Courier bag material and preparation method of courier bag

A technology of using materials and low density polyethylene, applied in the field of packaging materials, can solve the problems of fire, easy rupture, burning, etc., and achieve the effects of simple process, low cost and short time required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

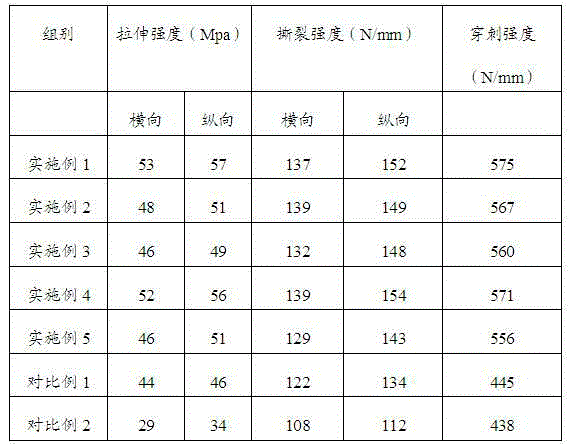

Examples

Embodiment 1

[0047] A kind of courier bag material provided in this embodiment, by weight, includes the following components:

[0048] 40 parts of film-grade low-density polyethylene;

[0049] 7 parts of film-grade high-density polyethylene;

[0050] 52 parts of film-grade linear low-density polyethylene;

[0051] 7 parts of mica with a median particle size of 10 μm;

[0052] Median particle diameter is 5 parts of calcium carbonate of 100nm;

[0053] Median particle diameter is 5 parts of palygorskite of 100nm;

[0054] 2 parts of decabromodiphenyl ether;

[0055] 3 parts of antimony trioxide;

[0056] 1.7 parts of chlorinated polyethylene;

[0057] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.15 part;

[0058] 1 part of titanate coupling agent;

[0059] The median particle size is 0.5 parts of 600 mesh zinc stearate.

[0060] Its preparation method is as follows:

[0061] The first step is to dry each material component;

[0062]...

Embodiment 2

[0065] A kind of courier bag material provided in this embodiment, by weight, includes the following components:

[0066] 35 parts of film-grade low-density polyethylene;

[0067] 5 parts of film-grade high-density polyethylene;

[0068] 50 parts of film grade linear low density polyethylene;

[0069] 5 parts of mica with a median particle size of 5 μm;

[0070] 4 parts of calcium carbonate with a median particle size of 50nm;

[0071] 1 part of palygorskite with a median particle size of 50nm;

[0072] 1 part of decabromodiphenyl ether;

[0073] 1 part of antimony trioxide;

[0074] 1 part of chlorinated polyethylene;

[0075] Antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.1 parts;

[0076] 0.1 parts of aluminate coupling agent;

[0077] The median particle size is 0.3 parts of 400 mesh zinc stearate.

[0078] Its preparation method is as follows:

[0079] The first step is to dry each material component;

[0080] In the second step, res...

Embodiment 3

[0083] A kind of courier bag material provided in this embodiment, by weight, includes the following components:

[0084] 45 parts of film-grade low-density polyethylene;

[0085] 10 parts of film-grade high-density polyethylene;

[0086] 55 parts of film grade linear low density polyethylene;

[0087] 10 parts of mica with a median particle size of 15 μm;

[0088] The median particle diameter is 7 parts of calcium carbonate of 200nm;

[0089] 9 parts of palygorskite with a median particle size of 200nm;

[0090] Decabromodiphenyl ether 2.5 parts;

[0091] 5 parts of antimony trioxide;

[0092] 2 parts of chlorinated polyethylene;

[0093] 0.25 parts of antioxidant N, N'-two (2-naphthyl) p-phenylenediamine;

[0094] 2 parts of titanate coupling agent;

[0095] The median particle size is 0.8 parts of zinc stearate of 800 meshes.

[0096] Its preparation method is as follows:

[0097] The first step is to dry each material component;

[0098] In the second step, 10 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com