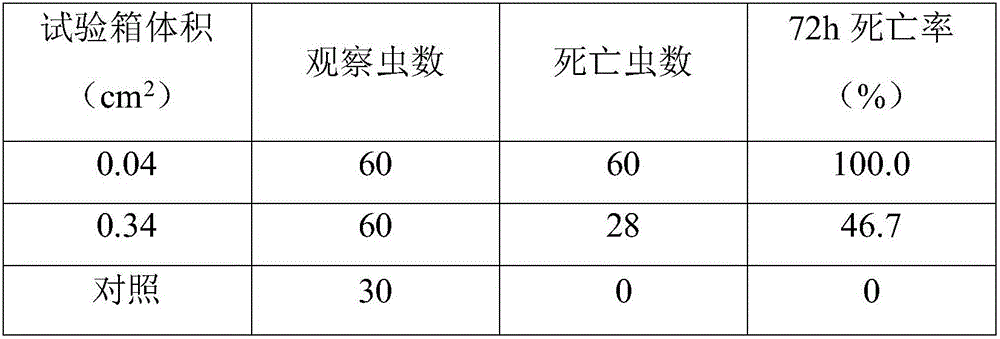

Flame-retardant insect-proof antibacterial mat for floor carpet and preparation method of mat

The invention belongs to the field of high polymer materials, and discloses a flame-retardant insect-proof antibacterial mat for a floor carpet.The flame-retardant insect-proof antibacterial mat is prepared from low-density polyethylene, high-density polyethylene, decabromodiphenyl ether, polyethylene resin, zinc stearate, antimonous oxide, polyethylene wax, medical stone, natamycin, beta-cyclodextrin, chitosan, silane coupling agent, traditional Chinese medicine additives, citric acid, foaming agent, monoglyceride and color master batch.The product is a green and pollution-free product and has high flame retardance and good insect-proof and antibacterial performance, can restrain breeding of viruses, insects, mites, ants and the like for a long time, can effectively protect the floor carpet, and is harmless to human bodies and free of hidden health and safety dangers in the use process.

Owner:山东丽芳洁环保材料有限公司

Anti-bacterial and high-intensity talcum powder modified polypropylene plastic

An anti-bacterial and high-intensity talcum powder modified polypropylene plastic comprises the following components in parts by weight: 100 parts of co-polypropylene, 20 to 40 parts of talcum powder, 2 to 4 parts of titanium dioxide, 10 to 15 parts of PP-g-MAH compatibilizer, 10 to 25 parts of decabromodiphenyl ether, 0.1 to 0.2 part of dimerization di(isooctyl) phosphate magnesium stearate, 10 to 20 parts of melamine cyanurate, 0.1 to 0.3 part of a composite antibacterial agent, 0.1 to 0.3 part of an antioxidant and 1 to 3 parts of auxiliaries.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Flame retardant plastic compositions

InactiveUS7553898B2High melting temperatureEqually distributedMaterial nanotechnologySpecial tyresPolyolefinPolymer science

A fire retardant composition that includes: a polyolefin and an additive package that includes a brominated polystyrene or decabromodiphenyl ether; a nanoclay; and metal oxide fillers in the nanometer particle range. The compositions can have high weight percentages of the additive package because of the compatibilizing effect of the nanoclay. The nanoclay is preferably a quantenary amine treated nanoclay, wherein the quantenary amine causes exfoliation of the nanoclay. The polyolefin is a polyethylene or a polypropylene and the preferred metal oxide is antimony oxide.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Whisker-reinforced polyethylene pipe used in coal mine and preparation method thereof

The invention discloses a whisker-reinforced polyethylene pipe used in a coal mine and a preparation method thereof. The whisker-reinforced polyethylene pipe used in a coal mine belongs to a modified polyethylene. The whisker-reinforced polyethylene pipe used in a coal mine is prepared from 10 to 30wt% of magnesium salt whiskers, 5 to 10wt% of superconducting carbon black, 5 to 15wt% of decabromodiphenyl ether, 2 to 8wt% of antimonous oxide, 2 to 5wt% of POE, 1 to 2wt% of processing assistants and the balance of high density polyethylene. The magnesium salt whiskers have diameters less than 1.0 micrometer, an average length of 10 to 60 micrometers and a length-diameter ratio of 30 to 80 micrometers. The preparation method guarantees excellent flame resistance and static resistance of the whisker-reinforced polyethylene pipe, obviously improves mechanical properties of the whisker-reinforced polyethylene pipe, solves the problem that a plastic pipe used in a coal mine contains a large amount of assistants so that mechanical properties of the plastic pipe are reduced, prolongs a service life of the whisker-reinforced polyethylene pipe, reduces environmental pollution and the damage on a human body in a flame retardance aspect, and guarantees usability and safety of the whisker-reinforced polyethylene pipe used in a coal mine.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com