Patents

Literature

3791 results about "Chlorinated polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorinated polyethylene (PE-C) is an inexpensive variation of polyethylene having a chlorine content from 34 to 44%. It is used in blends with polyvinyl chloride (PVC) because the soft, rubbery chlorinated polyethylene is embedded in the PVC matrix, thereby increasing the impact resistance. In addition, it also increases the weather resistance. Furthermore, it is used for softening PVC foils, without risking plasticizer migration. Chlorinated polyethylene can be crosslinked peroxidically to form an elastomer which is used in cable and rubber industry. When chlorinated polyethylene is added to other polyolefins, it reduces the flammability. Chlorinated polyethylene is sometimes used in power cords as an outer jacket.

Polyethylene rubber and processing method thereof

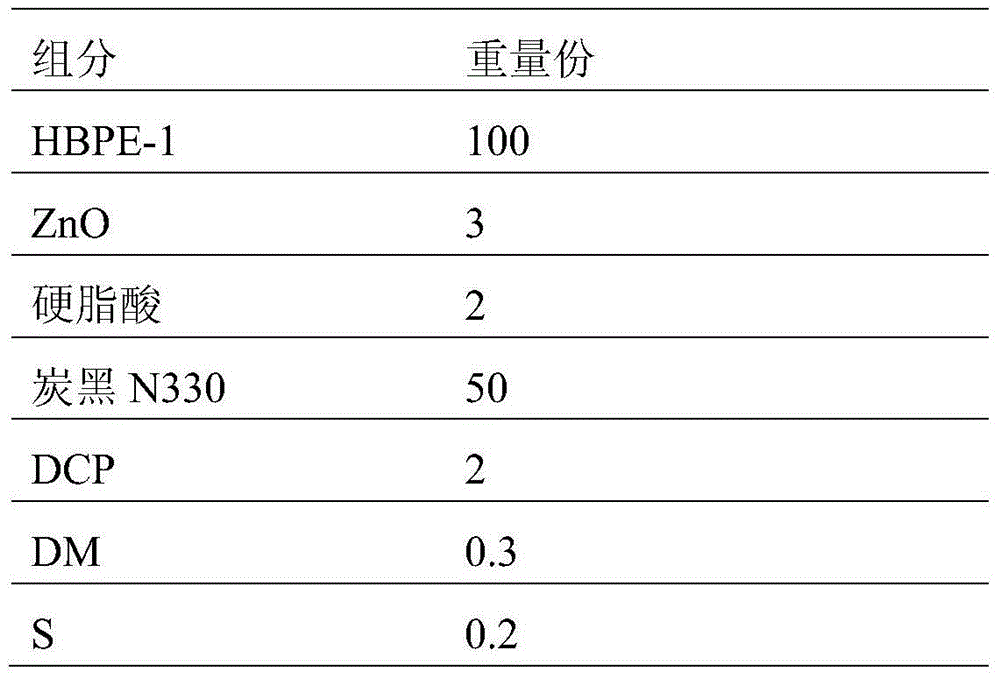

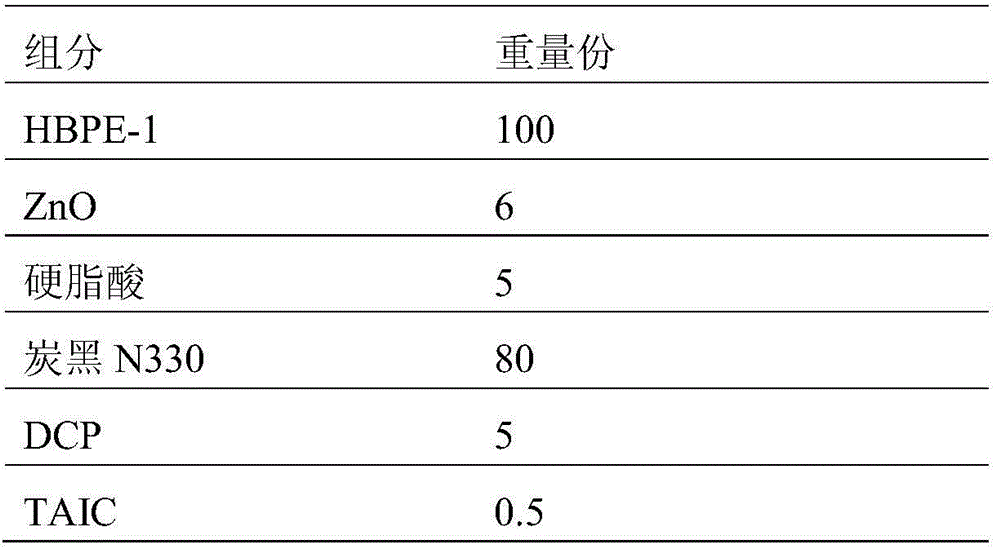

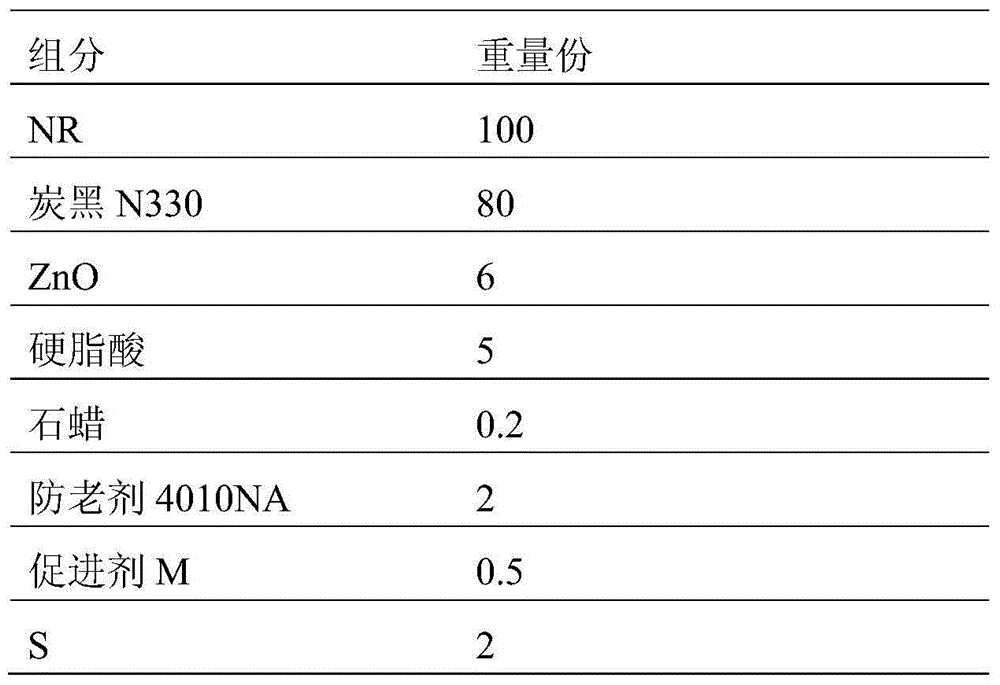

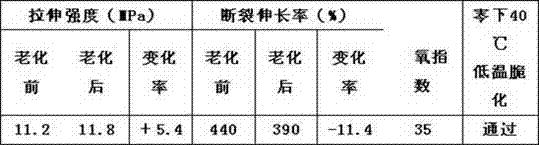

The invention belongs to the technical field of rubber, and particularly relates to polyethylene rubber and a processing method thereof. The polyethylene rubber comprises following raw materials by weight: 100 parts of hyper branched polyethylene, 50-80 parts of carbon black, 2-5 parts of a peroxide crosslinking agent, 0-6 parts of zinc oxide, 0-5 parts of a lubricant, 0.3-0.5 part of an accelerant, and 0-0.2 part of sulfur. Beneficial effects of the polyethylene rubber and the processing method thereof are that: the hyper branched polyethylene (HBPE) is sulfurized by utilization of a peroxide sulfurization system, has good mechanical performances through stress-strain performance tests, and has a characteristic of high elasticity of rubber. The processing method of the polyethylene rubber is totally different from preparation methods of chlorinated polyethylene rubber and chlorosulfonated polyethylene rubber at present. The polyethylene rubber and the processing method thereof break the limit that polyethylene can be only used for making plastic products, expand the application scope of the polyethylene, and largely increase the additional value of polyethylene homopolymers.

Owner:ZHEJIANG UNIV

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

Wood plastic composite material and its preparation method and application

A wood-plastics composition is prepared from used or waste plastics, wooden fibres for modifying plastics, and resin compatibilizer through fusing and proportionally mixing. Said resin compatibilizer is prepared from EVA, acrylic acid or acrylate and polyvinyl chloride through mixing. Its advantages are high strength toughness, and improved machinability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

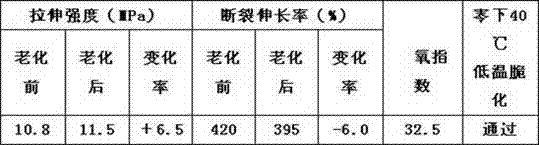

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Asphalt rubber waterproof coating material

ActiveCN102936460AUniform procedure is goodNot easy to embrittleConjugated diene hydrocarbon coatingsNatural rubber coatingsAcrylic resinStearic acid

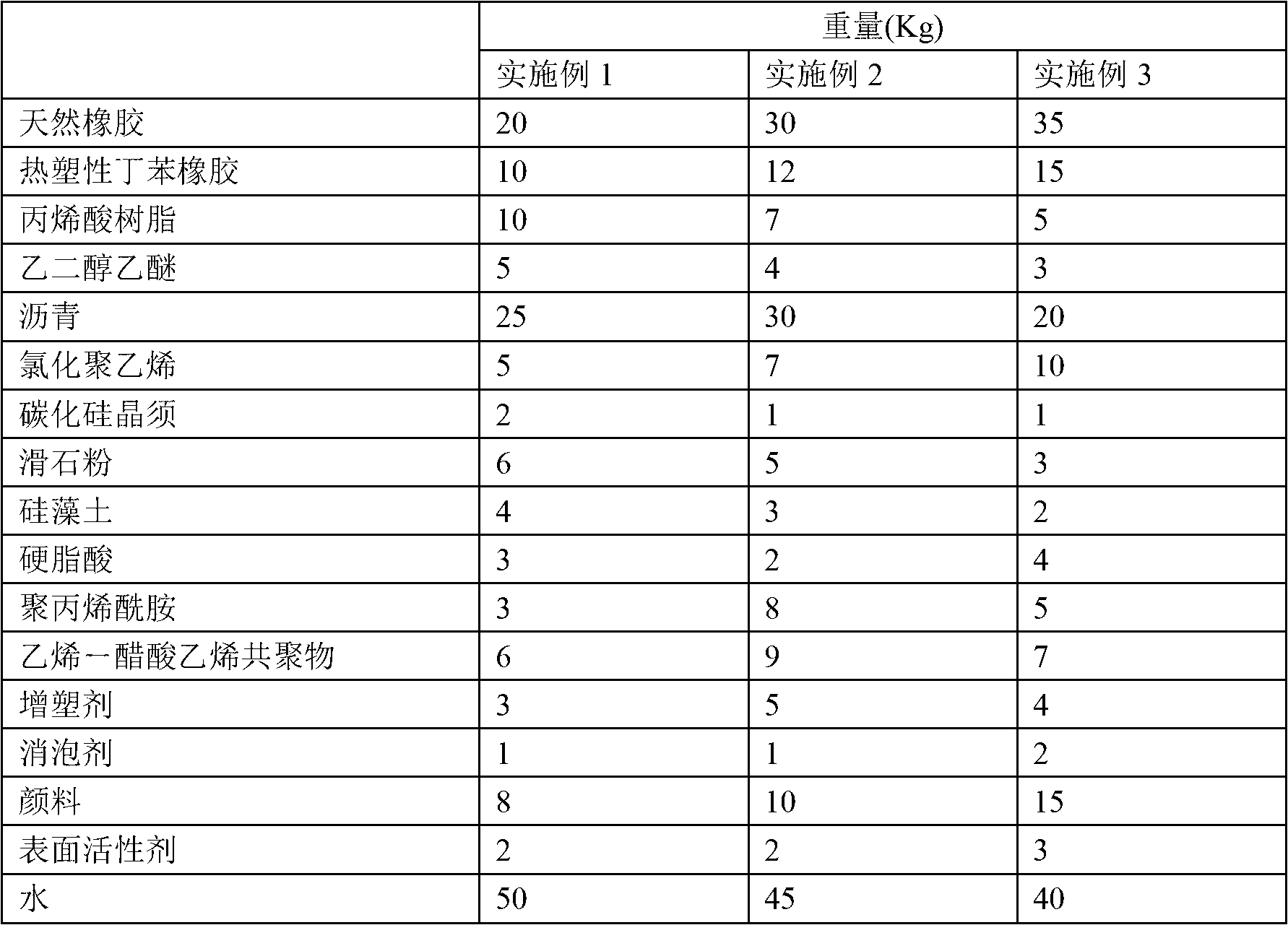

The present invention provides a rubber asphalt waterproof coating material, and belongs to the technical field of coating materials. The coating material is prepared from the following raw materials, by weight, 20-35 parts of a natural rubber, 10-15 parts of a thermoplastic styrene-butadiene rubber, 5-10 parts of acrylic resin, 3-5 parts of ethylene glycol ethyl ether, 20-30 parts of asphalt, 5-10 parts of chlorinated polyethylene, 1-2 parts of silicon carbide crystal whiskers, 3-6 parts of talc powder, 2-4 parts of diatomite , 2-4 parts of stearic acid, 3-8 parts of polyacrylamide, 6-9 parts of an ethylene-vinyl acetate copolymer, 3-5 parts of a plasticizer, 1-2 parts of a defoaming agent, 8-15 parts of a pigment, 2-3 parts of a surfactant, and 40-50 parts of water. The waterproof coating material provided by the embodiments still has good watertightness and good mechanical property after high temperature and high humidity destruction.

Owner:武汉飞盛建设工程有限公司

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059764A1Improve impermeabilityGood oil resistanceSynthetic resin layered productsSpecial tyresElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

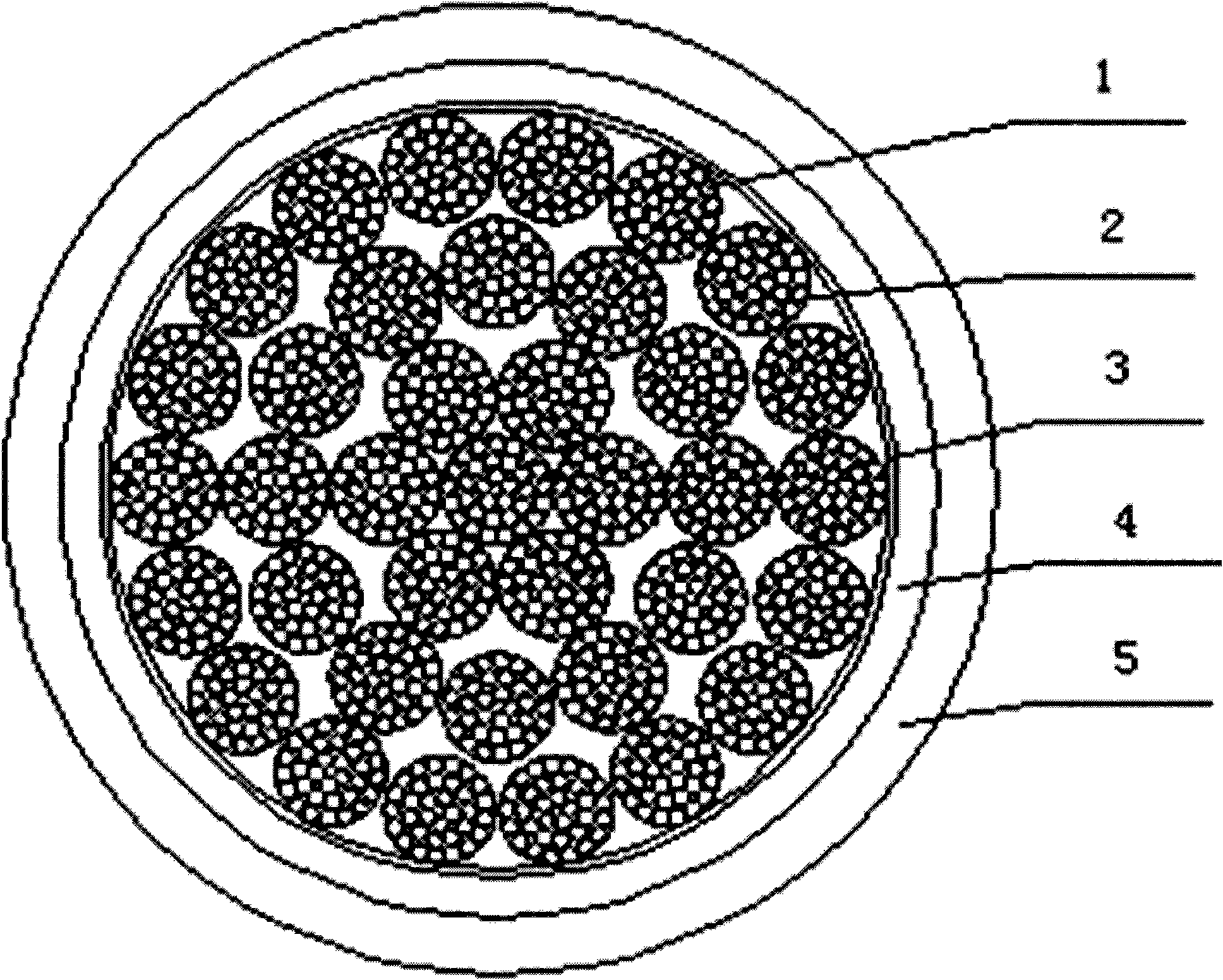

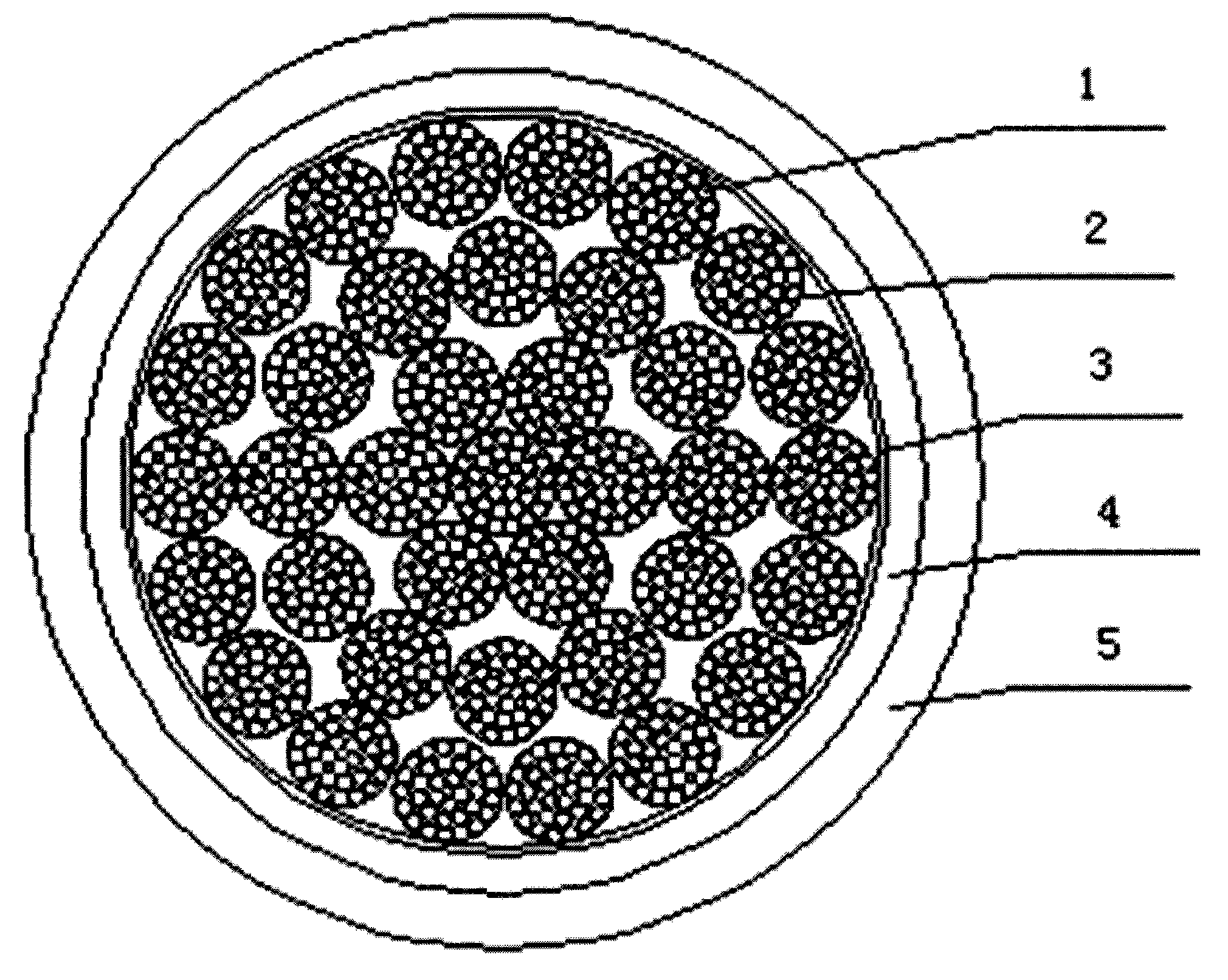

Mining cable rubber sheath glue

InactiveCN102516675AAccelerated vulcanizationImprove tear resistanceInsulated cablesInsulated conductorsPolymer sciencePlasticizer

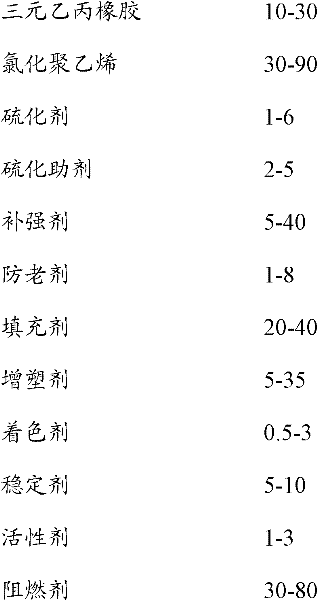

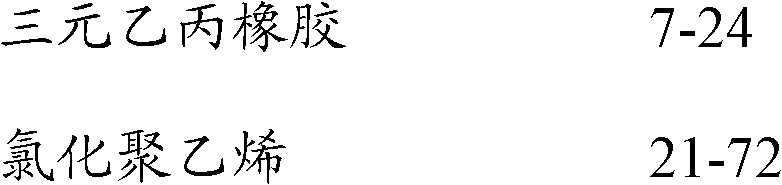

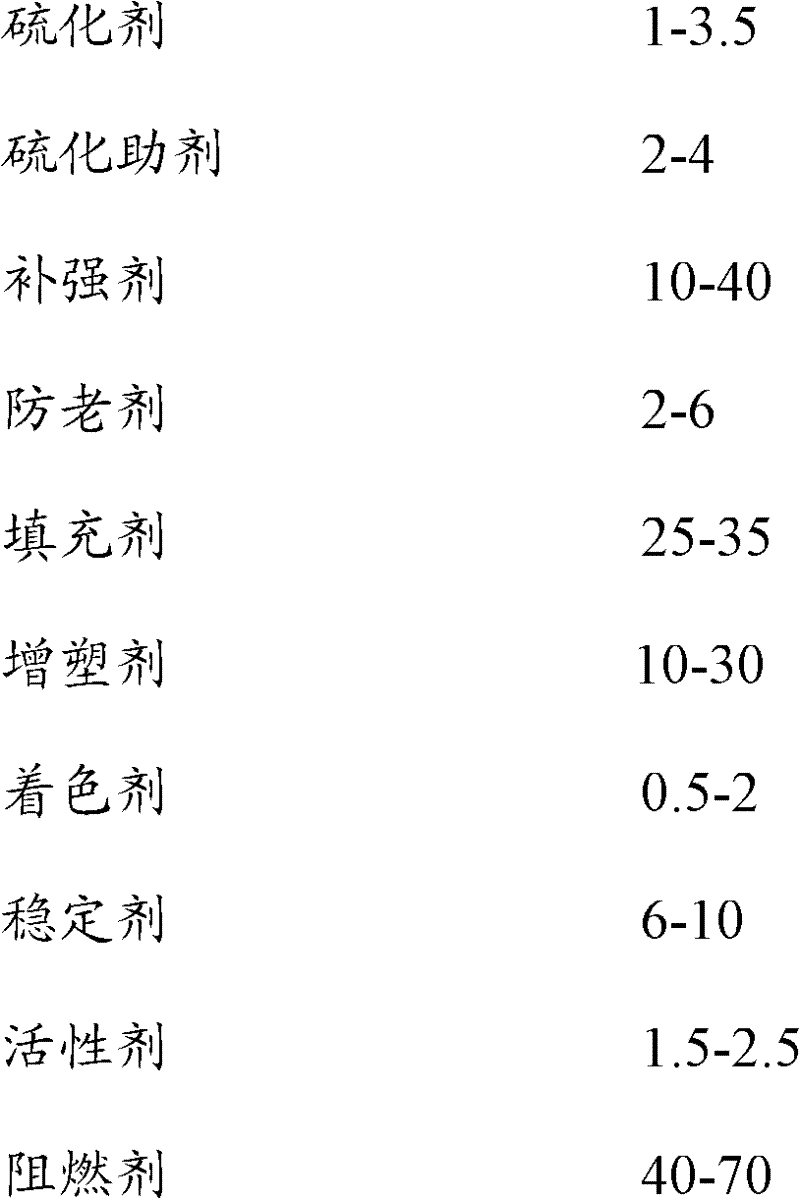

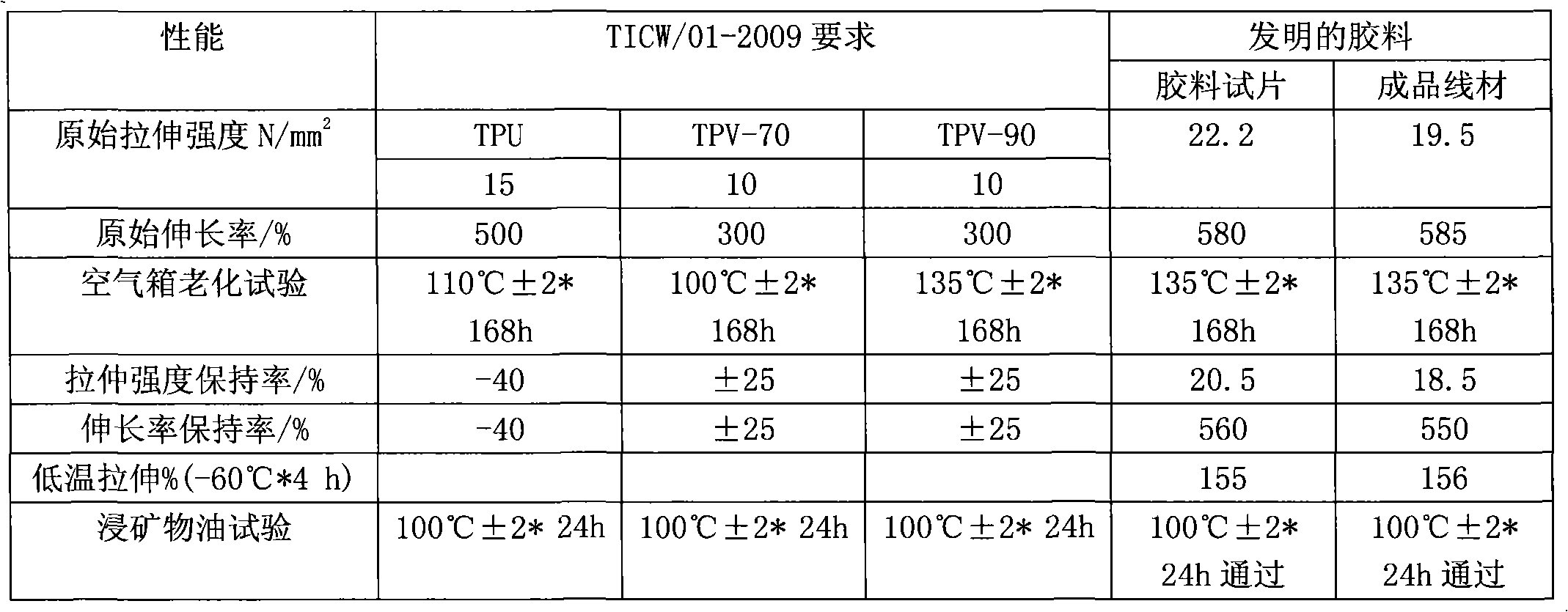

The invention relates to a mining cable rubber sheath glue, which comprises the following raw material components according to parts by weight: 10-30 parts of ethylene propylene diene monomer rubber, 30-90 parts of chlorinated polyethylene, 1-6 parts of vulcanizing agent, 2-5 parts of vulcanizing auxiliary agent, 5-40 parts of reinforcing agent, 1-8 parts of anti-aging agent, 20-40 parts of filling agent, 5-35 parts of plasticizer, 0.5-3 parts of coloring agent, 5-10 parts of stabilizing agent, 1-3 parts of active agent and 30-80 parts of fire retardant, wherein the mass ratio of the ethylene propylene diene monomer rubber to the chlorinated polyethylene is 1:3. In the mining cable rubber sheath glue, the chlorinated polyethylene is adopted to replace parts of ethylene propylene diene monomer rubber, the formula of the raw material is regulated, and the use cost of the prepared mining cable rubber sheath glue is lowered on the premise of satisfying the use standard of the mining cable.

Owner:ANHUI LAND GRP

Environment-friendly wood plastic floor and manufacturing method thereof

The invention discloses an environment-friendly wood plastic floor and a manufacturing method thereof, and belongs to the technical field of floors. The environment-friendly wood plastic floor is prepared from the following components in parts by weight: 25-55 parts of PVC plastic raw materials, 30-50 parts of wood fibers, 12-18 parts of calcium carbonate, 0.8-1.2 parts of lubricant, 0.1-2.5 parts of plasticizer, 1.5-3 parts of titanate coupler, 1.8-2.5 parts of thermal stabilizer, 0.2-0.6 parts of anti-ageing agent, 1-2 parts of chlorinated polyethylene and 2-5 parts of acrylate impact modifier. The environment-friendly wood plastic floor is a composite material prepared by taking the PVC plastics and the wood fibers as main raw materials, performing high molecular modification and processing by mixing and high-temperature extrusion equipment, has main advantages of plastics and wood, and is mildew-resistant, ageing-resistant, acid-base-resistant, insect-damage-resistant, nontoxic and harmless.

Owner:安徽浩峯塑业有限公司

Distortion-resistance wind power generation cable sheath materials and cable

InactiveCN101838424AImproves UV resistanceFunction increasePlastic/resin/waxes insulatorsFlexible cablesElastomerCross-link

The invention discloses a distortion-resistance wind power generation cable sheath material and a cable. The cable material comprises the following components in weight parts: 100 parts of chlorinated polyethylene, 10-30 parts of amorphism copolymer, 10-20 parts of cold-resistant plasticizer, 40-80 parts of reinforcing filler, 5-15 parts of nanosacle inorganic active agent, 2.5-5 parts of cross-linking agent, 2-5 parts of cross-linking assistant agent, 1-2.5 parts of antioxidant antiager and 10-30 parts of inorganic fire retardant, wherein the amorphism copolymer is a mixture of amorphism polyolefin thermoplastic elastomer and chlorinated polyethylene elastic body; and the nanoscale inorganic active agent is nanoscale zinc oxide and magnesium oxide. The cable of the invention has low-temperature resistance (-60DEG C)and distortion resistance, excellent flexibility, improves the homogenisieren property of the other materials by adding the nanoscale inorganic active materials, improves the molecular structure, has better flexibility because of the uvio-resistance, and has the characteristics of distortion, cold, oil and corrosion resistance and the like.

Owner:江苏凯诺电缆集团有限公司

Production method for chloroprene rubber adhesive

The invention discloses a production method for a chloroprene rubber adhesive. The product produced by the production method is a high-performance adhesive. The adhesive is produced by using chloroprene rubber as a main body and using raw materials including styrene, silicon dioxide, magnesium oxide, zinc oxide, polyisocyanates, polyester resin, vinyl trisilane, antiaging agent D and the like and by a certain process. The product is mainly used in the building industry for adhering ethylene propylene diene monomer rubber waterproof coiled material, chlorinated polyethylene-rubber blended waterproof coiled material, chlorinated polyethylene waterproof coiled material, sulfurized rubber plastic waterproof coiled material, chlorinated polyethylene plastic floorings and calcium plastic plates with concrete, cement, asbestos boards, wood and other materials.

Owner:张耀华

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

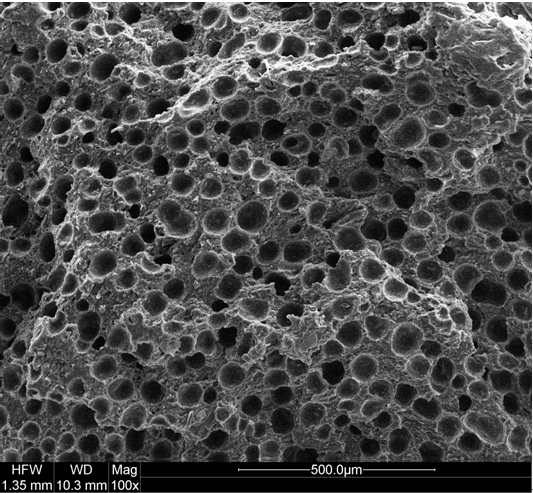

Micro-foaming wood plastic composite material plate for building template and preparation method thereof

The invention discloses a micro-foaming wood plastic composite material plate for a building template and a preparation method thereof. The wood plastic composite material consists of polrvinyl chloride, wood powder, lightweight active calcium carbonate, a foaming agent, a foaming stabilizer, polyethylene wax, a titanate coupling agent, chlorinated polyethylene, an adsorbent nano calcium oxide, an auxiliary foaming agent nano zinc oxide, a silicone processing adjuvant and reinforced fiber alkali-free glass fiber. The preparation method comprises the following steps of: mixing the wood powder and the nano calcium oxide powder at a high speed; adding the titanate coupling agent and then mixing at the high speed; adding the rest materials; mixing at the high speed and then mixing at a low speed to obtain a premix; extruding the premixing by using an extruder; and cooling very quickly to obtain the product. The micro-foaming wood plastic composite material plate has the characteristics ofhigh surface hardness, high flowability, high strength, high toughness, high dimensional stability, long service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

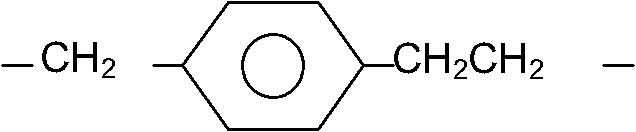

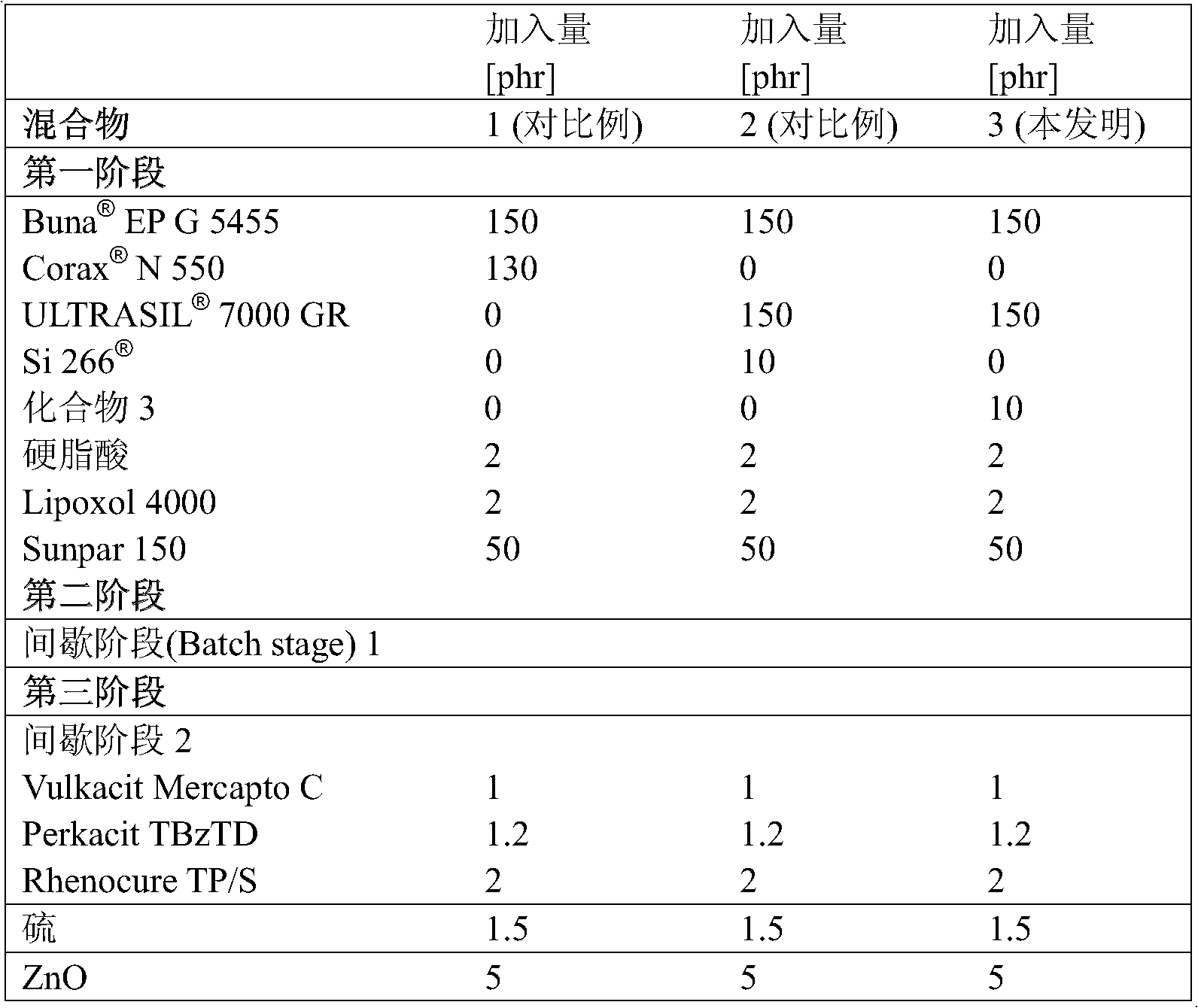

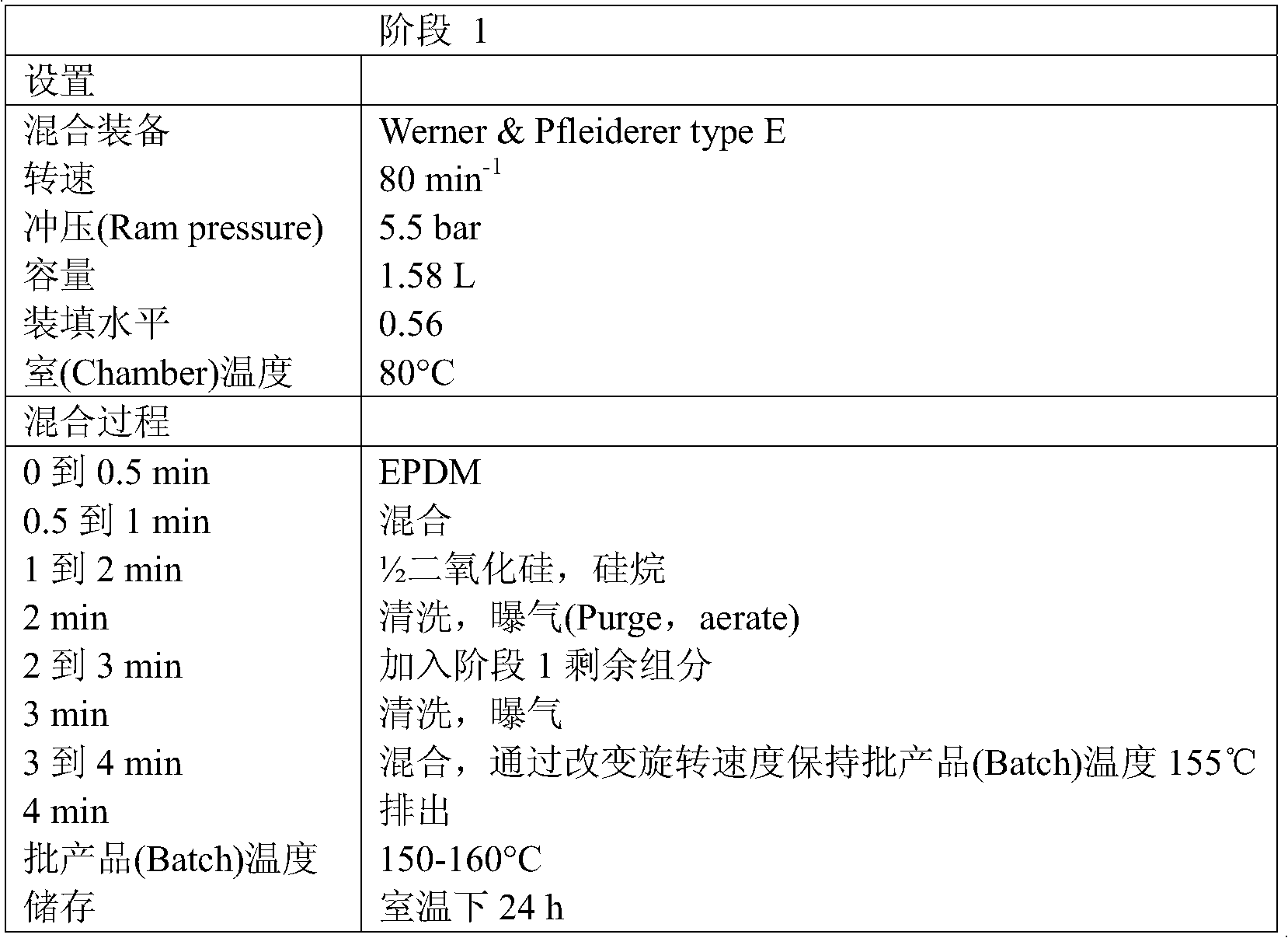

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN102653618AImprove performanceHeat resistantPlastic/resin/waxes insulatorsAntioxidantDioctyl terephthalate

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material and a preparation method thereof. The environment-friendly cold-resistant polyvinyl chloride cable material is prepared from the following raw materials in percentage by mass: 40-60% of polyvinyl chloride, 5-25% of dioctyl terephthalate, 5-25% of dioctyl adipate, 1-10% of chlorinated polyethylene, 5-25% of light activated calcium carbonate, 1-3% of lubricant, 2-8% of Ca-Zn composite stabilizer, 0.1-1% of antioxidant and 0.1-4% of pigment. The environment-friendly cold-resistant polyvinyl chloride cable material is mainly compounded from dioctyl terephthalate and dioctyl adipate. The cable material can be normally used in a low-temperature environment of -40 to -65 DEG C, has favorable shock resistance under low-temperature conditions, does not contain ortho-benzoic ether compounds, and is environment-friendly, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly and has poor shock resistance under low-temperature conditions.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD +1

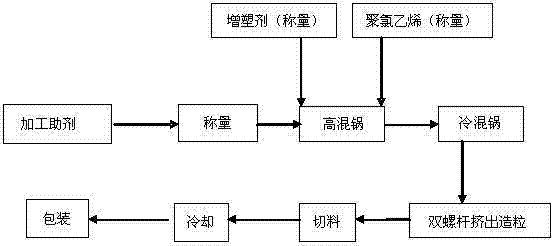

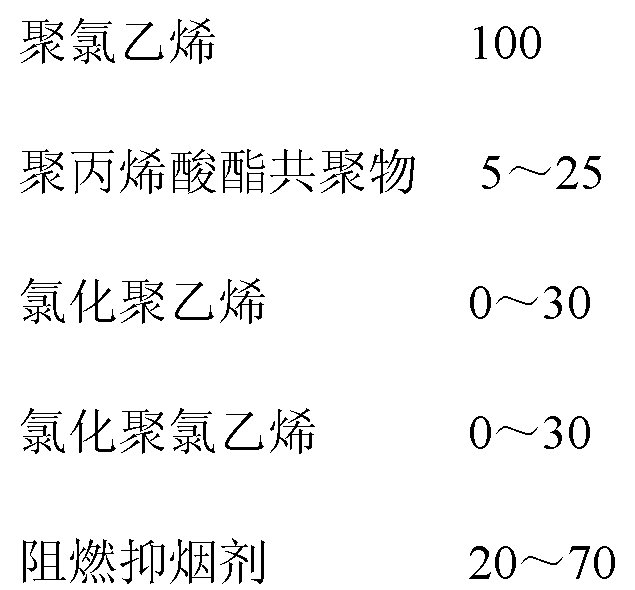

Composition for flame-retardant polyvinyl chloride (PVC) plastic foam board, product prepared from same, and preparation method thereof

The invention relates to a composition for a flame-retardant polyvinyl chloride (PVC) plastic foam board, and the flame-retardant PVC plastic foam board produced by a double screw extrusion method. The composition comprises the following components in part by weight: 100 parts of polyvinyl chloride, 5 to 25 parts of polyacrylate copolymer, 0 to 30 parts of chlorinated polyethylene, 0 to 30 parts of chlorinated polyvinyl chloride, 20 to 70 parts of flame retardant and smoke suppression agent, and 0 to 5 part of plasticizer, and also comprises a resin melt reinforcing agent and additives such as a foaming agent, a lubricating agent and a stabilizing agent and the like. After the produced flame-retardant PVC plastic foam board is detected by Shanghai Building Material and Component Quality Surveillance Office and State Laboratory of Fire Science (University of Science and Technology of China, Hefei), the oxygen index is more than or equal to 32, the smoke density grade is less than or equal to 75, the average combustion time is less than or equal to 30 seconds, the heat release rate is less than 250W / g, the heat conductivity is 0.047W / m.K, and the flame-retardant PVC plastic foam board meets the B1 requirement of GB / T8624-1997, and meets the V-0 standard of UL-94.

Owner:SHANGHAI YUANQI ENERGY TECH DEV

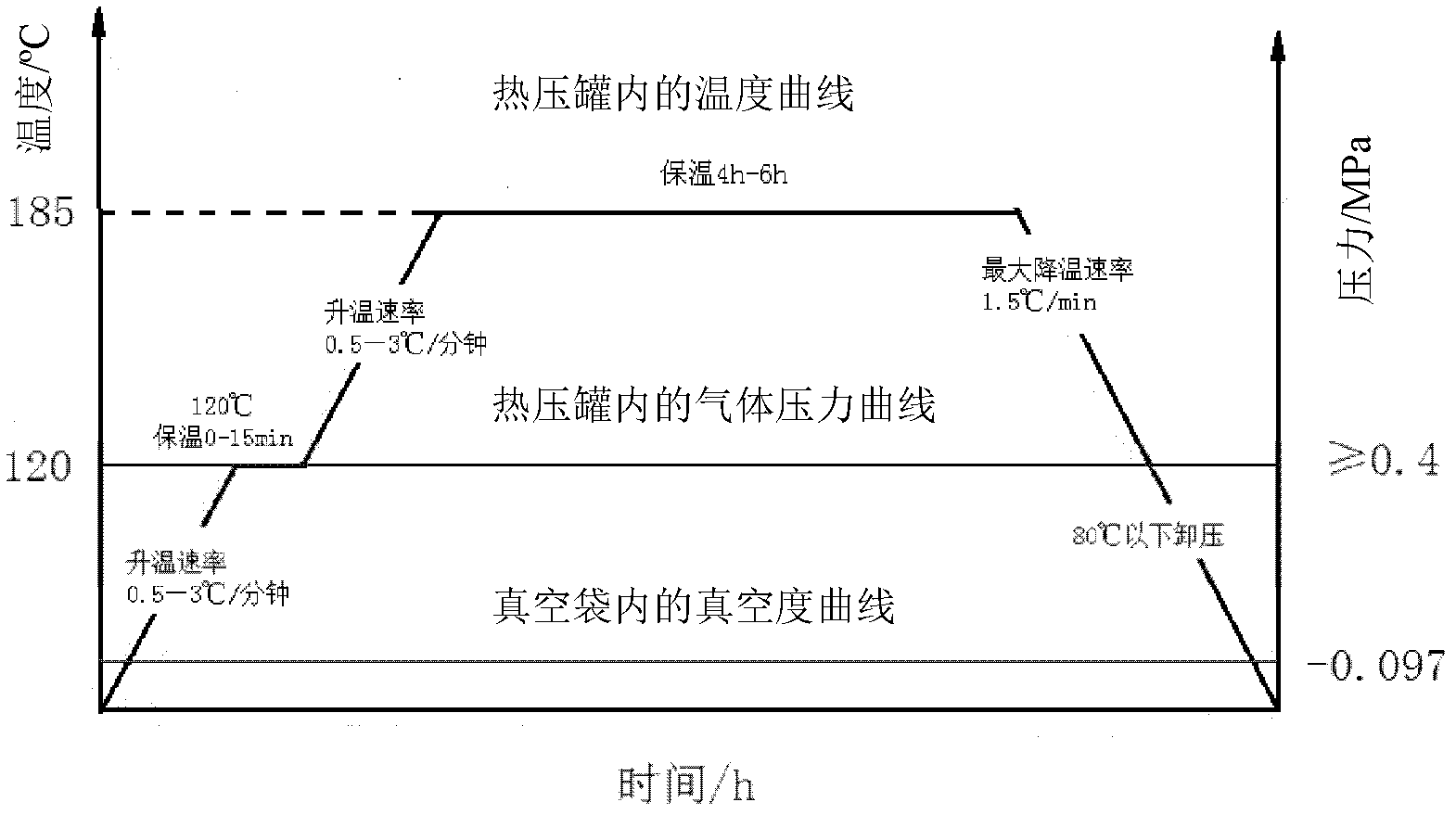

Embedded type high-temperature co-curing high-damping composite material and preparation process thereof

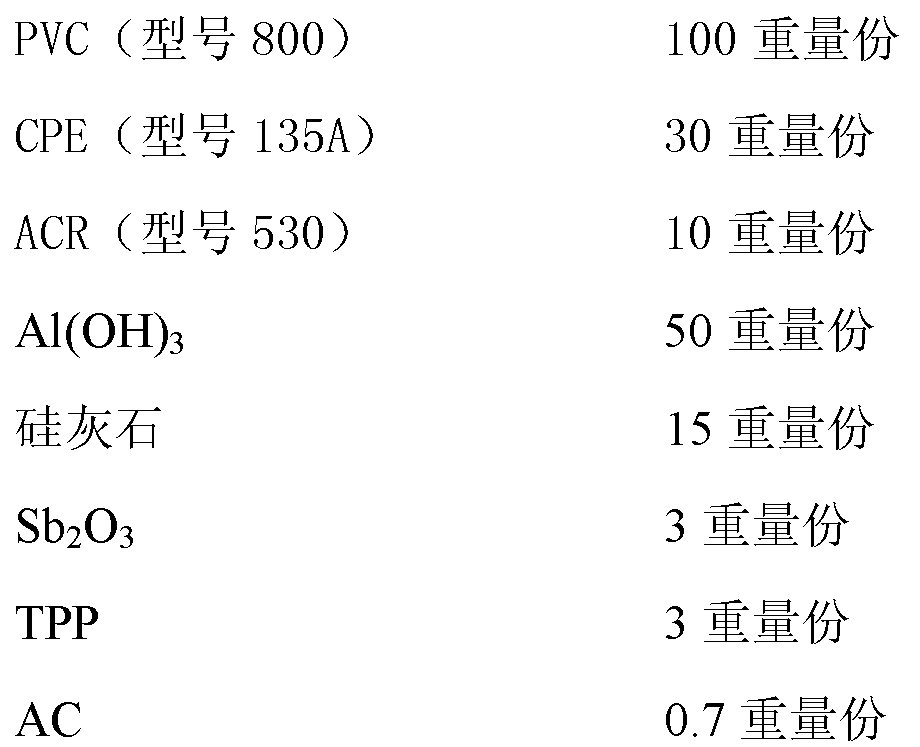

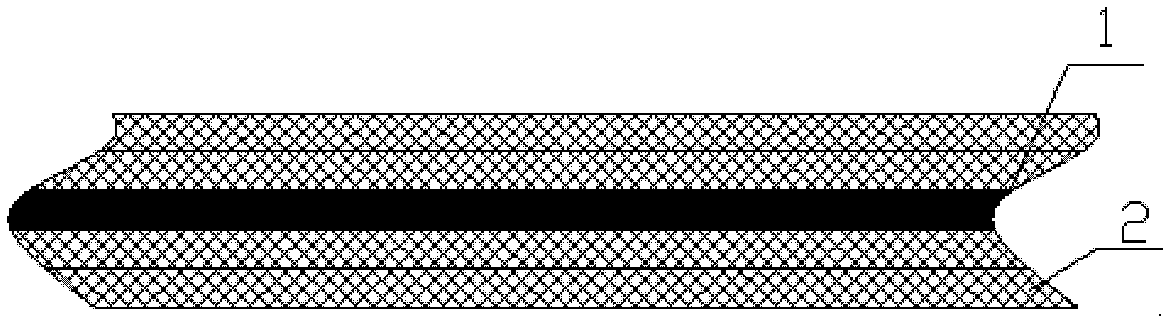

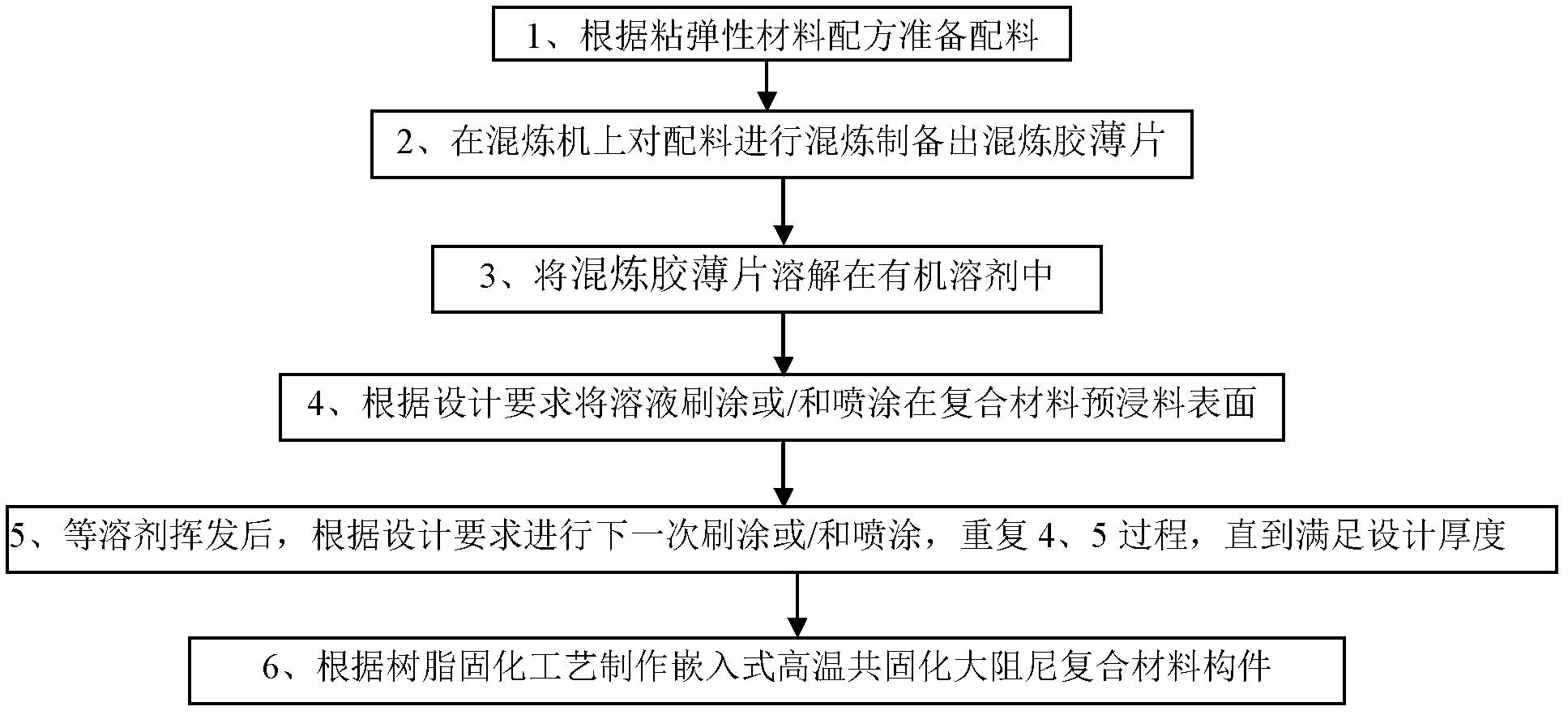

The invention discloses an embedded type high-temperature co-curing high-damping composite material. The embedded type high-temperature co-curing high-damping composite material comprises the following components in parts by weight: 92.5-93.5 parts of butyl rubber, 6.5-7.5 parts of chlorinated butyl rubber, 2.9-3.1 parts of chlorinated polyethylene, 3.9-4.1 parts of zinc oxide, 0.8-1 parts of stearic acid, 50-52 parts of carbon black and 5.9-6.1 parts of octyl phenolic resin. The invention also discloses a preparation method of the composite material. According to the method, the mixture of the butyl rubber and the chlorinated butyl rubber is taken as a main material, the mixture is dissolved in an organic solvent to be prepared into unvulcanized visco-elasticity damping material solution, the unvulcanized visco-elasticity damping material is brushed and coated on the prepreg surface of the composite material, by adopting a brush-coating method or / and spray-coating method, a damping layer is embedded in the structure of the composite material by being taken as a specific paving layer and then is processed into a damping-structure member of the embedded composite material by a co-curing process curve, and the damping-structure member of the embedded composite material has a wide application prospect in the high-tech fields such as high speed trains, aviation, aerospace and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

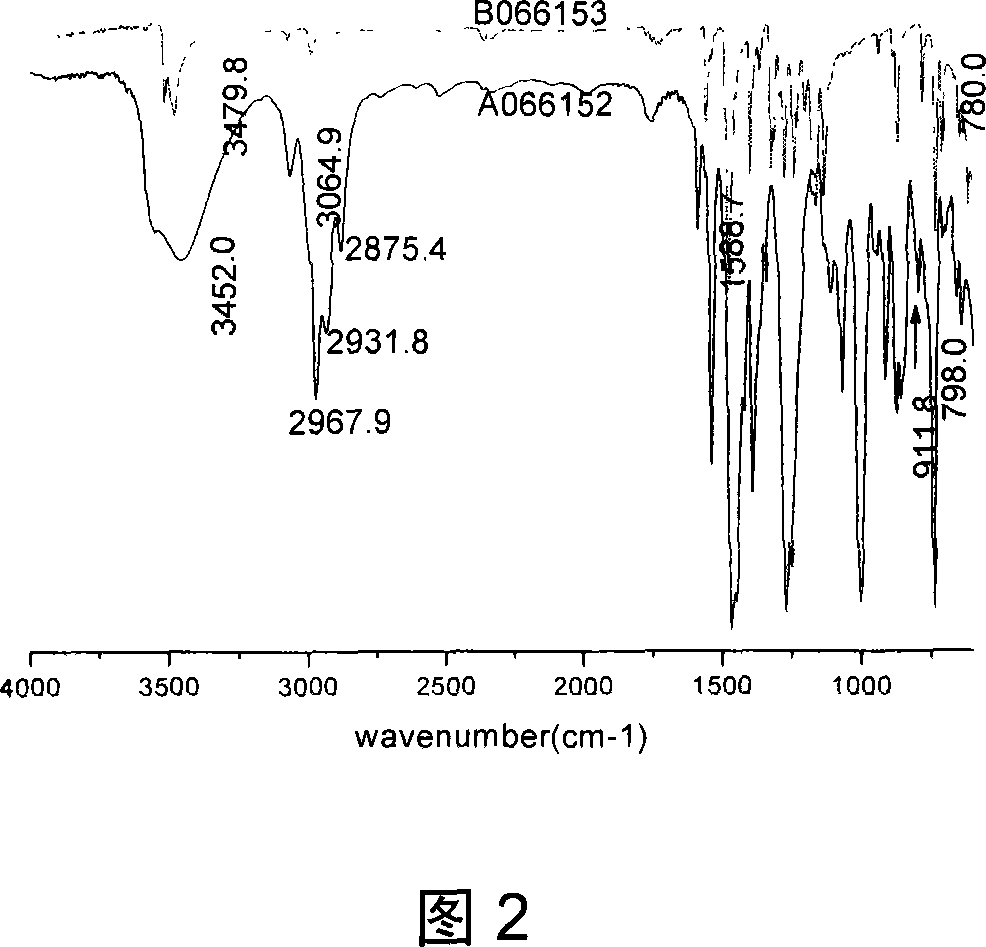

High performance chlorinated polyethylene-epoxy resin anticorrosive coating system

InactiveCN101691464AGive full play to corrosion resistanceGive full play to the bonding effectAnti-corrosive paintsPolyamide coatingsChemical industryEpoxy

The invention discloses a high performance chlorinated polyethylene-epoxy resin anticorrosive coating system, which consists of a surface coating, an intermediate coating and a prime coating which are matched, wherein the surface coating is a high performance chlorinated polyethylene anticorrosive finish paint; the intermediate coating is a high performance chlorinated polyethylene / epoxy resin semi-interpenetrating network anticorrosive middle coating; and the prime coating is an epoxy resin micaceous iron oxide anti-corrosive primer. The preparation for the coating system comprises the preparation of surface coating and the intermediate coating; the coating construction is orderly multi-layer coating construction on the surface of a metal substrate; and finally the functionally graded anticorrosive coating is formed so as to effectively improve interface bonding force and adhesive force of various layers and fully exert the corrosion resistance of the high performance chlorinated polyethylene and the substrate bonding function of the epoxy resin; and the functionally graded anticorrosive coating has good corrosion resistance, such as the resistance to acid, alkali, saline water, gasoline and the like, and also has good physical and mechanical properties, such as shock resistance and flexibility, so the functionally graded anticorrosive coating has important application value in anticorrosive fields such as steel structures, bridges, metallurgy, chemical industry and the like, in particular heavy duty anticorrosive field of petrochemical industry.

Owner:郭再春

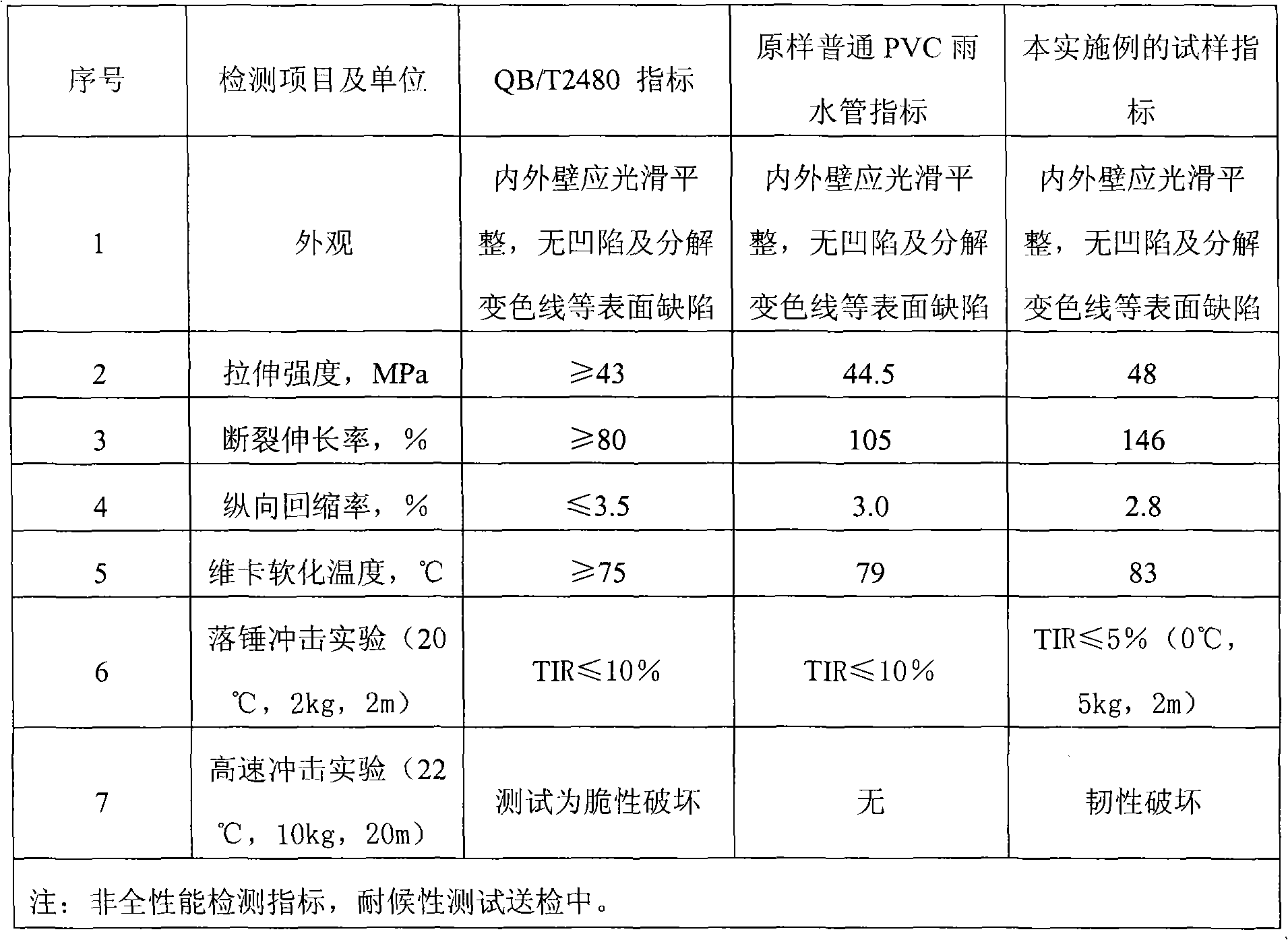

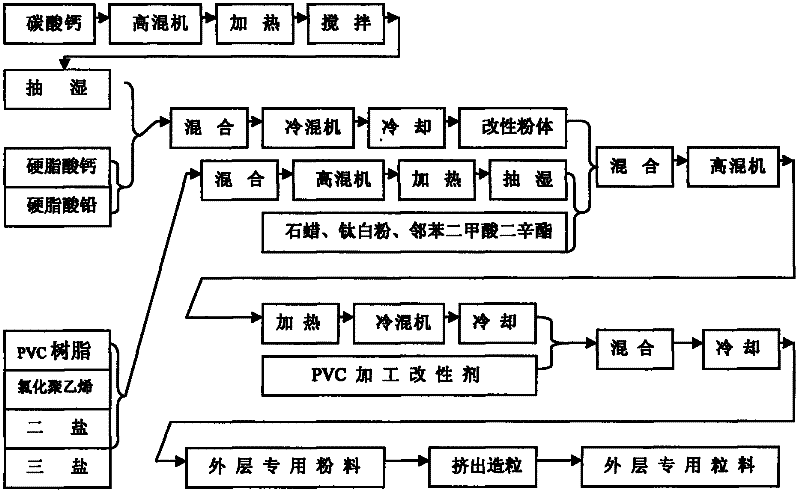

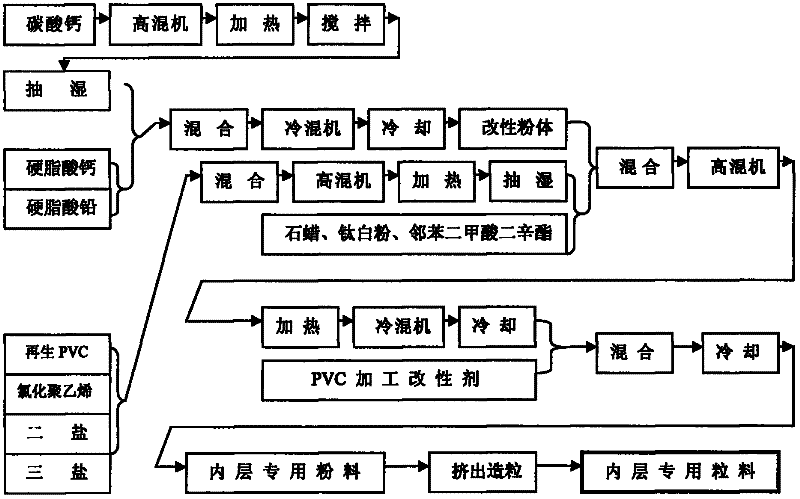

ASA/PVC co-extrusion ultra-weather resisting colorful rainwater pipeline

InactiveCN101581138AImprove toughnessImprove impact resistanceSynthetic resin layered productsRoof drainageAcrylic rubberAcrylonitrile

The invention discloses an ASA / PVC co-extrusion ultra-weather resisting colorful rainwater pipeline special for outdoor rainwater drainage. The traditional VPC rainwater pipelines are white, and are hard to be harmonized with the appearance of a building or be applied to western high altitude areas. The pipeline consists of an internal layer and an external layer, and is characterized in that the external layer is made of an ASA modified material, and comprises the following compositions: acrylonitrile, styrene, acrylic rubber terpolymer, complex pigment, chlorinated polyethylene, stearic acid, calcium stearate, nanometer calcium carbonate, compounded lubricant, titanium pigment, UV absorbent and antioxidizer; the internal layer is prepared by the following compositions: polyvinyl chloride, chlorinated polyethylene, calcium stearate, titanium pigment, organic stabilizer and PE wax. The external layer made of the ASA material has ultra-weather resistance and multiple colors to meet the requirement on the colorful pipeline in the market currently; and the internal layer greatly improves the toughness of the pipeline.

Owner:浙江中财管道衍生产品有限公司

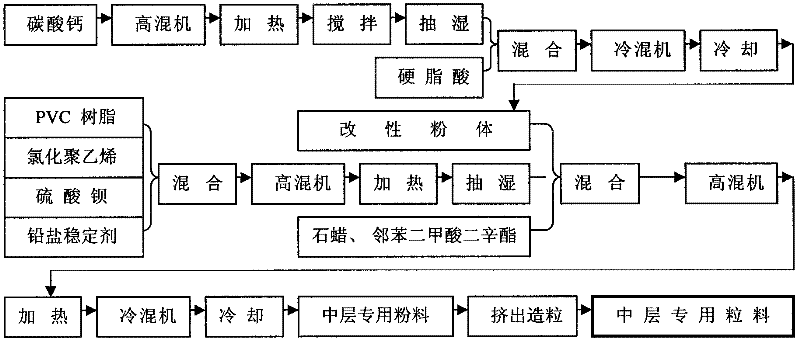

Three-layer noise reduction drainage pipe and manufacture method thereof

InactiveCN102313084AHigh strengthReduce impact noiseDomestic plumbingRigid pipesManufacturing cost reductionPolyvinyl chloride

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. The noise reduction middle layer is a sound-absorbing middle layer or a sound insulation middle layer made of expandable polyvinyl chloride composition materials. The above layers are prepared with the following materials. The impact-resistance outer layer is made of polyvinyl chloride resin, chlorinated polyethylene, dibasic lead phosphite, tribasic lead sulfate, calcium stearate, lead stearate, paraffin, PVC processing and modifying agent, active light calcium carbonate, titanium dioxide and dioctyl phthalate. The sound-absorbing middle layer is made of polyvinyl chloride resin, chlorinated polyethylene, lead salt stabilizer, calcium stearate, stearic acid, paraffin, dioctyl phthalate, active light calcium carbonate and barium sulfate. The sound insulation middle layer is made of polyvinyl chloride resin, methacrylic ester polymer and inorganic foaming agent. Compared with the outer layer, the impact-resistance inner layer comprises the same components with the outer layer, except that PVC is adopted instead of polyvinyl chloride resin. The noise of the drainage pipe can be effectively reduced and the intensity of the drainage pipe is enhanced.

Owner:ZHEJIANG SANLENG PLASTIC

Wood/plastic building template

The invention relates to a wood / plastic building template, which is characterized by being prepared by taking polyvinyl chloride (PVC) SG700-8, PVC SG1000-5, wood meal, light calcium carbonate, a foam control agent 530, a compound stabilizing agent, a processing aid ACR401, a lubricating modifier LS-303, polyethylene wax, paraffin, stearic acid 1801, high-density polyethylene wax, a foaming agent AC150P azobisformamide, a foaming agent NC azobisformamide, an impact modifier chlorinated polyethylene and 1-1.4% of soybean oil as the raw materials and carrying out high-temperature mixing, cooling and extrusion molding on the raw materials. The wood / plastic building template replaces the plywood and the bamboo templates in the building templates, has the characteristics of environmental protection, zero pollutant discharge, high use frequency, long use period, etc, conforms to the ideals of low-carbon discharge, forest protection and production environment improvement and is an environment-friendly material for building.

Owner:ANSHAN SENYU BUILDING MATERIALS

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20060270783A1Improve impermeabilityGood oil resistanceFibre treatmentFlexible pipesElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof; a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:YH AMERICA

Bamboo-plastic composite section bar

A bamboo plastic composite sectional material consists of PVC 100 proportion, bamboo-sand optical powder 100-200 proportion, barium stearate 0.6-1.0 proportion, CPE 4-6 proportion, lead stearate 0.6-1.0 proportion, industrial stearic acid 1-1.5 proportion, n-octyl ester phthalate 2-3.5 proportion, light calcium carbonate 15-45 proportion, stabilizer 3-6 proportion, ACR 2-6 proportion, foaming regulator 5-10 proportion, ADC foaming agent 1-2 proportion and polyvinyl wax 0.2-1.0 proportion. It costs low and is simple. It has better quality, strength and toughness and various uses. It can be used for door, window, decorative line and floor.

Owner:重庆星星套装门(集团)有限责任公司

Coloured PVC waterproof roll and its preparation method

InactiveCN1844294AHigh tensile strengthUniform plasticizationOther chemical processesNitrile rubberPolyvinyl chloride

The invention relates to a colored polyvinyl chloride water-proof coiled material, which is prepared from the following constituents (by weight portions): PVC resin 100 parts, phthalandione dioctyl or tributyl citrate 35+-5 parts, powdered nitrile rubber or chlorinated polyethylene 10+-2 parts, calcium carbonate 30+-10 parts, rare earth heat stabilizer 1.5+-0.5 parts, barium stearate0.3+-0.1 part, stearic acid 0.2+-0.1 part. The invention also discloses its preparing process.

Owner:JIANGSU HUAHONG RUBBER & PLASTIC

High chlorinated polyethylene coating containing stainless steel flakes and preparation method thereof

InactiveCN101633808AImprove physical performanceImprove shielding effectWax coatingsEpoxy resin coatingsChemical industryCoating system

The invention provides a high chlorinated polyethylene coating containing stainless steel flakes and a preparation method thereof. The coating comprises the following components in portion by mass: 100 portions of high chlorinated polyethylene resin, 10 to 250 portions of modified resin, 10 to 1,400 portions of the stainless steel flakes, 0 to 1,400 portions of pigment and filler, 0.1 to 10.5 portions of antifoaming agent, 0 to 175 portions of coupling agent, 0.3 to 10.5 portions of anti-settling agent, and 100 to 2,000 portions of solvent. The coating has the advantages that the coating has good anticorrosion performance, and can be widely applied to various corrosion environments such as acid, alkali, salt, sea water, soil, chemical industry atmosphere and the like; the protective lifetime of a coating system is prolonged; and the coating can be used as primer, intermediate coating, surface coating or bottom integral coating, can be packed separately, is convenient to construct and quick to dry, and can be constructed at the ambient temperature of between 20 DEG C below zero and 40 DEG C.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

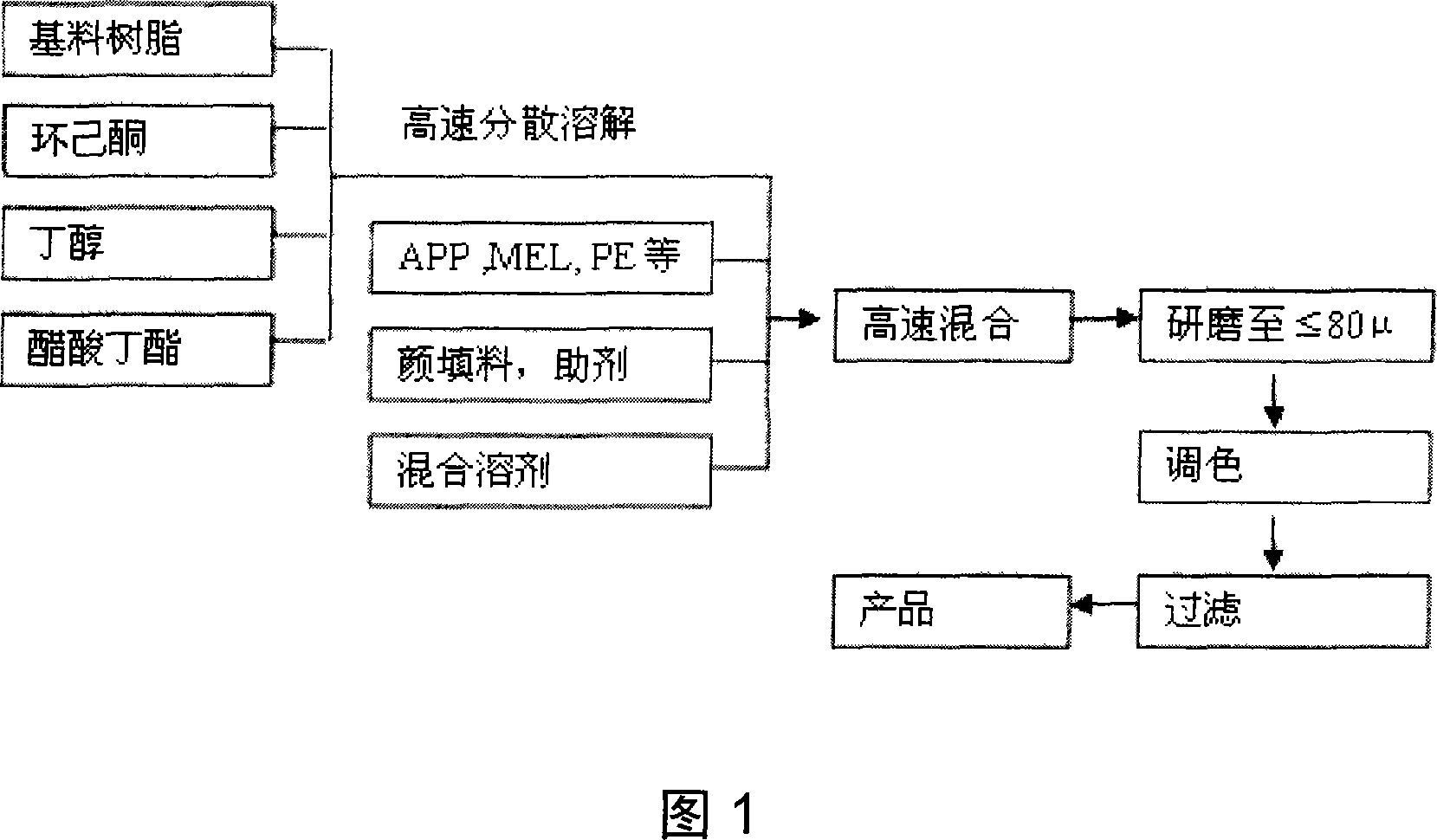

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Super thin expansion type fire-proof corrosion resistant paint for steel structure and its preparing method

The present invention relates to one double-function paint for fireproofing and anticorrosion of steel structure and its preparation process. Available paint has only single function of either fireproofing or anticorrosion and thus limited application range. The present invention adopts polyvinyl perchloride and organosilicon modified acrylic resin as main filming material and adds cyanuramide phosphate and expanding graphite into common polytriammonium phasphate as fireproof assistant to constitute foaming material. The present invention has greatly raised foaming rate and the foamed layer has thickness of 30-50 times the original coating thickness and fireproof limit up to 90 min. The paint has simple preparation process, low cost and wide application.

Owner:TONGJI UNIV

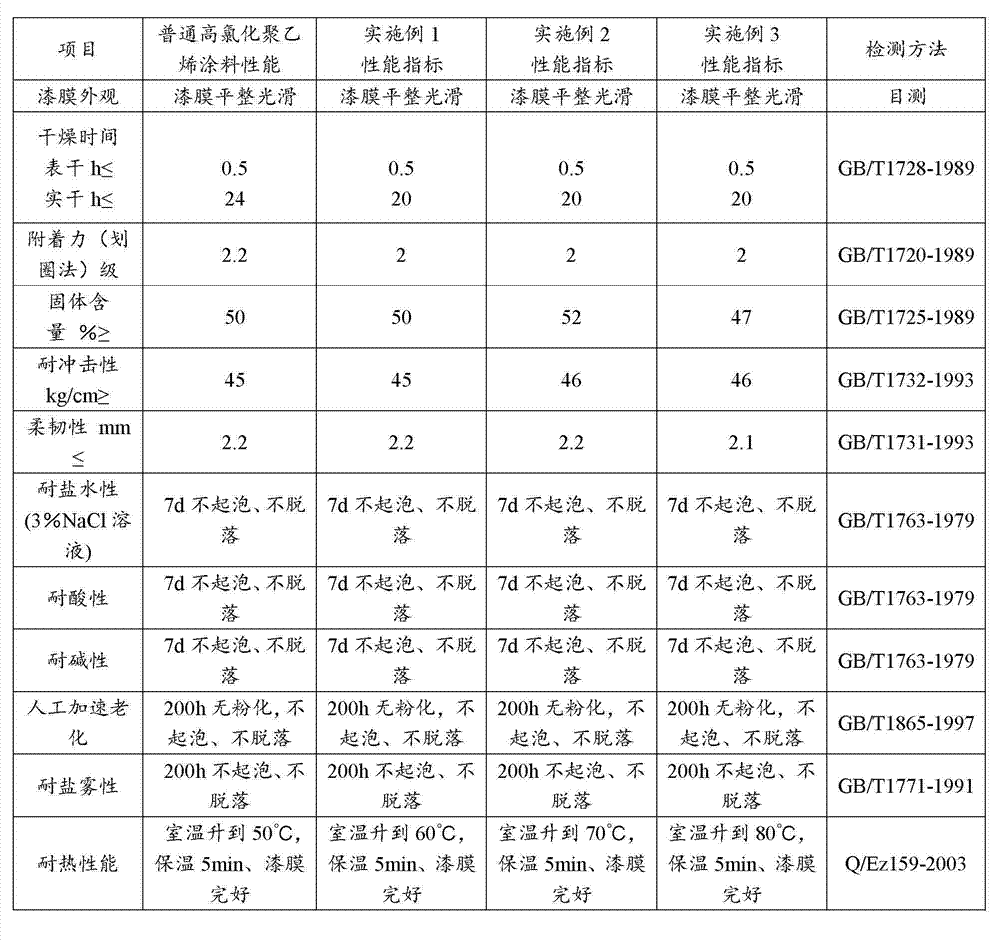

High chlorinated potyethlene anti-corrosive paint and preparation method thereof

ActiveCN102863854AImprove heat resistanceHigh bonding strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to heat-resistant high chlorinated potyethlene anti-corrosive paint and a preparation method thereof and belongs to the field of anti-corrosive paint. The paint comprises, by weight, 10-40 parts of high chlorinated polyvinyl chloride, 5-35 parts of epoxide resin, 5-25 parts of acrylic resin containing fluorine, 10-30 parts of fillers, 0.1-1 part of pigment, 0.05-0.5 part of dispersant, 0.05-0.5 part of plasticizer, 0.1-0.5 part of defoaming agent and 20-60 parts of solvent. The paint can be used at the temperature of 50-80 DEG C. The paint has the advantages of being good in heat resistance, corrosion resistance, coating and processability.

Owner:SHANDONG LIAOCHENG QILU SPECIAL PAINT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com